Patents

Literature

44results about How to "Increase gasification reaction rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

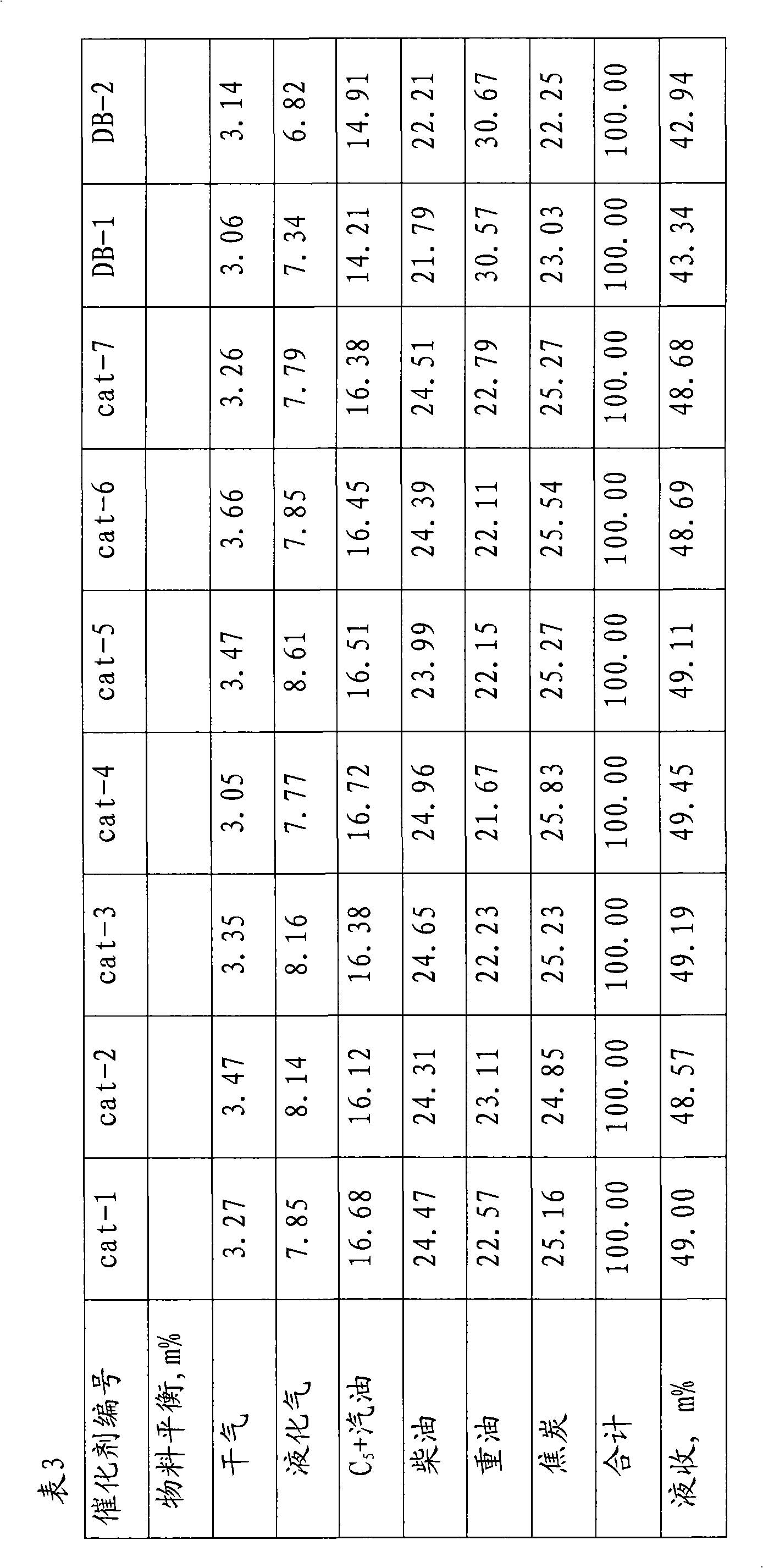

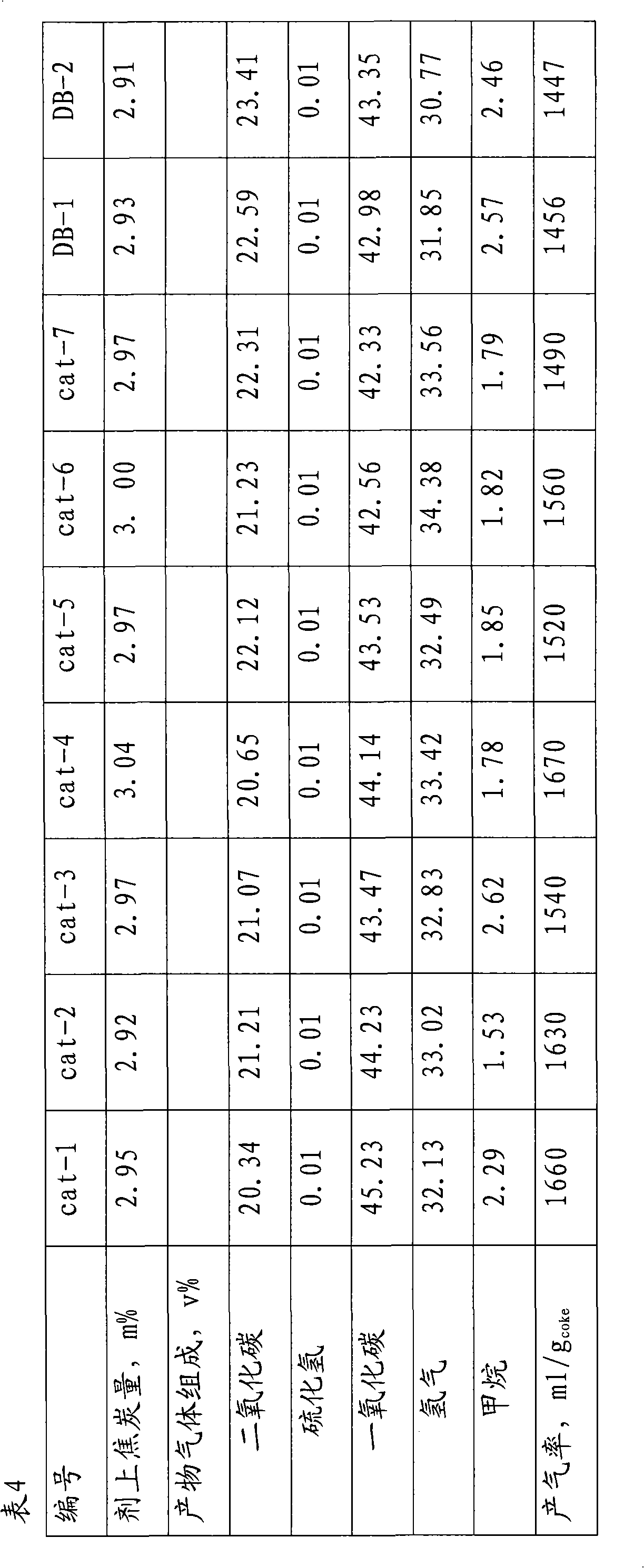

Catalyst with cracking and gasifying function and preparation method thereof

ActiveCN101757903AHas catalytic gasification reaction activityLarge specific surface areaCatalytic crackingMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalHydrocarbon

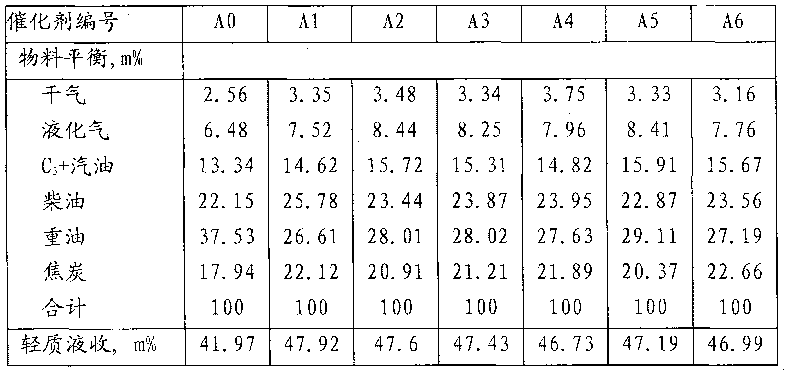

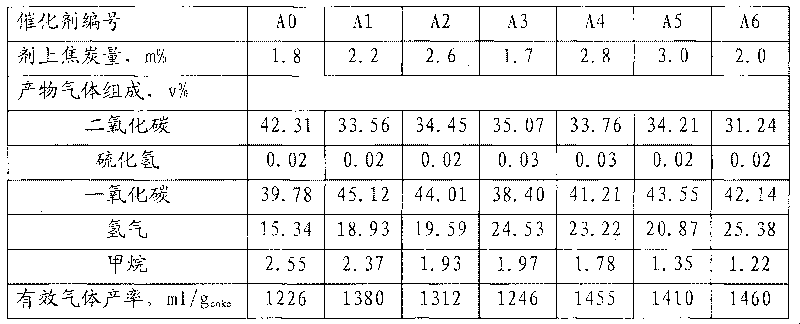

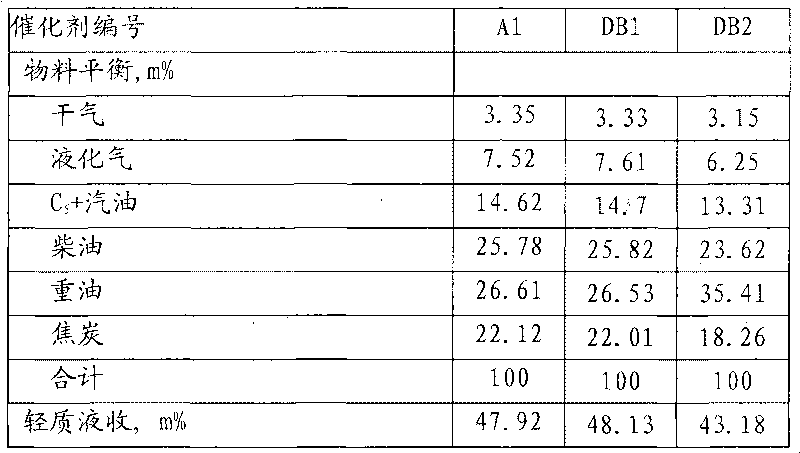

The invention relates to a catalyst with cracking and gasifying function, on the basis of the weight of the catalyst, which comprises: 35-60 percent of pseudo-boehmite, 2-10 percent of alumina sol, 20-49.5 percent of kaolin, 5-30 percent of alkali metals and alkaline-earth metals (by oxide), wherein the atomic ratio of the alkali metals to the alkaline-earth metals is (0.05-0.9):1. The catalyst has the optimization effects on the hydrocarbon oil cracking products distribution and the gasification effective gas productivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Inferior heavy oil cracking and gasifying catalyst

ActiveCN101898143AWeaken the effects of acidityHigh yieldCatalytic crackingMolecular sieve catalystsOil processingAlkaline earth metal

The invention discloses an inferior heavy oil cracking and gasifying catalyst, comprising carrier, binder, gasification active components and cracking active components, wherein the gasification active components are alkali metals and alkaline-earth metals, by taking the catalyst total content as a reference, the oxide content is 2-30%, the atom ratio of the alkali metals to the alkaline-earth metals is (0.05-1.1):1, and the cracking active components are shape selective zeolite with the silica alumina ratio within 20-200. The catalyst aims to the inferior heavy oil processing procedure, considers heavy oil cracking and coke high temperature gasification and improves light oil yield and coke gasification reaction rate obviously.

Owner:CHINA PETROLEUM & CHEM CORP +1

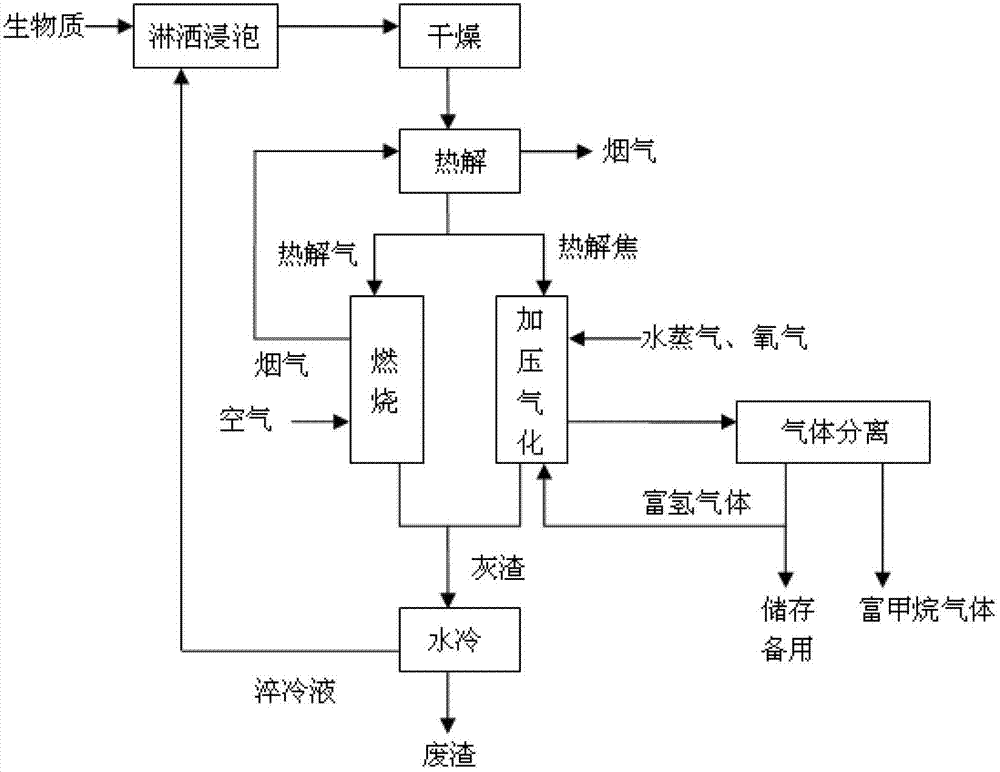

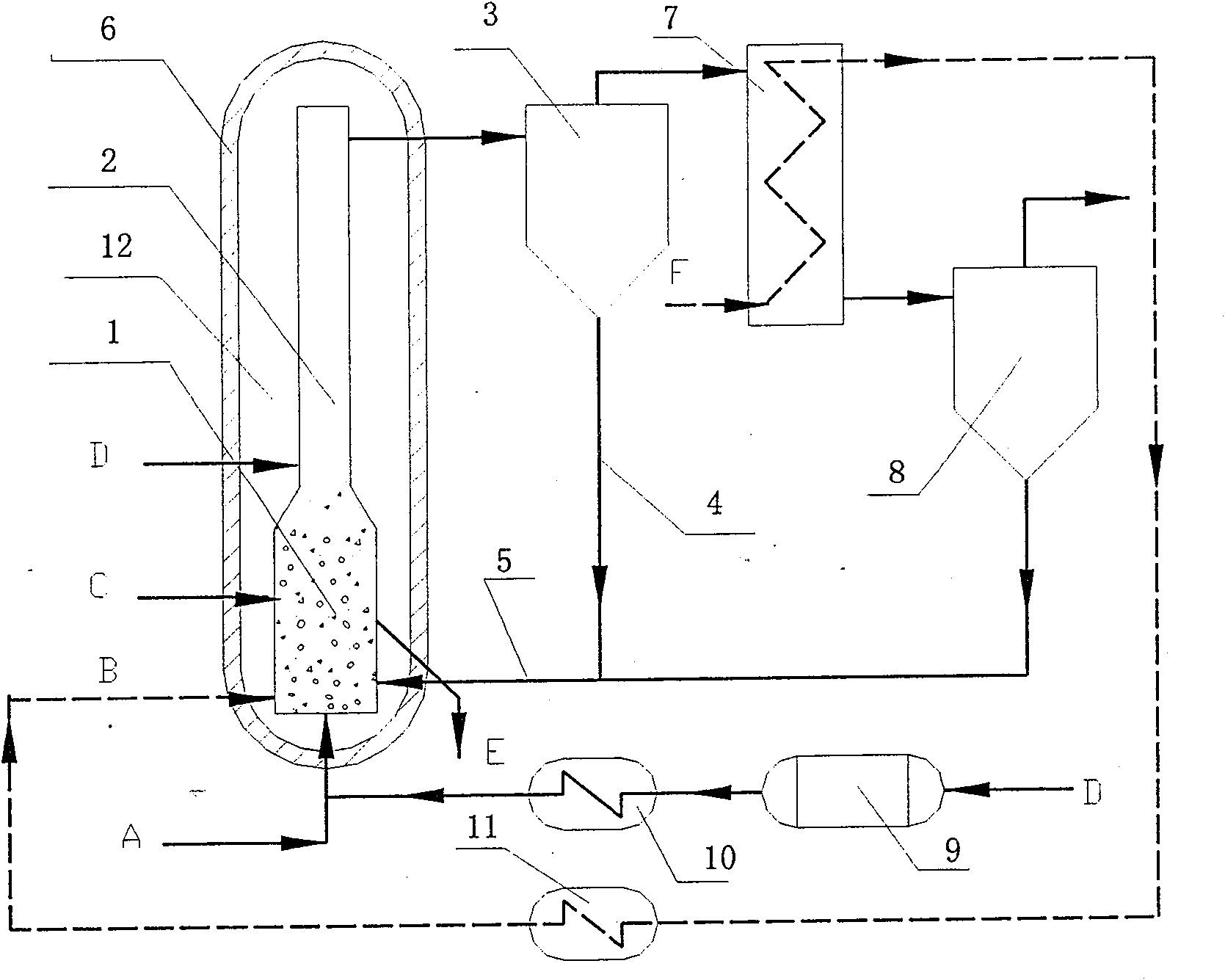

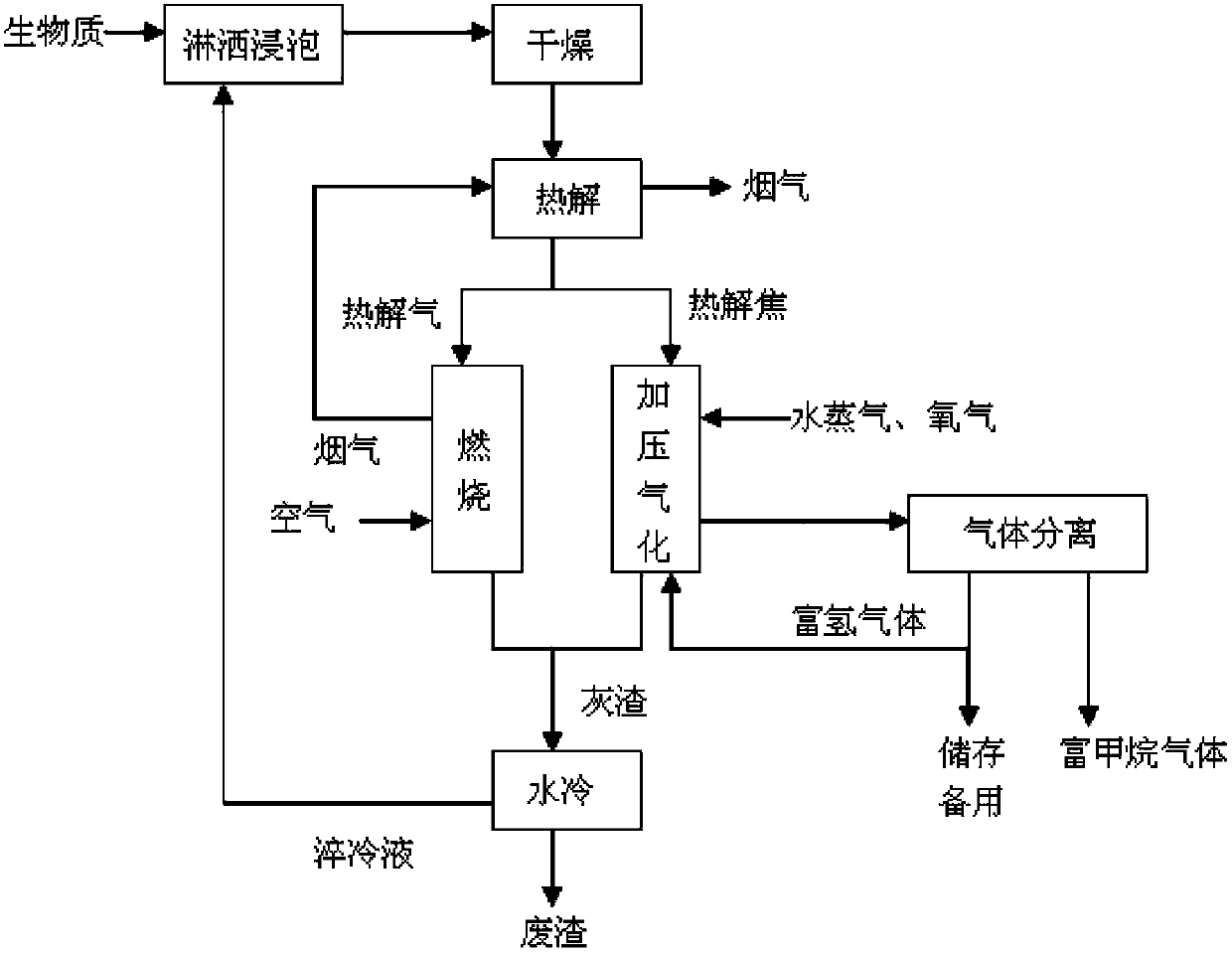

Method for preparing methane-rich gas through autocatalytic gasification of biomass

ActiveCN102786994AEasy to synthesizeImprove gasification efficiencyGaseous fuelsBiofuelsParticulatesAlkaline earth metal

The invention aims to provide a method for preparing methane-rich gas through cyclic utilization of alkali / alkaline earth metals contained in biomass for autocatalytic pyrolysis and autocatalytic pressurized gasification of the biomass. According to the method, water quenching is carried out on biomass ash so as to cyclically extract alkali / alkaline earth metals in the biomass ash, and the alkali / alkaline earth metals are sprinkled on and dipped in biomass; the biomass containing the alkali / alkaline earth metals undergoes autocatalytic pyrolysis at a low temperature of 280 to 320 DEG C at first, then a pyrolysis gas product enters into a combustion reactor and burns together with solid particles separated from a gasification reactor so as to supply heat for the process of pyrolysis, a pyrolysis solid product enters into the gasification reactor and undergoes autocatalytic pressurized gasification in a steam / oxygen atmosphere, hydrogen-rich gas is separated from crude synthetic gas produced in gasification and is returned to the pressurized gasification reactor, and the pyrolysis solid product is subjected to hydrogasification at the same time. With the method provide by the invention, biomass can be used for preparing methane-rich gas with low tar content, and high gasification efficiency is obtained. The method has the advantages of simple operation, less water consumption, strong technological adaptability and easy operation.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

High-efficiency low-temperature catalysis gasification method for coal

InactiveCN101319151AAvoid failureImprove catalytic performanceGasification with fuel pre-distillationCalcium hydroxideCoal

The present invention relates to a highly effective low temperature catalytic gasification method for coal. The method comprises the following steps that: an additive is mixed with coal at a pyrolysis temperature of between 500 and 900 DEG C, wherein the additive is selected from calcium hydroxide, lime and limestone, and the weight of the additive is between 5 and 20 percent of the that of the coal, and the pyrolysis lasts 15 to 60 minutes to carry out pretreatment passivation for the coal; and the coal processed by the pretreatment passivation is catalytically gasified.

