Patents

Literature

384results about How to "Soft and smooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Disperse dye composition suitable for basic dyeing

ActiveCN101649129AAvoid problems such as contaminationGuaranteed stabilityOrganic dyesDyeing processDisperse dyeColour fastness

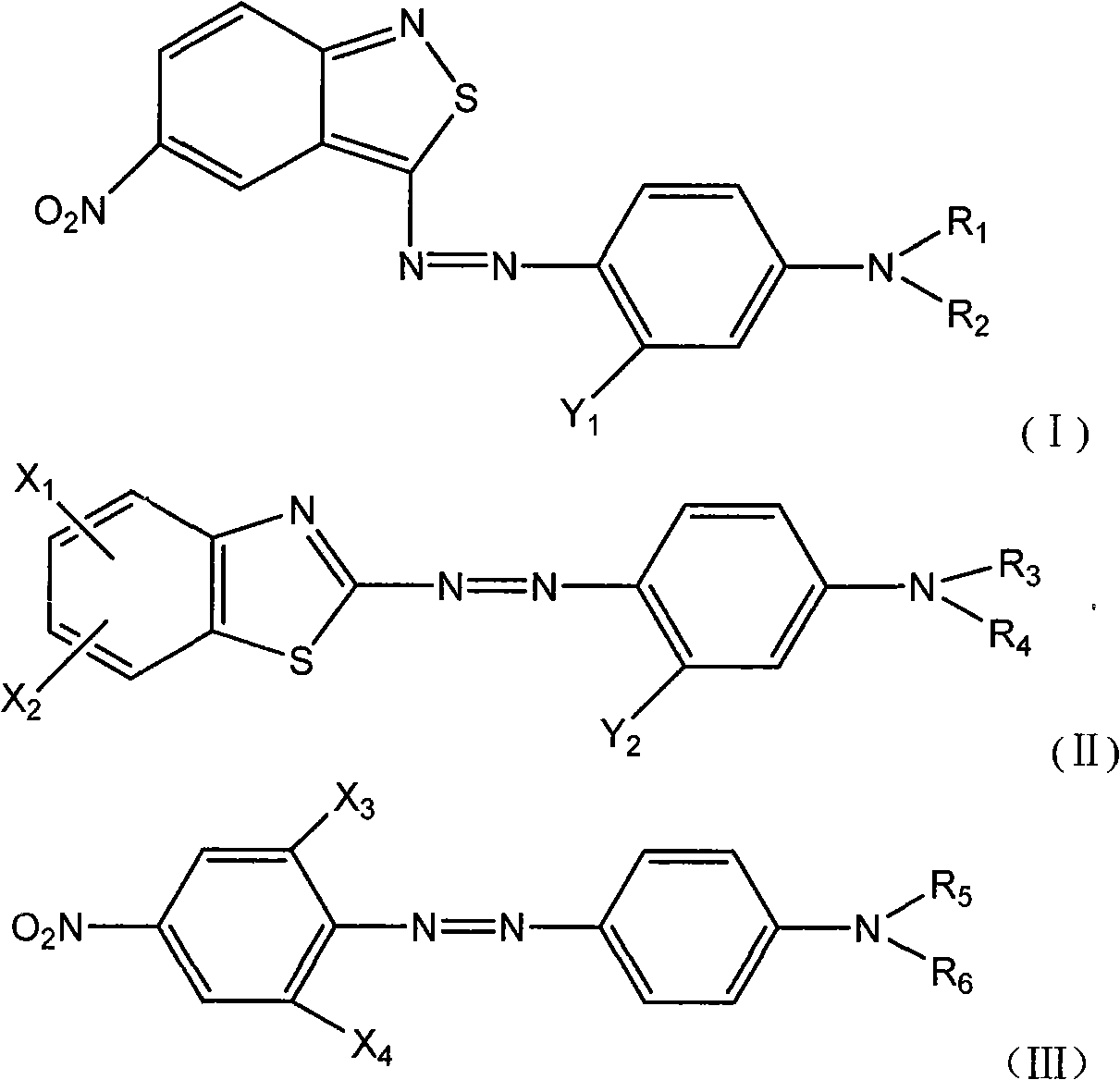

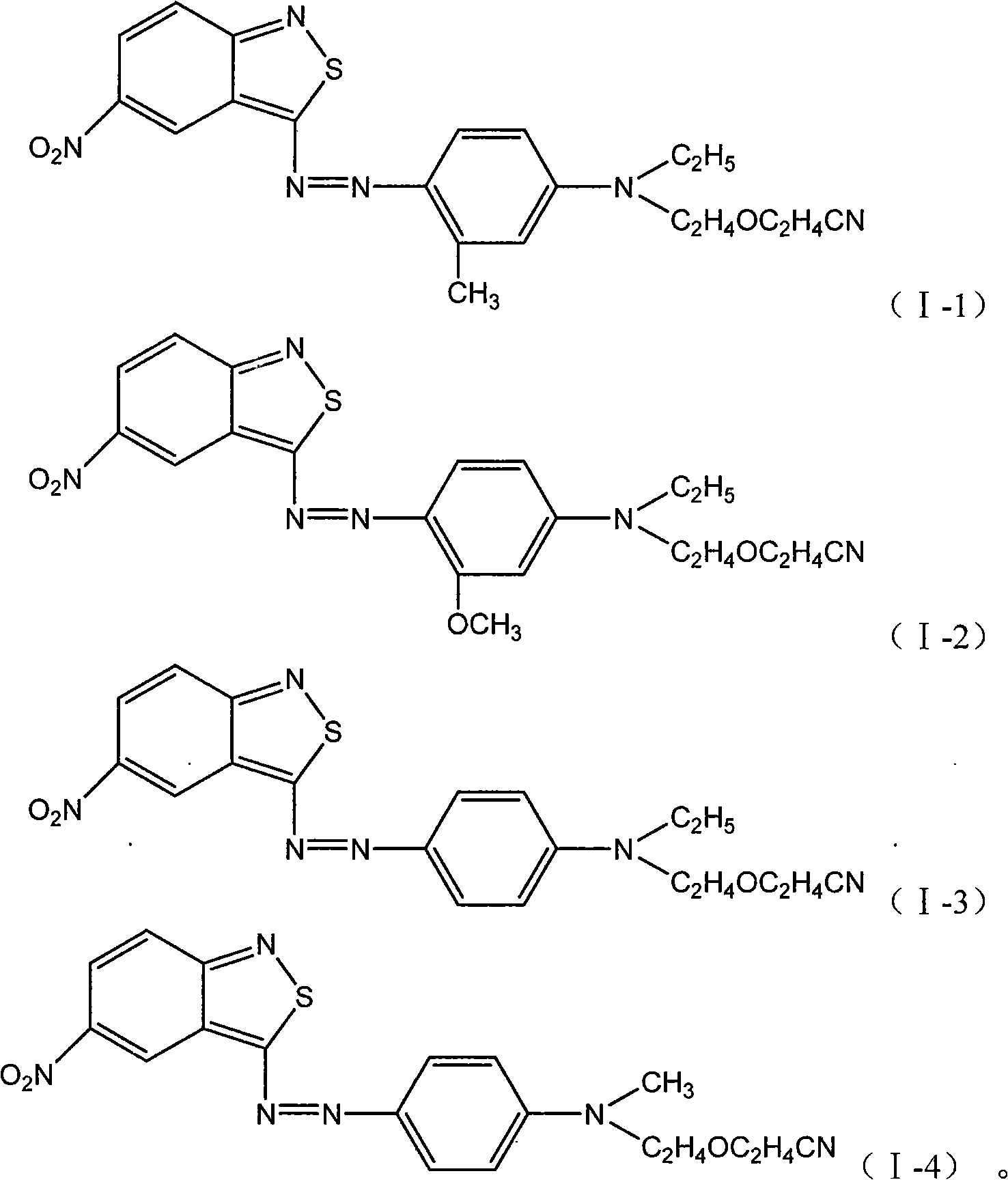

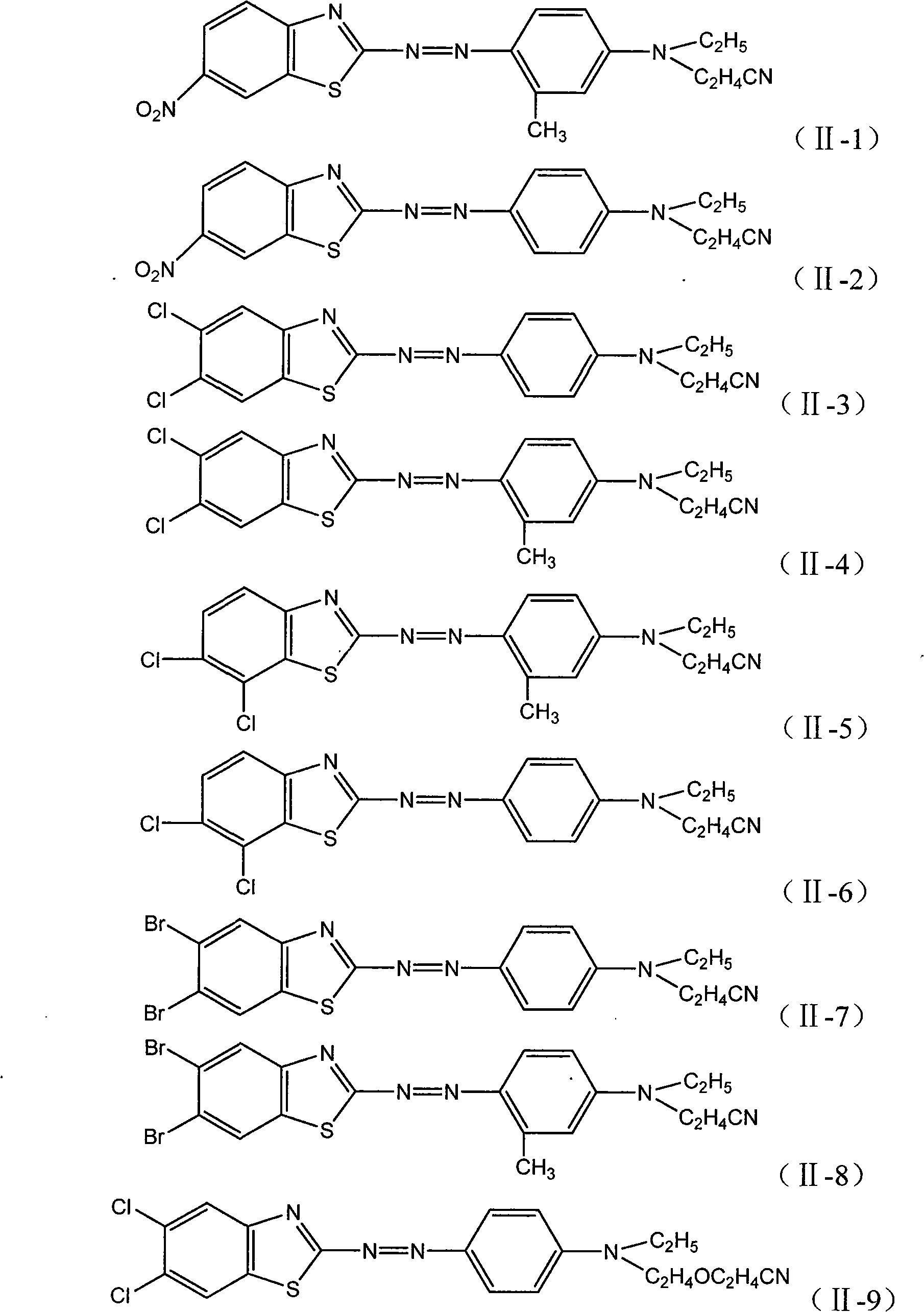

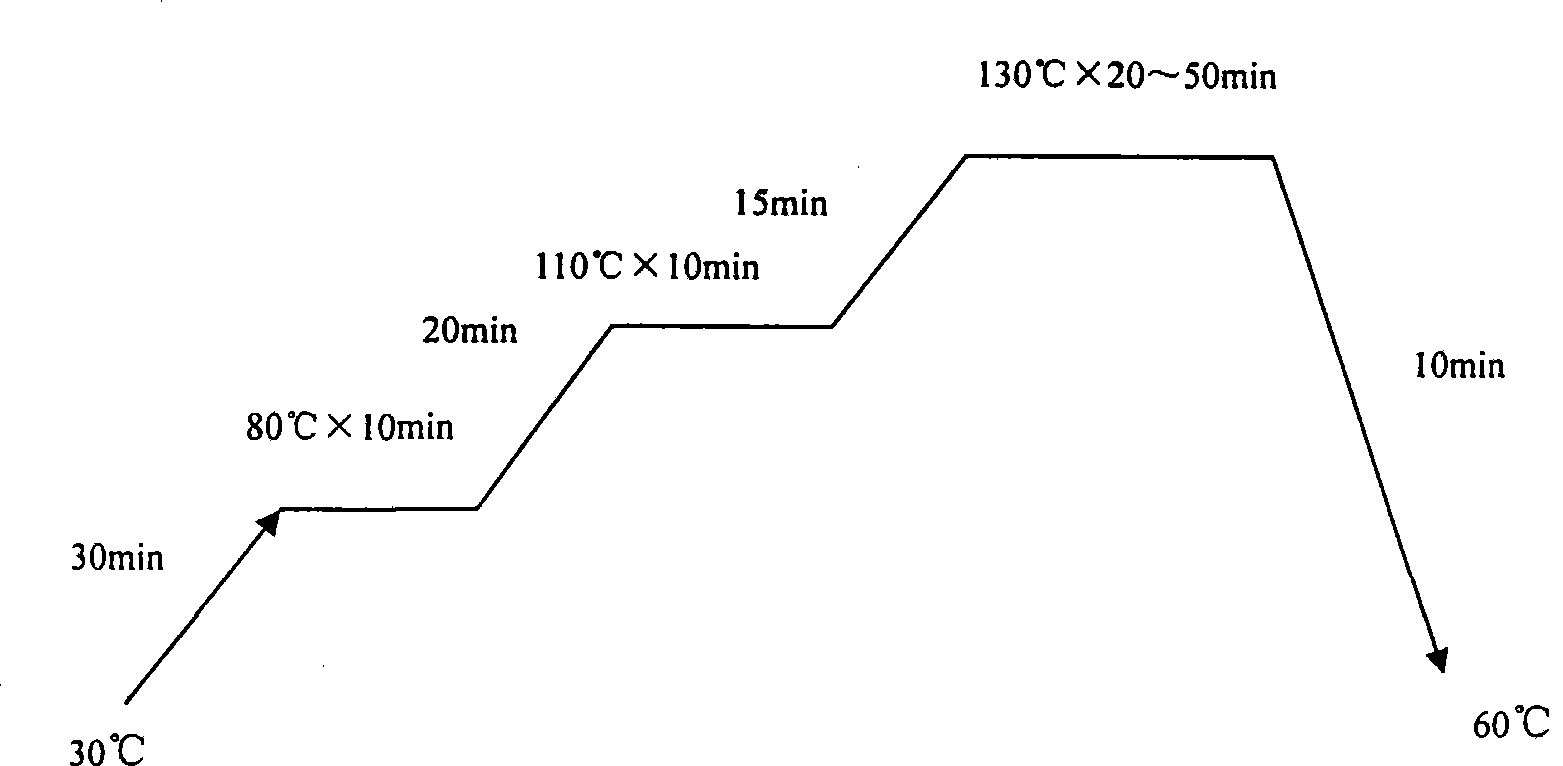

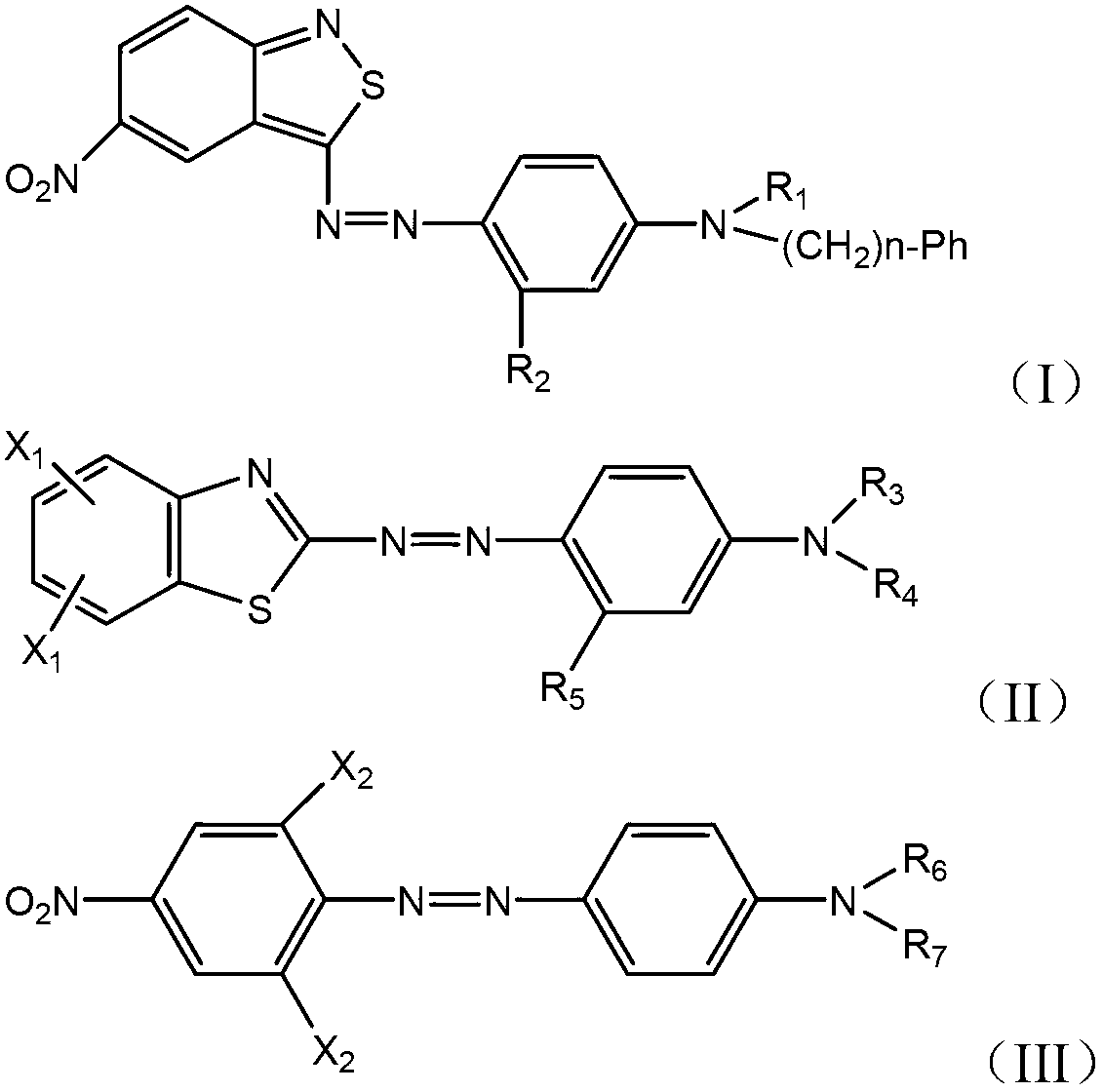

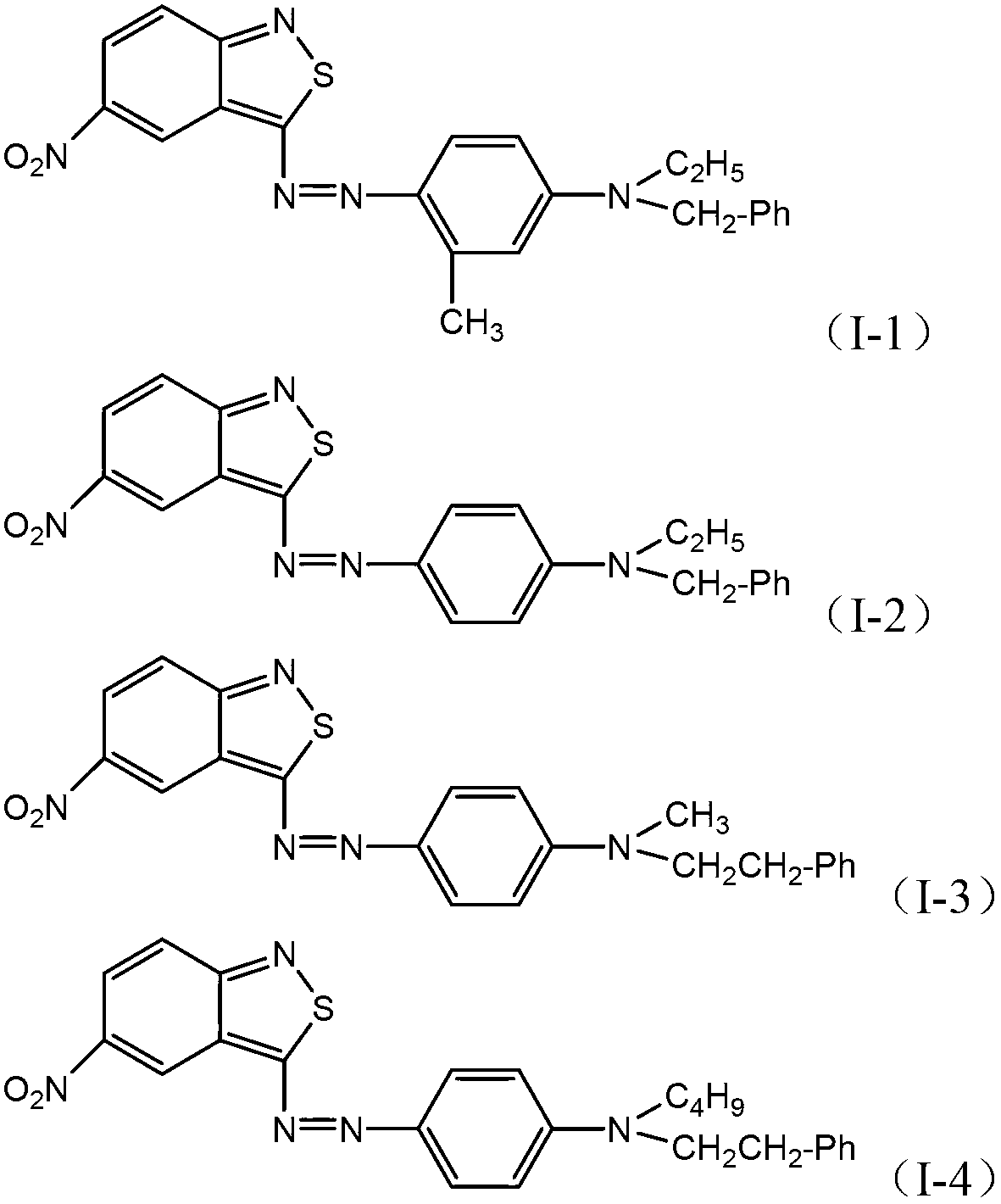

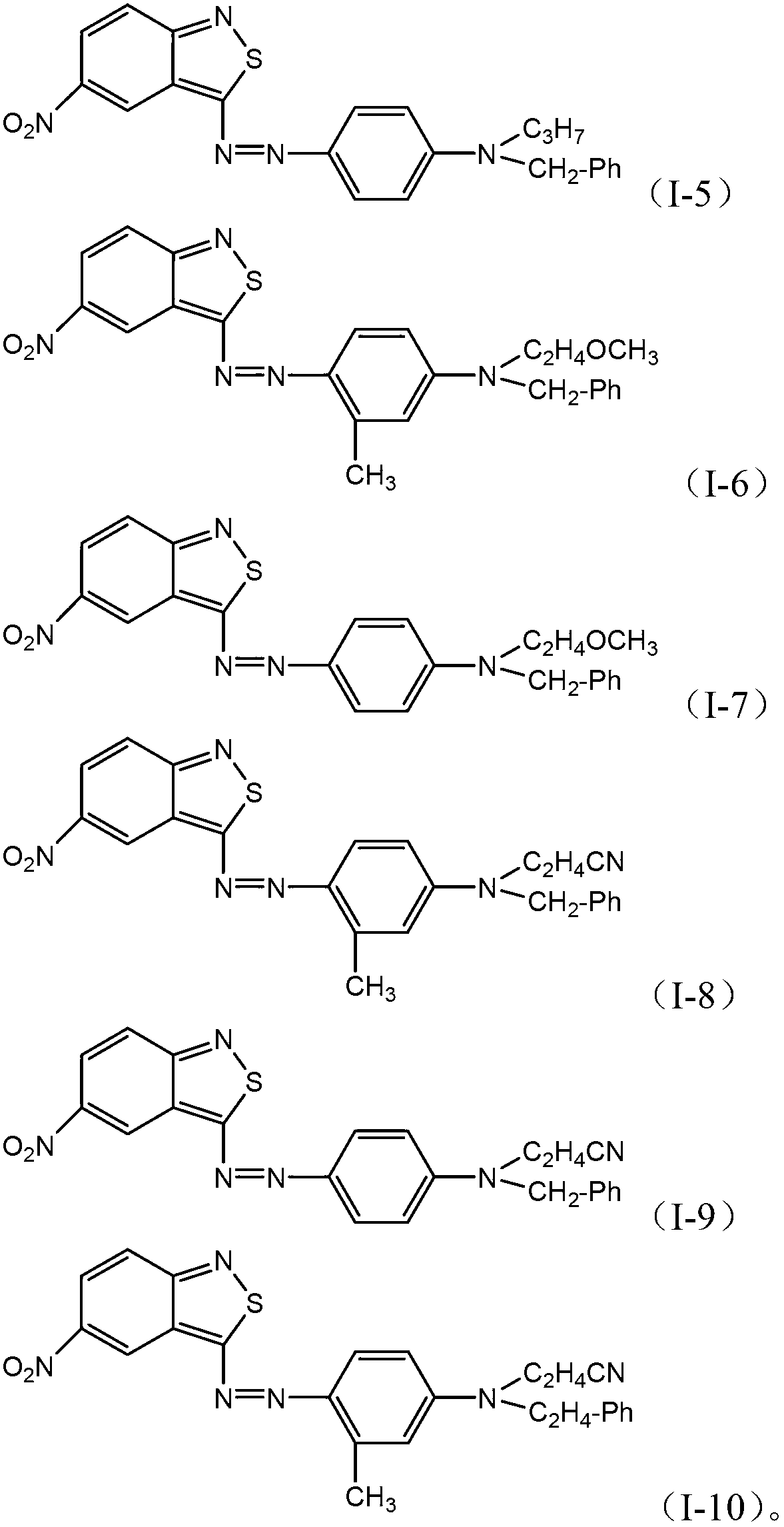

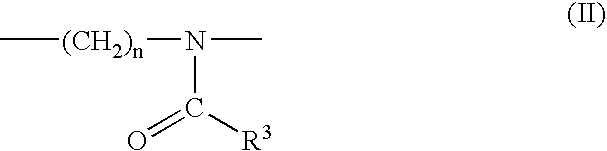

The invention provides a disperse dye composition suitable for basic dyeing, mainly comprising the following raw materials in percentage by weight: 40-95 percent of one or a plurality of blue dyeing components A with a structural formula (I), 1-25 percent of one or a plurality of red dyeing components B with a structural formula (II) and 4-50 percent of one or a plurality of orange dyeing components C with a structural formula (III). The disperse dye composition has a wide dependency range of pH values, and can dye in a pH value ranging from 4.0 to 10; dyed and woven fabrics with predominant color-fastness performance, such as full hues, washing fastness, and the like, can be obtained.

Owner:浙江龙盛染料化工有限公司

Hydrophilic block polyether amino silicone oil with amino branched chain, and preparation method and application thereof

The invention discloses hydrophilic block polyether amino silicone oil with an amino branched chain and a preparation method thereof. The hydrophilic block polyether amino silicone oil with the amino branched chain has the following structure as shown in the specification, wherein R1 is represented by formulas shown in the specification. The preparation method comprises the following steps: carrying out mixing reaction of tetramethyl dihydro disiloxane, polysiloxane and concentrated sulfuric acid, neutralizing with anhydrous sodium carbonate, carrying out reduced pressure pumping to remove a low-boiling-point substance, and thus obtaining silicone oil with the end containing hydrogen; carrying out mixing reaction of the silicone oil with the end containing hydrogen, allyl epoxy polyether and a catalyst, and thus obtaining epoxy silicone oil; carrying out mixing reaction of the epoxy silicone oil, polyether amine and a solvent, and thus obtaining block polyether amino silicone oil; and carrying out mixing reaction of the block polyether amino silicone oil, a silane coupling agent hydrolysate and an alkali catalyst, neutralizing with glacial acetic acid, and thus obtaining the hydrophilic polyether amino silicone oil with the amino branched chain.

