Patents

Literature

373results about How to "Shorten the lead time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength weathering steel and method for producing same

InactiveCN101792888AImprove economyGood weather resistanceTemperature control deviceMetal rolling arrangementsChemical compositionImpurity

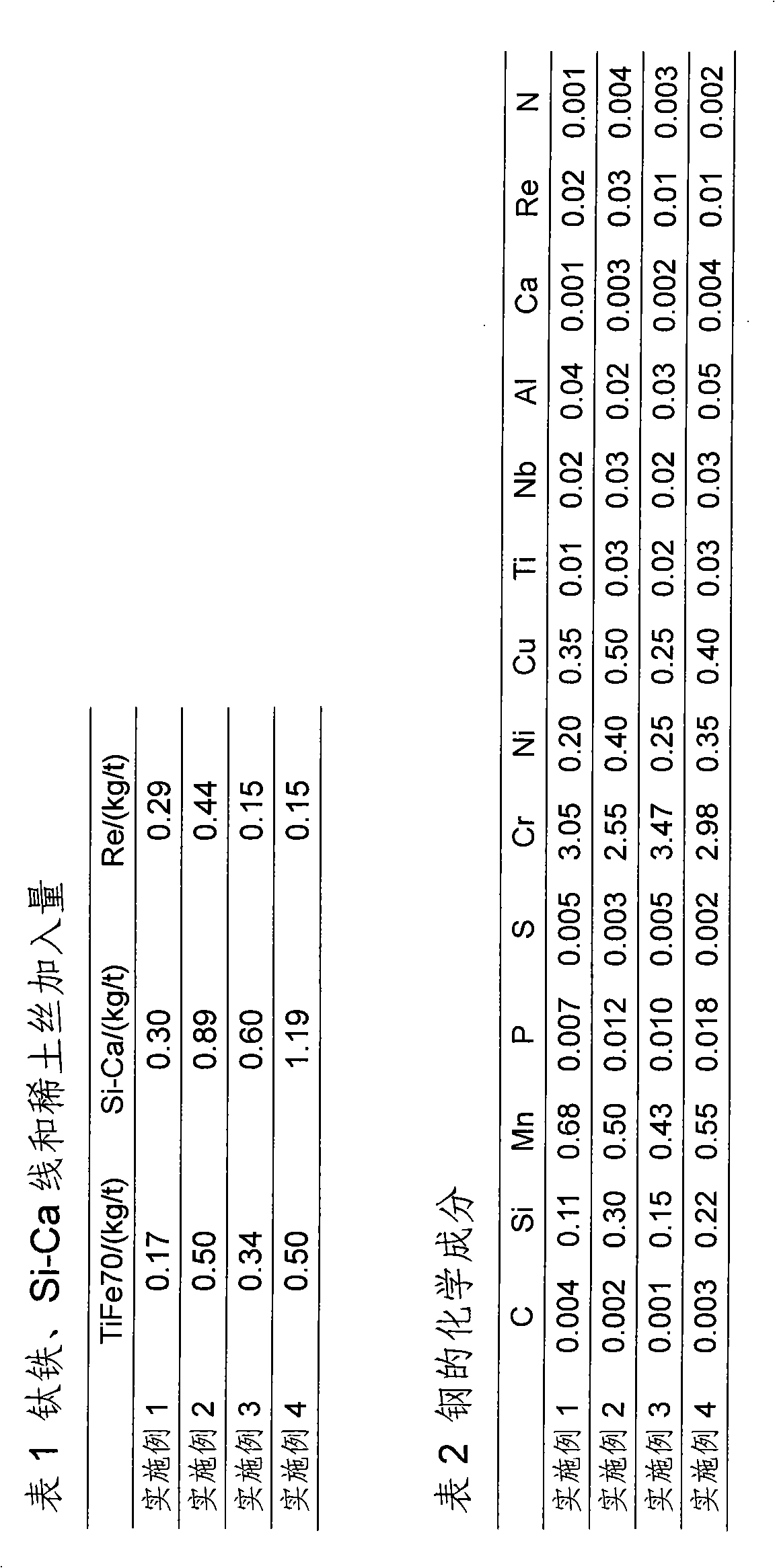

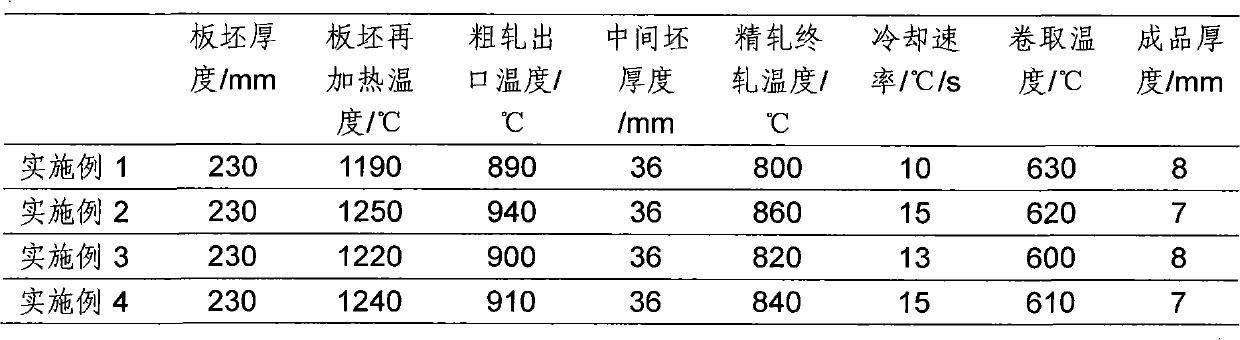

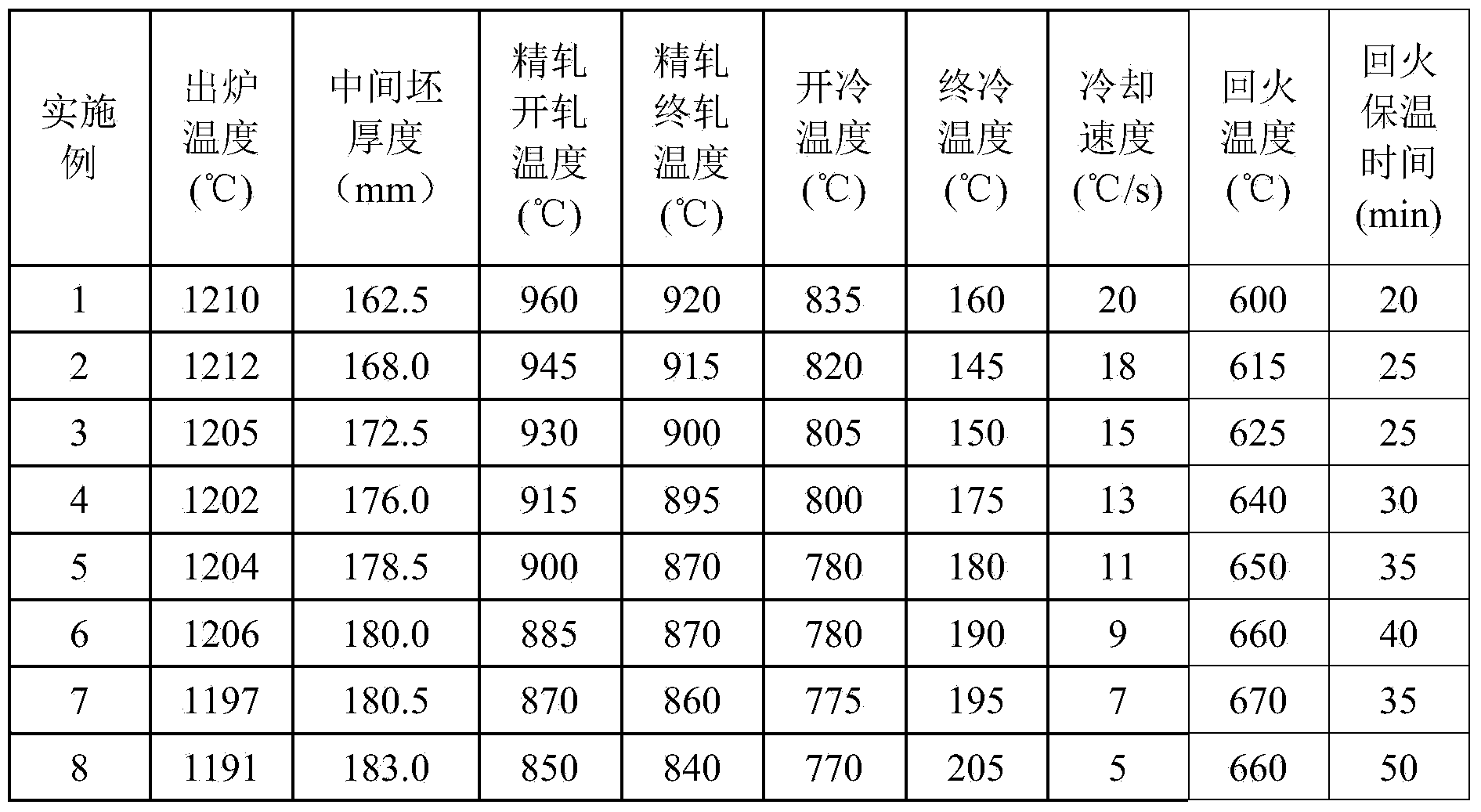

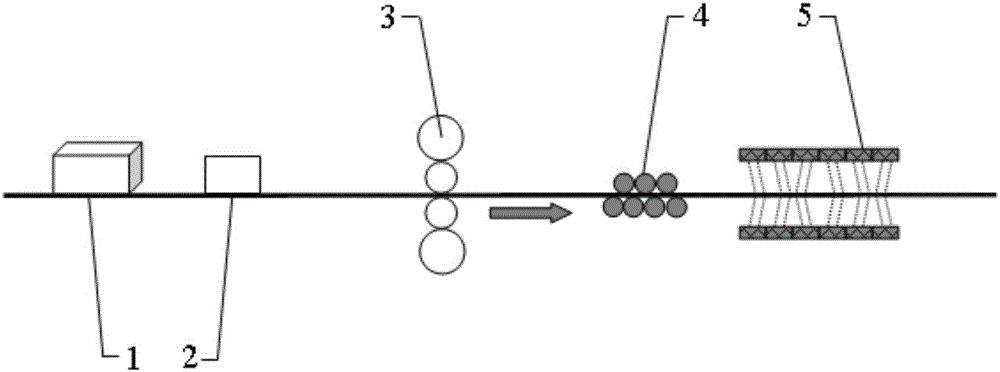

The invention relates to high-strength weathering steel and a method for producing same. The high-strength weathering steel comprises the following components by weight percent (wt%): 0.001-0.004 percent of C, 0.10-0.30 percent of Si, 0.40-0.70 percent of Mn, 0.020 percent of P or less, 0.008 percent of S or less, 2.50-3.50 percent of Cr, 0.20-0.40 percent of Ni, 0.25-0.50 percent of Cu, 0.01-0.03 percent of Re, 0.02-0.06 percent of Al, 0.001-0.004 percent of Ca, 0.001-0.005 percent of N, 0.01-0.03 percent of Ti, 0.01-0.03 percent of Nb and the balance of Fe and other inevitable impurities. After the molten iron is fully deoxidized and before the refining of the molten iron is finished, ferrotitanium is added to steel ladle, a Ca wire is fed to the steel ladle, a Re wire is fed into a continuous casting crystallizer, and a slab is reheated at 1180-1300 DEG C; the two-stage controlled rolling is adopted; the ratio of the thickness of the intermediate slab to the thickness of the finished product is controlled at 3.0; the refining outlet temperature is controlled at 890-1050 DEG C; the finishing rolling temperature is controlled at 800-860 DEG C; the rate of cooling after finishing rolling is controlled at 10-15 DEG C per second; and the winding temperature is controlled at 580-640 DEG C. The invention has the advantages that the relative corrosion rate of the weathering steel subjected to the 72h periodic infiltration is less than 30 percent compared with that of the steel Q345B, the weathering performance of the weathering steel is obviously better than the traditional high-strength weathering steel, and the weathering steel of the invention has the yielding strength of more than 550 Mpa and the elongation rate of more than 24 percent. The high-strength weathering steel of the invention can be applied to the fields of the railway truck, the container, the bridge, the communication, the power tower and the like.

Owner:SHOUGANG CORPORATION +1

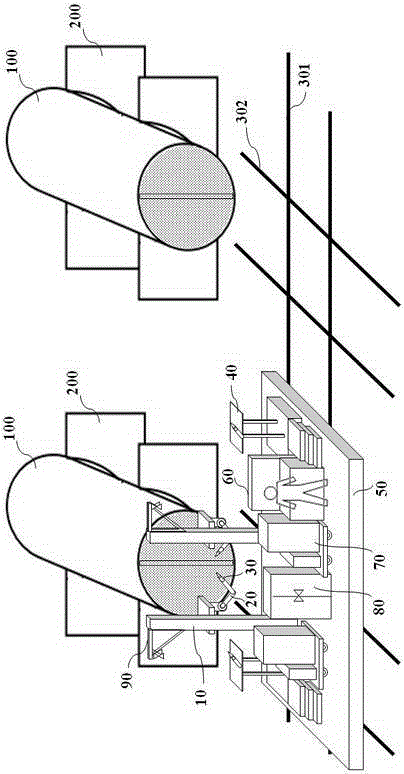

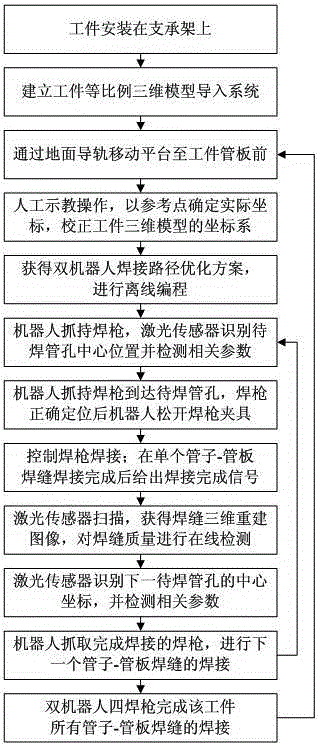

Robot welding system and welding method thereof

ActiveCN105195868AImprove work efficiencyHigh repeatabilityProgramme-controlled manipulatorHeat exchange apparatusLaser scanningVapor generator

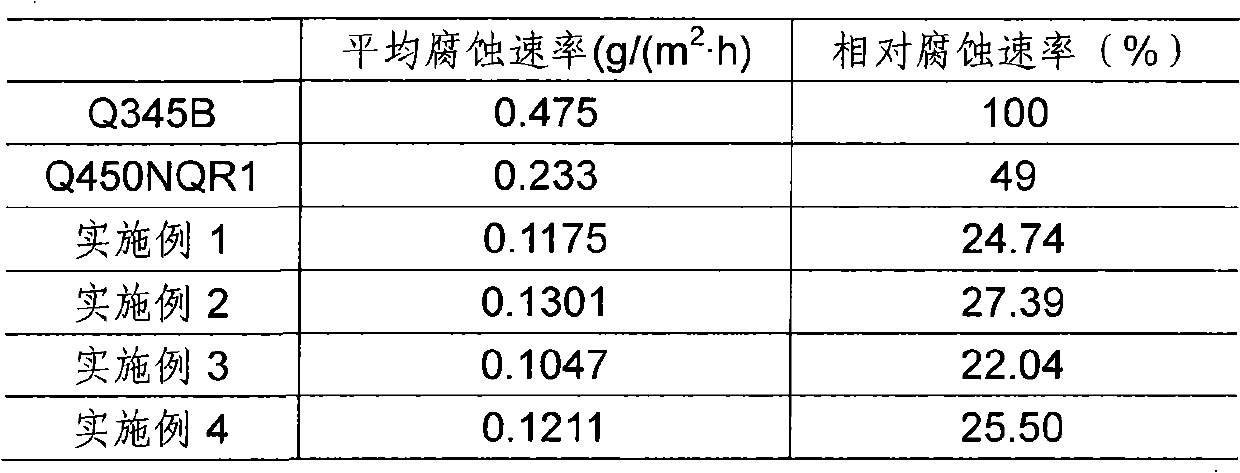

The invention provides a robot welding system and a welding method thereof and suitable for pipe-pipe plate welding for a vapor generator of a main device in a nuclear island. According to the invention, a path planning and off-line programming module is used for planning an anti-collision welding path for an industrial robot and performing off-line programming on a planned scheme; a laser scanning positioning module obtains the circle centre coordinate of a pipe hole according to scanning results and performing initial welding position identification and autonomous guiding; the two industrial robots controlled by a central control module are matched with four pipe-pipe plate welding guns to perform welding on all pipe-pipe plate welding lines on a pipe plate; and an on-line welding line quality detection module obtains a three-dimensional reconstruction image according to welding line laser scanning results and performing on-line detection on welding line quality according to morphologies of the welding lines. Due to adoption of the system and the method disclosed by the invention, the pipe-pipe plate welding efficiency is improved, and the stability of the welding line quality is ensured.

Owner:SHANGHAI ELECTRIC NUCLEAR POWER EQUIP CO LTD

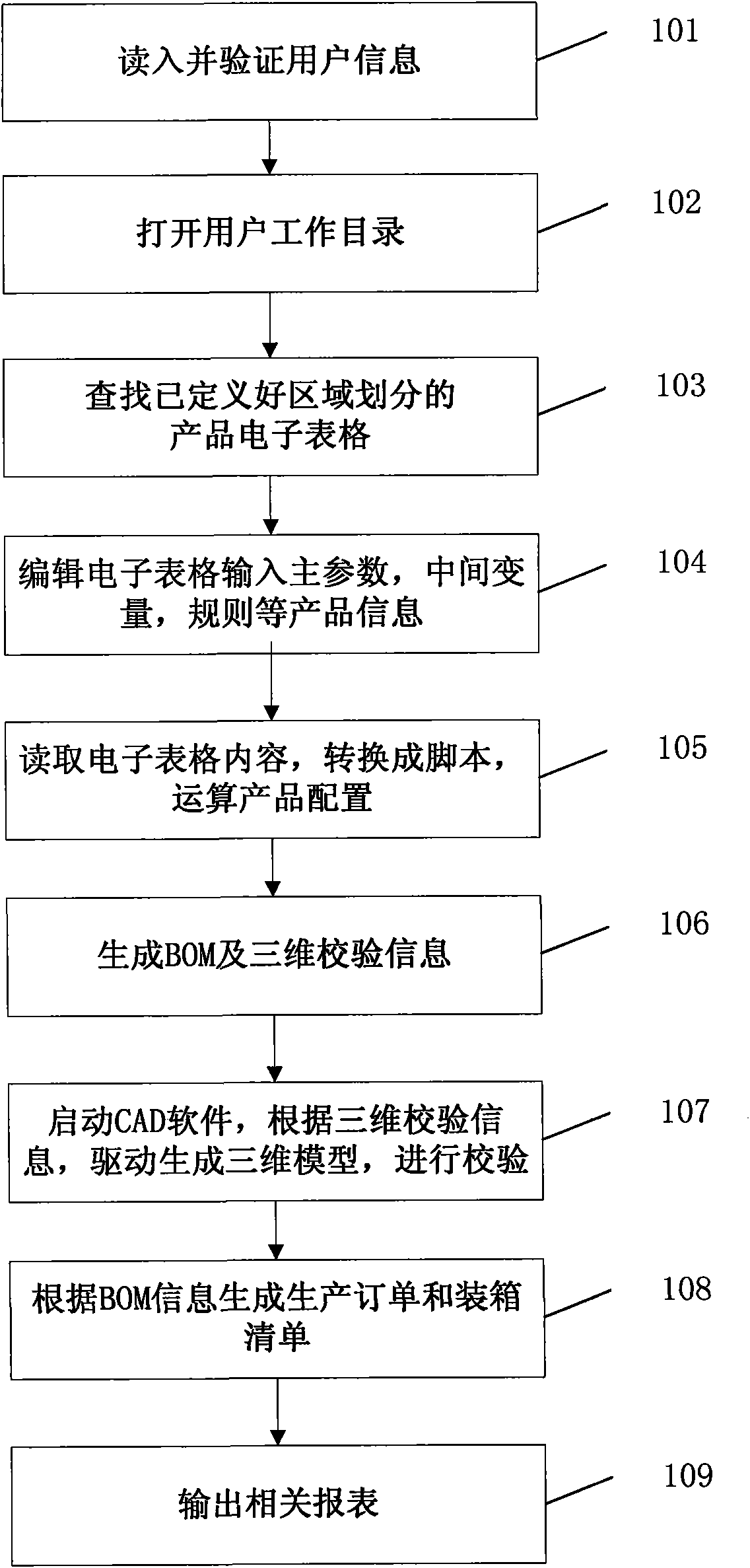

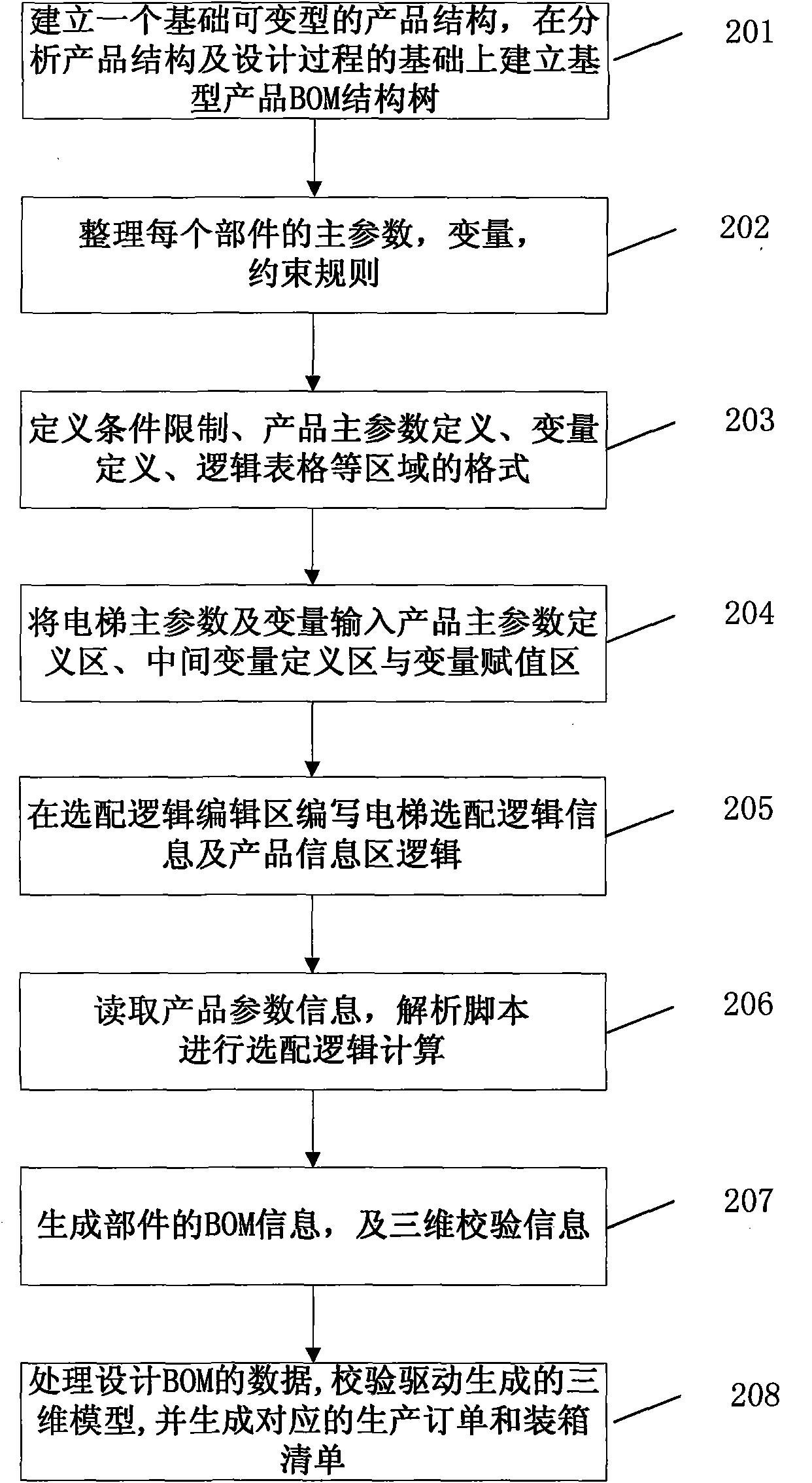

Method and device for realizing automatic product configuration by utilizing spreadsheet definition rule

InactiveCN102044016AEasy to compileReduce training costsResourcesSpecial data processing applicationsBill of materialsCad system

The invention relates to a method and device for realizing automatic product configuration by utilizing spreadsheet definition rule. The method comprises the following steps: defining a spreadsheet structure and inputting product related / configuration parameters; reading matching rules of spreadsheet definition by a system; automatically completing product matching by the system; after matching operation is completed, obtaining BOM (bill of material) data of the product by the system; and supporting importing the BOM data of the product into a three-dimensional CAD (computer aided design) system for design verification. The device comprises a data reading module, a formula management module, a naming management module and a formula generating module. The invention has the following beneficial effects: the spreadsheet form is used for replacing the traditional logical judgement program expression form; and the system modifies configuration conveniently and can automatically carry out non-standard design and customized contract processing rapidly and accurately, thus improving the accuracy and reducing the production cost.