Owner:EAST CHINA UNIV OF SCI & TECH

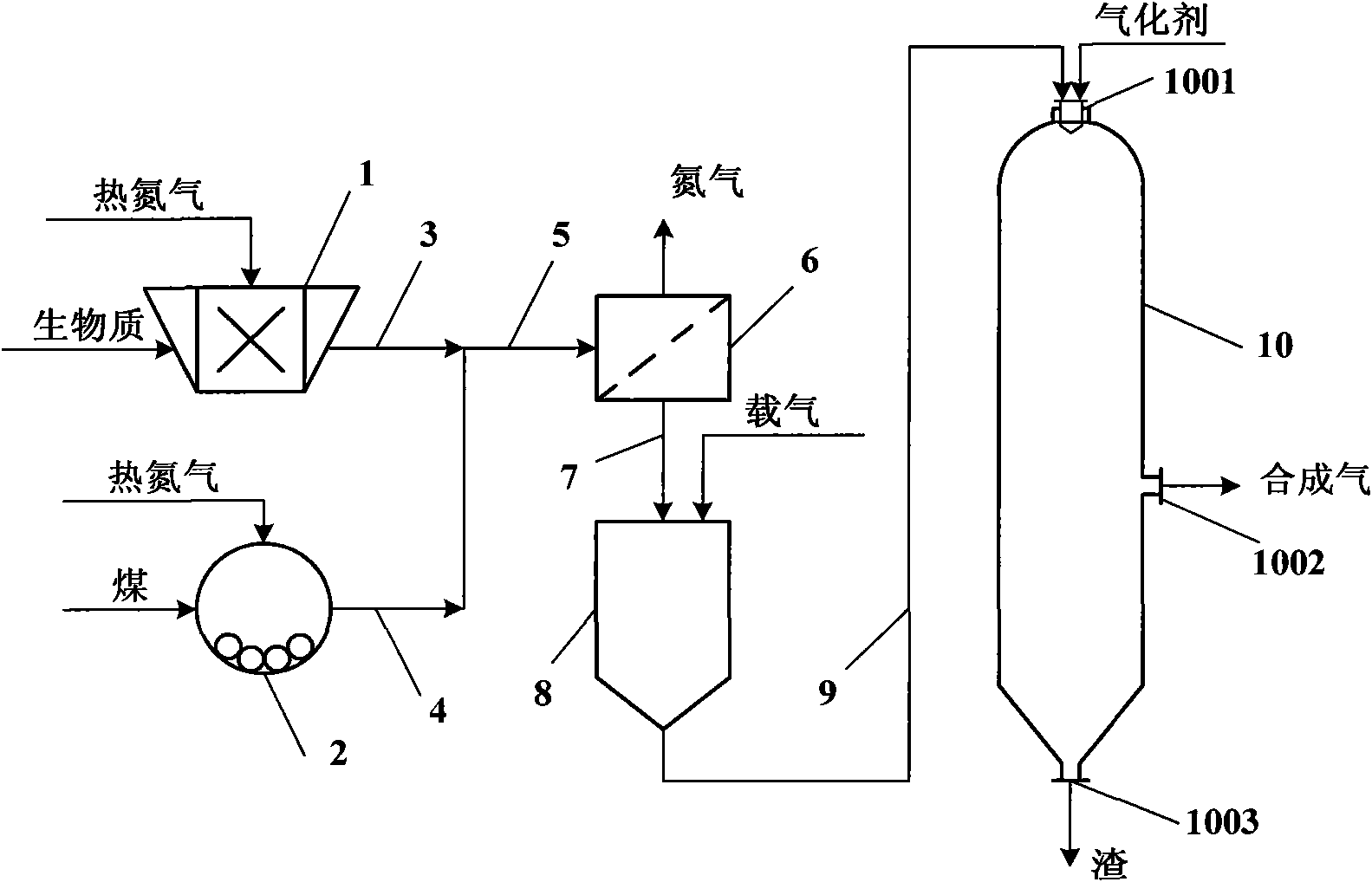

Biomass and coal fluidized bed co-gasification method

InactiveCN102786990ALow costIncrease profitGranular/pulverulent flues gasificationSyngasCombustion chamber

Owner:TAIYUAN UNIV OF TECH

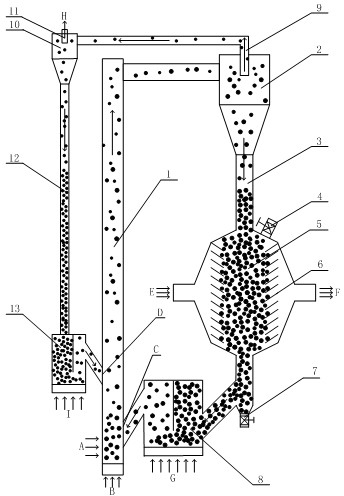

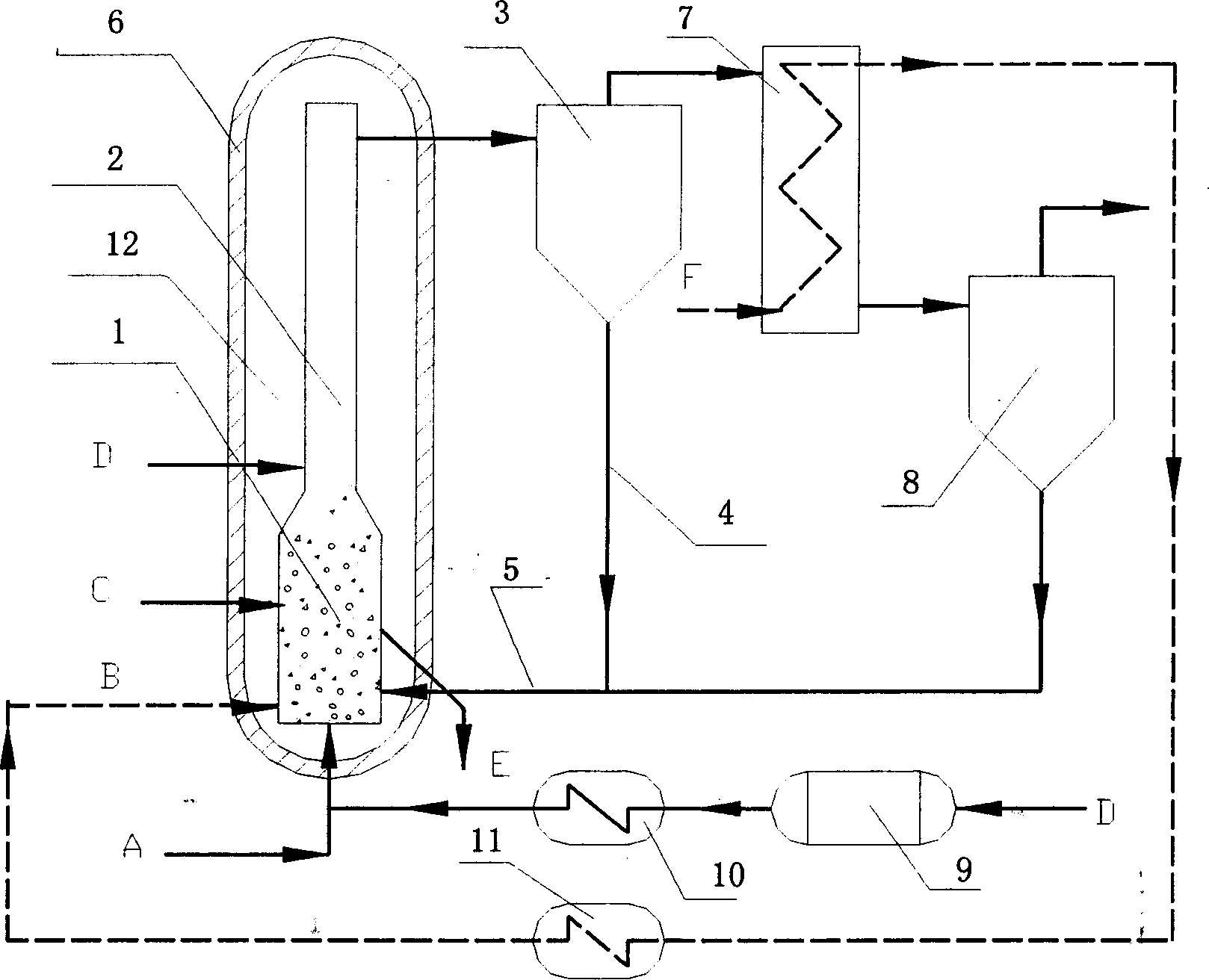

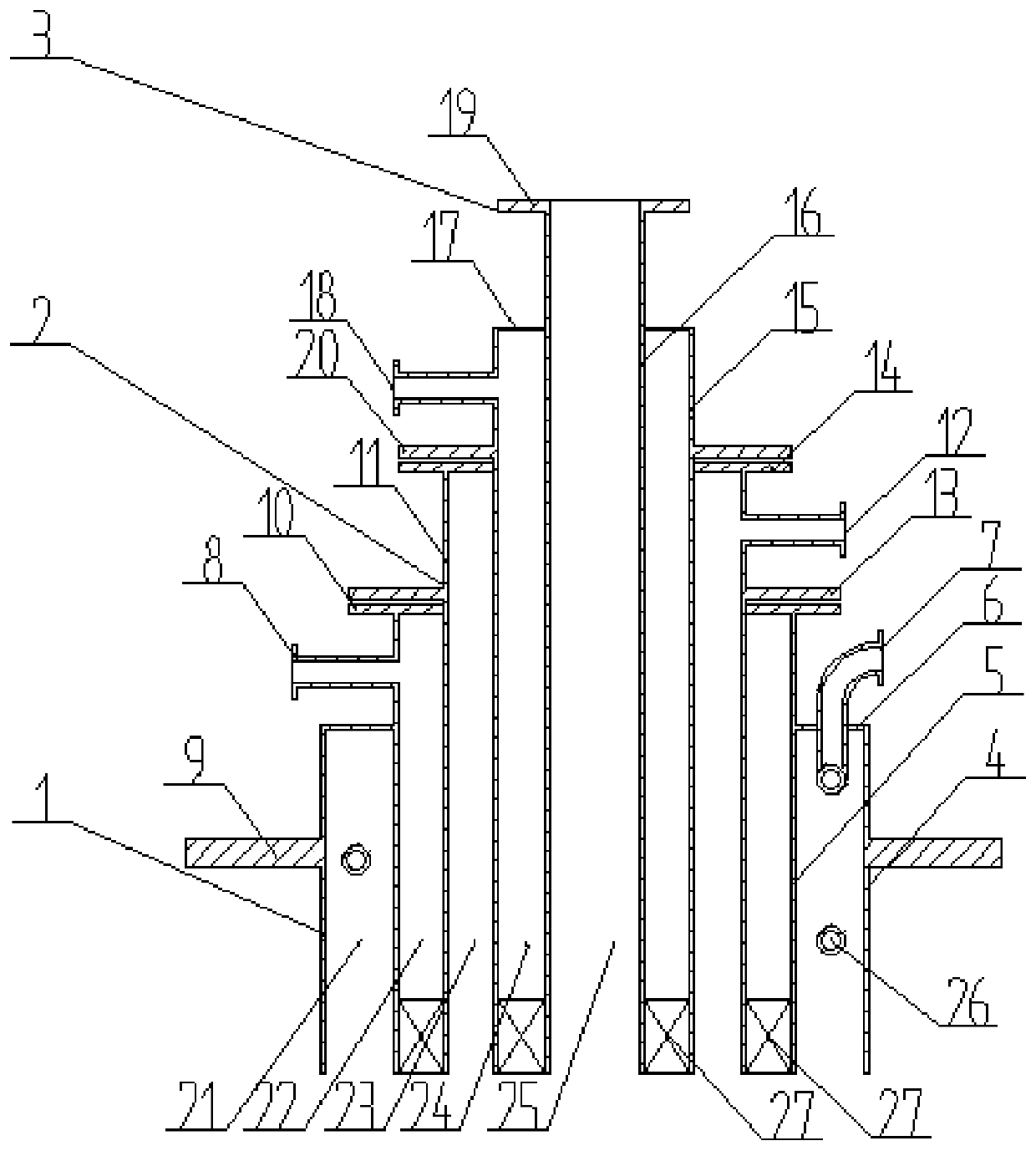

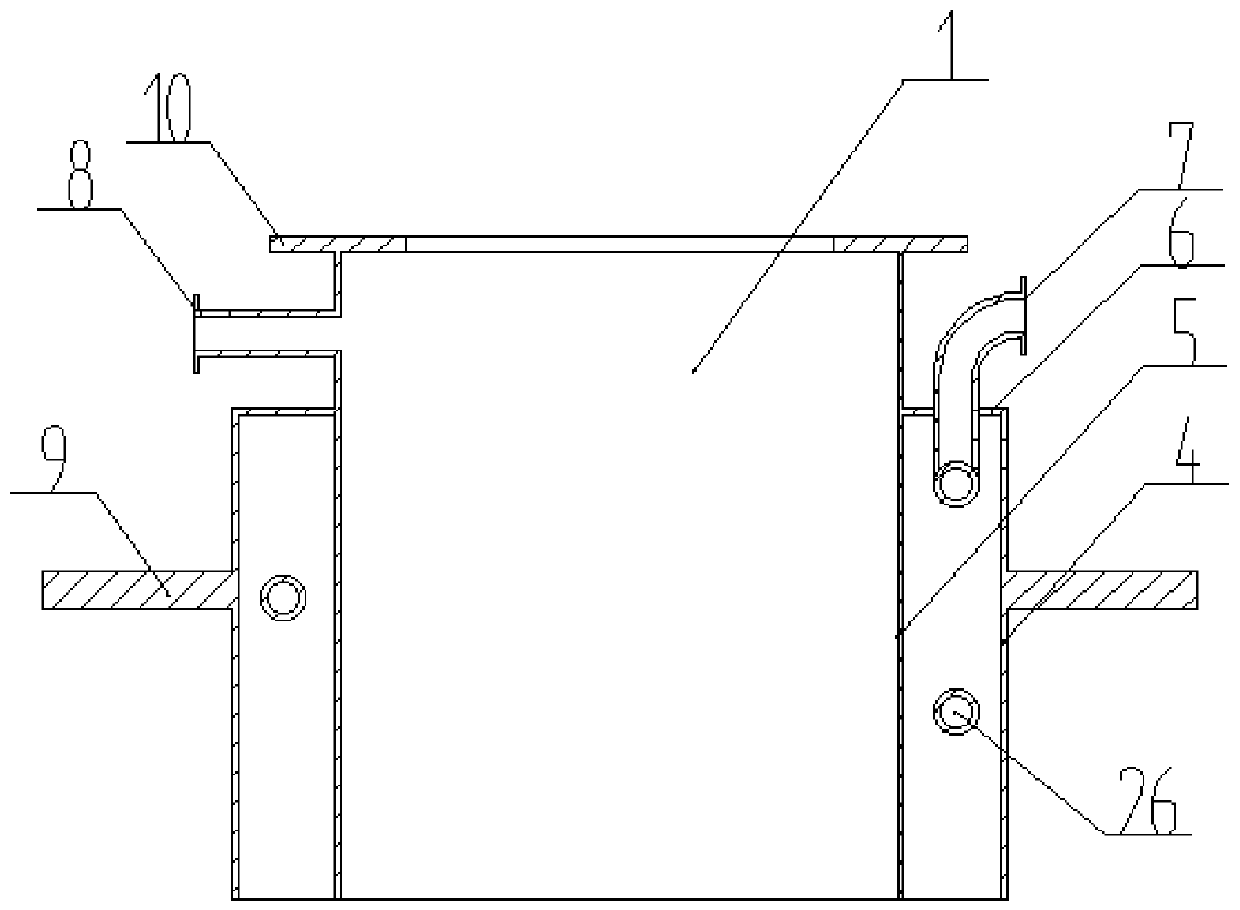

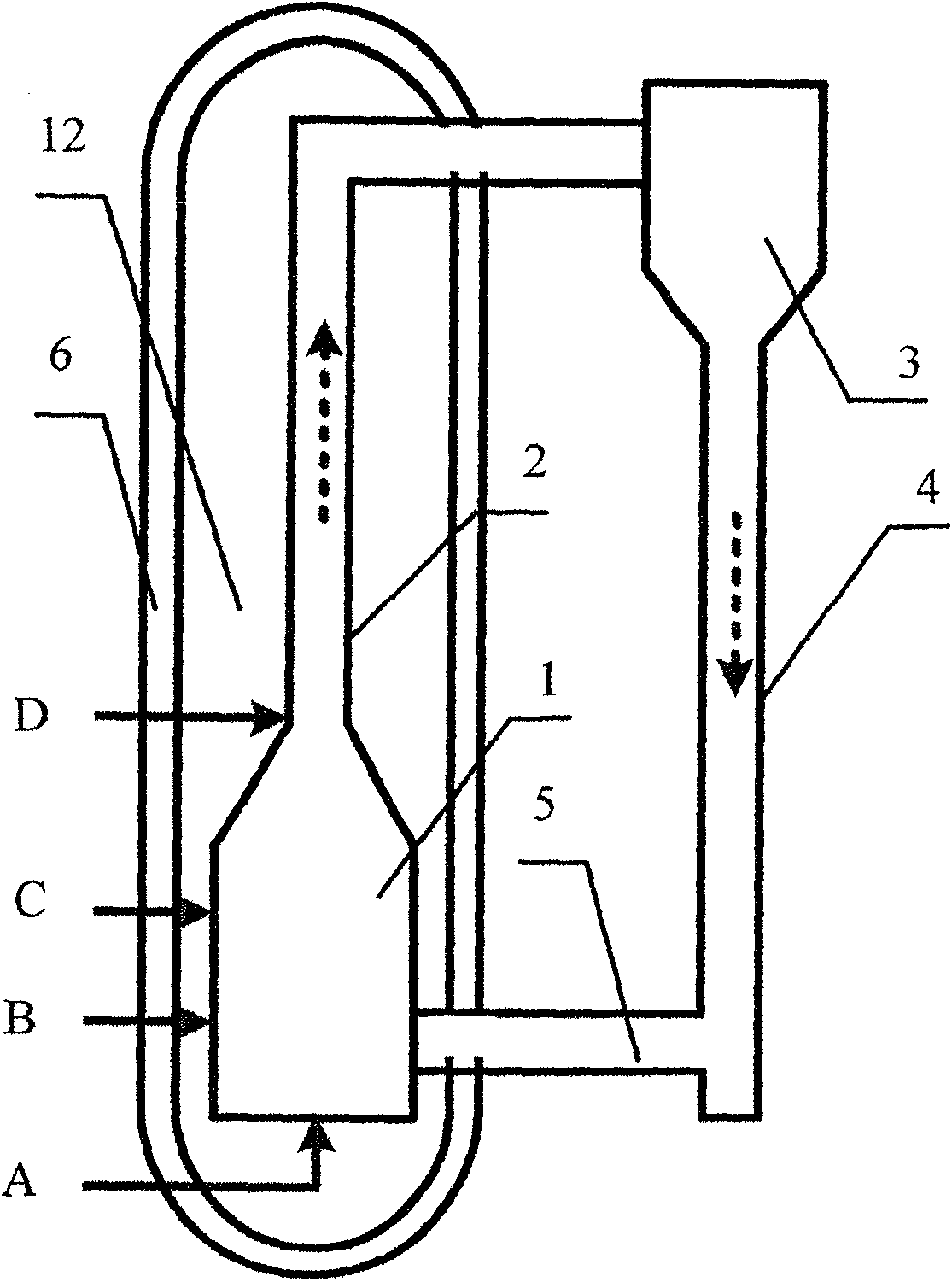

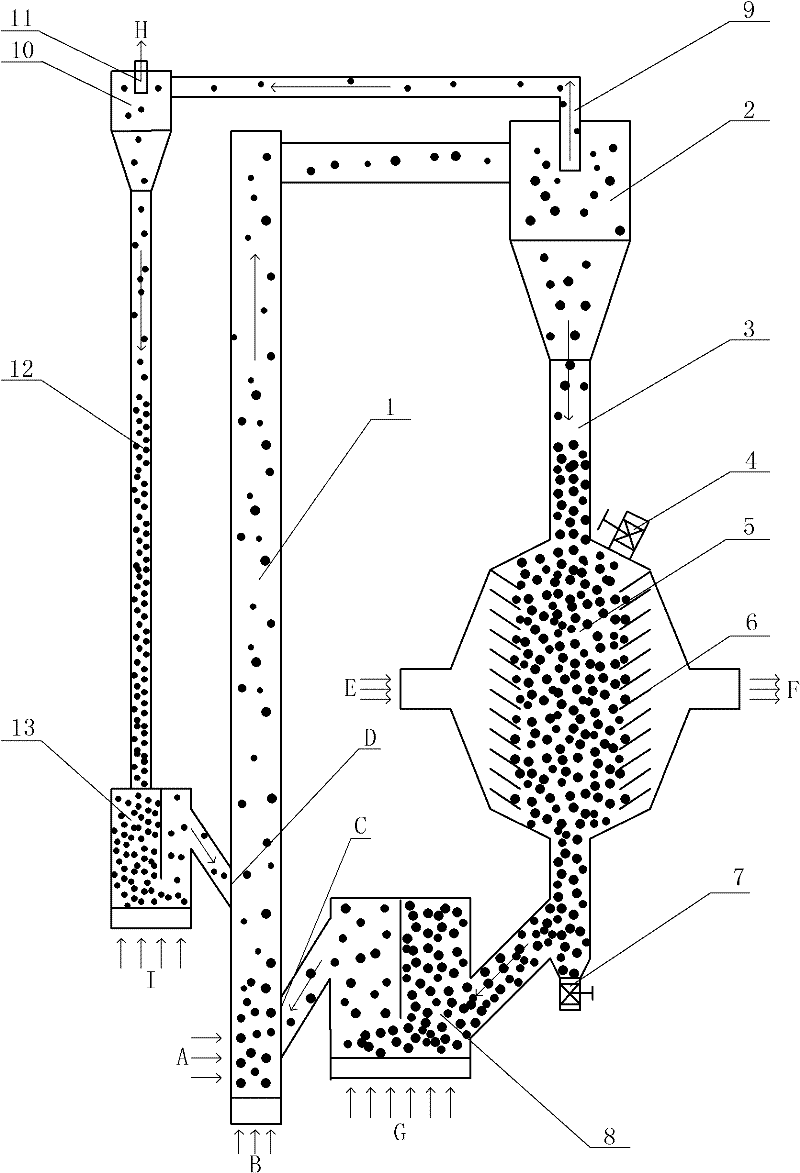

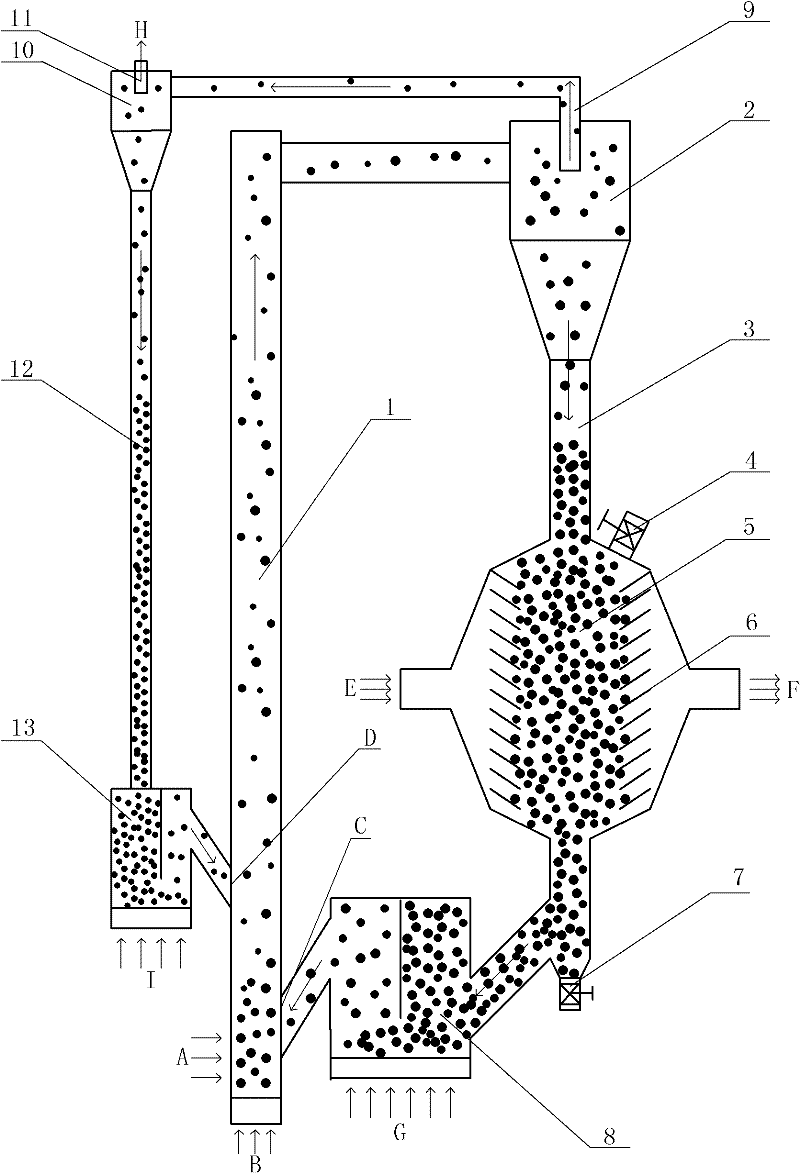

Method for separating CO2 through chemical looping combustion in coal pressure high-density circulating fluidized bed

