Patents

Literature

170results about How to "Reduce porosity defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

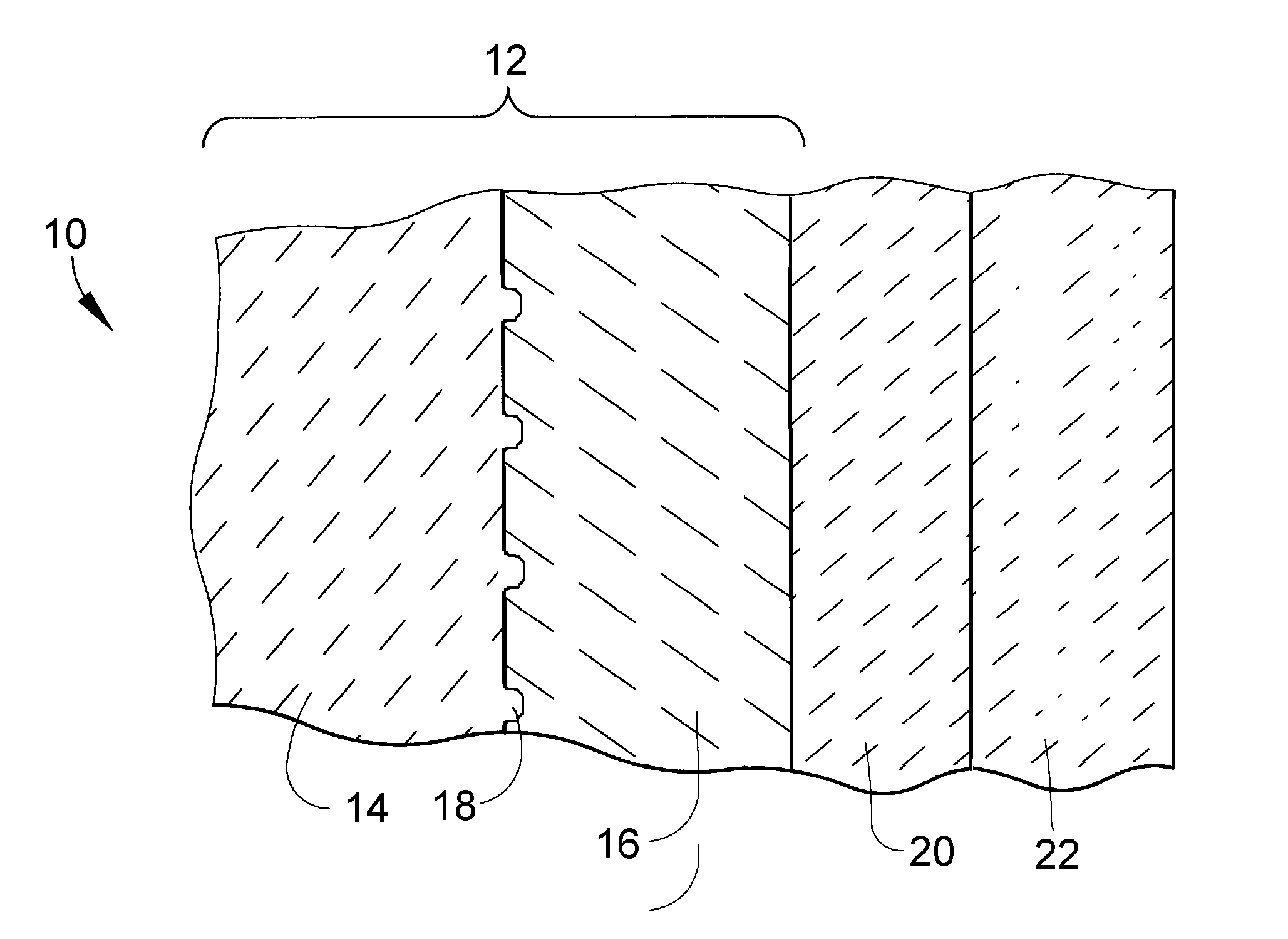

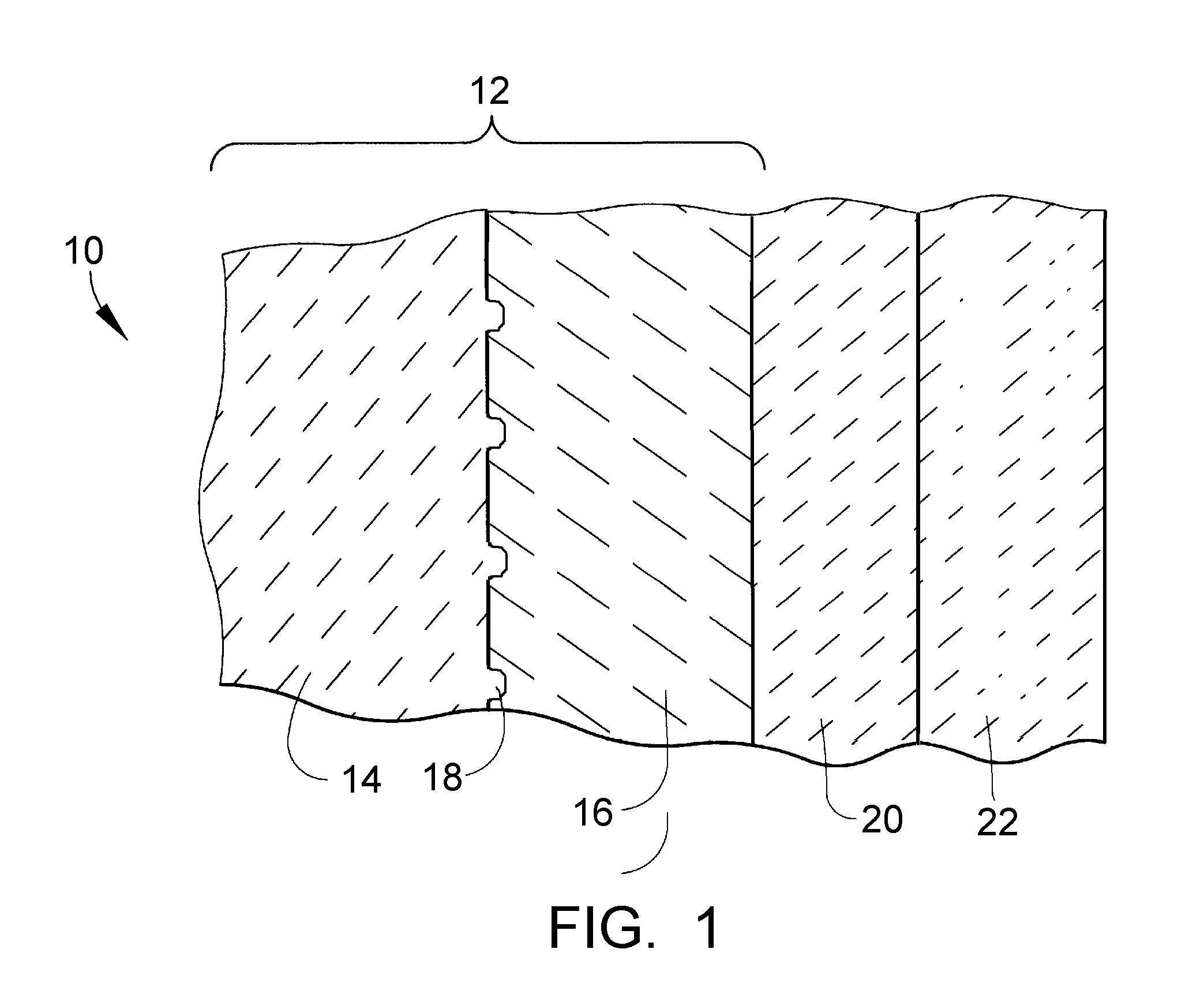

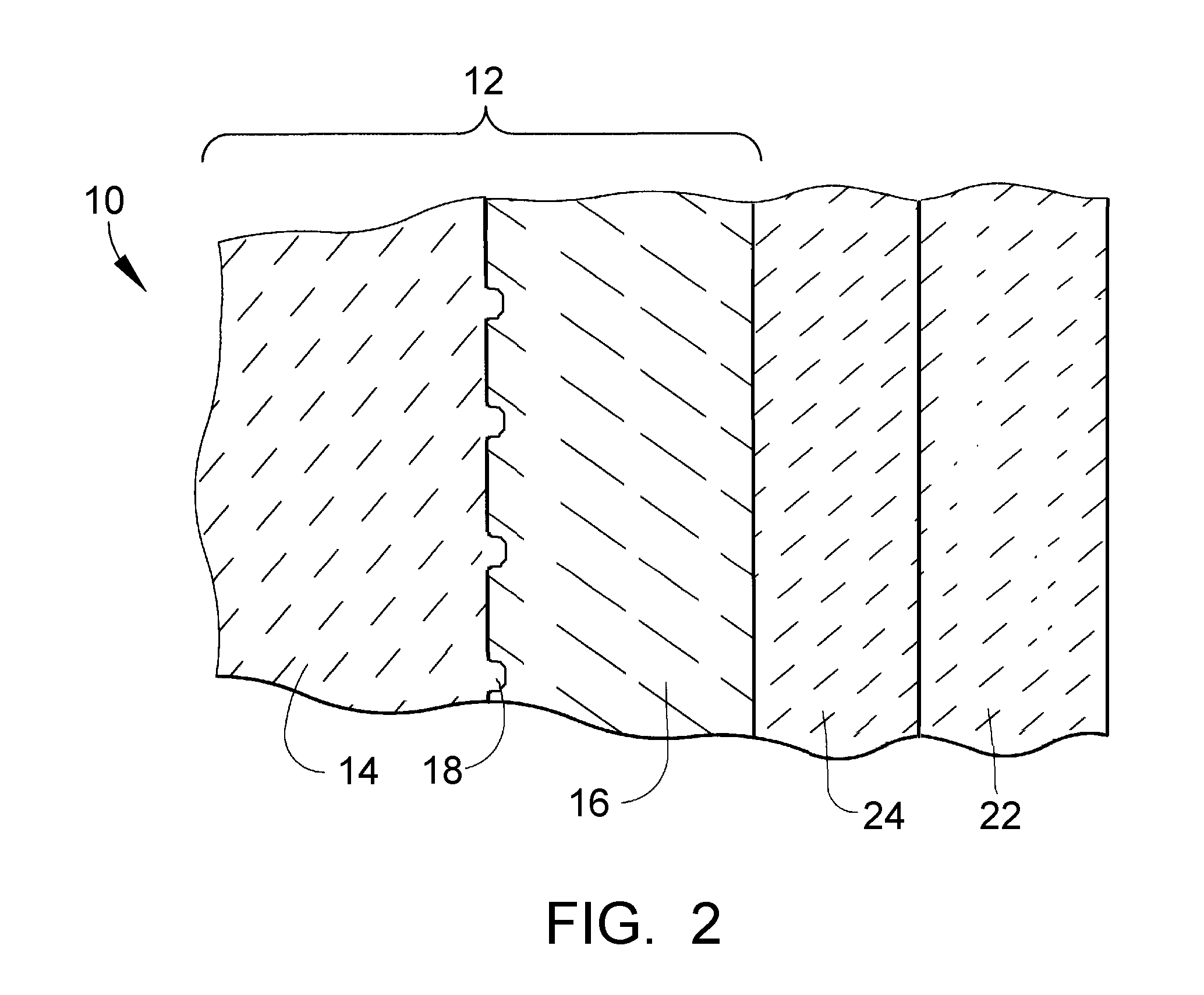

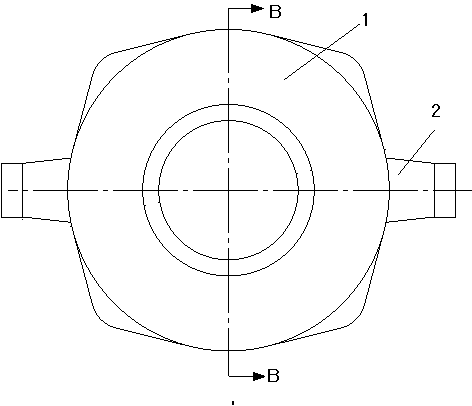

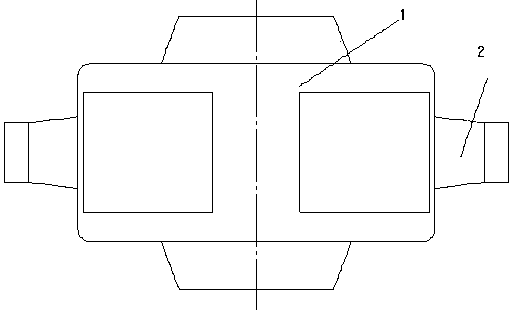

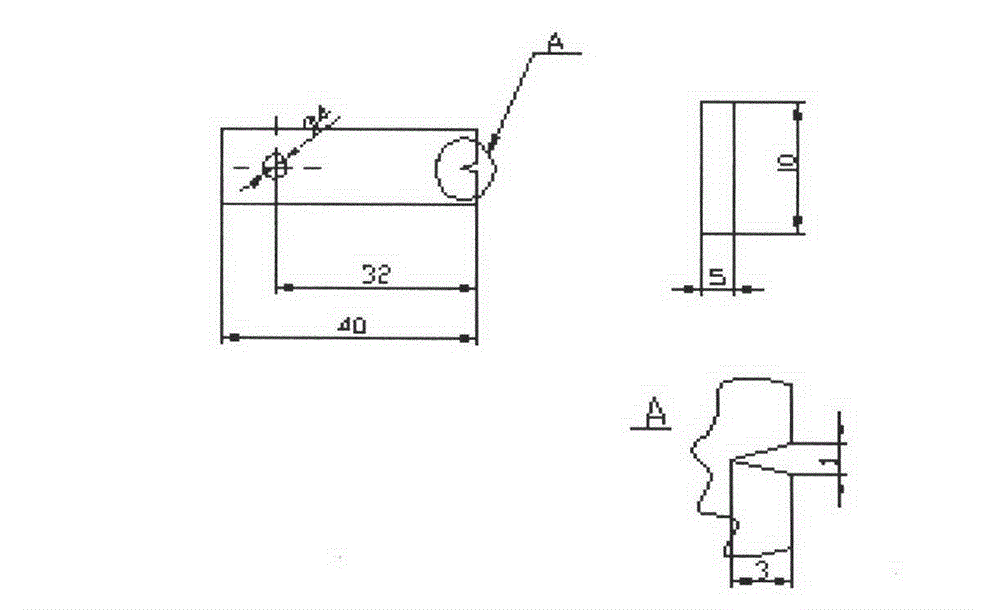

Gradient curvature raised roller of tension leveler for cogged ingot continuous casting and use method

ActiveCN104399924AIncrease the amount of deformationRealize the process purpose of extrusionStress concentrationMetallurgy

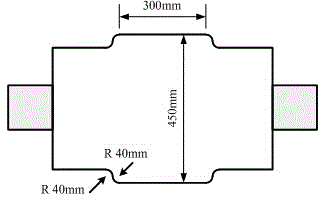

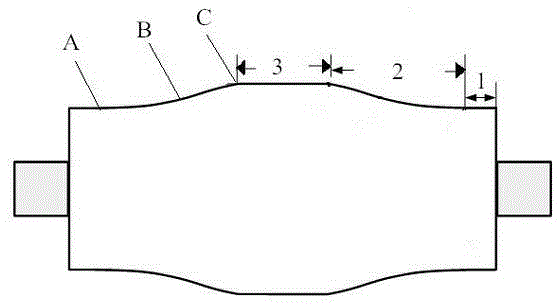

The invention belongs to the field of cogged ingot continuous casting production and especially relates to a gradient curvature raised roller of a tension leveler for cogged ingot continuous casting and a use method. The gradient curvature raised roller of the tension leveler provided by the invention is composed of a roller shaft and a roller body, wherein the roller body is composed of an edge area, a gradient curvature area and a flat roller area; the gradient curvature area is composed of an arcing area and an arc-varying area; the arc curvature between an arcing point and an arc-varying point of the arcing area is gradually increased; the arc curvature between the arc-varying point and an arc-ending point of the arc-varying area is gradually reduced; the flat roller area is raised relative to the edge area. At least four tension levelers with the gradient curvature raised rollers are used for pressing a cogged ingot continuous casting slab; during the pressing process, the average temperature of the surface of the continuous casting slab is controlled at above or equal to 800 DEG C and the temperature difference of surface center and corner is at below or equal to 150 DEG C; lastly, the continuous casting slab with improved central segregation and loosening is acquired. The smooth transition between the flat roller area and the raised roller area is realized by the gradient curvature raised roller provided by the invention and the crack defect caused by the stress concentration of the transition area is effectively avoided.

