Patents

Literature

242results about How to "Increase the amount of deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

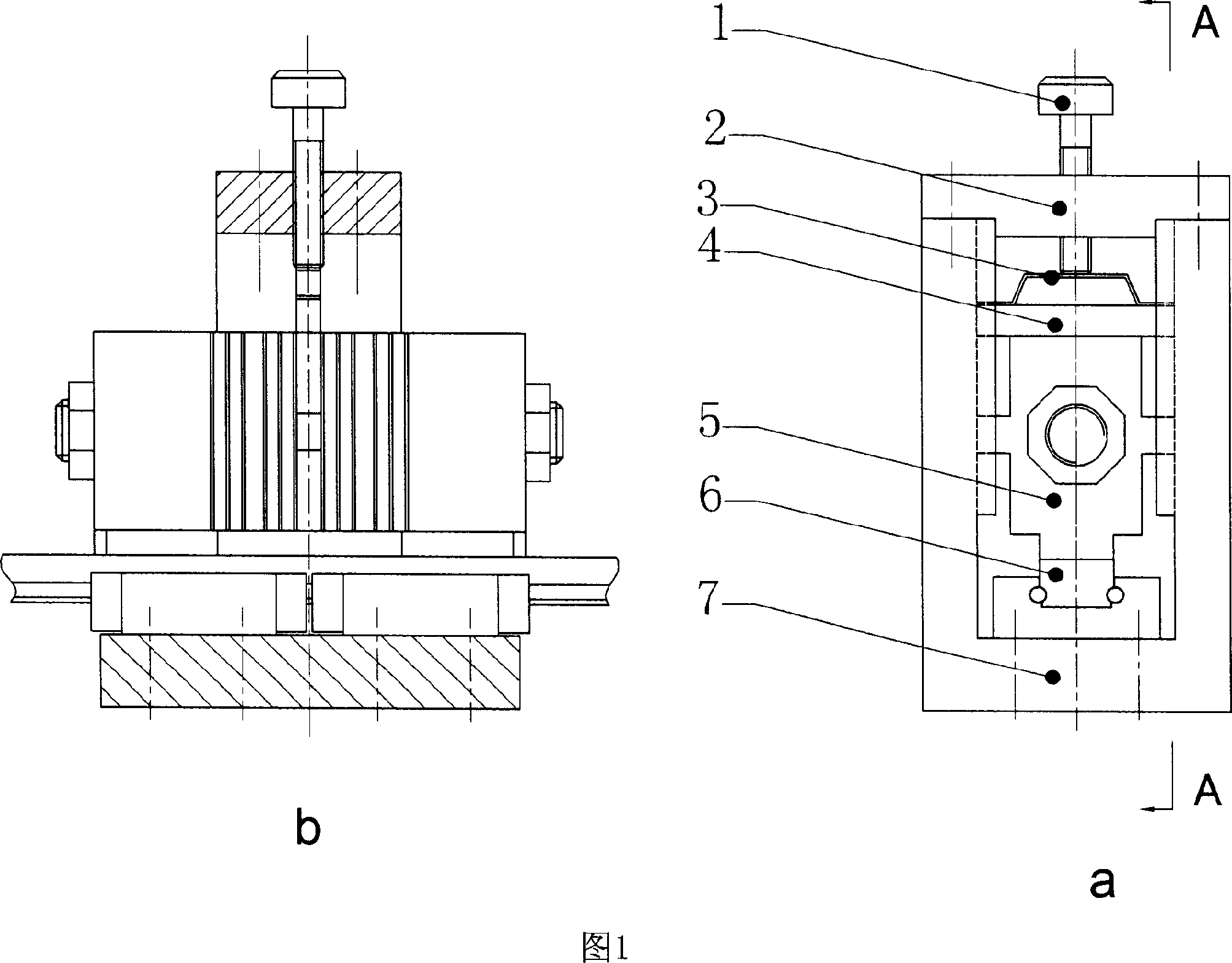

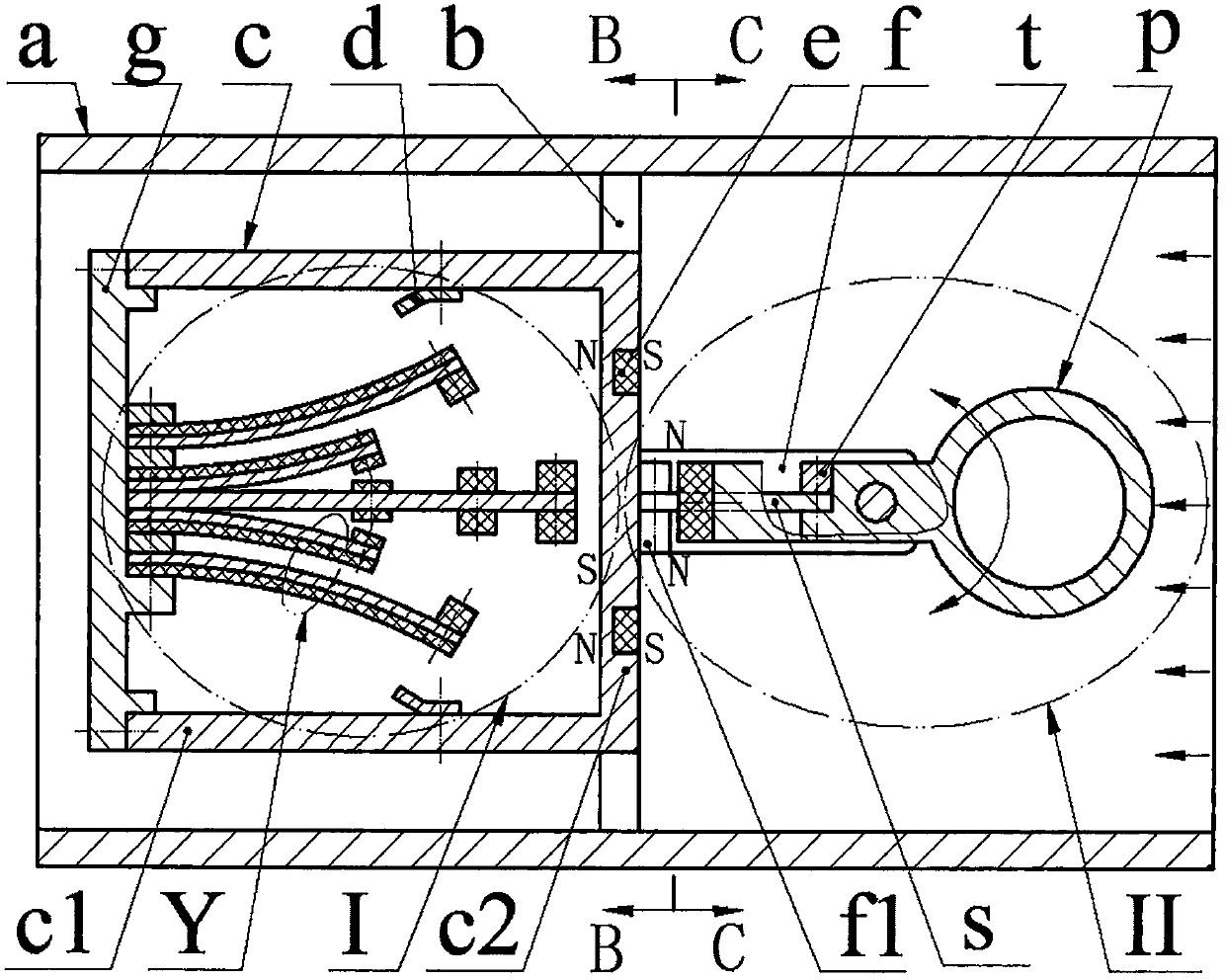

Prism longitudinal bend composite vibrator linear supersonic motor

InactiveCN101051798AThe resonance frequency is consistentImprove efficiencyPiezoelectric/electrostriction/magnetostriction machinesElastomerPrism

The linear ultrasound electrical motor (LUEM) includes drive oscillator, mover, chassis, and relevant locking gear for fastening them. The drive oscillator includes piezoelectric element and metal elastic body (MEB). The piezoelectric element includes piezoelectric ceramic piece (PCP) of bending vibration, and PCP of longitudinal vibration in use for generating rectilinear vibration. At least one dogtooth contacted to mover is setup on MEB. Slider of guiding bulge is setup on side of mover. The guiding bulge is corresponding to straight-line guidance groove setup on the chassis. The disclosed LUEM is longitudinal and bending composite driving LUEM with prism type oscillator. The drive oscillator is prism type longitudinal bending composite oscillator composed of connection terminals, longitudinal vibration rectangular PCP and front cover board fastened by double end bolts and nuts. The oscillator is as stator of LUEM to generate longitudinal and bending vibration.

Owner:SOUTH CHINA AGRI UNIV

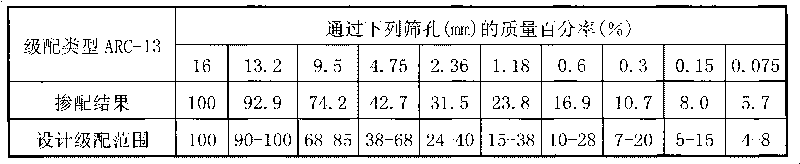

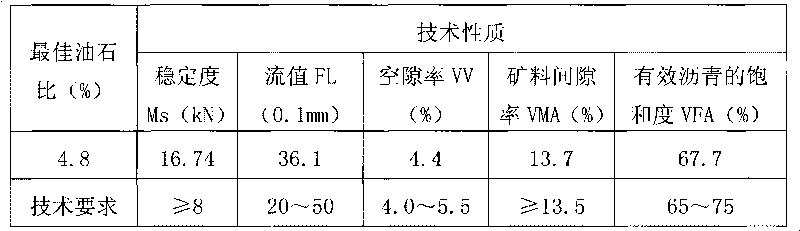

Method for enhancing bituminous mixture by adopting chopped basalt fibers

InactiveCN101712803AImprove high temperature stabilityFix rutsBuilding insulationsCrack resistanceWhole-life cost

The invention relates to a method for enhancing bituminous mixtures by adopting chopped basalt fibers, belonging to the technical field of novel compound materials. According to the invention, continuous basalt protofilaments or twistless rovings the surfaces of which are expanded into fibers in certain length, and then the fibers are used for enhancing the bituminous mixtures in a certain doping proportion and can be respectively used for maintaining the bituminous mixtures used for new construction and reconstruction and extension of highways and SMA and OGFC bituminous mixtures as well as fiber seals. In addition, the fibers can also be used for the enhancement of high-speed railway packing layer CA mortar and relevant hydraulic architectures. The chopped basalt fiber plays roles of enhancing, toughening and elasticizing the cracking prevention, crack resistance and reinforcement and 'bridging' in the enhanced bituminous mixtures, can obviously increase the anti-rutting ability of highways of the enhanced bituminous mixtures and reduces the whole life costs of the enhanced bituminous mixtures; if the fibers are used for high-speed railway plate-type ballastless tracks and CA mortar, the bending strength and the deformation resistance can be increased, i.e. the fibers play a role of crack prevention and crack resistance; in addition, the fibers have better anti-water leakage action if being used for Hydraulic and Hydro-Power Engineering.

Owner:ZHEJIANG GBF BASALT FIBER +1

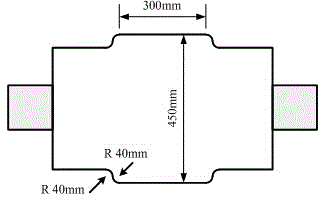

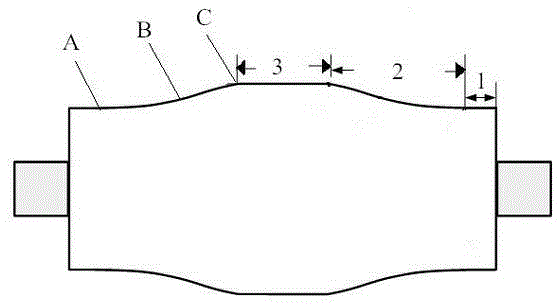

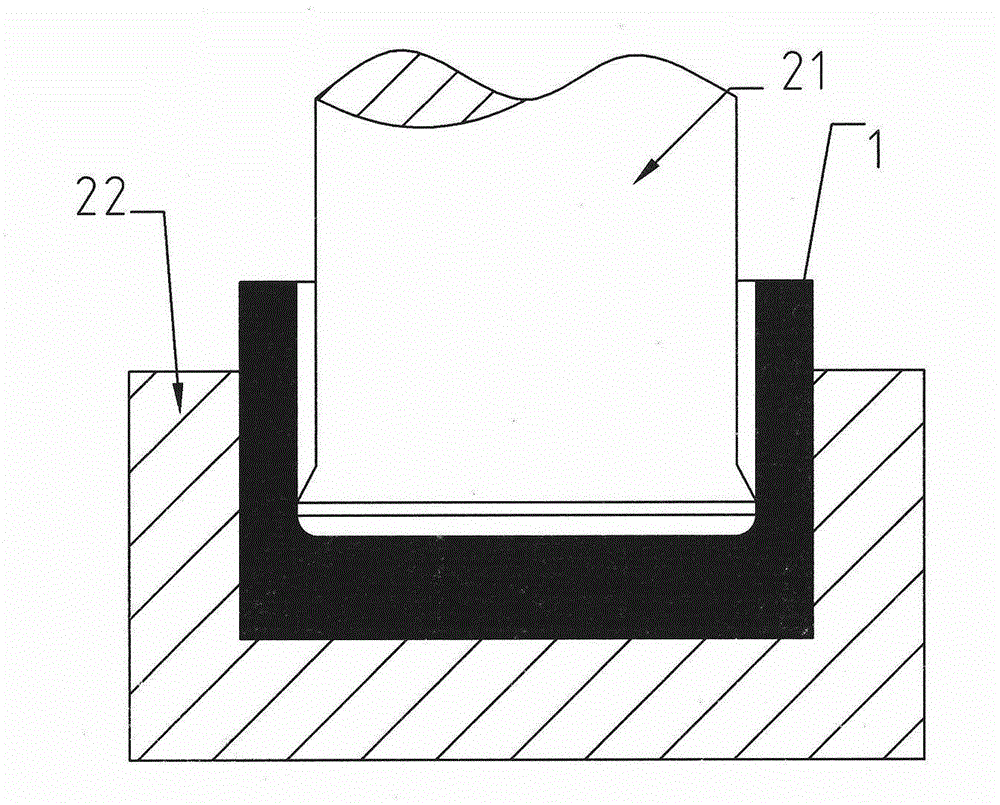

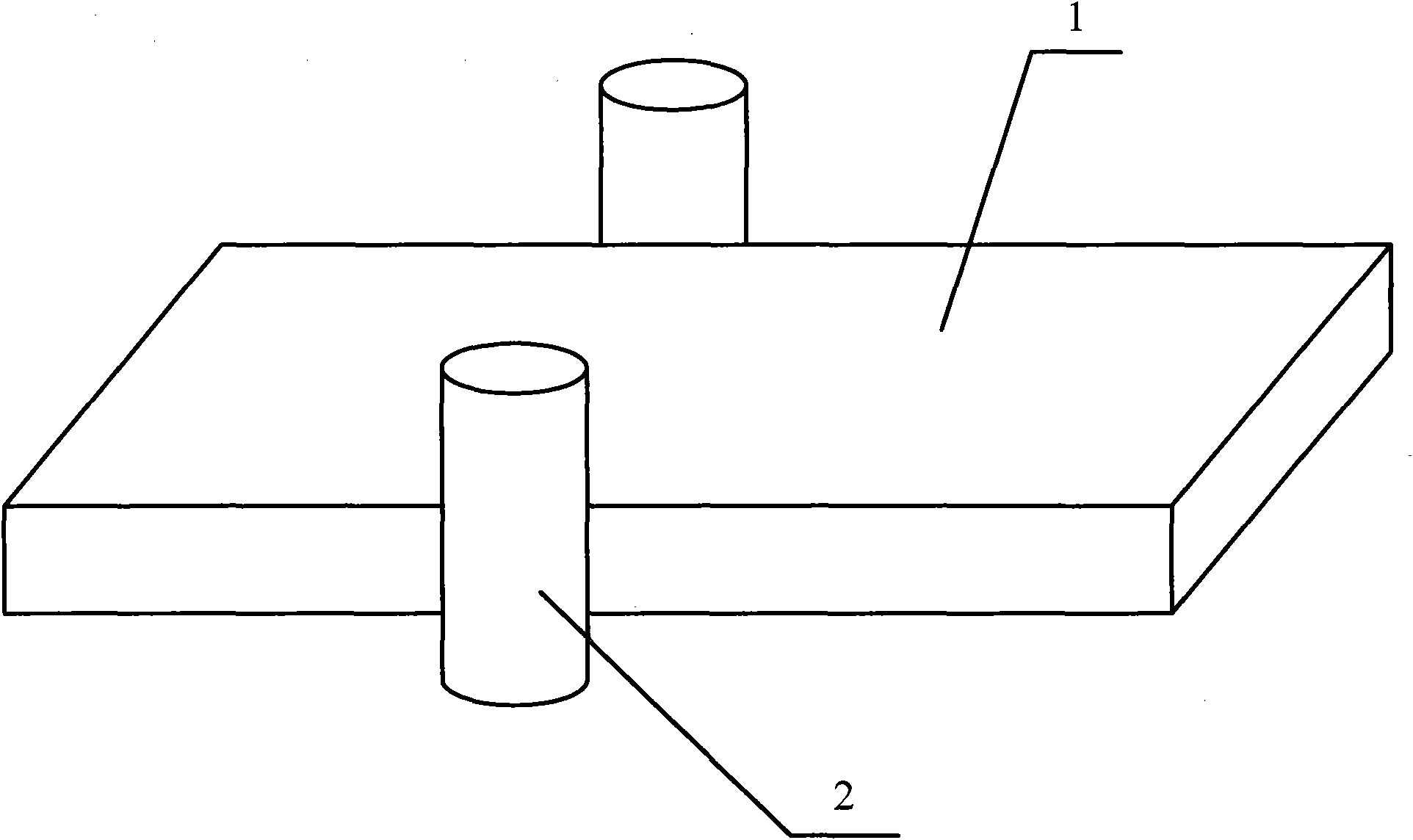

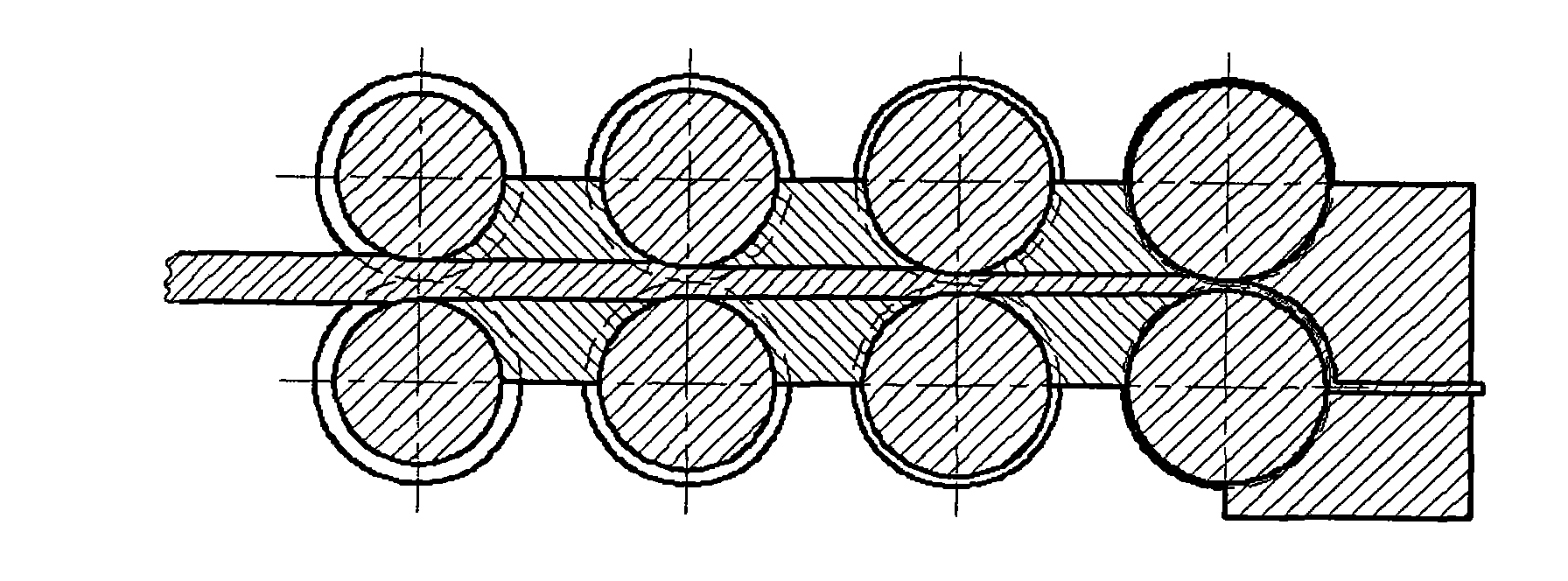

Gradient curvature raised roller of tension leveler for cogged ingot continuous casting and use method

ActiveCN104399924AIncrease the amount of deformationRealize the process purpose of extrusionStress concentrationMetallurgy

The invention belongs to the field of cogged ingot continuous casting production and especially relates to a gradient curvature raised roller of a tension leveler for cogged ingot continuous casting and a use method. The gradient curvature raised roller of the tension leveler provided by the invention is composed of a roller shaft and a roller body, wherein the roller body is composed of an edge area, a gradient curvature area and a flat roller area; the gradient curvature area is composed of an arcing area and an arc-varying area; the arc curvature between an arcing point and an arc-varying point of the arcing area is gradually increased; the arc curvature between the arc-varying point and an arc-ending point of the arc-varying area is gradually reduced; the flat roller area is raised relative to the edge area. At least four tension levelers with the gradient curvature raised rollers are used for pressing a cogged ingot continuous casting slab; during the pressing process, the average temperature of the surface of the continuous casting slab is controlled at above or equal to 800 DEG C and the temperature difference of surface center and corner is at below or equal to 150 DEG C; lastly, the continuous casting slab with improved central segregation and loosening is acquired. The smooth transition between the flat roller area and the raised roller area is realized by the gradient curvature raised roller provided by the invention and the crack defect caused by the stress concentration of the transition area is effectively avoided.

Owner:NORTHEASTERN UNIV

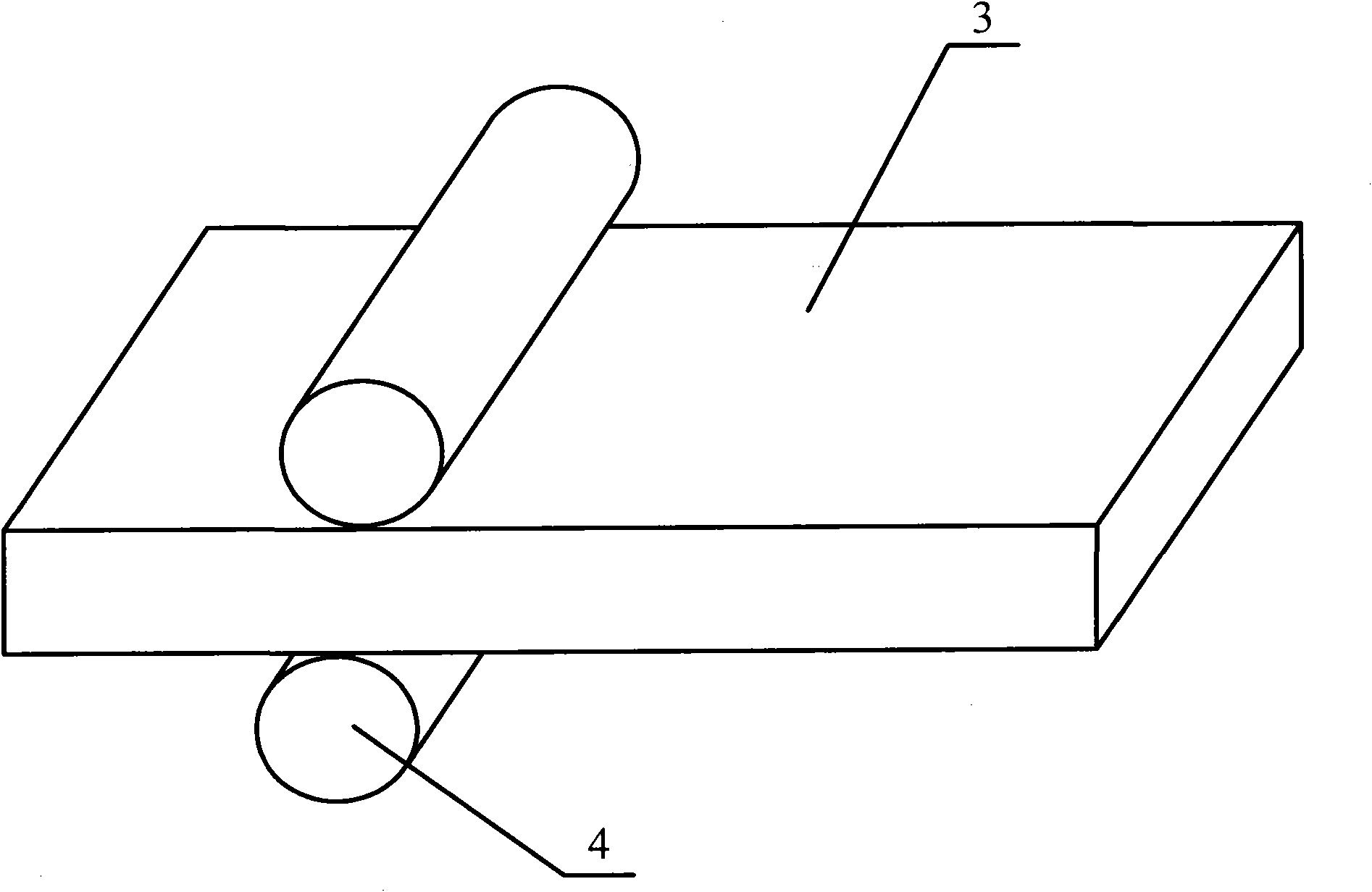

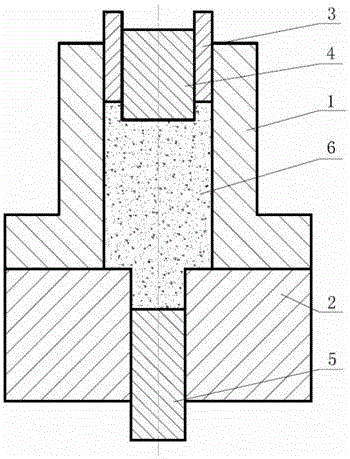

Method for extruding inner transverse rib of cylindrical piece

InactiveCN104624694AIncrease the amount of deformationExtend your lifeExtrusion diesExtrusion mandrelsEngineeringFiber

The invention provides a method for extruding an inner transverse rib of a cylindrical piece. Themethod comprises the following steps: (1) extruding a blank downwards by a left male die and a right male die; (2) moving the left male die and the right male die to the left and the right respectively to press working zones at the head parts of theleft male die and the right male die into a cylinder wall; (3) rotating a female die, and keeping the left male die and the right male die moving to the left and the right; (4) stopping the horizontal separation motion of the left male die and the right male die, extruding the blank again by the left male die and the right male die, and simultaneously keeping the female die rotating to form a cylinder wall with slant fiber texture; (5) stopping the female die from rotating, and combining the left male die and the right male die; (6) after combining the left male die and the right male die, integrally moving the left male die and the right male die downwards to extrude the blank; (7) separating the left male die and the right male die, and rotating the female die; (8) after finishing extrusion and rotation, drawing the left male die and the right male die close to each other; and (9) moving the left male die and the right male die upwards, and pushing an extruded piece out by an ejector rod so as to finish a complete extrusion and rotation process. Accordingto the method, the fiber texture of a cylinder body is distributed spirally and is slant,and the transverse and longitudinal comprehensive performance of the extruded piece is improved.

Owner:ZHONGBEI UNIV

Method for producing X65 pipe steel with low cost

InactiveCN101082106AIncrease profitIncrease the amount of deformationTemperature control deviceMetal rolling arrangementsChemical compositionHot rolled

The present invention discloses low cost process of producing X65 pipeline steel, which has reasonable metallurgical component design and is produced through EAF+LF smelting in an electric furnace, efficient continuous casting and rolling to form sheet billet and controlled cooling. The steel has components including C 0.046-0.060 wt%, Si 0.15-0.30 wt%, Mn 1.4-1.60 wt%, P 0.006-0.015 wt%, S 0.001-0.008 wt%, Nb 0.045-0.050 wt%, Ti 0.015-0.025 wt%, N 0.005-0.007 wt% and Fe and impurity for the rest. The process of the present invention can produce hot rolled X65 pipeline steel sheet coil of 6.0-10.0 mm thickness and meeting the requirement of API Spec 5L specification at low cost.

