Patents

Literature

393 results about "Calcium Sulfate Hemihydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

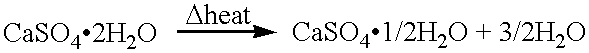

Calcium sulfate hemihydrate is a calcium salt that is used for a variety of purposes including: building materials, as a desiccant, in dentistry as an impression material, cast, or die, and in medicine for immobilizing casts and as a tablet excipient.

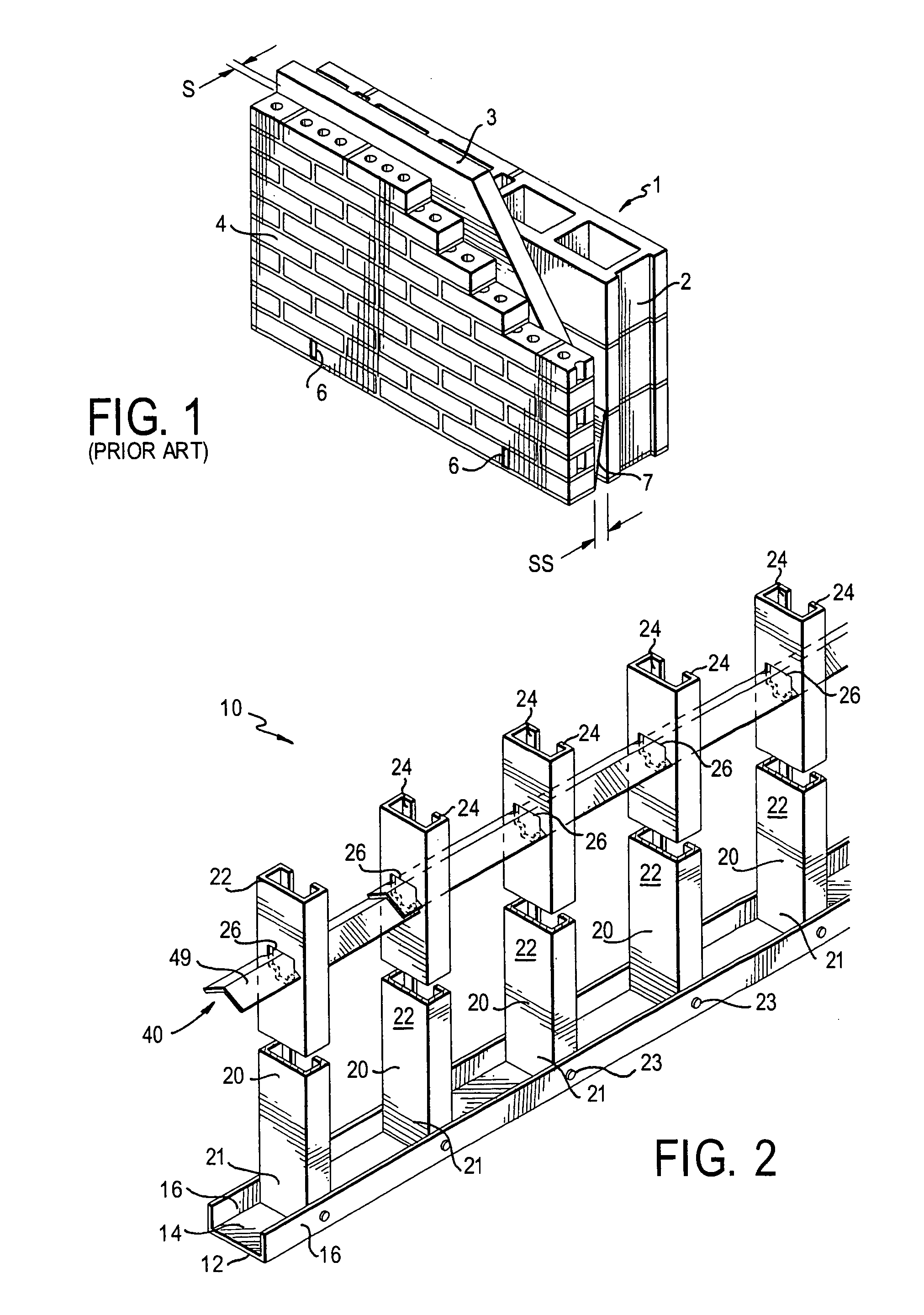

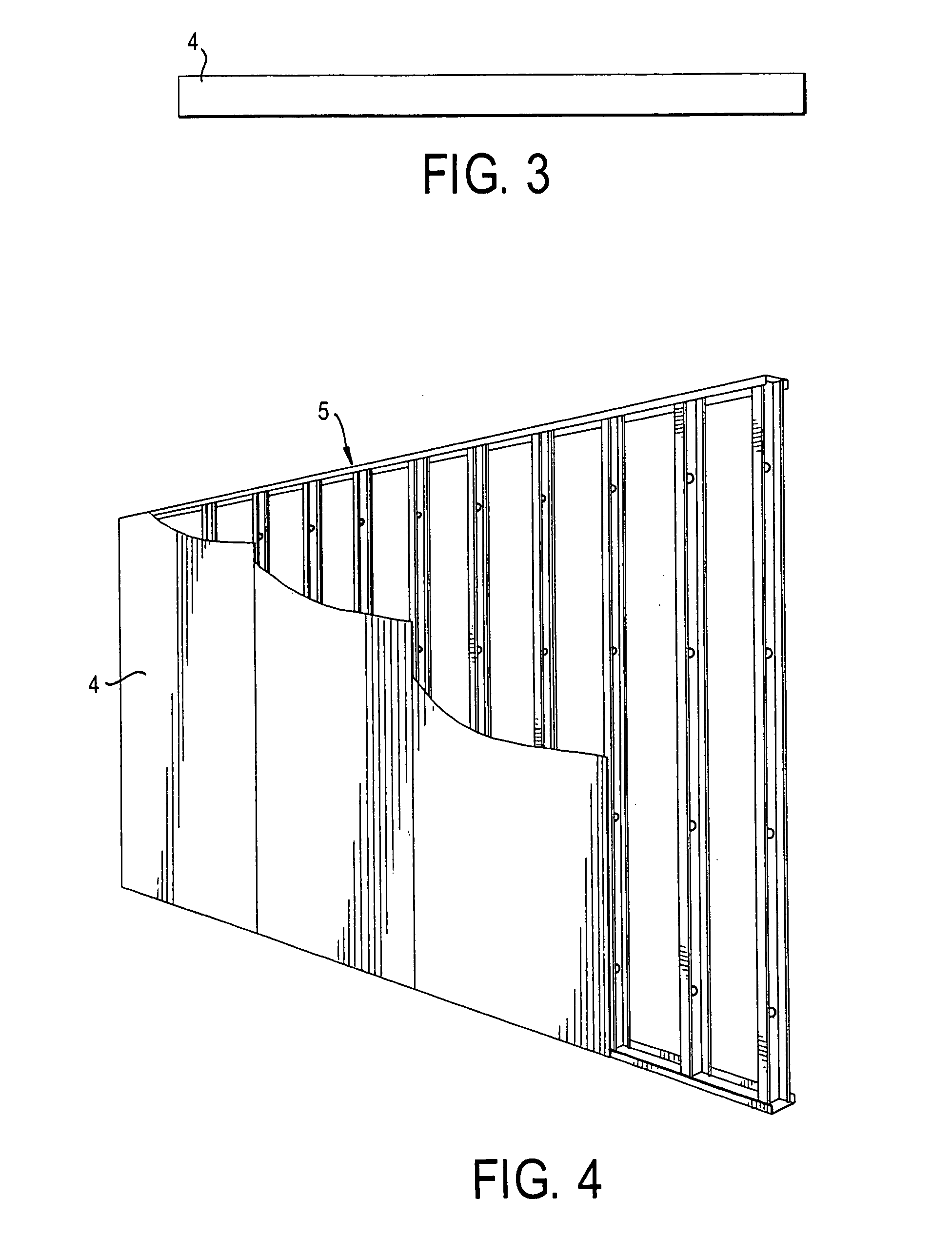

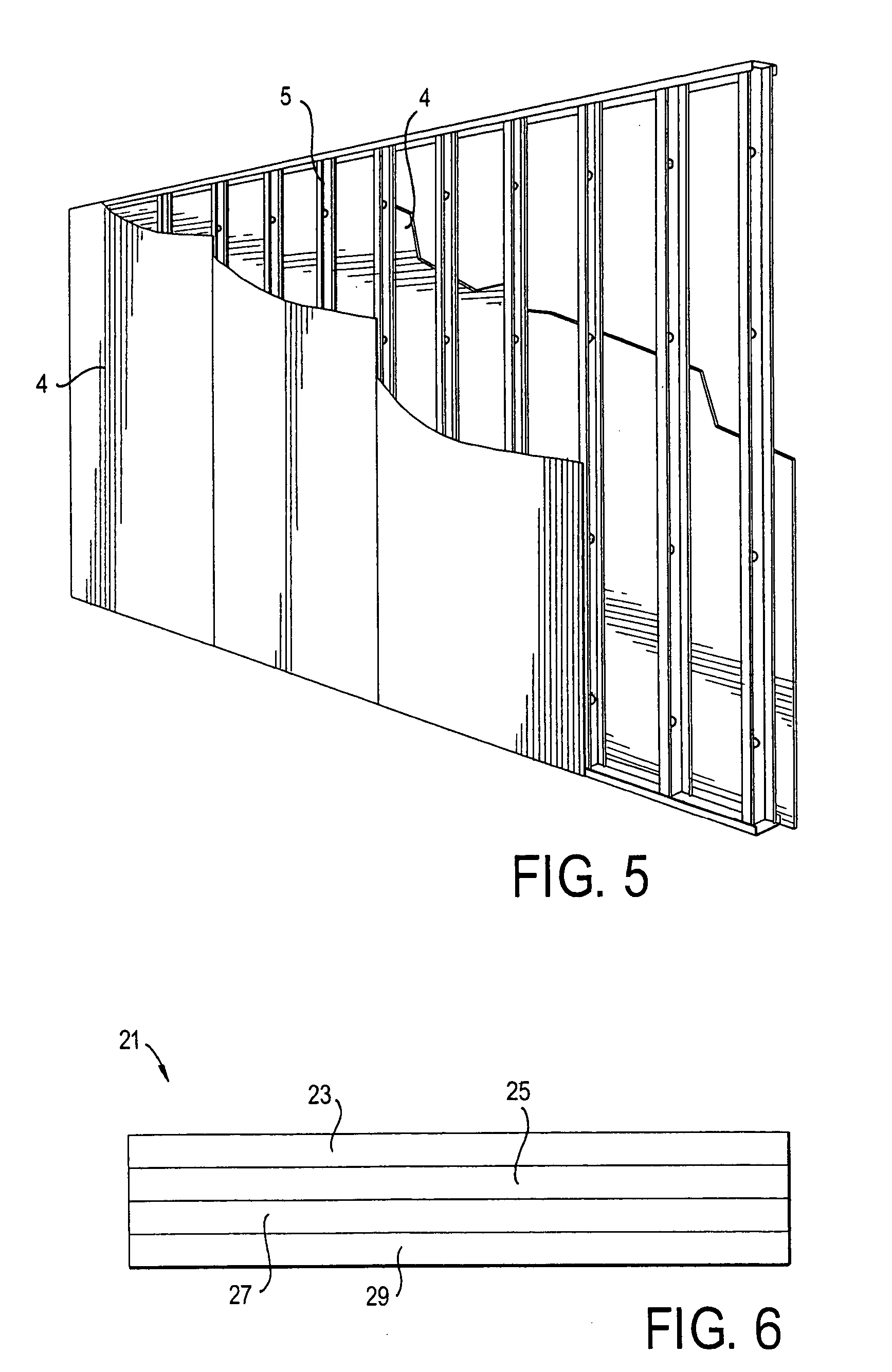

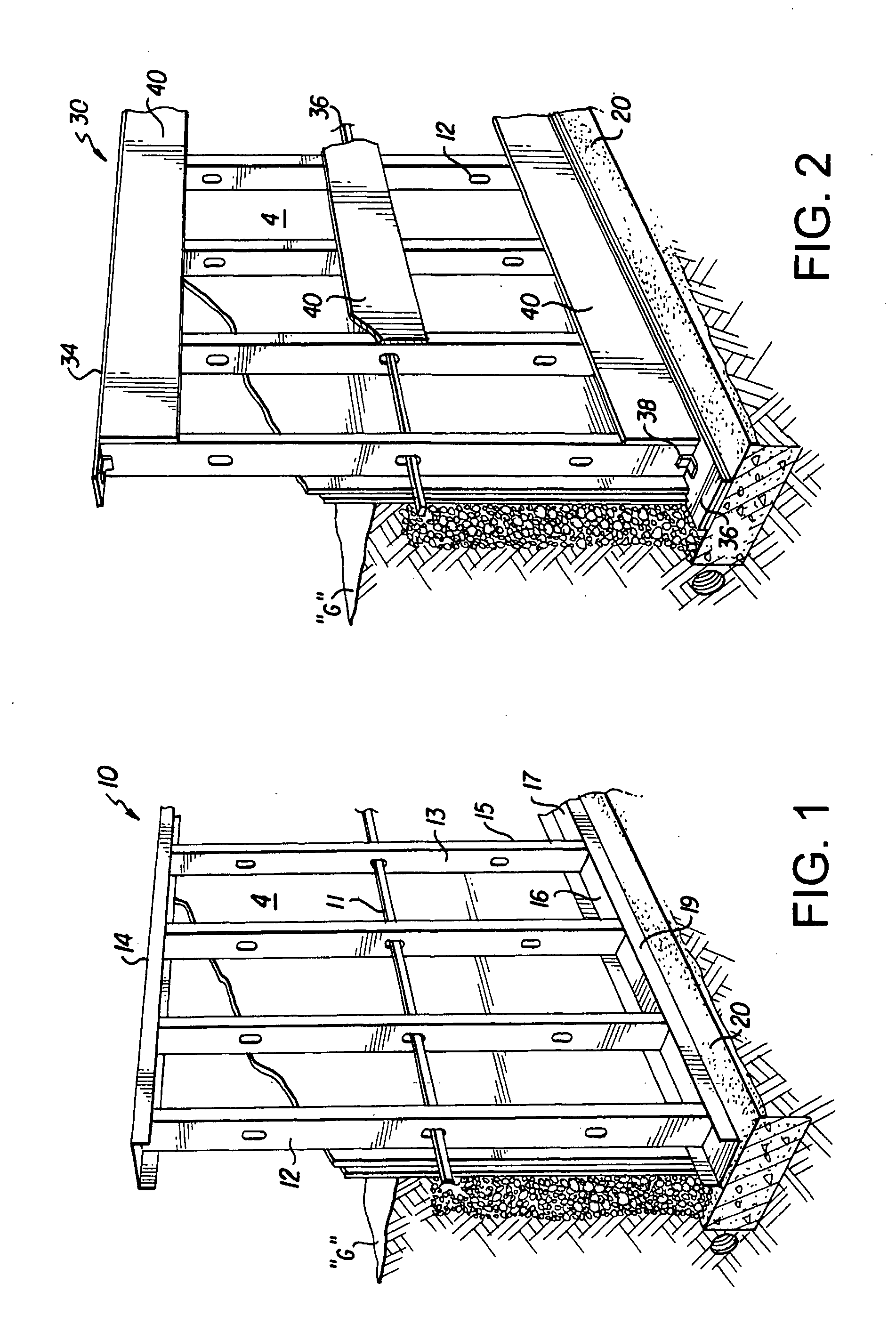

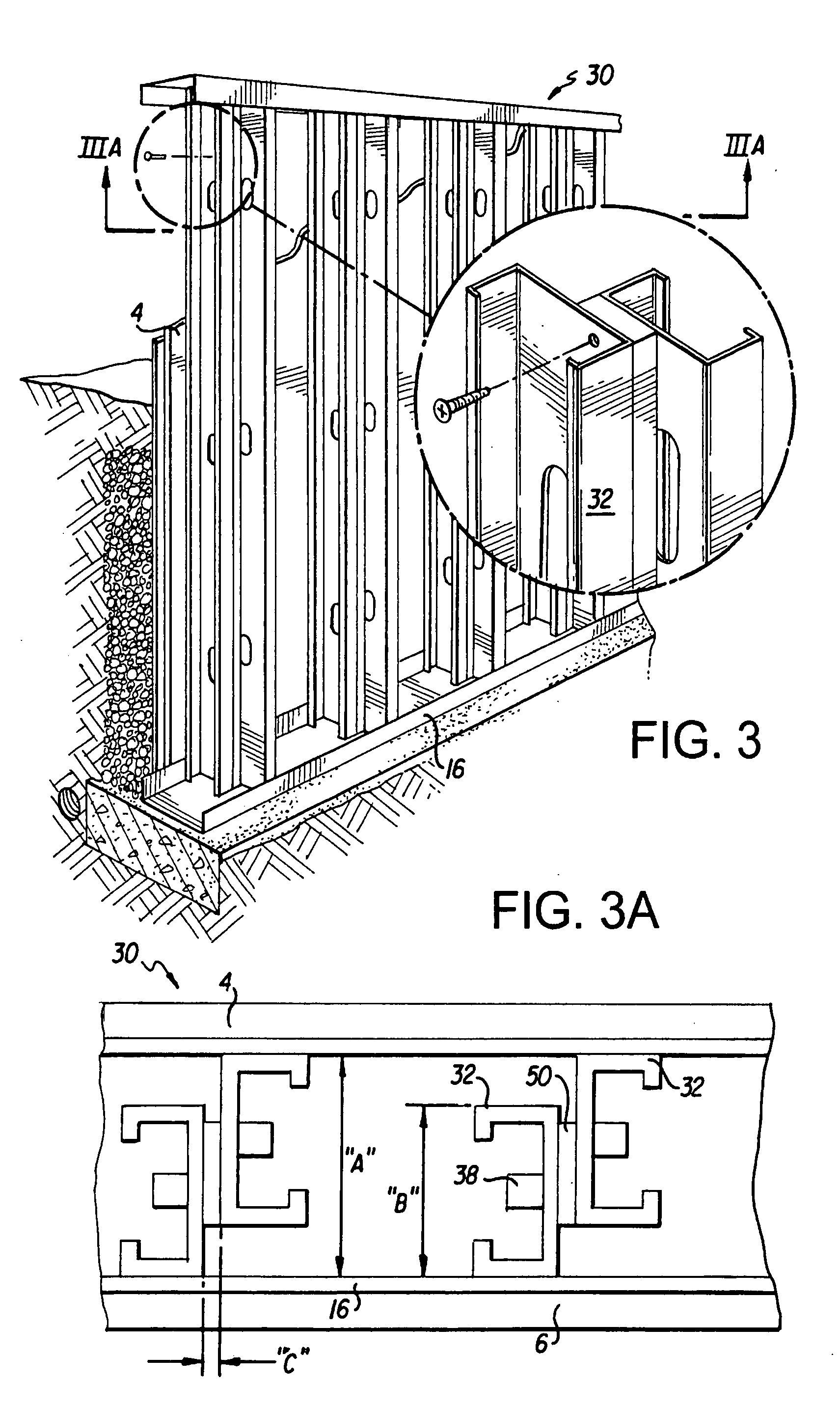

Non-combustible reinforced cementitious lighweight panels and metal frame system for a fire wall and other fire resistive assemblies

ActiveUS20060168906A1Reduce buildReduce capacityBuilding roofsSolid waste managementMicrosphereMetal framework

A fire resistive assembly including metal framing members, for example, C-joists, U-joists, open web joists, HAMBRO or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The assembly is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

Gypsum wood fiber product having improved water resistance

InactiveUS6010596AImprove water resistanceHigh strengthNon-fibrous pulp additionNatural cellulose pulp/paperFiberWax

An improved water resistant gypsum board is made by adding an aqueous wax emulsion containing a cationic surfactant to an aqueous slurry containing calcium sulfate and host particles at a slurry temperature which maintains calcium sulfate hemihydrate crystals. The wax emulsion is stable at the temperature of slurry which maintains the calcium sulfate hemihydrate. The slurry is then dewatered and rehydrated to form a gypsum board and dried at a temperature to melt the wax.

