Patents

Literature

170results about How to "High water pressure resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waterproof moisture permeation polyurethane paint used for textiles and preparation method

The invention relates to waterproof moisture permeation polyurethane paint used for textiles and a preparation method. The waterproof moisture permeation polyurethane paint is prepared from methyl diphenylene diisocyanate, toluene di-isocyanate, polyether glycol (with the molecular weight of 2000), linear dihydroxylated alkylsiloxane (with the molecular weight of 1000), polyester dihydric alcohol (with the molecular weight of 2000), trimethylolpropane, chain extending agents, sealing compounds, dibutyl tin laurate and solvents through the processes of pre-polymerization reaction, chain extension reaction and sealing reaction. The production process is simple, and the products have the advantages of self-crosslinking effect, soft hand feeling, good cold resistance performance, high moisture permeation performance, high water pressure resistance and little reduction after water pressure resistance washing.

Owner:郯城丰润粮机配件有限公司

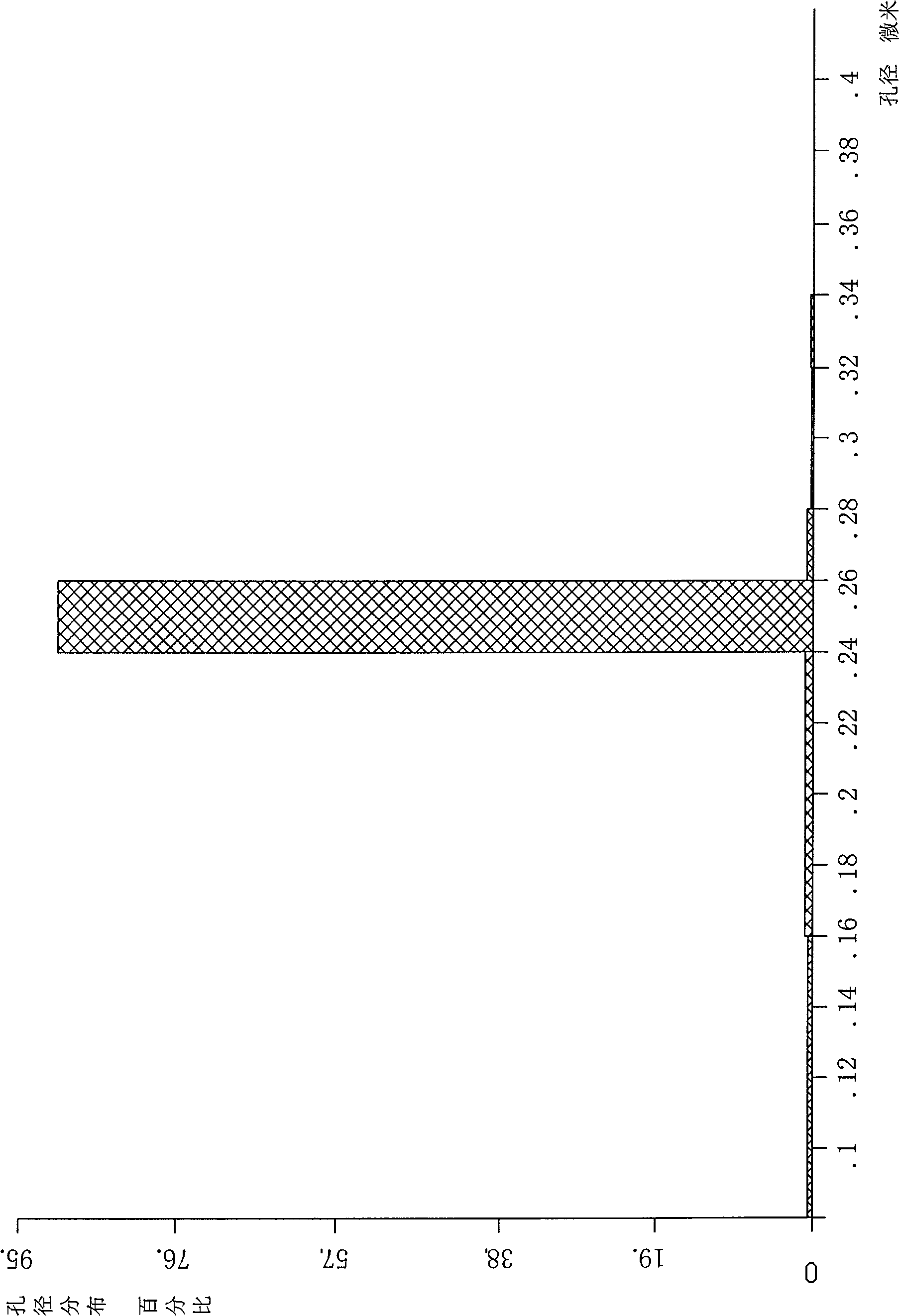

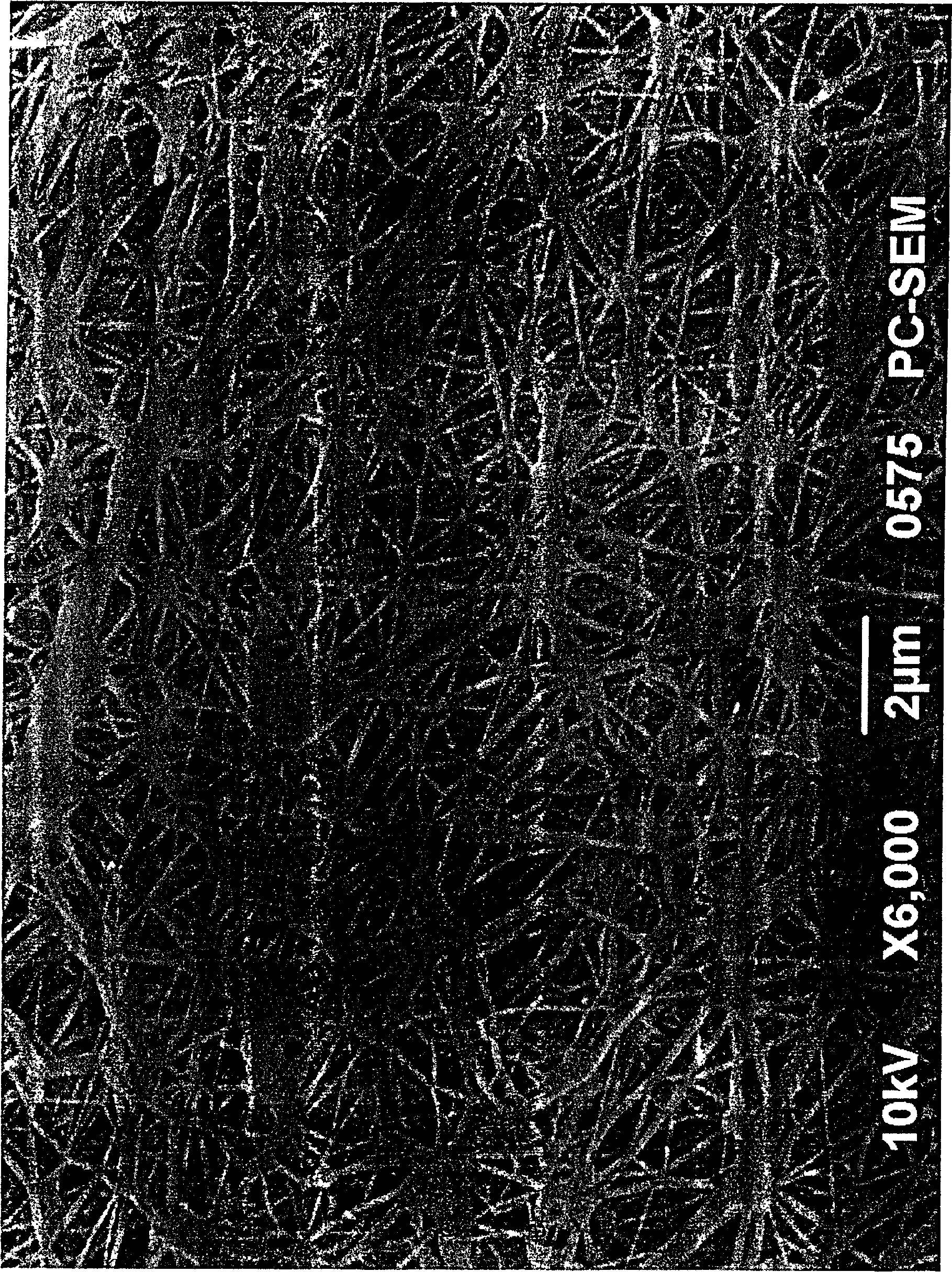

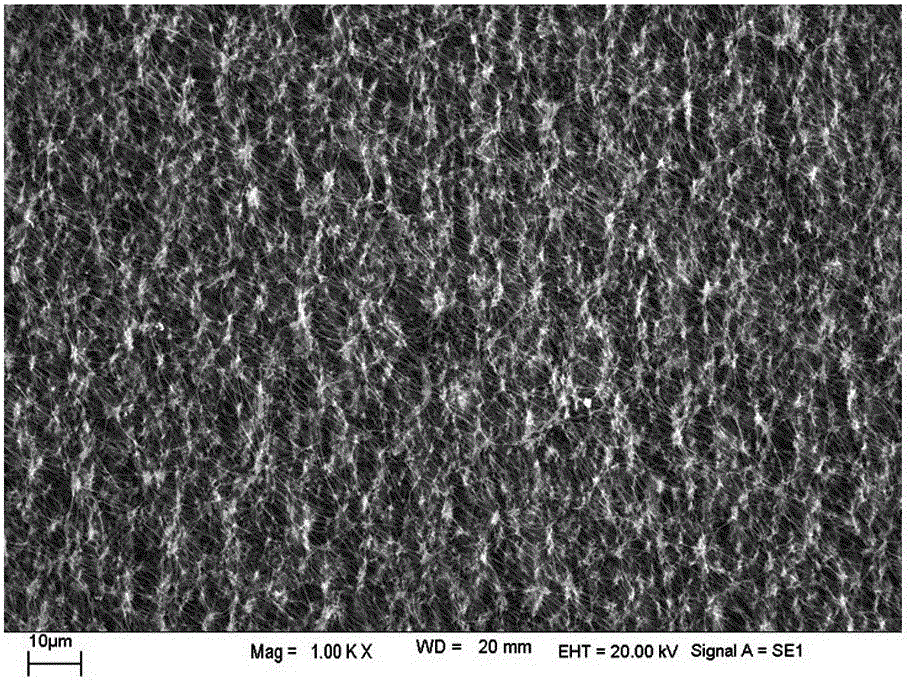

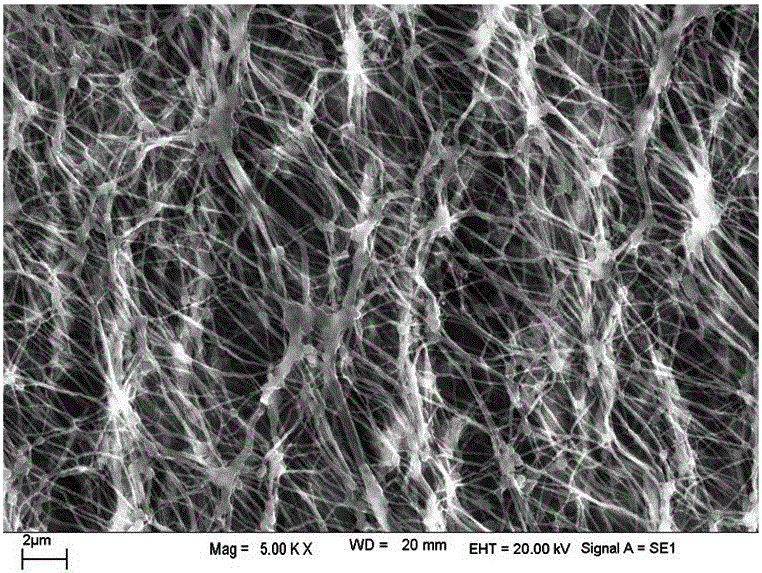

Polyfluortetraethylene nanofibre membrane and preparation method thereof

InactiveCN101543734BAvoid filter efficiencyHigh water pressure resistanceSemi-permeable membranesFlat articlesAir filtrationWater resistant