Owner:GUANGZHOU PEARL RIVER STEEL & IRON

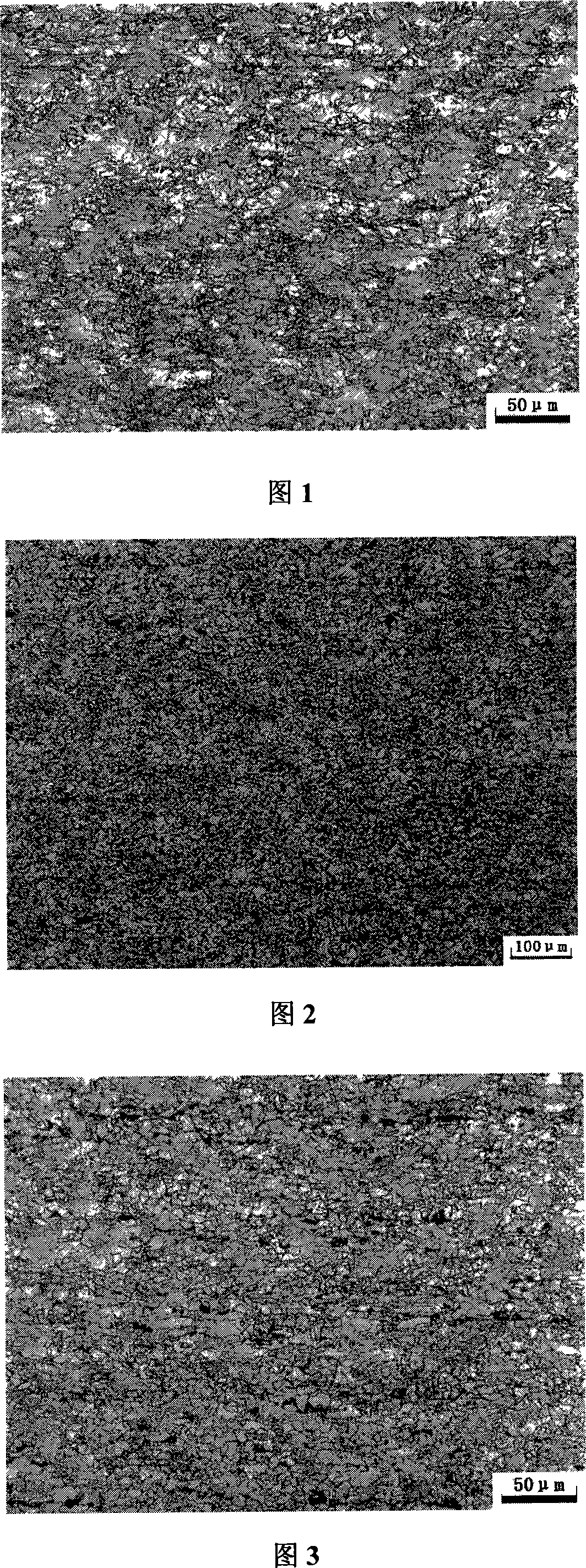

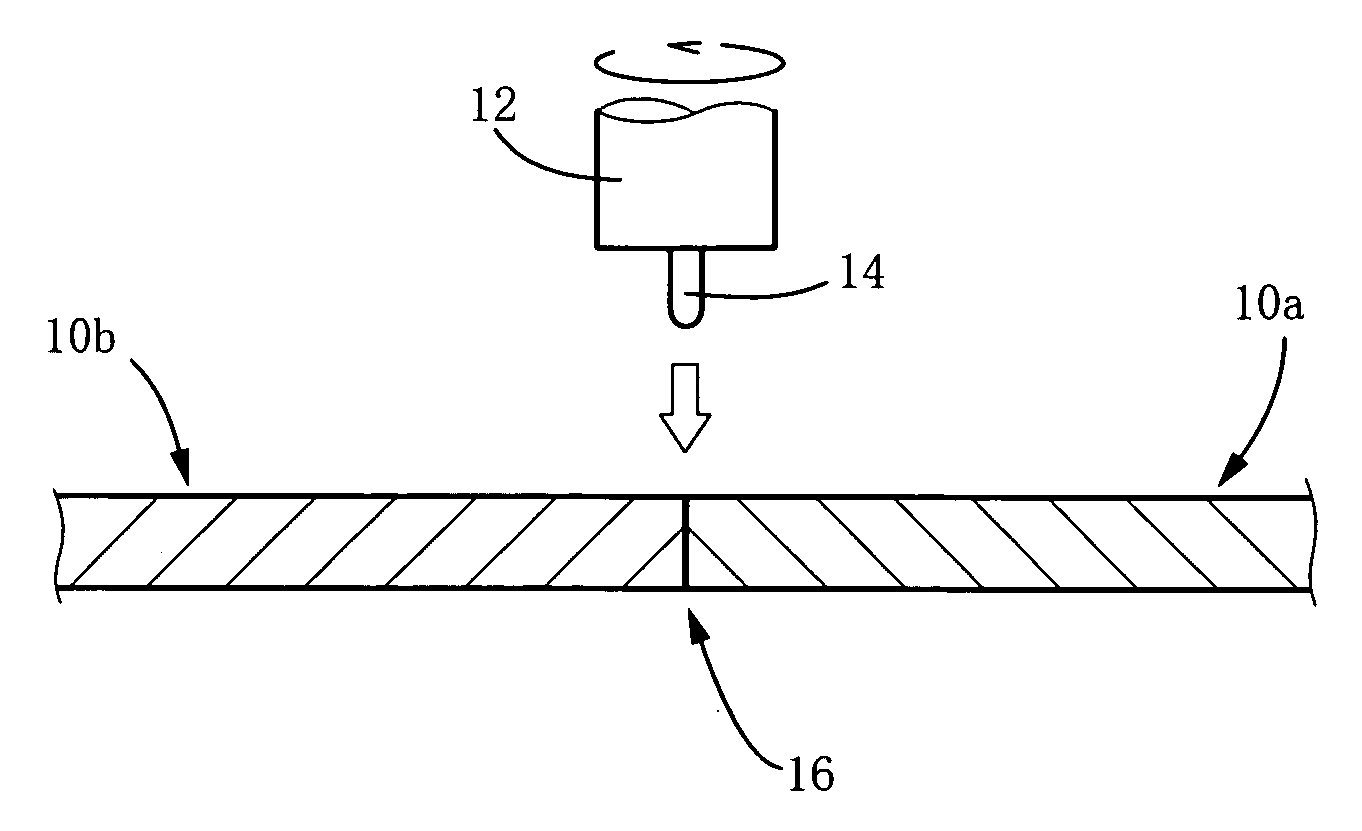

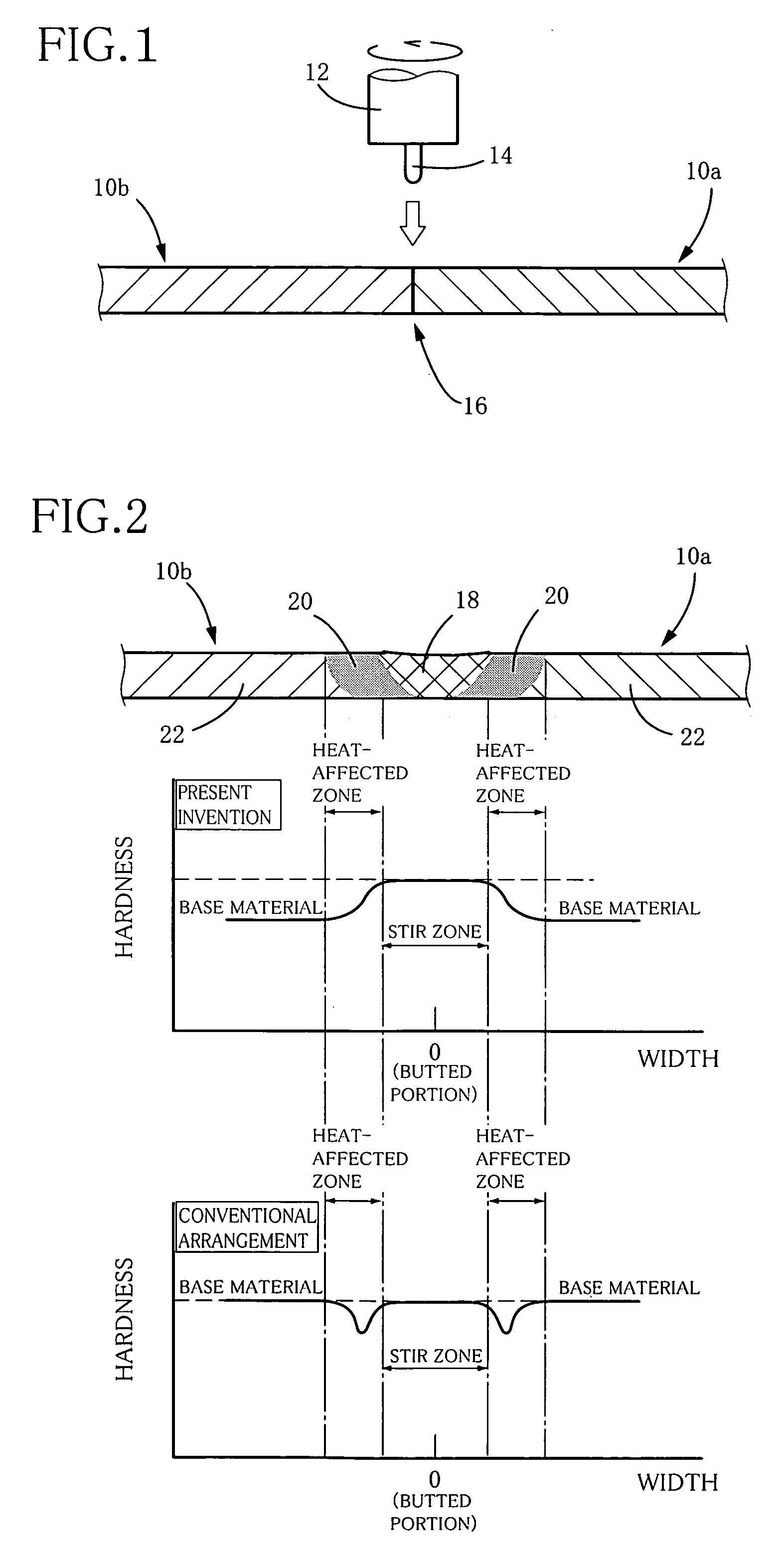

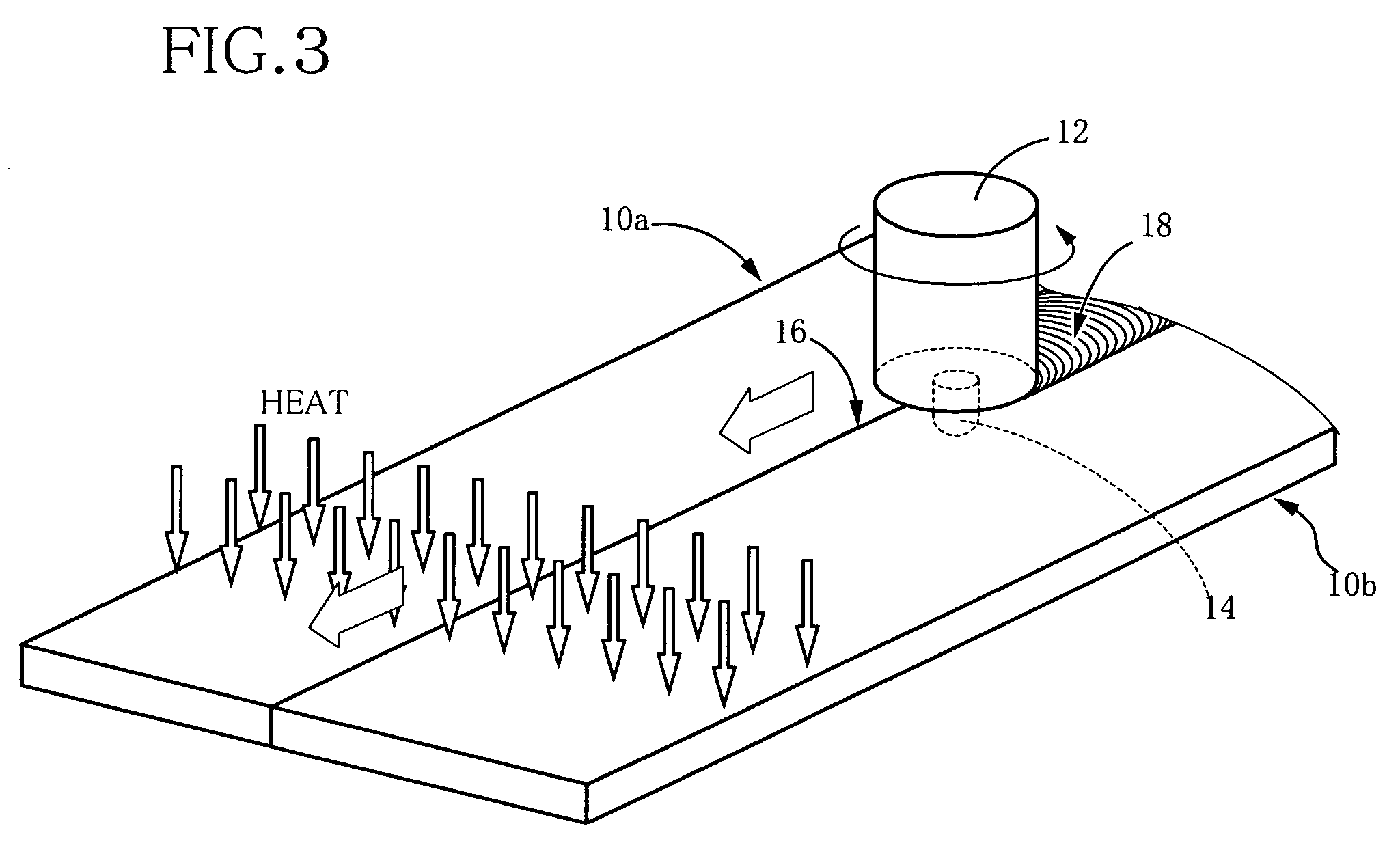

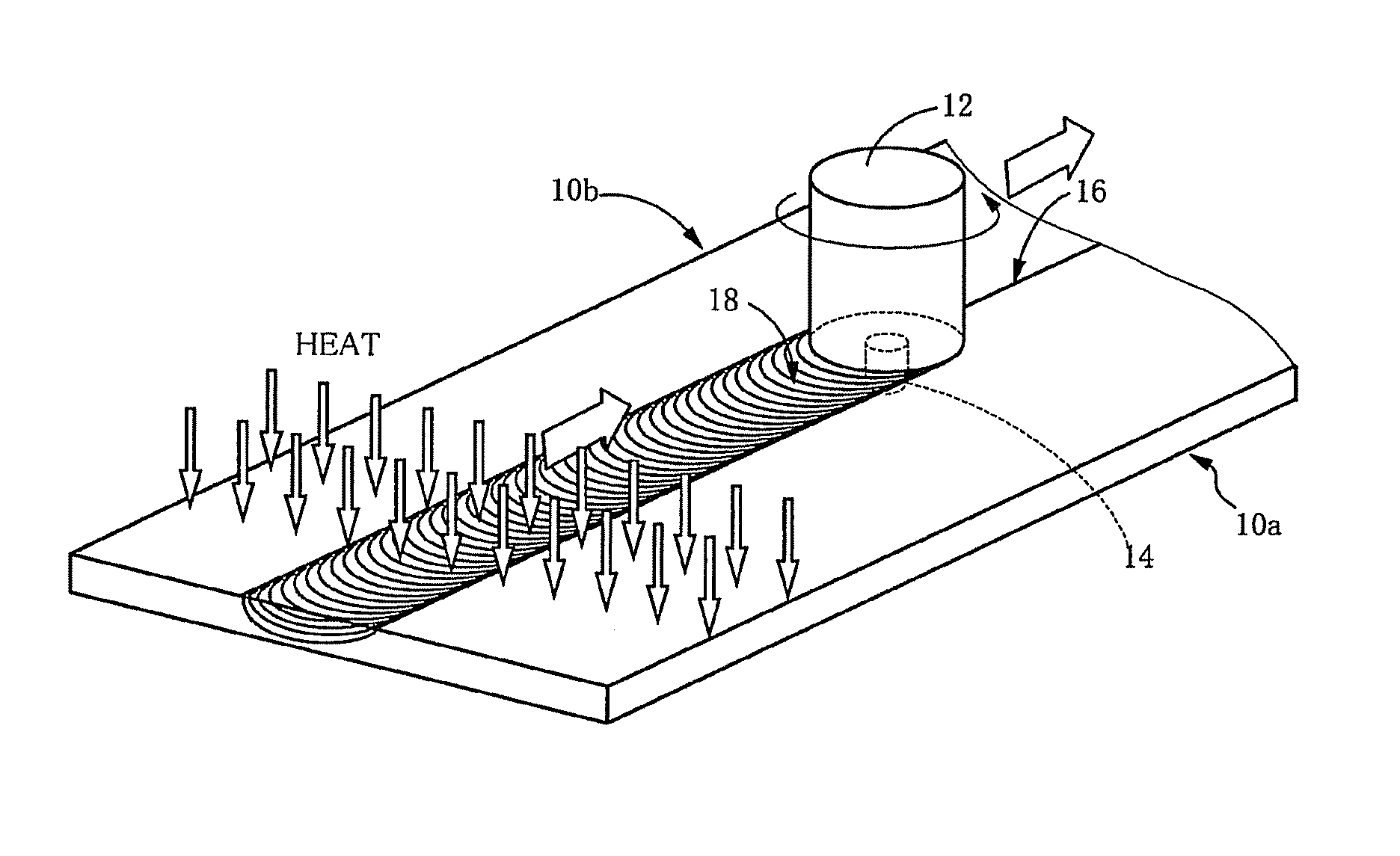

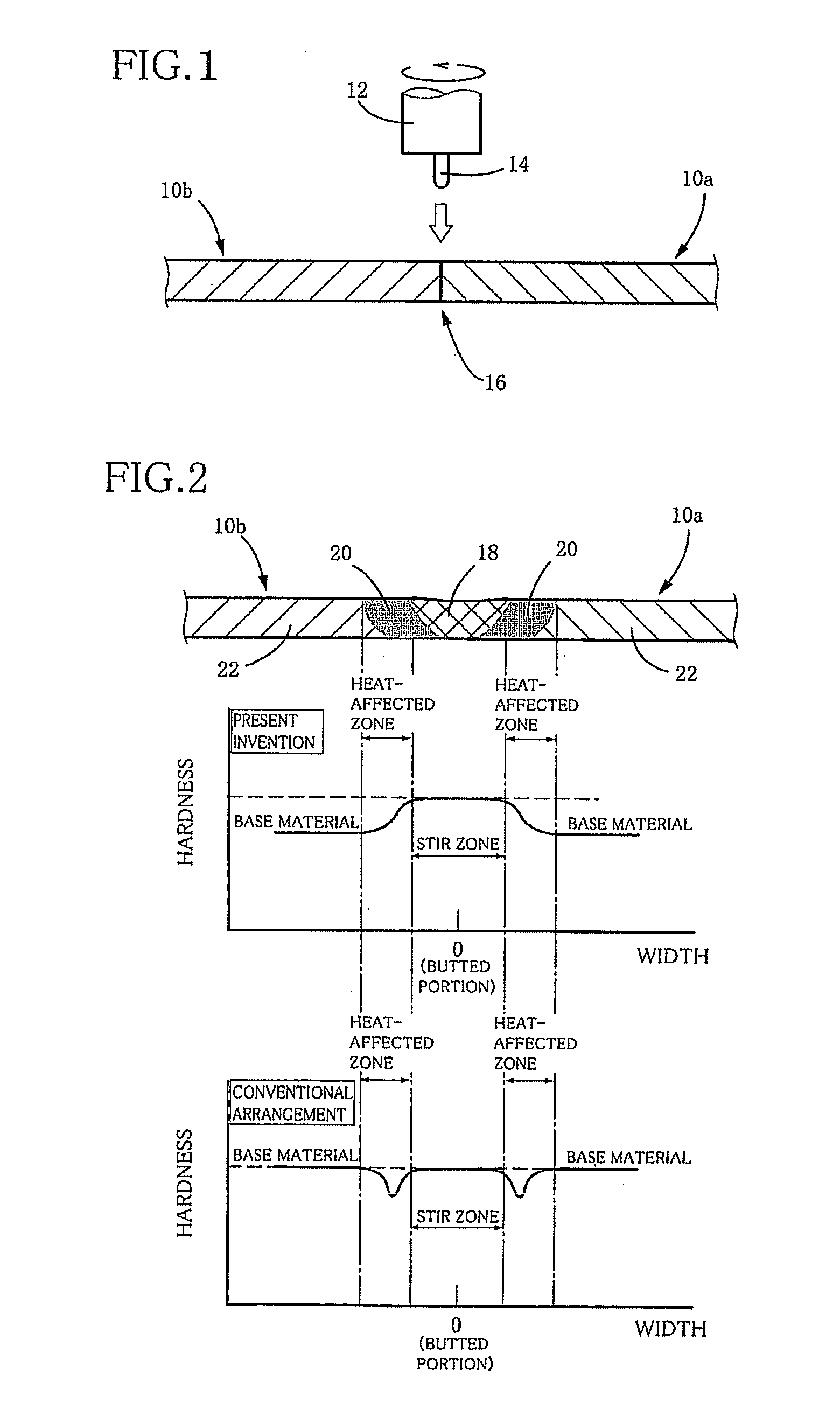

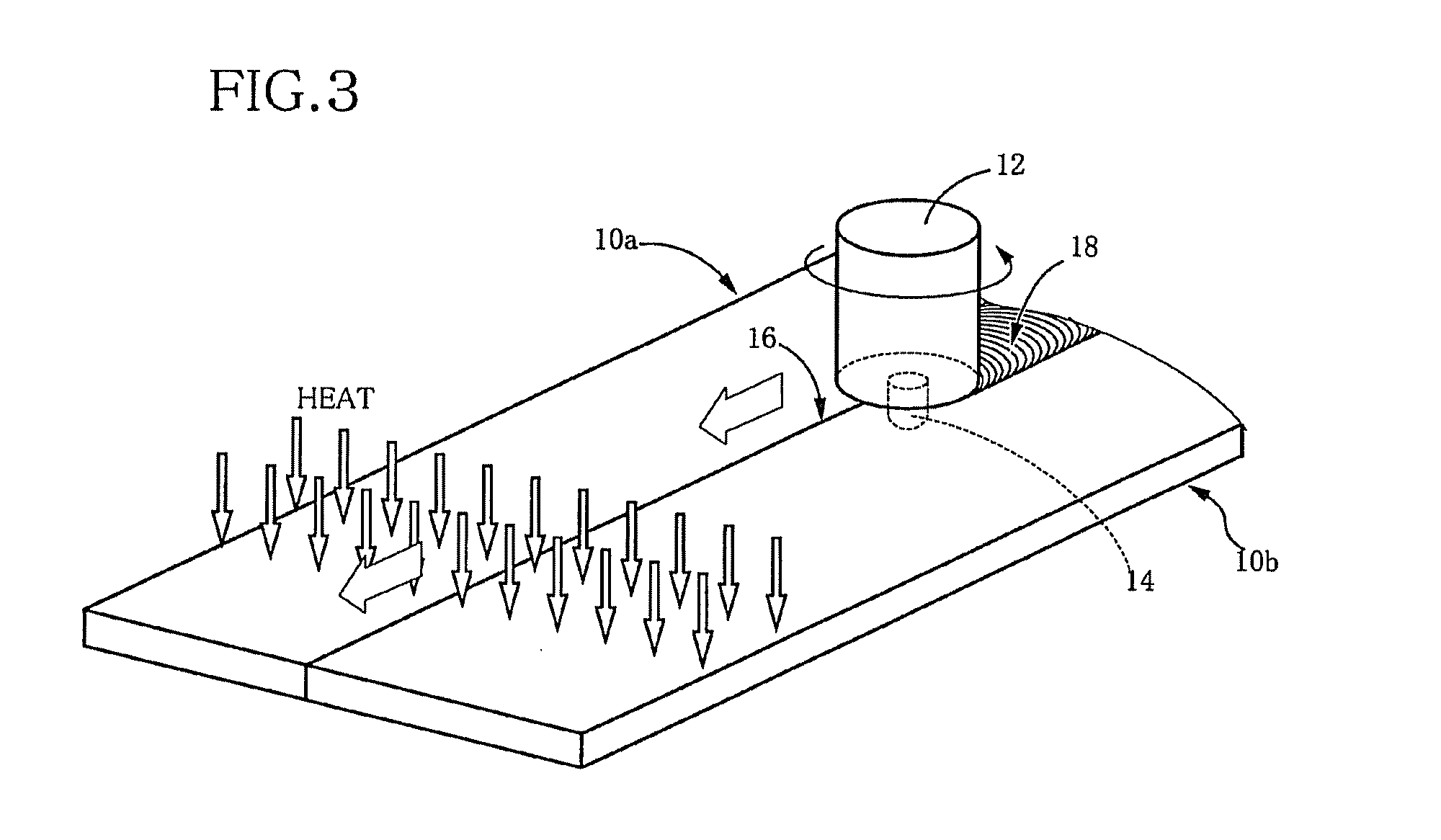

Method of joining heat-treatable aluminum alloy members by friction stir welding and joined product obtained by the method and used for press forming

InactiveUS20070138239A1Avoid stress concentrationReduce hardnessWelding/cutting media/materialsWelding/soldering/cutting articlesFriction stir weldingHeat treating

A method of joining heat-treatable aluminum alloy members by friction stir welding, including the steps of: a T4-treatment-performing step of performing a T4 treatment on heat-treatable aluminum alloy members so as to impart T4 temper to the heat-treatable aluminum alloy members; a joining step of joining the heat-treatable aluminum alloy members with T4 temper by friction stir welding to provide a joined product; and a reversion-treatment-performing step of performing a reversion treatment, the reversion-treatment-performing step being carried out prior to or after the joining step.