Owner:NORTHEASTERN UNIV

Narrow-gap laser-scanning multi-layer self-melting welding method based on prefabricated welding materials

InactiveCN105149786ASimplify the welding processPrecise control of single layer fill heightWelding/soldering/cutting articlesMetal working apparatusLaser processingThick plate

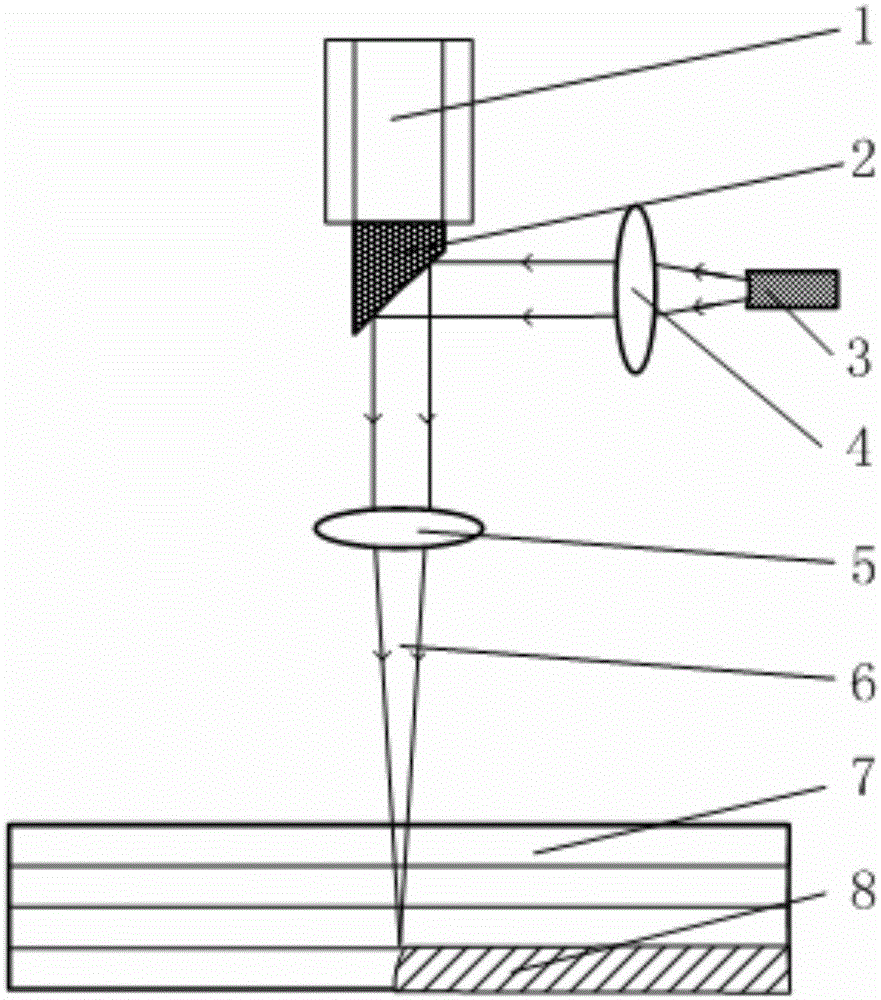

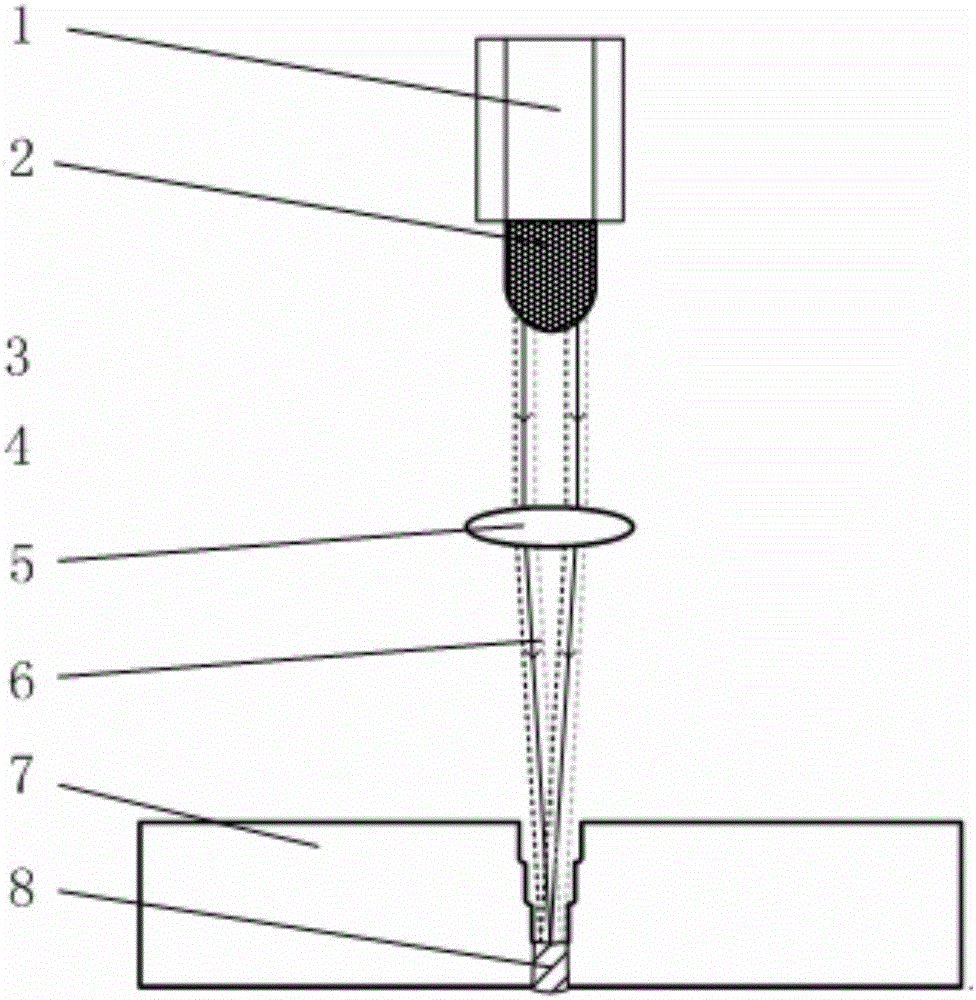

The invention belongs to the technical field of laser processing, and particularly relates to a narrow-gap laser-scanning multi-layer self-melting welding method based on prefabricated welding materials. The method aims at solving the problems that in the thick plate welding process, wire filling is difficult, and molten drop transition is not stable. According to the narrow-gap laser-scanning multi-layer self-melting welding method based on a prefabricated filling layer, a laser scanning welding technology and narrow-gap multi-layer filled welding are skillfully combined, therefore, a laser wire filling multi-layer welding mode for thick plate structure parts is converted into a laser self-melting multi-layer welding mode, and the single-layer filling height of a weld joint in a narrow-gap groove can be precisely controlled; due to the fact that the prefabricated filling layer can prevent the weld joint from shrinking, welding deformation can be further reduced, the thick plate welding process is greatly simplified, and the welding efficiency and the welding quality are improved. The method is suitable for narrow-gap laser welding of thin plates or thick plates of different thicknesses.

Owner:HARBIN INST OF TECH

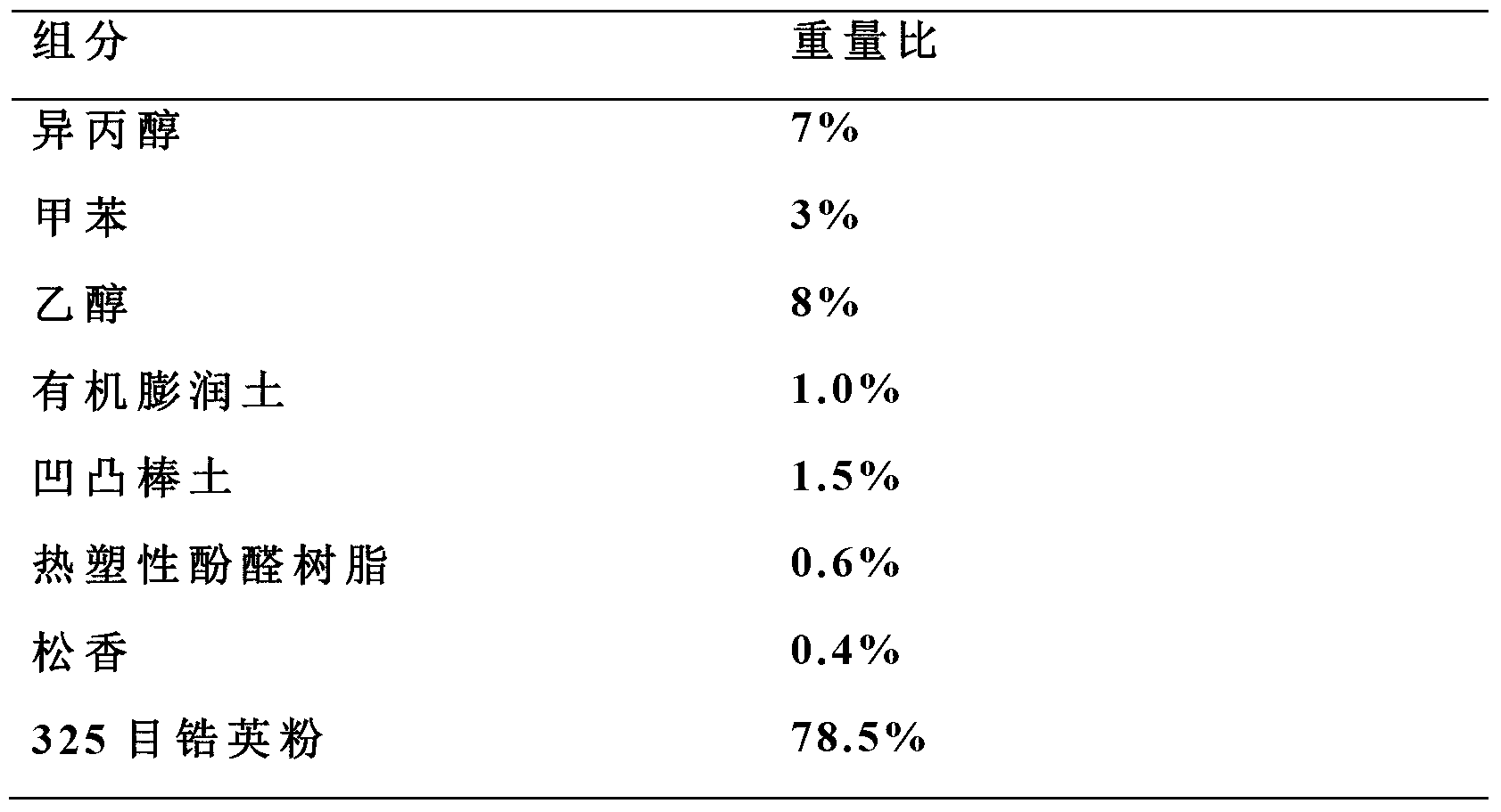

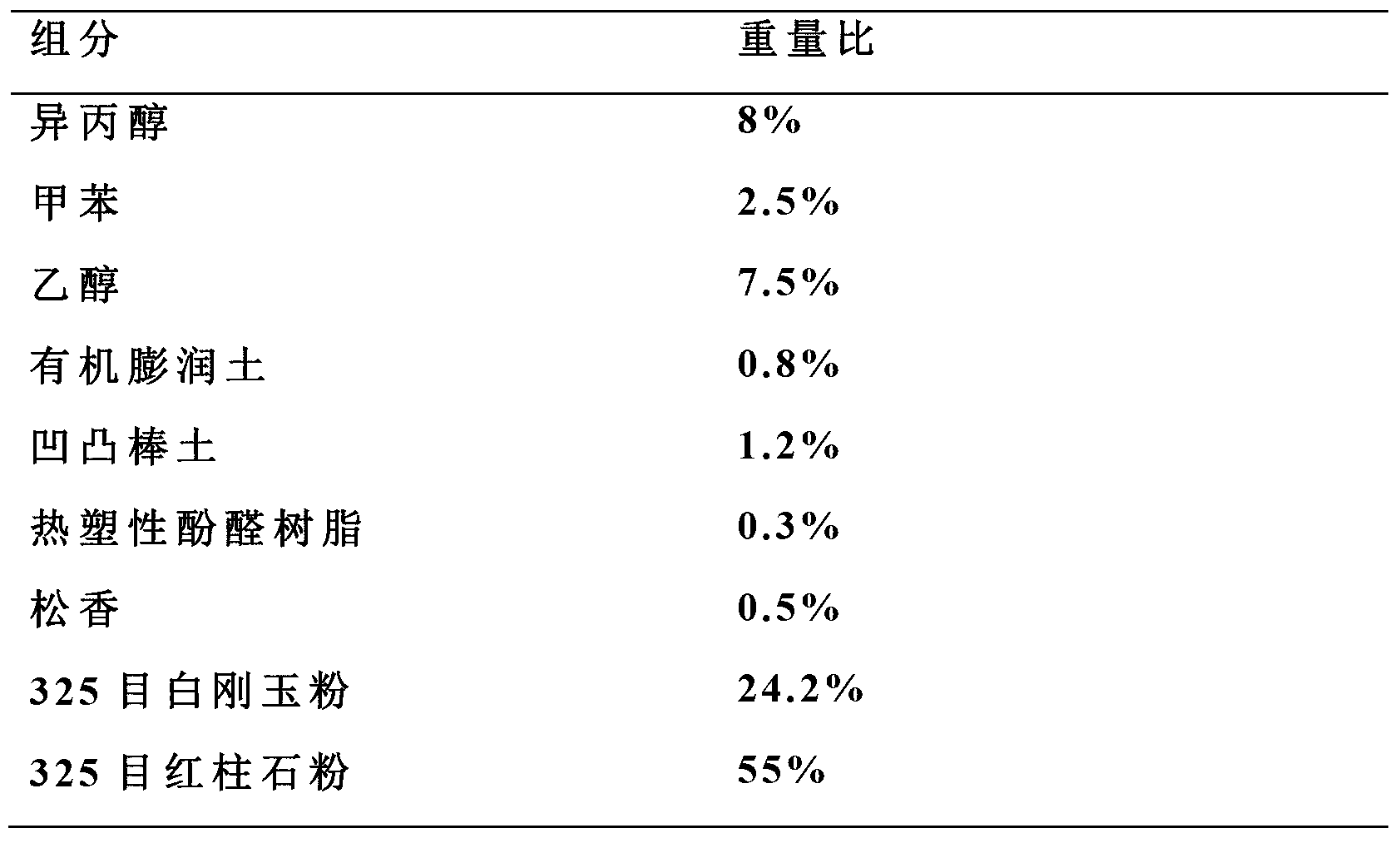

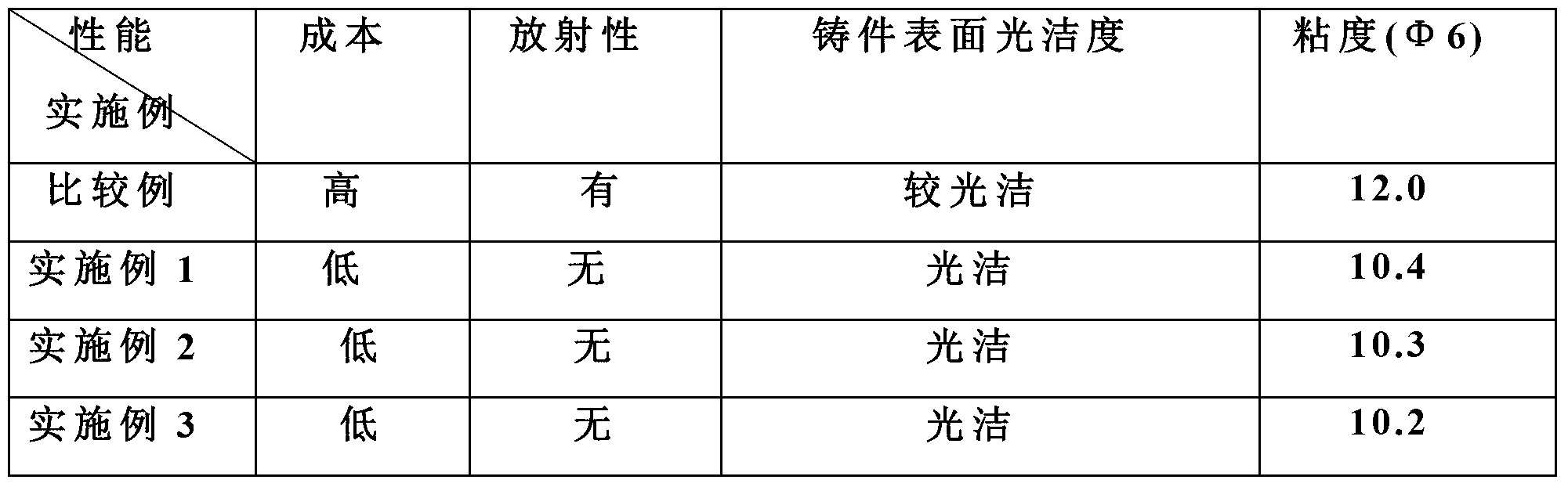

Zircon power alternative coating for casting and preparation method thereof

The invention discloses a zircon power alternative coating for casting, which is characterized in that a coating composition comprises carrier liquid consisting of isopropyl alcohol, toluene and ethanol, a suspending agent consisting of organobentonite and attapulgite, an adhesive consisting of thermoplastic phenolic resin and rosin, and refractory aggregate consisting of white alundum powder and andalusite powder. The coating composition comprises the following components by weight percent: 6-10 percent of isopropyl alcohol, 2-4 percent of toluene, 6-10 percent of ethanol, 0.5-1.5 percent of organobentonite, 1-2 percent of attapulgite, 0.2-1.0 percent of thermoplastic phenolic resin, 0.2-1.0 percent of rosin, 15-55 percent of white alundum powder and 15-55 percent of andalusite powder. Compared with the conventional common cast steel zircon power coating, the coating has high thixotropy and leveling property, is smooth and dense and has enough normal temperature and high-temperature strength, so that the casting roughness meets the quality requirement; and moreover, the zircon power alternative coating is low in gas outlet quantity and has proper shielding property, and the defects of the casting air holes can be obviously reduced.

Owner:SUZHOU XINGYE MATERIALS TECH

Method for casting valve body of flat gate valve

ActiveCN103433434AReduced horizontal projected areaGravity feeding is easy to implementFoundry mouldsFoundry coresMiddle lineImpurity

The invention discloses a method for casting a valve body of a flat gate valve, and belongs to the technical field of valve body casting processes. The method is technically characterized in that a valve body cavity is vertically formed between a sand mold and a sand core; a plurality of valve body heat preserving risers are uniformly arranged at the open end of the valve body through the sand mold; a flange heat preserving riser is arranged at the upper end of a flange plate on each of two sides; a first external chill is arranged at the lower end of each flange plate; a plurality of second external chills are uniformly arranged at the periphery of a valve belly below the middle line of a flange; a third external chill is arranged on the outer bottom surface of the blind end of a main body of the valve body; process supplementary ion is arranged in an inner hole of the flange plate on each of the two sides; a fourth external chill is arranged on each of two end surfaces of a valve seat table in an inner cavity of the valve body. Therefore, the probability of occurrence of casting impurities and pore defects is reduced by using a vertical pouring method, gravity feeding is easy to implement so as to be matched with the chilling action of each external chill, and castings can be fed in sequence, so that the internal quality of the castings is well improved.