Owner:SHENYANG NEU ZXTECH TECH

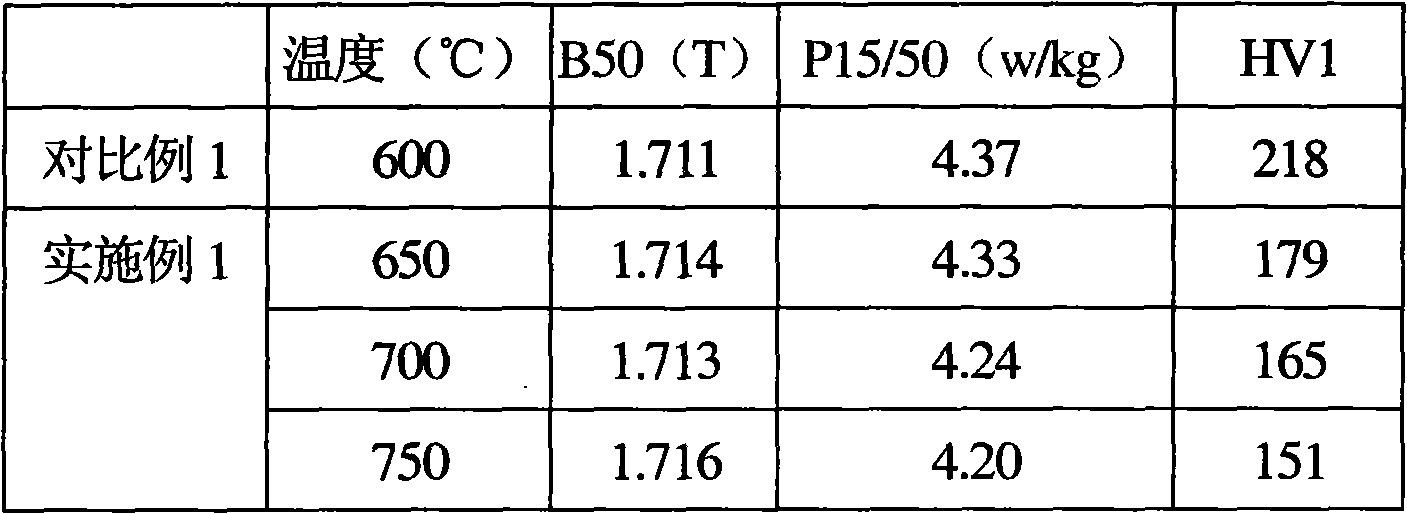

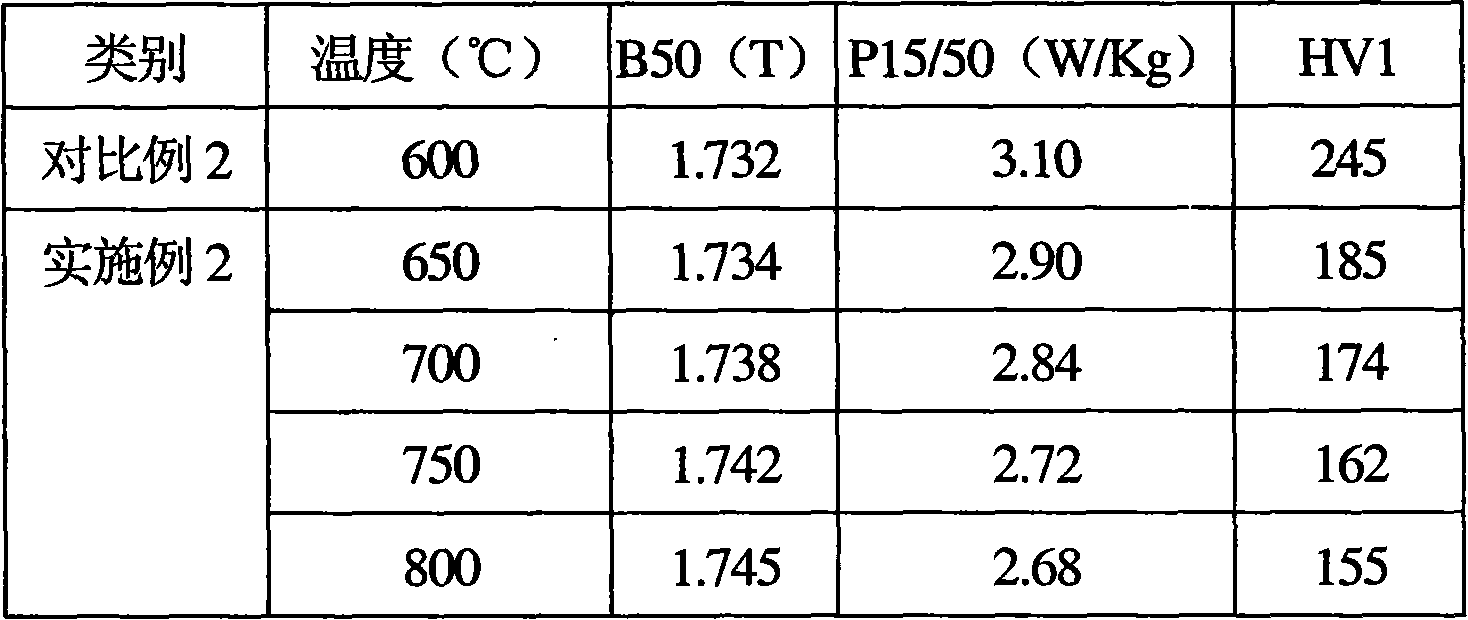

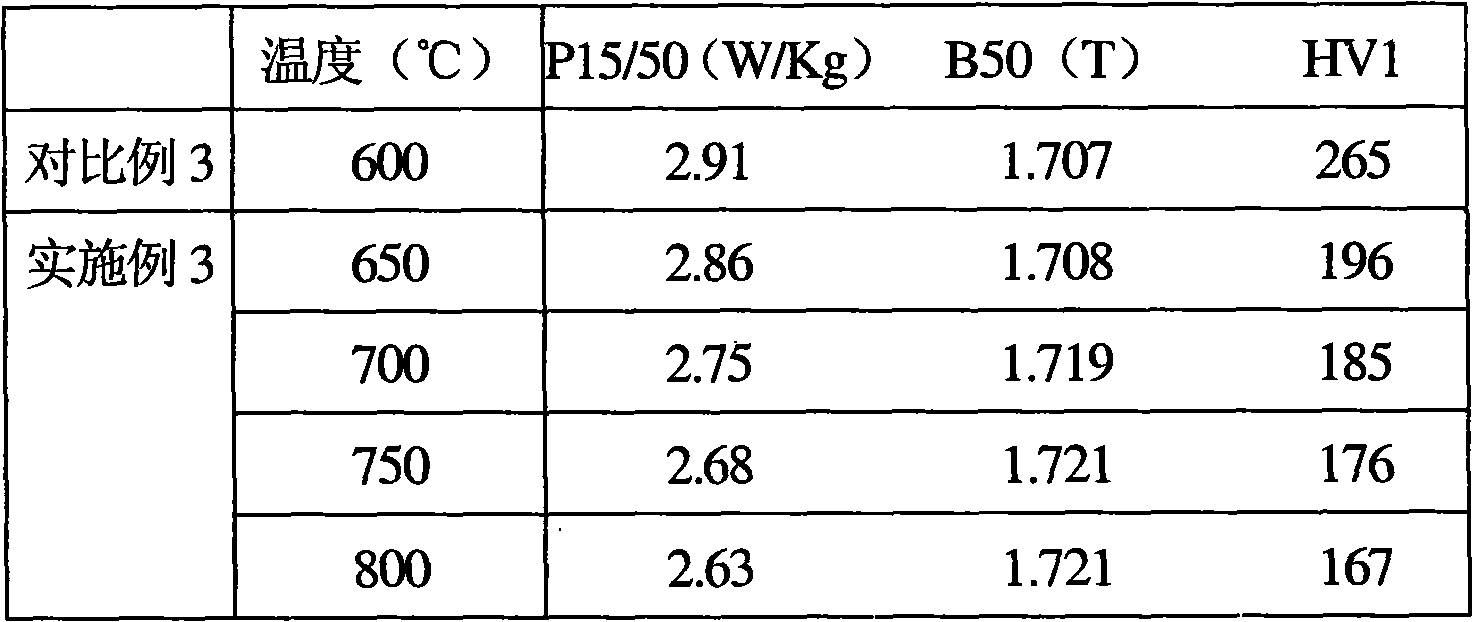

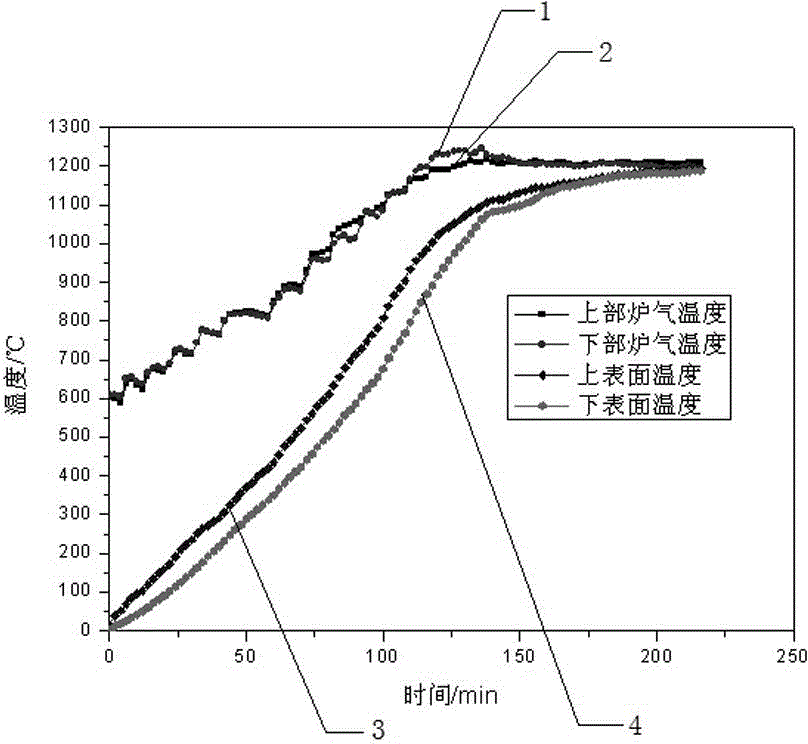

Coated semi-processed non-oriented electrical steel sheet and manufacturing method thereof

InactiveCN101654757AFulfil requirementsReduce iron lossFurnace typesHeat treatment furnacesChemical compositionSheet steel

The invention provides a coated semi-processed non-oriented electrical steel sheet and a manufacturing method thereof. The steel sheet comprises the following chemical compositions in percentage by mass: less than or equal to 0.003 percent of C, 1.00 to 2.30 percent of Si, 0.20 to 1.00 percent of Mn, 0.01 to 0.10 percent of P, 0.20 to 0.80 percent of Al, less than or equal to 0.005 percent of S, less than or equal to 0.005 percent of N, and the balance of Fe and inevitable impurities. The manufacturing method does not need electromagnetic stirring in slab continuous casting; when the content of Si is between 1.65 to 2.30 percent, a normalizing treatment procedure is added before the step of pickling; and an annealing condition is that: a temperature is between 650 and 800 DEG C, the annealing time is between 1 and 4 minutes and the annealing is carried out in a dry atmosphere of whole nitrogen. The coated semi-processed non-oriented electrical steel sheet has low iron loss, high magnetic induction, good mechanical property, simple procedure and low production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

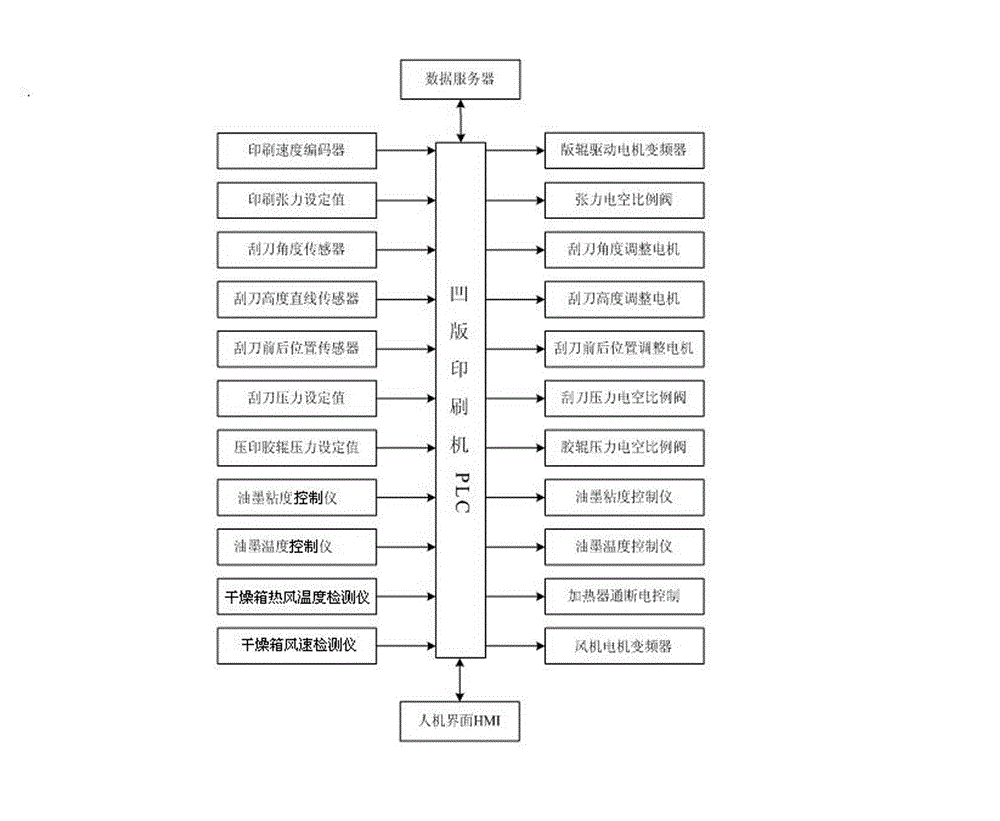

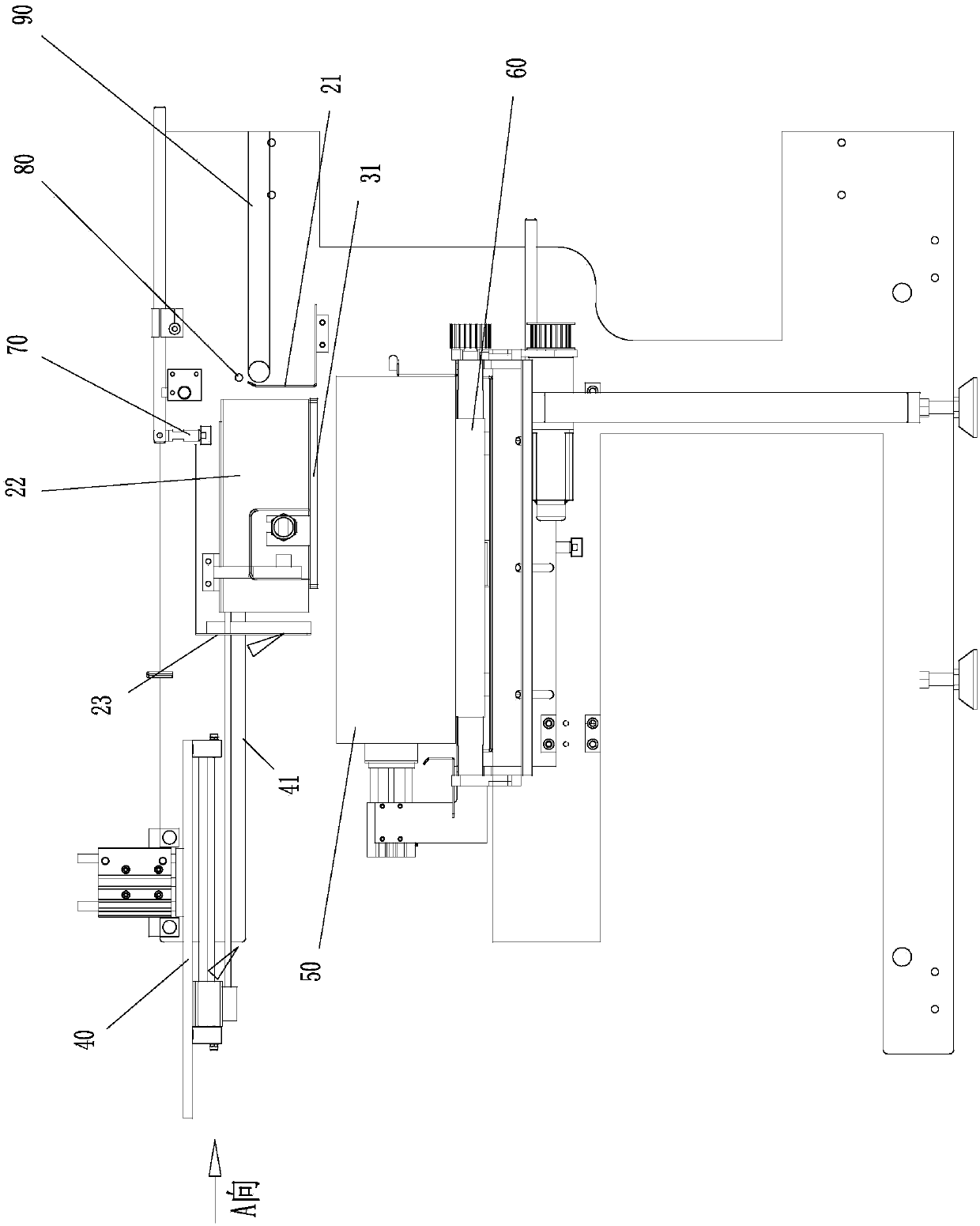

Intaglio press based on color management operation system

ActiveCN102717586ASimplify labor intensityReduce printing costsRotary intaglio printing pressPrinting press partsElectrical controlProgrammable logic controller

The invention relates to a press, in particular to an intaglio press based on a color management operation system, and solves the problems that labor strength is high, yield is low, printing cost is increased, and the like in the existing intaglio press. The intaglio press comprises an automatic ink feeding device, a scraper height adjusting mechanism, a scraper angle adjusting mechanism, a scraper longitudinal-position adjusting mechanism, a PLC (programmable logic controller) system and an electrical control system composed of a human machine interface and a data server. Ink strength controllers and ink temperature controllers are mounted on the automatic ink feeding device. The scraper height adjusting mechanism is achieved through a pinion and rack mechanism, the scraper angle is adjusted by a worm and gear mechanism, and the longitudinal position of a scraper is adjusted by a screw rod mechanism, so that labor strength of printing operators is simplified, waste of ink and printing stock caused in an initial printing adjusting procedure is reduced, printing cost is reduced, delivery cycle is shortened, speed and registering accuracy of the whole press are increased, and efficiency and yield are high.

Owner:YUNCHENG PLATE MAKING PRINTING MACHINERY MFG

On-line quenching and plate shape controlling technology for 12MnNiVR steel plate

ActiveCN103555914AImprove cooling efficiencyReduce the number of transshipmentsRare end control deviceWork treatment devicesWater flowEconomic benefits

The invention discloses on-line quenching and plate shape controlling technology for a 12 MnNiVR steel plate, comprising: a blank material cold installation step, a de-scaling step, a rough rolling step, a finish rolling step, a pre-straightening step and an on-line quenching step; wherein in the on-line quenching step, the steel plate enters a ultrafast cooling system with 18 groups of cooling headers, the ultrafast cooling system sets a water flow amount based on the steel plate target thickness, sets an area roller-way speed being 0.7-1.2m / s, sets a roller-way acceleration being 0.003-0.01m / s2, controls a cooling start temperature being 790-740 DEG C, and controlling a cooling final temperature being 180-270 DEG C, and the steel plate departs from the ultrafast cooling system when a cooling final temperature is 180-270 DEG C. The technology provided by the invention raises cooling uniformity, cooling efficiency and once plate shape qualified rate of an on-line quenched steel plate, simplifies a thermal refining technology flow of 12MnNiVR, and finally raises economic benefit of enterprises.

Owner:NANJING IRON & STEEL CO LTD

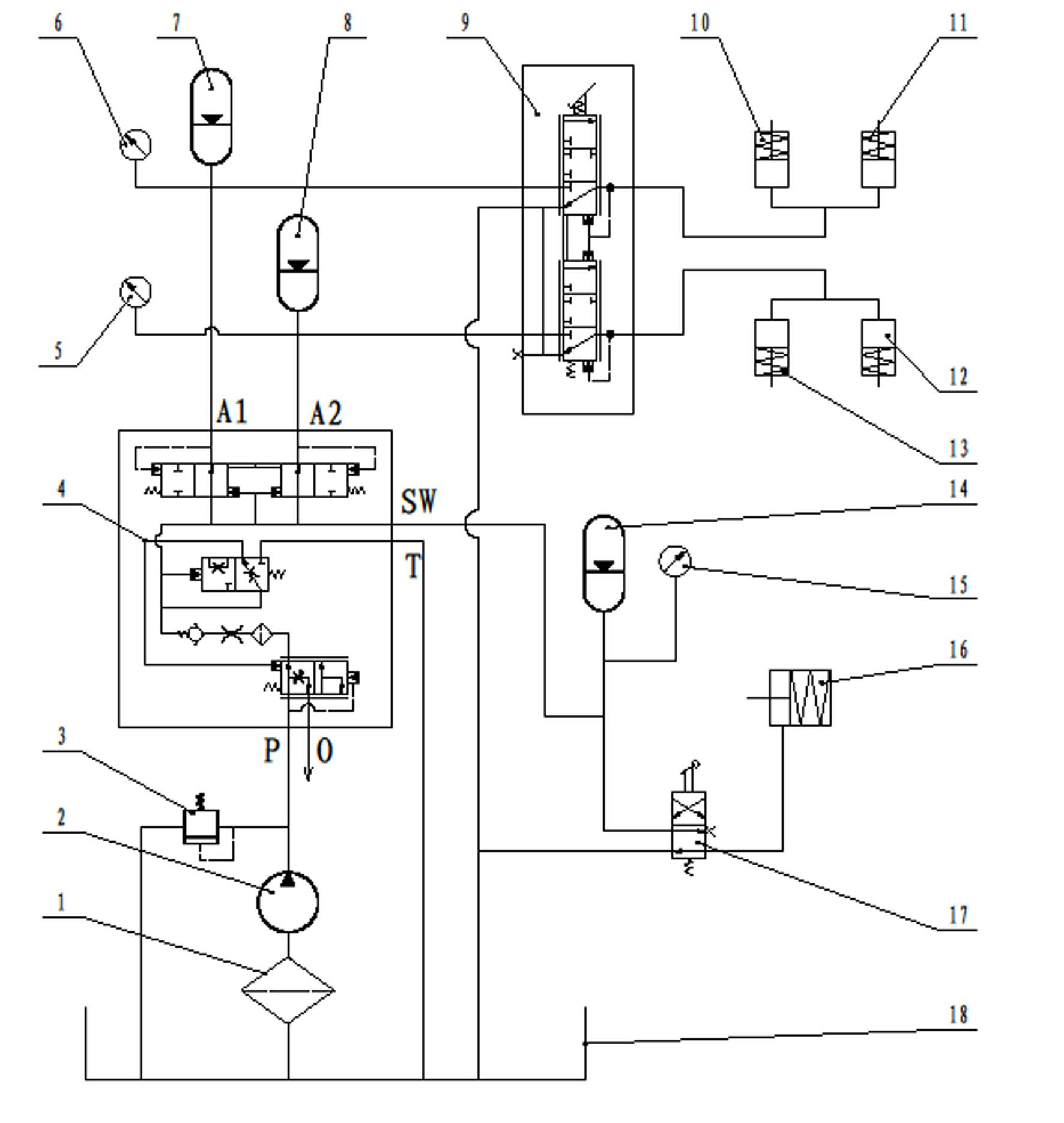

Double-tube fully-hydraulic braking device with closed wet-type multi-disc brakes for coal mine explosion-proof vehicle

ActiveCN102514562AImprove braking effectReduce labor intensityFluid braking transmissionDouble tubeHydraulic pump

The invention belongs to the technical field of braking devices of coal mine auxiliary conveying machinery, in particular to a double-tube fully-hydraulic braking device with closed wet-type multi-disc brakes for a coal mine explosion-proof vehicle. The invention aims to provide an explosion-proof, antipollution, stable, reliable and sensitive brand-new braking system. The braking device comprises a charging valve, wherein an oil feeding opening P of the charging valve is connected with a hydraulic pump, the oil opening A1 and opening A2 of the charging valve are connected with a front brake energy accumulator and a rear brake energy accumulator, and the oil opening SW is communicated with a parking braking oil pipe; the front and rear braking energy accumulators are connected with serial pedal braking valves respectively; the serial pedal braking valves are connected with a front service brake and a rear service brake respectively; parking braking energy accumulators are connected with parking braking valves; and parking braking valves are connected with parking brakes. The braking device meets the conditions for use in a special underground environment, can improve the braking efficiency and working efficiency and safety of the underground explosion-proof vehicle, reduce labor intensity, reduce casualty and accident rates and make underground conveying safer.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

