Patents

Literature

979results about How to "The production process is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano porous concrete taking thixotropic colloid as template agent and preparation method

InactiveCN105294141AHas a three-dimensional network microporous structureNo pollution in the processCeramicwareBrickThixotropy

The invention relates to porous concrete and a preparation method thereof, in particular to novel nano porous concrete which is prepared by taking thixotropic colloid as a template agent to form a uniform-water-phase three-dimensional network nano porous structure and adding cementing materials, fine aggregate, coarse aggregate, an admixture and an additive. The nano porous concrete has the characteristics of being light, high in strength and low in heat conductivity, can be prefabricated into bricks, building blocks, plates, and assembly type stairs, wallboards, balcony slabs and roof panel parts in a factory, can be also cast on a construction site, and further can be prepared into mortar, thereby having remarkable practical significance on promotion of development of housing industrialization and green building concrete material in our country.

Owner:浙江圣润纳米科技有限公司

Elastic polyester fibre and preparation method thereof

InactiveCN101126180AIncrease elasticityConvenient careFilament/thread formingMonocomponent polyesters artificial filamentFiberPolymer science

The invention relates to a springy polyester fiber and the preparing method. The technical problem of the invention to be solved is that the invention provides a springy fiber and the preparing method to make up the disadvantages of the capability of the spandex and the applying arrange. The springy fiber of the invention adopts the method of the compound filature and uses two screw extrusion machines to respectively melt the two components, and the product is obtained through the extrusion of the compound filature component. The invention is characterized in that the components of the springy fiber comprise two of the following high polymers which have heat shrinking capability difference: the high fasculation PETP, the PET, the PBT, the PTT with the weight proportion of 30-70:50.

Owner:ZHEJIANG HENGYI GRP CO LTD

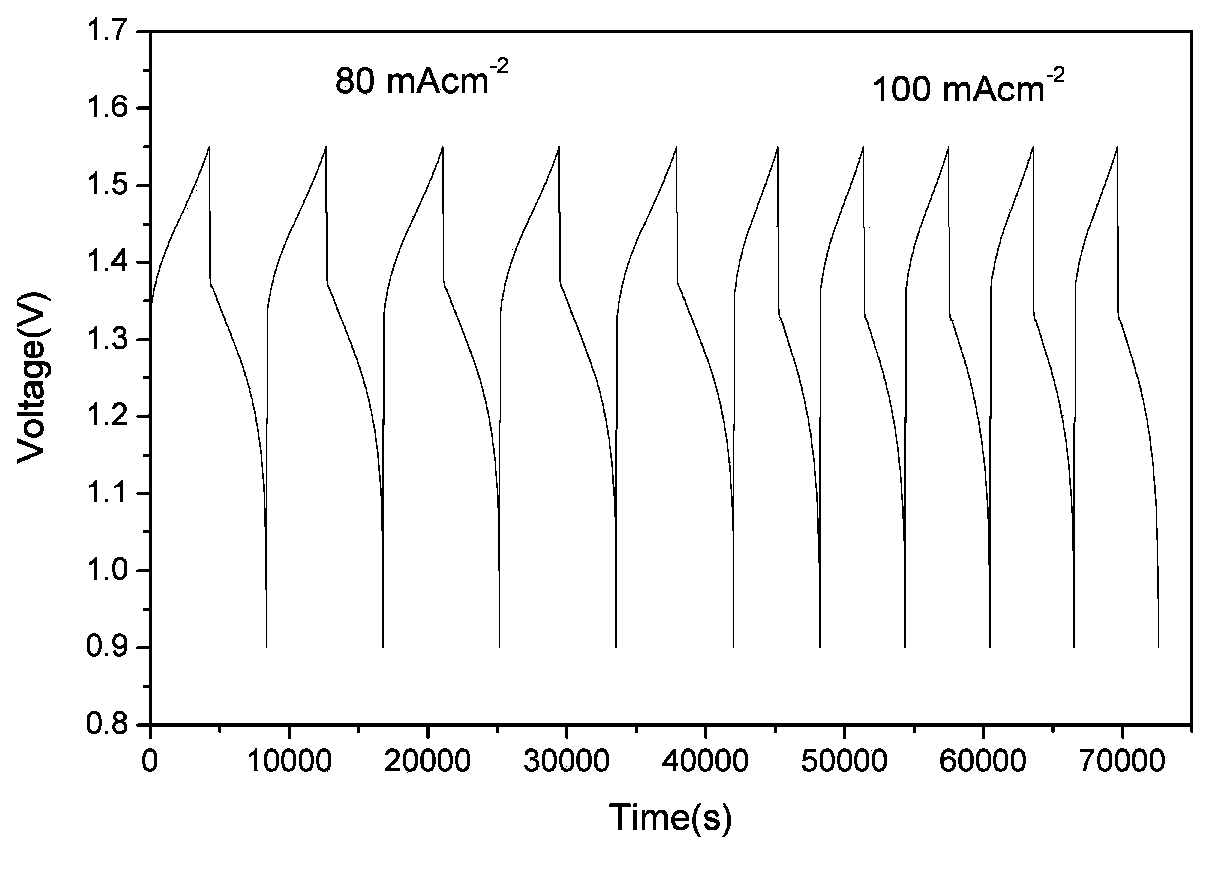

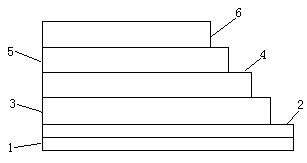

Bipolar plate for liquid flow energy storage battery and preparation method

ActiveCN103633336AEasy to buildReduce contact resistanceCell electrodesElectrical batteryInternal resistance

The invention relates to a bipolar plate for a liquid flow energy storage battery and a preparation method. The bipolar plate employs a carbon plastic composite plate with a thickness of 0.5-5mm as a matrix material. Conducting layers with a thickness of 1-1000 microns are coated on the surface of one side or surfaces of two sides of the matrix. The bipolar plate combines advantages of the carbon plastic composite plate and a graphite plate, decreases the contact resistance between an electrode and the bipolar plate, and finally decreases the Ohm internal resistance of the liquid flow energy storage battery. The bipolar plate raises the energy efficiency and the voltage efficiency of the liquid flow energy storage battery, and therefore the working current density is increased, thus weight, volume and cost of a battery with the same output power are all decreased.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Ultralight-weight proppant and preparation method thereof

The invention relates to an utralight-weight proppant and a preparation method thereof, belonging to the field of fracturing extraction of oil and gas wells. The preparation method of the utralight-weight proppant comprises the following steps: sintering 1-50 parts by weight of fly ash, 0.5-20 parts by weight of coal gangue, 20-50 parts by weight of clay and 10-30 parts by weight of bauxite whichare used as aggregate, and balling, thereby obtaining the utralight-weight haydite. The utralight-weight proppant provided by the invention utilizes industrial waste, and the production can be easilycontrolled; the sintering temperature is greatly lowered, ranging 1100-12500 DEG C; and the energy consumption is effectively lowered, and the energy can be saved by 20%. The percentage of damage of the utralight-weight proppant under 69 MPa is lower than 5%, the volume density is lower than 1.25g / cm<3>, and the apparent density is lower than 2.0g / cm<3>, so the utralight-weight proppant can completely substitute medium-density haydite.