Owner:UNITED STATES GYPSUM CO

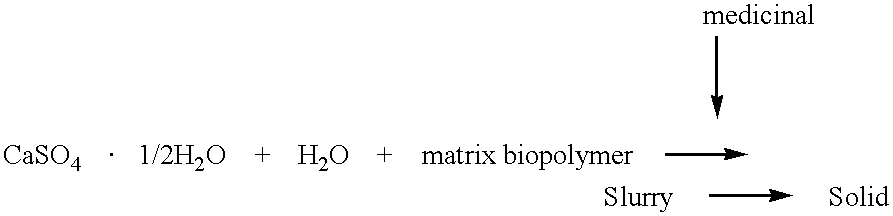

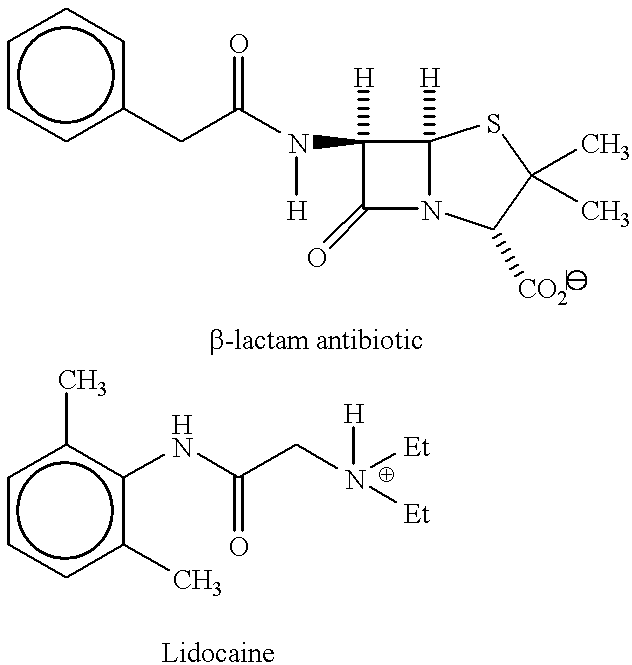

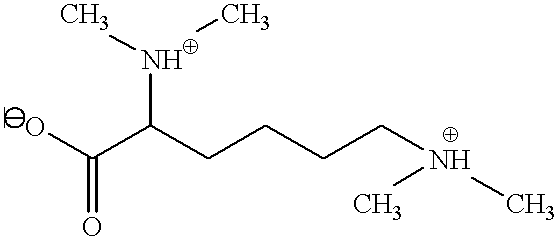

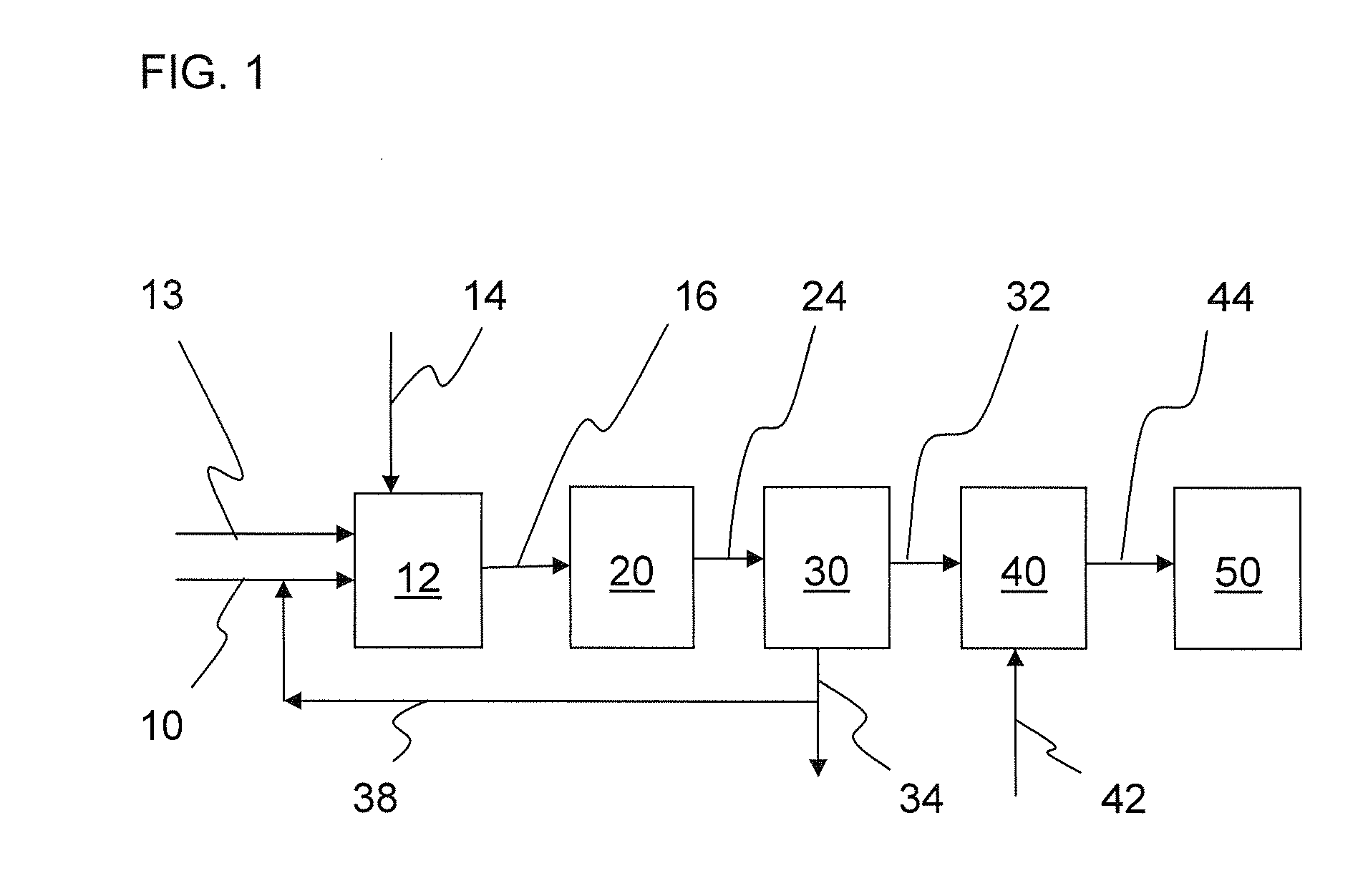

Inorganic-polymer complexes for the controlled release of compounds including medicinals

InactiveUS6391336B1Control releasePowder deliveryPeptide/protein ingredientsControlled releaseActive agent

This invention relates generally to the production and use of inorganic-polymer complexes for the controlled release of compounds including medicinals. The inorganic compound used is advantageously calcium sulfate-hemihydrate. The invention includes a composition for the controlled release of an active agent comprising: a) a hydrated or crystallized inorganic compound, and b) a matrix polymer which slows the release of the active agent, wherein the composition is a solid matrix due to the hydration or crystallization of the inorganic compound. Further included is a composition for the controlled release of an active agent comprising: a) a hydrated or crystallized inorganic compound, and b) a complexing agent which forms a salt or conjugate with the active agent, wherein the composition is a solid matrix due to the hydration or crystallization of the inorganic compound.

