Patents

Literature

104results about How to "Ensure product quality stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

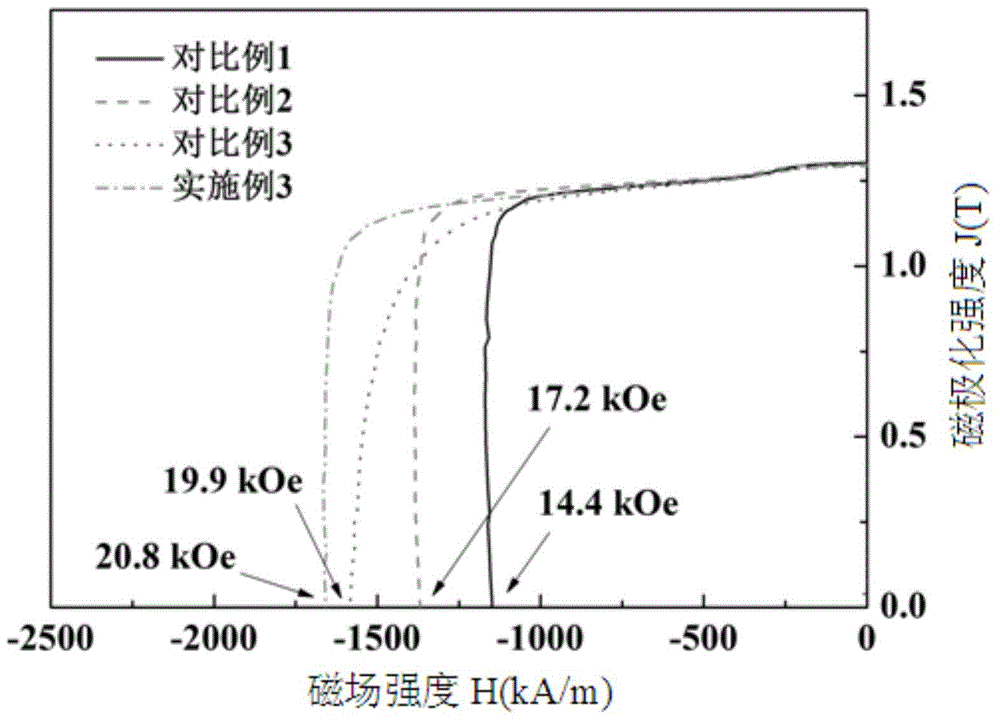

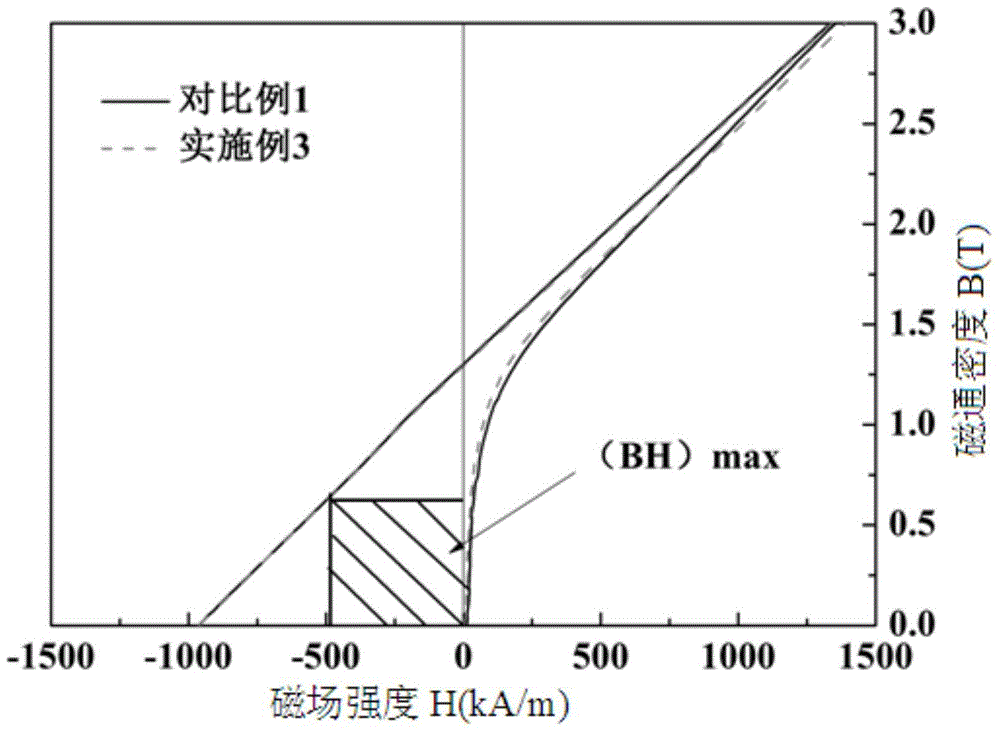

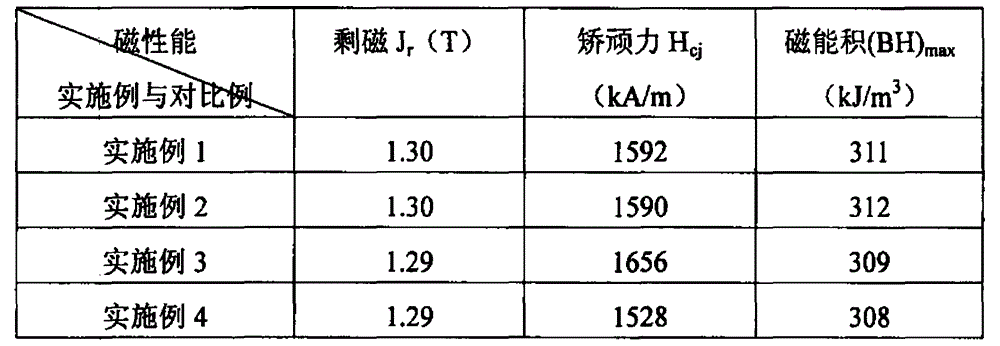

Grain boundary diffusion method for improving properties of sintered NdFeB magnets

ActiveCN104388951AIncreased diffusion kinetic energyLow melting pointInorganic material magnetismRare-earth elementDiffusion methods

The invention relates to a grain boundary diffusion method for improving properties of sintered NdFeB magnets. The grain boundary diffusion method comprises the following steps of stacking sintered NdFeB magnets and diffusion alloy sheets together and placing in a hot-pressing furnace; vacuumizing the hot-pressing furnace until the vacuum degree reaches a set value, heating the hot-pressing furnace, and when the temperature of the hot-pressing furnace reaches a set value, beginning to exert a pressure and maintaining the pressure and putting the diffused sample into a high-vacuum furnace for annealing, wherein the diffusion alloy sheets are low-melting-point eutectic diffusion alloys and are represented by R-TM, R is one or more of Sc, Y, La, Ce, Pr or Nd and TM is one or more of Ti, V, Cr, Mn, Fe, Co, Ni, Cu and Zn. Compared with the prior art, the sintered NdFeB magnets modified by the pressure diffusion method, which is provided by the invention, have the advantages of large diffusion depth of a diffusion agent, uniform distribution of grain boundary phases, high coercivity and the like, especially, low-melting-point diffusion alloys designed by the invention are free of expensive heavy rare earth element dysprosium and thus the cost of the raw materials is relatively low, the diffusion temperature is low and the energy consumption in the diffusion process is small.

Owner:SHANGHAI JIAO TONG UNIV

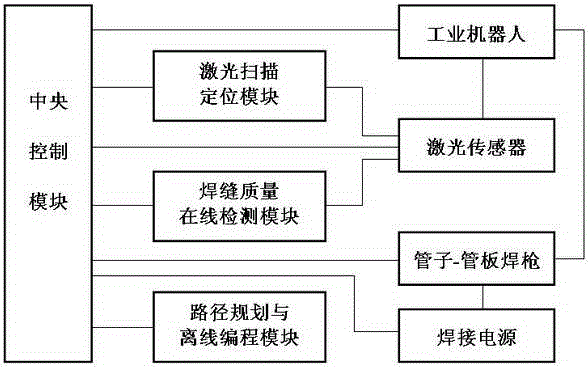

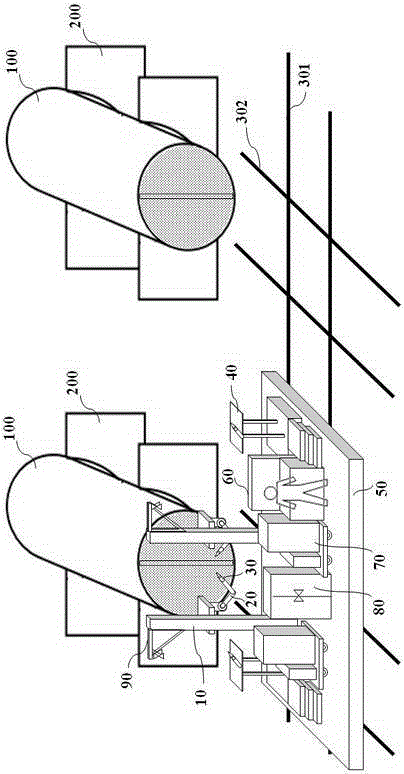

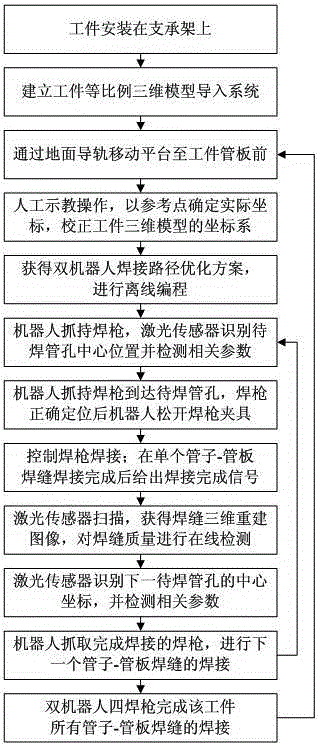

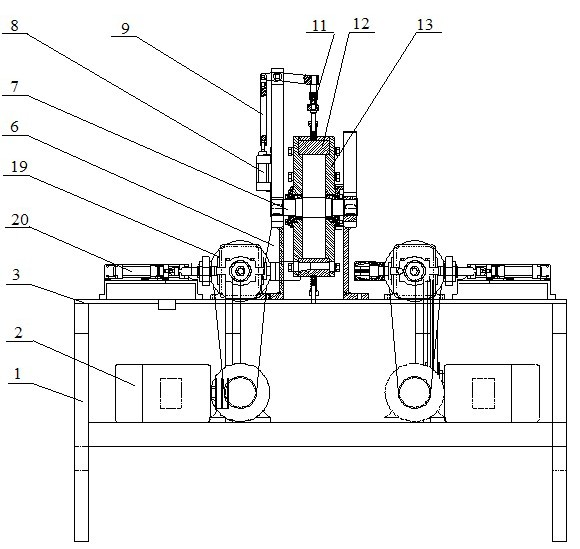

Robot welding system and welding method thereof

ActiveCN105195868AImprove work efficiencyHigh repeatabilityProgramme-controlled manipulatorHeat exchange apparatusLaser scanningVapor generator

The invention provides a robot welding system and a welding method thereof and suitable for pipe-pipe plate welding for a vapor generator of a main device in a nuclear island. According to the invention, a path planning and off-line programming module is used for planning an anti-collision welding path for an industrial robot and performing off-line programming on a planned scheme; a laser scanning positioning module obtains the circle centre coordinate of a pipe hole according to scanning results and performing initial welding position identification and autonomous guiding; the two industrial robots controlled by a central control module are matched with four pipe-pipe plate welding guns to perform welding on all pipe-pipe plate welding lines on a pipe plate; and an on-line welding line quality detection module obtains a three-dimensional reconstruction image according to welding line laser scanning results and performing on-line detection on welding line quality according to morphologies of the welding lines. Due to adoption of the system and the method disclosed by the invention, the pipe-pipe plate welding efficiency is improved, and the stability of the welding line quality is ensured.

Owner:SHANGHAI ELECTRIC NUCLEAR POWER EQUIP CO LTD

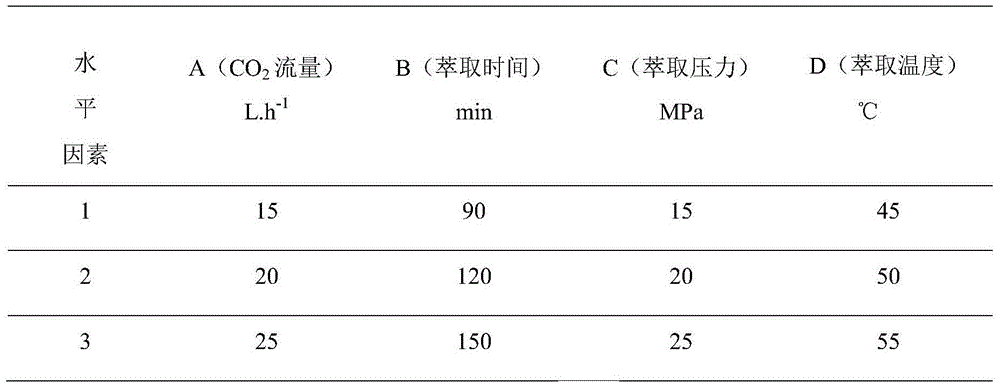

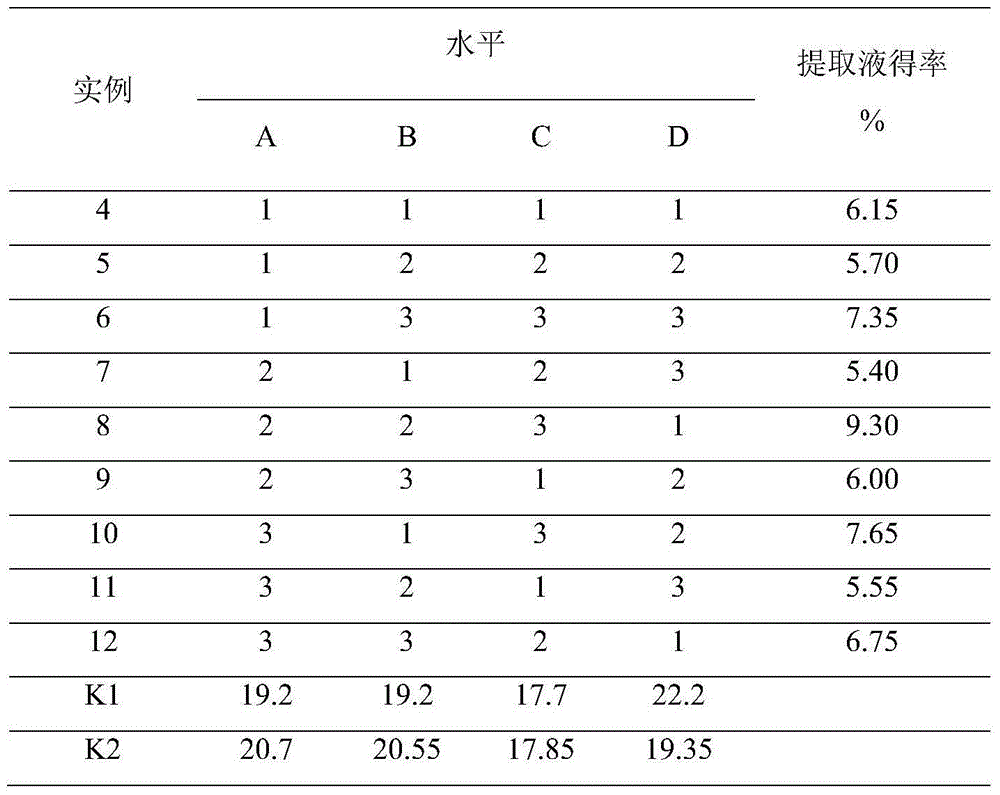

Method for preparing tobacco herbal fragrant substance for cigarette solution of electronic cigarette

ActiveCN104450186ANo pollution in the processHigh yieldTobacco treatmentEssential-oils/perfumesLiquid smokeSolvent

The invention discloses a method for preparing a tobacco herbal fragrant substance for cigarette solution of an electronic cigarette. The method comprises the steps that waste and inferior tobaccos are extracted in an ultrasound-enhanced supercritical extraction device for 1.5-2 hours at the temperature of 40-55 DEG C in the presence of an entrainer under the conditions that the ultrasonic frequency is 20KHz, the ultrasonic power is 100W, the flow rate of carbon dioxide of 10-20L / h and the extraction pressure is 15-25 MPa, so as to prepare a mixed solution of carbon dioxide and the tobacco herbal fragrant substance, wherein the entrainer is a mixed solvent of propylene glycol, ethanol and distilled water; the mixed solution is separated by virtue of a separation kettle at temperature of 45- 60 DEG C under the separation pressure of 7-12MPa to obtain the tobacco herbal fragrant substance. The tobacco herbal fragrant substance contains tobacco natural fragrant substance components, nicotine and the like and is applied to the cigarette solution of the electronic cigarette so that the cigarette solution of the electronic cigarette is endowed with the same sense organ characteristic and a satisfaction sense of smoking as common cigarettes. The extraction method is easy to carry out, low in cost, and stable and safe in product quality; the environment pollution is avoided; compared with the conventional supercritical extraction process, the method has the advantage that material consumption and energy consumption are reduced.

