Method for preparing chitin and its chitosan and chitosan oligosaccharide

A technology of chitin and chitosan, applied in the biological field, can solve the problems of polluted water environment, difficult extraction, huge energy consumption, etc., and achieve the effects of making full use of resources, improving comprehensive economic benefits, and improving production conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

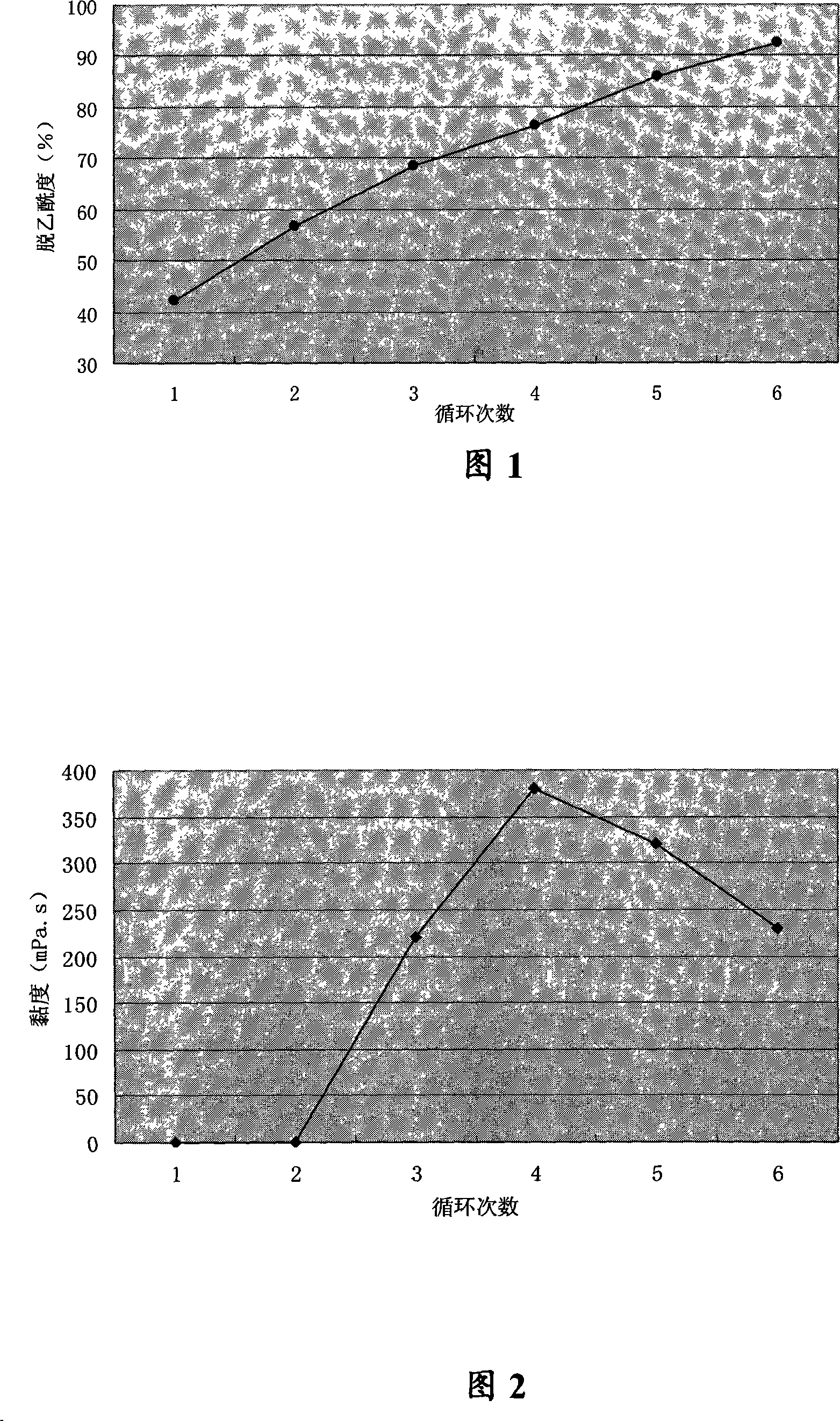

Image

Examples

Embodiment 1

[0052] Embodiment 1: the preparation of crab shell chitin

[0053] a. Take 10kg of river crab shells, wash, remove impurities, and dry, then immerse in 4-6% HCI for repeated soaking and decalcification, that is, take out the material every 2 hours, and soak it again after leaching the acid solution for 15 minutes; stop during the reaction Bubbles (carbon dioxide) are emitted, and the decalcification is terminated after continuing to soak for 2 hours.

[0054] b. Filtrate and separate the decalcified crab shell and calcium-containing acid solution (the filtrate will be treated separately), wash the decalcified shell material with water to neutrality, fully dry it, and pulverize it with a pin mill to a fine powder with an average particle size of 60-100 μm .

[0055] c. Boil the micropowder in water for 15 minutes, drain it, then add the clean warm water at 40°C with the ratio of solid: liquid = 1:4, suspend it in the reaction kettle, and then add the ratio of 1:1 Mix the crud...

Embodiment 2

[0057] Embodiment 2: the preparation of fly maggot chitosan

[0058] a. Pretreatment: Collect 30kg of fresh fly maggots, wash and remove impurities, fully drain and then mechanically break the skin, squeeze out the contents with a press (separately processed), collect the remaining skins, and dry until the moisture <10%, 0 Pre-freeze for 6 hours below ℃, and after hardening, use a centrifugal impact crusher to pulverize it to a fine powder with an average particle size of 150-250 μm (60-100 mesh).

[0059] b. The obtained fine powder was boiled in water for 15 minutes, drained, and then mixed with solid: liquid = 1:4, added to clean warm water at 40°C, suspended in the reaction kettle, and mixed according to the ratio of 1:1 Mix the crude enzyme solution with lipase and protease slowly, and carry out co-enzymatic degreasing and deproteinizing reaction. The reaction time is 18 hours. Most of the fat and protein are dissolved in the reaction solution. After the reaction is termi...

Embodiment 3

[0063] Embodiment 3: the preparation of aspergillus niger mycelium chitosan oligosaccharide

[0064] a. Pretreatment: 50kg of citric acid waste residue (mainly containing Aspergillus niger mycelium) collected by the food additive factory, drained with clear water until the humidity reaches 70%, and grind it with a colloid mill until the average particle size of the material is 20-60 μm. Micropowder.

[0065] b. Soak mycelium micropowder in hot water at 65°C for 30 minutes, pour it off, then add clean warm water at 40°C with a solid:liquid ratio of 1:4, and mix it with the same mycelium suspension in the reaction kettle, etc. The volume of lipase and protease crude enzyme solution (lipase: protease = 1:6) was mixed, stirred intermittently, and carried out the co-enzyme degreasing and deproteinizing reaction, the reaction time was 18h, and centrifuged (2500r / min) after the reaction was terminated. Solid and liquid separation.

[0066] c. Collect solids, wash 3 times with warm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com