Patents

Literature

34 results about "Aqua fortis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In alchemy, aqua fortis is nitric acid. Being highly corrosive, the solution was used in alchemy for dissolving silver and most other metals with the notable exception of gold, which can be dissolved using aqua regia or "regal water". Aqua fortis was prepared by mixing either sand, alum, or vitriol, or the last two together, with saltpeter, then distilling it by a hot fire. The gas collected from this condenses into aqua fortis. It was first described by alchemist Pseudo-Geber. Aqua fortis was useful to refiners for parting or separating silver from gold and copper; to the workers in mosaic for staining and coloring their woods; to other artists for coloring of bone and ivory, which is done by tinging the items with copper or verdigris, then soaking in aqua fortis. Some also turn it into aqua regia, by dissolving in a quarter of its weight of sal ammoniac, and then use this to stain ivory and bone, of a fine purple color. Book binders also put it on leather, making fine marble covers for books. Diamond cutters used it to separate diamonds from metalline powders. It was also used in etching copper or brass plates.

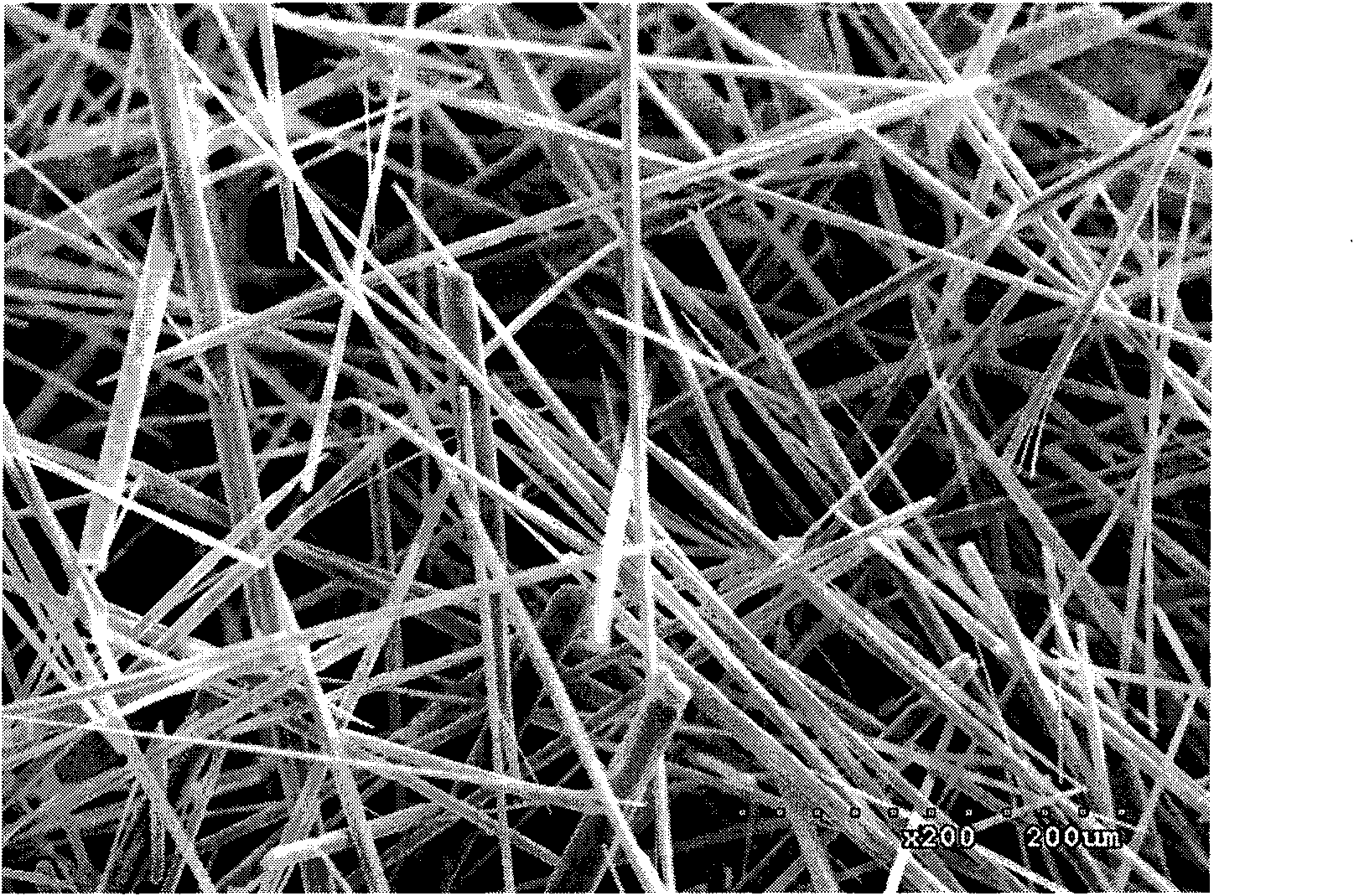

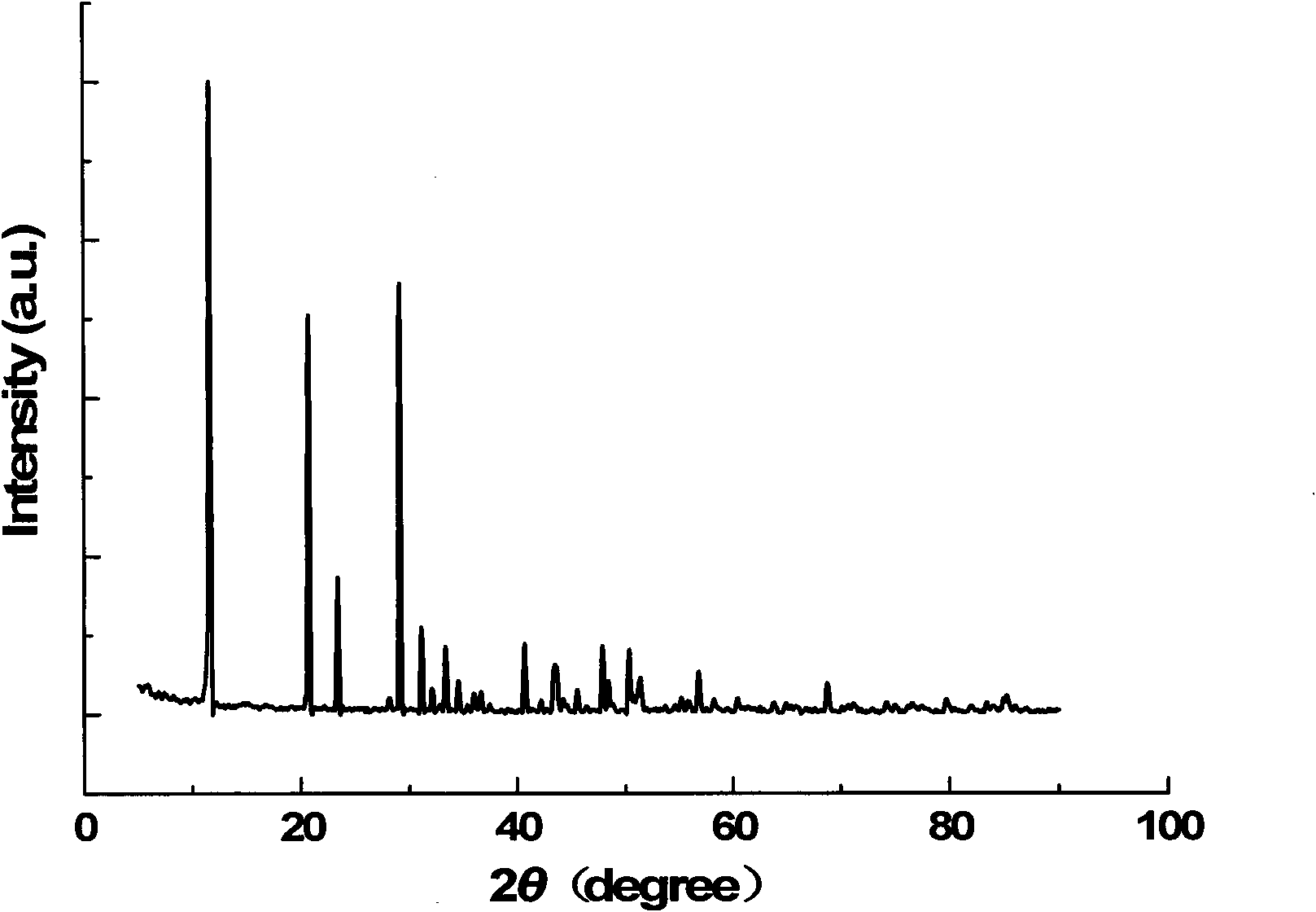

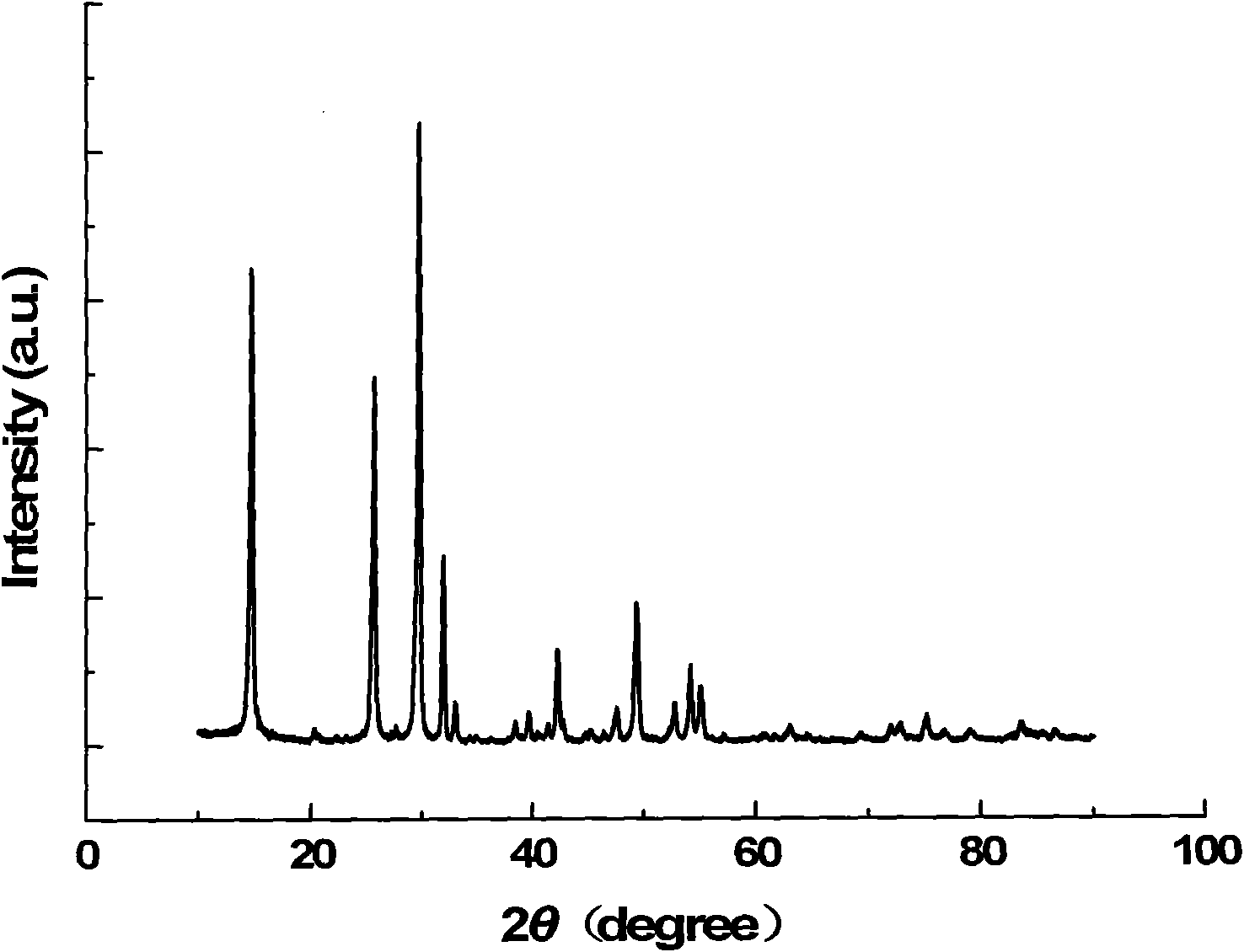

Method for producing dehydrated calcium sulfate whisker

InactiveCN101550585ANo emissionsReduce manufacturing costPolycrystalline material growthFrom normal temperature solutionsAnhydrous Calcium SulfateLixiviant

The invention provides a method for producing dehydrated calcium sulfate whisker, comprising: using copper, lead, zinc, aluminium, nickel, cobalt, stannum, non-ferrous metal secondary resource cycle utilizing, calcium nitrate solution produced in treating process of electroplating waste, calcium chloride solution, or mixed water solution of calcium nitrate and calcium chloride as raw material, using sulfuric acid as calcium ion precipitant, adding whisker shape regulating agent, controlling reaction condition, regenerating aqua fortis or hydrochloric acid lixiviant, and simultaneously producing ultralong and big length to diameter ratio calcium sulphate dihydrate whisker. After calcium sulphate dihydrate whisker is deposited from calcium nitrate solution, calcium chloride solution or the mixed solution of calcium nitrate and calcium chloride are deposited, the water solution is translated to be nitric acid solution, hydrochloric acid solution or a mixed solution of nitric acid and hydrochloric acid, returning back to leaching out or treating process for processing non-ferrous metal mineral substance, non-ferrous metal secondary resource or electroplating remove. The calcium sulphate dihydrate whisker is treated by microwave heating, forming calcium sulfate hemihydrate or anhydrous sulphate of calcium after dehydration.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

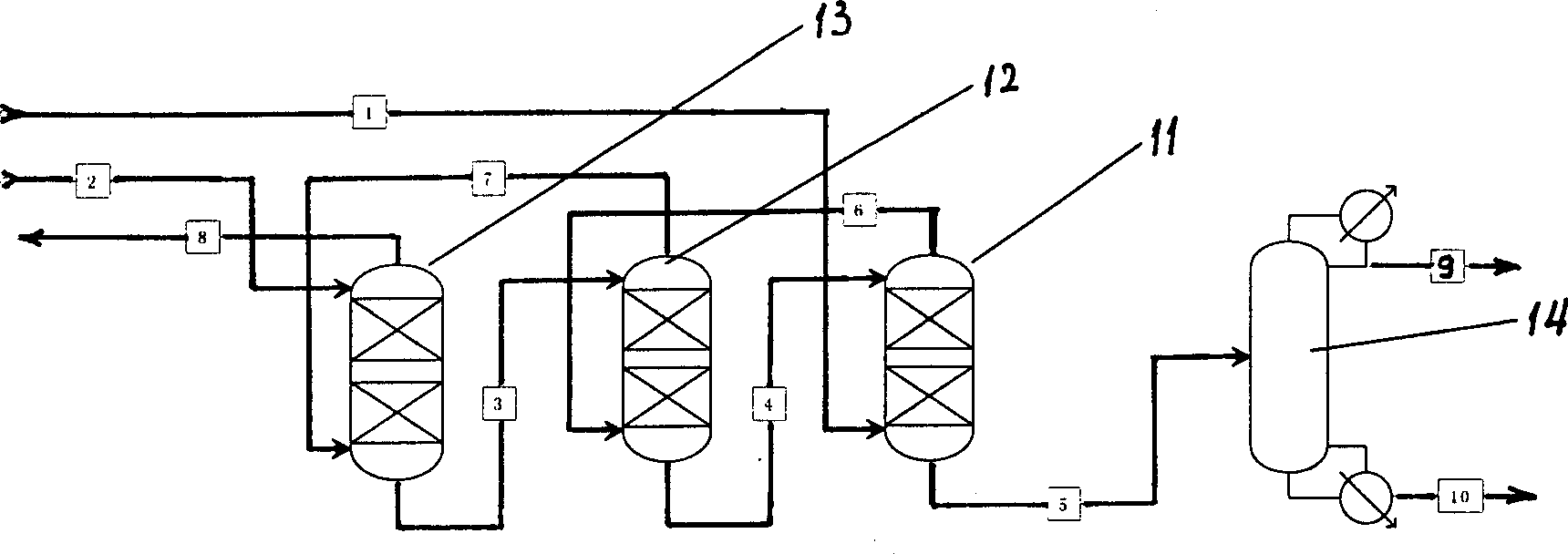

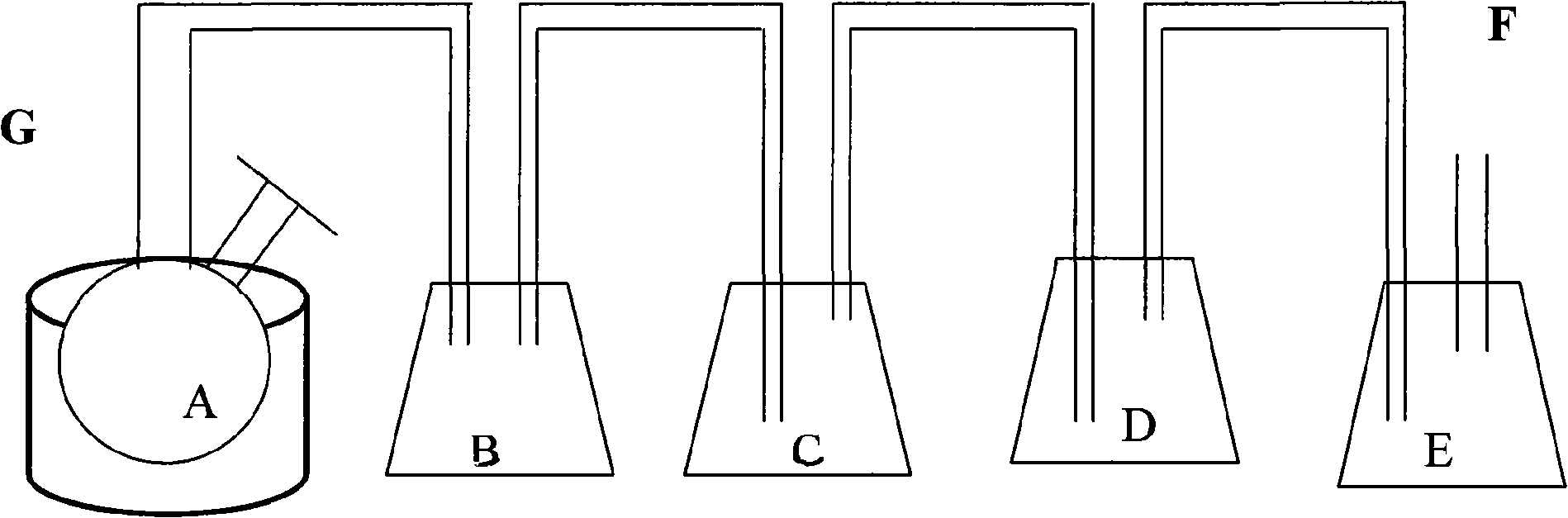

A nitric oxides (NOX) waste pollution control in industrial process and resource reclaiming method

