Patents

Literature

410results about How to "Improve production conditions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Light insulating brick prepared from fly ash, boiler slag, construction garbage and straw and preparation thereof

InactiveCN101298371ASimple preparation processEnergy savingSolid waste managementScrapAgricultural waste

The invention relates to a light-weight insulating brick produced by adopting pulverized fuel ash, furnace slag, building waste and stalk and a production method thereof. The materials of pulverized fuel ash, furnace slag, building waste, stalk, lime power, cement, gypsum, Na2SO4 and water are prepared according to the following mass ratio and are then mixed, molded and cured to product the light-weight insulating brick; the light-weight insulating brick comprises the following weight percentage of all ingredients of the raw materials: 36-55 parts of pulverized fuel ash, 6-20 parts of furnace slag, 26-35 parts of building waste, 3-15 parts of stalk, 12-15 parts of carbide slag, 8-14 parts of cement, 2-5 parts of gypsum, 1-3 parts of Na2SO4 and proper amounts of water. The method utilizes the industrial and agricultural wastes such as the pulverized fuel ash, furnace slag, building waste, stalk and so on to produce the light-weight insulating brick, and the brick is light in weight, heat-insulating, has high strength and meets the quality standard; furthermore, the production technique is simple and no wastewater, waste residue or exhaust gases is discharged, so the invention is energy-saving, pollution-free, low-cost and has good production condition.

Owner:李东升

Biological organic fertilizer prepared by using mushroom bran as raw material and preparation method thereof

ActiveCN102653479AIncrease profitAvoid pollutionBio-organic fraction processingOrganic fertiliser preparationOrganic fertilizerMushroom

The invention relates to a biological organic fertilizer, and particularly relates to a biological organic fertilizer prepared by using mushroom bran as a raw material and a preparation method thereof. The biological organic fertilizer is prepared by mixing mushroom bran, humic acid, raw chicken manure and a composite bacterial agent according to weight parts, and performing fermentation. On a weight basis, the ratio of the mushroom bran, humic acid, raw chicken manure and the composite bacterial agent is 1:0.08-0.1:0.08-0.1:1 / 300-1 / 400. The fertilizer of the invention can eliminate biological pollution of the mushroom bran; nutrient substances of the mushroom bran are made full use of for the production of the fertilizer; no harm is caused to the environment; and the reutilization of resources is realized.

Owner:LIAONING ACAD OF AGRI SCI

Camellia facial soap

InactiveCN102517174AAvoid harmModerate glycerin contentCosmetic preparationsToilet preparationsWater bathsOil and grease

The invention relates to camellia facial soap, which belongs to the field of washing products. The camellia facial soap is mainly and technically characterized by comprising the following main raw materials: 24-32g of camellia oil, 12-15g of coconut oil, 12-15g of palm oil, 12-15g of sweet almond oil, 20-23g of deionized water, 9-11g of NaOH and 2-3g of floral essential oil. A preparation method for the camellia facial soap comprises the following steps of: (1) putting the raw materials in a water bath container and stirring and mixing into liquid mixed oil; (2) slowly and completely dissolving the NaOH by using the deionized water; (3) slowly adding the liquid mixed oil into NaOH solution and completely mixing the liquid mixed oil with the NaOH solution; (4) adding the essential oil, andevenly stirring; (5) pouring into a mould and standing for 24-48 hours; and (6) demoulding after liquid soap is solidified, and putting in a cool ventilated place for 4-8 weeks for use. The camellia facial soap manufactured by the preparation method disclosed by the invention has proper glycerol content and good molding performance, has a face cleaning effect, a face protection effect, a disinfecting effect and a sterilization effect, has low requirements on production conditions and is low in production cost.

Owner:郴州邦尔泰苏仙油脂有限公司

Method for culturing pleurotus eryngii

InactiveCN102187785ASolve the chemical fertilizerSolve problems such as pesticide residuesHorticultureFertilizer mixturesPesticide residueMycelial cord

The invention discloses a method for culturing pleurotus eryngii. The method comprises the following steps of: selecting saw powder of alfalfa growing in organic soil, wild nuts in mountain and wild trees in mountain, mixing, fermenting, sterilizing, and inoculating the sterilized fermentation product to pleurotus eryngii hypha to culture to obtain mature pleurotus eryngii. By adopting the alfalfa growing in the organic soil, the problem that the alfalfa growing in common soil contains chemical fertilizer, pesticide residue and the like is solved, and harm of chemicals to a human body is solved; meanwhile, because the alfalfa is selected as one of the culture medium materials for culturing the pleurotus eryngii, the germination rate of the pleurotus eryngii can be increased by using the alfalfa to culture the pleurotus eryngii; and because the alfalfa is used as one of the culture medium materials, the growth speed of hypha can be increased, so that the production efficiency of the pleurotus eryngii is increased, and the economic benefit of the pleurotus eryngii is increased. The method has the advantages of achieving the best sterilization effect, saving the sterilization time, being simple and easy in material selection, saving a large amount of labor, reducing the production cost and increasing the economic benefit.

Owner:LUOYANG JIAJIALE AGRI PROD DEV

Polyvinyl chloride elastomer formula for flame-retarded mining flexible cable and its processing method

InactiveCN1676546AOvercome stickiness and blackeningOvercomes defects that can cause electrical crackingInsulated cablesInsulated conductorsElastomerRubber material

This invention relates to PVC elastomer formula for flame retarding mine use sofe cable and its processing technique. The formula includes the following contents(weight share): high polymerized PVC 100, low polymerized PVC 10-50, the plasticizer 60-120, tri-salt lead sulfate 2-5, disalt lead phosphate 2-5, disalt lead stearate 0.5-1.5 barium stearate 0.5-1.0, inflaming retarding agent 10-20, assistant retarding agent 2-7, antioxidant 0.1-1.0, bulking agent 10-30. The processing technique is as follows: match every group according to weight ratio and then past them; knead the pasting and powder under 90-110deg.C for 4-10 minutes, plasticize the kneaded mixture and particlize the processed rubber material and storage them. The elasticity of PVC of this invention can arrive the elasticity of rubber, and its electrical performance, hot endurance, inflaming retarding performance and tensile and breaking elongation are up to the standards.

Owner:JIANGWAN SPECIAL CABLE SHANGHAI

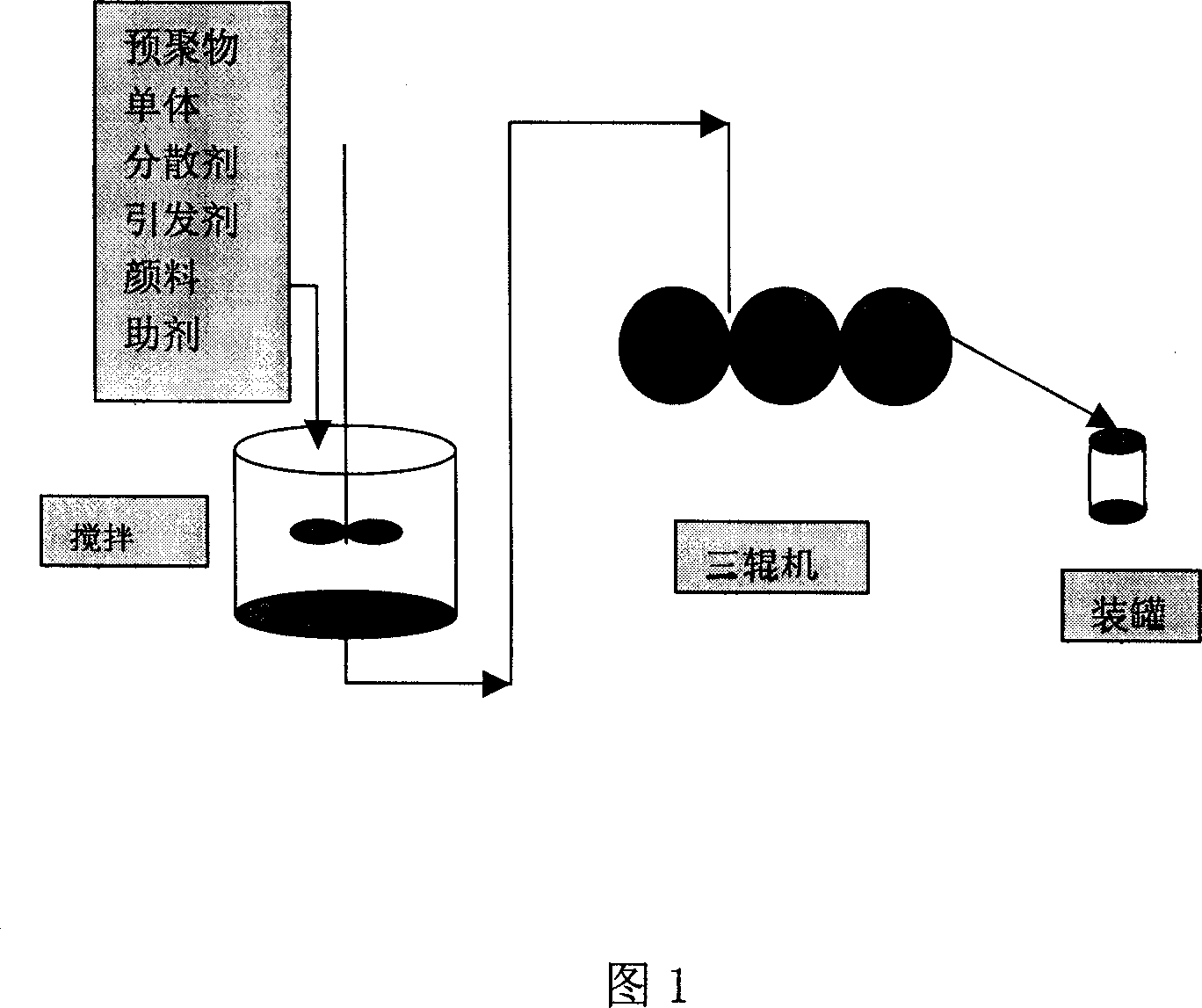

Environmental protection type tin printing ink solidified by ultraviolet light

This invention discloses environmentally friendly UV-curing tin plate ink, which comprises: acrylic acid prepolymer 50-70 wt.%, acrylic acid monomer 10-15 wt.%, initiator 5-10 wt.%, pigment 10-25 wt.%, dispersant and other additives 5-10 wt.%. The UV-curing tin plate ink is a color printing ink used on metal and cured by UV. The UV-curing tin plate ink has such advantages as low energy consumption, rapid curing, no VOC discharge, high efficiency, high safety and no pollution.

Owner:FOSHAN ROCKLINK CHEM

Process for preparing clindamycin phosphate injection

InactiveCN1969875AImprove production conditionsReduce the chance of infectionAntibacterial agentsOrganic active ingredientsPhosphateClindamycin Phosphate

The invention discloses a making method of clindamycinum phosphate injection, which is characterized by the following: dissolving certain quantity of clindamycinum phosphate into water; adding clindamycinum phosphate and sodium hydroxide alternately; maintaining pH value between 6.0 and 6.4; stirring evenly; setting constant volume to the density of injection; adding 0.05% needle active carbon to adsorb the injection; filtering through 0.45um micropore film or corresponding cylinder filter; sterilizing; canning; sealing; obtaining the product.

Owner:沈阳金峰医药科技有限公司 +1

Sepiolite-loaded nickel-based catalyst modified by two metals, as well as preparation method and application of sepiolite-loaded nickel-based catalyst

ActiveCN104923240ALow costEasy to makeCatalyst carriersCarboxylic acid nitrile preparationPotassiumReaction temperature

The invention relates to sepiolite-loaded nickel-based catalyst modified by two metals of potassium and lanthanum, as well as a preparation method and application of the sepiolite-loaded nickel-based catalyst to adiponitrile hydrogenation. The preparation method comprises the following steps: taking adiponitrile as a raw material and ethanol as a solvent, and taking sepiolite as a carrier of a catalyst to prepare a nickel-based sepiolite-loaded catalyst modified by potassium and lanthanum as additives. The preparation process of the catalyst comprises acid treatment on sepiolite, and steeping, drying, roasting and reducing of sepiolite after acid treatment. During the adiponitrile hydrogenation process, the reaction pressure is 1-2 MPa, and the reaction temperature is 100-120 DEG C. The catalyst has relatively high activity and 6-aminocapronitrile and hexamethylendiamine selectivity under relatively mild reaction conditions, the raw material of sepiolite is cheap and easy to obtain, and low in cost, and the catalyst is simple in preparation method, and has a good application prospect.

Owner:XIANGTAN UNIV

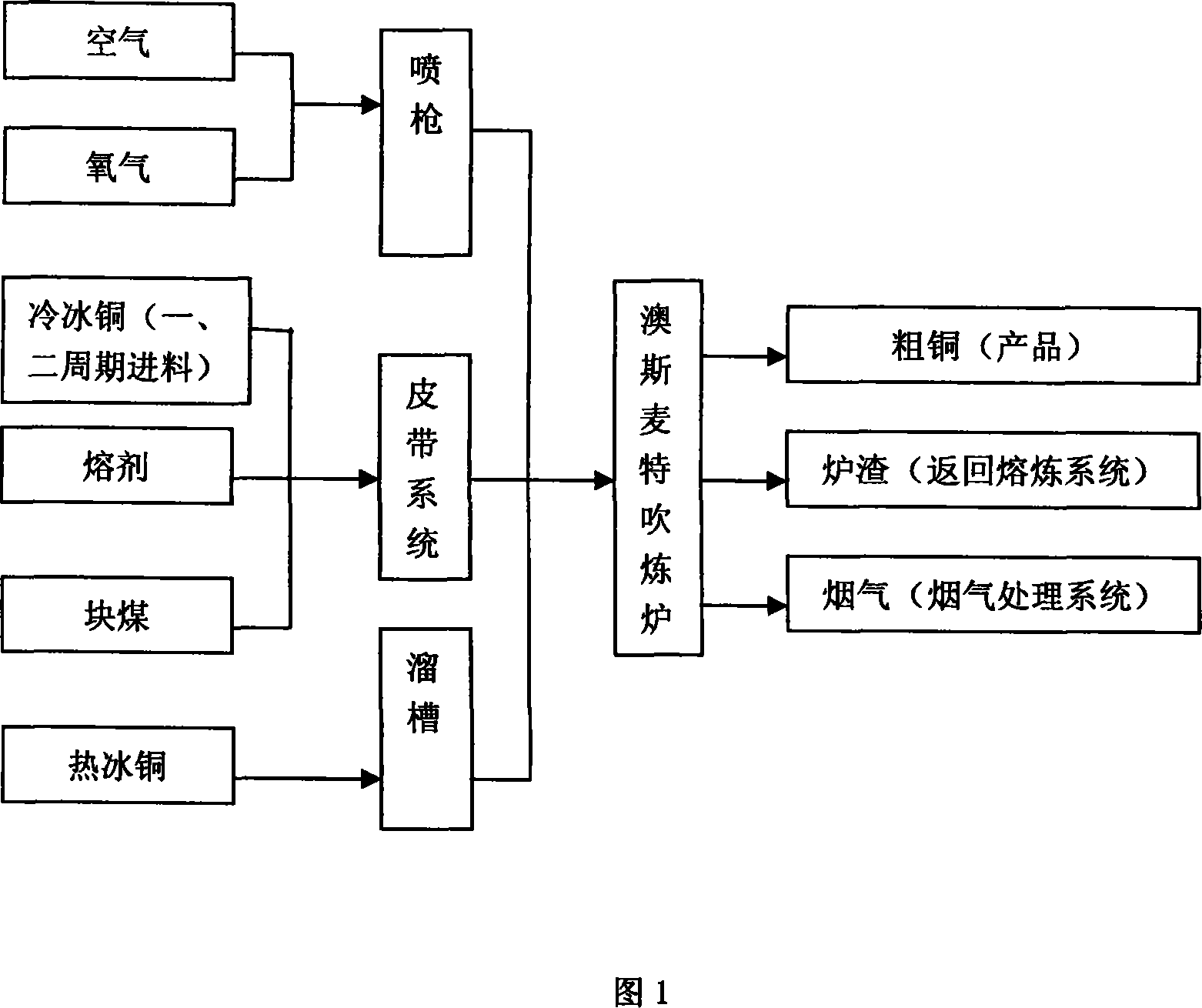

Oxygen-enriched air refining method for copper by using converting furnace

ActiveCN101148705AFix security issuesEasy to handleRotary drum furnacesCrucible furnacesFurnace temperatureMelting tank

The present invention is oxygen-enriched air copper refining process in a converting furnace. The process features the oxygen-enriched air converting in the condition of oxygen pressure higher than the inner layer air pressure and common air converting in other condition, the control of the furnace temperature with cold copper material in oxygen-enriched air converting, the control of the coarse copper product quality through stopping addition of cold copper material before finishing the air refining of coarse copper product, and the alternate addition of oxygen-enriched air and common air to avoid generation of foamed slag. The present invention has improved operation environment, raised converting rate, lowered fuel consumption and raised economic benefit.