Owner:ROYER BIOMEDICAL INC

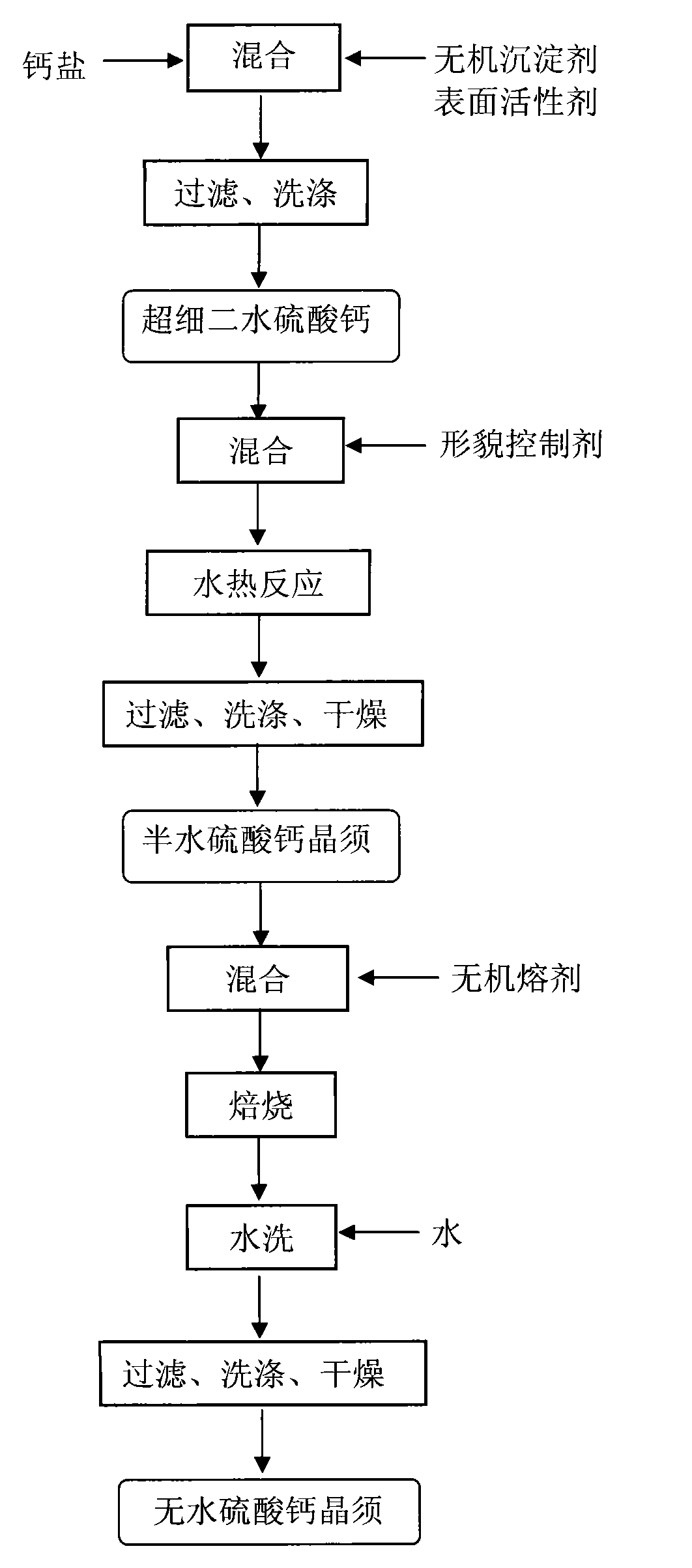

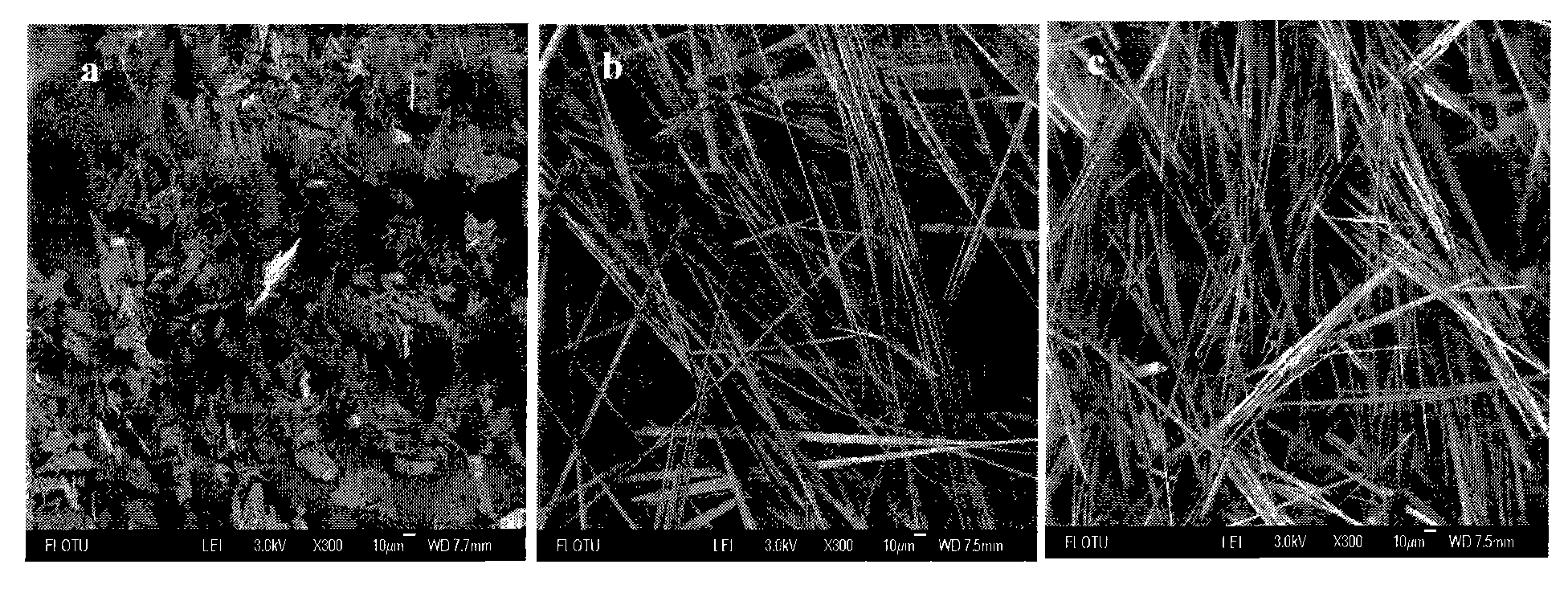

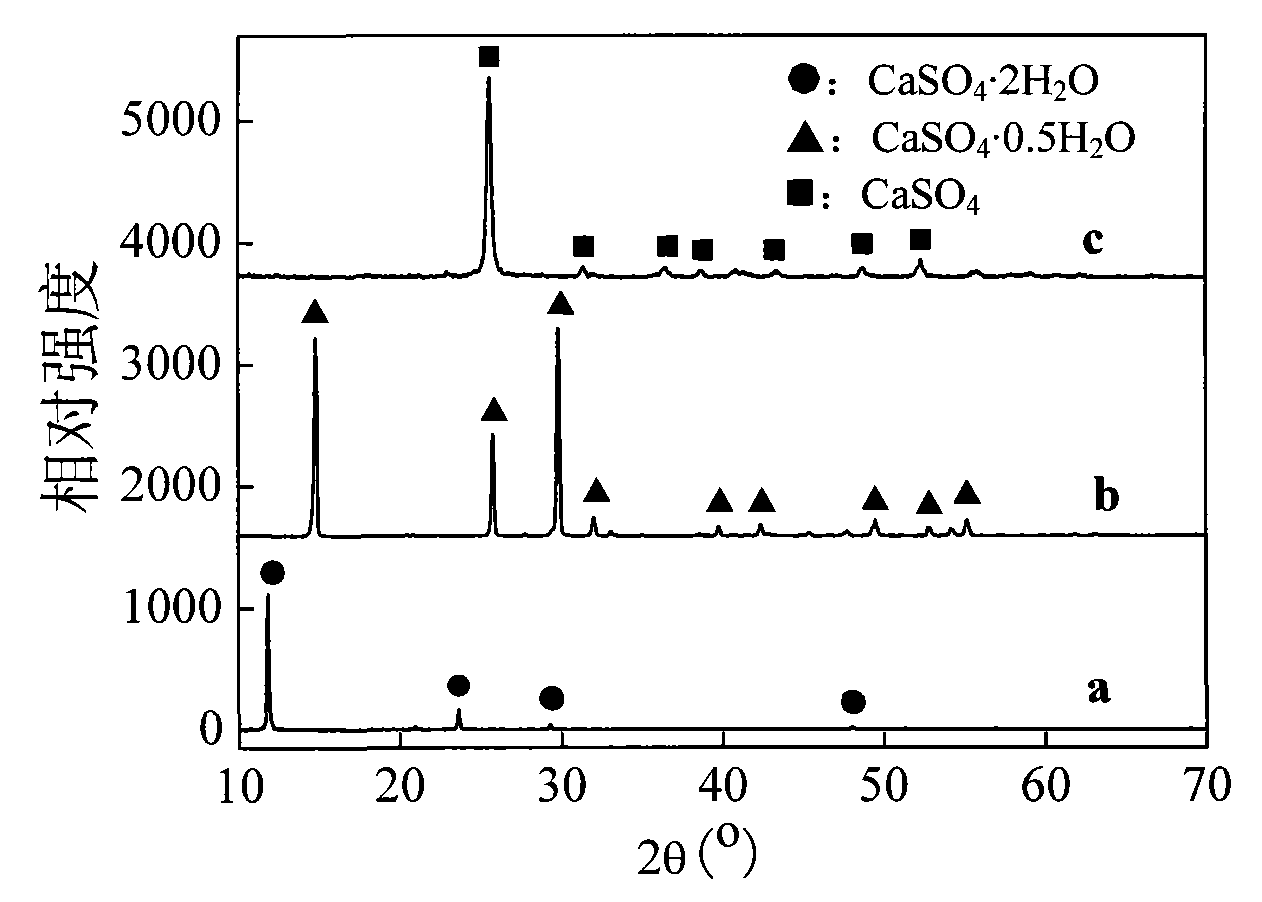

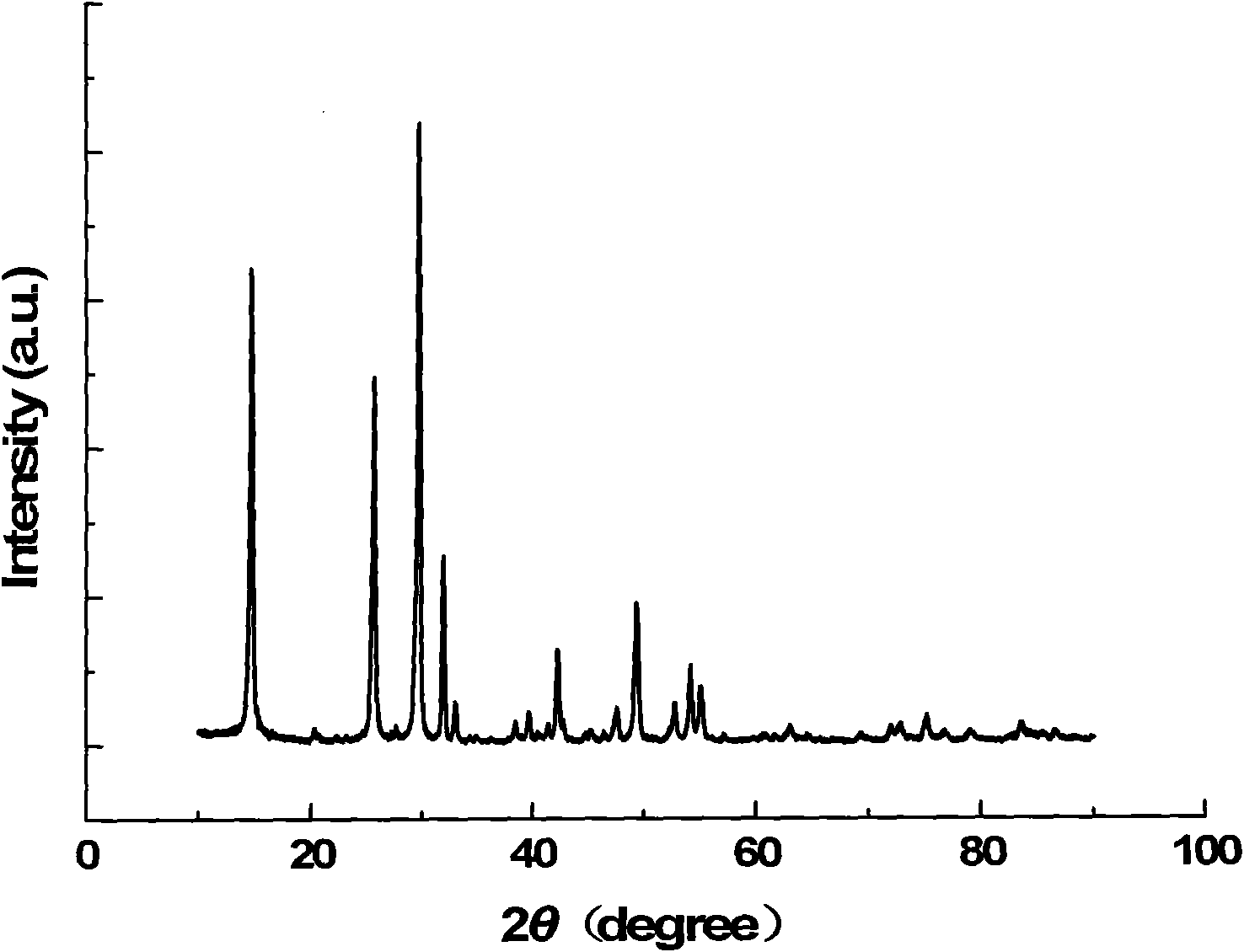

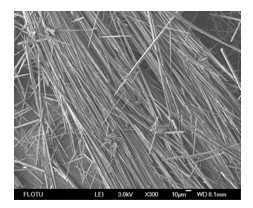

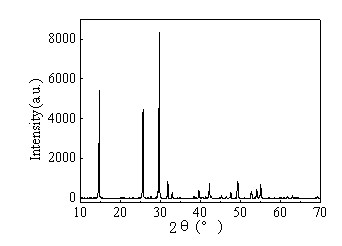

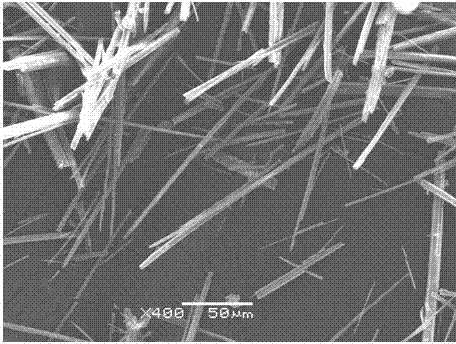

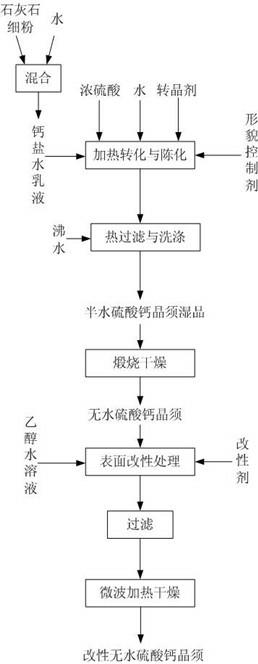

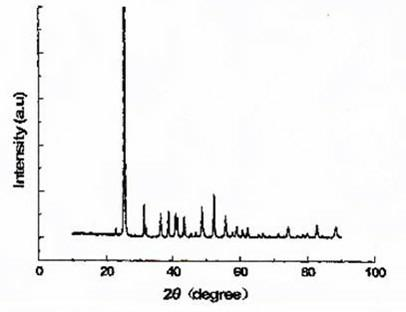

Preparation method of high length-diameter ratio anhydrous calcium sulfate whisker

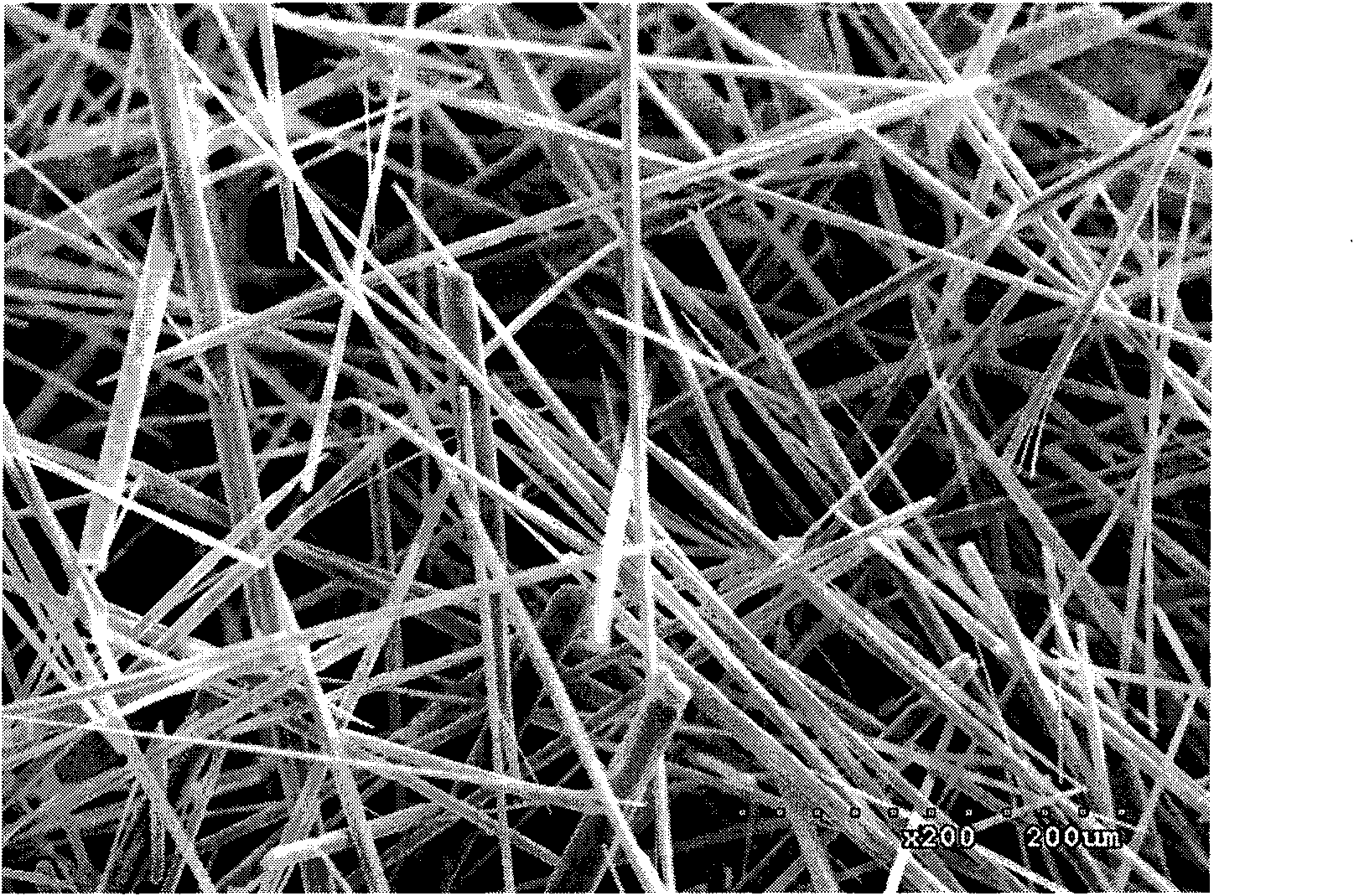

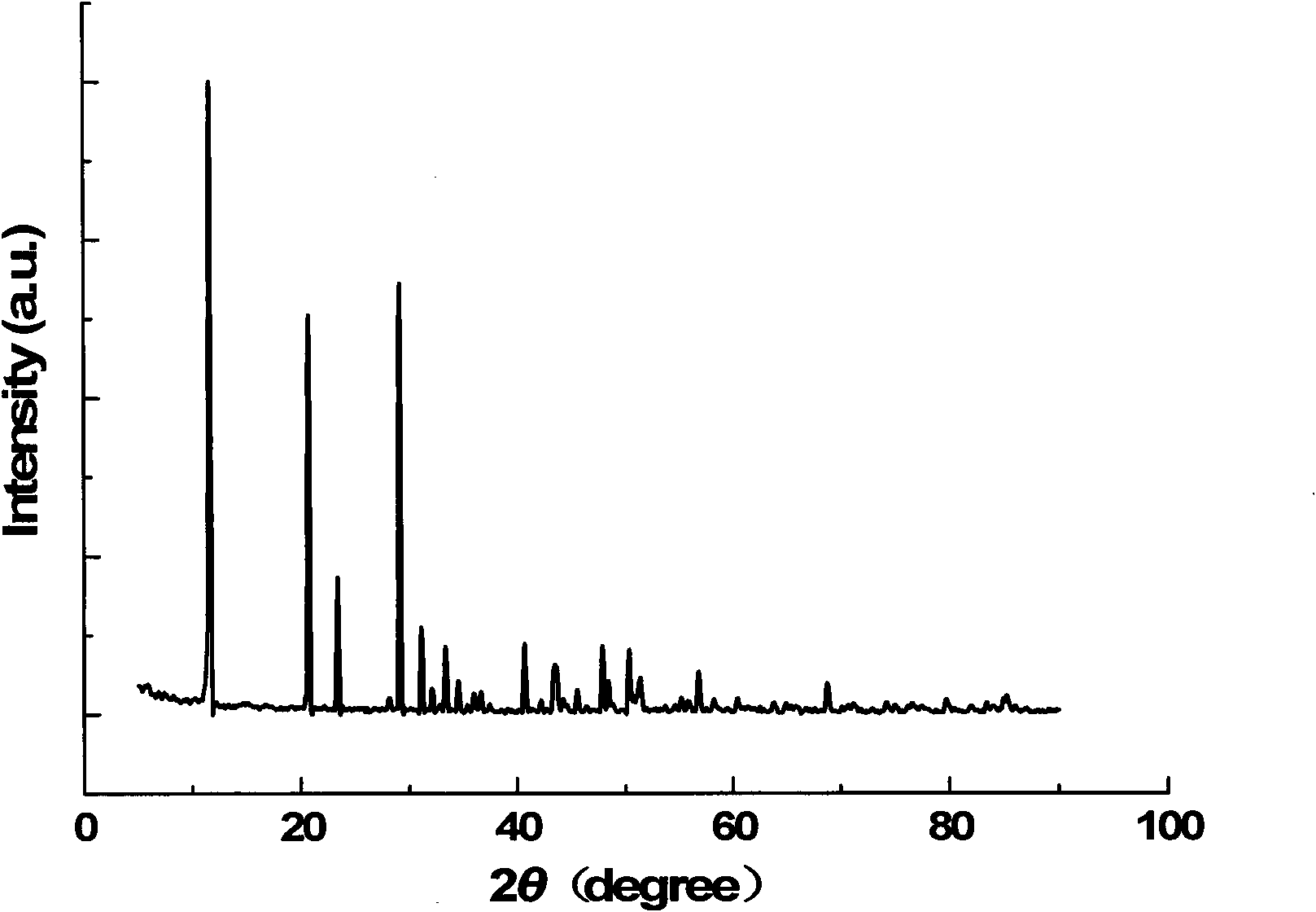

ActiveCN101671848AHigh crystallinityMorphological rulesPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfatePapermaking

A preparation method of high length-diameter ratio anhydrous calcium sulfate whisker belongs to the technical field of inorganic chemical material preparation. The method takes inorganic calcium saltand inorganic precipitant as raw materials and surfactant as dispersant, and includes the following steps: first preparing superfine calcium sulphate dihydrate precursor with good dispersion at the temperature of 10-90 DEG C; then adding the precursor into water solution containing shape control agent to conduct hydrothermal reaction for 0.5-10h at the temperature of 100-250 DEG C, and obtaining calcium sulfate hemihydrate whisker; mixing the calcium sulfate hemihydrate whisker with inorganic solvent; and roasting the mixture for 0.5-6h at the temperature 200-800 DEG C to obtain anhydrous calcium sulfate whisker with the length of 20-2000mum, the diameter of 0.5-20mum, the length-diameter ratio of 40-1000 and the main content greater than 95wt% after washing and drying. The technology is simple, the cost is low and the added value of the product is high. The prepared calcium sulfate whisker has large length-diameter ratio and regular shape and can be used as reinforcing material to beapplied in industries such as plastics, rubber, ceramics, cement, papermaking and the like.

Owner:TSINGHUA UNIV

Fiberboard with improved water resistance

ActiveUS7413603B2High strengthImprove waterproof performanceSolid waste managementWood working apparatusSlurryWater resistant

Articles, including fiberboard, are made from a pumpable, flowable slurry including alpha-calcined calcium sulfate hemihydrate anchored in pores of host particles, alpha-calcined calcium sulfate hemihydrate, a silicone compound, magnesium oxide, and water. The magnesium oxide catalyzes the reaction of the silicone compound into a silicone resin. In a preferred method of making a water resistant fiberboard calcium sulfate dihydrate is combined with the host particles and water to form a slurry which is heated under pressure to calcine the calcium sulfate dihydrate to form alpha-calcined calcium sulfate hemihydrate. After relieving the pressure, a silicone compound and magnesium oxide are added to the slurry. The slurry is dewatered to form a filter cake, which is then formed into a desired shape and allowed to set.

Owner:UNITED STATES GYPSUM CO

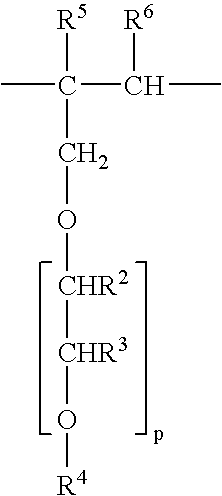

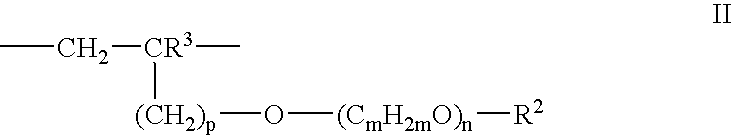

Modifiers for gypsum slurries and method of using them

InactiveUS20060280898A1Reducing dispersant dosageConserving fossil fuelLayered productsThin material handlingPhosphateSlurry

An improved gypsum slurry that includes water, calcium sulfate hemihydrate, a polycarboxylate dispersant and a modifier. The modifier is chemically configured to improve the efficacy of the polycarboxylate dispersant. Preferred modifiers include cement, lime, slaked lime, soda ash, carbonates, silicates and phosphates.

Owner:UNITED STATES GYPSUM CO

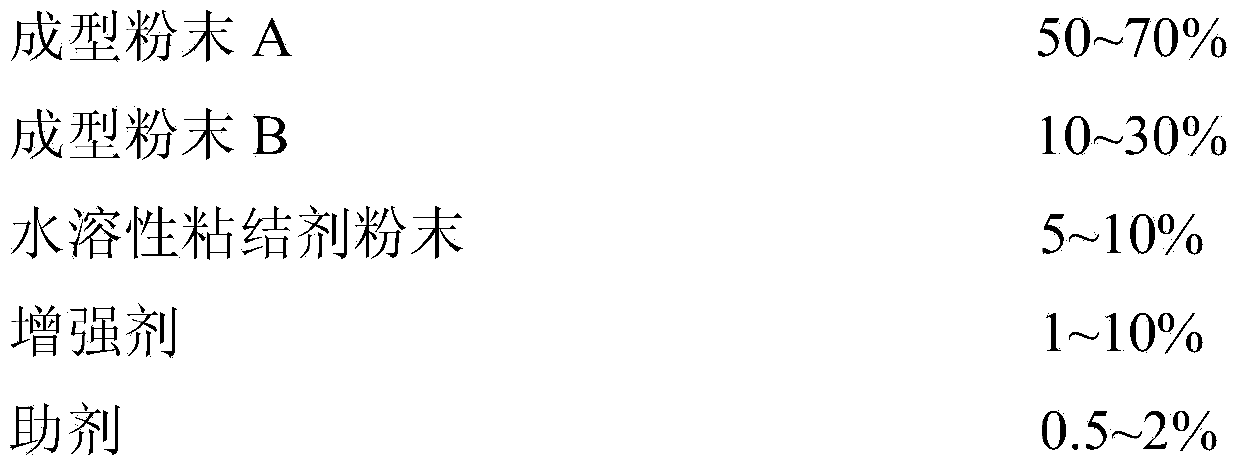

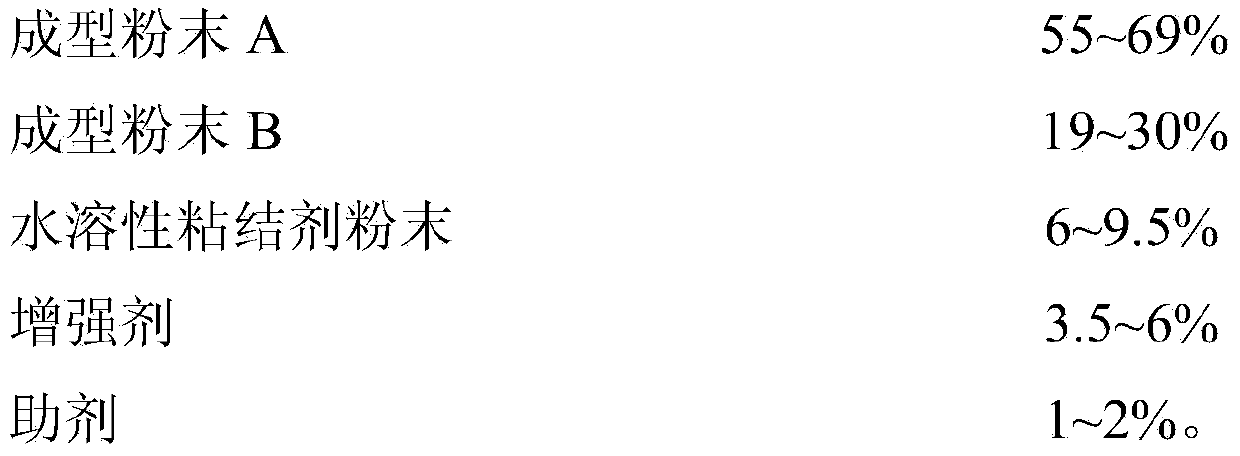

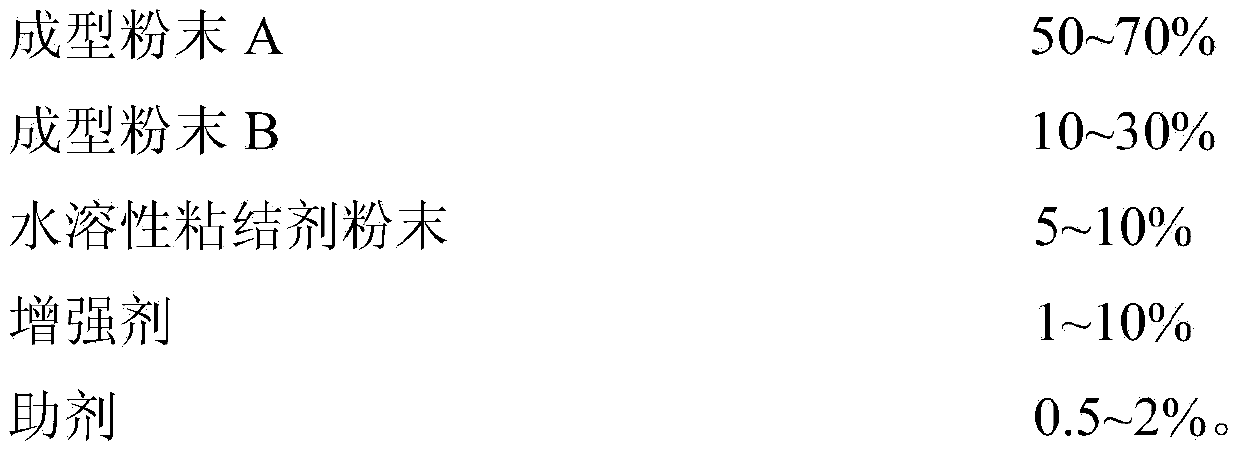

Rapid-molding powder material for three-dimensional printing as well as preparation method and application thereof

The invention belongs to the technical field of rapid-molding materials, and discloses a rapid-molding powder material for three-dimensional printing as well as a preparation method and application thereof. The rapid-molding powder material is prepared by mixing and drying the following components by mass percent: 50% to 70% of molding powder A, 10% to 30% of molding powder B, 5% to 10% of water-soluble bonder powder, 1% to 10% of enhancer and 0.5% and 2% of aiding agent, wherein the molding powder A is of alpha-type calcium sulfate hemihydrate gypsum powder; the molding powder B is at least one powder of thermoplastic resin powder, wax powder or hot melt adhesive powder. The obtained rapid-molding powder material can be used for preparing three-dimensional printing prototypes, rapid-molding moulds, medical moulds and the like, and has the advantages of high strength and accuracy, small dimensional deviation, good water resistance and difficult powder bonding.

