Patents

Literature

43results about How to "Uniform and stable airflow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

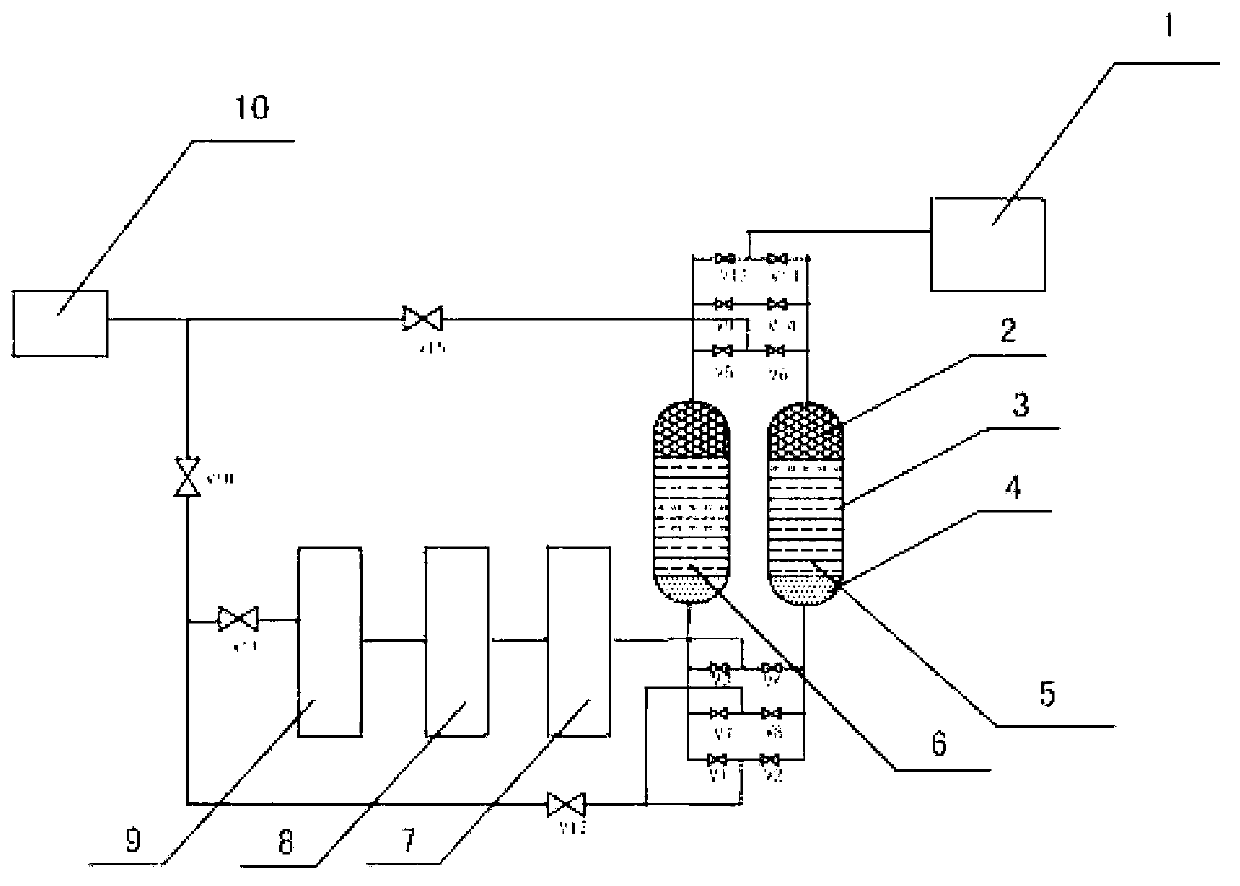

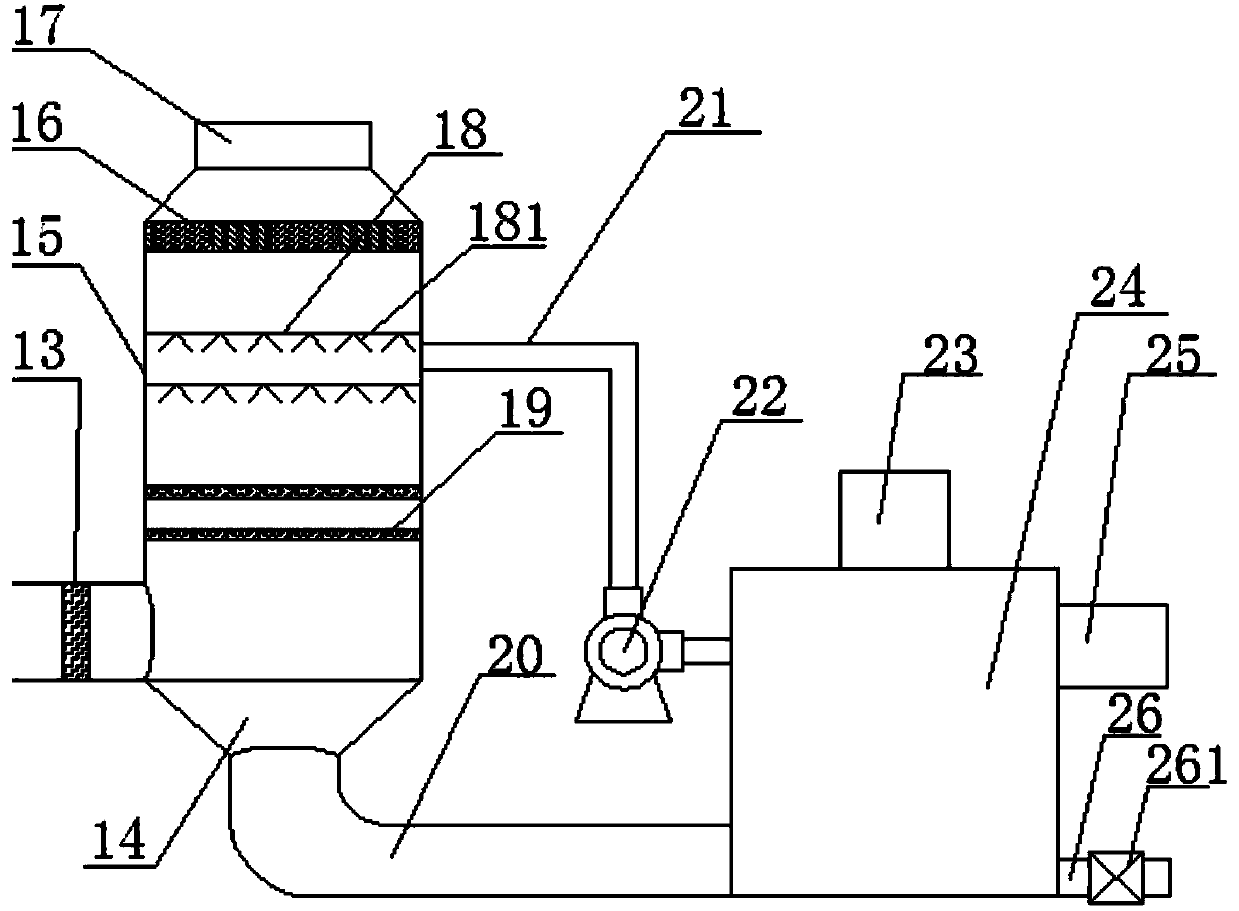

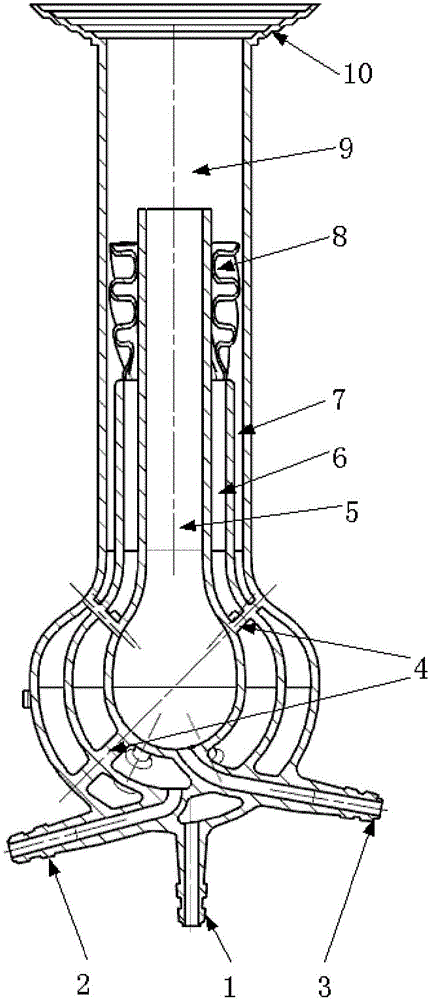

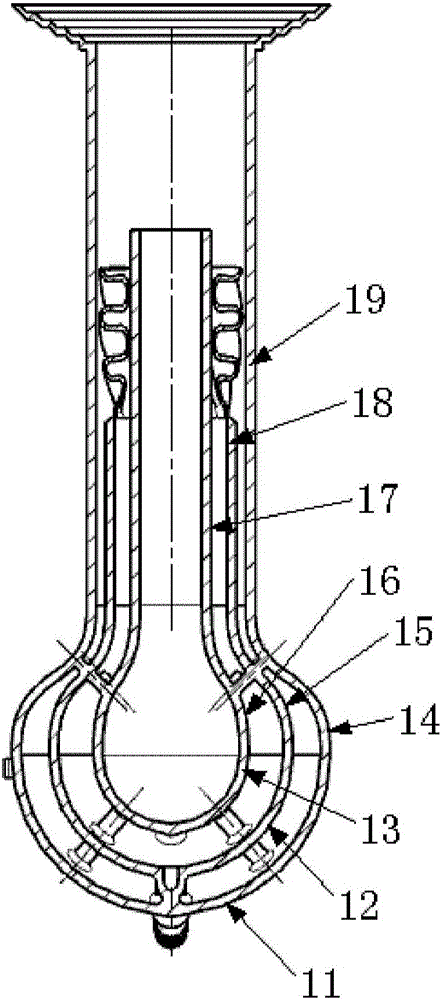

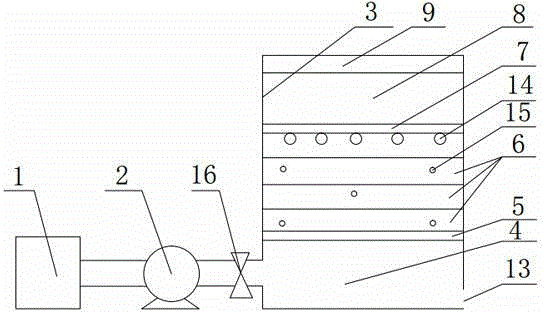

Waste heat regeneration absorption dryer

InactiveCN103272460ARealize external heat regenerationReduce power consumptionDispersed particle separationSorbentCooling effect

The invention belongs to the field of chemical equipment, and particularly relates to a waste heat regeneration absorption dryer. The waste heat regeneration absorption dryer comprises an air compressor, an absorption tower A, an absorption tower B, a first cooler, a second cooler, and a gas-water separator; valves of the absorption tower A and the absorption tower B are symmetrically arranged and use compressed air in the air compressor as a heat source during use, and the absorption tower A and the absorption tower B circularly work under programmed control. The waste heat regeneration absorption dryer fully utilizes waste heat of the compressor so that the power consumption of an electric heater, a fan and a steamer of traditional external heating or microheating drying is saved to achieve the external heating regeneration and maximally reduce the energy consumption; the two coolers are arranged so that the cooling effect is good; and the absorption towers have three-layer structures, and gas flow is distributed uniformly in a molecular sieve layer and an aluminum oxide layer under the action of a large water-absorption ball layer, so that the absorption time is prolonged, the absorption effect is enhanced, the gas flow is stable and uniform, the impact force on a sorbent is small, and the service life is prolonged.

Owner:山东道先为能源科技股份有限公司

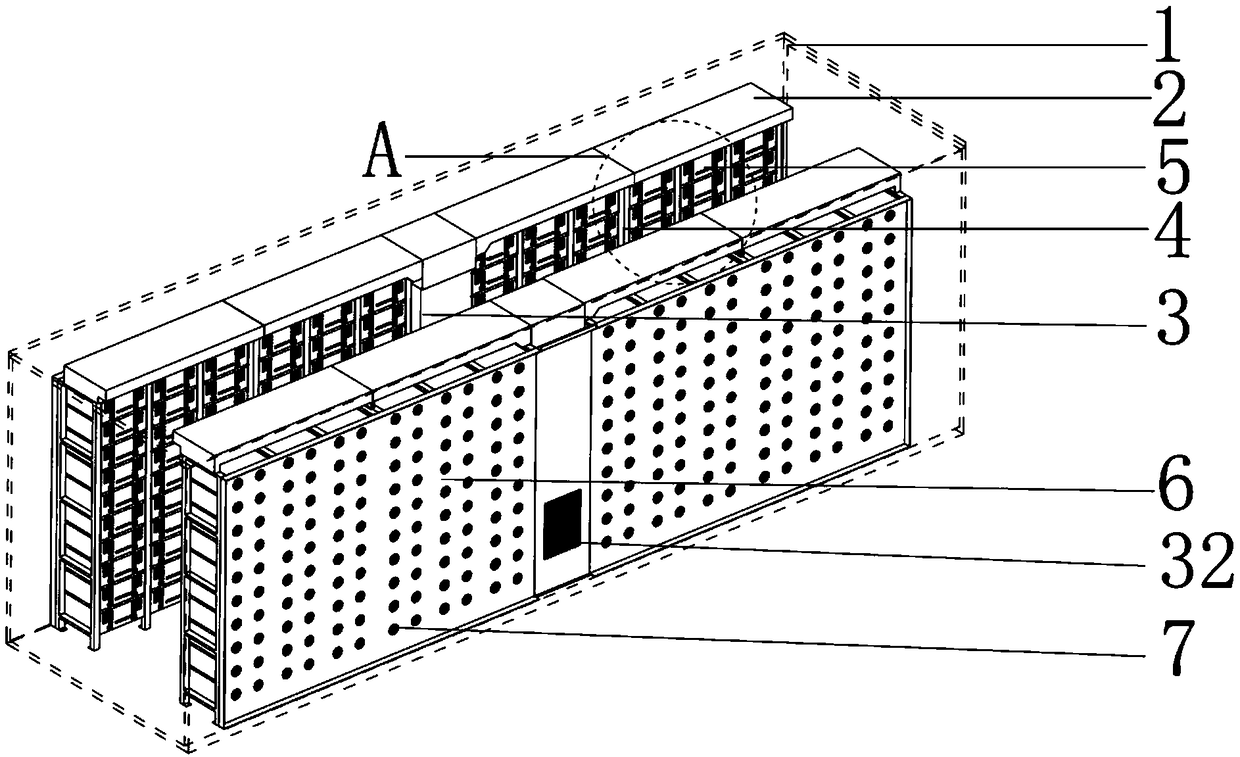

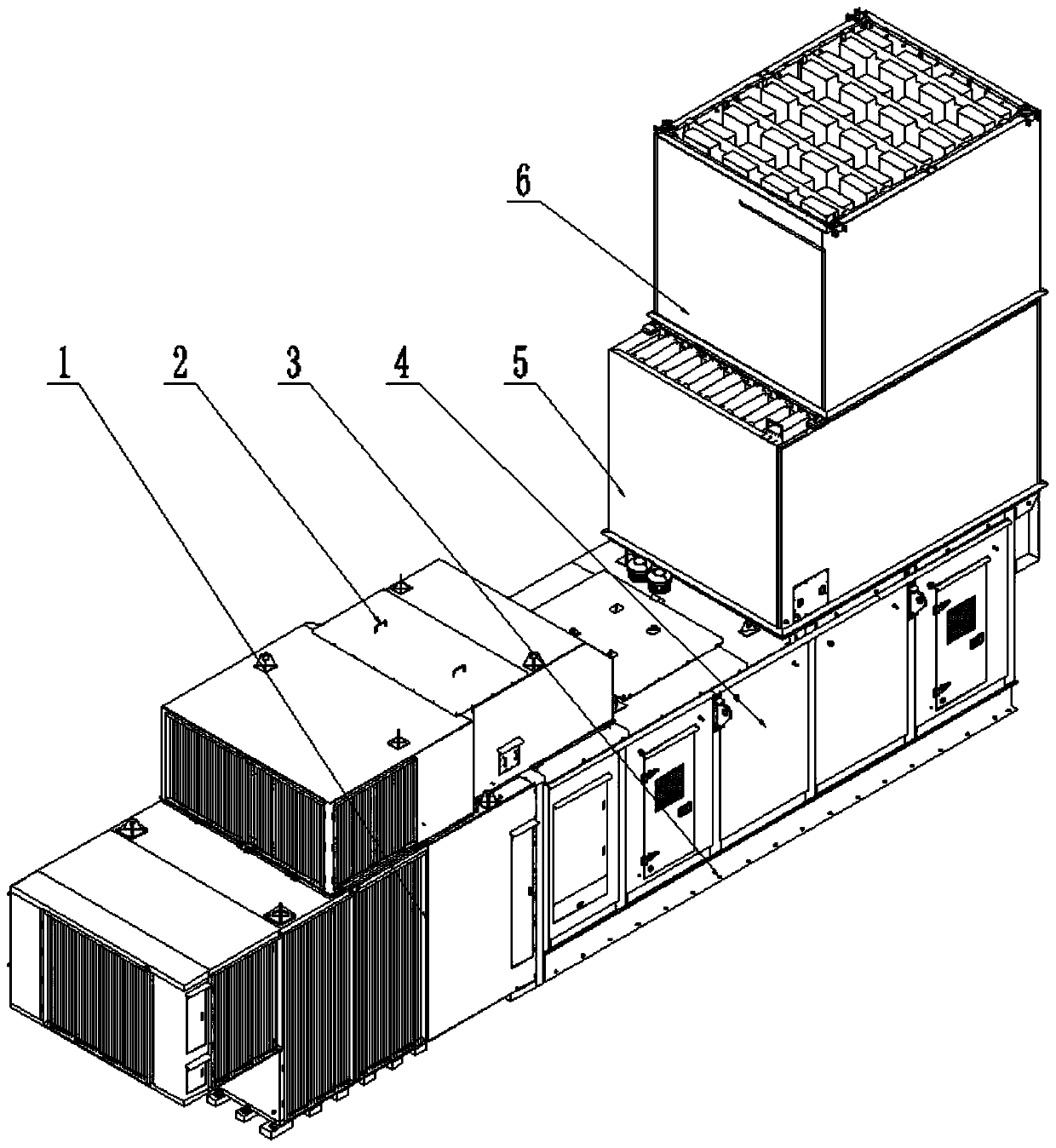

Battery container thermal management system

InactiveCN109066015ASpeed up the flowReduce wind pressureSecondary cellsCell component detailsTemperature controlPower flow

The invention provides a battery container heat management system, comprising a box, an air conditioner, an air duct, a battery rack and a fan, wherein an air outlet gap of the air duct is arranged ata front end of the battery rack for outputting air flow, and a fan is arranged at a back end of the battery rack for extracting air flow. The whole heat management system adopts the circulation modeof front air outlet and back air return, the air flow is uniform, the required air pressure is small, the energy is saved, waterproof and dustproof effects are achieved, the temperature control effectis good, and the high rate current (fast) charging and discharging can be realized.