InactiveCN1864812AGood governanceSimple processDispersed particle separationHydrogen NitrateHigh concentration

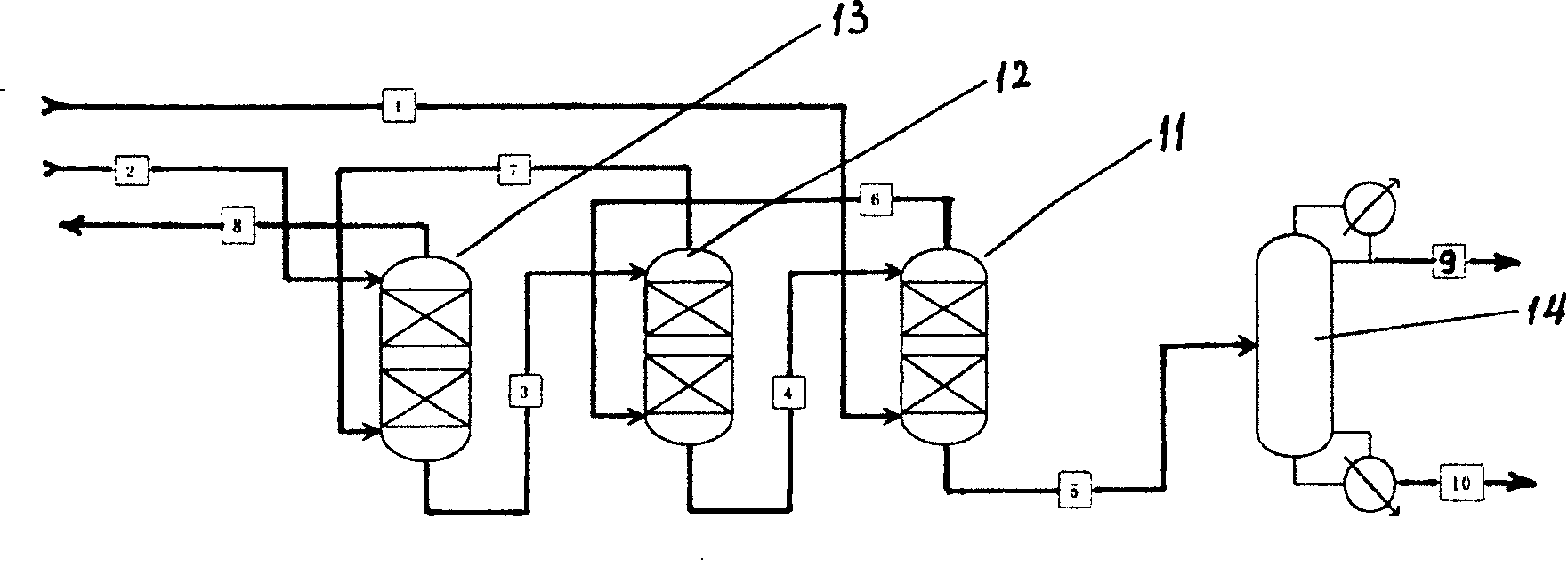

The invention relates to a method for treating and reusing waste gas containing nitrogen oxide generated in industrial process. It comprises following steps: mixing waste gas containing nitrogen oxide with air according to a certain proportion, plural serial adsorbing it in tower by introducing it from bottom of head tower, discharging it from top of tail tower, discharging generated hydrogene nitrate of low concentration from bottom of head tower, proceeding decompressing and thickening process in thickening tower, which includes bleaching and dewatering; hydrogen nitrate of low concentration is introduced from top of thickening tower, hydrogen nitrate of high concentration being 45-65% is discharged from bottom; supercharging nitrogen oxide extracted from thickening tower top with vacuum system, then introducing it into adsorbing process again; the water or diluted acid from thickening tower is used as adsorbent and is added from top of tail tower in adsorbing process and counter current contacts with gas in tower for mass transferring. The waste gas treatment effect is good, and the discharging concentration of nitrogen oxide in exhaust gas is less than 50 ppm; all the nitrogen oxide in exhaust gas is recycled to generate aqua fortis with mass concentration being more than 55%.

Owner:NANJING UNIV

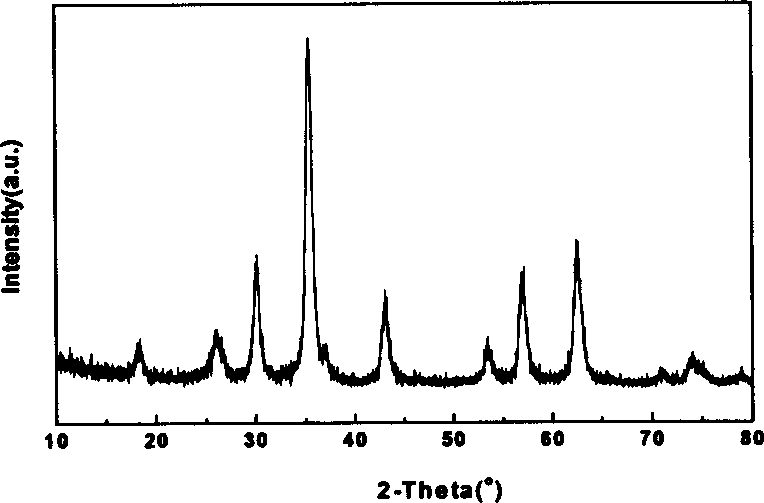

Process for preparing composite material of carbon nano tube/NiZn ferrite

InactiveCN1793421AStrong magnetismExcellent dielectric propertiesLiquid/solution decomposition chemical coatingMagnetic materialsSolubilityMass ratio

The invention discloses a carbon nanometer tube / nickel zinc ferrite composite material manufacturing method. It includes the following steps: manufacturing modified carbon nanometer tube by the backflow of the mixture of carbon nanometer tube and aqua fortis in oil bath; weighing solubility Ni2+, Zn2+, Fe3+ salt with curtain quantity relative ratio to add to distilled water to do ultra sonic dispersion at room temperature; adding to modified carbon nanometer tube with 1:10-15 mass ratio to Fe3+ to do ultra sonic dispersion again; using 4-8mol / l strongly alkaline solution to make the pH value bigger than 8; reacting for 3-24h in hot kettle; cooling to room temperature after full reaction; filtering; washing by distilled water until the pH value reaches 7; washing by alcohol; drying at 60-100 centigrade degree for 5-12h. The formed material has good magnetic, dielectric and electrical properties, and has extensive application prospect in high density magnetic recording material field, and son.

Owner:DONGHUA UNIV

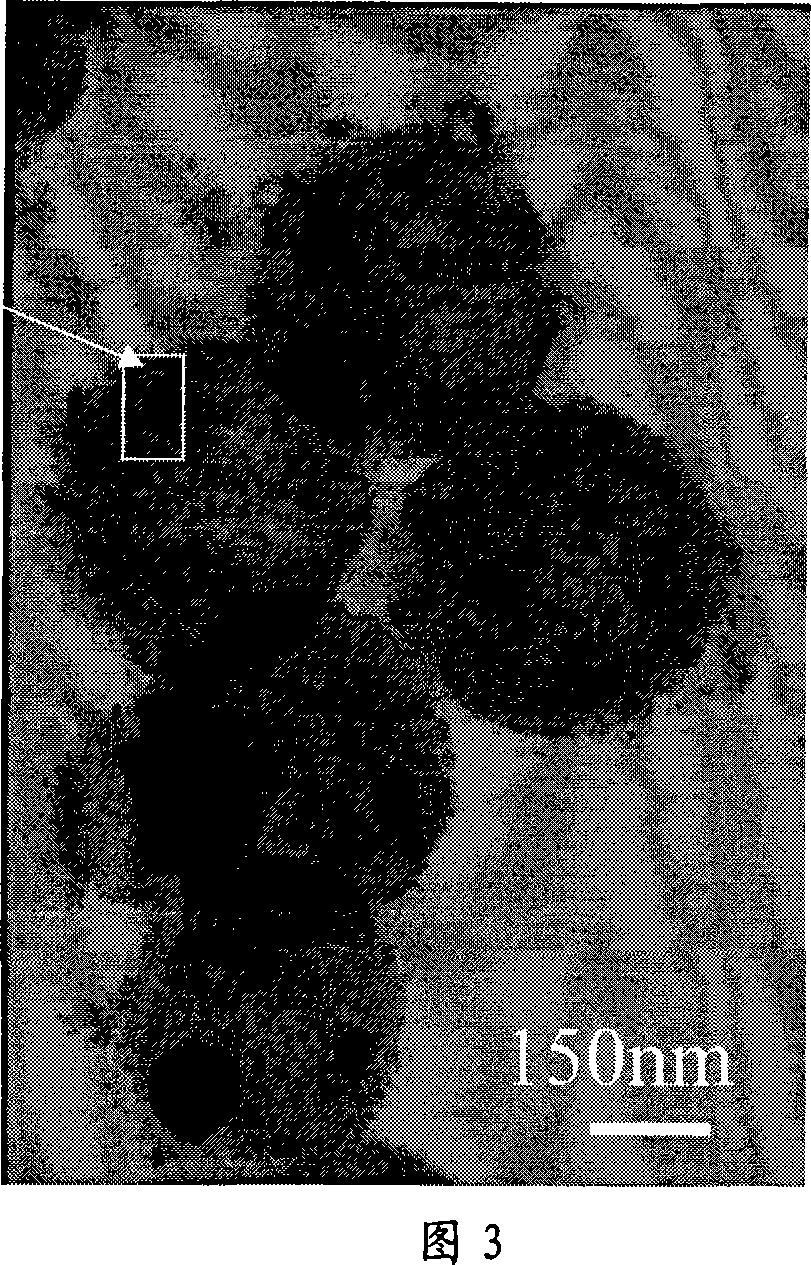

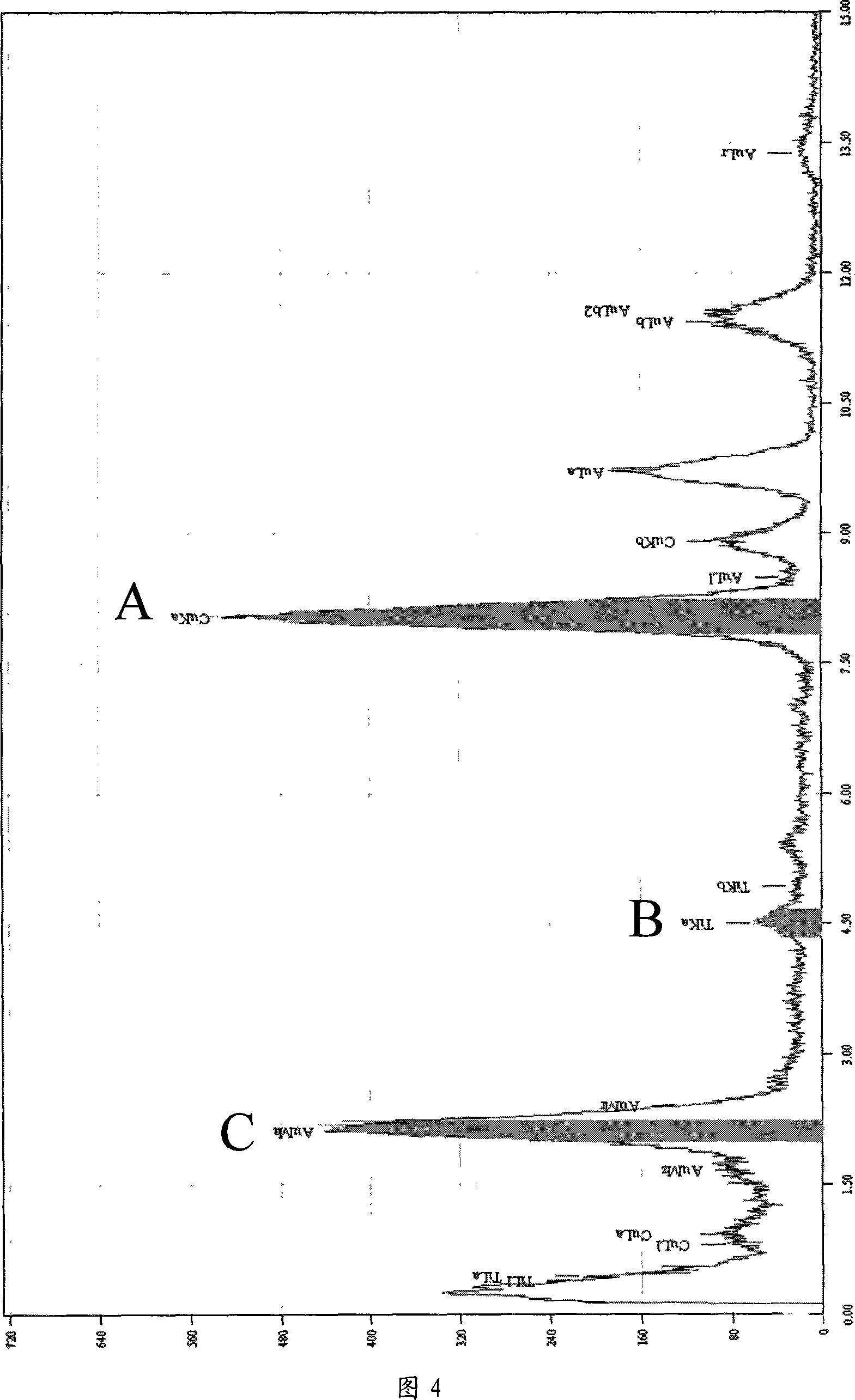

Method for preparing titanium dioxide hollow sphere containing gold nano particles

The making of titania hollow ball with nanometer grains features int eh making of carbon balls with gold core through high temperature seal conditions, picking out 1 g of the said carbon ball to scatter inside the water free ethandiol or glycerin in 2.5-20g / L, dropping 30-500 micro litter aqua fortis of 0.01-2 m / l, then butyl titanate 500-5000 micro litter in 0.1-3m / l in the speed of 10-100 micro litter per minute, flowing in the silicon oil for 60-180 minutes, depositing in 600-800deg.C and calcining for 60-200 mintues. The sealed hollow ball has seal volume providing the movement of the gold core. Size of the hollow ball inside gold core and shell thickness can be adjusted.