Owner:江阴市诺科科技有限公司

Method for fabricating soft knitting face fabric from cotton

InactiveCN101003936ADimensionally stableDoes not reduce strengthFabric breaking/softeningBiochemical fibre treatmentAgricultural engineeringSizing

The present invention discloses a processing method of flexible cotton knitted face fabric. Said processing method includes the following several steps: weaving, enzymatic washing, kiering and bleaching, dyeing, oversoftening, dewatering, opening, drying, sizing and pre-shrinking.

Owner:浙江盛泰服装集团股份有限公司

Printing method of different patterns of double surfaces of warp knitting plush single-layer blanket

ActiveCN103741364AAnti-stickingFeel smooth and plumpWarp knittingHeating/cooling textile fabricsRough surfaceEngineering

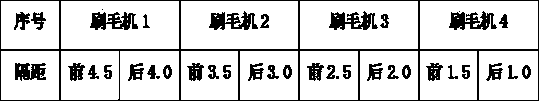

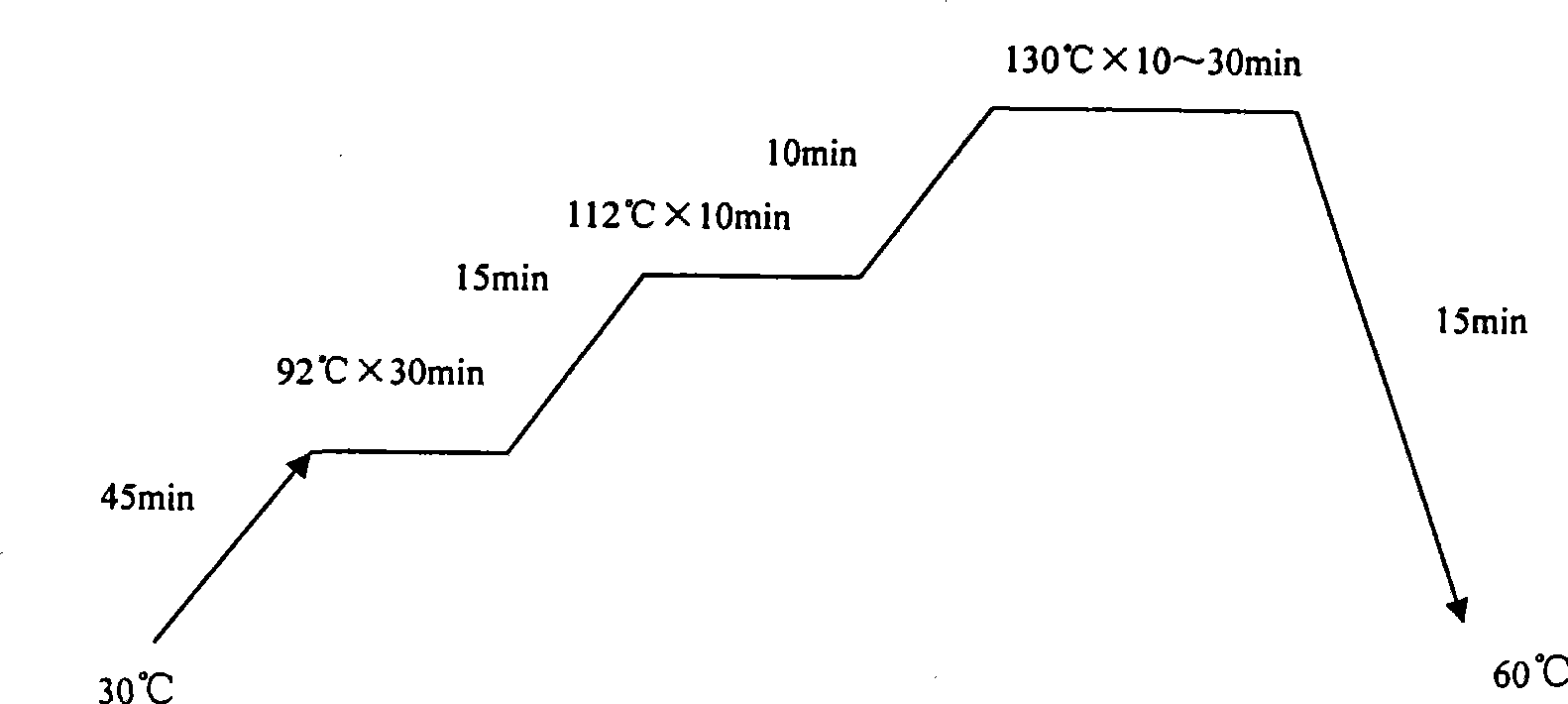

Provided is a printing method of different patterns of double surfaces of a warp knitting plush single-layer blanket. Appropriate raw materials are selected to be woven to form grey cloth, secondary removing presetting is conducted, and then pre-processing is conducted; after reverse-side napping tidying is conducted on the warp knitting plush grey cloth in a pre-processing procedure, various printing parameters are regulated according to gram weights and plush heights of the warp knitting plush single-layer blanket, the front side is printed firstly, then the reverse side is printed, and a semi-finished plush single-layer blanket with the different patterns on the front side and the reverse side is obtained; brushing, ironing, shearing, cloth cutting and edge covering are conducted on the front side and the reserve side of the semi-finished plush single-layer blanket, and the finished plush single-layer blanket is obtained. The printing method is reasonable in technology, the blanket with the different patterns on the front side and the reverse side can be obtained, product diversity is improved, the printing effect is good, white plush can not occur on the surface of the warp knitting plush single-layer blanket, the rough surface is glossy and bright, the plush surface is tidy, relatively elastic, and soft and smooth in hand feeling, and the warp knitting plush single-layer blanket achieves quality of a top-grade blanket.

Owner:连云港飞雁毛毯有限责任公司

Super-soft SS (spunbond and spunbond) nonwoven fabric and production process thereof

ActiveCN103132241AAppropriately meet the requirements of tender skinSoft and smoothNon-woven fabricsElastomerMasterbatch