ActiveCN102183014AIncrease the combustion reaction rateSolving the Response Matching ProblemFluidized bed combustionIndirect carbon-dioxide mitigationCycloneHigh density

The invention provides a method for separating CO2 through chemical looping combustion in a coal pressure high-density circulating fluidized bed, which comprises the following steps: coal particles and a gasifying agent are subjected to gasification reaction in a fuel reactor 1 of the coal pressure high-density circulating fluidized bed, and gasified products and oxygen carriers which return to the fuel reactor are subjected to combustion reaction to produce CO2 and H2O; smoke which is produced during the reaction and carries oxygen-lost oxygen carriers and carbon-containing coal ash enters a primary cyclone separator 2 for separation, and separated oxygen-lost oxygen carriers are in contact with transversely passing air for reaction in an air reactor 5 of a cross flow moving bed to be regenerated and are turned to the combustion reactor through a primary material returning device 8 to continuously participate in the combustion reaction; and separated smoke in the primary cyclone separator 2 further enters a secondary cyclone separator 10 for separation, solid particles secondarily separated are returned to the fuel reactor 1 through a secondary material returning device 13 to continuously participate in the combustion reaction, and H2O is removed from the separated gases through condensation to obtain high-purity CO2.

Owner:SOUTHEAST UNIV

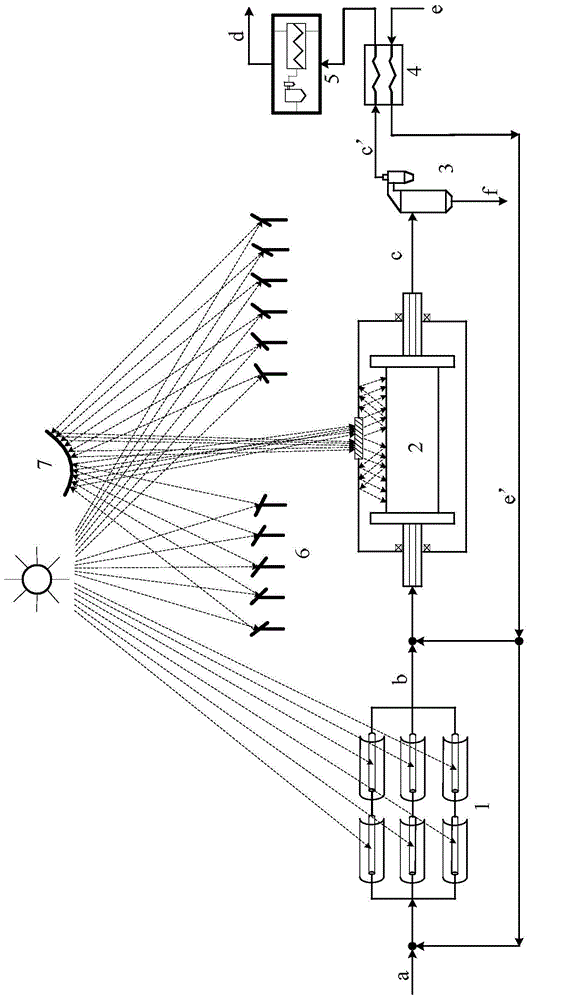

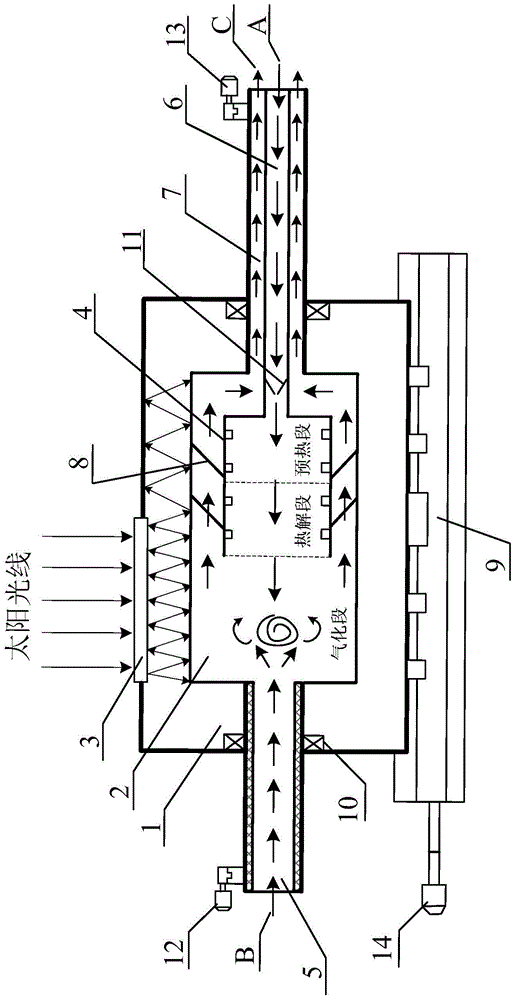

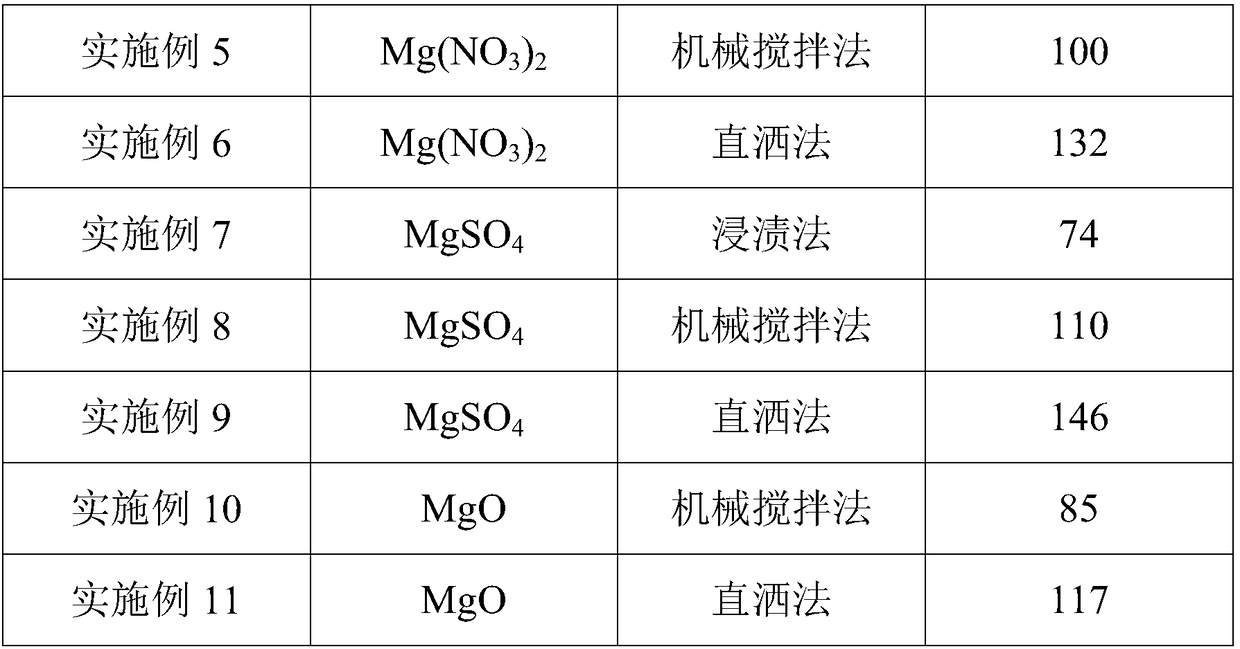

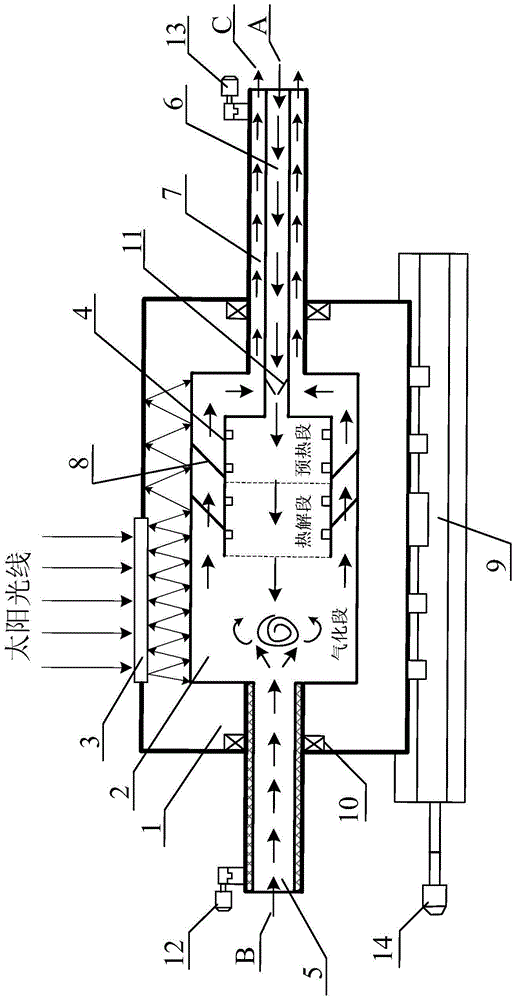

Combined trough-tower concentration manner-based solar gasification system

ActiveCN104862010AOptimizing Thermal Energy EfficiencyReduce irreversible lossEnergy inputCombined combustion mitigationTarProcess engineering

The invention discloses a combined trough-tower concentration manner-based solar gasification system which comprises an intermediate-temperature trough solar pyrolysis absorption reactor, a high-temperature rotating solar gasification reactor, a cyclone separator, an afterheat recovery device, a gas purification device, a heliostat field and a hyperboloid reflector. According to the system, different types of solar concentration devices and reactors are adopted for sequentially and independently finishing the pyrolysis and gasification reaction of a solid fuel, the intermediate-temperature trough solar pyrolysis absorption reactor is used for realizing the pyrolysis reaction of the solid fuel to obtain tar and coke at first, the heliostat field and the hyperboloid reflector are further used for acquiring high-concentration rate solar energy, and the high-temperature rotating solar gasification reactor is used for finishing reaction such as tar cracking and coke gasification; by the system, biomasses are efficiently gasified, the irreversible loss in a concentration gasification process is reduced, and the tar content of synthetic gas obtained by gasification is reduced.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

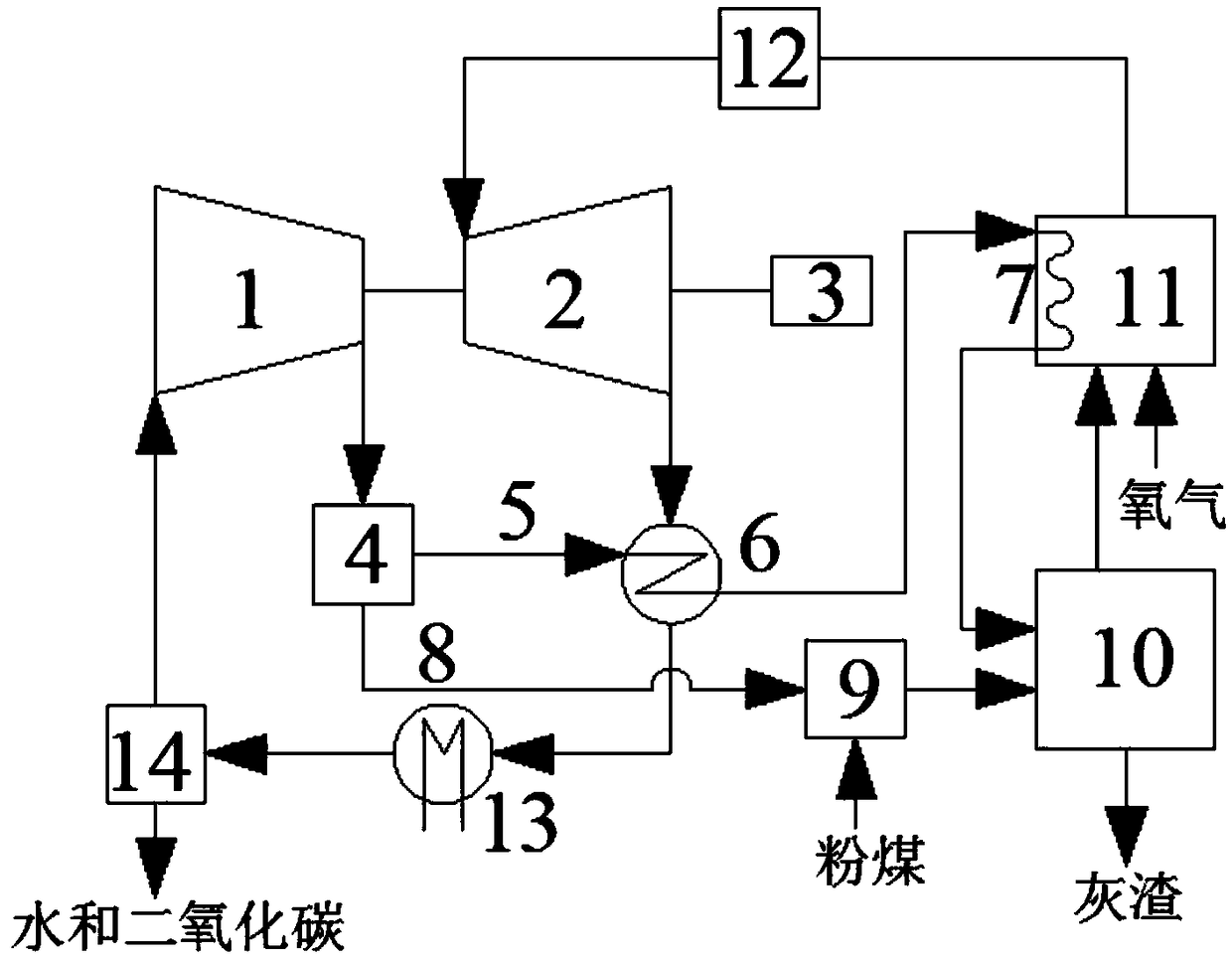

Supercritical carbon dioxide power generation and coal gasification coupled system and method

PendingCN108690661ARealize comprehensive utilizationReduce usageGasification processes detailsBulk chemical productionCombustion chamberProcess engineering

The invention provides a supercritical carbon dioxide power generation and coal gasification coupled system and method; the system comprises a supercritical carbon dioxide power generation system anda supercritical carbon dioxide coal gasification system. The supercritical carbon dioxide power generation system includes a compressor, a turbine, a power generator, a high pressure storage tank, a low pressure storage tank, a combustion chamber heat exchanger, a heat regenerator and a pre-cooler; the supercritical carbon dioxide coal gasification system includes a pulverized coal pressurizationdevice, a gasification furnace, a combustion chamber and a purifier. The system and method can adopt supercritical carbon dioxide as a gasification agent for coal gasification, and gasified coal gas is used in supercritical carbon dioxide power generation.

Owner:XIAN THERMAL POWER RES INST CO LTD

Clean synthesis gas and preparation method thereof

The invention relates to a preparation method of clean synthesis gas. The method comprises the following steps of: mixing dried biomass particles and dried coal powder uniformly to obtain the mixed particles; and feeding the mixed particles into an entrained flow gasifier by dense phase pneumatic transmission mode, and performing co-gasification on the mixed particles and a gasification agent to generate the clean synthesis gas. The invention also relates to the clean synthesis gas prepared by the method. In the preparation method of the clean synthesis gas, the co-gasification temperature of the entrained flow gasifier is high, the obtained synthesis gas dose not contain harmful ingredients, such as tar, phenol and the like, so the problem that the volatile content of the biomass is high and energy density is low, so secondary pollution is caused by decoking due to high the tar content of the synthesis gas which is gasified independently is solved; meanwhile, the use ratio of the biomass is increased, CO2 emission reduction is facilitated, large-scale, high-efficiency, clean and economic use of the biomass can be realized.

Owner:EAST CHINA UNIV OF SCI & TECH

Catalyst raw material used for catalytic coal gasification and application method thereof

ActiveCN105498746AManufacturing material requirements are not strictReduce manufacturing costGasification processes detailsMetal/metal-oxides/metal-hydroxide catalystsChemical reactionReaction rate

The invention relates to a catalyst raw material used for catalytic coal gasification and an application method thereof. The catalyst raw material is prepared by mixing vanadium oxide or vanadate or a vanadium-containing material and metal oxide, metal hydroxide or metal salt though quantification according to a vanadate chemical reaction. The catalyst raw material has the effects that 1) coal gasification can be completed under low temperature condition, no strict requirement on production materials of equipment is provided, the equipment can be manufactured by selecting common steel, manufacture cost of the equipment can be reduced; 2) gasification reaction rate is increased, gas production amount by unit time is increased, cost is saved, and energy consumption is reduced; 3) carbon dioxide and oxygen are employed as a gasifying agent, the carbon dioxide can be catalytically converted to combustible gas carbon monoxide, under same heat energy condition, coal can be saved by more than 35%, emission reduction for carbon dioxide can reach more than 35%; and 4) according to requirement of gas components by a subsequent technology, carbon dioxide, oxygen and vapour can be selected as the gasifying agent for producing synthetic gas containing hydrogen and methane, and carbon dioxide and oxygen can be used for producing high-density carbon monoxide gas.

