Patents

Literature

92results about How to "Fully blended" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

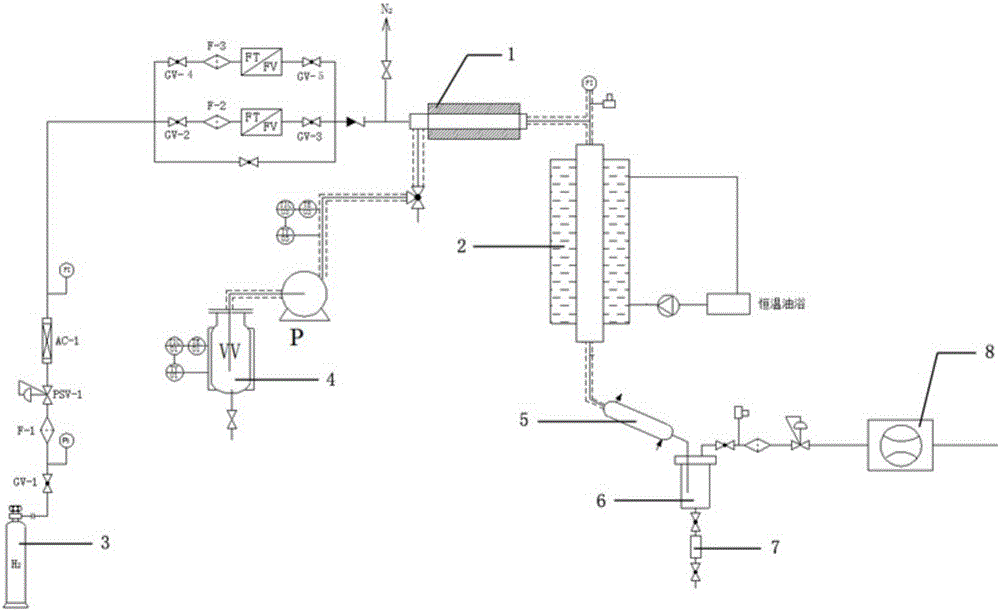

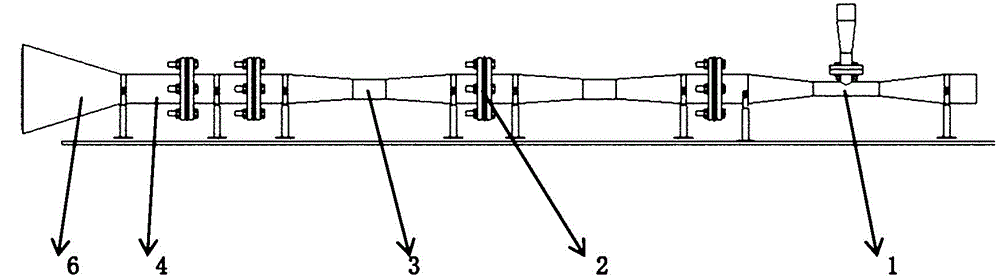

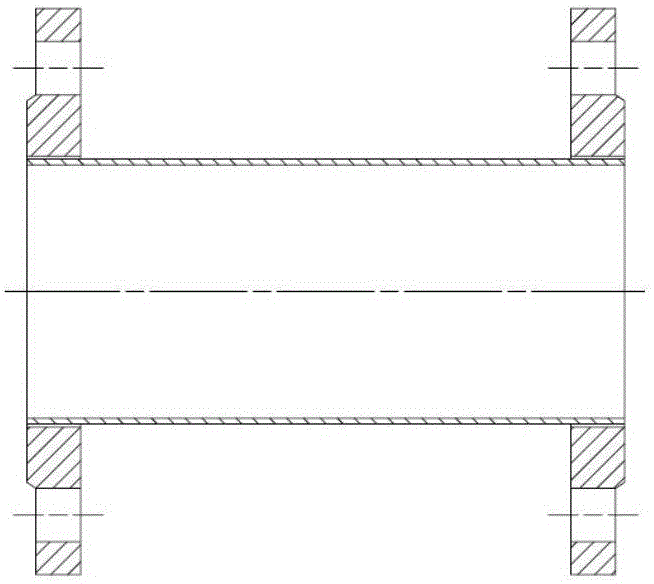

Continuous hydrogenation reaction system for liquid organic hydrogen storage carrier and hydrogenation reaction method

ActiveCN105060244AChange viscosityImprove responseHydrogenMetal/metal-oxides/metal-hydroxide catalystsTemperature controlHydrogenation reaction

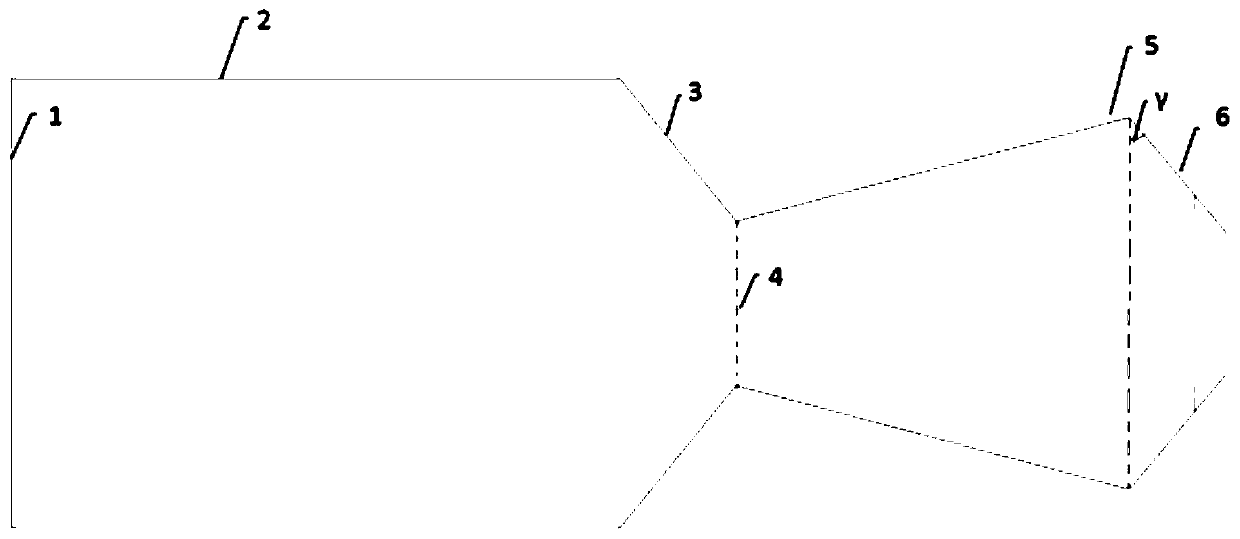

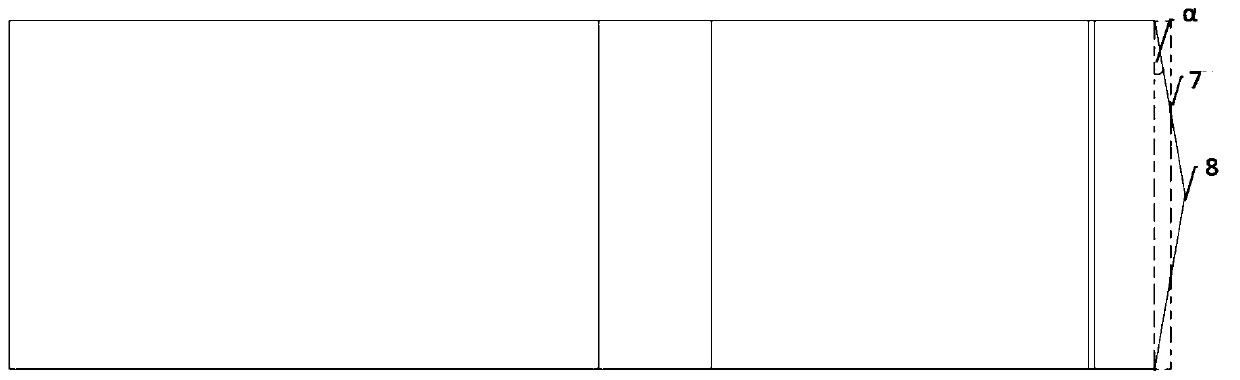

The invention discloses a continuous hydrogenation reaction system for a liquid organic hydrogen storage carrier and a hydrogenation reaction method. The system comprises a feeding system, preheaters, static bed reaction stills and separation devices. The feeding system is communicated with inlets of the preheaters through pipelines. Outlets of the preheaters are communicated with inlets of the static bed reaction stills through pipelines. Outlets of the static bed reaction stills are communicated with inlets of the separation devices through pipelines. The static bed reaction stills are filled with hydrogenation catalysts and inert materials. The interiors of the reaction stills are kept at the constant temperature through circulation heat conduction media in interlayers of the surfaces of the static bed reaction stills. According to the continuous hydrogenation reaction system, the single-tube type static bed reaction stills are mainly adopted, the single-tube type static bed reaction stills are filled with the hydrogenation catalysts and the inert materials, heat tracing and heating control systems are arranged in all the pipelines in the liquid feeding system to be used for conducting temperature-control heating on liquid flowing through the system, a plurality of sets of gas quality and flow controller systems are designed in the system, the preheaters in the system are designed to be gas-liquid blending type preheaters, and the hydrogenation effect of the liquid hydrogen storage carrier is improved beneficially.