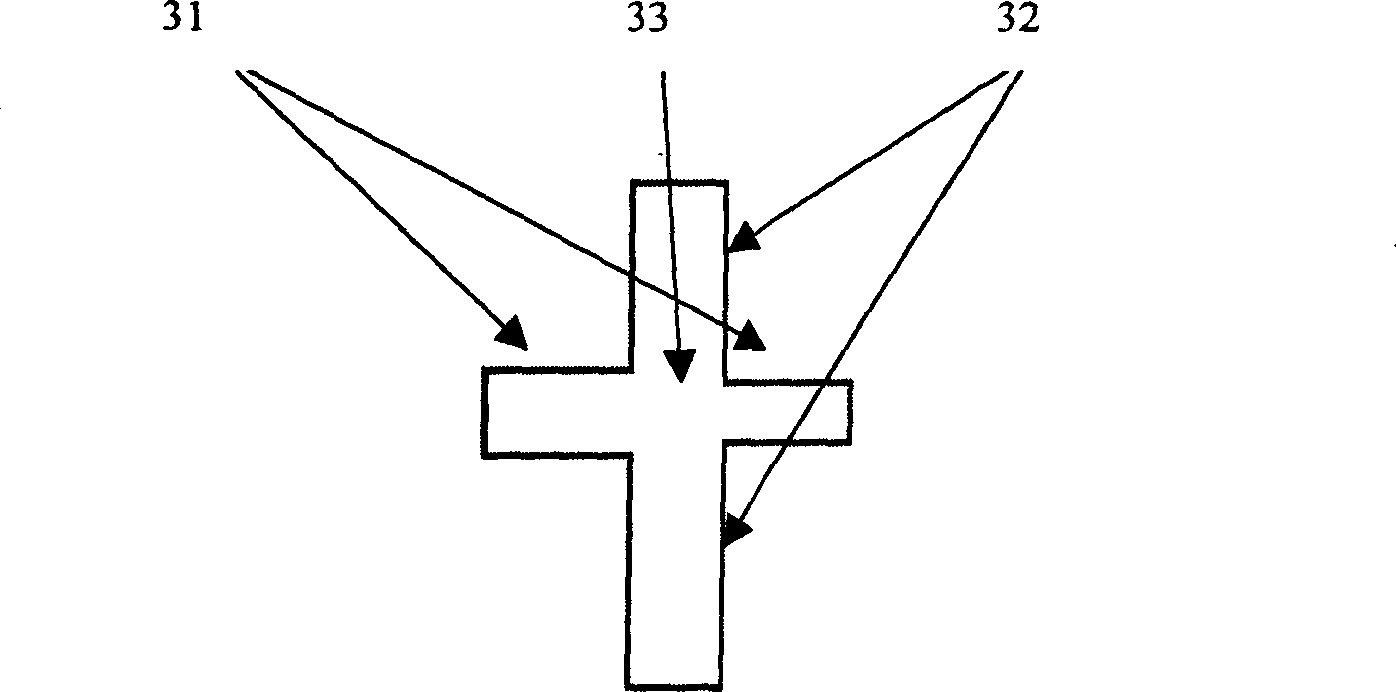

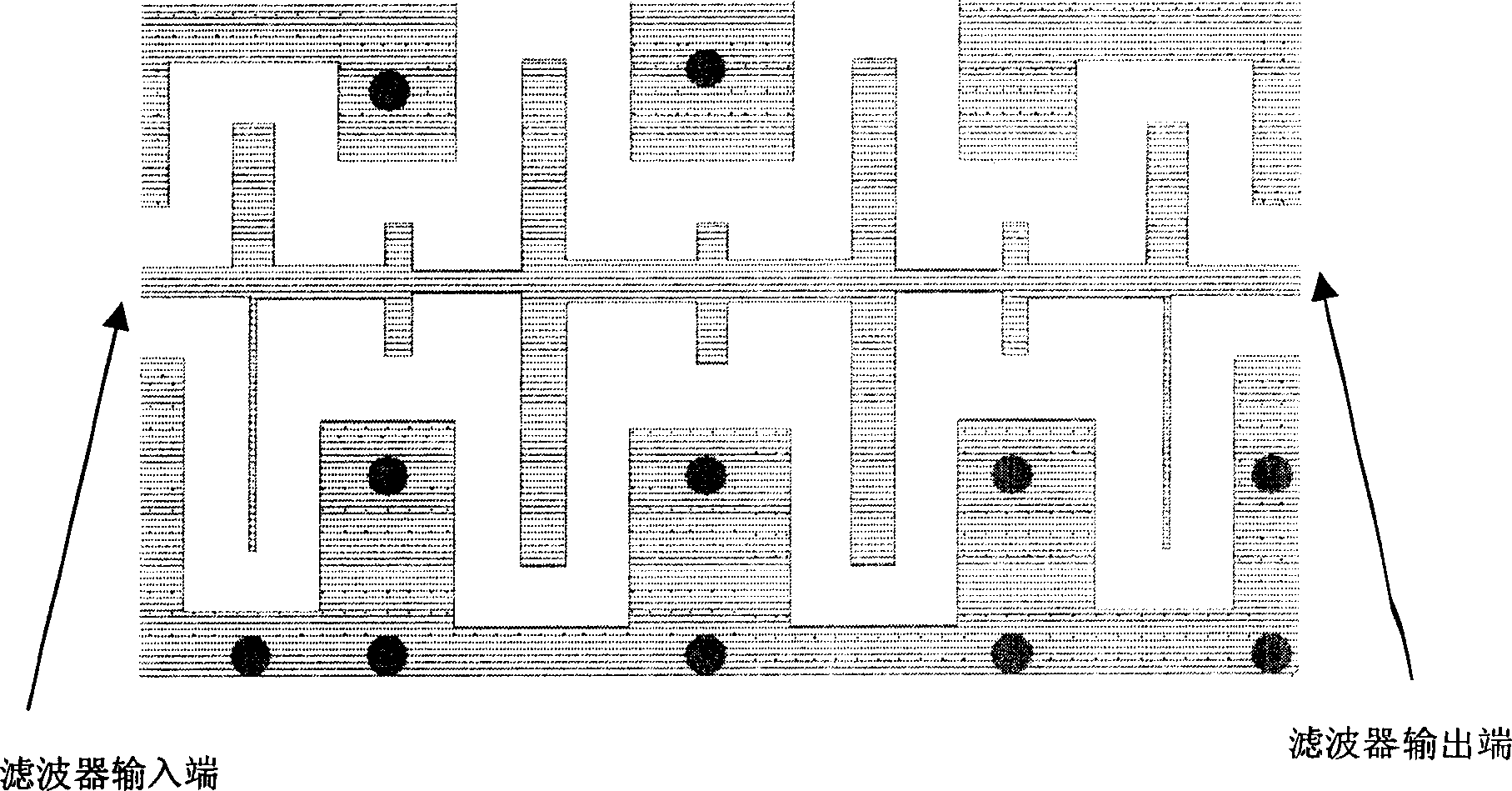

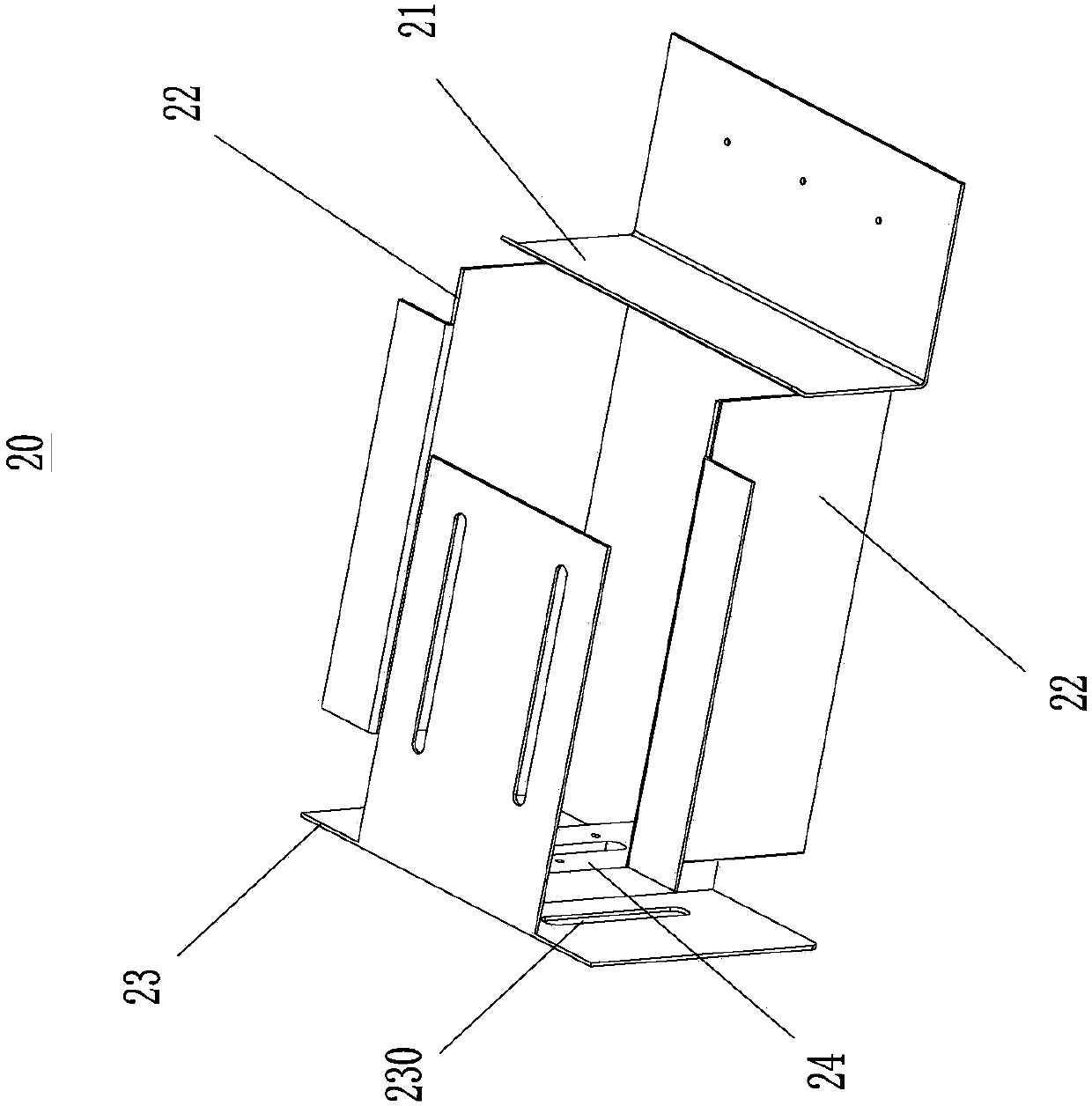

Suspended mictrostrip filter and duplexer and method for designing and debugging filter

InactiveCN1838476AHigh precisionImprove manufacturing yieldDiversity/multi-antenna systemsRadio relay systemsEngineeringLine filter

This invention discloses a suspending strip line filter and duplexer and filter's design and adjusting method. The filter includes a cavity formed by metal hull, the inner of the cavity has a PCB double-faced board which fixed at the side wall of the metal hull, between the up and down inner wall there has a certain air height; one side of PCB double-faced board etches cross nodel line transmission line with destined type. The frequency deviation index of the filter and duplexer is decided by the PCB double-faced board etches cross nodel line transmission line graph's processing precision, so it is easy to control and it has high disposal quality.

Owner:HUAWEI TECH CO LTD

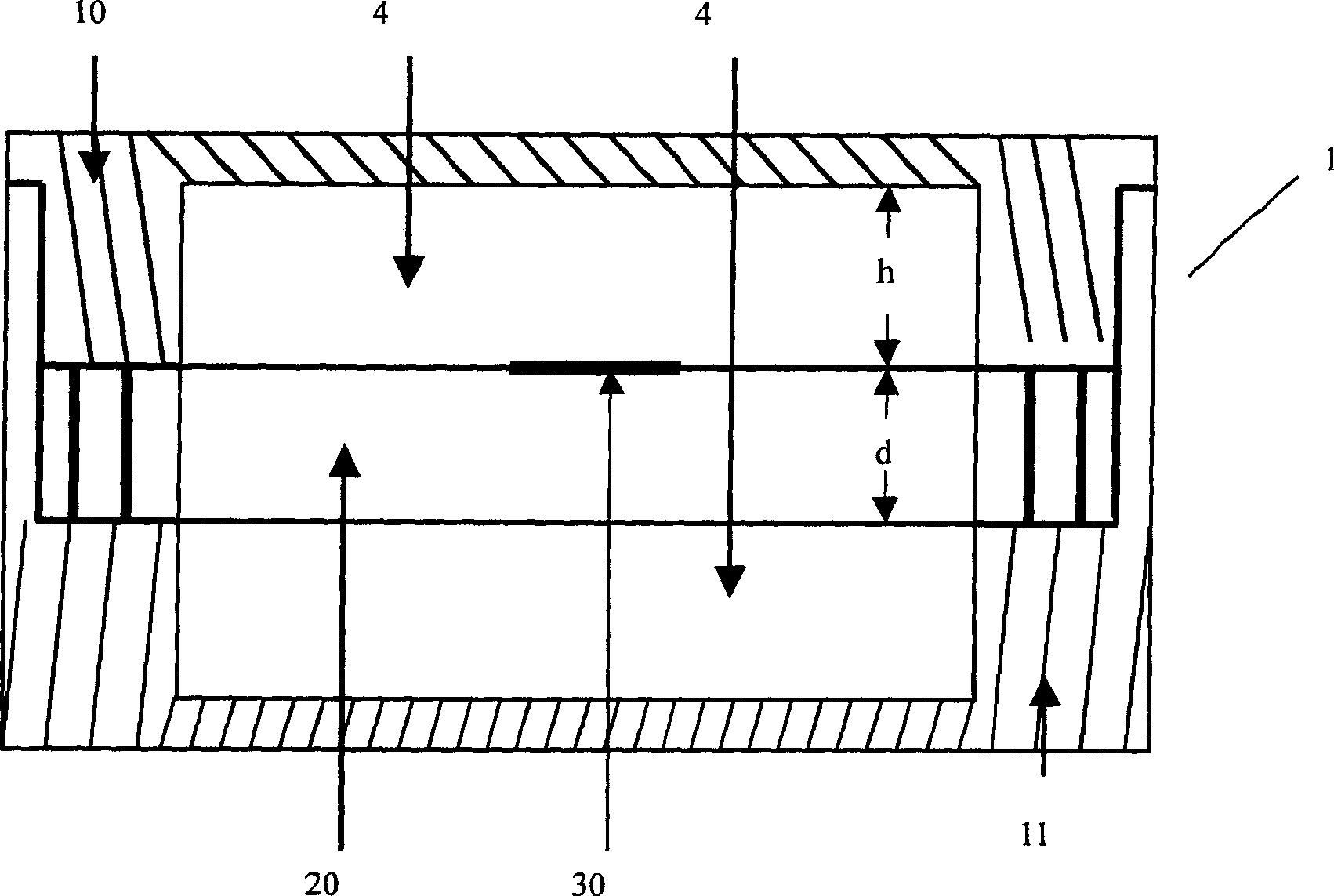

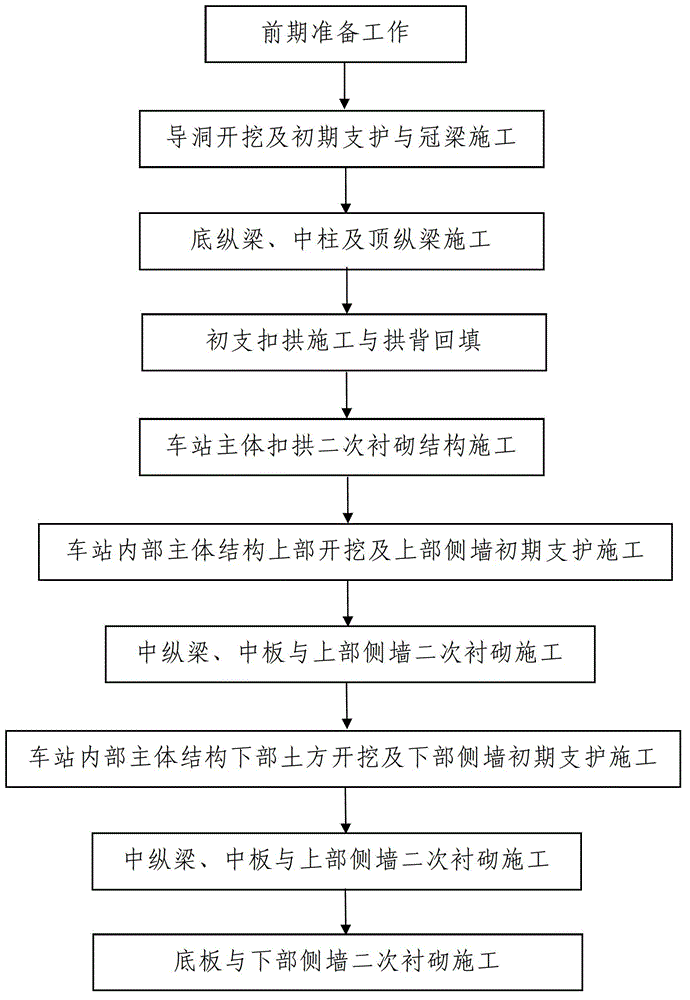

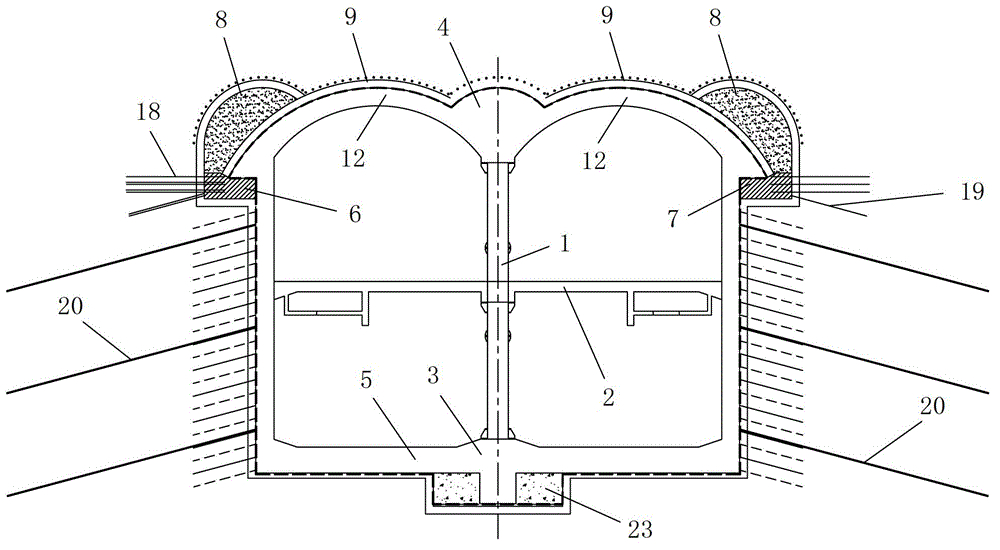

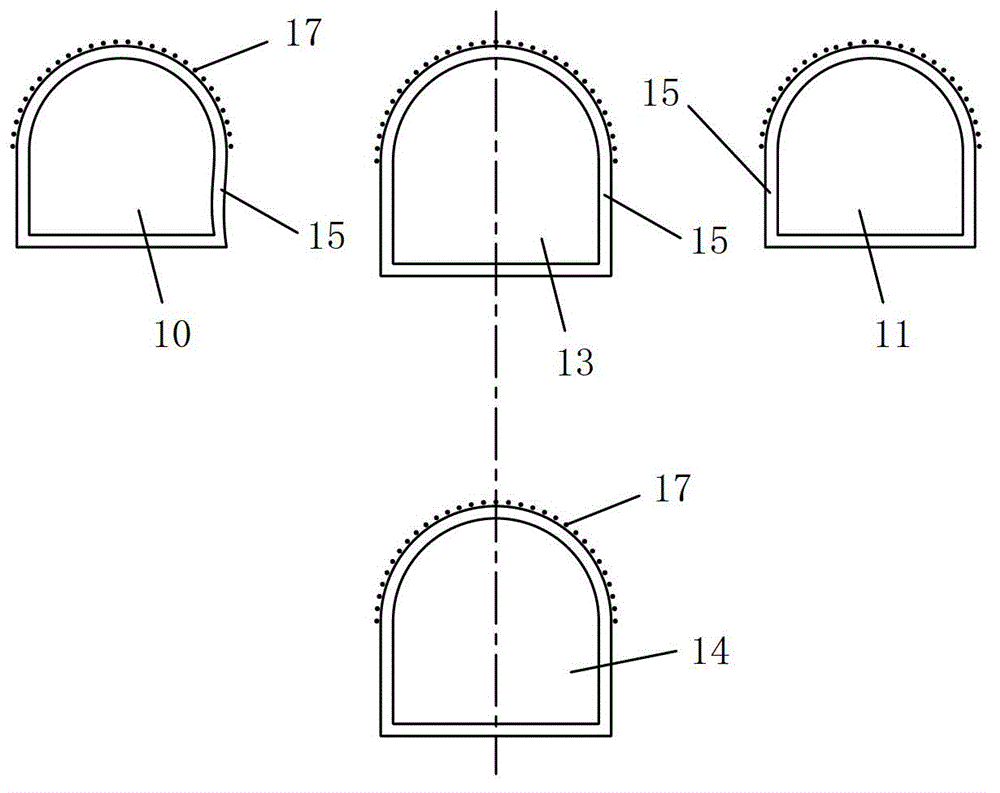

Main structure for metro long-span station and pillar arching construction method thereof

ActiveCN102748040AEasy constructionSimplify construction stepsUnderground chambersEngineeringLong span

The invention discloses a main structure for a metro long-span station and a pillar arching construction method thereof. The main structure comprises a station interior main structure, a plurality of middle pillars, a middle plate and a main arch part, wherein the station interior main structure is dug; the middle plate is located on the middle pillars; the main arch part is located right above the main structure; a bottom longitudinal beam is arranged at the bottom of the station interior main structure; a top longitudinal beam is arranged on the main arch part; and a middle longitudinal beam is arranged between adjacent middle pillars. The construction method comprises the following steps: 1) preparing in earlier stage; 2) digging a guiding hole and performing primary bracing and bridging construction; 3) constructing the bottom longitudinal beam, the middle pillars and the top longitudinal beam; 4) constructing a primary branch arch and refilling an arch back; 5) performing arch secondary lining construction; 6) digging the upper part of the main structure and constructing a primary branch of a side wall of the upper part; 7) performing secondary lining construction of the middle longitudinal beam, the middle plate and the side wall of the upper part; 8) digging the lower part of the main structure and constructing the primary branch of the side wall of the lower part; and 9) performing secondary lining construction for a base plate and the side wall of the lower part. The construction method provided by the invention has the advantages of reasonable design, simple construction step, convenience in realizing, small construction difficulty and high construction speed.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

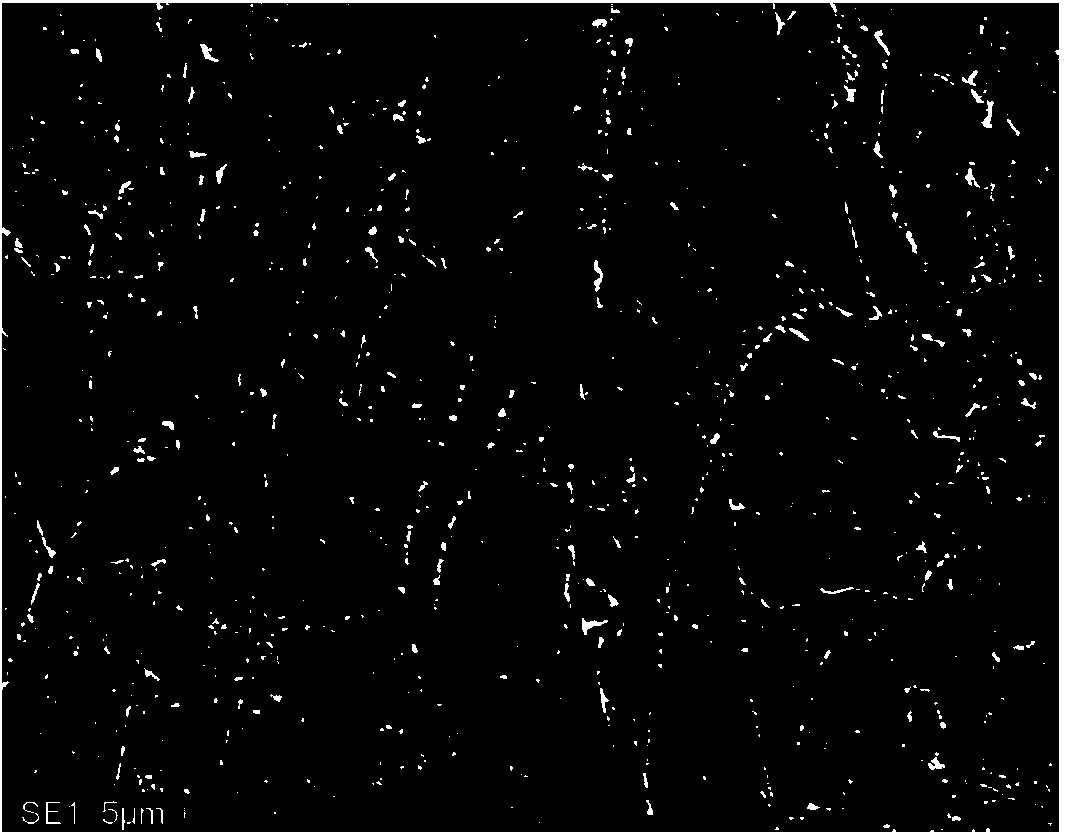

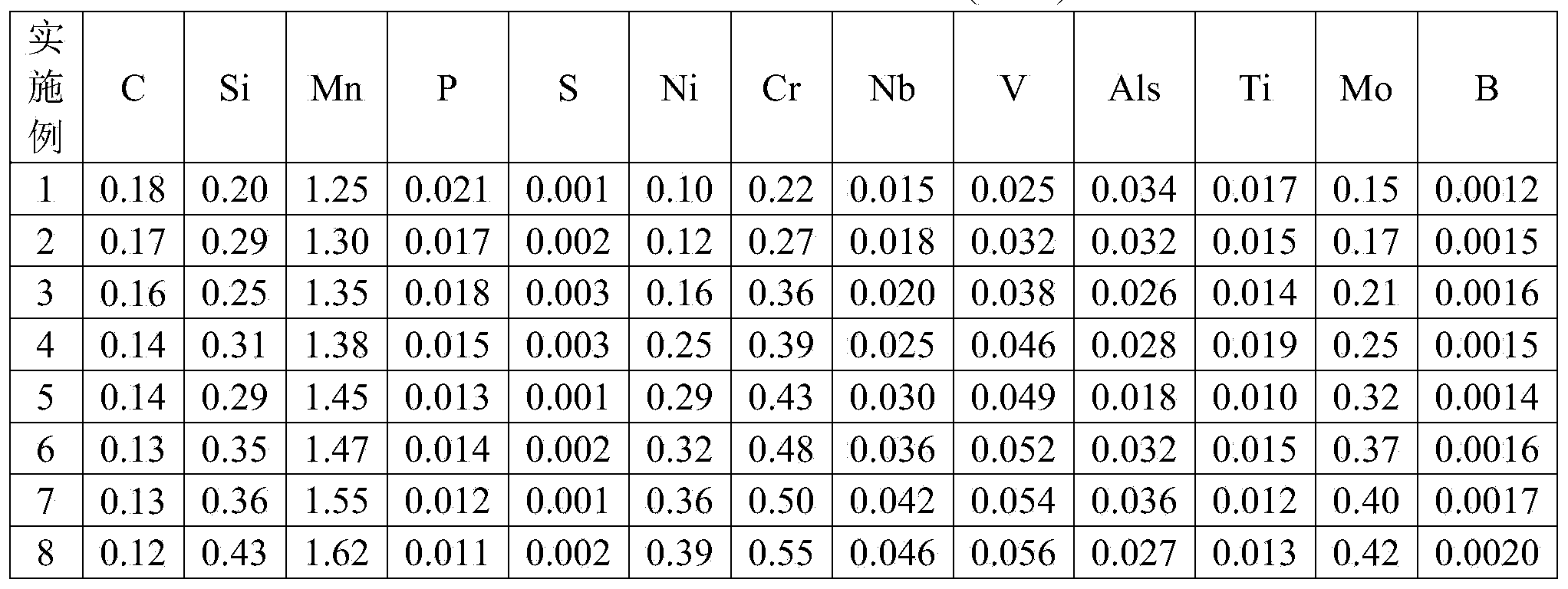

Steel plate with thickness of larger than 60mm and yield strength of 690MPa and preparation method of steel plate

The invention belongs to the fields of steel and iron and particularly relates to a steel plate with the thickness of larger than 60mm and the yield strength of 690MPa. The steel plate contains the following chemical components in percentage by weight: 0.10-0.20% of C, 0.15-0.50% of Si, 1.20-1.70% of Mn, 0.10-0.40% of Ni, 0.20-0.60% of Cr, 0.01-0.05% of Nb, 0.02-0.06% of V, 0.015-0.050% of Als, 0.008-0.025% of Ti, 0.15-0.45% of Mo, 0.0008-0.0030% of B, less than or equal to 0.025% of P, less than or equal to 0.008% of S, less than or equal to 40ppm of N, less than or equal to 20ppm of O, less than or equal to 2ppm of H and the balance of Fe and unavoidable impurities. The steel plate provided by the invention has favorable mechanical properties, plasticity and toughness, has the yield strength of larger than or equal to 690MPa, and can be applied to manufacture of large engineering machines or steel structures such as hydraulic supports for coal mines, heavy engineering machines, ocean platforms and the like.

Owner:SHANDONG IRON & STEEL CO LTD

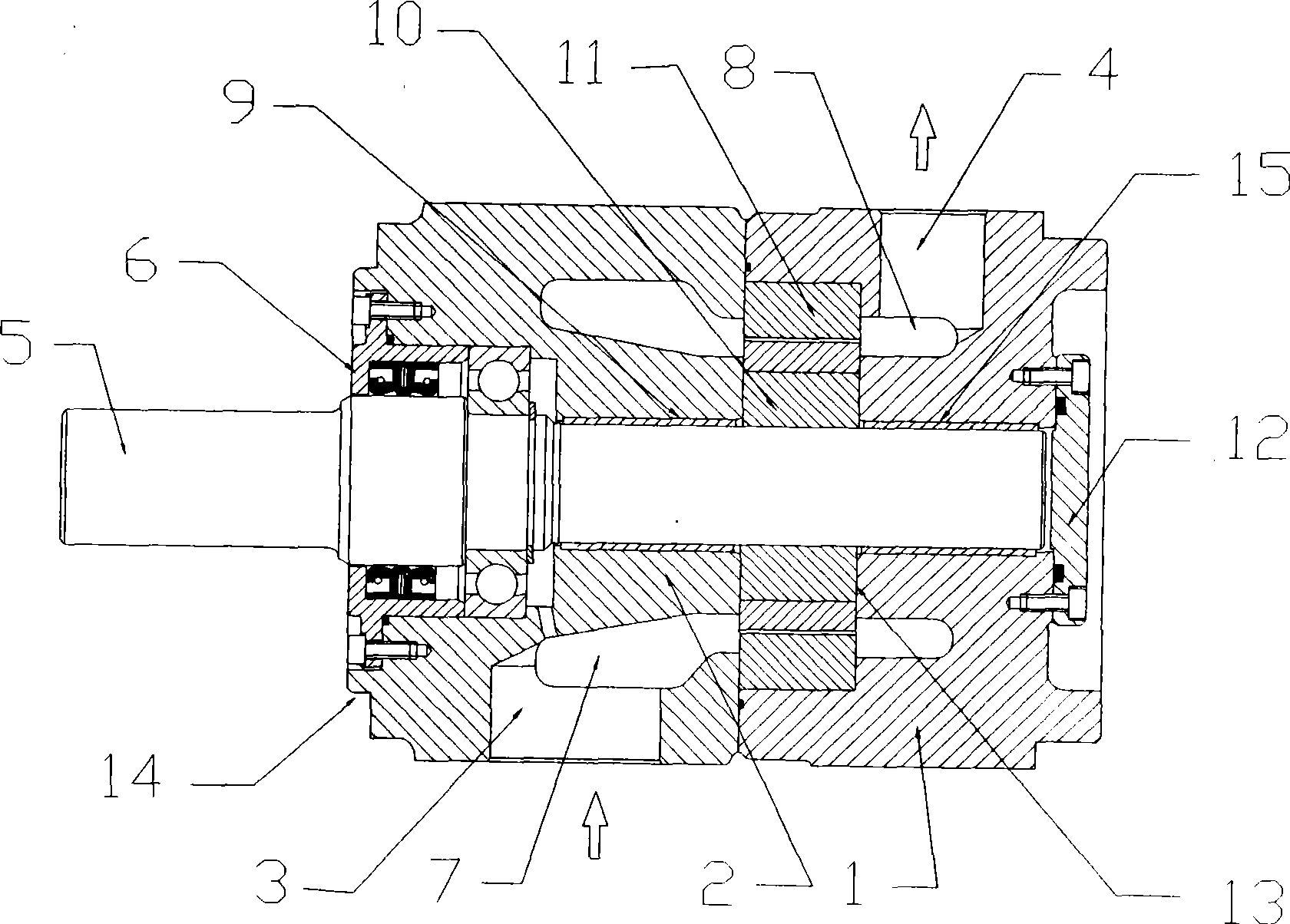

Modular internal gear pump or modular motor

InactiveCN101446286AGeneralizationReduce inventory requirementsEngine of intermeshing engagement typeRotary piston pumpsGear pumpModularity

The invention discloses a modular internal gear pump or a modular motor, comprising a plurality of generalized components such as a shell, an internal gear pair, an input shaft, a fixed shaft tray component, a floating shaft tray component, a flange cover component, a rear cover component and the like, so as to form a barbell type combined structure connected in series, thus realizing modularization of functions, combination of structures and universalization of parts. The invention has the advantages of good universalization of parts, flexible and simple assembly and excellent adaptability of structures, thus achieving the beneficial effects of reducing inventory of parts, shortening the cycle of production and goods delivery and reducing operation cost of products.