Owner:深圳市欣旺达能源科技有限公司

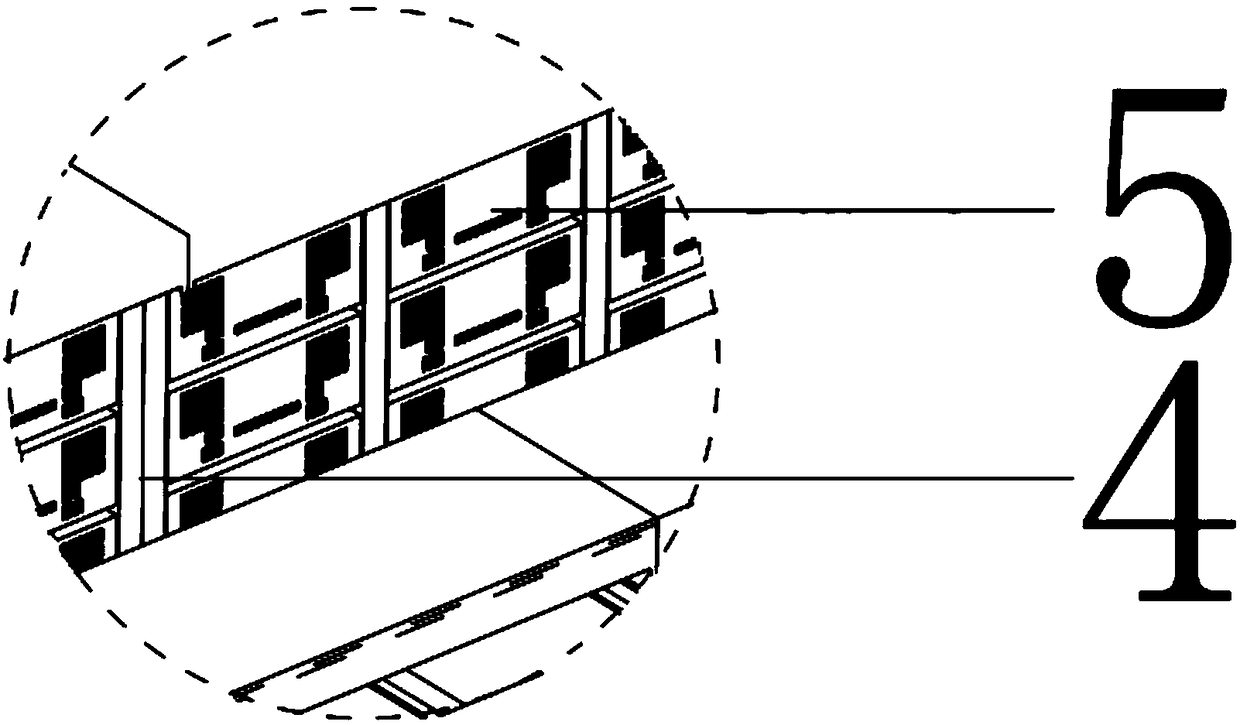

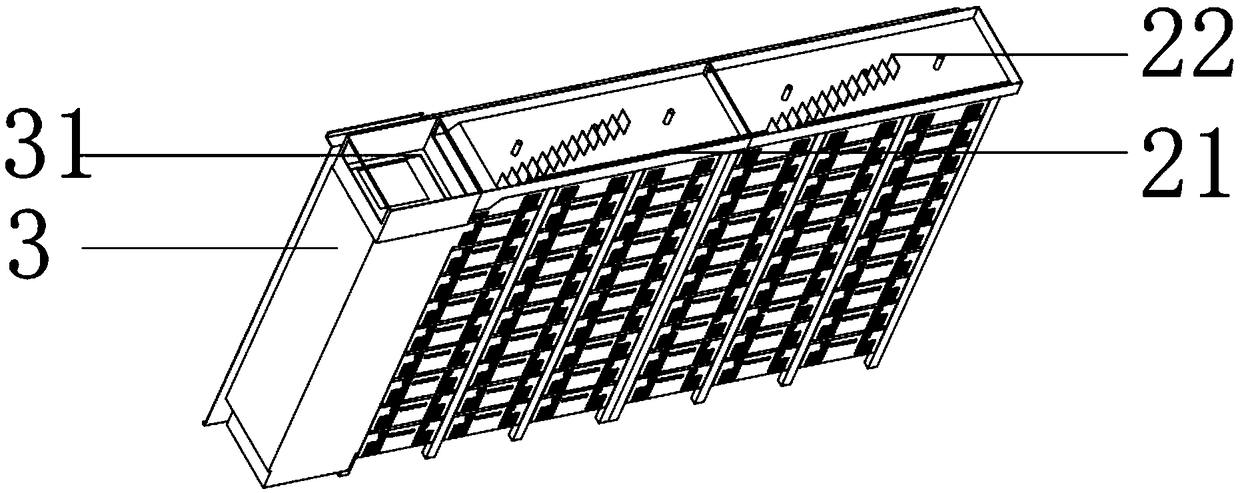

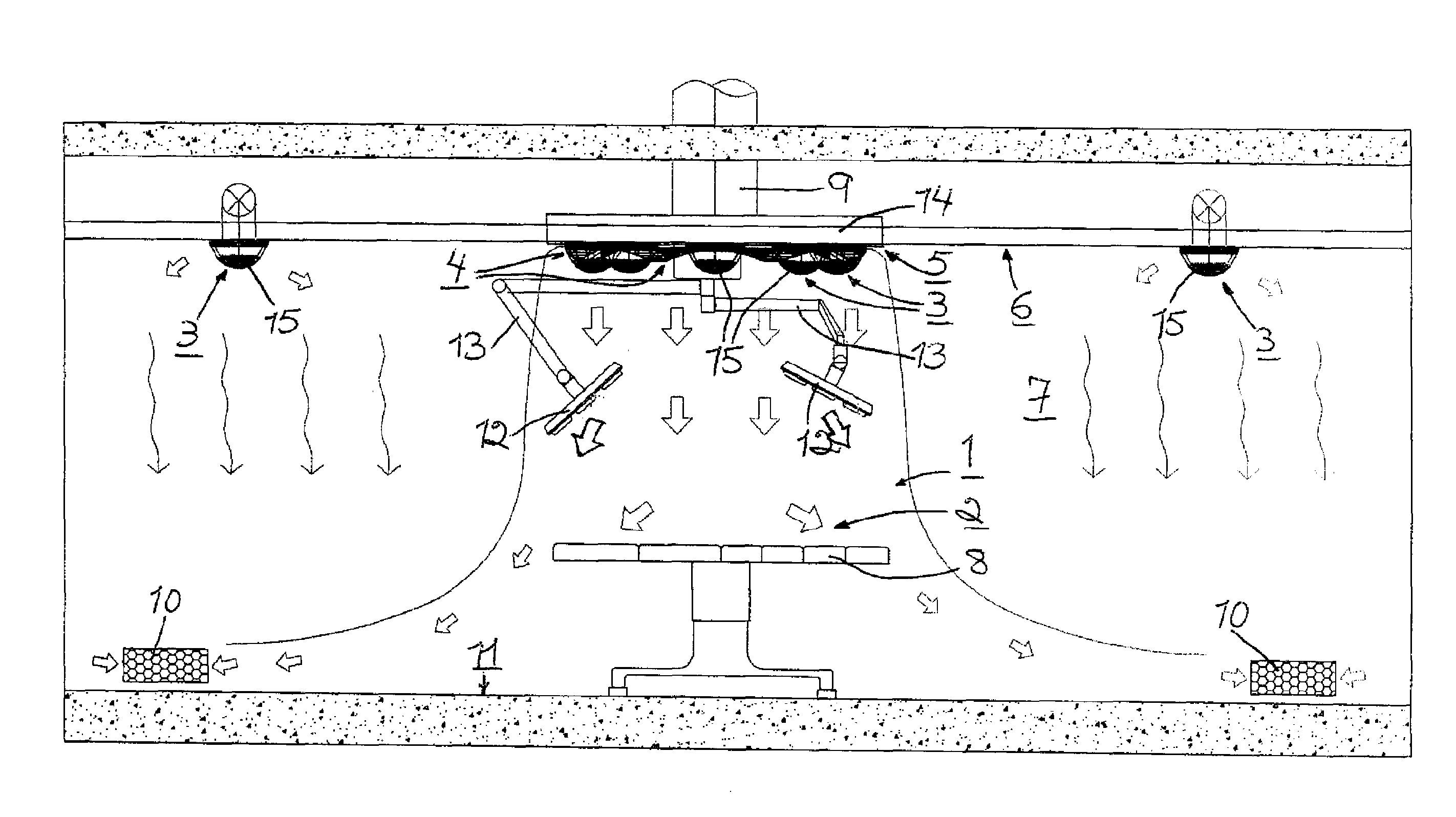

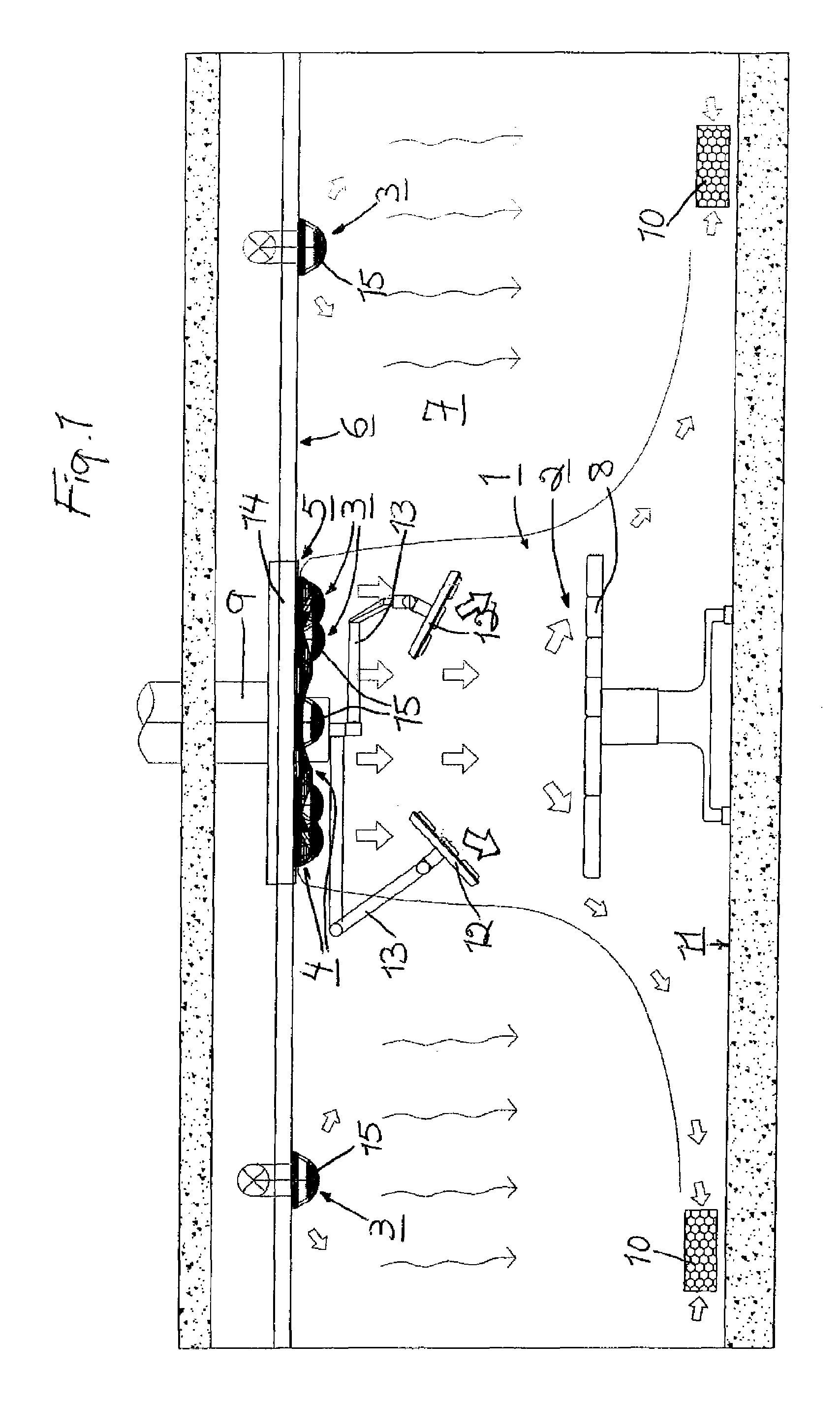

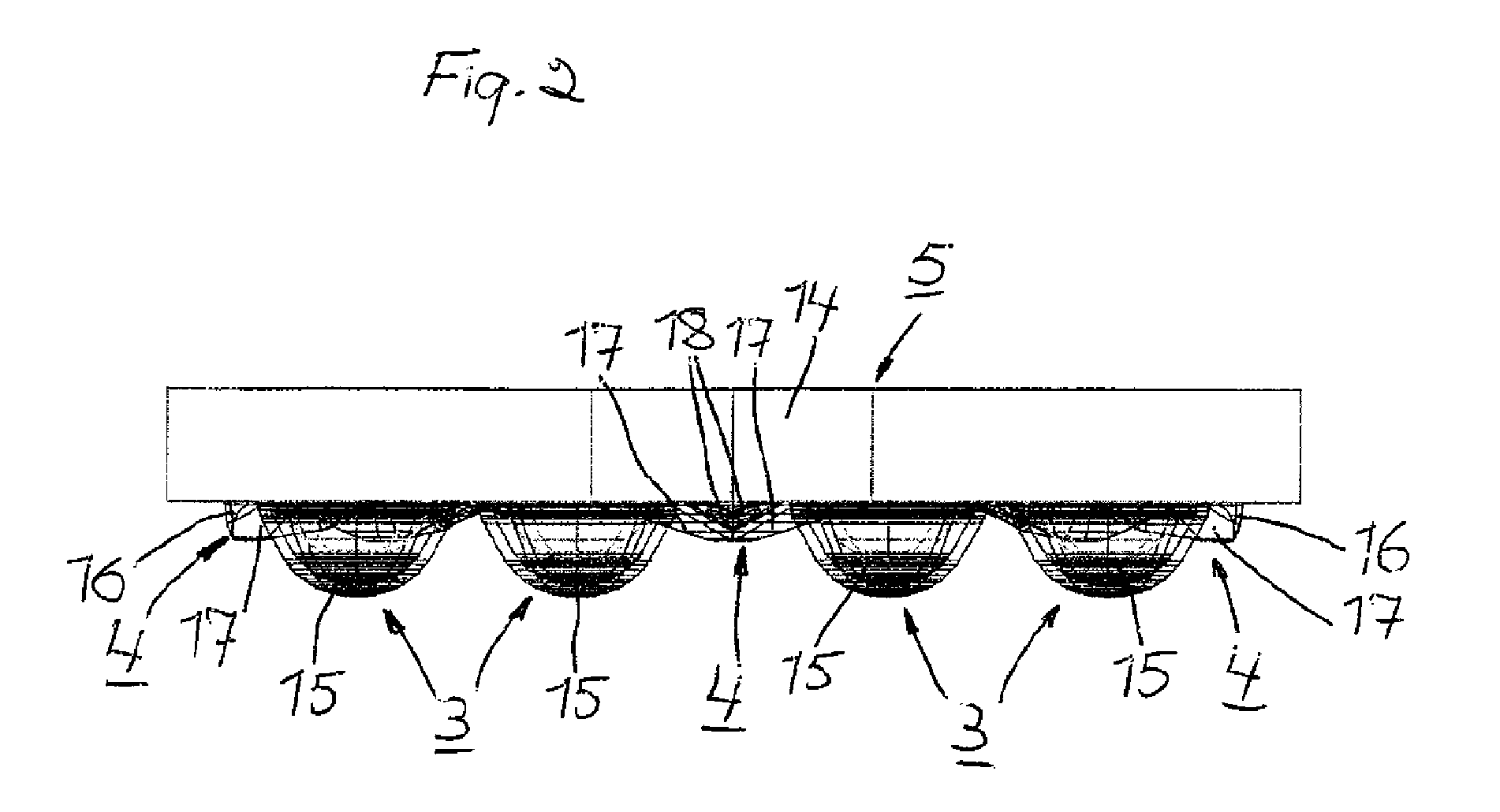

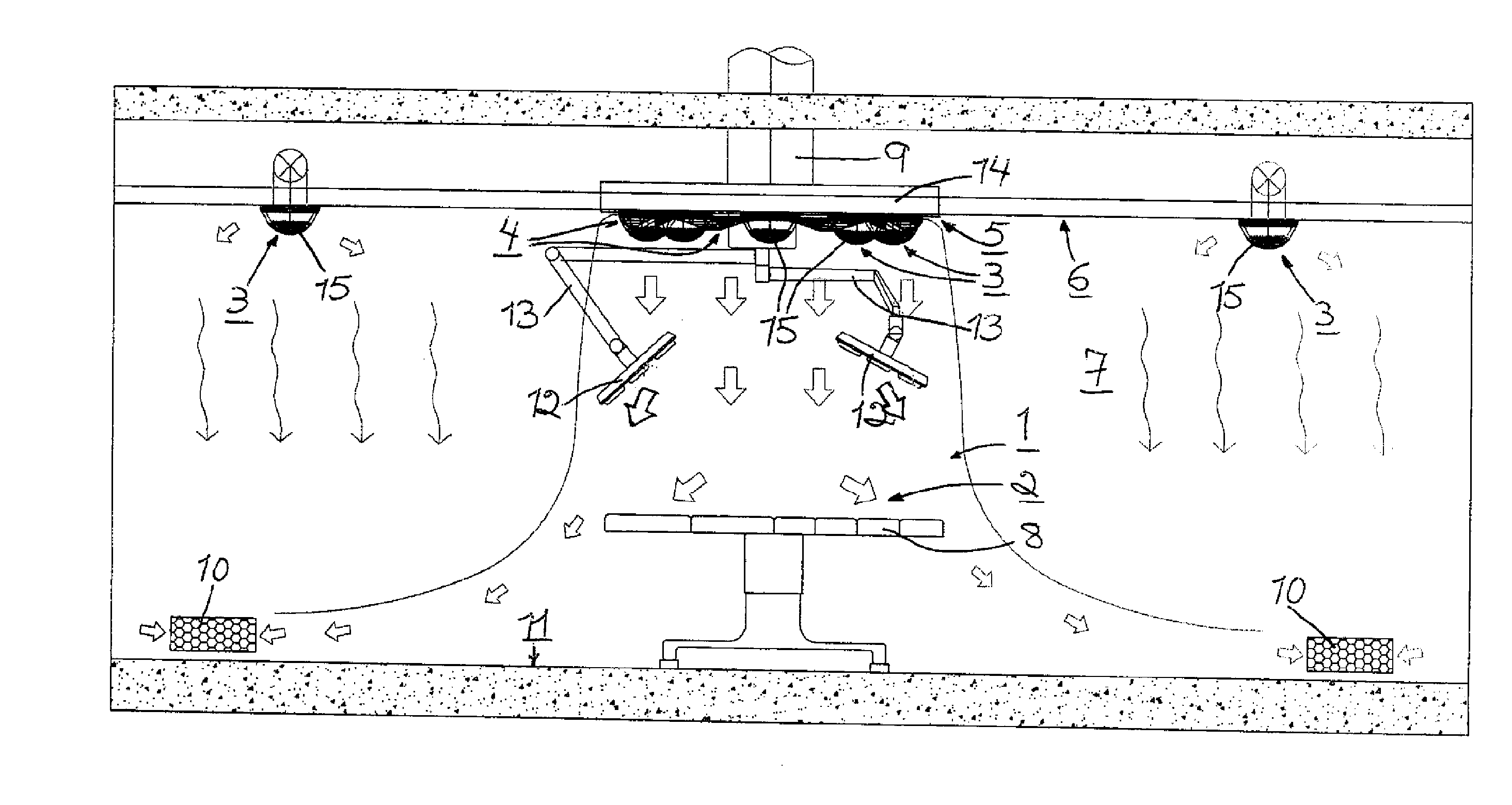

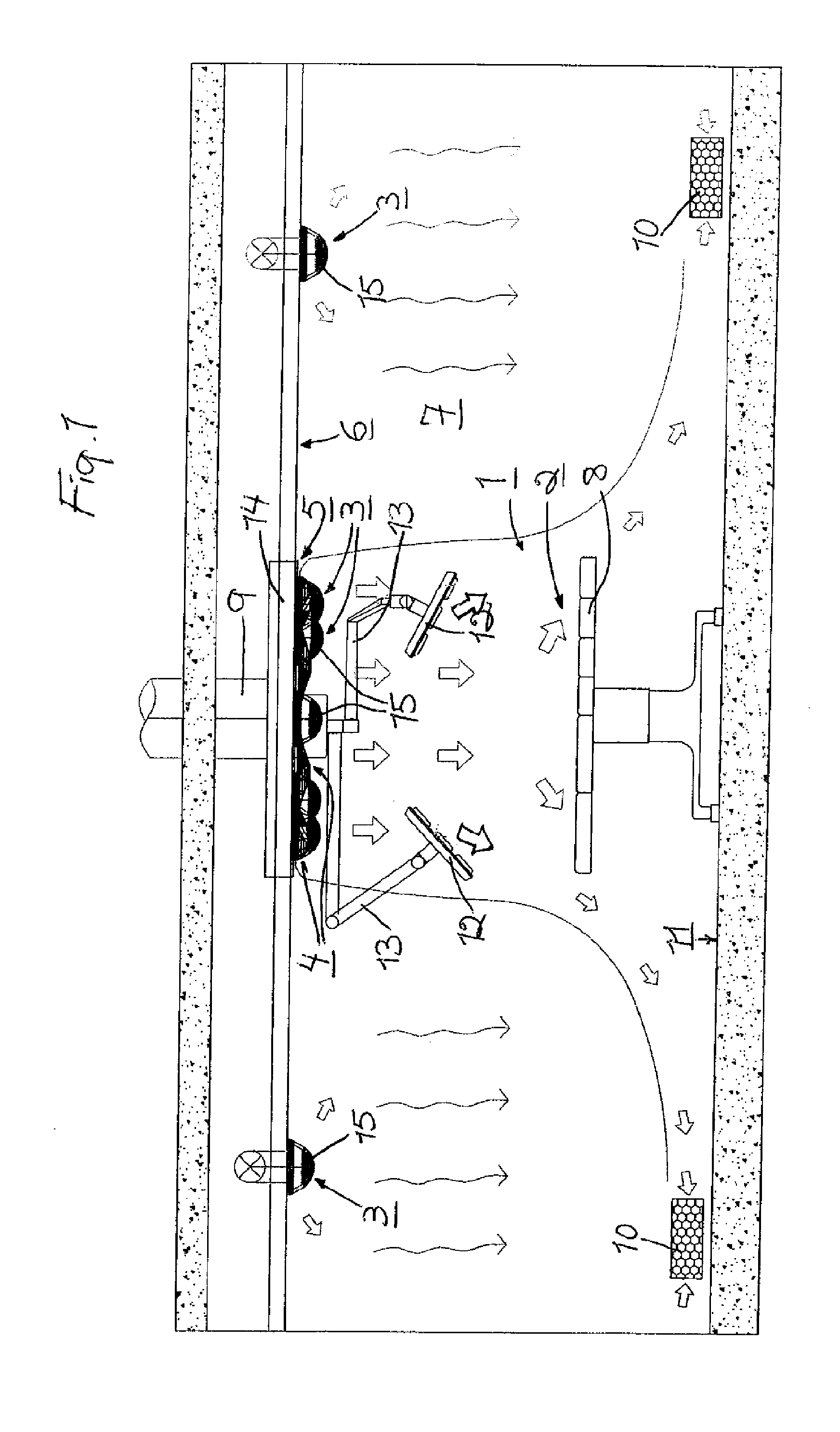

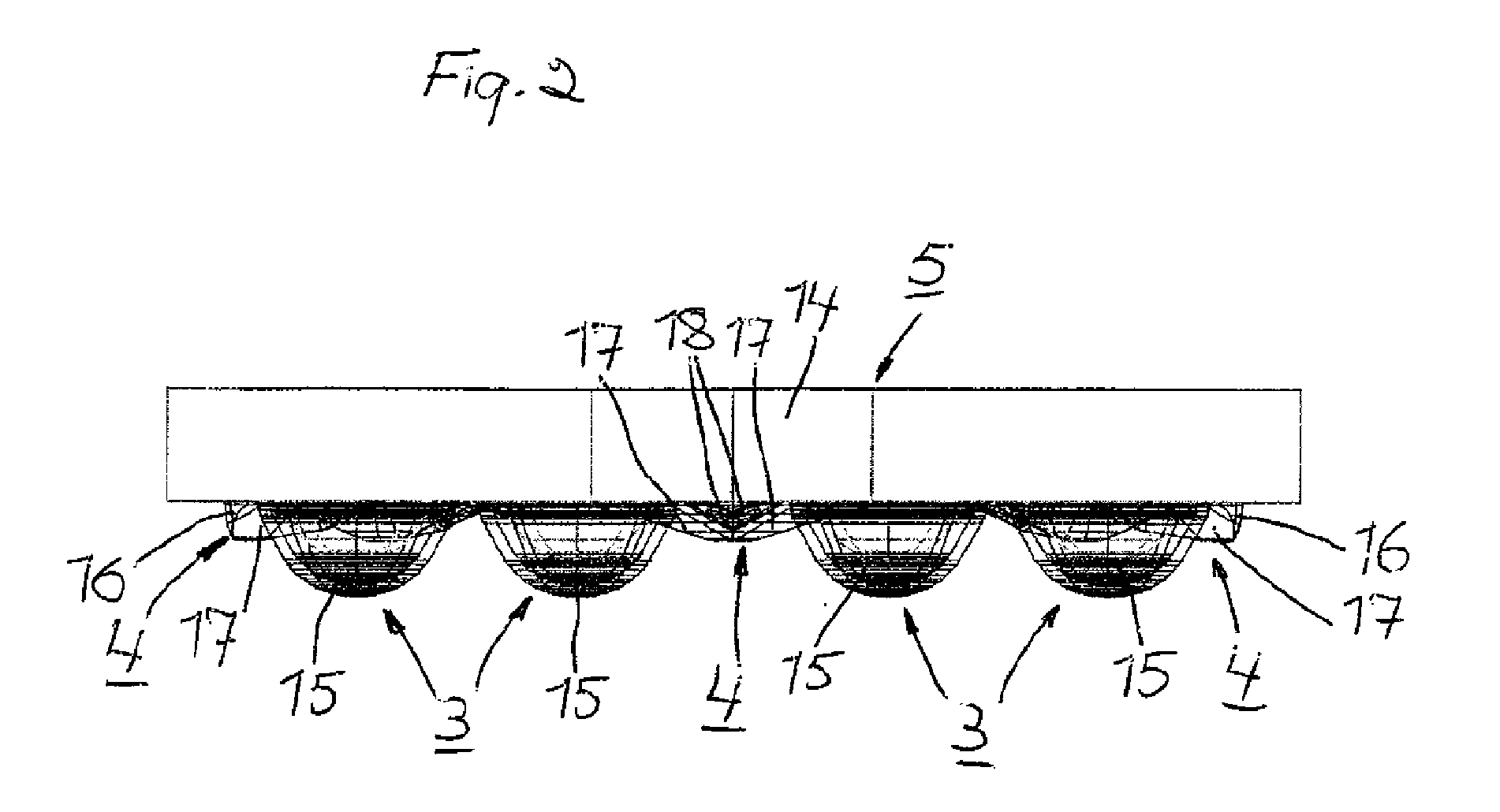

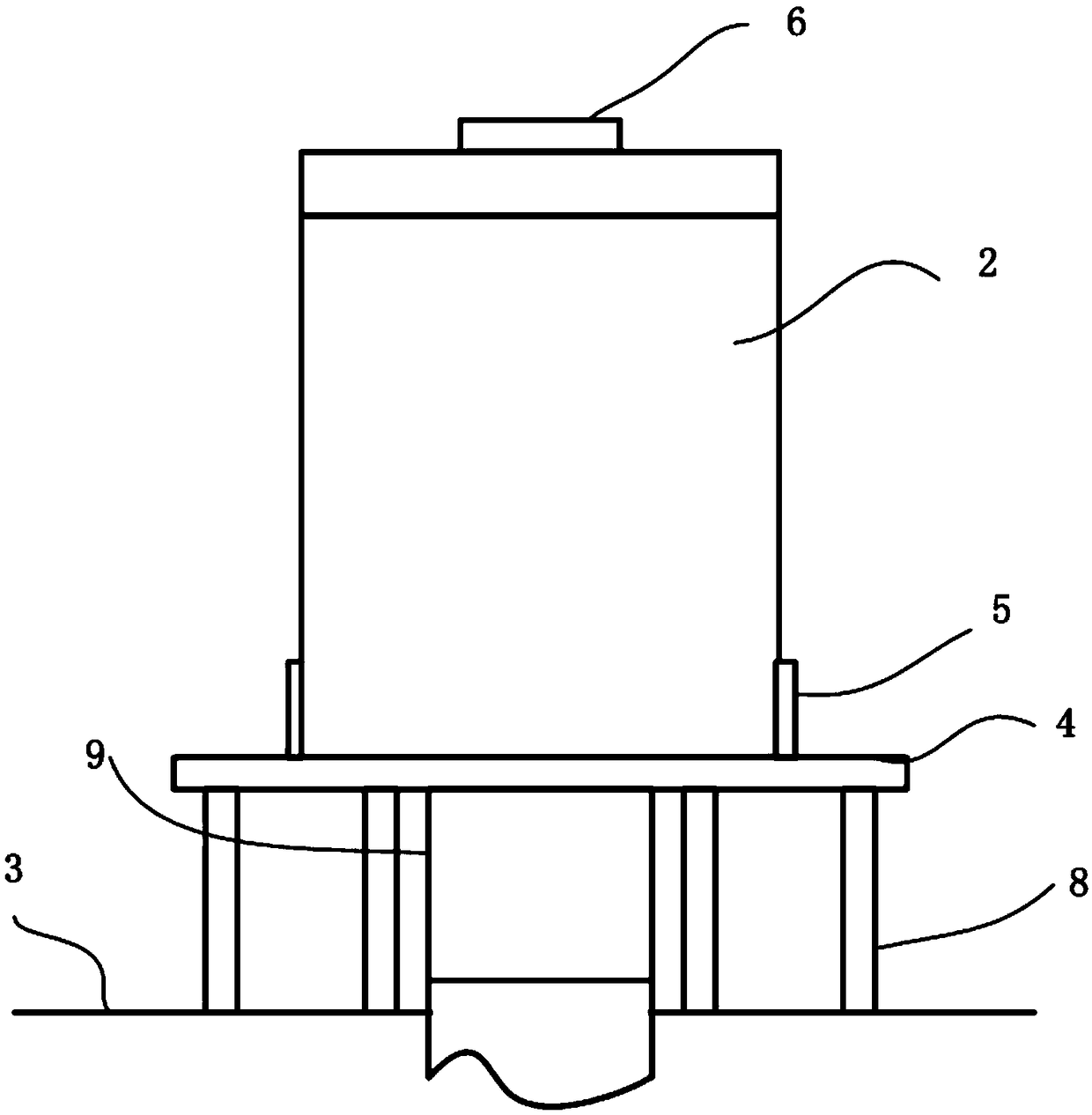

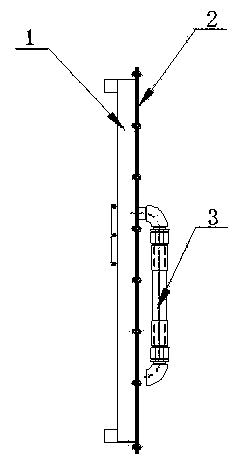

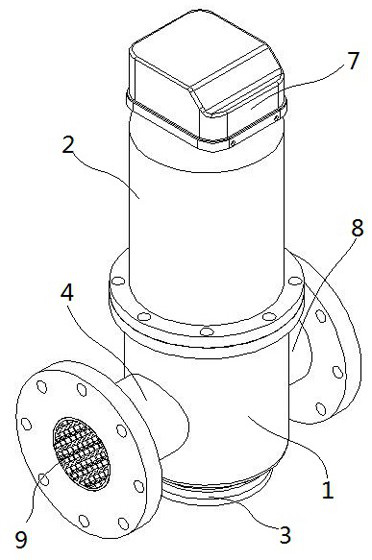

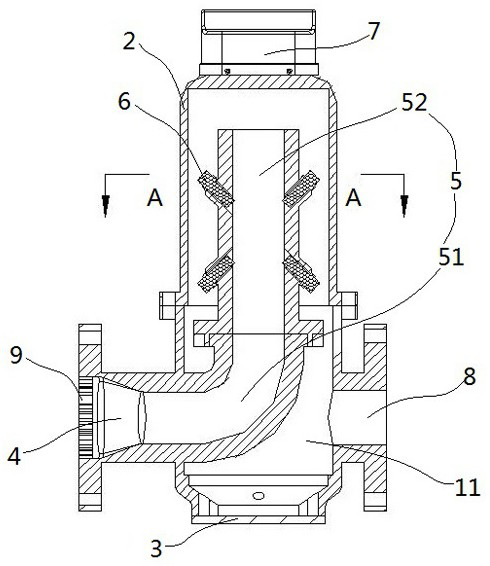

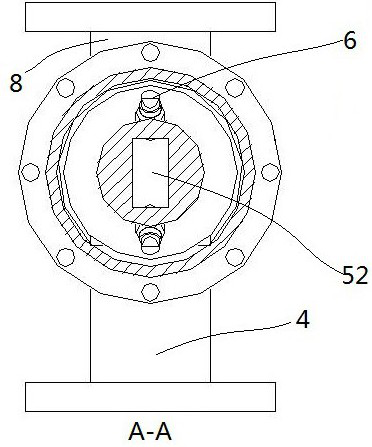

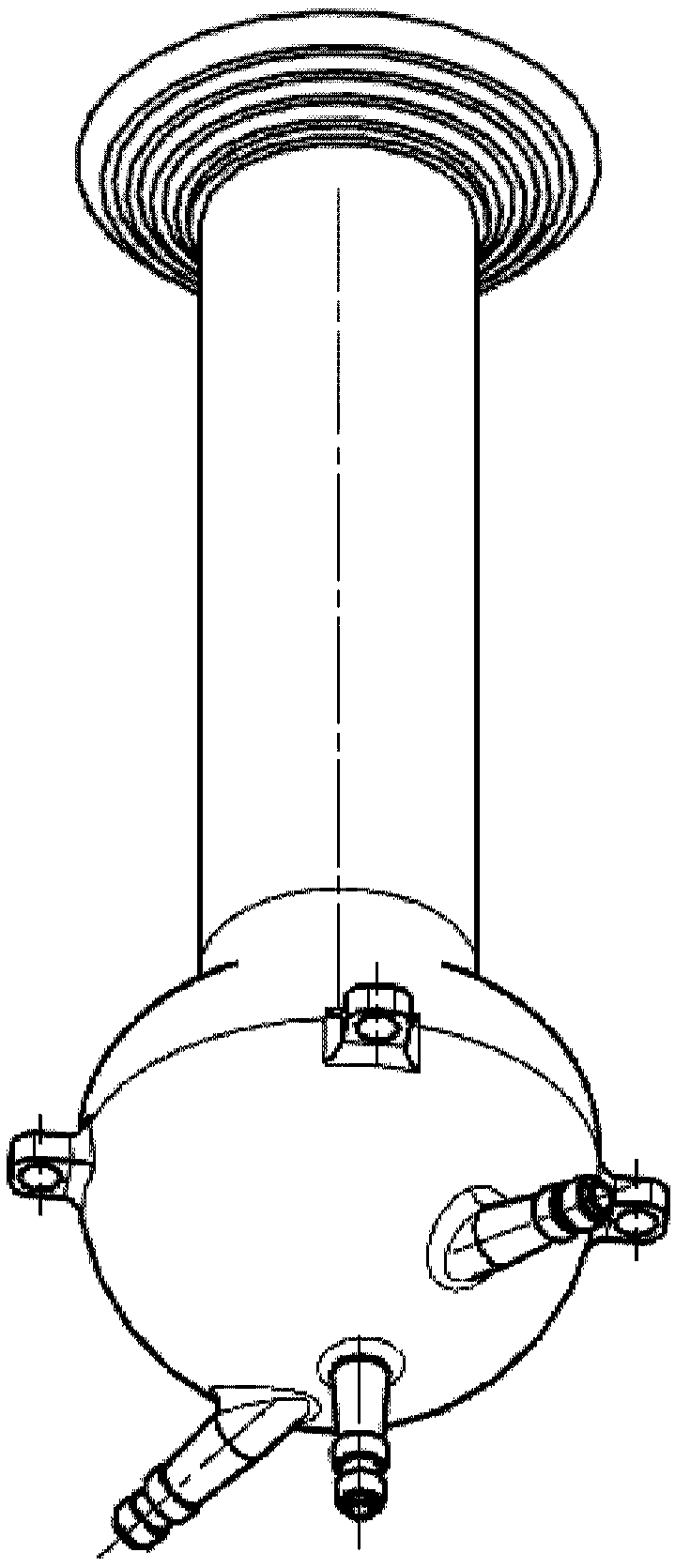

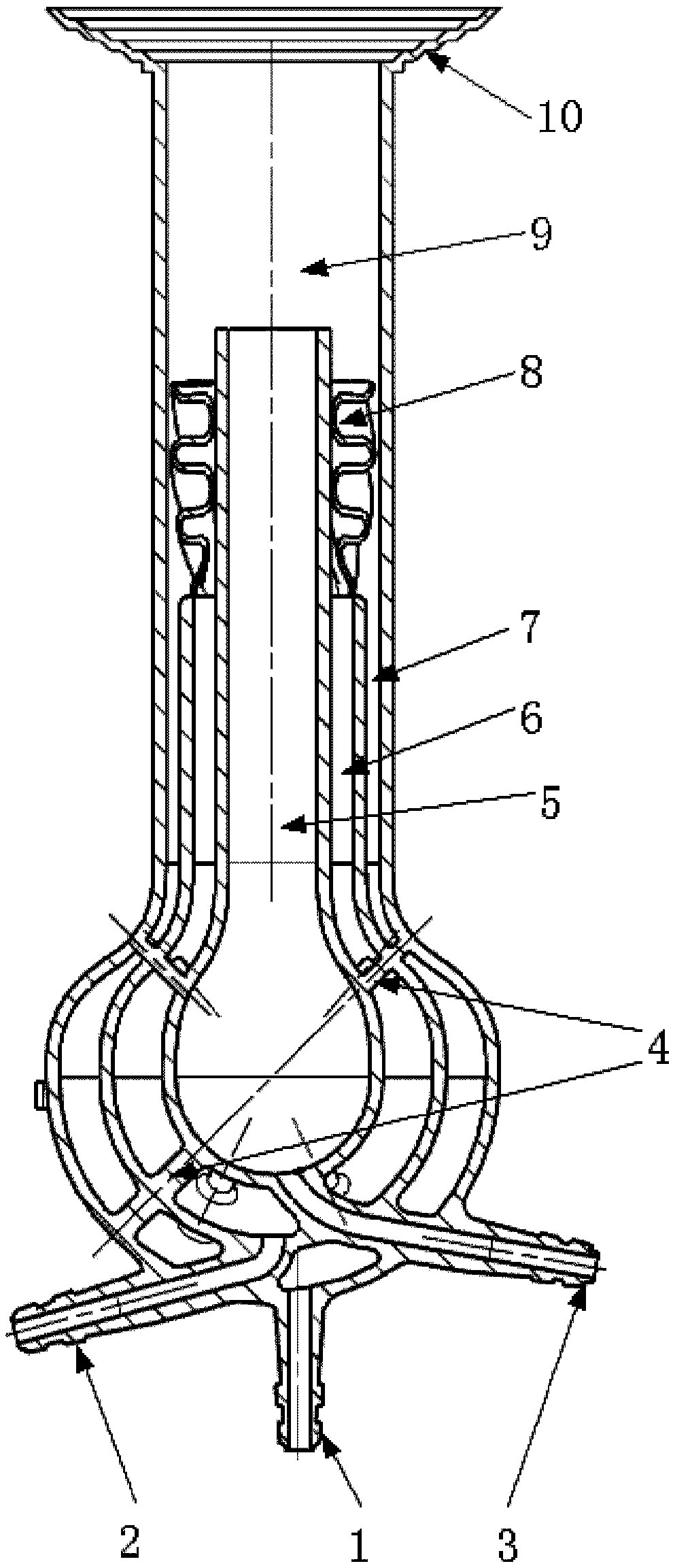

Ventilating device for providing a zone of clean air

ActiveUS8308536B2Uniform and stable airflowIncreased risk of contaminationDucting arrangementsMechanical apparatusClosed patternWaste management

The present invention relates to a ventilating device for providing a zone (1) of clean air between the ventilating device and a workplace region (2), which ventilating device comprises air supply units (3) adapted to generating laminar air flows intended to constitute said clean air zone. The ventilating device comprises at least three air supply units (3) disposed in a closed pattern and air stop and guide units (4) which prevent or hinder air with bacteria-bearing and other pollutant particles which surrounds the clean air zone (1) from being drawn in between the air supply units and into the clean air zone. The air stop and guide units (4) are also configured to guide parts of the air flows from adjoining air supply units (3) outwards from the centre of the clean air zone instead of towards the air supply units, and other parts of the air flows from adjoining air supply units in towards the centre of the clean air zone instead of towards the air supply units, thereby minimizing the increased downward velocity which occurs when the air flows from mutually adjacent air supply units meet in an uncontrolled manner.

Owner:AVIDICARE

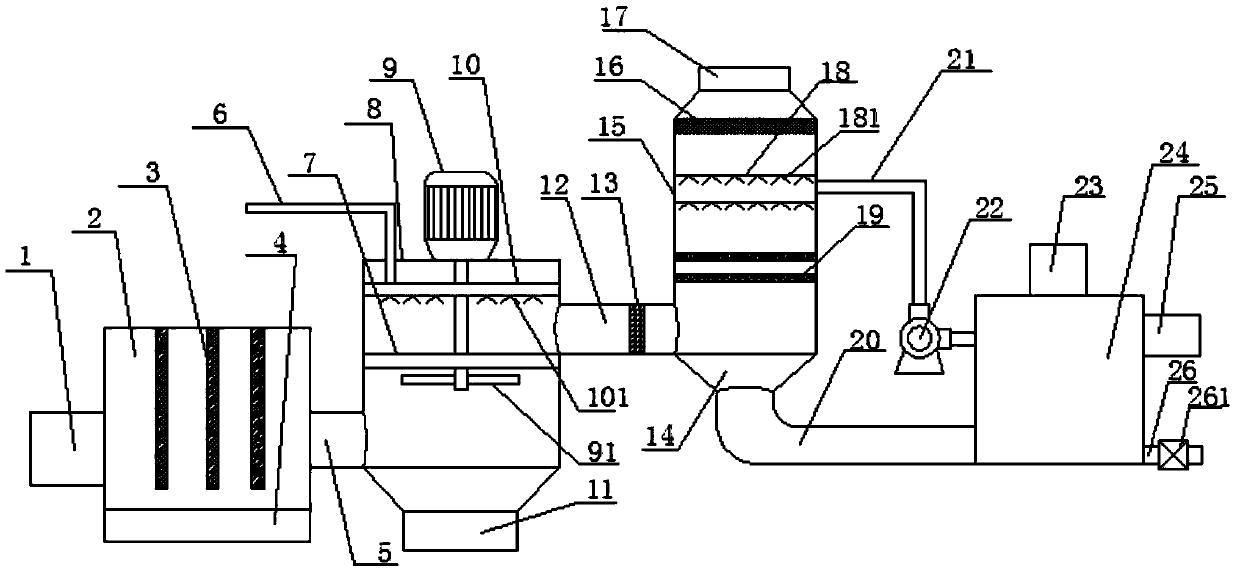

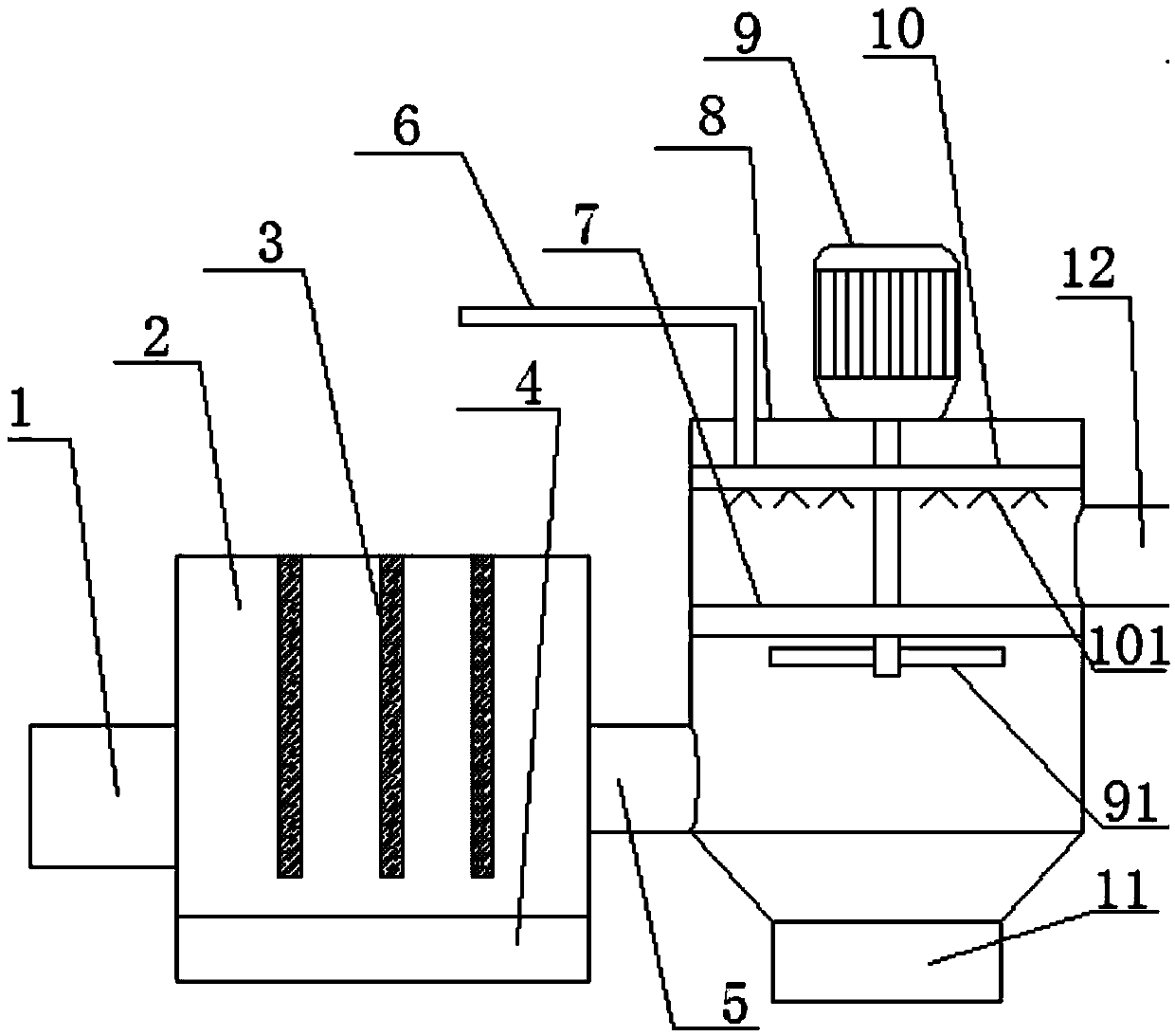

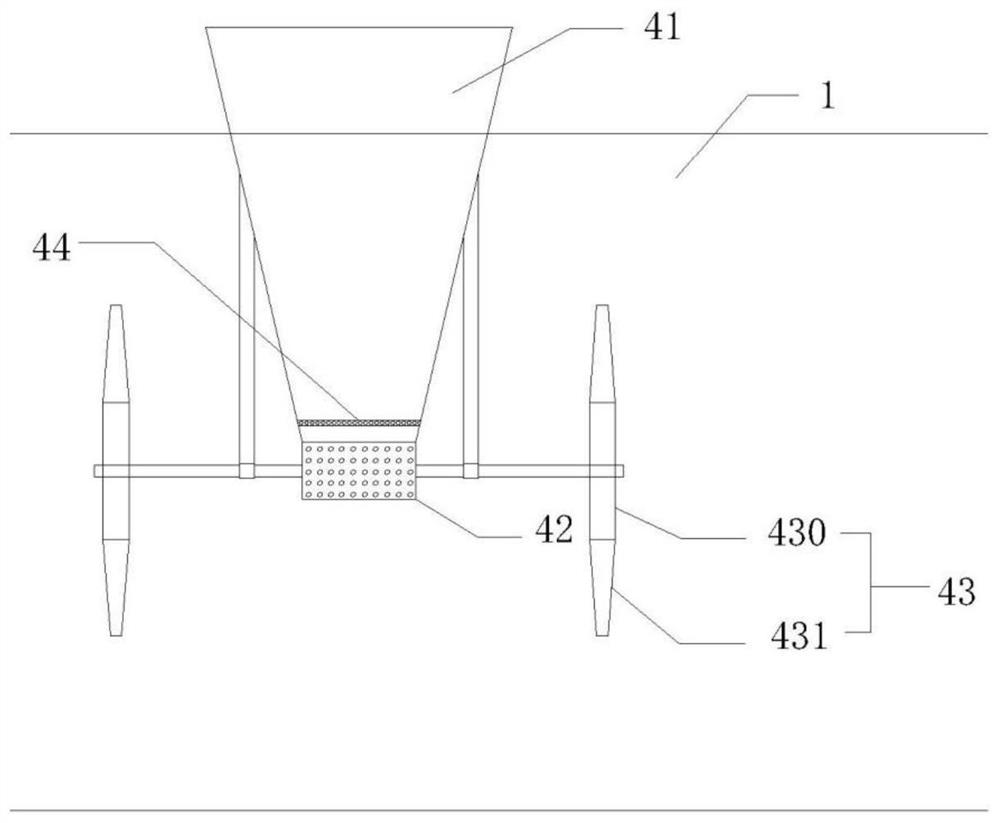

Dedusting and desulfurization integrated machine

InactiveCN104190190AImprove solubilityReduce the chance of foulingCombination devicesFlue gasEngineering

The invention discloses a dedusting and desulfurization integrated machine. The machine comprises an inlet flue, a filter chamber, a dust chamber, a desulfurizing tower, an outlet flue and a circulating pool, wherein the inlet flue is communicated with the filter chamber; the filter chamber is communicated with the dust chamber through a first flue gas passage; the dust chamber is communicated with the desulfurizing tower through a second flue gas passage; a uniformly distributing board is arranged in the second flue gas passage; the outlet flue is formed in the top of the desulfurizing tower; a circulating hole is formed in the bottom of the desulfurizing tower and communicated with the circulating pool through a circulating pipeline; the circulating pool is connected with a circulating pump; and the circulating pump is connected with the desulfurizing tower through a liquid inlet pipe. The machine disclosed by the invention has the advantages that the dedusting and the desulfurization can be integrally completed; the dedusting effect is good; a bag dedusting method is not adopted, so that the operating cost is saved; the flue gas is stable and uniform; the desulphurization efficiency is high; scale cannot be easily formed in the desulfurizing tower and the pipeline; the machine is simple and convenient to operate; and the system can be stably operated in a long term.

Owner:浙江润洁环境科技股份有限公司

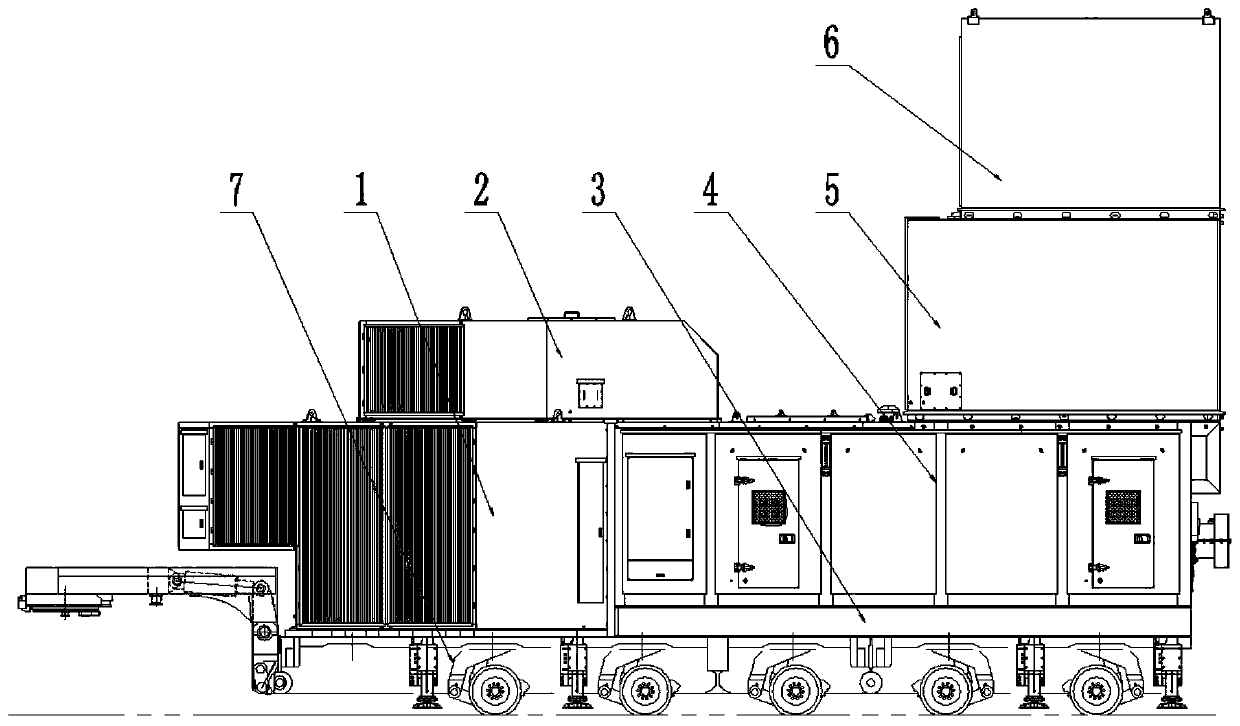

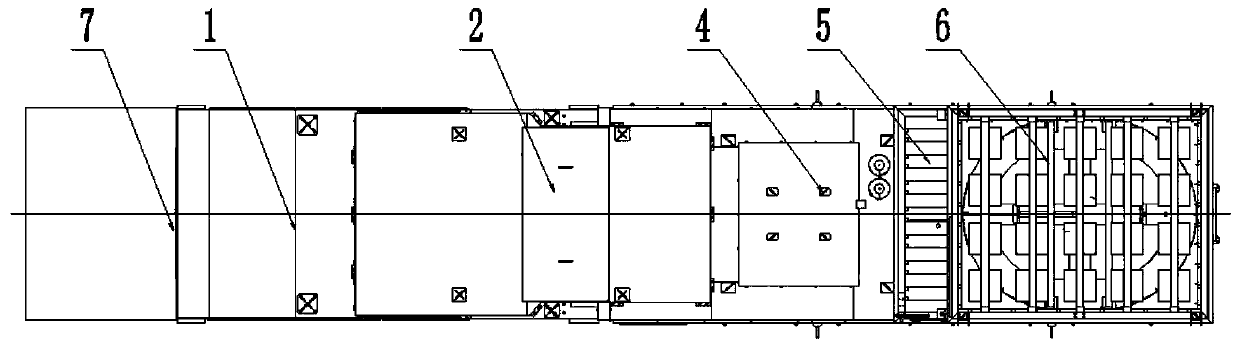

Supporting noise reduction system for combustion gas turbine mobile power station

ActiveCN111550314AEasy to moveImprove the noise reduction effectGas turbine plantsJet propulsion plantsPower stationNoise