Owner:山西北方铜业有限公司

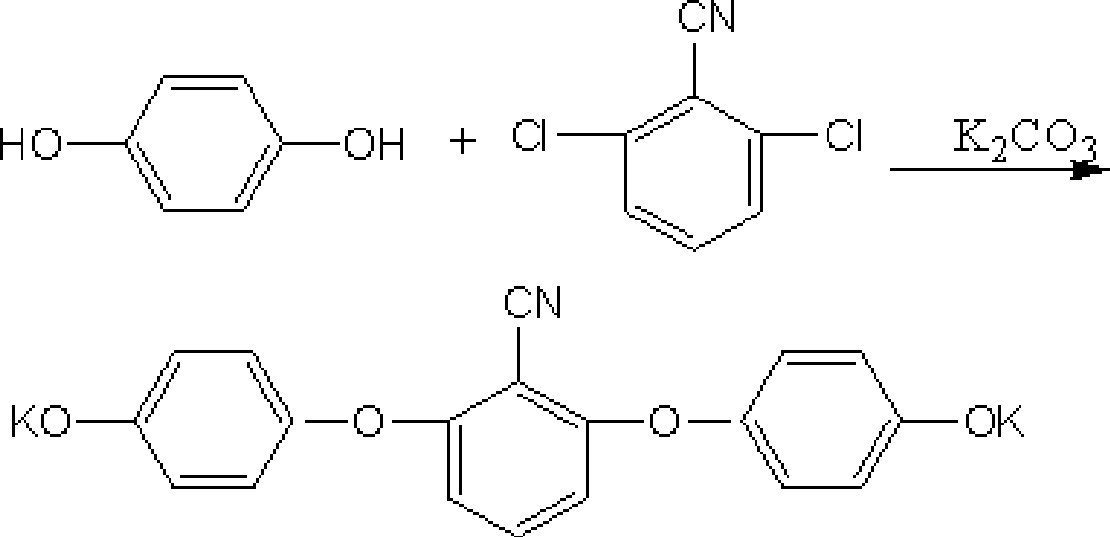

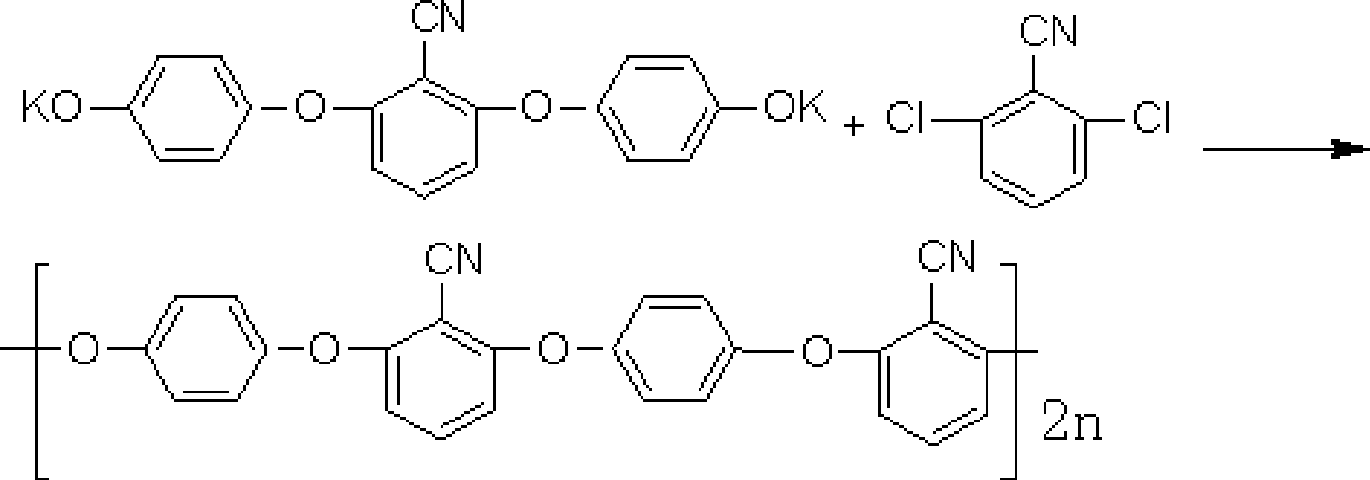

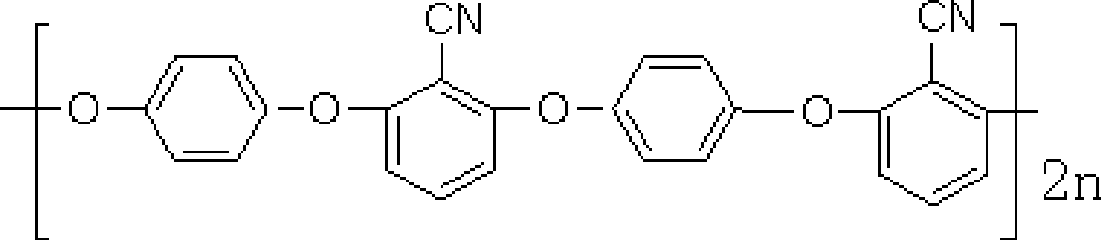

Industrial production method of semi-crystalline poly aryl ether nitrile

The invention relates to an industrial production method for semi-crystal poly(aromatic ether nitrile), which belongs to the field of polymer material. The method comprises the following steps: 2, 6-dichloro benzonitrile and hydroquinone are taken as raw materials; anhydrous potassium carbonate is taken as a catalyst; in the presence of a solvent and a dehydrating agent, the raw materials and the catalyst react under atmospheric pressure to obtain the poly(aromatic ether nitrile) homopolymer with low molecular weight and regular chain segments; and then the molecular weight of polymer is increased through pressurization, so as to obtain the semi-crystal poly(aromatic ether nitrile) polymer with high molecular weight. Due to the increase of crystallinity and molecular weight, the mechanical properties and heat resistance of the semi-crystal poly(aromatic ether nitrile) polymer are obviously improved.

Owner:SICHUAN FEIYA NEW MATERIAL

Method of manufacturing halogenated rubber like polymer

ActiveCN1903892AMeet the needs of halogenation reactionIncreased macroscopic reaction ratePolymer scienceWastewater

The present invention relates to a method for preparing halogenated rubber polymer, including reaction of unsaturated rubber polymer and halogenating agent. It is characterized by that said halogenation reaction is implemented in a closed drying system with screw extrusion press by adding raw material and additive and making them undergo the processes of plasticization, deaeration, softening, multistage halogenation, stabilizing, removing volatile matter and discharging material.