Owner:ZHENJIANG DALI HYDRAULIC MOTOR

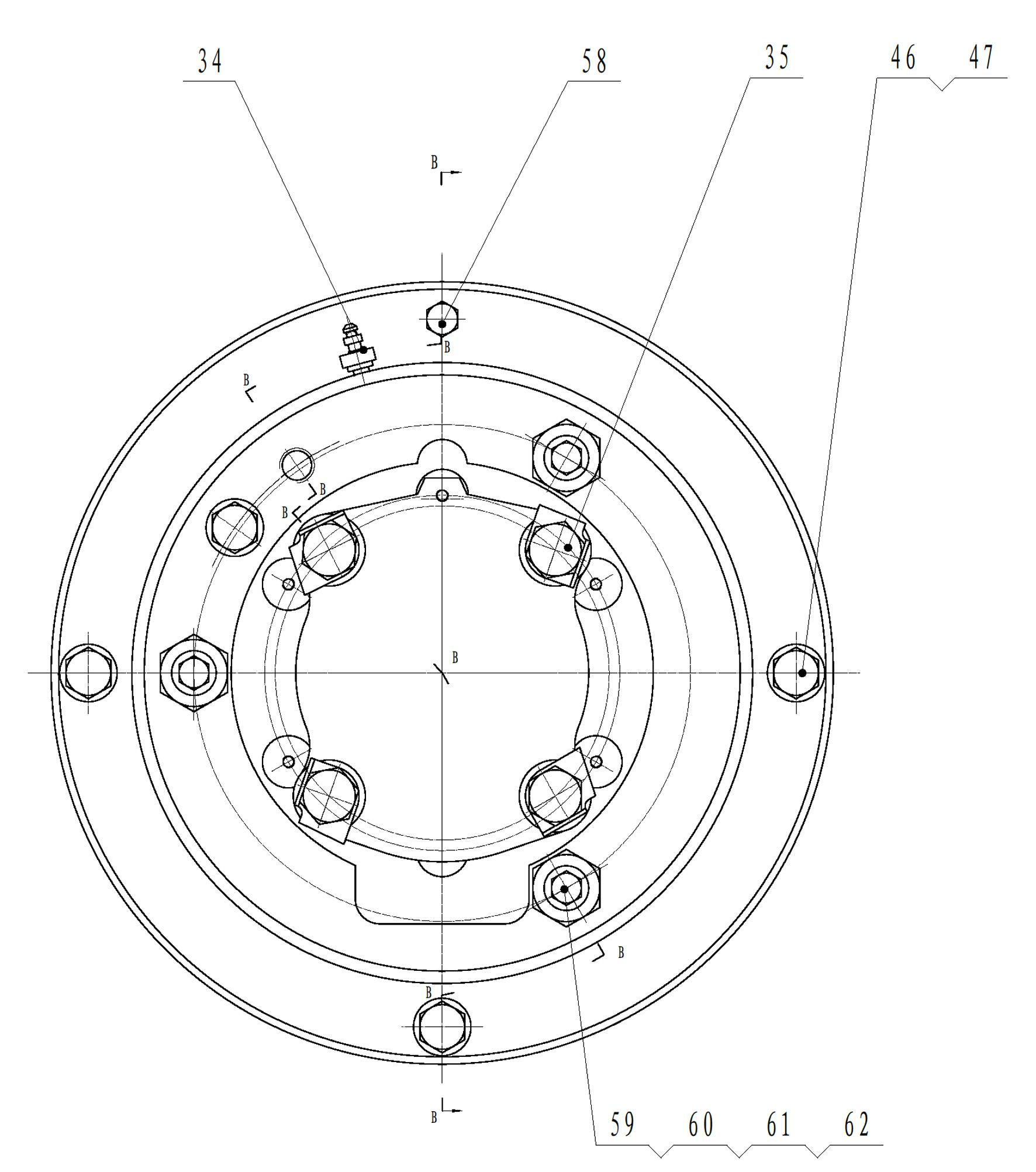

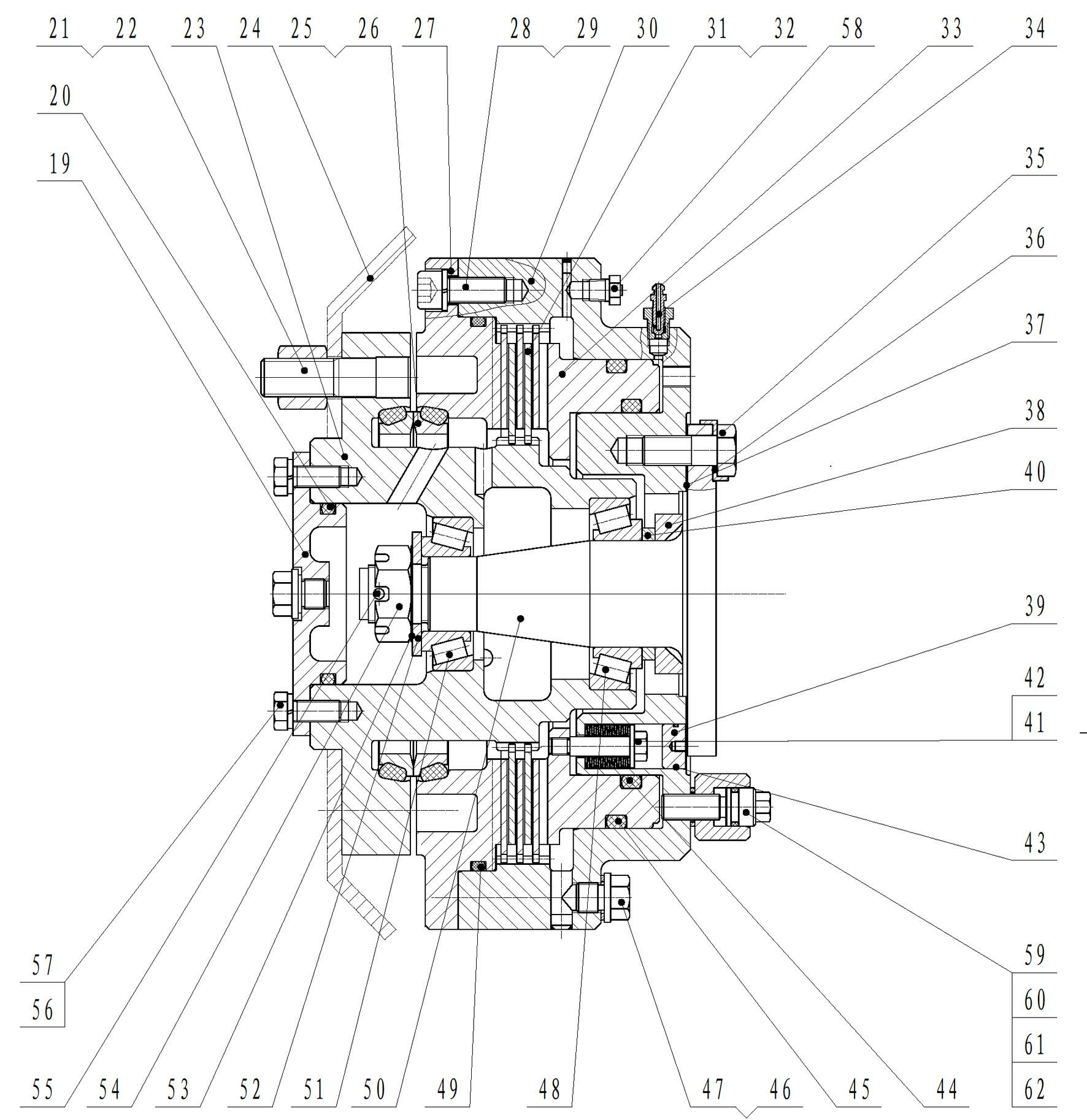

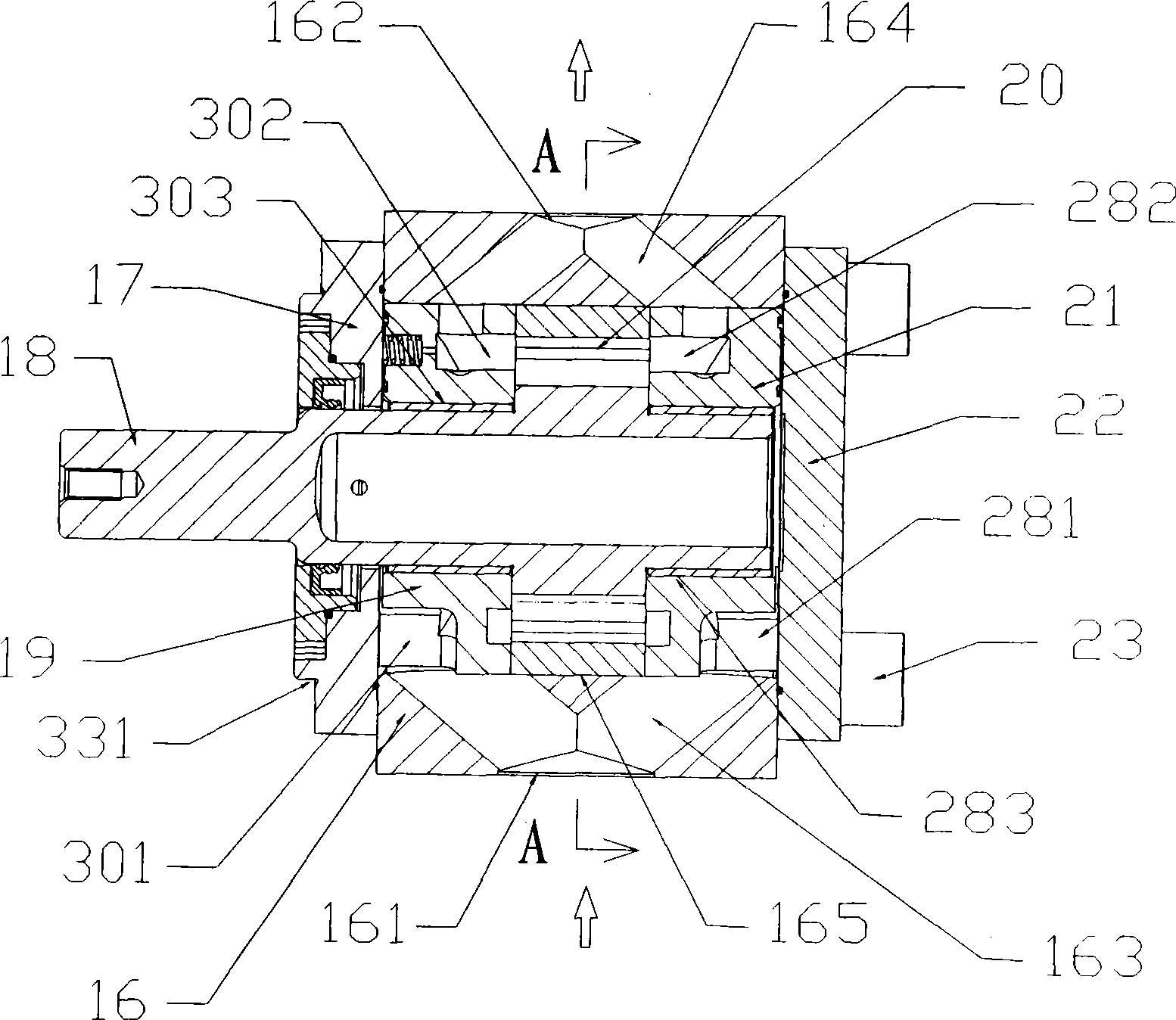

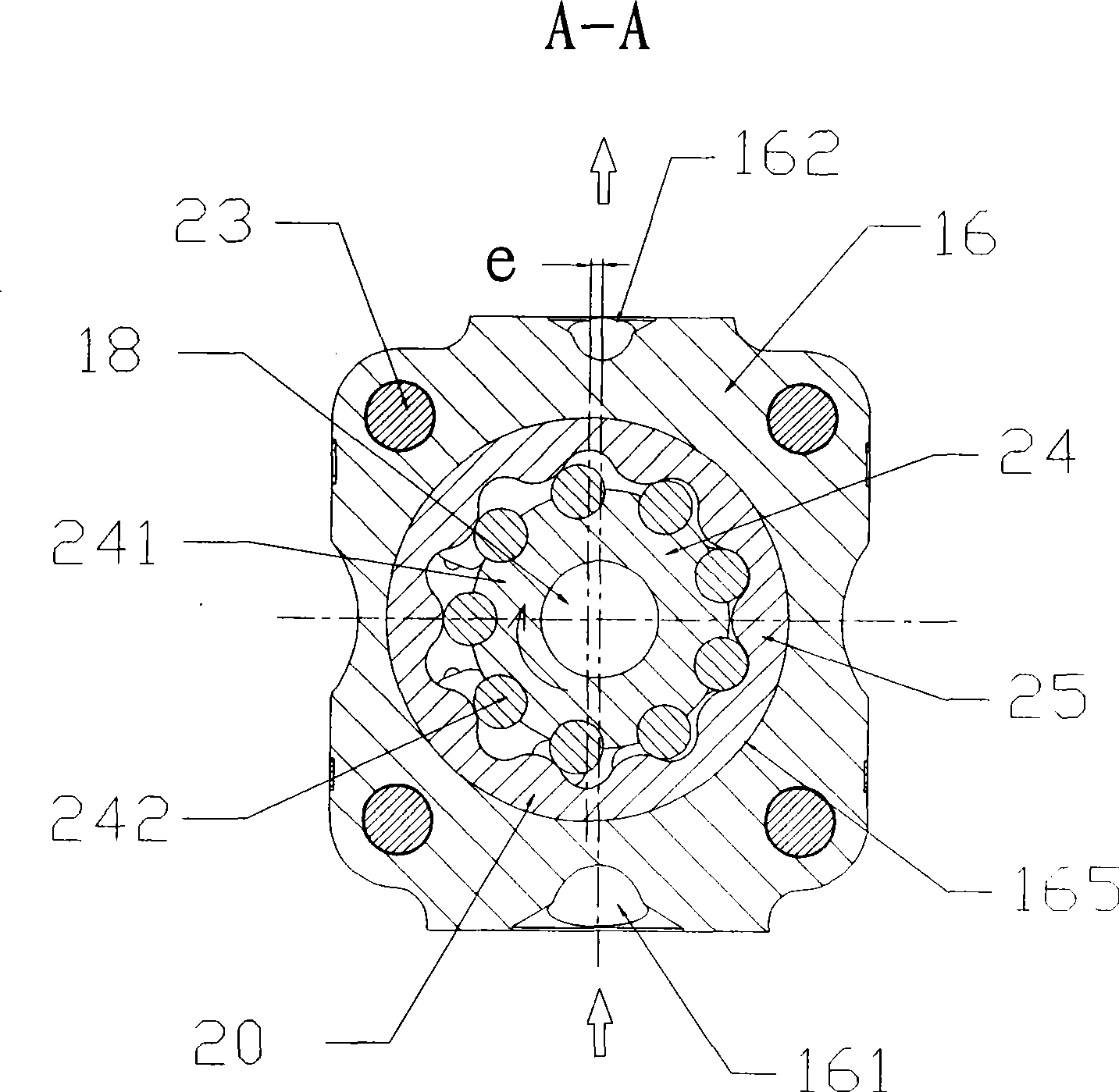

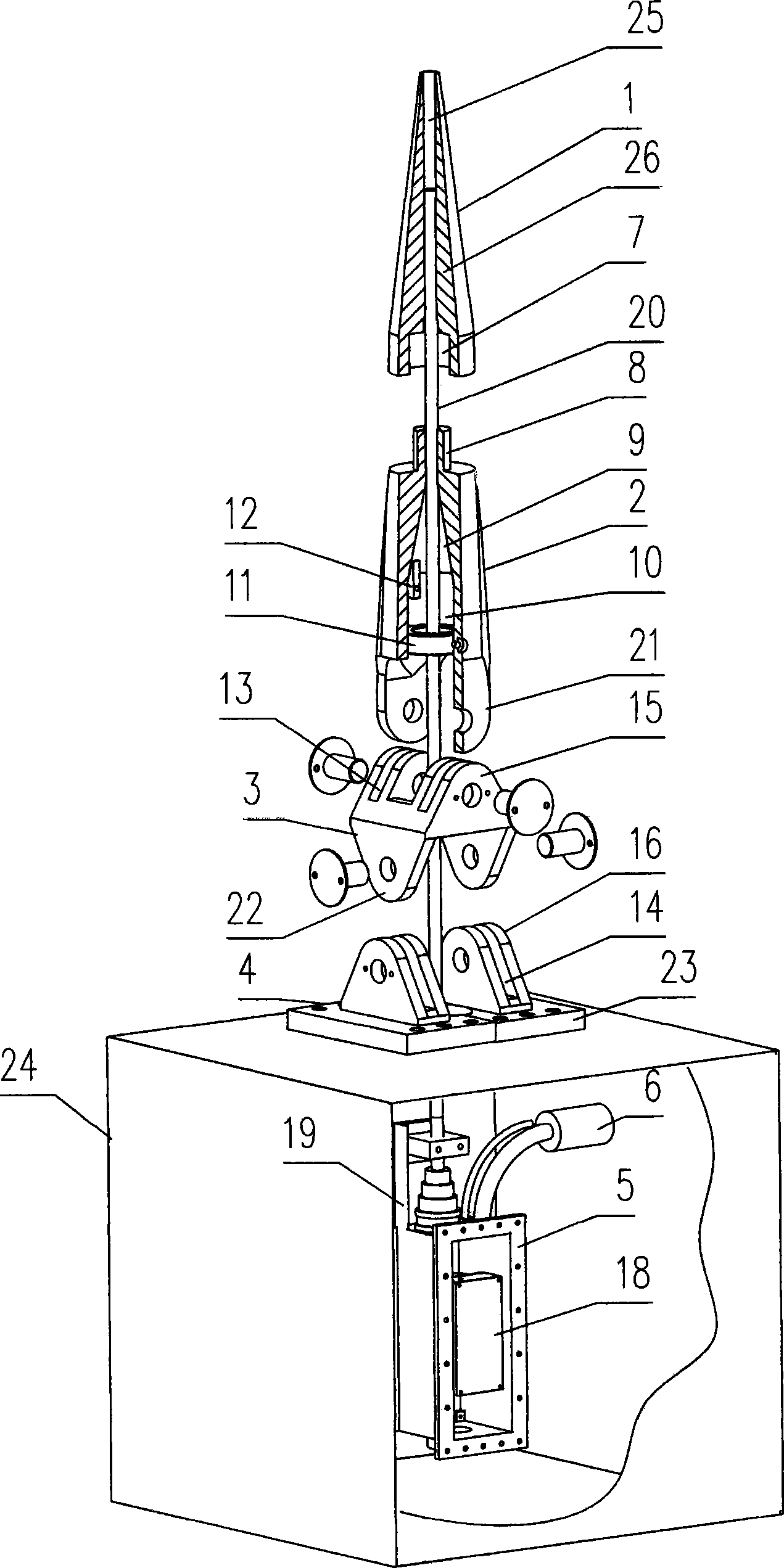

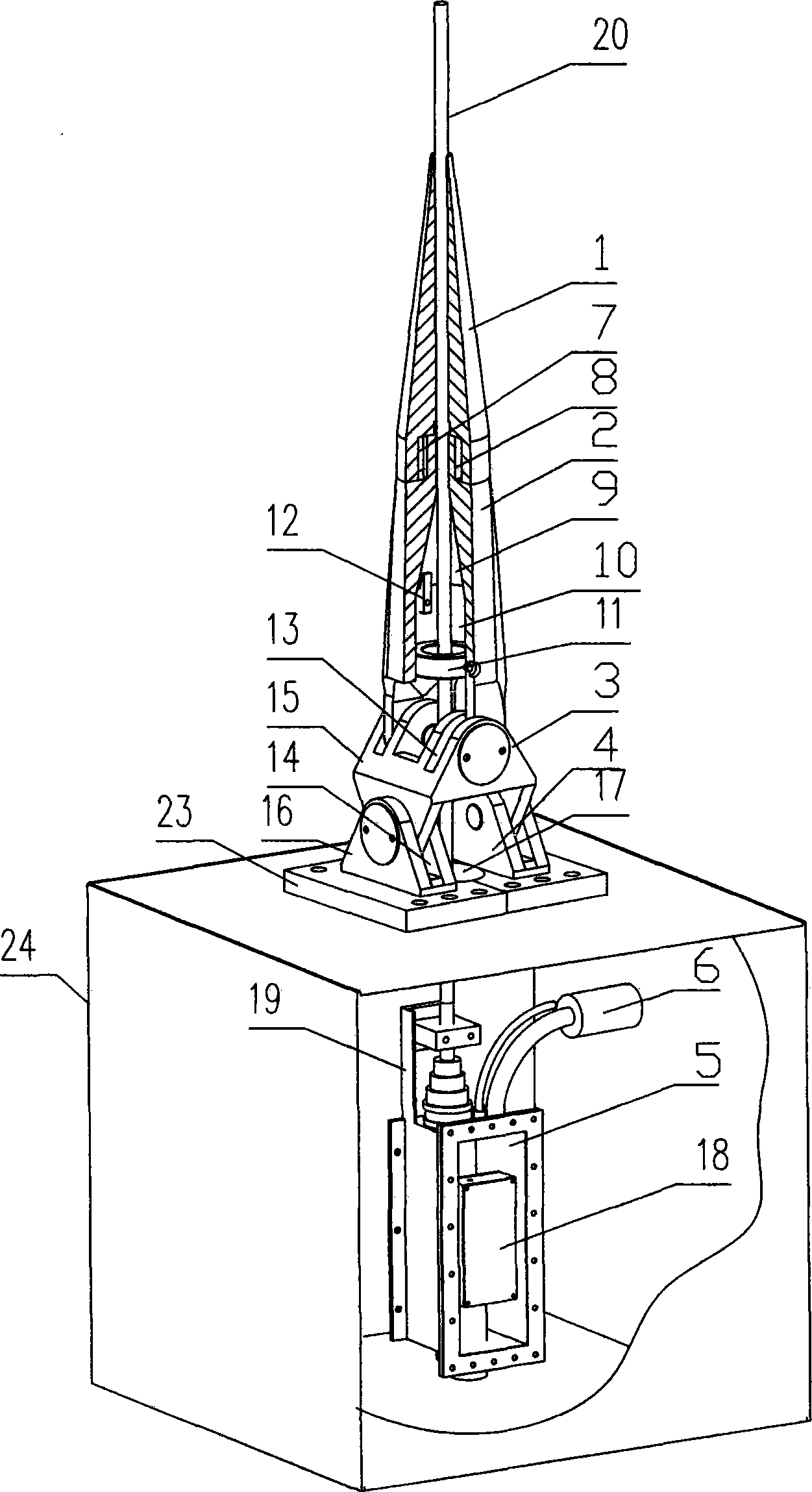

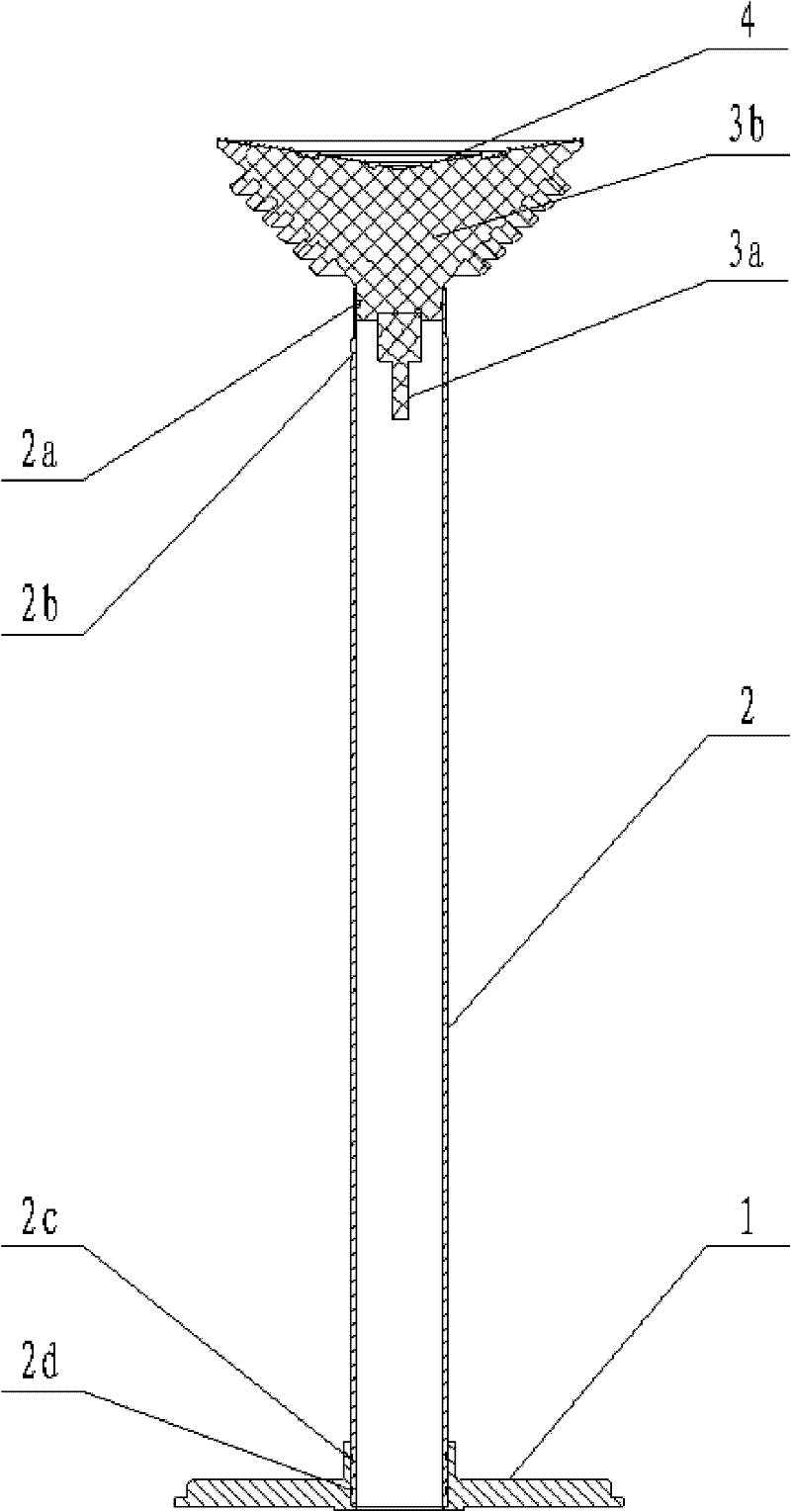

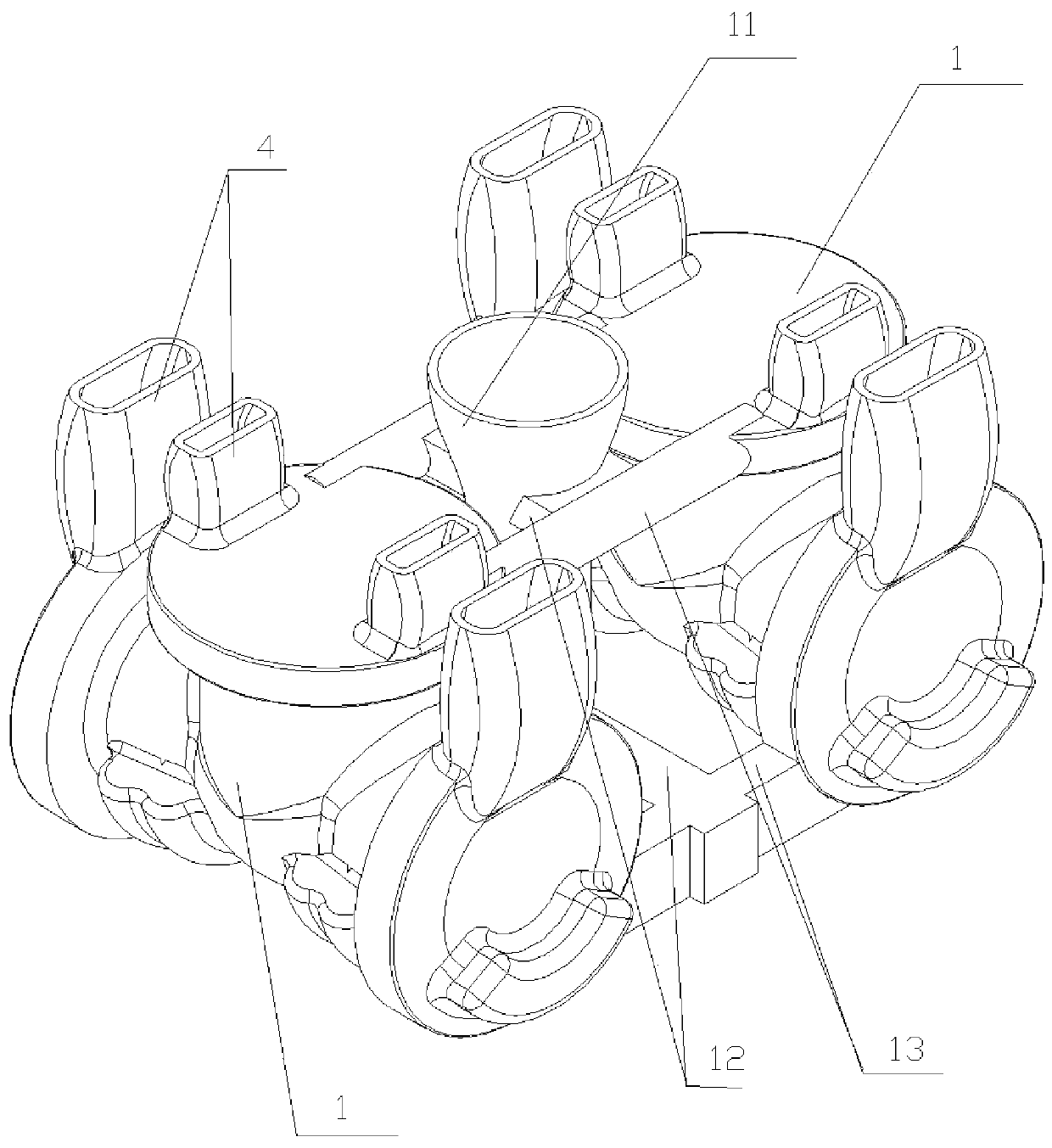

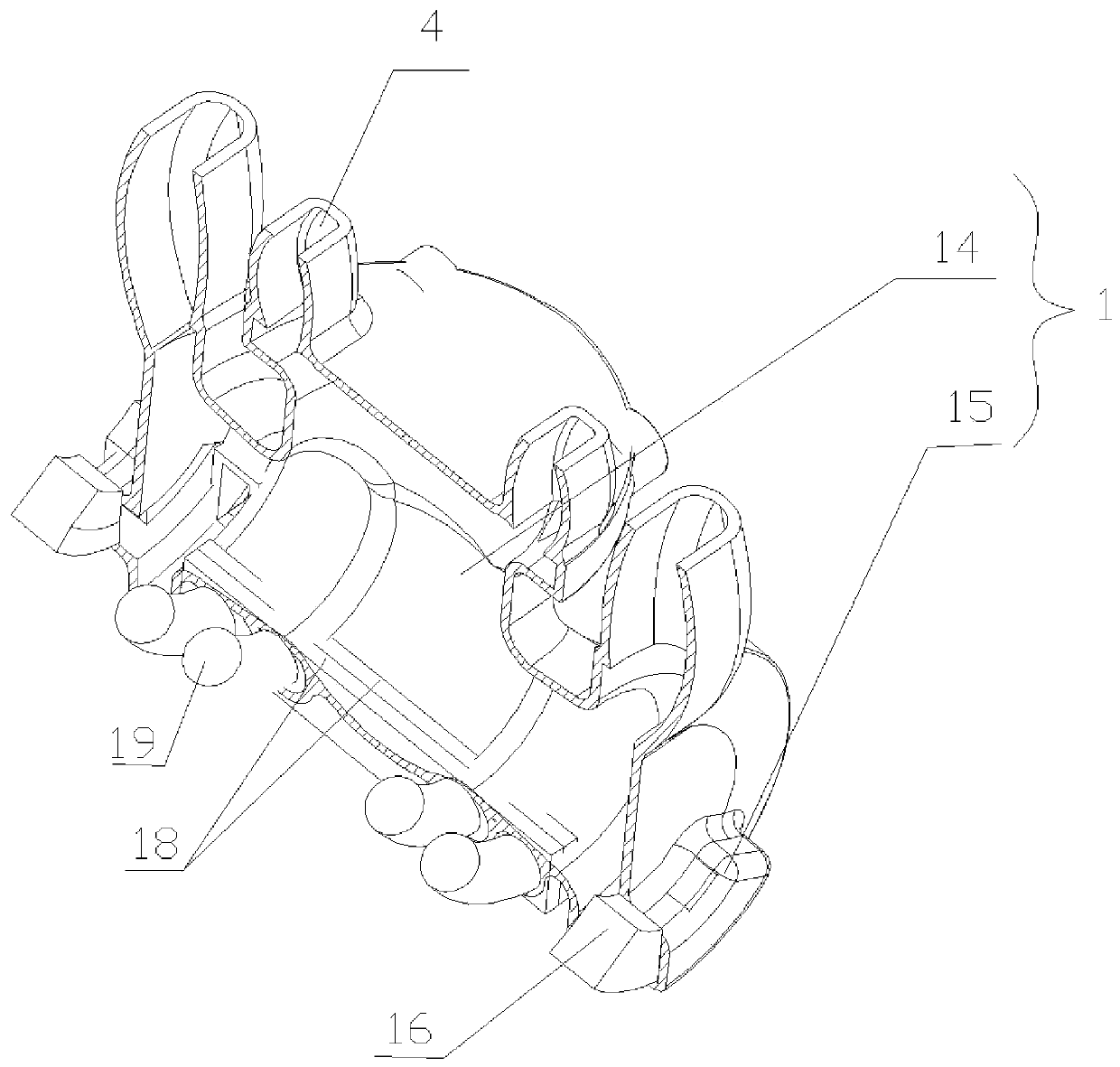

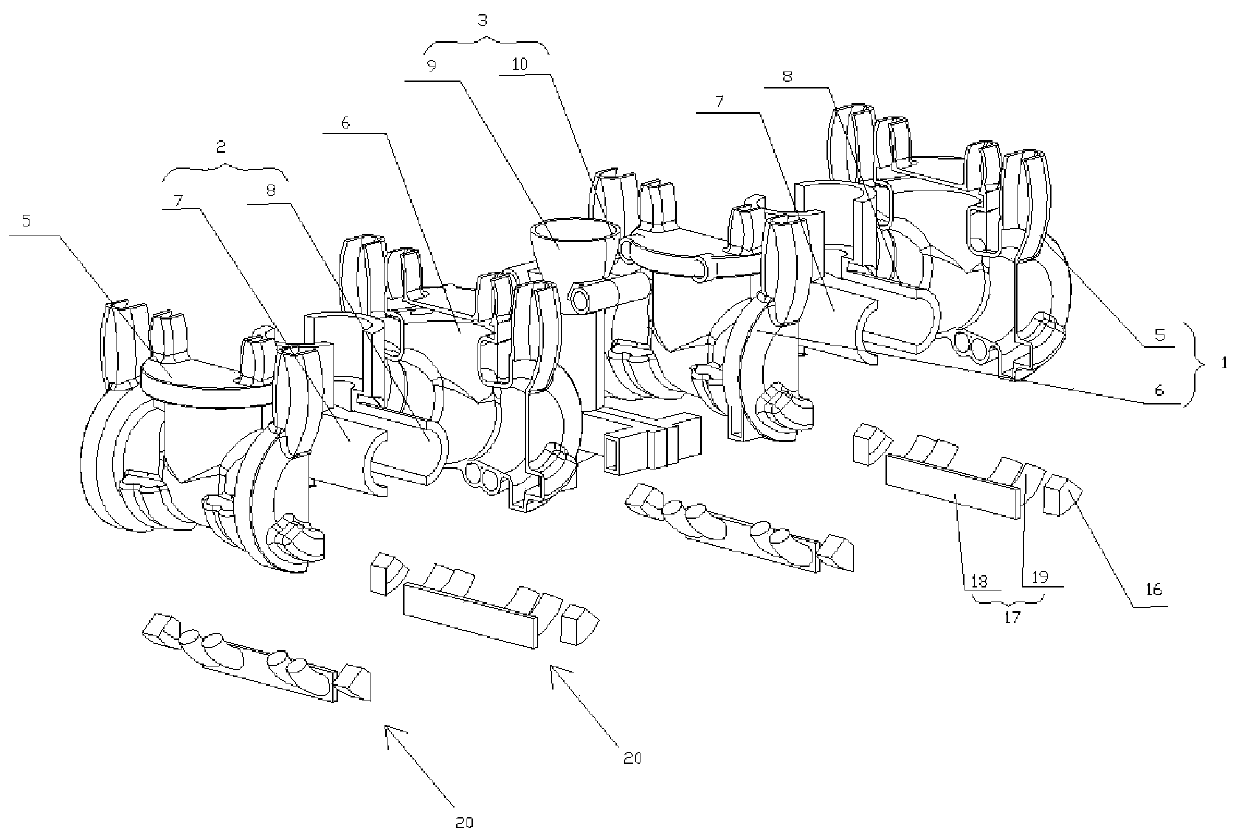

Universal bearing device for connecting steel cable and outboard surveying device and manufacturing method thereof

InactiveCN103928902AEasy signal connectionSimple and fast remakeRopes and cables for vehicles/pulleyCable junctionsCoaxial cableFailure rate

The invention discloses a universal bearing device for connecting a steel cable and an outboard surveying device. The universal bearing device for connecting the steel cable and the outboard surveying device comprises a distorting-resistant portion, a bearing portion, a rotating portion and a device mechanical connecting portion and is further provided with a junction box and an oil compensator. A manufacturing method of the universal bearing device for connecting the steel cable and the outboard surveying device comprises the steps that (1) an operation cable is pretreated; (2) the bearing portion is manufactured; (3) the rotating portion is manufactured and installed; (4) the junction box is manufactured and installed. The universal bearing device for connecting the steel cable and the outboard surveying device is suitable for connecting the steel structural operation steel cable used in the marine surveying process and the outboard marine surveying device. The bearing device is provided with a mechanical connecting bearing connector, a power source connecting bearing connector and a signal connecting bearing connector, connection is safe and reliable, the failure rate of the marine surveying device and losses caused by fracture of the steel cable are reduced, the universal bearing device for connecting the steel cable and the outboard surveying device is suitable for all the steel structural operation steel cables such as the armor photoelectric composite cable, the armor coaxial cable and the steel cable, the universality is extremely high, the universal bearing device for connecting the steel cable and the outboard surveying device is particularly suitable for connecting the large-scale deep marine surveying device and the steel cable and is an excellent device for connecting various marine surveying devices and the tail end of the steel cable.

Owner:国家海洋局北海海洋技术保障中心

Process for manufacturing thermal laminated silica gel trademark by die forming

InactiveCN104103213ASave transportation costs and reduce production costsReduce volumeStampsIdentification meansThermoplastic polyurethaneSilica gel

The invention discloses a process for manufacturing a thermal laminated silica gel trademark by die forming, which comprises the following steps of firstly, blending a TPU (thermoplastic polyurethanes) silica gel adhesive; then uniformly spraying or silk-printing the TPU silica gel adhesive on the surface of a hot melt adhesive film; next, carrying out baking; then taking out an obtained product and cooling and cutting the obtained product; scraping out the blended liquid silica gel or injecting the blended liquid silica gel into a die and laminating the die with the adhesive film product; carrying out sulfuration to obtain the thermal laminated silica gel trademark. The process provided by the invention is simple and convenient to operate and is easy to implement; the thermal laminated silica gel trademark product can be rapidly produced; a user can enable the thermal laminated silica gel trademark to be firmly laminated to a designated base material only by very simple hot-pressing laminating process; not only is the delivery cycle greatly shortened and production efficiency improved, but also transportation cost is saved and production cost is low; moreover, the thermal laminated silica gel trademark is firm to laminate, has a long service life, has no bubbles, has attractive appearance, has excellent decorating effect and product publicizing effect, can greatly promote product value so as to promote development of the related industries, such as the shoe accessory industry, the clothing industry and the jewelry industry, and is beneficial to large-area popularization and application.