Owner:SUMITOMO LIGHT METAL INDS LTD

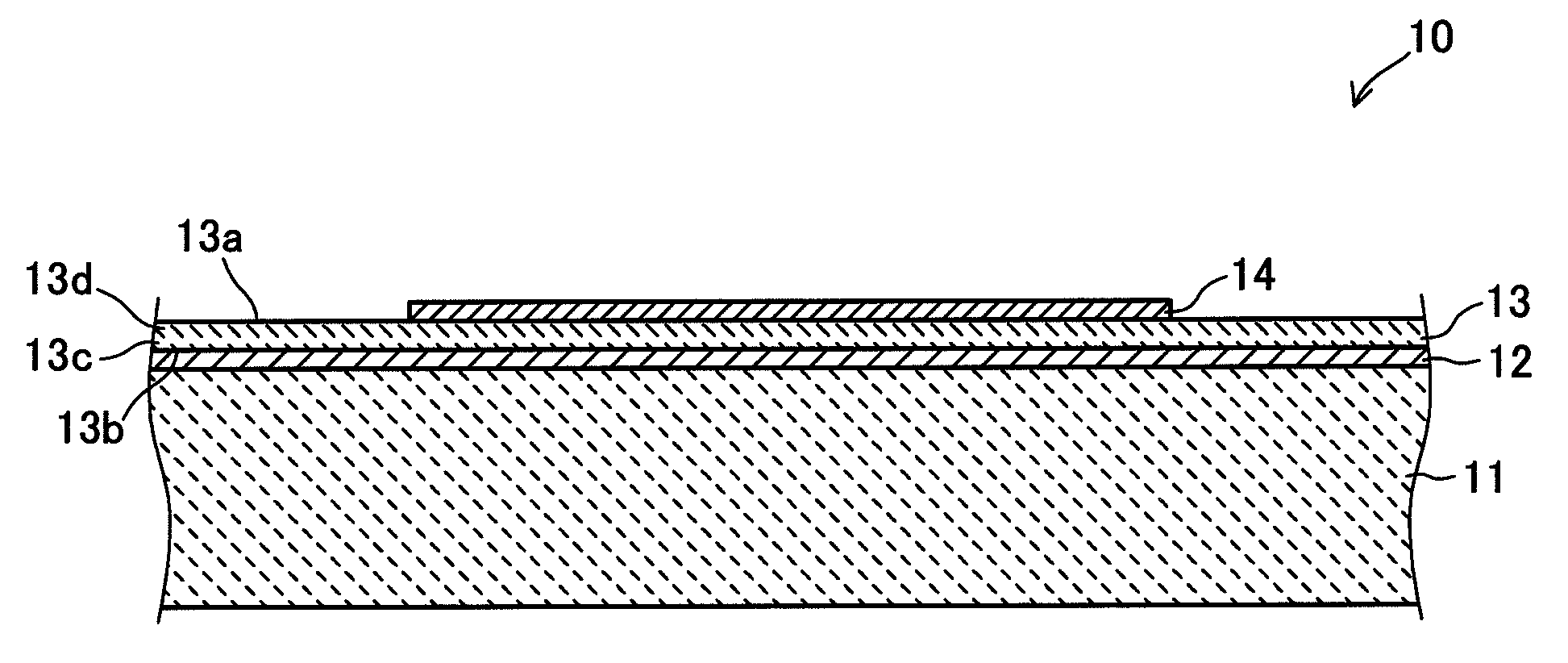

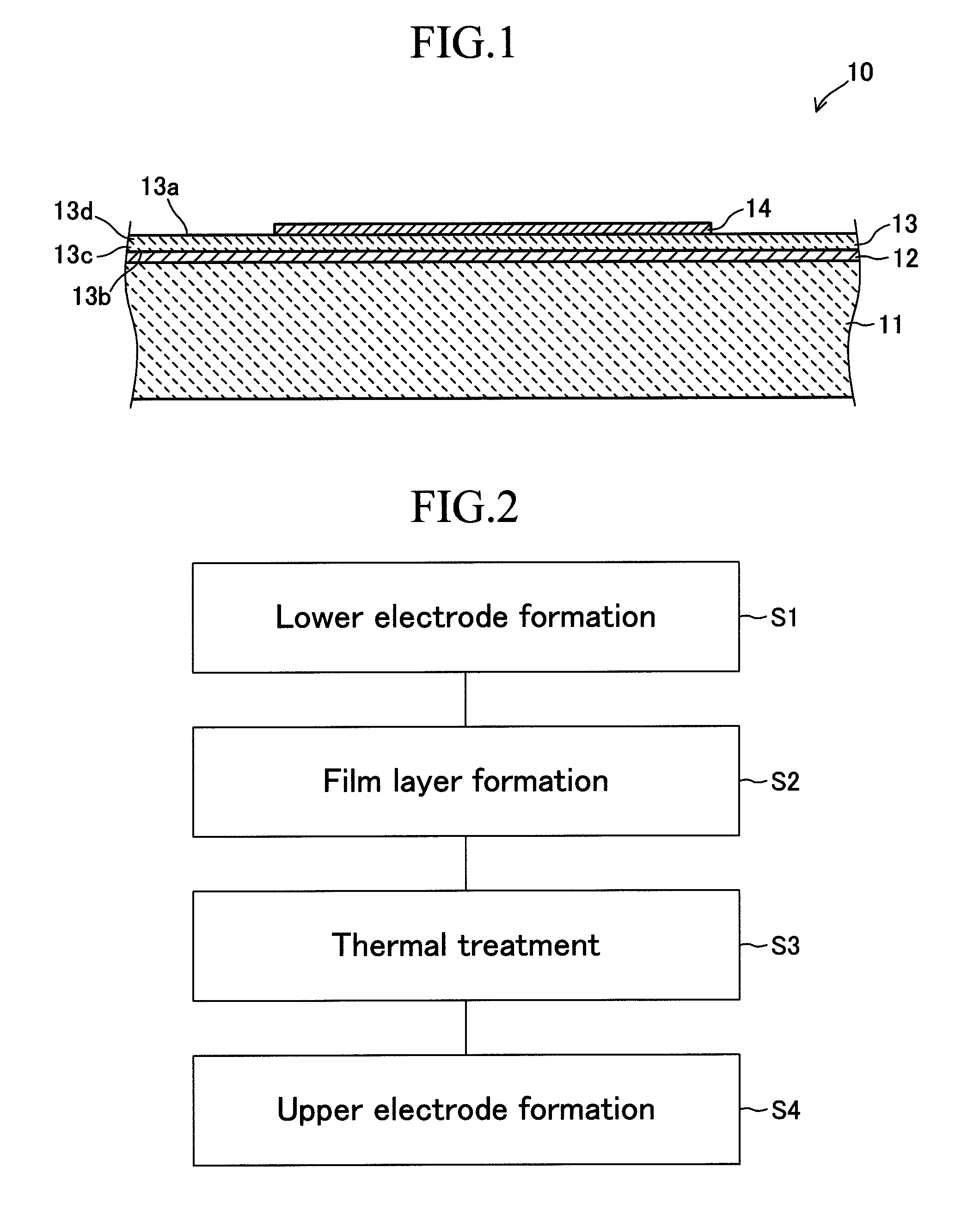

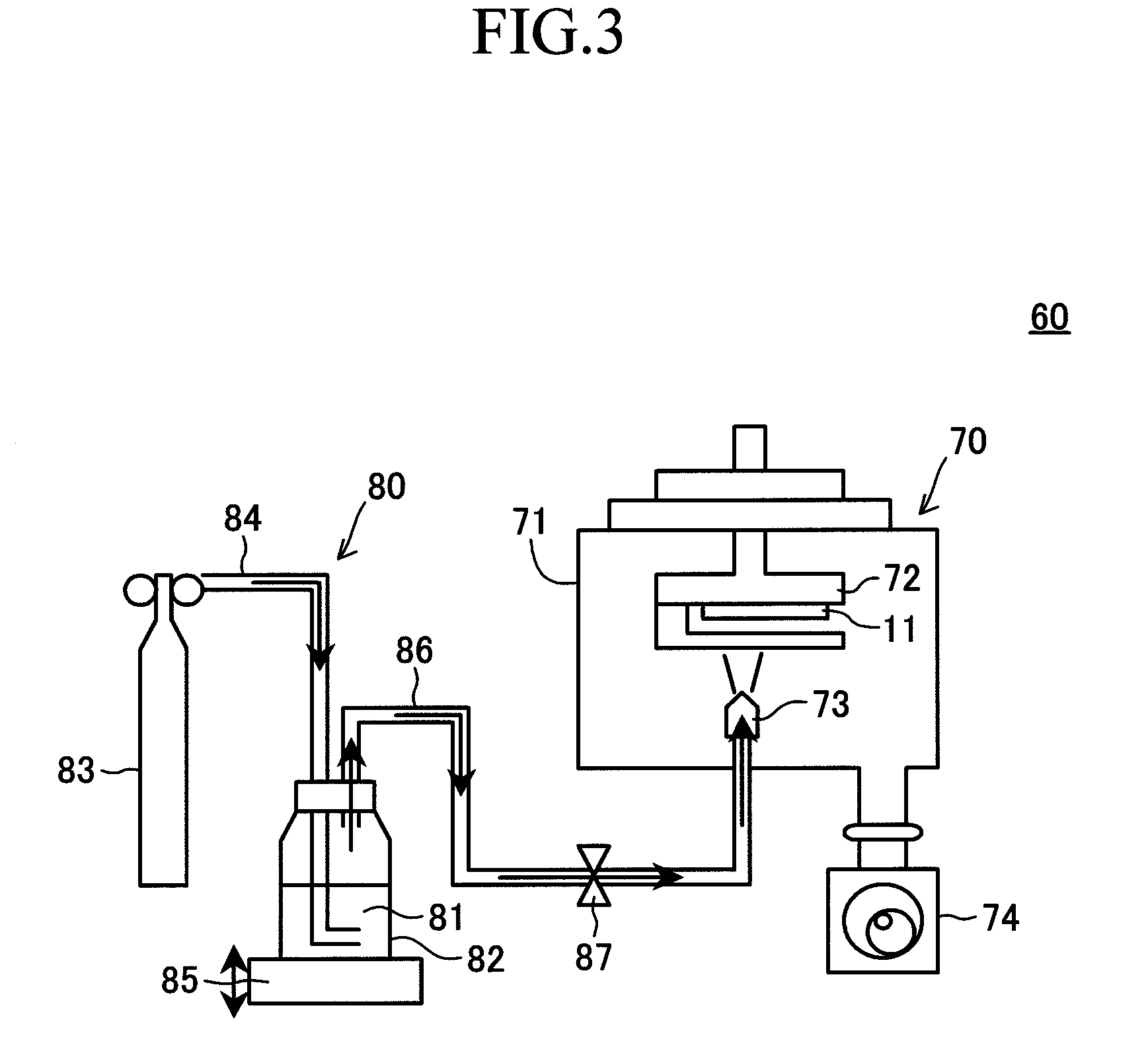

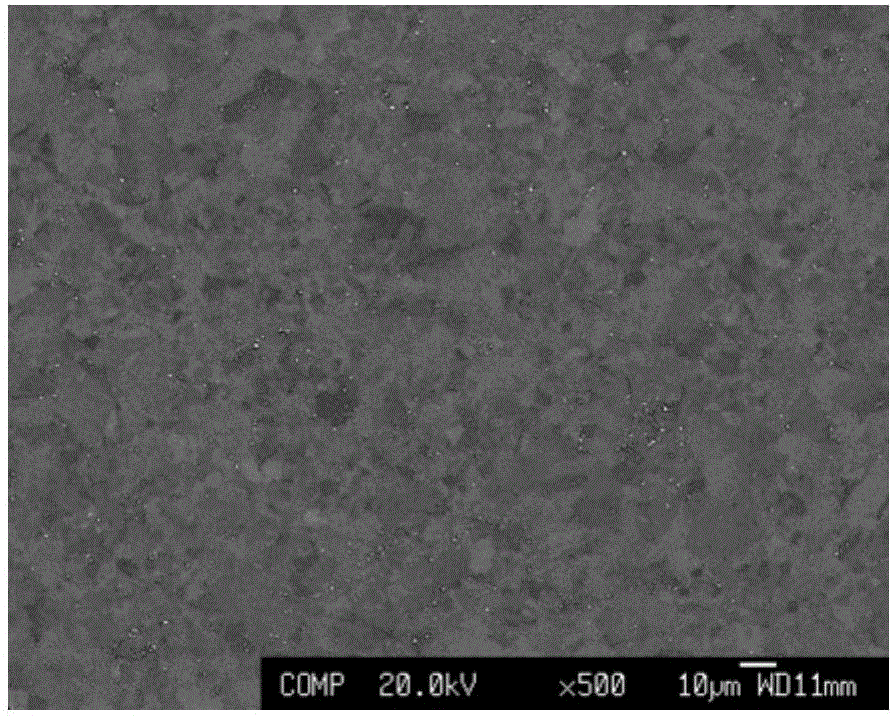

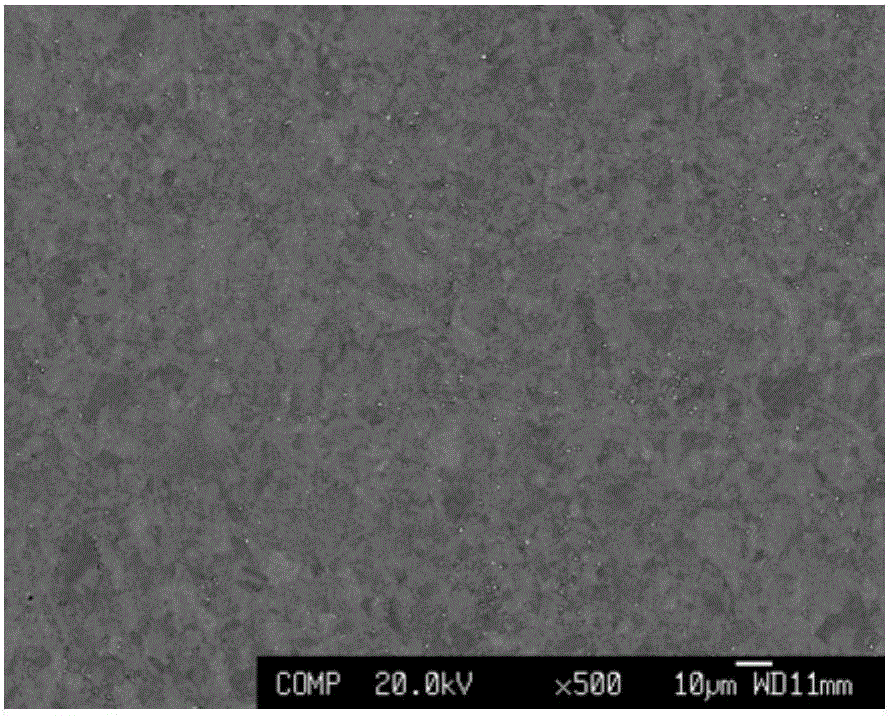

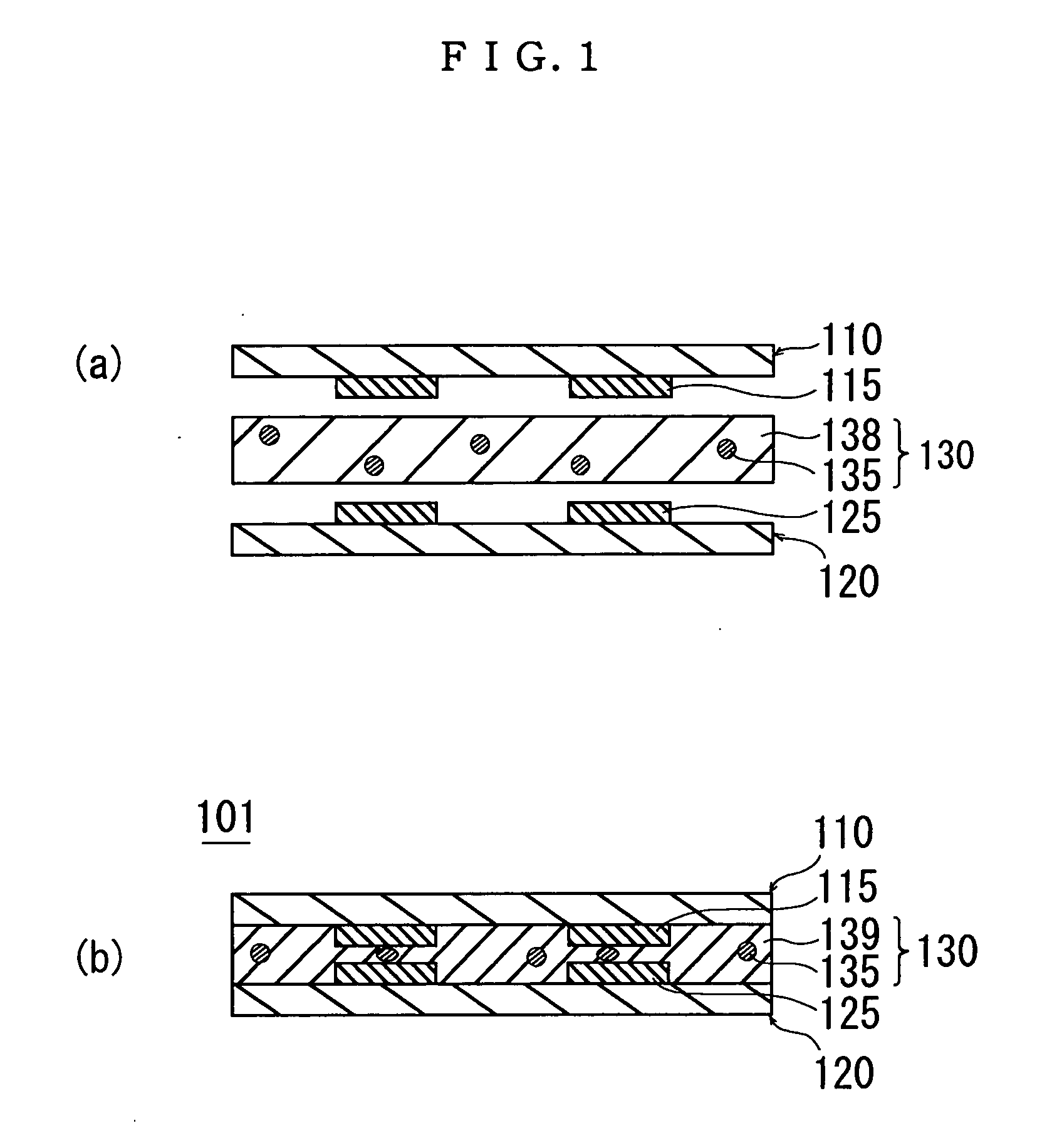

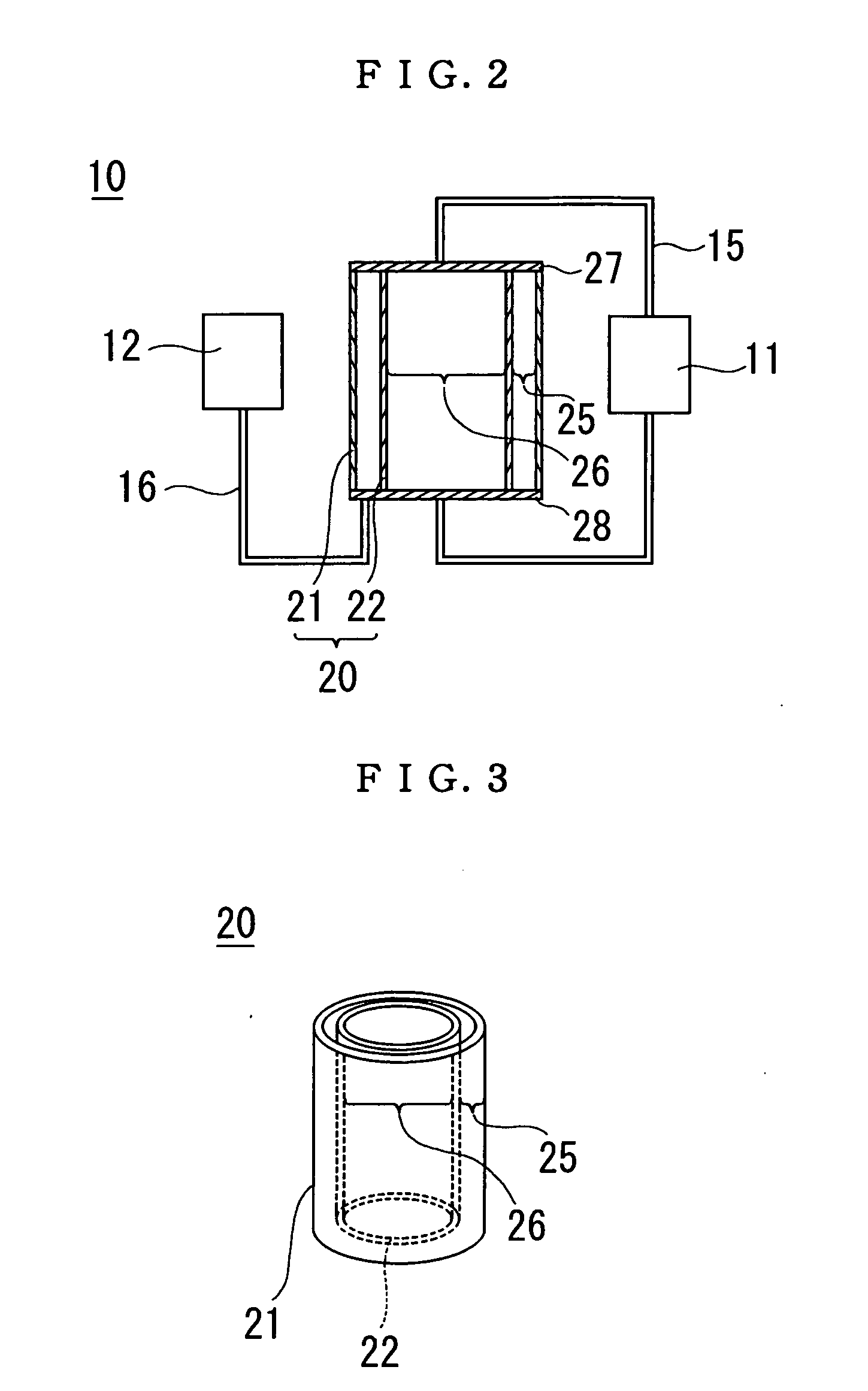

Dielectric device

InactiveUS20070222067A1Improve efficiencySuppress impairment of propertySemiconductor/solid-state device detailsNanoinformaticsOptoelectronicsFine particulate

The dielectric device includes a substrate, a lower electrode, a dielectric layer, and an upper electrode. The lower electrode is bonded onto the substrate. The dielectric layer is bonded onto the lower electrode. The dielectric layer is obtained through thermal treatment of a film layer formed by spraying of a powdery dielectric material and a fine-particulate metal. In the thus-formed film layer, the metal is dispersed in the matrix of the dielectric material. Thermal treatment of the film layer causes migration of the metal in the film layer. This metal migration causes a lower-electrode-adjacent portion and upper-surface-adjacent portion of the dielectric layer to have different metal contents.

Owner:NGK INSULATORS LTD

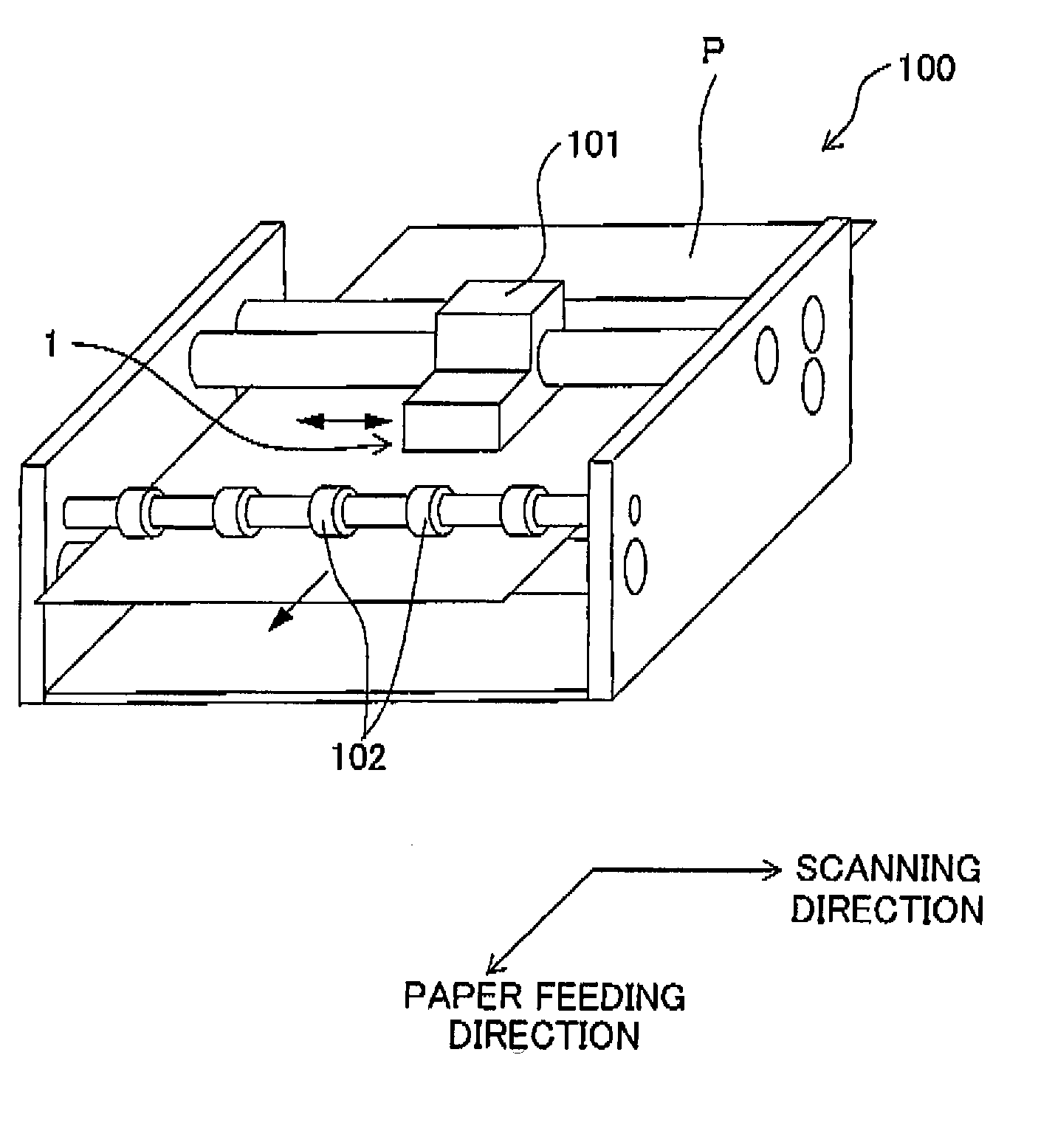

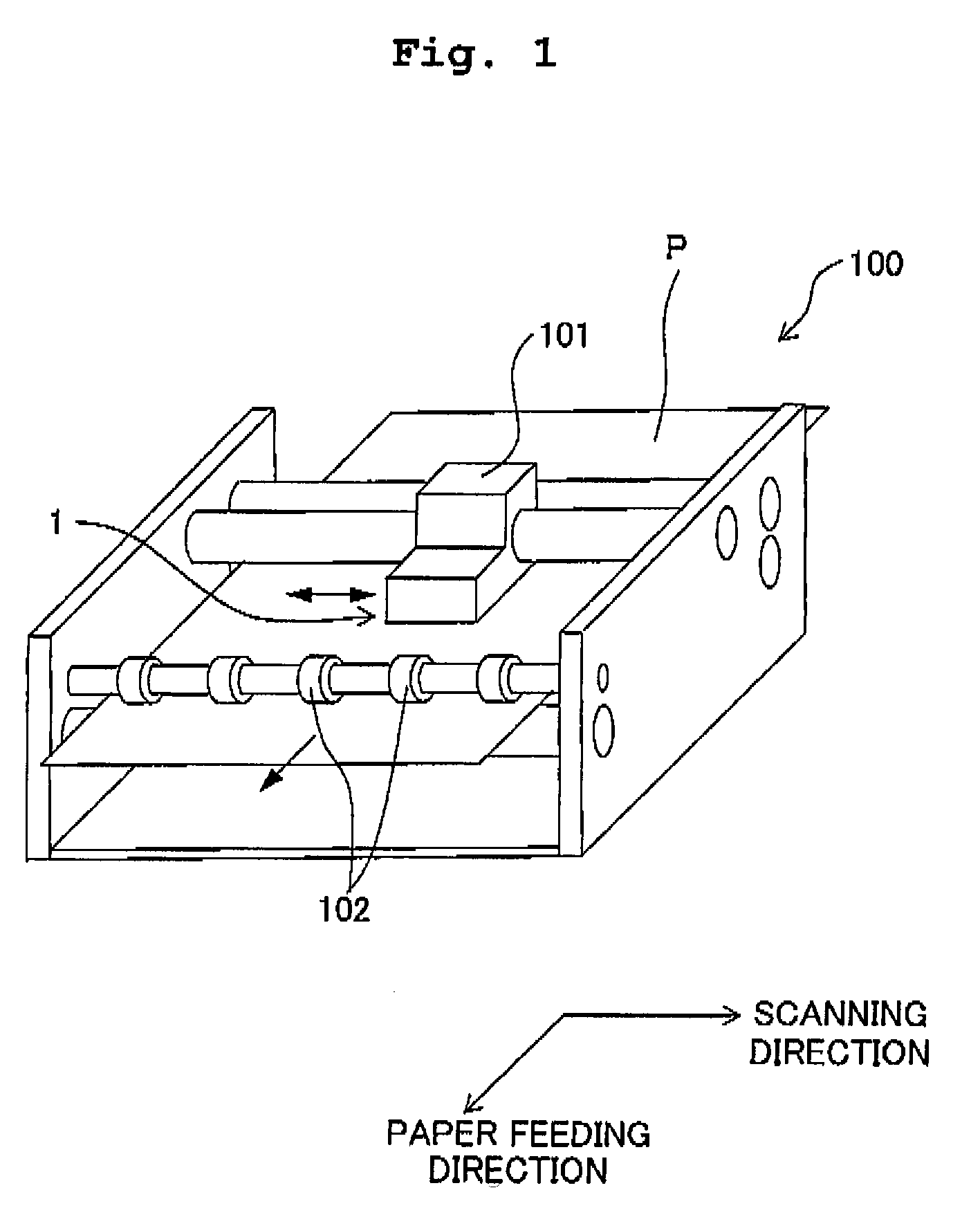

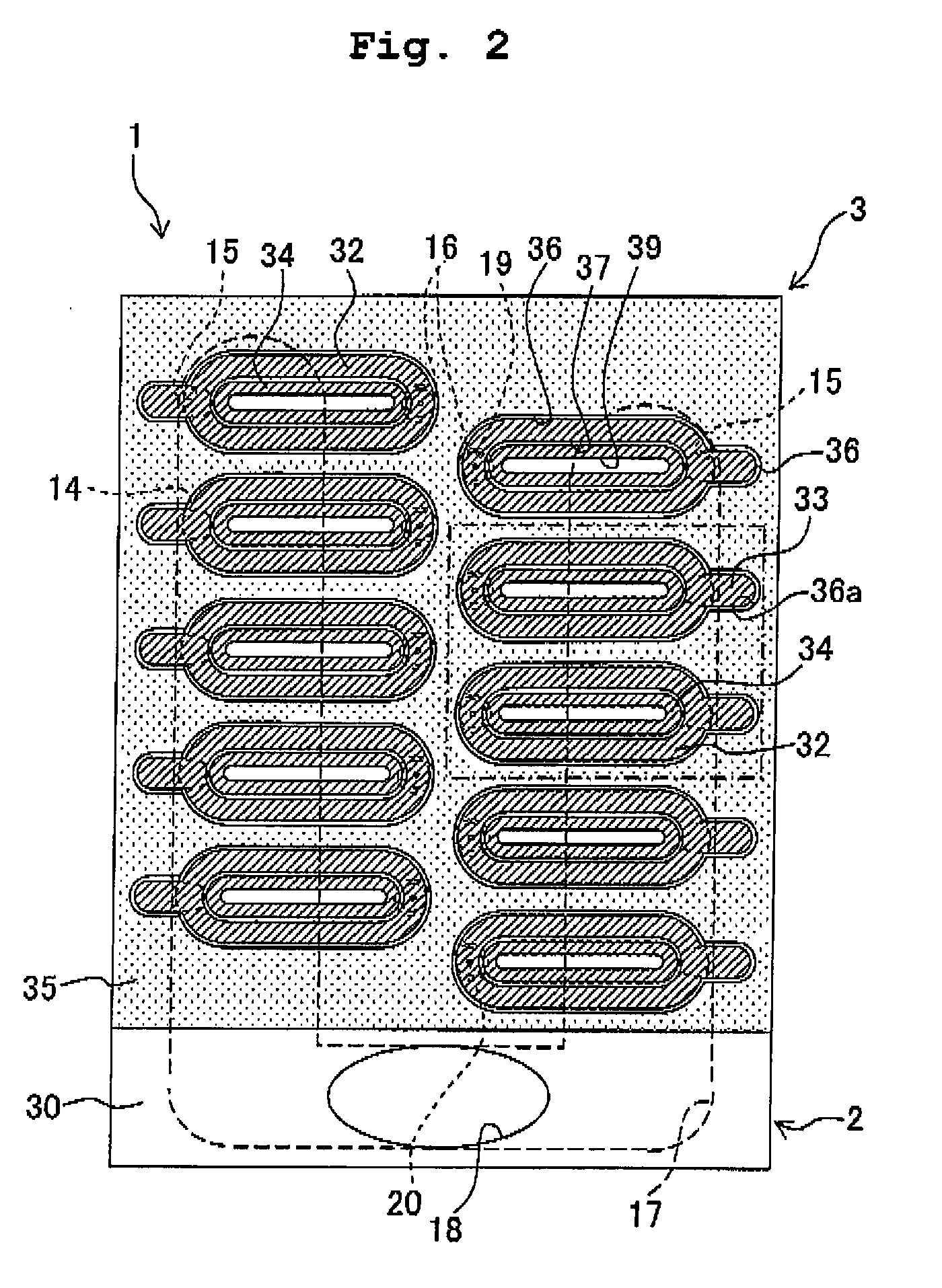

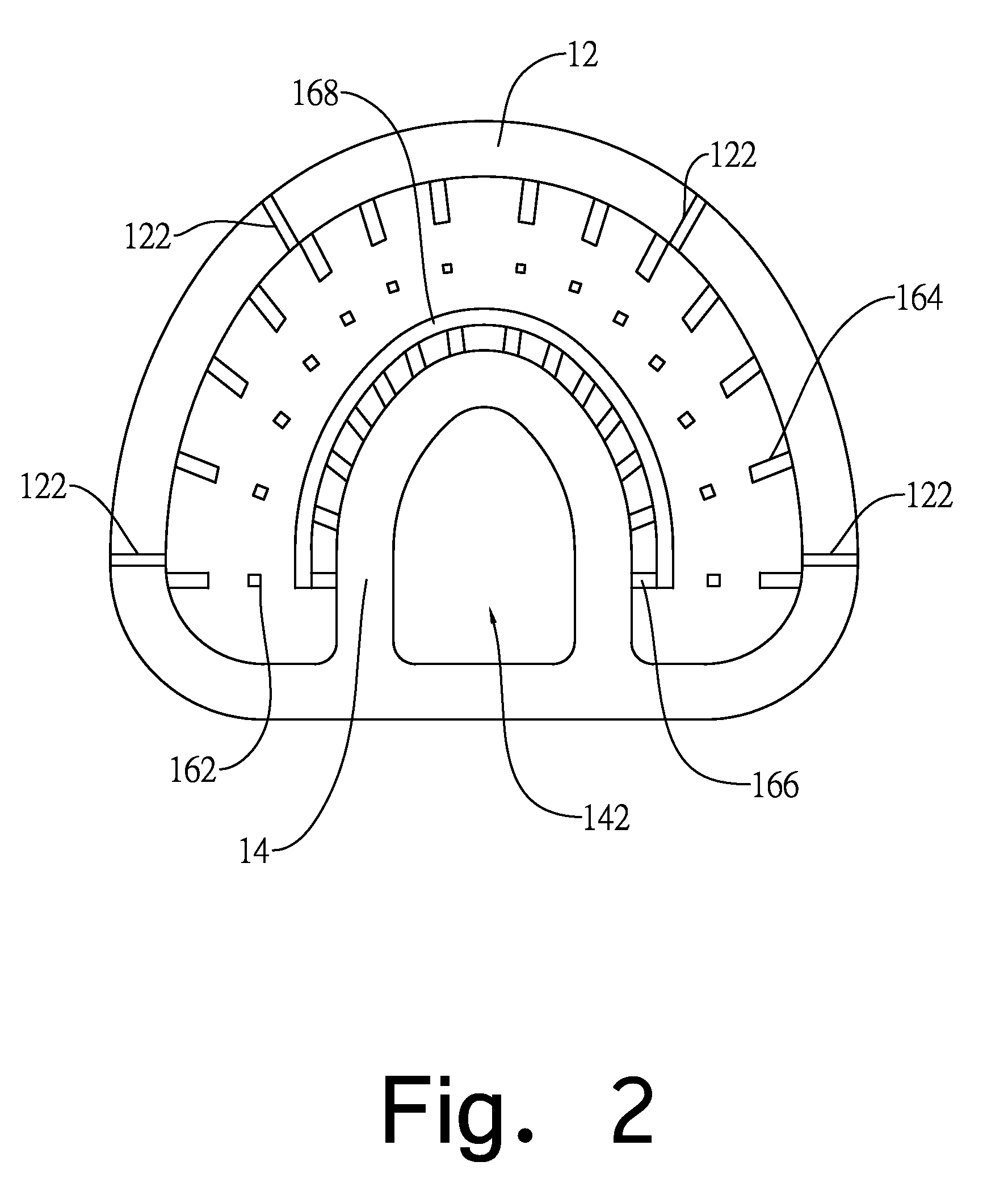

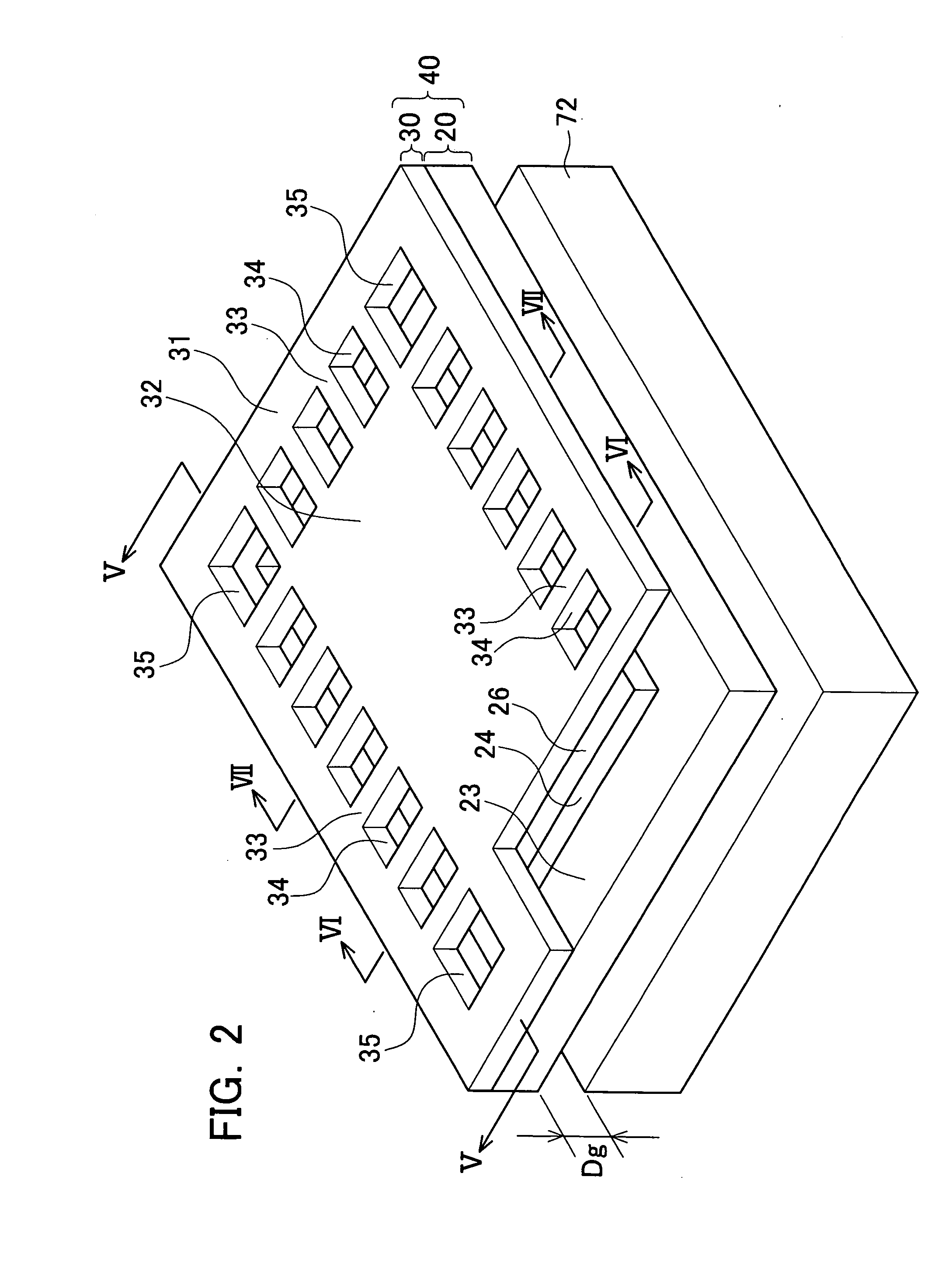

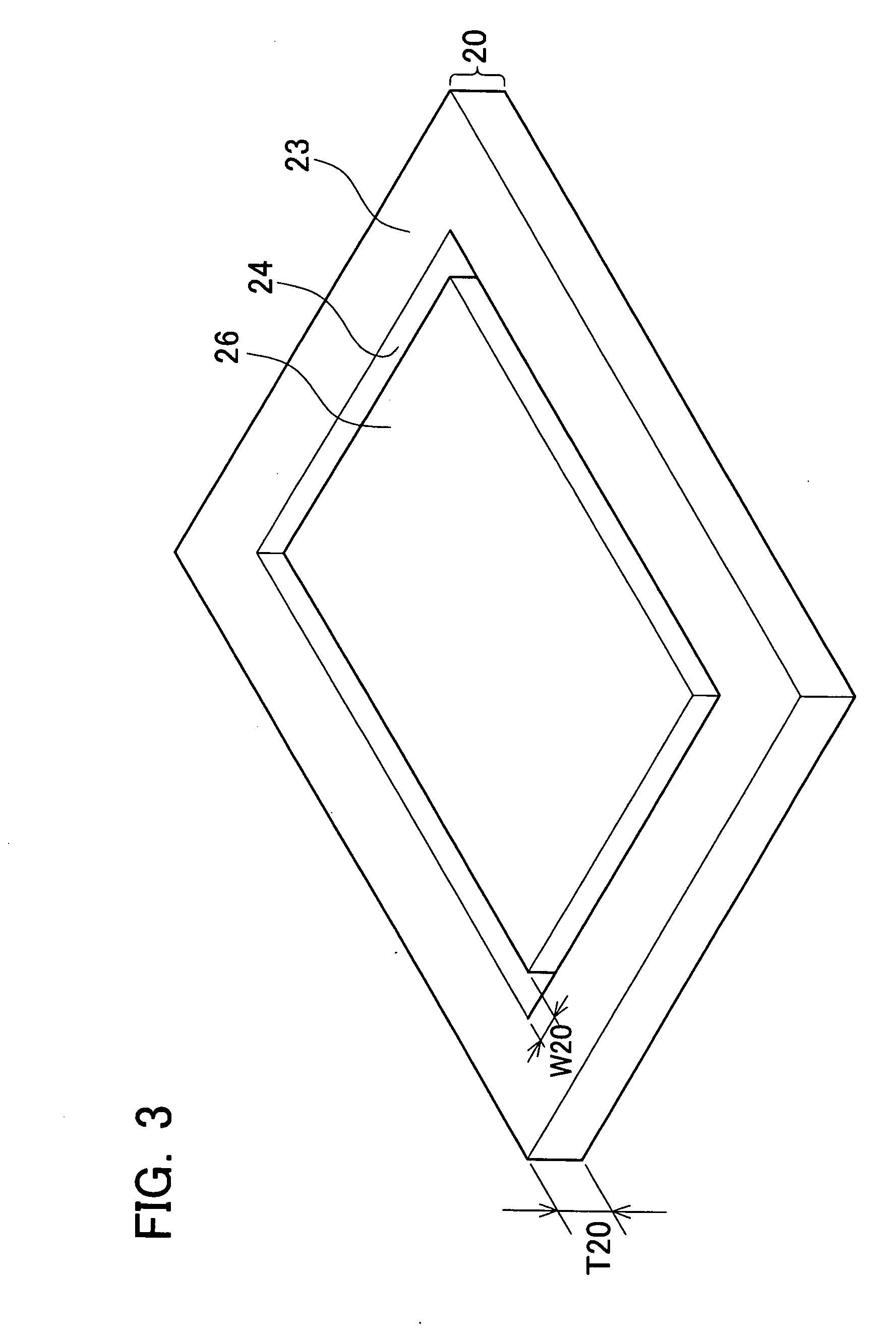

Liquid jetting head and method for producing the same

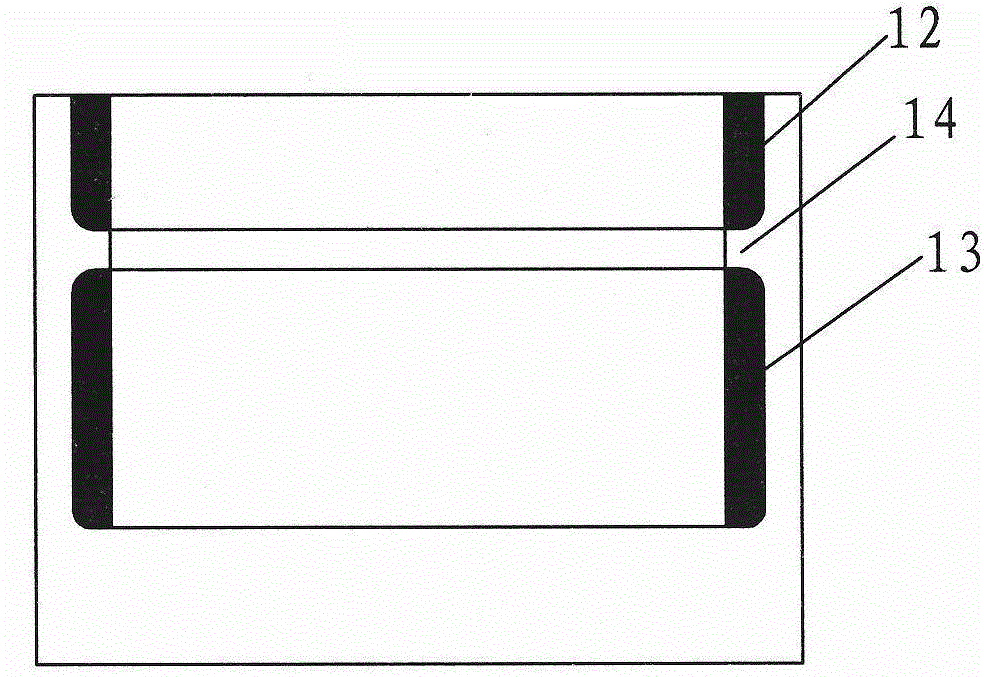

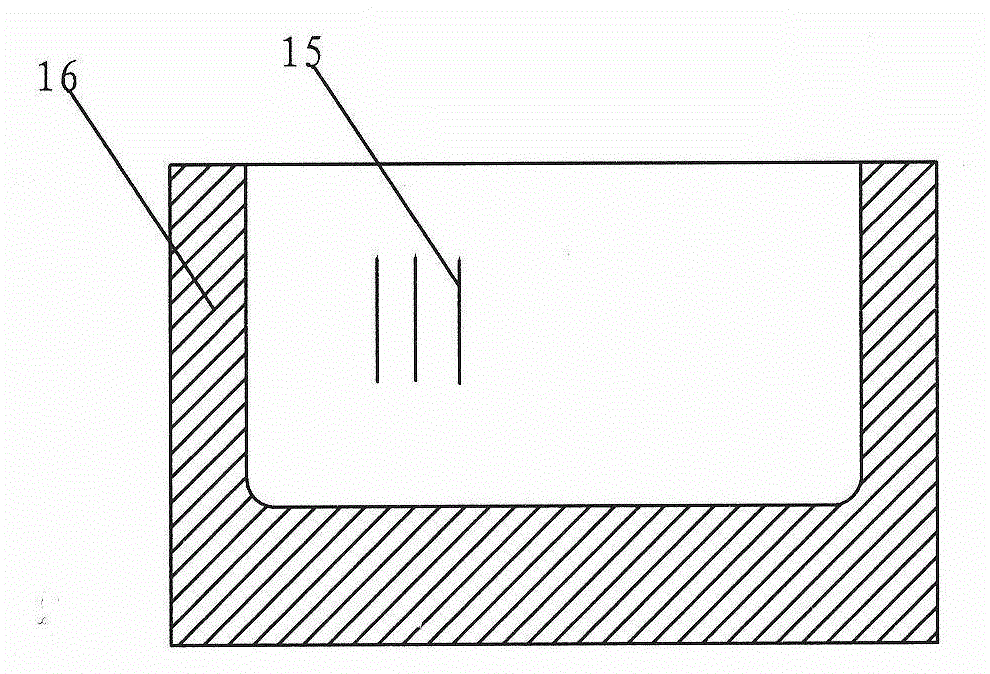

ActiveUS20070046736A1Increase consumptionIncrease the amount of deformationInking apparatusPiezoelectric actuatorsEngineering

An ink-jet head includes a channel unit in which a plurality of pressure chambers are formed; and a piezoelectric actuator which includes a vibration plate, a piezoelectric layer formed on an upper surface of the vibration plate, and an electroconductive layer formed on an upper surface of the piezoelectric layer. On an upper surface of the piezoelectric actuator, there are formed outer grooves each extended along an area overlapping with the periphery of each of the pressure chambers, and inner grooves each extended along one of the outer grooves at a portion inside of one of the outer grooves. Further, recesses deeper than the thickness of the electroconductive layer is formed in the piezoelectric actuator at portions each located inside of the one of the inner grooves. Accordingly, it is possible to improve a drive efficiency of the piezoelectric actuator.