Owner:江苏圣杰实业有限公司

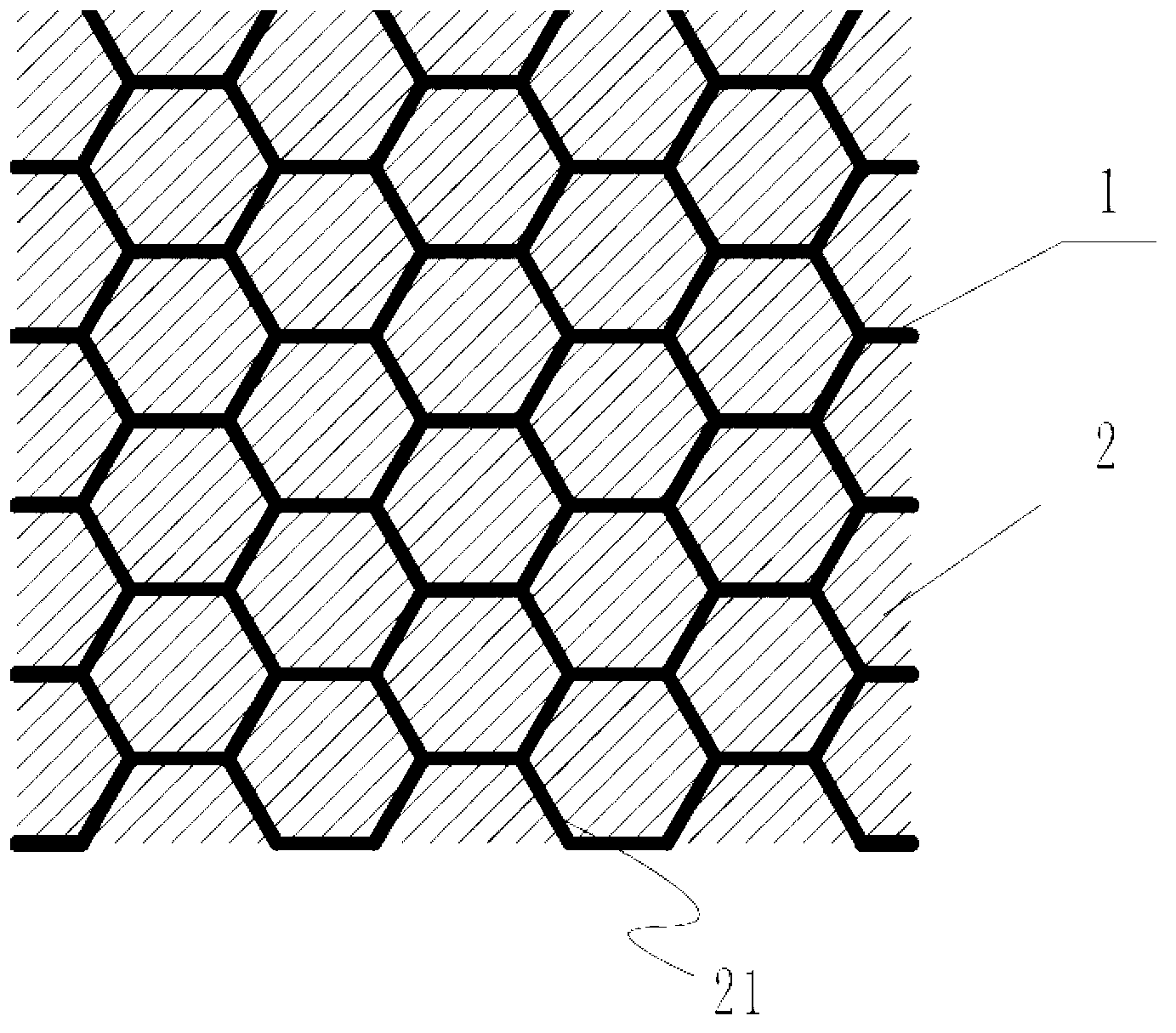

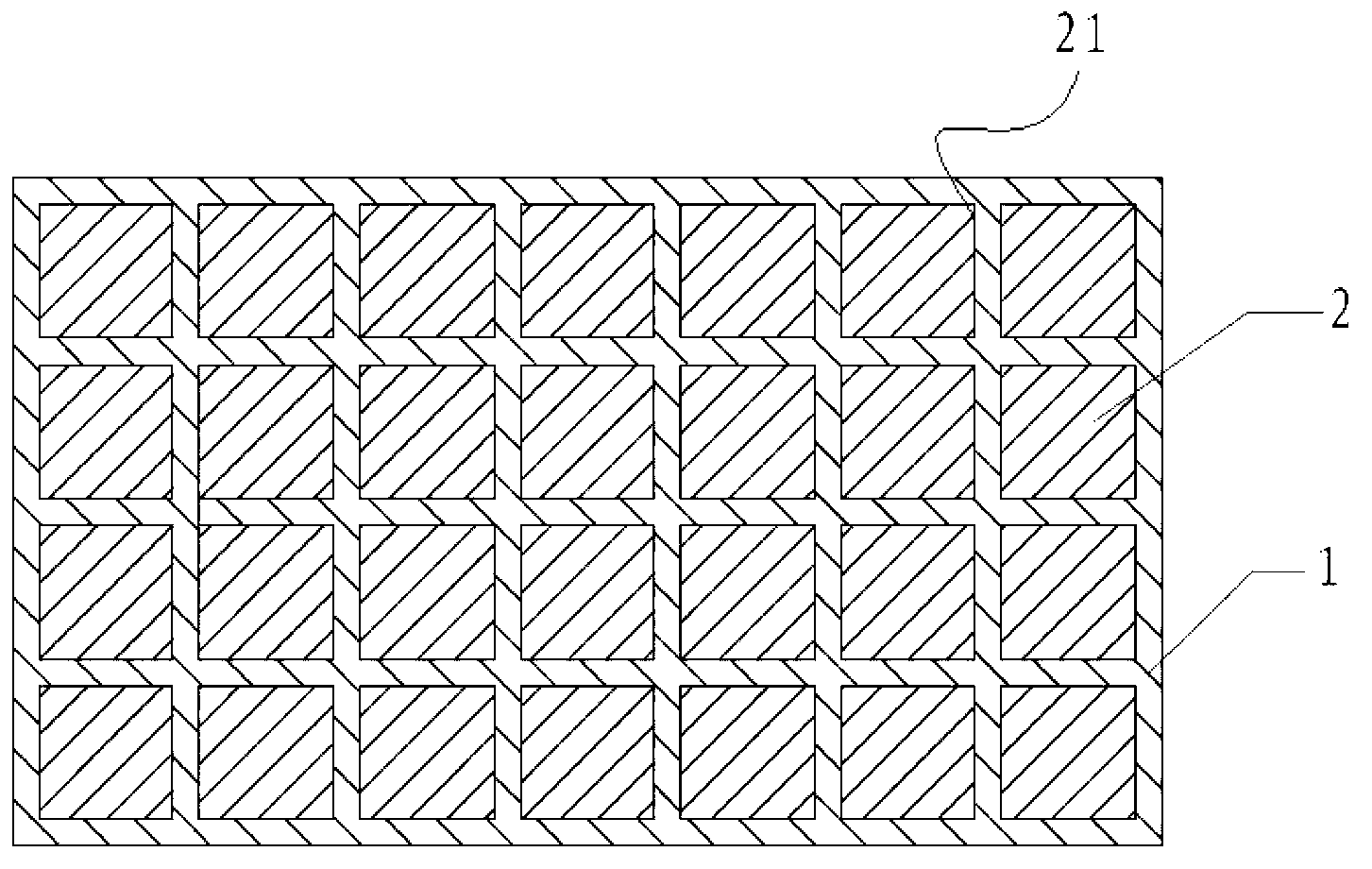

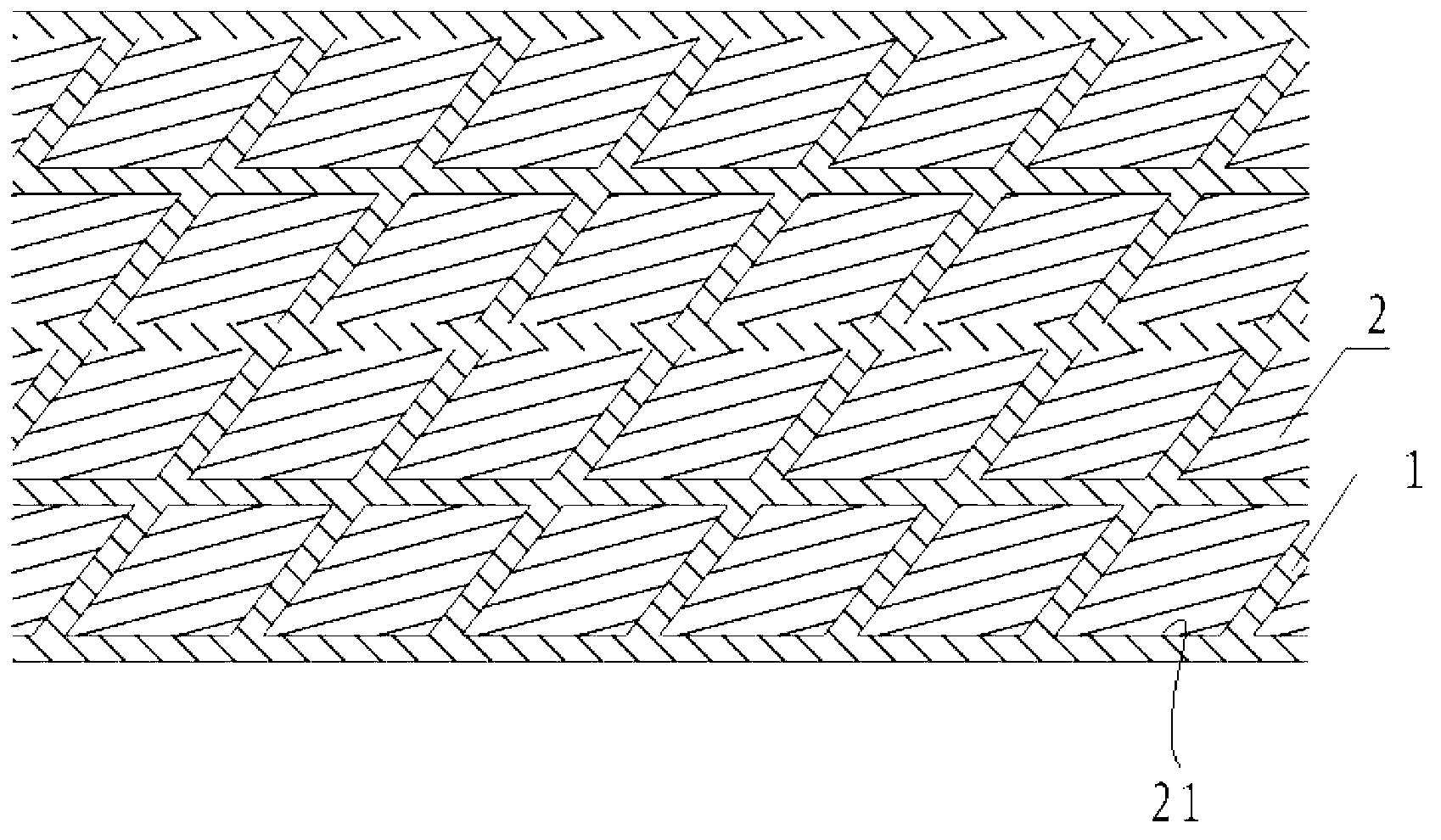

Special structural explosive for explosive cladding, explosive cladding method and explosive cladding device

ActiveCN103317222ASave explosivesReduce critical thicknessNon-electric welding apparatusShock waveExplosive cladding

The invention discloses special structural explosive for explosive cladding, an explosive cladding method and an explosive cladding device. The structural explosive comprises a filling plate, a plurality of cavities filled with the explosive are formed in the filling plate and distributed in a matrix. The special structural explosive for explosive cladding is formed by filling or injecting the explosive in the cavities of the filling plate. A layer of composite plate is mounted on each of two sides of the structural explosive, and the two composite plates are driven to move reversely after explosion to composite with two base plates in reserve directions. By the aid of an explosive filling method, explosive filling quality is guaranteed, critical thickness of stable explosive detonation is reduced, and energy utilization rate of explosive explosion is improved. The special structural explosive is convenient to use, and mechanized batch production can be realized. By the aid of the explosive cladding device, usage amount of the explosive is lowered, production cost is reduced, shock wave and noise pollution are reduced, and working environment of workers is improved.

Owner:UNIV OF SCI & TECH OF CHINA

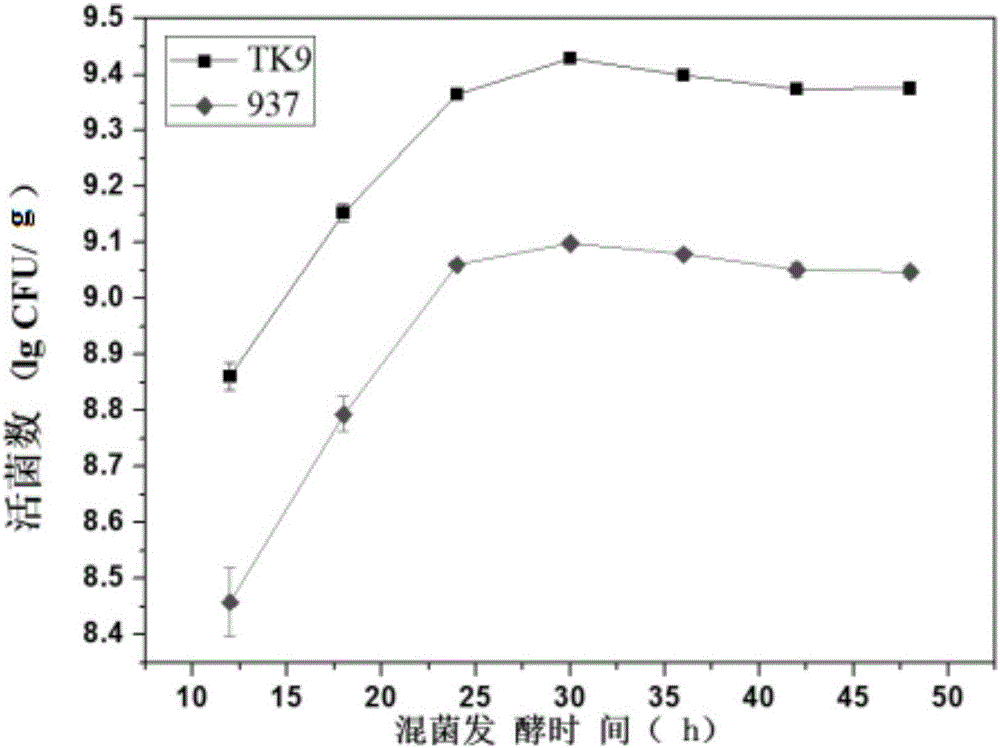

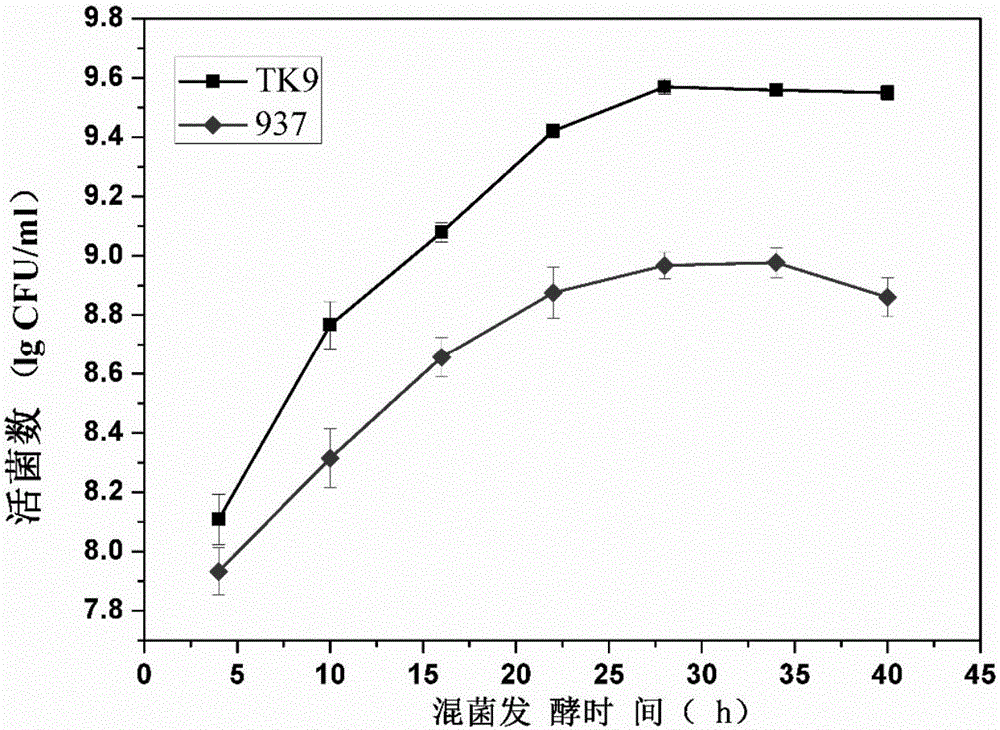

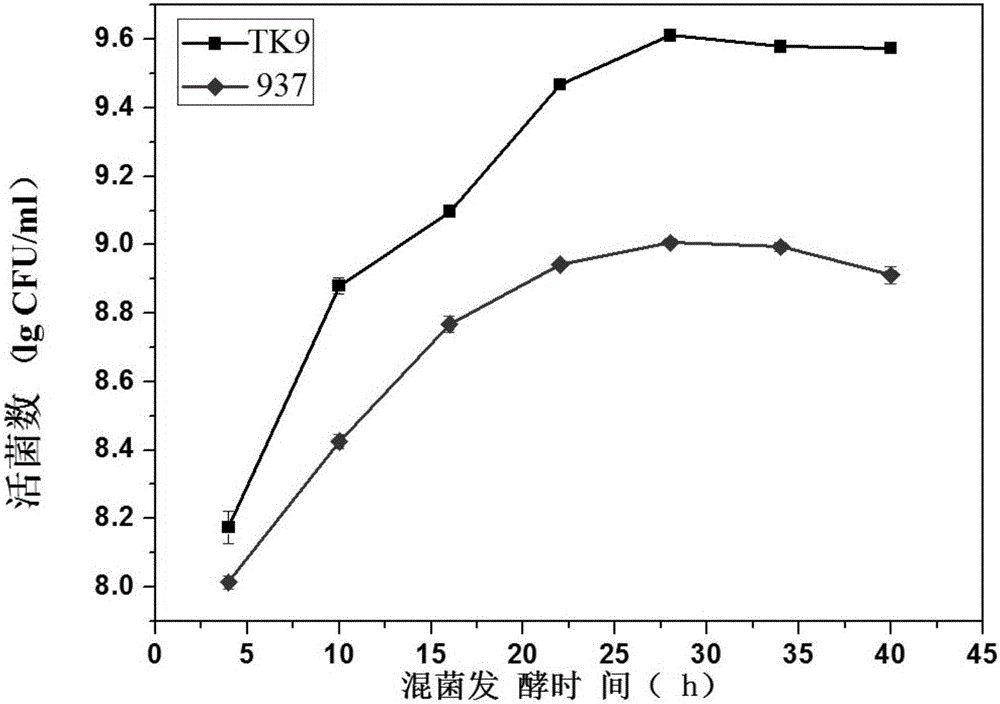

Method for producing probiotic functional food through buckwheat fermentation

InactiveCN105942084AIncreased amino nitrogen contentSignificant hypoglycemia, blood lipid and blood pressureFood scienceFunctional foodDisease

The invention belongs to the field of functional foods, in particular relates to a method for producing a probiotic functional beverage and probiotic functional food through buckwheat fermentation and discloses a method for preparing a probiotic liquid state fermentation beverage by using a lot of probiotic mixed strains liquid state fermentation buckwheat and a method for preparing probiotic food by using a lot of probiotic mixed strains solid state fermentation buckwheat. The preparation process is simple; through lactobacillus fementation or non-fermentation, buckwheat, as cereal foods, has antioxidant, antihypertensive and hypoglycemic effects and preventive effects on cardiovascular and cerebrovascular diseases to some extent, and can coordinate intestinal tracts at the same time, thus the probiotic fermentation beverage and the solid state fermentation food can satisfy the needs of different consumer groups.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Production method of poly ammonium phosphate

A process for preparing ammonium polyphosphate includes such steps as proportionally mixing polyphosphoric acid with the condensating agent chosen from urea, ammonium dicarbonate, melamine, bicynoamine, ammonium sulfate and their mixture, and reacting at 100-500 deg.C under 0.01-0.35 MPa for 5-210 min.

