Patents

Literature

45results about How to "Extend reaction residence time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

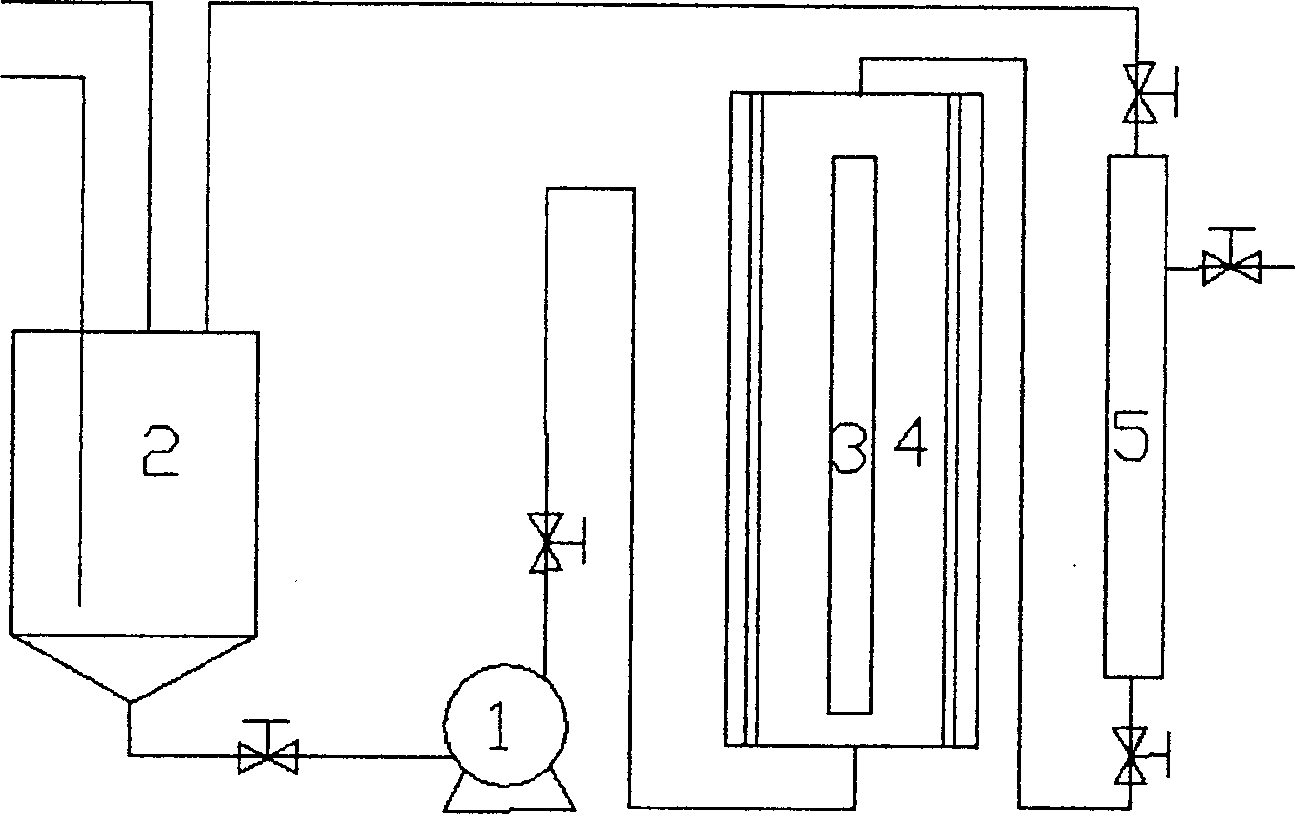

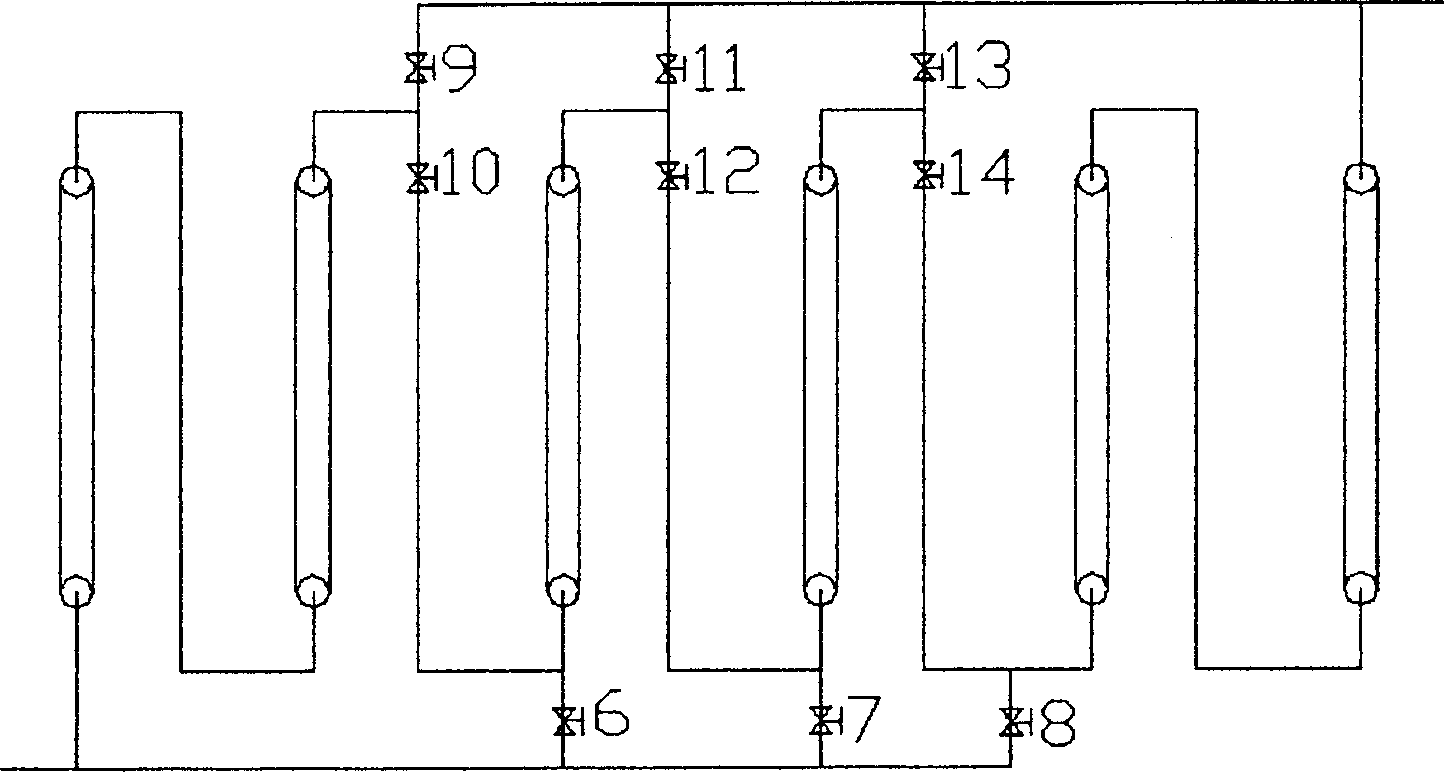

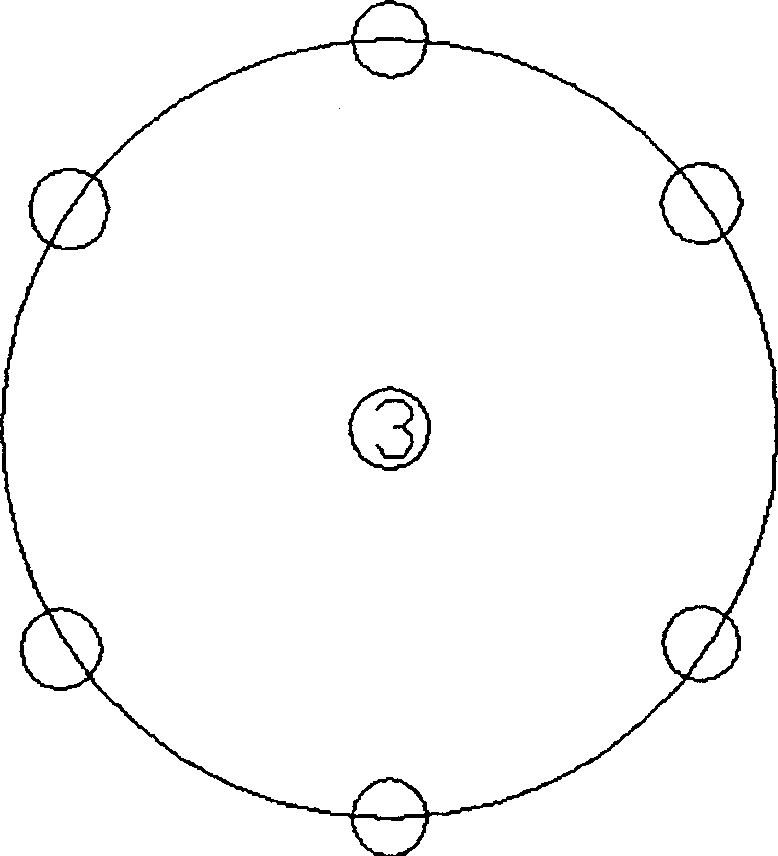

Light catalyst reaction device and processing technique for continuous degrading waste water containing organic contamination

InactiveCN1431155AHigh transparencyEasy to recycleWater/sewage treatment by irradiationEnergy based wastewater treatmentSemiconductor materialsPhotocatalytic reaction

A photocatalytic reactor equipment with granular or fibrous semiconductor material as catalyst for continuously degradating toxic organic sewage is composed of optical reactor, filter, pump and buffering tank. Its advantages are easy recovery of catalyst, high reaction efficiency, high optical utilization rate, and high treating capacity.

Owner:NANJING UNIV OF TECH

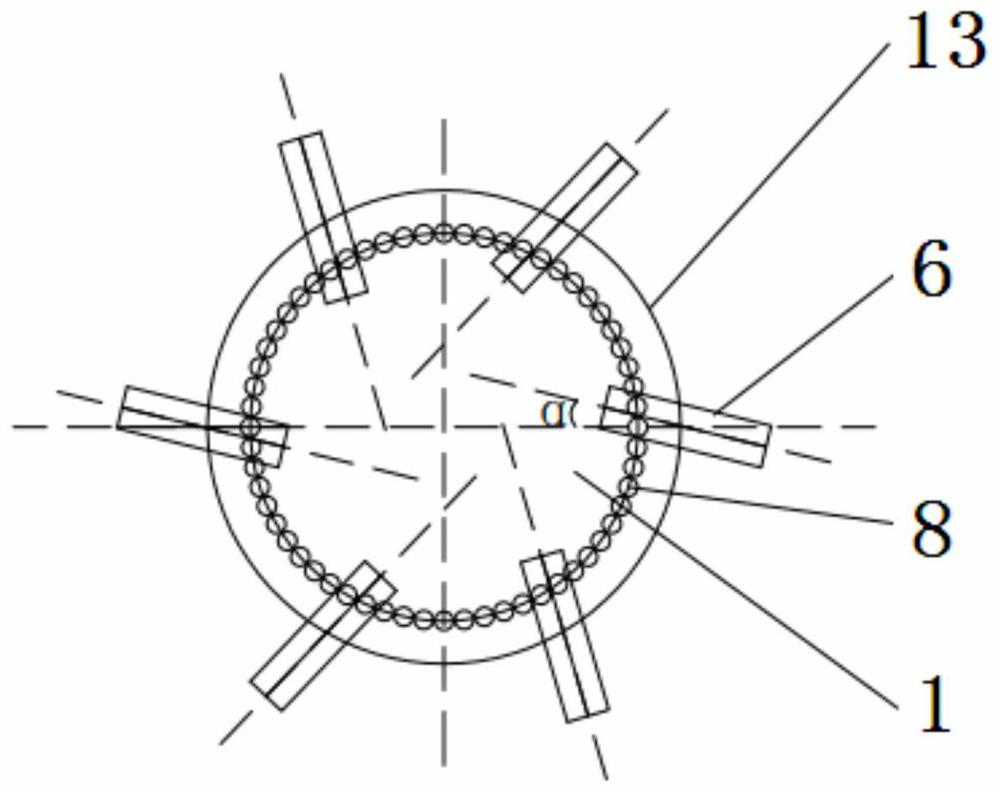

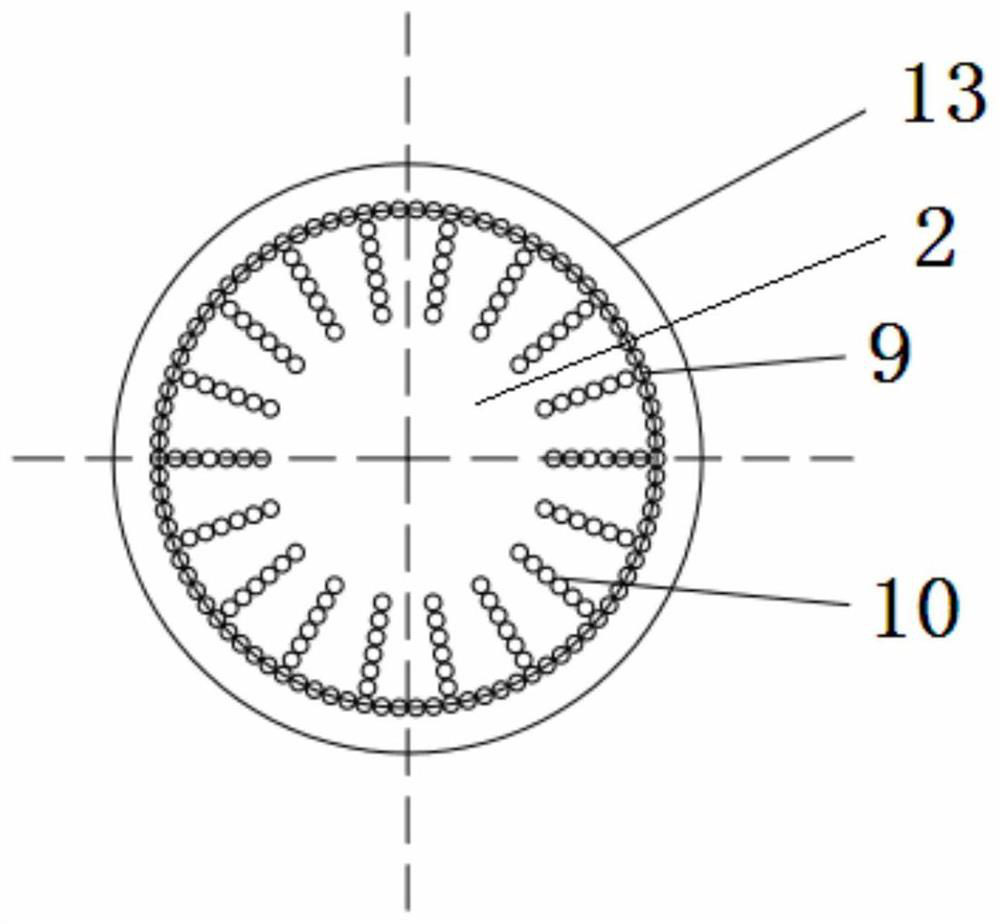

Reacting device

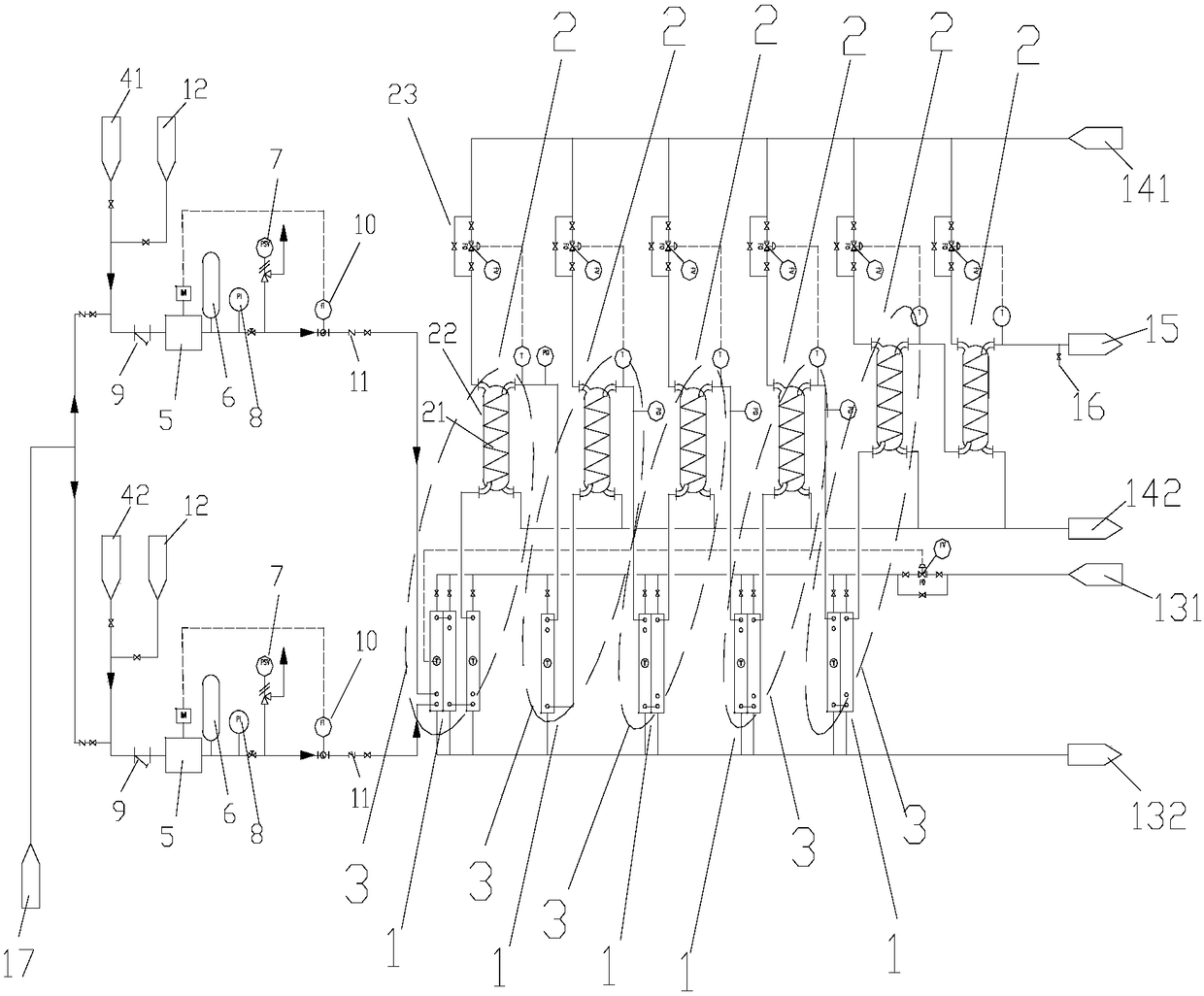

PendingCN108514855AWell mixedSolve the problem of constantly decreasing pressureChemical/physical/physico-chemical microreactorsMicroreactorResidence time

The invention provides a reacting device. The device comprises a micro reactor (1) and a tubular reactor (2), the tubular reactor (2) is located at the downstream of the micro reactor (1) in the flowing direction of reacting fluid, and the tubular reactor (2) is in series connection with the micro reactor (1). According to the reacting device, reacting materials can enter into the tubular reactingdevice to conduct smoother reaction after the reacting materials are violently mixed in the micro reactor; the problem of constantly reducing caused by the action of micro channel walls when the reacting materials perform flowing reaction in the micro reactor is effectively solved, and the pressure of the reacting materials can be ensured or maintained to ensure that the reacting materials can flow for a longer distance under the same feeding pressure, so that the reaction residence time is longer, the mixing degree is fully improved and the reaction efficiency is improved.

