Preparation method of silver iodide/platy bismuth-rich type bismuth iodide composite photocatalytic material

A composite photocatalysis and silver iodide technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as time-consuming and energy-consuming, and achieve less time-consuming and energy-consuming, mild conditions, and excellent The effect of photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

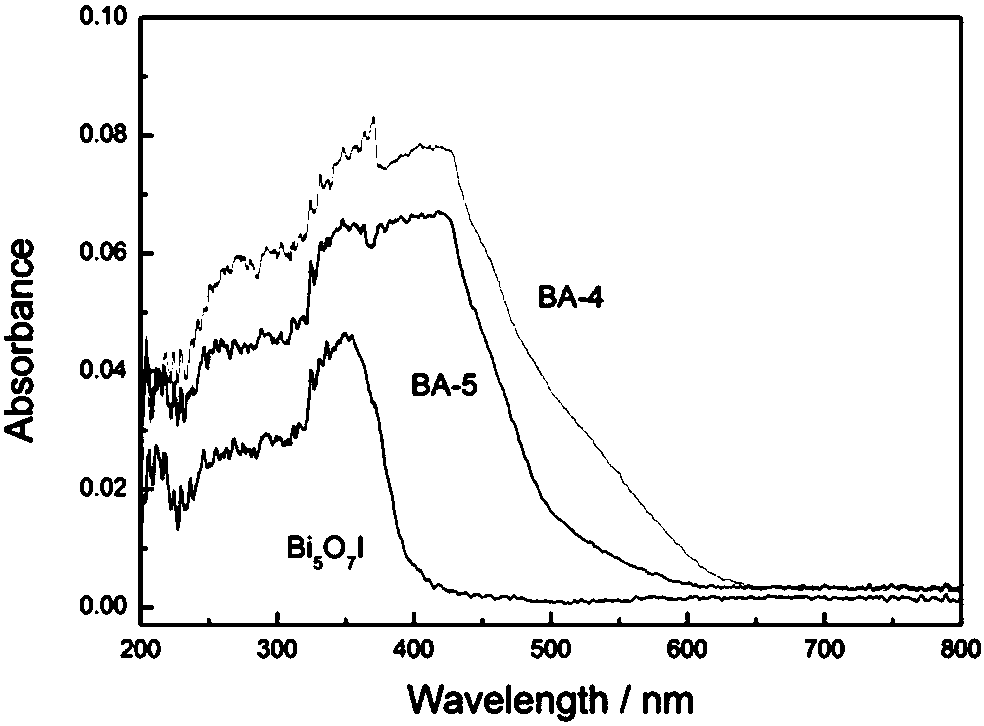

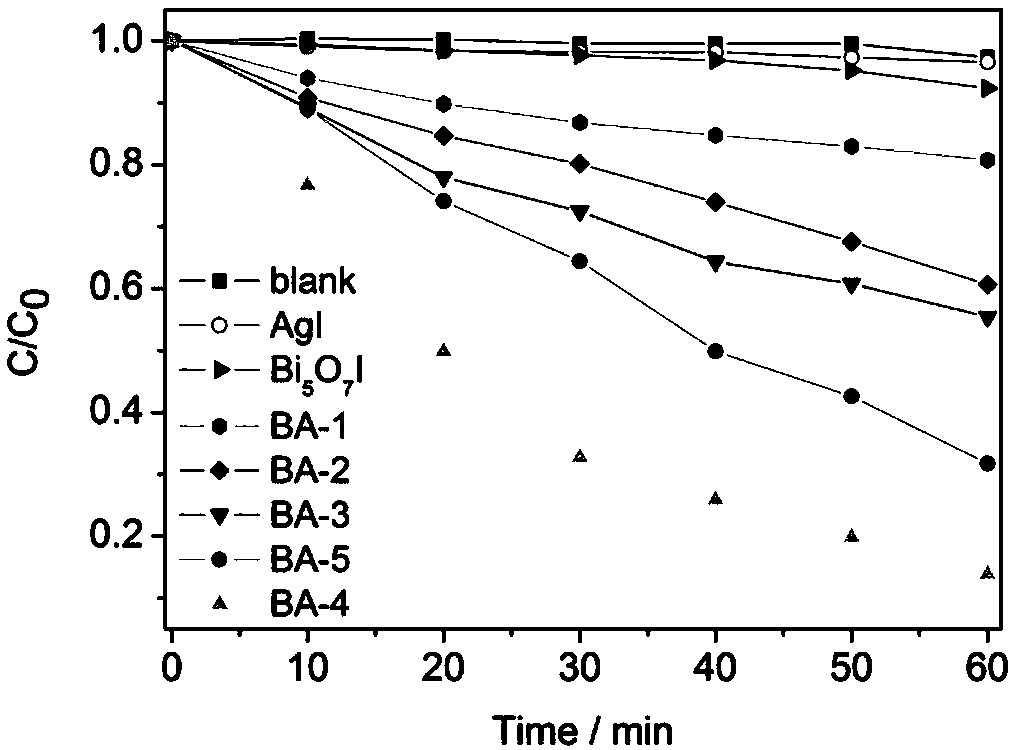

[0023] Example 1: Preparation of silver iodide / plate-shaped bismuth-rich bismuth oxyiodide composite photocatalytic material

[0024] ① Add 0.97g Bi(NO 3 ) 3 ·5H 2 O was uniformly dispersed in 30 mL of ethylene glycol, weighed 0.332 g KI and dissolved in 10 mL of deionized water, added dropwise to the bismuth nitrate suspension, and then adjusted the pH to 7 with 1.5 M ammonia water. After stirring at room temperature for 2 h, BiOI was obtained by centrifugation, washing with deionized water three times, washing with ethanol three times, and finally drying at 70 °C for 8 h.

[0025]②Weigh 0.5g of BiOI prepared above, and disperse evenly in 50mL of deionized water under the action of magnetic stirring, add 1M NaOH dropwise, and finally add 0.1M AgNO according to the molar percentage of Bi / Ag of 17.8%. 3 , after stirring at room temperature for 1h, AgI / Bi 5 o 7 Complex I, labeled BA-4, was centrifuged, washed three times with deionized water, washed three times with ethanol...

Embodiment 2

[0027] Example 2: Preparation of silver iodide / plate-shaped bismuth-rich bismuth oxyiodide composite photocatalytic material

[0028] ① Add 0.97g Bi(NO 3 ) 3 ·5H 2 O was uniformly dispersed in 30 mL of ethylene glycol, weighed 0.332 g KI and dissolved in 10 mL of deionized water, added dropwise to the bismuth nitrate suspension, and then adjusted the pH to 7 with 1.5 M ammonia water. After stirring at room temperature for 2 h, BiOI was obtained by centrifugation, washing with deionized water three times, washing with ethanol three times, and finally drying at 70 °C for 8 h.

[0029] ②Weigh 0.5g of BiOI prepared above, and disperse evenly in 50mL deionized water under the action of magnetic stirring, add 1M NaOH dropwise, and finally add 0.1M AgNO according to the molar percentage of Bi / Ag 25.0% 3 , after stirring at room temperature for 1h, AgI / Bi 5 o 7 Complex I, labeled BA-5, was centrifuged, washed three times with deionized water, washed three times with ethanol, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com