Owner:UNIV OF SCI & TECH OF CHINA

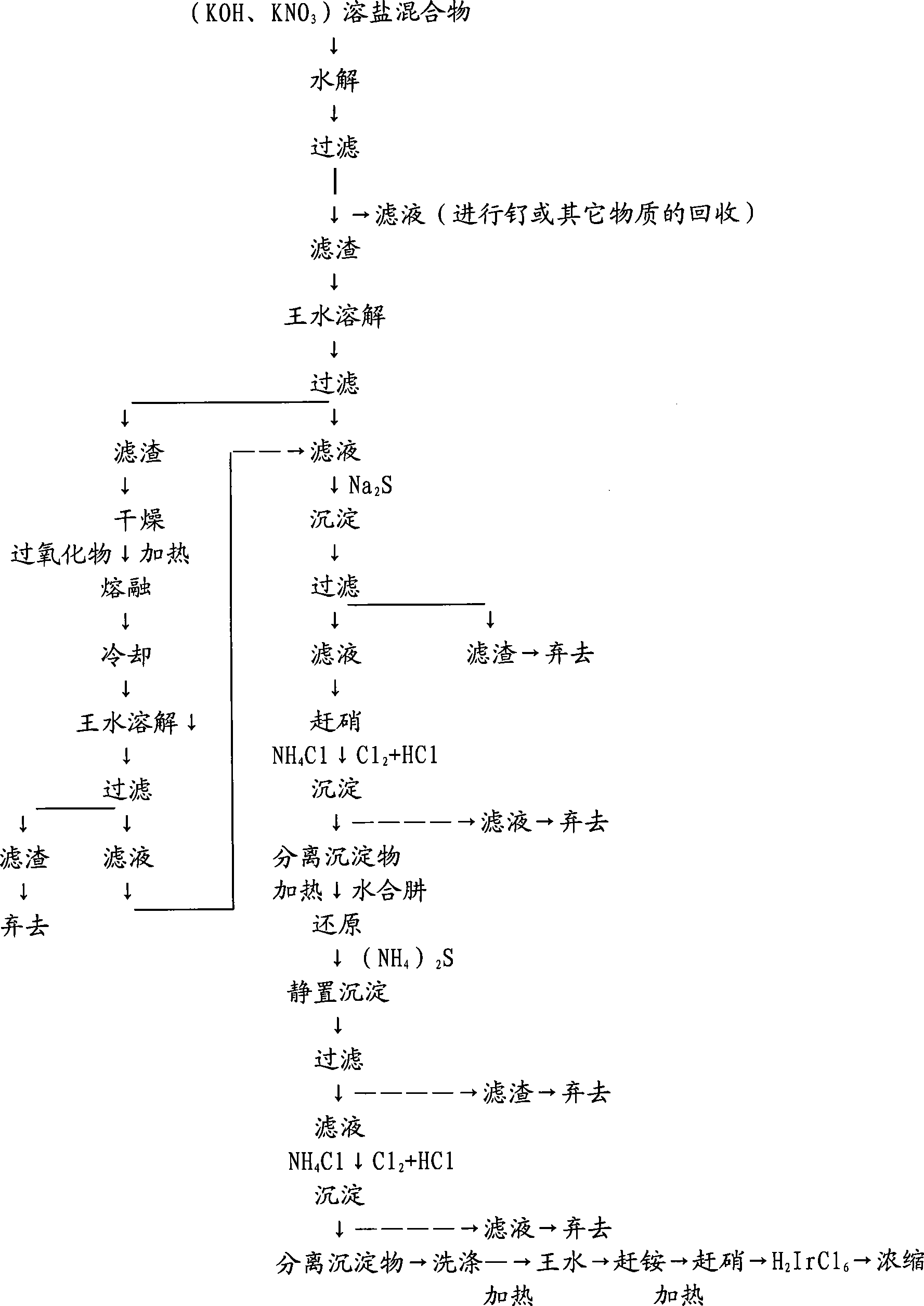

Method for extracting noble metal iridium from mixed oxide containing ruthenium, iridium, titanium, tin, zirconium and palladium

The method discloses a method for extracting noble metal iridium from a mixed oxide containing ruthenium, iridium, titanium, tin, zirconium and palladium. The method comprises the following steps: firstly, placing a mixed oxide containing noble metal ruthenium in a KOH and KNO3 mixed molten salt for dissolving; cooling the molten salt, immersing and dissolving the molten salt in water, and filtering and separating the solution; thirdly, adding aqua fortis in filter residue, carrying out heating for dissolving, generating chloro-iridic acid H2IrCl6 from the reaction, and carrying out filtration; fourthly, adding ammonium chloride into the filtrate obtained in the third step, leading in chlorine, generating sediment (NH4)2IrCl6, and carrying out filtration; fifthly, adding hydrazine hydrate into the sediment obtained in the fourth step, carrying out heating for dissolving, reducing the (NH4)2IrCl6 into (NH4)3IrCl6; sixthly, adding ammonium chloride into the filtrate obtained in the fifth step, leading in chlorine, generating sediment (NH4)2IrCl6, and carrying out filtration; and seventhly, adding aqua fortis in the sediment obtained in the sixth step, heating the mixture till boiling, and generating H(NH4)2IrCl6. The method can separate and extract the noble metal iridium from a waste electrode coating and a waste electrode cladding, and the recovery rate can be above 50 percent.

Owner:BLUESTAR BEIJING CHEM MACHINERY

Immune colloidal gold test strip for detecting organophosphorus pesticide and method for making same

This invention discloses one immune glue gold test bar and process method for organophosphorus in agriculture test technique field, wherein, the test bar comprises PVC underlay, adhesive agent layer, sample pad, combination pad, aqua fortis fiber film, weight band, test band, compare band, overlap band, water absorptive pad, limit line and arrow line. The process method comprises the following steps: processing the medicine BSA load protein coupler; processing the medicine special signal clone antigen; processing sheep, rabbit or mouse antigen IgG; processing glue gold; processing single clone antigen gold label.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

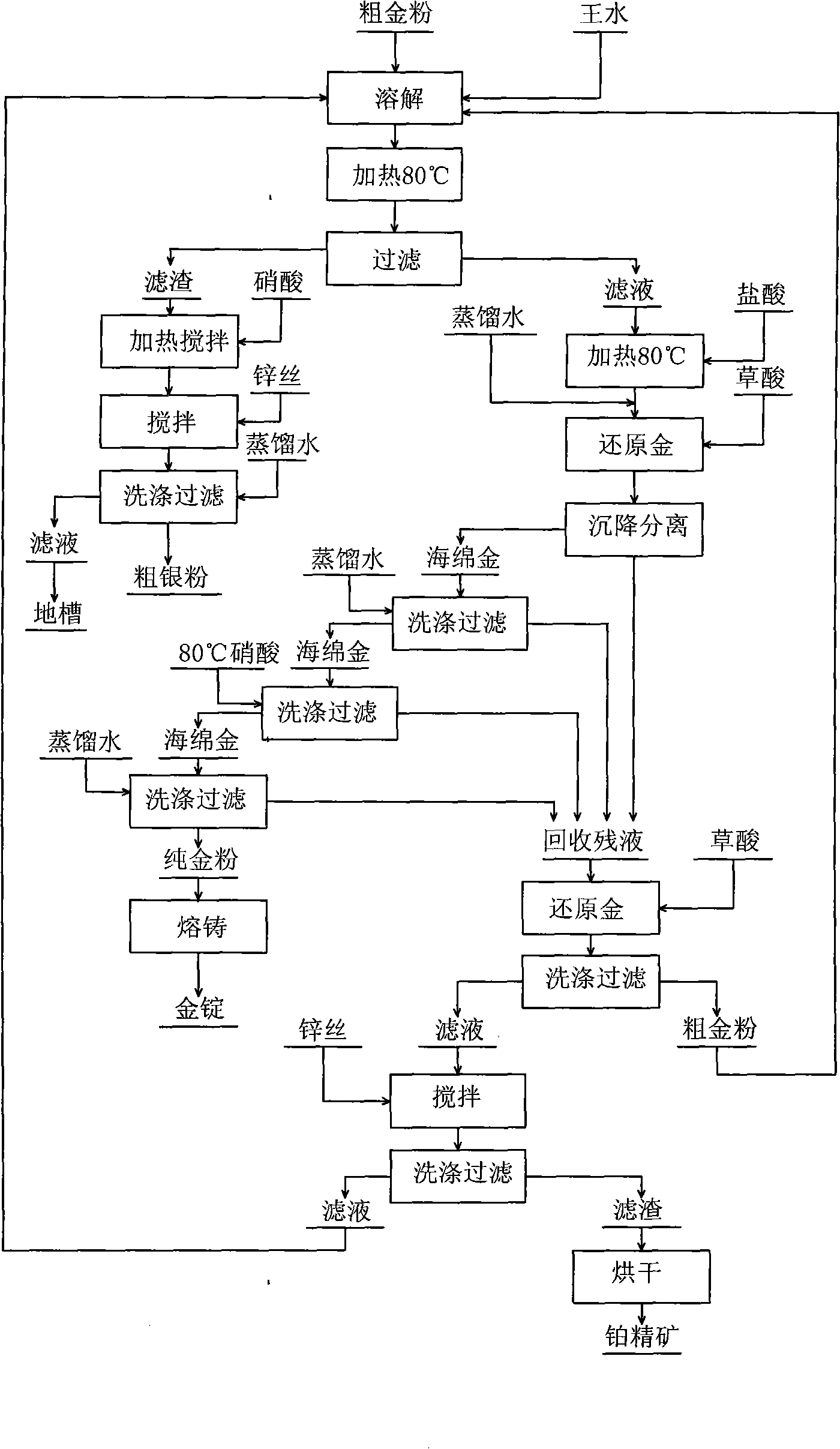

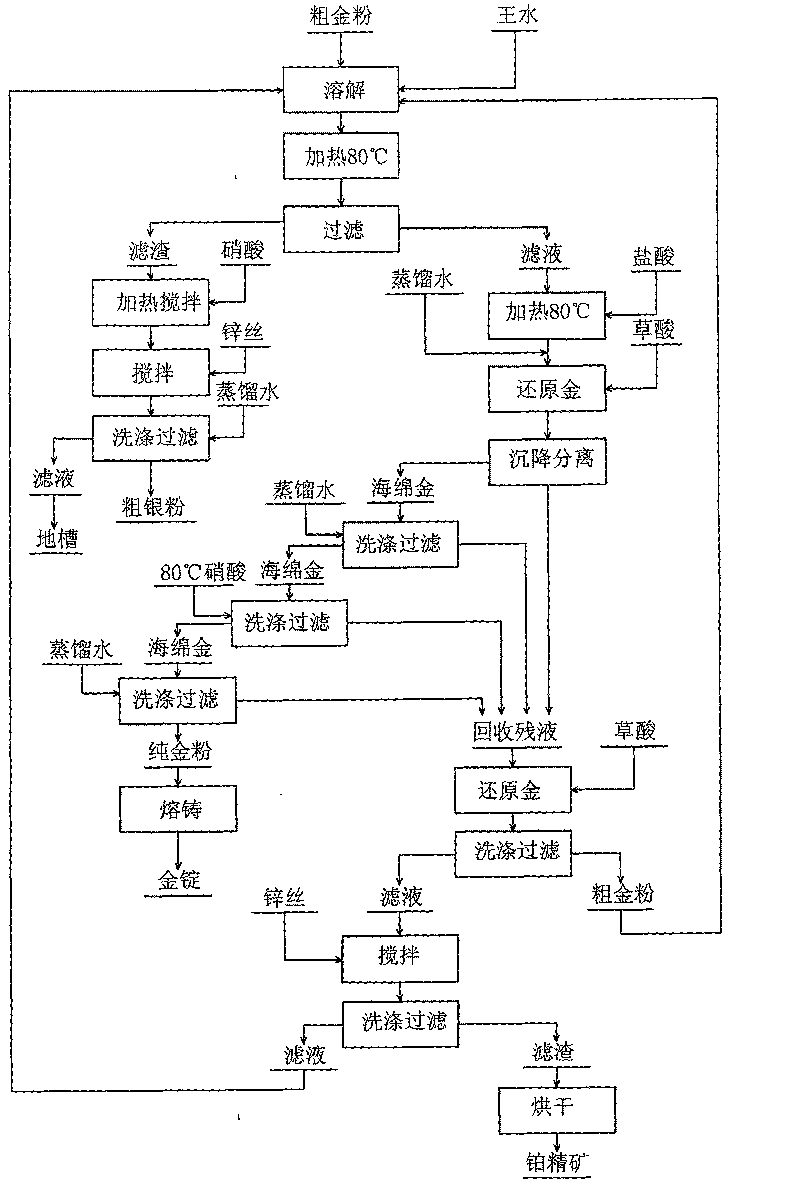

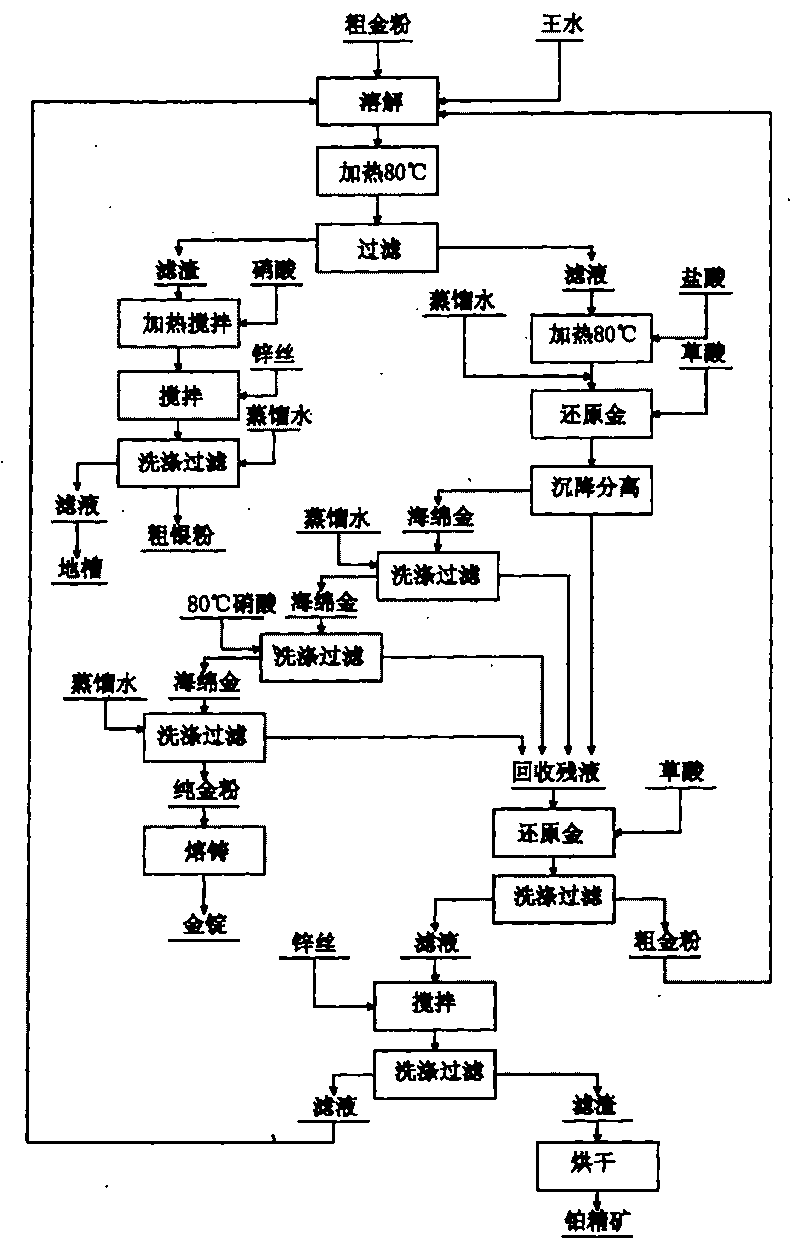

Gold wet purification process

The invention relates to a process for purifying gold by the wet method. Firstly, aqua fortis is used to remove silver; secondly, nitric acid is used to remove impurities such as bismuth and copper, etc.; the separation is performed by filtering; in the richly contained gold solution, the gold is reduced to gold powder deposited by an oxalic acid reducing agent with strong reducibility, and the impurities such as platinum, the bismuth and the copper, which are reduced simultaneously, are redissolved by nitric acid added later and enter the solution, and the solution is subjected to the filtering separation to obtain pure gold powder; and the pure gold powder is made to be ingot-shaped by fushion casting, and the finished gold ingots with a gold content of 99.99 percent are obtained. In the invention, the reduction reaction is made by oxalic acid at a low temperature, so that the process of the invention has the advantages of not causing environmental pollution, favorability for the heath of operators, lowering cost, shortening the period and obvious economic and social benefits.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

