Patents

Literature

48results about How to "Low in acetaldehyde" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acetaldehyde removal from methyl acetate by distillation at elevated pressure

ActiveUS20090107833A1Low in acetaldehydeEfficient AcH removalOrganic compound preparationDistillation regulation/controlChemistryDistillation

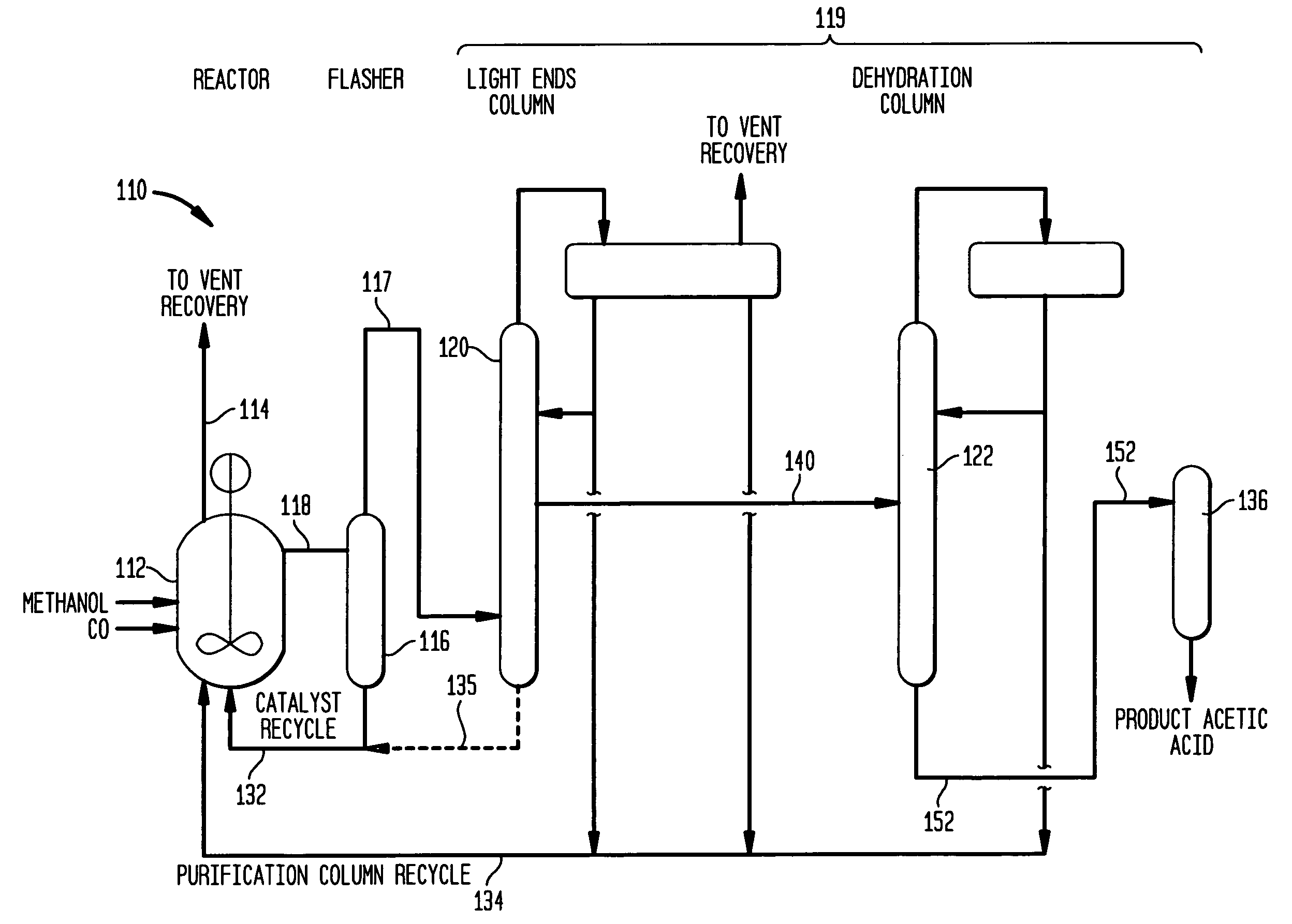

A method for removing acetaldehyde from a mixture of methyl acetate, methanol and acetaldehyde includes: (a) feeding the mixture of methyl acetate, methanol and acetaldehyde to a distillation column; (b) distilling the feed mixture of methyl acetate methanol and acetaldehyde at a pressure of 10 psig or more to generate an overhead vapor stream enriched in acetaldehyde as compared with the feed mixture and a residue stream depleted in acetaldehyde as compared with the feed mixture; and (c) withdrawing the residue stream depleted in acetaldehyde from the distillation column.

Owner:CELANESE INT CORP

Manufacturing method of copolyester for low acetaldehyde content of PET bottles

InactiveUS6489434B2Reduce productionLow in acetaldehydeLayered productsBottlesPolyethylene terephthalate glycolBottle

The present invention provides a manufacturing method of copolyester for low acetaldehyde content of PET bottles. The polyethylene terephthalate (PET) polymer is added with an appropriate modifier in order to decrease the production of acetaldehyde caused by pyrolysis side reaction during the blow molding process of PET bottles. The modifier comprises stabilizer and primary antioxidant, wherein the stabilizer is an inorganic phosphorous compound with an addition quantity of 0.003~0.5 weight % based on the weight of the total copolyester copolymer and the primary antioxidant is a hindered phenolic antioxidant containing Ca+2 with an addition quantity of 0.005~5.0 weight % based on the weight of the total copolyester copolymer. The present invention owns an improving effect of decreasing the production of side product-acetaldehyde at least 30% than those without the addition of said modifier.

Owner:NANYA PLASTICS CORP

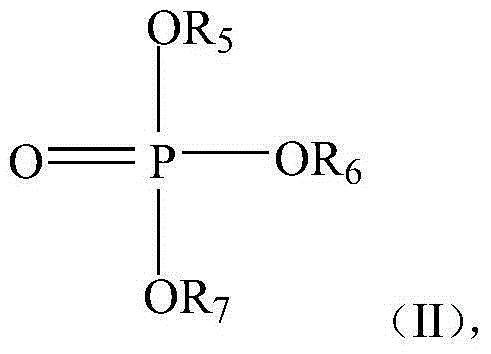

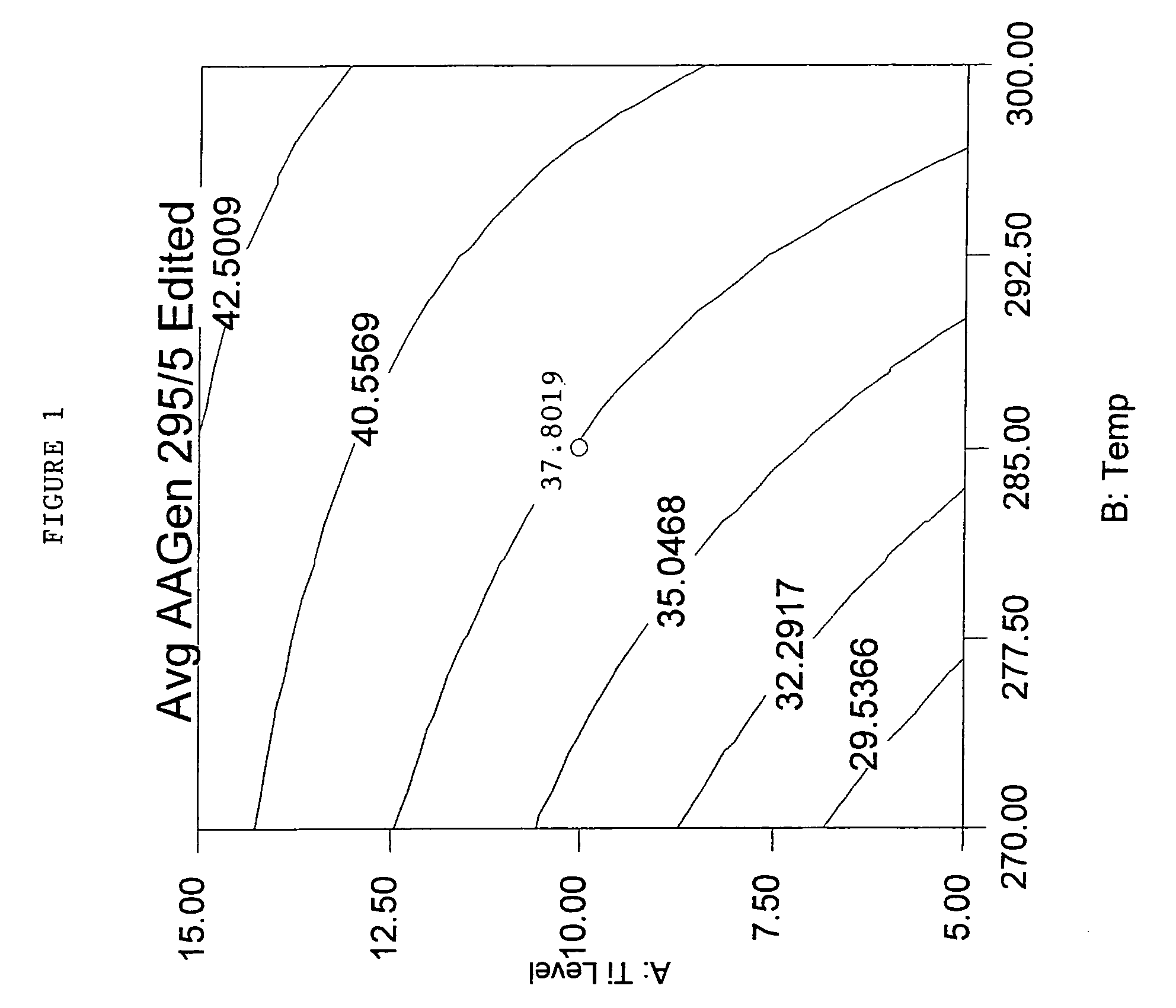

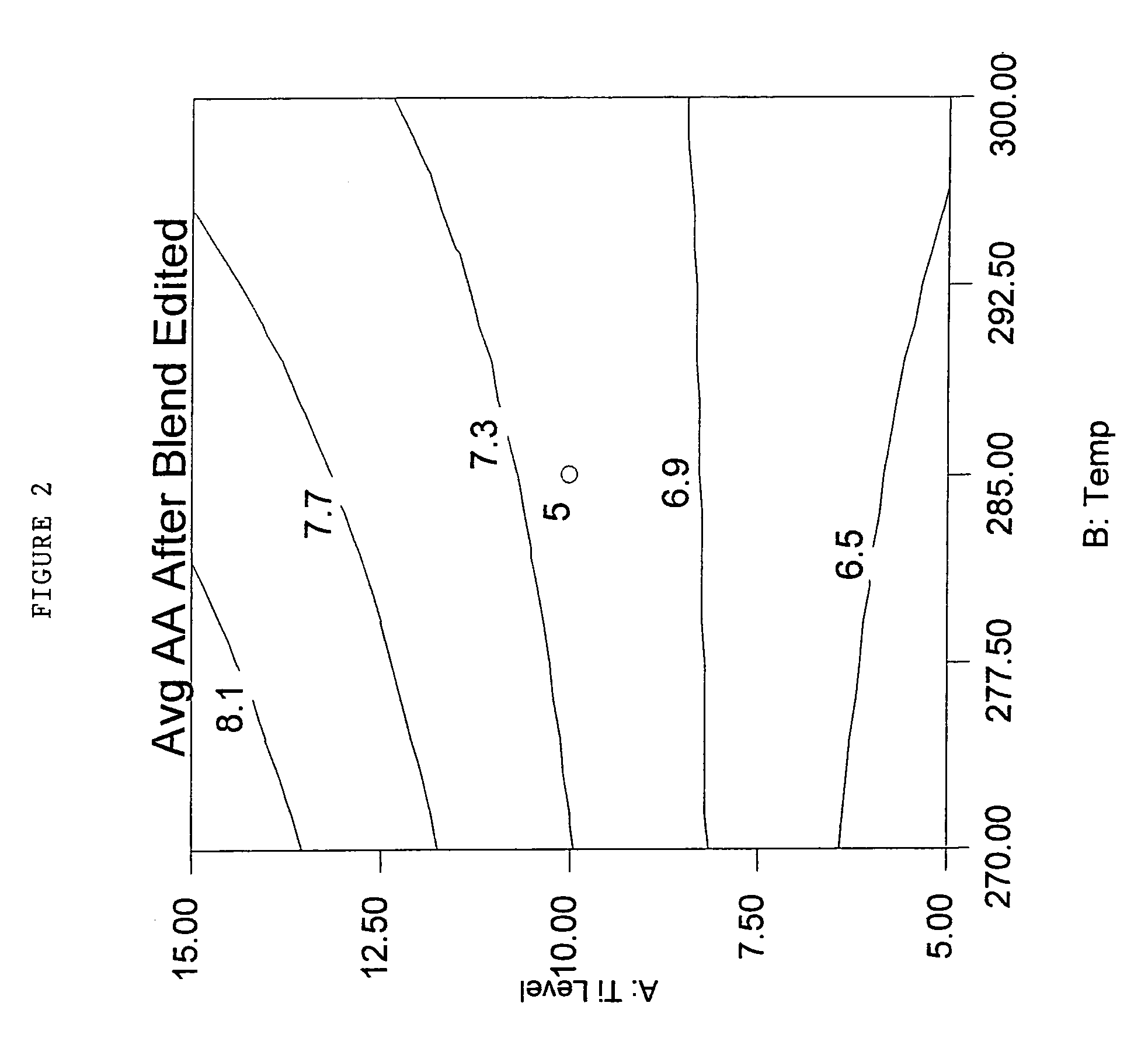

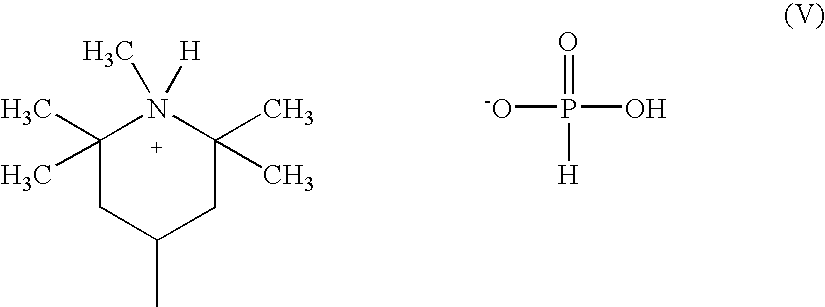

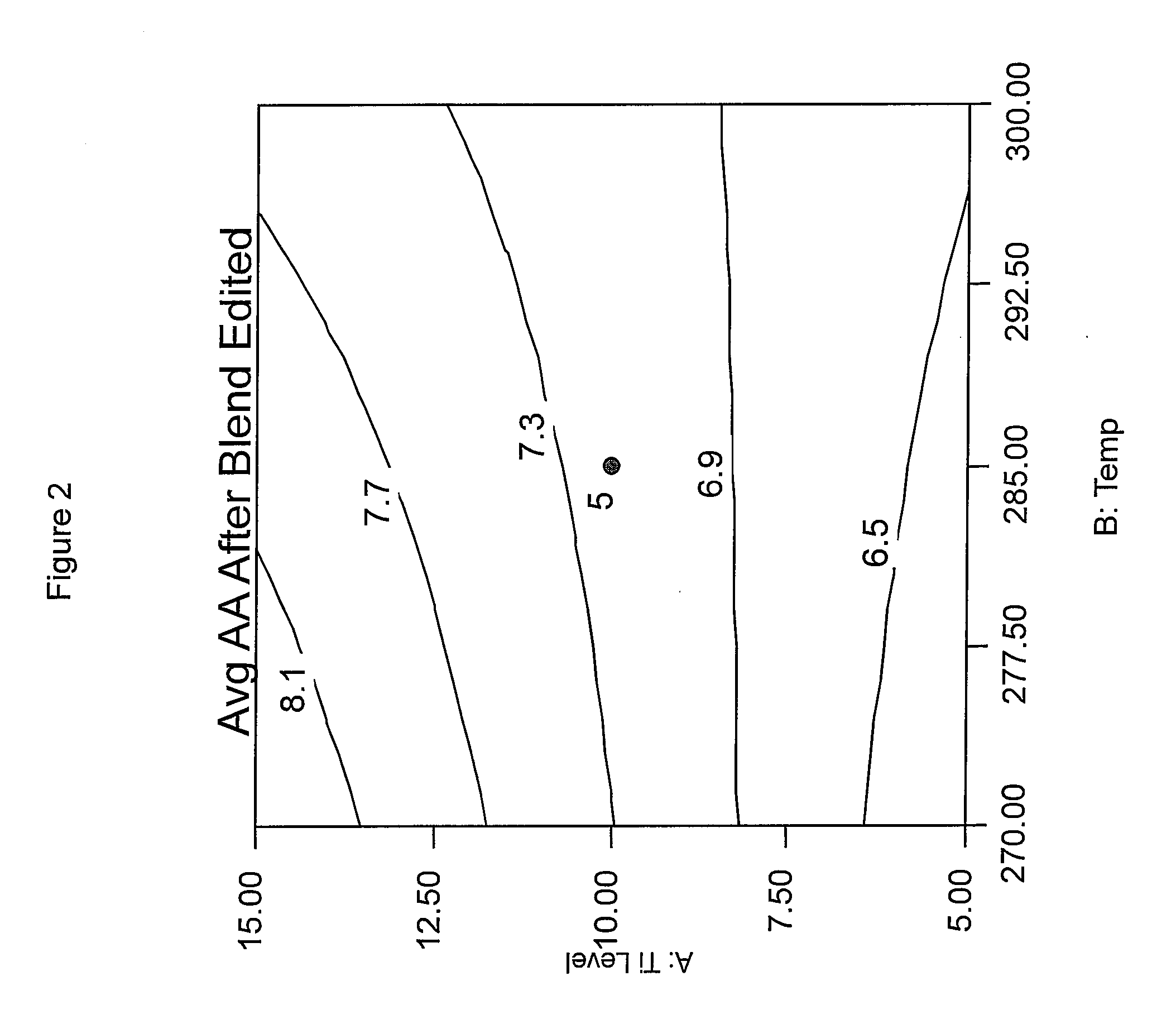

Phosphorus containing compounds for reducing acetaldehyde in polyesters polymers

InactiveUS20070066794A1High intrinsic viscosityLow in acetaldehydeOrganic-compounds/hydrides/coordination-complexes catalystsTobacco devicesPolyesterPolyethylene terephthalate glycol