Owner:BROTHER KOGYO KK

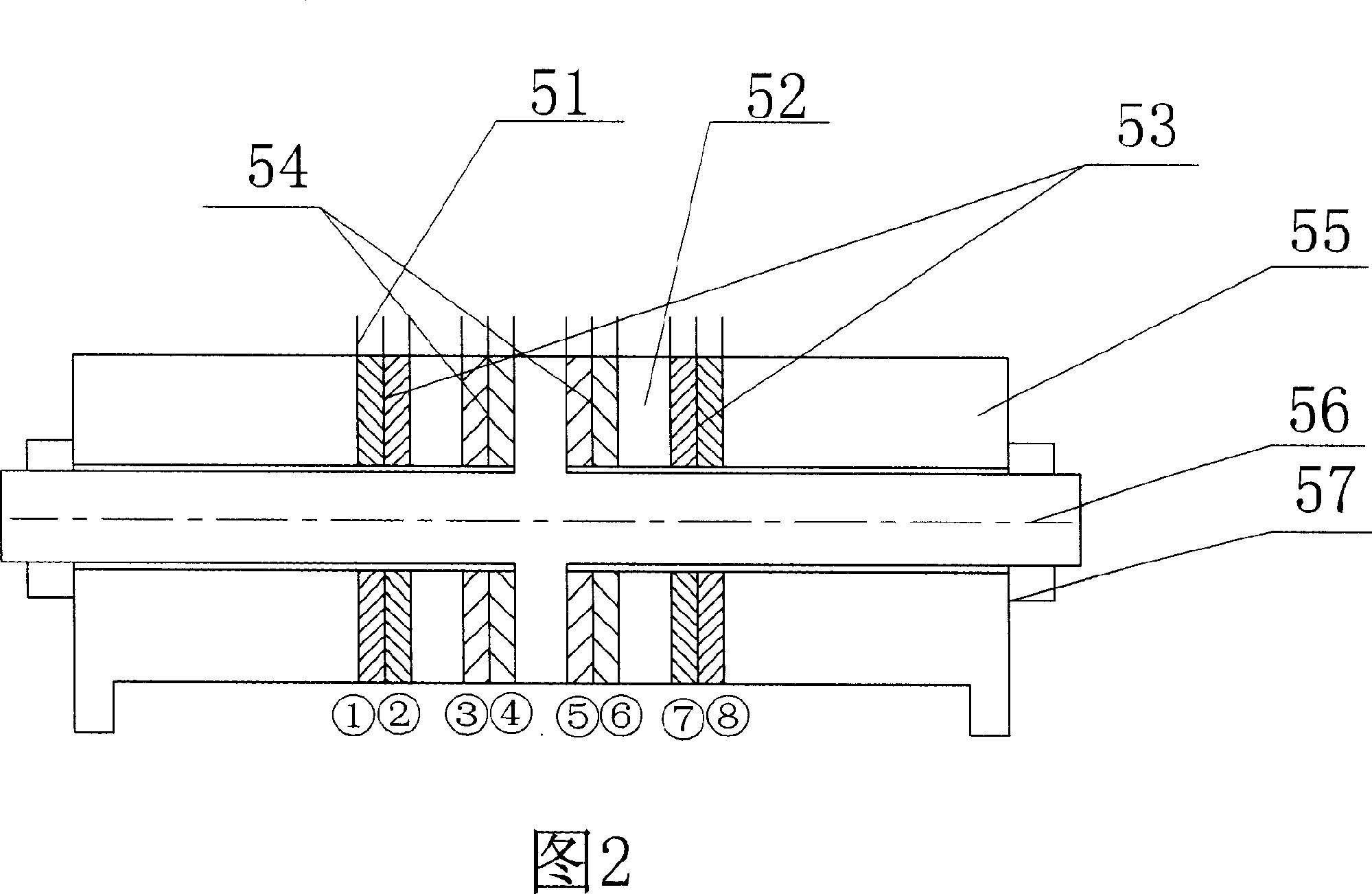

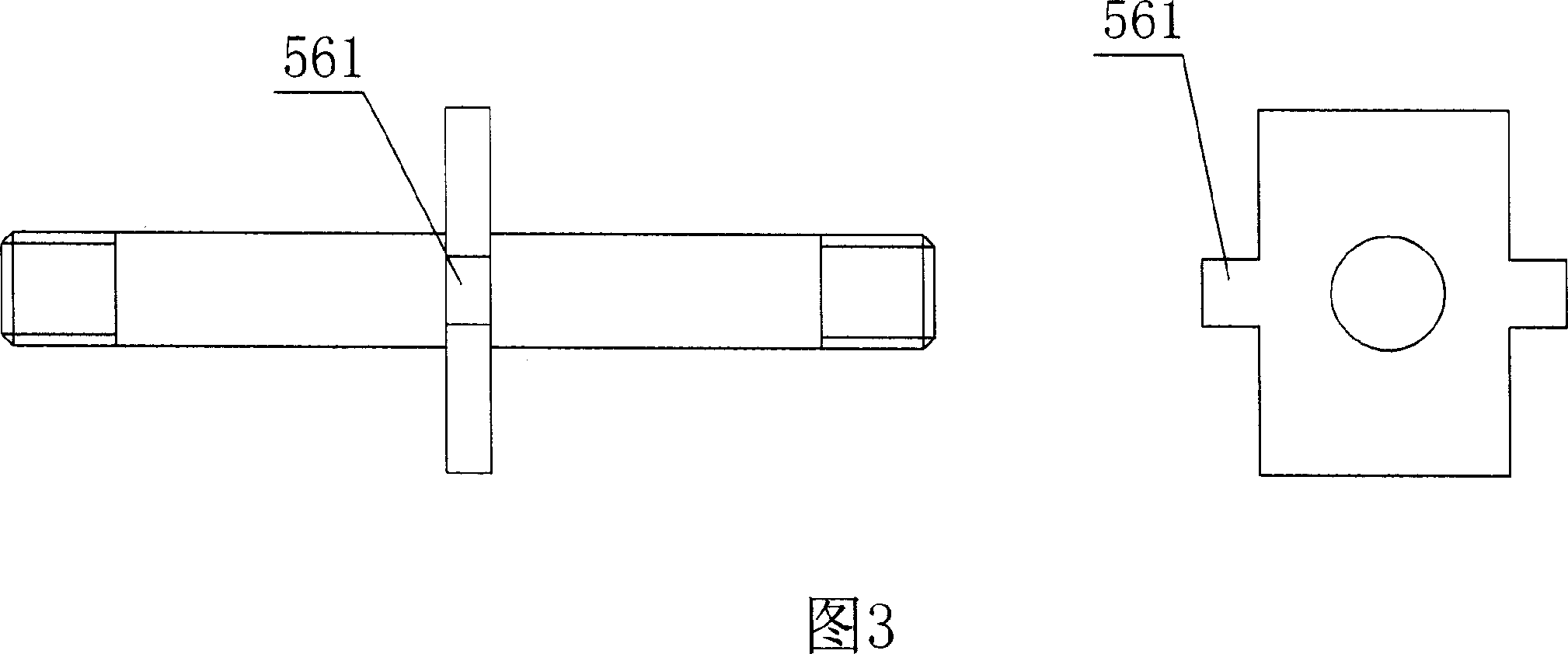

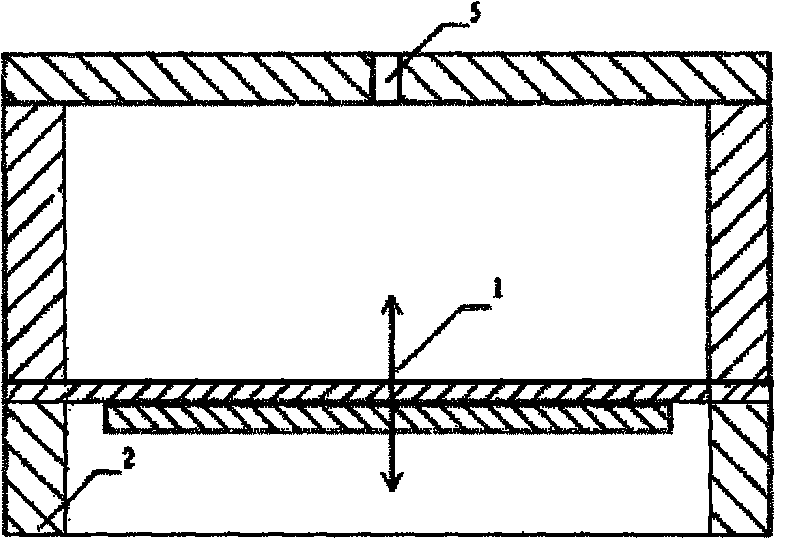

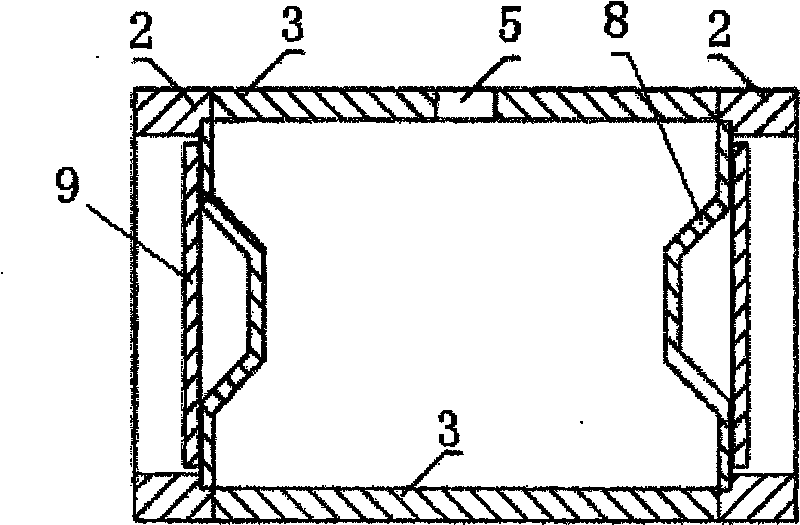

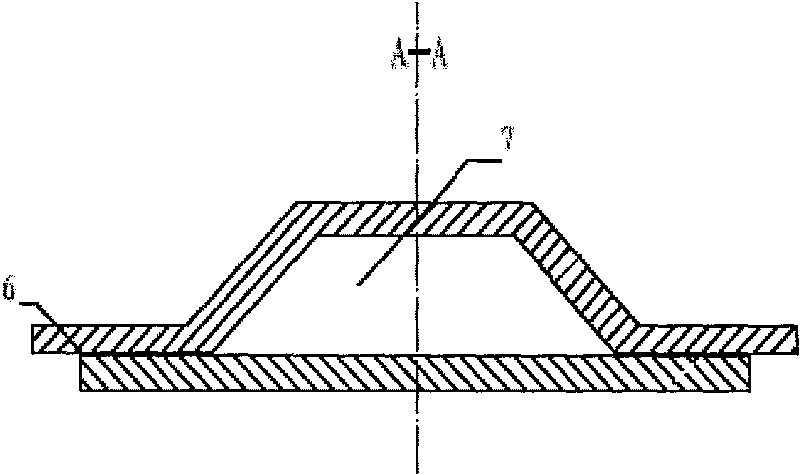

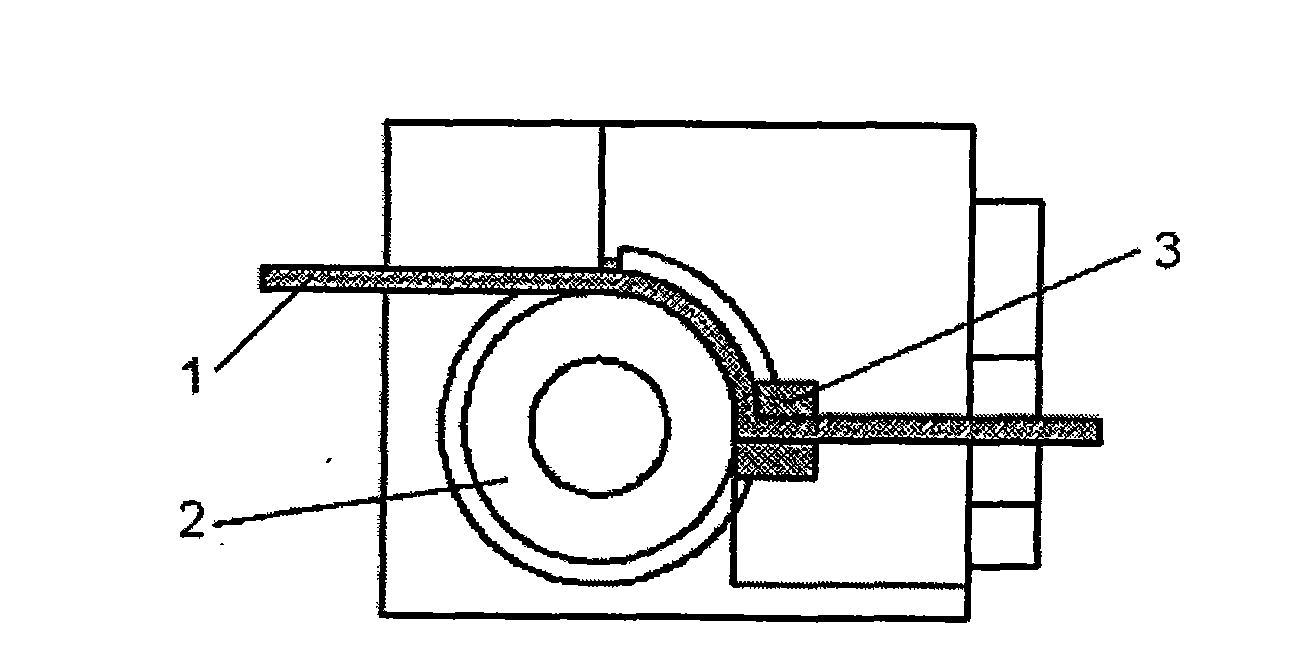

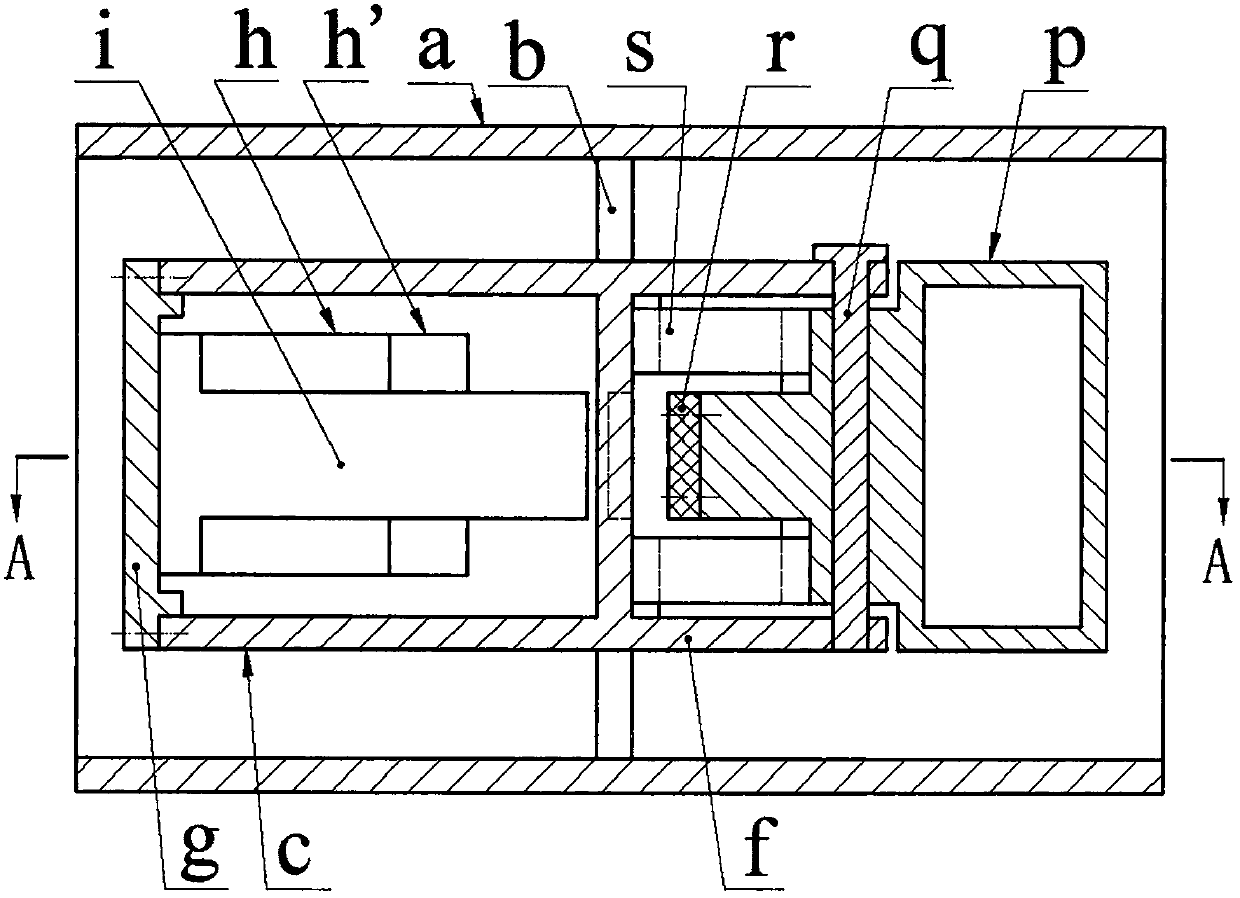

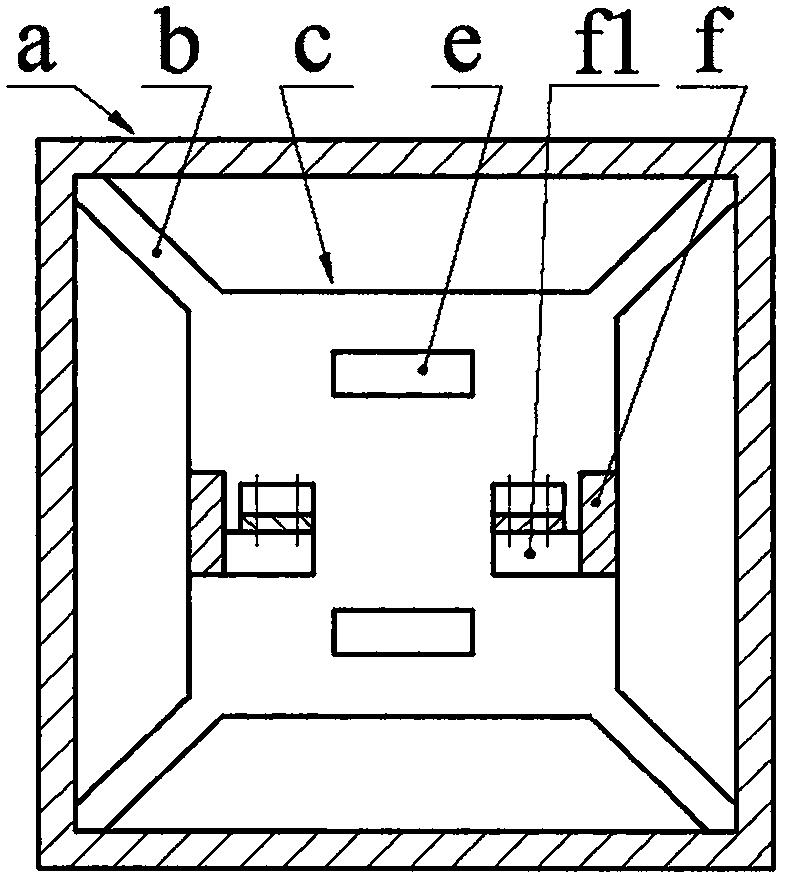

Synthetic jet actuator with double films, single chamber and single spout

InactiveCN101718235APositive piezoelectric effectEasy to liftPiezoelectric/electrostriction/magnetostriction machinesFlexible member pumpsCopper foilEngineering

The invention relates to a synthetic jet actuator with double films, a single chamber and a single spout. An installing surface (4) of a vibration film (6) is arranged on the surface of an inner hole at one end of a film bracket (2); the arched vibration film (6) formed by a PZT ceramic sheet (9) and an arched copper foil sheet (8) is fixed on the installing surface (4); the film brackets (2) are respectively fixed at both ends of a box body (3); the ratio of the diameter of the PZT ceramic sheet (9) to the diameter of the copper foil sheet (8) is 0.4-0.8; the ratio of the diameter of a trapezoid lower bottom of the copper foil sheet (8) to the diameter of the copper foil sheet is 0.3-0.7; the ratio of a trapezoid upper bottom of the copper foil sheet (8) to the diameter of the trapezoid lower bottom of the copper foil sheet is 0.4-0.95; and the trapezoid angle is 22 degrees-56 degrees. The invention can obtain higher amount of distortion, improves the energy conversion capacity, enables the spout to generate larger kinetic energy, and has good application prospects in the aspects of improving the lifting force of airfoils, improving the stalling characteristics of airfoils and enhancing mixing.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

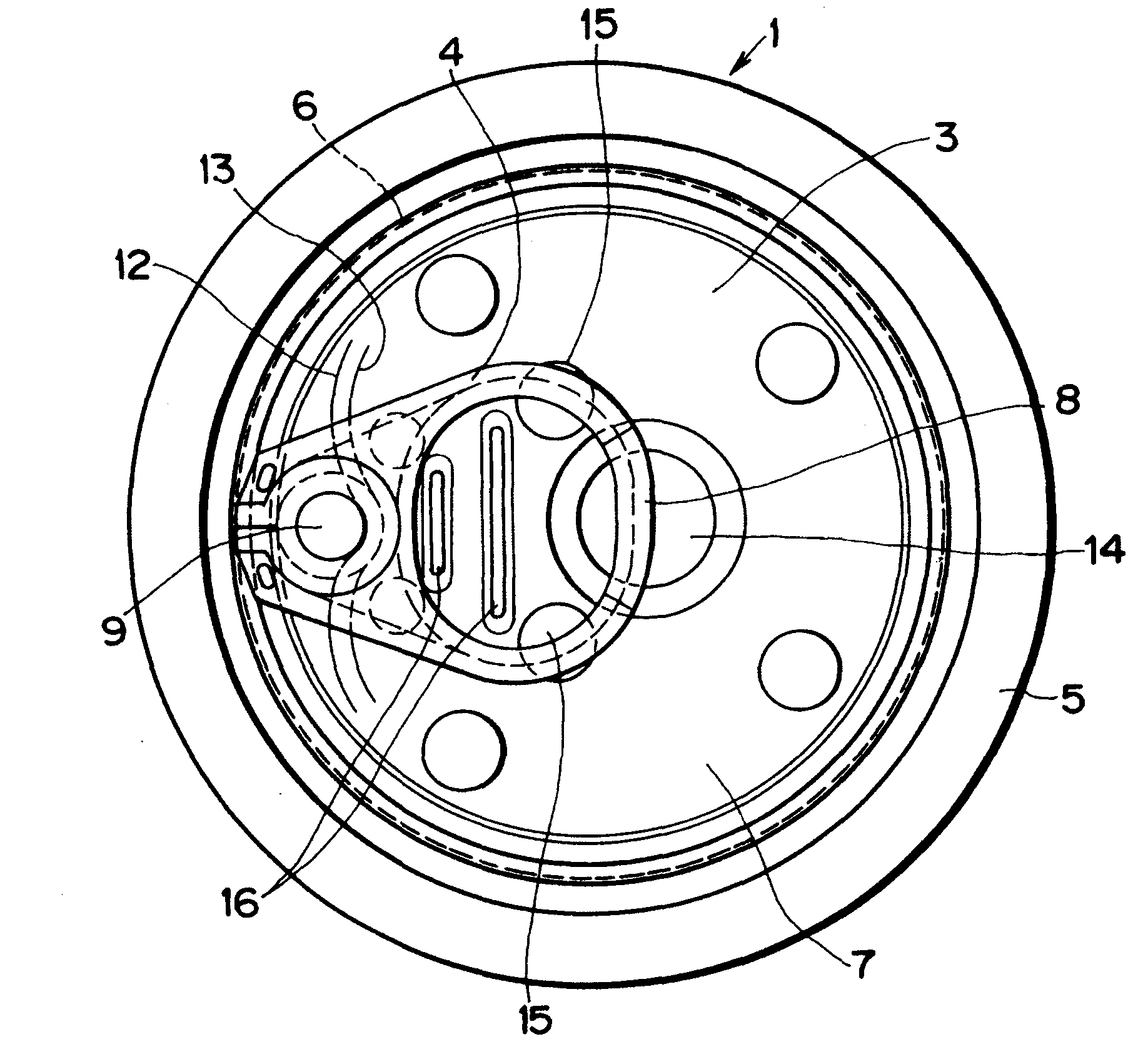

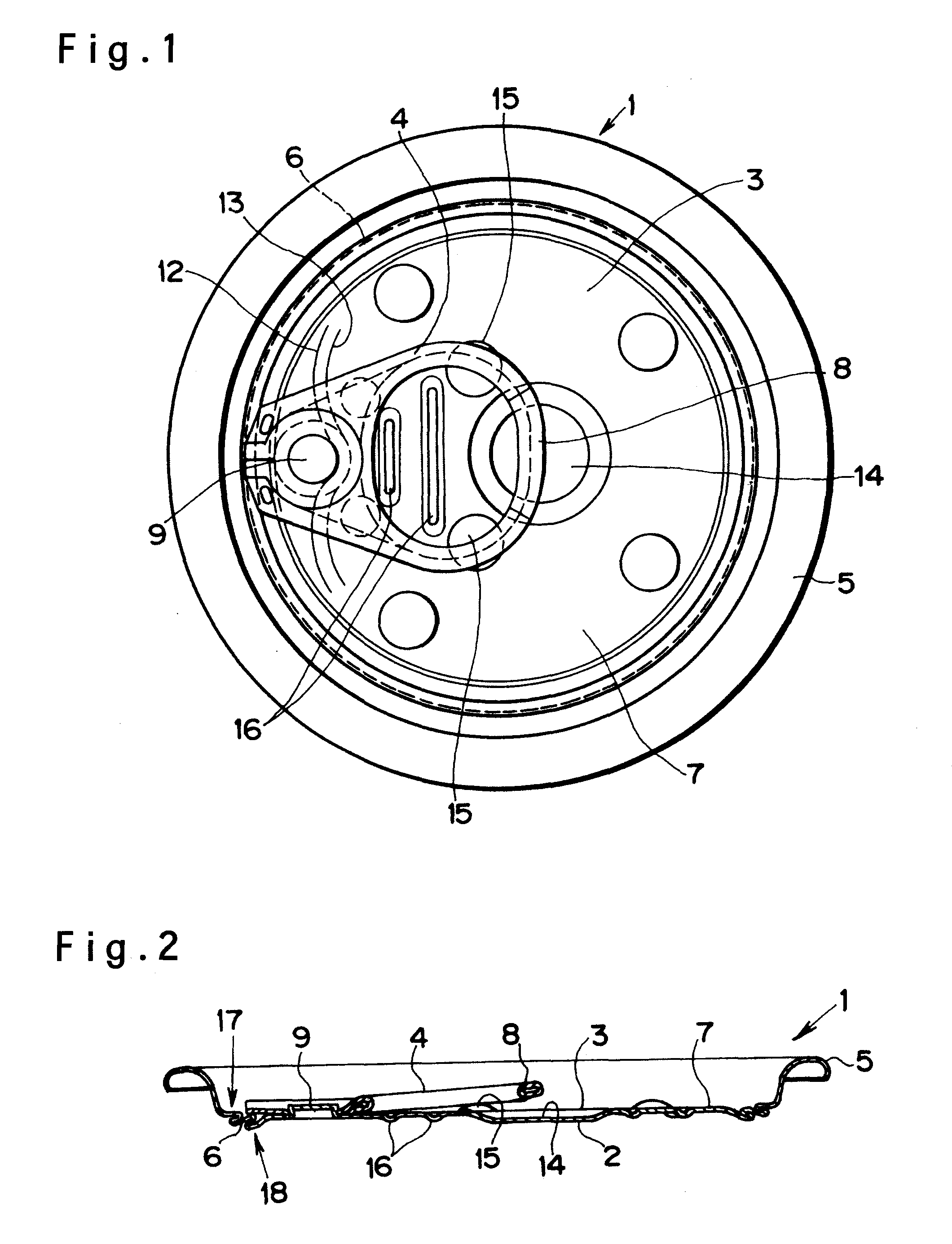

Easily-Openable Can Lid

An easy open can lid comprises an outer multilayered portion folded into three layers and enclosing the panel portion from outside of the score line, and an inner multilayered portion folded into three layers and enclosing the panel portion from inside of the score line. A leading edge of an outer protection portion as a folding portion between the first and second outer layers is flush with or situated outside of the score line, and a leading edge of an inner protection portion as a folding portion between the second and third inner layers is flush with or situated inside of the score line. An opening width of an inner interspace between the first and second inner layers is wider than that of an outer interspace between the second and third outer layers.

