Patents

Literature

37results about How to "Will not pulverize" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminium magnesium ferroalloy for molten steel deoxidization desulfuration and alloying and preparation method thereof

The present invention discloses one kind of Al-Mg-Fe alloy for deoxidizing and desulfurizing molten steel. The Al-Mg-Fe alloy is produced through special pressure working, rather than smelting in a common induction furnace. It is one kind of energy-saving high purity alloy with alloy recovering rate as high as 100 %, no pollution and capacity of lowering steel deoxidizing and desulfurizing cost. It is suitable for deoxidizing and desulfurizing molten steel for making different steel products.

Owner:赵宇

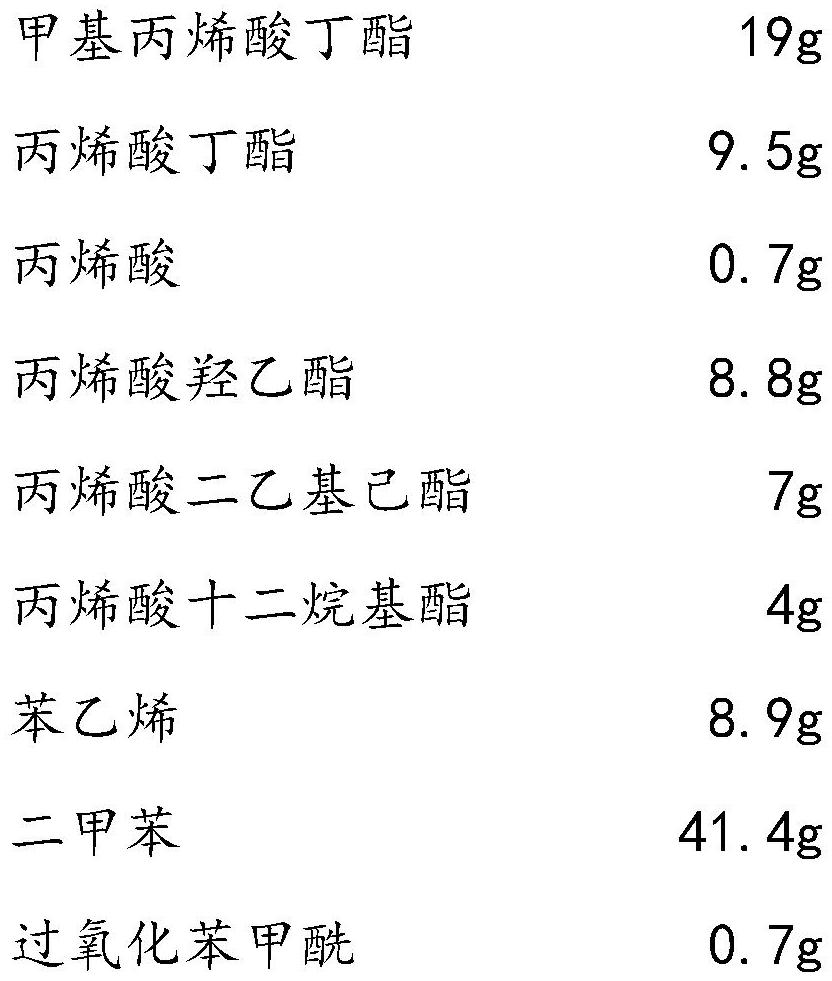

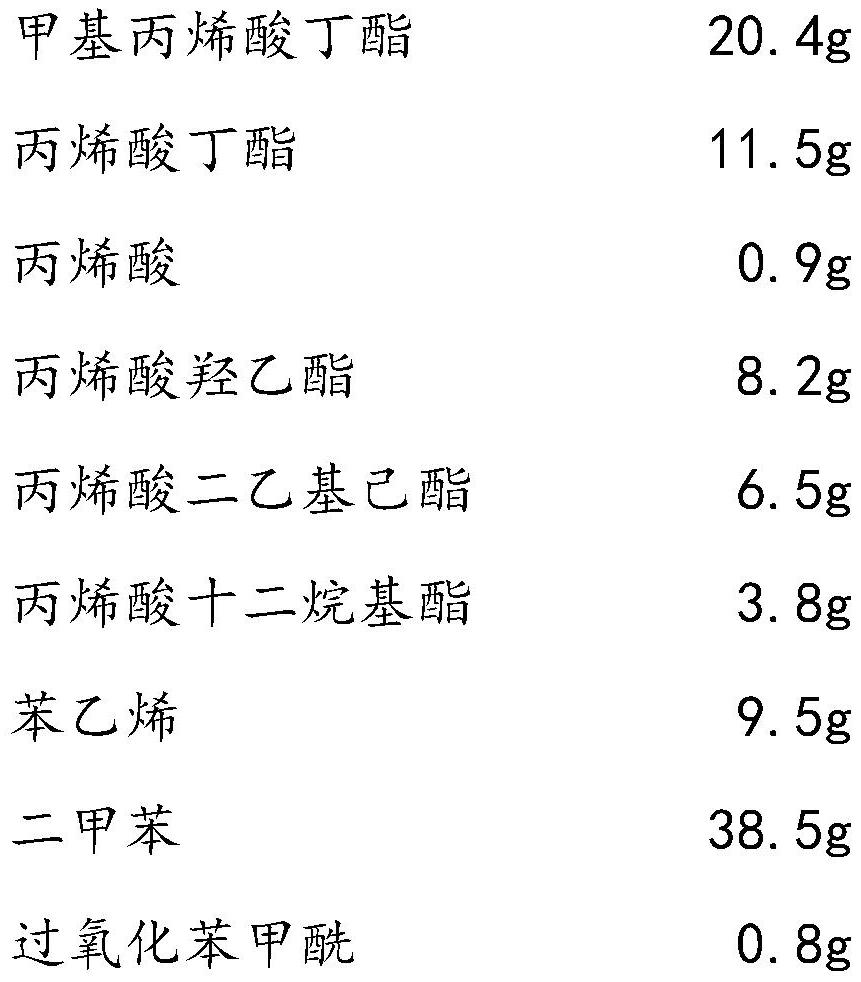

Methyl methacrylate (MMA) floor coating capable of rapidly solidifying

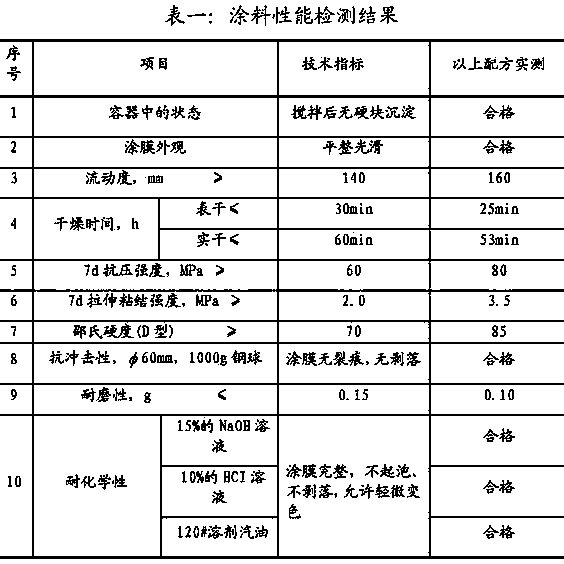

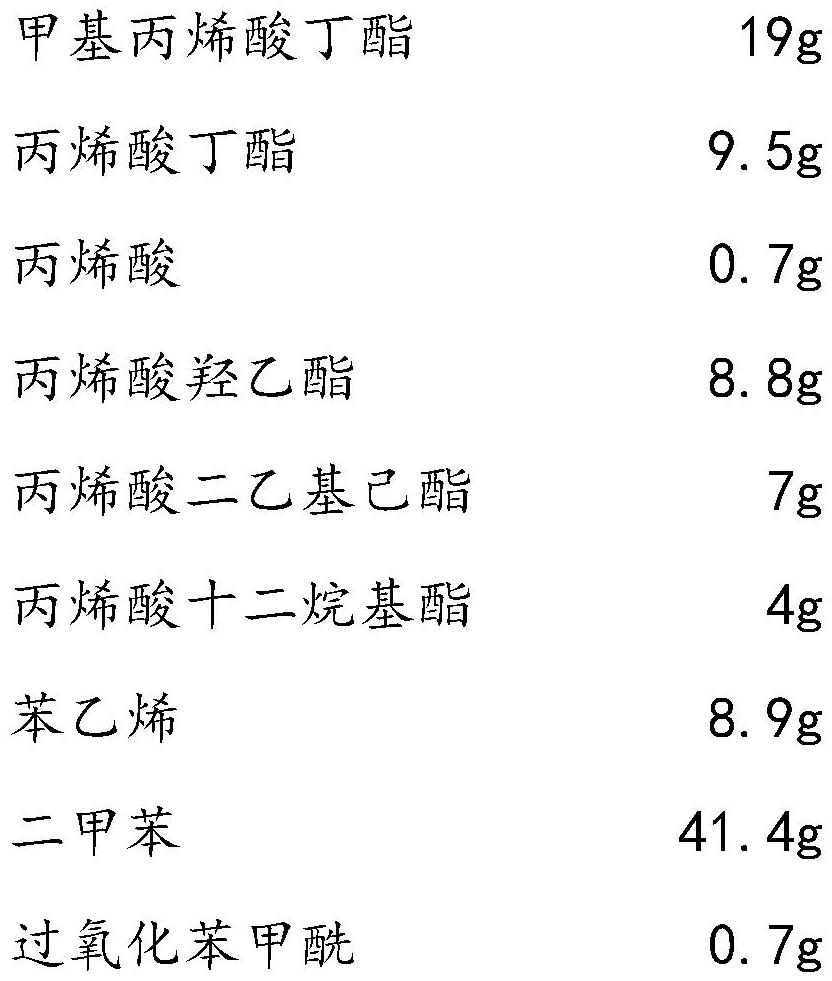

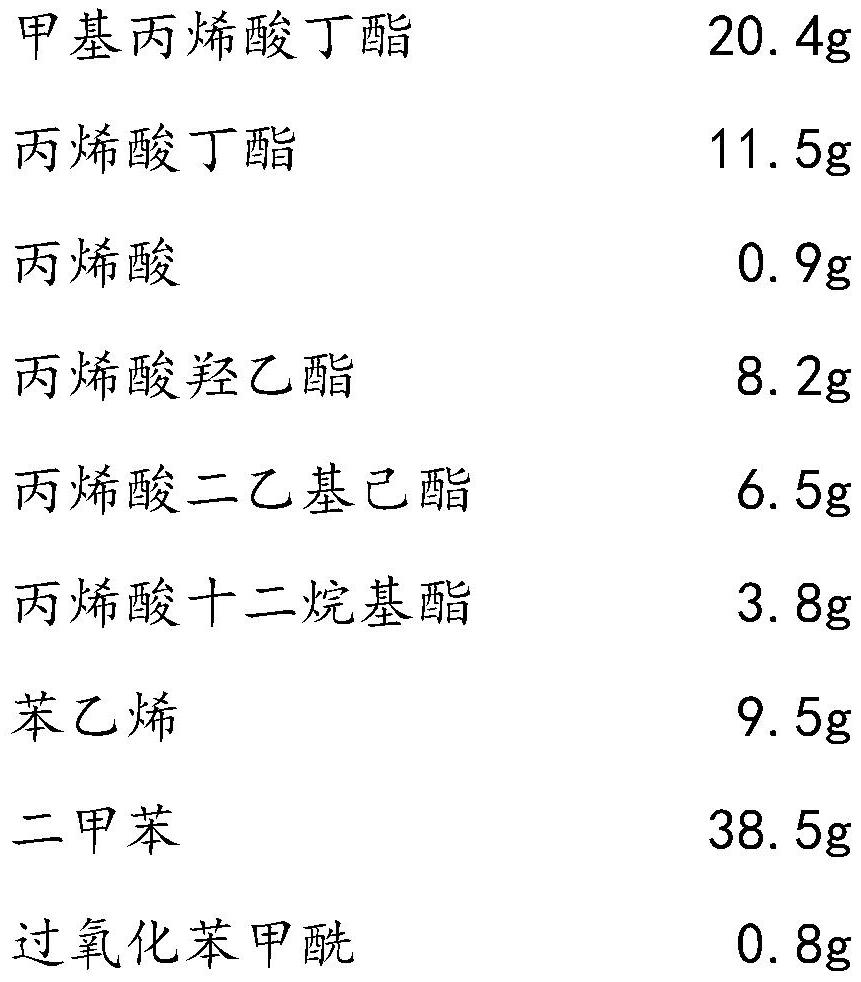

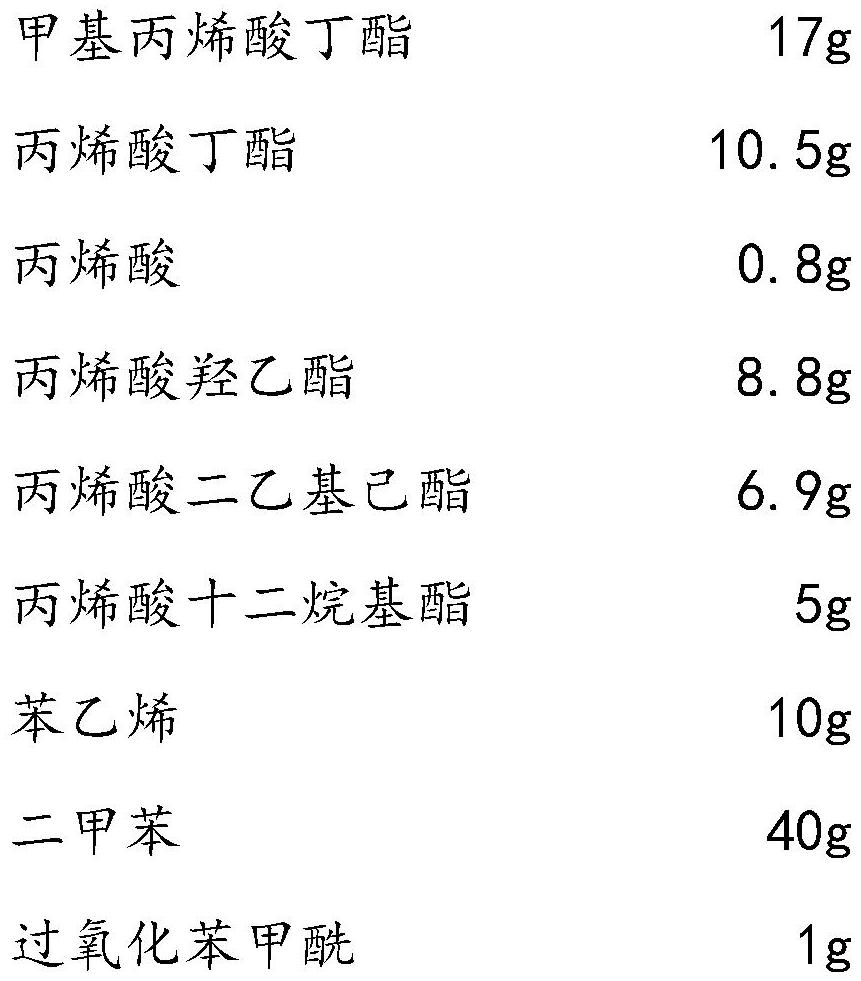

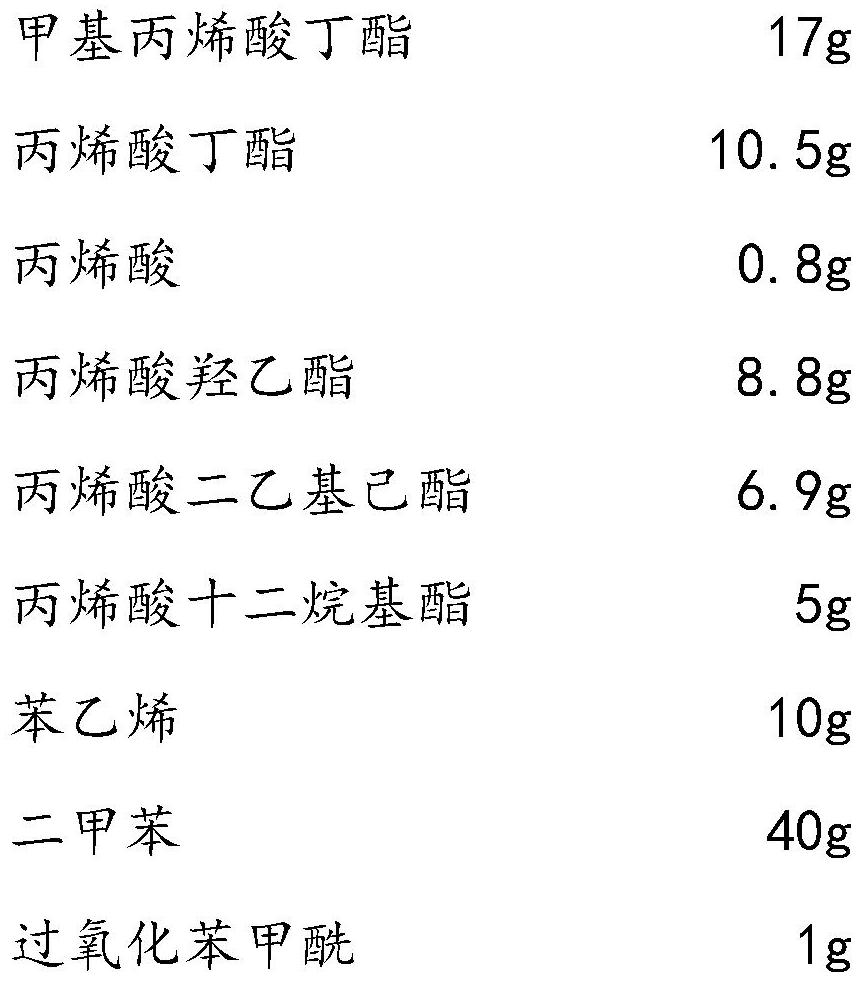

The invention relates to a methyl methacrylate(MMA) floor coating capable of rapidly solidifying. The methyl methacrylate(MMA) floor coating capable of rapidly solidifying can be prepared by two steps. First of all, according to a certain proportion, methyl methacrylate(MMA), butyl acrylate (BA), acrylic acid (AA) and benzoyl peroxide (BPO) are put into a reactor provided with a thermometer, a condenser and a stirrer for water bath heating to prepare an acrylate prepolymer for standby use; then at room temperature, a proper amount of the acrylate prepolymer is dissolved and diluted with a certain amount of MMA and BA, talcum powder, liquid wax, an auxiliary agent, an initiator and a solidifying accelerator are added, and fully stirred to obtain the floor coating, and the floor coating is prepared on site during construction, and can solidify 1 hour after the pavement. The MMA floor coating is short in solidifying time, less affected by temperature, excellent in performance, green, environmentally friendly, and wide in adaption field.