Owner:HIMILE MECHANICAL MFG +1

Preparation method for catalysis/adsorption material by taking kieselguhr as carrier

InactiveCN104226240AExtended stayHigh degree of oxidationOther chemical processesDispersed particle separationGlass fiberAlcohol

The invention discloses a preparation method for a catalysis / adsorption material by taking kieselguhr as a carrier. The preparation method comprises the following steps of adding 15-20 parts of absolute ethyl alcohol into 1 part of purified kieselguhr, then adding 1-3 parts of a metal compound, 0.1-0.3 part of aluminum oxide, 0.1-0.3 part of glass fibers, 0.02-0.04 part of nitric acid and 5-7 parts of deionized water in sequence under magnetic stirring for mixing and stirring; performing centrifugal washing on obtained substances by the deionized water; and drying washed ore pulp at first, and then calcining the ore pulp, thus obtaining the catalysis / adsorption material. The catalysis / adsorption material prepared by the method disclosed by the invention can prolong the retention time of organic pollutants in a reactor by using the adsorption capacity of kieselguhr, and loaded metal oxide can generate a relatively good catalytic oxidation effect in a discharging process, so that the oxidization degree of organic pollutants is increased.

Owner:杭州最清环保科技有限公司 +1

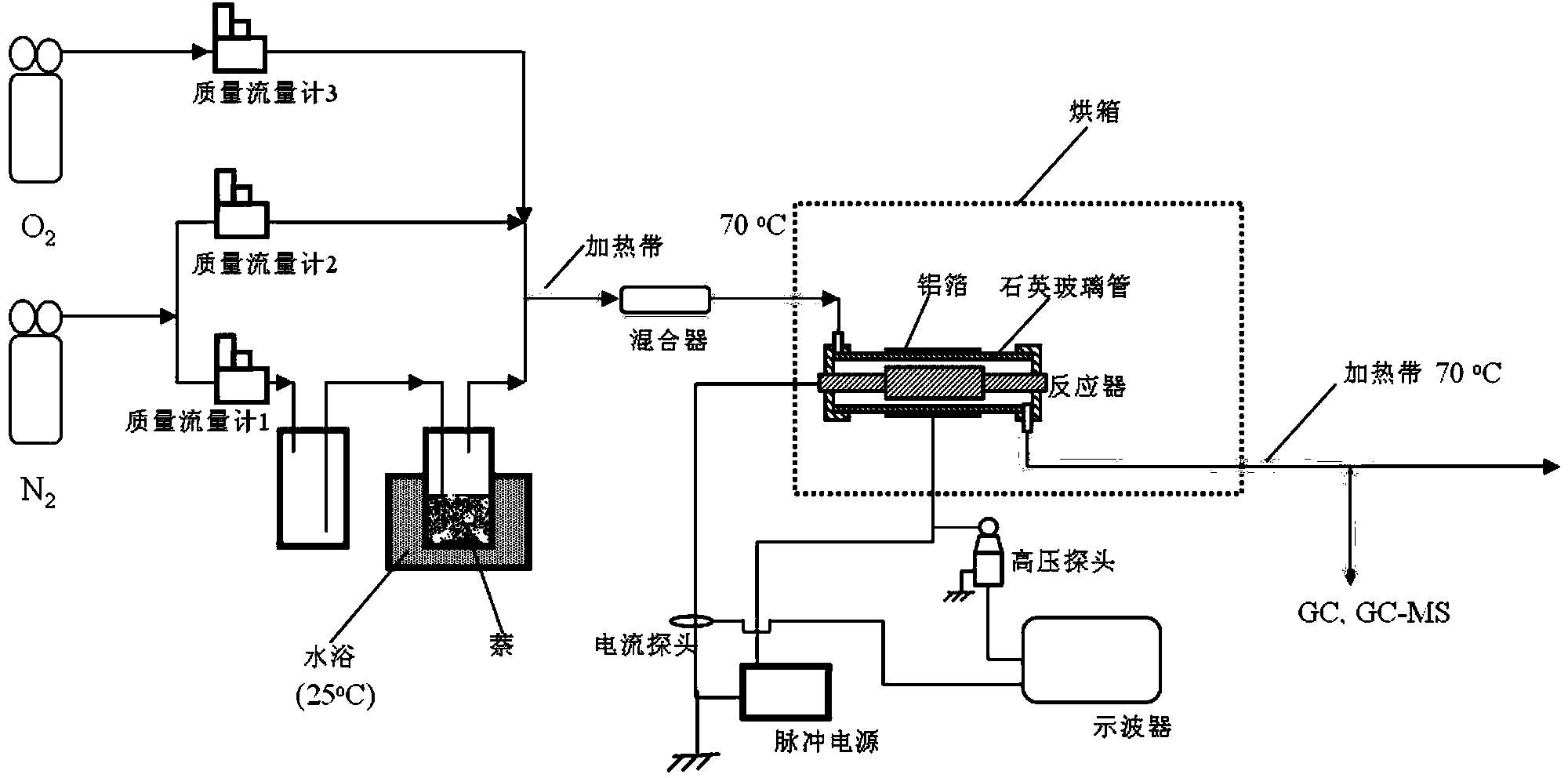

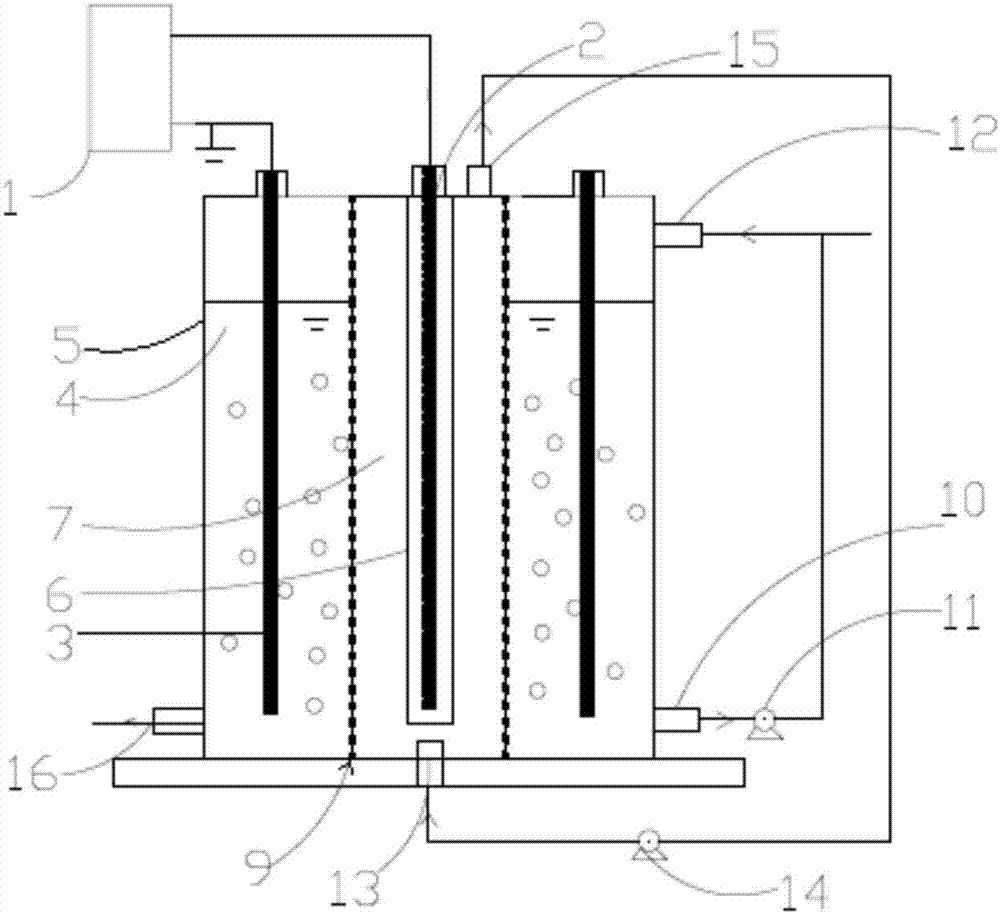

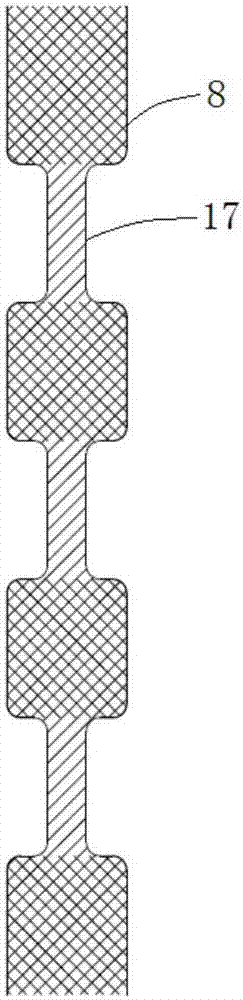

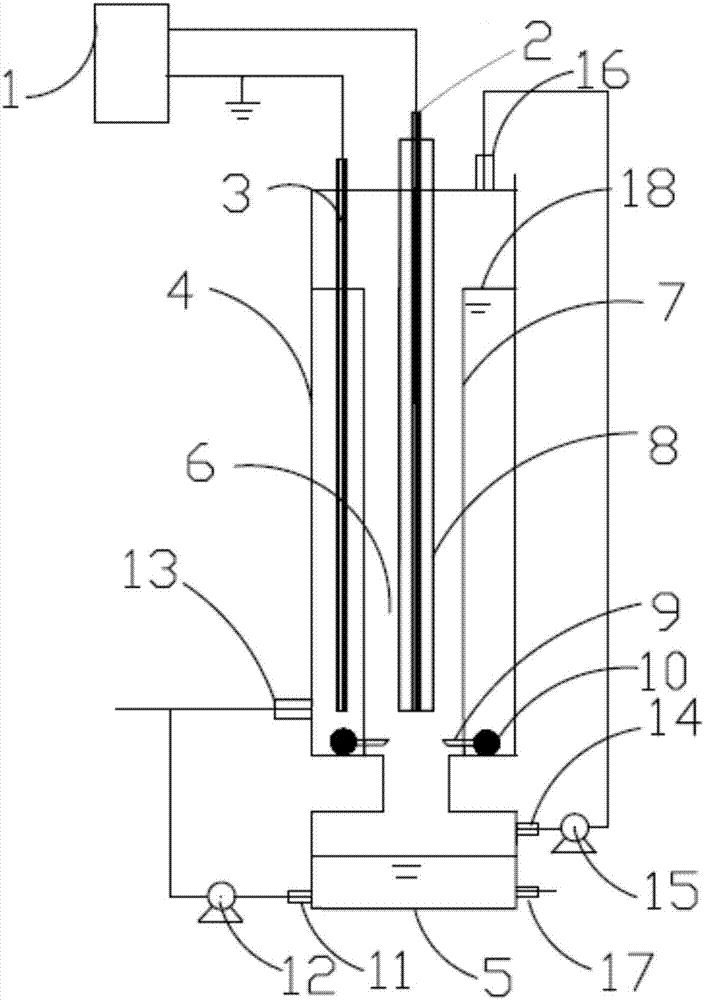

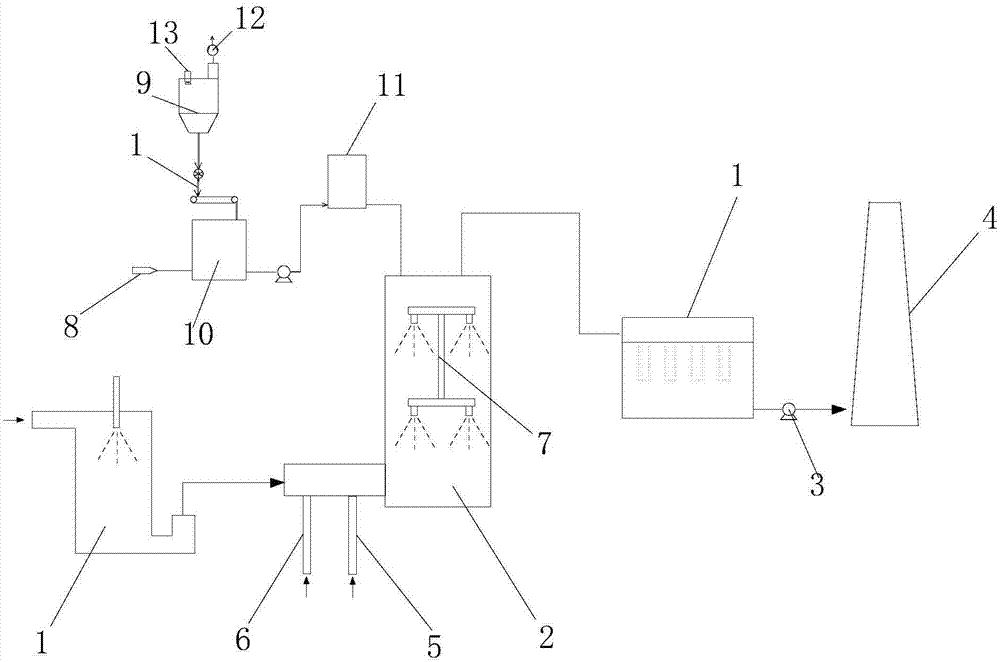

Efficient aerated plasma treatment organic wastewater device

InactiveCN107381710AAchieve degradationImprove processing efficiencyWater/sewage treatment by irradiationWater contaminantsWastewaterHigh pressure

The invention discloses an efficient aerated plasma treatment organic wastewater device which comprises a high-voltage electrode, a grounding electrode and a reaction vessel. The high-voltage electrode and the grounding electrode are connected with a positive electrode and a negative electrode of a plasma power supply, a microporous aeration pipe is arranged in the reaction vessel in a sleeving manner, an annular water channel is formed between the wall of the reaction vessel and the microporous aeration pipe, an inner medium pipe with a closed lower end is arranged in the microporous aeration pipe in a sleeving manner, the high-voltage electrode is embedded into the inner medium pipe, the grounding electrode is arranged in a closed discharging area formed between the microporous aeration pipe and the inner medium pipe in the annular water channel, a water inlet pipe and a backflow water outlet pipe are arranged on the upper portion and the lower portion of the annular water channel, and an air outlet and an air inlet are formed in the top and the bottom of the discharging area. According to the device, ozone generated by discharging plasmas is sufficiently utilized, and the device has a good application prospect and has the advantages of stable and high performance, no secondary pollution, rapidness, simple structure, high practicability and the like in the field of water treatment.

Owner:NANJING UNIV

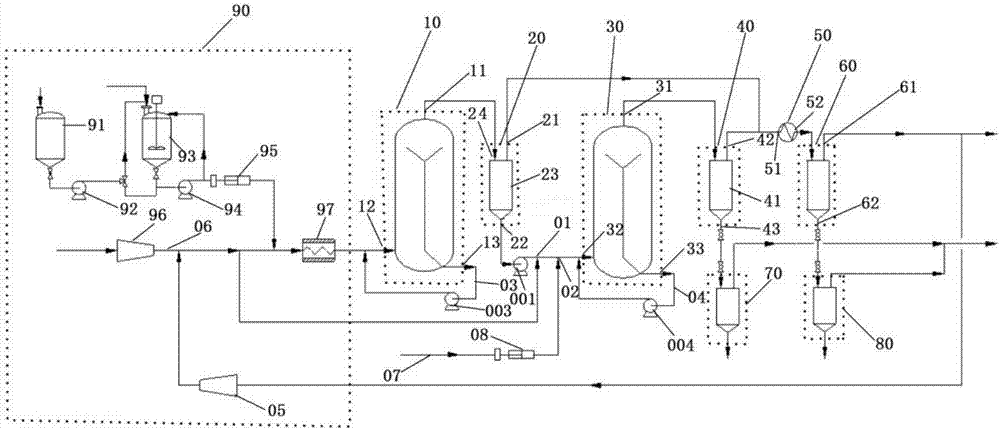

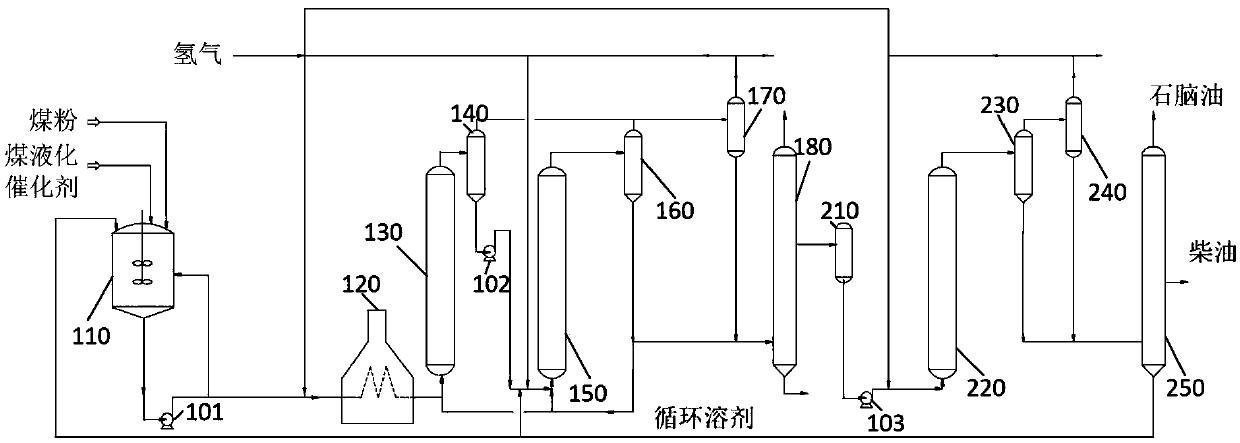

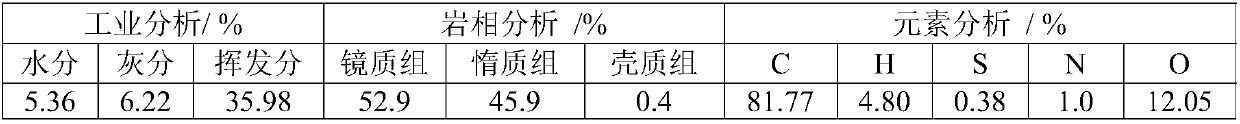

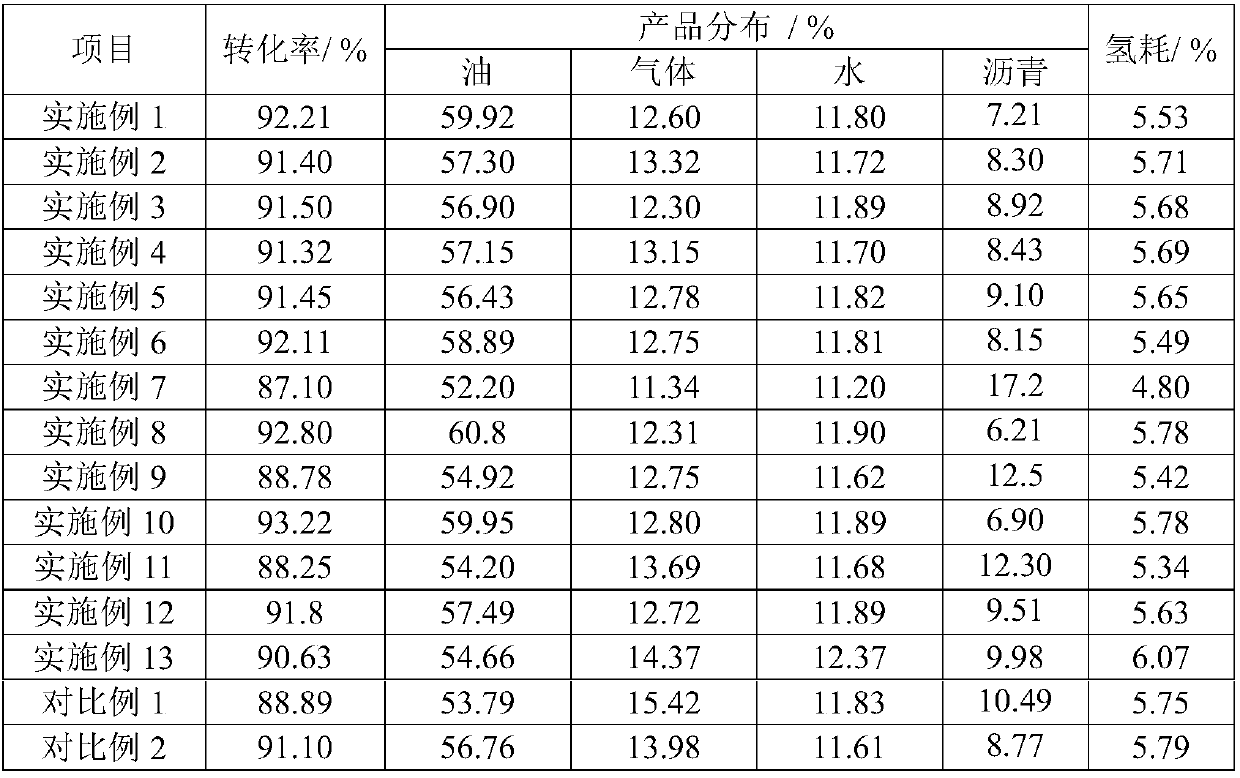

Coal liquefaction method and device

InactiveCN107057742APromotes deep liquefactionAchieve deep conversionLiquid hydrocarbon mixture productionProcess engineeringCoal slurry

The invention provides a coal liquefaction method and device. The coal liquefaction method comprises the steps as follows: first liquefaction reaction is carried out on coal slurry and hydrogen to obtain a first liquefied product, wherein the first liquefied product comprises a first gas mixture and a first heavy product and the first gas mixture comprises a first liquefied light oil and a first gas product; a first heavy product in the first liquefied product is separated and second liquefaction reaction is carried out on the first heavy product and the hydrogen to obtain a second liquefied product; and before or during the second liquefaction reaction, the method also comprises the step of adding a first hydrogenation catalyst to the first heavy product. Through the method and the device provided by the invention, the conversion rate and the oil yield of coal can be improved, and meanwhile, the hydrogen consumption and the gas yield are reduced.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Water curtain type discharge plasma efficient treatment device for organic wastewater

InactiveCN107512758AEasy to handleStrong disinfection abilityWater contaminantsWater/sewage treatment by electrochemical methodsWastewaterEngineering

The invention discloses a water curtain type discharge plasma efficient treatment device for organic wastewater. The treatment device comprises a high voltage electrode and a grounding electrode which are respectively connected with the positive and negative electrodes of the plasma power source, and an outer medium tube and an inner medium tube which are sleeved together, between the outer medium tube and the inner medium tube is a water curtain discharge area; wherein the outer wall of the outer medium tube is provided with an annular overflow groove, the outer groove wall of the annular overflow groove is higher than the tube wall of the outer medium tube, the grounding electrode is arranged in the annular overflow groove, the high-voltage electrode is embedded in the inner medium tube, the lower end of the inner medium tube is sealed, the lower end of the outer medium tube is communicated with a lower water tank, and the upper end of the annular overflow groove is sealed and provided with an air inlet pipe. The device takes full advantage of the ozone generated by the discharge plasma. In the field of water treatment, the device has the advantages of stable and high performance, no secondary pollution, high speed, simple structure, strong practicability and the like, and has a relatively good application prospect.