Owner:DAIWA CAN

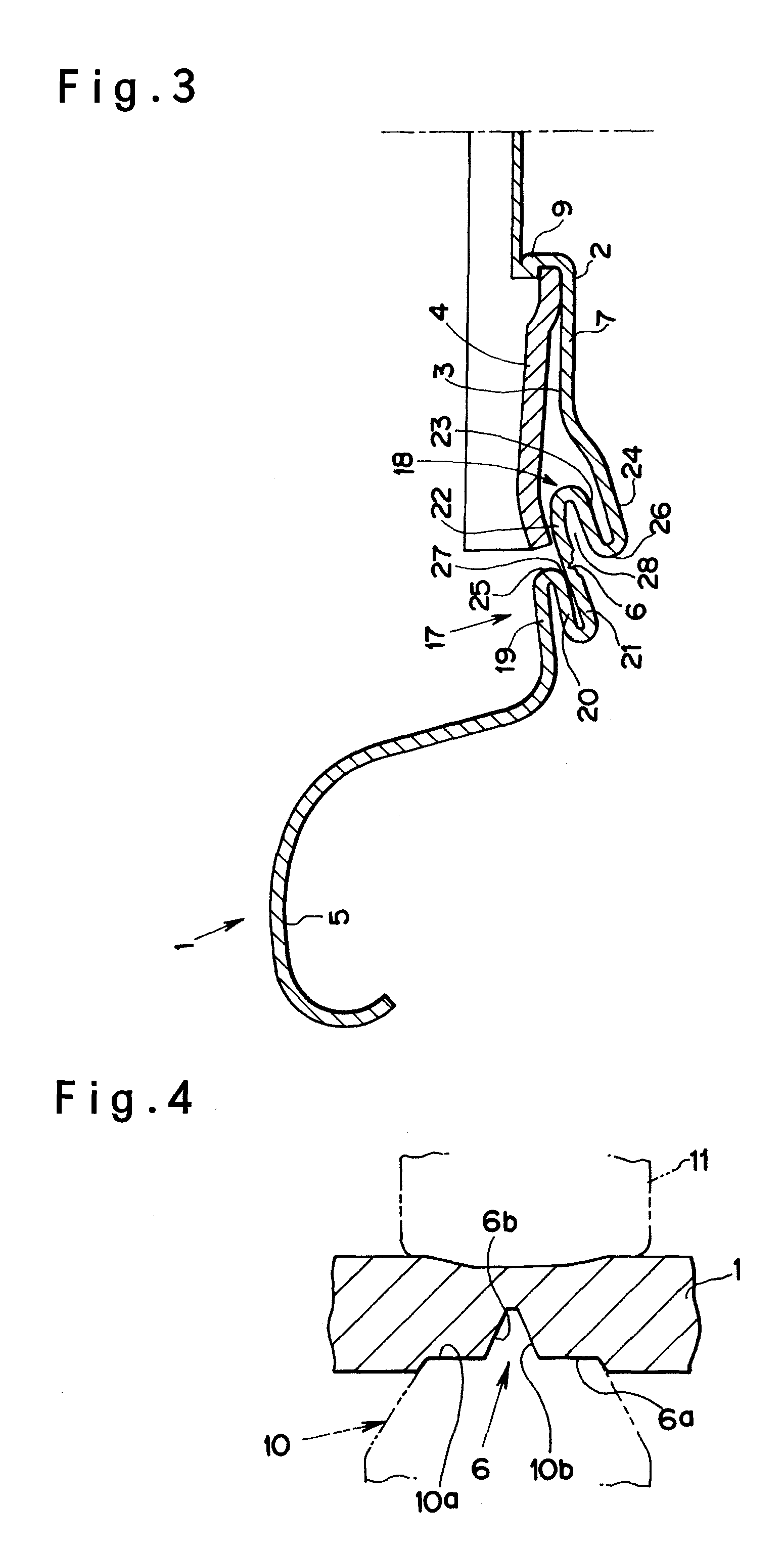

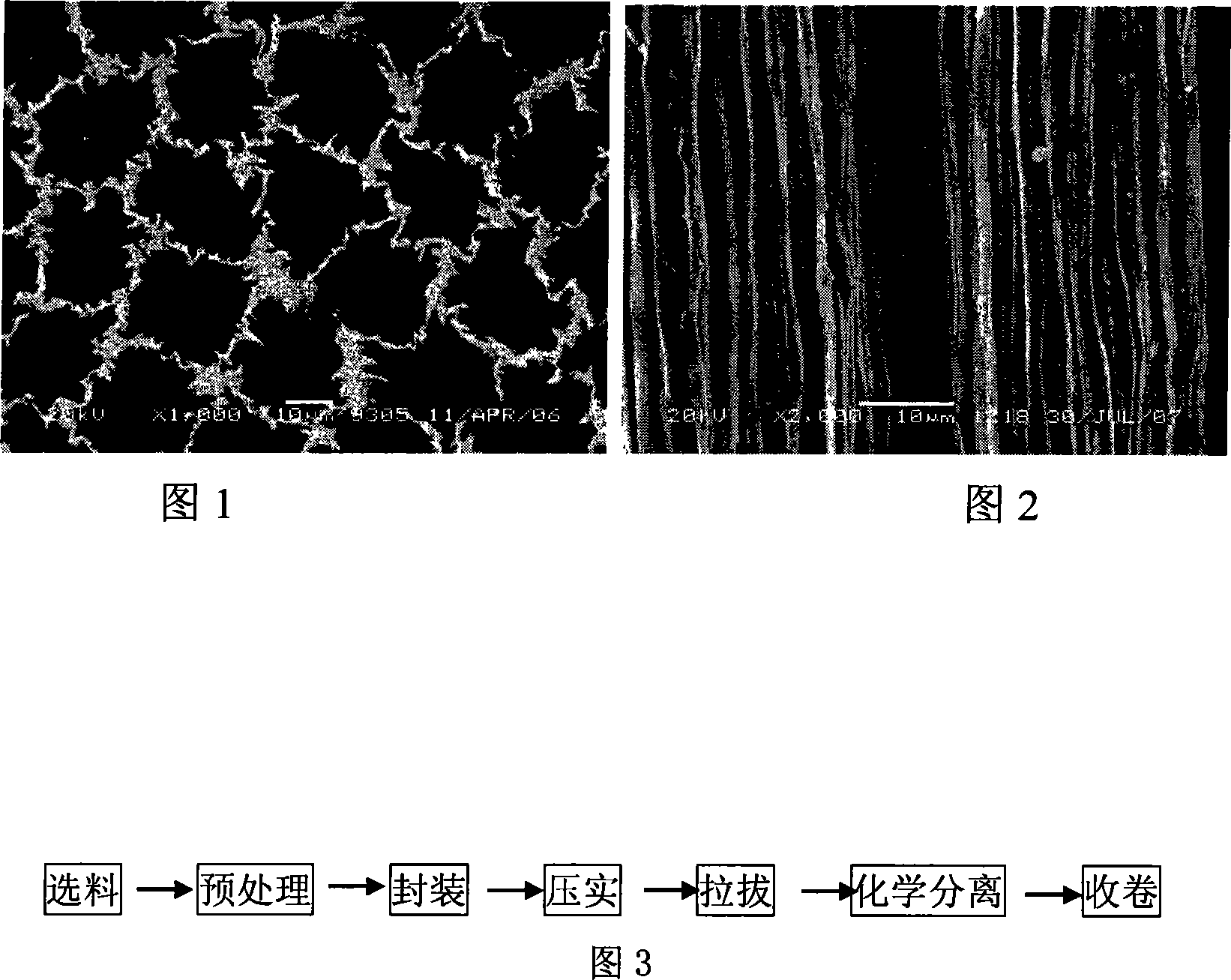

Fire resistant iron chromium aluminum filament and production technique

The invention relates to a high temperature resistant iron-chromium-aluminum fiber yarn and a preparing process, belongs to the field of stainless steel processing and obtains the iron-chromium-aluminum fibers by bundle drawing iron-chromium-aluminum wire rods embedded in base materials; the iron-chromium-aluminum fibers comprise iron and the following components (represented by wt. percent) of more than or equal to 0.005 percent and less than or equal to 0.03 percent of C, more than or equal to 15 percent and less than or equal to 27 percent of Cr, more than or equal to 5.95 percent and less than or equal to 7.0 percent of Al, more than or equal to 0.05 percent and less than or equal to 0.2 percent of Cu, more than or equal to 0.4 percent and less than or equal to 0.6 percent of Si, more than or equal to 0.2 percent and less than or equal to 0.4 percent of Mn, more than or equal to 0.03 percent and less than or equal to 0.04 percent of S, more than or equal to 0.010 percent and less than or equal to 0.045 percent of P and more than or equal to 0.01 percent and less than or equal to 0.04 percent of RE; the manufacturing process comprises the following procedures of material choosing, pretreatment, encapsulation, compaction, drawing, separation and rolling. The manufacturing process of the iron-chromium-aluminum fiber of the invention is suitable for drawing and processing high-aluminum iron-chromium-aluminum wire rods and can reach the yield of 98 percent with little influence on the environment.

Owner:HUNAN HUITONG ADVANCED MATERIALS

Method of joining heat-treatable aluminum alloy members by friction stir welding

InactiveUS20090250144A1Avoid stress concentrationReduce hardnessWelding/soldering/cutting articlesMetal working apparatusHeat treatedFriction stir welding

A method of joining heat-treatable aluminum alloy members by friction stir welding, including the steps of: a T4-treatment-performing step of performing a T4 treatment on heat-treatable aluminum alloy members so as to impart T4 temper to the heat-treatable aluminum alloy members; a joining step of joining the heat-treatable aluminum alloy members with T4 temper by friction stir welding to provide a joined product; and a reversion-treatment-performing step of performing a reversion treatment, the reversion-treatment-performing step being carried out prior to or after the joining step.

Owner:SUMITOMO LIGHT METAL INDS LTD

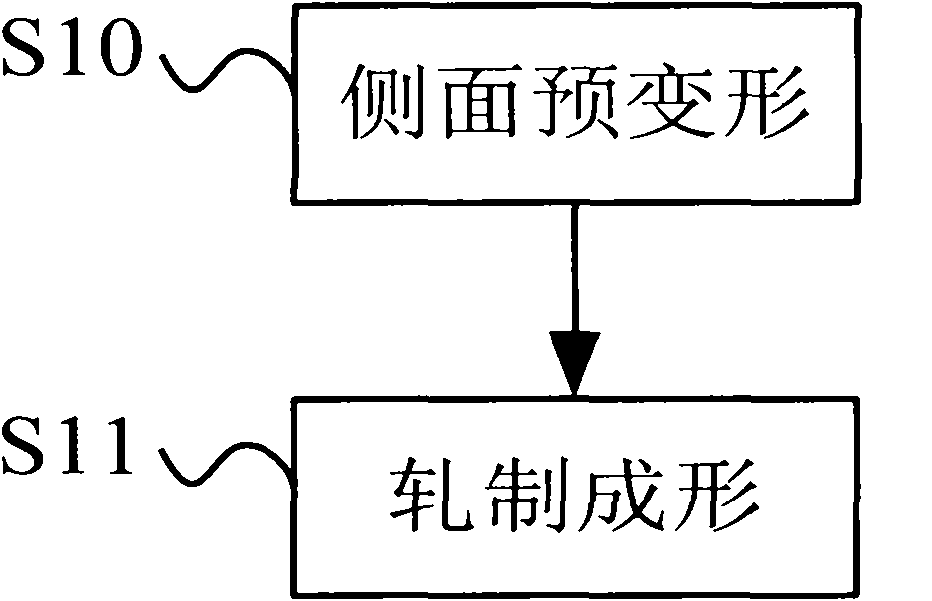

Rolling method of magnesium alloy plate and auxiliary rolling method thereof

InactiveCN102039308AReduce processing costsReasonable cost controlMetal rolling arrangementsCrystallitePre treatment

Owner:CHONGQING UNIV

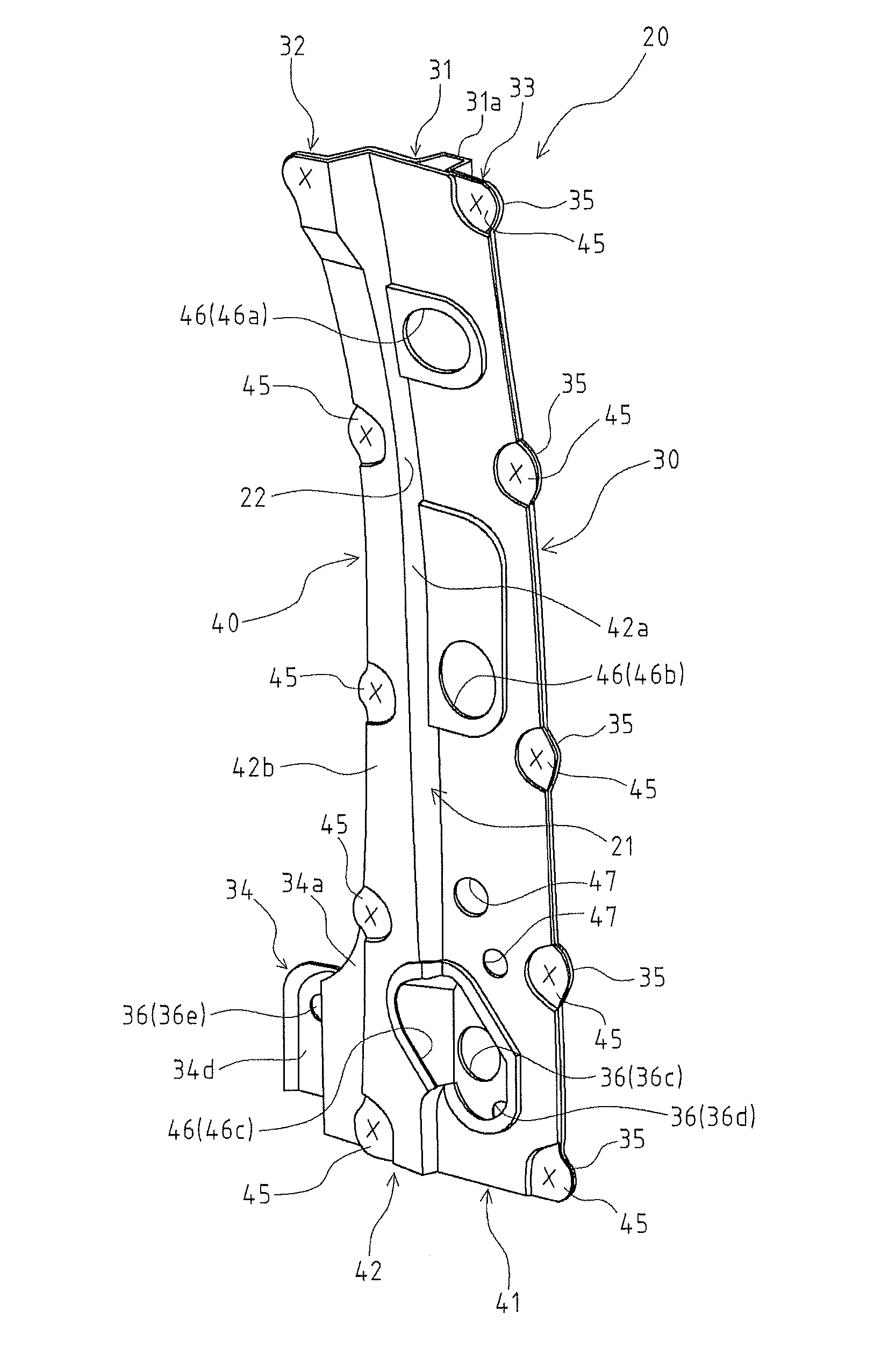

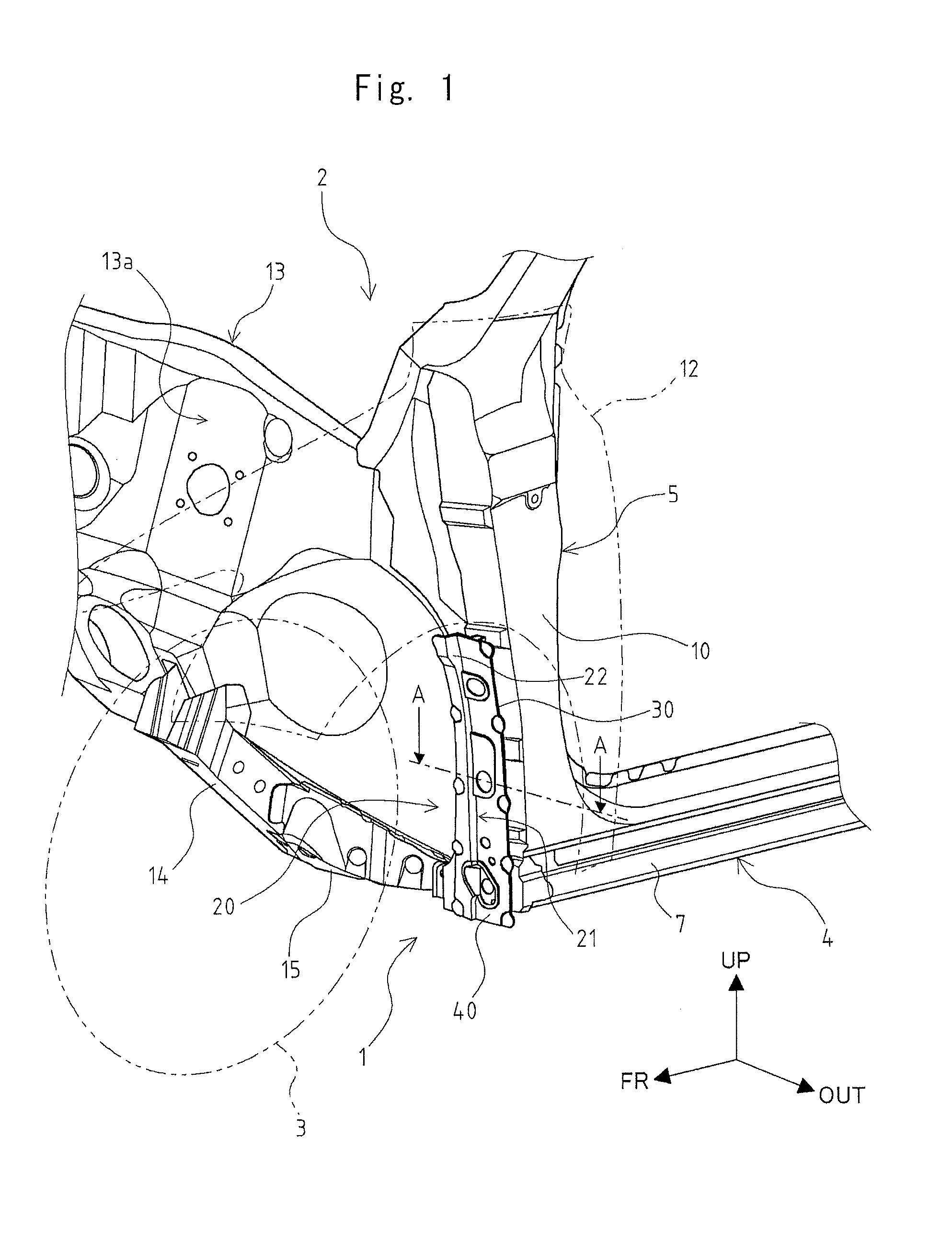

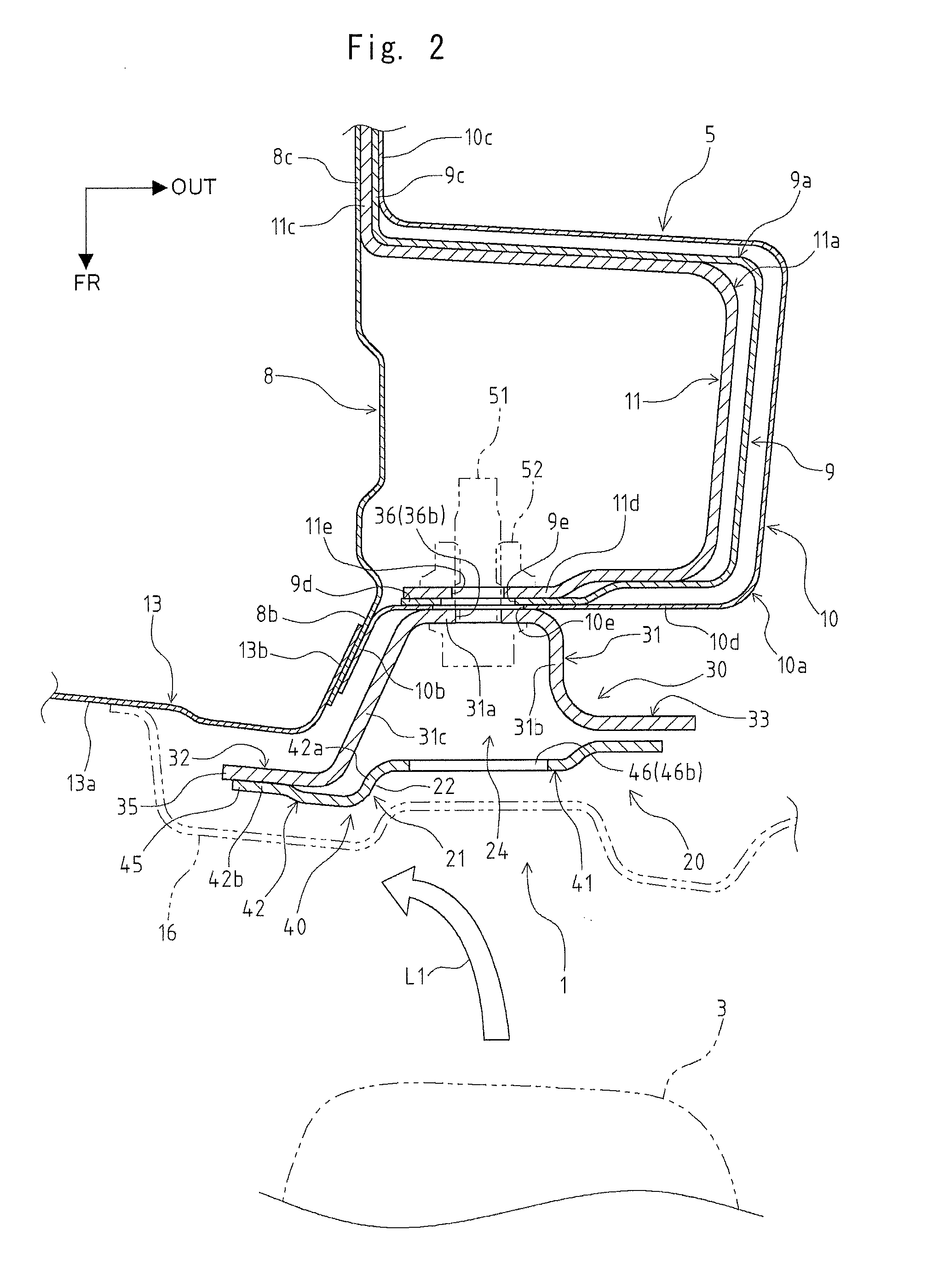

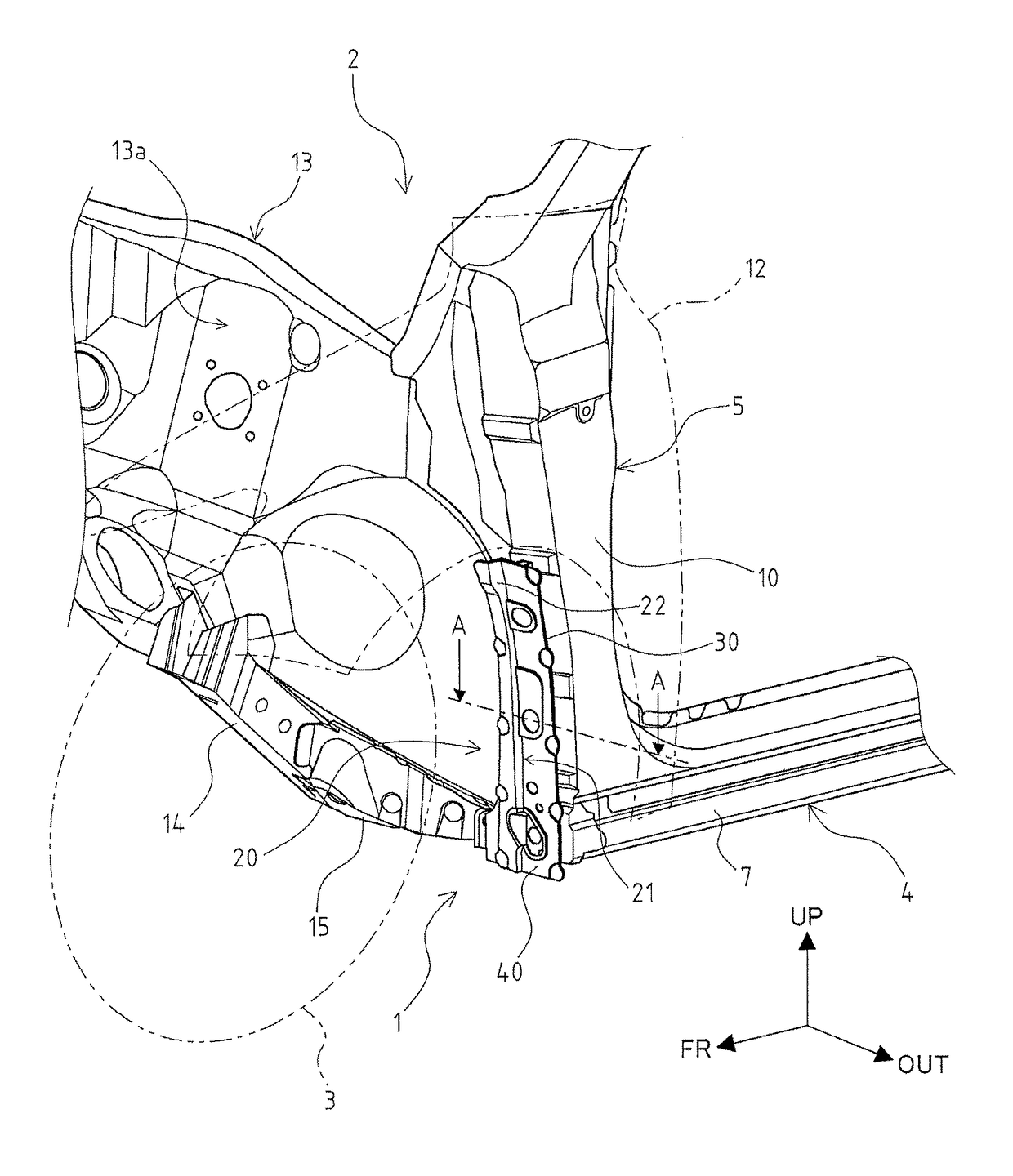

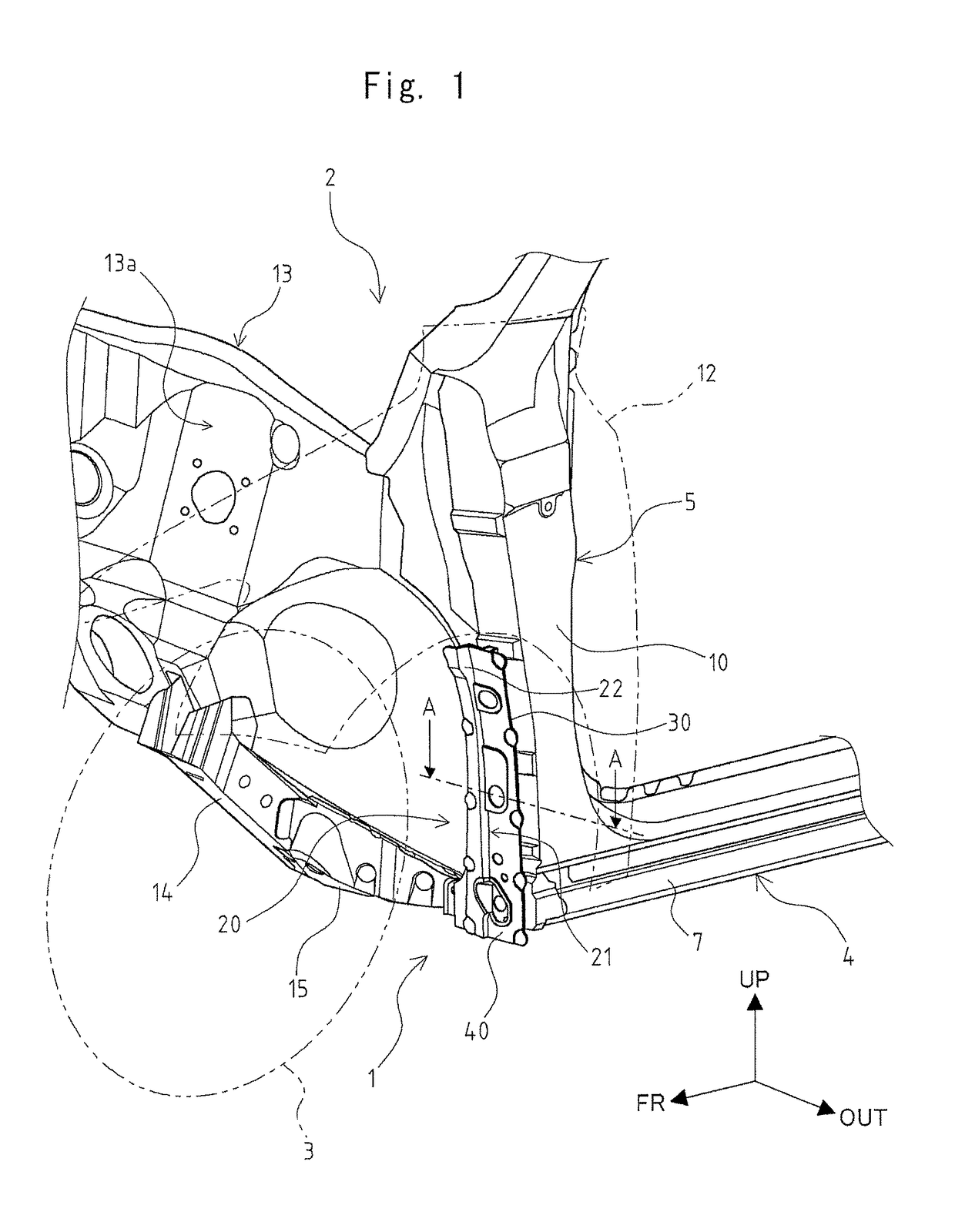

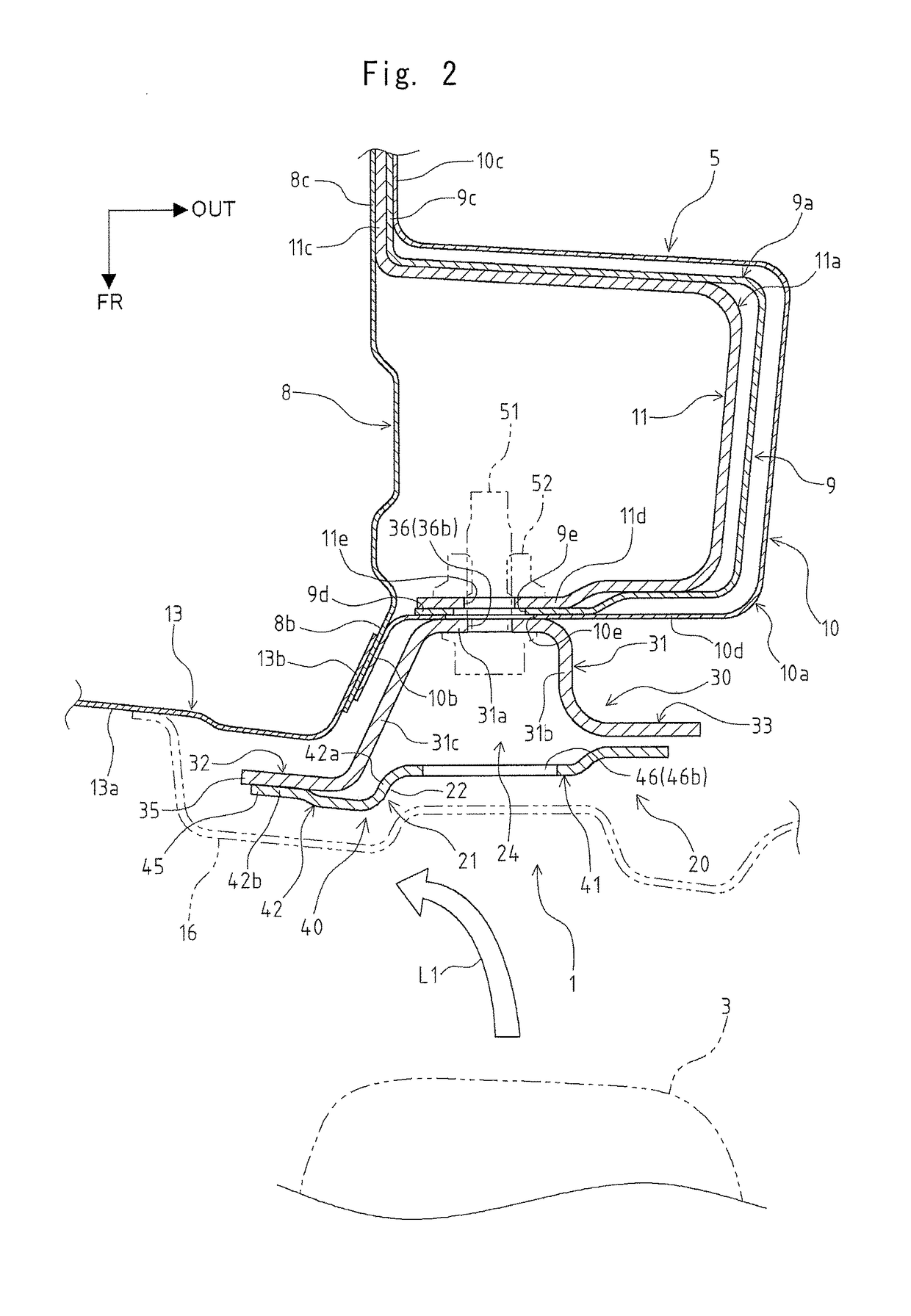

Vehicle front part structure

ActiveUS20160016612A1Improve securityReduce spacingSteering linkagesUnderstructuresGusset plateEngineering

Owner:TOYOTA MOTOR KYUSHU +1

Metal material large-strain processing method based on multi-pair wheel rolling and equal channel corner extrusion

The invention discloses a metal material large-strain processing method based on multi-pair wheel rolling and equal channel corner extrusion. The metal material large-strain processing method is characterized by comprising the following steps: firstly, blanks passes through multiple pairs of rolling wheels driven by power, and the gap between each pair of rolling wheels is adjusted so that the blanks reaches the designed thickness after being rolled by multiple pairs of rolling wheels; secondly, equal channel corner extrusion dies are installed at the outlets of the last pair of rolling wheels so that the blanks reaching the designed thickness through the rolling of the rolling wheels are continuously sheared and deformed under the drive of the last pair of rolling wheels and the extrusion of the dies and then are extruded out of the dies after turning an angle of 45 to 90 degrees in the original heading direction. The invention integrates the advantages of a multi-pair wheel rollingtechnique and an equal channel corner extrusion technique, is especially suitable for the large-strain deformation processing of thin plates, and can realize energy-saving, high-efficiency, continuousand uniform large-strain deformation processing of metal materials.