Owner:BEIJING QISINTAL SCI & TECH

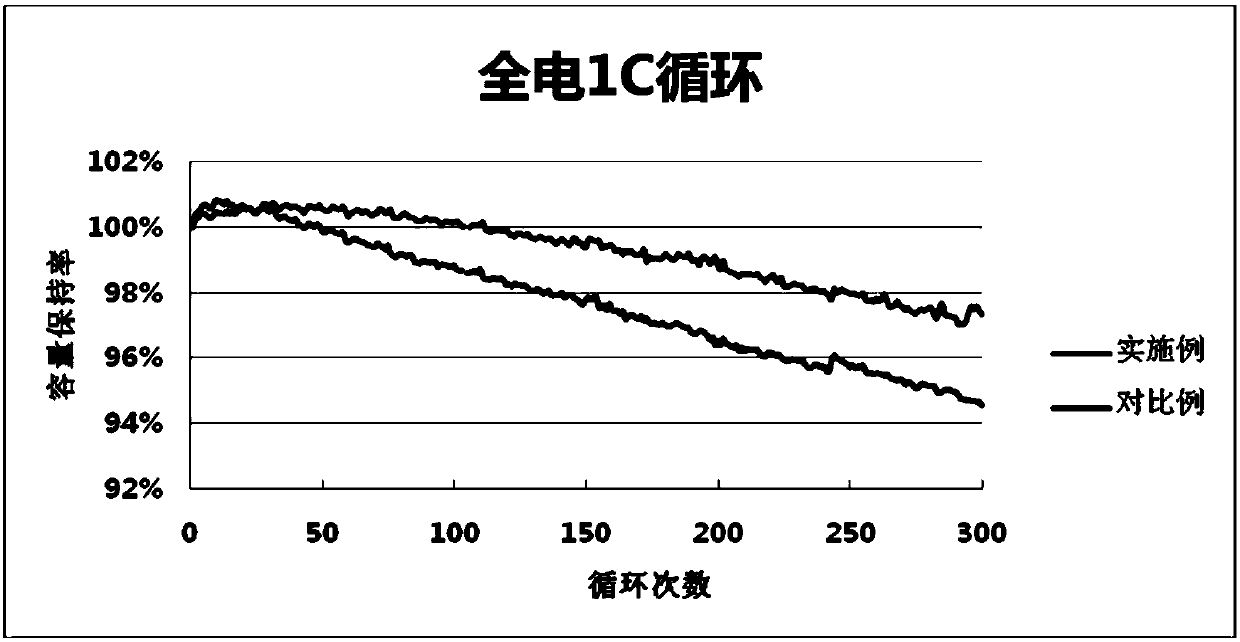

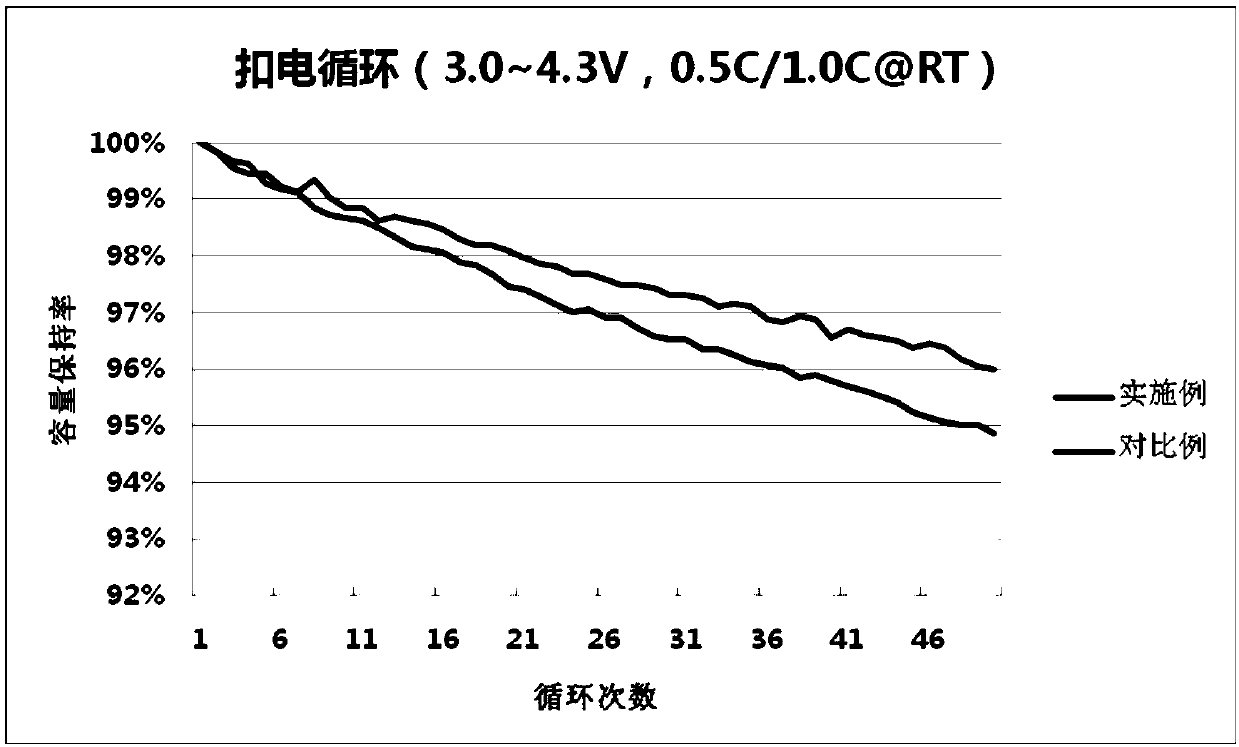

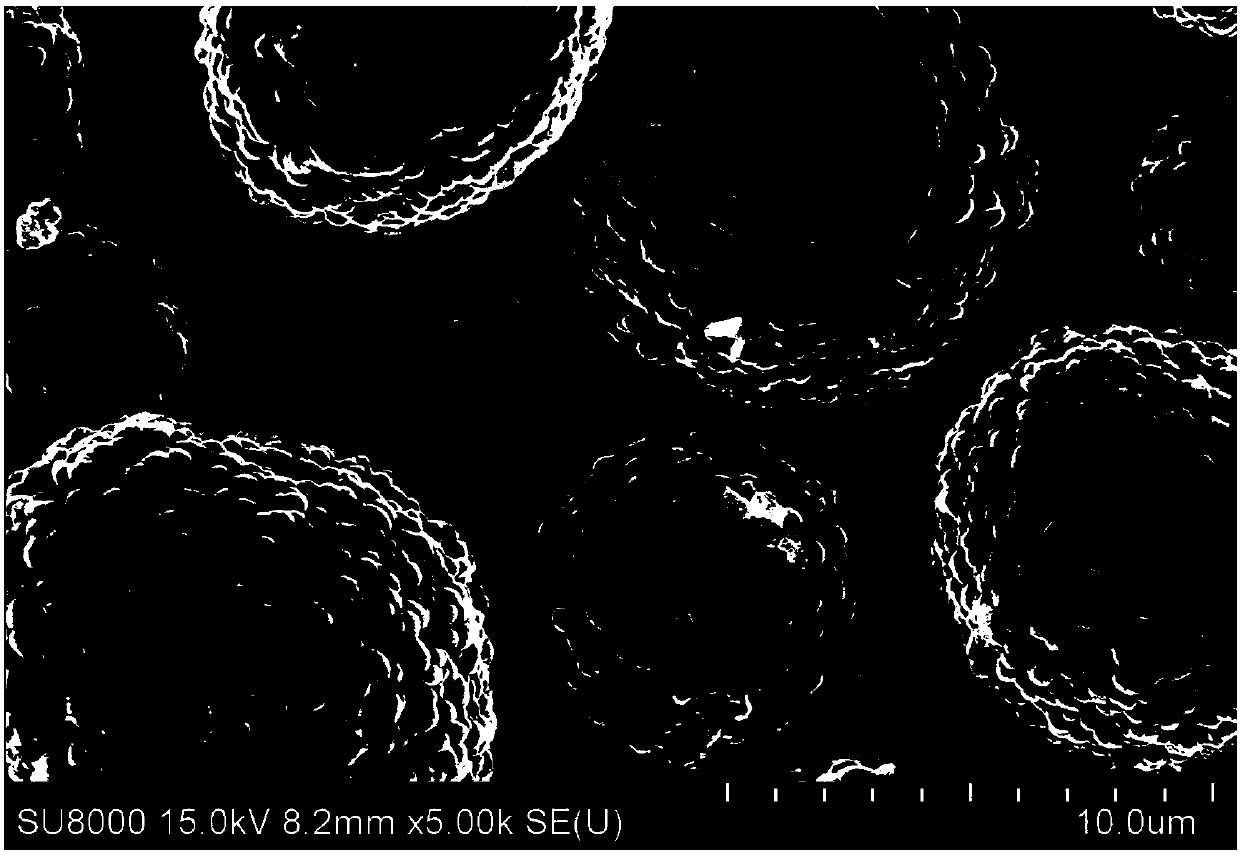

Modified high-nickel positive electrode material coated with fast ion conductor and preparation method of modified high-nickel positive electrode material

InactiveCN108023077AImprove cycle performanceImproved magnification performanceCell electrodesSecondary cellsElectrical conductorPhysical chemistry

The invention discloses a modified high-nickel positive electrode material coated with a fast ion conductor and a preparation method of the modified high-nickel positive electrode material. The high-nickel positive electrode material comprises a substrate, wherein the substrate is a compound LiNi<1-x-y>Co<x>Mn<y>M<z>O<2> shown in a formula I, in the formula I, x is more than 0 but less than or equal to 0.20, y is more than 0 but less than or equal to 0.20, z is more than 0 but less than or equal to 0.1, and M is arbitrary one or more of elements of Al, Mg, Ti, Zr, Mn, Ni, Sn, Co, Zn, W, Mo, Ru, Ca, Sr, Ba, B, Y, V and Nb. The preparation method comprises the following steps of washing and drying the high-nickel positive electrode material, uniformly mixing the high-nickel positive electrode material and an appropriate amount of coating agent, and performing sintering and sieving to obtain the modified high-nickel positive electrode material coated with the fast ion conductor. The fastion conductor is coated by washing and surface drying methods, the alkali amount of a surface of the positive electrode material is reduced, side reaction of the material and an electrolyte is reduced, and the high-temperature stability and the safety of the material are improved; and by doping and coating the surface with the fast ion conductor, the energy density, the rate performance and the cycle property of the material are improved, and the long cycle lifetime of a battery is finally prolonged.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

Aerogel core material capsule, paint prepared from same and preparation method of paint

InactiveCN105363396AAvoid destructionHigh surface area for strong adsorptionCoatingsMicroballoon preparationThermal insulationFilm-forming agent

The invention relates to an aerogel core material capsule, paint prepared from the same and a preparation method of the paint, in particular to the paint which is prepared by conducting encapsulation on aerogel particles through a suspension coating method and adding a film forming agent, reinforcement powder, function powder and an additive with the capsule, with aerogel particles as the core material, as the main thermal insulation component, and has the nanometer porous structure. Encapsulation is conducted on aerogel particles through the suspension coating method, it is avoided that water or other reagents permeate aerogel nano-pore particles to generate capillary force and damage porous structures, and therefore the paint of the complete nano-pore structure is prepared. The prepared paint has excellent thermal insulation performance and is easy to operate, low in production cost, green, environmentally friendly, safe, capable of being applied to thermal insulation and corrosion prevention of devices such as hearths, pipelines, valves and storage tanks in the fields of aviation and military, metallurgy forging, petroleum refining, electric power, ships and the like, and also capable of being used for heat preservation and thermal insulation in the field of construction.

Owner:浙江圣润纳米科技有限公司

Preparation method of rice noodles

ActiveCN103005299AControl the production processThe production process is easy to controlFood preparationRice flourAlpha-amylase

The invention discloses a preparation method of rice noodles. The preparation method comprises the steps of fermenting a raw material, resisting aging, grinding into pulp and steaming and further comprises the step of resisting aging secondarily after the steaming step, wherein the step of resisting aging secondarily comprises the substeps of contacting amylase with a rice slice obtained in the steaming step and putting aside the rice slice for 20-80 minutes at 30-80 DEG C; the amylase is alpha-amylase and / or beta-amylase; and the raw material is rice and / or unpolished rice. By the preparation method, the production process can be conveniently controlled, the rice noodles can be produced on a large scale, and the produced rice noodles are stable in quality and long in shelf life.

Owner:湖南金健米制食品有限公司

Radar aluminum plating transfer coating suitable for seamless molding process and preparation method thereof

InactiveCN101724325AEmission reductionSimple production processCoatingsCoatings without pigmentsCelluloseRadar

The invention relates to a radar aluminum plating transfer coating suitable for a seamless molding process and a preparation method thereof. The coating comprises the following components in percentage by weight: 0 to 4 percent of amino resin, 0 to 15 percent of cellulose ester resin, 3 to 28 percent of polyacrylate resin, 0 to 10 percent of nitro-cotton resin, 0 to 6 percent of vinyl acetate chlorate resin, 0 to 2.8 percent of additive, and 70 to 85 percent of solvent. The preparation method comprises the following steps of: adding the solvent and the resin components into a reaction kettle; stirring the mixture and then adding the additive into the mixture; and after adjusting the solid content and the viscosity, continuously stirring, cooling and filtering the mixture to obtain a product. Compared with the prior art, the radar aluminum plating transfer coating has the advantages of high production efficiency, low energy consumption, good process adaptability, good molding effect, easy elimination of seams, easy control of production, high smoothness degree, temperature resistance, good flexibility and the like.

Owner:SHANGHAI WEIKAI CHEM

Solid propping agent for oil-gas well fractrue

InactiveCN1508390ALess types of raw materialsSimple ingredientsFluid removalCeramic particleAluminium

The invention is about to improve the solid ceramic particle proppant of deep oil and gas well fracturing technique, the solid proppant composed of crude bauxitic clay fine powder and 6-10wt% manganese dioxide mineral fine powder. The manganese dioxide reacts with the bauxitic clay main material more completely under high temperature, largely reducing glass phase, and beneficial to raise the compactness of the resultant at the same time, able to largely heighten the guide-flow ability. The solid proppant: bulking density 1.65-1.8g / cu cm, apparent density 3.0-3.15g / cu cm, and breaking resistance (SY / T5108-1997) 86MPa not greater than 10%, the maximum able to reach 100MPa not greater than 10%.

