Patents

Literature

134results about How to "Improve one-time success rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

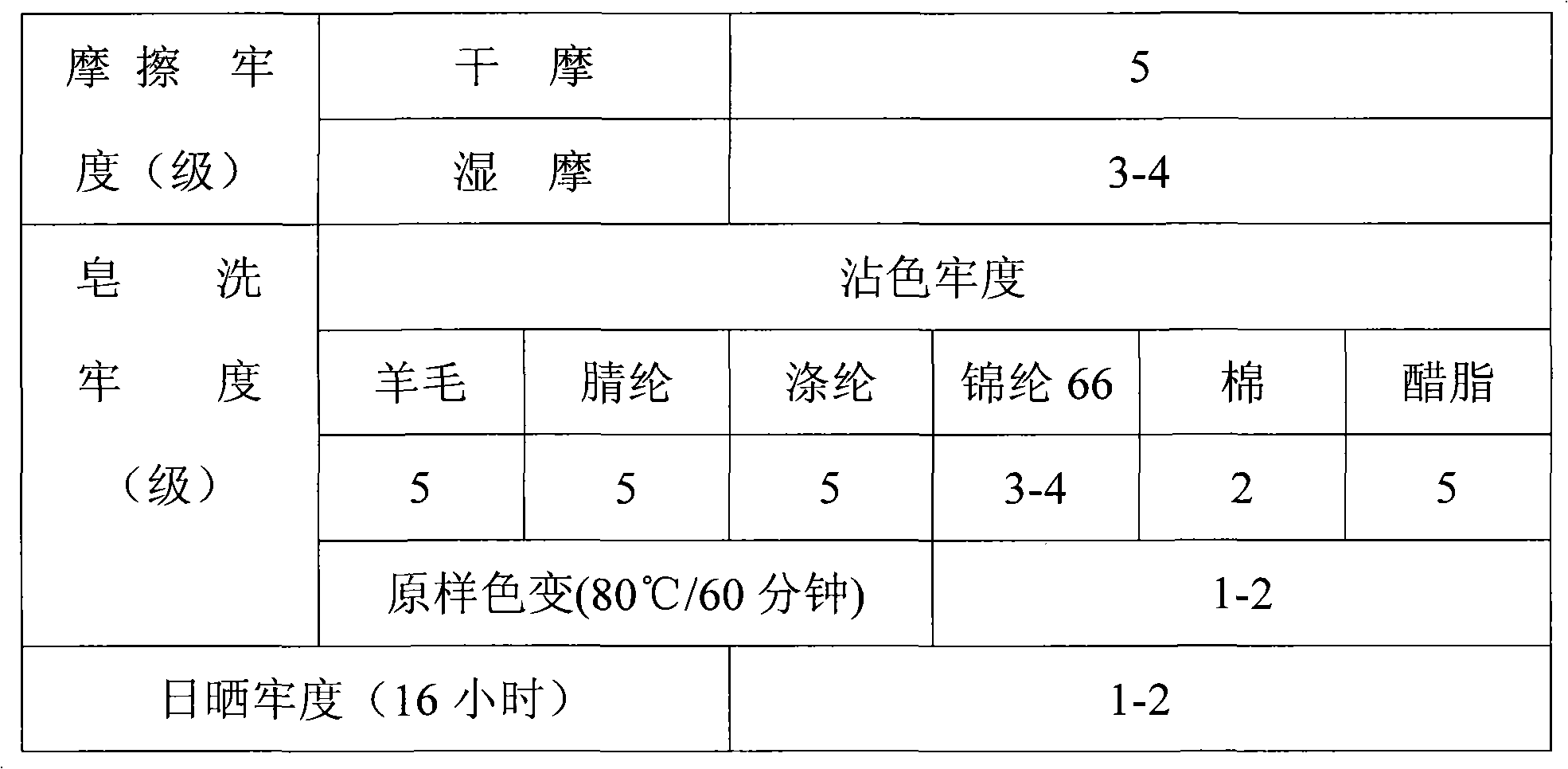

Disperse dye composition suitable for basic dyeing

ActiveCN101649129AAvoid problems such as contaminationGuaranteed stabilityOrganic dyesDyeing processDisperse dyeColour fastness

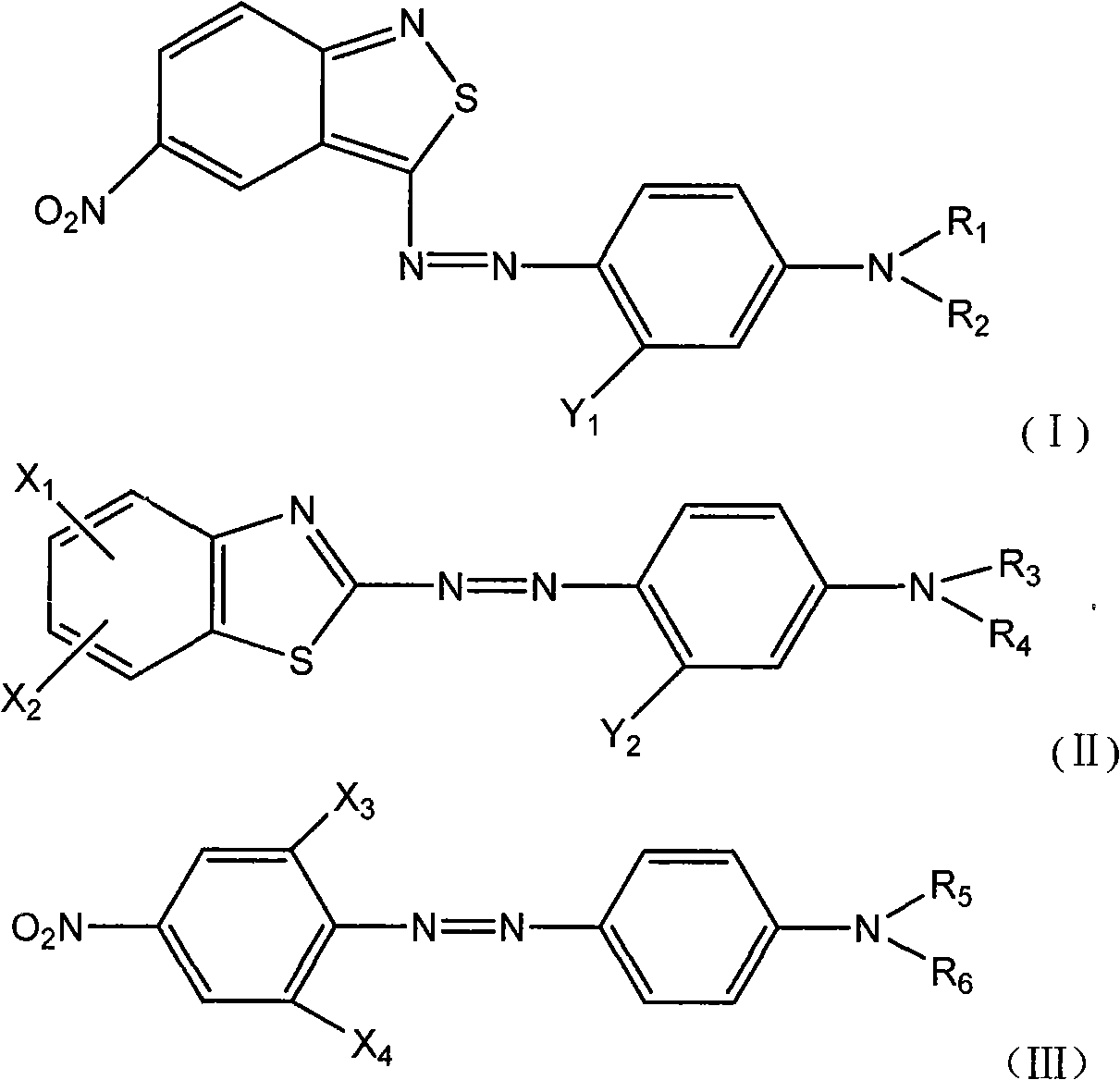

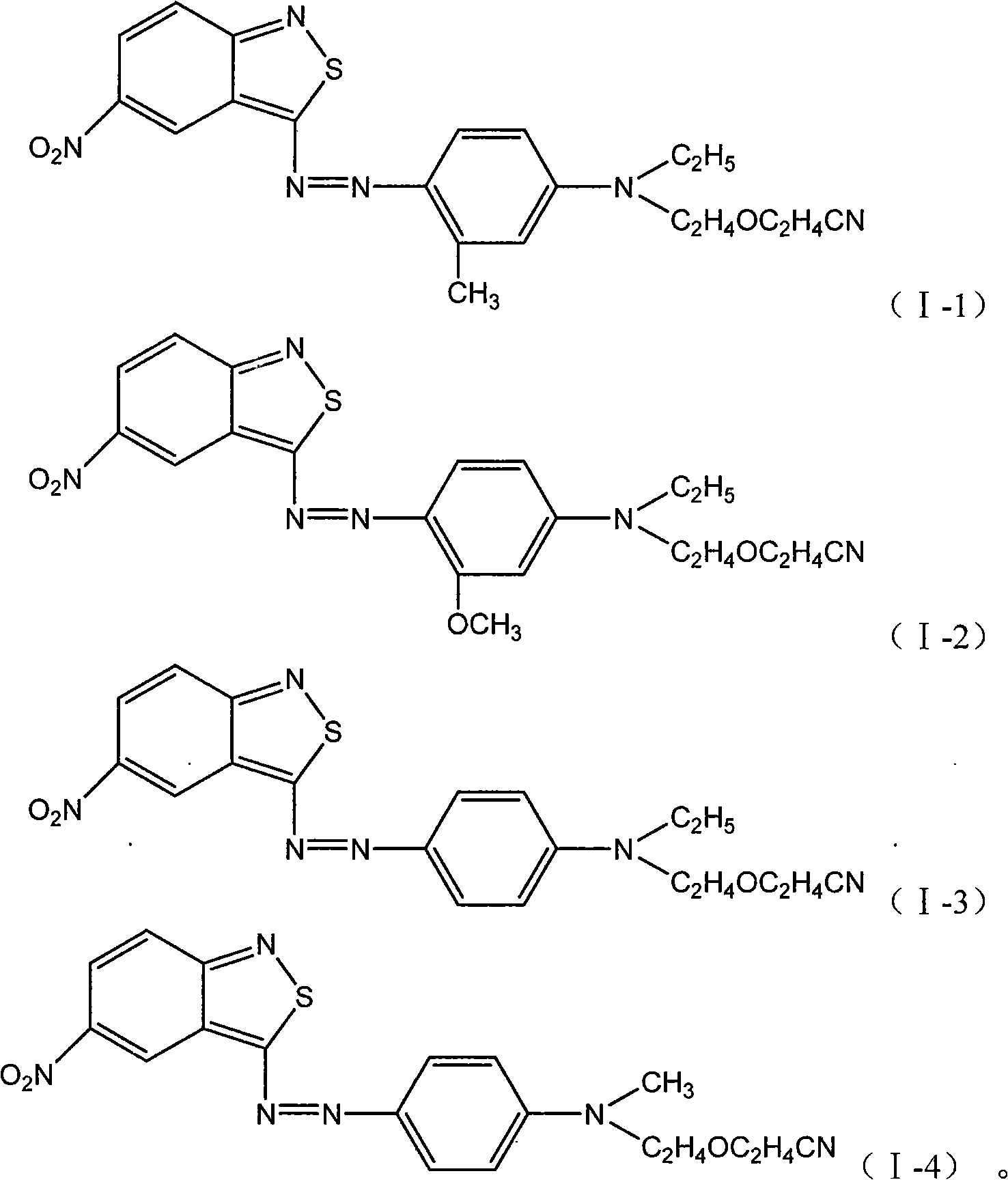

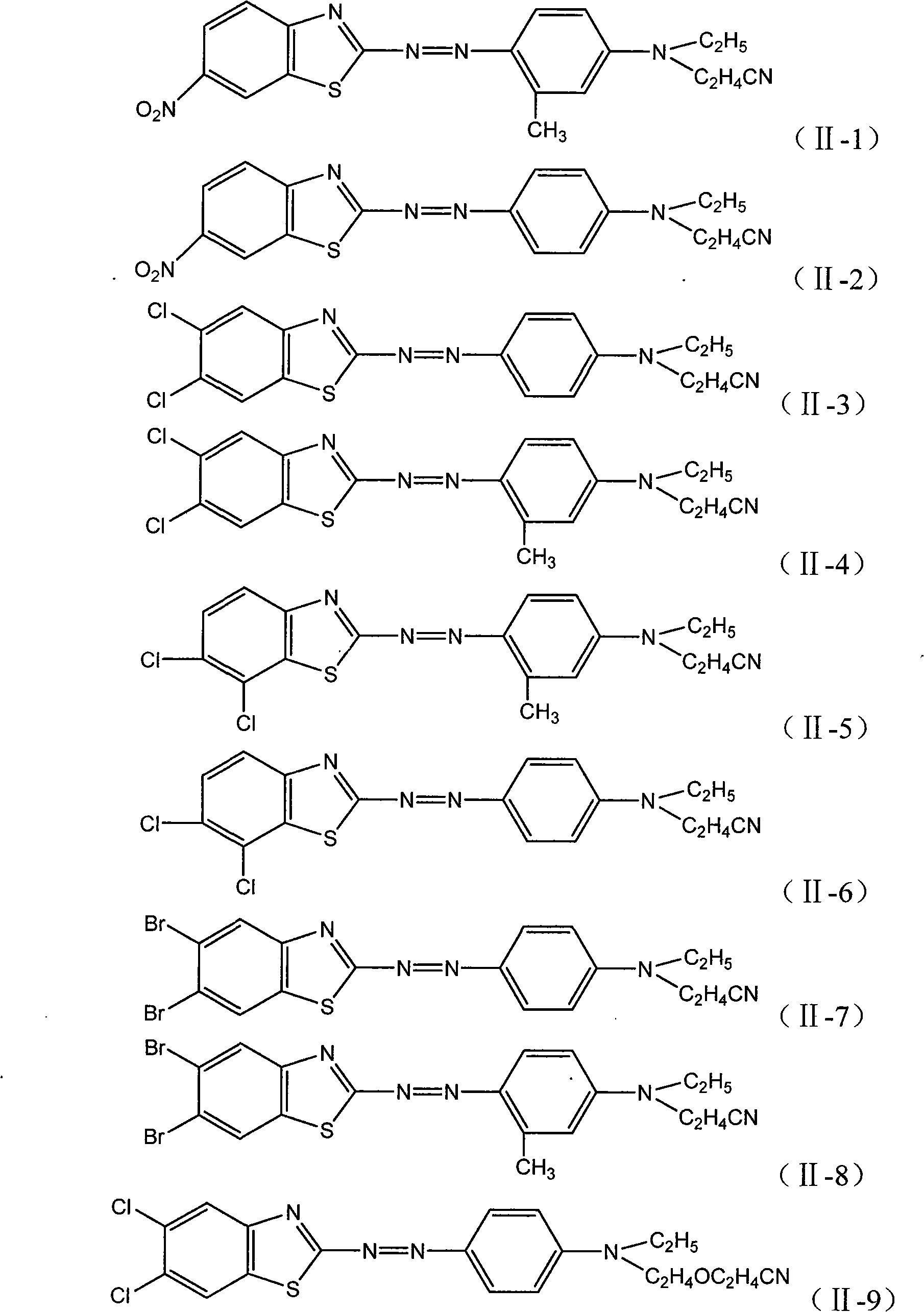

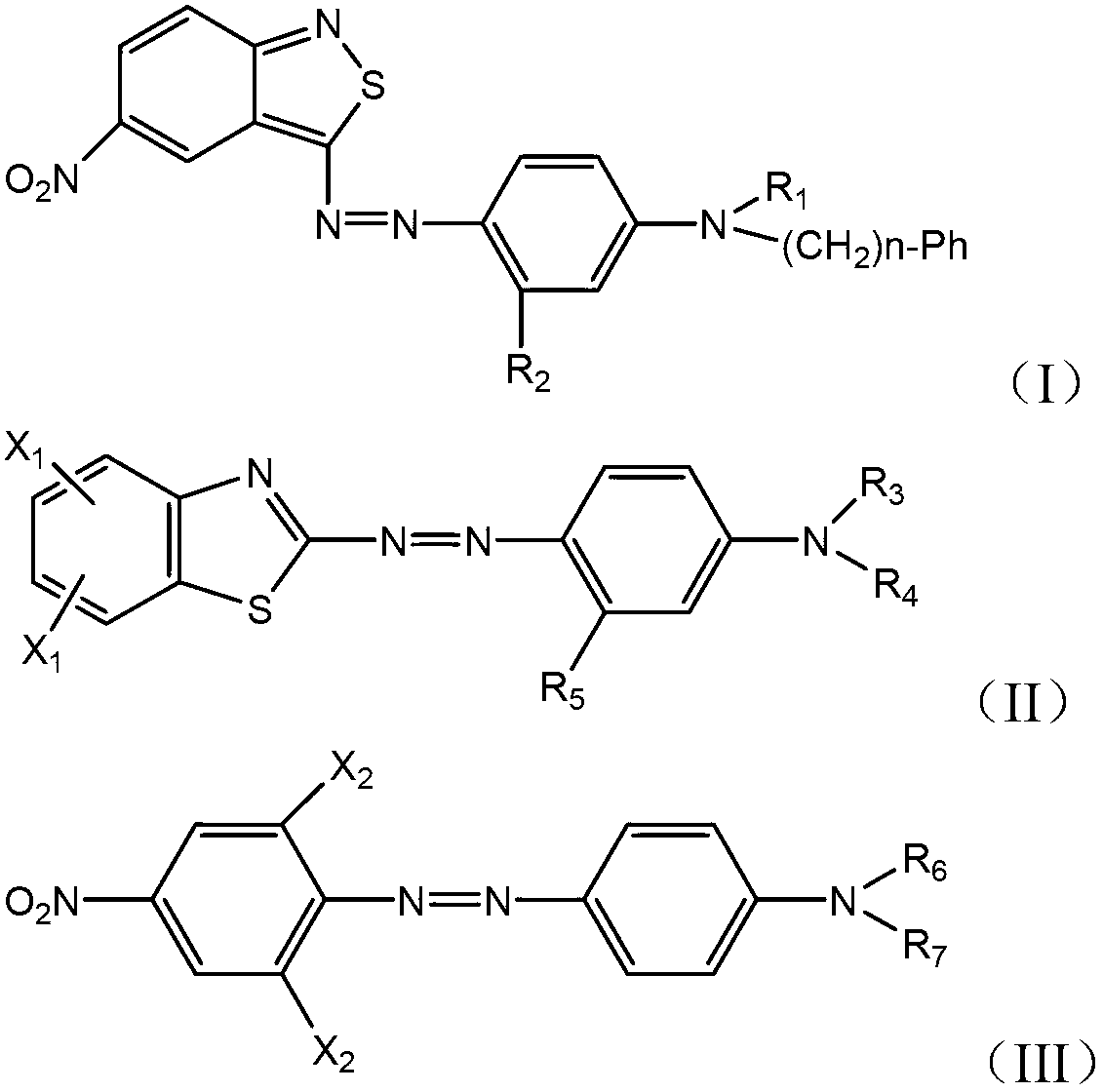

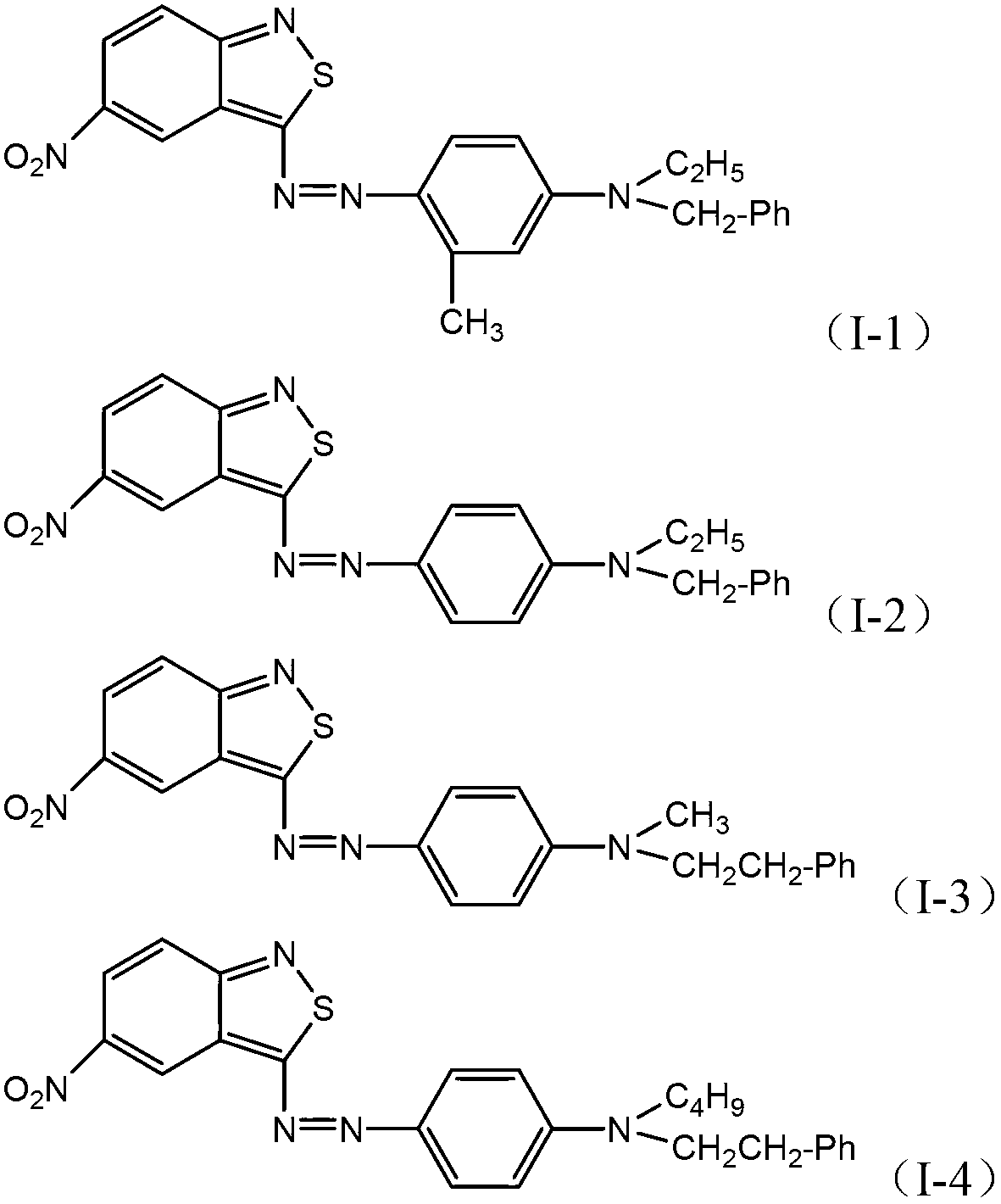

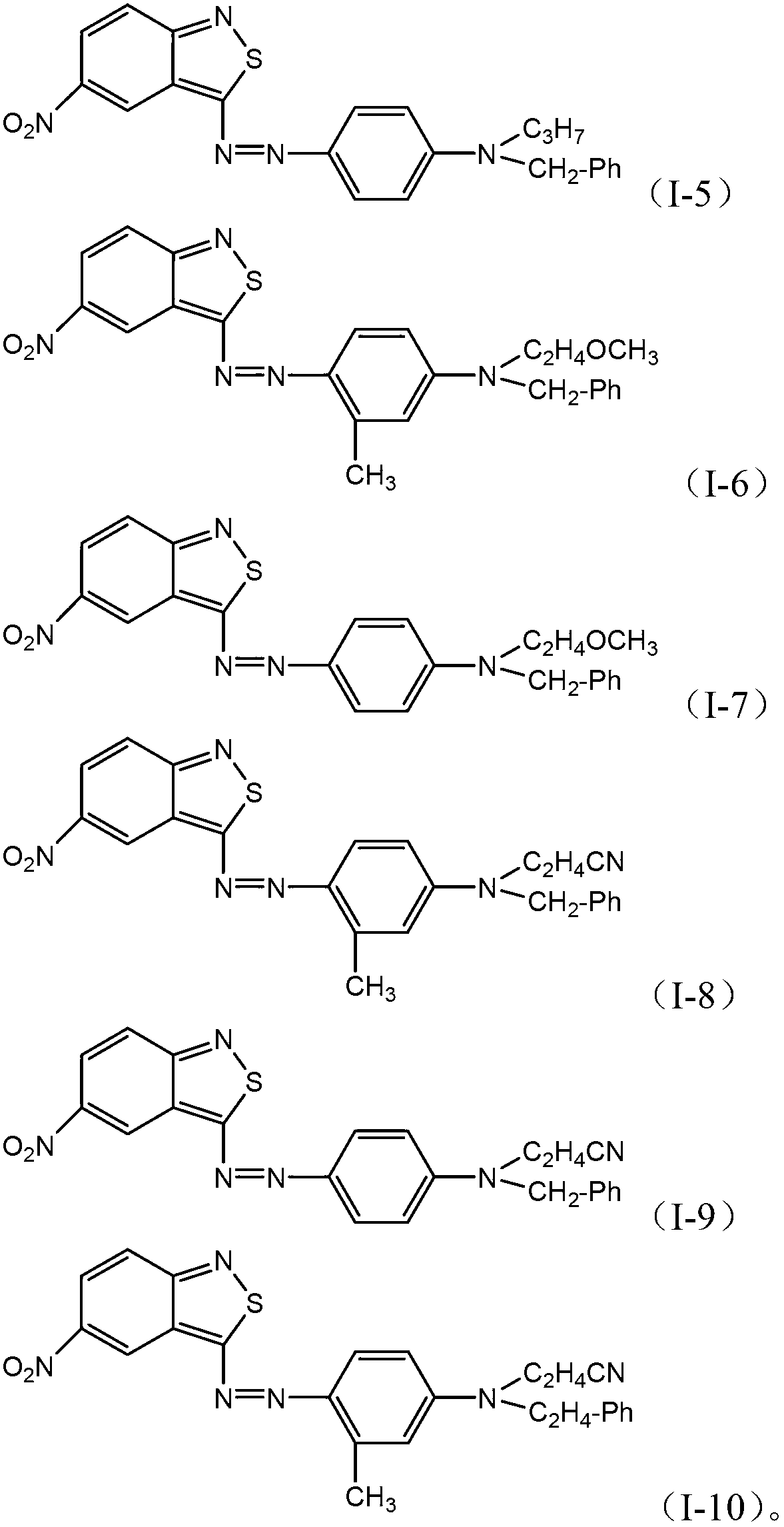

The invention provides a disperse dye composition suitable for basic dyeing, mainly comprising the following raw materials in percentage by weight: 40-95 percent of one or a plurality of blue dyeing components A with a structural formula (I), 1-25 percent of one or a plurality of red dyeing components B with a structural formula (II) and 4-50 percent of one or a plurality of orange dyeing components C with a structural formula (III). The disperse dye composition has a wide dependency range of pH values, and can dye in a pH value ranging from 4.0 to 10; dyed and woven fabrics with predominant color-fastness performance, such as full hues, washing fastness, and the like, can be obtained.