Owner:WUHAN HYNERTECH CO LTD

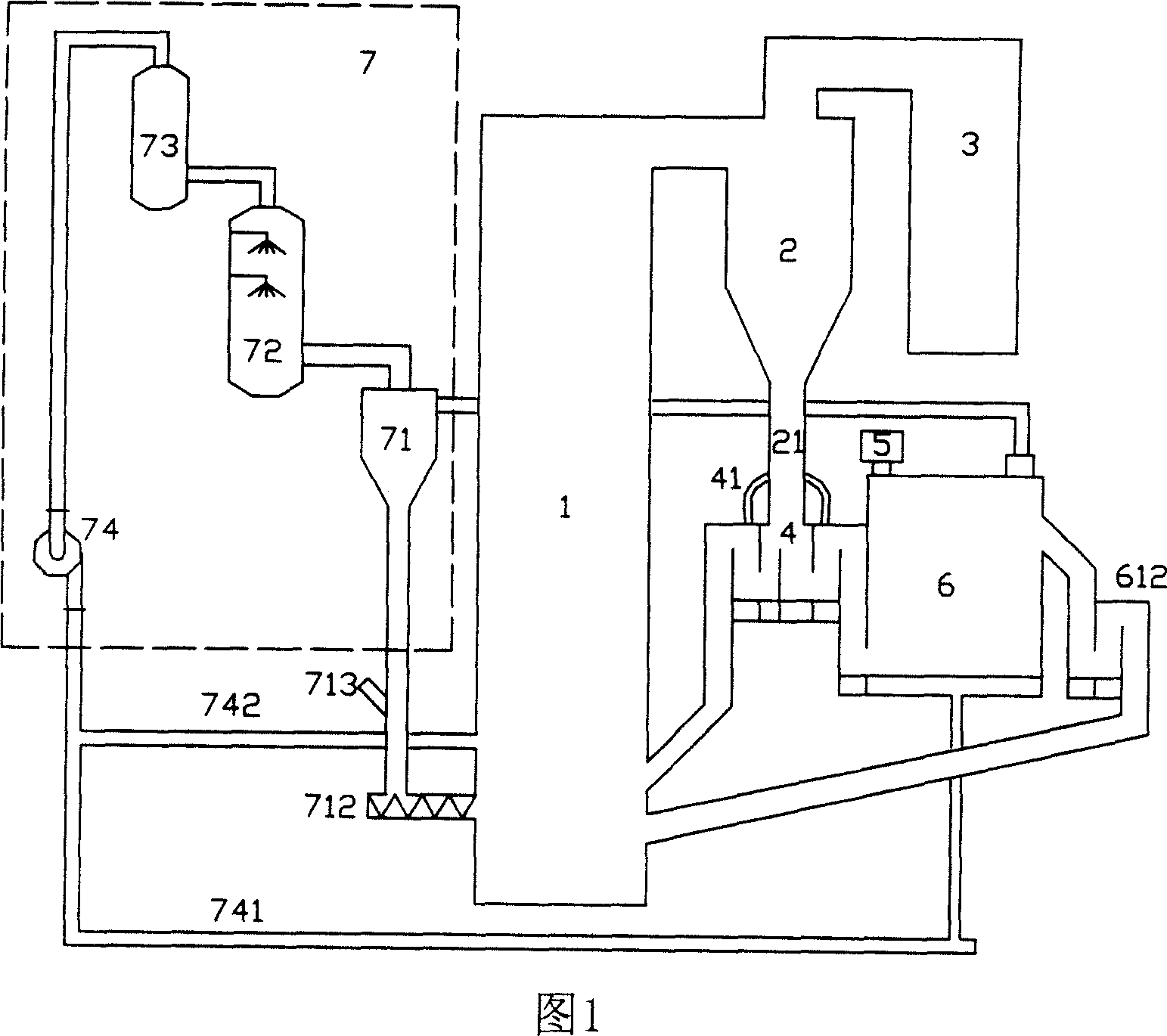

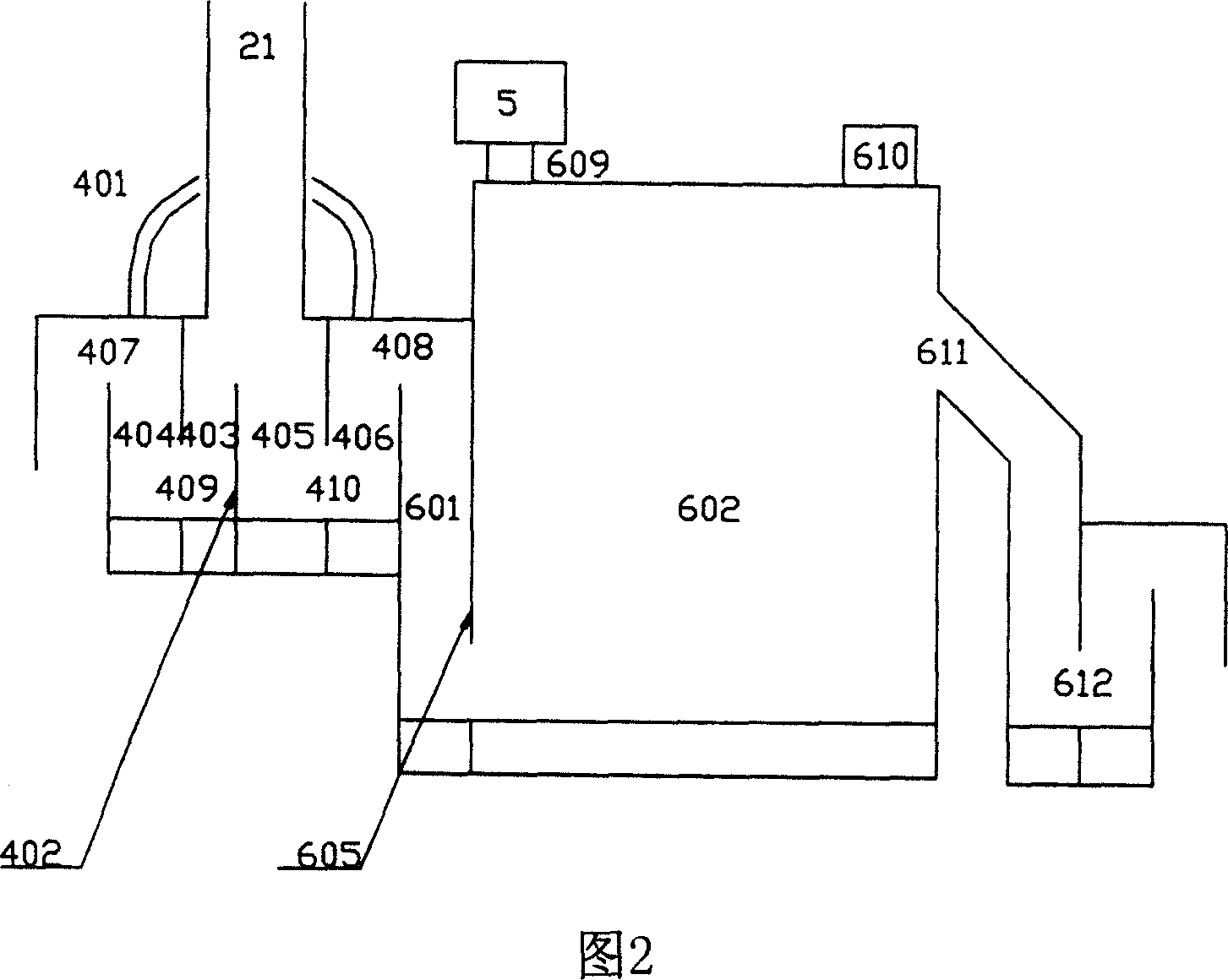

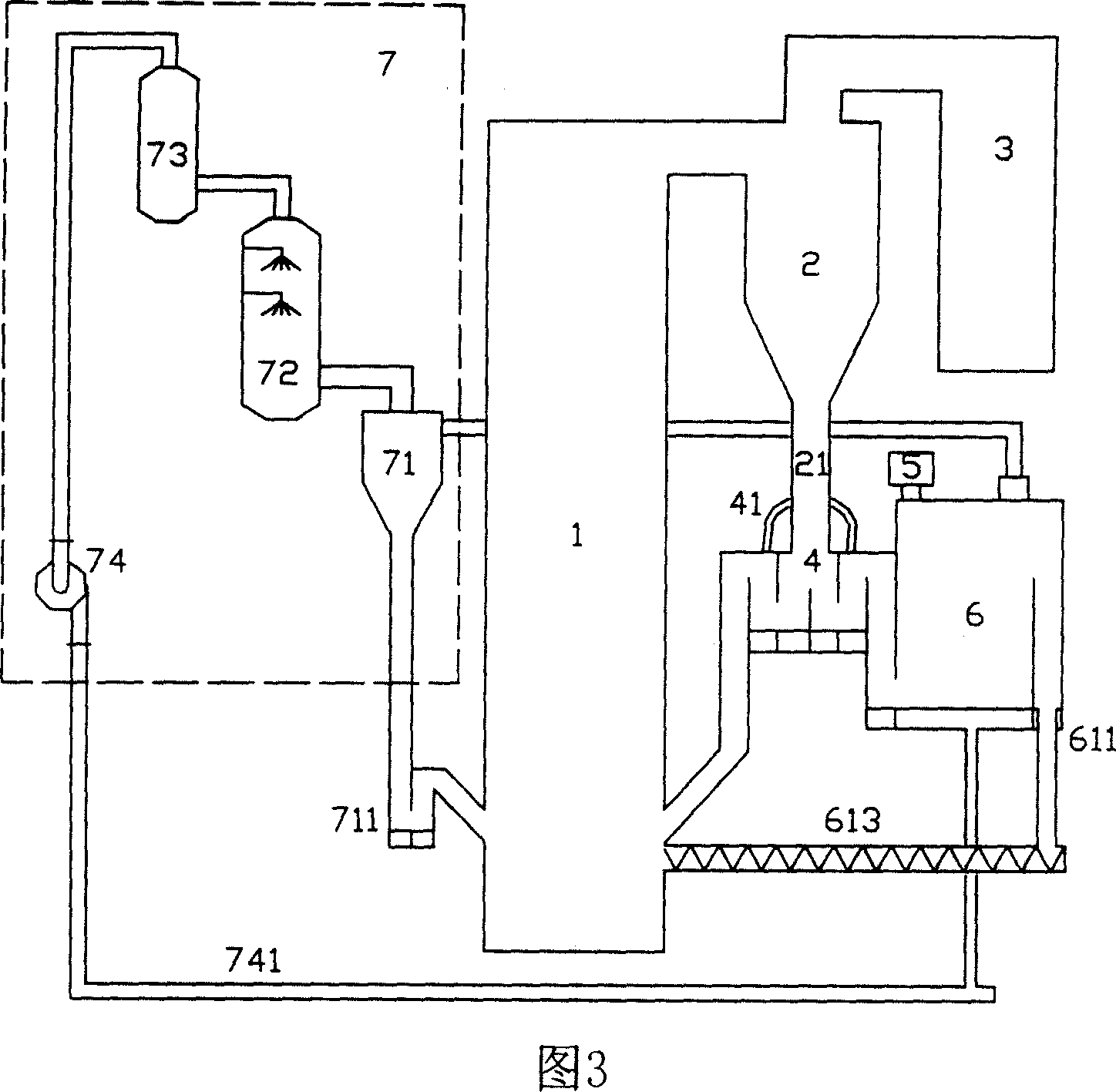

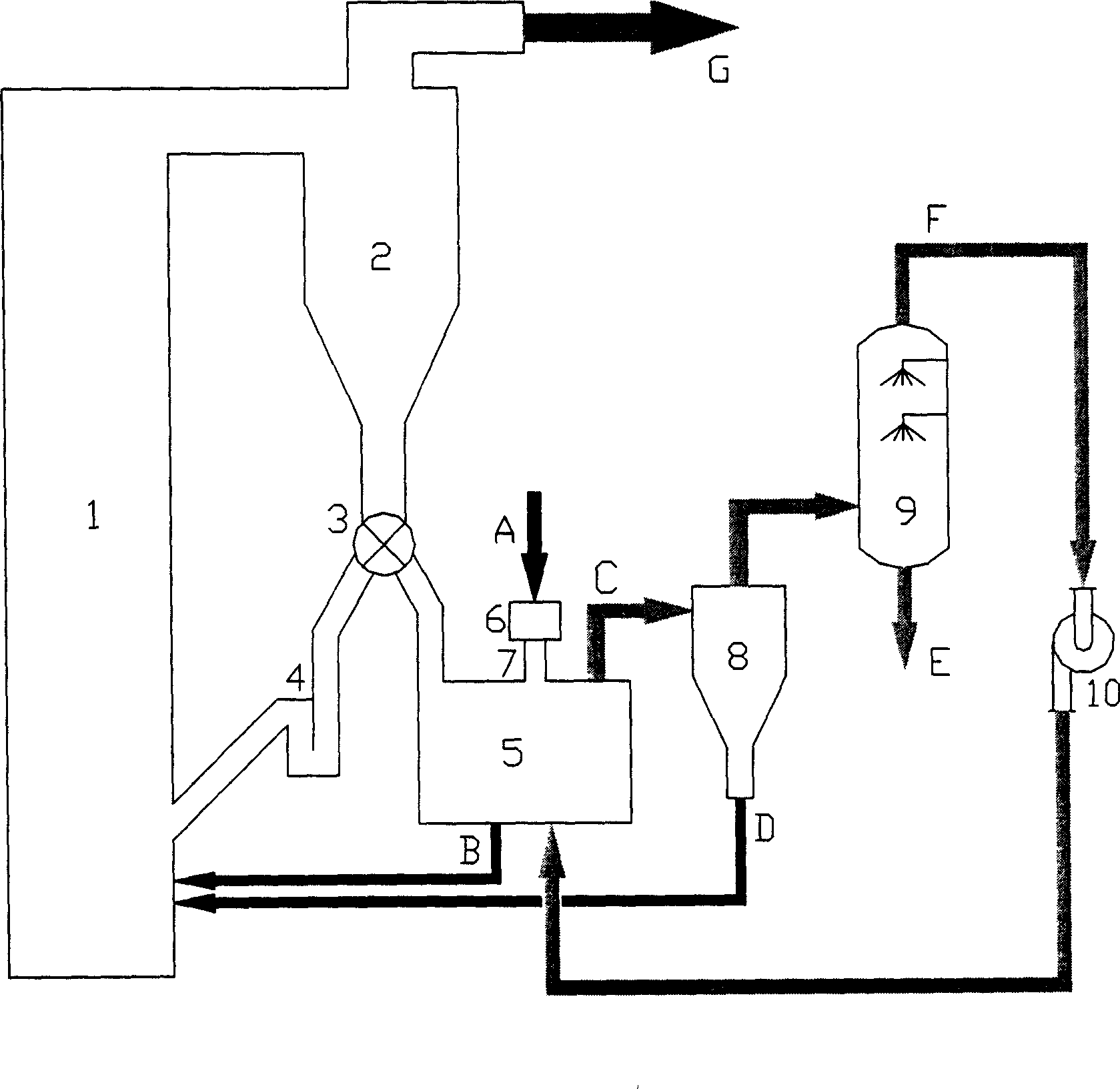

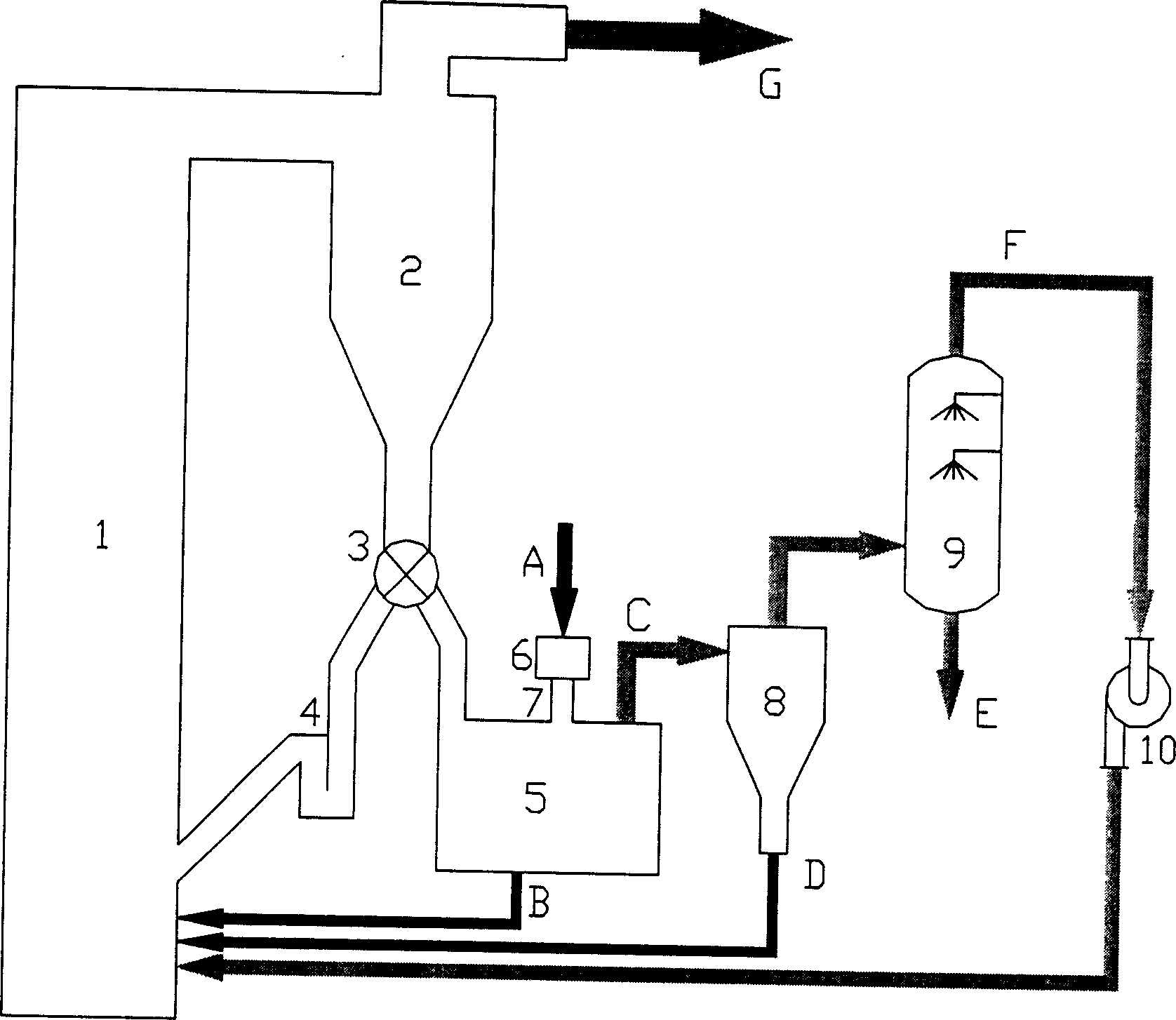

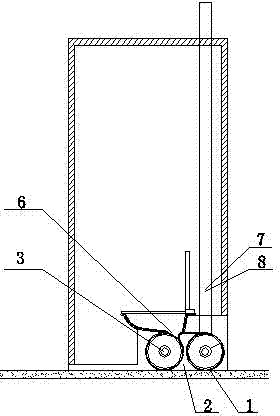

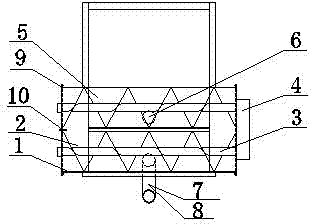

Wet sludge incinerating treatment apparatus with particle drier

ActiveCN1931752ASimplify the dry incineration processHeating fastSludge treatment by oxidationByproduct vaporizationSludgeFluidized bed

The wet sludge drying and incinerating treatment apparatus consists of a circulating fluidized bed incinerator hearth, a high temperature gas-solid separator, a tail gas flue, a hot ash distributing valve, a sludge disperser, a drier and an exhaust gas treating unit. The present invention completes the drying and incinerating of sludge in single apparatus, and has less heat loss and no exhaust of gas with bad smell.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

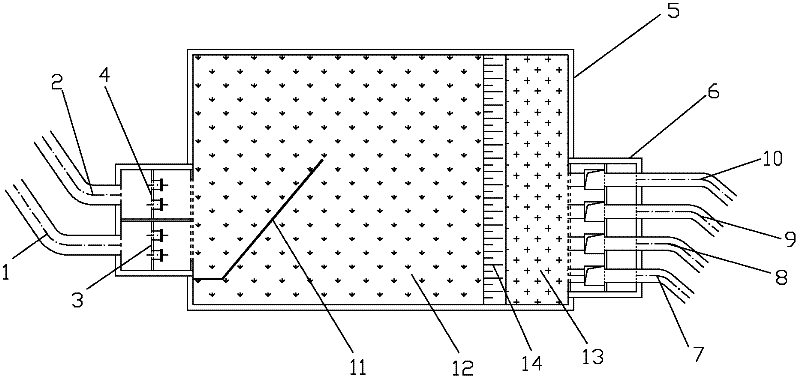

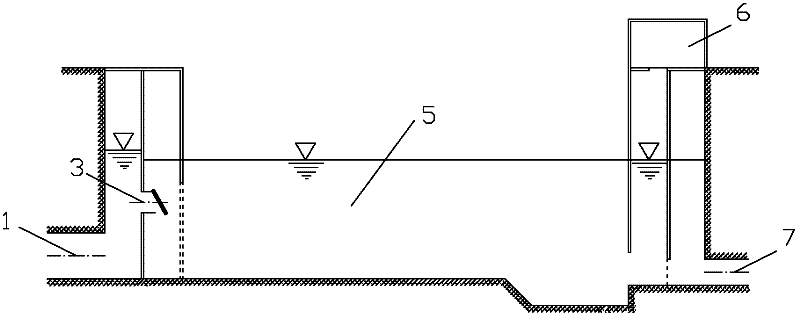

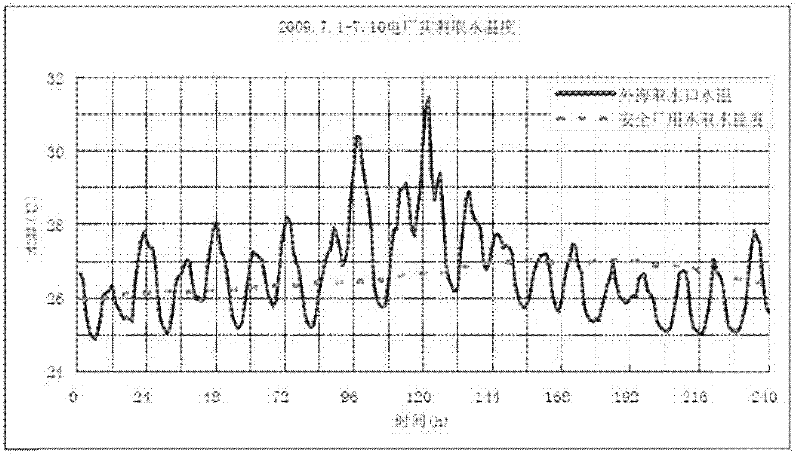

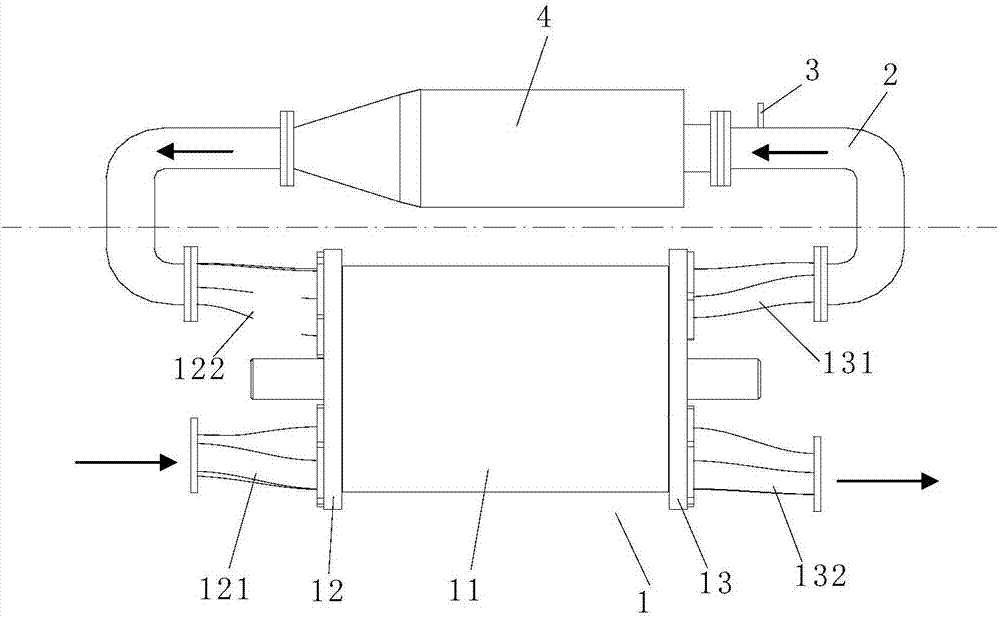

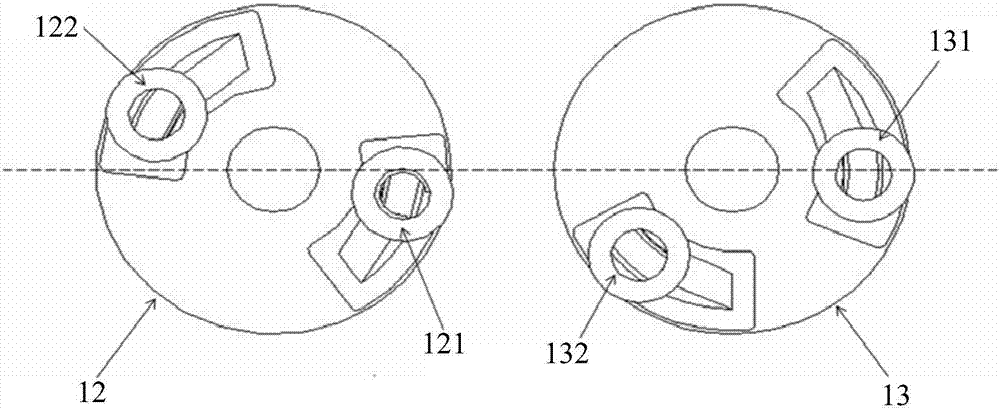

Selective inlet water temperature stabilizing device and water temperature value simulating and forecasting method

InactiveCN102359146ASmooth out water temperature peaksSmall water flowWater supply tanksHydraulic modelsSeawaterPeak value

The invention discloses a selective inlet water temperature stabilizing device. The selective inlet water temperature stabilizing device comprises a water reservoir, a clapper door inflow device and a water taking building, wherein the clapper door inflow device and the water taking building are respectively arranged on the two sides of the water reservoir; and the bottom of the water taking building is connected with a water taking culvert pipe. The invention also discloses a water temperature value simulating and forecasting method. According to the invention, external seawater used as a power plant safety plant water source flows in through the device while higher water level and lower temperature of the external seawater are obtained; and the external seawater is conveyed into a safety plant cooling water taking pump house after cold water and hot water are sufficiently mixed and the surface is cooled; therefore, the temperature of the water taken from the safety plant water is obviously reduced while being compared with the variation gradient and the peak value of the water temperature at the external seawater taking opening so that the high peak value of the water taking temperature can be stabilized, the reduction amplitude of the safety plant water temperature can be also forecasted after using the system and the device, and design parameters are provided for building the selective water temperature stabilizing device.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +2