Owner:宜兴东方石油支撑剂有限公司

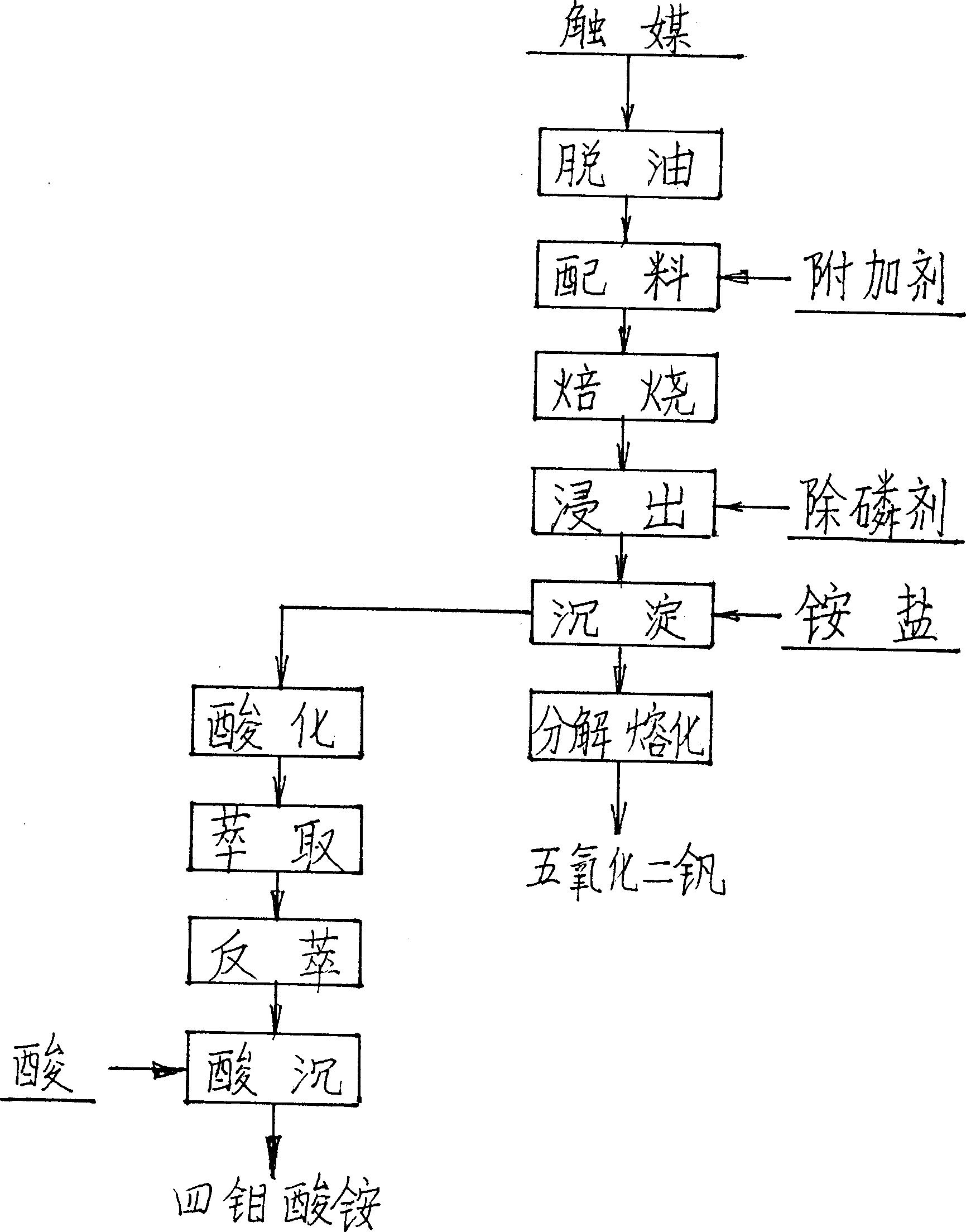

Wet process of extracting vanadium and/or molybdenum from waste catalyst

InactiveCN1453379ALess investmentReduce consumptionProcess efficiency improvementMagnesium saltAmmonium metavanadate

The present invention is wet process of extracting vanadium and / or molybdenum form waste petrochemical catalyst alumina carrier containing V, Mo and other elements. The wet process includes high-temperature deoiling the catalyst in natural granularity, mixing with sodium carbonate, high-temperature oxidation and roasting in a kiln or furnace to obtain water soluble sodium vanadate and sodium molybdate; countercurrent water soaking of the chamotte to obtain solution containing V and Mo in certain concentration, adding calcium salt and magnesium salt to eliminate P and other impurities, addingammonium salt solution into the clear solution to obtain ammonium metavanadate, decomposing and melting ammonium metavanadate to obtain V2O5 product; adding acid to the supernatant and organic phase extraction of Mo, ammonia water reverse extraction to obtain ammonium molybdate, and adding acid to precipitate ammonium tetramolybdate or molybdate product.

Owner:CITIC JINZHOU METAL

Polyvinyl chloride (PVC) wood-plastic foaming wood grain section and preparation method thereof

The invention discloses a polyvinyl chloride (PVC) wood-plastic foaming wood grain section and a preparation method thereof. The wood-plastic foaming wood grain section is prepared from the following raw materials: plastics, an organic filler, an aid, a modifier, a foaming agent, a wood grain masterbatch and the like. The preparation method comprises the following steps of: mixing a foaming mixed material and the wood grain masterbatch and co-extruding from an extruder in a conical twin screw extrusion production line according to a one-step process route; foaming and molding by using a foaming mold; and cooling and shaping by using a shaping mold to obtain the PVC wood-plastic foaming wood grain section. The PVC wood-plastic foaming wood grain section has the advantages of light weight, high specific strength, waterproofness, corrosion resistance and heat preservation, and has the processing characteristic that wood can be nailed, sawed and planed; in addition, the PVC wood-plastic foaming wood grain section has highly simulated solid wood appearance, natural and clear textures, and bright surface color, is an ideal wood-simulated wood-plastic product, and can be widely applied to building, transportation, packaging, home decoration and daily product markets.

Owner:北京欧尼克环保技术有限公司

Method of semi-vitreous extrusion molding manufacturing for portiforium type millipore plastics extrusions

InactiveCN101229682ASolve technical problemsSimplify the molding processPlastic materialsMelt extrusion

The invention relates to a method for preparing opening micropore plastic material though slack-melting, extruding and molding. The method includes the processes: after reaching from a feeding device arranged on a double piston extruder to a heating material cylinder, preheating plastic powder with particle size of 40-1500 meshes is extruded by the piston driven by a hydraulic driver and compacted, transported and heated constantly; when the surface temperature of the plastic powder reaches the melt temperature of Tf plus or minus 20 DGE C, the power is extruded from a machine head and a die. Then, extruding matters are cooled and set by a cooling-traction device and the products are finished. By regulating the particle size of the powder, addictive and forming process conditions and so on, the invention can control opening rate, size and distribution of the aperture; the invention has simple process, short production cycle, low forming temperature and pressure as well as short forming time; besides, the invention can greatly reduce the production cost can not be degraded easily when the plastic is processed and can be widely applicable to molding of the opening micropore products of thermoplastic powders, thermosetting power and so on.

Owner:SICHUAN UNIV

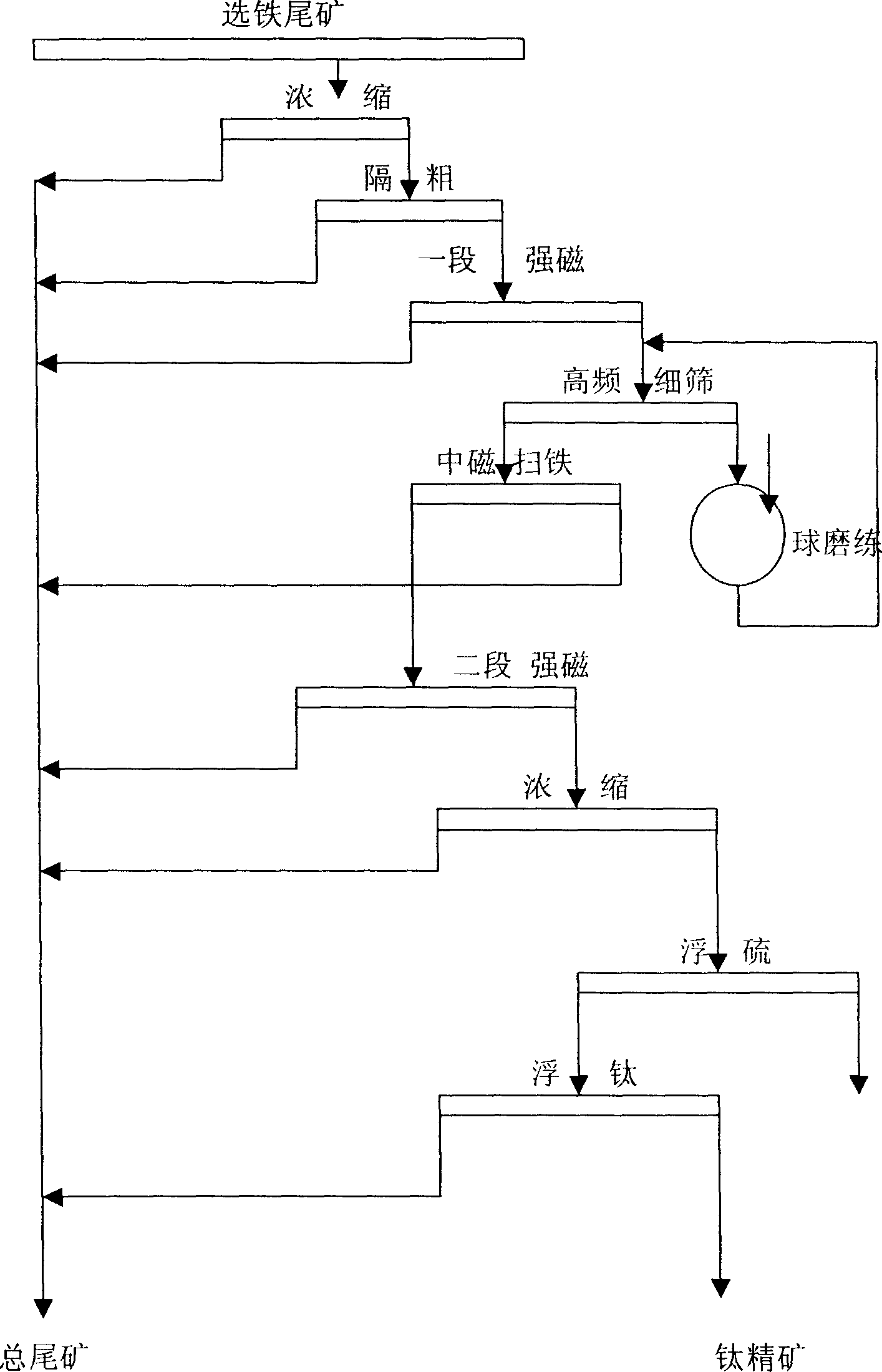

Floatation method of whole grade ilmenite

The invention discloses a titaniciron ore floatation method at full grades, which uses the tail mineral after the selection of V-Ti-bearing iron ore as raw material, and after a strong magnetic throwing at the magnetic field intensity of 1300 A to attain the ª‰TiO2 rubble titanium finished ore of 17-19%; then milling the rubble titanium ore in closed circuit, the acceptable product can via the weak magnetic iron selection enter the two-stage strong magnetic field in the magnetic field intensity of 750 A, to attain the ª‰TiO2 titanium finished ore of 22-24%; at last processes the reverse-floatation and desulfurization, the tail mineral can enter the floatation process at full grade, while the metal recovery rate can reach 34-36%. The invention has short process, lower cost, higher metal recovery rate, controllable production, and excellent economic benefits.