Owner:杨秋良

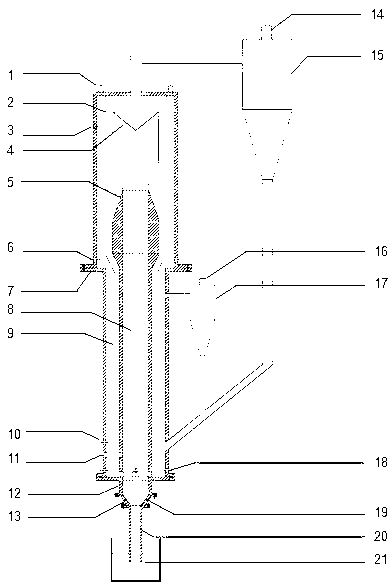

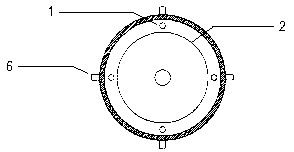

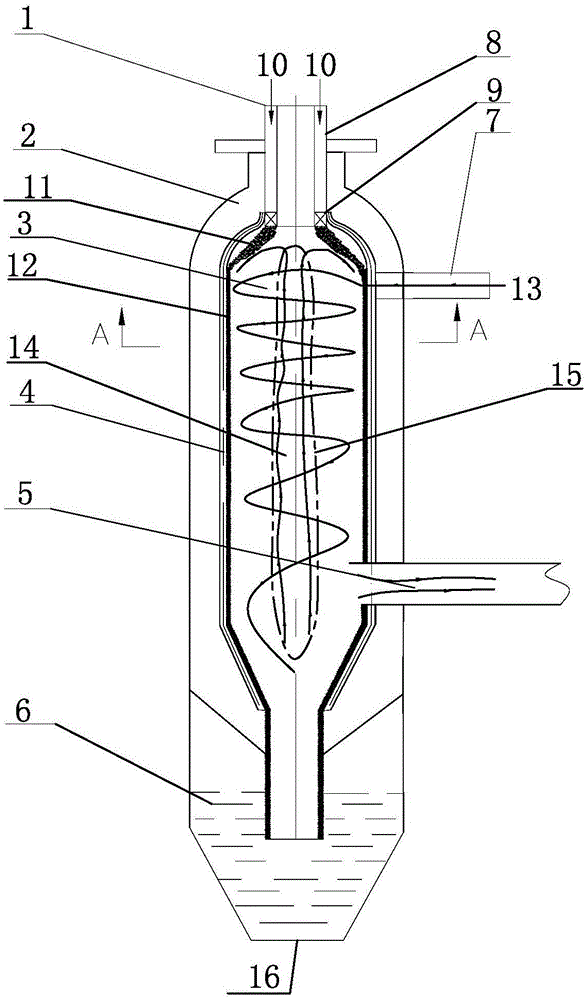

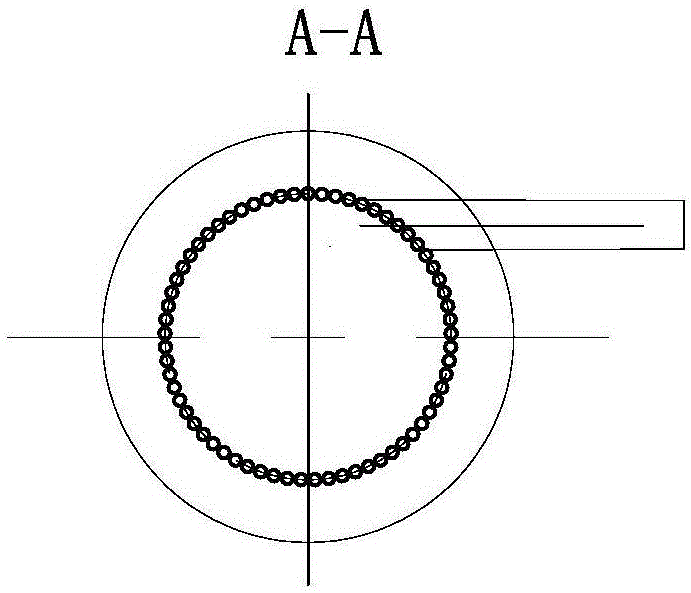

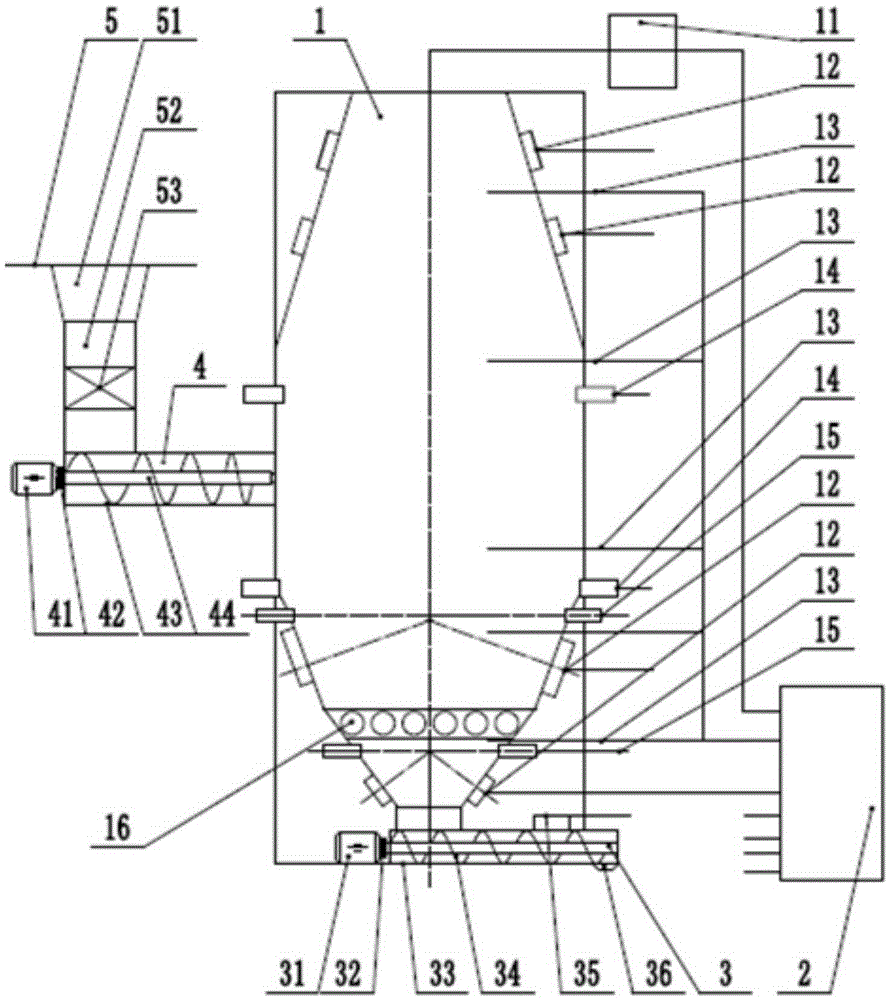

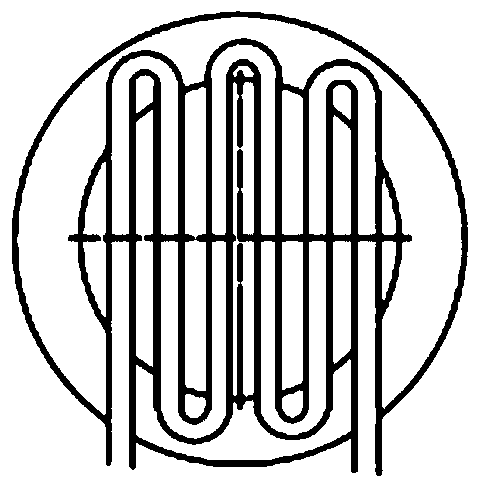

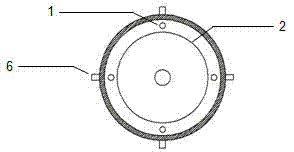

Gasifying agent strongly-rotating pulverized coal gasifying device and gasifying method

InactiveCN105132035AUniform thicknessWell mixedGranular/pulverulent flues gasificationHearthEngineering

The invention relates to a pulverized coal gasifying device and gasifying method, in particular to a gasifying agent strongly-rotating pulverized coal gasifying device and gasifying method. The invention aims at solving the problems that cinders are not uniformly hung on the wall surface of the gasifier in the prior art and the inner wall surface of the gasifier is burned out and corroded. A water-cooled wall of the device is installed in a gasifier body, the water-cooled wall consists of a plurality of vertical circular pipes, the water-cooled wall forms a rotary body gasifying hearth, a cinder basin is arranged at the bottom portion of the gasifier body, a synthesis gas passage is inserted into the lower portion of the gasifier body, a gasifying agent spray outlet is formed in the upper portion of the gasifier body, the gasifying agent spray outlet is inserted into the gasifying hearth along the tangential direction of the gasifying hearth, a pulverized coal burner is installed at the top portion of the gasifier body, the axis of the pulverized coal burner and the axis of the gasifying hearth are overlapped, and a pulverized coal passage with an annular cross section is arranged in the pulverized coal burner. The gasifying agent strongly-rotating pulverized coal gasifying device and gasifying method are used for the field of coal gasification.

Owner:HARBIN INST OF TECH

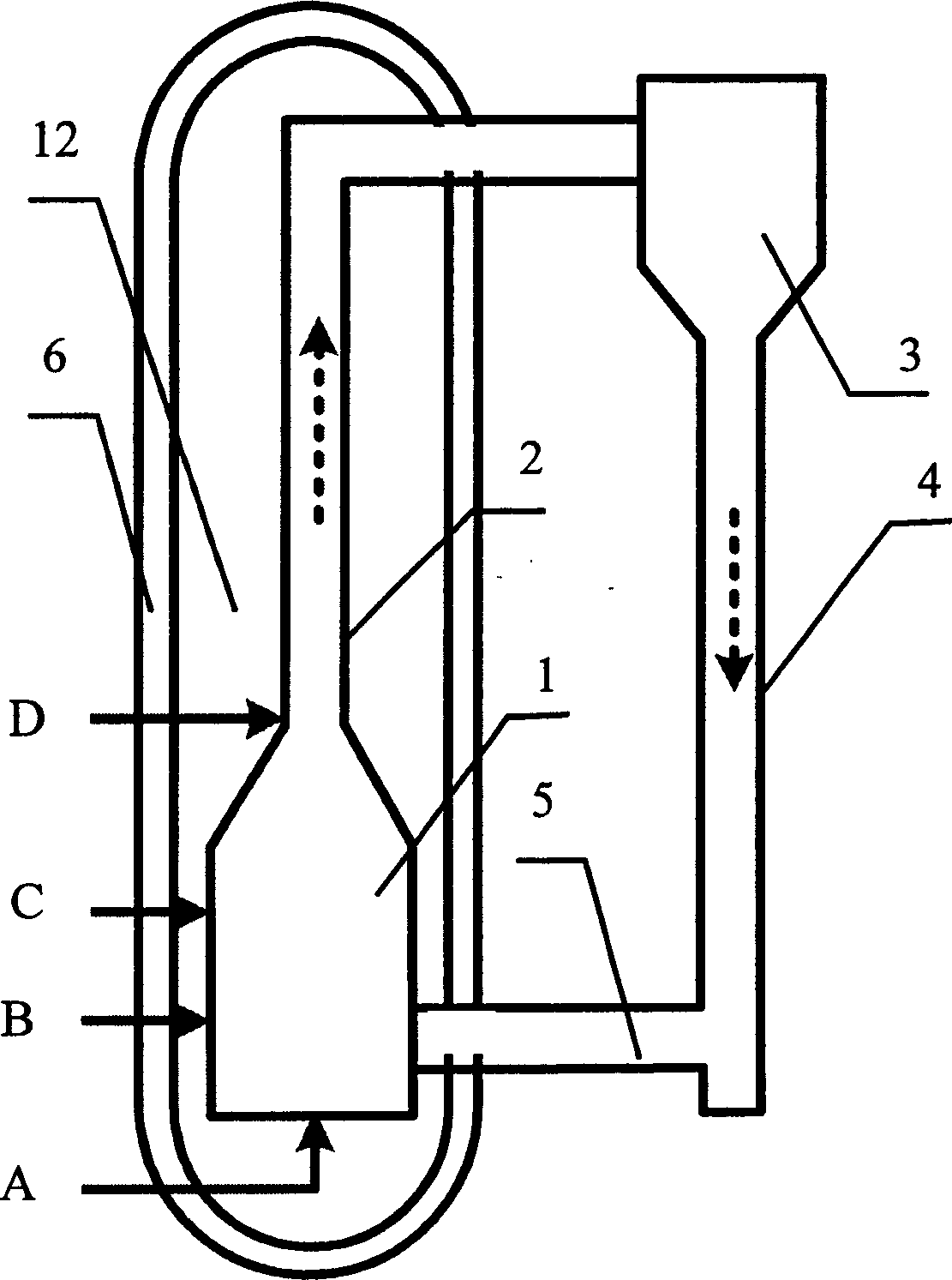

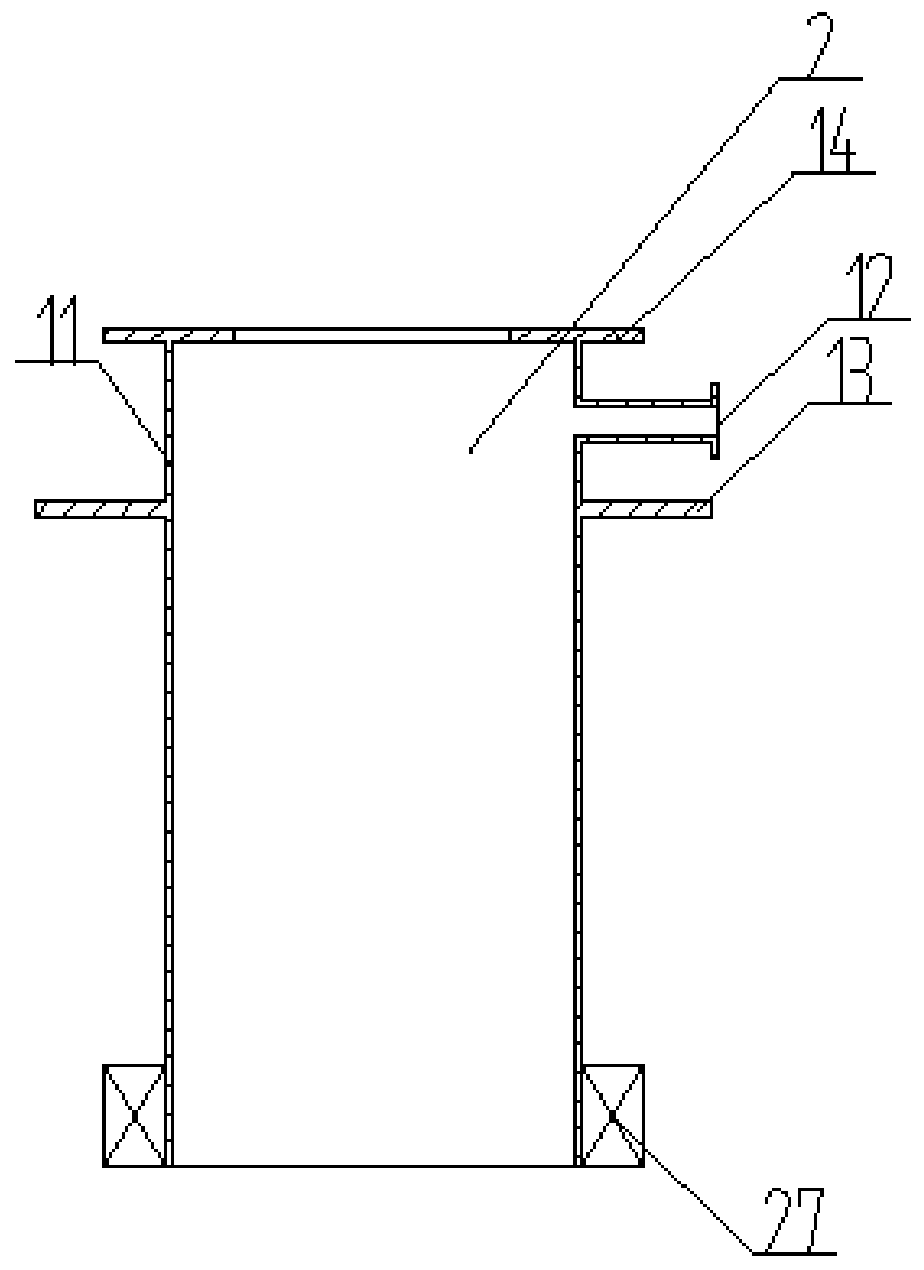

Catalytic coal gasifaction furnace of differential speed bed, and method of catalytic gasification

InactiveCN1916124AImprove removal efficiencyExtended stayCombined combustion mitigationGranular/pulverulent flues gasificationLow speedHearth

This invention discloses method and differential-speed bed furnace for catalytically gasifying high-ash, high-sulfur and high-ash-melting-point coal abundant in China. The hearth is set in a pressure shell. The hearth comprises a lower hearth and an upper hearth. The lower hearth is a chamber with a wide bed diameter, working at a low speed and high temperature. There are inlets for air, coal powder, limestone, steam and catalyst on both the bottom and lateral side of the lower hearth. The upper part of the lower hearth tapers to form the upper hearth working at a high speed and high temperature. The upper hearth has a shorter inner diameter than the lower hearth. The outlet of the upper hearth is connected with a cyclone separator with the lower part connected with a falling pipe. The lower part of the falling pipe is connected with a horizontal L-shaped valve. The other end of the L-shaped valve is connected with the lateral underside of the lower hearth.

Owner:NANTONG SANCHUANG MACHINE MFG +1

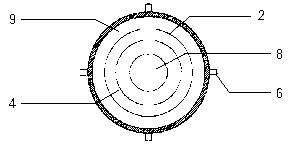

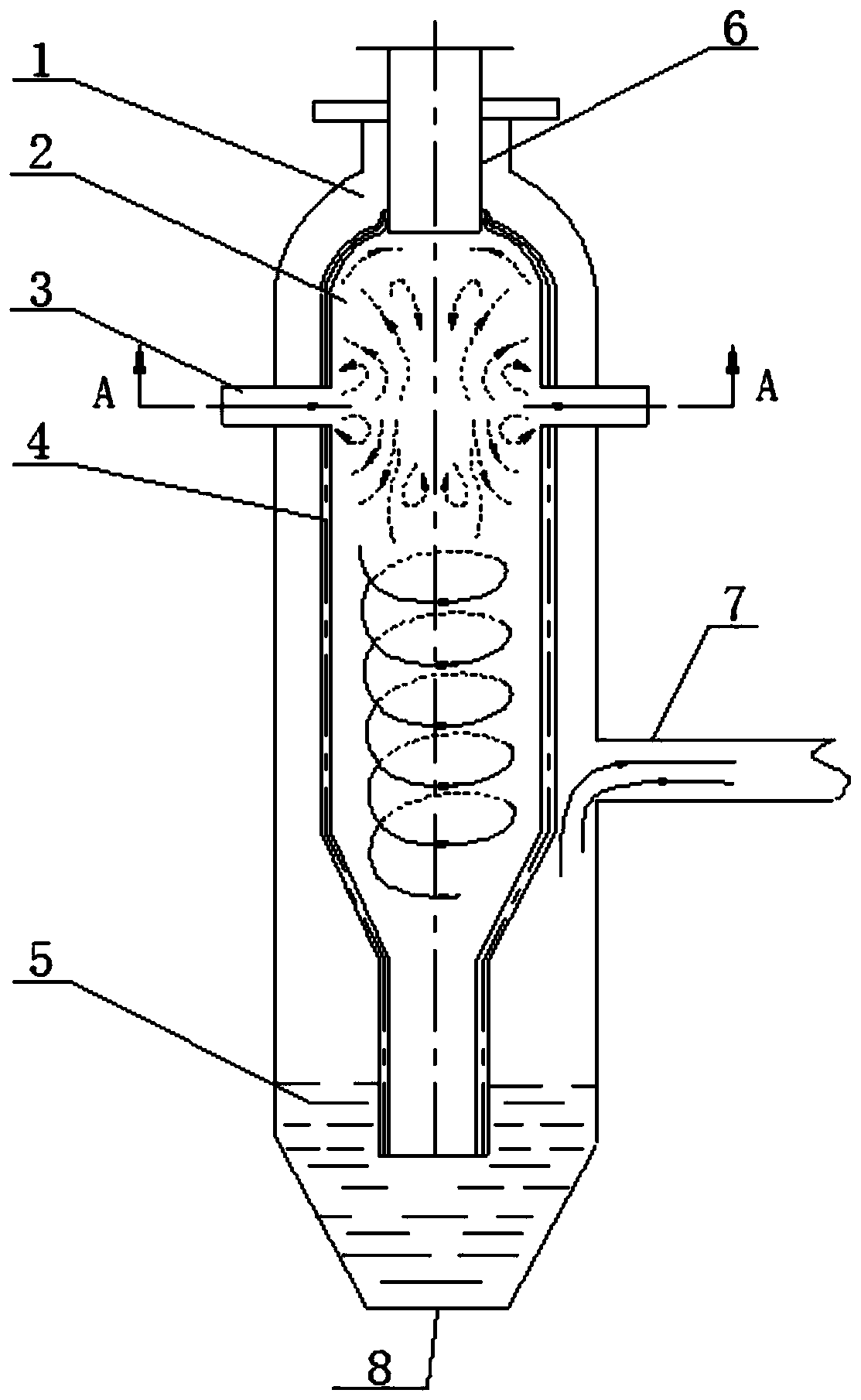

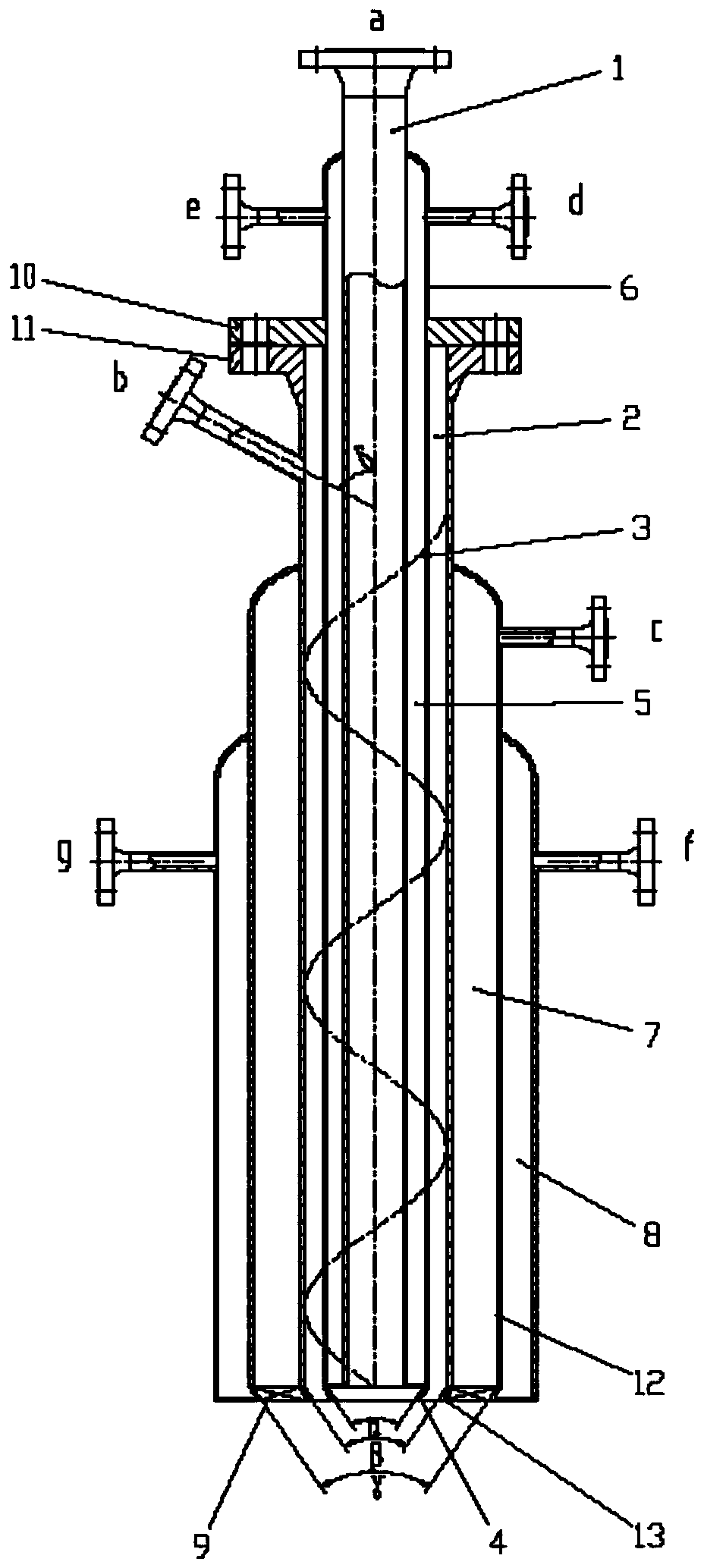

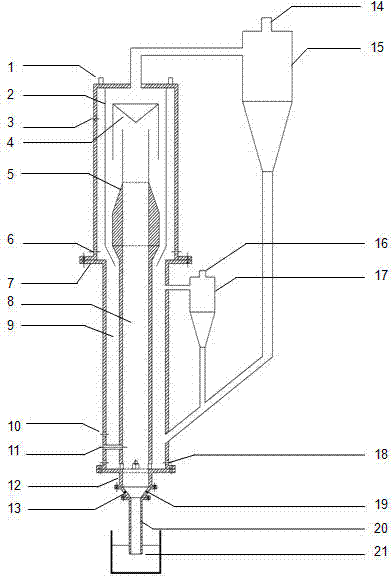

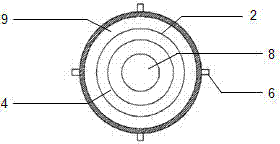

Solar high-temperature thermochemical gasification reactor

ActiveCN104877709AImprove utilization efficiencyReduce irreversible lossEnergy inputCombustible gas productionSyngasSolar energy storage

