Patents

Literature

88results about How to "Reasonable cost control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic mahjong machine

ActiveCN103861280ACompact and ingenious structureGuaranteed uptimeIndoor gamesEngineeringMechanical engineering

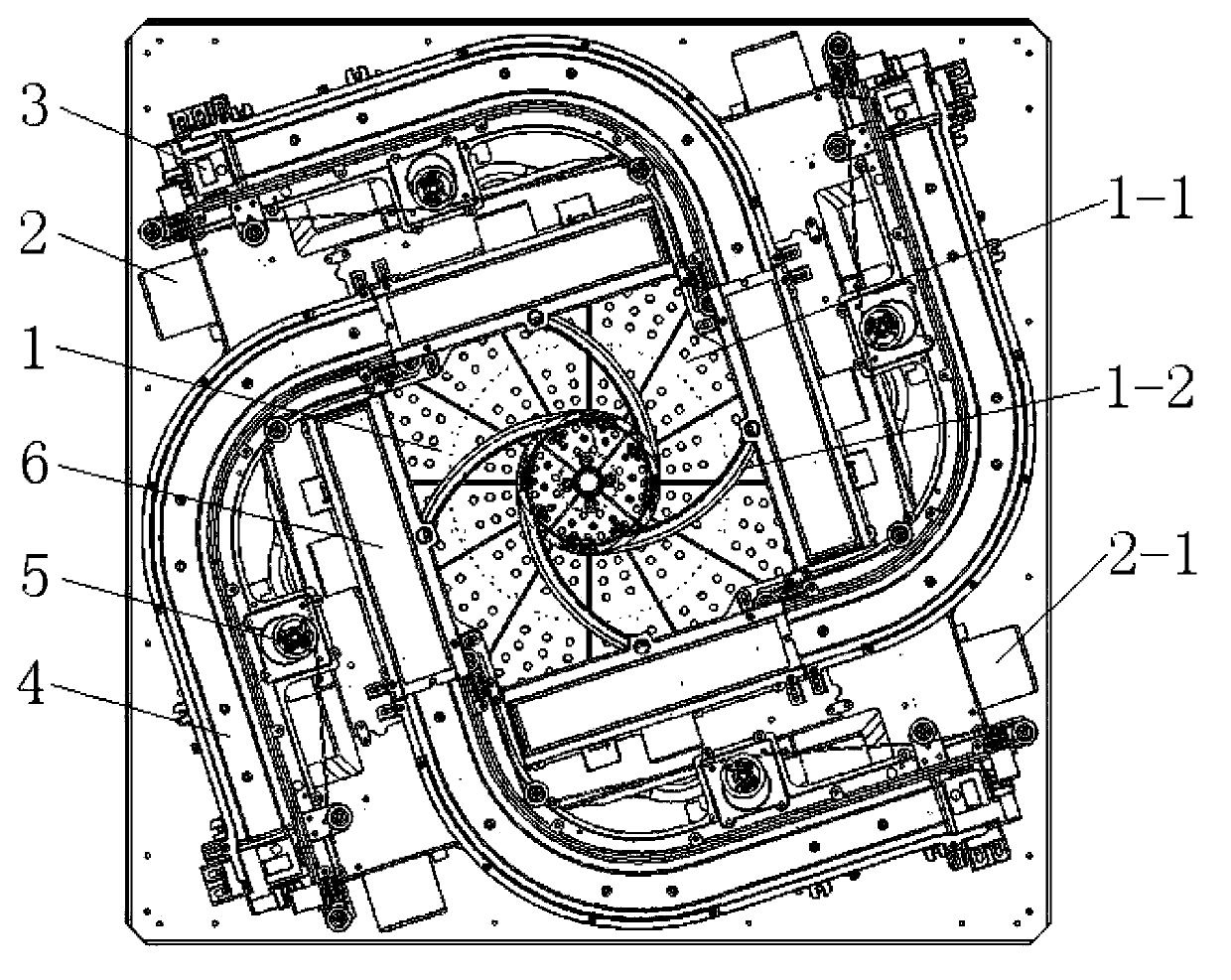

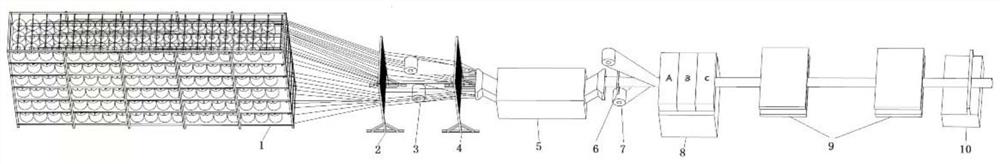

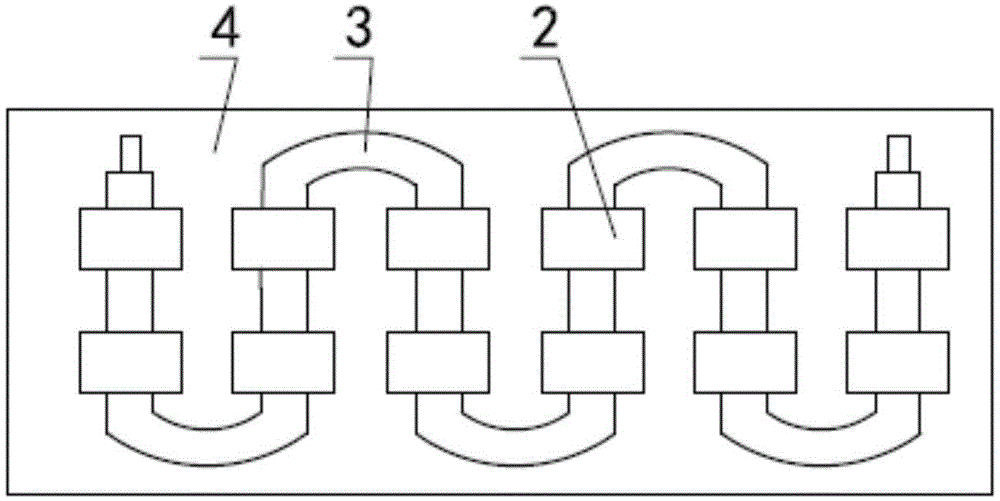

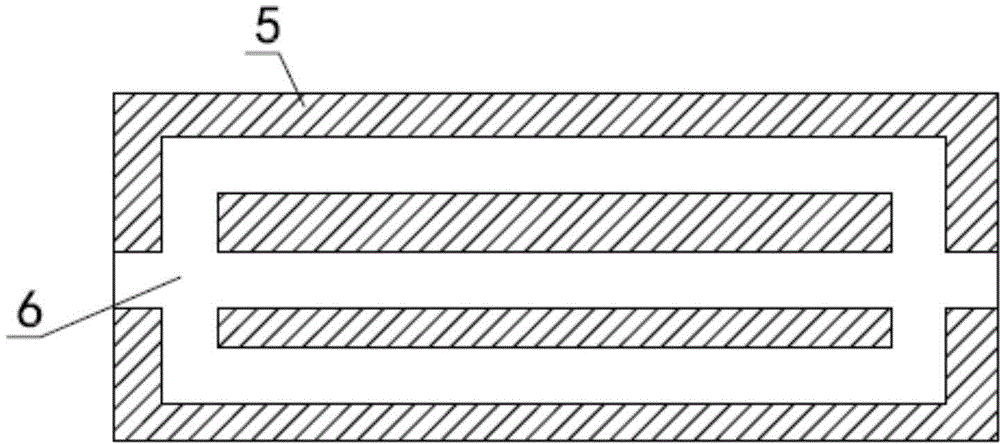

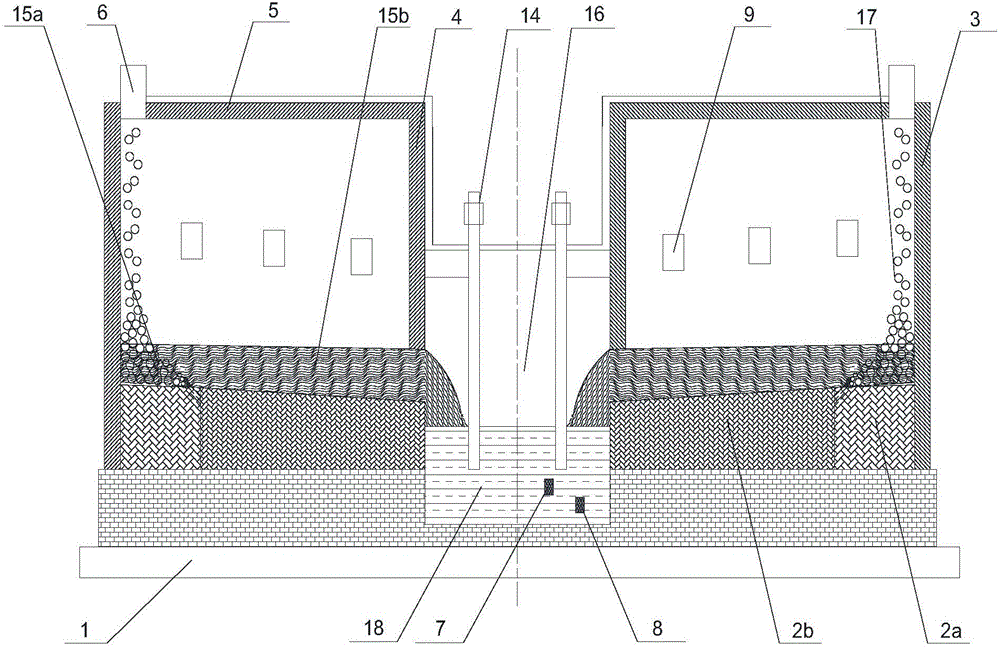

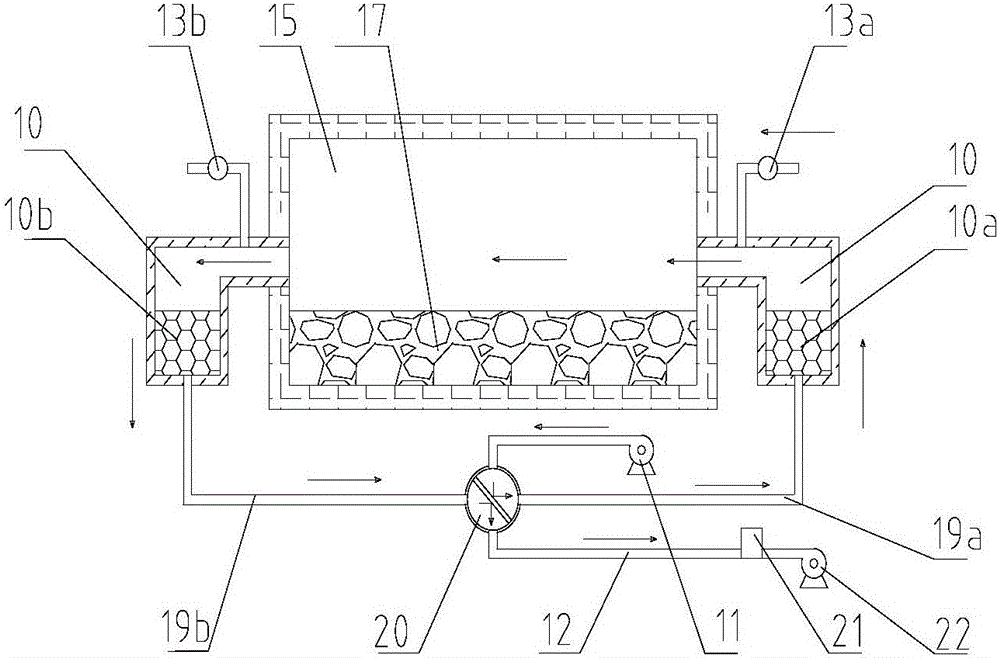

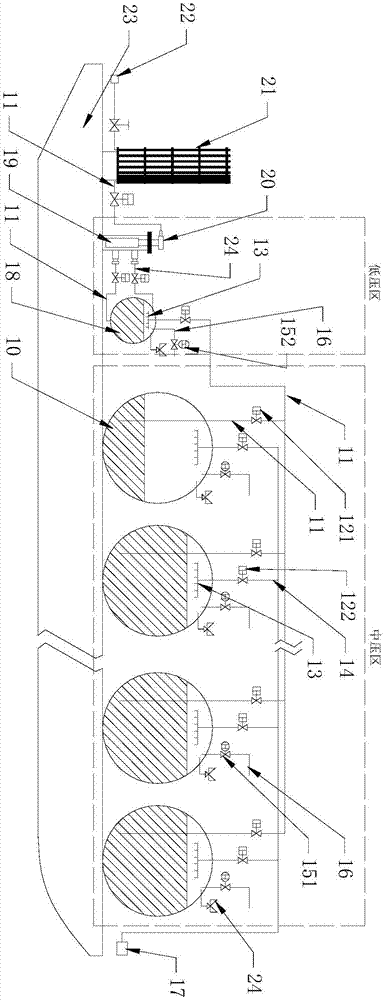

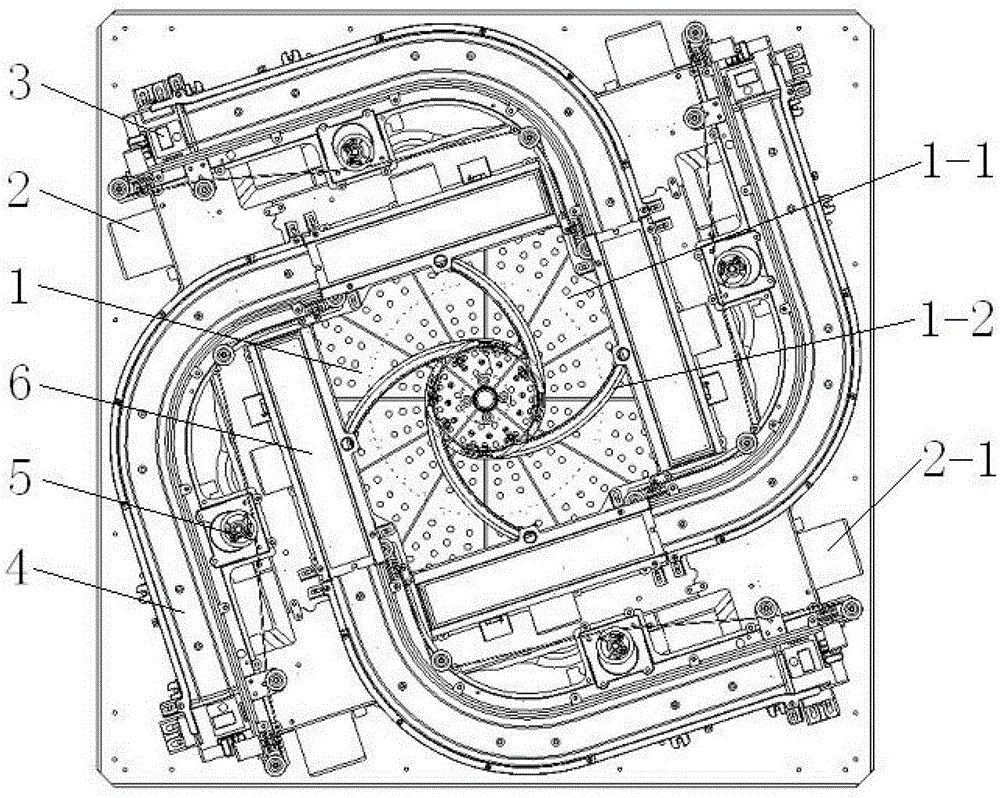

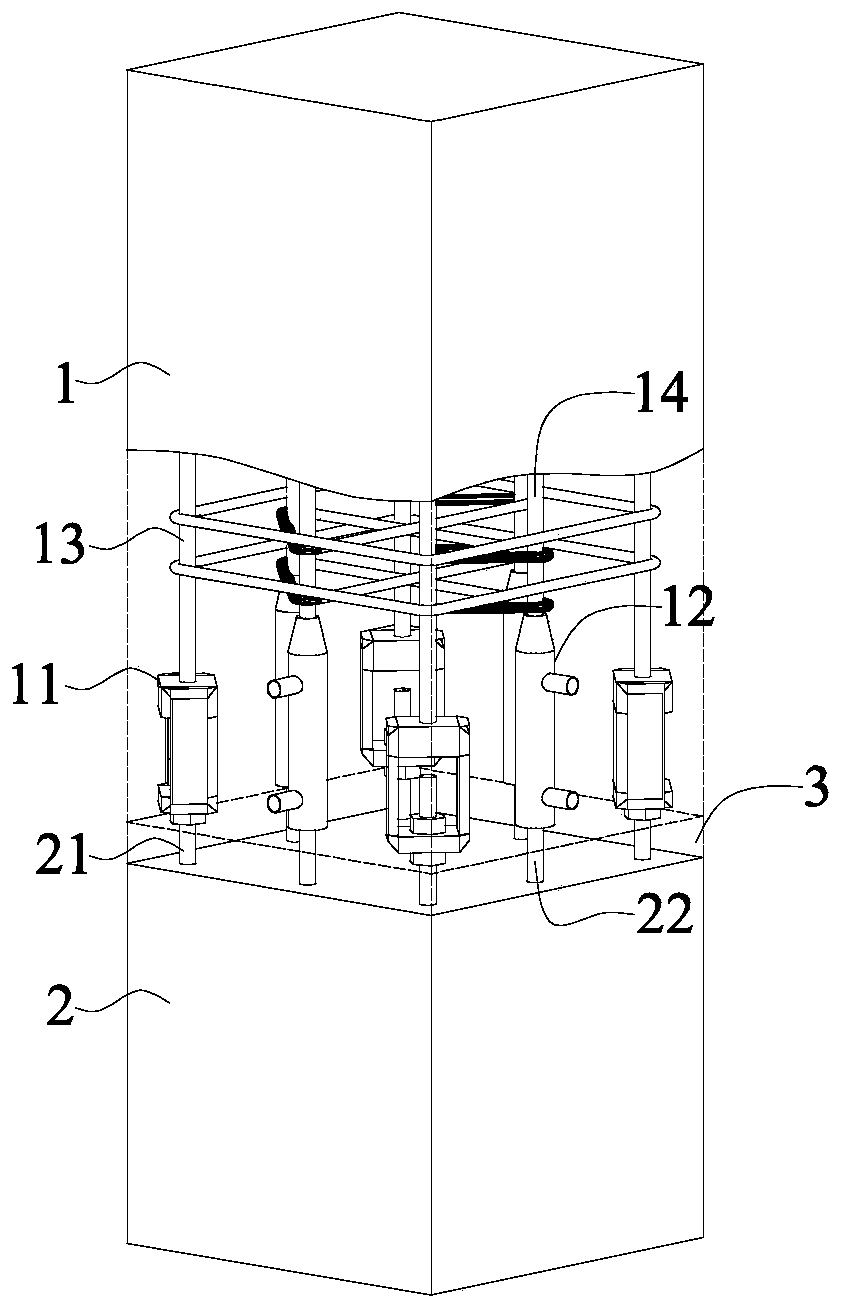

The invention discloses an automatic mahjong machine. The automatic mahjong machine comprises a shuffling mechanism, a conveying mechanism, a tile stacking, lifting and pushing mechanism, a rail mechanism, a tile sending driving mechanism and a tile sending mechanism; the conveying mechanism, the tile stacking, lifting and pushing mechanism, the rail mechanism, the tile sending driving mechanism and the tile sending mechanism are arranged at the periphery of the mahjong machine; an input end of the conveying mechanism is arranged at the edge of the shuffling mechanism; an output end of the conveying mechanism is connected with an input end of the tile stacking, lifting and pushing mechanism; the rail mechanism is arranged above the stacking mahjong pushing mechanism; an input end of the rail mechanism is connected with an output end of the tile stacking, lifting and pushing mechanism; an output end of the rail mechanism is connected with an input end of the tile sending mechanism. The automatic mahjong machine has the advantages of being compact and skillful in structure, stable in operation, reasonable in cost control and long in service life.