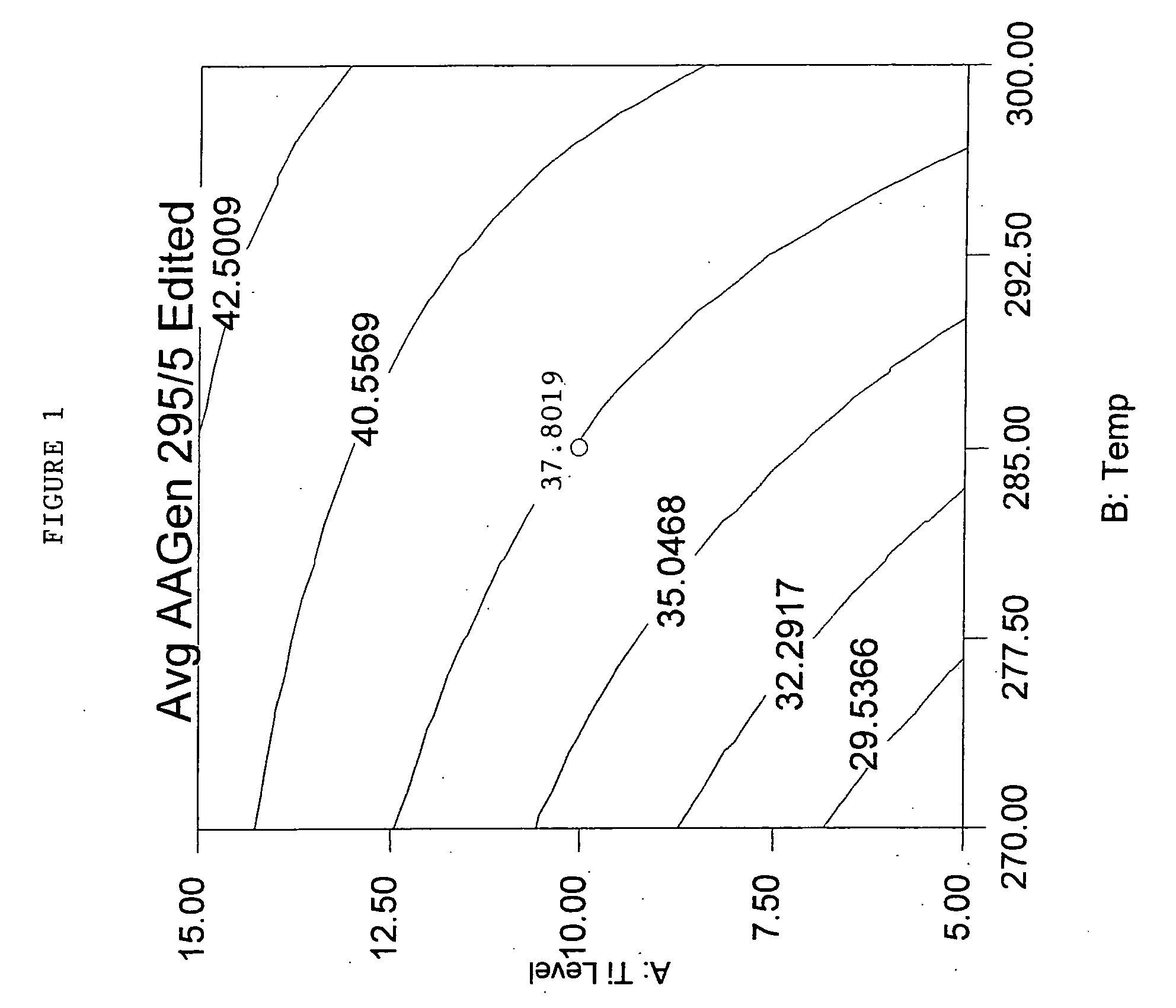

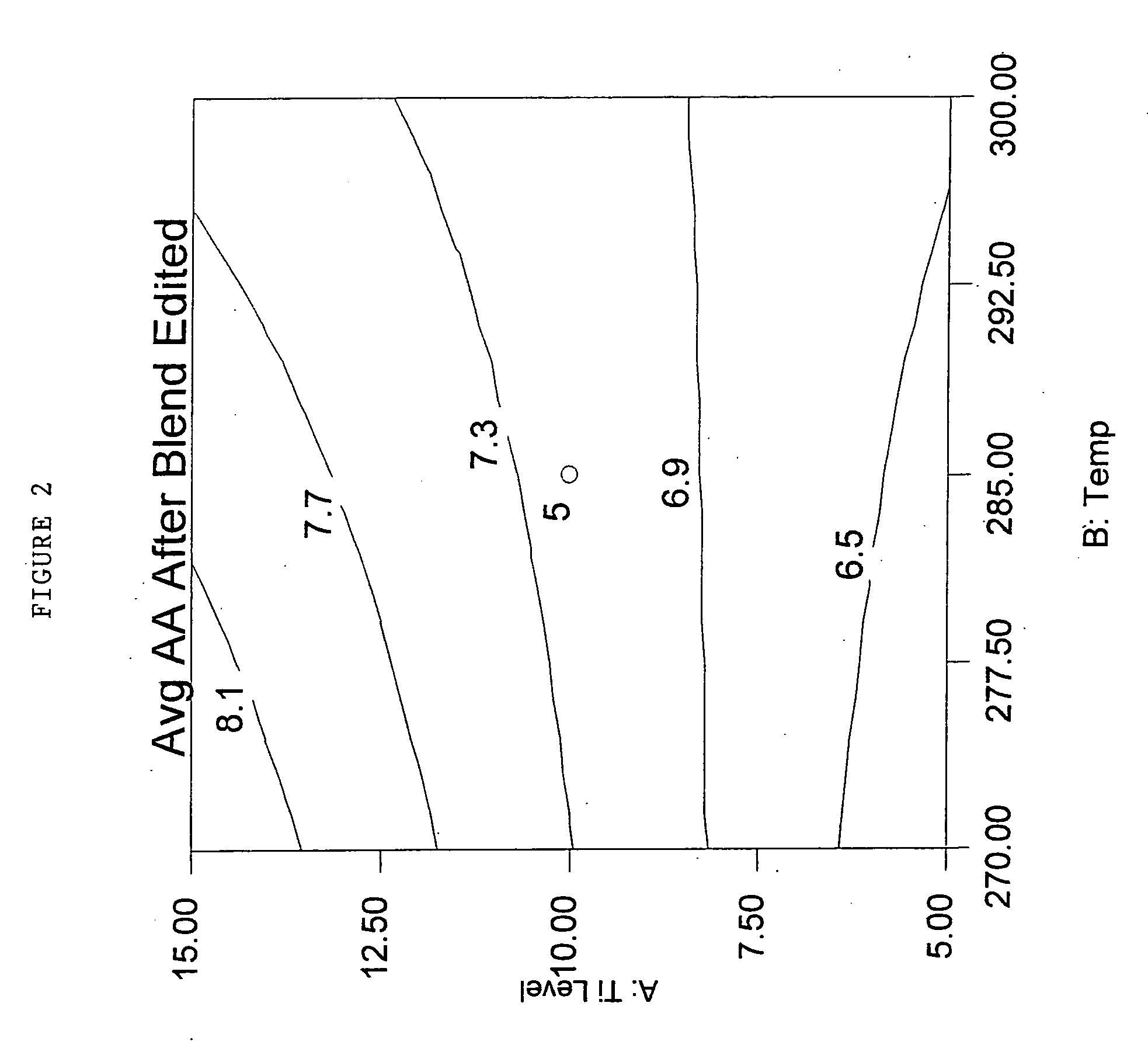

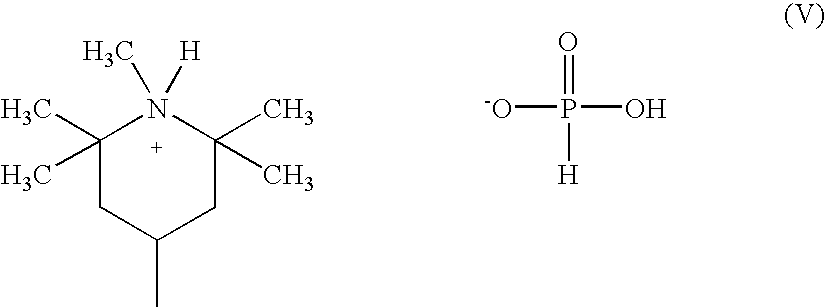

Polyesters whose polycondensation is catalyzed by titanium-containing catalysts and which are susceptible to acetaldehyde formation during polycondensation or subsequent molding operations are prepared with low finished acetaldehyde content and reduced acetaldehyde generation by adding an ammonium or amine salt of an oxyphosphorus-acid. Polyesters, especially polyethylene terephthalate, may be produced with high inherent viscosity in reduced processing time, without the necessity of further polymerization in the solid state.

Owner:GRUPO PETROTEMEX DE C V

Polyester composition and articles with reduced acetaldehyde content and method using hydrogenation catalyst

A polyester composition with reduced acetaldehyde concentration comprising polyester, at least one hydrogenation catalyst, and at least one source of reactive hydrogen. A method for making the polyester composition is also disclosed along with polyester articles made with the polyester composition. Suitable articles include containers such as bottles. A packaged beverage comprising a container made with the polyester composition is disclosed.

Owner:THE COCA-COLA CO

Purification process for epoxypropane

The invention discloses a method for purifying epoxy propane. Aldehyde in the epoxy propane is separated through the continuous operation of a reactor and a rectifying tower, a titanium-silicate molecular sieve is used as a catalyst, methanol is used as a solvent, propylene and hydrogen peroxide are taken as raw materials for an epoxidation reaction, and then crude epoxy propane is obtained through one-step or multi-step treatment. The crude epoxy propane and a sulfur-containing compound solution are mixed through a static mixer, then enter the reactor to react for certain time, and enter the rectifying tower for refinement, and the retention time of a mixed solution of the crude epoxy propane and the sulfur-containing compound solution in the reactor is between 5min and 1h. The method has the advantages that after the crude epoxy propane is purified by the method, the aldehyde content of the obtained crude epoxy propane is lower than 100ppm, thereby achieving good effect.

Owner:TIANJIN DAGU CHEM CO LTD +1

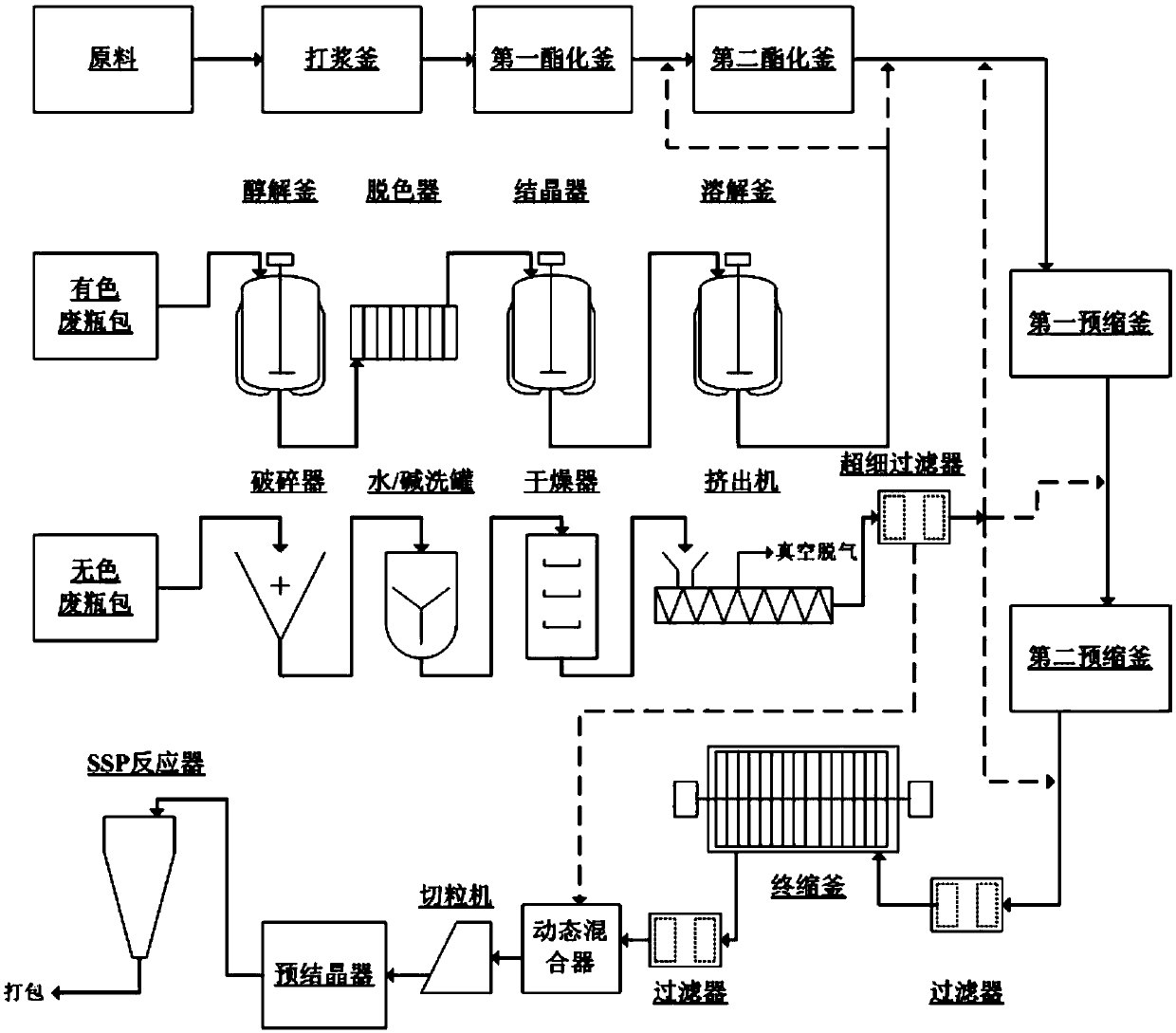

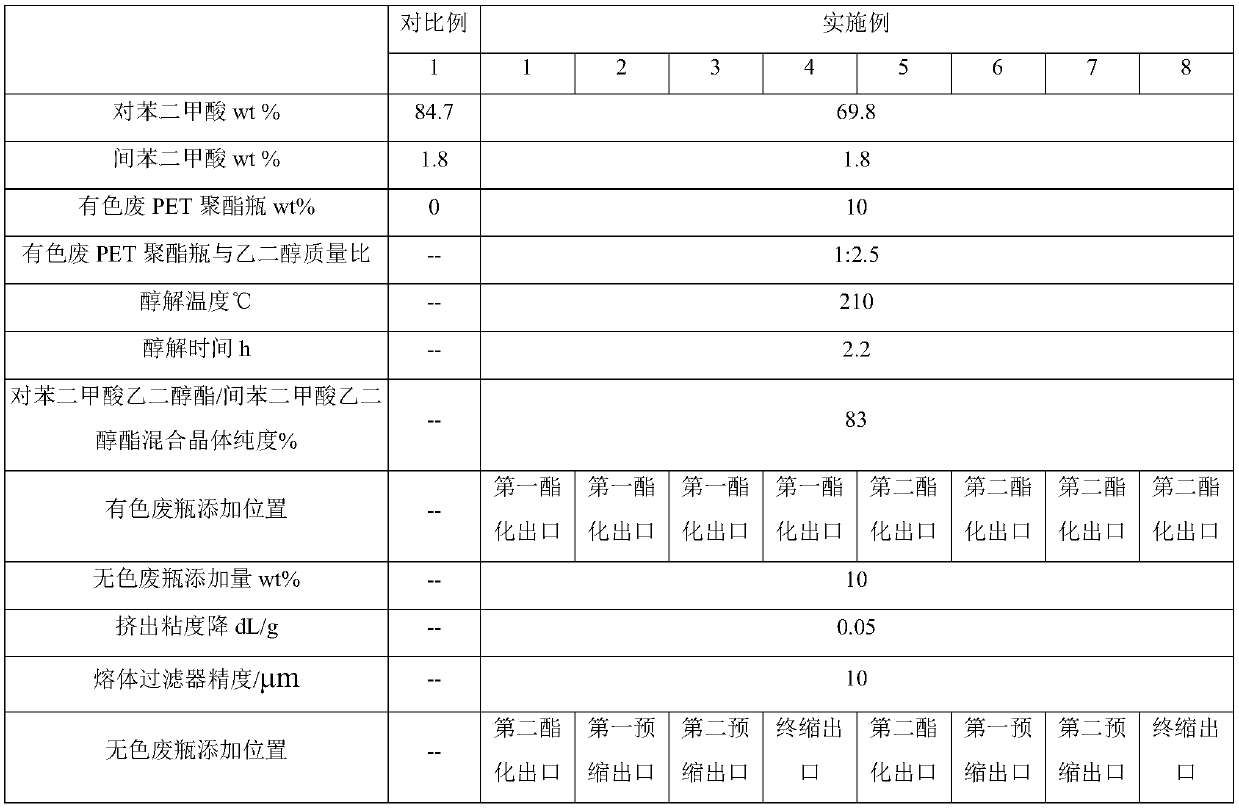

Method for preparing bottle-grade slices by recycling waste polyester bottles

ActiveCN111138641AImprove cleanlinessLow color requirementPlastic recyclingPolyesterTransesterification reaction