Owner:浙江龙盛染料化工有限公司

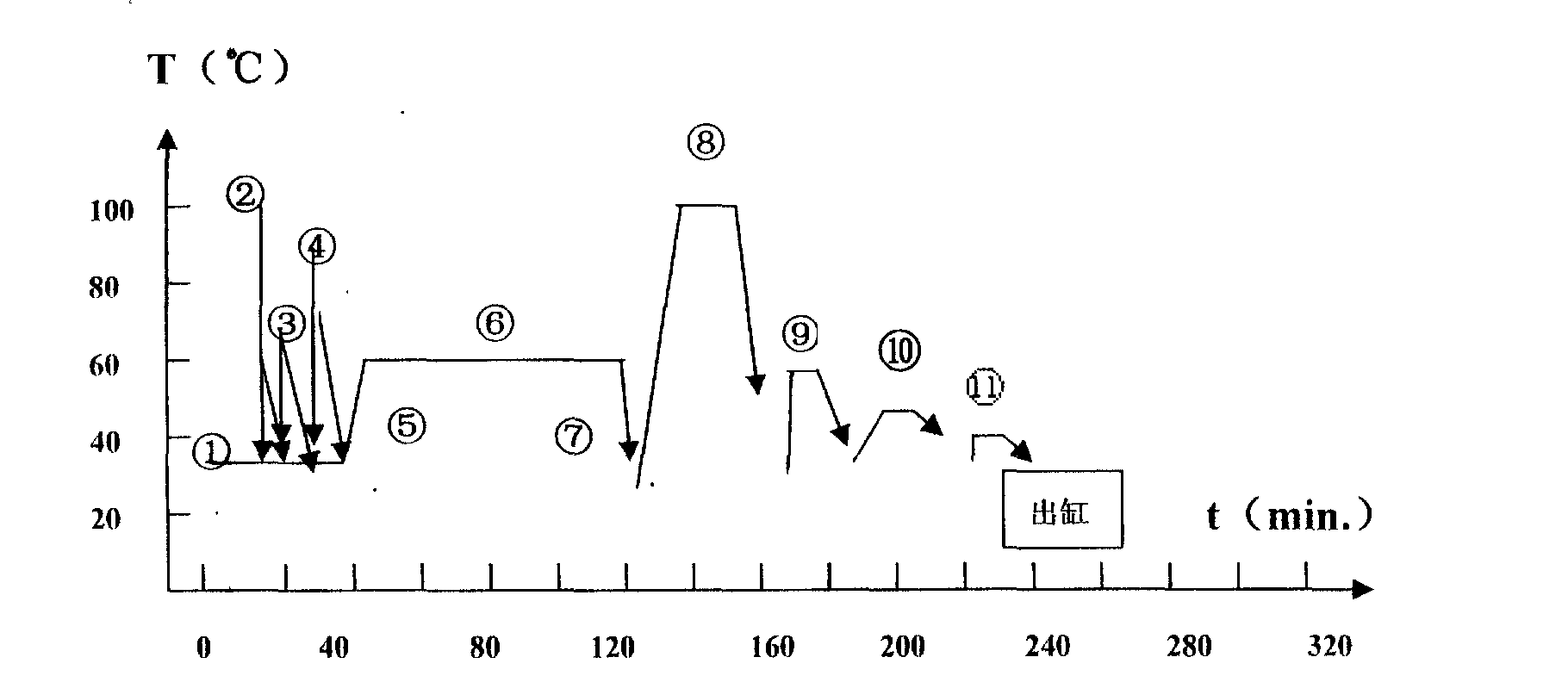

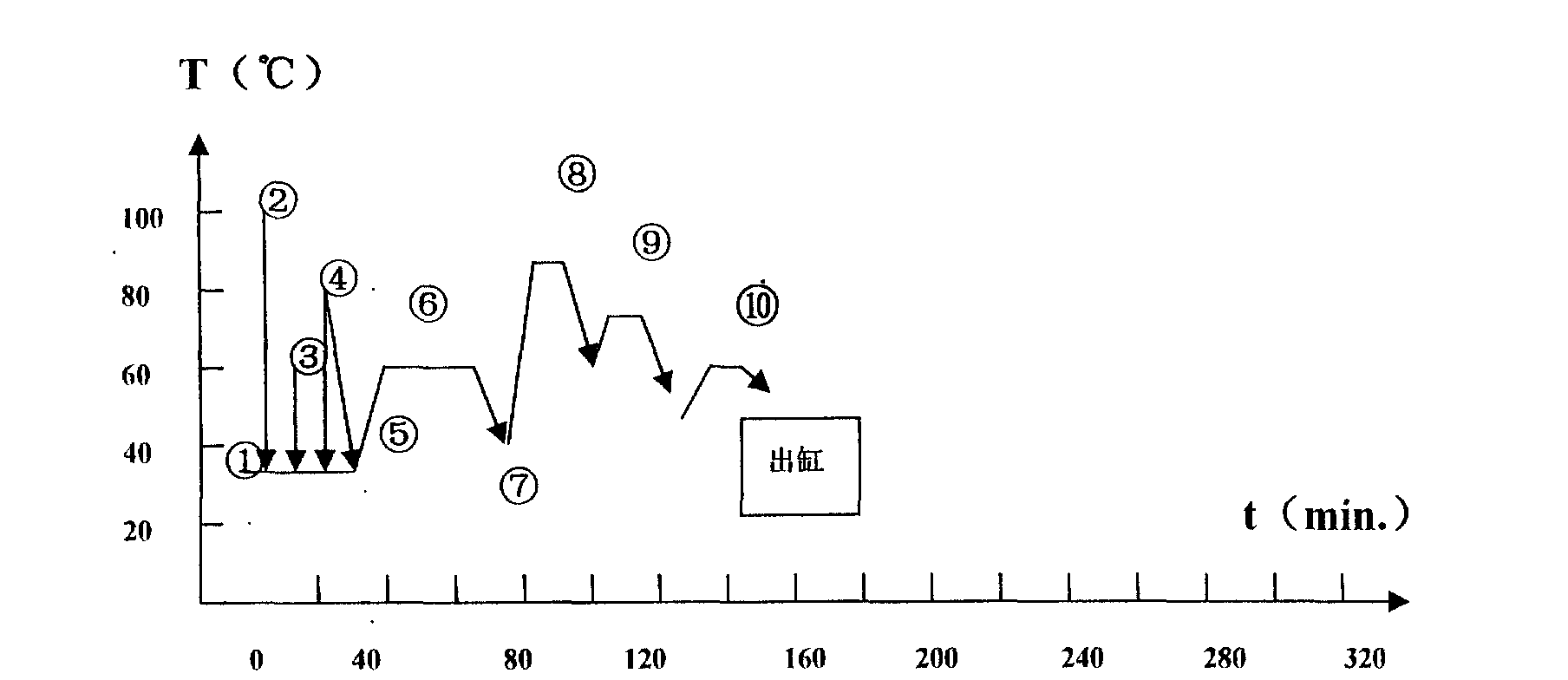

Reactive dye ultra-short rapid dyeing and fixation technology method

The invention relates to a reactive dye ultra-short rapid dyeing and fixation technology method. The method is realized by effectively minimizing auxiliary time such as feeding, shortening and optimizing post-processing processes, especially carrying soap boiling (one bath color mending) only once in advance to the greatest extend, merging washing, using less hot water and controlling the use of water aiming at various substances to be dyed according to dyeing requirements and the conditions of normal or abnormal and with the help of various accessory ingredients, thereby the reactive dye normal or abnormal dyeing conditions (especially mediate high color with a dye usage higher than 1percent of o. W. f) by the single one bath process, the multifunction composite one bath process, or the like, comprising pre-processing, dyeing, polishing with enzyme, and color mending, and even the pre-processing and the whole dyeing procedure in conventional equipment in an ultra-low bath ratio limit state can be completed well within 2.5-8h. The effects of thorough energy saving and emission reduction, efficiency increasing and consumption reduction, cleaner production and environmental protection are achieved.

Owner:罗海航 +1

Blue-to-black disperse dye composition

ActiveCN102746713AStrong alkali resistanceAvoid problems such as contaminationOrganic dyesDisperse dyeAlkali burn

The invention provides a blue-to-black disperse dye composition, which mainly comprises one or multiple blue dye ingredients A shown as the structure formula (I), one or multiple red dye ingredients B shown as the structure formula (II) and one or multiple orange dye ingredients C shown as the structure formula (III). The disperse dye composition has the advantages that the dying bottleneck of the existing ordinary disperse dye under the alkaline condition is broken through, the problems of white powder, color points and dyeing defect generation caused by the dyeing under the acid condition, the contamination on the inner wall of dyeing equipment caused by low polymers, and the like are solved, the dyeing quality is effectively improved, the stability and the reproducibility of the process are ensured, and the once success rate of the dyeing is improved. In addition, the prepared disperse dye has higher alkali resistance capability and can be applied to an alkali burnt-out process, the defect of single acid burnt-out color is overcome, and the requirements of the society on the aesthetic perception and the variety on clothing and decorations are met.