Owner:HARBIN UNIV OF SCI & TECH

Inorganic foaming filling and reinforcing composition for coal mine as well as using method and application thereof

ActiveCN104446624AResolution timeSolve the non-plasticUnderground chambersMaterial fill-upCoalMaterials science

The invention provides an inorganic foaming filling and reinforcing composition for a coal mine as well as a using method and application thereof. The inorganic foaming filling and reinforcing composition for the coal mine can be used as a novel safe plugging and reinforcing material, is especially suitable for plugging and reinforcing of the coal mine, and is the best water-proof, fire-proof, gas-proof, collapse-proof and accident-proof material.

Owner:廊坊坐城矿用材料有限公司

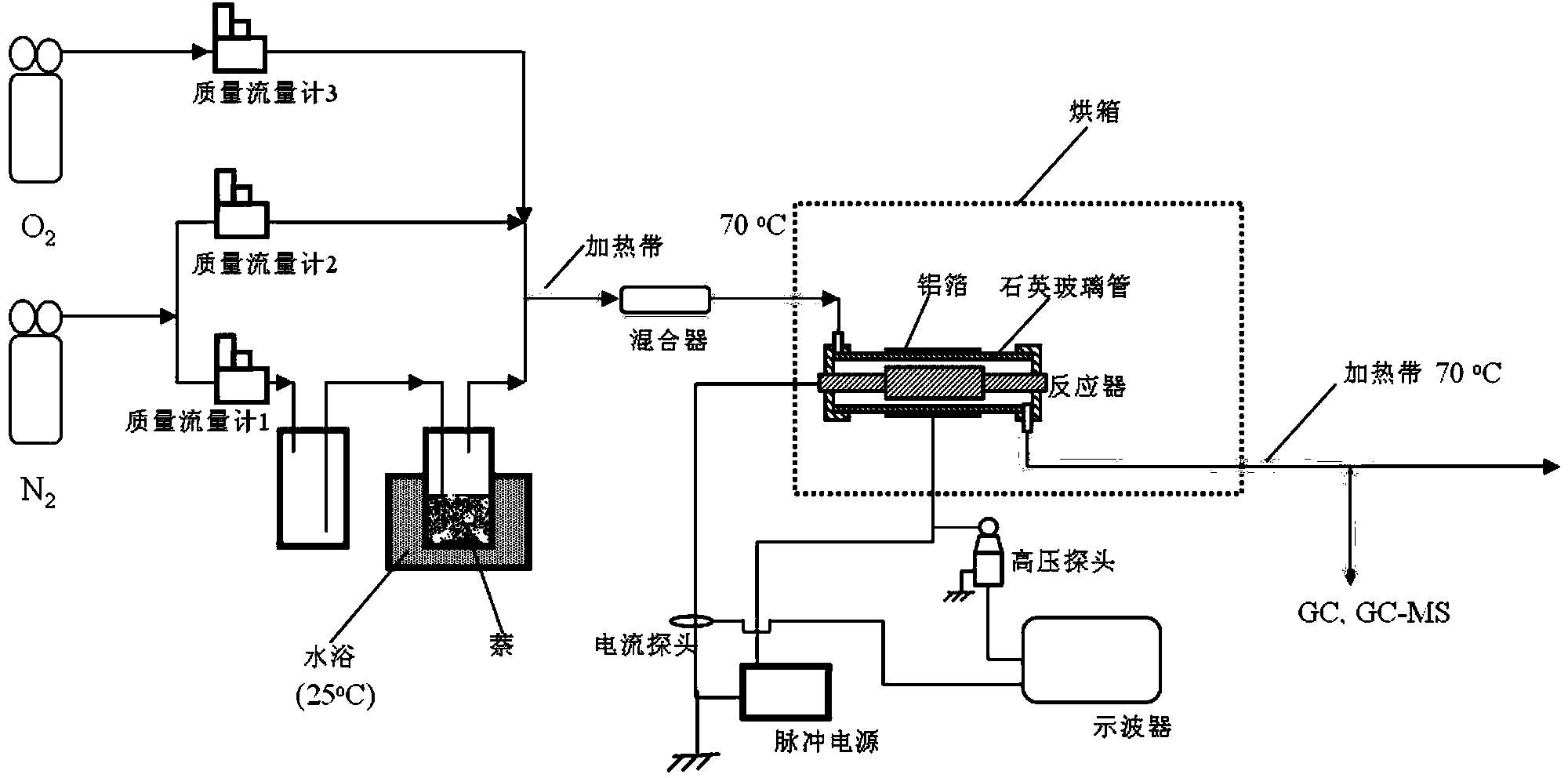

Preparation method for catalysis/adsorption material by taking kieselguhr as carrier

InactiveCN104226240AExtended stayHigh degree of oxidationOther chemical processesDispersed particle separationGlass fiberAlcohol

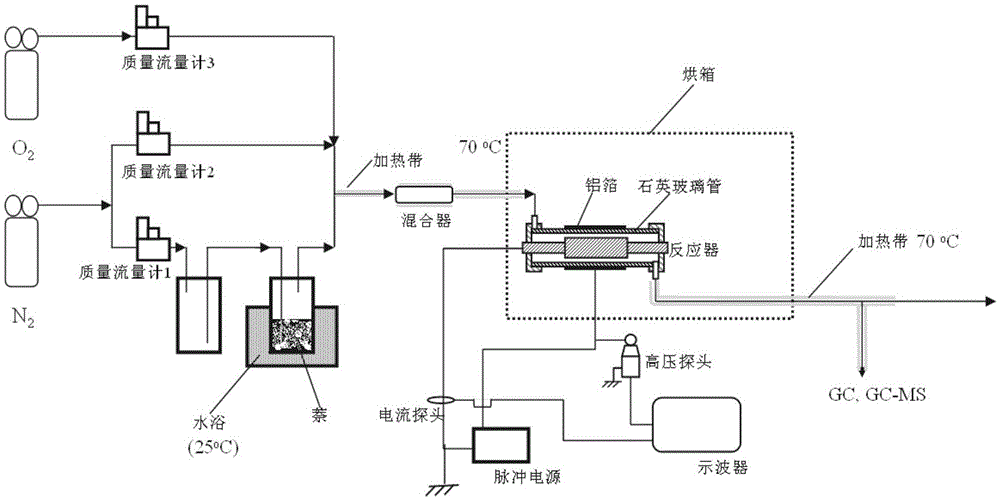

The invention discloses a preparation method for a catalysis / adsorption material by taking kieselguhr as a carrier. The preparation method comprises the following steps of adding 15-20 parts of absolute ethyl alcohol into 1 part of purified kieselguhr, then adding 1-3 parts of a metal compound, 0.1-0.3 part of aluminum oxide, 0.1-0.3 part of glass fibers, 0.02-0.04 part of nitric acid and 5-7 parts of deionized water in sequence under magnetic stirring for mixing and stirring; performing centrifugal washing on obtained substances by the deionized water; and drying washed ore pulp at first, and then calcining the ore pulp, thus obtaining the catalysis / adsorption material. The catalysis / adsorption material prepared by the method disclosed by the invention can prolong the retention time of organic pollutants in a reactor by using the adsorption capacity of kieselguhr, and loaded metal oxide can generate a relatively good catalytic oxidation effect in a discharging process, so that the oxidization degree of organic pollutants is increased.