Owner:NANJING UNIV

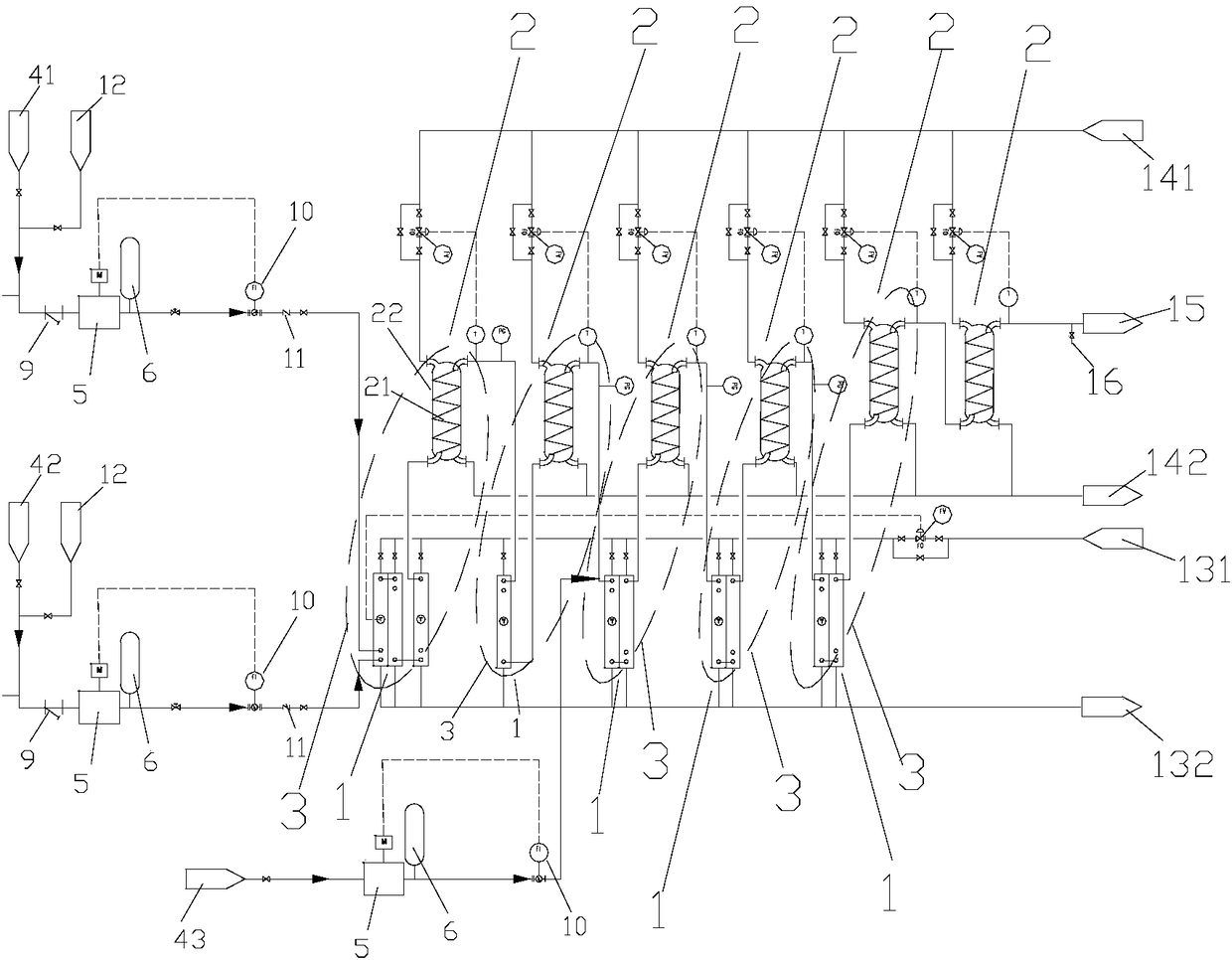

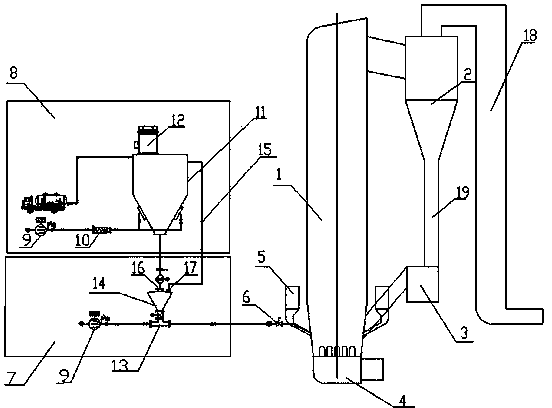

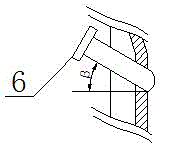

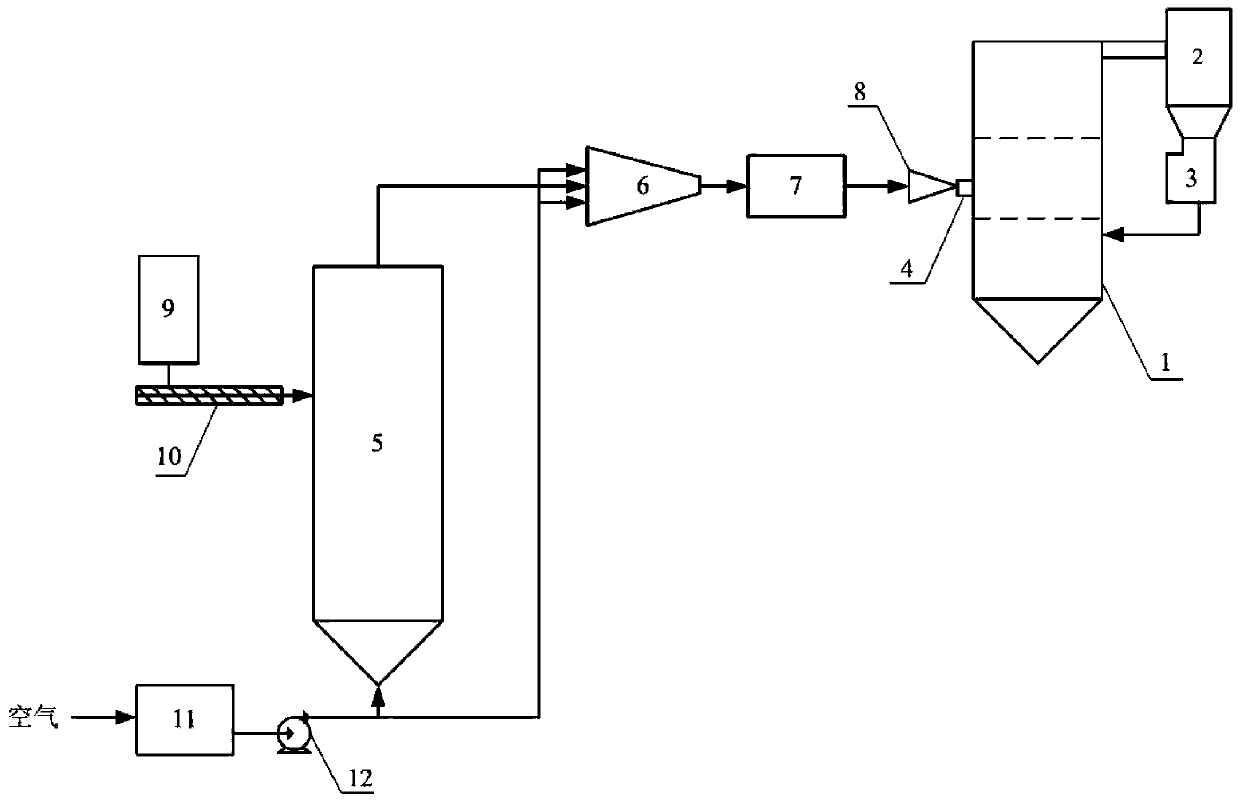

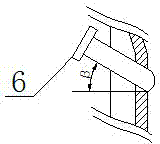

System for desulfurizing limestone in circulating fluidized bed boiler on basis of flow state reconstruction

InactiveCN103672874AExtend reaction residence timeImprove sulfur fixation effectFluidized bed combustionApparatus for fluidised bed combustionFluidized bedInlet valve

A system for desulfurizing limestone in a circulating fluidized bed boiler on the basis of flow state reconstruction comprises a hearth, a conveying mechanism, a storage bin mechanism and a pipeline, wherein the conveying mechanism comprises a temporary storage bin, a mixer and a fan; a temporary storage feed port and an exhaust port are formed in the upper part of the temporary storage bin; the storage bin mechanism comprises a storage bin, a warehouse top dust collector, a through pipeline, an electric heater and a fan; the system further comprises an air separator communicated with an exhaust gas outlet of the hearth, a return feeder, an air chamber arranged at the bottom of the hearth and led into the hearth from a primary air duct, secondary air pipes distributed on the front wall and the rear wall of the hearth, an inlet valve set communicated with the secondary air pipes and used for desulfurizing limestone in the boiler, a tail flue arranged at the top of the separator, as well as a return feeder leg integrated with the separator; the inlet valve set is connected with the mixer through the pipeline; and the return feeder is connected with the bottom of the return feeder leg. The system has the advantages that the structure is simple, the separation efficiency is high, discharging is facilitated and the like.

Owner:TAIYUAN BOILER GROUP +1

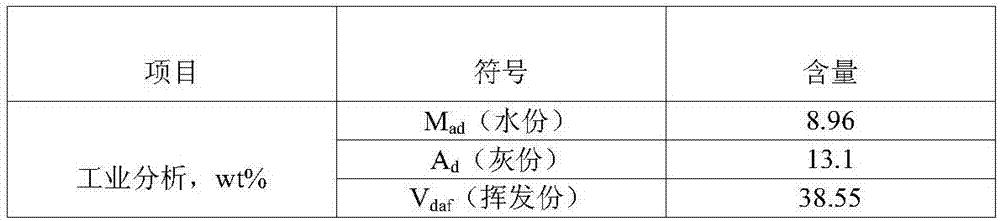

Method and device for coal direction liquefaction

ActiveCN108048121AImprove liquefaction conversionExtended stayLiquid hydrocarbon mixture productionHydrocarbon oils treatment productsLiquid productHydrogen

The invention provides a method and device for coal direction liquefaction. The method for the coal direct liquefaction includes the following steps of: S1, performing a first liquefaction reaction ona first raw material which includes coal slurry and hydrogen so as to obtain first liquefied products, and performing oil-gas separation on the first liquefied products to obtain a first liquid-phaseproduct; S2, performing a second liquefaction reaction on a second raw material which comprises the first liquid-phase product, hydrogen and a solvent so as to obtain second liquefied products, and performing oil-gas separation on the second liquefied products to obtain a second liquid-phase product; S3, performing distillation and catalytic hydrogenation treatment on a part of the second liquid-phase product so as to obtain a coal liquefaction product; and S4, performing the steps of S1-S3 repeatedly, wherein the first raw materials and / or the second raw materials also include the rest of the second liquid-phase product during the repeated operation. Through the method for the coal direct liquefaction, the liquefaction conversion rate and liquid product yield of coal can be improved, andthe resource utilization rate can be improved significantly.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

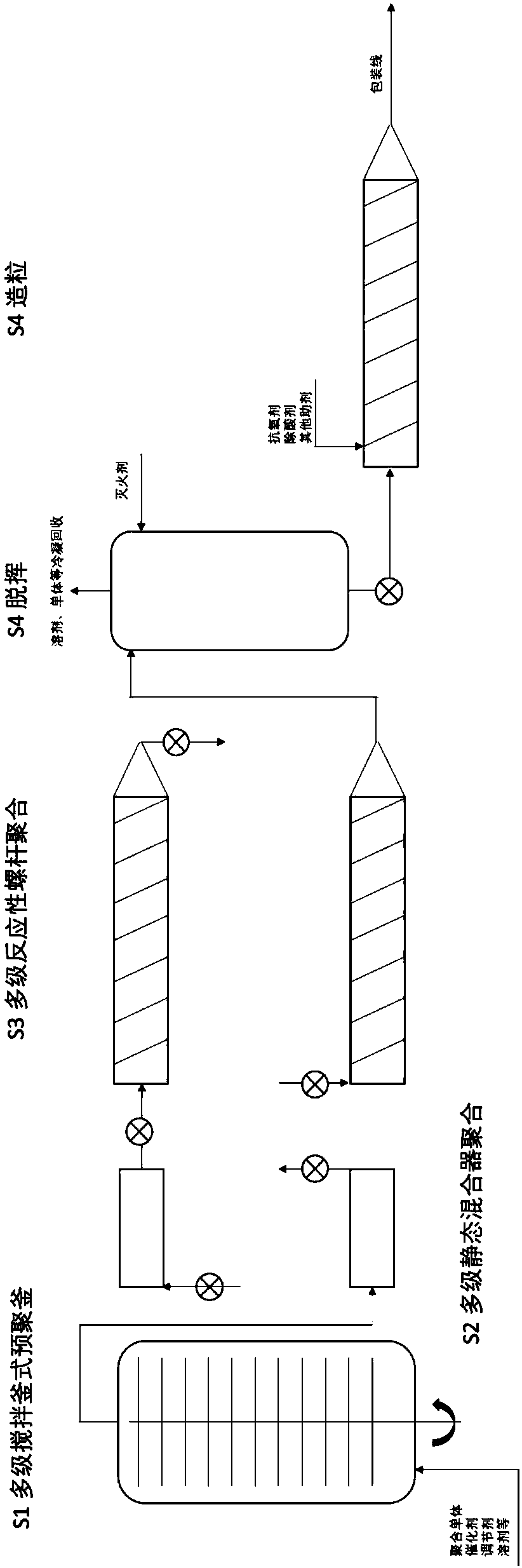

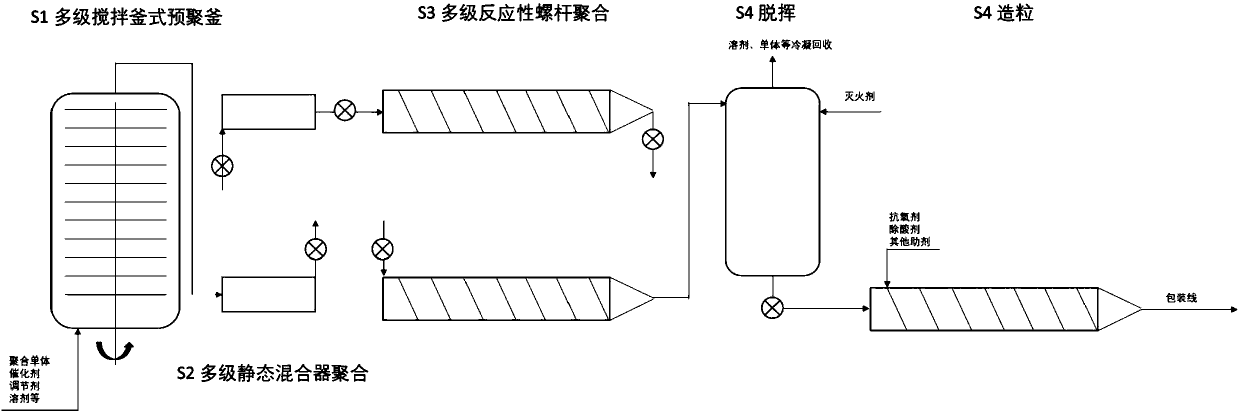

Method for continuously preparing polyolefin and polyolefin prepared therefrom

The invention discloses a method for continuously preparing polyolefin, particularly continuously preparing a polyolefin elastomer or a mixture thereof, and polyolefin prepared therefrom. The pre-polymerization is carried out by using a kettle reactor in the preparation process, and has the function of increasing the viscosity of the reaction system to facilitate the subsequent operation of a screw reactor; the static mixing polymerization is carried out by using a static mixer in the preparation process, and is used for further increasing the viscosity of the system and prolonging the reaction residence time; and the extrusion polymerization is carried out by using a reactive screw extruder in the preparation process to achieve the polymerization reaction under a high conversion rate anda high viscosity. The preparation method can be suitable for a wide variety of polyolefin, and is particularly suitable for the preparation of the polyolefin elastomer or the mixture thereof.

