Vector ducted tail rotor high-speed helicopter

A helicopter, high-speed technology, applied in the direction of rotorcraft, motor vehicles, aircraft, etc., can solve the problems of multi-coupling control channels, large pressure difference resistance, difficult to control, etc., to reduce aerodynamic noise, stable and uniform airflow, and improve aerodynamic efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and examples. It should be understood that the following examples are intended to facilitate the understanding of the present invention, and have no limiting effect on it.

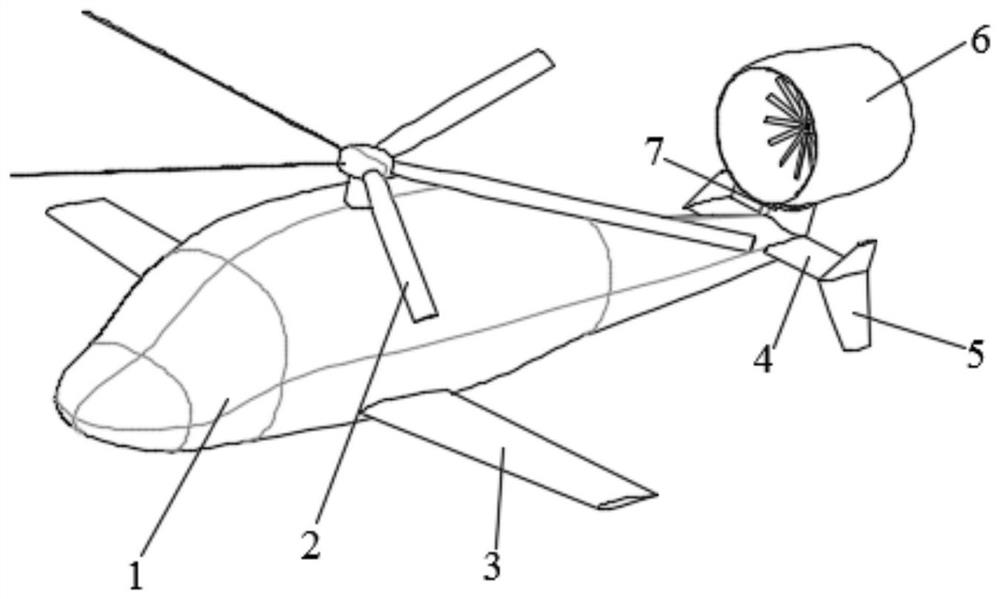

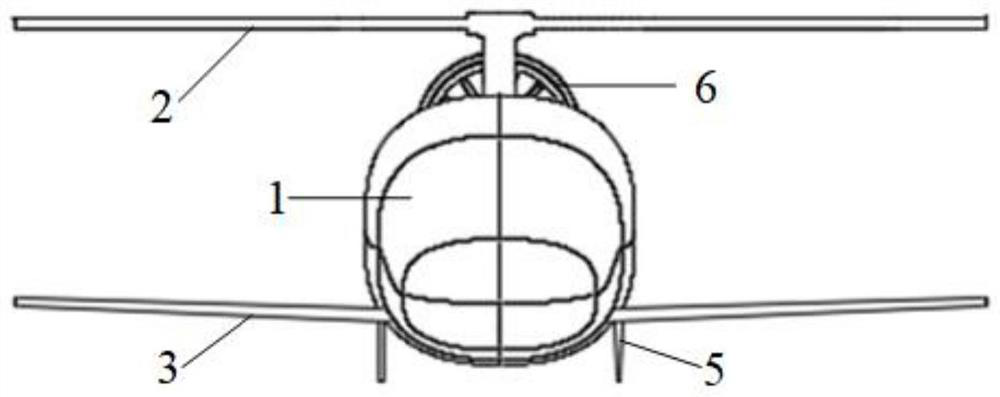

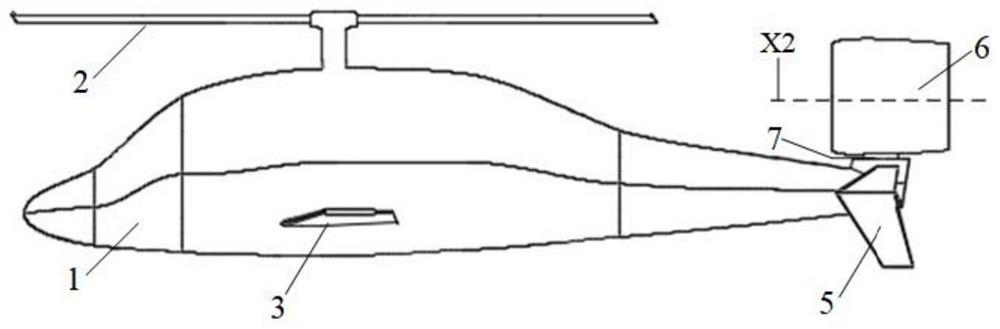

[0023] like Figure 1-5 As shown, the composite high-speed helicopter that adopts the ducted rotatable vector tail rotor provided by this embodiment includes a fuselage 1, a main rotor 2, a lift wing 3, a horizontal tail 4, a vertical tail 5, a ducted fan 6 and Duct rotating shaft 7. Wherein, the main rotor 2 is installed directly above the fuselage 1, and the lift wing 3 is symmetrically installed on the lower half of both sides of the fuselage 1, so as to weaken the unfavorable aerodynamic interference effect between the main rotor 2 and the lift wing 3. The horizontal stabilizer 4 is rigidly connected to both sides of the tail of the fuselage 1 symmetrically, and the vertical stabilizer 5 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com