A kind of jack for changing the rolling angle of the shield machine

A technology of shield machine and jack, which is applied to mining equipment, tunnels, earthwork drilling and mining, etc. It can solve the problems of cutterhead deformation and high risk of shield tunneling operation, so as to avoid cutterhead deformation, low construction risk and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

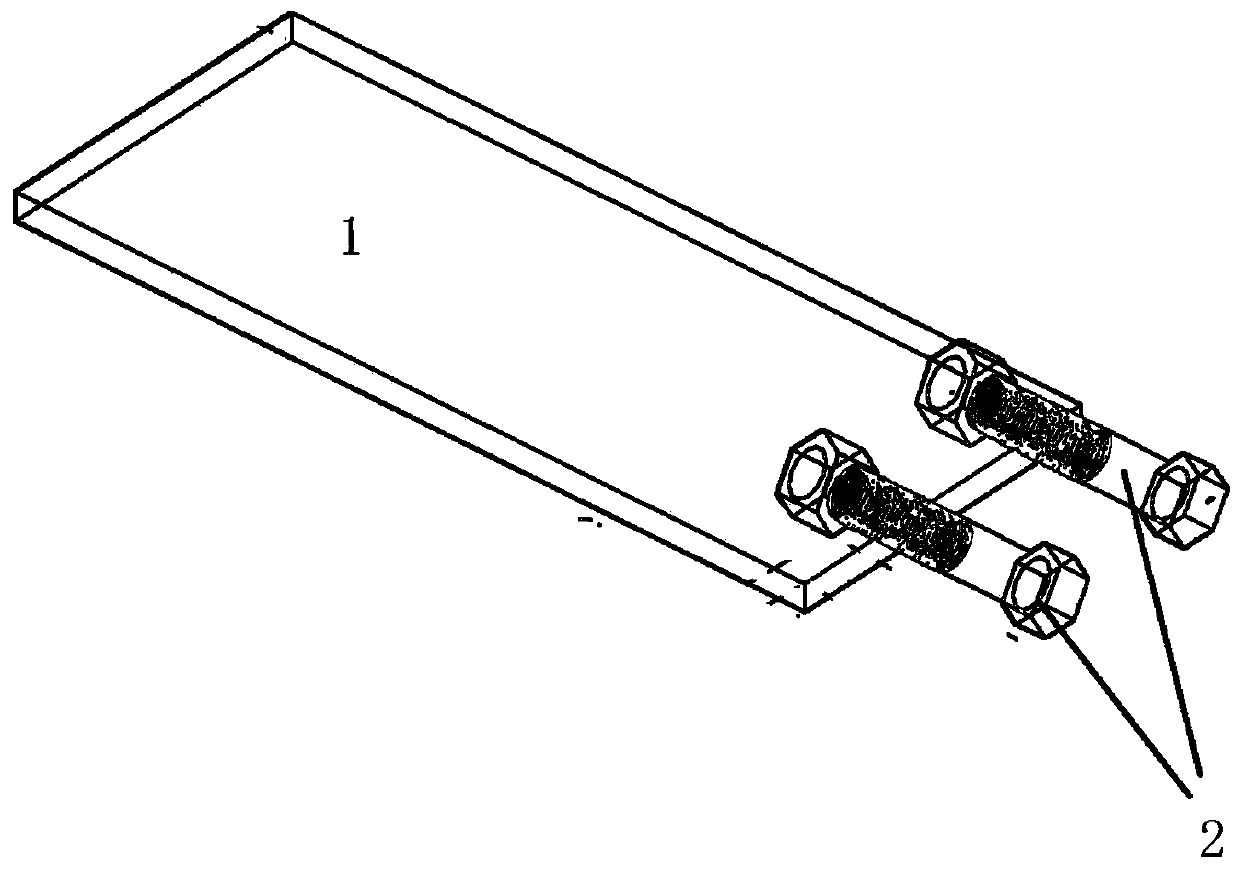

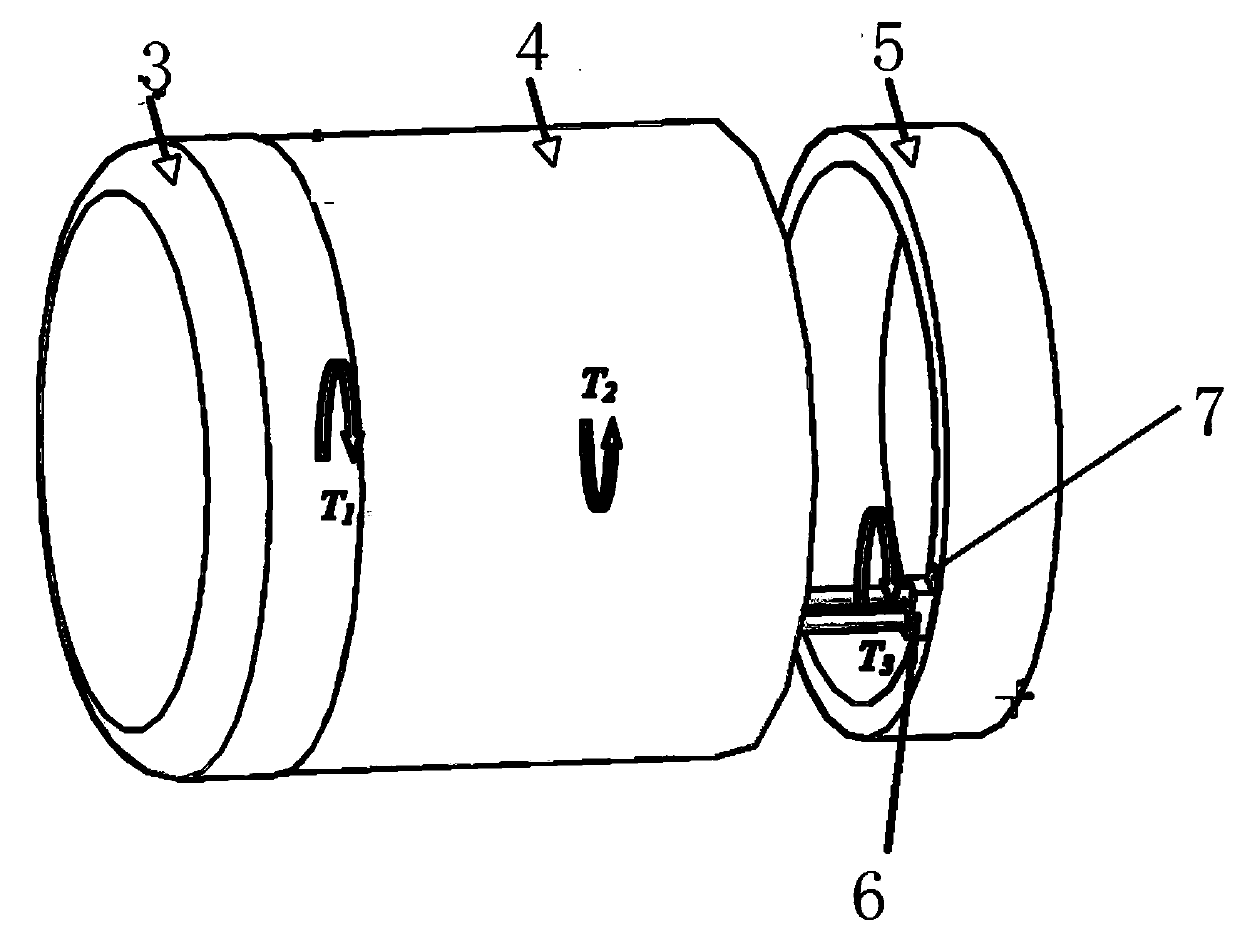

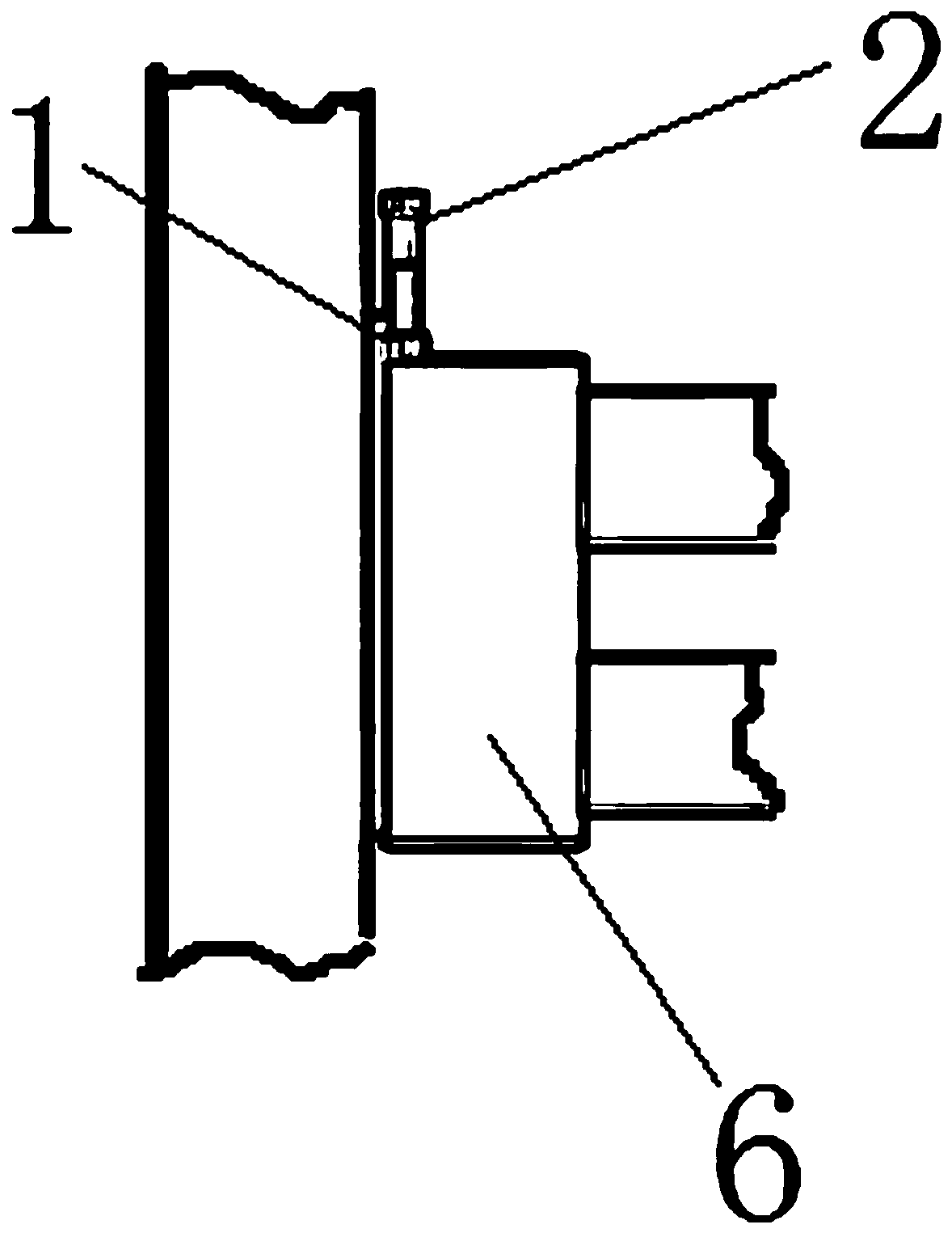

[0062] Such as Figure 1-5 As shown, a jack for changing the rolling angle of a shield machine is used to correct the rolling angle of the shield machine during shield construction. The shield machine includes a cutter head at the front end, a shield shell connected with the cutter head, and a rear of the shield shell The end of the shield shell is provided with a shield oil pump, and the shield oil pump support shoe is connected to the tube segment when it is stretched; the jack is provided at the contact point of the tube segment and the shield oil pump support shoe; the jack It includes a friction plate and an adjusting bolt fixed at the edge of the friction plate; when the jack is working, the jack friction plate is placed between the tube sheet and the shield oil pump support shoe in the extended state; the non-fixed end of the jack adjusting bolt is supported on At the supporting point; the operator rotates the adjusting bolt to move the friction plate between the tube sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com