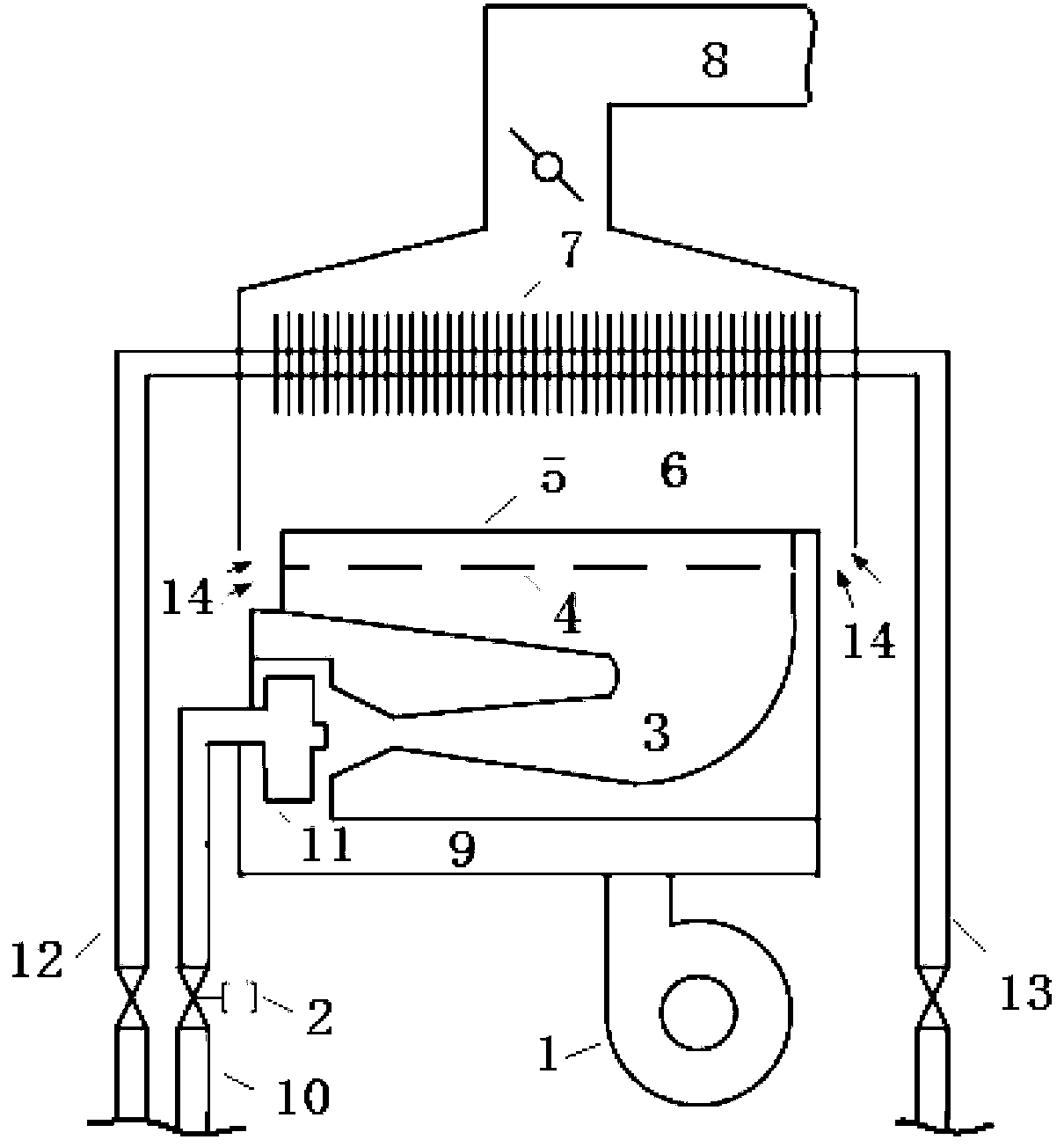

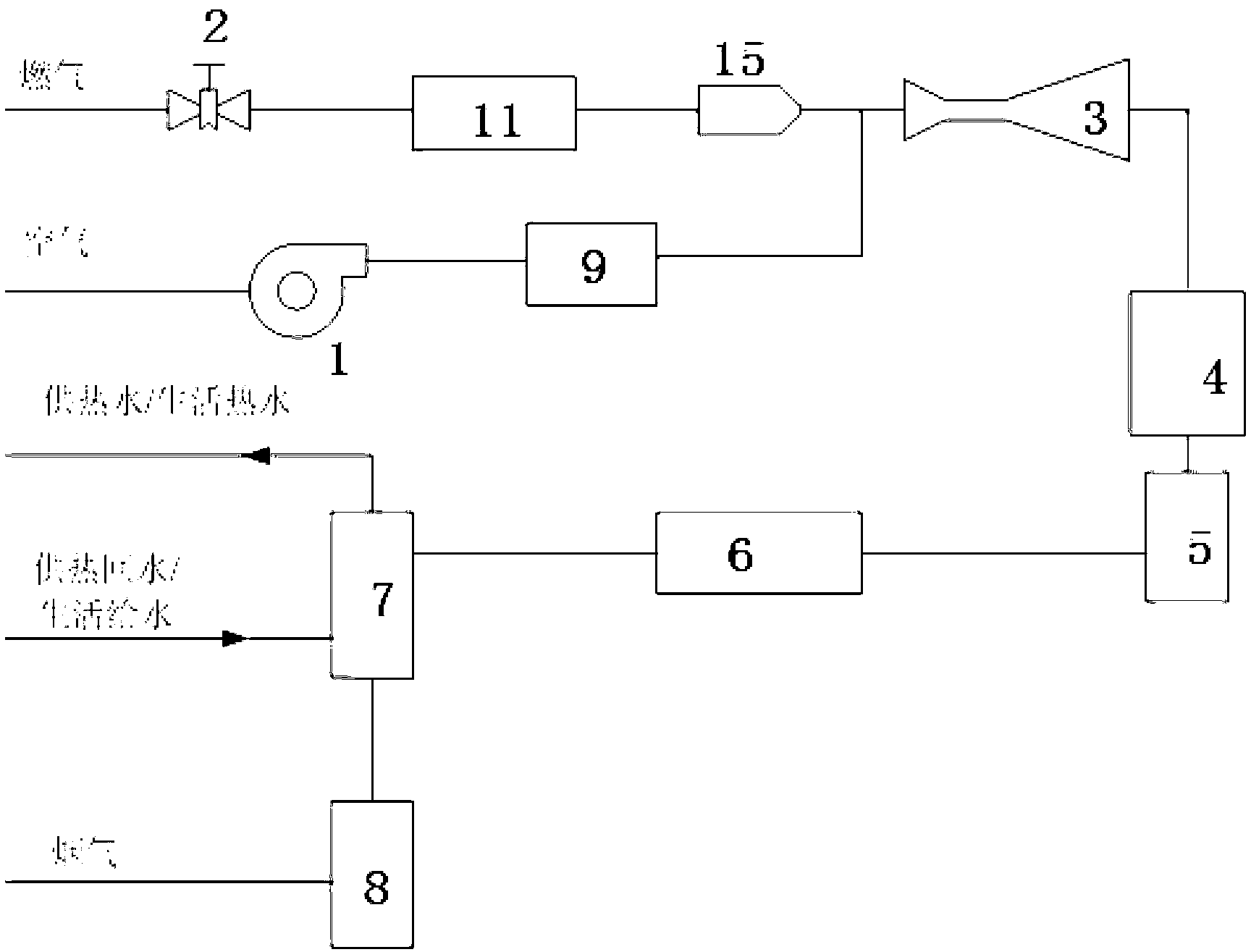

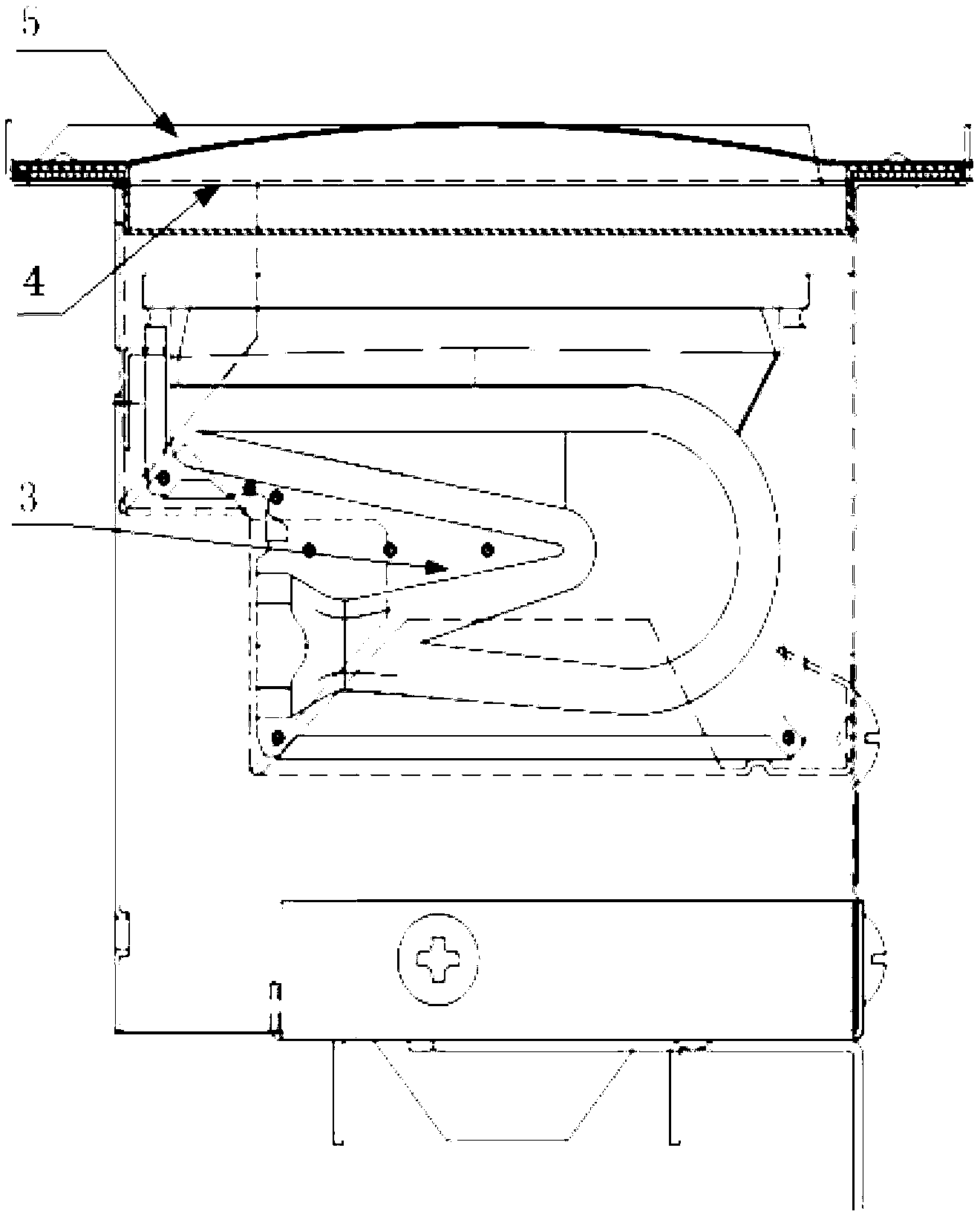

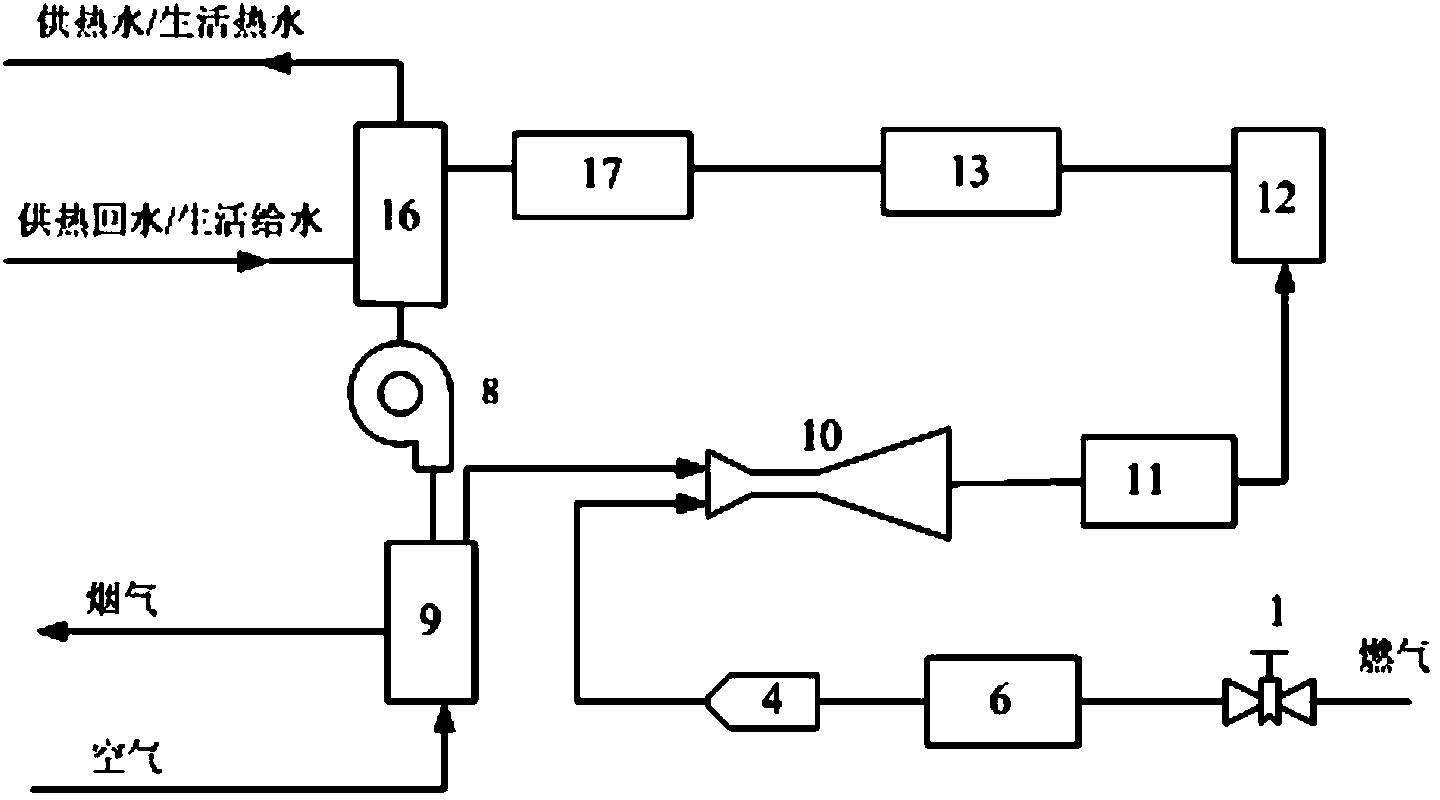

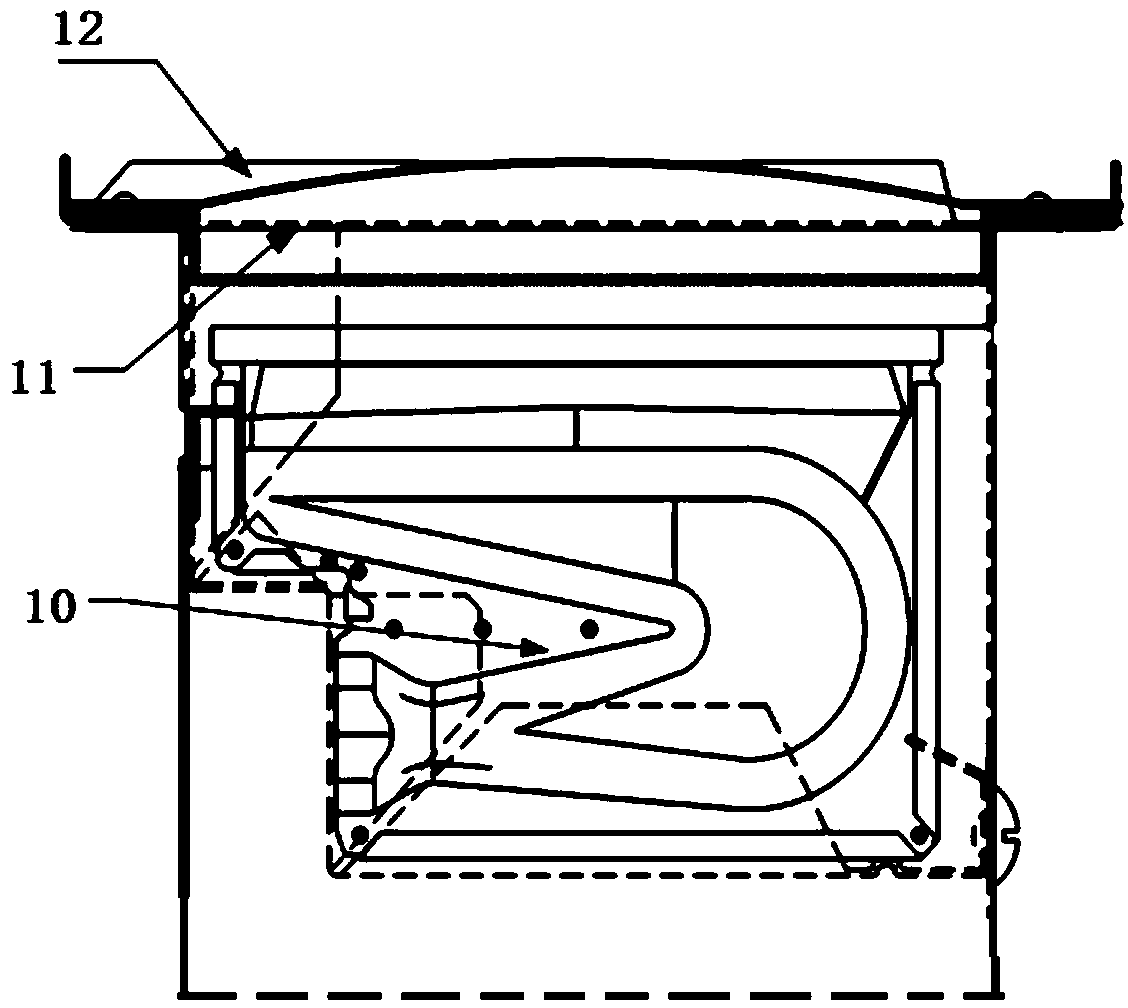

Positive-pressure-injecting type fully-premixed combustion heating device

InactiveCN103196218AEmission reduction effect is obviousEmission reductionWater heatersGaseous fuel burnerPositive pressureSafety control

The invention discloses a positive-pressure-injecting type fully-premixed combustion heating device comprising an air supply system, a fuel system, a combustor, a heat exchange system and a smoke exhausting system. The air supply system comprises a fan and an air distributing tube connected with an air supply port of the fan. The fuel system comprises a gas tube and a gas distributing tube connected with the gas tube. A group of gas nozzles are evenly arranged at the end of the gas distributing tube. Annular air inlet ports communicated with the air distributing tube are arranged on the peripheries of the gas nozzles. An injecting type mixer is arranged oppositely to the gas nozzles. A distributing hole plate and a fire hole plate are arranged at the top of the injecting type mixer from bottom to top. The combustor is arranged above the injecting type mixer, and an annular hole is arranged between the side wall of the combustor and the outer contour of the fire hole plate. The positive-pressure-injecting type fully-premixed combustion heating device is compact in structure, and safety control on the whole system is facilitated; gas and air are fully mixed during operation of the heating device, so that emission loads of carbon monoxide and nitric oxide in combustion products are low, and fully-premixed combustion of the gas and the air and low-pollutant emission during gas combustion are realized.

Owner:TIANJIN URBAN CONSTR COLLEGE

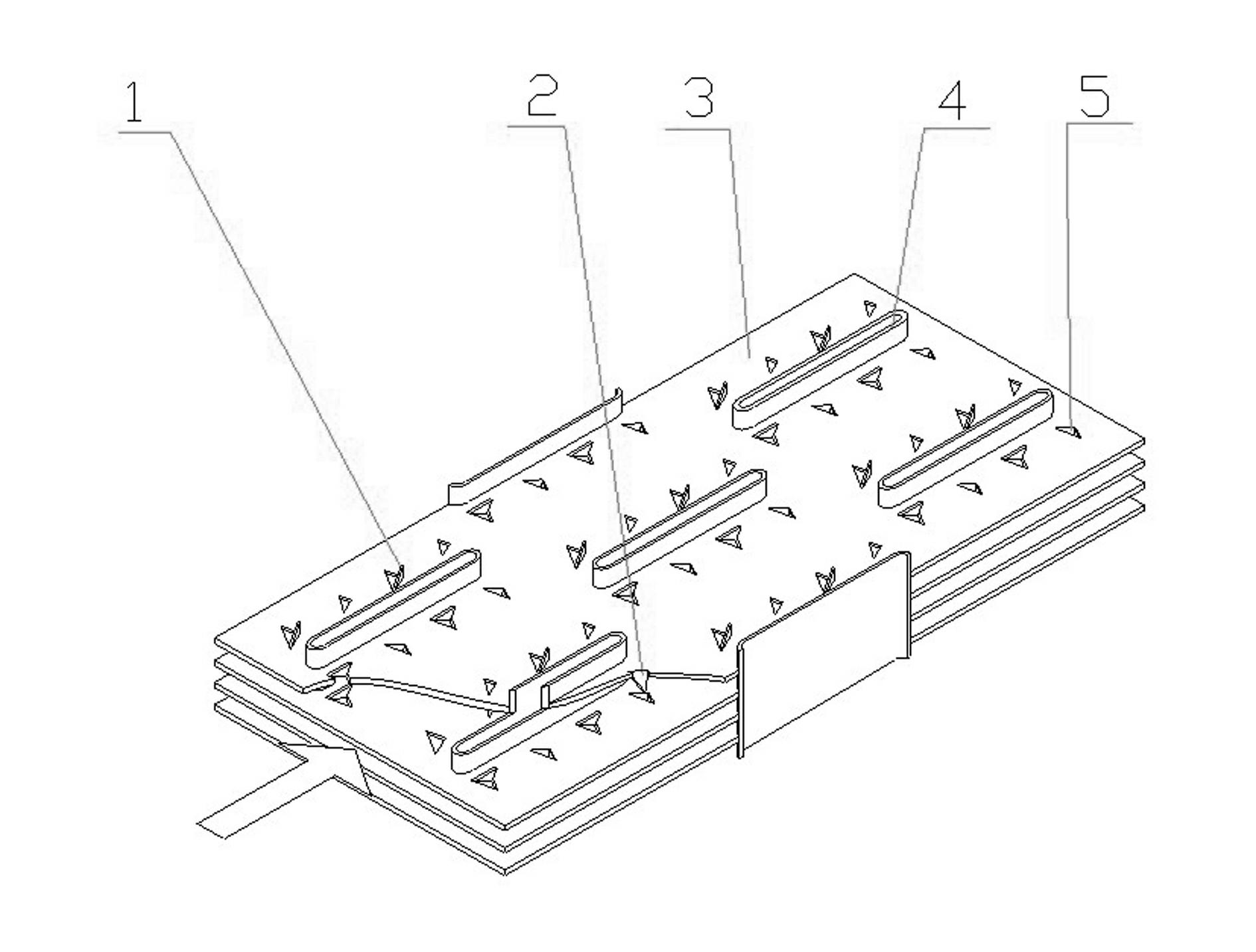

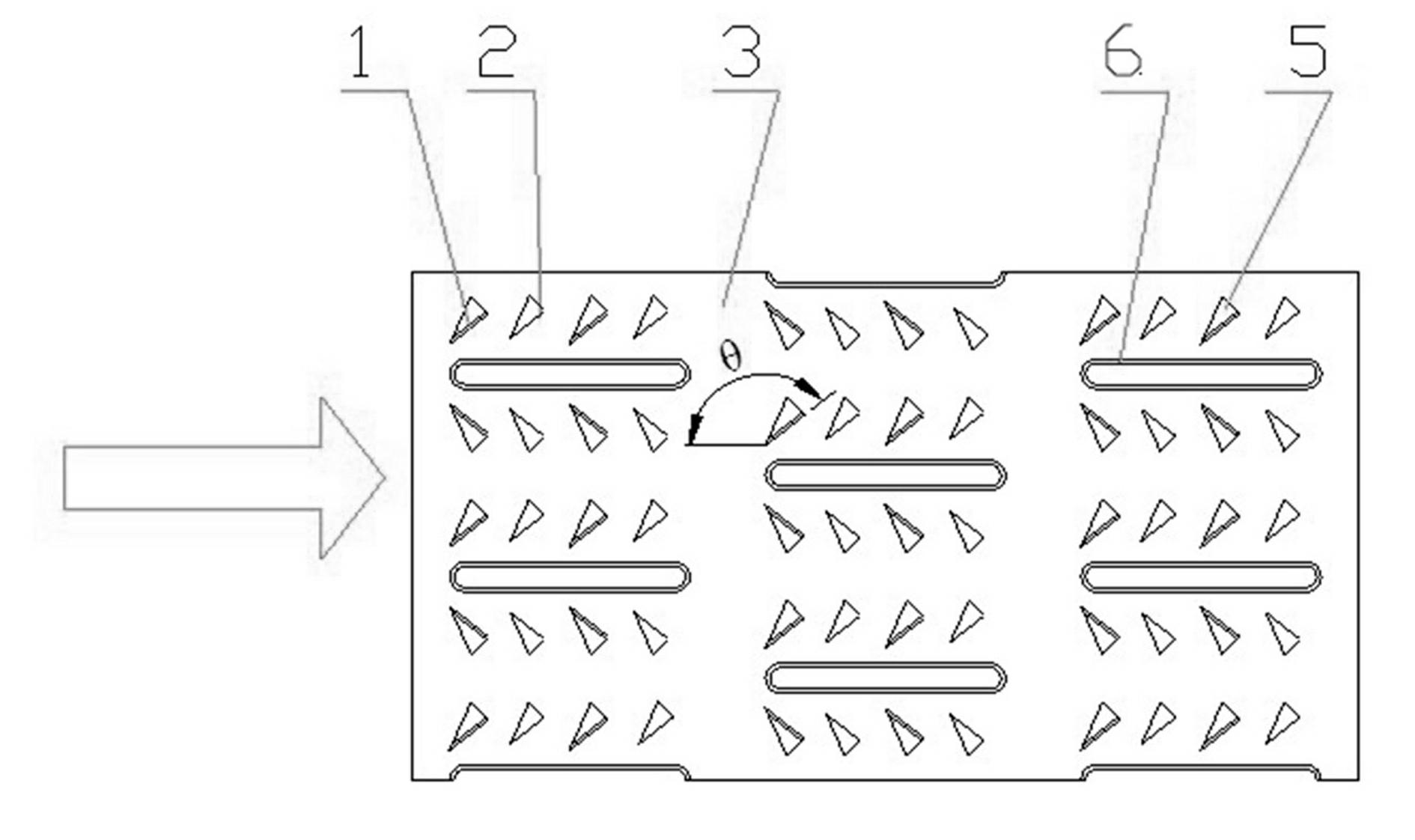

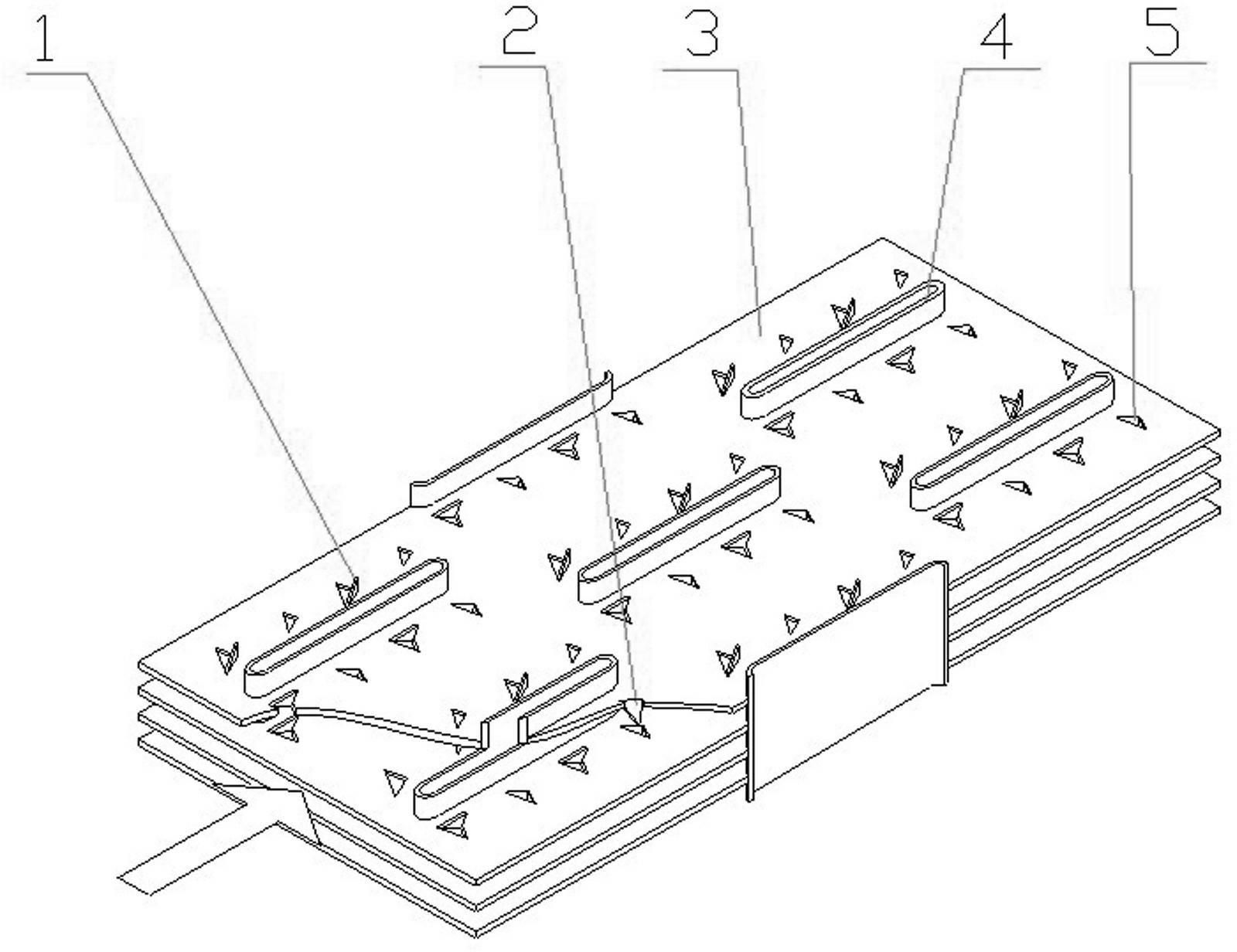

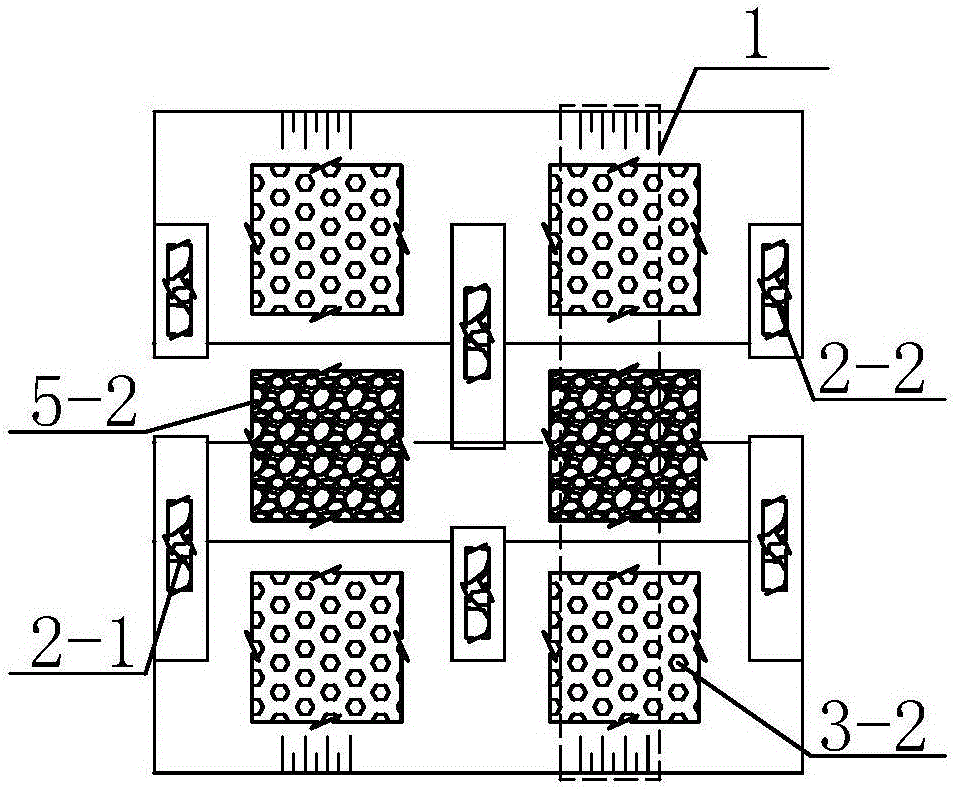

Flat tube-fin heat exchanger with double-side vortex generator

InactiveCN102121798AImprove heat transfer conditionsImprove heat transfer performanceStationary conduit assembliesHeat transfer modificationPhysicsEngineering

The invention discloses a flat tube-fin heat exchanger with a double-side vortex generator, which belongs to the technical field of flat tube-fin heat exchangers and comprises flat tubes arranged along the direction of air flow and fins sleeved on the flat tubes. The fins are provided with holes used for sleeving the flat tubes, two pairs of vortex generators facing upwards and two pairs of vortex generators facing downwards are stamped respectively by the upper side and the lower side of each hole, and corresponding small holes are left on the fins; and the front edge points of the first pair of the vortex generators facing upwards are located at front-end tangent lines of the holes used for sleeving the flat tubes, and the front edge points of the second pair of the vortex generators facing upwards are located at middle perpendicular lines of the holes used for sleeving the flat tubes. Compared with a traditional single-side fin for stamping the vortex generators, two sides of the fins disclosed by the invention are simultaneously turned over to stamp out the vortex generators, thereby the heat exchange capability of the fins can be improved, and the flow resistance of an air side can be simultaneously reduced. Moreover, the compactedness of a heat exchange device is increased, the power of a pump is reduced, and the energy sources are saved under an identical heat load.