The invention discloses super-soft SS (spunbond and spunbond) nonwoven fabric. The super-soft SS nonwoven fabric is mainly made from, by weight, 55-90 parts of polypropylene, 5-40 parts of elastomer, 1-4 parts of softener and 0.5-1 part of cooling masterbatch. The invention further discloses a production process of the super-soft SS nonwoven fabric. The production process includes the steps of preparing raw materials and auxiliary materials according to the proportion, mixing well, melt-compressing by a screw extruder to obtain viscous flow melt, sending the melt into a melt filter for filtration, allowing the melt to enter a spinning die head, allowing trickle of the melt to be extruded out of spinneret orifices, allowing a drafting air channel to draft and shape the trickle of the melt under the action of process cooling air so as to obtain fiber of certain strength, allowing the fiber to be evenly adsorbed to a forming conveyor belt by a diffusion air channel to form a continuous mesh fiber layer, and rolling the fiber mesh into the nonwoven fabric of certain longitudinal and transverse tension by a hot rolling mill. The SS nonwoven fabric produced according to the formula by the process is smaller than 1.5g in softness, and is as soft and smooth as silk to touch and highly suitable for shell fabrics of baby diapers.

Owner:JINJIANG XINGTAI NON WOVEN PRODS

Koala velvet and production method thereof

InactiveCN101440552ASolve looseSolve the feelWarp knittingHeating/cooling textile fabricsFiberMaterials preparation

The invention discloses koala flock and a method for manufacturing the same. The koala flock is manufactured by taking 56 to 83dtex Shaoguang flat cross section fibers or semi-Shaoguang flat cross section fibers as koala flock face fibers, and 56 to 76dtex terylene FDY as bottom fibers, whereinthe 56 to 83dtex Shaoguang flat cross section fiber or semi-Shaoguang flat cross section fiber is 30 to 85 portions, and the 56 to 76dtex terylene FDY is 15 to 50 portions. The method comprises production processes of material preparation, weaving, thermal shaping, dyeing, treatment after dyeing, dewatering, colored cloth shaping, front face gigging, finished cloth shaping, combing, scalding, clipping and the like, and the flat fibers are used to replace the conventional circular fiber, so that the simulated koala flock with unique style is produced. The height of the koala flock is between 0.5 and 7mm, and the koala flock touches soft and smooth, and can be widely used in the production of flock toys, indoor flock slippers, blankets, knitting flock and the like, and can fully meet market demands.