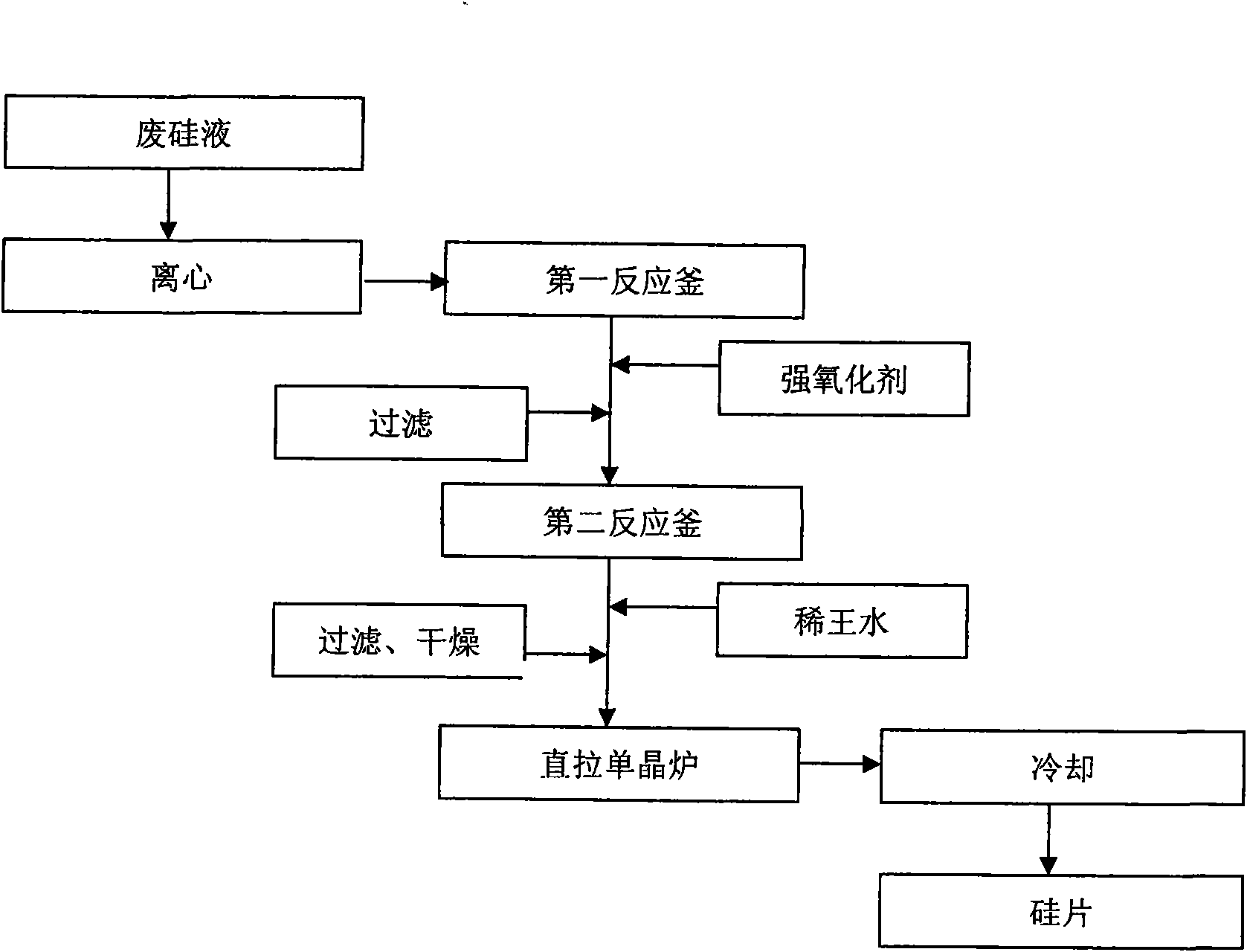

Method for recycling waste silicon solution

InactiveCN101683981AMeet the requirements of power generationMeet the indicator requirementsSiliconDownstream processingFiltration

The invention relates to a method for recycling a waste silicon solution, in particular to a method for recycling a waste silicon solution generated in cutting silicon chip sheets. The method is characterized by comprising the following steps: carrying out centrifugal separation on the waste silicon solution generated in cutting silicon bars by filter cloth with the pore diameter of 800-1,500 meshes, and then obtaining silicon powder; putting the silicon powder obtained after separation in a reaction kettle; adding a strong oxidizer to react, and then filtering the reaction solution so as to remove organic carbon impurities, wherein the strong oxidizer is one of concentrated sulfuric acid, hydrogen peroxide and nitric acid or a mixed solution prepared from concentrated sulfuric acid, hydrogen peroxide and nitric acid; putting the silicon powder obtained after secondary filtration in the reaction kettle; adding diluted aqua fortis to react, and then filtering and drying the reaction solution so as to remove metal and metal oxide impurities; and putting the silicon powder obtained after third filtration in a Czochralski single crystal furnace; sufficiently reacting in the single crystal furnace in vacuum at the temperature of 800-1,000 DEG C so as to remove surface impurities, then cooling, and finally obtaining solar-grade silicon sheets. Applying the method can recycle most silicon powder in the waste silicon solution, and the silicon powder can be used for manufacturing solar batteries by downstream processing, thereby not only saving resources, but also not generating environmental pollution.

Owner:ZHEJIANG YUHUI SOLAR ENERGY SOURCE

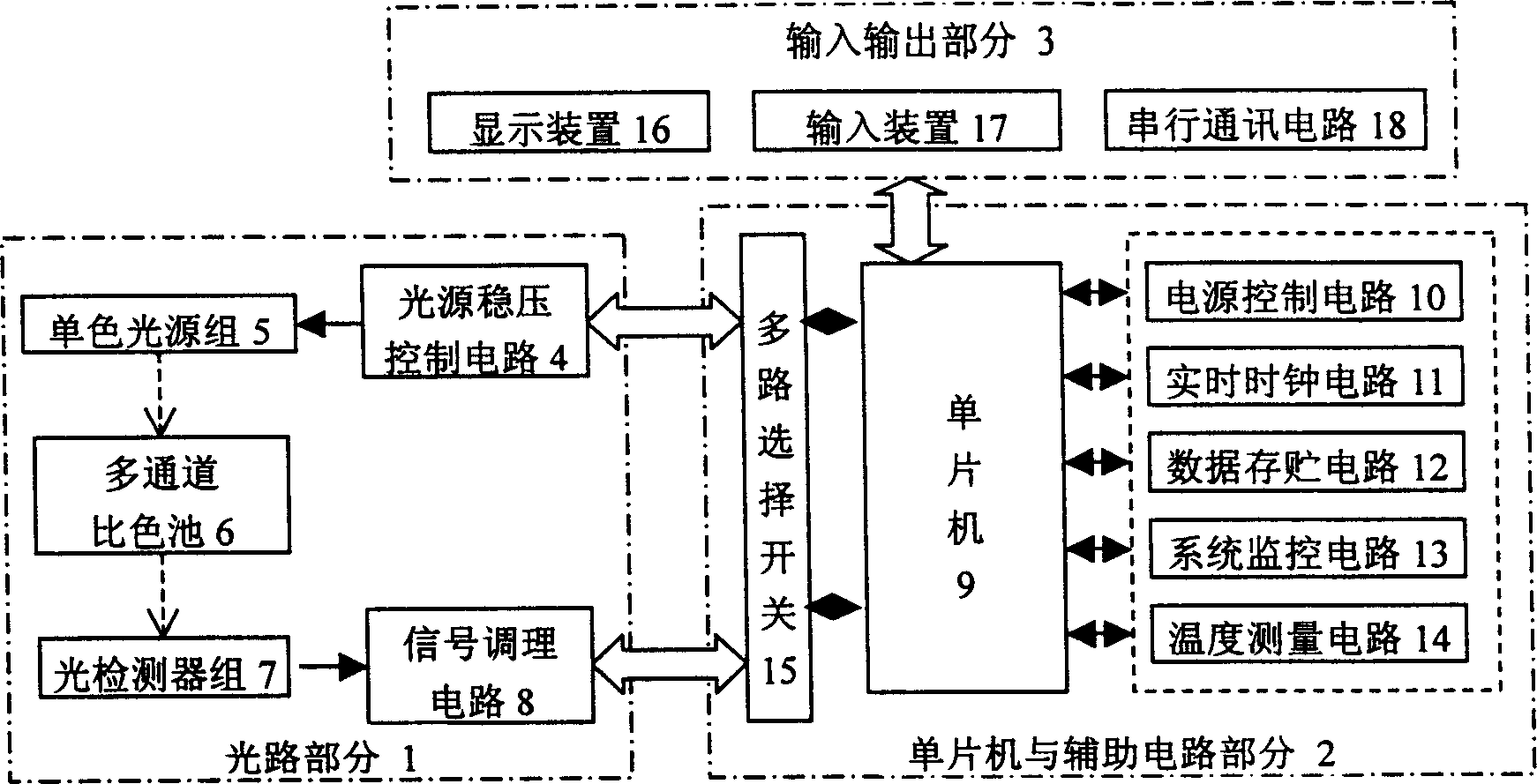

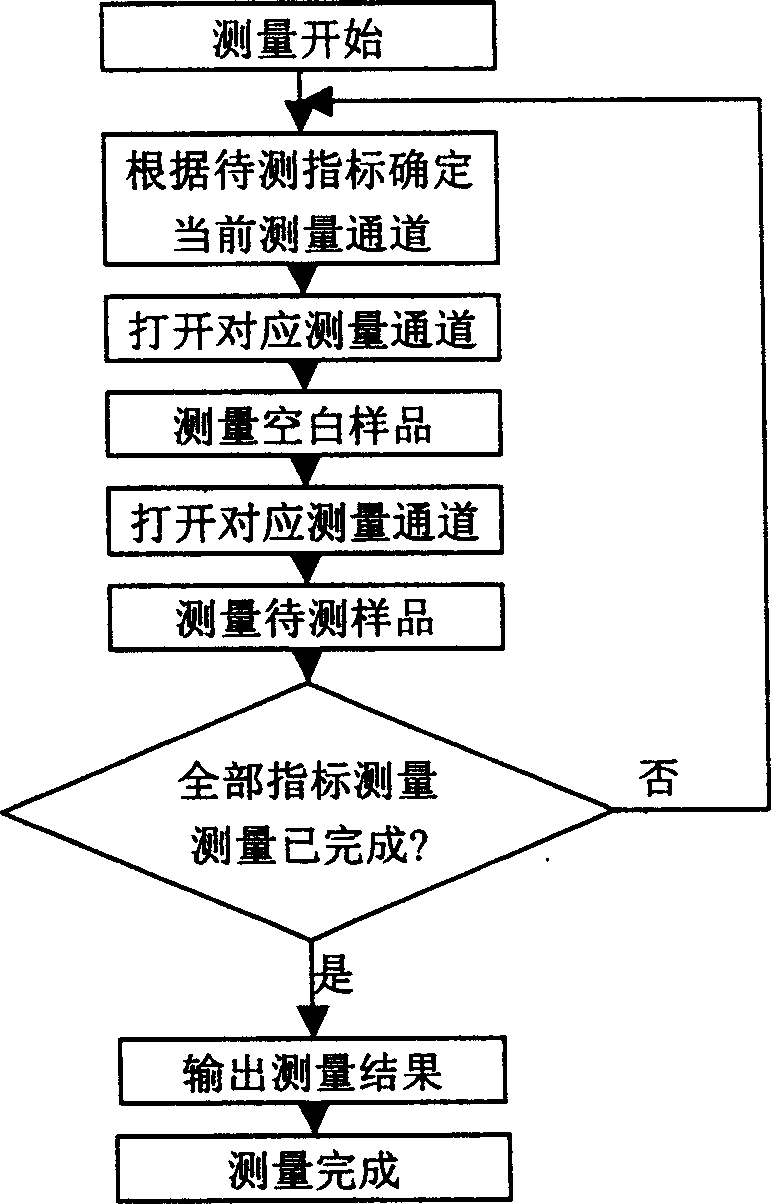

Multiple channel hand-held food safety detecting instrument

InactiveCN1595108ADirectly display concentrationSimple structureTransmissivity measurementsColor/spectral properties measurementsCyanide compoundHuman–machine interface

This invention discloses a multiple-path hand detection device for food safety, which comprises light path, single machine and assistant circuit and IO parts. The single machine and the assistant circuit are used in computer and control and the IO part are used in information input and output and the said light path comprises light source constant-pressure control circuit, monochromatic light source set, multiple-path color matching pool, photoelectric detector set and signal adjusting circuit. The device is characterized by double current and convenience and it can at same time detects out organ ophosphorus, carbamate chemicals, aqua fortis, nitrite, lead cyanide, cyanide, formaldehyde and sodium sulfoxylate formaldehyde, etc. This device is capable of on-spot detection and data storage and acquirement and result copy.

Owner:HUAZHONG UNIV OF SCI & TECH

Measuring method for harmful elements including lead, copper, chromium and cadmium in lotus root

InactiveCN101042349ALow detection limitReduce mistakesAnalysis by electrical excitationPlant poisonCadmium Cation