Owner:德兴市永达娱乐设备有限公司

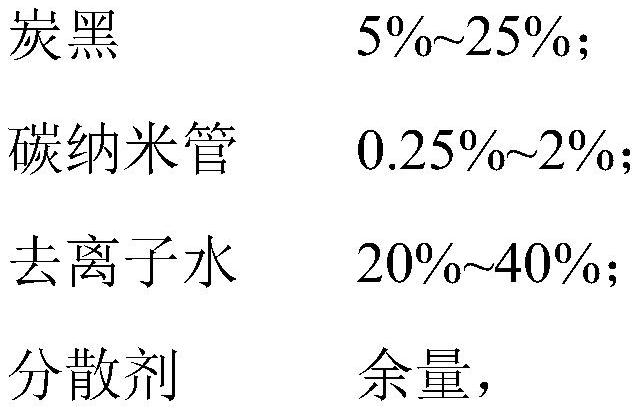

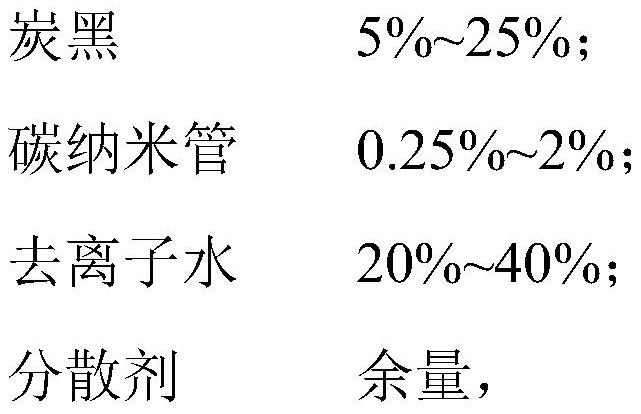

Carbon nanotube ultra-black coating and preparation method thereof

ActiveCN112011232AIncreased reflex difficultyIncrease black chromaRadiation-absorbing paintsChemistryCarbon black

The invention relates to the technical field of coating materials, and provides a carbon nanotube ultra-black coating and a preparation method thereof. The preparation method of the carbon nanotube ultra-black coating provided by the invention comprises the following steps: dispersing carbon black in a first dispersion liquid containing a first dispersing agent, an organic auxiliary agent and deionized water to obtain a first mixed system, and mechanically grinding the first mixed system to obtain a carbon black dispersion liquid, wherein the first dispersing agent is aqueous dispersion resin,preparing a second dispersion liquid mixed with a second dispersant and deionized water, dispersing carbon nanotubes in the second dispersion liquid to obtain a second mixed system, grinding the second mixed system, adding deionized water for dilution to obtain a carbon nanotube dispersion liquid, and carrying out mixing treatment on the carbon black dispersion liquid and the carbon nanotube dispersion liquid to obtain the ultra-black coating. Compared with an ultra-black coating singly taking carbon black as a pigment, the reflectivity of the carbon nanotube ultra-black coating provided by the invention is reduced.

Owner:SHENZHEN XIWAN TECH CO LTD

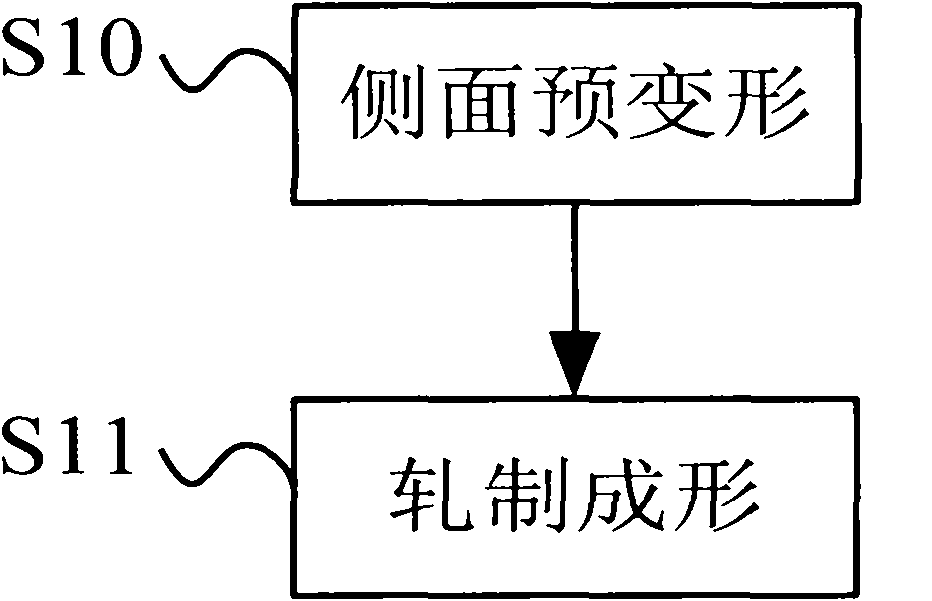

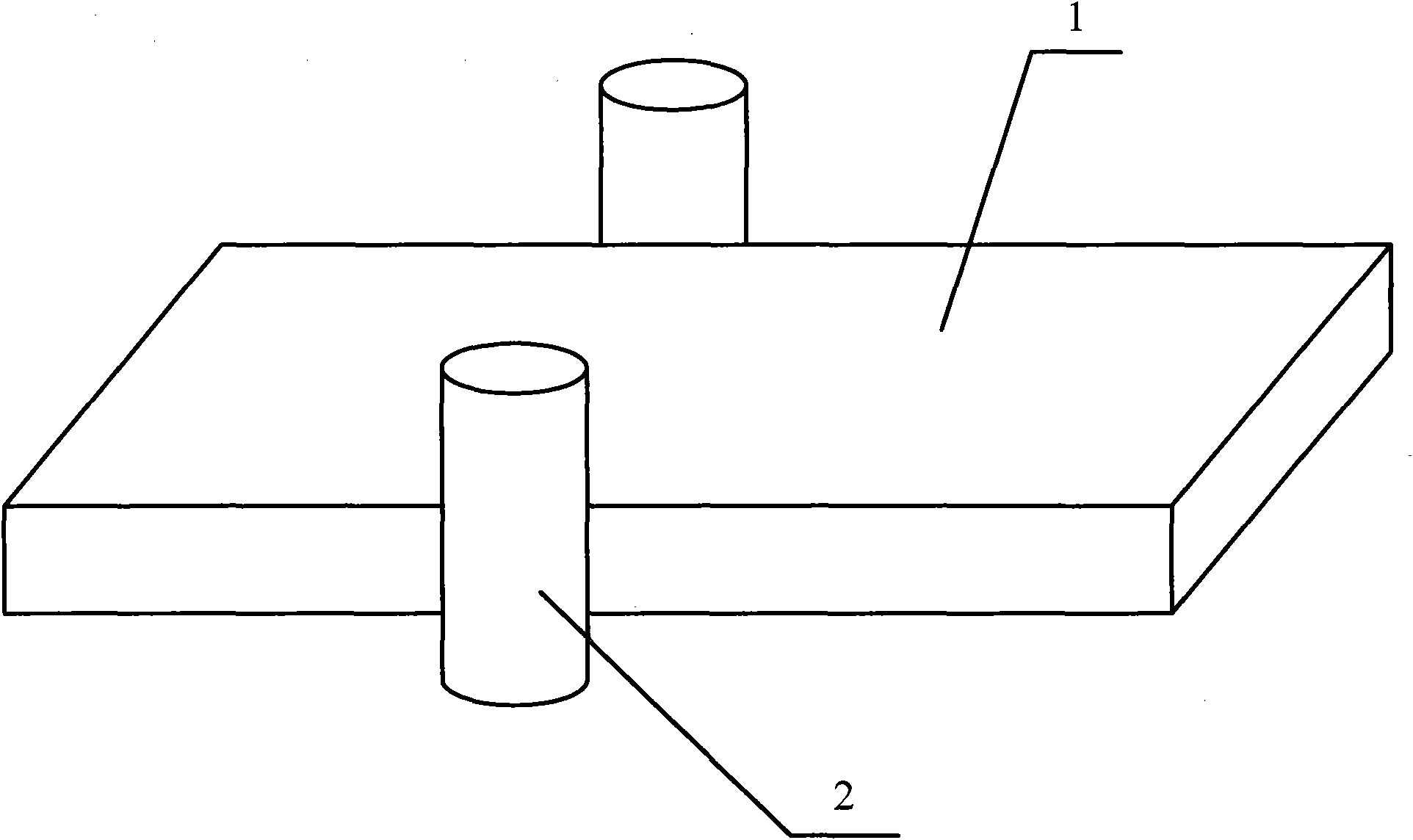

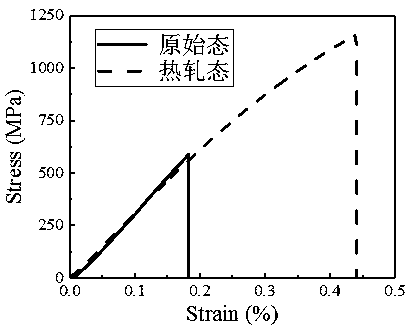

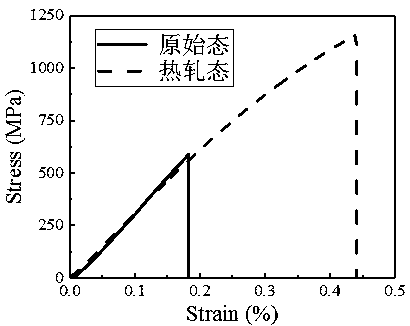

Rolling method of magnesium alloy plate and auxiliary rolling method thereof

InactiveCN102039308AReduce processing costsReasonable cost controlMetal rolling arrangementsCrystallitePre treatment

Owner:CHONGQING UNIV

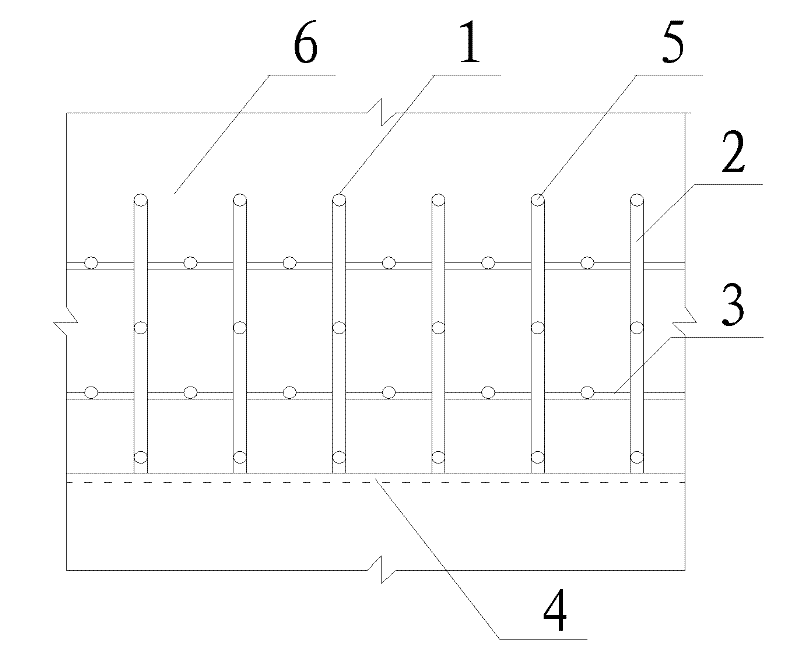

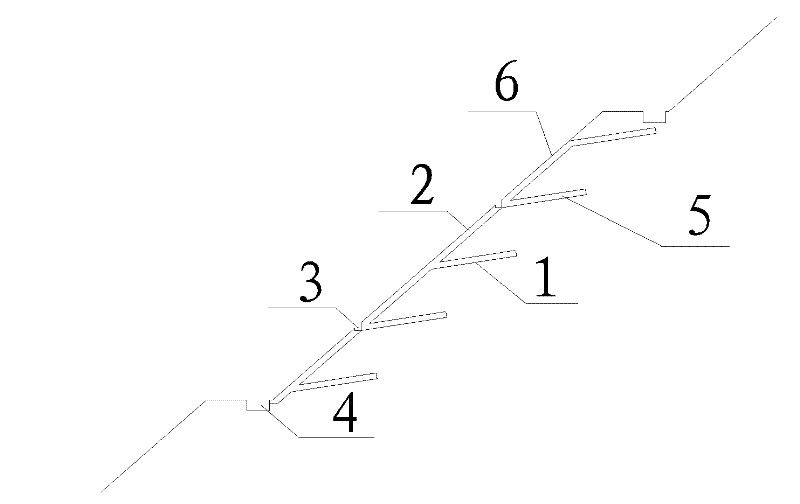

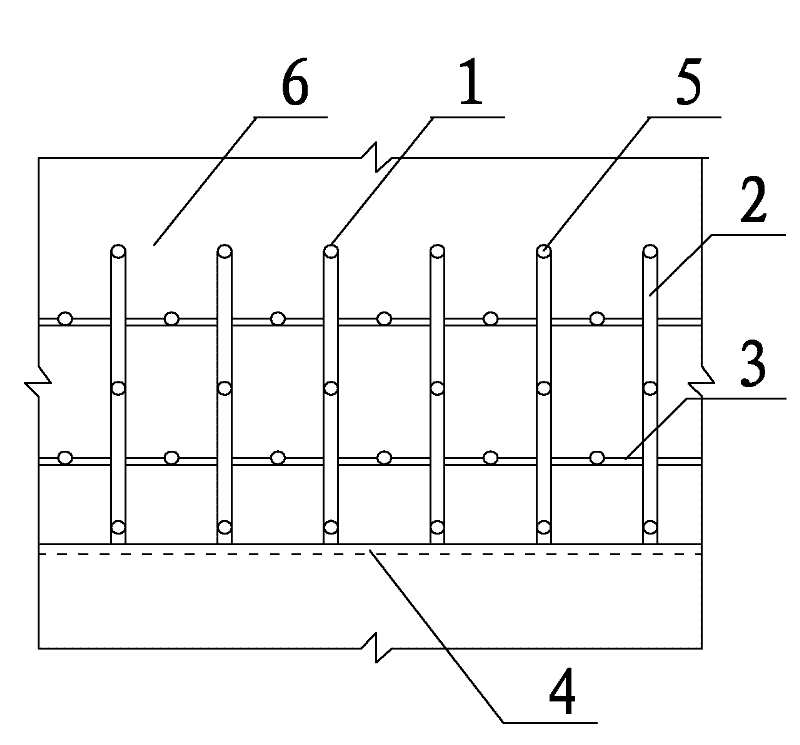

A slope shallow drainage system

The invention discloses a side slope shallow drainage system. The bottom platform of the side slope (6) is provided with drainage ditches (4), and multiple rows and rows of drainage boreholes are densely arranged on the side slope (6). (1), the distance between the drainage boreholes (1) is 2-3m, the depth is 3-4m, and the elevation angle is 0-10°, each of the drainage boreholes (1) is provided with Drainage pipe, the slope of the slope (6) is arranged with a longitudinal micro-drainage ditch (2) and / or a transverse micro-drainage ditch (3) docked with the outlet of each of the drainage pipes, the The longitudinal miniature water collection ditch (2) and / or the horizontal miniature water collection ditches (3) communicate with the drainage ditch (4). The invention is a side slope shallow layer drainage system for quickly and efficiently discharging the groundwater infiltrated by rainfall into the shallow layer soil of the side slope.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

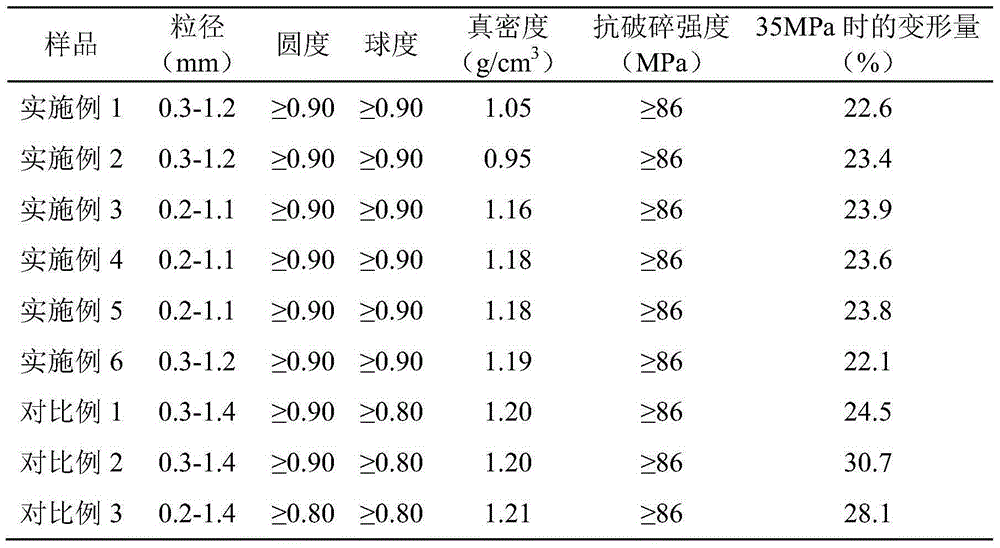

Low-density composite proppant, preparation method and applications thereof

The present invention provides a low-density composite proppant, which is prepared by carrying out a polymerization reaction on an oil phase and an aqueous phase, wherein the oil phase comprises, by weight, 60-90 parts of a monomer, 5-25 parts of a cross-linking agent, 0.01-10 parts of a filler, 0.1-5 parts of an initiator and 0-2 parts of a filler dispersant, and the aqueous phase comprises, by weight, 90-100 parts of water, 0.1-5 parts of a dispersant and 0.1-5 parts of an inorganic salt. The present invention further provides a preparation method of the proppant, wherein the preparation method comprises: uniformly mixing the dispersant, the inorganic salt and the water to obtain the aqueous phase, uniformly mixing the monomer, the cross-linking agent, the initiator, the filler and the optional filler dispersant to obtain the oil phase, mixing the oil phase and the aqueous phase, carrying out a polymerization reaction at a certain temperature to obtain a polymerization product system, and post-treating the obtained polymerization product system. The present invention further discloses applications of the proppant or the proppant prepared according to the method in reservoir fracturing reforming.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cold-resistant flame-retardant PVC cable material