Owner:GUANGDONG IND TECHN COLLEGE +1

Method for producing dehydrated calcium sulfate whisker

InactiveCN101550585ANo emissionsReduce manufacturing costPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfateLixiviant

The invention provides a method for producing dehydrated calcium sulfate whisker, comprising: using copper, lead, zinc, aluminium, nickel, cobalt, stannum, non-ferrous metal secondary resource cycle utilizing, calcium nitrate solution produced in treating process of electroplating waste, calcium chloride solution, or mixed water solution of calcium nitrate and calcium chloride as raw material, using sulfuric acid as calcium ion precipitant, adding whisker shape regulating agent, controlling reaction condition, regenerating aqua fortis or hydrochloric acid lixiviant, and simultaneously producing ultralong and big length to diameter ratio calcium sulphate dihydrate whisker. After calcium sulphate dihydrate whisker is deposited from calcium nitrate solution, calcium chloride solution or the mixed solution of calcium nitrate and calcium chloride are deposited, the water solution is translated to be nitric acid solution, hydrochloric acid solution or a mixed solution of nitric acid and hydrochloric acid, returning back to leaching out or treating process for processing non-ferrous metal mineral substance, non-ferrous metal secondary resource or electroplating remove. The calcium sulphate dihydrate whisker is treated by microwave heating, forming calcium sulfate hemihydrate or anhydrous sulphate of calcium after dehydration.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

Process for manufacturing ultra low consistency alpha- and beta- blend stucco

InactiveUS20080069762A1Cheap methodAid in reactivityCalcium/strontium/barium sulfatesFluidized bedSlurry

A process is disclosed for making a blend of alpha- and beta-stucco including a slurry calcination step to produce alpha calcium sulfate hemihydrate followed by a fluidized bed calcination step to produce beta calcium sulfate hemihydrate. The process starts with 50-75% gypsum-containing solids slurry, and then steam calcines the slurry in a first reactor to form partially calcined gypsum slurry which contains calcium sulfate dihydrate and alpha calcium sulfate hemihydrate. The partially calcined slurry is then dewatered. Then the filter cake is fed into a kettle to complete the calcination process by converting the calcium sulfate dihydrate of the filter cake material into beta calcium sulfate hemihydrate.

Owner:UNITED STATES GYPSUM CO

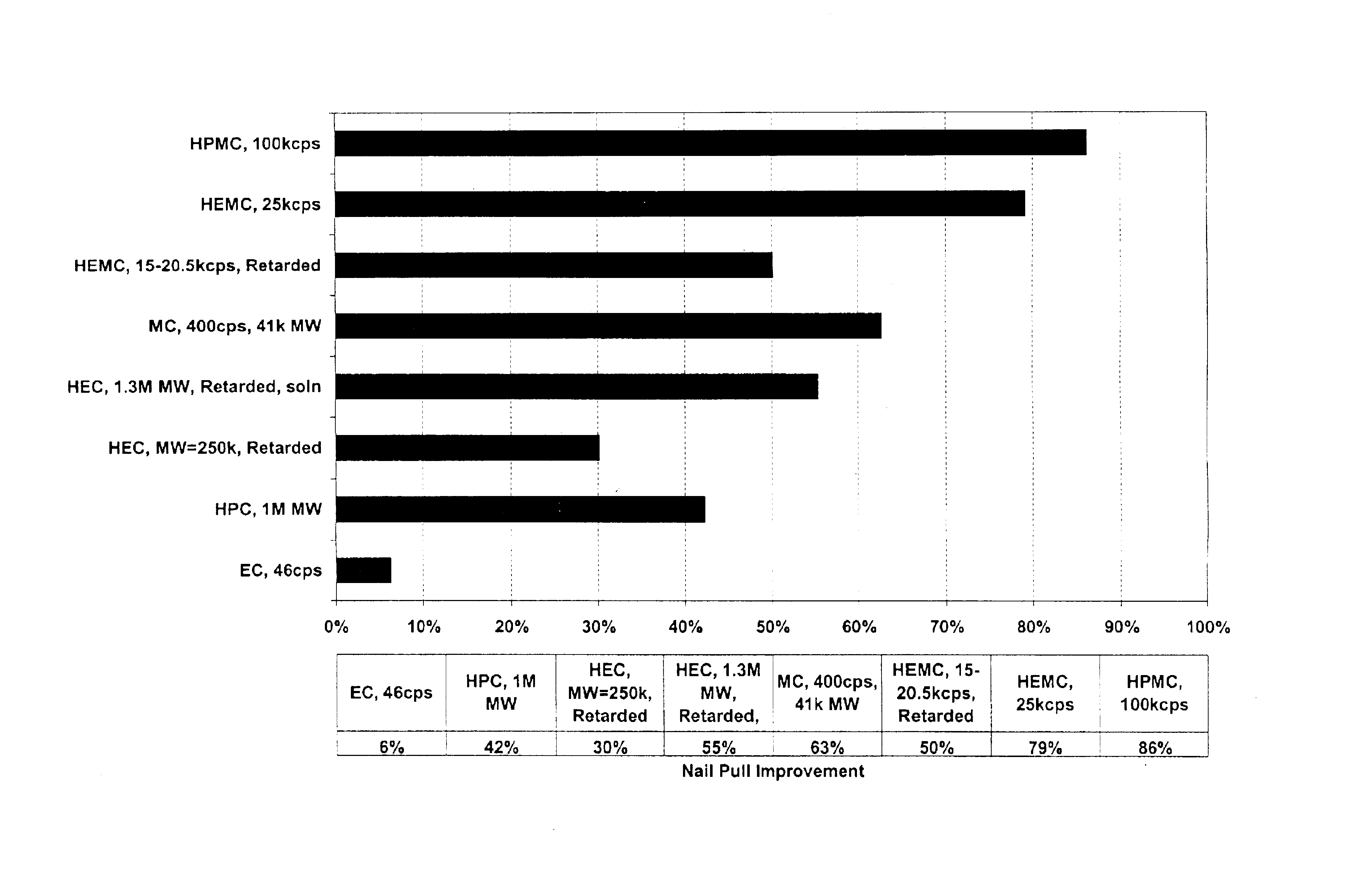

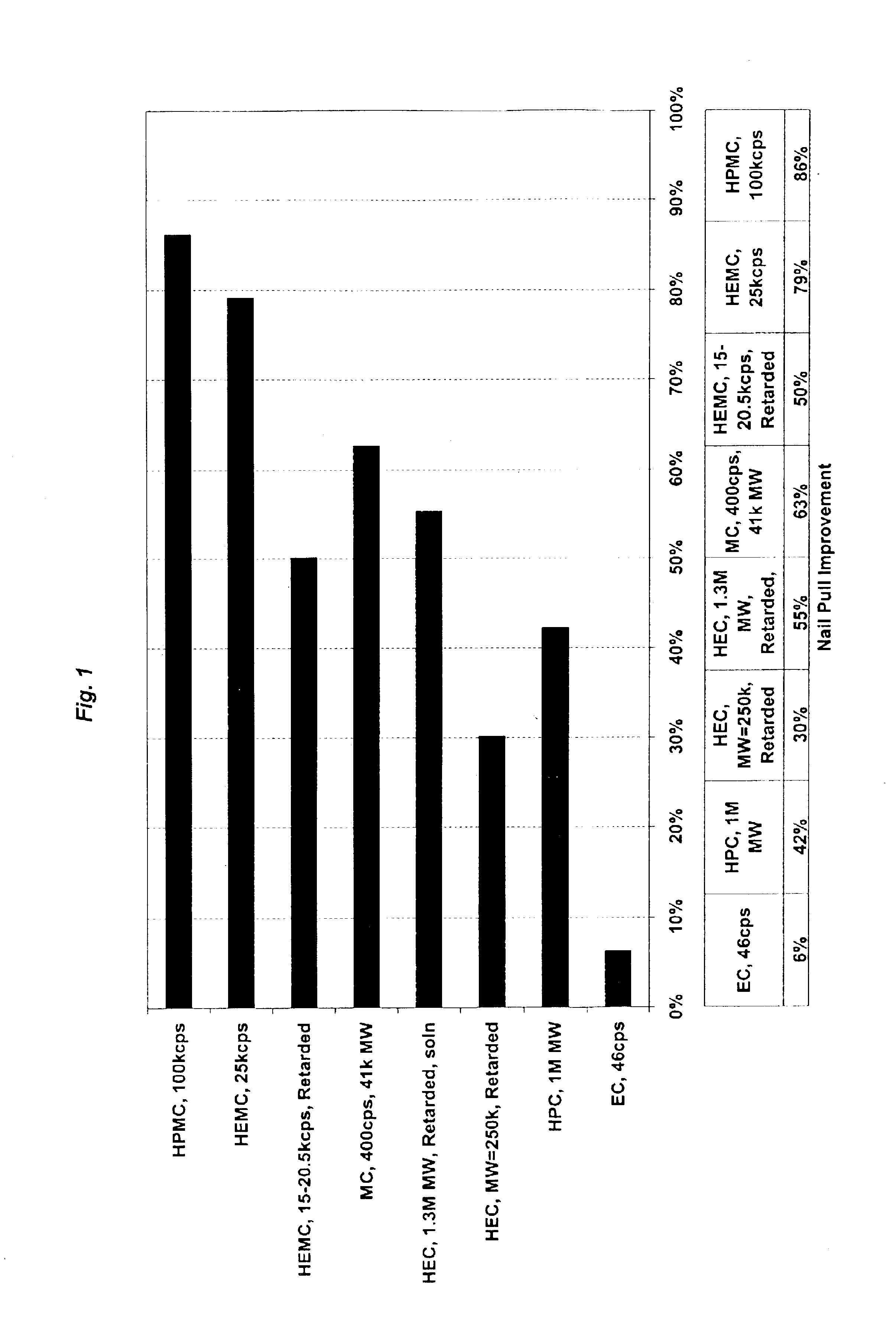

Reinforced wallboard

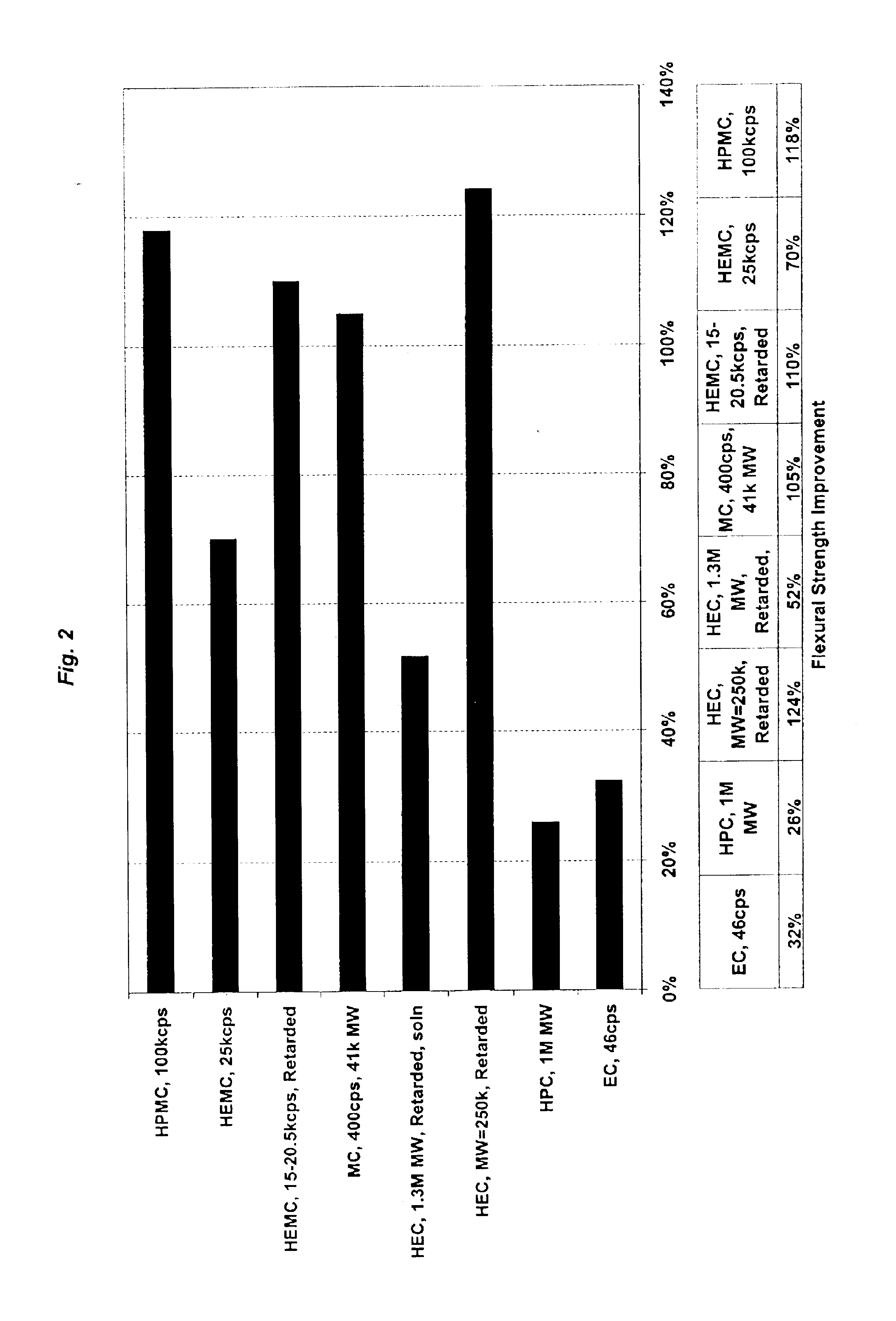

InactiveUS6841232B2Well mixedHigh viscosity gradeConstruction materialOther chemical processesCelluloseViscosity grade

A reinforced wallboard core is prepared from a slurry comprising a mixture of β-calcium sulfate hemihydrate, a cellulose ether additive other than CMC and an amount of water that is sufficient to form a slurry and resulting in a wallboard density of less than 0.8 g / cc. The β-calcium sulfate hemihydrate is hydrated by the water forming a wallboard core reinforced by the cellulose ether additive. The cellulose ether, having a molecular weight of at least about 20,000 and a viscosity grade of at least about 100 cps, is selected to give the reinforced wallboard core improved nail pull resistance and greater flexural strength than unreinforced wallboard of the same density. The reinforced wallboard core may be used for reduced-paper wallboard and / or for lightweight wallboard, for example.

Owner:SAINT GOBAIN PLACO SAS

Composite bone graft substitute cement and articles produced therefrom

ActiveUS7754246B2High mechanical strengthQuick changeAntibacterial agentsPeptide/protein ingredientsParticulatesTri calcium phosphate

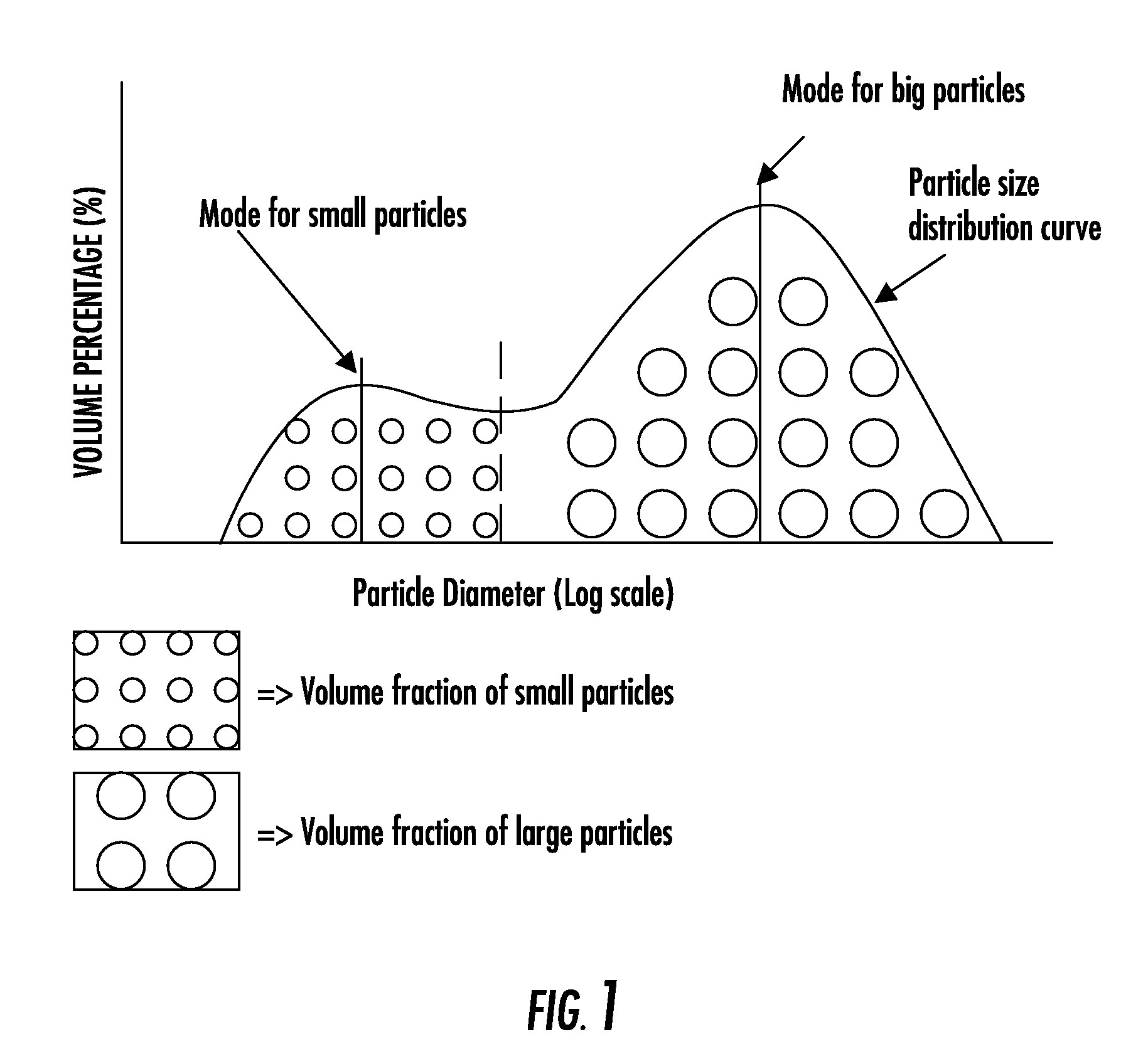

The invention provides a particulate composition adapted for forming a bone graft substitute cement upon mixing with an aqueous solution, including i) a calcium sulfate hemihydrate powder having a bimodal particle distribution and a median particle size of about 5 to about 20 microns, wherein the calcium sulfate hemihydrate is present at a concentration of at least about 70 weight percent based on the total weight of the particulate composition; ii) a monocalcium phosphate monohydrate powder; and iii) a β-tricalcium phosphate powder having a median particle size of less than about 20 microns. Bone graft substitute cements made therefrom, a bone graft substitute kit comprising the particulate composition, methods of making and using the particulate composition, and articles made from the bone graft substitute cement are also provided.