Owner:ZHEJIANG LONGSHENG GROUP +1

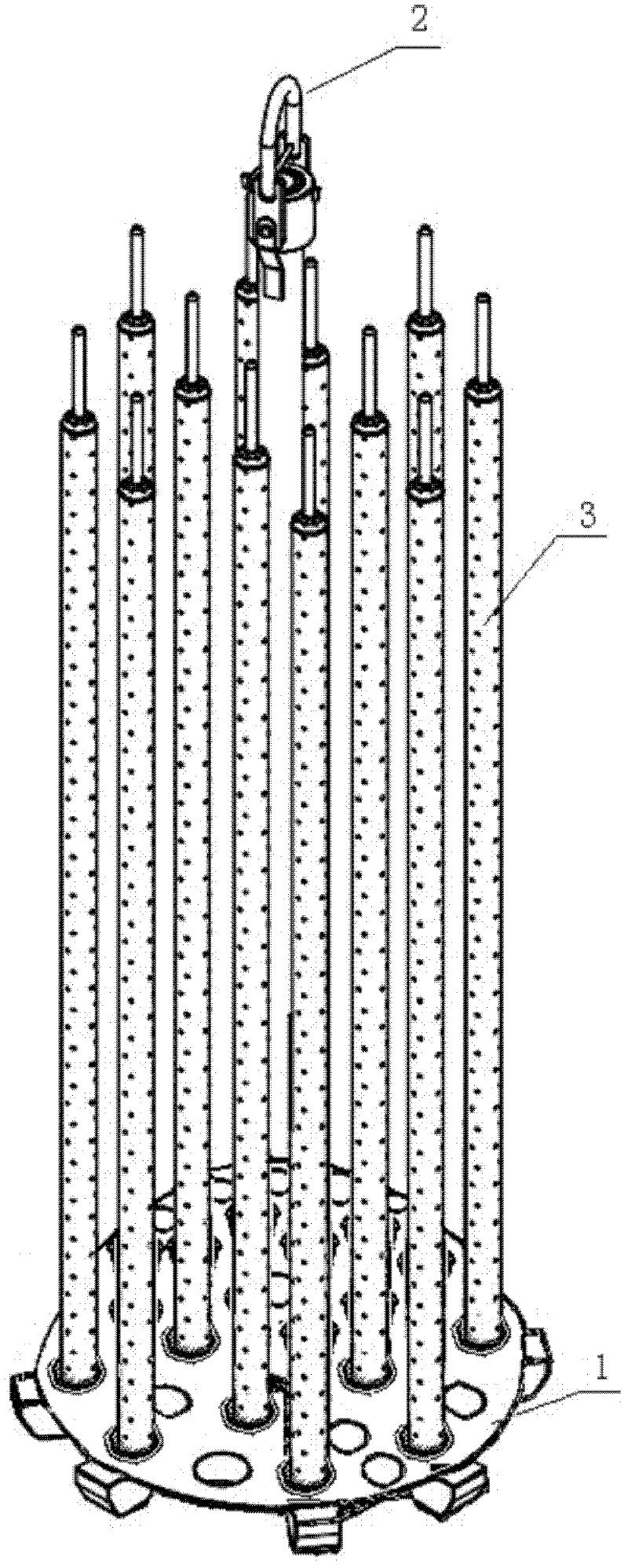

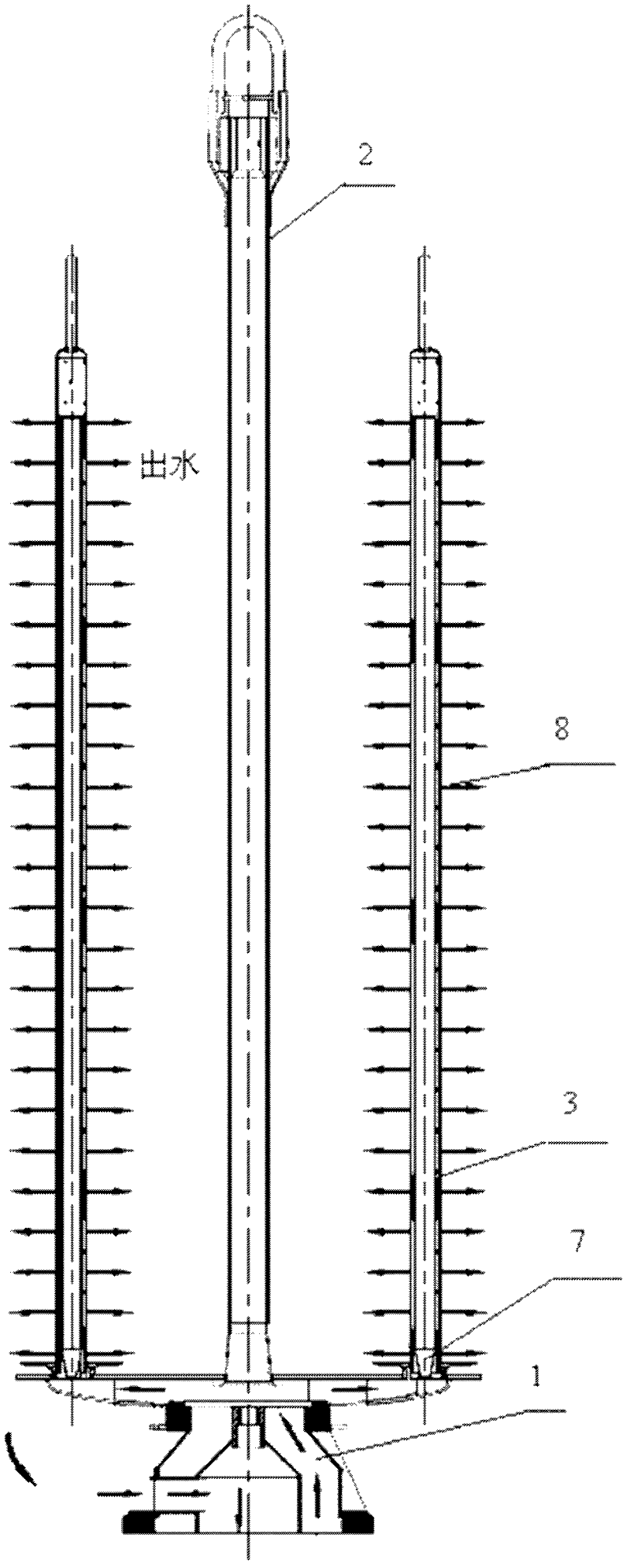

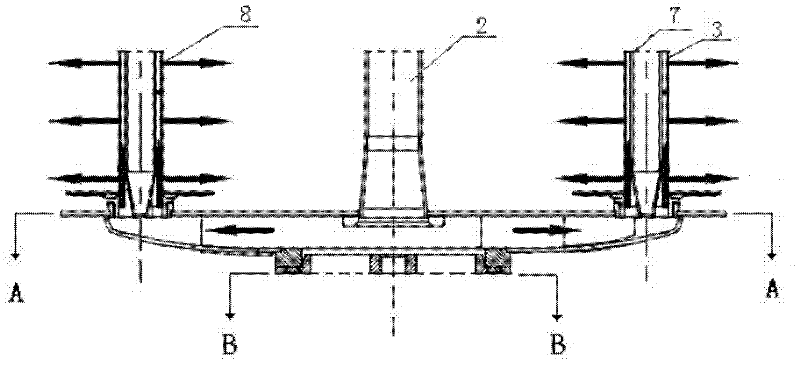

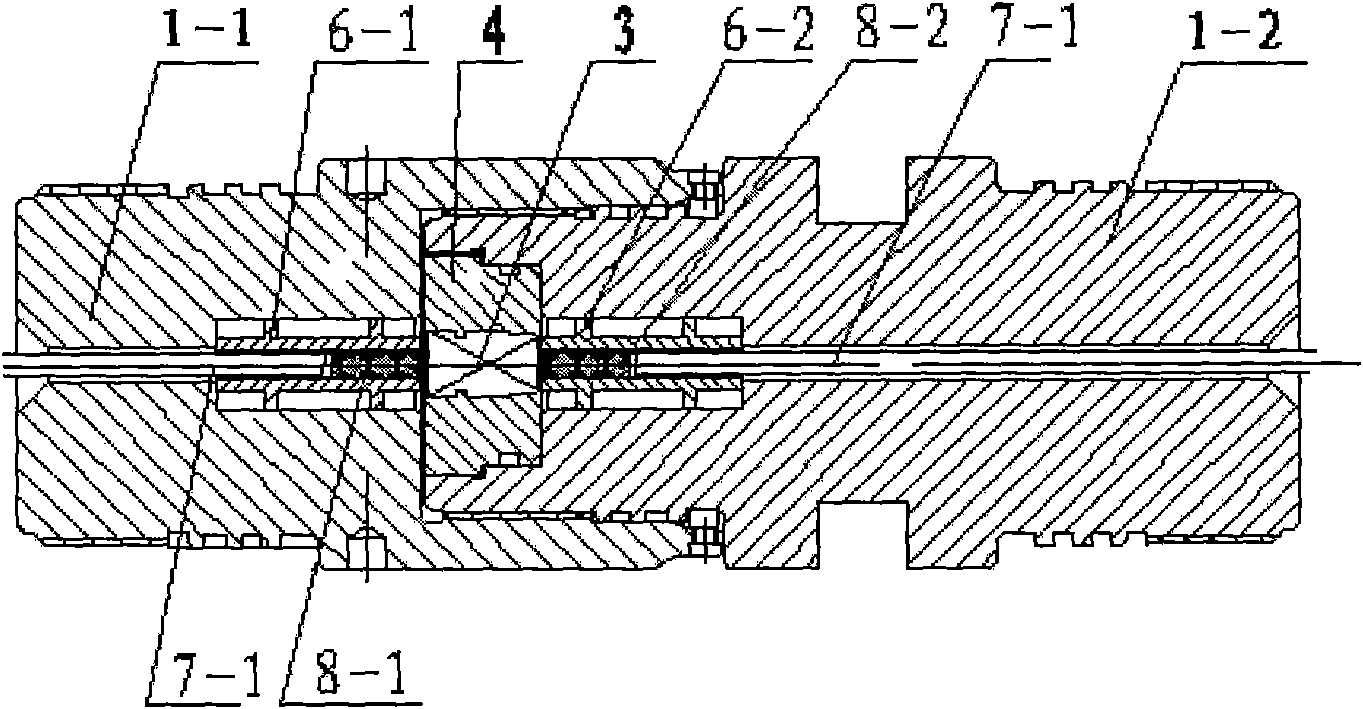

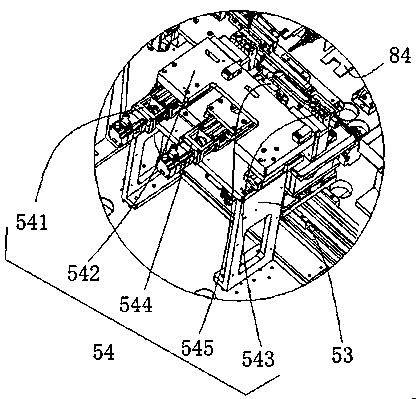

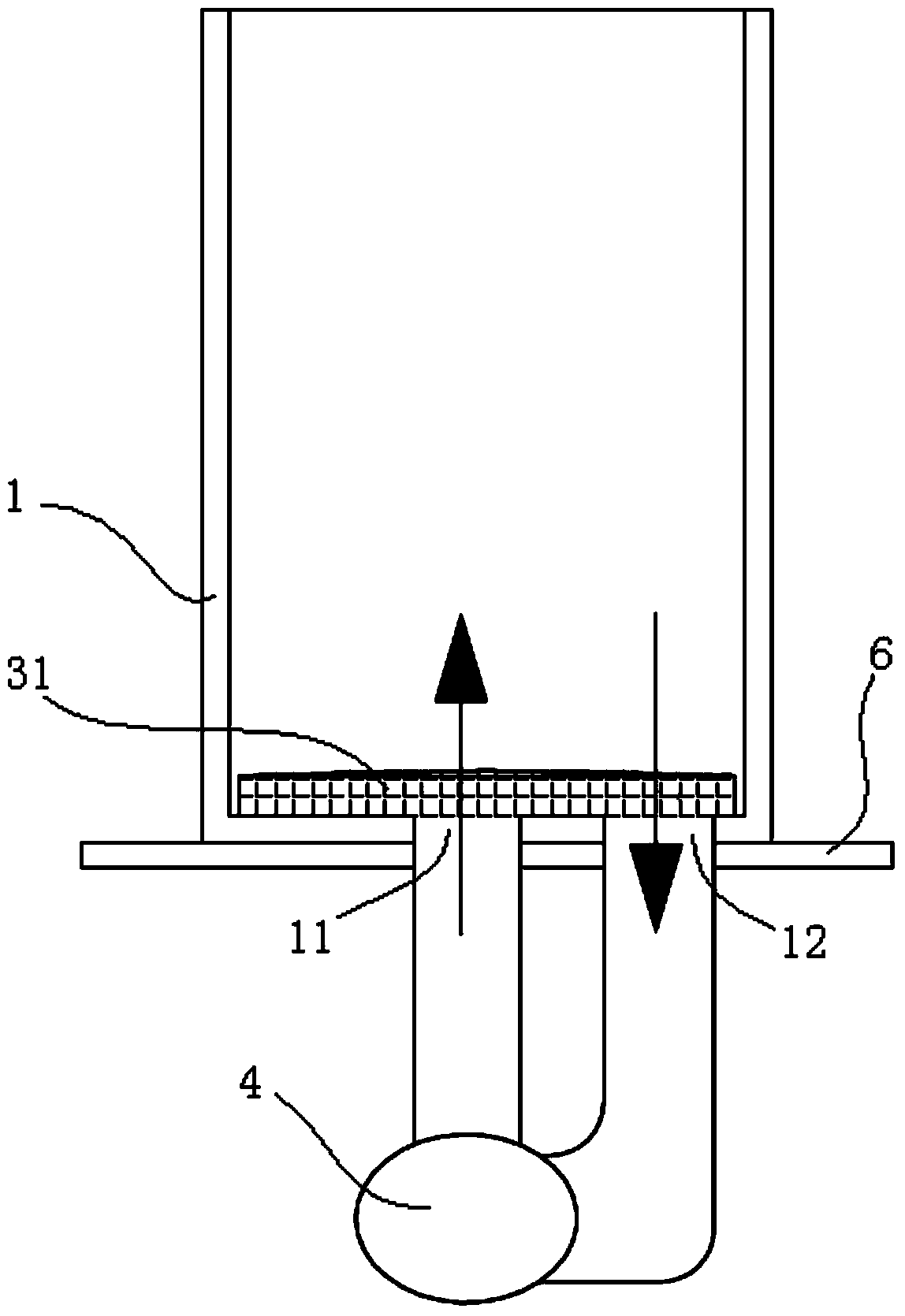

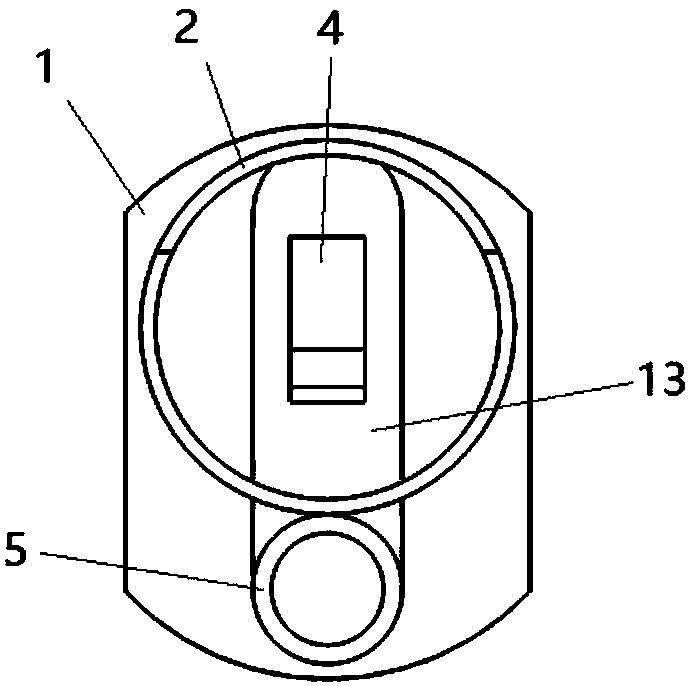

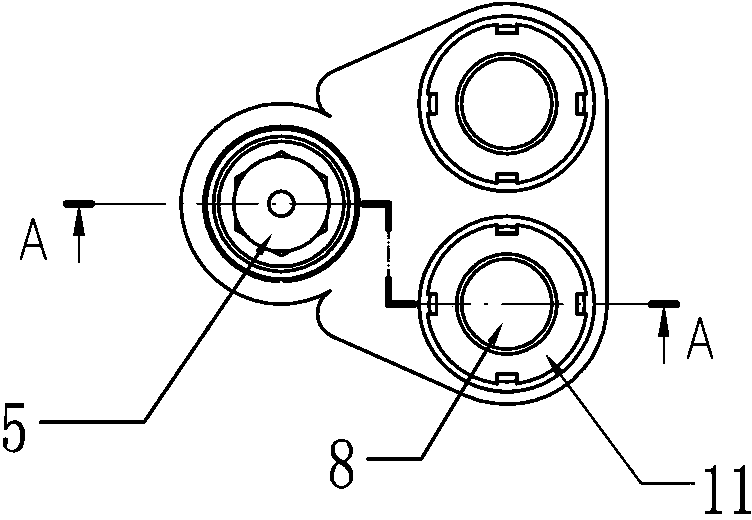

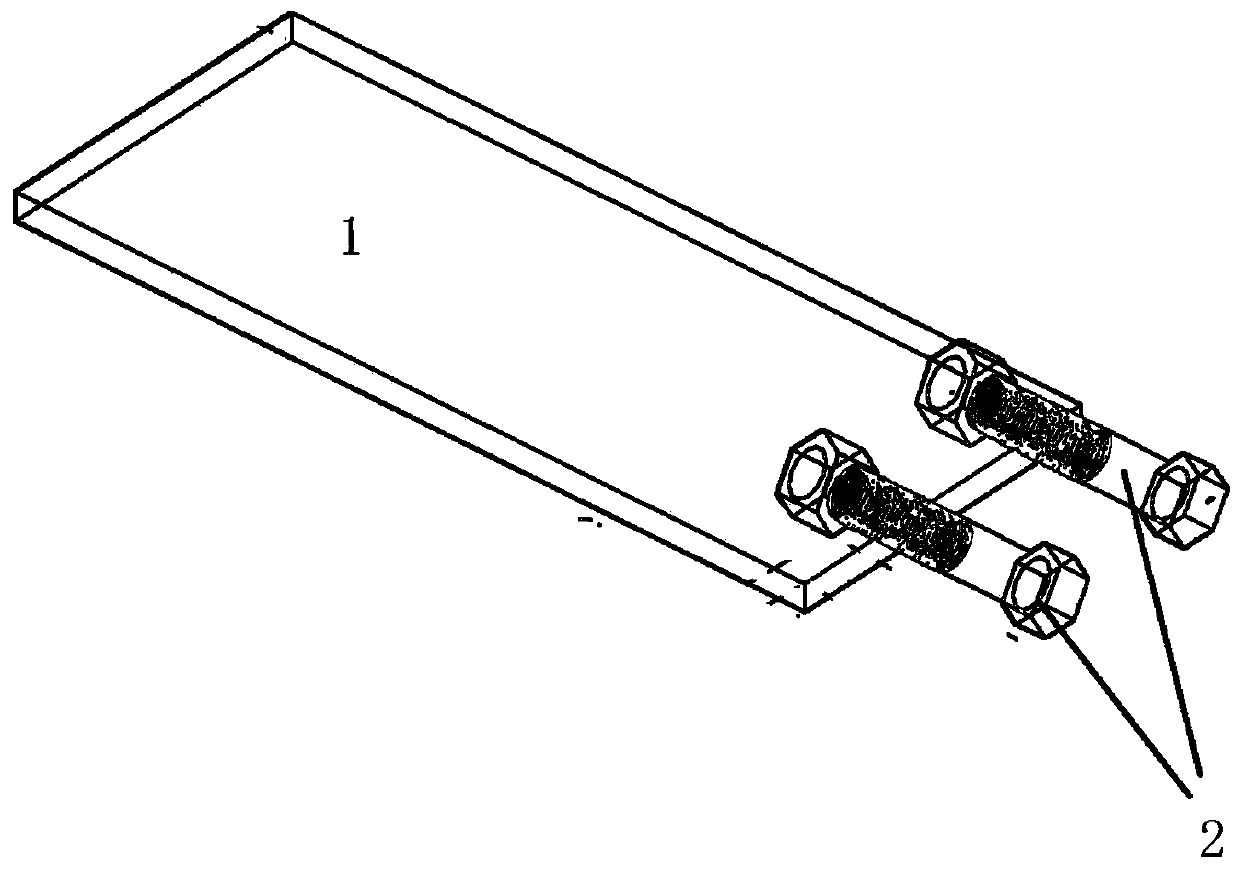

A creel device for an ultra-low liquor ratio yarn dyeing machine

InactiveCN102296436AReduce the cross-sectional areaGuaranteed coaxialityTextile treatment carriersLiquid/gas/vapor yarns/filaments treatmentWater bathsYarn

The invention discloses a creel device of a yarn dyeing machine with an ultra-low bath ratio, which comprises a sand table, a suspender and a yarn rod, wherein the upper surface of the sand table is in a disk shape; the lower end of the sand table is in a cavity structure; the yarn rod is in a hollow barrel structure; a water drum is arranged in the barrel of the yarn rod and is in a hollow or solid columnar structure; the center line of the yarn rod and the center line of the water drum are same; the ratio of the hollow internal diameter of the yarn rod and the external diameter of the waterdrum is 10:7-9; and the barrel of the yarn rod is evenly provided with a plurality of water outlets along the circumference of horizontal cross sections of different heights. The hollow barrel of theyarn rod disclosed by the invention is provided with the water drum, which is favorable for reducing the volume of dye liquor in the yarn rod and for reducing a water bath ratio; under the same main pump power, the water drum is favorable for improving the practical lift of a pipeline relatively, the flow rate of the dye liquor in the yarn rod is improved, the levelling property of cheeses of upper layers and lower layers can be better guaranteed, and the one-time success rate for dyeing is improved; and from the bottom to the top, the water outlets on the barrel of the yarn rod at the outer side of the water drum are thicker at the higher place of the yarn rod, which is favorable for realizing the purpose of even dye transfer.

Owner:高勋绿色智能装备(广州)有限公司

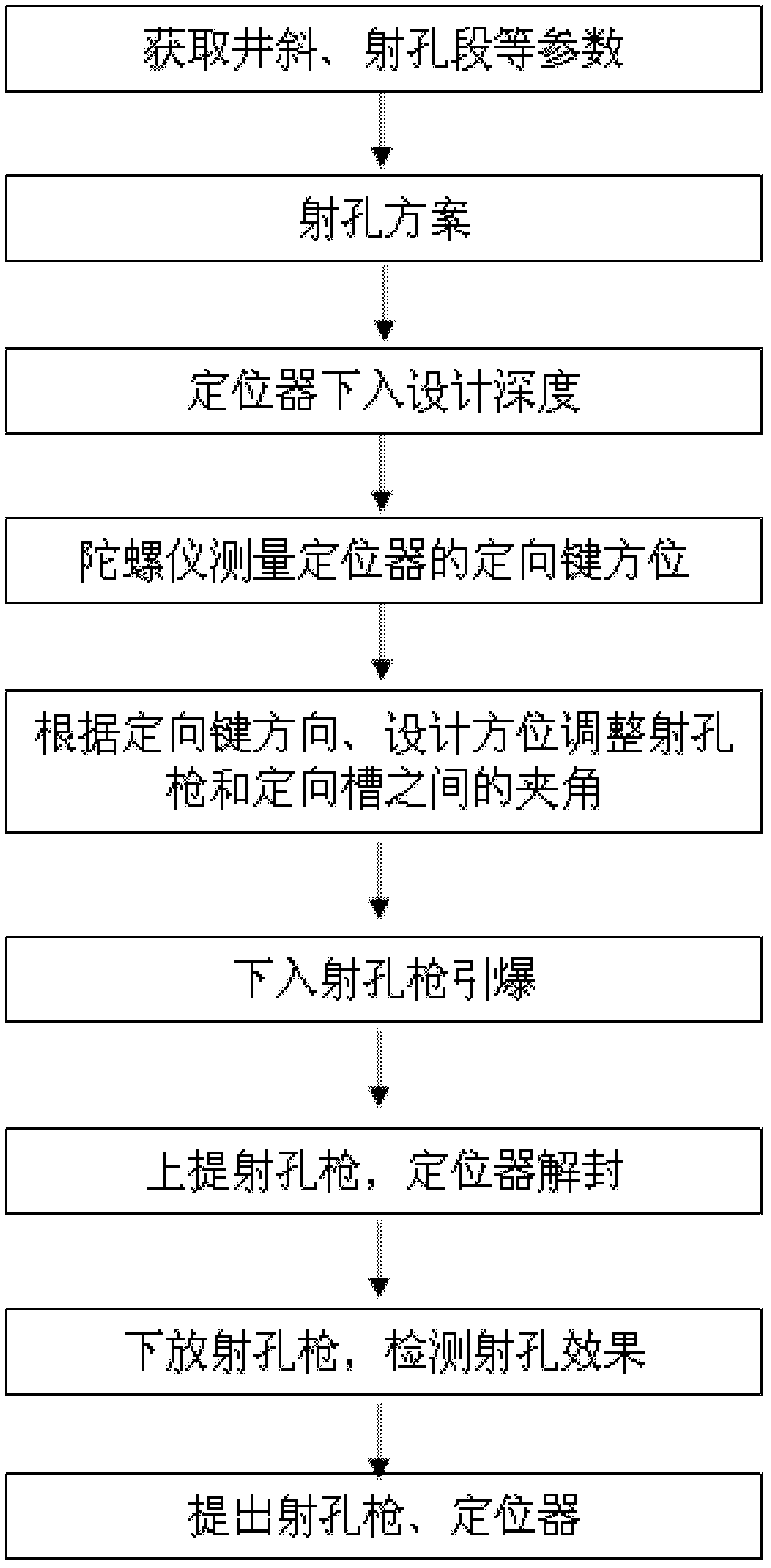

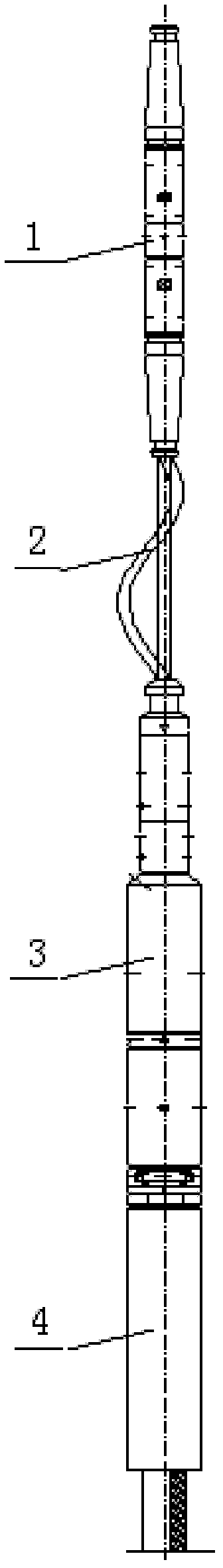

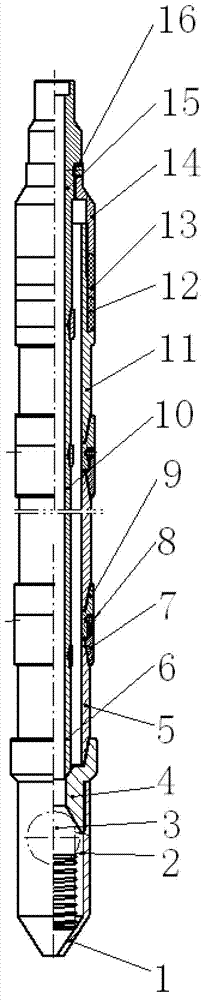

The Method of Using Cable Transmission to Realize Precise Oriented Perforation

ActiveCN102278098AImprove accurate depthChange the transmission methodFluid removalCable transmissionOblique angle

The invention relates to a method for realizing accurate oriented perforating by cable transmission, and is applied to the orientation perforating of a casing pipe well of an oil field during well completion. The method comprises the following steps of: sinking a positioning device and setting; sinking a gyro inclinometer, and measuring the accurate orientation of a guiding key on the upper part in the positioning device; sinking a perforating gun, orienting accurately, and perforating; and lifting the positioning device and the perforating gun to realize accurate oriented perforating construction by the cable transmission. The method has the advantages that: the oriented perforating of a well of which the maximum well oblique angle of the whole well exceeds 15 degrees and a well oblique angle of a perforating section is less than 30 degrees is realized; the period of perforating construction is reduced to 8 hours from 30 hours for the oriented perforating by oil pipe transmission, and the construction efficiency is improved; and the oil pipe transmission is replaced by the cable transmission, so the labor intensity is reduced.

Owner:PETROCHINA CO LTD

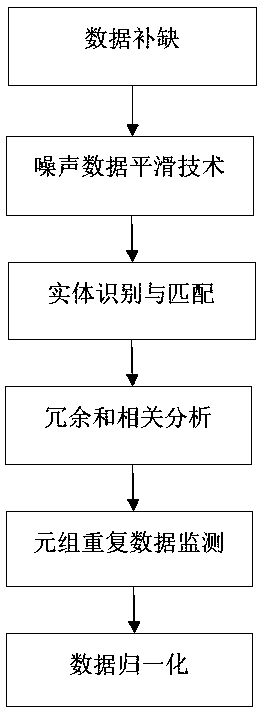

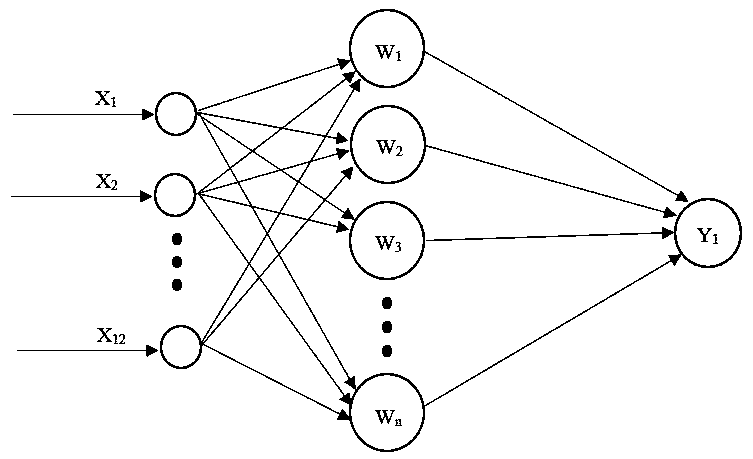

Drilling leakage crack width prediction method based on neural network data mining

The embodiment of the invention provides a drilling leakage crack width prediction method based on neural network data mining. The method comprises the steps that historical drilling data, a leakage stoppage case, an imaging logging real crack width and other data information of a target block are collected; data preprocessing is carried out on the collected data information, wherein the preprocessing content comprises data cleaning, integration and conversion; the preprocessed historical drilling data is used as input, the crack width is used as output, the imaging logging real crack width isused as a standard value, and a crack width prediction neural network model is obtained through supervision training and optimization; and the drilling instant data related to the target positive drilling well is imported into the neural network model, and the model automatically judges the corresponding well depth crack width at the moment. By utilizing the technical scheme provided by the embodiment of the invention, the crack width of the positive drilling well can be conveniently and accurately predicted in real time, so that decision support is provided for leakage stoppage constructionpersonnel, and the one-time leakage stoppage success rate of crack leakage is improved.

Owner:SOUTHWEST PETROLEUM UNIV

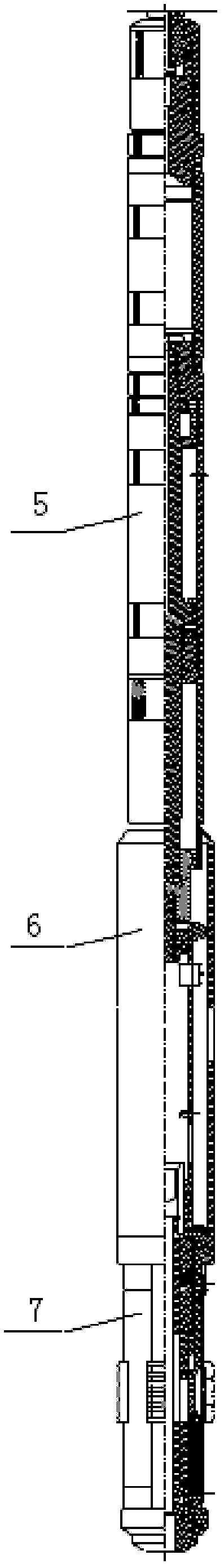

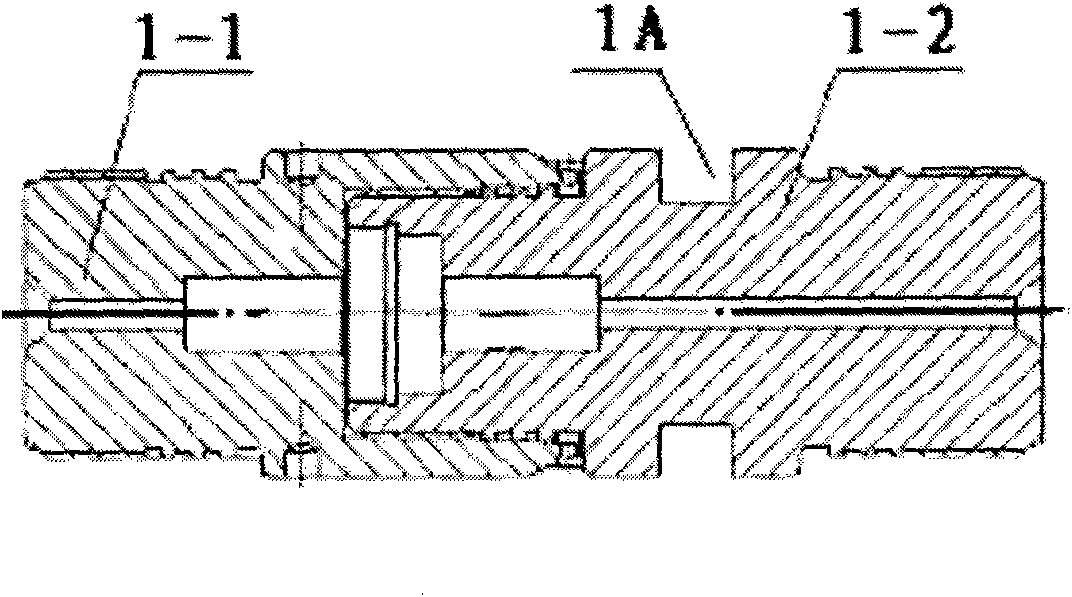

Detonation energization explosion-propagating device for perforating gun string

The invention discloses a detonation energization and transmission device for perforating gun strings, which comprises a body, an energizer, two detonating cords, two detonation tubes and a centralizing ring. The energizer is composed of a tube body, a point The ignition expansion tube formed by gunpowder and the expansion tube. The energizer is located in the middle of the main body and is centered by the centering ring, and the detonator and the detonating cord are on both sides in turn, and are centered by two centering sleeves. When forming a string of perforating guns, the two ends of the body are respectively connected to the upper and lower perforating guns, and the other ends of the two detonating cords are respectively connected to the perforating charges in the corresponding perforating guns. The invention is assembled between every two sections of perforating guns and interlayer guns in the perforating gun string used for oil and gas wells, which solves the problems of reliable perforation of the existing perforating gun string and reliable explosion transmission of the interlayer gun; Insufficient energy of the detonation equipment itself and the loss and attenuation of the detonation wave energy in the transmission process caused incomplete perforation and rework accidents such as gun jamming, which increased the reliability of perforation and improved the performance of perforation completion. security.