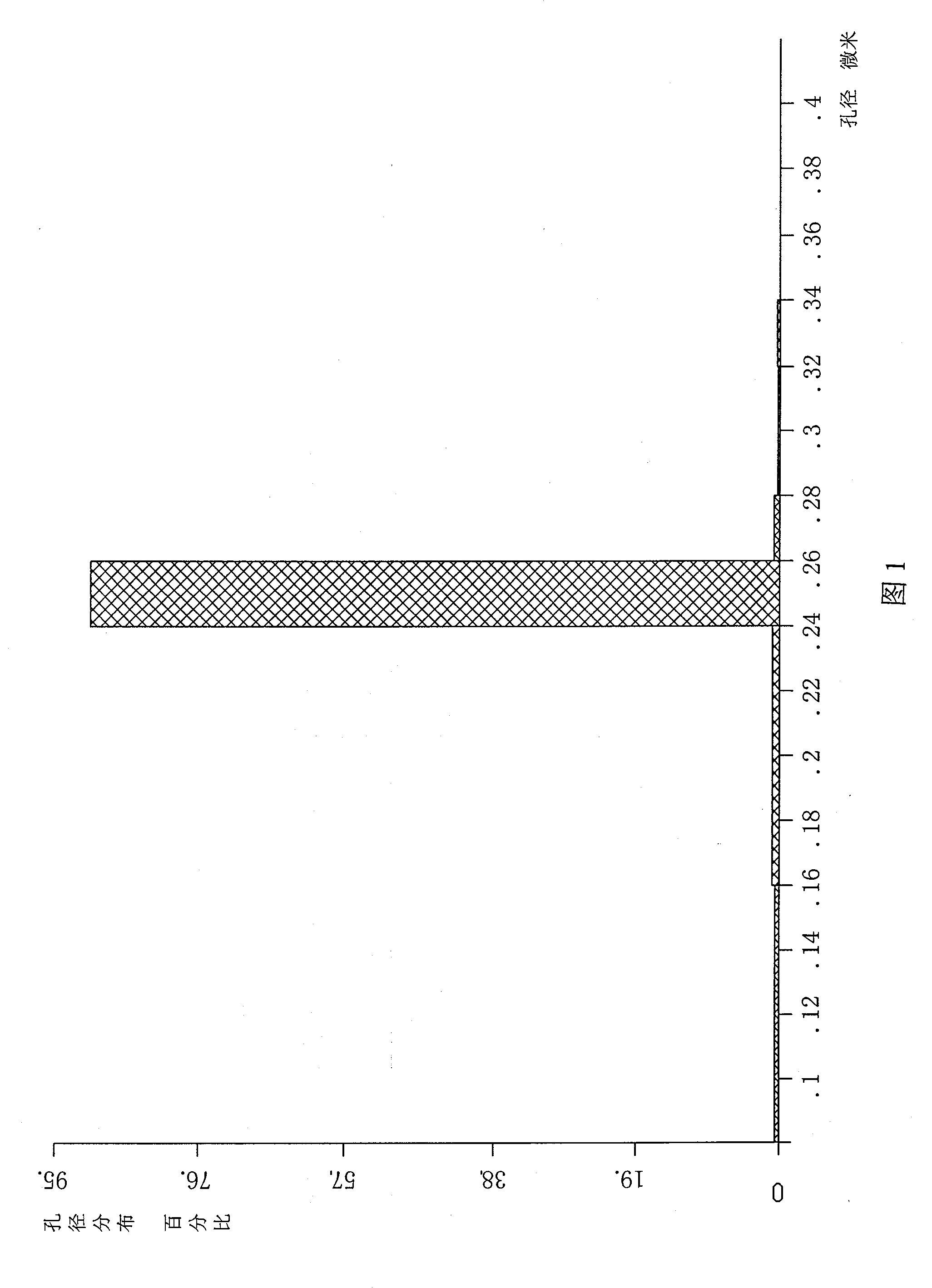

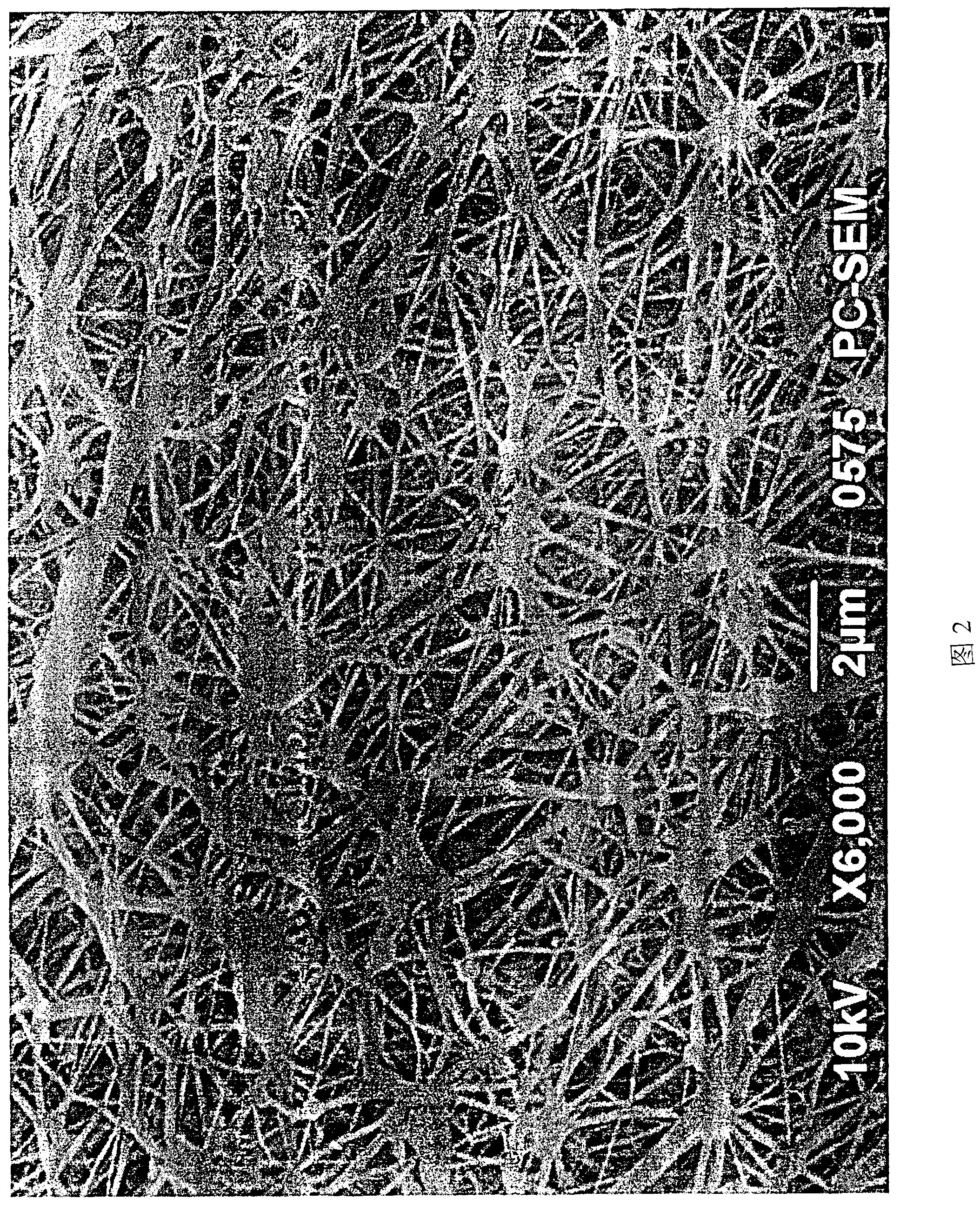

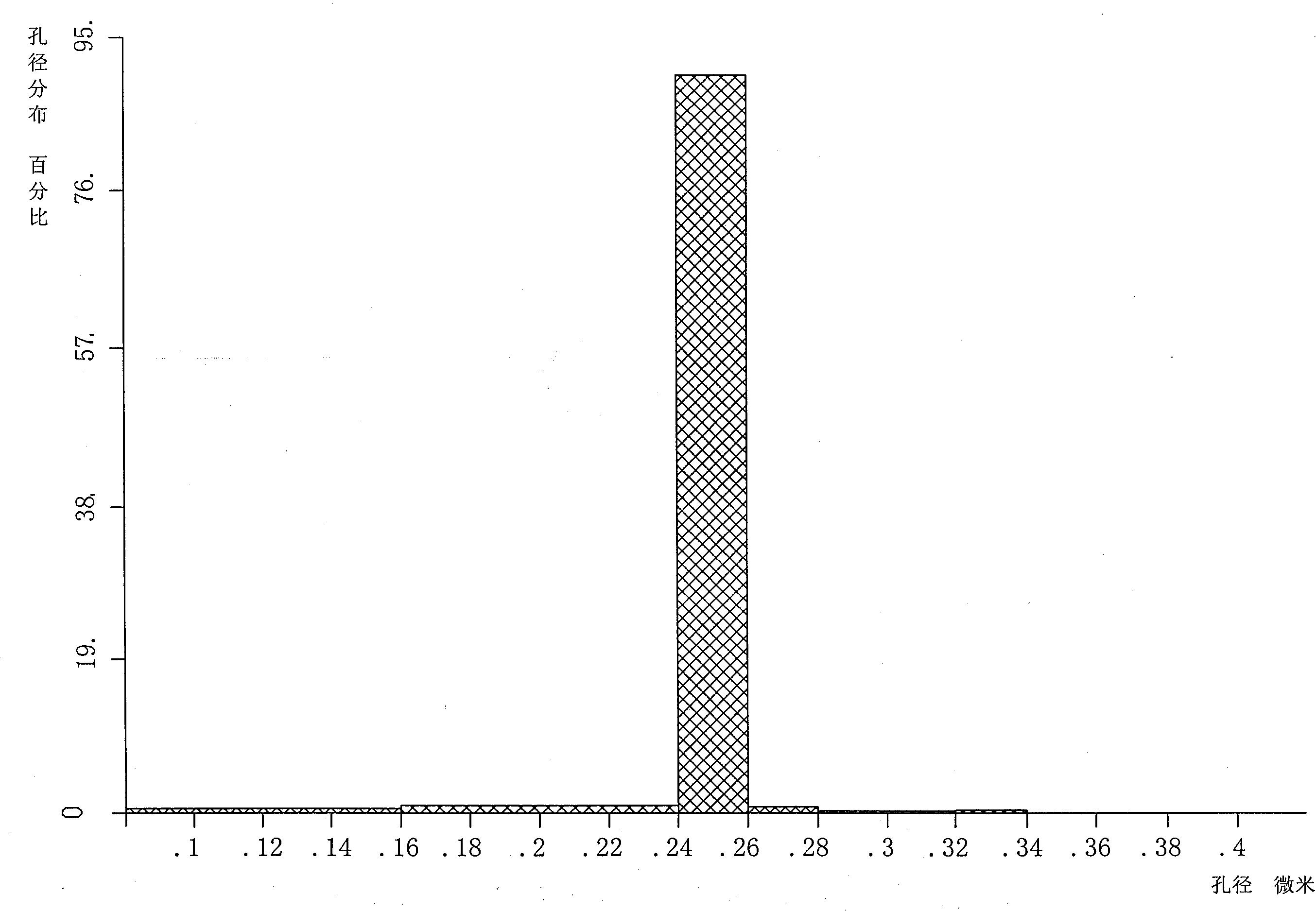

The invention relates to a polyfluortetraethylene nanofibre membrane and a preparation method thereof. The aperture distribution of the polyfluortetraethylene nanofibre membrane is concentrated within a range of + / -100 nanometers and occupies more than 90 percent of the total volume of each level aperture; the stretching process of the preparation method adopts low-temperature segmenting stretching, thus the stretching temperature is stable, the polyfluortetraethylene nanofibre membrane is uniformly heated, and giant molecule segmers are equally unfolded; the produced polyfluortetraethylene nanofibre membrane has concentrated aperture distribution and high uniformity so as to generate high water pressure resistance, long water resistant time and high membrane fibering degree, and the obstructing efficiency of bacteria reaches more than 99.99 percent, thereby the polyfluortetraethylene nanofibre membrane can meet the requirement of oil-water separation and high-end gas filtration of anoperation isolation mattress with high-pressure steam filtration and high water pressure resistance and can be used in fields of superclean room entering air filtration, and the like, such as medicaltreatment and health protection, health matter cultivation, semiconductor devices, integrated circuit, medicine, and the like.

Owner:北京千叶宝莲科技有限公司

Water-proof moisture-permeation coating agent composition and application thereof

InactiveCN101104752AGood hygroscopicityGood anti-adhesionNatural rubber coatingsPolyurea/polyurethane coatingsFiberHigh resistance

The invention relates to a waterproof and moisture-permeable coating agent composition, wherein, a certain amount of microporous lignocellulose fine powder is added into the coating agent with waterproof function, so that the coating agent has moisture permeable performance. The waterproof and moisture-permeable coating agent composition which is used as the coating agent for non-woven fabric, knitted fabric or woven fabric can be made into coated fabric and synthetic leather with waterproof and moisture permeable performances. Compared with the prior at, the invention has the advantages that: 1. the raw material is easy to be added, the process is available with high adaptability, no need to add new equipment; 2. on the premise that the waterproof performance is not decreased, the amount of moisture permeated is increased obviously and the anti-adhesion is improved; 3. the coated fabric and superfine fiber and artificial cover synthetic leather made by the invention has the advantages of fine moisture permeability, high resistance to water pressure and that the physical performance does not decrease.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

Preparing method of environment-friendly solvent-type electrostatic spinning waterproof and moisture-permeable membrane

ActiveCN107587268AImprove water resistanceGuaranteed stability and durabilityPhysical treatmentSynthetic fibresSolventElectrospinning

The invention provides a preparing method of an environment-friendly solvent-type electrostatic spinning waterproof and moisture-permeable membrane. The preparing method is characterized by comprisingthe steps of 1, preparing a high-molecular polymer solution with water or environment-friendly alcohols being solvents, adding a corresponding water-soluble or alcohol-soluble water repelling agent and cross-linking agent, and preparing a hydrophobic fiber membrane through an electrostatic spinning technology; 2, conducting aftertreatment on the fiber membrane to trigger a chemical crosslinking reaction between a polymer matrix and the cross-linking agent, reinforcing the water resistance of the fiber membrane and regulating the pore structure of the fiber membrane to obtain the environment-friendly solvent-type electrostatic spinning waterproof and moisture-permeable membrane. In the production process, no waste gas, waste water and solid waste are generated, the environment cannot be damaged, the prepared waterproof and moisture-permeable membrane does not contain toxic solvents, and in the actual application, the healthy of a wearer cannot be damaged; the resistance to water pressure of the fiber-based waterproof and moisture-permeable membrane is larger than or equal to 150 kPa, the moisture permeability is larger than or equal to 15,000 g / m<2> / d, the tensile breaking strengthis larger than or equal to 30 MPa, and the environment-friendly solvent-type electrostatic spinning waterproof and moisture-permeable membrane has a large application prospect in the field of functional protective clothes.

Owner:DONGHUA UNIV

Environmental-friendly and water-pressure-resistant tent leather and preparation method thereof

ActiveCN103835144ASolve environmental pollutionSolve pollutionSynthetic resin layered productsTextiles and paperEnvironmental resistanceWater based

The invention discloses environmental-friendly and water-pressure-resistant tent leather and a preparation method thereof. The preparation method comprises the following steps: adding preparations such as a water-based thickening agent, a defoaming agent, a leveling agent and a curing agent into water-based polyurethane resin, and carrying out mixing and vacuum defoaming to form a water-based polyurethane resin slurry surface layer, middle layer and binding bottom layer; and by a processing method with dry-process film transferring, firstly coating release paper with the surface layer, then coating the release paper with the middle layer and the binding bottom layer after drying and cooling, drying till the release paper is in a half-dry state, then attaching base cloth, drying, curing, cooling, stripping the release paper, bundling, and carrying out surface after-treatment, thus obtaining the environmental-friendly and water-pressure-resistant tent leather. The environmental-friendly and water-pressure-resistant tent leather disclosed by the invention has the advantages that the problems of environmental pollution and residue of organic solvents for preparing traditional tent synthetic leather are solved, and the water-pressure resistance, the yellowing resistance, the waterproof effect, the breathable function and the like of the tent leather are improved.