Owner:SHANDONG MOLONG PETROLEUM MACHINERY

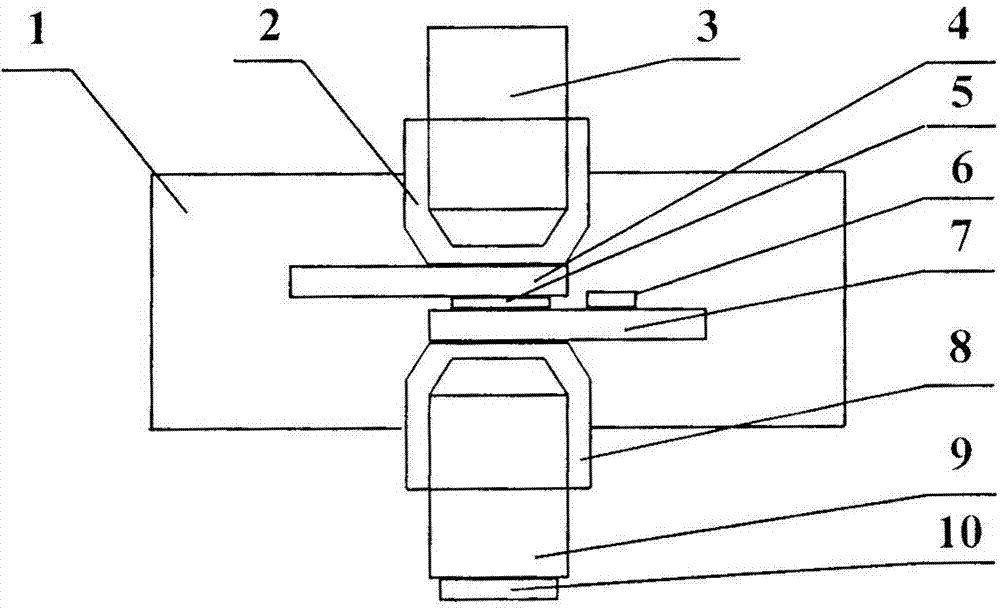

Resistance soldering method using graphite electrode and resistance soldering device

ActiveCN104259610ACombined with strong reliabilityImprove performanceSoldering apparatusWelding/soldering/cutting articlesPorosityChemical reaction

The invention discloses a resistance soldering method using a graphite electrode and a resistance soldering device. According to the resistance soldering method, the graphite electrode serves as a resistance soldering heating element which is used for soldering a hard alloy workpiece; the hard alloy soldered workpiece is placed in a closed steel soldering chamber; and when the graphite electrode is electrified and heated, carbon in the graphite electrode and oxygen surrounding the hard alloy soldering workpiece react chemically, so that oxygen in a local area at a soldering connection position is consumed. Oxygen-free porosity of a soldering connection brazing seam region between hard alloy and a steel substrate or between one piece of hard alloy and another piece of hard alloy can be realized, temperature fields of soldering connection portions are uniform, heating time is short, and efficiency is high. A graphite protecting device sleeves the graphite electrode and protects the graphite electrode from being damaged during resistance soldering pressurization. A pressure controller is arranged on the graphite electrode, pressure on the different soldering connection portions is not increased after the pressure of the graphite electrode reaches to a certain degree, and different demands of different soldering workpieces on external pressure are met.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Composite core for casting processes, and processes of making and using the same

InactiveUS20160175923A1Reduce the likelihood of a reactionIncrease chanceFoundry mouldsFoundry coresMetal alloyComposite ceramic

A composite ceramic core that, in combination with a shell mold, is suitable for use in a casting process to produce metal alloy components. The core and casting process make use of a highly leachable interior layer in combination with an exterior layer that is less reactive than the interior layer in the presence of common alloying elements. The interior layer contains at least one hollow channel that allows a point of entry for a leaching solution, as well as exit for gaseous byproducts generated during the casting process.

Owner:GENERAL ELECTRIC CO

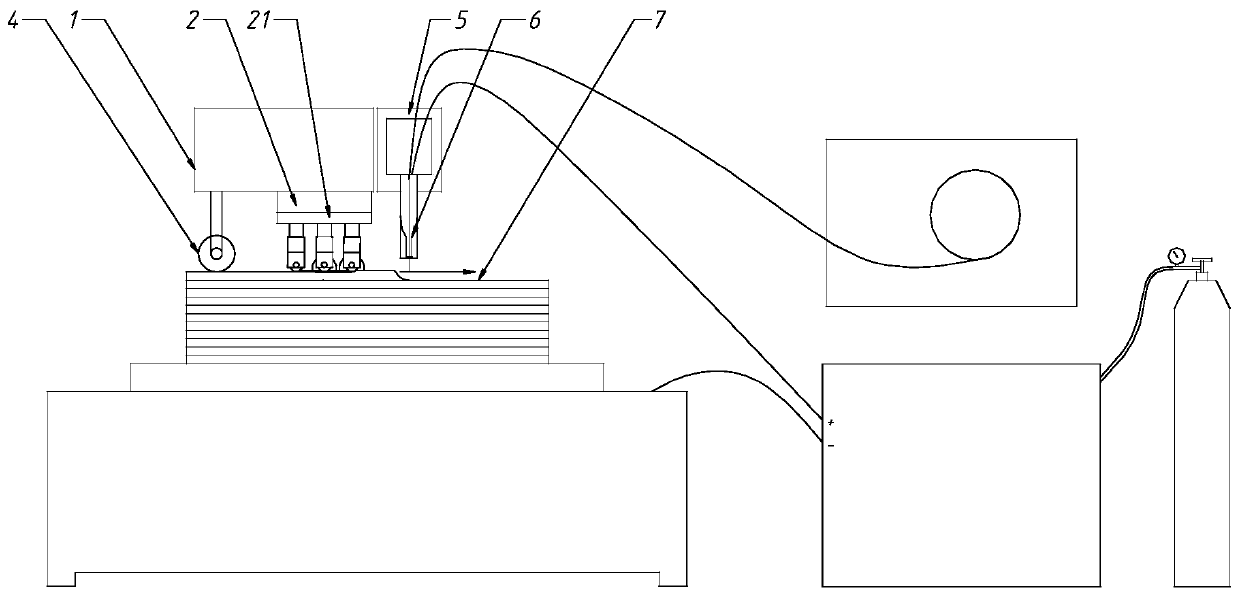

Arc wire feeding additive oblique roller combined wheel hot rolling manufacturing method and device

ActiveCN111215843ARapid coolingPreventing Dimensional Distortion ProblemsAdditive manufacturing apparatusOther manufacturing equipments/toolsEngineeringShearing deformation

The invention discloses an arc wire feeding additive oblique roller combined wheel hot rolling manufacturing method and device, and relates to the technical field of 3D printing. The wire feeding additive oblique roller combined wheel hot rolling manufacturing method and device are exquisite in structure, high in processing efficiency and good in processing effect, and can refine crystal grains ofan arc additive manufacturing formed part, improve compactness and reduce internal defects, thereby finally improving mechanical properties. The technical scheme of the invention is as follows: the manufacturing method comprises the following steps: (1) initialization; (2) arc wire feeding and material adding; (3) rolling; (3.1) strong shear deformation of an oblique roller; (3.2) primary flattening; (3.3) full flattening; (4) cooling; and (5) cutting of waste edges. The crystal grains of the arc wire feeding additive manufacturing formed part can be refined, the compactness is improved, internal defects are reduced, and the mechanical properties of the part are finally improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

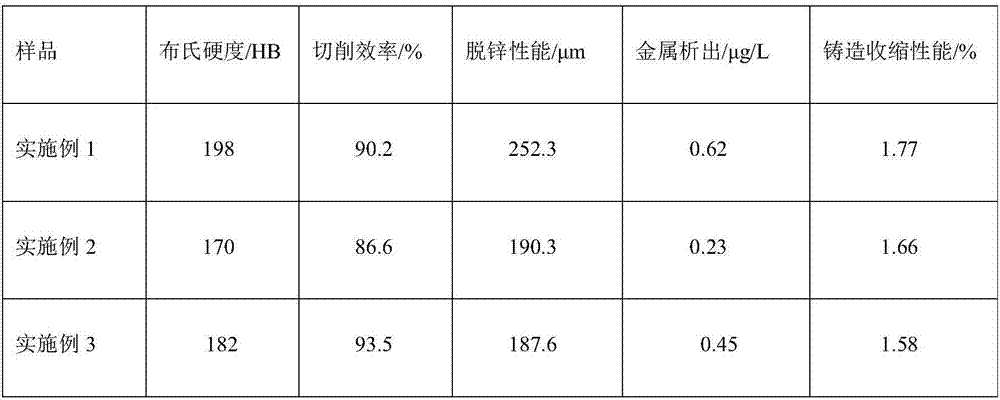

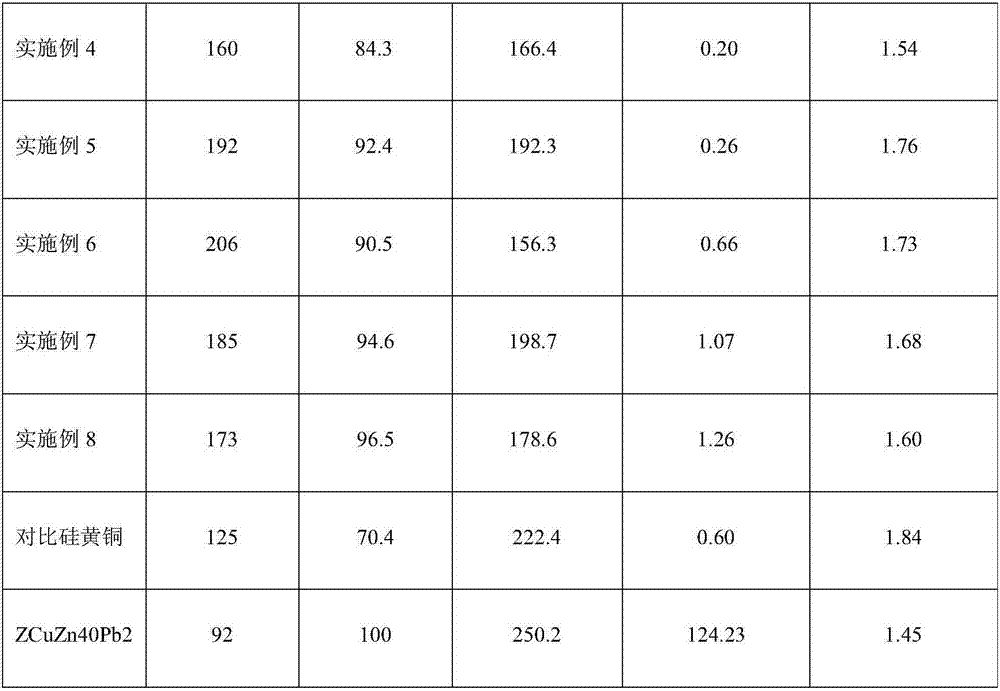

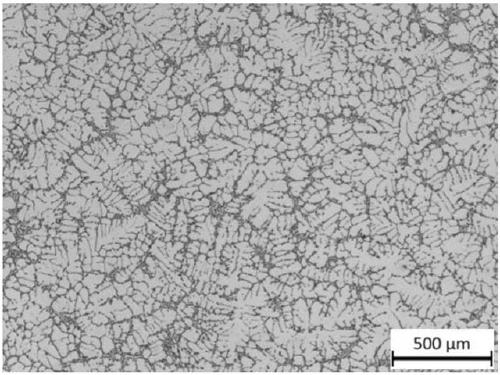

Manganese-contained free-cutting type silicon brass alloy as well as preparation method and application thereof

The invention discloses a manganese-contained free-cutting type silicon brass alloy. The alloy is composed of the following components, by weight percentage, 60.2-64.0wt% of Cu, 1.0-2.0wt% of Si, 0.2-1.0wt% of Al, 0.2-0.48wt% of Mn, 0.1-0.25 wt% of Pb, one or more of P, Mg and Sn, and the balance Zn and not greater than 0.5wt% of impurities, wherein the P accounts for 0.01-0.25wt%, the Mg accountsfor 0.01-0.25wt%, and the Sn accounts for 0.01-0.1wt%. The invention further discloses a preparation method for the alloy. The manganese-contained free-cutting type silicon brass alloy has the advantages of being excellent in dezincification corrosion resistance, good in casting property and cutting property, relatively low in cost and suitable for casting parts of a drinking water system, such as a faucet, a valve, a quick switch.

Owner:JOMOO KITCHEN & BATHROOM

Novel welding process for combining submerged-arc welding with CO2 gas shielded welding

InactiveCN102126089AImprove welding efficiencyImprove mechanical propertiesArc welding apparatusWelding power supplyProcess engineering

The invention discloses a novel welding process for combining submerged-arc welding with CO2 gas shielded welding. A welding power supply, a control box and a welding tractor of submerged-arc welding are adopted, a welding gun of CO2 gas shielded welding is arranged on the welding tractor, but CO2 gas is not used; and by using a welding wire of the gas shielded welding and a welding flux of the submerged-arc welding, a backing welding layer and a cosmetic welding layer of a working seam are welded through a wire feeding mechanism and the welding gun of the CO2 gas shielded welding. The invention improves the comprehensive mechanical property of the whole seam, ensures that the surface of the seam is formed smoothly and attractively, is beneficial to appearance detection, has improved welding process parameters compared with other welding methods, and can ensure effective weld penetration, low cost and high production efficiency.