Owner:杭州最清环保科技有限公司 +1

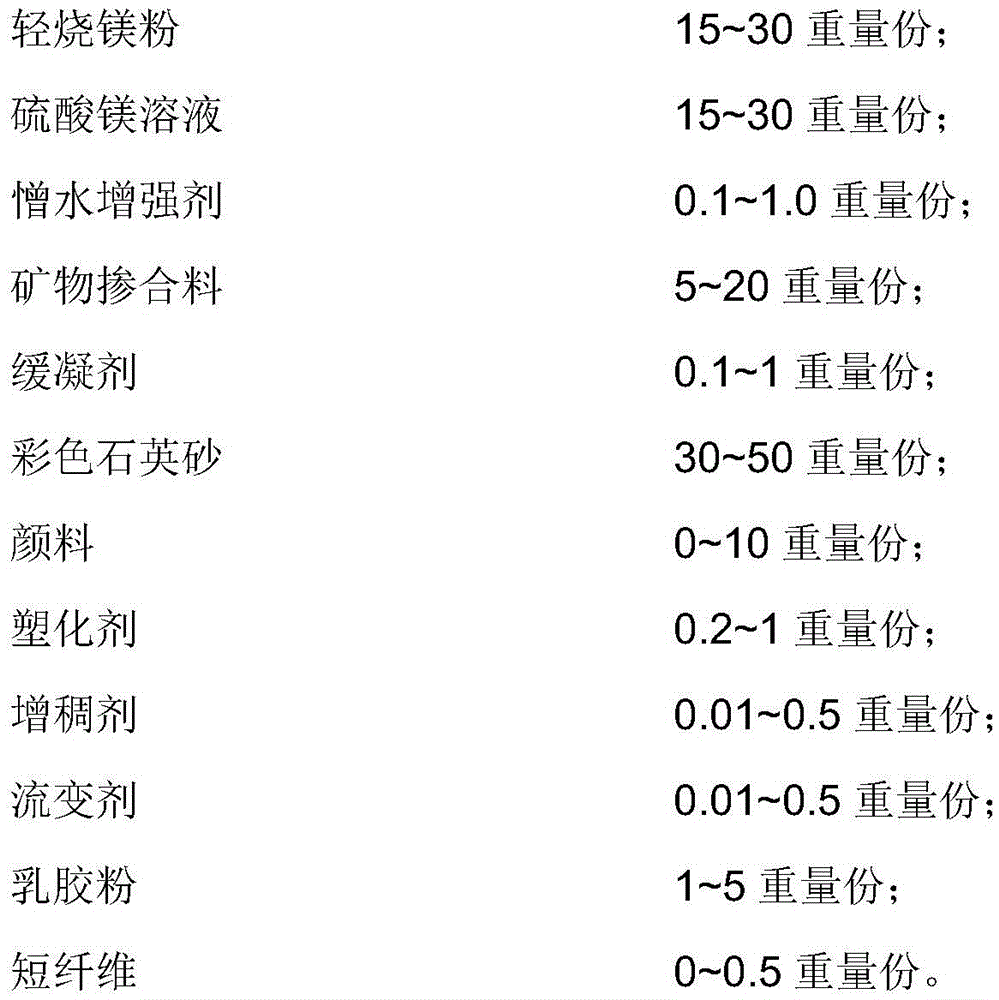

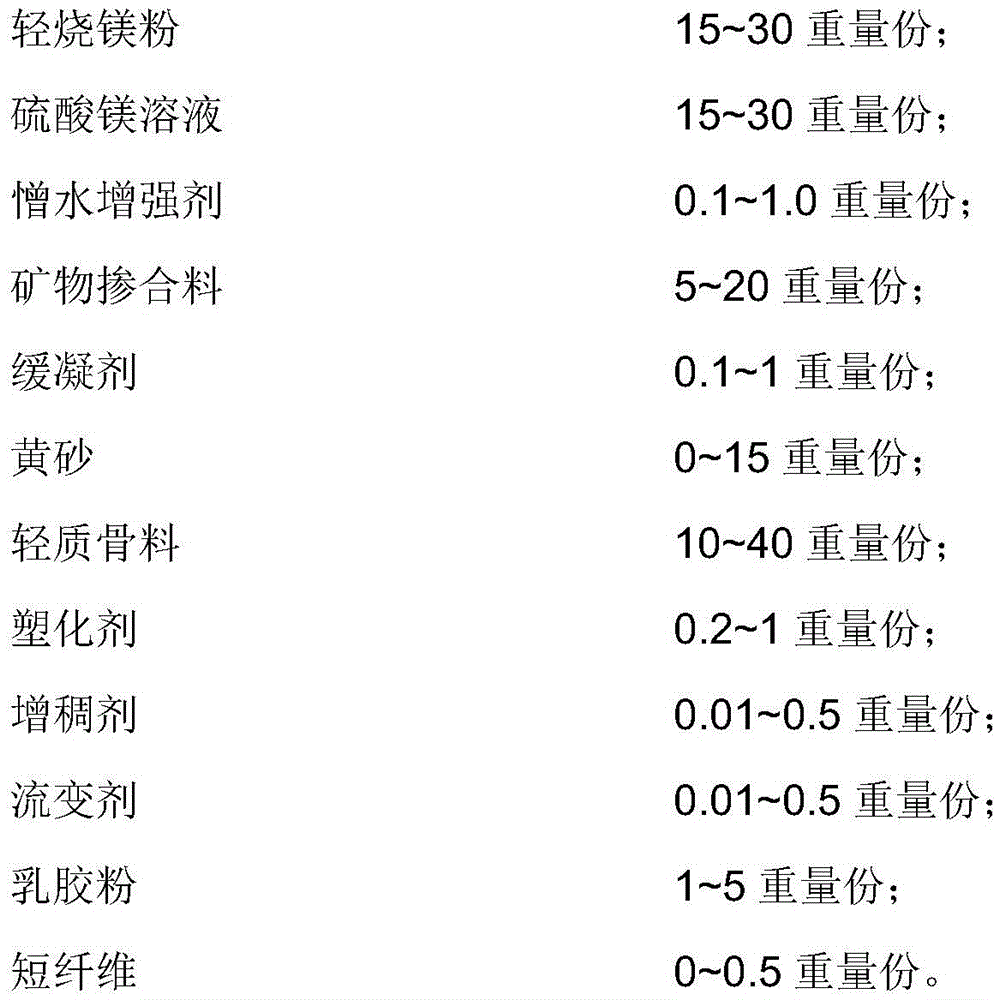

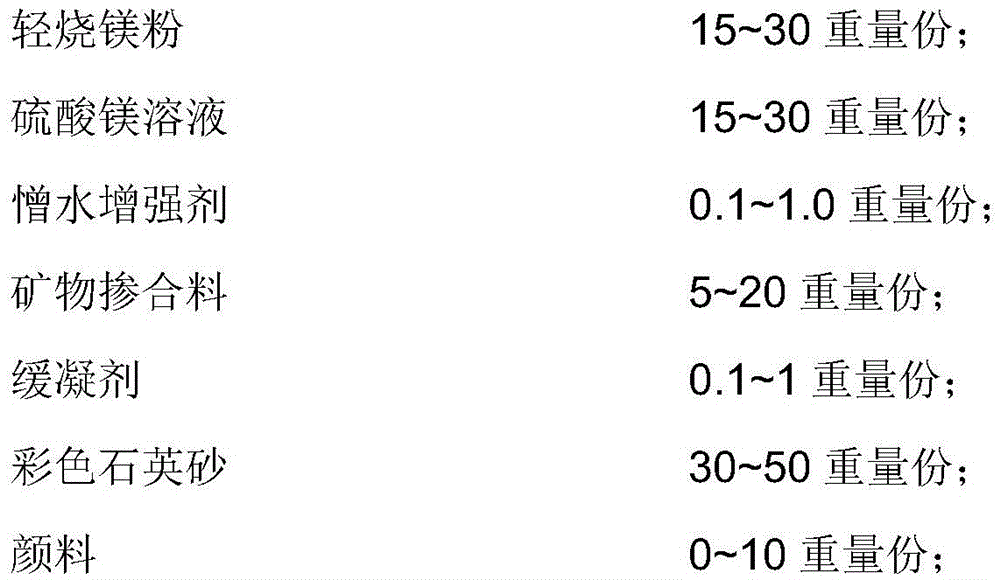

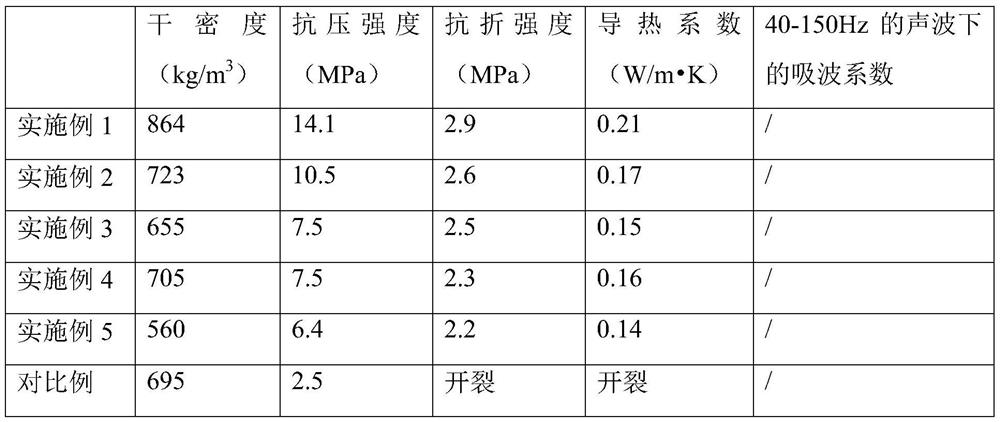

Environmentally-friendly fire-resistant magnesium oxysulfate decorative material and preparation method thereof

InactiveCN105601246AGood physical propertiesExcellent thermal insulation, sound insulation and fire preventionEnvironmentally friendlyMagnesium

The invention aims at overcoming the shortcomings of environmentally-friendly fire-resistant magnesium oxysulfate stone materials and providing an environmentally-friendly fire-resistant magnesium oxysulfate decorative material and a corresponding preparation method thereof. The environmentally-friendly fire-resistant magnesium oxysulfate decorative material has a good appearance effect, good physical and chemical properties, excellent heat preservation and insulation properties and sound-and-fire proofing performance, meanwhile has good weather-resistant performance, has very strong durability and color stability in various severe climatic environments, is not pulverized, does not shed and is difficult to discolor.

Owner:SHANGHAI APE STONE

Method for producing granular potassium chloride

InactiveCN102690143AParticle roundingFlat surfacePotassium fertilisersFertilizer mixturesChloride potassiumFertilizer

The invention relates to a method for producing granular potassium chloride and belongs to the technical field of manufacture of fertilizers. The method comprises the specific steps of preparation of a binder and pelleting of powdered potassium chloride; adding polyacrylic emulsion, whose solid content is 53%, in water in a container to uniformly agitate the polyacrylic emulsion and water, then sequentially adding benzyl alcohol, ethylene glycol, sodium benzoate and polyvinyl butyral in proportions, and fully and uniformly agitating the mixture. The process may be batch production or continuous production. If the process is batch production, the powdered potassium chloride is added to a disk pelletizer, and the binder is sprayed into rotary materials in proportion and pelletized into balls. The product is prepared by drying, cooling and sieving. If the process is continuous production, the powdered potassium chloride is added to a disk or rotary drum granulator; the binder is continuously sprayed into the rotary material in proportion and pelletized into balls, and the product is prepared by drying, cooling and sieving. The product is round and intact in particles, smooth in surface and high in strength. The product can be used as a bulk-blended fertilizer material. The top potassium oxide content of the product can be up to 59.5%.

Owner:HENAN LEEF FERTILIZER

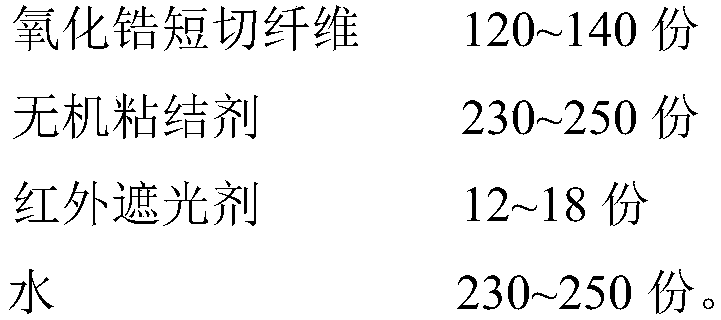

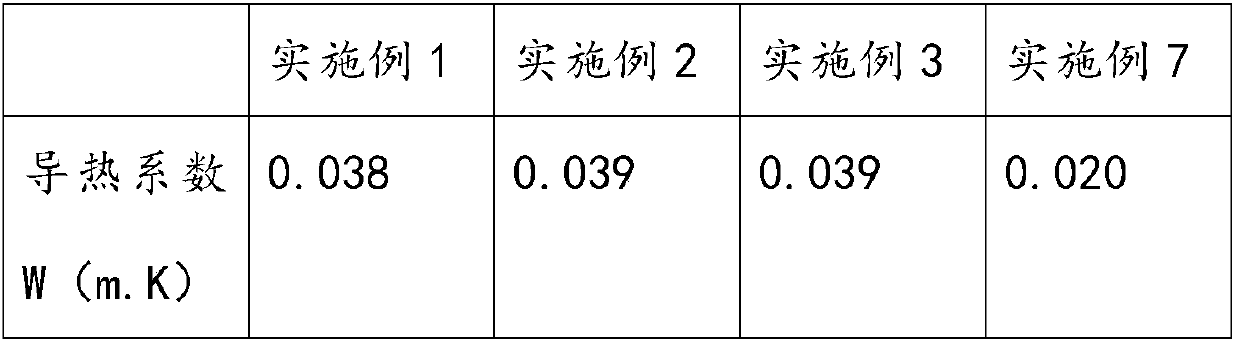

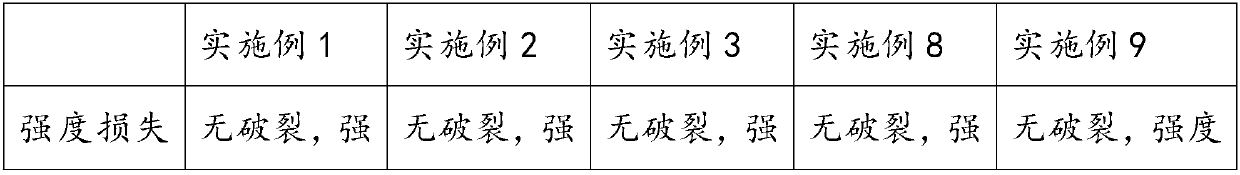

Improved zirconium oxide fiber plate and preparation method thereof

The invention discloses an improved zirconium oxide fiber plate, which is characterized in that on the basis of the existing fiber plate preparation process, through the addition of inorganic bondingagents and infrared light-screening agents, the zirconium oxide fiber plate with high pressure-resistant intensity and low high-temperature heat conduction rate can be prepared, wherein the inorganicbonding agent is mainly basic silicon sol; the infrared light-screening agent is mainly rutile type titanium dioxide or potassium hexatitanate whiskers. The density of the prepared zirconium oxide fiber plate is 0.6 to 0.8 g / cm<3>; the room temperature pressure-resistant intensity is 3.0 to 5.0 MPa; when the thickness of the sample is 1 cm, in the stable state, the hot surface temperature is 1000DEG C; the cold surface temperature is 270 to 300 DEG C; the hot surface temperature is 1200 DEG C; the cold surface temperature is 310 to 330 DEG C.

