Patents

Literature

501 results about "Weathering steel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weathering steel, often referred to by the genericized trademark COR-TEN steel and sometimes written without the hyphen as corten steel, is a group of steel alloys which were developed to eliminate the need for painting, and form a stable rust-like appearance after several years' exposure to weather.

Method for improving performance of 700MPa grade V-N micro-alloying high-strength weathering steel

InactiveCN101161849AImprove low temperature impact toughnessGood formabilityTemperature control deviceMetal rolling arrangementsChemical compositionHigh intensity

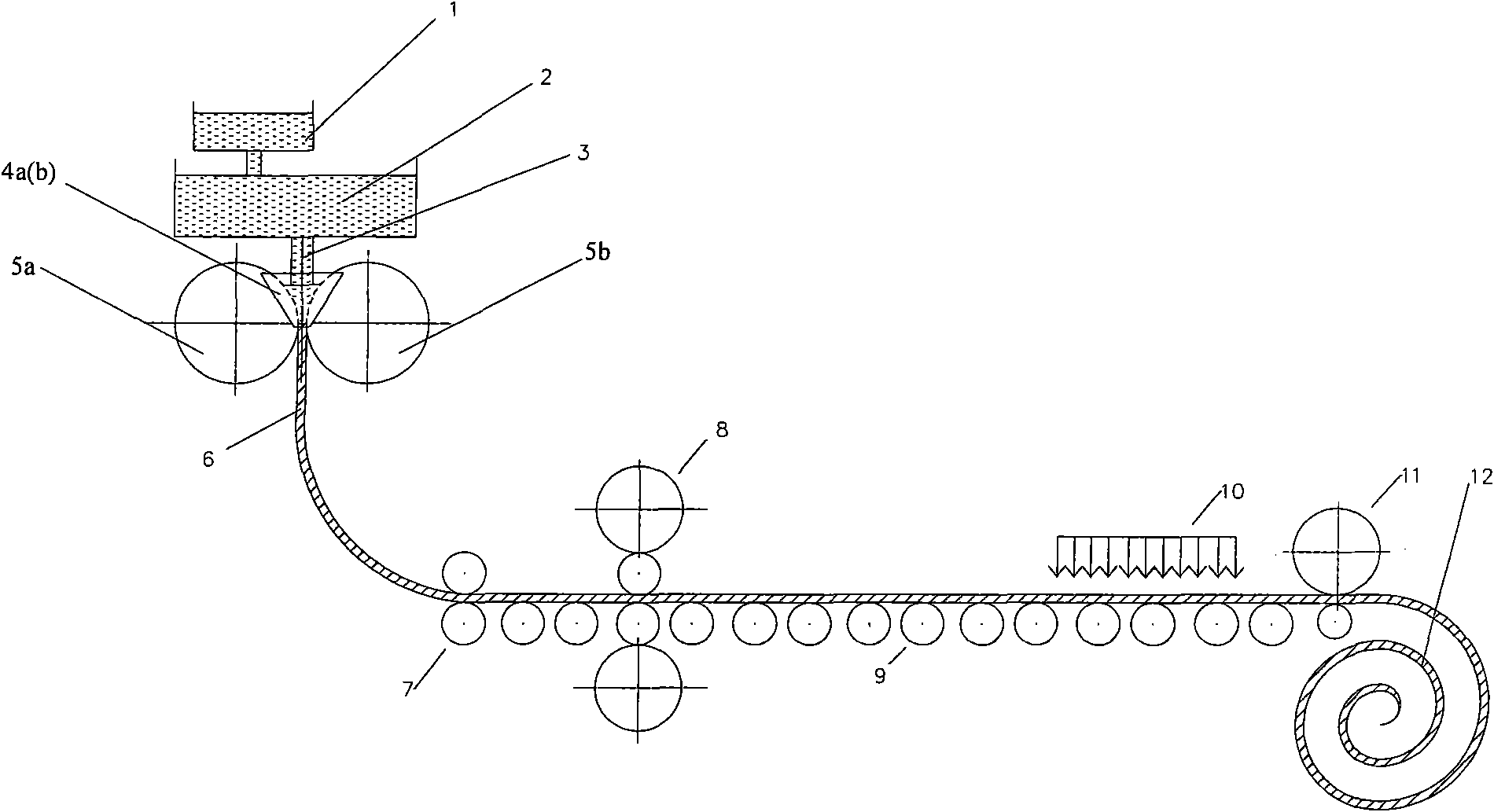

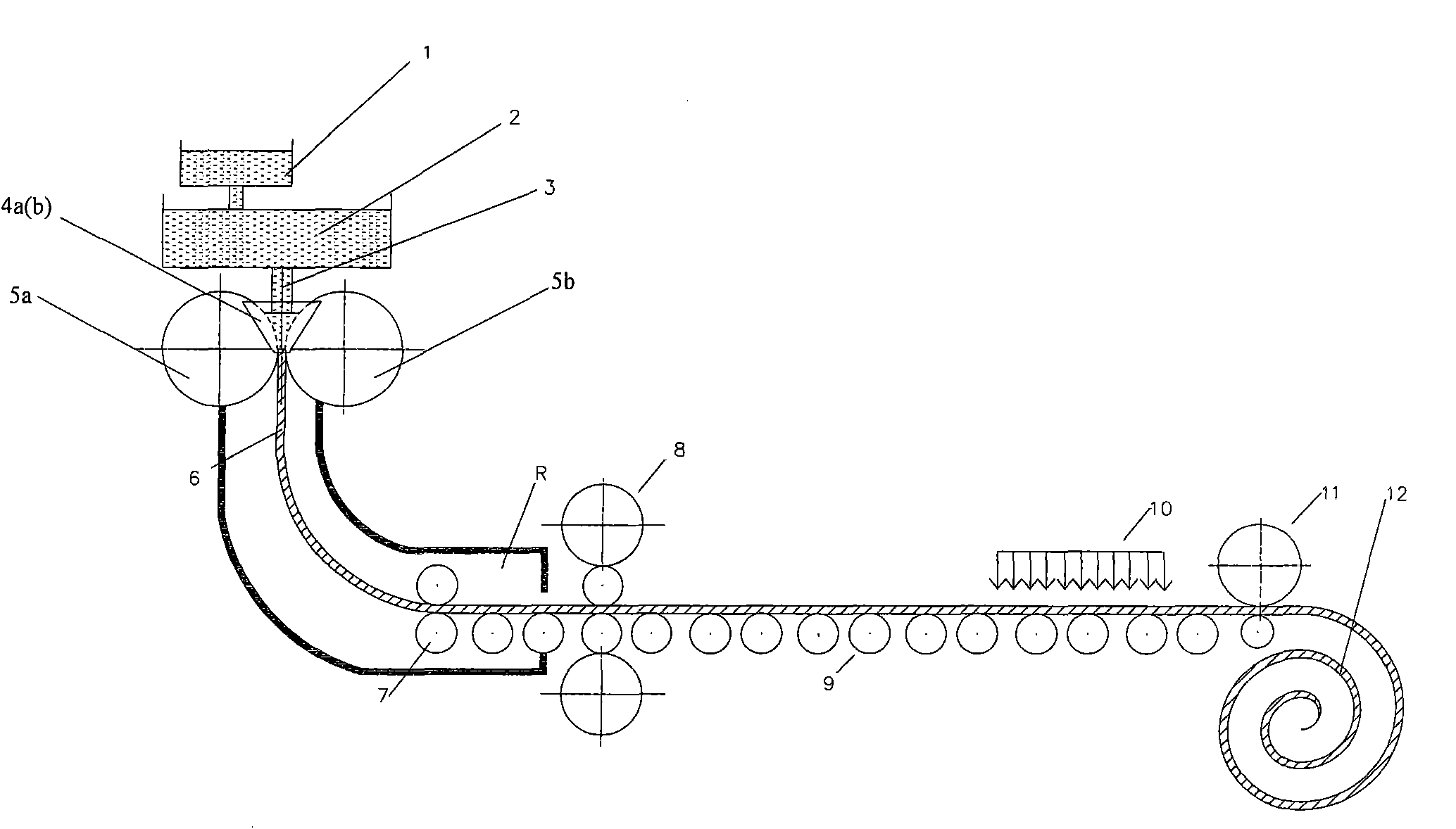

The invention discloses a method for improving the performance of 700 MPa grade V-N microalloyed high strength weathering steel. The method is specific to the characteristics of the sheet billet continuous casting and tandem rolling technology and metallurgy component, and adopts an electric furnace or a revolving furnace to smelt, refine, continuously cast sheet billet which directly enters into a roller hearth to heat after a casting blank concretes, or soaking furnace, hot rolling, laminar flow cooling and wind-up process flow. The chemical composition of molten steel is :C occupies less than or equal to 0.08Wt. percent, Si occupies from 0.25 to 0.75Wt. percent, Mn occupies from 0.2 to 2.0Wt.percent, P occupies less than or equal to 0.025Wt. percent, S occupies less than or equal to 0.040Wt. percent, Cu occupies from 0.25 to 0.60Wt. percent, Cr occupies from 0.30 to 1.25 Wt.percent, Ni occupies less than or equal to 0.65Wt. percent, V occupies from 0.02 to 0.20Wt. percent and N occupies from 0.015 to 0.030 Wt. percent. The invention takes full advantages of the characteristics of the sheet billet continuous casting and tandem rolling short flow process and adopts the V-N microalloyed technique to produce 700 MPa grade high strength weathering steel under the thinning function of VN and V (C, N) nanometer scale precipitate on crystal grain in casting blank of the sheet billet continuous casting and tandem rolling flow and the theory of precipitation strength. By the optimization design of the metallurgy component of V-N microalloyed 700MPa grade high strength weathering steel, the invention increases the low temperature impact ductility of coil of strip and improves the shaping property.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Method for producing 700Mpa V-N microalloyed high-strength air corrosion-resistant steel based on sheet bar continuous casting tandem rolling process

InactiveCN1884608AHigh strengthGood formabilityTemperature control deviceMetal rolling arrangementsSheet steelChemical composition

This invention exposed the producing method of V-N microalloyed high strength weathering steel which produced with near net shape con-casting technology. It is smelted in electric furnace or converter, refined, con-casted, casted, then directly sent into roller hearth furnace or soaking pit, hot-rolled, laminar cooled, coiled. The liquid steel's chemical elements are (Wt.%): C: <=0.08%, Si: 0.25- 0.75%, Mn: 0.8-2.0%, P: 0.070-0.150%, S: <=0.040%, Cu: 0.25-0.60 %, Cr: 0.30-1.25 wt%, Ni: <=0.65%, V: 0.05-0.20%, N: 0.015-0.030%. This invention can get the high intensity, formation, weathering, joining character stably. The alloying cost is relatively low. So it can be used to produce container, carriage, and other industry facility.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Weathering steel with yield strength of 550MPa level and manufacturing method thereof

InactiveCN101994064AMeet the requirements of reducing the self-weight of componentsMeet the requirements of self-respectTemperature control deviceSheet steelUltimate tensile strength