Owner:WUHUA ENERGY TECH CO LTD

Method for dyeing vivid fluorescent green on cotton knitwear

InactiveCN101597867AMeet the requirements of bright colorMeet quality indicatorsDyeing processFluorescenceEmerald

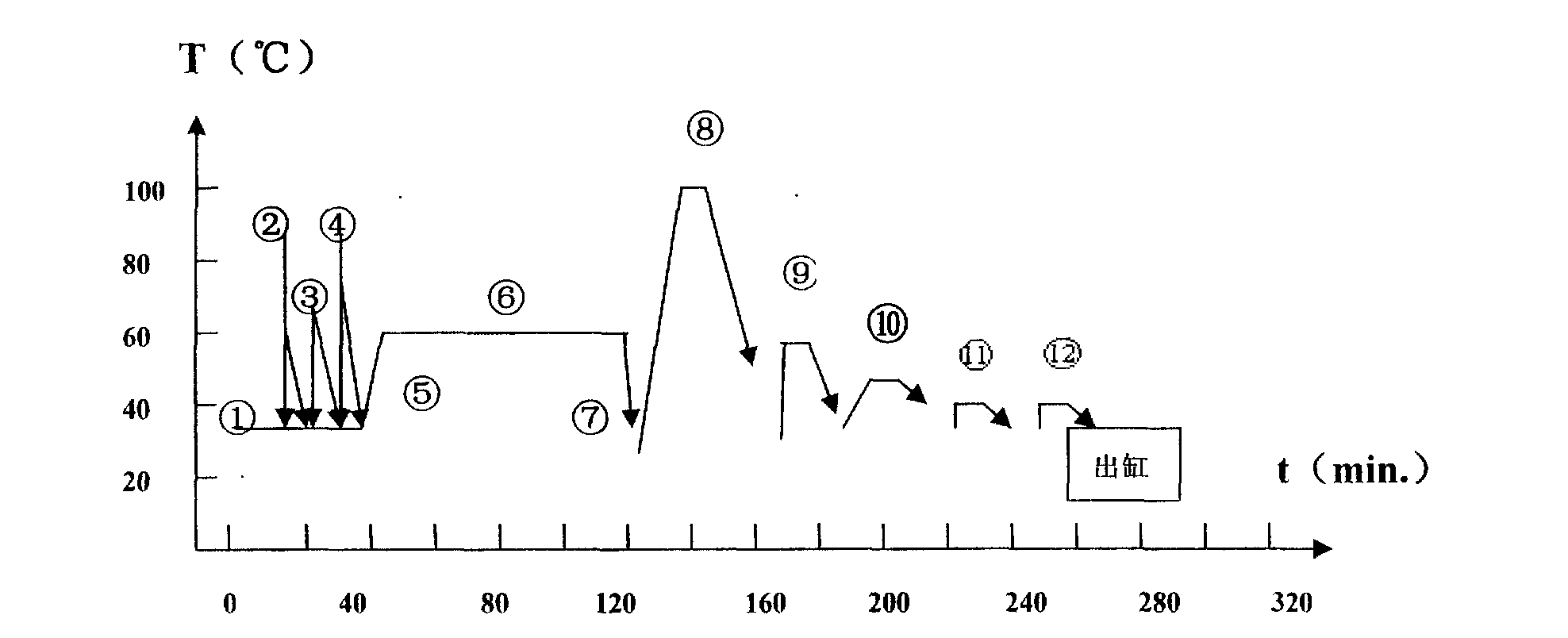

The invention relates to a method for dyeing cotton knitwear, in particular to a method for dyeing fluorescent green on cotton knitwear. The method comprises the following steps: 1) pretreating grey cloth; 2) placing the grey cloth and eightfold weight of water into a dye vat; 3) heating the grey cloth and the water to a temperature of 60 DEG C, adding reactive emerald blue MZ-HGN, 7GFF fluorescent yellow and salt into the dye vat in sequence to reserve the temperature for 30 minutes; 4) continuously heating the mixture to a temperature of 80 DEG C, and gradually adding calcined soda for fixation, and reserving the temperature for 30minutes; 5) continuously heating the mixture to a temperature of 100 DEG C, and reserving the temperature for 15 minutes; 6) comparing the grey cloth with a sample, cooling the grey cloth to a temperature of 70 DEG C, and removing dye liquor; 7) washing the grey cloth with water twice after the steps; 8) washing the water washed grey cloth with soap once at a temperature of 90 DEG C; 9) washing the grey cloth which is washed by the soap for 2 or 3 times with water; 10) carrying out softening treatment on the water washed grey cloth at 40 DEG C, reserving the temperature for 15 minutes and taking the grey cloth out of the dye vat; 11) dehydrating the grey cloth; 12) drying the grey cloth; 13) shaping the grey cloth. The cloth dyed through the method not only can meet the requirement of clients on color brightness, but also achieves the corresponding quality index.

Owner:ZHEJIANG YINHE PRINTING & DYEING

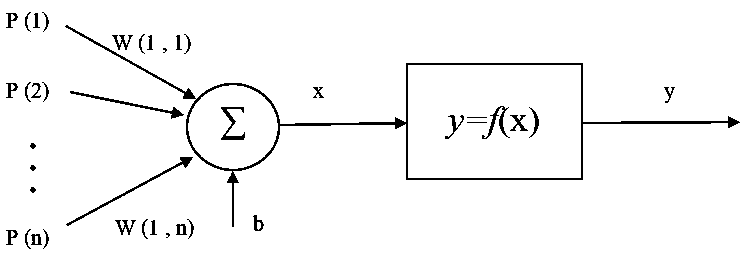

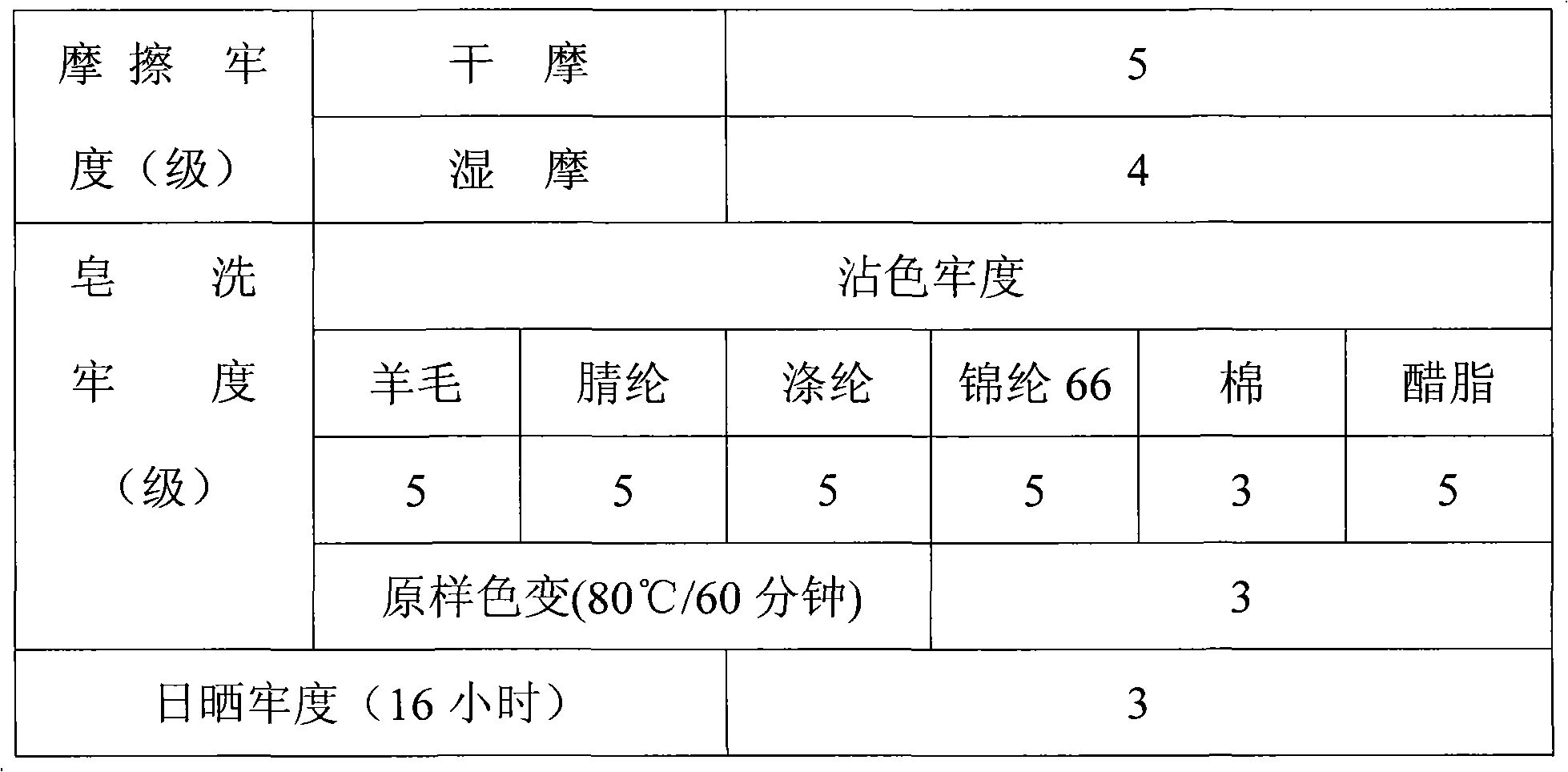

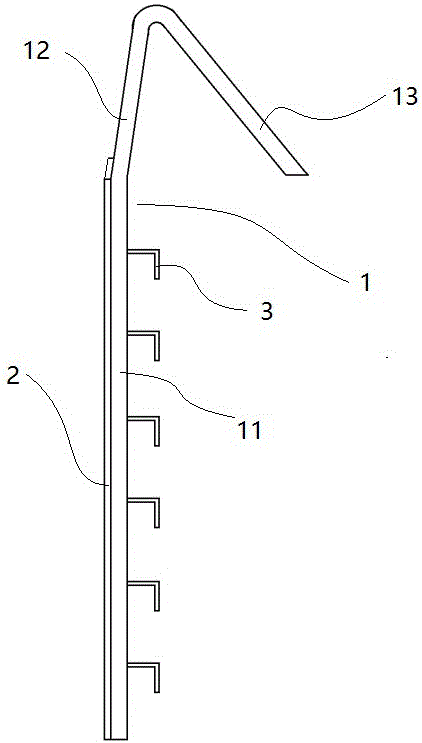

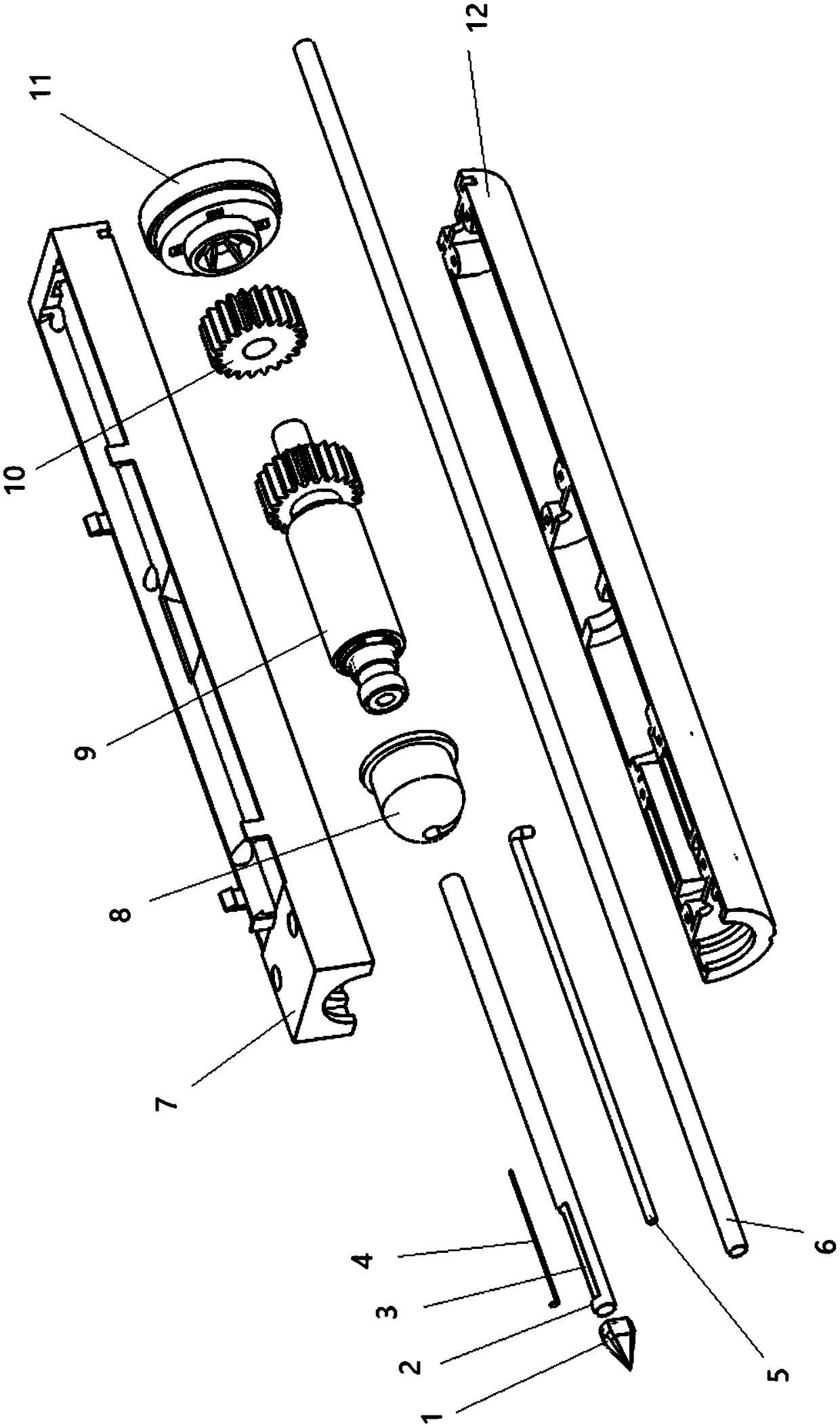

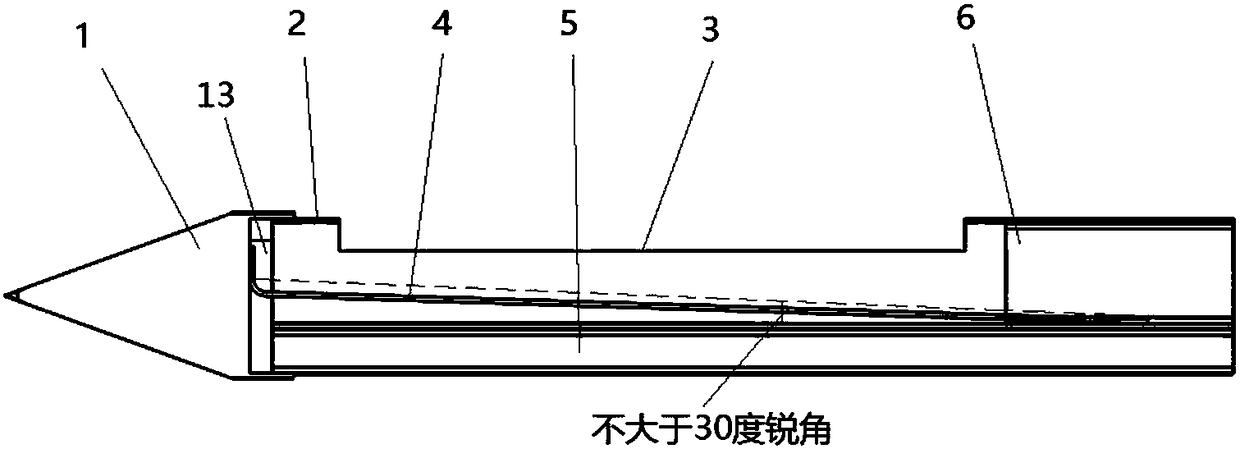

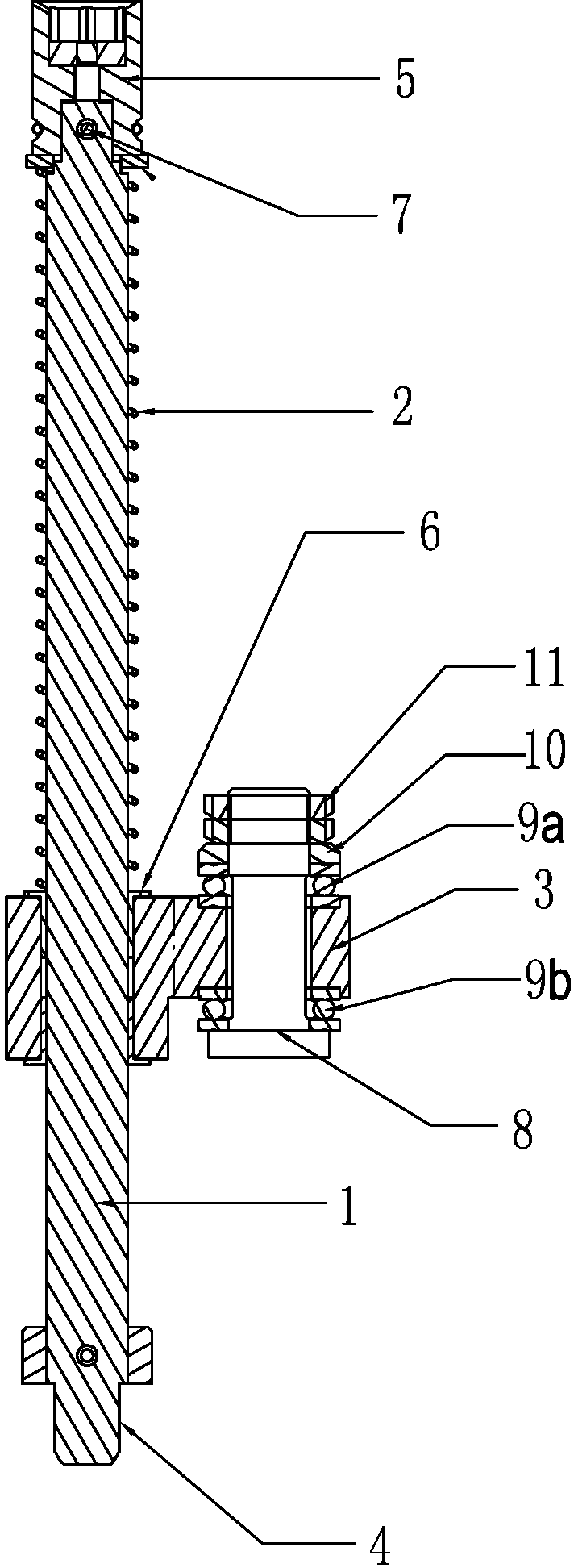

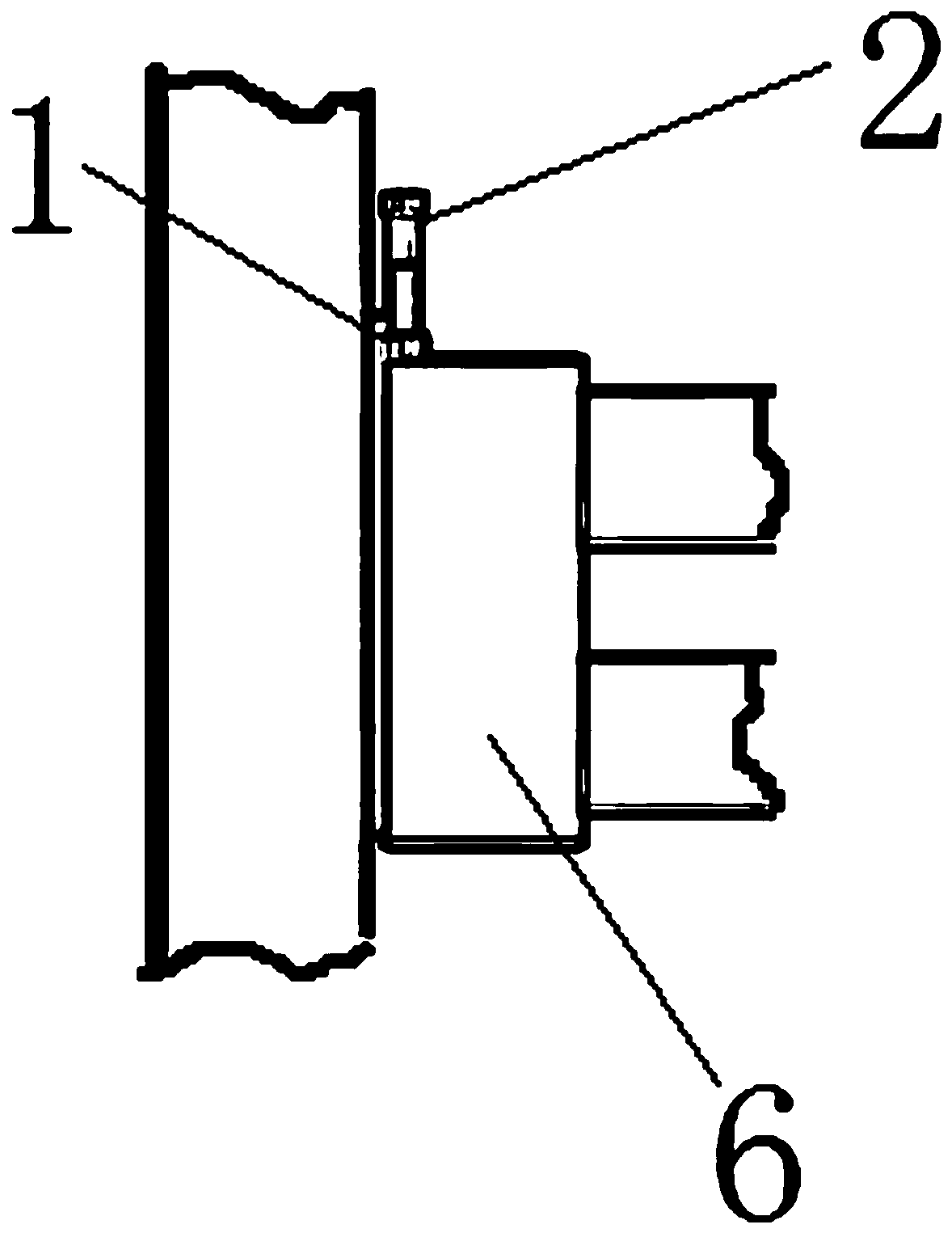

Fishing needle, fishing device and fishing method for fishing a soft material in tube for oil gas well

InactiveCN102747976AEasy to operateImprove one-time success rateBorehole/well accessoriesAcute angleSoft materials

The invention discloses a fishing needle, a fishing device and a fishing method for fishing a soft material in a tube for an oil gas well. The fishing needle comprises a fishing rod (2); at least one fishing pin (3) is arranged on the peripheral surface of the lower section of the fishing rod; and an included angle alpha formed between the axes of the fishing pin and the fishing rod in the upward direction is an acute angle. The fishing device comprises the fishing needle, a hoisting mechanism and a steel wire rope, wherein the upper end of the fishing rod is connected with the hoisting mechanism by the steel wire rope. The fishing method comprises the following steps that: 1, the fishing needle is placed into an orifice of the tube for the oil gas well, the fishing needle is lowered down and the depth of the falling material is determined; and 2, the steel wire rope is recovered by 5 to 8m, then the hoisting mechanism is controlled to rapidly lower down the steel wire rope, the fishing rod and the fishing pin of the fishing needle pierce into the falling material, an inverted hook is formed after the fishing pin pierces into the falling material and the hoisting mechanism hoists the steel wire rope to lift the fishing needle and the falling material to the orifice so as to take out of the falling material. The invention can solve the problem that the soft irregular material falls into the tube after the well is drilled and in the testing operation and is difficult to take out.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Grey dyeing production method for removing chemical pulp and oligomers

ActiveCN104213441AEasily biodegradableLong-term storage stabilitySucessive textile treatmentsBiochemical fibre treatmentOligomerDesizing

The invention relates to a printing and dyeing method, and especially relates to a grey dyeing production method for removing chemical pulp and oligomers. The method comprises the following steps: selecting a sample cloth, carrying out pretreatment desizing, pre-setting a grey, singeing the grey, preparing a complex formulation assistant according to a formula, using the complex formulation assistant according to a ratio, carrying out alkali amount reduction in a sample jar, designing a dyeing formula, carrying out jar dyeing on the sample, carrying out hot setting, singeing the obtained color body, washing by water, drying, carrying out oiling setting, carrying out after-finishing calendering, carrying out after-finishing full decatizing, and examining the obtained finished product. The grey dyeing production method for removing chemical pulp and oligomers has the advantages of dyeing stability increase, effective increase of the one-time success rate, reduction of the dyeing repairing rate, and obvious energy saving and emission reduction effects, produced fabrics have good handle resilience, drapability and flexibility, and various quality indexes of the fabrics can meet requirements of clients.