Owner:YINGDU BRIDGE STEEL STRUCTURE ENG

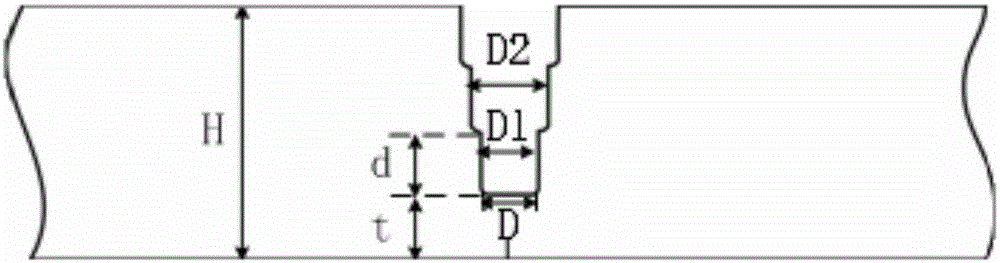

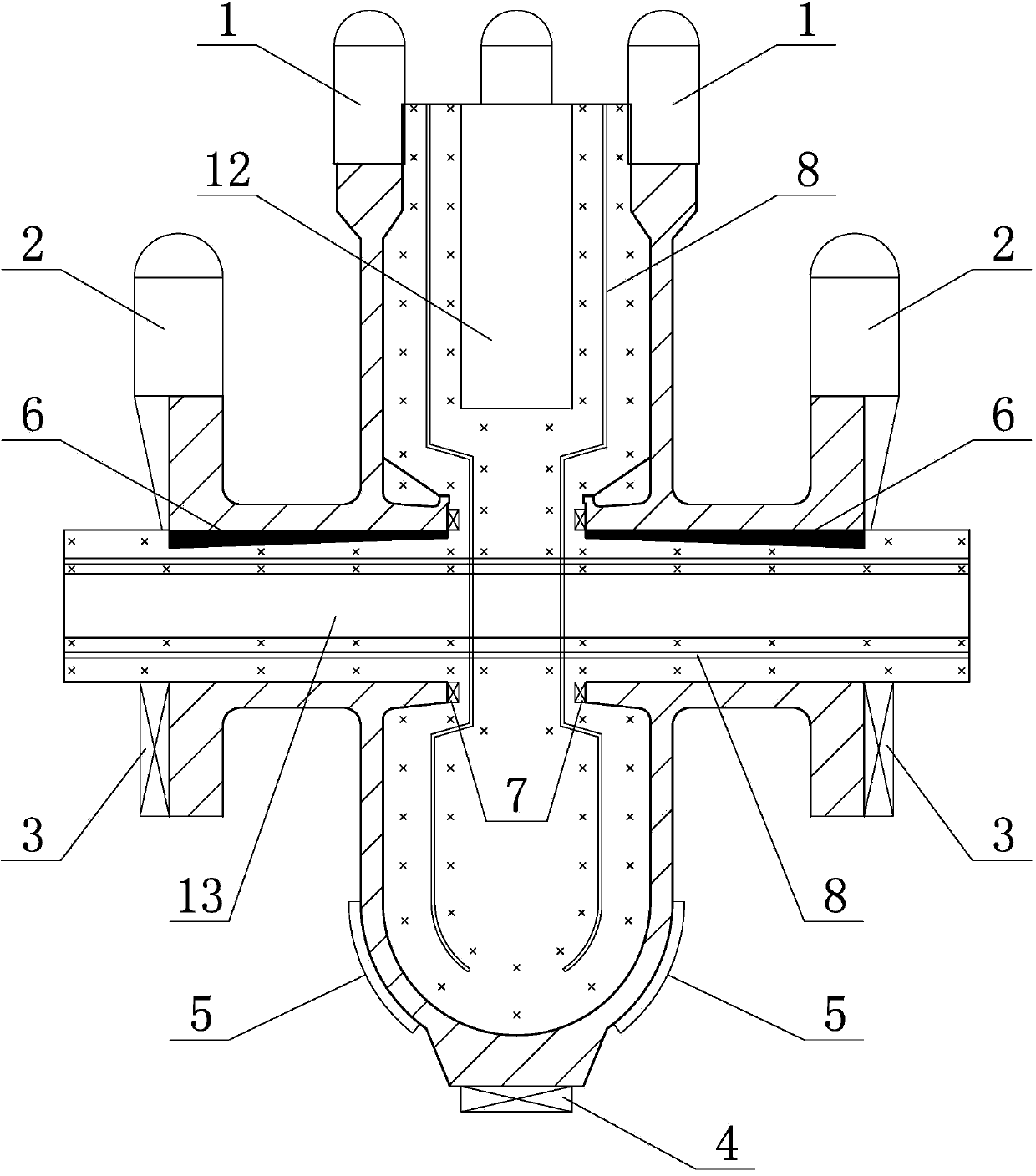

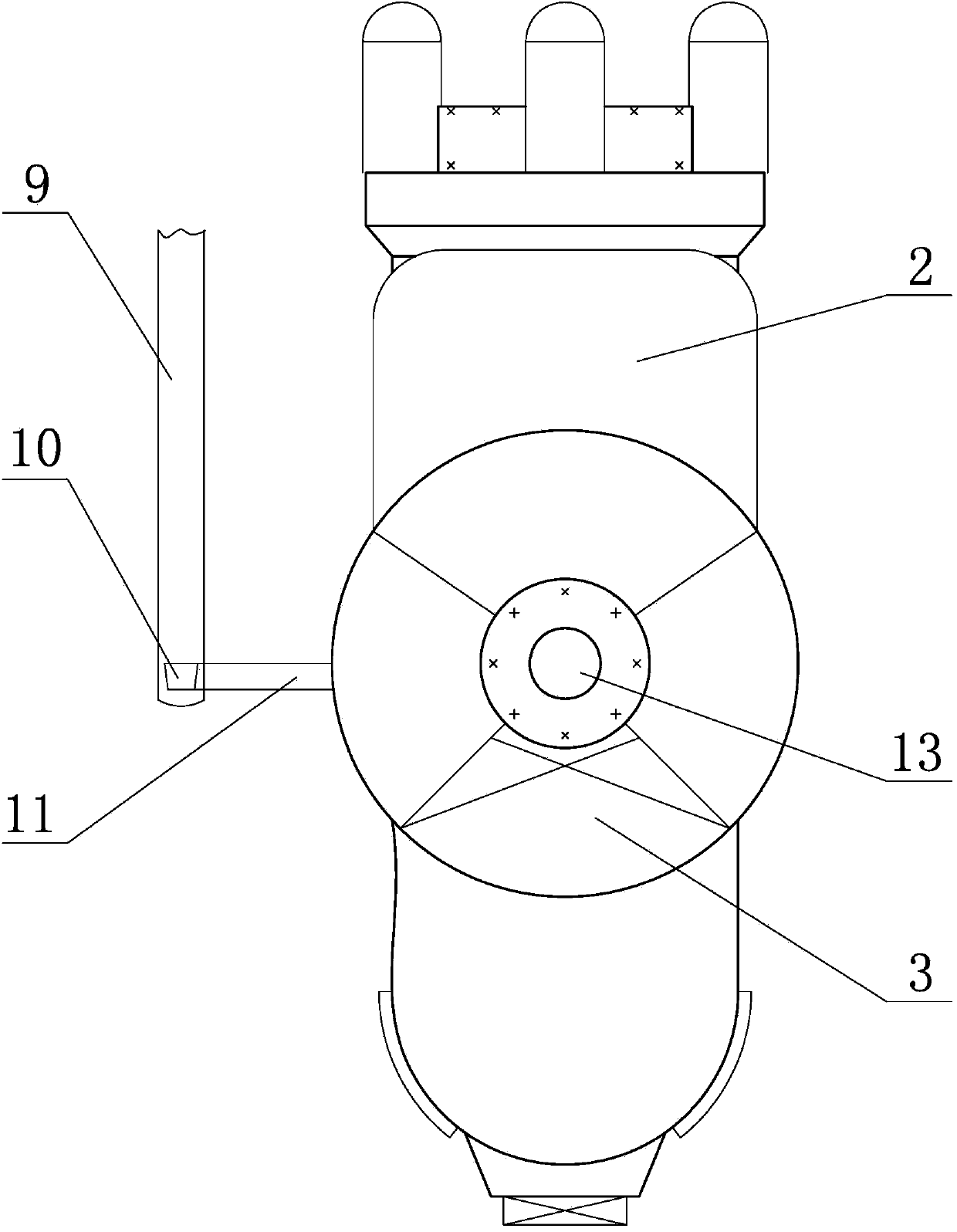

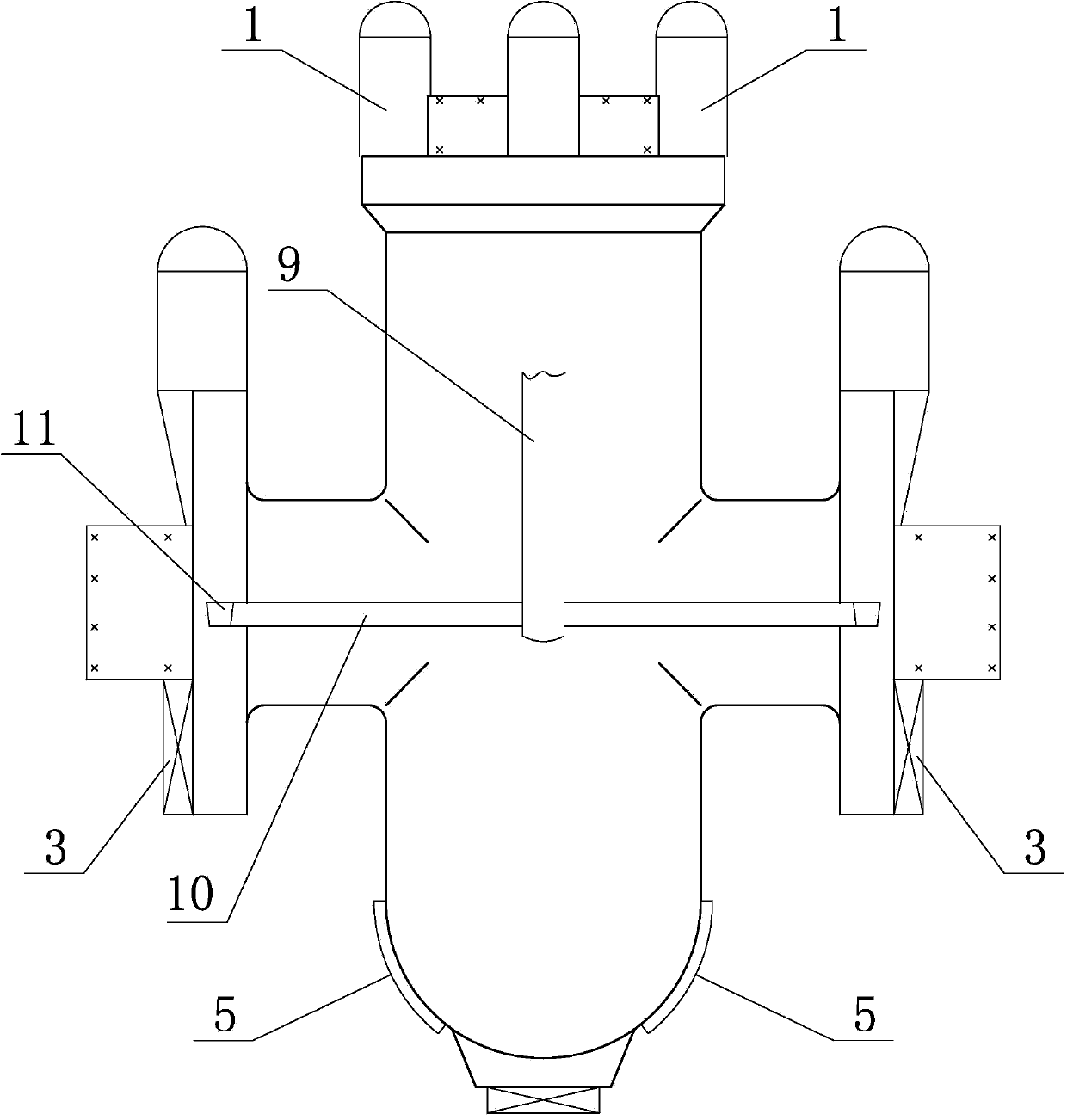

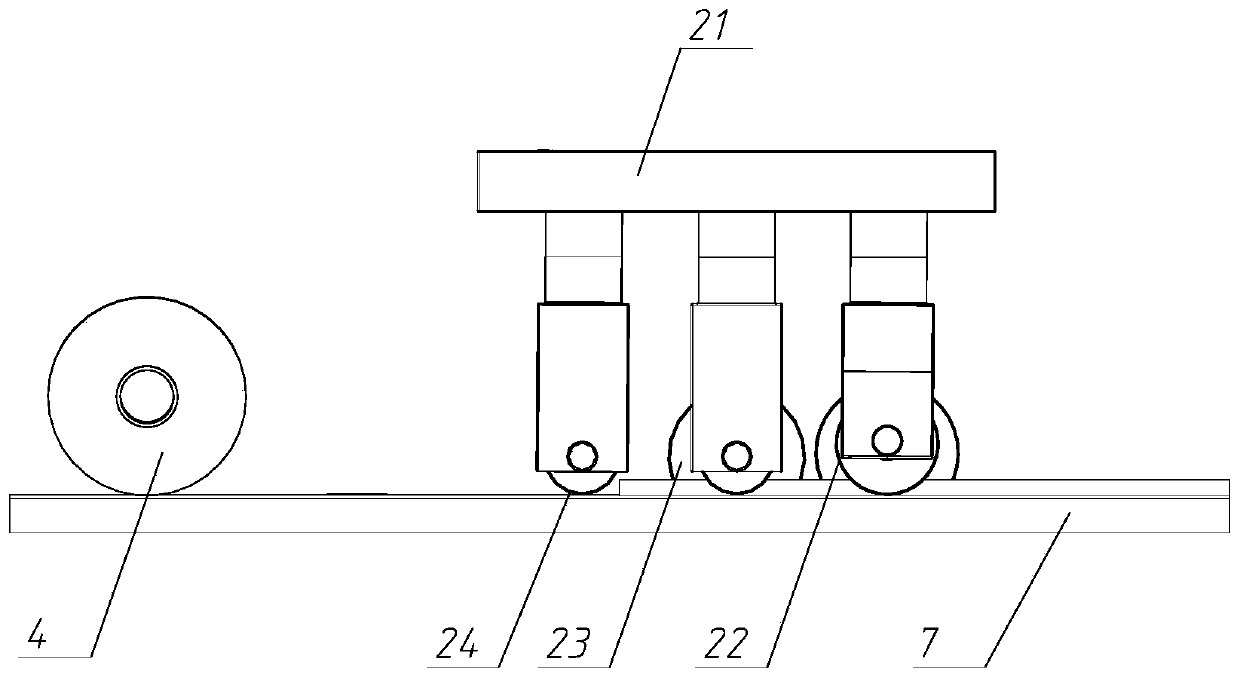

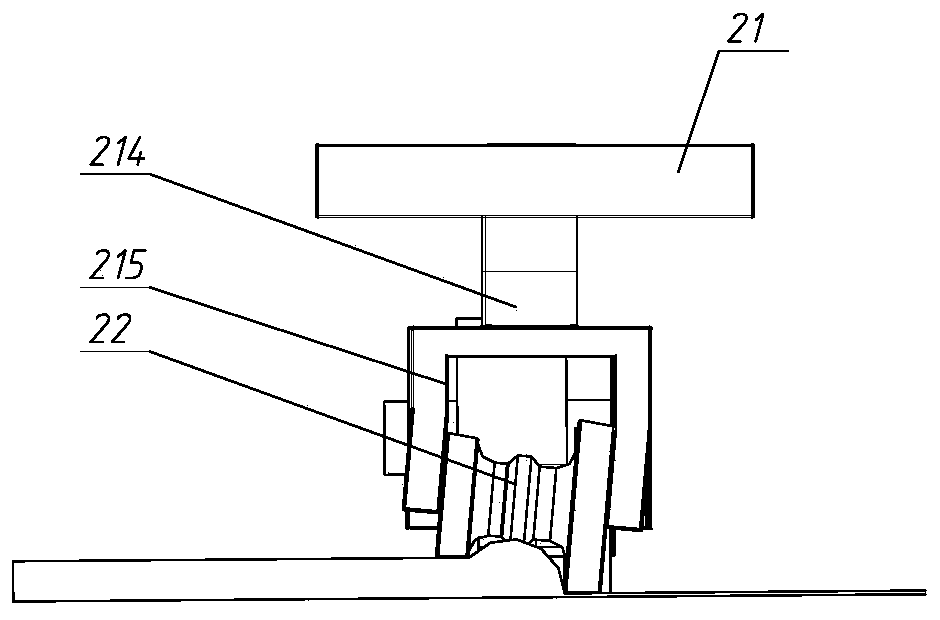

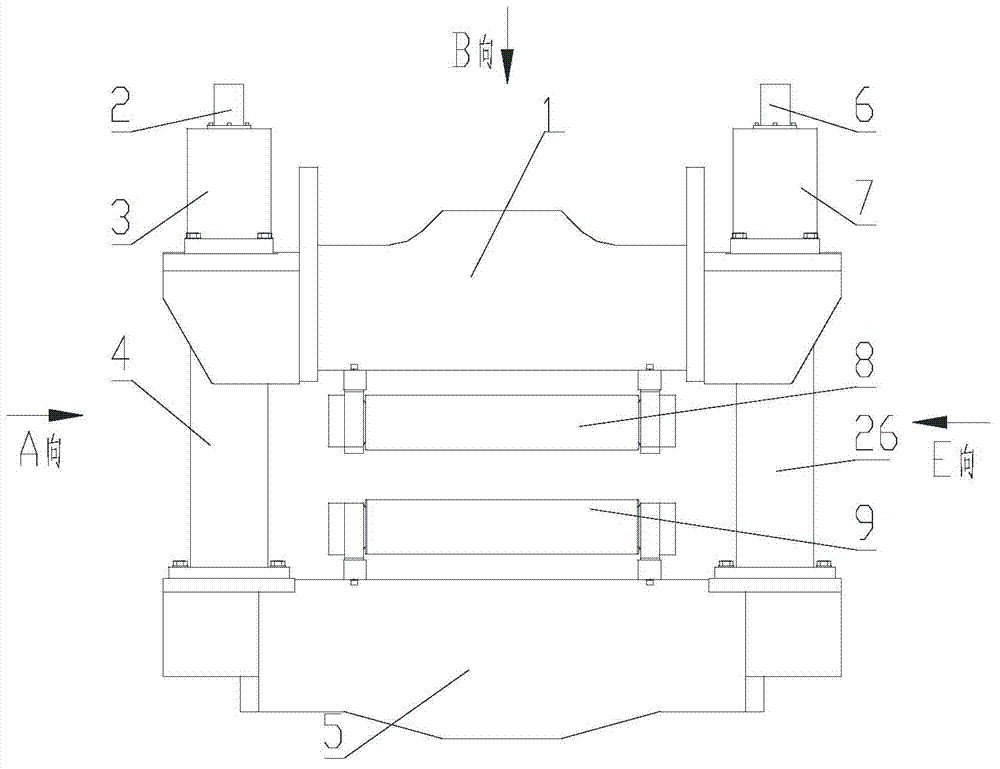

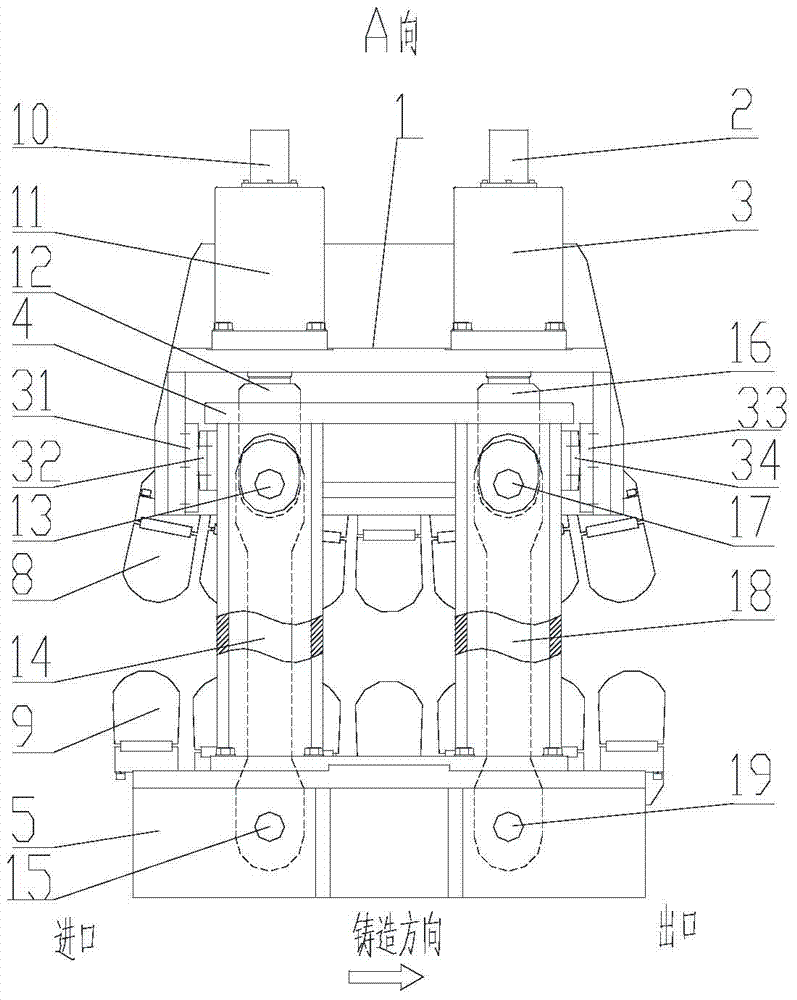

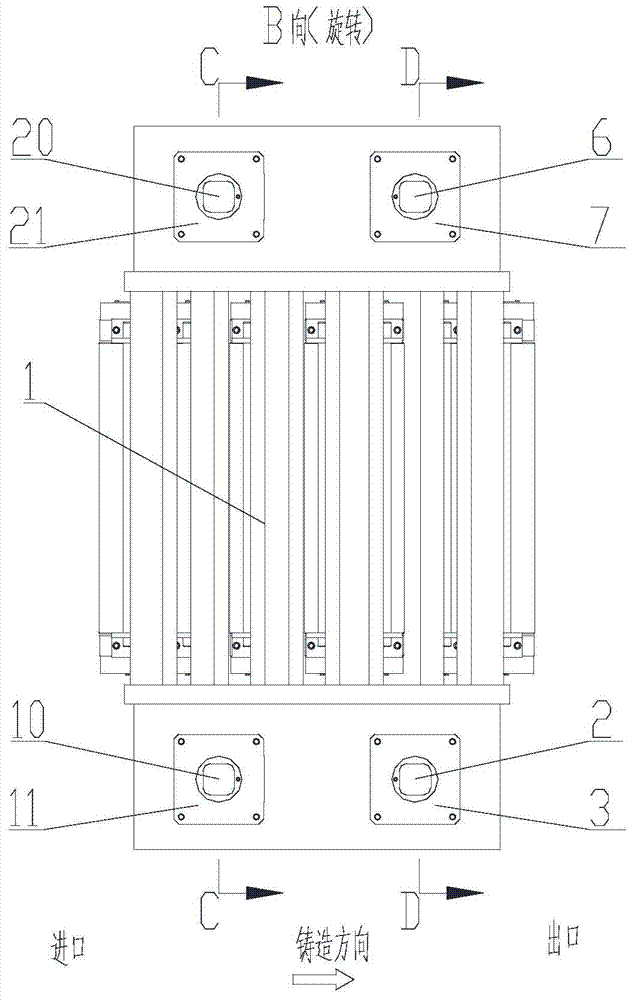

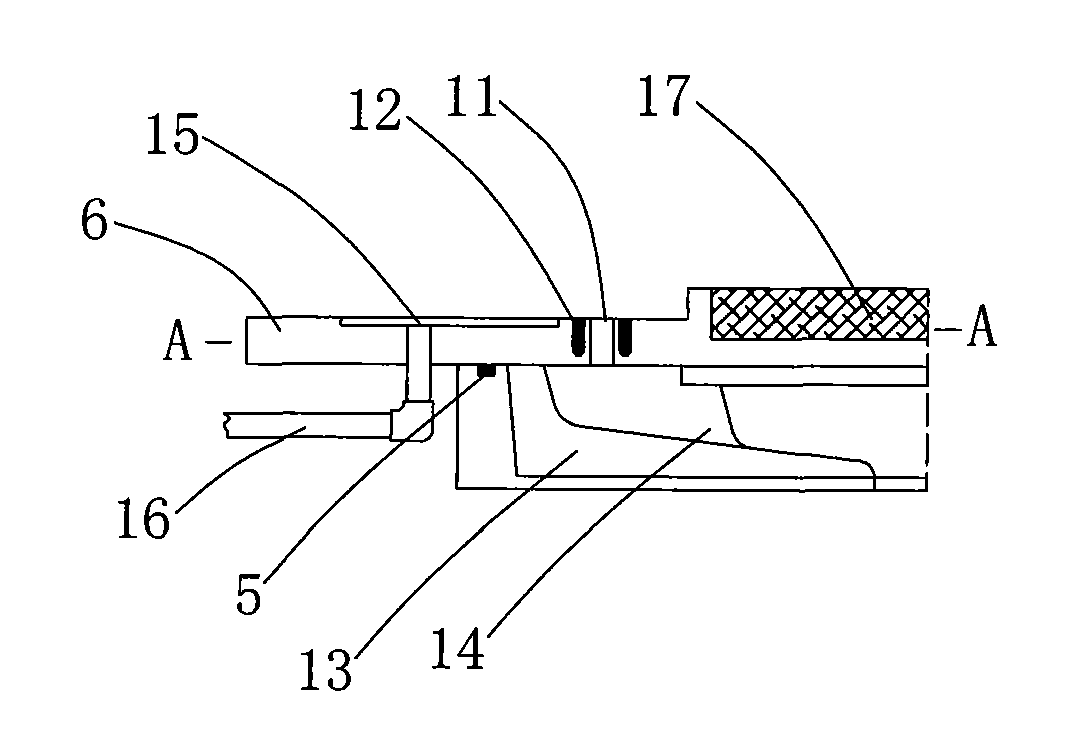

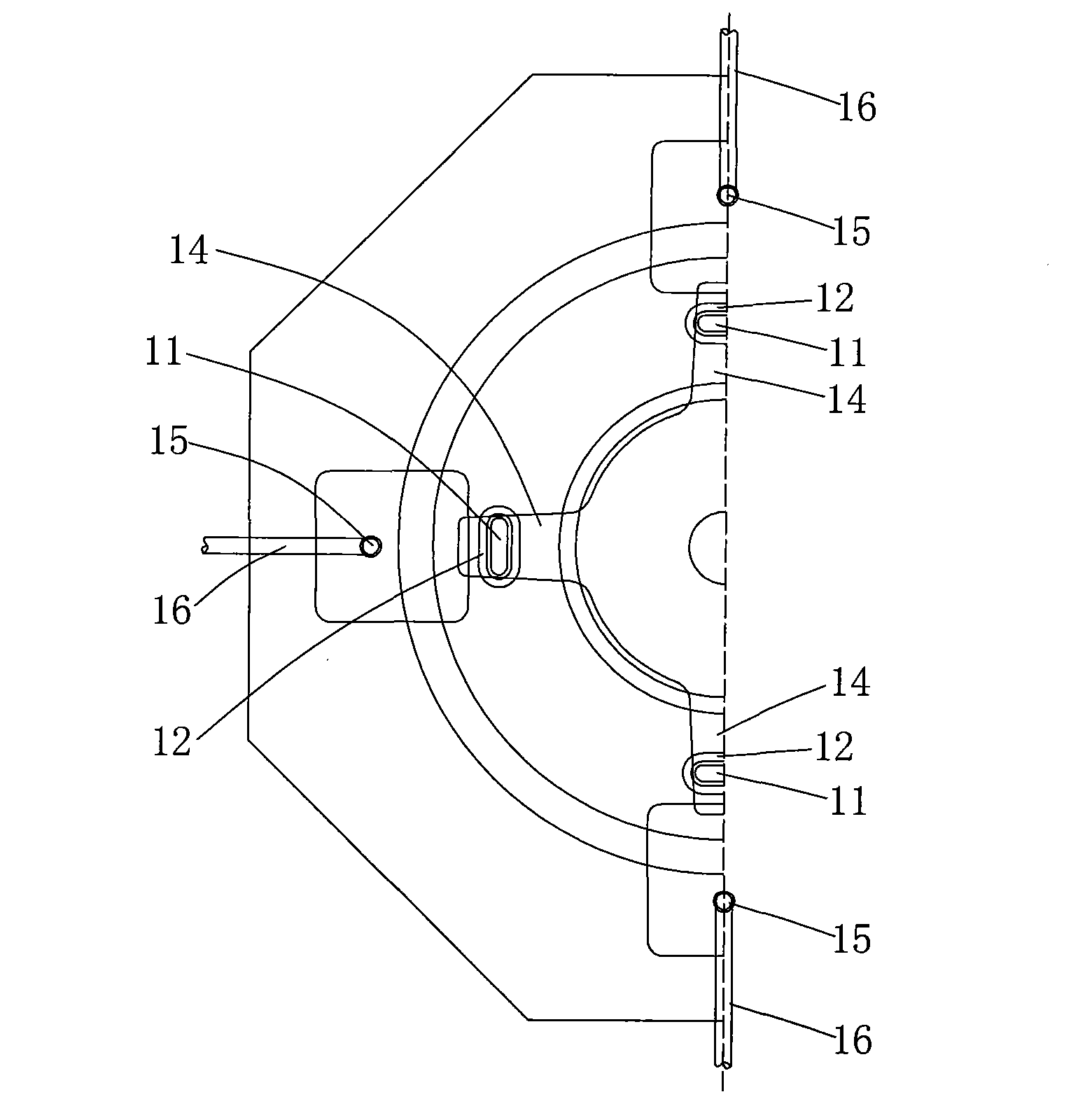

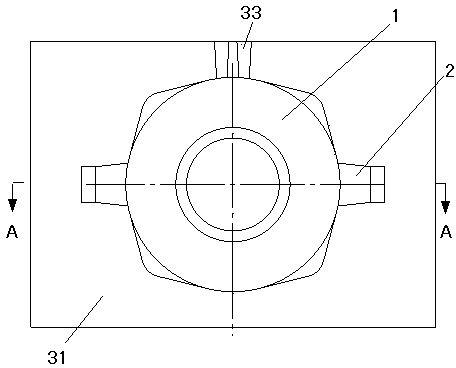

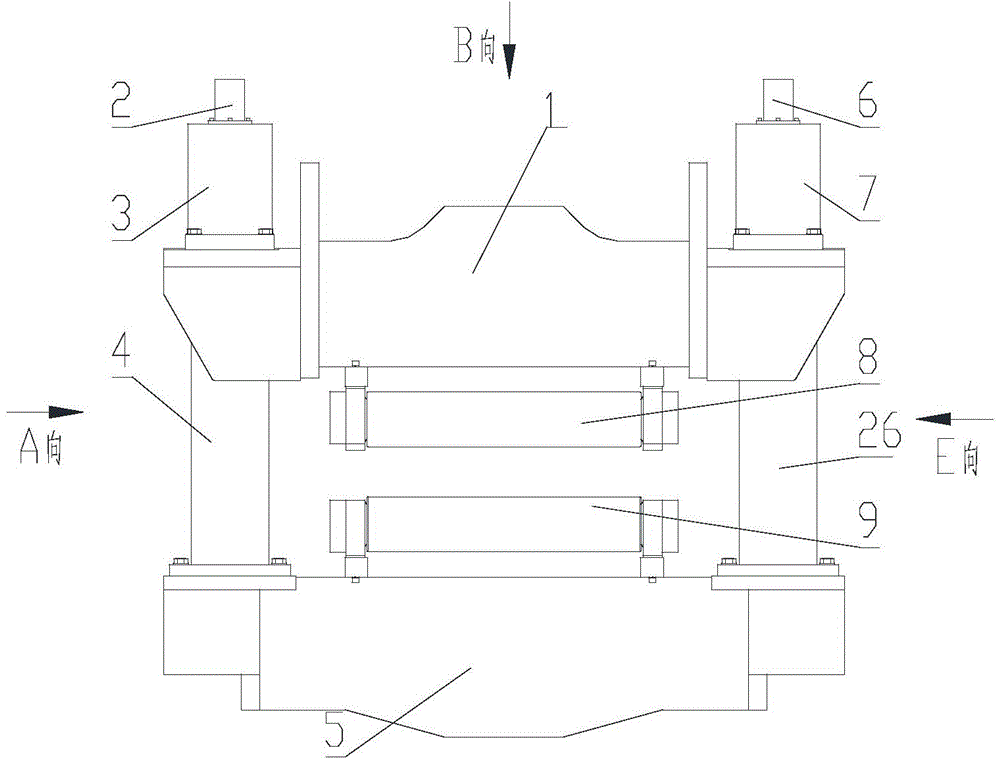

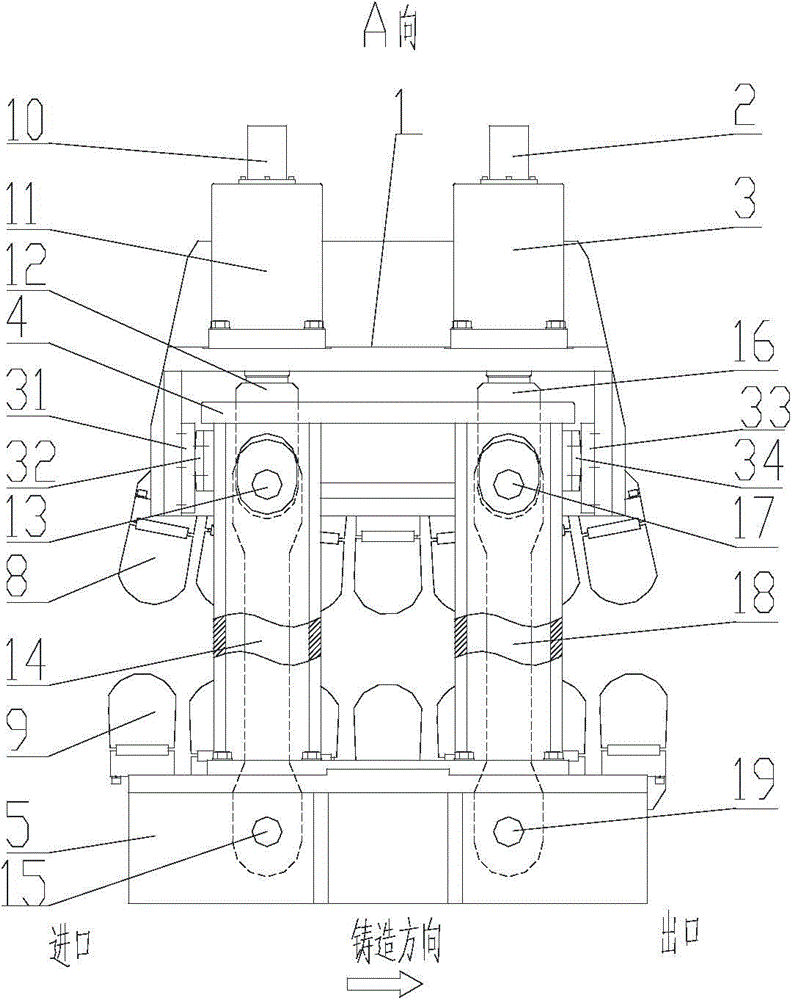

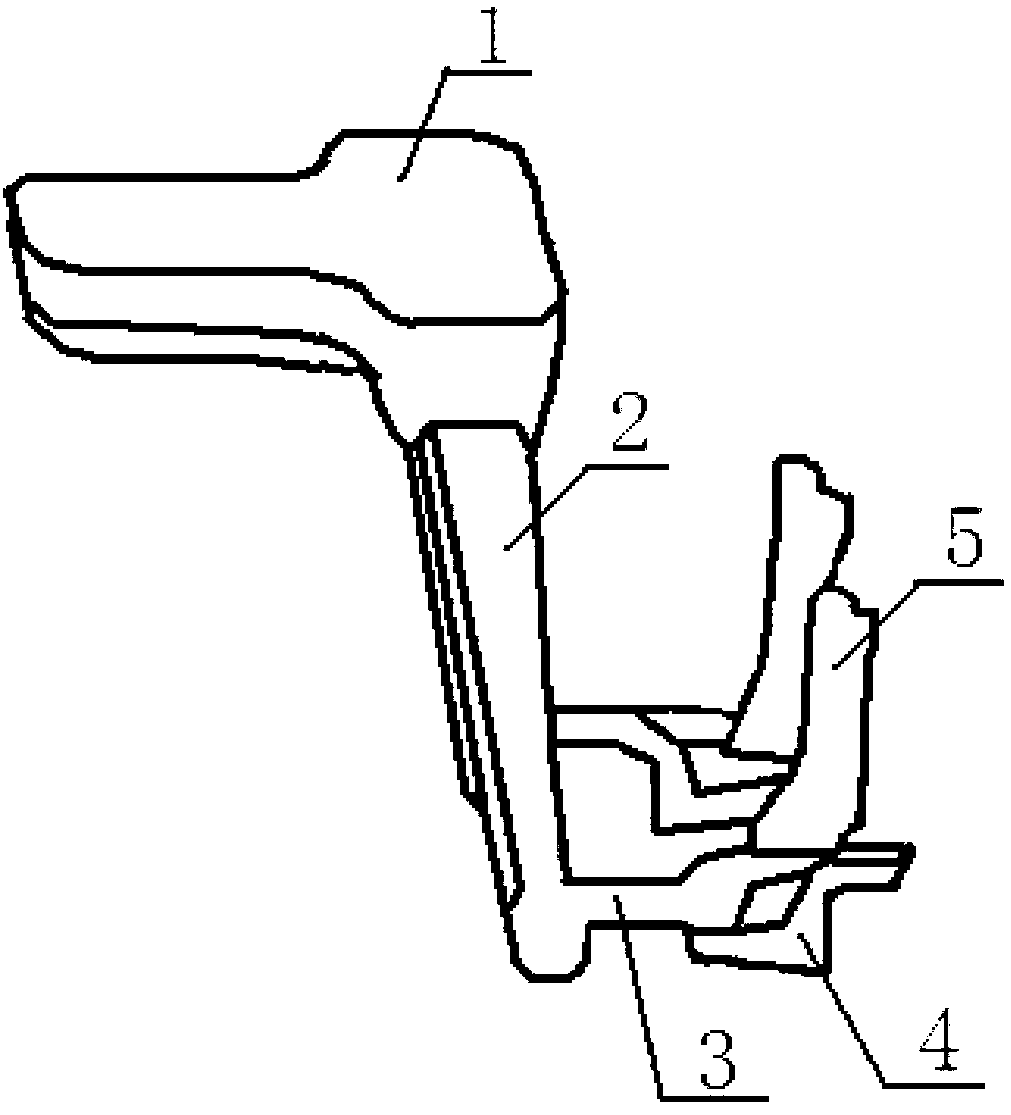

Sector segment structure capable of compositely pressing continuous casting solidification tail end of extra-thick plate

The invention provides a sector segment structure capable of compositely pressing the continuous casting solidification tail end of an extra-thick plate. An inner arc roller, an outer arc roller, an upper frame, a lower frame and side frames have enough strength and rigidity, four sensors and four oil cylinder assemblies are installed in the parts, the stretching or retraction strokes of the first oil cylinder assembly, the second oil cylinder assembly, the third oil cylinder assembly and the fourth oil cylinder assembly are controlled by detecting the first displacement sensor, the second displacement sensor, the third displacement sensor and the fourth displacement sensor, and then the opening degree between the inner arc roller and the outer arc roller of a sector segment is controlled, and the continuous casting solidification tail end of the extra-thick plate can be compositely pressed.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Preparation method for environment-friendly casting material

The invention discloses a preparation method for an environment-friendly casting material. The preparation method includes the steps of wax mold preparation, surface layer coating preparation, surface sand hanging, back layer coating preparation, back sand hanging, steam dewaxing, roasting and the like. According to the preparation method, fine wood bits and crop straw fibers serve as shell manufacturing materials, so that the using amount of refractory matter is reduced, and environmental protection is facilitated; reasonable matching is adopted, so that the breathability is increased on the premise that the shell strength is guaranteed; and cellular material attapulgite is adopted, so that exhausting is facilitated, the defect of casting air holes is reduced, the rate of finished products is increased, and meanwhile the weight of the mold shell is reduced.