Owner:ZHANGJIAGANG JINGDONG KNITTING PLUSH

Blue-to-black disperse dye composition

ActiveCN102746713AStrong alkali resistanceAvoid problems such as contaminationOrganic dyesDisperse dyeAlkali burn

The invention provides a blue-to-black disperse dye composition, which mainly comprises one or multiple blue dye ingredients A shown as the structure formula (I), one or multiple red dye ingredients B shown as the structure formula (II) and one or multiple orange dye ingredients C shown as the structure formula (III). The disperse dye composition has the advantages that the dying bottleneck of the existing ordinary disperse dye under the alkaline condition is broken through, the problems of white powder, color points and dyeing defect generation caused by the dyeing under the acid condition, the contamination on the inner wall of dyeing equipment caused by low polymers, and the like are solved, the dyeing quality is effectively improved, the stability and the reproducibility of the process are ensured, and the once success rate of the dyeing is improved. In addition, the prepared disperse dye has higher alkali resistance capability and can be applied to an alkali burnt-out process, the defect of single acid burnt-out color is overcome, and the requirements of the society on the aesthetic perception and the variety on clothing and decorations are met.

Owner:ZHEJIANG LONGSHENG GROUP +1

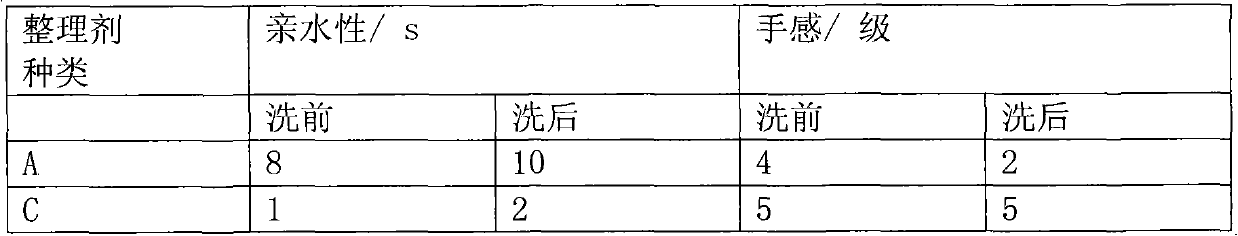

Preparation method of hydrophilic amino silicone oil

The invention discloses a preparation method of hydrophilic amino silicone oil. The invention is characterized in that the preparation method comprises the following steps: A. the preparation of low-hydrogen silicone oil: siloxane ring body, high-hydrogen silicone oil, blocking agent and acid are mixed for reaction and are cooled, and the pH is adjusted; B. the preparation of epoxy silicone oil: the prepared low-hydrogen silicone oil, alkenyl epoxy compound and catalyst are mixed for reaction and are cooled; and C. the preparation of hydrophilic amino silicone oil: the prepared epoxy silicone oil, organic amine and solvent are mixed for reaction, and the solvent is distilled. The bonding is firmer in the form of a chemical bond when the hydrophilic amino silicone oil prepared by the method reacts with the fabric, and the hydrophilic amino silicone oil is washable, has soft effect of the common amino silicone oil, no yellowing and good smoothness and antistatic property, and can be widely used in fabric finishing.

Owner:HUBEI COLOR ROOT TECH CO LTD

Production process of high-count and high-density long stapled cotton shirt fabric

ActiveCN105671727AImprove permeabilityImprove wear resistanceSucessive textile treatmentsDry-cleaning apparatus for textilesYarnHigh density

The invention relates to a production process of a high-count and high-density long stapled cotton shirt fabric. The finished product fabric is prepared from long stapled cotton yarns sequentially by processes of slashing, weaving, singeing, desizing, boiling-off, cold pad batch dyeing, liquid ammonia mercerized finishing, moist-cure anti-crease finishing and preshrinking, and the long stapled cotton yarns adopt 140s / 2 celo compact-spun GIZA45 long stapled cotton yarns and are woven into twill weaves. According to the production process provided by the invention, the long stapled cotton yarns are used as raw materials; technologies of cold pad batch dyeing, liquid ammonia mercerized finishing and moist-cure anti-crease finishing are combined; the energy-saving environmental-friendly high-count and high-density shirt fabric is developed; the high-count and high-density long stapled cotton shirt fabric has soft and comfortable hand feeling, fine and soft gloss and excellent wear comfort, mode-holding nature and anti-crease property and can be free of ironing; the comprehensive technology of the product reaches the domestic advanced level; the high-count and high-density long stapled cotton shirt fabric has wide market prospect and social and economic benefits; meanwhile, the energy-saving environmental-friendly fabric production process reduces pollution to the environment and makes a contribution to development of a cleaning fabric processing technology and social sustainable development.

Owner:FUJIAN SEPTWOLVES IND

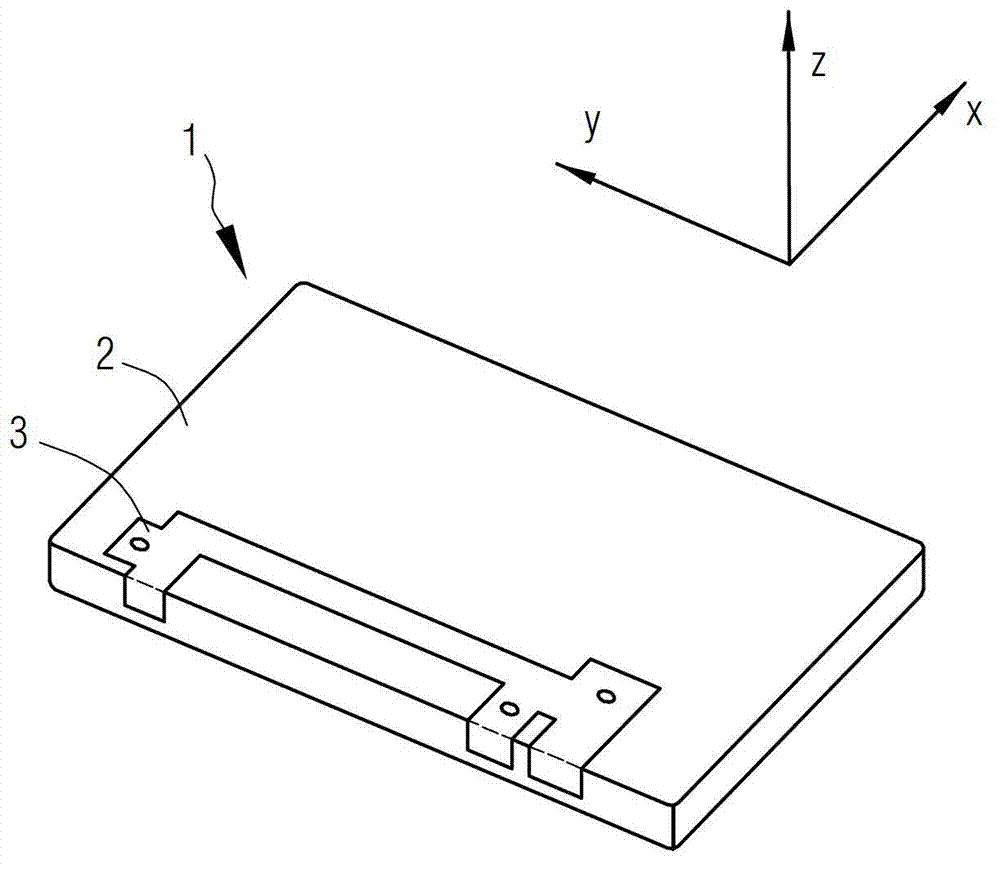

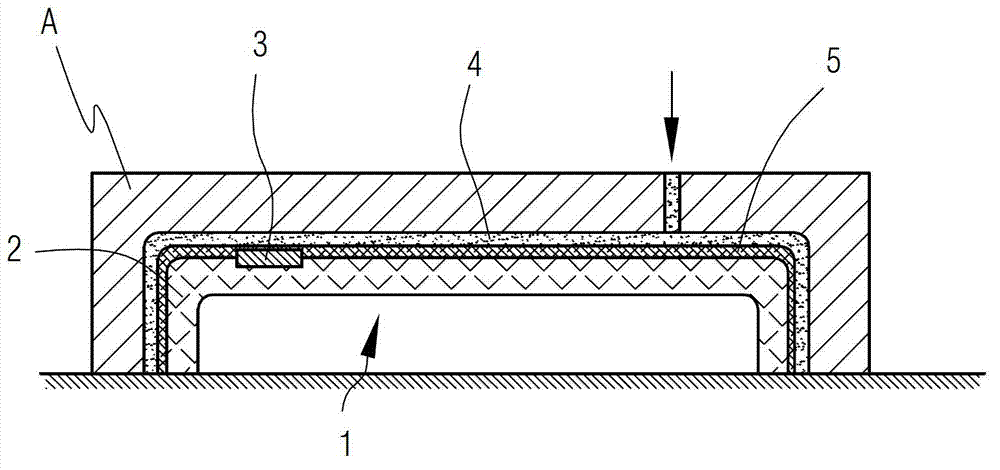

Electronic device housing and manufacturing method therefor

ActiveCN102781187AStrong tear resistanceHigh tensile strengthAntenna supports/mountingsCasings/cabinets/drawers detailsEngineeringSilica gel

The invention discloses an electronic device housing and a manufacturing method for the electronic device housing. The manufacturing method comprises the following steps: forming a metal antenna on the surface of an active plastic layer of the electronic device housing by an LDS (Laser Direct Structuring) technology; spraying a layer of bottom coating agent on the surface of the active plastic layer and the surface of the metal antenna; moulding a layer of liquid silica gel on the surface of the active plastic layer sprayed with the bottom coating agent and the surface of the metal antenna in an injection way, drying the liquid social gel to form a silica gel protective layer. According to the electronic device housing and the manufacturing method for the electronic device housing, the silica gel protective layer is moulded on the surface of the electronic device housing in an injection way by liquid silica gel, and can be suitable for various different using environments for the electronic device housing, can be manufactured to be very soft or relatively hard, and has high anti-tearing and anti-stretching strength; simultaneously, the product is diversified in colour, smudginess-resistant, chemical-resistant, and soft and smooth in hand feeling.

