Patents

Literature

56results about How to "Pure shade" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Disperse dye composition suitable for basic dyeing

ActiveCN101649129AAvoid problems such as contaminationGuaranteed stabilityOrganic dyesDyeing processDisperse dyeColour fastness

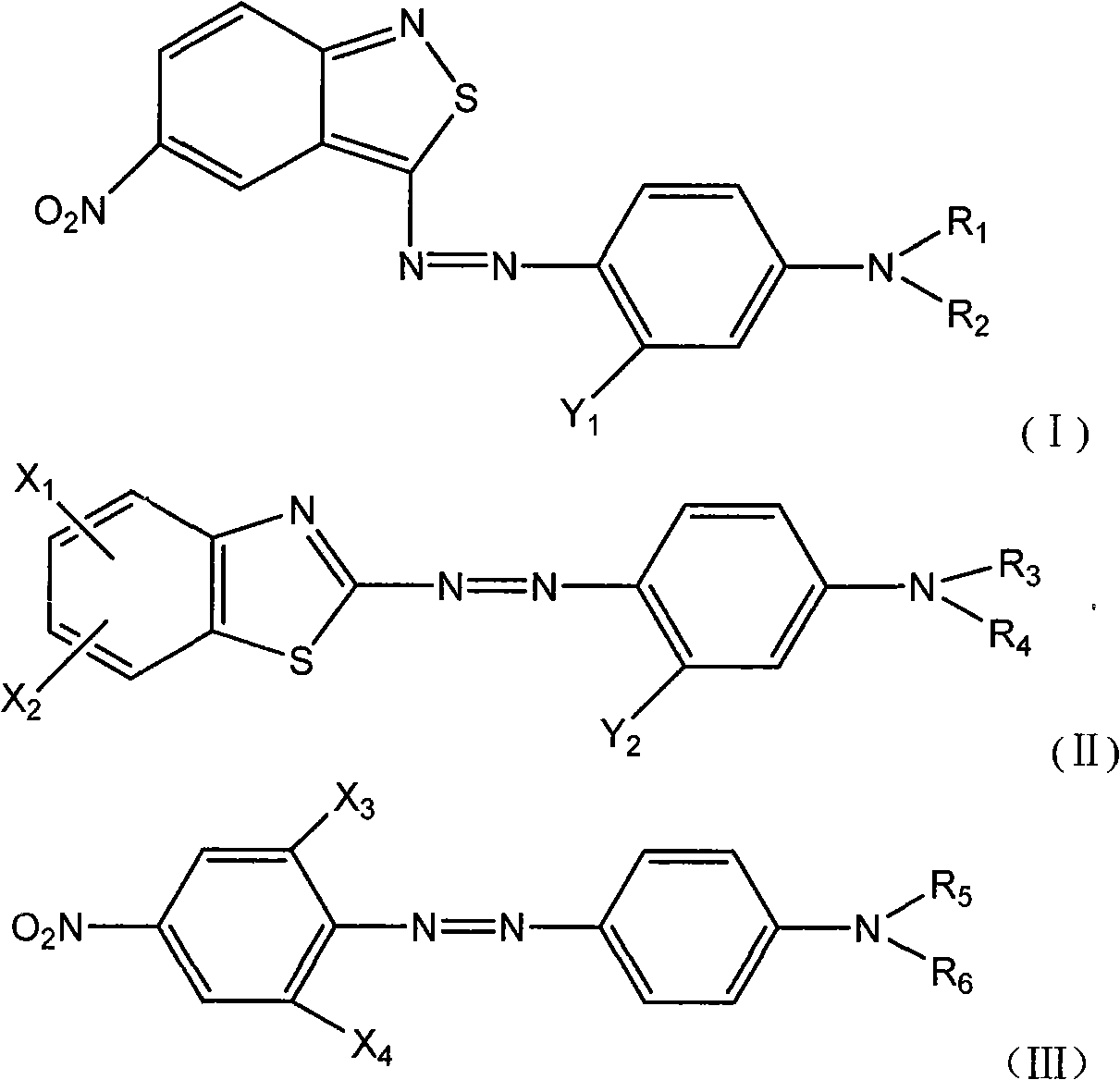

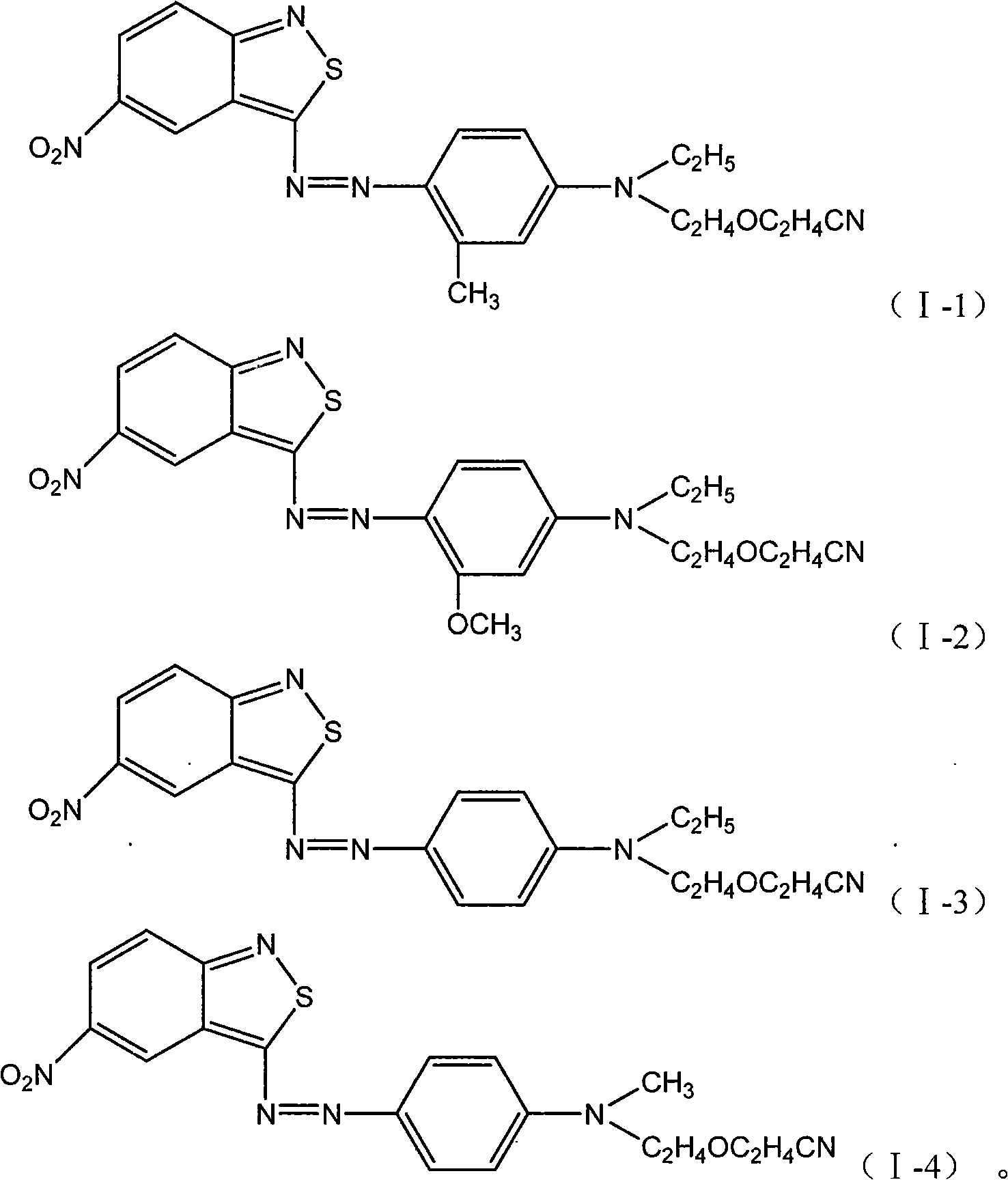

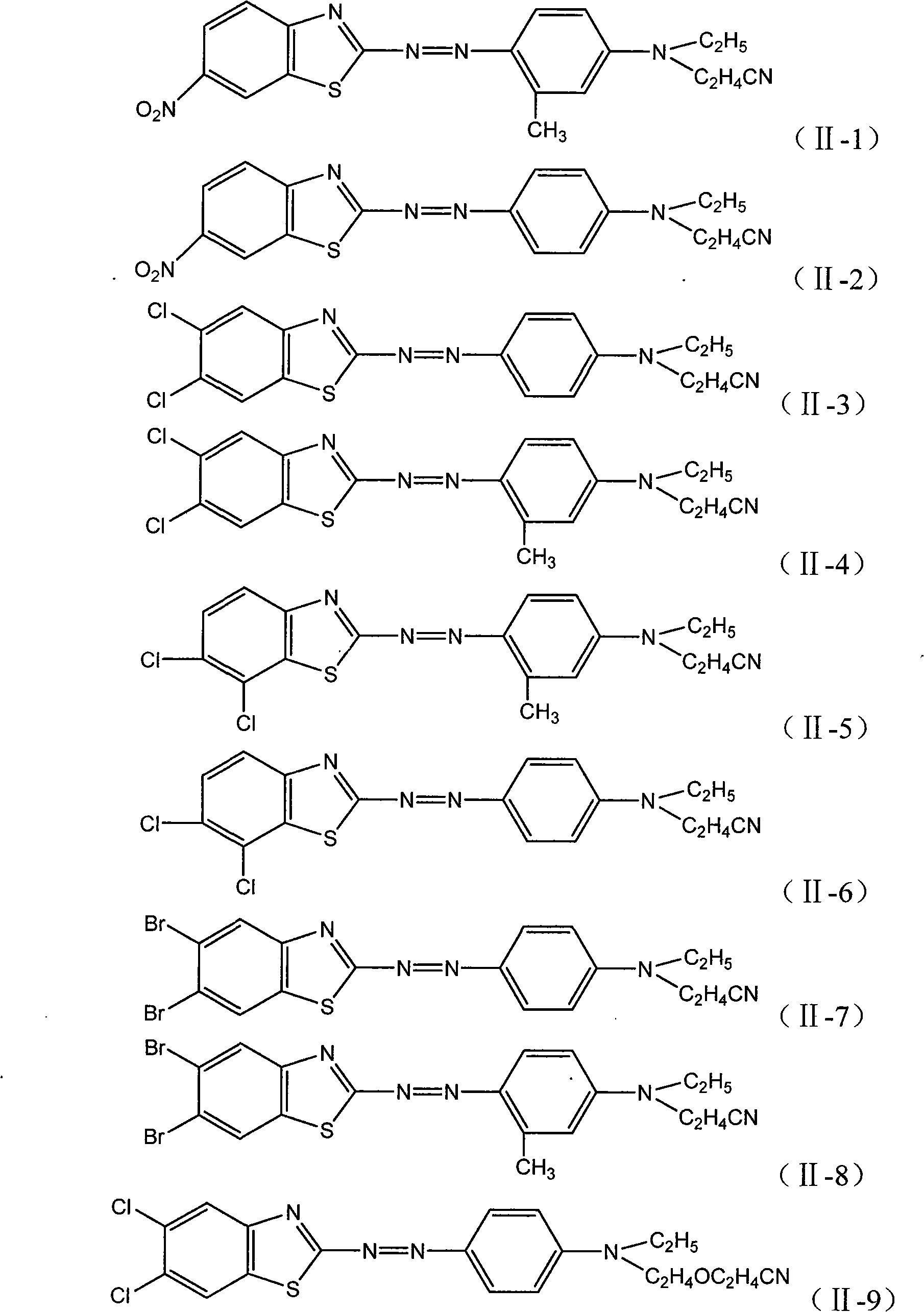

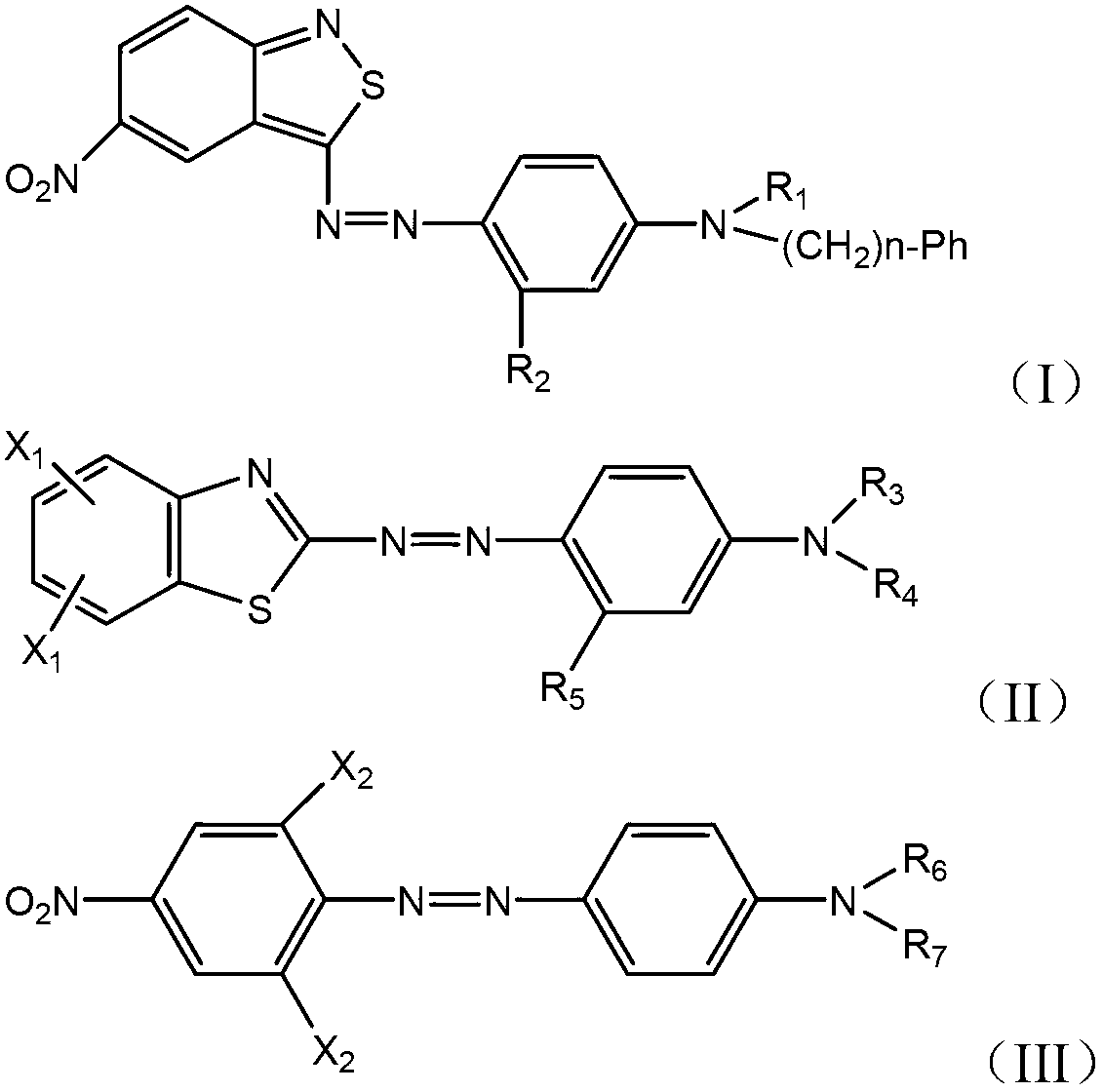

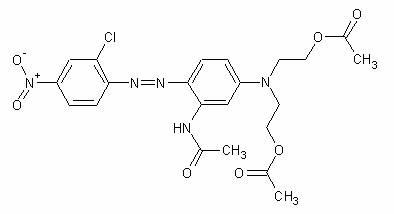

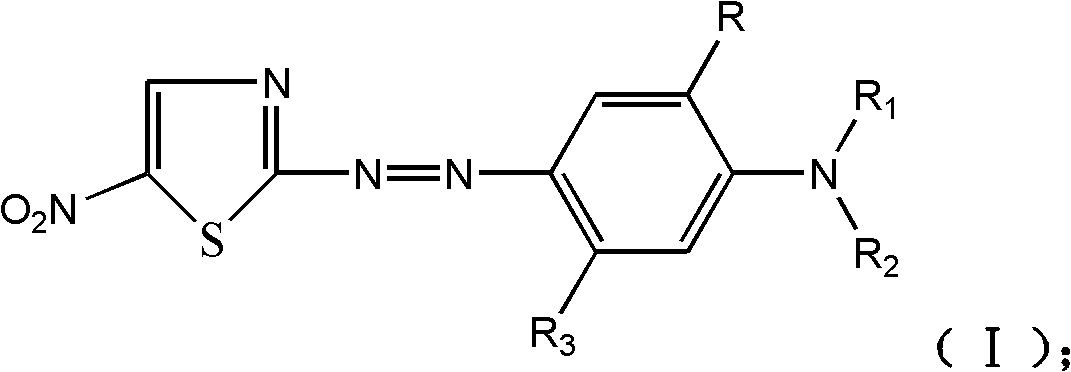

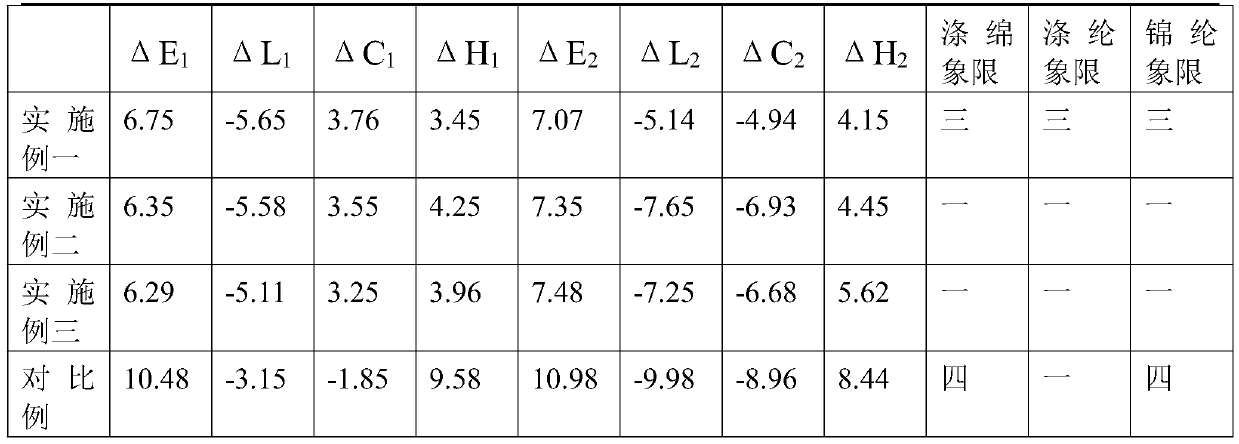

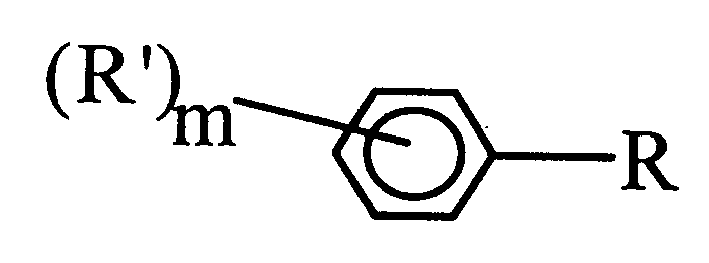

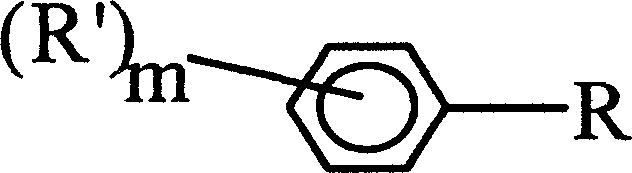

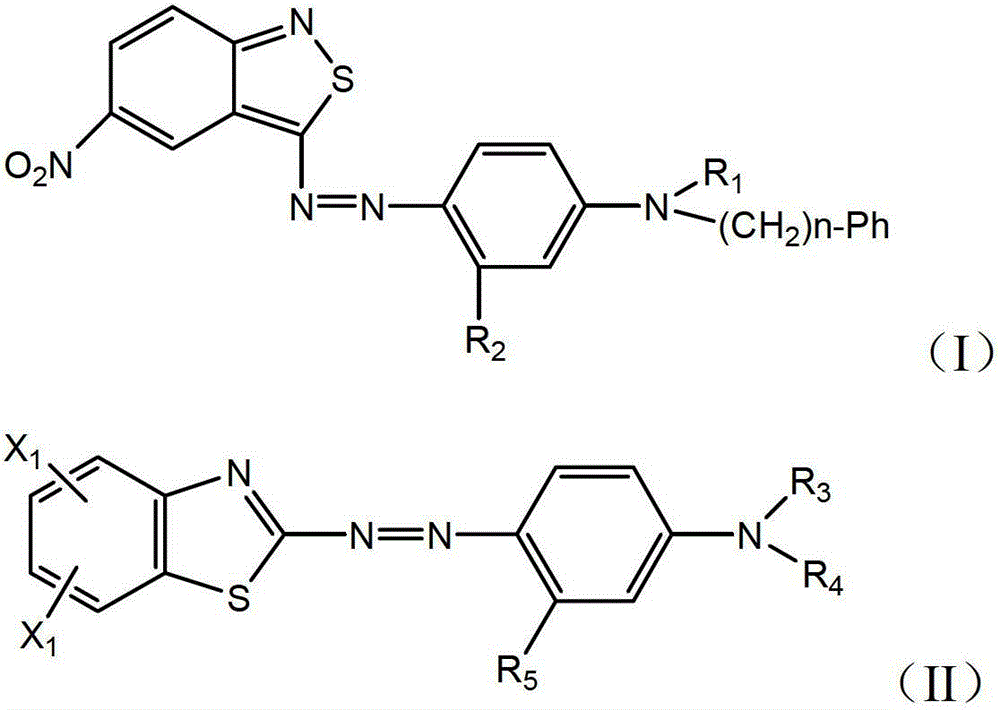

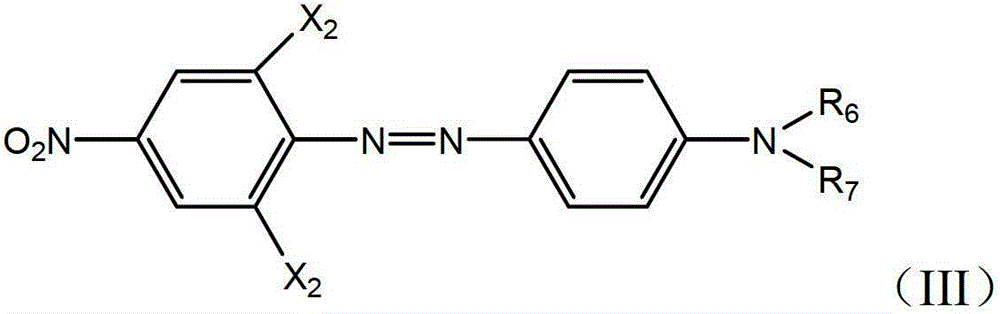

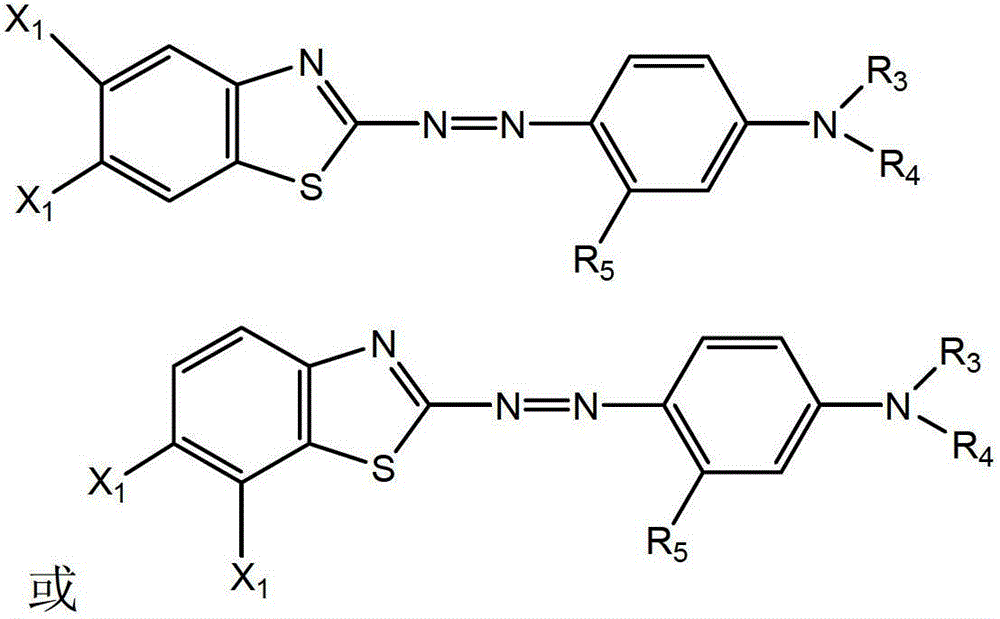

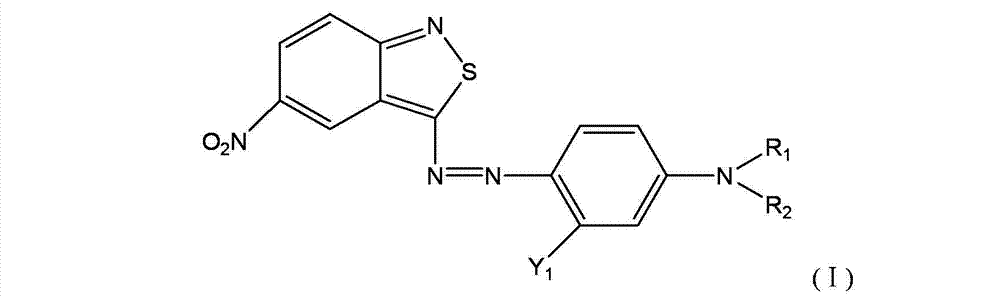

The invention provides a disperse dye composition suitable for basic dyeing, mainly comprising the following raw materials in percentage by weight: 40-95 percent of one or a plurality of blue dyeing components A with a structural formula (I), 1-25 percent of one or a plurality of red dyeing components B with a structural formula (II) and 4-50 percent of one or a plurality of orange dyeing components C with a structural formula (III). The disperse dye composition has a wide dependency range of pH values, and can dye in a pH value ranging from 4.0 to 10; dyed and woven fabrics with predominant color-fastness performance, such as full hues, washing fastness, and the like, can be obtained.

