A kind of electron beam welding method of dense rectangular girth weld on outer annular surface

A technology of electron beam welding and outer ring surface, applied in electron beam welding equipment, welding equipment, metal processing equipment, etc., can solve the problem that the process stability of a single weld has not been fully considered. The butt gap of the square annular weld increases, and the head of the support plate is prone to cracks, which reduces the probability of welding defects, is conducive to symmetrical distribution, and improves stability and margin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

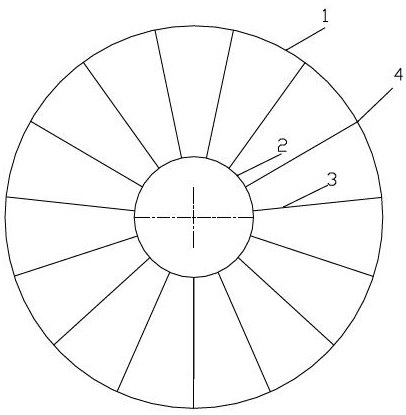

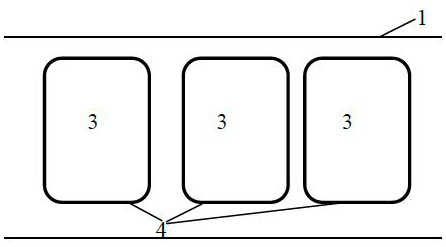

[0039] Taking the casing structure on the outer ring surface with 15 rectangular annular welds as an example, the casing structure is as follows: figure 1 As shown, it consists of three parts: the outer ring 1, the inner ring 2 and the support plate 3 (15 pieces including the support plate head). The welding position 4 of the rectangular girth weld is shown in the figure, and there are 15 pieces in total. The diameter of the outer ring is 900mm, the width is more than 120mm, and the wall thickness is 2-3mm. The position size of the rectangular girth weld is 30~90mm×30~90mm, and the fillet radius is 5~12mm, such as figure 2 shown.

[0040] The welding scheme is as follows:

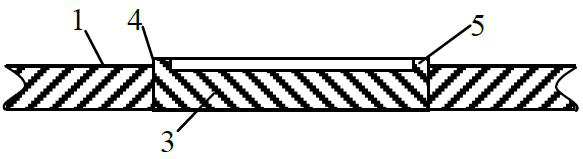

[0041] (1) According to the structural characteristics of the square circular weld, keep the thickness of the outer ring surface 1 (including the rectangular hole) unchanged at 2-3 mm, and set a boss structure 5 with a thickness increased by 0.5 mm at the welding position 4 of the support plate head 3 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com