Patents

Literature

6768 results about "Dicarboxylic Amino Acids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The most widely used dicarboxylic acid in the industry is adipic acid, which is a precursor used in the production of nylon. Other examples of dicarboxylic acids include aspartic acid and glutamic acid, two amino acids in the human body. The name can be abbreviated to diacid.

Polyester process

A process for the preparation of an unsaturated polyester which comprises (i) reacting an organic diol with a cyclic akylene carbonate in the presence of a first catalyst to thereby form a polyalkoxy diol, and (ii) optionally adding thereto a further amount of cyclic alkylene carbonate in the presence of a second catalyst, and (iii) subsequently polycondensing the resulting mixture with a dicarboxylic acid.

Owner:XEROX CORP

Dicarboxylic acid foamable vehicle and pharmaceutical compositions thereof

ActiveUS20080044444A1Convenient vehicle for topical deliveryGood treatment effectPowder deliveryBiocideDicarboxylic acidCarboxylic acid

The present invention teaches a foamable pharmaceutical carrier comprising a benefit agent, selected from the group consisting of a dicarboxylic acid and a dicarboxylic acid ester; a stabilizer selected from the group consisting of at least one surface-active agent; at least one polymeric agent and mixtures thereof; a solvent selected from the group consisting of water, a hydrophilic solvent, a hydrophobic solvent, a potent solvent, a polar solvent, a silicone, an emollient, and mixtures thereof, wherein the benefit agent, stabilizer and solvent are selected to provide a composition that is substantially resistant to aging and to phase separation and or can substantially stabilize other active ingredients. The invention further relates to a foamable composition further containing a liquefied hydrocarbon gas propellant.

Owner:VYNE THERAPEUTICS INC

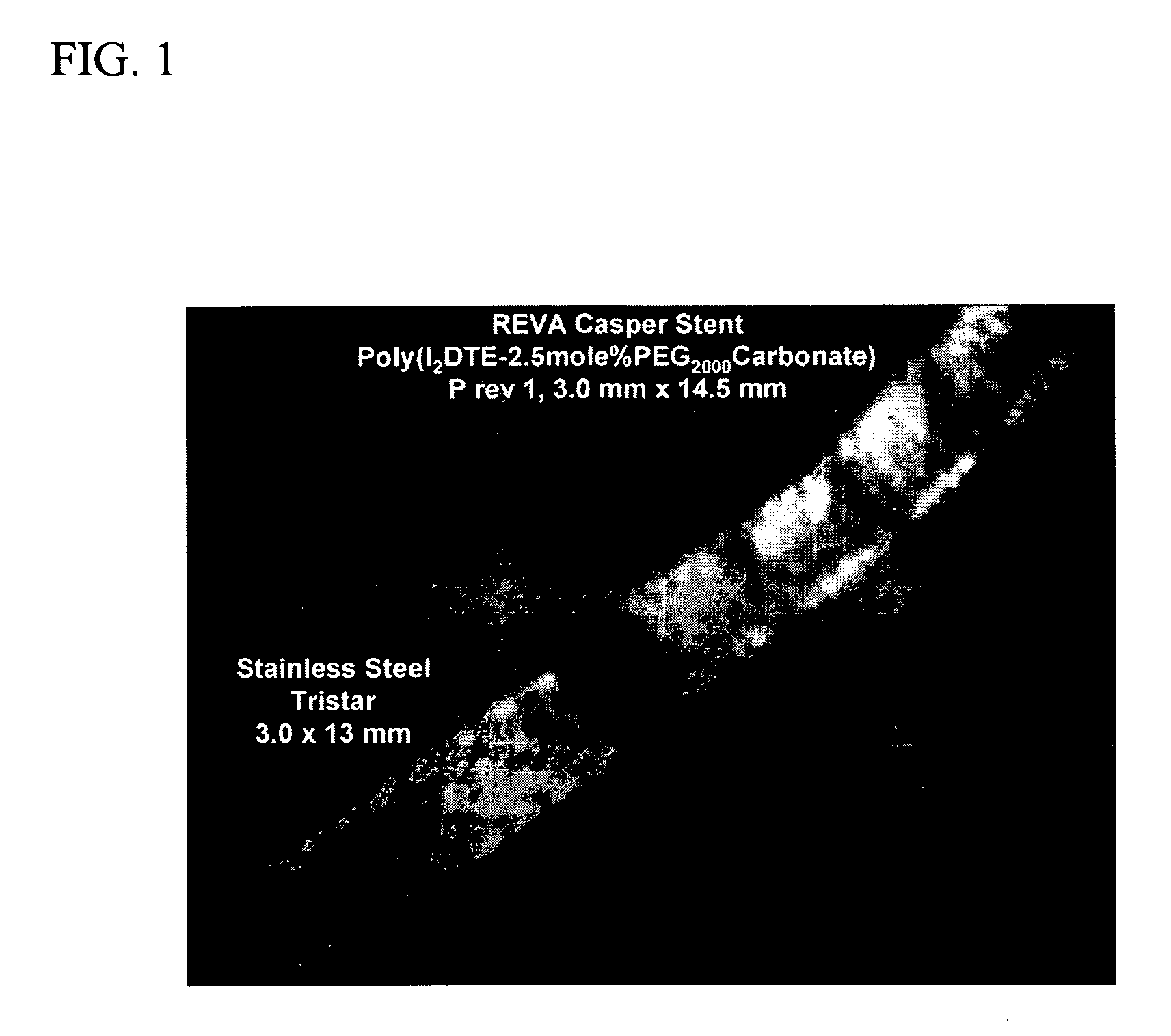

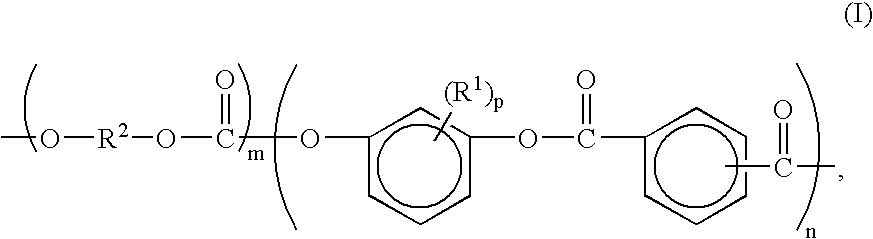

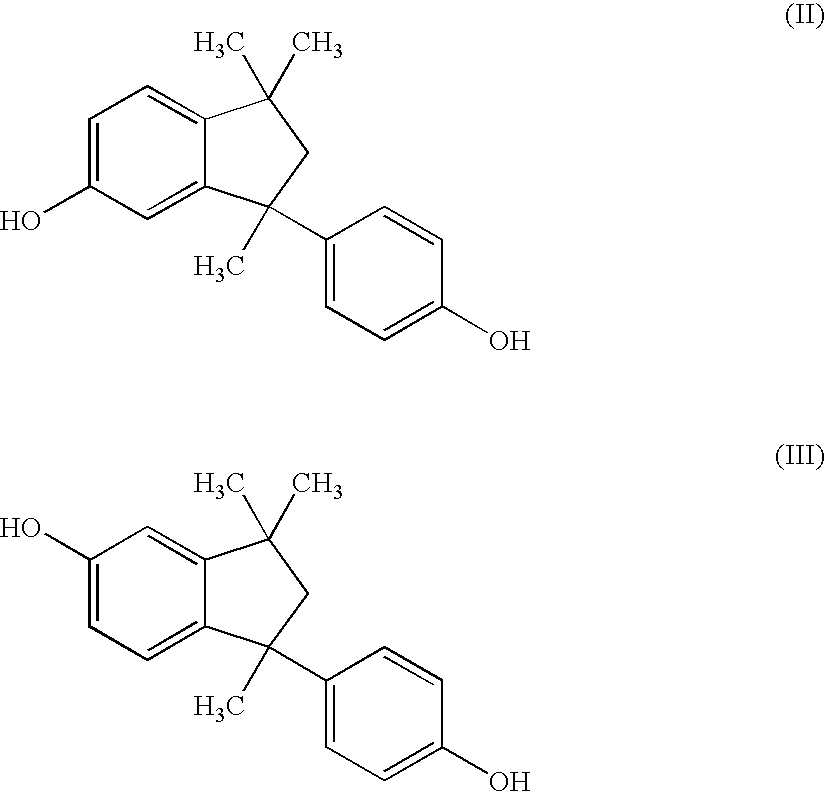

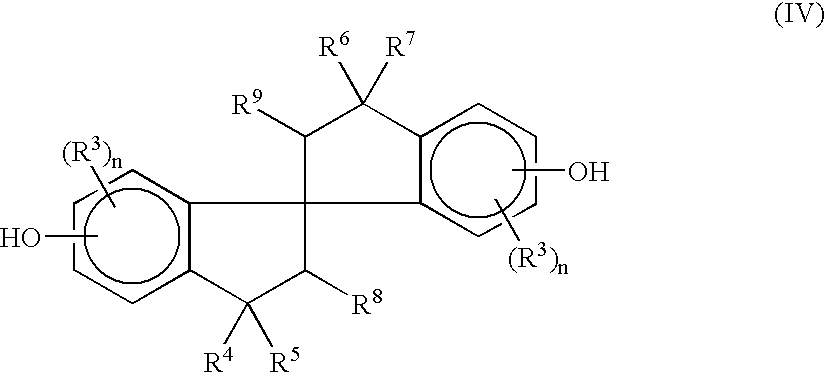

Radiopaque polymeric stents

Preferred embodiments of the present invention relate to polymeric medical devices, such as stents. More particularly, the polymeric compositions disclosed herein comprise halogen-containing, tyrosine-derived diphenols, optionally in conjunction with other groups, such as dicarboxylic acids and / or poly(alkylene oxide), such that the medical devices made from these polymeric compositions are bioresorbable and inherently radiopaque, and exhibit physicomechanical properties consistent with the intended uses of such devices.

Owner:RUTGERS THE STATE UNIV

Semiaromatic polyamide molding compositions and their use

ActiveUS20080274355A1High strengthLow water absorptionPigmenting treatmentNon-fibrous pulp additionHexamethylenediamineAramides