Owner:CHINA TOBACCO SHANDONG IND

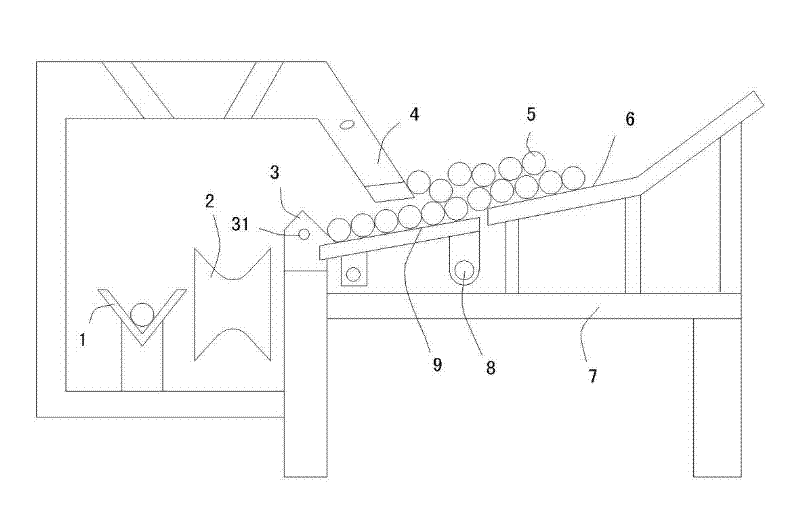

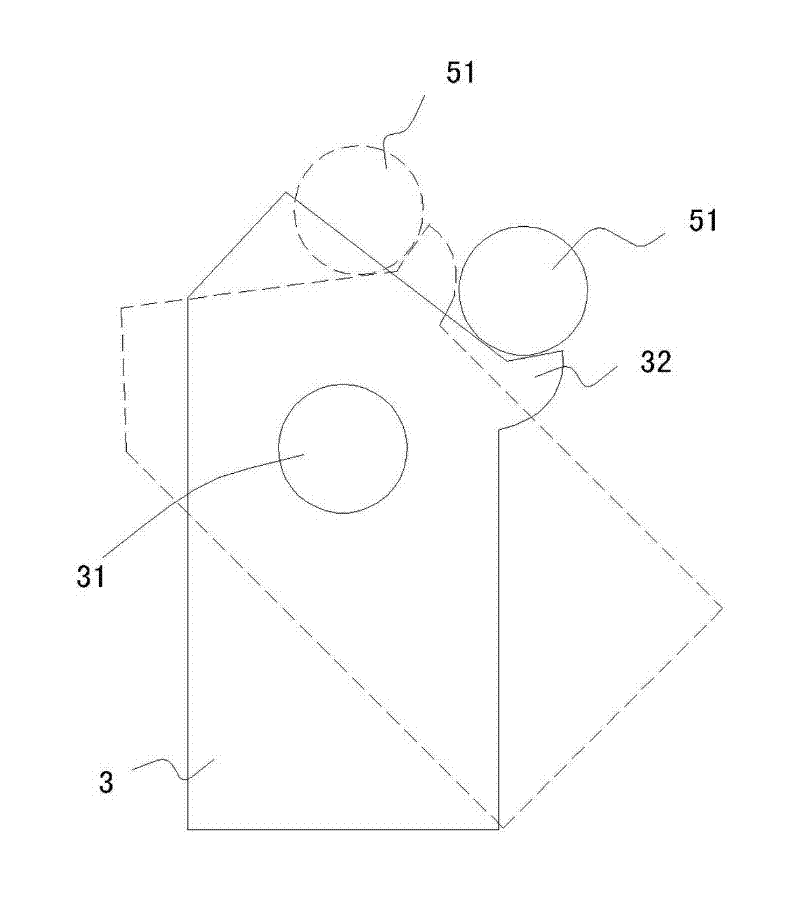

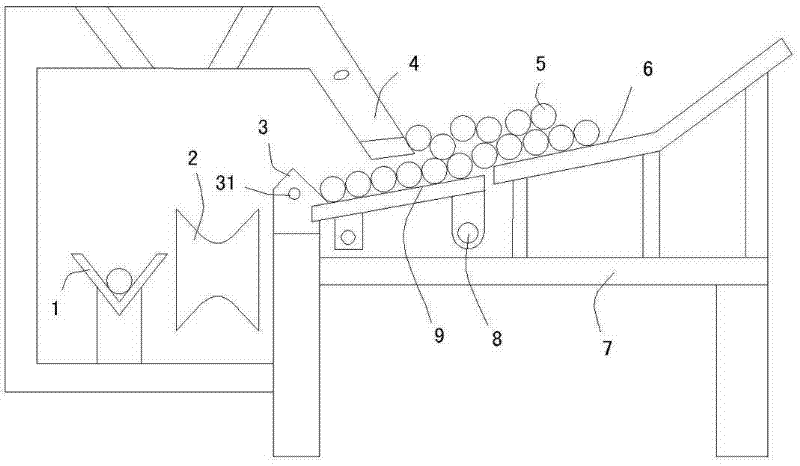

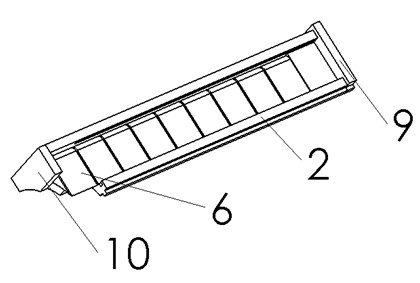

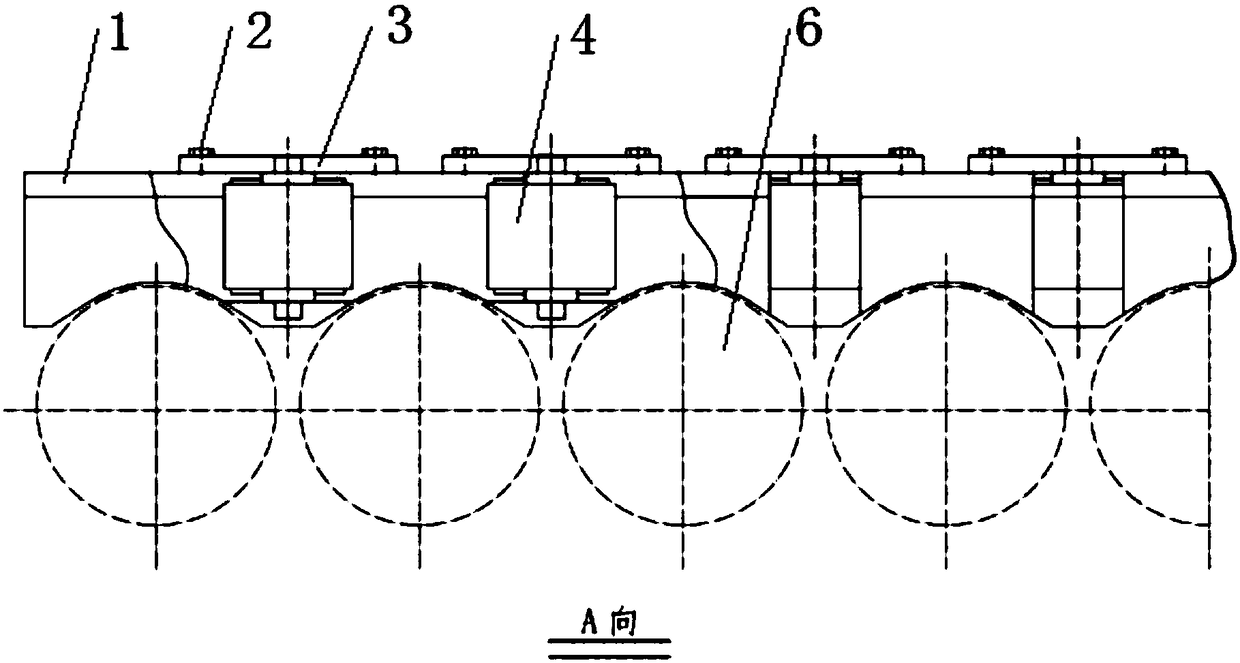

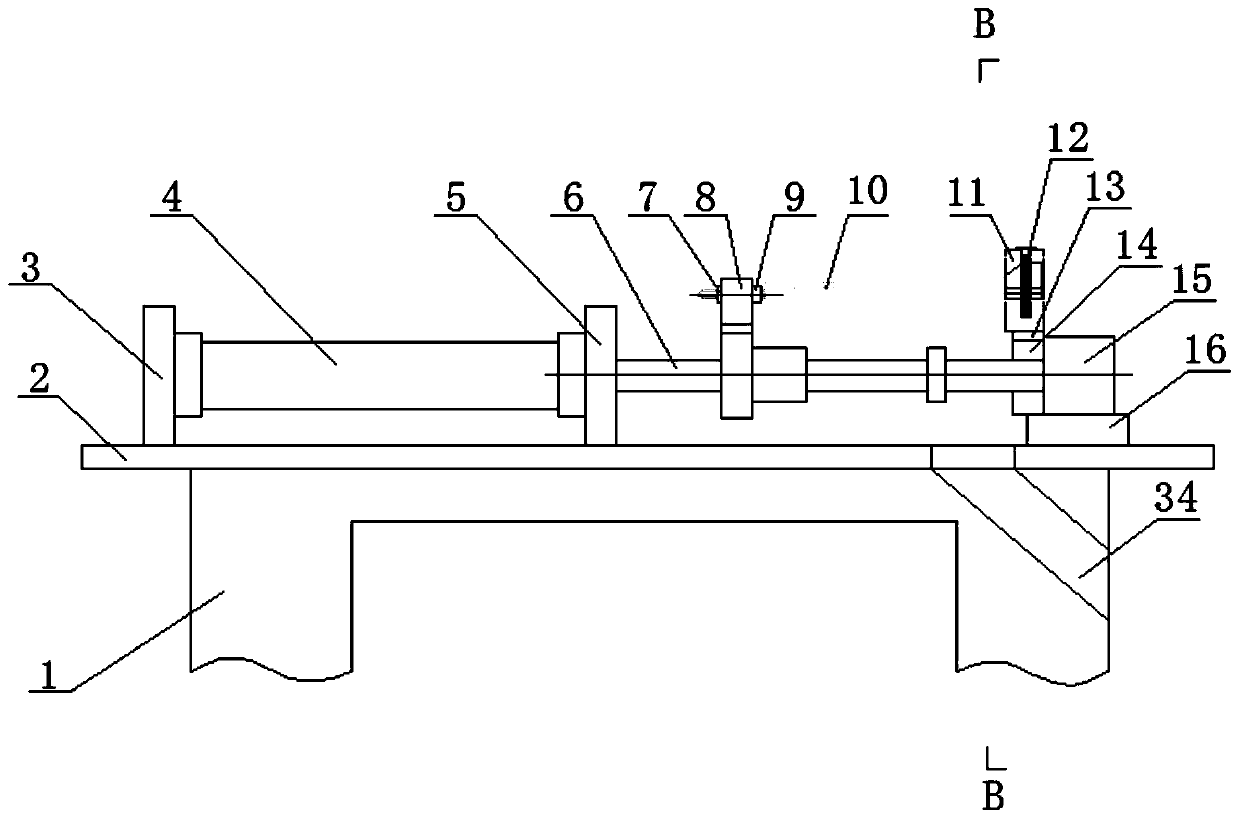

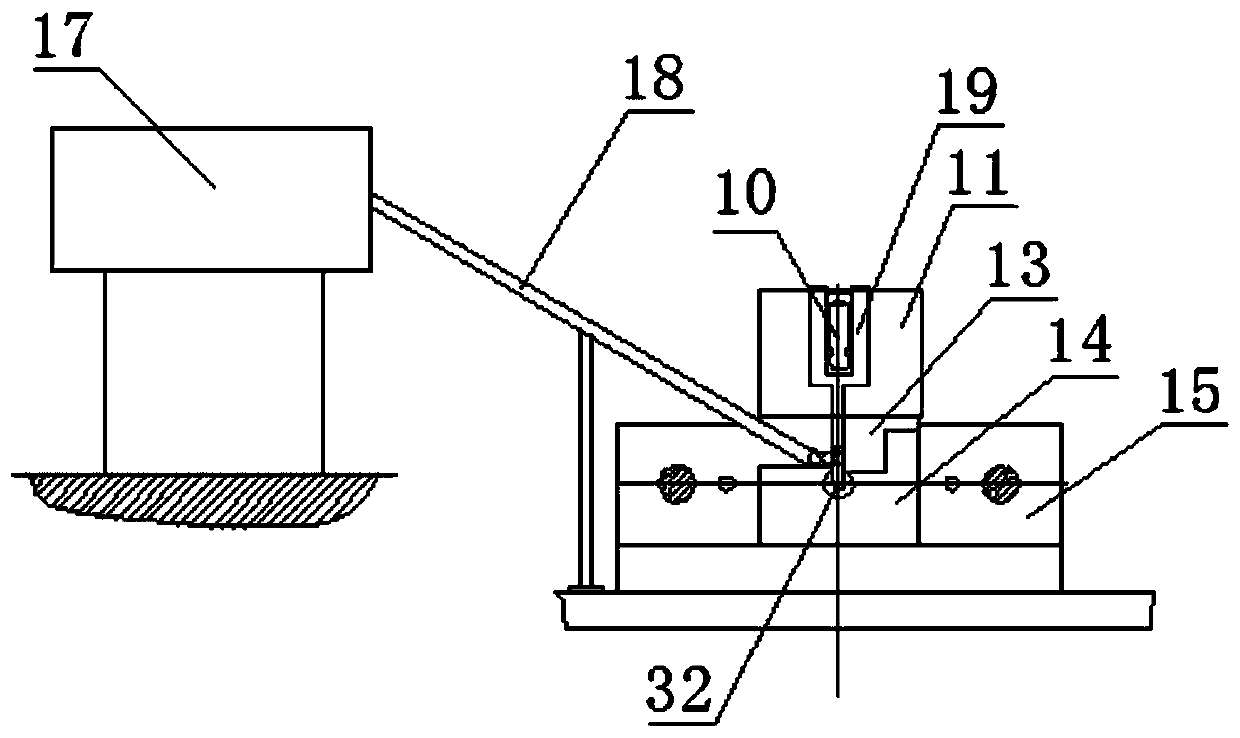

Automatic material distributing and conveying device of cold-drawn steel tubes

InactiveCN102527757AIncrease labor intensityHigh degree of automationEngineeringUltimate tensile strength

The invention relates to an automatic material distributing and conveying device of cold-drawn steel tubes. The automatic material distributing and conveying device comprises a frame, wherein the top surface of the frame is of a working face for stacking source steel tubes, and the automatic material distributing and conveying device is characterized in that the working face comprises two sections, namely a fixed inclined plane and a vibrating inclined plane, and the vibrating inclined plane is positioned at the downstream part of the fixed inclined plane; a flow limiting plate is arranged above an inlet of the vibrating inclined plane; a vertical turnover material stirring device and an axial feeding device are sequentially arranged on one side of the outlet end of the vibrating inclined plane; and the axial feeding device comprises a plurality of rolling wheels which are mounted axially relative to the source steel tubes and material turning rods arranged at the gaps between the rolling wheels. According to the automatic material distributing and conveying device, material distributing and conveying of the source steel tubes can be completed by utilizing the fixed inclined plane and the vibrating inclined plane, and the source steel tubes can be automatically conveyed to a V-shaped working groove under the action of the vertical turnover material stirring device and the axial feeding device, so that the automatic material distributing and conveying device has the advantages of low labor intensity, good operating environment, high degree of automation and continuous production, can realize the purpose of reliably ensuring quality and is further conductive to eliminating potential safety hazard.

Owner:浙江伦宝管业股份有限公司

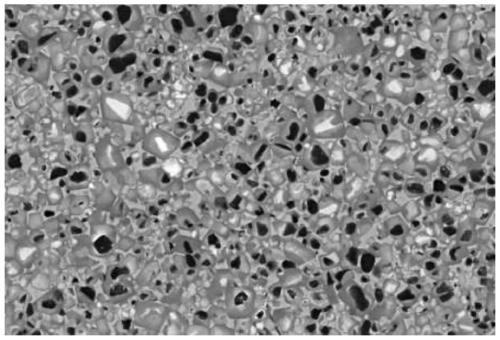

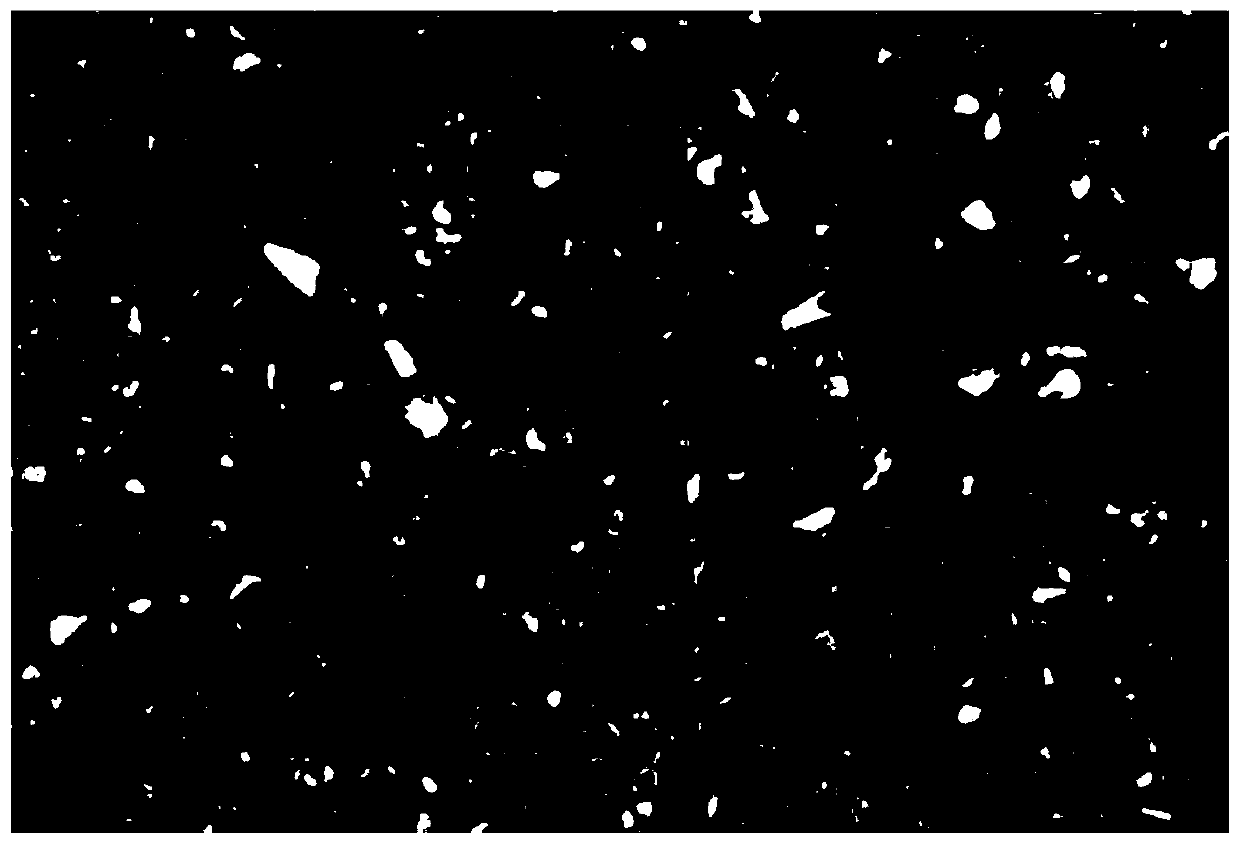

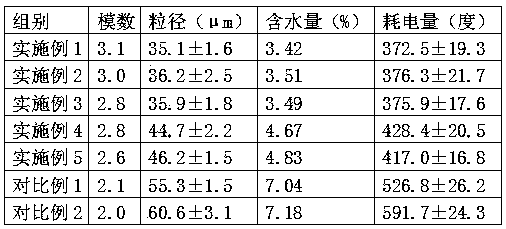

Ti (C, N)-based metal ceramic cutter material and preparation method thereof

ActiveCN109972015AImprove toughnessImprove wear resistanceTurbinesOther manufacturing equipments/toolsSpray GranulationCarbide

The invention provides a Ti (C, N)-based metal ceramic cutter material and a preparation method thereof. The cutter material comprises the following raw materials in percentage by mass: 20.5-55. 5 percent of Ti (C0.5, N0.5), 0-35.5 percent of (Ti39.8W46.9) C, 0-15 percent of WC, 0-12 percent of TiC, 10-11 percent of Mo2C, 5-7 percent of TaC, 0-1.5 percent of VC, 6-9 percent of Co, 6-9 percent of Ni and 0-1 percent of C. The preparation method comprises the steps of material mixing and wet milling, spray granulation, die forming and degreasing and sintering. The material provided by the invention has the beneficial effects that the bending strength, the hardness, the fracture toughness, the wear resistance and the like of Ti (C, N)-based metal ceramic are improved by adjusting the relationship between carbide and carbonitride, thereby effectively improving the cutting performance of a cutter.