ActiveCN104072914AImprove flame retardant performanceImprove cold resistancePlastic/resin/waxes insulatorsPlasticizerStearic acid

The invention relates to a cold-resistant flame-retardant PVC cable material containing the following components in parts by weight: 100 parts of PVC resin, 33-40 parts of DOP, 12-8 parts of DOTP, 3-5 parts of epoxidized soybean oil, 1-30 parts of vinyl acetate, 30-50 parts of inorganic filler, 4-6 parts of antimony trioxide, 0.1-0.2 part of polyethylene wax, 0.1-0.2 part of stearic acid and 2-5 parts of calcium and zinc composite stabilizer. The cold-resistant flame-retardant PVC cable material provided by the invention has more excellent flame retardant property, so that a cable is prevented from becoming a fire spreading source in a fire; the cold-resistant flame-retardant PVC cable material is remarkable in cold resistance, so that the cable can bear a colder environment; the parts of the used cold-resistant plasticizer and flame retardant are remarkably reduced, so that the formula cost is controlled more reasonably.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH +1

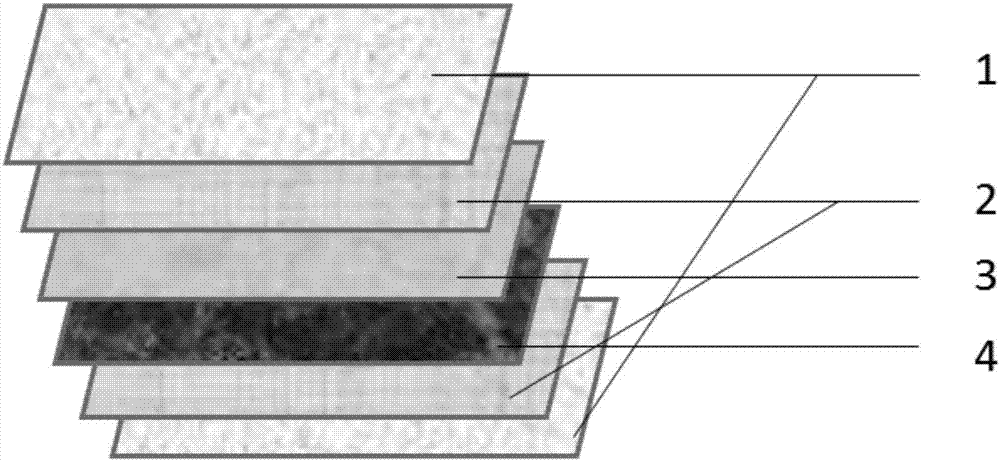

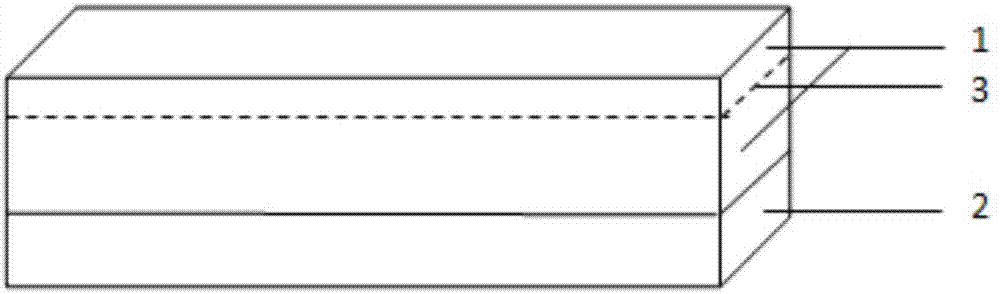

Rice straw composite vegetation substrate module used for desertification land treatment

InactiveCN107006288AImprove survival rateFast growthGrowth substratesCulture mediaGrowth plantVegetation

The invention discloses a rice straw composite vegetation substrate module used for desertification land treatment. The module sequentially comprises an upper non-woven cloth lining mesh layer, an upper straw fiber layer, a dry and compressed composite plant growth substrate layer, a lower straw fiber layer and a lower non-woven cloth lining mesh layer. The straw composite substrate can provide a relatively good water and fertilizer microhabitat for plant growth on desertification land, the plant survival rate is higher, growth speed is higher, the survival time is longer, and the vegetation ecological restoration efficiency is improved. The rice straw composite substrate module is used, substrate modules can be freely combined and spliced according to geological characteristics and demands in a tile adhering mode, and installation is very convenient. The straw substrate module is convenient to transport and store.

Owner:SOUTHWEAT UNIV OF SCI & TECH

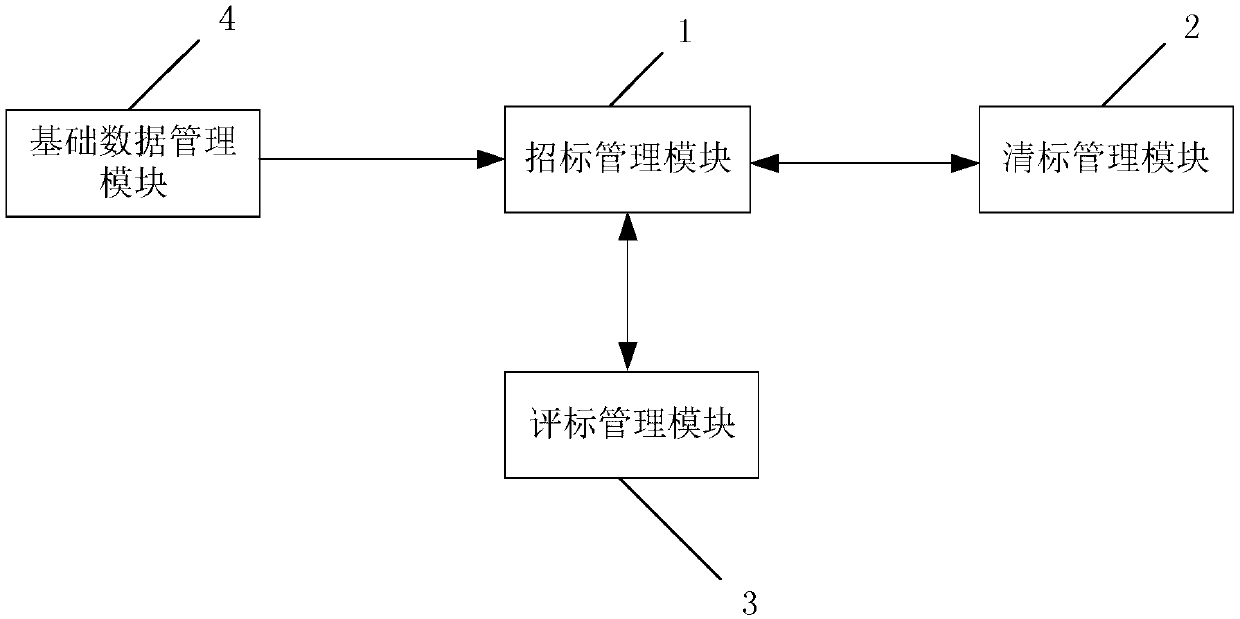

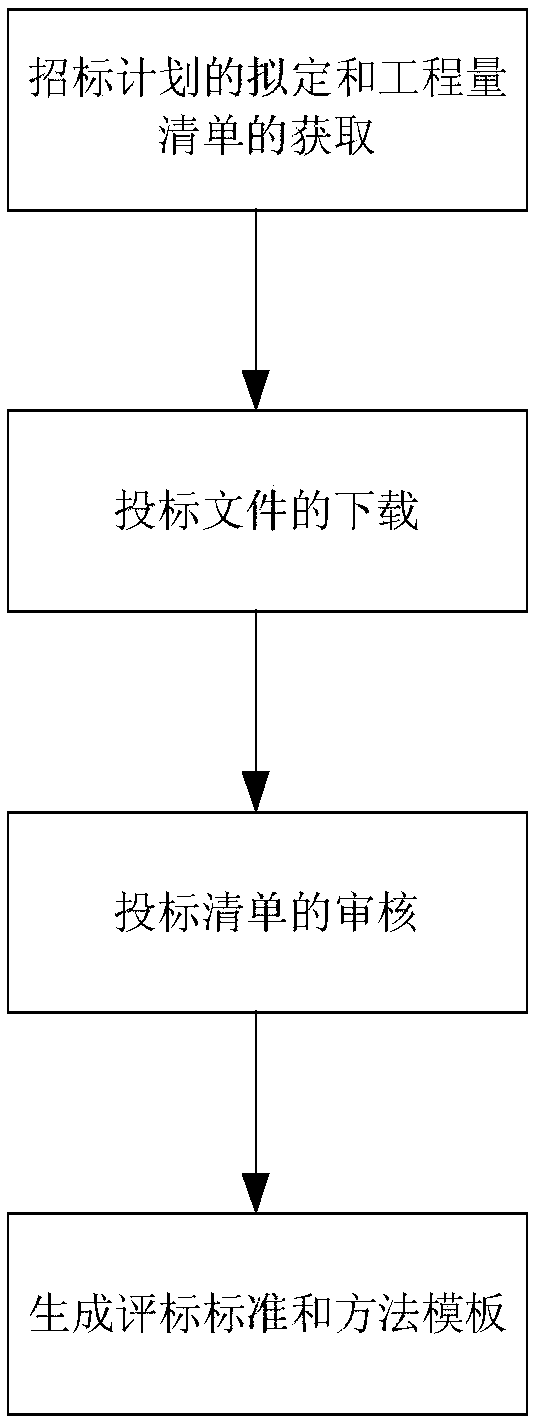

Bill of quantities (BOQ)-based tendering and bidding management control system and control method thereof for technical renovation overhaul project of power grid

PendingCN107833108ALow costReasonable cost controlBuying/selling/leasing transactionsResourcesProgram planningPower grid

The invention relates to a bill of quantities (BOQ)-based tendering and bidding management control system and a control method thereof for the technical renovation overhaul project of a power grid. Compared with the prior art, the defect that no BOQ-based centralized treatment is available for tendering and bidding data in the prior art can be solved. The method comprises the steps of drawing up abidding plan and obtaining a BOQ; downloading a bidding document; checking a bidding list; generating an evaluation standard and a method template. According to the invention, the content of the BOQis automatically converted into a controlled bidding price file, and the project cost can be reasonably controlled. Meanwhile, the rapid bidding clearing and evaluating of tendering and bidding projects for the technical renovation overhaul project of the power grid can be realized at the same time. The working efficiency and the working accuracy of the tendering and bidding management are improved.

Owner:EAST INNER MONGOLIA ELECTRIC POWER COMPANY +1

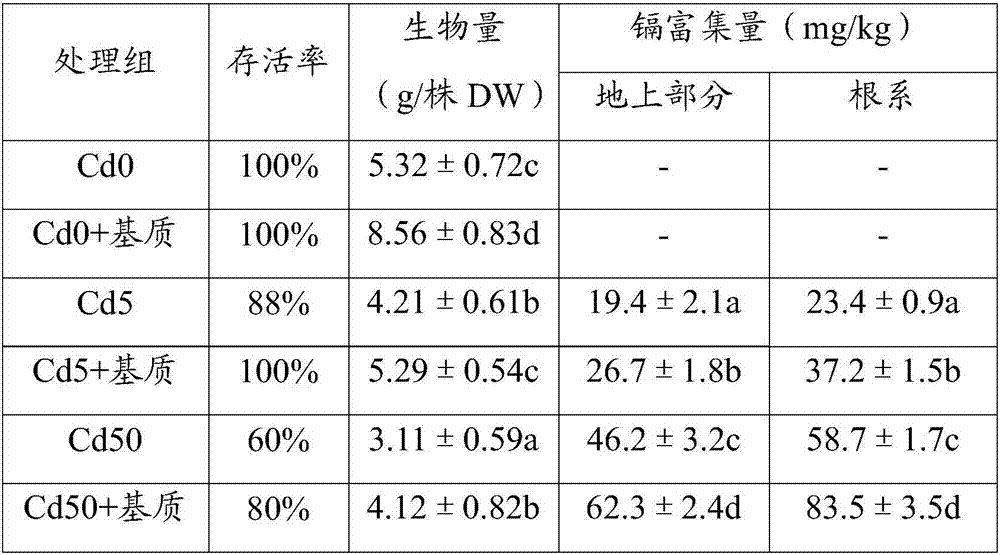

Compound rice straw substrate for promoting phytoremediation on cadmium polluted soil and preparation method and application thereof

ActiveCN107006158AImprove survival rateFast growthContaminated soil reclamationCultivating equipmentsRice strawYeast

The invention discloses a compound rice straw substrate for promoting phytoremediation on cadmium polluted soil and a preparation method and application thereof. The compound rice straw substrate comprises an upper substrate layer and a lower substrate layer, wherein the upper substrate layer is prepared from 55-65 parts of composted rice straw substrate particles, 10-20 parts of rice straw long fiber, 5-10 parts of composted animal waste, 5-10 parts of nitrogen phosphorus and potassium compound fertilizer, 0.5-1 part of plant rhizosphere fertilizer and 1-3 parts of biodegradable polymer adhesion agent, and the lower substrate layer is prepared from 85-95 parts of composted rice straw substrate particles, 3-5 parts release agent coated soil chelating agent, 0.5-1 part of soil yeast powder and 1-3 parts of biodegradable polymer adhesion agent. The survival rate of the plants restored by the composite substrate is higher, the growth speed is higher, the survival time is longer, and accordingly the phytoremediation efficiency is improved.