Owner:LANZHOU SCISKY AQUEOUS POLYMER MATERIAL CO LTD

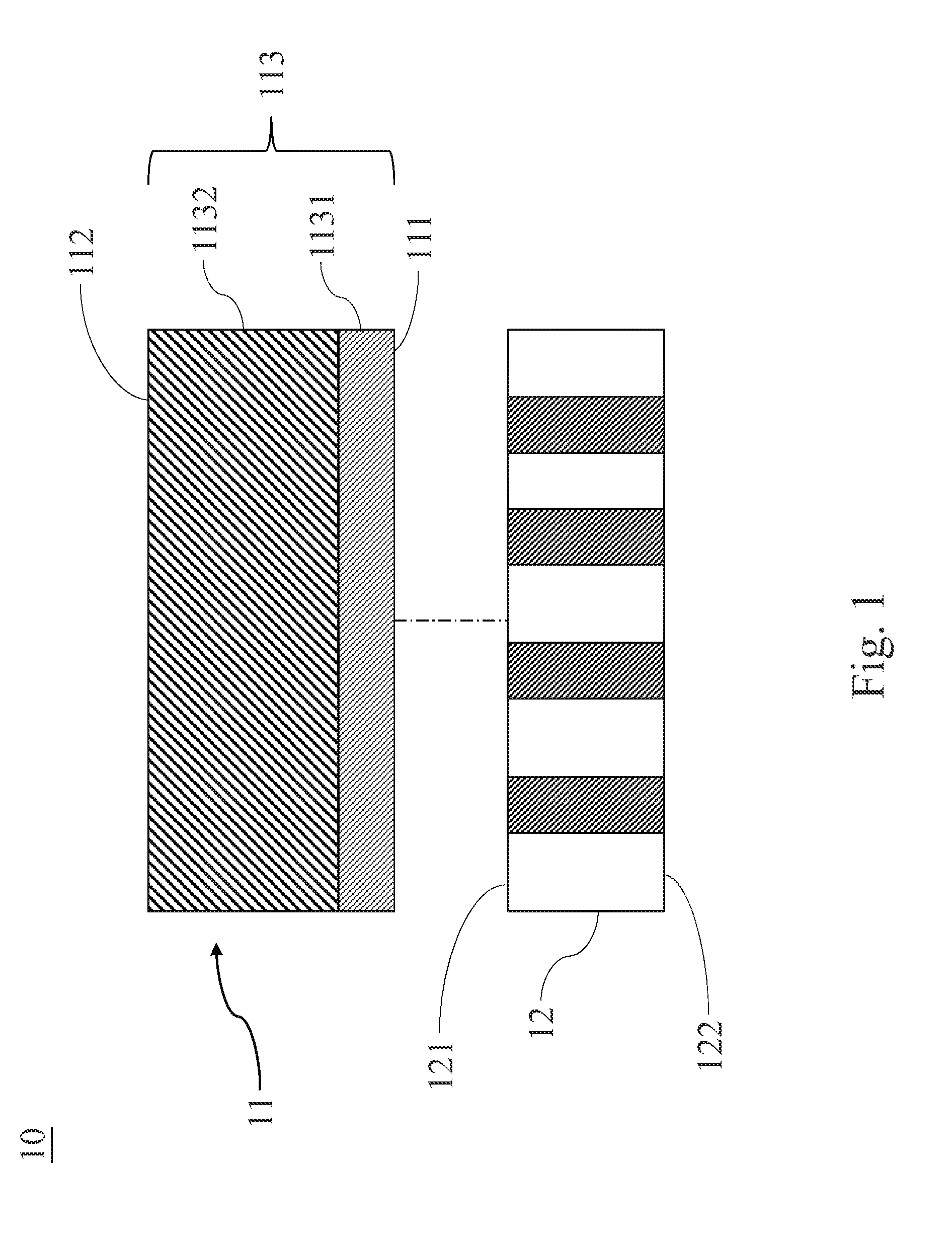

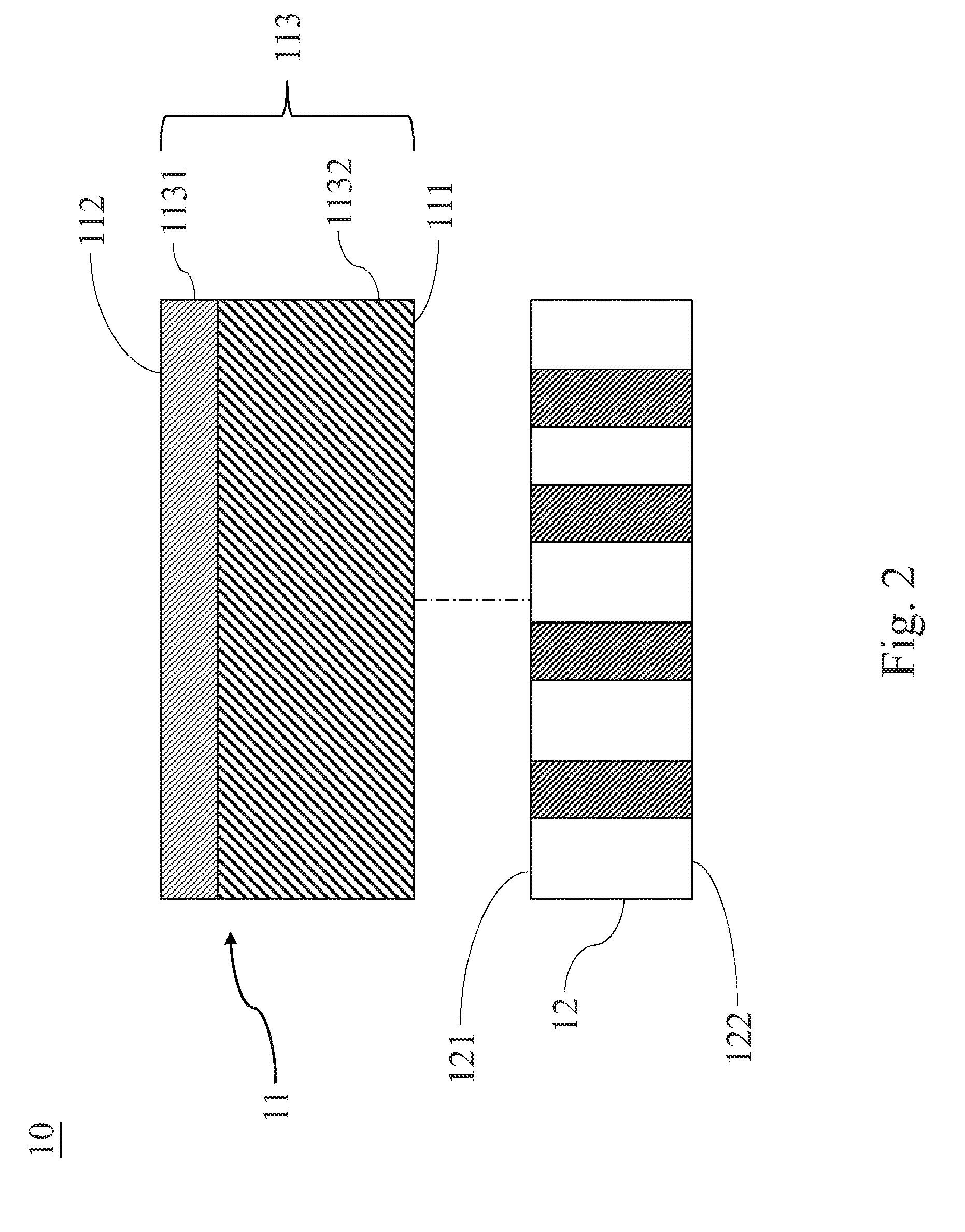

Water-proof and dust-proof membrane assembly and applications thereof

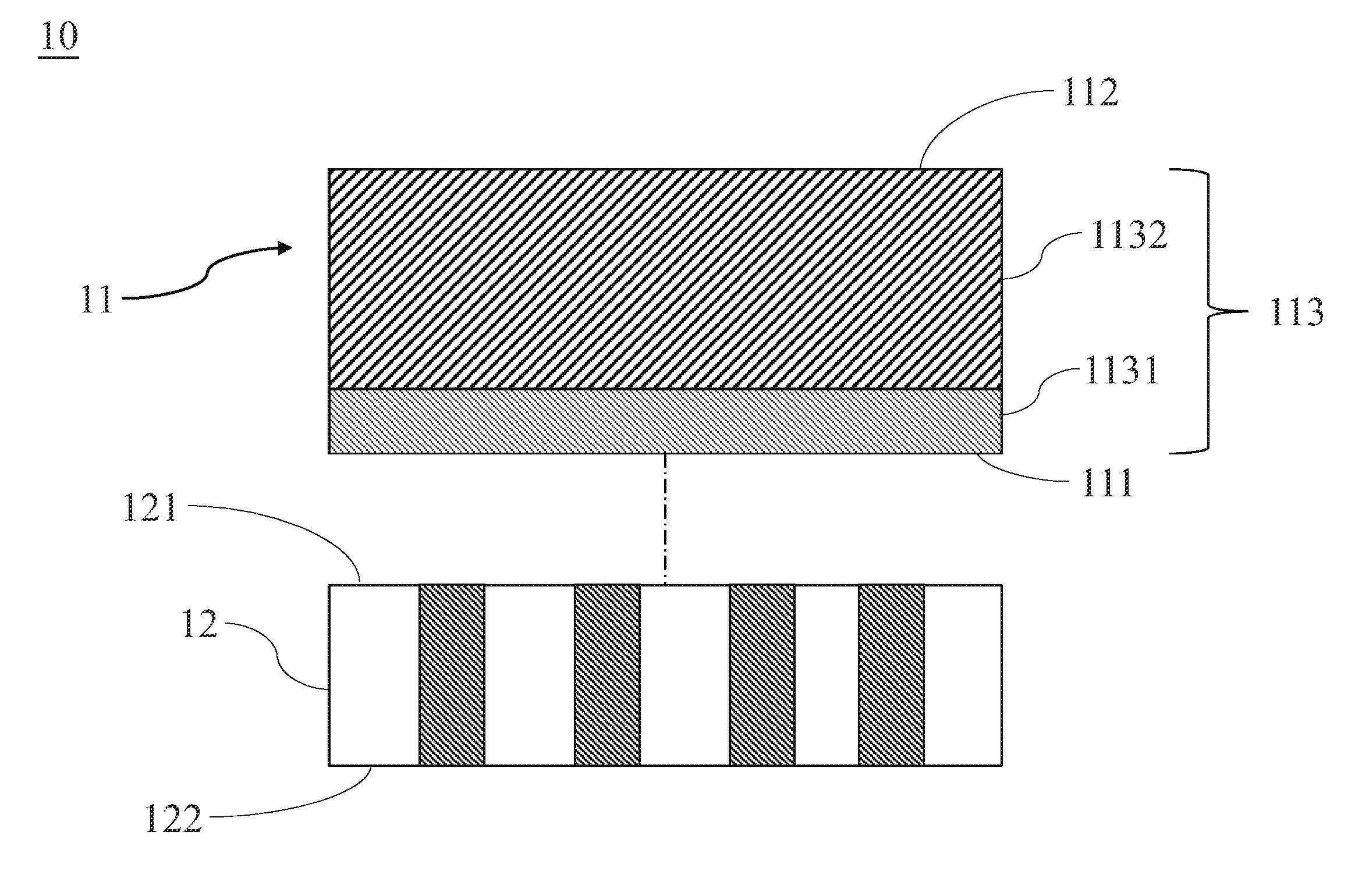

ActiveUS20110188247A1Improve support strengthImprove pressure resistanceCombination devicesDispersed particle filtrationPore diameterMembrane configuration

Disclosed is a water-proof and dust-proof membrane assembly and applications thereof. The water-proof and dust-proof membrane assembly comprises a body and a supporting member. The body is of membrane and has a first surface, a second surface, and an asymmetric porous structure formed between the first surface and the second surface of the body. The asymmetric porous structure has a thickness ranging between 1 μm and 1000 μm, a first volumetric porosity ranging between 5% and 99%. The asymmetric porous structure has plural pores, and each pore has a pore diameter between 0.01 μm and 15 μm. The supporting member is of a polymeric material and has a first contacting surface, a second contacting surface, and a second volumetric porosity which is greater than the first volumetric porosity. The first contacting surface of the supporting member is adhered to the first surface of the body.

Owner:EF MATERIALS IND

Polyethylene nonwoven fabric and nonwoven fabric laminate containing the same

InactiveUS6548432B1High water pressure resistanceImprove uniformityLayered productsWoven fabricsDisposable diaperPOLYETHYLENE WAX

A polyethylene nonwoven fabric is produced by the meltblowing process using a resin composition comprising a polyethylene (A) and a polyethylene wax (B). The fabric is made up with fine fibers having a small fiber diameter and good formation. A nonwoven fabric laminate containing at least one layer comprising the polyethylene nonwoven fabric is excellent in softness, water impermeability and interlaminar bond properties. In particular, the laminate of a meltblown nonwoven fabric comprising the polyethylene nonwoven fabric and a spunbonded nonwoven fabric made up with a conjugate fiber comprising a propylene-based polymer (a) and an ethylene-based polymer (b) provides good uniformity and excellent softness, gas permeability, water impermeability and interlaminar bond strength. The laminate is advantageously used as substrate materials for sanitary goods such as disposable diapers and for packaging materials.

Owner:MITSUI CHEM INC

Method for preparing nano polytetrafluoroethylene microporous membrane

InactiveCN102151493AHigh nanofiber contentHigh physical and mechanical strengthSemi-permeable membranesPorosityFiber

The invention discloses a method for preparing a nano polytetrafluoroethylene microporous membrane, which comprises: mixing high-molecular-weight polytetrafluoroethylene dispersion resin and lubricating oil according to a weight ratio of (4-6):1, extruding a pasty material in an extruder at 20 to 120 DEG C, calendering the pasty material into a belt in a calender, and transversely stretching the belt by 0 to 8 times; removing oil in an oven at 50 to 300 DEG C to obtain a dry membrane, and stretching at 335 to 390 DEG C; and finally, performing thermosetting to obtain the polytetrafluoroethylene microporous membrane with an average thickness of 1 to 300 micrometers, an average aperture smaller than or equal to 180 nanometers, a porosity more than or equal to 78 percent, a water pressure resistance more than or equal to 3kg / cm<2>, and a moisture permeability more than or equal to 10,000 grams of water per square meter per day. The obtained microporous membrane has high nano fiber content and high mechanical strength such as tensile strength. The super-small nano micropores can meet the application requirements for higher water pressure resistance or better filtering effect.

Owner:上腾新材料科技(苏州)有限公司

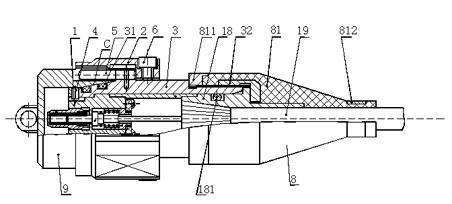

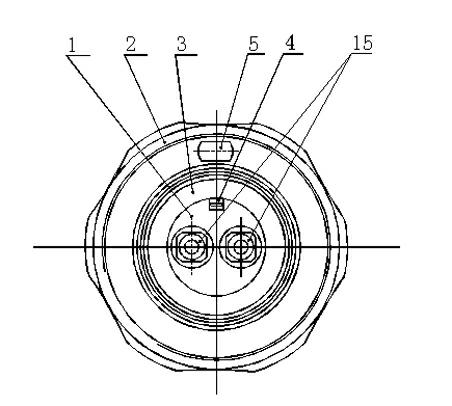

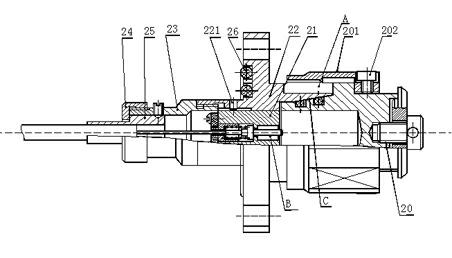

Underwater optical cable connector

The invention relates to an optical cable connector, and provides an underwater optical cable connector, which is capable of meeting requirements on water tightness and tensile performance, and providing detachable and movable connection. The underwater optical cable connector is characterized in that mutually matched cone structures are arranged on a plug shell and a socket shell respectively sothat the plug shell and the socket shell can be in gapless sealing connection by means of insertion, a sealing connection structure is arranged between a plug and an optical cable, the space between the plug shell and a tensile taper sleeve is sealed by an 'O'-shaped sealing ring, and a sealing tail sleeve for sealing is formed in the space between the optical cable and a tail part of the whole plug by mean of integral die casting. The movable sealing connection structure is arranged between the plug and a socket of the underwater optical cable connector, the two shells are connected by cones, no gap is reserved between the inner cone and the outer cone, the space between the cones is sealed by the 'O'-shaped sealing ring, the inner cone and the outer cone are locked by a connecting nut, and the underwater optical cable connector is simple in structure, reliable in performance, extremely high in water pressure resistance and convenient in connection and detachment.

Owner:SHANGHAI FANGAO COMM TECH

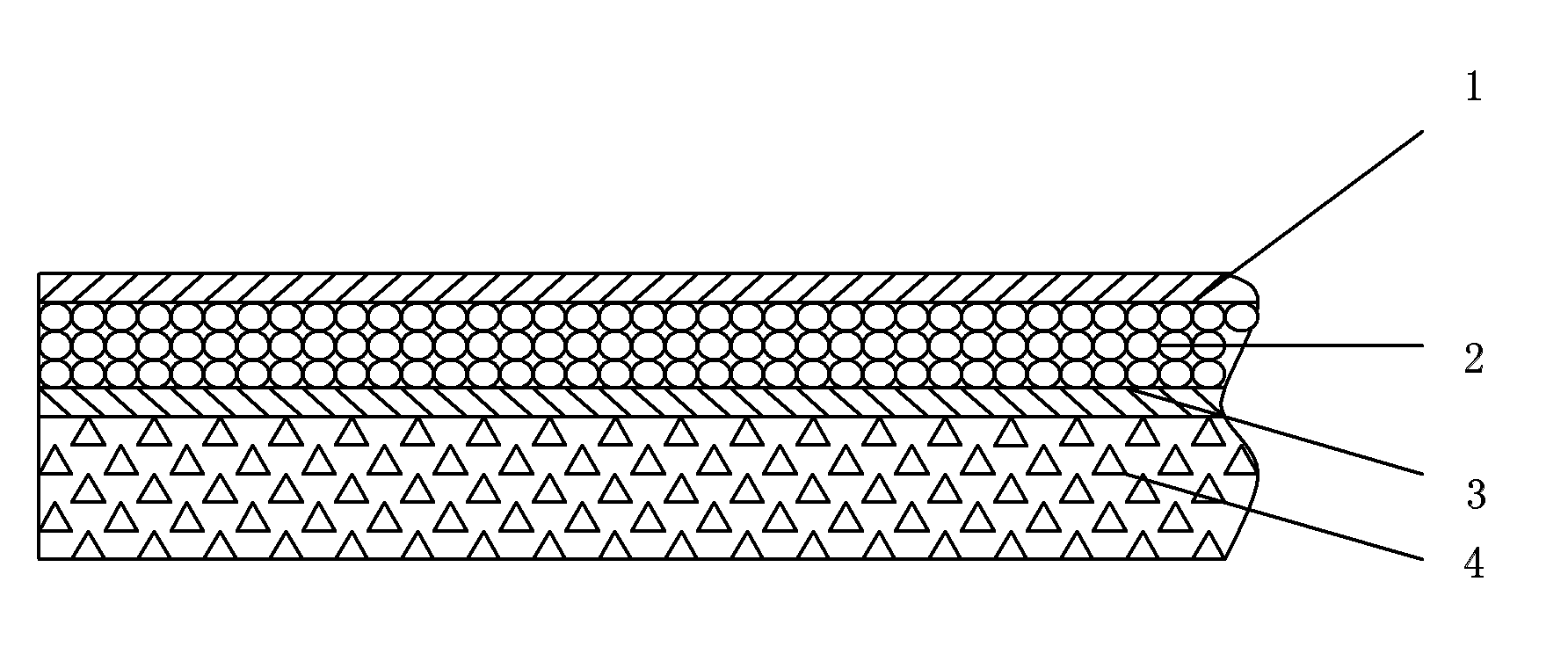

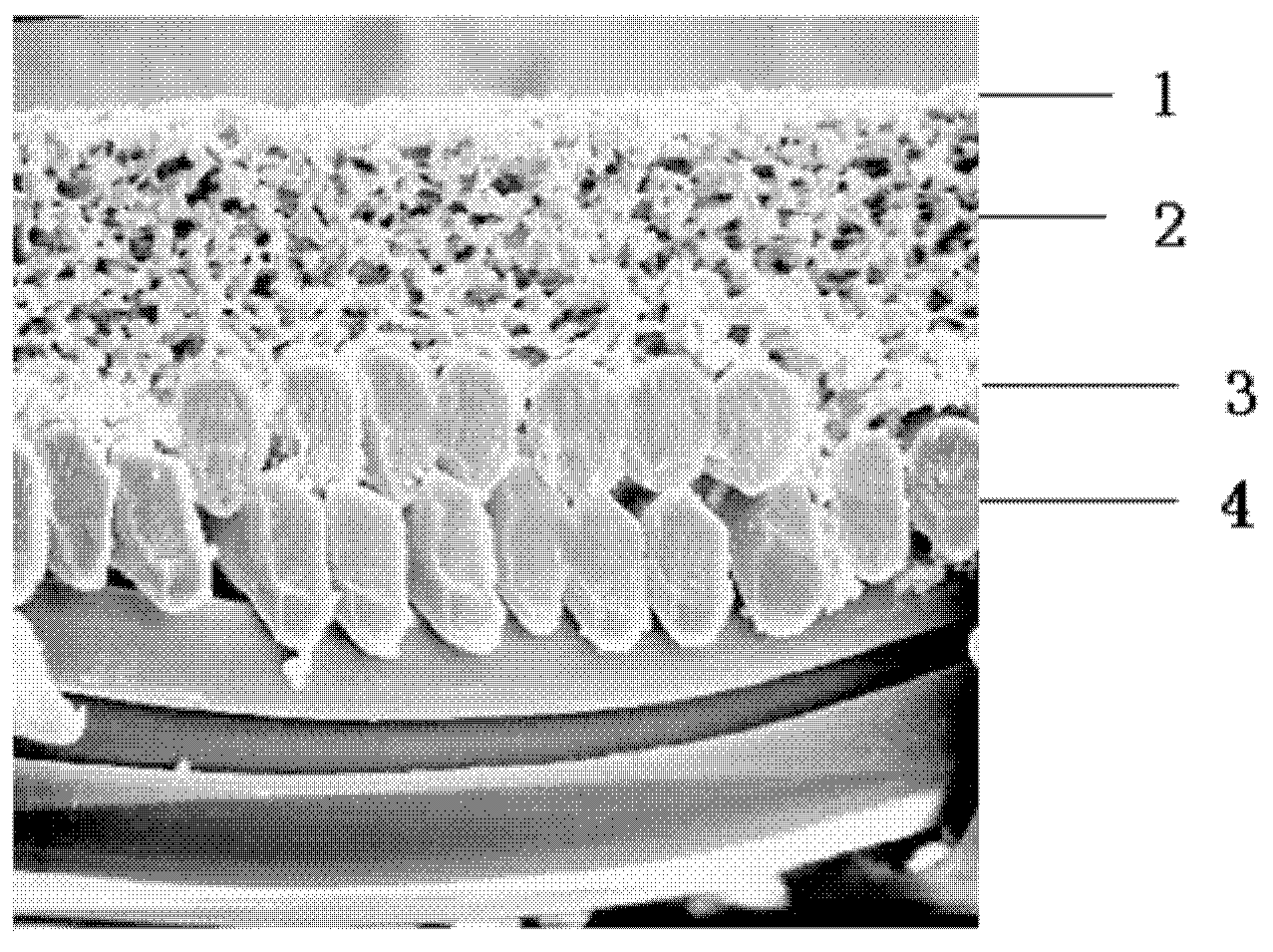

Coating fabric with high water pressure resistance and high moisture penetrability and preparation process thereof

InactiveCN101929081AReduced drainage resistanceImprove wear resistanceSynthetic resin layered productsLiquid/gas/vapor removal by scrapingWear resistantPolyurethane coating

The invention discloses a coating fabric with high water pressure resistance and high moisture penetrability, which comprises a bearing layer, a waterproof layer coated on the bearing layer, a micropore layer coated on the waterproof layer and a protective layer coated on the micropore layer, wherein the protective layer is a wear-resistant coating with a micropore structure and is a hydrophilic waterproof and penetrable polyurethane coating with a hydrophilic function; the micropore layer in the middle is a micropore waterproof and penetrable polyurethane coating with a micropore structure; and the bottom layer of the fabric coating is a waterproof layer which has favorable film formation property and can provide a hydrophilic waterproof and penetrable polyurethane coating with high water pressure resistance. The fabric provided by the invention has the characteristics of higher water pressure resistance, high penetrability and wearing comfortability.