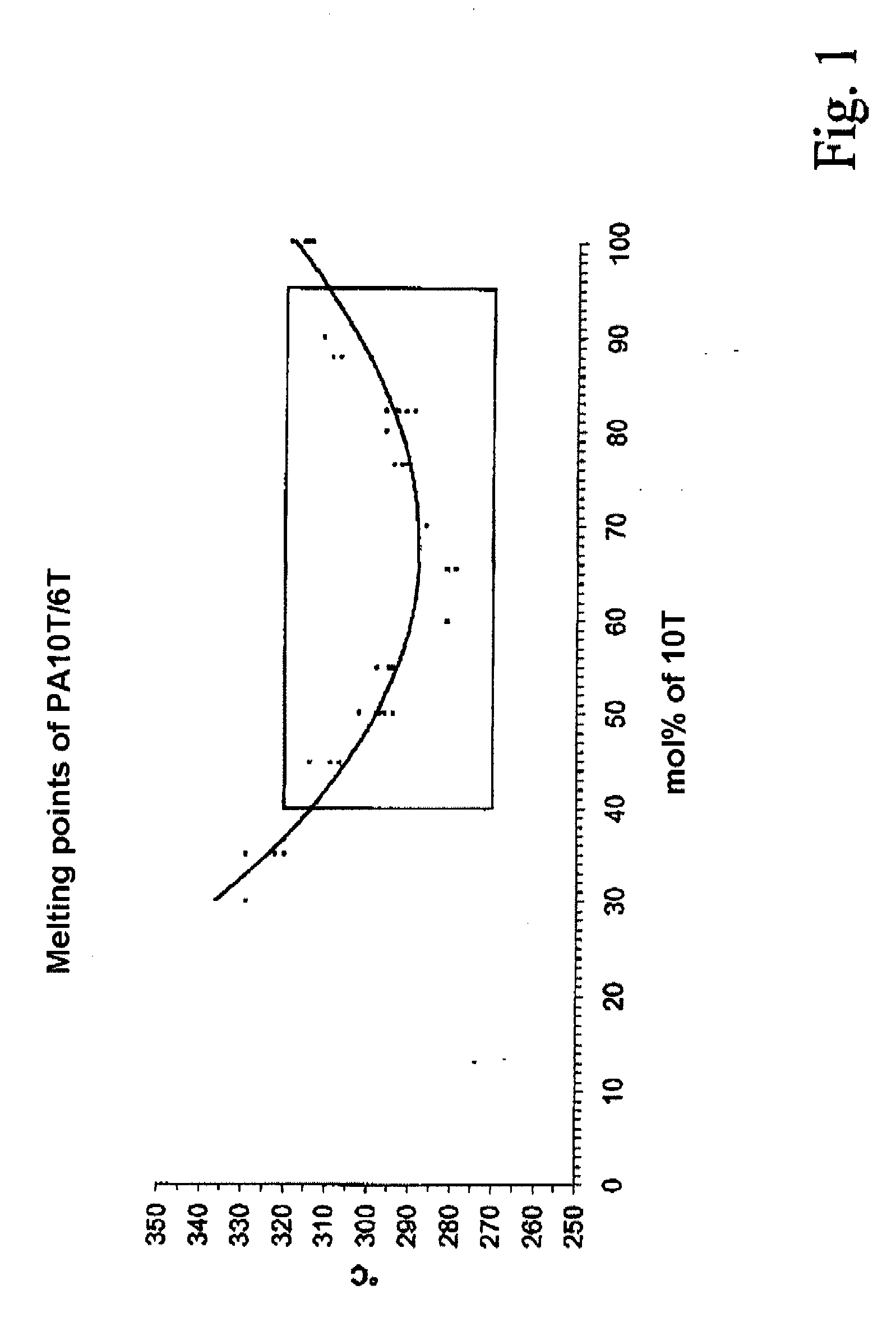

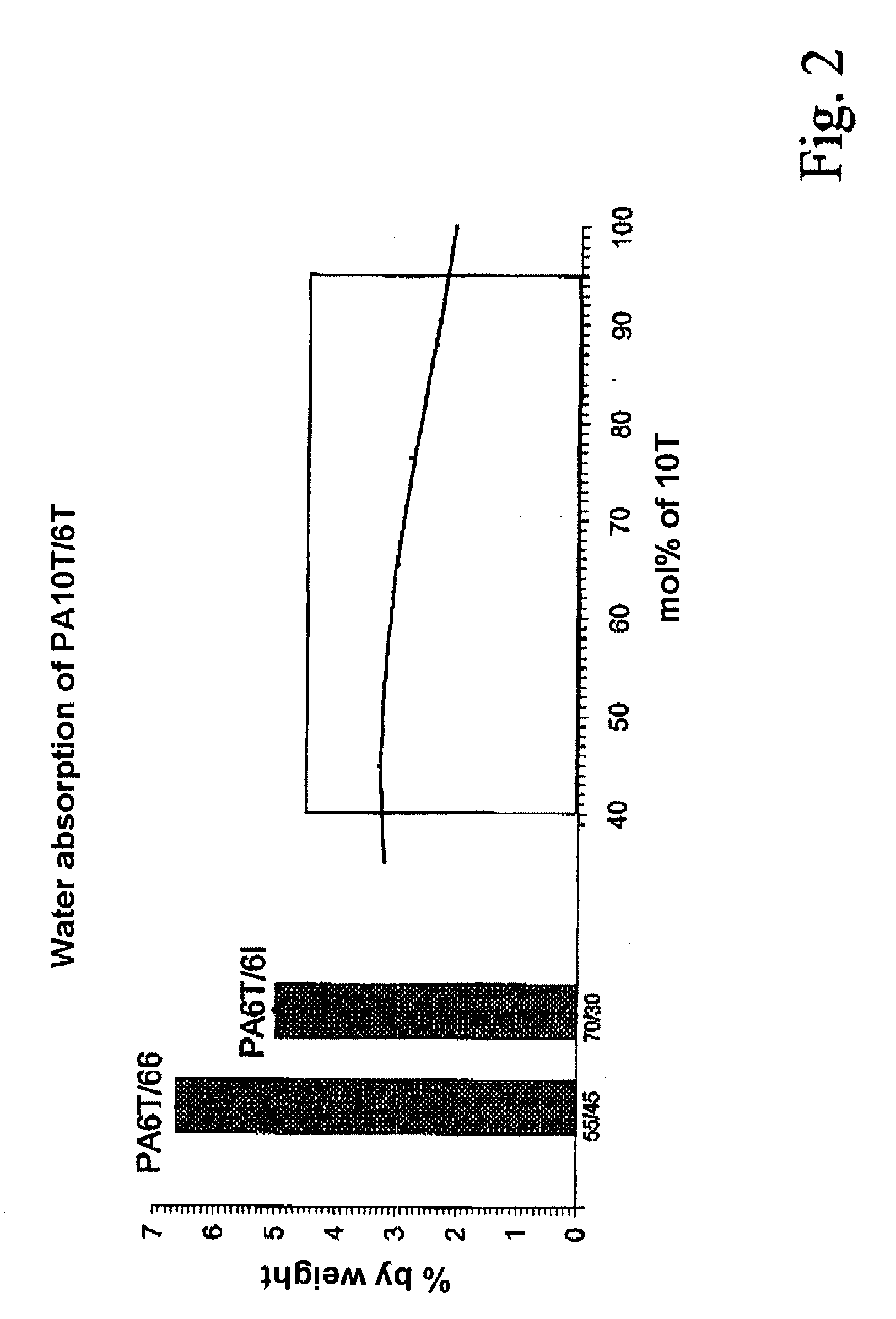

A polyamide molding composition with the following constitution is described:(A) from 30 to 100% by weight of at least one 10T / 6T copolyamide, where this is composed of(A1) from 40 to 95 mol % of 10T units, formed from the monomers 1,10-decanediamine and terephthalic acid(A2) from 5 to 60 mol % of 6T units, formed from the monomers 1,6-hexanediamine and terephthalic acid(B) from 0 to 70% by weight of reinforcing materials and / or fillers(C) from 0 to 50% by weight of additives and / or further polymerswhere the entirety of components A to C is 100%, with the proviso that in component (A) up to 30 mol %, based on the entirety of the dicarboxylic acids, of the terephthalic acid can have been replaced by other aromatic, aliphatic, or cycloaliphatic dicarboxylic acids, and with the proviso that in component (A) up to 30 mol % of 1,10-decanediamine and respectively 1,6-hexanediamine, based on the entirety of the diamines, can have been replaced by other diamines, and with the proviso that not more than 30 mol % in component (A), based on the entirety of the monomers, can have been formed via lactams or amino acids. Uses of this polyamide molding composition are moreover described, as also are processes for the preparation of these polyamide molding compositions.

Owner:EMS PATENT AG

Method to produce aromatic dicarboxylic acids using cobalt and zirconium catalysts

InactiveUS6153790AAvoid problemsEfficient removalOrganic compound preparationChemical recyclingOrganic acidWater vapor

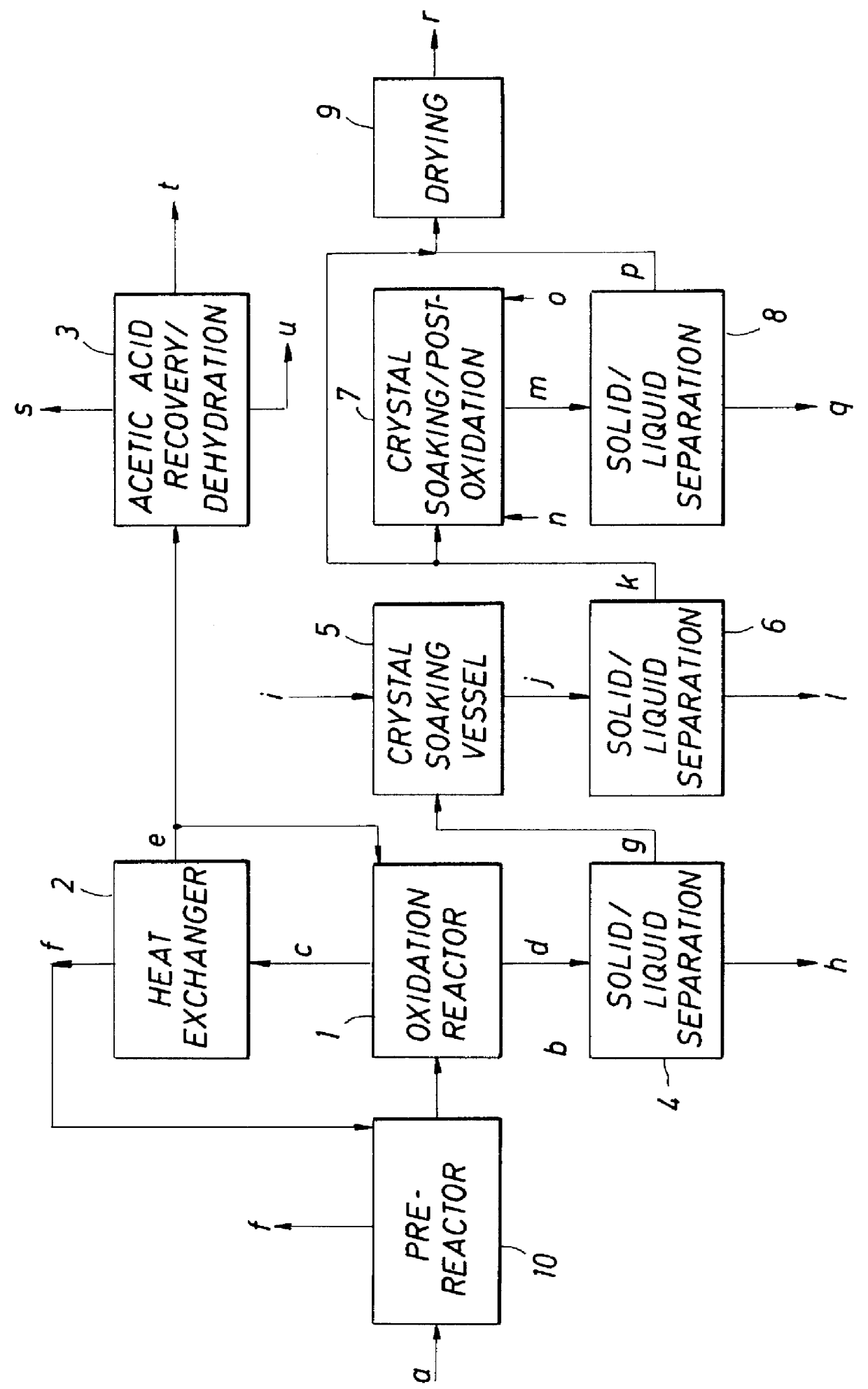

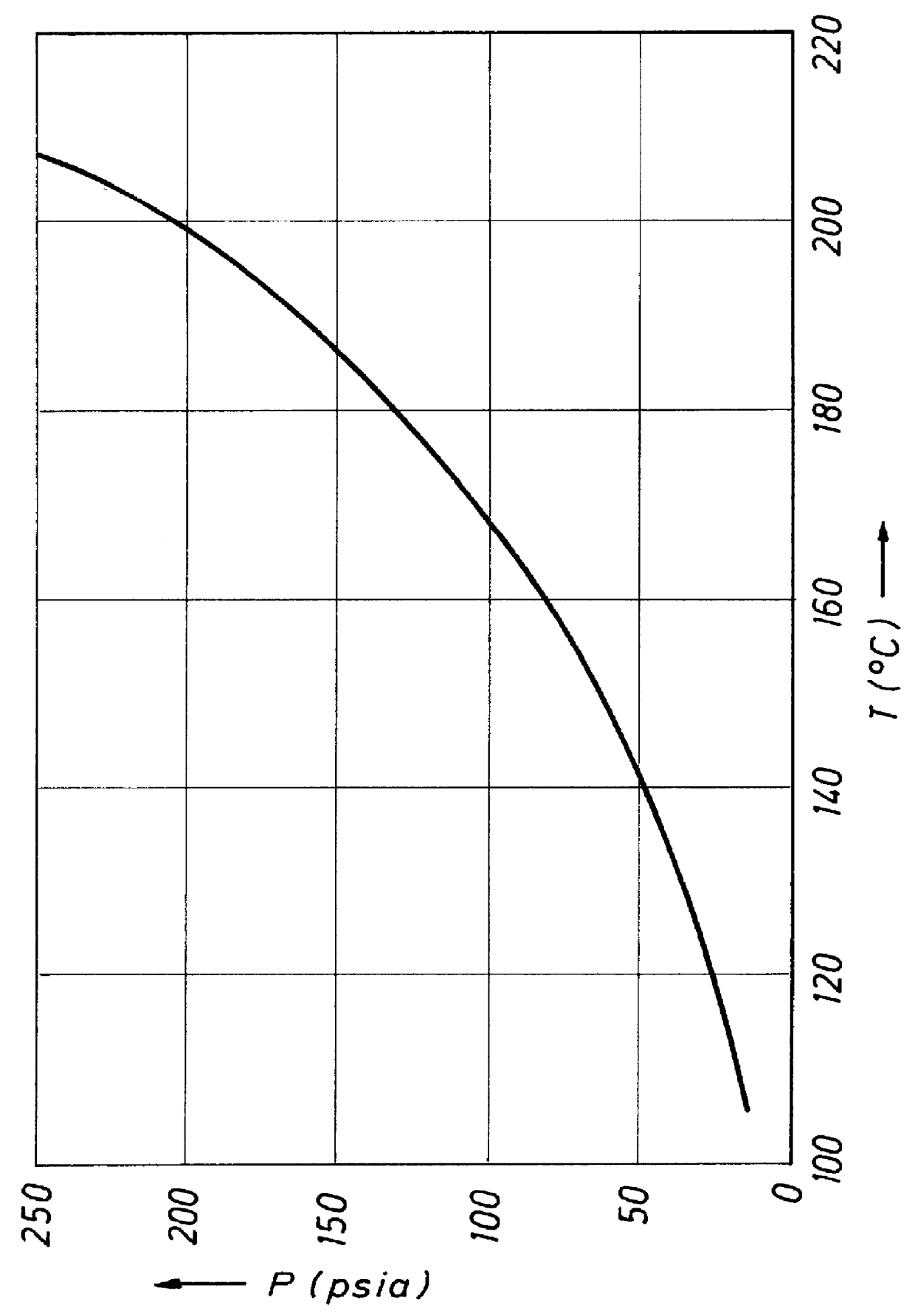

A process to produce terephthalic acid is provided, the process including the steps of: providing a feed stream comprising a dialkyl substituted aromatic and in an organic acid solvent: contacting the feed stream with an oxidant, the oxidant containing at least 50% by volume oxygen and at an oxygen partial pressure of at least 1 psia, at a temperature between about 80 DEG C. and about 130 DEG C., in the presence of a catalyst system comprising zirconium and cobalt, wherein the contacting is done in a stirred tank reactor; removing from the stirred tank reactor a vapor stream comprising the organic acid, water vapor and unreacted oxidant; condensing at least a portion of the organic acid and water from the vapor stream; separating at least a portion of the water from the organic acid back to the stirred tank reactor; returning at least a portion of the condensed organic acid back to the stirred tank reactor; continuously recovering from the stirred tank reactor a product comprising a diacid substituted aromatic; isolating solid crystals of diacid substituted aromatic from the reactor product; and recovering from the solid crystals a diacid substituted aromatic having a purity of preferably at least 97% by weight.