Owner:ZHUZHOU HUARUI PRECISION CUTTINGS TOOLS CO LTD

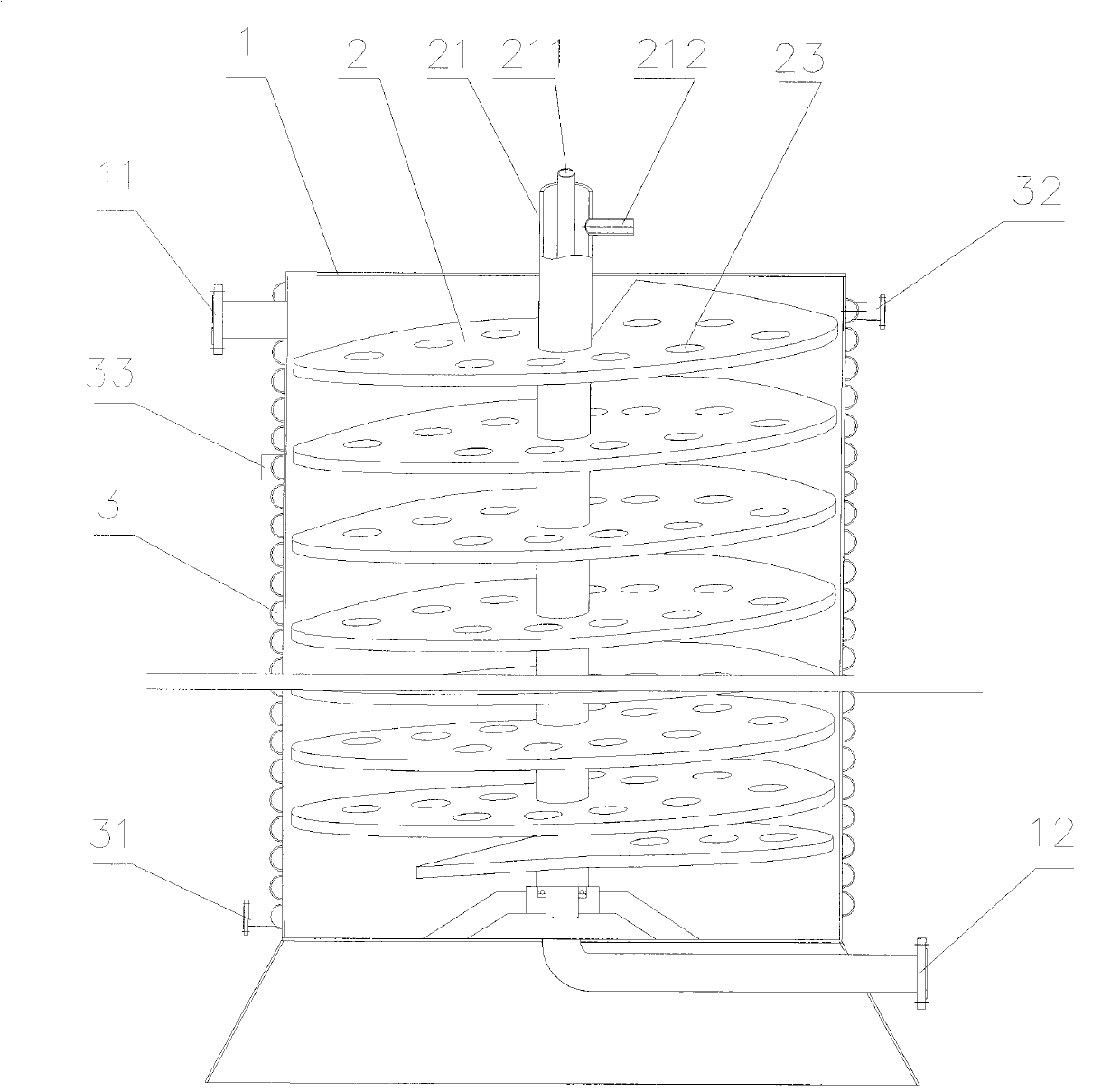

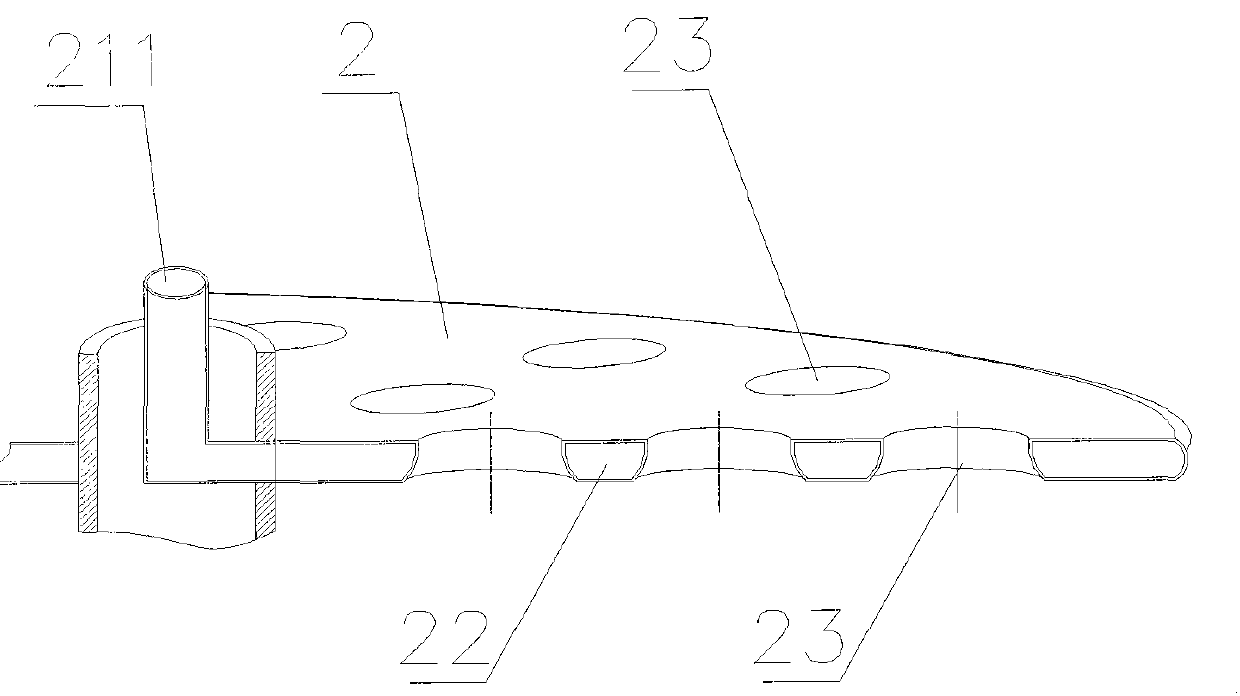

Vertical continuous-cooling crystallization machine

ActiveCN103585781APromote formationMeet the principle requirements of continuous crystallization processSolution crystallizationEngineeringWater jacket

The invention discloses a vertical continuous-cooling crystallization machine. The vertical continuous-cooling crystallization machine comprises an outer cylinder and a spiral stirring paddle. The spiral stirring paddle is erected in the outer cylinder. The outer wall of the outer cylinder is provided with a cooling water jacket. The spiral stirring paddle is arranged in a top suspension way. A shaft of the spiral stirring paddle has a sleeve-type hollow shaft structure. Cavities are formed in blades of the spiral stirring paddle. Upper and low ends of each one of the cavities are communicated with the shaft having the sleeve-type hollow shaft structure. The vertical continuous-cooling crystallization machine has the advantages that 1, a housing jacket and the hollow blades of the spiral stirring paddle are combined and cooling water is fed into the combined structures simultaneously so that a heat exchange area is greatly improved and a crystal yield is greatly improved; 2, the spiral stirring paddle can rotate by 360 degrees so that no-dead corner medium cooling is realized, formation of crystal nucleuses and stable and natural growth of crystals are promoted, a cooling rate is improved and product quality stability is guaranteed; and 3, intelligent configuration improves productivity and reduces a cost.

Owner:姜向前

Processing technology for white carbon black with low water content

ActiveCN103803559ARigorous and perfect processEasy to operateSilicaSoluble glassPulp and paper industry

The invention discloses a processing technology for white carbon black with the low water content. The processing technology provided by the invention has the advantages that rice hull ash is utilized as a raw material, soluble glass is obtained through the rice hull ash subjected to alkali lye treatment, and a white carbon black finished product is obtained through acidification sedimentation and three-section drying. The processing technology provided by the invention has the advantages that the technology steps are rigorous, technology parameters are definite, the white carbon black is subjected to three-section drying treatment, the content of water of the white carbon black is low, the particle size distribution is uniform, particles are small, energy is recycled, and the white carbon black processing technology is environmentally-friendly and efficient.

Owner:QUECHEN SILICON CHEM

Method for pre-stretch bending of metal thick slab and numerical control machining forming of high-rib wallboard with curvature

The invention relates to a method for pre-stretch bending of a metal thick slab and numerical control machining forming of a high-rib wallboard with curvature, and mainly solves the problems that residual stress is high, the streamline of a molded surface is poor, deviation between an actual curved surface shape and a theoretical shape is large and the like in the conventional forming method. The method mainly comprises the following steps of: the pre-stretch bending of the metal thick slab, and the numerical control machining forming of the high-rib wallboard with the curvature. The method aims to greatly reduce the workload of the subsequent assembly process, improve production efficiency and whole quality and prolong service life. The residual stress in the slab is controlled by stretching and bending deformation modes in the pre-stretch bending process, so that the shape of the slab is approximate to the curved surface shape of the wallboard; the release process of the residual stress is controlled, and new residual stress is not generated or a little new residual stress is generated by controlling numerical control machining environment, process and parameters in the wallboard forming process, so that the forming quality of the wallboard is ensured; and numerical control machining is used as the final process of wallboard production in the method, so that product quality and process stability can be ensured to a great extent, and the designed theoretical shape of the wallboard can be ensured to the greatest extent.

Owner:SHENYANG AEROSPACE UNIVERSITY

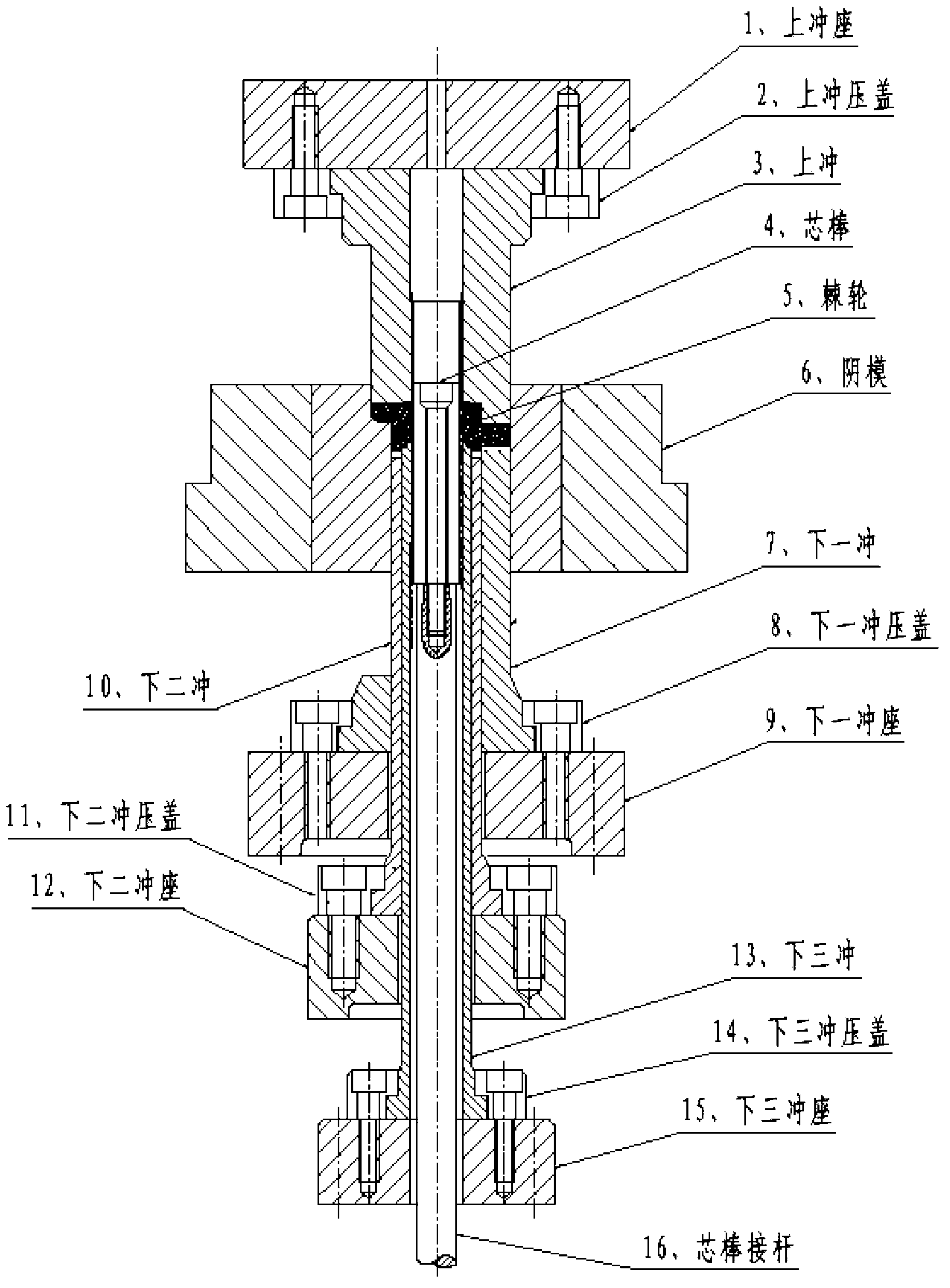

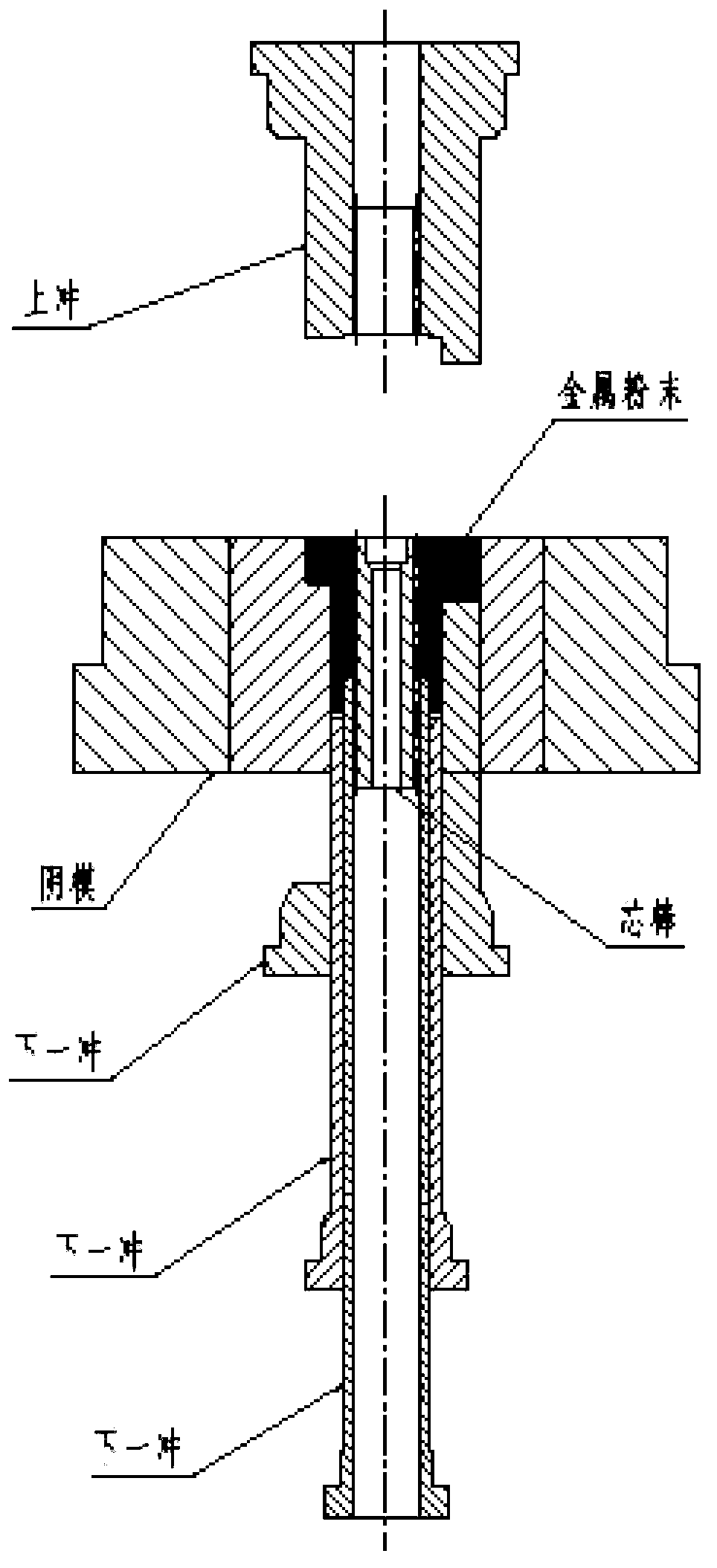

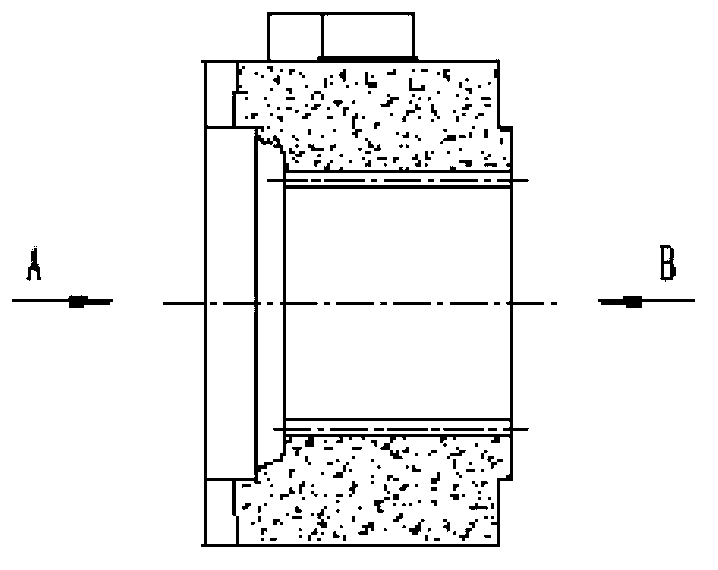

Method for manufacturing starting ratchet wheel of motorcycle

Provided is a method for manufacturing a starting ratchet wheel of a motorcycle. Metal powder serves as a raw material and is sintered after compression forming in a mould. The method is characterized in that pressure for compression is 80-115 tons, and dwell pressure for demoulding is 9-15 tons. The metal powder serves as the raw material, is alloyed into alloy steel by compressing and sintering, and is completely free of mechanical cutting, and accordingly waste of steel materials is avoided, steel resource is greatly saved, and the produced starting ratchet wheel of the motorcycle has mechanical performance of the alloy steel, the mechanical performance and overall quality of the starting ratchet wheel are further improved, and production efficiency is also greatly increased. The method is simple in production process, the starting ratchet wheel is high in precision and fine in consistency, and stability of quality of products in mass production is guaranteed.

Owner:重庆聚能粉末冶金股份有限公司

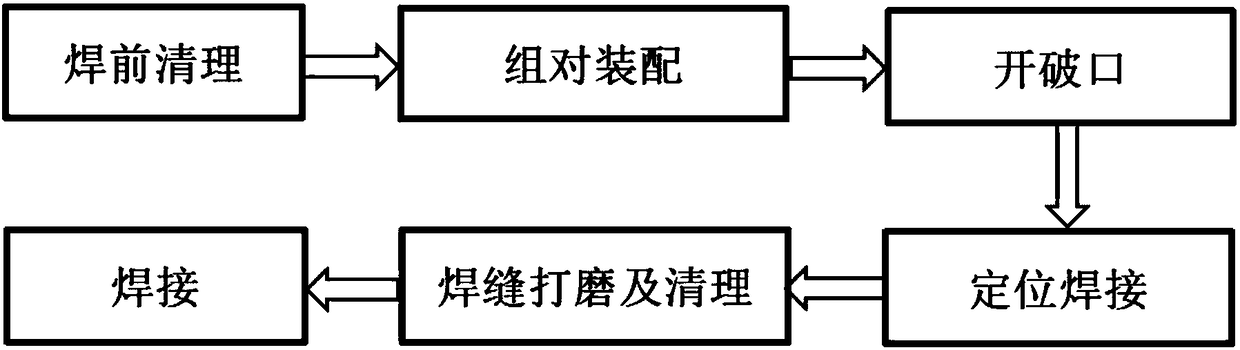

Friction stir welding method for aluminum alloy with fusion welding positioning welding seams

InactiveCN108581175AImprove welding qualityImprove pass rateWelding/soldering/cutting articlesNon-electric welding apparatusFriction weldingWeld seam

The invention belongs to the technical field of welding, and relates to a friction stir welding method for an aluminum alloy with fusion welding positioning welding seams. The friction stir welding method comprises the steps that a to-be-welded workpiece is subjected to pre-welding cleaning; the to-be-welded workpiece is coupled and assembled through a clamping tool; a groove is formed in a pre-welded point-fixed position; the groove is subjected to positioning welding; the welding seams are ground and cleaned; and the welding seams of the to-be-welded workpiece are subjected to friction stirwelding. A series of problems that in an existing friction stir welding process, joint coupled gaps are not liable to be controlled, the friction stir welding quality is unstable, and the requirementfor a tool is high are solved.