Owner:YUNNAN CHEM RES INST

1-polyolefin halogenation production method

InactiveCN101671412AMeet the needs of halogenation reactionIncreased macroscopic reaction ratePolyolefinProcess equipment

The invention relates to a 1-polyolefin halogenation production method which is characterized in that continuous plastication (mixing), degasification, ultrasonic wave visbreaking, softening, multistage halogenation, neutralization and stabilization, devolatilization, ultrasonic wave temperature reduction and stripping and slicing measurement are realized in a sealing drying system in a double-screw extruder reactor to produce the halogenated polyolefin. Compared with the traditional process, the process flow is shortened by three fourth, which saves investment and energy power consumption; the halogen content of the halogenated polyolefin can be controlled, and does not contain corrosive acid gas, so that the equipment can not be corroded severely, is the modern green engineering, and canwidely replace the process equipment of the current halogenated polyolefin.

Owner:江苏圣杰实业有限公司

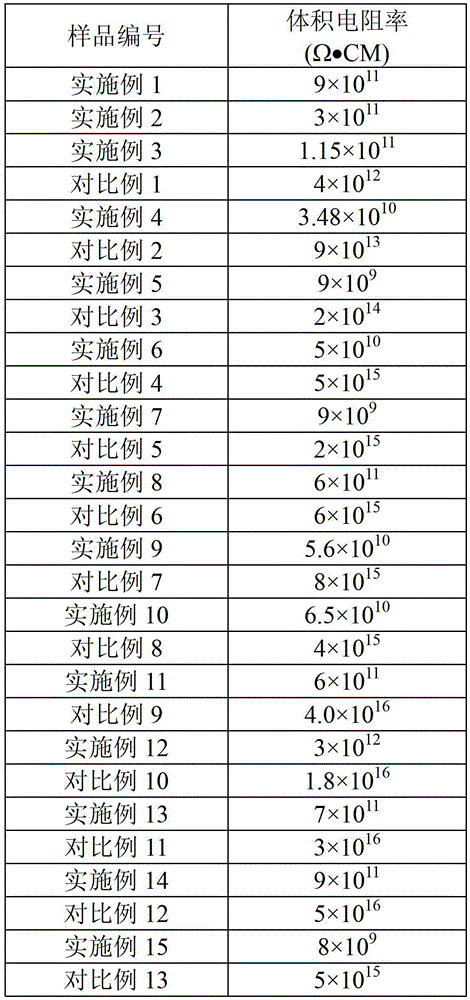

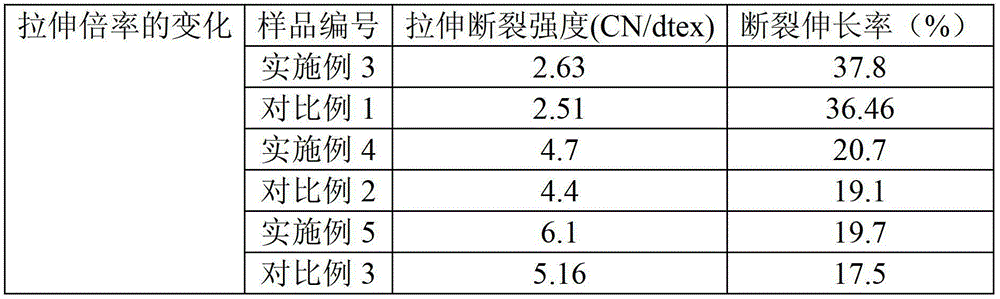

Polymer/filler/metal composite fiber and preparation method thereof

ActiveCN104099684AImprove breaking strengthElectrical properties are not affectedElectroconductive/antistatic filament manufactureMonocomponent polyolefin artificial filamentFiberPolymer science

The invention relates to polymer / filler / metal composite fiber. The polymer / filler / metal composite fiber comprises polymer fiber containing metal short fiber and a filler, the metal short fiber is distributed in the polymer fiber as a dispersion phase and is in parallel distribution along the shaft of the polymer fiber, and the filler is dispersed in the polymer fiber and is distributed among the metal short fiber; the filler is not fused at a polymer processing temperature; a metal is a low-melting-point metal, is at least one selected from single-composition metals and metal alloy, and has the melting point between 20 DEG C and 480 DEG C and lower than the polymer processing temperature; the volume ratio of metal short fiber to polymer fiber is 0.01:100-20:100; and the weight ratio of the filler to the polymer is 0.1:100-30:100. By using the composite fiber, the volume resistivity is reduced, the wire fracture rate is reduced, and the surface of the fiber is smooth. The preparation method is simple, relatively low in production cost and easy for industrialized batch production.

Owner:CHINA PETROLEUM & CHEM CORP +1

Gas protection solid welding wire for 1000 MPa high-strength steel welding and preparing and welding methods of gas protection solid welding wire

ActiveCN106312372AHigh strengthImprove impact toughnessArc welding apparatusWelding/cutting media/materialsSocial benefitsPower station

The invention discloses a gas protection solid welding wire for 1000 MPa high-strength steel welding and preparing and welding methods of the gas protection solid welding wire. Chemical ingredients of the welding wire include, by weight, 0.07-0.13 part of C, 0.3-0.5 part of Si, 1.8-2.3 parts of Mn, 2.7-3.2 parts of Ni, 0.3-1.2 parts of Cr, 0.4-0.85 part of Mo, 0.01-0.1 part of Ti, 0.01-0.03 part of Al, 0.008 part or below of P, 0.005-0.010 part of S, 0.3 part or below of Cu, 0.01-0.035 part of Nb and the balance Fe. The welding wire can replace an imported welding wire, the construction cost of high-strength steel for large hydropower stations, water pumping and energy storage power stations and the like can be remarkably reduced, and remarkable economic benefits and social benefits are achieved.