Owner:SHELL OIL CO

Multifunctional Dispersants

The present invention provides a composition comprising the product prepared by hearing together: (a) a dispersant; and (b) a 1,3-dicarboxylic acid or 1,4-dicarboxylic acid of an aromatic compound, or a reactive equivalent thereof; and at least one of: (c) 2,5-dimercapto-1,3,4-thiadiazole or a hydrocarbyl-substituted 2,5-dimercapto-1,3,4-thiadiazole, or an oligomer thereof; (d) a borating agent; and (e) a phosphorus acid compound, or a reactive equivalent thereof, said heating being sufficient to provide a reaction product of (a), (b), and (c), (d), or (e), which is soluble in an oil of lubricating viscosity. The invention further provides a use for the composition.

Owner:THE LUBRIZOL CORP

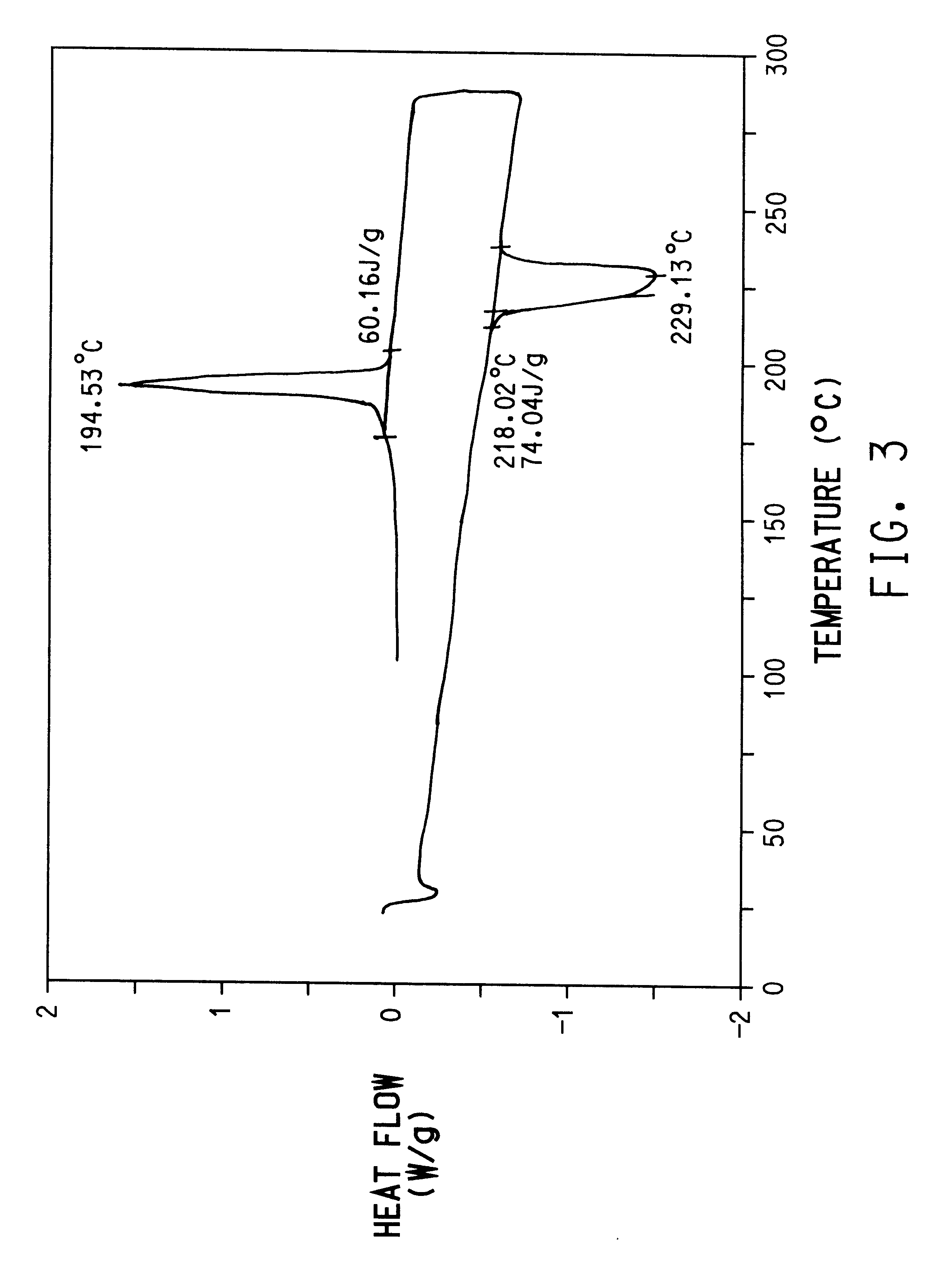

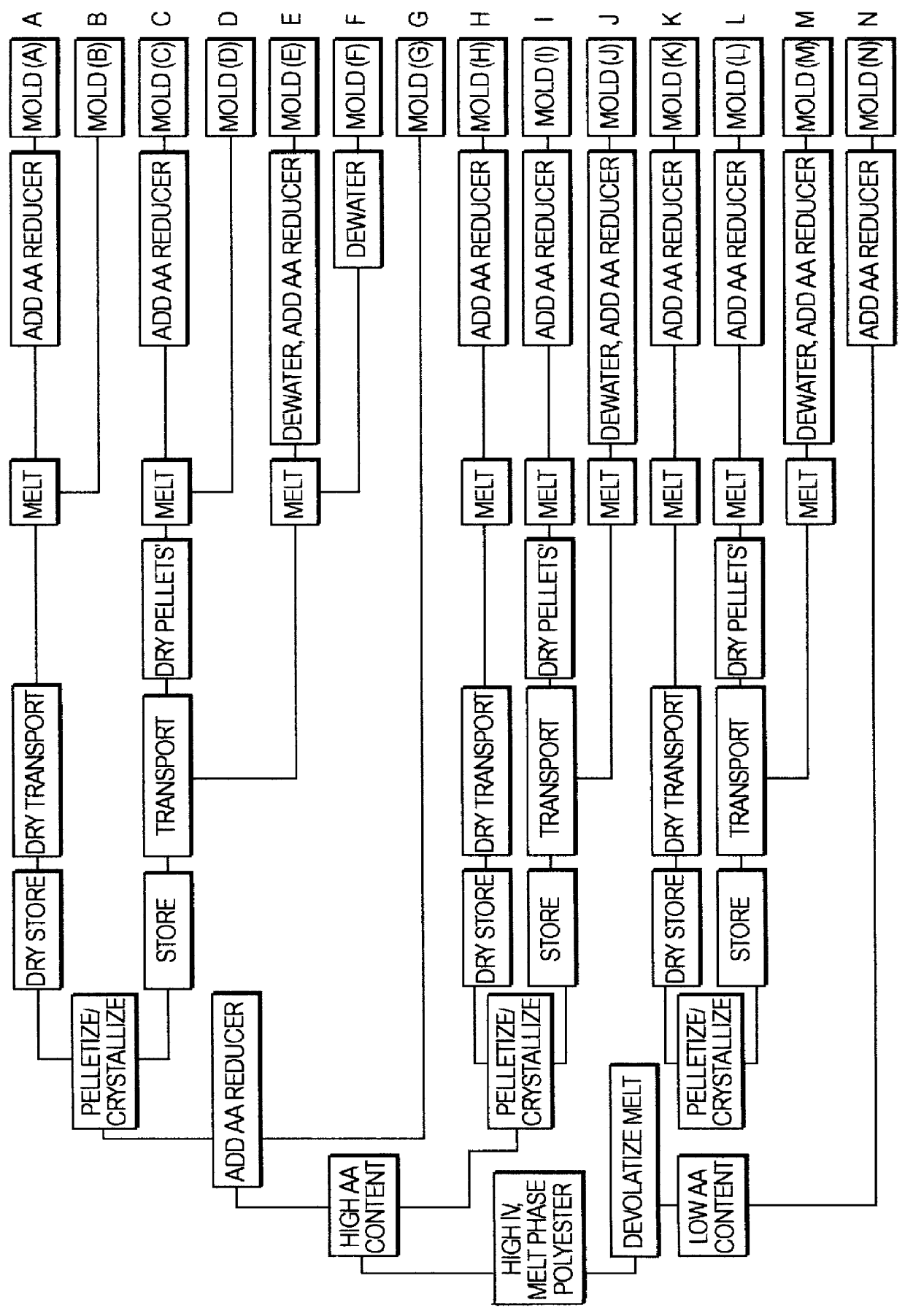

Process for producing pet articles with low acetaldehyde

The present invention discloses a process for producing molded, shaped or extruded articles comprising the steps of: a) melt reacting, in the presence of a catalyst which is substantially free of Co compounds, at least one glycol and at least one dicarboxylic acid to form a polyester having an I.V. of at least about 0.5 dL / g, wherein said at least one glycol is selected from the group consisting of glycols having up to 10 carbon atoms and mixtures thereof and said dicarboxylic is selected from the group consisting of alkyl dicarboxylic acids having 2 to 16 carbon atoms, aryl dicarboxylic acids having 8 to 16 carbon atoms and mixtures thereof; b) adding an acetaldehyde reducing additive to said polyester to form a reduced acetaldehyde polyester; and c) forming said reduced acetaldehyde polyester into articles directly from step b. Thus, the present invention provides a process for directly producing from the melt article having extremely low acetaldehyde content.