Owner:青岛博泰美联化工技术有限公司

Preparation method of engine component

InactiveCN105537518AReduce usageReduce porosity defectsFoundry mouldsFoundry coresFiberEnvironmental resistance

The invention discloses a preparation method of an engine component. The preparation method comprises the steps of mold shell preparing, alloy burdening, melting and pouring, cooling, posttreatment and the like. A TiAl-based titanium aluminum compound is adopted as a component material, and therefore the engine component can continuously work for a long time at high temperature, performance is improved, and the service life is prolonged; wood bits and crop straw fibers are adopted as shell manufacturing materials, the usage amount of refractory matter is lowered, and environment friendliness is facilitated; a reasonable ratio is adopted, and air permeability is increased on the premise of guaranteeing the strength of a shell; a porous material, attapulgite, is adopted, air exhaust is facilitated, blowhole defects of the component are reduced, and the yield is increased; and meanwhile the weight of the mold shell is reduced.

Owner:青岛博泰美联化工技术有限公司

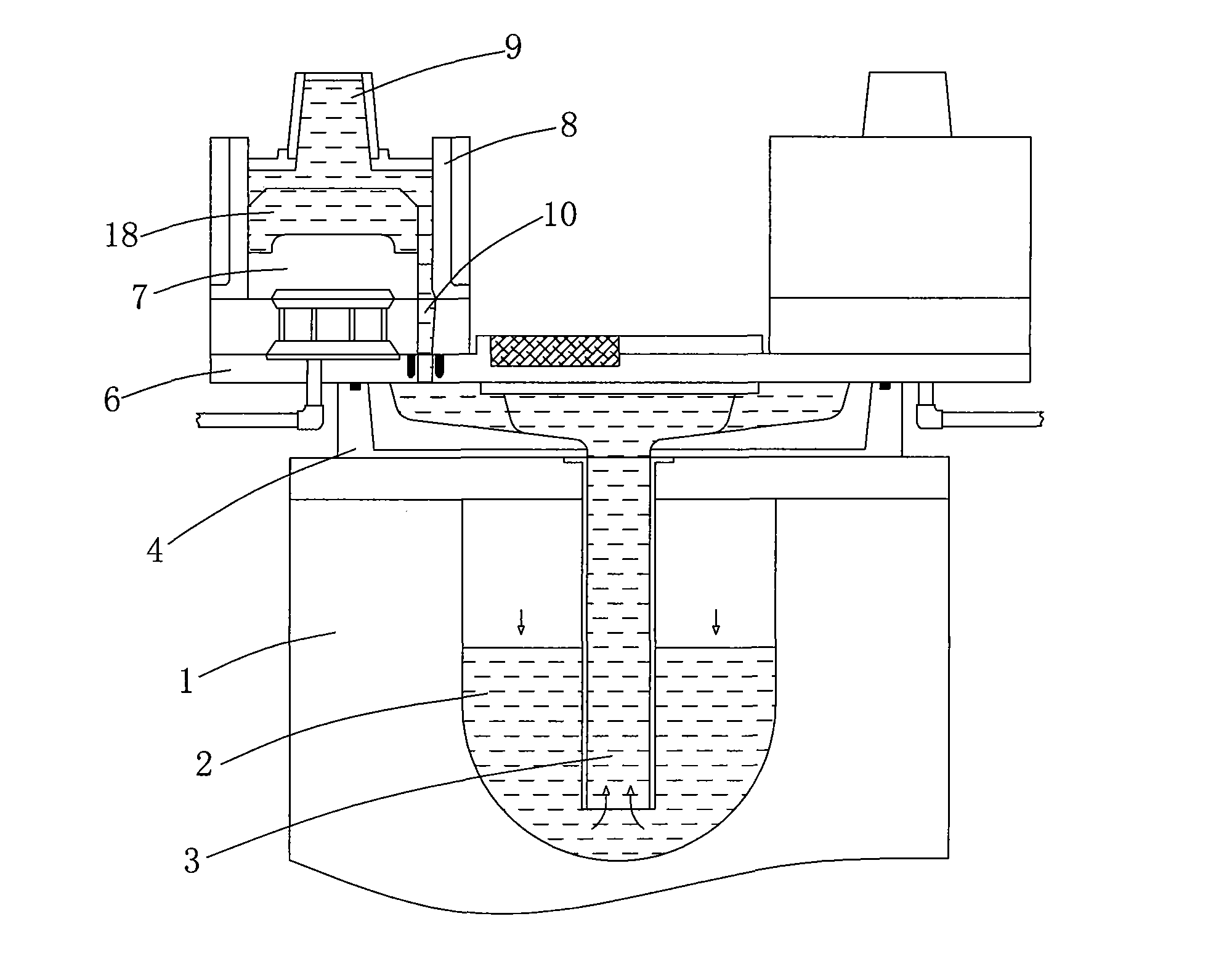

Aluminum alloy pattern block low-pressure casting equipment and low-pressure casting and gravity feeding compound process

The invention discloses aluminum alloy pattern block low-pressure casting equipment. A disk-type runner substrate is arranged on a crucible, and the lower end of a riser tube passes through the center hole of the runner substrate and then stretches into the crucible; a runner cover board is hermetically covered on the runner substrate, a plurality of casting moulds are distributed on the runner cover board, a feed head is arranged at the upper end of each casting mould, and an inner runner is arranged at the lower end of each casting mould; and a main runner is laid in a hollow cavity between the runner substrate and the runner cover board, a plurality of runner channels are distributed on the main runner, and the runner channels are respectively communicated with the inner runners of the casting moulds and the upper port of the riser tube. The invention can solve the secondary pollution problem of aluminum liquid in the partitioning and casting process of aluminum alloy pattern blocks and achieve simultaneously casting a plurality of aluminum alloy pattern block castings, and is beneficial to improving the casting production efficiency.

Owner:合肥大道模具有限责任公司

Casting sand core hot box and sand core molding method

ActiveCN104162632AShorten molding timeAvoid Fragile PhenomenaFoundry moulding apparatusHot boxRefractory

The invention discloses a casting sand core hot box and a sand core molding method. According to the hot box, the middle of a movable mold cavity is fixedly connected with a short part of a conical bar; a long part of the conical bar is a conical cylinder; the long part of the conical bar is connected with a filling piece; the filling piece is connected to the conical bar; a conical columnar hole is formed in the middle position of the filling piece; the filling piece is connected with the conical bar through the conical columnar hole; a center line of the conical bar is perpendicular to a mold clamping line of the hot box, and the sand core is molded according to a sequence of adding the filling piece, clamping the mold, sand adding, sand ejection, heating, swinging and rotating, cooling, opening the clamp and taking out the mold. With the adoption of refractory matters and other intermediate filling pieces, a small amount of laminating core sand is used, the production cost is reduced, exhaust is promoted in the casting process, defects are reduced, and the yield of the product is improved.

Owner:SHANDONG BAODING HEAVY IND

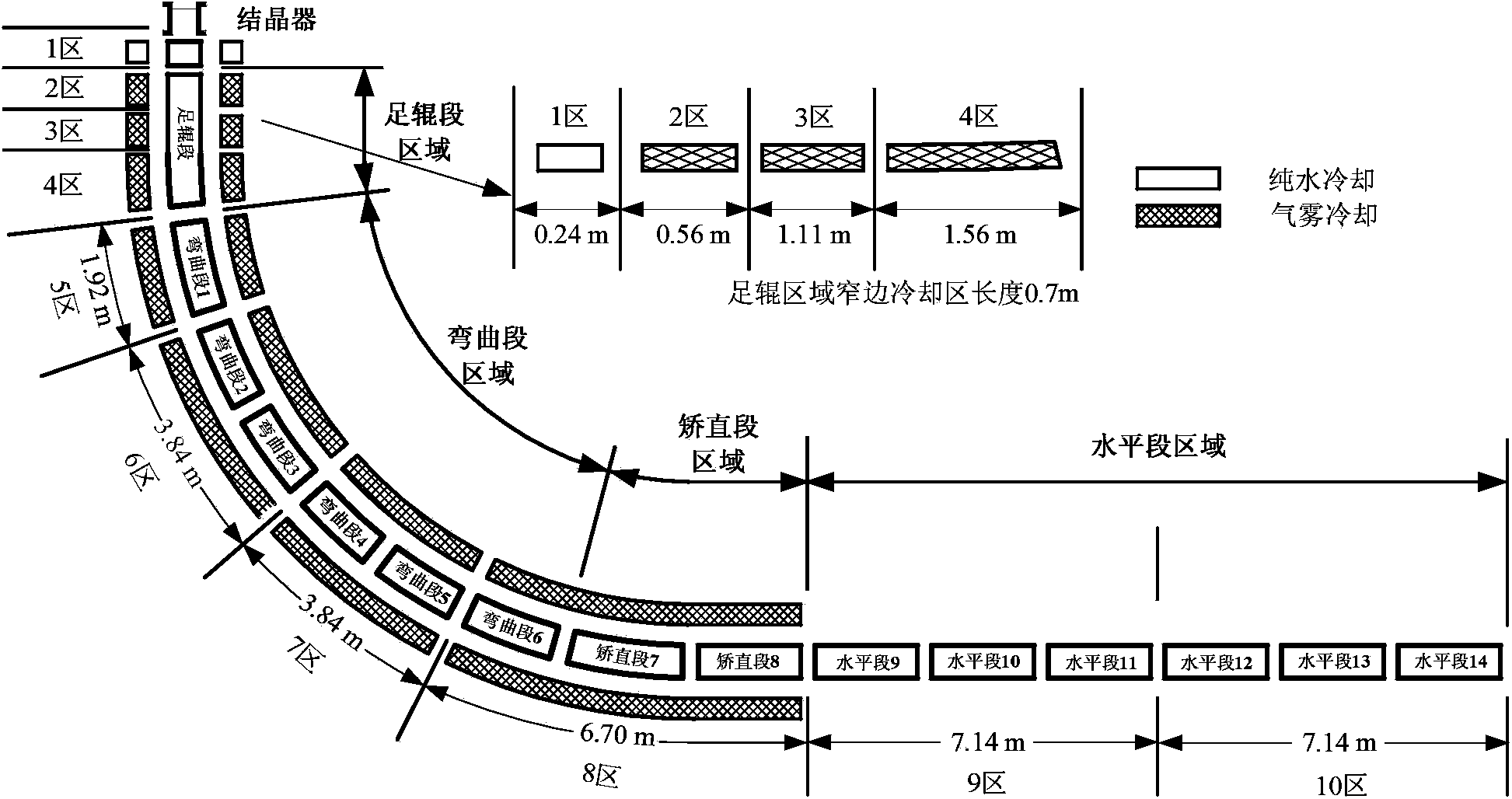

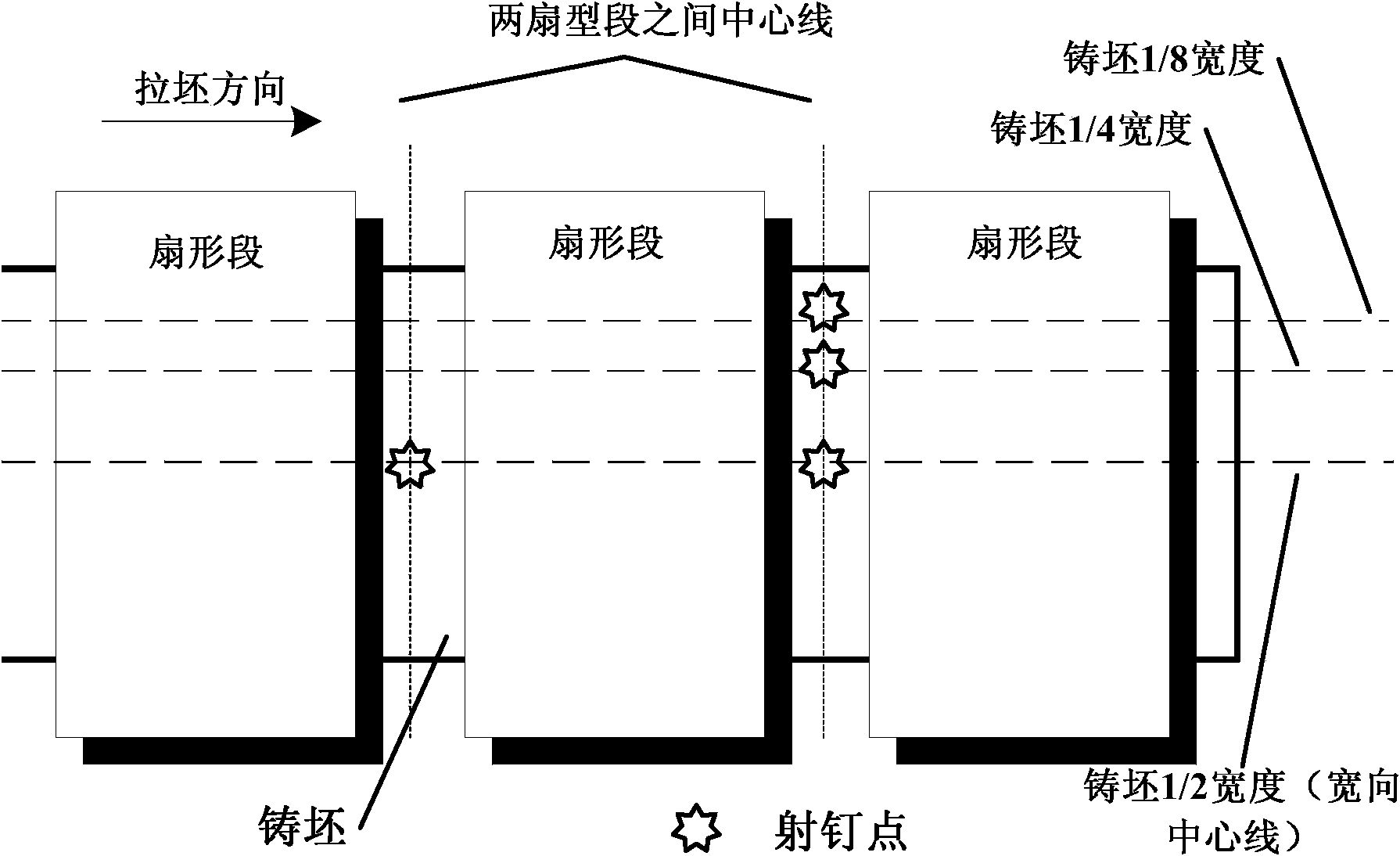

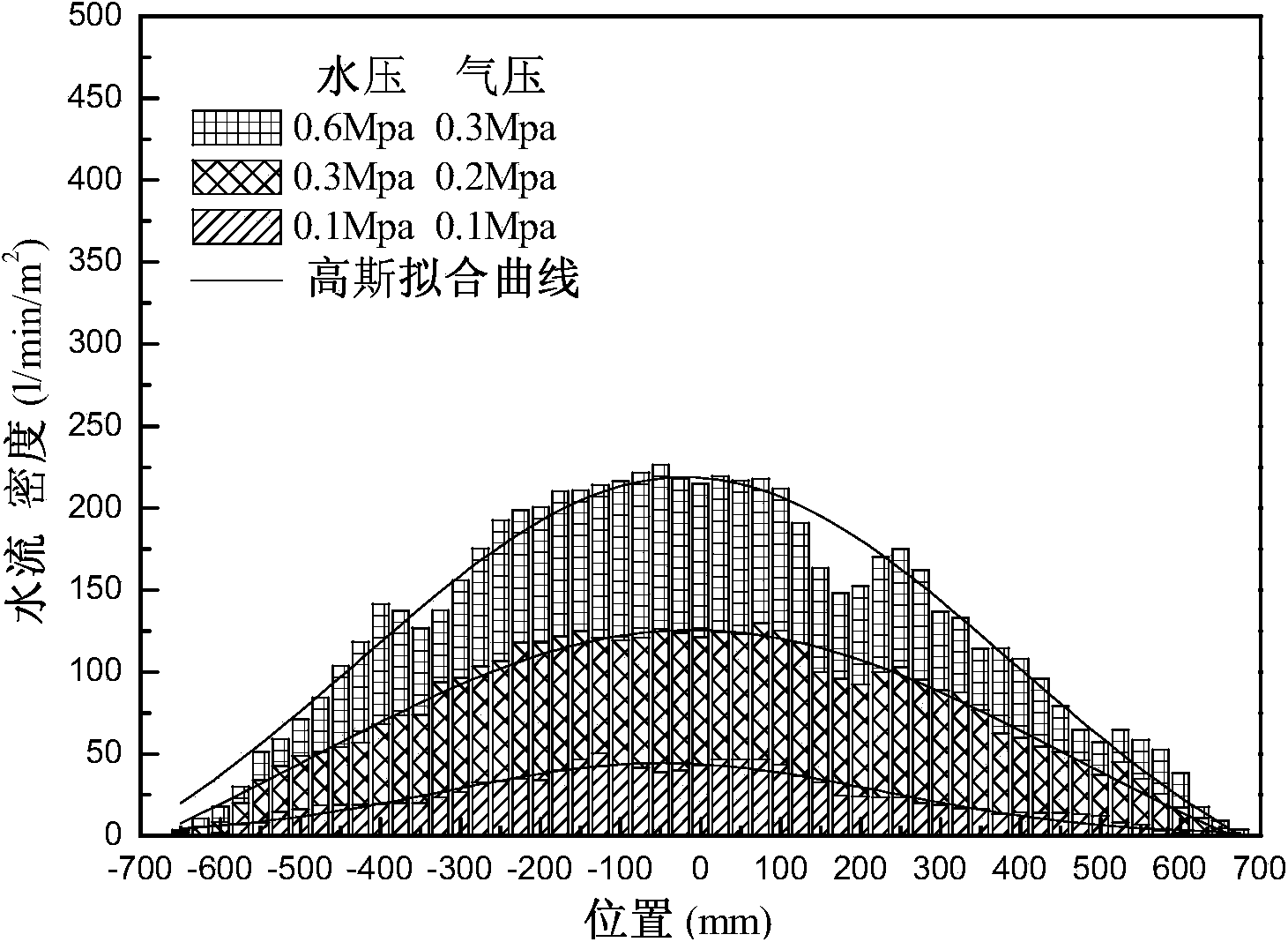

Control method of soft-reduction depressed region of wide and thick plate continuous casting blank

The invention relates to a control method of a soft-reduction depressed region of a wide and thick plate continuous casting blank. The control method is implemented according to the following steps that (1) the non-uniform solidified tail end morphology is determined; (2) the soft-reduction depressed starting point and finishing point positions of the continuous casting blank in different width positions are determined; (3) the soft-reduction depression rate is regulated: the soft-reduction depression rate is set to be 0.8 to 2.2mm / m in a region Pend-Pend<1 / 2>; the soft-reduction depression rate is set to be 0.4 to 1.6 mm / m in a region Pend<1 / 2>-Pend. The control method provided by the invention is adopted for setting the soft-reduction depression rate, aiming at a determining method of the soft-reduction depressed region of a solidified blank case of the wide and thick plate continuous casting blank under the non-uniform growth condition, the implementation effect of a soft-reduction process is ensured, the segregation and loosening defects of a cross section center line of the wide and thick plate continuous casting blank can be effectively overcome, and good application prospects are realized.