Owner:南京理工宇龙新材料科技股份有限公司

Preparation method of spherical lithium-sulfur battery cathode material, and product

InactiveCN109378466AMade quicklyReduce manufacturing costPositive electrodesLi-accumulatorsAdhesiveLithium–sulfur battery

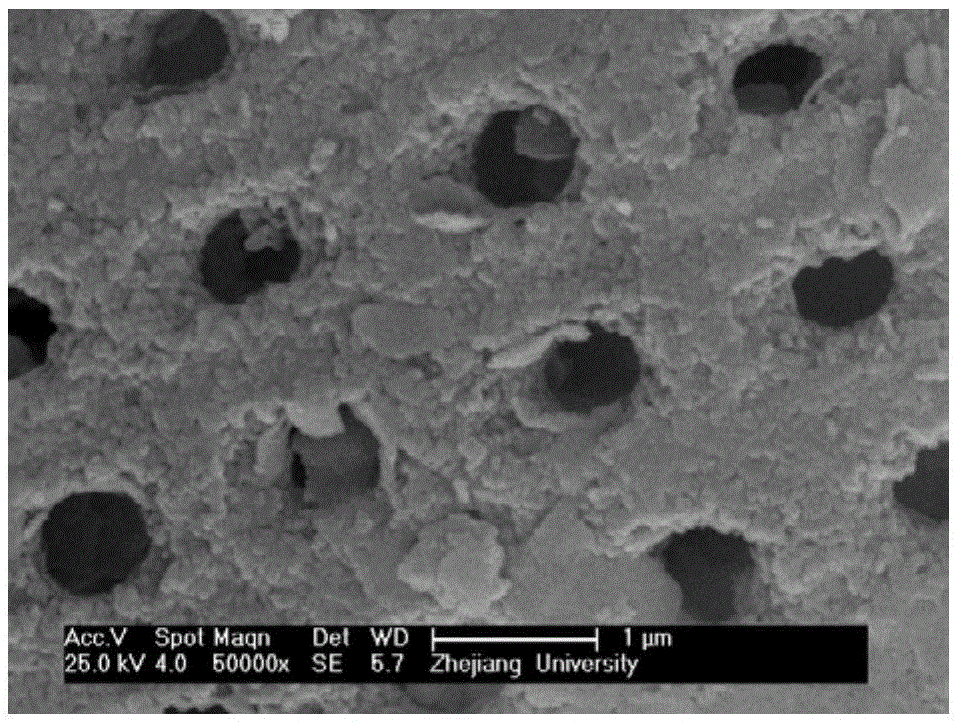

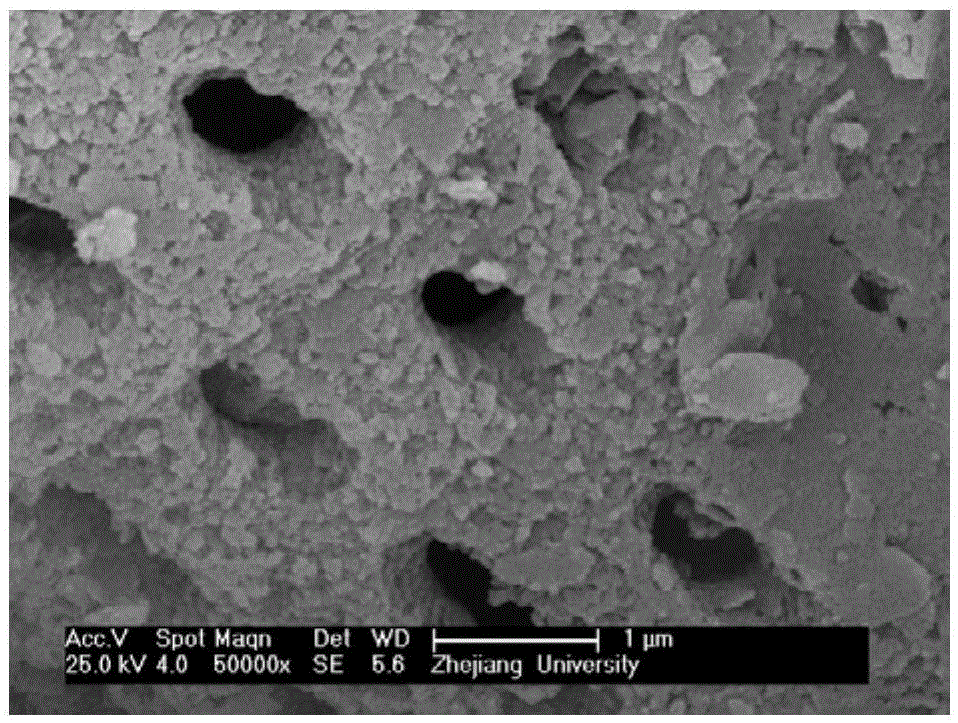

The invention discloses a preparation method of a spherical lithium-sulfur battery cathode material, and further discloses the spherical lithium-sulfur battery cathode material prepared through the method. The preparation method comprises the steps: a sulfur precursor, a carbon source, an adhesive and a polar adsorption additive are dispersed into water, after even stirring, spray drying is conducted, and the monodisperse spherical cathode material is prepared. The spherical lithium-sulfur battery cathode material is constituted by sulfur, a carbon carrier, a polymeric additive and the polar adsorption additive; and the spherical lithium-sulfur battery cathode material is presented to be a spherical particle or a monodisperse spherical particle under a scanning electron microscope, whereinthe spherical particle is evenly distributed with the sulfur and formed by carbon nano tubes which are mutually staggered and entangled, and the monodisperse spherical particle is evenly distributedwith the sulfur and formed by graphene sheets which are mutually staggered and entangled. The preparation method is simple, the lithium-sulfur battery cathode material can be quickly prepared, the prepared spherical lithium-sulfur battery cathode material has the high adsorption capacity and electrical conductivity, and monodispersity, and can be effectively loaded with the sulfur, and a formed conductive network is practically available.

Owner:HENAN NORMAL UNIV

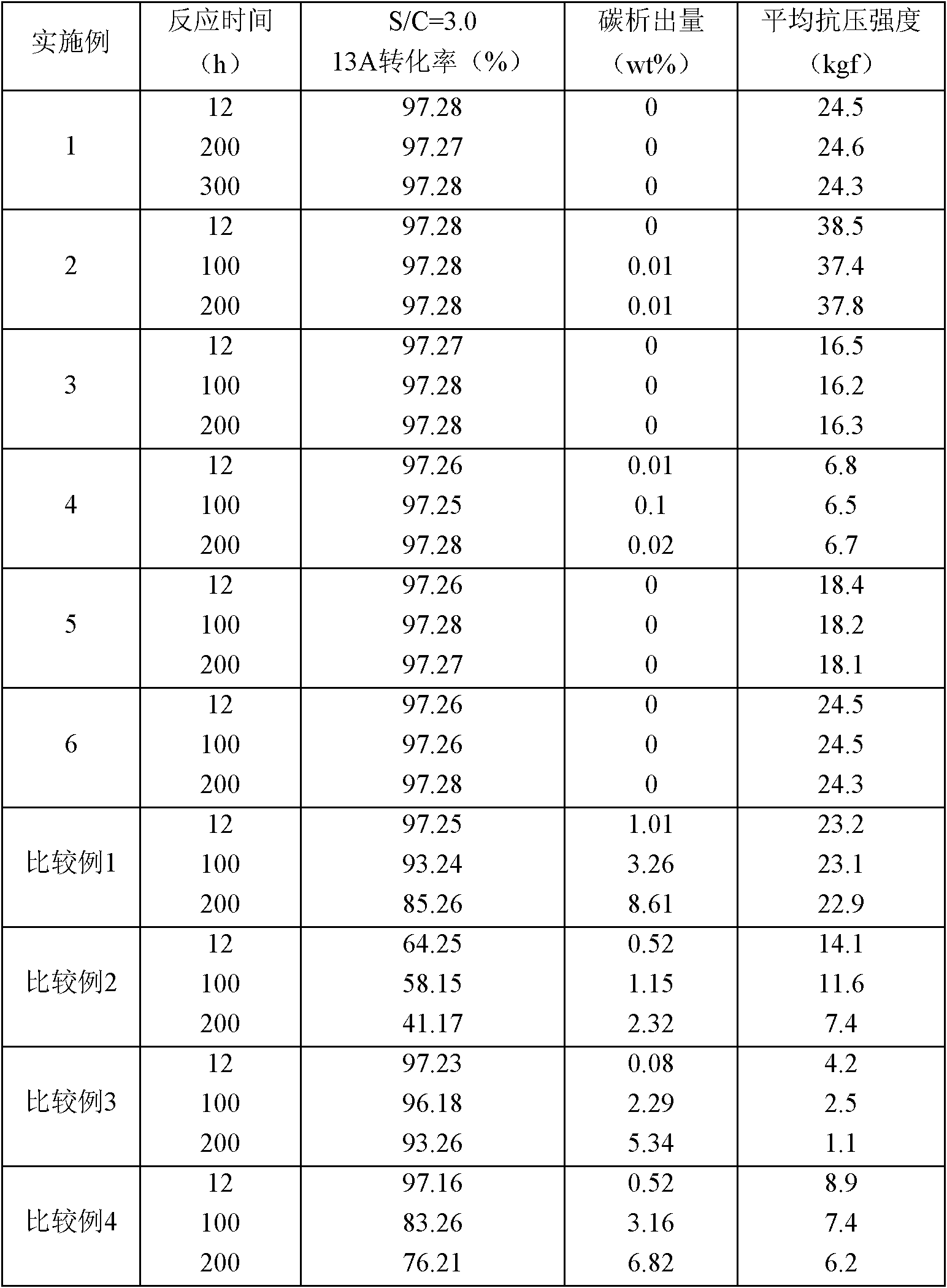

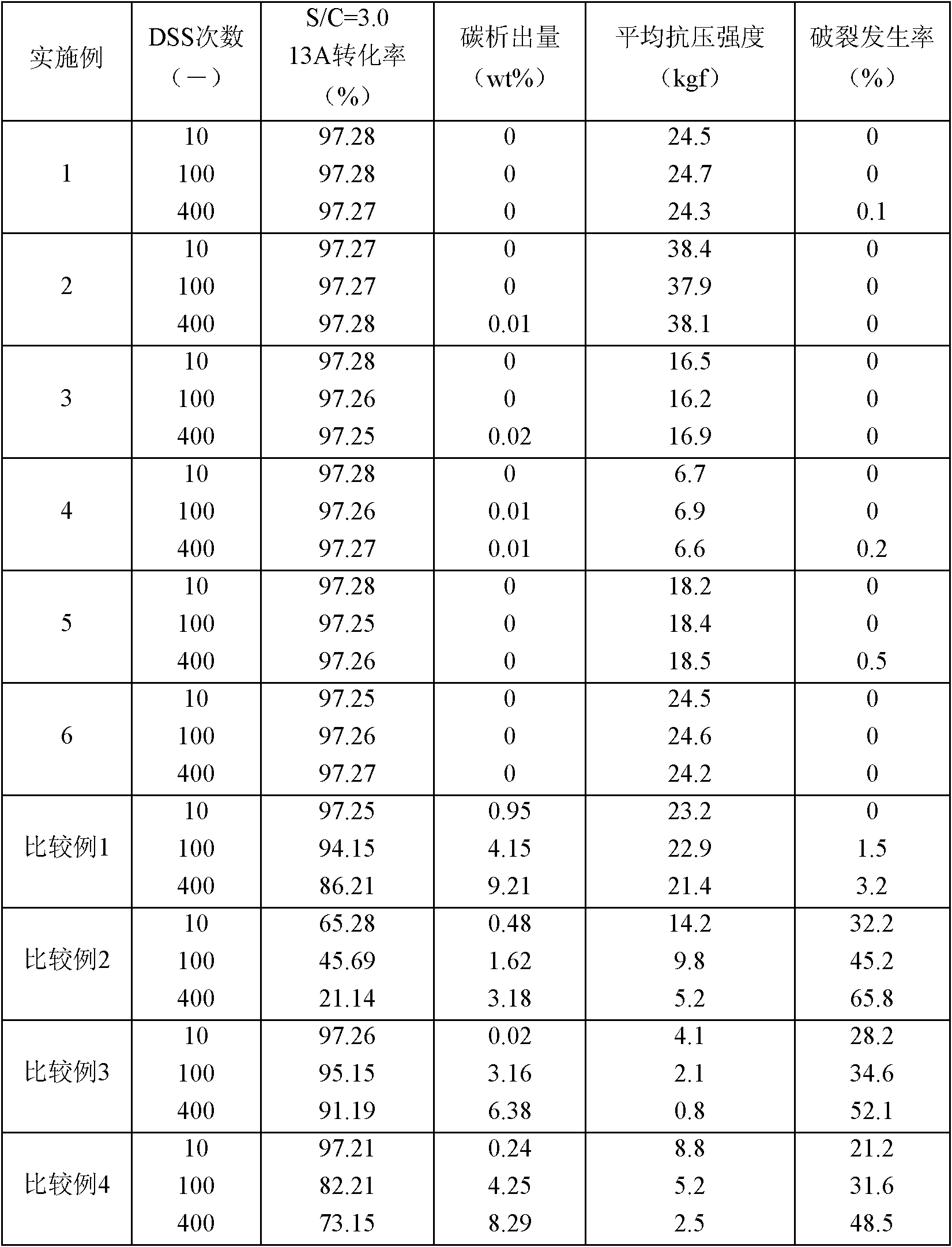

Porous catalytic object for decomposing hydrocarbon and process for producing same, process for producing hydrogen-containing mixed reformed gas from hydrocarbon, and fuel cell system

ActiveCN102574103AIncrease contact areaIncrease the areaHydrogenMolecular sieve catalystsHigh resistanceDecomposition

Disclosed is a porous catalytic object for decomposing hydrocarbons which comprises a porous composite oxide and nickel metal having a particle diameter of 1-25 nm, the porous composite oxide at least containing magnesium and / or calcium and further containing aluminum, the porous catalytic object being characterized by having an average compressive strength of 5 kgf or higher and having a displacement length of 0.05 mm or longer when compressed at a load of 5 kgf. The porous catalytic object is less expensive as a porous catalytic object for decomposing hydrocarbons, has excellent catalytic activity with respect to the decomposition and removal of hydrocarbons, has excellent resistance to poisoning by sulfur, has high resistance to caulking even under low-steam conditions, has a compressive strength and a displacement length which render the object optimal for DSS operations, and has excellent durability.

