Method for welding anticorrosion steel pipeline with no internal repaired mouth

A technology for steel pipelines and joints, applied in the field of anti-corrosion steel pipelines without internal joint joint welding, can solve the problems of bottoming weld bead pollution, affecting corrosion resistance, complicated processes, etc., to reduce the difficulty of butt welding, improve welding quality, Guaranteed effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The invention provides a welding method for steel pipelines without internal repairing, and its specific implementation steps are as follows:

[0034] (1) Surfacing steps

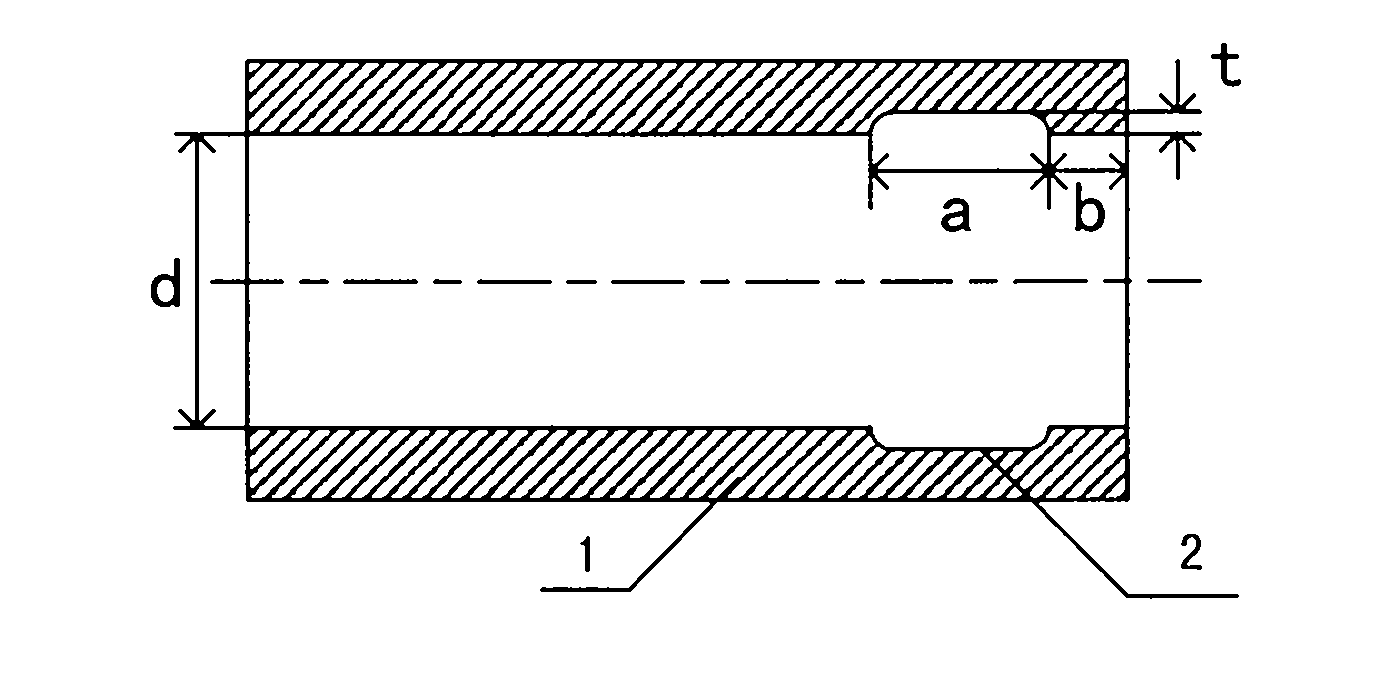

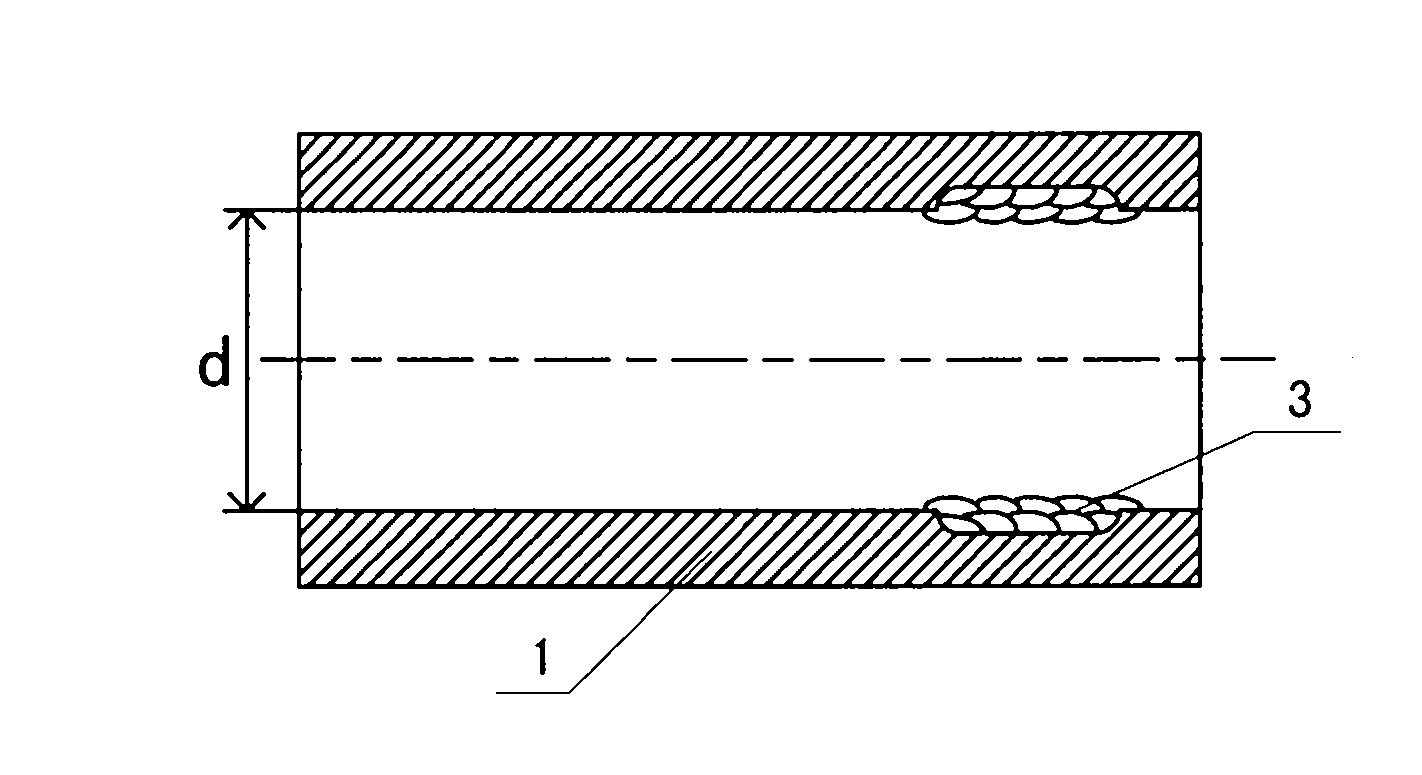

[0035] A certain distance b from the inner wall of the steel pipe to the end is 5mm, and a groove with a depth t of 1mm and a length of 20mm is machined in advance, and the two ends of the groove are rounded to prevent unfused defects. Surfacing a certain thickness of corrosion-resistant alloy material on the groove, such as stainless steel or nickel-based alloy welding wire, etc., the welding method adopts argon tungsten arc welding, and the thickness of the surfacing layer should be greater than the depth of the groove to ensure that the weld metal will cover the groove fill up.

