Method for producing dehydrated calcium sulfate whisker

A technology of calcium sulfate whisker and calcium sulfate dihydrate, which is applied to the preparation of dehydrated calcium sulfate whiskers and the field of preparing calcium sulfate whiskers at the same time, can solve the problem of calcium nitrate or calcium chloride waste water, increase leakage and pollute the environment, and increase transportation costs. and other problems to achieve the effect of reducing production costs, reducing reunion, and reducing electroplating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

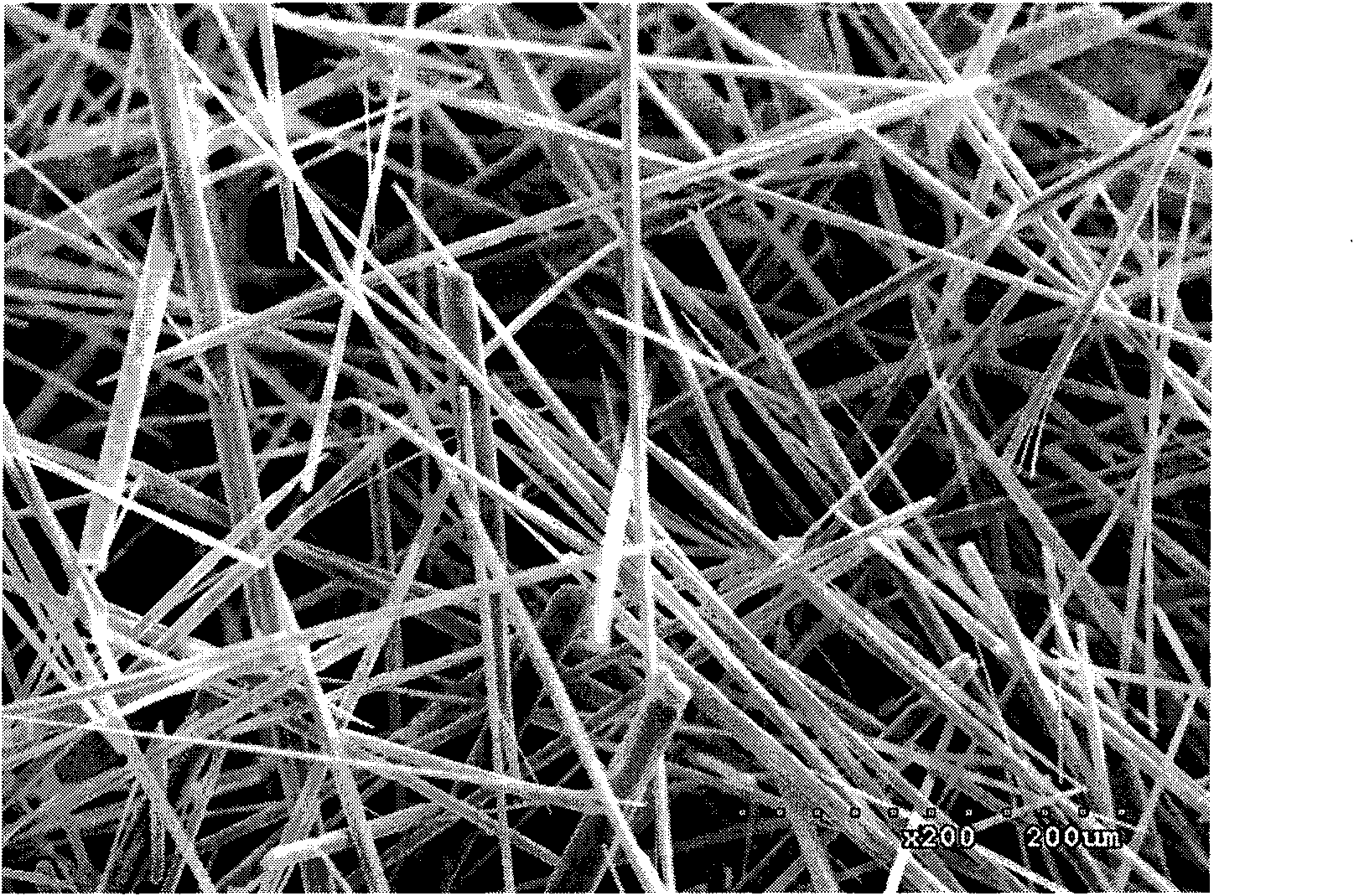

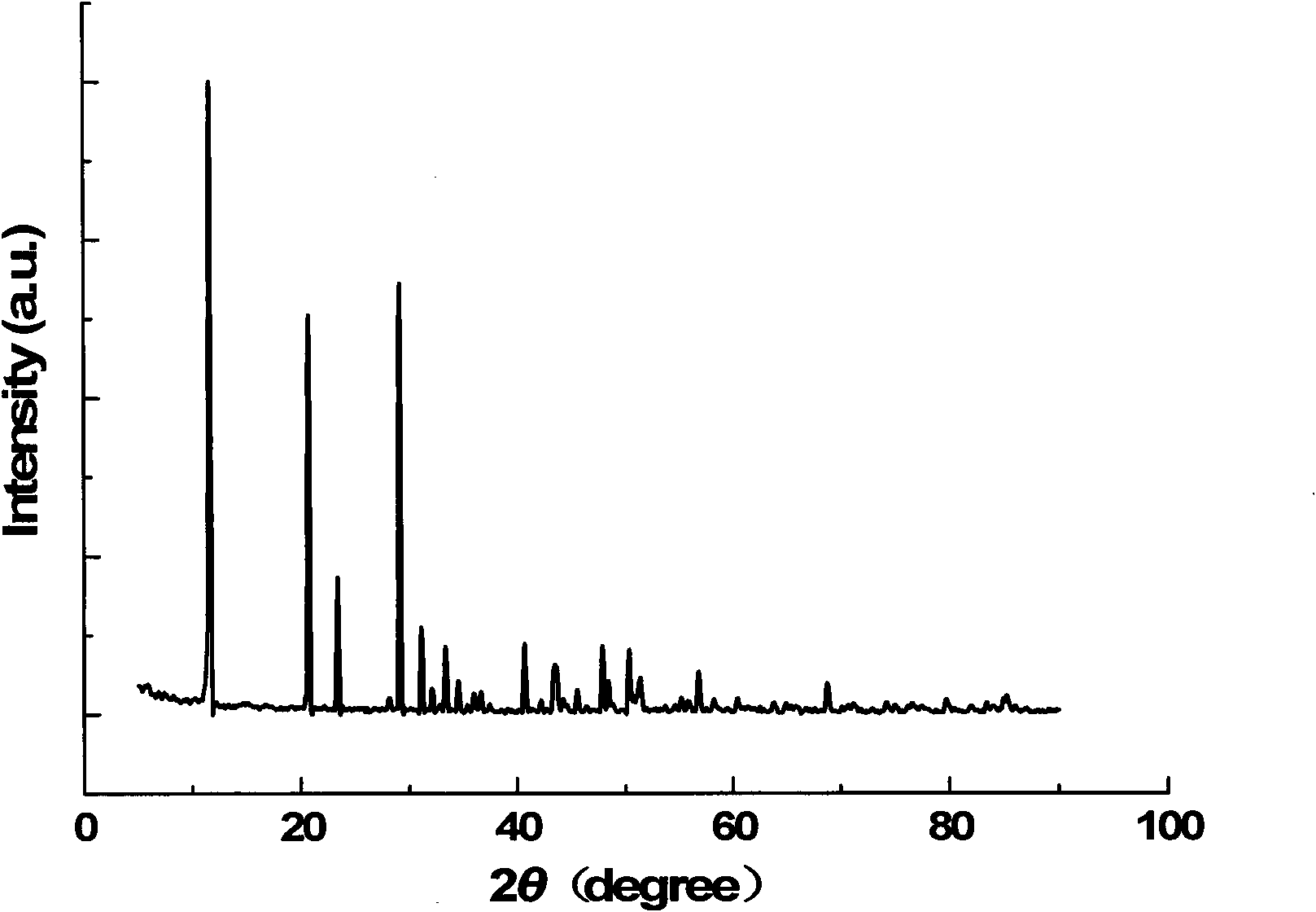

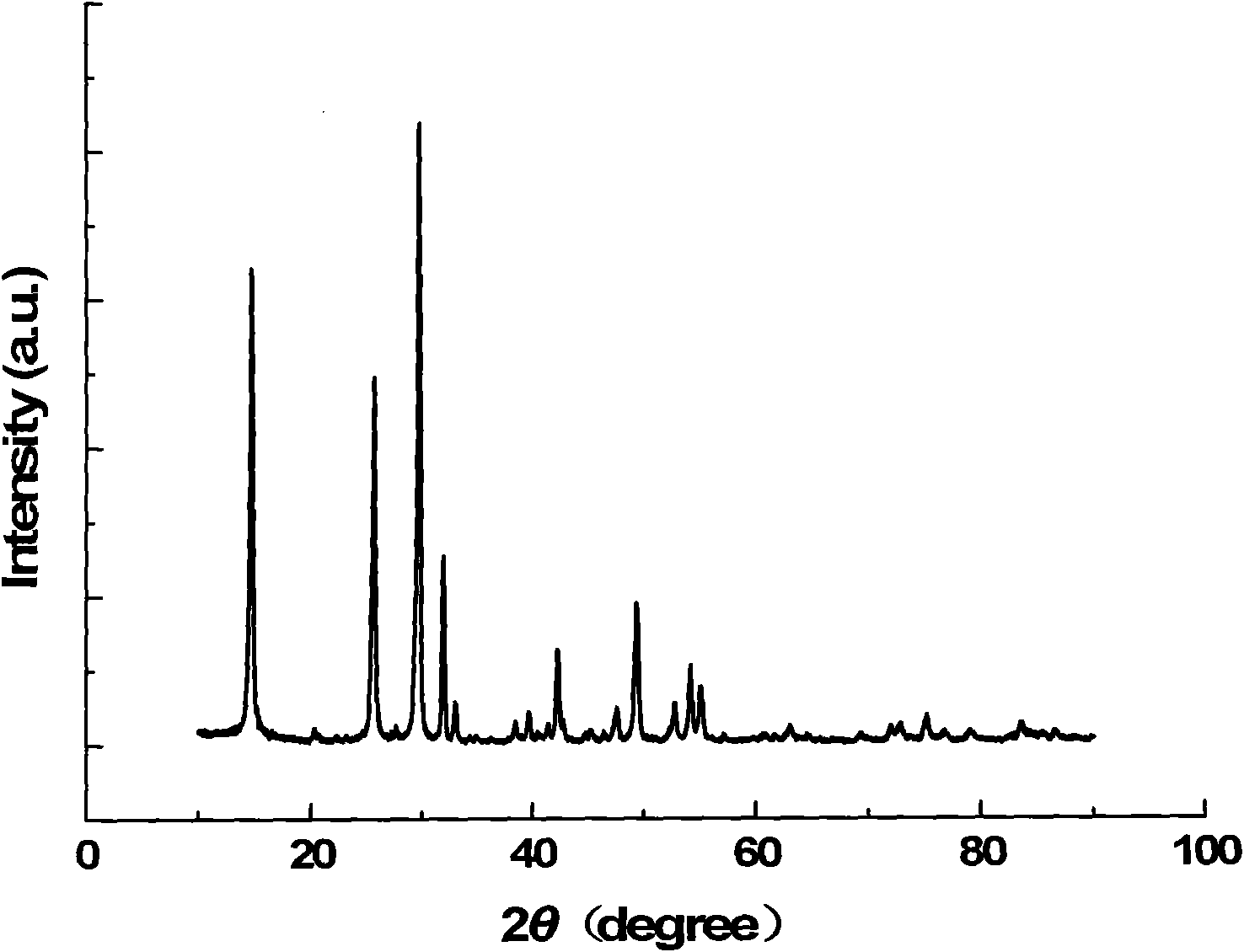

[0033] The present embodiment provides a kind of preparation method of dehydrated calcium sulfate whisker, specifically comprises: measure the calcium nitrate aqueous solution 3000ml that produces in the process of processing nickel-containing mineral when taking nitric acid as leaching agent, wherein calcium ion concentration is 61.3g / L, Add 10 mL / L glycerin or oleic acid and heat it to 50°C. When the temperature of the calcium nitrate aqueous solution reaches 50°C, keep stirring. Get 240ml of 98% concentrated sulfuric acid in