Patents

Literature

137results about How to "Reliable production process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

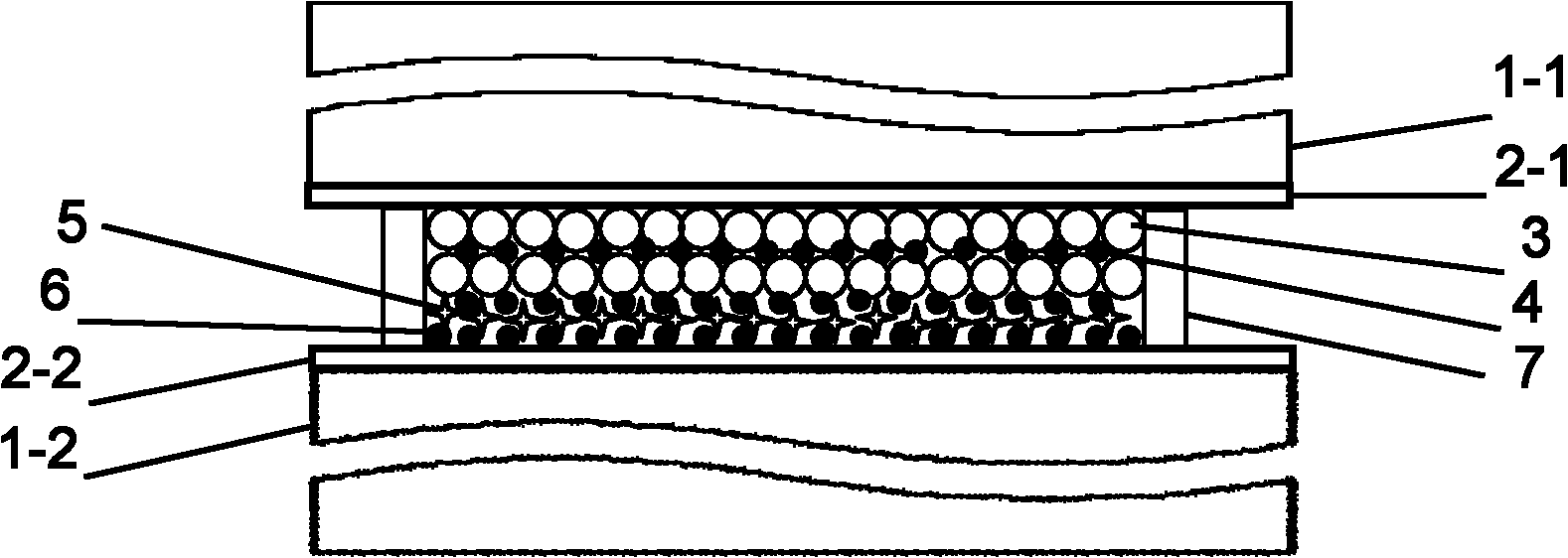

Graphene dye sensitized solar cell and production method thereof

InactiveCN102148099AMaterials are readily availableLow costLight-sensitive devicesFinal product manufactureSputteringSolar cell

The invention discloses a graphene dye sensitized solar cell and a production method thereof. The solar cell comprises a light anode comprising transparent upper base material and graphene conducting layer, a porous nano semiconductor film and a dye sensitizer, oxidation reduction electrolyte solution, a counter electrode comprising a lower base and graphene conducting layer and a composite catalytic layer as well as a film shell. The production method comprises the steps of preparing the light anode, preparing the counter electrode, encapsulating and injecting the electrolyte solution. In the invention, graphene with an available raw material, low cost, good conductive performance, extremely high flexibility and good ductibility is adopted as the conducting layer, the flexible transparent material is adopted as a substrate, and platinum metal particles are embedded on the graphene conducting layer of the counter electrode by adopting adsorption instead of magnetron sputtering to form the composite catalytic layer. Thus, the invention has the characteristics that the raw material is available, the production cost is low, the production process is simple and reliable, the flexible solar cell can be produced and applied to the flexible field, and the application range is effectively expanded.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