[0036] (2) Machining steps

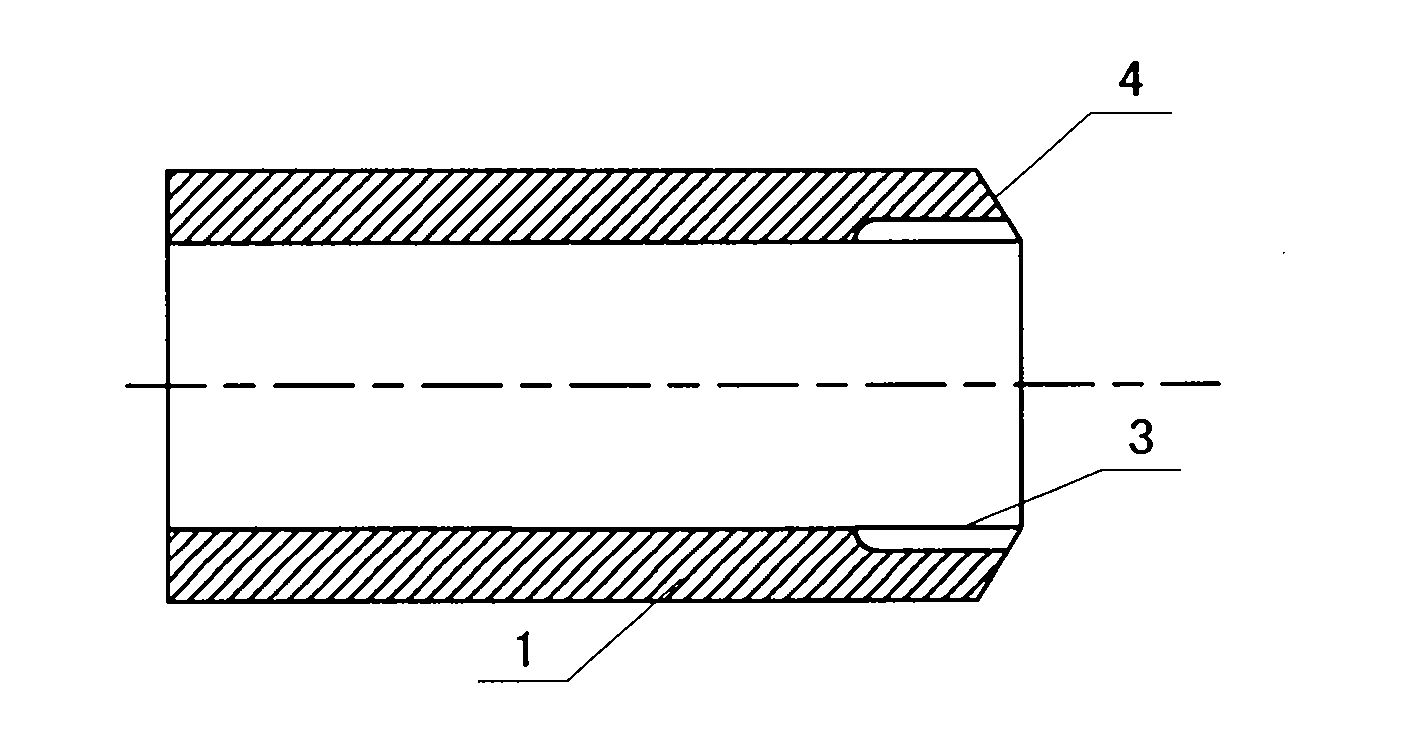

[0037] After the surfacing is completed, the pipe end is machined into a V-shaped butt joint groove. After the machining, the length of the remaining surfacing layer should be 19 mm, and the...

Embodiment 2

[0043] The invention provides a welding method for steel pipelines without internal repairing, and its specific implementation steps are as follows:

[0044] (1) Surfacing steps

[0045] A certain distance b from the inner wall of the steel pipe to the end is 15mm, and a groove with a depth t of 4mm and a length of 40mm is machined in advance, and the two ends of the groove are rounded to prevent unfused defects. Surfacing a certain thickness of corrosion-resistant alloy material on the groove, such as stainless steel or nickel-based alloy welding wire, etc., the welding method adopts argon tungsten arc welding, and the thickness of the surfacing layer should be greater than the depth of the groove to ensure that the weld metal will cover the groove fill up.

[0046] (2) Machining steps

[0047] After the surfacing is completed, the pipe end is machined into a V-shaped butt joint groove. After machining, the length of the remaining surfacing layer should be 35 mm, and the su...

Embodiment 3

[0053] In the Q245R carbon steel pipe with a pipe diameter of Φ76mm and a wall thickness of 9mm, a groove with a length of 22mm and a depth of 2mm is opened at a distance of 10mm from the pipe end, and a corrosion-resistant alloy is surfacing on the groove by argon tungsten arc welding , The filling material can choose 316L or 625 nickel-based alloy welding wire to ensure that the filling metal will fill the groove. The end of the pipe body after surfacing is processed with a V-shaped groove, the groove angle is 40°, the length of the remaining surfacing layer after machining is 20mm, and the transition between the surfacing layer and the inner wall of the pipe is smooth. Spray a layer of 2mm thick polyethylene powder coating on the inner wall of the steel pipe, and the coating covers 10mm of the surfacing metal. The two steel pipes whose inner walls have been sprayed with anti-corrosion coating are butt-connected, and spot-fixed along the circumference of the groove, and a sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com