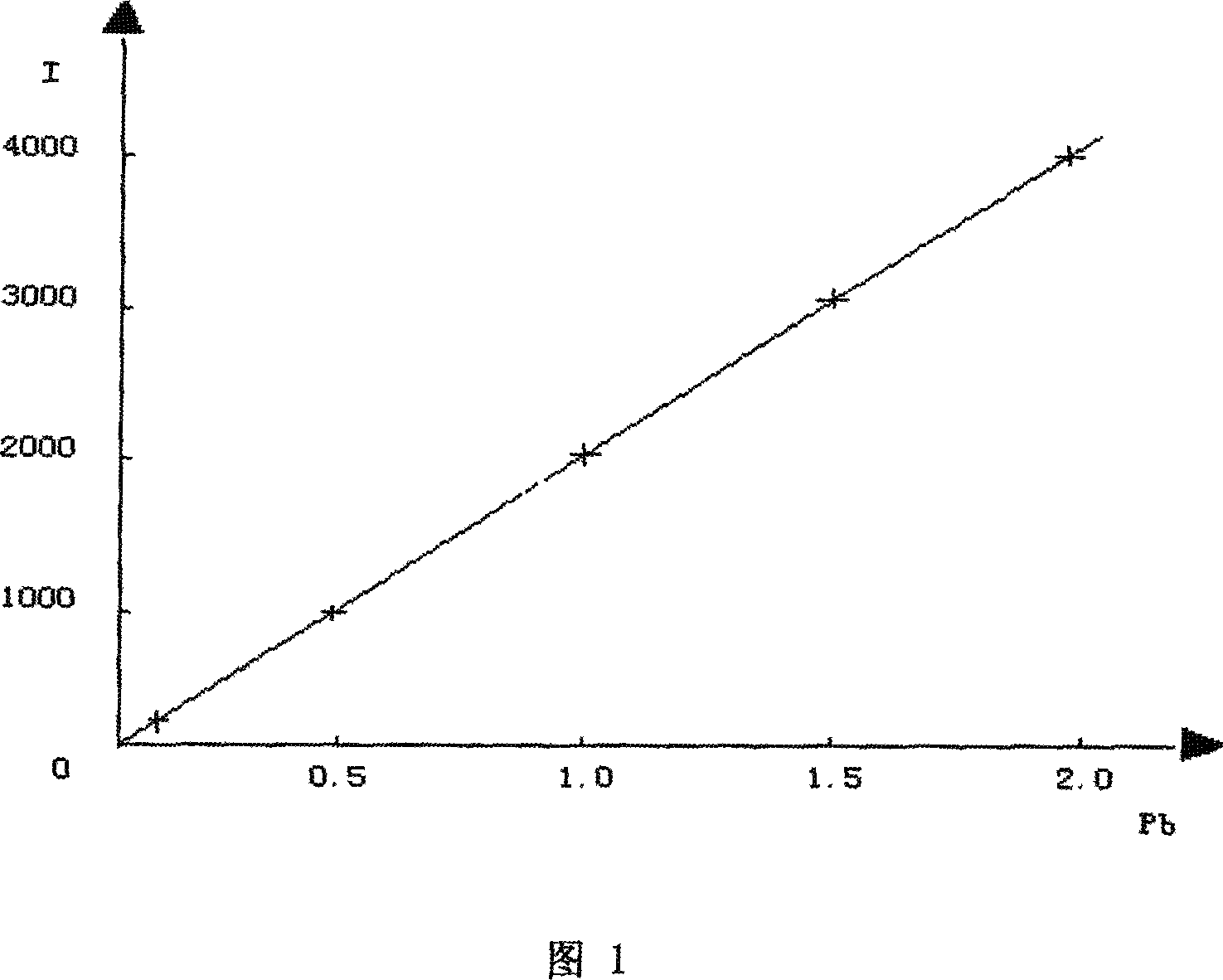

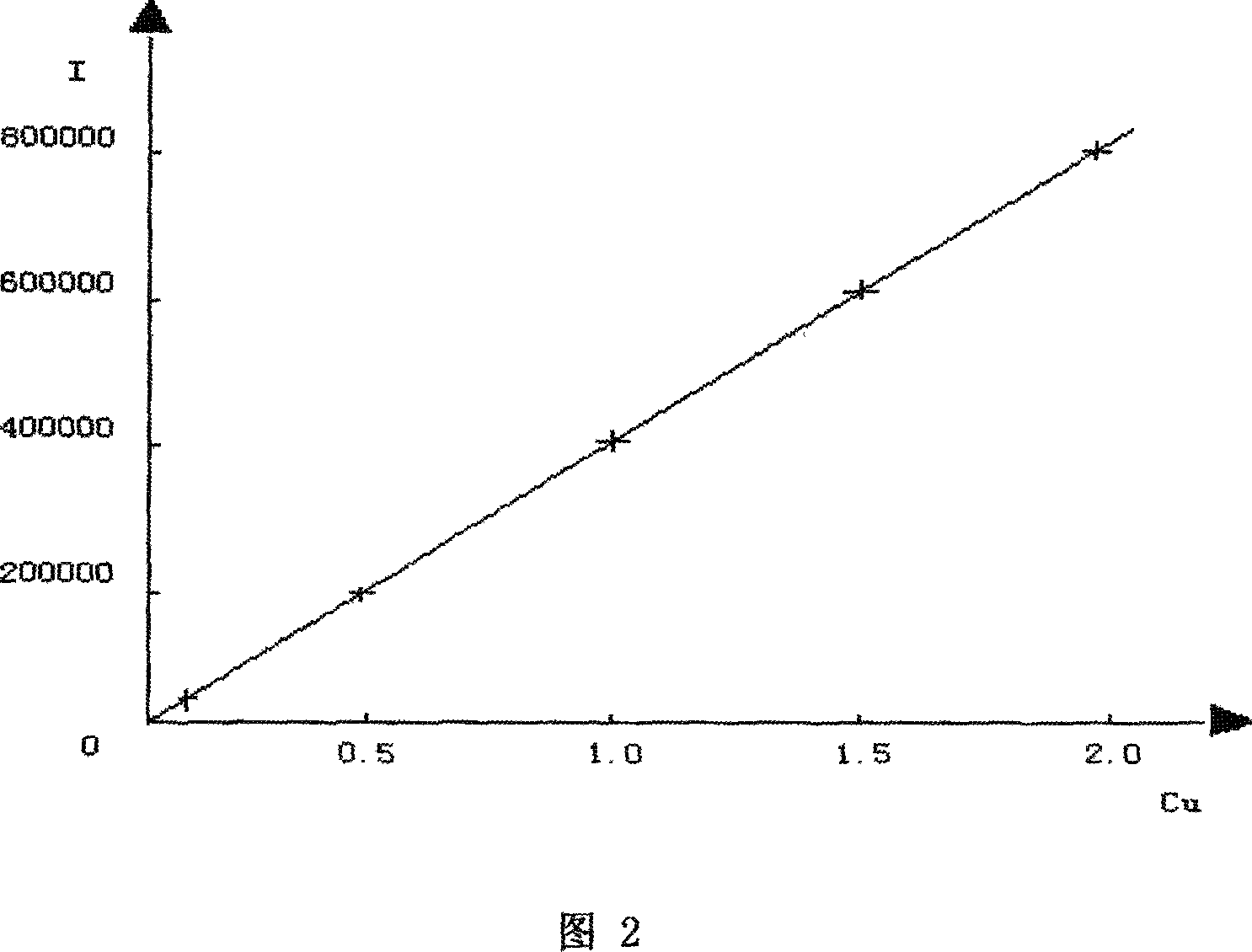

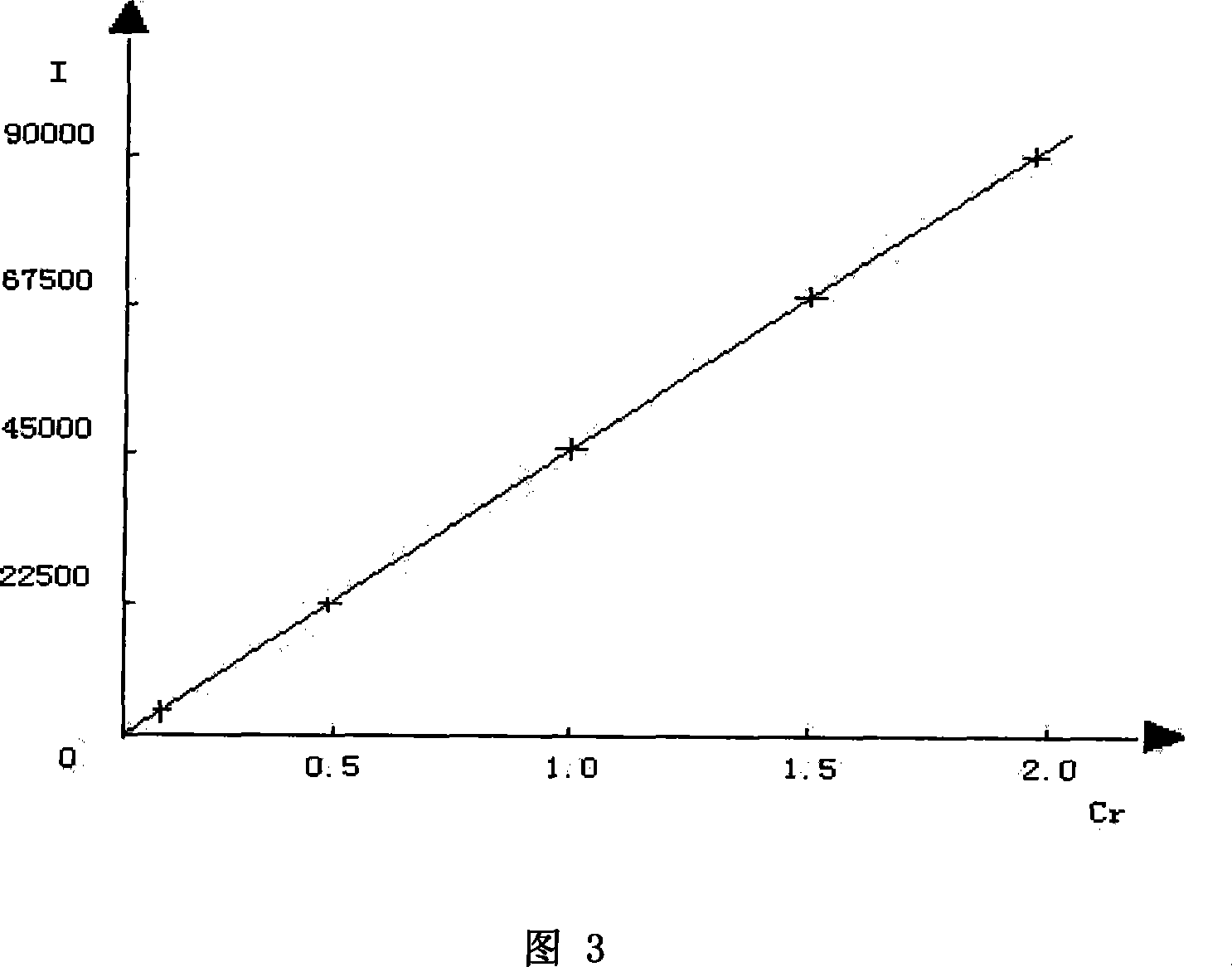

This invention relates to eat plant poison element of lead, copper, chromium and cadmium test method, which comprises the following steps: a, taking lotus root sample for cutting, mixing in the anti-acid container; b, on 30 to 40 ml aqua fortis and Fraude's reagent mixture each 10 gram; c, transplanting to heat board to generate brown gas and tanking down; d, then putting on heat board till the Fraude generates white smokes with remaining 0.5 to 1ml; e, cooling the liquid and adding 1 to 2ml aqua fortis each 10 gram and adding stilled water to 50 ml for mixing; f, using sense couple plasma atom emission spectrum device to draw correction curve; g, according to the tested spectrum intensity in step f, computer checks their concentration form the curve to compute the content.

Owner:CHECKOUT & QUARANTINE TECH CENT YUNNAN ENTRY &EXIT CHECKOUT & QUARANTINE BUR

Testing method for harmful element arsenic of cigarette paper

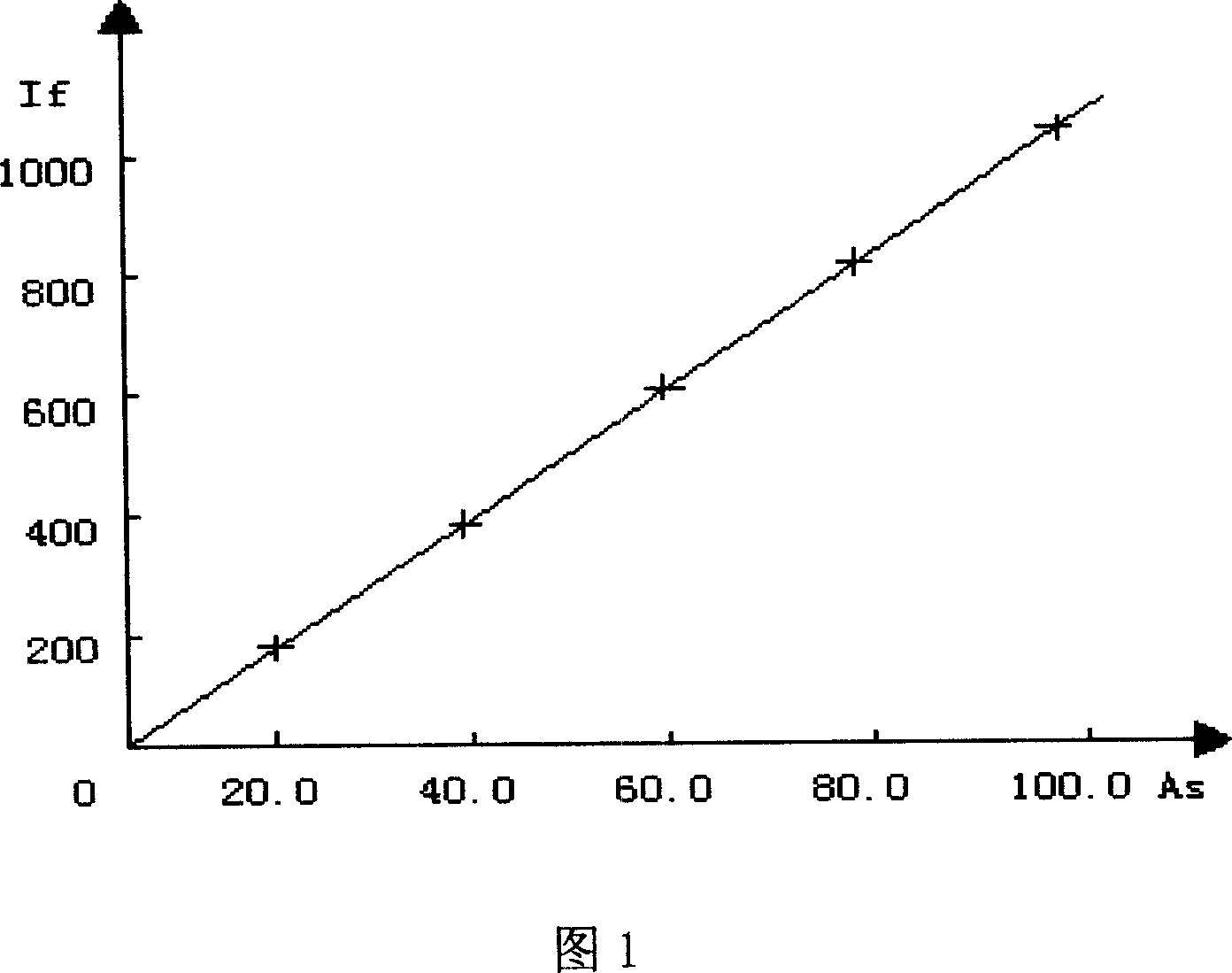

This invention relates to one analysis and test method for micro element, which comprises the following steps: a, cutting and mixing cigarette paper sample into anti-acid container; b, adding 10-20ml aqua fortis, Fraude's reagent mixture per gram; c, heating on board with temperature of 150 to 180 degrees to generate brown gas for cooling; d, transferring to above heating board near drying with 0.5-1ml left; e, cooling the above liquid and solving alcaine for 3mol / L then adding 10ml ascorbic acid and sulfourea and then adding alcaine of 3mol / L to 25ml; f, using atom fluorescence meter to draw correction curve; g, using step e to test fluorescence intensity to get the concentration to compute arsenic content.

Owner:CHECKOUT & QUARANTINE TECH CENT YUNNAN ENTRY &EXIT CHECKOUT & QUARANTINE BUR

Silicon carbide boat cleaning method

InactiveCN101359581AImprove thermal stabilityPromote precipitationSemiconductor/solid-state device manufacturingCleaning using liquidsManganeseMetal impurities

The invention discloses a carborundum boat washing method which includes the steps of cleaning the surface, soaking with aqua fortis, soaking with hydrofluoric acid, heat treatment, surface treatment, flame polish, etc. Through the step of soaking with aqua fortis, metal impurities such as iron, manganese, cuprum, natrium, kalium and the like left on the carborundum boat can be got rid of. The annealing treatment of putting the carborundum boat in an annealing furnace can accelerate the precipitation of the impurities in the carborundum boat, eliminate stress and improve thermal stability of the carborundum boat. The carborundum boat washed through the method is of nearly the same cleanliness, colour and luster and use effect with a new carborundum boat. The carborundum boat washing method is good in washing effect and the cost is only 1 / 10-1 / 30 of the cost of a new carborundum boat, thus greatly reducing production cost of the corporation.

Owner:HUZHOU DONGKE ELECTRONICS QUARTZ

Dog anti rabies virus antibody colloidal gold immunochromatography assay detection reagent plate and preparation method thereof

This invention relates to one anti-rabies virus antigen gold immune analysis test agent board and its process method, which comprises the following steps: paving glass fiber paper and aqua fortis fiber film on the underlay film of polyethylene board and polychloroethylene underlay film; covering the film onto the test line and comparison line; the test line is added with gold detector ester polymer film; the comparison line side is added with water absorptive pad; the test line is to cover the virus protein. This invention process method is to cover virus protein analysis film by glue gold label rabbit anti-virus IgG multi-clone antigen to process gold detection combination pad.