Owner:TAIHE IRON MINE CHONGQING IRON & STEEL GROUP MINING

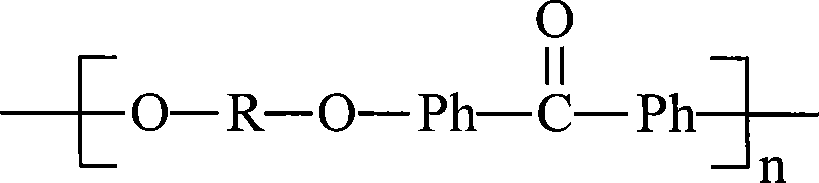

Preparation method for polyetheretherketone

The invention relates to a process for preparing polyetheretherketone products, which is characterized in that the process comprises adopting Na2CO3 to be condensating agent, leading 4, 4'- difluorobenzophenone, hydroquinone and diresorcinol to have polymerization reaction, improving the reaction temperature after producing the relative prepolymer, and secondly adding hydroquinone to be chain extender to react for a period of time to prepare polyetheretherketone products with high viscosity.

Owner:JILIN ZHONGYAN HIGH PERFORMANCE PLASTIC

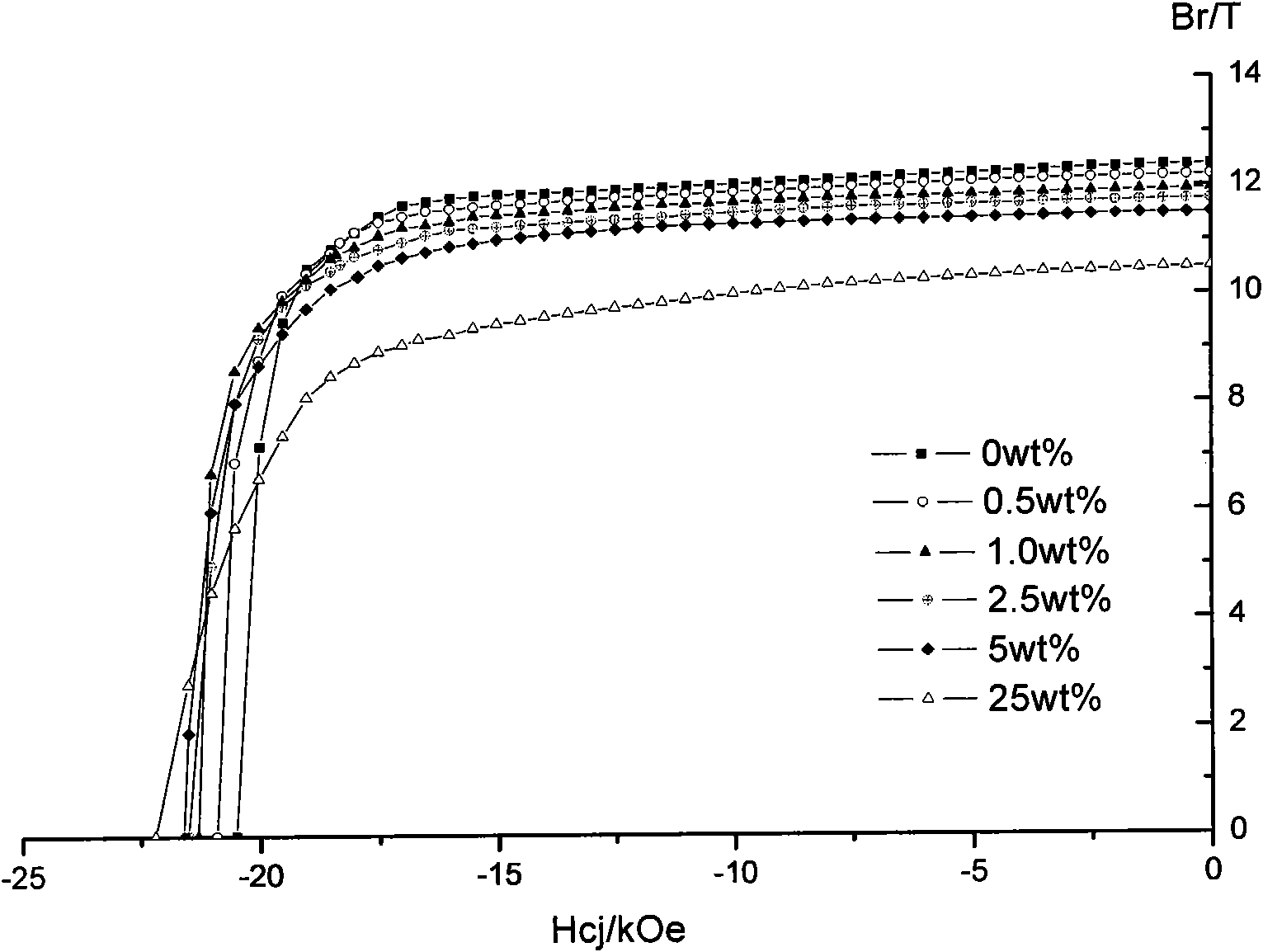

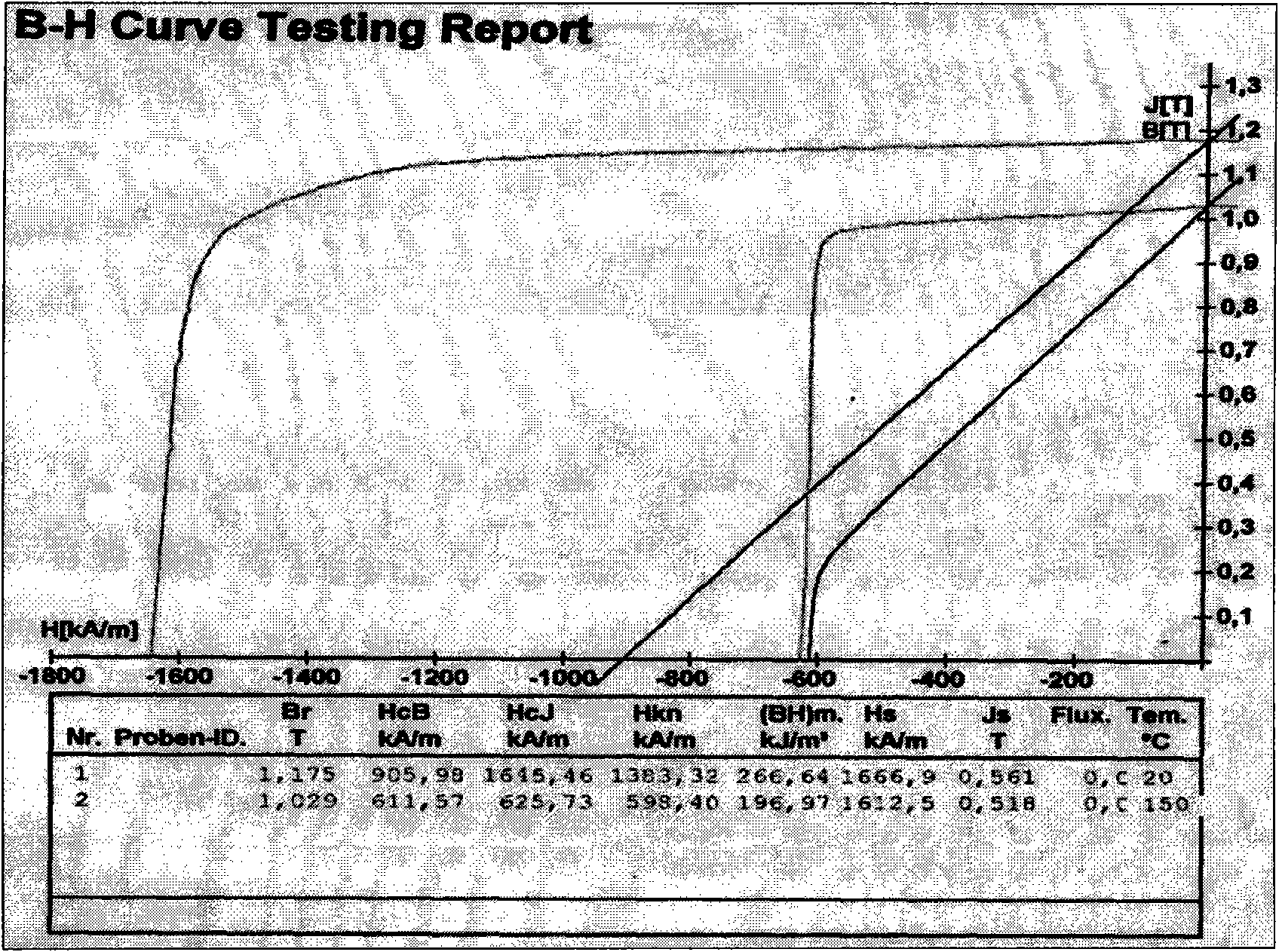

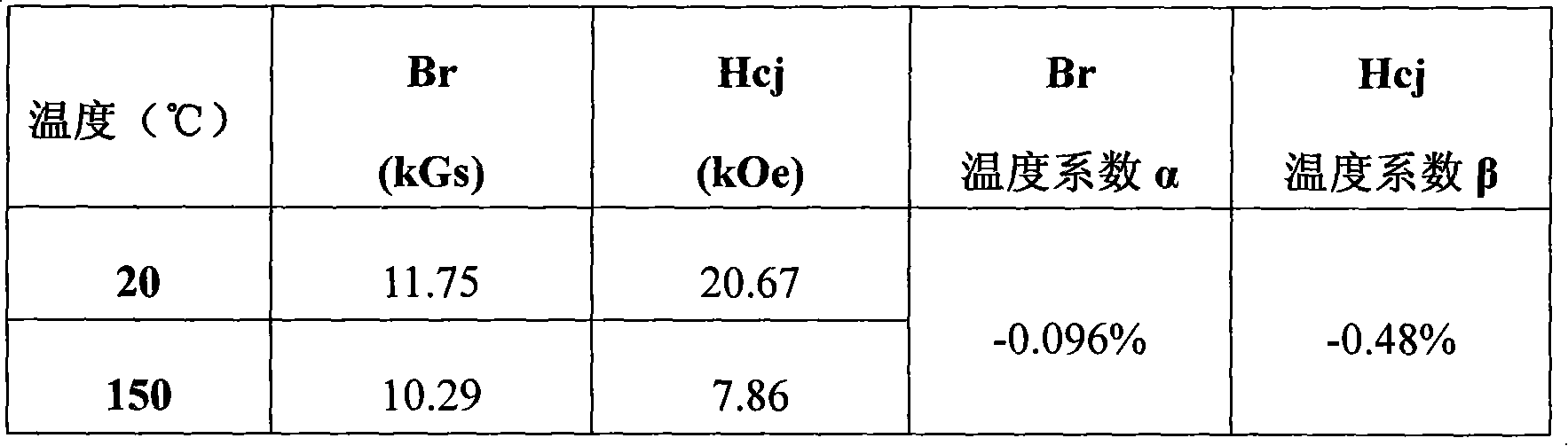

Gadolinium-containing sintered rare earth permanent magnet alloy and preparation method thereof