Owner:INST OF CHEM CHINESE ACAD OF SCI

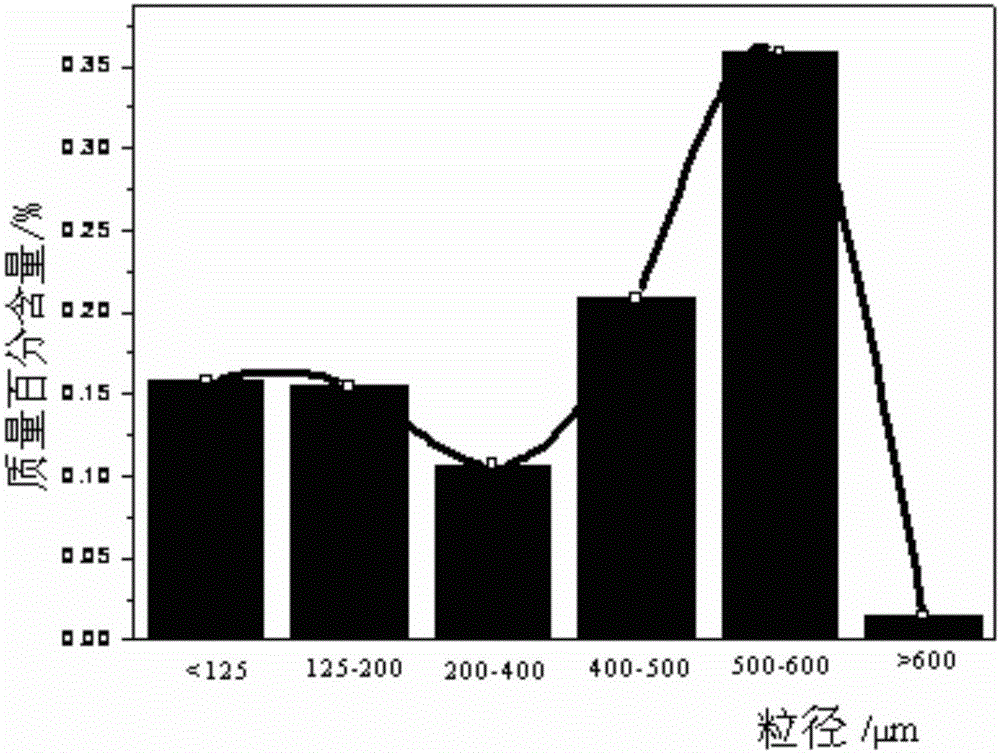

Method for producing baking soda large in particle size

ActiveCN105819471AExtend reaction residence timeCrystal growthBicarbonate preparationSlurrySeed crystal

The invention discloses a method for producing baking soda large in particle size .The method comprises the following steps that seed crystals are put into a reaction crystallizer; mother liquor is introduced into the reaction crystallizer till the liquor level reaches an alkali liquor circulating outlet, and the solid-to-liquor ratio in the reaction crystallizer is controlled to be (0.05-0.15):1; alkali liquor and carbon dioxide containing mixed gas are introduced into the reaction crystallizer for reacting, meanwhile, the mixed liquor in the reaction crystallizer is circulated to an alkali liquor circulating inlet from the alkali liquor circulating outlet, and an external circulating system is set up; under the action of the external circulating system, baking soda crystals obtained through reacting are suspended in the reaction crystallizer, upper-layer fine grains are discharged to a large production system, lower-layer baking soda crystal slurry is discharged, the discharged lower-layer baking soda crystal slurry is thickened, dried and separated, and the baking soda product large in particle size is obtained .Reacting and crystallizing are integrated, the large-particle baking soda product with the grain size ranging from 20 mesh to 60 mesh can be continuously prepared, cost is low, and technological operation is easy.

Owner:TIANJIN BOHUA YONGLI CHEM IND +1

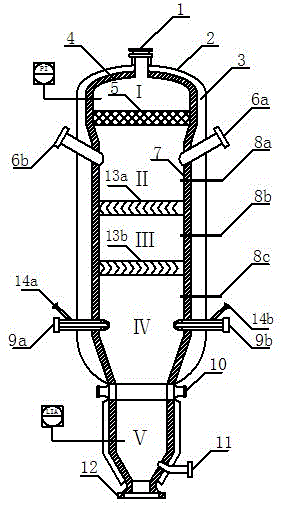

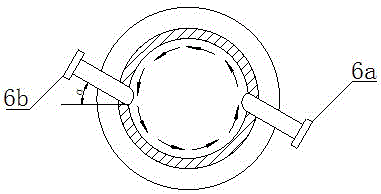

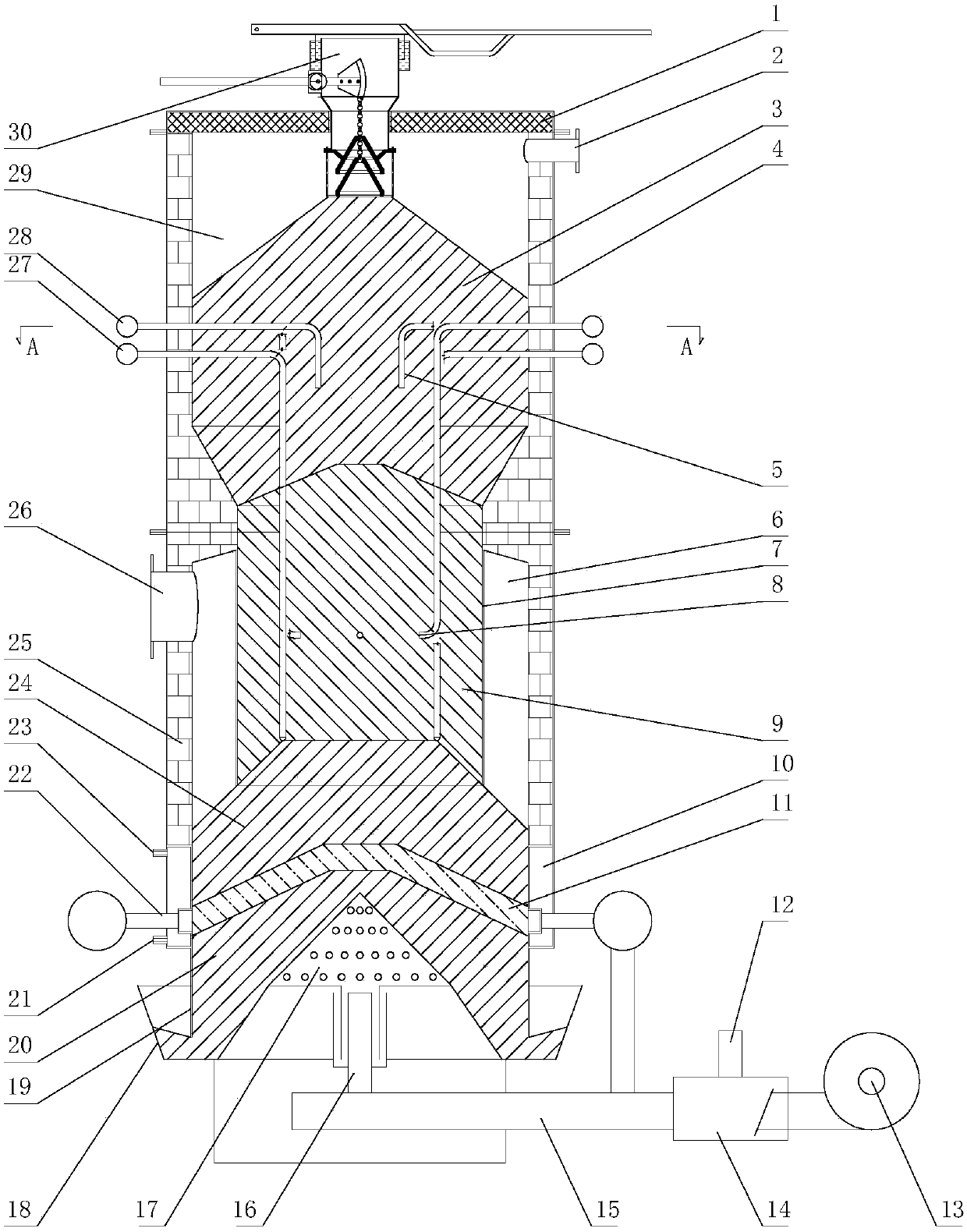

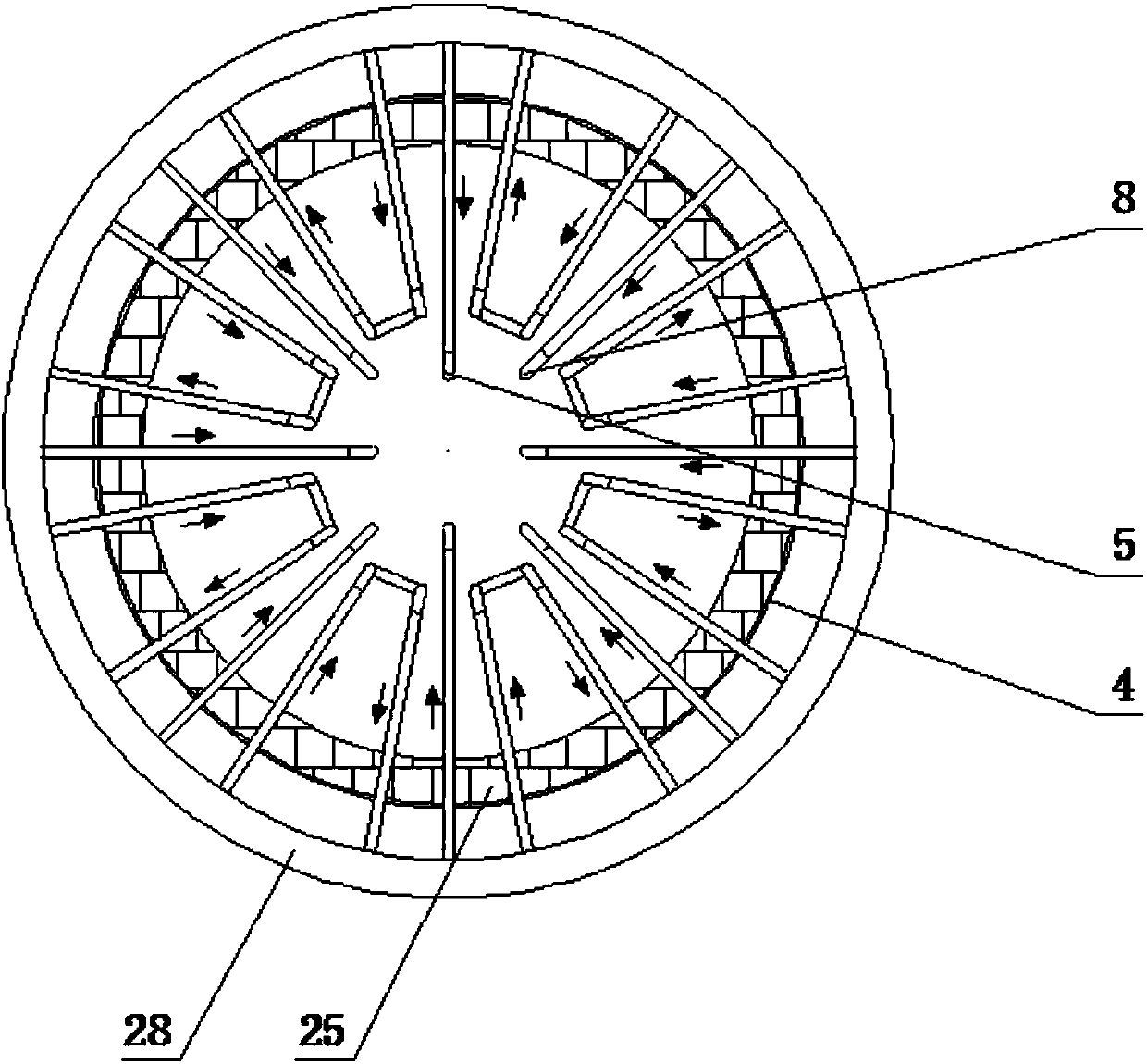

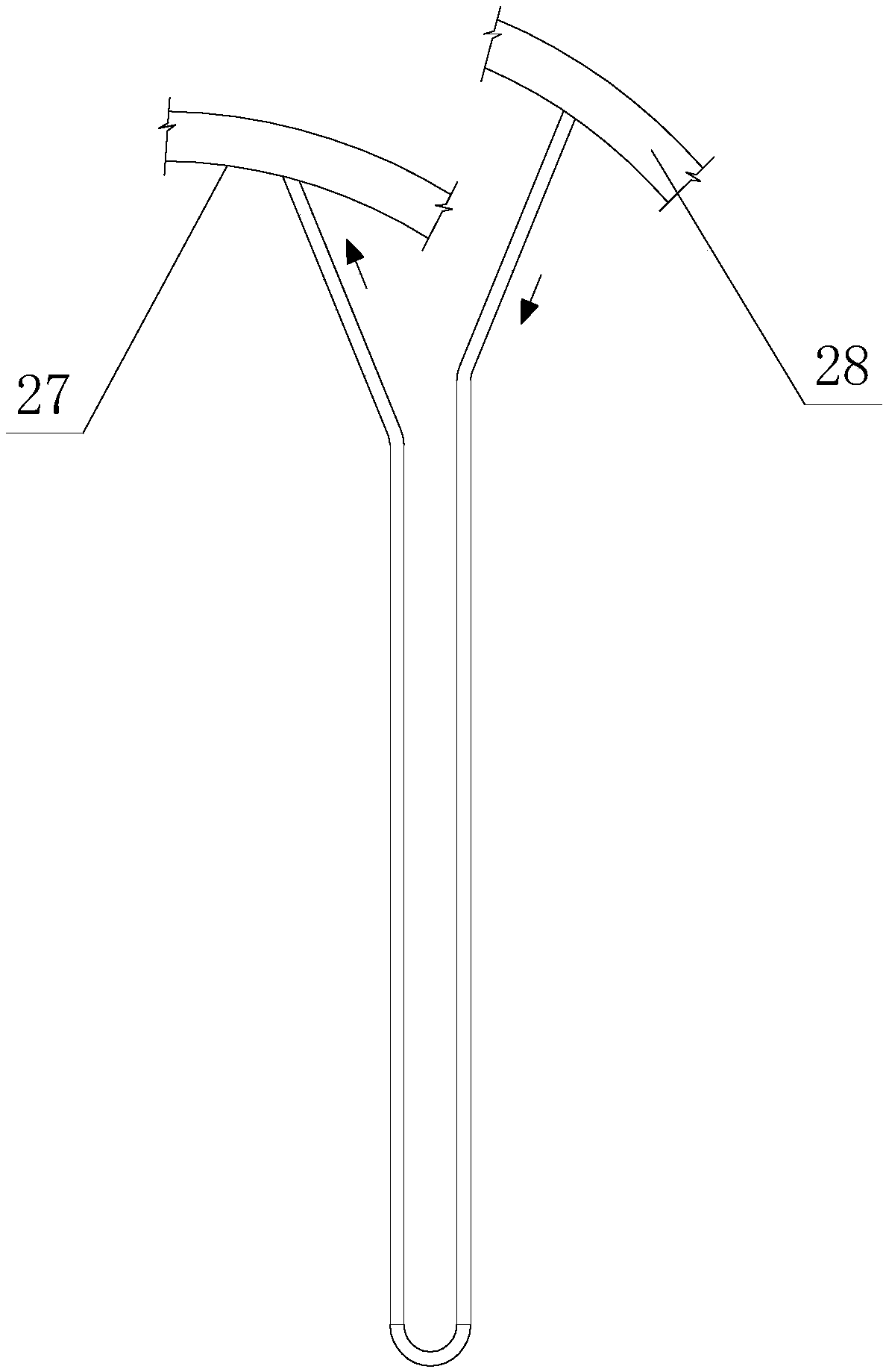

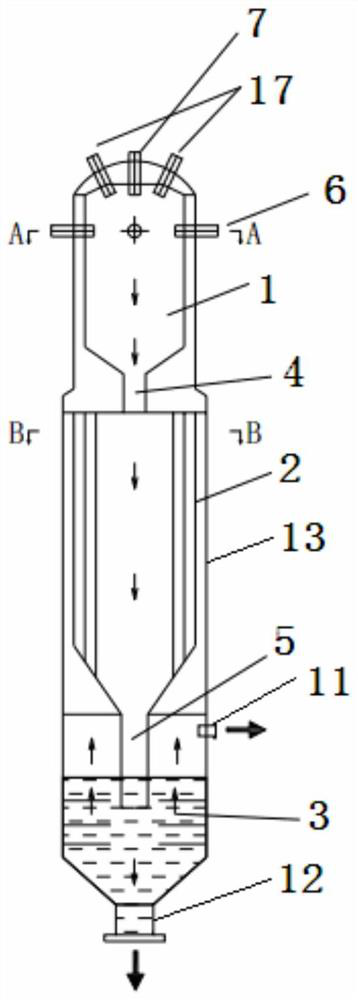

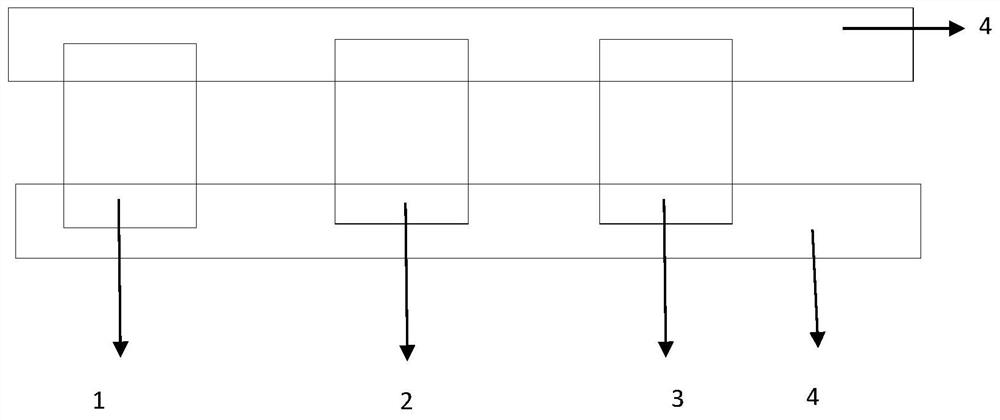

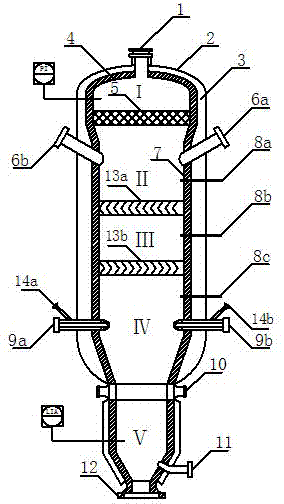

Pyrolysis device for processing desulfurization waste liquid in partial oxidation environment

InactiveCN103951131AAchieve recyclingFlexible operationMultistage water/sewage treatmentLiquid wastePartial oxidation

The invention discloses a pyrolysis device for processing desulfurization waste liquid in a partial oxidation environment. The pyrolysis device comprises a pressure-bearing housing, a jacket, an insulating layer and a refractory brick which are arranged from outside to inside and connected together, and a gas separation section I, a spray pyrolysis section II, a mixed flow pyrolysis section III, an inactive salt pyrolysis section IV and a pyrolysis salt chilling section V are communicated from top to bottom to treat the desulfurization waste liquid in the partial oxidation environment. The device adopts a segmental treatment mode, so that decomposition of aromatic compounds and organic matters in the desulfurization waste liquid is ensured in the partial oxidation environment, COD and sulfides in the generated wastewater are reduced, meanwhile, pyrolysis of the inactive salt in the desulfurization waste liquid in the reducing atmosphere is ensured; therefore, the pollution problem of the desulfurization waste liquid is thoroughly solved and effective components in the desulfurization waste liquid can be recycled.