Owner:WUHAN J H BIO TECH

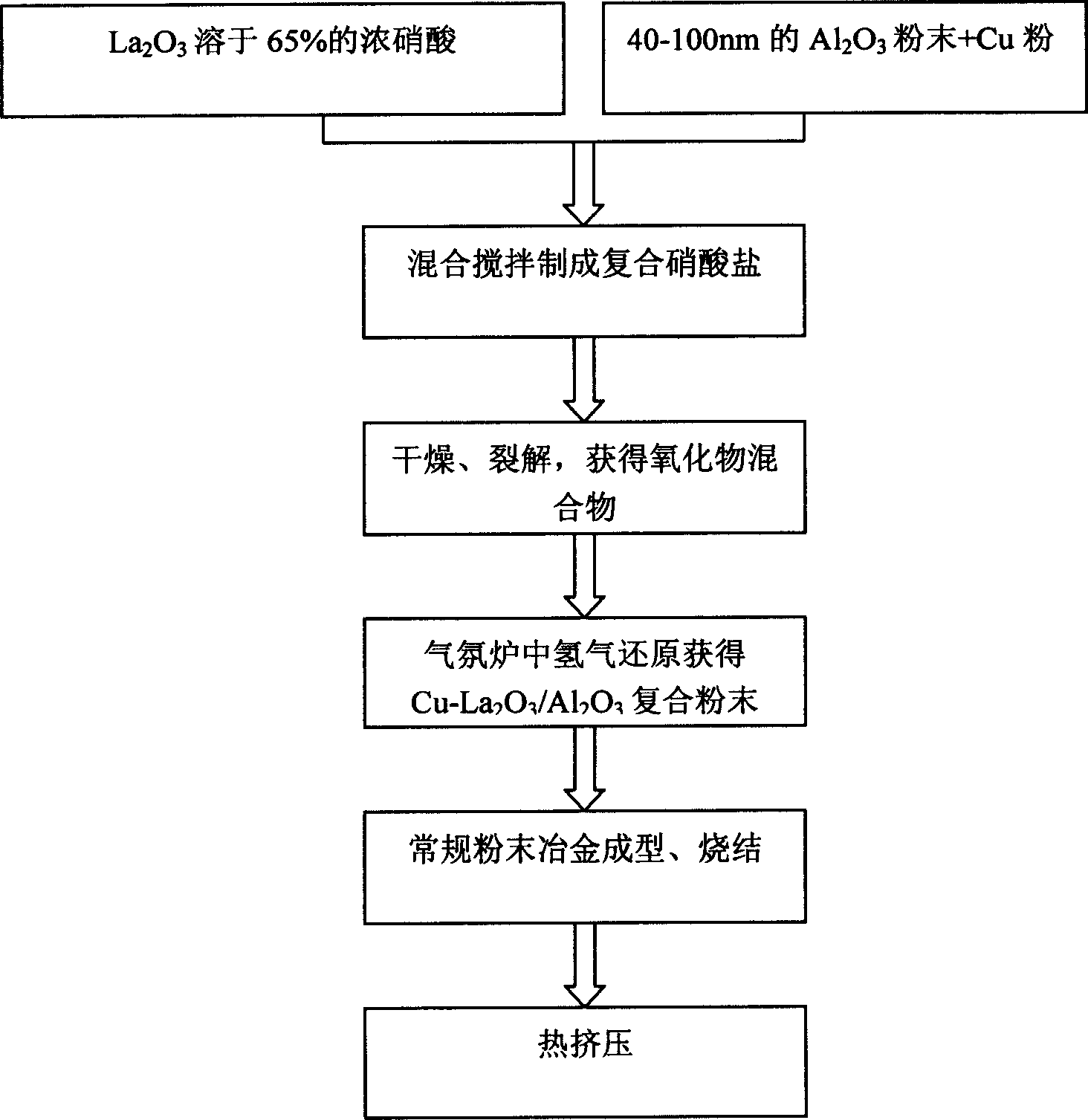

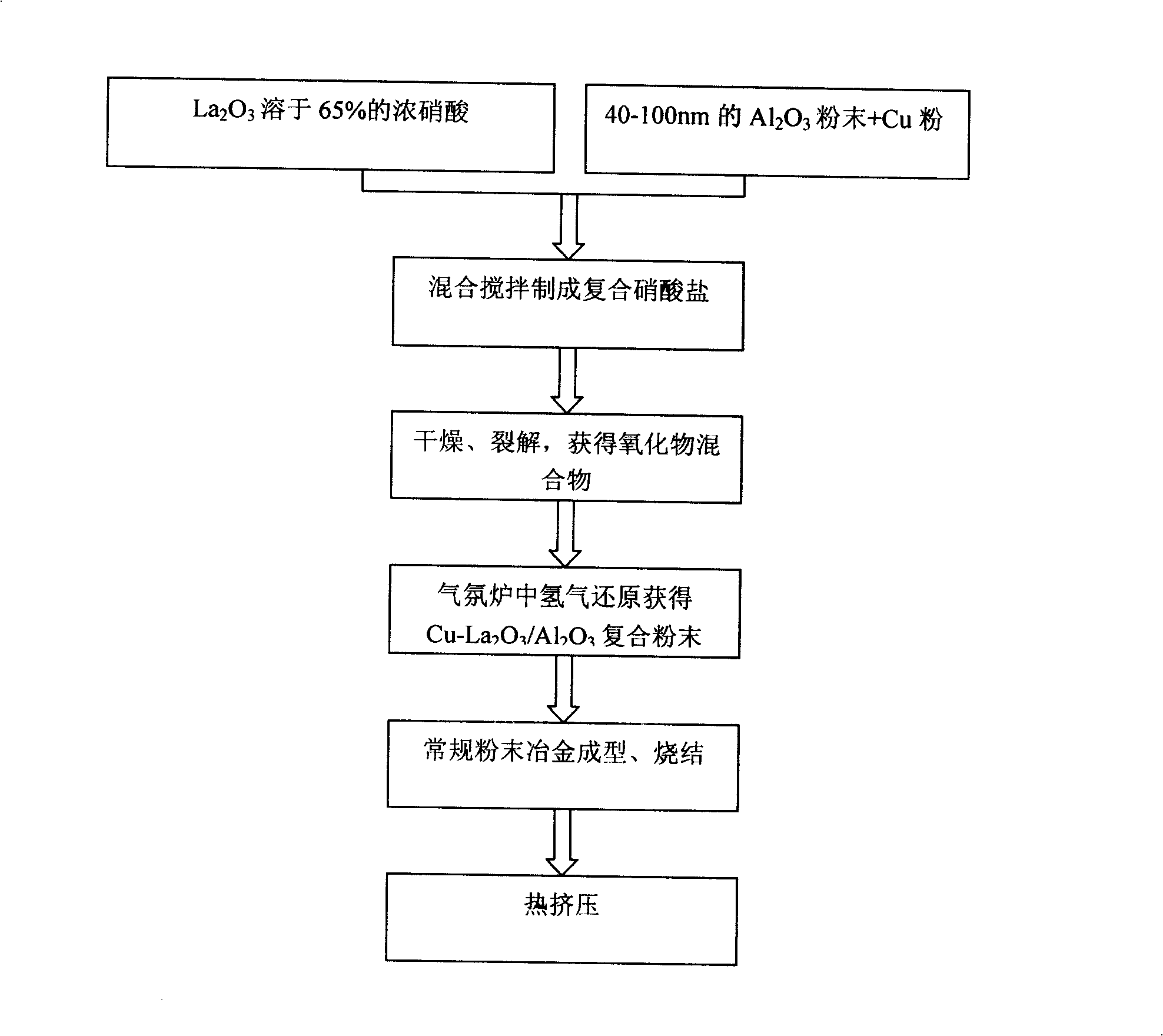

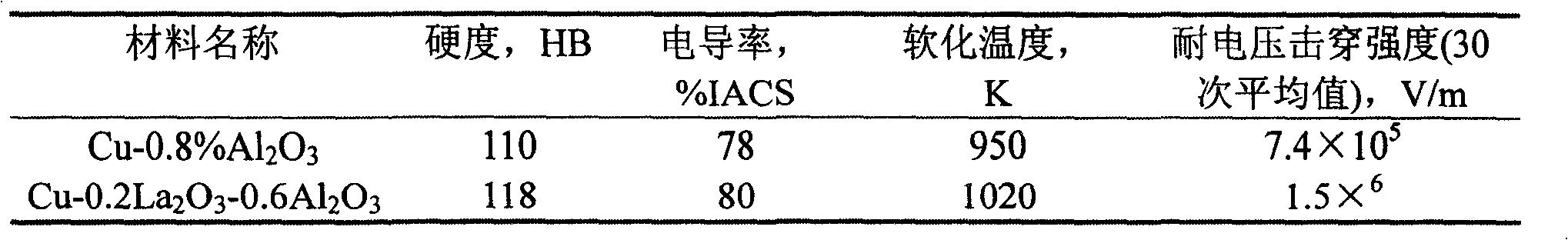

Cu-La2O3/Al2O3 composite material and its preparing method

The invention discloses Cu-La202 / Al203 composite material that is made up from 0.2-1wt% La 203, 0.6-3wt% Al203, and the rest is Cu. The producing process includes the following steps: dissolving La203 into 65% aqua fortis to make lanthanum nitrate solution, adding Al203. After adding distilled water to dilute, adding copper powder to make copper nitrate, drying the mixture solution, cracking to gain lanthana, copper oxide, and alumina powder, taking deoxidization to the mixture powder by hydrogen to gain Cu-La 203 / Al203 composite powder, pressure molding the powder, sintering and hot extruding, the material would be gained. The invention has the advantages of simple technology, low cost and more excellent capability than Cu / Al203.

Owner:XIAN UNIV OF TECH

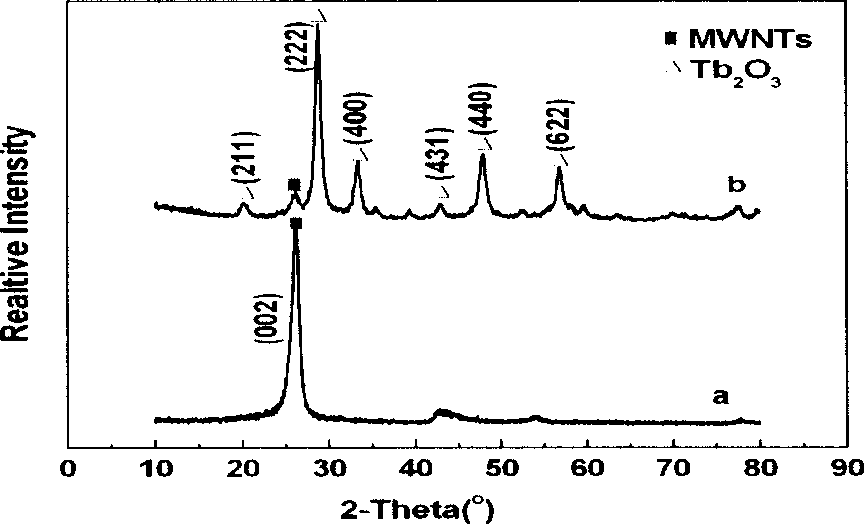

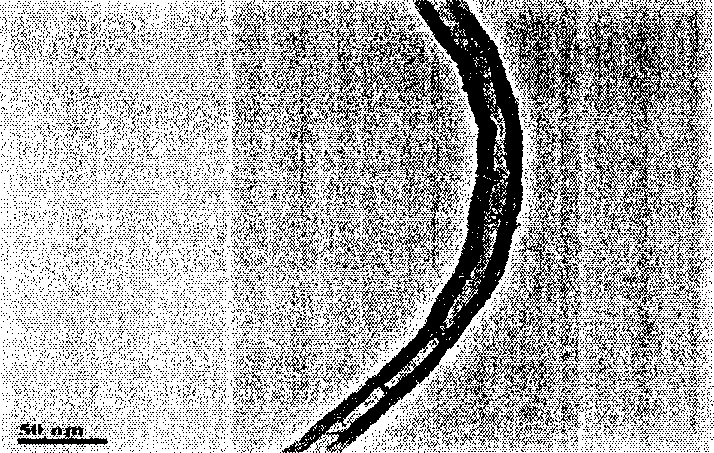

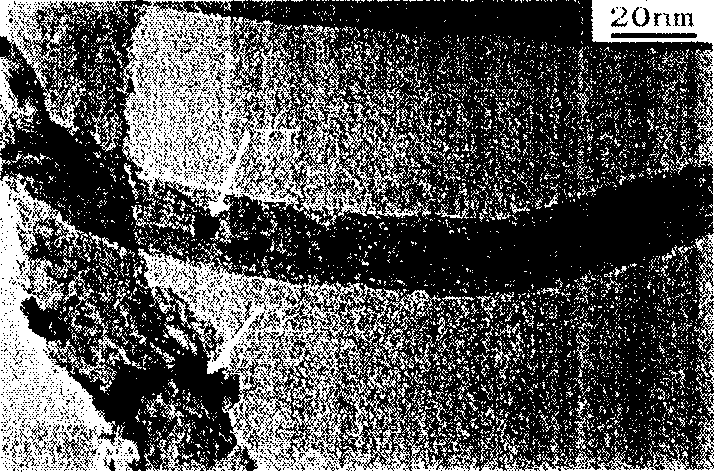

Method for preparing terbium oxide assembled carbon nano tube composite material

The invention relates to a preparation method for Tb2O3 assembled carbon nanometer tube compound material. Dissolve Tb2O3 in the aqua fortis, the preparation of Tb(NO3)3 crystal, under the room temperature, joined the carbon nano tube in the aqua fortis which included Tb(NO3 )3, supersonic disperser, 120 íµ - 140 íµ oil baths backflow 3 - 8 hours, when the backflow intermixture temperature drop to room temperature, carried on 15 - 70mol / l soluble alkali Titration, the filter diaphragm filtered, washes, dry 5 - 12 hours in 60 - 100 íµ; In the inert atmosphere, when the room temperature rise to 250 íµ, then maintains 1 - 2 hours, then elevates temperature to 400 - 700 íµ, maintains 0.5-3 hour, cools to the room temperature, then forms Tb2O3 assemblies carbon nanometer tube compound material. Advatages: simple method, good catalysis, good electricity and optical performance.

Owner:DONGHUA UNIV

Active alumina catalyst, and its preparation method and use

InactiveCN1579617AHigh purityLow impurity contentCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsAluminium hydroxideStone dust

The invention relates to a catalyst technology, concretely, an active alumina catalyst and its producing method. Components of the active alumina catalyst are: Na 0.8-0.1 percents, Fe<0.1 percent the others are alumina whose purity is over 99 percent. The producing approach is: using aluminium hydroxide powder or (and) bodhmite powder as material; evenly mixing aluminium hydroxide powder or (and) bodhmite with aqua fortis solution deployed by deionized water; forming, drying in 100-150deg.C for 2-8 hours, baking in 400-600deg.C for 3-20 hours, bolstering and getting production. Adopting the invention can improve selectivity and yield of compound alkyl sulfide and alkyl sulfhydrate, esp. dimethyl sulfide and methanethiol.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