InactiveCN101630557AThe temperature coefficient of coercive force decreasesCoercive force temperature coefficient β decreasesMagnetic materialsGadoliniumRare earth

The invention relates to a gadolinium-containing sintered neodymium-iron-boron rare earth permanent magnet alloy and a preparation method thereof. The permanent magnet alloy comprises components in the following formula: Re[alpha]Gd[beta]B[gamma]MxNyFe[100-alpha-beta-gamma-x-y], wherein the weight percentage beta of the gadolinium element is more than 0.50 and less than or equal to 25. Through the method for adding the Gd element into a sintered Nd-Fe-B magnet, a sintered Nd-Fe-B permanent magnet with high coercive force and high temperature resistance is prepared. The coercive force temperature coefficient beta of the prepared magnet is reduced, so the coercive force of the magnet at high temperature is improved and the magnet has the high temperature resistance.

Owner:NINGBO KONIT IND +1

600MPa grade high-strength weathering steel and preparation method thereof

InactiveCN101225498ASimple chemical compositionThe production process is easy to controlMetal rolling arrangementsChemical compositionThin slab

The invention discloses a 600MPa high strength weathering steel and the manufacturing method, which is characterized in that: the 600MPa high strength weathering steel adopts electric stove-thin slab continuous casting and rolling process for preparation; the main chemical components of the refined molten steel for preparing the high strength weathering steel are: C: 0.045 wt % to 0.07wt%, Si: 0.10 wt % to 0.29wt%, Mn: 0.8 wt % to 1.5wt%, P: 0.005 wt% to 0.030wt%, S: 0.002 wt% to 0.008 wt%, Cu: 0.20 wt% to 0.5wt%, Cr: 0.3 wt% to 0.7wt%,Ni: 0.15 wt % to 0.35wt%, Ti: 0.06 wt% to 0.079wt%, Nb: 0.035 wt% to 0.050wt%, Alt: 0.025 wt% to 0.050wt%. The 600MPa high strength weathering steel has the advantages of low cost, strong competitiveness, cold formability, good welding performance and application to tower frame, heavy duty automobile, bridge, container, railway vehicle manufacture.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Method for preparing beta-carotin from Blakeslea trispora fermentation broth

The invention relates to a method for preparing beta-carotin from Blakeslea trispora fermentation broth, which comprises the following steps of: filtering Blakeslea trispora fermentation broth to obtain wet mycelia; vacuum-drying the wet mycelia to obtain dry mycelia of which the water content is less than 10%; milling and pulverizing the dry mycelia; screening, leaching the dry mycelia with dichloromethane which is 15-20 times of the dry mycelia by mass, evaporating to concentrate the leaching liquor until the concentration of beta-carotin is not lower than 50000 mu g / ml, keeping the temperature, and filtering to obtain the wet crude product of beta-carotin crystals; and dissolving the wet crude product with dichloromethane, filtering, evaporating to concentrate until the concentration of the beta-carotin is not lower than 50000 mu g / ml, keeping the temperature, filtering, and vacuum-drying to obtain the beta-carotin crystals. The method has the advantages of short technical process,less operation steps, easy control on production process, high product content, low cost, high yield, only one solvent used in the overall process and suitability for industrial production.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

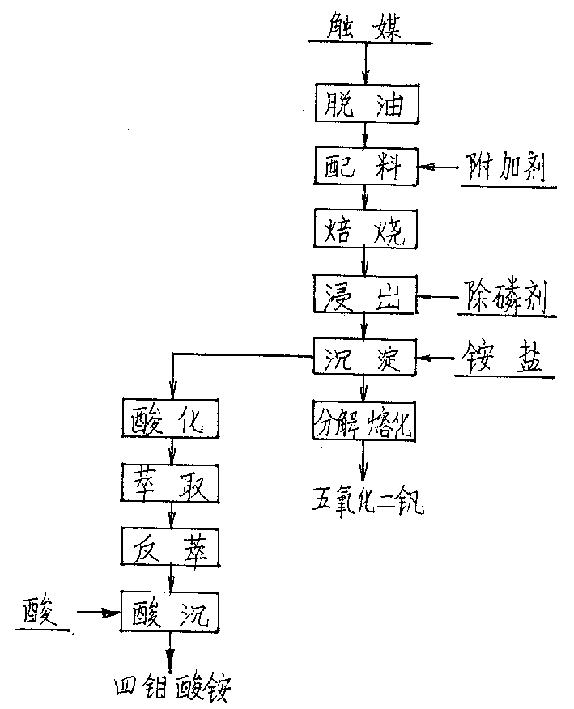

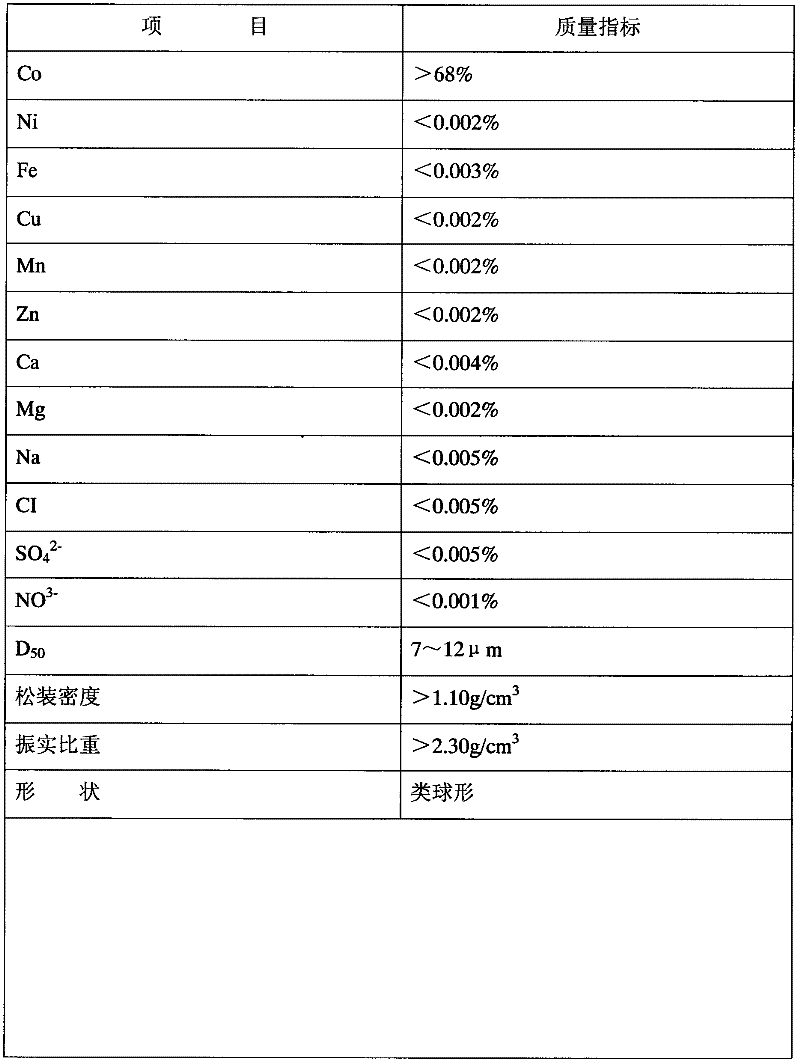

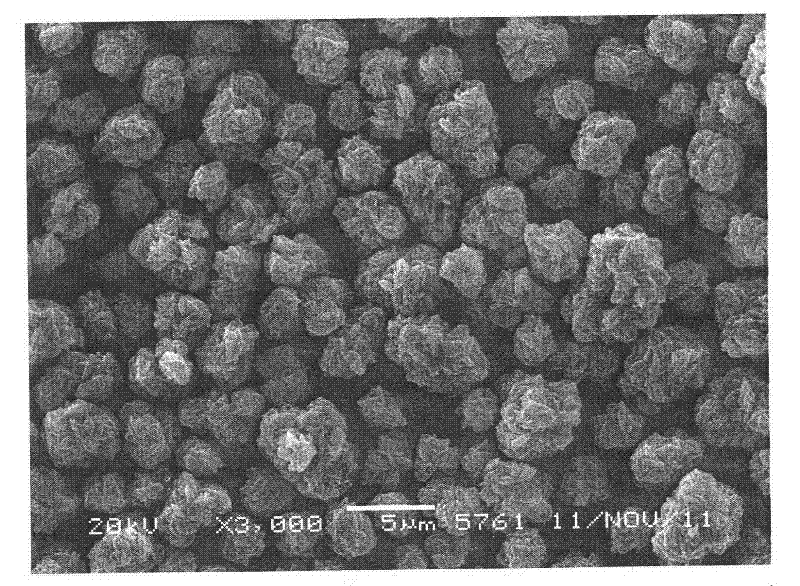

Method for producing hydroxy cobalt oxide

InactiveCN102689933AThe production process is easy to controlImprove product qualityCobalt oxides/hydroxidesEthylene diamineReaction temperature

The invention discloses a method for producing hydroxy cobalt oxide, comprising the following steps of: firstly, preparing a cobaltous sulfate solution with cobalt content of 75-85g / l; adjusting a pH value of the solution to be 3.0-4.5; adding EDTA (Ethylene Diamine Tetraacetic Acid) into the solution according to the proportion of cobalt to EDTA of 100:(1-3); preparing sodium hydroxide solution with alkali concentration of 7-9mol; performing cocurrent flow on two solutions and flowing into a reaction groove; introducing the air for performing synthetic reaction; controlling the reaction temperature to be between 50 and 70 and a pH value to be between 10.0 and 12.0 for reacting for 15-25 hours; flowing into an aging groove for aging for 50-60 minutes; and finally, filtering, washing and slurrying to prepare a hydroxy cobalt oxide solid product. According to the method, the production process is controllable, particles of the product are uniformly distributed with good consistency, the shape is spherical and the product has good dispersibility; and the production process is free of ammonia nitrogen pollution, so that continuous production is realized, and the equipment utilization rate and the production efficiency are improved.