Owner:NORTHEASTERN UNIV

PEPSET resin moulding and sand cyclic utilization clean casting technology

ActiveCN103934411AFast and uniform curingLower regenerationFoundry mouldsMould handling/dressing devicesProcess engineeringRaw material

The invention relates to a PEPSET resin moulding and sand cyclic utilization clean casting technology. The technology comprises the following steps: using raw materials to carry out PEPSET resin sand moulding: putting a sand core into a mould cavity, closing the mould cavity by using an automatic mould closer, then casting with molten iron; shaking out the sands after the moulding of product; transferring the old sands into a waste sand regeneration processing system; wherein the regenerated sands can be applied to a cold box core blower to manufacture sand cores, thus the addition amount of new sands is reduced, and the cyclic utilization of old sands is achieved.

Owner:LAIZHOU XINZHONGYAO MACHINERY

Preparation method for automobile charging turbine

InactiveCN105618679AReduce usageReduce porosity defectsFoundry mouldsMetallic material coating processesFiberAfter treatment

The invention discloses a preparation method for an automobile charging turbine. The preparation method comprises the steps of preparing a mould shell, batching an alloy, smelting and casting, cooling, carrying out after-treatment and the like. According to the preparation method, a TiAl-based titanium-aluminum compound is used as a charging turbine material, so that the charging turbine can continuously work for a long time at a high temperature, the performances of the charging turbine are improved, and the service life of the charging turbine is prolonged; fine sawdust and crop straw fibers are adopted as shell-making materials, so that use of refractory matters is reduced, and therefore, the preparation method is beneficial for environmental protection; and a reasonable proportion is adopted, gas permeability is increased on the premise of ensuring shell strength, and a porous material, namely attapulgite is adopted, so that gas exhaustion is facilitated, blowhole defects of the charging turbine are reduced, the yield is increased, and the weight of the mould shell is reduced.

Owner:青岛博泰美联化工技术有限公司

Environment-friendly type manufacturing method for car supercharging turbine

InactiveCN105506377AReduce usageReduce porosity defectsBlade accessoriesFoundry mouldsFiberRefractory

The invention discloses an environment-friendly type manufacturing method for a car supercharging turbine. The environment-friendly manufacturing method includes the steps of mold shell manufacturing, alloy burdening, smelting pouring, cooling, aftertreatment and the like. According to the environment-friendly type manufacturing method, a TiAl-based titanium aluminum compound serves as a supercharging turbine material, and long-time continuous work can be done at a high temperature, so that the performance is improved, and the service life is prolonged; fine wood bits and crop straw fibers are adopted as shell making materials, so that the using amount of refractory matter is reduced, and environmental protection is facilitated; the reasonable proportion is adopted, so that the breathability is improved on the premise that the shell strength is guaranteed; and a cellular material, namely attapulgite, is adopted, so that exhausting is facilitated, the defect of air holes of the supercharging turbine is reduced, the finished product rate is increased, and meanwhile the weight of a mold shell is reduced.

Owner:青岛博泰美联化工技术有限公司

Forming technology of air cylinder cover casting

InactiveCN103084541AReduce usageReduce sand disposal costsFoundry mouldsFoundry coresShrinkage porosityMulti element

The invention discloses a forming technology of an air cylinder cover casting. The forming technology of the air cylinder cover casting comprises the following steps of: firstly modeling the appearance profile and a sand core of the cylinder cover casting by adopting precoated sand; then assembling an outer model and the sand core and putting into a sand box; and then filling in dry sand or dry stones for pouring. According to the invention, the technology of combining precoated sand modeling and dry sand (stone) mold casting is adopted, the outer model moulding sand is molded and is assembled with the moulding sand, and is put into the sand box, the mold thickness adopts dry sand / stones to replace resin sand completely, and pouring is carried out after the dry sand / stones is / are compacted. Because the dry sand (stone) has no bonding agent and has good permeability, gases generated during pouring can be exhausted rapidly and smoothly; mold filling is stable; and because the metal liquids at the upper part are lower than metal liquids at the lower part, sequential condensation and dead head feeding are carried out smoothly; the mold-filling capacity is high; defects of cavity shrinkage, shrinkage porosity, incapability of pouring and the like can be prevented easily; and moreover, one-mold multi-element processing is easy to realize, and the production efficiency and casting technology yield are improved.

Owner:贵州英吉尔机械制造有限公司

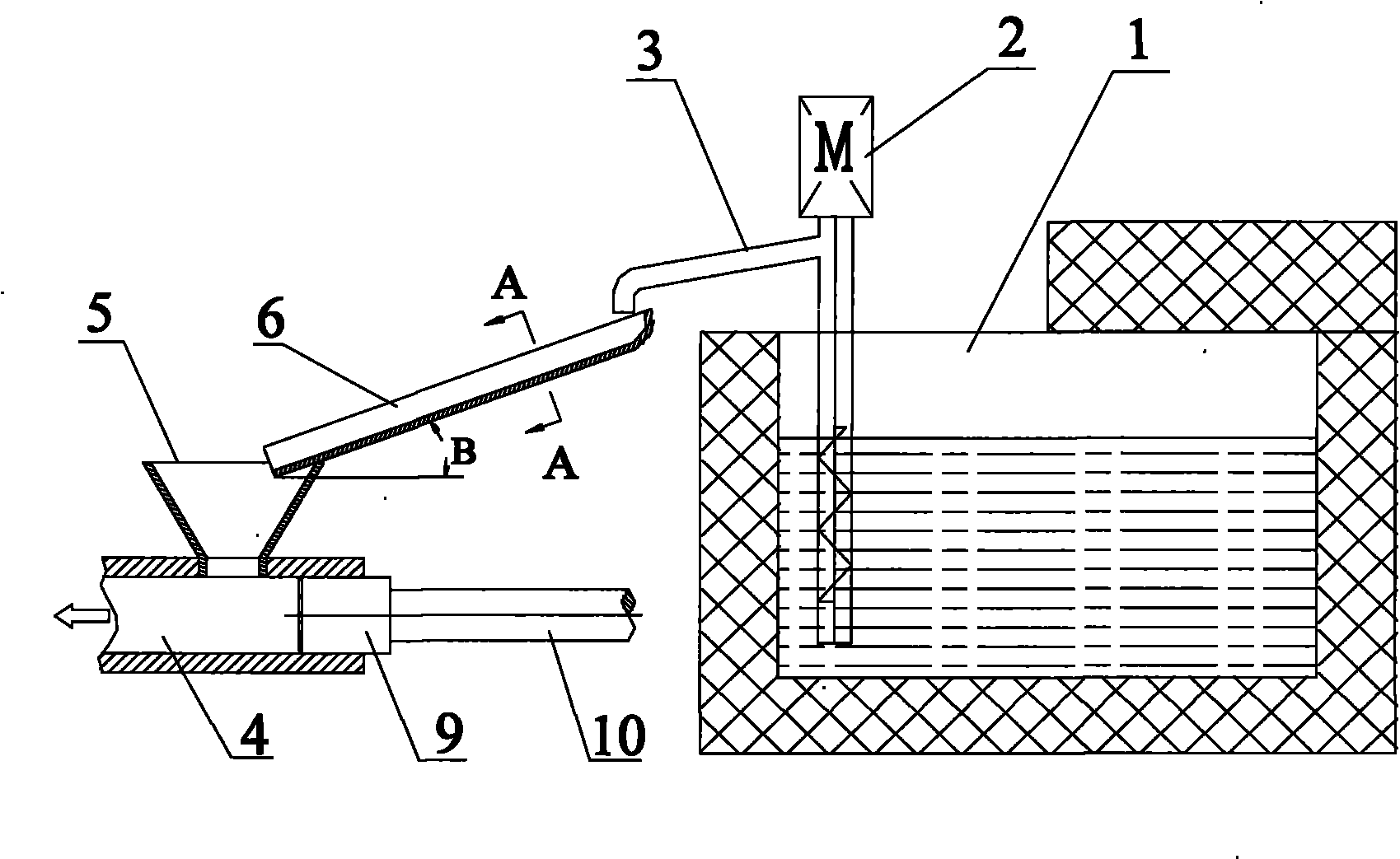

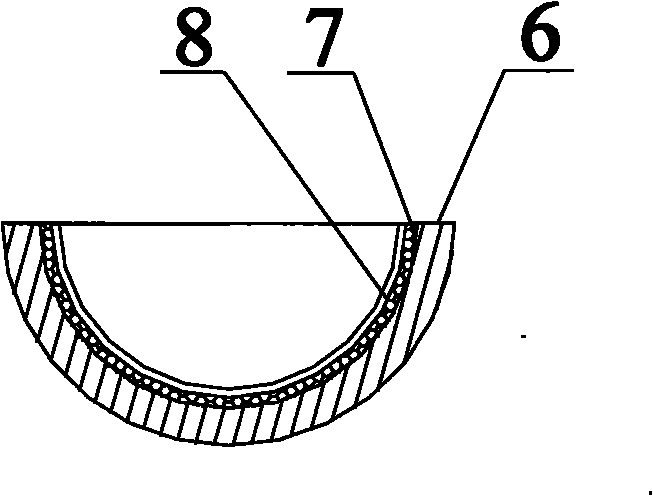

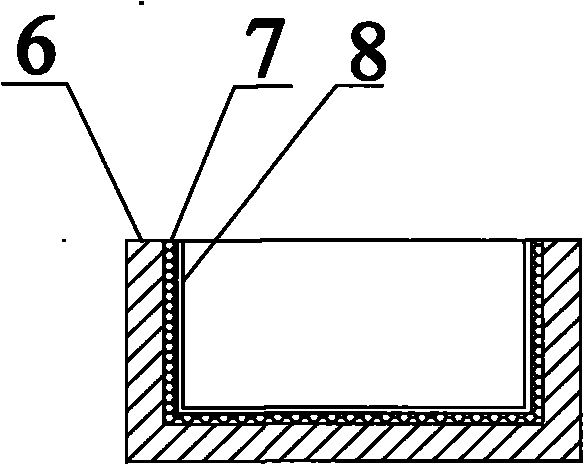

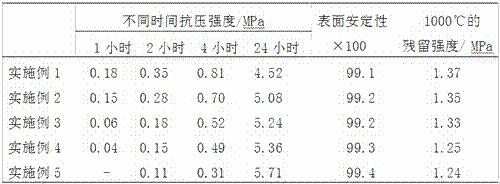

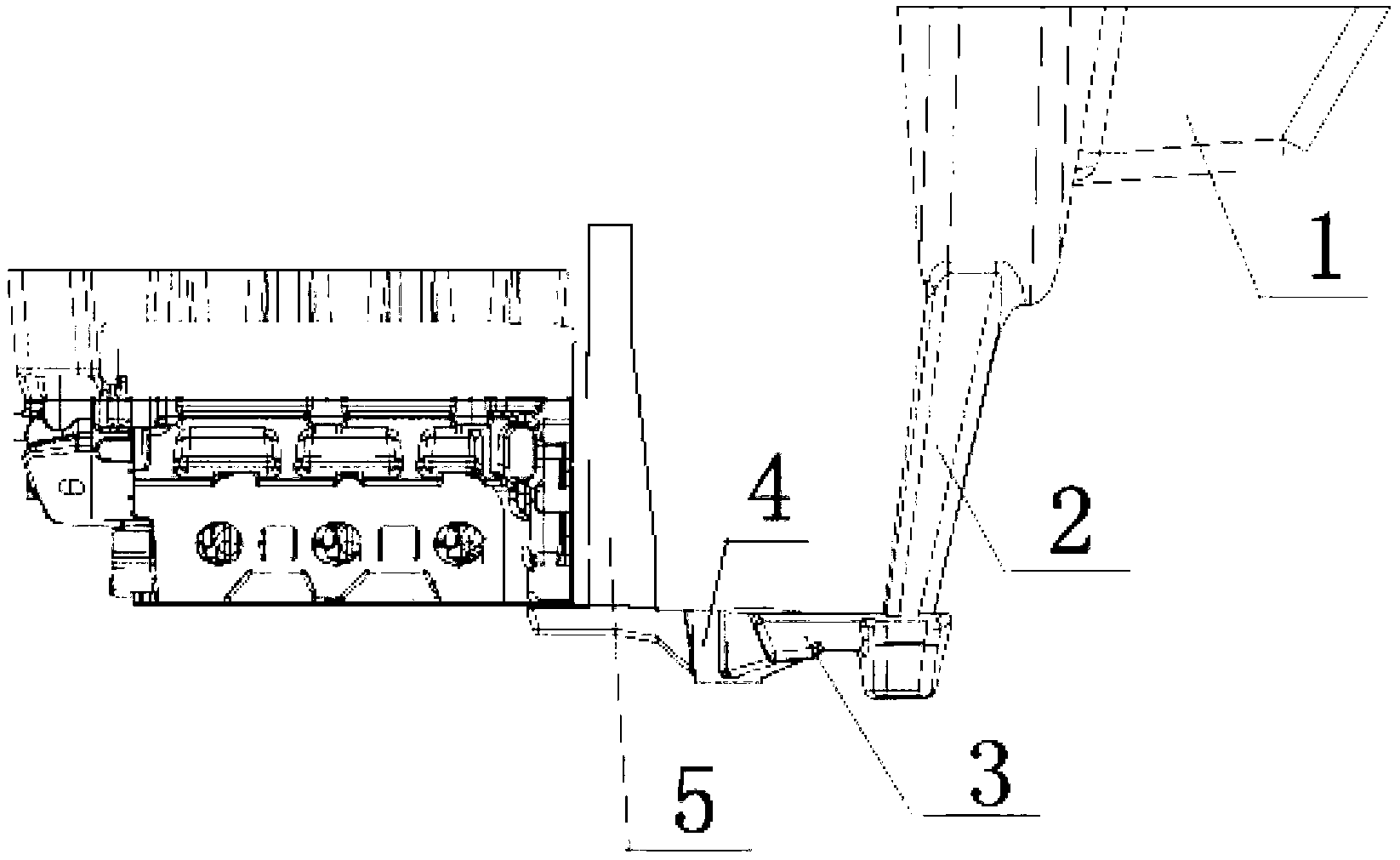

Ultra-low speed aluminum alloy die-casting system

The invention provides an ultra-low speed aluminum alloy die-casting system. The system comprises an aluminum alloy die casting machine and a heat preserving furnace, wherein the heat preserving furnace is provided with a quantitative pouring pump, wherein the quantitative pouring pump is connected with a liquid conveying pipeline; the outlet end of the liquid conveying pipeline is provided with a liquid conveying groove connected to a funnel on a die-casting chamber channel; a refractory mortar layer is laid on the surface of the liquid conveying groove; a release coating layer is sprayed on the surface of the refractory mortar layer; a release coating layer is uniformly coated on the surface of the funnel; the thickness of the release coating layer is between 3 and 5 millimeters; and an included angle between the liquid conveying groove and an ejection horizontal plane is between 15 and 25 degrees. The invention also provides an alloy melt temperature control range and an operation specification for the heat preserving furnace of the system. Through system setting, molten metal flows through a chute and the funnel before casting; and due to the adoption of small-angle ultra-low speed die casting and shaping, the molten metal flows stably without eddy current or splashing, gas inclusion in a shaping process is decreased, the surface of a casting molded by die casting is flat and smooth, crystal particles are fine and air holes inside a product have a small number of defects.