Owner:TODA IND

Sintering method for silicon manganese alloy dust

The invention provides a sintering method for silicon manganese alloy dust. According to the method, high temperature resistant coke powder used as a sintering adhesive of manganese mineral powder and dust and a plant fiber serving as combustion improver are sintered at the temperature of 800-1,200 DEG C to obtain massive porous sintered products. The finished product has high mechanical strength, the situations of dusting in the sintering process and massive dust generation in the melting process can be avoided. The sintering method is a good method for treating dust and fine mineral powder in manganese plants, and is low in production cost and high in treatment quality.

Owner:广西敏诚矿业股份有限公司

Composite foamed cement board good in water-resistance property and preparation method of composite foamed cement board

InactiveCN104446262ANot easy to crackGood water resistanceSolid waste managementCeramicwareAluminium saltsSodium silicate

The invention provides a composite foamed cement board good in water-resistance property. The cement board is prepared from the following components in parts by mass: 140-160 parts of silicate cement, 15-20 parts of coal ash, 3-5 parts of gypsum, 0.3-0.5 part of polypropylene fiber, 0.1-0.3 parts of polypropylene fiber, 0.4-0.6 parts of sodium metasilicate, 0.2-0.4 parts of calcium stearate, 0.3-0.5 parts of triethanolamine, 2-3 parts of aluminum sulfate, 0.4-0.6 parts of magnesium chloride, 0.1-0.3 parts of sodium nitrate, 0.8-1.2 parts of a foaming agent, 0.3-0.5 parts of a foam stabilizer, 3-6 parts of a water repellent and 125-135 parts of water. The composite foamed cement board good in water-resistance property, disclosed by the invention, is high in tensile strength and compressive strength; during exterior wall thermal insulation construction, the composite foamed cement board can be used for preventing the exterior wall from cracking, and is good in water-resistance property, free from pulverization in water, consistent in pore size in the foamed board and excellent in heat insulation property.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Smelting method of calcium-silicon alloy

InactiveCN101984102AEmission reductionTo achieve the effect of energy saving and emission reductionSilicon alloyIntermediate frequency

The invention belongs to the technical field of metallurgy, in particular relates to a smelting method of calcium-silicon alloy, comprising the steps of putting the raw materials of ferrosilicon, metallic calcium and crushed aggregates of metallic silicon into an intermediate frequency furnace, and smelting under the temperature of 1250 to 1350 DEG C to obtain the calcium-silicon alloy. Compared with the traditional method, in the invention, the different raw materials and devices are used, thus the carbon dioxide discharge is extremely low during the smelting process, the power consumption is far lower than that of other smelting methods, but the quality is higher. As a result, the smelting method of calcium-silicon alloy achieves the effects of energy conservation and emission reduction, and enhances the product quality of the calcium-silicon alloy.

Owner:ANYANG CITY XINYI ALLOY

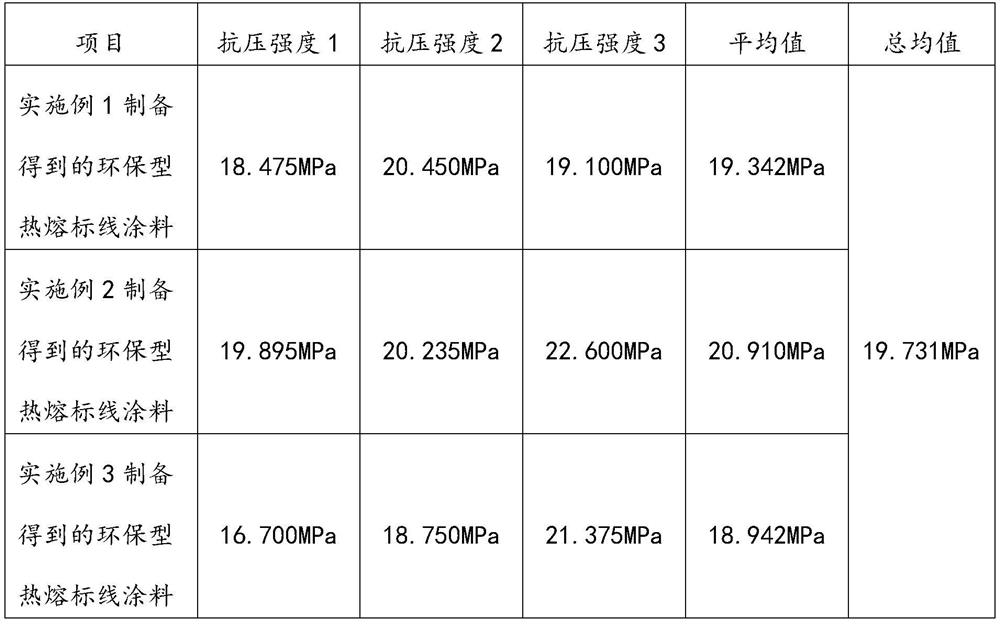

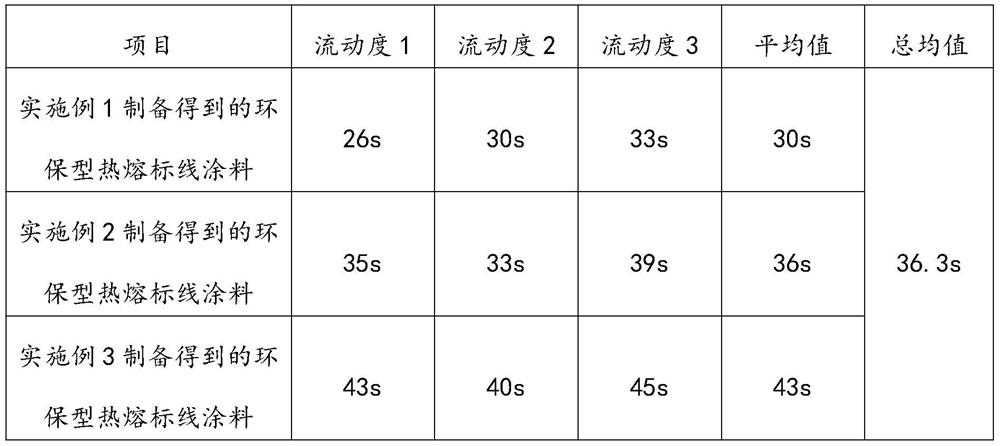

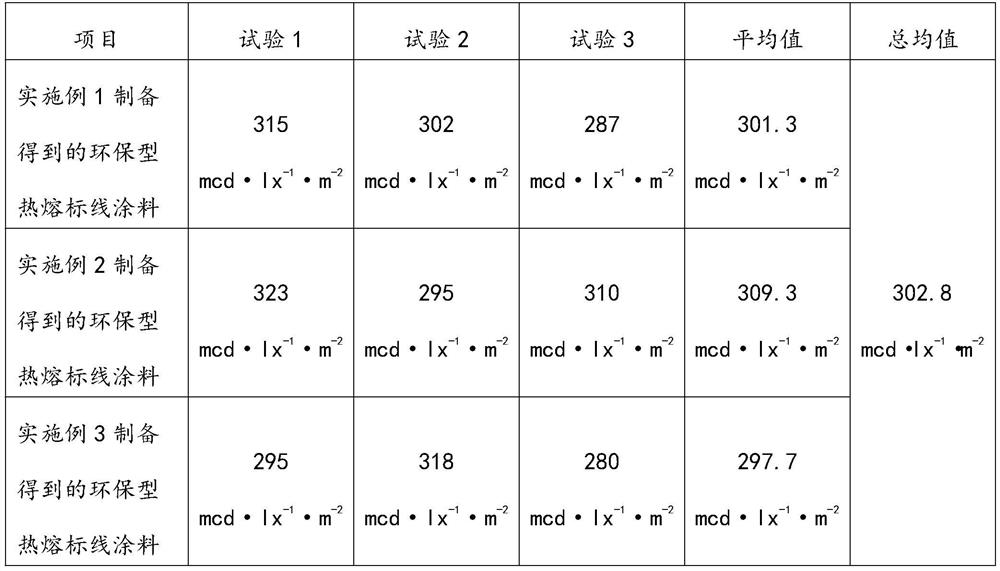

Environment-friendly hot-melt marking coating and preparation method thereof

InactiveCN111635688AImprove liquidityHigh compressive strengthConjugated diene hydrocarbon coatingsReflecting/signal paintsCompressive resistanceNitrile rubber

The invention discloses an environment-friendly hot-melt marking coating and a preparation method thereof, and belongs to the technical field of environment-friendly hot-melt marking coatings. The environment-friendly hot-melt marking coating is prepared from, by weight, 13-15 parts of modified C5 petroleum resin, 6-8 parts of a pigment, 27-29 parts of quartz sand, 26-28 parts of ground calcium carbonate, 1-3 parts of castor oil, 2-4 parts of polyethylene wax, 1-3 parts of powdered acrylonitrile-butadiene rubber and 20-23 parts of glass beads. The invention also discloses a preparation methodof the environment-friendly hot-melt marking coating. The environment-friendly hot-melt marking coating has the advantages of good fluidity, high compressive strength, short drying time, high softening point, good flexibility, water resistance, acid and alkali resistance, good light reflection performance and the like.