Owner:辽宁忠旺铝合金精深加工有限公司

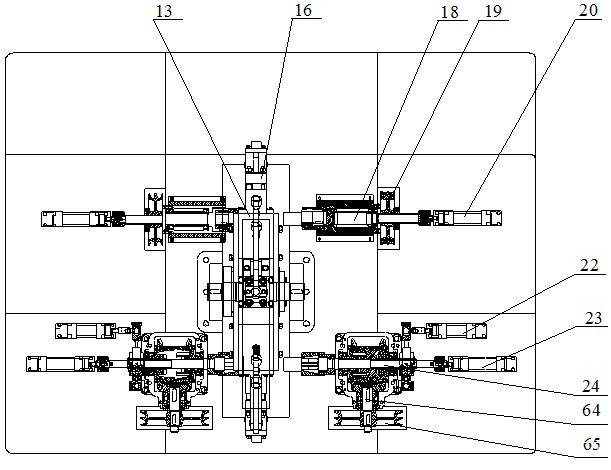

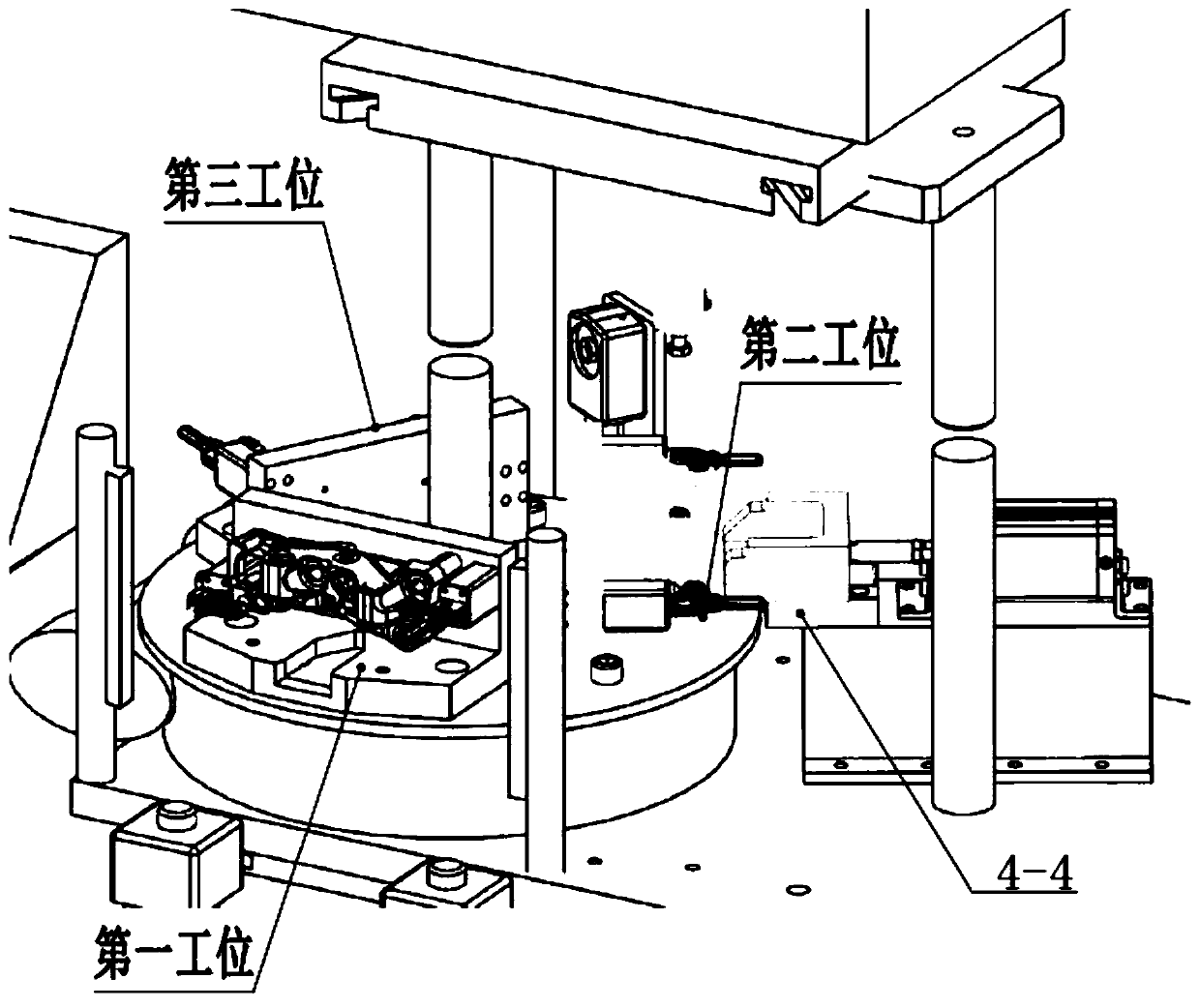

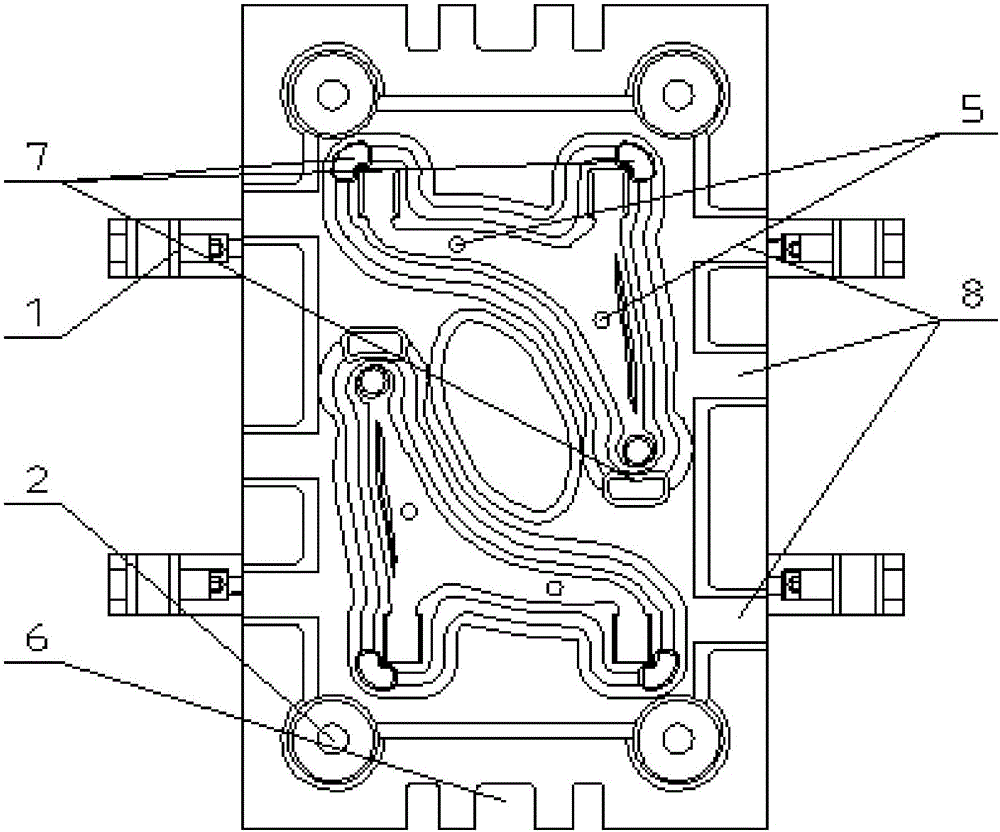

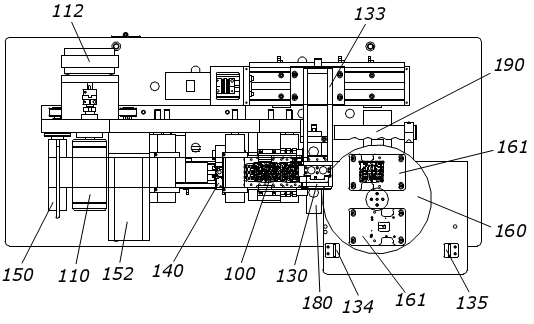

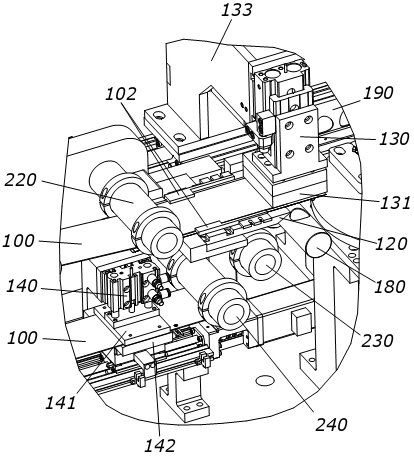

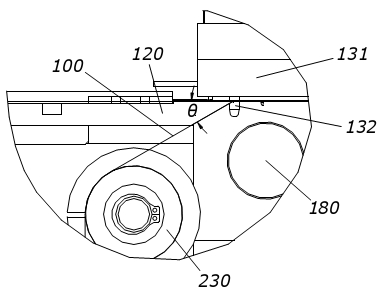

Automatic machining machine tool for four-station valve body

ActiveCN102528462AOvercome the disadvantage of needing to process on multiple machine toolsImprove processing efficiencyOther manufacturing equipments/toolsMetal working apparatusHydraulic cylinderGear drive

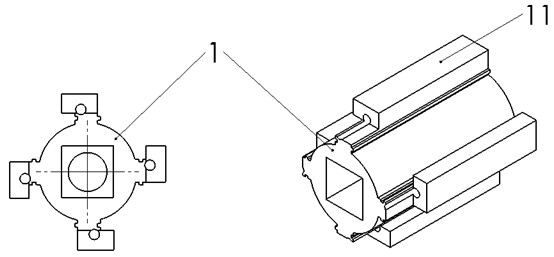

The invention discloses an automatic machining machine tool for a four-station valve body, which comprises a rotary disc, wherein the rotary disc is connected with a gear through a clutch, and a rack moves left and right to drive the gear meshed with the rack to rotate under the action of a hydraulic cylinder; the gear drives the rotary disc to rotate through the clutch to realize the conversion of the stations, and four stations are uniformly distributed on the circumference of the rotary disc; a first station is positioned right above the rotary disc, a second station is positioned at the left of the rotary disc, a third station is positioned right below the rotary disc, and a fourth station is positioned at the right of the rotary disc; a workpiece to be machined is installed and positioned on the first station, is bored on the second station, is tapped on the third station, and is taken down on the fourth station so as to complete the four working procedures of feeding, boring, tapping and discharging. According to the automatic machining machine tool provided by the invention, the defect that the workpiece needs to be machined on a plurality of machine tools is overcome, the machining efficiency is greatly improved, the labor cost is saved, and the stability of product quality is ensured.

Owner:日照纬润机电科技有限公司

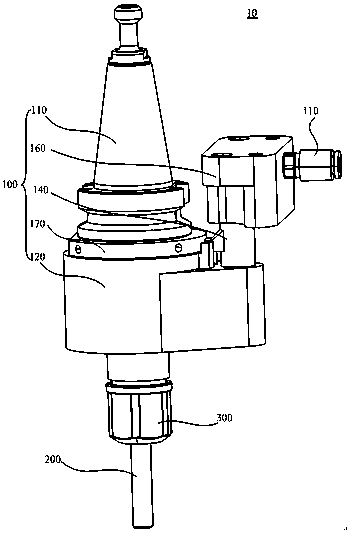

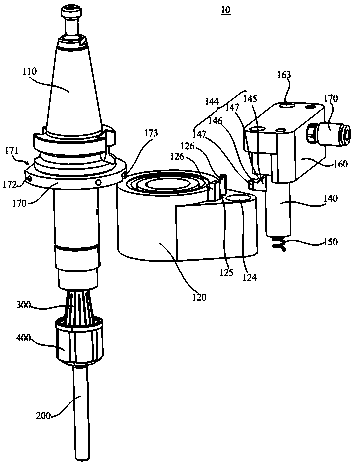

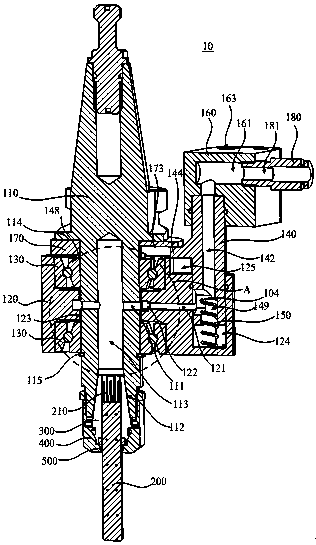

External-cooling-into-internal-cooling tool handle and external-cooling-into-internal-cooling tool handle assembly

ActiveCN110605428AQuick changeAvoid manual adjustmentMachine tool componentsMilling cuttersSpray nozzleEngineering

The invention relates to an external-cooling-into-internal-cooling tool handle and an external-cooling-into-internal-cooling tool handle assembly. The external-cooling-into-internal-cooling tool handle comprises a tool handle body, a positioning ring, a bearing base, bearings, a positioning pillar, an elastic piece and a tool changing block. When the tool handle body needs to be assembled or takendown, a mechanical arm grabs the tool handle body to make the tool handle body stretch into or separated from a main shaft, then the tool handle body moves downwards or acts on the positioning pillardownwards, then a first clamping part and a second clamping part are loosened or clamped, and then the tool handle body freely rotates or gets limited. Internal cooling lubricating is achieved through an internal cooling tool; meanwhile, positioning is achieved through the first clamping part on the positioning ring and the second clamping part on the positioning pillar, the purpose of quickly changing a tool handle is achieved, manual adjustment of the position or jetting angle of a nozzle is avoided, the efficiency is improved, the labor cost is lowered, and quality stability of the productis guaranteed.