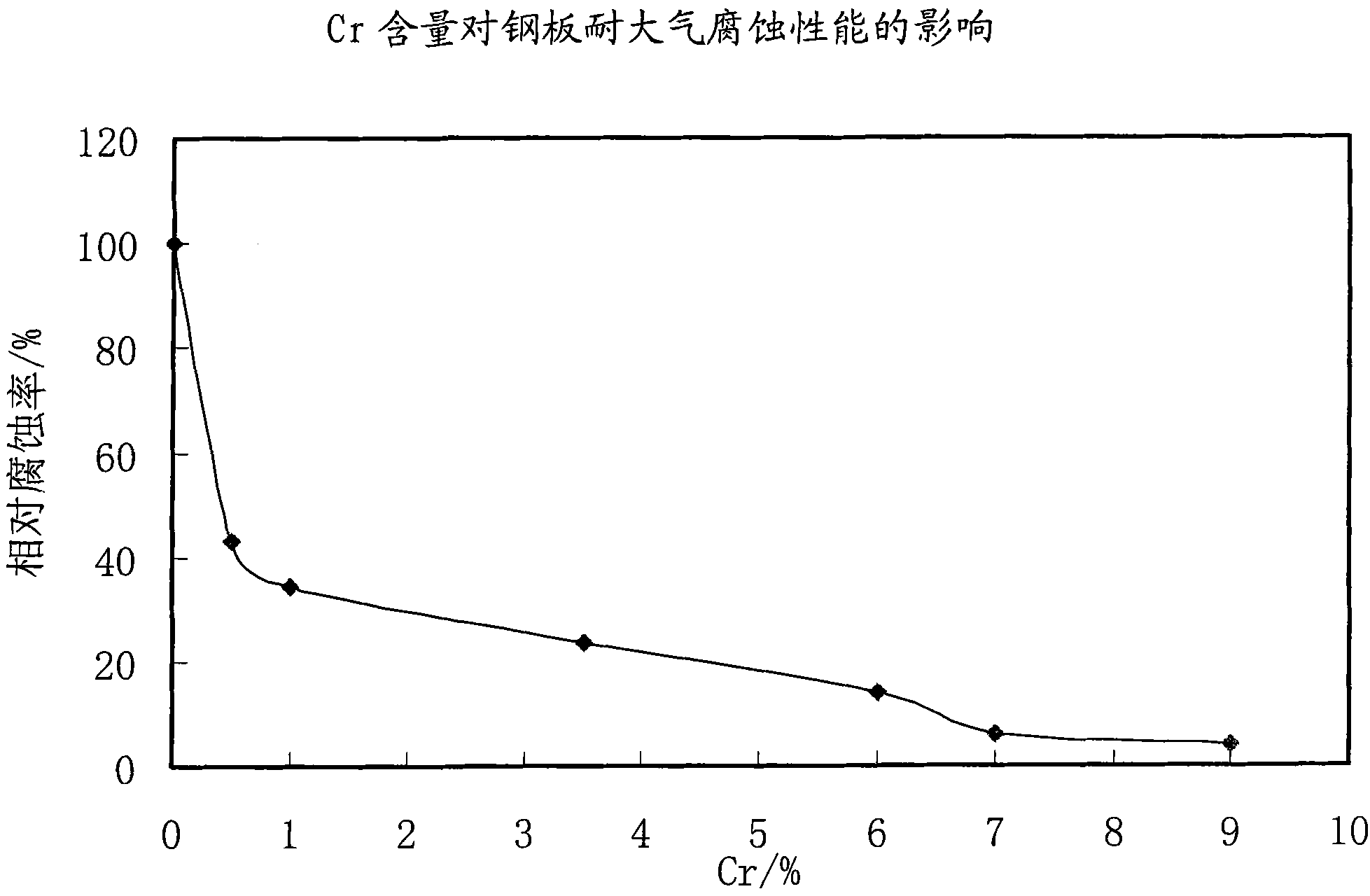

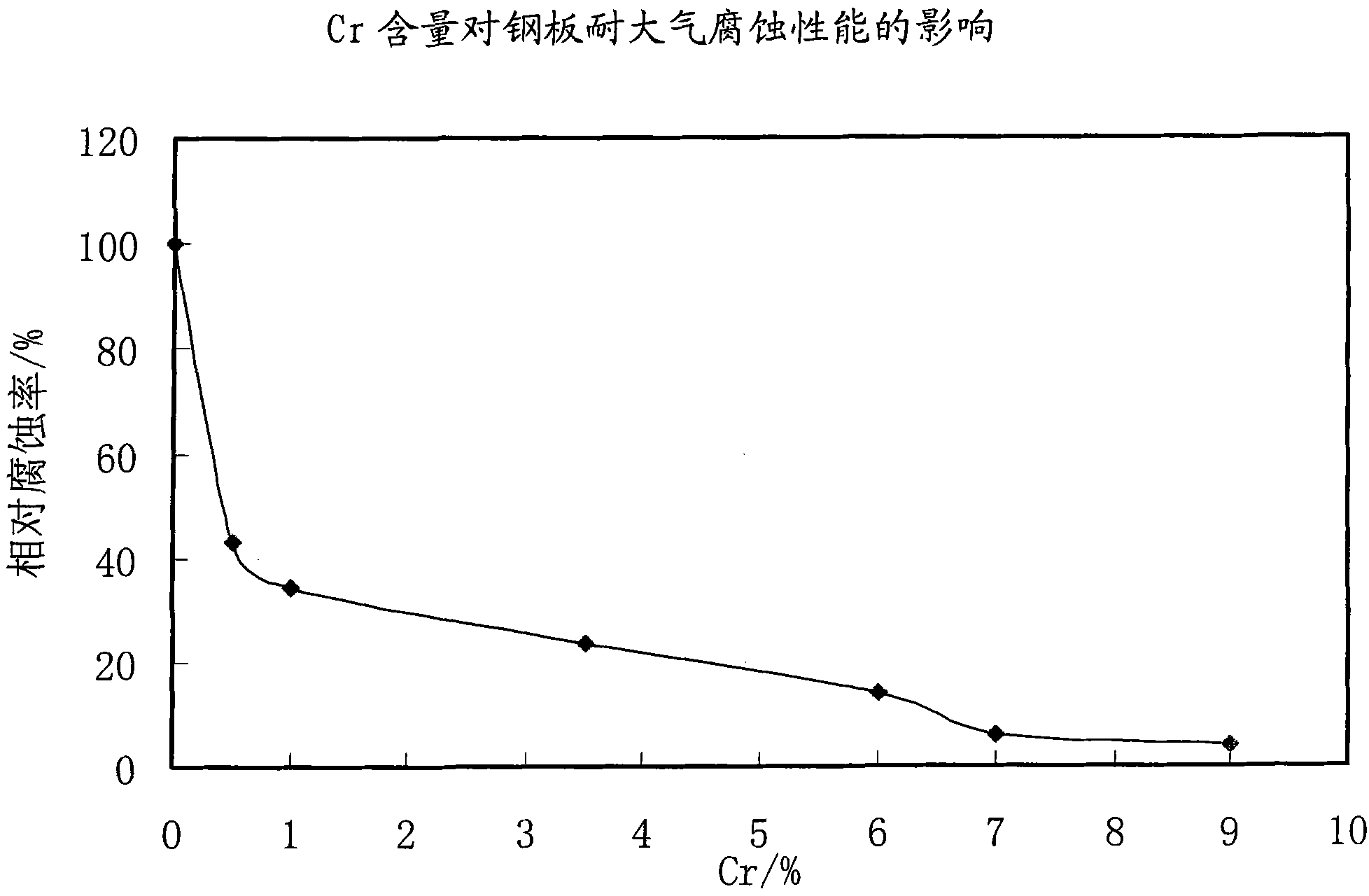

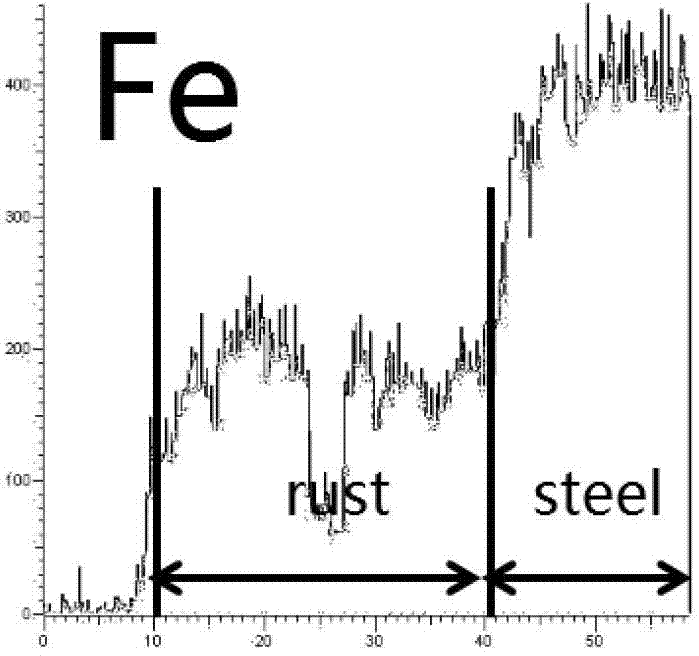

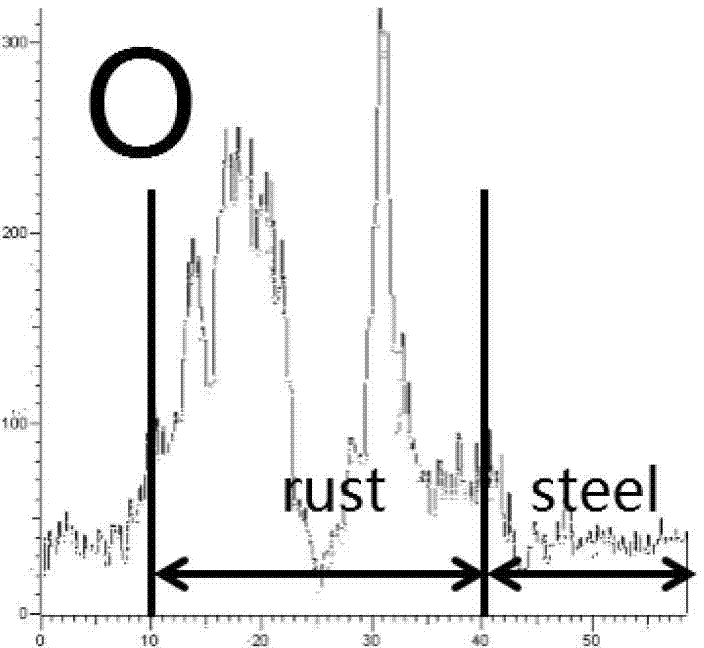

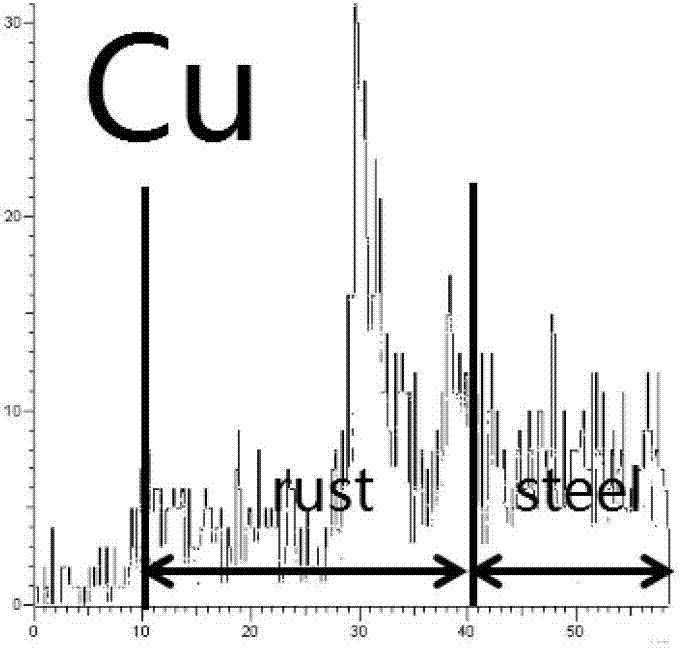

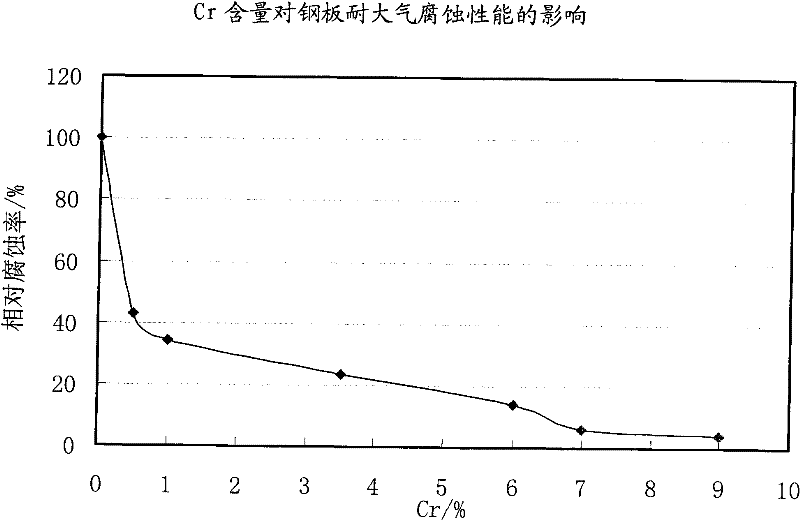

The invention relates to weathering steel with the yield strength of 550MPa level and the advantages of excellent toughness and high corrosion resistance, and a manufacturing method thereof. The weathering steel comprises the following components: 0.02 to 0.08wt% of C, 0.15 to 0.55wt% of Si, 0.2 to 1.0wt% of Mn, less than or equal to 0.01wt% of P, less than or equal to 0.006wt% of S, 0.2 to 0.5wt% of Cu, 2.5 to 7.0wt% of Cr, 0.2 to 1.2wt% of Ni, 0.02 to 0.06wt% of Nb, 0.01 to 0.05wt% of Al, less than or equal to 0.05wt% of N, 0.01 to 0.10wt% of Ti and the balance of Fe and the unavoidable impurities. The steel plate made of the steel has the yield strength more than 550MPa and excellent toughness, and the relative corrosion rate is simultaneously reduced by one time on the basis of the traditional weathering steel so as to satisfy the requirement of enhancing the corrosion resistance of the steel for railway vehicles and reach the purposes of prolonging the service duration and reducing the maintenance cost.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength weathering steel and method of manufacturing same

InactiveCN1970818AReduce control requirementsUniform microstructureRoll mill control devicesHeat treatment process controlSolubilityMetallurgy

The invention discloses a high-strength weatherabile steel and manufacturing method in the low-alloy steel making domain, which is characterized by the following: adding low-carbon and Cu-Cr-Ni-Mo-Nb into two or more composite additives; controlling carbon content with maximum solubility in the alpha-Fe at 0.0218% under normal temperature; reducing carbon-permeating evolution; affirming main control tissue evenly.

Owner:武钢集团有限公司 +1

High-strength weathering steel and method for producing same

InactiveCN101792888AImprove economyGood weather resistanceTemperature control deviceMetal rolling arrangementsChemical compositionImpurity