Owner:GRUPO PETROTEMEX DE C V

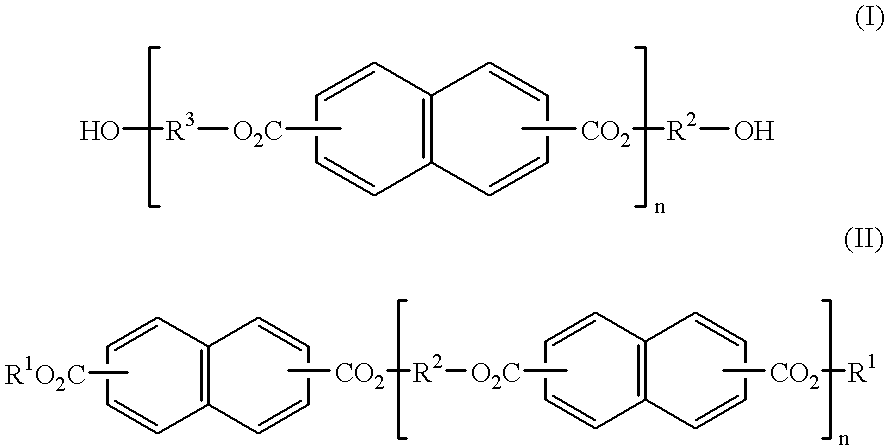

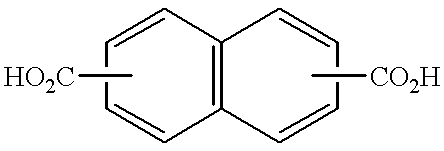

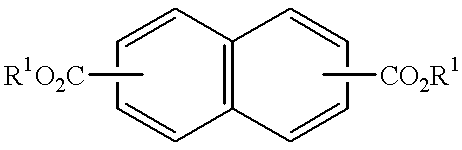

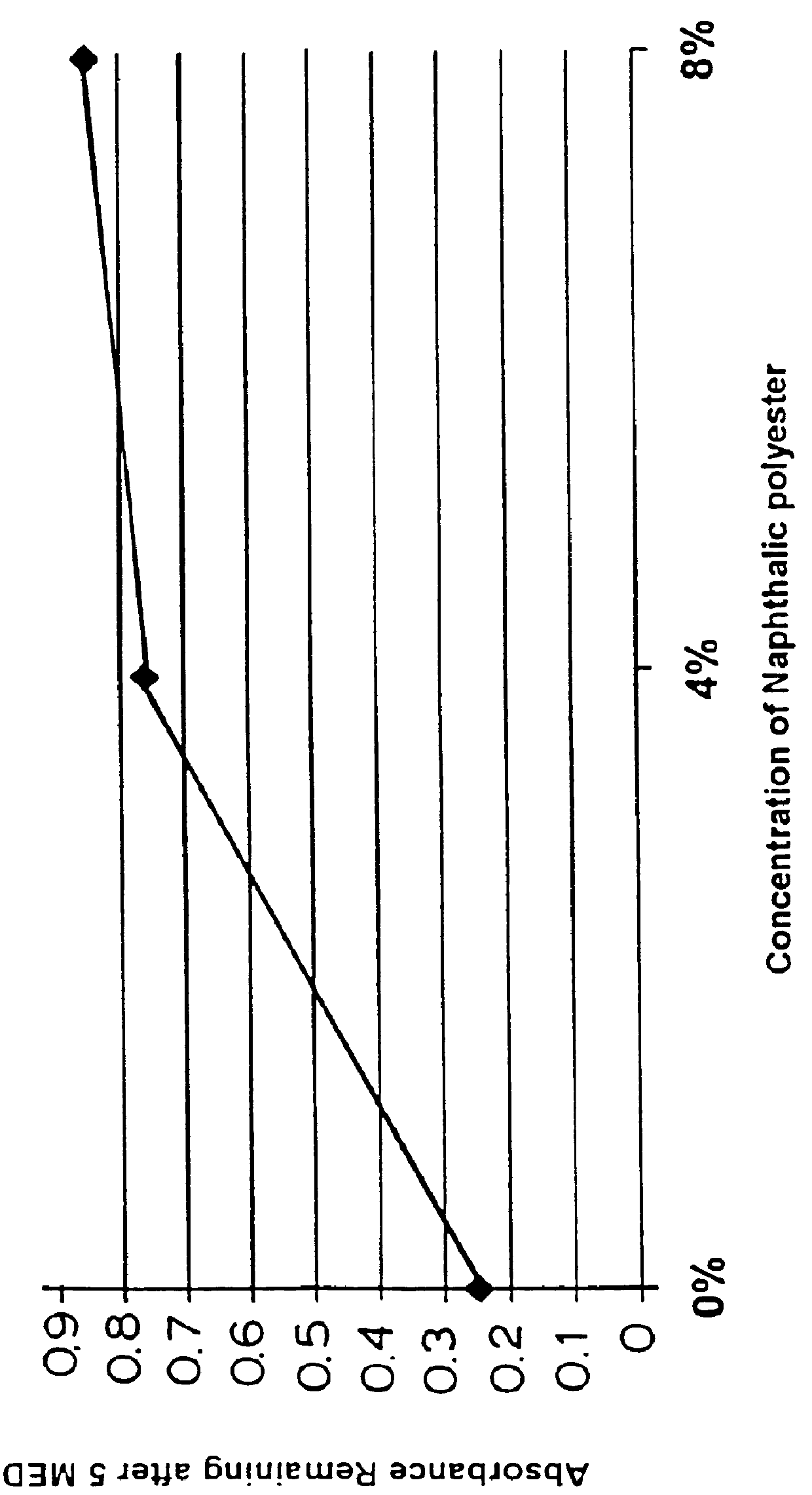

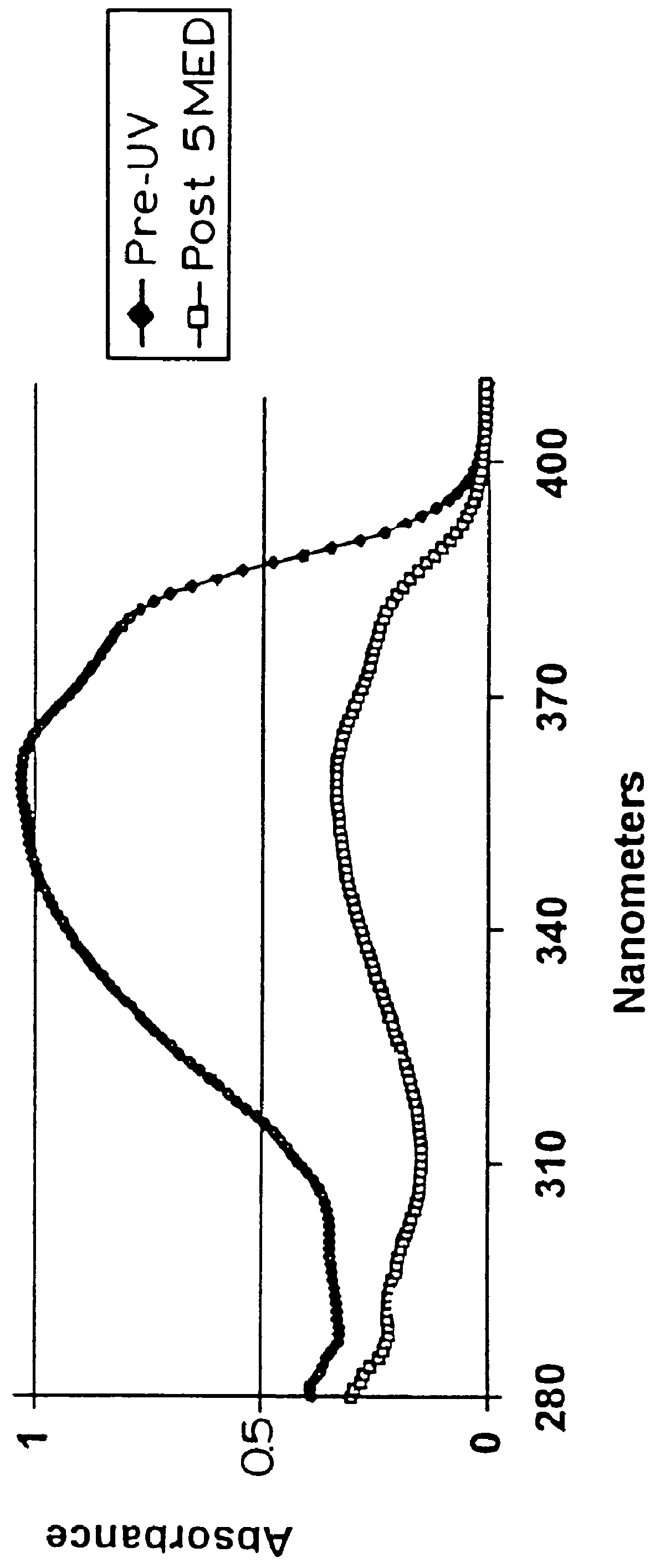

Diesters of naphthalene dicarboxylic acid

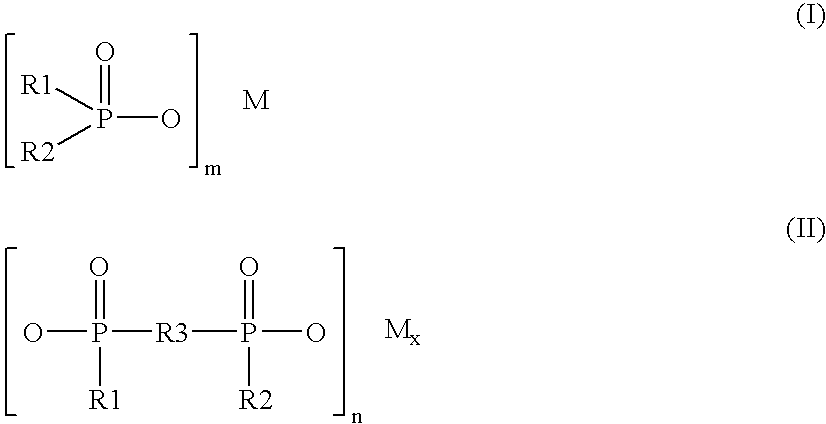

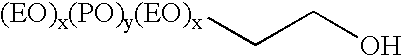

A hair-treating composition containing a diester or polyester of a naphthalene dicarboxylic acid having compound formula (I) or (II), or mixtures; for imparting gloss and / or hair color stabilization:wherein each R1, same or different, is an alkyl group having 1 to 22 carbon atoms, a diol having the structure HO-R2-OH, or a polyglycol having the structure HO-R3-(-O-R2-)m-OH, wherein R2 and R3, same or different, are each an alkylene group, sight chain or branched, having 1 to 6 carbon atoms, and wherein m and n are each 1 to about 100, or a mixture thereof. These diesters and polyesters of formula (I) or (II) are quite effective in stabilizing the dibenzoylmethane derivative UV-A filter compounds making them more effective, and effective for longer periods of time.

Owner:SYMRISE GMBH & CO KG

Biodegradable polyesters

InactiveUS6120895AMonocomponent copolyesters artificial filamentPolyurea/polyurethane coatingsFiberPolymer science

PCT No. PCT / EP97 / 04908 Sec. 371 Date Mar. 17, 1999 Sec. 102(e) Date Mar. 17, 1999 PCT Filed Sep. 19, 1997 PCT Pub. No. WO98 / 12242 PCT Pub. Date Mar. 20, 1998Biodegradable polyesters based on A) 95-99.99 mol % of at least one polyester A containing as monomeric building blocks of an acid component comprising a11) 20-95 mol % of at least one aliphatic or cycloaliphatic dicarboxylic acid or its ester-forming derivative and a12) 5-80 mol % of at least one aromatic dicarboxylic acid or its ester-forming derivative and at least one dihydroxy compound or at least one amino alcohol or their mixtures, and B) 0.01-5 mol % of a mixture comprising mono-, bi-, tri-, tetra- and higher-nuclear isocyanurates or corresponding compounds containing two, three or four functional groups capable of reacting with the end groups of polyester A, or mixtures of the isocyanurates and the corresponding compounds, as well as molding compositions comprising said polyesters, their manufacture and their use in the manufacture of moldings, filsm, fibers and coatings.

Owner:BASF AG

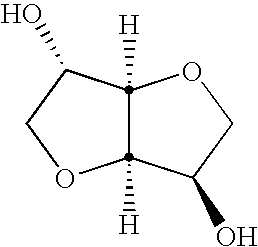

Method for making isosorbide containing polyesters

This invention relates to a process for producing a polyester comprising the steps of:(g) obtaining an aqueous homogenous solution of isosorbide;(h) feeding the aqueous homogenous solution of step (a) into a reactor;(i) feeding one or more glycols and one or more dicarboxylic acids either into the aqueous solution of step (a) or into the reactor of step (b) either prior to, during and / or subsequent to step (b);(j) esterifying the reactor contents at sufficient temperatures and pressures, and optionally in the presence of suitable catalysts, to effect esterification;(k) forming a prepolymer; and(l) polycondensing the prepolymer at sufficient temperatures and pressures in the presence of a suitable catalyst to effect polycondensation to form a polyester.

