Fuel nozzle, solid fuel combustion system and preheating combustion method

A fuel inlet and nozzle technology, which is applied in the field of clean and efficient combustion of solid fuel, can solve the problems of difficult to achieve ultra-low NOx emission and stable combustion, and achieve the effect of increasing the reaction residence time and the conversion rate of hot semi-coke fuel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. But following embodiment only limits to explain the present invention, and protection scope of the present invention should comprise the whole content of claim, and by the narration of following embodiment, those skilled in the art can fully realize the whole content of claim of the present invention.

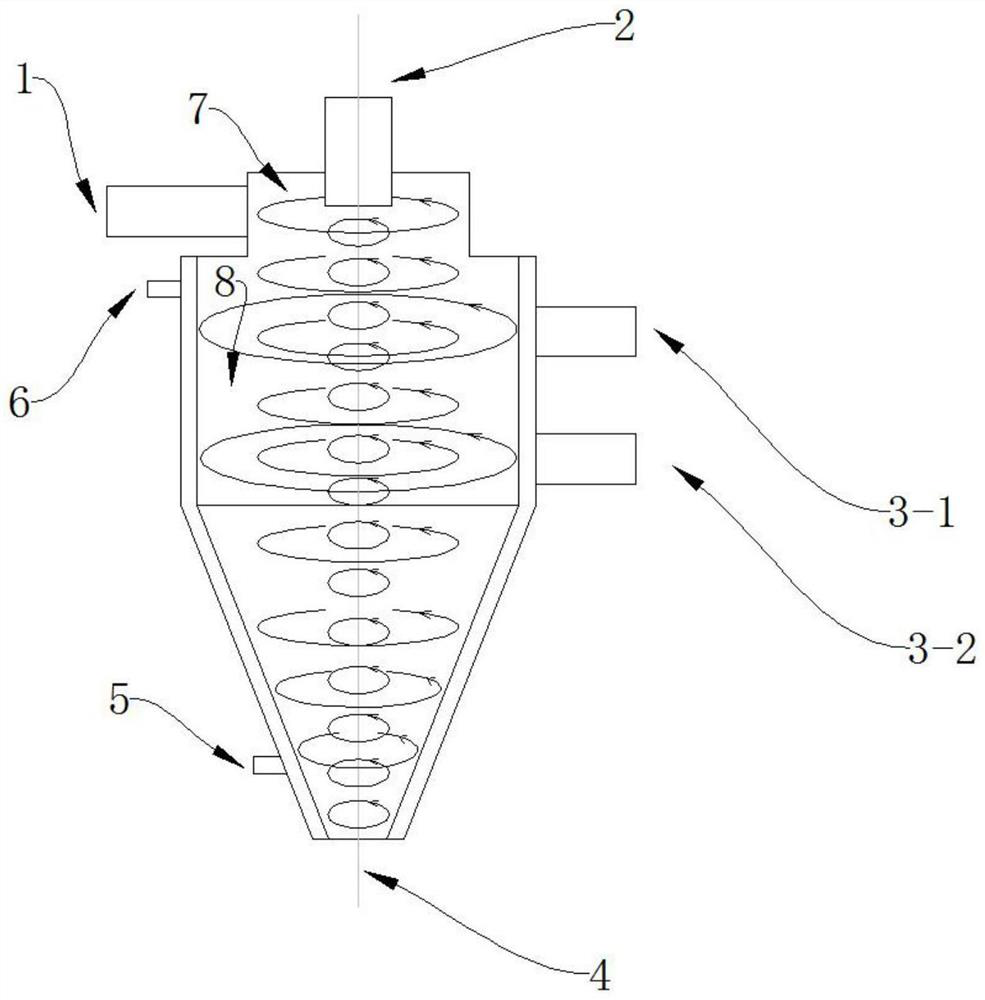

[0047] The invention relates to an ultra-low NOx separation cavity nozzle with wide load adjustment and low load stable combustion.

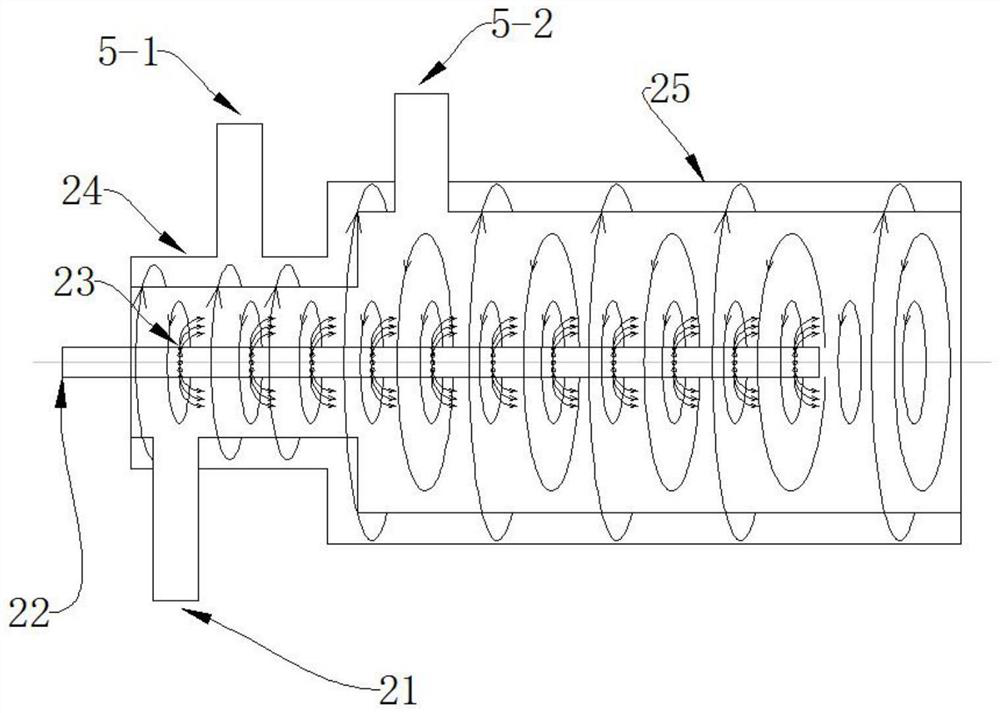

[0048] A specific embodiment of the present invention, such as figure 1 As shown, an ultra-low NOx separation chamber nozzle with wide load adjustment and low load stable combustion, the separation chamber nozzle includes a straight cylinder part and a cone cylinder part from top to bottom. The cone part is fixedly connected with the lower part of the straight part, a top cover is arranged above the straight part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com