Owner:SOUTHWEAT UNIV OF SCI & TECH

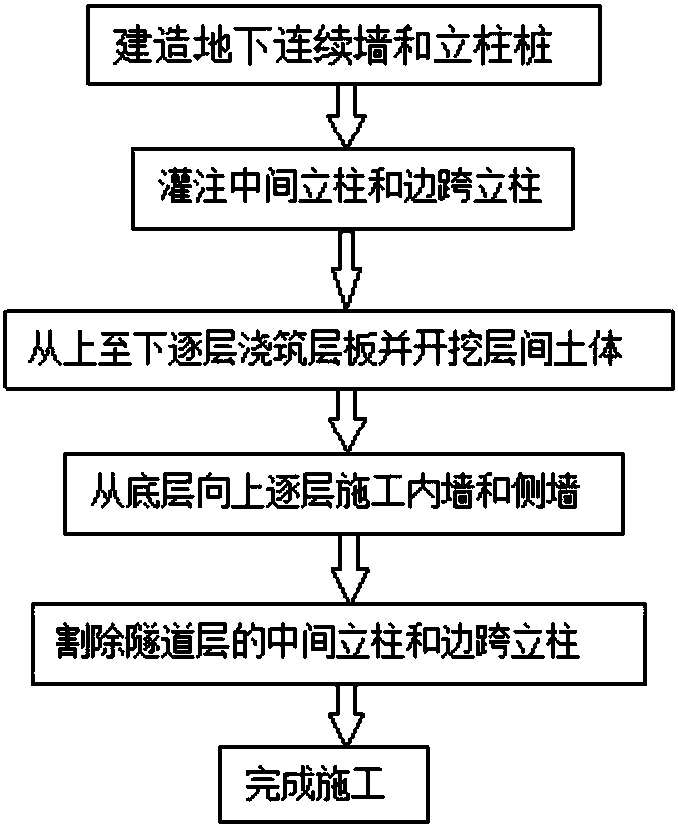

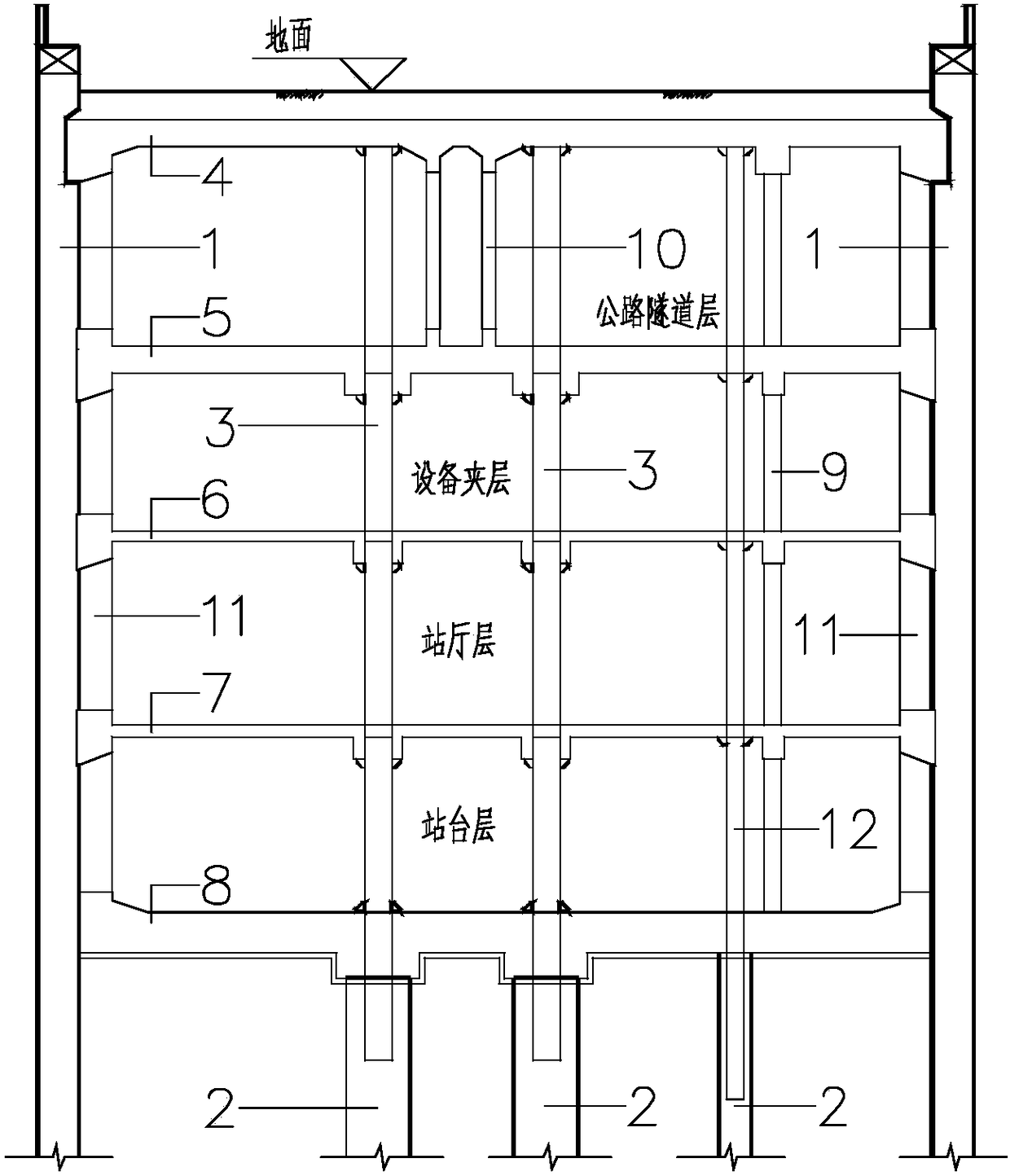

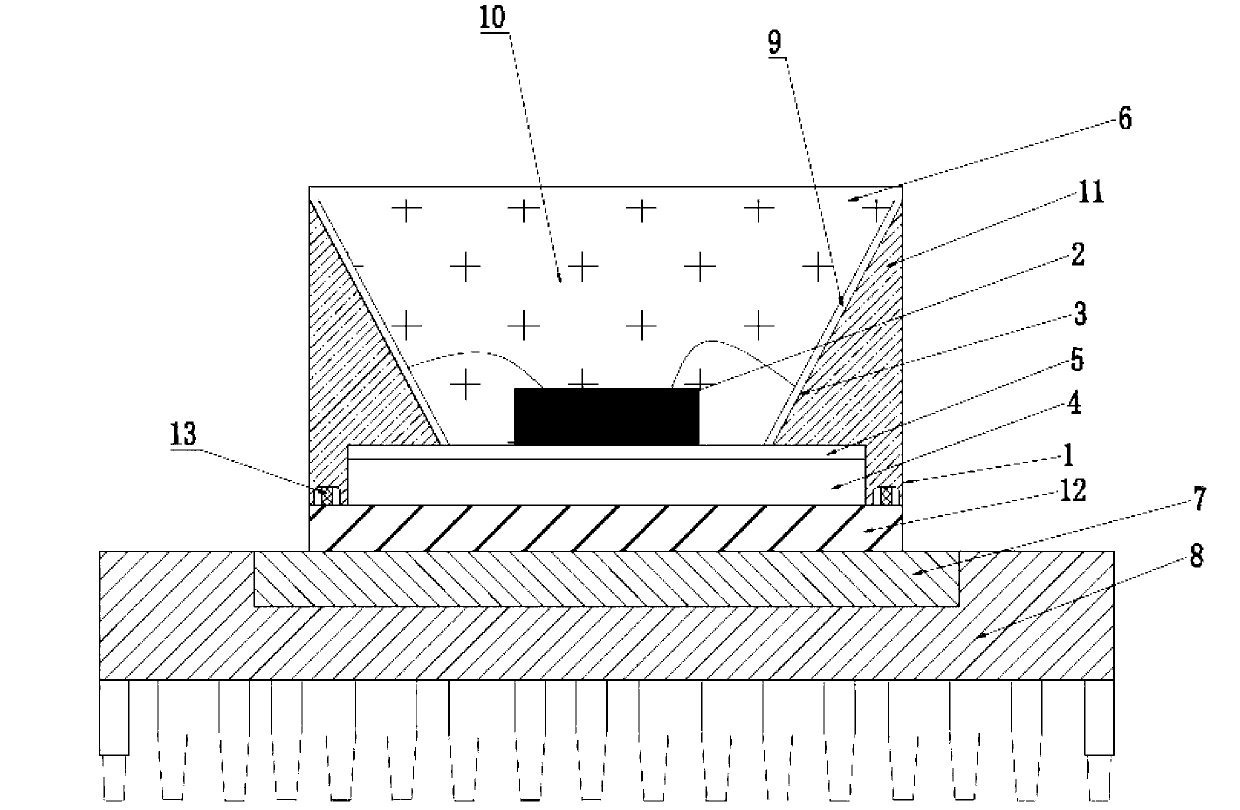

Construction method for subway stations in combined construction of highway and subway

InactiveCN108571321ASolve construction problemsEnsure safetyUnderground chambersTunnel liningSlurry wallSubway station

The invention belongs to the technical field of underground space construction, and particularly relates to a construction method for subway stations in combined construction of highway and subway. The method specifically comprises the following steps: S1 constructing an underground continuous wall and casting a plurality of column piles on the inner side of the underground continuous wall; S2 aligning steel pipes and hoisting the steel pipes on the column piles and pouring concrete to form intermediate columns and side span columns of a concrete steel pipe structure; S3 constructing structural roofs and intermediate structure layers from top to bottom gradually and excavating a soil body below a plate till pouring of a structural base slab is completed; S4 constructing structural side walls from bottom to top layer by layer and simultaneously constructing side span structure inner walls and highway tunnel structure inner walls; S5 cutting off the intermediate columns and the side spancolumns of the top layer to complete the construction. The method can effectively solve the problem that the stress conversion multilayer underground structure is difficult to construct, ensures smooth stress conversion of the main body structure, meanwhile can reasonably control the cost, ensures the safety of a foundation pit and the external structures, and is suitable for the construction ofthe subway stations in combined construction of the highway and the subway.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Light-emitting diode (LED) packaging structure

InactiveCN103107276AReasonable cost performanceImprove cooling effectSemiconductor devicesHeat conductingCost Controls

The invention discloses a light-emitting diode (LED) packaging structure which comprises a packaging base plate and an LED chip. The packaging base plate is provided with at least one reflecting cup which is groove-shaped. A heat conducting substrate is arranged between the LED chip and the packaging base plate. A silver base is adopted by the heat conducting substrate to serve as a heat lining material. The heat conducting substrate is fixedly connected with the packaging base plate through tin soldering. Heat emitted by an LED is rapidly conducted through heat absorption copper blocks. Due to the fact that the copper blocks are added between a radiator which is made of aluminum, and the LED, a heat dissipation effect is further strengthened. Due to the fact that tin pieces serve as connecting materials between crystal particles and a heat lining, a heat conducting effect is further strengthened. In addition, cost performance of the radiator is fully taken into consideration, radiators with different characteristics are combined together, and efficient heat dissipation is achieved, the LED packaging structure is reasonable in cost control and simple in structure, and the LED packaging structure improves a lighting effect.

Owner:孙雪刚

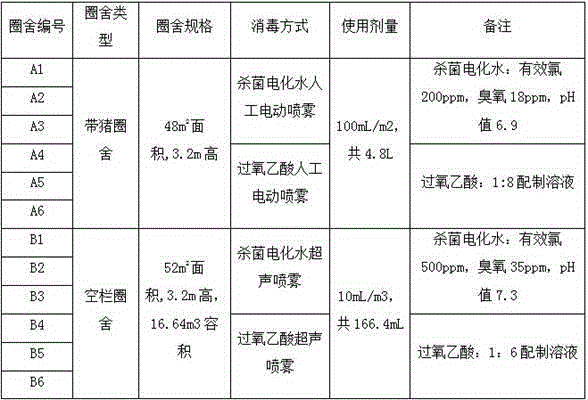

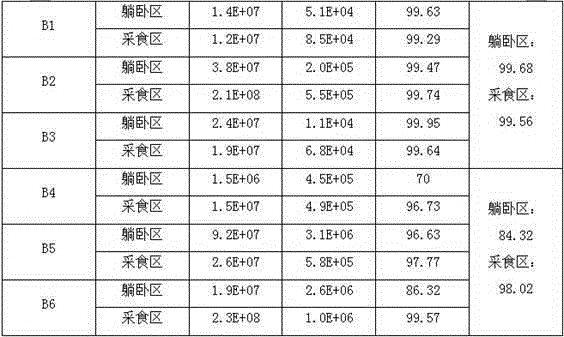

Application of electrified water for piggery disinfection

InactiveCN105012973AReduces pungent odorsNo irritating smellLavatory sanitoryChemicalsPathogenic microorganismLivestock breeding

The invention relates to an application of electrified water for piggery disinfection, and belongs to the technical field of livestock breeding. The electrified water is applied to the piggery disinfection, and the problems that in an existing piggery disinfection mode, medicinal residues exist, the cost is high, and the electrified water is not applied to the piggery disinfection are solved. The electrified water is adopted to conduct disinfection on internal environment of a piggery, personnel and vehicles coming in and going out the piggery and the like, pathogenic microorganisms are effectively killed, the transmission route of the pathogenic microorganisms is cut off, the purpose of epidemic prevention is achieved, the morbidity is decreased, the cost is reduced, and the breeding benefit is promoted.

Owner:TONGWEI

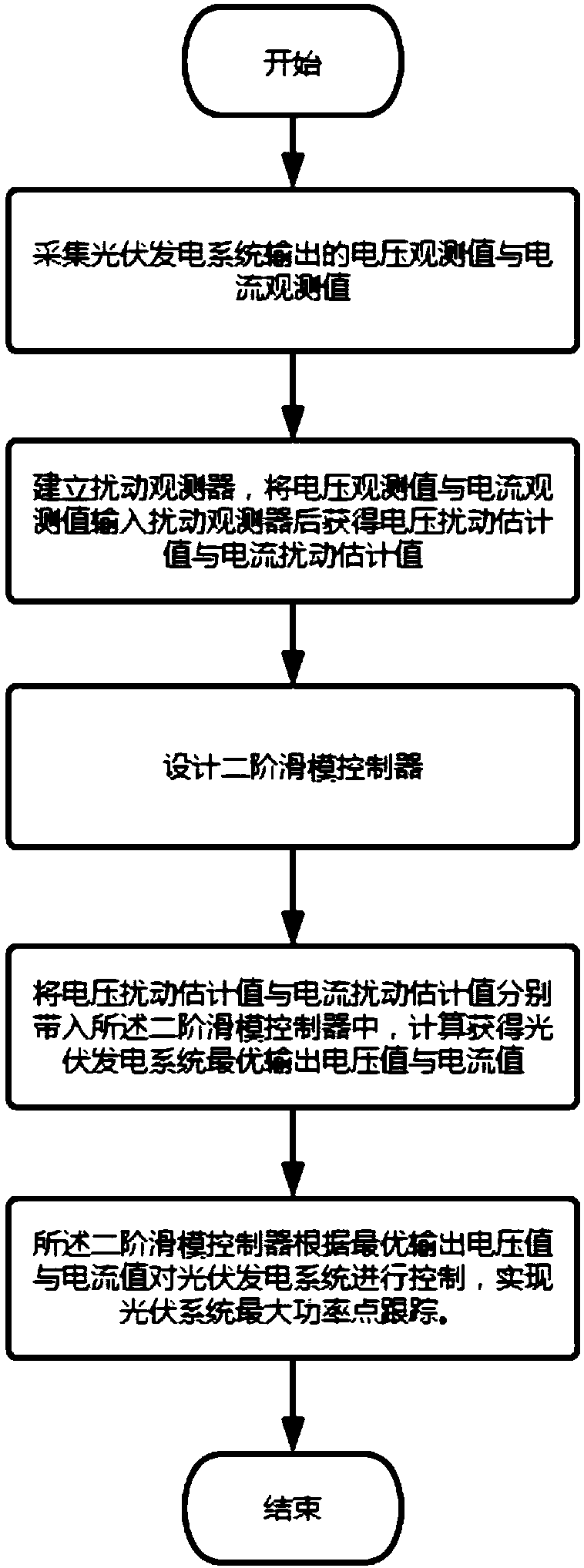

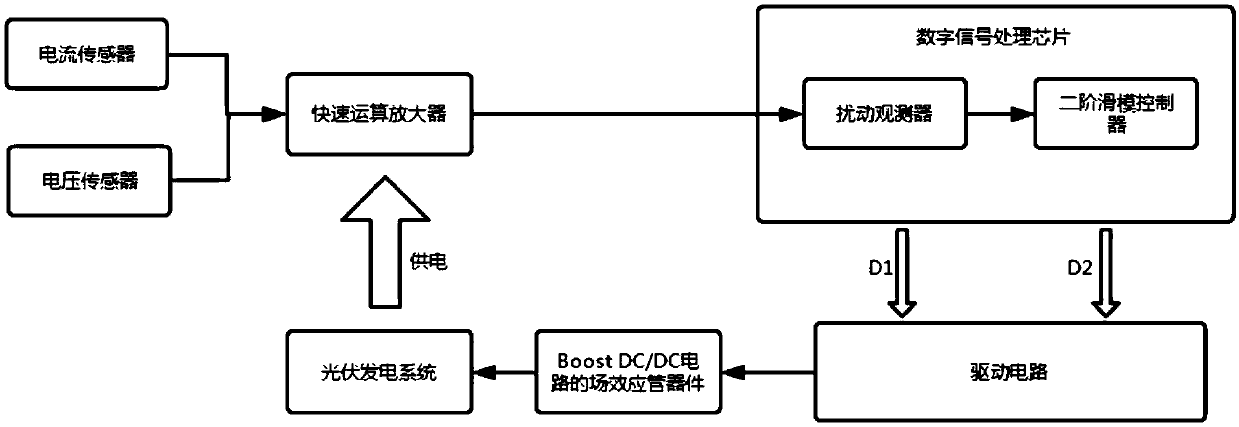

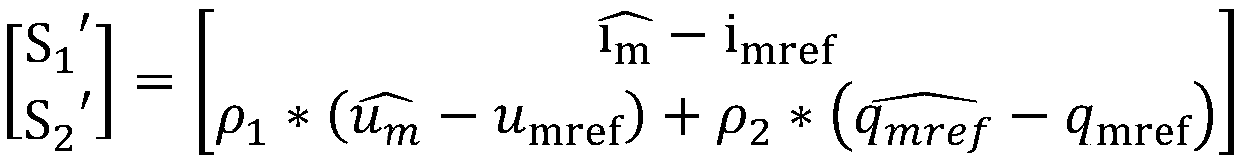

Maximum power tracing method and system of photovoltaic system

InactiveCN109062316AImprove power generation efficiencyImprove robustnessPhotovoltaic energy generationElectric variable regulationEngineeringMaximum power point tracking

The invention provides a maximum power tracing method and system of a photovoltaic system. A disturbance observer can be built according to various uncertainty factors such as non-linearity, parameteruncertainty and random shadow environment during working of a photovoltaic power generation system, a voltage disturbance estimation value and a current disturbance estimation value are obtained after a voltage observation value and a current observation value are input the disturbance observer, a sliding plane is calculated according to the voltage disturbance estimation value and the current disturbance estimation value, an actual control voltage and a control current are obtained by sliding-mode control on the two disturbance estimation value, and maximum power point tracing of photovoltaic power generation is finally achieved. Maximum power tracing of the photovoltaic system under a local shadow environment is achieved, and the maximum power point capturing capability of the photovoltaic system and the system control robustness are improved.

Owner:HAINAN POWER GRID CO LTD ELECTRIC POWER RES INST

Redundancy support method based on DP3 (Dynamic Positioning 3) drilling ship benefit fast Ethernet system

ActiveCN103744400AEfficient configurationEfficient managementProgramme total factory controlNetworked systemEmbedded system

The invention provides a redundancy support method based on a DP3 (Dynamic Positioning 3) drilling ship benefit fast Ethernet system. A network system is divided into a network A and a network B which are of A60 division, all NETWORK SWITCH BOXes are designed as groups A and B according to the network A and the network B, and all work stations are simultaneously connected to paths A and B; any one of the network A and the network B is simultaneously connected to all controllers and sensors in main DP and a standby DP; when any point on the network A has a fault, the system automatically judges and acquires data by virtue of the network B, and the reverse is true. A modular design is adopted, the redundancy support method completely conforms to the DPS3 (Data Processing Station 3) standard and can be used for realizing efficient allocation, management and scheduling of electrical energy of a drilling ship; the system structure is concise and clear, and the cost control is reasonable; the stability, security and reliability of the system can be obviously improved.

Owner:上海中远船务工程有限公司

Preparation method of high-purity tungsten plate easy to machine

InactiveCN111155069AHigh purityImprove compactnessChemical vapor deposition coatingHigh densityChemical vapor deposition

The invention belongs to the technical field of refractory metal special machining, and relates to a preparation method of a high-purity tungsten plate easy to machine. The method comprises three technological processes of tungsten plate blank preparation through chemical vapor deposition, rolling and annealing. Chemical vapor deposition tungsten is modified through a cooling rolling method, finally, stress relief annealing is conducted on the obtained tungsten plate, and the high-performance tungsten plate is obtained. The problem that the ductility is poor at the room temperature is solved,and the advantages of high purity and large density are reserved. The method is simple in technology, large-batch preparation can be achieved, and size regulation and control can be conducted according to different application backgrounds.

Owner:KUNMING UNIV OF SCI & TECH

Mouse cage cast aluminum rotor with low loss

InactiveCN104935134AReduce active lossLow resistivityAsynchronous induction motorsPunchingElectric machine

The invention belongs to the asynchronous motor manufacturing field. In order to solve a technical problem that a current mouse cage cast aluminum rotor has large loss, the invention provides a mouse cage cast aluminum rotor with low loss. The rotor is formed through stacking rotor punching sheets. Punching grooves of the rotor punching sheets are superposed so as to form a rotor groove. The rotor is characterized in that a copper conducting bar is embedded in the rotor groove; a cast aluminum conducting bar is formed through a cast aluminum operation in a gap between the copper conducting bar and the rotor groove. By using the rotor of the invention, there are the following advantages that the rotor possesses a low electrical resistivity and low rotor active loss compared to a traditional cast aluminum rotor; compared to a cast copper rotor, a technology of the cast aluminum rotor is simple and industrialization is convenient to realize. Simultaneously, according to a need, a proportion relation of a copper conducting bar area and a cast aluminum conducting bar area is adjusted; the resistivity is adjusted; under the condition of reducing the rotor active loss, product cost is reasonably controlled.

Owner:SHANDONG HUALI ELECTRIC MOTOR GRP

Embedded strip for epoxy resin-based fiber-reinforced high-modulus wind turbine blade, equipment and process

PendingCN111873490AHigh strengthGood adhesionFinal product manufactureMachines/enginesEpoxyGlass fiber

The invention discloses an embedded strip for an epoxy resin-based fiber-reinforced high-modulus wind turbine blade, equipment and a process. The embedded strip comprises a composite material body andcomposite surface felts which are arranged on the upper surface and the lower surface of the composite material body; the composite material body is a glass fiber reinforced epoxy resin composite material; and glass fibers comprise twistless roving glass fibers, bulked yarn glass fibers and glass fiber cloth, the twistless roving glass fibers and the bulked yarn glass fibers are uniformly arranged in the composite material body in multiple layers in the length direction to form a multi-layer structure, and at least one layer of glass fiber cloth is arranged in the multi-layer structure in thelength direction. The embedded strip is a high-modulus embedded strip reinforced by epoxy resin-based fibers, and the embedded strip manufactured by the method has the advantages of high modulus, certain toughness and ageing resistance, and can meet the production requirements of blades of units with the power of less than 7MW at present.