Owner:EASTMAN CHEM CO

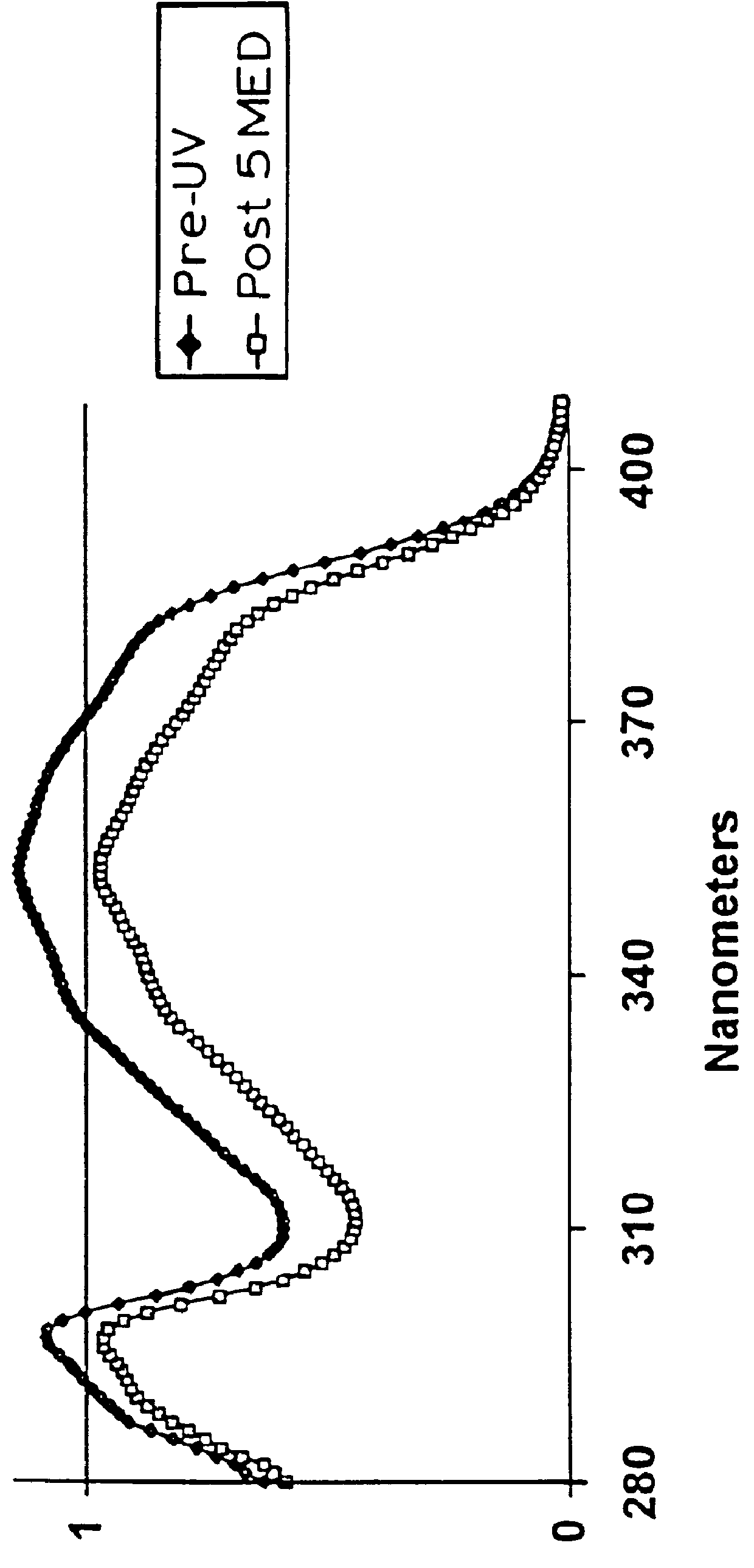

Photostable sunscreen compositions containing dibenzoylmethane derivative, e.g., PARSOL TM 1789, and diesters of naphthalene dicarboxylic acid photostabilizers and enhancers of the sun protection factor (SPF)

InactiveUS6126925AEffective hair color protectionHigh SPFCosmetic preparationsToilet preparationsDicarboxylic acidSun Protection Factors

A sunscreen composition containing a UV-A dibenzoylmethane derivative, such as 4-(1,1-dimethylethyl)-4'-methoxydibenzoylmethane (PARSOL TM 1789), and a stabilizer for the dibenzoylmethane derivative having structure (I): wherein each R', same or different, is an alkyl group, straight or branched chain, having 1 to 22 carbon atoms. These diesters of structure (I) are quite effective in stabilizing the dibenzoylmethane derivative UV-A filter compounds making them more effective, and effective for longer periods of time.

Owner:SYMRISE GMBH & CO KG

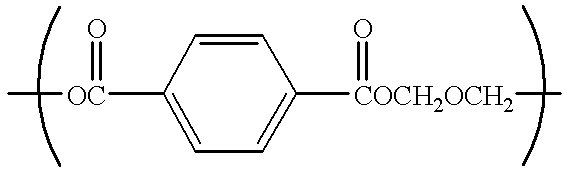

Articles derived from compositions containing modified polybutylene terephthalate (PBT) random copolymers derived from polyethylene terephthalate (PET)

ActiveUS20070275242A1Useful performance propertyPlastic recyclingSpecial tyresPolytetramethylene terephthalatePolyethylene terephthalate glycol

Compositions of matter including articles derived from (a) from 5 to 99.99 wt % of a modified polybutylene terephthalate random copolymer that (1) is derived from polyethylene terephthalate and (2) contains a at least one residue derived from polyethylene terephthalate selected from the group consisting of antimony, germanium, diethylene glycol groups, isophthalic acid groups, cis isomer of cyclohexane dimethanol, trans isomer of cyclohexane dimethanol, sodium benzoate, alkali salts, napthalane dicarboxylic acids, 1,3-propane diols, cobalt, cobalt-containing compounds, and combinations thereof, and (b) from 0.01 to 95 wt. % of a member selected from the group consisting of (1) fillers, (2) a carboxy reactive component, (3) polyethyelene terephthalate, (4) a component including a polycarbonate and an impact modifier. The articles may be derived from various conversion processes, e.g., injection molding processes, extrusion processes, thermoforming processes, melt-blown process.

Owner:SHPP GLOBAL TECH BV

Polyarylates for drug delivery and tissue engineering

InactiveUS20050165203A1Prevent microparticle migrationControl ratePowder deliveryLayered productsMedicineTyrosine

Owner:RUTGERS THE STATE UNIV

Dental adhesive composition

This invention discloses a dental adhesive composition comprising (A) a polymerizable monomer comprising an acidic-group containing polymerizable monomer such as 11-methacryloyloxy-1,1-undecane dicarboxylic acid, (B) a mixed filler of a spherical filler substantially consisting of a non-crosslinking polymethyl methacrylate and a spherical filler substantially consisting of a non-crosslinking polyethyl methacrylate; and (C) a polymerization initiator; and a dental adhesive kit comprising the above dental adhesive composition in combination with a dental primer comprising (D) an acidic-group containing polymerizable monomer, (E) an aryl borate, (F) an organosulfinic acid salt and (G) water. The dental adhesive composition exhibits good operability and improved adhesion performance.

Owner:TOKUYAMA DENTAL CORP +1

Sulfonated aliphatic-aromatic copolyesters and shaped articles produced therefrom

ActiveUS20050027098A1High crystallinityHigh heat distortion temperatureLayered productsCeramic shaping apparatusPolymer scienceCopolyester

Sulfonated aliphatic-aromatic copolyesters and articles made therefrom, and processes for producing the sulfonated aliphatic-aromatic copolyesters and articles are provided. Articles that can be made from the sulfonated aliphatic-aromatic copolyesters include films, coatings and laminates. Some of the compositions and articles are biocompostable. The films can further be used to form shaped articles such as sheets, food packaging such as sandwich wraps, thermoformed containers, and coatings for, for example, films and other substrates. The sulfonated aliphatic-aromatic copolyesters are derived from copolyesters produced from aliphatic-aromatic copolyesters formed from an aromatic dicarboxylic acid component, an aliphatic dicarboxylic acid component, a first glycol component consisting of 1,4-butanediol, a second glycol component, and optionally, a polyfunctional branching agent.

Owner:DUPONT POLYMERS INC

Addition of UV absorbers to PET process for maximum yield

InactiveUS20050008885A1Promote condensation polymerizationSynthetic resin layered productsThin material handlingUltravioletDicarboxylic acid

The present invention is a method for efficiently incorporating a UV absorber into a polyester resin. The method includes forming a reaction mixture comprising a diol component, a diacid component selected from the group consisting of dicarboxylic acids, dicarboxylic acid derivatives, and mixtures thereof, an antimony containing compound, a phosphorus containing compound, a metal containing compound, and a UV absorber. The reaction mixture is polymerized in a polycondensation reaction system. In another embodiment of the present invention, the UV absorber is added while the reaction products from one reactor are transferred to the next reactor in the polycondensation reaction system. A polyester composition having the UV absorber incorporated therein is also disclosed.

Owner:EASTMAN CHEM CO

Lubricating Oil Composition

ActiveUS20080020950A1Facilitate depositionEasy to wearOrganic chemistryAdditivesSulfonateAlkaline earth metal

An internal-combustion engine lubricating oil composition has a P content of not greater than 0.09 mass %; a S content of not greater than 0.3 mass %; and a sulphated ash content of not greater than 1 mass %. It contains the following additives: as sole ashless, nitrogen-containing dispersant, and providing from 0.03 to 0.07 mass % of nitrogen in the lubricating oil composition, at least one ashless, nitrogen-containing derivative of a polyalkenyl-substituted mono- or dicarboxylic acid, anhydride or ester, the polyalkenyl-substituted mono- or dicarboxylic acid, anhydride or ester being made from a polyalkene exclusively by the thermal “ene” reaction; as sole overbased metal detergent, at least one overbased alkaline earth metal sulfonate; and at least one viscosity modifier.

Owner:INFINEUM INT LTD

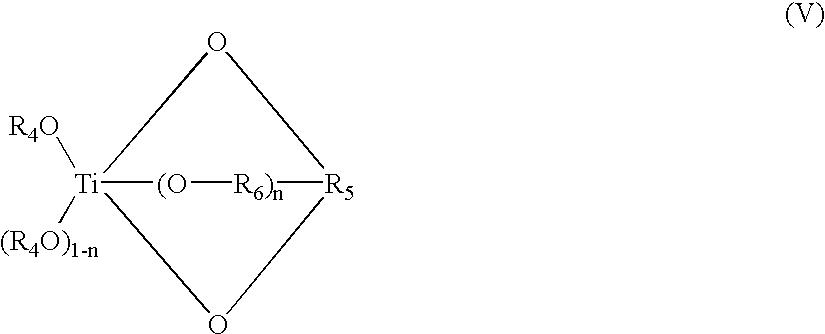

Catalyst for polyester production, process for producing polyester using the catalyst, polyester obtained by the process, and uses of the polyester

InactiveUS6346070B1High catalytic activityLow in acetaldehydeLactams stabilisationDevelopersFiberPolyester

The present invention provides a catalyst for polyester production capable of producing a polyester with high catalytic activity and a process for producing a polyester using the catalyst. The catalyst for polyester production comprises a solid titanium compound which is obtained by dehydro-drying a hydrolyzate obtained by hydrolysis of a titanium halide and which has a molar ratio (OH / Ti) of a hydroxyl group (OH) to titanium (Ti) exceeding 0.09 and less than 4. The present invention also provides a method to obtain a polyester having a small increase of the acetaldehyde content during the molding. This method comprises bringing a polyester, which is obtained by the use of a titanium compound catalyst and in which the reaction has been completed, into contact with a phosphoric ester aqueous solution or the like having a concentration of not less than 10 ppm in terms of phosphorus atom. The present invention further provides a polyester having excellent transparency and tint and molded products of the polyester such as a blow molded article, a film, a sheet and a fiber. The polyester is obtained by polycondensing an aromatic dicarboxylic acid or an ester-forming derivative thereof and an aliphatic diol or an ester-forming derivative thereof in the presence of a catalyst for polyester production which comprises a polycondensation catalyst component comprising a solid titanium compound and a co-catalyst component comprising a magnesium compound. This polyester has a titanium content of 1 to 100 ppm, a magnesium content of 1 to 200 ppm and a weight ratio (Mg / Ti) of magnesium to titanium of not less than 0.01.