Owner:CONPROFE TECH GRP CO LTD +1

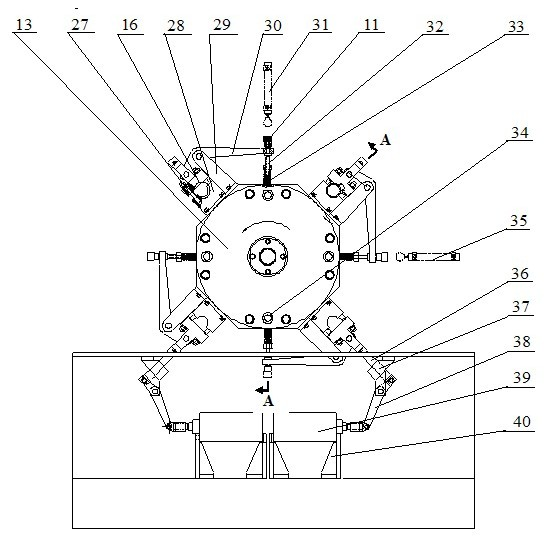

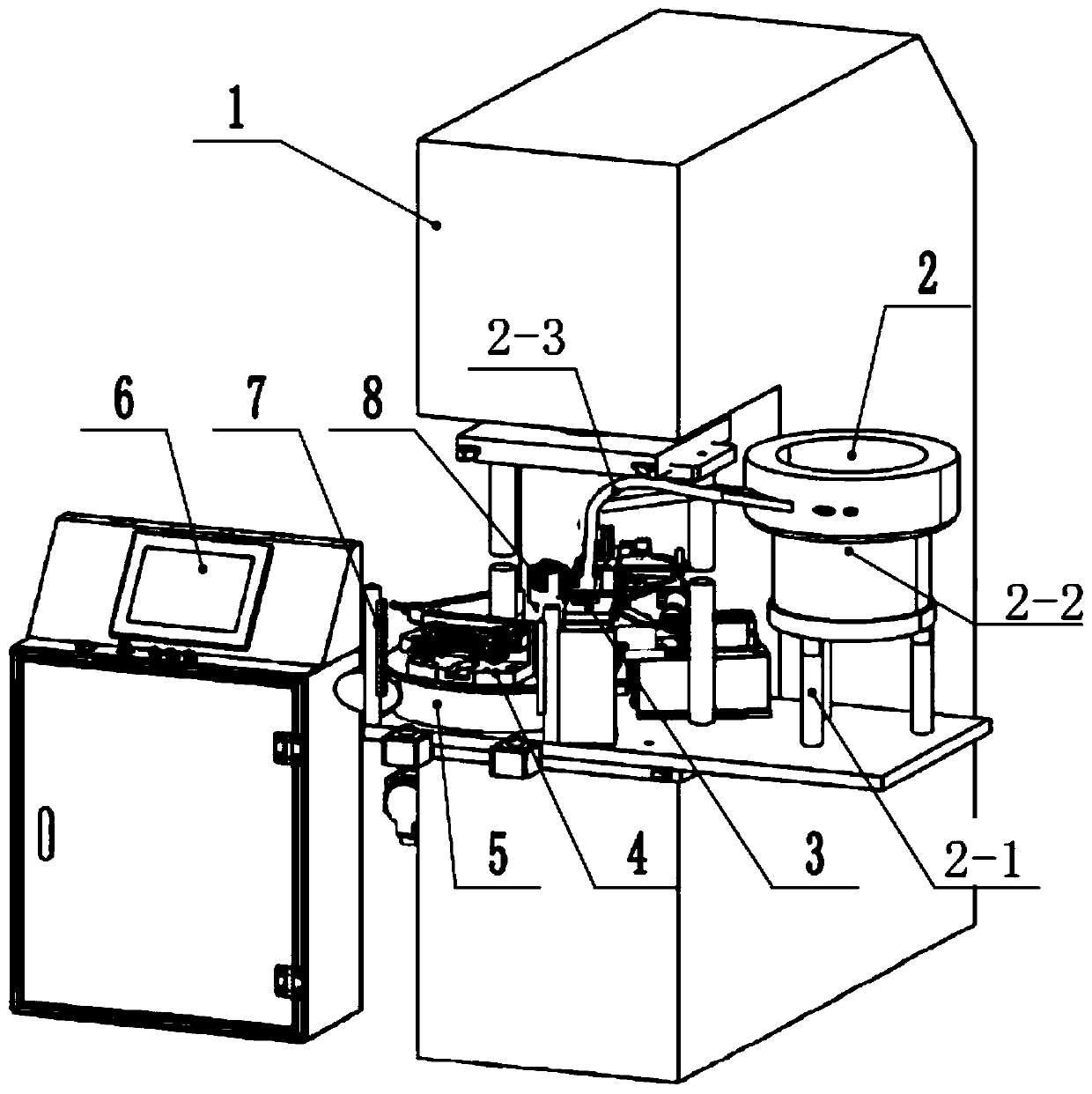

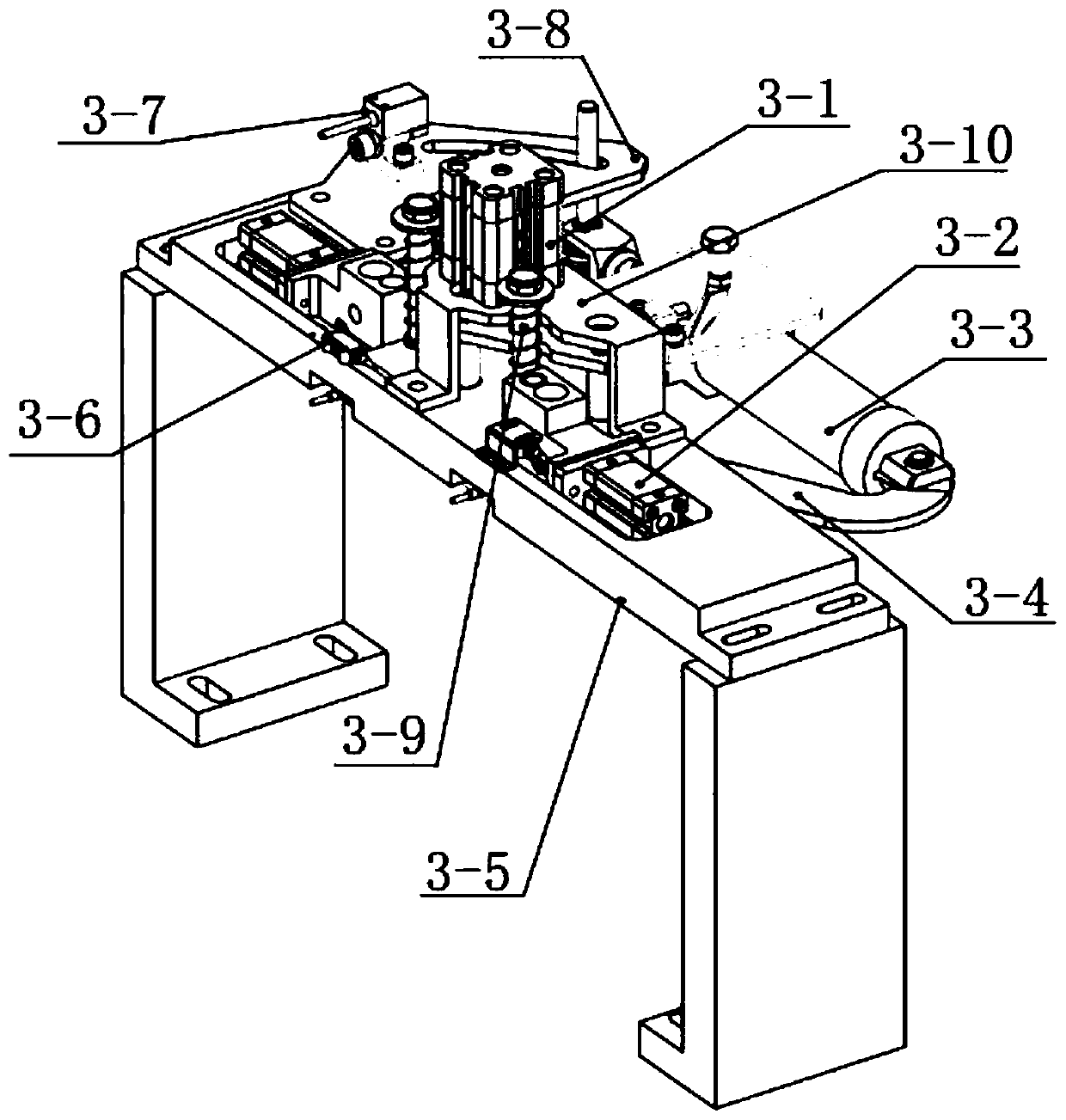

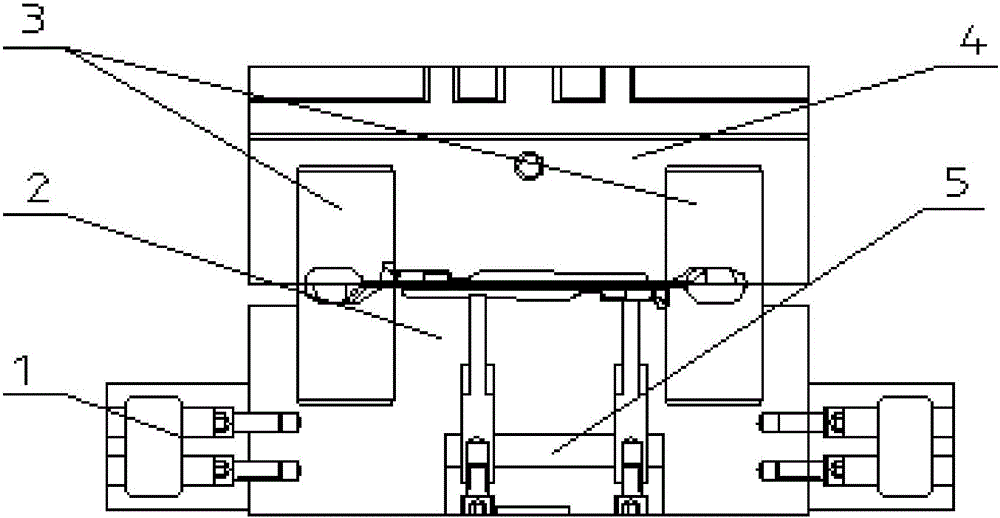

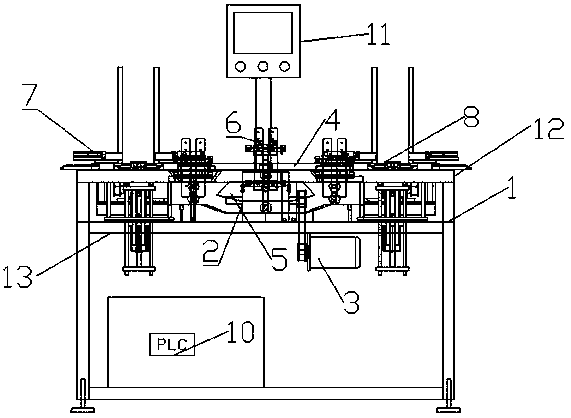

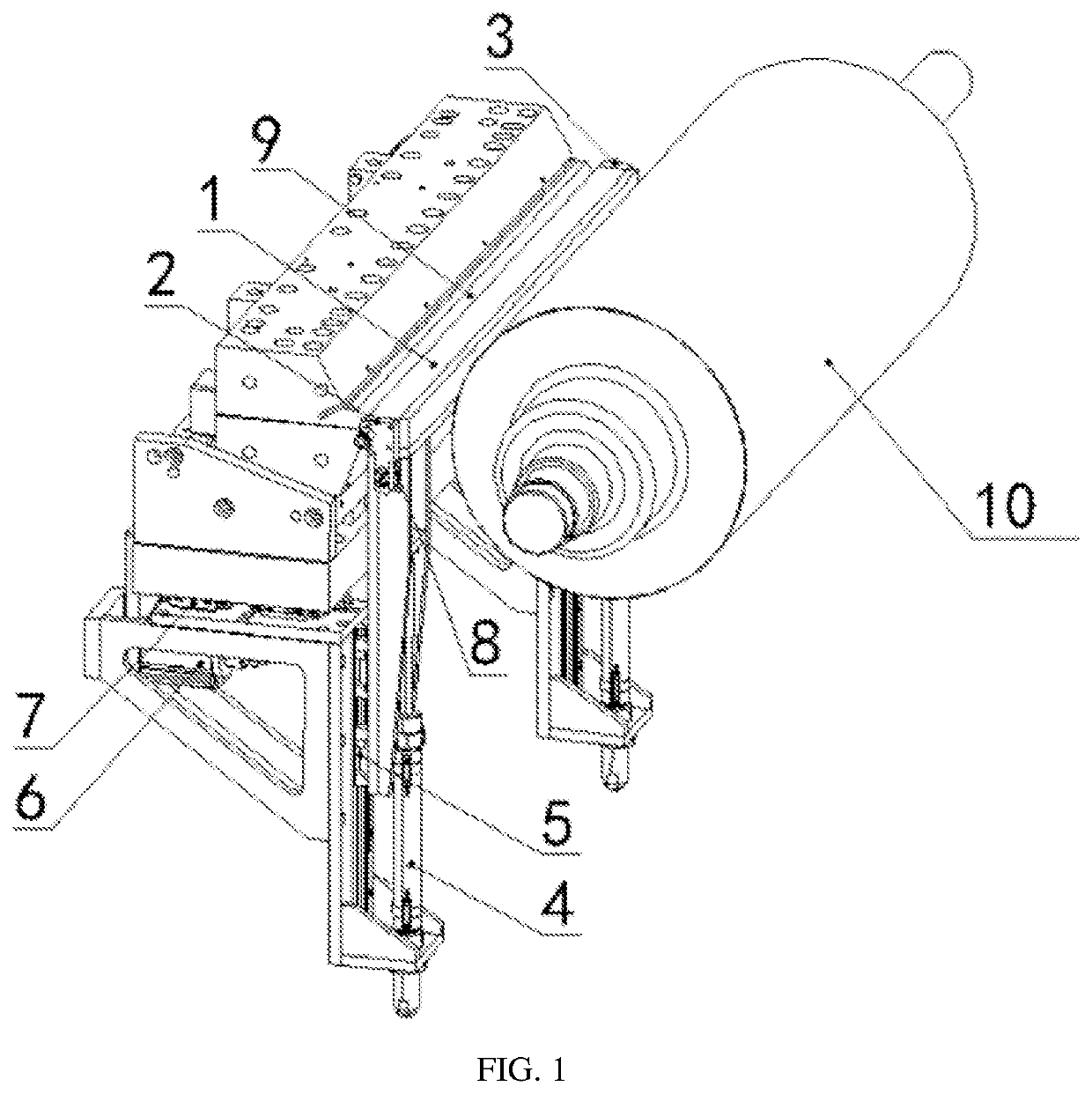

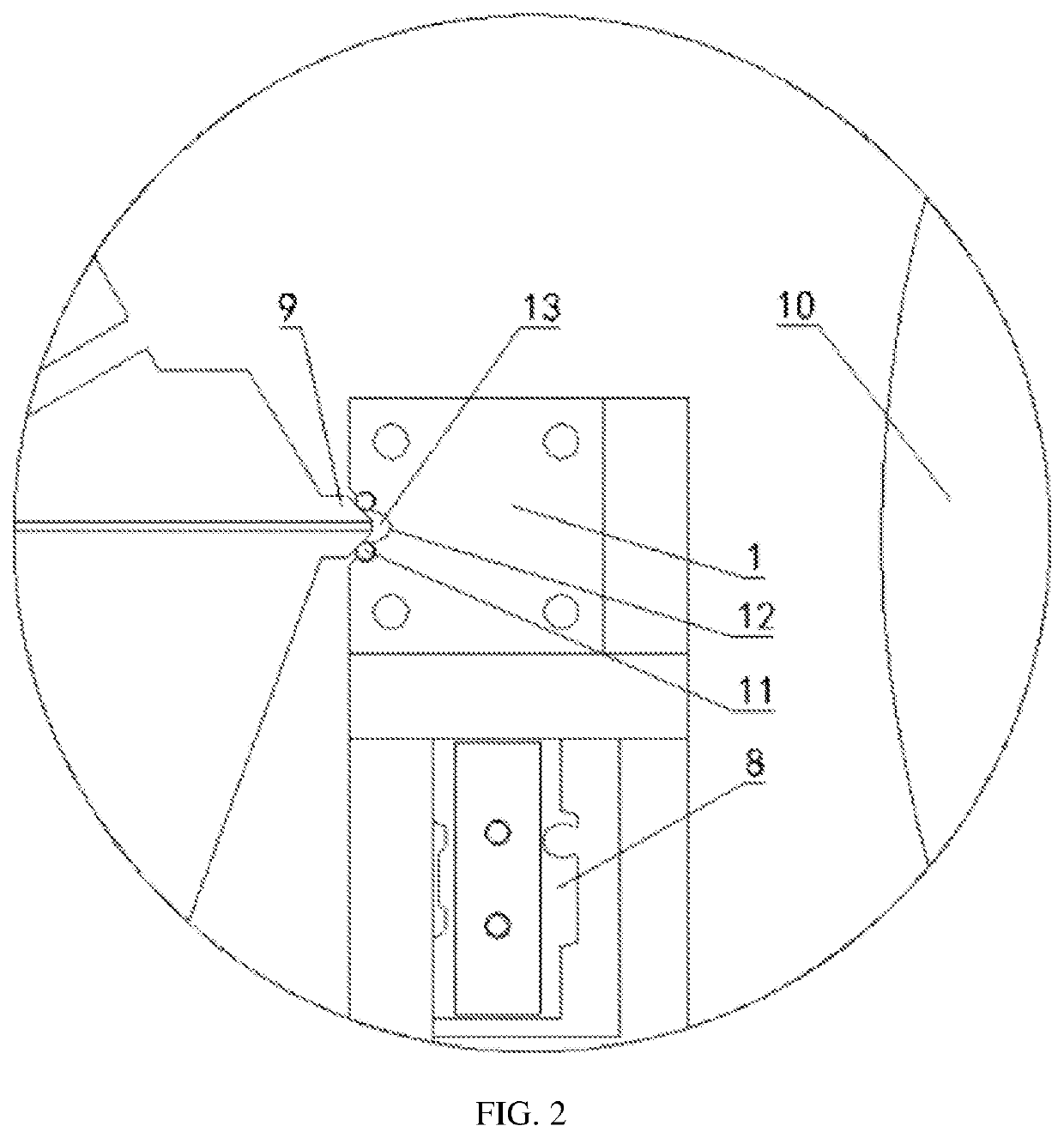

Automatic pressing device of split pins

PendingCN110280997AReduce the number of laborReduce labor costsMetal working apparatusPunchingGrating

The invention discloses an automatic pressing device of split pins. The automatic pressing device of split pins comprises a pressing machine, an automatic feeder, an split pin pre-tightening mechanism, a clamp part, a servo indexing rotation disc part, a safe grating part, a vision detection device and an electric control cabinet operation panel, wherein the automatic feeder, the split pin pre-tightening mechanism, the servo indexing rotation disc part, the safe grating part and the vision detection device are mounted on a platform surface of the pressing machine; the servo indexing rotation disc part is connected with the clamp part; multi-station accurate rotation and indexing of the clamp part can be achieved; the split pin pre-tightening mechanism is arranged in a second station direction and is aligned to a center position of a punching head of the pressing machine, so that center positions of the pre-tightened split pins, the center position of the punching head of the pressing machine and a center position of a workpiece pin hole are concentric. Through the automatic pressing device of the split pins, the defects of inconsistent directions of split pins, great pressing size accuracy deviation and low production efficiency during manually pressing are solved.

Owner:上海嘉朗实业南通智能科技有限公司

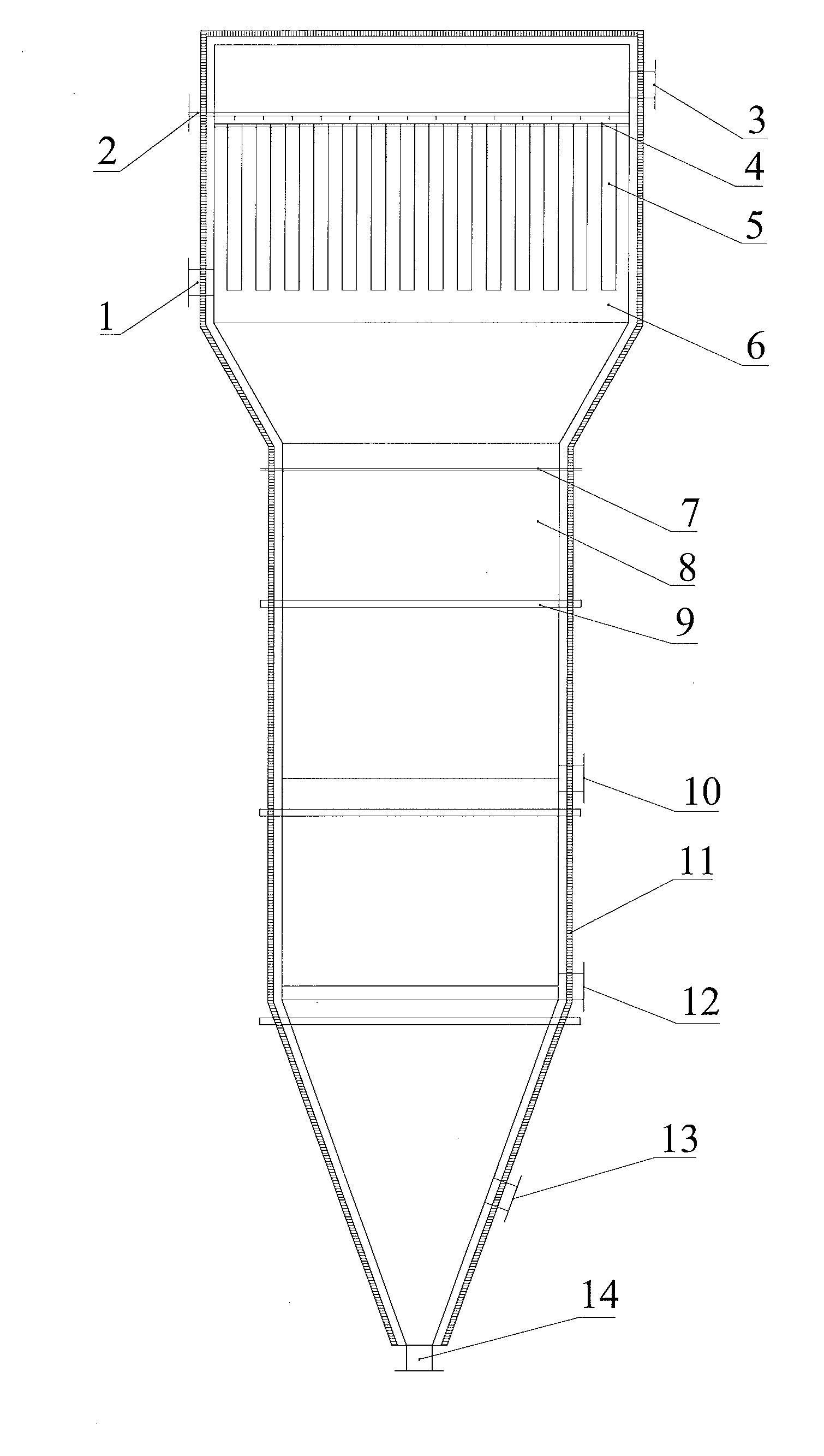

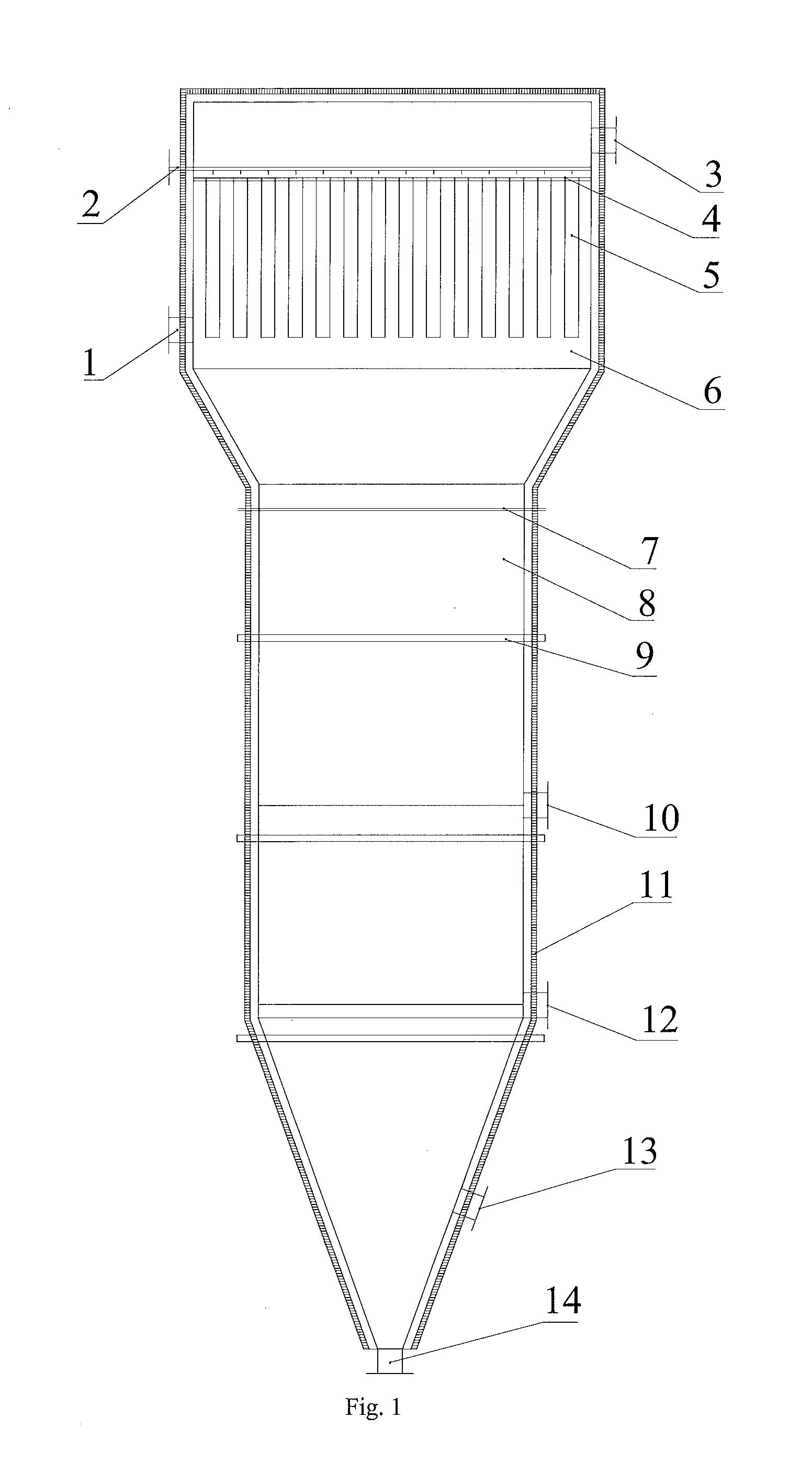

Deacidification process and apparatus thereof

ActiveUS20150044128A1Improve the immunityLarge fluctuationsGas treatmentSilicaProcess engineeringAtmosphere

A deacidification apparatus and a deacidification process using the apparatus are disclosed. The deacidification apparatus includes a deacidification furnace, of which a furnace upper section, a furnace middle section and a furnace lower section are provided in upper, middle and lower portions respectively, wherein a gas-solid mixture inlet (1), a exhaust outlet (3) and a filtered air port (2) are provided on the furnace upper section, a product outlet (13) is provided on the furnace lower section, the upper portion of the deacidification is mounted with a filter (5) to which the gas-solid mixture inlet (1), the exhaust outlet (2) and the filtered air port (3) are connected, the filtered air port (2) is connected with a gas pulse device and a vacuum device by a three-way connecting device, and the exhaust outlet (3) is connected with atmosphere or connected with the vacuum device.

Owner:GUANGZHOU GBS HIGH TECH & IND

Continuous preparation method of polyester polyol

The invention relates to a continuous preparation method of polyester polyol. The method comprises three reaction stages including esterification, flash evaporation and polycondensation. The esterification reaction is performed at 130-260 DEG C, preferably, 180-240 DEG C and more preferably, 200-230 DEG C, the esterification rate is about 50%-95%, and the loss of raw material polyhydric alcohols can be reduced when the esterification reaction is performed at the higher temperature. Small molecules such as water and the like can be removed efficiently and quickly through flash evaporation, thereaction speed can be increased, the production time can be saved, and energy consumption can be reduced. A mixture of a catalyst and polyester polyol is fed, catalyst hydrolysis can be effectively reduced in thermodynamics and kinetics in a ligand change manner, and the dosage of the catalyst can be reduced. The polyester polyol produced with the technology has the advantages of low catalyst residues, low color number and stable product quality.