Owner:浙江龙盛染料化工有限公司

Blue-to-black disperse dye composition

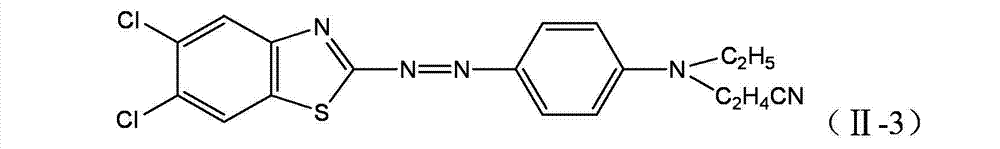

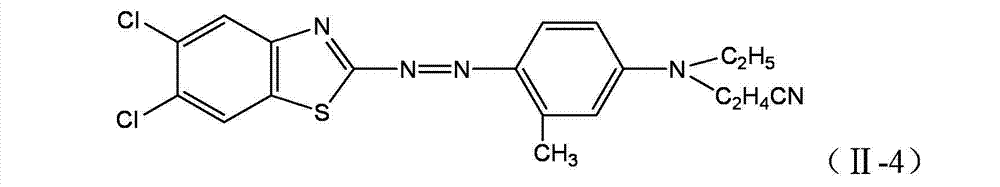

ActiveCN102746713AStrong alkali resistanceAvoid problems such as contaminationOrganic dyesDisperse dyeAlkali burn

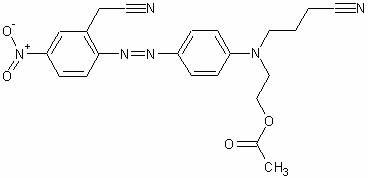

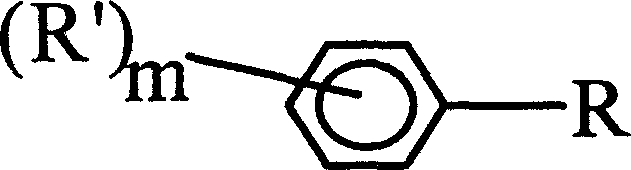

The invention provides a blue-to-black disperse dye composition, which mainly comprises one or multiple blue dye ingredients A shown as the structure formula (I), one or multiple red dye ingredients B shown as the structure formula (II) and one or multiple orange dye ingredients C shown as the structure formula (III). The disperse dye composition has the advantages that the dying bottleneck of the existing ordinary disperse dye under the alkaline condition is broken through, the problems of white powder, color points and dyeing defect generation caused by the dyeing under the acid condition, the contamination on the inner wall of dyeing equipment caused by low polymers, and the like are solved, the dyeing quality is effectively improved, the stability and the reproducibility of the process are ensured, and the once success rate of the dyeing is improved. In addition, the prepared disperse dye has higher alkali resistance capability and can be applied to an alkali burnt-out process, the defect of single acid burnt-out color is overcome, and the requirements of the society on the aesthetic perception and the variety on clothing and decorations are met.

Owner:ZHEJIANG LONGSHENG GROUP +1