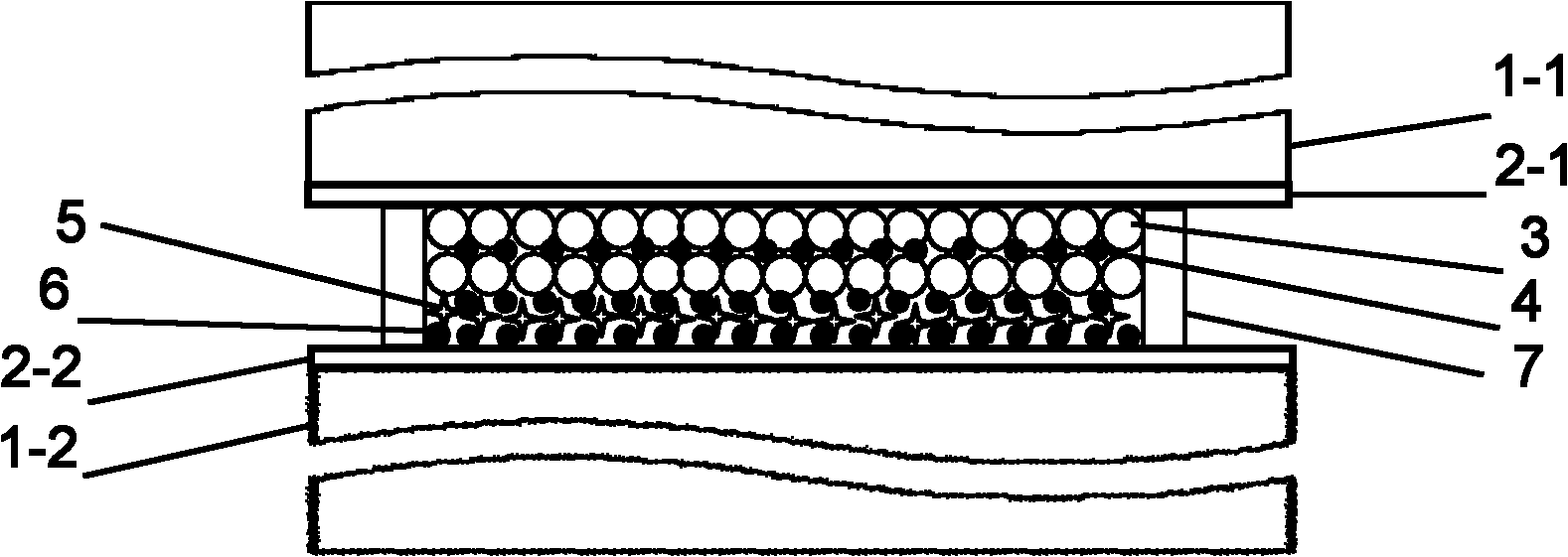

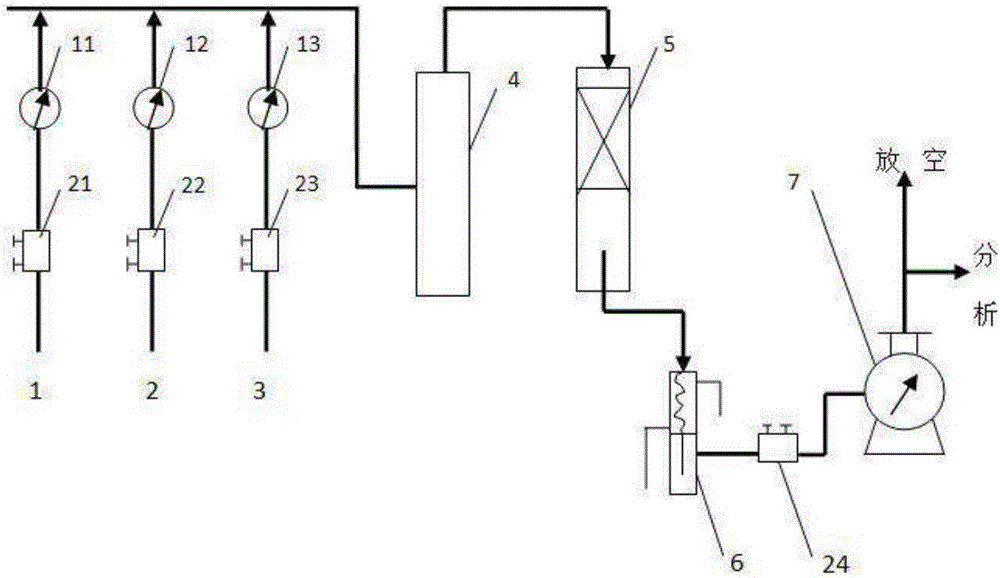

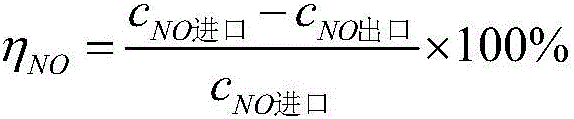

Medium and low temperature denitration catalyst and preparation method thereof

ActiveCN106492791AReduce oxidation activityHigh activityHeterogenous catalyst chemical elementsDispersed particle separationCeriumStearic acid

The invention provides a medium and low temperature denitration catalyst, and belongs to the technical field of denitration catalysts. The catalyst is prepared from ultrafine titanium dioxide, strontium-doped cerium manganese calcium titanium ore type composite oxides, vanadium pentoxide, tungsten trioxide, molybdenum trioxide and stannic oxide; glass fiber is used as an enhancing agent; carboxymethylcellulose and polyoxyethylene are used as bonding agents; stearic acid is used as a lubricating agent. The invention also relates to a preparation method of the medium and low temperature denitration catalyst. The concrete preparation method comprises the steps of preparation of the strontium-doped cerium manganese calcium titanium ore type composite oxides, preparation of carrier materials, preparation of powder catalysts, extrusion forming of honeycomb-shaped catalysts and post treatment of honeycomb-shaped denitration catalysts. The denitration catalyst prepared by the method has the advantages of high denitration efficiency, good sulfur-resistant and waterproof performance, reliable production process and the like in the wide temperature range from 180 DEG C to 350 DEG C; the requirements of oxynitride removal from industrial smoke gas in industries of coking, petrifaction, furnaces and the like can be met; wide application prospects are realized.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

High-filler paper and production method thereof

InactiveCN102433796AHigh whitenessIncrease the addition ratioInorganic compound additionPulp material addition processesCalcium silicatePlant fibre

The invention discloses high-filler paper and a production method thereof. The high-filler paper contains 30 to 60 mass percent of filler, and the filler is active calcium silicate; in the step of adding the filler, after the active calcium silicate in an amount which is 40 to 70 percent of the total mass of the active calcium silicate and the pulp is fully stirred and dissolved to form emulsion,the emulsion is guided into a covered pulp storage tank or a pre-making pulp storage tank and fully stirred and mixed with plant fibers; the filler adding proportion of the high-filler paper is improved, so that the consumption of the plant fibers is greatly reduced at the same time of improving the performance of the paper; and according to the production method for the high-filler paper, the adding process of the papermaking filler is simplified, the filler and the plant fibers can be fully mixed uniformly, and the internal bonding force is increased, so that the performance of the paper isimproved.

Owner:GUONENG PAPER IND

Preparation method of attapulgite-based solid acid catalyst for vegetable fat epoxidation

ActiveCN103657696AImprove thermal stabilityHigh catalytic activityPhysical/chemical process catalystsFatty acid chemical modificationSolid acidAdditional values

The invention discloses a preparation method of an attapulgite-based solid acid catalyst for vegetable fat epoxidation. The preparation method comprises the steps of synthesizing phosphotungstic acid peroxide serving as a catalyst for fat epoxidation; then performing purification, acid modification and organic modification on attapulgite; and finally, loading the phosphotungstic acid peroxide on the organically modified attapulgite serving as a carrier to obtain the load type solid acid catalyst. According to the preparation method, the performance of the phosphotungstic acid peroxide is improved, the repeated use of the phosphotungstic acid peroxide is realized, the application range of the attapulgite is expanded, and the additional value of the attapulgite is increased; the attapulgite-based solid acid catalyst has the characteristics of easiness in separation of the catalyst from products, zero pollution, no corrosion to equipment, simplicity in post-treatment of the products, reutilization, simple regeneration process and the like.

Owner:盱眙凹土能源环保材料研发中心 +1

Combined thermoplastic elastic body for automotive glass guide groove sealing strip and production method thereof

ActiveCN101670771AReduce wearReduce coefficient of frictionEngine sealsVehicle sealing arrangementsThermoplastic elastomerEngineering

The invention relates to a combined thermoplastic elastic body for an automotive glass guide groove sealing strip and a production method thereof. The combined thermoplastic elastic body comprises a thermoplastic elastic body A, a thermoplastic elastic body B and a thermoplastic elastic body C, wherein the thermoplastic elastic body A and the thermoplastic elastic body B are subjected to coextrusion lamination to form a linear sealing strip; the thermoplastic elastic body C and the linear sealing strip formed by the coextrusion lamination of the thermoplastic elastic bodies A and B are subjected to thermal injection molding adhesion to form an angular sealing strip through thermal injection molding; because the thermoplastic elastic body A has the characteristics of low friction coefficient and high abrasion resistance, the manufactured sealing strip is abrasion-resistant and has low abrasion to the glass; because the thermoplastic elastic body B has high elasticity, weather resistanceand sealing property and can carry out coextrusion lamination with the thermoplastic elastic body A, the manufactured sealing strip has high sealing property, strong anti-ageing performance and longservice life; and because the thermoplastic elastic body C has higher adhesive property and can form firm thermal injection molding adhesion with a coextrusion lamination product of the thermoplasticelastic bodies A and B, the sealing strip has the reliable performance.

