Method for reclaiming platinum-silver-iodine form platinum-containing silver iodide slag

A technology for silver iodide and platinum silver, which is applied in the field of wet process technology for separating and extracting platinum, silver and iodine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

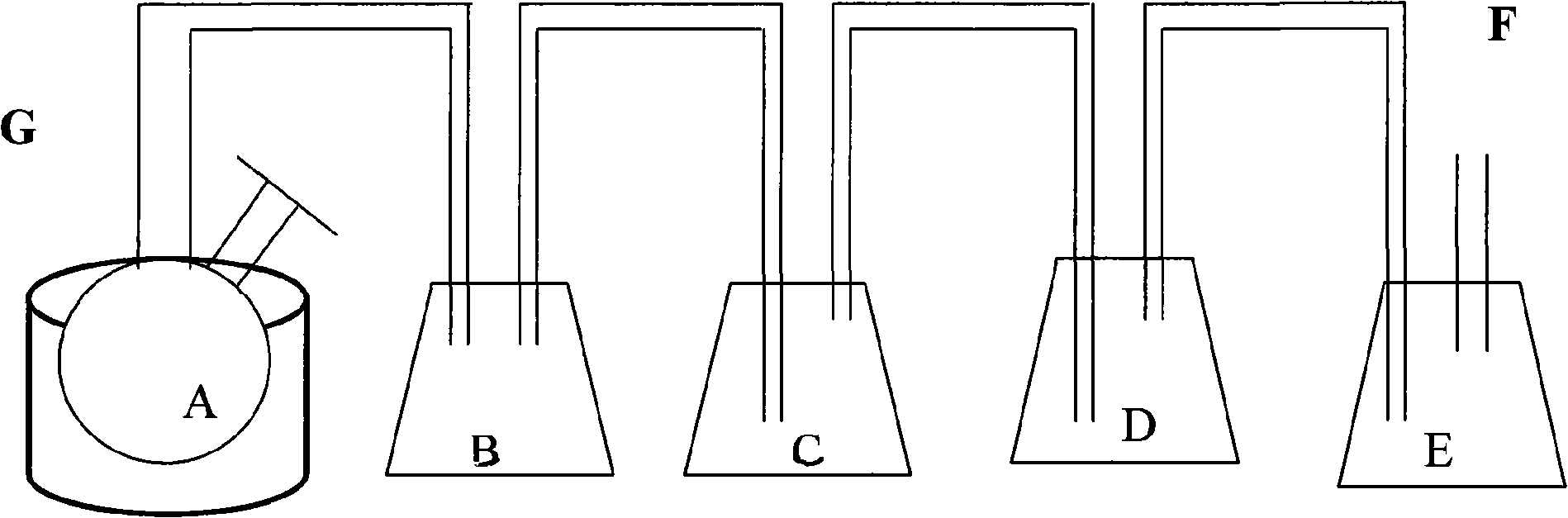

[0022] Embodiment 1, invention described equipment and preparation thereof:

[0023] (1), get analyzed, dry 2000 grams of silver iodide slag containing platinum, slowly add 70000 milliliters of aqua regia, in figure 1 In the equipment shown, slowly heat up to 120°C, react for 3 hours, cool down, filter the silver chloride precipitate, and wash thoroughly; (2), filter the liquid at 0-5°C, slowly add 20% NaOH dropwise solution, to PH=7-8, filter the sucked elemental iodine, continue heating and concentrating the filtered solution to a small volume, cool and filter, add 100 grams of NH4CL solution to the filtrate, precipitate (NH4)2PtCL6, filter (NH4)2PtCL6 precipitate, and fully wash , dry and burn to obtain metallic platinum; (3), adjust the silver chloride precipitation in (1) to be alkaline, and reduce it with hydrazine hydrate to obtain metallic silver, the yield of platinum is 93%, the yield of iodine is 80%, and the silver The yield is 98%.

[0024] According to atomic a...

Embodiment 2

[0025] Embodiment 2, invention described equipment and preparation thereof:

[0026] (1), get analyzed, dried 1500 grams of silver iodide slag containing platinum, slowly add / into 5300 milliliters of aqua regia, in figure 1 In the equipment shown, slowly heat up to 120°C, react for 2 hours, cool down, filter the precipitated silver chloride, and wash thoroughly. (2) Slowly add 20% NaOH solution dropwise to the filter solution at 0-5°C until PH = 7-8, filter the sucked elemental iodine, continue heating and concentrating the filter solution to a small volume, cool and filter, add 75% of the filtrate Gram of NH4CL solution, precipitate (NH4)2PtCL6, filter (NH4)2PtCL6 precipitate, and fully wash, dry and burn to obtain metal platinum. (3), adjust the silver chloride precipitation of (1) to be alkaline, and obtain silver metal through reduction with hydrazine hydrate, the yield of platinum is 92%, the yield of iodine is 81%, and the yield of silver is 99.7%.

[0027] According t...

Embodiment 3

[0028] Embodiment 3, invention described equipment and preparation thereof:

[0029] (1), get analyzed, dried 3000 grams of platinum-containing silver iodide slag, slowly add / into 10000 milliliters of aqua regia, in figure 1 In the equipment shown, slowly heat up to 120°C, react for 3 hours, cool down, filter the precipitated silver chloride, and wash thoroughly. (2) Slowly add 20% NaOH solution dropwise to the filter solution at 0-5°C until PH = 7-8, filter the sucked elemental iodine, continue heating and concentrating the filter solution to a small volume, cool and filter, add 150 to the filtrate Gram of NH4CL solution, precipitate (NH4)2PtCL6, filter (NH4)2PtCL6 precipitate, and fully wash, dry and burn to obtain metal platinum. (3), the silver chloride precipitation of (1), is adjusted to alkalescence, and hydrazine hydrate reduction obtains metal silver, and the yield of platinum is 92%, the yield of iodine is 79%, and the yield of silver is 99.9%.

[0030] According t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com