Owner:LOVEPAC CONVERTING BEIJING +1

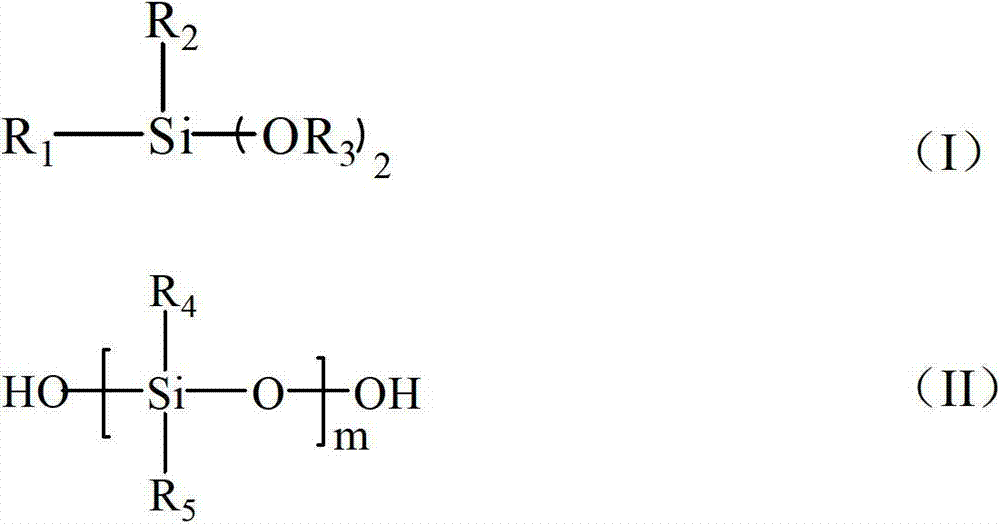

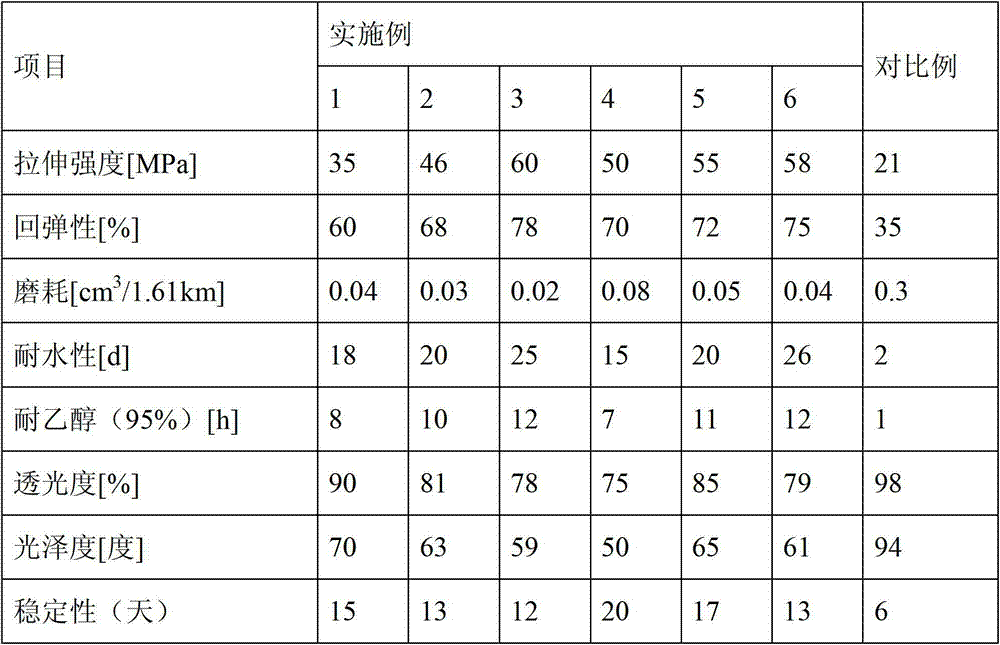

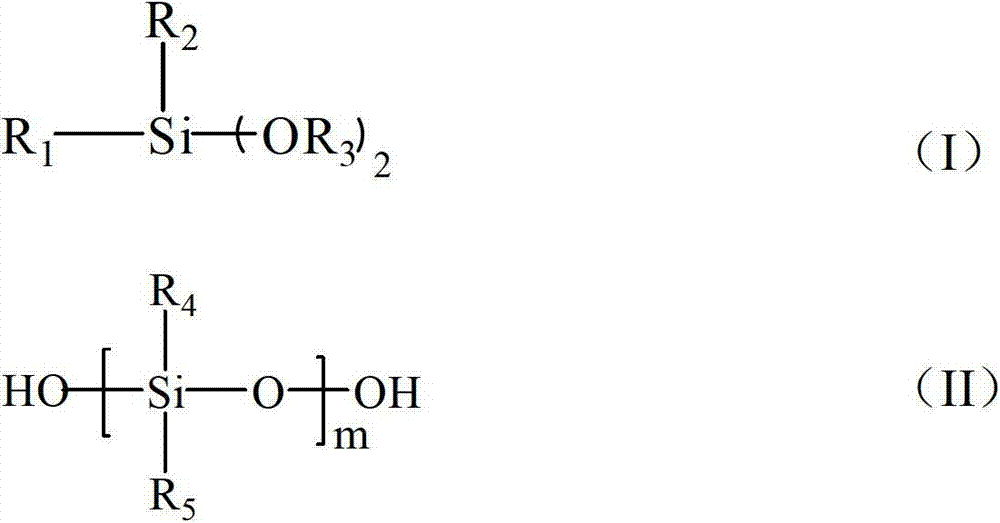

Waterborne polyurethane elastic dispersion and preparation method thereof

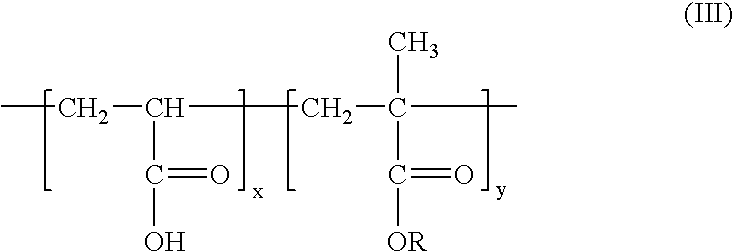

ActiveCN103087286AHigh tensile strengthIncrease elasticityFibre treatmentPolyurea/polyurethane coatingsPolyurethane dispersionPolymer science

The invention relates to a preparation method of waterborne polyurethane elastic dispersion. The method comprises the following steps: (1) synthesizing a siloxane polymer: polymerizing a compound as shown in formula (I) and the compound as shown in formula (II) to get the siloxane polymer; and (2) preparing the waterborne polyurethane elastic dispersion, wherein the raw material comprises the siloxane polymer obtained in the step (1). After the elastic polyurethane dispersion provided by the invention forms a film, the waterborne polyurethane elastic dispersion has not only excellent tensile strength, rebound elasticity, wear resistance, water resistance and ethanol tolerance, but also soft and smooth hand feeling and high light transmission; and an additional filler is not required, a product has high light extinction or frosted appearance by only adjusting components, after the film is formed, the elastic polyurethane dispersion is soft, and the elastic polyurethane dispersion is suitable for paper, cloth, leather and other soft substrates, and the preparation process is simple and easy to operate.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

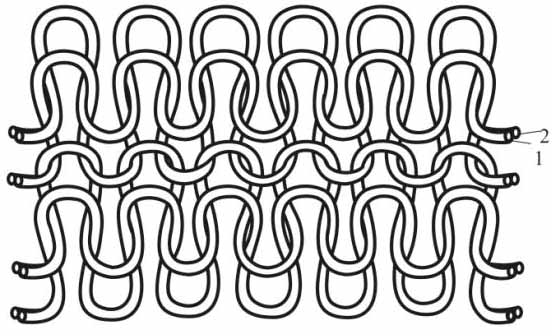

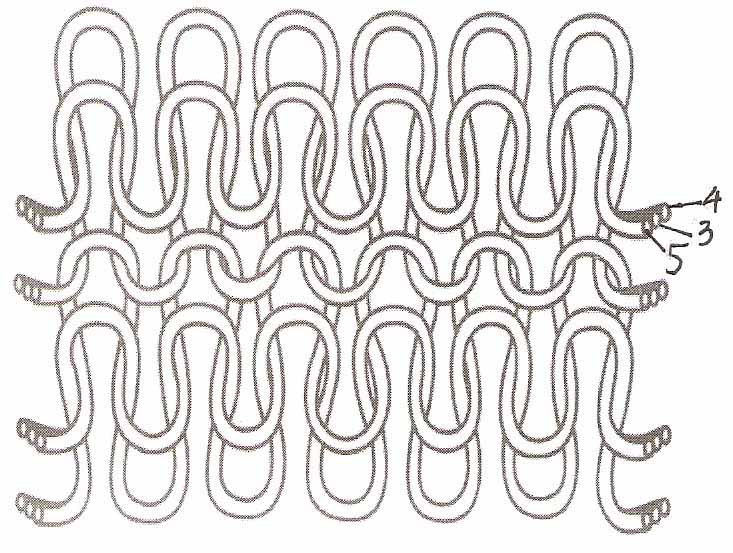

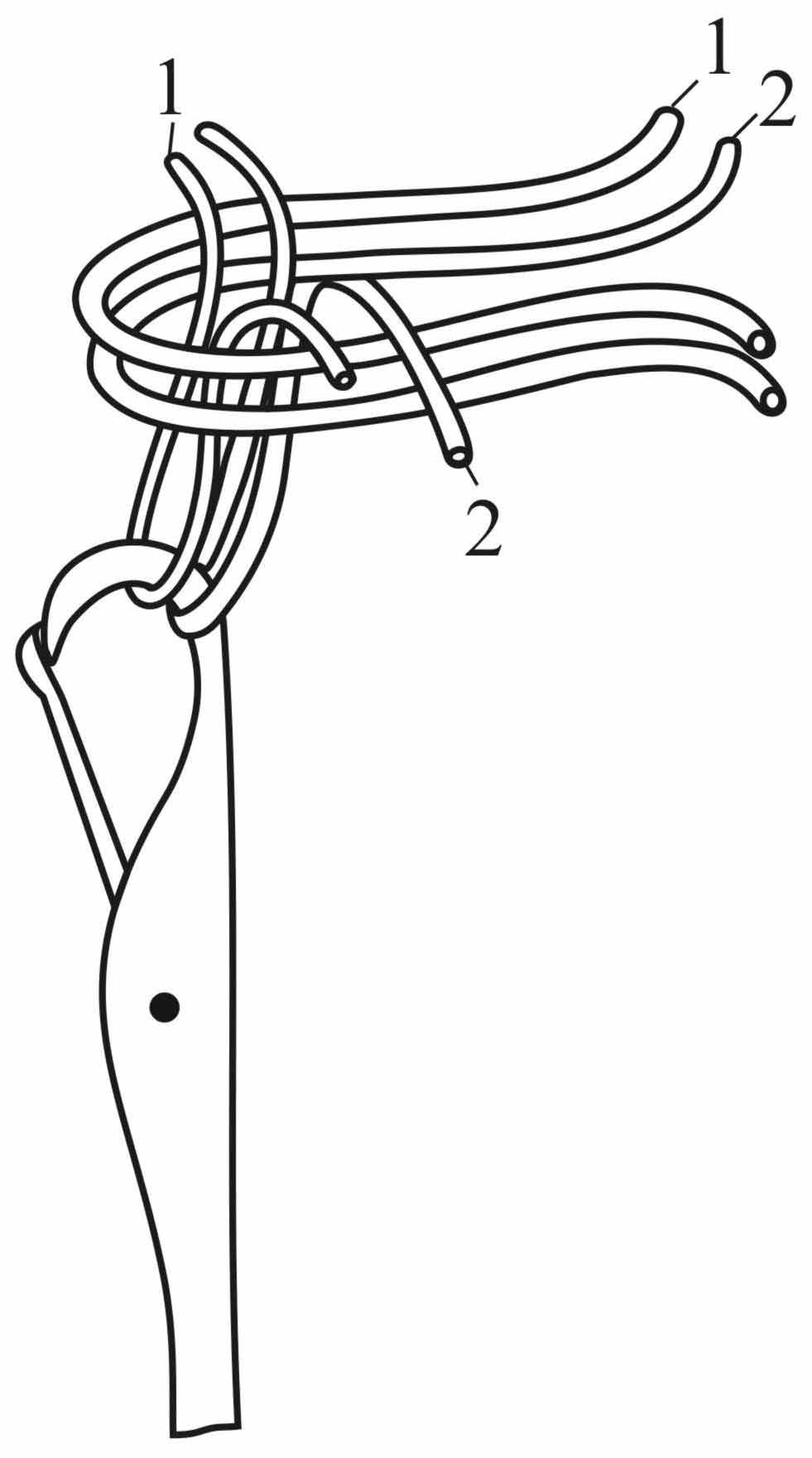

Electromagnetic radiation resistant knitted fabric and weaving method thereof

The invention discloses a knitted electromagnetic radiation resistant fabric and a weaving method thereof. The fabric is a plain stitch-based or 1+1 rib-based all-plated tissue knitted fabric, all coils in the fabric are formed by superposing at least two coils, one kind of yarn is exposed at one side of the fabric, and the other kind of yarn is exposed at the other side of the fabric; and one kind of yarn is common yarn or polyurethane core-spun yarn, and the other kind of yarn is conductive fiber yarn. The fabric produced by adopting the weaving method organically combining the common yarn or the polyurethane core-spun yarn and the conductive fiber yarn has electromagnetic radiation resistance, and the electromagnetic radiation resisting capacity of the fabric can reach over 99 percent. The fabric has the advantages of soft and smooth handfeel, good moisture permeability, bright color, washing resistance, subtleness and good wrinkle resistance.

Owner:JIANGSU TANGWEAR IND

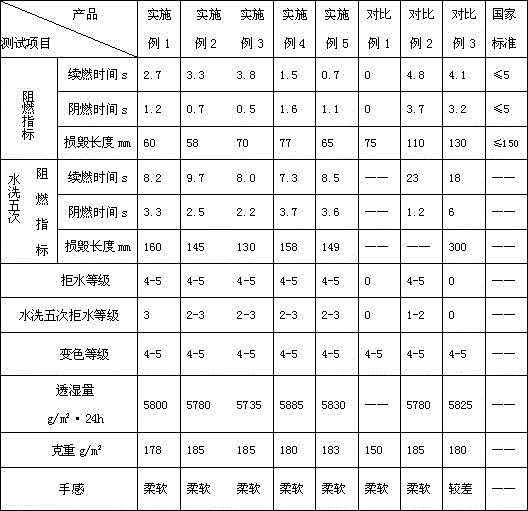

Durable flame-retardant, water-repellent, waterproof and moisture permeable finishing method of polyester fabric

ActiveCN106049049AEffective Flame RetardancyDoes not affect flame retardancyFireproof paintsHeat resistant fibresPolyesterAdhesive

The invention relates to a durable flame-retardant, water-repellent, waterproof and moisture permeable finishing method of a polyester fabric. A flame-retardant and water-repellent finishing agent is prepared from 20-30 parts of cyclic phosphate flame retardants, 60-70 parts of water, 1-1.5 parts of isocyanate cross-linking agents, 3-5 parts of fluorocarbon copolymer waterproof agents and 2-5 parts of NaOH with 10% mass concentration. A bottom coating adhesive is prepared from 100 parts of polyether polyurethane polymer under-coating adhesives, 5-10 parts of methylbenzene, 5-10 parts of butanone, 2 parts of isocyanate cross-linking agents, 1 part of accelerant and 25-35 parts of organic phosphorus-nitrogen flame retardants. A surface coating adhesive is prepared from 100 parts of polyether polyurethane polymer top-coating adhesives and 35-45 parts of methylbenzene. The fabric is padded, calendered, under-coated and top-coated with water repellents to achieve finishing by the flame-retardant and water-repellent finishing agent, the bottom coating adhesive and the surface coating adhesive.