Owner:南通江洲工程材料科技有限公司

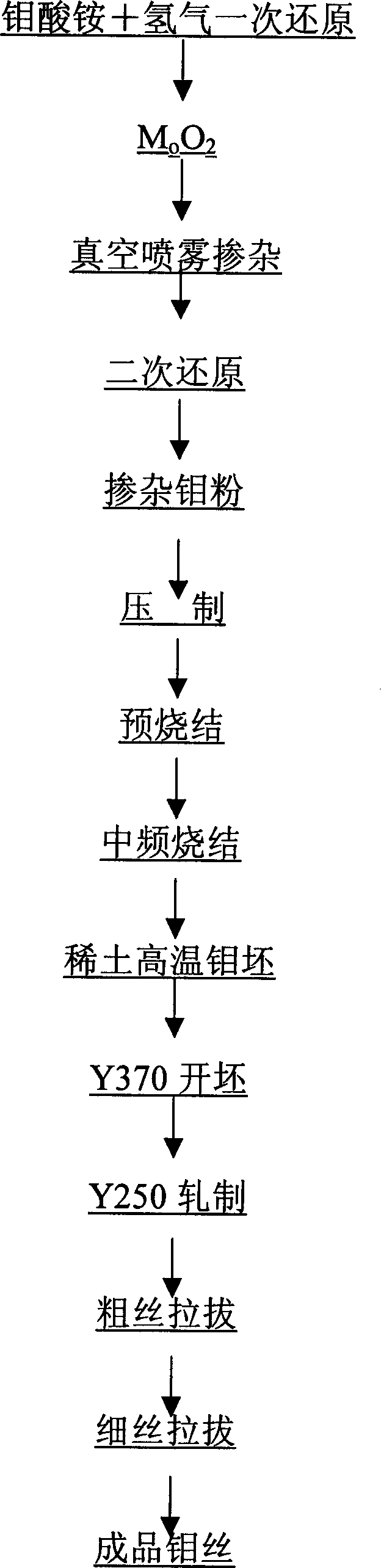

Rare earth molybdenum alloy wire and preparation method thereof

InactiveCN1876875ARaise the recrystallization temperatureHigh strengthTemperature control deviceHeat treatment process controlRare earthAlloy

The invention relates to a rare-earth molybdenum alloy wire and its process for preparing. The invention is characterized in that the said alloy wire contains two rare-earth oxides including lanthanum oxide and Y oxide(mass %) which is 0.4 %-1.0% of the alloy amount and the proportion by weight of lanthanum oxide and Y oxide is 4:1. The process for preparing is different from the traditional powder metallurgy productive technology, which includes performing double-cone vacuum drying and liquid-solid doping at molybdenum dioxide stage, then performing secondary reduction to prepare binary rare-earth doping molybdenum powder, finally preparing rare-earth doping molybdenum wire with Mo-La-Y of 0.5-0.8mm diameter by impression, agglomeration and pressure processing procedure. Compared with the pure molybdenum, the product is of good high-temperature behavior and high recrystallization temperature which increases by 300-500 DEG C than the pure molybdenum, and is of high intensity and abrasive resistance, low ductility and long durability, which has wide application in the mechanical process industry.

Owner:JINDUICHENG MOLYBDENUM CO LTD

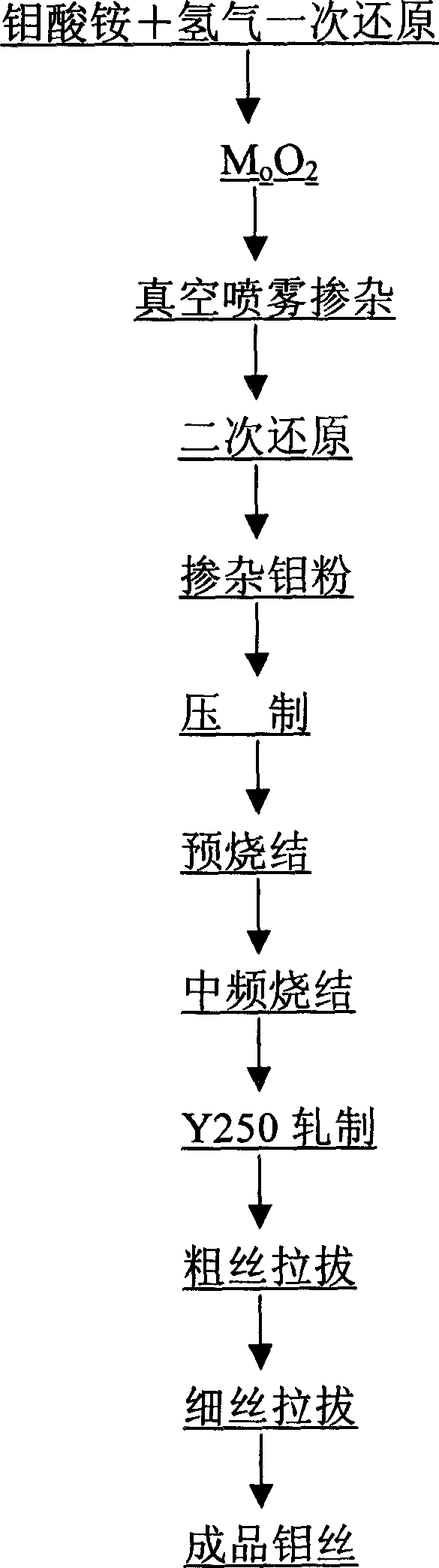

Mo-La-Ce rare earth molybdenum alloy wire and preparation method thereof

InactiveCN1876874ARaise the recrystallization temperatureHigh strengthTemperature control deviceHeat treatment process controlCerium nitrateHigh rate

The invention relates to a Mo-La-Ce rare-earth molybdenum alloy wire and its process for preparing. The invention is characterized in that the said molybdenum alloy wire contains 0.4 %-1.0% lanthanum oxide and cerium oxide(mass %) and the proportion by weight of lanthanum oxide and cerium oxide is 4:1. The process for preparing is different from the traditional powder metallurgy productive technology, which includes performing vacuum drying and liquid-solid doping for molybdenum dioxide, lanthanum nitrate and cerium nitrate solution, then performing secondary reduction to prepare binary rare-earth doping molybdenum powder, finally preparing rare-earth doping molybdenum wire with Mo-La-Ce of 0.5-0.8mm diameter by impression, agglomeration and pressure processing procedure. The raw materials of this invention is cheap and facile, and the prepared molybdenum wire is of high tensile strength, strong abrasive resistance and simple process and is inflexible, and has high rate of finished products, good compatibility and long durability.