Owner:AGNOVOS HEALTHCARE

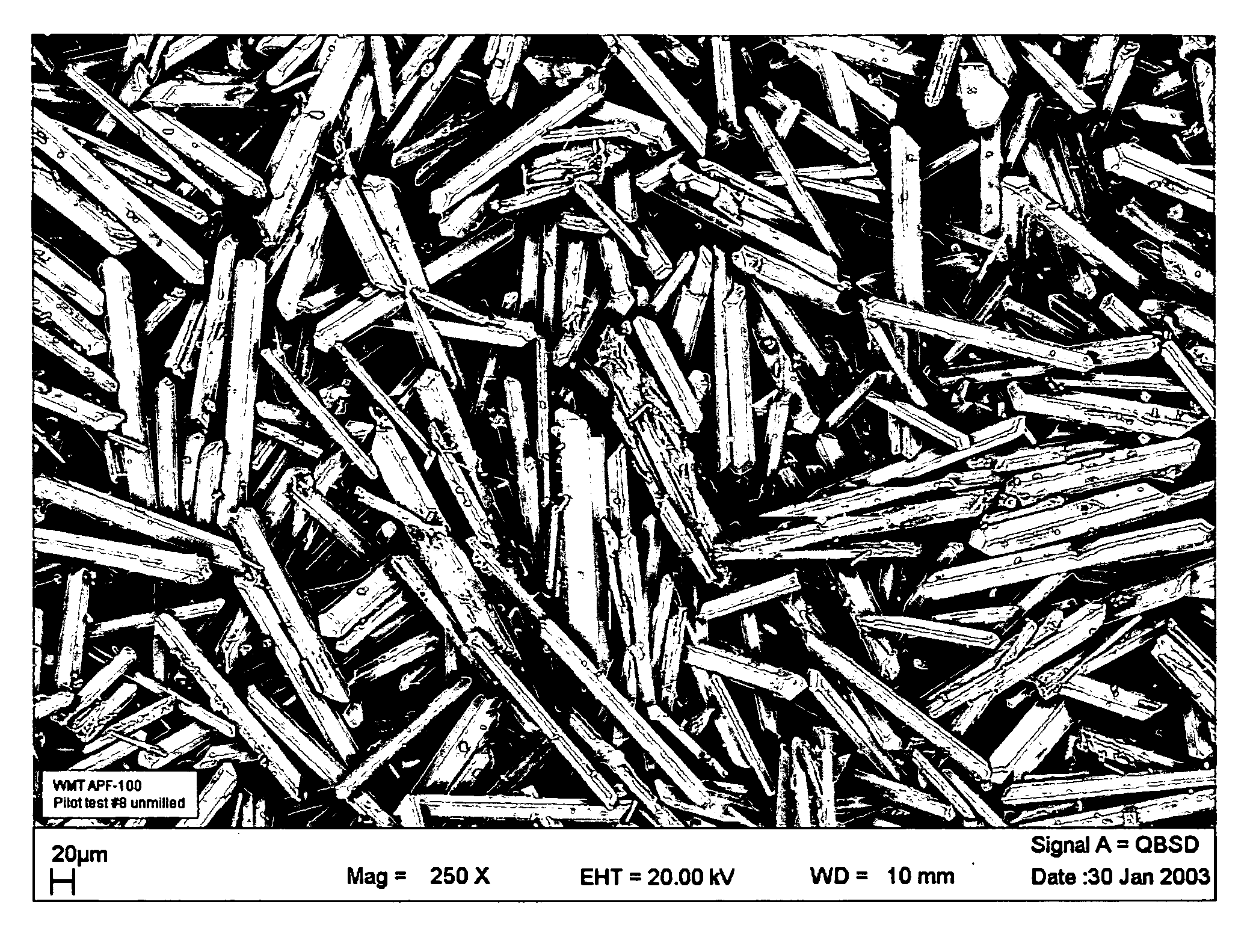

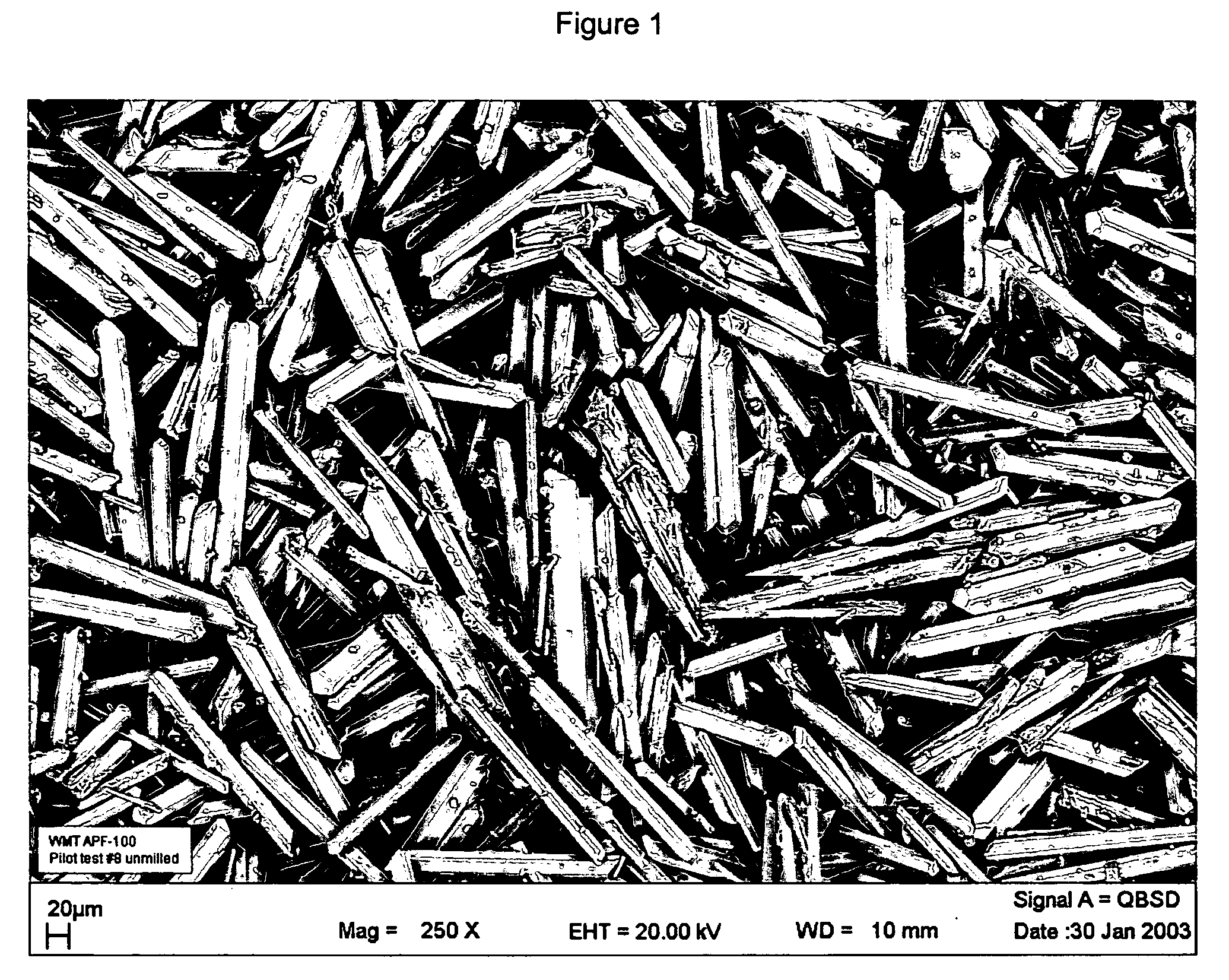

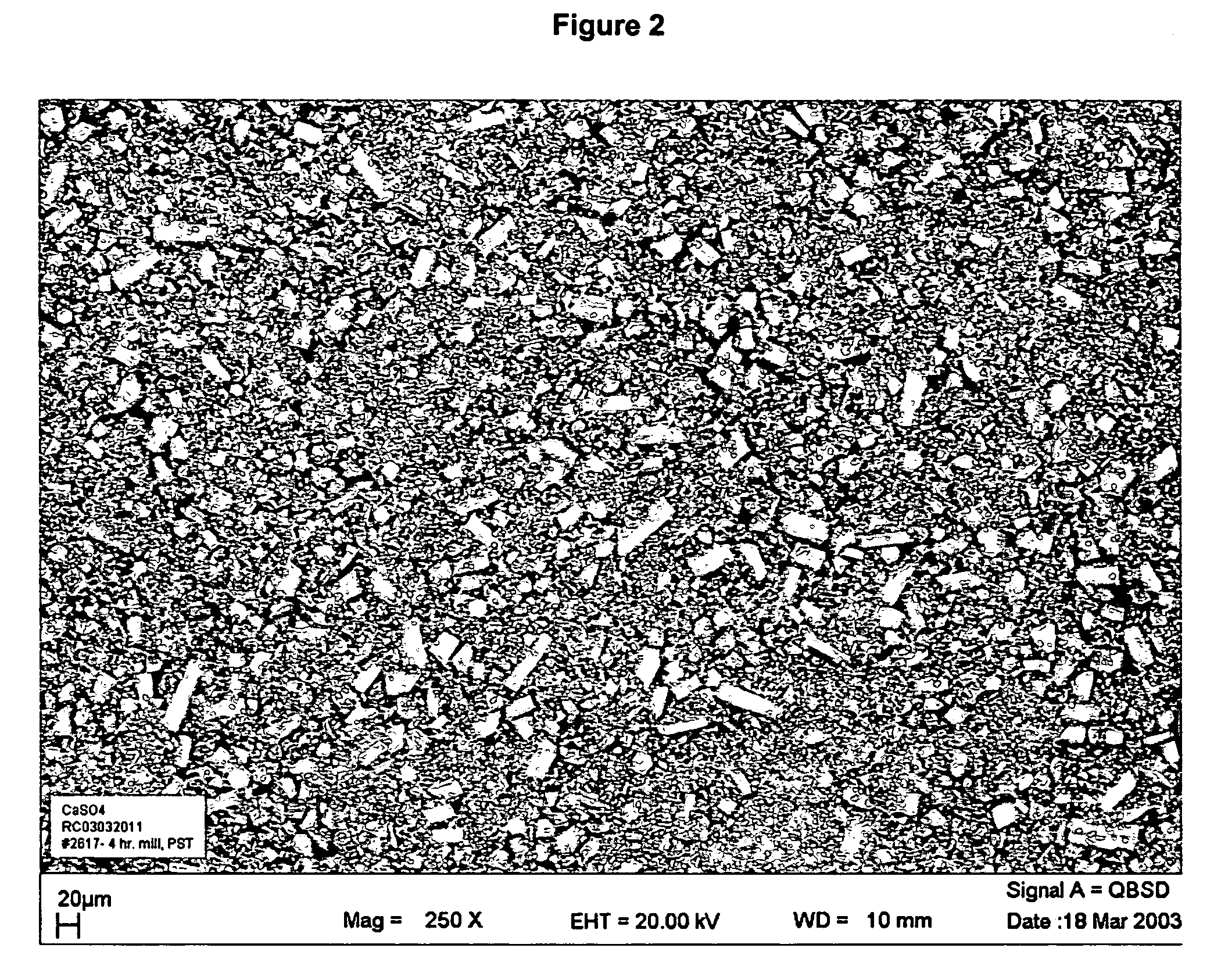

Calcium sulphate-based composition and methods of making same

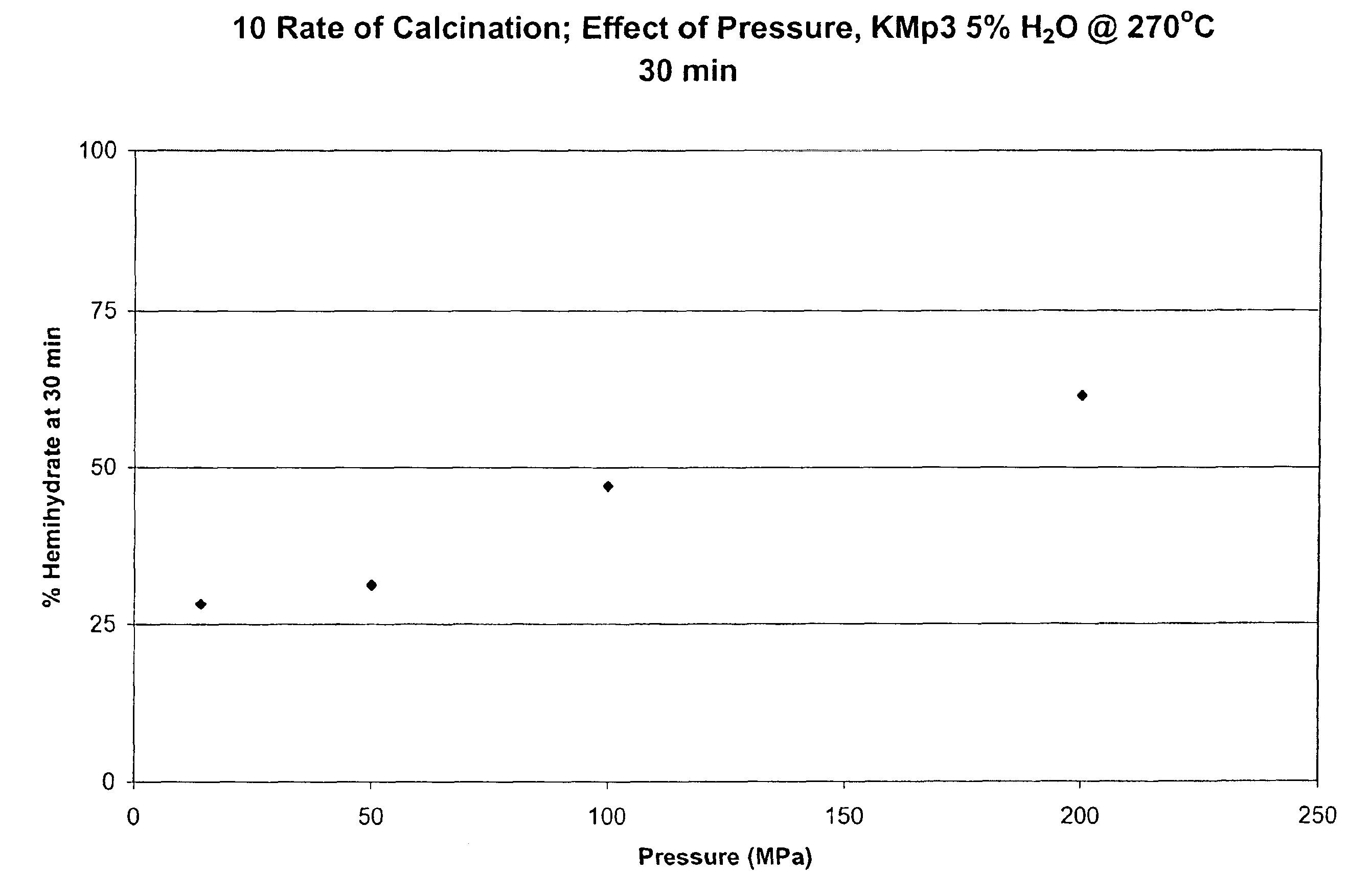

InactiveUS6964704B2Good crystal shapeSolid waste managementCalcium/strontium/barium sulfatesHigh pressureBriquette

Owner:G B TECH LLC

Compositions suitable for use as joint compounds and related methods

ActiveUS20080305252A1Formaldehyde freeAntifouling/underwater paintsLayered product treatmentJoint compoundCalcium Sulfate Dihydrate

The invention provides a composition useful as a joint compound comprising water, a filler comprising one or more of calcium carbonate, calcium sulfate dihydrate or calcium sulfate hemihydrate, a binder and / or a biocide, wherein the composition after curing is formaldehyde-free.

Owner:UNITED STATES GYPSUM CO

High strength flooring compositions

InactiveUS20050250888A1Antifouling/underwater paintsMixing operation control apparatusGreek letter betaSlurry

A composition is disclosed for a mixture to be used in conjunction with water for preparing a slurry that hydrates to form a high strength flooring compound. The mixture includes from about 50% to about 98% by weight calcium sulfate hemihydrate, having at least 25% of the calcium sulfate hemihydrate in the beta-calcined form. A polycarboxylate dispersant is included in the mixture in amounts from about 0.2% to about 10% by weight. The mixture also includes 0.05-50% by weight enhancing component. When combined with recommended amounts of water, a slurry is formed that is useful as a flooring composition.