Owner:DONGGUAN EONTEC CO LTD

Inorganic precoated sand and preparation method thereof

InactiveCN106424535AEmission reductionImprove production environmentFoundry mouldsFoundry coresInorganic phosphateOrganic compound

The invention discloses inorganic precoated sand. The inorganic precoated sand is prepared from raw materials in parts by weight as follows: 80-90 parts of crude sand, 0.3-3 parts of a curing agent, 0.01-0.1 parts of a polyacrylamide modifying agent, 2-10 parts of a binder and 0.04-0.6 parts of calcium stearate. The invention further discloses a preparation method of the inorganic precoated sand. The method comprises steps as follows: (1) the crude sand and the curing agent are mixed; (2) the polyacrylamide modifying agent is added for a reaction; (3) the binder is added and mixed for a reaction; (4) the calcium stearate is added and mixed for a reaction. The prepared inorganic precoated sand is high in strength and good in collapsibility, according to the preparation method, inorganic phosphate of a basic metal replaces organic resin of traditional precoated sand to be used as the binder, intake of organic compounds is avoided, discharge of toxic and hazardous gases is reduced, and the production environment of workers is greatly improved.

Owner:HEFEI RENCHUANG CASTING MATERIAL CO LTD

Water glass sand hardener

InactiveCN101941043ASlow down the rate of hydrolysisHigh strengthFoundry mouldsFoundry coresPhosphoric acidChemistry

The invention discloses a water glass sand hardener which is composed of the following components in percentage by weight: 20-80% of organic ester, 6-24% of phosphoric acid with the mass concentration of 80%, 2-8% of soluble acid phosphate, 1-4% of urea and 11-44% of water. The preparation method is as follows: mixing and dissolving the soluble acid phosphate and the urea into the water to form a solution; and evenly mixing with the phosphoric acid and the organic ester to obtain the water glass sand hardener. The water glass sand hardener of the invention has the advantages of convenient use, good hardening effect, low cost and controllable hardening speed, can obviously lower the water glass addition and obviously improves the moulding sand collapsibility.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Fan-shaped segment structure and method for realizing continuous casting, solidification and tail end composite pressing of super-thick plate

The invention discloses a fan-shaped segment structure and a method for realizing continuous casting, solidification and tail end composite pressing of a super-thick plate. An inner arc roller, an outer arc roller, an upper framework, a lower framework, a side framework I and a side framework II have sufficient strength and rigidity; four sensors and four oil cylinder assemblies are arranged in the components; the extension or retraction strokes of a first oil cylinder assembly, a second oil cylinder assembly, a third oil cylinder assembly and a fourth oil cylinder assembly are controlled by detecting a first displacement sensor, a second displacement sensor, a third displacement sensor and a fourth displacement sensor, so that the opening degree between the inner arc roller and the outer arc roller of a fan-shaped segment is controlled. The conventional pressing amount and a large compressing amount are implemented according to the solid fractions of different casting blanks, so that continuous casting, solidification and tail end composite pressing of the super-thick plate are realized.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

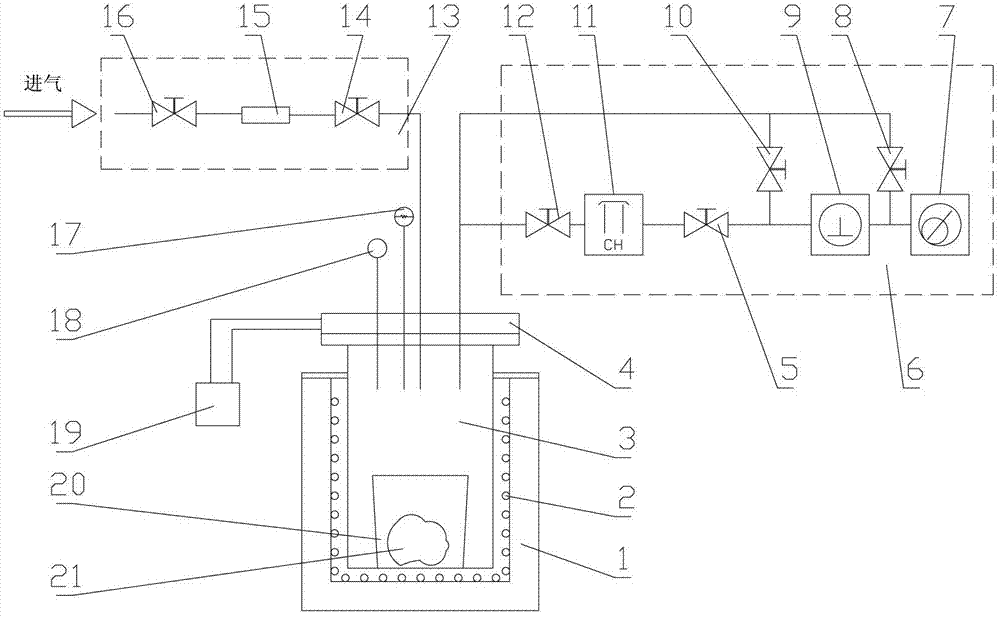

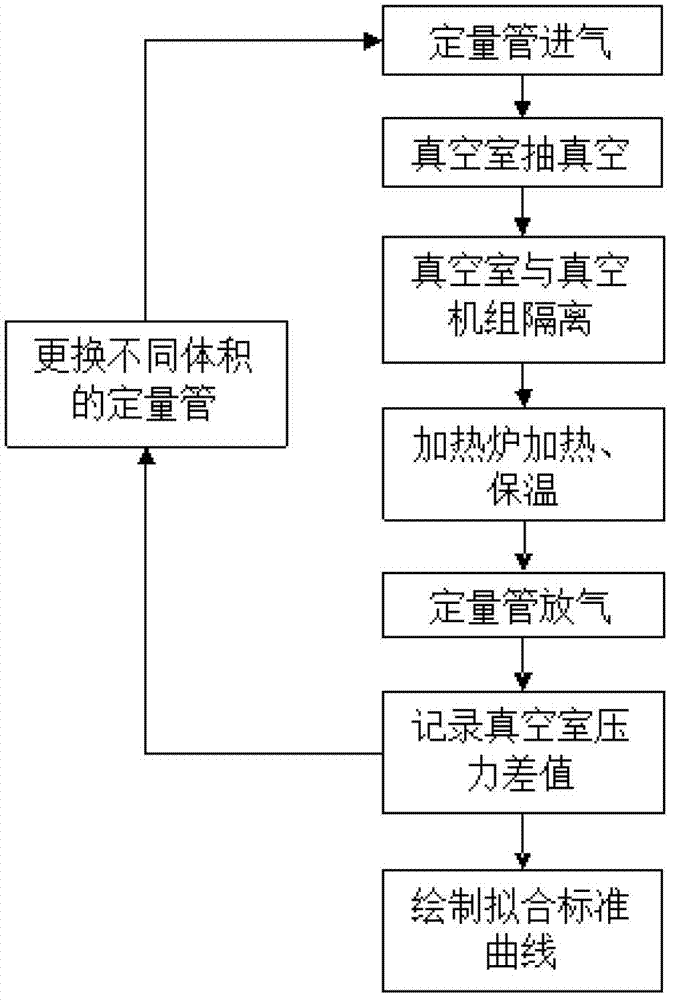

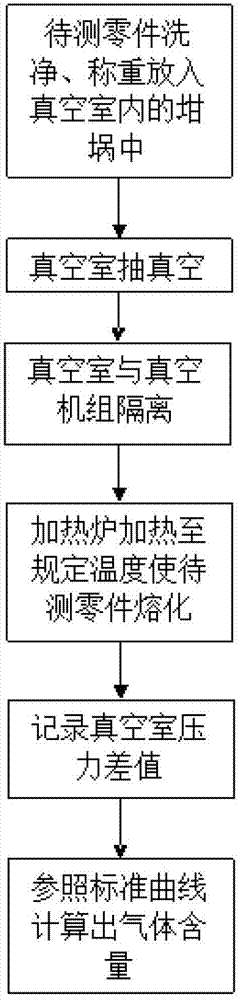

Method and device for quantitatively measuring content of gas inside aluminum alloy die casting

InactiveCN103196786AHigh measurement accuracyWorking conditions and process improvement and optimizationMaterial analysisQuantitative determinationVacuum pressure

Owner:HUAZHONG UNIV OF SCI & TECH

Low-nickel nitrogen-containing austenitic stainless steel non-consumable electrode gas shielded welding wire and preparation method thereof

ActiveCN111876680AReduce nickel contentReduce porosity defectsWelding/cutting media/materialsSoldering mediaHeat-affected zoneSS - Stainless steel

The invention discloses a low-nickel nitrogen-containing austenitic stainless steel non-consumable electrode gas shielded welding wire and a preparation method thereof. The invention belongs to the technical field of welding material preparation and welding machining processes thereof. The low-nickel nitrogen-containing austenitic stainless steel non-consumable electrode gas shielded welding wireand the preparation method solve the technical problems that when an existing austenitic stainless steel welding wire is used for conducting non-consumable electrode gas shielded welding on low-nickelnitrogen-containing austenitic stainless steel, nitrogen loss, air holes, hot cracks in a weld joint area and nitride precipitation in a heat affected zone are prone to being generated in a welded joint, and consequently pitting corrosion is caused. The low-nickel nitrogen-containing austenitic stainless steel non-consumable electrode gas shielded welding wire comprises the following chemical components including, by weight, 0.03% to 0.08% of C, 0.30% to 0.65% of Si, 6.50% to 8.50% of Mn, less than or equal to 0.05% of P, less than or equal to 0.01% of S, 17.50% to 18.50% of Cr, 2.20% to 2.90% of Ni, 0.03% to 0.10% of Mo, 1.00% to 2.00% of Cu, 0.15% to 0.35% of N, less than or equal to 0.05% of Co, less than or equal to 0.05% of the sum of Nb, Ti and V and the balance iron. The method comprises the steps of smelting, wire rod hot rolling and welding wire drawing, and finally the welding wire is obtained. According to the low-nickel nitrogen-containing austenitic stainless steel non-consumable electrode gas shielded welding wire and the preparation method, solid solution nitrogen is used for partially replacing nickel, and grain refinement can be promoted while nitrogen is effectively subjected to solid solution strengthening.

Owner:HARBIN WELDING INST LTD +2

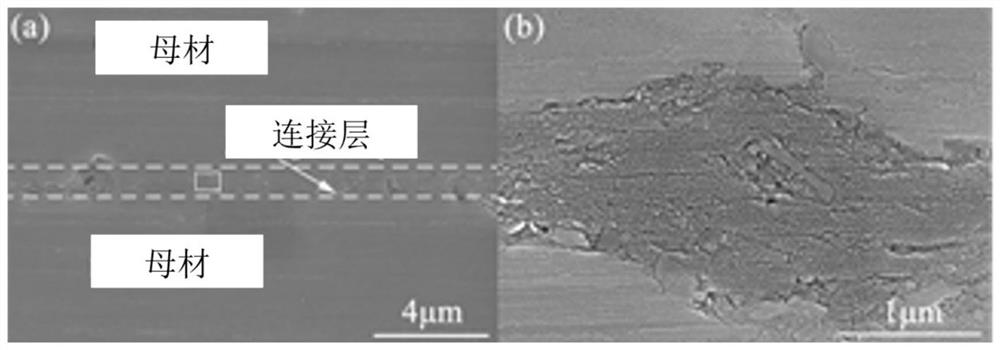

Silicon carbide ceramic connection method and silicon carbide cladding

The invention discloses a silicon carbide ceramic connection method and a silicon carbide cladding, and the silicon carbide ceramic connection method comprises the following steps: S1, taking liquid polycarbosilane as a precursor, and adding a curing agent for curing treatment; S2, enabling the cured polycarbosilane to be subjected to heating pretreatment, and forming precursor powder; S3, mixing the precursor powder and an organic solvent to prepare slurry; S4, smearing the slurry between a SiC cladding tube and an end plug which are matched with each other, and forming a sandwich connection structure; and S5, performing high-temperature curing and cracking treatment on the sandwich connection structure, so that the slurry forms a connection layer which is tightly connected between the SiC cladding tube and the end plug. According to the silicon carbide ceramic connection method, high-strength connection of the SiC cladding and the end plug at a low temperature (less than or equal to 1500 DEG C) and without pressure is realized, filler does not need to be added, the pore defect of a middle connection layer is reduced, and the air tightness of a formed joint is improved; and the connection process is simple and has low requirements on equipment, and the cost is reduced.

Owner:CHINA NUCLEAR POWER TECH RES INST CO LTD +3

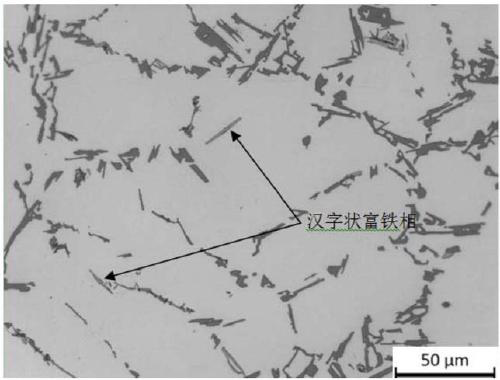

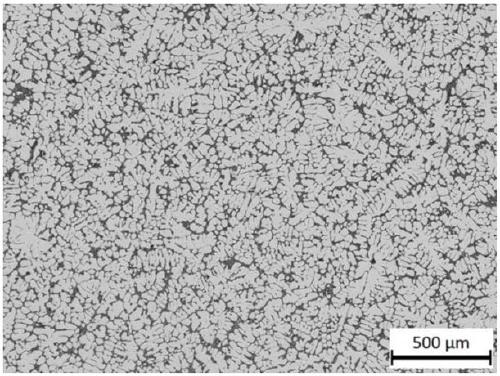

Composite alterant of cast aluminum alloy for iron-enriched phase alteration and alteration method thereof

The invention discloses a composite alterant of a cast aluminum alloy for iron-enriched phase alteration and an alteration method thereof, and relates to the field of composite alteration of the castaluminum alloy. The composite alterant comprises an Mn agent, an Al-RE intermediate alloy and an Al-Sr intermediate alloy, wherein the Mn agent is an Al-Mn intermediate alloy or a Mn additive; the adding ratio of the Mn agent is 30-90% of the Fe content in the cast aluminum alloy; the RE adding amount of the Al-RE intermediate alloy is 0.05-0.2% of the melt mass of the cast aluminum alloy; and theSr adding amount of the Al-Sr intermediate alloy is 0.02-0.05% of the melt mass. The composite alterant is specifically suitable for a high-strength and high-toughness cast aluminum silicon alloy with low Fe content and a die-cast aluminum silicon alloy with high iron content, and can achieve synchronous refining of three structures of alpha-Al, eutectic silicon and an iron-enriched phase to improve the alloy ductility.

Owner:GUANGDONG INST OF NEW MATERIALS

Gap type pouring system for casting aluminum alloy metal type cylinder cover

InactiveCN103223469AQuality improvementReasonable heat distributionFoundry mouldsFoundry coresSlagFiltration

The present invention relates to a gap type pouring system for casting an aluminum alloy metal type cylinder cover, and belongs to the technical field of cylinder cover casting systems. The gap type pouring system comprises a gate cup, wherein the lower end of the gate cup is connected with two vertical runners, the terminal end of the vertical runner is connected with a horizontal runner, the bottom of the horizontal runner is provided with a filtration screen groove, the terminal end of the horizontal runner is provided with a gap type inner runner along a cast height direction, and the horizontal runner and the gap type inner runner are communicated. According to the gap type pouring system, improvement is performed based on a metal type bottom pouring type pouring, the gap type inner runner is arranged on the front end of the cast, structure design is reasonable, promotion is easy achieved, stable aluminum water filling molding is ensured, phenomena such as aluminum water oxidation, slag inclusion, pore forming and the like are effectively prevented, and cast quality is improved.

Owner:WUHU LERUISI INFORMATION CONSULTING

Multi-component zinc-aluminium alloy capable of enhancing thermal fatigue property

ActiveCN102719705AImprove plasticityImprove thermal fatigue resistanceThermal fatigueMedium frequency

A multi-component zinc-aluminium alloy capable of enhancing thermal fatigue property belongs to the technical field of zinc-aluminium alloy preparation and is characterized in that No.A00 industrial aluminium ingots, No.0 zinc ingots, electrolytic copper, composite modifier (including 20 to 30 percent of Ni, 15 to 25 percent of Ti, 5 to 15 percent of Mn, 5 to 15 percent of Cr, 5 to 10 percent of Si, 5 to 10 percent of Ce, 5 to 10 percent of La, 1 to 6 percent of Y, 1 to 6 percent of Nb, 1 to 6 percent of V and the balance of aluminium) and pure magnesium are adopted as materials. Calculated according to percentage by weight, 27 to 29 percent of Al, 2 to 2.5 percent of Cu (added in the form of aluminium-copper master alloy containing 50 percent of copper), 0 to 1.2 percent of composite modifier, 0.01 to 0.02 percent of Mg and the balance of Zn are weighed and then smelted in a medium-frequency induction smelting furnace. An ordinary metal mold is adopted to cast round rod-shaped billets, the round bar-shaped billets are machined into test bars which come up to national standard, and thermal fatigue samples are then taken from the billets.

Owner:SHENZHEN MINGLIDA PRECISION MACHINERY

SiCf/SiC composite material and preparation method thereof

The invention relates to a SiCf / SiC composite material and a preparation method thereof. The preparation method comprises the following steps: (1) mixing carbon black and silicon carbide micro powderwhich are used as solid phases with water, adding an adjuvant agent, performing ball grinding for mixing, mechanically stirring the mixture in vacuum, and debubbling the mixture to obtain dipping slurry; (2) dipping silicon carbide fiber cloth in the dipping slurry for vacuum-pressure dipping to obtain a fiber cloth dipped material, starching the fiber cloth dipped material for thicknessing, adhering and stacking the material, burying the material with water-absorbent resin, placing the material into a mold for cold isostatic pressing, and drying and thermally treating the mold to obtain a carbon-containing preform, wherein a silicon carbide fiber contains a boron nitride interface; (3) performing reactive melt infiltration on the carbon-containing preform, thus obtaining the SiCf / SiC composite material. The preparation method can be simplified, the production energy consumption can be reduced, and the production efficiency can be improved; pore defects in the carbon-containing preformcan be substantially reduced, so that the compactness of the SiCf / SiC composite material is increased, and the content of residual silicon is reduced at the same time.

Owner:CHINA BUILDING MATERIALS ACAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com