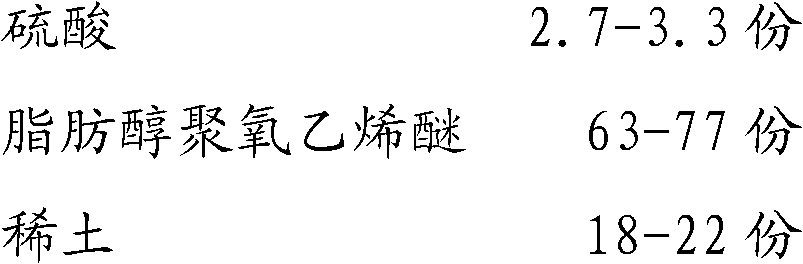

Low-temperature dyeing process of fiber fabric

ActiveCN103966867AGuaranteed functionAvoid damageFibre treatmentDyeing processFiberProcess engineering

The invention provides a low-temperature dyeing process of a fiber fabric. The low-temperature dyeing process comprises the processes of pretreatment, pre-sizing, dyeing, reduction clearing, fixing, softening treatment, drying, sizing, calendaring and rolling. In the dyeing process, the highest temperature does not exceed 100 DEG C, mild dyeing is carried out by using a gradual warming method and pH value regulation is carried out through a buffer solution, so that a proper acid environment required during the dyeing is satisfied and the dyeing effect is excellent; during the dyeing, a leveling agent is added to ensure that the dyeing is uniform; anhydrous sodium sulphate is added to postpone the dyeing process of the pigment and the temperature rises slowly at the same time, so that the uniform dyeing is ensured; a smoothing agent is added to prevent the scratching and local fibrillation; a penetrant and a diffusant are added to ensure that the penetration and the diffusion of the dyeing are relatively good; by means of the strict control in the aspects of temperature, acid, auxiliaries, time and the like, the low-temperature dyeing process of the fiber fabric has the advantages that the dyeing firmness is high, the dyeing is uniform, the dyeing stability is good and the effect is excellent at low temperature.