The invention discloses a method for preparing bottle-grade slices by recycling waste polyester bottles. According to the method, colored bottles are subjected to alcoholysis, decoloration, crystallization, dissolution and other methods to obtain high-purity BHET, and then the high-purity BHET enters a reaction system; the melt of colorless bottles is injected into a condensation polymerization reaction system through melt extrusion to participate in a transesterification reaction of primary melt, and harmful gas is further removed in the reaction process to improve the cleanliness of the melt; and the crystallization rate is reduced by optimizing the addition amount of a raw material IPA, the intrinsic viscosity of the melt can be flexibly adjusted after the alcoholysis product, the recovered melt and the primary melt pass through a reactor, and volatile substances generated by degradation in the alcoholysis and melting processes of the recovered bottles can be effectively removed byvirtue of disc vacuum film formation. The method has the advantages that the amount of recycled waste polyester bottles can be adjusted, the color requirement of the waste polyester bottles is low, the intrinsic viscosity of the product is stable, the acetaldehyde content is low, and the crystallization rate is consistent with the crystallization rate of raw materials. Compared with the existing bottle-to-bottle technology, the method of the invention can be applied to the fields of food-grade bottle slices such as water bottles, carbonic acid bottles, oil bottles and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

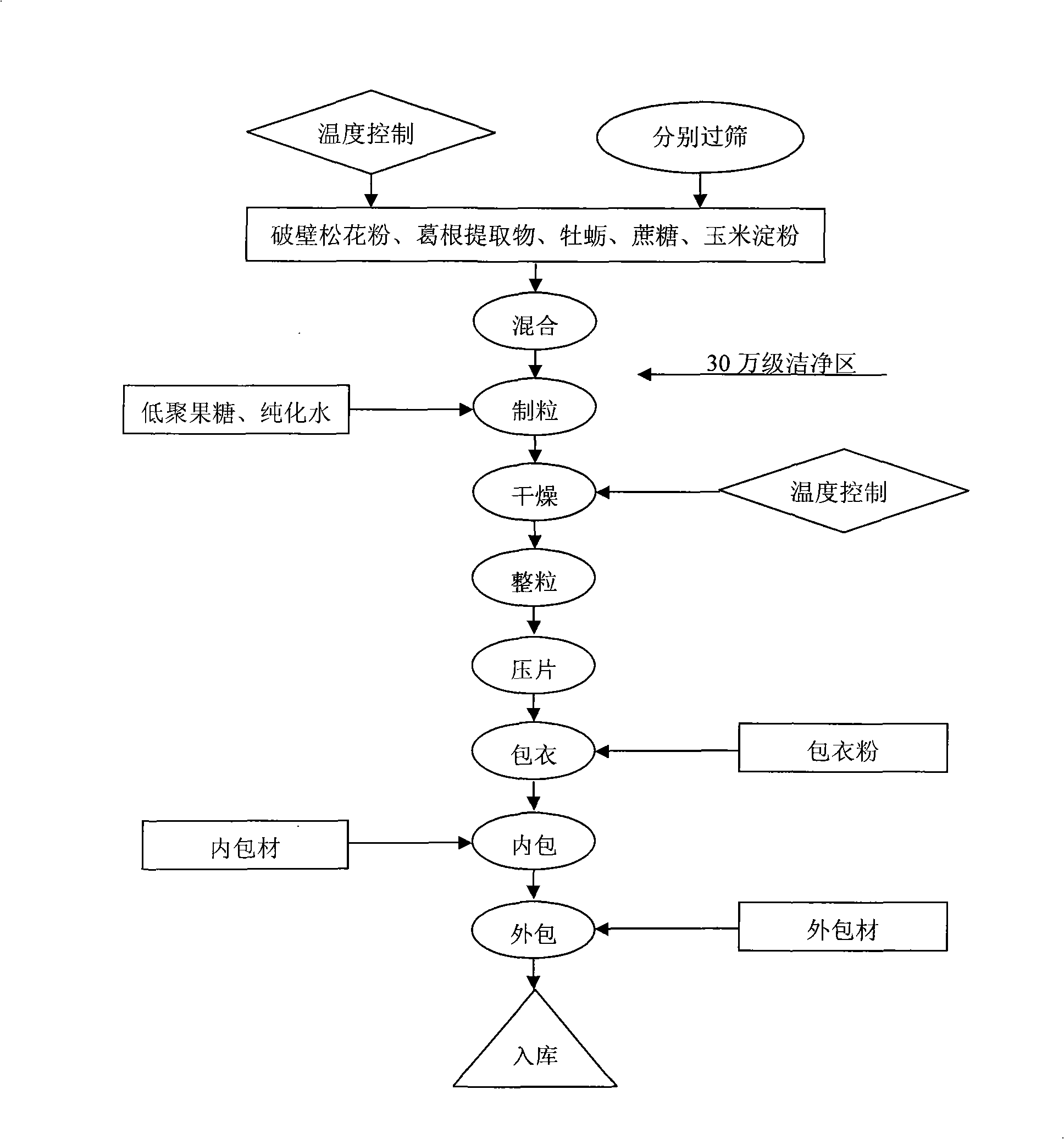

Piny flower kudzu root slice prescription for relieving or neutralizing the effect of alcohol to protect liver and preparation thereof

InactiveCN101401840ATo promote metabolismHigh activityOrganic active ingredientsNervous disorderDecompositionOyster

The invention relates to a recipe containing piny flowers and kudzuvine root pieces for relieving alcohol and protecting liver and a preparation process thereof. The recipe comprises the following raw materials in weight percentage: 40 to 60 grams of wall-broken piny flower powder, 150 to 200 grams of kudzuvine root extractive, 100 to 150 grams of oyster, 80 to 150 grams of white granulated sugar, 100 to 150 grams of corn starch, 20 to 50 grams of fructooli-osaccharide, and 100 to 250 grams of purified water. The kudzuvine root extractive is 40 percent of pueraria total flavonoids, and the fructooli-osaccharide is one or the mixture of kestose, nystose and cane pentasaccharides. The recipe has the advantages of relieving alcohol on the aspects of protecting liver, reducing alcohol absorption, accelerating alcohol decomposition and the like, protecting the body from being damaged by alcohol, and relieving drunken symptom under the conditions of increasing the drinking capacity of a drinker or drinking equivalent wine, and has remarkable alcohol relieving effect, can reduce ALT and AST content in the liver of a drunken mouse remarkably, and has remarkable liver protecting effect.

Owner:中国林业科学研究院松花粉研究开发中心

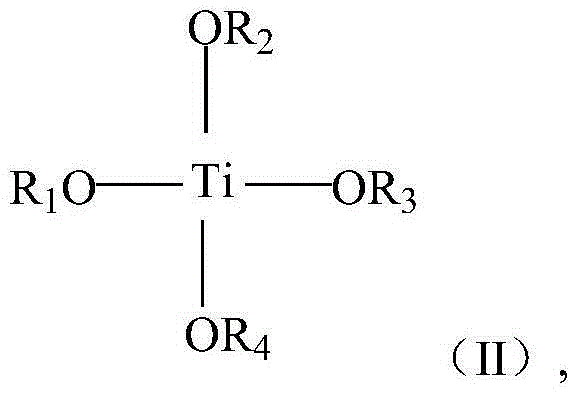

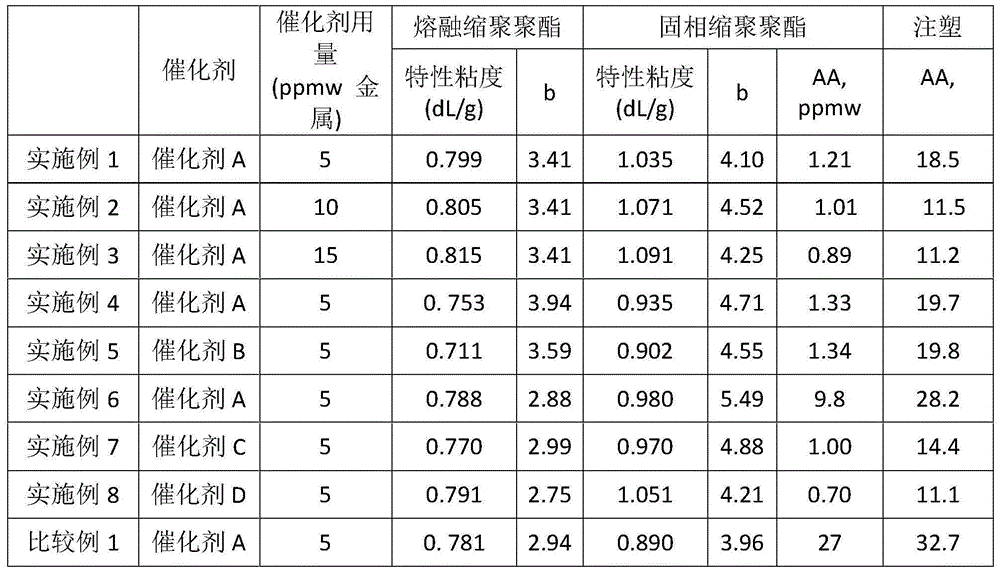

Method for producing low-acetaldehyde polyester product

The invention relates to a method for producing a low-acetaldehyde polyester product. The method is mainly used for solving the problem that the residual of acetaldehyde in polyester bottles prepared by a titanium-series catalyst is relatively high. According to the method, through adopting the technical scheme that a catalyst, which is prepared through carrying out a reaction on the following raw materials: (1) a titanium compound A with a general formula as follows: Ti(OR)4, wherein R is selected from C1-10 straight-chain or branched alkyl; (2) diol B with 2 to 10 carbon atoms; (3) a metal compound C selected from IA of the periodic table of elements; (4) at least one aliphatic organic acid D selected from organic acids; (5) at least one phosphate compound E selected from phosphorus compounds; and (6) at least one metal compound F selected from IIA, IB, IIB, VIIB and VIII of the periodic table of elements, is used, the problem is better solved, so that the method can be applied to the industrial production of polyesters with low acetaldehyde residual.

Owner:CHINA PETROLEUM & CHEM CORP +1

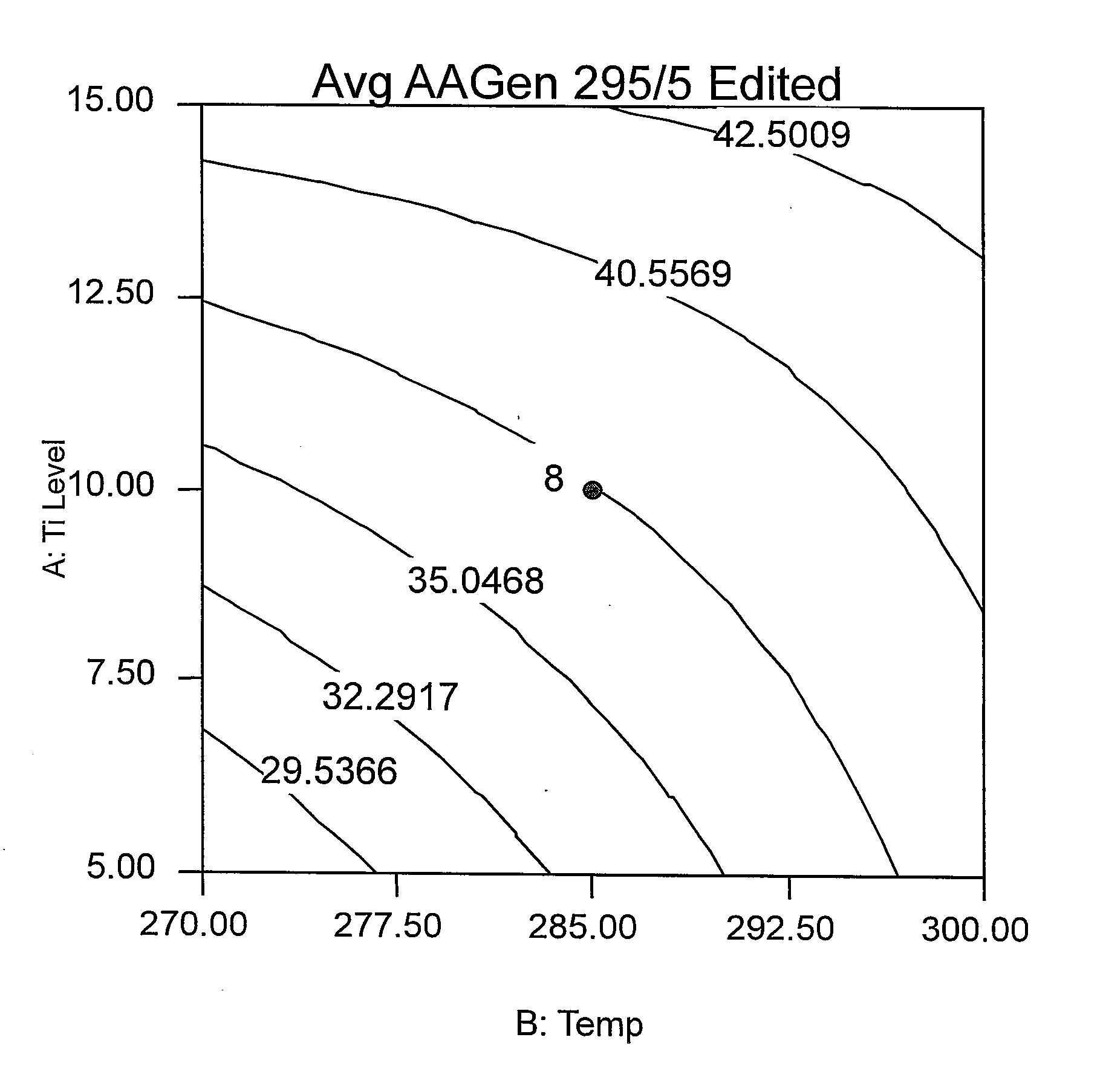

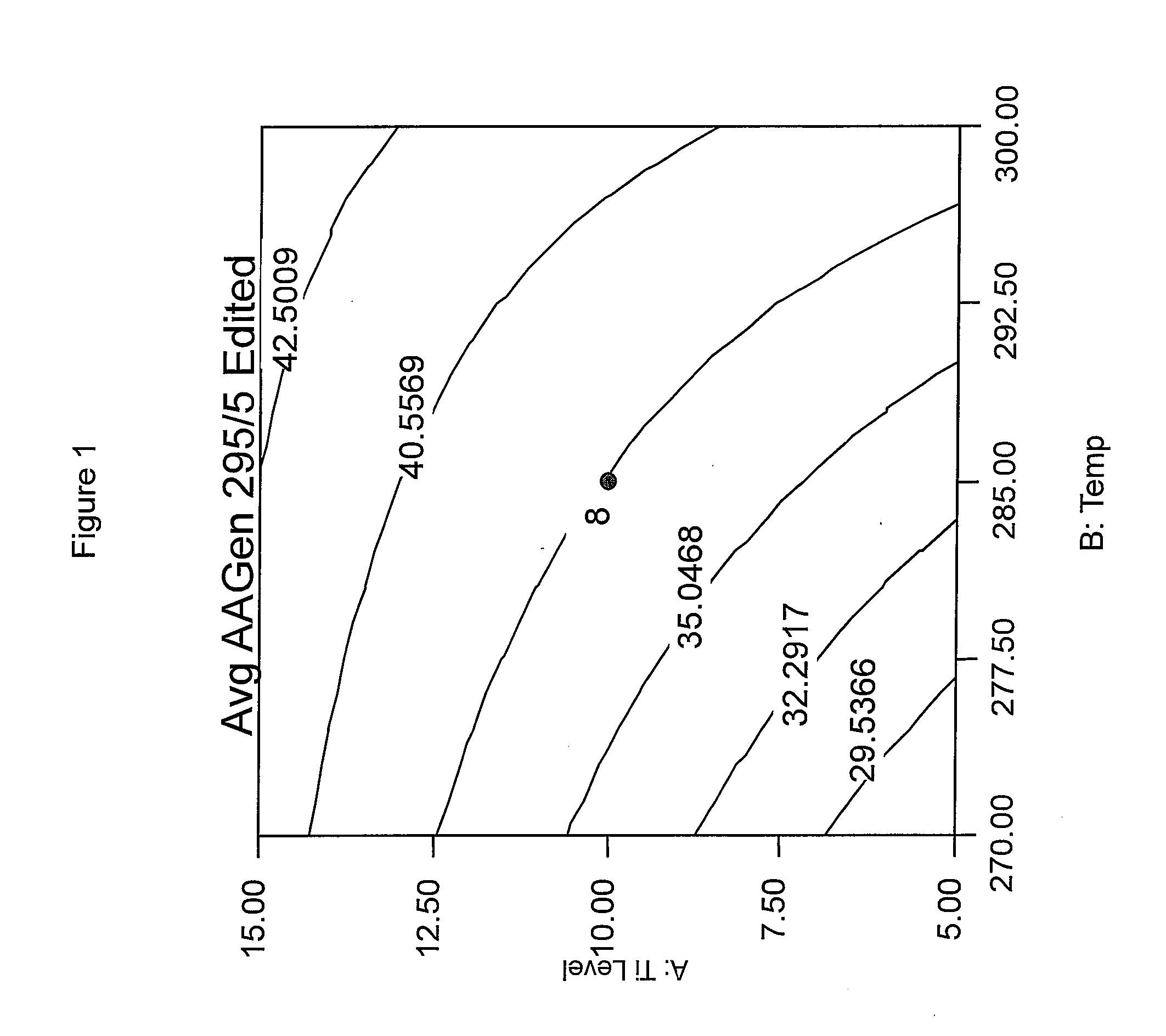

Phosphorus containing compounds for reducing acetaldehyde in polyesters polymers

InactiveUS7655746B2High intrinsic viscosityLow in acetaldehydeOrganic-compounds/hydrides/coordination-complexes catalystsTobacco devicesPolyesterPolyethylene terephthalate glycol

Polyesters whose polycondensation is catalyzed by titanium-containing catalysts and which are susceptible to acetaldehyde formation during polycondensation or subsequent molding operations are prepared with low finished acetaldehyde content and reduced acetaldehyde generation by adding an ammonium or amine salt of an oxyphosphorus-acid. Polyesters, especially polyethylene terephthalate, may be produced with high inherent viscosity in reduced processing time, without the necessity of further polymerization in the solid state.