Owner:CHINESE TEXTILE ACAD +1

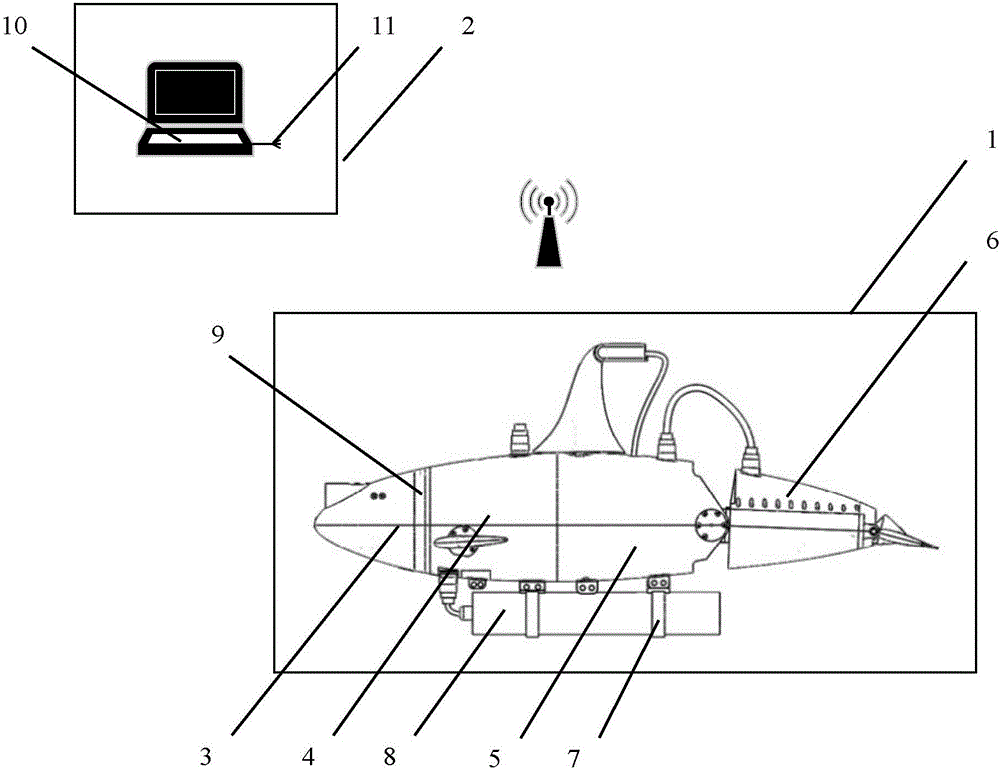

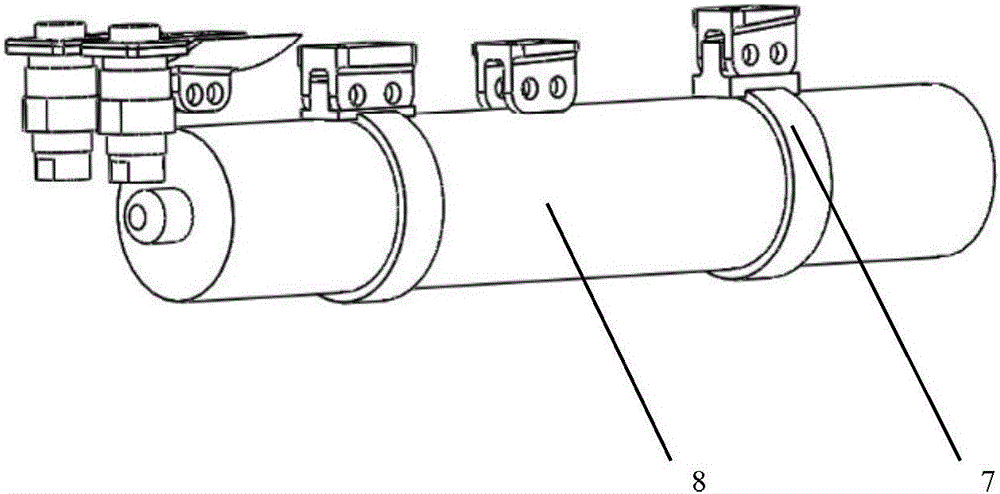

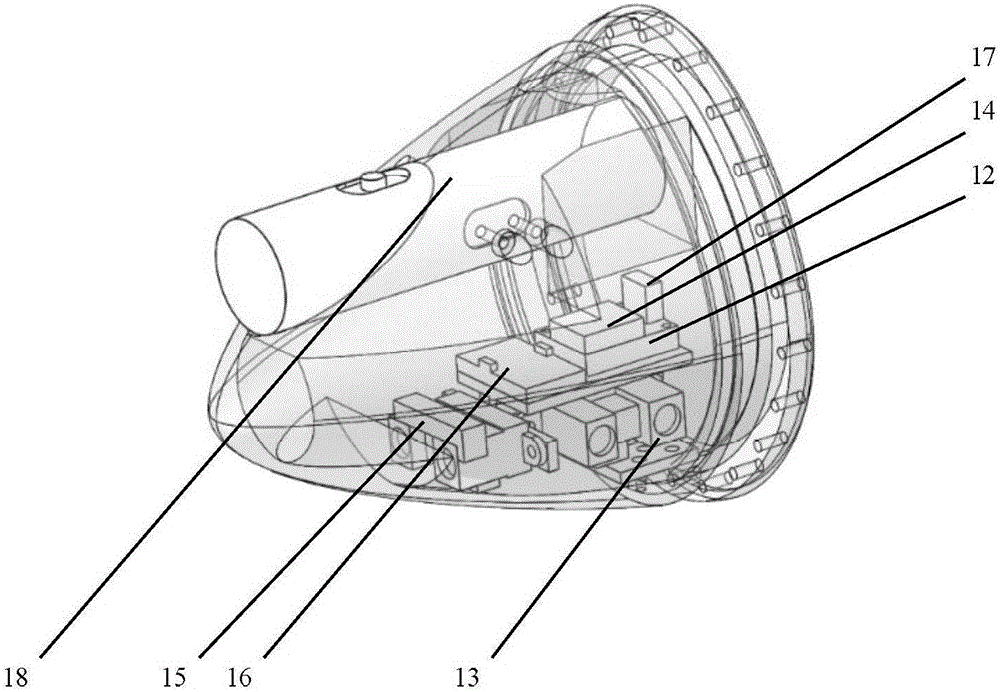

Bionic robotic dolphin for water quality monitoring

ActiveCN105775082AFlexible snorkelingAchieving locomotion controlTransmission systemsTesting waterComputer monitoringEngineering plastic

The invention discloses a bionic robotic dolphin for water quality monitoring. The bionic robotic dolphin comprises a bionic robotic dolphin body and an upper computer monitoring system. Information interaction between the bionic robotic dolphin body and the upper computer monitoring system is achieved in a radio frequency mode. According to the bionic robotic dolphin body, killer whale spindle low-resistance streamline appearance is adopted, a pressure-resistance shell is manufactured with polyformaldehyde engineering plastic, and the bionic robotic dolphin body comprises a water quality sensor module, a transparent head cabin, a pectoral fin cabin, a master control cabin and a tail joint cabin. The water quality sensor module is provided with different types of water quality sensors according to water quality monitoring requirements. A pectoral fin driving module is mounted in the pectoral fin cabin. The master control cabin is provided with a dorsal fin driving module and a tail joint driving module. The tail joint cabin is provided with a tail fin driving module. Maneuvering motions of advancing, steering, diving, floating and the like of the bionic robotic dolphin body can be achieved. By utilizing high maneuvering, low disturbance, non-pollution and the like of the bionic robotic dolphin body, water quality monitoring tasks are completed in narrow, complex and dynamic underwater environments by carrying the water quality sensors.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Method for preparing lasting super-hydrophobic modified polypropylene hollow fiber membrane

InactiveCN102688704AHigh water pressure resistanceImprove breathabilitySemi-permeable membranesPolypropylenePhotoinitiator

The invention relates to a method for implementing super-hydrophobic modification on a polypropylene hollow fiber membrane material, in particular to a method for preparing a lasting super-hydrophobic modified polypropylene hollow fiber membrane. The method comprises the following steps of: respectively dissolving fluorine ester containing unsaturated double bonds, acrylate containing a long alkyl chain, dithiol and a photo-initiator into an acetone solution to prepare a modification solution, soaking a polypropylene membrane treated by normal pressure plasmas into the modification solution, performing ultraviolet irradiation, washing, airing, and thus obtaining a fluorine-containing and long alkyl chain grafted modified polypropylene membrane material. A uniform, lasting and stable super-hydrophobic layer containing fluothane and the long alkyl chain is formed on the surface of the polypropylene membrane material, so that the hydrophobic polymer membrane is endowed with excellent super-hydrophobic property, high water pressure resistance and high air permeability; and the method is simple, good in treatment effect and low in cost, does not produce environment pollution, and is efficient and energy-saving.

Owner:SUZHOU XINER ENVIRONMENTAL TECH CO LTD

Polyfluortetraethylene nanofibre membrane and preparation method thereof

InactiveCN101543734AAvoid filter finenessAvoid filter efficiencySemi-permeable membranesFlat articlesAir filtrationWater resistant

The invention relates to a polyfluortetraethylene nanofibre membrane and a preparation method thereof. The aperture distribution of the polyfluortetraethylene nanofibre membrane is concentrated within a range of + / -100 nanometers and occupies more than 90 percent of the total volume of each level aperture; the stretching process of the preparation method adopts low-temperature segmenting stretching, thus the stretching temperature is stable, the polyfluortetraethylene nanofibre membrane is uniformly heated, and giant molecule segmers are equally unfolded; the produced polyfluortetraethylene nanofibre membrane has concentrated aperture distribution and high uniformity so as to generate high water pressure resistance, long water resistant time and high membrane fibering degree, and the obstructing efficiency of bacteria reaches more than 99.99 percent, thereby the polyfluortetraethylene nanofibre membrane can meet the requirement of oil-water separation and high-end gas filtration of an operation isolation mattress with high-pressure steam filtration and high water pressure resistance and can be used in fields of superclean room entering air filtration, and the like, such as medical treatment and health protection, health matter cultivation, semiconductor devices, integrated circuit, medicine, and the like.

Owner:北京千叶宝莲科技有限公司

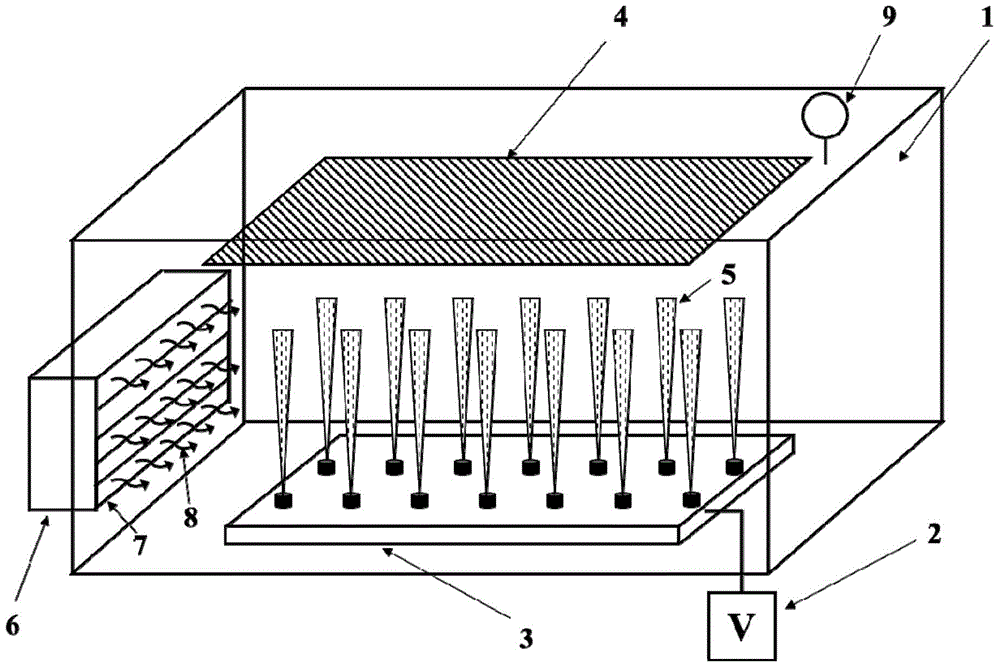

Electrostatic spinning method and device of fiber-based waterproof moisture-permeable film high in moisture-permeable flux

ActiveCN104452109AGood waterproof and moisture permeabilityPorosity is easy to controlNon-woven fabricsPorosityFiber

The invention relates to an electrostatic spinning method and device of a fiber-based waterproof moisture-permeable film high in moisture-permeable flux. The electrostatic spinning method includes that during electrostatic spinning, polymer solution jet flow is injected at a certain included angle with air of a certain temperature and / or lateral air flow of non-solvent steam, and polymer molecules in the jet flow are quickened to be separated and solidified into fibers; water-pressure resistance of the electrostatic spinning film, namely the fiber-based waterproof moisture-permeable film high in moisture-permeable flux is greater than or equal to 100kPa, and the moisture-permeable flux is greater than or equal to 15000g / m<2> / d. The electrostatic spinning device is composed of an electrostatic spinning box, a high-voltage direct-current power supply, an electrostatic spinning hydraulic system, a spinning jet and a receiving base material, and a steam generation and air supply system is mounted on one side of the electrostatic spinning box. The fiber-based waterproof moisture-permeable film produced by the method has the advantages of small bore diameter, controllable adhesion degree and high porosity; the film is high in water-pressure resistance and moisture-permeable flux when used in the waterproof and moisture-permeable areas, and is wide in actual application prospect.