Owner:DANDONG UNIK TEXTILE

Semi-durable ramie nonwoven material for home textiles and production method thereof

InactiveCN102220674AGood for healthImprove protectionPattern makingNon-woven fabricsUltraviolet lightsNonwoven fabric

At present, natural fibrilia non-woven fabric materials are partial to a heavy type, and are mainly applied to the field of materials for automobiles, but the application of the natural fibrilia non-woven fabric materials to the field of home textiles is limited. The invention provides a semi-durable ramie nonwoven material for the home textiles, which comprises a matrix material and a surface modification layer formed by padding the matrix material in finishing liquid, wherein the matrix material comprises the following components in percentage by mass: 80 to 90 percent of ramie combed noil fibers and 10 to 20 percent of polylactic acid bi-component fibers; the finishing liquid comprises the following components in percentage by mass: 97.5 to 99.4 percent of polyacrylate bonding agent, 0.2 to 1.5 percent of hydrophilic organic silicon softening agent and 0.1 to 0.5 percent of penetrating agent; and the thickness of the ramie nonwoven material for the home textiles is between 0.5 and 1.5 millimeters, and the weight is between 60 and 120 grams / square meter. The semi-durable ramie nonwoven material has the functions of light weight, thinness, washability, antibacterium, acarid prevention, static resistance and ultraviolet light prevention, is soft in handfeel, and can be degraded completely after being discarded.

Owner:JIAXING UNIV

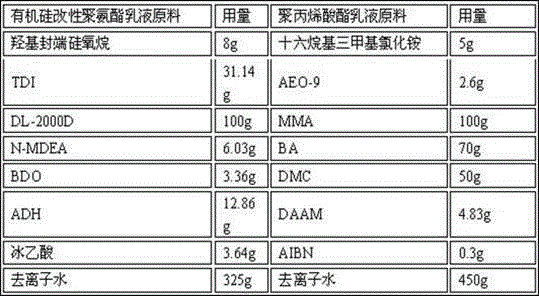

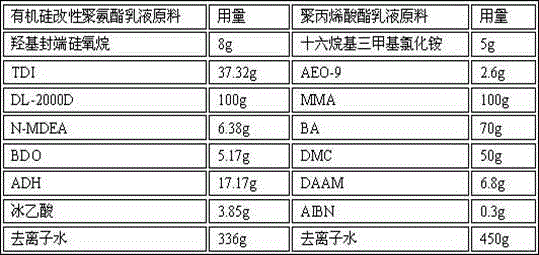

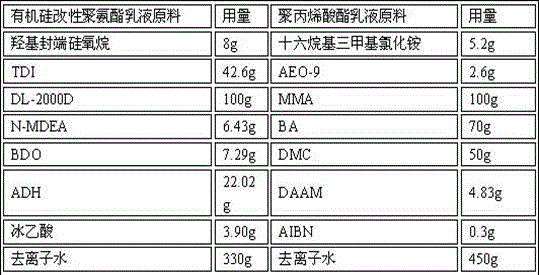

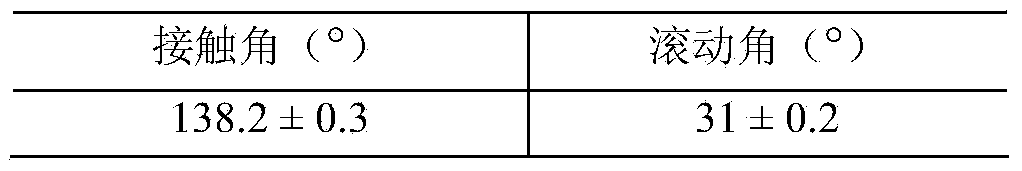

Cationic organosilicon modified waterborne PUA fabric coating adhesive with self crosslinking structure and preparation method thereof

InactiveCN106149381AImprove mechanical propertiesImprove water resistanceFibre treatmentPolyesterDiacetonamine

The present invention discloses a preparation method of a cationic organosilicon modified waterborne PUA fabric coating adhesive with a self crosslinking structure, the method is as follows:(1)using polyisocyanate and hydroxyl-terminated polysiloxane for synthesis of an-NCO-group-terminated prepolymer;(2)adding polyether or polyester glycol for reaction;(3)reacting with a cationic hydrophilic chain extender for a period of time, and further reacting with adipic dihydrazide(ADH)to obtain a hydrazine-terminated cationic waterborne polyurethane emulsion;(4)using acrylate monomers and diacetone acrylamide(DAAM)for preparing a hydrazide-group-containing polyacrylate emulsion; and(5)mixing the hydrazine-terminated cationic waterborne polyurethane emulsion and the hydrazide-group-containing polyacrylate emulsion in a certain proportion to obtain the self-crosslinking cationic organosilicon modified waterborne PUA fabric coating adhesive. The self-crosslinking cationic organosilicon modified waterborne PUA fabric coating adhesive avoids the use of a harmful crosslinking agent, has the advantages of being environmental-friendly, high in water pressure resistance, good in mechanical properties, low in cost, and dyeable and the like, and can be used for coating finishing of nylon fabrics.

Owner:WUYI UNIV

Preparation method of polyester staple fiber

InactiveCN101285218AStable supplyHigh strengthFilament/thread formingMonocomponent polyesters artificial filamentYarnPolymer science

The invention aims to provide a method for preparing polyester staple fiber. The invention is characterized in that the method adopts the process route of directly spinning melt mass to manufacture, and uses purified terephthalic acid (PTA) and ethylene glycol (EG) as raw materials and adds small quantities of mono-pentaerythritol, DEG, antimony trioxide, titanium dioxide and other catalysts, flatting agents and stabilizing agents. The method uses the process flow of five autoclaves polymerization to perform polyreaction so as to receive the melt which is finally spun into tows, and prepares the polyester staple fiber via primary drawing, secondary drawing, 18 roller tension heat setting, third drawing, crimping, relaxation heat setting and cutting. The method has the advantages of stable raw material supply, high product strength, few defects, good crimp, moderate oil applying rate and stable dry-heat shrinkage percentage; products prepared by the method have good spinnability, so that yarn spun by the product is high in each quality index, and produced textile has soft and smooth hand feeling; and the manufacturing cost is lower than chip spinning, so that the marketing competitive power of the products is stronger.

Owner:JIANGSU JIANGNAN HIGH POLYMER FIBER

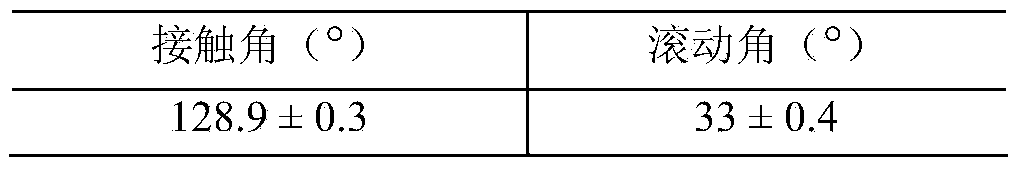

Preparation method of organic/inorganic hybridization nano super-hydrophobic fiber film

ActiveCN103820945AComprehensive collectionUniform diameter distributionNon-woven fabricsFiberPolymer science

The invention relates to a preparation method of an organic / inorganic hybridization nano super-hydrophobic fiber film. The method comprises the steps of dissolving a polymer carrier in water, and heating and stirring to obtain a polymer carrier solution; mixing tetraethoxysilane, water, zinc acetate and phosphoric acid, and stirring at the room temperature to obtain a mixing solution; uniformly mixing the mixed solution and the polymer carrier solution, then performing electrostatic spinning, drying in vacuum, forging, cooling and dipping in HCl solution, and drying to obtain a SiO2 porous nano fiber film; compositing and laminating the SiO2 porous nano fiber film, pouring a liquid, and drying in vacuum to obtain the organic / inorganic hybridization nano super-hydrophobic fiber film. The super-hydrophobic nano inorganic fibers have superhigh hydrophobic performance which can be maintained under the conditions of humidity, low temperature and the like without the FAS processing, is smooth and soft in hand feeling, gets rid of the limitation of the economic cost of an organic fluorocarbon and APEO and the environment-friendly limitation, and has the advantages of low price, no pollution, wide applicable range and the like.

Owner:DONGHUA UNIV +1

Silk digital ink-jet printing method

InactiveCN105002762ANo dischargeNo pollutionDyeing processAnimal fibresTextile printerPolymer science

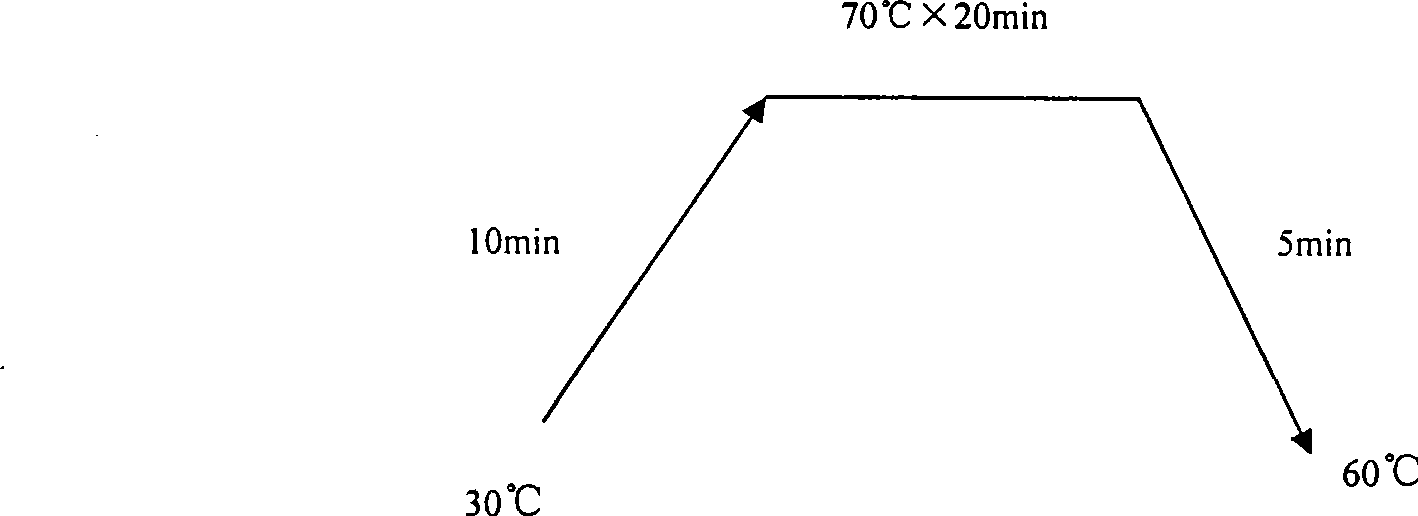

The invention discloses a novel silk digital ink-jet printing method. The novel silk digital ink-jet printing method comprises carrying out fabric pre-treatment: heating a silk fabric to a temperature of 30-35 DEG C for pre-treatment, carrying out sizing on the pre-treated silk fabric by a sizing machine at a sizing temperature of 50-60 DEG C, carrying out drying at a drying temperature of 80-95 DEG C by an infrared drying device, making a file, carrying out ink-jet printing by a digital ink-jet printing device and carrying out dye fixation under saturated vapor at a temperature of 60-65 DEG C for 10-15min. The silk digital ink-jet printing method improves printing effects and color fastness, is free of special treatment on ink, does not need a high heating temperature, produces small damage to the fabric and realizes good hand feeling.