Owner:SICHUAN XIYE NEW MATERIAL

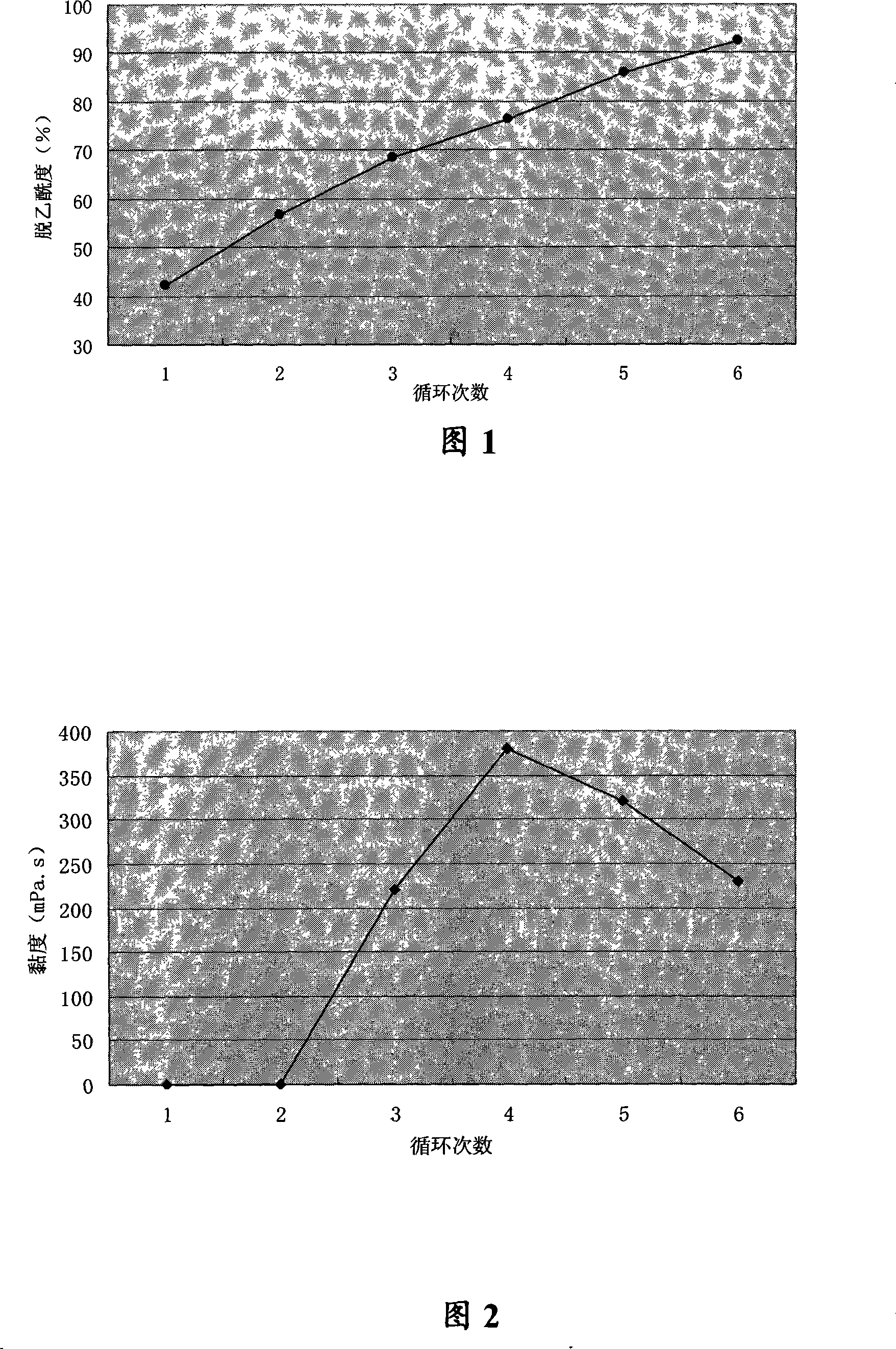

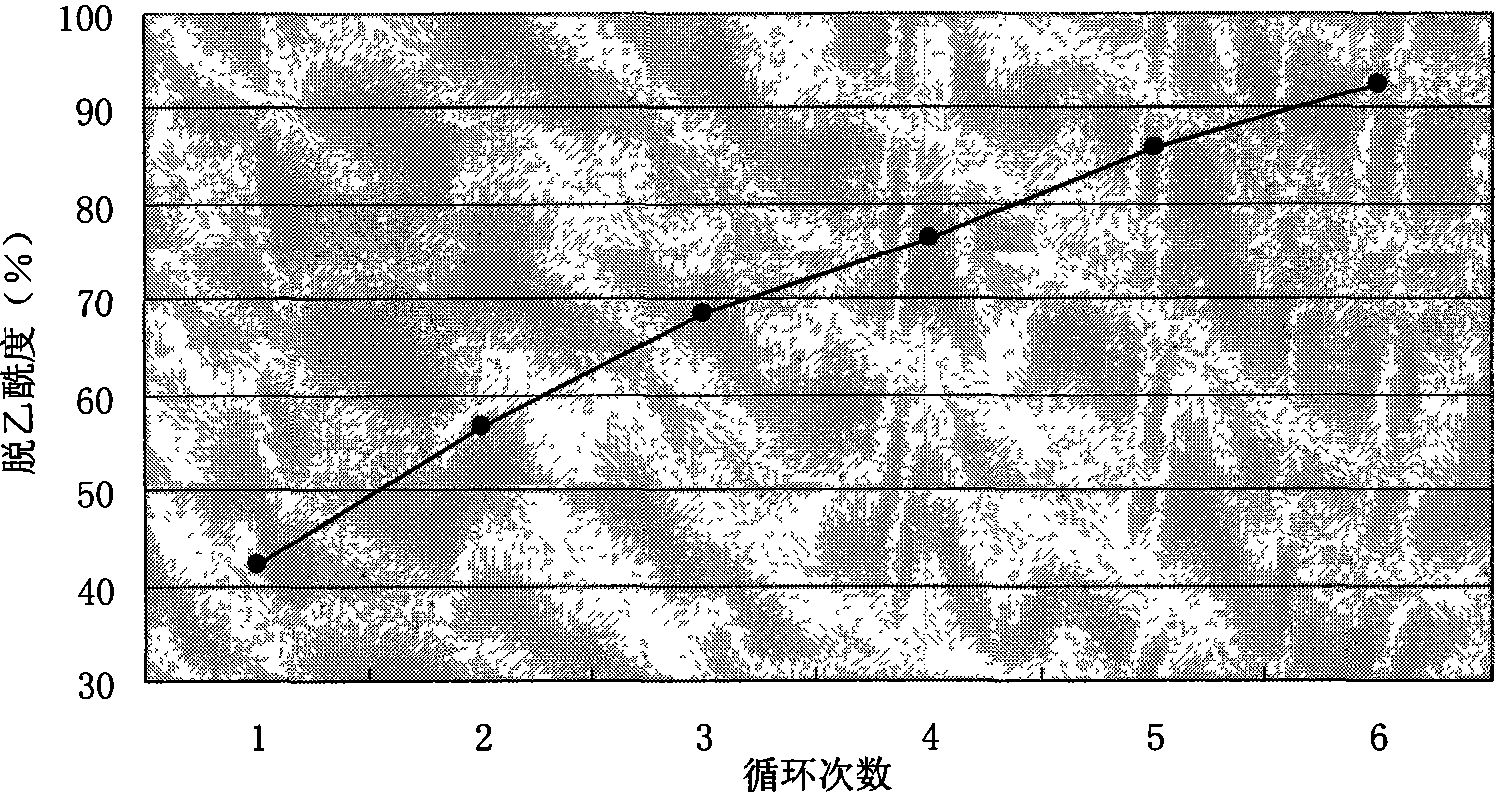

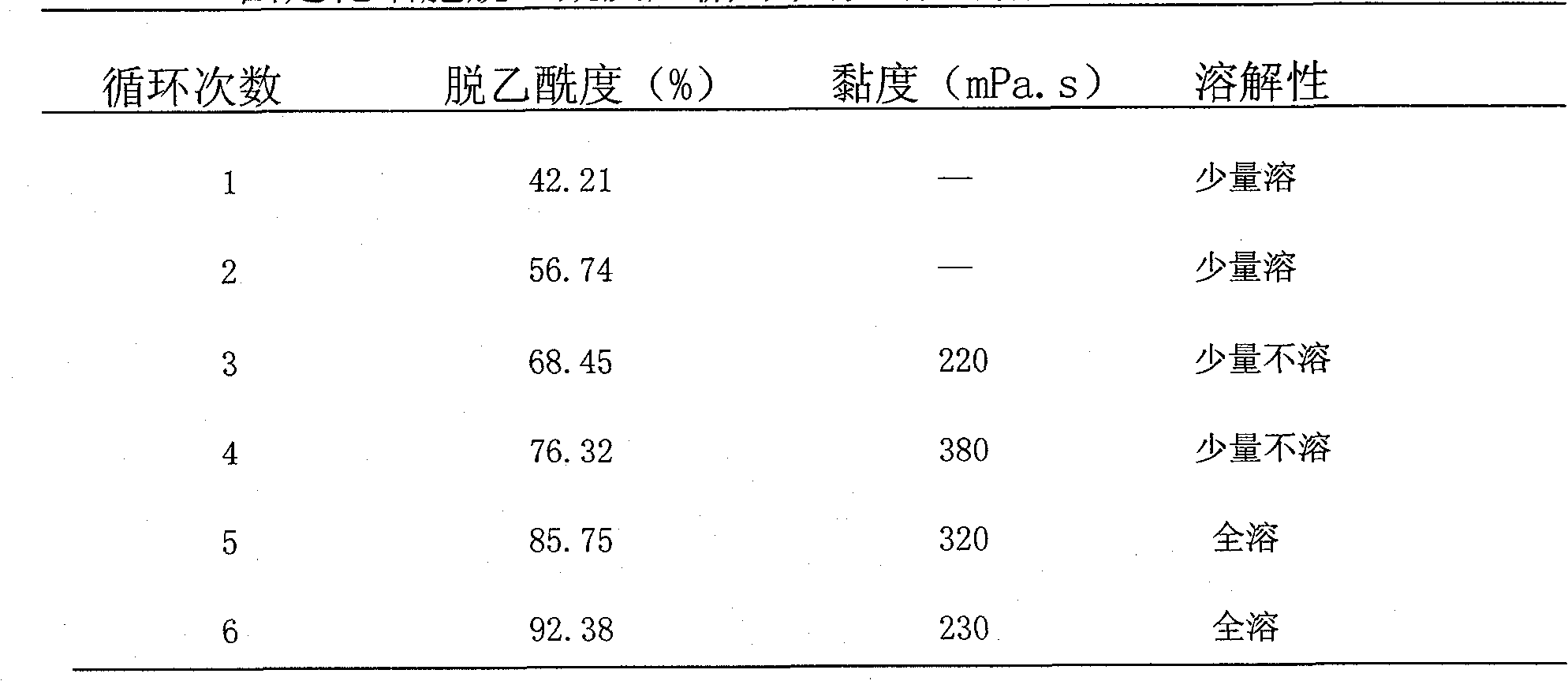

Method for preparing chitin and its chitosan and chitosan oligosaccharide

InactiveCN101144097BTake advantage ofImprove production conditionsMicroorganism based processesFermentationSolubilityBioreactor

The present invention relates to a method for preparing chitin and chitosan oligosac charide. The method comprises the steps that usual raw materials such as the crust of shrimp and crab, the insect crust or the fungal mycelia, etc. are micronized through the dry process or wet process; the carapace material of the obtained fine powder raw material is decalcified with the chemical process, and then is defatted and deproteinized with the method of micro-organism compound enzyme coarse enzyme liquid co-enzymolysis, and the insect and fungus fine powder thereof is directly defatted and deproteinized; a whole cell immobilizing bioreactor of a chitin deacetylase high-yield producing strain is prepared, to perform the circulatory deacetylation to the chitin and then obtain chitosan with corresponding degree of deacetylatoion; obligate anaerobic acid-producing bacterium and high-yield producing chitosan bacterium are utilized, the chitosan is submerged and fermented in the liquid, to obtain chitosan oligosaccharide with high water solubility. The present invention has the advantages that the method is helpful to fully utilize the resources, and makes the waste to the worth, at the same time, the default of the manufacturing process of the chemical process can be avoided, the production efficiency is improved, the energy is saved, the consumption is reduced, the byproduct with corresponding high value added can be produced, the comprehensive economic benefits of the relative secondary industry are obviously improved, the industrial development is promoted, and the multi-win effectis attained.

Owner:重庆百奥帝克微生态科技有限公司

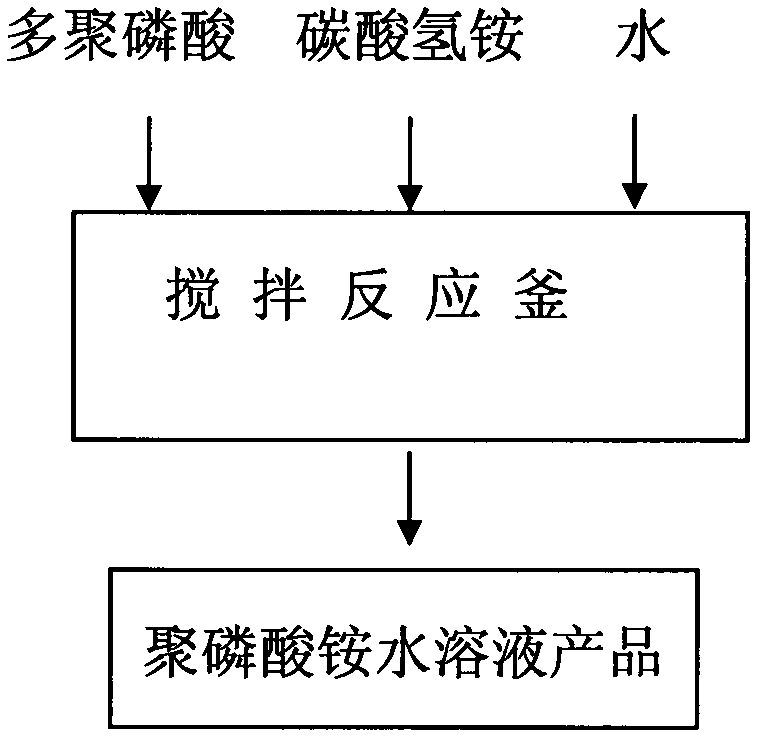

Method for preparing low-polymerization-degree ammonium polyphosphate aqueous solution

ActiveCN103373717AReduce processReduce difficultyPhosphorus compoundsChemical industryEnvironmental resistance

The invention belongs to the technical field of phosphate production in inorganic chemical industry and discloses a novel method for producing a low-polymerization-degree ammonium polyphosphate aqueous solution by using low-temperature methods. Commonly-used ammonium polyphosphate production methods are mainly high-temperature thermal polymerization methods, and methods capable of producing ammonium polyphosphate by using the low-temperature methods do not exist at home and abroad. According to the method, polyphosphoric acid with the concentration of 100% to 120% serves as a main raw material, is adjusted by adding an appropriate amount of water and is mixed with ammonium bicarbonate under a natural, low-temperature and normal-pressure condition, stirring and reacting are carried out, and then, the low-polymerization-degree ammonium polyphosphate aqueous solution with the nitrogen content higher than 11%, the phosphorus pentoxide content higher than 37% and the main content of a dipolymer (ammonium pyrophosphate) is produced in batches, is widely used as a fireproofing flame retardant, a plant nutrient solution (liquid fertilizer) and the like and has high practical values. The method is simple in production operation, high in yield and low in energy consumption, is safe and environmental-friendly and does not need high temperature, the requirements for the performance of equipment and materials are lowered greatly, and the large-scale continuous production is easy to realize.

Owner:BLACK P2 USA INC

Preparation method of Ni-based catalyst modified by aid Pt supported by multi-wall carbon nanotube as carrier and application

InactiveCN107649148AImprove hydrogenation activityWeaken energyOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsPlatinumCarbon nanotube

The invention discloses a preparation method of a Ni-based catalyst modified by an aid Pt supported by multi-wall carbon nanotubes as a carrier and application. The preparation method comprises the following steps: firstly, performing acid modification on multi-wall carbon nanotubes by using nitro-sulfuric acid; by taking the multi-wall carbon nanotubes as a carrier, putting precursor salts of platinum and nickel according to the multi-wall carbon nanotubes to hexachloroplatinic acid hexahydrate and nickel nitrate hexahydrate according to a mass ratio of (5-10):(0.1-0.5):(5-10); further addingdeionized water, performing ultrasonic stirring, drying, and performing roasting and reduction, thereby finally obtaining an expected catalyst Pt-Ni / MWCNT. The catalyst prepared by using the method is low in cost, economic and effective, good in universality, good in environmental-friendliness, free of equipment corrosion and good in circulation property, and is relatively high in activity and relatively high in p-aminophenol selectivity under a relative gentle reaction condition in a process that p-aminophenol is prepared from nitrobenzene through one-step hydrogenation rearrangement, the production conditions can be improved, the production cost is reduced, and the product quality is improved.

Owner:XIANGTAN UNIV

Carbon-free ladle brick and preparation method thereof

ActiveCN102515794ASolve the problem of non-scouring resistance and aggregate powder separationGood structural flexibilityThermal expansionConstruction aggregate

The invention discloses a carbon-free ladle brick and a preparation method thereof. The carbon-free ladle brick is prepared by using bauxite chamotte, a corundum raw material, magnesium oxide and alumina micro powder as main raw materials, adding iron oxide, a magnesium chloride solution, sodium hexametaphosphate and canary dextrin, mixing the above-mentioned materials by using special procedures, storing an obtained mixed for 30 min, carrying out compression molding and drying the mixture at a temperature of 200 DEG C for 24 h. According to the invention, iron oxide and alumina micro powder are enabled to exist in gaps between aggregate and powder and form hercynite with a low thermal expansion coefficient at a medium-high temperature, and no excess iron oxide enters into a matrix, which enables the ladle brick to have good high temperature stability and anti-stripping performance; therefore, the problem that molten steel carburetting caused by high temperature melting loss of a refractory brick influences smelting quality is overcome, and the prepared carbon-free ladle brick has excellent performances of high strength, washing resistance, a long service life, etc.

Owner:山西高科耐火材料股份有限公司

Process for casting heat-resistant steel or wear-resistant alloy steel by evaporative pattern casting (EPC)

InactiveCN103084542AReduce internal defectsDense structure of castingFoundry mouldsFoundry coresAdhesiveGraphite

The invention discloses a process for casting heat-resistant steel or wear-resistant alloy steel by evaporative pattern casting (EPC). The process comprises the following steps of: purchasing raw materials, blending the materials, performing steelmaking, manufacturing a pattern, preparing a coating, brushing the coating, drying, pouring, testing, thermally processing, polishing, and packaging and warehousing. The invention further provides ingredients of the raw materials. The ingredients respectively are 0.3-0.8% of copper, 0.1-0.3% of molybdenum and 0.2-0.5% of chromium; molybdenum is added together with waste steel in a melting process; and copper is added together with molten iron into ladles in a tapping process. The invention also provides a preparation method of the coating. The coating comprises the following components in percentages by weight: 50-80% of fireproof material, 0.5-4% of adhesive, 1-3% of suspending agent, 0.5-3% of sodium dihydrogen phosphate and the balance of water, wherein the fireproof material is composed of bauxite, alundum powder, graphite powder or mullite powder. By adopting the method disclosed by the invention, effects of low cost, short processing period and good quality are achieved, the process of the method is reasonable, and the preparation effects of the raw materials and the coating are good, so the method is applicable to mass production and large-scale production.