Owner:JINDUICHENG MOLYBDENUM CO LTD

High temperature molybdenum alloy wire and its preparing method

InactiveCN1900338ASimple processHigh tensile strengthTemperature control deviceHeat treatment process controlAlloyHigh wear resistance

The present invention is high temperature molybdenum alloy wire and its alloy consists of K 0.05- 1.0 wt%, Si 0.1-0.5 wt% and Al 0-0.05 weight %, except Mo, O and inevitable impurities. The alloy is prepared through double cone vacuum dry liquid-solid doping in the MoO2 stage, secondary reduction to preparing K, Si and Al doped Mo powder, pressing, sintering and other steps, and is further produced into molybdenum alloy wire of 0.5-0.8 mm diameter through press work and other steps. The molybdenum alloy wire has high tensile strength, high wear resistance, simple production process and other advantages.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Method for preparing carbon/carbon cylinder by using winding technology

InactiveCN108191448AReduce manufacturing costProcess production cycle time is shortFurnace componentsGas emission reductionFiberCarbonization

The invention provides a method for preparing carbon / carbon cylinder by using a winding technology. The method comprises the following steps that (1)a graphite material is utilized to design, manufacture and form a mold according to the dimension of the cylinder; (2) product structures of a sealed type cylinder and a structural type cylinder are designed respectively according to the using functional requirements of the cylinder; (3) winding forming is conducted by using a winding machine; (4) solidification treatment is conducted; (5) carbonization treatment is conducted; (6) CVD (chemical vapor deposition) densifying treatment is conducted; (7) high temperature treatment is conducted; and (8) machining forming is conducted. Compared with a traditional carbon / carbon cylinder production technology, the method has the following advantages that (1) the product is designed and formed in net dimension, the machining allowance of the finished product is less, the production cost is as low as 60% of the traditional technological cost; (2) the fiber content of the product is high, the basic density of the green body of the formed product is high, the product period is short, the machiningallowance is saved, and the strength is high, the method can achieve the sealing function of the carbon / carbon cylinder, the furnace internal thermal treatment efficiency is effectively improved, theservice life of a furnace external heat preservation material is prolonged, and the carbon / carbon cylinder can serve as a gas transmission pipeline, and has the generalization performance, the innovation advantage and the batch production advantage.

Owner:AEROSPACE RUITIAN CARBON MATERIALS CO LTD

Lanthanum microdoped molybdenum alloy wire preparation method

The invention discloses a making method of high-temperature metal molybdenum filament with trace lanthanum, which comprises the following steps: reducing molybdenum oxide in the vacuum twice; punching; sintering; rolling; drawing; obtaining the Mo-La alloy filament.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Preparation method of Stefan parchment paper

InactiveCN101768896AFlexible operationStable production processVegetable/imitation parchmentEnergy consumptionRaw material

The invention relates to a preparation method of Stefan parchment paper, comprising the following steps of adopting 30-50% of goods hard wood pulp and 50-70% of goods needle wood pulp in the concentration of 4.0-5.0% for slurry compounding in base paper developing process, wherein the pulping degree is 34-42 degrees SR; the pulp material is made into paper after being beaten; then the base paper is dyed via the dyestuff composed of 5-25% of thickening agent and 5-25% of permeating agent, coated, calendered and cut. The preparation method of Stefan parchment paper has flexible and simple operations, stable and reliable production technique, cheap raw material, low energy consumption, quite little waste water and small pollution; and the Stefan brown paper obtained through the method has good softness of the paper surface, strong three-dimensional sense, bright colour and strong visual effect of sheepskin.

Owner:MCC MEILI CLOUD COMPUTING IND INVESTMENT CO LTD

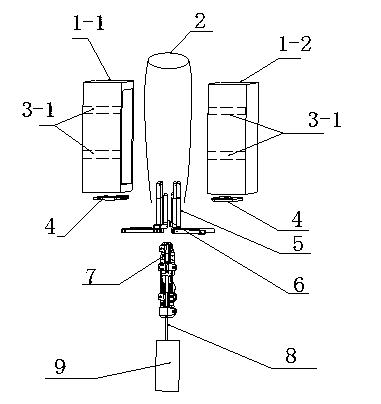

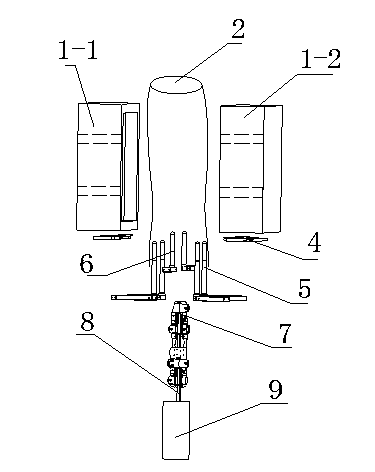

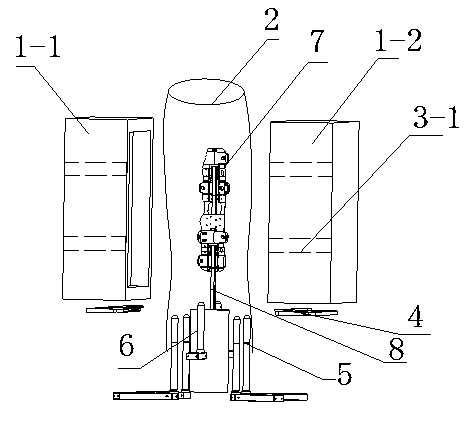

Molding method of hollow body with built-in component

The invention relates to a molding method of a hollow body with a built-in component. The method is characterized in that the method comprises the following steps: 1, arranging the built-in assembly on a built-in assembly fixing rod; 2, closing a tension device; 3, blanking, and allowing a cylindrical material base to be extruded from an upper end and slowly descend after the tension device is completely closed; 4, opening the tension device in the descending process of the material base to form an opening convenient for the pass of the built-in assembly; 5, ascending the built-in assembly to a final position after passing through the opening to complete the ascending process of the internal assembly; 6, pre-blowing a gas to the material base to complete a pre-blowing process; 7, allowing a die to be semi-closed; 8, taking the built-in assembly fixing rod out of the die mechanism; 9, fully closing the die; 10, blowing a high pressure gas to the material base to complete a gas blowing process; and 11, taking out the above obtained hollow body with the built-in component. The above technical scheme reduces the pollution to the environment, and protects the environment.