Owner:TAIYUAN UNIV OF TECH

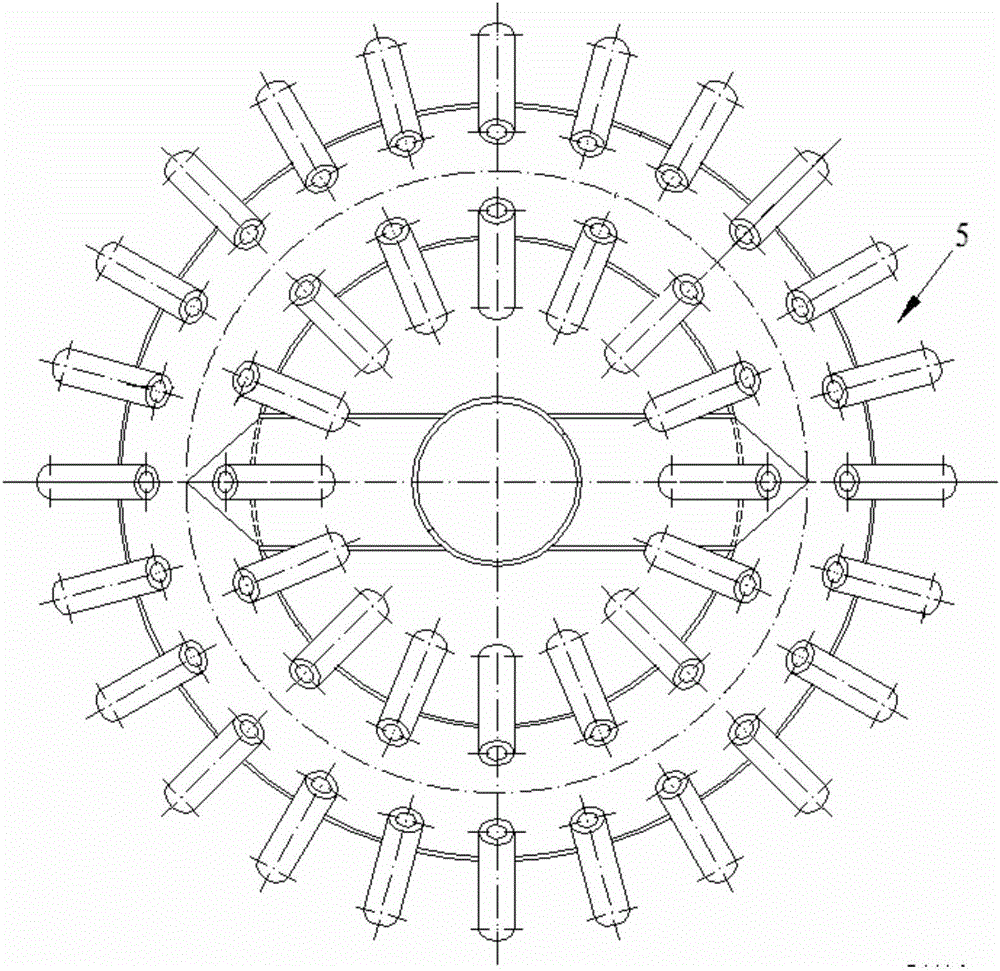

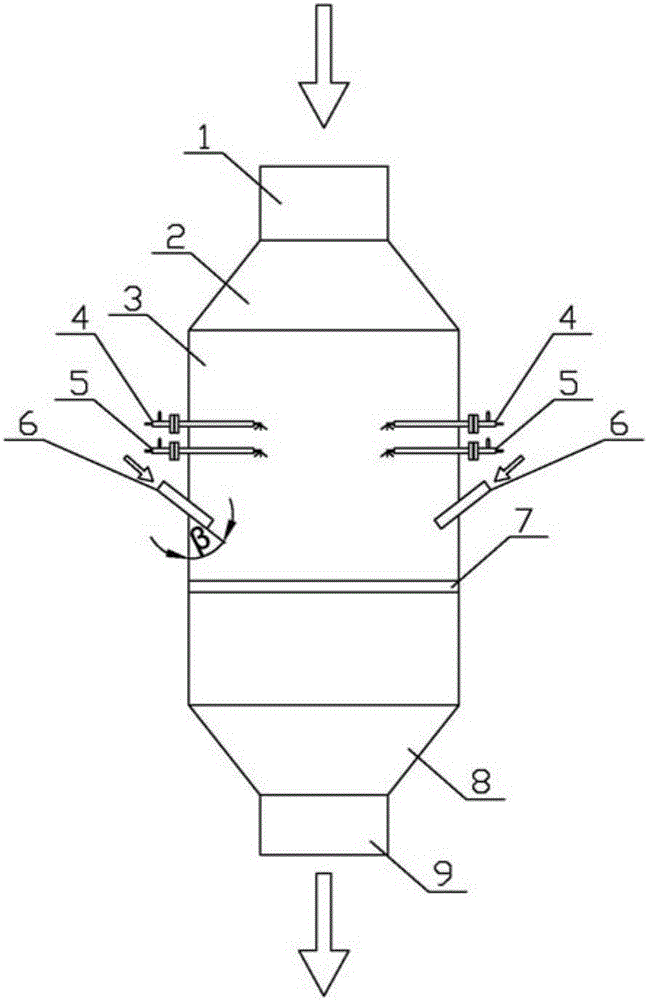

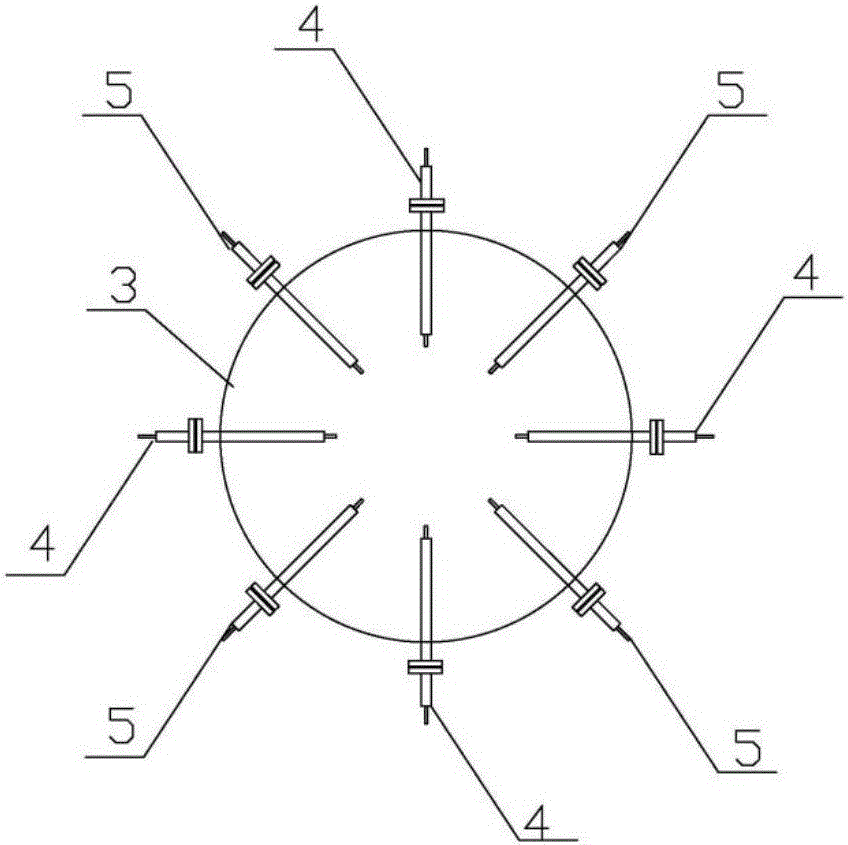

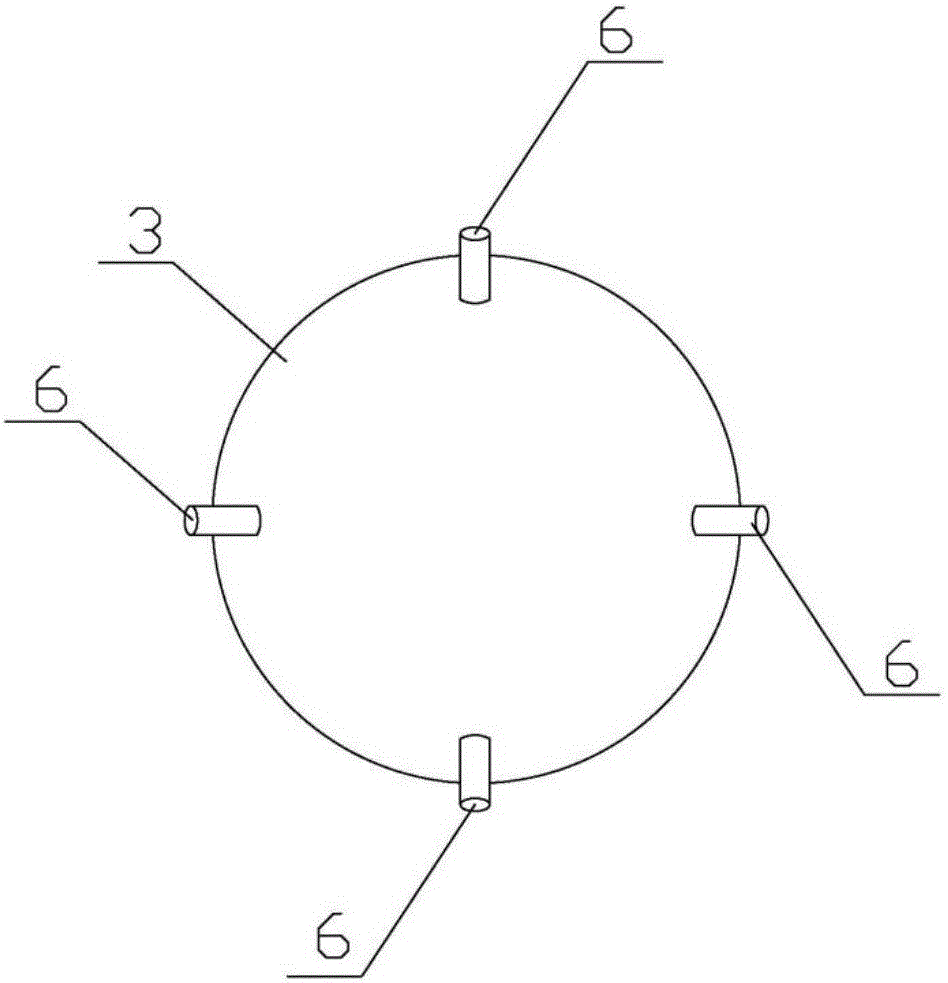

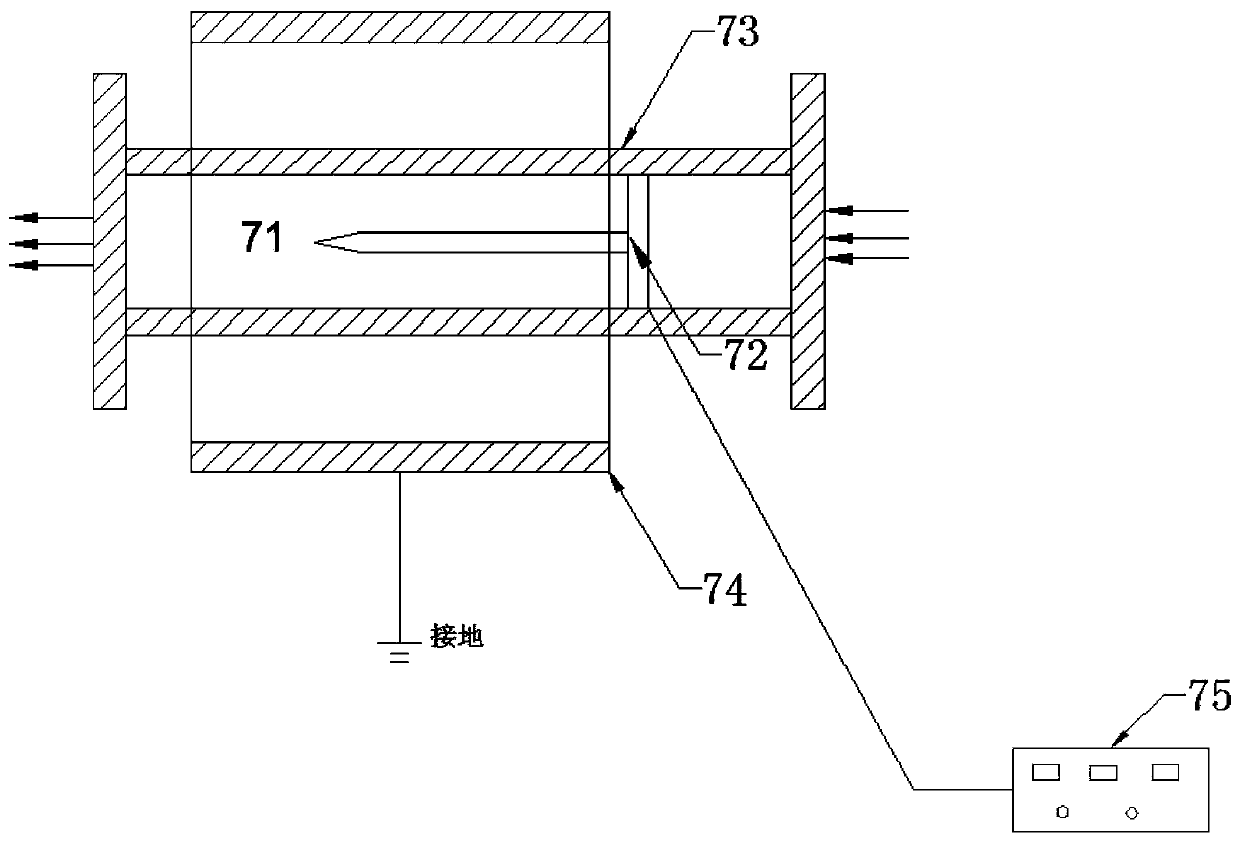

Urea backmixing and pyrolysis apparatus applicable to SCR denitration system and pyrolysis method

ActiveCN106082271AOvercoming sticky wallsOvercome efficiencyDispersed particle separationAmmonia preparation/separationCombustionDecomposition

The invention discloses a urea backmixing and pyrolysis apparatus applicable to a SCR denitration system and a pyrolysis method. The apparatus comprises a tower body; the tower body is provided with, from top to bottom, a combustion-supporting wind pipeline, an inlet variable-diameter section, a pyrolytic reaction section, an outlet variable-diameter section and an outlet pipeline; the pyrolytic reaction section is provided with a spray gun layer, a compensation wind pipeline layer and a gas flow equalizing plate from top to bottom; the number of the spray gun layer is at least one; and the spray gun layer is provided with a plurality of spray guns used for spraying an atomized urea solution, the plurality of spray guns are uniformly and radially distributed on the tower wall of the pyrolytic reaction section, and the spraying direction of each of the spray guns downwardly extending along the axial direction of the pyrolytic reaction section. According to the invention, the urea solution is mixed with combustion-supporting wind for primary pyrolysis and then with compensation wind for secondary pyrolysis, so the mixing degree of the urea solution and hot gas is promoted and generation of urea deposit and crystal is prevented; thus, the decomposition efficiency of the urea solution is improved.

Owner:FUJIAN LONGKING +1

Method for preparing 2, 4-dinitroaniline by using microreactor

PendingCN111635322AIncrease productivityReduce energy consumptionOrganic compound preparationChemical industryMicroreactorChlorobenzene

The invention relates to the technical field of preparation of 2, 4-dinitroaniline, in particular to a method for preparing 2, 4-dinitroaniline by using a microreactor. The method comprises the following steps: (1) preparing equipment, namely preparing a preheater, the microreactor and two chromatographic pumps; (2) connecting reaction equipment, respectively connecting two chromatographic pumps with the preheater and the micro-reactor, then connecting the preheater with the micro-reactor, and putting the preheater and the microreactor into a constant-temperature oil bath after the connectionis completed; (3) conveying a reaction material, namely conveying ammonia water to the preheater at a preset flow rate, conveying the molten 2, 4-dinitrochlorobenzene to the microreactor at a preset flow rate, and mixing and reacting with the ammonia water to obtain 2, 4-dinitroaniline; and (4) after the reaction of the material in the step (3) is completed, preparing the redundant ammonia gas into ammonia water again for reuse through an ammonia gas recovery device, and continuing to reuse the ammonia generated by the reaction of ammonium chloride generated by the reaction and potassium hydroxide. Tthe method has the characteristics of high production efficiency, low energy consumption, economy, environmental protection, safety and reliability.

Owner:杭州迈科瑞科技有限公司

Solid waste gasifying system and solid waste gasifying method

PendingCN107723030AHeating up fastDehydration fastGasification processes detailsGasification with fuel pre-distillationSlagSpray nozzle

The invention discloses a solid waste gasifying system and a solid waste gasifying method. Currently, solid wastes are disposed mainly by incineration so as to cause secondary environmental pollutioneasily. According to the solid waste gasifying system, an air distribution mechanism is arranged at the bottom part of a furnace body; a primary air inlet of the air distribution mechanism is communicated with a gasifying fan by a one-way mixer, and a secondary air inlet of the air distribution mechanism is communicated with an inner cavity of the furnace body by a ring-shaped air duct, and is also communicated with an air outlet of the one-way mixer; a mixed steam inlet of the one-way mixer is communicated with a high-temperature steam outlet; the inner part of the furnace body is divided into an upper empty layer, a drying cavity, a dry distillation cavity, a lower empty layer, a reducing cavity, an oxidizing cavity and an ash slag cavity; dry steam spraying nozzles communicated with a high-temperature steam inlet are distributed in the drying cavity; dry distillation steam spraying nozzles communicated with the high-temperature steam inlet are distributed in the dry distillation cavity; high-temperature steam coils are distributed in the drying cavity and the dry distillation cavity and are communicated with the high-temperature steam inlet and the high-temperature steam outlet;and a dry distillation gas outlet is formed in the upper empty layer and a reducing gas outlet is formed in the lower empty layer. The solid waste gasifying system and the solid waste gasifying method disclosed by the invention have the advantages that the solid waste can be continuously transformed into combustible gas and cured furnace slag for high-temperature sintering, so that the harmless purpose is achieved.