Owner:CHAOHU LETTER BUILDING MATERIALS MACHINERY & EQUIP LIMITED

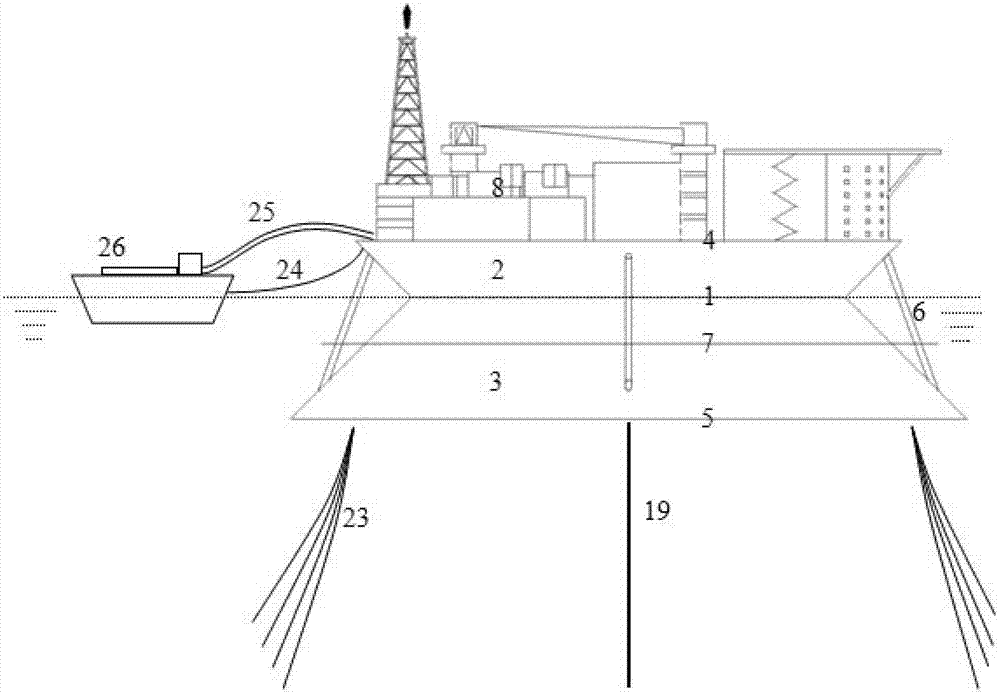

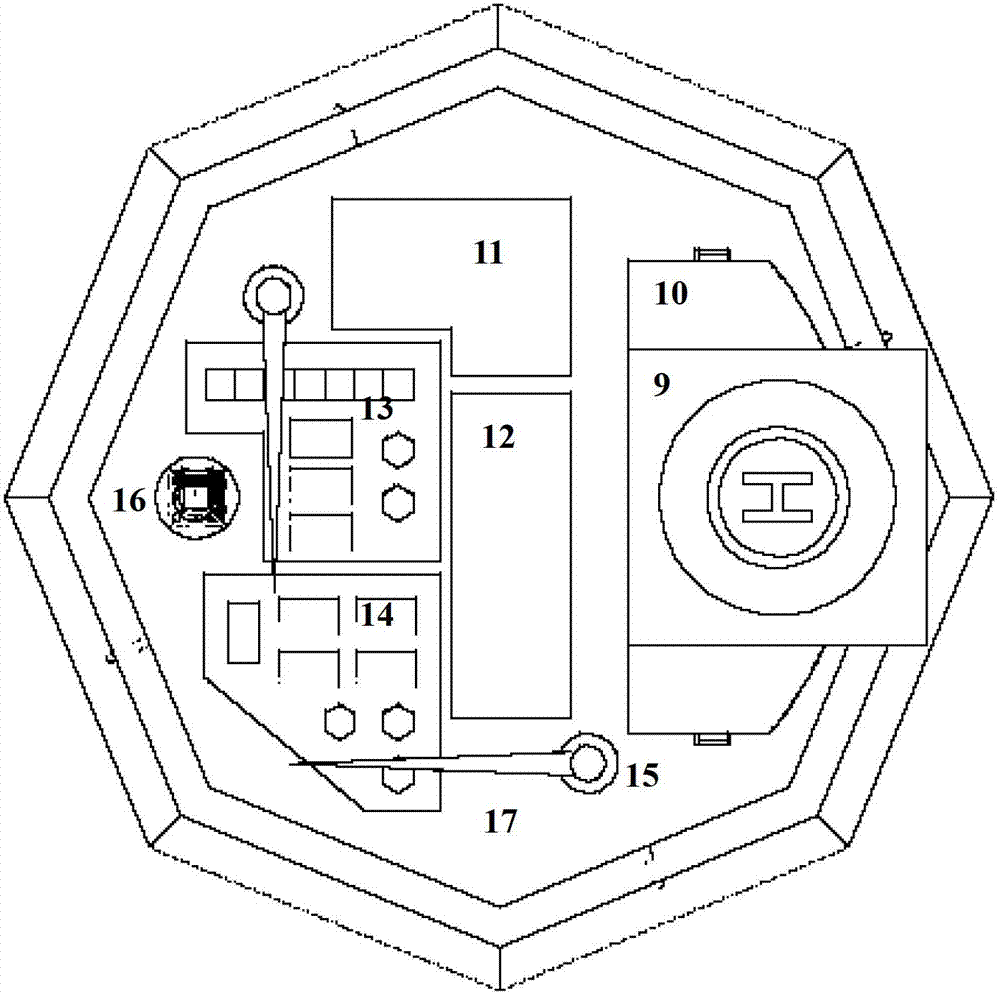

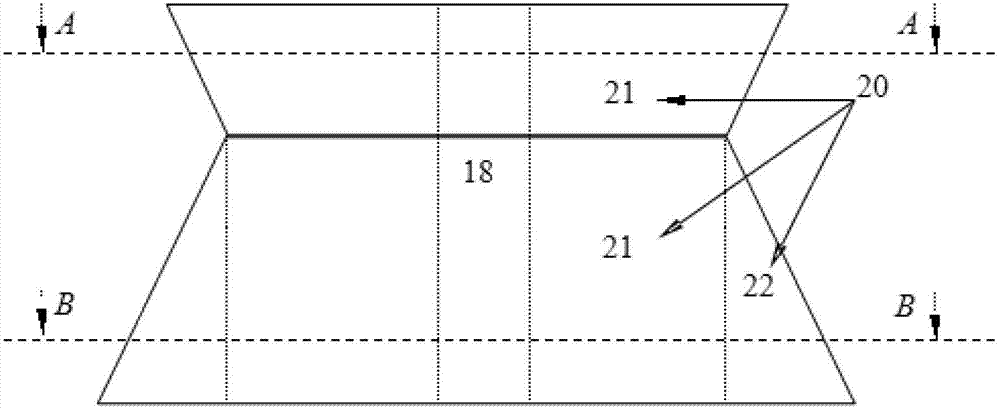

Butting octagonal frustum pyramid type floating production and oil storage system

ActiveCN103171743AFacilitate the realization of drillingFacilitate the realization of miningFloating buildingsMarine engineeringUltimate tensile strength

The invention discloses a butting octagonal frustum pyramid type floating production and oil storage system. A floating body of the butting octagonal frustum pyramid type floating production and oil storage system is provided with an upper structural body in an octagonal frustum pyramid shape and lower structural body in a regular octagonal frustum pyramid shape. Under a combined state, the bottom face, with a small area, of the upper structural body is fixedly connected with the bottom face, with a small area, of the lower structural body to form a connecting surface. The axis of the upper structural body and the axis of the lower structural body are arranged in an identical straight line, the bottom, with a big area, of the upper structural body is an upper deck of a floating structure, and the bottom, with a big area, of the lower structural body is a lower bottom of the floating structure. The connecting surface is the full loading water plane line of the floating structure. On the basis of the mentioned structure, a mooring locating module, an oil and gas production module, a storage module, an outward conveying module and other function modules are arranged to form a novel floating type production and oil storage system. The floating body has the appearance characteristics similar to a hourglass, the butting octagonal frustum pyramid type floating production and oil storage system can make up the defects of a traditional floating production and oil storage system at the aspects of seakeeping performance, strength fatigue, pipeline layout and the like, and the functions of the butting octagonal frustum pyramid type floating production and oil storage system are expanded.

Owner:DALIAN UNIV OF TECH

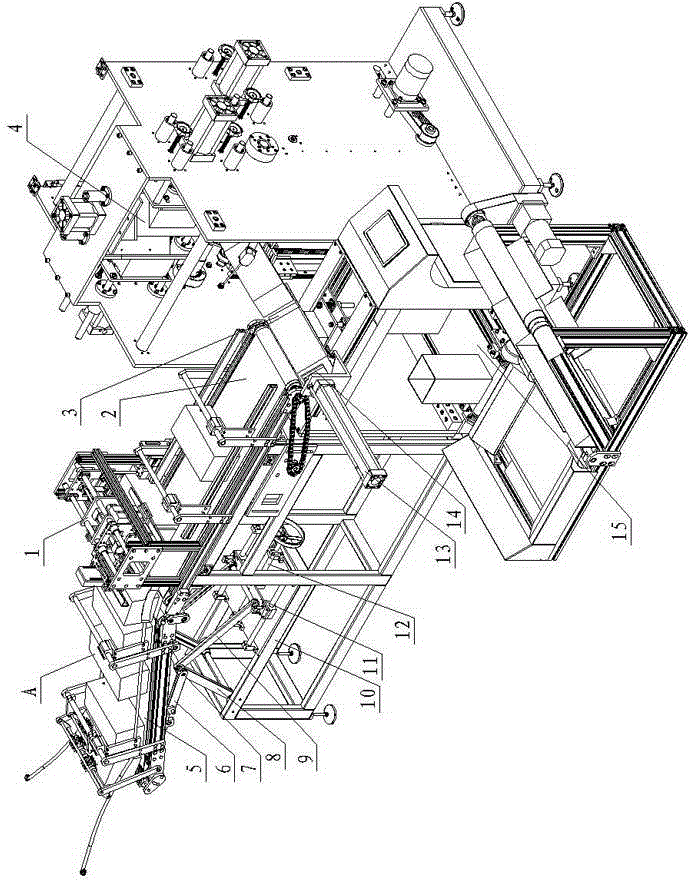

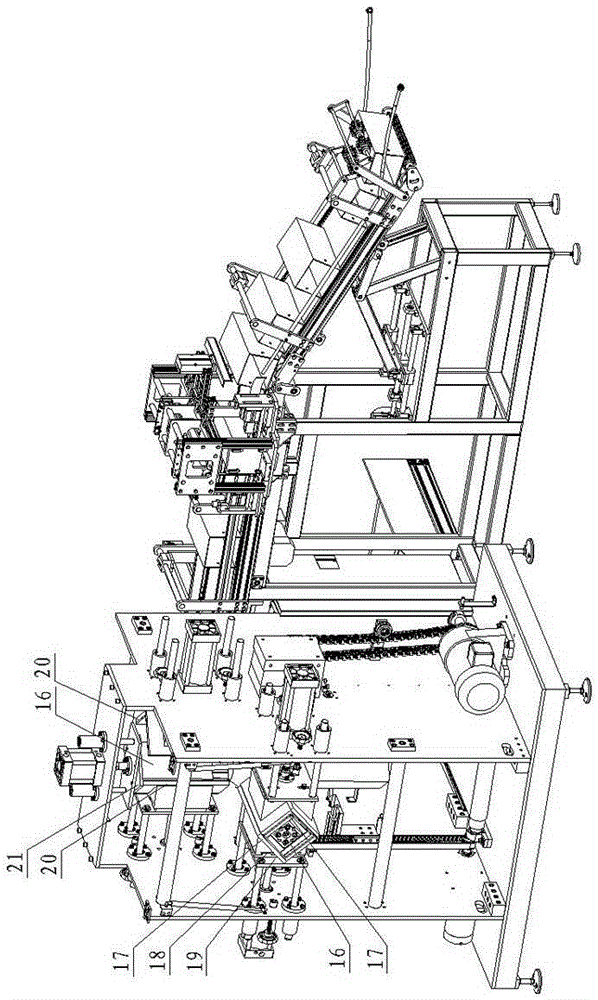

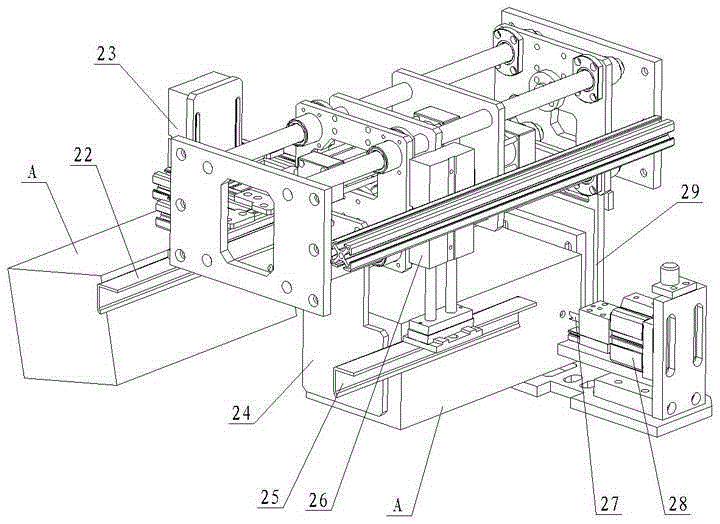

Full-automatic bubble pressing machine

ActiveCN105328931ASimple structureImprove production conditionsPaperhangingContainer making machineryAssembly lineEngineering

The invention discloses a full-automatic bubble pressing machine. The full-automatic bubble pressing machine is characterized by comprising a box feeding mechanism and a bubble pressing mechanism; the bubble pressing mechanism comprises an upright turnplate which is connected with a dividing device and provided with a plurality of bubble pressing bottom dies corresponding to a box feeding station, bubble pressing stations and a box discharging station; wine boxes are automatically conveyed to the box feeding station by the box feeding mechanism and are pushed onto the bubble pressing bottom dies by a box feeding pushing assembly; the bubble pressing stations are provided with bubble pressing moving dies which are movably arranged and conduct bubble pressing on the wine boxes arranged on the bubble pressing bottom dies in a sleeving mode; the box discharging station is provided with a box taking-off pushing assembly to push the wine boxes away from the bubble pressing bottom dies; an automatic perforating machine is arranged on a conveying platform of the box feeding mechanism, and the conveying platform is composed of a front part and a rear part; the front conveying platform is arranged in an inclining mode, and the height of the box feeding end of the front conveying platform can be adjusted through a height adjusting assembly; the box discharging end of the front conveying platform is arranged in a swing mode. The full-automatic bubble pressing machine is simple in structure and better in bubble pressing effect, and meanwhile has an automatic perforating function, so that assembly line production is easy to achieve.