Owner:GRUPO PETROTEMEX DE C V

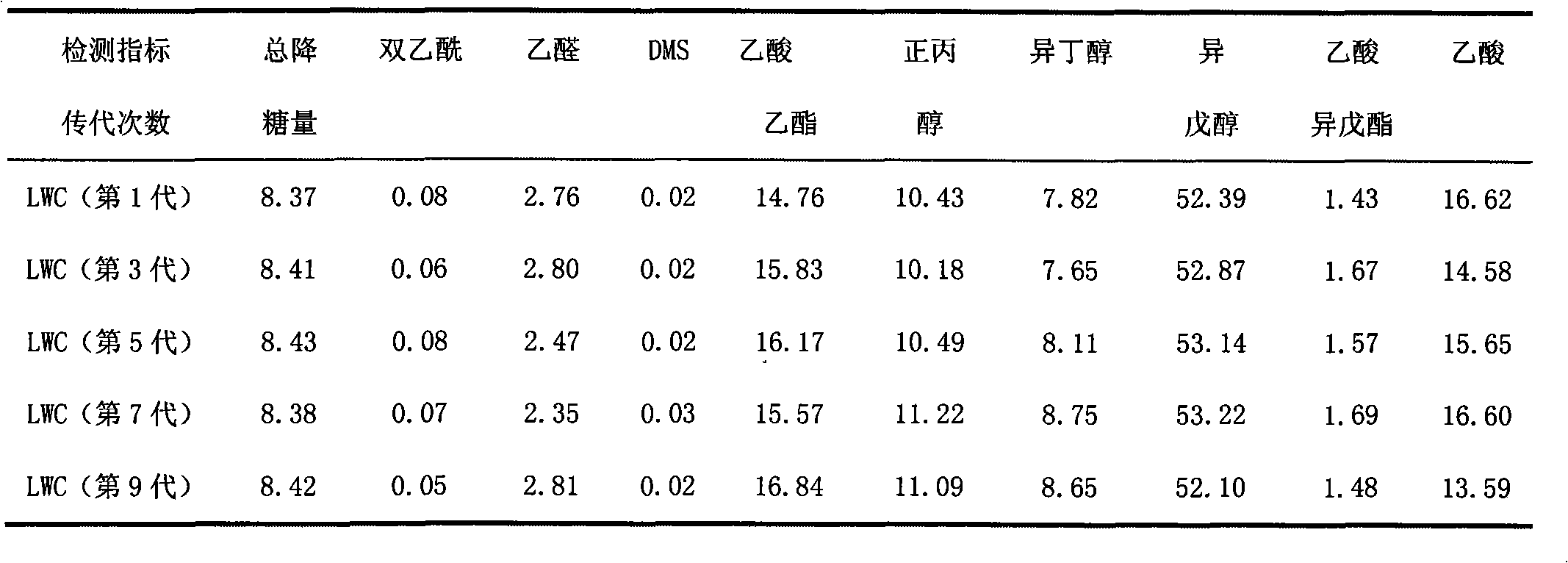

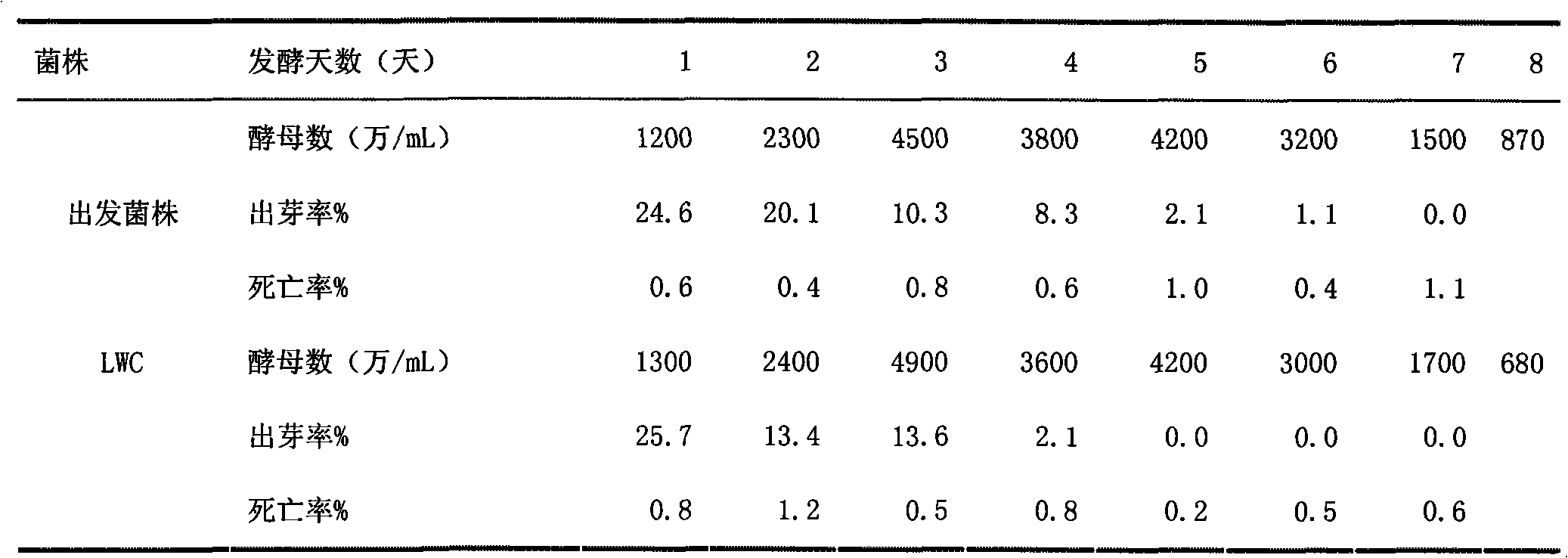

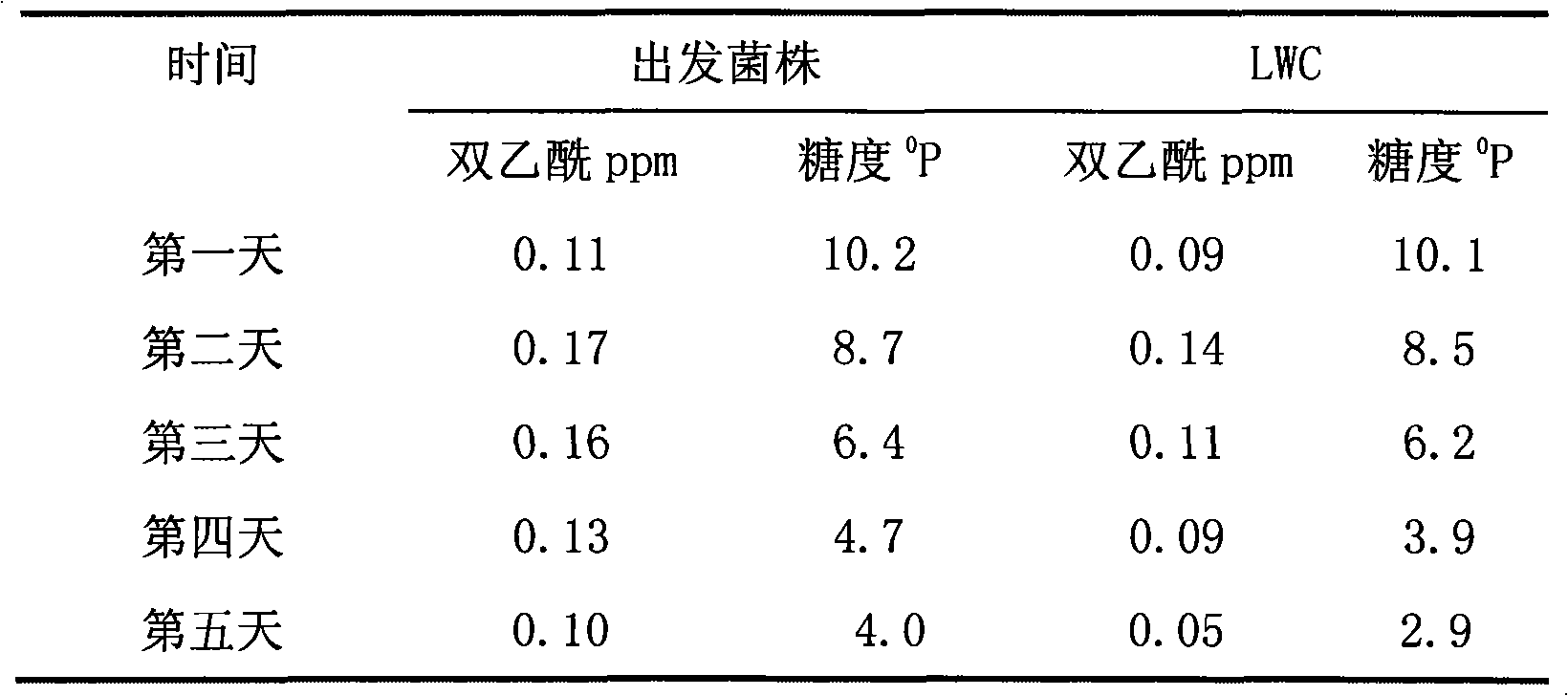

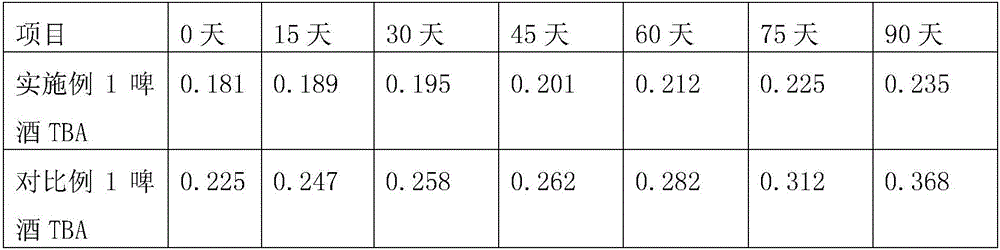

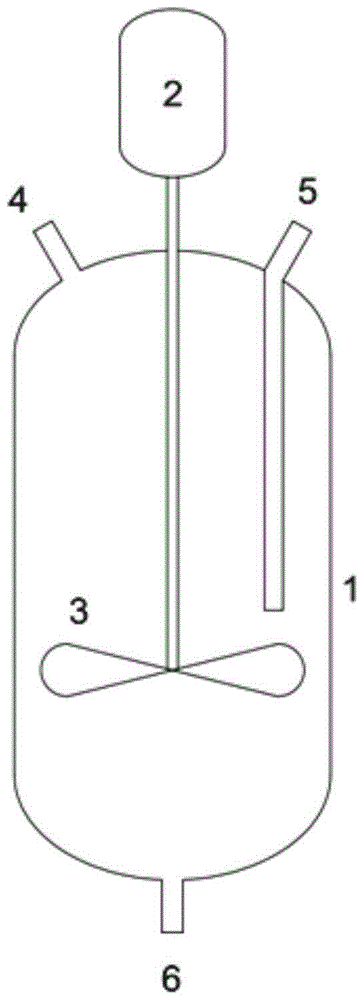

Yeast strain of beer and application thereof

InactiveCN101665772AHigh positive mutation rateIncrease mutagenic effectFungiBeer fermentationBiotechnologyMicroorganism

The invention discloses a yeast strain of beer and the application thereof in the aspect of beer fermentation. The strain of the beer-brewing yeast (saccharomyces cerevisiae) provided by the inventionis preserved in the China General Microbiological Culture Collection Center, and the preservation number is CGMCC No.3217. The selecting and breeding method of the strain comprises the following steps: activating the original starting strain, injecting ions for mutation, mutating by laser, primarily sieving by using wort and agar flat plate culturing medium, sieving again by using a fermentationbung, testing genetic stability, and performing a pilot-scale test. The yeast strain of beer is an excellent yeast strain of beer and has a potential suitable for large production of beer breweries.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD

Preparation method of common yam rhizome beer

InactiveCN106190676AMeet quality requirementsInhibition of reproductionWort preparationMicroorganism based processesMicrofiltrationRhizome

The invention relates to a brewing method of common yam rhizome beer. According to the method, Lager yeast is selected and used, malt and common yam rhizomes are adopted as raw materials, saccharification, main fermentation and after-fermentation are carried out, the temperature, the pressure and the fermentation degree are controlled in the after-fermentation process, and the common yam rhizome beer is obtained after clarification and microfiltration. The prepared beer has typical malt and hop fragrance and has a balanced and coordinated taste; foam is pure white and fine, and the beer is more tasty and refreshing to drink; the healthcare effect of common yam rhizomes is achieved.

Owner:山东喜啤士生物科技有限公司

High-viscosity copolyester and preparation method

The invention relates to high-viscosity copolyester. The high-viscosity copolyester is characterized by containing the following components: terephthalic acid PTA and isophthalic acid IPA which are taken as binary acid as well as ethylene glycol MEG, methyl propanediol MPD and diethylene glycol DEG which are taken as dihydric alcohol, wherein the molar ratio of the binary acid to mixed dihydric alcohol is 1:(1.04-2), the usage amount of isophthalic acid accounts for 0-10mol% of the total usage amount of the binary acid, the usage amount of methyl propanediol accounts for 1-38mol% of the totalusage amount of the dihydric alcohol, and the usage amount of the diethylene glycol accounts for 0-1.8mol% of the total usage amount of the dihydric alcohol. The invention also relates to a preparation method of the high-viscosity copolyester. Compared with the prior art, the invention has the advantages that the preparation method is reasonable, and the obtained high-viscosity copolyester has theadvantages of high viscosity, high brightness and low acetaldehyde content.

Owner:ZHEJIANG WANKAI NEW MATERIAL

Method for preparing EVA elastomer

The invention discloses a method for preparing EVA elastomer. The method included the step of controlling the pressure of ethylene to make the ethylene completely liquefied in a single reactor with alcohols as a solvent, so that the ethylene and the vinyl acetate are subjected to liquid-liquid single-phase copolymerization and the EVA elastomer is obtained. According to the method based on the existing EVA-elastomer-solution polymerization process, the pressure of ethylene is controlled to make the ethylene completely liquefied so that the liquid-liquid copolymerization can improve the comonomer contact efficiency as well as the solubility of ethylene in the liquid phase, complete the solution single-phase copolymerization, and greatly improve the monomer copolymerization rate and the diffusion as well as the initiator efficiency of the free radicals in the copolymer solution. According to the application requirements of different polymerization products, by adjusting the solvent, the method greatly improves the copolymerization rate and the high solid content of a high-viscosity system. Using the single-reactor process, the method is also capable of avoiding the high-cost and complex-manipulation problem resulting from a raw-material process device of the multi-reactor process. Therefore, the method has high industrial application value.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for reducing content of acetaldehyde in granulated polyester slice

The invention relates to a method for reducing content of acetaldehyde in granulated polyester slice. The method comprises the steps of: cooling a polycondensation reactant, which is prepared by performing esterification and polycondensation to materials, with cooling water and then sized-dicing the polycondensation reactant to acquire a slice; the method is characterized by adding bicarbonate to the cooling water, wherein the bicarbonate is sodium bicarbonate, potassium bicarbonate, magnesium bicarbonate, calcium bicarbonate or ammonium bicarbonate; the added amount of the bicarbonate to the cooling water is 0.1-5% by weight; and the temperature of the cooling water ranges from 35 DEG C to 40 DEG C. The method has the advantages of greatly reducing the content of acetaldehyde in the sized-diced slice, so that the quality of the product is simply and economically improved.

Owner:CHINA RESOURCES PACKAGING MATERIALS CO LTD

High heat absorption high-brightness bottle-grade polyester chip and preparation method thereof

InactiveCN104017337AImprove absorption of infrared heating energyHigh transparencyPolyesterTitanium nitride

The invention relates to a high heat absorption high-brightness bottle-grade polyester chip which is characterized by containing titanium nitride and barium sulfate, wherein the weight content of titanium nitride in the polyester chip is 3-30ppm; the weight content of barium sulfate in the polyester chip is 0.1-5ppm. The invention further relates to a preparation method of the high heat absorption high-brightness bottle-grade polyester chip. The bottle-grade polyester chip provided by the invention has the advantages of high heat absorption and high brightness.