Owner:ZHEJIANG HANGMIN STOCK

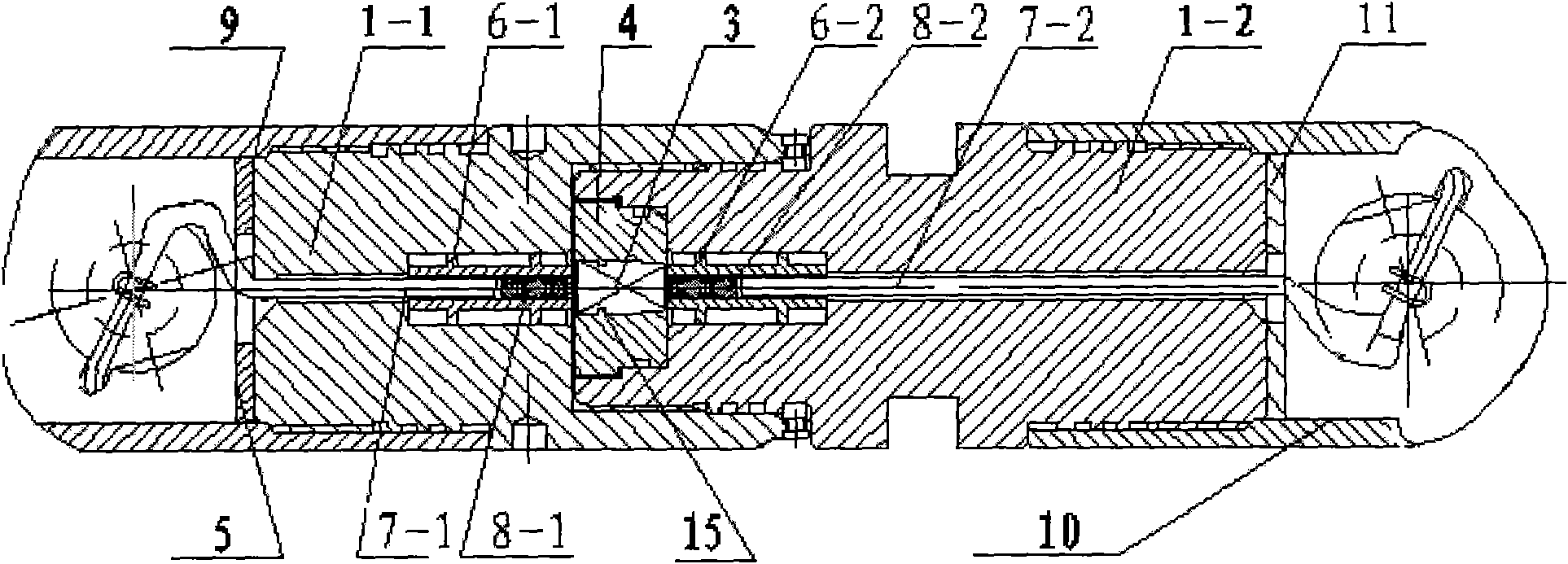

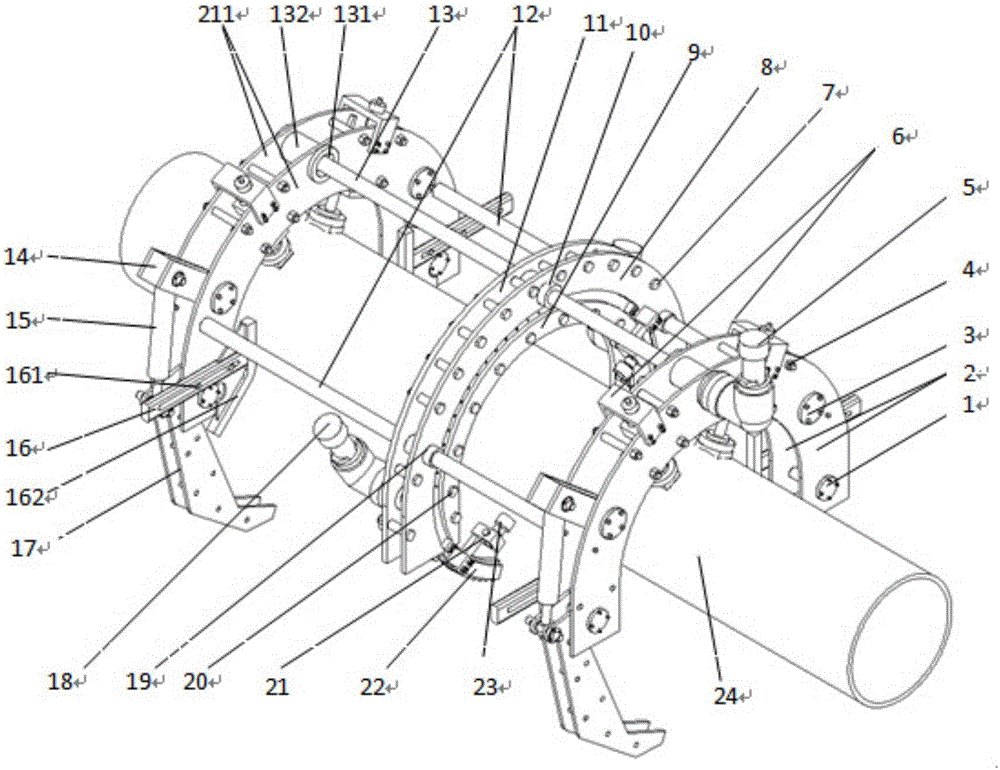

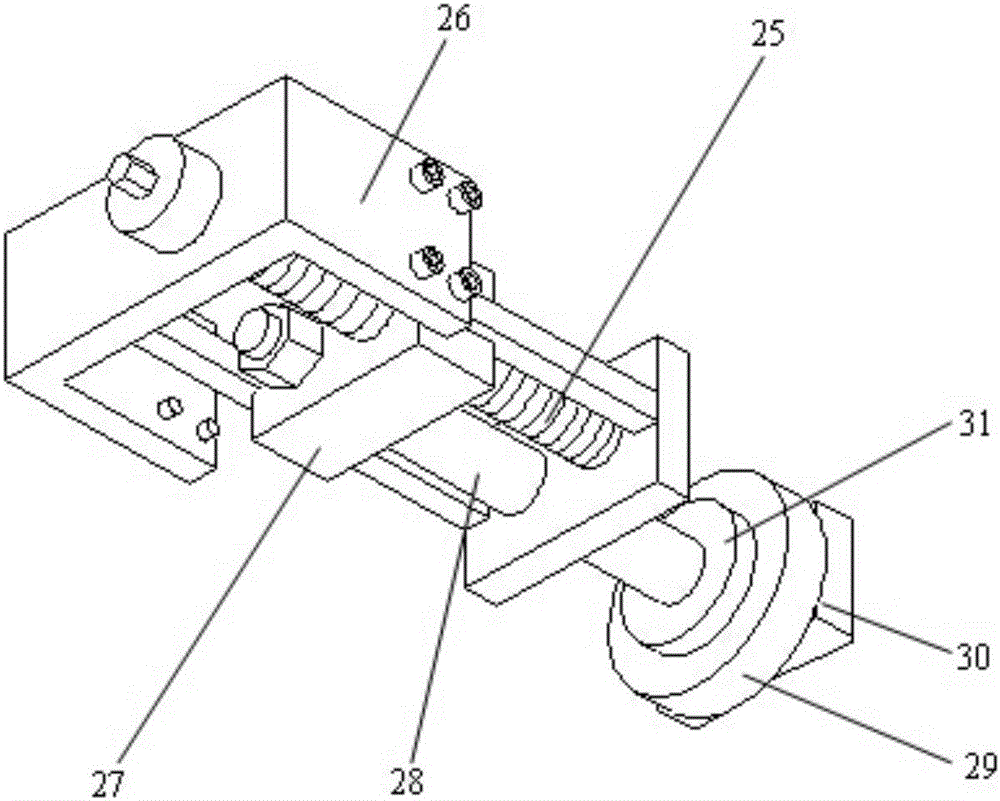

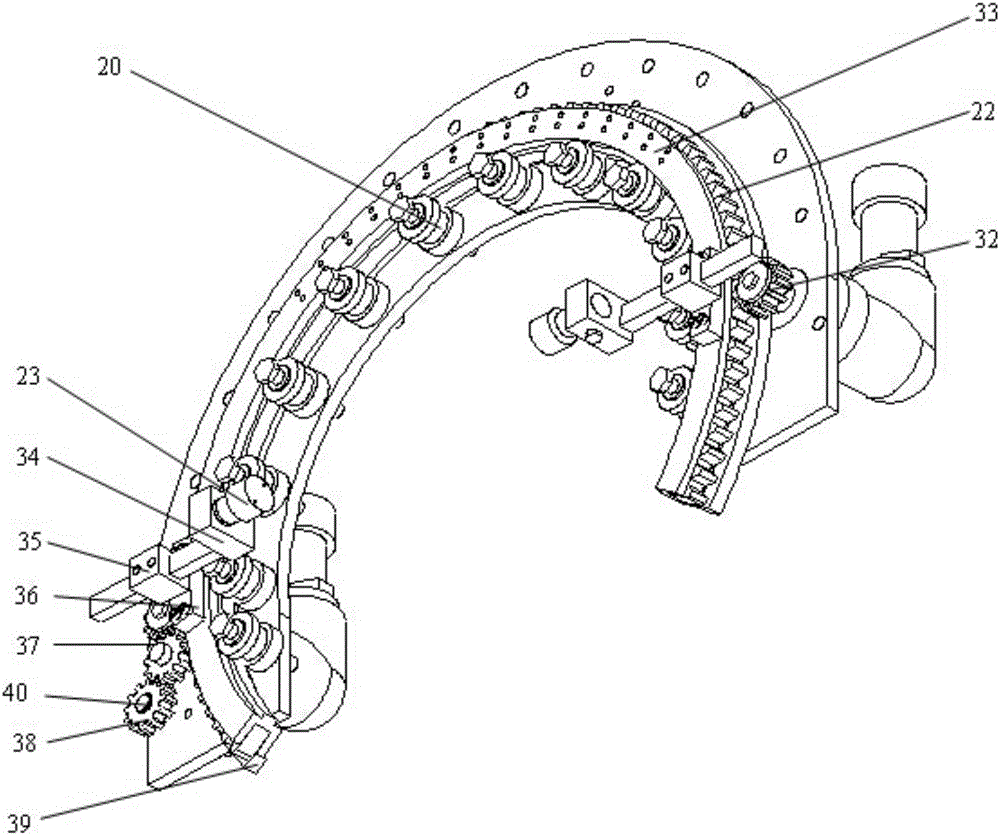

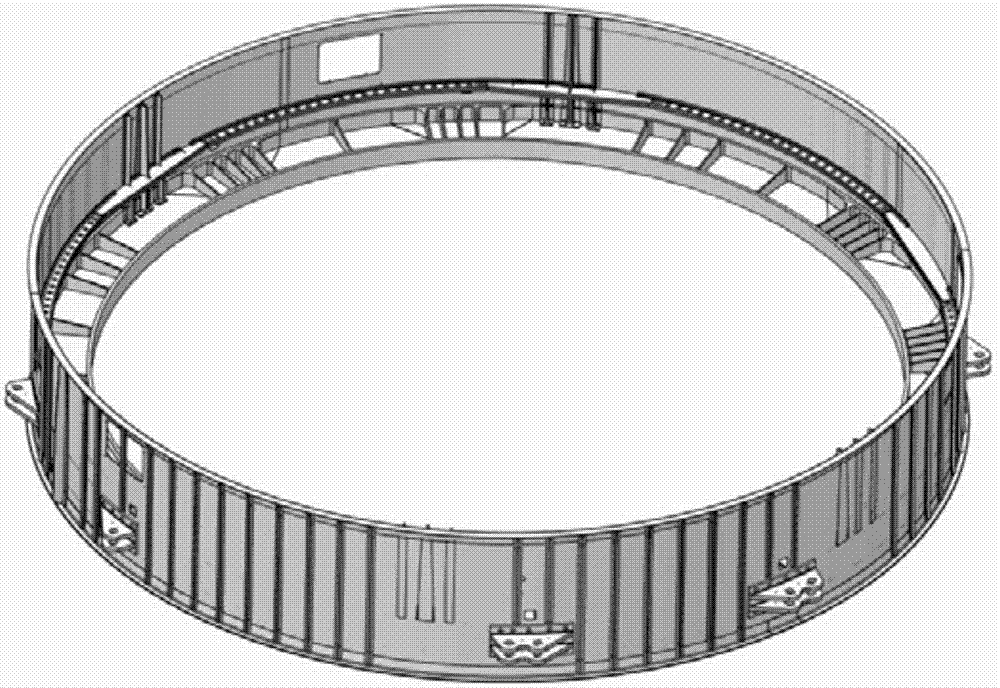

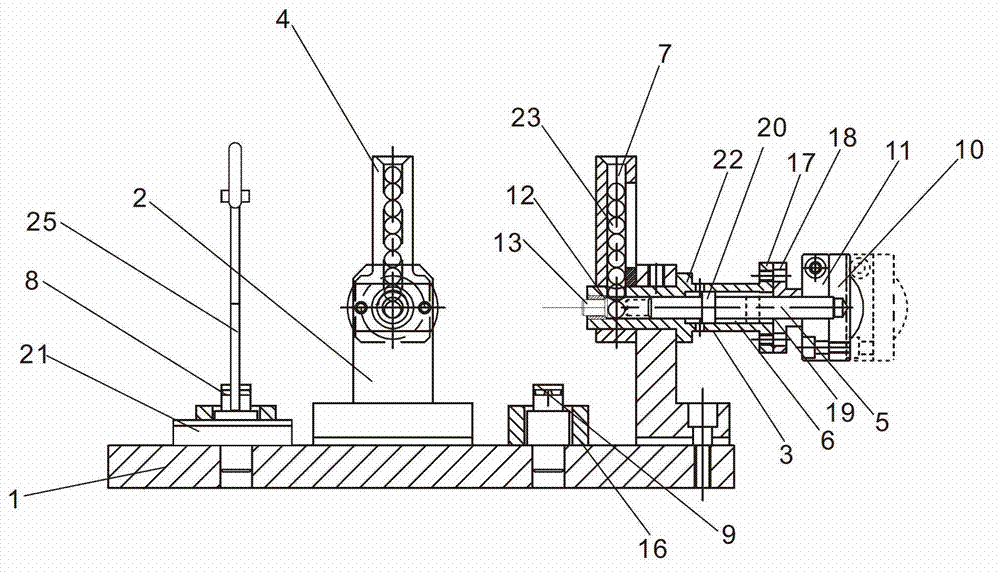

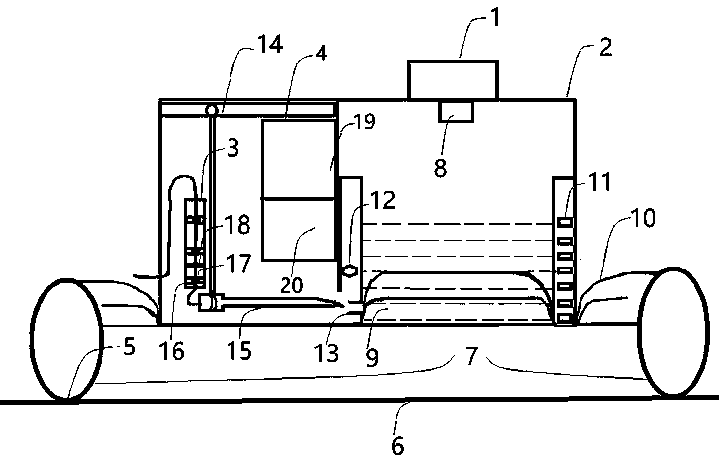

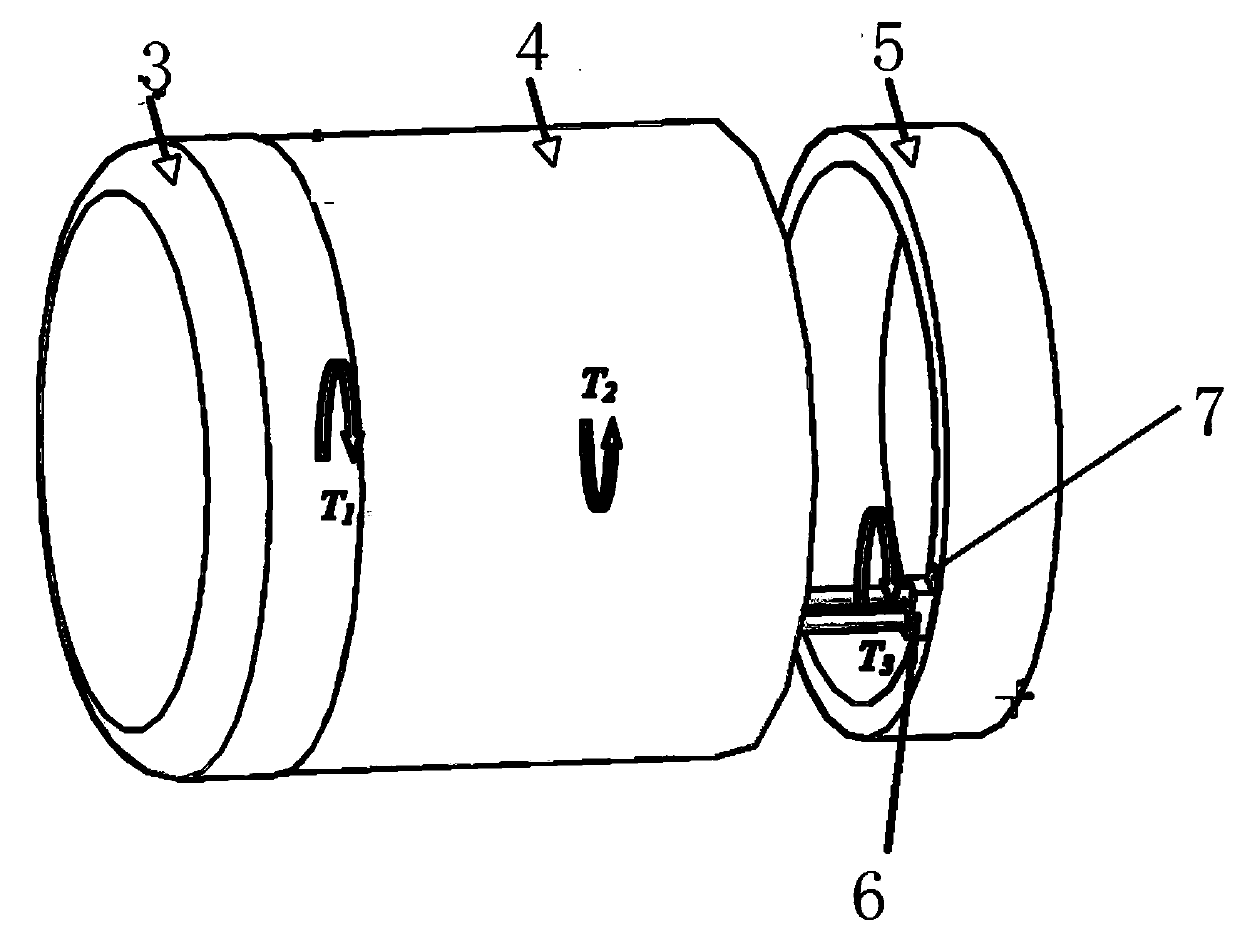

Three-dimensional measuring equipment for submarine pipelines

InactiveCN105043225AEffective 3D ImagingImprove one-time success rateMechanical solid deformation measurementsAxial displacementOcean bottom

The invention discloses three-dimensional measuring equipment for submarine pipelines, which comprises a main bracket, a hydraulic clamping mechanism symmetrically disposed on the main bracket, a concentric positioning device, an axial displacement mechanism and a circumferential rotation mechanism. The main bracket is composed of a guide rod used for connecting a front support with a rear support. The hydraulic clamping mechanism is composed of oil cylinders arranged on the front and rear supports. The oil cylinders are connected with clamping claws. The concentric positioning device comprises a fixed seat fixed on the front and rear supports, and the fixed seat is internally provided with a screw. The screw is provided with a support rod. The axial displacement mechanism comprises an upper motor fixed on the front support, a rolling bearing installed at the upper part of the rear support, and a second semi-circular frame structure arranged between the front and rear supports. The circumferential rotation mechanism comprises a lower motor arranged on the second semi-circular frame structure, and a plurality of rollers connected with the second semi-circular frame structure. By means of the three-dimensional measuring equipment, a bent submarine pipeline or other heavily deformed / damaged submarine pipelines can still be accurately measured. Therefore, the one-shot success rate of the repair job is improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