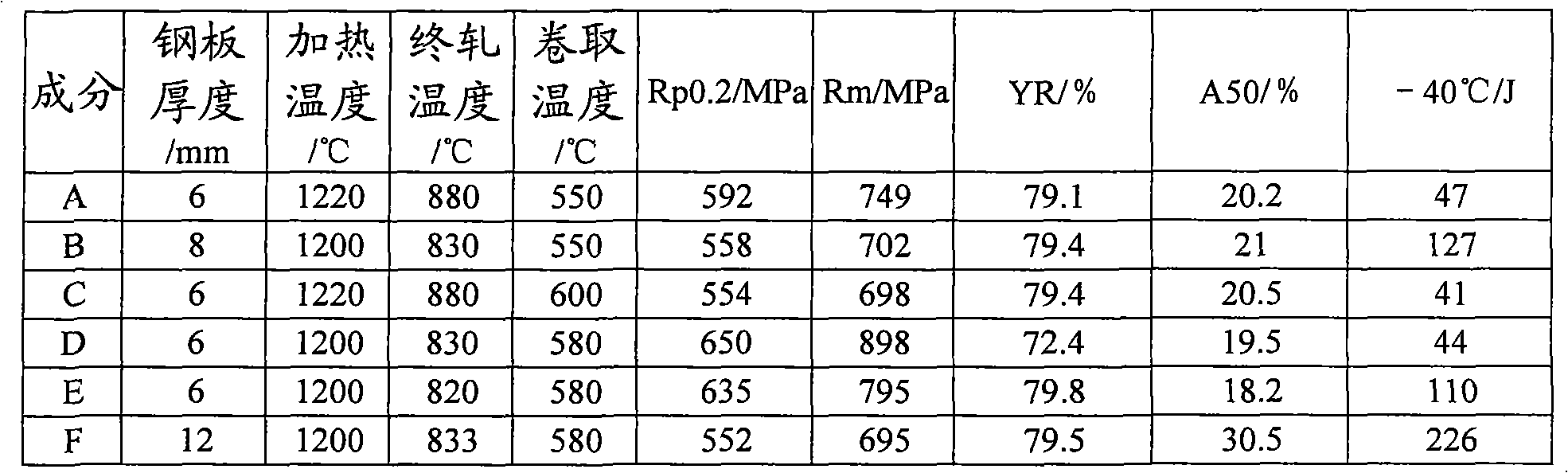

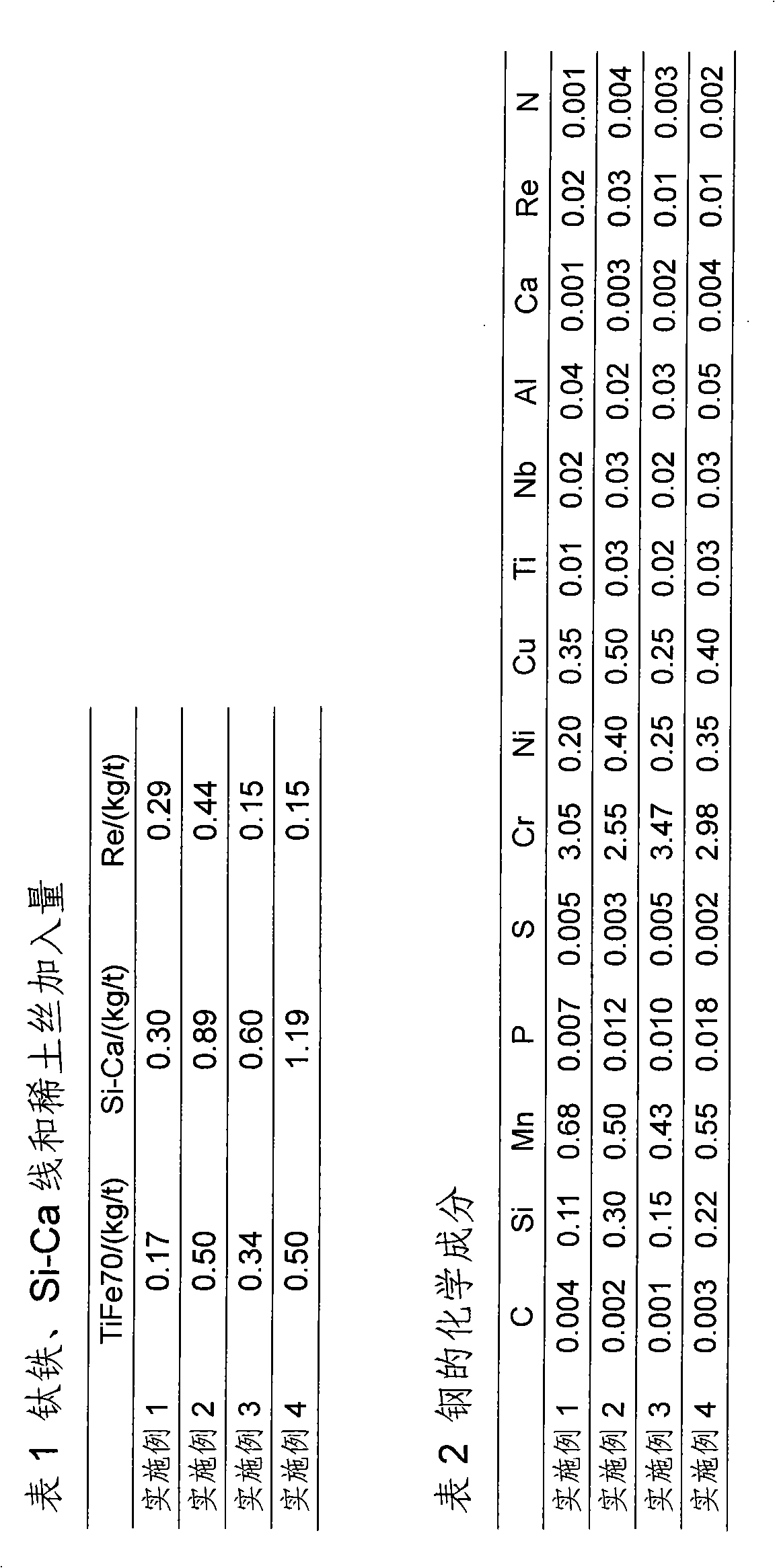

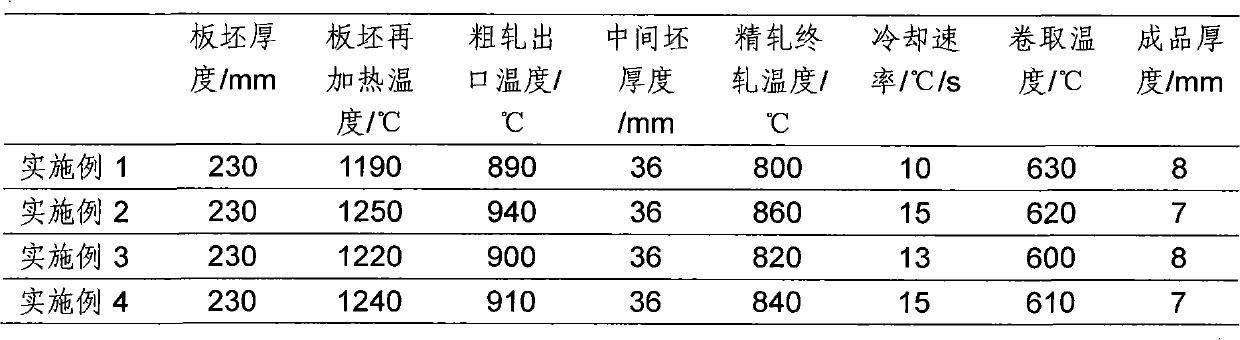

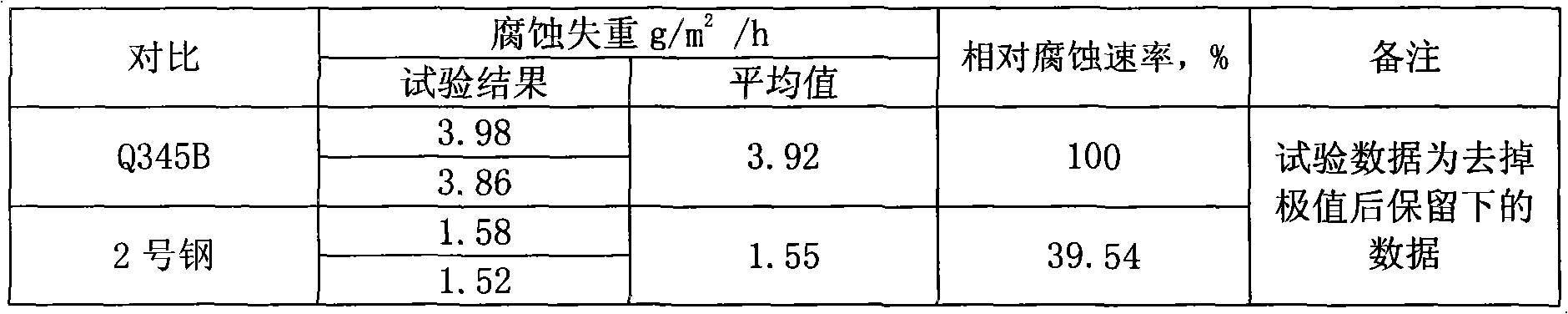

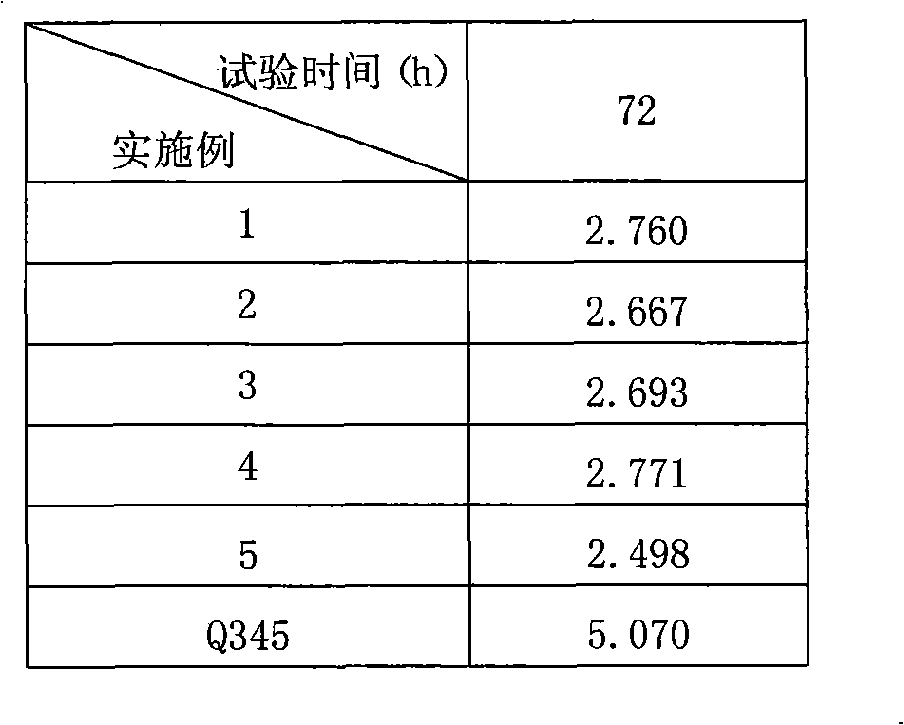

The invention relates to high-strength weathering steel and a method for producing same. The high-strength weathering steel comprises the following components by weight percent (wt%): 0.001-0.004 percent of C, 0.10-0.30 percent of Si, 0.40-0.70 percent of Mn, 0.020 percent of P or less, 0.008 percent of S or less, 2.50-3.50 percent of Cr, 0.20-0.40 percent of Ni, 0.25-0.50 percent of Cu, 0.01-0.03 percent of Re, 0.02-0.06 percent of Al, 0.001-0.004 percent of Ca, 0.001-0.005 percent of N, 0.01-0.03 percent of Ti, 0.01-0.03 percent of Nb and the balance of Fe and other inevitable impurities. After the molten iron is fully deoxidized and before the refining of the molten iron is finished, ferrotitanium is added to steel ladle, a Ca wire is fed to the steel ladle, a Re wire is fed into a continuous casting crystallizer, and a slab is reheated at 1180-1300 DEG C; the two-stage controlled rolling is adopted; the ratio of the thickness of the intermediate slab to the thickness of the finished product is controlled at 3.0; the refining outlet temperature is controlled at 890-1050 DEG C; the finishing rolling temperature is controlled at 800-860 DEG C; the rate of cooling after finishing rolling is controlled at 10-15 DEG C per second; and the winding temperature is controlled at 580-640 DEG C. The invention has the advantages that the relative corrosion rate of the weathering steel subjected to the 72h periodic infiltration is less than 30 percent compared with that of the steel Q345B, the weathering performance of the weathering steel is obviously better than the traditional high-strength weathering steel, and the weathering steel of the invention has the yielding strength of more than 550 Mpa and the elongation rate of more than 24 percent. The high-strength weathering steel of the invention can be applied to the fields of the railway truck, the container, the bridge, the communication, the power tower and the like.

Owner:SHOUGANG CORPORATION +1

High-performance weather-proof building structural steel and manufacturing method thereof