Owner:CHINA RESOURCES PACKAGING MATERIALS CO LTD +1

Catalyst for polyester production, process for producing polyester using the catalyst, polyester obtained by the process, and uses of the polyester

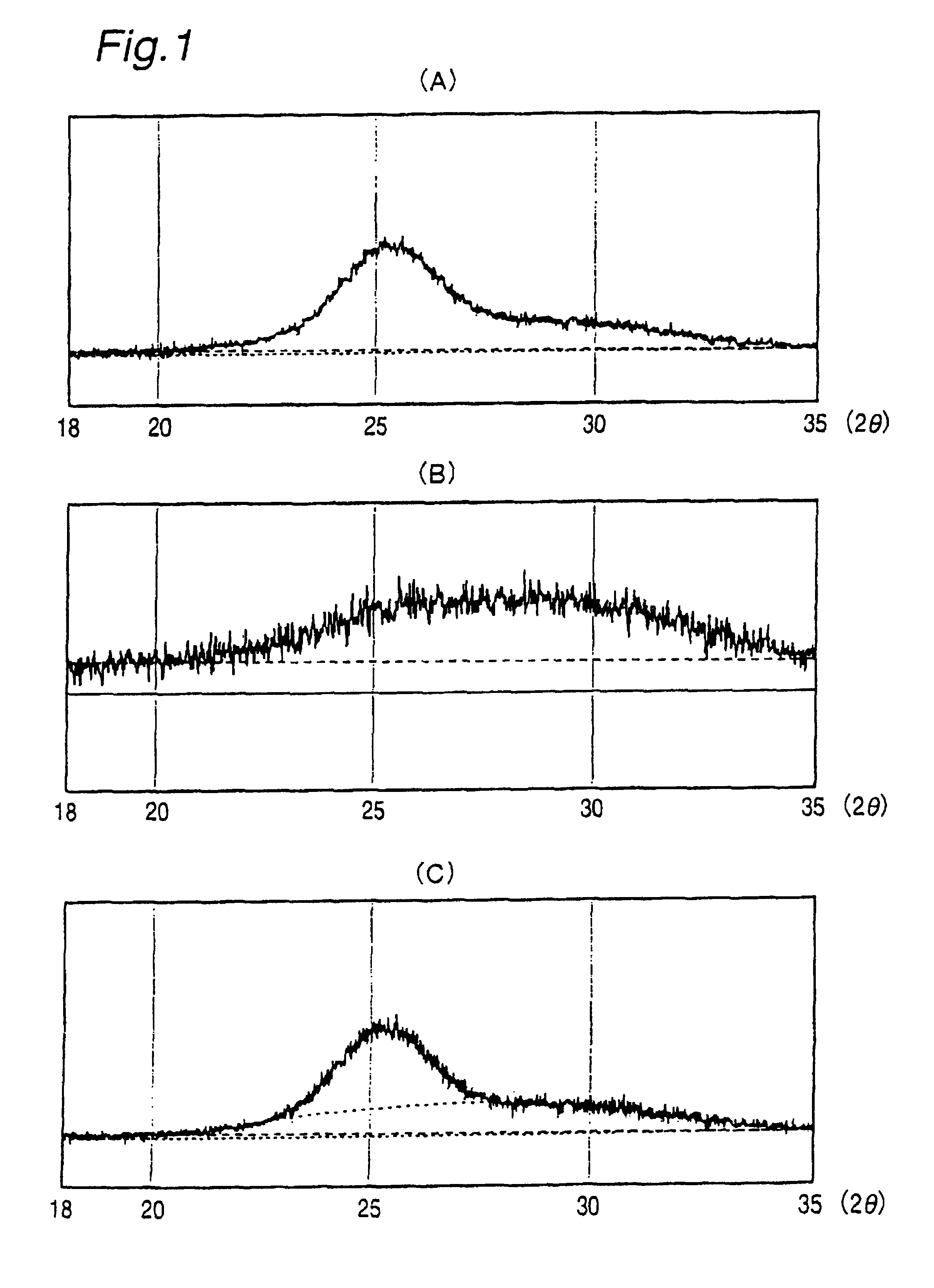

InactiveUSRE40571E1High catalytic activityHigh transparencyLactams stabilisationOrganic-compounds/hydrides/coordination-complexes catalystsPolyesterDiol

The present invention provides a catalyst for polyester production capable of producing a polyester with high catalytic activity, a process for producing a polyester using the catalyst and a polyester produced thereby. The catalyst comprises a solid titanium compound obtained by dehydro-drying a hydrolyzate obtained by hydrolysis of a titanium halide and which has a molar ratio (OH / Ti) of a hydroxyl group (OH) to titanium (Ti) exceeding 0.09 and less than 4. In the process, the polyester is obtained by polycondensing an aromatic dicarboxylic acid, or an ester-forming derivative thereof, and an aliphatic diol, or ester-forming derivative thereof, in the presence of the catalyst. The resulting polyester has excellent transparency and tint, a titanium content of 1 to 100 ppm, a magnesium content of 1 to 200 ppm and a magnesium to titanium weight ratio of not less than 0.01.

Owner:MITSUI CHEM INC

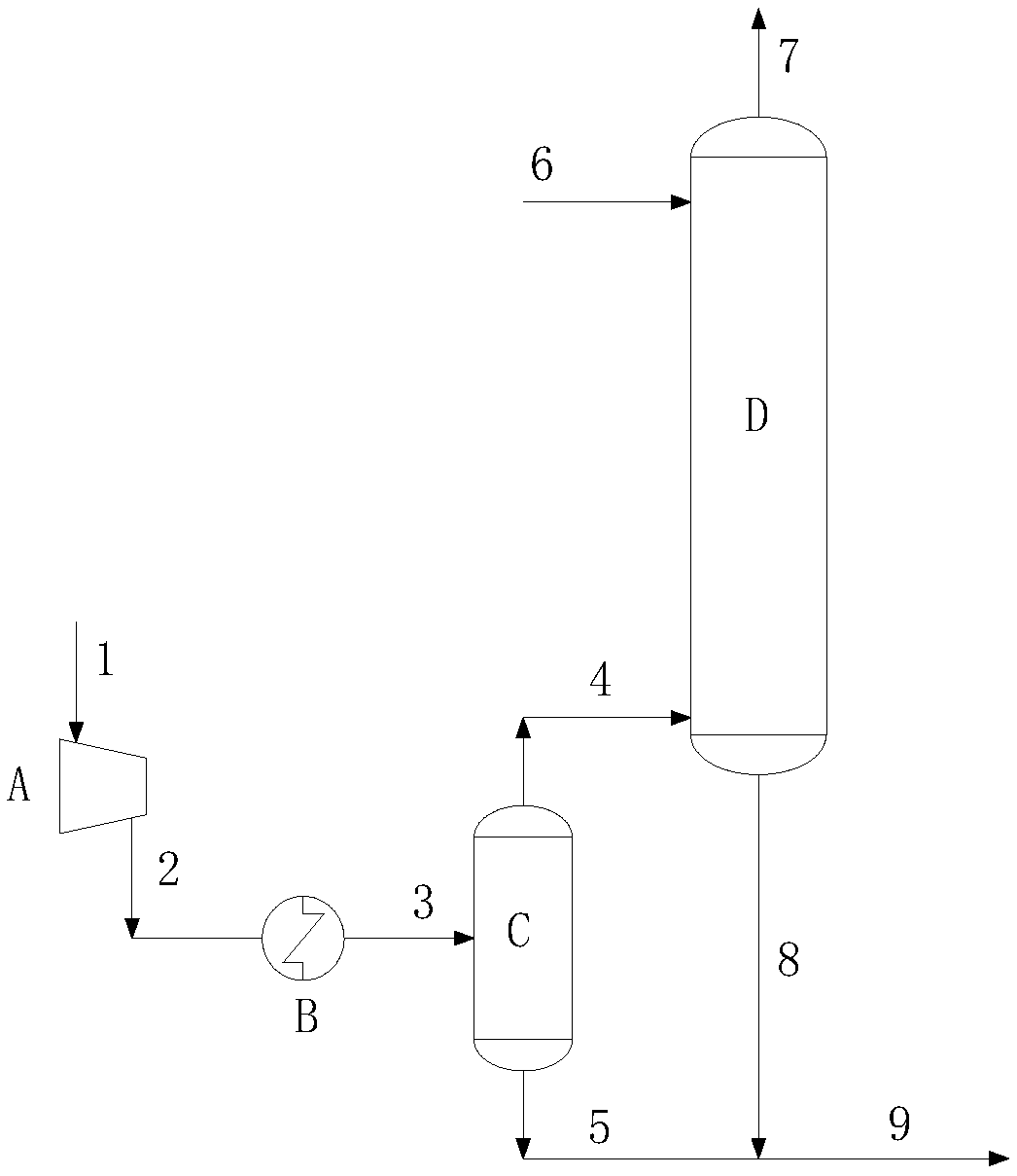

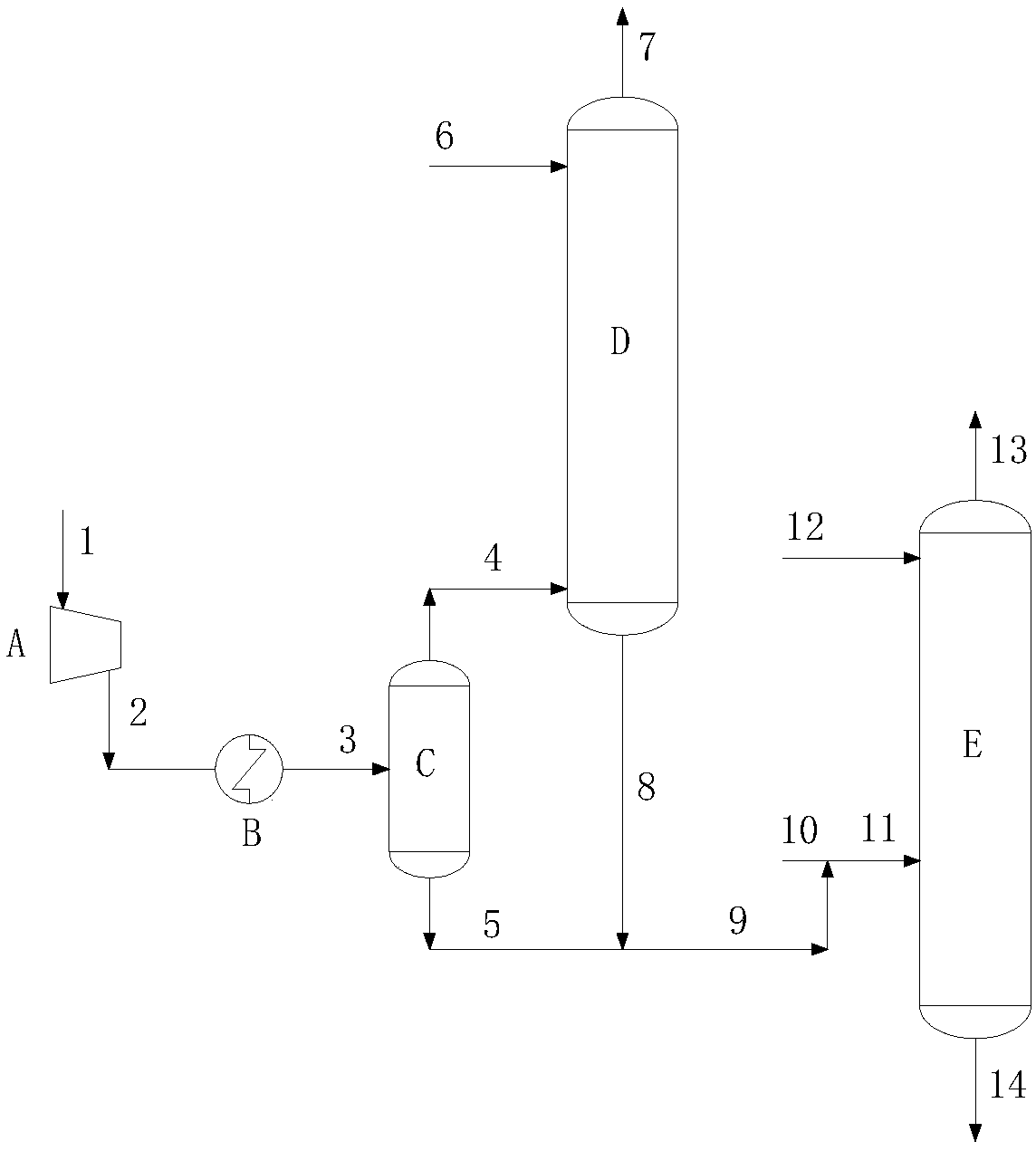

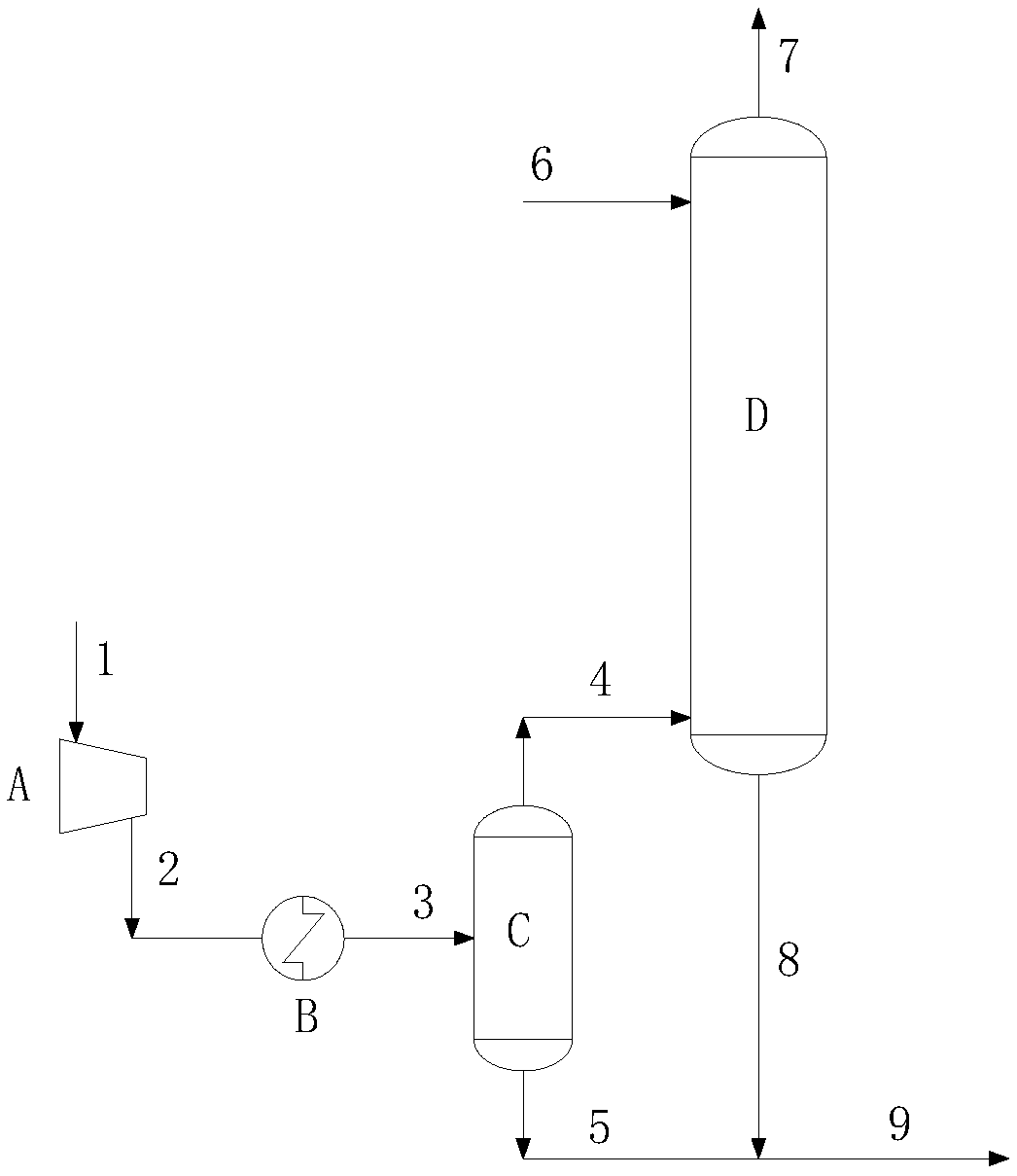

Method for recovering alkylene oxide

ActiveCN111116516AReduce water and acetaldehyde contentLow in acetaldehydeOrganic chemistryAlkaneVapor–liquid separator

The invention relates to a recovery method for alkylene oxide. The method comprises: feeding tail gas containing alkylene oxide, nitrogen, water and acetaldehyde into a pressurizing unit (such as a compressor); pressurizing; feeding into a cooler, and cooling; carrying out gas-liquid separation on the cooling liquid by a gas-liquid separator; making the gas phase enter the bottom of an absorptiontower, and making a cold extracting agent enter the middle upper portion of the tower; and carrying out post-treatment such as flare removal and the like on the gas phase at the top of the absorptiontower, mixing the tower kettle liquid phase and the liquid phase at the bottom of the gas-liquid separator, and feeding the mixture into the extractive rectification tower of an alkylene oxide refining unit to recover alkylene oxide, so that the alkylene oxide in the tail gas can be effectively recovered, the content of the alkylene oxide in the discharged tail gas is reduced, the VOCs discharge problem is effectively solved, and the method is used for industrial production of an alkylene oxide device.

Owner:CHINA PETROLEUM & CHEM CORP +1

Phosphorus containing compounds for reducing acetaldehyde in polyesters polymers

InactiveUS20100048783A1High intrinsic viscosityLow in acetaldehydeOrganic-compounds/hydrides/coordination-complexes catalystsHollow filament manufacturePolyesterPolyethylene terephthalate glycol

Polyesters whose polycondensation is catalyzed by titanium-containing catalysts and which are susceptible to acetaldehyde formation during polycondensation or subsequent molding operations are prepared with low finished acetaldehyde content and reduced acetaldehyde generation by adding an ammonium or amine salt of an oxyphosphorus-acid. Polyesters, especially polyethylene terephthalate, may be produced with high inherent viscosity in reduced processing time, without the necessity of further polymerization in the solid state.