Owner:YAPP AUTOMOTIVE PARTS

Method for producing marble art paper

The invention relates to a method for producing marble art paper, comprising the following steps: selecting 20% of softwood pulp and 80% of bleached eucalyptus pulp, controlling the beating degree of the pulps within 34-35 DEG SR, the screening concentration of the pulps at 0.9-1.0%, the quantification of paper at 95 g / m<2>. And the surface absorption weight at 20-30 g / m<2>; and dyeing the paper twice, wherein during the first dyeing, a dye is added to a paper machine flow which is conveyed to a high tank, and the liquid dye is directly added to the high tank to be mixed with the pulps, and during the second dyeing, at an initial phase of dehydration and screening of the pulp flow, the dye is sprayed onto a paper machine screen part through a spraying device, and natural and soft simulated cloud patterns or marble patterns are formed through shaking the paper machine screen part and naturally dispersing the dye so as to obtain the marble art paper. The marble art paper has the advantages of easiness in production, reliable production process, high operability, soft paper surface color, abundant colors and cloud pattern effects. The marble art paper is mainly applied to package of special products, book cover, high-order offices and the like.

Owner:SHANDONG KAILI SPECIAL PAPER

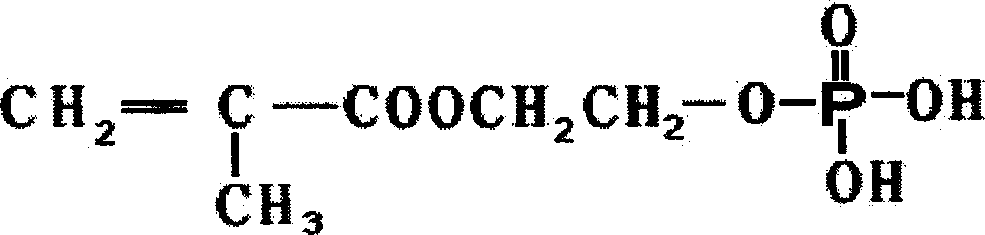

Methacrylic acid phosphoric acid ester slushing polymerisable emulsifier and its preparing method

InactiveCN101161333AWill not migrateImprove water resistanceTransportation and packagingMixingMethacrylatePhosphoric Acid Esters

The present invention relates to a phosphate methacrylate antirust polymerisable emulsion with rust and the preparing technique thereof. The chemical structural formula of the phosphate methacrylate antirust polymerisable emulsion with rust is: and the method is: mixing the methacrylate-beta-hydroxyethyl, phosphoric acid and toluene according to the mass ratio, and adding the hydrochinone with 0.5% of the gross mass of methacrylate-beta- hydroxyethyl and phosphoric acid; decompressing and stirring the system, heating the reactant to 55 to 60 DEG C, separating the generated water from the boiling flask with the water segregator, and the solution A is obtained when the raw material has reacted for 5h; then decompressing the solution A and distilling the dissolvent toluene; taking out the product when the reaction has completed. Except for the common advantage of the common polumerisable emulsion the invention has the unique predominance: namely without adding the iron red or zinc phosphate in preparing the aqueous antirust coating with rust, and processing the antirust with rust function which is not processed by the common emulsion, the invention is a functional polymerisable emulsion and is evidently better than the traditional emulsion.

Owner:NORTHWEST NORMAL UNIVERSITY

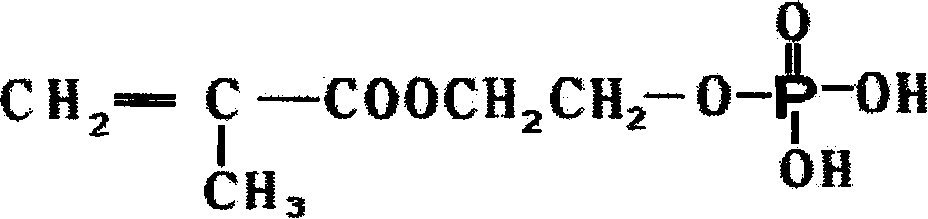

Method and device for preparing high-strength and high-conductivity copper-carbon nano-tube composite material under magnetic field

ActiveCN105696059ASave energyReliable production processElectrolytic coatingsMagnetohydrodynamicsContact resistance

The invention discloses a method and device for preparing a high-strength and high-conductivity copper-carbon nano-tube composite material under a magnetic field. A dispersing agent is added to enable a bilayer structure to be formed on a carbon nano-tube particle surface, an outer-layer dispersing agent polar end and a plating solution have the higher affinity, the wetting degree of carbon nano-tube particles by the plating solution is improved, and uniform dispersion distribution of the particles is facilitated; in the plating process, the exerted magnetic field and an electric field interact to generate the magnetohydrodynamic effect caused by Lorentz force, so that the mass transfer effect of the planting solution is enhanced, and the uniformity of the plating solution is improved; the nano-tube particles are stretched in the axial direction under the effect of the Lorentz force, and are orderly arranged in an orientation manner under the effect of the magnetic field; meanwhile, adhesive force between the composite electrodeposition nano-tube particles and a metal belt base plate is increased due to the effect of the magnetic field, and compactness and stability of a copper-carbon nano-tube composite plating layer are improved; and due to the fact that the phenomenon that copper ions are wrapped with a nano-tube exists, the contact resistance between the nano-tube and a metal base plate is reduced, and therefore the conductivity of the copper-carbon nano-tube composite material is effectively improved.

Owner:SHANGHAI UNIV

Method for manufacturing organic supercapacitor electrode plate

The invention provides a method for manufacturing an organic supercapacitor electrode plate. The method comprises the following steps of: manufacturing an aluminum foil pretreatment coating, adding an adhesive into deionized water, and uniformly stirring at normal temperature; adding a conductive agent, absolute ethanol, a carbon nano tube and sodium carboxymethyl cellulose, stirring at a high speed and dispersing to obtain the coating; uniformly coating the manufactured pretreatment coating on an aluminum foil by employing a coating process, coating active substance slurry on the pretreated aluminum foil, and drying to manufacture the electrode plate. A corrosive aluminum foil is replaced by a common aluminum foil, the cost of raw materials is effectively reduced, and the production operability and stability are improved; meanwhile, after the aluminum foil is pretreated, internal resistance of the supercapacitor is greatly reduced, and high-power output performance of the product is improved.

Owner:JIANGSU FRONT NEW ENERGY

Process for producing knitted and dipped PU (polyurethane) gloves by using dimethyl sulfoxide

InactiveCN101849717AAvoid stimulationProtect your healthFibre treatmentProtective garmentWater bathsDrying time

The invention provides a process for producing knitted and dipped PU (polyurethane) gloves. The process comprises the following steps of: dipping knitted gloves into a solvent, wherein the solvent is prepared from polyurethane resin and DMSO (dimethyl sulfoxide) according to the proportion of 1:1.4-1:1.9, the solvent temperature is maintained to be higher than 20 DEG C, and the polyurethane resin is synthesized by the participation of dimethyl sulfoxide; carrying out water bath treatment on the dipped knitted gloves; drying the knitted gloves subjected to the water bath treatment, wherein the drying time is for 50-60 min, and the drying temperature is 100-110 DEG C; and recycling the DMSO in the solvent from the water in the water bath with a vacuum depressurization method. The invention also provides a solvent for the process for producing the knitted and dipped PU gloves, wherein the solvent is prepared from the polyurethane resin and the DMSO according to the proportion. The invention also provides gloves produced by using the process for producing knitted and dipped PU gloves.