Owner:杨三强 +5

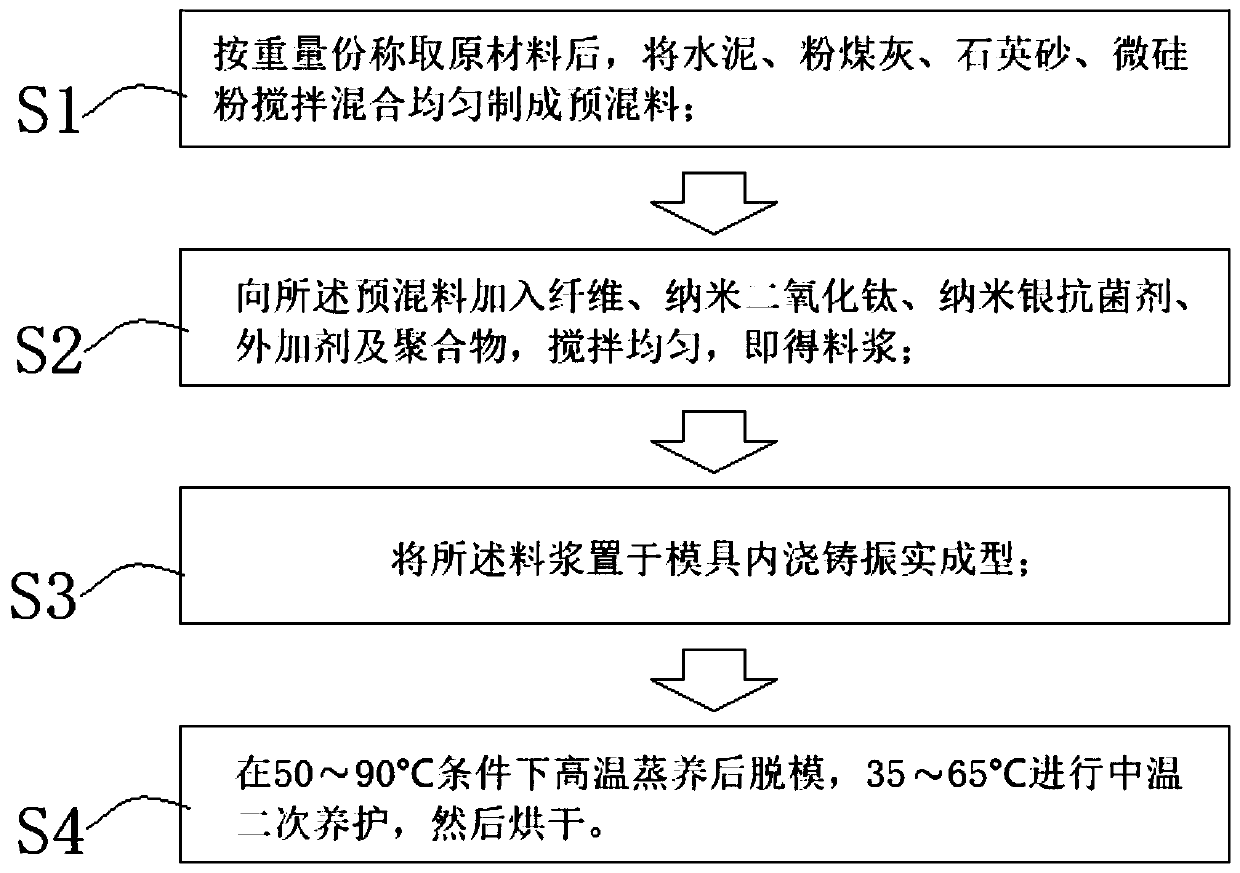

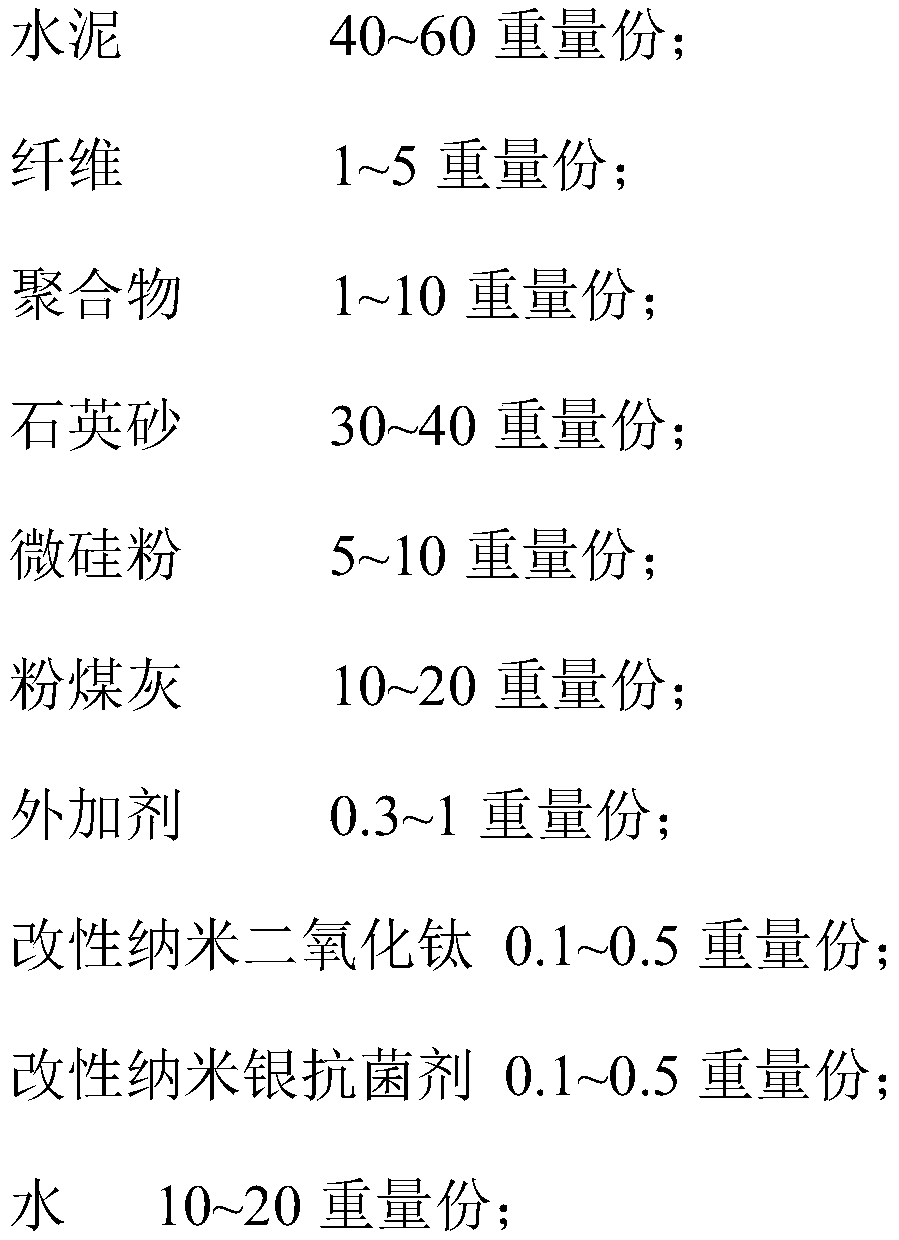

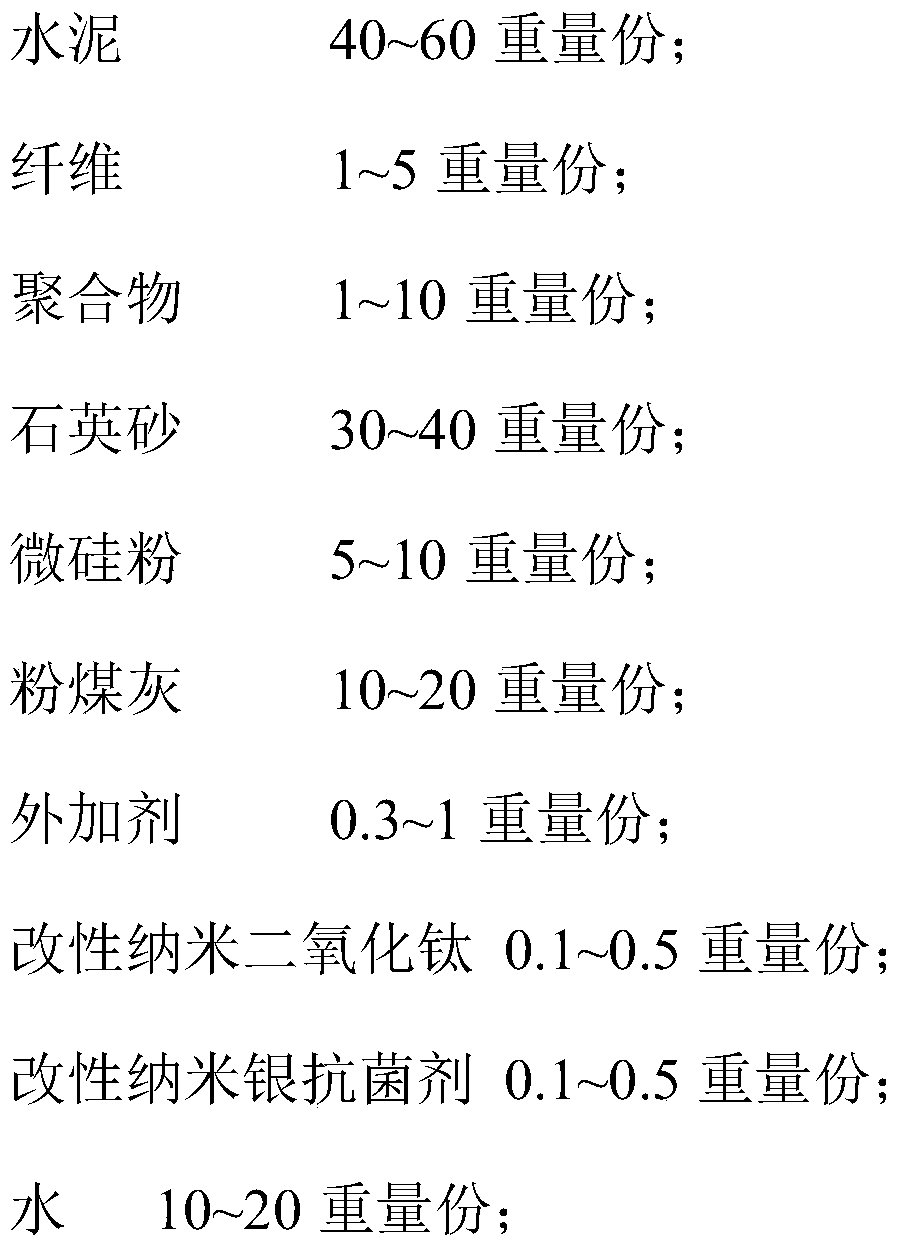

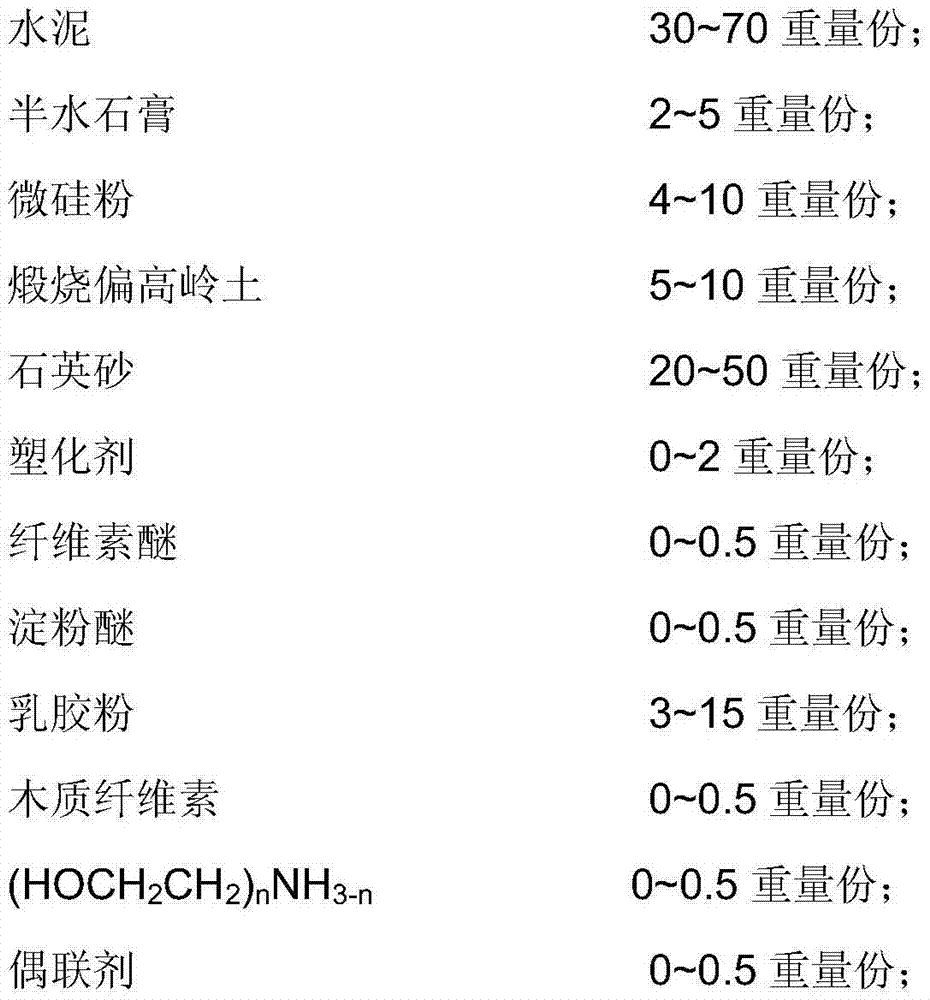

Modified decorative concrete material and preparation method thereof

ActiveCN110903064AGood antibacterial propertiesPrevent mildewSolid waste managementFiberNitric oxide

The invention relates to a modified decorative concrete material and a preparation method thereof. The material comprises cement, fiber, polymer, quartz sand, silica fume, fly ash, an additive, modified nano titanium dioxide and a modified nano silver antibacterial agent. The concrete material has the beneficial effects that through the addition and application of the modified nano titanium dioxide, the concrete material is combined with nitric oxide in the sun and converted into harmless nitrate, and nitric oxides in air can be cleaned; through addition and application of the modified nano-silver antibacterial agent, the concrete material has a very good antibacterial property, and mildew spots and pollution resistance on the surface of concrete can be effectively prevented.

Owner:上海睿申景观工程有限公司

Smelting method for silicon calcium alloy

The invention discloses a smelting method for silicon calcium alloy. First raw materials including 40 to 60 parts of silicon iron powder and 15 to 25 parts of metallic silicon powder are fed into a medium frequency furnace, and after the temperature is increased to 1200 to 1400 DEG C, smelting is conducted for 25 to 30 minutes; and an obtained melt liquid is injected into a transfer package containing 25 to 35 parts of metallic calcium grains, and then is poured into a mould and cooled to the ordinary temperature to be crushed, so as to obtain finished silicon calcium alloy. The invention has the advantages as follows: no carbon-based material is used in the raw materials, so that the emission amount of carbon dioxide is low and pollution to the atmospheric environment is avoided; and about 400-degree electricity is consumed for producing one ton of finished silicon calcium alloy, so that the electrical consumption is far lower that that of other smelting methods. In the finished silicon calcium alloy, the contents of silicon and calcium are greatly increased, so that the finished silicon calcium alloy has higher quality, can not be pulverized, and can greatly improve the quality of steel products when used as an additive.