Owner:WANHUA CHEM GRP CO LTD

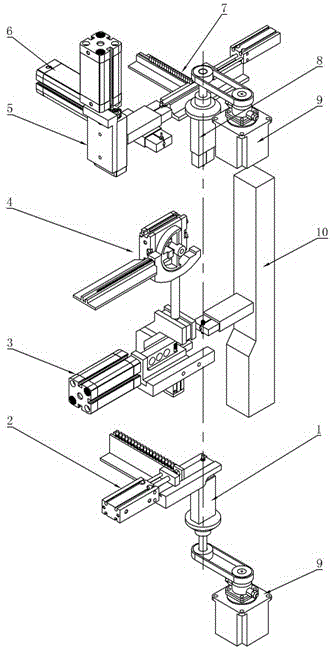

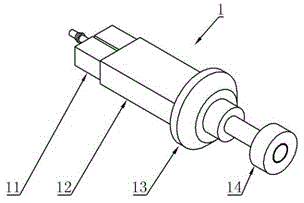

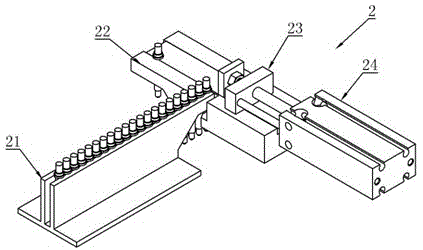

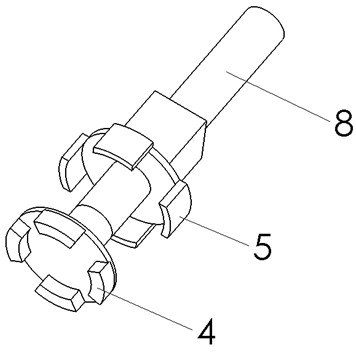

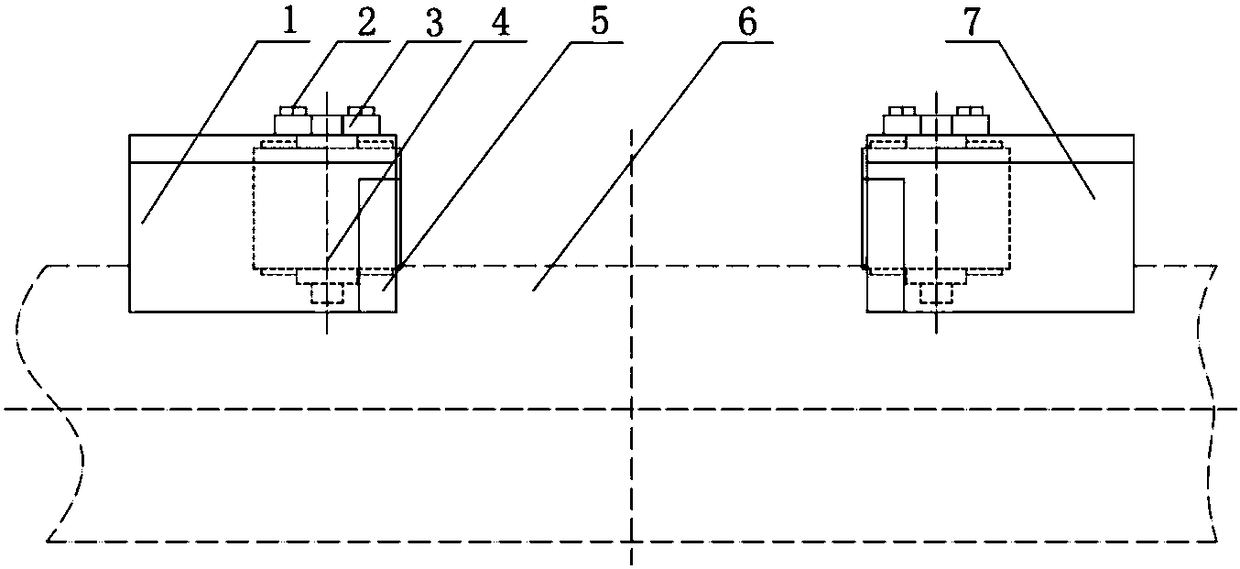

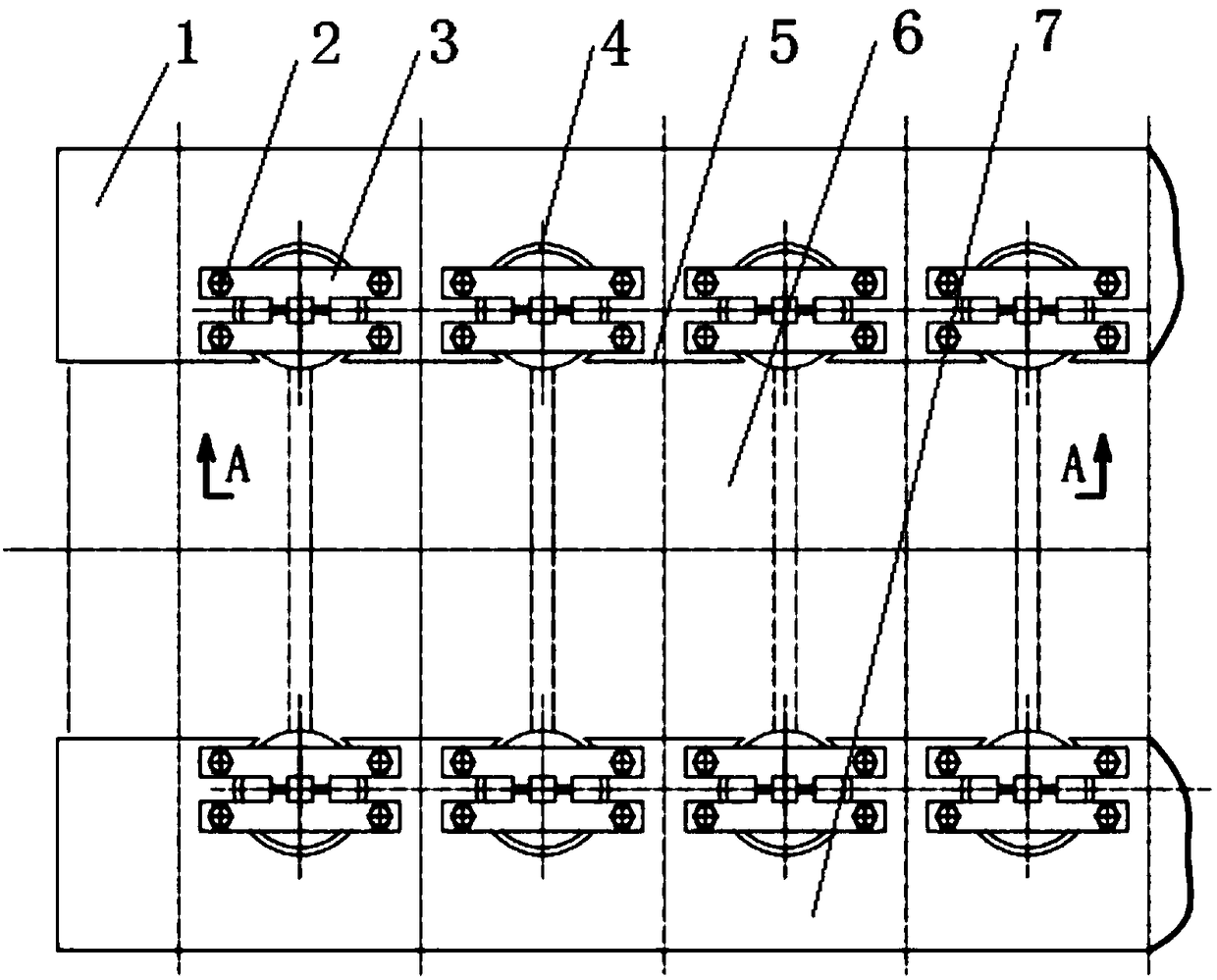

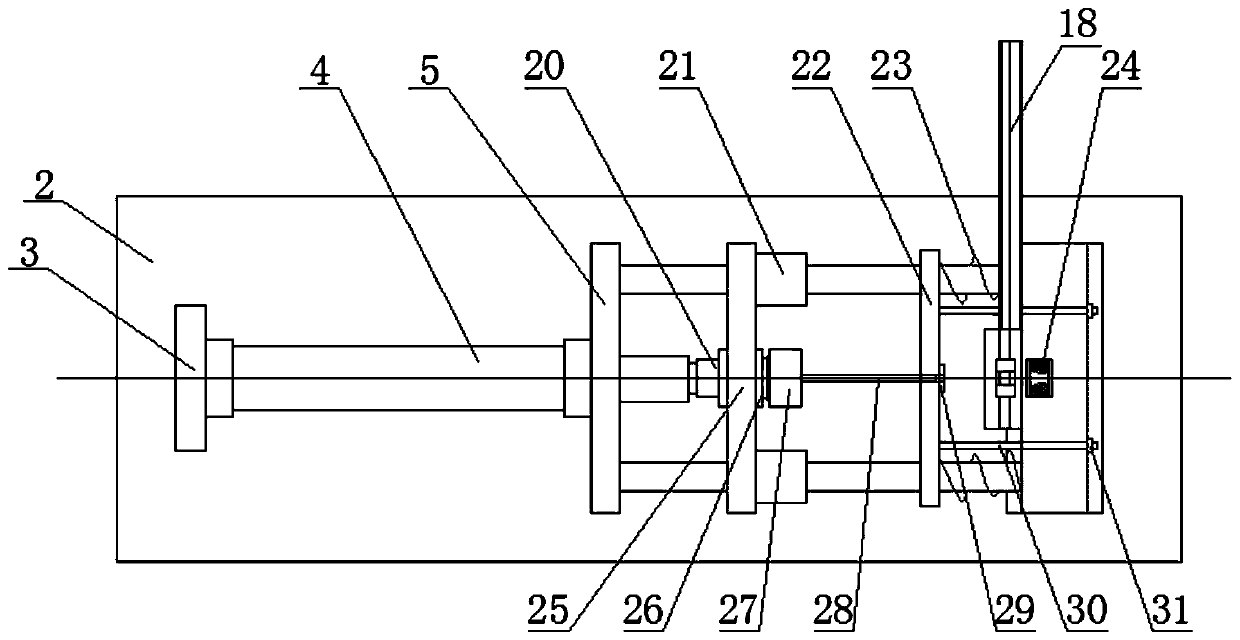

Automatic assembling device for flexible shaft

ActiveCN105414956AAvoid causingHigh degree of automationAssembly machinesMetal working apparatusElectric machineryControl theory

The invention discloses an automatic assembling device for a flexible shaft. The flexible shaft is formed by assembling connectors at the two ends of a spring. The automatic assembling device for the flexible shaft comprises an automatic spring supply mechanism, a spring positioning, clamping and feeding mechanism, two automatic connector supply mechanisms, two connector positioning and clamping rotating shaft mechanisms and two rotating torque control mechanisms. According to the automatic assembling device for the flexible shaft, positioning and screwing of the spring and the connectors of the flexible shaft are achieved through the automatic mechanical devices such as the automatic spring supply mechanism, and the automatic degree is high; torque clutches are adopted in the rotating torque control mechanisms; when torque is increased to a certain extent, driving force is lost between the torque clutches and rotating shafts of servo motors of the control mechanisms; scrapped products caused when the torque is excessively large and the spring and the connectors are screwed excessively are avoided, and the production cost is lowered; and the clutch torque can be adjusted by adjusting adjustment screw rods and nuts, and the requirement for assembling different flexible shafts is met.

Owner:宁波韵声机芯制造有限公司 +1

Die for forging production of aluminum alloy control arms

InactiveCN105710268ARapid positioningQuick installationForging/hammering/pressing machinesControl armAluminium alloy

The invention provides a mold for forging and producing an aluminum alloy control arm, and the mold is composed of an upper mold (4), a guide column (3) and a lower mold (2). The beneficial effect of the present invention is that, by designing the connection, guide and positioning structures of the mold design, the requirements of the automatic production of the control arm can be met, and the production of multiple pieces in one mold can be realized.

Owner:CITIC DICASTAL

Donkey-hide gelatin cake cutting machine

ActiveCN106490282AIncrease productivityNovel structureConfectionerySweetmeatsEngineeringElectric control

The invention discloses a donkey-hide gelatin cake cutting machine. The donkey-hide gelatin cake cutting machine comprises a screw cap, a material pushing bar, a knife dish component, a material holding box, a machine body, foundations, a motor and a control switch, wherein a cover cap and a material pushing cavity are arranged on the screw cap, and an opening at the bottom of the screw cap is communicated with the knife dish component; the material pushing bar can be inserted into a hollow passageway of the material pushing cavity; the knife dish component is installed at the upper part of the machine body, and a cutting blade is horizontally installed in a weld knife dish and can rotate around a rotating shaft; the material holding box is movably arranged on one side of the machine body and is located below a discharge hole of the weld knife dish; the machine body provides installing bases for all the components; the foundations comprise a machine body foundation and an electronic control module installed on the machine body foundation; the motor is installed inside the machine body through a motor support and is connected to the rotating shaft of the cutting blade; the control switch controls start and stop of the motor. According to the donkey-hide gelatin cake cutting machine, quantitative cutting of the decocted donkey-hide gelatin cake barstock can be achieved, blanking is uniform and stable, bonding and damage of donkey-hide gelatin blocks can be avoided, appearance of a donkey-hide gelatin cake slice product is improved, convenience is brought to eating of a client, the situation that a finger accidentally touches the cutting blade from a material feeding opening is prevented, and thus the safety of operating personnel is guaranteed.

Owner:SHAN DONG DONG E E JIAO

High-transparency and low-shrinkage thermoplastic polyurethane elastomer and preparation method thereof

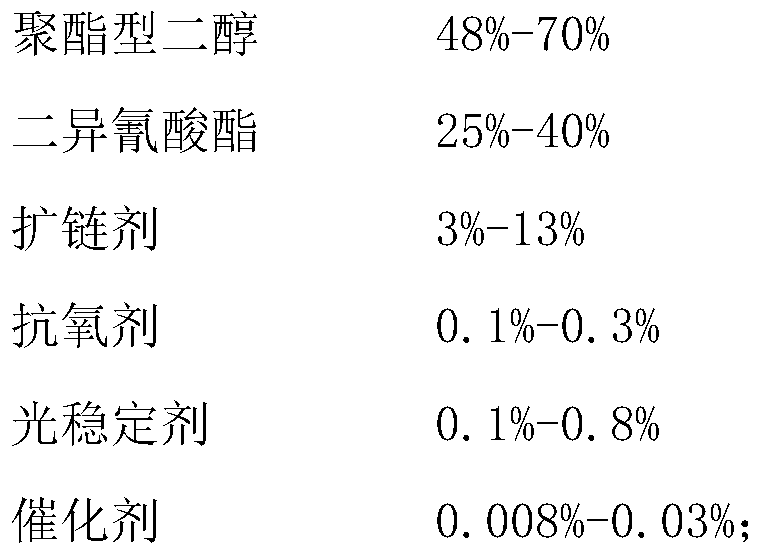

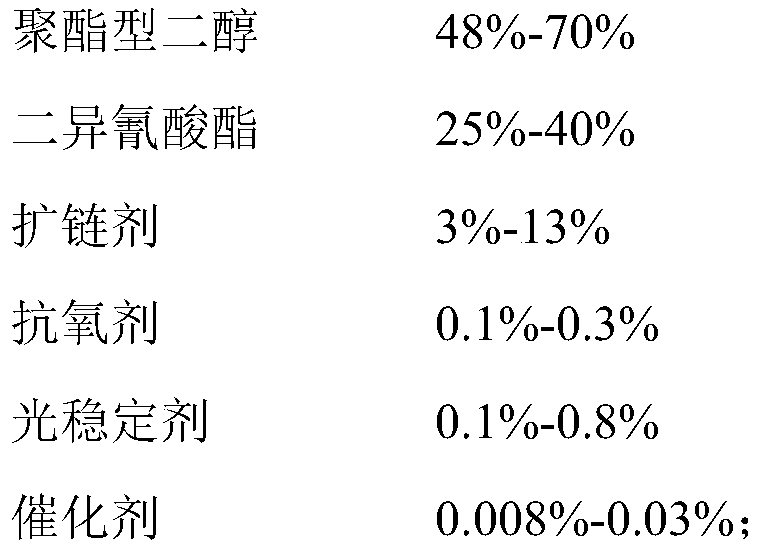

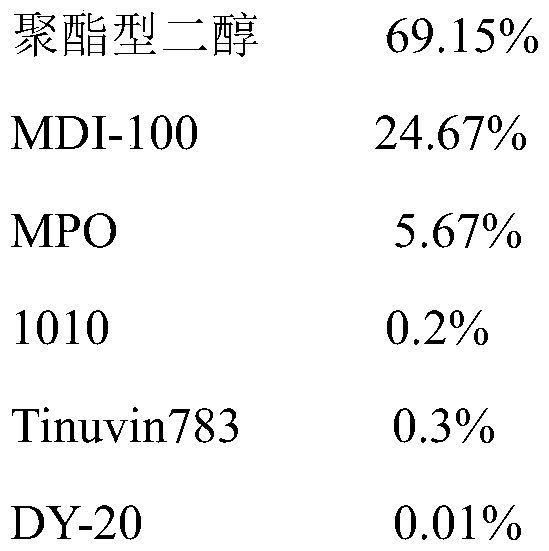

The invention relates to a high-transparency and low-shrinkage thermoplastic polyurethane elastomer and a preparation method thereof and belongs to the technical field of thermoplastic polyurethane. The high-transparency and low-shrinkage thermoplastic polyurethane elastomer comprises raw materials in percentage by mass as follows: 48%-70% of polyester diol, 25%-40% of diisocyanate, 3%-13% of a chain extender, 0.1%-0.3% of an antioxidant, 0.1%-0.8% of a light stabilizer and 0.008%-0.03% of a catalyst. The high-transparency and low-shrinkage thermoplastic polyurethane elastomer has lower shrinkage and higher transparency. The invention also provides the simple and easy preparation method.