Owner:浙江宝石蝶围巾有限公司

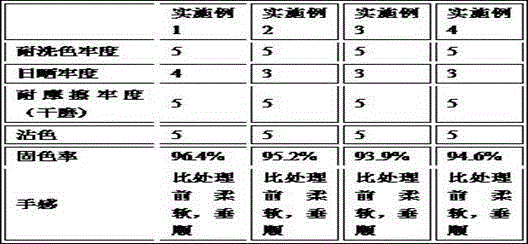

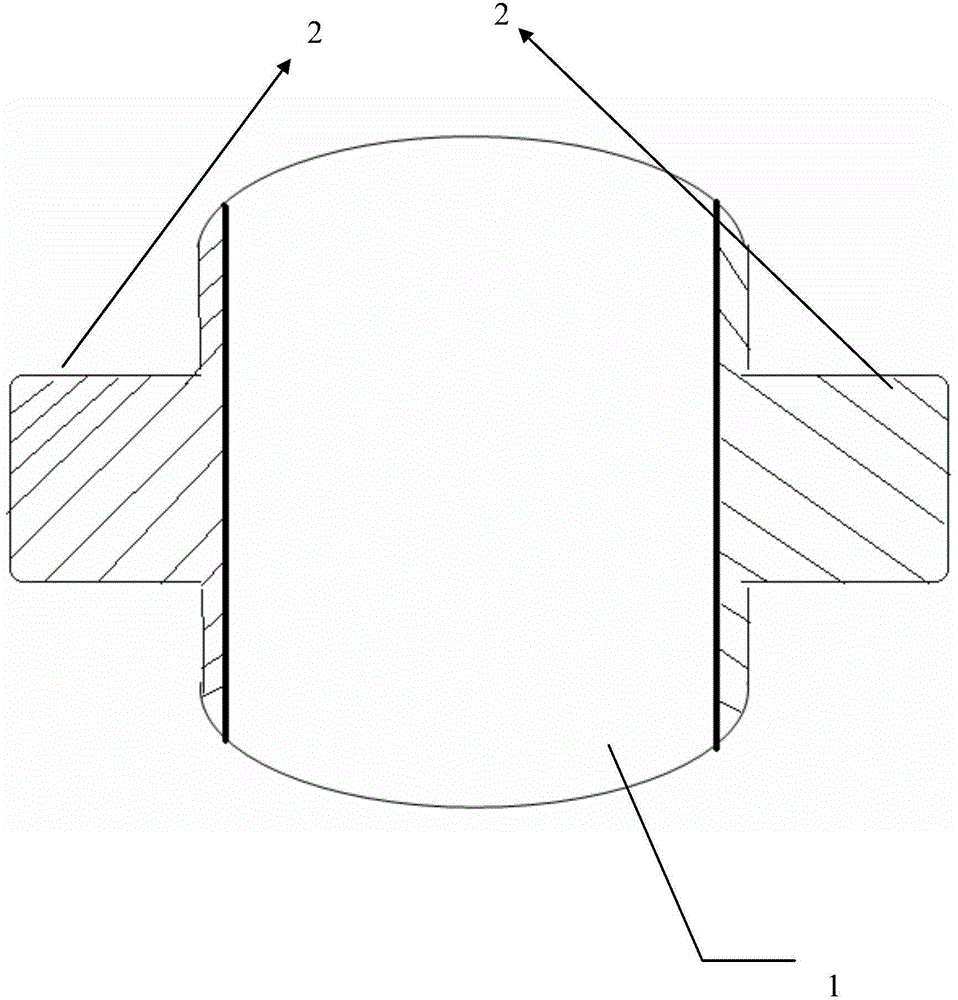

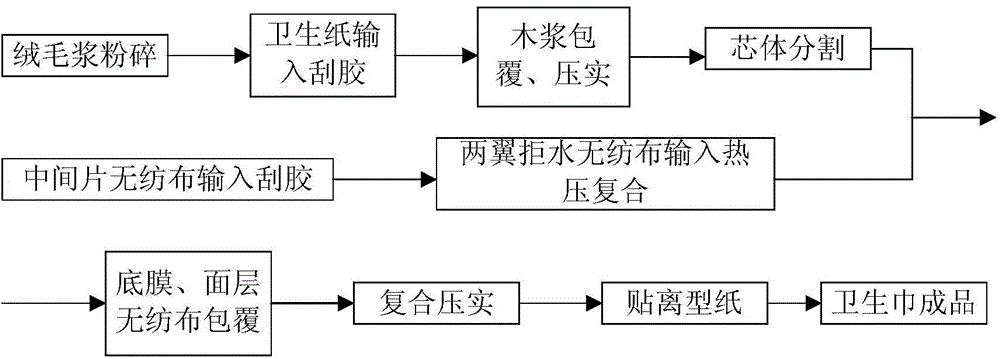

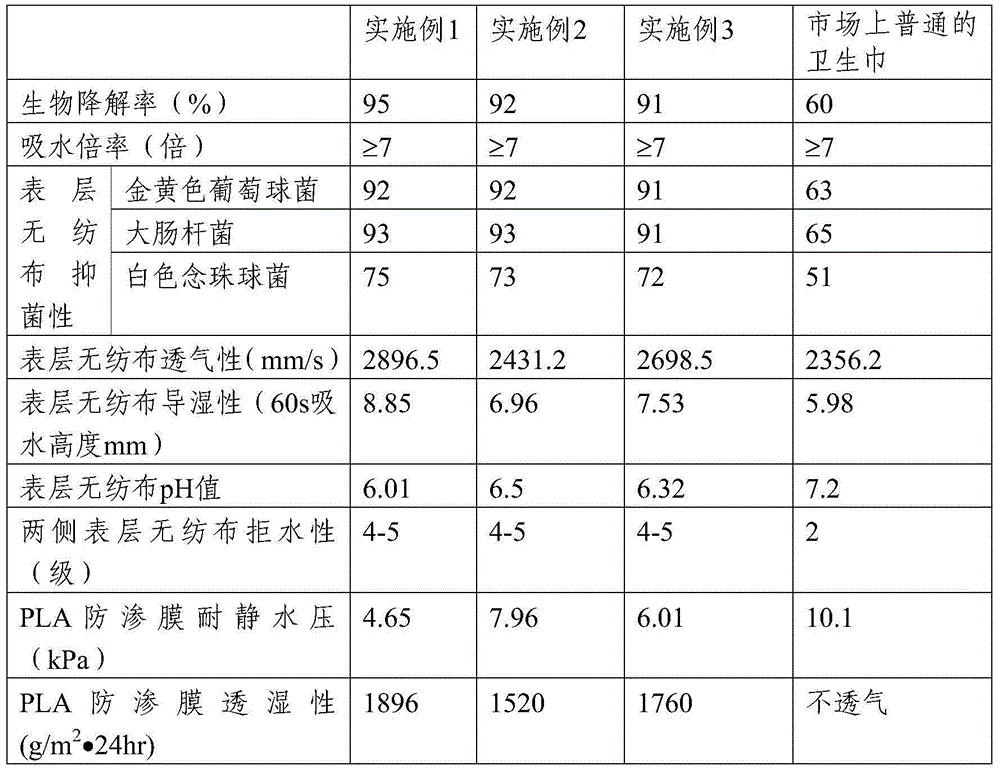

Anti-side leakage degradable polylactic acid sanitary napkin and preparation method thereof

The invention provides an anti-side leakage sanitary napkin, which includes a surface non-woven fabric and a bottom impermeable membrane disposed from the inside out. The surface non-woven fabric has a three-piece structure, the intermediate piece of surface non-woven fabric and the two-wing surface non-woven fabrics are sticked together, and the space between the intermediate piece of surface non-woven fabric and the bottom impermeable membrane is filled with a toilet paper coated wood pulp cellulose absorption core. The surface of the sanitary napkin provided by the invention is composed of 100% polylactic acid fiber or PLA / PBHV fiber hot blast nonwoven fabric. The polylactic acid fiber retains the original characteristics and does not cause any damage. As polylactic acid is formed by polymerization of lactic acid molecules as monomers and spinning, polylactic acid molecules with short molecular chains possibly exist on the fiber surface, so that the pH value of a polylactic acid non-woven fabric surface shows weak acidity and is consistent with that of human body skin. Also an odor removal function is provided. The lateral two pieces of non-woven fabrics have greater gram weight and thickness than the intermediate piece, and side leakage cannot be caused.

Owner:马鞍山同杰良生物材料有限公司

Production process of flannel mould color burnt-out blanket

ActiveCN103385626AUse resource spaceLow costSucessive textile treatmentsBlanketEngineeringBurning out

The invention relates to a production process of a flannel mould color burnt-out blanket. The production process comprises the steps of raw material selection, weaving, printing pretreatment, printing and aftertreatment. The production process has the beneficial effects that the process is transferred to a circular screen printer to be operated, so that the resource space of a factory is greatly utilized, the cost is reduced, and the register is preciser; the traditional acidic burnt-out mode is broken through, alkaline burnt-out is adopted, so that the burnt-out variety is increased, and the diversity of the market is enriched; and the flannel burnt-out blanket integrates the characteristics of a burnt-out processing process and a foam printing process in unique styles of elegant and novel appearance, soft and smooth handfeel, graceful pendency and beautiful color, and forms cavities by a burnt-out process, and the phenomenon of sloughing or wadding loosing in the washing process can be prevented by the foam printing process after the cavities are formed.

Owner:ZHEJIANG TRUELOVE GROUP

Flannel fabric

The invention discloses flannel fabric which comprises yarn and is knitted from the yarn. The flannel fabric is characterized in that the yarn is dacron low-stretch yarn DTY (Draw Textured Yarn), the fiber number of which is 40D-100D, and the specification of the single yarn number of the dacron low-stretch yarn DTY is 144F-576F. The basic knitting tissue of the flannel fabric is warp rib weave and is double-side gigging or one-side gigging and can achieve a gigging face after gigging. The flannel fabric prepared by the invention has soft and smooth handfeel, is light and thin, keeps higher strength and elasticity and recovery capability of Dacron fabric and has the advantages of good heat resistance, excellent chemical property and the like; in addition, since the dacron low-stretch yarn DTY is artificial fiber and has low cost and more raw materials in comparison with wool, the flannel fabric has brighter market prospects.

Owner:ZHEJIANG TONGHUI TEXTILE

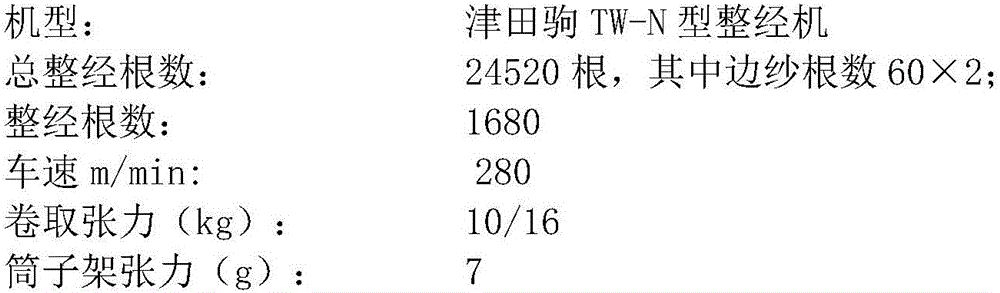

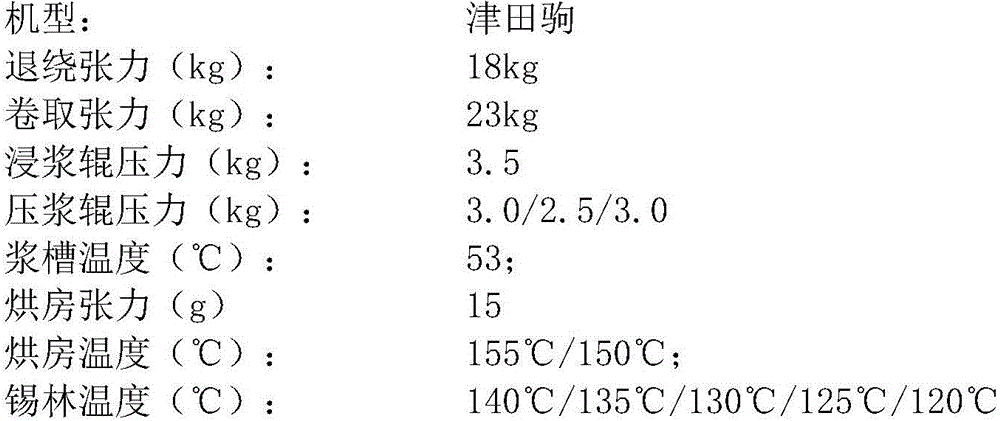

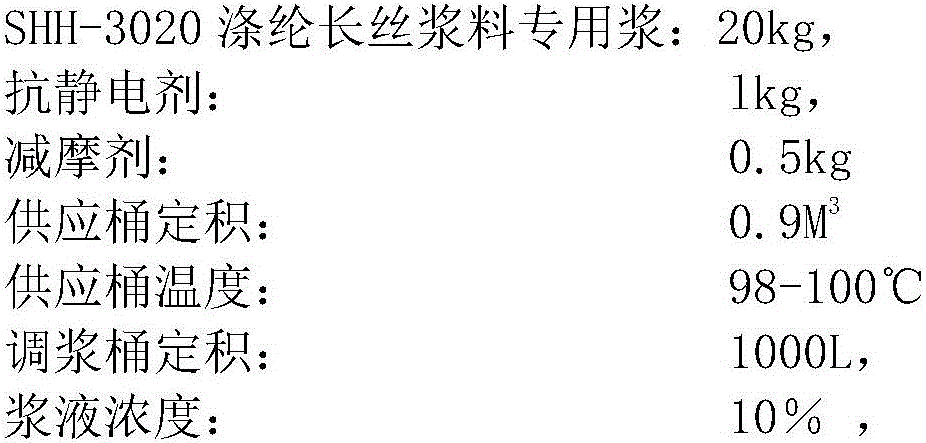

Jacquard acetic acid filament home textile fabric and production method thereof

ActiveCN106012214AGood coloring effectSoft touchHeating/cooling textile fabricsDry-cleaning apparatus for textilesSocial benefitsAcetic acid

