Biological bone cement

A bone cement, bio-based technology, applied in tissue regeneration, medical science, prosthesis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

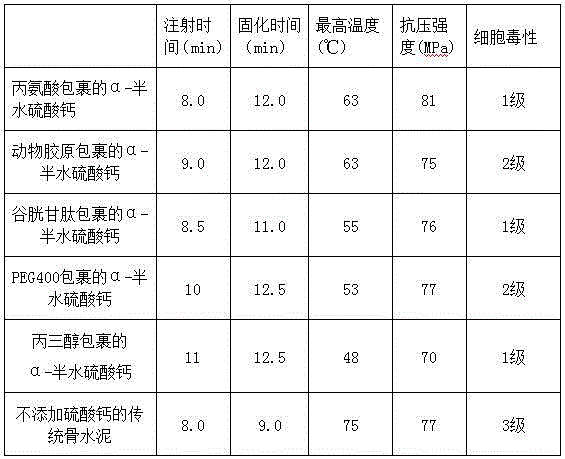

[0036] Example 1: Effect of α-Calcium Sulfate Hemihydrate Coated with Different Materials on the Performance of Bone Cement

[0037] (1) Alanine-coated calcium sulfate hemihydrate (10.6%), animal collagen-coated calcium sulfate hemihydrate (10.6%), glutathione-coated calcium sulfate hemihydrate (10.6%) , Polyethylene glycol (PEG400)-coated α-calcium sulfate hemihydrate (10.6%), glycerol-coated α-calcium sulfate hemihydrate (10.6%) and PMMA (70.7%), zirconium oxide (16.7%), BPO (2%) is mixed uniformly to obtain bone cement powder.

[0038] (2) Add N,N-dimethyl-p-toluidine (0.75%) and hydroquinone (0.75%) to the pre-mixed MMA (98.5%), dissolve and mix by stirring to obtain bone cement liquid Agent.

[0039] (3) Using a bone cement mixing and mixing system, add the powder first according to the powder-to-liquid mass ratio of 2:1, add the corresponding liquid ingredients, and mix well, the bone cement has 5-8 minutes injection time, and the bone will be obtained after solidification. ...

Embodiment 2

[0044] Example 2: The effect of different initiators in the liquid on the performance of bone cement

[0045] (1) Glutathione-coated α-calcium sulfate hemihydrate (10.6%) and acrylic acid and methyl methacrylate copolymer (70.7%), zirconia (16.7%), and BPO (2%) are mixed uniformly, Obtain bone cement powder.

[0046] (2) Add camphorquinone (1.5%) or N,N-dimethyl-p-toluidine (1.5%) to the premixed MMA (98.5%), dissolve and mix by stirring to obtain a bone cement liquid.

[0047] (3) Using a bone cement mixing and mixing system, add the powder first according to the powder-to-liquid mass ratio of 2:1. After adding the corresponding liquid ingredients and mixing well, the bone cement has 5-8 minutes injection time, and the bone will be obtained after solidification. cement.

[0048] According to the bone cement industry standard, the maximum temperature and curing time of bone cement were measured, the bone cement was injected into a suitable mold and cured for 1 hour, compressive sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com