Owner:DONGHUA UNIV

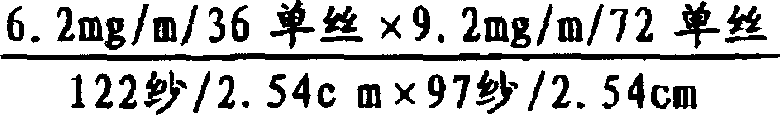

Superfine fiber high-density fabric and production method thereof

InactiveCN101748542ACompact structureHigh water pressure resistanceFibre typesWoven fabricsMicrofiberWeft yarn

The invention discloses a superfine fiber high-density fabric and a production method thereof. Warp yarns and weft yarns consist of superfine fiber yarns completely, and the cover coefficient of the finished product is over 2,600. The production method comprises that: the warp yarns and the weft yarns adopt the superfine fiber yarns having a precursor filament number or fiber-opened filament number of below 1.10 D for weaving, and a gray fabric is prepared. The fabric has the advantages of plump and soft handfeel, certain body, excellent mouldability, and comfort. The fabric also has water pressure resistance of 600 mm H2O after washing for 20 times, has excellent windproof and anti-acarien function, and is an ideal material for sports and casual wear.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

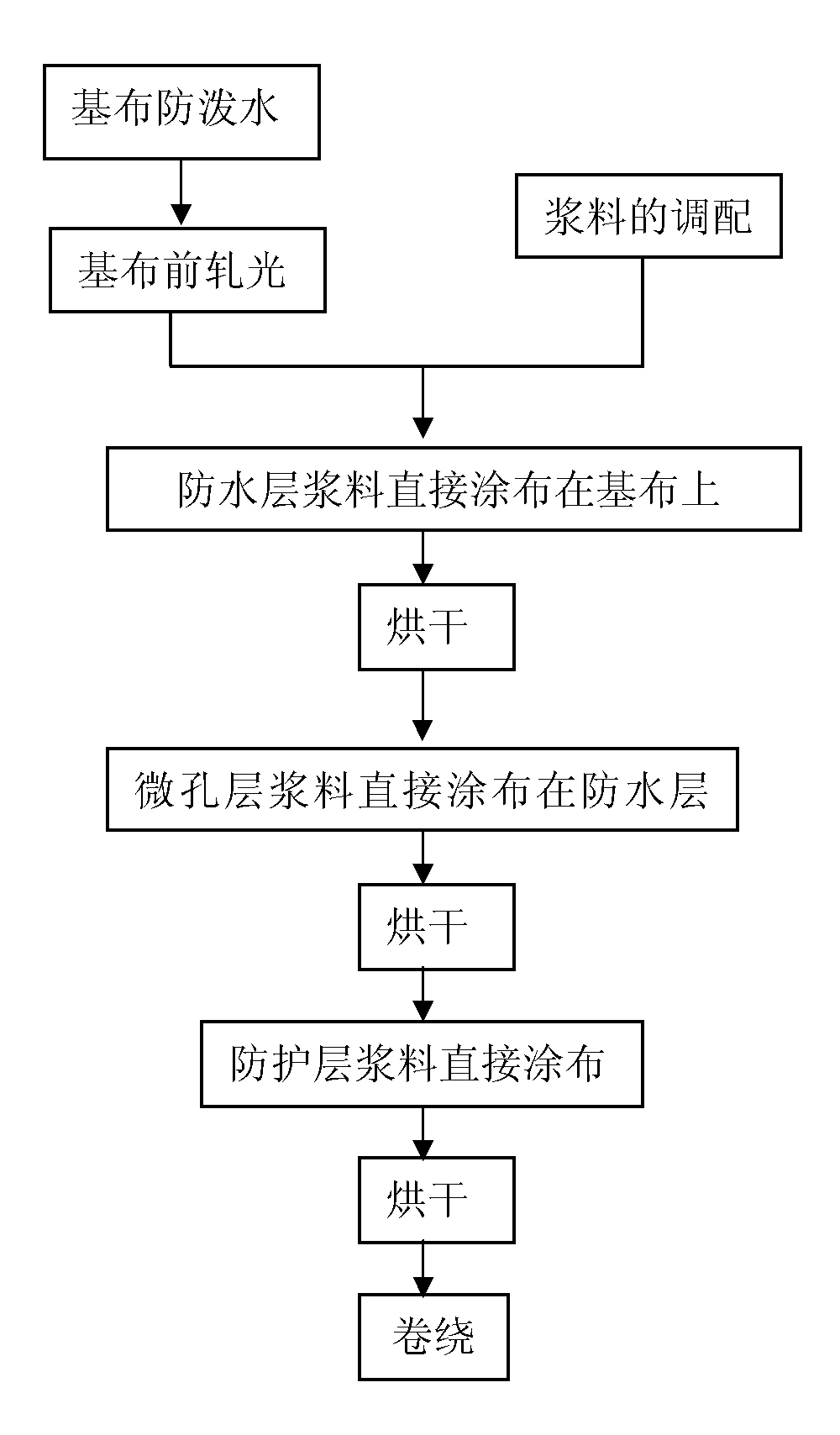

Micro porous dry-method waterproof and moisture-permeable fabric and production method thereof

InactiveCN101768872AImprove the disadvantage of poor wear resistanceWith waterproof and moisture-permeable functionSynthetic resin layered productsTextiles and paperNon solventFunctional movement

The invention discloses a micro porous dry-method waterproof and moisture-permeable fabric and a production method thereof. The fabric can be used for outdoor functional sportswear, brand readymade clothes, jackets, sport shoes, bedding and the like. The production method comprises the following steps of: uniformly coating a moisture-permeable fabric and a waterproof backing material on release paper in sequence; giving grains by rolling compound base fabrics through a transfer method; and volatilizing non-solvents and solvents in the fabric and the backing material at different degrees by baking with an oven at different degrees to make the fabric have the waterproof and moisture-permeable functions. The fabric produced by the method overcomes the defect of poor water-resisting property because the conventional hydrophilic imporous thin film fabric swells when wet, has good moisture permeability and hydraulic pressure performance and widens applied range of the waterproof and moisture-permeable fabric.

Owner:吴新民

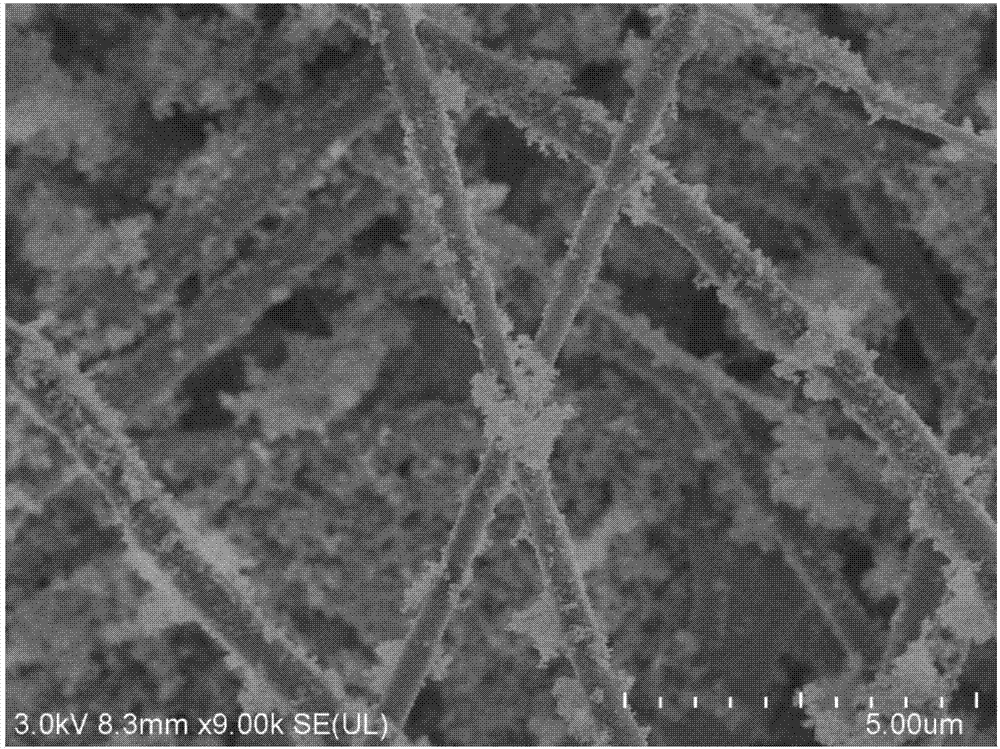

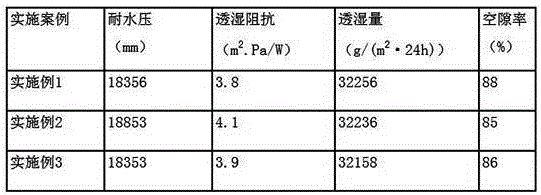

Ultra-high-flux nano-fiber waterproof gas-permeable membrane and preparation method thereof

ActiveCN107326653AAvoid destructionAvoid attenuationLiquid repellent fibresNon-woven fabricsPorosityFiber

The present invention relates to an ultra-high-flux nano-fiber waterproof gas-permeable membrane and a preparation method thereof, and belongs to the field of textile technology material synthesis. The ultra-high-flux nano-fiber waterproof gas-permeable membrane is prepared from the following two components such as bifunctional group-modified nano-silica particles and a polymer nano-fiber membrane, wherein the nano-fiber membrane uses the bifunctional group-modified nano-silica particles as the adhesive between fibers, such that the rub resistance of the membrane material can be enhanced, the nano-fiber surface roughness can be increased, and the water resistance of the fiber membrane can be increased. According to the present invention, the prepared ultra-high-flux nano-fiber waterproof gas-permeable membrane has characteristics of small pore size, high porosity and enhanced adhesion structure, can provide advantages of high water resistance, high moisture permeable flux and high strength in the waterproof and moisture permeation field, has the moisture permeation flux of more than or equal to 18000 g / m<2> / d, has the water resistance of more than or equal to 100 kPa, and has wide practical application prospects.

Owner:温明昊

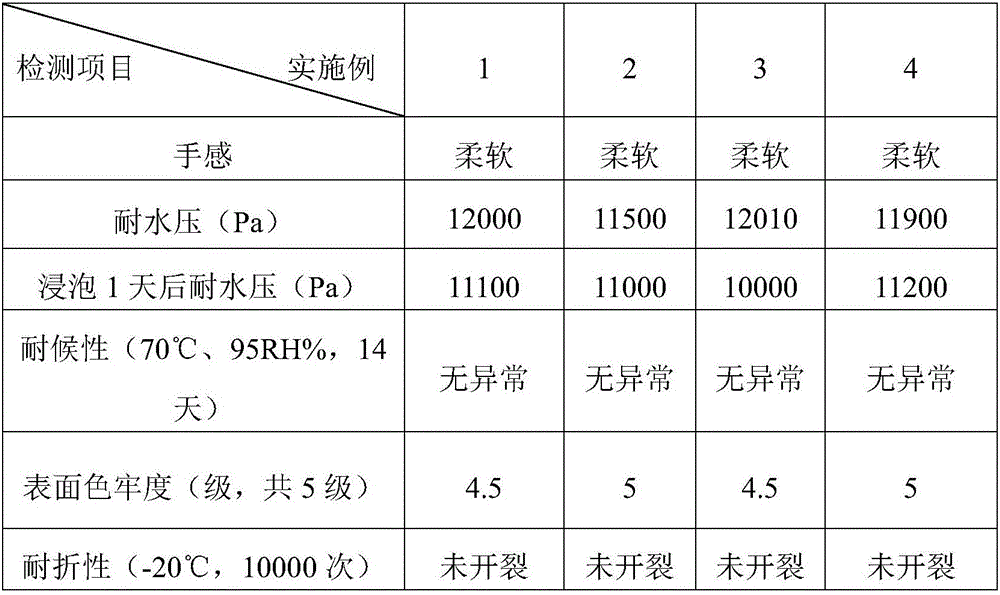

Water-based dry method foaming raincoat leather and preparation method thereof

InactiveCN106012564AImprove environmental standardsStop air bubblesTextiles and paperDefoaming AgentsChemistry

The invention provides water-based dry method foaming raincoat leather and a preparation method thereof. A water-based thickening agent, a defoaming agent, a flatting agent and other preparations are added into waterborne polyurethane resin, slurry on the surface layer, the middle layer, and the foaming layer and the bottom layer of waterborne polyurethane resin slurry is prepared through mixing and vacuum defoaming; through a dry method film moving processing method, release paper is firstly coated with the surface layer, the surface layer is coated with the middle layer after being dried and cooled, the middle layer is coated with the foaming layer after being dried and cooled, and the foaming layer is coated with the bottom layer after being dried and cooled; after low-temperature drying, base cloth is attached at high temperature, drying, curing and cooling are carried out, the release paper is stripped, split rolling and surface aftertreatment are carried out, and the water-based dry method foaming raincoat is obtained. The obtained water-based dry method foaming raincoat has good washing and water pressure resistance, and the water pressure resistance is still 10,000 MPa or above after washing; the water-based dry method foaming raincoat leather is soft in hand feeling, resistant to wrinkles, high in real leather sense, good in breathability and high in washing and water pressure resistance and completely meets the needs of the market for raincoat leather.

Owner:HEFEI KETIAN WATERBORNE TECH CO LTD +2

Non-woven polypropylene fabric

Provided is a non-woven fabric produced by using a polypropylene-based resin composition containing a specific low-crystalline polypropylene. The non-woven fabric is a non-woven fabric obtained by achieving reductions in denier values of fibers, the non-woven fabric being excellent in dispersibility of the fibers.

Owner:IDEMITSU KOSAN CO LTD

Fluorine-containing polymer and water- and oil-repellent agent

ActiveCN101981070AGood film formabilityGood waterproof and oil-proofLiquid repellent fibresWoven fabricsEmulsionFluorine containing

A water- and oil-repellent agent is an aqueous emulsion containing a fluorine-containing polymer. The fluorine-containing polymer comprises (a) a fluorine-containing monomer, and (b) a crosslinkable monomer, wherein the monomers (a) and (b) are polymerized in the presence of a chain transfer agent to produce the fluorine-containing polymer.

Owner:DAIKIN IND LTD

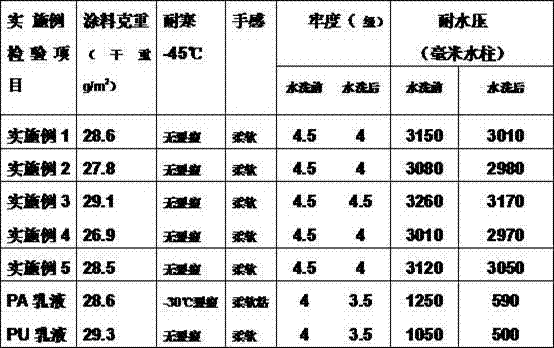

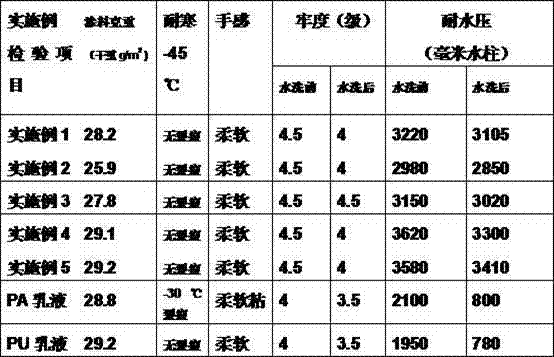

Polyacrylate-modified polyurethane aqueous coating emulsion with high water pressure resistance and preparation method thereof

The invention discloses a preparation method of a polyacrylate-modified polyurethane aqueous coating emulsion with high water pressure resistance which is used for textile. The emulsion is prepared from isophorone diisocyanate, bis(hydroxymethyl) butyric acid, polybutadiene diol, neopentyl glycol, isophorone diamine, triethylamine, deionized water, styrene, butyl acrylate, hydroxyethyl methacrylate and initiator. The preparation method is simple and convenient, the solid content is 45%, and the prepared emulsion has the advantages of soft handfeel, good cold resistance, solvent resistance andfirmness, high water pressure resistance and aqueous environmental-friendliness.