Owner:郑州万隆冶金炉料有限公司

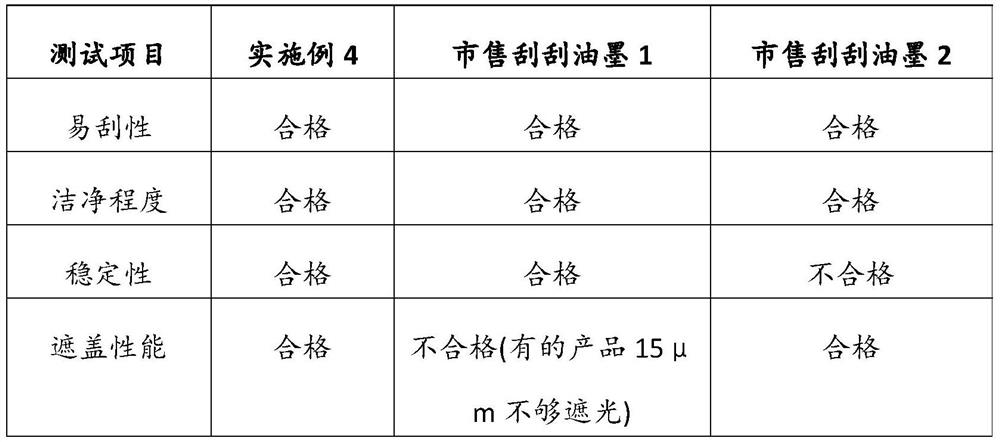

Scraping ink as well as preparation method and application thereof

The invention provides scraping ink as well as a preparation method and application thereof. The scraping ink is prepared from the following raw materials: color paste, water-based resin, a leveling agent, a thickener and an antifoaming agent. According to the scraping ink, the water-based scraping ink is prepared by compounding the color paste, the water-based resin, the leveling agent, the thickener and the antifoaming agent, so that the scraping ink is green and environment-friendly, and can be suitable for various printing modes. The scraping layer obtained by printing is good in covering property, still has excellent covering property even if the thickness is as thin as 1-5 microns, and meets the national standard and cold light source irradiation requirements. Besides, the prepared scraping layer is balanced between wear resistance and easy scraping performance, and is not easy to wear and fall off in production and circulation links while being easy to scrape. When the prepared scraping layer is used for scraping, the ink is agglomerated and cannot be pulverized, and the cleaning degree is high. The performance of the scraping ink is stable, and the situation that ink is obviously difficult to scrape off due to long storage time is avoided.

Owner:허난구오안일렉트릭머터리얼컴퍼니리미티드

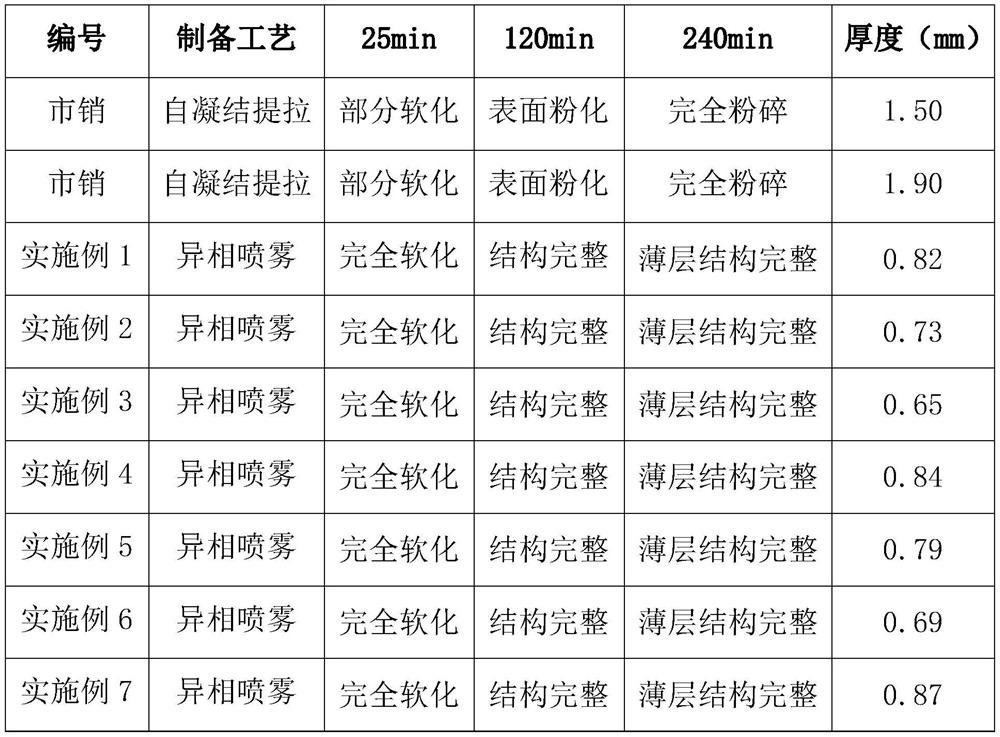

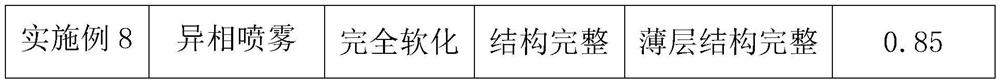

Process for preparing thin-layer artificial meat by heterogeneous spraying method

InactiveCN112273528AImprove toughnessGreat tasteFood coatingVegetable proteins working-upBiotechnologySalt solution

The invention relates to processing of artificial meat food, and belongs to the field of food processing. The invention relates to a process for preparing thin-layer artificial meat by a heterogeneousspraying method, which comprises the following steps: preparing a protein emulsion and a gel aqueous solution into a solidification base phase, and preparing a condensed ionic salt I solution and a thickener into an induction phase; atomizing the induction phase, spraying the induction phase onto the surface of the solidification base phase, inducing to form a condensation film on the surface ofthe solidification base phase, and transferring the condensation film into a curing solution for curing to obtain the thin-layer artificial meat. The prepared thin-layer artificial meat product can becompletely softened after being soaked in water for a short time, and the structural toughness of the thin-layer artificial meat product can still be effectively kept even if the thin-layer artificial meat product is soaked for 240 min for a long time, and the thin-layer artificial meat product cannot be pulverized. The thickness of the thin-layer artificial meat prepared by the process is controlled to be less than 1mm, and the taste and the toughness of the thin-layer artificial meat are obviously improved compared with those of the existing commercially available products.

Owner:珠海市澳加联盈生物科技有限公司 +1

Acrylic acid flexible anticorrosive primer and preparation method thereof

ActiveCN112680078AGood weather resistanceGood construction performanceAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceCrazing

The invention provides an acrylic acid flexible anticorrosive primer and a preparation method thereof. The primer is composed of a component A and a component B according to a weight part ratio of 100: (15-20), wherein the component A is prepared from flexible acrylic resin liquid with a solid content of greater than 45 percent, a dispersing agent, a leveling agent, an adhesion promoter, an ultraviolet light absorber, a diluent, titanium dioxide, zinc yellow, talcum powder, zinc phosphate, mica powder, light calcium carbonate and bentonite; and the component B is an elastic isocyanate resin liquid with a solid content of more than 90%. The primer can cover telescopic vibration cracks generated during equipment operation due to elastic modulus difference among various base materials, and has elongation at break of larger than or equal to 100%, tensile strength of larger than or equal to 10 Mpa, and an excellent anti-corrosion function.

Owner:天津灯塔涂料工业发展有限公司

Antioxidation coating for high temperature billet

The invention relates to an antioxidation coating for a high temperature billet. The antioxidation coating comprises an aggregate and a glass washing liquid of which mass is 35 to 60% of mass of the aggregate, wherein the aggregate comprises magnesia brick powder, fused magnesite, quartz sand and high-aluminum powder. The aggregate in the antioxidation coating has ideal high-temperature resistance and water resistance, and does not cause expansion between raw material molecules at a high temperature. The glass washing liquid has excellent adhesion. Therefore, the antioxidation coating does not powder, crack and fall off, is suitable for surface coating of various types of billets and prevents billet oxidation.

Owner:本钢第三轧钢厂 +2

Corrosion-resistant thermosetting powder coating, and preparation method thereof

InactiveCN106634407AStrong corrosion resistanceLong-lasting color retentionFireproof paintsAnti-corrosive paintsCorrosion resistantWeather resistance

The invention belongs to the field of coating, and provides a corrosion-resistant thermosetting powder coating, and a preparation method thereof. The corrosion-resistant thermosetting powder coating mainly comprises, by weight, 30 to 50 parts of epoxy resin, 3 to 8 parts of a curing agent, 8 to 12 parts of polyester resin, 2 to 5 parts of a surface accessory ingredient, 3 to 8 parts of phenolic resin, 10 to 20 parts of barium sulfate, 1 to 3 parts of a pigment, 3 to 8 parts of aluminum powder, 3 to 6 parts of carbon powder, and 1.2 to 1.8 parts of a light stabilizing agent. The corrosion-resistant thermosetting powder coating possesses thermal oxidation resistance and photooxidation resistance at the same time, and excellent corrosion resistance, weather resistance, ultraviolet optical rotation resistance, aging resistance, and stability; color preserving capacity lasts for a long term; no pulverization, crazing, or peeling is caused after long term of ultraviolet irradiation; problems of conventional powder coating that weather resistance and ultraviolet optical rotation resistance are poor, adhesive force is easily reduced, pulverization, crazing, and peeling are easily caused; and powder coating service life is prolonged.

Owner:FUJIAN WANAN IND

High wear-proof and cracking resistant color surface decorative building material

InactiveCN102951888BRealistic colorsImprove adhesionCovering/liningsCrack resistanceHigh wear resistance

Owner:SHANGHAI APE STONE

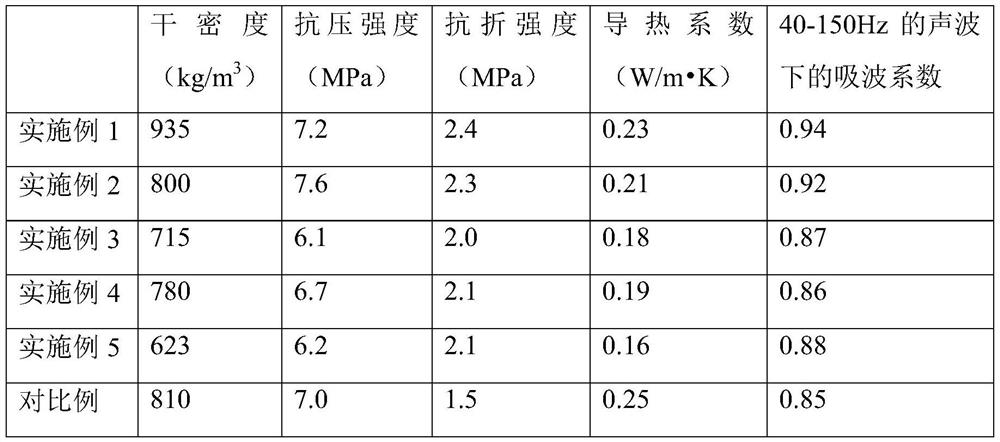

A kind of light artificial culture stone and preparation method thereof

InactiveCN103422643BReasonable workmanshipLight weightCovering/liningsCeramic shaping apparatusFoaming agentThermal insulation

A light artificial cultural stone provided by the invention comprises a surface layer and a bottom layer, the surface layer covers the outer surface of the bottom layer, and the bottom layer includes a foam agent, a foam stabilizer and ceramsite. The preparation method is by pouring the prepared bottom layer slurry in a mold and vibrating forming. The composition ratio of the lightweight artificial cultural stone of the invention is scientific, and the preparation method is reasonable. The self-weight of the product is reduced, and the thermal insulation, sound insulation, fire resistance and pan-alkali resistance of the product are improved. It has extremely strong durability and color stability in various harsh climate environments, will not be powdered, peeled off, and is not easy to change color.