Owner:马加德

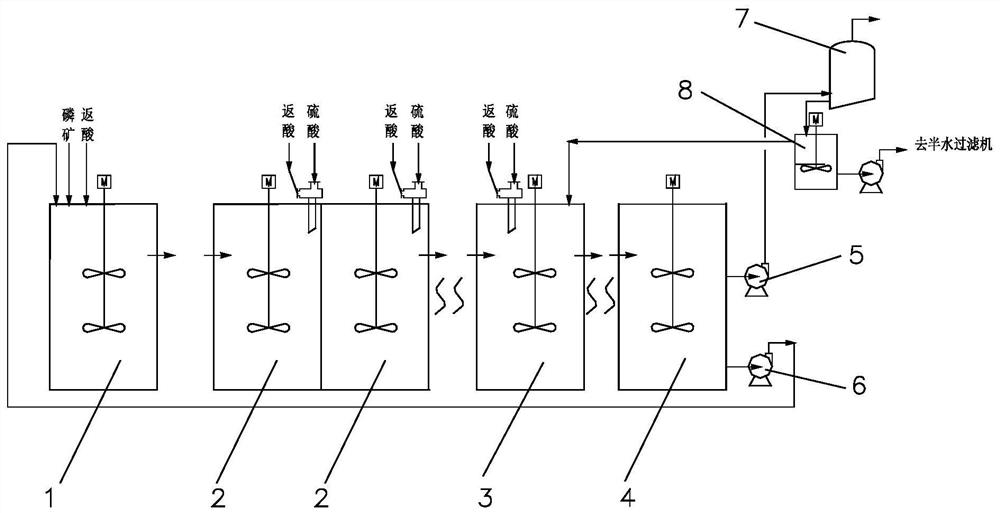

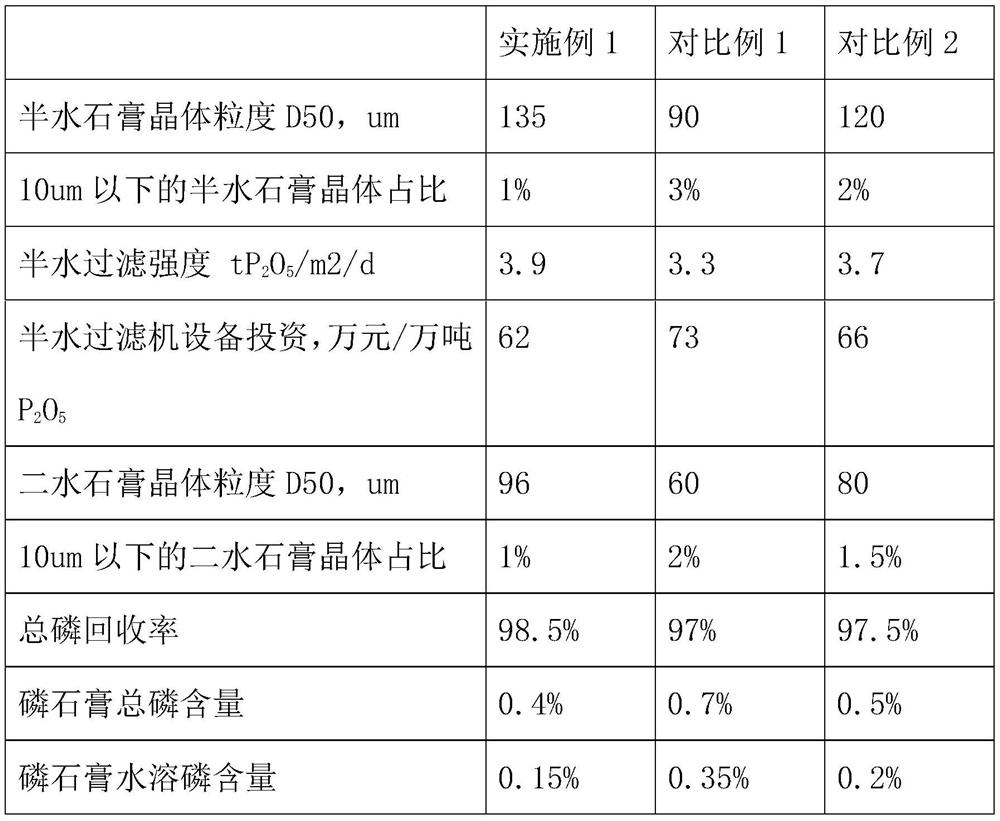

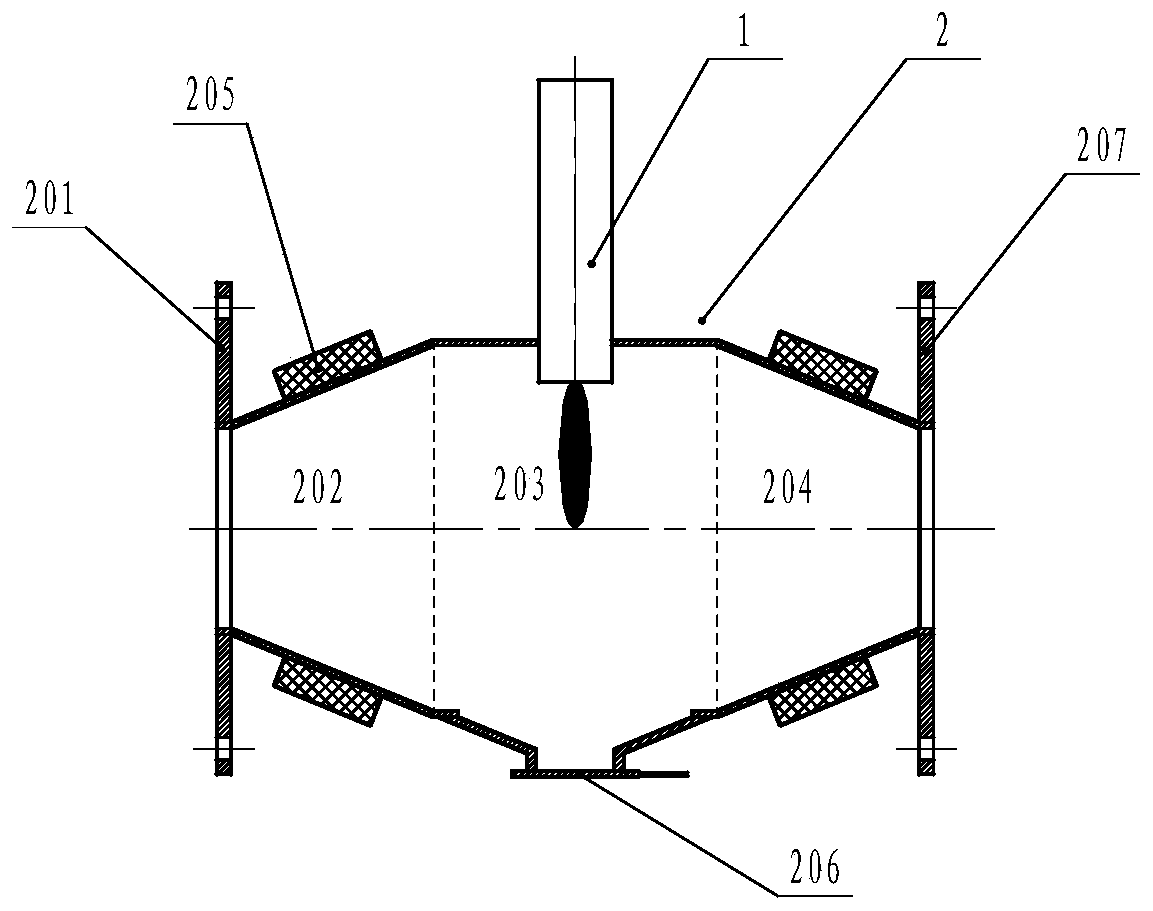

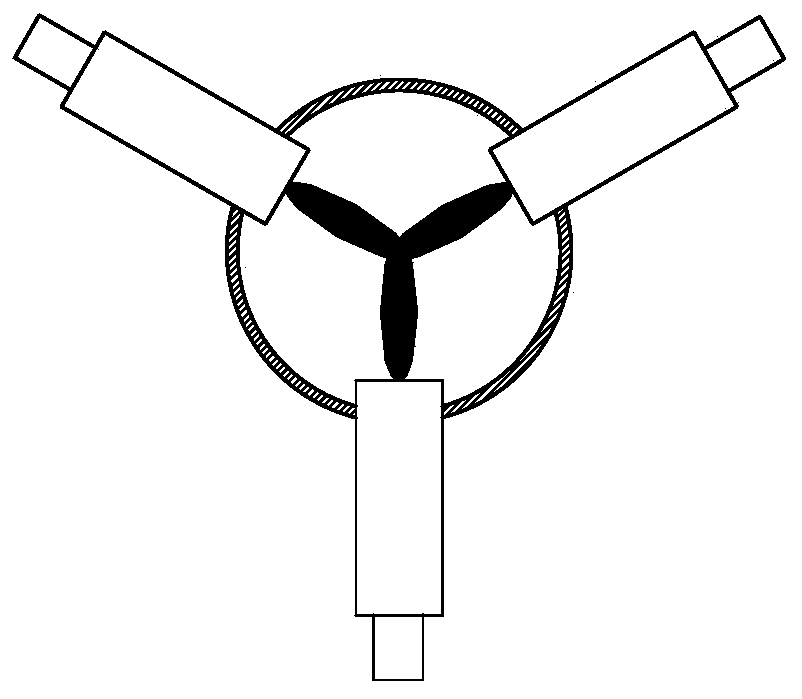

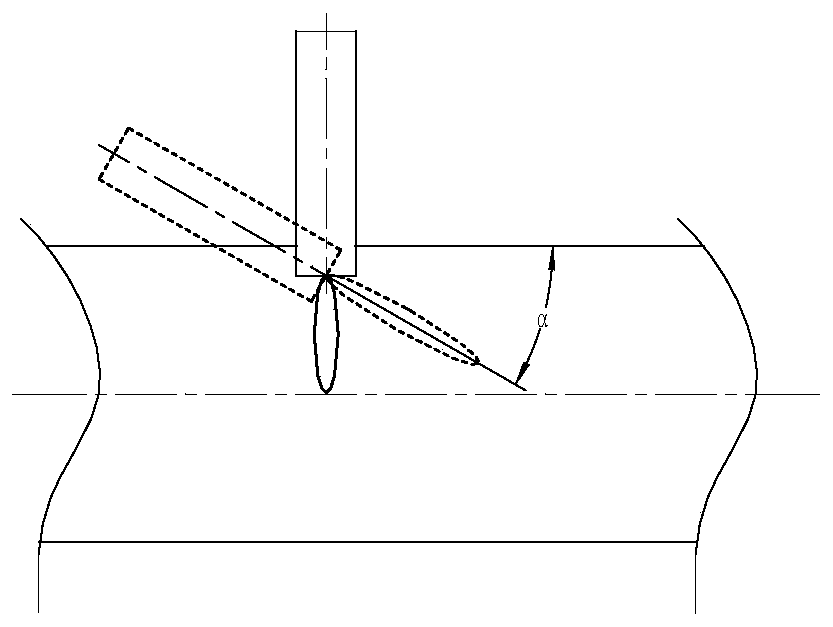

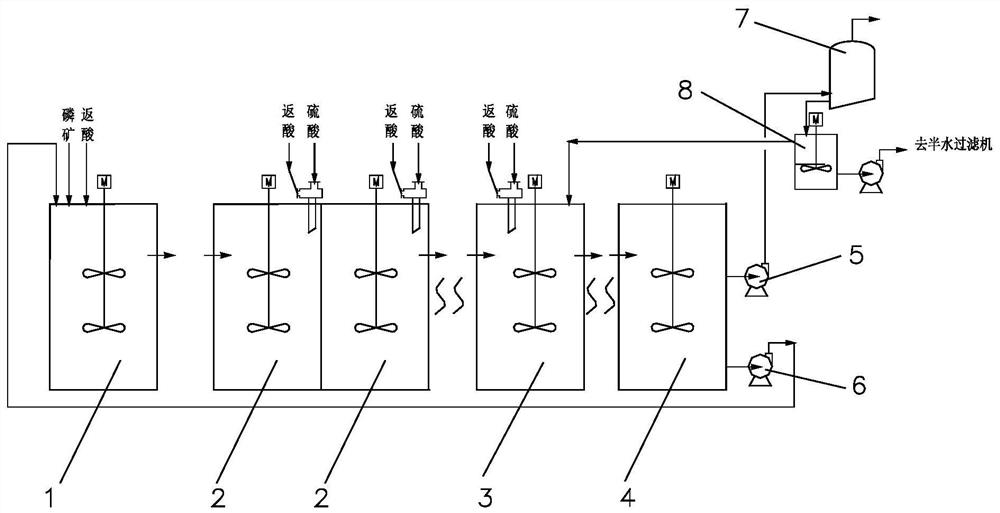

Method for controlling coarse crystallization of semi-hydrated gypsum

ActiveCN113185160AStable growthUniform particle sizeCalcium/strontium/barium sulfatesPhosphorus compoundsSulfatePhysical chemistry

The invention discloses a method for controlling coarse crystallization of semi-hydrated gypsum, which comprises the steps of 1, firstly feeding phosphorite into a premixing area, mixing with returned acid, and quickly decomposing; 2, feeding the slurry discharged from the premixing area into a dissolving area, and fully dissolving the slurry in the presence of returned acid and sulfuric acid to avoid generating a compact calcium sulfate wrapping film; 3, feeding the reaction slurry discharged from the dissolving area into a crystallization area, and crystallizing and growing in the presence of concentrated sulfuric acid; and 4, feeding the reaction slurry out of the crystallization region into a curing region, and further growing the semi-hydrated gypsum crystals. The method is simple, easy to control, high in yield and capable of effectively obtaining coarse and large semi-hydrated gypsum crystals with good uniformity.

Owner:WUHUAN ENG

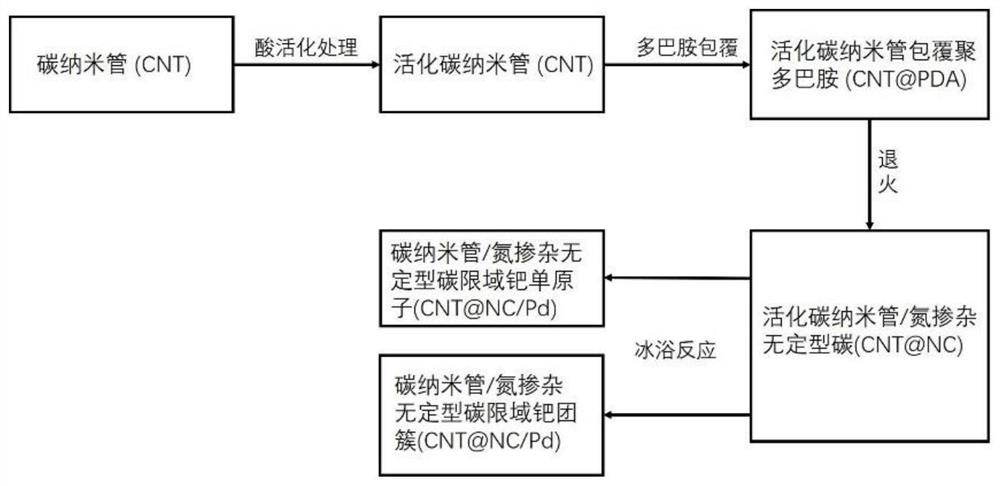

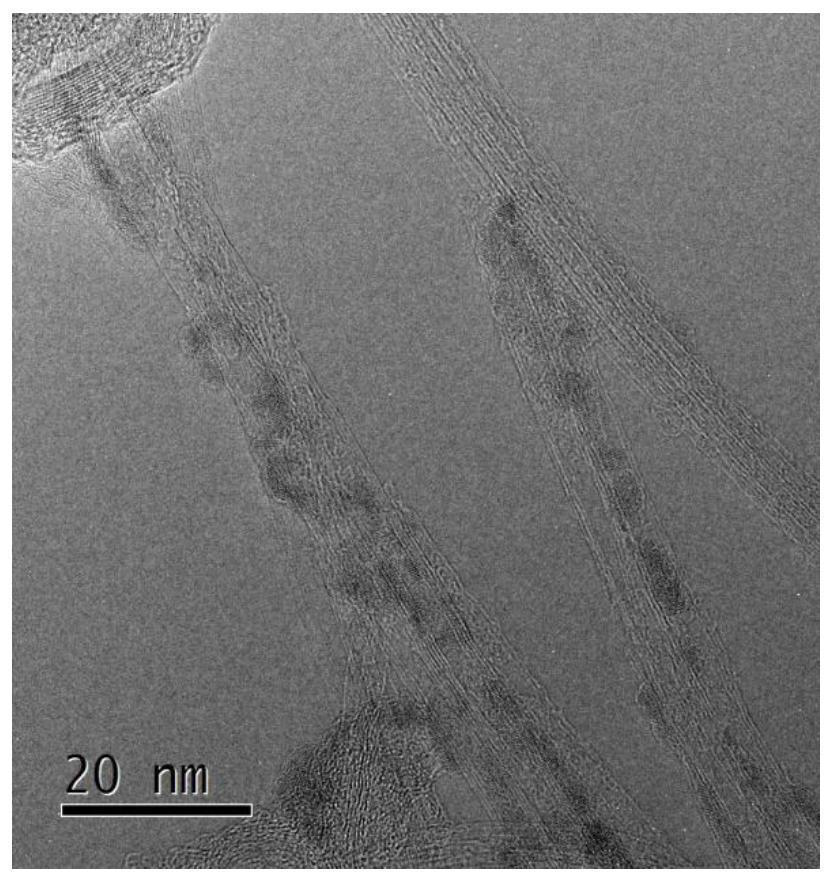

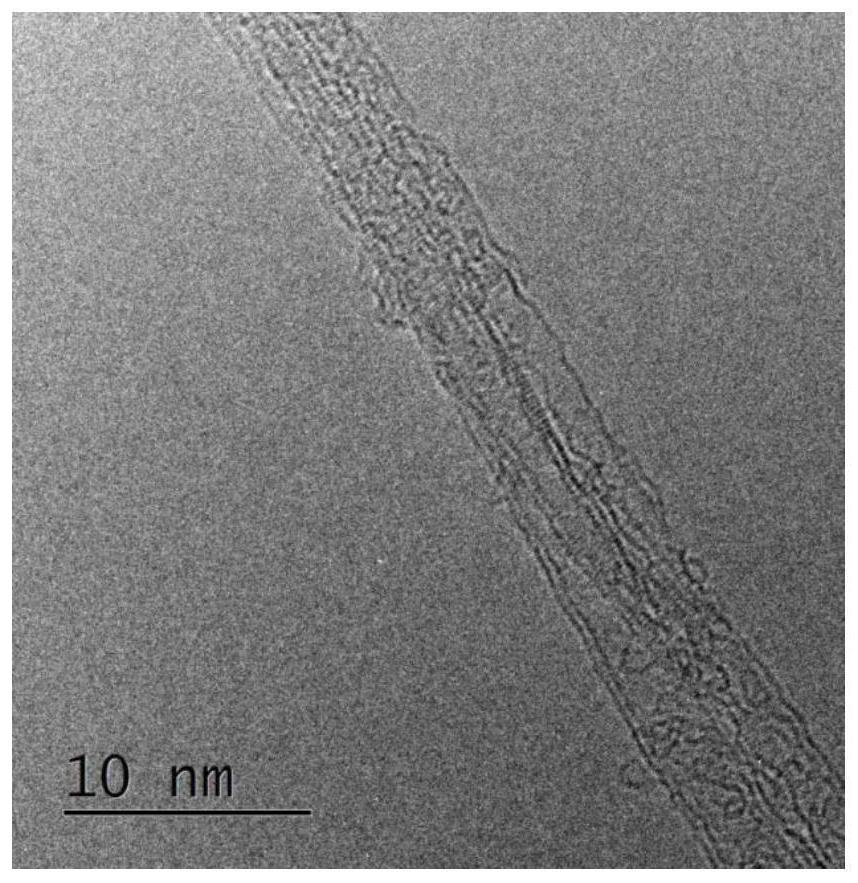

Size-adjustable palladium-based catalyst limited by carbon nanotubes as well as preparation method and application of size-adjustable palladium-based catalyst

ActiveCN111659372AThe method is simple and easyExtend reaction residence timePhysical/chemical process catalystsOrganic compound preparationNitro compoundReduction of nitro compounds

The invention belongs to the technical field of catalysts, and particularly relates to a size-adjustable palladium-based catalyst limited by carbon nanotubes as well as a preparation method and an application of the size-adjustable palladium-based catalyst. By improving the whole process flow and the reaction conditions and parameters (such as types and proportions of reaction raw materials, reactant concentration and reaction temperature) of all key process steps, precious metal active substances are limited in the inner cavity of the carbon nano tube, and the metal size can be regulated andcontrolled by controlling the reaction conditions. The preparation method is simple in process, convenient to operate, cheap and easily available in reaction materials, and capable of preparing the confinement catalyst with specific catalytic performance according to specific requirements, including a carbon nano tube confinement palladium monatomic catalyst and a carbon nano tube confinement palladium cluster catalyst, so that accurate regulation and control between the loading capacity and the size are realized. The prepared palladium-based catalyst can be used for catalyzing a reduction reaction of an aromatic nitro compound and shows excellent catalytic activity.

Owner:ZHUHAI FUDAN INNOVATION INST

High-yield hydrated crystalline phase reconstruction wet-process phosphoric acid production technology

ActiveCN113173566AImprove overall recoveryAvoid acid accumulationPhosphorus compoundsHydration reactionO-Phosphoric Acid

The invention discloses a high-yield hydrated crystalline phase reconstruction wet-process phosphoric acid production technology. The technology comprises a semi-hydrated reaction filtration process and a dihydrate reaction filtration process, and the semi-hydrated reaction filtration process comprises the steps of premixing, dissolving, crystallizing, curing and semi-hydrated filtration; and the dihydrate reaction filtration process comprises a conversion step and a dihydrate filtering step. According to the invention, through gradient control of the relationship between the sulfate ion concentration and the CaO concentration in different stages of the semi-hydrated reaction, the crystal size is increased, the crystal is kept stable, and the semi-hydrated gypsum crystal with uniform particle size is obtained; by changing the circulation path of the slurry, the reaction retention time is prolonged, and the growth of semi-hydrated gypsum crystals in a relatively stable environment is ensured; coarse, uniform and stable dihydrate gypsum crystals are obtained by controlling the degree of supersaturation of a dihydrate reaction, the filtering performance is good, the content of water-soluble phosphorus in the dihydrate gypsum is reduced, and the filtering yield is improved; and by reasonably utilizing the filtrate and the flushing water, the wastewater discharge is reduced, and the total yield of P2O5 is increased.