Owner:LIAONING FIXED STAR FINE CHEM

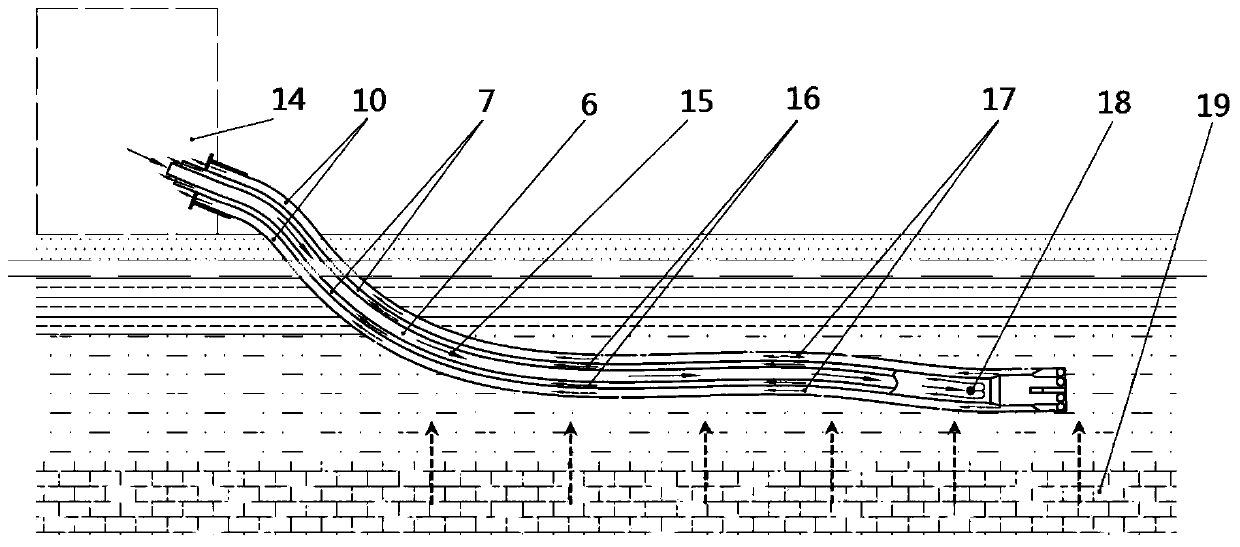

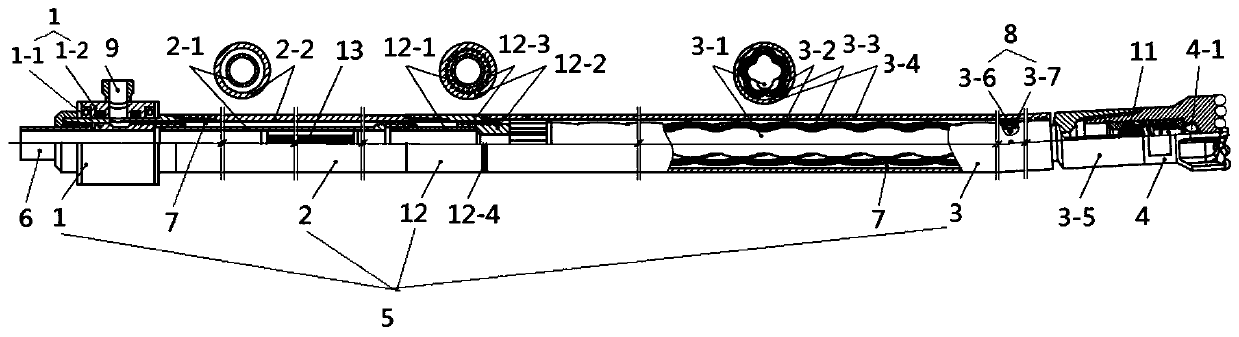

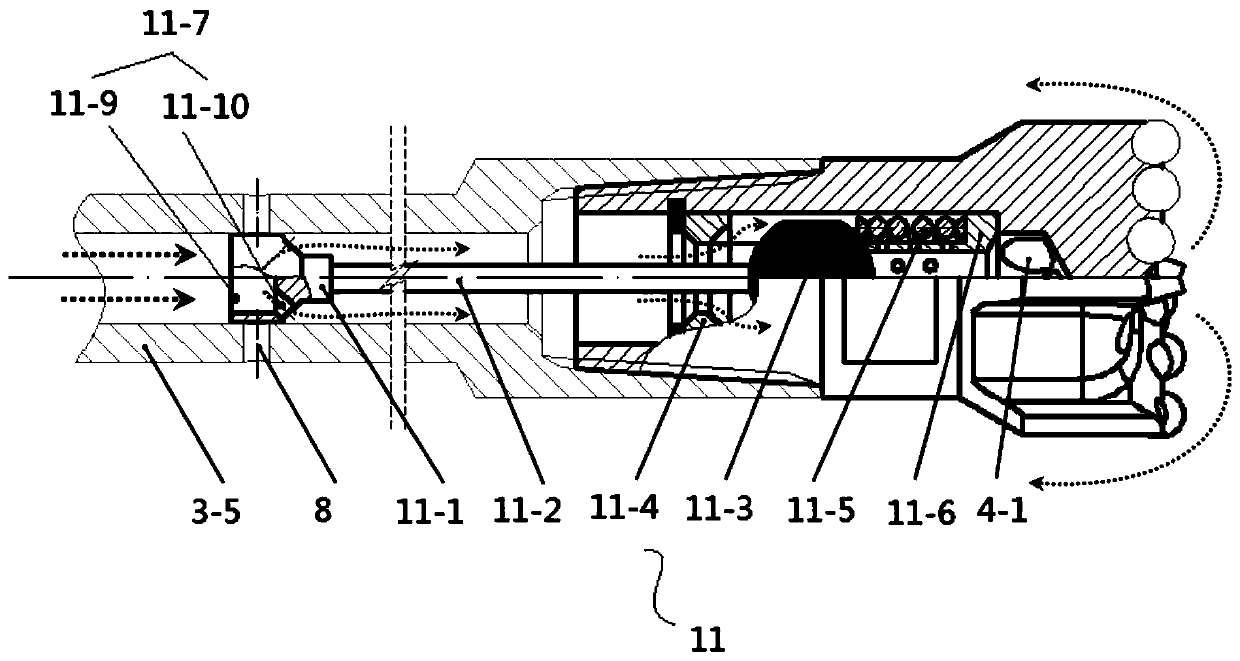

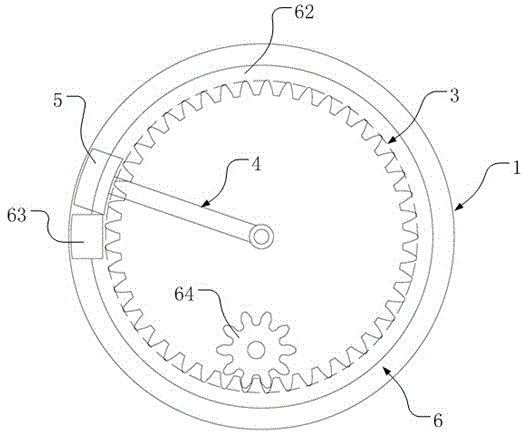

Underground coal mine water hole prevention and control high-water-pressure water jacking directional drilling tool and drilling method

The invention discloses an underground coal mine water hole prevention and control high-water-pressure water jacking directional drilling tool and drilling method. The directional drilling tool comprises a drill string body and a directional drill bit which are connected in sequence, and an inner annular hollow flow channel is arranged around the external of the drill string body; a ''Y-type'' structure flush fluid circulation flow channel consisting of a central flow channel and the inner annular hollow flow channel and an outer annular hollow flow channel formed between the drilling tool anda bore wall, the flush liquid is always flowing in the ''low back pressure'' state, the ''reactive'' load of a mud pump is substantially reduced, the effective utilization rate of the hydraulic energy can be improved by 15% or above, and it is ensured that the normal working and output torque parameters of the hole bottom power drilling tool do not change significantly under the working conditionof large water inrush of the high water pressure formation towards the inside of a hole. The drilling tool can normally directionally drill in the formation water outlet pressure condition of 6.0MPaor above, so that the downhole directional drilling water pressure resistance is improved by 50% or above, and the water jacking directional drilling hole-forming depth is 500m or above.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

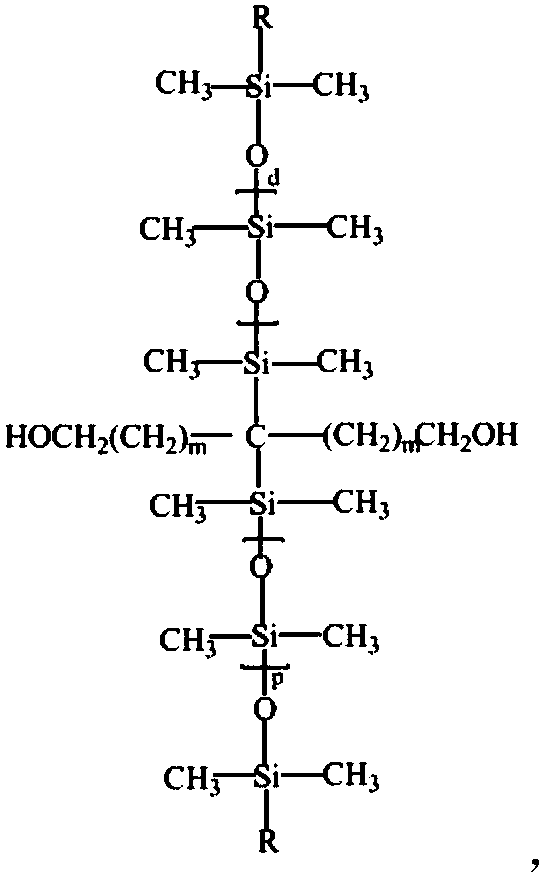

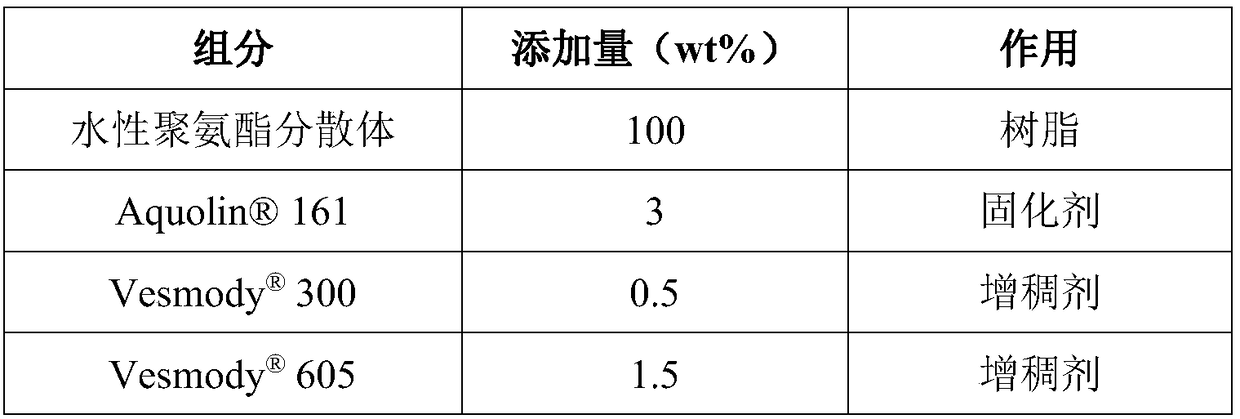

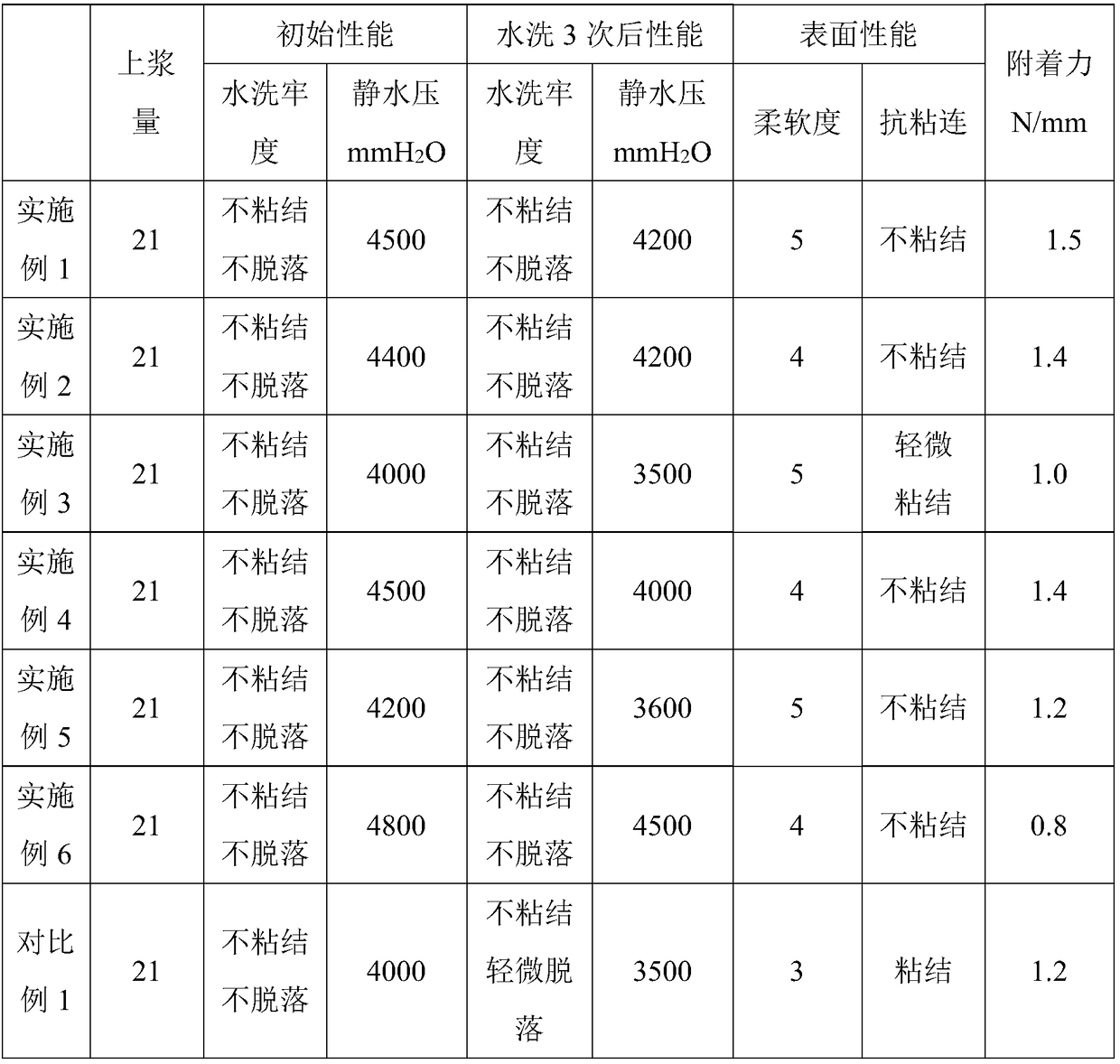

Water-based polyurethane dispersoid for dry coating primer as well as preparation method and application thereof

The invention discloses a water-based polyurethane dispersoid for a dry coating primer as well as a preparation method and application thereof. The polyurethane is obtained by polymerizing the following raw materials: a) at least one diisocyanate; b) at least one polyether glycol and / or polyester glycol; c) at least one polyether or polyester polyol with functionality degree more than or equal to3; d) at least one micromolecular polyol chain extender containing active hydrogen; e) at least one carboxylic acid hydrophilic chain extender containing active hydrogen; f) at least one polyamine micromolecular chain extender containing active hydrogen; and g) at least one organosilicone polyol containing active hydrogen, wherein the molecule side chain contains organosilicone. The water-based polyurethane dispersoid for the dry coating primer can achieve good anti-adhesion effect on the premise of guaranteeing soft hand feeling of resin.

Owner:WANHUA CHEM GRP CO LTD

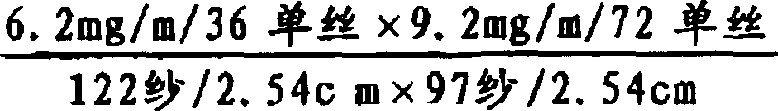

Water-vapor-permeable waterproof composite fabric and waterproof textile article

InactiveCN1229222CPermeableSufficiently permeableSynthetic resin layered productsTextiles and paperElastomerPolymer science

A water-vapor-permeable waterproof composite fabric having high flexibility, water pressure resistance and water laundering resistance is constituted from a substrate fabric and a polyether-ester elastomer (PEE-A) film layer laminated to the substrate fabric through a polyether-ester elastomer (PEE-B) binder layer, each of PEE-A and PEE-B including polyalkylene glycol residues, alkyleneglycol residues and dicarboxylic acid residues, in which composite fabric, (1) the PEE-A contains 5 to 25 % by mass of polyethyleneglycol residues, (2) the PEE-A film layer is 5 to 5 mu thick, (3) the PEE-B has a melting temperature of at least 20 DEG C below that of the PEE-A and (4) the PEE-B binder layer is present in an amount of 2 to 20 g / m<2>.