Owner:SHANDONG INOV POLYURETHANE

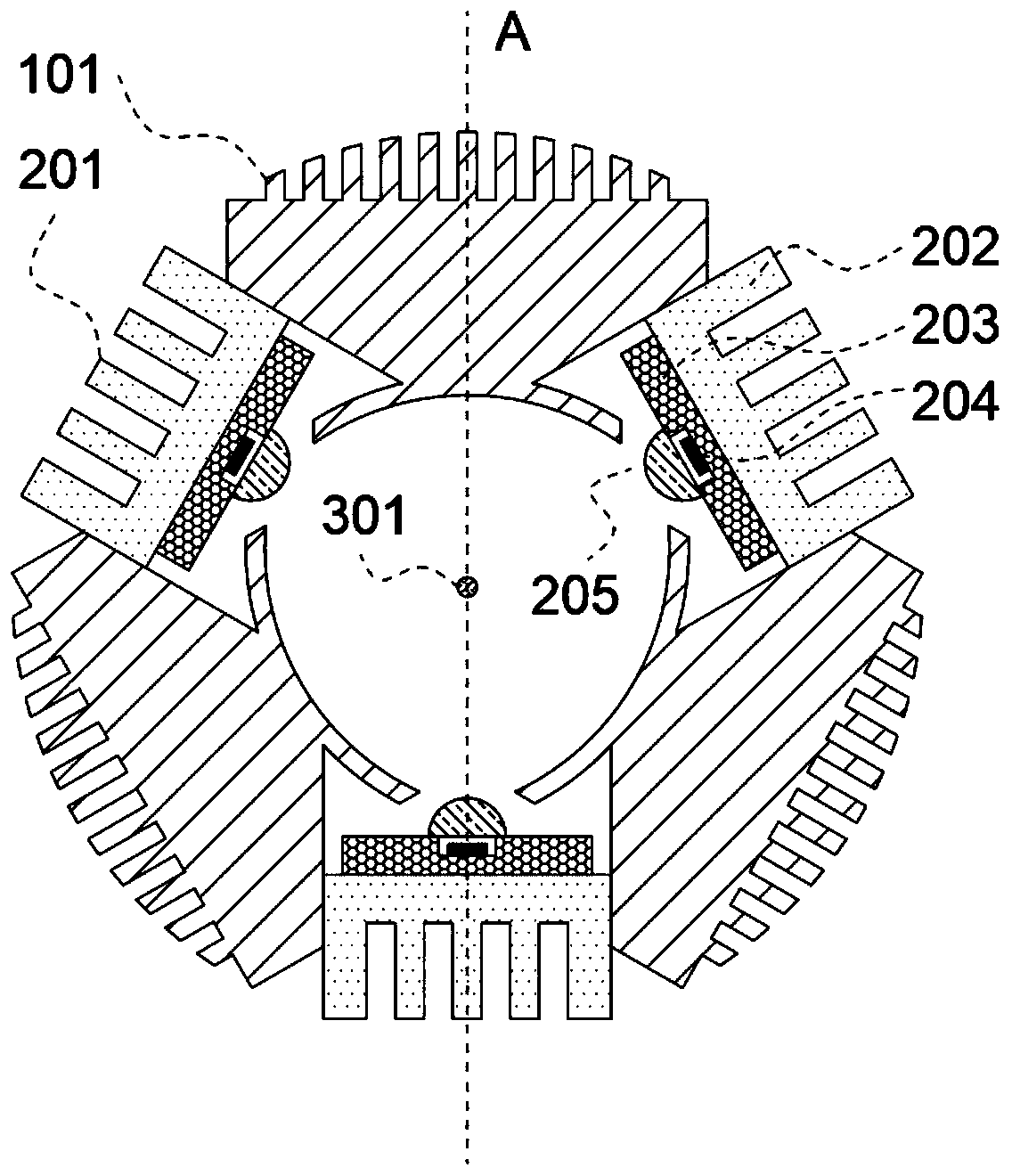

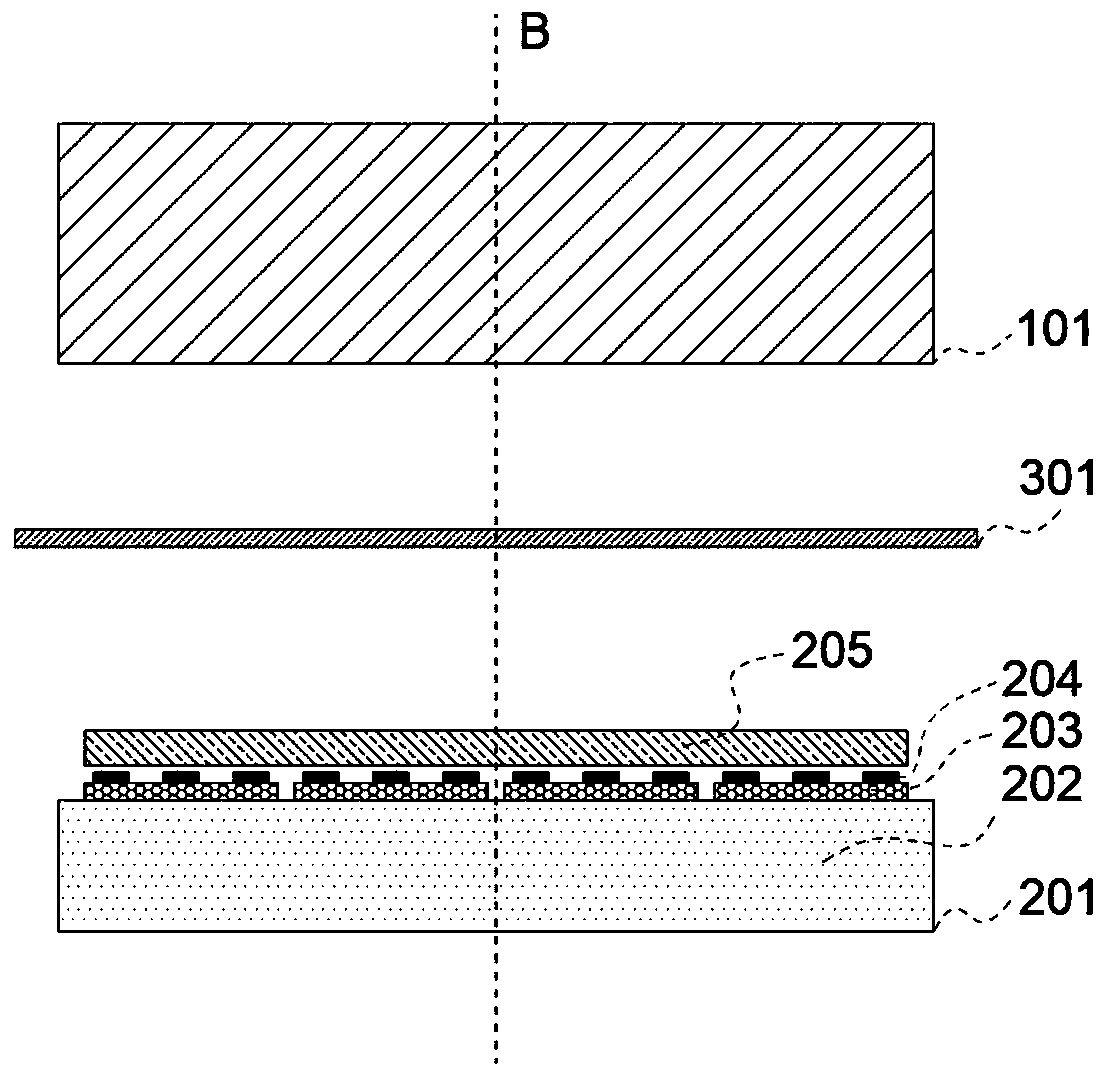

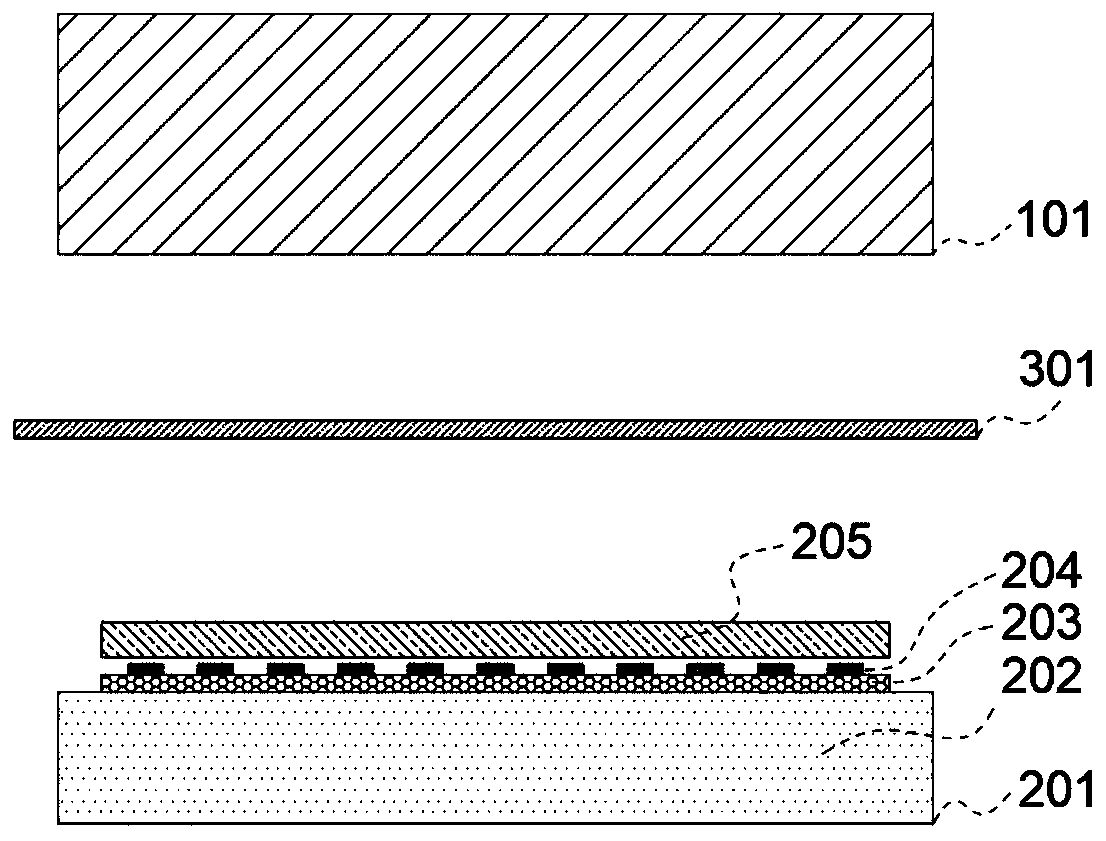

Automatic assembling work head device of curved-surface magnet of voice coil motor

InactiveCN102497062AImplement automatic assemblyReduce dependenceManufacturing dynamo-electric machinesMagnetic tension forceDevice form

The invention discloses an automatic assembling work head device of a curved-surface magnet of a voice coil motor. The device comprises: an automatic feed warehouse, an outbound warehouse positioning device formed by a rotation adsorption magnet and a built-in baffle plate, a push-rod blanking mechanism and a non-magnetic shell. The feed warehouse is uniformly embedded around the shell. The push-rod blanking mechanism is fixed at a position which has an interval of a specific angle with the feed warehouse. The outbound warehouse positioning device is located under the shell and a rotating shaft passes through a central section of the shell and is connected with the external motor. Batch magnets are loaded into the automatic feed warehouse before magnetization and after the magnetization, the magnets mutually generate an expulsive force. A rotation adsorption magnet drives the magnet to be assembled on an exit on a lower part of the feed warehouse to be separated from the warehouse and be positioned. The residual magnets automatically feed under common effects of a gravity and a magnetic force. The push-rod blanking mechanism pushes the positioned magnets into the voice coil motor shell so as to complete the assembling. According to the invention, batch magnetization of the voice coil motor magnets and continuously automatic assembling can be realized. Production efficiency of the voice coil motor can be increased. Artificial cost can be reduced and product quality can be guaranteed.

Owner:ZHEJIANG UNIV

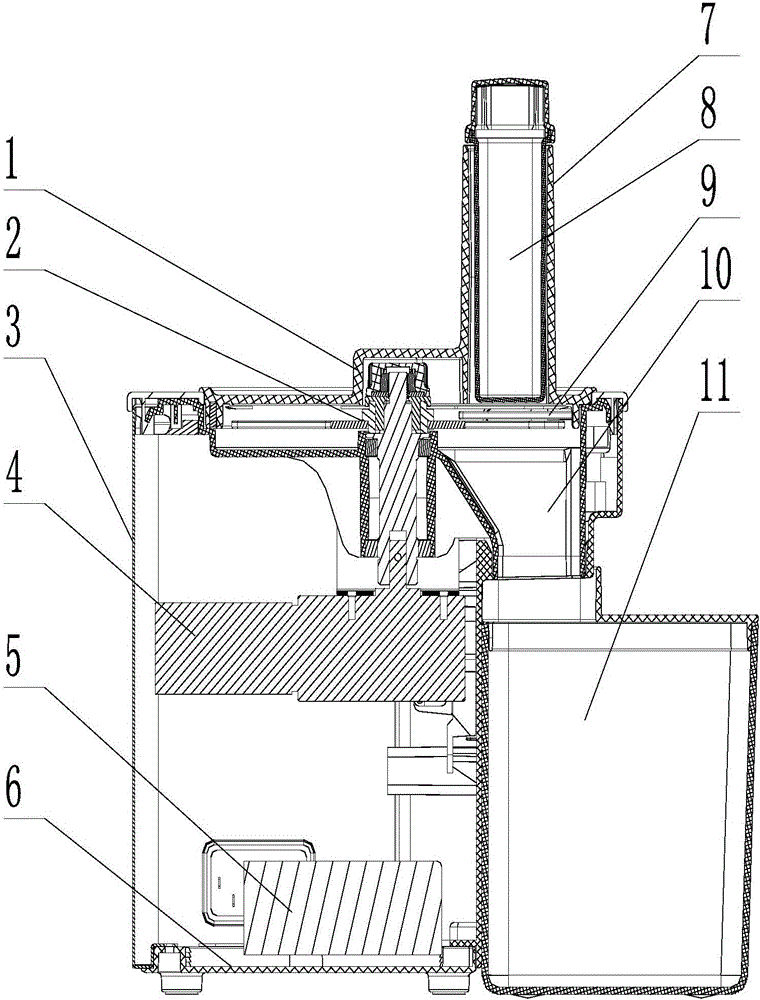

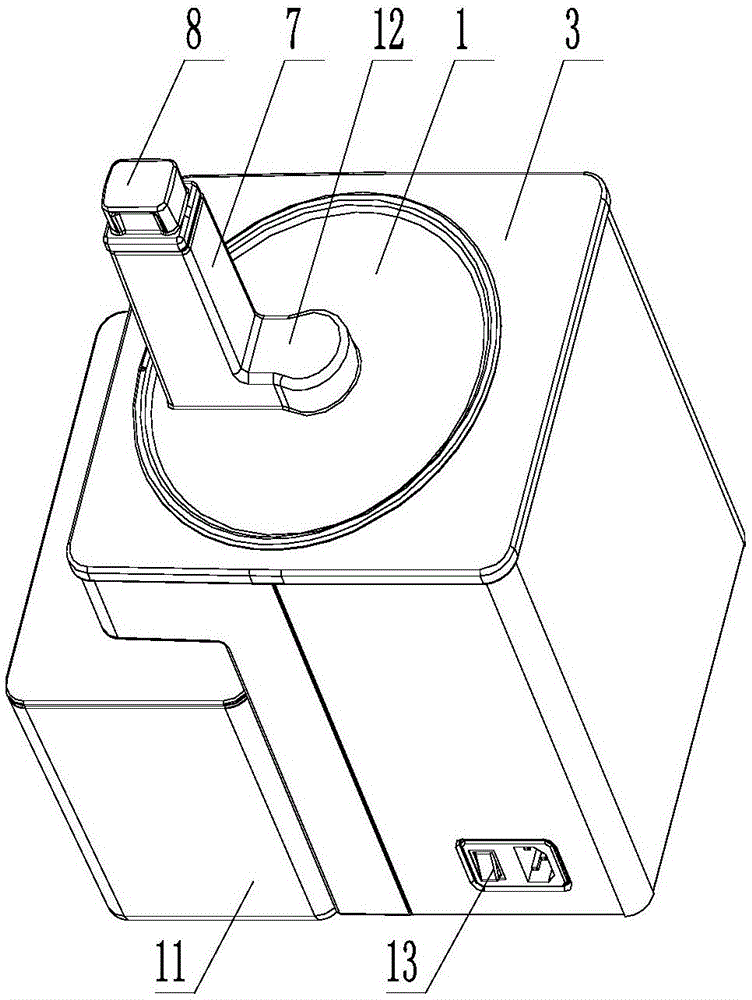

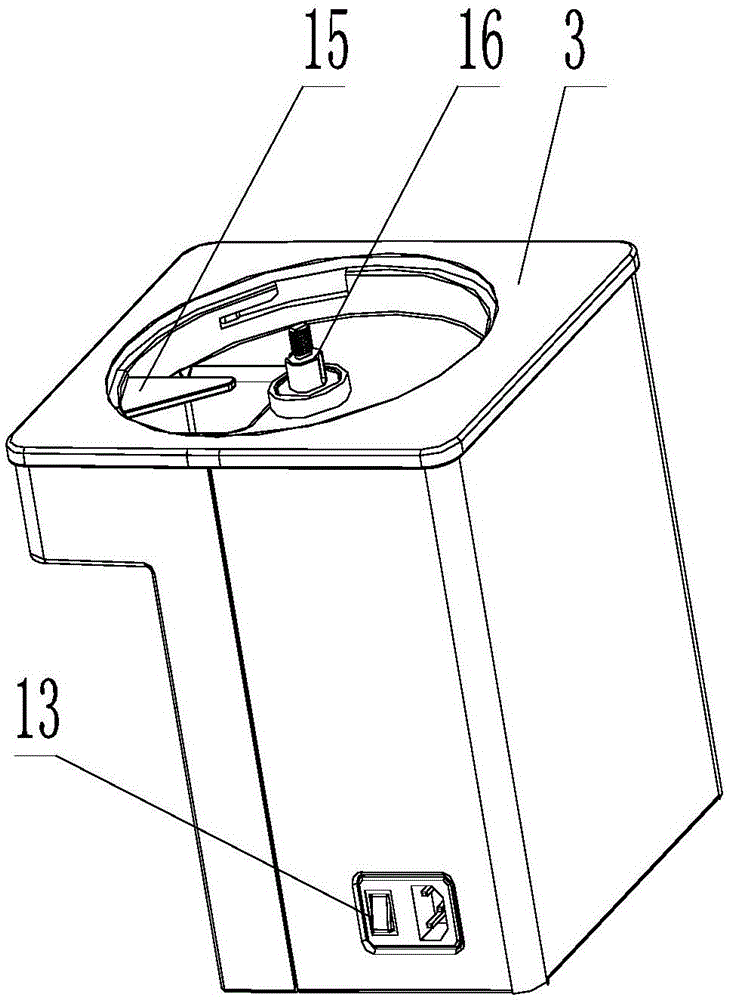

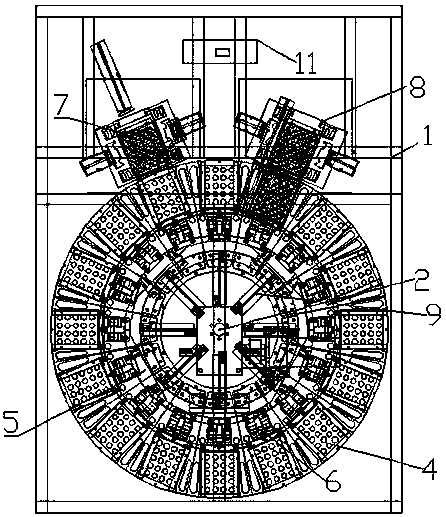

Rotating disc type automatic voltage reduction device for lithium-manganese button cells

PendingCN108155395AEnsure stable qualityHigh degree of automationPrimary cell manufactureAssembling battery machinesLithiumButton battery

The invention relates to a rotating disc type automatic voltage reduction device for lithium-manganese button cells. The rotating disc type automatic voltage reduction device comprises a frame, an upper flat plate and a lower flat plate are arranged on the frame, a feeding mechanism, a discharging mechanism and a touch screen are arranged on the upper flat plate, and a speed regulating motor and acam indexer are arranged on the lower flat plate. A cam mechanism is arranged on the upper flat plate and comprises a cam and a rolling wheel, and an output end of the speed regulating motor is connected with the cam. The rotating disc type automatic voltage reduction device has advantages that accuracy in positioning of the lithium-manganese button cells is achieved, automatic feeding and discharging can be realized, and quality stability and uniformity of products subjected to voltage reduction are guaranteed; the rotating disc type automatic voltage reduction device comprises sixteen stations, voltage reduction of sixteen units of cells can be realized in each rotating lap of a rotating disc, production efficiency is remarkably improved and production cost is reduced as compared with those of manual voltage reduction, manual operations are replaced by the rotating disc type automatic voltage reduction device, automation of enterprises is improved, labor intensity of operators is relieved, and labor cost is reduced.

Owner:山东信湖新能源科技有限公司

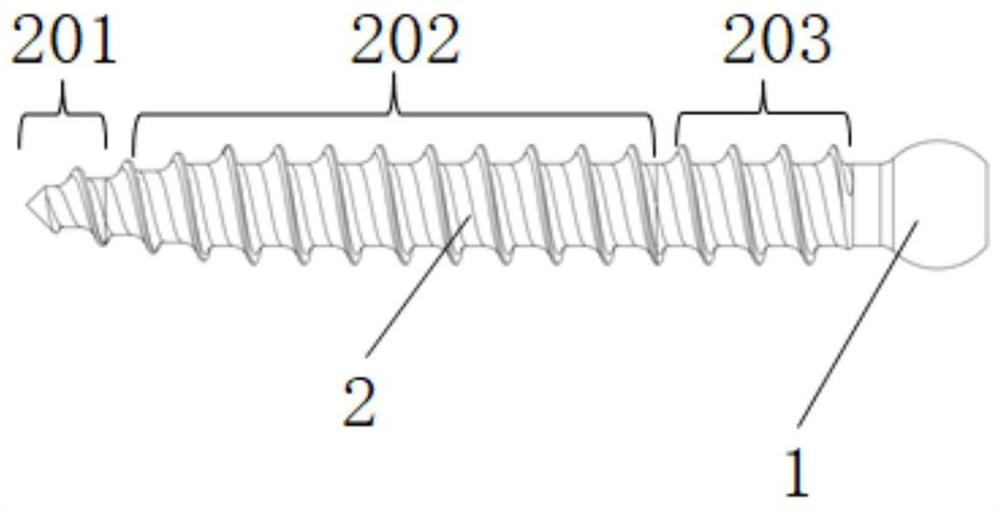

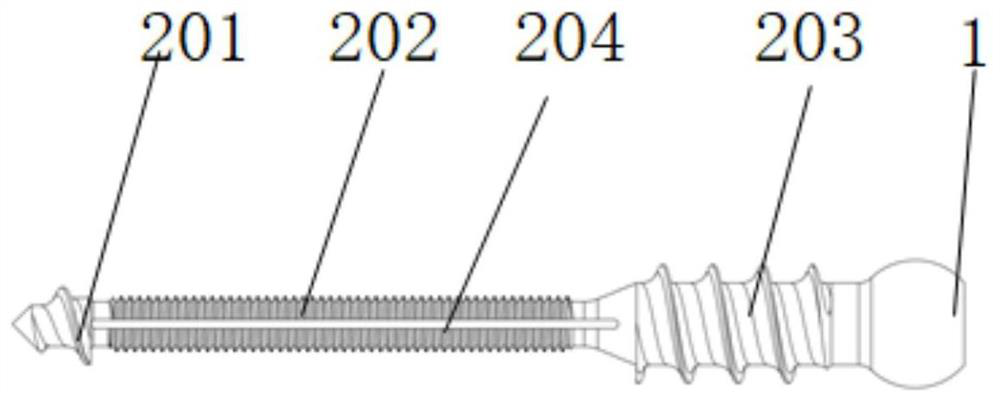

Medical bone nail for orthopedics department and preparation method thereof

PendingCN113209389ATackling degenerative diseasesReduce exposureInternal osteosythesisFastenersPoly ether ether ketoneBiomedical engineering

The invention discloses a medical bone nail for orthopedics department and a preparation method thereof. The bone nail comprises a core shaft and carbon fiber reinforced polyether-ether-ketone wrapping the core shaft, the core shaft of the bone nail is made of Ti6Al4V titanium alloy, the core shaft structurally comprises a nut and a screw rod, the screw comprises a rod head part, a rod middle part and a rod tail part, the carbon fiber reinforced polyether-ether-ketone wraps the outer part of the rod middle part, and the diameter of the rod middle part wrapped by the carbon fiber reinforced polyether-ether-ketone is consistent with that of the rod head part; wherein the rod tail part is one end, close to the nut, of the screw rod and is provided with at least four threads, and the rod head part is the other end of the screw rod. The medical bone nail has excellent biological tissue compatibility, not only solves a problem of degeneration of adjacent bones and joints caused by stress shielding after surgery, but also solves problems of chronic vertebral pain caused by bioelectric potential difference and degenerative diseases of adjacent bone segments caused by stress shielding after surgery adopting a traditional orthopedic titanium alloy bone nail.

