Water-vapor-permeable waterproof composite fabric and waterproof textile article

A composite material and water vapor technology, applied in textiles and papermaking, synthetic resin layered products, layered products, etc., can solve the problems of coating film damage, waterproof performance of coated fabrics, etc., and achieve excellent washing resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

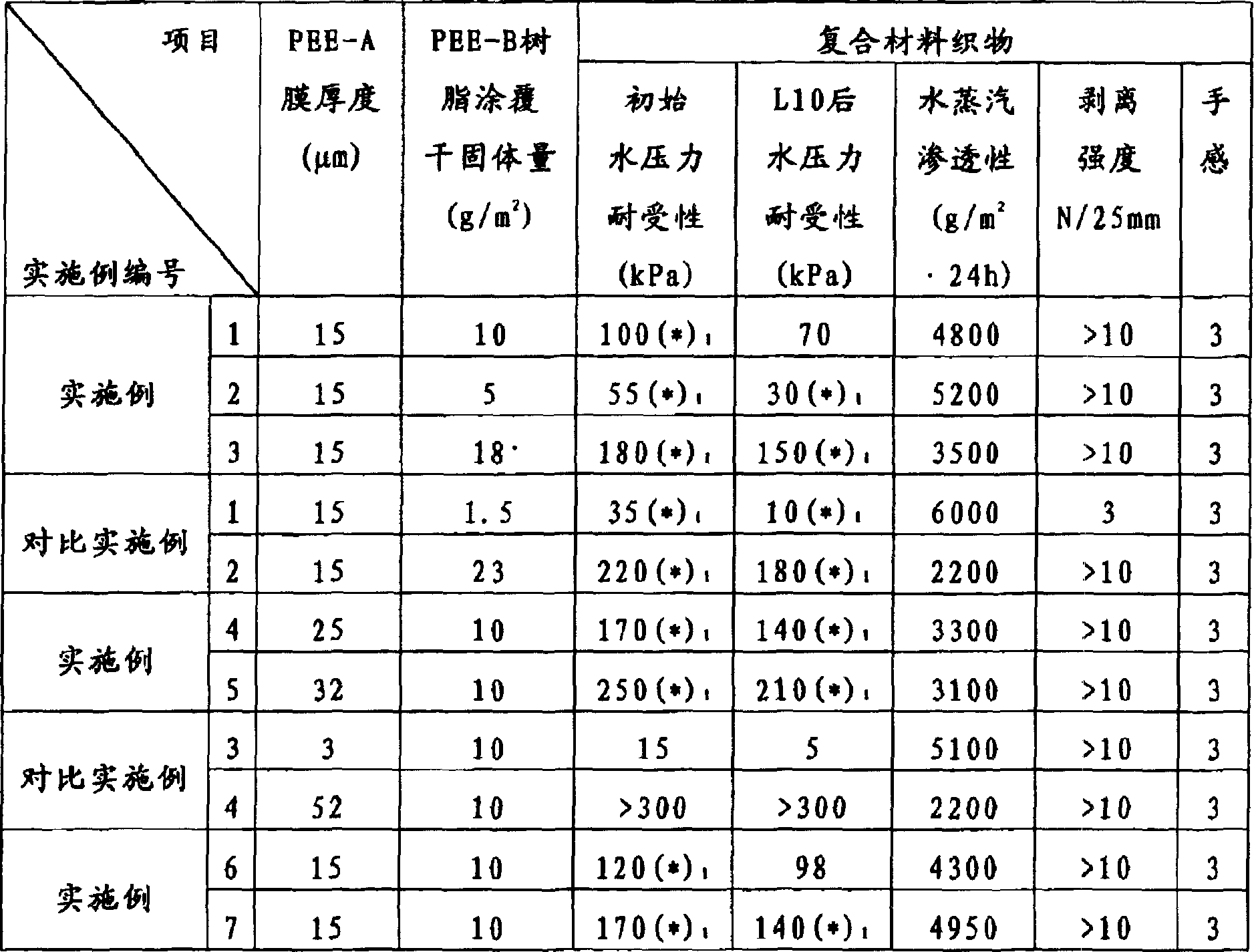

[0135] The invention will be further illustrated by examples, which are representative only and do not limit the scope of the invention in any way. The tests for the polymers used in the examples and the properties of the products in the examples were carried out as follows.

[0136] (1) Intrinsic viscosity (IV) of polyetherester elastomer (PEE)

[0137] The intrinsic viscosity of PEE is measured at a temperature of 35° C. in a mixed solvent composed of phenol and tetrachloroethane in a mixing weight ratio of 6:4.

[0138] (2) Melting temperature of PEE

[0139] The melting temperature of PEE was measured by a differential scanning calorimeter (model: DSC 29290, manufactured by TAINSTRUMENT) in a nitrogen stream at a temperature increase rate of 10° C. / min.

[0140] (3) The content of ethylene glycol or butanediol in PEE

[0141] The content of ethylene glycol or butanediol in PEE was measured at 90 MHz by using an FT-NMR analyzer (model: R1900 manufactured by HITACHI LIMIT...

preparation Embodiment 1

[0175] (Preparation of PEE-A-1 to PEE-A-8 resins)

[0176] In the preparation of PEE-A-1, a reaction mixture of the following substances was placed in a reactor equipped with a still: 194 parts by mass of dimethyl terephthalate (DMT) and 43.3 parts by mass of ethylene glycol (EG), the butanediol (TMG) of 72 mass parts, the average molecular weight of 124 mass parts is the catalyst that is made up of the polyethylene glycol (PEG) of 4,000 and 0.39 mass part; Then in from While removing by-products consisting of methanol in the reactor, it was subjected to a transesterification reaction at a temperature of 220° C. for 10 minutes. After the transesterification reaction was completed, the resulting reaction mixture was put into a reactor equipped with a stirrer, a nitrogen introduction inlet, a pressure drop outlet and a still, and it was heated to 240° C. with 0.31 parts by mass of heat A stabilizer (trademark: SUMILIZERGS, produced by SUMITOMO CHEMICAL CO., LTD.) was mixed; the...

preparation Embodiment 2

[0192] (Preparation of PEE-B resin)

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com