Owner:绍兴洁彩坊印染有限公司

Staining method for aramid fiber

ActiveCN104695239AReduce pollutionAvoid damageBiochemical fibre treatmentFibre typesColour fastnessAramid

The invention provides a staining method for aramid fiber. The staining method comprises the steps of preprocessing, preshaping, staining, reduction clearing, color fixing, soft processing, drying, shaping, calendaring and rolling. According to the staining method, DEET is added in to serve as a dye carrier, and the staining effect and efficiency are improved; meanwhile, substitute alkali is adopted to replace a conventional soda substance, and not only is the usage amount decreased, but also the color fixing effect is enhanced to enable the washability of the aramid fiber is further enhanced; the reduction clearing and color fixing processes are added, and therefore the staining fastness is good; green and environmental-friendly non-formaldehyde TCD-R is adopted in the color fixing process, the fiber is dried step by step after color fixing, and therefore the firmness of the fiber is greatly improved; the soft processing process is added, the color fastness and softness of fabric are improved, the roughness of the fabric is reduced, and therefore the fabric is fluffy and rich in elasticity.

Owner:SUZHOU ZHILVE INTELLECTUAL PROPERTY OPERATION CO LTD

Dyeing and spinning method for loose cotton fiber

InactiveCN1487132ARough and hardReduce cylinder differenceYarnLiquid/gas/vapor textile treatmentFiberAgricultural engineering

The present invention is one dyeing and spinning method of cotton, cotton sliver, lap and other loose cotton fiber and alters the traditional first spinning and then dyeing process into the first dyeing and then spinning process. The present invention can produce color cotton with less color difference, soft hand feeling and high color fastness and can reach special fabric style incapable of being reached in common dyeing and finishing process.

Owner:BROS EASTERN

Salt-free dyeing process for natural silk fabric

InactiveCN104746365AReduce pollutionAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsFiberInorganic salts

The invention provides a salt-free dyeing process for natural silk fabric. The salt-free dyeing process comprises the following steps: pre-treatment, pre-setting, modified treatment, dyeing, soaping, fixation, after-treatment, drying, setting, calendaring and rolling. The fabric is subjected to modified treatment with a cationic modifying agent, so that the dyeing rate of the fabric is increased; and the difficulty in the subsequent dyeing step is reduced. In the dyeing procedure, inorganic salts such as anhydrous sodium sulphate or table salt are not used, so that the pollution is reduced. Due to the addition of the soaping and fixation processes, the dyeing fastness is good. Green environment-friendly aldehyde-free TCD-R is adopted in the fixation process; and the fiber is gradually dried after fixation, so that the fastness of the fiber is greatly improved. Due to the addition of the after-treatment process, the color fastness and the softness of the fabric are improved; the roughness sense of the fabric is relieved; and the fabric is fluffy and elastic.

Owner:太仓市宝明化纤有限公司

Preparation method of superfine coating pigment paste for coloring of Lyocell fiber stock solution

InactiveCN102127312AGood dispersionNo precipitationOrganic dyesPigment addition to spinning solutionColour fastnessPolymer science

The invention relates to a preparation method of superfine coating pigment paste for the coloring of a Lyocell fiber stock solution, belonging to the field of fine chemical industry. In the invention, with a polymerizable dispersing agent as a main adjuvant, a superfine pigment dispersion is prepared through high-speed dispersion, and then an initiator and a comonomer are dropwise added to the dispersion, then continuously dispersed with a high speed and heated to react for a certain time so that the polymer is coated on the surface of pigment. The prepared superfine coating pigment paste for the coloring of the Lyocell fiber stock solution has high dispersion stability, good compatibility with a Lyocell fiber spinning solution and high spinnability; and Lyocell fiber coloring filaments obtained through spinning have coloring uniformity, pure color and cluster and excellent color fastness and save the follow-up dyeing and processing.

Owner:JIANGNAN UNIV

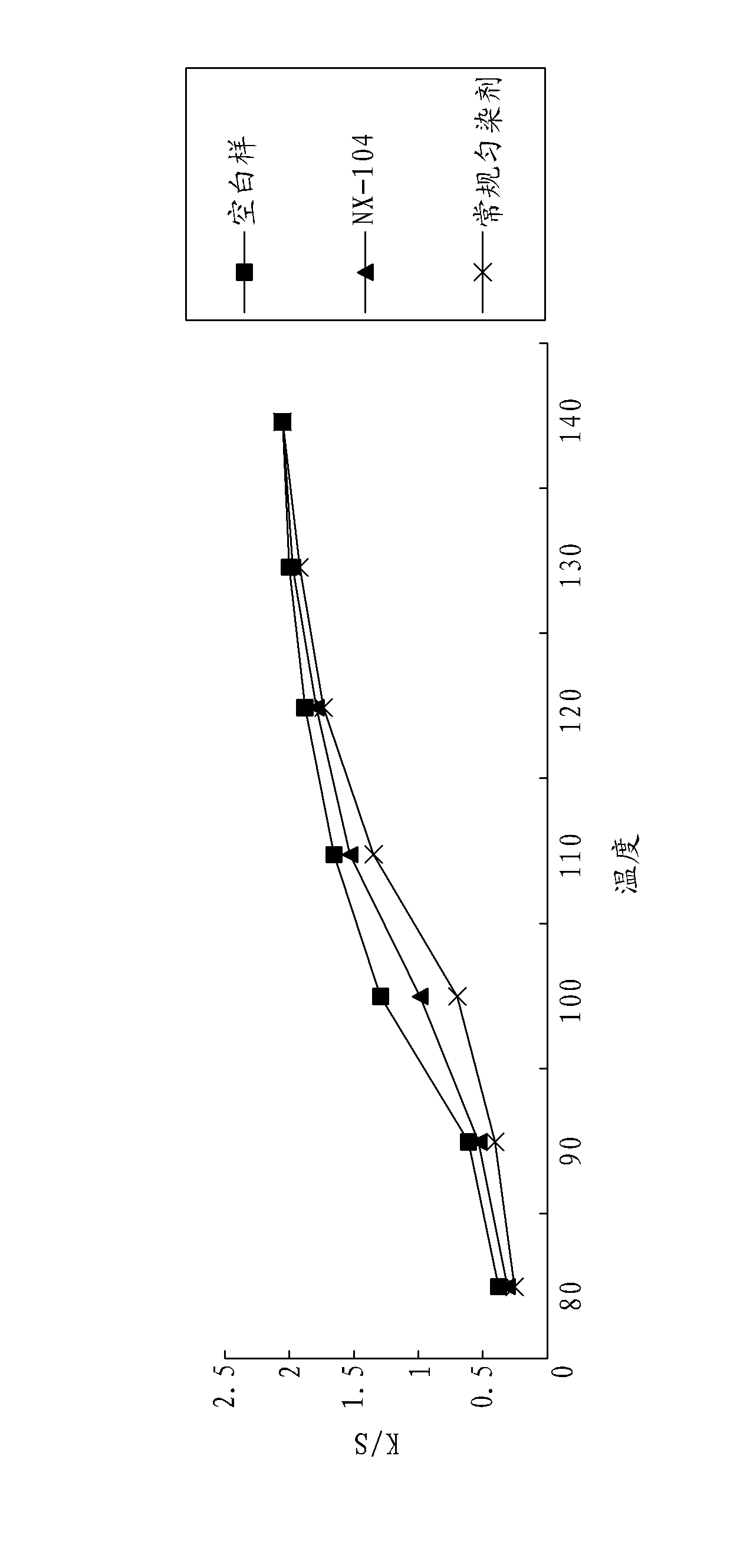

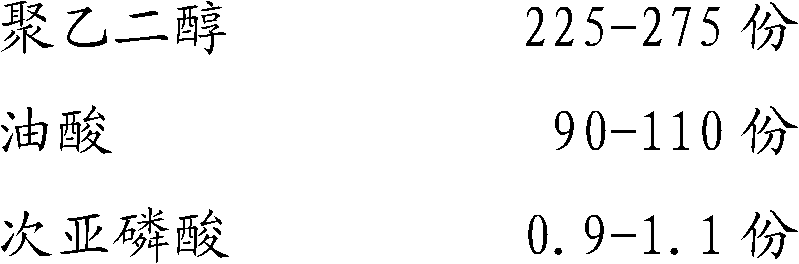

Multifunctional high-temperature oil removing levelling agent

The invention discloses a multifunctional high-temperature oil removing levelling agent, which specifically contains the following raw materials by weight: 225-275 parts of polyethylene glycol, 90-110 parts of oleic acid, 0.9-1.1 parts of hypophosphorous acid, 2.7-3.3 parts of sulfuric acid, 63-77 parts of fatty alcohol-polyoxyethylene ether and 18-22 parts of rare earth. The sulfuric acid and the phosphorous acid serve as catalysts to enable mixed polyethylene glycol and oleic acid to perform esterification to produce corresponding esterified substance with high-efficiency decontamination and oil removing effects. The esterified substance, an appropriate amount of the fatty alcohol-polyoxyethylene ether and the rare earth are mixed in a compound mode. Principally by means of assistant-dyeing property of the rare earth, a compound agent having the functions of levelling property, dispersity, decoloration, synchronous dyeing property and the like apart from the oil removing function isobtained. Obtained fabrics have the advantages of being pure and normal in color tone, full, good in sense of touch and the like. The multifunctional high-temperature oil removing levelling agent increases first-rate product rate of dyeing machine fabrics, enables oil removing and level dyeing to be performed in the same bath, greatly shortens technological process, lowers production cost, and achieves the beneficial effect of energy saving and emission reduction.

Owner:JINJIANG NANXING PRINTING & DYEING MATERIAL

Bleaching water for preventing elastic jeans from loss of elasticity by washing and application of bleaching water

InactiveCN104532539ABright shadePure shadeDry-cleaning apparatus for textilesBleaching apparatusAcetic acidCellulose

The invention relates to bleaching water for preventing elastic jeans from loss of elasticity by washing and application of the bleaching water. The bleaching water is prepared from the following components in parts by weight: 30-40 parts of a polysulfanilamide derivative, 1-5 parts of a monoamine and polyamine mixture, 0.1-1 part of EDTA tetrasodium salt and 5-15 parts of a polyamino acid derivative. The application specifically comprises the following steps: (1) desizing the bleaching water; (2) enzymatic washing the bleaching water by cellulose; and (3) chlorine bleaching the bleaching water. Compared with the prior art, the bleaching water provided by the invention has the obvious advantages of preventing spandex from loss of elasticity and the like.