Owner:沙晓林

Method for producing hot-melting artistic anti-fake paper

ActiveCN101250838AGood compatibility and binding forceGood mix distribution characteristicsWater-repelling agents additionPulp beating methodsFiberHot melt

The invention relates to a method for preparing hot melt art antifalsification paper, which comprises the following steps: firstly, selecting wood fiber to do fluff and one-time beating, selecting RRXW commodity fiber and fluorescent fiber to process and beat, mixing wood fiber pulp, RRXW fiber pulp and fluorescent fiber pulp according to the proportion of 82: 15: 3, doing blending and beating, charging chemical findings and assistant to blend, dehydrating, modeling, decorating, adopting hot wind dry, far infrared dry and seal dry to do polybasic modeling dry, gluing paper to do non-contact dry, and improving the gluing effect. The multiple fiber allocation of the invention enables pulp to be provided with good compatibility connection and even blend distribution property, higher dry-wet strength, physics, appearance property and the polybasic modeling drying ensures the paper dry effect and the RRXW fiber against damaging. The method for preparing hot melt art antifalsification paper is simple in preparation, reliable in preparation technique, strong in operation and superior in hot melt property and antifalsification property.

Owner:SHANDONG KAILI SPECIAL PAPER

Production method of industrial super capacitor active carbon

ActiveCN102502627AReduce manufacturing costGood environmental protection and safetyCarbon compoundsBiomassPetroleum

A production method of industrial super capacitor active carbon adopts high-quality petroleum coke; a modified material is selected from a high-quality gelatin carbonized material and / or a high-quality biomass carbonized material; an activator is selected from high-purity potassium hydroxide powder; the mixture is stirred and pretreated by carbonization; an activation reaction is completed in an activation furnace; an activation reactor has filler-type labyrinth seal design; little air passing through the labyrinth is controlled and consumed by the spontaneous combustion of the sealed fillers; oxygen is effectively isolated, and the reaction is protected. discharging is performed after activator recovery, boiling with acids, and repeatedly washing; then drying, grinding, and vacuum packaging and warehousing are performed. The production process is short and practical; the quality control is stable and reliable; the production is low in cost and free of pollution; directional modification and continuous mechanized large-scale production of the product are realized.

Owner:陶文康

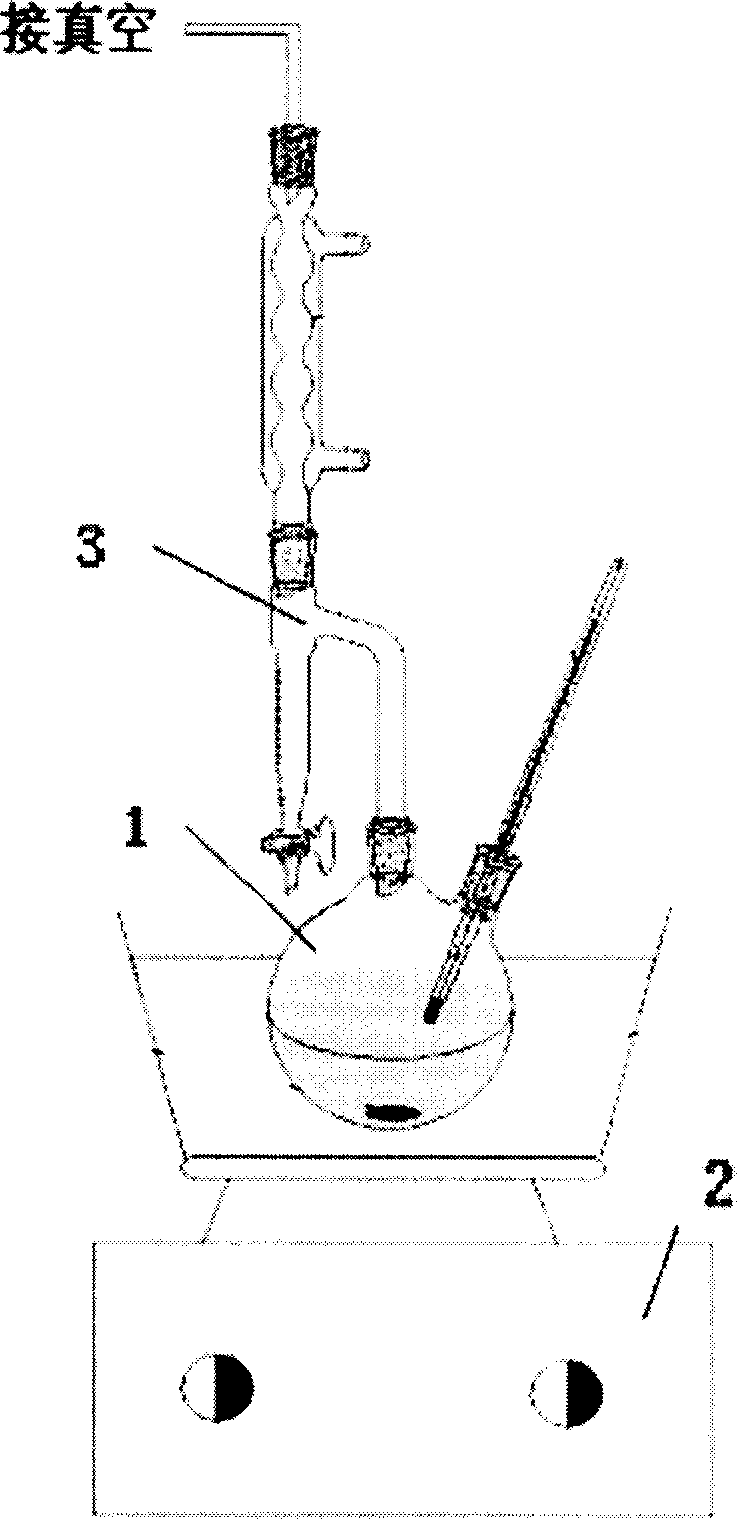

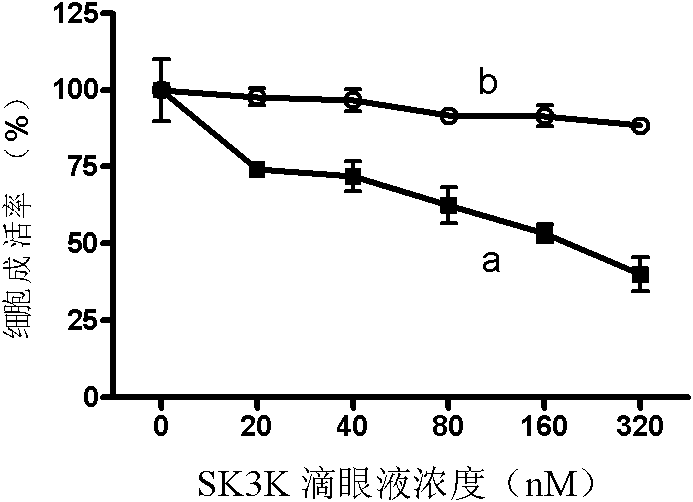

Eye drops and preparation method thereof

ActiveCN101961486ASimple ingredientsLow costOrganic active ingredientsSenses disorderEpitheliumOphthalmology