Owner:LANZHOU JIAOTONG UNIV

Wet sludge drying and incinerating treatment method employing circulating fluidized bed with particle dryer

ActiveCN1880849ALarge adjustment rangeAerodynamics won't happenIncinerator apparatusSludgeFluidized bed

The invention relates to a method for burning wet sludge with cycle fluid bed with grain drier, wherein in the cycle fluid bed burning furnace or the cycle fluid bed burning furnace burns the wet sludge whose water content is 60-90%; the drying and burning are integrated in one device; the wet sludge being dried in the grain drier is feedback to the hearth with cycle ash to be burnt, to avoid the water content of wet sludge into the tail smoke channel with the high temperature smoke of hearth, but be leaded out with the fluid airflow of grain drier, to reduce the heat loose; and the discharge gas of grain drier, via dust cleaning and wet removing, is used or fed into hearth to be burnt, without smelly gas in the process.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Negative-pressure injection type full-premix sectional combustion heating device

InactiveCN103727653AEmission reductionLow costWater heatersGaseous fuel burnerCombustion chamberElectromagnetic valve

The invention relates to a negative-pressure injection type full-premix sectional combustion heating device which comprises a shell, a fuel sectional supply system, a combustion chamber, a heat exchange system and an induced draft type smoke exhaust system. The fuel sectional supply system comprises gas pipes and a gas distribution cavity connected with the gas pipes, an electromagnetic valve A, an electromagnetic valve B, gas inlet cavities and gas nozzles are further arranged on the gas distribution cavity, annular gas inlets which are communicated with the shell are formed in the outer peripheries of gas nozzle groups in a surrounding manner, an injection type mixer is arranged at a position aligned with each gas nozzle, and a distribution orifice plate and a fire orifice plate are sequentially arranged on the top of each injection type mixer from bottom to top; the combustion chamber is arranged above the injection type mixers. The negative-pressure injection type full-premix sectional combustion heating device has the advantages that the negative-pressure injection type full-premix sectional combustion heating device is compact in structure, and is high in load regulating ratio range owing to a sectional combustion control technology, gas and air can be thoroughly mixed with each other when the heating device runs, a full-premix combustion mode is adopted, emission loads of carbon monoxide and nitrogen oxide in combustion products are low, and a low pollutant emission effect can be realized in gas combustion procedures.

Owner:TIANJIN CHENGJIAN UNIV

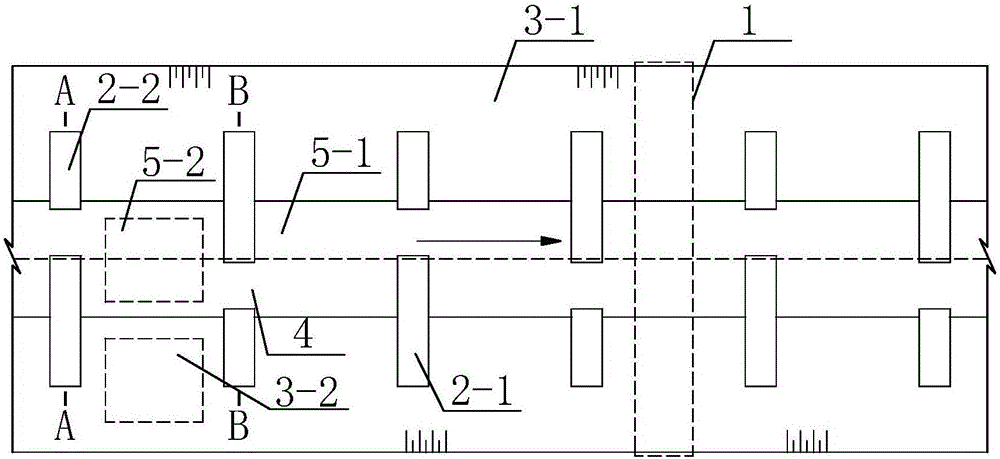

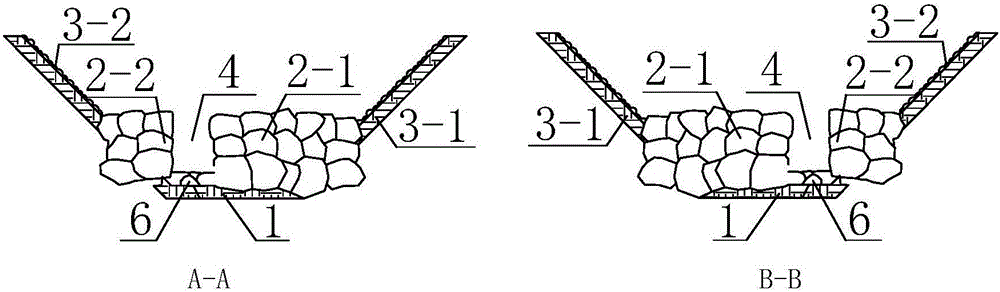

Staggered type cyclopean wall imitated natural channel

InactiveCN105887776AEasy constructionLow costBarrages/weirsClimate change adaptationStone wallEcological environment

The invention provides a staggered type cyclopean wall imitated natural channel and belongs to the field of water conservancy projects. The staggered type cyclopean wall imitated natural channel comprises a concrete base, bank slopes, vertical seams, long cyclopean walls, short cyclopean walls, field building stones, a bottom slope, bottom slope boulders and a cyclopean sill. According to the imitated natural channel, the long cyclopean walls and the short cyclopean walls are arranged in the channel in a staggered mode to divide the imitated natural channel into a plurality of pools, and the vertical seams are reserved between the long and short cyclopean walls from side to side. The field building stones are laid on the concrete base to form the bank slopes, the bottom slope boulders are laid on the concrete base to form the sloping bottom slope, and the cyclopean sill is constructed at the bottoms of the vertical seams. According to the staggered type cyclopean wall imitated natural channel, the energy dissipation structure of traditional technical fish ways is optimized, and an eco-friendly migration channel is created for fishes; the manufacturing cost is low, the channel is suitable for large water level variation amplitude, the variety of passing fishes is large, and natural river ecological environment can be simulated; the staggered type cyclopean wall imitated natural channel is easy to rebuild after being constructed and is an ecological compensation project high in adaptability.

Owner:SICHUAN UNIV

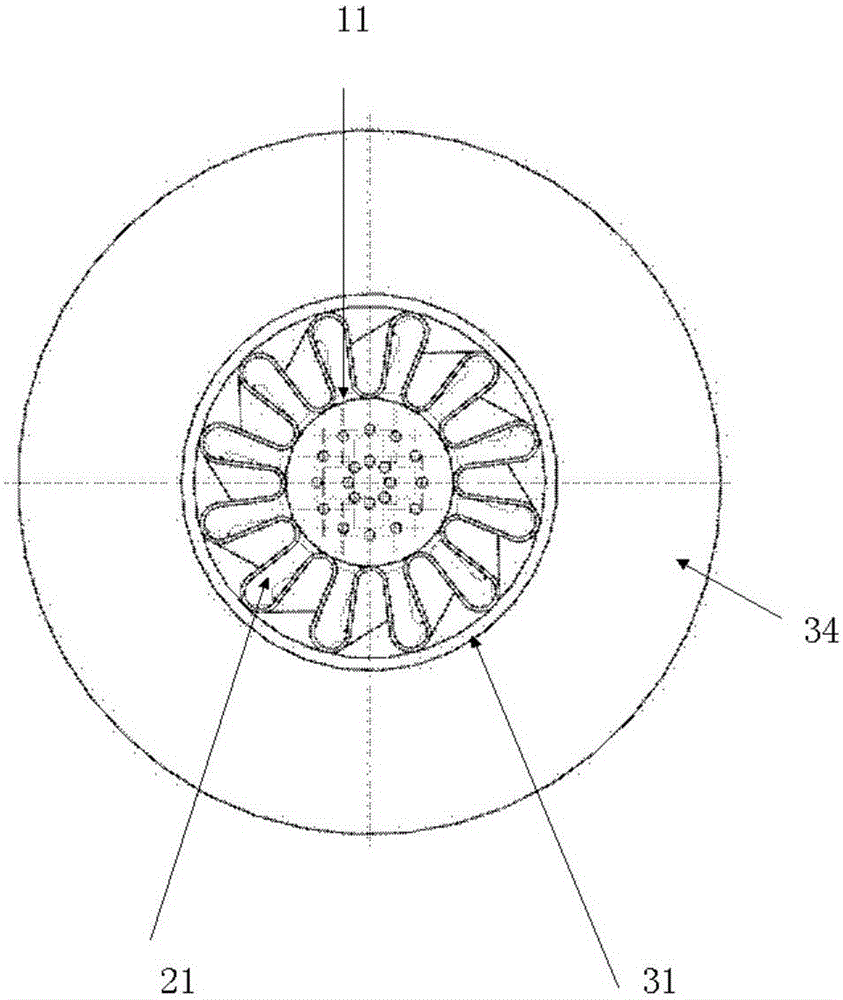

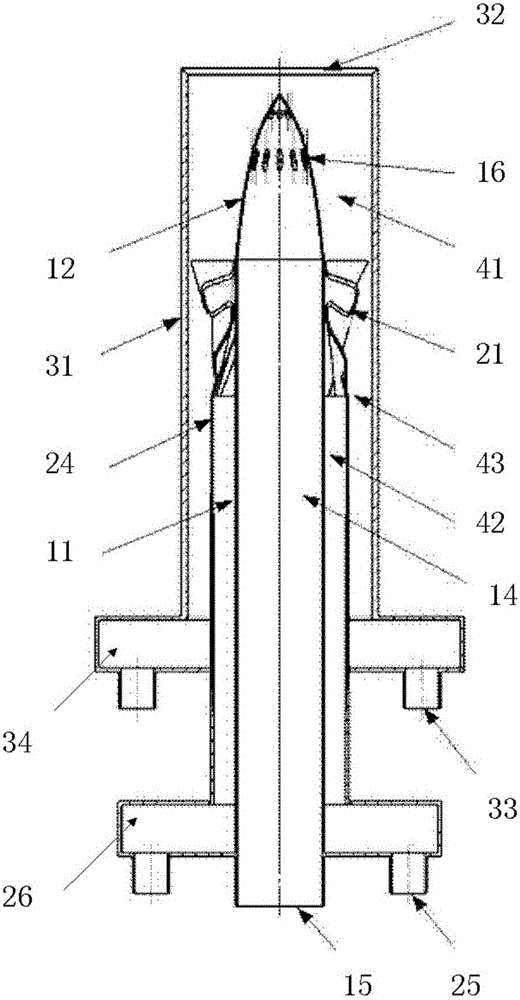

Nozzle for premixed combustion, nozzle array and combustor

ActiveCN105757716AReduce the impactIncrease tempering marginContinuous combustion chamberCombustorFlameout

The invention provides a nozzle for premixed combustion.A dilution zone is formed among the fluid outlet end of an inner-layer gas inflow structure, an outer-layer cylinder of an outer-layer gas inflow structure and the top ends of M layers of middle gas inflow structures, the influence of tempering on the nozzle and a combustor is lowered, and the tempering margin is increased.Oblique flow channels are formed between two adjacent wave rotational structures, between the corresponding wave rotational structure and an inner-layer cylinder and between the corresponding wave rotational structure and the outer-layer cylinder, combustion efficiency is improved, emissions of pollutants are reduced, flameout and flame pulsation are avoided, and the stability of combustion is improved.A drainage channel, an inner-side passageway and an outer-side passageway are formed by a supporting cylinder, the inner-layer cylinder and the outer-layer cylinder, and the stability, completeness and efficiency of combustion are further improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Clean burning bio-coal

InactiveUS20100263271A1Reducing greenhouse gas emissionEmission reductionBiofuelsSolid fuelsFiberGreenhouse

A clean burning bio-coal consists of 70˜90 wt % of bio-fiber material and 1˜20 wt % of coal material. With the above composition percentages for the bio-fiber material and the coal material, emission of greenhouse gases and pollution gases during burning of the bio-coal can be reduced, total heat energy producible from the bio-coal is high enough to satisfy requirements in industrial activities, and a high burn-out rate of the bio-coal can be advantageously achieved.

Owner:LAI KUEI TSAI

Nozzle for widening tempering margin, nozzle array and combustor

ActiveCN106247408AUniform and stable airflowImprove stability and reliabilityContinuous combustion chamberGaseous fuel burnerAirflowFuel gas

The invention provides a nozzle for widening a tempering margin, a nozzle array and a combustor. A rectifying device of the nozzle can enable currents of fuel gas and air entering the nozzle to become more stable and uniform, so that the tempering caused by hot spots in combustion can be effectively prevented; a step-shaped expansion section of the nozzle can stop propagation of the tempering to the upstream, so that the tempering margin is widened; and as a direct passing way wave structure and a center cone are arranged in an inner-layer cylinder of the nozzle, the combustion efficiency is further improved, the pollutant discharge is reduced, and the combustion state is improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

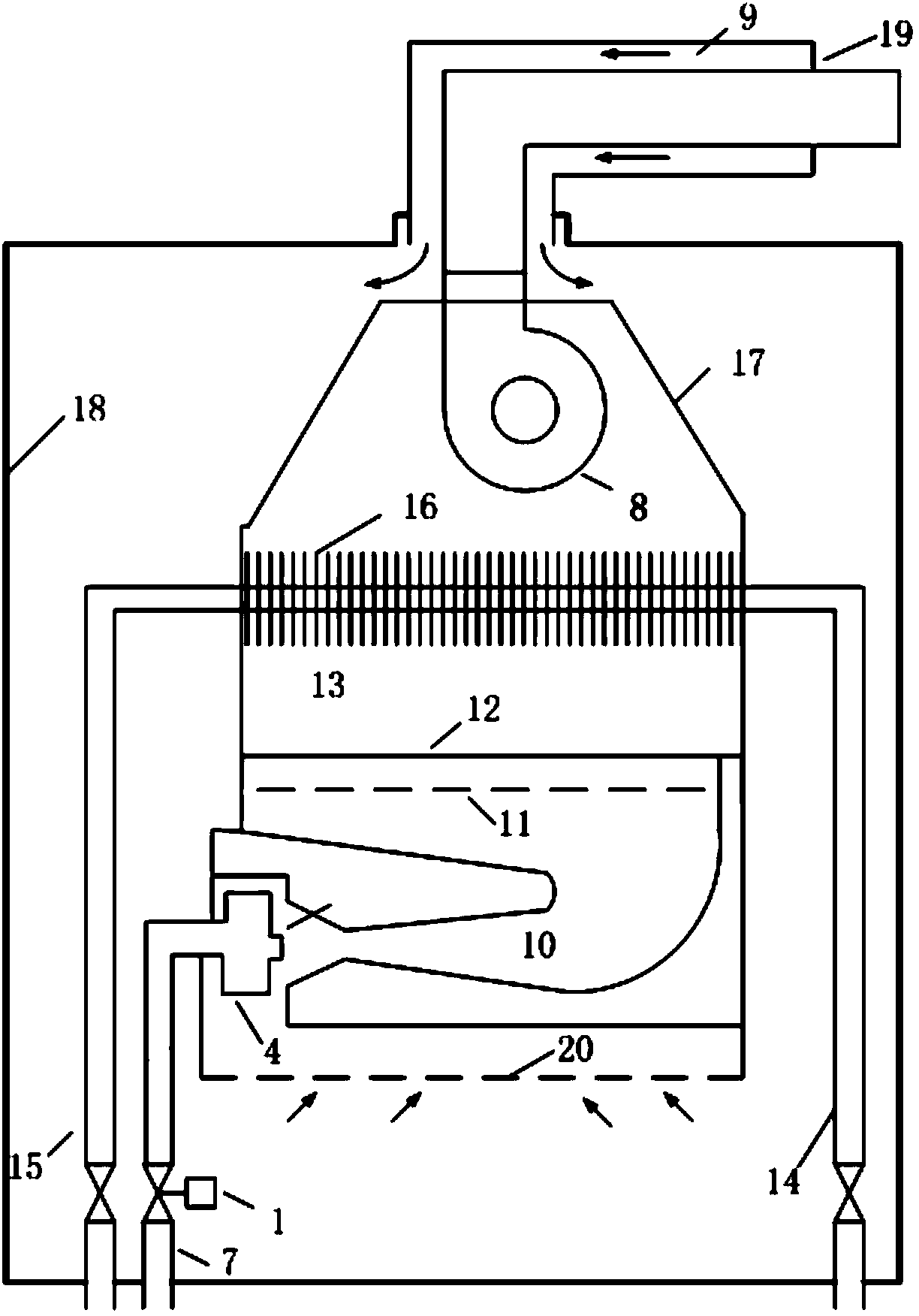

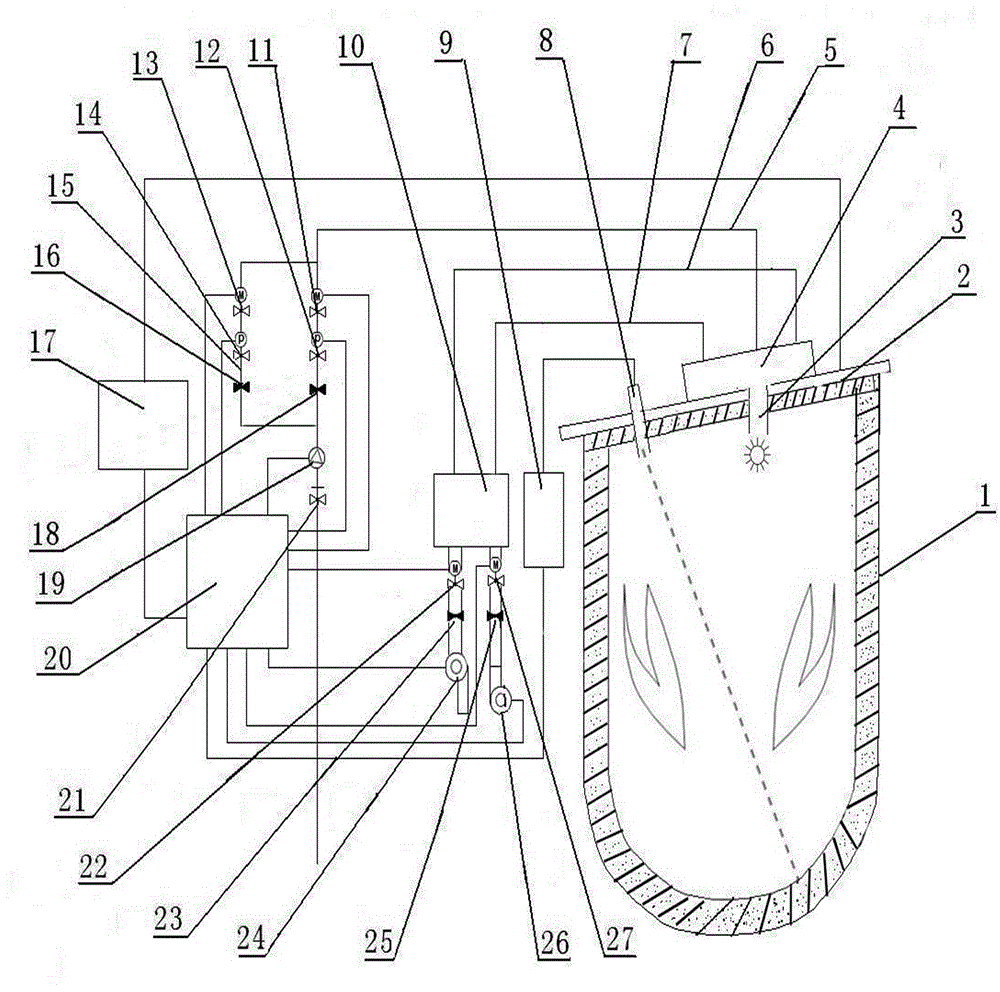

Precise baking device for steel ladles

ActiveCN103978194AHigh control precisionReduce consumptionMelt-holding vesselsCasting parameters measurement/indication devicesSteelmakingThermal energy

The invention relates to a baking device for steel (iron) ladles in a steelmaking production procedure and particularly relates to a precise baking device for various steel (iron) water tanks which are newly built, coldly repaired, dried, turned over and rapidly heated online. The problem in a steelmaking process that heat loss of liquid steel in a liquid steel transportation process from a steelmaking procedure to a continuous casting procedure is great is solved. The precise baking device structurally comprises a steel ladle, a steel ladle cover, an infrared temperature measurement device, an infrared probe, a control cabinet, a self-pre-heating type burner and a heat accumulator, wherein the infrared temperature measurement device, a gas pipeline and an air pipeline are connected with the control cabinet to increase the control precision; the heating reliability and the measurement and control reliability are improved. The baking device is ingenious in design; the heating quality is completed, the gas consumption is reduced and the controllability of heating equipment is stabilized; the baking temperature of the steel ladles is improved and the tapping temperature is reduced; the baking device has the important effects of prolonging the service life of a furnace body, increasing the steel output, reducing the consumption of raw materials, reducing the cost per ton of steel and guaranteeing the smooth proceeding of continuous casting.

Owner:SHANXI DAYANG CHUANGJI TECH

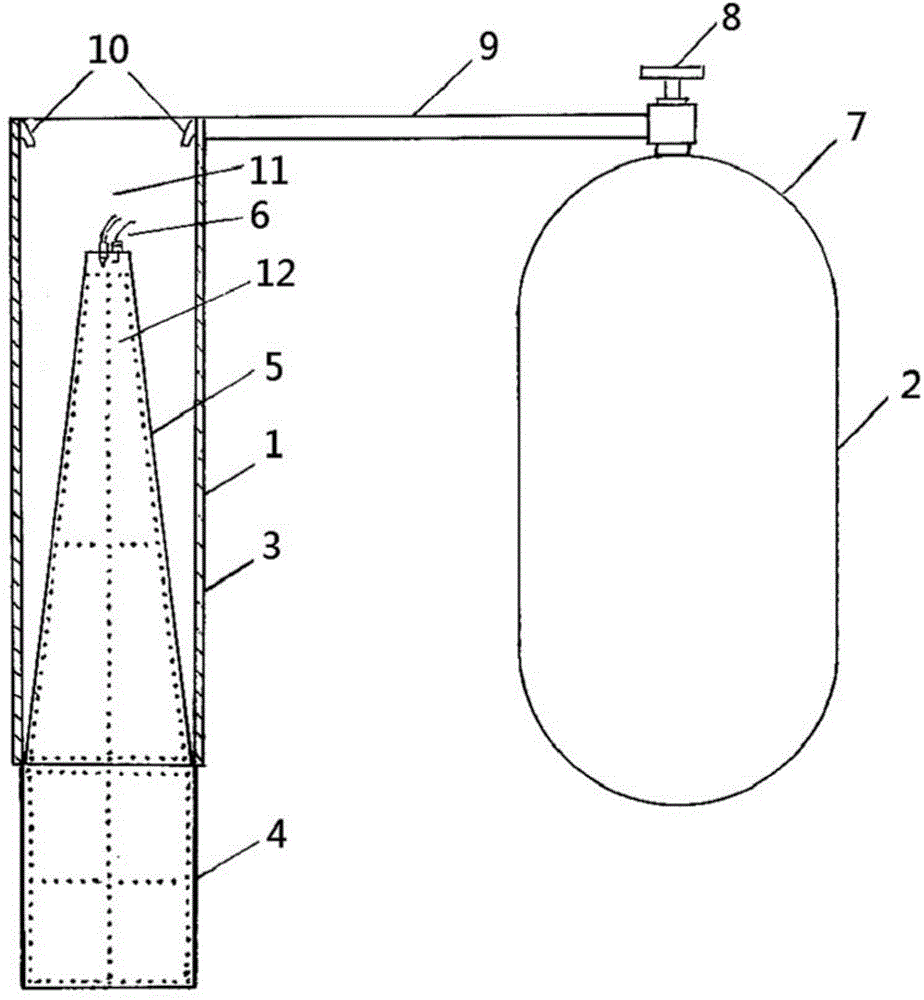

Ramjet started in static state

InactiveCN104131915AImprove combustion efficiencyGuarantee stable combustionRam jet enginesSpray nozzleRamjet

The invention provides a ramjet started in a static state. The ramjet started in the static state comprises a ramjet body and a starting device. The ramjet body comprises a shell, an exhaust nozzle, a flame tube, an oil spray nozzle and an igniter. The starting device comprises a high pressure gas storage tank, a valve, a gas conveying tube and a gas spray nozzle. The ramjet started in the static state has the advantages of being capable of being started in the static state, stable in combustion and lower in cost, solving the problems existing in an existing ramjet, and better keeping the original advantages.