The invention discloses a supporting noise reduction system for a combustion gas turbine mobile power station, and relates to the technical field of prevention of noise pollution. The system comprisesa sound insulation box body used for mounting a combustion gas turbine, wherein the bottom of the sound insulation body is fixedly mounted on a suspending body frame through a sound attenuation system underframe, and wheels are mounted at the bottom of the suspending body frame; an inlet gas sound attenuation system is connected to one end of the sound insulation box body, and an intake air soundattenuation system is arranged above the inlet gas sound attenuation system and communicates with a gas inlet of the sound insulation box body; and a first-stage exhaust sound attenuation system is arranged at the top of the other end of the sound insulation box body, a second-stage exhaust sound attenuation system is mounted at the top of the first-stage exhaust sound attenuation system, and thefirst-stage exhaust sound attenuation communicates with an exhaust port of the sound insulation box body. According to the supporting noise reduction system for the combustion gas turbine mobile power station, noise produced by the combustion gas turbine during working is reduced, and the working environment is protected.

Owner:HARBIN CHENGLIN TECH

Nozzle for widening tempering margin, nozzle array and combustor

ActiveCN106247408AUniform and stable airflowImprove stability and reliabilityContinuous combustion chamberGaseous fuel burnerAirflowFuel gas

The invention provides a nozzle for widening a tempering margin, a nozzle array and a combustor. A rectifying device of the nozzle can enable currents of fuel gas and air entering the nozzle to become more stable and uniform, so that the tempering caused by hot spots in combustion can be effectively prevented; a step-shaped expansion section of the nozzle can stop propagation of the tempering to the upstream, so that the tempering margin is widened; and as a direct passing way wave structure and a center cone are arranged in an inner-layer cylinder of the nozzle, the combustion efficiency is further improved, the pollutant discharge is reduced, and the combustion state is improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

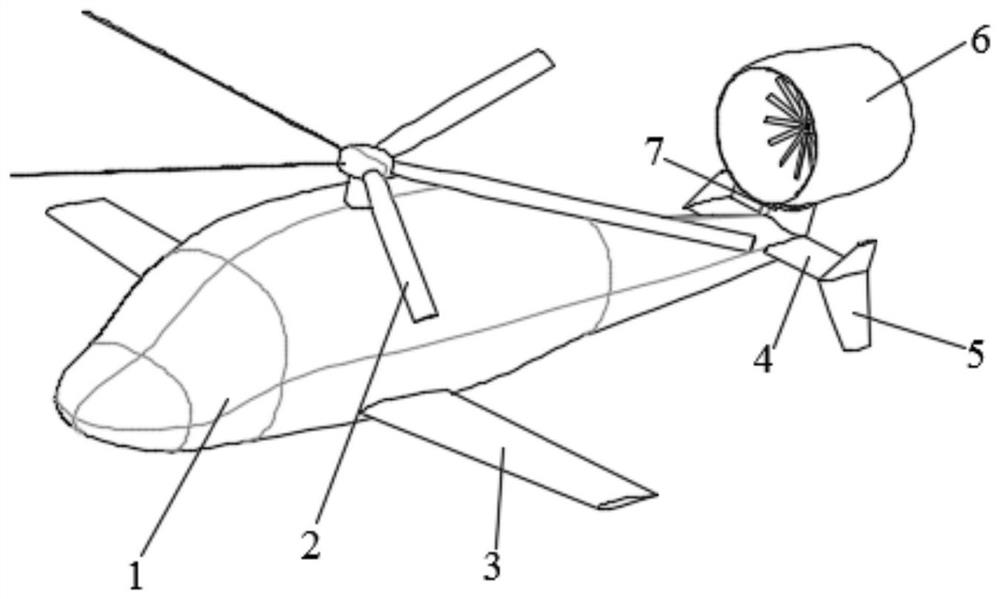

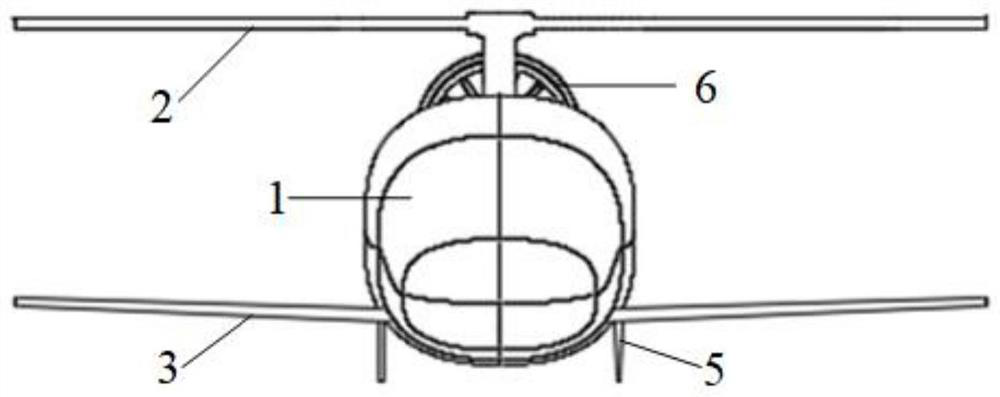

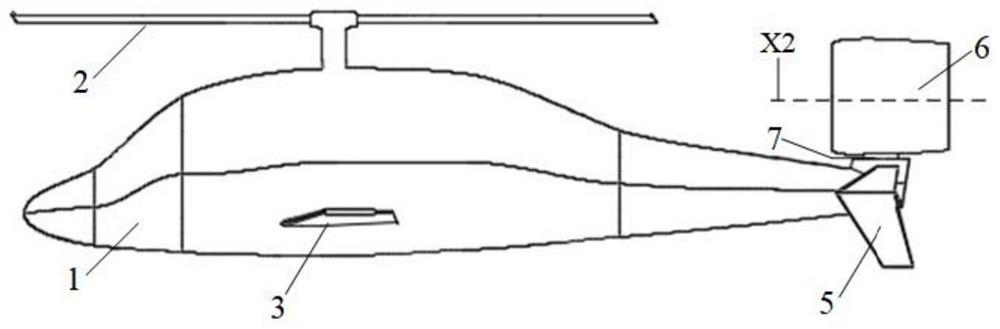

Vector ducted tail rotor high-speed helicopter

PendingCN113022847ARaise forward speed limitForward flight speed limit increasedRotocraftFlight vehicleClassical mechanics

The invention belongs to the field of aerodynamic layout design of aircrafts, and particularly relates to a vector ducted tail rotor high-speed helicopter which comprises a fuselage, a main rotor, lift wings, a horizontal empennage, a vertical empennage and a ducted fan, and an air inlet of the ducted fan faces the fuselage, is rotatably connected with the upper portion of the tail of the fuselage and can horizontally rotate above the tail of the fuselage; when the helicopter flies forwards at a high speed, an angle alpha is formed between the central axis of the ducted fan and the central axis of the fuselage and is larger than or equal to 0 degree and smaller than 90 degrees, and alpha is equal to 90 degrees during hovering and low-speed flying. Vector control of tail thrust is achieved by horizontally rotating the whole ducted fan, the defect of a common ducted tail rotor in control efficiency is overcome, control efficiency and action efficiency are improved, and the flight speed is greatly increased. In addition, the number of control channels of the vector ducted tail rotor system is relatively small, and the operation steps of a pilot are simplified; and as the tail of the ducted fan is not provided with a pneumatic control surface, airflow in a wake flow area is more stable and uniform, and flight is safer.