Owner:MITSUI CHEM INC

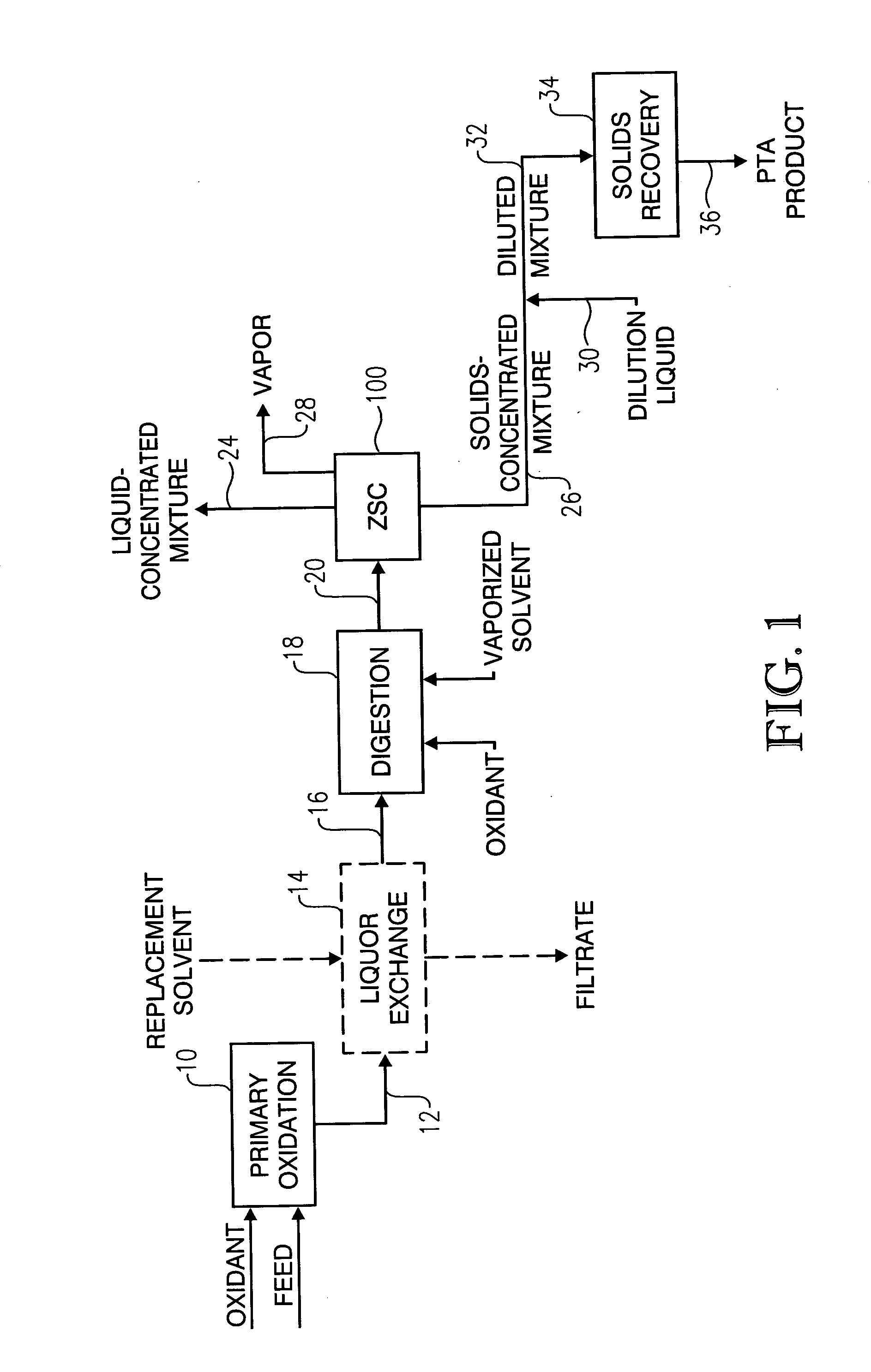

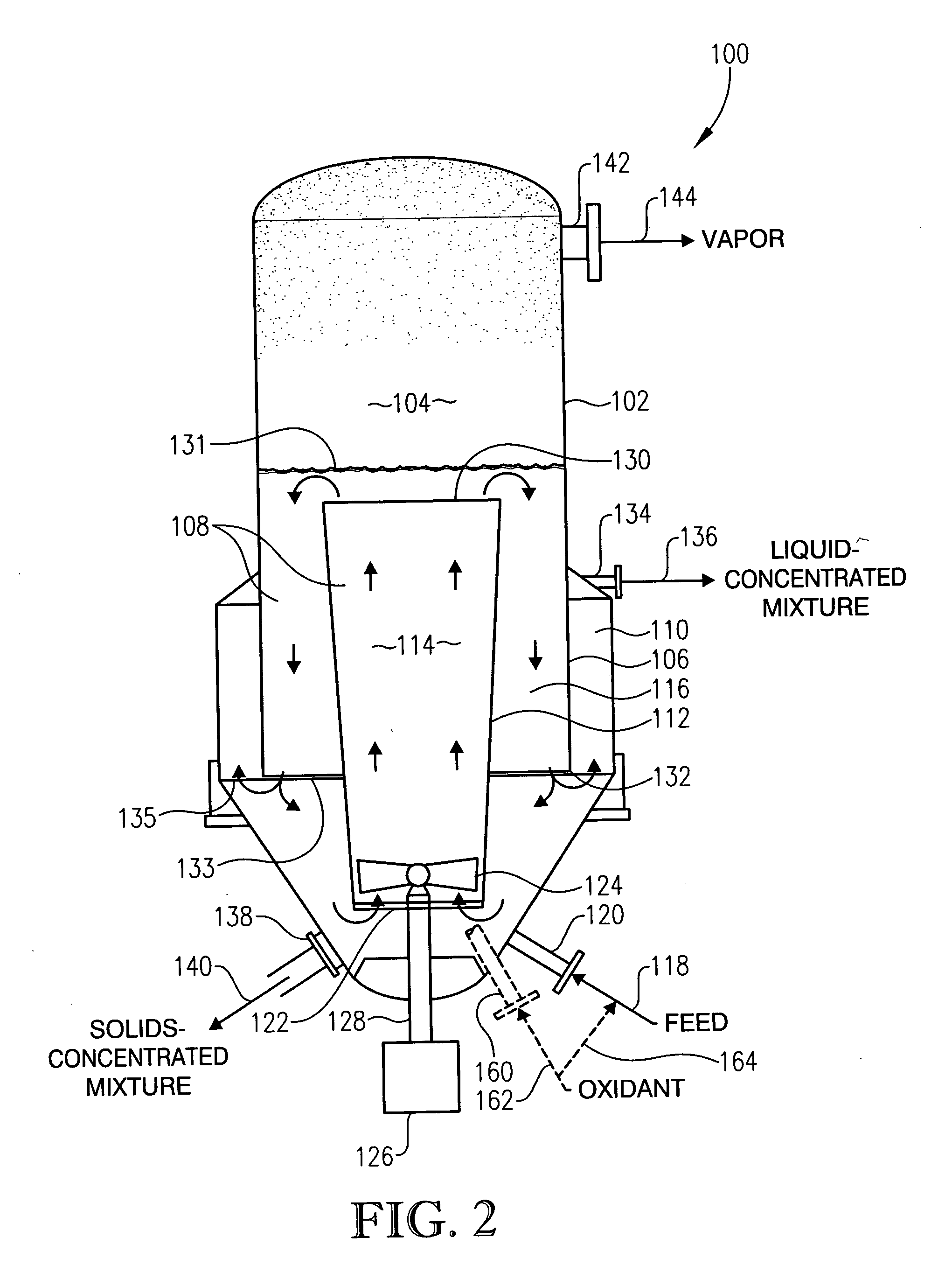

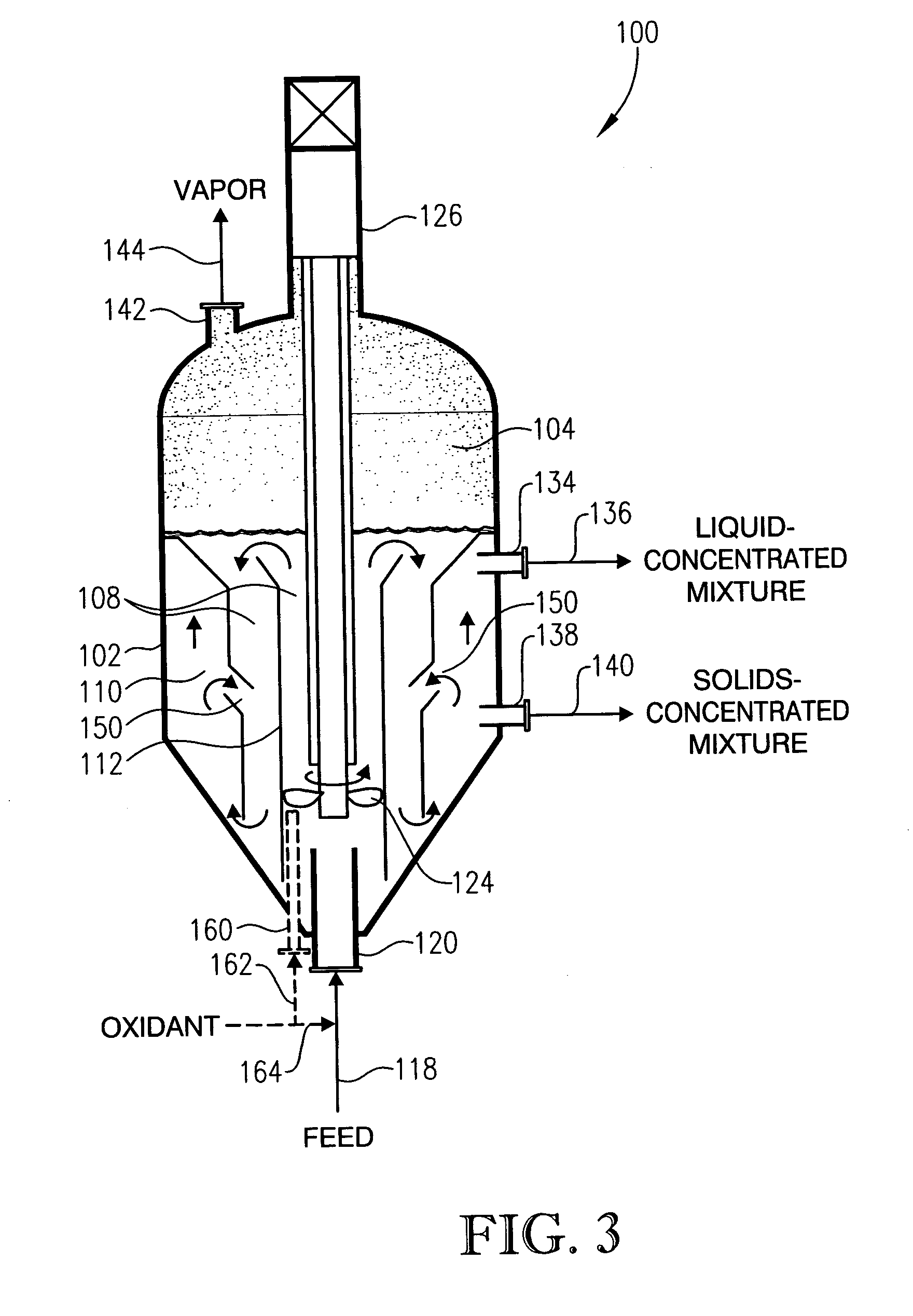

Optimized production of aromatic dicarboxylic acids

ActiveUS20060047166A1Organic compound preparationCrystallization by component evaporationDicarboxylic acidCarboxylic acid

Disclosed is an optimized process and apparatus for more efficiently producing and purifying aromatic dicarboxylic acids (e.g., terephthalic acid). The optimized system employs at least one zoned slurry concentrator to enhance purification of the aromatic dicarboxylic acid.

Owner:ALPEK POLYESTER SA DE CV

Fuel additives to maintain optimum injector performance

ActiveUS20090282731A1Maximize driveabilityMaximize fuel economyLiquid carbonaceous fuelsFuel additivesHydrogenCarboxylic acid

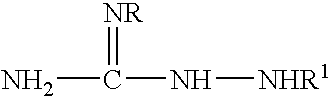

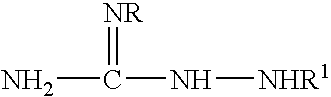

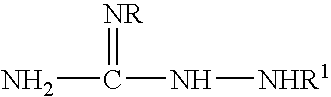

A diesel fuel, diesel fuel additive concentrate and method for improving the performance of fuel injectors for a diesel engine are provided. The diesel fuel includes a major amount of middle distillate fuel; and a reaction product of a hydrocarbyl substituted dicarboxylic acid or anhydride and an amine compound or salt. The amine compound has the formulawherein R is selected from the group consisting of a hydrogen and a hydrocarbyl group containing from about 1 to about 15 carbon atoms, and R1 is selected from the group consisting of hydrogen and a hydrocarbyl group containing from about 1 to about 20 carbon atoms. The reaction product contains at least one amino triazole group and is present in the fuel in an amount sufficient to improve the performance of diesel fuel injectors.

Owner:AFTON CHEMICAL

Dicarboxylic acid foamable vehicle and pharmaceutical compositions thereof

The present invention teaches a foamable pharmaceutical carrier comprising a benefit agent, selected from the group consisting of a dicarboxylic acid and a dicarboxylic acid ester; a stabilizer selected from the group consisting of at least one surface-active agent; at least one polymeric agent and mixtures thereof; a solvent selected from the group consisting of water, a hydrophilic solvent, a hydrophobic solvent, a potent solvent, a polar solvent, a silicone, an emollient, and mixtures thereof, wherein the benefit agent, stabilizer and solvent are selected to provide a composition that is substantially resistant to aging and to phase separation and or can substantially stabilize other active ingredients. The invention further relates to a foamable composition further containing a liquefied hydrocarbon gas propellant.

Owner:FOAMIX PHARMACEUTICALS LIMITED

Molding composition based on polyetheramides

ActiveUS20050014842A1Increase melt viscosityAdequate long-lasting flexibilityBiocideOrganic active ingredientsEtherDicarboxylic acid

A composition suitable for molding is provided having the following components: I. from 97 to 80 parts by weight of a polyetheramide, having units based on one or more linear aliphatic diamines having from 6 to 14 carbon atoms, one or more linear aliphatic or aromatic dicarboxylic acids having from 6 to 14 carbon atoms, and one or more polyetherdiamines having at least 3 carbon atoms per ether oxygen and having primary amino groups at the chain ends, II. from 3 to 20 parts by weight of a rubber containing one or more functional groups; and where the total of the parts by weight of I and II is 100; and moldings produced therefrom.