Owner:张善沐

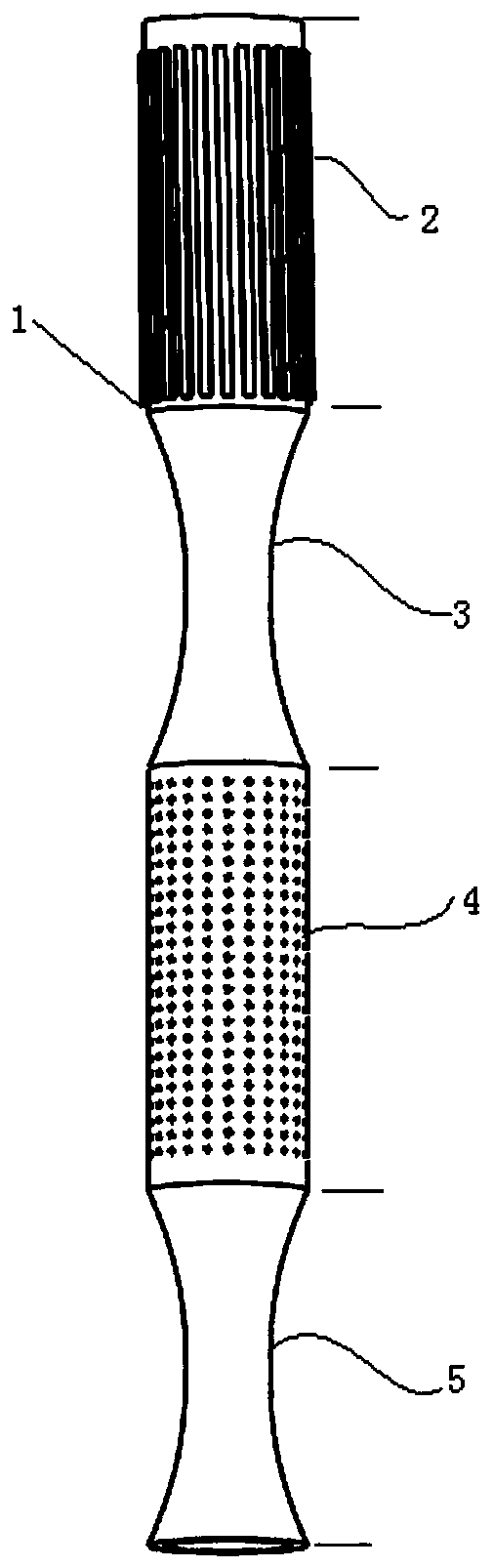

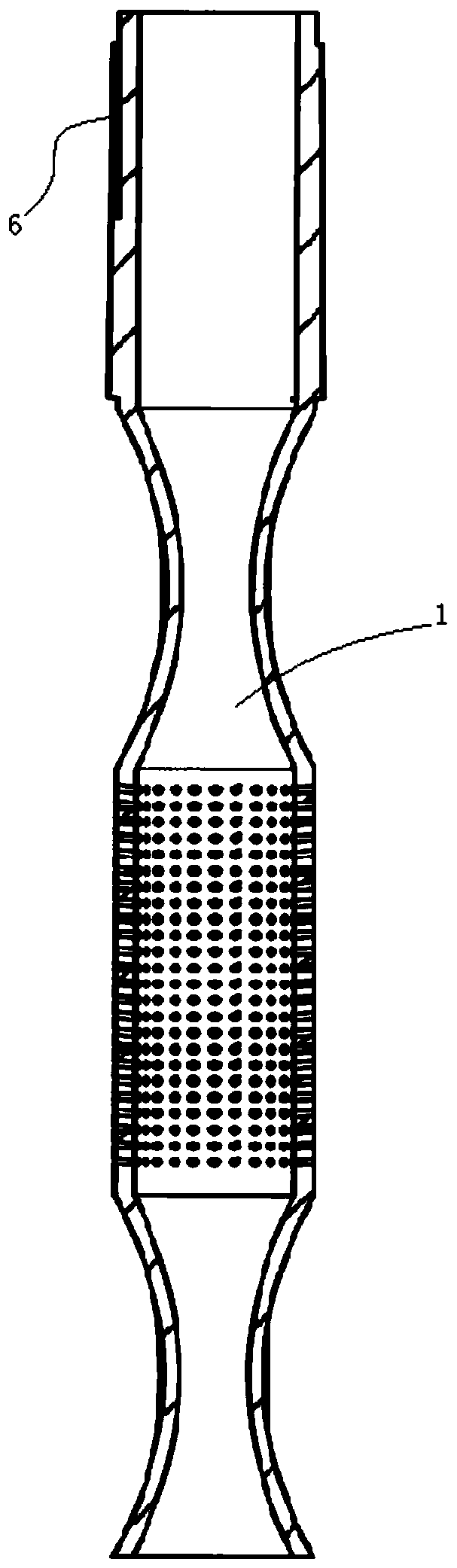

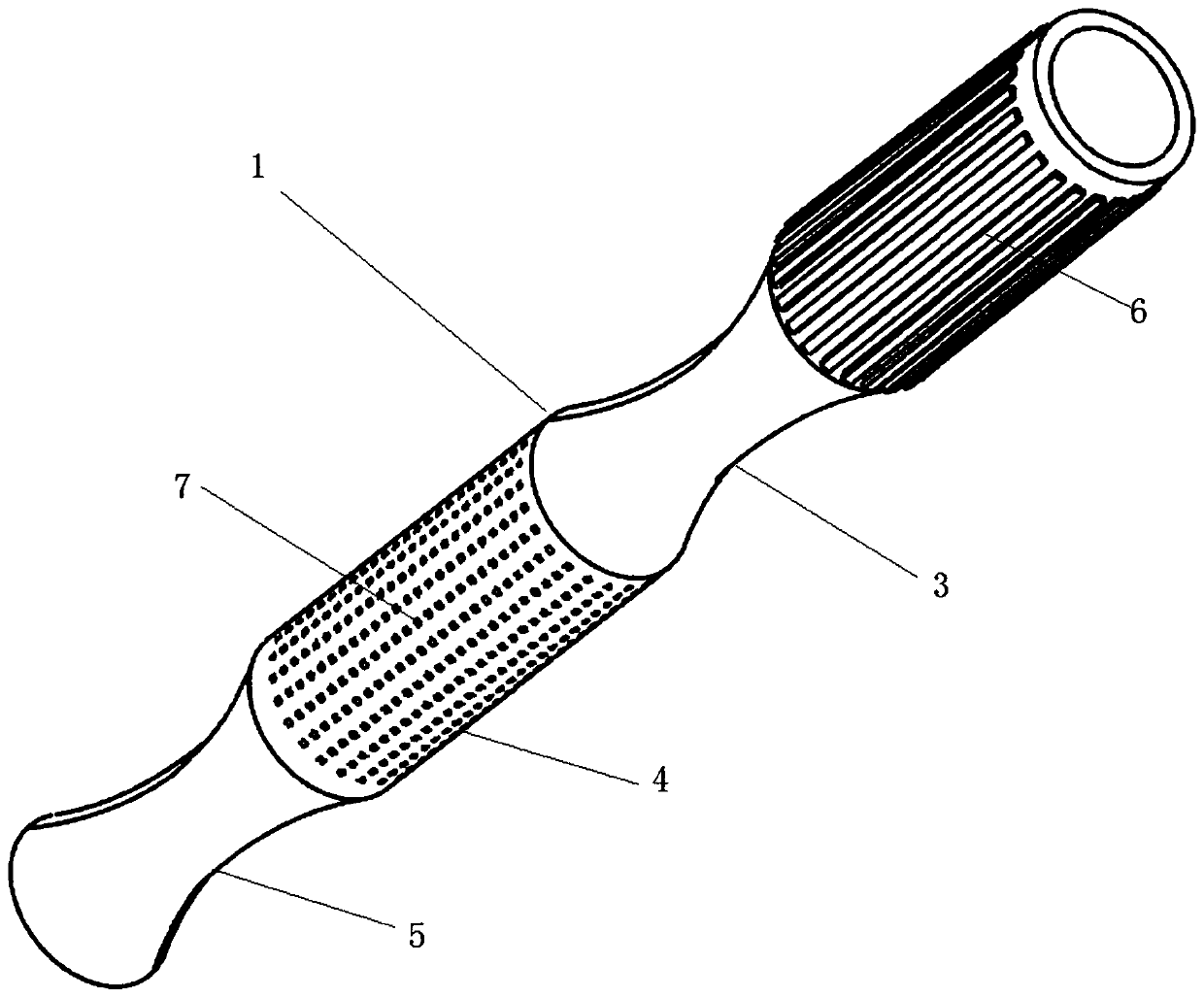

Evaporating pipe structure for engine combustion chamber and engine combustion chamber structure

ActiveCN110375331AAdd room for mixingImprove heat transfer effectContinuous combustion chamberCombustion chamberJet flow

The invention discloses an evaporating pipe structure for an engine combustion chamber and an engine combustion chamber structure. An internal concave curved surface section composed of at least two cambered surfaces is utilized, two column cambered surfaces arranged symmetrically are adopted in each cambered surface, the internal concave curved surface section adopts a gradual contracting and gradual stretching structure, mixed gas flows through an evaporating pipe, a backflow area is formed in the internal concave curved surface section, the speed is reduced, the mixed space of fuel oil andair is increased, stay time in the evaporating pipe is prolonged, the contact area of the mixed gas and the wall face of the evaporating pipe is increased, and gas heat exchange is enhanced. By meansof the gradual contracting and gradual stretching curved wall face, the strong shearing effect brought by the gas enables the fuel oil and the air to be mixed more fully. Fins are arranged on the outer surface of a first cylinder section, heat exchange between high-temperature airflow in a flame cylinder and the evaporating pipe is enhanced, and the temperature in the evaporating pipe is increased. Mixing holes form oblique holes to jet flow to enable air to directly impact oil fog, atomizing evaporation of the fuel oil is promoted, the atomizing and evaporating effect of the fuel oil in the evaporating pipe is enhanced, the fuel oil is combusted fully, and emission of pollutants is reduced while the combustion efficiency is improved.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

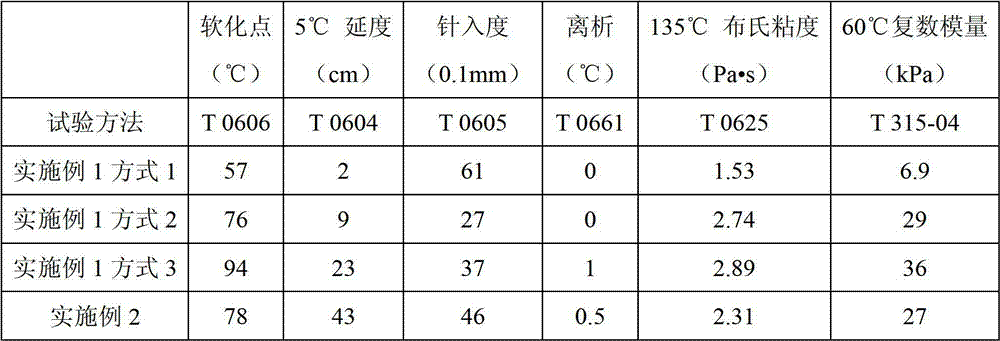

Composite modified asphalt preparation process

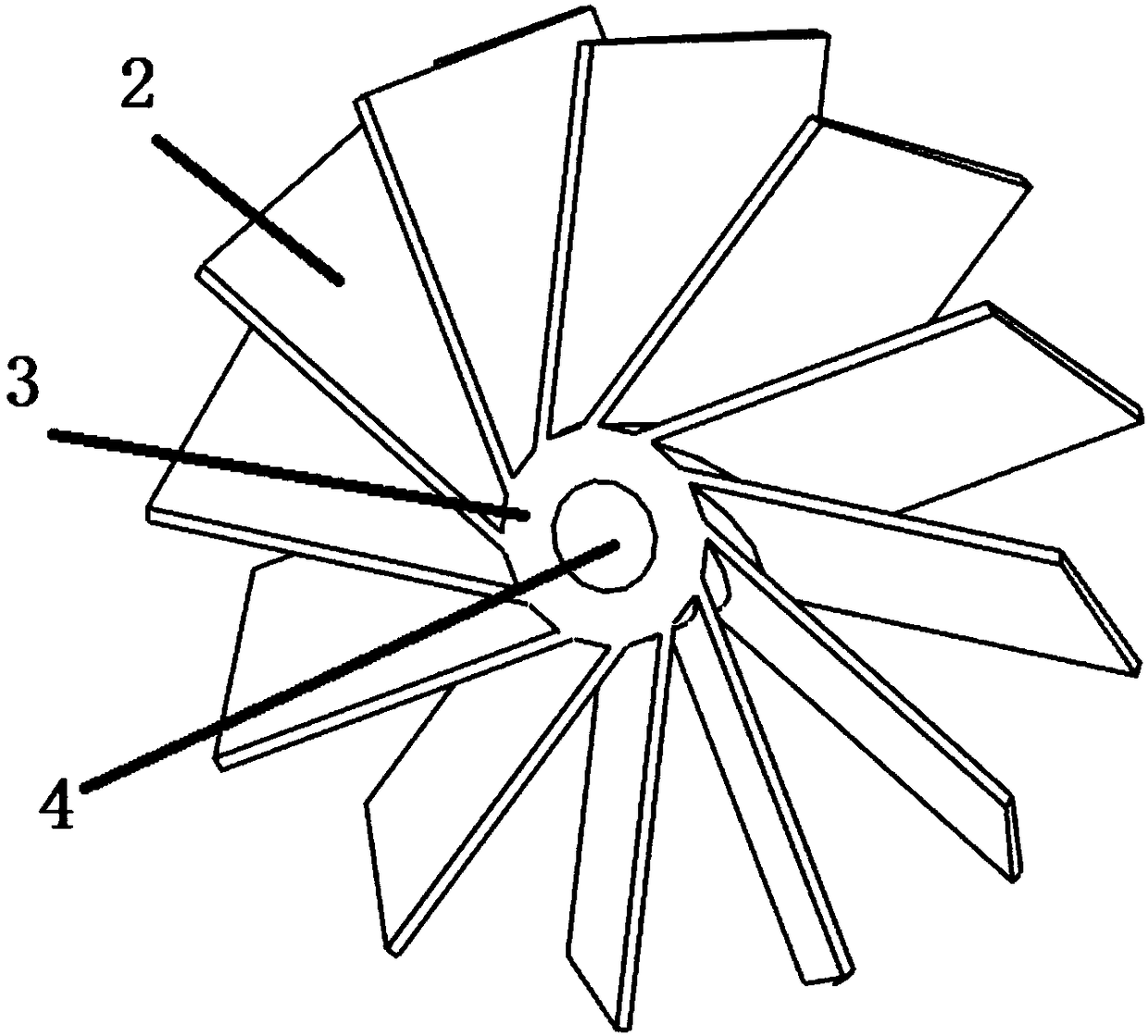

ActiveCN102773935AGood compatibilityGood storage stabilityBuilding insulationsImpellerChemical reaction

The invention relates to composite modified asphalt preparation process, in particular to a stirring mixing device adopting sawtooth impellers or turbine impellers and applying to chemical modified asphalt. The device can expose active base groups inside an asphalt micelle through high shear force so as to promote generating of chemical reactions and can achieve full mixing of a modifying agent and asphalt through strong discharging capacity. The preparation process includes: adding a polymer modification agent after base material asphalt is heated, using a propeller impeller stirrer and swelling to obtain modified asphalt mother batch; and changing the stirrer into the turbine impeller or sawtooth impeller mixing device, adding chemical modifier composite, and keeping stirring for a period of time at the temperature of 130-180 DEG C so as to obtain composite modified asphalt products. The process effectively achieves composite of polymer modifying and chemical modifying of asphalt and obtains modified asphalt products good in compatibility and storage stability.

Owner:CHINA NAT CHEM COMM CONSTR GRP CO LTD +2

High-efficiency and low-pollution core engine

ActiveCN106895439AIncrease unit powerImprove efficiencyContinuous combustion chamberIndirect carbon-dioxide mitigationAirflowCombustion chamber

The invention relates to a high-efficiency and low-pollution core engine, and relates to a gas turbine. The high-efficiency and low-pollution core engine is provided with a wave rotor, a pipeline, a fuel inlet and a flameless combustion chamber, wherein the wave rotor comprises a rotor, an air inlet end port plate and an outlet end port plate; the air inlet end port plate and the air outlet end port plate are correspondingly arranged at two sides of the rotor; parallel air channels are arranged in a circle on the rotor; a wave rotor air inlet and a reflowing smoke inlet are formed in the air inlet end port plate; a high-temperature low-oxygen mixed gas outlet and a smoke outlet are formed in the air outlet end port plate; the wave rotor air inlet, the reflowing smoke inlet, the high-temperature low-oxygen mixed gas outlet and the smoke outlet are used as inlets and outlets of gas medium; the rotor is rotated relative to the air inlet end port plate and the air outlet end port plate so as to regularly open and close an inlet and an outlet of a rotor channel; the pipeline is connected with the wave rotor and the flameless combustion chamber to form a flowing channel through which the reflowing smoke entering the pipeline can be mixed with air to generate high-temperature low-oxygen mixed gas; the fuel inlet is formed in the pipeline or / and the flameless combustion chamber.

Owner:XIAMEN UNIV

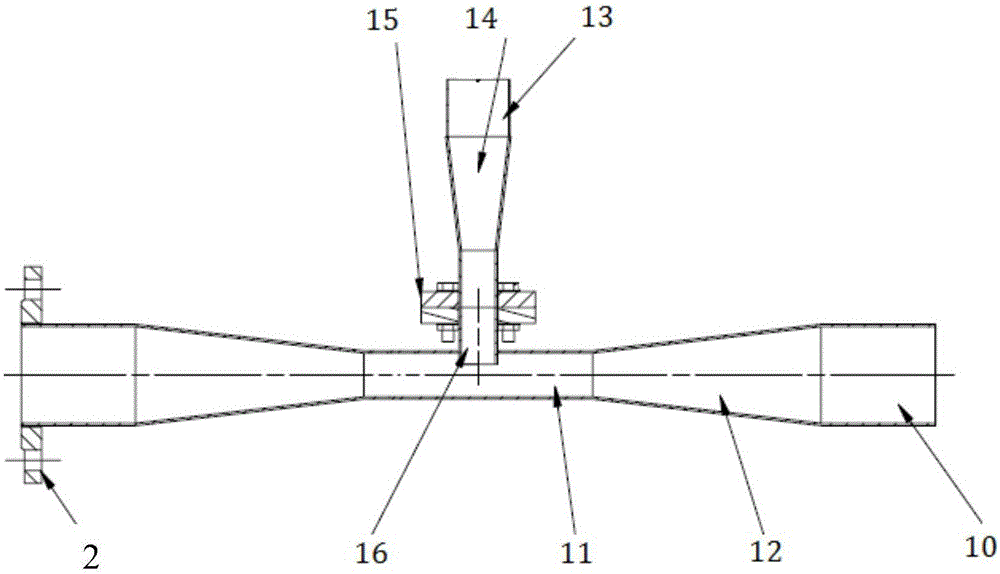

Throat deviating type pneumatic thrust vectoring nozzle with fuel supplementing and thrust augmenting functions and control method

ActiveCN105298683AGuaranteed performanceReduce rear body dragJet propulsion plantsFuel oilStreamflow

The invention discloses a throat deviating type pneumatic thrust vectoring nozzle with fuel supplementing and thrust augmenting functions. An inner flowing channel of the nozzle comprises a front part contraction section of a first throat, the first throat, a front part expansion contraction section of a second throat, and the second throat which are arranged in sequence. The fuel supplementing and thrust augmenting functions are achieved through a fuel oil jet nozzle arranged at a top point of the first throat or achieved in a manner of doping fuel into a secondary flow filled nearby the first throat and then combusted at the downstream of the first throat. According to the method, the fuel oil injecting angle, speed and flow rate of the fuel oil jet nozzle can be controlled, or the ratio of the fuel to air in the secondary flow and the magnitude of the secondary flow rate can be controlled, so as to achieve the control of a vectoring angle of the nozzle as well as the throat area, and meanwhile, the fuel supplementing and thrust augmenting functions can be also achieved. The method is important for the accelerated flying of an aircraft adopting the throat deviating type pneumatic thrust vectoring nozzle in the air.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

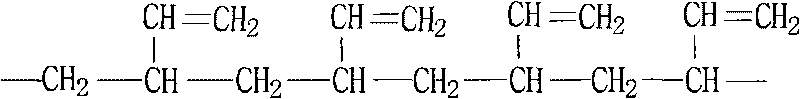

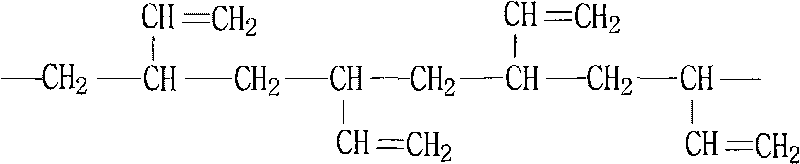

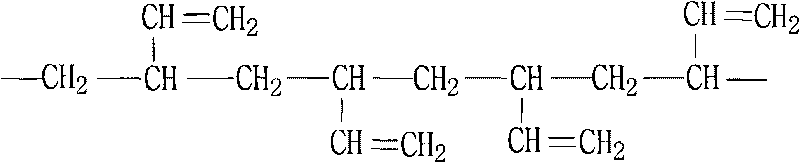

Method for preparing syndiotactic poly1,2-butadiene thermoplastic elastomer

The invention relates to a method for preparing a syndiotactic poly1,2-butadiene thermoplastic elastomer, which comprises the following steps: initiating the polymerization of 1,3-butadiene monomer in hexane solution of a synthetic rubber through the addition of 1,2-configurational units by using iron catalysts to form a uniform blend of 1,2-butadiene and synthetic rubber, wherein the catalysts comprise iron isooctanoate or iron naphthenate, diethyl phosphate, triisobutyl aluminium and aluminium triethyl; the adding sequence of the catalysts is that any components are combined or two aluminum alkyls are mixed first and then combined with the other two components optionally; in a polymerization system, every 1,000 millilitres of hexane solution contains 90 to 140 grams of 1,3-butadiene monomer, and the adding amount of the rubber is 0.1 to 25 grams; and the polymerization initiating temperature is 60 to 90 DEG C. The blend has the properties of the typical thermoplastic elastomers and can be used for modifying thin films, shoe soles, tubular materials, rubbers and plastics.