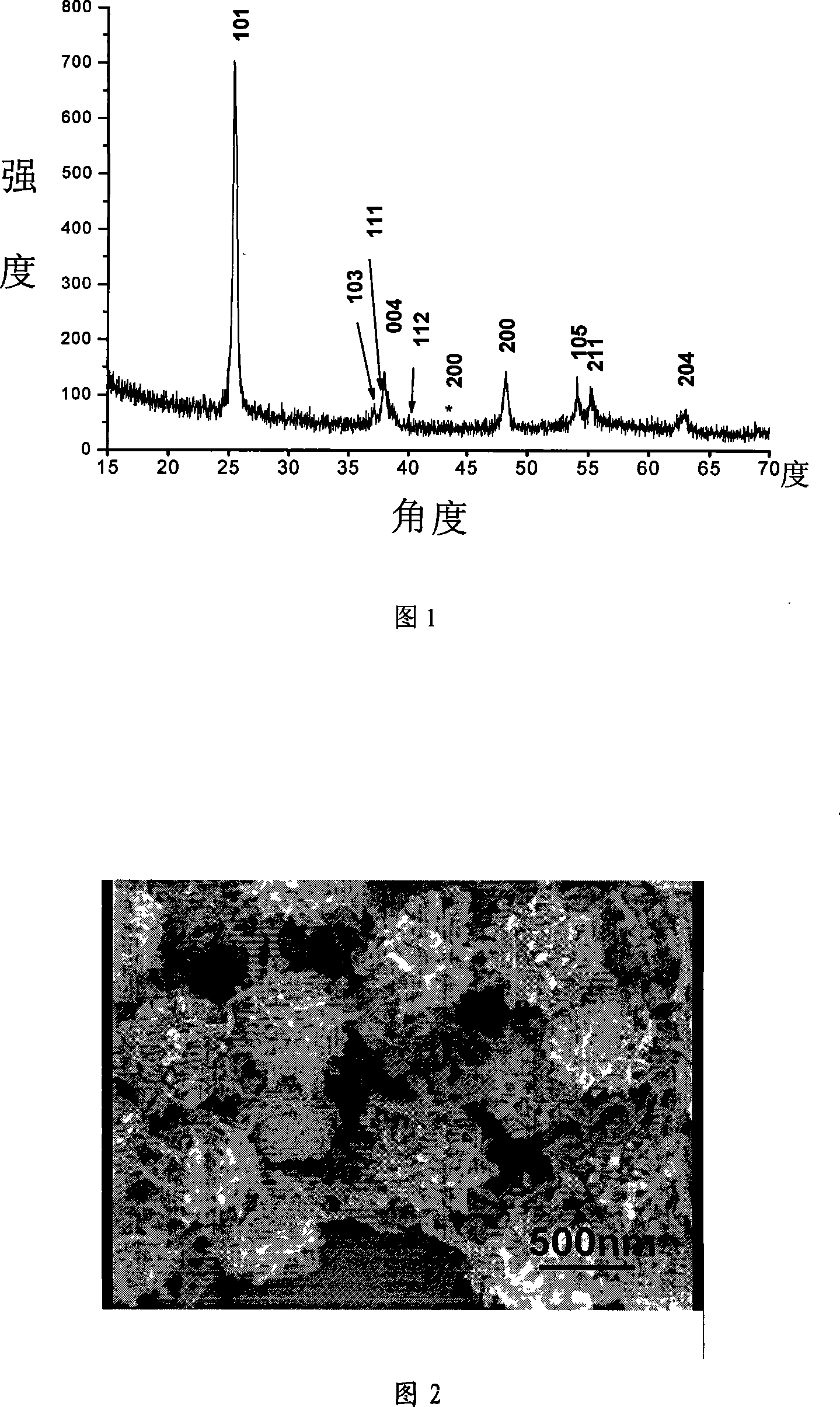

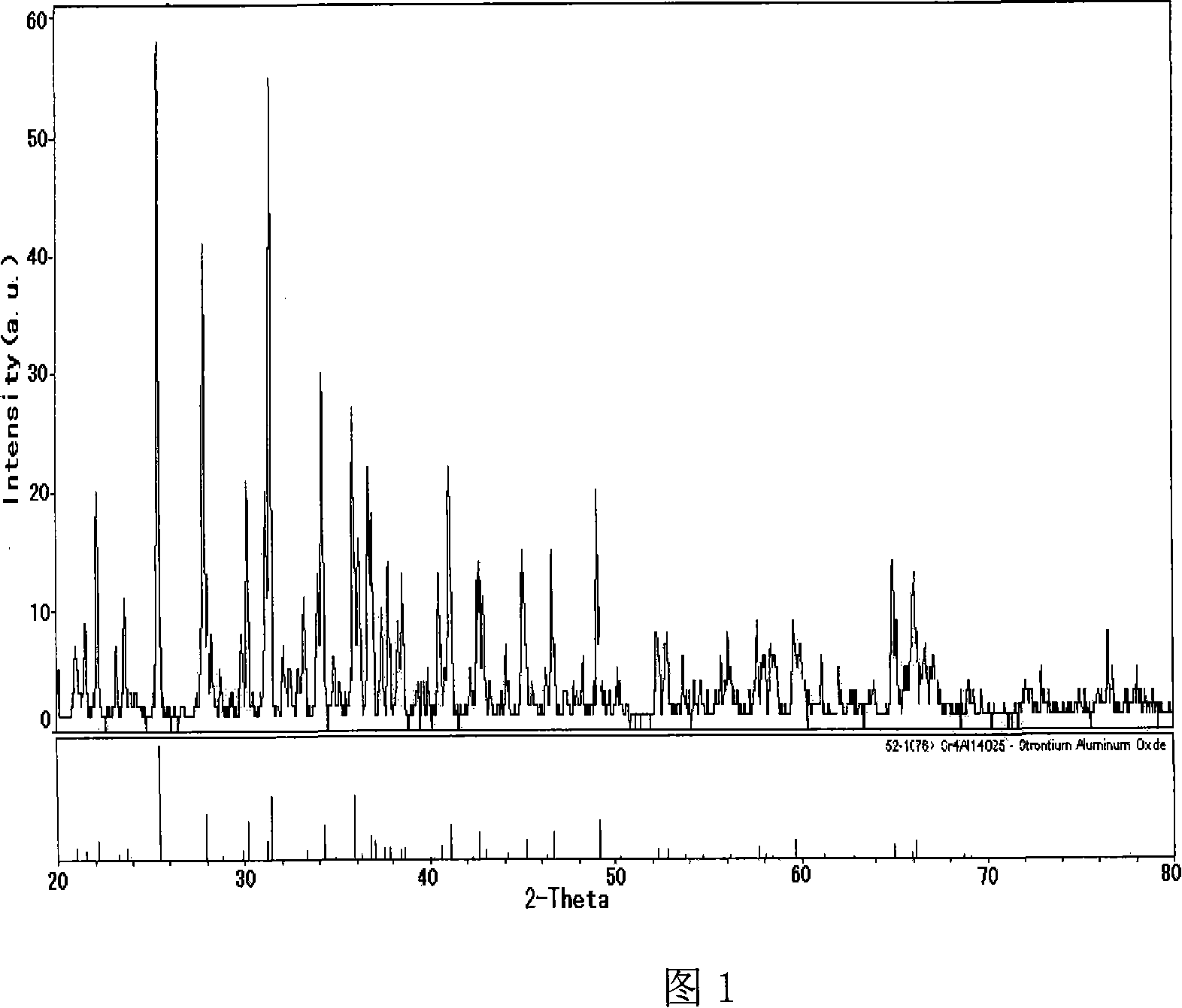

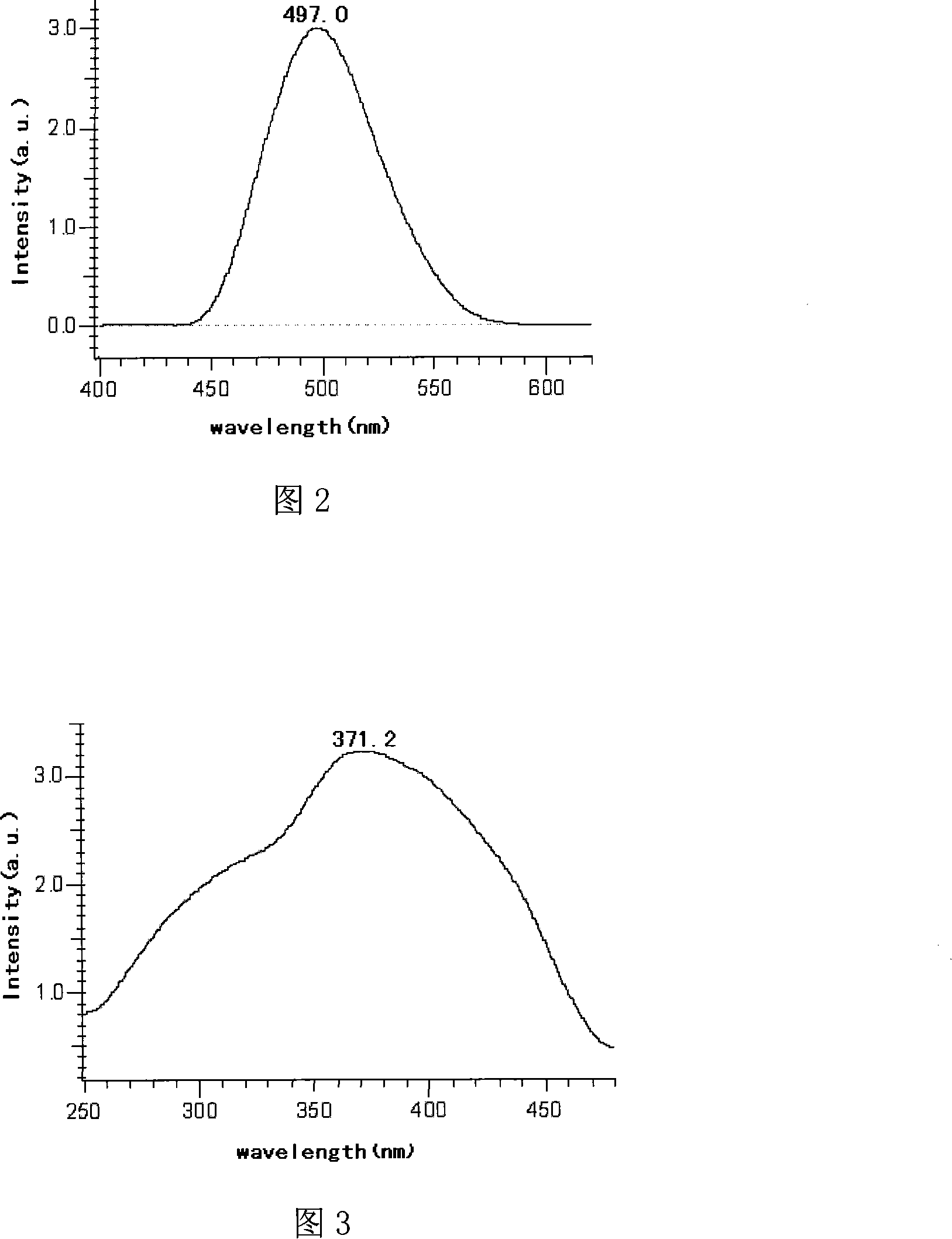

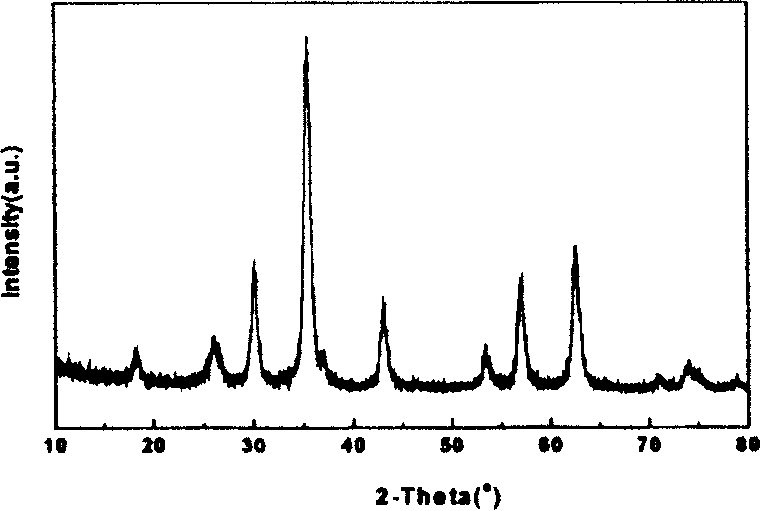

Aluminate luminescent material and preparation method thereof

InactiveCN101214988AImprove luminous efficiencyLong afterglowRare earth metal compoundsLuminescent compositionsAluminateDysprosium

The invention discloses a luminescent material of aluminate and a process for preparation. The material employs ionic water to prepare chloridate solution of Al and aqua fortis solution of Eu and Dy, mixes NH4HCO3 solution to deposit, after being heated and stirred, forms gel, scours and separates the gel and adds analytical pure SrO, after ultrasonically vibrating, stirring and hydrothermal reaction, mixing in H3BO3 solution , after drying sintering, luminescent material is obtained. The general formula is M (4-x-y), OmAl14 O25: Eux, REy, wherein x=0.001-0.08, y=0.001-0.08, M is strontium and RE is dysprosium. Compared with the prior art, the luminescent material of aluminate of the invention has the advantages of high luminous efficiency, long afterglow time, low energy consumption and short preparing circle, besides, the sintering of high temperature method is not serious, the particles are small and uniform. Compared with luminescence by co-precipitation method, the luminous efficiency is high, the afterglow time is long and the crystalling phase is pure.

Owner:EAST CHINA NORMAL UNIV

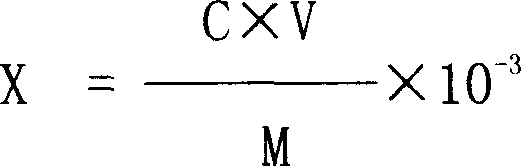

Method for determination of rare-earth content in nodularizer

InactiveCN1924559AImprove stabilityGood reproducibilityMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationRare-earth elementFluohydric acid

This invention discloses one nodularizer rare earth content testing method, which comprises the following steps: making test liquid and silicon, and the specimen liquid process steps are composed of aqua fortis and fluohydric acid specimen resolving, using boracic acid resolving over fluohydric acid to resolve the generated dinitrogen tetroxide by to process weak acid specimen liquid; the silicon process steps comprises the following steps: forming blue complex compound with azophosphon and rare earth element with largest absorption wavelength as 680nm with iron, titanium and calcium as mask with oxalic acid and with other metal element independent to measure the rare earth content by spectrophotometer.

Owner:SICHUAN DONGFENG ELECTRIC MACHINARY WORKS CO LTD

Process for preparing composite material of carbon nano tube/NiZn ferrite

InactiveCN100383279CStrong magnetismExcellent dielectric propertiesLiquid/solution decomposition chemical coatingMagnetic materialsSolubilityHigh density

Owner:DONGHUA UNIV

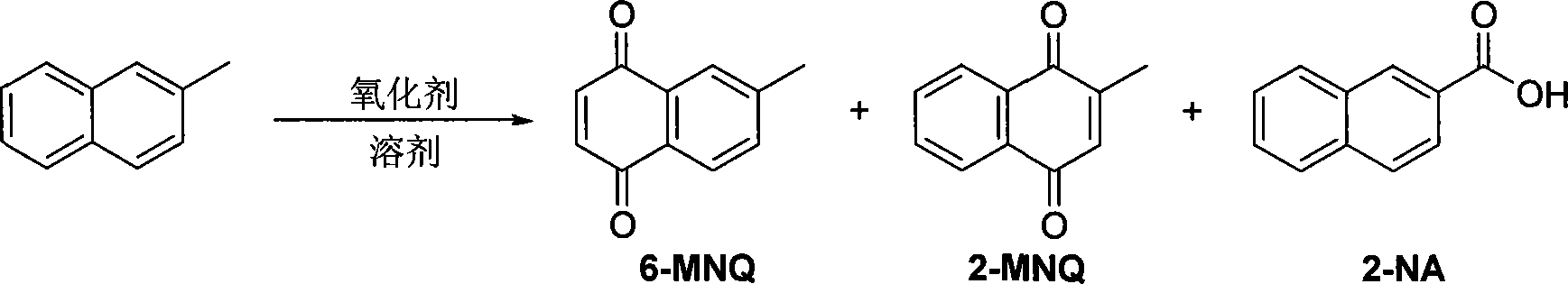

Process for preparing 2-methyl-1,4-naphthaquinoue using 2-methyl-naphthalene

InactiveCN101070279AHigh regional selectivityHigh yieldQuinone preparation by oxidationRegioselectivityNitration

This invention relates to a method of using 2 - methylnaphthalene as raw material to prepare 2-methyl-1 naphthaquinone, belongs to chemical engineering technique region. The invention includes nitration, reduction and oxidation reaction three steps. The nitration adopts fuming nitric acid or aqua fortis as nitryl reagent, gain gross product 2-methyl-1-nitronaphthalene; gross product under ordinary pressure takes catalytic hydrogenation by reducing reaction, translated into 2 - methylnaphthalene amine; catalyzer used for hydrogenation is Pd / C; oxidation reaction oxidize above offspring into end product, and the oxidizer is dioxide manganese, hydrogen peroxide and so on. The invention has merits of high oxidative regioselectivity, mild reaction conditions, simple handling and security, high yield and low cost.

Owner:上海力智生化科技有限公司

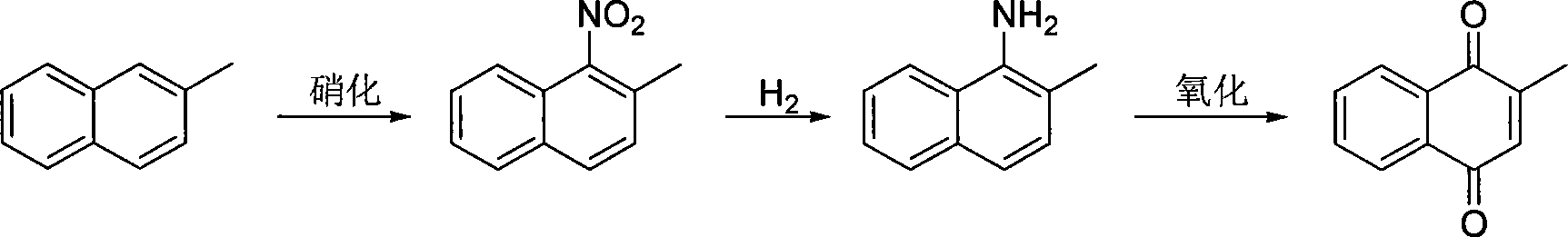

Method for continuously dilution diluting aqua fortis and controlling generation of NO2

The invention relates to a method for continuously diluting aquafortis and controlling the production of NO2, which is characterized in that the method comprises the following steps: causing the auqafortis to flow through a flat-bottomed channel; continuously spraying water to the surface of flowing nitric acid from the upper part, so that the auqafortis and the water are mixed during the flowing process; and collecting diluted nitric acid by using a container arranged at the other low end of the flat-bottomed channel. An interlayer is arranged at the bottom part of the flat-bottomed channel; and a cooling medium is introduced into the interlayer, so as to further reduce and dilute the temperature of the nitric acid. The invention has the advantages that the water is continuously sprayed on the surface of the flowing nitric acid to increase and dilute the contact area of a heating part, air and the cooling medium; and liquid finishes the mixture during the flowing process and immediately carries away heat generated to control heat accumulation during the diluting process, so that the temperature of the heating part is reduced, the decomposition of the nitric acid is controlled or avoided, and the continuous and automatic diluting process of the auqafortis is achieved.

Owner:陈淮银

Method for preparing Co3O4 composite film on surface of single crystal silicon

InactiveCN101748490AGood anti-frictionSolving Tribological ProblemsAfter-treatment detailsPretreated surfacesComposite filmSilanes

The invention relates to a method for preparing a Co3O4 composite film on the surface of single crystal silicon. A single crystal substrate with a processed surface is used as a base material, sulfonic silane is prepared on the surface by a self-assembly method, then the substrate is put in a Co3O4 dispersion, and the Co3O4 composite film is prepared on the surface. The method comprises the following steps: immersing the substrate in aqua fortis for heating for 5-6 hours; taking out and cleaning with deionized water; putting in a hydroxylation solution for processing for 1 hour at room temperature; immersing in a prepared mercapto silane solution after cleaning and drying, standing for 6-8 hours and taking out; washing, drying with nitrogen, and putting in nitric acid; oxidating end thiol into sulfonyl in situ, then putting the substrate in a Co3O4 suspension, standing for 2-24 hours at the temperature of 20-60 DEG C, and taking out; drying with nitrogen after washing, and obtaining the composite film deposited with Co3O4 on the surface. The method can reduce a friction coefficient from 0.8 in no film to 0.1 and has very obvious antifriction action.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