Owner:GRUPO PETROTEMEX DE C V

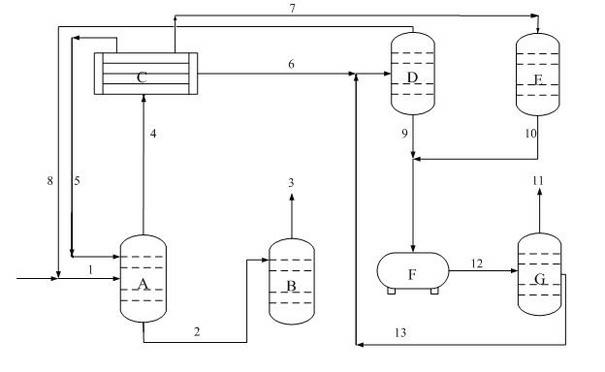

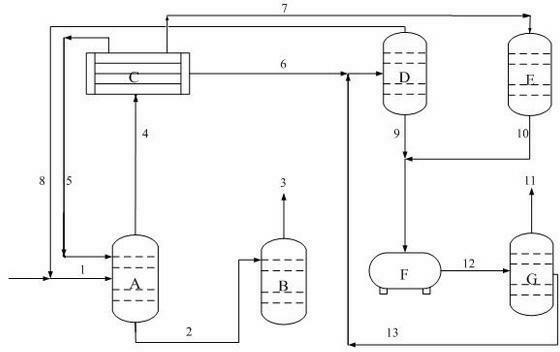

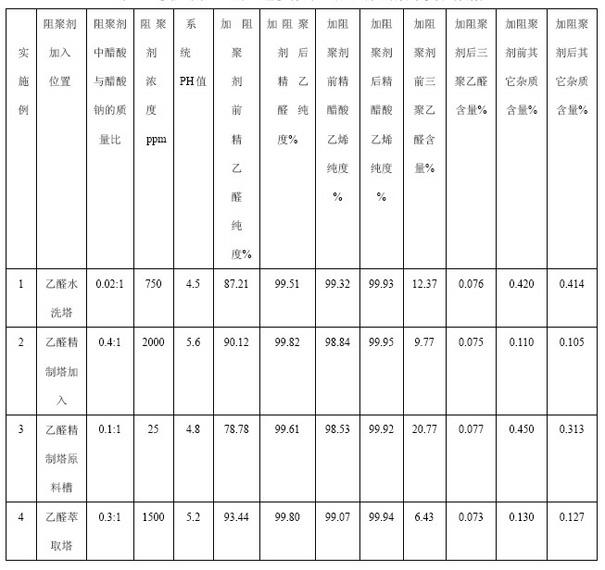

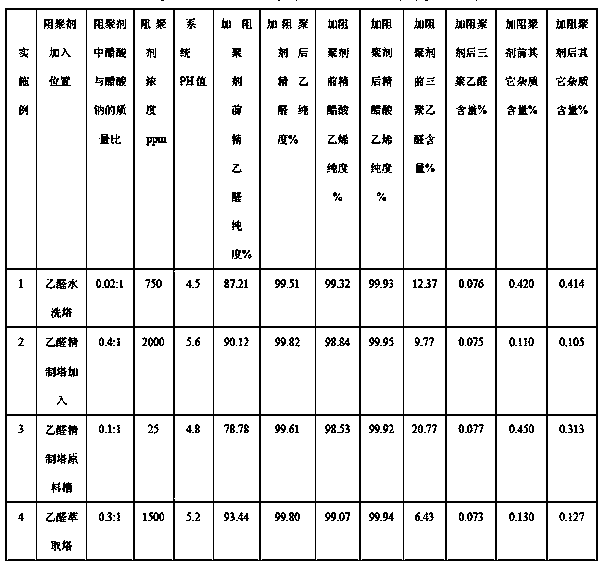

Method for inhibiting polymerization of acetaldehyde in polyvinyl alcohol and vinyl acetate production process

ActiveCN102675066AGood effectFailure to achieve the purpose of polymerization inhibitionKetenes preparationSodium acetateChemical industry

The invention belongs to the field of chemical industry, and provides a method for inhibiting polymerization of acetaldehyde in a polyvinyl alcohol and vinyl acetate production process, which is implemented in a way that: in the acetaldehyde refinement and recycling process, a polymerization inhibitor is added to prevent acetaldehyde from self-polymerization, and the pH value of the acetaldehyde water solution is regulated to 4.5-5.6; and the polymerization inhibitor is a mixed solution of acetic acid and sodium acetate in a mass ratio of (0.02-0.4):1, and the addition concentration of the polymerization inhibitor is 25-2000ppm. The method provided by the invention has the advantages of favorable polymerization inhibition effect, low cost and the like, and can obviously enhance the quality of vinyl acetate and recovery rate of acetaldehyde; and the polymerization inhibitor can not be easily decomposed and has stable properties.

Owner:HUNAN XIANGWEI

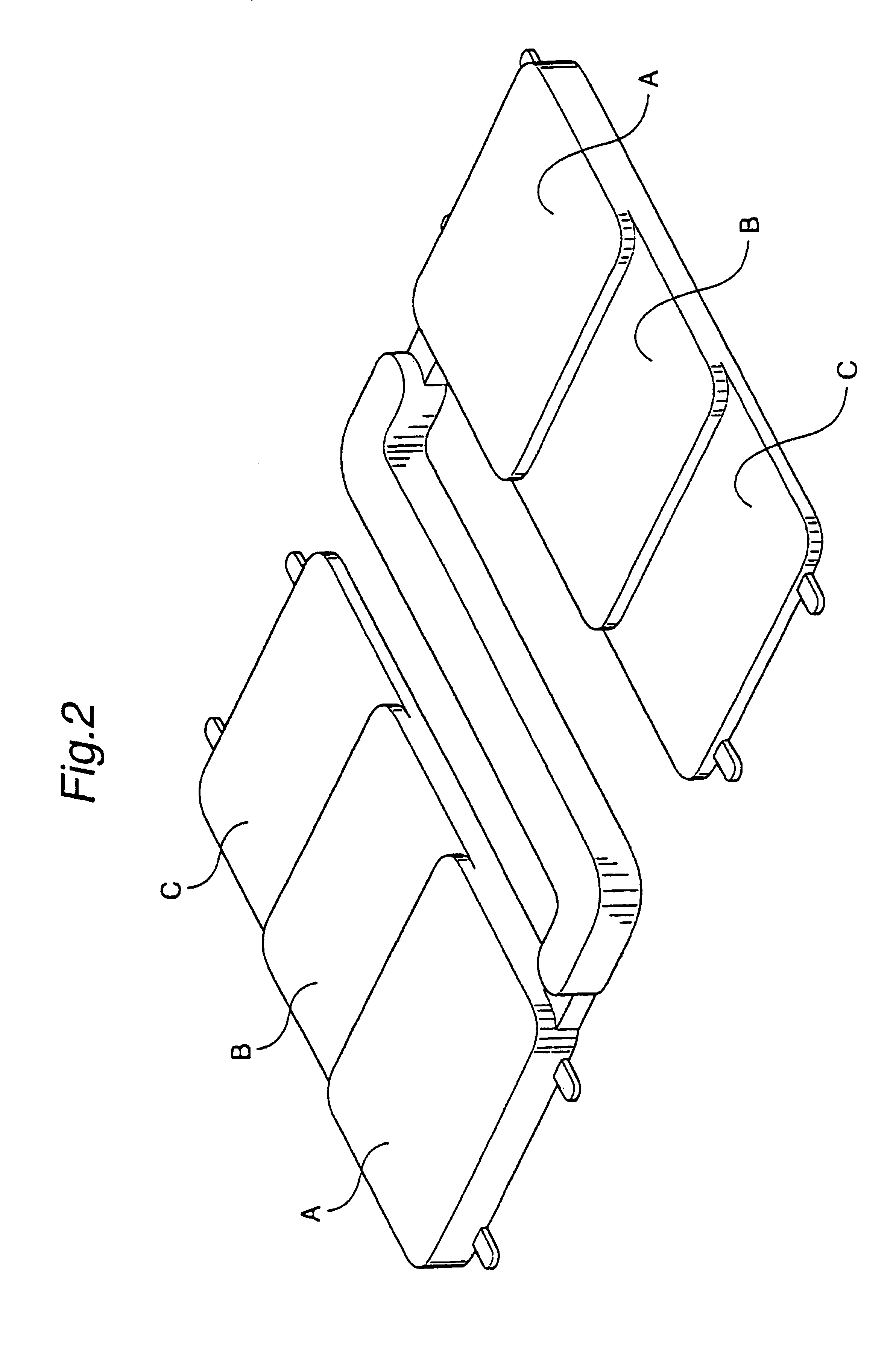

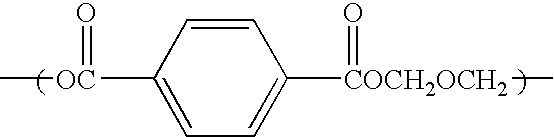

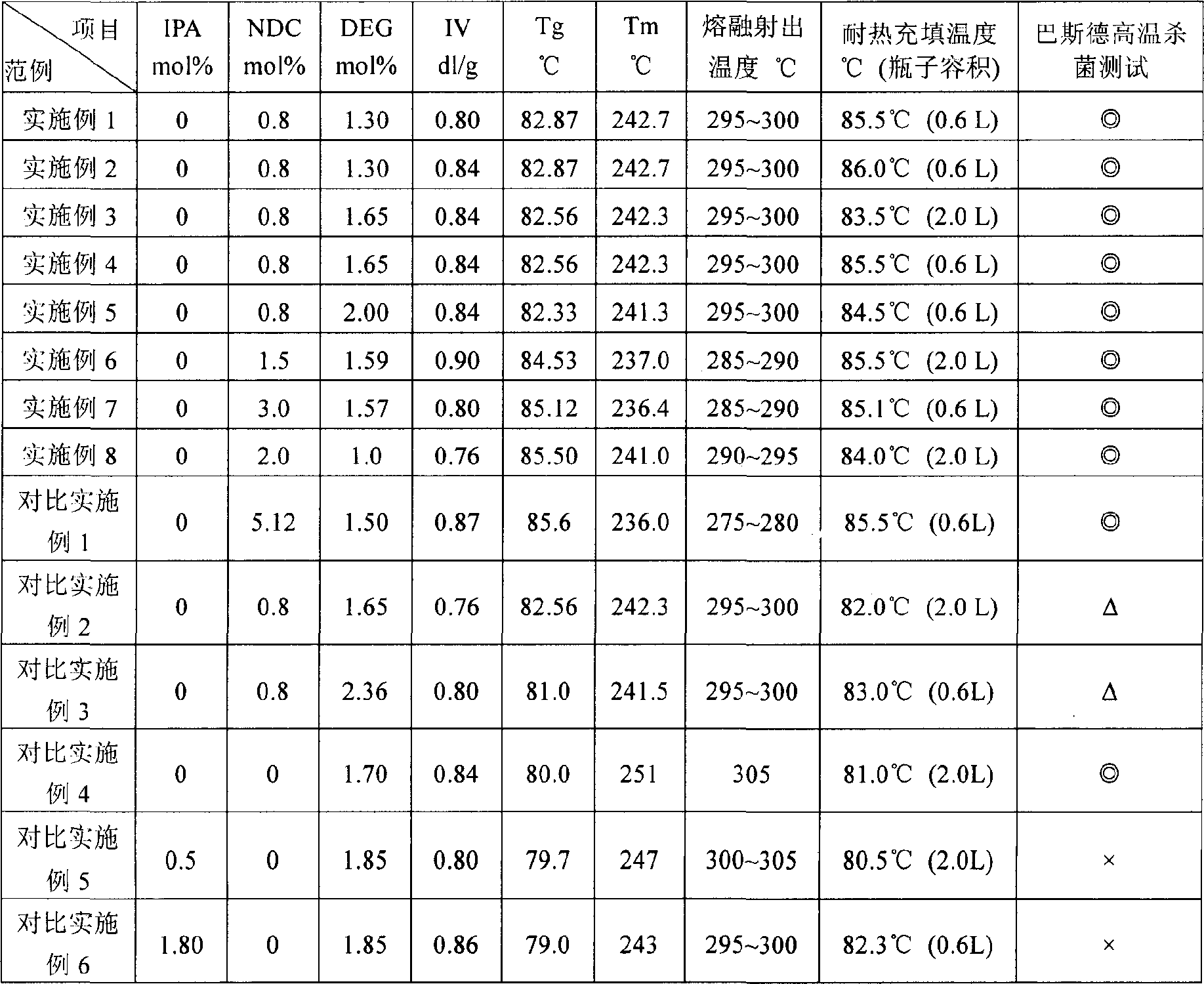

Copolyester and polyester bottle made of same

A copolyester contains proportionally glycol terephthalate, naphthalene ring component and diethanediol. It is suitable for preparing the polyester filling bottle with high filling temp (more than 82 deg.C), so it can suffer from the high-temp pasteurization.

Owner:NANYA PLASTICS CORP

Yeast strain and application thereof

InactiveCN101691544AHigh positive mutation rateIncrease mutagenic effectFungiBeer fermentationBiotechnologyPrimary screening

The invention discloses a beer yeast strain and an application thereof in beer fermentation. The invention provides a saccharomyces cerevisiae Z5 with a preservation number of CGMCC No 3218. A breeding method of the yeast strain comprises the following steps: preparation of an original parent strain, activation in a test tube, ion implantation mutagenesis, laser mutagenesis, wort agar plate primary screening, fermentation bung secondary screening, passage stability test and pilot test. The yeast strain is an excellent beer yeast strain and has a potential of large-scale production of beer breweries.

Owner:山东新银麦啤酒有限公司

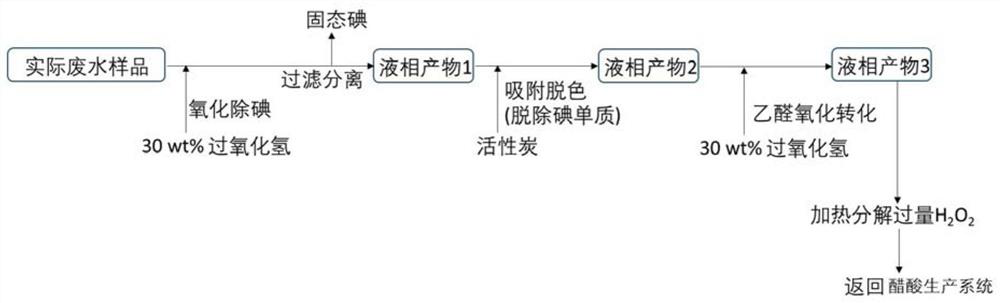

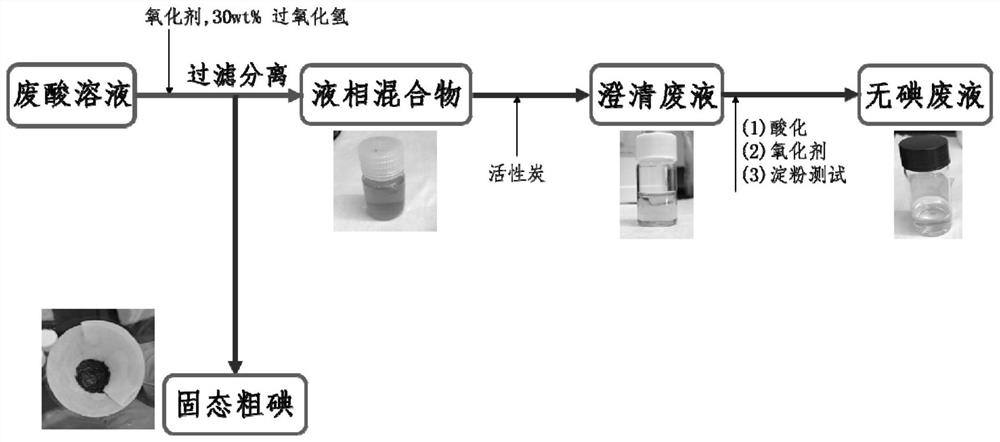

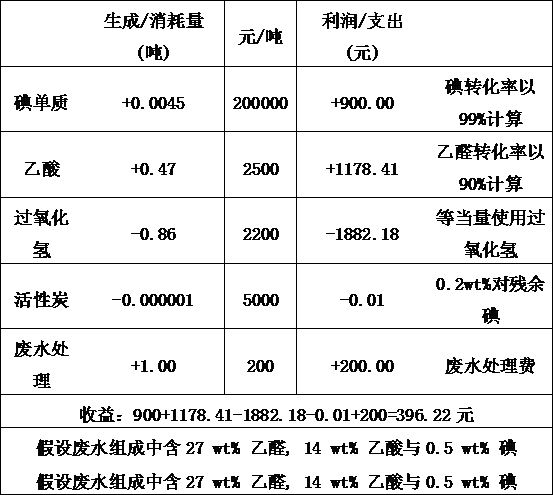

Acetic acid production wastewater treatment process

ActiveCN112919678AHigh yieldLow in acetaldehydeOrganic compound preparationIodineActivated carbonFluid phase

The invention discloses an acetic acid production wastewater treatment process which comprises the following steps: adding a hydrogen peroxide aqueous solution into acetic acid production wastewater, and reacting hydrogen peroxide with iodide ions in the wastewater to generate elemental iodine; filtering out the solid iodine elementary substance generated by the reaction from the wastewater, wherein the residual liquid is a liquid-phase product 1; adding activated carbon powder into the treated liquid phase product 1; filtering the treated liquid phase product 1, and separating out activated carbon in the liquid phase product 1 so that residual liquid is a liquid phase product 2; and adding an aqueous hydrogen peroxide solution into the treated liquid-phase product 2, reacting hydrogen peroxide with acetaldehyde in the liquid-phase product 2 to generate acetic acid, converting the liquid into a liquid-phase product 3, and conveying the liquid-phase product 3 to an acetic acid production system to separate acetic acid. According to the acetic acid production wastewater treatment process, iodine in the wastewater can be converted into iodine simple substances to be recycled, acetaldehyde in the wastewater is converted into acetic acid, the yield of acetic acid is increased, and environmental pollution is avoided.