Owner:PETROCHINA CO LTD

Micro engine flame tube with internal and external hedging guide vane

InactiveCN108131687AExtended stayIncrease the degree of blendingContinuous combustion chamberCombustionFuel oil

The invention provides a structural design scheme of a micro engine flame tube with internal and external hedging guide vanes. Compared with a traditional micro engine flame tube, by arranging the internal guide vanes and the external guide vanes on the portions, close to the front end of the flame tube, of an inner shell and an outer shell of the flame tube, airflow entering the flame tube from an external primary hole becomes rotating inward airflow with three kinds of component velocities in the axial direction, the tangent direction and the radial direction, the velocity of the airflow entering the flame tube from an internal primary hole adopts outwards rotating, and the internal airflow and the external airflow are encountered and subjected to hedging in the flame tube; on one hand,the airflow velocity is lowered to form a low velocity zone, the internal airflow structure of the flame tube is improved, and then stable combustion is achieved; on the other hand, the hedging area has very high scale of turbulence, fuel oil is sprayed into the area to be better mixed with air, and combustion is more thorough.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

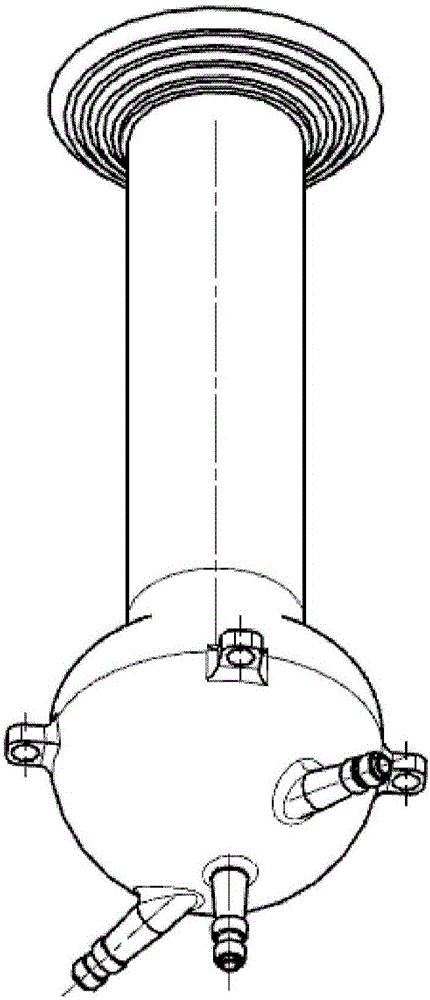

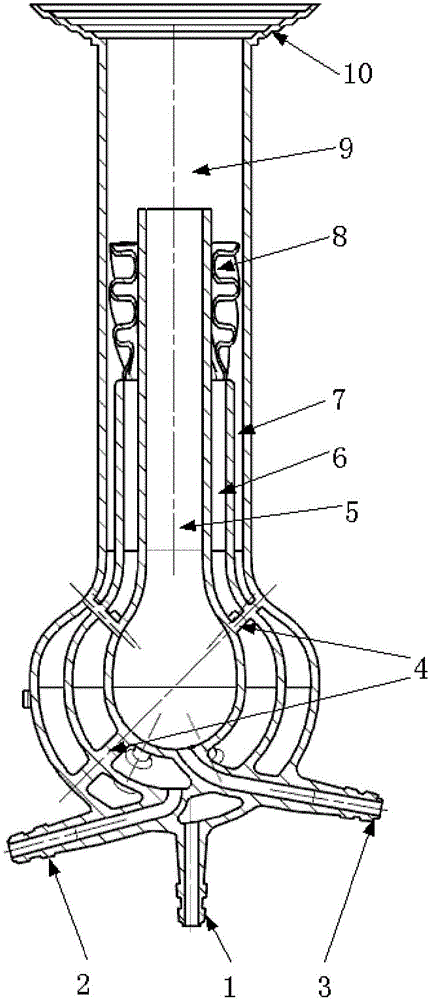

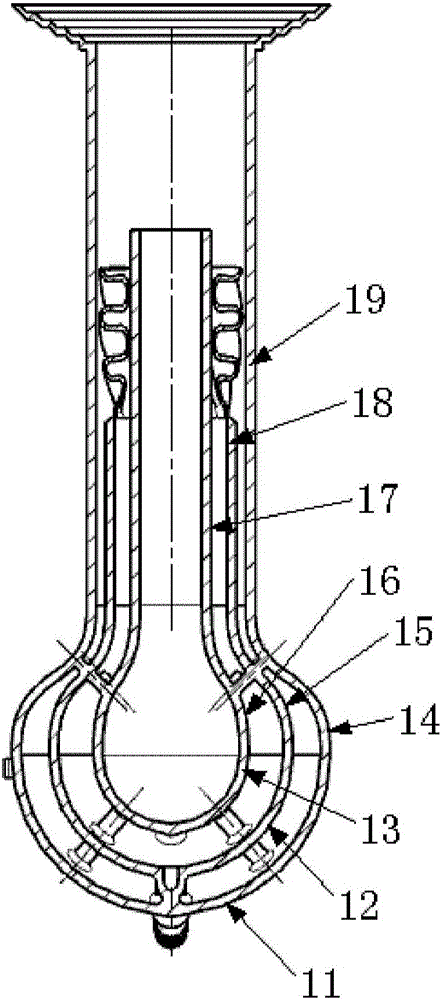

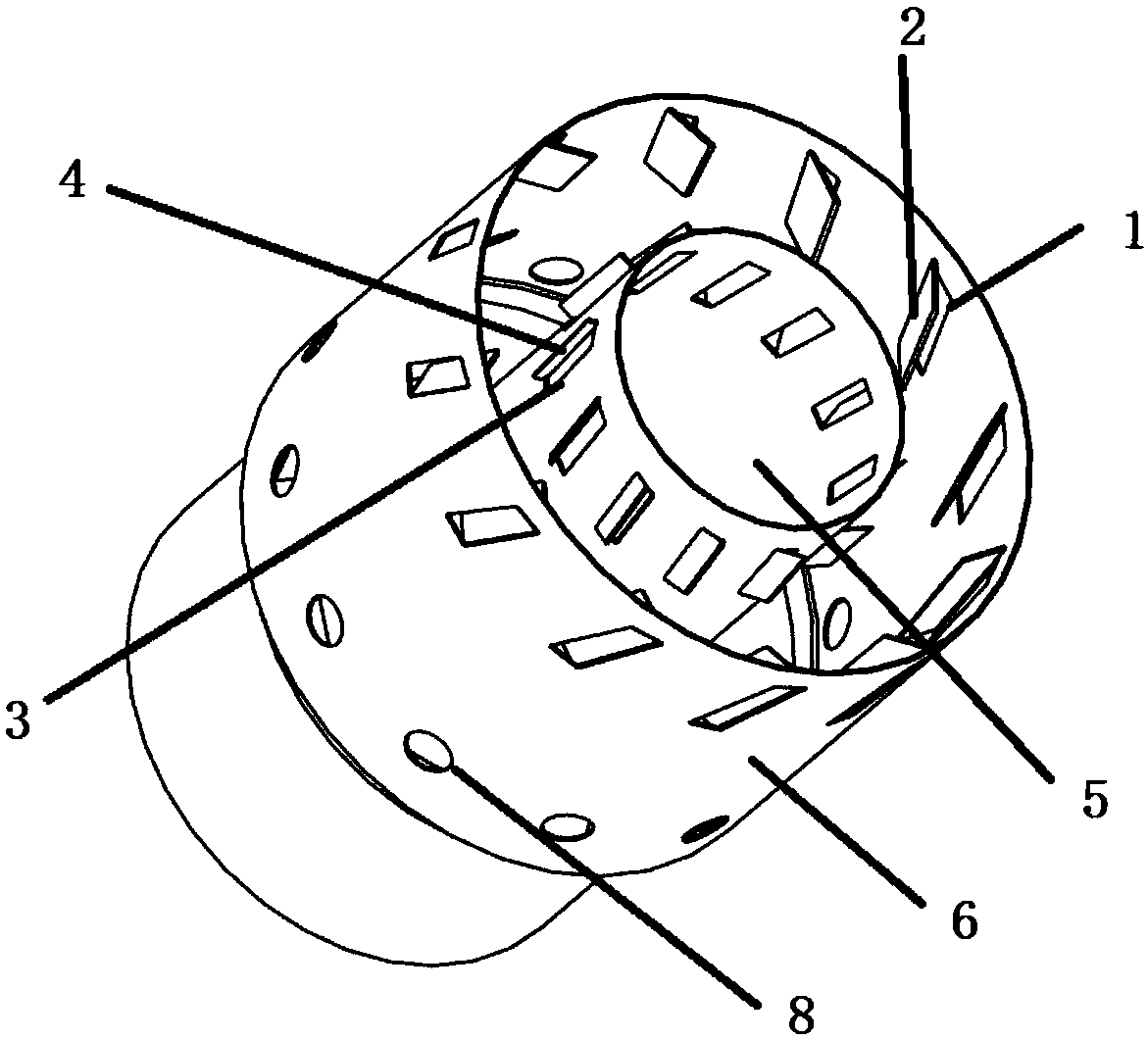

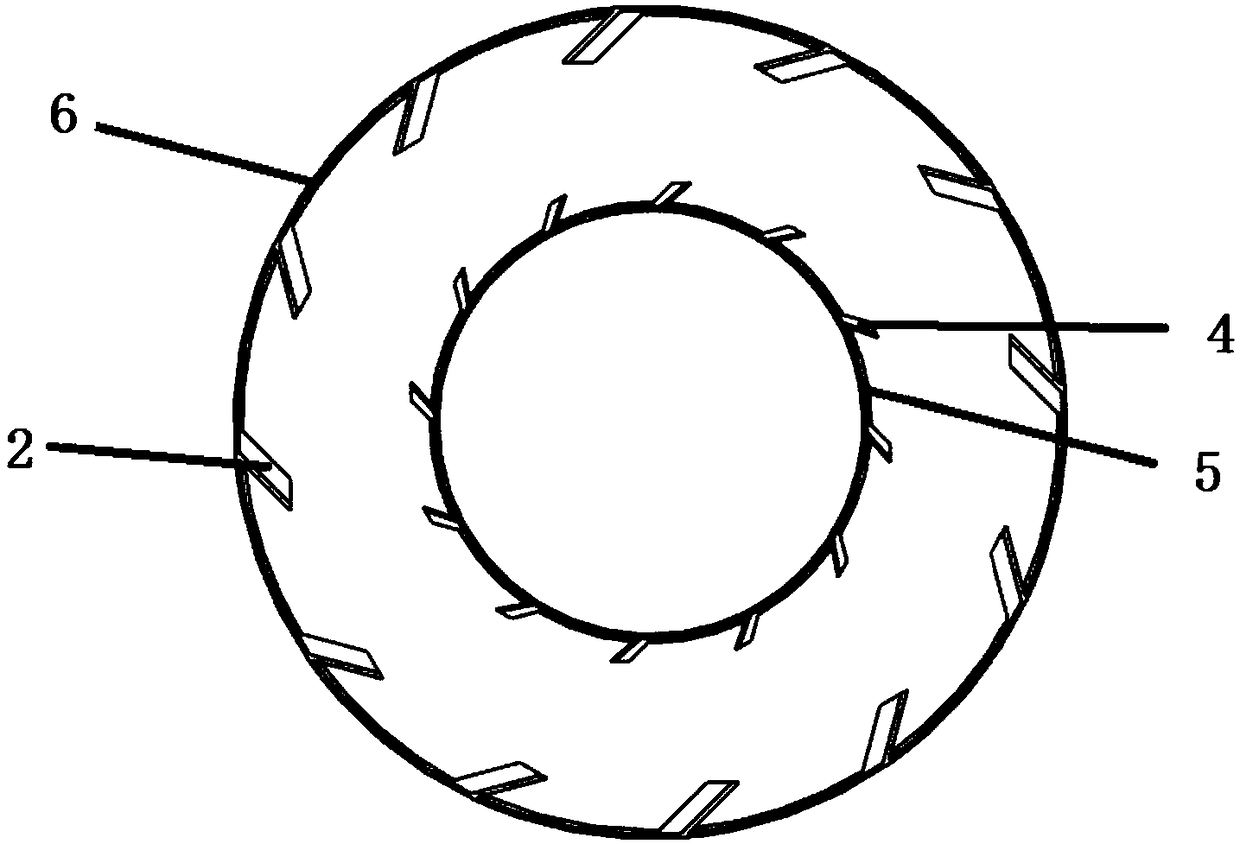

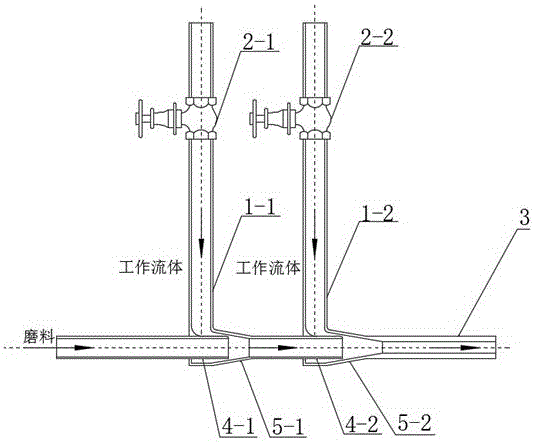

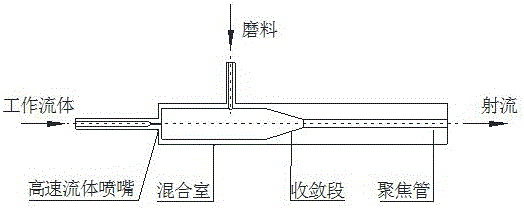

Post-mixing type abrasive water jet nozzle based on annular jet

ActiveCN106312837AReduce friction and impact wearAbrasive Waterjet StabilizationBlast gunsSpray nozzleAbrasive water jet

The invention discloses a post-mixing type abrasive water jet nozzle based on annular jet. The post-mixing type abrasive water jet nozzle comprises an annular nozzle and a secondary annular nozzle which are successively arranged from front to back, wherein a straight pipe section used for sucking abrasive is arranged at the inlet of the annular nozzle; a high-pressure water jet working fluid pipeline is arranged on the side of the annular nozzle; a convergent section and a secondary straight pipe section stretching into the inlet of the secondary annular nozzle are successively arranged at the outlet of the annular nozzle; a high-pressure water jet secondary working fluid pipeline is arranged on the side of the secondary annular nozzle; a secondary convergent section and a focusing pipe are arranged at the outlet of the secondary annular nozzle. The working fluid successively enters the annular nozzle and the secondary annular nozzle; then abrasive particles and abrasive-water mixture are sucked; the abrasive particles are mixed and accelerated; finally, the focusing pipe can form high-speed abrasive water jet. Through the post-mixing type abrasive water jet nozzle, the abrasive and the water can be efficiently and uniformly mixed; the abrasion to the focusing pipe caused by non-uniform mixing of the abrasive and the water can be reduced; the energy utilization rate can be increased; and the cutting perform of the abrasive jet can be improved.

Owner:WUHAN UNIV

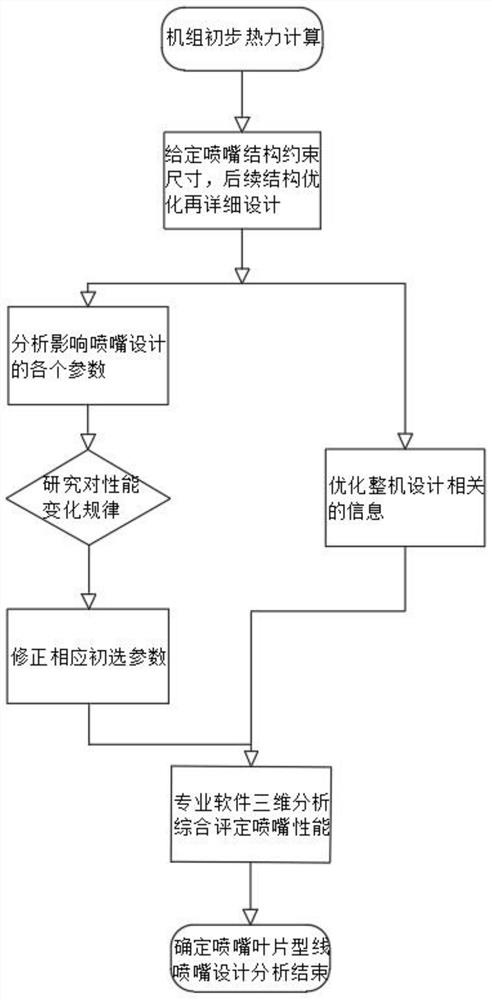

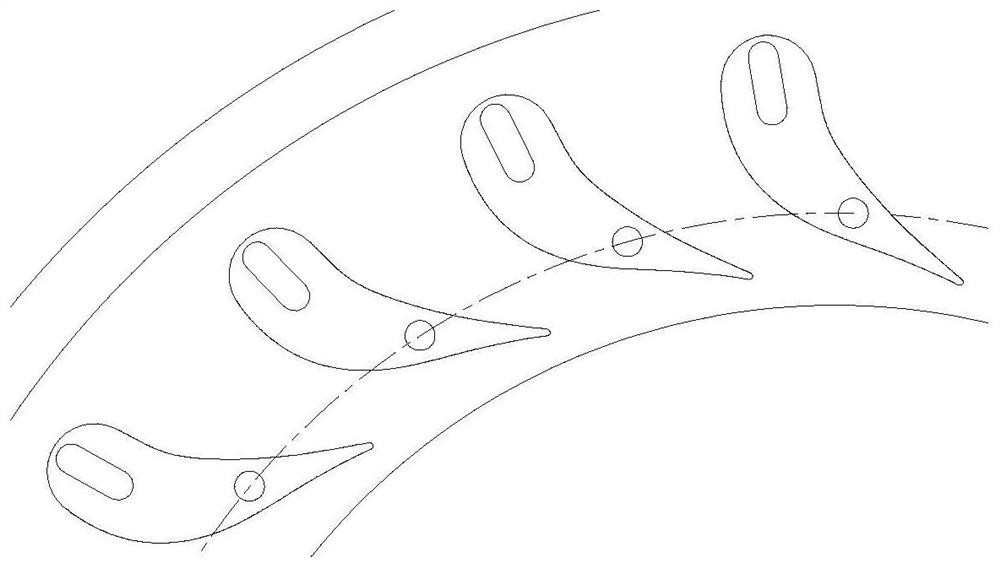

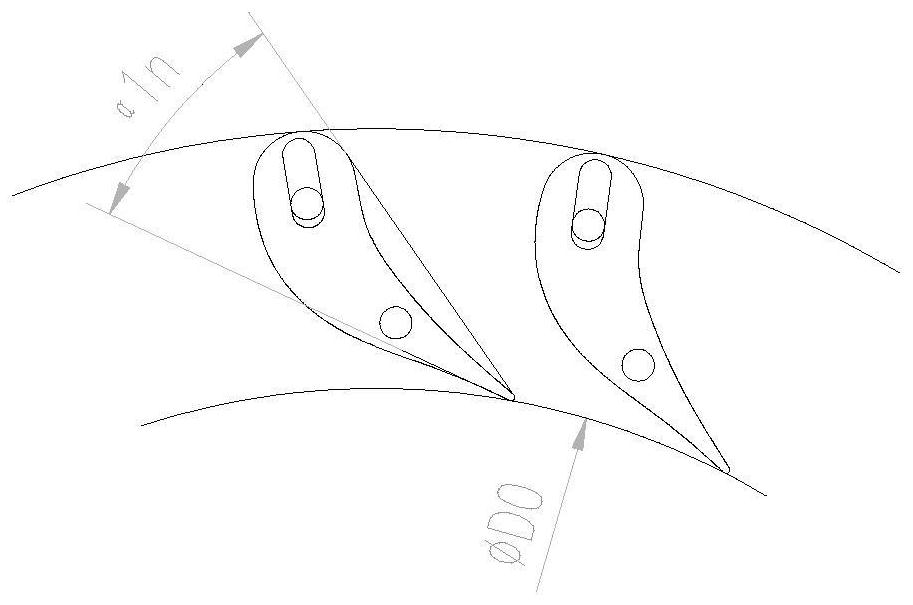

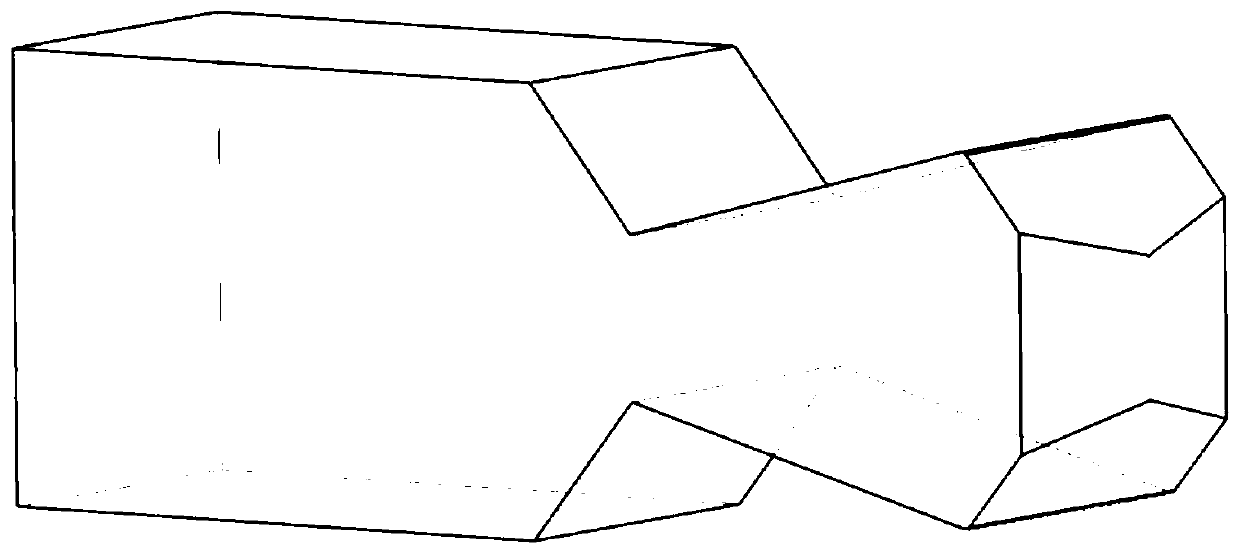

Design method of adjustable nozzle blade of megawatt radial turbine expander

The invention relates to a design method of an adjustable nozzle blade of an expander, and belongs to the field of radial turbine. The design method aims to solve the problem of high cycle fatigue caused by direct impact on an impeller due to nonuniformity of airflow of a nozzle outlet because the nozzle blade is not designed in the prior art. The design method comprises the following steps of giving the limited size of a nozzle mechanism, analyzing all parameters which influence the nozzle design, researching the law of change in performance, correcting the corresponding primary parameter andcomprehensively evaluating the nozzle performance through three-dimensional analysis of professional software. The unique design method for correcting the blade is created, so that the airflow of thenozzle outlet is uniform, and the impact on the impeller is reduced.

