Method for producing hydroxy cobalt oxide

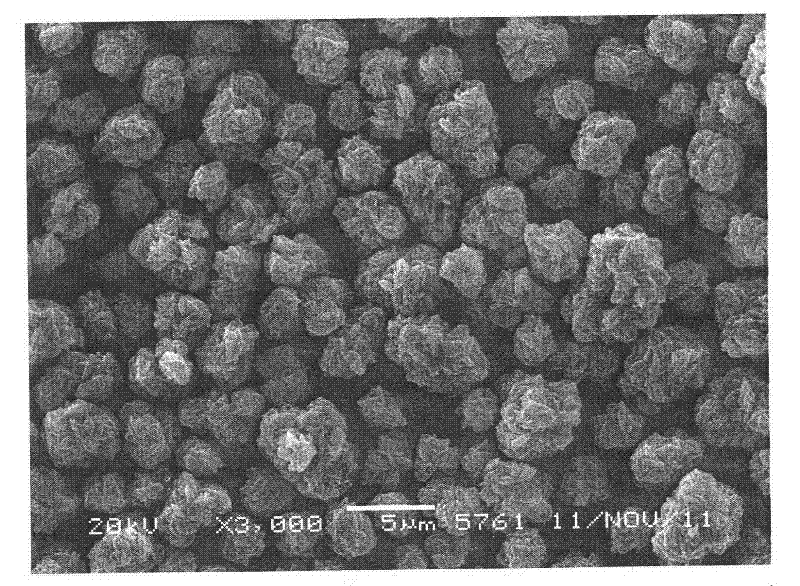

A technology of cobalt oxyhydroxide and production method, which is applied in the direction of cobalt oxide/cobalt hydroxide, etc., which can solve the problems of uncontrollable particle size and shape, uneven distribution of product particles, and difficult treatment of ammonia nitrogen waste, so as to improve the utilization rate of equipment and work efficiency, good consistency, and controllable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The production steps are as follows:

[0029] 1. Preparation of cobalt sulfate solution

[0030] When the cobalt content control index of the cobalt solution to be prepared is 80g / l, in the rated volume of 10m 3 Add cobalt sulfate solution raw material 8m of cobalt content to be 100g / l in the preparation tank of 3 , turn on the stirring blade, add pure water to the rated volume elevation of the preparation tank, stir for 5 to 10 minutes, add hydrochloric acid, adjust the pH value of the solution to 3.5, take samples to analyze the cobalt content, and add the additive EDTA according to the ratio of cobalt:EDTA=100:2 , and then pumped into the high-level cobalt liquid storage tank.

[0031] 2. Preparation of sodium hydroxide solution

[0032] When the lye concentration control index to be prepared is 8mol, in the rated volume of 10m 3 Add 6.67m of sodium hydroxide solution when the concentration is 12mol in the preparation tank 3 , turn on the stirring blade, add pur...

Embodiment 2

[0040] The production step 1 of this example is basically the same as that of Example 1, except that the following parameters are different: the cobalt content control index of the cobalt sulfate solution to be prepared is 75g / l, and adding cobalt sulfate 8.33m of cobalt content of 90g / l in the preparation tank 3 , adjust the pH value of the solution to 3.0, and add the additive EDTA according to cobalt: EDTA=100: 1.

[0041] The production step 2 of this example is basically the same as that of Example 1, except that the following parameters are different: the alkali concentration control index to be prepared is 7mol, and adding a concentration of 10mol of sodium hydroxide solution 7m in the preparation tank 3 .

[0042] The production step 3 of this example is basically the same as embodiment one, only following parameters are different: the flow of cobalt sulfate solution is 100L / h, the flow of sodium hydroxide solution is 60L / h, and the air flow is 8m 3 / h.

[0043] The ...

Embodiment 3

[0045] The production step 1 of this example is basically the same as that of Example 1, only the following parameters are different: the cobalt content control index of the cobalt sulfate solution to be prepared is 85g / l, and adding cobalt sulfate 7.73m of cobalt content in the preparation tank is 110g / l 3 , adjust the pH value of the solution to 4.5, and add the additive EDTA according to cobalt: EDTA=100:3.

[0046]The production step 2 of this example is basically the same as that of Example 1, except that the following parameters are different: the alkali concentration control index to be prepared is 9mol, and adding a concentration of 15mol of sodium hydroxide solution 6m in the preparation tank 3 .

[0047] The production step 3 of this example is basically the same as embodiment one, only following parameters are different: the flow of cobalt sulfate solution is 500L / h, the flow of sodium hydroxide solution is 350L / h, and the air flow is 15m 3 / h.

[0048] The produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com