High-transparency and low-shrinkage thermoplastic polyurethane elastomer and preparation method thereof

A technology of thermoplastic polyurethane and low shrinkage, applied in the field of thermoplastic polyurethane, can solve problems such as appearance impact, achieve the effect of simplifying the production process, achieving high consistency and low shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

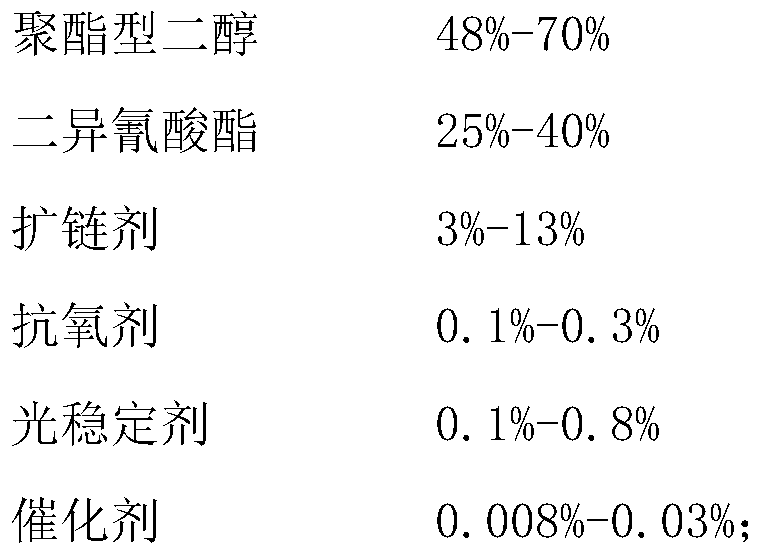

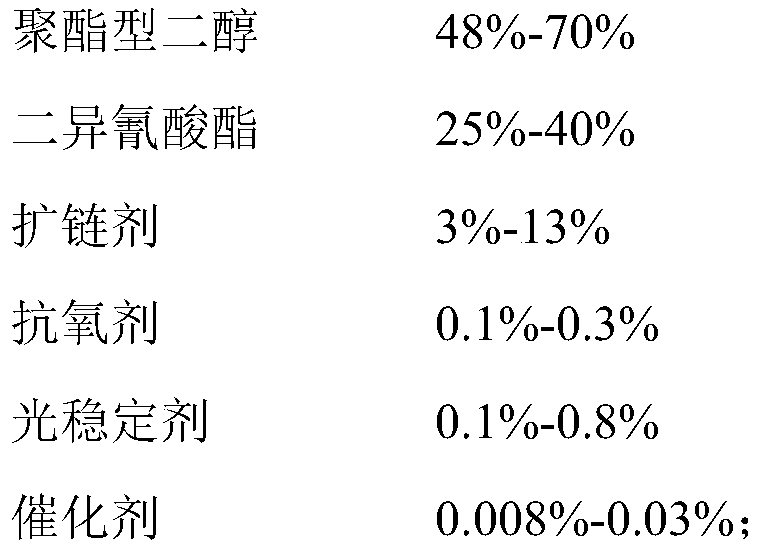

[0030] The high transparency and low shrinkage thermoplastic polyurethane elastomer is made of the following raw materials in mass percentage:

[0031]

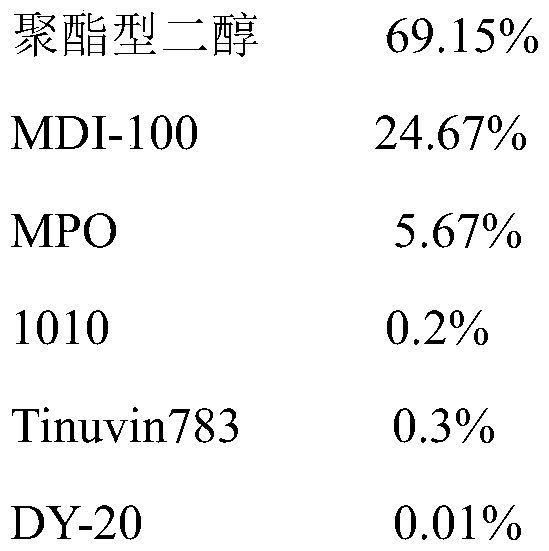

[0032] Described polyester diol molecular weight is 3000.

[0033] The polyester diol is composed of dibasic acid and dibasic alcohol. A (terephthalic acid component) / B (adipic acid) in the dibasic acid component is 5% / 95%. The diol component is 1,4-butanediol.

[0034] Preparation process: Polyester diol, 1010, DY-20, Tinuvin 783 are mixed and heated to 140±10°C, fully mixed; MDI-100 is heated to 50±5°C; MPO is heated to 50±5°C; after heating The raw materials are injected into the conveyor belt through the high-speed mixing head after being accurately measured, and the materials are fully matured during the process of the conveyor belt passing through the drying tunnel. The TPU sheets that pass through the drying tunnel are broken by a pulverizer, and the TPU chips are sent to the twin-screw extruder, and the final pr...

Embodiment 2

[0036] The high transparency and low shrinkage thermoplastic polyurethane elastomer is made of the following raw materials in mass percentage:

[0037]

[0038] Described polyester diol molecular weight is 2000.

[0039] The polyester diol is composed of dibasic acid and dibasic alcohol. A (terephthalic acid component) / B (adipic acid) in the dibasic acid component is 7% / 93%. The diol component is a mixture of ethylene glycol and 1,4-butanediol, and the mixing ratio is 1:1.

[0040] Preparation process: Polyester diol, 1010, DY-20, Tinuvin 783 are mixed and heated to 140±10°C, mixed well; HDI is heated to 50±5°C; PDO is heated to 50±5°C; the heated raw materials After accurate metering, it is poured into the conveyor belt through the high-speed mixing head, and the material is fully matured when the conveyor belt passes through the drying tunnel. The TPU sheets that pass through the drying tunnel are broken by a pulverizer, and the TPU chips are sent to the twin-screw ext...

Embodiment 3

[0042] The high transparency and low shrinkage thermoplastic polyurethane elastomer is made of the following raw materials in mass percentage:

[0043]

[0044] Described polyester diol molecular weight is 1000.

[0045] The polyester diol is composed of dibasic acid and dibasic alcohol. A (terephthalic acid component) / B (adipic acid) in the dibasic acid component is 10% / 90%. The diol component is a mixture of ethylene glycol and 1,2-propylene glycol, and the mixing ratio is 1:1.

[0046] Preparation process: Polyester diol, 626, TPT, Tinuvin 783 are mixed and heated to 140±10°C, fully mixed; MDI-100 is heated to 50±5°C; MPO is heated to 50±5°C; the heated raw materials After accurate metering, it is poured into the conveyor belt through the high-speed mixing head, and the material is fully matured when the conveyor belt passes through the drying tunnel. The TPU sheets that pass through the drying tunnel are broken by a pulverizer, and the TPU chips are sent to the twin-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com