Owner:JIANGSU JITRI-TOPSOE JOINT RES & DEV CENT CO LTD +2

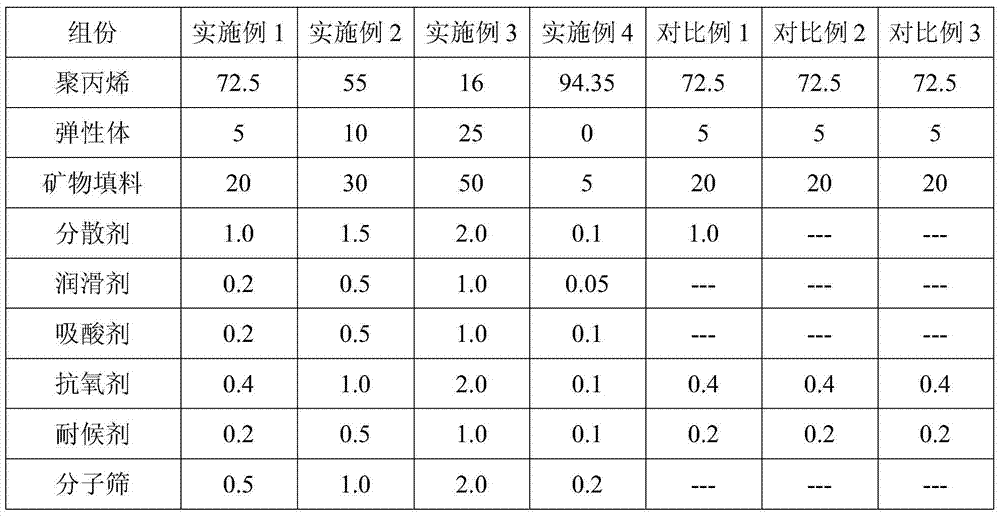

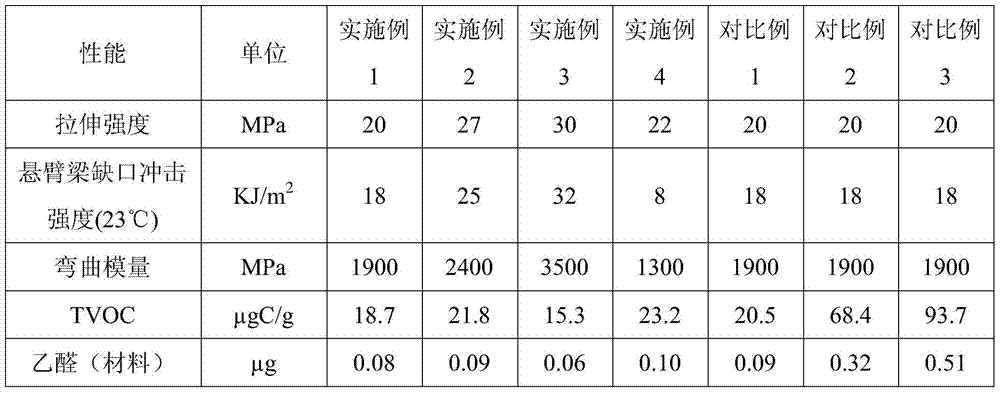

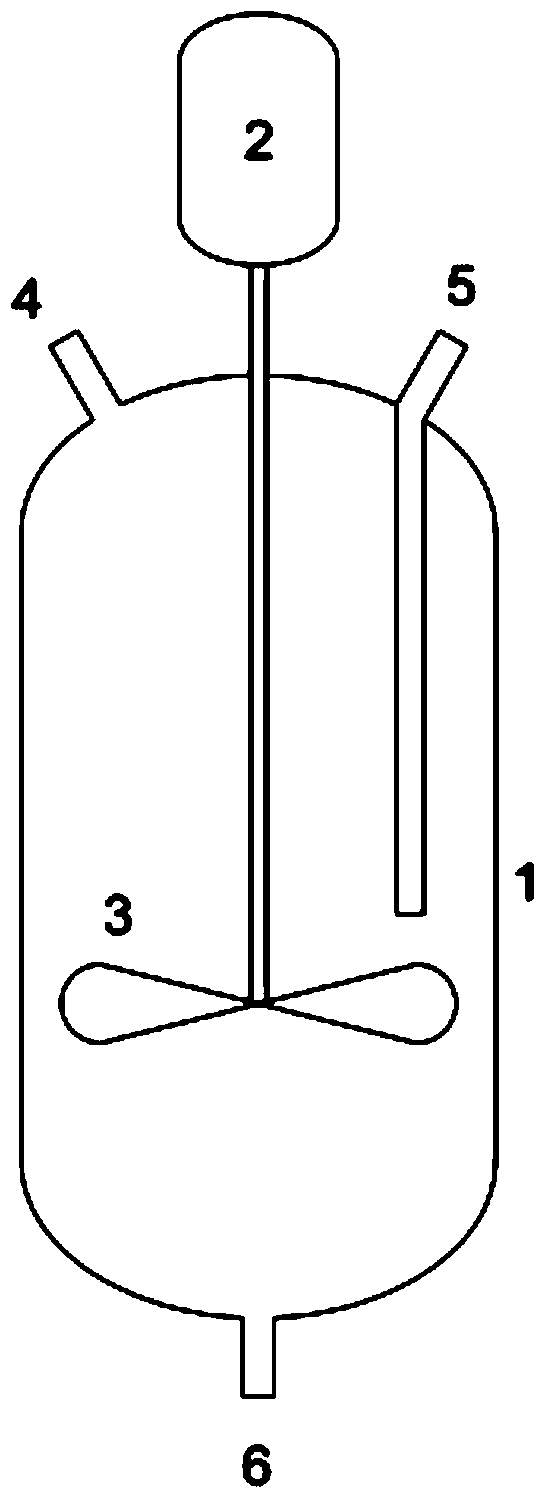

A kind of low-voc polypropylene material and its preparation method and application

The invention relates to a low-VOC (volatile organic compound) polypropylene material as well as a preparation method and an application thereof. The polypropylene material is prepared from raw materials in percentage by weight as follows: 15-95% of polypropylene, 0-25% of an elastomer, 5-50% of mineral filler, 0.1-2% of a dispersing agent, 0.05-1% of a lubricant, 0.05-1% of an acid acceptor, 0.1-2% of an antioxidant, 0.1-1% of a weather resistance agent and 0.2-2% of a molecular sieve, wherein the acid acceptor is a compound of stearate and a metal oxide, and the dispersing agent is purified water, acetone or a mixture of the purified water and the acetone. The prepared low-VOC polypropylene material has the characteristics of low VOC and low acetaldehyde, does not produce acetaldehyde during injection molding, can be applied to injection molding of automotive interior parts and can meet the VOC requirement.

Owner:TIANJIN KINGFA NEW MATERIAL

A kind of method for preparing eva elastomer

The invention discloses a method for preparing EVA elastomer. The method included the step of controlling the pressure of ethylene to make the ethylene completely liquefied in a single reactor with alcohols as a solvent, so that the ethylene and the vinyl acetate are subjected to liquid-liquid single-phase copolymerization and the EVA elastomer is obtained. According to the method based on the existing EVA-elastomer-solution polymerization process, the pressure of ethylene is controlled to make the ethylene completely liquefied so that the liquid-liquid copolymerization can improve the comonomer contact efficiency as well as the solubility of ethylene in the liquid phase, complete the solution single-phase copolymerization, and greatly improve the monomer copolymerization rate and the diffusion as well as the initiator efficiency of the free radicals in the copolymer solution. According to the application requirements of different polymerization products, by adjusting the solvent, the method greatly improves the copolymerization rate and the high solid content of a high-viscosity system. Using the single-reactor process, the method is also capable of avoiding the high-cost and complex-manipulation problem resulting from a raw-material process device of the multi-reactor process. Therefore, the method has high industrial application value.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for inhibiting polymerization of acetaldehyde in polyvinyl alcohol and vinyl acetate production process

Owner:HUNAN XIANGWEI

Bottle grade polyester chip with low acetaldehyde content and preparation method thereof

InactiveCN101633737AReduce generationReduce the amount of acetaldehyde producedPolyesterPolyanhydrides

The invention relates to a bottle grade polyester chip with low acetaldehyde content, which is characterized in that in the bottle grade polyester chip, hydroxylated polydiene accounts for 0.1 to 5% of the total weight of the bottle grade polyester chip, polyanhydride chain extender accounts for 0.1 to 5% of the total weight of the bottle grade polyester chip, and transition metal carboxylate accounts for 0.005 to 0.5% of the total weight of the bottle grade polyester chip; under the action of the polyanhydride chain extender, the hydroxylated polydiene is polymerized on the main chain of the polyester; the intrinsic viscosity of the bottle grade polyester chip is 0.8 to 0.9dl / g. The invention also relates to a preparation method of the bottle grade polyester chip with low acetaldehyde content, and has the advantages that the generation amount of acetaldehyde is extremely low in the product processing process, with the content of acetaldehyde being less than 2ppm.

Owner:CHINA RESOURCES PACKAGING MATERIALS CO LTD

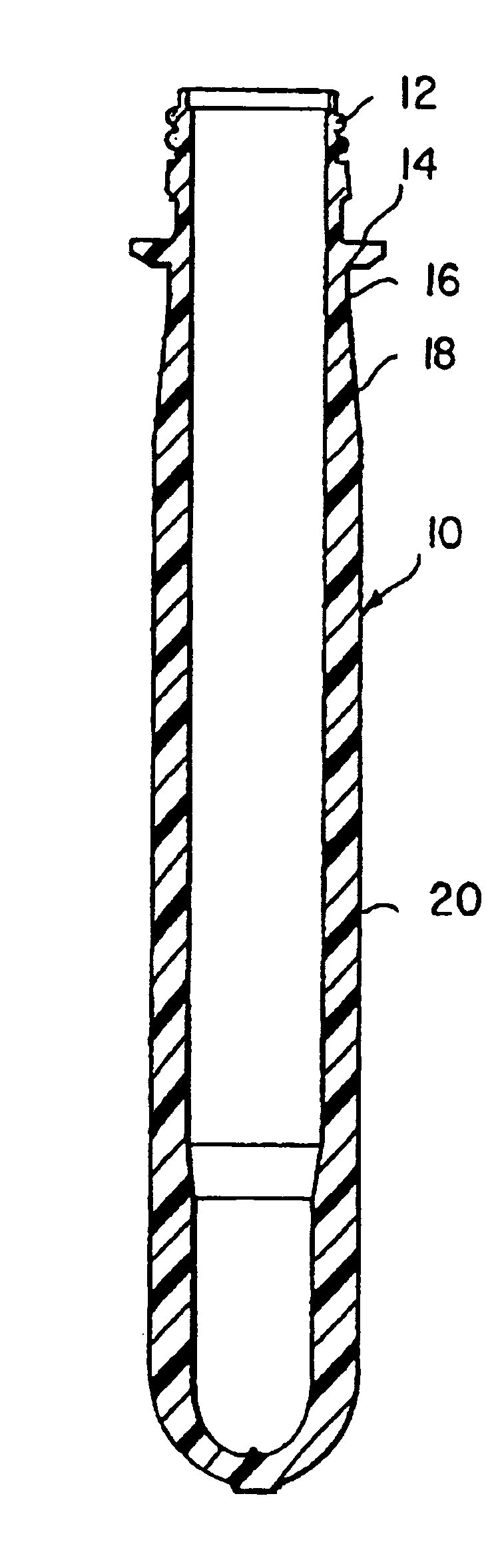

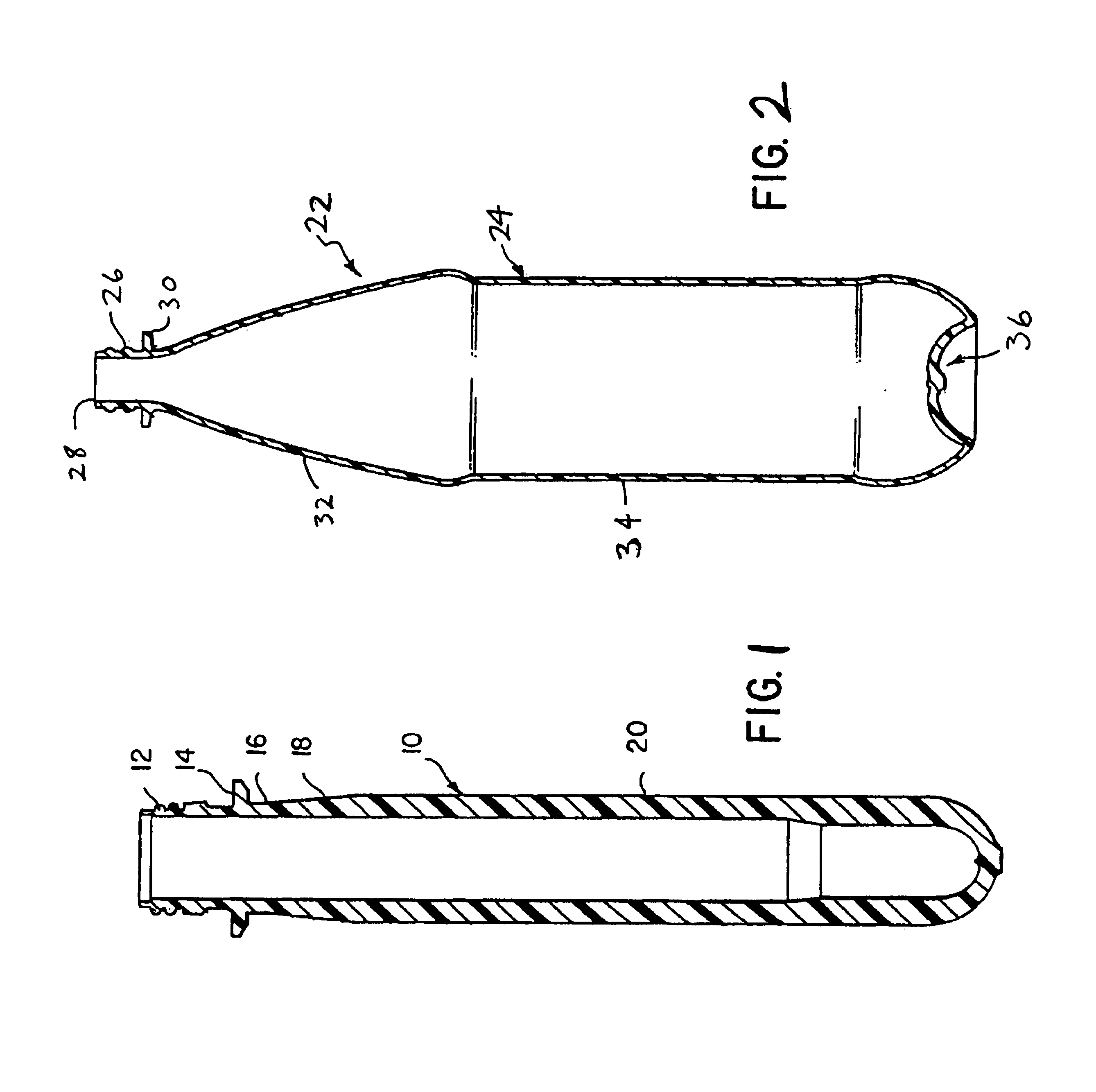

PET Polymer with Improved Properties

InactiveUS20110031210A1Reducing DEG content of polyesterReduce the ratioBottlesSynthetic resin layered productsPolyesterPolymer science

Polyester compositions having desirable injection molding properties and that retain good crystallization rates and natural stretch ratio characteristics are described. These polyesters are suitable for the manufacture of beverage containers, bulk continuous filaments, and other articles that can benefit from such improved properties.