Owner:湖南红太阳电源新材料股份有限公司

Nano-zinc oxide/acrylic ester grafting composite emulsion and preparation thereof

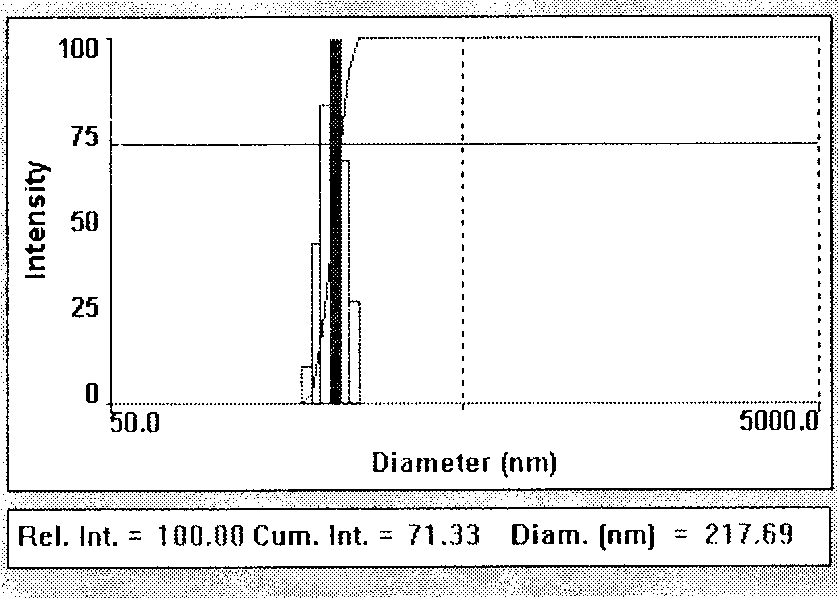

InactiveCN101372527AUniform particle sizeImprove coating efficiency and grafting rateNano zinc oxideNanometre

The invention relates to the manufacturing field of nano composite emulsion materials, in particular to graft nano zinc oxide / polyacrylate composite emulsion and a manufacturing method thereof. Firstly an initiator azobisisovaleric acid is anchored on the surface of nano zinc oxide particles, two portions of hexadecane are added to 100 portions of mixed monomers, and 5 portions of nano ZnO particles anchoring the azo initiator are added and ultrasonically oscillated for 20 minutes to form an oil phase pre-dispersion solution. The pre-dispersion solution is added to an emulsifier aqueous solution and dispersed by a high-shear dispersion homogenizer at high speed for 30 minutes to form a mini-emulsion. The mini-emulsion is transferred to a reactor, heated to the temperature of 75 DEG C, with polyreaction initiated for 3 hours, and then heated to the temperature of 85 DEG C, polymerized for 2 hours, cooled to room temperature and discharged. The invention solves the problems of high cost and poor stability of the nano composite emulsion prepared by coupling agents, and low encapsulation efficiency and graft ratio of nano polymer composite particles. The composite emulsion has the advantages of simple preparation process, low cost, even particle size, good performance, high encapsulation efficiency and graft ratio of the nano-particles, forms nano monodisperse state in the polymer, and is suitable for the fields of coating materials, leather finishing materials, adhesives and functional plastics.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

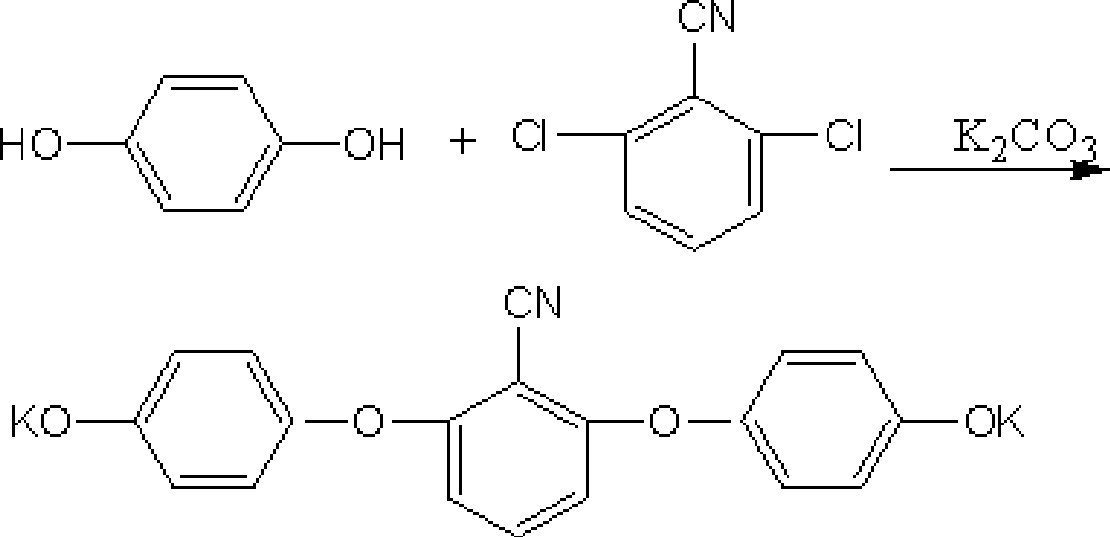

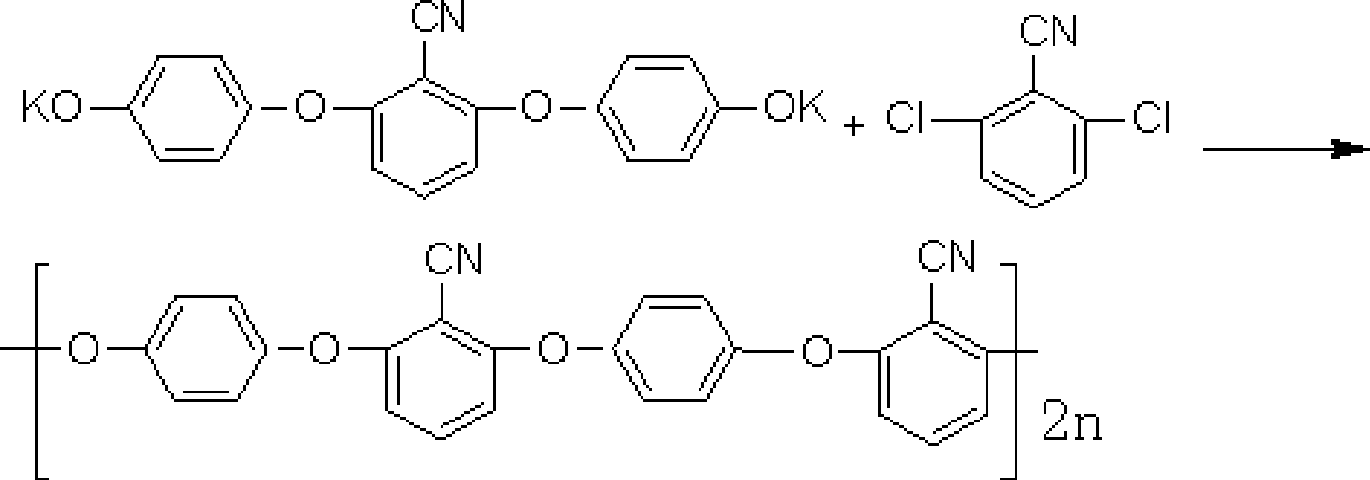

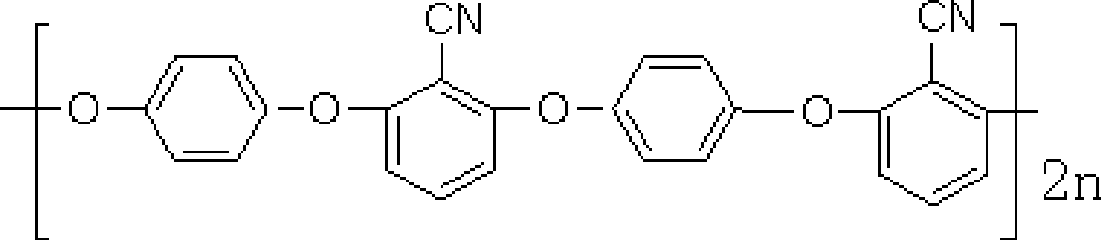

Polyarylether carbonitrile industrial production method

The industrial process of polyarylethernitrile, this invention relates to the Synthesis of polyarylethernitrile. Adding 2, 6-dichlorocyanobenzene, polyhydric phenol, anhydrous potassium carbonate, solvent NMPA, toluene in autoclave, heating-up the autoclave to 100-200 deg C in the condition of 2. 0-2. 5MPa in autoclave, heating-up the autoclave to 150-300deg C after 2-6h heat preservation, taking out the fixed object of autoclave after 1-6h heat preservation, getting the polyarylethernitrile after washing by boiling-water, desiccation and granulation. The production condition of this invention is easy to realize, the industrial process is easy to control, and the produced polyarylethernitrile is low in cost and suit to use of multirealm.