The invention discloses a solar high-temperature thermochemical gasification reactor. The reactor mainly comprises a black body cavity, a reaction chamber, a flow guiding column, a gas guide pipe, a solid guide pipe, servomotors and the like. By using the reactor, solar energy can be more efficiently used for driving solid hydrocarbon fuels such as coal, biomass and the like to be subjected to gasifying reaction and independently completing processes such as preheating, pyrolyzing, gasifying and the like contained by the gasifying reaction, so that the conversion of the solar energy to high-quality synthetic gas can be realized, and the current problems of high solar energy storage difficulty, poor renewable energy source conveying stability and the like are solved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

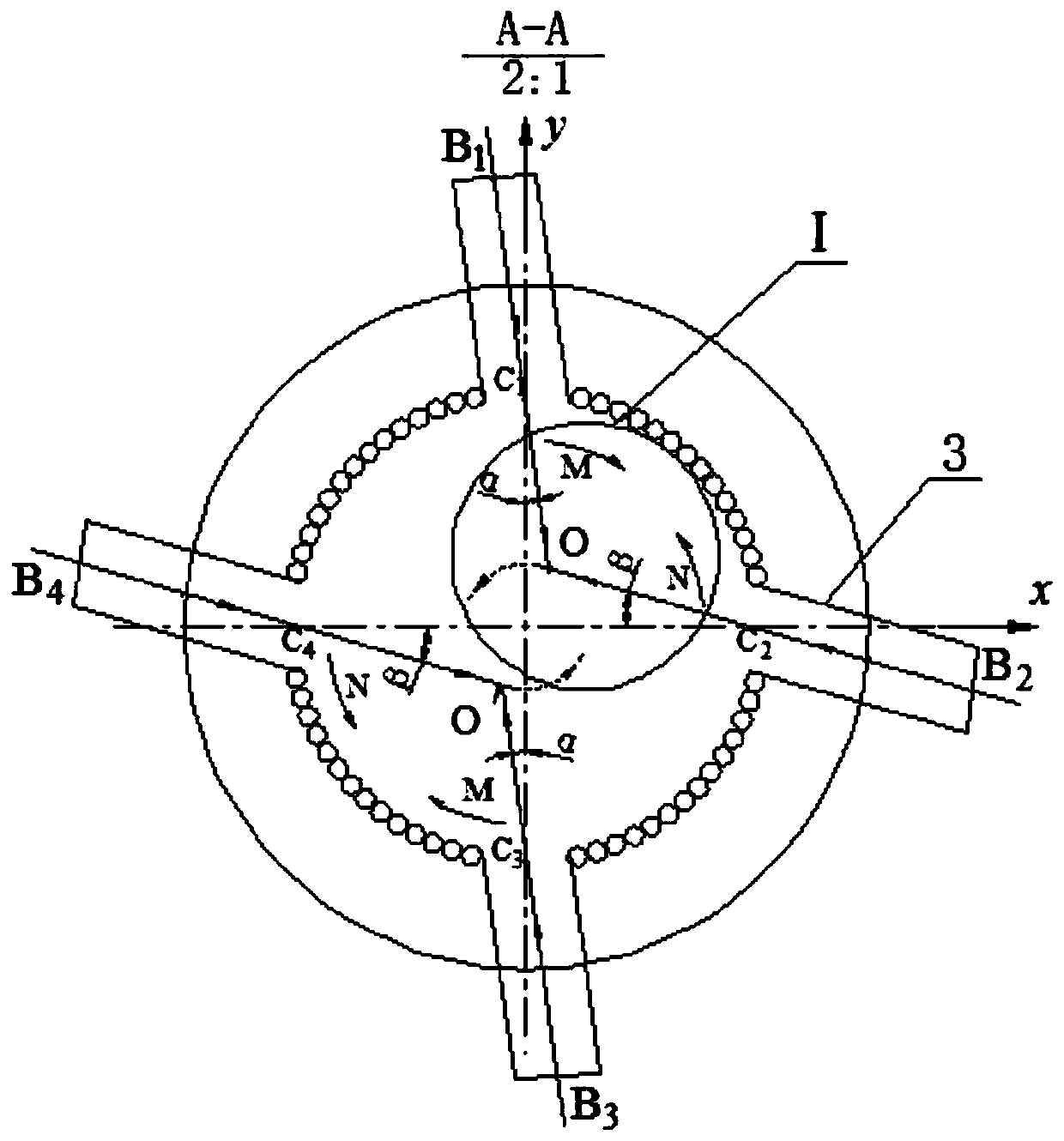

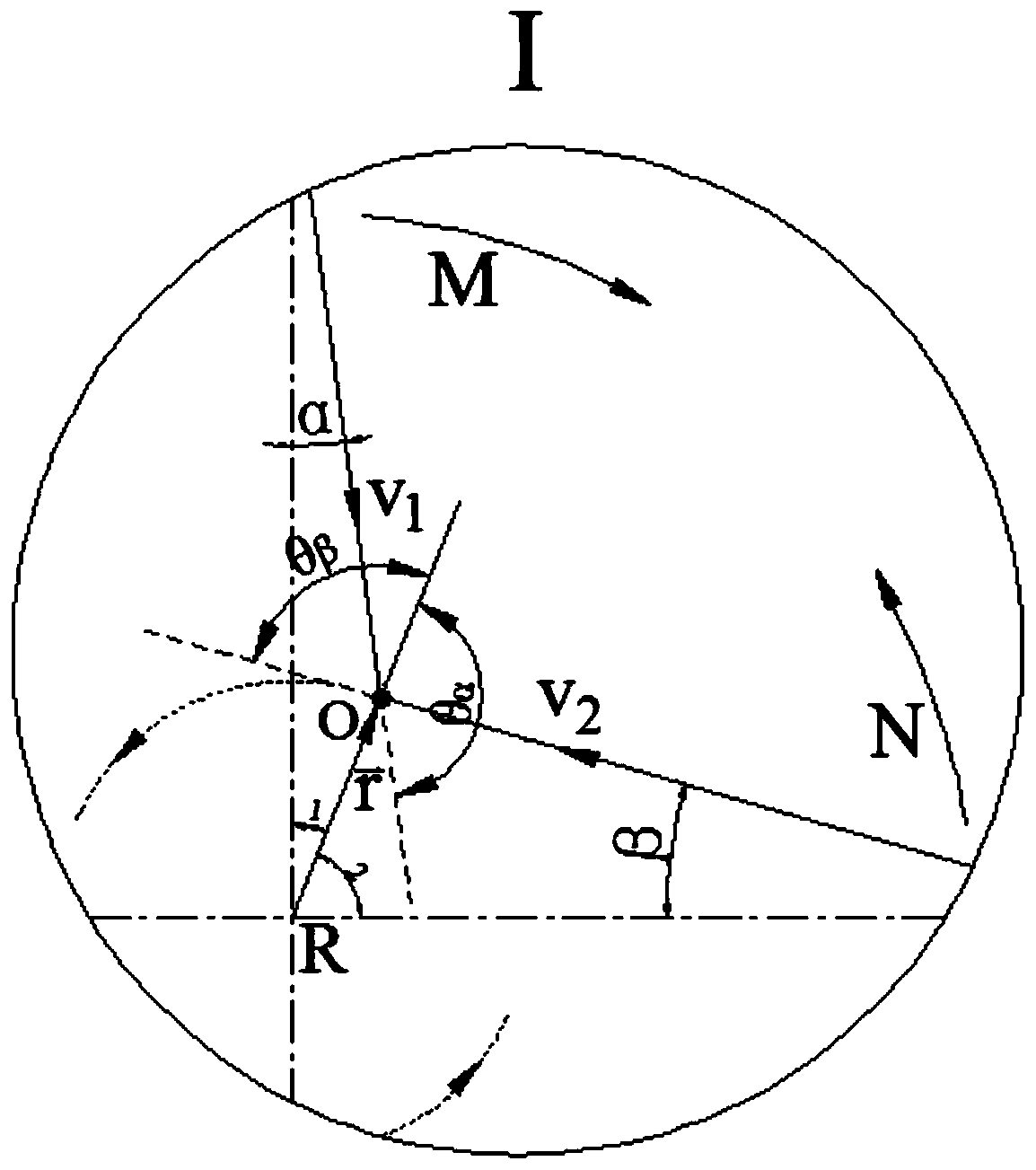

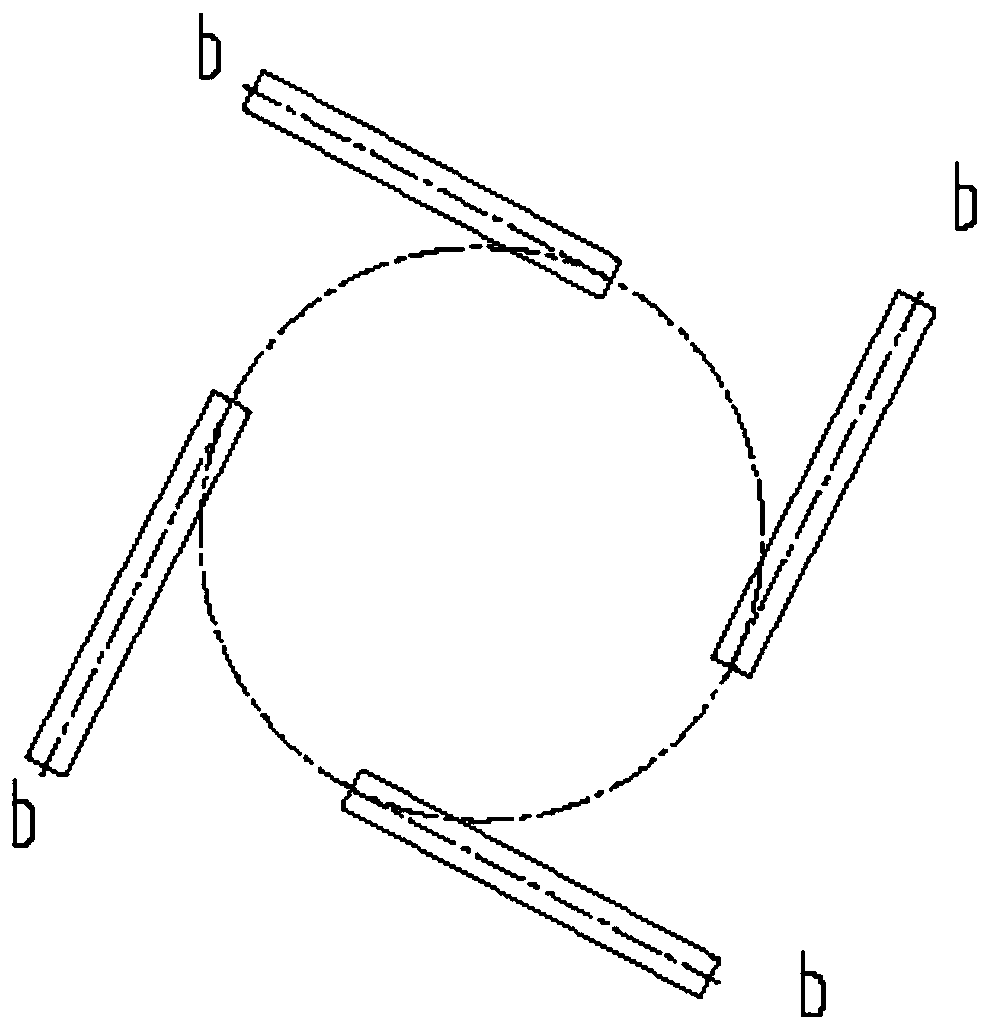

Entrained flow gasifier device with four forward and reverse rotating burners and gasification method

ActiveCN110452737AWell mixedImprove carbon conversionGasification processes detailsGranular/pulverulent flues gasificationSlagEngineering

The invention relates to an entrained flow gasifier device and a gasification method utilizing the device, particularly to an entrained flow gasifier device with four forward and reverse rotating burners and a gasification method, and aims to solve the problems of gasifier water-cooled wall burning loss, low carbon conversion rate and the like caused by unreasonable burner arrangement mode of existing multi-burner entrained flow gasifiers. The entrained flow gasifier device with four forward and reverse rotating burners includes a gasifier body, burners, a water-cooled wall, an igniter burner,a slag tank and a synthesis gas channel. The four burners, i.e. burner B1, burner B2, burner B3 and burner B4 are located on a same horizontal plane, and are evenly distributed along the circumference of the gasifier body in order, the intersection points of center lines and the water-cooled wall surface are C1, C2, C3, and C4 respectively, the center lines of B1 and B2 intersect at point O, andthe center lines of B3 and B4 intersect at point O'; the included angle alpha of C1O and C1C3, and the included angle beta of C2O and C2C4 satisfy that: alpha is greater than 0 and smaller than beta and beta is less than 45 degrees, or beta is greater than 0 and smaller than alpha and alpha is less than 45 degrees. The entrained flow gasifier device provided by the invention is used for the entrained flow gasification field.

Owner:HARBIN INST OF TECH

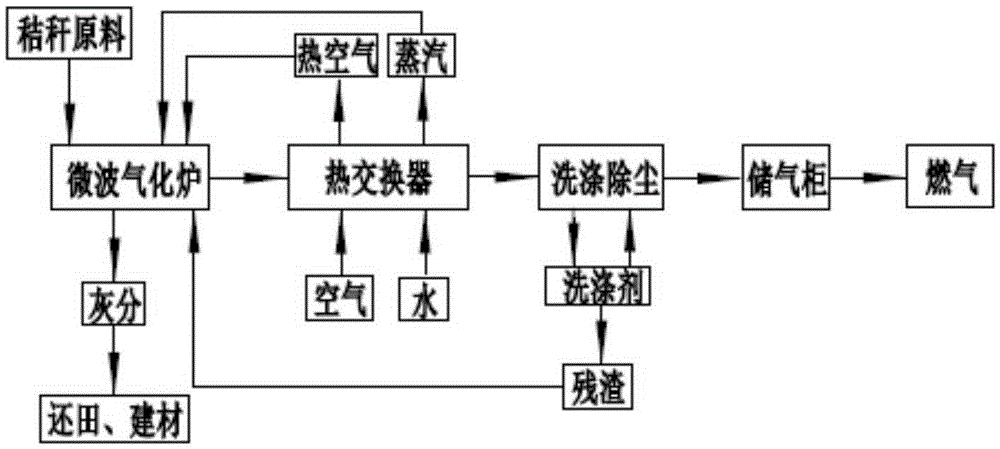

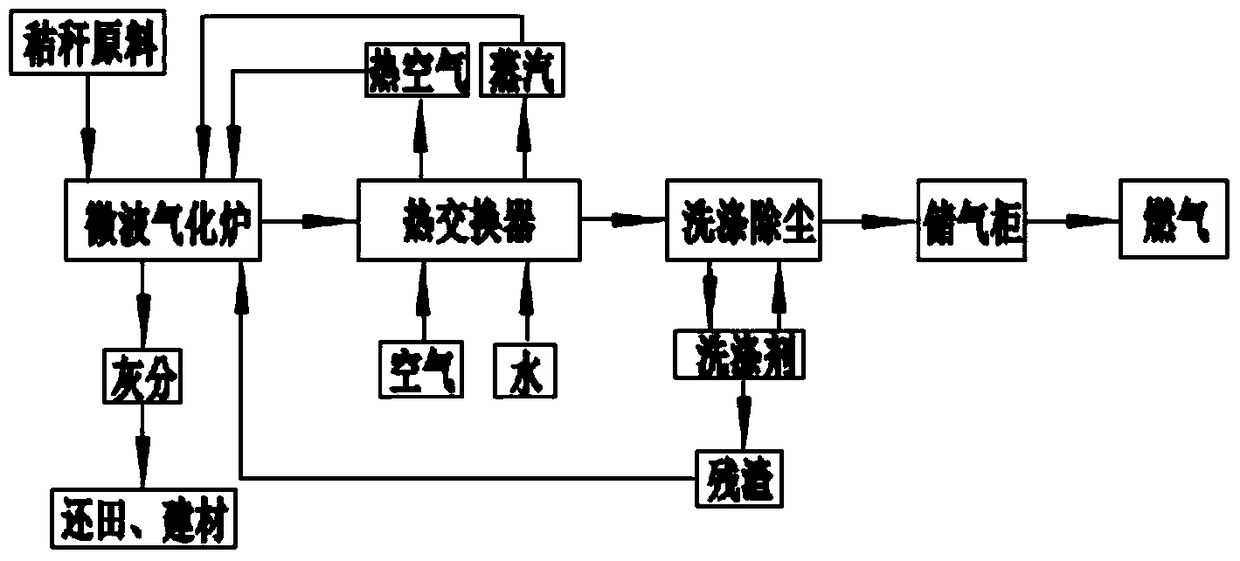

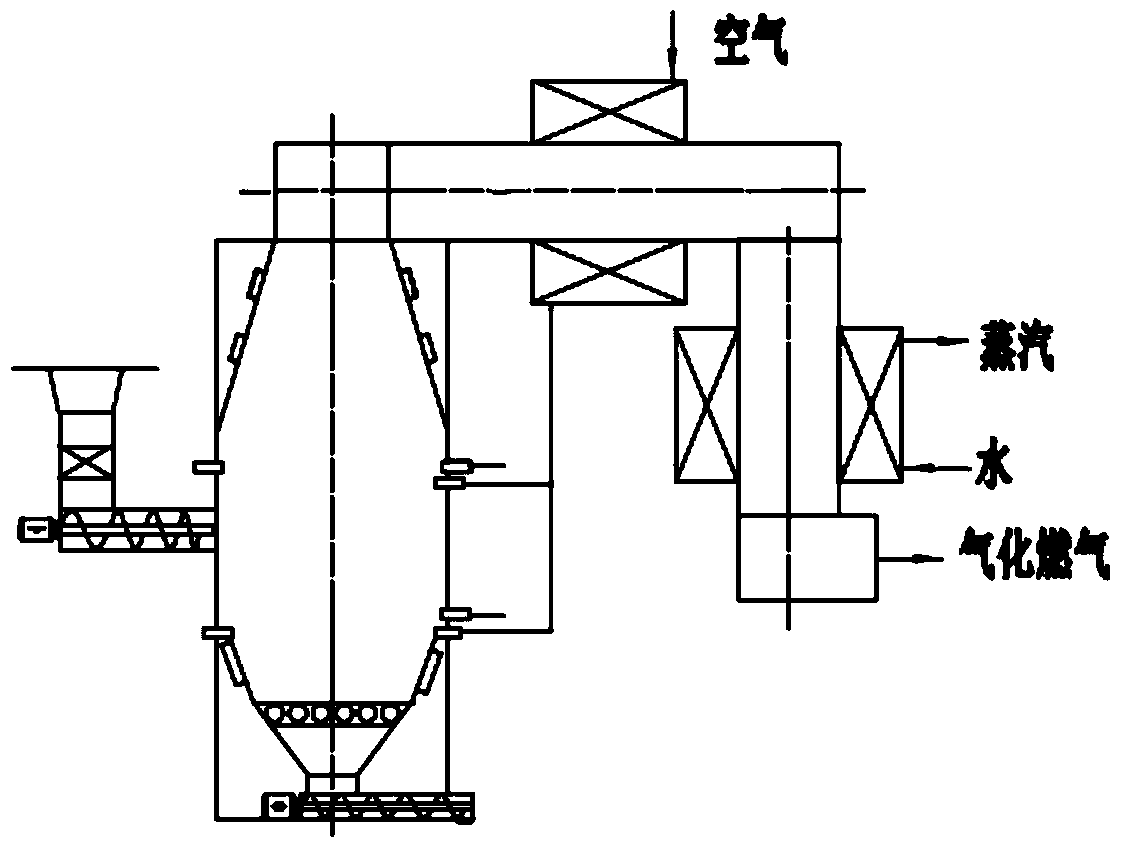

Biomass gas making system and biomass gas making technology based on microwave heating

ActiveCN105349186AImprove conversion rateIncrease gas production rateGasifier feeding meansEnergy inputEngineeringClean energy

The invention discloses a biomass gas making system and a biomass gas making technology based on microwave heating. The biomass gas making system comprises a microwave gasifier, a heat exchanger, a cleaning and dedusting device and a gas accumulation device, wherein the microwave gasifier, the heat exchanger, the cleaning and dedusting device and the gas accumulation device are sequentially connected; the heat exchanger is used for carrying out heat exchange with gas generated by the microwave gasifier; air and water enter the heat exchanger from one end of the heat exchanger and can be input into the microwave gasifier through the other end of the heat exchanger after being subjected to the heat exchange with the gas generated by the microwave gasifier; a residue outlet of the cleaning and dedusting device is connected with the microwave gasifier. The biomass gas making system disclosed by the invention has the beneficial effects that a biomass gasifying conversion process can be strengthened by utilizing the combined action of heat of materials per se and microwave auxiliary heating, the temperature needed for splitting and gasifying of plant materials can be rapidly reached, the gas production rate is high, and efficient and clean energy conversion on biomass type waste resources can be realized; sensible heat and waste heat which are generated during a gas making process can be fully utilized, the heat utilization rate is high, and the energy source is saved; automatic feeding and automatic discharging can be realized by the whole gas making device, the automation degree is high, and the safety is high.

Owner:山东知周环境科技有限公司

High-temperature gasification nozzle for petroleum coke

PendingCN110079363AImprove atomization effectIncrease gasification reaction rateGasification processes detailsGranular/pulverulent flues gasificationOxygenInternal temperature

The invention provides a high-temperature gasification nozzle for petroleum coke. The high-temperature gasification nozzle for petroleum coke comprises an oxygen spray pipe, an inner layer cooling jacket and a petroleum coke powder spray pipe which are coaxially arranged front inside to outside, wherein an oxygen inlet is formed in the upper part of the oxygen spray pipe, and the lower part vertically extends to form an oxygen outlet; an inner layer coolant inlet and an inner layer coolant outlet are formed in the upper part of the inner layer cooling jacket, and the lower part vertically extends to the bottom of the oxygen spray pipe and is sealed; petroleum coke guide rotating blades are coaxially arranged outside the inner layer cooling jacket; multiple petroleum coke feed inclined pipes are arranged at the upper part of the petroleum coke powder spray pipe, the lower part of the petroleum coke powder spray pipe vertically extends to the bottom of the inner layer cooling jacket to form annular space, and the inner wall of the petroleum coke powder spray pipe is in radial sealing contact with the petroleum coke guide rotating blades. The inner layer cooling jacket can control internal temperature of the nozzle, prevent overtemperature deformation and wear and prevent non-smooth flowing of petroleum coke powder, and the service life of the nozzle is prolonged.

