Copper-tin alloy contract wire for electrified railway and continuous manufacturing process thereof

A technology of electrified railways and copper-tin alloys, applied in the direction of electrical components, metal/alloy conductors, circuits, etc., can solve problems that affect product production efficiency and product quality, reduce the success rate of one-time connection, and reduce the mechanical properties of copper-tin alloys, etc. , to achieve the effect of improving splicing quality and first-time success rate, ensuring production continuity and production efficiency, and product quality is not affected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

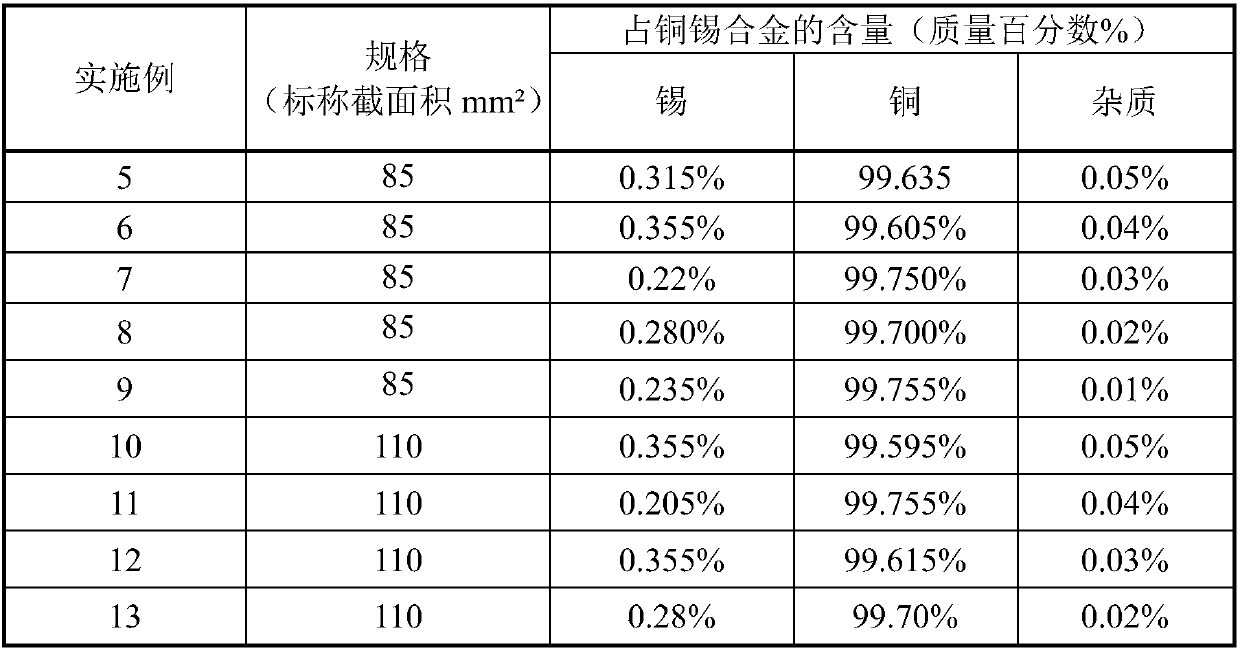

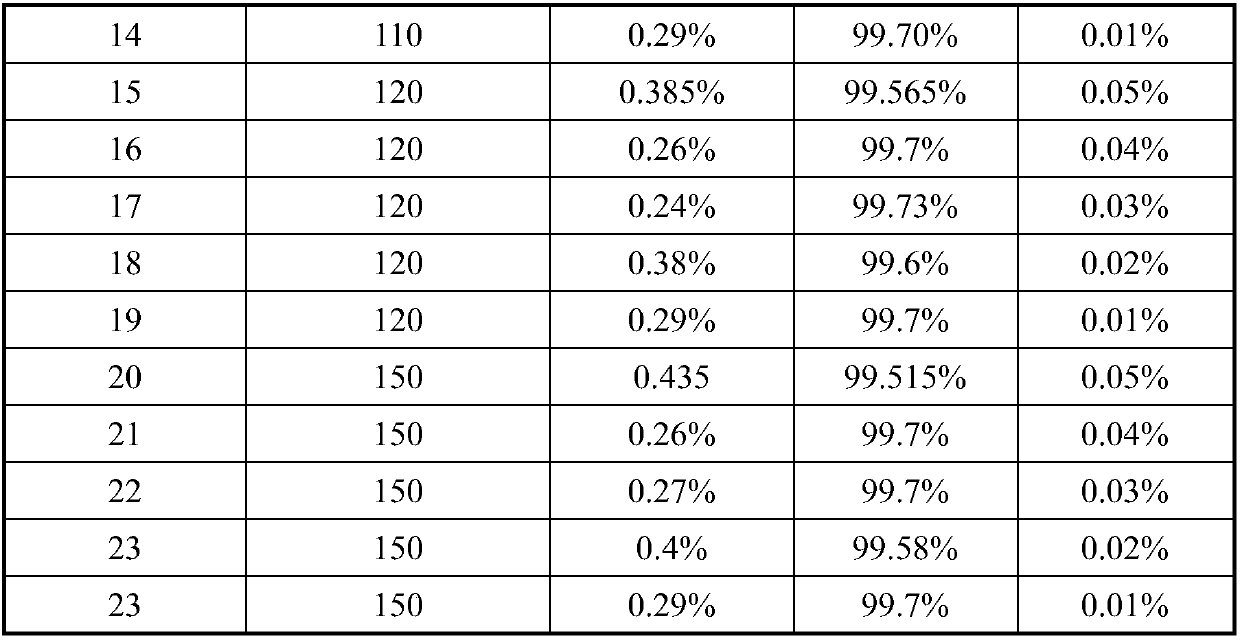

Embodiment 1

[0020] In the present invention, first, high-purity cathode copper (accounting for 99.755% of the total amount) is added into the upper furnace for melting as a raw material, and then according to the production process, 0.195% metal tin by weight is added to the copper liquid, and graphite rods are used to After stirring to make the alloy composition uniform, the billet rod is started. Then feed the tin-containing alloy upper lead drawn out into the continuous extruder to make a 20mm extruded rod, and then connect the end of the extruded rod with the tail of the extruded rod on the pay-off frame of the drawing machine with flash butt welding. Mark the joint, cut the finished copper-tin alloy contact wire from the extruded rod at the joint, and continue drawing to make 85mm 2 Finished copper-tin alloy contact wire.

Embodiment 2