Owner:UNITED STATES GYPSUM CO

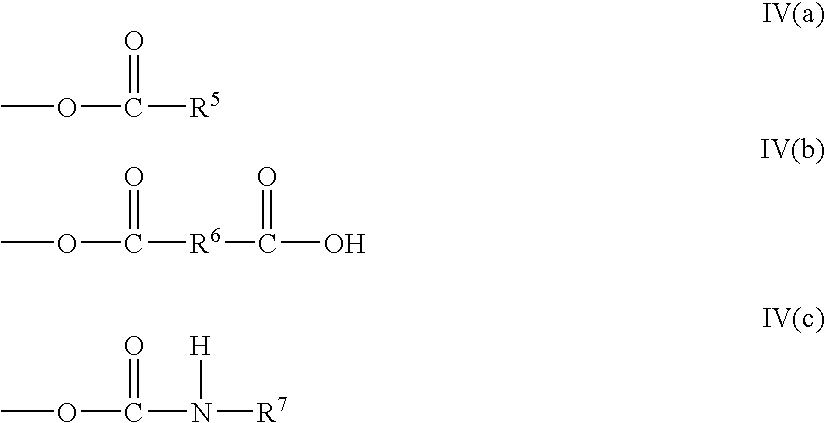

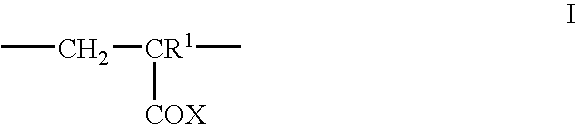

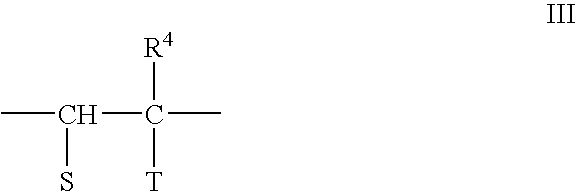

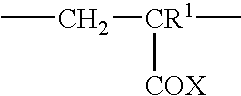

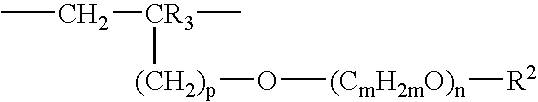

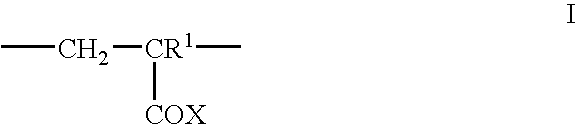

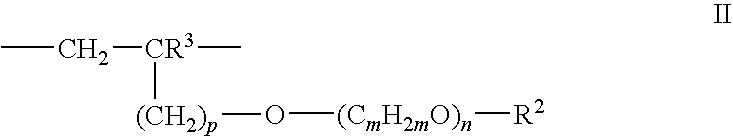

Fast drying gypsum products

A slurry is made including water, at least 50% by weight calcium sulfate hemihydrate, and a specific polycarboxylate dispersant prepared using at least three repeating units. A first repeating unit is a vinyl ether-type repeating unit. A second repeating unit includes a maleic acid-type repeating unit. A third repeating unit includes an acrylic acid-type repeating unit. The polymer dispersant has a molecular weight of from about 20,000 to about 80,000 Daltons. The slurry made from this composition can be made at reduced water levels to speed drying and reduce drying costs.

Owner:UNITED STATES GYPSUM CO

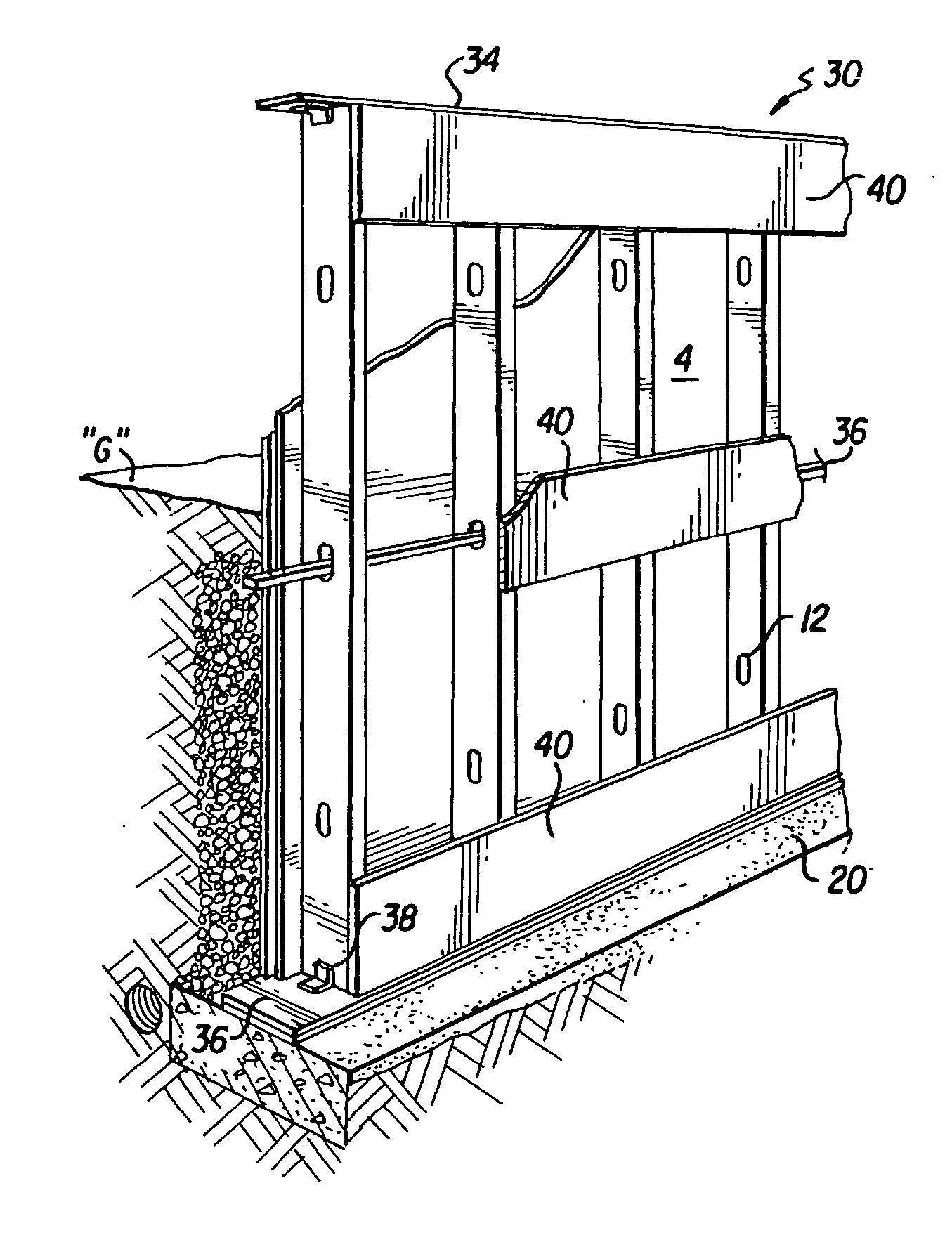

Non-combustible reinforced cementitious lightweight panels and metal frame system for building foundations

ActiveUS20070294974A1Alleviate bearing capacityStiffen and strengthen and toughen panelSolid waste managementWallsMicrosphereCement board

A foundation system includes metal framing members that support a reinforced, lightweight, dimensionally stable cementitious panel. The foundation system is non-combustible, water durable, mold and rot resistant, and termite resistant. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

Preparation method of calcium sulfate hemihydrate crystal whiskers high in length diameter ratio

InactiveCN102677177AMorphological rulesUniform particle sizePolycrystalline material growthFrom normal temperature solutionsHemihydrate Calcium SulfatePhysical chemistry

The invention discloses a preparation method of calcium sulfate hemihydrate crystal whiskers high in length diameter ratio. The method includes firstly subjecting soluble inorganic calcium salt and inorganic sulfate to coprecipitation at the temperature of 10-90 DEG C, activating for 1-6 hours at the temperature of 40-150 DEG C to obtain a precursor after filtering and washing, adding the precursor into a hydrothermal medium with crystal form control agent for hydrothermal treatment for 2-10 hours at the temperature of 80-180 DEG C, washing, filtering and drying hydrothermal products, and then obtaining calcium sulfate hemihydrate crystal whiskers in the diameter of 0.1-4 micrometers, the length of 20-3000 micrometers and the length diameter ratio of 50-1000, uniform in shape and identical in size. The preparation method is simple, mild in conditions and low in cost of materials which are easy to obtain, and is easy to industrially popularize. The main content of the calcium sulfate hemihydrate crystal whiskers prepared by the preparation method is larger than 98%, and the calcium sulfate hemihydrate crystal whiskers are uniform in shape and diameter and high in additional value and can be expectedly used as high-performance reinforcing materials for the industries of ceramics, plastics, rubber and paper making and the like.

Owner:KUNMING UNIV OF SCI & TECH

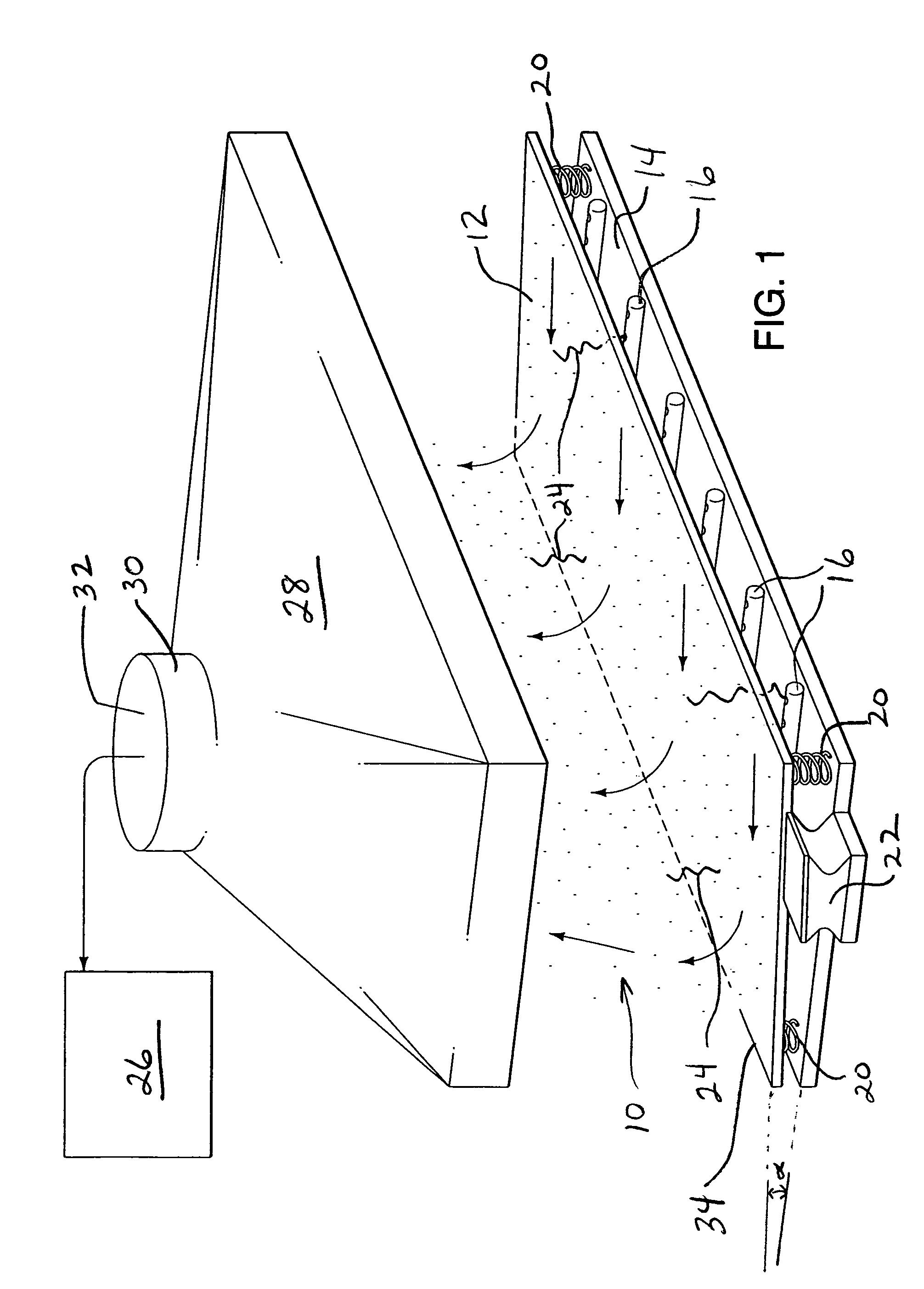

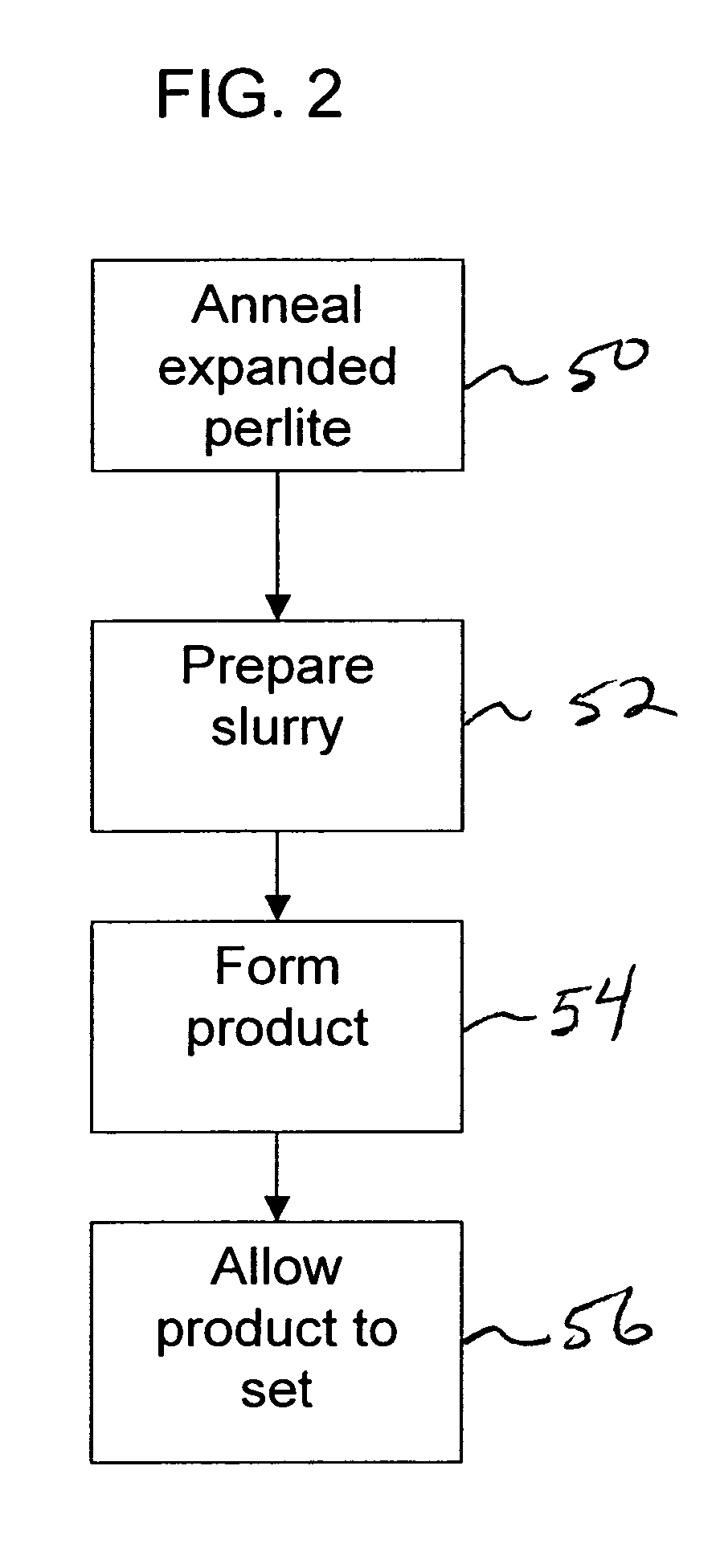

Expanded perlite annealing process

InactiveUS7381261B1Reduce its water intakeReduce weightNon-fibrous pulp additionNatural cellulose pulp/paperCombustorSlurry

This invention is directed to a method of reducing the water demand of expanded perlite that includes obtaining a vibrating screen supported at an angle and placing expanded perlite on the vibrating screen. The expanded perlite is moved over the screen past toward a burner at a rate that heats the expanded perlite to a temperature sufficient to anneal it. The expanded perlite is then moved away from the burner and allowed to cool. Another embodiment of this invention is directed to a method of making a gypsum product. The method includes annealing perlite by the method described above, then preparing a slurry of calcium sulfate hemihydrate, additives, water and the annealed perlite. The slurry is formed into the shape of the gypsum product and allowed to set. This process is particularly useful in making gypsum panels and acoustical panels that benefit from the use of lightweight materials.