Owner:TEIJIN LTD

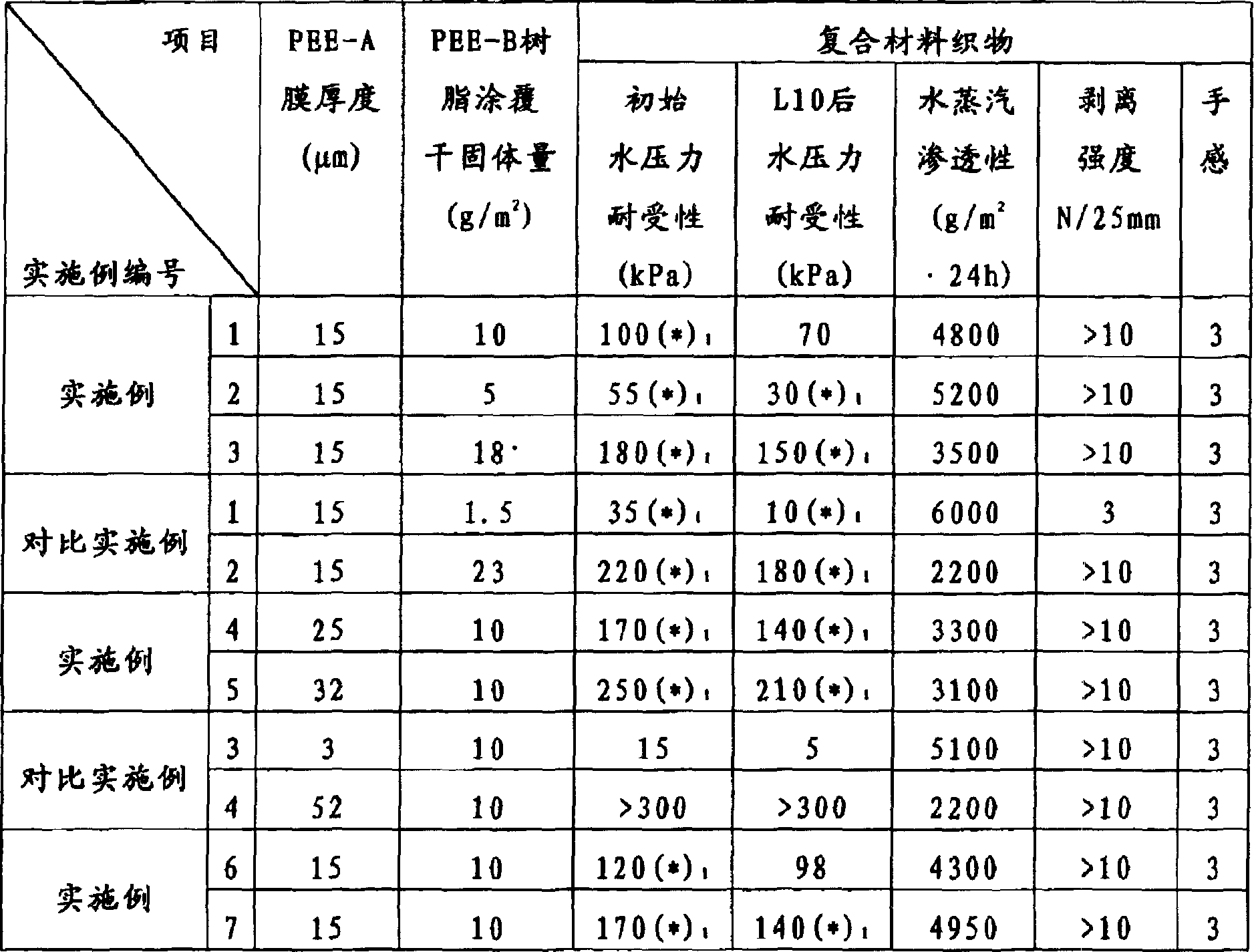

Fabric super-hydrophobic surface preparation method

ActiveCN109837758AGood chemical stabilityIncreased durabilityPhysical treatmentVegetal fibresWater bathsCross-link

The invention provides a fabric super-hydrophobic surface preparation method. The method at least includes steps: well mixing polydimethylsiloxane, hydroxyl polydimethylsiloxane, polymethylhydrosiloxane and a cross-linking agent to obtain polysiloxane finishing liquid; coating the fabric surface with the polysiloxane finishing liquid, and uniformly spreading a layer of sodium chloride particles onthe fabric surface to obtain a deposited coating; curing the deposited coating, subjecting the cured fabric to water-bath ultrasonic treatment, and drying to form the fabric super-hydrophobic surface. A super-hydrophobic fabric prepared according to the method is excellent in chemical stability and mechanical durability and has great water pressure resistance and breathability, a static contact angle of the super-hydrophobic surface reaches 155.47 degrees, a rolling angle is 5.5 degrees, breathability reaches 90.06mm / s, water pressure resistance reaches 2733Pa, and hydrophobicity of the fabric is almost unchanged after repeated washing and wear.

Owner:HEBEI BENFA GARMENT CO LTD

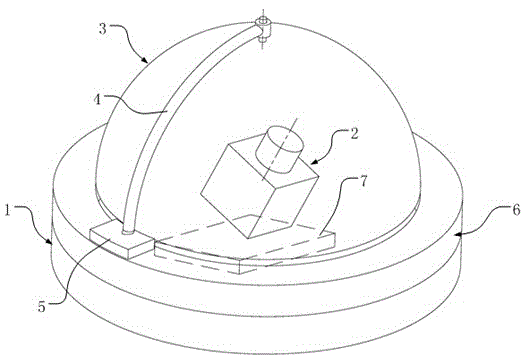

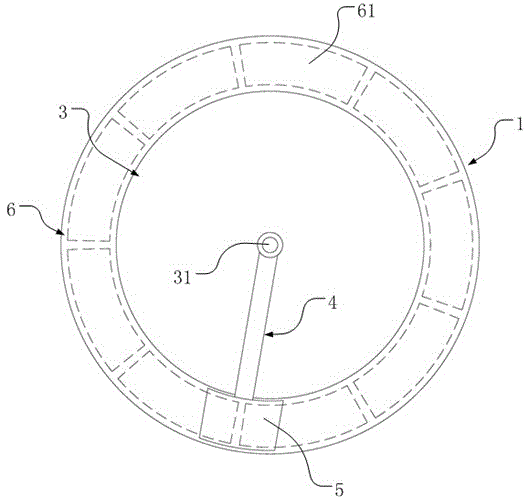

Automatic cleaning system for video capture window of underwater monitoring device

ActiveCN105478397AGuaranteed long-term useHigh water pressure resistanceCleaning using toolsHinge angleBusbar

The invention discloses an automatic cleaning system for a video capture window of an underwater monitoring device. The automatic cleaning system comprises a disc-shaped base, a video capture module and a transparent window cover. The outer surface of the window cover is a rotation curved surface which is formed in the manner that a busbar with one end on the center axis rotates around the center axis by a circle. The center axis of the window cover is coaxial with the center axis of the base. A cleaning scraper is arranged on the outer wall of the window cover in a striding manner. The inner edge of the cleaning scraper is attached to the outer surface of the window cover in a matched manner. The cleaning scraper is hinged to the window cover and can rotate around a hinge shaft. The part, between the cleaning scraper and the window cover, of the hinge shaft is coaxial with the center axis of the window cover. The cleaning scraper is driven by external force to rotate around the hinge shaft.

Owner:GUANGZHOU SEA DOG PHOTOELECTRIC SCI & TECH CO LTD

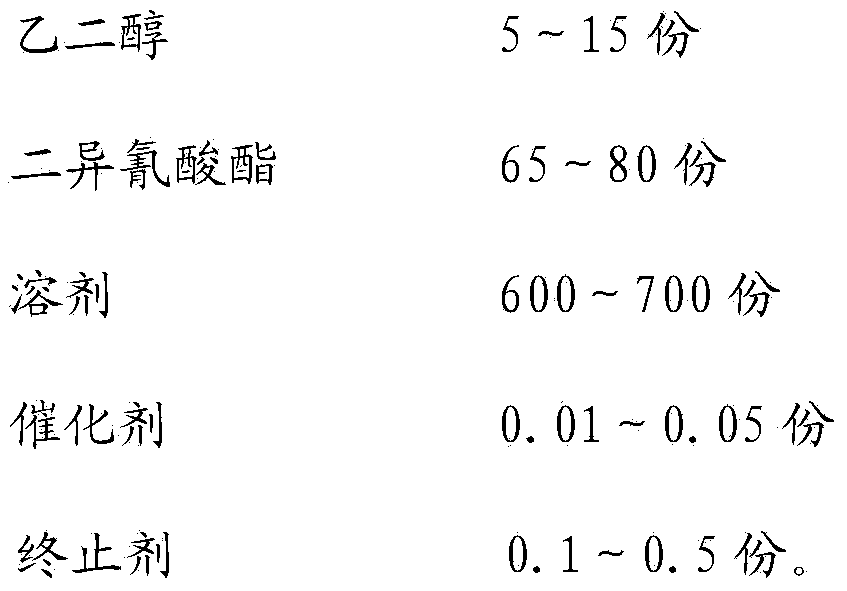

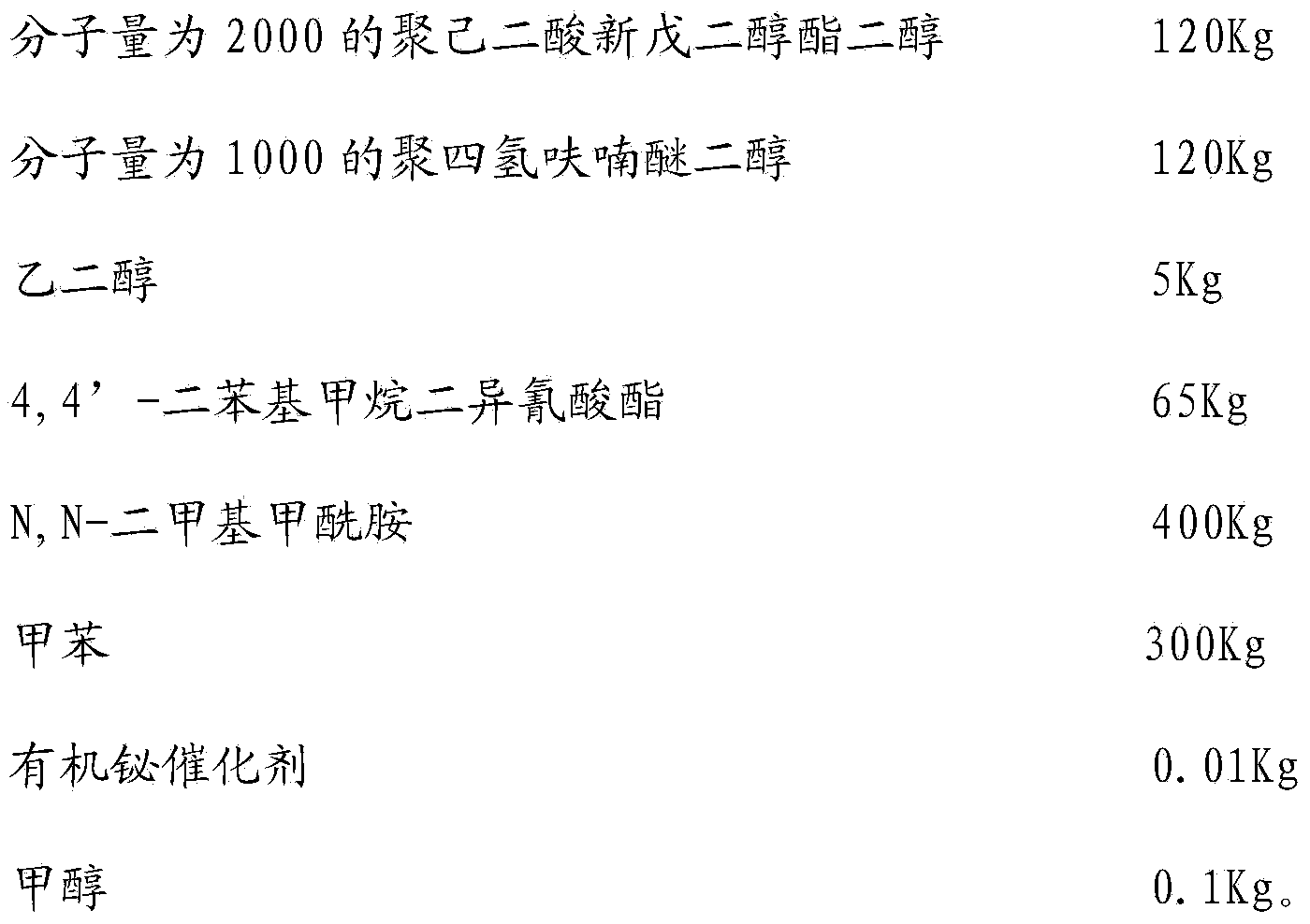

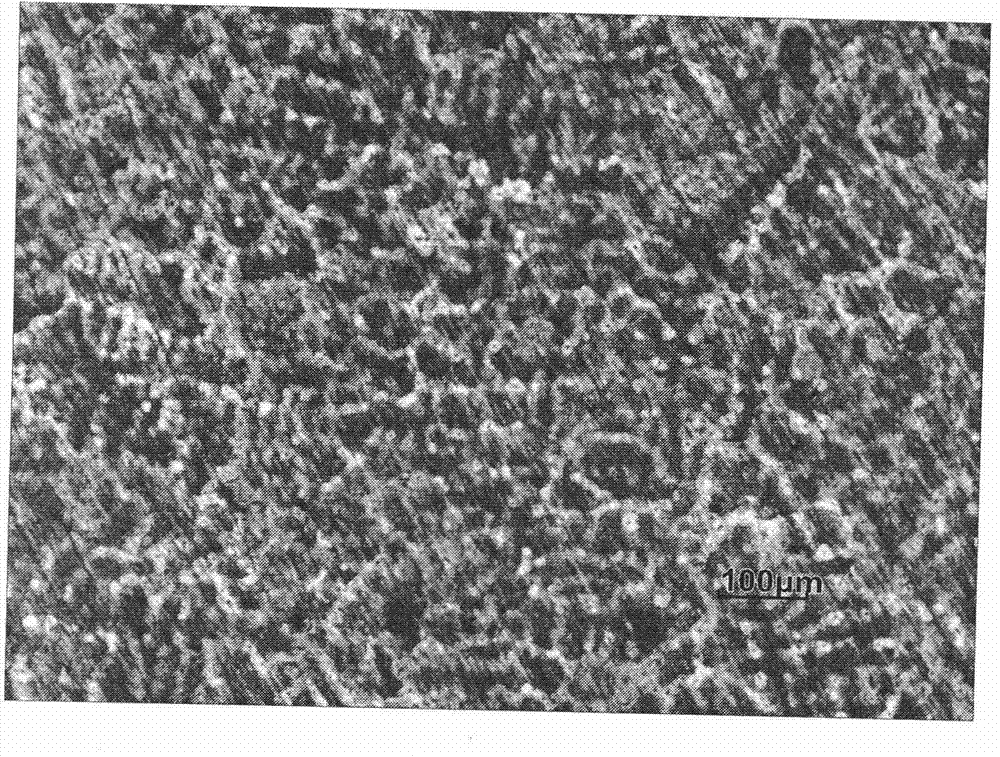

Polyurethane resin for synthetic leather with high water pressure resistance

The invention discloses polyurethane resin for synthetic leather with high water pressure resistance. The polyurethane resin is mainly prepared from the following raw materials in parts by weight: 80-120 parts of polyester glycol, 80-120 parts of polyether glycol, 5-15 parts of glycol, 65-80 parts of diisocyanate, 600-700 parts of solvent, 0.01-0.05 part of catalyst and 0.1-0.5 part of terminator. By adopting the technical scheme, the prepared polyurethane resin disclosed by the invention has excellent water pressure resistance and has the characteristics of water resistance, hydrolysis resistance and the like; the synthetic leather prepared in a manner that the polyurethane resin is adopted as a surface layer has excellent water resistance and weatherability.