Owner:CHINA HUANQIU CONTRACTING & ENG CO LTD +1

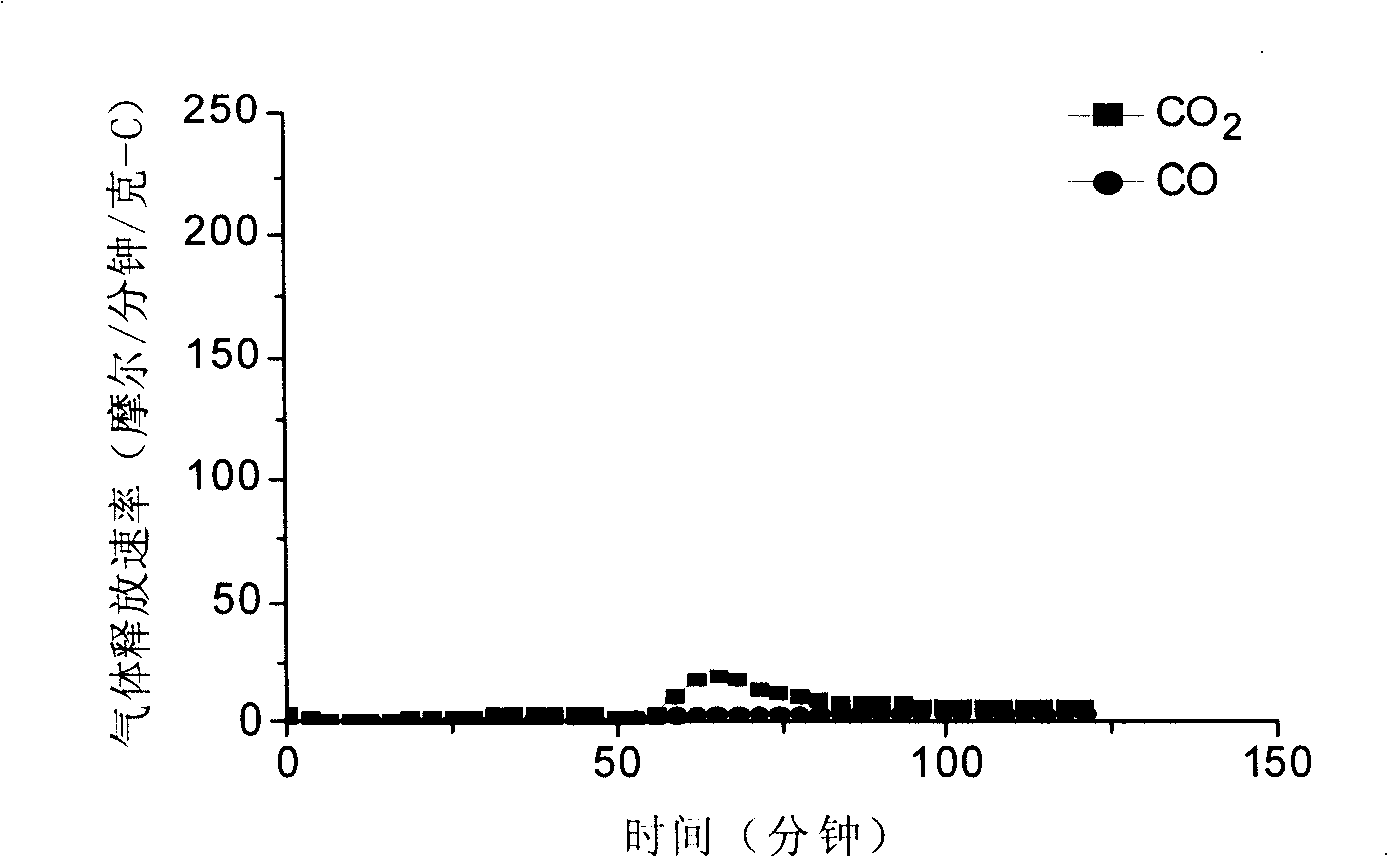

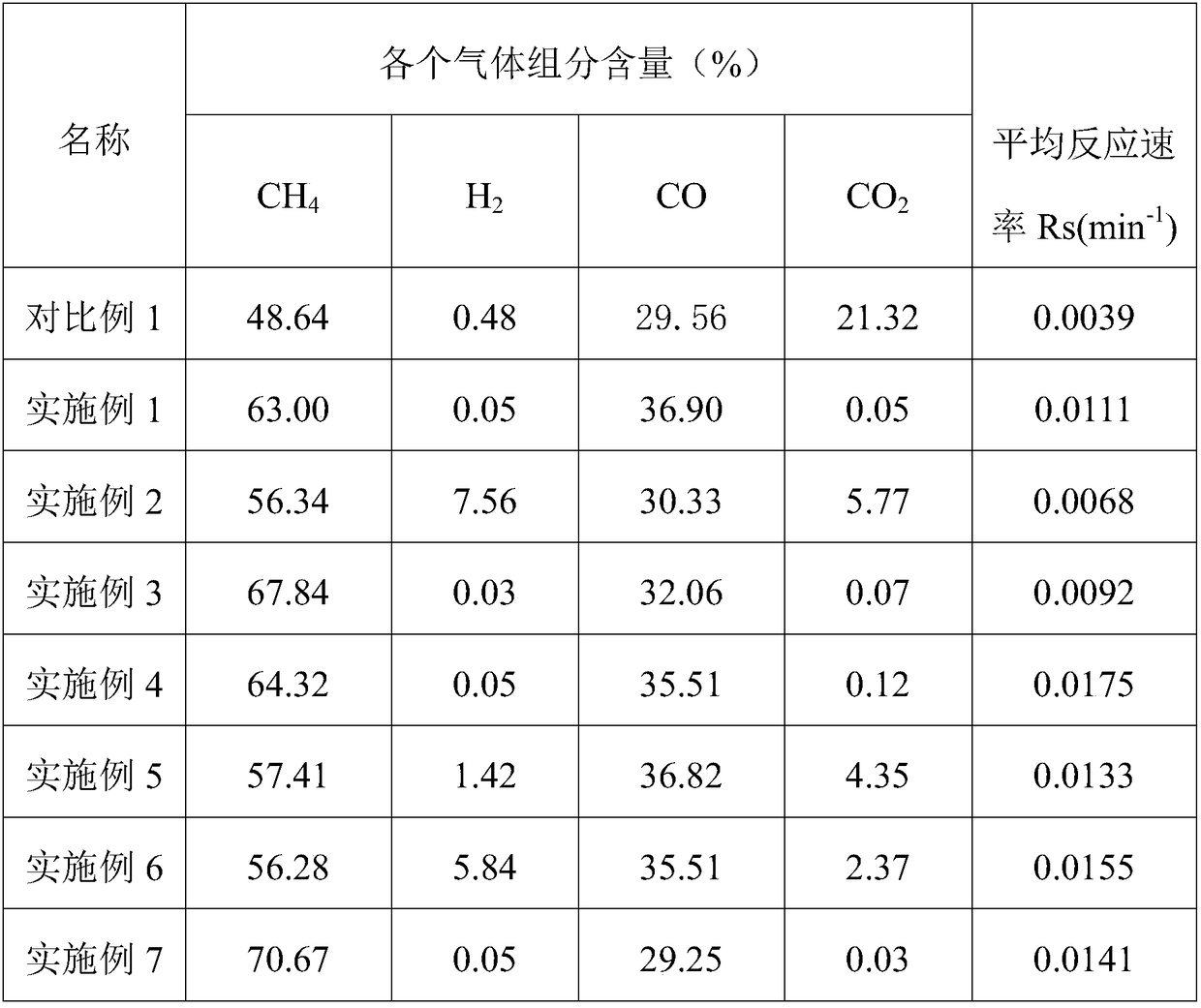

Method for preparing methane by petroleum coke catalytic gasification

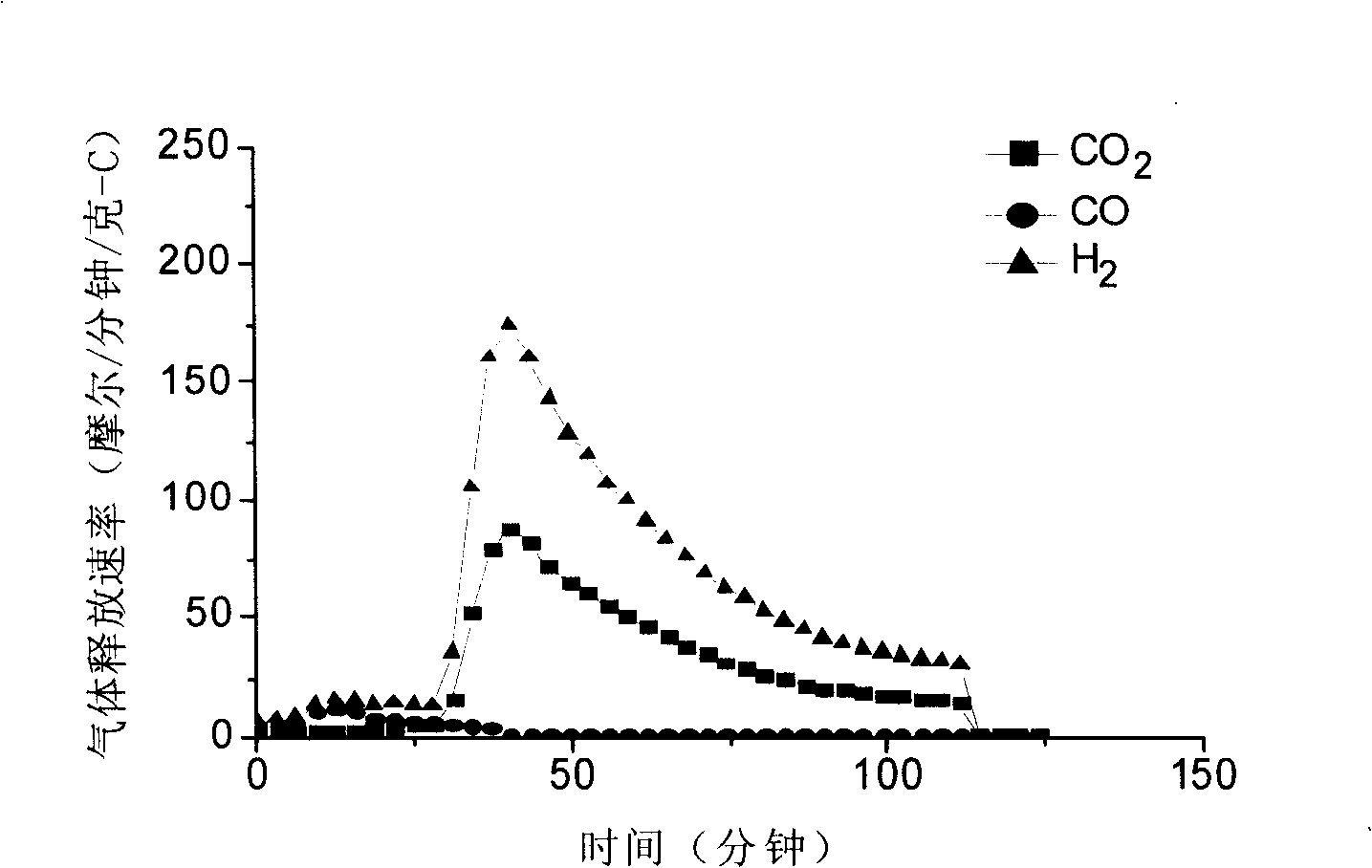

InactiveCN108641752AIncrease gasification reaction rateIncrease contentGasification processes detailsBulk chemical productionChemistryFluidized bed

The invention discloses a method for preparing methane by petroleum coke catalytic gasification. According to the method, a catalyst is mixed with petroleum coke by adopting a dry mixing method to obtain an experimental sample; the experimental sample is put in a fluidized bed, and performs a catalytic gasification at a temperature of 700 DEG C and a reacting pressure of 10MPa under a work condition that the mass ratio of vapor to the petroleum coke is 1 to prepare methane gas. By adopting the method, the petroleum coke is catalytically gasified by utilizing the catalyst, the gasifying reaction activity can be greatly improved, the average reaction rate can be accelerated, the content of methane can be remarkably increased, and efficient and clean utilization of the petroleum coke can be realized.

Owner:NORTHEASTERN UNIV

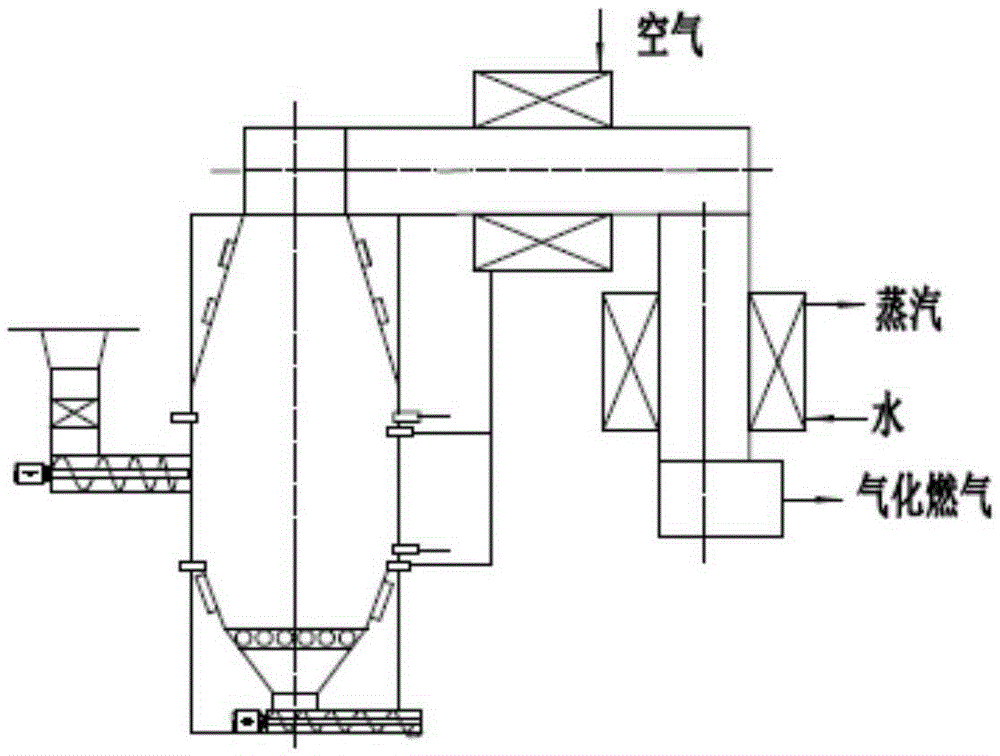

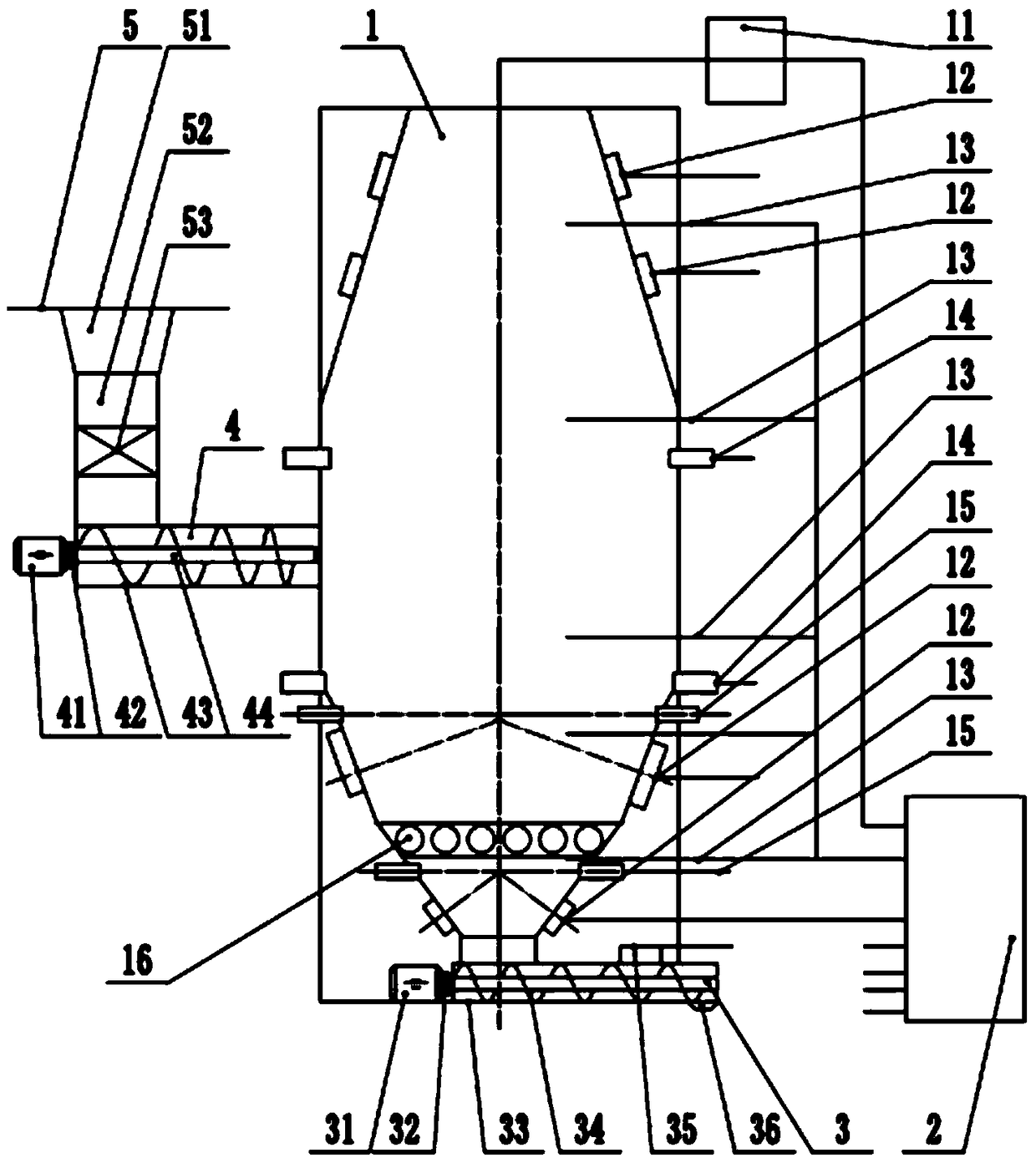

Biomass material microwave assisted pyrolysis gasification device and its application method

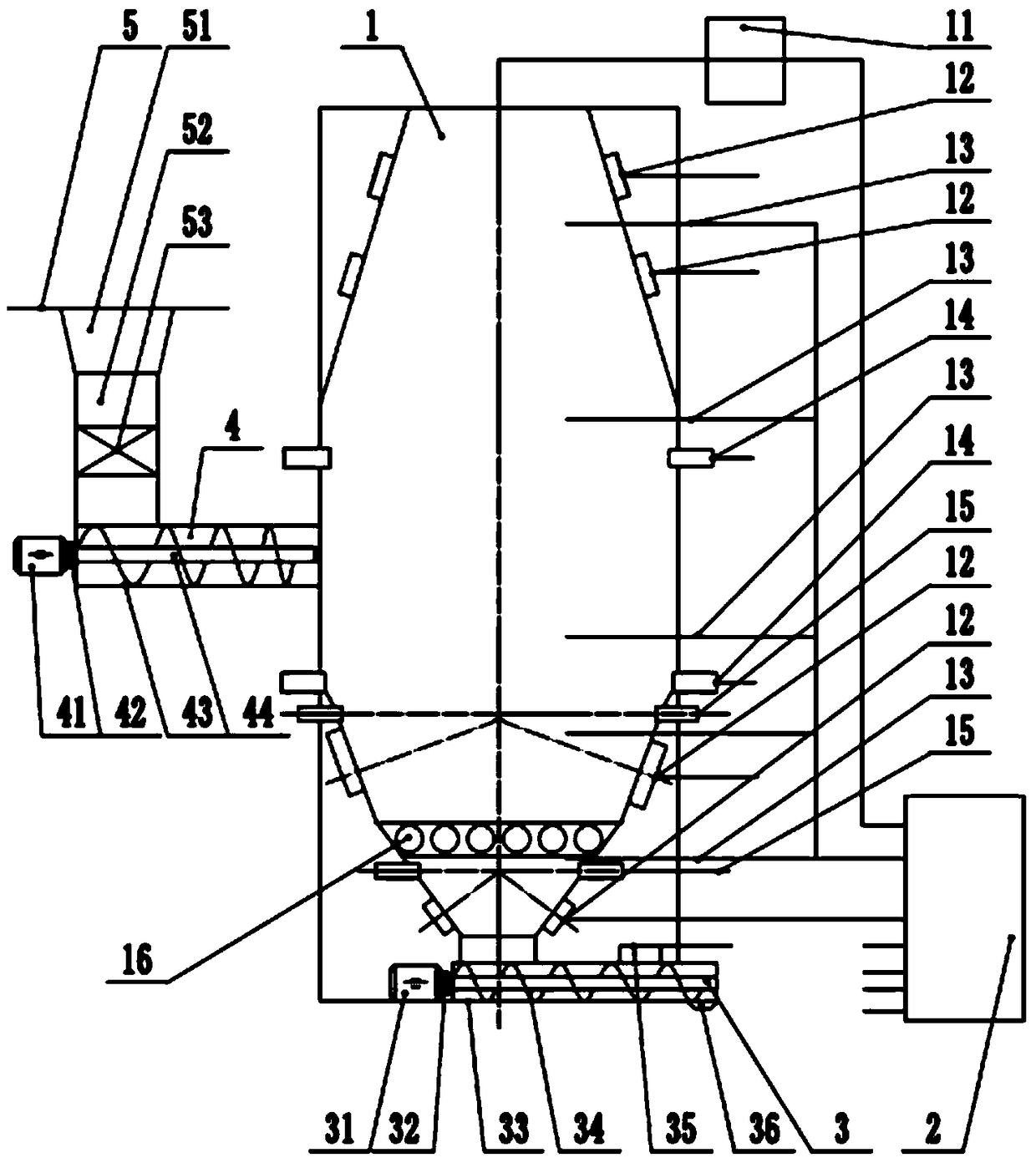

ActiveCN105368497BIncrease gasification reaction rateIncrease gas production rateEnergy inputGasification processes detailsGeneration processGeneration rate

The invention discloses a biomass material microwave-assisted pyrolysis gasification device, and an application method thereof. The biomass material microwave-assisted pyrolysis gasification device comprises a microwave gasification furnace; the microwave gasification furnace comprises a housing; the diameter of the upper end and the diameter of the lower end of the microwave gasification furnace are smaller than the diameter of the middle part of the microwave gasification furnace; microwave generators are arranged on the external side wall of the housing; the lower end of the housing is provided with a dust discharging conveying device; one side of the housing is provided with a biomass material inlet; the housing is provided with a plurality of steam inlets and a plurality of steam outlets; and a heat exchange tube is horizontally arranged in the housing. According to the biomass material microwave-assisted pyrolysis gasification device, gasification conversion process of biomass is promoted under the combined action of the heat energy of materials and microwave-assisted heating, a temperature needed by plant material pyrolysis gasification is reached rapidly, gas generation rate is high, high efficiency clean energy conversion of biomass waste resources can be realized; sensible heat and waste heat generated in gas generation processes are used fully, heat energy utilization efficiency is high, energy is saved, the biomass material microwave-assisted pyrolysis gasification device is capable of realizing automatic charging and discharging, automation degree is high, and safety is high.