Owner:东莞洛克橡塑制品有限公司 +1

Extra-thick container steel plate with excellent low-temperature impact toughness at center

The invention relates to an extra-thick container steel plate with excellent low-temperature impact toughness at the center. The production thickness of the extra-thick container steel plate is 60 to100 mm. The extra-thick container steel plate comprises the following chemical components: 0.13-0.20% of C, less than or equal to 0.40% of Si, 1. 00-1.60% of Mn, less than or equal to 0.015% of P, less than or equal to 0.005% of S, 0.01-0.05% of Als, less than or equal to 0.080% of Nb+V+Ti, 0.20-0.50% of Ni, less than or equal to 0.30% of Cu, less than or equal to 2 ppm of H, and the balance of Feand inevitable impurity elements, and at the same time, the conditions that the mass percent of CEV is less than or equal to 0.43%, and w(Nb+V+Als) / w(Ti) is larger than or equal to 3 and less than orequal to 8 are met. A structure near the surface of the steel plate is tempered sorbite, and a structure at a part that is 1 / 4 of the steel plate thickness and a structure at a part that is 1 / 2 of the steel plate thickness are bainite. The lateral impact energy -50 DEG C KV2 at a part that is 1 / 4 of the plate thickness is larger than or equal to 150 J; and the lateral impact energy -50 DEG C KV2at a part that is 1 / 2 of the plate thickness is larger than or equal to 80 J. A manufacturing method comprises the following manufacturing processes of molten iron pretreatment, converter smelting, ladle furnace refining, vacuum degassing treatment, continuous casting, casting blank capped cooling, casting blank heating, controlled rolling, controlled cooling, stacking for slow cooling, and tempering. An online quenching process is adopted to ensure that the steel plate has excellent strength and toughness, and at the same time, online quenching can significantly shorten the delivery cycle.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

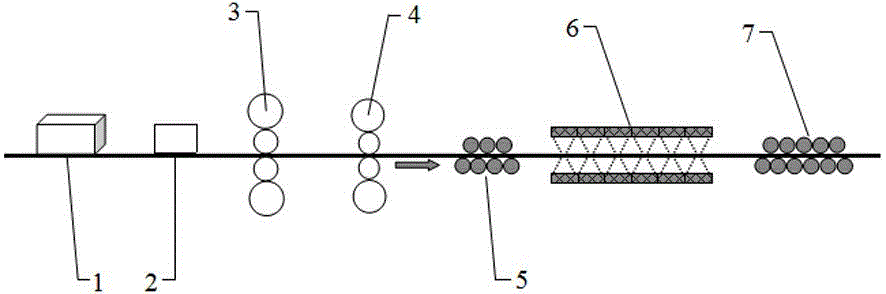

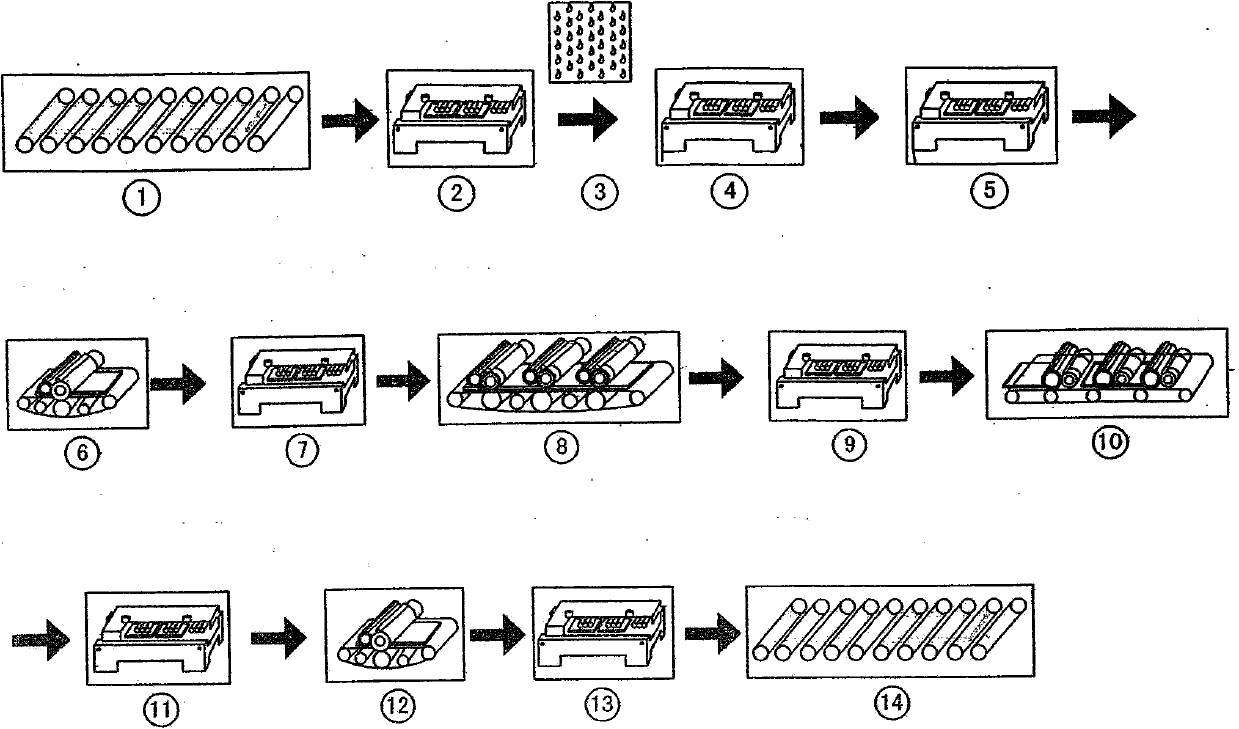

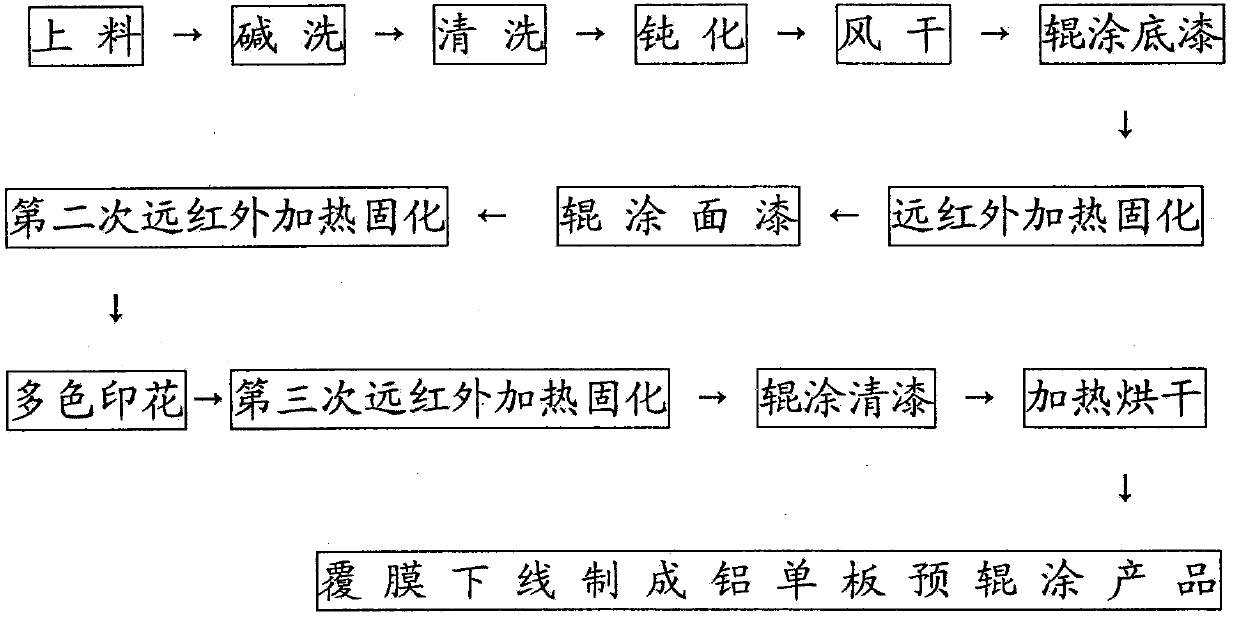

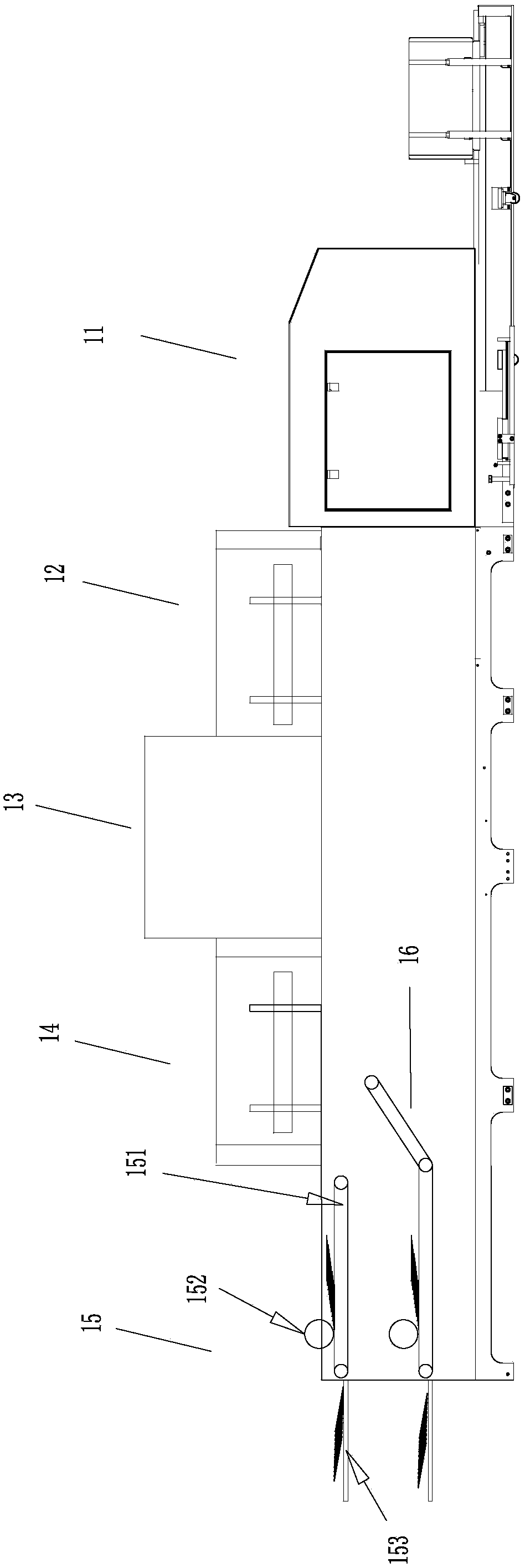

Novel aluminum veneer pre-roll-coating production line and process technology

InactiveCN103990589AEasy to changeSolve problemsPretreated surfacesCoatingsProduction lineColor printing

The invention provides a novel aluminum veneer pre-roll-coating production line and a process technology and relates to the technical field of machinery. A series of key technologies including alkaline washing, cleaning, passivation, coating, printing and drying are adopted, and a front conveying belt, an alkaline washing machine, a cleaning machine, a chromate-free passivation device, a baking oven, a precise single-roller priming paint coating machine, a far infrared baking oven, a three-roller coating machine, a far infrared device, a multi-color stereoscopic printing machine, a far infrared machine, a precise single-roller priming paint coating machine, a curing baking oven and a rear conveying belt are sequentially placed to form the novel aluminum veneer pre-roll-coating production line. The process technology is that an aluminum veneer pre-roll-coating product is manufactured through feeding, alkaline washing, cleaning, passivation, air-drying, priming paint roll-coating, far-infrared heating and curing, finishing coat roll-coating, secondary far-infrared heating and curing, multi-color printing, third far-infrared heating and curing, varnish roll-coating, heating and drying and film coating and off-line operation. The novel aluminum veneer pre-roll-coating production line and the process technology are used for aluminum veneer roll-coating and are novel in concept, reasonable in design, simple and ingenious in structure, stable and reliable in effect and low in cost and facilitating manufacture, usage and popularization.

