Multi-performance coating filter material and preparation method

A filter material and coating technology, applied in the field of multi-performance coating filter material and preparation, can solve problems such as no technical disclosure materials, etc., and achieve the effect of increasing the consistency of filter pore size, avoiding peeling and falling off, and arranging uniformly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

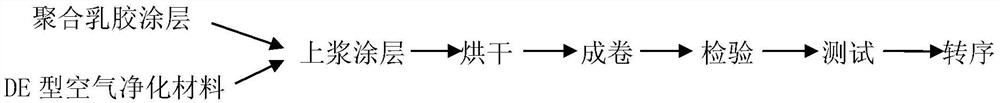

Method used

Image

Examples

Embodiment 1

[0040] (1) Emulsification: Add 20 grams of itaconic acid, 350 grams of ethyl acrylate, 71 grams of allyl polyoxyalkyl epoxy ether, ethyl-2 methyl 1,3 dioxopentyl- 10 grams of 4-base acrylate, 42 grams of methyl methacrylate, 2 grams of fatty alcohol polyoxyethylene ether XL-90, 550 grams of deionized water, and stirred and emulsified for 20 minutes to prepare an emulsion.

[0041] (2) Initiate polymerization reaction: get 20% of the total amount of emulsion, namely 209 grams, add in the reactor, be warming up to 80-82 ° C, add the mixed solution of 1.27 grams of initiator ammonium persulfate and 50 grams of water, initiate, in At this temperature, the remaining 836 grams of the emulsion was added dropwise, and the mixed solution of 0.63 grams of ammonium persulfate and 50 grams of water was added dropwise, and the dropwise addition was completed in 1-2 hours. -40℃, adjust the pH to 7±0.5 with ammonia water;

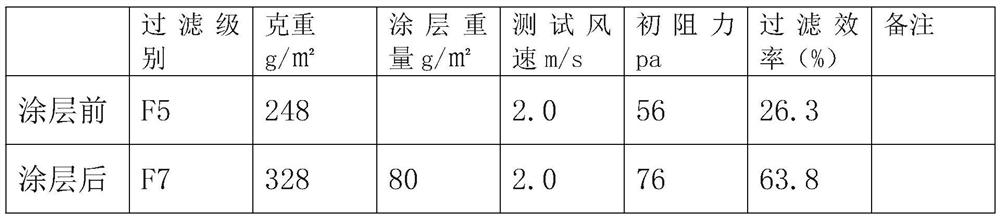

[0042] (3) Compounding: according to different ventilation requirem...

Embodiment 2

[0048] The weight ratio of raw materials is: 20.5 grams of itaconic acid, 355 grams of ethyl acrylate, 72 grams of allyl polyoxyalkyl epoxy ether, ethyl-2 methyl 1,3 dioxopentyl-4 acrylate 10.5 grams, 43 grams of methyl methacrylate, 2.1 grams of fatty alcohol polyoxyethylene ether XL-90, 2.1 grams of ammonium persulfate, 580 grams of deionized water, 70 grams of polymer emulsion, 27 grams of water, and Liaoning Xingxing Fine Chemical Co., Ltd. The thickener FS-300H of production is 3g, and the technological process of production is with embodiment 1.

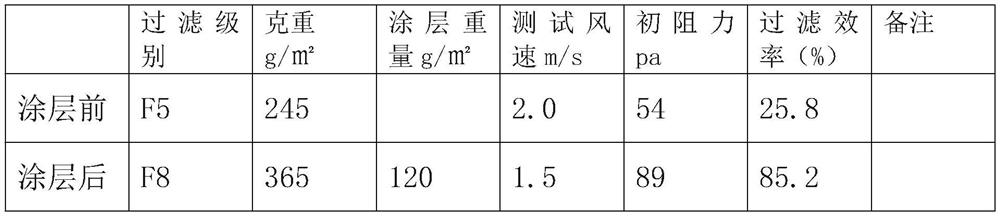

[0049] Coating: Sizing weight: 120g / ㎡, speed: 8m / nim, drying temperature 140℃.

[0050] The DE type air filter material grade is F5, and the filter grade after sizing is F8.

[0051] Comparison table of performance indicators before and after DE air filter material coating

[0052]

Embodiment 3

[0054] The weight ratio of raw materials is: 21 grams of itaconic acid, 360 grams of ethyl acrylate, 73 grams of allyl polyoxyalkyl epoxy ether, ethyl-2 methyl 1,3 dioxopentyl-4 acrylate 10.5g, 4g methyl methacrylate, 2.g fatty alcohol polyoxyethylene ether XL-90, 2.1g ammonium persulfate, 600g deionized water, 80g polymer emulsion, 17g water, and Liaoning Xingxing Fine Chemical Co., Ltd. The thickening agent FS-300H of production is 3g, get the polymerization emulsion 70g, add water 27g and the thickening agent FS-300H that Liaoning Xingxing Fine Chemical Co., Ltd. produces is 3g, and the technological process of production is with embodiment 1.

[0055] Coating: Sizing weight: 160g / ㎡, speed: 6m / nim, drying temperature 140℃.

[0056] The DE type air filter material grade is F5, and the filter grade after sizing is F9.

[0057] Comparison table of performance indicators before and after DE air filter material coating

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com