Owner:BEIHANG UNIV

Biological method-based compound compost odor filtering device and method

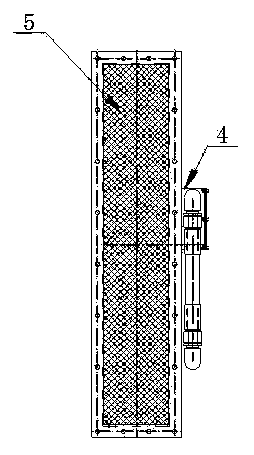

ActiveCN104923066ASimple structureEasy to relateDispersed particle separationAir quality improvementEngineering plasticEngineering

The invention discloses a biological method-based compound compost odor filtering device and method. The biological method-based compound compost odor filtering device is characterized in that odor generated in a vessel composting process is introduced into an odor treatment device with a concrete structure through a water-cooled temperature adjustment device, a draught fan and a one-way valve; a concrete trench allowing gas to be uniformly distributed is formed in the bottom of the device; a concrete cover plate with gas holes is arranged at the upper part of the device; tracks are laid on the cover plate; a drawer-type housing is arranged on the tracks and made of engineering plastic, and gas holes are uniformly distributed in the lower part of the drawer-type housing; the housing is filled with double ball bodies made of engineering plastic uniformly; white-rot fungi are inoculated to the upper half part of an inner ball of the double ball bodies to form a first-stage filtering layer; the odor generated in the composting process enters a second-stage active soil filtering layer after being buffered, adsorbed and partially degraded by the first-stage filtering layer, and finally lawns are planted on the surface of the soil filtering layer. Through the adoption of the two-stage compound compost odor processing device, the problems that pure soil filtering layer particles are likely to block a filtering material, the filtering material on the lower layer is likely to be dry, air flow fluctuates remarkably, and the energy consumption is high are solved.

Owner:ZHEJIANG WANLI UNIV

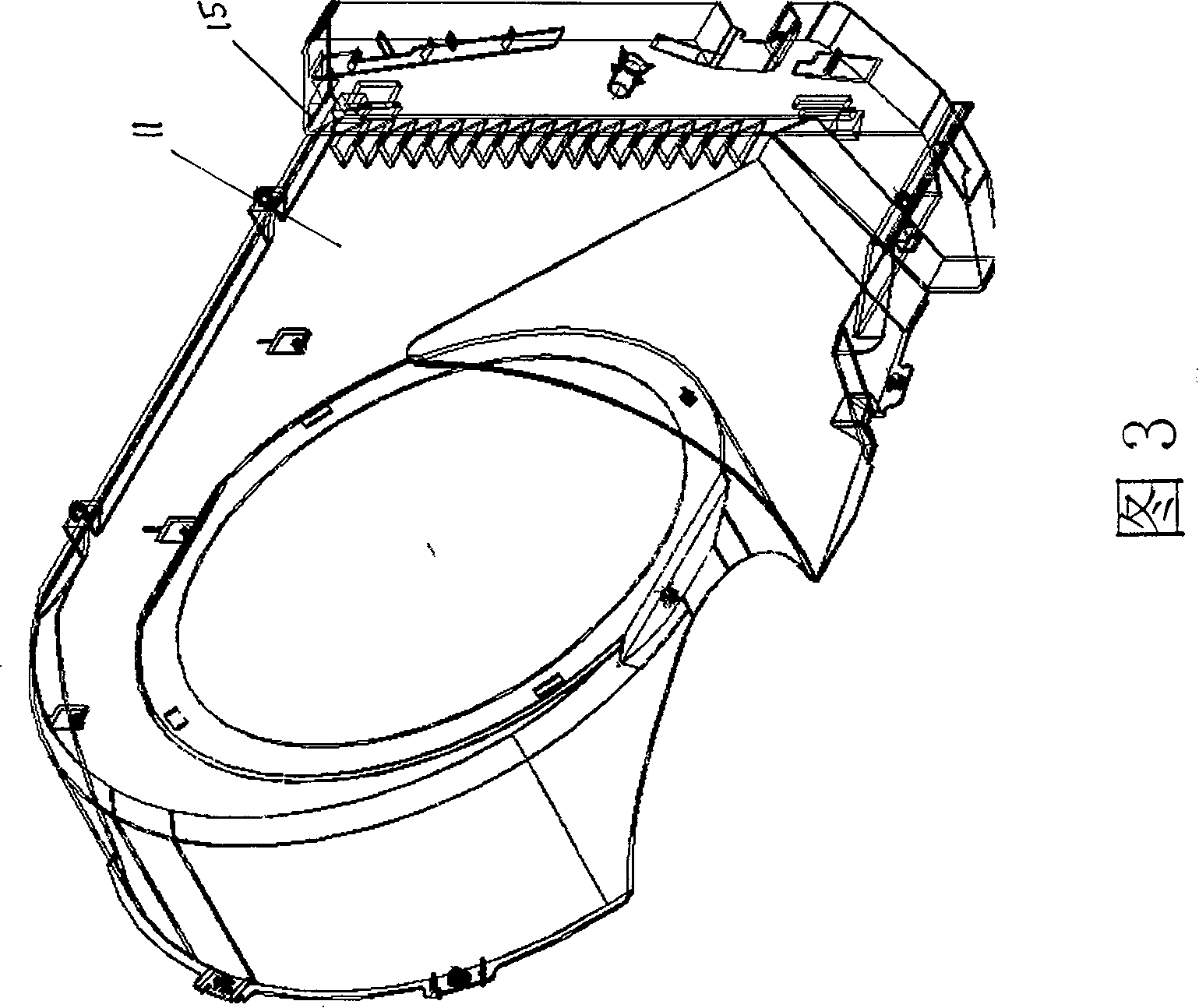

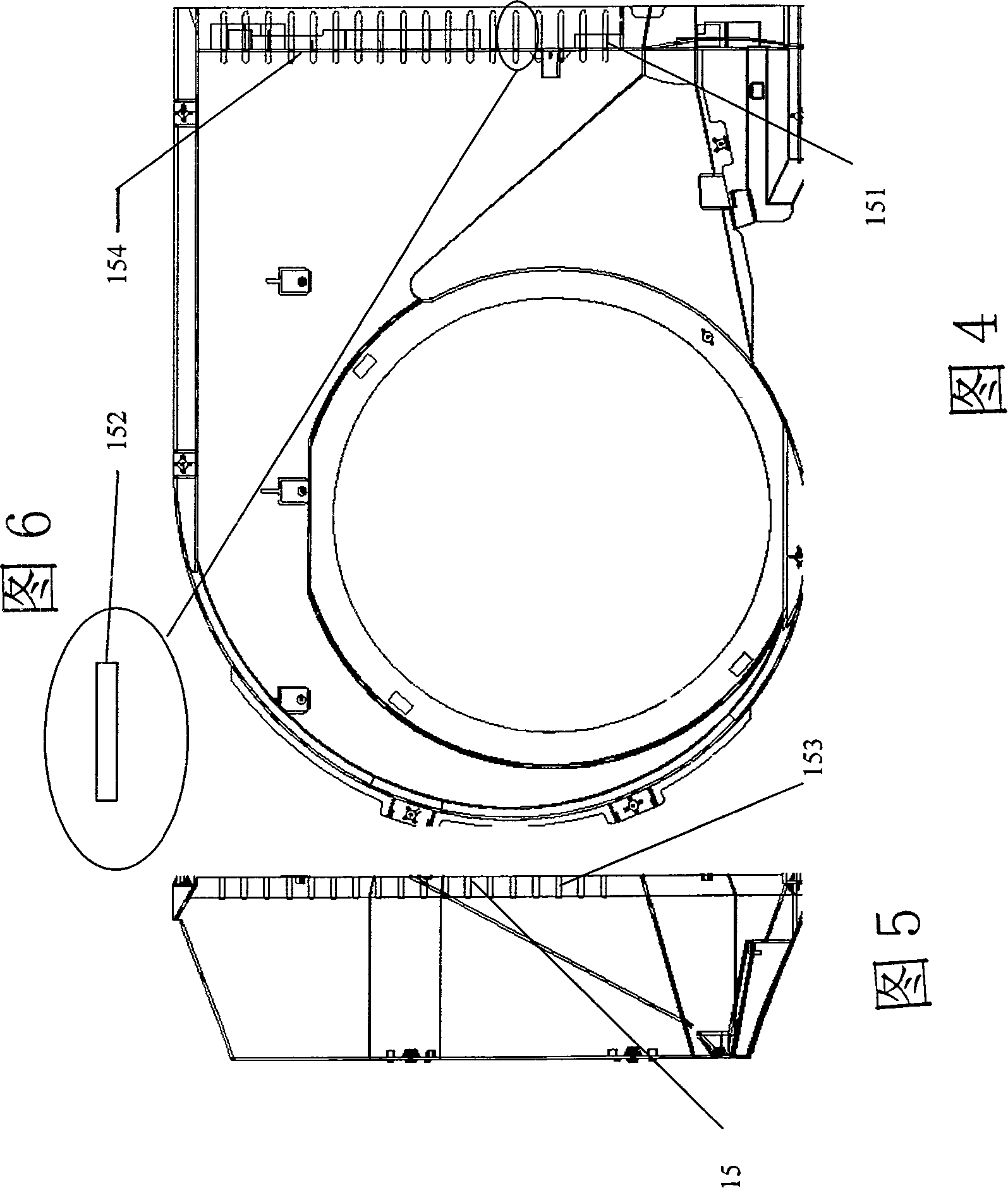

Turbocharger housing structure of cabinet air conditioner

InactiveCN101191656AImprove work performanceUniform and stable airflowHeating and ventilation casings/coversWork performanceTurbocharger

The present invention provides an indoor unit turbine housing structure of cabinet air conditioner. The indoor unit turbine housing structure of cabinet air conditioner comprises a turbine housing body connected with a back cover plate, wherein, a turbine tongue, a spiral curve, a field angle, a fan, as well as a gap between the fan and the turbine tongue are arranged on the turbine housing body. The improvement of the present invention lies in that an outlet of the turbine housing body is alternately provided with flow guiding blades, which improves the airflow channel at the outlet of the turbine housing body, makes the airflow channel at the outlet part more optimized, ensures the uniform and smooth outlet air of airflow, can effectively reduce the vortex flow appearing at the turbine housing outlet part, and is advantageous to the cool-heat exchange of airflow at the part of a heat exchanger. Meanwhile, the present invention decreases noise, improves the working performance of air conditioners, and meet the environmental protection requirements.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