Owner:HARBIN ELECTRIC POWER GENERATION EQUIP NAT ENG RES CENT CO LTD

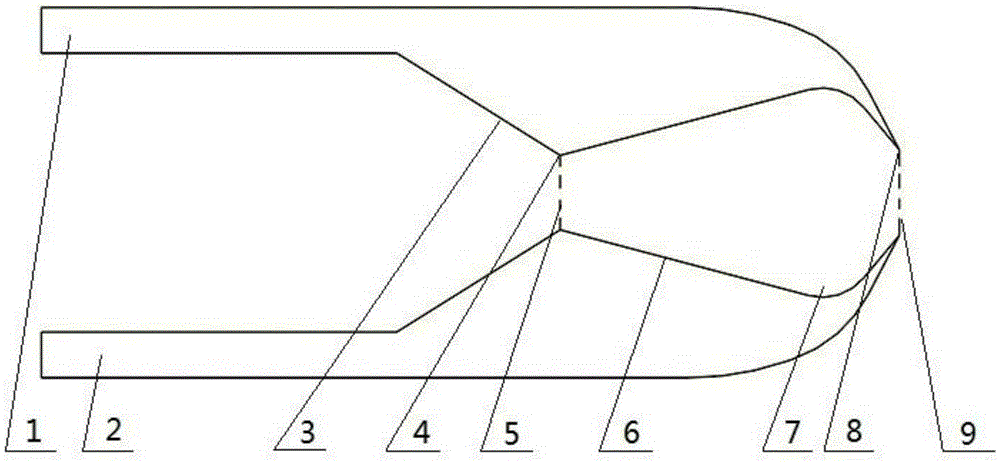

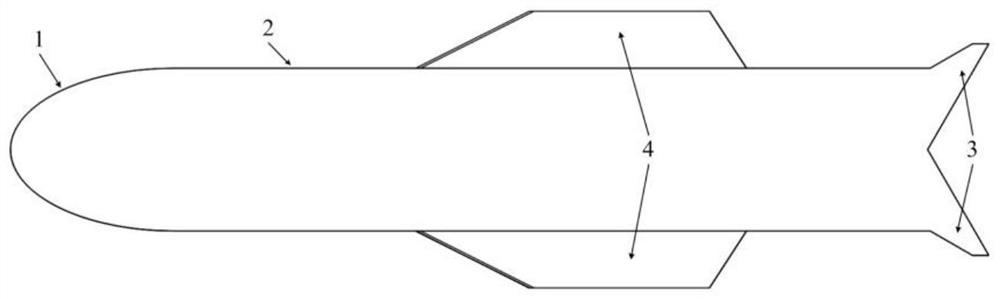

Throat offset type pneumatic vectoring exhaust nozzle with saw-tooth-shaped solid tabs at outlet

The invention discloses a throat offset type pneumatic vectoring exhaust nozzle with saw-tooth-shaped solid tabs at an outlet. The throat offset type pneumatic vectoring exhaust nozzle comprises an exhaust nozzle body, wherein a flow channel in the exhaust nozzle sequentially comprises an exhaust nozzle inlet, an isometric section, a first throat front part convergent section, a first throat, a second throat front part expanding section, a second throat front part convergent section and a second throat; and the saw-tooth-shaped solid tabs are arranged on upper and lower wall surfaces at the downstream of the second throat front part convergent section and a projection area of the outlet of the exhaust nozzle is not changed. According to the throat offset type pneumatic vectoring exhaust nozzle disclosed by the invention, the saw-tooth-shaped solid tabs which are inclined toward are arranged at upper and lower sides of the outlet; and an infrared stealth function of the exhaust nozzle is improved under the condition that the projection area of the outlet is equal to an original projection area. Compared with a standard throat offset type pneumatic vectoring exhaust nozzle with a rectangular outlet section, the exhaust nozzle provided by the invention can be used for effectively reducing the speed of a flow spraying central line and reducing the length of a core region and noisesthrough reinforcing flow spraying and blending of the outlet; and meanwhile, the exhausting temperature is reduced and the infrared stealth function is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

High-wear-resistance lubricating oil and preparation method thereof

InactiveCN110835574AIncrease activationImprove anti-wear and anti-friction performanceRotary stirring mixersTransportation and packagingVulcanizationActive agent

The invention discloses high-wear-resistance lubricating oil, which is prepared from the following raw materials by weight: 80 to 90 parts of base oil, 2 to 3 parts of nano tungsten disulfide, 0.4 to0.6 part of a surfactant, 0.8 to 1 parts of a defoamer and 1.5 to 2 parts of an antiwear additive. The invention also discloses a preparation method of the lubricating oil. According to the lubricating oil, the nano tungsten disulfide is uniformly dispersed in the lubricating oil through the compounding of the nano tungsten disulfide and the surfactant, and the anti-wear and anti-friction effect of the nano-particles is exerted; by adding the anti-wear additive, a composite protective film is generated at the bearing friction interface and has excellent anti-wear and anti-friction performance;the lubricating oil is processed through special processing equipment, the lubricating oil can be fully, thoroughly and efficiently blended and processed so that components are evenly dispersed in the lubricating oil to exert corresponding effects and to ensure quality of the lubricating oil. The wear-resistant high-quality lubricating oil is obtained and suitable for tapered roller bearings, heavy-duty gear and other fields.

Owner:安徽中天石化股份有限公司

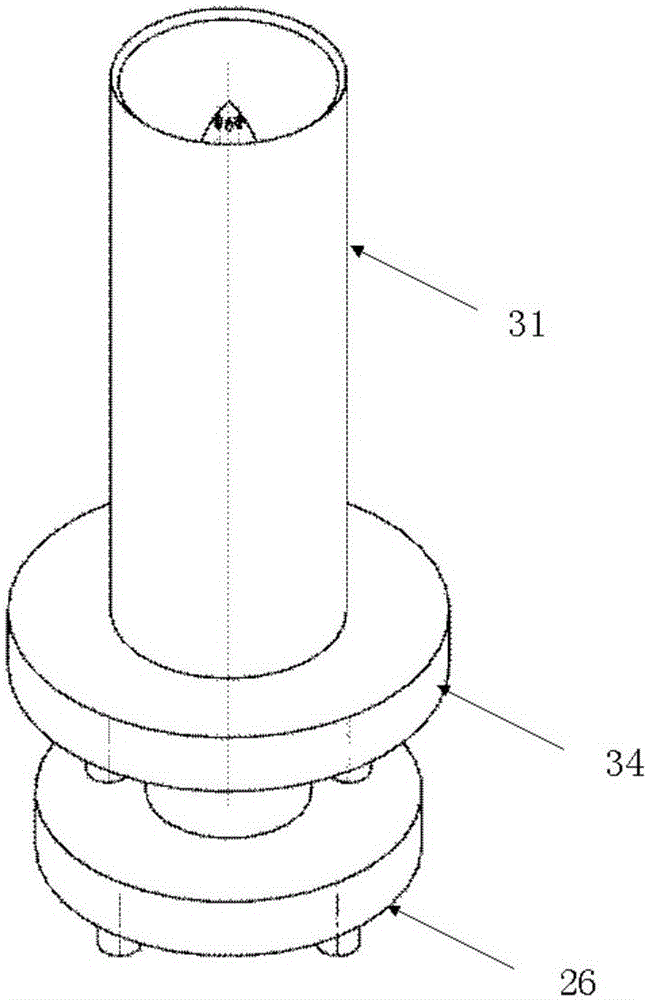

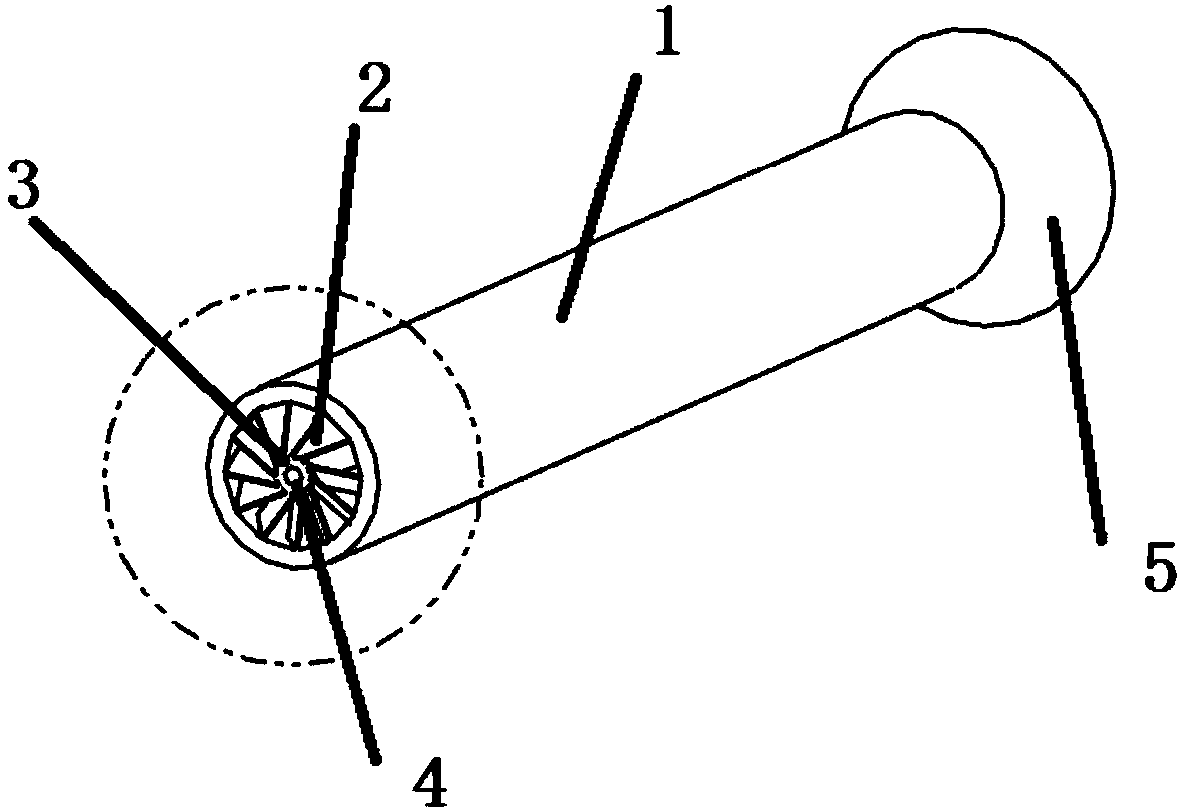

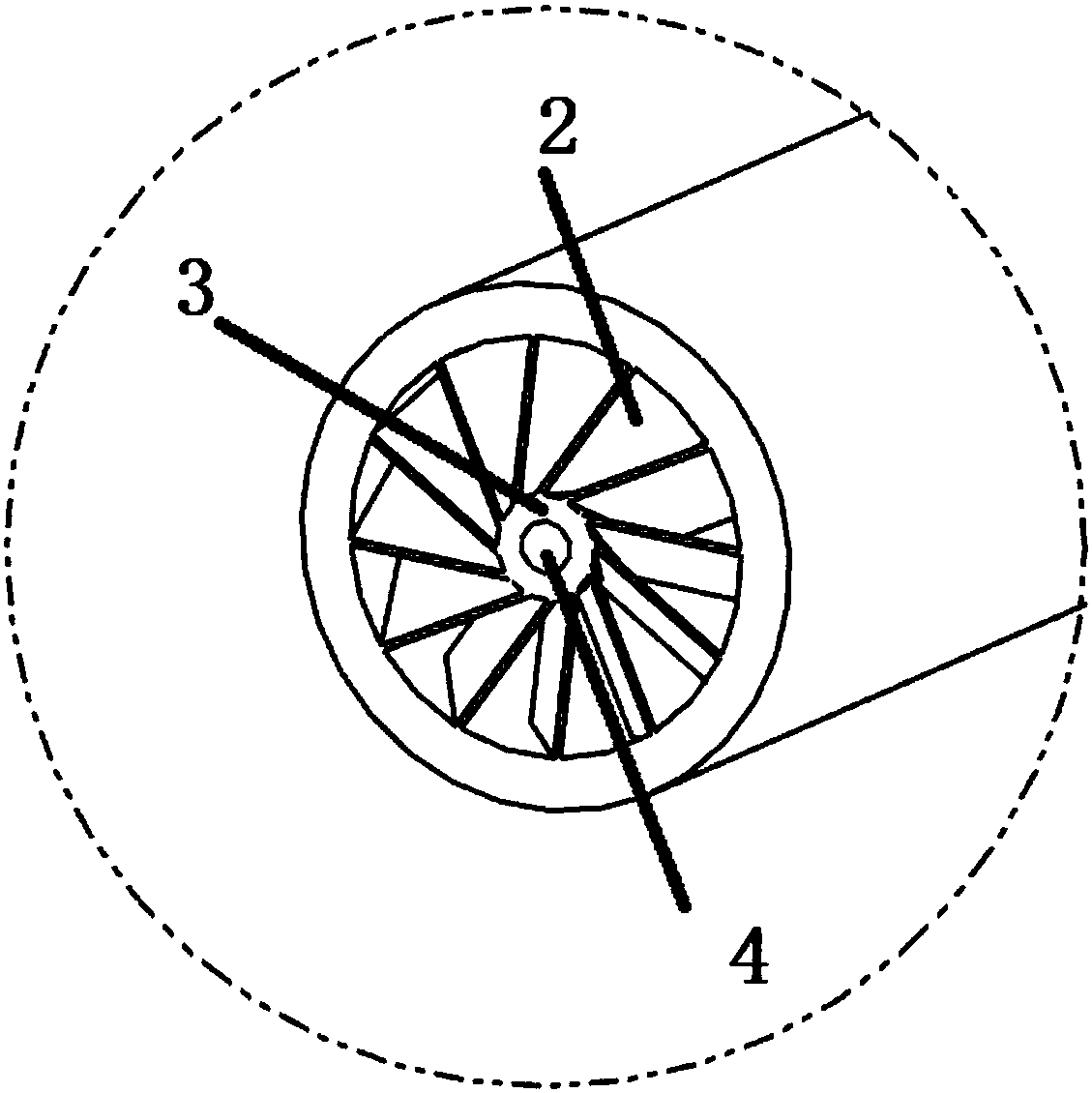

Pulse detonation engine

ActiveCN109882315ASimple structureReduce weightIntermittent jet plantsTurbine/propulsion air intakesMechanical engineeringPulse detonation engine

The invention relates to a pulse detonation engine. The detonation engine comprises a detonation tube and an air inlet part; the air inlet part comprises conical flow guide caps, at least one annularV-shaped groove flow guide plate, annular flow guide plates and a support; the flow guide caps and the annular V-shaped groove flow guide plates are arranged on the support; the support and the annular flow guide plates are fixedly connected with the detonation tube; the openings of the conical flow guide caps and the openings of the annular V-shaped groove flow guide plates face the outlet of thedetonation tube; the annular flow guide plate is inclined towards the side of the outlet of the detonation tube; the conical flow guide caps and the annular V-shaped groove flow guide plates are sequentially distributed in the axial direction of the detonation tube towards the outlet and are sequentially distributed from inside to outside in the radial direction of the detonation tube; the conical flow guide caps, the annular V-shaped groove flow guide plates and the annular flow guide plates are arranged at intervals, and the orthographic projections of every two adjacent ones on a plane inthe axial direction of the detonation tube have an overlapped area; and the orthographic projections of every two adjacent ones on a plane in the radial direction of the detonation tube have an overlapped area.