Owner:西安永兴科技发展有限公司

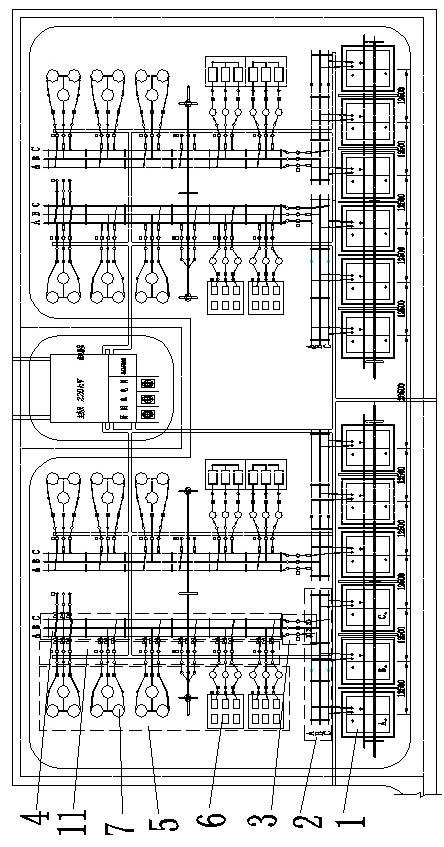

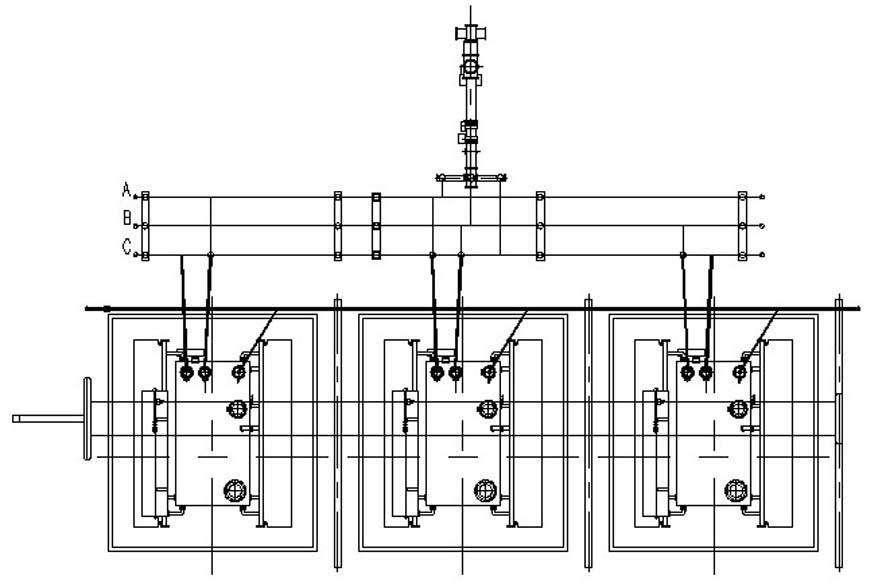

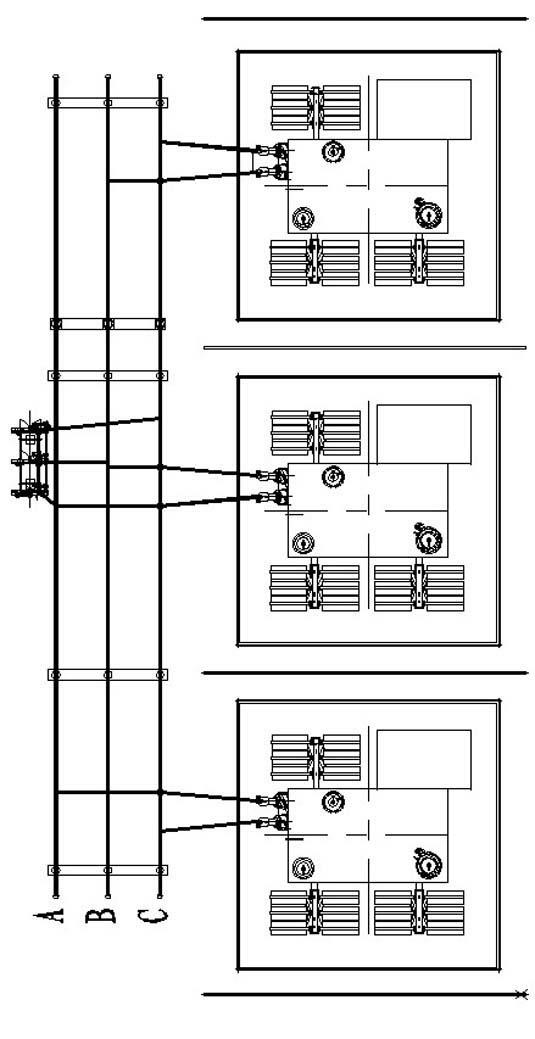

66kv side structure of compact 500kv main transformer

InactiveCN102570329AIn line with the development trend of electric power technologyReduce layout sizeNon-enclosed substationsBus-bar/wiring layoutsShunt capacitorsEngineering

A 66kv side structure of a compact 500kv main transformer comprises an A, B, C three-phase transformer. The three-phase transformer is connected to a main loop through a triangle bus. The main loop is connected with a 66kv bus and a switch branch loop. The 66kv bus and the switch branch loop are connected with each branch loop. The branch loop comprises: a capacitance branch loop and a reactance branch loop. The capacitance branch loop comprises: a shunt capacitor group and a series reactor connected with the shunt capacitor group. The reactance branch loop comprises a three-phase reactor. The triangle bus uses a gas insulation bus to complete triangle winding. In the capacitance branch loop, A, B, C three phases are superposed to place in the each shunt capacitor group. In the reactance branch loop, the reactor is a superposition-type dry parallel hollow reactor or a magnetic-shielding parallel reactor.

Owner:HENNAN ELECTRIC POWER SURVEY & DESIGN INST +5

Anti-fracture instrument cable material

InactiveCN104927315AGood fracture resistanceFormula cost control is reasonablePlastic/resin/waxes insulatorsPOLYETHYLENE WAXPhosphite ester

The invention discloses an anti-fracture instrument cable material. The anti-fracture instrument cable material comprises, by weight, 20-40 parts of PBT resin, 5-10 parts of SEBS resin, 5-10 parts of trioctyl trimellitate, 5-10 parts of phosphorous ester, 3.5-5.5 parts of gamma-glycidoxy propyl trimethoxy silane, 10-20 parts of aluminium hydroxide flame retardant, 2-5 parts of polyethylene wax, 0.5-2 parts of potassium persulfate, 0.1-0.2 part of montmorillonite, 2.5-4.5 parts of zinc stearate and 0.1-0.2 part of titanium dioxide. The anti-fracture instrument cable material has more excellent anti-fracture performance, cables can be prevented from being fractured in the using and mounting processes or in various environments, and formula cost control is more reasonable.

Owner:ANHUI TIANYUAN CABLE

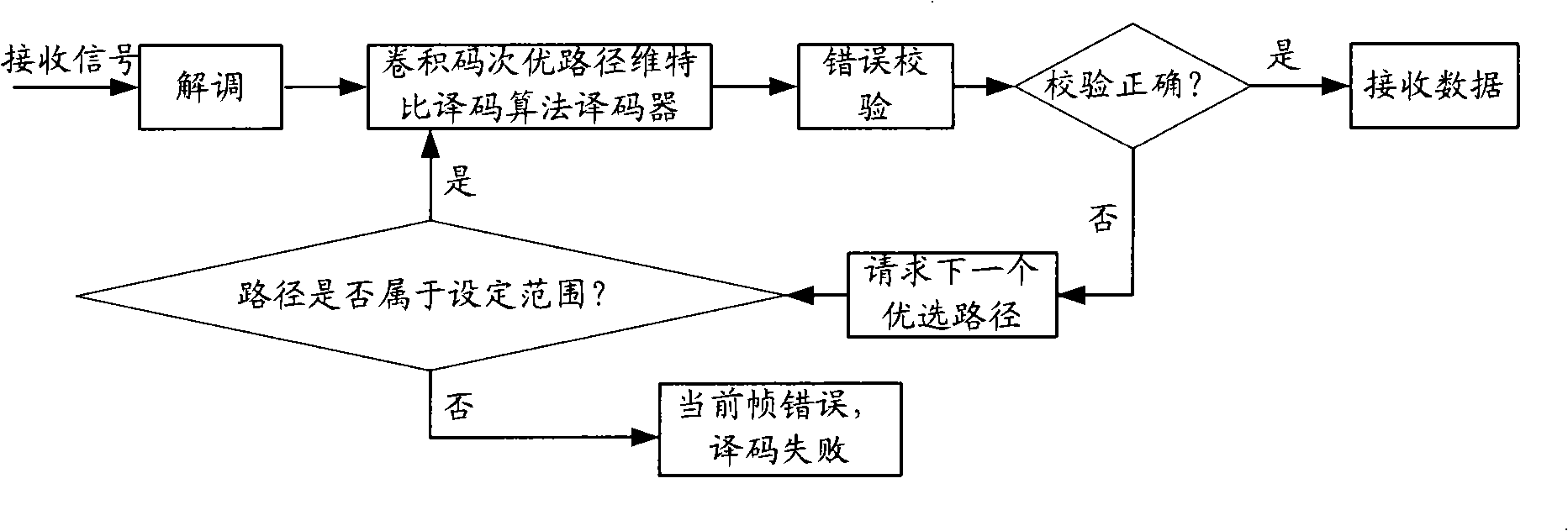

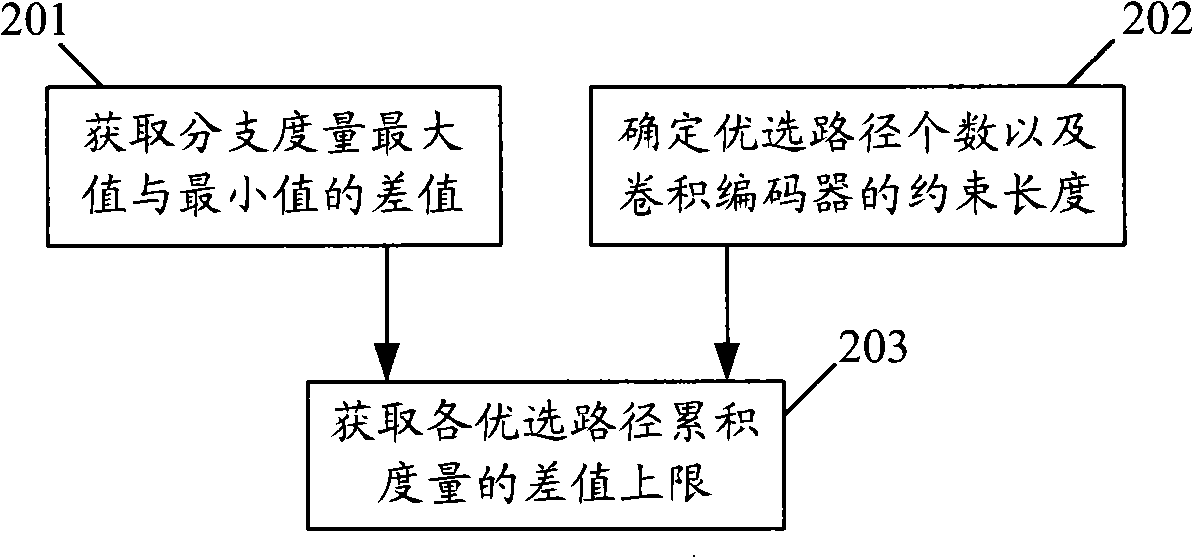

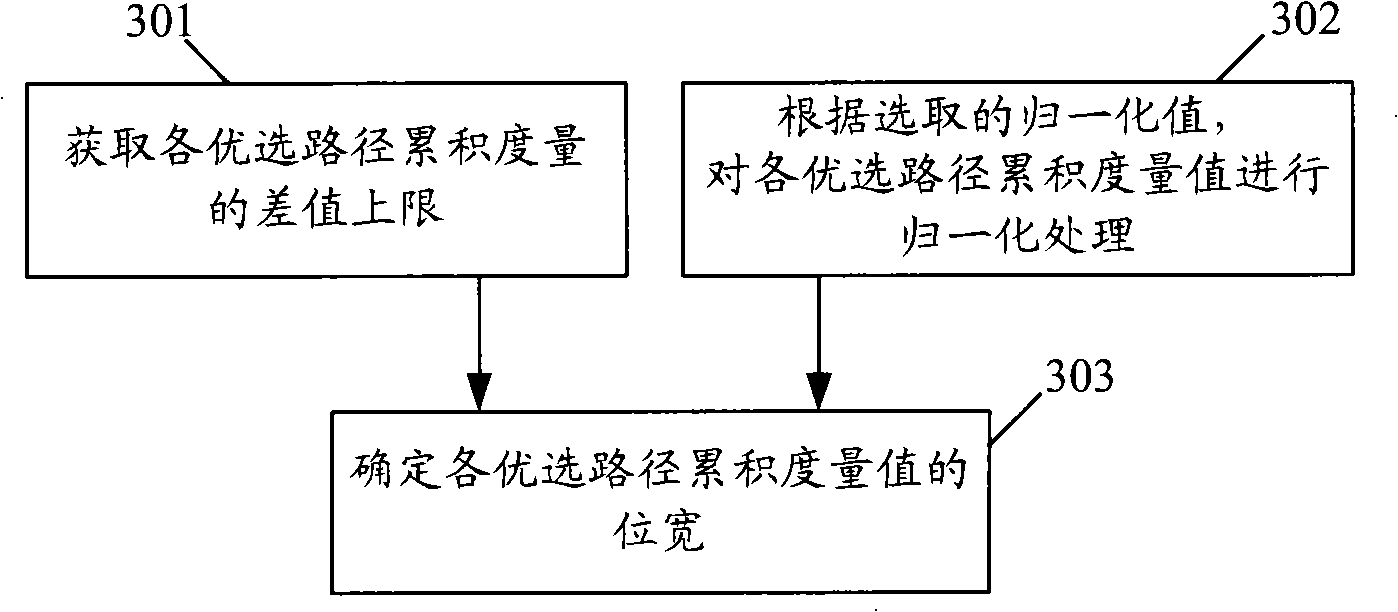

Difference value toplimit acquiring method, point fixing method and apparatus

ActiveCN101321035AGuaranteed fixed-point performanceReasonable cost controlError preventionComputer sciencePoint method

The embodiment of the invention discloses a difference upper limit obtaining method, a fixed point method and a device thereof, wherein the difference upper limit obtaining method comprises: obtaining the difference of the maximum and the minimum of the branch measurement; determining the number of the preferred path and the constraint length of the convolutional coder; obtaining the difference upper limit of the cumulated measurement of the preferred path. The fixed point method includes: obtaining the difference upper limit of the cumulated measurement of the preferred path; performing the normalization process on the cumulated measurement of the preferred path according to the selected normalization value; determining the bit wide of the cumulated measurement of the preferred path according to the selected normalization value and the difference upper limit of each cumulated measurement of the preferred path. The difference upper limit obtaining method can effectively guide the acquisition of the difference upper limit of the cumulated measurement of the preferred path, furthermore, the fixed point bit width can be reasonably arranged through performing the fixed point on the cumulated measurement of the preferred path after being normalized, which ensures the performance of the fixed point of the encoder and reasonably controls the complexity and the cost of the encoder.

Owner:SHANGHAI HUAWEI TECH CO LTD

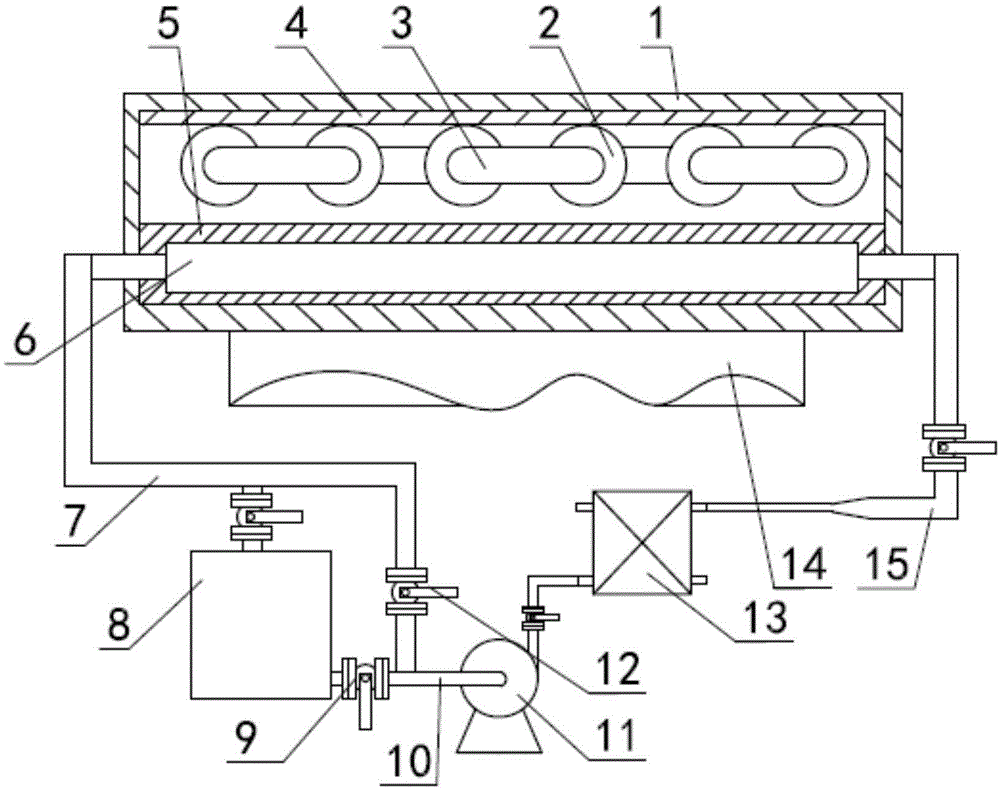

Electrically-heated and water-cooled foam forming upper mold

The invention relates to an electrically-heated and water-cooled foam forming upper mold, belonging to the technical field of foam forming molds. The upper mold comprises an upper mold frame and a heat conducting aluminum block, wherein an insulating plate, an electric heating wire and the heat conducting aluminum block are sequentially arranged in the upper mold frame from top to bottom, a cooling water passage is transversely formed in the heat conducting aluminum block, the left side of the cooling water passage is communicated with a cooling water outlet pipeline, the right side of the cooling water passage is communicated with a cooling water inlet pipeline, and a water tank, a delivery pump and a cooler are sequentially arranged between the cooling water outlet pipeline and the cooling water inlet pipeline. The upper mold is simple in structure, facilitates the design of a foam forming mold, and ensures the qualified rate of a product; under the coordination of the water tank, the delivery pump and the cooler, the cooling time after the product is formed is greatly shortened, and the production efficiency is effectively improved.