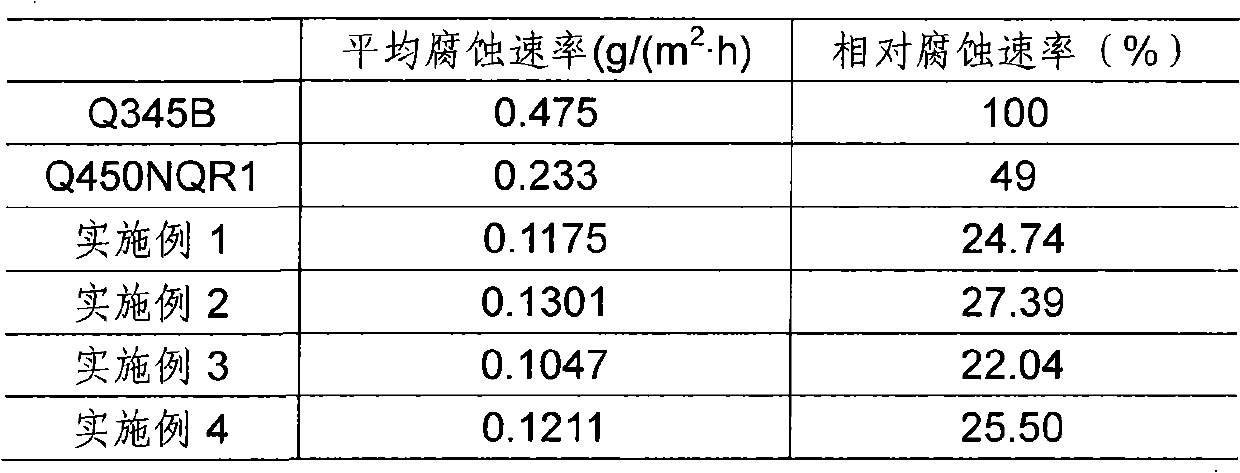

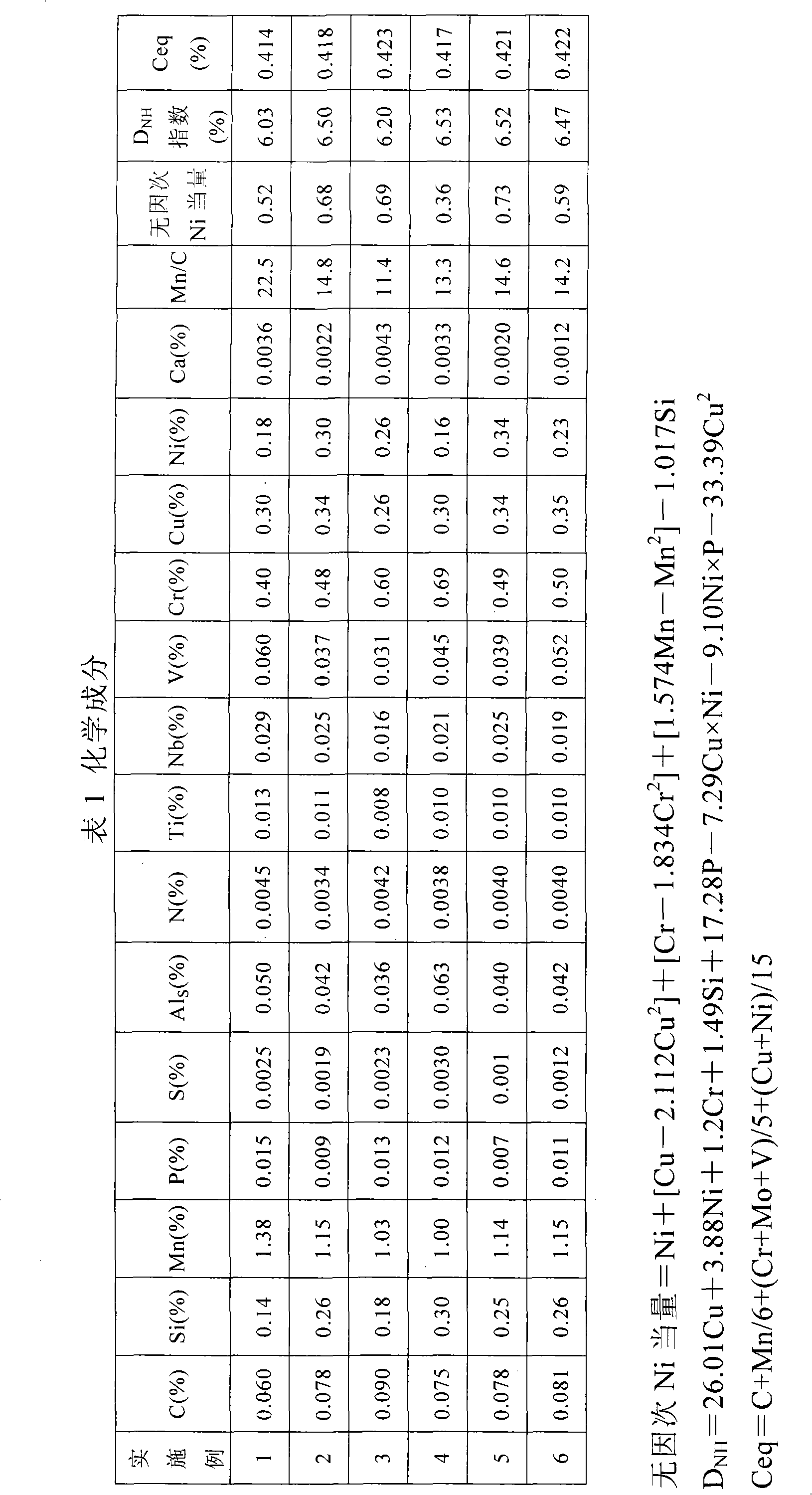

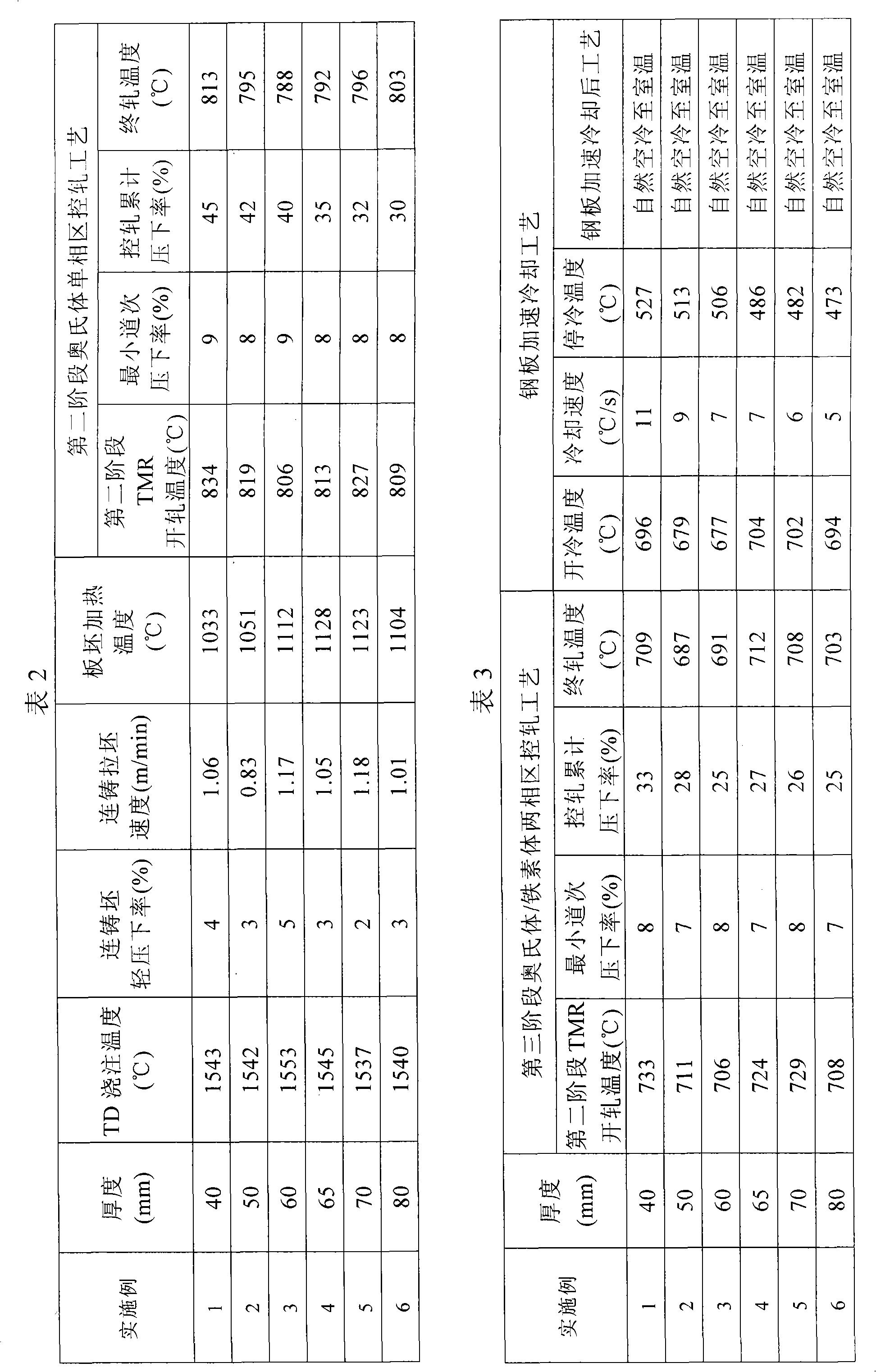

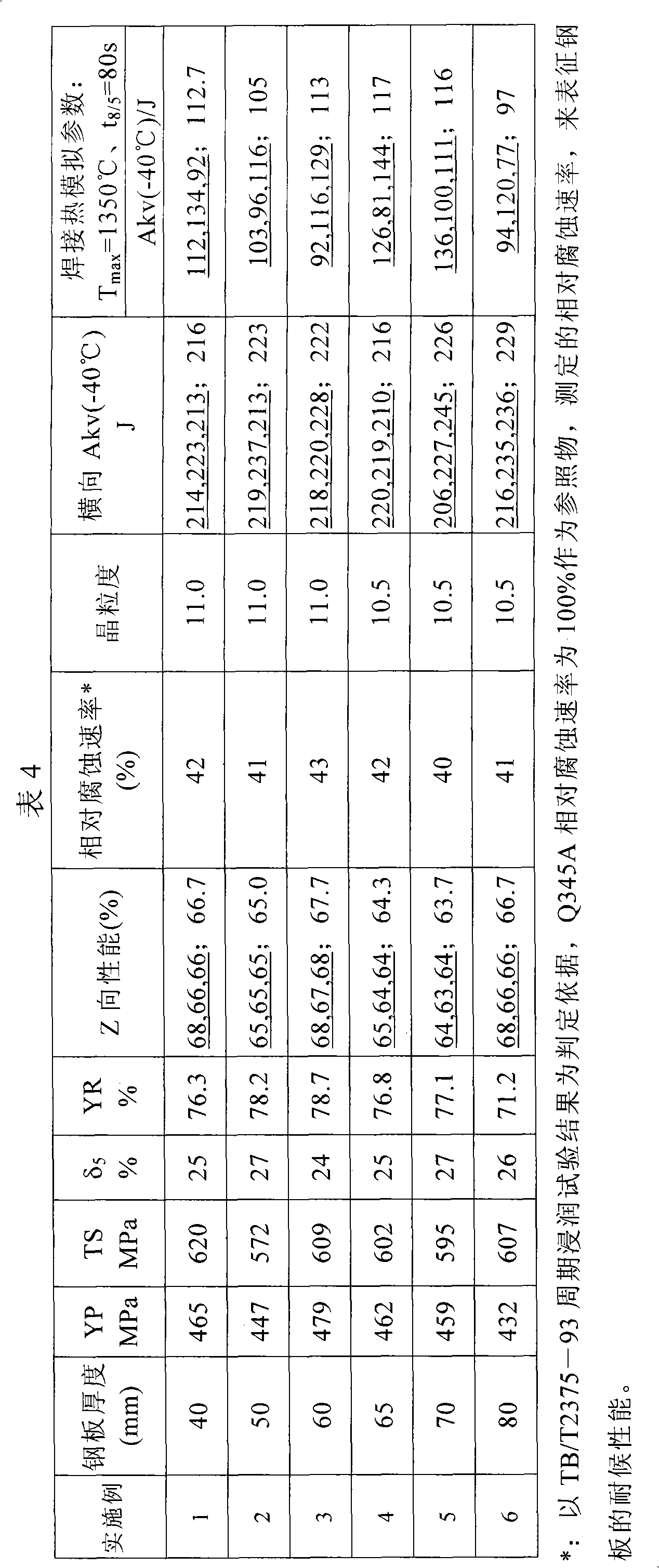

The invention relates to high-performance weather-proof building structural steel and a manufacturing method thereof. The composition system of low C-medium Mn-low N-micro Nb alloying-ultramicro Ti processing low content alloy weather-proof steel is taken as foundation, the acid solution Als content in the steel is increased properly, and the range of the acid solution Als content is controlled; the zero dimension Ni equivalent weight is controlled to be more than or equal to 0.35, the Ceq is less than or equal to 0.425%, and the Mn / C is more than or equal to 10; the weather-proof property index DNH is more than or equal to 6.0%; and the Ca is processed, the Ca / S is controlled within the range of 1.0-3.0, and Ca*S 0.28 is less than or equal to 1.0*10<-3>. By adopting a TMCP technique, a weather-proof steel plate with good toughness, strong plasticity matching, low yield ratio, atmosphere corrosion resistance, excellent weldability and anti-fatigue performance can be obtained, is especially suitable for non-coating high-rise building structure and bridge structure, and can realize stable batch industrialized production with low cost.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

Weathering steel with yield strength of more than 700MPa and manufacturing method thereof

InactiveCN101994063AMeet the requirements of reducing the self-weight of componentsGood atmospheric corrosion resistanceTemperature control deviceSheet steelUltimate tensile strength

The invention relates to Cr-containing weathering steel with the yield strength of more than 700MPa, good toughness and high corrosion resistance, and a manufacturing method thereof. The weathering steel comprises the following components in percentage by weight: 0.02 to 0.10 percent of C, 0.1 to 0.4 percent of Si, 0.3 to 1.3 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.006 percent of S, 0.2 to 0.5 percent of Cu, 2.5 to 10 percent of Cr, 0.2 to 1.0 percent of Ni, 0.02 to 0.06 percent of Nb, 0.01 to 0.05 percent of Al, less than or equal to 0.005 percent of N, 0.02 to 0.10 percent of Ti and the balance of Fe and inevitable impurities. A steel plate made of the steel has the yield strength of more than 700MPa and good toughness; meanwhile, the relative corrosion rate of the steel is reduced by one time compared with that of the conventional weathering steel, so the steel meets the requirement of improving the corrosion resistance of steel for railway vehicles and fulfils the aims of prolonging the service life and reducing maintenance cost.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength weathering resistant steel and its preparation method

The invention provides high-strength weathering resistant steel and its preparation method. The high-strength weathering resistant steel is characterized by comprising the following chemical components: by weight, C being less than or equals to 0.06% and greater than or equals to 0.05%, Cu being less than or equals to 0.35% and greater than or equals to 0.25%, Si being less than or equals to 0.45% and greater than or equals to 0.36%, Mn being less than or equals to 1.00% and greater than or equals to 0.80%, Al being less than or equals to 0.065% and greater than or equals to 0.055%, Ni being less than or equals to 0.19% and greater than or equals to 0.10%, Cr being less than or equals to 0.50% and greater than or equals to 0.41%, Mo being less than or equals to 0.15% and greater than or equals to 0.05%, Ti being less than or equals to 0.02% and greater than or equals to 0.01%, V being less than or equals to 0.030% and greater than or equals to 0.016%, Nb being less than or equals to 0.010% and greater than or equals to 0.005%, B being less than or equals to 0.008% and greater than or equals to 0.005%, S being less than or equals to 0.010%, P being less than or equals to 0.025%, N being less than or equals to 0.005%, and the balance being Fe. According to the invention, a plurality of microalloy elements such as Al, Mo, V, Nb, B and the like are added into components of traditional weathering resistant steel so as to carry out combination alloying. Thus, contents of Cu and P in weathering resistant steel are reduced, copper brittleness and phosphorus brittleness hazards caused by Cu and P in weathering resistant steel are eliminated, and strength and weatherability of the steel are raised.

Owner:JIANGYIN ZHENGBANG TUBE MAKING

Low-cost non-quenched and tempered high-strength weathering steel with yield strength level of 700MPa and manufacturing method thereof

InactiveCN101921965AAdd corrosion resistant elementsLow costUltimate tensile strengthContinuous rolling

The invention provides low-cost non-quenched and tempered high-strength weathering steel with yield strength level of 700MPa for containers and a manufacturing method thereof. Based on the carbon manganese structural steel composition, the reinforcement effect is enhanced by adding a proper amount of micro-alloy elements such as Nb, Ti, Cu, Cr, Ni and the like, adopting a controlled rolling and controlled cooling technique, taking production characteristics of a normal hot continuous rolling machine into consideration and using a high-Ti component design. Meanwhile, Si content is reduced and high cold forming performance is ensured. The weathering steel for the containers comprises the following components in percentage by weight: 0.05 to 0.10 percent of C, less than or equal to 0.15 percent of Si, 1.5 to 2.0 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.01 percent of S, 0.3 to 0.8 percent o Cr, 0.2 to 0.4 percent of Cu, 0.15 to 0.4 percent of Ni, 0.09 to 0.15 percent of Ti, 0.02 to 0.08 percent of Nb, less than or equal to 0.005 percent of N, less than or equal to 0.002 percent of O and the balance of Fe and inevitable impurities. The yield strength is over 700MPa, the tensile strength is over 800MPa and the elongation is over 18 percent.