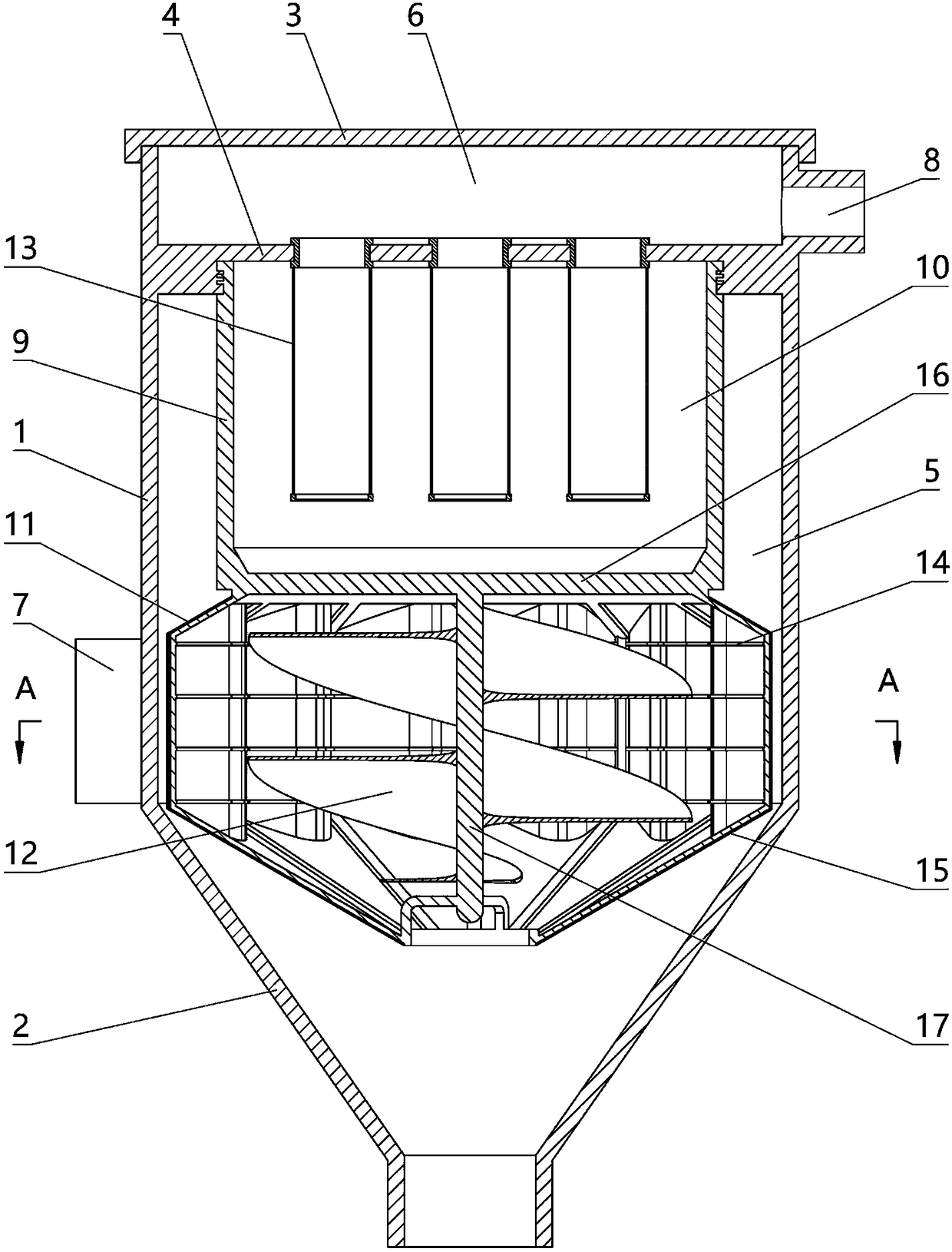

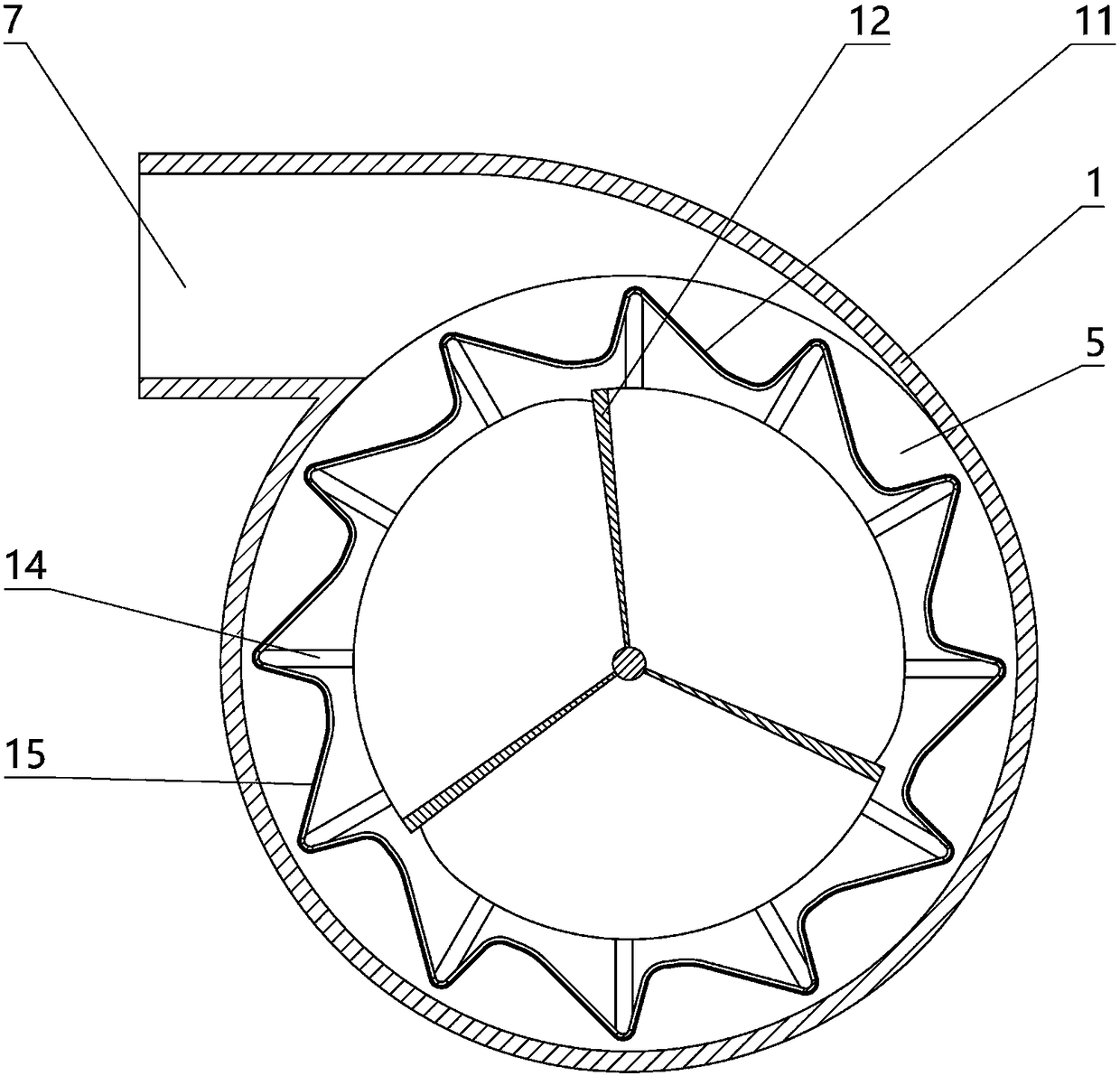

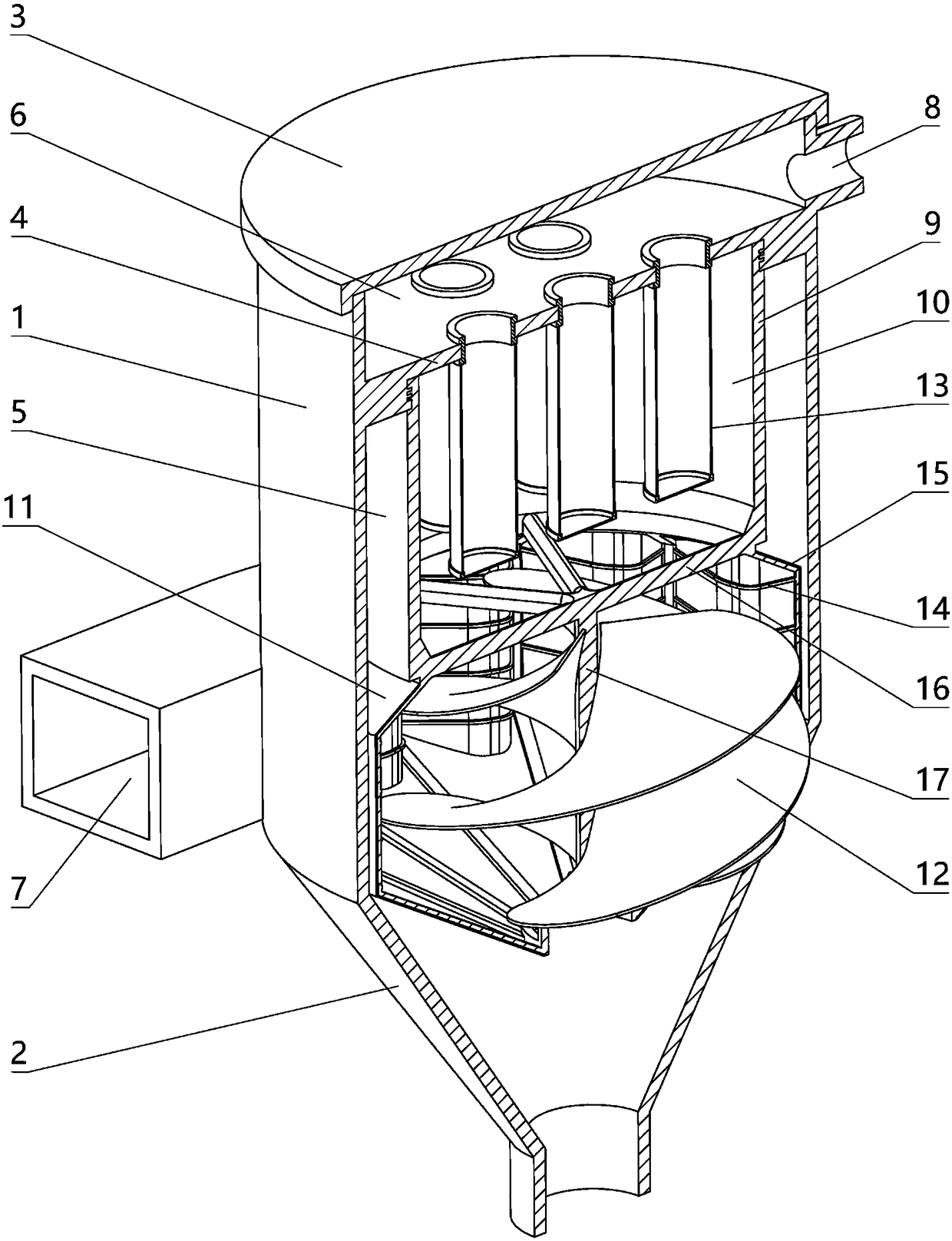

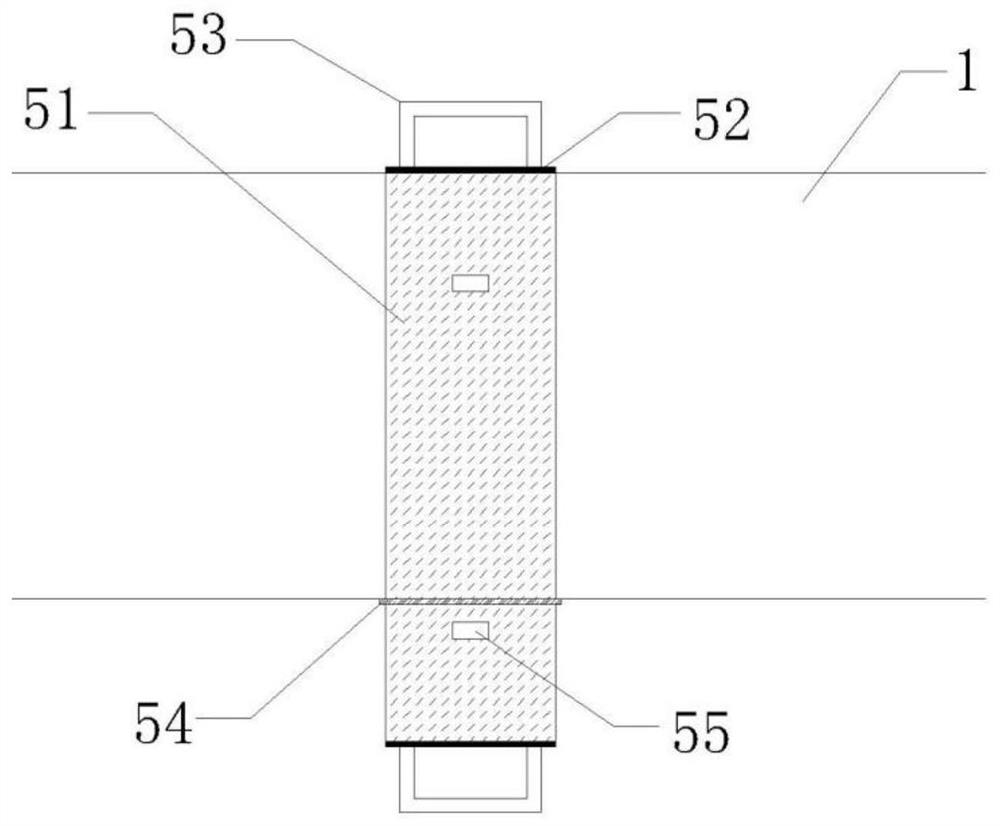

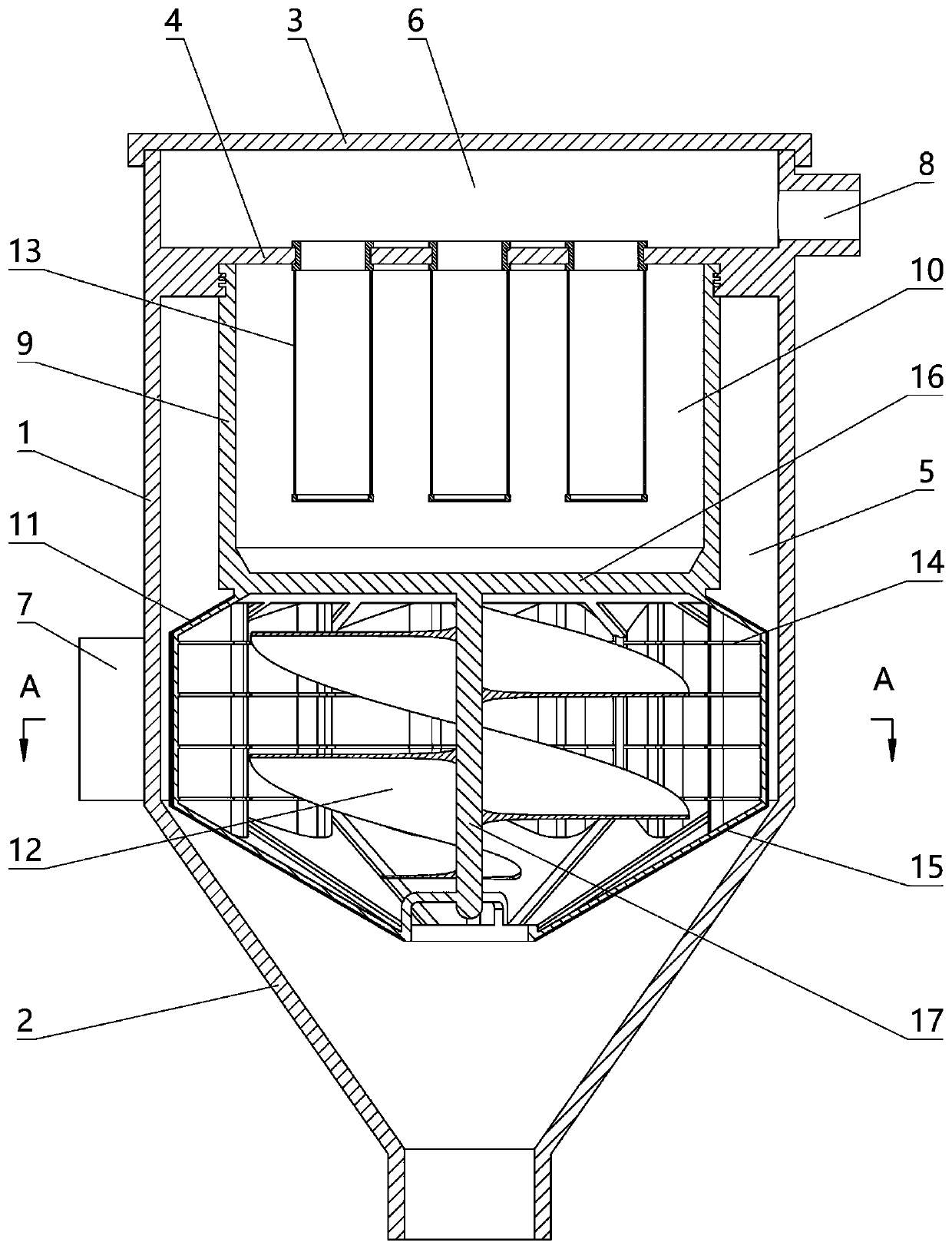

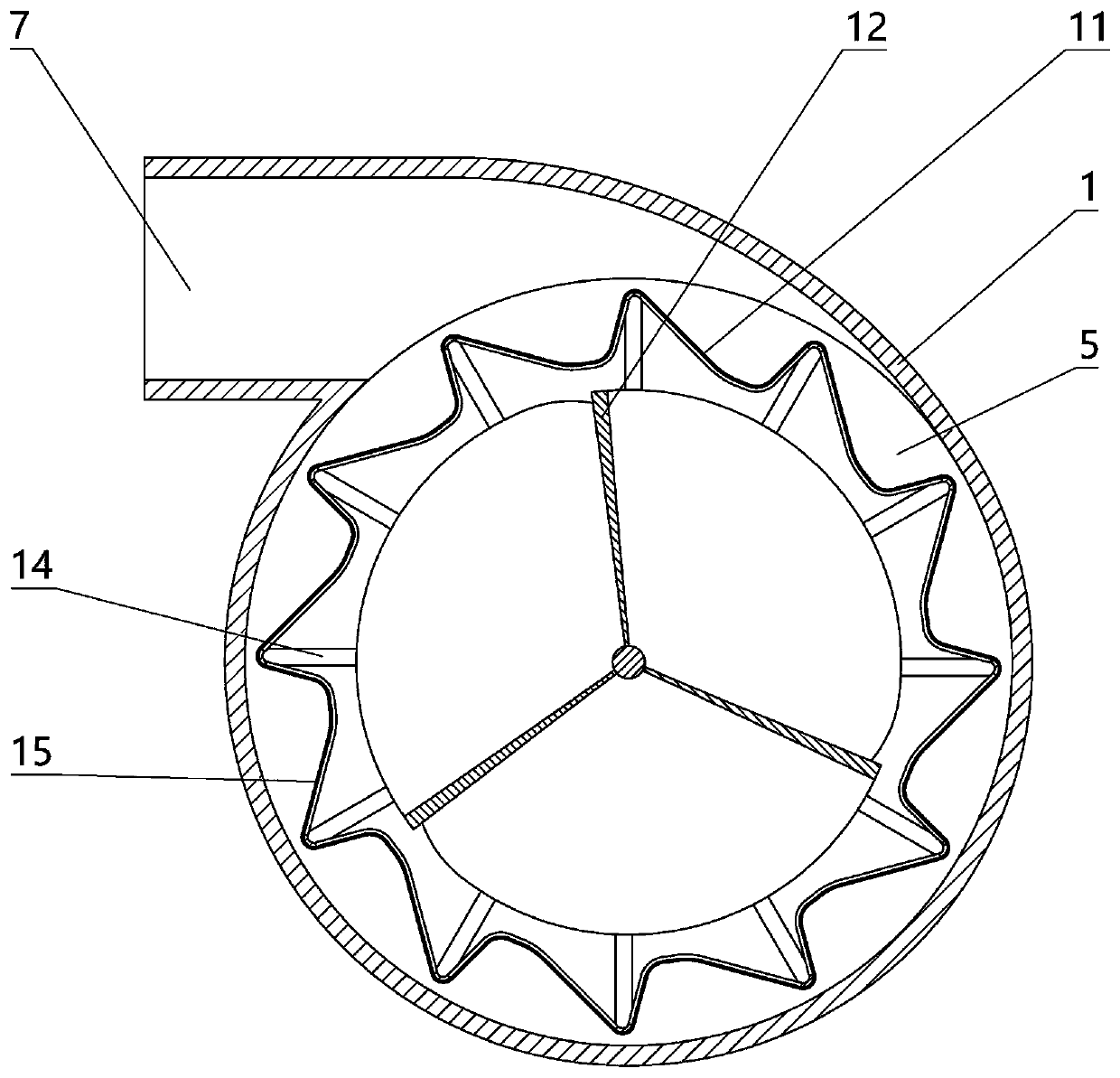

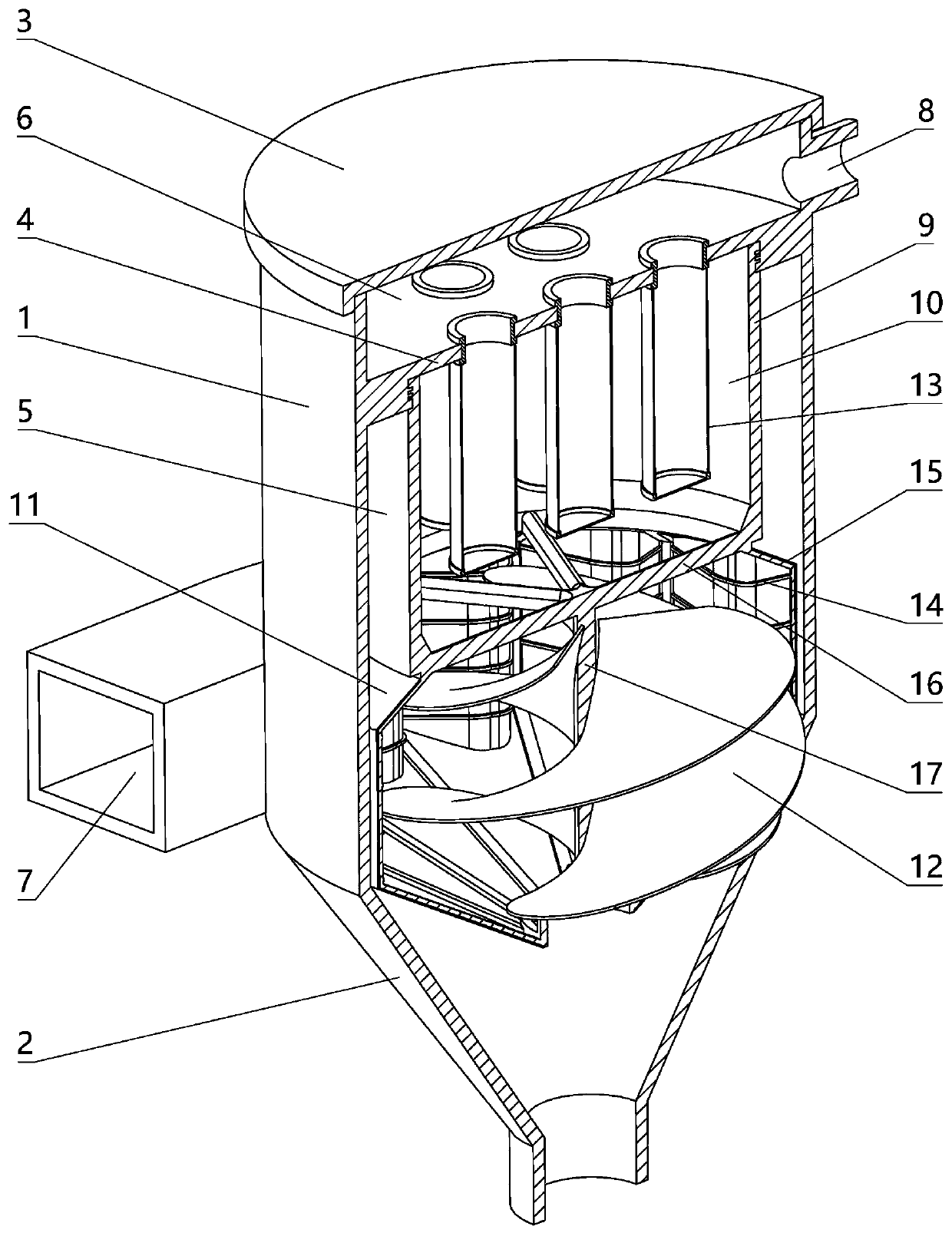

Multistage filtering deduster

ActiveCN108554108AEven and consistent airflowStable pressureCombination devicesPulp and paper industry

The invention relates to a multistage filtering deduster. The multistage filtering deduster comprises a shell, an ash bucket, a cover plate and a horizontally arranged separator plate mounted at the inner side of the shell, the separator plate divides the inner side of the shell into an upper part and a lower part which are not communicated, the ash bucket is mounted below the shell, the cover plate is mounted above the shell, a mixed flow chamber is formed among the shell, the ash bucket and the separator plate, a flow collecting chamber is formed among the shell, the cover plate and the separator plate, the shell is provided with an air inlet communicated with the mixed flow chamber, and the shell is provided with an air outlet communicated with the flow collecting chamber; the separatorplate is provided with an axially-vertically-arranged inner cylinder placed in the mixed flow chamber, the inner cylinder is rotatably connected with the separator plate, and a flow guiding chamber is formed at the inner side of the inner cylinder; the inner cylinder is provided with a special-shaped filter bag with opened top and bottom, placed below the inner cylinder, the vertical position ofthe special-shaped filter bag corresponds to the position of the air inlet, and the inner cylinder is provided with a pressurization fan placed at the inner side of the special-shaped filter bag; andthe separator plate is provided with a plurality of vertically-arranged micro-porous filter bags placed in the flow guiding chamber, and the upper ends of the micro-porous filter bags upwards go through the separator plate and are connected with the separator plate.

Owner:XINYI HONGRUN QUARTZ SILICA POWDER

Ventilating device for providing a zone of clean air.

ActiveUS20100291859A1Uniform and stable airflowIncreased risk of contaminationDucting arrangementsMechanical apparatusClosed patternWaste management

The present invention relates to a ventilating device for providing a zone (1) of clean air between the ventilating device and a workplace region (2), which ventilating device comprises air supply units (3) adapted to generating laminar air flows intended to constitute said clean air zone. The ventilating device comprises at least three air supply units (3) disposed in a closed pattern and air stop and guide units (4) which prevent or hinder air with bacteria-bearing and other pollutant particles which surrounds the clean air zone (1) from being drawn in between the air supply units and into the clean air zone. The air stop and guide units (4) are also configured to guide parts of the air flows from adjoining air supply units (3) outwards from the centre of the clean air zone instead of towards the air supply units, and other parts of the air flows from adjoining air supply units in towards the centre of the clean air zone instead of towards the air supply units, thereby minimizing the increased downward velocity which occurs when the air flows from mutually adjacent air supply units meet in an uncontrolled manner.

Owner:AVIDICARE

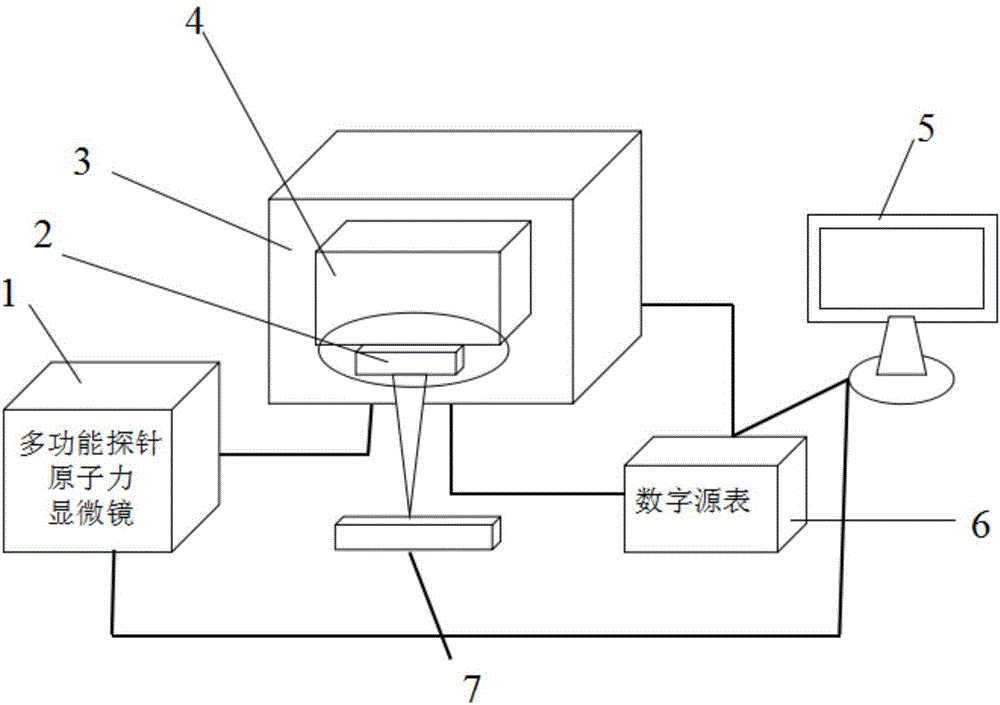

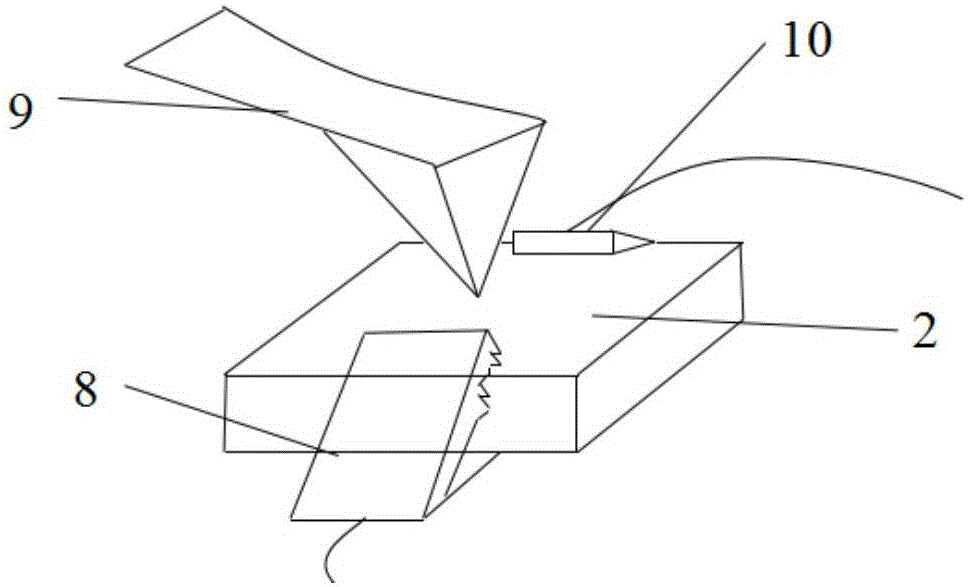

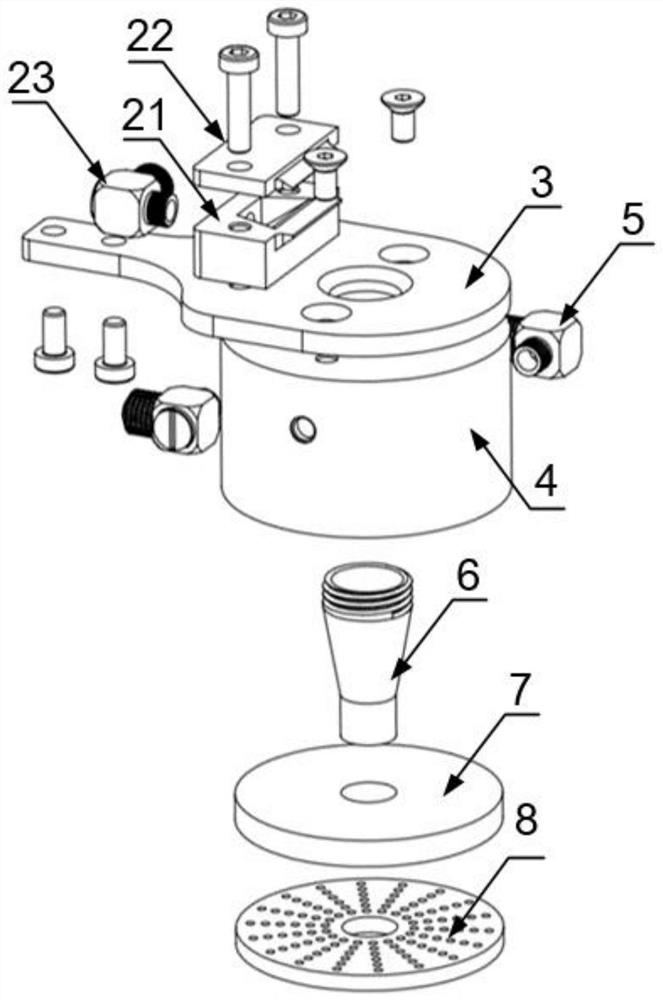

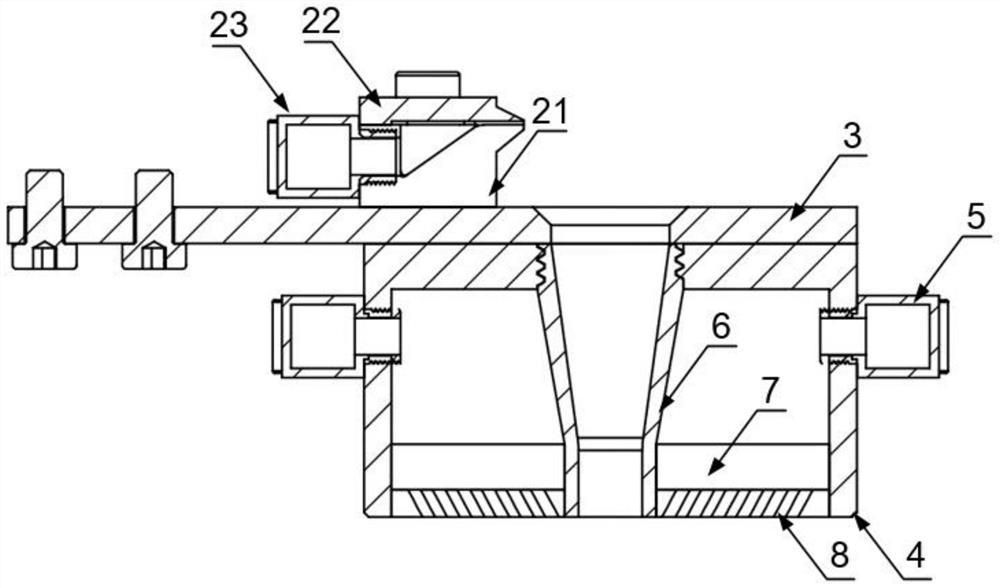

In-situ photoelectric multifunctional coupling atomic force microscope testing system

InactiveCN106353535AUniform and stable airflowEasy to operateSimultaneous control of multiple variablesScanning probe microscopyIonizationPhysics

The invention discloses an in-situ photoelectric multifunctional coupling atomic force microscope testing system. The in-situ photoelectric multifunctional coupling atomic force microscope testing system comprises a light source and volt-ampere testing system of a photoelectric device, a multifunctional probe atomic force microscope system and an atmosphere protection system, wherein the light source and volt-ampere testing system of the photoelectric device comprises a fixture, a light source and a digital source meter; the multifunctional probe atomic force microscope system comprises a multifunctional probe, a laser emitter, a laser spot position detector, a laser detector, a data outgoing line and a computer display; the atmosphere protection system comprises a box, a gas inlet and outlet device, a spiral air current forming device, a temperature and humidity control device, a gas storage device, an occlusion design sliding door and an observing window. The testing system has the advantages that a photoelectric testing part and a multifunctional probe atomic force microscope are organically combined together in an integrated system, so that macroscopic photoelectric performance and microscopic information such as microscopic change information of electronics, ionization, polarization and the like of working samples can be tested synchronously in situ in real time.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