Owner:CHONGQING GUOHUA PACKAGING PROD

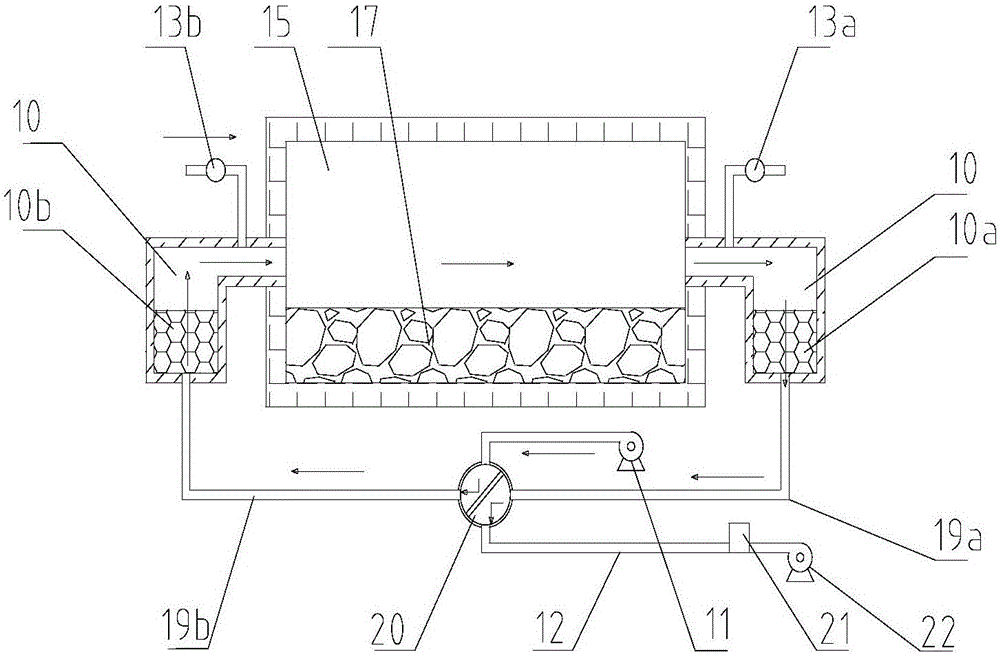

Smelting furnace heated through combination of heavy oil burning, gas burning and electric arc heating

PendingCN106500507AMelting fastPrevent oxidationCrucible furnacesWaste heat treatmentGraphite electrodeCombustor

The invention discloses a smelting furnace heated through combination of heavy oil burning, gas burning and electric arc heating. The smelting furnace comprises a furnace body arranged on a furnace base, the furnace body comprises a side wall, a furnace top, and a fire resistant furnace bottom arranged on the furnace base; a hearth of the furnace body is divided into two parts including a smelting area and a settling area, a furnace bottom of the settling area is lower than a furnace bottom of the smelting area, the furnace bottom of the smelting area adopts an inclined type, one end, adjacent to the settling area, of the smelting area tilts down and is communicated with the settling area, a feed port is formed in a furnace top at one end, far from the settling area, of the smelting area, burners are arranged on opposite two side walls in the smelting area, a graphite electrode penetrating through the furnace top is arranged on the settling area, and a slag discharge port and a hot metal discharge port are respectively formed in the bottom of the settling area. The smelting furnace combines the advantages of gas burning heating and electric arc heating, and has the advantages of low smelting cost, environmental friendliness, high product quality, high handling capacity of single furnace, wide applicability of raw materials, high recovery rate and the like.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