Owner:WUHUAN ENG

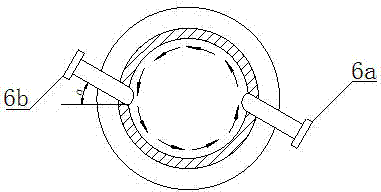

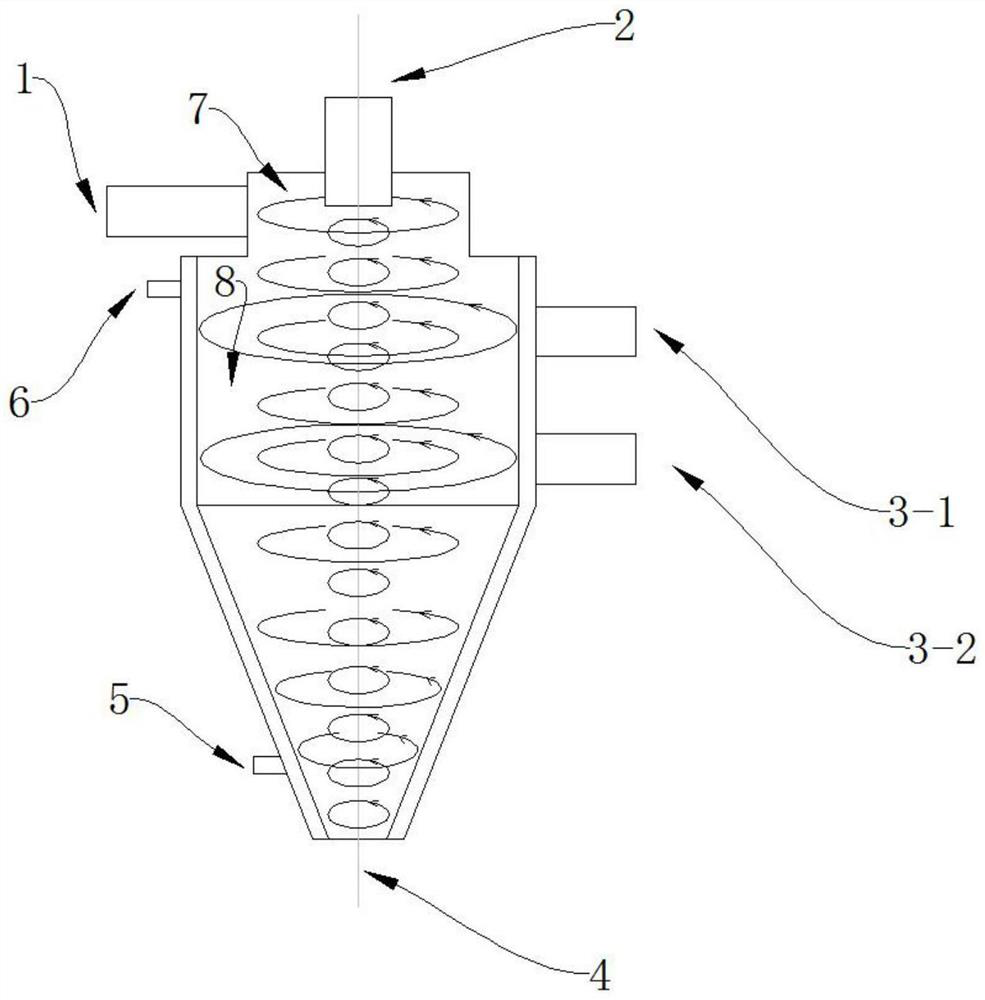

Purification treatment method and apparatus of solid waste pyrolysis gasification synthesis gas

PendingCN110184095AAchieving expansion slowdownExtend reaction residence timeGas treatmentDispersed particle separationEngineeringAlternating current

The invention relates to a purification treatment method and apparatus of a solid waste pyrolysis gasification synthesis gas, and belongs to the technical field of pollutant emission control. The apparatus applies a three-phase alternating current arc plasma torch to purify and treat a synthesis gas generated by a treatment process of solid waste pyrolysis gasification and the like. In the apparatus, a gas to be treated is subjected to expansion and deceleration, a reaction residence time is increased, the thorough mixing of the gas to be treated with a high temperature plasma in a reaction chamber is increased, a uniform high-temperature region and a controlled atmosphere formed by a circumferential uniform distribution manner of a three-phase alternating current plasma are utilized, under the action of the high temperature plasma, tar, dioxin and other macromolecular organic substances containing in the gas to be treated are directly decomposed into small molecular chain hydrocarbonswithout combustion, and thus the synthesis gas purification function is achieved under conditions that combustible components in the synthesis gas are not burned.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

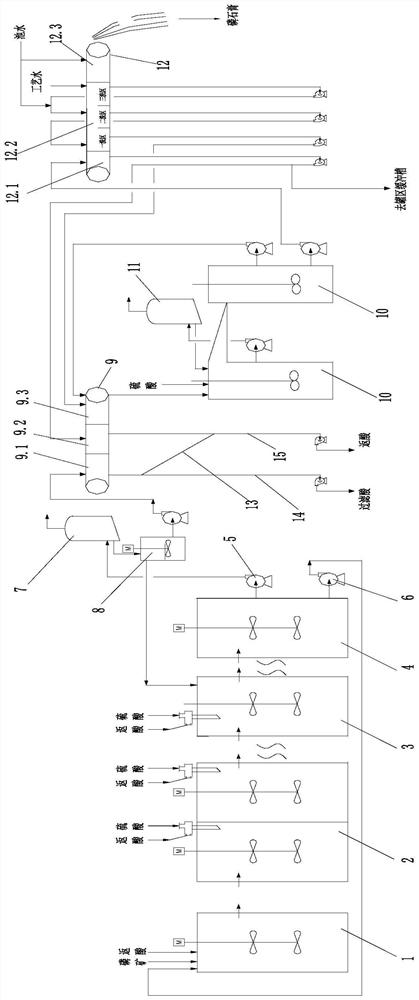

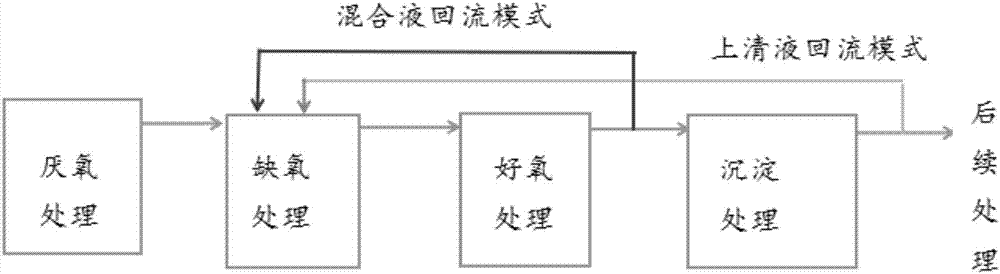

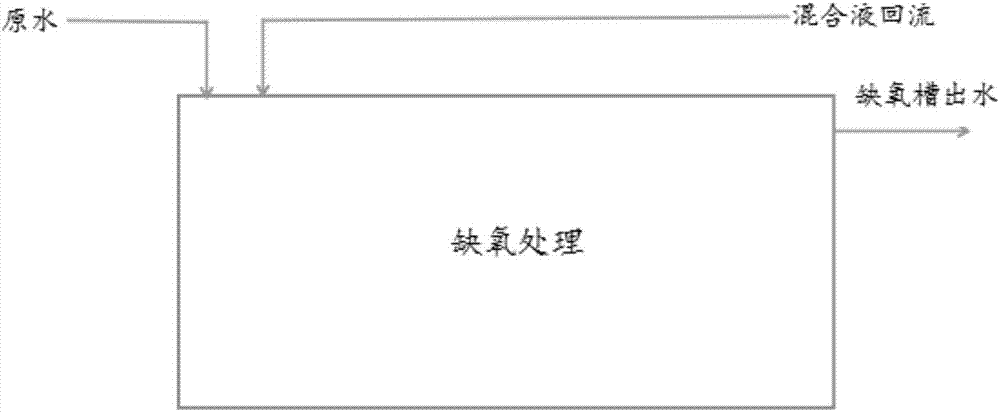

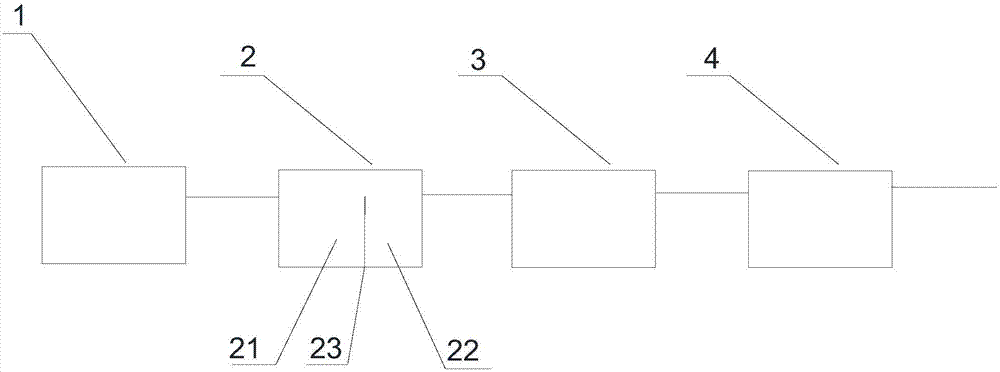

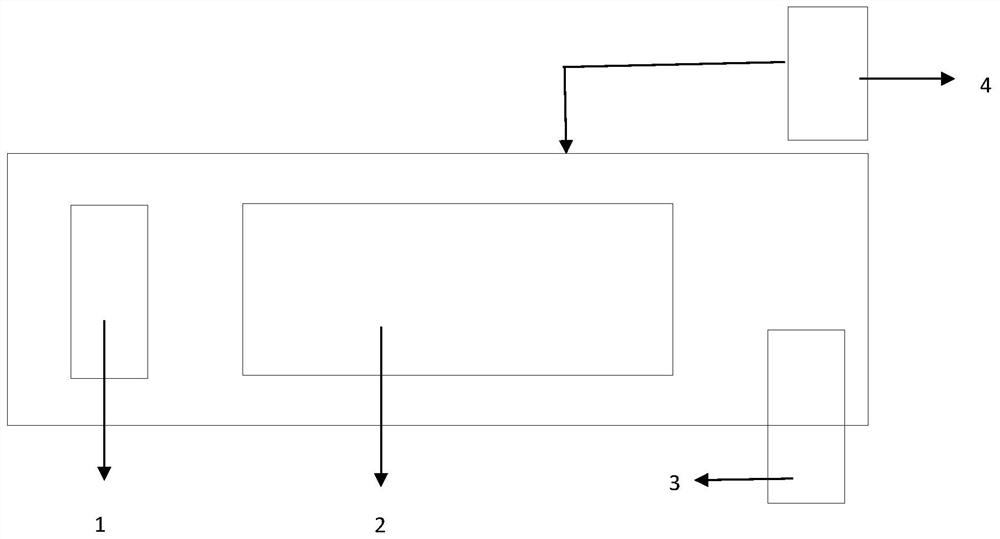

Denitrification device for coking wastewater mixed liquid and method for improving denitrification ability of coking wastewater

InactiveCN107200429AImprove nitrogen removal efficiencyReduce processing loadWater contaminantsTreatment with aerobic and anaerobic processesAlkalinityRetention time

The invention provides a denitrification device for coking wastewater mixed liquid and a method for improving denitrification ability of coking wastewater. The device comprises an anaerobic tank, an anoxic tank, an aerobic tank and a settling tank which communicate with one another successively, wherein a good carbon source case and a carbon-source-free case are arranged in the anoxic tank; the good carbon source case is arranged at a water outlet end of the anoxic tank; the carbon-source-free case is arranged at a raw water and mixed liquid inlet end of the anoxic tank; and the good carbon source case is in half isolation from the carbon-source-free case. The denitrification device has the beneficial effects that the total nitrogen of water drained from an A / O system is greatly reduced, treatment load of rear denitrification is greatly reduced, therefore, reaction retention time of rear denitrification is reduced, and the investment and the running cost are reduced; and meanwhile, alkalinity produced by high denitrification efficiency is improved, consumption of alkali liquor for nitrification of an aerator tank can be reduced, the running cost of the aerator tank is reduced, and therefore, the denitrification device is dual-purpose.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

Multi-nozzle gasification furnace with top auxiliary burners and application of multi-nozzle gasification furnace

PendingCN114214094AReduce energy consumptionImprove energy utilizationEnergy inputGranular/pulverulent flues gasificationThermodynamicsSlag

The multi-nozzle gasification furnace comprises a hollow furnace body, a reaction chamber, a radiation waste boiler chamber and a chilling chamber are sequentially arranged in the furnace body from top to bottom, the reaction chamber is communicated with the radiation waste boiler chamber through a gas-slag channel, a downcomer is arranged at the lower end of the radiation waste boiler chamber, and the chilling chamber is communicated with the reaction chamber through a gas-slag channel. The lower end of the descending pipe extends into the chilling chamber; a plurality of main burners are arranged on the outer side wall of the reaction chamber, and an ignition start-up burner and a plurality of auxiliary burners are arranged at the top of the reaction chamber. The invention further provides a using method of the multi-nozzle gasification furnace with the top auxiliary burner. According to the multi-nozzle gasification furnace with the top auxiliary burner and the application of the multi-nozzle gasification furnace, the reaction retention time is prolonged, the carbon conversion rate of the gasification furnace is increased, the energy consumption is greatly reduced, the operation cost is reduced, and the requirement for environmental protection is met.

Owner:广西华谊能源化工有限公司 +1

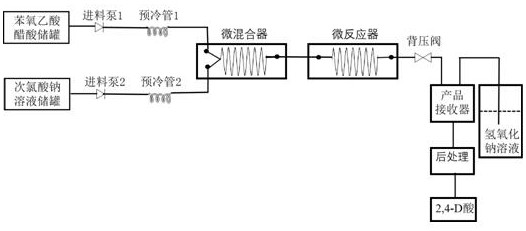

Method for preparing 2, 4-D acid by using micro-reaction device

ActiveCN112521268AEasy to operate and controlImprove securityOrganic compound preparationCarboxylic compound preparationPhenoxy acetic acidMicroreactor

The invention discloses a method for preparing 2, 4-D acid by chlorinating phenoxyacetic acid by using a micro-reaction device. The method comprises the steps: dissolving phenoxyacetic acid in glacialacetic acid to obtain a glacial acetic acid solution of phenoxyacetic acid, and pumping the glacial acetic acid solution of phenoxyacetic acid into a pre-cooling pipe 1 of the micro-reaction device for pre-cooling; pumping a sodium hypochlorite solution into a pre-cooling pipe 2 of the micro-reaction device for pre-cooling; then pumping the two solutions into a micro-mixer in the micro-reaction device to be fully mixed; introducing the mixed solution into a micro-reactor of the micro-reaction device for reaction; after the reaction is finished, carrying out post-treatment on the reaction solution to obtain the 2, 4-D acid. The preparation method of the 2, 4-D acid can overcome the problems that an expensive solvent and a complex catalyst need to be used, many byproducts are produced and the like in the existing 2, 4-D acid post-chlorination technology, the continuous degree of the production process is high, the safety of the production process can be greatly improved, and the yield of the product is increased.

Owner:ZAOZHUANG UNIV +1

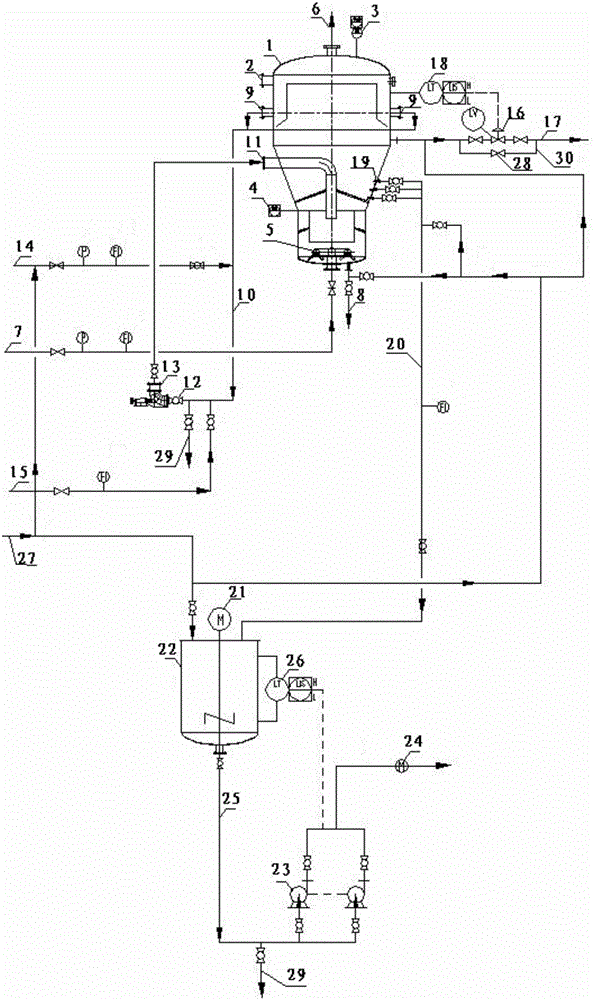

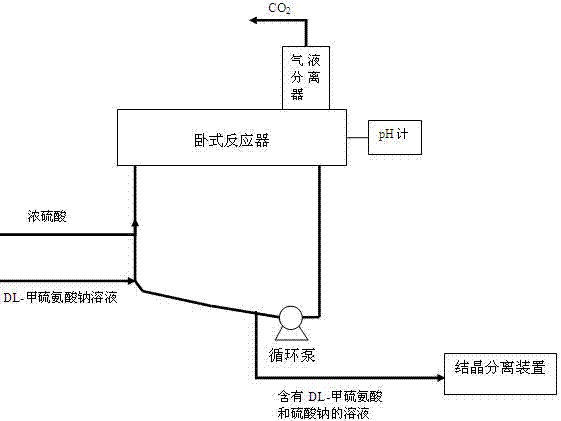

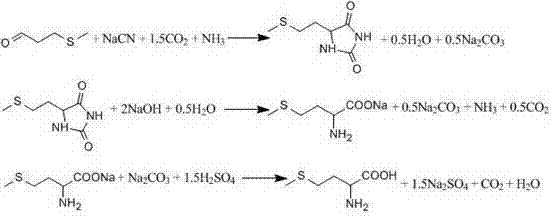

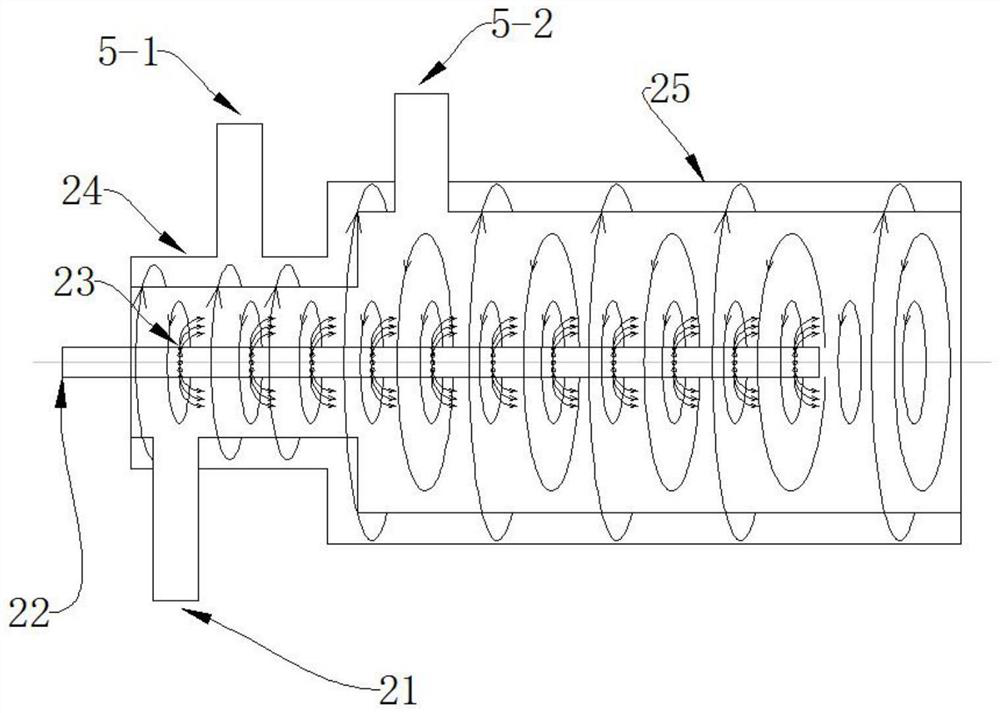

Method for preparing DL-methionine

ActiveCN102633699BReduce generationHigh purityOrganic compound preparationSulfide preparationDL-methionineRetention time

Disclose is a device for preparing DL-methionine, comprising a reaction unit and a crystallization separation unit. The reaction unit is a horizontal reactor. A liquid outlet of the horizontal reactor is in communication with an inlet of a circulating pump, and an outlet of the circulating pump is separately in communication with a liquid inlet of the horizontal reactor and a liquid inlet of the crystallization separation unit. After being in communication, the circulating pump and the horizontal reactor form a circulating system whose total volume is equal to 3-5 times the feed volume. Also disclosed is a method for preparing DL-methionine by using the foregoing device, comprising: continuously feeding an aqueous solution of DL-methionine salt and concentrated sulfuric acid into the horizontal reactor for neutral reaction; dividing the liquid discharged from the liquid outlet of the horizontal reactor into two parts through the circulating pump; and returning one part of the liquid to the horizontal reactor to be forcedly circulated in the volume equal to 3-5 times the feed volume, and introducing the other part of the liquid to the crystallization separation unit to precipitate DL-methionine crystals to obtain DL-methionine. By using the device and method, a great deal of heat released through the neutral reaction is evenly dissipated, and the reaction retention time is prolonged, which is beneficial to complete reaction; large-scale continuous industrial production is realized, and byproducts are reduced as much as possible.