Owner:JIANGSU UNIV

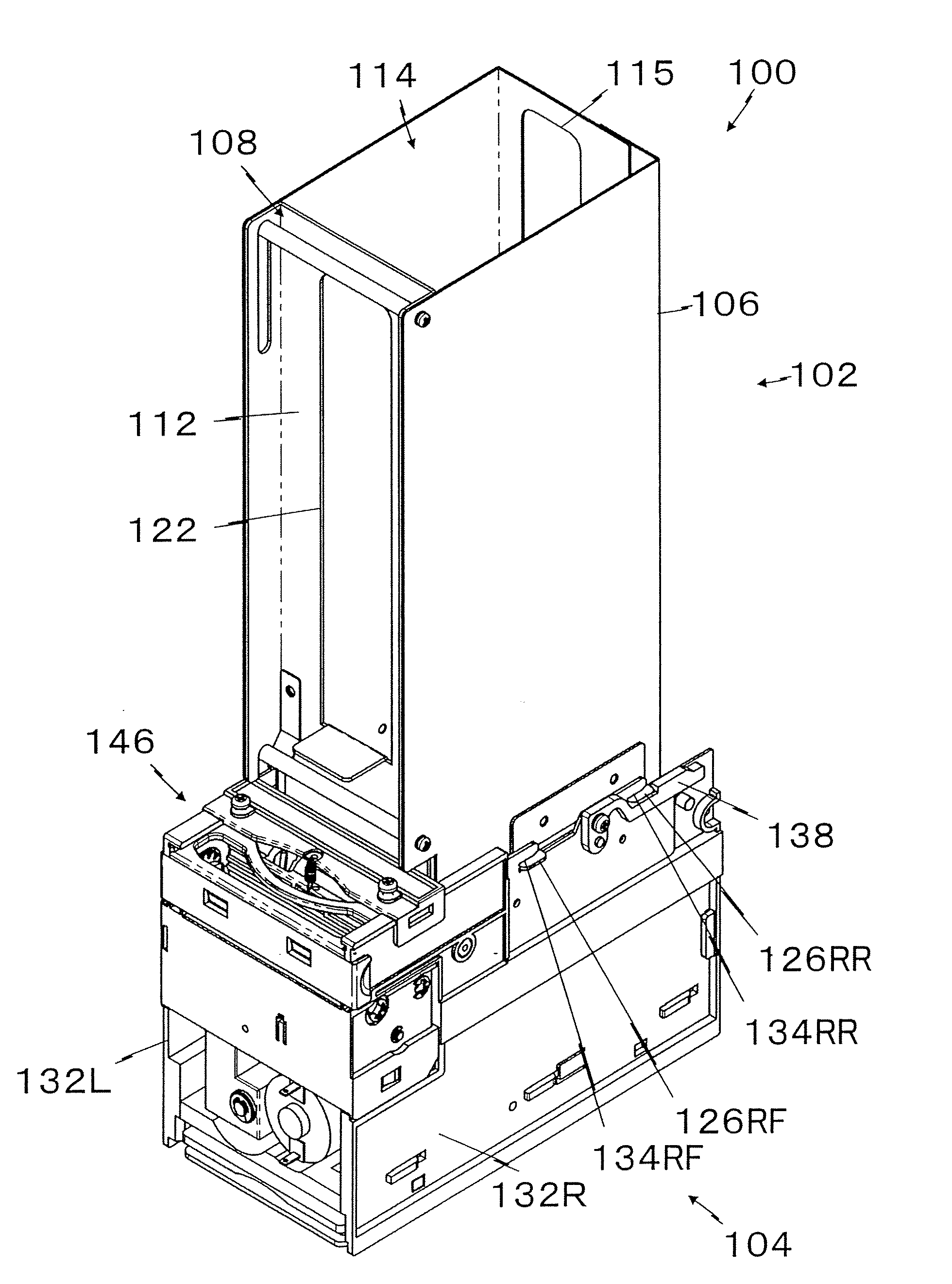

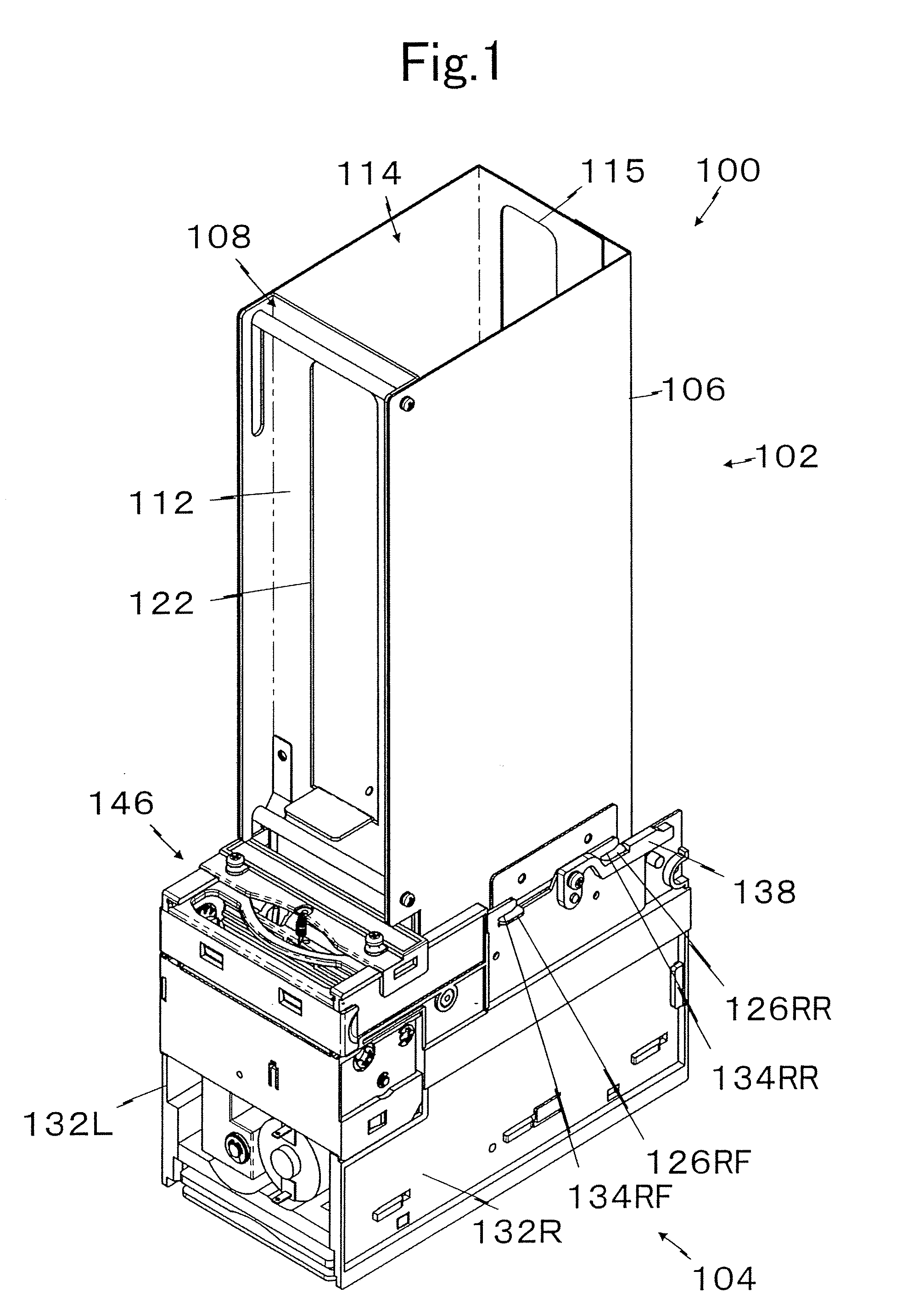

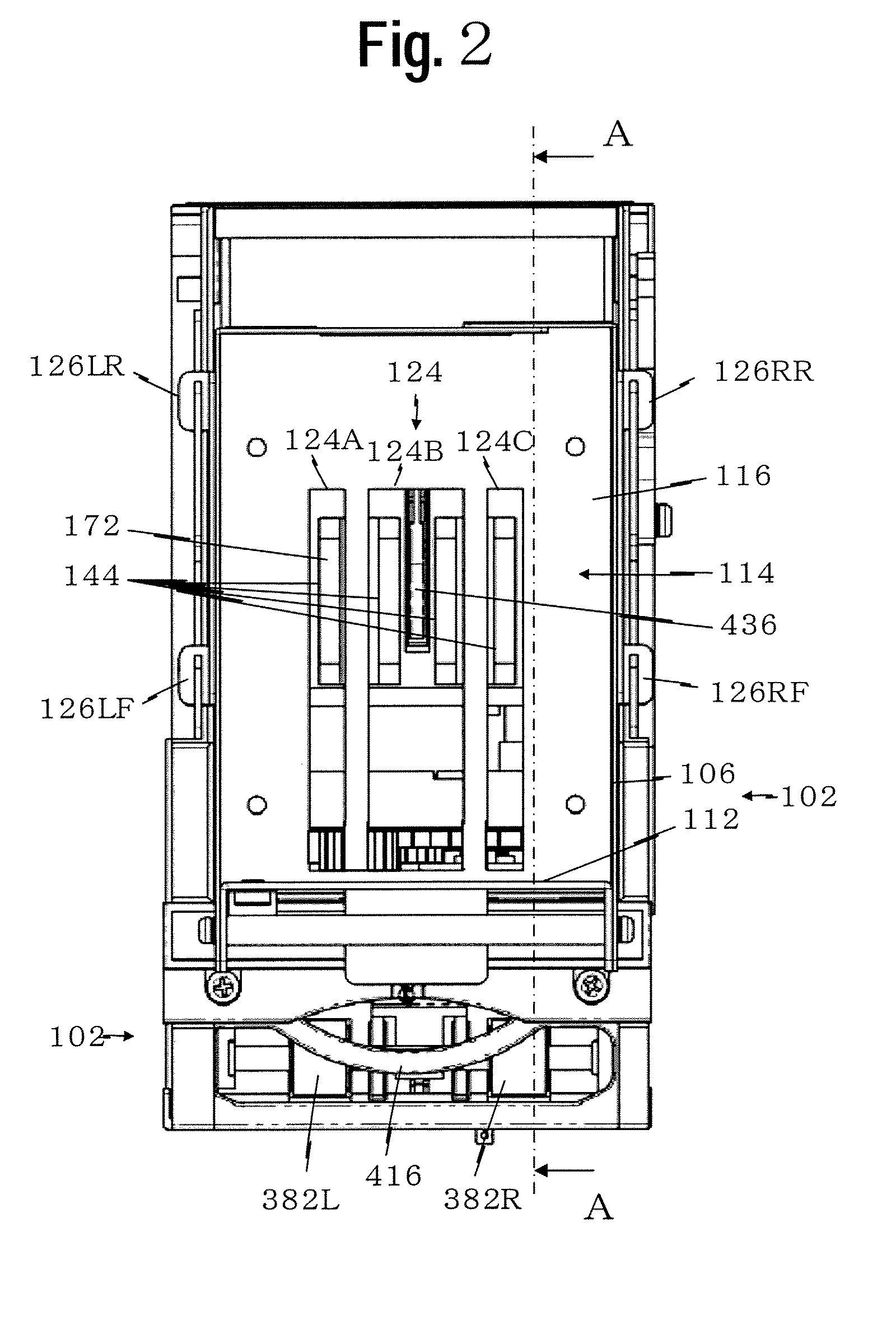

Card dispensing apparatus

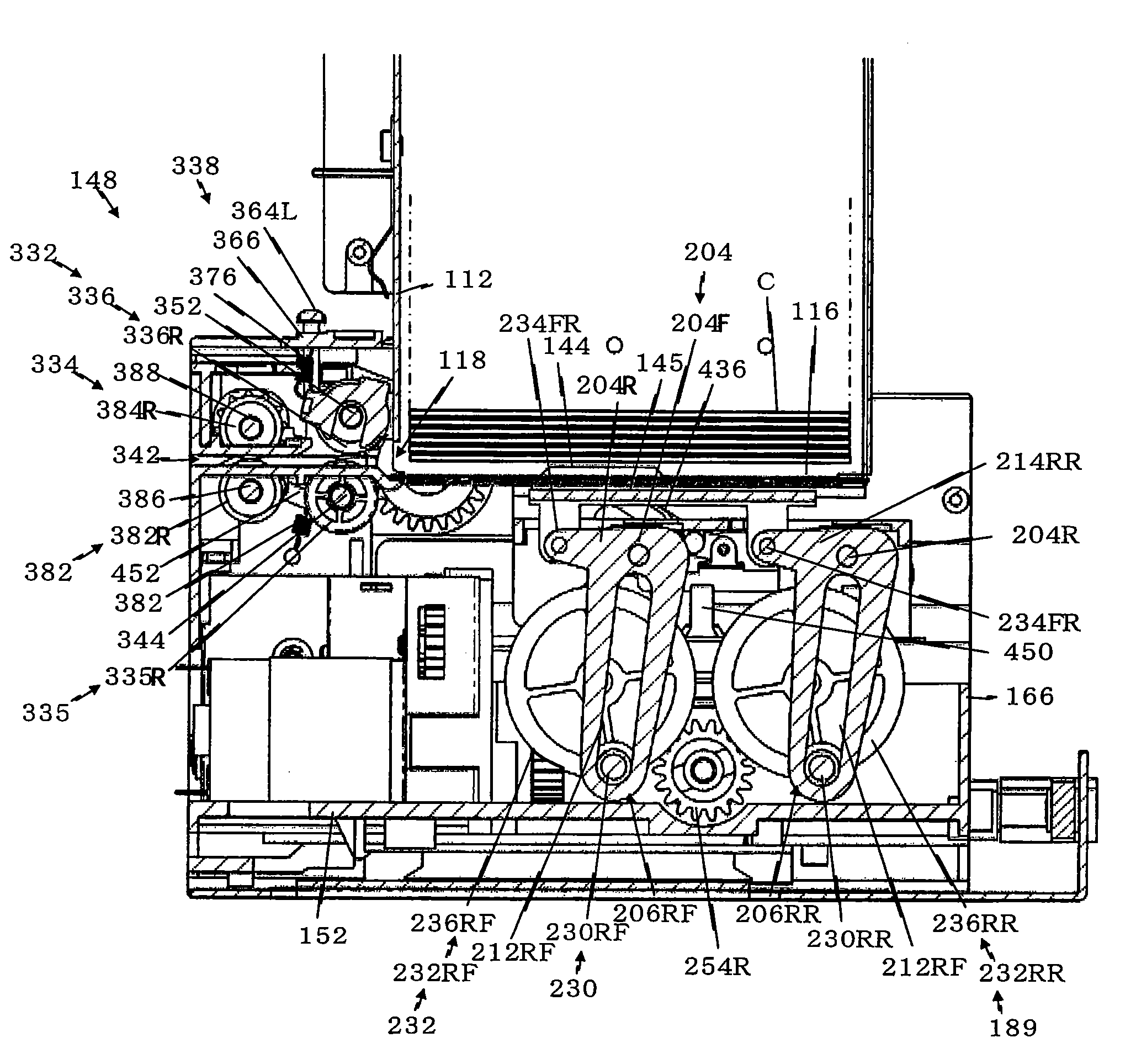

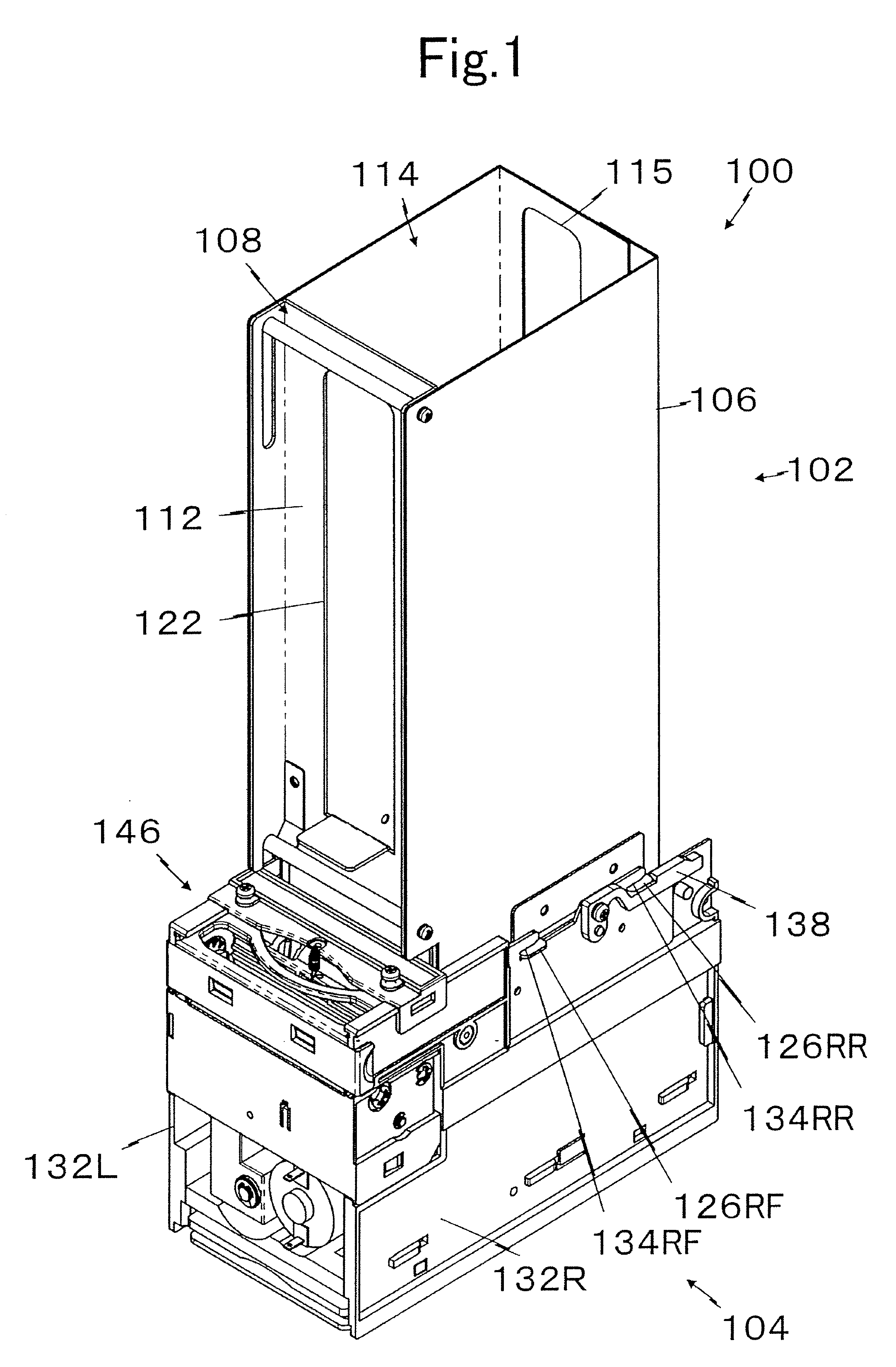

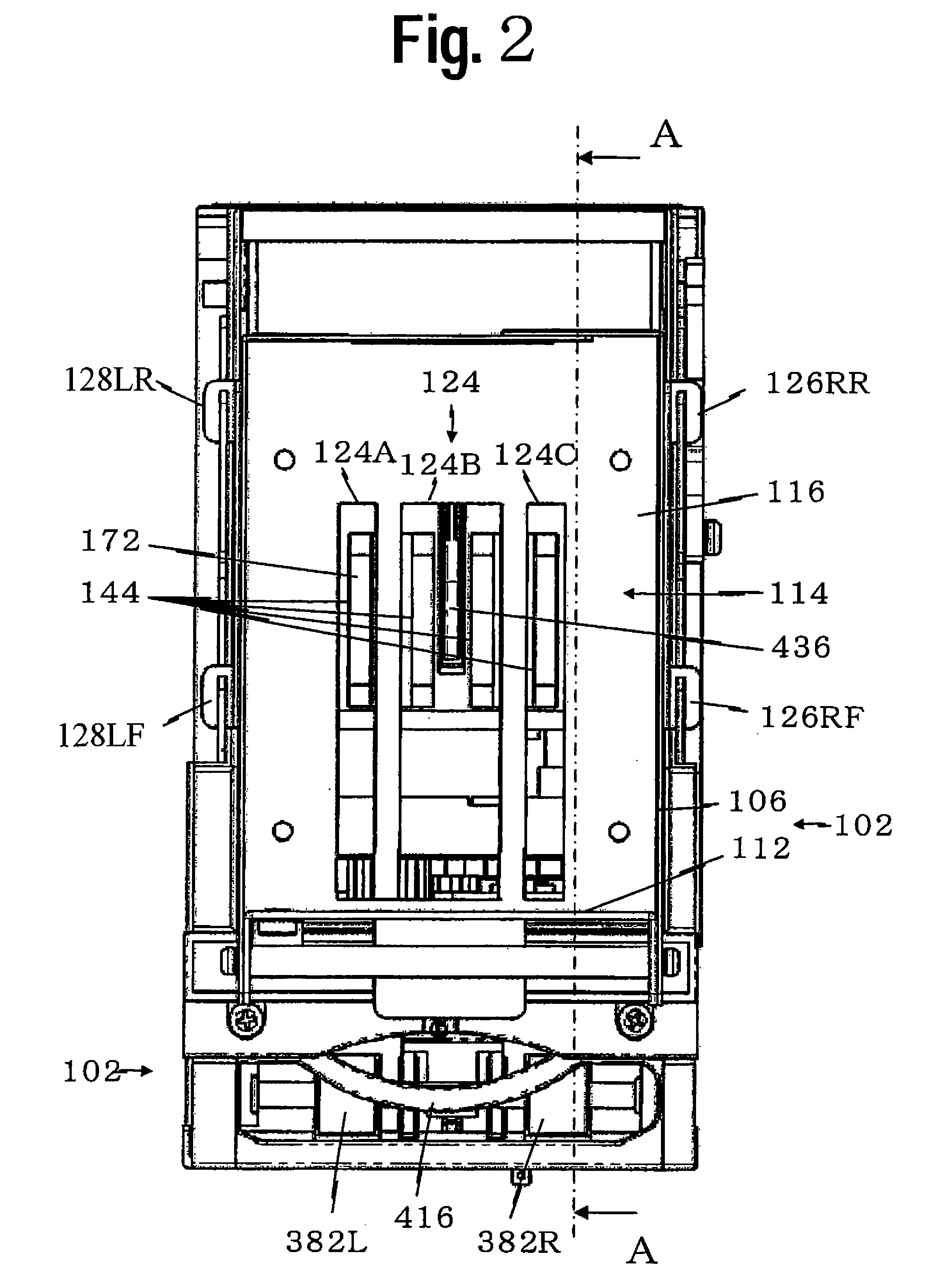

ActiveUS20090001095A1Reduce contact pressureLow costConveying record carriersCoin-freed apparatus detailsRelease pointEngineering

A card dispensing apparatus having a compact configuration has a housing to support a stack of cards on a fixed base. Openings in the base member can permit surfaces from a conveying member to extend into the housing and contact a surface of the lowest card. The conveyer member can move horizontal to a release point and retract beneath the base member to return to an initial position. A movement unit provides a cyclic looping movement of the conveyer member into and out of the housing for transporting cards. A feed unit positioned at the dispensing point of the cards can grasp and release the cards from the card dispensing apparatus.