Owner:SHANDONG IRON & STEEL CO LTD

Technology of producing Ti micro alloyed high weather resistant steel plate using thin plate blank continuous casting continuous milling process

InactiveCN1785543AGood weather resistanceGood welding performanceMetal rolling arrangementsSheet steelHigh intensity

A conticasting and tandem rolling technology for manufacturing the high-strength and-weatherability Ti-microalloyed steel plate includes such steps as smelting, refining, conticasting, solidifying, heating, hot rolling, laminar flow cooling and coiling. Its advantages are high strength, high shaping performance, high weatherability and high weldability.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Weathering steel and manufacturing method thereof

The invention discloses weathering steel, which comprises the following chemical compositions in percentage by weight: 0.06 to 0.12 percent of C, 0.20 to 0.40 percent of Si, less than or equal to 1.6 percent of Mn, 0.08 to 0.22 percent of P, less than or equal to 0.008 percent of S, 0.01 to 0.06 percent of Al, 0.20 to 0.80 percent of Cu, 0.40 to 0.75 percent of Cr, 0.12 to 0.40 percent of Ni, 0.001 to 0.006 percent of Ca and the balance of iron and inevitable impurity elements. The weathering steel is manufactured by a thin strip continuous casting process. The manufacturing process comprises the following steps of: performing deep desulfurization on molten steel, performing composite blowing on the top and bottom of a converter, performing RH vacuum circular degassing process, and simultaneously performing calcium treatment; performing twin-roll continuous casting, and making the temperature of the molten steel in a molten bath not lower than 1,535DEG C; controlling rolling in the reduction ratio of not less than 30 percent; controlling cooling at the speed 30 to 50 DEG C / s; and coiling at the temperature of between 600 and 650 DEG C. The weathering steel of which the texture is acicular ferrite has good weatherability and can be widely applied to structural materials.

Owner:BAOSHAN IRON & STEEL CO LTD

Hydrojet pretreatment method for accelerating stabilization of rust layer on surface of weathering resistant steel

InactiveCN102925884AAvoid pollutionReduce complexityMetallic material coating processesPretreatment methodWeather resistance

The invention relates to a hydrojet pretreatment method for accelerating the stabilization of a rust layer on the surface of weathering resistant steel, belonging to the technical field of steel material corrosion prevention. 0.1-3 percent by weight of NaCl, 0.3-3 percent by weight of FeSO4, 0.1-3 percent by weight of CuSO4 and 0.3-3 percent by weight of NaHSO3 are mixed with water uniformly to obtain a surface treating agent of the weathering resistant steel, wherein the surface treating agent is sprayed on the surface of the weathering resistance steel. Chemical materials in a solution react with a steel base to generate a uniform and compact protective rust layer, so that the weathering resistant steel is more attractive in a use process, and rust liquid loss is prevented and the environment can be protected from being polluted. The hydrojet pretreatment method is convenient to operate and short in period, and can be widely applied to weathering resistant steel engineering structures of bridges, buildings and traffics.

Owner:UNIV OF SCI & TECH BEIJING

Cr-contained weathering steel with excellent toughness and high corrosion resistance

InactiveCN102127717AGood atmospheric corrosion resistanceImprove low temperature toughnessTemperature control deviceToughnessWeathering steel

The invention relates to a Cr-contained weathering steel with high corrosion resistance and a manufacture method thereof. The weathering steel is prepared from the following components in percentage by weight: 0.01-0.06 percent of C, 0.1-0.4 percent of Si, 0.2-0.8 percent of Mn, not more than 0.01 percent of P, not more than 0.006 percent of S, 0.2-0.5 percent of Cu, 2.5-7.0 percent of Cr, 0.2-1.2 percent of Ni, 0.01-0.05 percent of Al, not more than 0.005 percent of N, 0.01-0.10 percent of Ti and the balance of Fe and inevitable impurities. The relative corrosion rate of the weathering steel is decreased twice on the basis of traditional weathering steel and can be served in atmosphere environment; the preferred weathering steel has the yield strength over 460 MPa and excellent toughness, meets the requirement of steel for railway vehicles and achieves the aims of prolonging service length and decreasing maintenance cost.

Owner:BAOSHAN IRON & STEEL CO LTD

High-performance bridge weathering steel containing Mo and preparation method thereof

The invention belongs to the field of manufacture of low-alloy steel, in particular to high-performance bridge weathering steel containing Mo and a preparation method thereof. The invention provides bridge weathering steel containing Mo with the high performance, which comprises the following chemical components by mass percent: 0.02-0.05 percent of C, 0.20-0.30 percent of Si, 1.0-1.50 percent of Mn, at most 0.02 percent of P, at most 0.010 percent of S, 0.20-0.40 percent of Cu, 0.40-0.60 percent of Cr, 0.20-0.40 percent of Ni, 0.1-0.30 percent of Mo, 0.04-0.07 percent of Nb, 0.005-0.015 percent of Ti, at most 0.02 percent of Al and the balance of Fe and inevitable impurities. The high-performance bridge weathering steel containing Mo adopts two stages of rolling. The rough rolling and bloom rolling temperature of the first stage is 1050-1070 DEG C, the precision rolling and bloom rolling temperature of the second stage is 900-950 DEG C, and the finish rolling temperature is 800-850 DEG C. The high-performance bridge weathering steel containing Mo disclosed by the invention has good mechanical property, welding performance and atmospheric-corrosion resistance performance. The high-performance bridge weathering steel containing Mo adopts an Ultra-low carbon design, and the production cost is low.

Owner:NORTHEASTERN UNIV LIAONING +1

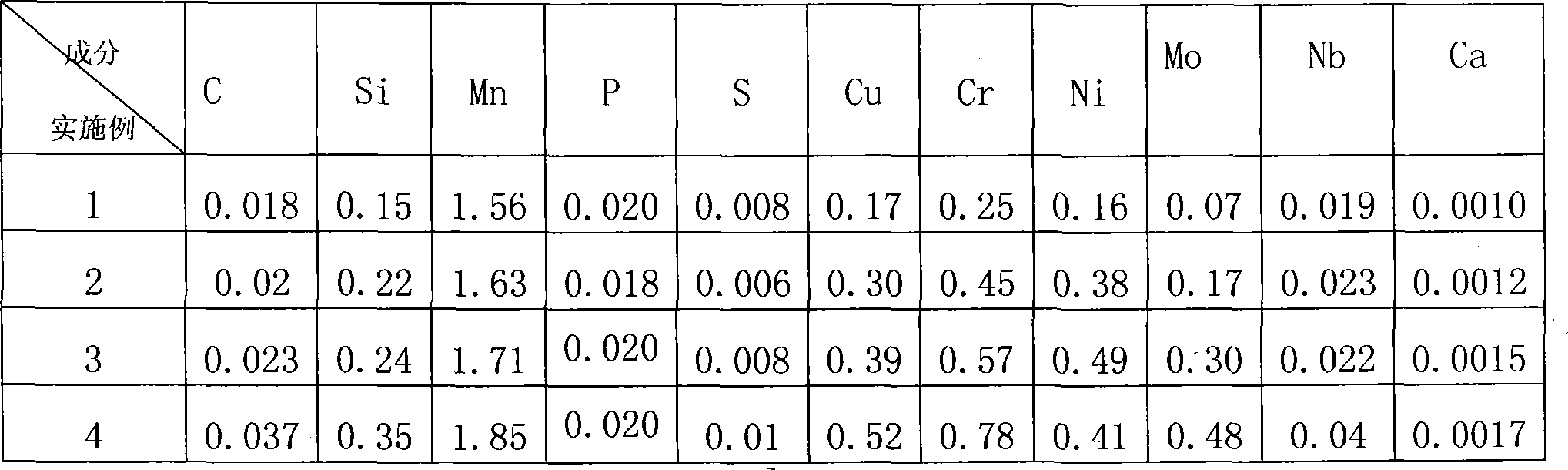

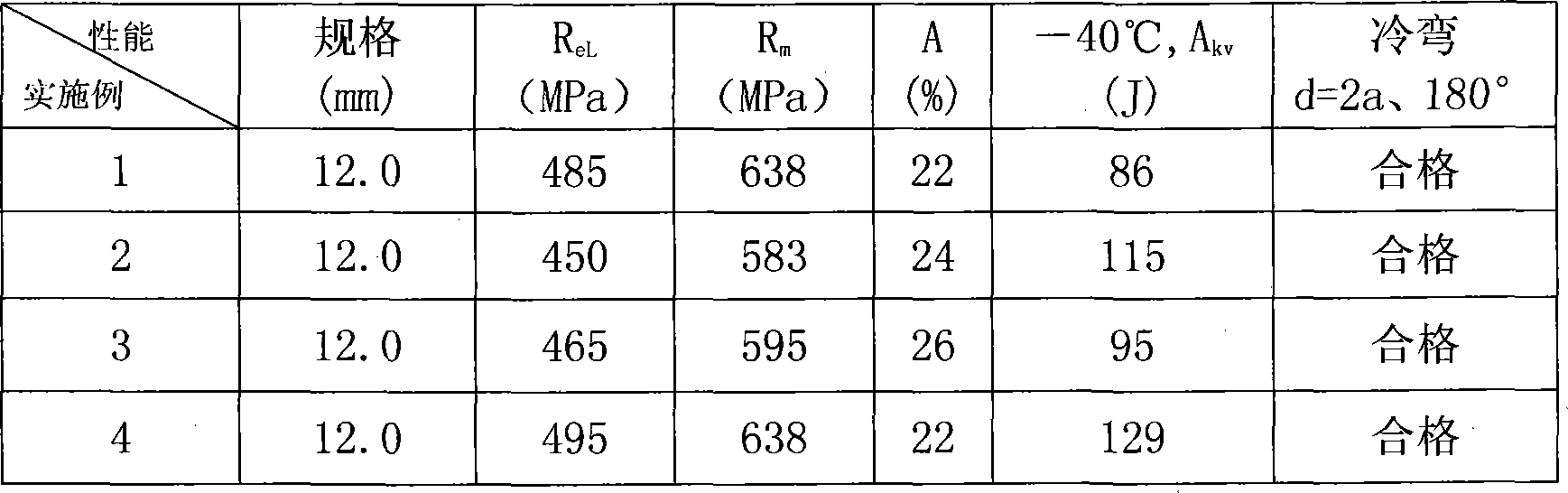

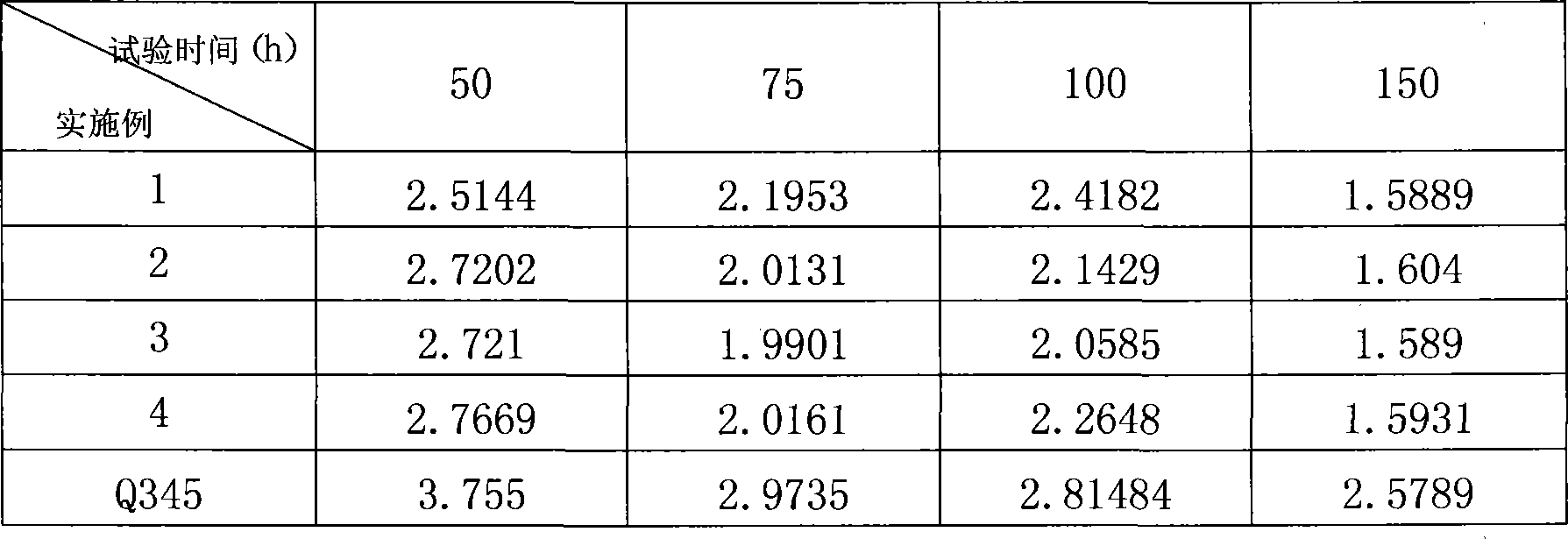

Ultra-low carbon hot rolling weather-resisting steel with yield strength more than 450MPa

InactiveCN101235470AGood mechanical propertiesSimple chemical compositionMechanical propertyAtmospheric corrosion

The invention provides ultra-low carbon hot rolling weathering steel whose yield strength is more than 450MPa aiming at the defects of existing weathering steel that the mechanical property and the atmospheric corrosion resistance are bad and the C content is over high, which is composed of components with following weight percent: C 0.01-0.05%, Si 0.10-0.40%, Mn 1.50-1.90%, P<=0.02%, S<=0.010%, Cu 0.15-0.55%, Cr 0.20-0.80%, Ni 0.10-0.50%, Mo 0.05-0.50, Nb 0.01-0.05% and Ca 0.0010-0.0020, and allowance is Fe and unavoidable impurity. The strength grade of the steel of the invention is higher than that of traditional steel and the steel has excellent low temperature impact toughness, welding performance and atmospheric corrosion resistance, and adopts ultra-low carbon design, which is beneficial for extending and applying.