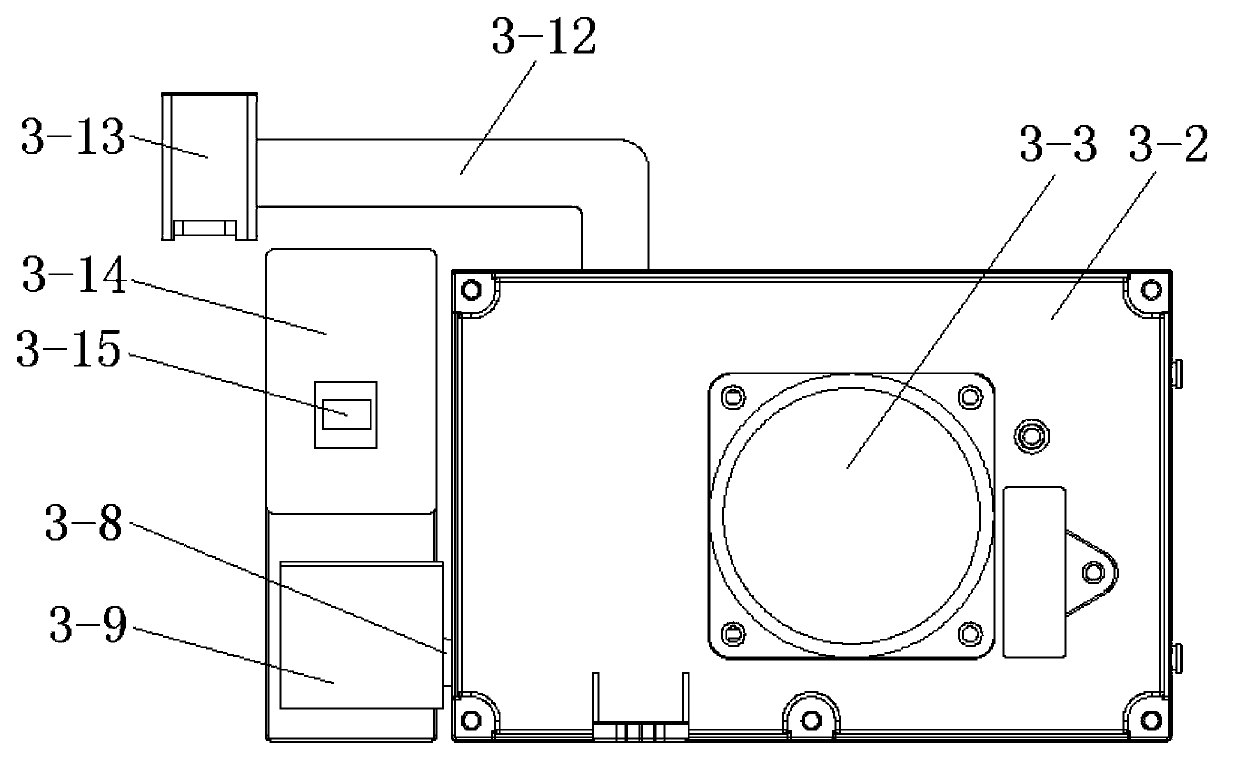

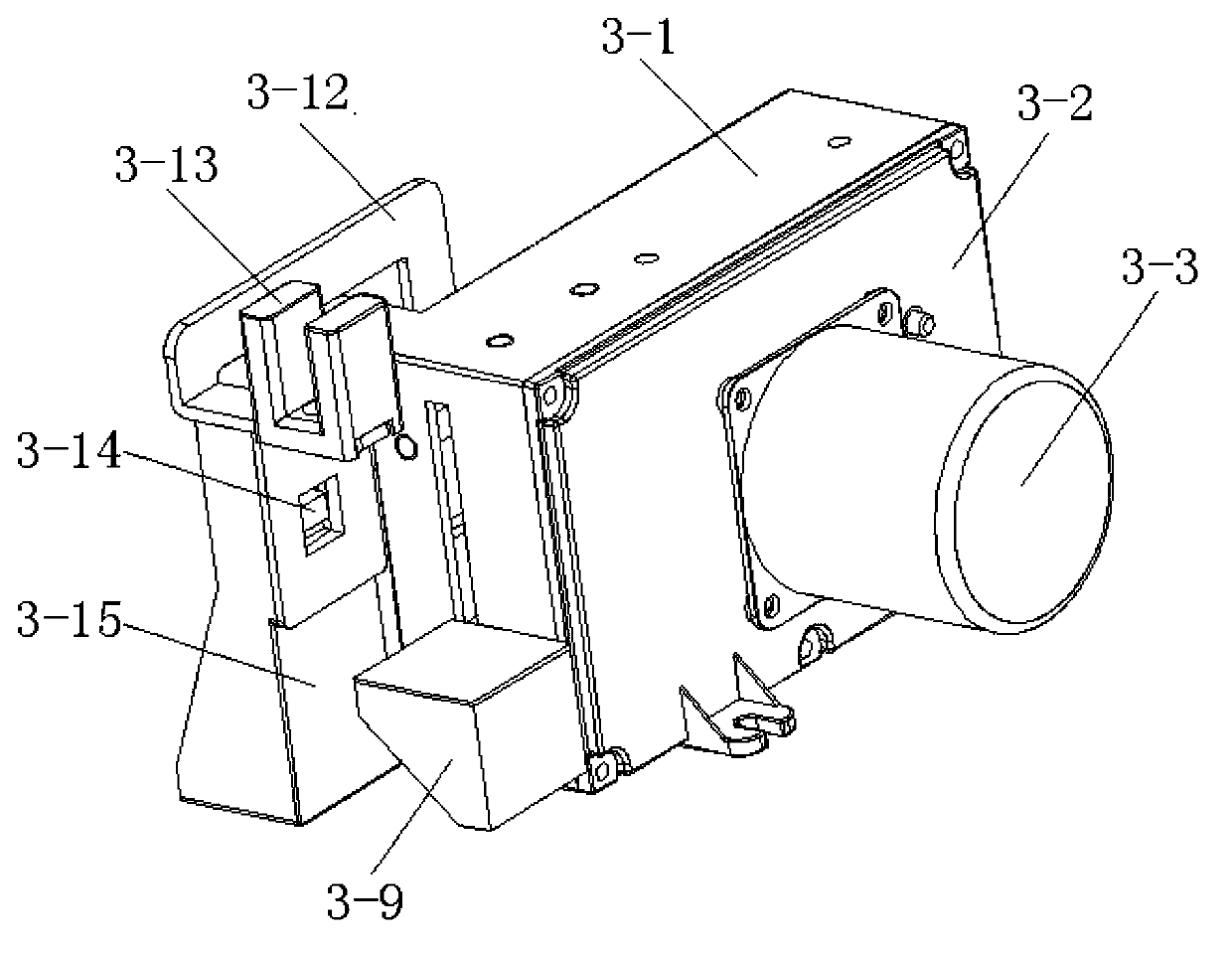

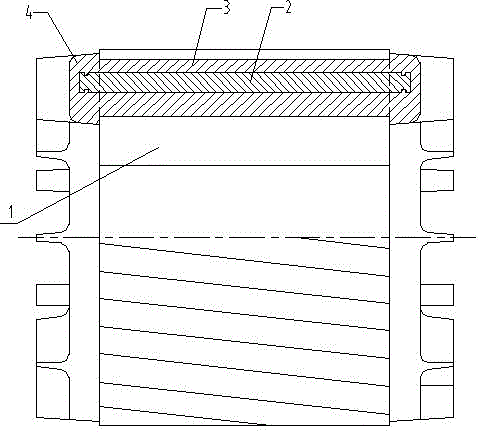

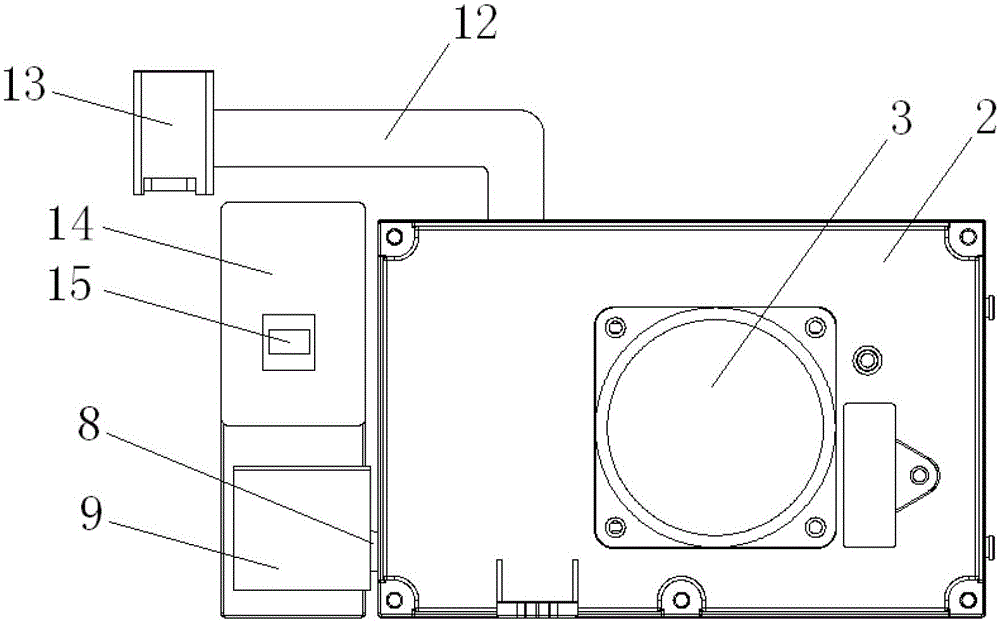

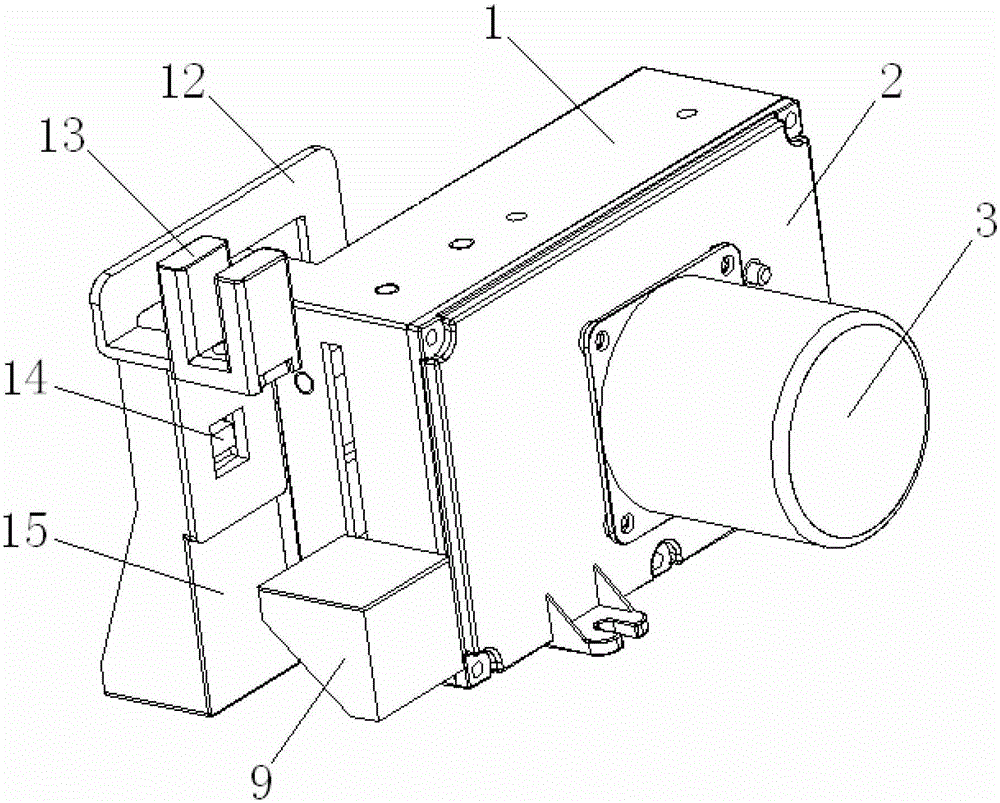

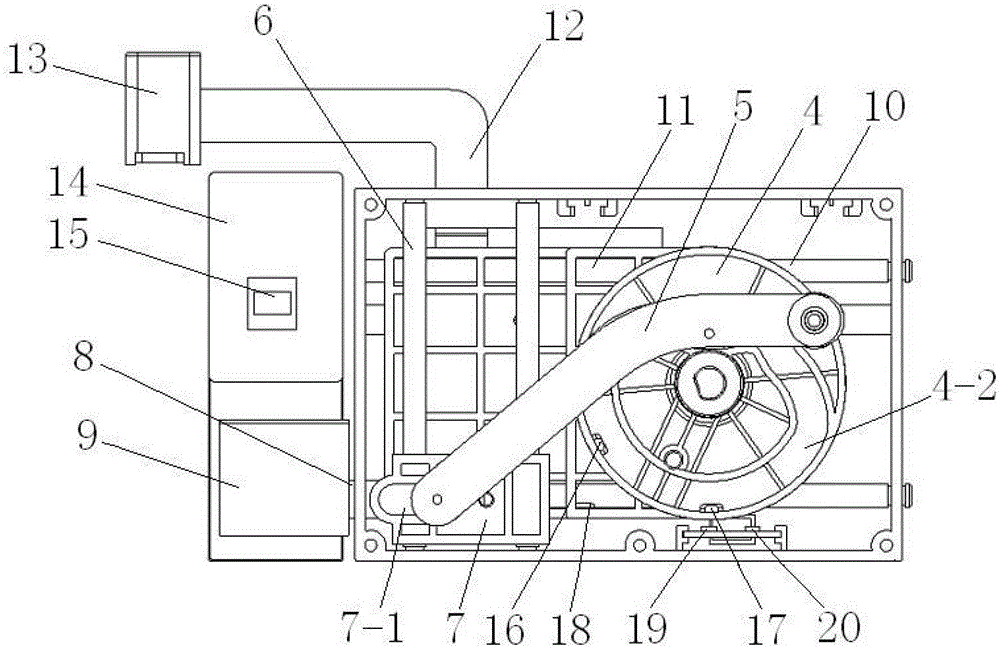

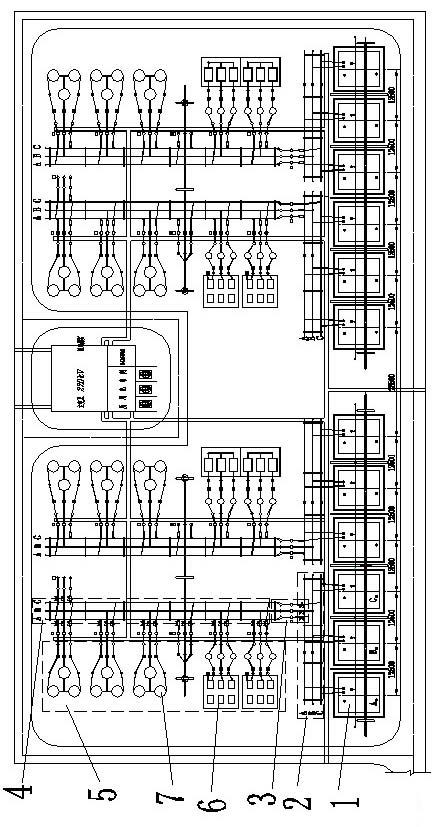

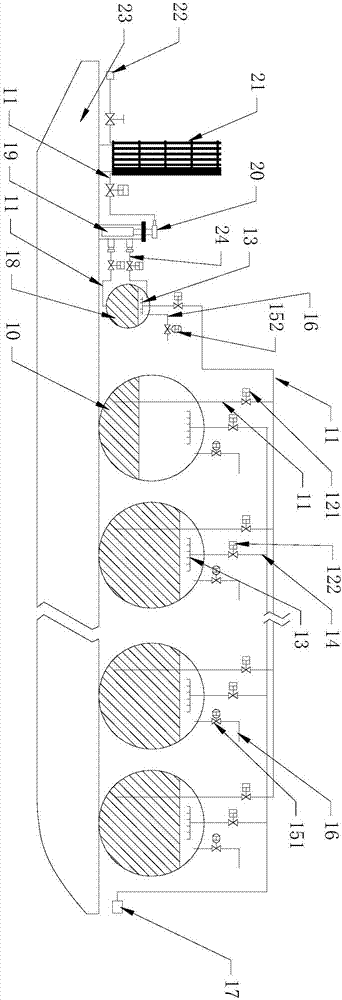

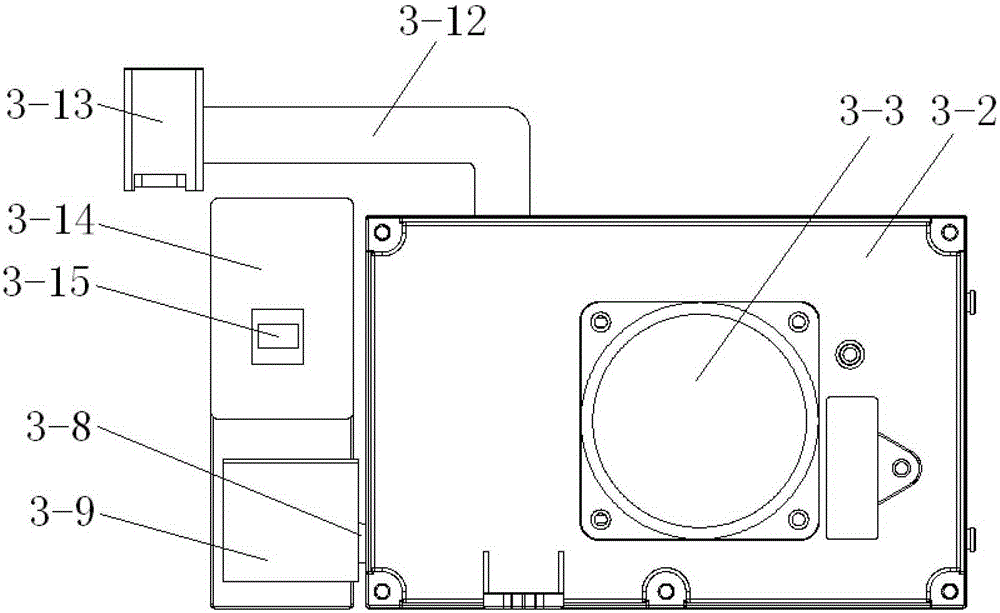

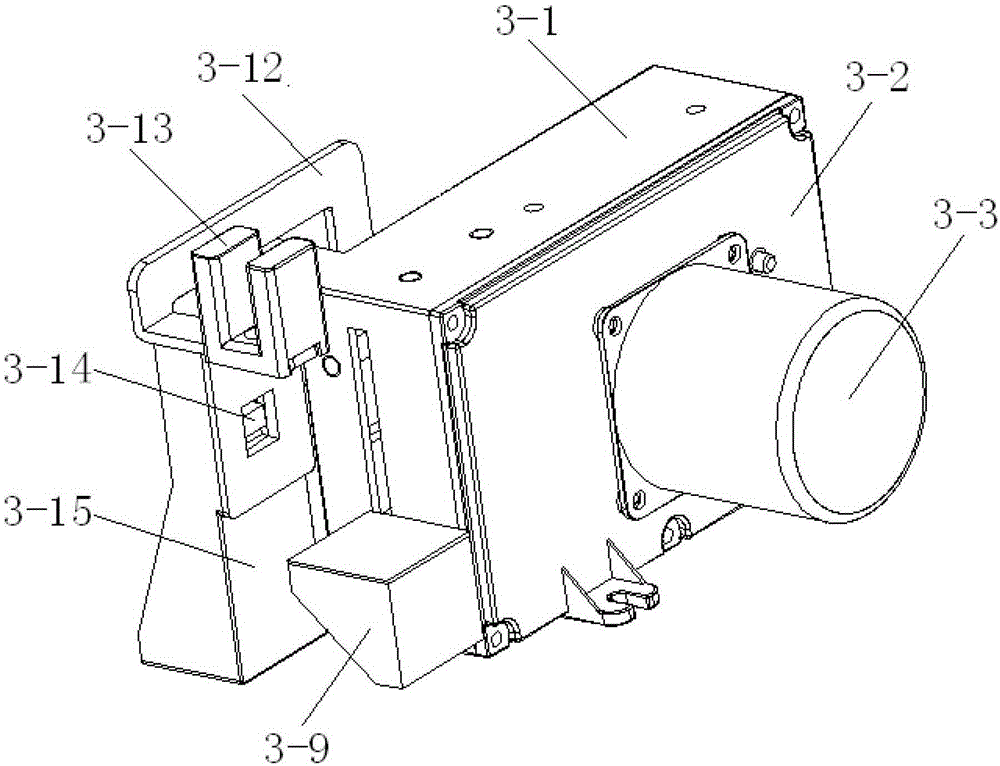

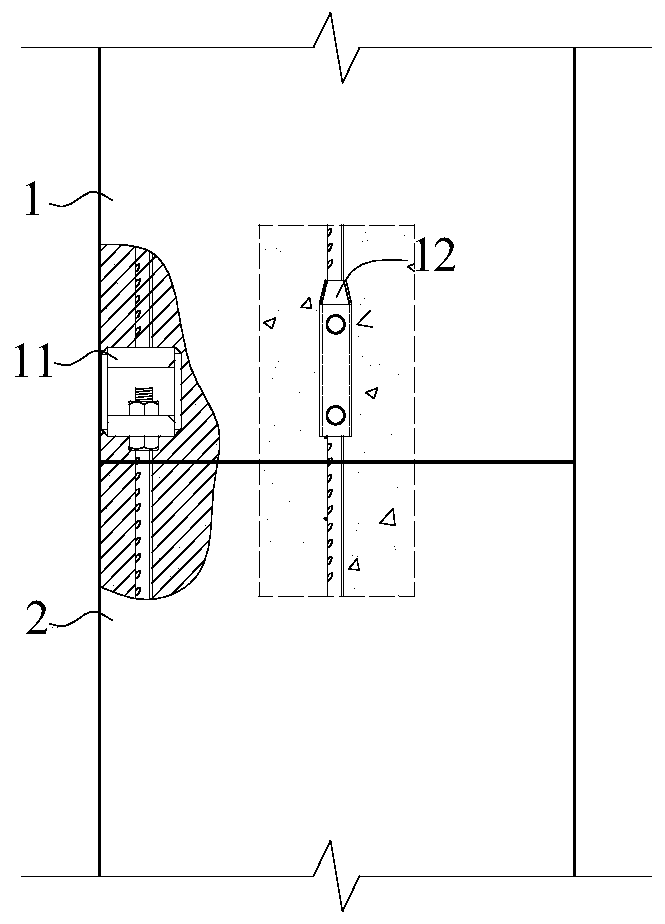

A stacking and pushing system of a mahjong machine

The invention discloses a tile stacking, lifting and pushing system of a mahjong machine. The tile stacking, lifting and pushing system of the mahjong machine comprises a machine head box, a motor frame, a motor, a tile pushing scored pulley, a swing piece, a vertical sliding rod, a vertical sliding block, a tile receiving seat connection rod, a tile receiving seat, a horizontal sliding rod, a horizontal sliding block, a tile pushing head connection rod, a tile pushing head and a mahjong blocking seat; one side of the tile pushing scored pulley drives the swing piece to drive the vertical sliding rod to perform lifting motion; the other side of the tile pushing scored pulley drives the horizontal sliding rod to perform horizontal motion. According to the tile stacking, lifting and pushing system of the mahjong machine, the purpose of sending mahjong tiles into a guide rail above a tile pushing component and a conveying component is achieved easily and ingeniously due to matching of the tile-pushing scored pulley and the like, a tile lifting motion is added between a tile stacking motion and a tile pushing motion, the structure is compact and ingenious, the tile stacking motion, the tile-lifting motion and the tile-pushing motion can be achieved just through one motor, the operation is stable, and cost control is reasonable. In addition, signal magnetic steel is matched with a Hall element, so that automatic detection and intelligent control can be achieved, overload operation of the motor can be prevented, and service life of the device can be prolonged.

Owner:宋拥良

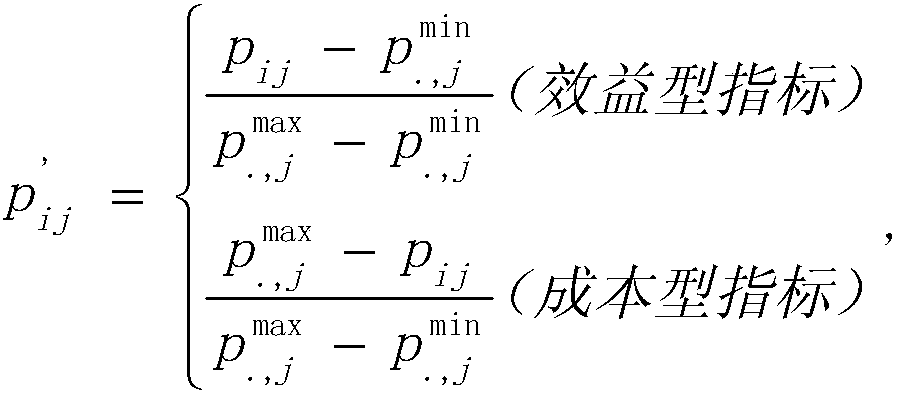

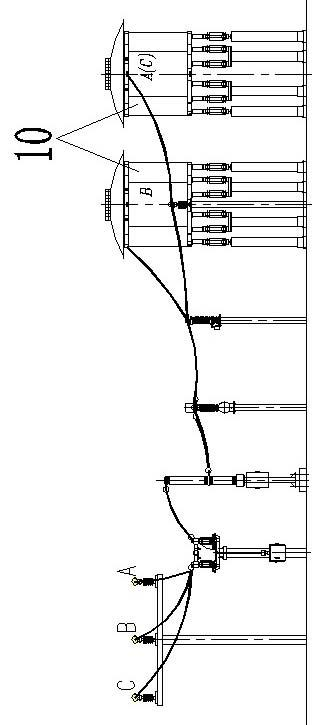

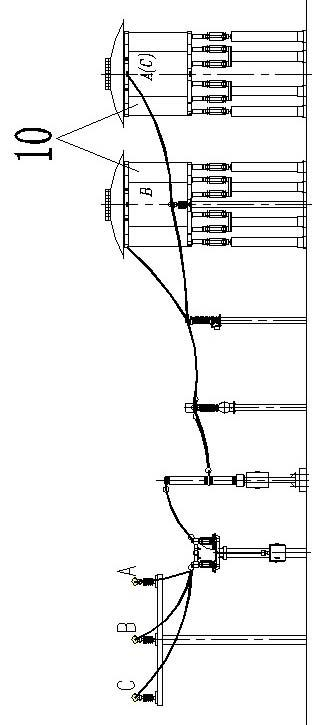

Method for evaluating low noise conductor of uhv ac transmission line

The invention relates to a method for evaluating the low noise wires of 1000kV ultra-high voltage alternative current transmission lines, comprising an evaluation factor, an evaluation range, an evaluation standard and a measurement method, wherein the evaluation factor means the audible noise; the evaluation range uses the 100 strip regions at two sides of the projections of the edge wires of a transmission line as the audible noise range; the evaluation standard means that the limit value of the audible noise is 52dB(A) and the limit value at populated country is 45dB(A); the measurement method means doing measurement at the projection of the edge wires and the 15m, 20m, 50m and 100m parts outside from the projections. The invention considers the characters of low noise wires of 1000kV transmission lines to provide a reasonable low noise wire evaluation method for 1000kV transmission lines, and the invention can reduce the noise of ultra-high voltage transmission and transformation projects according to the evaluation method, and can reasonably control the project costs.

Owner:WUHAN HIGH VOLTAGE RESEARCH INSTITUTE OF STATE GRID

Compact 35kv side structure of 500kv main transformer

InactiveCN102570330ASmall footprintImprove structural strengthNon-enclosed substationsBus-bar/wiring layoutsElectricityThree-phase

The invention relates to a compact 35kv side structure of a 500kv main transformer, which comprises an A, B, C three-phase transformer which is connected with a main circuit by a triangular bus, the main circuit is connected with a 35kv bus which is connected with all branch circuits, and each branch circuit comprises a capacitance branch circuit and a reactance branch circuit; the capacitance branch circuit comprises a parallel capacitor set and a serial rector connected with the parallel capacitor set; the reactance branch circuit comprises a three-phase reactor; the triangular bus adopts a dry insulated bus for accomplishing a triangular winding; A, B, C three phases are overlaid in each parallel capacitor set in the capacitance branch circuit; and in the reactance branch circuits, the reactors are piled dry parallel air-core reactors or magnetic-shielding parallel reactors.

Owner:HENNAN ELECTRIC POWER SURVEY & DESIGN INST +5

Floating liquefied natural gas (LNG) storage and gasification device, control system and control method

ActiveCN107514541AAvoid problems requiring land occupationSolve the problem that it can only dock in deep water areas such as portsVessel mounting detailsWaterborne vesselsContinuous flowPressure difference

The invention belongs to the technical field of liquefied natural gas (LNG) storage and gasification, and relates to a floating storage and gasification device which constantly supplies natural gas fuel to port natural gas users and power stations. The floating storage and gasification device comprises at least one medium-pressure region storage tank arranged on a ship body, a low-pressure region buffer tank, an immersed pump box and an LNG gasification device, wherein the low-pressure region buffer tank, the immersed pump box and the LNG gasification device are sequentially connected with the medium-pressure region storage tanks. Limited to industrial standards, liquid outlets of the low-cost medium-pressure region storage tanks with outer layers made of a carbon steel material are formed in the tops of tank bodies, continuous flow of LNG is achieved through the working air pressure difference between the medium-pressure region storage tanks and the low-pressure buffer tank, and then continuous supply of the high-pressure LNG is achieved. The floating LNG storage and gasification device has the advantages of being convenient to dock, low in manufacturing cost, capable of achieving continuous gas supplying, easy to control and the like.

Owner:GTE GLOBAL TIANJIN

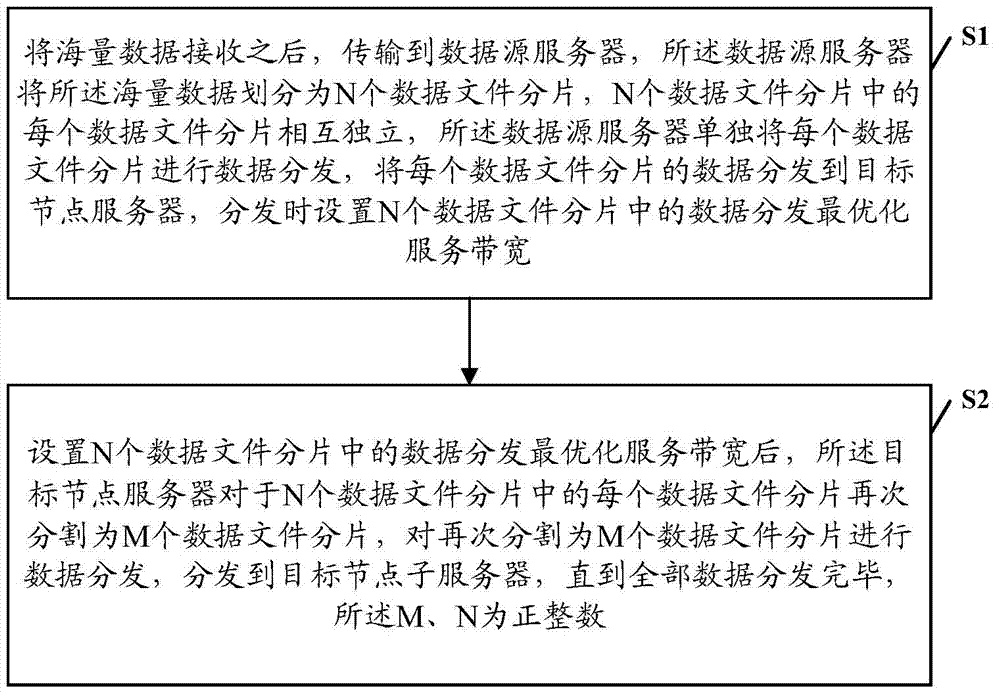

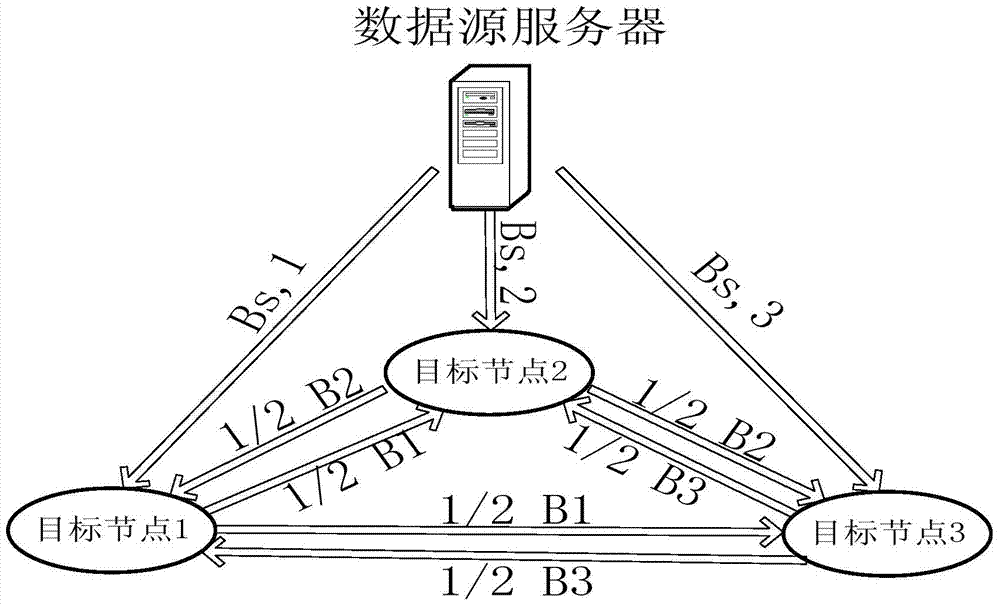

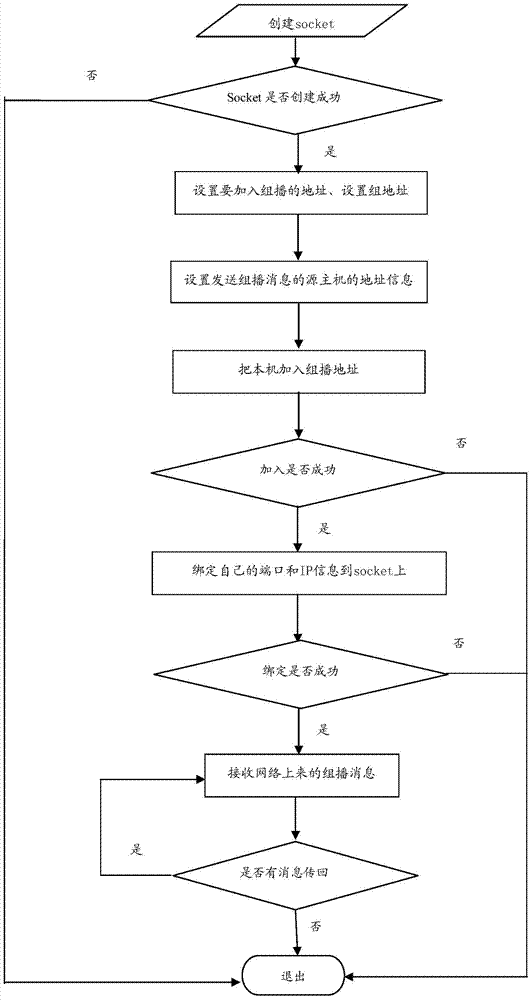

Digital recording and processing device for mass data of audio and video

InactiveCN104270410ARealize collection recordPerfect surgeTransmissionSelective content distributionDigital recordingAnalog front-end

The present invention discloses a digital recording and processing device for mass data of audio and video. The digital recording and processing device is characterized by including a multimedia processor, an analog front end circuit, a DDR memory, a power source, a power source protective circuit, a Beidou module, a 3G module, an audio and video input circuit and a communication circuit, wherein an output end of the power source is connected to an input end of the power source protective circuit, an output end of the power source protective circuit is connected to an input end of the multimedia processor, an information output end of the DDR memory is connected to an information input end of the multimedia processor, a signal output end of the Beidou module is connected to the input end of the multimedia processor, a signal input end of the audio and video input circuit is connected to a signal input end of the analog front end circuit, a signal output end of the analog front end circuit is connected to the input end of the multimedia processor, a signal output end of the 3G module is connected to the input end of the multimedia processor, and the communication circuit is connected to the input end of the multimedia processor.