Owner:YANGZHOU TIANCHEN FINE CHEM

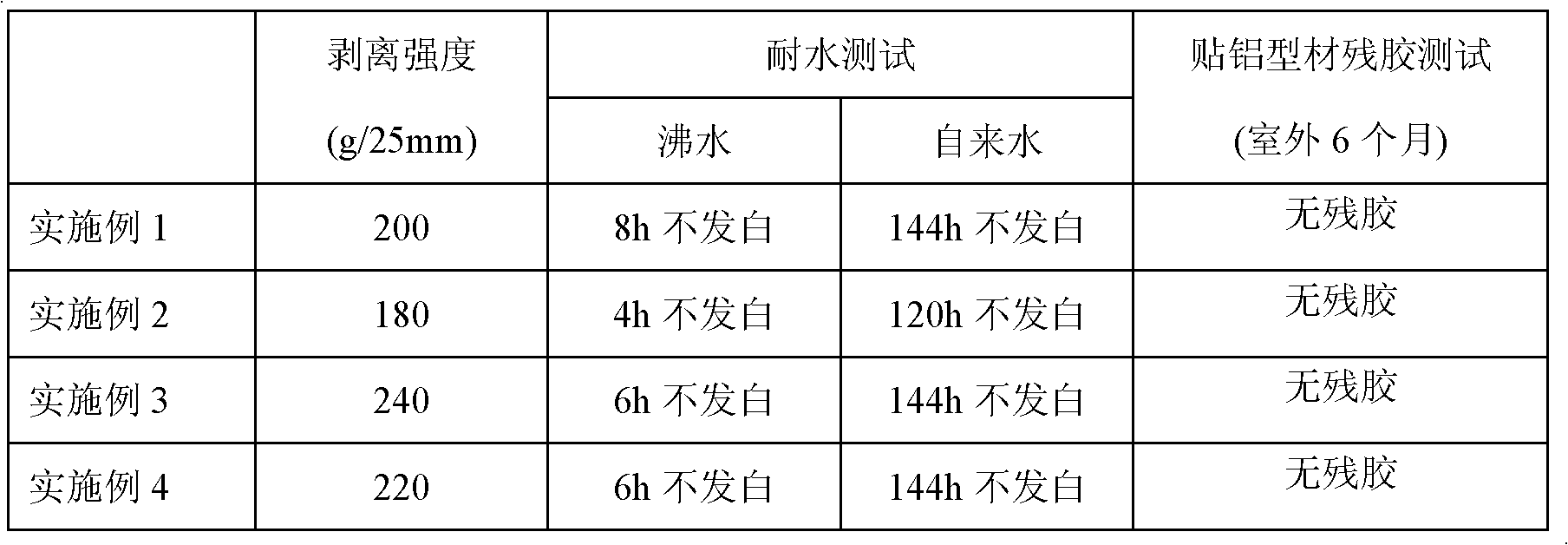

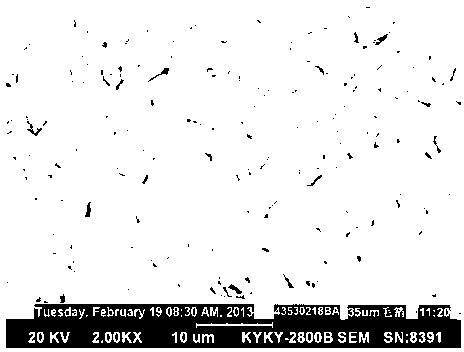

Water-blush-resistant fluoride and siloxane modified waterborne pressure-sensitive adhesive and polyethylene protective film

ActiveCN102504733APromote migrationImprove water resistanceFilm/foil adhesivesEster polymer adhesivesEmulsion polymerizationFluoride

The invention discloses a preparation method of a water-blush-resistant fluoride and siloxane modified waterborne pressure-sensitive adhesive for a polyethylene protective film, and the method is used for synthesizing a cross-linking type water-blush-resistant fluoride and siloxane modified waterborne pressure sensitive adhesive with less emulsifier dosage and excellent performance by introducing an organic siloxane monomer and a fluoride-containing vinyl monomer to perform copolymerization modification in a polymerizing process, compounding by utilizing an emulsifier, and adopting a seed emulsion polymerization method. The invention also provides a preparation method of the polyethylene protective film, and the prepared protective film is excellent in water blush resistance, and guarantees that the surface of a protected material does not have residual adhesive of the torn film and is not polluted after the protective film is used outdoors for a long time according to the requirement.

Owner:无锡达美新材料有限公司

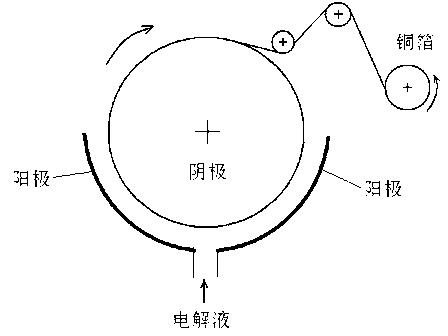

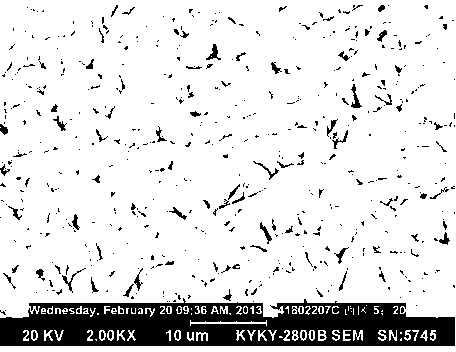

Mixed additive for removing internal stress of electrolytic copper foil and method for producing low-stress copper foil

ActiveCN103173812AThe production process is easy to controlProduct quality is stableCopper foilHydroxyethyl cellulose

The invention relates to a mixed additive for removing internal stress of an electrolytic copper foil and a method for producing a low-stress copper foil and belongs to the technical field of production of a high-precision electrolytic copper foil. The mixed additive for removing internal stress of the electrolytic copper foil comprises gelatin, hydroxyethyl cellulose and liquid additive. The method for producing the low-stress copper foil by using the mixed additive comprises the steps of preparing high-purity cathode copper and sulfuric acid into mixed solution of sulfuric acid and copper sulfate at 60-95 DEG C under the condition of stirring in the presence of air, wherein Cu<2+> is 85-100g / L and H2SO4 is 100-120g / L; adjusting the temperature of electrolyte to 45-60 DEG C and the flow to 50-70m<3> / h; adding 20-50mg / L of Cl<->, adding the mixed additive, with a drum titanium tube which continuously rotates as a cathode and arc titanium as an anode, carrying out copper electrolytic deposition and lastingly stripping to obtain 12-70 microns copper foil under the condition of the direct current of which the current density is 55-70A / dm<2>. The thickness of the copper foil is controlled by adjusting the rotation speed of the cathode; and the obtained copper foil has excellent performances.

Owner:SHANDONG JINBAO ELECTRONICS

Method for producing nickel-cobalt metal powder

The invention discloses a preparation method for nickel cobalt metal powders, which belongs to the technical field for preparation of non-ferrous metal metallurgy, powder metallurgy and material preparation. The preparation method is characterized in that nanometer or ultrafine nickel and cobalt metal powders is adopted as a seed crystal, which is mixed with ammoniacal water solution with nickel sulfate, cobalt sulfate, ammonia and ammonium sulfate, the preparation method adopts a hydrometallurgical hydrothermal hydrogen reducing technology and a device thereof, and the nanometer, ultrafine or tenuous nickel powder, cobalt powder and nickel cobalt alloy powder are prepared through the procedures such as ingredient, high-pressure hydrothermal hydrogen reduction, filtration, washing, drying and the like. The preparation method can be used for the field such as hydrogen storage alloy, galvanization, catalyst, sintering activating agent, magnetic materials, electric conduction slurry, battery materials, wave-absorbing materials, hard alloy, multi-layer porcelain capacitor, powder metallurgy and the like. The preparation method has the advantages of simple raw materials, simple process, short technological process, low manufacturing cost, controllable manufacturing process, high production efficiency, even graininess of metal powders, controllable size and composition and good quality of products.

Owner:张建玲

Hydrochloric acid-extraction method for preparing rutile titanium white

The invention discloses a hydrochloric extraction method to prepare rutile-type titan white, which comprises: decomposing the ilmenite with hydrochloric acid and iron powder to reduce high-valence ferrum; separating titanium tetrachloride with solvent extraction to form water liquid with given concentration; adding macromolecular organics for thermal hydrolyzation; filtering, bleaching, and obtaining high-pure fine grain of metatitanic acid; treating with salt, microwave drying, calcining at 900Deg, screening, and obtaining the product. This method needs low energy consumption, and fits to low or rich grade material.

Owner:陈泽安

Multifunctional bio-charcoal and preparation method thereof

The invention relates to a multifunctional bio-charcoal and a preparation method thereof. According to the technical scheme, the preparation method comprises the steps of dipping biomass into 1-15wt% caustic alkali solution for 1-50h, washing with water to be neutral, and drying to obtain treated biomass; then charring the treated biomass in a tube furnace in mixed gas at 300-900 DEG for 1-130h to obtain the multifunctional bio-charcoal. The biomass is one of rice straw, wheat straw, sawdust, wood, green grass, fruit peel and animal tissue waste; the biomass contains 30-60wt% of volatile organic carbon of charcoal, 10-40wt% of fixed carbon, 1-30wt% of ash and 10-60wt% of water. The preparation method disclosed by the invention has the characteristics of low production cost, high yield, simple process, controllable production process and environment friendliness, and the prepared multifunctional bio-charcoal has a good adsorption effect on heavy metals and high stability and can be used for repairing water bodies, solid matrixes and soil which are polluted by heavy metals.

Owner:WUHAN UNIV OF SCI & TECH

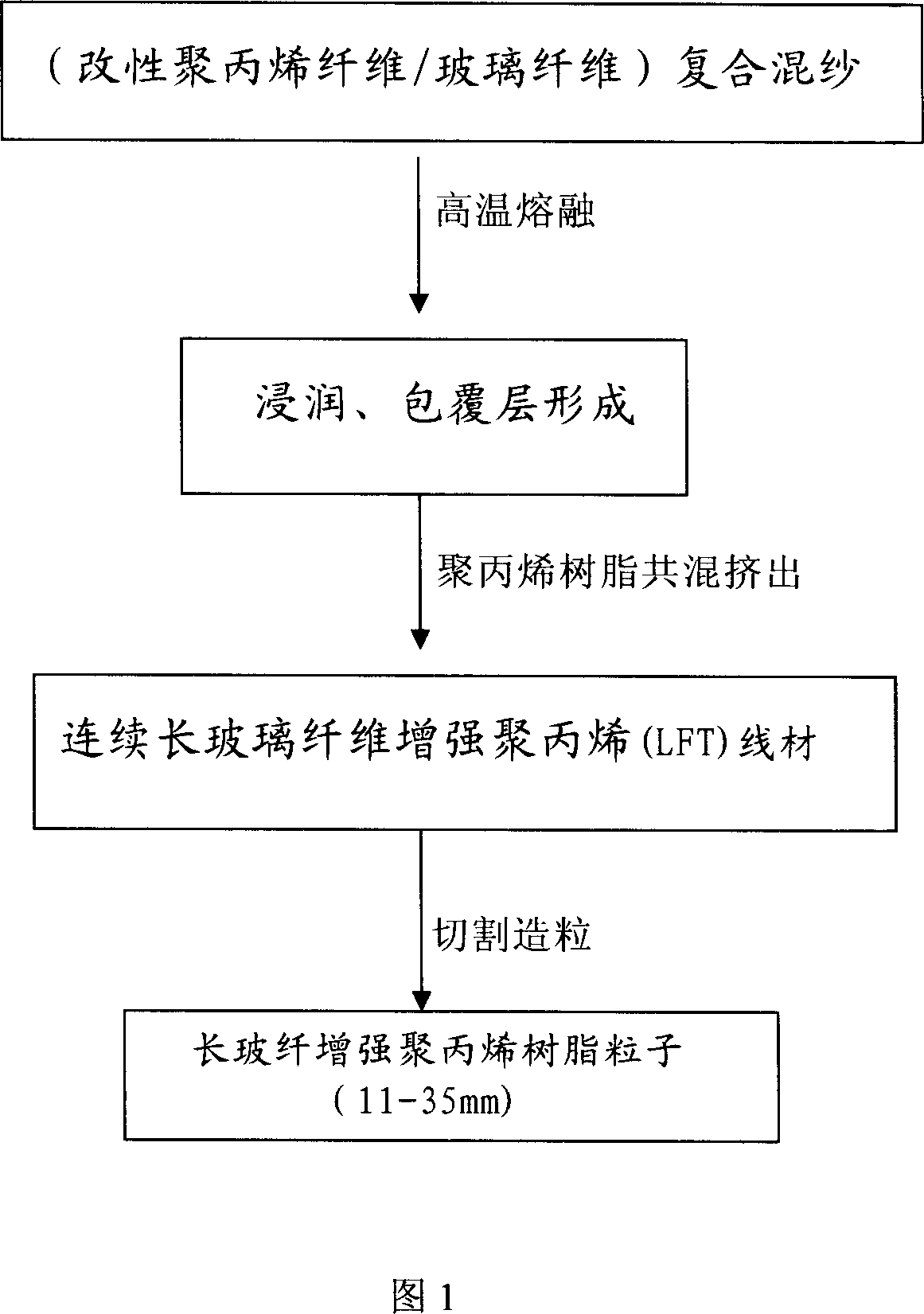

Continuous long glass fiber reinforced profax resin granular material preparation method