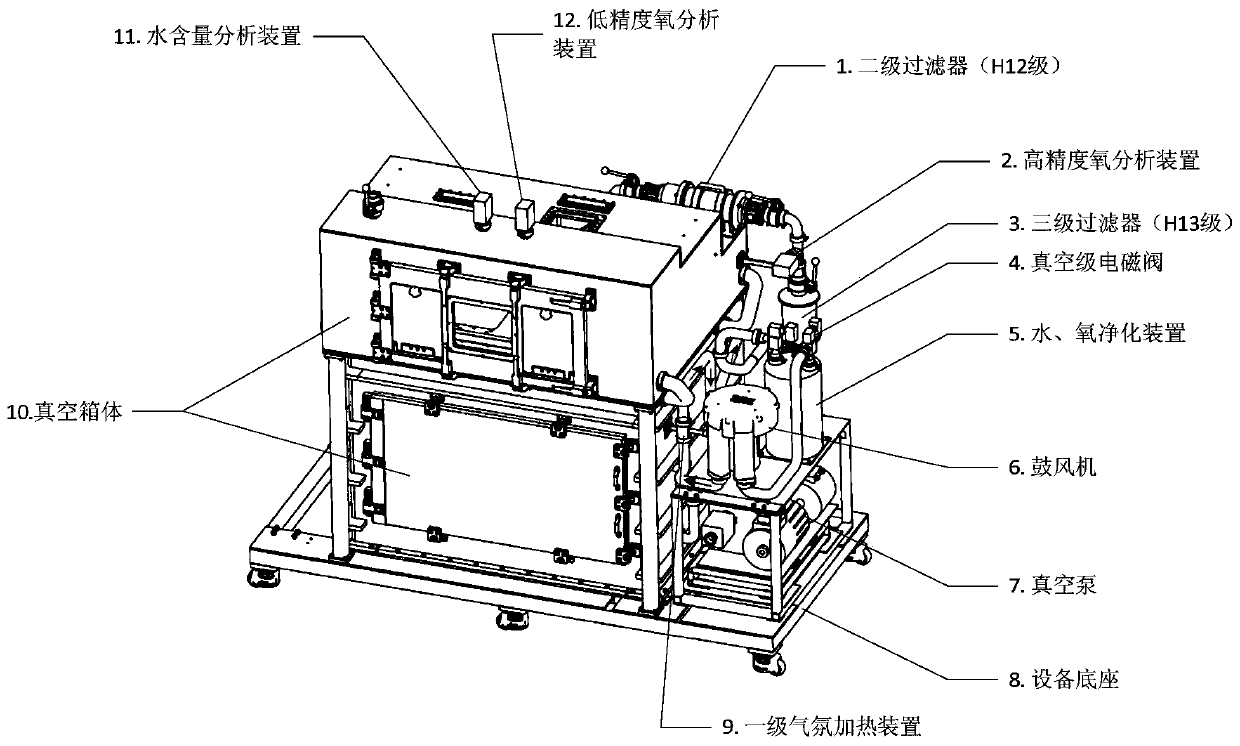

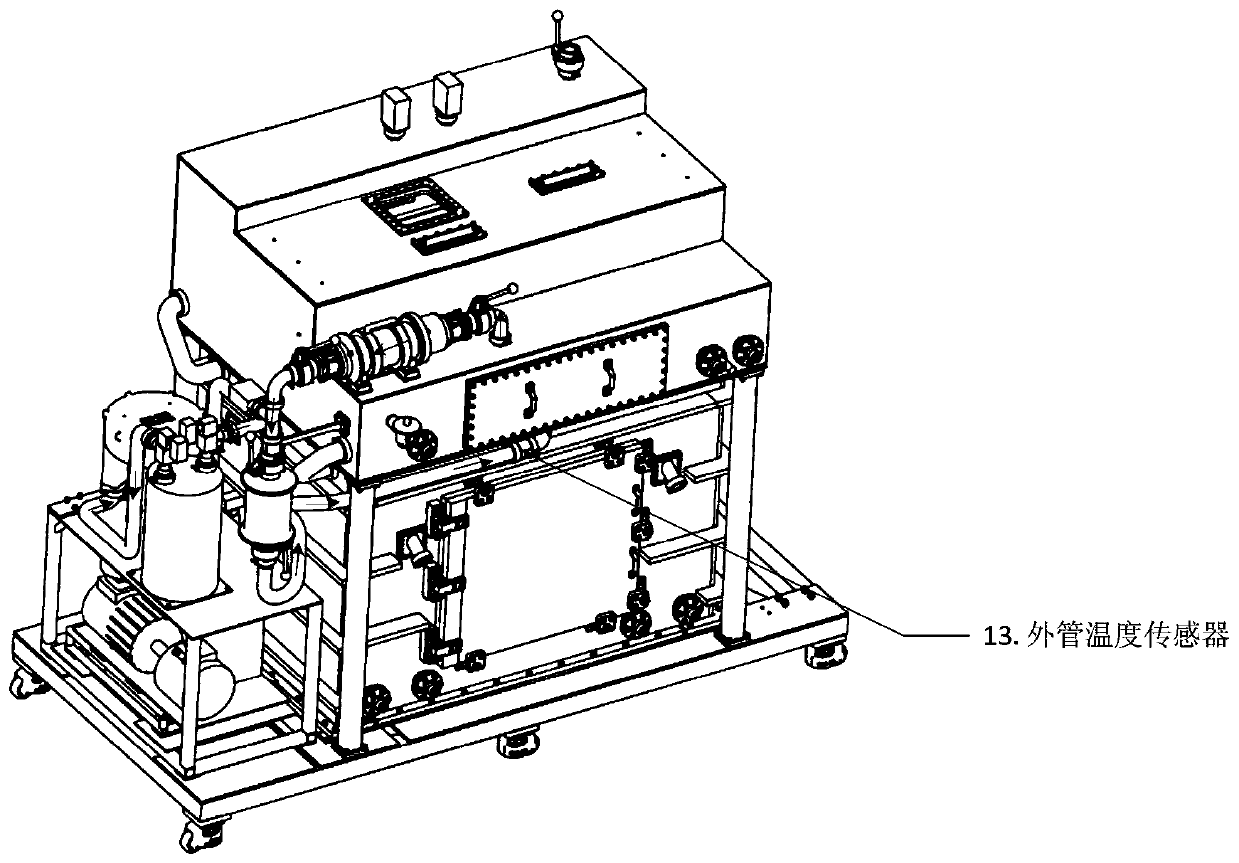

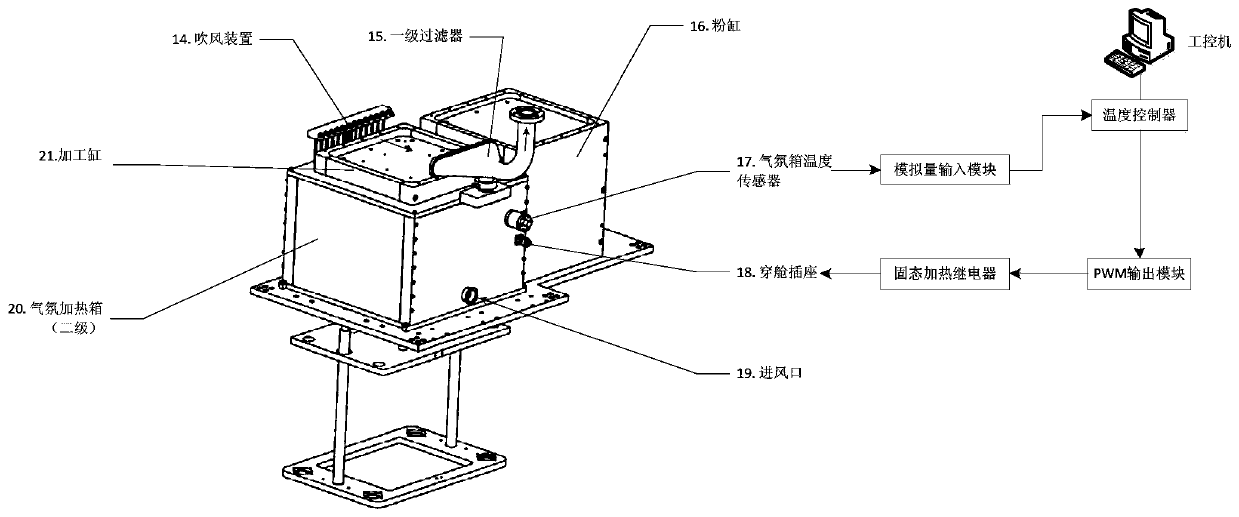

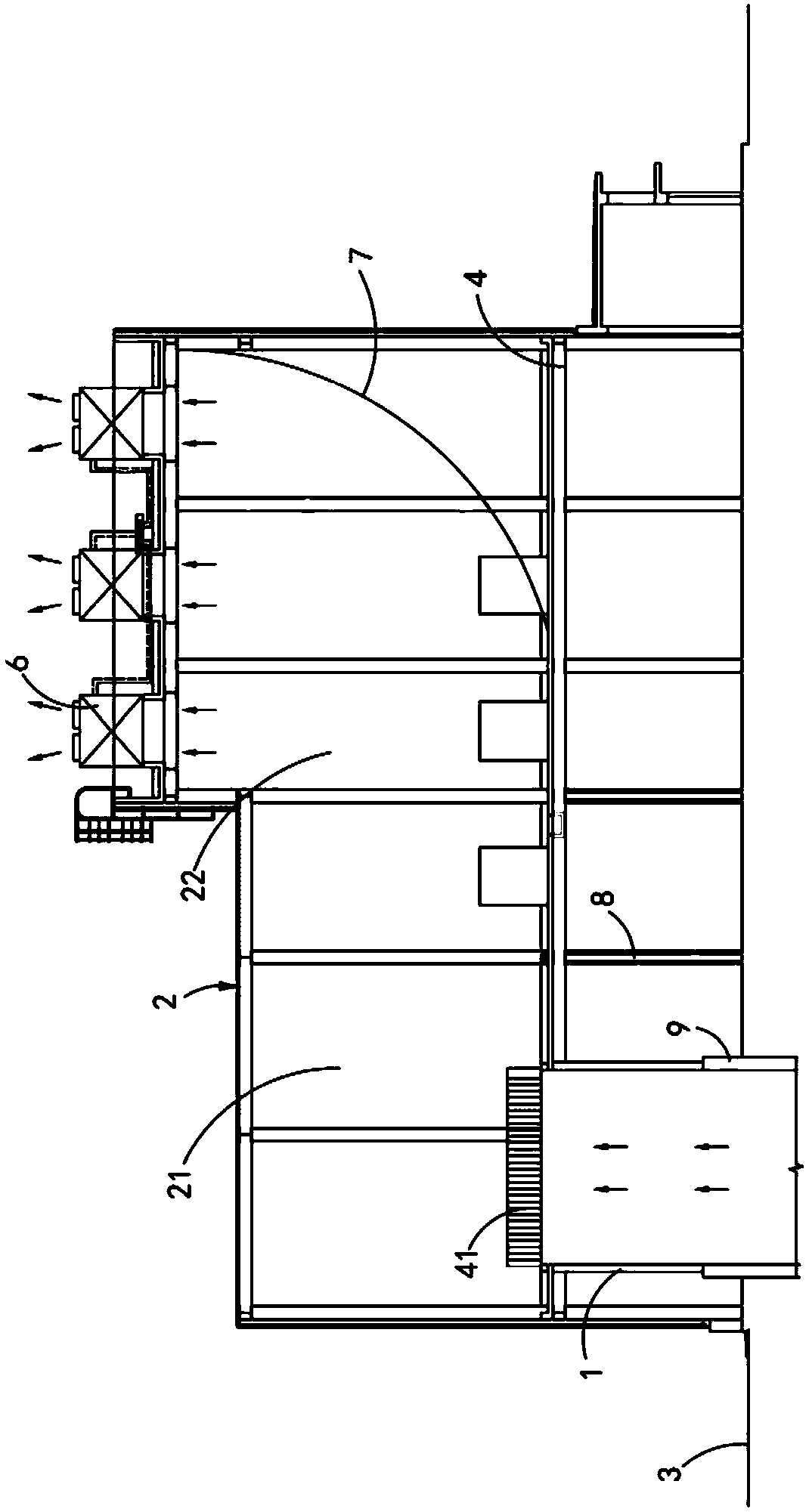

Three-dimensional (3D) printing device and method for improving workpiece molding quality

ActiveCN110027216AAvoid spreadingHigh quality moldingAdditive manufacturing apparatusManufacturing environment conditioningFilter systemEngineering

The invention relates to three-dimensional (3D) printing device and method for improving the workpiece molding quality. The 3D printing device comprises a tank, a filter system, an air blower, an airblowing device, a powder cylinder, a processing cylinder and an atmosphere heating tank, wherein the tank is a vacuum tank; the air blower arranged on the outer part of the vacuum tank blows air intothe vacuum tank; the atmosphere heating tank is used for heating the atmosphere around the processing cylinder, so that constant hot air blowing is maintained in a processing area during the processing stage, and a workpiece is ensured to be cooled according to a preset cooling gradient in the cooling stage; and in the whole printing process, the atmosphere around the processing cylinder is blownout through the air blowing device and is then filtered through the filter system.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

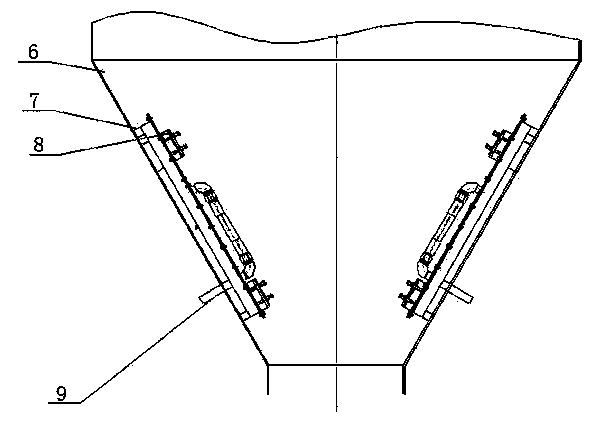

Mine return air guiding device

PendingCN109162747AAvoid accidental damageAvoid hard contactTunnel/mines ventillationCouplingEngineering

The invention provides a mine return air guiding device for guiding the discharge of return air of a mine. The mine return air guiding device comprises an air introducing cylinder installed at an airguiding cylinder of a mine mouth in an upward extending mode and an air guiding cylinder communicating with the air introducing cylinder, the air guiding cylinder is horizontally arranged and is connected to the ground through support rods, the air introducing tube and the mine mouth are in tight coupling, and the air guiding tube and the air introducing tube are in tight coupling.

Owner:CHINA ENFI ENGINEERING CORPORATION

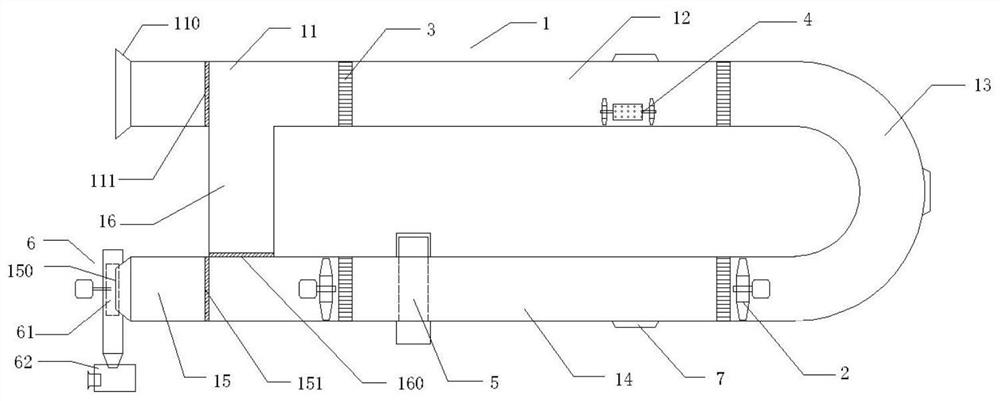

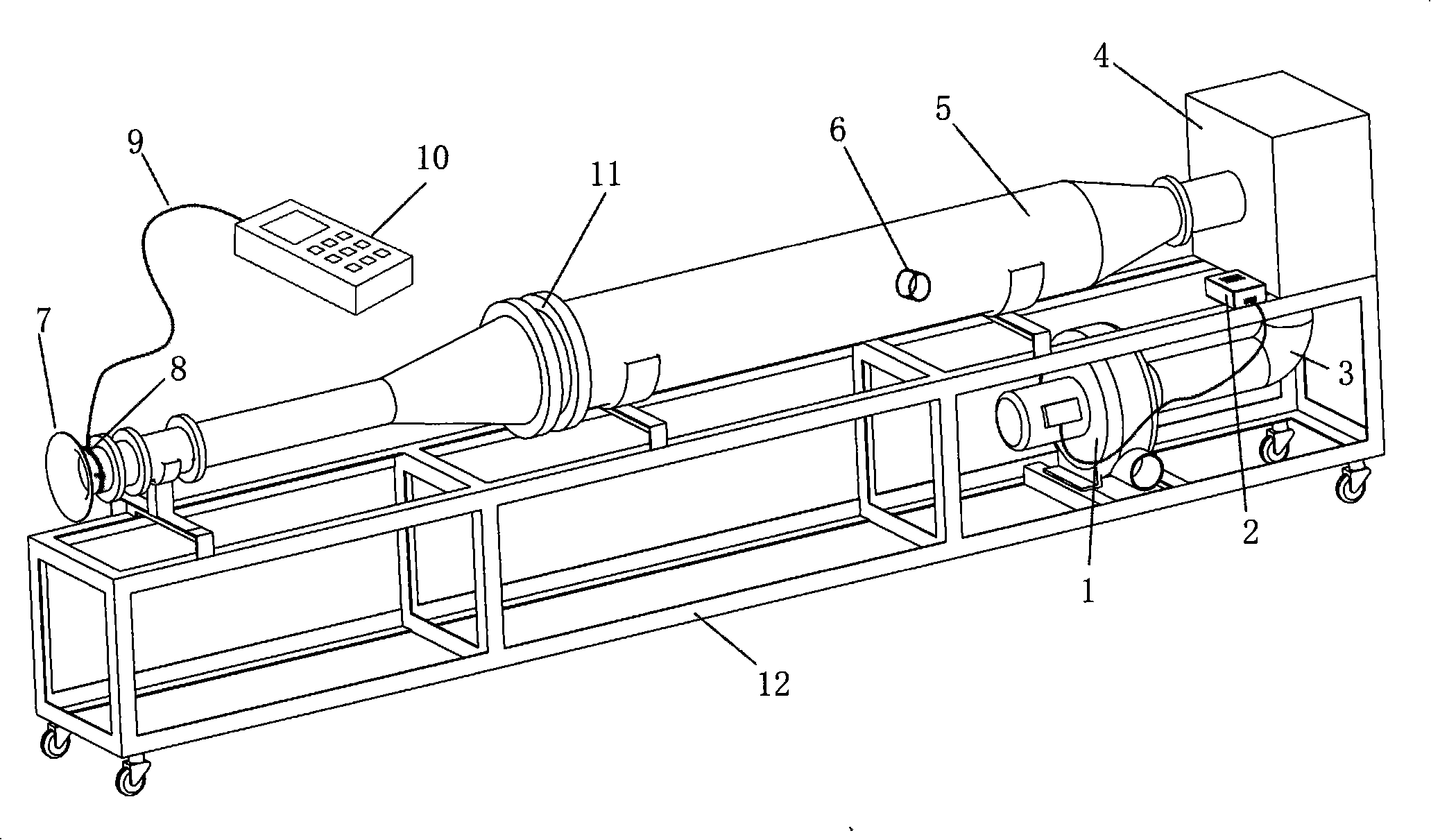

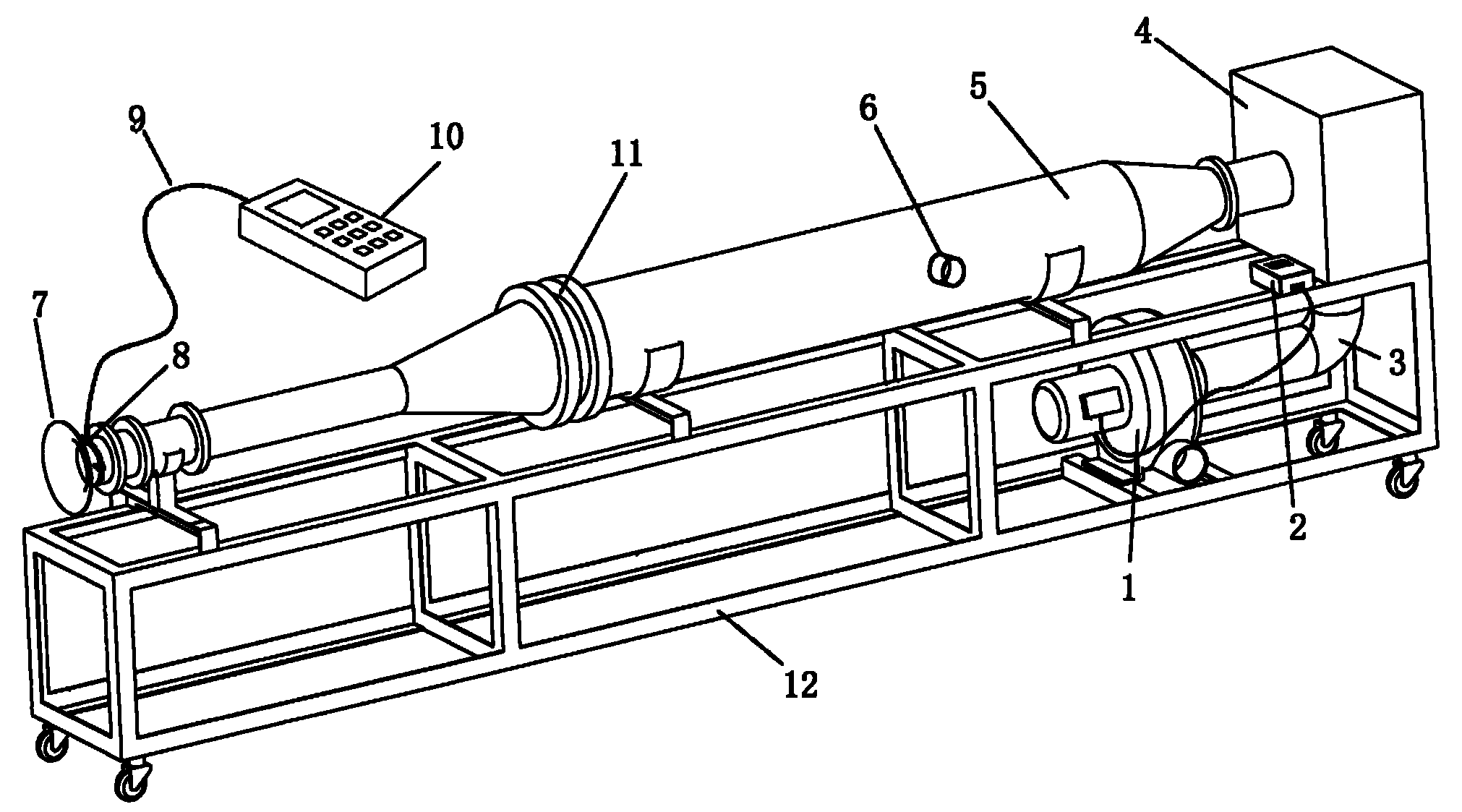

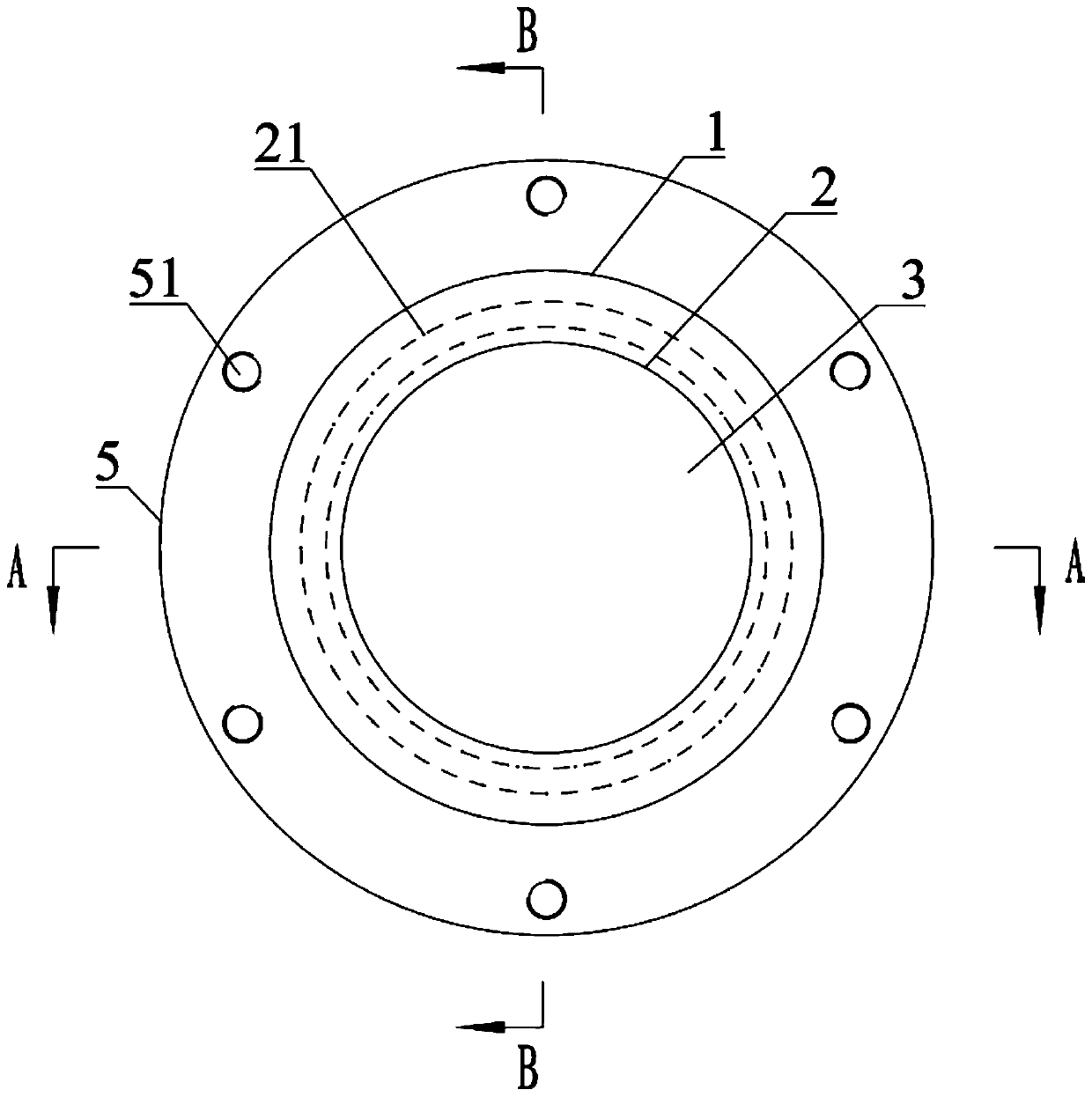

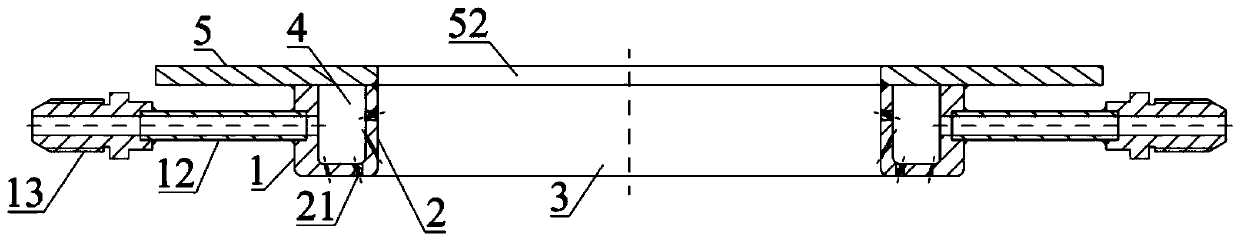

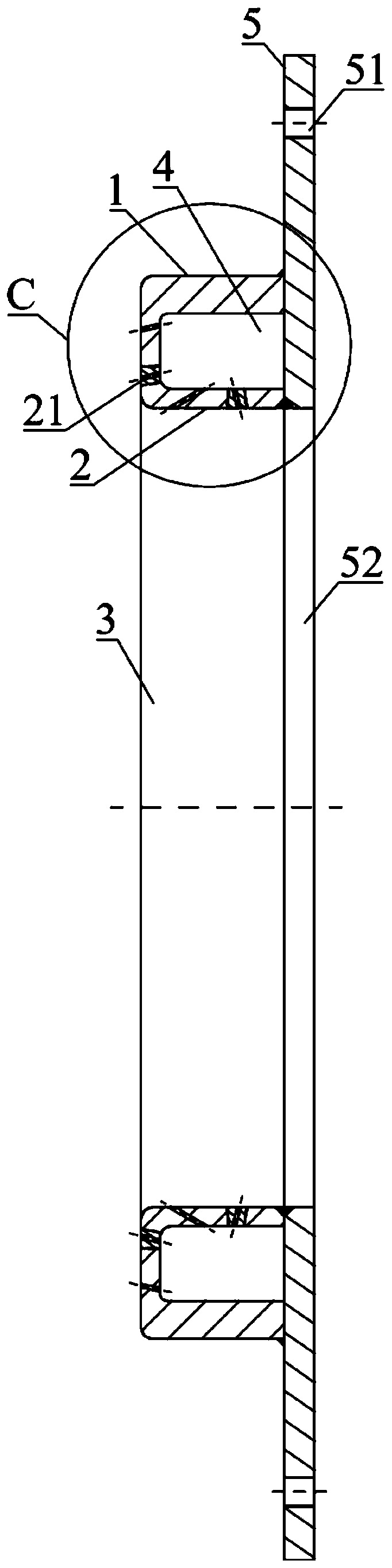

Annular dust concentration measuring instrument correction device and use method thereof

PendingCN113049458AEasy to operateSimple structureParticle suspension analysisMeasuring instrumentHoneycomb

The invention discloses an annular dust concentration measuring instrument correction device and a use method thereof. The correction device comprises an annular wind tunnel, fans, powder honeycombs, a dust generation mechanism and a detection mechanism, the annular wind tunnel comprises an air inlet section, a steady flow section, a first corner section, a test section, an air outlet section and a second corner section which are sequentially connected in a clockwise direction; the fans are respectively arranged at the positions close to the front end and the rear end in the test section, and the honeycombs are respectively arranged at the front end and the rear end of the test section and are positioned between the two fans; and the dust generation mechanism is arranged in the steady flow section, and the detection mechanism is arranged in the test section and is positioned between the two honeycombs. According to the annular wind tunnel, the occupied area is saved, the energy consumption of a test system is reduced, the two fans rotating in the opposite directions are installed on the test section, the transverse wind flow influence is eliminated while continuous wind flow is provided for the test section, the honeycombs are installed between the fans, bias flow formed by the first corner section is reduced, and the correction test is completed by continuously and repeatedly using the annular dust airflow.