Owner:LONGJAR SHANGHAI IND

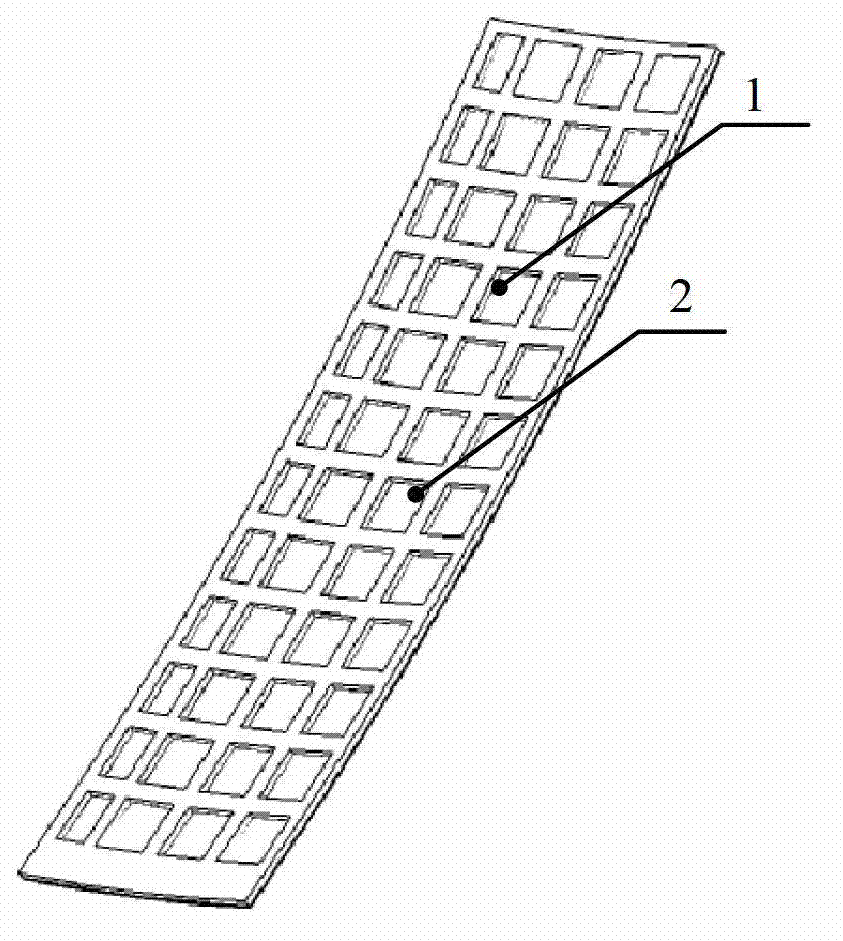

Coiling machine side guide plate with long service life

InactiveCN108580582AExtend the service life of a machineReduce replacement frequencyRolling resistanceRolling-element bearing

The invention relates to a coiling machine side guide plate with long service life. The coiling machine side guide plate comprises a side guide plate body and an idler wheel assemblies, wherein the side guide plate body comprises a left side guide plate body and a right side guide plate body; a plurality of idler wheel assemblies are arranged on the inner sides of the side guide plate body; each of the idler wheel assemblies comprises an idler wheel, a rolling bearing, a penetrating cover and a sealing element; the upper ends of the rolling bearings of the idler wheel assemblies are assembledon a fixed chuck plate; the fixed chuck plate is fixed on the side guide plate body through a bolt; and lower ends of the rolling bearings of the idler wheel assemblies are mounted on a guide plate body lower plate. According to the coiling machine side guide plate, the idle wheels can rotate freely, and as the rolling friction coefficient of the idler wheels is small, the generated friction forceis small, scratch to two side faces of a steel strip and burr generation are greatly reduced, and product quality and productions stability are ensured; and in addition, as the friction force is lowered, the abrasion loss is reduced, onetime looming service life of the side guide plate is greatly prolonged, the changing frequency of the side guide plate is reduced, the operating efficiency of a production line is improved and the operating cost is lowered.

Owner:SD STEEL RIZHAO CO LTD

Ultraviolet irradiation device for cable curing

PendingCN109848016ASimple structureEasy to usePretreated surfacesCoatingsProduction rateUltraviolet lights

The invention discloses an ultraviolet irradiation device for cable curing. The ultraviolet irradiation device comprises a complex number of ultraviolet light source components and a complex number ofmirror components, and the ultraviolet light source components and the mirror components are arranged around a designated area; the ultraviolet light source components and the mirror components are arranged in sequence alternately, and all the light emission ends of the ultraviolet light source components and the reflective surfaces of the mirror components face the designated area; and when an irradiated object is placed in the designated area, a part of ultraviolet light emitted from any ultraviolet light source component can directly penetrate into a first area of the irradiated object, and the other part of the ultraviolet light can be reflected by at least one reflection component to areas beyond the first area in the irradiated object. According to the ultraviolet irradiation devicefor cable curing, the use efficiency and irradiation uniformity of UV-LED irradiation light can be improved, and the coating and coloring production rate of optical fiber cables can be improved effectively, and reaches 3000 m / min and above; and the product quality stability in the high speed production process can be ensured.

Owner:南京新趋势光电有限公司

Transverse automatic stretching device suitable for long-thin-wall pipe blank

PendingCN110180937AIncrease productivityNo safety hazardShaping toolsMetal-working feeding devicesPull forceEngineering

The invention discloses a transverse automatic stretching device suitable for a long-thin-wall pipe blank. The transverse automatic stretching device comprises an oil cylinder fixed to a workbench, abase and a guide column arranged between the oil cylinder and the base. The guide column is in sliding connection with a guide plate. The guide plate is connected with a male die and a piston rod of the oil cylinder. A female die is arranged in the base. The left side face of the base is connected with a feeding plate. The feeding plate is provided with a positioning sleeve corresponding to the female die. A feeding mechanism and a material return mechanism are further included. The feeding mechanism comprises a sliding block fixing plate arranged on the feeding plate, a feeding sliding blockcapable of sliding up and down along the sliding block fixing plate, a tension spring and a push plate which is in linkage with the guide plate, wherein the tension spring connects the feeding slidingblock with the sliding block fixing plate and constantly keeps the feeding sliding block with the downward sliding tension. The material return mechanism comprises a material return plate and a material return spring, wherein the material return plate is in sliding fit with the guide column and is located on the right side of the guide plate. According to the transverse automatic stretching device, one stretching action can be finished in each cycle, the middle pause time can be neglected, the production efficiency is high, and potential safety hazards are avoided.

Owner:ZHEJIANG GARDEN ELECTRONICS EQUIP

Nanometer fungus dietary fibers and use thereof

PendingCN107692242AImprove implantation rateHigh proliferation rateFood ingredient functionsBiotechnologyFreeze-drying

The invention relates to the field of functional foods and medicine materials, in particular to nanometer fungus dietary fibers and use thereof. The nanometer fungus dietary fibers disclosed by the invention are made from raw materials namely edible and medicinal funguses, and the nanometer fungus dietary fibers of which the granules are 200-300nm in particle diameter are made through technological processes of removing impurities, performing soaking in polished glutinous rice vinegar, performing rinsing, performing vacuum drying, performing superfine crushing, performing nanocrystallization crushing, performing sieving, performing freeze drying and the like. Through test, the nanometer fungus dietary fibers disclosed by the invention can significantly increase the implantation rate and the proliferation rate of probiotics; when the nanometer fungus dietary fibers are combined with the probiotics for preparing functional foods or medicines, the addition quantity of active probiotics can be reduced to a great extent, the cost and the price of products can be reduced, and the quality stability and the action effects of the products can be guaranteed.

Owner:山东惠民齐发果蔬有限责任公司

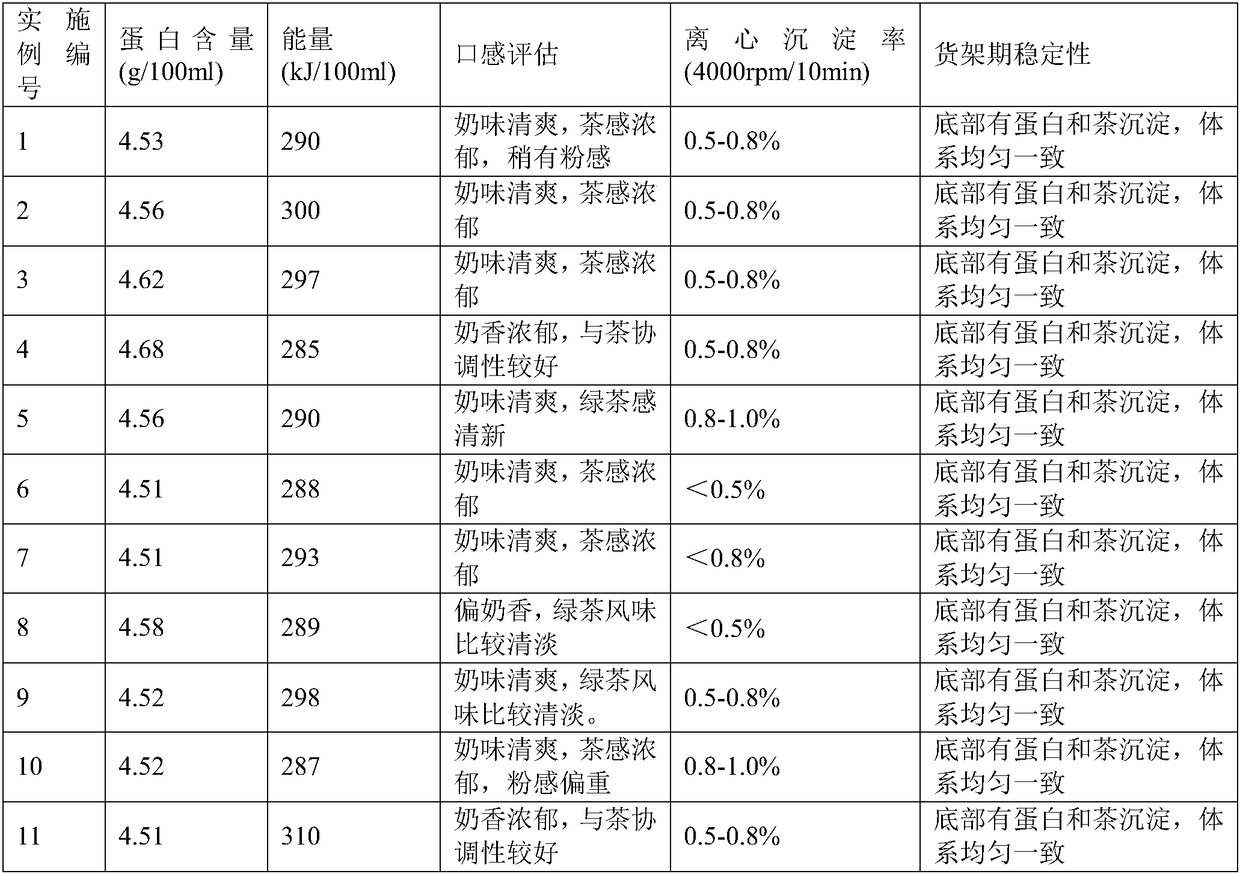

Fruit juice milk tea beverage based on high proteins and preparation method thereof

ActiveCN109007035AGuarantee the feasibility of normal continuous productionEnsure product quality stabilityMilk preparationPre-extraction tea treatmentEmulsionFruit juice

The invention relates to the field of foods, and discloses a fruit juice milk tea beverage based on high proteins and a preparation method thereof. The invention successfully applies a high protein concept, fruit juice raw materials and an online spray tea extraction technology to the production process of high-protein milk tea beverage products, can meet the requirements of long-term continuous production through special formula compatibility and emulsion stability system construction, can realize the normal mouth feel and stable quality of the product within the shelf life at the same time,and can realize the production process and packaging mode of ultra-clean hot filling with PET bottles.

Owner:HANGZHOU WAHAHA TECH +1

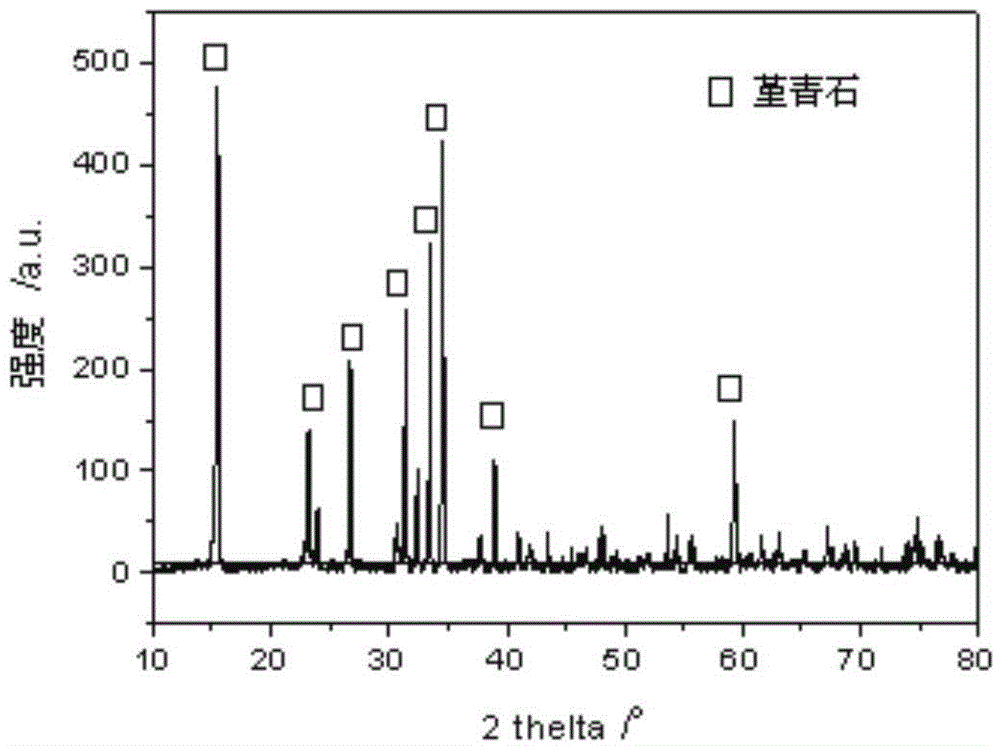

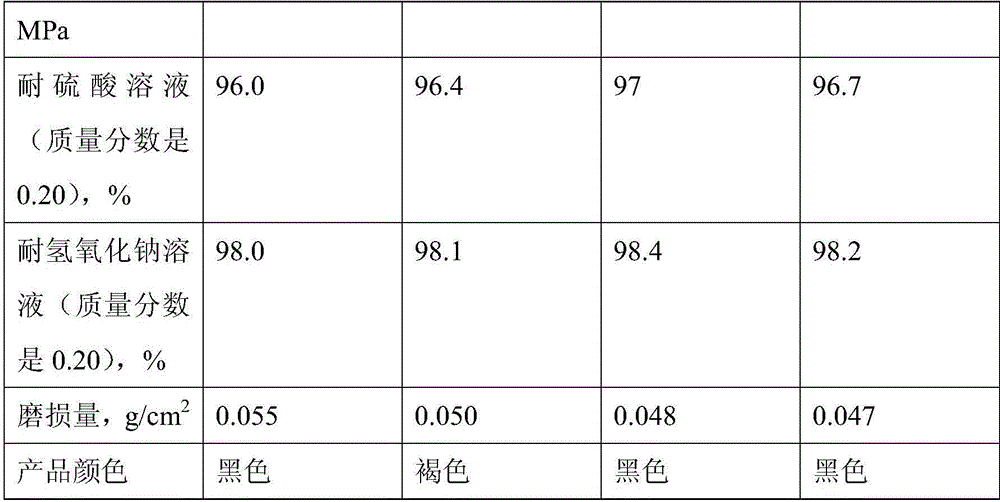

Glass ceramic board for industrial protection and preparation method thereof

ActiveCN103553342AExact ingredient matchGuaranteed melting characteristicsMetallurgyRoom temperature

The invention discloses a glass ceramic board for industrial protection and a preparation method thereof. The preparation method comprises the following steps: 1) preparing raw materials according to requirements of the system CaO-MgO-Al2O3-SiO2 and allowing the raw materials to comprise the basic compound components consisting of, by weight, 50 to 55% of SiO2, 8 to 10% of MgO, 12 to 14% of CaO, 8 to 10% of Al2O3, 3 to 5% of FeO, 2 to 4% of Na2O and K2O, 6 to 8% of CaF2 and 3% of TiO2; 2) uniformly mixing the raw materials and carrying out melting and homogenization so as to obtain glass liquid; 3) subjecting the glass liquid to continuous calendering molding and annealing; 4) directly sending an annealed glass plate to a nucleation and crystallization furnace on line for nucleation and crystallization; and 5) and subjecting a glass ceramic plate having undergone nucleation and crystallization to on-line cutting and cooling to room temperature so as to obtain the glass ceramic board for industrial protection.

Owner:ZHEJIANG UNIV

On-line automatic cleaning apparatus of slit extrusion type coating die for lithium battery and cleaning method thereof

PendingUS20220105668A1Increase productivitySave human effortLiquid surface applicatorsFinal product manufactureSolenoid valveStructural engineering

An on-line automatic cleaning apparatus of slit extrusion type coating die for lithium battery and a method associated therewith are provided. The cleaning apparatus includes: a die lip, a coating steel roller, and a cleaning mechanism disposed therebetween. The cleaning mechanism includes a cleaning chamber which includes elongated sealing strips and a flow-guiding arc groove. Front and rear ends of the cleaning chamber are connected to an inlet sealing plate and an outlet sealing plate respectively. The flow-guiding arc groove is in contact with and presses upper and lower sloped surfaces of the die lip through the elongated sealing strips to seal and thereby define a closed cleaning tunnel. The inlet and outlet sealing plates are in contact with and press two ends of the closed cleaning tunnel respectively for circumferential sealing. An inlet and an outlet are connected to pipes having solenoid valves installed thereon.

Owner:JIANGSU KATOP AUTOMATION CO LTD

Automatic high-speed sticking equipment of elastic key pieces

The invention discloses automatic high-speed sticking equipment of elastic key pieces, which is used for stripping off the elastic key pieces stuck on a material belt and sticking the elastic key pieces on a circuit board. The automatic high-speed sticking equipment comprises an unwinding roll, a stripping knife, a material absorbing plate and a material winding roll, wherein the unwinding roller is used for unwinding a roll-shaped material belt stuck with the elastic key pieces; the stripping knife is used for matching with a material pressing roll to strip off the elastic key pieces stuck on the material belt; the material absorbing plate is used for accurately positioning and absorbing the elastic key pieces and pressing and sticking the elastic key pieces on the circuit board; and the material winding roll is used for recovering the material belt after the elastic key pieces are stripped off. In the automatic high-speed sticking equipment, due to adoption of the technical means of integrating emptying, stripping, absorbing, pressing and winding, the manual stripping, sticking and pressing of the elastic key pieces are replaced, and the uncertainty of manual operation is eliminated, so that not only is the labor cost increasing day by day reduced, but also the production efficiency is greatly improved simultaneously on the basis of ensuring the quality stability of a product, the requirement for batched bulk-order type production is met, and the blank of the procedure of sticking the elastic key pieces on mobile portable equipment such as a mobile phone and the like in the field of automation control is filled.

Owner:盐城博思维信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com