Owner:FIBER CHEM BIOLOGICAL CHEM

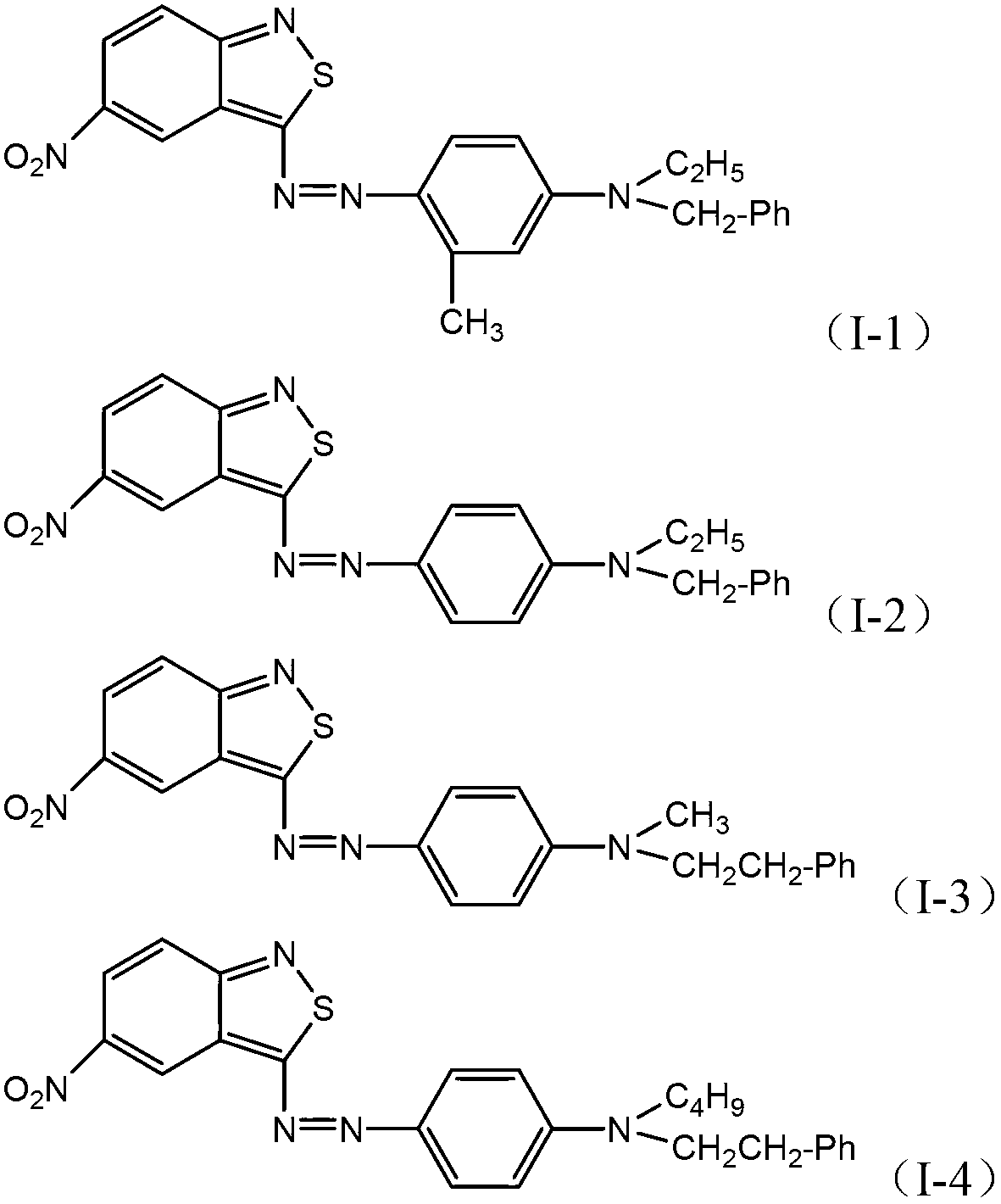

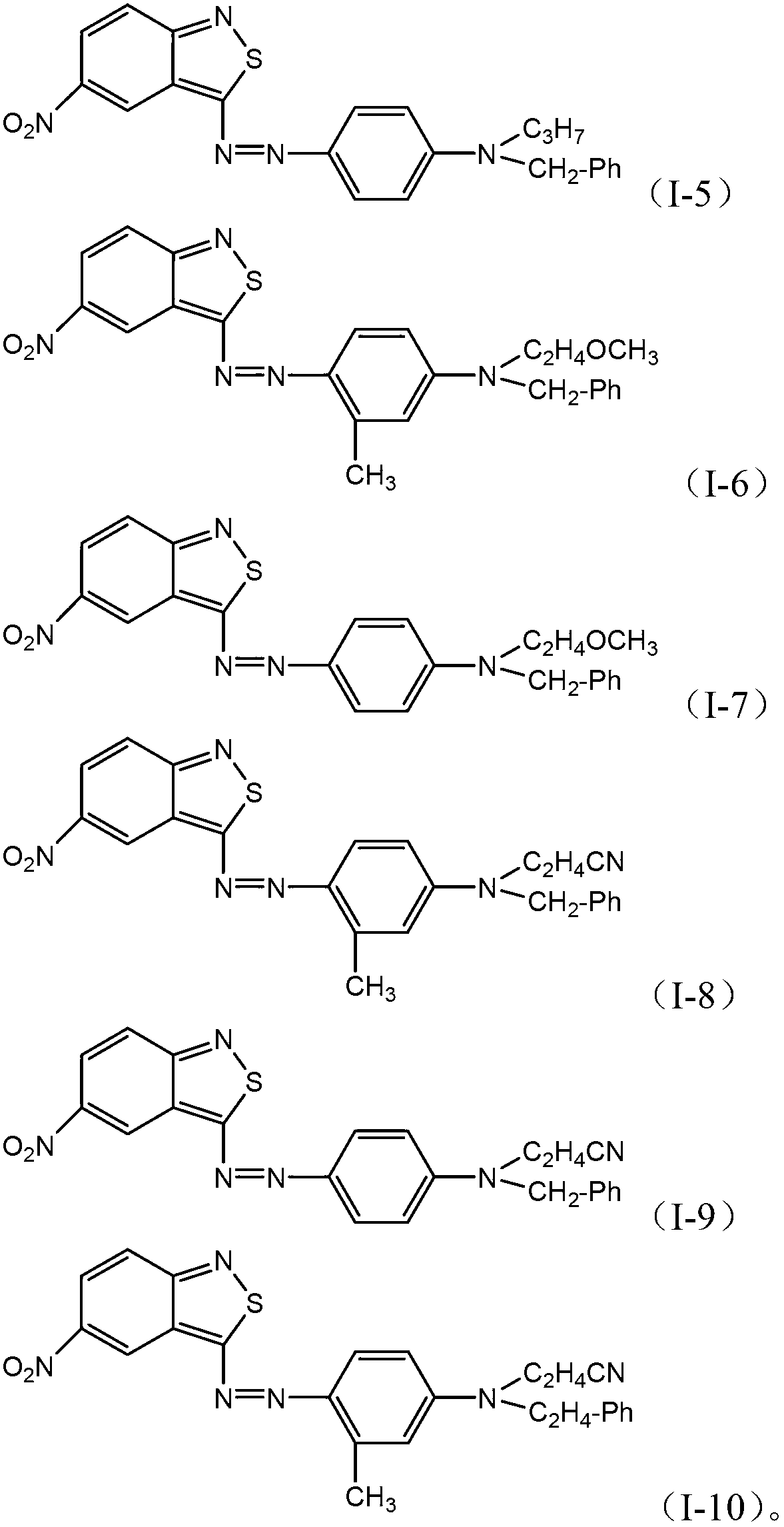

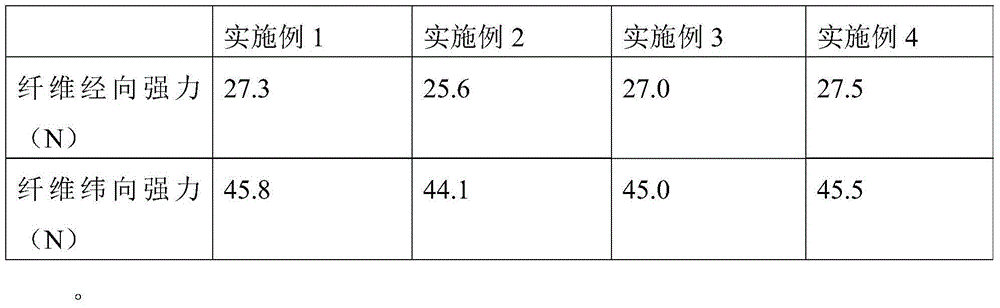

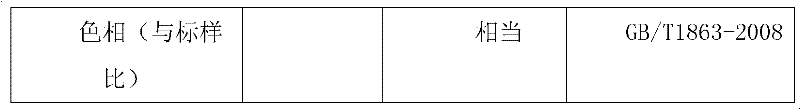

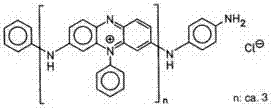

Nano disperse black combined dye and preparation method thereof

The invention discloses a nano disperse black combined dye and a preparation method thereof, and relates to the field of processing in dye and intermediate industries. The combined dye comprises a dye and an aid, the mass ratio of the dye to the aid is 1: (1-4.5), and the dye is one or more of compounds shown as a formula I; the aid is formed by mixing anionic surfactant and nonionic surfactant in a mass ratio of (100-85)%: (0-15)%; in the formula I, R1 is H, Cl, Br or CN; R2 is H, Cl or NO2; R3 is H or OCH3; R4 is H or NHCOCH3; and R5 and R6 are mutually independent C2H5, C2H4OCOCH3, C2H4OCH3 or C2H4CN. Under the same dyeing condition, compared with the conventional black disperse dye for dyeing a polyester fabric, the nano disperse black combined dye has the advantages that the L value of the fabric is reduced by 21.3 percent, and the K / S value is improved by 18.6 percent.

Owner:SHAOXING UNIVERSITY

Nylon-terylene pseudo-stripe cloth

The invention discloses a nylon-terylene pseudo-stripe cloth, warp yarns adopt A nylon, weft yarns adopt B terylene, and a five-heddle satin texture is adopted; wherein the A nylon is super bright circular-hole yarn with 30 denier of fiber number, the B terylene has 150 denier of fiber number and is formed by 48 fibers which are super bright cation yarns; in the dyeing and finishing process, the color of nylon circular-hole yarn A and the color of the cation yarn B are not stuck mutually, and the colored light thereof is pure; the invention solves the problem in the prior art and provides the nylon-terylene pseudo-stripe cloth which has leather-feeling cloth surface and artistic visual sense.

