A kind of high corrosion-resistant and weather-resistant steel and its manufacturing method

A manufacturing method and technology of weathering steel, which are applied in the field of weathering steel and its manufacturing, can solve the problems of inability to meet the needs of weathering steel for high strength and weight reduction in atmospheric corrosion resistance, failure to use without coating, and low corrosion resistance alloys, etc. Achieve the effect of shortening the supply cycle, reducing the use and maintenance costs, and excellent low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

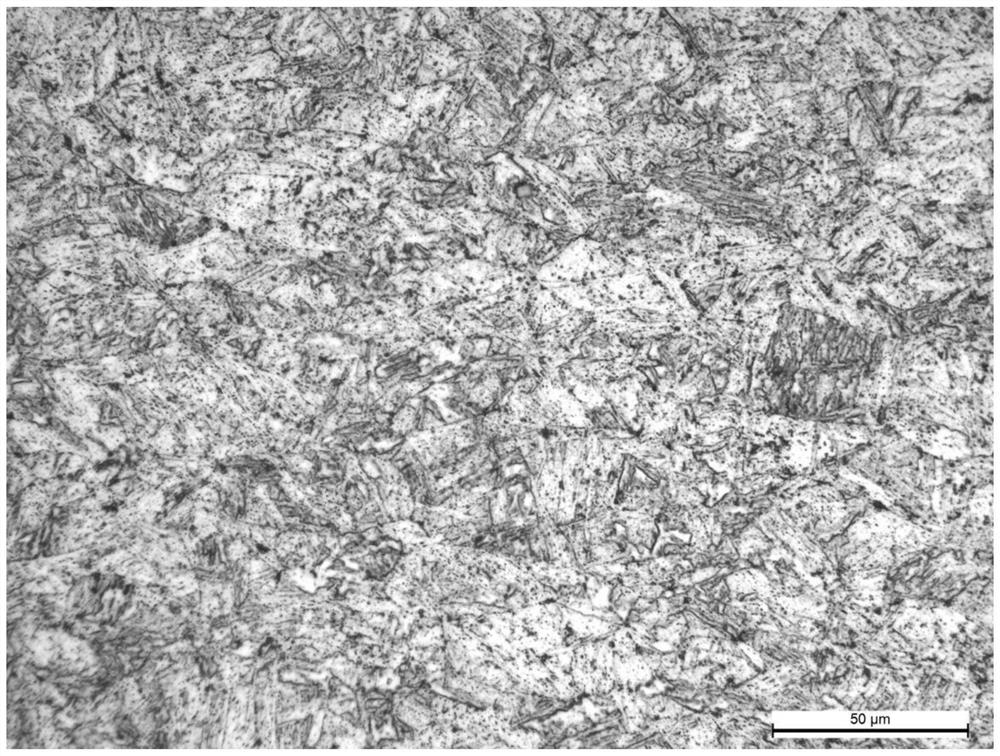

Image

Examples

Embodiment 1-6

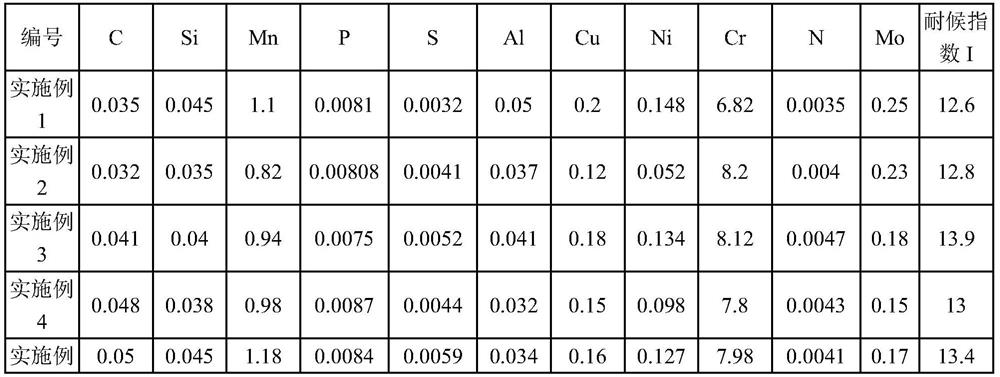

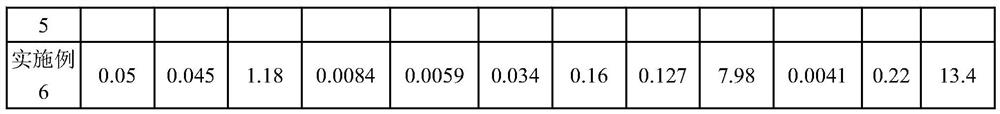

[0050] Table 1 lists the mass percentage (wt%) of each chemical element in the high corrosion-resistant and weather-resistant steel of Examples 1-6. Table 1. (wt%, the balance is Fe and other inevitable impurity elements except P, S and N)

[0051]

[0052]

[0053] It can be seen from Table 1 that compared with the prior art, each embodiment of this case does not use high content of P, but through reasonable element composition design, especially the combination of corrosion-resistant alloy elements (such as Cu, Ni and Cr) , to achieve a weather resistance index I of 12.0-14.0, and then achieve a significant improvement in corrosion resistance.

[0054] In addition, each embodiment of this case utilizes the solid solution strengthening of C and Cr and the phase transformation strengthening of C to improve the strength of the steel types involved in this case, especially the mass percentage of C controlled at 0.03-0.05%. There is no excessive carbide formation to avoid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com