Owner:六盘水市钟山区荣科风洞厂

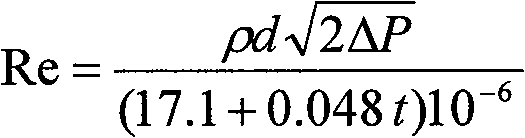

Standard flow type micro wind speed calibration apparatus and calibration method thereof

InactiveCN101303367BShorten the lengthEven airflowTesting/calibration of speed/acceleration/shock measurement devicesAir velocityElectric machine

The invention discloses a standard flow micro wind velocity calibration device which is characterized in that: a wind inlet port is a standard flow tube connected with a diverging rectification wind tube; the diverging rectification wind tube is connected with a standard air duct that is connected with a static pressure box; the static pressure box is connected with the suction inlet of a centrifugal fan by a hose; an inverter is connected with the motor of the centrifugal fan by an electrical wire; the standard flow tube is provided with a static pressure acquisition hole connected with a micropressure difference meter by a rubber tube; the standard air duct is provided with a wind velocity measuring hole, connected with the static pressure box by a flange and adopts a negative pressure manner to introduce air; the whole device is fixed on a wheelbarrow. According to the law of conservation of mass, the standard average wind velocity of the standard air duct can be calculated by standard flow and then tube axis wind velocity can be obtained by theoretical arithmetic according to the distribution and flow characteristic of flow in tubes and is taken as the wind velocity of a standard point. The device of the invention has the advantages of convenient operation, high precision, strong stability, stable adjustment velocity and convenient movement, etc.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

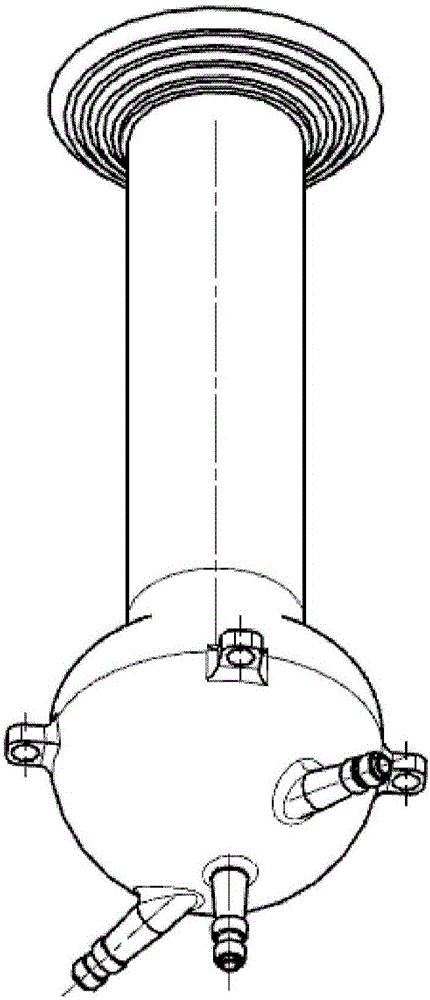

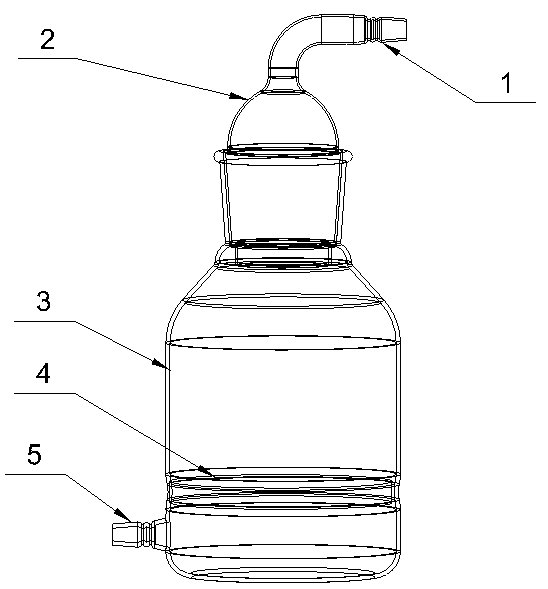

Culture bottle for sulfur hexafluoride permeation tube

InactiveCN103243024AUniform and stable airflowBioreactor/fermenter combinationsBiological substance pretreatmentsWater bathsSulfur hexafluoride

The invention discloses a culture bottle for a sulfur hexafluoride permeation tube. The culture bottle comprises a bottle body and a bottle cap, wherein a gas outlet is formed in the top of the bottle cap; a gas inlet is formed in the bottom of the bottle body; and a gas distribution plate is arranged above the gas inlet in the lower part of the bottle body. The culture bottle can meet the requirements of substances which need to be cultivated under the conditions of specific temperature and specific flowing gas. The culture bottle can be placed in a water bath pot or a culture box and is convenient to use. The culture bottle is provided with the specific gas distribution plate, so gasflow in the bottle is uniform and stable.

Owner:HENAN AGRICULTURAL UNIVERSITY

A multi-stage filter dust collector

The invention relates to a multi-stage filter dust collector, which comprises a shell, an ash hopper, a cover plate and a horizontal partition installed inside the shell, and the partition divides the inside of the shell into two parts that are not connected up and down. , the ash hopper is installed below the shell, the cover plate is installed above the shell, a mixed flow chamber is formed between the shell, the ash hopper and the partition, a collecting chamber is formed between the shell, the cover plate and the partition, and the shell There is an air inlet connected to the mixed flow chamber, and an air outlet connected to the collecting chamber on the shell; there is an inner cylinder placed vertically in the mixed flow chamber on the partition, and the inner cylinder is connected to the partition by rotation. The inner side of the inner cylinder forms a drainage chamber; the inner cylinder has a special-shaped filter bag with upper and lower openings placed under the inner cylinder. The vertical position of the special-shaped filter bag corresponds to the position of the air inlet. Booster fan; there are multiple vertically arranged microporous filter bags placed in the drainage chamber on the partition, and the upper end of the microporous filter bag penetrates upward through the partition and is connected with the partition.

Owner:XINYI HONGRUN QUARTZ SILICA POWDER

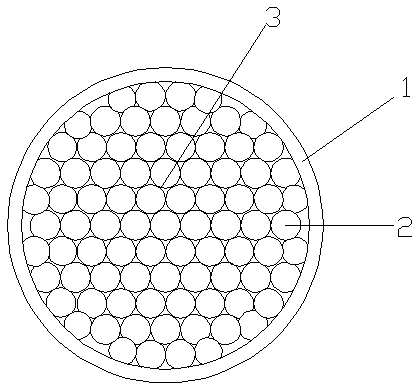

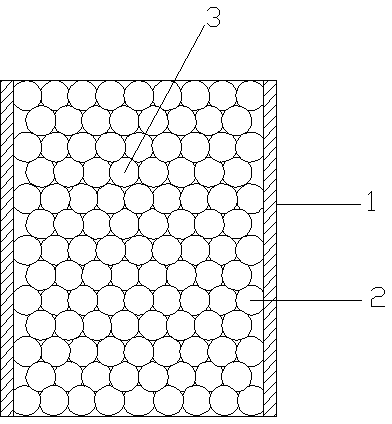

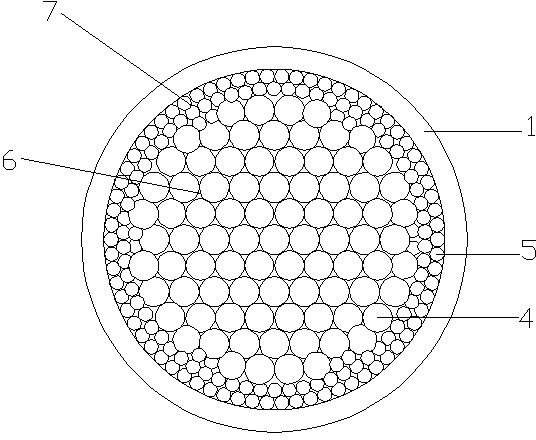

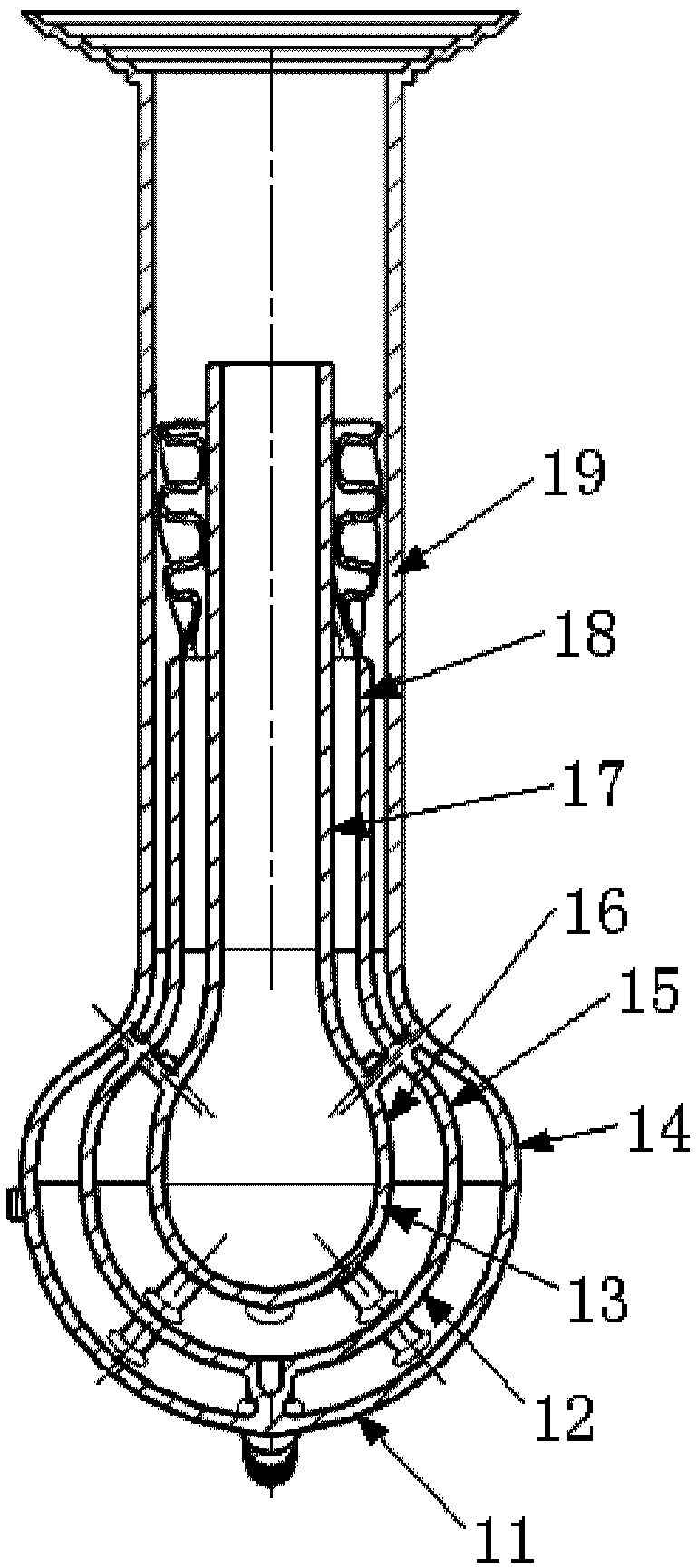

Heat exchanger of Stirling engine

ActiveCN103306850BEasy to manufactureReduce processing costsHot gas positive displacement engine plantsPlate heat exchangerEngineering

The invention discloses a heat exchanger of a Stirling engine. The heat exchanger of the Stirling engine comprises a heat exchanger shell. The heat exchanger shell is of a cylindrical structure; globoids are arranged in the heat exchanger shell; the globoids are full of the interior of the heat exchanger shell; the globoids are pairwise contacted and connected mutually to form a heat exchanger body; the inner wall of the heat exchanger body is fixedly connected with the outer side face of the heat exchanger body; the globoids can be made of stainless steel or copper; the heat exchanger body is manufactured by performing hot press molding on the globoids. Therefore, the heat exchanger of the Stirling engine disclosed by the invention has the following beneficial effects: the heat exchanger body is very low in manufacturing and processing cost; the contact area between gas and the globoids in the heat exchanger body is very large, so that the heat exchange area is large, and the heat exchange efficiency is very high; when the gas passes the heat exchanger body, an edge effect does not exist, so that the edge heat loss is reduced, and the heat exchange efficiency is improved; gas flow flowing through the heat exchanger body is uniform and stable and is fully contacted with the surfaces of the globoids, so that the heat exchange efficiency is high.

Owner:上海欧威仕电气有限公司

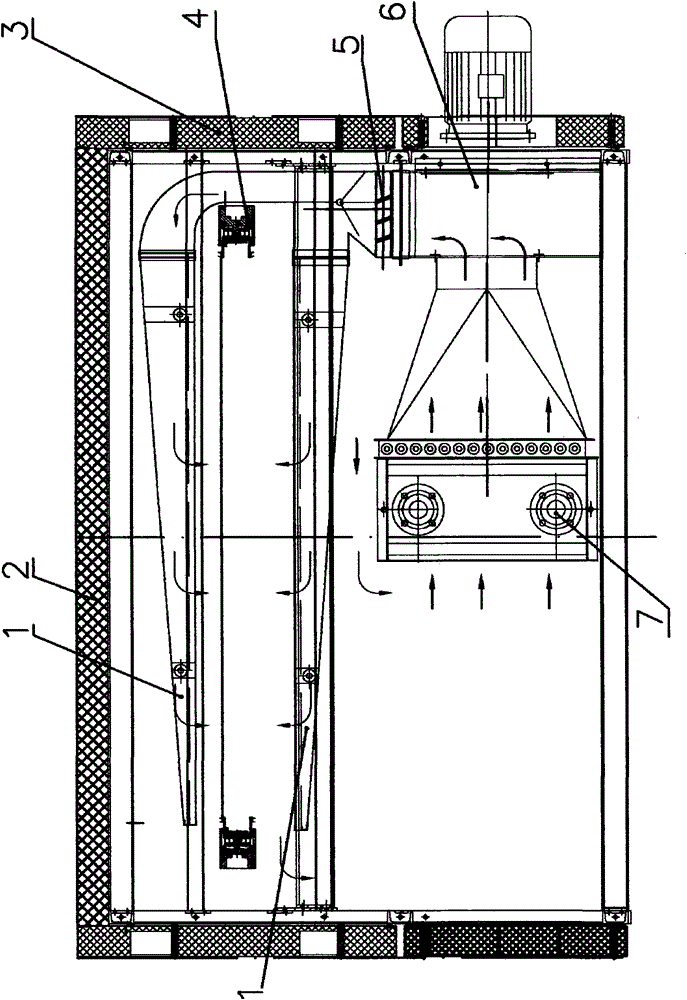

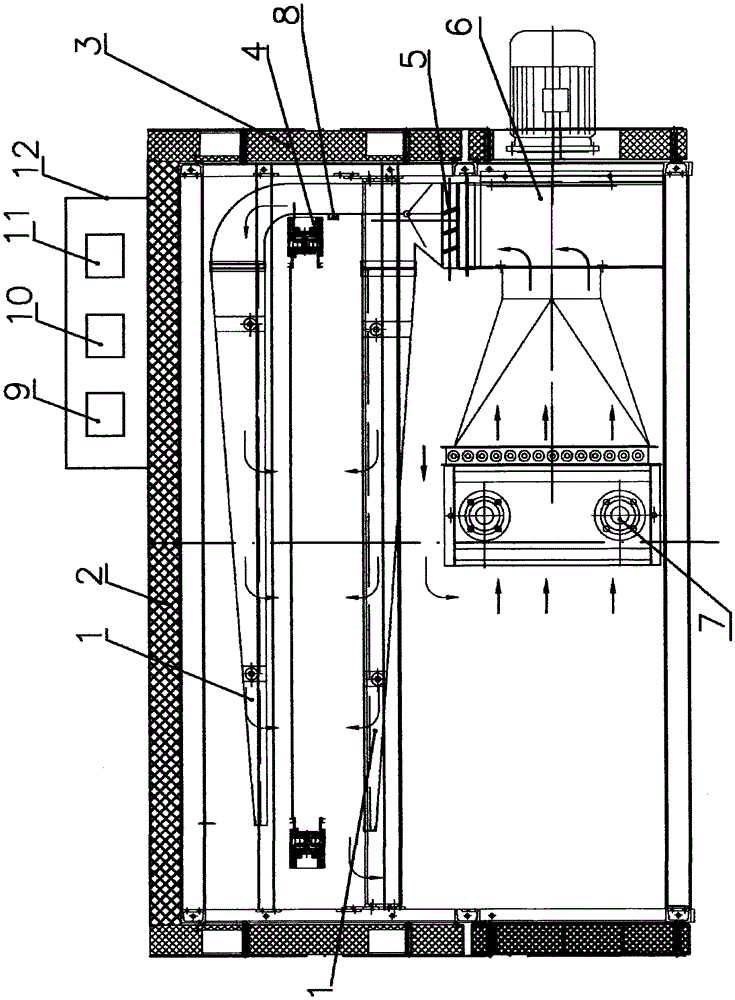

Drying oven with double air channels for heat setting machine

InactiveCN104420037AEven and smooth airflowLow air resistanceTextiles and paperEnvironmental resistanceHeating system

The invention discloses a drying oven with double air channels for a heat setting machine. The drying oven comprises a heat-insulation oven body and two hot-air blowing devices. The hot-air blowing devices are positioned in the heat-insulation oven body, a heat-insulation door is arranged on the heat-insulation oven body, the hot-air blowing devices are connected with a flow guide plate, the flow guide plate is connected with air outlets of a fan, air inlets of the fan are sequentially connected with a natural gas heating system, and the two hot-air blowing devices are respectively positioned above and below needle plates. The drying oven has the advantages that the flow guide plate is arranged at the air outlets of the fan and is connected with the hot-air blowing devices, the double air channels can be formed by the two hot-air blowing devices, the two hot-air blowing devices are respectively positioned above and below the needle plates, accordingly, airflow can uniformly smoothly flow, resistance on the airflow can be reduced, and heat setting effects can be guaranteed; the drying oven is provided with the natural gas heating system and is high in heating-up speed, the heating-up preparation time of the drying oven can be shortened, the drying oven is low in pollution and easy to maintain, the energy utilization rate of the drying oven can be maximized, accordingly, production requirements can be met, the production cost can be greatly reduced, integral production procedures are environmental friendly, and energy can be saved in the integral production procedures.

Owner:WUXI CITY HUAYANG DYEING & FINISHING MACHINERY

Flexible air distribution system applied to medicine warehouse

PendingCN114034096AGood disassembly effectStable supportDucting arrangementsMechanical apparatusPolyesterDistribution system

The invention discloses a flexible air distribution system applied to a medicine warehouse, and belongs to the technical field of flexible air supply of cloth bag air ducts. Cloth bag air ducts are hung on a top frame of a medicine warehouse in a distribution mode of a plurality of sections, the intersections of the plurality of sections of the cloth bag air ducts can be sewn by adopting high-strength polyester or polypropylene fiber raw white threads, so that the plurality of sections of the cloth bag air ducts can be communicated with one another; buckles or hook-and-loop fasteners are arranged in the sewing lines of the cloth bag air ducts,so that the cloth bag air ducts can be conveniently fixed to the top frame of the medicine warehouse; an air supply sections of the cloth bag air ducts supply air through open holes; two sets of air supply holes are formed in the 4 o'clock direction, the 8 o'clock direction, the 5 o'clock direction and the 7 o'clock direction separately, and one set of air supply holes is formed in the 6 o'clock direction; the air supply holes in the 4 o'clock direction, the 5 o'clock direction, the 6 o'clock direction, the 7 o'clock direction and the 8 o'clock direction can supply air to medicine frames of different heights, direct blowing is avoided; and barrel-shaped filter screen frameworks are arranged in the cloth bag air ducts, so that the good dustproof and supporting performance is achieved. The cloth bag air duct air supply system has the good disassembly performance.

Owner:WUHAN UNIV OF SCI & TECH

Heat setting machine with intelligent control device

InactiveCN104420103AReduce resistanceUniform and stable airflowHeating/cooling textile fabricsThermal insulationEngineering

The invention discloses a heat setting machine with an intelligent control device. The heat setting machine comprises an incubator body and two hot air blowing devices in the incubator body, wherein the incubator body is provided with a thermal insulation door; the hot air blowing devices are connected with a deflector, the deflector is connected with the air outlet of a fan, the air inlet of the fan is sequentially connected with a natural gas heating system, and the two hot air blowing devices are positioned above and below a needle plate; an online temperature detection sensor is arranged on the inner wall of the incubator body; a temperature control device is arranged at the upper part of the incubator body; a data analyzer, a data processor and a linkage power switch are arranged in the temperature control device; the online temperature detection sensor is electrically connected with the data analyzer; the data analyzer is electrically connected with the data processor; and the data processor is electrically connected with the linkage power switch. The heat setting machine has the advantages that airflow is uniform and smooth, airflow resistance is reduced, the heat setting effect is ensured, the automation degree is high and the safety performance is good.

Owner:WUXI CITY HUAYANG DYEING & FINISHING MACHINERY

A kind of air cooling device and plasma generator for plasma generator

ActiveCN109041395BGuaranteed uptimeReduce the temperaturePlasma techniquePlasma generatorEngineering

The present invention relates to an air-cooled device and a plasma generator for a plasma generator. The air-cooling device comprises an air-cooling device body and a mounting cavity for mounting a discharge tube of a plasma generator. The air-cooling device body comprises an inner shell and an outer shell. The mounting cavity is surrounded by an inner wall surface of the inner shell. A cavity isarranged between the outer shell and the inner shell, and the cavity forms a cooling air cavity; At least one air inlet hole for supply that cooling gas into the cool gas chamber is arranged on the housing, one end or both ends of the inner shell and the air-cooling device body are provided with a plurality of jet holes for discharging the cooling gas in the cooling gas chamber, The opening axes of the plurality of jet holes are respectively arranged at different angles with respect to the axial direction of the mounting chamber, so that the cooling gas discharged from the plurality of jet holes can be discharged to different positions of the discharge tube at different angles. The air cooling device of the invention has high cooling efficiency and uniform cooling, and can ensure efficientand stable operation of the plasma generator.

Owner:中国空气动力研究与发展中心超高速空气动力研究所

Detachable type dry powder material gasifying tool

InactiveCN103418297AEasy to cleanUniform and stable airflowTransportation and packagingMixersAir compressorDry powder

A detachable type dry powder material gasifying tool comprises a gasifying tool base, a gasifying layer face, a gasifying layer face pressing plate, a gas inlet pipe and a gas flow dividing chamber. The detachable type dry powder material gasifying tool is characterized in that the gasifying tool base is arranged to be a rectangular groove, a connecting plate with a bolt hole is arranged on a groove opening edge, the connecting plate is provided with the gasifying layer face which covers a groove opening, the gasifying layer face pressing plate with the bolt hole is arranged on the side of the gasifying layer face and corresponds to the connecting plate on the gasifying tool base, the gasifying layer face pressing plate and the connecting plate are connected together through a bolt, a rectangular gas flow dividing chamber with a sealing cover is arranged in the middle of one side of the gasifying tool, a flow dividing plate with small evenly-densely-distributed holes is arranged on a communicating hole of the gasifying tool base and the bottom of the gas flow dividing chamber, a gas inlet pipe is arranged on the upper side face of the gas flow dividing chamber, the gas inlet pipe, a stand type cone-shaped lower dust tank gas inlet and an air compressor are connected, the bottom of the gasifying tool base is arranged on the side wall of a cone-shaped lower dust tank in an attaching mode, and the gasifying tool is fixed on the side wall of the cone-shaped lower dust tank through the connecting plate arranged on the side wall of the cone-shaped lower dust tank and the fixing bolt which fixes the gasifying layer face.

Owner:山东胜油固井工程技术有限公司

Ultrasonic flowmeter with rectangular flow channel

PendingCN112798066ASuitable for measurementUniform and stable airflowVolume/mass flow measurementData connectionEngineering

The invention discloses an ultrasonic flowmeter with a rectangular flow channel. The ultrasonic flowmeter comprises: a body; n upper cover and a lower cover, wherein the upper cover is arranged on the body in a covering mode, the lower cover is arranged at the bottom of the body in a covering mode, and the upper cover is communicated with the interior of the body to form a flowmeter inner cavity;, a gas inlet pipe section connected with the side surface of the body; a flow measuring pipe section connected with the gas inlet pipe section and communicated with the flowmeter inner cavity; a plurality of ultrasonic probes distributed in the flow measuring pipe section; a flowmeter head arranged on the upper cover and in data connection with the multiple ultrasonic probes; and a gas outlet pipe section connected with the side surface of the body. According to the invention, the rectangular flow channel is adopted, airflow is more stable and uniform, and the ultrasonic flowmeter is more suitable for flowmeter measurement; an internal and external separation structure is adopted, so that even if the external part is impacted, the internal flow measuring pipe section is not influenced; a bent vertical structure is adopted, so that the horizontal space is more saved, and the installation applicability is high; and the arrangement of multiple ultrasonic probes is adopted, so that the result is more accurate and mutually redundant.

Owner:苍仪科技(上海)有限公司

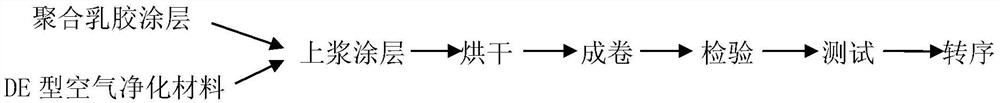

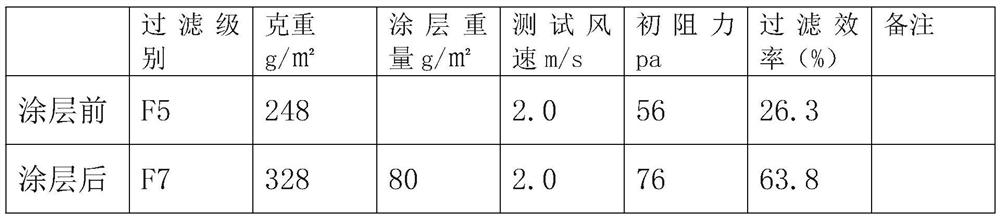

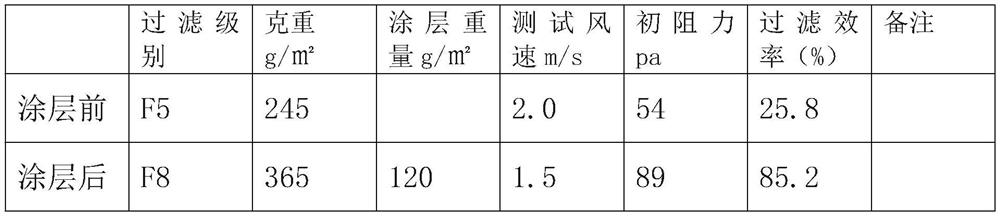

Multi-performance coating filter material and preparation method

ActiveCN113087857BImprove filtration efficiencySoft and smoothMembrane filtersFiltration separationCoated membraneEpoxy

The present invention is a kind of polymer latex coating, and the raw materials used are: 20-21 g of itaconic acid, 350-360 g of ethyl acrylate, 71-73 g of allyl polyoxyalkylene epoxy ether, 71-73 g of ethyl -2-methyl 1,3-dioxopentyl-4-yl acrylate 10-10.5g, methyl methacrylate 42-44g, fatty alcohol polyoxyethylene ether XL-90 2-2.3g, ammonium persulfate 1.9- 2.1g, deionized water 550-600g, mixed into a polymer emulsion. Take 80g of polymerization emulsion, add 17g of water and 3g of thickener, stir to thicken evenly, filter out the material to obtain the product. The coating film material can improve the filtration efficiency of the filter material while maintaining the original technical performance by coating the surface of the air outlet side.