Owner:EVONIK OPERATIONS GMBH

Biodegradable non-toxic gear oil

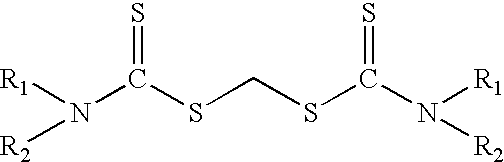

A biodegradable lubricating oil composition especially useful as a gear oil employs a synthetic alcohol ester basestock formed from mono- and dipentaerythritol with certain mono- and dicarboxylic acids or dicarboxylic acid anhydrides and an effective amount of a polyoxyalkylene alcohol demulsifying agent, a combination of alkylated organic acid and ashless succinimide rust inhibitors and an ashless dithiocarbamate antiwear and extreme pressure agent.

Owner:EXXON RES & ENG CO

Methods for converting linear polyesters to macrocyclic oligoester compositions and macrocyclic oligoesters

InactiveUS6525164B2Low viscosityCost-effectivePreparation by ester-hydroxy reactionOrganic compound preparationPolyesterDicarboxylic acid

Owner:LIQUID THERMO PLASTICS

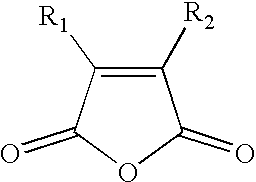

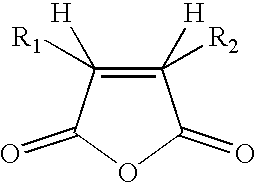

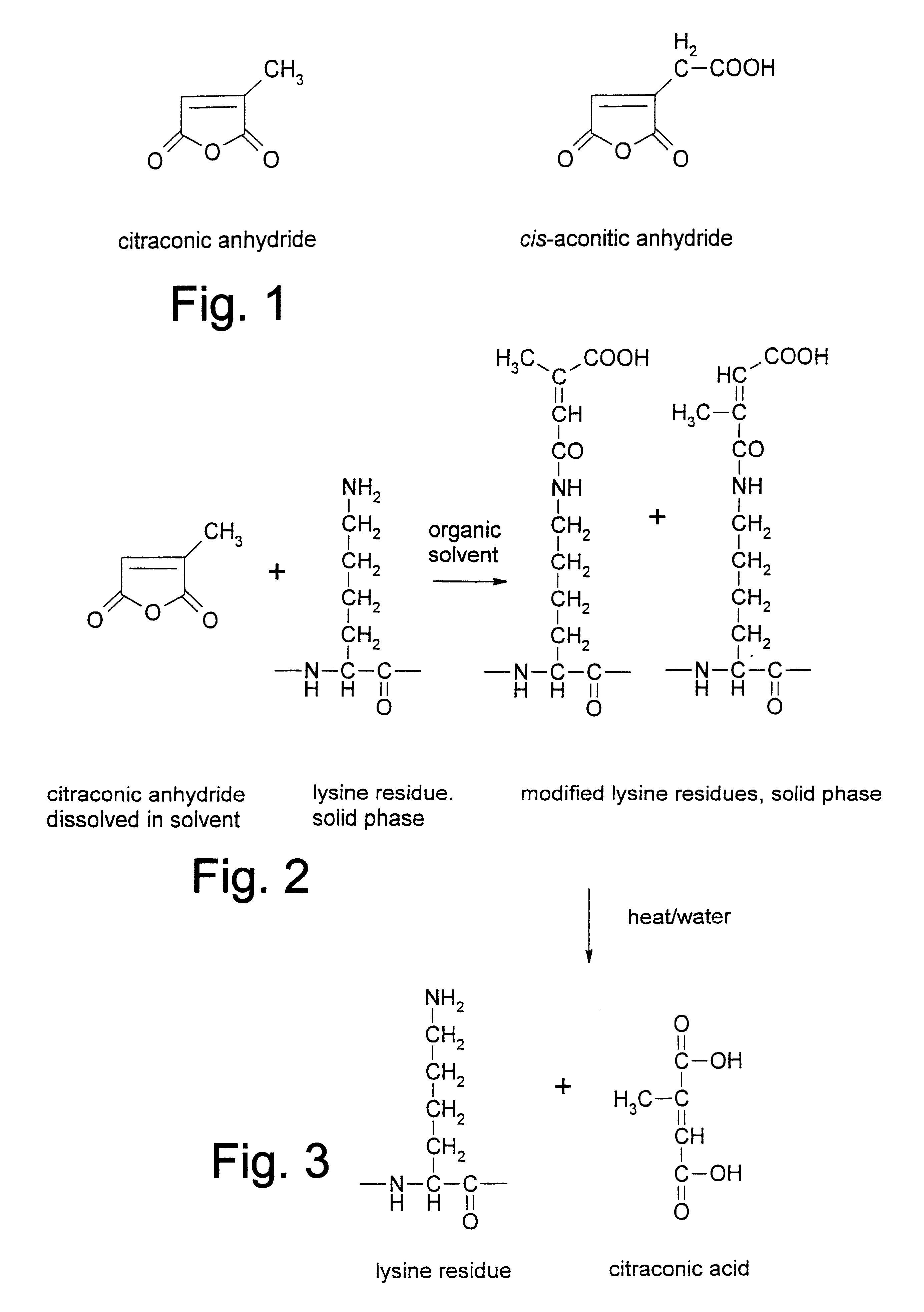

Reversible inactivation enzymes

InactiveUS6479264B1Microbiological testing/measurementPeptide preparation methodsOrganic solventDicarboxylic acid

A method for reversibly inactivating thermostable DNA polymerase or ligase, which method comprises reacting a mixture of the thermostable DNA polymerase or ligase with a dicarboxylic acid anhydride, wherein the reaction is carried out using a dried DNA polymerase or ligase in an anhydrous aprotic organic solvent, the dicarboxylic acid anhydride being also substantially anhydrous, whereby the reaction results in essentially complete inactivation of enzyme activity.