Owner:NINGXIA UNISPLENDOUR TIANHUA METHIONINE CO LTD

Dry-wet combined sulphur removal system for waste incineration flue gas

InactiveCN106861391ANothing producedReduce consumptionCombination devicesGas treatmentCooling towerBaghouse

The invention discloses a dry-wet combined sulphur removal system for waste incineration flue gas. The dry-wet combined sulphur removal system for the waste incineration flue gas belongs to the technical field of flue gas desulfurizationenvironment protection, and comprises a cooling tower, an absorption tower, a bag-type dust collector and a chimney connected sequentially, wherein a water atomization spray head is arranged on the top part of the cooling tower; a flue gas inlet is formed in the top part of the cooling tower; a flue gas outlet is formed in the bottom part of the cooling tower; an activated carboninjection pipe and a powderyslaked lime injection pipe are arranged on a gas flue for connecting the cooling tower and the absorption tower; the absorption tower is connected with a quick limeserous fluid inlet pipe; the quick limeserous fluid inlet pipe is connected with a quick limeserous fluidbatching system. After the waste incineration flue gas passes through the dry-wet combined sulphur removal system provided by the invention, the smoke dust is reduced to be around 30mg / m<3>, the HCl is reduced to be around 50mg / m<3>, and the SOX is reduced to be around 200mg / m<3>.

Owner:HEFEI TIANXIANG ENVIROMENT PROJECT

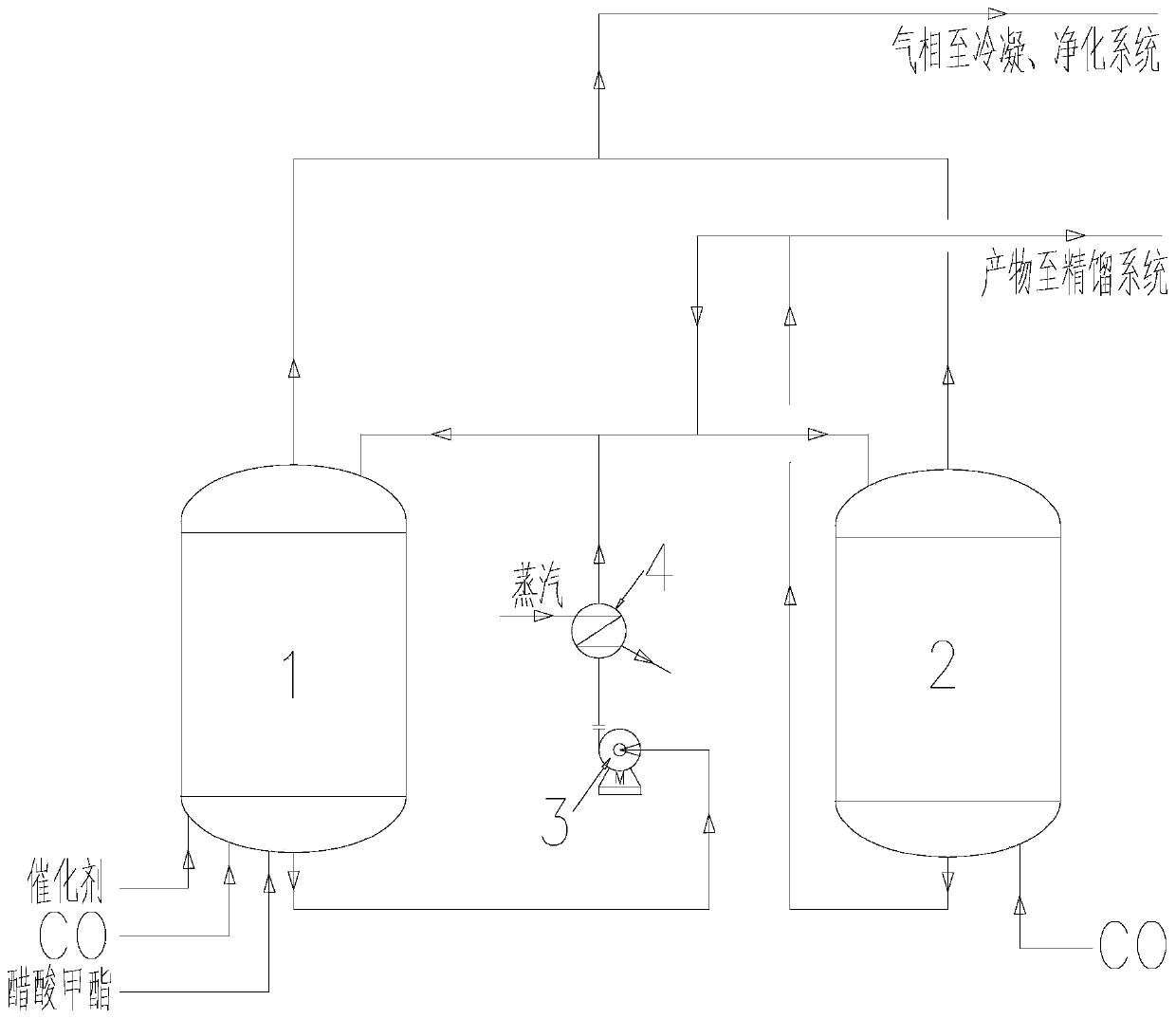

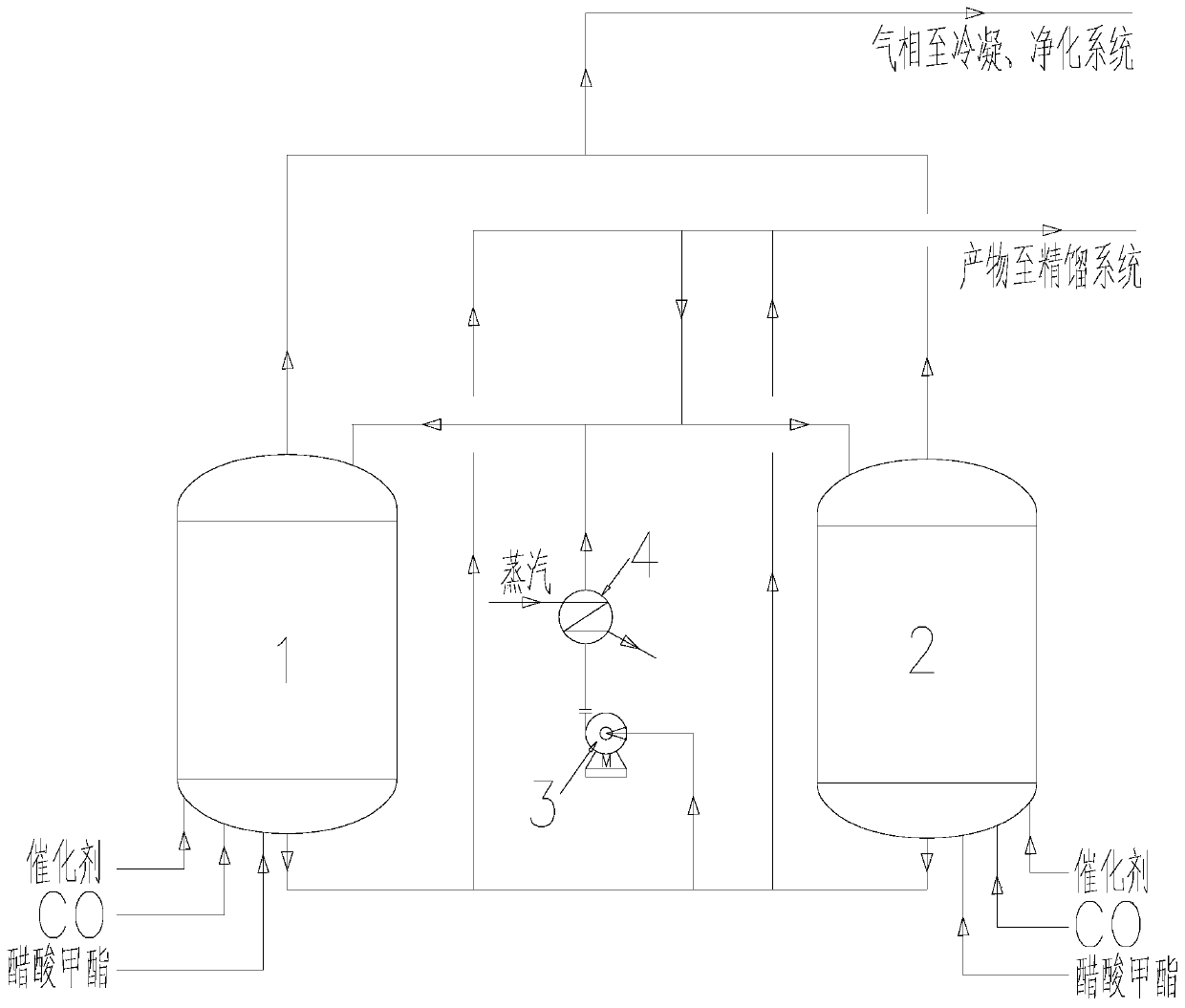

A kind of technique of low-pressure oxo synthesis of acetic anhydride

ActiveCN106892812BExtend reaction residence timeIncrease conversion rate per passCarboxylic acid anhydrides preparationAcetic anhydridePtru catalyst

The invention discloses a system and a process for synthesizing acetic anhydride from low-pressure carbonyl. The system comprises a reaction kettle group, wherein the reaction kettle group is an assembly formed by connecting at least two reaction kettles in series or in parallel; in case of serial connection, a pump and a heat exchanger are arranged between every two adjacent serially connected reaction kettles; carbon monoxide, methyl acetate and a catalyst enter the system from the first stage of reaction kettle in the reaction kettle group; materials at the bottom of the reaction kettle enters the next stage of reaction kettle after being pumped out through the pump and heated through the heat exchanger till a product in the last stage of reaction kettle is fed into a distillation system; reaction kettles from the second stage to the last stage are all provided with pipelines for feeding the carbon monoxide; in case of parallel connection, carbon monoxide, methyl acetate and the catalyst enter every reaction kettle in the reaction kettle group; and the materials at the bottom of each reaction kettle flow back into every reaction kettle after being pumped out through the pumps and the heat exchangers, and a product in each reaction kettle is fed into the distillation system.

Owner:YANKUANG GRP CO LTD

Method for controlling coarse crystallization of hemihydrate gypsum

ActiveCN113185160BStable growthUniform particle sizeCalcium/strontium/barium sulfatesPhosphorus compoundsSulfatePhysical chemistry

Owner:WUHUAN ENG

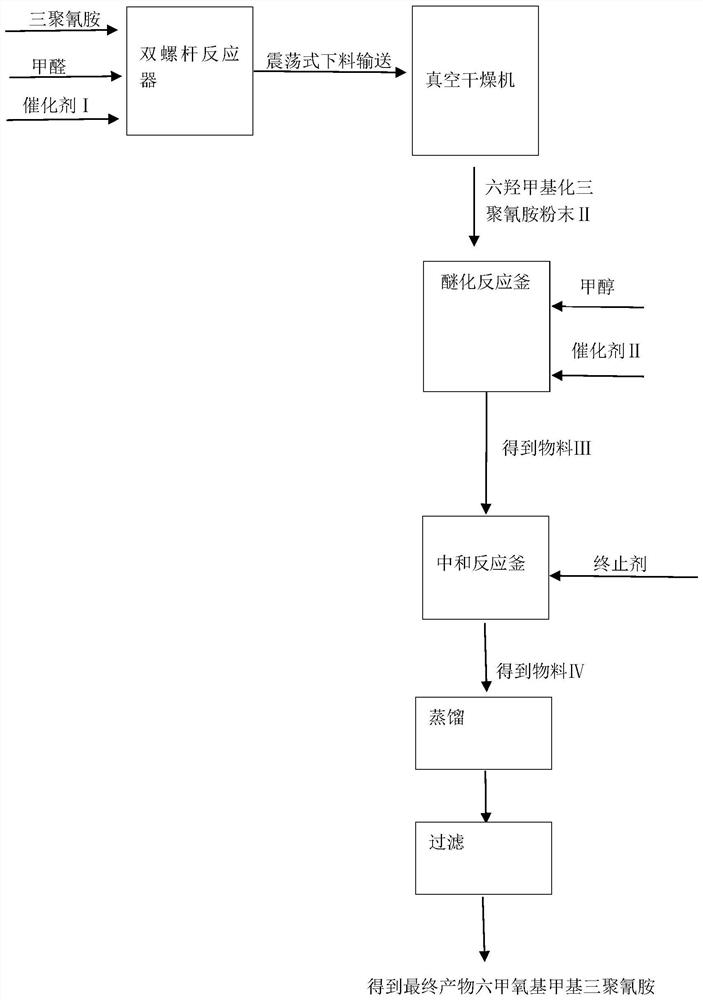

Continuous and stable production of highly etherified hexamethoxymethylmelamine preparation method

ActiveCN111205235BImprove self-cleaning abilityHigh degree of basicizationOrganic chemistryHexa(methoxymethyl)melaminePtru catalyst

Owner:JIANGSU CHANGNENG ENERGY SAVING NEW MATERIALS SCI & TECH

In-furnace desulfurization method of circulating fluidized bed boiler

InactiveCN109731449AOvercoming the problem of sharp drop in desulfurization efficiencySynergistic removalDispersed particle separationFluidized bedEngineering

The invention provides an in-furnace desulfurization method of a circulating fluidized bed boiler, which comprises the steps of introducing a desulfurizing agent and fire coal into a furnace body of the circulating fluidized bed boiler, allowing to react, feeding a superfine composite additive into the circulating fluidized bed boiler from a secondary air hole of the circulating fluidized bed boiler, and carrying out in-furnace desulfurization. The method of the invention combines the in-furnace desulfurizing agent and a superfine composite additive spraying technique, so that super-low emission of SO2 can be stably achieved. The problems are solved that, for instance, traditional wet and semi-dry desulfurization processes have large coverage, secondary pollution is caused, water resourceconsumption is high, and operation cost is high.

Owner:YANKUANG GRP CO LTD +1

Pyrolysis device for processing desulfurization waste liquid in partial oxidation environment

InactiveCN103951131BRestricted accessReduce generationMultistage water/sewage treatmentLiquid wastePartial oxidation

The invention discloses a pyrolysis device for processing desulfurization waste liquid in a partial oxidation environment. The pyrolysis device comprises a pressure-bearing housing, a jacket, an insulating layer and a refractory brick which are arranged from outside to inside and connected together, and a gas separation section I, a spray pyrolysis section II, a mixed flow pyrolysis section III, an inactive salt pyrolysis section IV and a pyrolysis salt chilling section V are communicated from top to bottom to treat the desulfurization waste liquid in the partial oxidation environment. The device adopts a segmental treatment mode, so that decomposition of aromatic compounds and organic matters in the desulfurization waste liquid is ensured in the partial oxidation environment, COD and sulfides in the generated wastewater are reduced, meanwhile, pyrolysis of the inactive salt in the desulfurization waste liquid in the reducing atmosphere is ensured; therefore, the pollution problem of the desulfurization waste liquid is thoroughly solved and effective components in the desulfurization waste liquid can be recycled.

Owner:TAIYUAN UNIV OF TECH

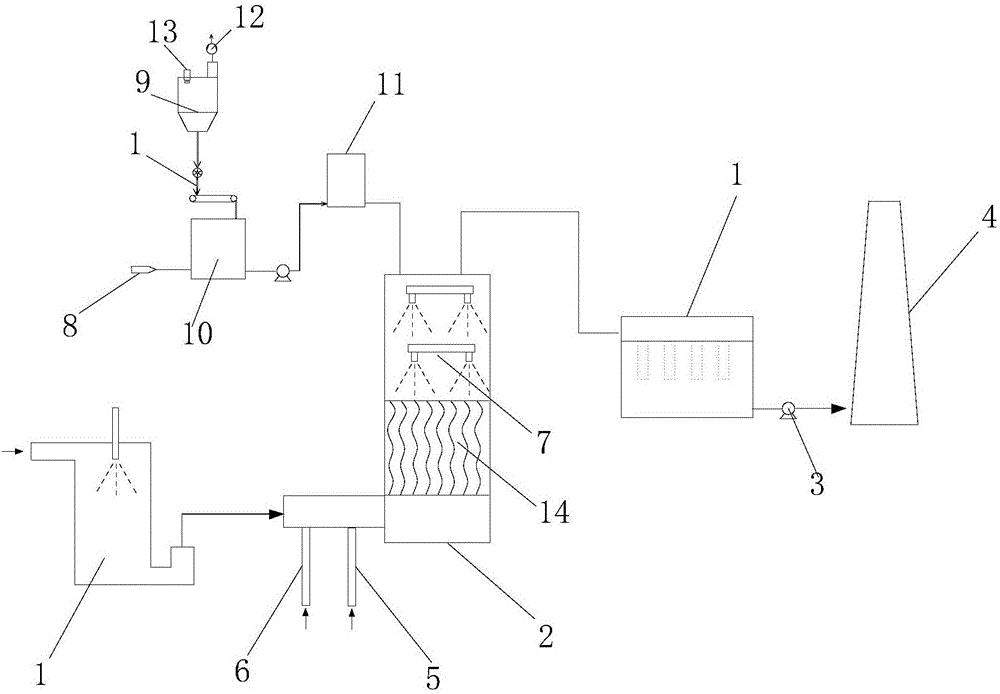

Garbage incinerator smoke gas treatment system

InactiveCN106823766ANothing producedReduce consumptionCombination devicesGas treatmentBaghouseSlurry

The invention discloses a garbage incinerator smoke gas treatment system, and belongs to the technical field of smoke gas desulfurization environment protection. The garbage incinerator smoke gas treatment system comprises a temperature reducing tower, an absorption tower, a cloth bag dust remover and a chimney in sequential connection, wherein a water atomization spray head is arranged at the top of the temperature reducing tower; a smoke gas inlet is formed in the top of the temperature reducing tower; a smoke gas outlet is formed in the lower part of the temperature reducing tower; a secondary spraying device is arranged on the top of the absorption tower; a ripple water film absorbing device is arranged under the secondary spraying device; an active carbon spraying pipe and a powdery slaked lime spraying pipe are arranged on a flue for connecting the temperature reducing tower and the absorption tower; the absorption tower is connected with a quicklime slurry feeding pipe; the quicklime slurry feeding pipe is connected with a quicklime slurry proportioning system. After the garbage incineration smoke gas passes through the system, the smoke dust is reduced to about 30mg / m<3>; the HCl is reduced to about 40mg / m<3>; the SOX is reduced to about 150mg / m<3>.

Owner:HEFEI TIANXIANG ENVIROMENT PROJECT

Fuel nozzle, solid fuel combustion system and preheating combustion method

PendingCN114251652AImprove conversion rateExtend reaction residence timeEnergy inputIndirect carbon-dioxide mitigationCombustion systemSolid fuel

The invention discloses a fuel nozzle, a solid fuel combustion system and a preheating combustion method. The nozzle comprises a straight cylinder part, and a cover is arranged above the straight cylinder part; a secondary air inlet is formed in the cover; the straight cylinder part comprises two cylinder sections with different diameters, the two cylinder sections with different diameters are fixedly connected, and the preheating fuel inlet and the tertiary air inlet are respectively formed in the two cylinder sections with different diameters. And the preheated fuel inlet is used for introducing preheated fuel. On the basis of preheating modification nitrogen reduction of the preheating combustor, re-gasification nitrogen reduction of a nozzle of the separation cavity, longitudinal on-way multi-layer tertiary air addition, airflow rotation of the separation cavity, on-way layered secondary gasification, nitrogen reduction and reaction retention time increase are achieved, the conversion rate of hot semicoke fuel is increased, and ultralow NOx emission and stable combustion are achieved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com