Owner:WUJIANG JIXING TEXTILE

High-temperature leveling agent and production process thereof

The invention relates to a high-temperature leveling agent and a production process thereof, belonging to the technical field of fabric dyeing and finishing. The cotton leveling agent is characterized by being prepared from raw materials in a special proportion through adopting the following steps of: firstly, esterifying glycerol ether and oleic acid under the catalysis of sulphuric acid to generate olein; and then, compounding the olein and secondary alkane sulfonate and mixing by using isopropanol as a solvent to obtain the high-temperature leveling agent. The product provided by the invention has favorable leveling property, combustion retardance, dyeing transfer, dispersibility, achromicity and synchronous dyeing; the processed fabrics have pure color and luster, fullness and good hand feeling, ensure the top-quality product rate of the dyed fabrics, lighten the processing load of effluents, decrease the production cost and have favorable economic benefits and social benefits.

Owner:淄博正邦知识产权企划有限公司

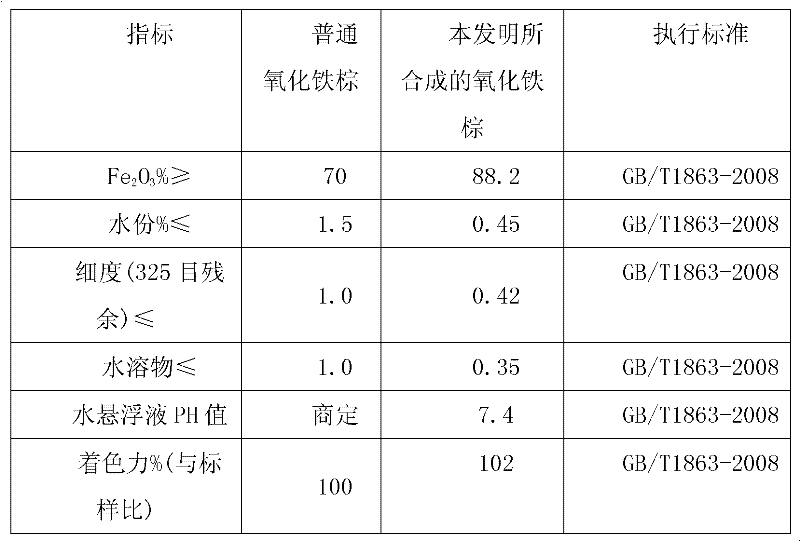

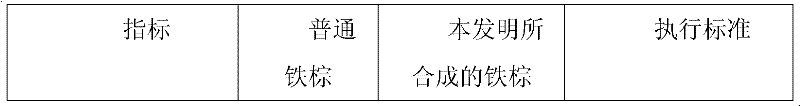

Preparation method of iron oxide brown

The invention discloses a preparation method of iron oxide brown, comprising the following steps of: adding ferrous sulfate and liquid caustic soda into a closed reaction kettle to be mixed to form a material slurry; adding water to adjust the concentration of the material slurry to 10-12%; raising a temperature to a value in a range of 80-85 DEG C and then slowly adding sodium nitrite while introducing oxygen, then starting spraying equipment to sufficiently mix the material slurry, the oxygen and NO which is generated in a reaction process; continuously sampling in the reaction process and comparing with a standard sample; stopping the reaction after the color light of a product is approximate to that of the standard sample; and carrying out filter pressing on the fetched material slurry, washing, drying and crushing to obtain the product. Iron oxide brown produced by the method of the invention has the advantages of stable quality, pure color light, simple synthesis method and convenience for operation.

Owner:ANHUI MINGZHU PIGMENT TECH

Direct dyeing process for chemical fiber

InactiveCN104762828AReduce pollutionAvoid damageBiochemical fibre treatmentHeating/cooling textile fabricsInorganic saltsColour fastness

The invention provides a direct dyeing process for a chemical fiber. The direct dyeing process for the chemical fiber comprises the steps of pretreatment, pre-shaping, modification treatment, dyeing, soaping, color fixing, after-treatment, drying, sizing, calendaring and rolling. According to the direct dyeing process for the chemical fiber, the modification treatment is added, so that performances of a chemical fabric are subjected to the modification treatment basically, the dyeing degree of the fabric is increased, and the difficulty of a subsequent dyeing step is reduced; during dyeing, the mass utilization of inorganic salt is avoided; furthermore, substitute alkali is used for replacing a conventional sodium carbonate substance, so that the consumption is reduced, a color fixation effect is also improved, and the washing fastness of the chemical fiber is further improved; soaping and color fixing processes are added, so that the dyeing fastness is good; environment-protection formaldehyde-free TCD-R is utilized in the color fixing process, and color-fixed fibers are gradually dried, so that the firmness of the fibers is greatly improved; the post-treatment process is added, so that the color fastness and the flexibility of the fabric are improved, the roughness of the fabric is reduced, and the fabric is fluffy and has high resilience.

Owner:TAICANG CHENGLE CHEM FIBER

Process for synthesizing iron oxide brown

The invention discloses a process for synthesizing iron oxide brown, comprising the following steps of: feeding a ferrous sulfate solution into a reaction kettle; slowly adding caustic soda liquid in three times; then heating to a temperature in the reaction kettle of 75-78 DEG C and incubating for 50-70 min; adding water to dilute mixed slurry until solid content of the mixed slurry is 8-10%; slowly adding sodium nitrite into the reaction kettle and introducing oxygen simultaneously; then turning on spraying equipment to sufficiently mix the slurry, oxygen gas and NO which is generated in a reaction process; continuously sampling and comparing a sample with a standard sample in the reaction process; stopping the reaction when the colored light of a product is similar to the yellowish-brown or reddish brown colored light of standard sample; and carrying out plate pressure filtration, washing, drying and crashing the taken-out slurry so as to obtain the product. The iron oxide brown produced by the invention includes brownish red iron oxide brown and brownish yellow iron oxide brown. Compared with the traditional method for preparing the iron oxide brown by physically mixing iron oxide red, iron oxide black and iron oxide yellow, the iron oxide brown produced by the invention is stable in quality and pure in colored light, the synthesis method is simple and the operation is convenient.

Owner:ANHUI MINGZHU PIGMENT TECH

Cotton loose fiber dyeing method

InactiveCN1528975ASmall chromatic aberrationReduce lossDyeing processLiquid/gas/vapor fibres/slivers/rovings treatmentFiberChemistry

The invention discloses a dyeing process method for loose fiber of cotton, sliver, and cotton roll. It includes changes the traditional process of spinning-before-dyeing into the one of dyeing-before-spinning. The method uses azo dyes to dye the loose cotton, the dyed loose cotton is colorful cotton with five colors, the color includes red, yellow, brown and black. It can be produced without special appliances, especially applies to small industry, the color difference of the product is small, the product is soft, pluffy, it solves the problem of color floating, fading, contaminating, cotton joint, bad color firm rate. It reduces yarn back, high speed cone winding process.

Owner:余姚久丰染色厂有限公司

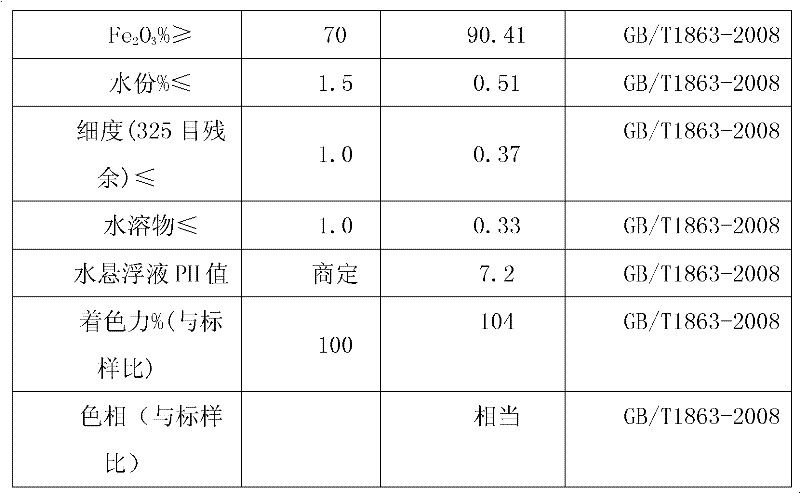

Aniline black pigment producing method

The invention discloses an aniline black pigment producing method. The aniline black pigment producing method comprises the following steps of: taking aniline as a raw material, and adding hydrochloric acid to synthesize an aniline hydrochloride solution; adding a hydroxyl copper phosphate catalyst, and dripping hydrogen peroxide; and after reaction, filtering, cleaning, drying and grinding to obtain aniline black pigment. In the aniline black pigment producing method, dichromate is not taken as an oxidant, thus avoiding chromium pollution; the hydroxyl copper phosphate catalyst coordinates with the hydrogen peroxide oxidant, thus improving the yield of the aniline black pigment; the produced obtained aniline black pigment is pure in color and luster and is blue phase black; and the production is simple and convenient.

Owner:LIAONING FIXED STAR FINE CHEM

Processing method of ultra-white pure cotton knitted fabric

InactiveCN103643476AHigh whiteness indexPure shadeBleaching apparatusVegetal fibresOxygenColored light

The invention discloses a processing method of ultra-white pure cotton knitted fabric. The method comprises the following steps: 1) knitting; 2) carrying out acid and alkali compound cracking; 3) bleaching by oxygen and whitening, namely adding water at the bath ratio of 2:9, orderly adding 3-4g / L degreaser, 3-4g / L hydrogen peroxide stabilizer and 15g / L caustic soda liquid, warming to 70 DEG C, adding 27g / L hydrogen peroxide to process for 25 minutes, adding 1-2owf% of fluorescent brightener, warming to 90 DEG C, preserving heat for 75 minutes, and draining away water; 4) dewatering, scutching and drying; 5) carrying out resin molding; 6) re-bleaching and whitening, namely adding water at the bath ratio of 2:9, orderly adding 3-4g / L degreaser, 1-2g / L hydrogen peroxide stabilizer and 6-7g / L liquid caustic soda, warming to 75 DEG C, adding 2-3g / L hydrogen peroxide to process for 20 minutes, adding 1-2owf% of fluorescent brightener, warming to 95 DEG C, preserving heat for 65 minutes, and draining away water; 7) dewatering and drying; 8) molding; and 9) preshrinking. The pure cotton knitted fabric processed by the method is high in whiteness index, anti-yellowing, and pure and natural in colored light.