Owner:肇庆鑫盈装饰材料有限公司

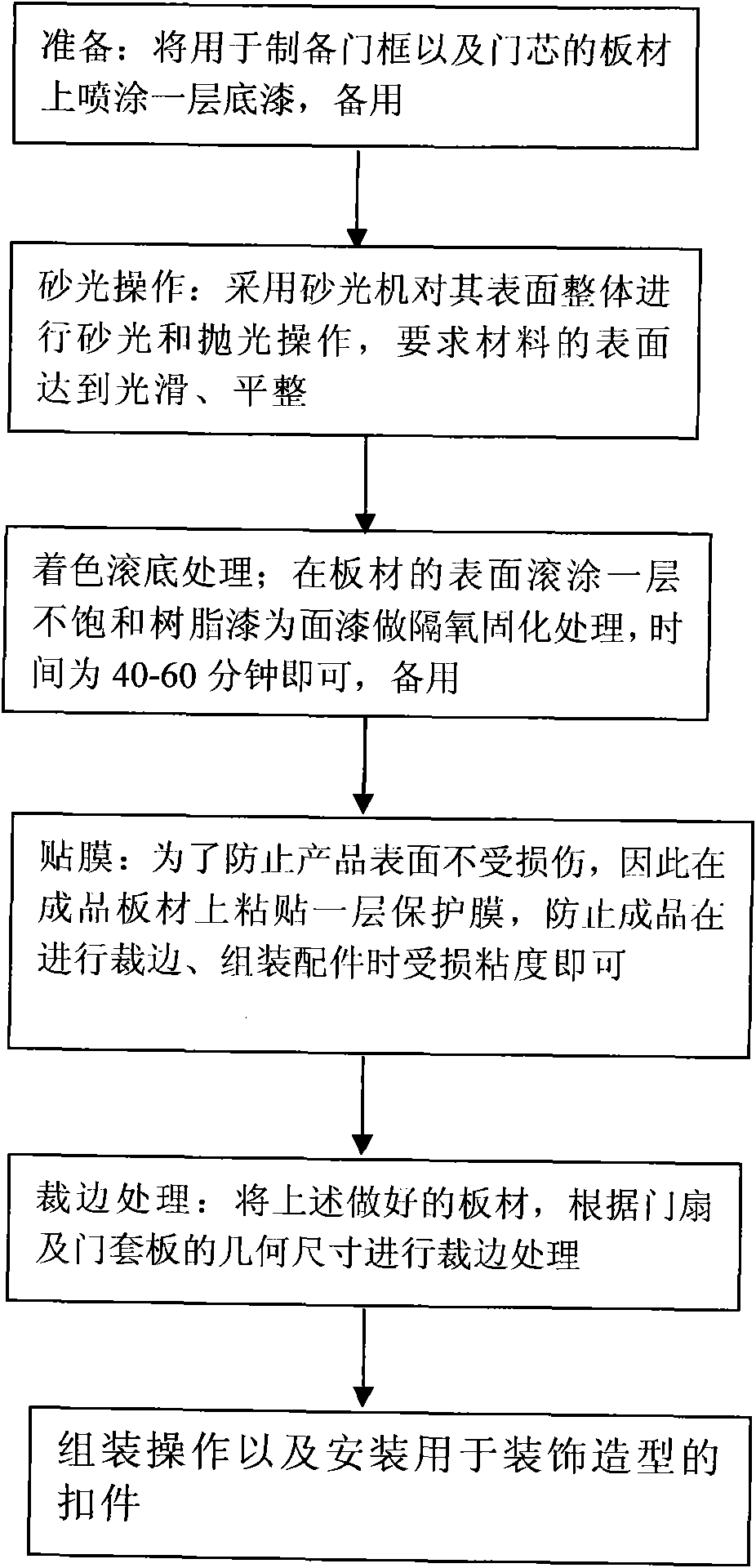

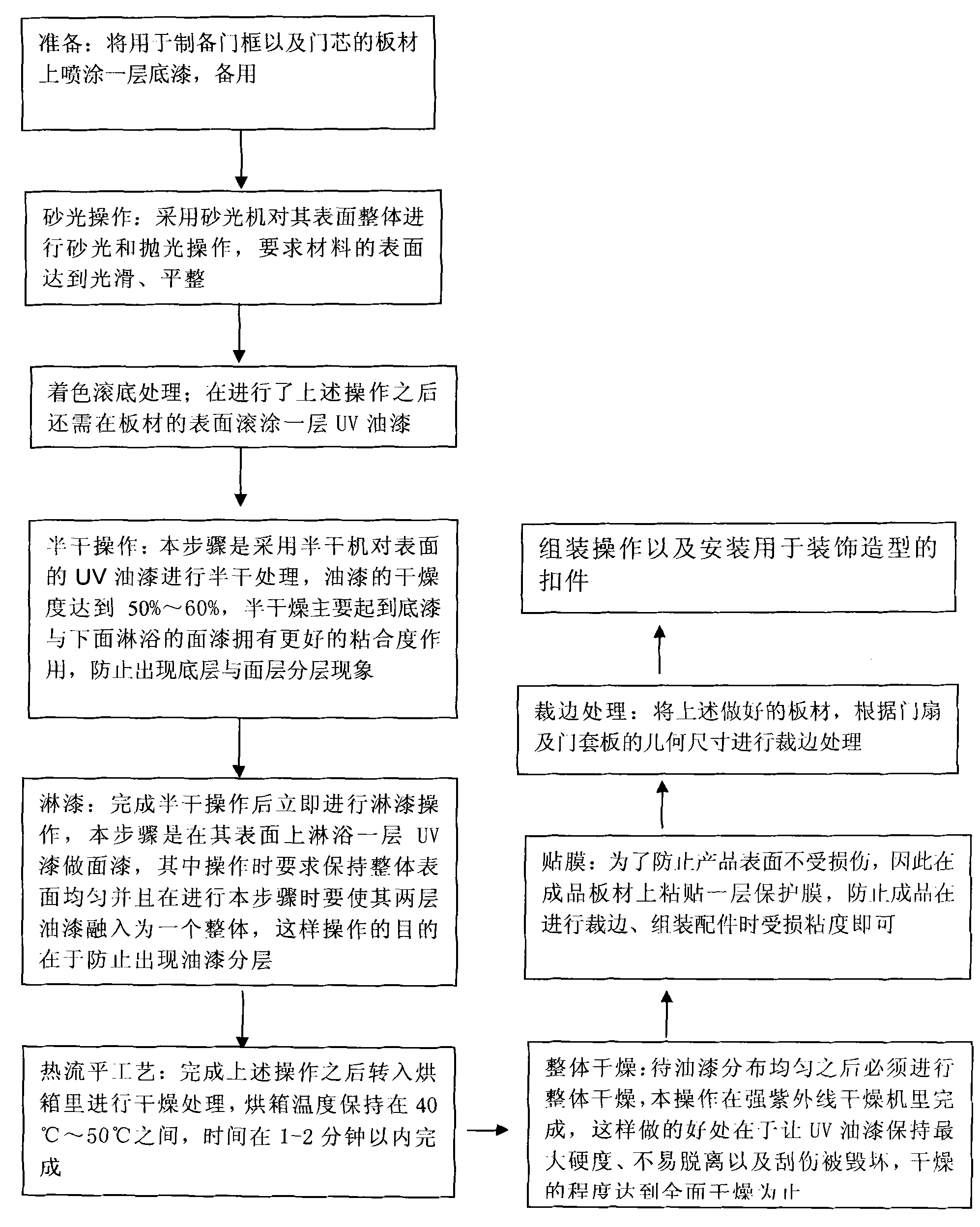

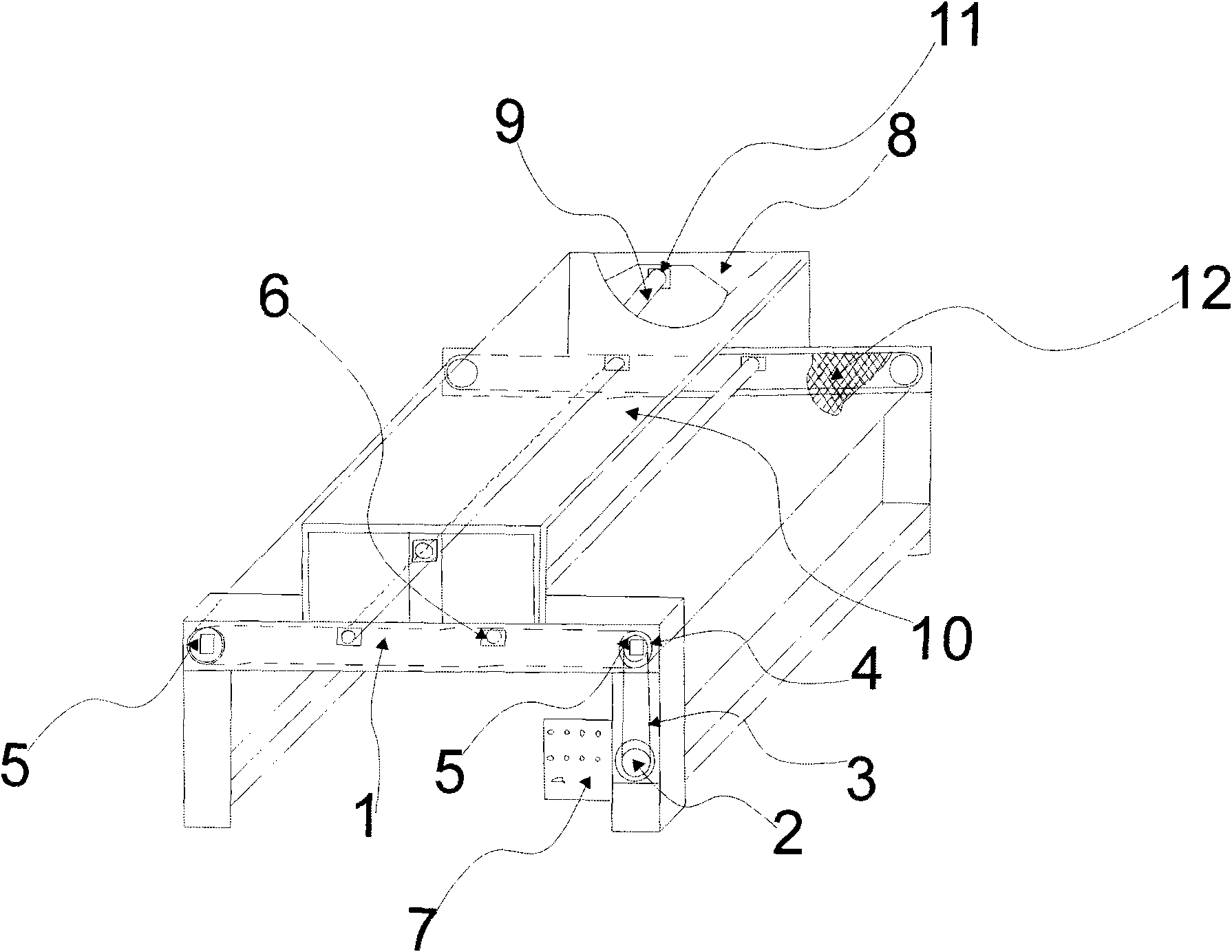

Manufacturing process of wood door and half drying machine

InactiveCN101871307ANot easy to shrinkNot easy to expandPretreated surfacesCoatingsManufacturing engineering

The invention discloses a manufacturing process of a wood door, which is characterized by comprising preparation, sanding operation, colorizing and bottom rolling treatment, lamination, trimming treatment, assembling operation, decorative and shaping fastening piece installation and final entire packaging. The process prevents expansion and contraction in door vertical frame, cross beam and other places. In the invention, the surface oil paint stripping and layering can be prevented by adopting half drying operation, paint spraying, a thermal leveling process and overall drying operation, time is saved and product quality is improved. At the same time, the invention also provides a half drying machine for half drying operation.

Owner:CHENGDU TIANCHENG SHENGMU DOOR

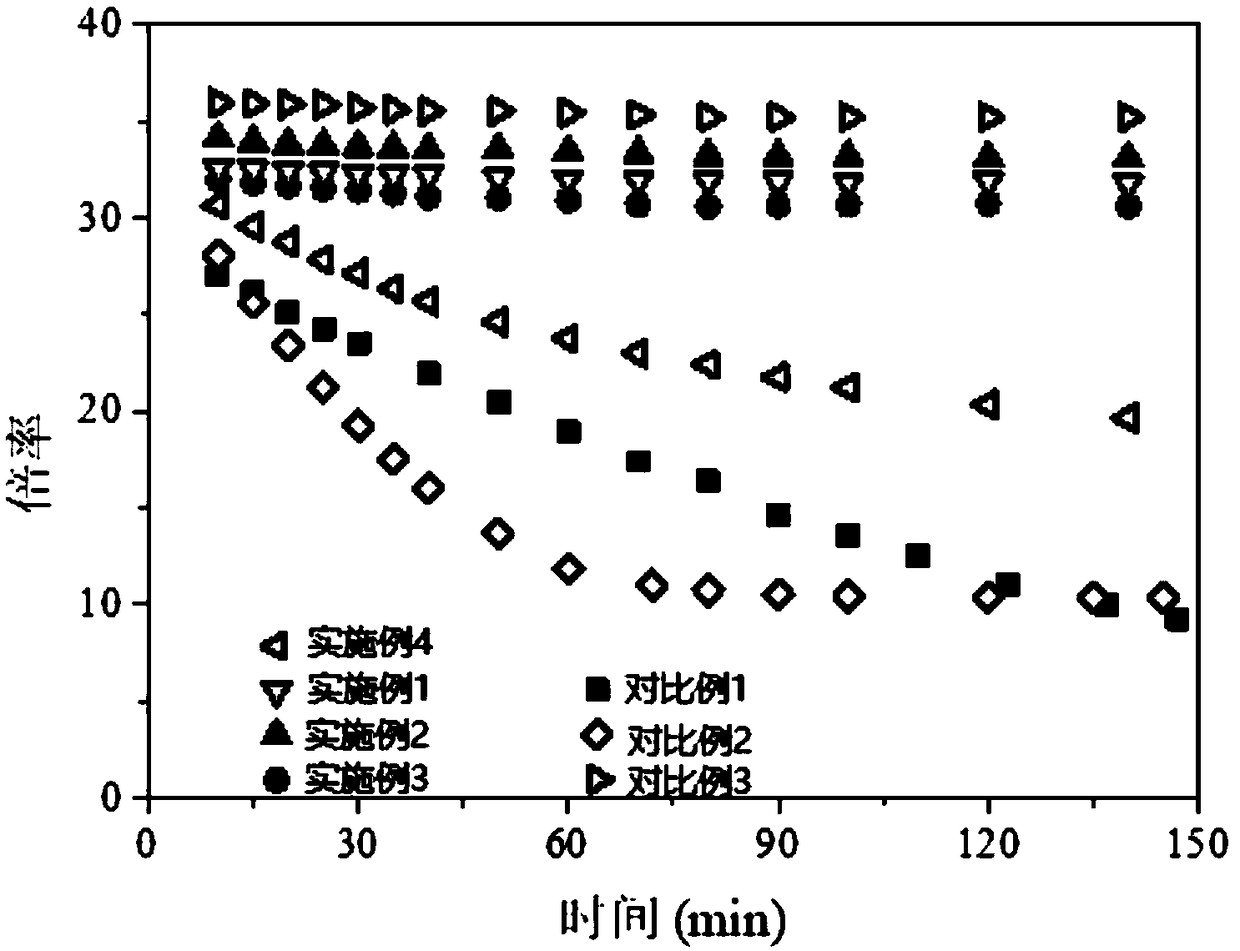

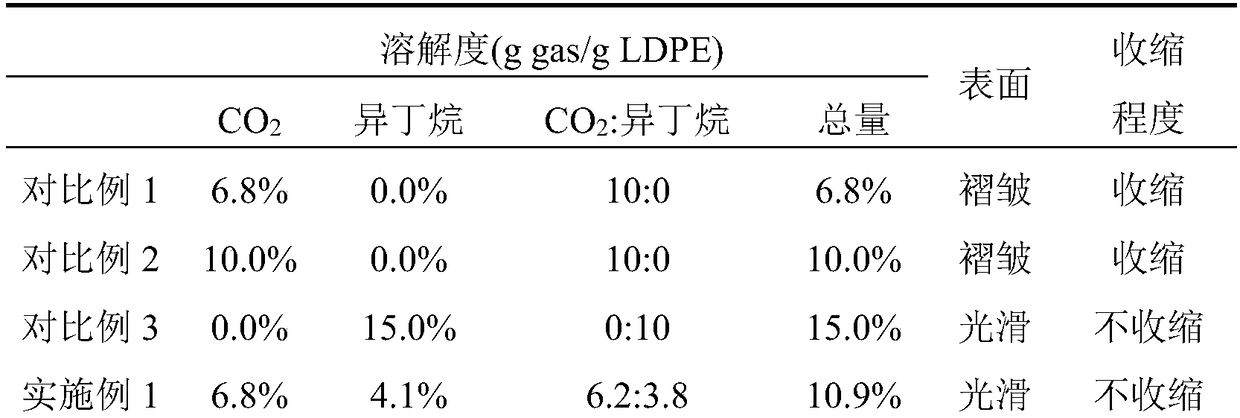

EPE pearl wool material and preparation method thereof

The invention discloses an EPE pearl wool material and a preparation method thereof. The EPE pearl wool material contains the following raw material components in parts by weight: 90-100 parts of LDPEresin particle materials, 0.5-3 parts of a nucleating agent, 1-3 parts of monoglyceride, 0.1-5 parts of a stable master batch and 10-20 parts of a mixed foaming agent, wherein the mixed foaming agentcontains a mixture of CO2 and butane, the weight of CO2 is less than or equal to 75% of the total weight of the mixed foaming agent, and the use amount of CO2 is not zero. By selecting proper types and proportions of the mixed foaming agent as well as the components, the foaming agent in the foam holes can be exchanged with air as quickly as possible in the premise that the foam holes of the EPEpearl wool material do not collapse and the product does not shrink, and the storage curing process of the EPE pearl wool material is shortened; the EPE pearl wool material has condense and uniform foam holes and relatively good properties such as buffer shockproof property; and the curing period required for stabilizing the foam holes is shortened, so that the supply period of the product is shortened.

Owner:EAST CHINA UNIV OF SCI & TECH +1

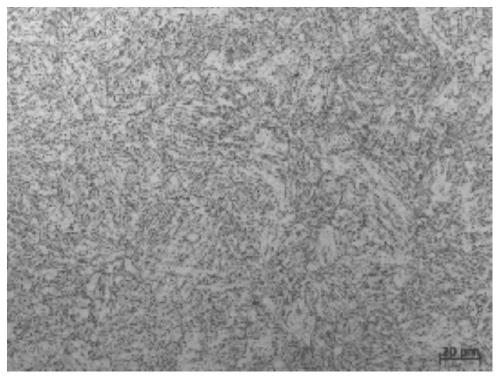

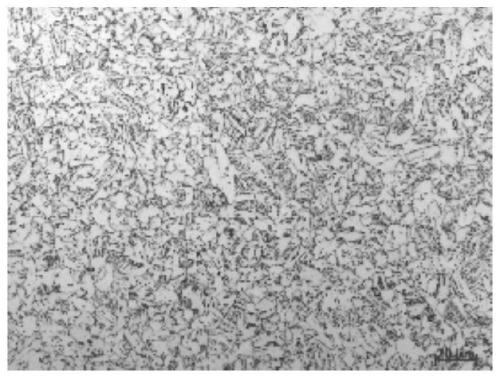

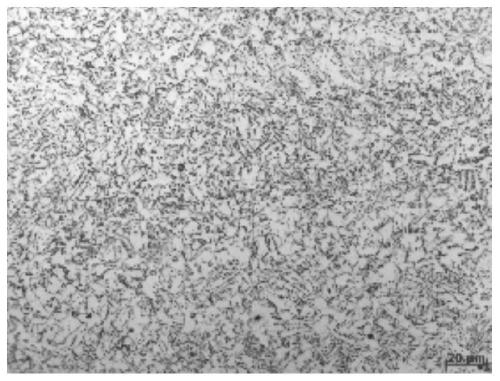

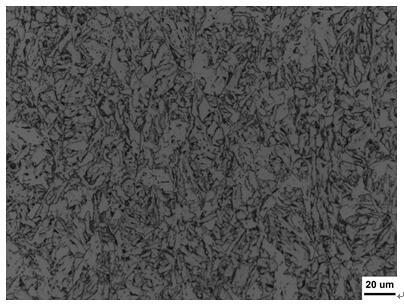

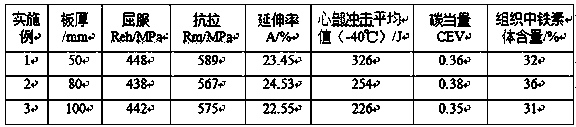

Production method of polyphase structure high tenacity ship plate steel EH40

The present invention discloses a production method of polyphase structure high tenacity ship plate steel EH40. The steel includes the following chemical compositions by weight percentage: carbon=0.04-0.08, silicon 0.15-0.35, manganese=1.50-1.60, phosphorus less than and equal to 0.015, sulfur less than and equal to 0.005, niobium less than and equal to 0.02-0.03, titanium less than and equal to 0.008-0.02, aluminum=0.015-0.05, nickel=0.30-0.40, and the remaining of Fe and inevitable impurities. The process steps include smelting, continuous casting, rolling, relaxation and cooling. The methodof the present invention breaks through the limitation of compression ratio for rolling continuously cast bloom by the traditional TMCP process without additional thermal treatment process; high tenacity steel plate with a low temperature impact requirement of below -40 DEG C is produced, the maximum thickness may reach 100 mm, and the product can be widely applied to manufacturing of thick plates in various fields such as shipbuilding, maritime work, wind power, bridge, architecture and engineering machinery; and the method of the present invention can be realized by using the current equipment and process condition of a steel mill, which does not increase investment and equipment upgrading, and further improve the production efficiency and realizes energy conservation and consumption reduction.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

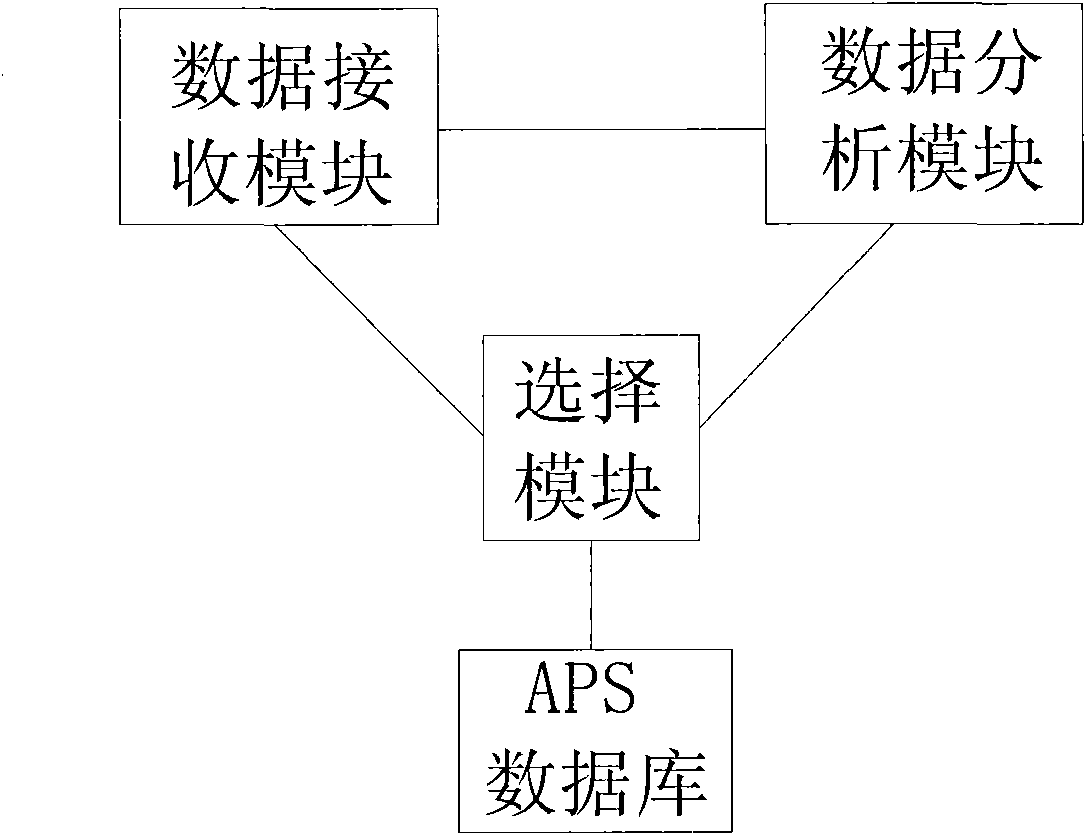

Advanced planning and scheduling system

InactiveCN102117434AOptimize production planIncrease production capacityResourcesManagement processAdvanced planning and scheduling

The invention relates to an advanced planning and scheduling system. The advanced planning and scheduling system comprises a selection module, a data receiving module and a data analysis module which are mutually and respectively connected. Therefore, the system can be used for monitoring the difference of data tables in various versions and recording and tracking the execution result of the advanced planning and scheduling system so as to operate history data and further continuously execute the imported efficiency analysis of the advanced planning and scheduling system, to be convenient for a planner to adjust modeling parameters or change the management flow according to the condition, and to ensure that the advanced planning and scheduling system can gradually approach to the execution result.

Owner:QINGDAO PENGHAI SOFT CO LTD

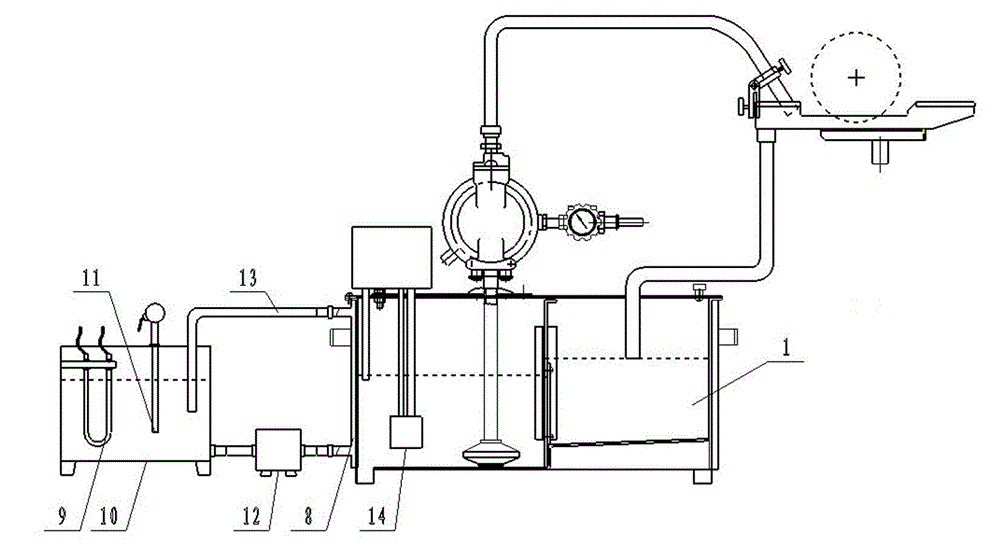

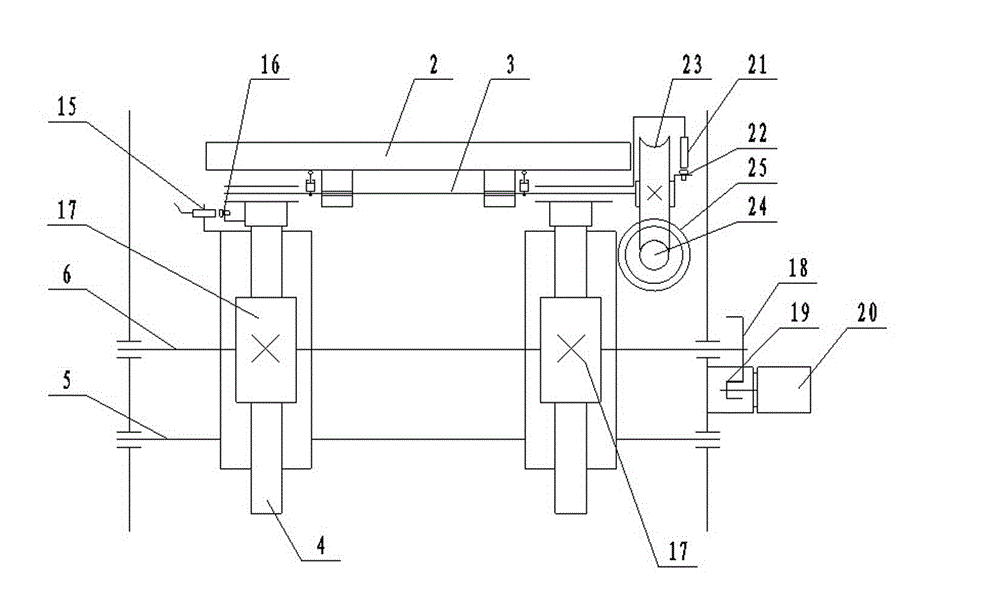

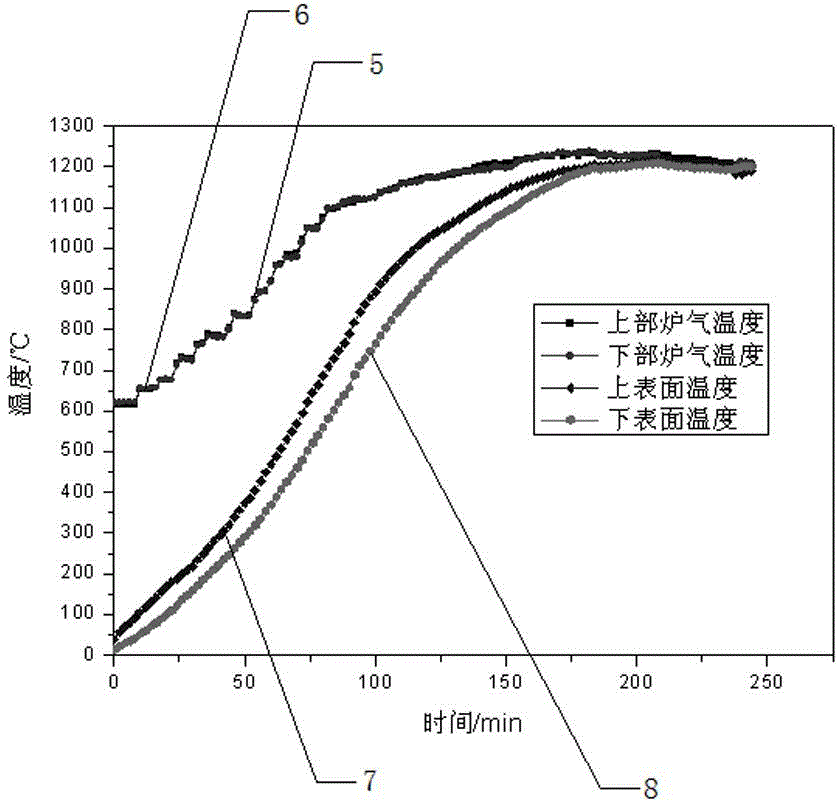

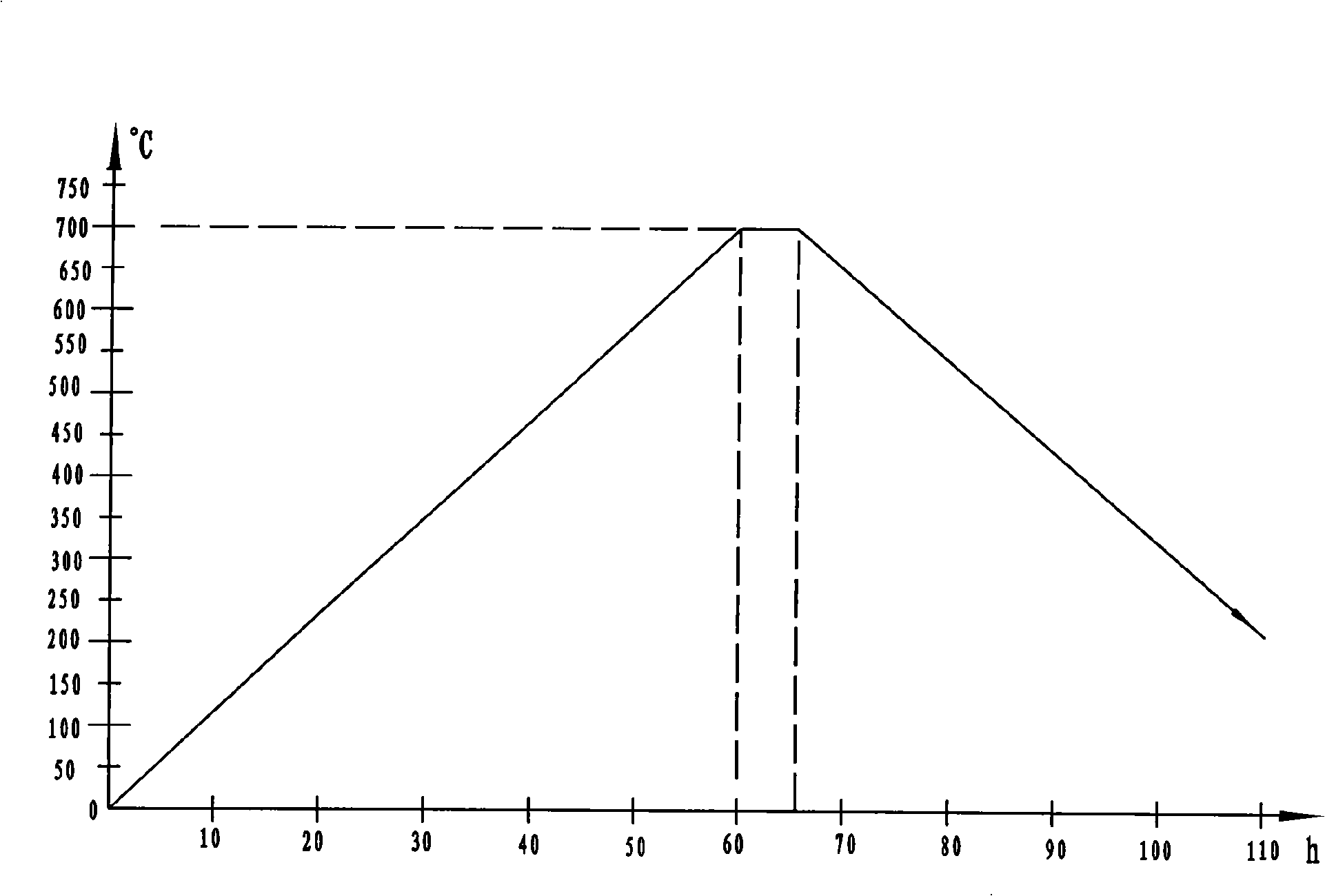

Spheroidizing annealing process for medium carbon steel plate in bell furnace

InactiveCN101307378AReduce heat treatment processReduce consumptionElectrical resistance and conductanceTube furnace