Owner:ASAHI SEIKO CO LTD

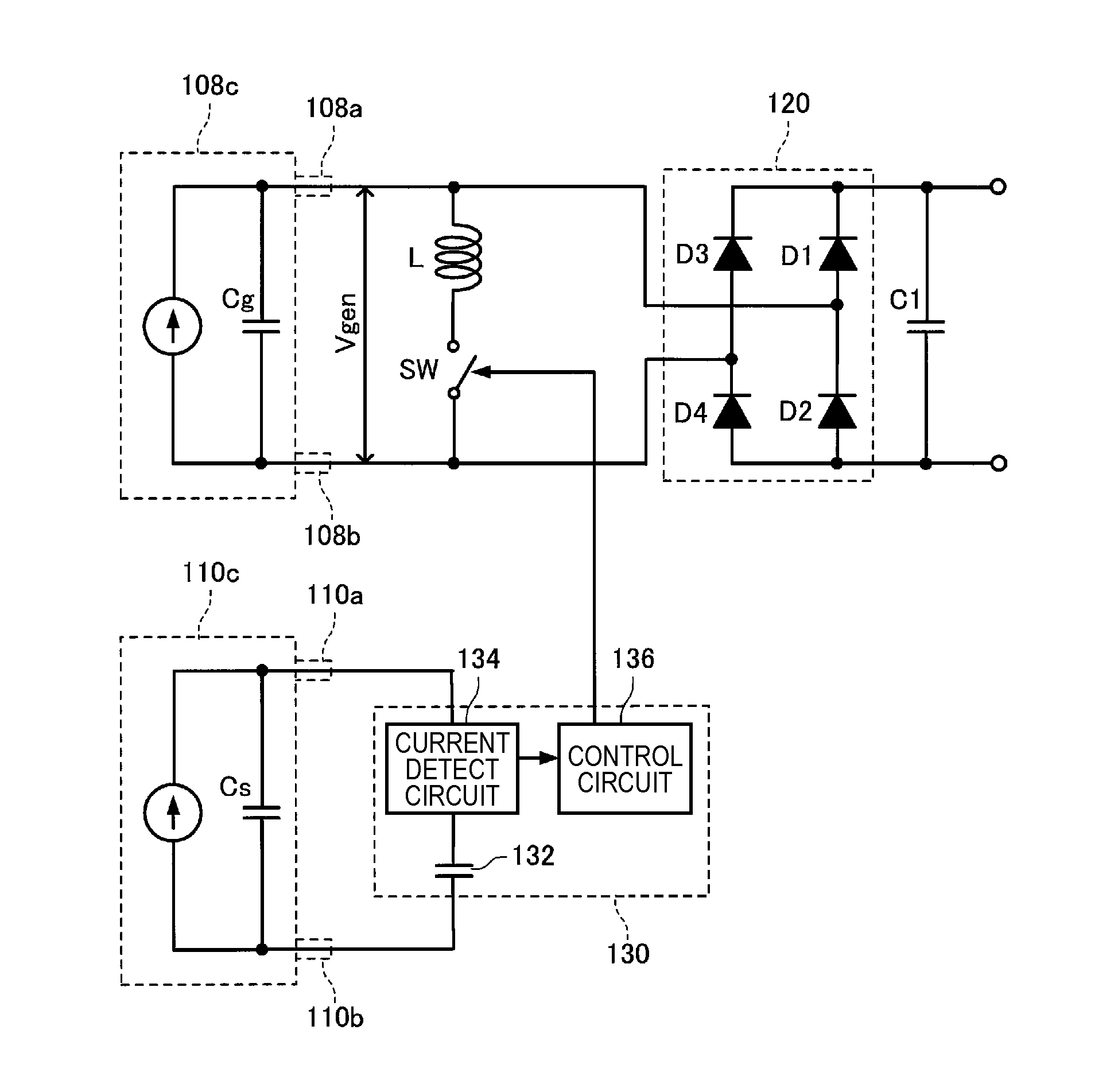

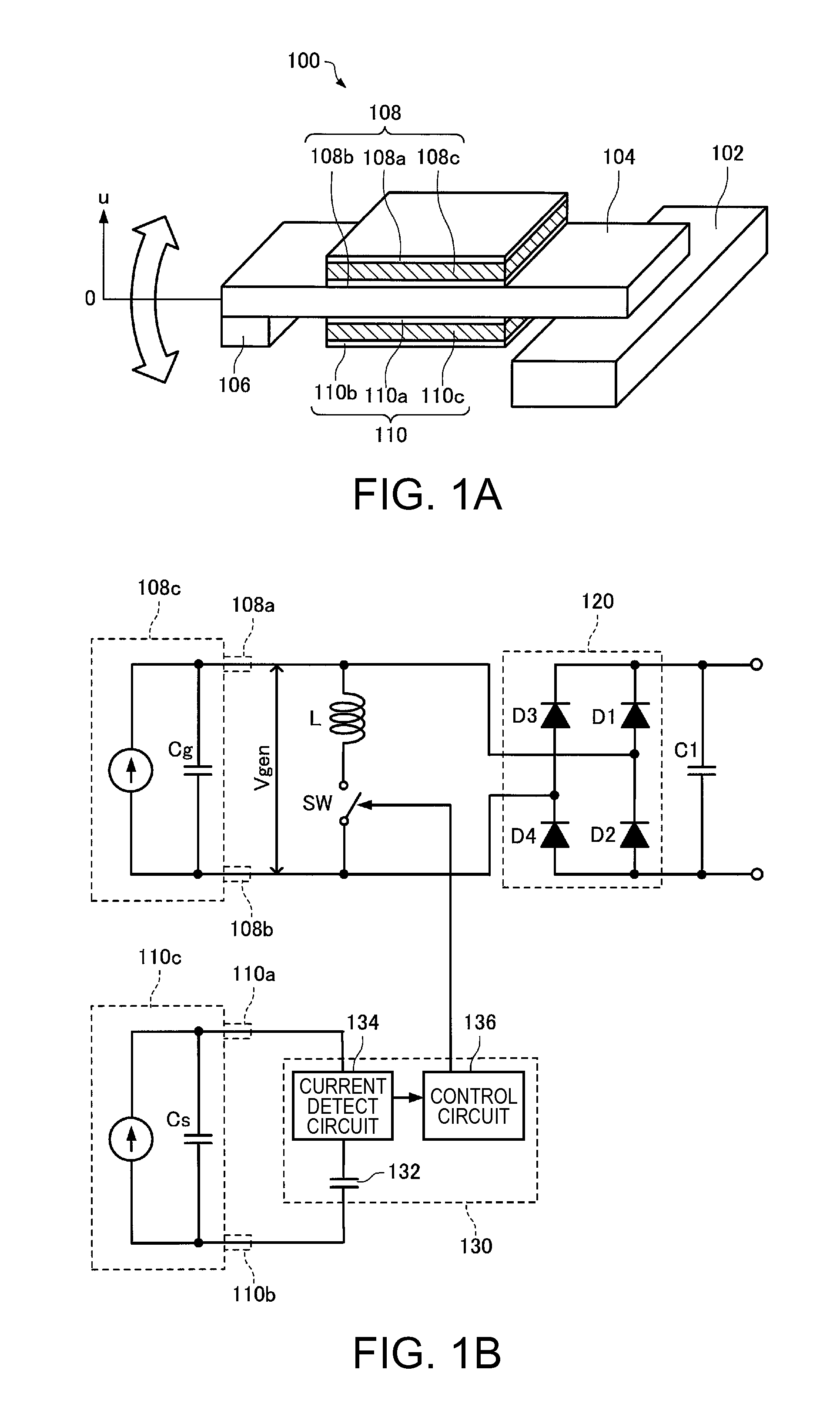

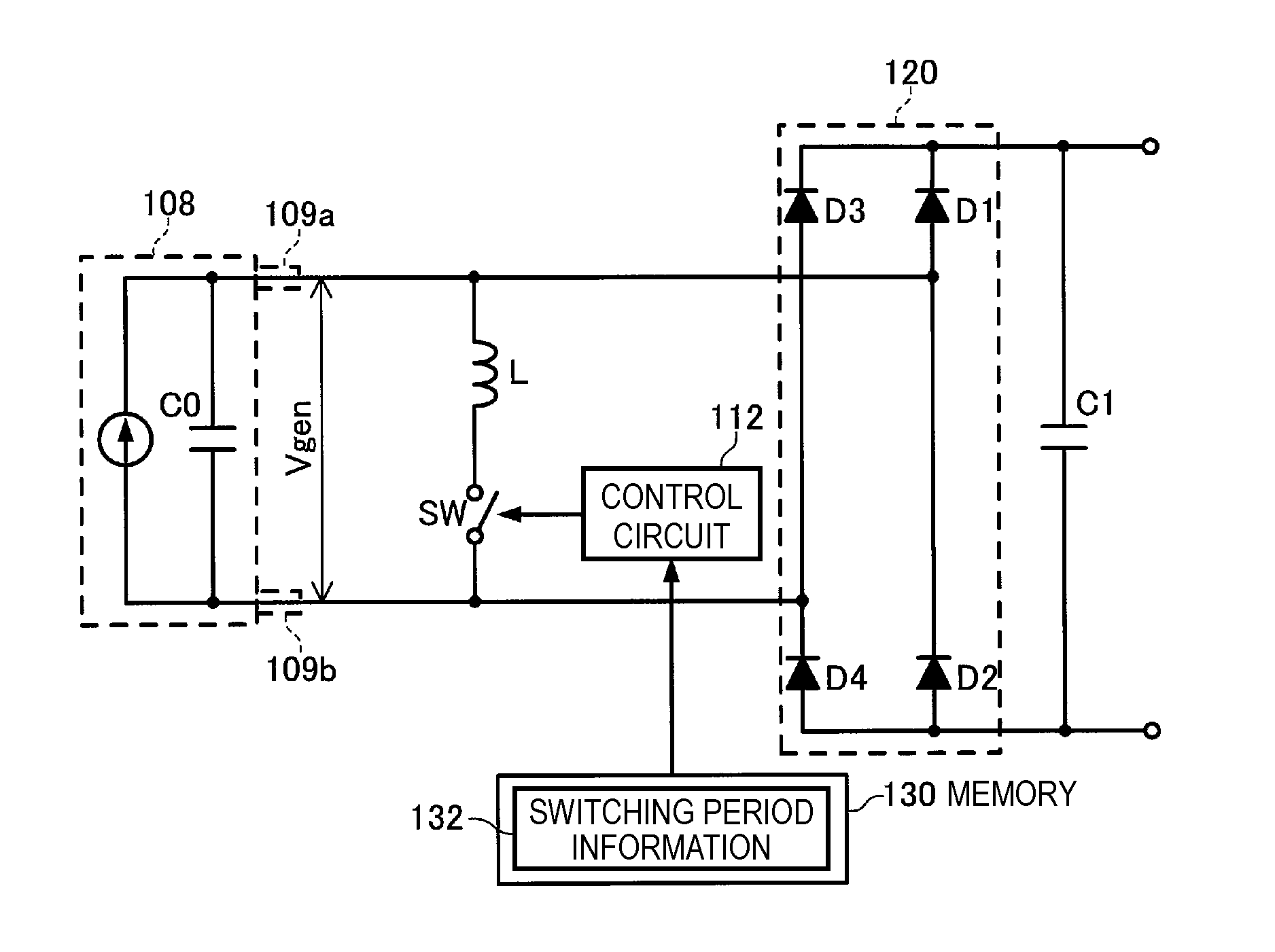

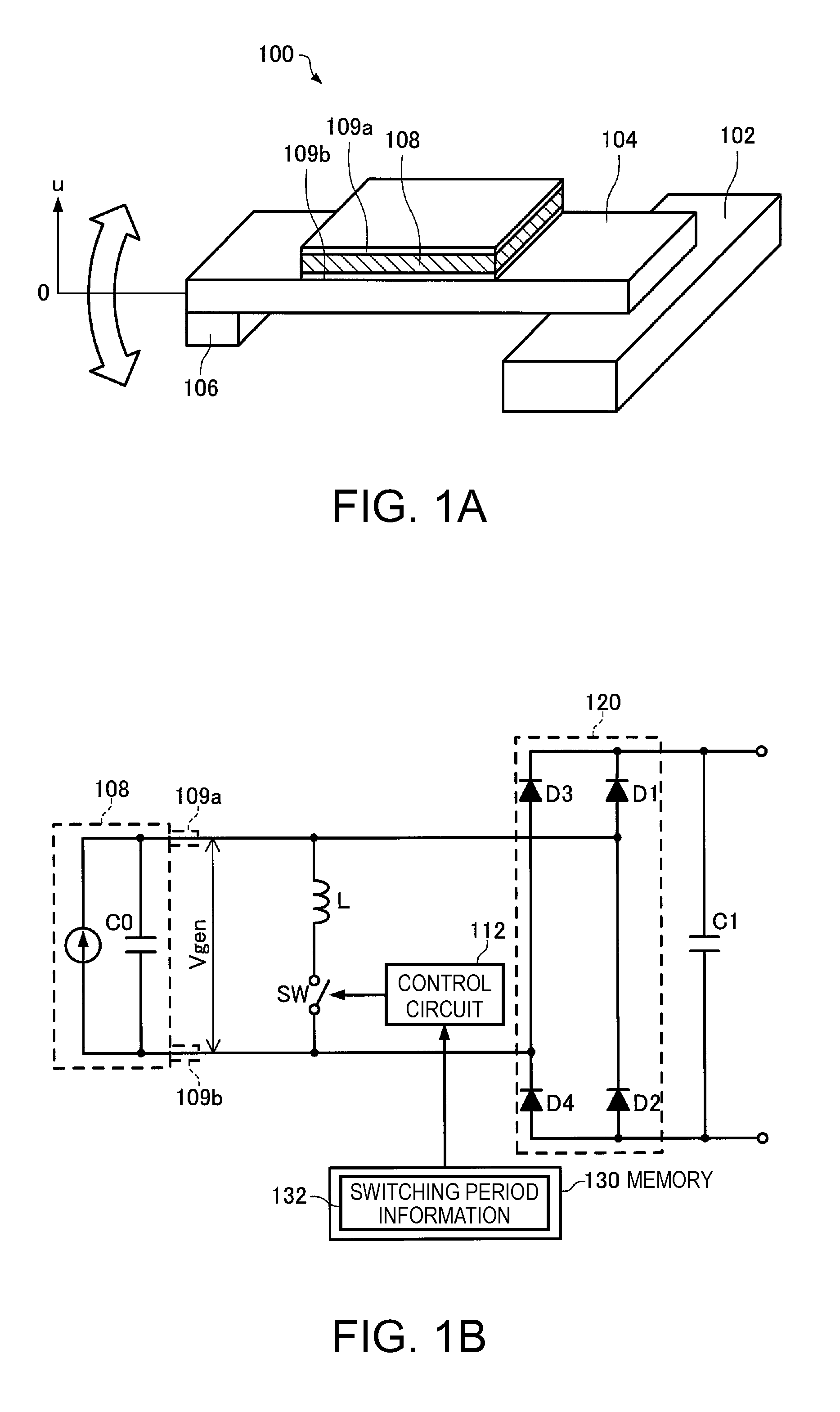

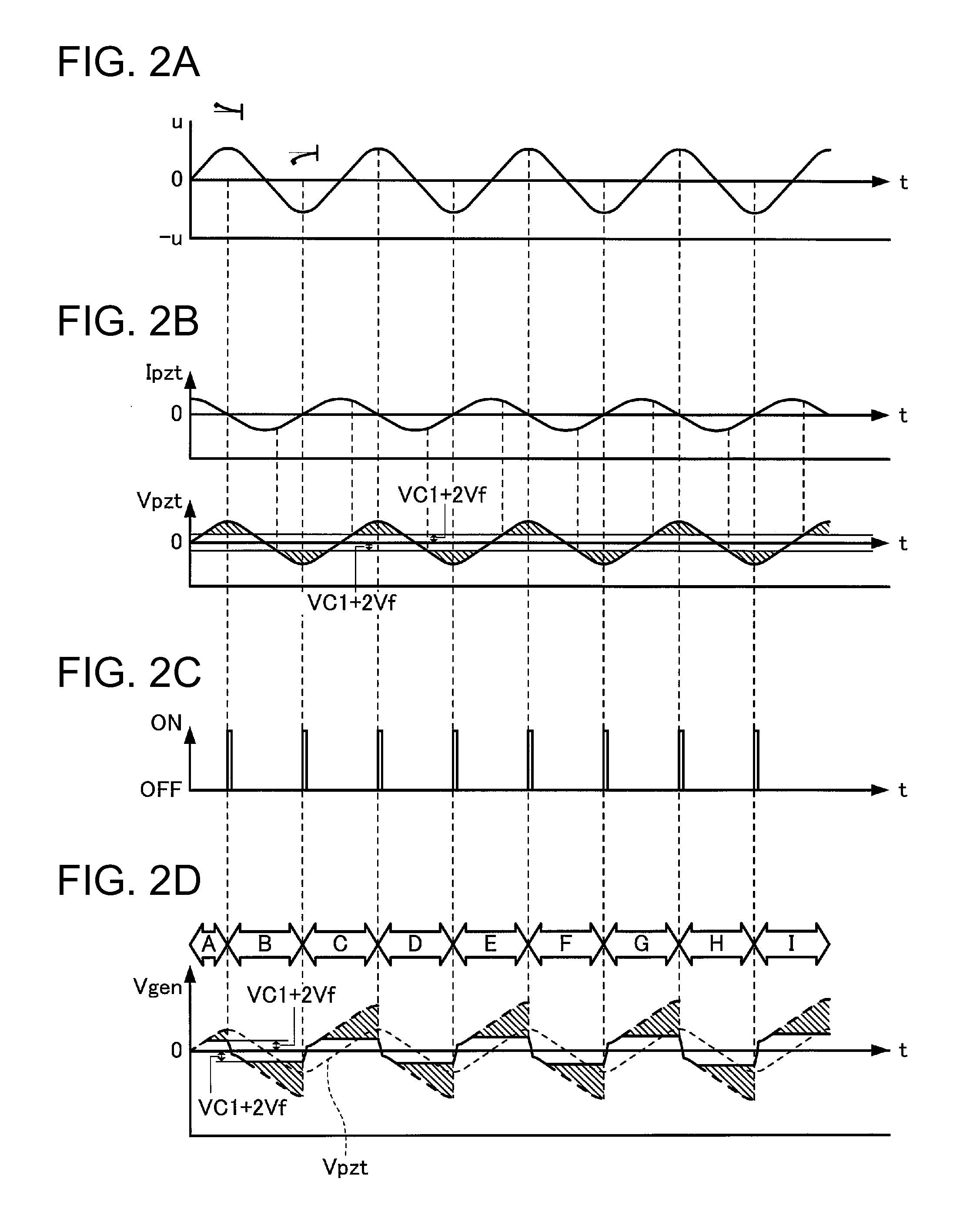

Power generation unit, electronic apparatus, transportation device, and method of controlling power generation unit

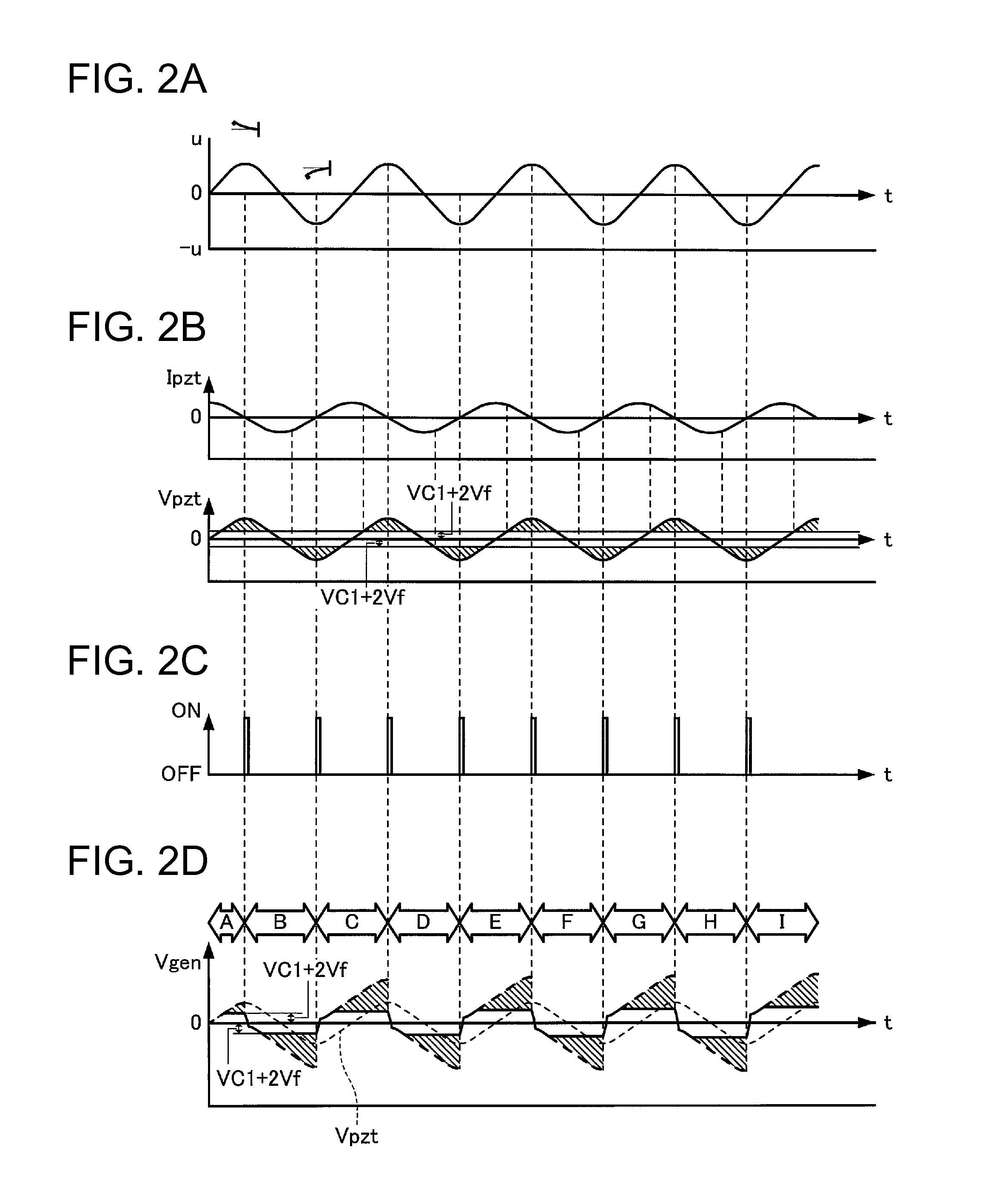

InactiveUS20130082566A1Efficient supplyGenerate electricityPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesControl powerElectrical connection

A power generation unit includes a deforming member (a beam) adapted to deform while switching a deformation direction, a first piezoelectric device provided to the deforming member (the beam), a second piezoelectric device provided to the deforming member (the beam), an inductor electrically connected to the first piezoelectric device, a switch disposed between the first piezoelectric device and the inductor, and a control section adapted to detect a voltage generated in the second piezoelectric device, and if the voltage detected has a level one of equal to and higher than a predetermined level, electrically connect the first piezoelectric device and the inductor to each other using the switch.

Owner:SEIKO EPSON CORP

Card dispensing apparatus

ActiveUS7980420B2Increase the amount of deformationIncrease contact areaConveying record carriersCoin-freed apparatus detailsEngineeringMechanical engineering

Owner:ASAHI SEIKO CO LTD

Staged heating, extruding and form-controlling method of powder superalloy component

The invention provides a staged heating, extruding and form-controlling method of a powder superalloy component. Through use of good liquidity of powder materials and by the aid of the deformation temperature and pressure which are changed in stages, the powder materials reach preliminary densification under the low temperature and pressure, and powder particles are retained and have surface activity and liquidity to a certain degree; then the deformation temperature and pressure are increased, and the plastic deformation parameters such as the motion direction of a mold and the deformation speed are combined, so that superalloy powder flows and forms a certain shape; during the process, pores among the powder particles are completely eliminated, and full densification is reached; and meanwhile, through circulatory alternation action of forward extrusion and backward extrusion, certain strain conditions are exerted on the powder particles, coarse particles are changed into fine crystal particles, component formation is finished, and a full compact powder component is prepared, so that solidification-structure-formation integration of the powder component is achieved. A powder superalloy forging stock with the compact structure and even and fine crystal particles can be obtained.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Vehicle front part structure

ActiveUS9821853B2Reduce spacingIncrease the amount of deformationSuperstructure subunitsGusset plateMechanical engineering

Owner:TOYOTA MOTOR KYUSHU +1

Power generation unit, electronic apparatus, transportation device, and method of controlling power generation unit

ActiveUS20130082572A1Increase in generation amountDeformation amount of deformingPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesInductorElectricity

A power generation unit includes a beam (a deforming member) having a piezoelectric element and deforming while switching a deformation direction, an inductor electrically connected to the piezoelectric element, a switch disposed between the piezoelectric element and the inductor, a memory (a storage section) adapted to store switching period information (information of a characteristic vibration period of the beam), and a control circuit (a control section) adapted to control one of a timing at which the switch is set to a conductive state and a timing at which the switch is set to a nonconductive state in accordance with the switching period information stored in the memory.

Owner:SEIKO EPSON CORP

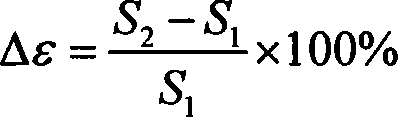

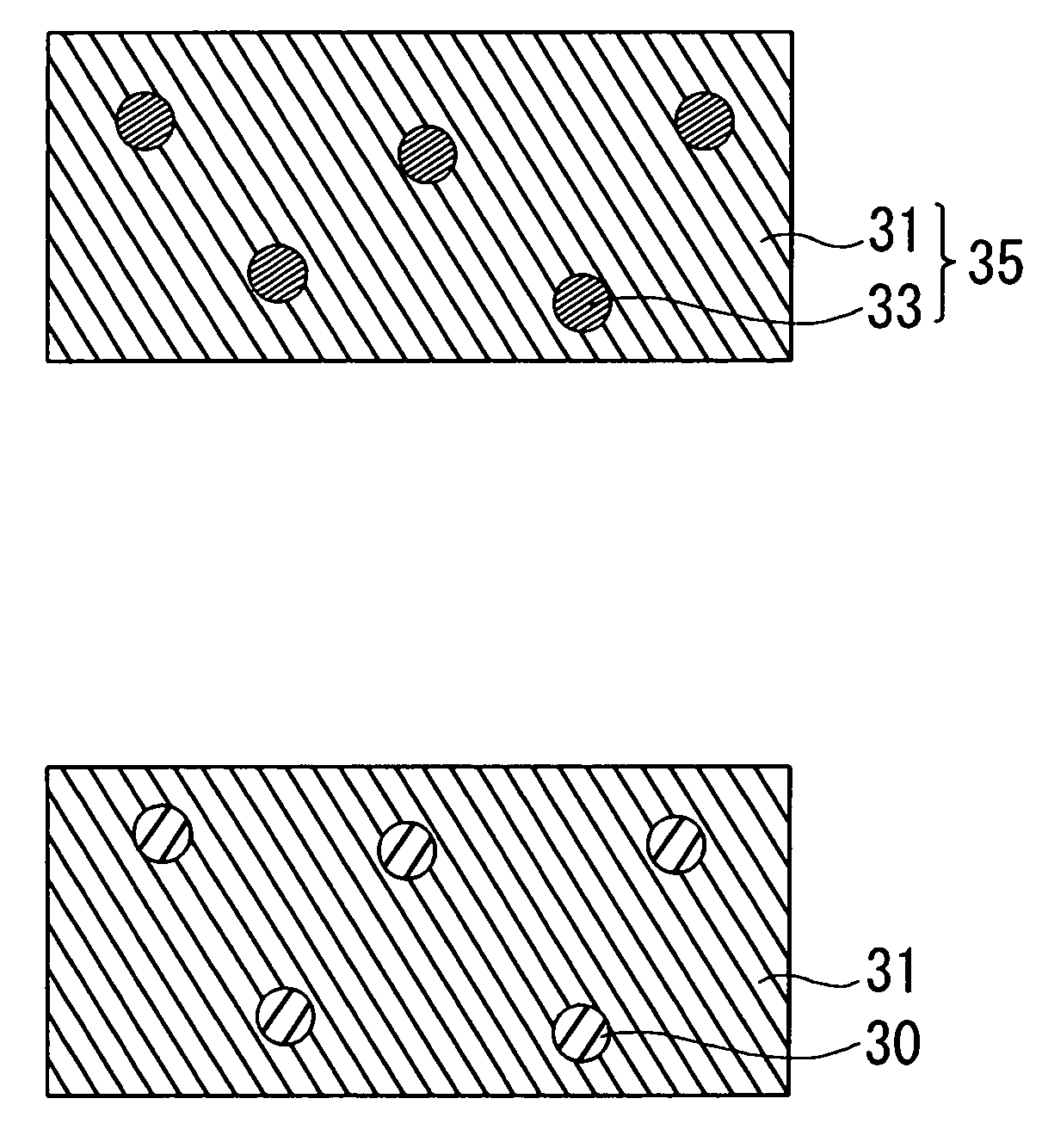

Resin particle, conductive particle and anisotropic conductive adhesive containing the same

InactiveUS20050228144A1Improve conduction reliabilitySufficient compression deformation ratioGlass/slag layered productsWood layered productsAcrylic resinConductive coating

Resin particles comprised of an acrylic resin. Not only is the maximum compression deformation ratio thereof as great as 60% or more but also the load required for 60% compression deformation is as small as 60 mN or less. Wiring boards are therefore coupled in using an anisotropic conductive adhesive obtained by first manufacturing conductive particles having a conductive coating formed on a resin particle surface of the resin particles by adhering a conductive material to the surface of the above resin particles as a core. On dispersing the conductive particles in an adhesive material, the conductive particles sandwiched between metallic wires of the wiring boards are greatly deformed by a small load, so that the electrical devices having a high conduction reliability can be obtained.

Owner:SONY CORP

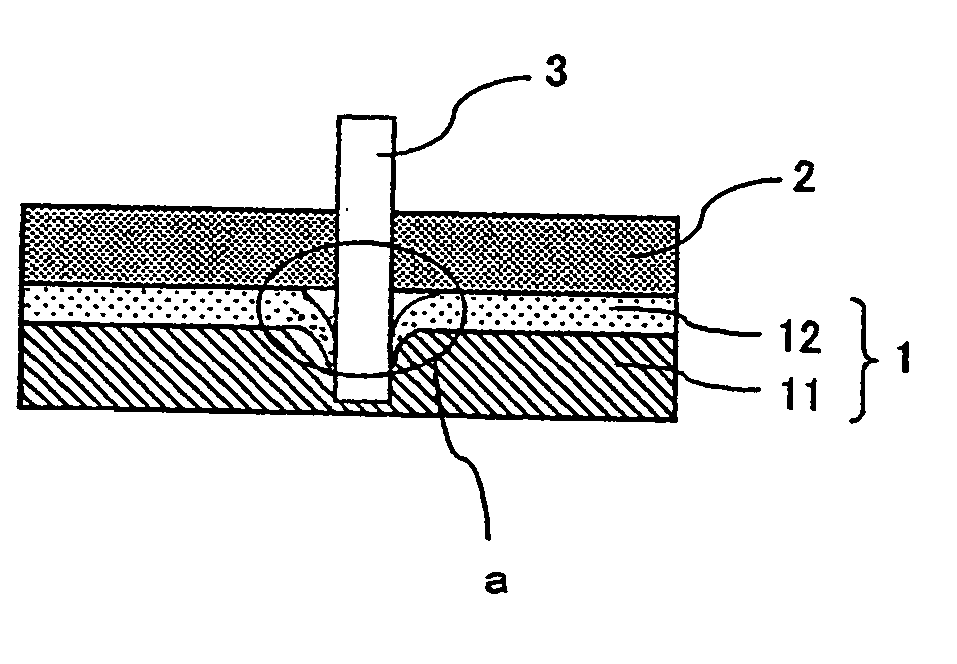

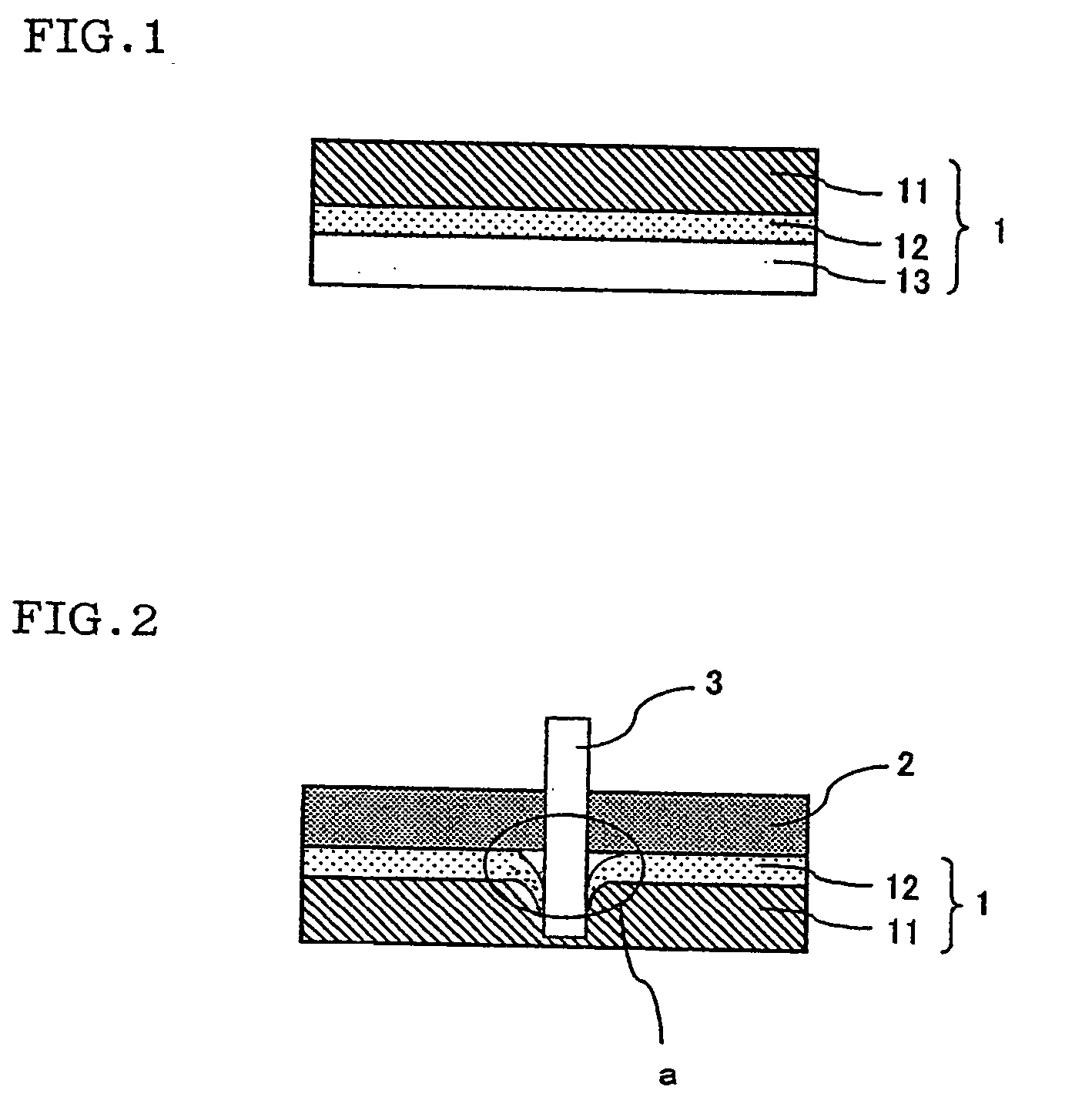

Dicing adhesive sheet and dicing method

InactiveUS20050000638A1High peel adhesionSuppress and prevent deformationLamination ancillary operationsSolid-state devicesSemiconductorSilicon

A dicing adhesive sheet having a base film and an adhesive layer formed on the base film is characterized in that the thickness of the adhesive layer ranges from 1 to 10 μm and the adhesive layer has an sticking temperature such that the adhesion measured when 180° peeling at 23° C. of the dicing sheet is conducted (the peeling rate is 300 mm / min) after it is applied to a silicon mirror wafer is 10 N / 25 mm or more. In a dicing method using such a dicing adhesive sheet, the production yield of a diced body such as a semiconductor wafer is high, and chipping the dicing is prevented.

Owner:NITTO DENKO CORP

Piezoelectric vibration-type pipe flow generator

ActiveCN107332473AIncrease the amount of deformationEasy to limitPiezoelectric/electrostriction/magnetostriction machinesElectricityElectric machine

The invention relates to a piezoelectric vibration-type pipe flow generator, which belongs to the field of fluid power generation and pipeline monitoring. The inner wall of the pipeline is provided with an inner cylinder; the outer side of the bottom wall of the inner cylinder is embedded with fixed magnets, and ear plates are arranged; the left end cover of the inner cylinder wall is provided with two groups of piezoelectric vibrators and an excitation reed; each piezoelectric vibrator group at least comprises two piezoelectric vibrators whose end parts are loaded with levitated magnets; the excitation reed is loaded with levitating magnets and an excited magnet; the levitating magnets and the levitated magnets are arranged with like magnetic poles arranged oppositely; the substrate of the piezoelectric vibrator is arranged close to the excitation reed; the excited magnet and the fixed magnet are arranged with opposite magnetic poles arranged oppositely; the exciter is arranged on the ear plate through a pin shaft, and an exciting magnet on a swinging arm of the exciter and the excited magnet are arranged with opposite magnetic poles arranged oppositely; and one end of a balance reed is arranged on a ribbed slab and the other end is arranged on the connection plate of the swinging arm. The piezoelectric vibration-type pipe flow generator has the advantages that a multi-degree-of-freedom system is realized, and the frequency band is wide; the piezoelectric vibrators are not contacted with the fluid, a piezoelectric plate only bears compressive stress, the fixed magnet can realize amplification and limiting, the reliability is high, and the power generation amount is large.

Owner:ZHEJIANG NORMAL UNIVERSITY

Normal temperature adhesive composition and preparation method thereof

InactiveCN101698782AGood pressure sensitivityIncrease the amount of deformationNatural rubber adhesivesEster polymer adhesivesAnti-Adhesion AgentAntioxidant

The invention discloses a normal temperature adhesive composition, which comprises emulsion one, emulsion two, an anti-adhesion agent, a wetting agent, an antioxidant, a defoaming agent, ammonia and water, wherein the emulsion one is one of acrylosilane emulsion, pure acrylic emulsion, styrene-acrylate emulsion, vinyl acetate / acrylic emulsion and vinyl acetate-acetate copolymer emulsion; the molecular weight of the emulsion one is smaller than 100,000 and the glass state temperature thereof is between -2 and +45DEG C; the emulsion two is one of polyacrylic emulsion, SIS latex and natural latex; and the molecular weight of the emulsion two is between 300,000 and 1,000,000, and the glass state temperature thereof is between -50 and -80DEG C; and the raw materials are added one by one, and the mixture is mixed, stirred, dispersed evenly to prepare the normal temperature adhesive composition. The sealing composition finally achieves effective sealing under the condition of different sealing pressures by properly adjusting a ratio of an adhesion system to a pressure-sensitive system according to different sealing conditions.