Owner:WUHAN IRON & STEEL (GROUP) CORP

High-toughness weather-resistant steel plate with yield strength of 550MPa and preparation method of high-toughness weather-resistant steel plate

ActiveCN108486466AGood welding performanceExcellent cold forming performanceToughnessAtmospheric corrosion

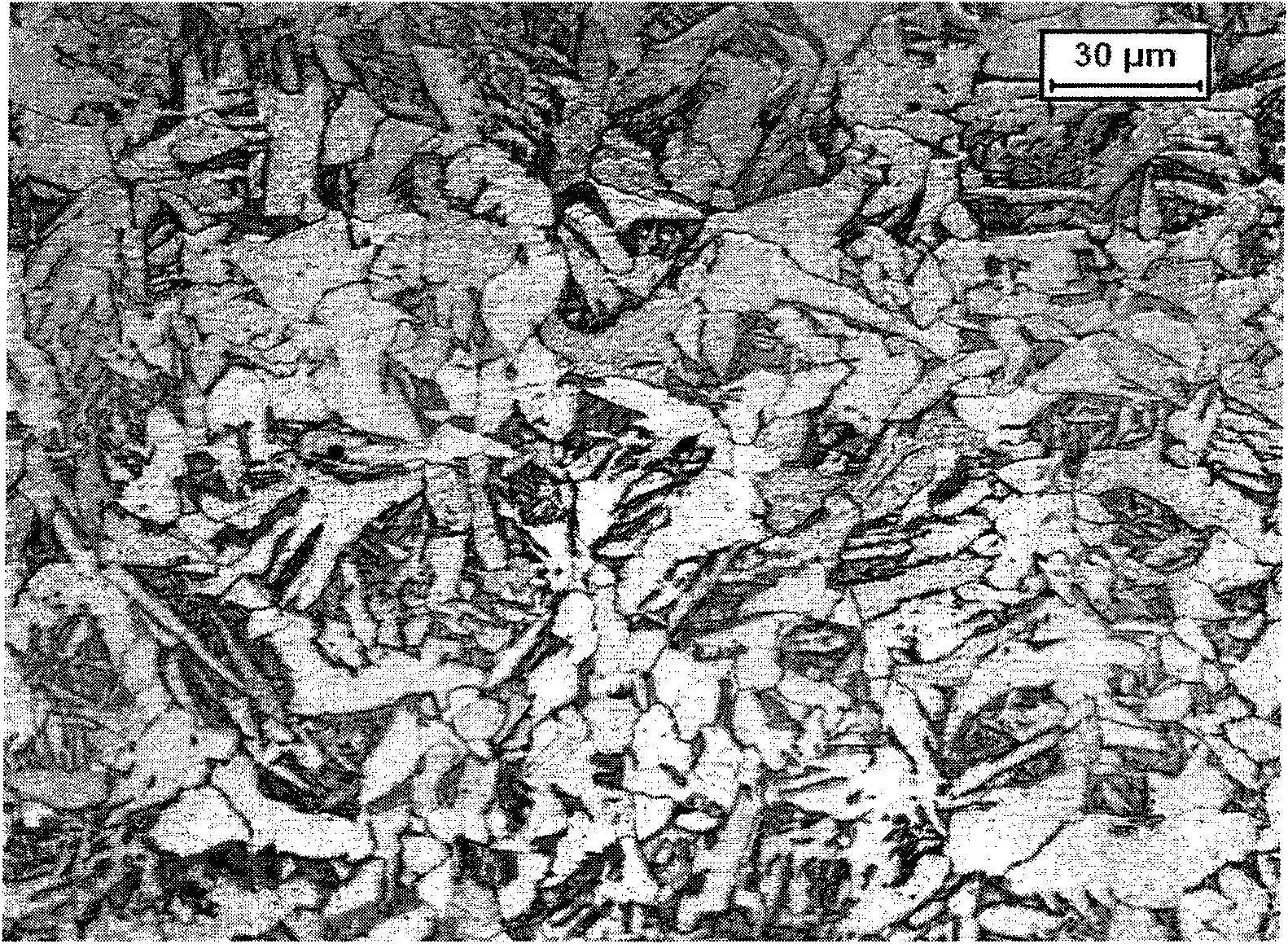

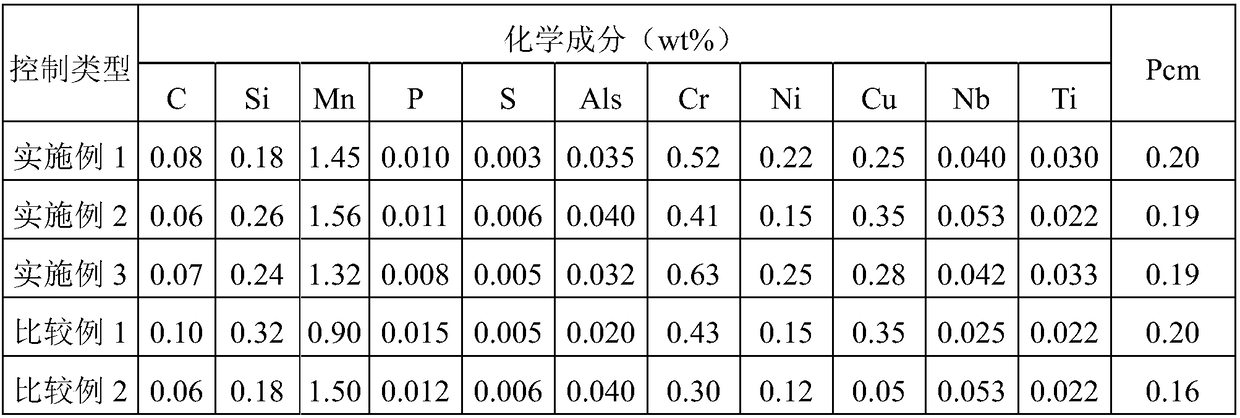

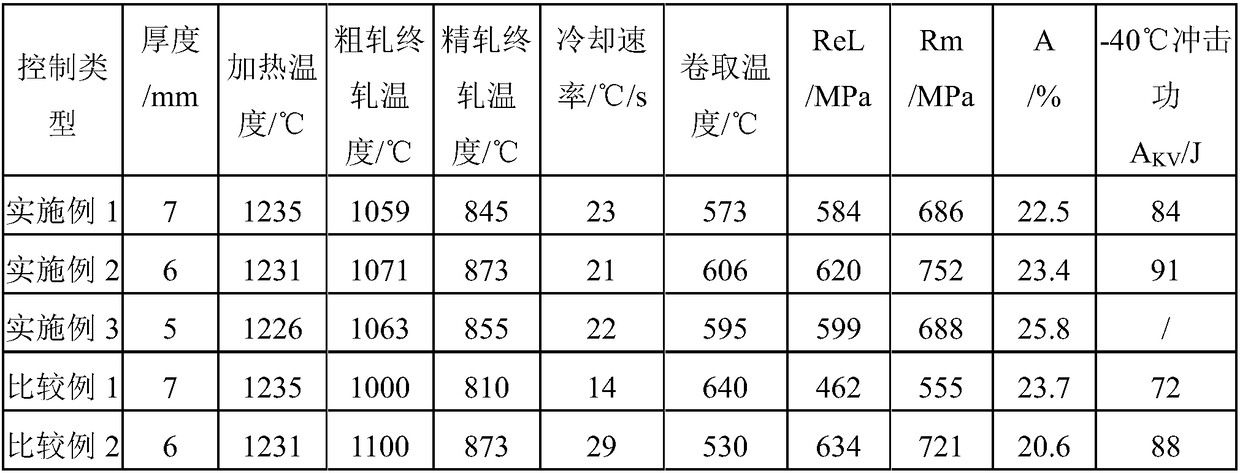

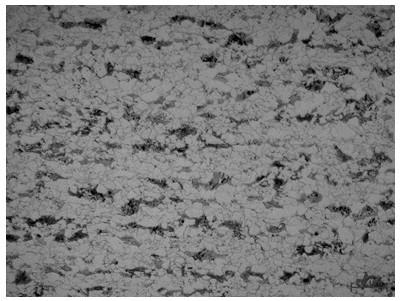

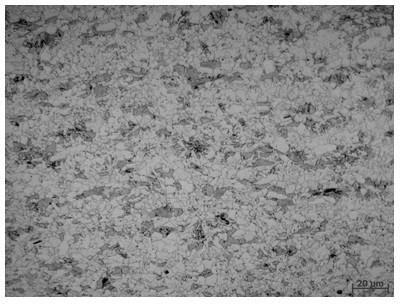

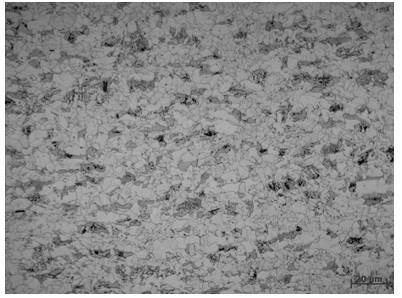

The invention discloses a high-toughness weather-resistant steel plate with the yield strength of 550MPa and a preparation method of the high-toughness weather-resistant steel plate. The high-toughness weather-resistant steel plate is prepared from the following chemical components by weight percent: 0.05 to 0.10 percent of C, 0.10 to 0.40 percent of Si, 1.20 to 1.70 percent of Mn, less than or equal to 0.012 percent of P, less than or equal to 0.008 percent of S, 0.40 to 0.80 percent of Cr, 0.15 to 0.40 percent of Ni, 0.25 to 0.40 percent of Cu, 0.015 to 0.040 percent of Als, 0.030 to 0.070 percent of Nb, and 0.010 to 0.040 percent of Ti, and the balance of Fe and unavoidable impurities, wherein Pcm is equal to C+Si / 30+(Mn+Cu+Cr) / 20+Mo / 15+Ni / 60+V / 10+5B and less than or equal to 0.20 percent. The microscopic tissue of the weather-resistant steel plate obtained according to the method disclosed in the invention is composite-phase tissue of ferrite, granular bainite and little pearlite,the ReL is 560 to 650MPa, Rm is 680 to 780MPa, A is 22.0 to 26.0 percent, and the longitudinal Charpy V-type impact power KV2 is greater than 70J at the temperature of -40 DEG C, and the high-toughness weather-resistant steel plate has excellent welding performance, cold bending forming performance and atmospheric corrosion resistance.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

600MPa grade high-strength weathering steel and preparation method thereof

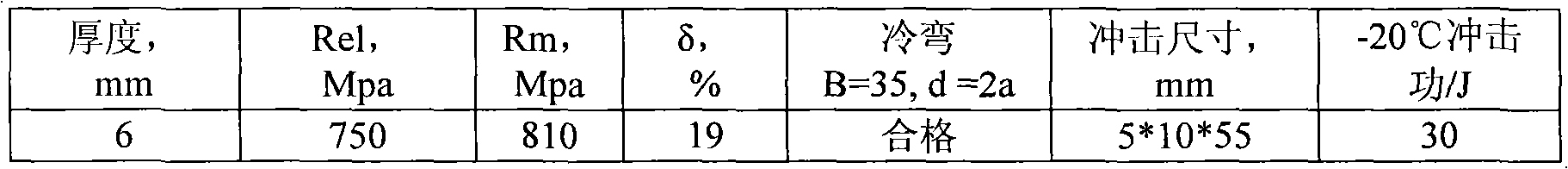

InactiveCN101225498ASimple chemical compositionThe production process is easy to controlMetal rolling arrangementsChemical compositionThin slab

The invention discloses a 600MPa high strength weathering steel and the manufacturing method, which is characterized in that: the 600MPa high strength weathering steel adopts electric stove-thin slab continuous casting and rolling process for preparation; the main chemical components of the refined molten steel for preparing the high strength weathering steel are: C: 0.045 wt % to 0.07wt%, Si: 0.10 wt % to 0.29wt%, Mn: 0.8 wt % to 1.5wt%, P: 0.005 wt% to 0.030wt%, S: 0.002 wt% to 0.008 wt%, Cu: 0.20 wt% to 0.5wt%, Cr: 0.3 wt% to 0.7wt%,Ni: 0.15 wt % to 0.35wt%, Ti: 0.06 wt% to 0.079wt%, Nb: 0.035 wt% to 0.050wt%, Alt: 0.025 wt% to 0.050wt%. The 600MPa high strength weathering steel has the advantages of low cost, strong competitiveness, cold formability, good welding performance and application to tower frame, heavy duty automobile, bridge, container, railway vehicle manufacture.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