Owner:浙江海垟科技有限公司

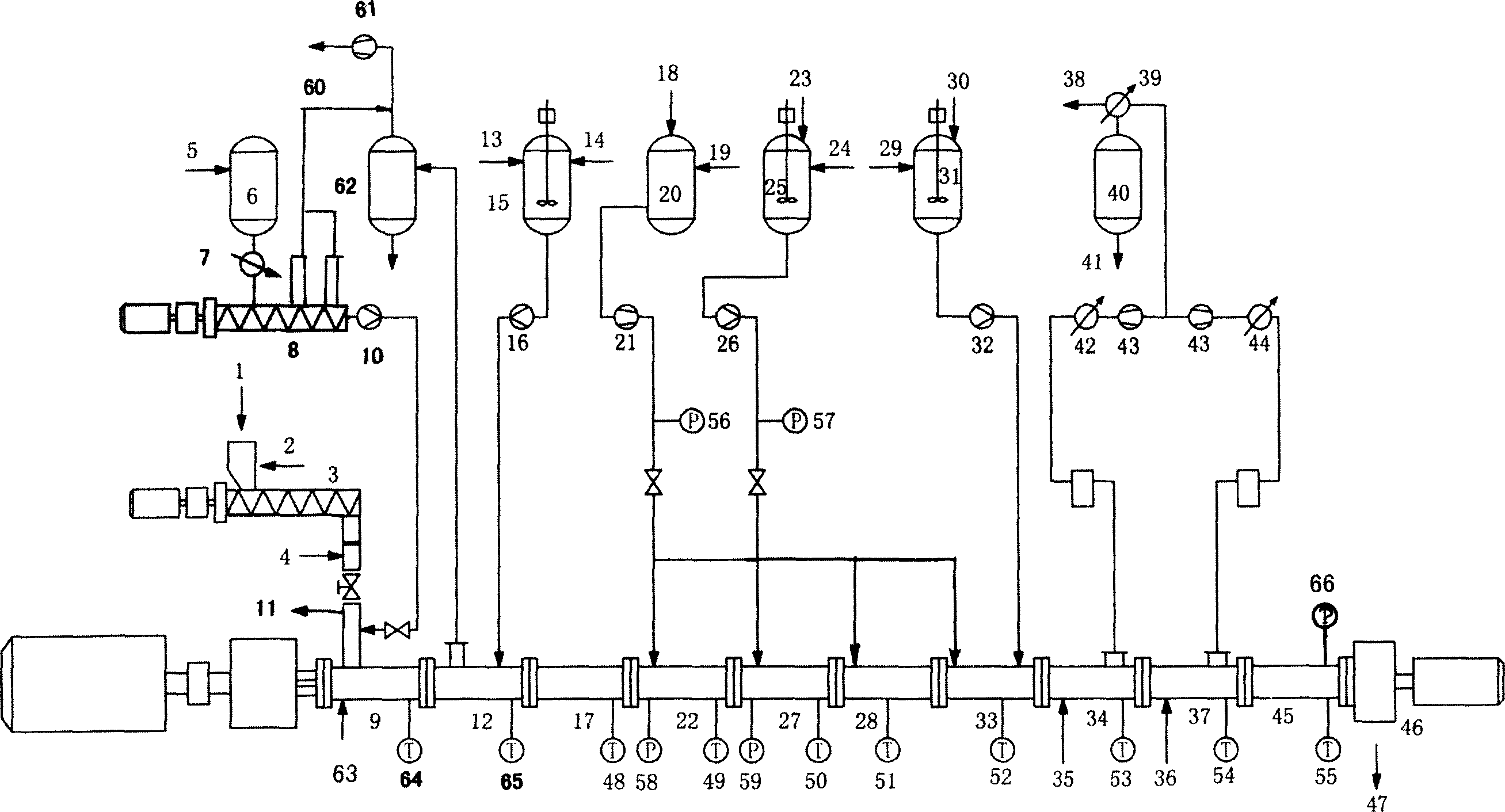

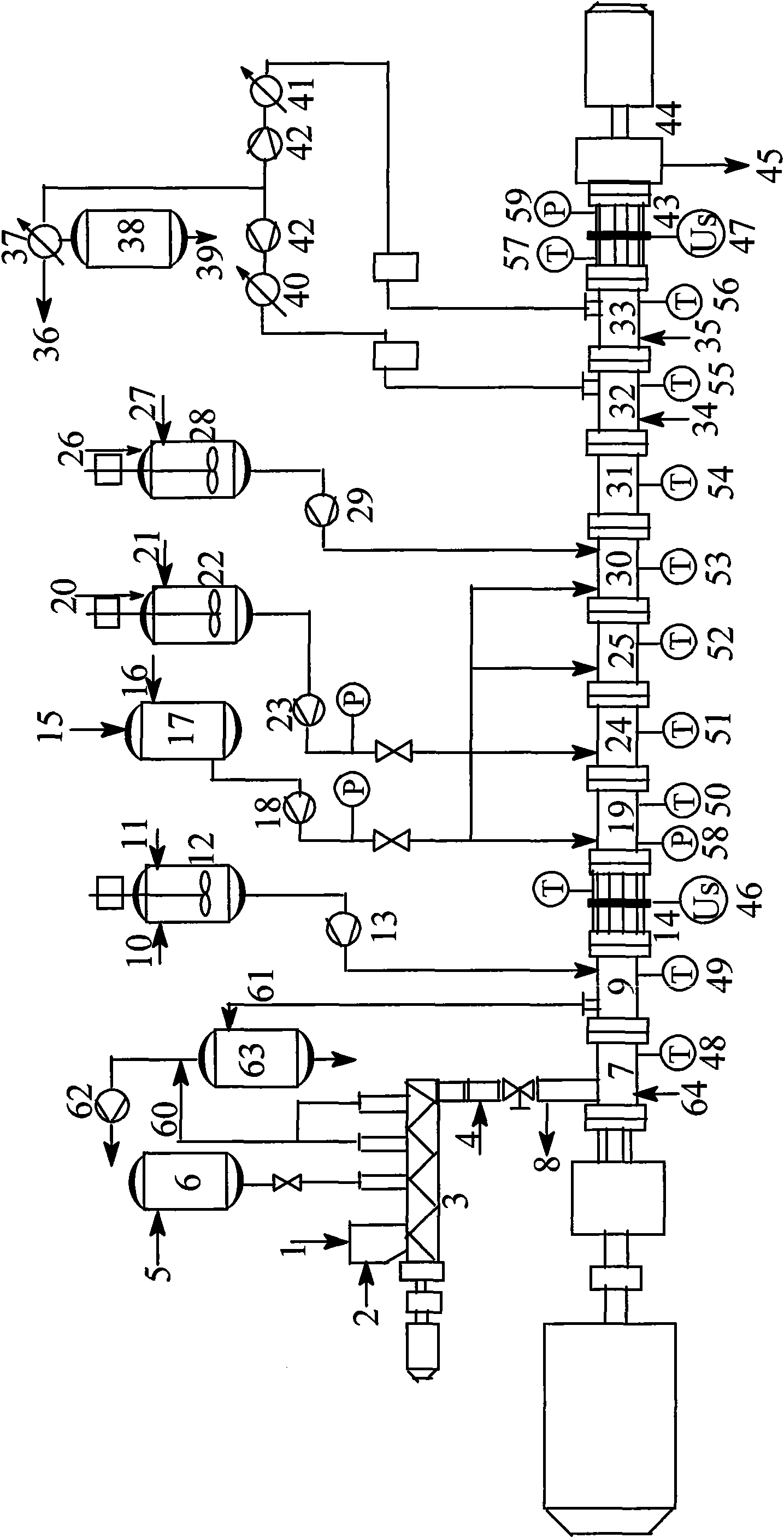

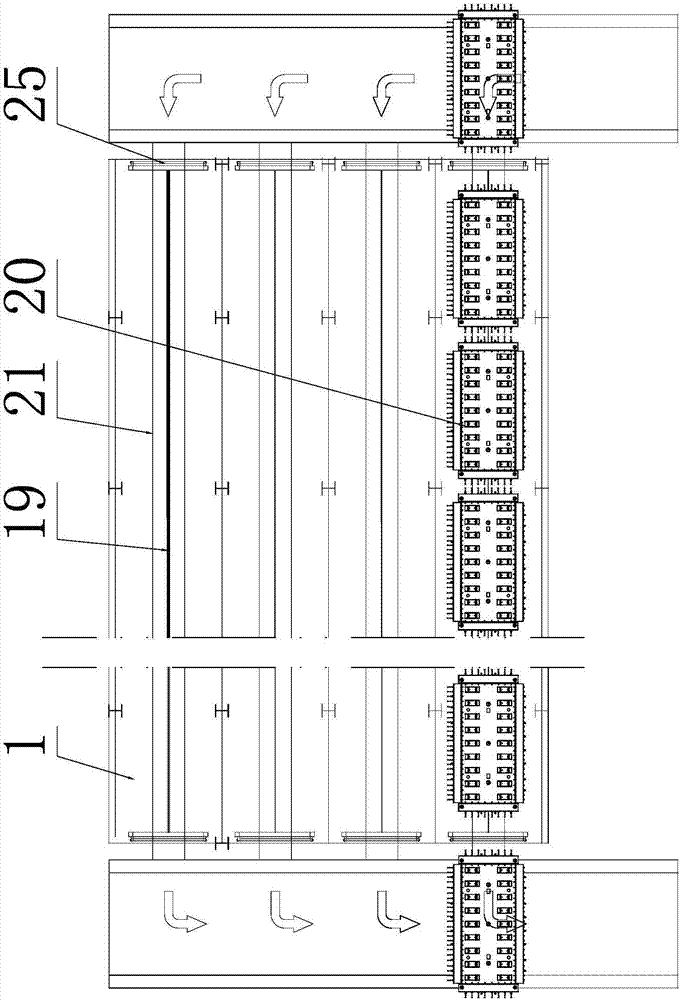

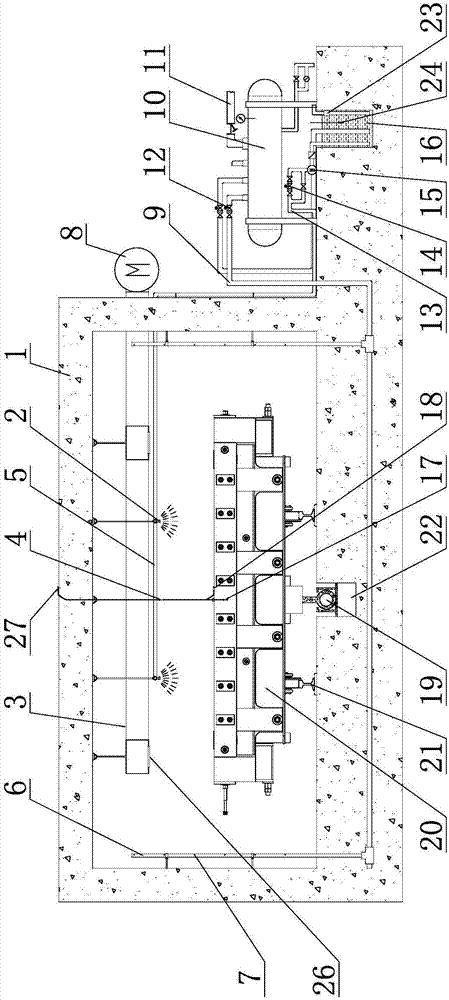

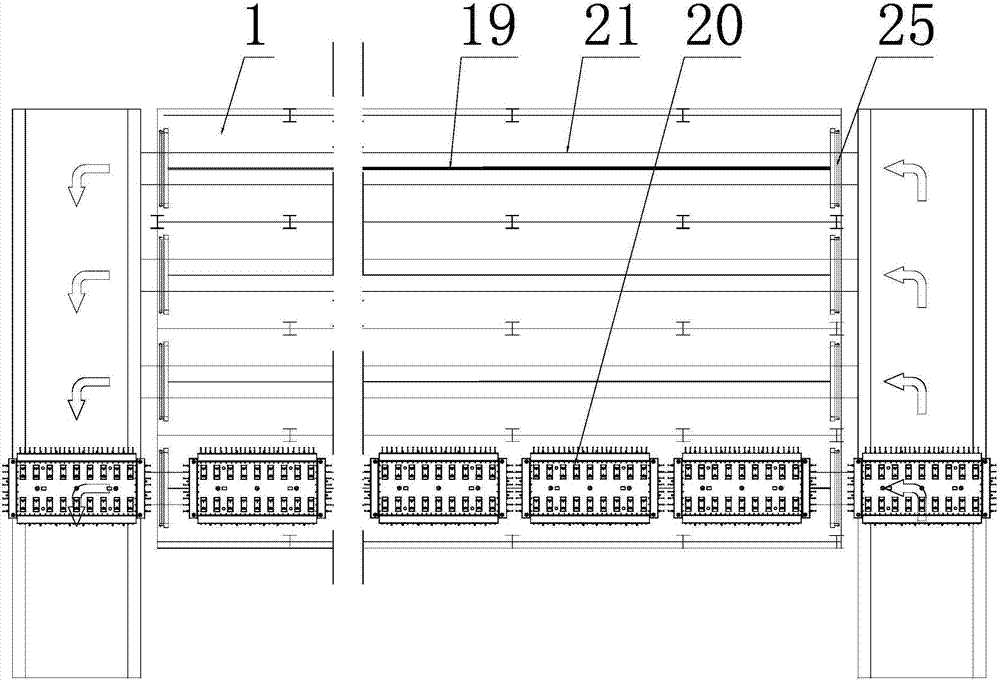

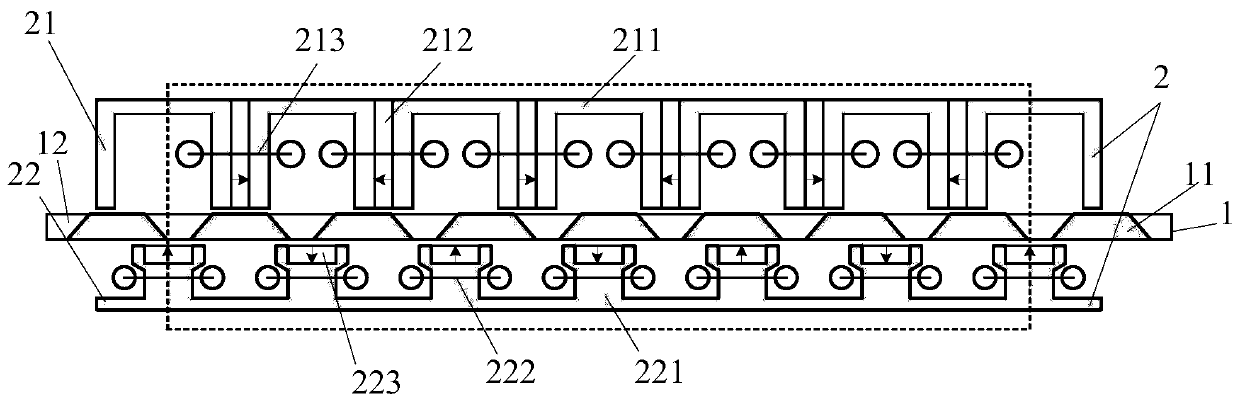

Pre-tensioning method prestressed concrete track board production line maintaining system and application thereof

PendingCN108000694ARapid productionImprove maintenance efficiencyCeramic shaping apparatusAutomatic controlAssembly line

The invention belongs to production of track boards, and particularly relates to a pre-tensioning method prestressed concrete track board production line maintaining system and application thereof. The maintaining system comprises a steam-maintaining chamber which is arranged between working tracks matched with a mold and provided with an automatic door, a nozzle which is arranged in the steam-maintaining chamber and connected with a constant temperature water supply device, a temperature detection device and a temperature control device, wherein the temperature detection device and the temperature control device are connected with a center control device; a walking track and a transfer pulling device used for pulling a mold are arranged on the ground in the steam-maintaining chamber; thewalking track is connected with the working tracks outside the steam-maintaining chamber; the temperature and humidity detection device comprises a core temperature and humidity sensor, a surface layer temperature and humidity sensor and an environment temperature and humidity sensor; and the temperature control device comprises a steam supply device and an air cooling device. The technical problems that in the prior art, maintaining measures are simplex, and existing standard requirements cannot be met are effectively solved, and the maintaining system has the advantages that the existing standard requirements are well met, high-efficiency assembly line production can be achieved, and automatic control is achieved easily.

Owner:河北益铁机电科技有限公司 +3

Preparation of nano aluminum oxide without hard coacervation

InactiveCN1583567AEfficient removalEliminate hard agglomerationAluminium oxide/hydroxide preparationAluminium oxides/hydroxidesAluminium nitrateNano al2o3

A process for preparing nano-alumina without hard conglomerations includes such steps as proportionally and respectively dissolving aluminium nitrate and ammonium carbonate in secondary distilled water to obtain their solutions, adding polyethanediol to them to obtain their composite solutions, mixing them together, stirring, centrifugal dewatering, drying, azeotropic distilling, and high-temp calcining.

Owner:WUHAN UNIV

Magnesium desulphurization method for molten iron pretreatment and powder used thereby

The invention belongs to the steel metallurgic technical field and in particular relates to a hot metal pretreatment magnesium desulfurization method and the adopted powder, wherein, the powder comprises magnesium metal powder and is characterized in that the powder also comprises premelting magnesium desulfurization accelerating agent which is made from blast furnace slag and lime through production processes such as raw material selection, impurity removal and drying, mix crushing and passivating treatment; by means of the prior blowing equipment, the magnesium metal powder and the premelting magnesium desulfurization accelerating agent are mixed according to a certain proportion or are jointly injected into hot metal for desulfurization. The method is simple and feasible and the made powder can replace pure lime powder, therefore, the invention has the advantages of energy saving, high efficiency and environmental protection; moreover, the method can greatly reduce the pretreatment cost of hot metal and increases hot metal yield.