The invention provides eye drops and a preparation method thereof, and relates to the eye drops. The invention provides the eye drops which have the advantages of shorter action time, lower cost, better effect and capacity of resisting corneal neovascularization and quickly repairing epithelium compared with the conventional eye drops, and a preparation method thereof. The eye drops comprise the following components in percentage by volume: 0.1 to 5 percent of bovine serum, 5 to 15 percent of thickener, 1 to 5 percent of pH regulation solution, 0.1 to 2 percent of osmotic pressure buffer, 0.5to 2 percent of antibiotic, 5 to 30 percent of original solution of kallikrein-binding protein (SA3K) and the balance of balanced salt solution. According to a prescription of the eye drops, the preparation method comprises the following steps of: adding the thickener, the bovine serum, the antibiotic and the original solution of SA3K into the balanced salt solution; uniformly mixing; regulating the pH value to be 7.2 to 7.4 by using the pH regulator; regulating the osmotic pressure to be 350 to 380mOsm / L by using the osmotic pressure buffer; and filtering and degerming by using a membrane toobtain the SA3K eye drops.

Owner:XIAMEN UNIV

Imitated rice paper production method

ActiveCN103103860AObvious appearanceStrong water absorptionPulp liquor regenerationWater-repelling agents additionAdditive ingredientPaper manufacturing

The invention relates to an imitated rice paper production method. The method includes the steps of pulp preparation, paper manufacturing with pulp of a paper machine, surface sizing, drying after the surface sizing, dividing and packaging, and the like. Green wingceltis bark pulp, hemp pulp and tendril straw are chosen as raw material, and big tapered refiner is adopted to perform pulping process; the paper manufacturing with the pulp of the paper machine is carried out by the utilization of a round mesh paper machine with seal-type paper injection, a round mesh cage is arranged on a cylindrical framework of the round mesh paper machine, stainless steel wires are evenly arrayed and welded along the peripheral direction, and size parameters of an ox horn channel of a round mesh groove are particularly set. Softening agent is added in surface sizing liquid, and the using amount of the softening agent is 7% of absolutely dry amount of modified starch. The imitated rice paper production method is easy in processing and manufacturing, simple in technological process, simple in surface sizing liquid ingredient, and easy to operate and control, and therefore manufactured paper product has texture characteristics of rice paper, the requirements of ink embellishing and water-absorbing quality, high bulk, softness, good printing eligibility, small deformation and the like are met, and the imitated rice paper production method is an ideal rice paper manufacturing method.

Owner:SHANDONG KAILI SPECIAL PAPER

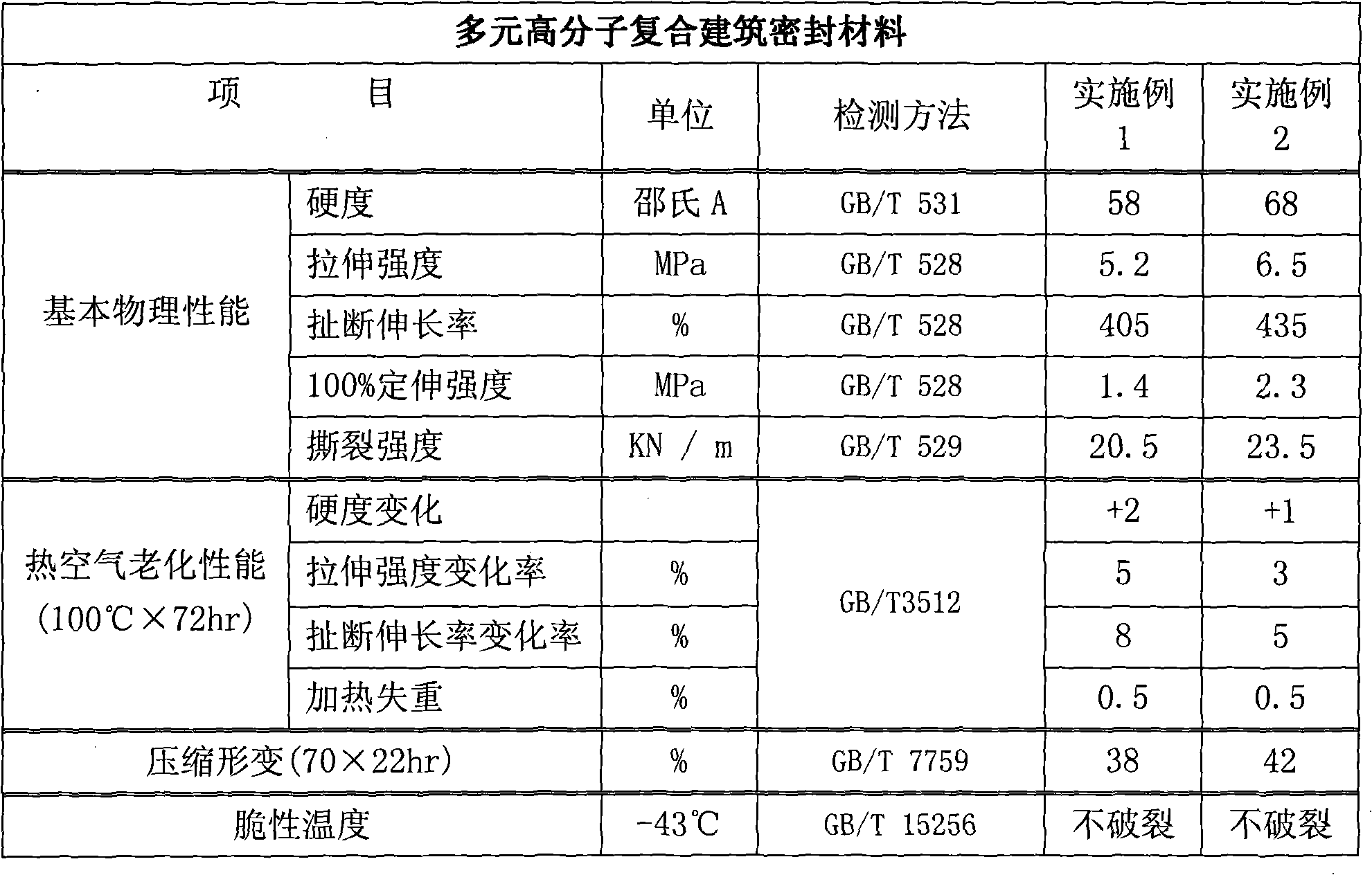

Multicomponent high molecular composite construction sealing materials and production process thereof