Owner:AECC HUNAN AVIATION POWERPLANT RES INST

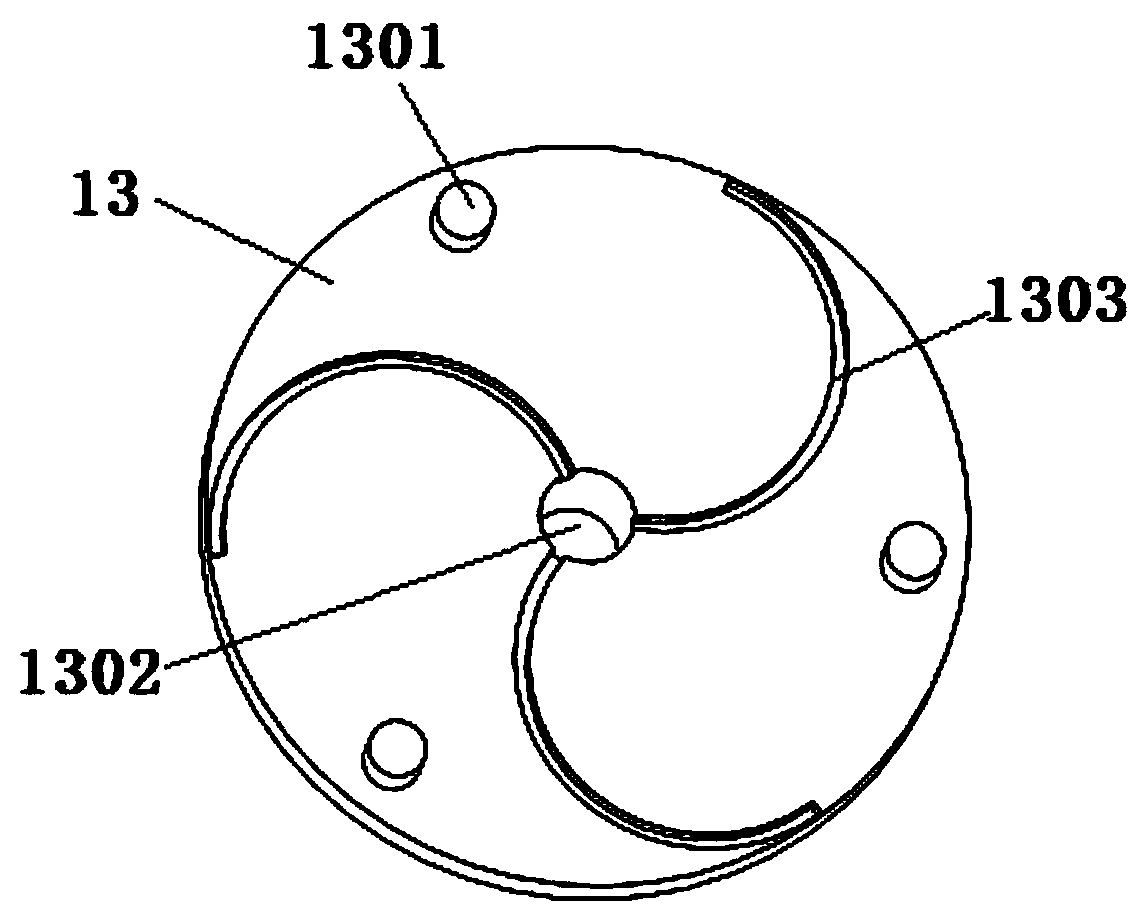

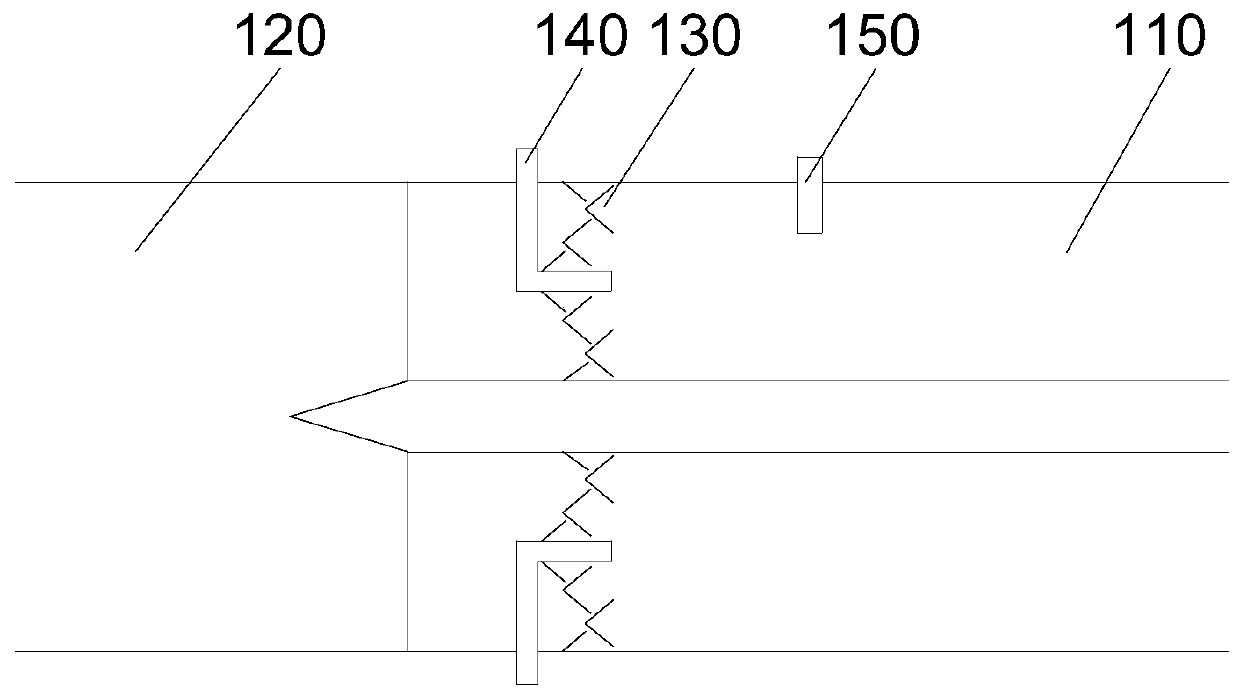

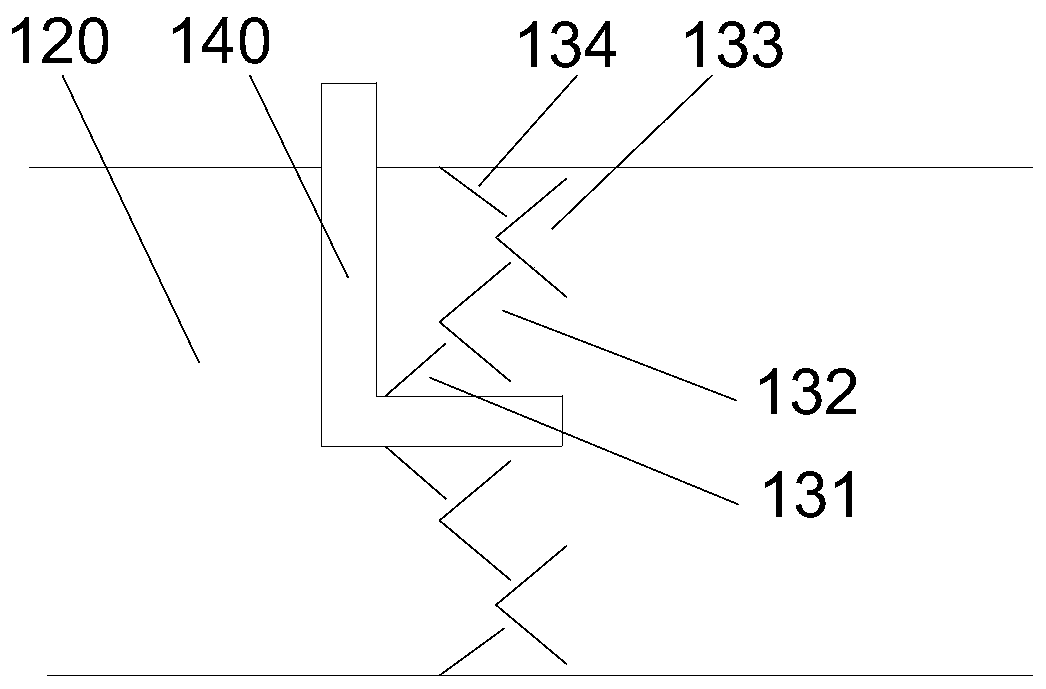

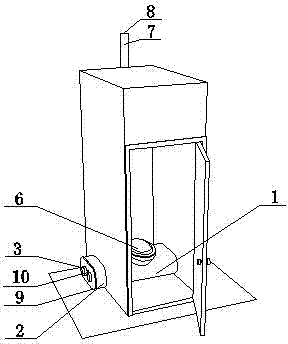

Flushing-free non-discharge ecological toilet

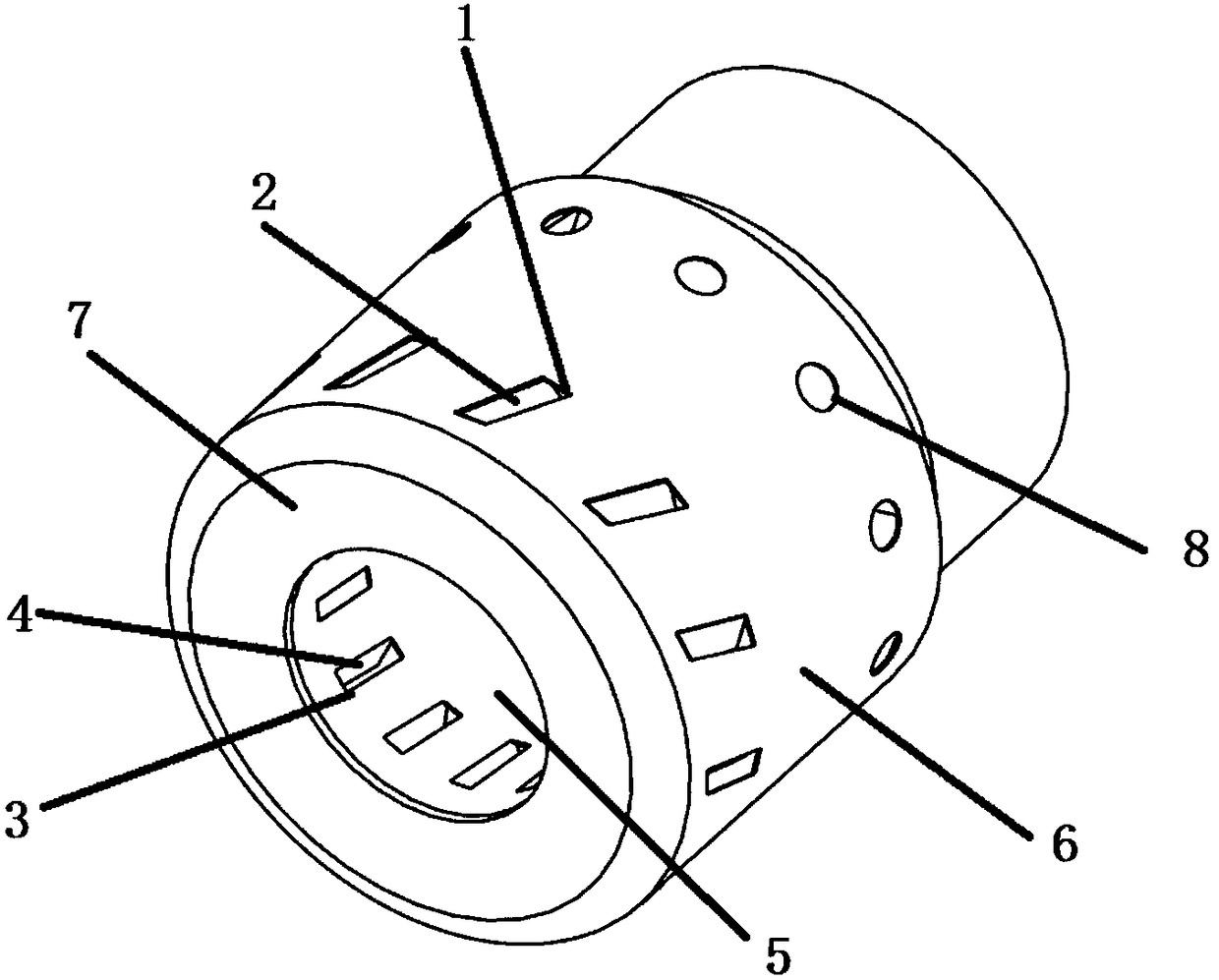

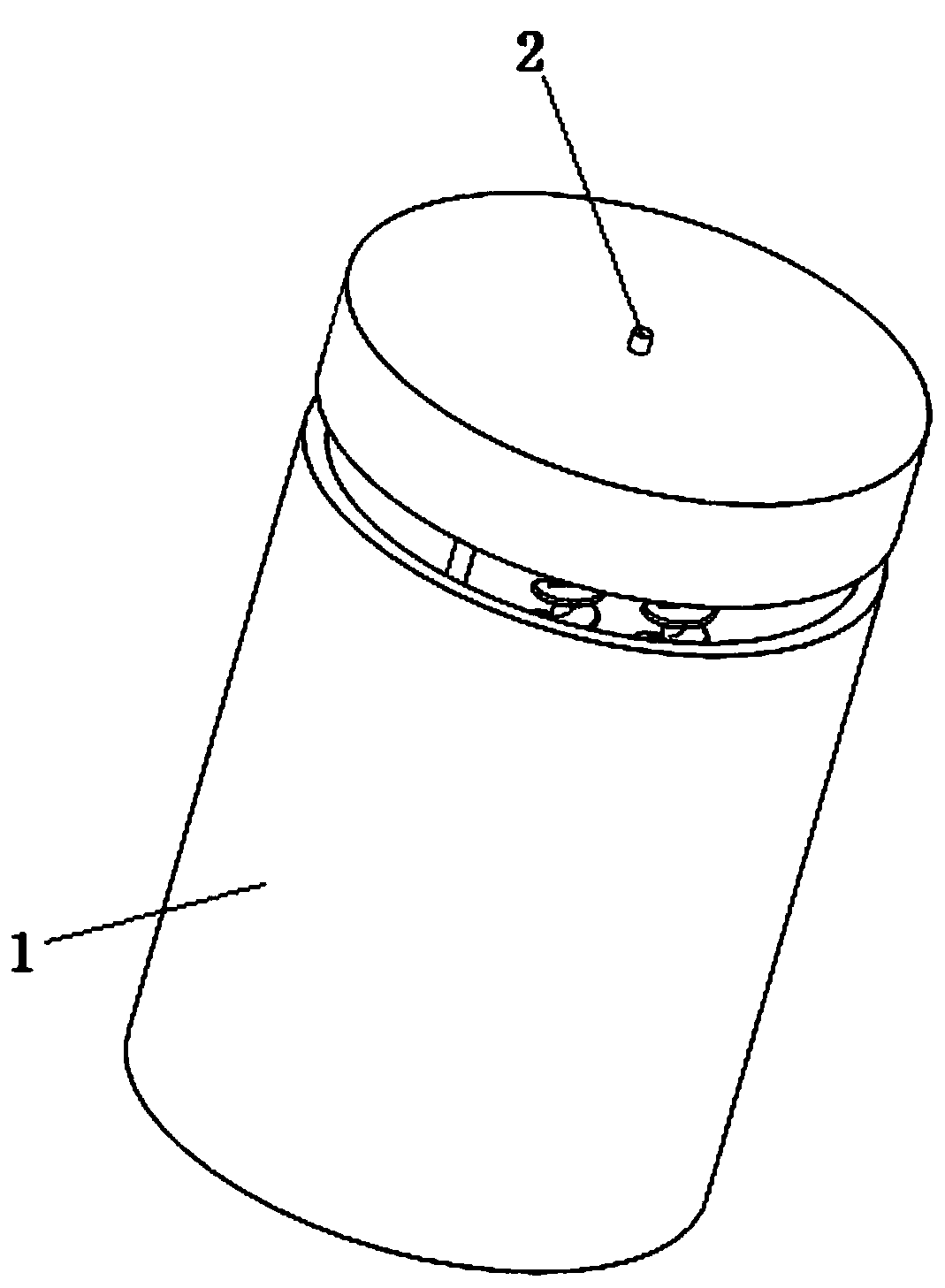

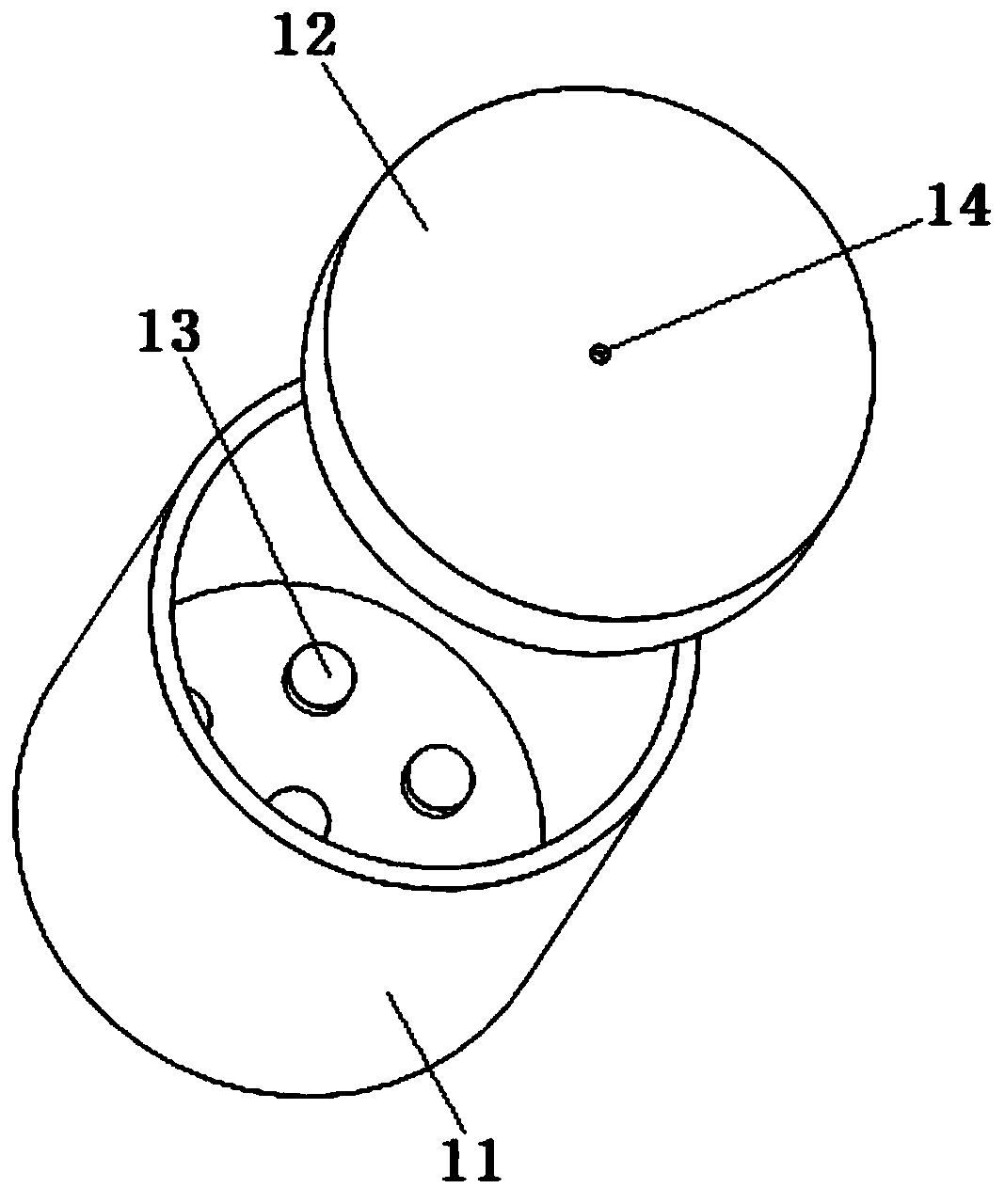

ActiveCN102488475BFully blendedNo dead endsBathroom accessoriesBiological sludge treatmentBiochemical engineeringToilet

The invention relates to the technical field of flushing-free non-discharge ecological toilets with new structures, in particular to a flushing-free non-discharge ecological toilet, which comprises a biochemical reactor for degrading excrement, wherein a shell of the biochemical reactor is two cylinders which are parallel, and two ends of the cylinders are communicated by a waisted box body to form an annular closed container; auger delivery stirring devices are arranged in the cylinders; one end of each cylinder is provided with a motor and a variable-speed transmission device, and the other end of each cylinder is provided with a gate; a pedestal pan or a squatting pan is arranged above the biochemical reactor; an opening above one cylinder is communicated with a lower discharge hole of the pedestal pan or the squatting pan, and a hole on the lateral upper side of the other cylinder is connected with a tube cylinder and an exhaust fan; and biological base stocks are filled into the cylinders. The flushing-free non-discharge ecological toilet has a simple and compact structure, a large volume ratio, a small size, light weight, high sealing performance and high heat-insulating performance, is reliably connected, saves energy and is easy to use and popularize, and people can go to the toilet without barriers.

Owner:众信嘉华张家口科技有限公司

Gas-solid mixing conveying device capable of achieving even distribution and application of gas-solid mixing conveying device

The invention provides a gas-solid mixing conveying device capable of achieving even distribution and application of the gas-solid mixing conveying device. According to the gas-solid mixing conveying device, a single horizontal pipeline is manly composed of a sand feeding segment, reducing and enlarging segments, a rectification segment and an outlet segment, all of which are connected in sequence; the sand feeding segment is a tee joint, a horizontal pipeline part of the sand feeding segment is mainly composed of straight pipelines at the two ends, a straight pipeline in the middle and variable-sectional pipelines at the two ends and the middle, and a vertical pipeline part of the sand feeding segment is inserted in the straight pipeline close to the center of the horizontal pipeline part; each reducing and enlarging segment is mainly composed of straight pipelines at the two ends, a straight pipeline in the middle and variable-sectional pipelines at the two ends and the middle; the outlet segment is an annular expansion nozzle; and multi-layer rectification nets are arranged between the sand feeding segment, the reducing and enlarging segments, the rectification segment and the outlet segment. The gas-solid mixing conveying device can be applied to mixing of solid particles (fine particles) of 1-200 micrometers and gas flow, and fine grains entering in the radial direction are homogenized at an axial and circumferential outlet to enter an annular channel of a particle separator.

Owner:SHANGHAI JIAO TONG UNIV

Production process of biodegradable membrane

The invention discloses a production process of a biodegradable membrane. The production process comprises the following steps: (1) preparing konjak leach liquor, and sealing and preserving at a coldplace for later use; (2) mixing the konjak leach liquor with microcrystalline cellulose so as to obtain a konjak cellulose emulsion; (3) dissolving polybutylene succinate powder into chloroform to prepare a polybutylene succinate solution; (4) mixing N-ethyl imidazole and sodium alginate into the polybutylene succinate solution and the konjak cellulose emulsion; (5) performing coating and calendaring filming on the commixed emulsion, thereby obtaining the biodegradable membrane. The polybutylene succinate and the konjak are adopted as basic materials, the polybutylene succinate can be easily decomposed and metabolized by multiple microorganisms in the nature or enzymes in animals and plants, the konjak is rich in cellulose, the cellulose has the advantages of reproducibility, biodegradability, hydrophilia, chemical stability, biocompatibility and the like, and thus the prepared membrane is excellent in decomposability.

Owner:JIESHOU CITY TIANHONG PACKAGING MATERIAL

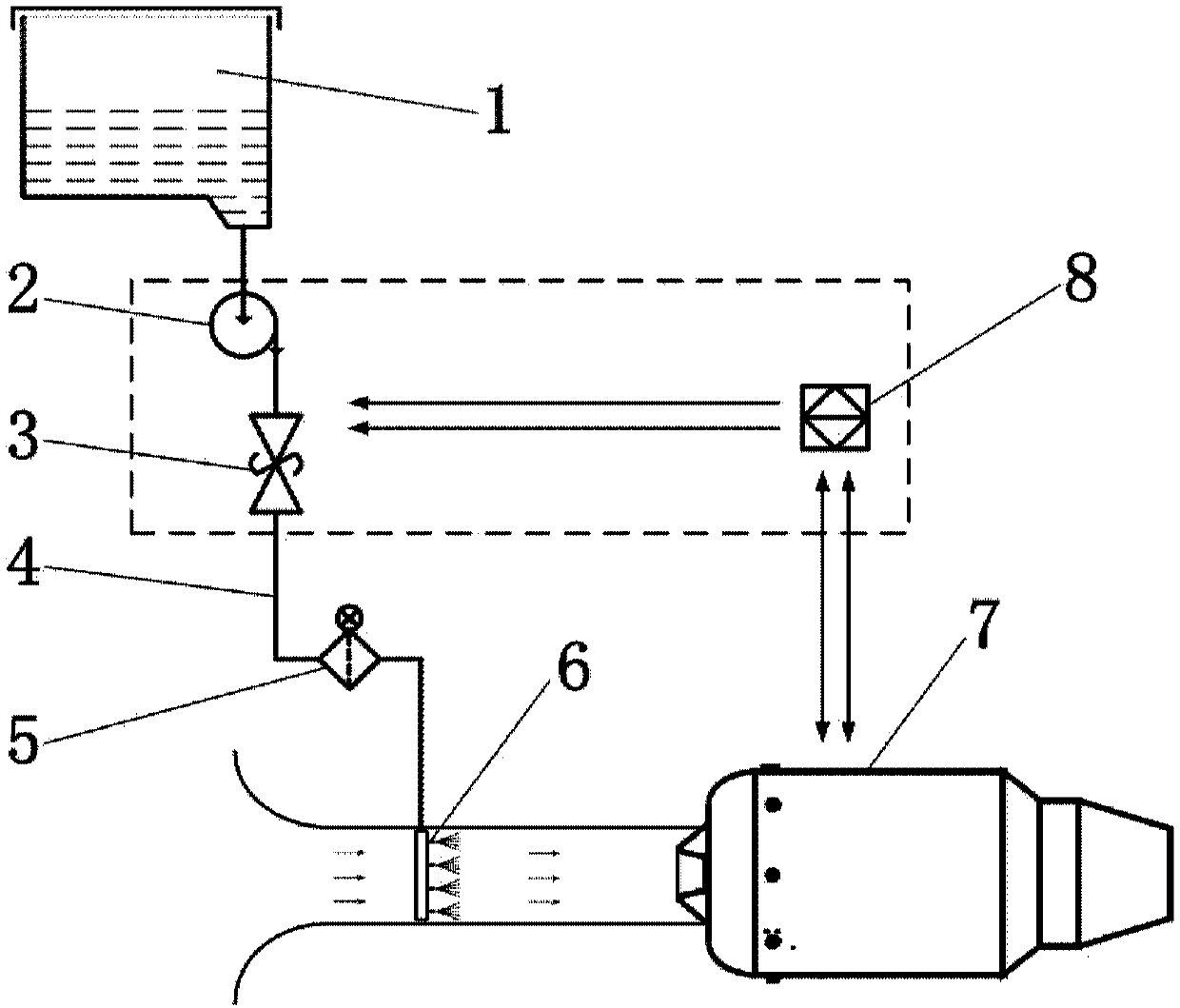

Water or methyl alcohol spraying thrust increasing system suitable for small turbojet engine

InactiveCN107842423ALow costReduce technical difficultyGas turbine plantsJet propulsion plantsCombustion chamberFuel oil

The invention discloses a turbojet engine. The turbojet engine comprises an air inlet way, an air compressor, a combustion chamber, a turbine, a tail spraying pipe, and a thrust increasing device. Airenters the turbojet engine through the air inlet way. The air compressor is arranged behind the air inlet way so that the pressure of air entering through the air inlet way can be increased. Air passes through the air compressor and then enters the combustion chamber to be mixed with fuel oil to be mixed and combusted, and expansion acting is conducted. The turbine and the air compressor are coaxially arranged on an engine shaft so that high-temperature and high-pressure gas flowing out of the combustion chamber can push the turbine to rotate. High-temperature and high-pressure gas flowing out of the turbine continues to expand in the tail spraying pipe and is discharged in the axial direction of the engine. The thrust increasing device sprays liquid into the air inlet way so that the inlet flow of the turbojet engine can be increased.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Micro engine combustion chamber evaporation pipe with inlet rotational flow blades

InactiveCN108167863AExtended stayEnhance the effect of atomization and evaporationContinuous combustion chamberCombustion chamberFresh air

The invention discloses a micro engine combustion chamber evaporation pipe with inlet rotational flow blades. The rotational flow blades are arranged on an inlet of the evaporation pipe, when air enters the evaporation pipe, under the rotation effect of the inlet rotational flow blades, rotational flows with the axial direction, radial direction and tangent speed dividing are generated, due to thehigh turbulence level and the shear effect of the rotational air flow, fresh air and fuel oil can be mixed more sufficiently, due to axial speed reduction, the staying time of the air flow and the fuel oil in the evaporation pipe is prolonged, fuel oil and air mixing is facilitated. On the other hand, the rotational air flow in the evaporation pipe increases the convection heat exchange coefficient, heat exchange between the wall face and the air flow can be enhanced, the fuel oil atomization evaporation effect is reinforced, and combustion is more sufficient. The higher rotational flow strength is kept in the evaporation pipe, the rotational flow blades are arranged in the evaporation pipe, and the staying time and the mixing degree of the fuel oil in the evaporation pipe can be furtherimproved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

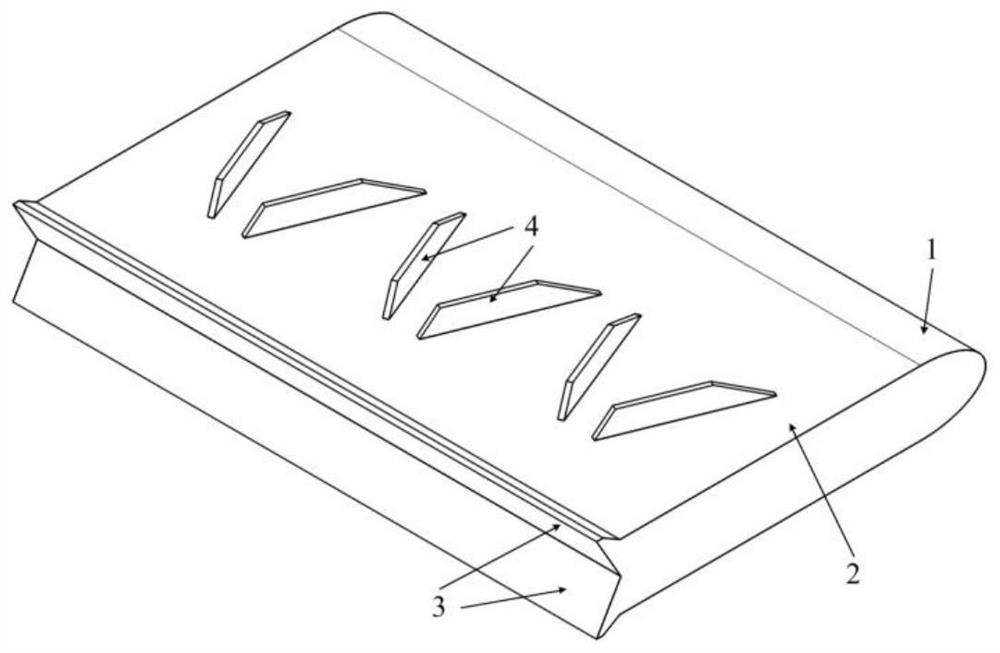

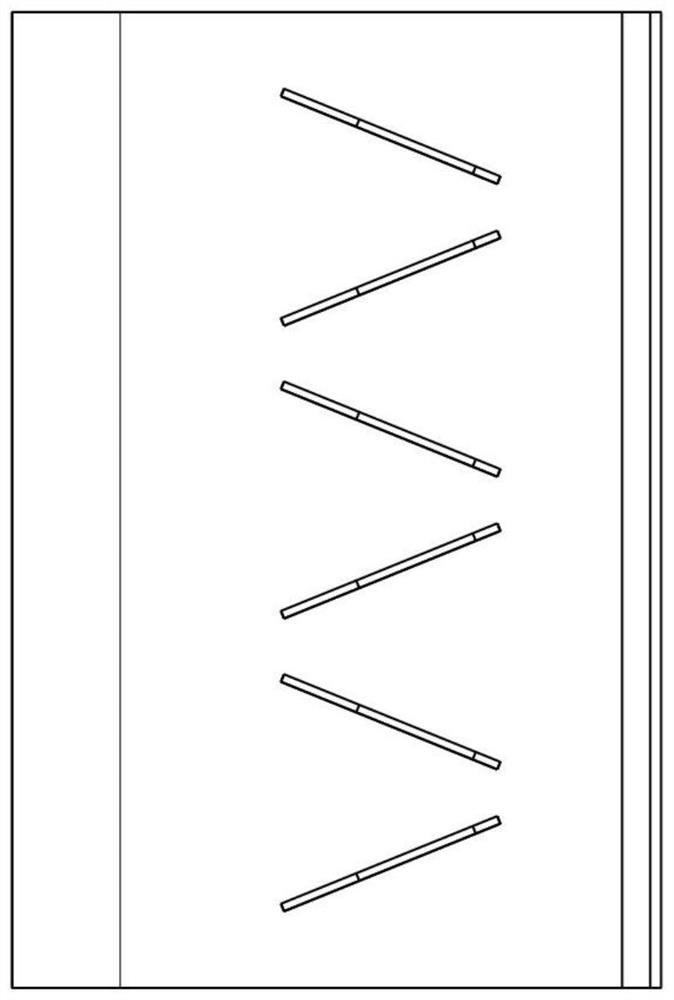

Support plate flame stabilizer with fin vortex generators

ActiveCN113701190AImprove flame stabilitySpread fastContinuous combustion chamberFlame propagationEngineering

The invention relates to a support plate flame stabilizer with fin vortex generators. The support plate flame stabilizer mainly comprises a front edge, a straight section and a V-shaped tail edge, and 3-5 pairs of trapezoidal fin vortex generators are arranged on each of the two side surfaces of the straight section. The support plate flame stabilizer with the fin vortex generators has the advantages and beneficial effects of good flame stability, high flame propagation speed, small flow resistance loss and high combustion efficiency.

Owner:NANCHANG HANGKONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com