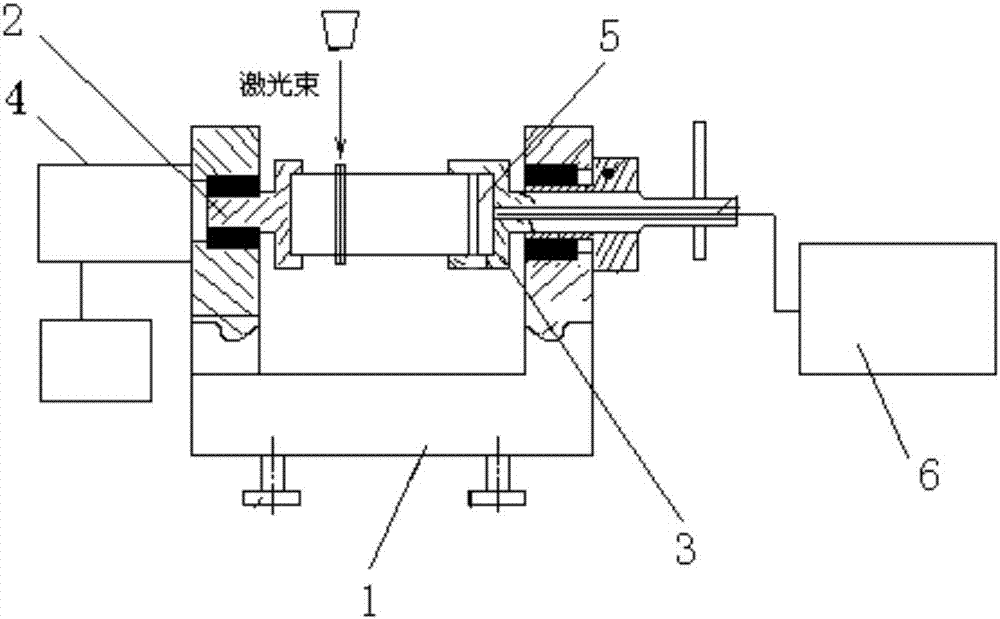

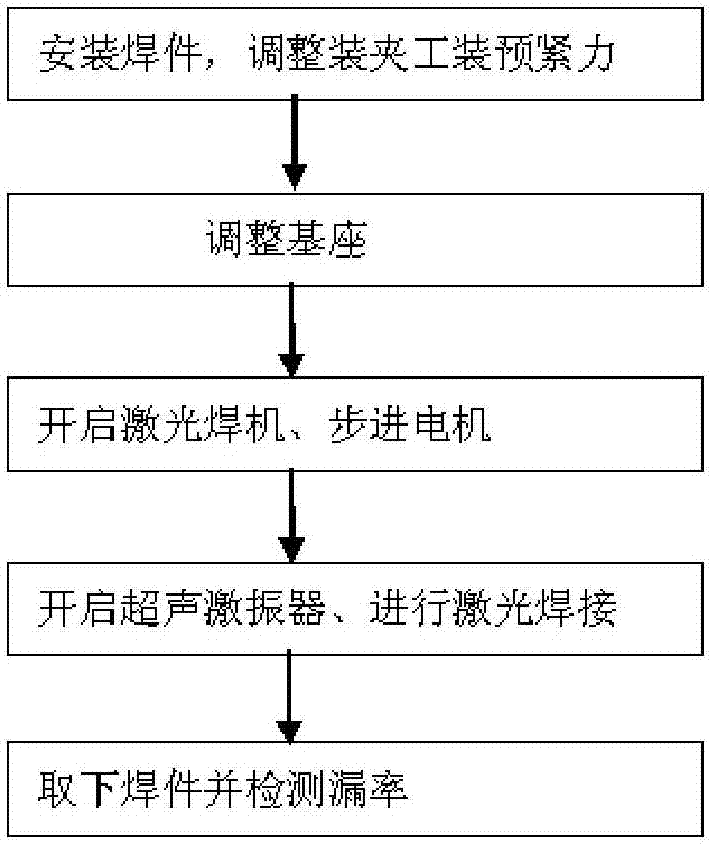

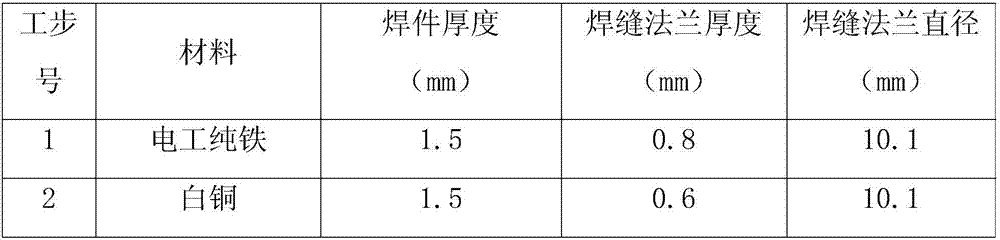

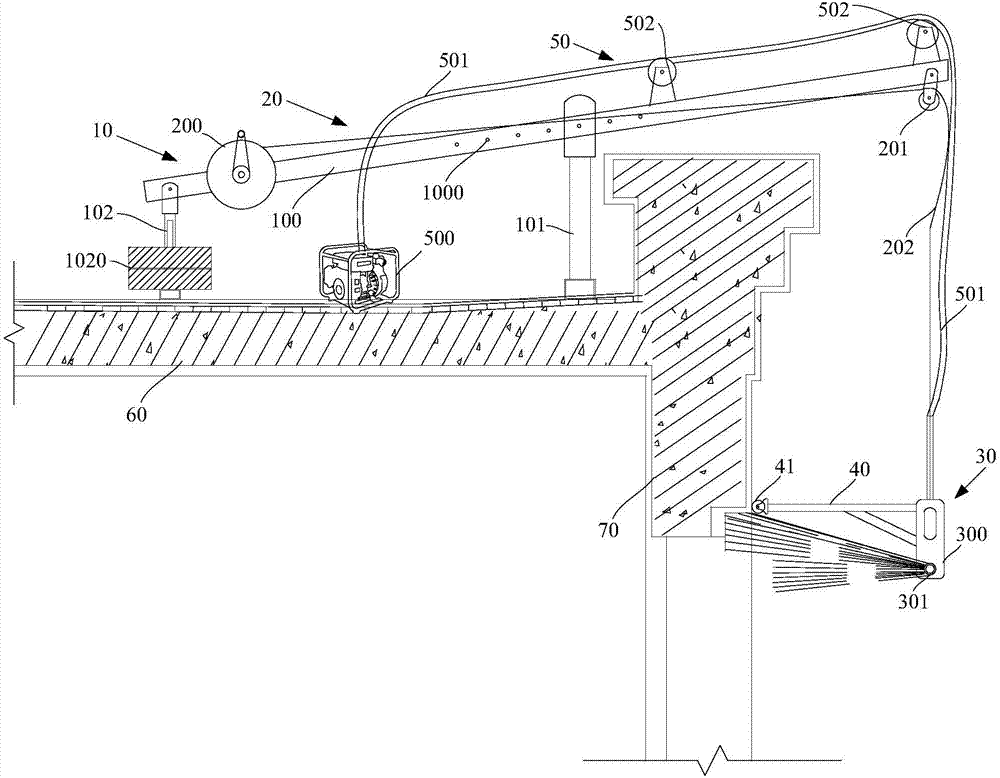

Ultrasonic assisted laser welding device and method for dissimilar metal materials

ActiveCN106914700ARealization of ultrasonic excitationImprove one-time success rateLaser beam welding apparatusUltrasonic assistedUltrasonic vibration

The invention discloses an ultrasonic assisted laser welding device and method for dissimilar metal materials. As an ultrasonic vibration exciter is introduced to a laser-welded rotary clamping tool, in the welding process, the ultrasonic vibration excitation with the frequency being 15k-2MHz applied to a dissimilar metal weldment is realized. The one-time success rate of the dissimilar metal weldment is increased, the production cost is reduced, and the production efficiency is improved. The ultrasonic assisted laser welding method improves the sealing performance of a test piece and can achieve the level of leakage rate less than 1*10-9Pa m3 / S.

Owner:CHINA AEROSPACE TIMES ELECTRONICS CORP

Exterior wall water pouring test device, and method for carrying out water pouring test employing same

InactiveCN106969883ALimit spray distanceImprove one-time success rateDetection of fluid at leakage pointStructural engineeringEngineering

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

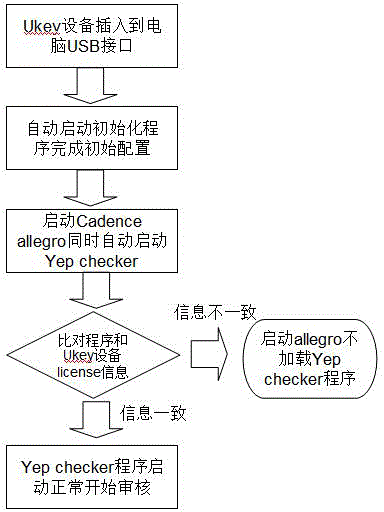

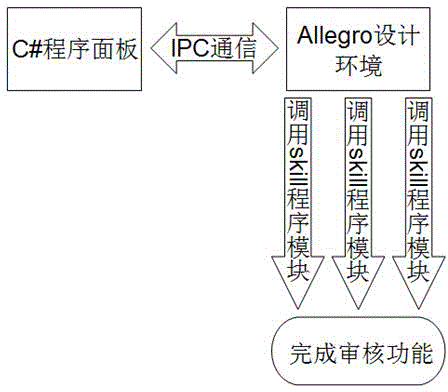

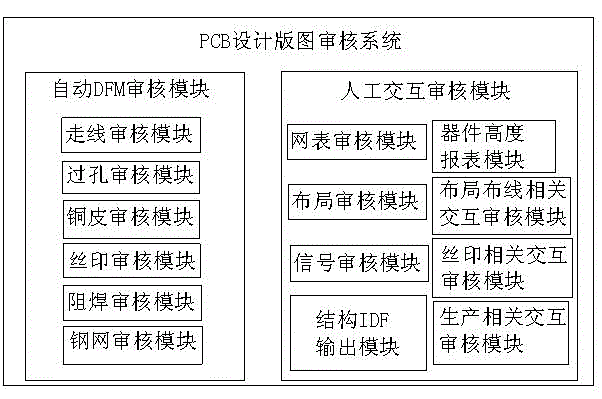

PCB design layout audit device

ActiveCN104573243AImprove one-time success rateShorten the development cycleSpecial data processing applicationsResistEngineering

The invention discloses a PCB design layout audit device, the PCB design layout audit device comprises a device storage, the device storage is provided with the an automatic DFM audit module and a man-machine interaction audit module; the automatic DFM audit module comprises a line audit module, a via hole audit module, a copper sheet audit module, a silk screen audit module, a solder resist audit module and a steel mesh audit module; the man-machine interaction audit module comprises a netlist audit module, a layout audit module, a signal audit module, a structure IDF output module, a device height reporting module, a locating and wiring related interaction audit module, a silk screen related interaction audit module and a production related interaction audit module. The audit system is independently prepared into the electronic product device to be conveniently used by the customers in a plug and play mode, and the audit system is not limited by the mounting computer anymore. The Ukey device is inserted into the computer for the corresponding engineer and the PCB design audit can be executed according to the requirement from the engineer.

Owner:SHANGHAI TAIQI ELECTRONICS TECH CONSULTATIONCO

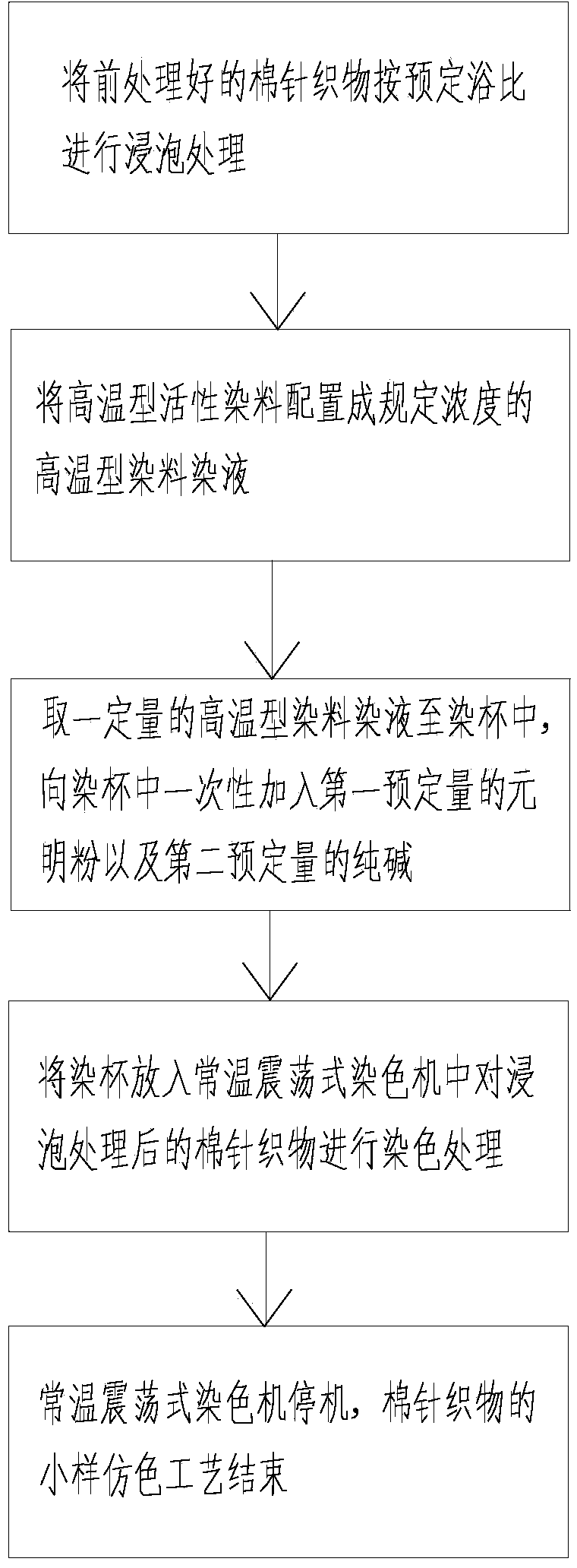

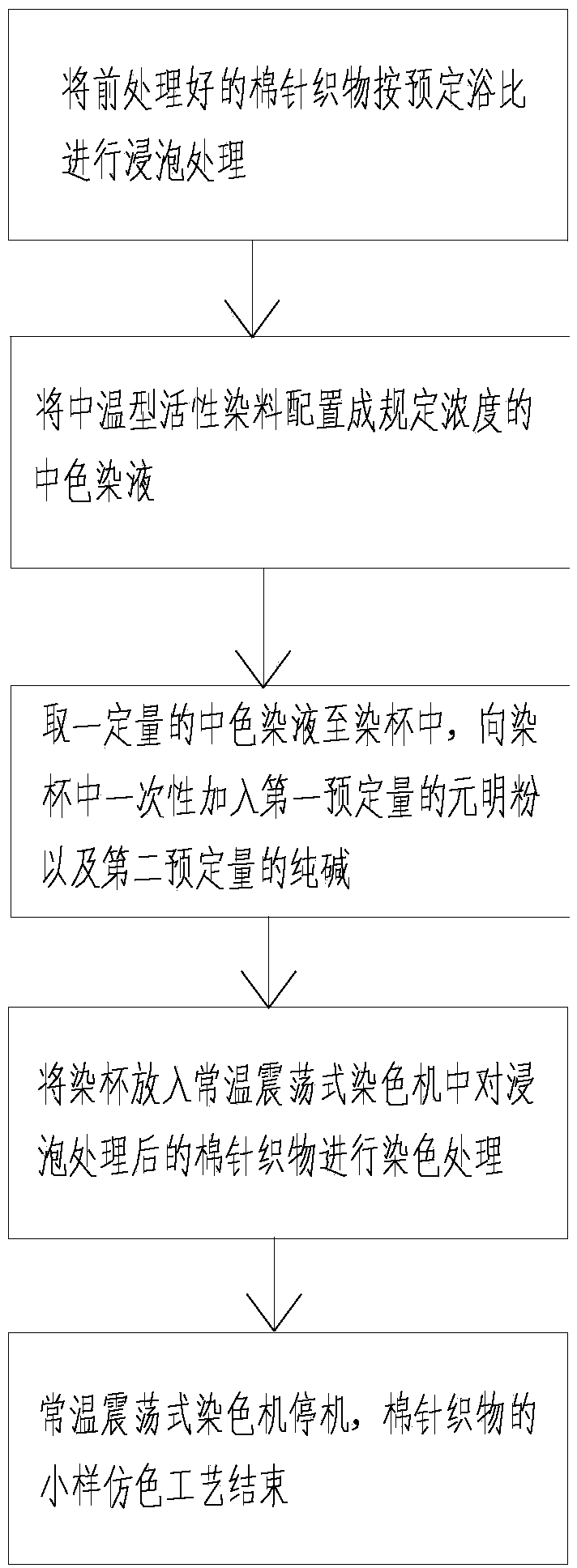

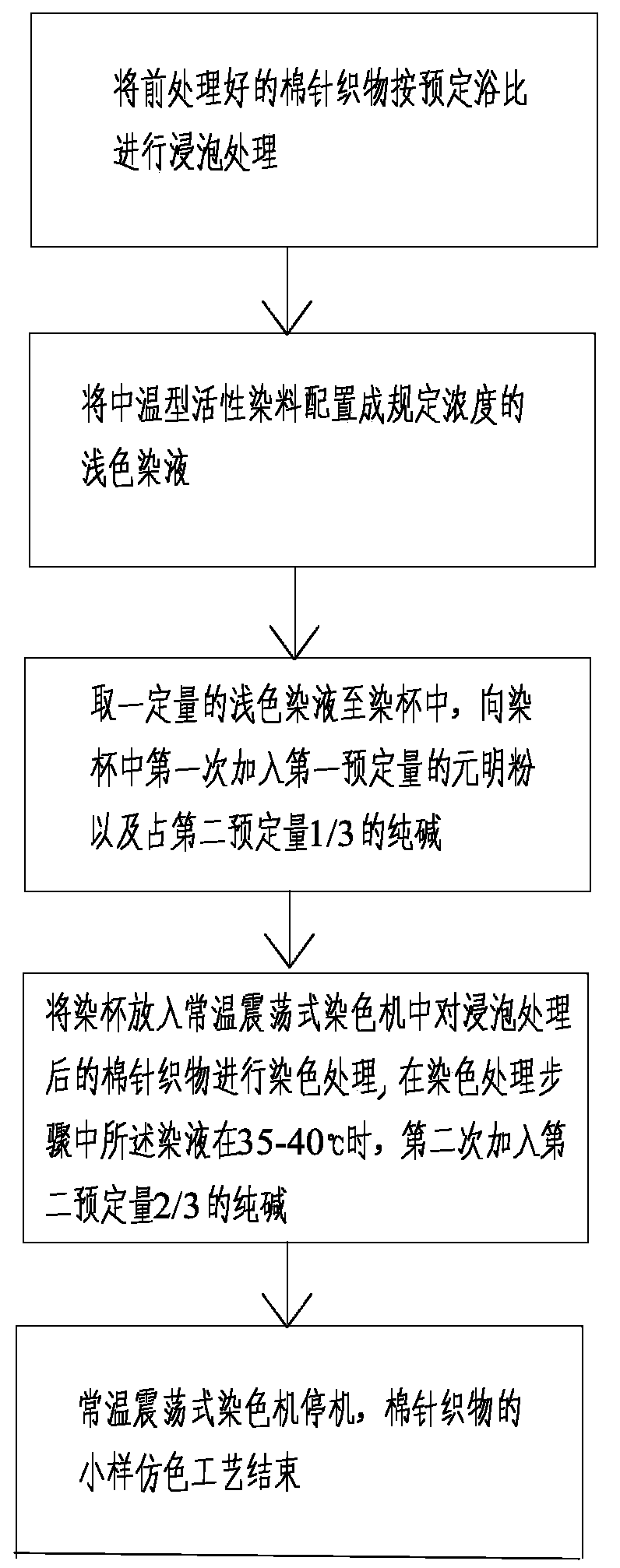

Hand sample color imitation process for cotton knitted fabric

ActiveCN103924462AGood reproducibilityImprove one-time success rateTextile treatment dyeing devicesDyeing processDark colorHue

The invention discloses a hand sample color imitation process for cotton knitted fabric. The hand sample color imitation process is mainly designed to overcome the defect that the reproducibility of the color phase of a hand sample and the color phase of a bulk sample is low due to a traditional hand sample dyeing process. The hand sample color imitation process for the cotton knitted fabric comprises the steps of hand sample soaking treatment, dyeing liquid preparation, additive adding and dyeing treatment. In the step of additive adding, anhydrous sodium sulphate of a first preset amount and sodium carbonate of a second preset amount are added to high-temperature dye liquor or neutral color dye liquor or dark color dye liquor at one time, or the anhydrous sodium sulphate of the first preset amount and the sodium carbonate one third of the second preset amount are added to light color dye liquor for the first time. In the step of dyeing treatment of the light color dye liquor, when the dye liquor is 35 DEG C to 40 DEG C, the sodium carbonate of two thirds of the second preset amount is added for the second time. The reproducibility of the dyeing hand sample and bulk sample of the cotton knitted fabric can be effectively improved, the one-time success rate of bulk sample dyeing is improved, and production cost is lowered.

Owner:JIHUA 3543 KNITTING CLOTHING

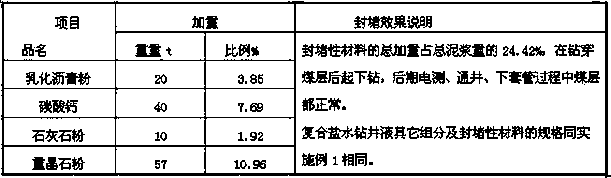

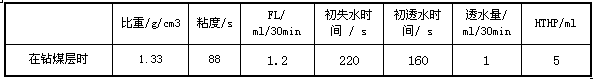

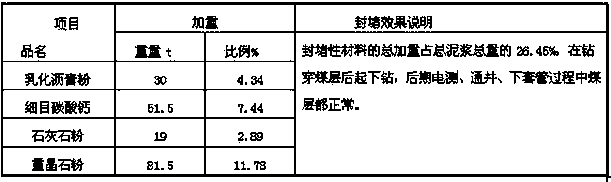

Compound saltwater drilling fluid for plugging fractures of coal seam

ActiveCN103589406AImprove one-time success rateReduce processing complexityFlushingDrilling compositionCelluloseCarboxymethyl starch

The invention relates to a compound saltwater drilling fluid for plugging fractures of a coal seam, and belongs to the field of petroleum drilling. The compound saltwater drilling fluid is characterized by comprising components in percentage by mass as follows: 6%-8% of calcium carbonate, 4%-6% of emulsified asphalt powder, 10%-12% of barite, 2%-4% of limestone powder, 3%-4% of carboxymethyl starch, 8%-10% of sodium formate, 4%-6% of industrial salt, 2%-4% of potassium chloride, 0.6%-0.8% of polyanionic cellulose and the balance of clear water, wherein emulsified asphalt, calcium carbonate, barite and limestone powder are generally termed as plugging materials. By means of the compound saltwater drilling fluid, the one-time success rate of well completion of an inclined shaft section is increased greatly, the collapse of the coal seam is greatly reduced, the construction period of the inclined shaft section is shortened, and the work efficiency is improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

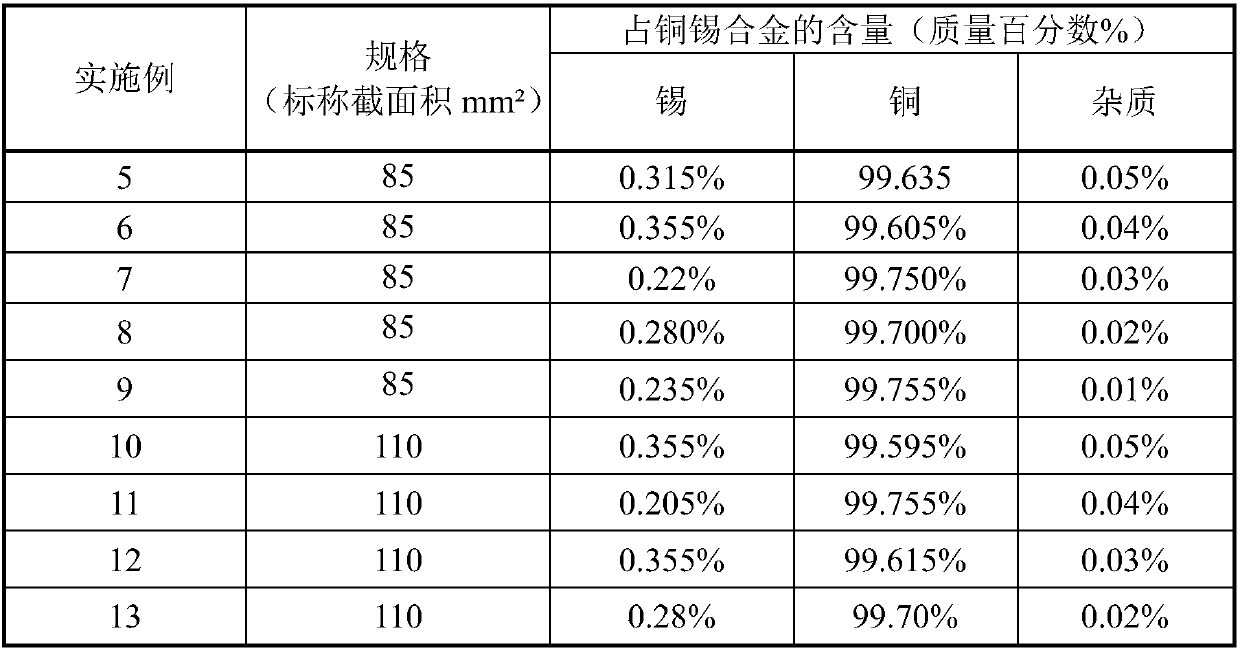

Copper-tin alloy contract wire for electrified railway and continuous manufacturing process thereof

ActiveCN107723504ARealize continuous productionMeet physical and chemical performance requirementsSingle bars/rods/wires/strips conductorsConductive materialButt weldingAlloy

The invention discloses a copper-tin alloy contract wire for an electrified railway and a continuous manufacturing process thereof. The alloy of the copper-tin alloy contract wire comprises the following components in weight ratio: 0.195-0.435% of metallic tin, 99.755-99.515% of metallic copper and 0.05% of other impurities. The continuous manufacturing process aims at different types of copper-tin alloy contract wires to produce and controls the content range of tin of a copper-tin alloy extrusion stem, so that the copper-tin alloy extrusion stem can conduct flash butt welding, and then continuous production is realized. The continuous manufacturing process can ensure the one-time success rate of continuity of the copper-tin alloy extrusion stem and the production efficiency.