Owner:山东知周环境科技有限公司

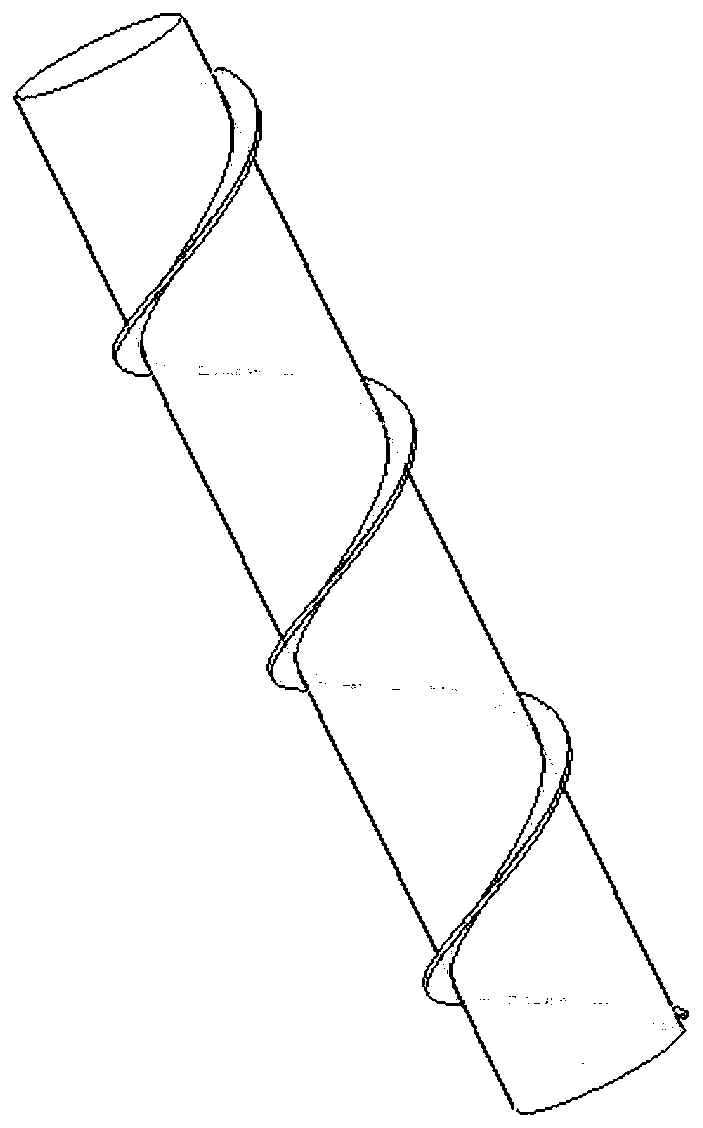

Combined gasification burner and use method thereof

PendingCN110093190AIncrease contact areaFully blendedGranular/pulverulent flues gasificationEngineeringResidence time

The invention relates to a combined gasification burner and a use method thereof. The burner comprises a first component, a second component and a third component, wherein the first component, the second component and the third component are coaxially and sequentially sleeved from outside to inside, the first component, the second component and the third component are independent of each other, and are integrally connected by fasteners, and the first component and the third component respectively have a separate fuel channel and an oxidant channel. Compared with the gasification burner only having the single-path fuel and the single-path oxidant, the combined gasification burner of the embodiments of the present invention increases the numbers of the fuel channels and the oxidant channels,increases the contact area between the fuel and the oxidant, ensures the rapid, complete and uniform doping of the fuel and the oxidant, and improves the fuel conversion rate and the burner performance in the case of the same total feeding amount, the same gasification chamber reaction space and the same residence time.

Owner:BEIJING AEROSPACE MWAY TECH CO LTD

Biomass and coal fluidized bed co-gasification method

InactiveCN102786990BLow costIncrease profitGranular/pulverulent flues gasificationSyngasCombustion chamber

The invention discloses a biomass and coal fluidized bed co-gasification method. The method comprises the following steps: biomass and coal are crushed and mixed to form biomass-coal mixture, the biomass-coal mixture is added to a fluidized bed gasification outer barrel and is gasified under the effect of a gasifying agent, and gas generated by gasification reaction is discharged through a cyclone separator; meanwhile, the biomass-coal mixture is added to a combustion inner barrel, coal coke which is not gasified in the gasification outer barrel and the entered compressed air are subjected to combustion reaction, and then ascend along the gasification inner barrel; and the coal coke enters an inertia separator to be gasified circularly along with a combustion gas flow, high-temperature flue gas and the biomass-coal mixture are subjected to countercurrent heat exchange and are discharged by a cyclone separator, and ash residue is discharged from the bottom. According to the biomass and coal fluidized bed co-gasification method, the gasification process and the combustion process of the biomass and coal are separated, the circulation of high-temperature material provides heat for the gasification reaction, heat is also directly exchanged through the thermal radiation and convection of a combustion chamber and a gasification chamber, the heat loss is reduced, meanwhile the production efficiency is improved, and the heat value of synthesis gas is high.

Owner:TAIYUAN UNIV OF TECH

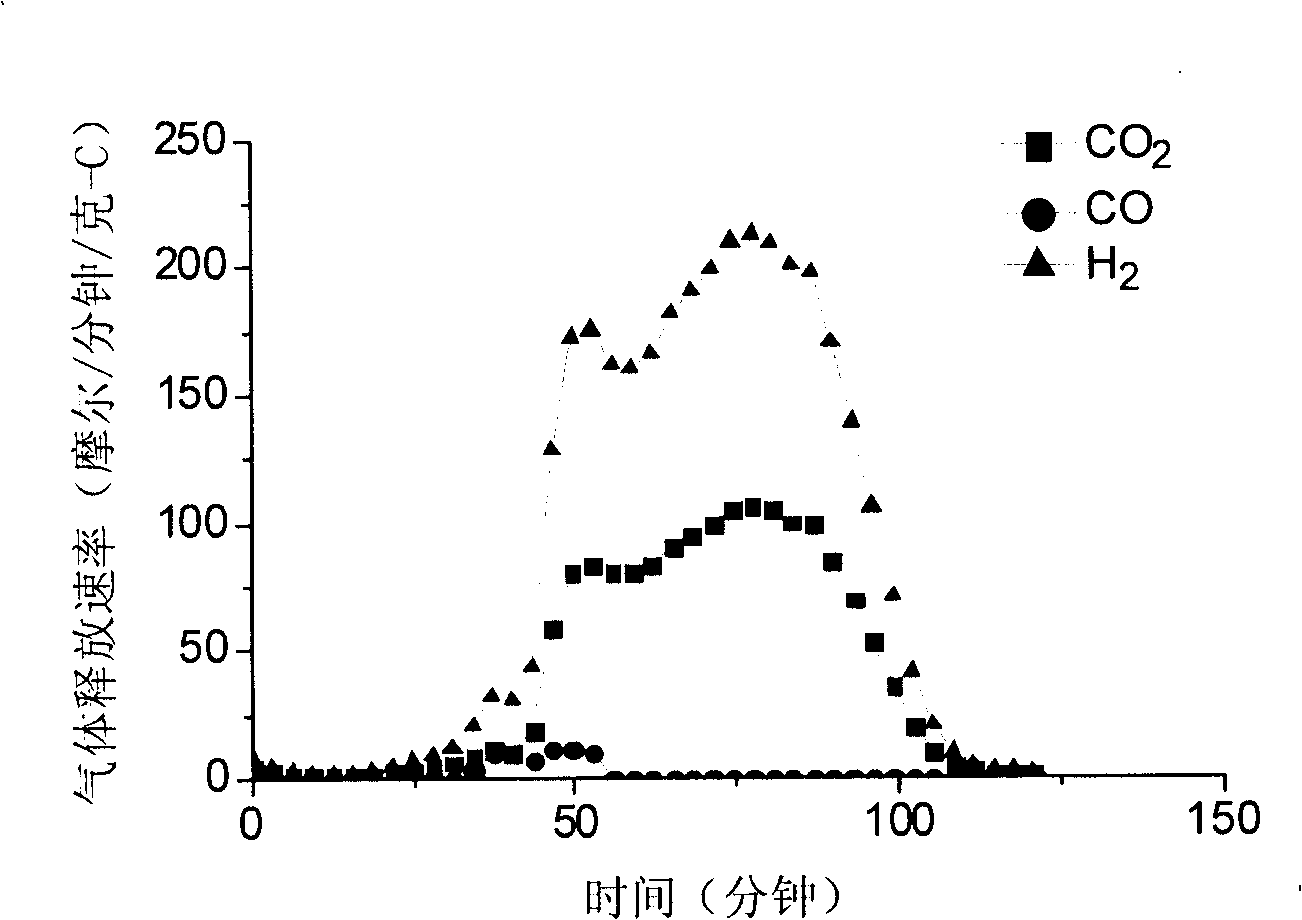

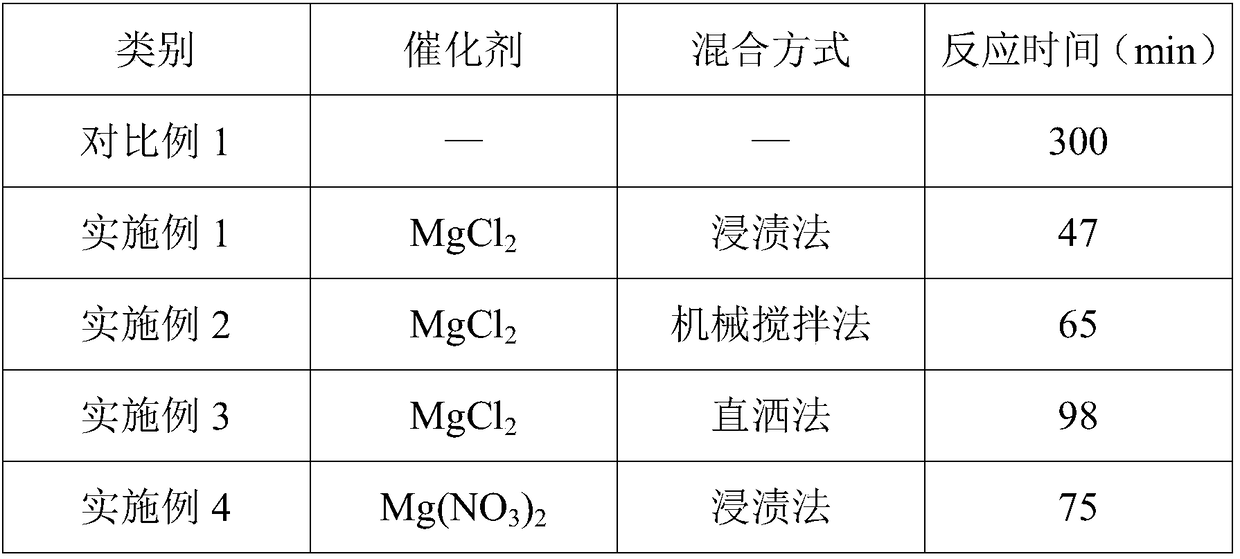

Method for catalytic gasification of petroleum coke

InactiveCN108587687AAbundant resourcesWide variety of sourcesGasification processes detailsFixed-bed gasificationReaction rateFixed bed

The invention relates to the field of petroleum coke gasification and particularly relates to a method for catalytic gasification of petroleum coke. The method comprises through a mechanical mixing method, a dipping method or a direct sprinkling method, mixing a magnesium compound catalyst and petroleum coke to obtain catalyst-supported petroleum coke and then feeding the catalyst-supported petroleum coke into a fixed bed gasification furnace so that the materials undergo a gasification reaction. The method utilizes the catalyst to catalytically gasify petroleum coke so that the gasification reaction rate is greatly improved and the reaction time is shortened by 1.45 to 8.4 times. The catalyst is a magnesium-based compound and has the advantages of low price, convenient recycling and the like.

Owner:NORTHEASTERN UNIV

A solar gasification system based on slot-tower combined with light concentration

ActiveCN104862010BOptimizing Thermal Energy EfficiencyReduce irreversible lossEnergy inputCombined combustion mitigationHigh concentrationCoal gasification

The invention discloses a combined trough-tower concentration manner-based solar gasification system which comprises an intermediate-temperature trough solar pyrolysis absorption reactor, a high-temperature rotating solar gasification reactor, a cyclone separator, an afterheat recovery device, a gas purification device, a heliostat field and a hyperboloid reflector. According to the system, different types of solar concentration devices and reactors are adopted for sequentially and independently finishing the pyrolysis and gasification reaction of a solid fuel, the intermediate-temperature trough solar pyrolysis absorption reactor is used for realizing the pyrolysis reaction of the solid fuel to obtain tar and coke at first, the heliostat field and the hyperboloid reflector are further used for acquiring high-concentration rate solar energy, and the high-temperature rotating solar gasification reactor is used for finishing reaction such as tar cracking and coke gasification; by the system, biomasses are efficiently gasified, the irreversible loss in a concentration gasification process is reduced, and the tar content of synthetic gas obtained by gasification is reduced.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

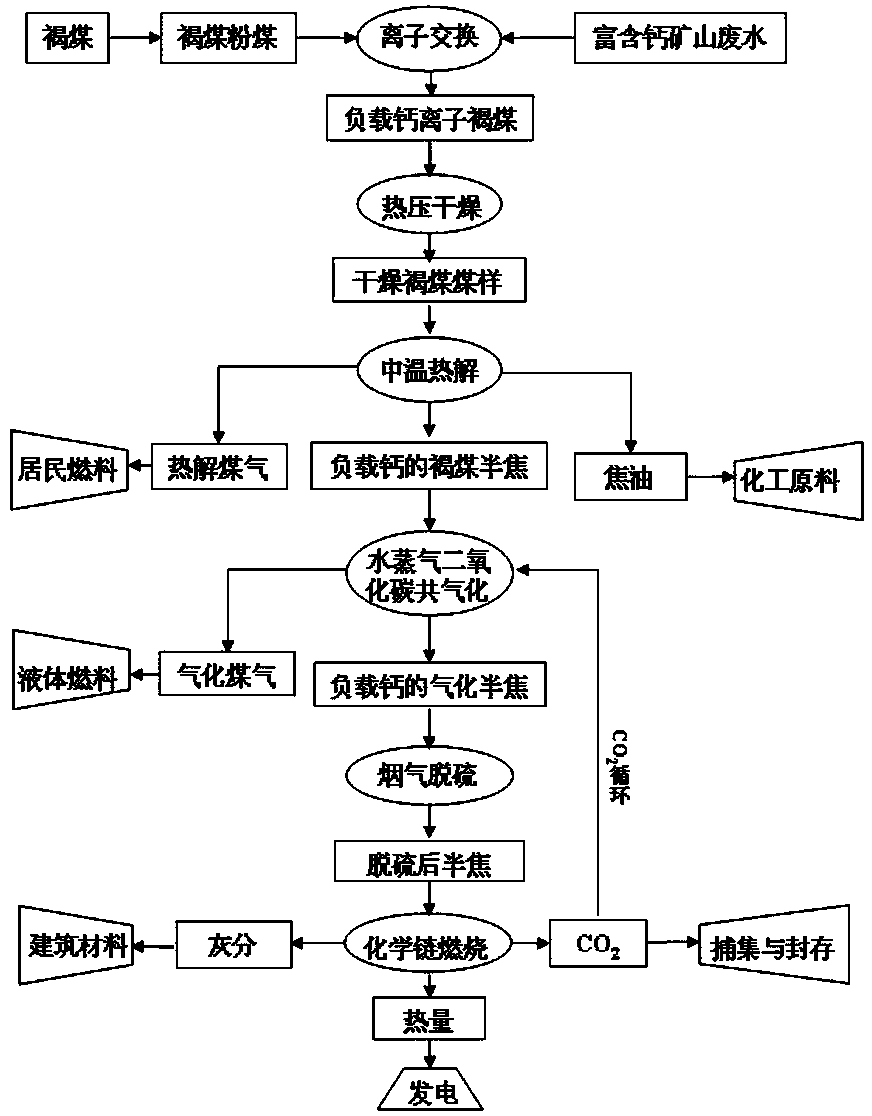

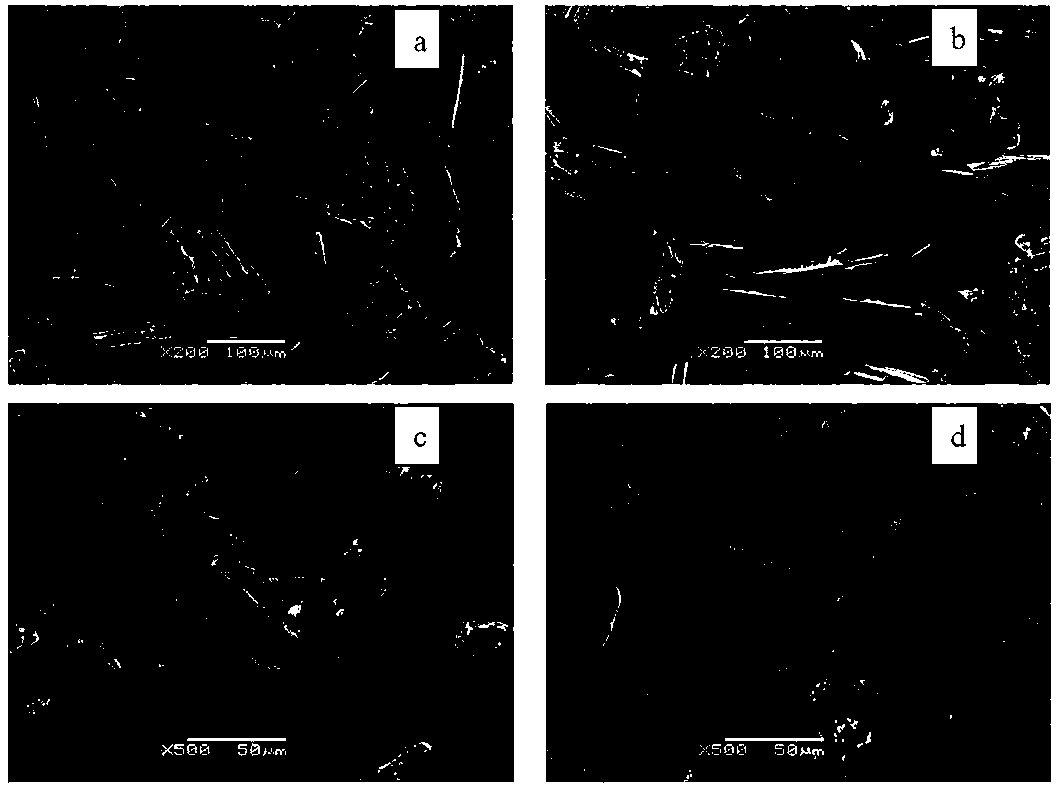

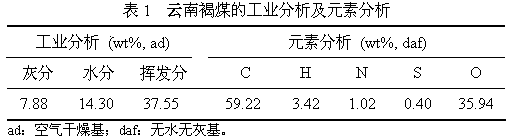

Method for efficient resource utilization of lignite

ActiveCN108285799AEfficient use ofPromote conversionLiquid hydrocarbon mixture productionSpecial form destructive distillationIon exchangeChemical products

The invention relates to a method for efficient resource utilization of lignite. The method includes the steps that ion exchange of lignite with mine wastewater containing calcium ions is performed, medium-temperature pyrolysis is performed on the lignite loaded with the calcium ions to obtain pyrolysis semi-coke, water vapor and CO2 are used for co-gasification activation of the pyrolysis semi-coke, the semi-coke loaded with calcium after gasification is obtained and used for flue gas desulfurization, the vulcanized semi-coke is obtained for chemical chain combustion to obtain heat in the semi-coke, and generated CO2 is partially returned to the co-gasification activation step for recycling. According to the method, various coal chemical technologies such as pyrolysis, gasification, fluegas desulfurization and chemical chain combustion are integrated, secondary energy and various chemical products are obtained, efficient grading and resource utilization of the lignite are achieved, the carbon discharge amount in the utilization process of the lignite are decreased, and effective utilization of the calcium ions in the mine wastewater is achieved.

Owner:TAIYUAN UNIV OF TECH

Catalytic coal gasifaction furnace of differential speed bed, and method of catalytic gasification

InactiveCN100577774CImprove removal efficiencyExtended stayCombined combustion mitigationGranular/pulverulent flues gasificationLow speedHearth

Owner:NANTONG SANCHUANG MACHINE MFG +1

Device for separating carbon dioxide through chemical-looping combustion in coal pressurizing high-density recirculating fluidized bed

ActiveCN102087023BExtended staySolving the Response Matching ProblemFluidized bed combustionIndirect carbon-dioxide mitigationReaction rateMoving bed

The invention discloses a device for separating carbon dioxide through chemical-looping combustion in a coal pressurizing high-density recirculating fluidized bed. Gasification reaction is carried out on coal particles and a gasification agent in a pressurizing high-density recirculating fluidized bed fuel reactor 1; and a gasification product and an oxygen carrier returning back to the fuel reactor 1 performs redox reaction to generate CO2 and H2O. The device comprises the pressurizing high-density recirculating fluidized bed fuel reactor (1), a primary cyclone separator (2), a primary dipleg (3), a fresh oxygen carrier particle feeder (4), a cross flow moving bed air reactor (5), a grid plate (6), an inactivation oxygen carrier discharging device (7), a primary material returner (8), a primary exhaust pipe (9), a secondary cyclone separator (10), a secondary exhaust pipe (11), a secondary dipleg (12) and a secondary material returner (13). By using the device in the invention, the reaction matching problem caused by the quantity grade difference existing in combustion and the oxygen carrier reaction rate is solved, thus the combustion efficiency of the coal, the separated CO2 concentration and the final gathering rate of the CO2 are greatly improved.