addition, it is added dropwise in the calcium nitrate aqueous solution, and stirring speed is 300rpm, dihydrate calcium sulfate crystal whisker is constantly separated out (the XRD pattern of dihydrate calcium sulfate crystal whisker is consistent with PDF card No. 33-0311 ). After about 23 minutes, all 240ml of concentrated sulfuric acid was added dropwise, and the stirring was continued for 10 minutes. The calcium sulfate dihydrate whiskers are filt...

Embodiment 2

[0035] This embodiment provides a method for preparing dehydrated calcium sulfate whiskers, which specifically includes: measuring the mixed aqueous solution of calcium nitrate and calcium chloride produced in the process of treating cobalt-containing cemented carbide waste when a mixture of nitric acid and hydrochloric acid is used as the leaching agent 3000ml, in which the calcium ion concentration is 70.1g / L, add 20mL / L glycerin or oleic acid, and heat it to 65°C. When the temperature of the mixed aqueous solution of calcium nitrate and calcium chloride reaches 65°C, keep stirring. Take another 270ml of 98% concentrated sulfuric acid, dilute it to a volume of 700ml, heat it to 65°C, and then add it dropwise to the mixed aqueous solution of calcium nitrate and calcium chloride. The stirring speed is 350rpm, and calcium sulfate dihydrate whiskers are continuously precipitated. After about 40 minutes, all 700ml of dilute sulfuric acid aqueous solution was added dropwise, and t...

Embodiment 3

[0037] The present embodiment provides a preparation method of dehydrated calcium sulfate whiskers, which specifically includes: measuring 3000ml of calcium nitrate aqueous solution produced in the process of electroplating stripping when nitric acid is used as the leaching agent, wherein the concentration of calcium ions is 53.6g / L, adding 10mL / L glycerol, heated to 40°C. When the temperature of the calcium nitrate aqueous solution reaches 40°C, keep stirring and add 20 mL / L of glycerin or oleic acid. Another 200ml of 98% concentrated sulfuric acid was taken, diluted to a volume of 800ml, heated to 40°C, and then added dropwise to the aqueous calcium nitrate solution with a stirring speed of 400rpm, and calcium sulfate dihydrate whiskers were continuously precipitated. After about 40 minutes, all 800ml of dilute sulfuric acid aqueous solution was added dropwise, and the stirring was continued for 10 minutes. Calcium sulfate dihydrate whiskers are filtered from the aqueous so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com