Owner:侯马飞

Lead-free bronze alloy and application thereof

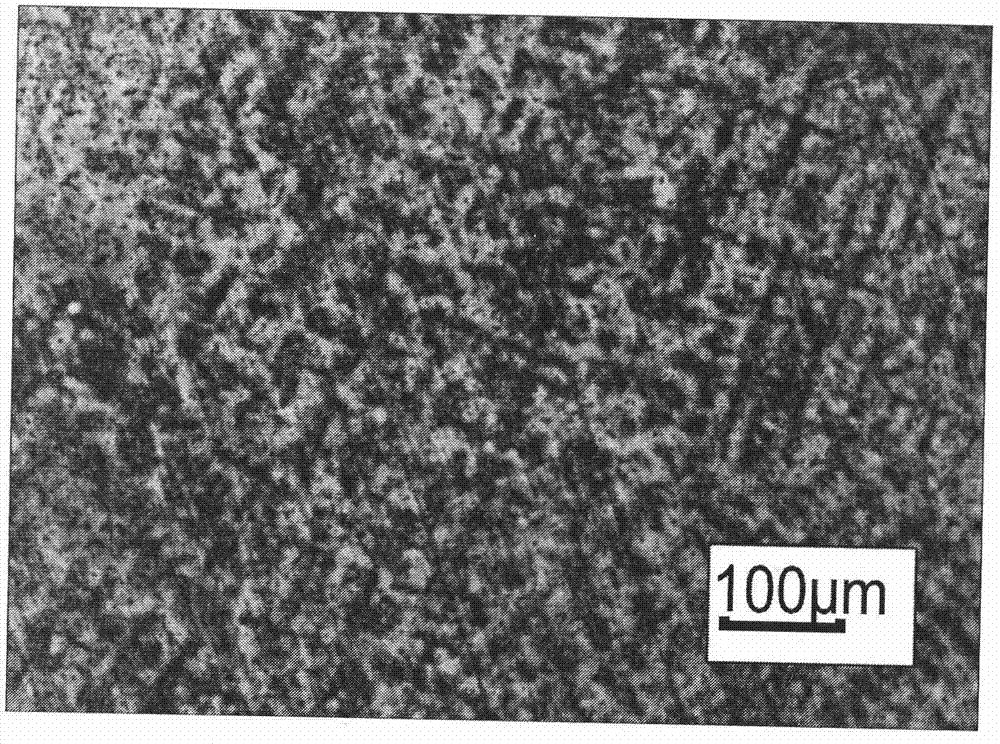

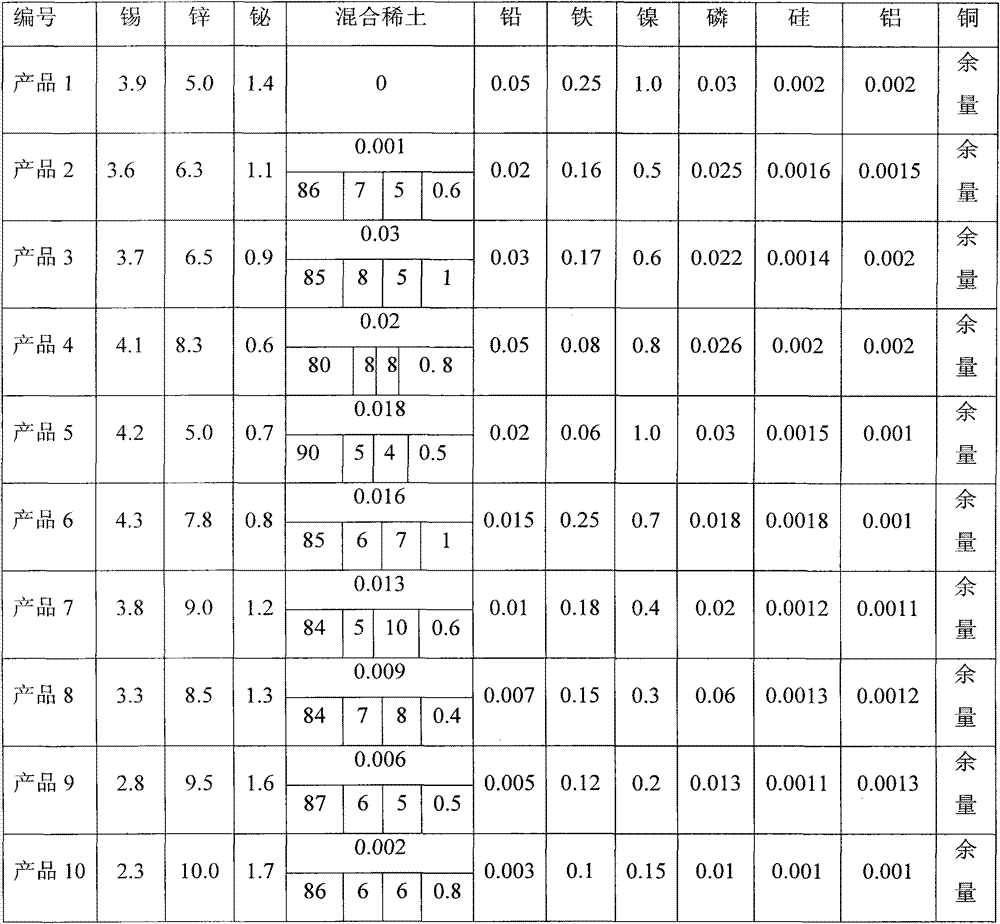

The invention discloses a lead-free bronze alloy and an application thereof. The lead-free bronze alloy comprises the following chemical components by mass percent: 2.3-4.3 percent of stannum, 5.0-10.0 percent of zinc, 0.6-1.7 percent of bismuth, 0.002-0.02 percent of misch metal, equal to or less than 0.05 percent of lead, equal to or less than 0.25 percent of iron, equal to or less than 1.0 percent of nickel, equal to or less than 0.03 percent of phosphor, equal to or less than 0.002 percent of silicon, equal to or less than 0.002 percent of aluminum and the balance of copper, wherein the misch metal contains 80-90 percent of lanthanum, 5-8 percent of cerium, 4-10 percent of praseodymium and equal to or less than 1.0 percent of neodymium by mass percent. The alloy basically contains no lead, is harmless to human bodies and environments, is easily cut and suitable for low pressure casting and gravity casting, and has good erosion resistance; and the bronze alloy is suitable for casts of a drinking water system.

Owner:安新县华昌合金厂

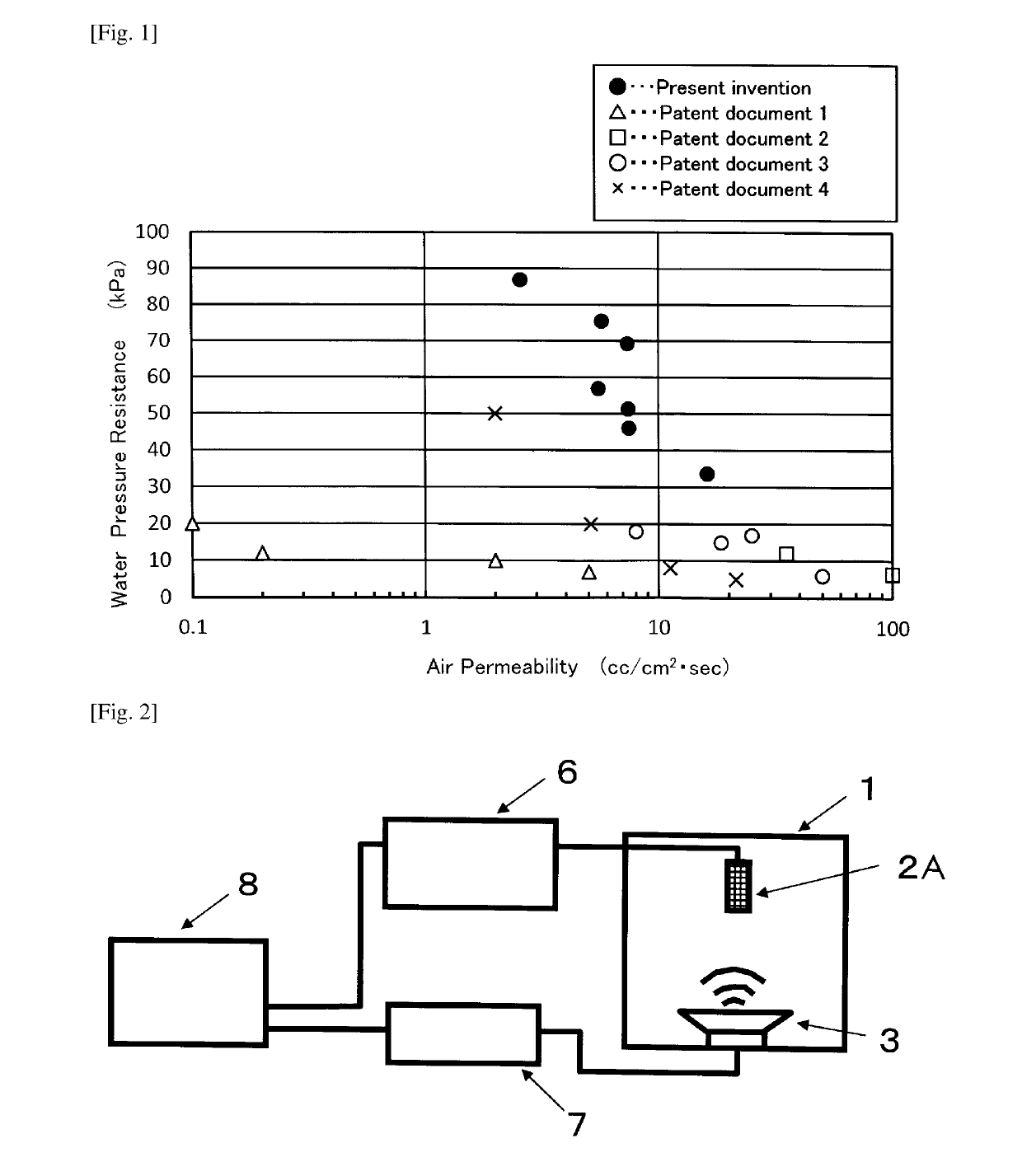

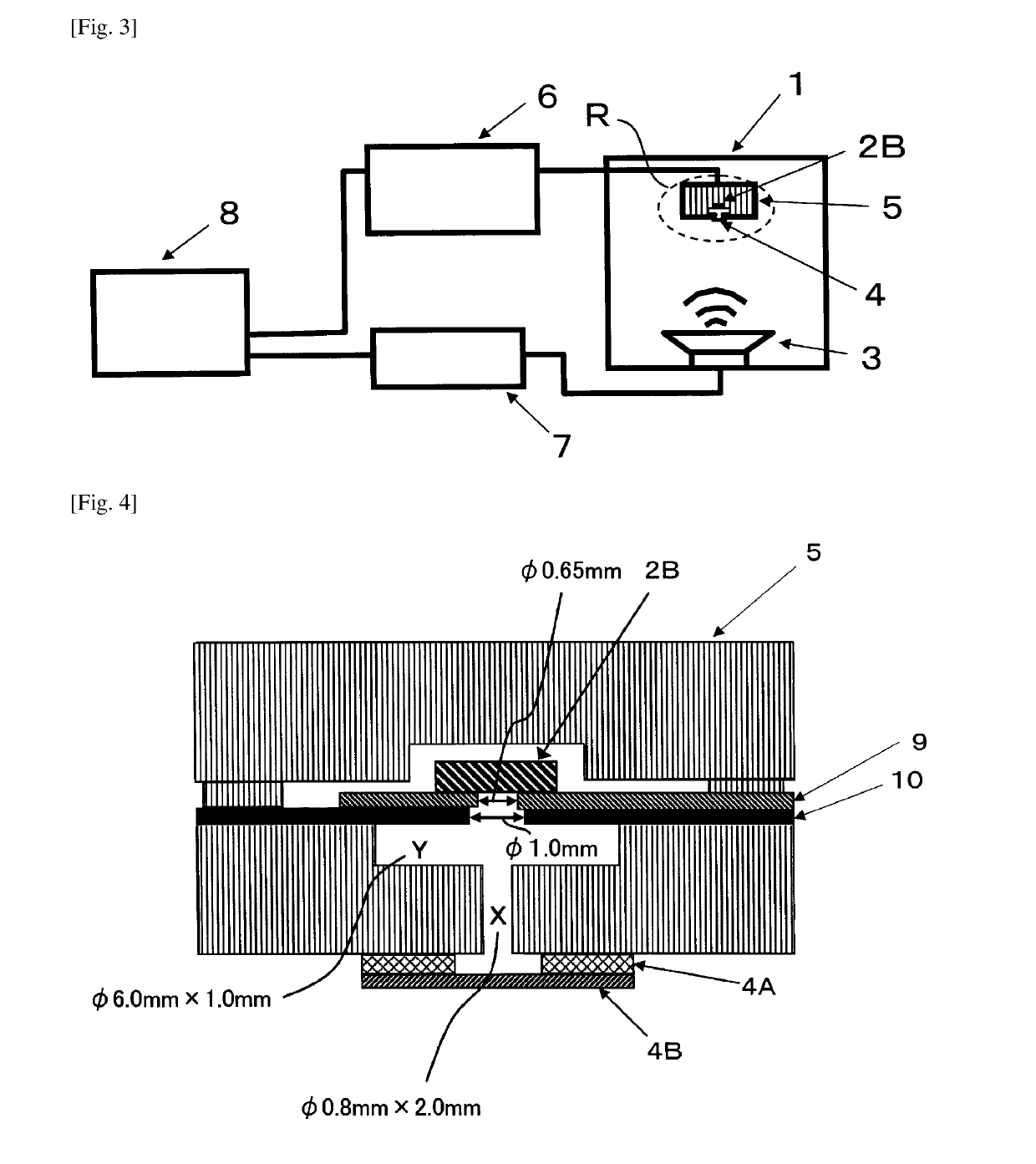

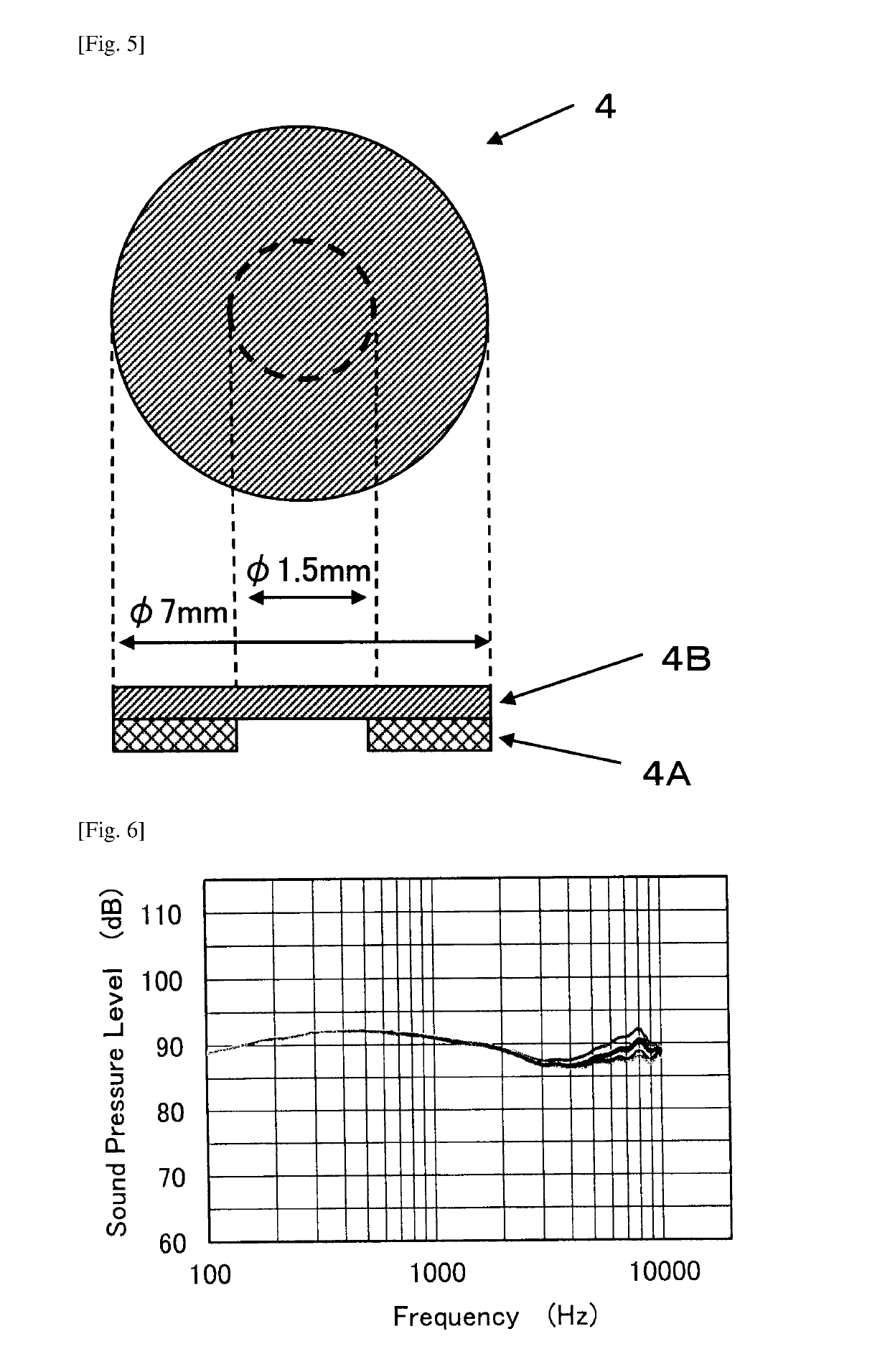

Waterproof sound-transmissive cover, waterproof sound-transmissive cover member and acoustic device

ActiveUS20190268679A1Improve breathabilityImprove waterproof performanceLoudspeaker screensMouthpiece/microphone attachmentsEngineeringHigh pressure

The waterproof sound-transmissive cover is characterized by providing a frequency response curve with a difference between a maximum sound pressure level and a minimum sound pressure level of 13.0 dB or less in the range of frequencies from 3 kHz to 8 kHz, and an insertion loss at 1 kHz of less than 14.0 dB, and said cover comprising: a porous film having (1) a water pressure resistance measured according to JIS L1092 water penetration test method B (high pressure method) of 20 kPa or more, and air permeability measured according to JIS L1096 method A (Frazier type method) of 3.0 cc / cm2·sec or more, and (2) a tensile strength measured according to ASTM standards D412 of 5.5N or more.

Owner:W L GORE & ASSOC GK

Preparation method for highly water-pressure-resistant, highly air permeable and highly wet permeable garment film

ActiveCN106363926AHigh water pressure resistanceImprove breathabilityFlat articlesMilitary UniformsActive agent

The invention discloses a preparation method for a highly water-pressure-resistant, highly air permeable and highly wet permeable garment film. The preparation method comprises the following steps of: mixing dispersed polytetrafluoroethylene resin powder with a solvent and a surfactant in a certain mass ratio; and performing maturing, blank-making, extrusion molding, calendering, one-time drawing, desolventizing, intermediate-temperature secondary longitudinal drawing, low-temperature secondary transverse drawing, high-temperature thermal treatment and sizing and the like. The method is simple in batch production process, and controllable and environmental-friendly in production process, quality is stable and appearance is good. The film has the characteristics of being highly water-pressure-resistant, great in air and wet permeability, washable, stable in chemical property and the like. The film is particularly suitable for the field of outdoor waterproofness, air permeable and wet permeable garments, shoes, military uniforms and the like.

Owner:北京佳膜环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com