Electrically-heated and water-cooled foam forming upper mold

A foam forming and water cooling technology, applied in the field of foam forming molds, can solve the problems of slow cooling speed and reduce product qualification rate, and achieve the effects of fast heating speed, convenient mold design and reasonable cost control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

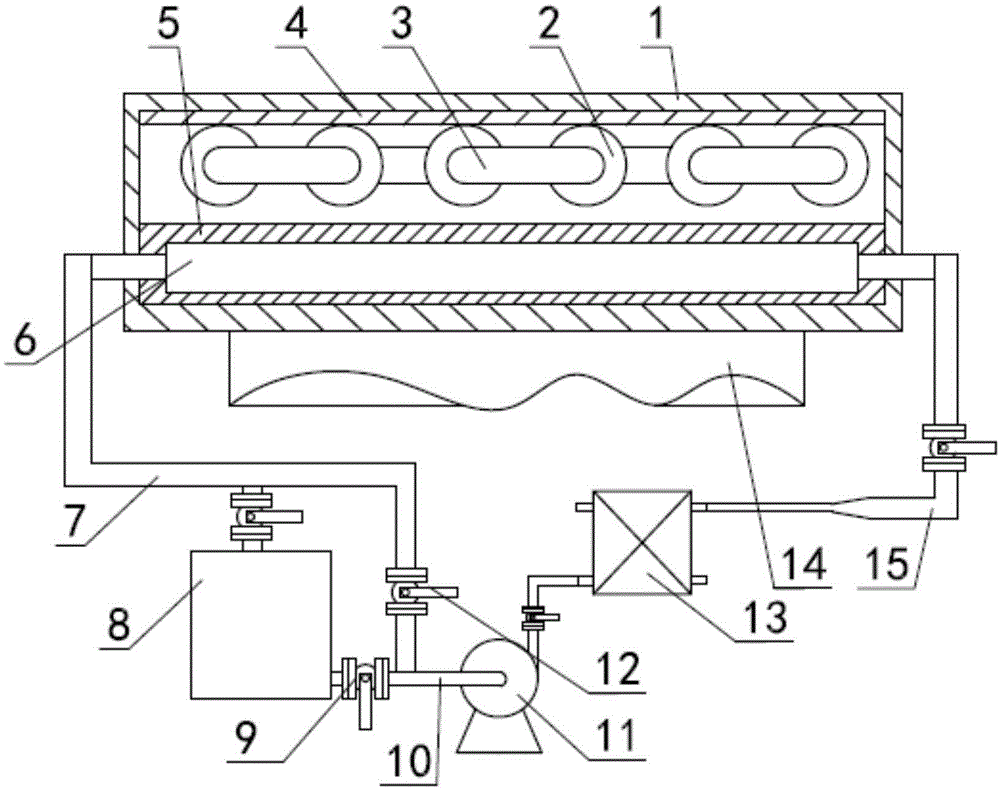

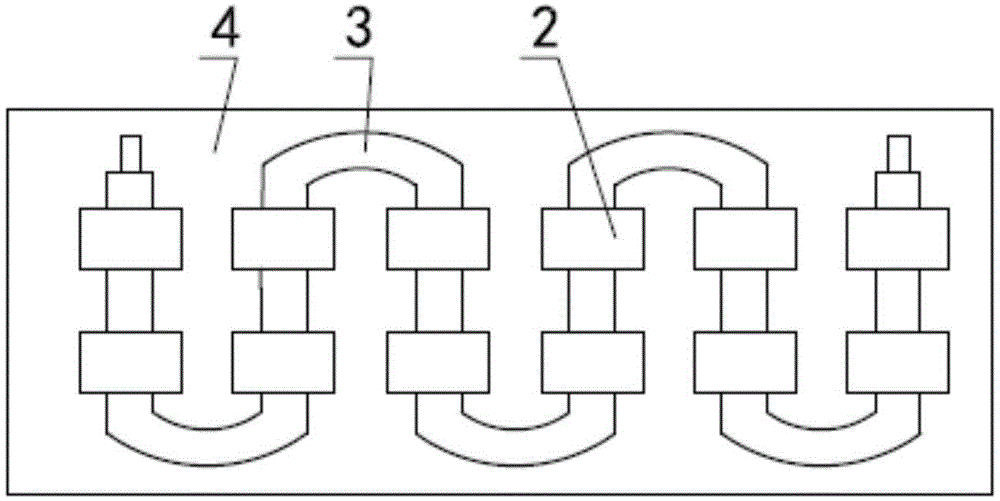

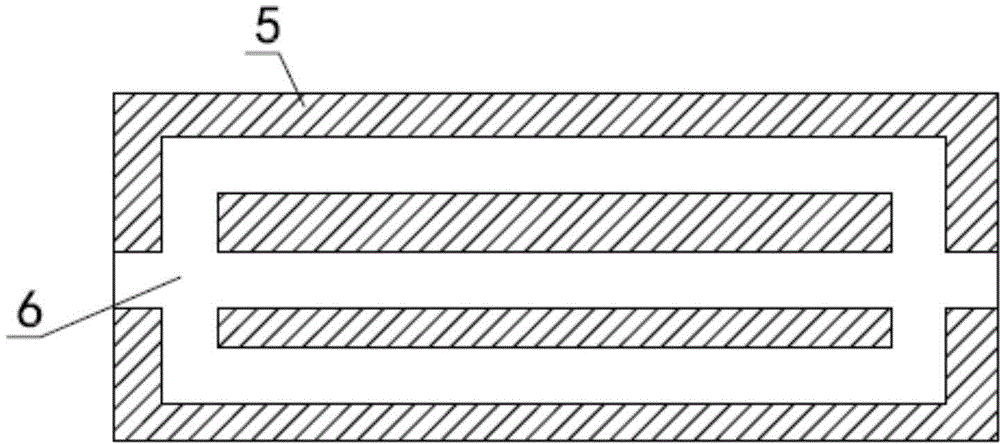

[0018] Such as figure 1 As shown, the electric heating and water-cooling type foam molding upper mold includes an upper mold frame 1 and a heat-conducting aluminum block 5, and an upper mold 14 is installed at the bottom of the upper mold frame 1. It is characterized in that: the upper mold frame 1 is a hollow structure, and The inside of the mold frame 1 is provided with an insulating plate 4, a heating wire 3 and a heat-conducting aluminum block 5 in sequence from top to bottom. The heating wire 3 is installed on the bottom of the insulating plate 4 through a sleeve 2 made of ceramic material, and the top of the insulating plate 4 is fixed on the upper mold frame. 1, the heat-conducting aluminum block 5 is closely attached to the inner bottom of the upper mold frame 1, the distance between the heating wire 3 and the heat-conducting aluminum block 5 is 20 mm, and the heat-conducting aluminum block 5 is provided with a cooling water channel 6 horizontally inside the cooling wat...

Embodiment 2

[0023] This embodiment is changed on the basis of the first embodiment, the distance between the heating wire 3 and the heat-conducting aluminum block 5 is changed to 30 mm; the thickness of the insulating plate 4 is changed to 10 mm. Others are the same as embodiment one.

Embodiment 3

[0025] This embodiment is changed on the basis of the first embodiment, the distance between the heating wire 3 and the heat-conducting aluminum block 5 is changed to 50 mm; the thickness of the insulating plate 4 is changed to 8 mm. Others are the same as embodiment one.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com