Owner:西安西电光电缆有限责任公司 +1

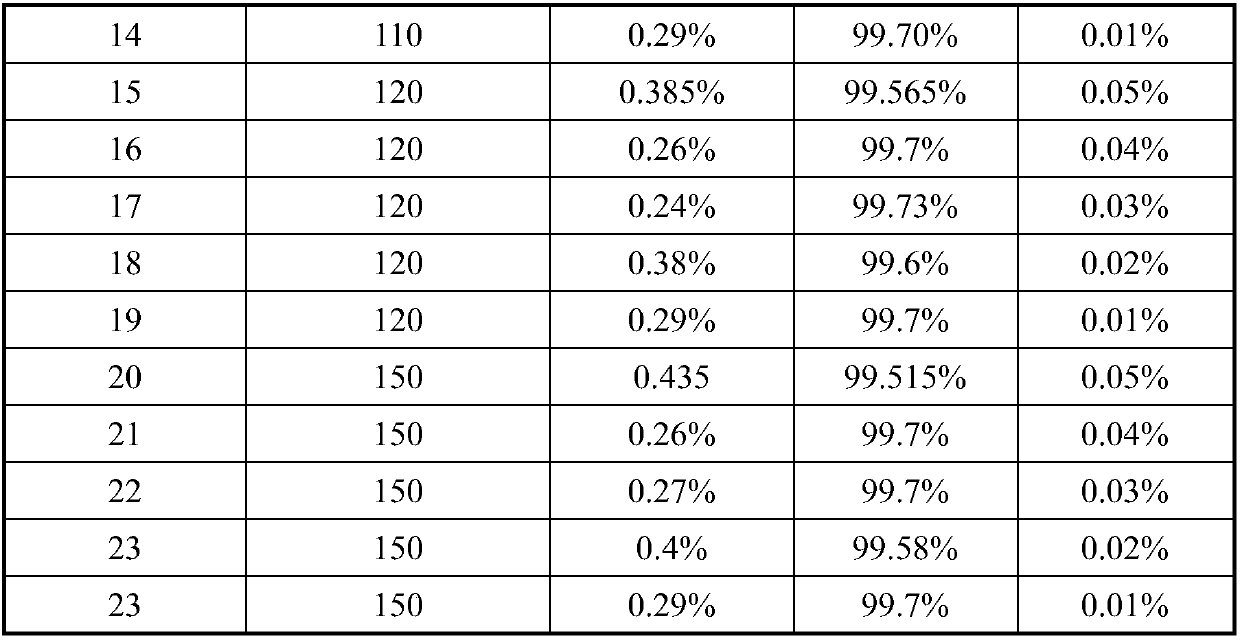

Maturity-based design method for digital prototype of carrier rocket

ActiveCN106951589AEffective top-level guidanceRealize parallel collaborationGeometric CADDesign optimisation/simulationControlled releaseProcess engineering

The invention discloses a maturity-based design method for a digital prototype of a carrier rocket. The method comprises the steps of firstly building an assembly framework model, and creating and releasing geometric shape constraints for sub-systems in the assembly framework model; secondly building a main force bearing structure model, and realizing coordinated matching of structure design, performance simulation, material preparation and tool design of a main force bearing structure; thirdly building a functional structure detail model, and ensuring the functional structure detail model to have assemblability and repairability; finally finishing digital mock-up of sub-stages of the carrier rocket and the digital prototype of the whole rocket, and ensuring coordinated matching of the sub-stages and the digital prototype of the whole rocket; and performing technical state solidification, and finishing controlled release. According to the method, parallel coordination is realized, the design quality is effectively improved, the design modification and repetition are reduced, and the one-time success rate of general assembly is increased.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG +1

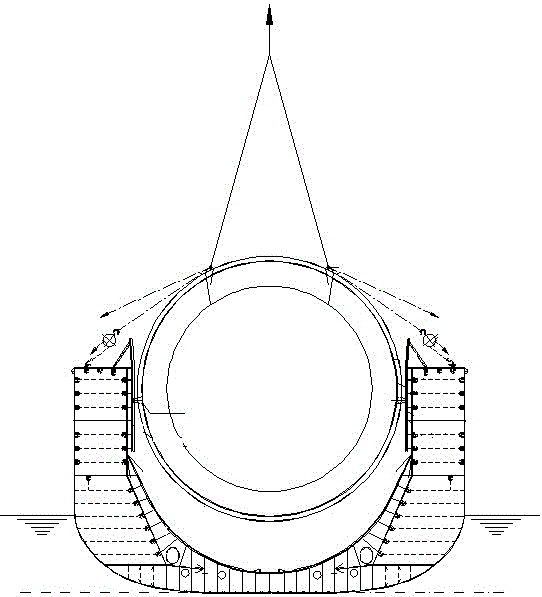

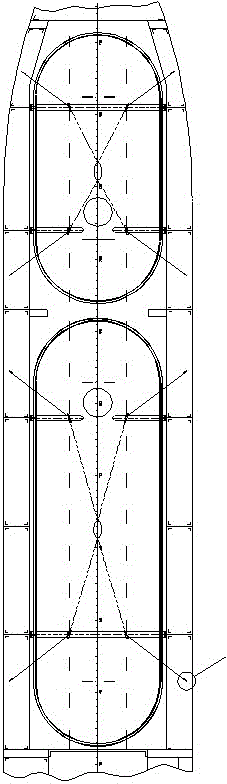

Method for positioning liquid tank quickly and accurately during building of liquefied ship

The invention relates to a method for positioning a liquid tank quickly and accurately during the building of a liquefied ship. The method comprises the following steps: setting a guide plate and a lifting point on the liquid tank separately; mounting a detachable guide device in the mounting position of the liquid tank on a ship body segment; welding an operating eye plate on a deck, connecting a steel wire rope on hoisting equipment on the lifting point to lift the liquid tank above the mounting position, and connecting a chain block with the lifting point and the operating eye plate separately to position the liquid tank; pouring epoxy resin at the mounting position of the liquid tank, starting the hoisting equipment to enable the liquid tank to fall down, controlling the falling stability of the liquid tank by the chain block, and enabling the guide plate to clamp in the specially designed guide device; enabling the liquid tank to fall down to the mounting position quickly under accurate control; dismantling the steel wire rope and the chain block and dismantling the reusable guide device. The one-time positioning method provided by the invention has the characteristics of accuracy and quickness in hoisting, and the dismantled guide device can be reused repeatedly after hoisting.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

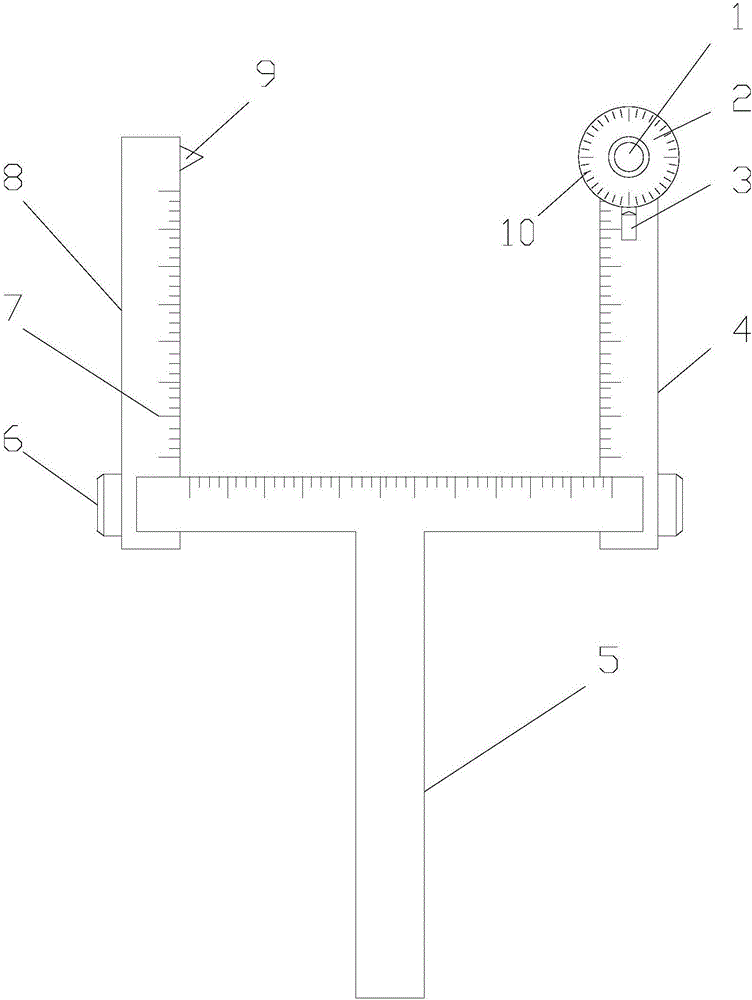

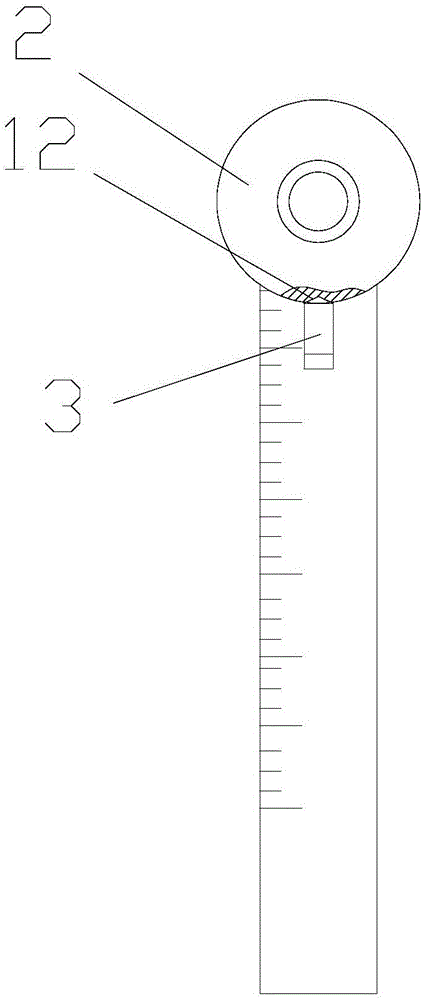

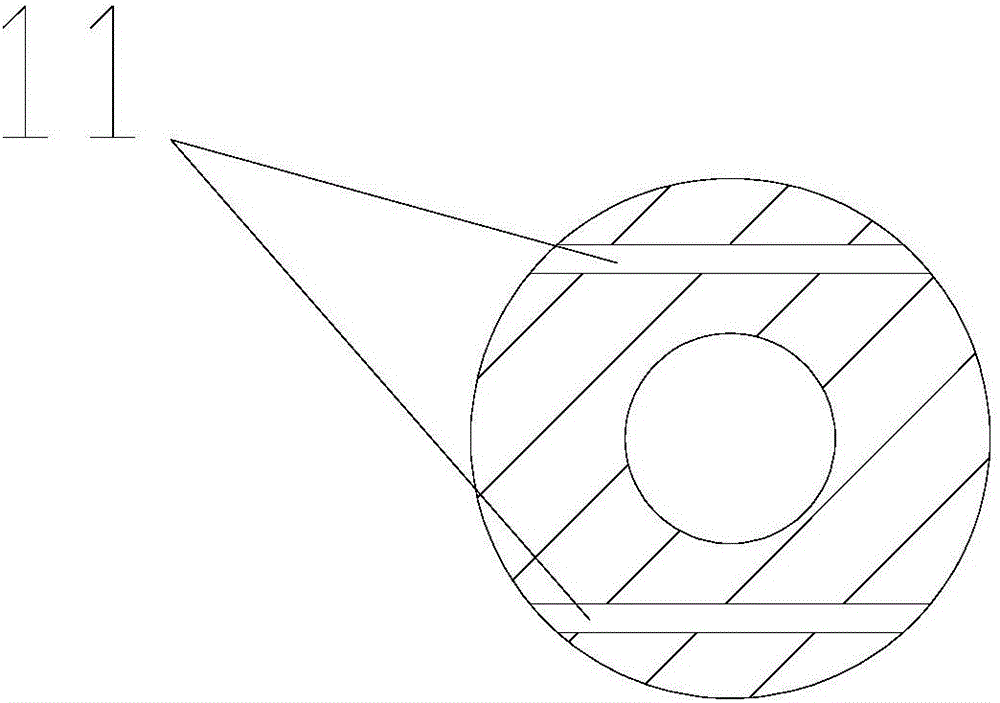

Kirschner wire guider

The invention discloses a kirschner wire guider.The kirschner wire guider comprises a guider support, a positioning point arranged on the guider support and a guide channel used for controlling the drilling direction of a kirschner wire.The axis of the guide channel can be adjusted to pass the positioning point.The guider can precisely guide the drilling direction of the kirschner wire in surgery, and therefore the success rate of kirschner wire fixing surgery can be effectively increased, and surgery pains of patients can be relieved.

Owner:丁勇 +1

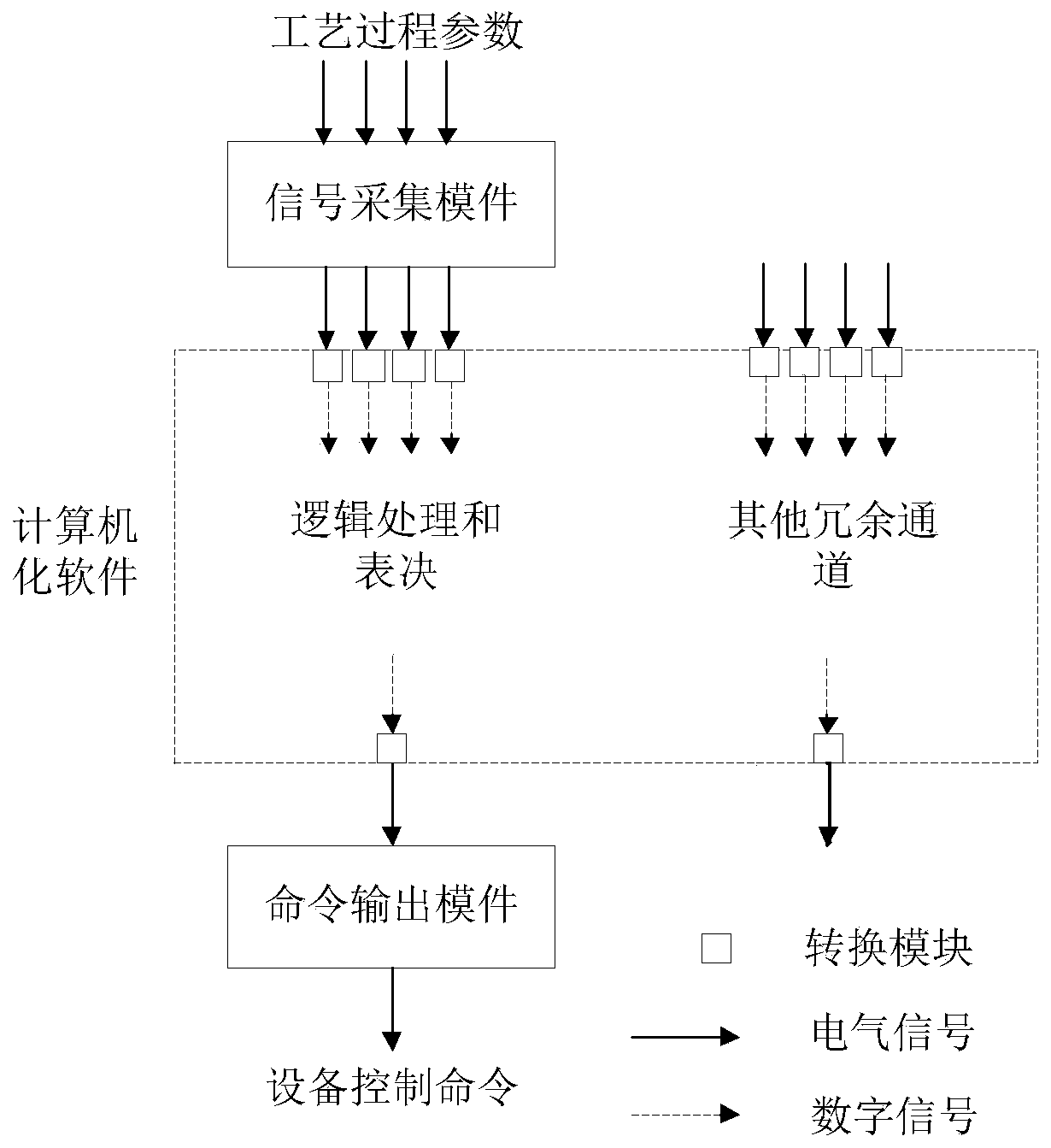

Simulation test system and test method of nuclear power station safety level DCS system

InactiveCN111444056AReduce on-site manpowerLow costFunctional testingSoftware testing/debuggingNuclear powerControl engineering

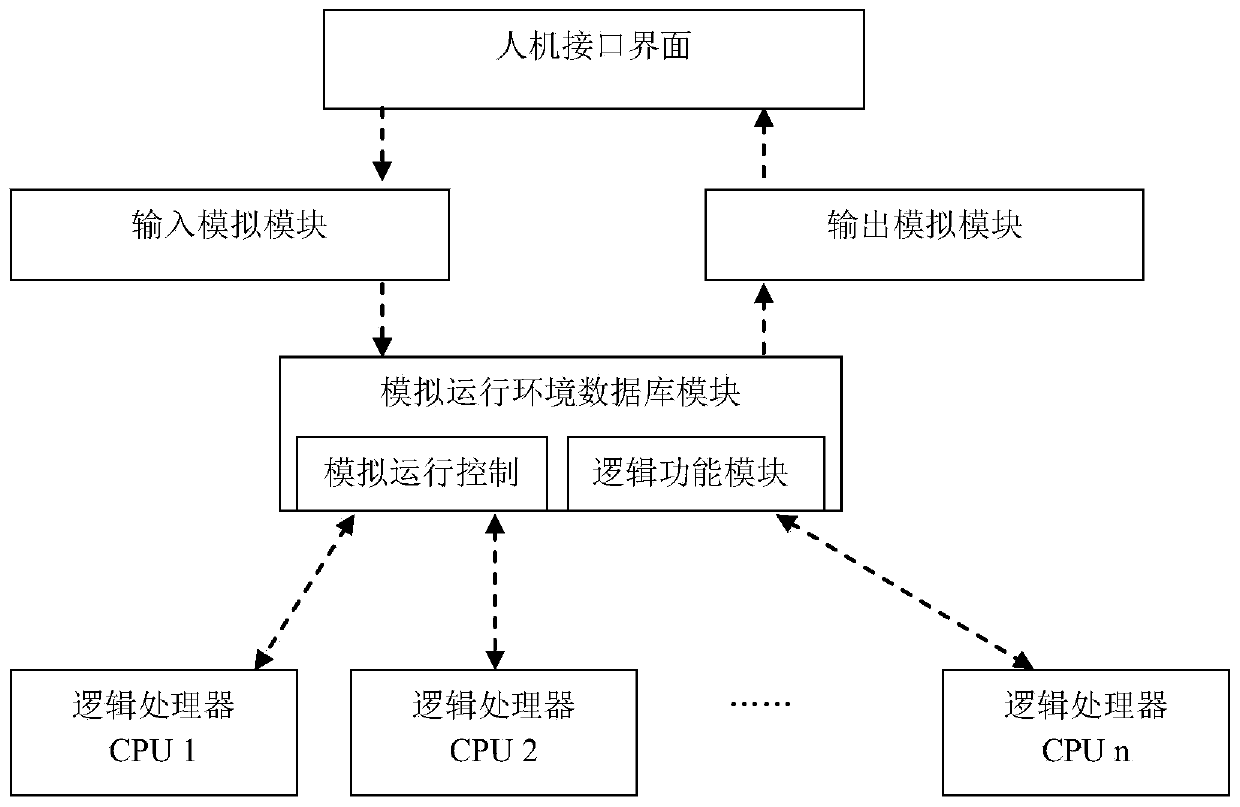

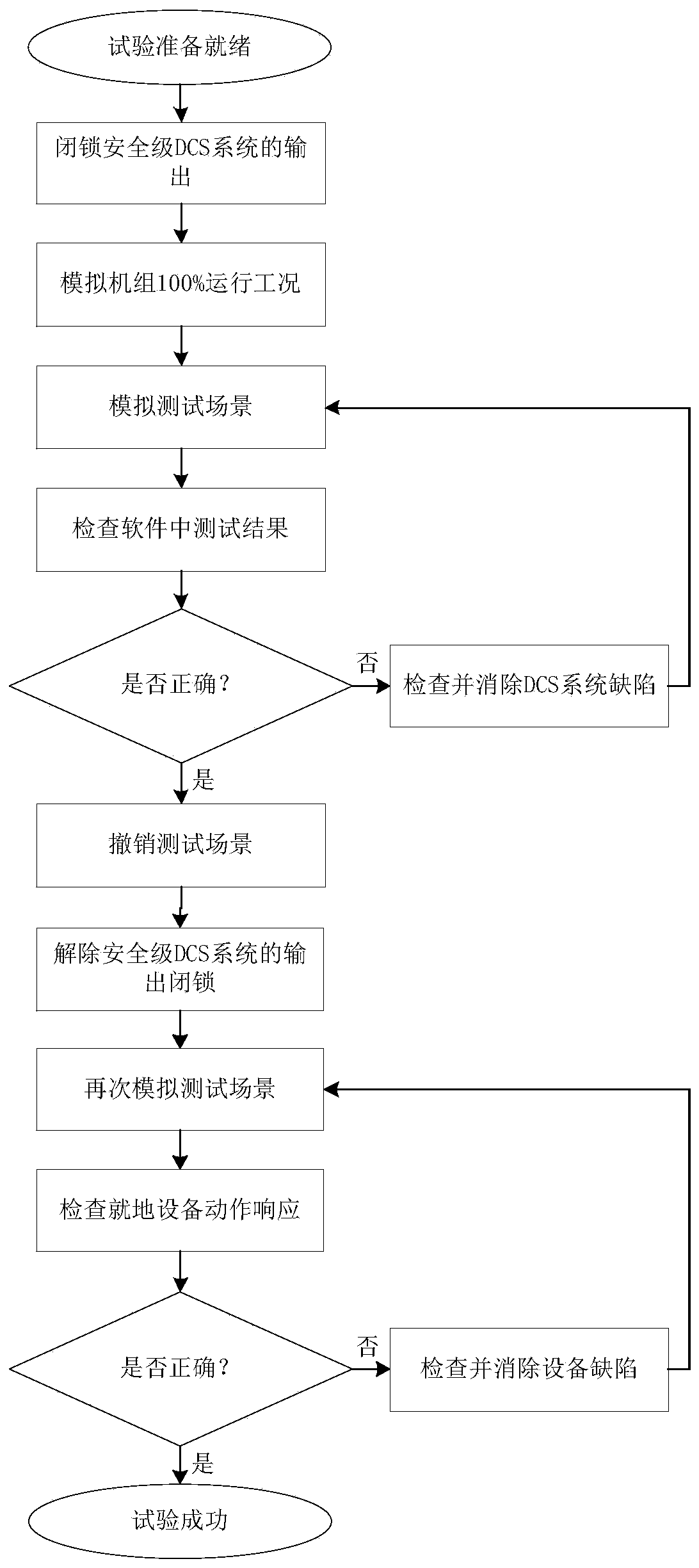

The invention belongs to the technical field of nuclear power station digital instrument control system debugging. The invention particularly relates to a simulation test system and test method of a nuclear power station safety level DCS system. The system comprises a man-machine interface, an input simulation module, an output simulation module, a simulation operation environment database moduleand a plurality of logic processors, the input simulation module is connected between the input end of the simulation operation environment database module and the man-machine interface, and the output simulation module is connected between the output end of the simulation operation environment database module and the man-machine interface; and the simulation operation environment database moduleis also connected with the plurality of logic processors. According to the method, the simulation test of the dynamic working condition of the safety-level DCS system is established during nuclear power station debugging, any hardware facility does not need to be introduced, the field manpower and material cost is reduced, and the debugging efficiency is improved.