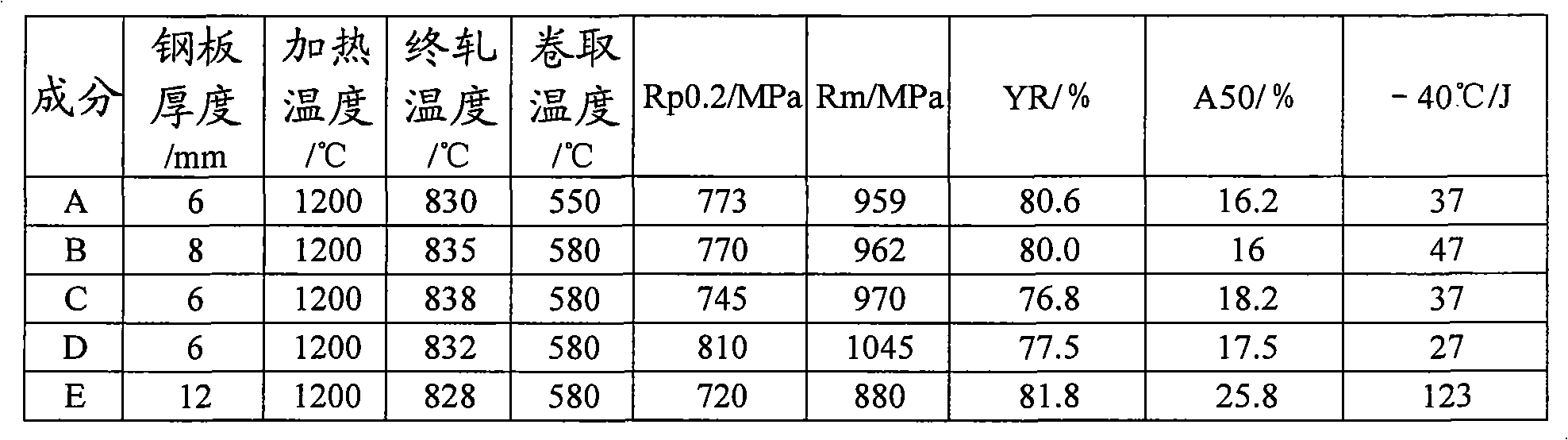

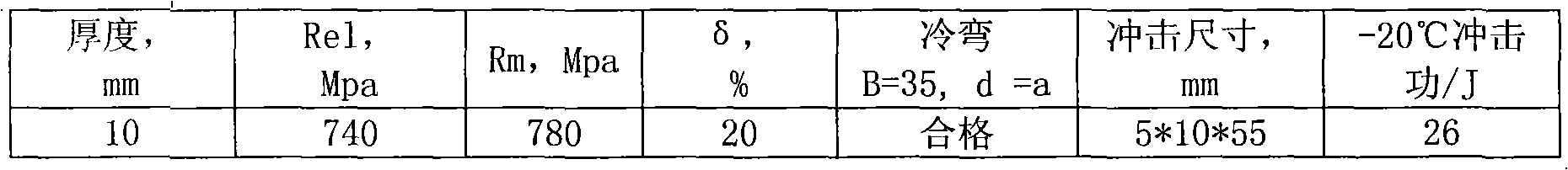

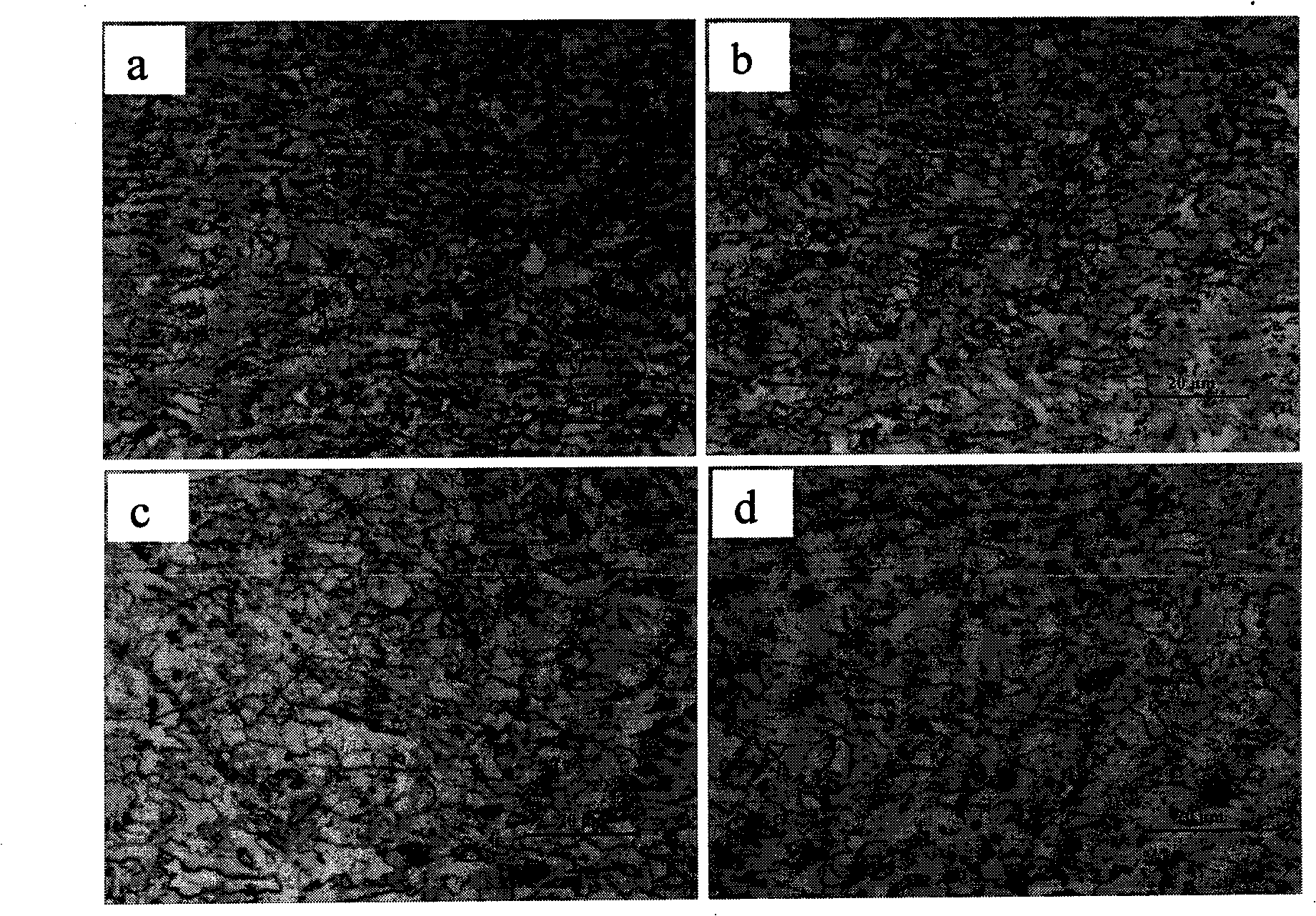

Ti microalloyed ultra-fine grain hot rolled steel at 700MPa class and production method thereof

InactiveCN101525717AAvoid consumptionAdjust cooling rateTemperature control deviceChemical compositionAbsorbed energy

The invention belongs to the technical field of high-strength weathering steel production, in particular discloses a Ti microalloyed ultra-fine grain hot rolled steel of 700MPa class and a production method thereof. The method utilizes the thin-slab continuous casting and rolling process to further perfect rolling and cooling control aspects by the readjustment of chemical compositions, is combined with the suitable control of grain ultrafining and TiC precipitation strengthening action, comprehensively improves the impact property and particularly improves the low-temperature impact toughness. The invention truly and reasonably matches with the strength and the toughness of the prior high-strength steel of 700MPa class, and the combination properties comprise: the yield strength is larger than or equal to 700 MPa, the tensile strength is larger than or equal to 750 MPa, the specific elongation is larger than or equal to 14 percent, and the impact absorbing energy Akv of a semi-size specimen (5*10*55mm) at 20 DEG C below zero is larger than or equal to 33 J. The production method enables the hot rolled steel to have high strength and high toughness and widens the range of practical application of the high-strength steel of 700MPa class.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

Ultra-low carbon hot rolling weathering steel with yield strength larger than 550MPa

InactiveCN101407892AGood mechanical propertiesSimple chemical compositionMechanical propertyWeathering steel

The invention discloses an ultra low carbon hot rolling weathering steel with the yield strength of more than the grade of 550MPa and belongs to the manufacturing field of low alloy steel. The steel consists of the compositions with the following weight percentages: 0.01 to 0.05 percent of C, 0.10 to 0.40 percent of Si, 1.20 to 1.70 percent of Mn, equal to or less than 0.02 percent of P, equal to or less than 0.010 percent of S, 0.15 to 0.80 percent of Cu, 0.40 to 1.25 percent of Cr, 0.10 to 0.50 percent of Ni, equal to or less than 0.40 percent of Mo, 0.03 to 0.06 percent of Nb, equal to or less than 0.050 percent of Ti, 0.0010 to 0.0020 percent of Ca and the residual quantity of Fe and unavoidable impurities. The steel has good mechanical properties, the yield strength of equal to or more than 550MPa and the tensile strength of equal to or more than 650MPa which are both higher than that of traditional weathering steel. Besides, Ti is included in the compositions of the steel.

Owner:武钢集团有限公司

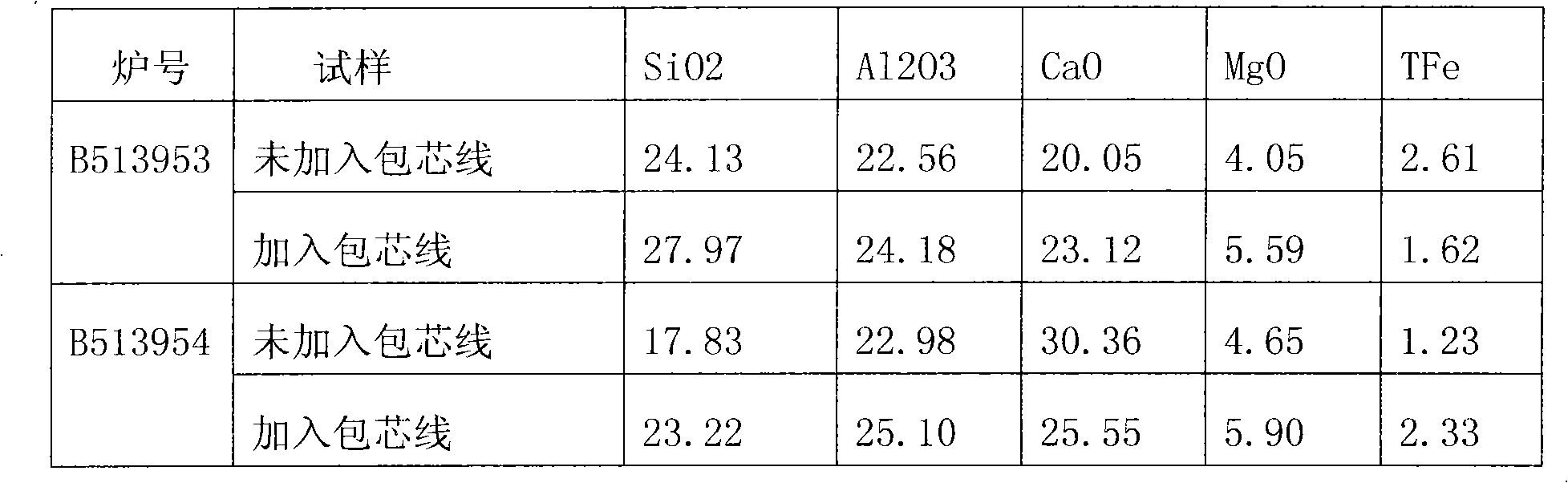

Novel weathering resistant steel microalloying compound core-spun yarn

The invention discloses a novel weathering resistant steel microalloying compound core-spun yarn comprising a steel sheath and a powdery inner core, wherein the powdery inner core is composed of the following chemical ingredients in percentage by weight: 20% of Ca, 0.5% of Mg, 38% of Si, 1.2% of Ba, 1.9% of rare-earth metal, 3.2% of Zr, 1.6% of Ti, 0.5% of B, 0.9% of Mo, 0.5% of Mn, 0.9% of Nb, 0.6% of V and the balance of Fe and inevitable impurity. The invention can obviously refine steel microstructure, improves the decay resistance of steel and lowers C, P and S content in steel by reasonably designing the chemical ingredients; and meanwhile the invention can reduce the amount of parts of alloy elements in steel so as to lower cost.

Owner:HUBEI KMK WELDING MATERIALS

Method for manufacturing SPA-H high-strength atmospheric corrosion resistance steel by using continuous annealing machine set

ActiveCN102230138AHigh strengthEasy to reinforceRoll mill control devicesFurnace typesProduction lineMechanical equipment

The invention provides a method for manufacturing SPA-H high-strength atmospheric corrosion resistance steel by using a continuous annealing machine set, belonging to the field of rolling of cold rolled strips. Parameters of a hot rolling process are as follows: the heating temperature is 1180-1260 DEG C, the final rolling temperature is 860+ / -20 DEG C, the rolling temperature is 610+ / -20 DEG C, and the cold rolling screwdown rate is controlled within a range of 35-60% according to different specifications. The temperature of a continuous annealing heating section is 800+ / -20 DEG C, the temperature of a soaking section is 800+ / -20 DEG C, the temperature of a slow cooling section outlet is 680+ / -20 DEG C, the temperature of a quick cooling section outlet is 430+ / -20 DEG C, the temperature of an overageing section is 400+ / -20 DEG C, the process speed is 150-200 mpm, the soaking time is 200-250 s, and the leveling elongation is 1.2+ / -0.3 %. The method provided by the invention has the following advantages that: the SPA-H high-strength atmospheric corrosion resistance steel generally manufactured on a hot rolling production line in the prior art is successfully manufactured on the continuous annealing machine set by using the cold rolling process while the hot rolling production machine set is affected by factors like limit specifications and mechanical equipment capacities and the like; and the cold rolling process, continuous annealing process and other processes are optimized in such a way that the manufactured high-strength atmospheric corrosion resistance steel has high strength and good elongation.

Owner:SHOUGANG CORPORATION

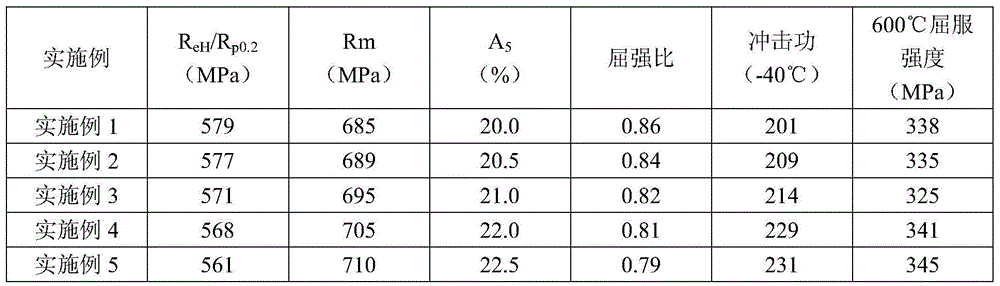

Q460-grade fire-resistant weathering steel and preparation method thereof

ActiveCN104561819AImprove high temperature yield strengthSimple designWeather resistanceFire resistance

The invention discloses a Q460-grade fire-resistant weathering steel which comprises the following chemical components in percentage by weight: 0.01-0.20% of C, 0.1-0.4% of Si, 0.5-1.5% of Mn, 0.1-1.0% of Cr, at most 1.0% of Ni, at most 1.0% of Cu, 0.01-0.05% of Nb, 0.01-0.05% of Ti, at most 0.015% of P, at most 0.0020% of S, and the balance of Fe and inevitable impurities, wherein the total amount of the impurity elements does not exceed 0.05%. The steel is subjected to smelting and two-stage rolling, so the prepared steel has excellent fire resistance and weather resistance. The method cancels the component of the precious metal Mo, and enhances the grade of the finished steel.

