Dedusting and desulfurization integrated machine

A desulfurization all-in-one machine and dedusting room technology, applied in the direction of dispersed particle separation, chemical instruments and methods, combined devices, etc., can solve the problems of desulfurization equipment blockage, lower desulfurization efficiency, large dust content, etc. Uniformity and stability, the effect of saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

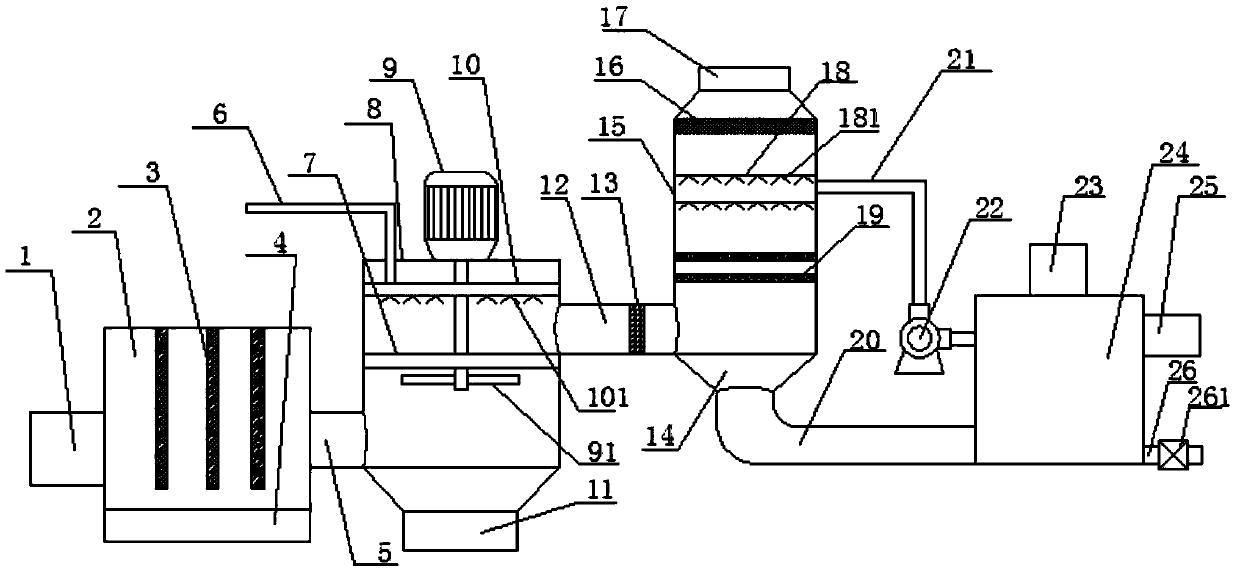

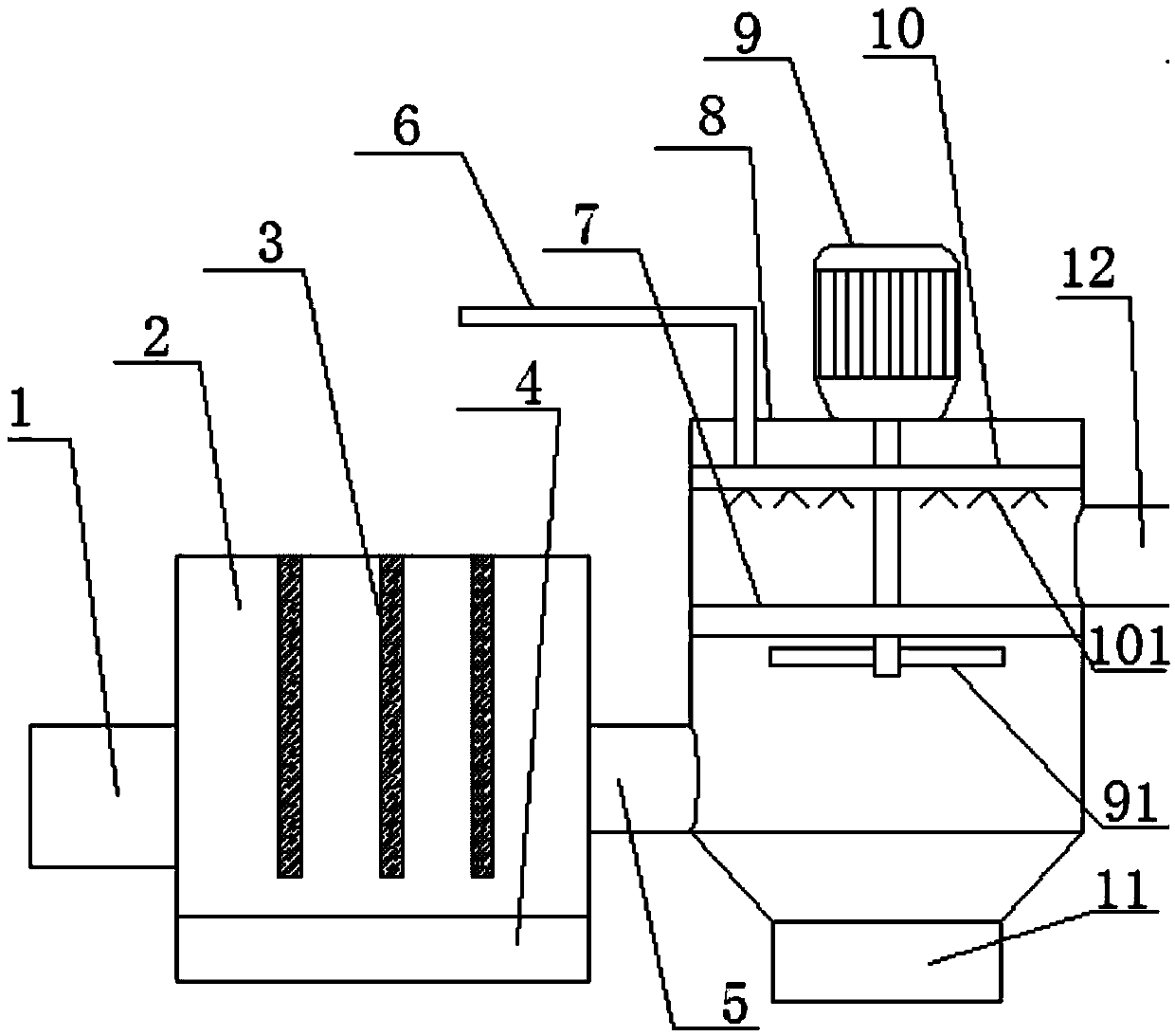

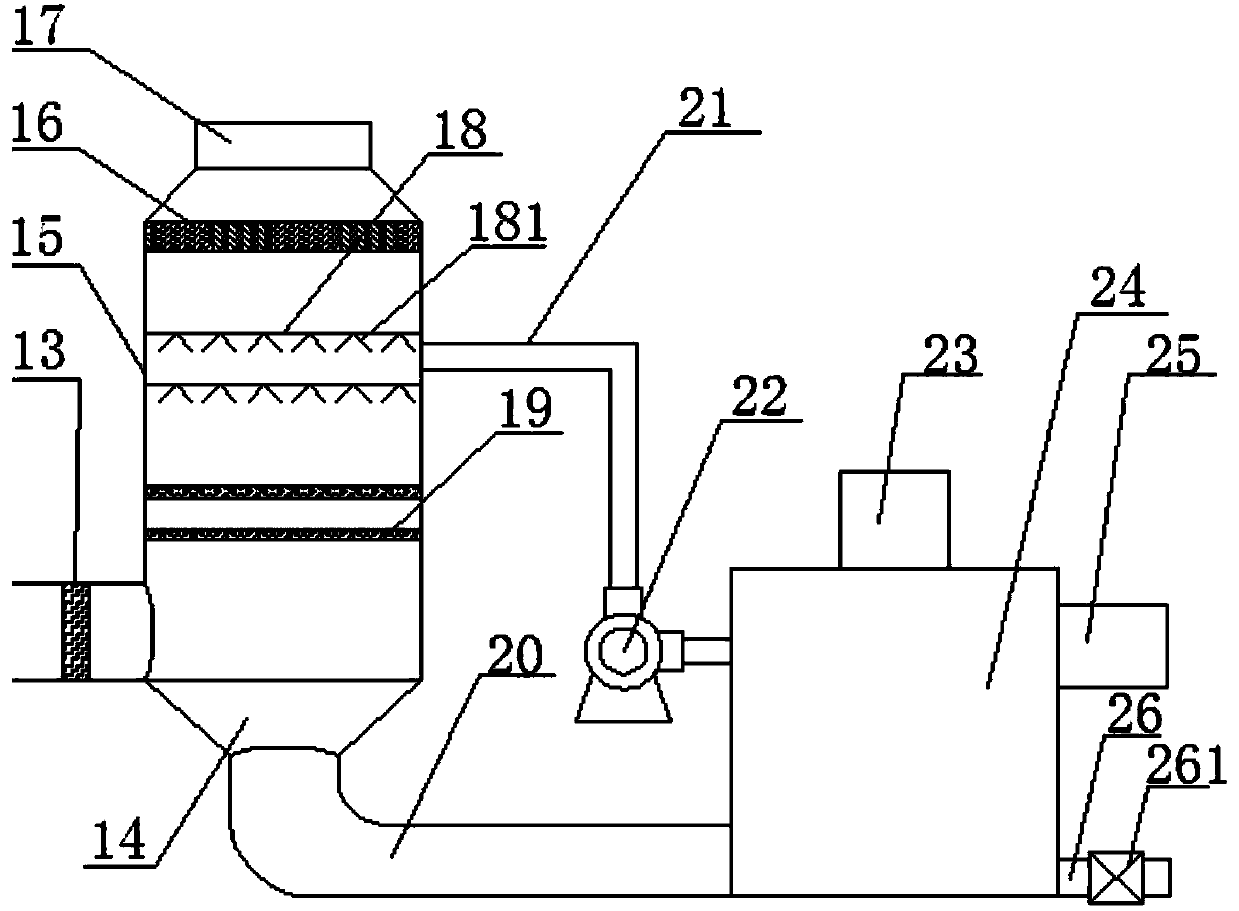

[0021] refer to Figure 1 ~ Figure 3 , the present invention includes an inlet flue 1, a filter chamber 2, a dust removal chamber 8, a desulfurization tower 15, an outlet flue 17 and a circulation pool 24, the inlet flue 1 communicates with the filter chamber 2, and the filter chamber 2 communicates with the dust removal chamber 8 is connected through the first flue gas passage 5, and the dust removal chamber 8 is connected with the desulfurization tower 15 through the second flue gas passage 12. The second flue gas passage 12 is provided with a uniformly distributed plate 13, and the top of the desulfurization tower 15 has an outlet smoke 17, the bottom of the desulfurization tower 15 has a circulation port 14, the circulation port 14 is connected with the circulation pool 24 through the circulation pipe 20, the circulation pool 24 is connected with the circulation pump 22, and the circulation pump 22 is connected with the desulfurization tower 15 through the liquid inlet pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com