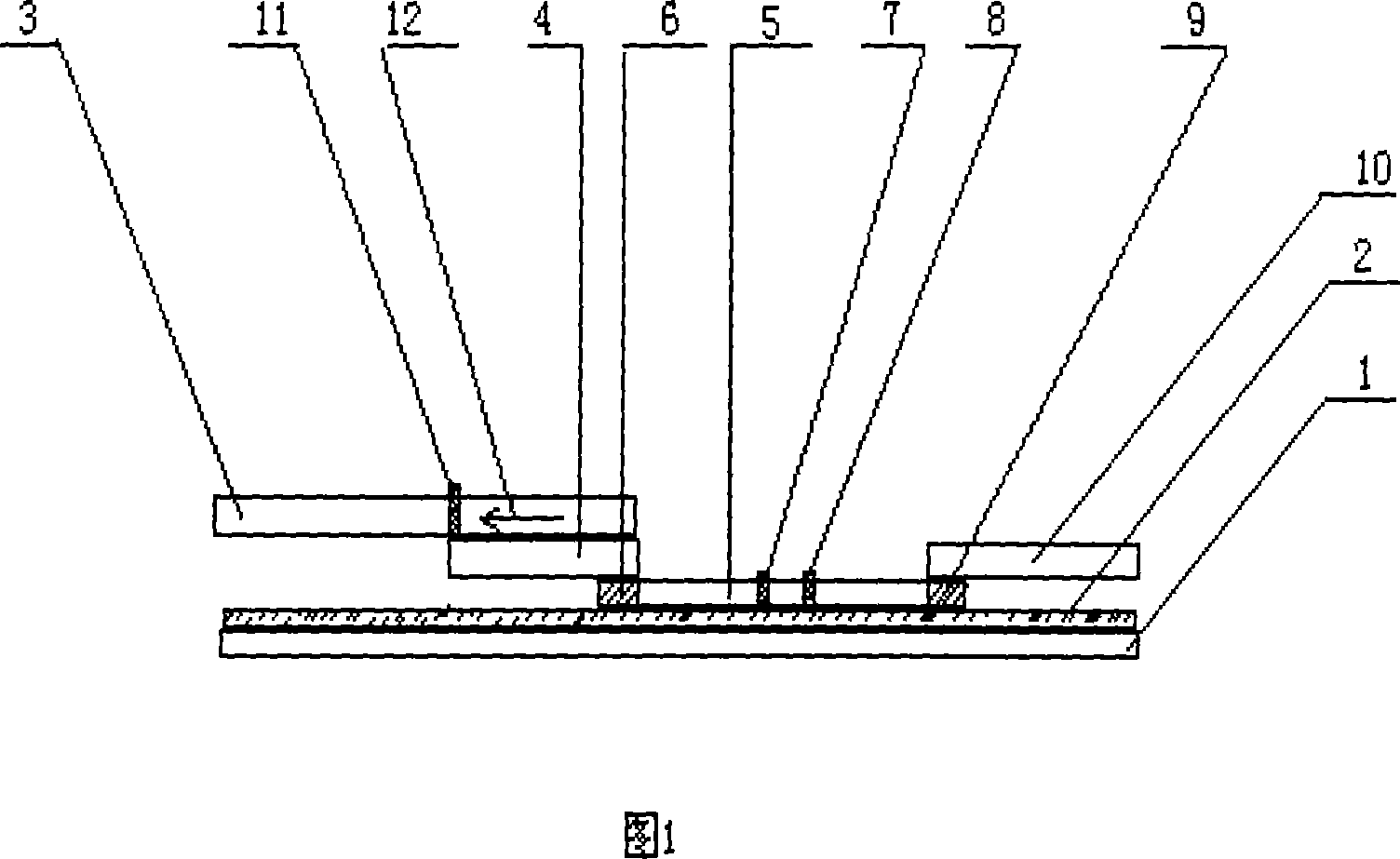

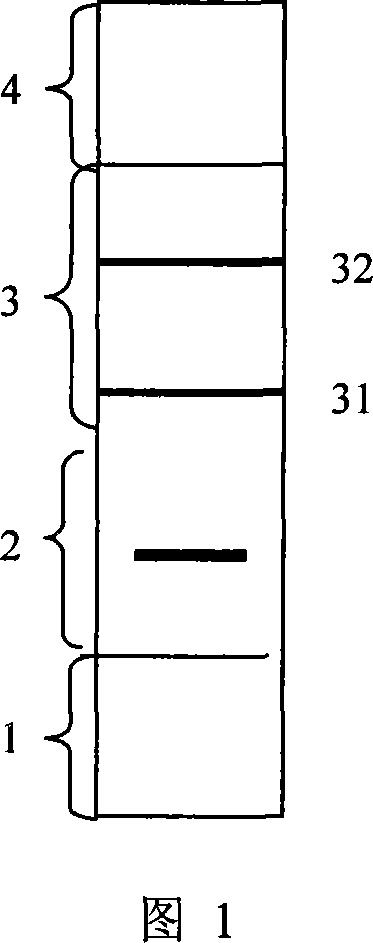

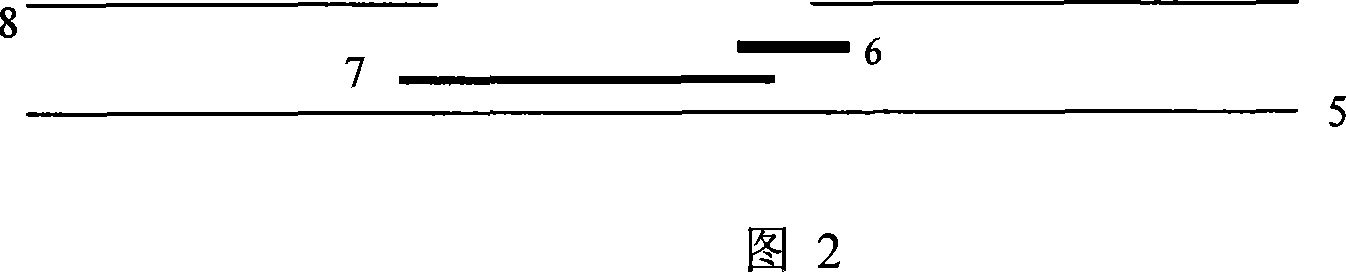

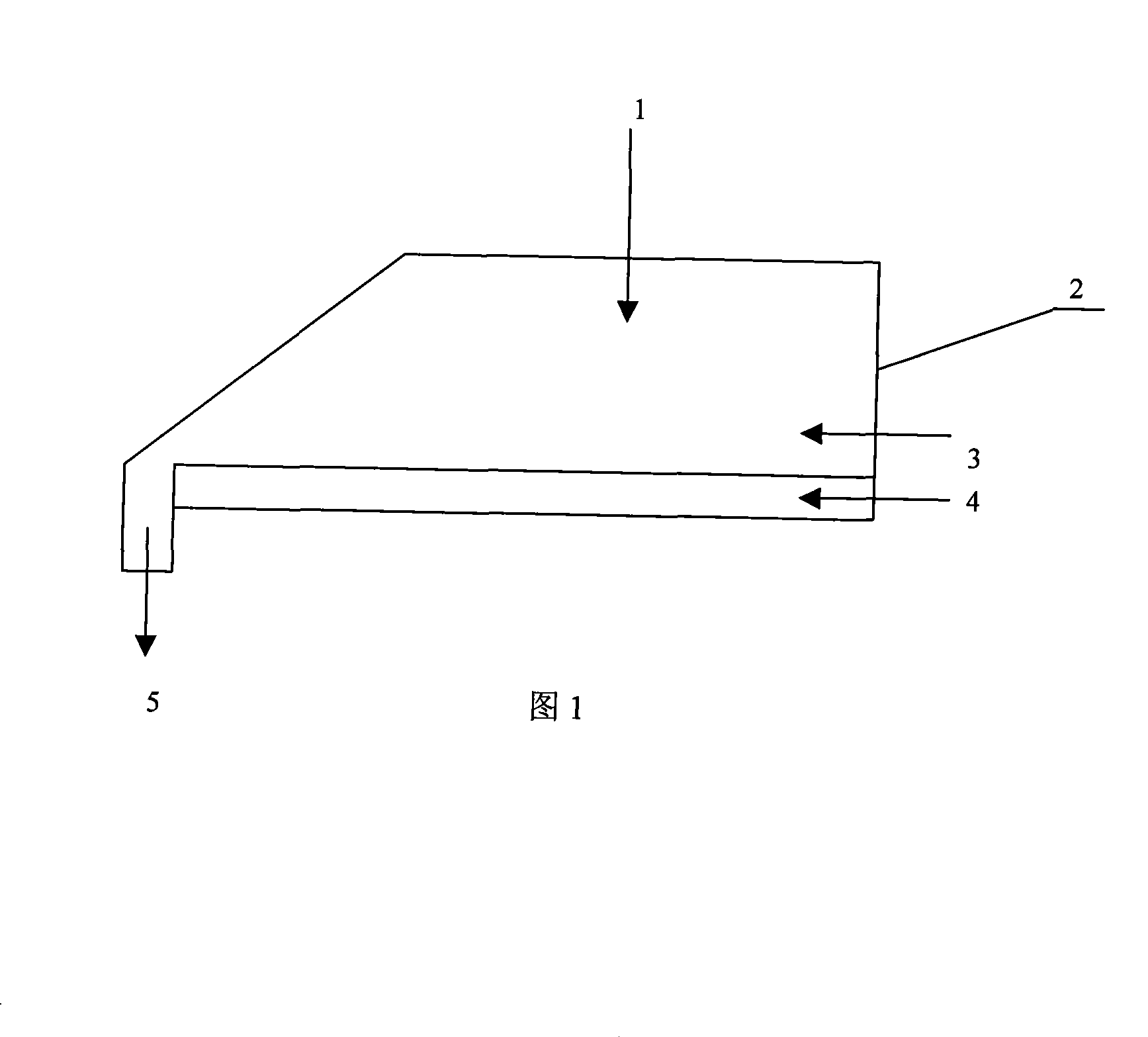

Method for reclaiming platinum-silver-iodine form platinum-containing silver iodide slag

The invention relates to a method for recycling platinum, silver and iodine from platinum-containing silver iodide slag or silver iodide and a device for recycling platinum, silver and iodine. The method comprises the steps that: (1) putting platinum-containing silver iodide slag into a 20L reactor shown in the figure 1, slowly adding aqua fortis, slowly warming up to boil, and reacting under usual conditions; (2) cooling and filtering after reaction, adjusting the acidity of the filtrate by sodium hydroxide, separating simple substance iodine, filtering the simple substance iodine, concentrating the filtrate to get ammonia chloroplatinate sediment by adding ammonium chloride, burning to get metal platinum; and (3) getting silver chloride sediment from above sediment and reducing hydrazine hydrate to get metal silver. The key process is that platinum-containing silver iodide slag environment-friendly reacts with an oxidizer in a specific device, and platinum, silver and iodine are recycled at the same time. The invention provides a method for clean production, environment-friendly production, environment-polluted iodine recycle and platinum and silver recycle form platinum-containing silver iodide slag or silver iodide produced during platinum anticancer drugs production.

Owner:KUNMING GUIYAN PHARMA

Silicon carbide boat cleaning method

InactiveCN101359581BImprove thermal stabilityPromote precipitationSemiconductor/solid-state device manufacturingCleaning using liquidsManganeseMetal impurities

The invention discloses a carborundum boat washing method which includes the steps of cleaning the surface, soaking with aqua fortis, soaking with hydrofluoric acid, heat treatment, surface treatment, flame polish, etc. Through the step of soaking with aqua fortis, metal impurities such as iron, manganese, cuprum, natrium, kalium and the like left on the carborundum boat can be got rid of. The annealing treatment of putting the carborundum boat in an annealing furnace can accelerate the precipitation of the impurities in the carborundum boat, eliminate stress and improve thermal stability of the carborundum boat. The carborundum boat washed through the method is of nearly the same cleanliness, colour and luster and use effect with a new carborundum boat. The carborundum boat washing method is good in washing effect and the cost is only 1 / 10-1 / 30 of the cost of a new carborundum boat, thus greatly reducing production cost of the corporation.

Owner:HUZHOU DONGKE ELECTRONICS QUARTZ

Etch combination

InactiveCN1873054BReduce surface tensionFacilitated DiffusionAnionic surface-active compoundsDetergent mixture composition preparationAcetic acidEtching

The invention provides a etching compound, using said compound to carry out wet etching for TFT grid wiring material Al-Nd / Mo bilaminar membrane or Mo / Al- Nd / Mo three-layer membrane, which forms film transistor liquid crystal displayer, the wet etching employs single process by way of no undercut by lower membrane Al- Nd or Mo; the taper is good and configuration of Mo monolayer film of source / drain wiring material is outstanding. The etching compound comprises phosphoric acid, aqua fortis, acetic acid, acetic acid surface activator and water.

Owner:DONGJIN SEMICHEM CO LTD

A nitric oxides (NOX) waste pollution control in industrial process and resource reclaiming method

InactiveCN100396360CGood governanceSimple processDispersed particle separationHydrogen NitrateHigh concentration

The invention relates to a method for treating and reusing waste gas containing nitrogen oxide generated in industrial process. It comprises following steps: mixing waste gas containing nitrogen oxide with air according to a certain proportion, plural serial adsorbing it in tower by introducing it from bottom of head tower, discharging it from top of tail tower, discharging generated hydrogene nitrate of low concentration from bottom of head tower, proceeding decompressing and thickening process in thickening tower, which includes bleaching and dewatering; hydrogen nitrate of low concentration is introduced from top of thickening tower, hydrogen nitrate of high concentration being 45-65% is discharged from bottom; supercharging nitrogen oxide extracted from thickening tower top with vacuum system, then introducing it into adsorbing process again; the water or diluted acid from thickening tower is used as adsorbent and is added from top of tail tower in adsorbing process and counter current contacts with gas in tower for mass transferring. The waste gas treatment effect is good, and the discharging concentration of nitrogen oxide in exhaust gas is less than 50 ppm; all the nitrogen oxide in exhaust gas is recycled to generate aqua fortis with mass concentration being more than 55%.

Owner:NANJING UNIV

Load-type foamed aluminum catalyst for removing dimethyl formamide by use of supercritical water oxidization

InactiveCN106423210AImprove removal efficiencyImprove stabilityWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsSupercritical water oxidationSubstance M

The invention discloses a load-type foamed aluminum catalyst for removing dimethyl formamide by use of supercritical water oxidization. The load-type foamed aluminum catalyst for removing dimethyl formamide by use of supercritical water oxidization is prepared by virtue of the following steps: washing foamed aluminum, and then modifying the washed foamed aluminum with AgNO3, thereby obtaining a substance M; modifying a mixed solution prepared from polyvinyl pyrrolidone, methanol, gold trichloride, concentrated hydrochloric acid and sodium borohydride by the substance M, thereby obtaining a substance N; modifying a mixed solution prepared from SrCl2, CoCl2, concentrated aqua fortis, urea and ammonium fluoride by the substance N, thereby obtaining a substance O; modifying a mixed solution prepared from tetra-n-butyl titanate, tetraethyl orthosilicate and acetylacetone by the substance O, thereby obtaining a substance P; modifying a mixed solution prepared from ZrCl4, MgCl2 and InCl3 by the substance P, thereby obtaining a substance Q; and modifying a mixed solution prepared from PbCl2, BiCl3, NaOH, Na2CO3 and CdCl2 by the substance Q, thereby obtaining a substance, namely the load-type foamed aluminum catalyst for removing the dimethyl formamide by use of supercritical water oxidization.

Owner:北京清水润土环保科技有限公司

Cu-La2O3/Al2O3 composite material and its preparing method

The invention discloses Cu-La202 / Al203 composite material that is made up from 0.2-1wt% La 203, 0.6-3wt% Al203, and the rest is Cu. The producing process includes the following steps: dissolving La203 into 65% aqua fortis to make lanthanum nitrate solution, adding Al203. After adding distilled water to dilute, adding copper powder to make copper nitrate, drying the mixture solution, cracking to gain lanthana, copper oxide, and alumina powder, taking deoxidization to the mixture powder by hydrogen to gain Cu-La 203 / Al203 composite powder, pressure molding the powder, sintering and hot extruding, the material would be gained. The invention has the advantages of simple technology, low cost and more excellent capability than Cu / Al203.

Owner:XIAN UNIV OF TECH

Gold wet purification process

The invention relates to a process for purifying gold by the wet method. Firstly, aqua fortis is used to remove silver; secondly, nitric acid is used to remove impurities such as bismuth and copper, etc.; the separation is performed by filtering; in the richly contained gold solution, the gold is reduced to gold powder deposited by an oxalic acid reducing agent with strong reducibility, and the impurities such as platinum, the bismuth and the copper, which are reduced simultaneously, are redissolved by nitric acid added later and enter the solution, and the solution is subjected to the filtering separation to obtain pure gold powder; and the pure gold powder is made to be ingot-shaped by fushion casting, and the finished gold ingots with a gold content of 99.99 percent are obtained. In theinvention, the reduction reaction is made by oxalic acid at a low temperature, so that the process of the invention has the advantages of not causing environmental pollution, favorability for the heath of operators, lowering cost, shortening the period and obvious economic and social benefits.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

Method for preparing ZrO2 compound film on surface of monocrystalline silicon wafer

InactiveCN101412636ANo pollution in the processImprove wear resistanceComposite filmRoom temperature

The invention provides a method for preparing ZrO2 composite film on the surface of a monocrystalline silicon slice, which comprises the following steps: soaking the monocrystalline silicon slice in aqua fortis to be heated for 5 to 6 hours; taking out the monocrystalline silicon slice, cleaning the monocrystalline silicon slice by using deionized water, and drying the monocrystalline silicon slice; immersing the monocrystalline silicon slice in solution of which the volume ratio of H2SO4 to H2O2 is 70 to 30 to be treated for 1 hour at room temperature; immersing the monocrystalline silicon slice in the prepared mercaptosilane solution after cleaning and drying, and taking out the monocrystalline silicon slice after the mixture is kept standing for 6 to 8 hours; blowing the monocrystalline silicon slice by using nitrogen after cleaning; and placing the monocrystalline silicon slice in salpeter solution with mass concentration of between 30 and 60 percent to react for 2 hours at a temperature of between 50 and 80 DEG C so as to oxidize terminated mercapto to sulfonic group in situ; finally, immersing the monocrystalline silicon slice in the prepared ZrO2 suspending liquid to be kept stand for 2 to 24 hours at a temperature of between 20 and 60 DEG C; and taking out and cleaning the monocrystalline silicon slice, and blowing the monocrystalline silicon slice by using the nitrogen to obtain the monocrystalline silicon slice of which the ZrO2 composite film is deposited on the surface. The method can reduce the friction coefficient from 0.8 of no film to 0.1, thereby having obvious antifriction function.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com