Owner:GRUPO PETROTEMEX DE C V

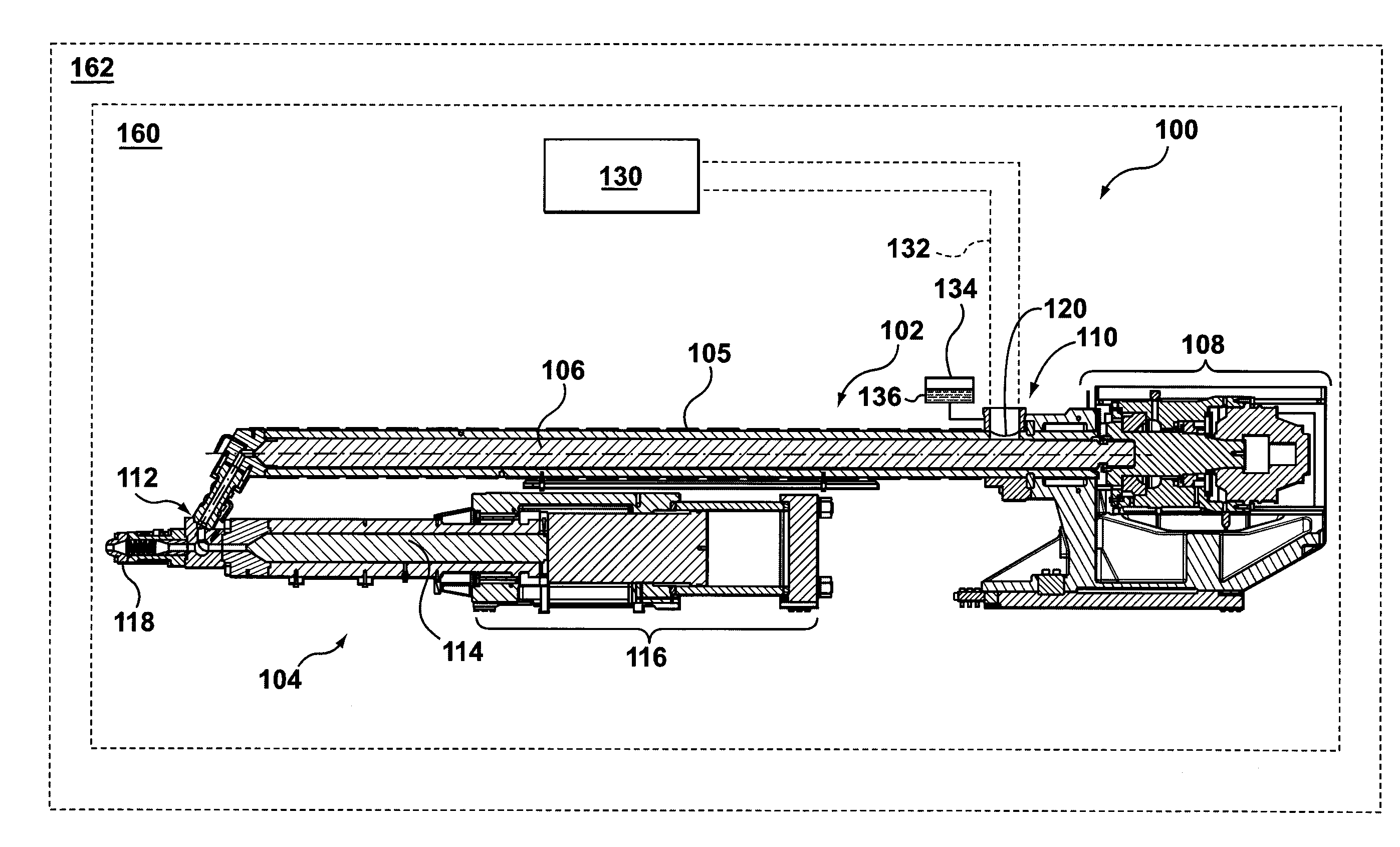

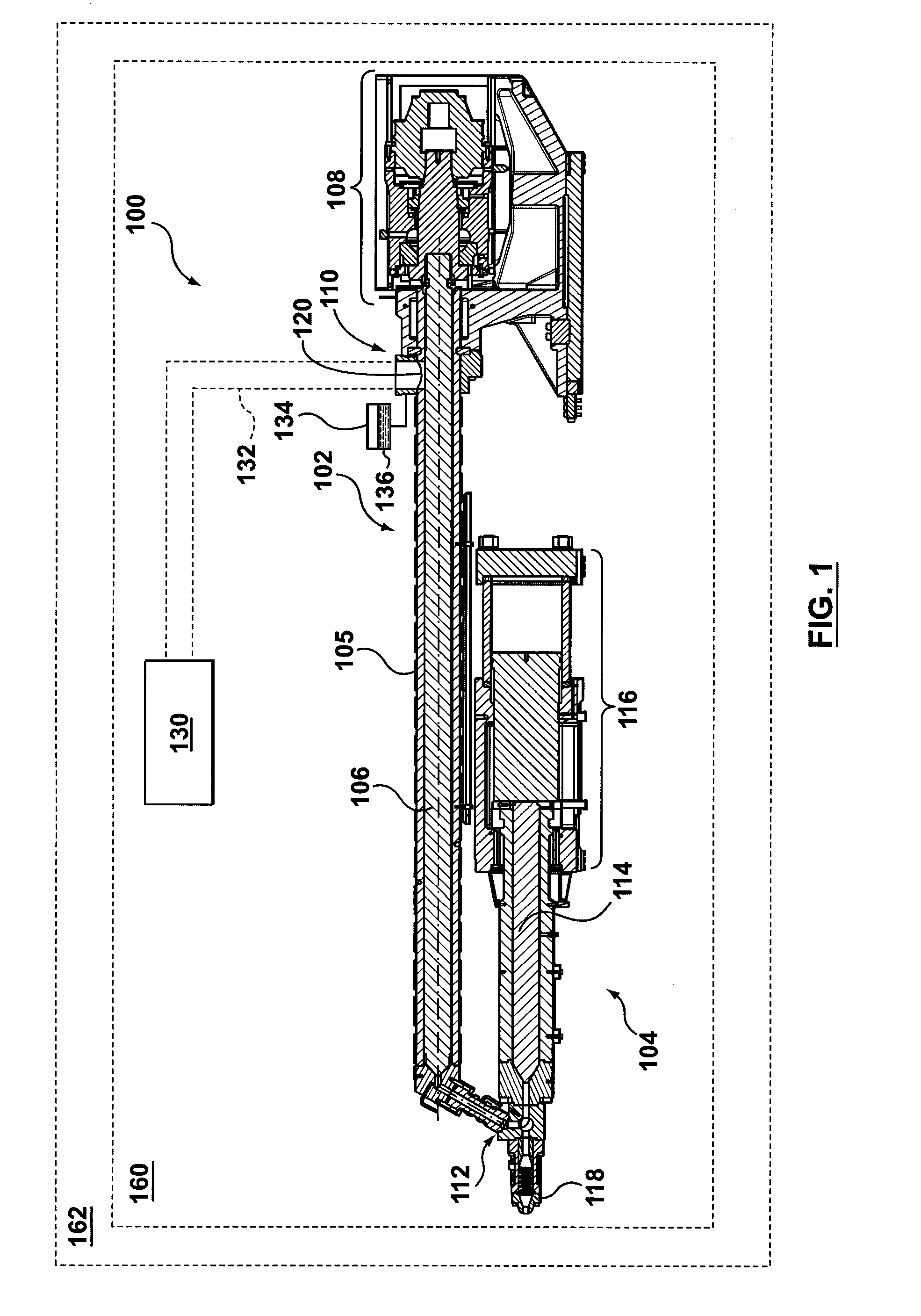

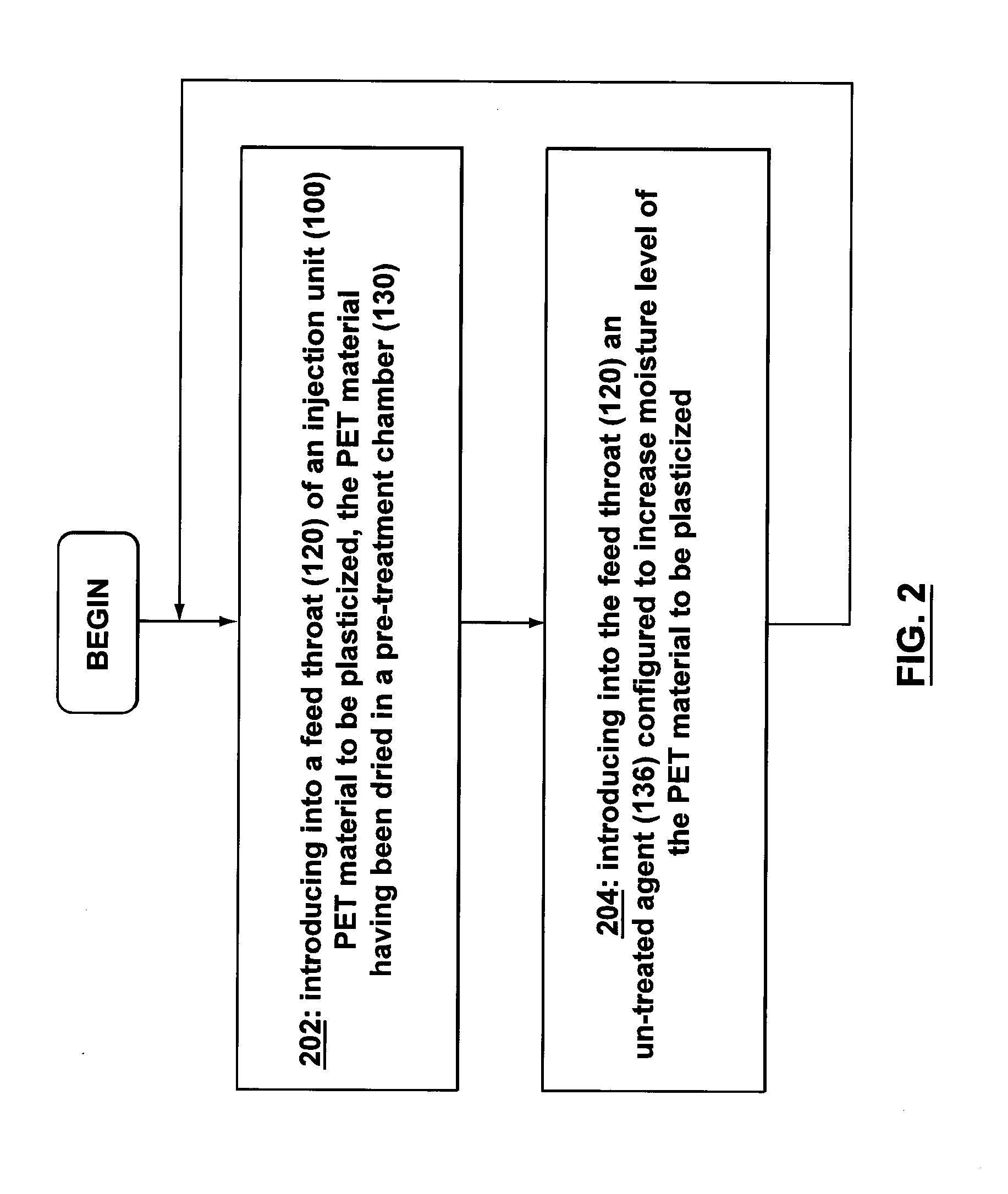

Method of decreasing acetaldehyde level in a molded article

InactiveUS20110172318A1Low in acetaldehydeImprove the level ofDough mixing/kneading machinesEngineeringPre treatment

There is provided a method (200) for decreasing acetaldehyde level in a molded article. The method (200) of decreasing acetaldehyde content in a molded article to be produced comprises introducing (202) into a feed throat (120) of an injection unit (100) a PET material to be plasticized, the PET material having been dried in a pre-treatment chamber (130); and introducing (204) into the feed throat (120) an un-treated agent (136) configured to increase moisture level of the PET material to be plasticized. In some embodiments of the present invention, the un-treated agent (136) is also configured to provide additional lubrication to the plasticizing screw (106).

Owner:HUSKY INJECTION MOLDING SYST LTD

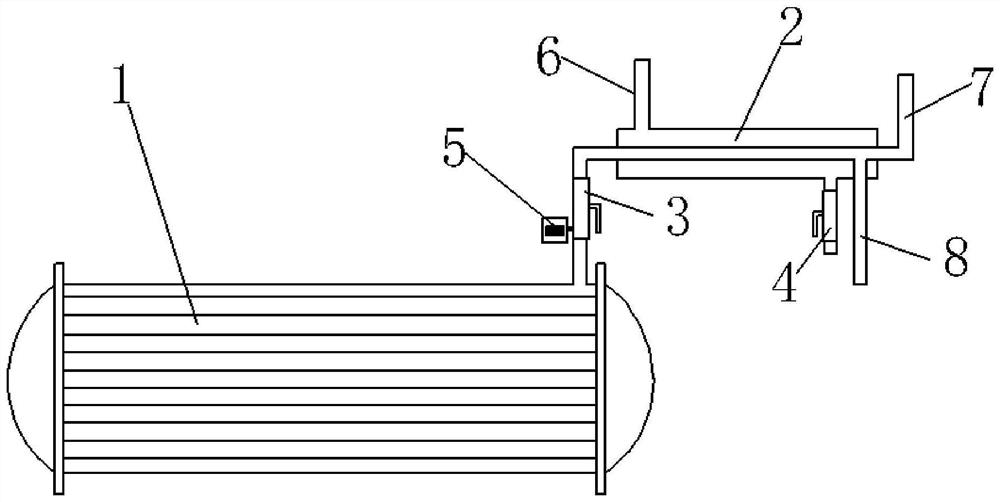

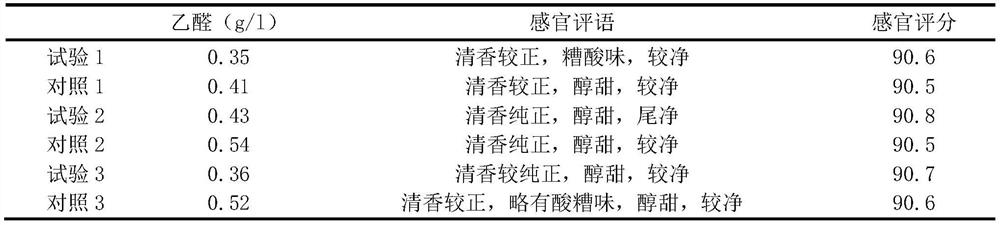

Transformation method of Baijiu distillation equipment and distillation equipment

InactiveCN113214953ALow in acetaldehydeReduce procurement costsAlcoholic beverage preparationDistillationProcess engineering

The invention relates to a transformation method of Baijiu distillation equipment and the distillation equipment. An extension part is additionally arranged above a condenser of original distillation equipment, the extension part is provided with the condenser, the condenser communicates with an inner pipe of the condenser of the original distillation equipment, and the extension part and the condensation equipment synchronously perform condensation operation while the original distillation equipment performs distillation operation. The acetaldehyde in the Baijiu product is removed by utilizing the boiling point difference of acetaldehyde and ethanol, and different types of condensers can be selected for the extension part according to actual requirements. The modification method is easy and convenient to operate, acetaldehyde removal can be achieved without additionally purchasing equipment, and the equipment purchasing cost can be effectively reduced.

Owner:JING BRAND

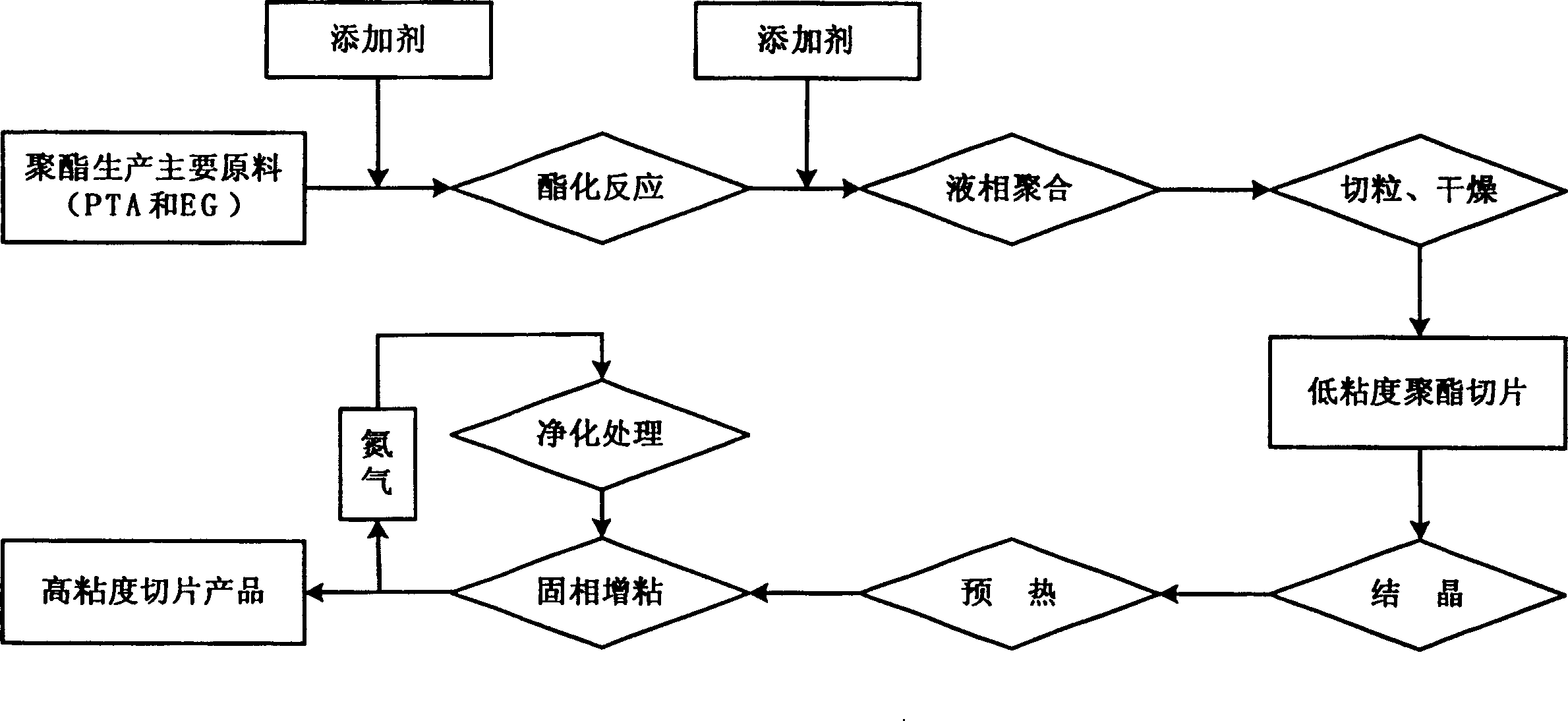

Process for producing high viscosity polyester resin having low acetaldehyde content

The invention relates to a production method of high-viscosity polyester resin with relatively low acetaldehyde content. The invention focuses on the whole process of polyester production from liquid phase polymerization to solid phase polycondensation, and proposes targeted improvement measures and specific technical solutions for reducing AA: adjust the production formula in the liquid phase polymerization stage, add additives containing cobalt, sodium, and phosphorus, The reaction speed is accelerated, the degradation speed is slowed down, and the degradation by-products are significantly reduced. The AA content in the obtained low-viscosity chips is below 100-120ppm; in the SSP stage, through process optimization, the adjustment of the viscosity increase range of the resin during preheating and reaction process is realized. , which is more conducive to the removal of acetaldehyde. On the premise of ensuring other quality indicators, the AA content in the product is lower than 1.0ppm, which can meet the requirements of food packaging under the most stringent conditions. The technical scheme has reliable process and stable operation, and is especially suitable for producing polyester resin for mineral water packaging by adopting conventional SSP process.

Owner:SINOPEC YIZHENG CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com