The invention relates to a medium carbon steel plate bell-type furnace spheroidizing annealing method, which orderly comprises the following steps that: (1) a hot-rolled blank steel coil is subject to the cutting and acid cleaning; (2) the longitudinal rolling is adopted, and the rolling deformation is between 28 and 41 percent; (3) the single sheet stack annealing is adopted, and a steel plate is loaded into an electric heating bell-type furnace; wherein, a. a plate temperature thermocouple is adopted to control the temperature, and at least two armored thermocouples are inserted; b. the heating in the furnace adopts two-section type furnace platform and furnace mantle resistance bands; c. protective gas in the furnace platform and the furnace mantle is nitrogen; d. after the steel sheet is loaded into the furnace, a safety cover and a heating mantle are fastened to electrify and increase the temperature for 60 to 70 hours, the heat preservation is performed for 4 to 6h when the temperature is increased to between 690 and 720 DEG C, and the surface temperature of the steel plate is less than or equal to 720 DEG C during the heat preservation; e. then the heating mantle is hoisted away to cool naturally, and the steel plate is taken out of the furnace when the temperature of the core of the steel plate is cooled to be below 250 DEG C. The medium carbon steel plate bell-type furnace spheroidizing annealing method adopts one-time annealing, and the spheroidizing qualification rate of metallurgical structures is apparently improved.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

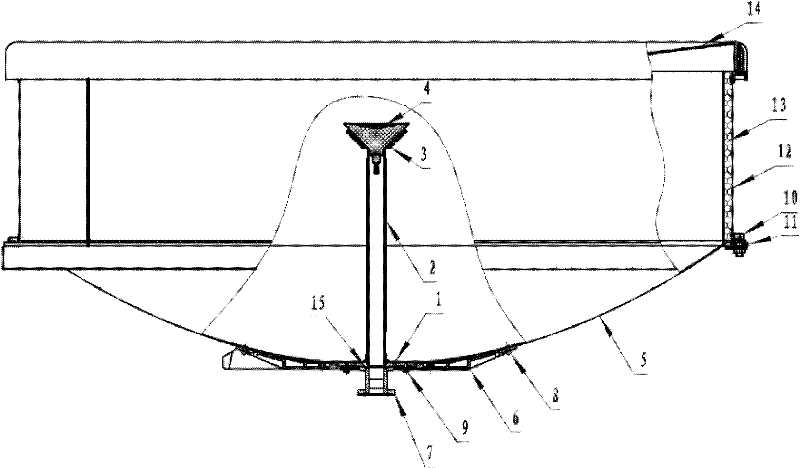

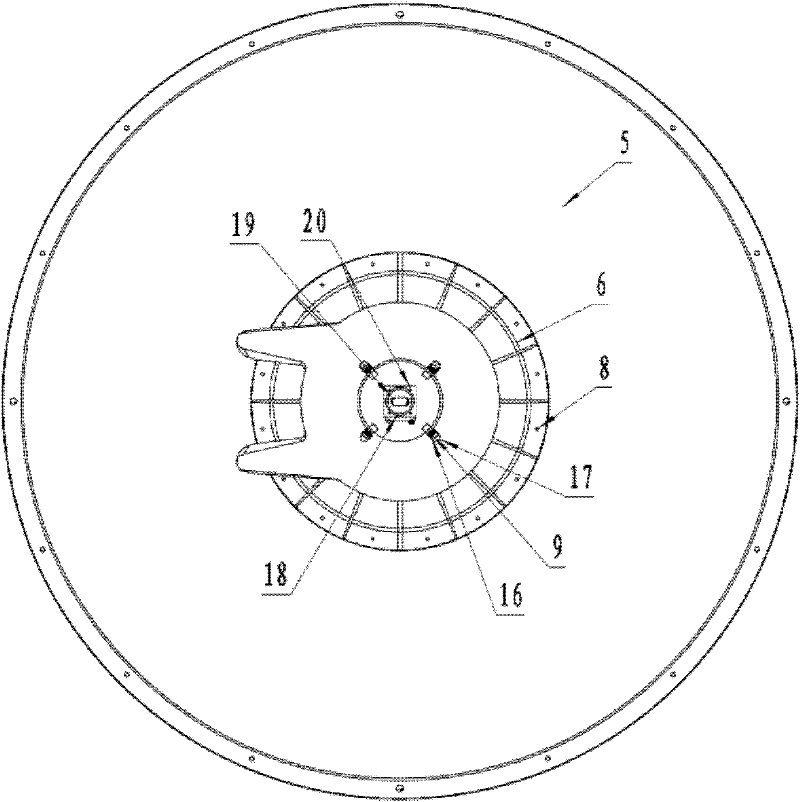

Microwave parabolic antenna with long-focus feedback super-high performance

ActiveCN102570050AEnhance F/B and other featuresEliminate occlusionAntenna couplingsElectricityPunching

The invention discloses a microwave parabolic antenna with long-focus feedback and super-high performance. The microwave parabolic antenna comprises a standard rotary parabolic main reflector, a round waveguide pipe, a dielectric sputtering plate, an auxiliary reflector, a feed source connecting disc, a metal shielding ring and other assembling and mounting parts, wherein the standard rotary parabolic main reflector is formed through punching or spinning; the round waveguide pipe feeds electricity along the axial line direction of the main reflector; the dielectric sputtering plate is shaped and rotationally symmetric; the auxiliary reflector is formed by metal-plating on the bottom surface of a dielectric sputtering plate; the feed source connecting disc is used for connecting the round waveguide pipe with the main reflector together; the metal shielding ring is connected to the outer edge of the main reflector; and the round waveguide pipe, the feed source connecting disc and the dielectric sputtering plate are positioned on the axial line of the main reflector and are bonded and assembled together to form a core of the whole antenna. The microwave parabolic antenna with long-focus feedback and super-high performance is excellent in performance, lower in cost, attractive in appearance, high in practicability and high in consistency, can be used in a microwave circuit concentrating place, is easy to machine and is more suitable for mass production.

Owner:XIAN PUTIAN ANTENNA

Precoated sand casting process of cast steel valve

InactiveCN109940127AAccelerate solidificationEliminate shrinkage, shrinkage, etc.Foundry mouldsFurnace typesSand castingMolten steel

The invention relates to a precoated sand casting process of a cast steel valve. The process specifically comprises the following steps of firstly preparing a sand shell by using precoated sand as a raw material, baking the sand shell, pouring molten steel into the sand shell, taking down a to-be-cast valve after the to-be-cast valve is naturally cooled, solidified and formed, and obtaining a valve casting; and finally carrying out shot blasting, riser cutting, heat treatment, secondary shot blasting and finishing on the valve casting to obtain a valve blank, specifically, the method for manufacturing the sand shell by using the precoated sand as the raw material comprises the following specific steps of preparing a half shell or a half core by using the precoated sand as the raw material;and repairing and spraying the half shell and the half core of a valve body / valve cover while hot, and assembling to obtain the sand shell, specifically, the time consumption of the repairing processof the half core of the valve body / valve cover and the repairing process of the half shell needs to controlled to be less than or equal to 120 seconds; and in the spraying process, the temperature ofthe half shell and the temperature of the half core of the valve body / valve cover are kept 60 DEG C or above. The cast steel valve produced by the process is high in pressure test qualified rate.

Owner:YUANDA VALVE GRP CO LTD

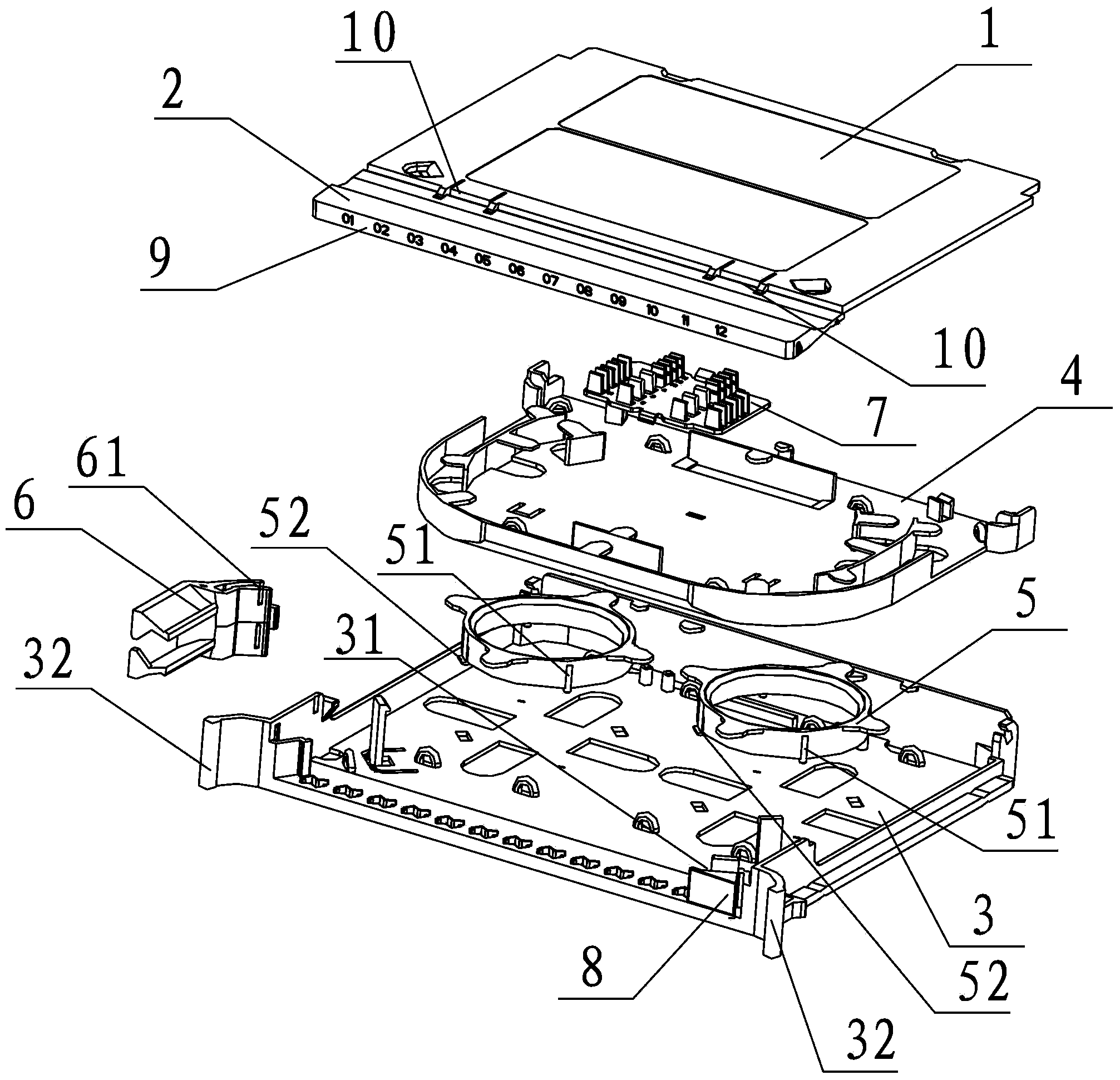

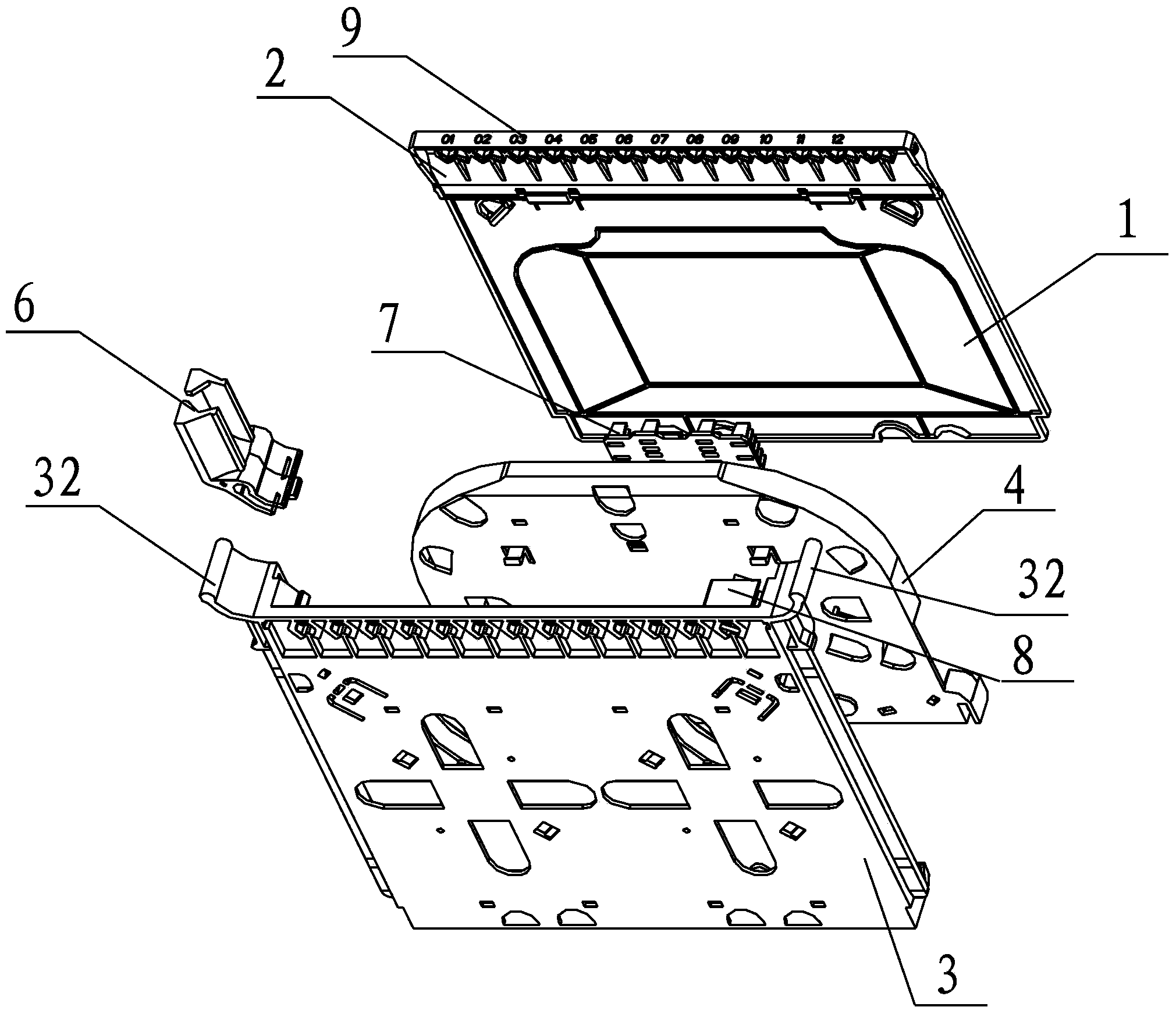

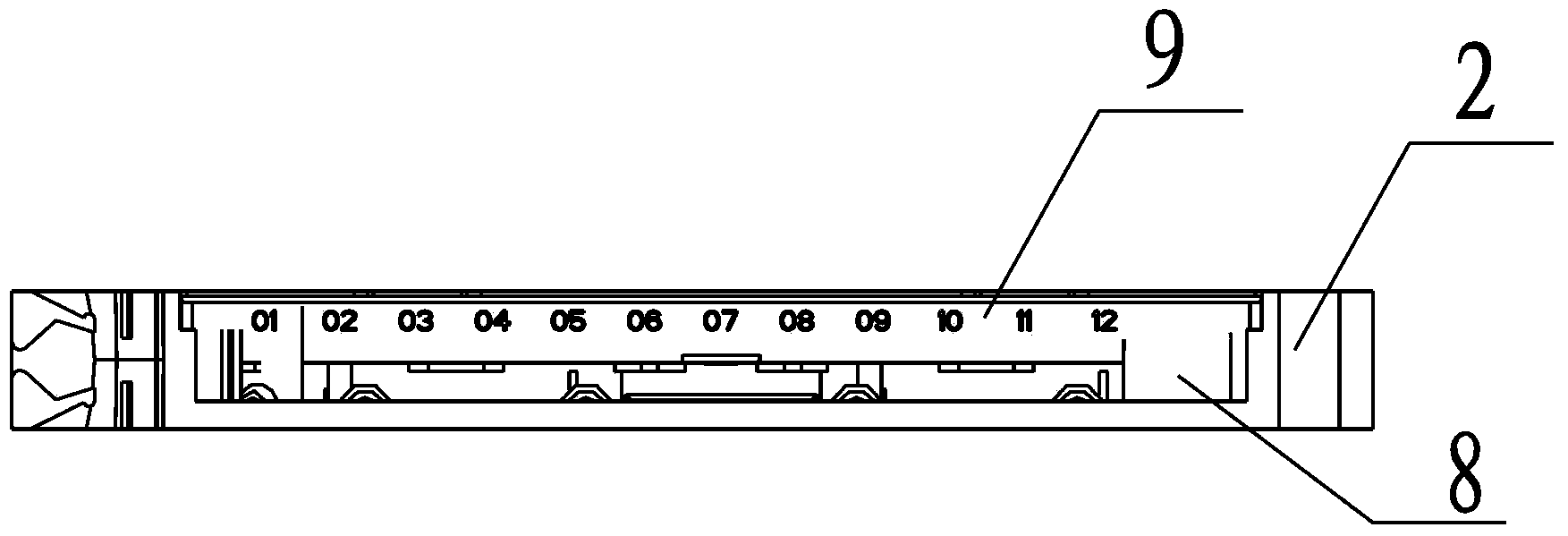

Multifunctional optical fiber melting-matching tray

The invention relates to a multifunctional optical fiber melting-matching tray which comprises a rear cover plate, a front cover plate, a melting-welding chip, a melting-welding disc, a wrapping post, a terminal disc and a wire sleeve. The front cover plate is installed on one side of the rear cover plate, the melting-welding chip is installed on the melting-welding disc, an opening hole is formed in the melting-welding disc, the wrapping post is a circle with a wrapping lug, the wrapping lug penetrates through the opening hole in the melting-welding disc, the wrapping post is installed on the terminal disc, and the rear cover plate, the melting-welding chip, the melting-welding disc, the wrapping post and the terminal disc are sequentially arranged in the sequence from top to bottom. The wire sleeve is installed on the terminal disc, and the front cover plate is installed on the rear cover plate through a rotating shaft. The multifunctional optical fiber melting-matching tray can meet belt-shaped or bundle-shaped tail fibers of a plurality of adapters and movable connectors matched with the adapters and meet left-and-right fiber outlet of wiring, box-type optical branching devices below 1:32 and 2:32 can be installed, according to the multifunctional optical fiber melting-matching tray, varieties of trays are reduced, the period of goods preparation is shortened, and the management cost is reduced.

Owner:上海乐通通信设备(集团)股份有限公司 +1

On-line quenching and plate shape control process of wide and thick plate for water and electricity

ActiveCN106350645ASave resourcesShorten the development cycleFurnace typesHeat treatment process controlElectricityProduction line

The invention relates to an on-line quenching and plate shape control process of wide and thick plate for water and electricity. According to the process, jet cooling on-line quenching is performed by using positive jetting, positive jetting and reverse jetting as one unit; in a jet impact region, cooling water and the surface of a steel plate perform heat exchange; meanwhile, most of cooling water is limited in the jet impact region using the positive jetting, positive jetting and reverse jetting as the unit. According to the thickness specification classification of the (wide) thick plate for water and electricity; the passing type cooling or swinging type cooling on-line quenching is selected; the maximum heat exchange efficiency of cooling water and the steel plate is realized; a good cooling plate shape is obtained. The process has the advantages that the temperature uniformity of an on-line quenching steel plate through plate is ensured; the off-line quenching of the (wide) thick plate for water and electricity is transplanted to on-line production; the production flow is simplified; the production cost is reduced; meanwhile, heat treatment production line resources are saved; the cargo supply period is shortened.

Owner:NANJING IRON & STEEL CO LTD

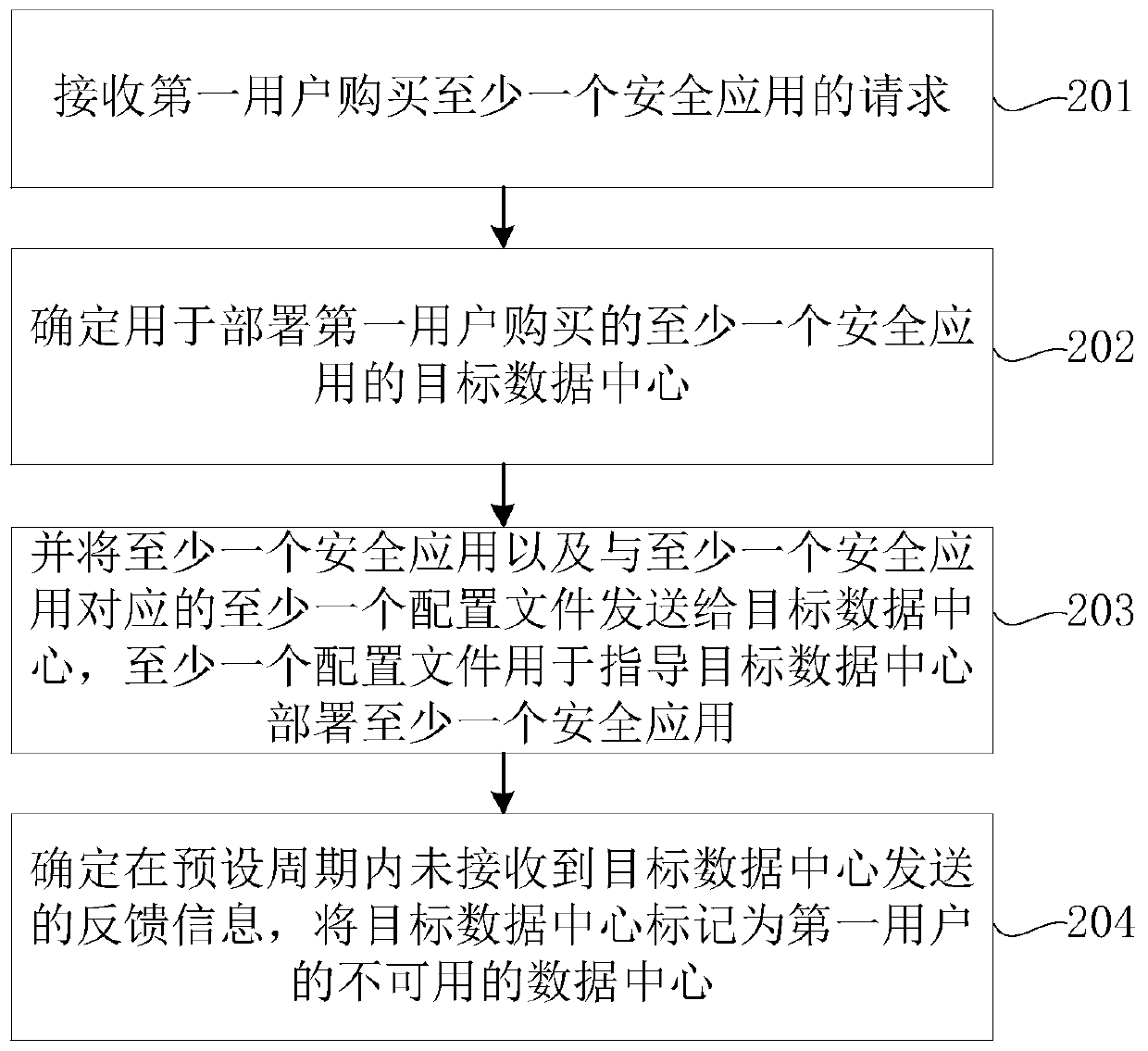

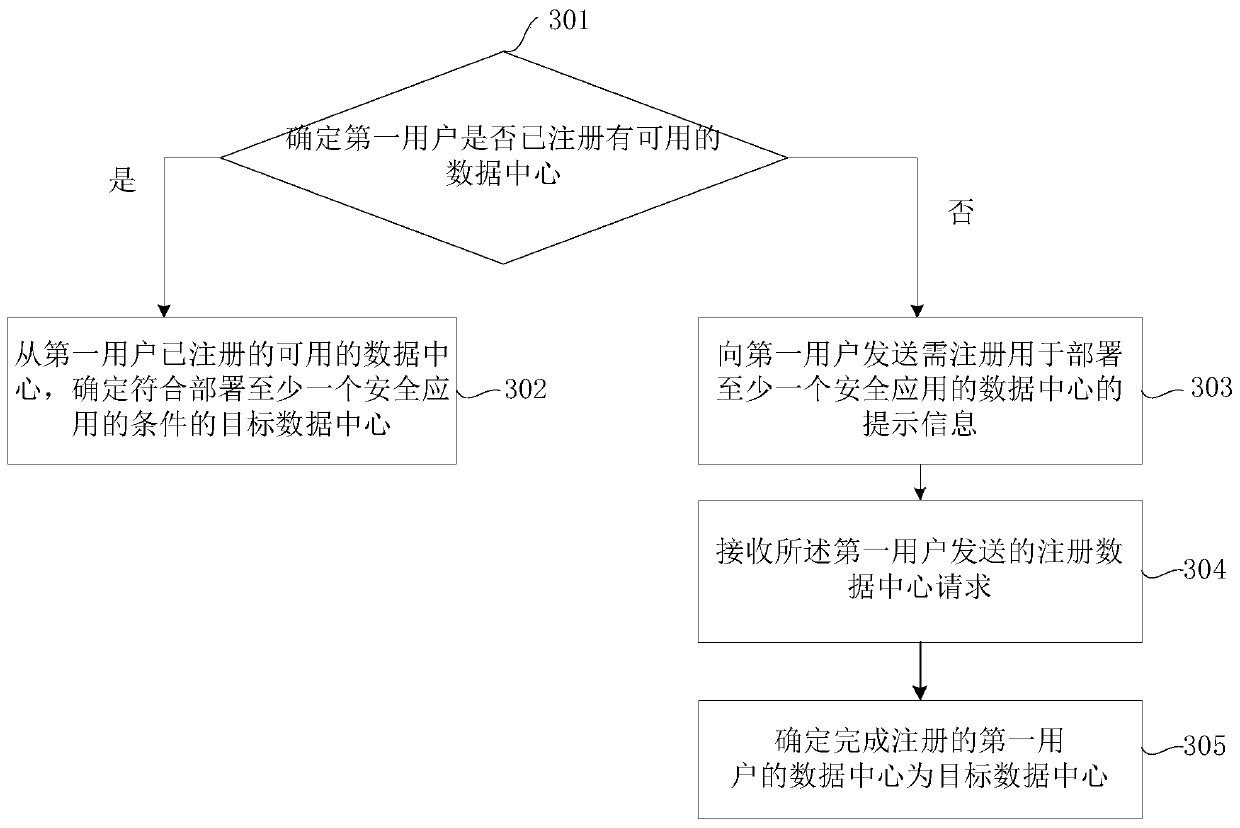

Secure application delivery method and device and storage medium

InactiveCN109710270AImprove responsivenessShorten the lead timeProgram/content distribution protectionSoftware deploymentComputer securityDelivery methods

The invention relates to the technical field of Internet, and discloses a security application delivery method and device and a storage medium, which are used for improving the response capability ofsecurity service and improving the reliability of the security service in the case of security conditions, and the method comprises the following steps: receiving a request of a first user for purchasing at least one security application; determining a target data center used for deploying at least one security application purchased by the first user; and sending the at least one security application and at least one configuration file corresponding to the at least one security application to the target data center, wherein the at least one configuration file is used for guiding the target data center to deploy the at least one security application.

