Process for producing high viscosity polyester resin having low acetaldehyde content

The technology of a polyester resin and a production method is applied in the production field of high-viscosity polyester resin with low acetaldehyde content, can solve the problems such as difficulty in further reducing AA content, and achieves reliable production process, reduced acetaldehyde content, and improved product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

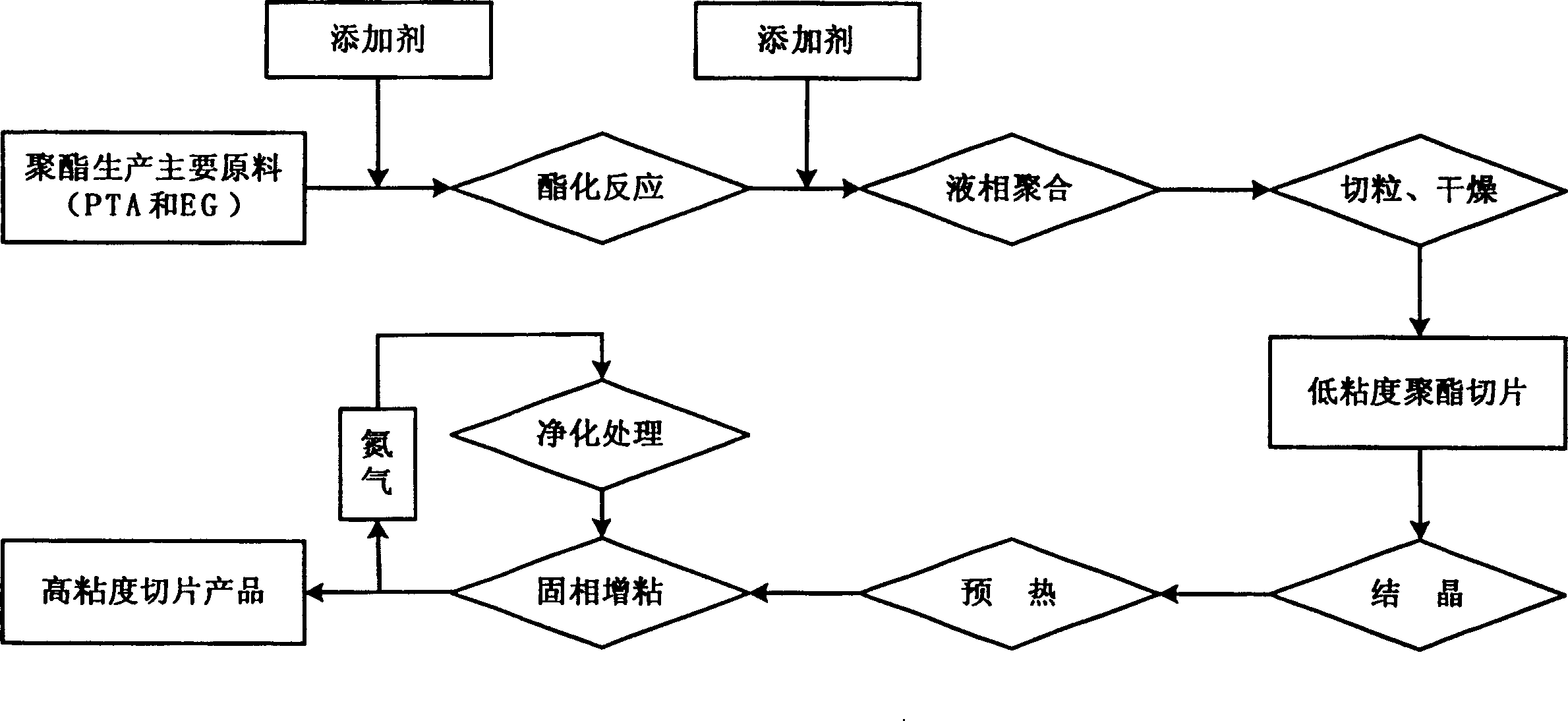

Method used

Image

Examples

Embodiment 1

[0022] Using purified terephthalic acid PTA and ethylene glycol EG as the main raw materials, the conventional liquid phase polymerization process is used to produce low-viscosity polyester chips. The device adopts a five-pot process of two-stage esterification, two-stage pre-condensation and one-stage final polycondensation. Before the esterification reaction, germanium oxide containing a small amount of sodium salt is added according to the weight ratio of PTA to 100ppm, and the additive is mixed together with the main raw materials and then enters the esterification tank for reaction. Control the residence time of the esterification reaction to make the esterification rate 97%. Then, after the esterification reaction, phosphoric acid H was added according to the weight ratio of 750ppm to PTA 3 PO 4 , into the polycondensation tank for three-stage liquid-phase melt polymerization under negative pressure, pelletized and dried to obtain low-viscosity polyester chips with an i...

Embodiment 2

[0025] Using purified terephthalic acid PTA and ethylene glycol EG as the main raw materials, the conventional liquid phase polymerization process is used to produce low-viscosity polyester chips. The device adopts a three-pot process of one-stage esterification and two-stage polycondensation. Before the esterification reaction, germanium oxide containing a small amount of sodium salt is added according to the weight ratio of PTA to 200ppm, and the additive is mixed together with the main raw materials and then enters the esterification tank for reaction. Control the residence time of the esterification reaction to make the esterification rate 95%. Then, after the esterification reaction, phosphoric acid H was added according to the weight ratio of 900ppm to PTA 3 PO 4 , into the polycondensation tank for liquid-phase melt polymerization under negative pressure, pelletized and dried to obtain low-viscosity polyester chips with an intrinsic viscosity of 0.64dl / g. After detect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com