The invention discloses a preparing method of fiber reinforced polypropylene resin particle of continuous long-glass (LGFPP), which comprises the following steps: blending 20-80% composite yarn with glass fiber, 5-60% thermoplastic polypropylene resin and 1-15% adjuvant; heating; fusing; squeezing; graining; setting the weight rate of modified polypropylene fiber and glass fiber at 1:99-50:50 as the component of composite yarn.

Owner:TAIAN SAIGANG COMPOSITE MATERIAL

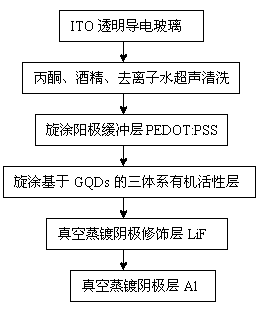

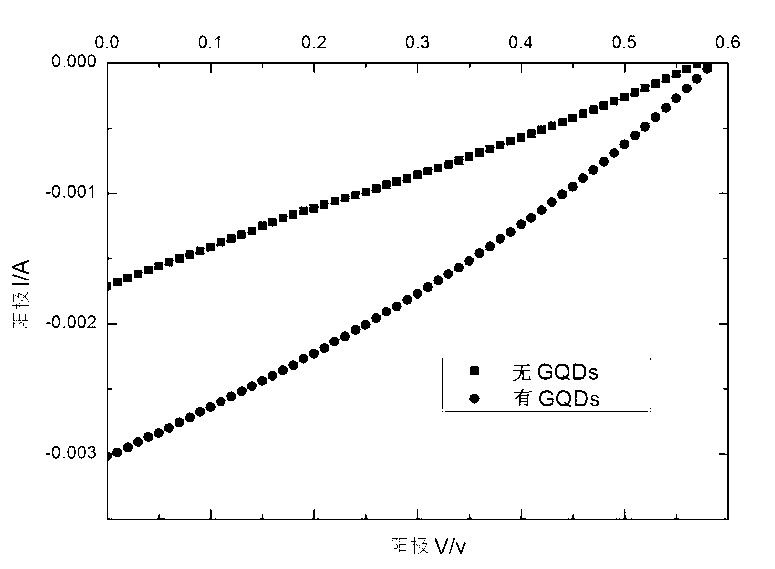

Three-system organic photovoltaic device based on graphene quantum dots and preparation method of three-system organic photovoltaic device

InactiveCN103022357AIncrease short circuit currentHigh dissociation efficiencyFinal product manufactureSolid-state devicesChlorobenzeneEvaporation

The invention relates a three-system organic photovoltaic device based on graphene quantum dots and a preparation method of the three-system organic photovoltaic device. According to the preparation method, the design limitation of an original binary organic photovoltaic device is broken through, and a spin coating technique and a thermal evaporation film plating technique are adopted on transparent conductive glass to reach the purpose of enhancing the device energy conversion efficiency. The three-system organic photovoltaic device uses a three-system coexistence system including an organic donor and an organic acceptor as well as the graphene quantum dots as an organic active layer, the donor and the acceptor are dissolved in chlorobenzene containing the graphene quantum dots in a certain proportion, and a three-system coexistence structure active layer is prepared only by only requiring the spin coating, so that the cost is low, the operation is simple and the conversion efficiency of the organic photovoltaic device is effectively improved.

Owner:FUZHOU UNIV

Industrial production method of semi-crystalline poly aryl ether nitrile

The invention relates to an industrial production method for semi-crystal poly(aromatic ether nitrile), which belongs to the field of polymer material. The method comprises the following steps: 2, 6-dichloro benzonitrile and hydroquinone are taken as raw materials; anhydrous potassium carbonate is taken as a catalyst; in the presence of a solvent and a dehydrating agent, the raw materials and the catalyst react under atmospheric pressure to obtain the poly(aromatic ether nitrile) homopolymer with low molecular weight and regular chain segments; and then the molecular weight of polymer is increased through pressurization, so as to obtain the semi-crystal poly(aromatic ether nitrile) polymer with high molecular weight. Due to the increase of crystallinity and molecular weight, the mechanical properties and heat resistance of the semi-crystal poly(aromatic ether nitrile) polymer are obviously improved.

Owner:SICHUAN FEIYA NEW MATERIAL

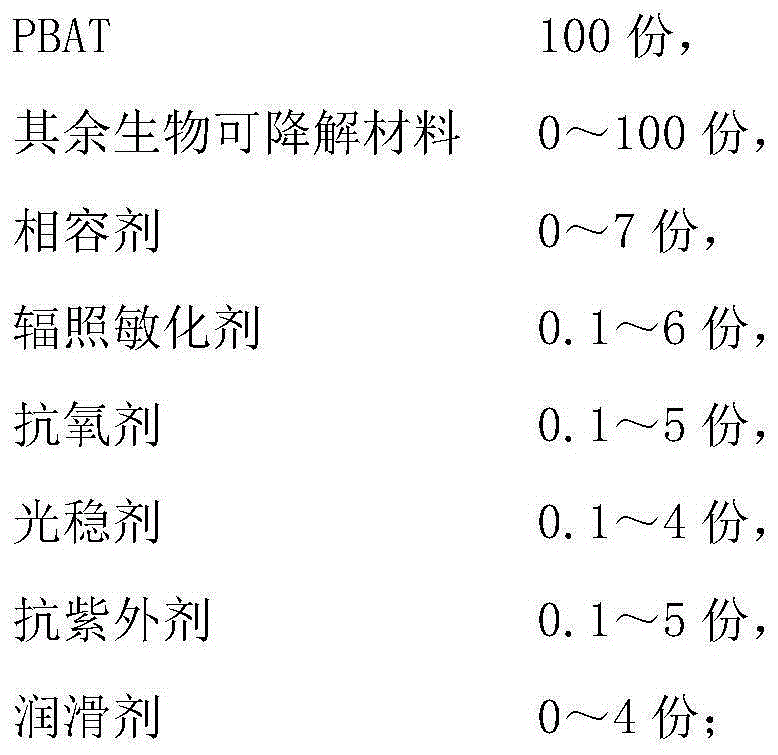

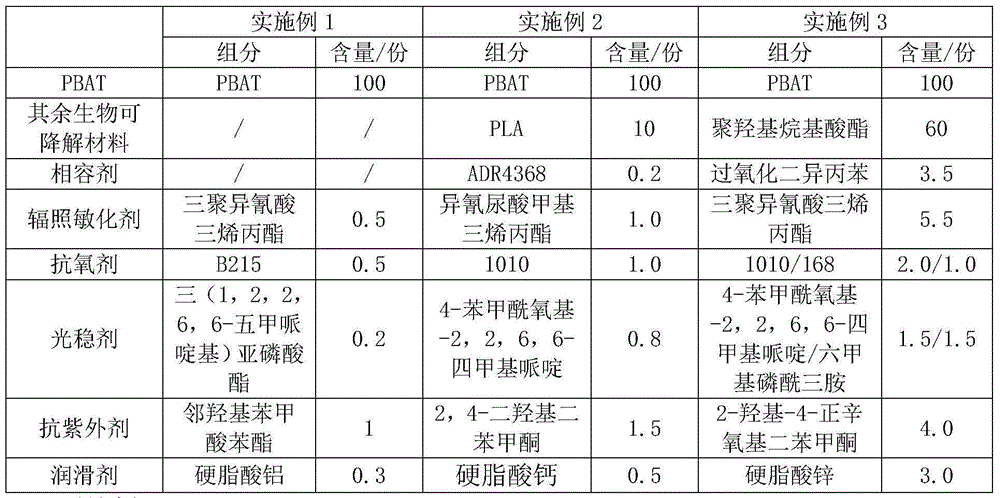

PBAT composite film based on irradiation modification and preparation method thereof

The invention discloses a PBAT composite film based on irradiation modification and a preparation method thereof. The composite film comprises, by weight, 100 parts of PBAT, 10-100 parts of remaining biodegradable materials, 0.1-7 parts of compatilizer, 0.1-6 parts of irradiation sensitizer, 0.1-5 parts of antioxidant, 0.1-4 parts of light stabilizer, 0.1-5 parts of anti-ultraviolet agents and 0-4 parts of lubricant. Compared with the prior art, by means of the PBAT composite film based on the irradiation modification, the biodegradability of the material is maintained, the excellent mechanical strength, barrier performance, aging resistance and the like are achieved, and the application of the biodegradable film is expanded.

Owner:SHANGHAI HONGRUI CHEM PROD CO LTD

Lactobacillus plantarum and application thereof in rice wine brewing

ActiveCN103421723AWill not harmCompliance with safety regulationsBacteriaMicroorganism based processesMicroorganismReady to use

The invention discloses Lactobacillus plantarum and application of the Lactobacillus plantarum in rice wine brewing and belongs to the field of food biotechnology. The bacterial strain is named Lactobacillus plantarum. The bacterial strain is obtained from rice milk in a screened mode, the bacterial strain is preserved in the China general microbiological culture collection center in September 3, 2013, and the preservation number is CGMCC No.8097. The Lactobacillus plantarum and a ready-to-use starter of the Lactobacillus plantarum can be used for rice wine brewing, so that the production process is controllable and slightly affected by seasons, operation is simple and convenient, and the Lactobacillus plantarum has important significance in the innovation of the rice wine brewing technology.

Owner:JIANGNAN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com