Weathering steel with yield strength of more than 700MPa and manufacturing method thereof

A weathering steel, controlled cooling technology, applied in temperature control and other directions, can solve the problems of increasing manufacturing cost and manufacturing difficulty, unfavorable steel plate welding and toughness, affecting welding performance, etc., achieving excellent atmospheric corrosion resistance and reducing use and maintenance costs. , Guarantee the effect of the supply cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

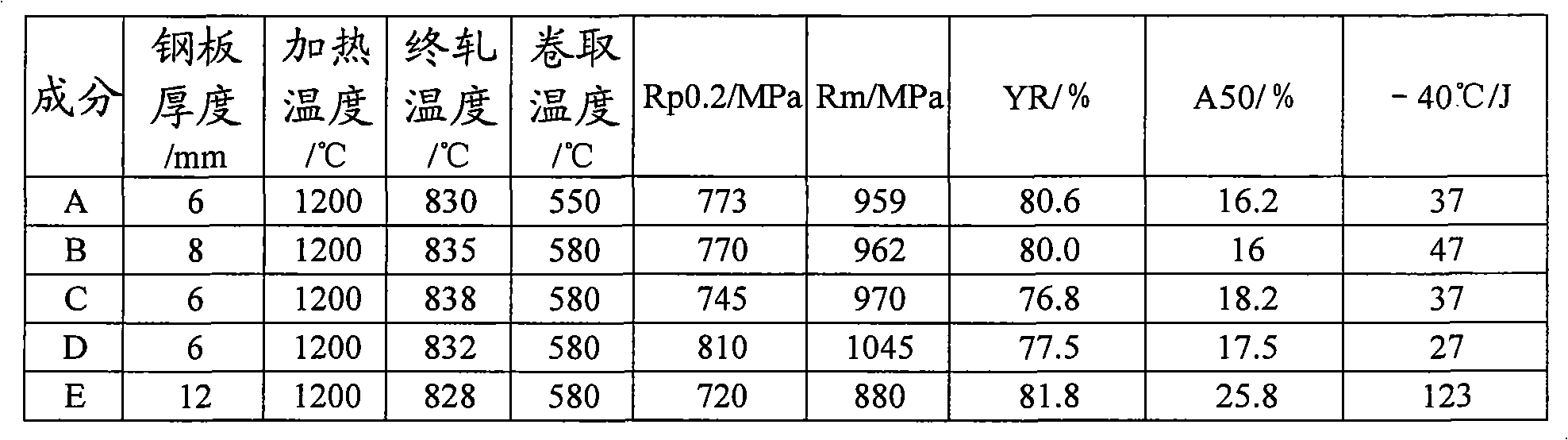

[0033]According to the composition requirements of the steel grade of the present invention, the steel of the present invention was smelted on a 500 kg vacuum induction furnace in a laboratory, and the chemical composition of each embodiment is shown in Table 1. The billet heating temperature is above 1200°C, the final rolling temperature is 800-900°C, after rolling, it is cooled to 550°C-650°C for coiling, and then air-cooled to room temperature. The mechanical properties of the obtained steel are shown in Table 2.

[0034] The chemical composition (wt %) of each embodiment of the present invention of table 1

[0035] Element

[0036] Table 2 The mechanical properties of each embodiment steel of the present invention

[0037]

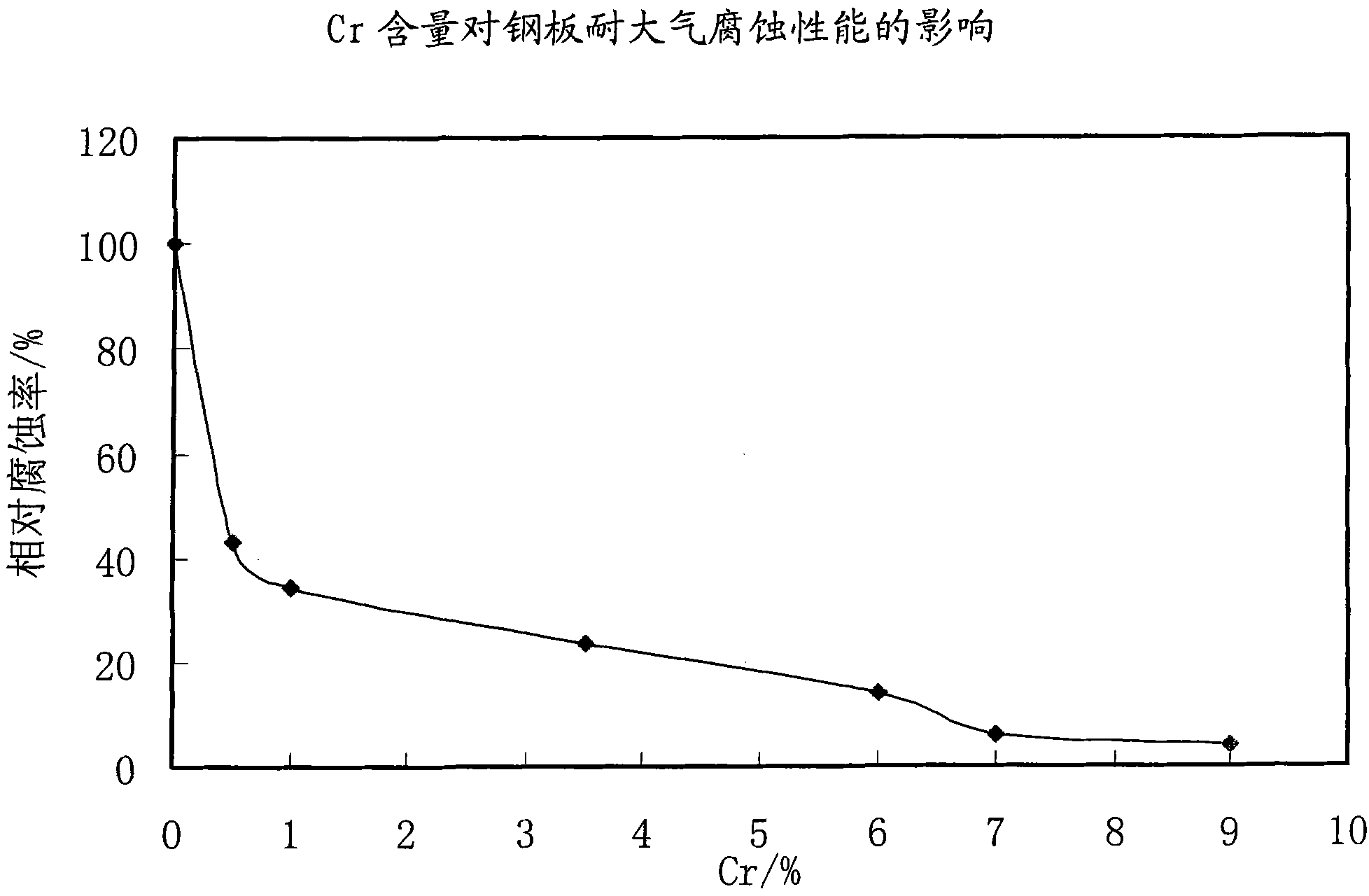

[0038] Taking ordinary carbon steel Q345B and high-strength weathering steel Q450NQR1 as comparison samples, a 72h periodic infiltration and cyclic corrosion test was carried out according to the periodic infiltration corrosion test metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com