Owner:JIANGSU NUCLEAR POWER CORP

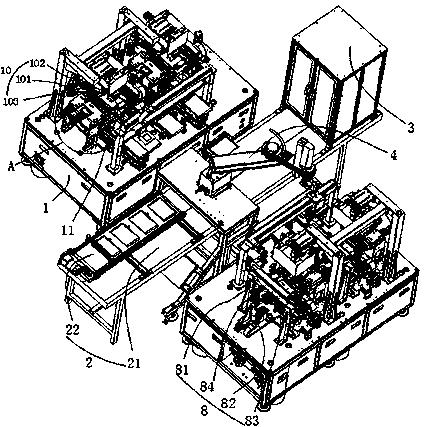

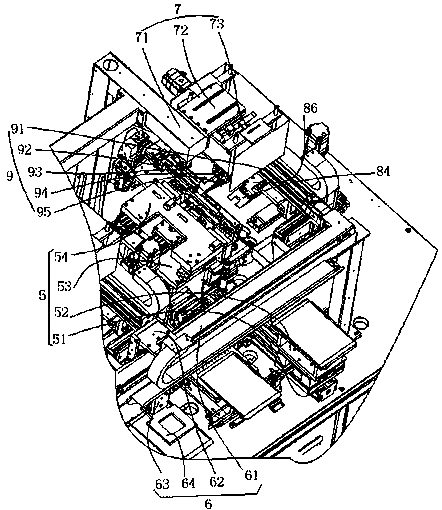

Bending machine for double-layer flexible circuit board

PendingCN110913584ASave human effortHigh precisionMultilayer circuit manufactureRobot handFlexible circuits

The invention discloses a double-layer flexible circuit board bending machine, a conveying device is arranged on one side of a rack, a visual positioning mechanism is arranged on the conveying device,and a mechanical arm feeding and discharging mechanism is arranged on the upper portion of the conveying device; the double-layer flexible circuit board bending mechanism is arranged on the rack in an array mode, the carrying mechanism is arranged at the discharging end of the double-layer flexible circuit board bending mechanism, the AOI positioning and detecting mechanism is located above the double-layer flexible circuit board bending mechanism, and the pre-shifting and pre-pressing mechanism is located in front of the double-layer flexible circuit board bending mechanism. According to theinvention, actions from separation of the double-layer flexible circuit board to film tearing and from lamination of the double-layer flexible circuit board to shaping and bending are all automatically completed by the equipment, so that the manpower is effectively saved, the bending accuracy is improved, and the one-time yield is as high as 99.7%; the core technology of the product is not only suitable for bending the flexible circuit board of the display screen of the tablet personal computer, but also capable of meeting the bending requirements of mobile phones and other flexible circuit boards adopting flexible circuit board products, and particularly suitable for the most popular flexible AMOLED display technology at present.

Owner:厦门微亚智能科技股份有限公司

Flexible first-time sand control sandblasting technique pipe

InactiveCN103244082AImprove one-time success rateResume normal productionFluid removalEngineeringShear pin

The invention relates to the technical field of oilfield workover sand control operation, in particular to a flexible first-time sand control sandblasting technique pipe. Multiple slotted screens of the pipe are mutually connected through flexible connectors to form a slotted screen string, each flexible connector comprises a flexible connector lower adaptor and a flexible connector upper adaptor which are connected and are locked through a flexible connector locking screw, the lower end of the slotted screen string is connected with a ball seat with the lower end connected with a guiding shoe nib, the upper end of the slotted screen string is connected with a hanger body through the flexible connectors, a hanger sealing rubber sleeve and a rubber sleeve distance ring are sleeved on the hanger body, a compression rubber sleeve adaptor is disposed at the upper end of the rubber sleeve distance ring and is in screwed connection with the hanger body, and the upper end of the compression rubber sleeve adaptor is in screwed connection with a hanger spindle and fixed through a shear pin. By the technique pipe, first-time success rate of sand control of large-curvature wells is improved, sand control cost is lowered, sand control time effectiveness is improved, and production of sand control wells is resumed timely.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

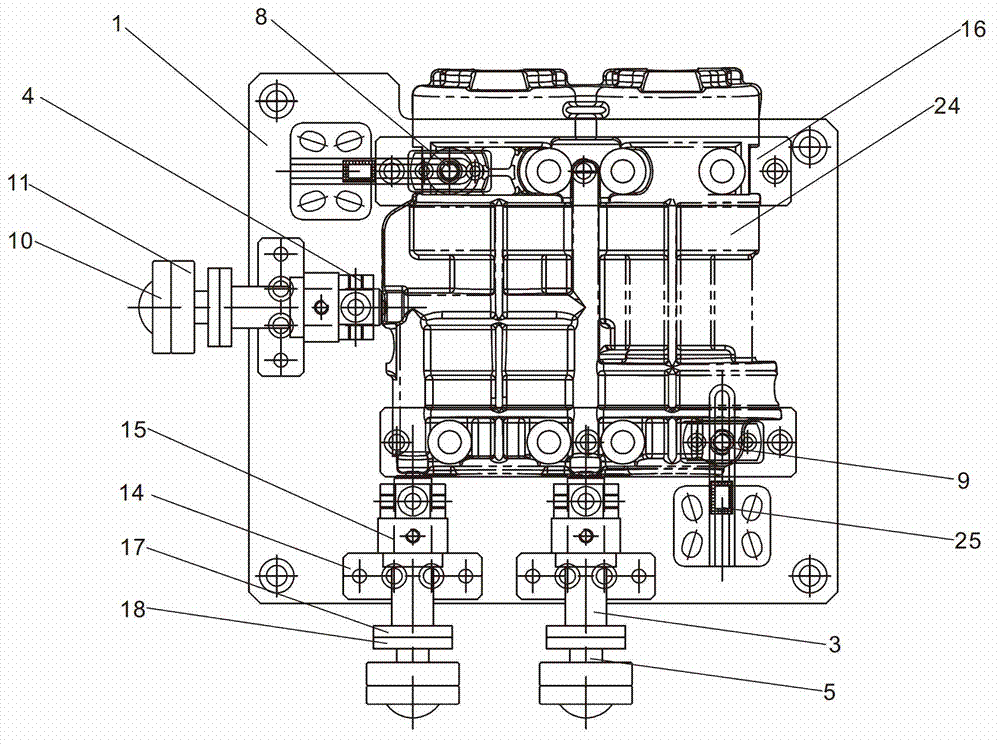

Crankshaft box balancing bearing cover oil passage steel ball press fitting tool

ActiveCN103111975AEasy to fixEfficient deliveryWork holdersMetal-working hand toolsCrankcaseSteel ball

The invention provides a crankshaft box balancing bearing cover oil passage steel ball press fitting tool. The crankshaft box balancing bearing cover oil passage steel ball press fitting tool comprises a base plate. A steel ball press fitting mechanism and a balancing bearing cover positioning mechanism are arranged on the base plate. The steel ball press fitting mechanism comprises a support seat, a steel ball guiding sleeve, a steel ball material storehouse and a steel ball pressing rod. The support seat is fixed on the base plate. The steel ball guiding sleeve is arranged on the support seat in a sleeved mode. A guiding sleeve pipeline with openings at two ends is arranged in the steel ball guiding sleeve. A diameter of the guiding sleeve pipeline is smaller than two times of a diameter of the balancing bearing cover oil passage steel ball. The steel ball material storehouse is fixedly connected with the steel ball guiding sleeve in a perpendicular mode. A steel ball storage pipe cavity is arranged in the steel ball material storehouse. A diameter of the steel ball storage pipe cavity is fit with the diameter of the balancing bearing cover oil passage steel ball. The steel ball storage pipe cavity is communicated with the guiding sleeve pipeline. The steel ball pressing rod is connected with the guiding sleeve pipeline in a sliding mode. The crankshaft box balancing bearing cover oil passage steel ball press fitting tool is convenient, reliable and safe to carry out the work of the crankshaft box balancing bearing cover oil passage steel ball press fitting. Working quality and working efficiency are greatly improved.

Owner:ZHEJIANG GEELY POWERTRAIN CO LTD +2

Colored wide and dense cotton belt and dyeing method thereof

ActiveCN104294503ASolve the problem of uneven dyeingUniform colorBleaching apparatusBiochemical treatment with enzymes/microorganismsPulp and paper industryThermal water

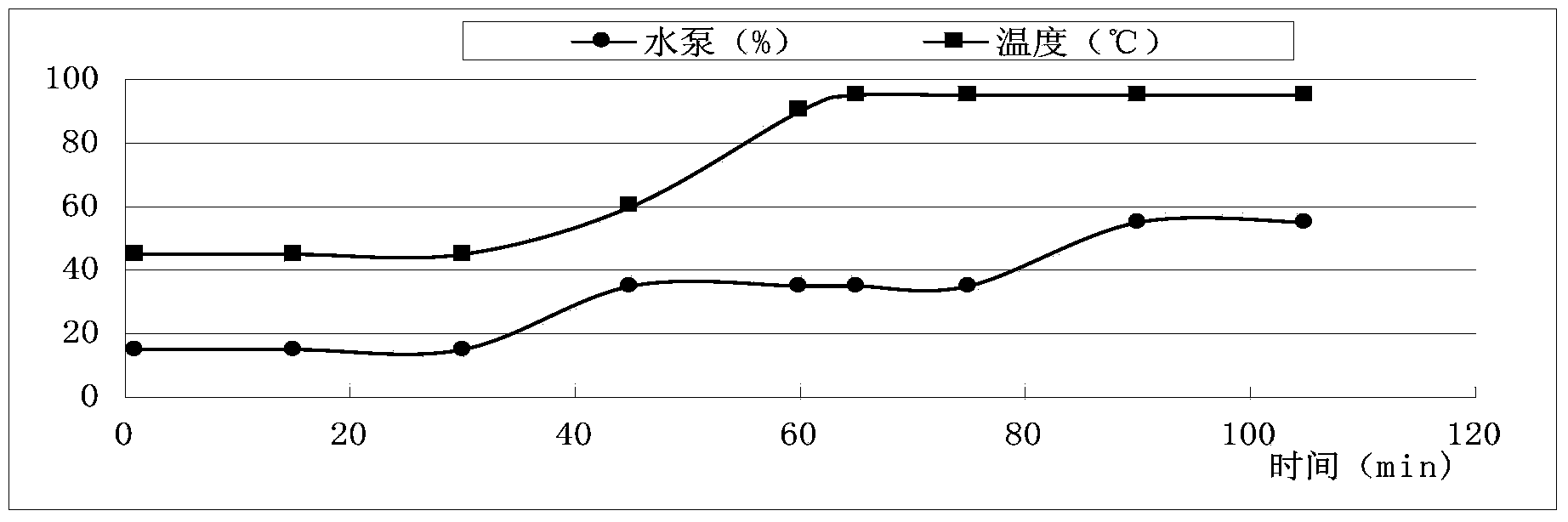

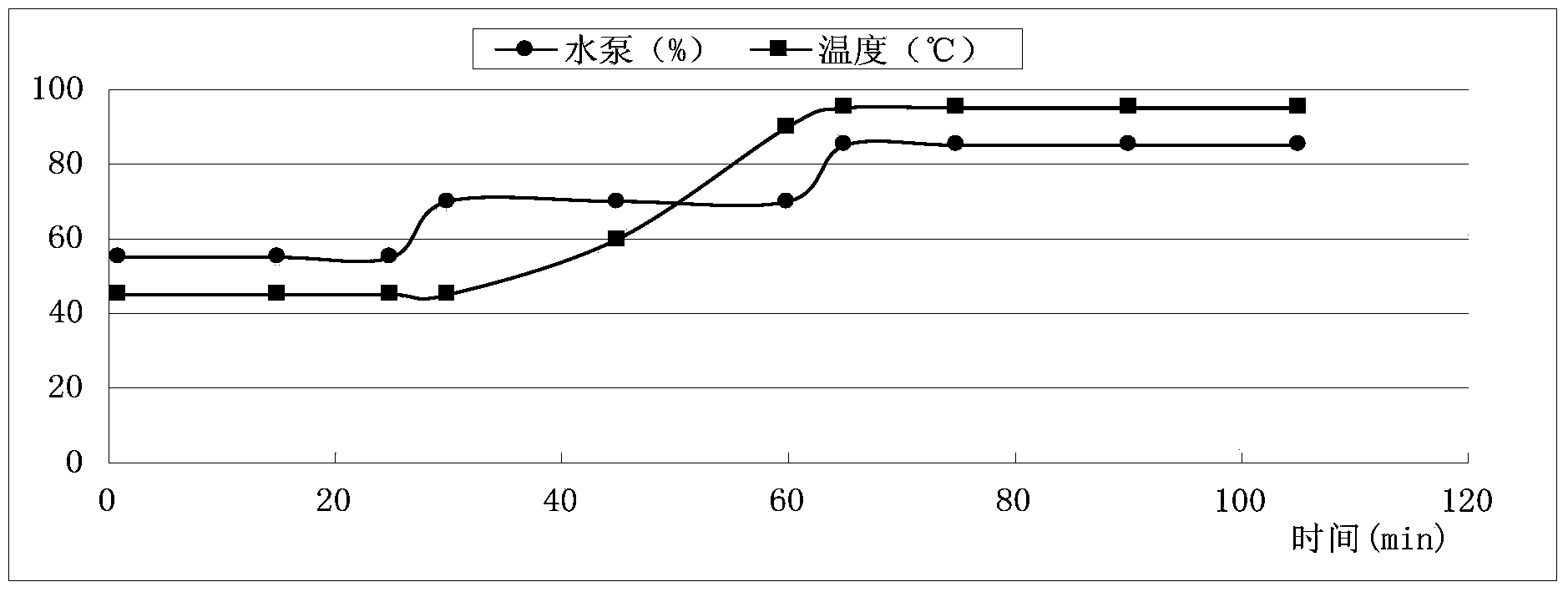

The invention discloses a colored wide and dense cotton belt and a dyeing method of the colored wide and dense cotton belt and belongs to the technical field of textile dyeing. The dyeing method comprises the following steps of (1) preshrinking the wide and dense cotton belt, wherein the wide and dense cotton belt is immersed in hot water with the temperature ranging from 50 DEG C to 90 DEG C for 15 to 50 minutes, and then dehydration is carried out, wherein the bath ratio is 1:5-20; (2) winding the belt, wherein the preshrunk wide and dense cotton belt is evenly wound around a dyeing shaft; (3) conducting pretreatment, wherein the dyeing shaft with the wound wide and dense cotton belt is placed in a dyeing device for pretreatment, specifically, the start pump speed of a water pump of the dyeing device is 10 percent to 15 percent of the maximum pump speed, the pump speed of the water pump is increased by 15 to 25 percent every 20 to 40 minutes, the pump speed is increased to 80 to 90 percent of the maximum pump speed finally, and pretreatment is carried out for 40 to 60 minutes at the final pump speed; (4) conducting dyeing, wherein the pretreated wide and dense cotton belt is dyed. By the adoption of the dyeing method, the obtained colored wide and dense cotton belt has the advantages of being even in color, free of wrinkles and folds. The dyeing method can be widely applied to dyeing production of wide and dense cotton belts.

Owner:广东康派环创科技有限公司

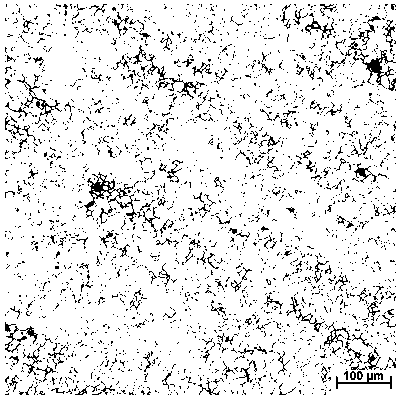

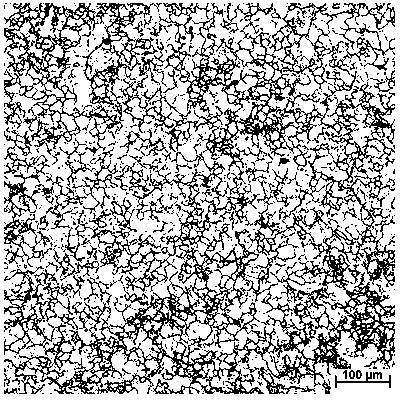

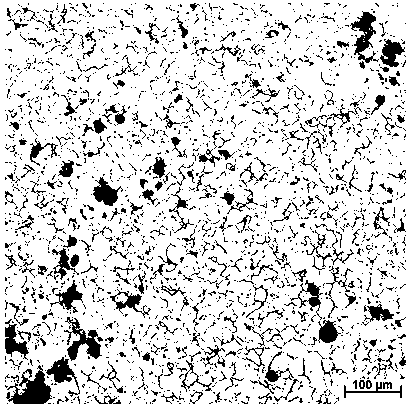

Preparation method of sample for detecting austenite grain size of steel by oxidation method

InactiveCN111426534AExpand the inspection areaImprove one-time success ratePreparing sample for investigationSaline waterAustenite grain

The invention discloses a preparation method of a sample for detecting austenite grain size of steel by an oxidation method. The preparation method comprises the steps of (1) taking the sample; (2) polishing the detection surface of the sample; (3) placing the polished sample detection surface upwards in a furnace for heat treatment, heating the sample with the carbon content (mass fraction) not larger than 0.35% at the temperature of 890 + / -10 DEG C, heating the sample with the carbon content (mass fraction) larger than 0.35% at the temperature of 860 + / -10 DEG C, and carrying out quenching in cold water or saline water after heat preservation is conducted for 1 h; (4) dropwise adding a hydrochloric acid solution to the detection surface of the sample subjected to heat treatment, and after bubbles appear on the surface of the sample, washing with clear water and blow-drying; (5) polishing the detection surface; and (6) corroding by using a 15% hydrochloric acid alcohol solution, washing by using the alcohol solution, and drying for later detection. The sample obtained by the method is larger in detection area and higher in sample preparation success rate.

Owner:SHIJIAZHUANG IRON & STEEL

Anti-clogging sampling structure and sampling probe with same and sampling system with sampling probe

PendingCN108652683ATo achieve the purpose of tissue cuttingAvoid cloggingSurgical needlesVaccination/ovulation diagnosticsMedicineSurgical site

The invention relates to an anti-clogging sampling structure and a sampling probe with the same and a sampling system with the sampling probe. According to the anti-clogging sampling structure, an elastic device is arranged in an anti-clogging sampling channel, a puncture head is connected to one end of the elastic device, and the other end of the elastic device is always in an inner tube during the sampling process. A certain space always exists between the elastic device and the inner wall of an outer tube to prevent the size of tissue adsorbed into the anti-clogging sampling channel duringthe sampling process from exceeding the size of the anti-clogging sampling channel, so that the anti-clogging effect is achieved. The anti-clogging sampling structure further includes two fluid flow channels, the two fluid flow channels are disposed at both ends of a sampling tank, and the tissue is fixed by negative pressure suction. The anti-clogging sampling structure and the sampling probe with the same and the sampling system with the sampling probe have the beneficial effects that through the arrangement of the elastic device and the two fluid flow channels, the anti-clogging performanceof the channel is effectively improved, the integrity of tissue cutting is ensured, the functions of tissue adsorption, rotary cutting sampling, and surgical site irrigation are combined together, and the one-time success rate of a surgery is improved.

Owner:戴凌虹

Bolt tightening device

InactiveCN104369144ASolve the problem of tightening failureImprove one-time success ratePower driven toolsMetal-working hand toolsThrust bearingEngineering

The invention discloses a bolt tightening device. The bolt tightening device mainly comprises a drive rod system, two same floating devices and an installing base. The section of the installing base is triangular. The drive rod system is installed on one vertex angle of the installing base, the two floating devices are installed on the other two vertex angles of the installing base respectively, and the drive rod system mainly comprises a drive rod, a compression spring and a socket spanner. Each floating device mainly comprises a short shaft, an upper thrust bearing, a lower thrust bearing and a nut. The short shafts are inserted into the installing base, and the diameter of the short shafts is smaller than the inner diameter of the upper thrust bearings and the inner diameter of the lower thrust bearings. Because the floating devices are arranged between the drive rod and a supporting plate, the problem that due to the unadjustable position of the drive rod, a bolt fails to be tightened is solved, and the success rate of tightening the bolt at a time is greatly increased.

Owner:JIANGSU HUAXIA HEAVY IND

Automatic superficial venipuncture and catheterization equipment

The invention belongs to the field of medical equipment, and particularly relates to intelligent equipment for improving the one-time success of superficial venipuncture and catheterization, and a usemethod thereof. In order to solve the problem of a low one-time success rate of superficial venipuncture and catheterization, the invention focuses on solving two core problems of venous displacementand a limited safety range of a puncture diameter line when venipuncture and catheterization are carried out. A near-infrared illumination imaging vein positioning assembly is used to analyze, automatically identify and select a puncture vein; a vein fixing and puncture assembly is designed to realize vein fixing and innovate a safe puncture and catheterization method; a blood return recognitionassembly is used to realize the monitoring feedback of superficial venipuncture and catheterization, and judge whether the puncture is successful or not; a disinfection film-sticking assembly is usedto realize skin disinfection before puncture and indwelling needle film-sticking fixing after puncture; and a support fixing assembly designed according to anatomy is used to complete comfortable support fixing of a limb where a venipuncture site is located. The beneficial effects are that the certainty of the success of superficial venipuncture is greatly improved, the pain of patients is reduced, and the medical safety is improved.

Owner:杜学军 +1

A kind of jack for changing the rolling angle of the shield machine

The invention provides a jack used for changing the rolling angle of a shield tunneling machine. The jack is used for the rolling angle correction of the shield tunneling machine during shield construction. The shield tunneling machine comprises a cutter head located on a front end, a shield shell connected to the cutter head and a duct piece located on the rear portion of the shield shell. The tail of the shield shell is provided with a shield tunneling machine oil pump. A shield tunneling machine oil pump supporting boot is connected to the duct piece when being stretched. The jack is arranged at the contact point of the duct piece and the shield tunneling machine oil pump supporting boot. The jack comprises a friction plate and an adjusting bolt fixed to the edge of the friction plate.When the jack works, the jack friction plate is arranged between the duct piece and the shield tunneling machine oil pump supporting boot in a stretching state. The non-fixed end of the adjusting boltof the jack is supported at a support point. An operation person rotates the adjusting bolt so that the friction plate moves between the duct piece and the supporting boot, and the jack friction plate applies a force to the shield shell through the supporting boot to correct the rolling angle of the shield tunneling machine. The jack is particularly suitable for the timely correction of the uncontrolled rolling angle of the shield tunneling machine when an earth pressure balance shield passes through complex formations such as muddy soil and the like for a long distance.

Owner:POWERCHINA RAILWAY CONSTR +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com