Owner:CHONGQING HUILIAN INFORMATION TECH

An automatic mahjong machine

ActiveCN103861280BCompact and ingenious structureGuaranteed uptimeIndoor gamesControl engineeringMechanical engineering

The invention discloses an automatic mahjong machine. The automatic mahjong machine comprises a shuffling mechanism, a conveying mechanism, a tile stacking, lifting and pushing mechanism, a rail mechanism, a tile sending driving mechanism and a tile sending mechanism; the conveying mechanism, the tile stacking, lifting and pushing mechanism, the rail mechanism, the tile sending driving mechanism and the tile sending mechanism are arranged at the periphery of the mahjong machine; an input end of the conveying mechanism is arranged at the edge of the shuffling mechanism; an output end of the conveying mechanism is connected with an input end of the tile stacking, lifting and pushing mechanism; the rail mechanism is arranged above the stacking mahjong pushing mechanism; an input end of the rail mechanism is connected with an output end of the tile stacking, lifting and pushing mechanism; an output end of the rail mechanism is connected with an input end of the tile sending mechanism. The automatic mahjong machine has the advantages of being compact and skillful in structure, stable in operation, reasonable in cost control and long in service life.

Owner:德兴市永达娱乐设备有限公司

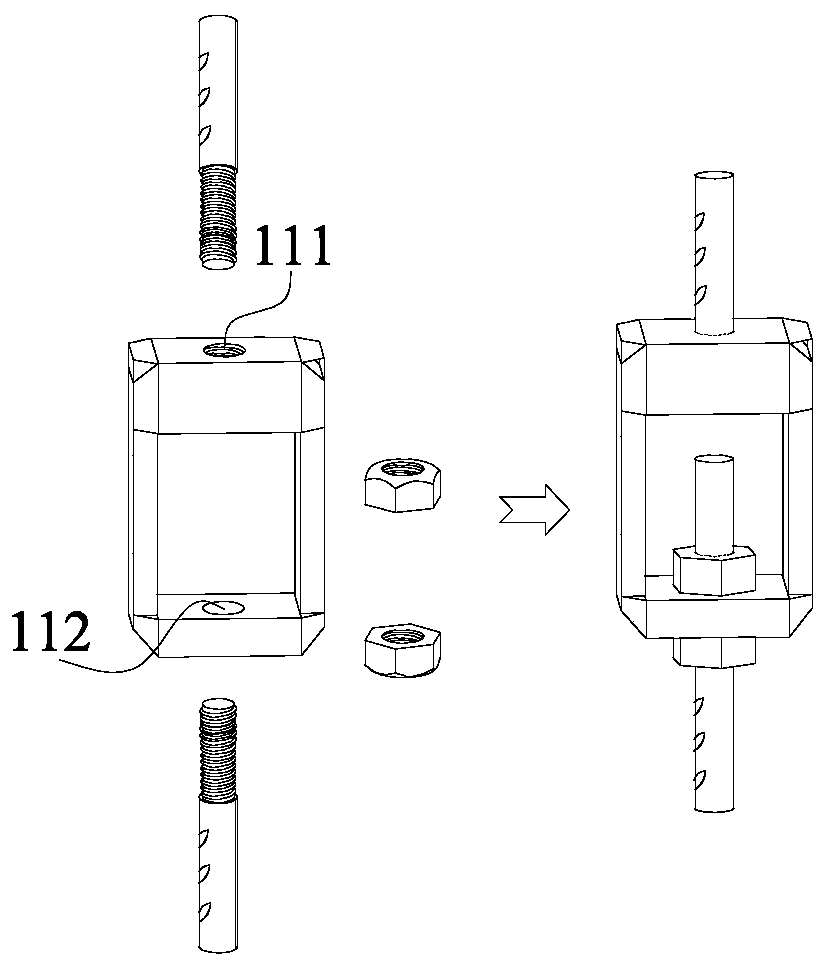

Self-supporting prefabricated column hybrid connection and construction method thereof

ActiveCN111236536AReduce usageSelf-supportingStrutsBuilding material handlingArchitectural engineeringRebar

The invention discloses a self-supporting prefabricated column hybrid connection and a construction method thereof. The hybrid connection comprises an upper prefabricated column and a lower prefabricated column, wherein screw bolt connecting elements and sleeves are arranged at the bottom of the upper prefabricated column; a first longitudinal steel bar and a second longitudinal steel bar are arranged in the upper prefabricated column; a third longitudinal steel bar and a fourth longitudinal steel bar are arranged in the lower prefabricated column; the screw bolt connecting elements are respectively connected with the first longitudinal steel bar and the third longitudinal steel bar; the sleeves are respectively connected with the second longitudinal steel bar and the fourth longitudinal steel bar; and an enclosure region is formed between the lower prefabricated column and the sleeves through post pouring. The method comprises the following steps of fastening the first longitudinal steel bar and the screw bolt connecting element; fastening the end part of the second longitudinal steel bar and the sleeve; pre-burying the screw bolt connecting elements, the sleeves, the first longitudinal steel bar and the second longitudinal steel bar; fastening the third longitudinal steel bar and the screw bolt connecting element; extending the fourth longitudinal steel bar into the sleeve; pouring grouting materials into the sleeves; and forming the enclosure region through post pouring. After the connection is completed, a load can be borne immediately; lateral support is not needed; the construction efficiency is high; and the construction cost is favorably reduced.

Owner:SOUTHEAST UNIV

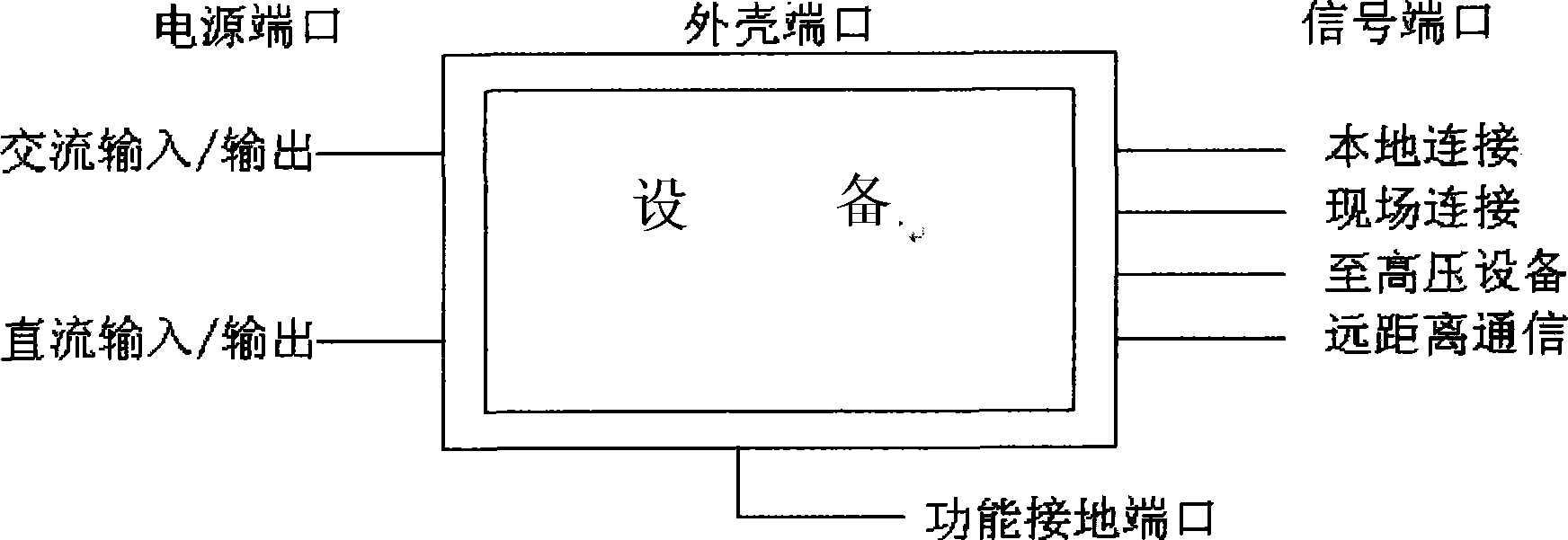

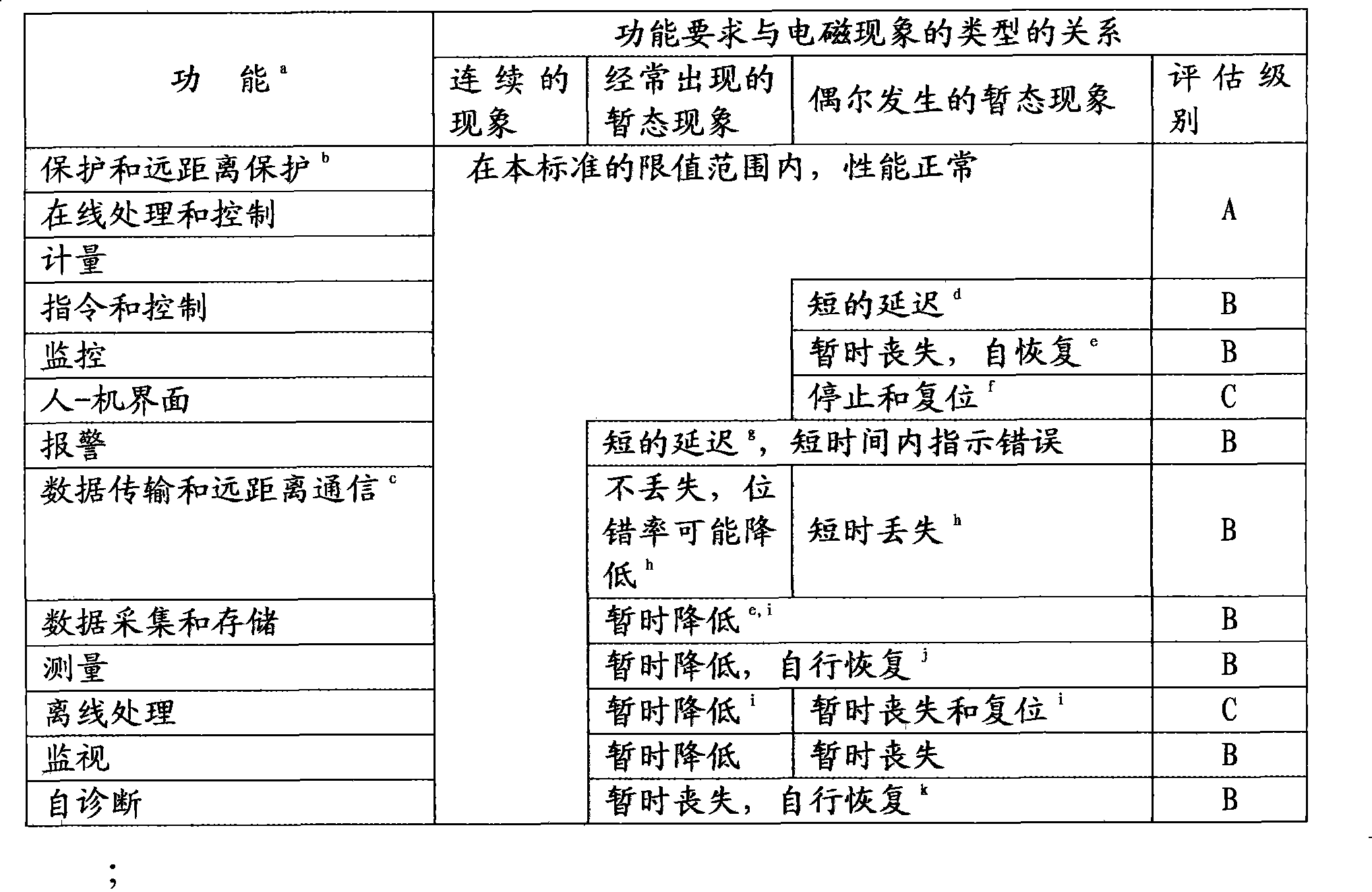

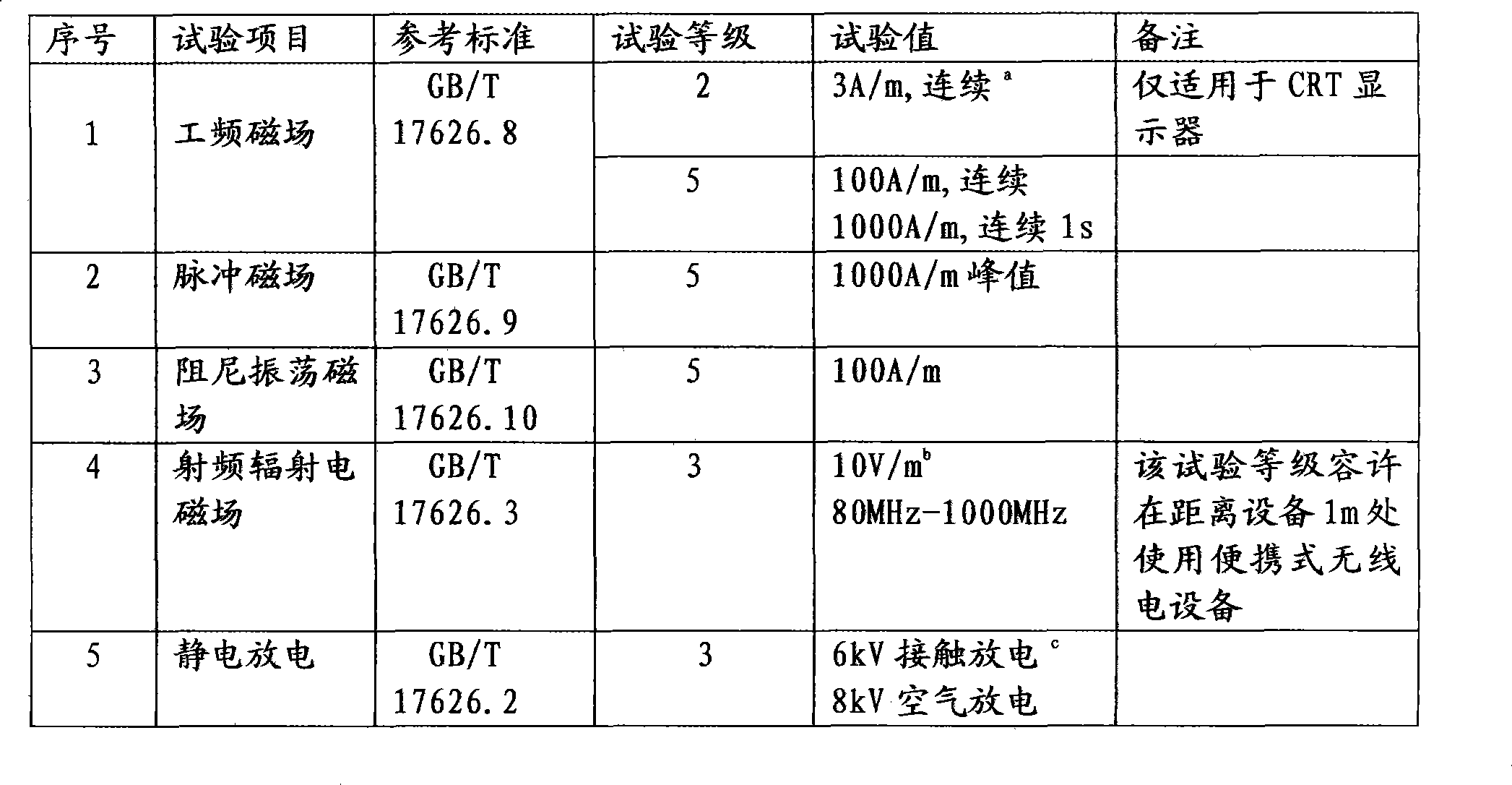

Noise immunity measuring method for protecting secondary equipment in cabinet

InactiveCN101477161ACorrectly regulate safe and reliable operating conditionsCorrect operating conditionsElectrical testingEngineeringTest item

The invention relates to a noise immunity determination method for secondary equipment inside a small protection room, which comprises a determination range, determination level and requirement, a determination criterion, and a measurement method, wherein the determination level and requirement have decisive effect on a determination result, and are test classes and test values of various test items. The method is a safe, reliable, simple and practical evaluation method; and the noise immunity performance of the secondary equipment is correctly standardized through the method, which is an important evidence for reducing engineering cost.

Owner:STATE GRID ELECTRIC POWER RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com