Owner:SOUTHEAST UNIV

Method for preparing methane-rich gas through autocatalytic gasification of biomass

ActiveCN102786994BReduce generationReduce yieldGaseous fuelsBiofuelsParticulatesAlkaline earth metal

The invention aims to provide a method for preparing methane-rich gas through cyclic utilization of alkali / alkaline earth metals contained in biomass for autocatalytic pyrolysis and autocatalytic pressurized gasification of the biomass. According to the method, water quenching is carried out on biomass ash so as to cyclically extract alkali / alkaline earth metals in the biomass ash, and the alkali / alkaline earth metals are sprinkled on and dipped in biomass; the biomass containing the alkali / alkaline earth metals undergoes autocatalytic pyrolysis at a low temperature of 280 to 320 DEG C at first, then a pyrolysis gas product enters into a combustion reactor and burns together with solid particles separated from a gasification reactor so as to supply heat for the process of pyrolysis, a pyrolysis solid product enters into the gasification reactor and undergoes autocatalytic pressurized gasification in a steam / oxygen atmosphere, hydrogen-rich gas is separated from crude synthetic gas produced in gasification and is returned to the pressurized gasification reactor, and the pyrolysis solid product is subjected to hydrogasification at the same time. With the method provide by the invention, biomass can be used for preparing methane-rich gas with low tar content, and high gasification efficiency is obtained. The method has the advantages of simple operation, less water consumption, strong technological adaptability and easy operation.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

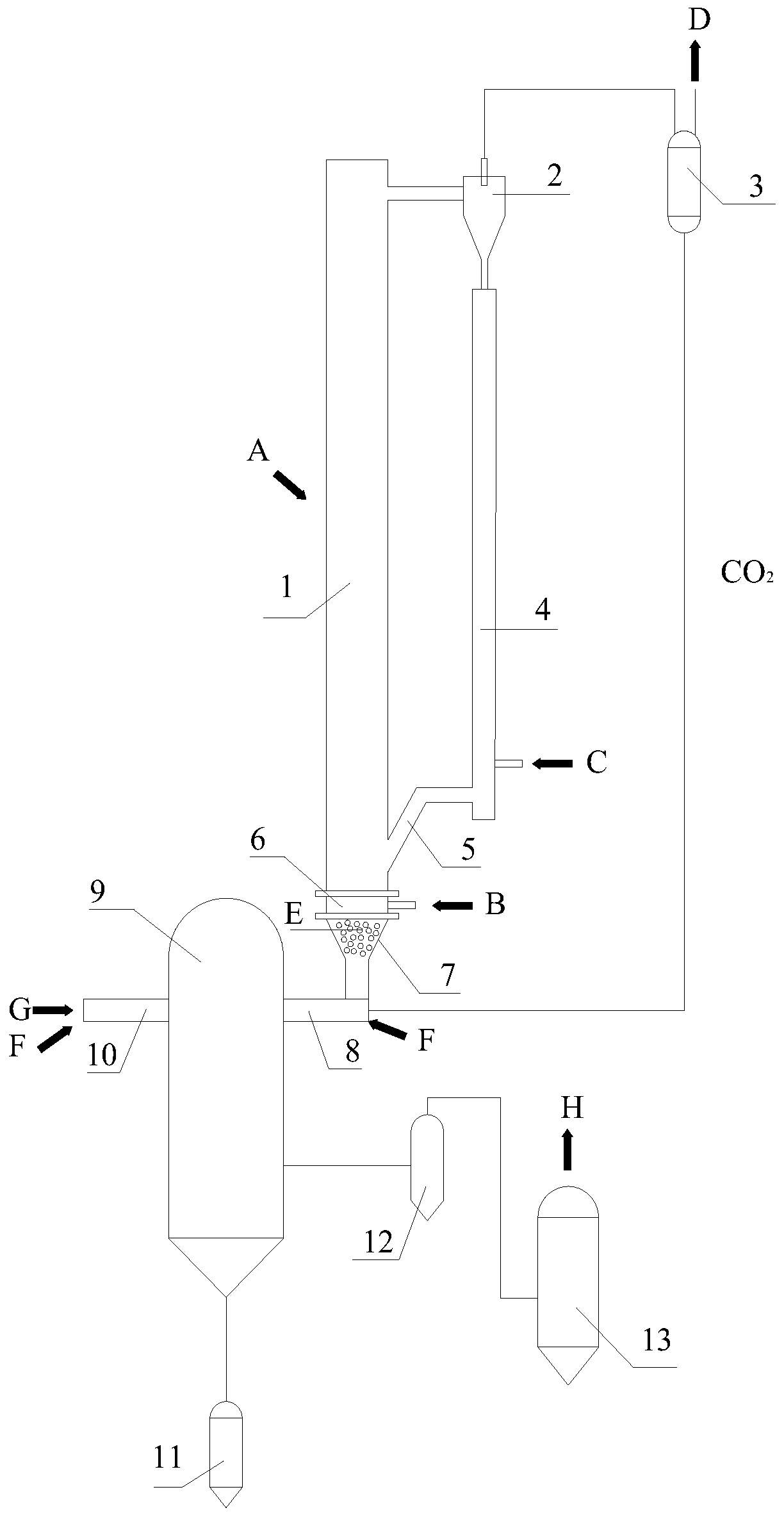

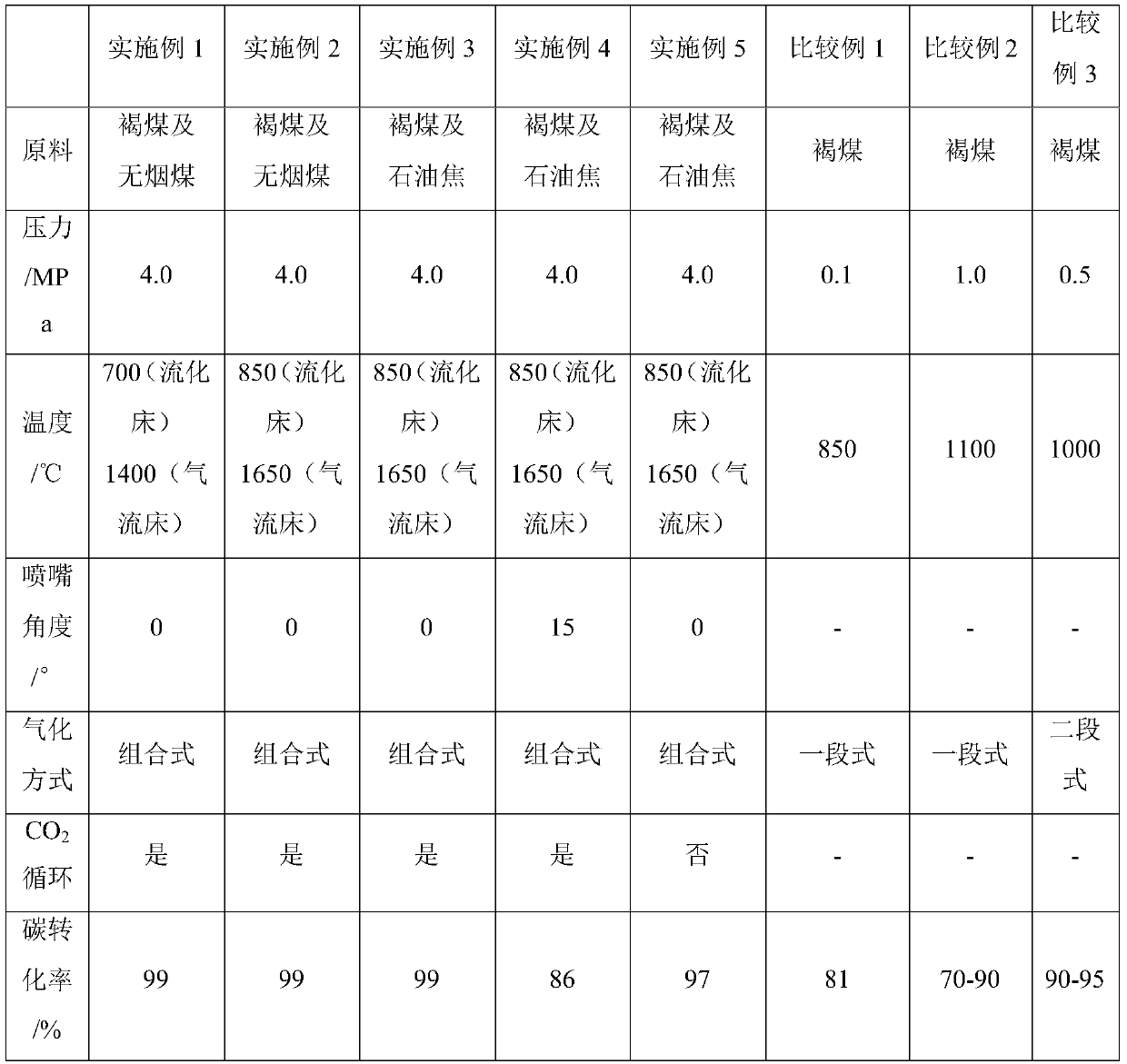

Circulating fluidized bed-entrained bed combined gasification method and device

ActiveCN107916140BRealize secondary useLow costGasification processes detailsBulk chemical productionSyngasPtru catalyst

The invention relates to a CFB (circulating fluidized bed)-entrained flow bed combined gasification method and device and solves the problems of poor coal applicability and low carbon conversion ratein the prior art. With the adoption of combination of a CFB reactor and an entrained flow bed reactor, the method comprises steps as follows: low-rank coal containing a catalyst reacts with a gasifying agent in the CFB reactor to produce synthesis gas rich in methane, ash residues serving as the raw material and the catalyst of the entrained flow bed reactor are sent into the entrained flow bed reactor through nozzles to impact with high-rank coal or petroleum coke and subjected to a reaction under the action of the gasifying agent, synthesis gas is produced, therefore, carbon residues in theash residues of the CFB reactor are effectively utilized, the carbon conversion rate is increased, and wide raw material adaptability to the low-rank coal, the high-rank coal and petroleum coke is realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

A solar high temperature thermochemical gasification reactor

ActiveCN104877709BImprove utilization efficiencyReduce irreversible lossEnergy inputCombustible gas productionBlack bodyServomotor

The invention discloses a solar high-temperature thermochemical gasification reactor. The reactor mainly comprises a black body cavity, a reaction chamber, a flow guiding column, a gas guide pipe, a solid guide pipe, servomotors and the like. By using the reactor, solar energy can be more efficiently used for driving solid hydrocarbon fuels such as coal, biomass and the like to be subjected to gasifying reaction and independently completing processes such as preheating, pyrolyzing, gasifying and the like contained by the gasifying reaction, so that the conversion of the solar energy to high-quality synthetic gas can be realized, and the current problems of high solar energy storage difficulty, poor renewable energy source conveying stability and the like are solved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Biomass gas production system and process based on microwave heating

ActiveCN105349186BImprove conversion rateIncrease gas production rateEnergy inputCombustible gas productionProduction rateMicrowave

The invention discloses a biomass gas making system and a biomass gas making technology based on microwave heating. The biomass gas making system comprises a microwave gasifier, a heat exchanger, a cleaning and dedusting device and a gas accumulation device, wherein the microwave gasifier, the heat exchanger, the cleaning and dedusting device and the gas accumulation device are sequentially connected; the heat exchanger is used for carrying out heat exchange with gas generated by the microwave gasifier; air and water enter the heat exchanger from one end of the heat exchanger and can be input into the microwave gasifier through the other end of the heat exchanger after being subjected to the heat exchange with the gas generated by the microwave gasifier; a residue outlet of the cleaning and dedusting device is connected with the microwave gasifier. The biomass gas making system disclosed by the invention has the beneficial effects that a biomass gasifying conversion process can be strengthened by utilizing the combined action of heat of materials per se and microwave auxiliary heating, the temperature needed for splitting and gasifying of plant materials can be rapidly reached, the gas production rate is high, and efficient and clean energy conversion on biomass type waste resources can be realized; sensible heat and waste heat which are generated during a gas making process can be fully utilized, the heat utilization rate is high, and the energy source is saved; automatic feeding and automatic discharging can be realized by the whole gas making device, the automation degree is high, and the safety is high.

Owner:山东知周环境科技有限公司

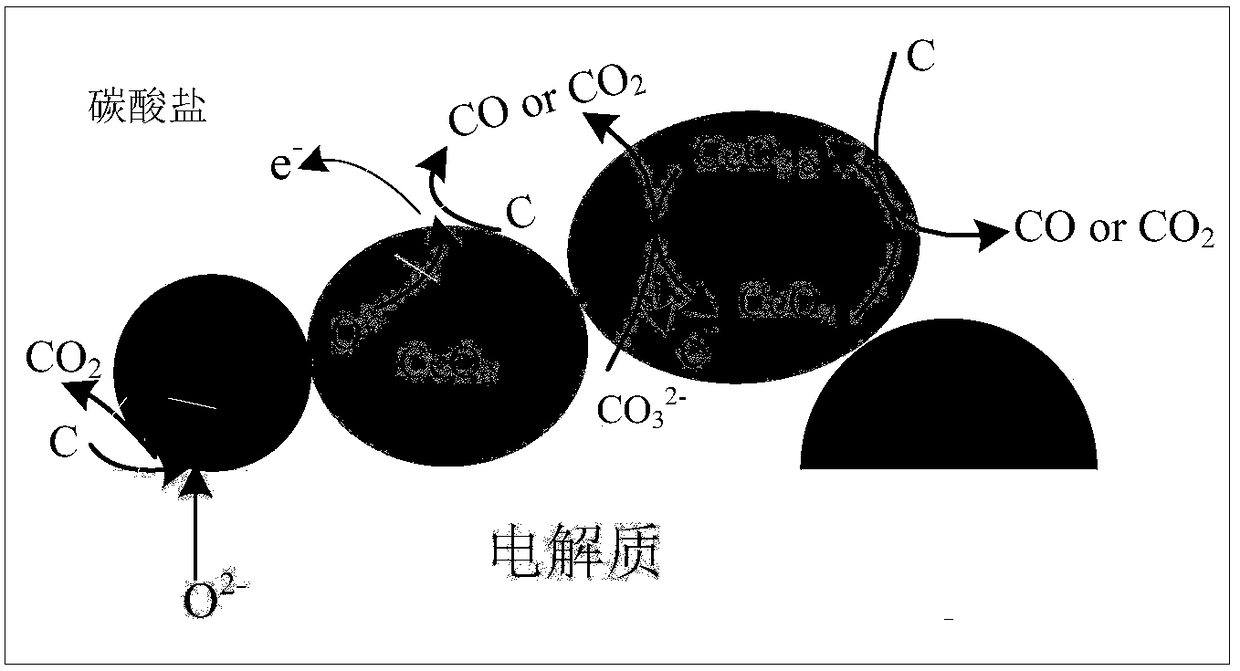

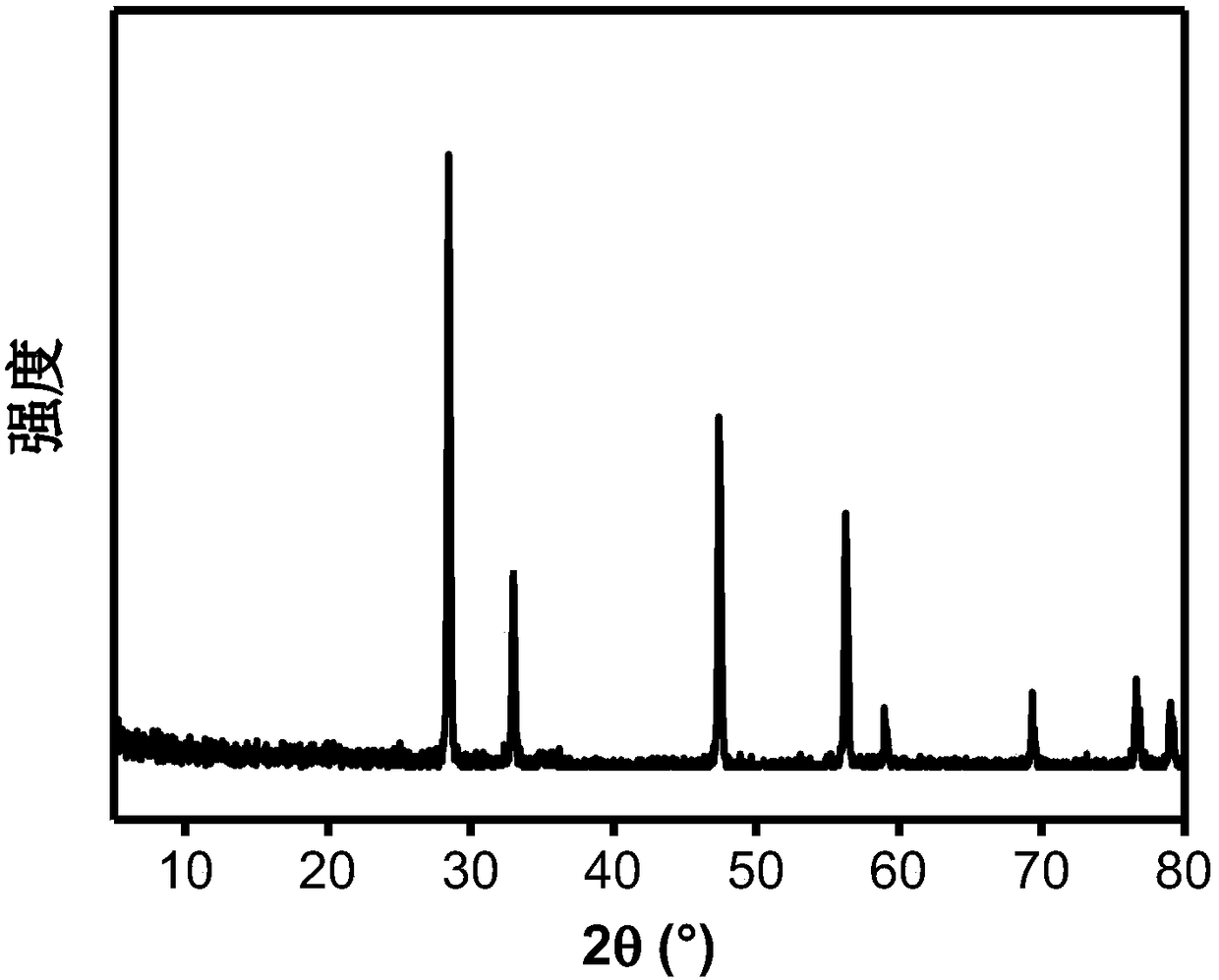

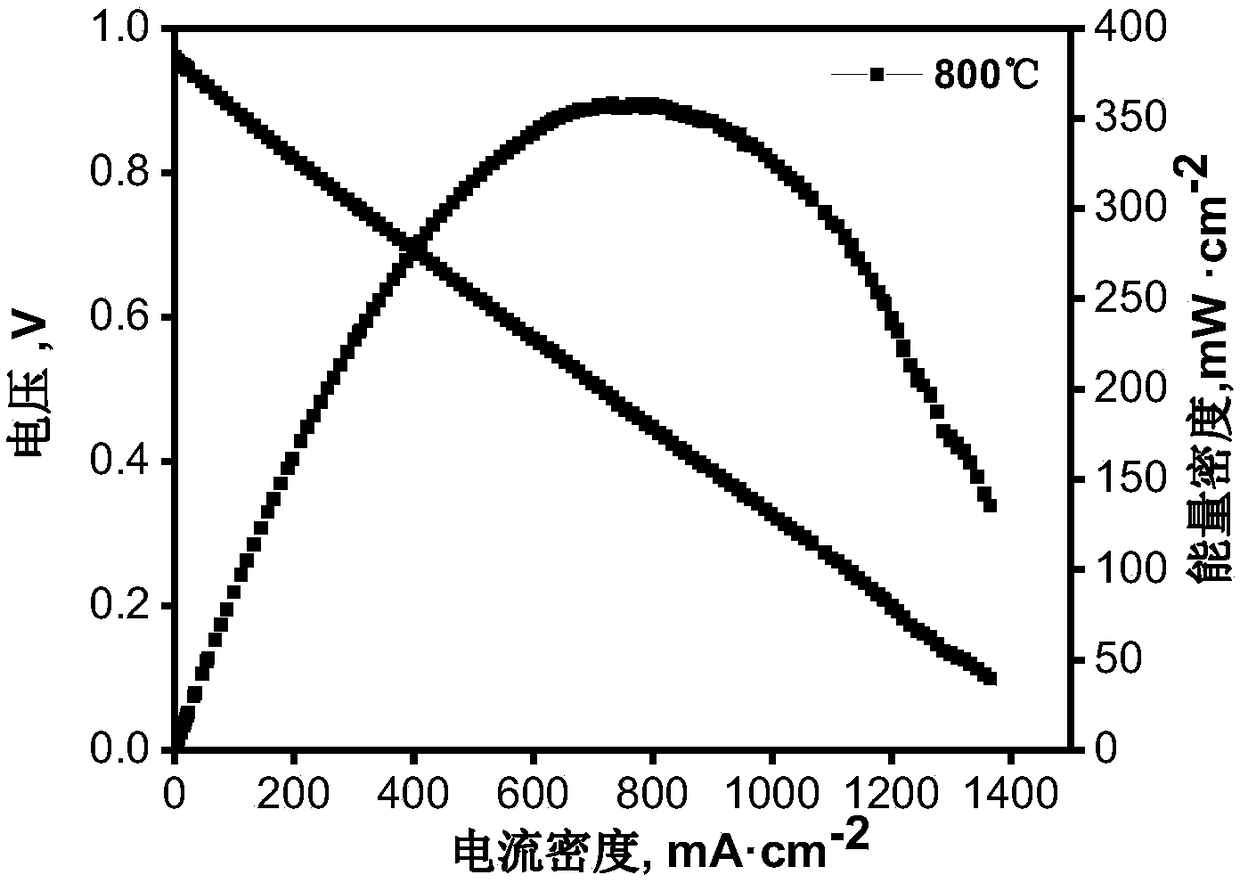

A direct carbon fuel cell anode with dual electrocatalytic functions

ActiveCN105742653BImprove output performanceIncreased reactive sitesCell electrodesElectrical conductorReaction rate

The invention relates to a direct carbon fuel cell anode with dual electric catalytic functions, and belongs to the technical field of clean energy. The anode material is prepared by compounding nanoparticle as a conductive phase on the inner and outer parts of transition element-codoped CeO2 as a catalytic active phase of the anode and a porous framework. The prepared anode material has dual electrocatalysis effects on carbon fuel, can be used as an excellent ion conductor, transfers O<2-> generated by a cathode to the electrode surface and increases the electrode reaction active sites; the anode material can be applied to electrochemical oxidation of an intermediate catalytic carbon; and the power output of the cell is improved. The anode material disclosed by the invention is assembled into a direct carbon fuel cell for power generation, so that the three-phase interface length is prolonged; the fuel gasification reaction rate is improved; corrosion of molten carbonate to an electrolyte is avoided; and the lifetime of the cell is prolonged.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com