Owner:INST OF METALLURGICAL TECH DONGBEI UNIV SHENYANG

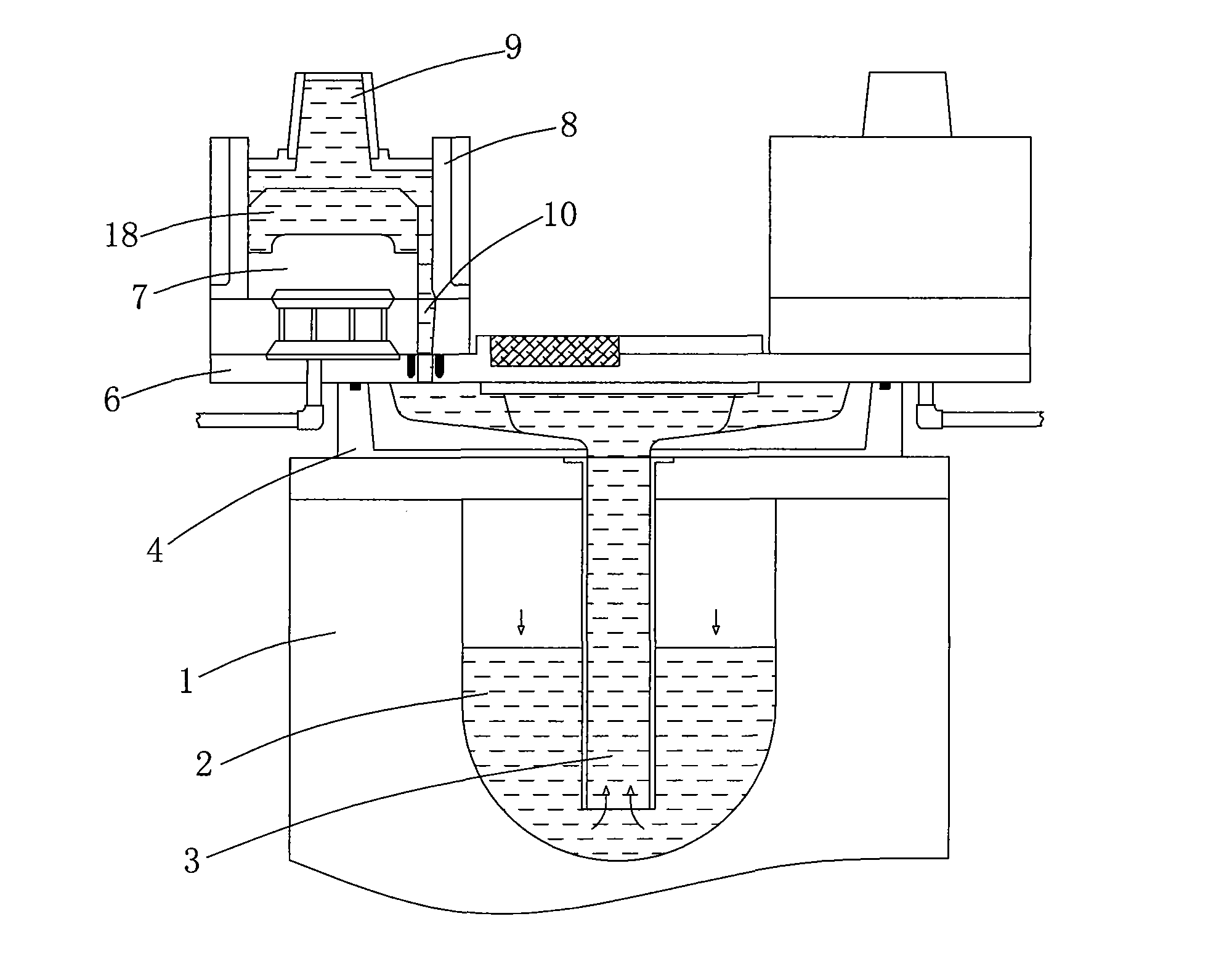

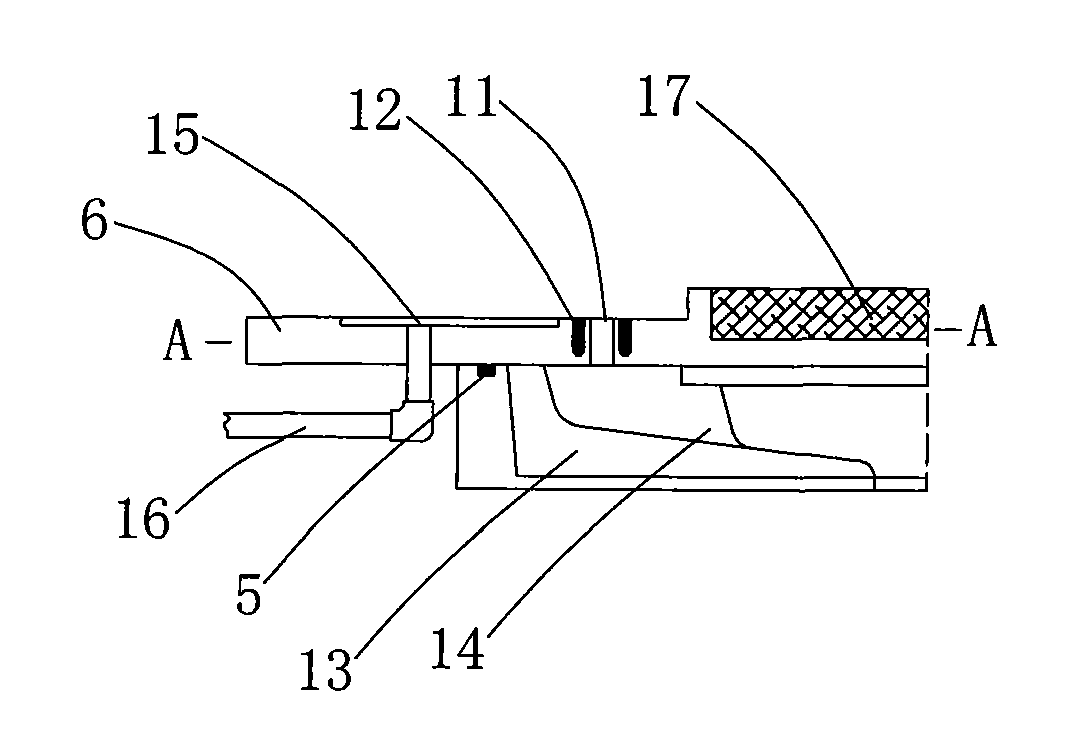

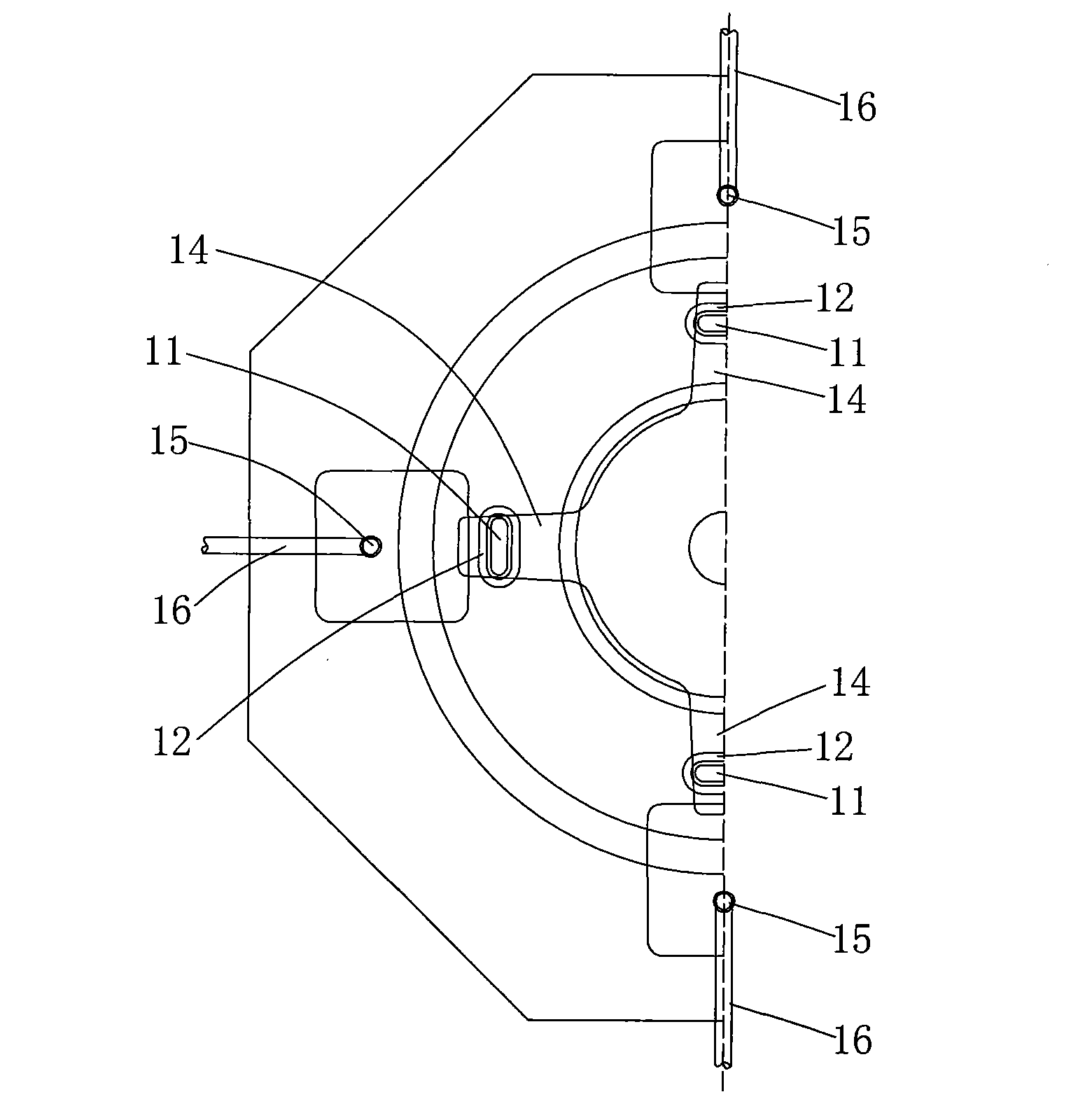

Aluminum alloy pattern block low-pressure casting equipment and low-pressure casting and gravity feeding compound process

The invention discloses aluminum alloy pattern block low-pressure casting equipment. A disk-type runner substrate is arranged on a crucible, and the lower end of a riser tube passes through the center hole of the runner substrate and then stretches into the crucible; a runner cover board is hermetically covered on the runner substrate, a plurality of casting moulds are distributed on the runner cover board, a feed head is arranged at the upper end of each casting mould, and an inner runner is arranged at the lower end of each casting mould; and a main runner is laid in a hollow cavity between the runner substrate and the runner cover board, a plurality of runner channels are distributed on the main runner, and the runner channels are respectively communicated with the inner runners of the casting moulds and the upper port of the riser tube. The invention can solve the secondary pollution problem of aluminum liquid in the partitioning and casting process of aluminum alloy pattern blocks and achieve simultaneously casting a plurality of aluminum alloy pattern block castings, and is beneficial to improving the casting production efficiency.

Owner:合肥大道模具有限责任公司

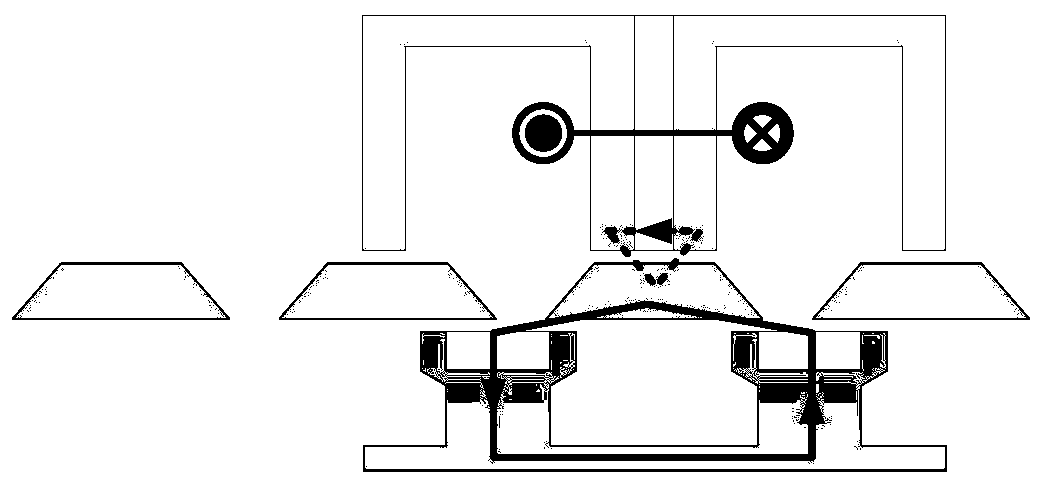

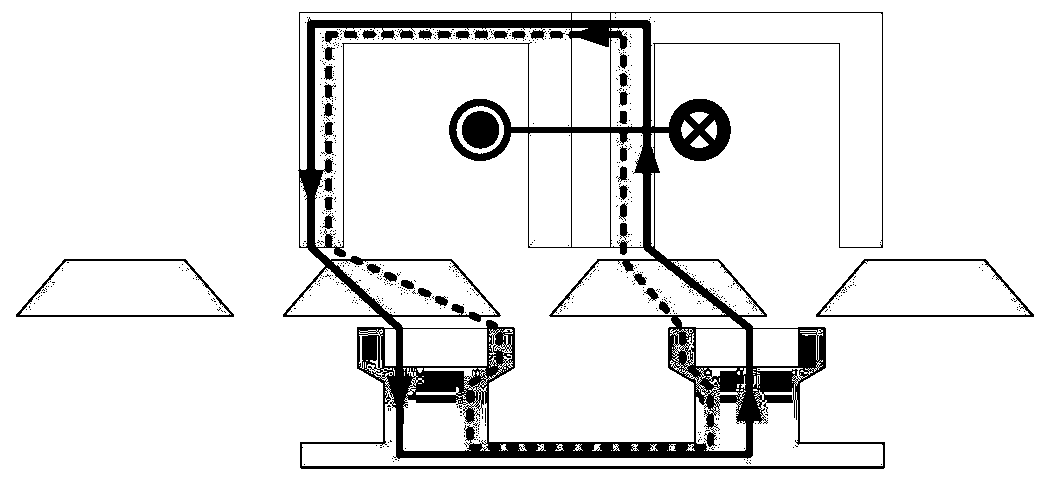

An asymmetric double permanent magnet hybrid excitation switch flux linkage linear motor

ActiveCN108155775BIncrease thrust densityIncrease the areaPropulsion systemsConstant powerElectric machine

Owner:ZHEJIANG UNIV

Method for extracting coconut oil and byproducts from fresh coconut pulp

The invention relates to a method for extracting coconut oil and byproducts from fresh coconut pulp, which comprises the following steps: peeling and crushing shells of coconuts to obtain fresh whitecoconut pulp, crushing the fresh white coconut pulp and grinding the fresh white coconut pulp and buffer solution, then adding enzyme into the mixture to carry out extraction, filter-pressing the extract, separating dietary coconut fibers and the filtrate, centrifugating the filtrate, and separating emulsified coconut oil and coconut protein solution so as to obtain the coconut oil and coconut protein powder respectively. The coconut oil processed by the method has fresh character and can be directly eaten or applied, and the byproducts comprising the dietary coconut fibers and the coconut protein powder can be used as food accessories or additives, so the method improves the utilization level of the coconut pulp and the extraction rate of the coconut oil, and has high economic benefit andgood application prospect.

Owner:海南省粮油科学研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com