Owner:NANTONG GAOMENG NEW MATERIAL

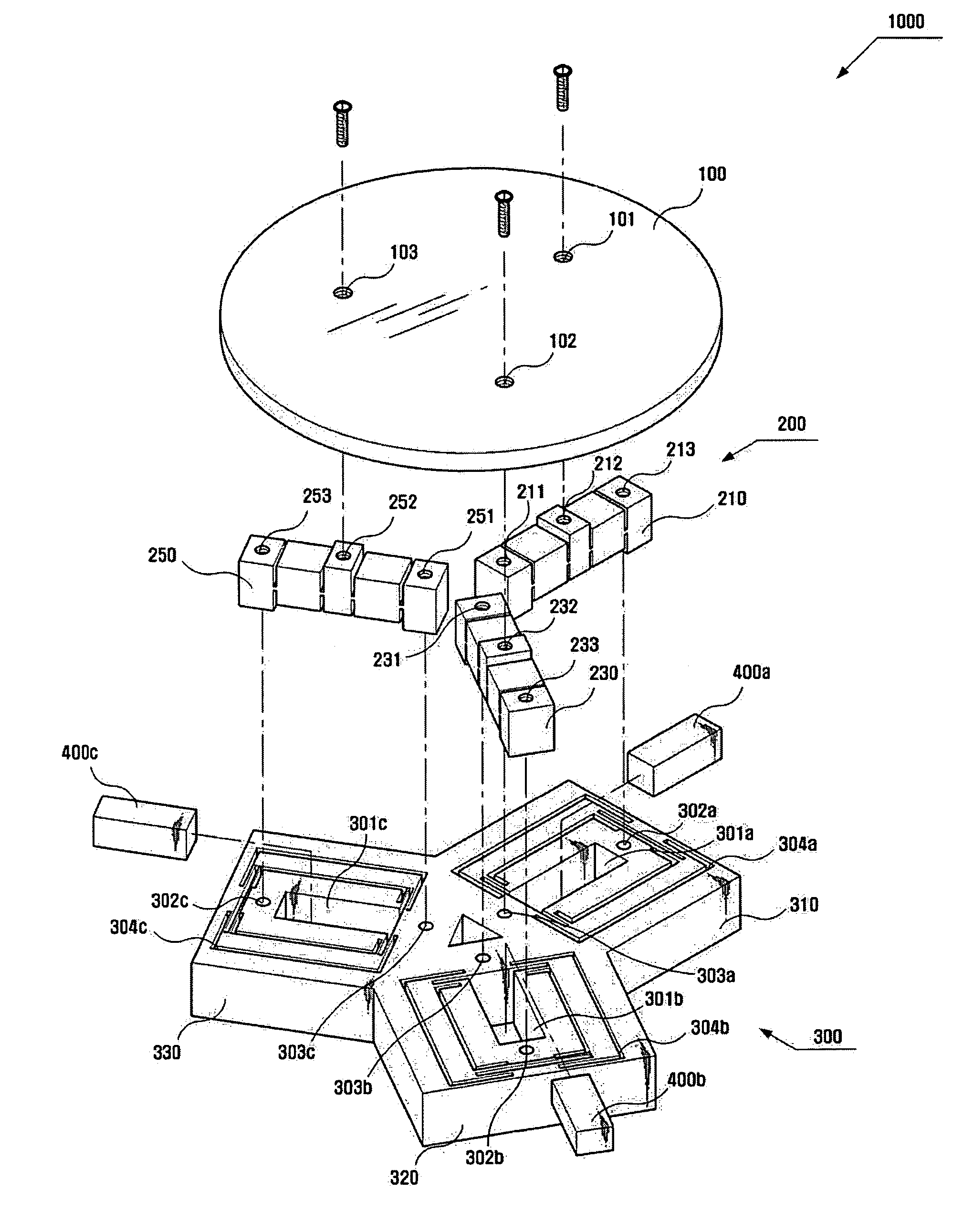

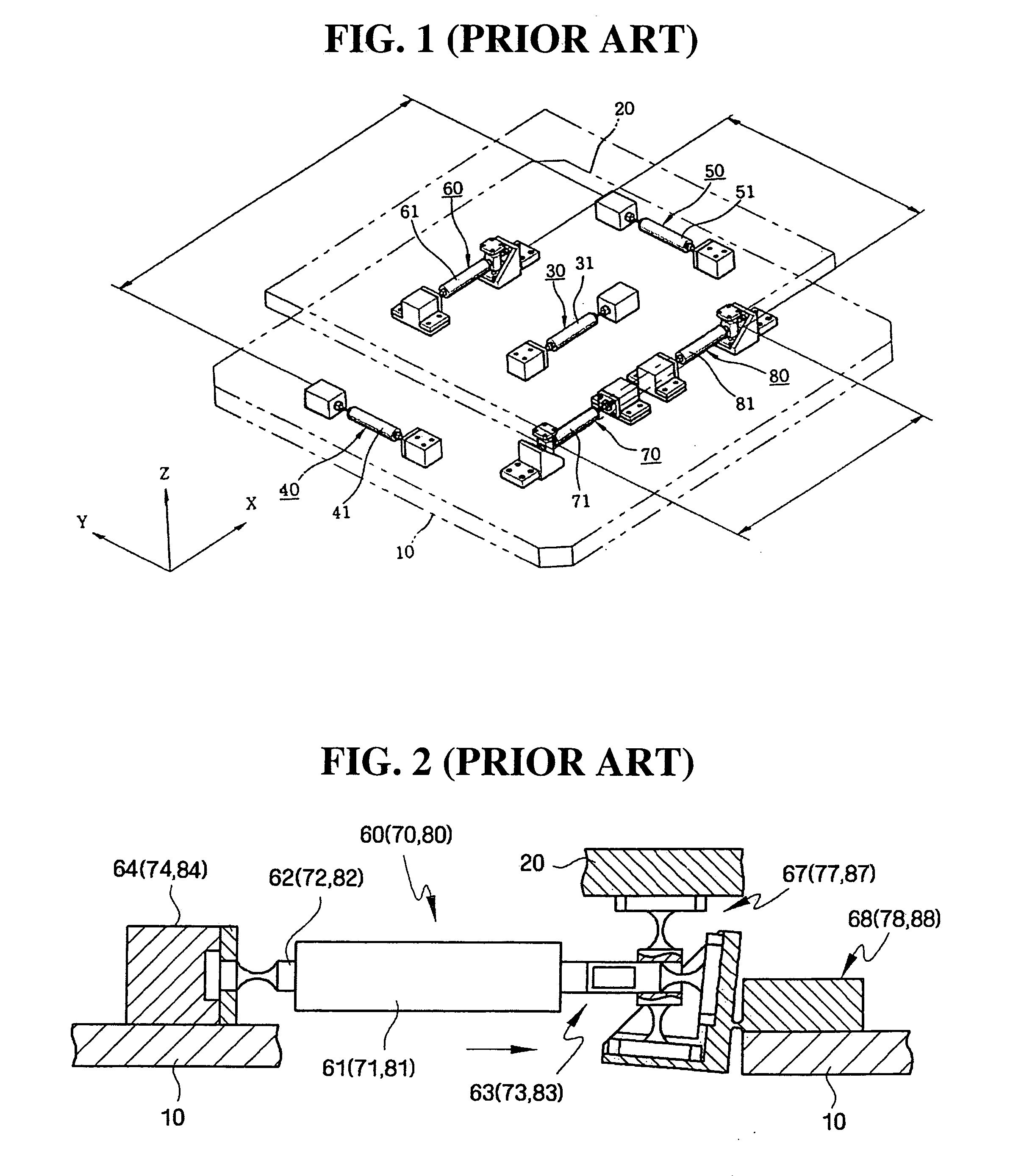

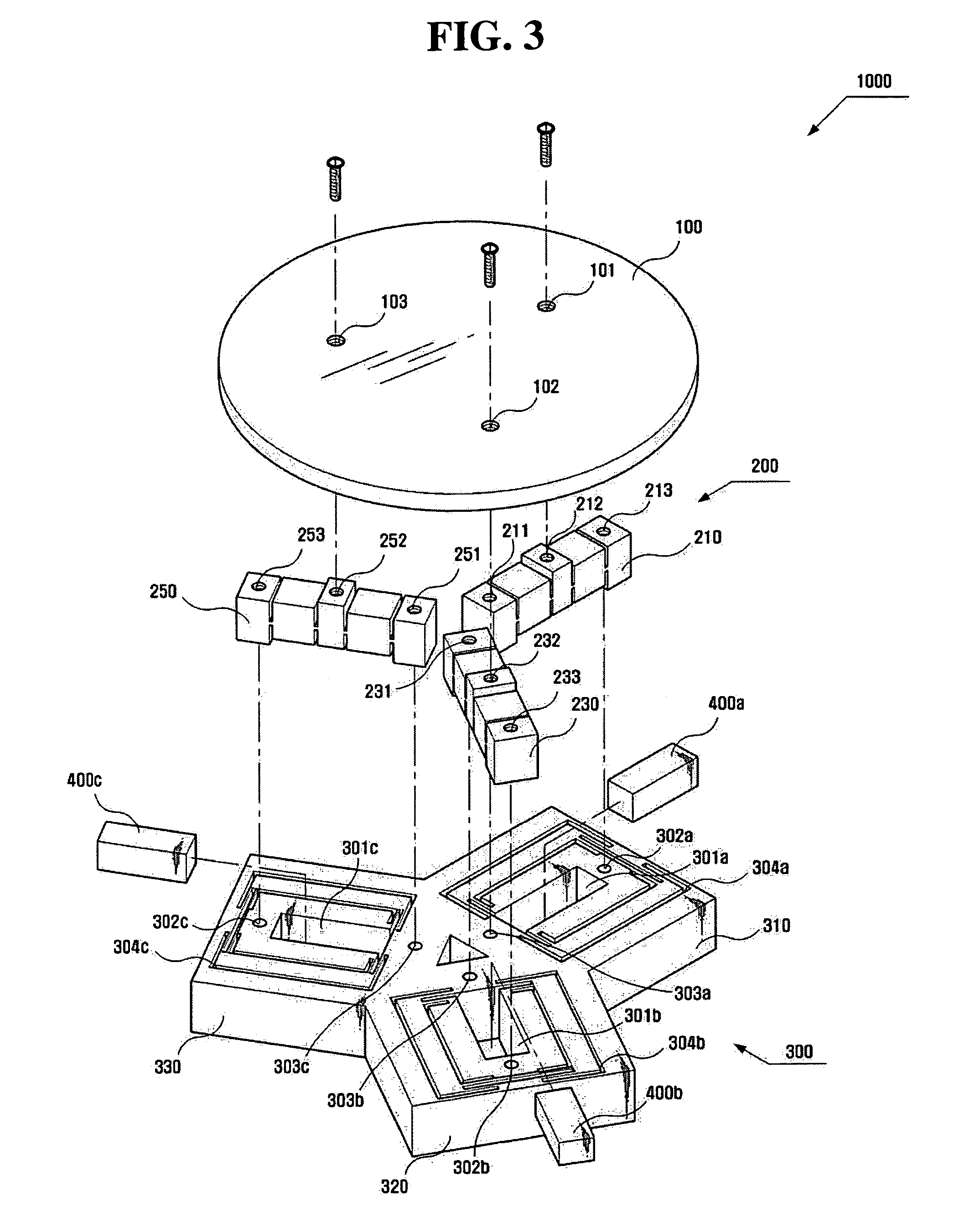

Micro position-control system

InactiveUS7218032B2Move in wideGood precisionAutomatic control devicesPrecision positioning equipmentThree degrees of freedomPiezoelectric actuators

A micro position-control system capable of more precisely controlling three degree-of-freedom motions, namely, a Z-direction motion and X-axis and Y-axis rotations. The micro position-control system includes a base including a plurality of base units disposed at equal angles from the center of a motion stage, holding piezo actuators parallel to a direction of the disposition of the base units, a plurality of bridge units disposed to face the base units, converting a displacement in a length direction of the piezo actuators into a displacement that is vertical with respect to a bottom surface of the base, the motion stage making at least one of a translation motion in the vertical direction, a rotation about a first axis perpendicular to the vertical direction, and a rotation about a second axis perpendicular to both the vertical direction and the first axis, and a control unit controlling the piezo actuators.

Owner:SAMSUNG ELECTRONICS CO LTD

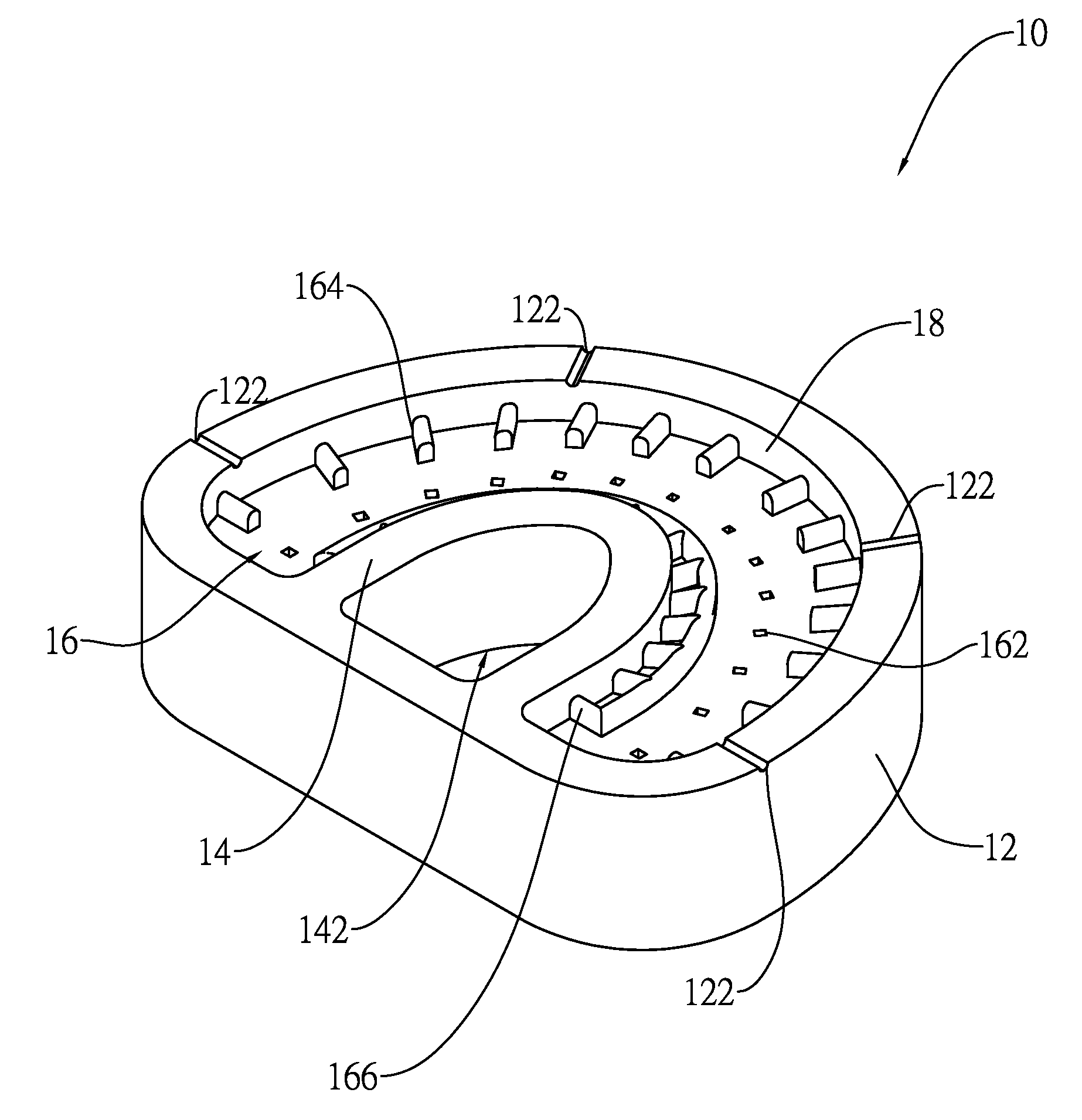

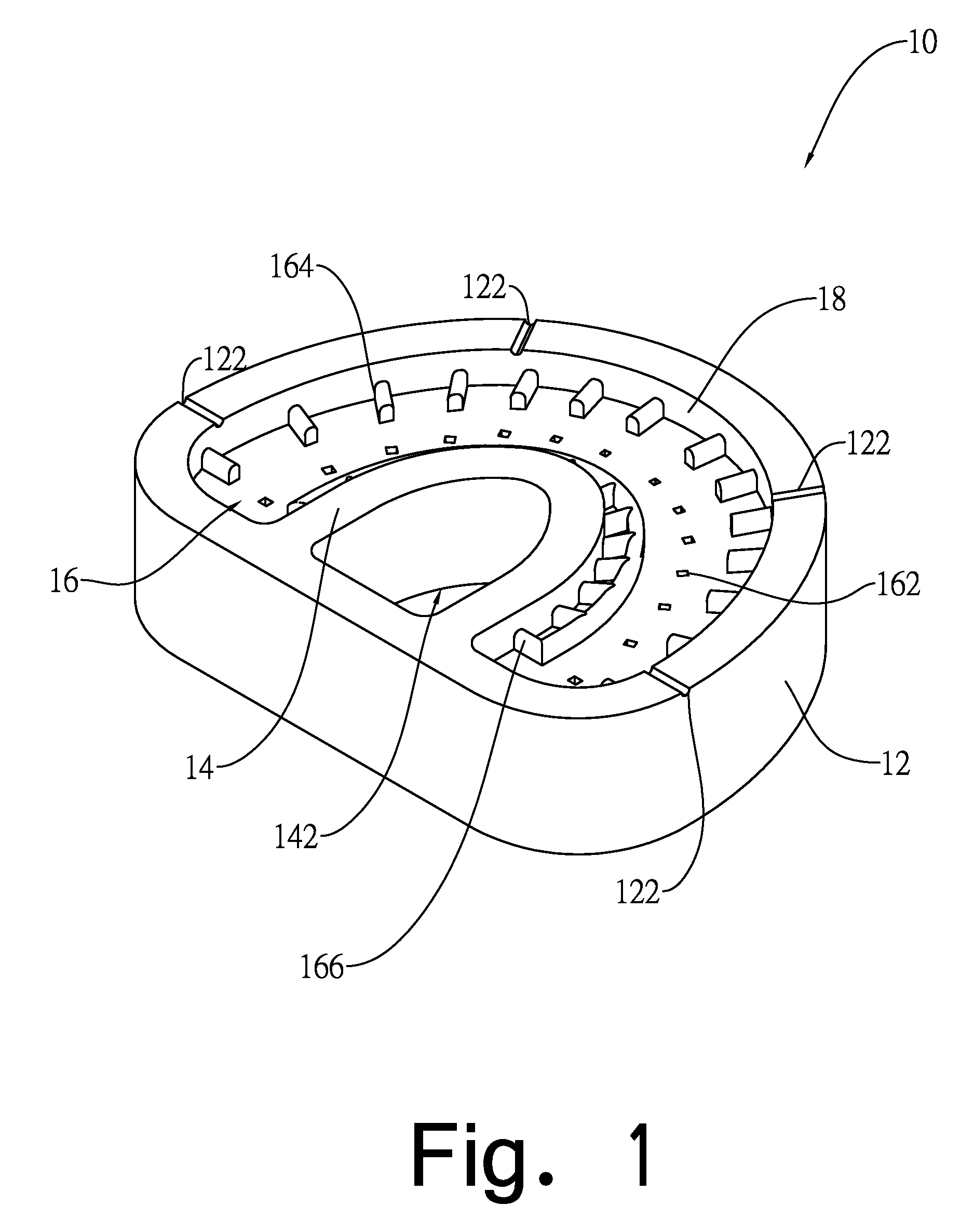

Plaster dental cast gum plate molding mold

InactiveUS20090208895A1Consume moreIncrease the amount of deformationImpression capsPlaster CastsDental cast

A plaster dental cast gum plate molding mold for molding a plaster dental cast gum plate having pins is disclosed. The body of the mold is made of an elastic material, having a cavity surrounded by a smoothly arched inner wall, a smoothly arched outer wall and a bottom wall, a plurality of insertion holes cut through the bottom wall for the insertion of a respective pin, and a plurality of alignment pegs respectively perpendicularly extending from the smoothly arched outer wall and suspending in the cavity so that the molded plaster cast gum plate has dents corresponding to the alignment pegs for quick recognition of the locations of the pins after positioning of the plaster cast gum plate on a base plate and bonding of a dental cast to the flat top surface of the plaster cast gum plate for enabling the dentist to cut one individual tooth model accurately.

Owner:SONG YOUNG INT

Stencil masks, method of manufacturing stencil masks, and method of using stencil masks

InactiveUS20070077501A1Easy to manufactureEfficient use ofElectric discharge tubesNanoinformaticsSurface patternElectrical conductor

The present invention presents a stencil mask in which various surface patterns can be formed, and in which deformation is suppressed when charged particles are introduced. A stencil mask of the present invention is provided with a semiconductor stack. A first penetrating hole corresponding to an ion introducing area is formed in a first semiconductor layer of the semiconductor stack, and second penetrating holes are formed in a second semiconductor layer, these second penetrating holes having a width greater than the width of the first penetrating hole. The first penetrating hole and the second penetrating holes communicate and pass through the semiconductor stack. Beam members extending between adjacent second penetrating holes connect portions of the first semiconductor layer separated by the first penetrating hole.

Owner:TOYOTA JIDOSHA KK

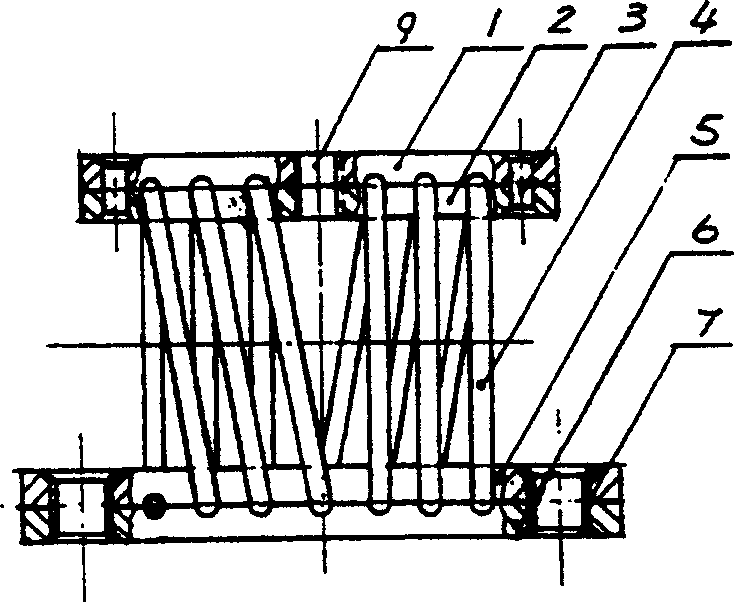

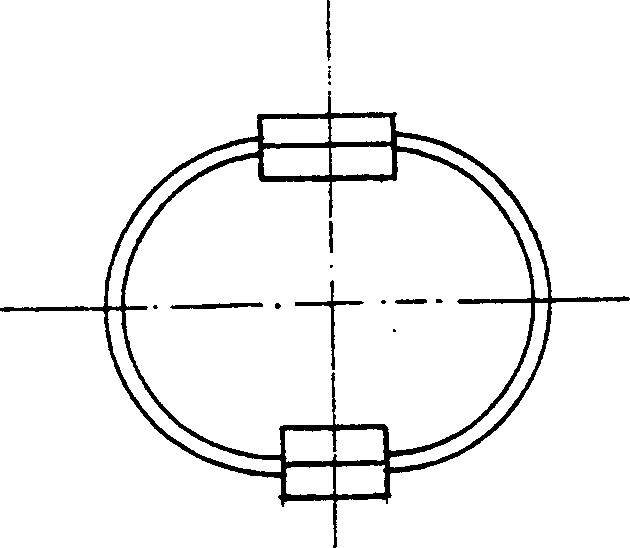

Compostie damp rubber wirerope shock-resistance isolator

InactiveCN1529069ANo strong secondary impactOptimize layoutLow internal friction springsEngineeringShock resistance

The invention is a kind of compound damp rubber steel cable shock resistance and vibration isolating device, belongs to the mechanism field. The skeleton structure of the invention is made up of the upper clamping board, the subjacent clamping board and the spiral high intensity steel cable between the two boards, the two boards are riveted together with clinch and hollow clinch, or connected with head embedded clinch, there sets a tap or straight hole connected to the device and base on the two boards, the above mentioned metal pieces are all covered in the special structure form rubber. The invention solves bid damp, three-dimension deformation and low system free frequency needed by the device, the steel rope won't be rusted, it can use high intensity steel cable to upgrade the intensity, carrying ability, deformation quantity and the binding intensity of rubber.

Owner:SHANGHAI JIAO TONG UNIV

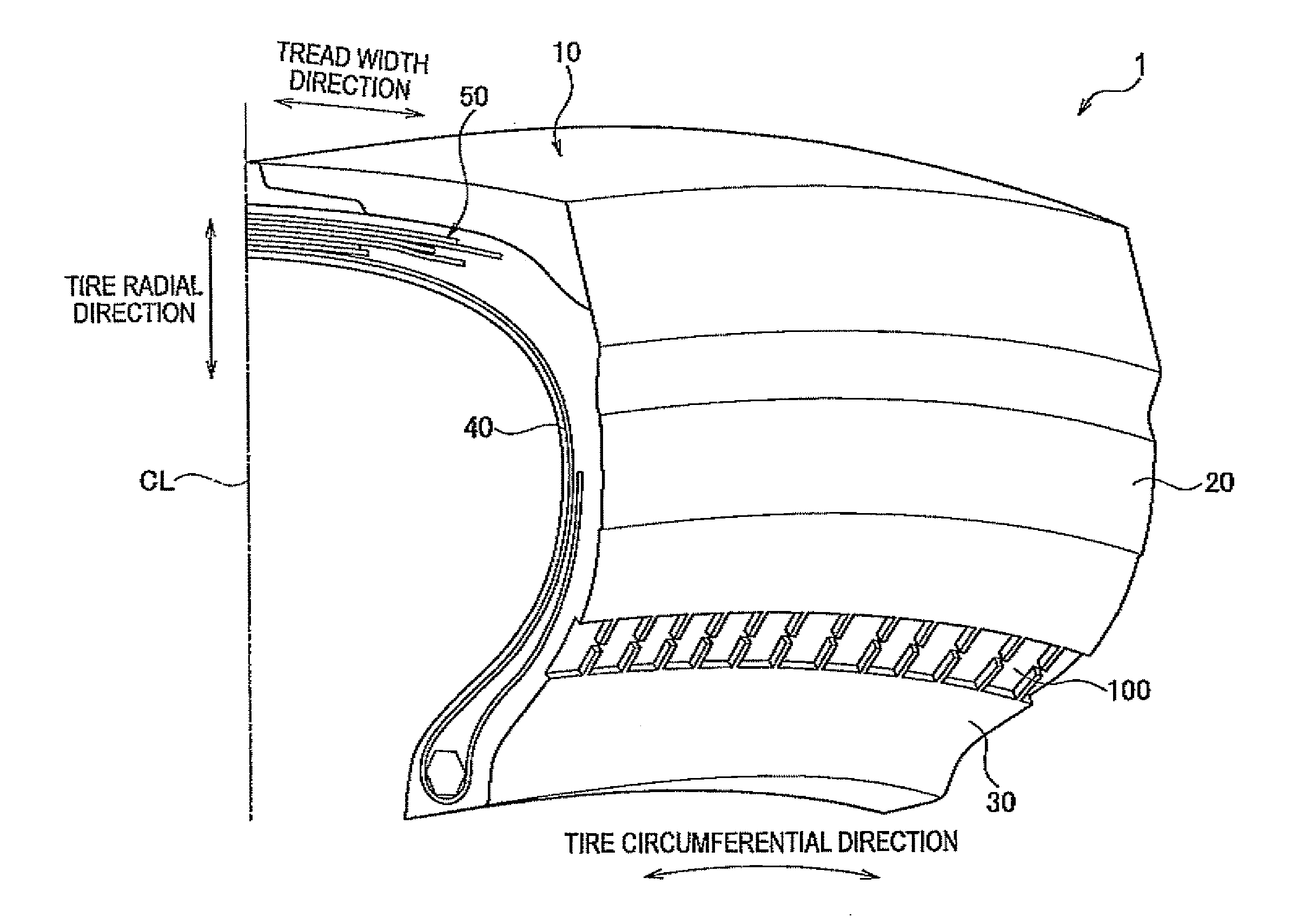

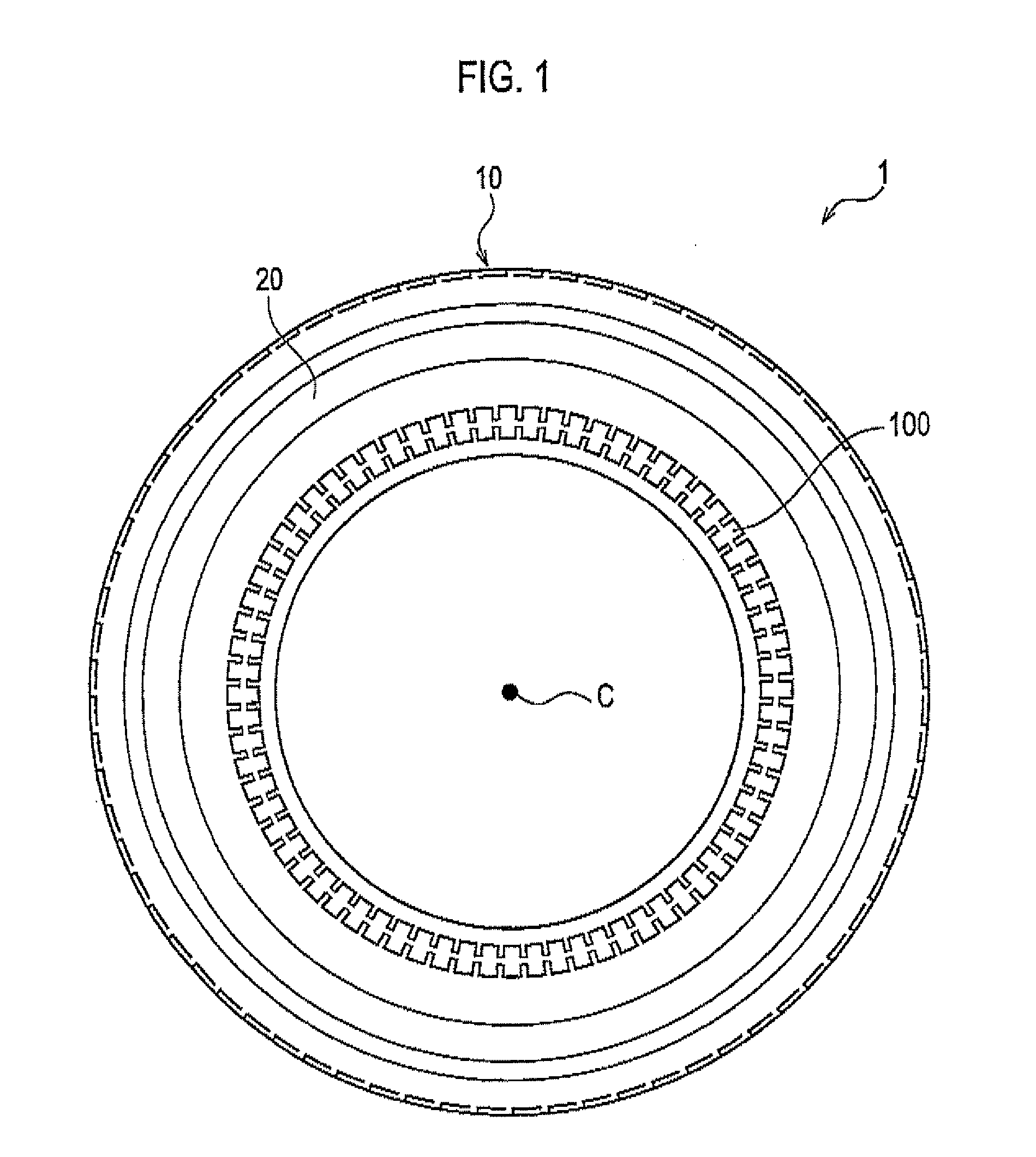

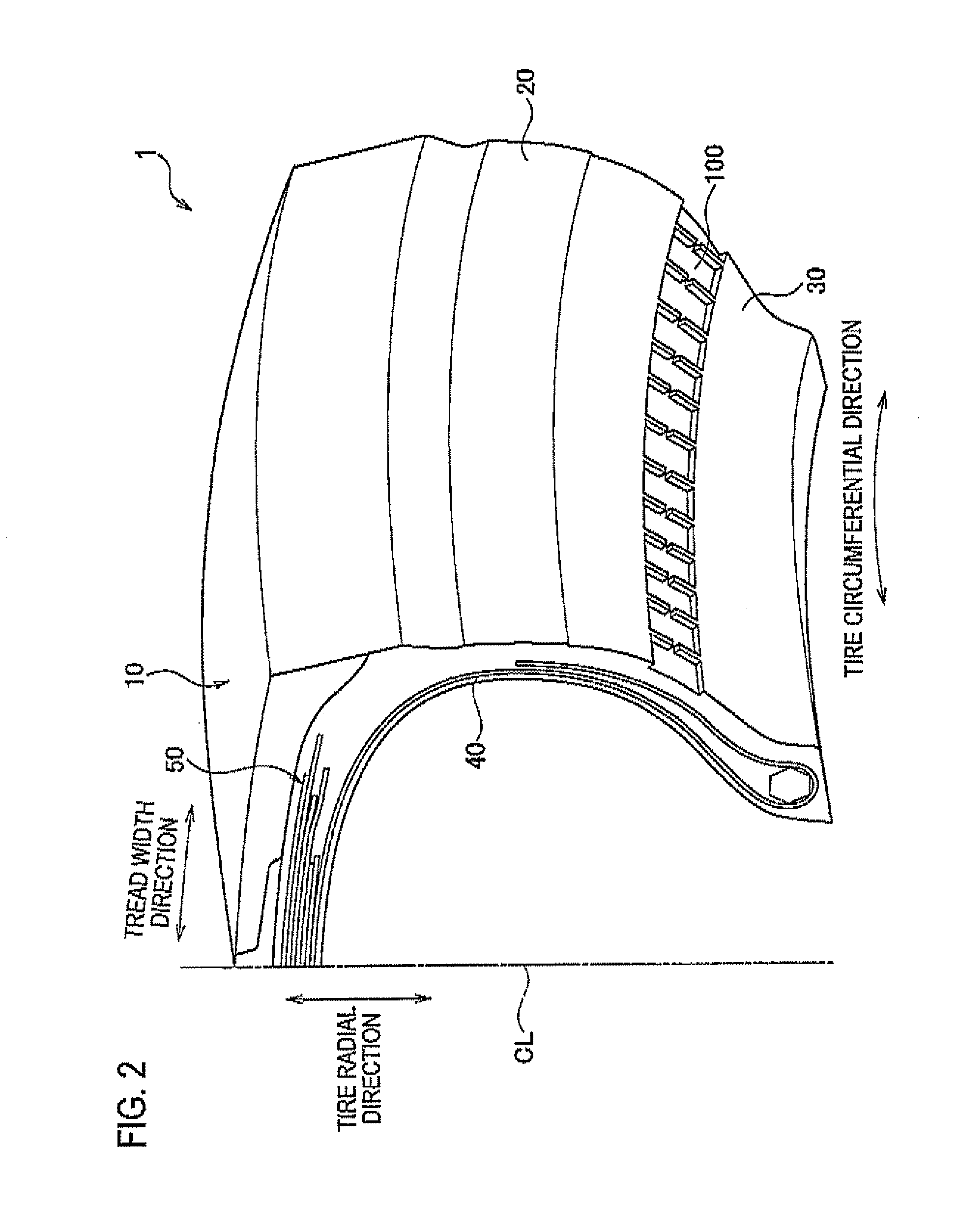

tire

InactiveUS20130168002A1Suppress increaseImprove staminaHeavy duty tyresHeavy duty vehicleEngineeringMechanical engineering

Circumferential recesses have: first blocks protruding outward in the tire tread width direction, the first blocks having radial outer end sections and radial inner front end sections; and second blocks protruding outward in the tire tread width direction, the second blocks having radial inner end sections and radial outer front end sections. The radial inner front end sections of the first blocks and the radial outer front end sections of the second blocks are separated from each other in the tire circumferential direction or in the tire radial direction.

Owner:BRIDGESTONE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com