Owner:CHANGSHU XINLEI KNITTING

High-temperature environmentally-friendly chemical fiber dyeing technology

InactiveCN107164976AGuaranteed functionAvoid damageBiochemical treatment with enzymes/microorganismsDyeing processFiberCellulose

The invention relates to a high-temperature environmentally-friendly chemical dyeing technology. The technology comprises preprocessing, pre-setting, dyeing, water washing, soaping, dye fixation, softening, drying, setting and winding. A stepped heating dyeing method is adopted, and the heating and cooling rates and the dyeing time are strictly controlled, so dyeing of a fiber fabric has high fastness, the dyeing is uniform, and the dyeing has good stability; an anti-dyeing salt S is added in the dyeing process, so the destroy of potential aldehyde groups in cellulose molecules in chemical fiber filaments to a dye is greatly improved, thereby a dyed product has pure color light, the color difference of dyeing is avoided, and the reappearance and the stability of the dyeing are good. Chemical fiber filaments finally produced in the invention have the advantages of uniform dyeing, stability, strong recurrence, elasticity, softness and high dyeing fastness.

Owner:ZHANGJIAGANG JINYI CHEM FIBER

Dye mixture for fur dyeing

The invention discloses a dye mixture for fur dyeing. The dye mixture consists of a dye component and an auxiliary component and dyes the fur by a discharge dyeing technology to obtain better color tone and perfect white discharge property; and the problem of limited varieties with good white discharge property suitable for fur is solved. The dye mixture has good color fastness after discharge, ironing fastness of level 4-5, rubbing fastness of level 5, light fastness of level 5, high dye-uptake and good white discharge property; and moreover, the monomer has bright color tone, the dye mixture has pure color tone, for example, the black color tone has good black degree, and the quality of fur can be obviously improved in application.

Owner:河北嘉泰化工科技有限公司

Dyeing process for treasure island suede microfiber leather and wastewater recycle technique in dyeing process

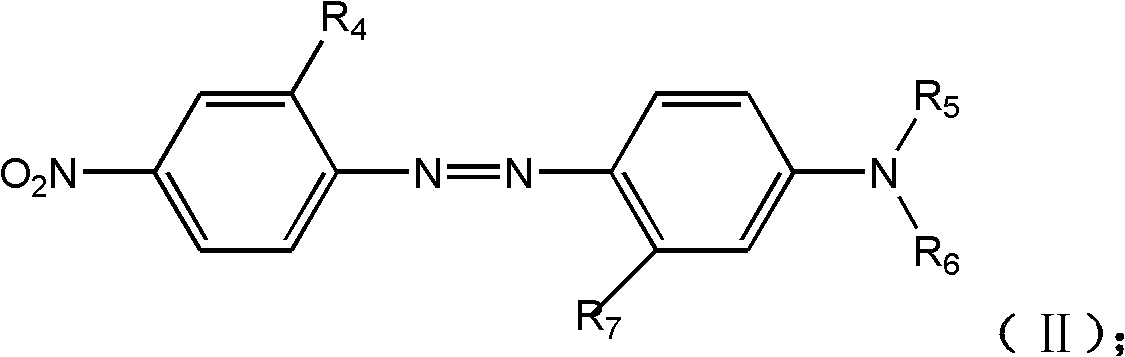

InactiveCN107338652AReduce the rate of dyeingGood dyeing rateFibre treatmentTextile treatment machine arrangementsWastewaterEngineering

The invention discloses a dyeing process for treasure island suede microfiber leather. The dyeing process comprises the following steps of a base cloth processing sub-process and a dyeing sub-process, wherein in the base cloth processing sub-process, the steps of dipping, solidifying, washing, dyeing, coating and surface grinding are utilized to obtain the treasure island suede microfiber leather, and the dyeing sub-process is carried out at a high temperature; in the dyeing sub-process, the treasure island suede microfiber leather is dyed at 26-28 DEG C for initial dyeing, then the temperature is increased to 57-63 DEG C at an increase speed of 1 DEG C / min and the treasure island suede microfiber leather is kept at the temperature of 57-63 DEG C for 13-14 minutes; the temperature is increased to 82-86 DEG C at an increase speed of 1 DEG C / min and the treasure island suede microfiber leather is kept at the temperature of 82-86 DEG C for 14-16 minutes; the temperature is increased to 111-113 DEG C at an increase speed of 0.6-1 DEG C / min and the treasure island suede microfiber leather is kept at the temperature of 111-113 DEG C for 18-21 minutes; finally, the temperature is decreased to 68-71 DEG C at the speed of 1.5-1.8 DEG C / min. The invention also discloses a wastewater recycle technique in the dyeing process of the treasure island suede microfiber leather, and according to the dyeing process for the treasure island suede microfiber leather and the wastewater recycle technique in the dyeing process of the treasure island suede microfiber leather, the dyeing time can be shortened by controlling the dyeing temperature, the time and time periods of temperature rising and temperature decreasing; for the dyeing process, the dyeing rate and color fastness of the dyed base cloth are good, dyeing is balanced evenly, the color of the dyed base cloth is deep and dense, and the color brightness is pure; finished products have the advantages of both a microfiber material and a leather material, and recovered DMF from the wastewater generated in the dyeing process can be reused so as to reduce damage to the environment and surrounding workers; the dyeing process for the treasure island suede microfiber leather and the wastewater recycle technique in the dyeing process of the treasure island suede microfiber leather are environment-friendly and can save energy.

Owner:泉州众信超纤科技股份有限公司

Processing technology for improving yarn shrinkage rate of microcapsule fragrant fabric tapes

A disclosed processing technology for improving the yarn shrinkage rate of microcapsule fragrant fabric tapes comprises the following steps: yarn fixing, loosening, dyeing, post-treatment and softening processing. By using a dry blowing machine to perform dry blowing on yarns before dyeing, yarns are fully fixed and the shrinkage rate of the yarns is fully improved; and the dyeing process successively comprises multiple times of water washing at different temperature, so that dyeing is uniform, the color light is pure and the color is uniform; and a microcapsule fragrant finishing agent and an environmental-environment acrylic softening adhesive are added in the dyeing process.

Owner:JIANGSU GOLDEN AUTUMN ELASTIC FABRICS

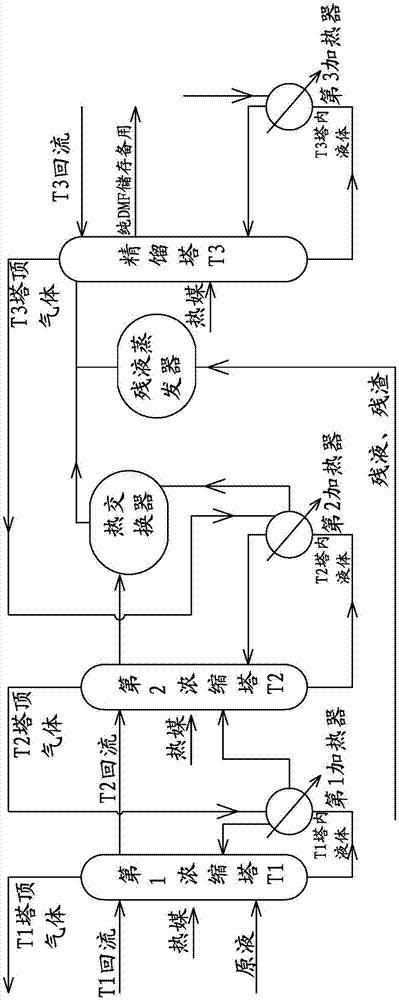

Dyeing and finishing process for Chinese velvet

InactiveCN106638025AEmission reductionGood colorHeating/cooling textile fabricsDyeing processAcid washingSewage

The invention discloses a dyeing and finishing process for Chinese velvet. The dyeing and finishing process combines the steps of hot washing, acid washing, dyeing and water washing and a process flow is shortened, so that the water amount in a production process is reduced and the emission of sewage is reduced, and furthermore, energy saving and emission reduction are realized. Meanwhile, a fabric dyed and finished by the dyeing and finishing process has good dyeing yield and pure colored light.

Owner:ZHEJIANG DONGSHENG DYEING & PRINTING CO LTD

Flax-viscose plain cloth and manufacturing method thereof

The invention discloses a flax-viscose plain cloth. The warps and wefts of the flax-viscose plain cloth are composed of yarns A and yarns B, wherein 30 threads of the yarns A and the yarns B are twisted into two strands, each strand comprises 60% of the yarns A and 40% of the yarns B, the yarns A are flax and the yarns B are viscose. According to the invention, the defects of the prior art are solved, and the flax-viscose plain cloth provided by the invention has the advantages of purer tone and fine and smooth cloth surface.