Owner:ADVANCED BIOTECHNOLOGIES LTD

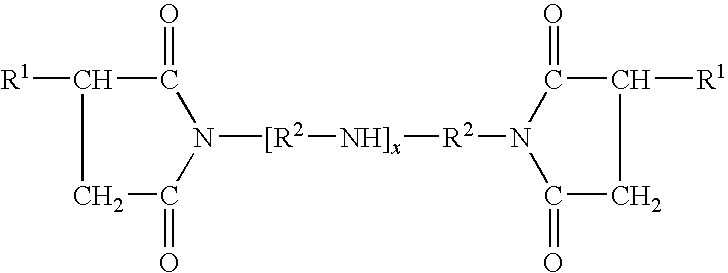

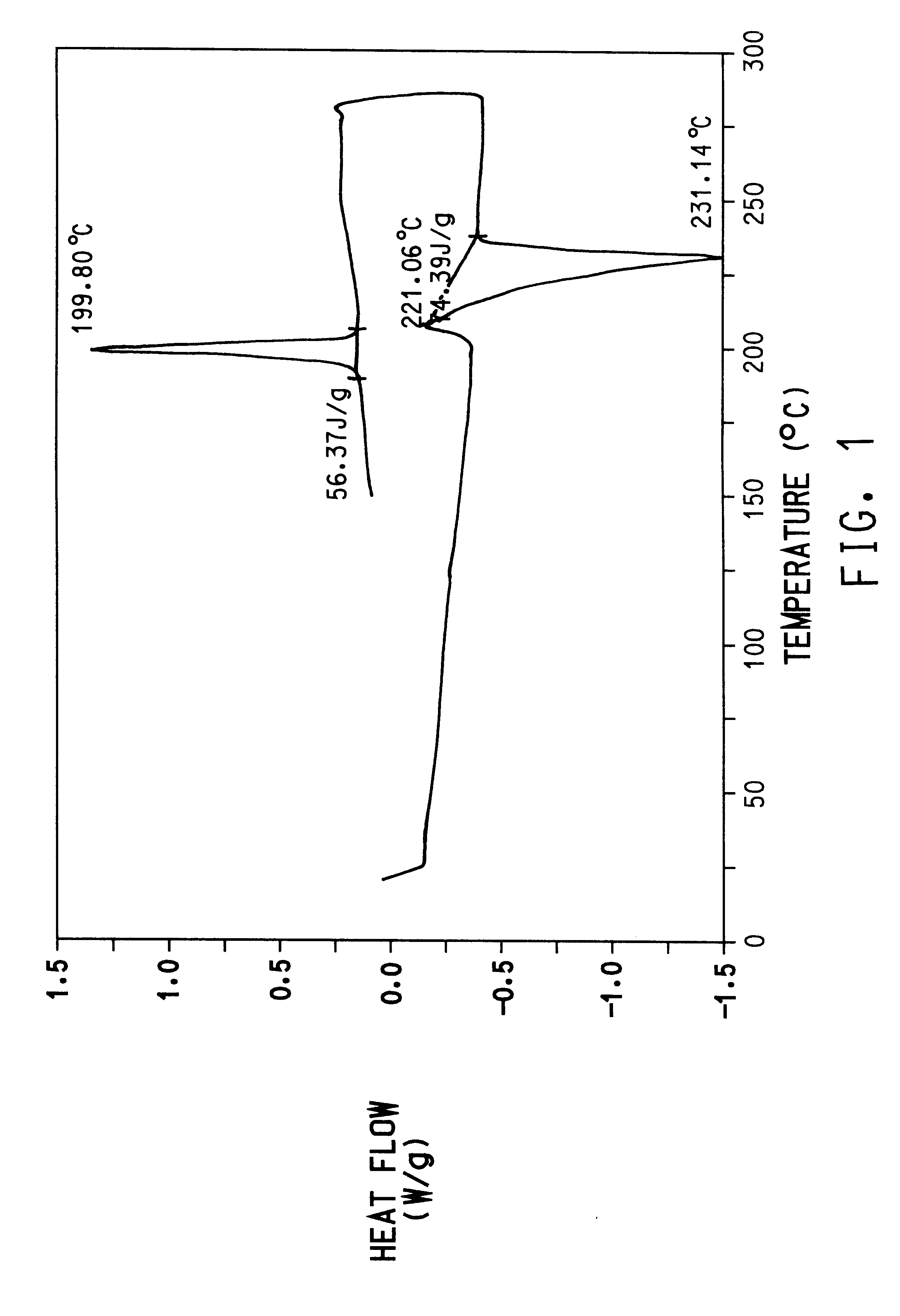

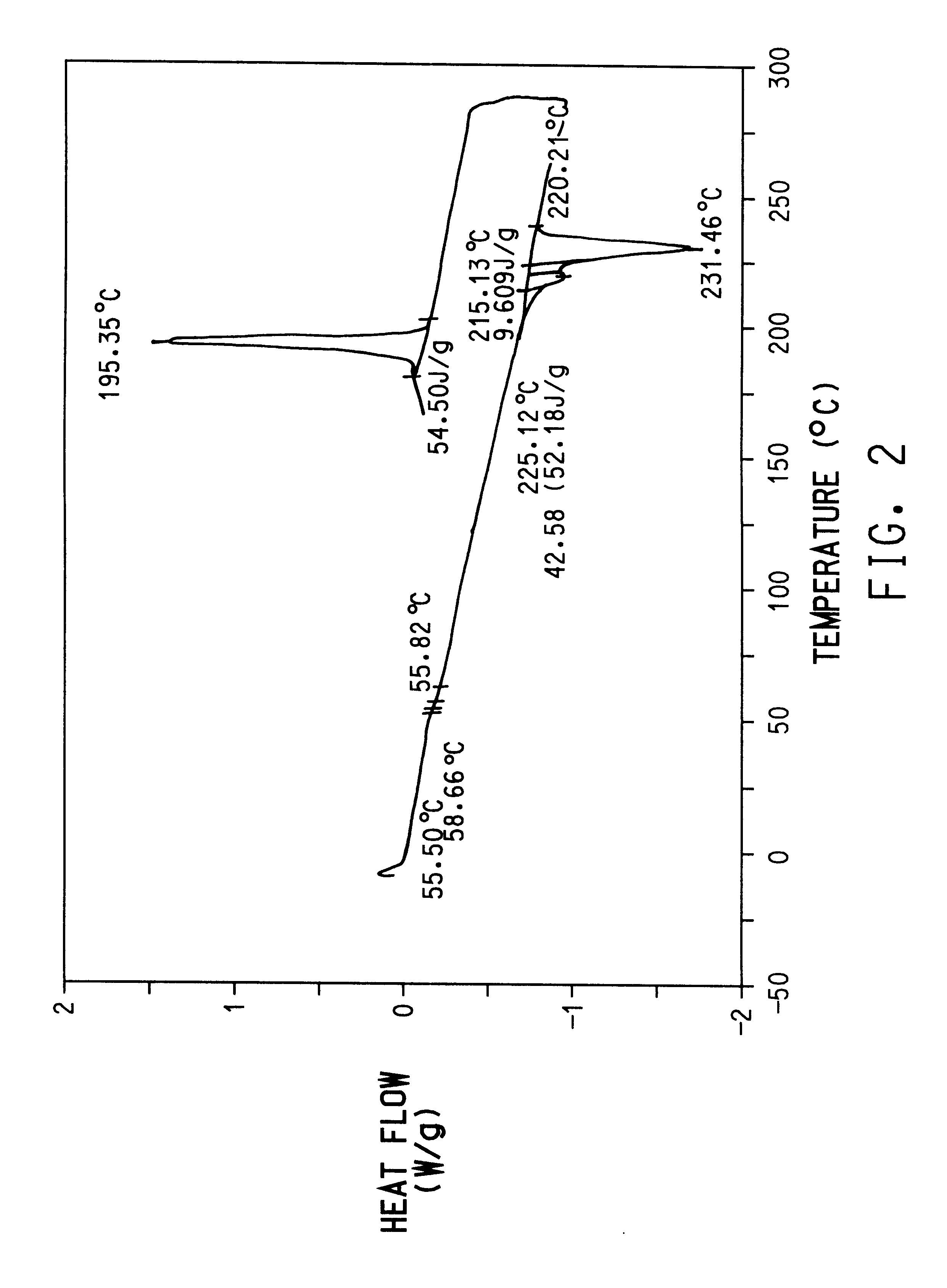

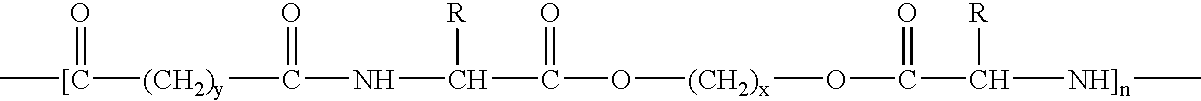

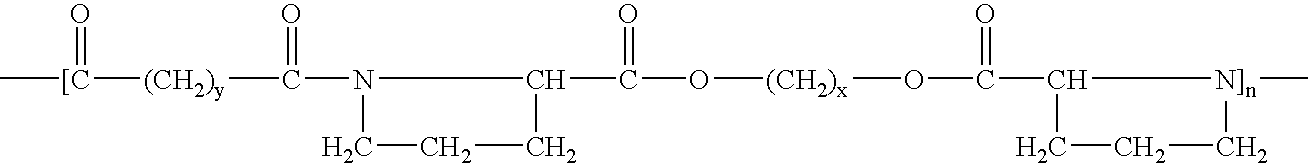

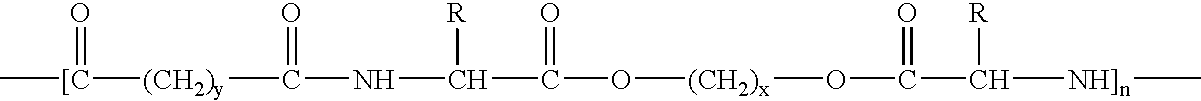

Biologically absorbable coatings for implantable devices based on poly(ester amides) and methods for fabricating the same

Owner:ABBOTT CARDIOVASCULAR

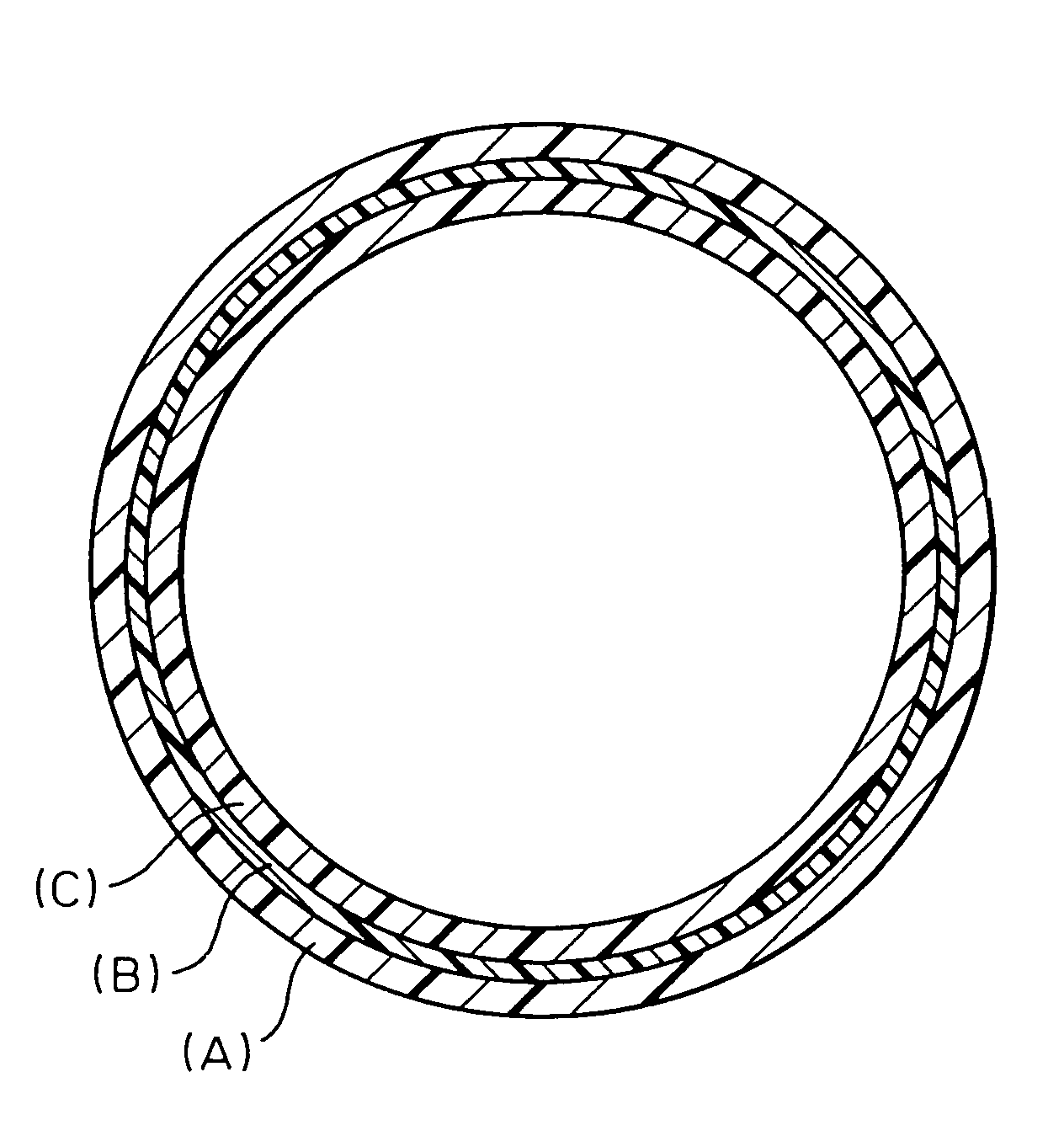

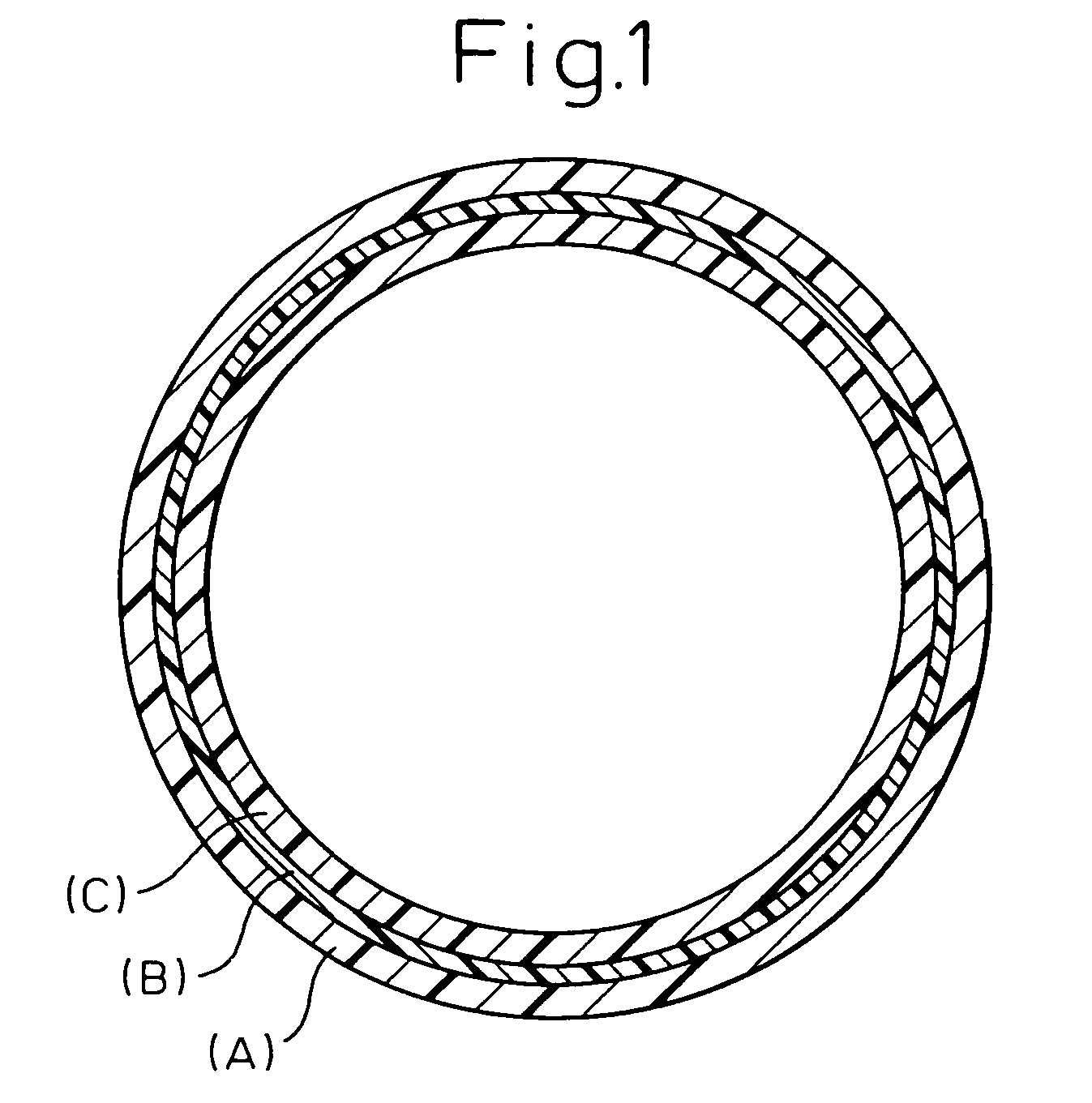

Multi-layer structure

ActiveUS6989198B2Improve penetration resistanceLarge containersRefuse receptaclesCarboxylic acidNylon 11

A multi-layer structure excellent in the barrier properties against alcohol gasoline, particularly hydrocarbon components, and also excellent in the interlayer adhesion, low-temperature impact resistance, heat resistance and chemical resistance is provided. The stractive is a multi-layer structure comprising two or more layers including at least a layer (a) comprising (A) nylon 11 and / or nylon 12 and a layer (b) comprising (B) a polyamide resin (nylon 9T) consisting of a dicarboxylic acid component and a-diamine component, with 60 to 100 mol % of the dicarboxylic acid component being a terephthalic acid and 60 to 100 mol % of the diamine component being a diamine component selected from 1,9-nonanediamine and 2-methyl-1,8-octanediamine, and preferably further including a layer (c) comprising (A) nylon 11 and / or nylon 12 or (C) nylon 6.

Owner:KURARAY CO LTD +1

Weatherable multilayer articles and method for their preparation

InactiveUS20040253428A1Avoid insufficient thicknessRelieve stressSynthetic resin layered productsThin material handlingPolyesterPolymer science

Disclosed are weatherable multilayer articles comprising (i) a coating layer comprising a block copolyestercarbonate comprising structural units derived from at least one 1,3-dihydroxybenzene and at least one aromatic dicarboxylic acid, (ii) a second layer comprising a polymer comprising carbonate structural units, (iii) an adhesive layer comprising a polyester with structural units derived from at least one glycol and at least one dibasic carboxylic acid, and (iv) a substrate layer, wherein the coating layer is in contiguous contact with the second layer, and the adhesive layer is in contiguous contact with the second layer and the substrate layer. Also disclosed is a method for making the multilayer article.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Polyester derived from biomass resources and method for production thereof

ActiveUS20090171037A1Reduce deteriorationStable supplyBio-packagingMicroorganism based processesPolyesterDiol

The present invention provides a resin capable of contributing greatly to solve environmental problems and problems related to exhaustion of fossil fuel resources and having physical properties suited for practical use.The polyester according to the present invention has a diol and a dicarboxylic acid as constituent components and has an amount of terminal acid of 50 equivalents / metric ton or less.

Owner:MITSUBISHI CHEM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com