Owner:UNITED STATES GYPSUM CO

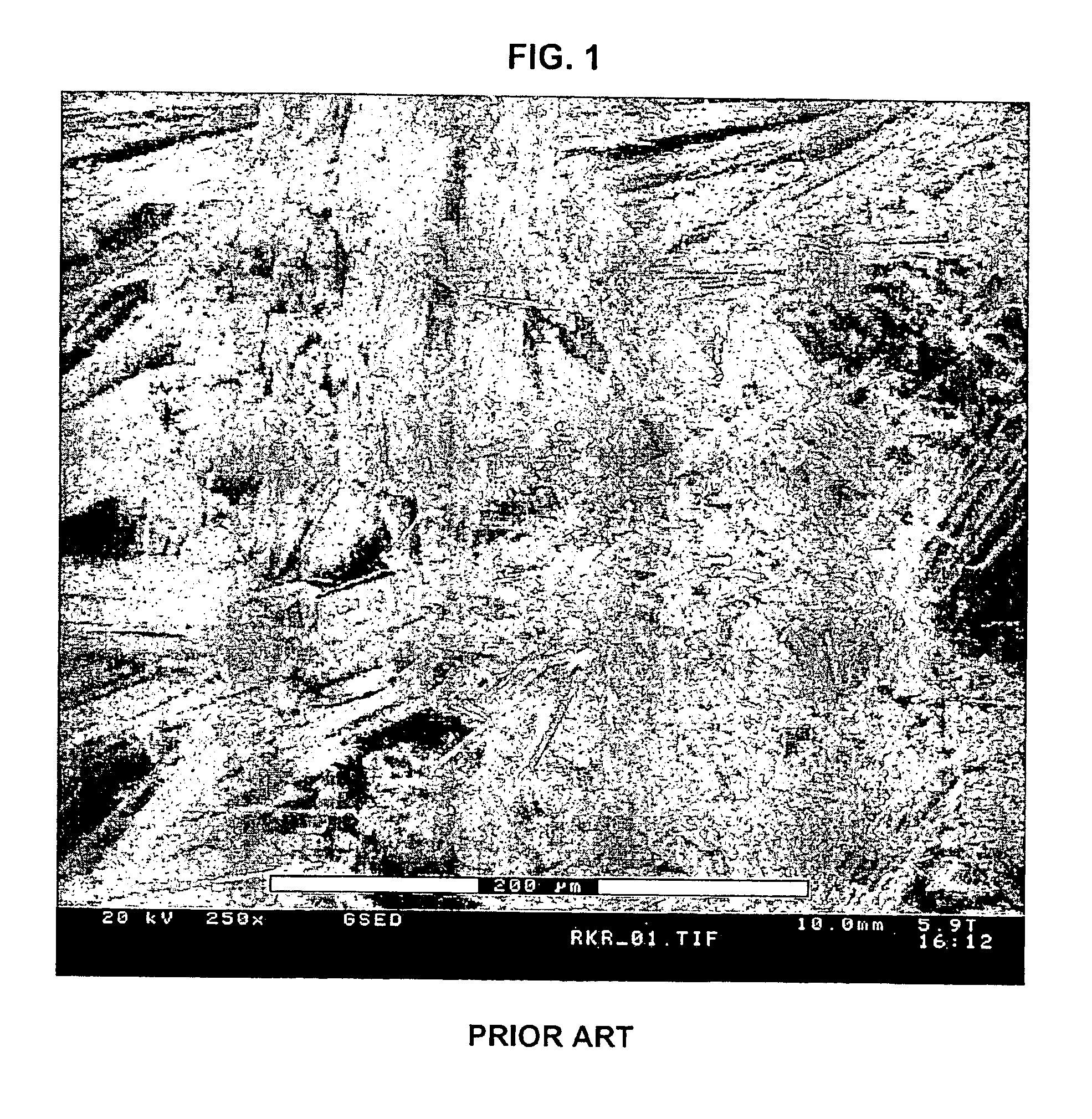

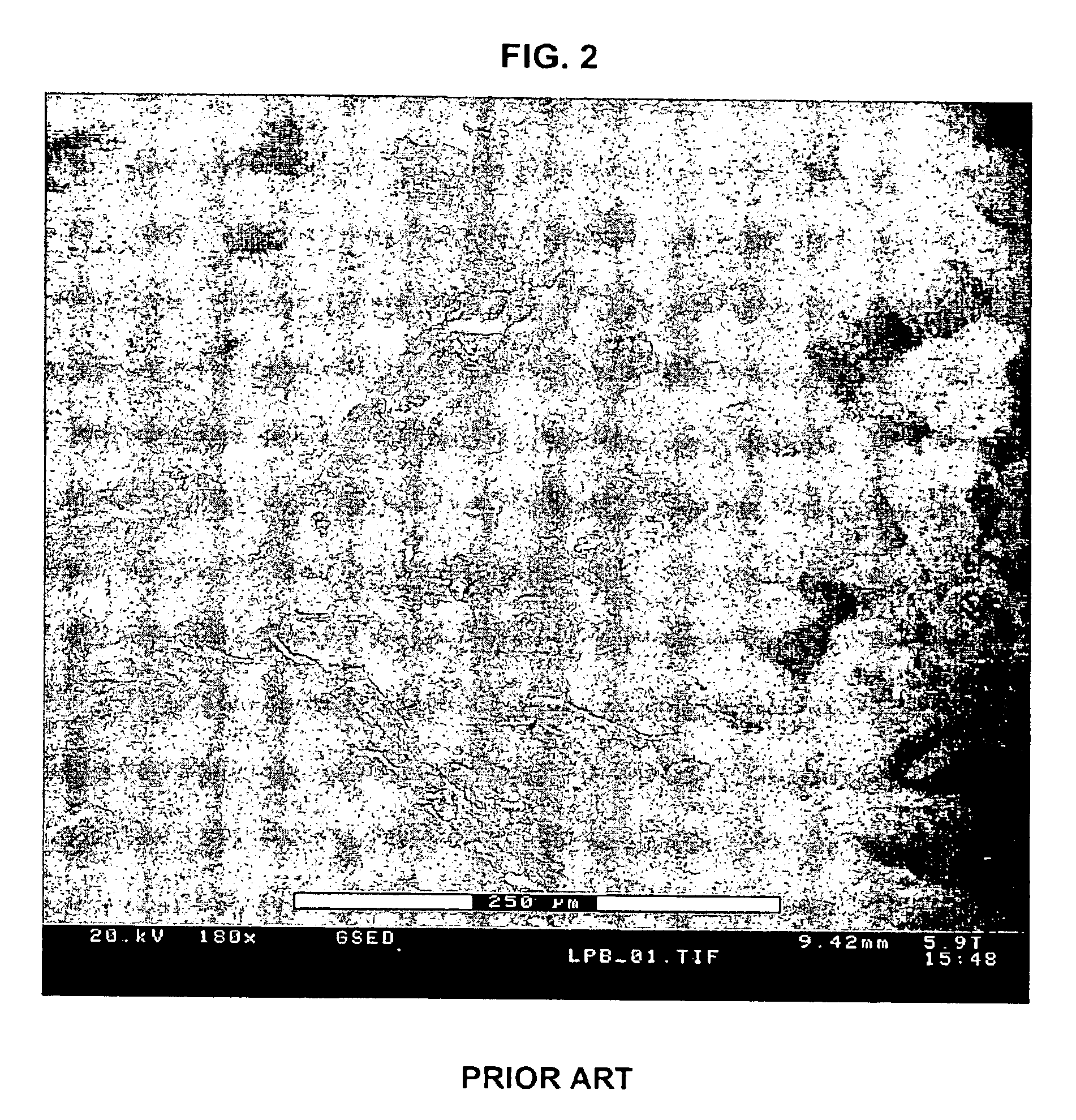

Fiberboard with improved water resistance

ActiveUS20070056478A1High strengthImprove waterproof performanceSolid waste managementWood working apparatusSlurryWater resistant

Articles, including fiberboard, are made from a pumpable, flowable slurry including alpha-calcined calcium sulfate hemihydrate anchored in pores of host particles, alpha-calcined calcium sulfate hemihydrate, a silicone compound, magnesium oxide, and water. The magnesium oxide catalyzes the reaction of the silicone compound into a silicone resin. In a preferred method of making a water resistant fiberboard calcium sulfate dihydrate is combined with the host particles and water to form a slurry which is heated under pressure to calcine the calcium sulfate dihydrate to form alpha-calcined calcium sulfate hemihydrate. After relieving the pressure, a silicone compound and magnesium oxide are added to the slurry. The slurry is dewatered to form a filter cake, which is then formed into a desired shape and allowed to set.

Owner:UNITED STATES GYPSUM CO

High strength flooring compositions

InactiveUS20060280970A1Improve the problemUse of compositionWater-setting substance layered productSlurryHigh intensity

A composition is disclosed for a mixture to be used in conjunction with water for preparing a slurry that hydrates to form a high strength flooring compound. The mixture includes from about 50% to about 98% by weight calcium sulfate hemihydrate. A three repeating unit polycarboxylate dispersant is included in the mixture in amounts from about 0.2% to about 10% by weight. The repeating units include a polyether repeating unit, an acrylic acid-type repeating unit and a maleic acid-type repeating unit. A modifier that enhances the efficacy of the dispersant is also a component of the mixture. When combined with recommended amounts of water, a slurry is formed that is useful as a flooring composition.

Owner:UNITED STATES GYPSUM CO

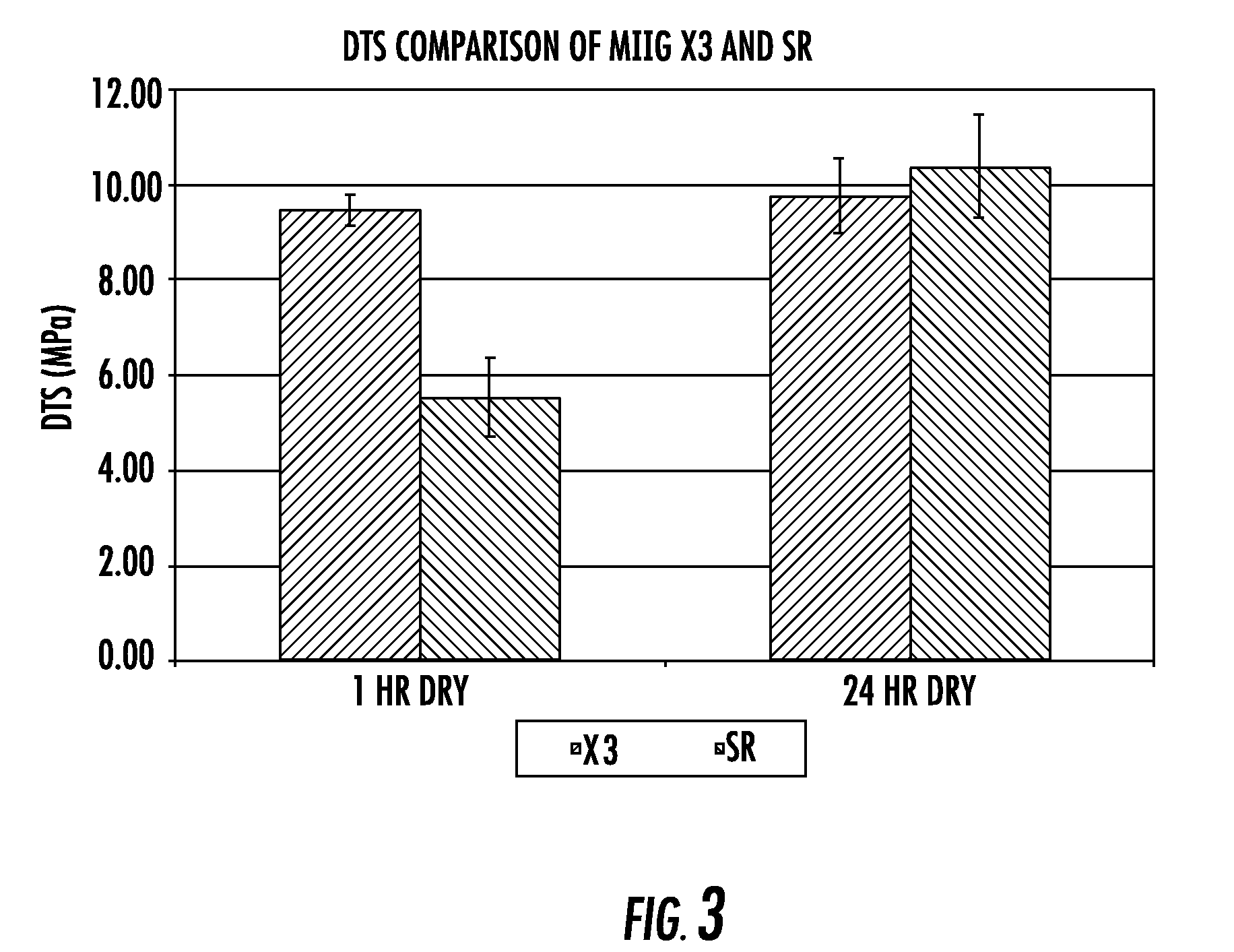

Injectable resorbable bone graft material, powder for forming same and methods relating thereto for treating bone defects

An injectable resorbable bone graft material, and methods of using the same, provide increased compressive strength after injection in a bone defect. The bone graft material is made from calcium sulfate hemihydrate having a thick stubby rod-like crystalline structure and low water-carrying capacity.

Owner:WRIGHT MEDICAL TECH

Pottery plaster formulations for the manufacture of plaster molds

InactiveUS6398864B1Efficient processImprove water absorptionCeramic shaping apparatusPotassium sodium tartratePotassium sulfate

A plaster composition for making molds for reproduction by casting is disclosed. Calcium sulfate hemihydrate, potassium sulfate and potassium sodium tartrate are mixed together. The potassium sulfate and potassium sodium tartrate are in a ratio of from about 1:1 to about 10:1. Potassium sodium tartrate is present in an amount of from about 1 to about 10 pounds per ton of dry calcium sulfate hemihydrate, and the total of the potassium sulfate and potassium sodium tartrate is from about 2 to about 35 pounds per ton of calcium sulfate hemihydrate. Methods of making and using molds of this composition are also disclosed.

Owner:UNITED STATES GYPSUM CO

Method for preparing calcium sulfate crystal whisker in low cost

InactiveCN102965721AIncrease profitReduce manufacturing costPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfateHigh pressure

The invention discloses a method for preparing calcium sulfate crystal whisker in low cost and relates to a method for preparing the calcium sulfate crystal whisker. The method comprises the following steps of: crushing raw materials consisting of ground limestone and anhydrite, treating the crushed ground limestone and anhydrite by a sulfuric acid solution, adding a crystal growth substance to prepare a mixture solution, preparing calcium sulfate hemihydrate crystal whisker with higher length-diameter ratio by a hydrothermal synthesis method at high temperature under high pressure, and carrying out filtering, washing and high-temperature crystal water removing steps on the calcium sulfate hemihydrate crystal whisker to obtain high-quality anhydrous calcium sulfate crystal whisker products. The calcium sulfate crystal whisker prepared by the method disclosed by the invention can be applied to high polymer material such as plastic and rubber to improve the performances of polymer materials by serving as a reinforcing material. The method disclosed by the invention has the advantages of low production cost, simple operation and high additional value of products.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Hydraulic cement compositions and method of forming floor underlayment

InactiveUS20080057206A1Good synergySufficient early strengthLiquid surface applicatorsSolid waste managementSlagPortland cement

The present invention provides a floor underlayment cement composition comprising at least about 95% by weight, based on the weight of the composition, of a hydraulic cementitious mixture and at least about 0.03% by weight, based on the weight of the composition, of a superplasticizer. The hydraulic cementitious mixture includes in the range of from about 35% to about 65% by weight, based on the weight of the mixture, of ground, granulated blast furnace slag, and in the range of from about 35% to about 65% by weight, based on the weight of the mixture, of a gypsum component selected from the group consisting of alpha-calcium sulfate hemihydrate, beta-calcium sulfate hemihydrate and mixtures thereof. It is not necessary to include Portland cement or aluminous cement in the hydraulic cementitious mixture. A floor underlayment slurry and a method of forming a high strength floor underlayment on a floor substrate are also provided.

Owner:HARRISON GYPSUM

Production method of high-reinforcement modified anhydrous calcium sulfate crystal whiskers

InactiveCN102534773ASimple processThorough responsePolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfateCalcium EDTA

The invention discloses a preparation method of high-reinforcement modified anhydrous calcium sulfate crystal whiskers. The method comprises the following steps that: firstly, limestone powder is added into stirred water to be prepared into calcium salt aqueous emulsion; then, sulfuric acid and crystal modifiers are sequentially added into the stirred water to be prepared into sulfuric acid water solution; next, the calcium salt aqueous emulsion containing 1 mol part of Ca<2+> is added into the sulfuric acid water solution containing 2 mol parts of SO4<2-> with the temperature reaching 100 to 110 DEG C, then, morphology control agents are added, the materials are subjected to stirring and aging for 2 to 3.5 hours under the temperature condition being 110 to 120 DEG C, leaching and washing are carried out, and calcium sulfate hemihydrate crystal whisker wet products are obtained; the calcination drying finally is carried out under the temperature condition higher than 200 DEG C to obtain the anhydrous calcium sulfate crystal whiskers; and then, the surface modification treatment is carried out to finally obtain the high-reinforcement modified anhydrous calcium sulfate crystal whiskers. The preparation method has the advantages that the product quality is high, the cost is low, the preparation process is short, the reaction condition is mild, and in addition, green and environmental-friendly effects can be realized.