Owner:SHANGHAI APE STONE

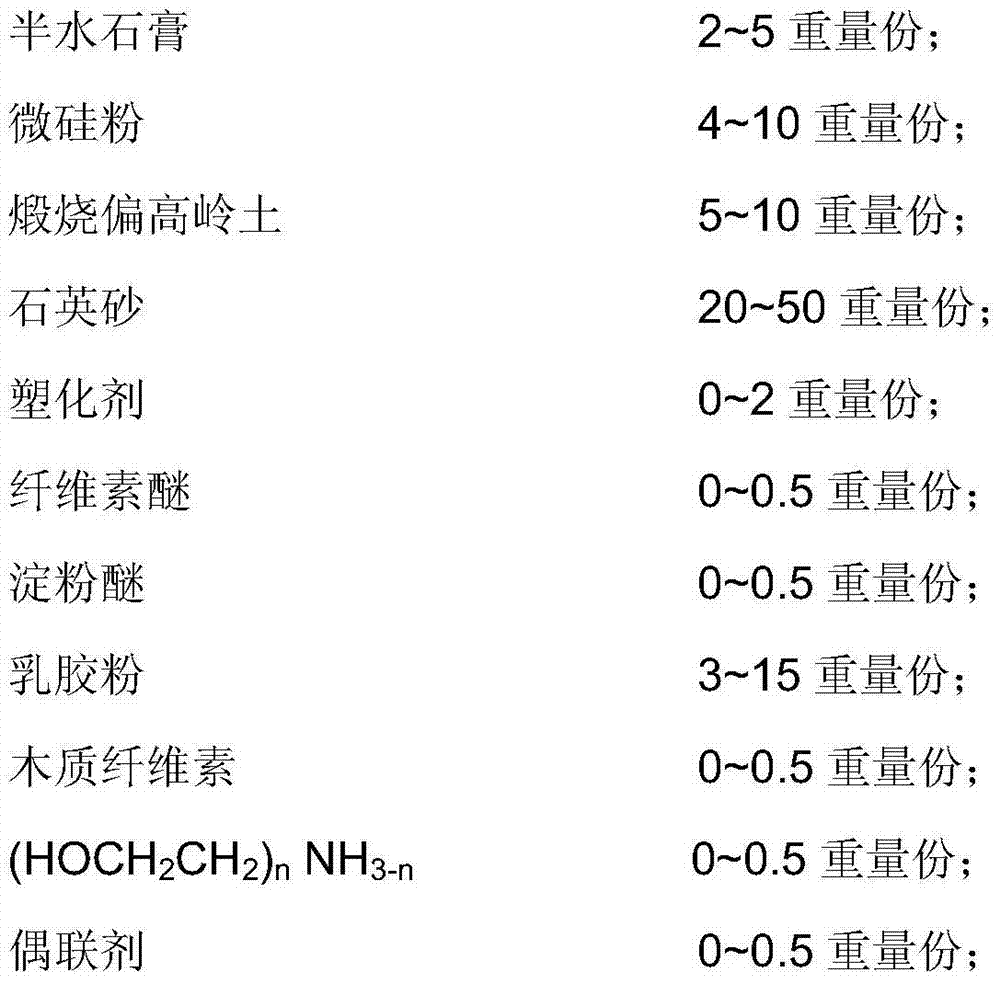

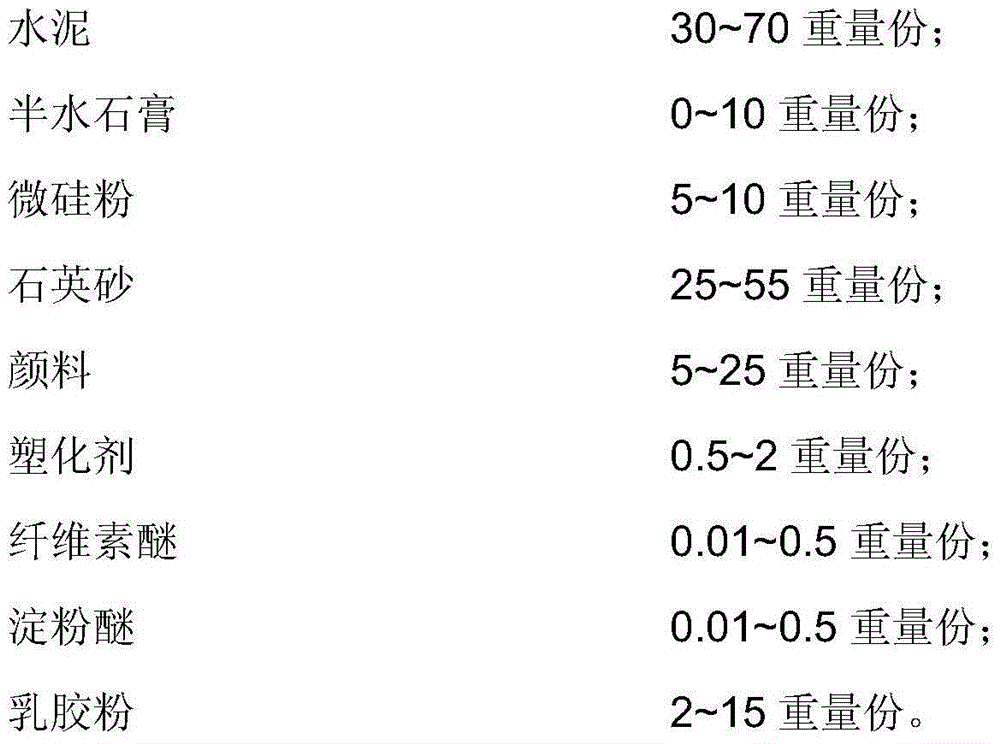

Composition for preparing inorganic polymer material and method for preparing material

ActiveCN111439941BImprove fire resistanceImprove stress resistanceCeramicwareThermal insulationUltimate tensile strength

The invention relates to the field of building materials, and discloses a composition for preparing inorganic polymer materials. Based on the total weight of the composition, the composition contains 73.6-91.9% by weight of aluminum-silicon raw materials, 4-17 % by weight crystallization enhancer, 4-9% by weight soluble alkali metal compound and 0.1-0.4% by weight blowing agent. The invention also discloses a preparation method of the inorganic polymer material based on the composition. The inorganic polymer material prepared by the composition is relatively low in production cost, and has better compression resistance after high-temperature treatment; at the same time, it has better strength performance, fire resistance performance and heat preservation performance, no harmful gas is generated during high-temperature heating, and no powder change.

Owner:上海百奥恒新材料有限公司

Inorganic environment-friendly high-strength composite fireproof heat-insulation plate

The invention discloses an inorganic environment-friendly high-strength composite fireproof heat-insulation plate. The inorganic environment-friendly high-strength composite fireproof heat-insulationplate comprises, by weight, 150-250 parts of 525 cement, 100-200 parts of high-calcium powder, 150-250 parts of medium materials, 10-30 parts of adhesive powder, 20-40 parts of sodium silicate, 10-30parts of silicon and calcium powder, 10-30 parts of setting accelerators, 5-15 parts of foaming agents, 100-200 parts of 425 cement and 20-80 parts of inorganic fibers. The inorganic environment-friendly high-strength composite fireproof heat-insulation plate has the advantages that good heat-insulation effects can be realized by the inorganic environment-friendly high-strength composite fireproofheat-insulation plate, the inorganic environment-friendly high-strength composite fireproof heat-insulation plate has moderate density, is good in fire resistance and can be quickly solidified and dried under low-temperature conditions, and the construction time for constructing the inorganic environment-friendly high-strength composite fireproof heat-insulation plate in the north in autumns andwinters can be shortened.

Owner:河北坐城建材科技有限公司

A kind of acrylic flexible anticorrosion primer and preparation method thereof

ActiveCN112680078BGood weather resistanceGood construction performanceAnti-corrosive paintsPolyurea/polyurethane coatingsPolymer scienceCrazing

The invention provides an acrylic flexible anti-corrosion primer and a preparation method thereof. The primer is composed of component A and component B, and the ratio of component A and component B is 100:15-20 by weight Component A consists of flexible acrylic resin liquid with a solid content greater than 45%, dispersant, leveling agent, adhesion promoter, ultraviolet absorber, thinner, titanium dioxide, zinc yellow, talcum powder, zinc phosphate, mica powder, Composed of light calcium and bentonite; component B is an elastic isocyanate resin solution with a solid content greater than 90%; the primer can cover the stretching vibration cracks and elongation at break caused by the difference in elastic modulus between various substrates during equipment operation. Elongation ≥ 100%, tensile strength ≥ 10Mpa, and has excellent anti-corrosion function.

Owner:天津灯塔涂料工业发展有限公司

Preparation method of catalyst/adsorption material with diatomite as carrier

InactiveCN104226240BIncrease concentrationExtend reaction residence timeOther chemical processesDispersed particle separationGlass fiberCatalytic oxidation

The invention discloses a preparation method of a catalyst / adsorption material with diatomite as a carrier, comprising: adding 15 to 20 parts of absolute ethanol to 1 part of purified diatomite, and adding 1-3 parts of metal compound, 0.1-0.3 part of alumina, 0.1-0.3 part of glass fiber, 0.02-0.04 part of nitric acid and 5-7 parts of deionized water are mixed and stirred; the resultant is centrifugally washed with deionized water; After washing, the pulp is first dried and then calcined; the catalyst / adsorption material is obtained. The catalytic / adsorbing material prepared by this method can use the adsorption capacity of diatomite to prolong the residence time of organic pollutants in the reactor, and at the same time, the supported metal oxide can produce a strong catalytic oxidation during the discharge process, thereby Increase the degree of oxidation of organic pollutants.

Owner:杭州最清环保科技有限公司 +1

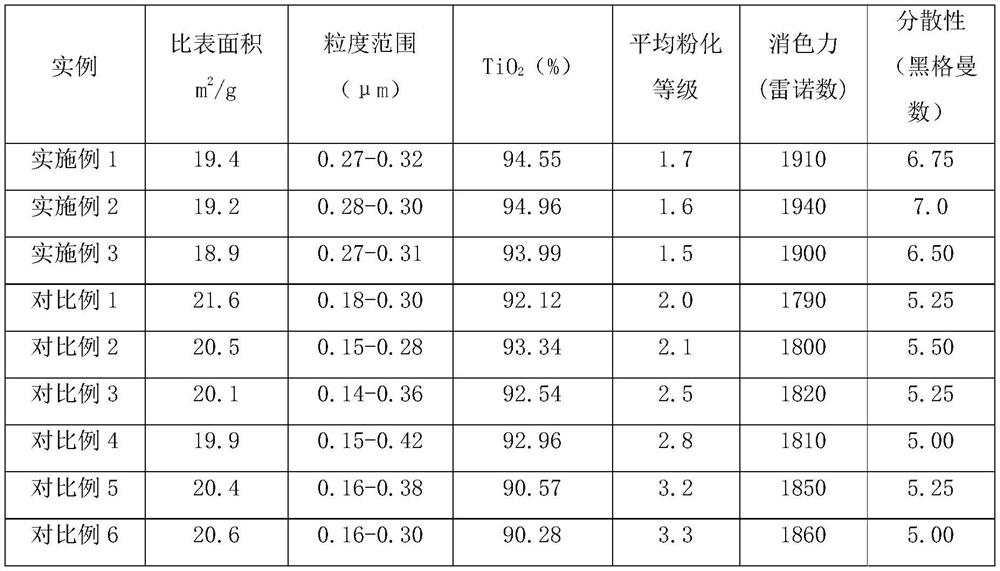

A kind of preparation method of high durability anti-powdering rutile type ultrafine titanium dioxide

ActiveCN111662574BHigh glossGood dispersionTitanium dioxidePigment physical treatmentWeather resistanceZinc

The invention discloses a preparation method of high-durability anti-pulverization rutile type ultrafine titanium dioxide, and belongs to the field of preparation of inorganic metal compounds. In thepreparation process, a flocculating agent and impurity removing agent mixed sedimentation method is adopted; impurities in the reduced titaniferous solution A are fully separated out and thus the prepared titanium dioxide has extremely high glossiness, extraordinary covering power and coloring power and is easy to disperse; in the calcining step, the rotating speed of the kiln body in the calcining process, the calcining temperature and the calcining time of the materials in the kiln body are controlled, the prepared rutile type titanium dioxide has better weather resistance and is not liableto pulverize, yellow and lose gloss after being placed for a long time, the obtained product is coated with zinc, zirconium and aluminum, the durability is improved, and the produced rutile type titanium dioxide has good pulverization resistance.

Owner:GUANGDONG HUI YUN TITANIUM IND CORP LTD

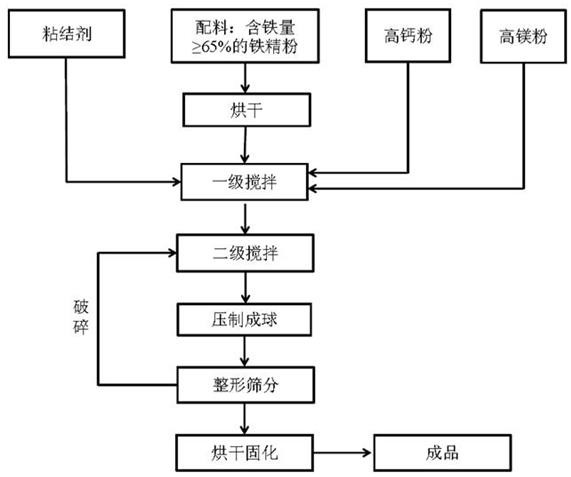

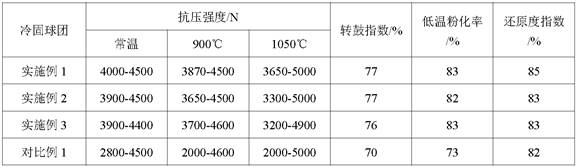

Preparation method and application of blast furnace sintering-free cold-bonded pellets

InactiveCN114525402ASolve technical problems that cannot meet the performance requirements of blast furnace ironmakingReduce usageBlast furnace detailsProcess efficiency improvementIron powderBlast furnace smelting

The invention relates to the technical field of blast furnace smelting, and provides a preparation method and application of a blast furnace sintering-free cold-bonded pellet, and the preparation method comprises the following steps: S1, burdening: preparing fine iron powder of which the iron content is greater than or equal to 65%; s2, the fine iron powder in the S1 is dried until the moisture content is 3%-5%; s3, carrying out primary stirring on the fine iron powder in the S2, a binder, high-calcium powder and high-magnesium powder to obtain a mixture; s4, carrying out secondary stirring on the mixed material; s5, pressing into balls; s6, the balls are shaped and screened; and S7, the pellets of the oversize materials are dried and cured, and the blast furnace sintering-free cold-bonded pellets are obtained after drying. The invention further provides application of the blast furnace sintering-free cold-bonded pellets in blast furnace ironmaking. By means of the technical scheme, the problem that in the prior art, cold-bonded pellets cannot meet the requirement for furnace charge entering a blast furnace is solved, and meanwhile the problems that in a traditional pre-ironmaking technology, pollution is heavy, energy consumption is high, and carbon emission in the ironmaking process is high are solved.

Owner:唐山金沙燃烧热能股份有限公司

Complex deoxidizer for steelmaking and preparation method thereof

The invention discloses a complex deoxidizer for steelmaking, which comprises the following components in percentage by weight: 5 to 9 percent of calcium (Ca), 10 to 24 percent of silicon (Si), 12 to 19 percent of manganese (Mn) and the balance of Fe, accompanying elements of Al and Mg, and inevitable impurities. The invention also discloses a method for preparing the complex deoxidizer for steelmaking, and the complex deoxidizer is prepared from the following raw materials in proportion (in percentage by weight): 60 to 70 percent of raw manganese ore in which Mn accounts for more than or equal to 32 percent, 12 to 16 percent of silica with the silicon content more than or equal to 98 percent, 10 to 16 percent of lime with the CaO content more than or equal to 90 percent and 5 to 8 percent of iron scale with Fe oxide content more than or equal to 75 percent. The complex deoxidizer and the preparation method have the advantages of low cost of the raw materials, low energy consumption of unit product, reasonable proportion of alloying elements, no segregation, strong substitution and high strength of product, high density and low smelting point of alloy, easy absorption for alloyingelements in molten steel, good deoxidation, desulfurization and dephosphorization effects, and high metal yield.

Owner:曹承

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com