[0022] In the present invention, first, high-purity cathode copper (accounting for 99.745% of the total amount) is added as a raw material into the upper induction furnace for melting, and then according to the production process, 0.205% metal tin by weight is added to the copper liquid, and graphite rods are used to After stirring to make the alloy composition uniform, the billet rod is started. Then feed the tin-containing alloy upper lead drawn out into the continuous extruder to make a 20mm extruded rod, and then connect the end of the extruded rod with the tail of the extruded rod on the pay-off frame of the drawing machine with flash butt welding. Mark the joint, cut the finished copper-tin alloy contact wire from the extruded rod at the joint, and continue drawing to make 110mm 2 Finished copper-tin alloy contact wire.

Embodiment 3

[0024] In the present invention, high-purity cathode copper (accounting for 99.735% of the total amount) is firstly added into the upper furnace for melting as a raw material, and then according to the production process, 0.215% metal tin by weight is added to the copper liquid, and graphite rods are used to After stirring to make the alloy composition uniform, the billet rod is started. Then feed the tin-containing alloy upper lead drawn out into the continuous extruder to make a 20mm extruded rod, and then connect the end of the extruded rod with the tail of the extruded rod on the pay-off frame of the drawing machine with flash butt welding. Mark the joint, cut the finished copper-tin alloy contact wire from the extruded rod at the joint, and continue drawing to make 120mm 2 Finished copper-tin alloy contact wire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com