Owner:丹东天皓净化材料有限公司 +1

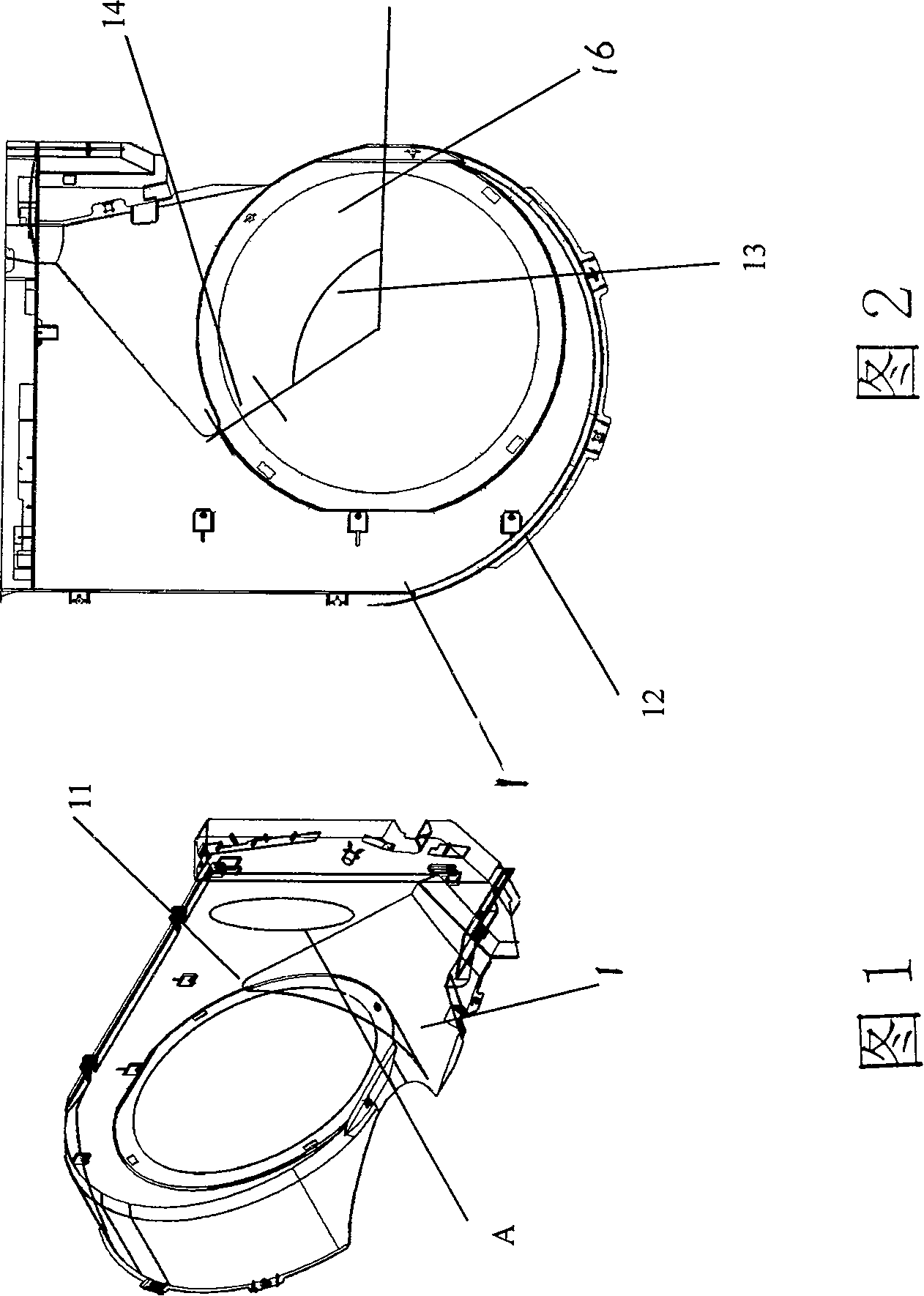

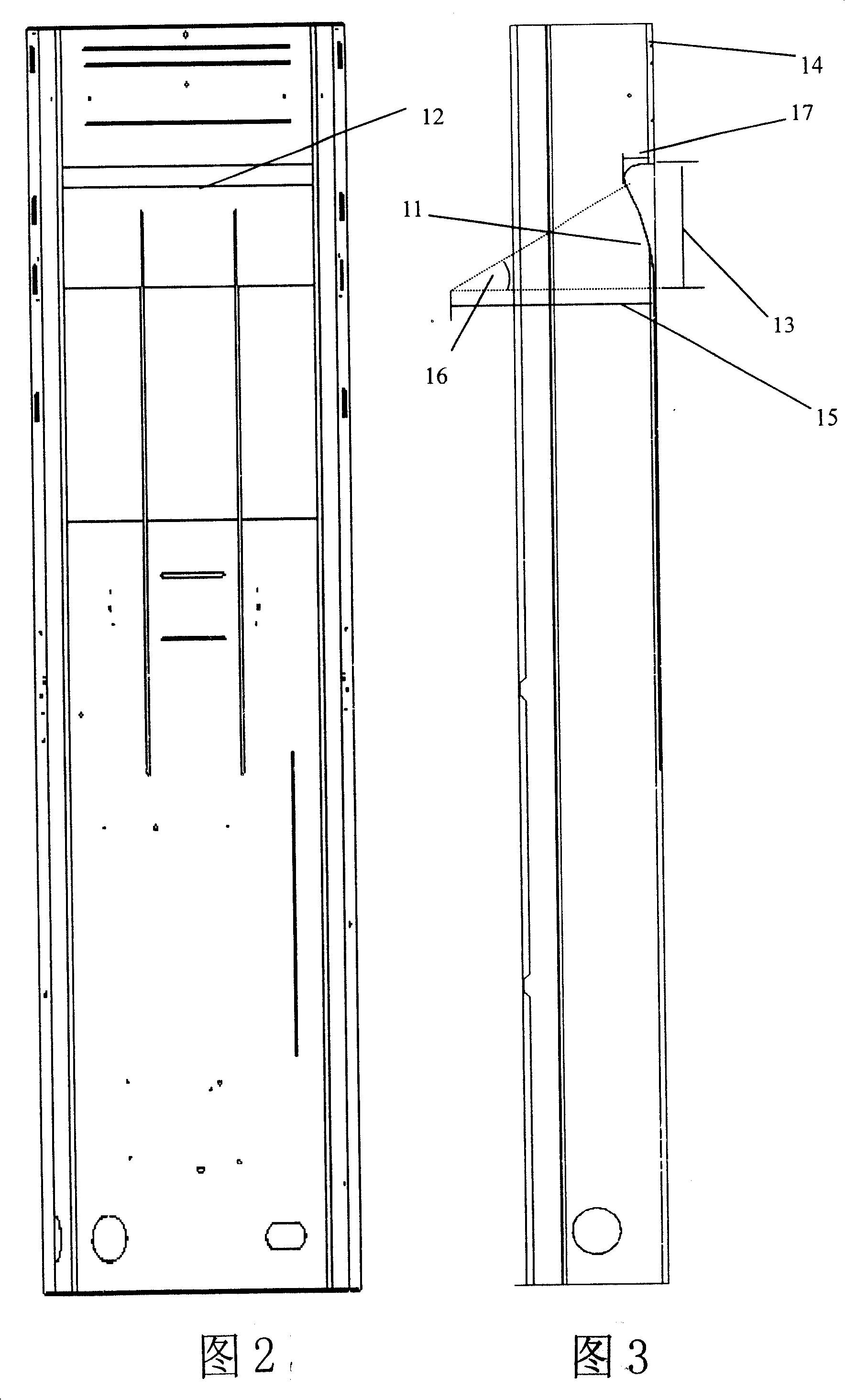

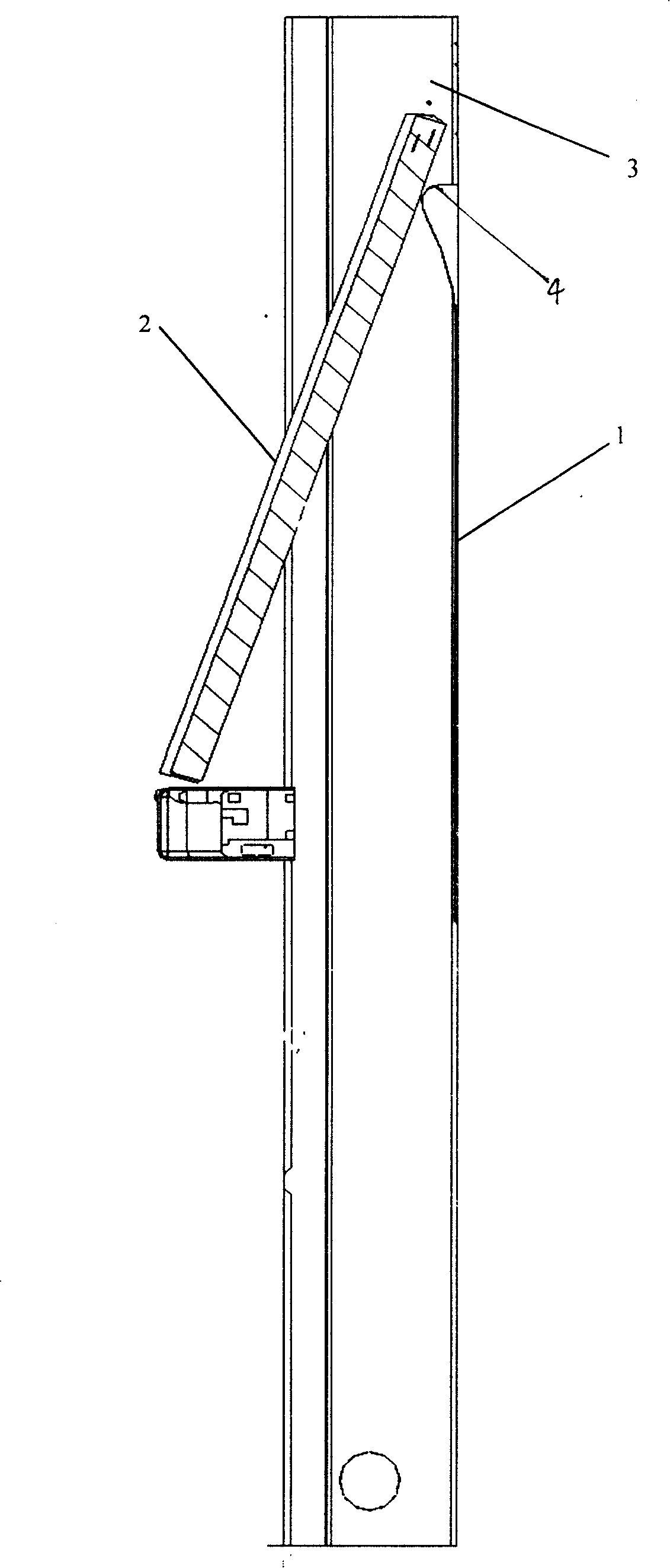

Rear cover plate structure of indoor machine for cabinet air conditioner

InactiveCN101173820AImprove work performanceHigh strengthHeating and ventilation casings/coversPlate heat exchangerWork performance

The invention provides a rear cover plate structure of cabinet air conditioner indoor unit , comprising a plate body. The invention is characterized in that: an inner arc part of a body stamping is straightly connected with the upper part of the rear cover plate body; the width of the inner arc part is less than the width of the heat exchanger, the length of the inner arc part is 800 to 1000 mm, the distance between the top of the inner arc part and the installation position of the heat exchanger upper part is 50 to 100 mm, the arc radius of the inner arc part is 350 to 360 mm, the central angle is Pi / 18-Pi / 6 degrees, the depth of the inner arc part is 100 to 500 mm. The invention has the advantages of increasing the rear cover plate intensity, optimizing the airflow passage of the casing, reducing noises effectively, making airflow outlet uniformly and properly, improving the working performance of the air conditioner, and meeting the environmental protection.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

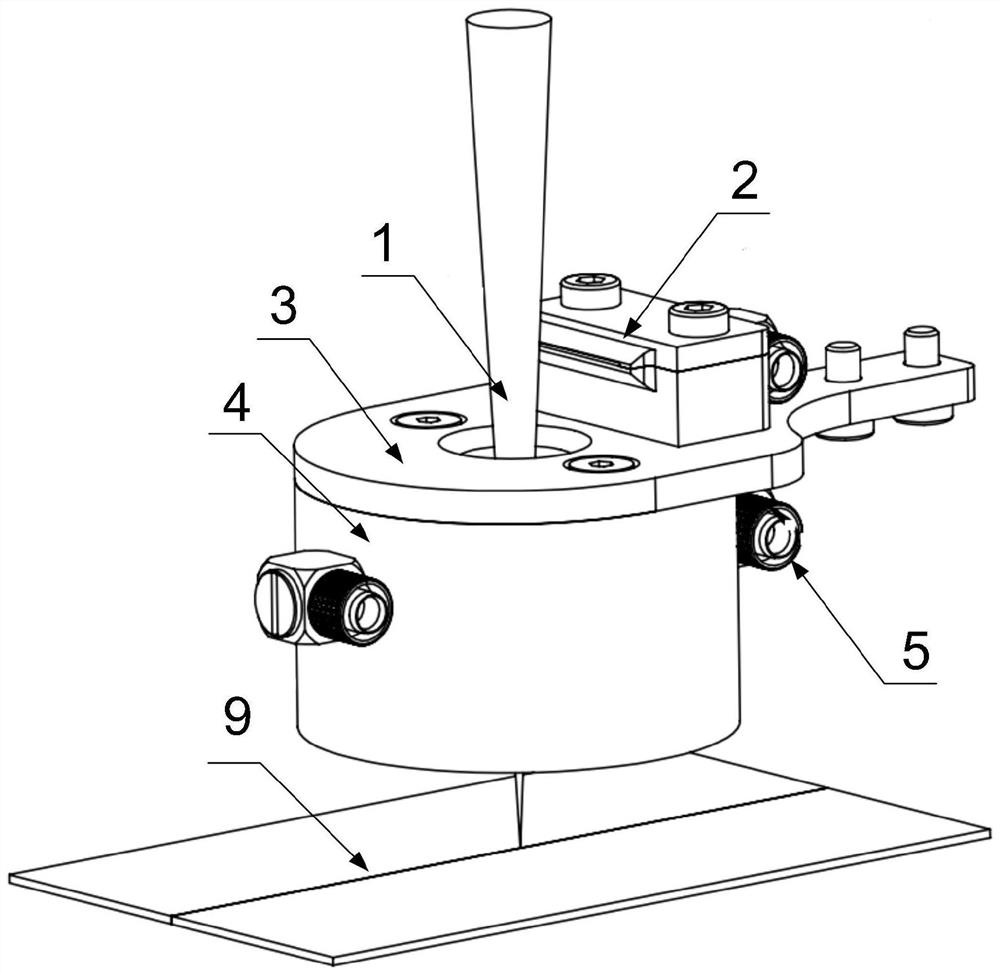

Laser welding shielding gas device

PendingCN112207434ALarge coverage areaReal-time gas protectionLaser beam welding apparatusShielding gasEngineering

The invention discloses a laser welding shielding gas device. The laser welding shielding gas device comprises a gas knife assembly, a connecting support, a gas cavity, a gas cavity pipe joint, a high-temperature-resistant nozzle, a gas homogenizing filter plate and a gas flow guide plate. The gas knife assembly is installed above the connecting support. The upper portion of the gas cavity is installed below the connecting support in a seamless manner. The gas homogenizing filter plate is located below the gas cavity and is in interference fit with the inner wall of the gas cavity. The gas cavity pipe joint is installed on the outer side wall of the gas cavity. The upper end of the high-temperature-resistant nozzle is in interference fit with a through hole in the middle of the top wall ofthe gas cavity. A through hole is formed in the position, facing the upper end of the high-temperature-resistant nozzle, of the connecting support. The lower end of the high-temperature-resistant nozzle is in interference fit with a through hole in the middle of the gas homogenizing filter plate. The gas flow guide plate is located below the gas homogenizing filter plate. Laser penetrates througha hollow channel of the high-temperature-resistant nozzle to weld a welding workpiece, and meanwhile, shielding gas enters the gas cavity from the gas cavity pipe joint and then penetrates through the gas homogenizing filter plate to provide a large-range shielding gas atmosphere for a weld joint. The laser welding shielding gas device can disperse photoinduced plasmas in a laser channel.

Owner:四川中久大光科技有限公司

Nozzle, nozzle array and burner for widening tempering margin

ActiveCN106247408BImprove stabilityImprove reliabilityContinuous combustion chamberGaseous fuel burnerWave structureCombustor

The invention provides a nozzle for widening a tempering margin, a nozzle array and a combustor. A rectifying device of the nozzle can enable currents of fuel gas and air entering the nozzle to become more stable and uniform, so that the tempering caused by hot spots in combustion can be effectively prevented; a step-shaped expansion section of the nozzle can stop propagation of the tempering to the upstream, so that the tempering margin is widened; and as a direct passing way wave structure and a center cone are arranged in an inner-layer cylinder of the nozzle, the combustion efficiency is further improved, the pollutant discharge is reduced, and the combustion state is improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

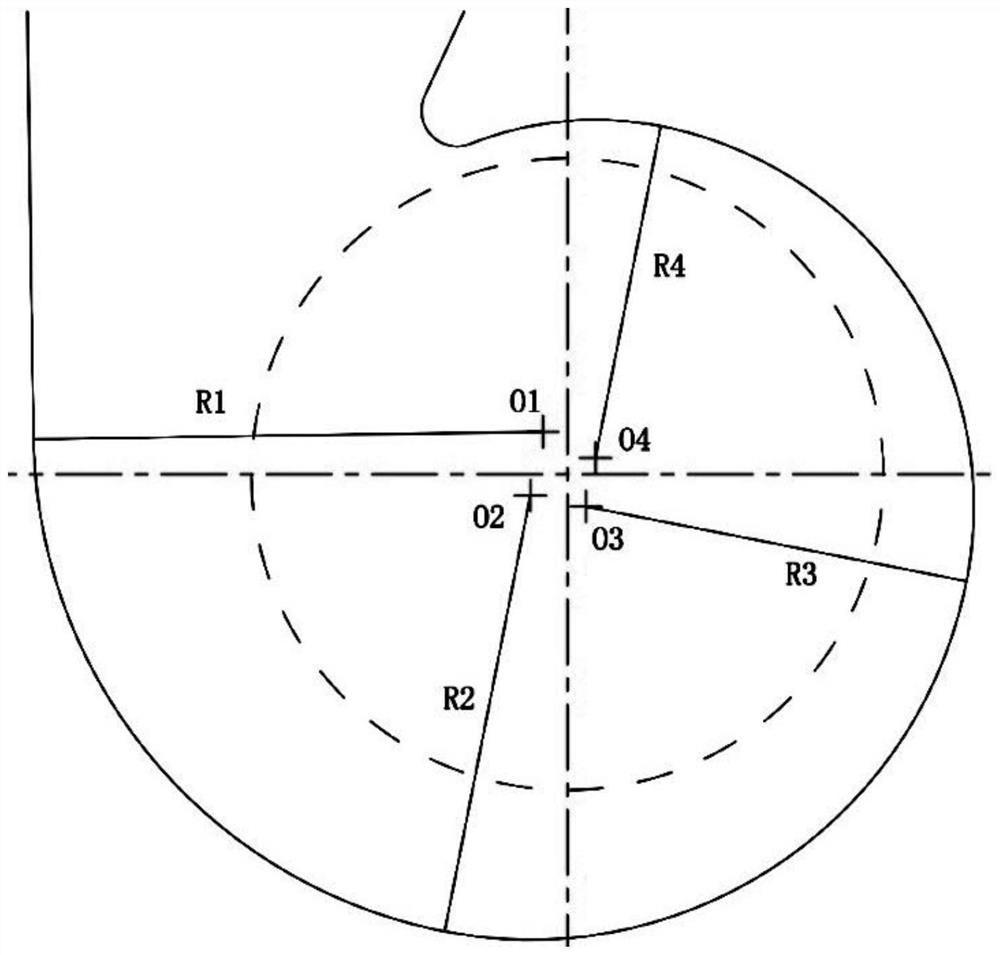

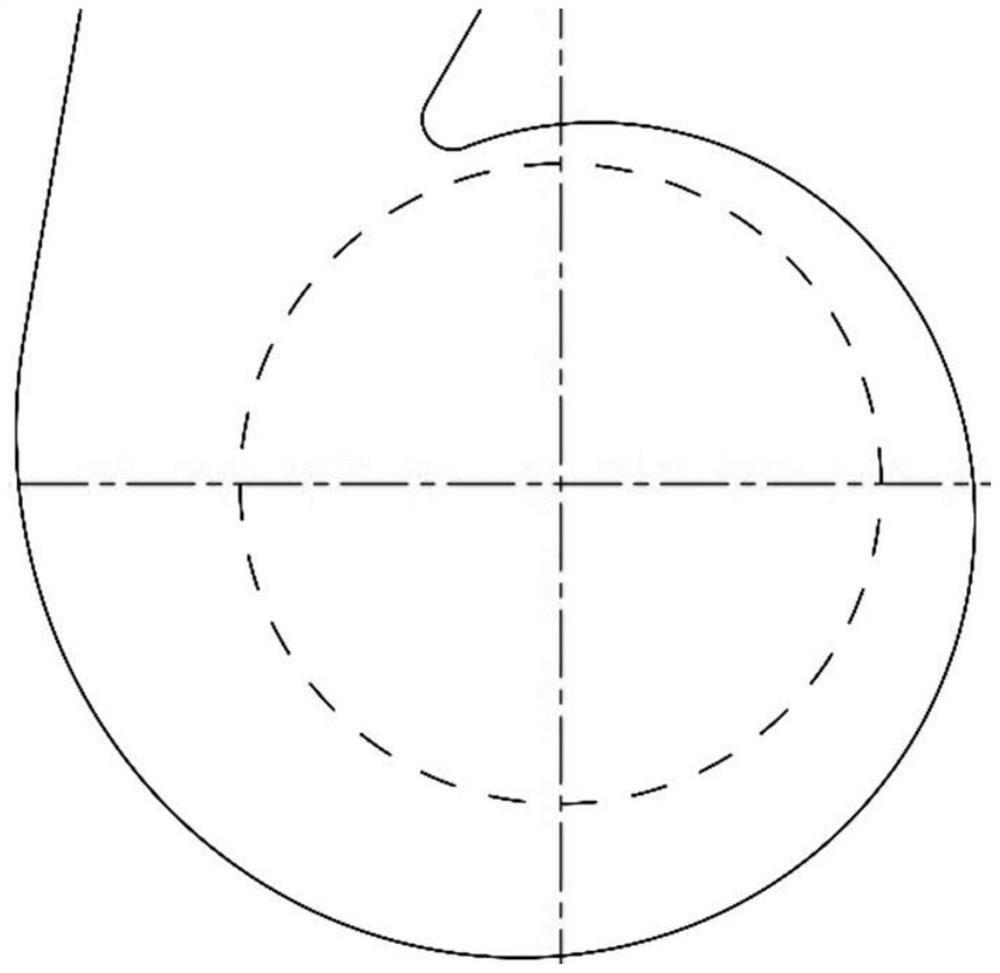

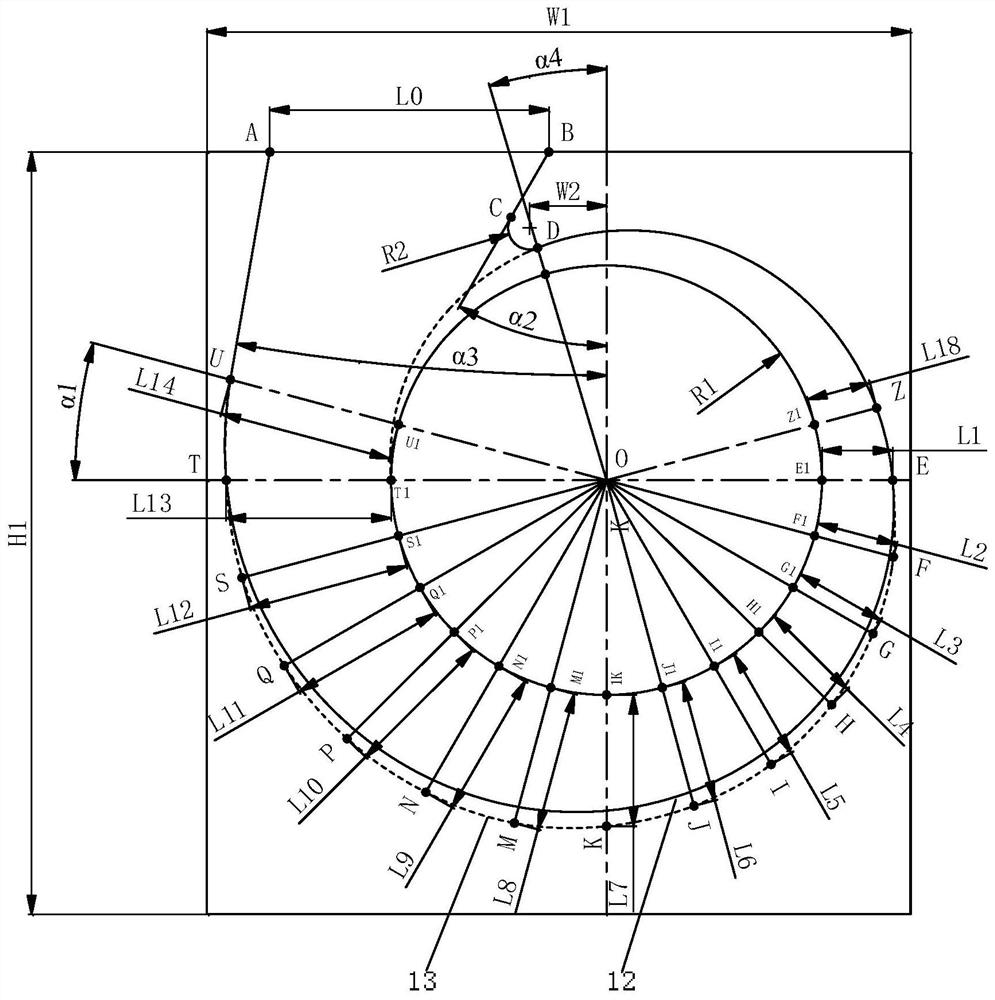

Volute molded line drawing method, check valve molded line drawing method, air duct structure and range hood

PendingCN113849932ANo mutationFacilitate partial correctionGeometric CADDesign optimisation/simulationEngineeringStraight segment

The invention relates to the technical field of extractor hood design, in particular to a volute molded line drawing method, a check valve molded line drawing method, an air duct structure and a range hood. The volute molded line drawing method provided by the invention comprises steps: on the basis of the volute first molded line generated by the logarithmic spiral line, increasing the opening degree of a first spiral line segment gradually and equivalently according to the area, and then re-fitting into a second spiral line segment; fitting the second spiral line segment with a first straight line segment, a second straight line segment, a volute tongue molded line and a third straight line segment of the volute first molded line to form a final volute second molded line; compared with an existing volute molded line generation method, the volute molded line drawing method provided by the invention has the advantages that the advantages of a logarithmic spiral line are reserved, meanwhile, local correction can be conveniently and quickly performed on the volute molded line according to limiting conditions, so that the volute molded line is uniformly increased and is not abruptly changed, finally, airflow acceleration in a volute is more uniform and stable, pressure pulsation is reduced, and aerodynamic noise is lowered.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com