Owner:NSFOCUS INFORMATION TECHNOLOGY CO LTD +1

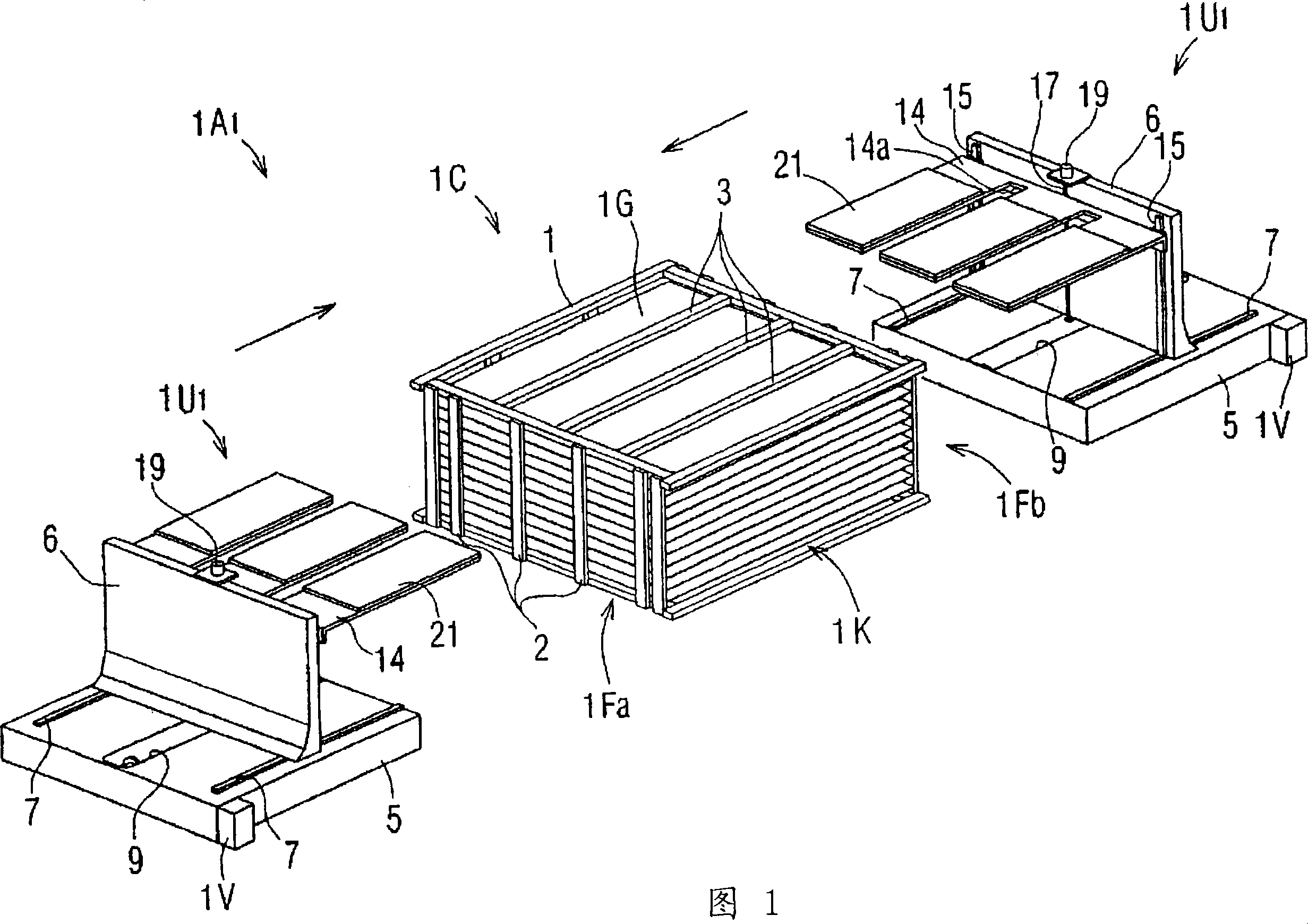

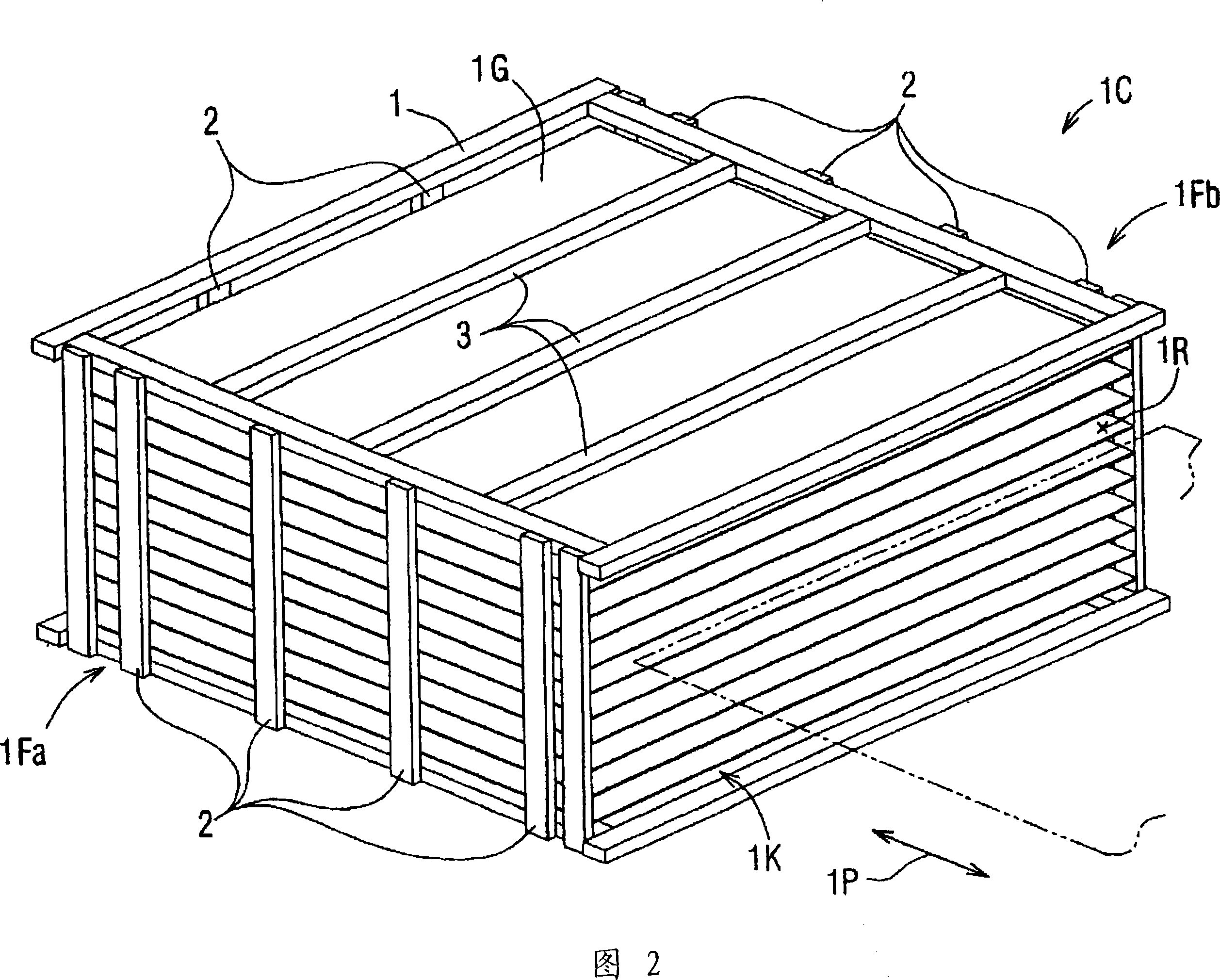

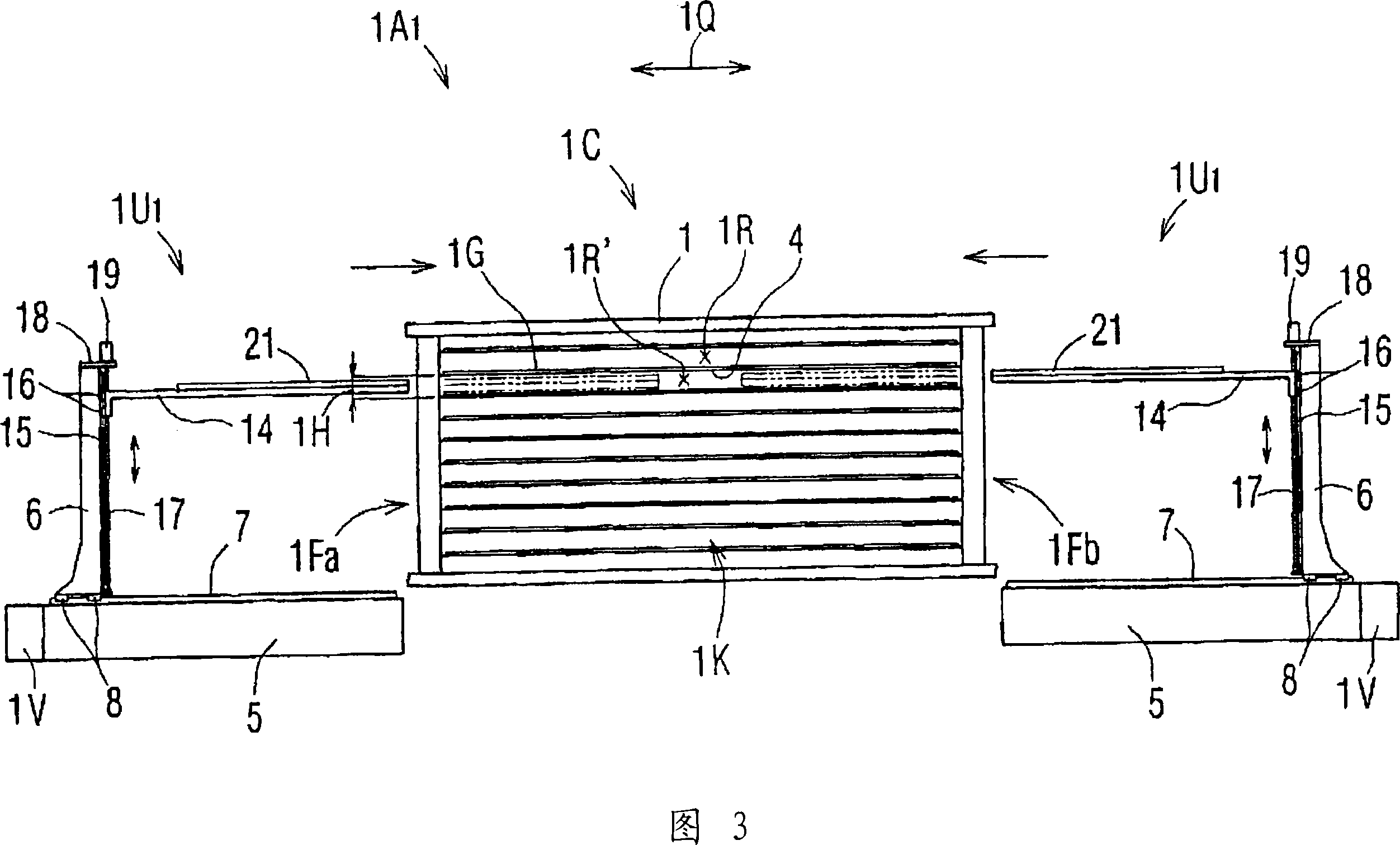

Substrate carrying in/out apparatus, substrate carrying method and device thereof

InactiveCN101188206AReduce in quantityShort production timeSemiconductor/solid-state device manufacturingCharge manipulationEngineeringDischarge pressure

Owner:SHINKO ELECTRIC CO LTD

Box collecting machine used after detection of electronic printed products and inspection machine for small-piece printed products

PendingCN107934636AHigh degree of automationImprove work efficiencyPile receiversArticle deliveryEngineeringPallet

The invention discloses a box collecting machine used after detection of electronic printed products and an inspection machine for small-piece printed products based on the box collecting machine. Thebox collecting machine comprises a baffle mechanism which is arranged corresponding to an output port of a waste discharging machine, and the baffle mechanism forms a rectangular frame; an upper airblowing mechanism which blows air downwards is installed above an upper opening of the rectangular frame, a supporting plate paper collecting mechanism is installed below an lower opening of the rectangular frame, a turnover box conveying mechanism is arranged below the supporting plate paper collecting mechanism, and a turnover box is arranged on the turnover box conveying mechanism; the output port of the waste discharging machine is provided with a photoelectric counter; and a needle insertion paper collecting mechanism is installed beside the baffle mechanism. According to the box collecting machine and the inspection machine, automatic paper collecting and boxing of the detected electronic printed products can be realized by the box collecting machine, and damages such as scratch to the surface of the electronic printed products is prevented.

Owner:HEBEI TIANYUHENG TECH CO LTD

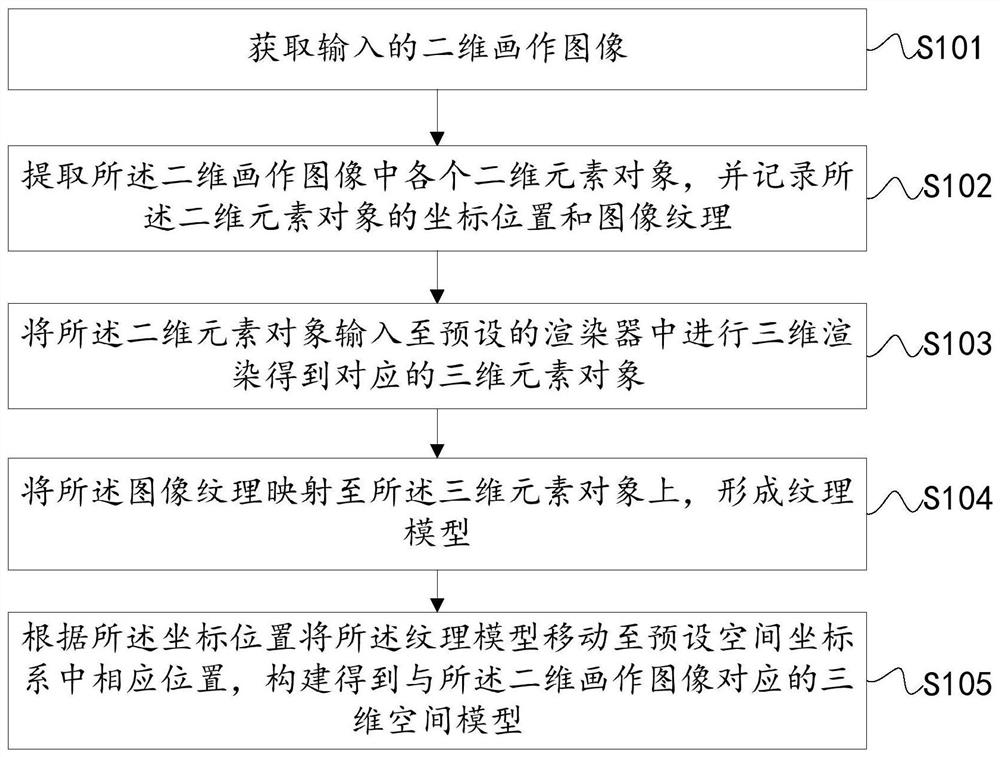

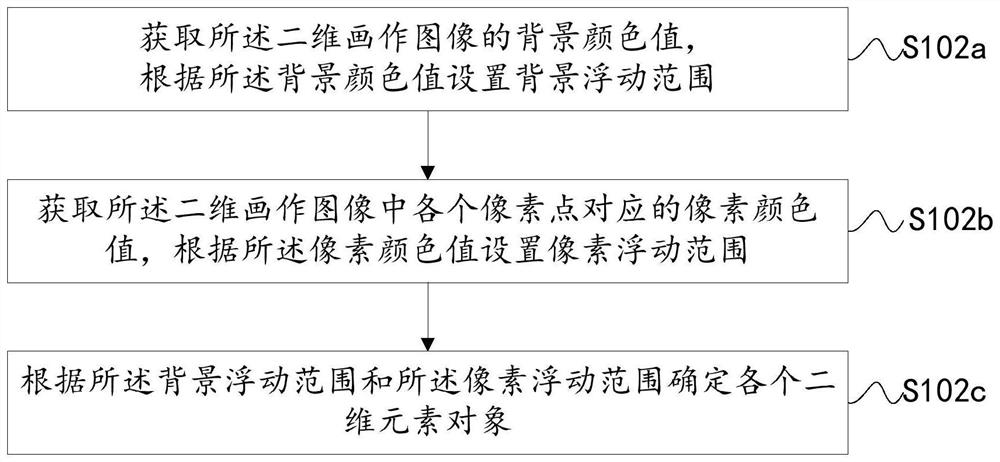

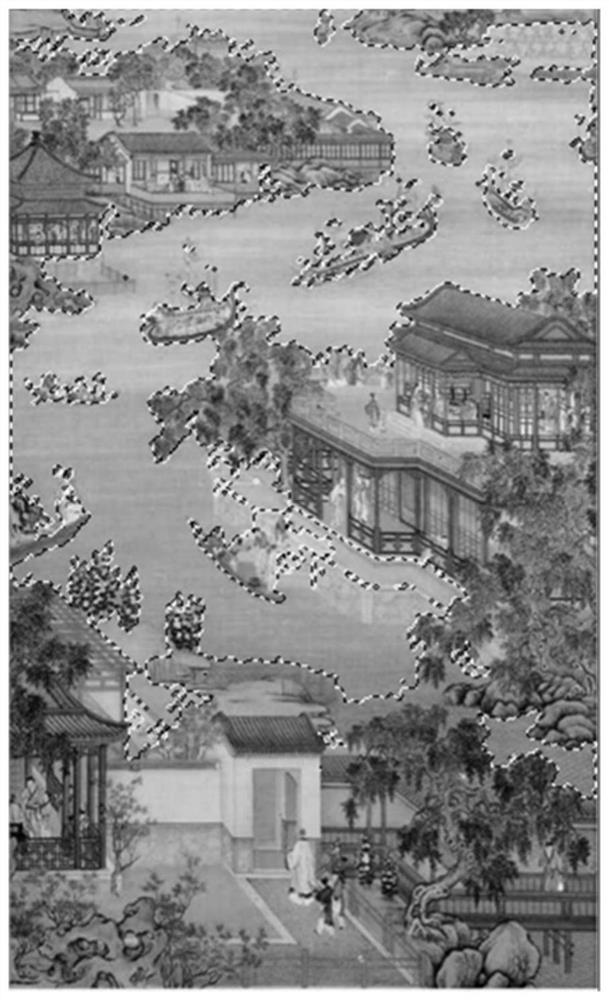

Three-dimensional model construction method based on two-dimensional painting, electronic equipment and storage medium

ActiveCN111612880AImprove modeling efficiencyImprove fitManufacturing computing systems3D-image renderingGraphicsEngineering

The embodiment of the invention discloses a three-dimensional model construction method based on two-dimensional painting, electronic equipment and a storage medium. The technical scheme provided by the embodiment of the invention comprises steps of inputting the two-dimensional element objects in the extracted two-dimensional drawing image into a renderer to perform graphic extension on all the two-dimensional element objects to obtain corresponding three-dimensional element objects, and attaching image textures of the obtained two-dimensional element objects to the three-dimensional elementobjects to perform final graphic rendering. Through the method, the modeling work of the painting work can be quickly and effectively carried out; automatic modeling and element alignment of the three-dimensional model are realized through a preset renderer; according to the embodiment of the invention, the method improves the modeling efficiency of the painting work, greatly reduces the deliveryperiod of a modeling project of the painting work, can achieve the better display of the display content in the painting work through the three-dimensional model, provides a better artistic immersionfeeling for a user, improves the user experience, and achieves a better artistic spreading purpose.

Owner:广州欧科信息技术股份有限公司 +1

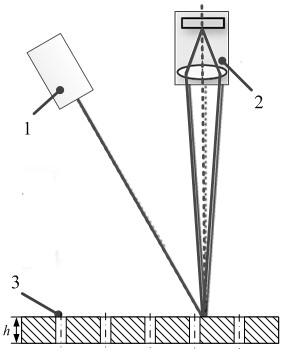

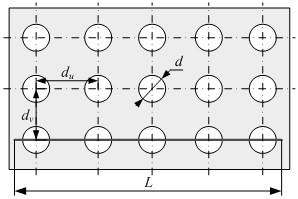

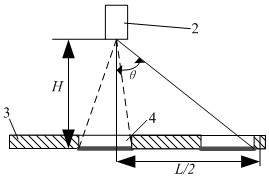

Composite material panel array hole detection method based on line laser scanning

ActiveCN112763486AImprove detection efficiencyAvoid misjudgmentMaterial analysis by optical meansUsing optical meansLaser scanningEngineering

The invention discloses a composite panel array hole detection method based on line laser scanning, which comprises the following steps of: projecting line laser to the surface of a detected object by adopting a laser device, acquiring laser stripes passing through the surface of the detected object by an industrial camera, further acquiring the outer surface data and hole bottom data of a panel, acquiring hole section data line by line from point cloud data acquired by scanning, judging whether the holes are transparent or not through analysis and processing of the point cloud data, and detecting the through hole rate of the whole panel. The method can be used to quickly and reliably detect the through hole rate of the array holes in aircraft panel parts, improves the detection efficiency and the delivery progress of products, and has good practicability. According to the invention, the line laser scanning technology and the point cloud processing technology are integrated, and rapid detection of the through hole rate of the array holes of the aircraft panel is realized.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

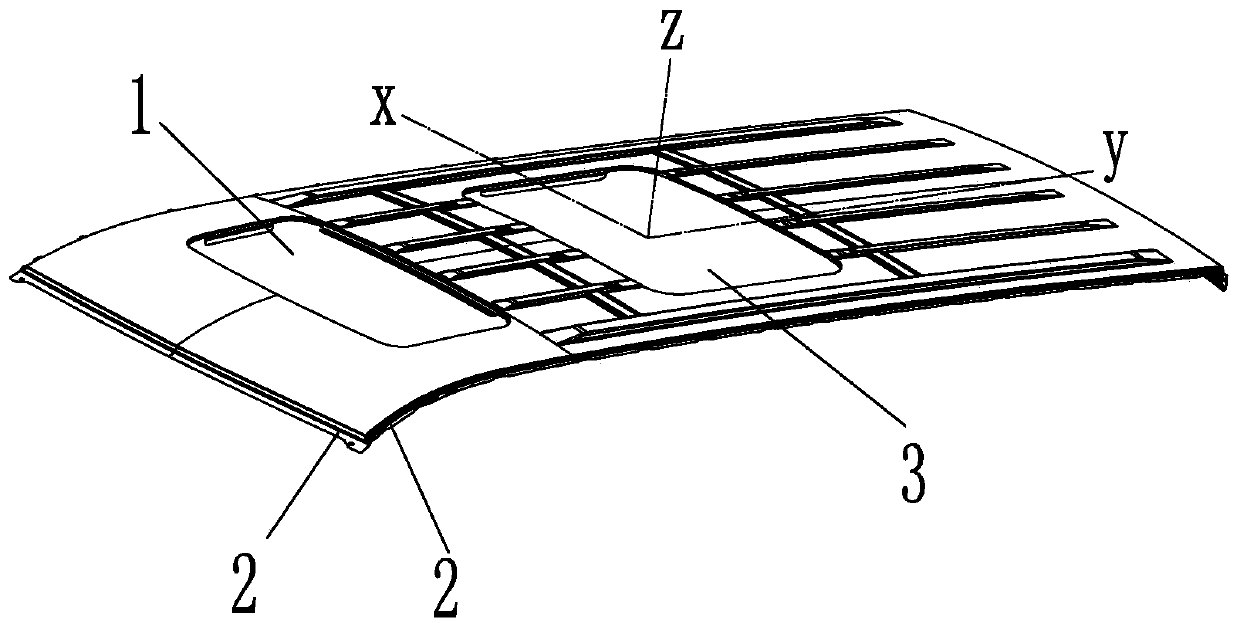

Stamping process profile compensation method for vehicle roof cover with sunroof

The invention discloses a stamping process profile compensation method for a vehicle roof cover with a sunroof. A stamping process for the vehicle roof cover with the sunroof comprises the following four procedures: 1. drawing; 2. trimming, punching and side shaping; 3. trimming, flanging and shaping; 4. trimming, punching, side punching, side shaping and upward flanging. As for the stamping process profile compensation method, die profiles from the first procedure to the third procedure are compensated. Through the method of the invention, the stamping process profiles are compensated by thepreliminary CAE analysis, and the process compensation scheme is formulated at the process design stage, thereby greatly reducing the die debugging workload, shortening the die forming cycle of complicated panel dies such as the roof cover, reducing die development costs, and improving the quality of the large panel dies.

Owner:柳州业泰汽车零部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com