Owner:WUJIANG CITY HONGHUI APPAREL

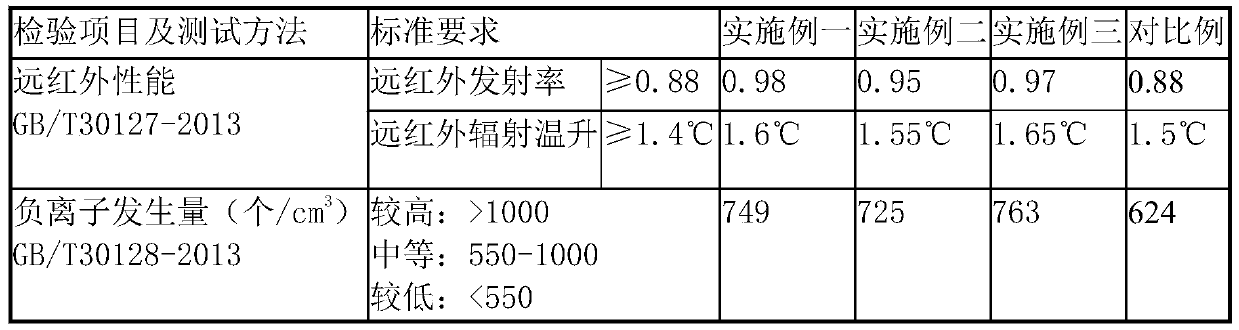

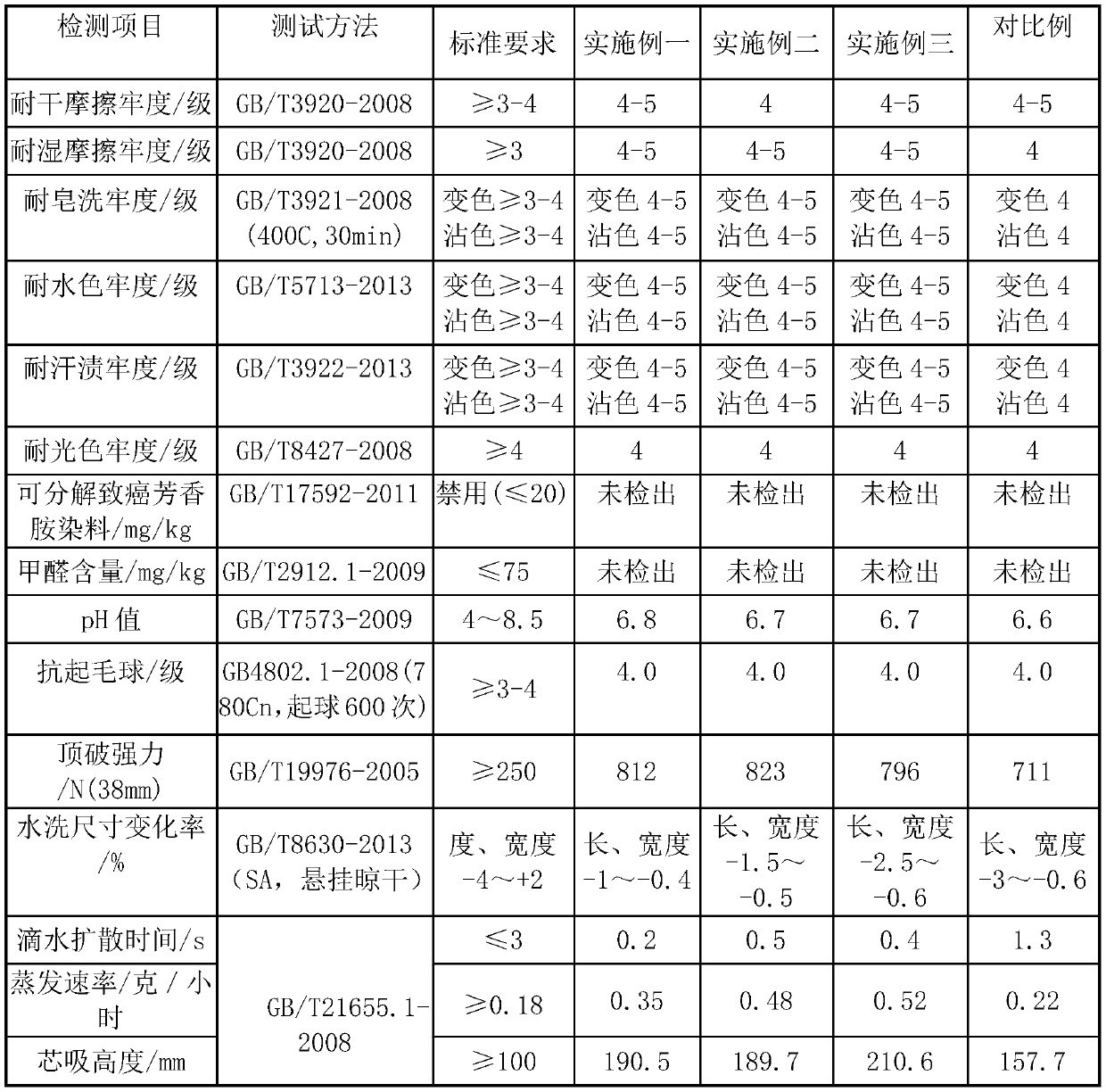

Dyeing process of far-infrared antibacterial fabric

InactiveCN110485175AReduce consumptionGood dyeing with same colorWeft knittingBiochemical fibre treatmentYarnElectricity

The invention discloses a dyeing process of a far-infrared antibacterial fabric. The dyeing process comprises the following steps of preparation of a gray fabric, dyeing pretreatment, dyeing, soapingaftertreatment and (5) shaping aftertreatment. The gray fabric is woven from germanium-bearing polyester silks and spandex core-spun yarns by adopting a double-sided circular machine. According to therelated dyeing process of the far-infrared antibacterial fabric, the knitted fabric of the germanium-bearing polyester silks and spandex core-spun yarns is dyed by adopting a one-bath method, so thatthe two components have good dyeing homochromatism and high color fastness. By adopting the one-bath and one-step method, compared with an original process, the production time is shortened by 50%, and the production efficiency is greatly improved; compared with a two-bath and two-step process and a one-bath and two-step process, the yield can be effectively increased. Because the production timeis shortened and the consumption of water, electricity and steam is also decreased correspondingly, the production cost is reduced. The warming, cooling and reduction cleaning processes are mainly reduced. The shade of the produced color is pure, the coincidence rate is high, and the sample comparing difficulty is reduced.

Owner:嘉兴市华利印染股份有限公司

Anti-oxidation single component aromatic hydrocarbon solvent used in copper phthalocyanine synthesis

InactiveCN1532175AImprove protectionGuarantee the safety of useOrganic chemistryPorphines/azaporphinesBoiling pointRefractive index

The present invention relates to aromatic hydrocarbon solvent, and is especially oxidationproof single-component aromatic hydrocarbon solvent used in synthesizing copper phthalocyanine. It features the boiling point of 200-220 deg.c, density of 0.86-0.89 and refractivity of 1.5060-1.5080, and has the advantages of being environment friendly and non-toxic, high yield and high purity of copper phthalocyanine product and high oxidation resistance. The solvent may be used in preparing C.I. blue pigment with high strength and pure color.

Owner:赵维绳

A kind of dyeing process of nylon fiber

InactiveCN104711874BReduce pollutionAvoid damageBiochemical fibre treatmentFibre typesDisperse dyeAcid dye

The invention provides a dyeing process of nylon fiber. The dyeing process comprises the following steps: pretreatment, presetting, dyeing soaping, color fixing, after finishing, drying, setting, calendering and winding. The dyeing process provided by the invention has the advantages that in the dyeing procedure, disperse dyes and acidic dyes are used for carrying out dyeing according to the own property of the nylon fiber, so that the dyeing effect is improved; the soaping and color-fixing processes are added, so that the dyeing firmness is good; in the color fixing process, environment-friendly formaldehyde-free TCD-R is adopted, and the fiber is dried in a step-by-step manner after color fixation, so that the firmness of the fiber is greatly improved; the after-finishing process is added, so that the color firmness and softness of the fabrics are improved and increased, the roughness of the fabrics is reduced, and further the fabrics are fluffy and elastic.

Owner:袁英英

Blue-to-black disperse dye composition

ActiveCN102746713BStrong alkali resistanceAvoid problems such as contaminationOrganic dyesDisperse dyeAlkali burn

The invention provides a blue-to-black disperse dye composition, which mainly comprises one or multiple blue dye ingredients A shown as the structure formula (I), one or multiple red dye ingredients B shown as the structure formula (II) and one or multiple orange dye ingredients C shown as the structure formula (III). The disperse dye composition has the advantages that the dying bottleneck of the existing ordinary disperse dye under the alkaline condition is broken through, the problems of white powder, color points and dyeing defect generation caused by the dyeing under the acid condition, the contamination on the inner wall of dyeing equipment caused by low polymers, and the like are solved, the dyeing quality is effectively improved, the stability and the reproducibility of the process are ensured, and the once success rate of the dyeing is improved. In addition, the prepared disperse dye has higher alkali resistance capability and can be applied to an alkali burnt-out process, the defect of single acid burnt-out color is overcome, and the requirements of the society on the aesthetic perception and the variety on clothing and decorations are met.

Owner:ZHEJIANG LONGSHENG GROUP +1

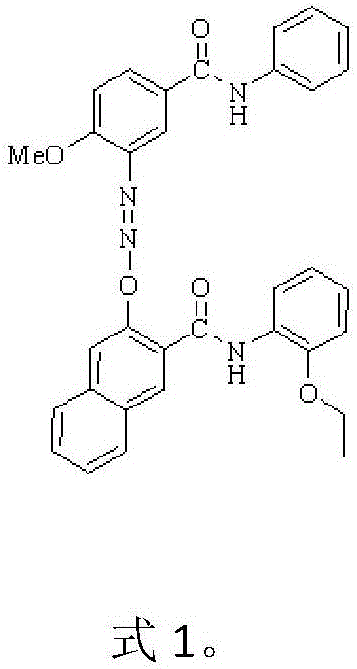

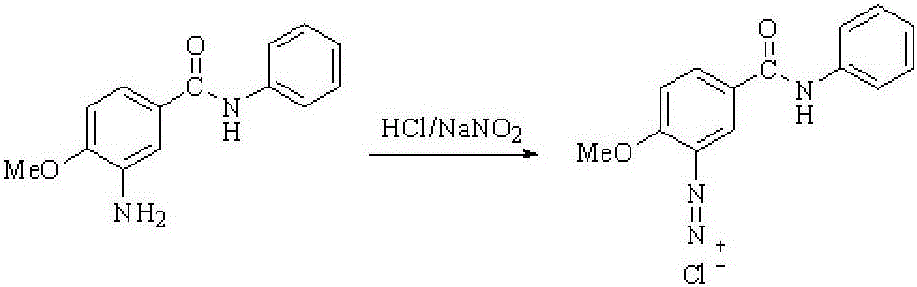

Organic rose-bengal pigment, preparation method thereof and application of pigment in water-based coating printing paste or ink

The invention provides an organic rose-bengal pigment, a preparation method thereof and application of the pigment in water-based coating printing paste or ink. A red base KD, hydrochloric acid and sodium nitrite perform diazotization reaction to generate red base KD diazonium salt; an azoic coupling component AS-PH reacts with sodium hydroxide to generate azoic coupling component AS-PH salt; then the red base KD diazonium salt and the azoic coupling component AS-PH salt perform coupling reaction to obtain the organic rose-bengal pigment. The water-based coating printing paste and ink prepared by adopting the organic rose-bengal pigment has the biggest advantage that when the color is light, a pure, bright and unique blue-phase color tone is shown.

Owner:HUNAN XINLIHUA NANO TECH

Disperse dye composition suitable for basic dyeing

ActiveCN101649129BAvoid problems such as contaminationGuaranteed stabilityOrganic dyesDyeing processColour fastnessDisperse dye

The invention provides a disperse dye composition suitable for basic dyeing, mainly comprising the following raw materials in percentage by weight: 40-95 percent of one or a plurality of blue dyeing components A with a structural formula (I), 1-25 percent of one or a plurality of red dyeing components B with a structural formula (II) and 4-50 percent of one or a plurality of orange dyeing components C with a structural formula (III). The disperse dye composition has a wide dependency range of pH values, and can dye in a pH value ranging from 4.0 to 10; dyed and woven fabrics with predominant color-fastness performance, such as full hues, washing fastness, and the like, can be obtained.

Owner:浙江龙盛染料化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com