Owner:NANJING IRON & STEEL CO LTD

Flux cored wire for gas shielded welding of weathering steel

InactiveCN101745755AMeet welding requirementsWelding/cutting media/materialsSoldering mediaChemical compositionCarbon steel

The present invention relates to a flux cored wire for the gas shielded welding of weathering steel. The wire consists of a steel strip and a core. The steel strip is a carbon steel strip. The core comprises components of the following percentages by weight: 34 to 38% of TiO2, 2.0% of NaF2, 3 to 5% of SiO2, 11 to 12% of Mn, 3 to 5% of Ti-Fe, 5 to 6% of Si-Fe, 3 to 5% of Mg, 2 to 3% of Ni, 3.0 to 4.0% of Cr, 2.0 to 2.5% of Cu, 0.1 to 0.3% of Zr and the balance of ferrous powder. The flux cored wire has excellent welding technical performance, mechanical properties and anti-corrosion properties. The chemical compositions, the mechanical properties and the anti-corrosion properties of deposited metal all meet the welding requirements of weathering steel Q450NQR1. The present invention provides a flux cored wire suitable for weathering steel Q450NQR1.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

Weather resistance steel argon-rich gas shielded welding wire for high-intensity railway vehicle

InactiveCN101357425AMeet the high requirements of weld seam resistance to atmospheric corrosionGood weather resistanceWelding/cutting media/materialsSoldering mediaChemical compositionWeather resistance

The invention discloses an argon-rich gas-shielded welding wire of high-strength weathering steel used in railway cars, which is prepared by the following chemical components according to mass percentage: 0.2-0.35 percent of Cu, 0.3-0.7 percent of Cr, 0.2-to 0.6 percent of Ni, 0.05-0.1 percent of C, 0.3-0.5 percent of Si, 1.2-1.45 percent of Mn, P which is less than or equal to 0.015 percent, S which is less than or equal to 0.015 percent, the rest of Fe and unavoidable impurities. The welding wire is characterized by high weatherability, high strength, good flexibility, good resistance to welding cold crack, and the like, and the tensile strength thereof is more than 600MPa and the low-temperature impact property Axv is equal to or more than 146J at minus 40 DEG C. The welding wire adopts argon-rich gas as shield gas and has stabilized arcs, little splash, no air hole and good welding appearance when in welding. Furthermore, weld joints have an excellent matching effect with the high-strength weathering wheel used in the railway cars.

Owner:HUBEI KMK WELDING MATERIALS

Weathering steel hot-rolled thin belt without P segregation and manufacturing method thereof

The invention discloses a weathering steel hot-rolled thin belt without P segregation and a manufacturing method thereof. The weathering steel hot-rolled thin belt comprises the following chemical components in percentage by mass: C: 0.07-0.12%; Si: 0.30-0.50%; Mn: 0.4-0.55%; P: 0.06-0.15%; S: not more than 0.02 % and more than 0; Cr: 0.6-0.8%; Ni: 0.03-0.11%; Cu: 0.2-0.5%; Al: not more than 0.046% and more than 0; B: not more than 0.003% and more than 0, and the balance of iron and impurity elements. The weathering steel hot-rolled thin belt disclosed by the invention is low in cost and free from central P segregation and flaky MnS inclusions.

Owner:SHAGANG GROUP +2

Weathering resistant steel for low-cost 550MPa hot rolling container and manufacturing method thereof

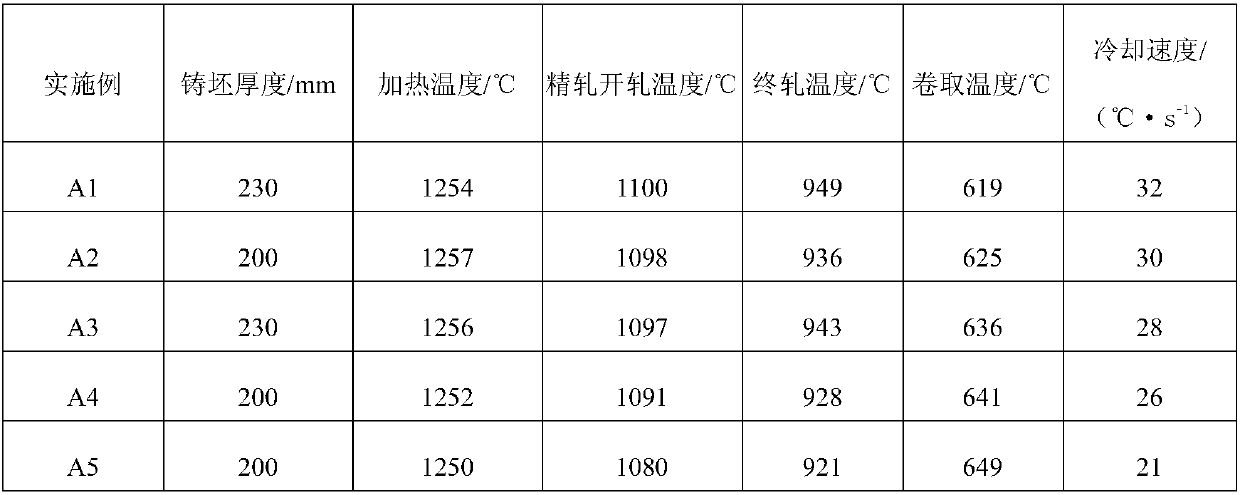

The invention discloses low-cost 550MPa hot-rolled container weathering steel and a manufacturing method thereof. Steel contains C 0.049%~0.069%, Si 0.20%~0.30%, Mn 0.51%~0.79%, P≤0.020%, S≤0.006%, Als 0.015%~0.045%, Cr 0.31%~0.41%, Ni 0.079 %~0.099%, Cu 0.21%~0.29%, Ti 0.057%~0.077%, N≤0.006%, and the rest are Fe and unavoidable impurities. The thickness of the slab is 200-230mm, the heating temperature of the slab is ≥1250°C, the starting temperature of the finishing rolling is 1080-1100°C, the finishing rolling temperature is 921-949°C, laminar cooling is adopted after rolling, and the cooling rate is >20°C / s, the coiling temperature is 619~649℃, after coiling, enter the slow cooling hood for slow cooling, if the thickness of the finished product is ≤2.0mm, it needs to be leveled. The thickness of the steel plate is 1.5~5.0mm, which is used in the container industry.

Owner:ANGANG STEEL CO LTD

Steel for high-strength weather-proof low-alloy electric force bar and preparing method thereof

InactiveCN101144139ALow costEasy to controlTemperature control deviceElectric forceChemical composition

The present invention relates to steel with high intensity and weatherability used for low alloy power rods and the preparation method thereof. The weathering steel has the chemical composition and the weight percentage content that C is 0.06-0.12 percent, Si is 0.15-0.35 percent, Mn is 1.0-1.40 percent, S is less than or equal to 0.030 percent, P is less than or equal to 0.030 percent, Cu is 0.15-0.30 percent, Al is less than 0.04 percent, Nb is 0.01-0.03 percent, and the residual is Fe and microimpurity. The present invention performs combined blown converter smelting, LF ladle refining, soft argon blowing, and sheet billet continuous casting by using the prior equipment and the conventional process production, and performs microalloying treatment through adjusting the content of partial elements. By accurately controlling the processing condition, the economic weathering steel with good atmospheric corrosion resistant performance and comprehensive mechanical performance can be produced.

Owner:LAIWU IRON & STEEL GRP

Weathering steel with low yield ratio and high strength and production method of weathering steel

ActiveCN109161793AGuaranteed corrosion resistanceImprove toughnessEarthquake resistanceChemical composition

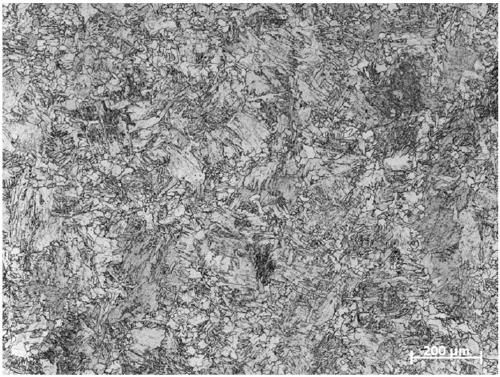

The invention discloses weathering steel with low yield ratio and high strength and a production method of the weathering steel. The weathering steel comprises chemical components in percentage by mass as follows: 0.08%-0.10% of C, 0.25%-0.30% of Si, 1.30%-1.50% of Mn, smaller than or equal to 0.010% of P, smaller than or equal to 0.010% of S, 0.25%-0.30% of Ni, 0.45%-0.50% of Cr, 0.25%-0.35% of Cu, 0.02%-0.04% of Al, 0.020%-0.030% of Nb, 0.010%-0.020% of Ti and the balance of Fe and inevitable impurity elements. The production method comprises processes as follows: smelting, continuous casting, casting blank heating, rolling control and cooling control. With adoption of composition design and rolling control and cooling control technologies, corrosion resisting property of the steel is guaranteed, the fine and uniform ferrite+bainite+pearlite structure is obtained, and toughness and earthquake resistance of the steel are improved.

Owner:HEBEI IRON AND STEEL

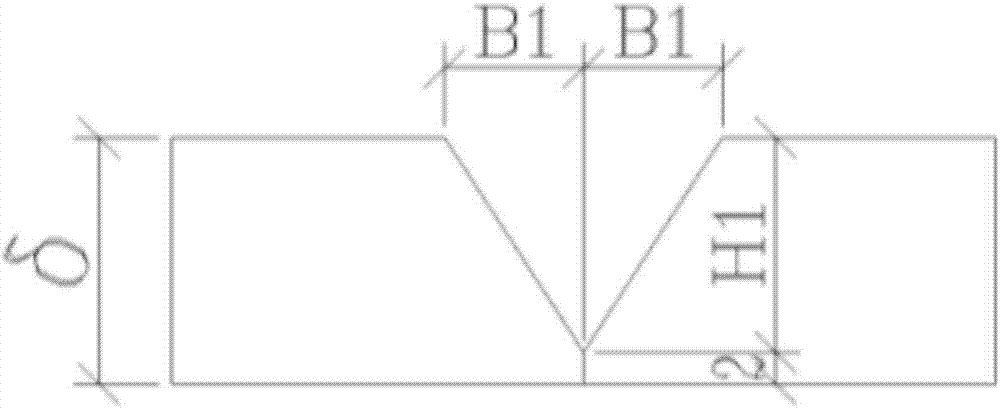

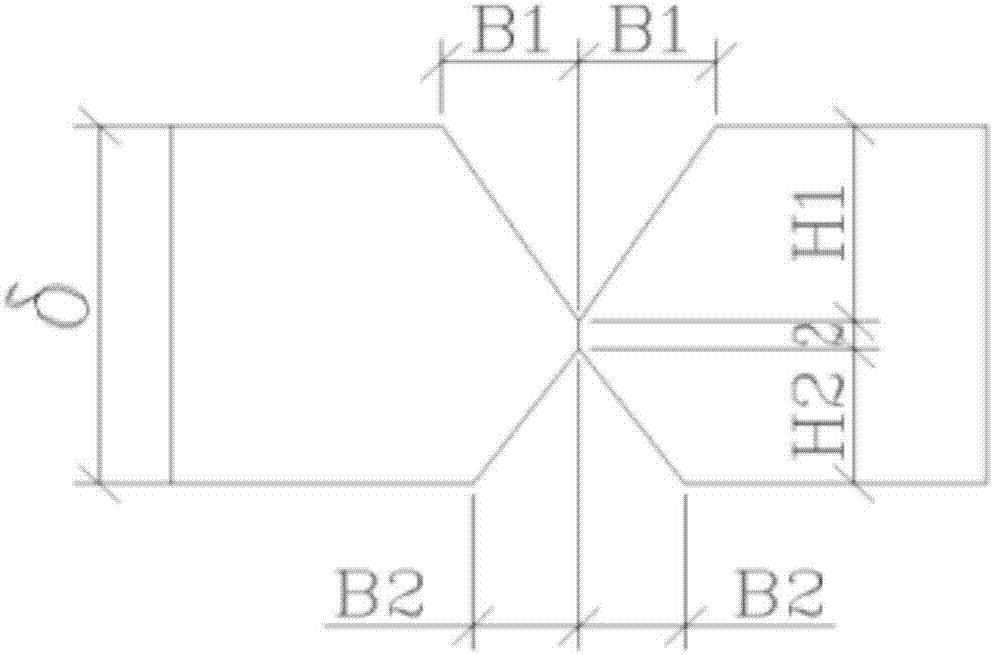

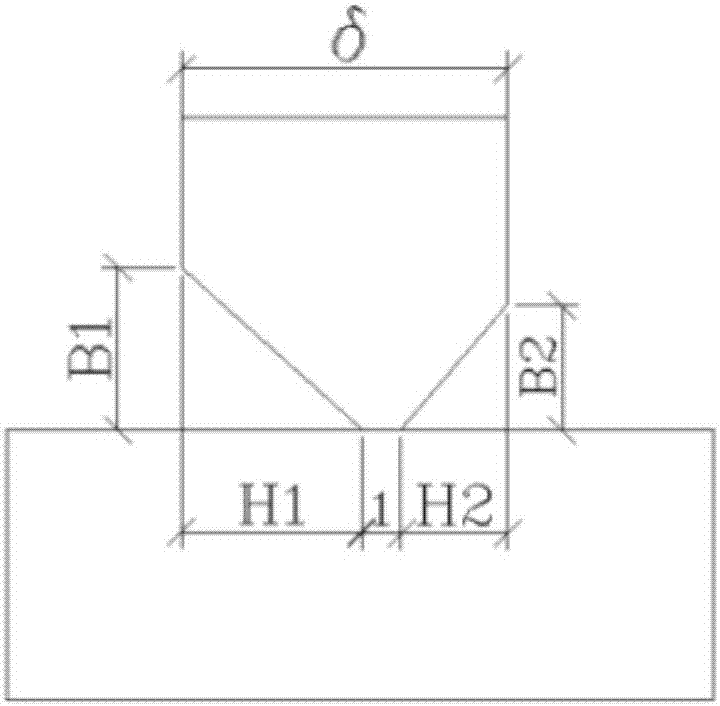

Welding method for Q420qENH coating-free weathering steel for steel bridge

InactiveCN106956064AGuaranteed compatibility of ingredientsSolve weather resistanceArc welding apparatusWelding/cutting media/materialsFillet weldWeather resistance

A welding method of Q420qENH coating-free weather-resistant steel for steel bridges, the Q420qENH coating-free weather-resistant steel has an atmospheric corrosion resistance index I≥6.5, a welding sensitivity index Pcm≤0.23, and when the welded joint form is a butt weld, The combined welding process of solid wire gas-shielded welding for backing and submerged arc automatic welding for filling and covering is adopted; when the welding joint form is T-shaped penetration fillet weld, the gas-shielded welding process of flux-cored welding wire is adopted; the welding joint form is single-sided bridge deck When welding double-sided formed joint welds, a combined welding process of solid wire gas shielded welding for bottoming and submerged arc automatic welding for filling and covering is used. The atmospheric corrosion resistance index I of the welding wire in the present invention is ≥ 6.5, and the relative corrosion rate of the deposited metal is ≤ 8%, which ensures that the welding seam matches the composition of the steel plate, and solves the weather resistance of the welding seam of the coating-free weather-resistant steel. Coating the weather-resistant steel bridge solved the technical bottleneck.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

High-strength weathering steel thin strip and production method thereof

Owner:SHAGANG GROUP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com