The invention provides a jacquard acetic acid filament home textile fabric. Warp is semi-dull polyester filaments with the specification of 50D / 72F, and warp density is 200 pieces per inch. Weft is 75 D acetic acid filaments, and weft density is 96.5 pieces per inch. The structure is a large jacquard fabric. The breadth of the finished product is 160 cm. A production method of the fabric includes the steps that firstly, weaving is conducted, wherein weaving is conducted through warping by means of a warping machine, sizing by means of a filament sizing machine, re-beaming by means of a combining machine, leasing by means of a leasing machine, drafting and weaving by means of a rapier jacquard loom; secondly, dyeing is conducted, wherein dyeing is conducted through unwinding, desizing, dyeing, dewatering, scotching and setting. The fabric is flat, fine, smooth in cloth surface, soft in hand feeling, light, thin, cool, easy to wash, quick to dry, high in color fastness, good in air permeability, gentle and elegant. Reagents of the fabric successfully meet the requirement for comfort and cool of home textile summer quilt fabric of people, and the fabric has high addition value and wide market prospects and is remarkable in economic and social benefit.

Owner:JIANGSU YUEDA HOME TEXTILE

Packaging material and its preparing method

InactiveCN1748997AHigh tensile strengthImprove barrier propertiesSynthetic resin layered productsConductor CoilLubricant

The packing material is three-layered material, including the outer layer of LDPE, LLDPE, MPE, white mica, antiblocking agent and lubricant; the middle layer of LDPE, LLDPE, MPE, white premix and black premix; and the inner layer of LDPE, LLDPE and MPE. The preparation process includes the following steps: feeding material with material bin, heating to melt, extruding in extruder, foaming, debubbling and drawing corona treatment, cutting and winding. The packing material has few plastic smell, high flatness and flexibility, good brightness, high tension strength, high blocking property, less oxidation and less electrostatic adsorption.

Owner:北京联宾塑胶印刷有限公司

Production method of rabbit hair, cashmere and silk three-in-one face fabric

InactiveCN101225568ASoft and smoothNatural elegant lusterHeating/cooling textile fabricsLiquid/gas/vapor removalYarnEngineering

The invention relates to a triad producing method of clothing face fabric with rabbit hair, cashmere and silk, which is characterized in that: the raw material comprises 14% of the silk, 39% of the rabbit hair, 44% of the wool and 3% of the cashmere, the clothing face fabric with rabbit hair, cashmere and silk is made by the processes of dyeing, garneting, spun yarn, warping, weaving and after-finishing. The triad producing method of clothing face fabric with rabbit hair, cashmere and silk has the advantages of gathering the elasticity and heat retention of the wool, and the excellent properties of the rabbit hair and the silk, soft and satiny hand feeling, natural and elegant luster, excellent heat retention, and suitable for the demand of higher consumption level stratum.

Owner:江阴市天鹅制呢厂有限公司

Special high-temperature resistant waterproof air and moisture permeable resin for coating printing and preparation method thereof

InactiveCN103265682AImprove heat resistanceGood flexibilityFibre treatmentMoisture permeabilitySilsesquioxane

The invention discloses special high-temperature resistant waterproof air and moisture permeable resin for coating printing and a preparation method thereof. The resin is prepared by the following steps of: obtaining a prepolymer through a reaction between polyether polyol and diisocyanate; and modifying the prepolymer by use of polyhedral oligomeric silsesquioxane to obtain the resin, wherein the average molecular weight of the resin is 50000-150000g / mol, the viscosity is 60000-100000cps / 25 DEG C, and the solid content of the resin is 30-55%. In the polyurethane resin prepared by the method disclosed by the invention, the moisture permeability can reach 7500g / m<2>.24H, and the water pressure resistance is greater than 10000mmH2O; moreover, the polyurethane resin has the processing characteristic of tolerating a temperature of 200-230 DEG C for continuous 30S during coating printing; and the resin has highly-permeable coating and soft and smooth handfeel, and is washable and very suitable for the direct coating and coating printing technology of fabric coating processing.

Owner:宜兴市华夏化工材料有限公司

Cosmetic preparation

ActiveUS20050266057A1Not greasy to skinSoft and smoothCosmetic preparationsHair removalEmulsionUltimate tensile strength

The invention relates to a cosmetic preparation containing a crosslinked (meth) acrylic acid ester resin powder having a compression strength of 0.7 to 10 kgf / mm2. The invention also relates to a cosmetic preparation, for example, in the form of a cosmetic sheet, powder spray cosmetic, gel cosmetic, two phase separable cosmetic, emulsion cosmetic or the like.

Owner:KAO CORP

Comfortable skin-care warming health-care hollow porous yarn, and preparation method and application thereof

The invention provides a preparation method and application of a comfortable skin-care warming health-care hollow porous yarn. The comfortable skin-care warming health-care hollow porous yarn is formed by firstly blending and then processing such six hollow fibers (one or more fibers) as fine staple cotton fibers, seashell fibers (or Amicor antibiotic fibers or Cleancool fibers), water-soluble polyvinyl short fibers (or water-soluble polyvinyl filaments), kawo kawo fibers ( or Viloft fibers or Prolivon fibers or antibiotic hollow polyester fibers or Porel hollow fibers or Poral hollow fibers or micropore polyester fibers) and the like. The product has a body temperature adjustment effect, keeps a human body to always feel comfortable, is good in stiffness, feels soft and smooth, is good in drapability, unique in appearance and good in wrinkle resistance, enables a wearer to feel comfortable and is fluffy in texture, thereby being suitable for production of high-grade knitting machine woven fabrics, cold-proof underwear, bedding articles and the like.

Owner:ZHONGYUAN ENGINEERING COLLEGE

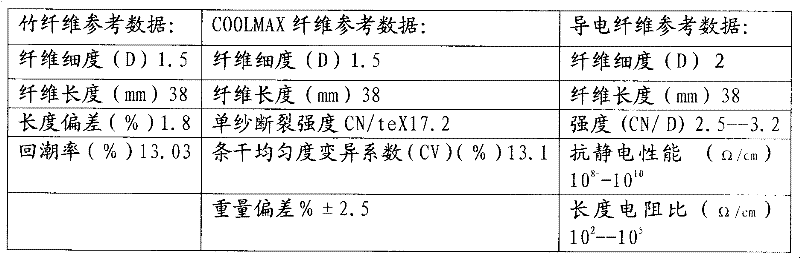

Bamboo fiber, Coolmax fiber and conductive fiber blended yarn and method for producing same

The invention discloses a bamboo fiber, Coolmax fiber and conductive fiber blended yarn and a method for producing the same. The bamboo fiber, Coolmax fiber and conductive fiber blended yarn has functions and characters of the three types of fibers, has complementary advantages, and has unique nobility by being spun by siro-spinning technology. The functional yarn can be used for knitting and tatting. A fabric made of the bamboo fiber, Coolmax fiber and conductive fiber blended yarns has the functions and characters of high strength, fine shape retention, high breathability, high moisture absorption, high sweat releasing, antibiosis, dust proofing, electrostatic resistance, ultraviolet resistance, environment-friendliness, easiness in caring, resistance to washing, stable size, softness and smoothness in touch and the like, is especially suitable for being made into knitted sports underwear, underpants, T-shirts, sportswear, shirts, hats and the like, and contributes to clothing grade increase and improvement on people's life quality, and commercial opportunities are supplied to textile enterprises. Therefore, great social benefit and economic benefit are achieved.

Owner:SHAOXING HENGMEI FANCY SILK +1

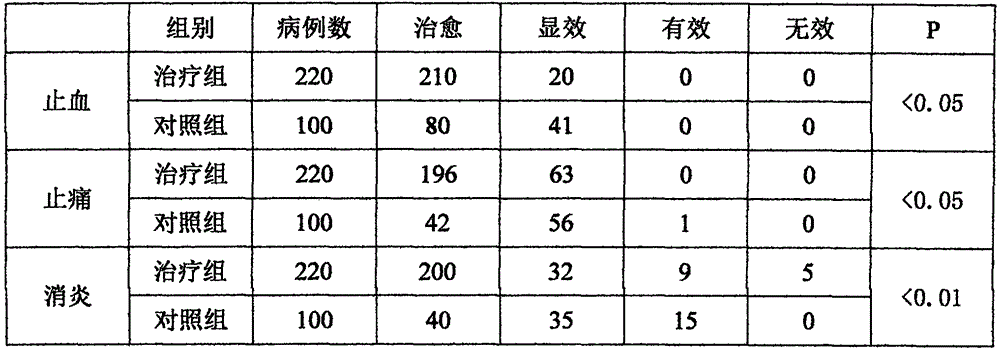

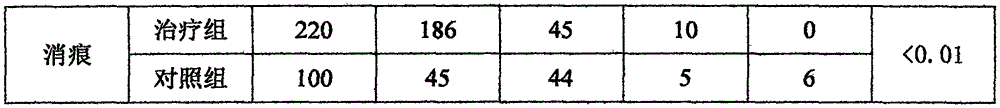

Adhesive bandage containing graphene oxide ingredient and preparation method thereof

ActiveCN105288695AExcellent sterilization performanceSoft and smoothAbsorbent padsBandagesIonChemistry

The invention discloses an adhesive bandage containing graphene oxide ingredient, and belongs to the technical field of medical apparatuses. The technical main points comprise that the adhesive bandage is composed of a matrix and an active ingredient used to coat the matrix, and the active ingredient is mainly prepared from the following compositions in parts by weight: 0.01-1.5 parts of graphene oxide, 1-5 parts of an ionic liquid, 0.5-3.6 parts of a quaternary ammonium salt surfactant, 0.1-0.5 part of carboxymethylcellulose sodium, 0.2-0.8 part of polyacrylamide, 0.5-2.0 parts of tween, 1-9 parts of polyethylene glycol, 3-12 parts of glycerin, 5-25 parts of medical vaseline, and 1-20 parts of deionized water. A wound treated by the adhesive bandage is fast cured, and no scar is left, and a clinic treatment test proves that the total effective rate is 100%. The prepared adhesive bandage possesses considerable ideal efficacies of diminishing inflammation and stopping bleeding, dispersing swelling and healing wound, astringing exudation and promoting tissue regeneration and the like.

Owner:张建刚

Method for producing blended yarn of Shengma fiber and cotton

The invention relates to a method for producing blended yarn of Shengma fiber and cotton. A required cone yarn is produced by selecting suitable Shengma fibers and cotton fibers, combining the Shengma fibers with a cotton comber on a drawing after blowing, carding and predoubling, and performing a roving process, a spinning process and a winding process. In the method, the blowing process has the characteristics of carding more and beating less, catching frequently and rarely, low beater speed, less fly fiber, and heavier pressure; the carding process has the characteristics of suitable carding; the drawing process has the characteristics of light quantitation, heavy pressure, low speed, primary predoubling and secondary blending; the roving process has the characteristics of light quantitation, heavy pressure, low speed and high twisting degree; and the spinning process has the characteristics of low speed, high twist factor and suitable temperature and humidity. A plus material of the blended yarn of the Shengma fiber and the cotton produced by the method of the invention has cotton texture; a fabric has the characteristics of soft, smooth and fluffy handfeel, high moisture adsorption performance and ventilation property, high warmth retention property, high bacteria and mildew resistance, high drapability, bright color and luster, plump and smooth fabric surface organization, lightness and comfort for a wearer, and capacity of being used for knitted underwear, leisure wear, towel supplies, beddings and the like.

Owner:JIHUA 3509 TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com