Owner:四川万润非金属矿物材料有限公司

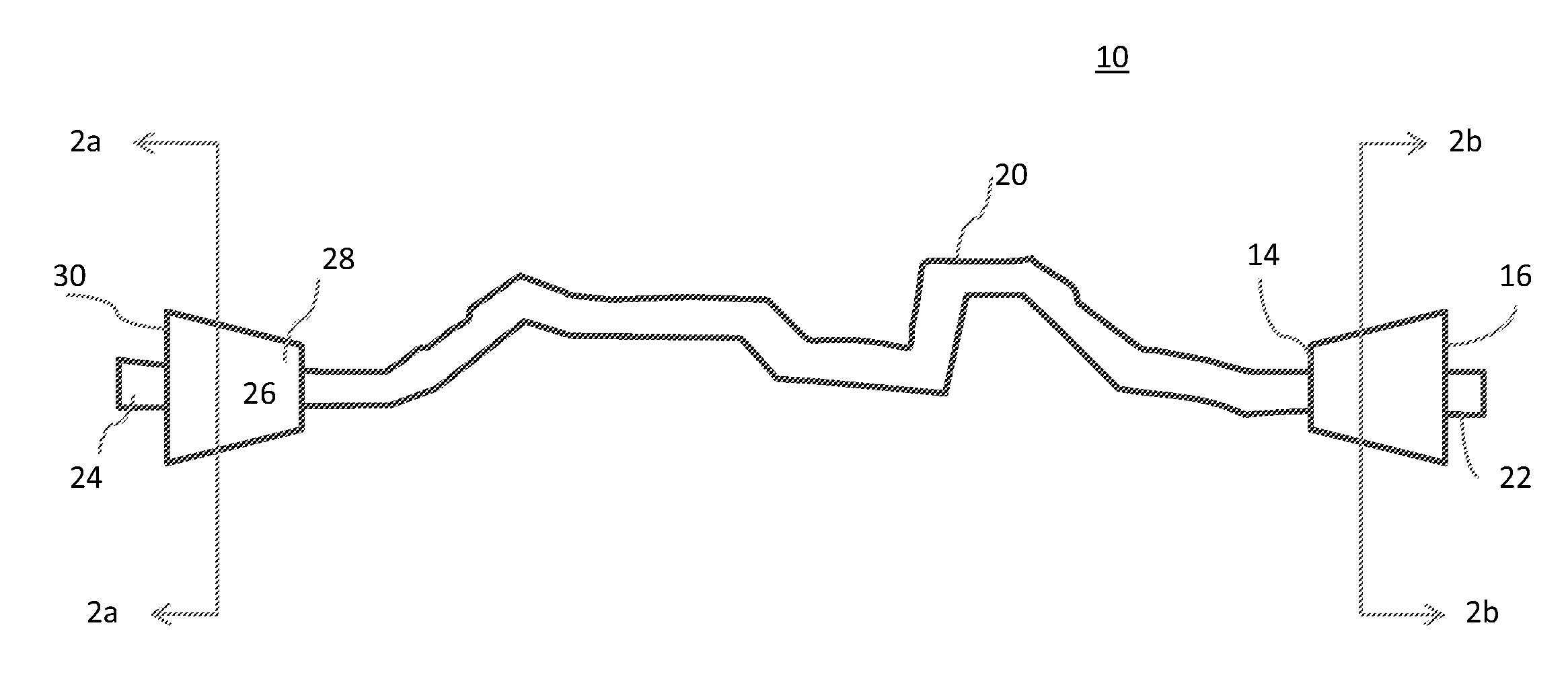

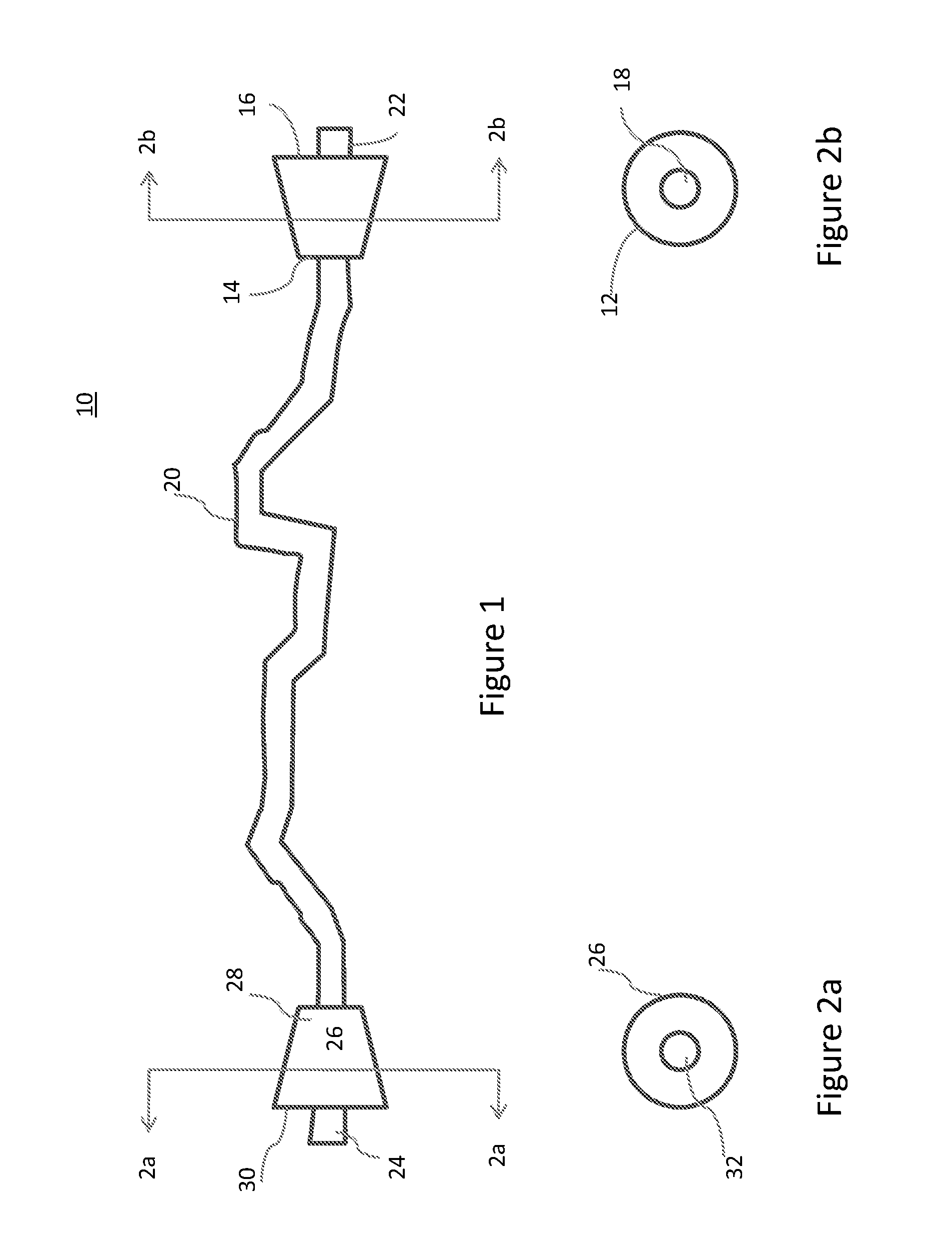

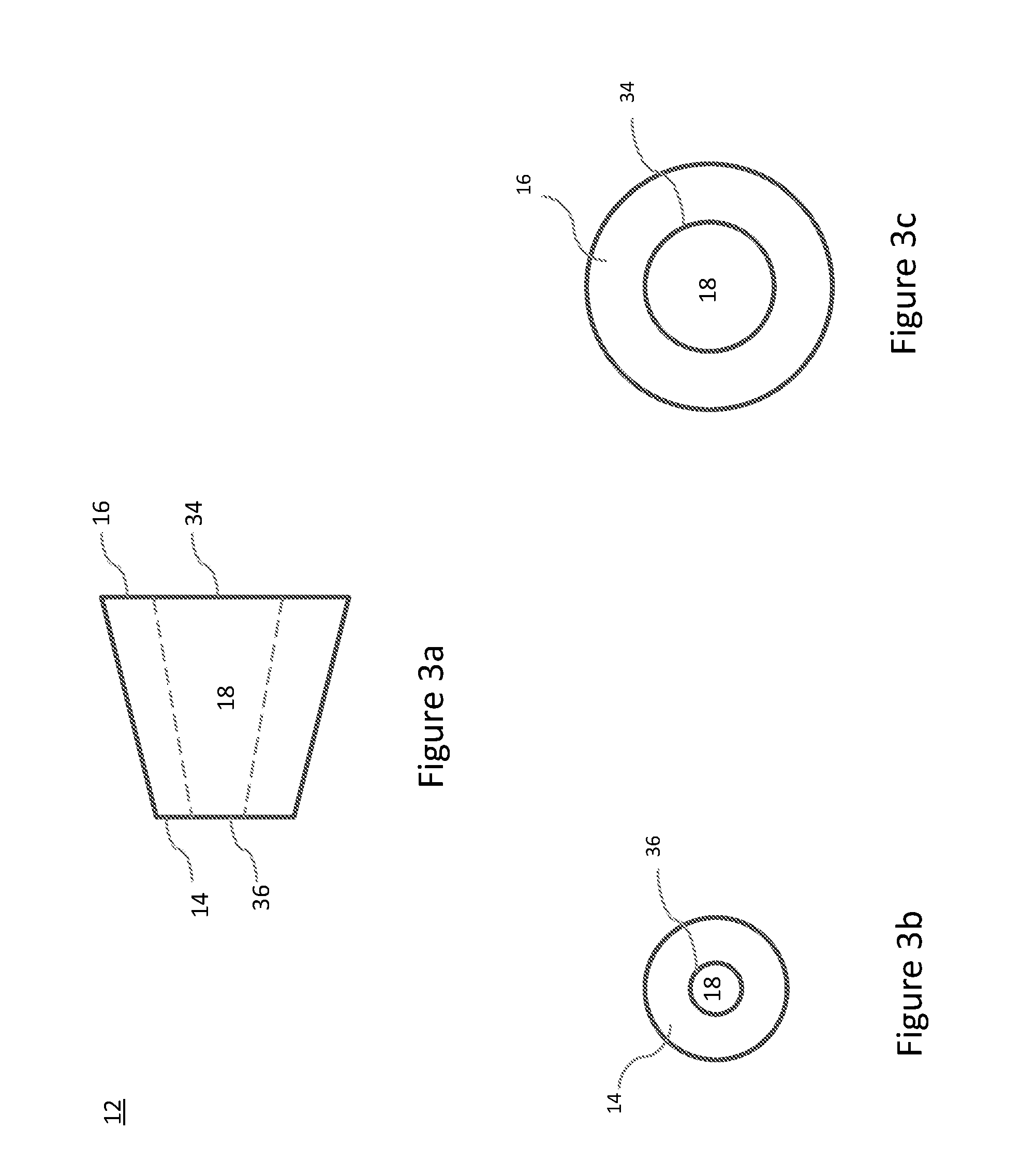

Composite bone grafts, particulate bone-calcium sulfate constructs, and methods of treating joint injuries

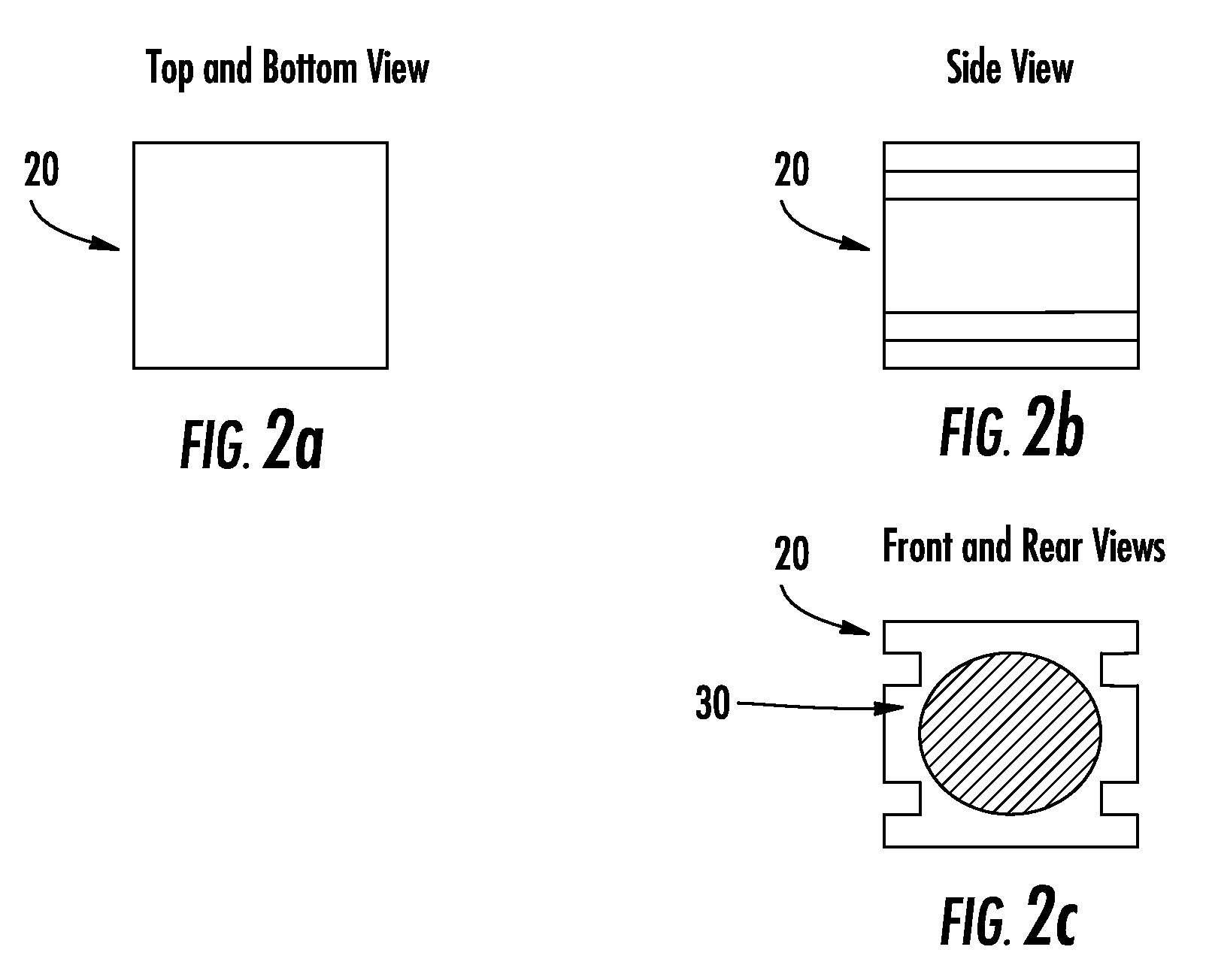

InactiveUS20110208305A1Easy to handleEliminate needBone implantLigamentsSolid componentCalcium phosphate product

A solid implantable bone construct (12) shaped like a cylinder, a cone, or a frustum, for anchoring ligament implants. The bone construct (12) can include a bone component and a biocompatible solid component. The bone component can include particulate bone of between 75 and 600 microns, powdered bone of 75 microns or smaller in size, or both. The biocompatible solid component can include calcium sulfate hemihydrate, a calcium phosphate product, or both. The bone component can be between 5 and 50 wt-% of the construct (12) and the biocompatible solid component can be at least 50 wt-% of the construct (12). Also disclosed is a composite graft (10) comprising a first bone dowel (12) and a ligament (20) and a method of securing one bone to another using the composite graft (10).

Owner:VIVEX BIOLOGICS GRP INC

Gypsum compositions with naphthalene sulfonate and modifiers

An improved gypsum slurry that includes water, calcium sulfate hemihydrate, a naphthalene sulfonate dispersant and a modifier. The modifier is chemically configured to improve the efficacy of the naphthalene sulfonate dispersant. Preferred modifiers include cement, lime, slaked lime, soda ash, carbonates, silicates and phosphates.

Owner:UNITED STATES GYPSUM CO

Fast drying gypsum products

Owner:UNITED STATES GYPSUM CO

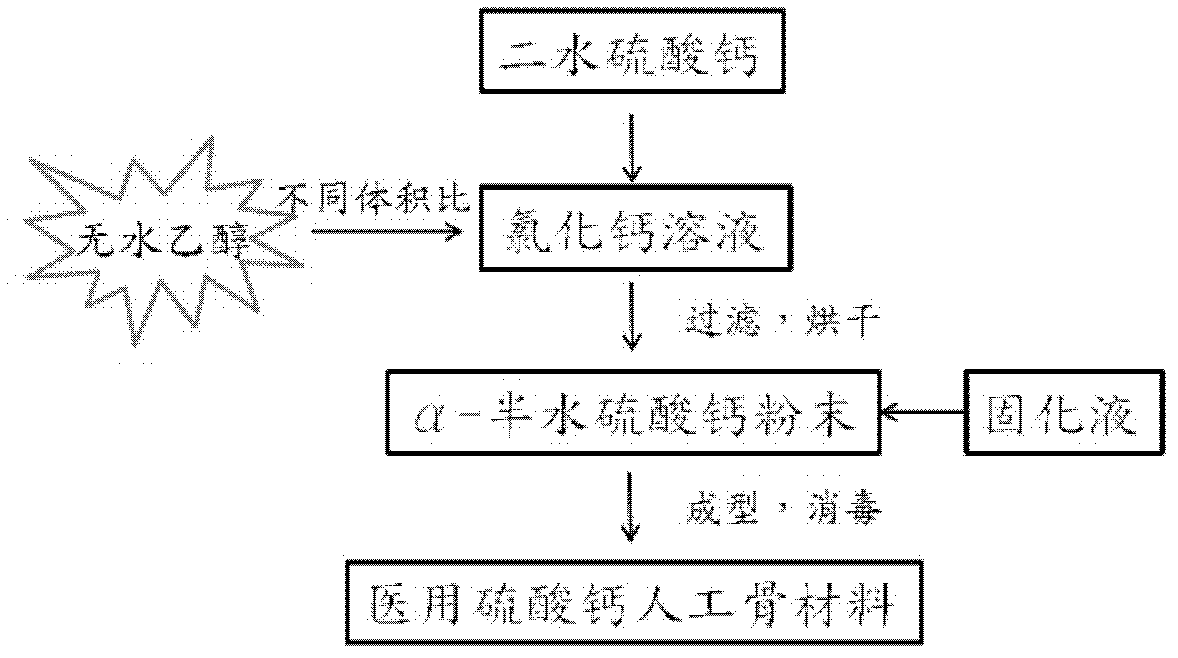

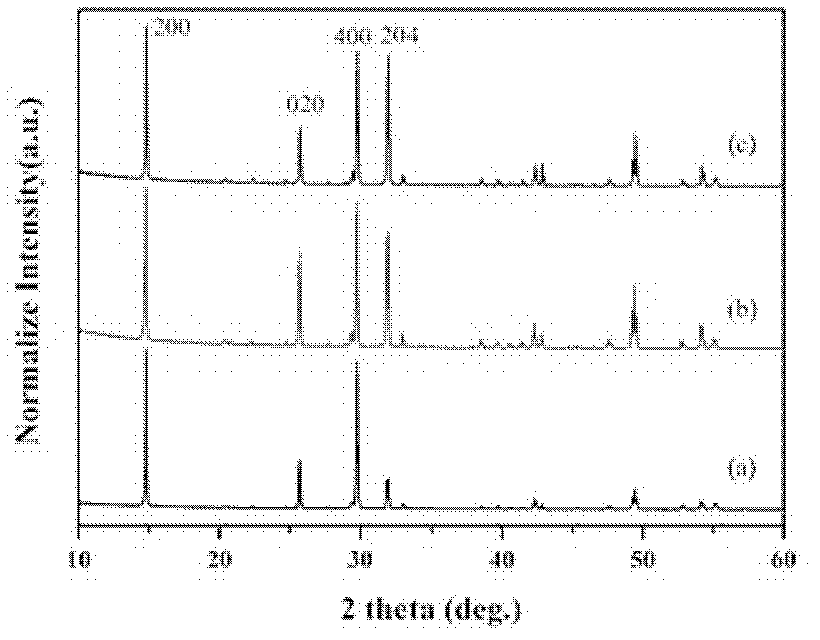

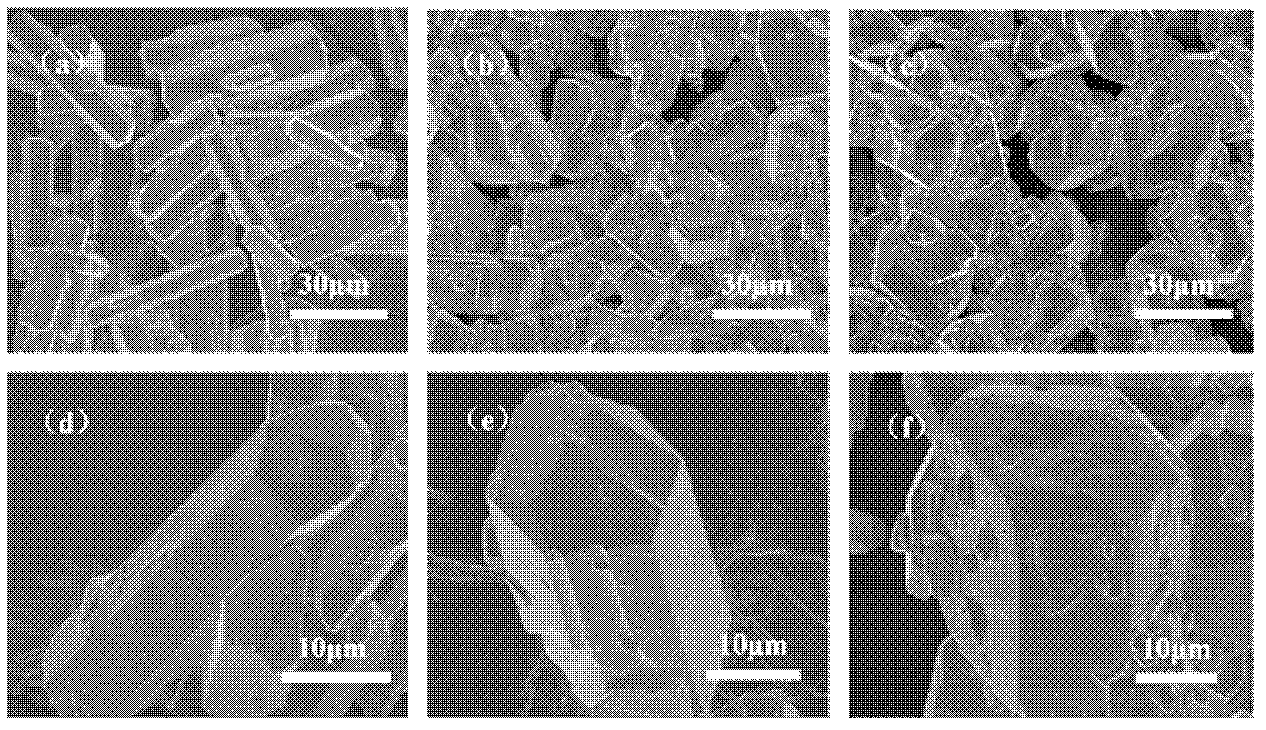

Preparation methods of medical alpha-calcium sulfate hemihydrate powder and calcium sulfate artificial bone material

ActiveCN102633287AImprove grain morphologySmall sizeCalcium/strontium/barium sulfatesProsthesisArtificial boneParticle-size distribution

The invention discloses preparation methods of medical alpha-calcium sulfate hemihydrate powder and a calcium sulfate artificial bone material, belonging to the field of medical biomaterials. According to the invention, alpha-calcium sulfate hemihydrate is prepared by adding anhydrous alcohol to a reactant liquid containing calcium chloride, a crystal modifier and distilled water, wherein the volume ratio of the anhydrous alcohol to the distilled water is 0.01-2, so that the crystal water of calcium sulfate dihydrate is partially removed in the reactant liquid. Due to the modification effect of the anhydrous alcohol, the grain morphology and size of the alpha-calcium sulfate hemihydrate powder are effectively improved, and isometric or approximately isometric alpha-calcium sulfate hemihydrate powder with high purity and uniform crystal structure and particle size distribution is obtained. A medical calcium sulfate artificial bone material prepared by mixing and curing the alpha-calcium sulfate hemihydrate powder with a curing liquid can effectively improve the compressive strength, prolong the degradation time and improve the biological performance, so that the medical calcium sulfate artificial bone material has high performance and good application prospects in the technical fields of medical bone transplantation and bone repair.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method of making a low-dust building panel

InactiveUS20080308968A1Cleaner workplaceQuantity minimizationWood working apparatusFlat articlesWaxRoom temperature

A dust-reducing building panel is made by selecting a dedusting agent that is a solid at room temperature but that melts to form composite particles by at least one of agglomerating and surface adsorption of fines under conditions selected from the group consisting of cutting, abrading or sanding. The dedusting agent is used to make a slurry including water and a hydraulic material selected from the group consisting of calcium sulfate hemihydrate and cement. After the slurry is made, it is deposited onto a facing material and formed into a panel. The building panel is then allowed to set. Some embodiments of the building utilize a dedusting agent that includes natural or synthetic waxes.

Owner:UNITED STATES GYPSUM CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com