InactiveCN101307219AHigh strengthIncrease elasticityOther chemical processesBuilding insulationsComposite constructionVulcanization

The invention relates to a building sealing material prepared by compounding a plurality of polymer materials and a method for preparing the same. The cross linkage in phase state is preformed on materials such as a ethylene-octylene multipolymer, polypropylene, a styrene elastic body, ethylene propylene diene rubber and a filler so that the processed material has the advantages of various polymer materials to make up the deficiency of various polymer materials; the advanced dynamic vulcanization reaction extrusion technology is adopted so that various polymer materials in a composition system are formed in a structure of crossing network and undergoes sufficient cross linkage; various polymer materials are scattered evenly in the polypropylene continuous phase in form of particles so that the processed building sealing material evidently improves the performances such as strength, elasticity, weather resistant property, compression resistance, and permanent deformation resistance, compared with the prior material; meanwhile, the antifatigue and anti-chemical product properties and the stability are improved evidently; the production technology is reliable, the maneuverability is strong, and the automation degree of production is high; therefore, the building sealing material has great pratical and popularized values.

Owner:南通江洲工程材料科技有限公司

Submicron aperture composite membrane based on heavy ion microporous membrane as well as preparation method and application thereof

PendingCN111068520AImprove mechanical propertiesSolve the mechanical propertiesUltrafiltrationWater/sewage treatment bu osmosis/dialysisPhysical chemistryThin membrane

The invention provides a submicron aperture composite membrane based on a heavy ion microporous membrane, which comprises an ultrathin heavy ion microporous membrane layer and a support layer, the ultrathin heavy ion microporous membrane layer is compounded on the support layer, and the thickness of the ultrathin heavy ion microporous membrane layer is 0.5-2 microns. The composite membrane provided by the invention is thin in thickness, large in flux and good in mechanical property. The preparation method provided by the invention is based on innovation of a traditional method, wherein the supporting layer is added on the heavy ion microporous membrane layer, then compounding is carried out in a hot pressing or glue compounding mode, and then etching and cleaning are carried out, so that the problem that a thin film material is broken and cannot be etched due to the fact that the thin film material is too thin in the etching process can be solved. According to the composite membrane prepared by the method, the separation layer is greatly reduced in thickness (more than 5 microns) compared with a conventional heavy ion microporous membrane, so that the flux can be increased by 2.5-10 times. The method is stable and reliable in production process, and a reliable production technology is provided for application of the heavy ion microporous membrane with the submicron aperture.

Owner:惠州市科近离子膜材料研究院 +1

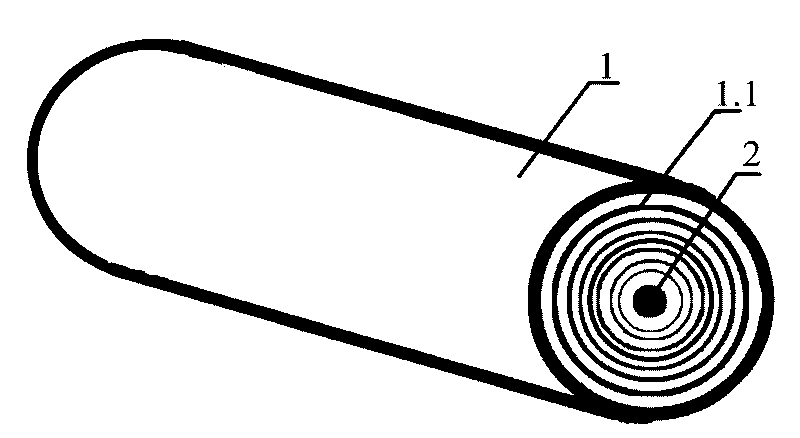

Method for producing nano graphite field emission vacuum electronic cathode

InactiveCN101764007ACathode cross-sectional area is smallSimple production processCold cathode manufactureElectronPotassium permanganate

The invention belongs to the field of vacuum electronic element and device production and a method for producing field emission microwave vacuum electronic cathode by using a nano graphite material. The method comprises: processing industrial expanded graphite sheets at high temperature to produce wormlike expanded graphite; processing the wormlike expanded graphite with solution of concentrated sulfuric acid and potassium permanganate to produce nano graphite sheets; washing the nano graphite sheets to remove acid and purifying the nano graphite sheets by using ultrasonic waves and centrifugation; filtering and drying the nano graphite sheets and forming a film; rolling up the film to produce a nano graphite cylinder; and subjecting the nano graphite column to calcining and post treatment to obtain the nano graphite cylindrical cathode. The method has the characteristics that: the production process is simple, reliable, low in energy consumption and high in production efficiency; the produced electronic cathode has a small cross section and high stability, can emit high-intensity current in use, makes the industrial production realized easily; and the like. The method overcome the drawbacks of the prior art such as difficult use in field emission microwave tubes, digital tubes, projection tubes and other tube vacuum electronic elements, complicated production process, low production efficiency, high production cost and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

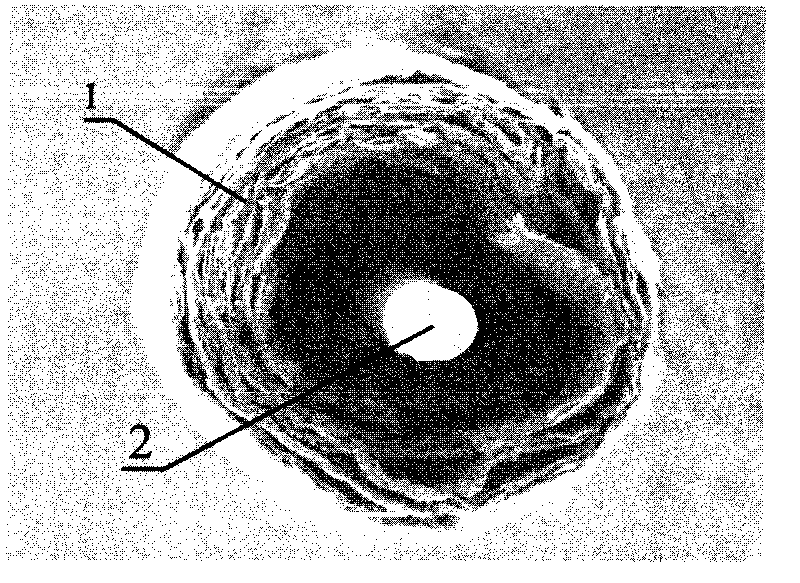

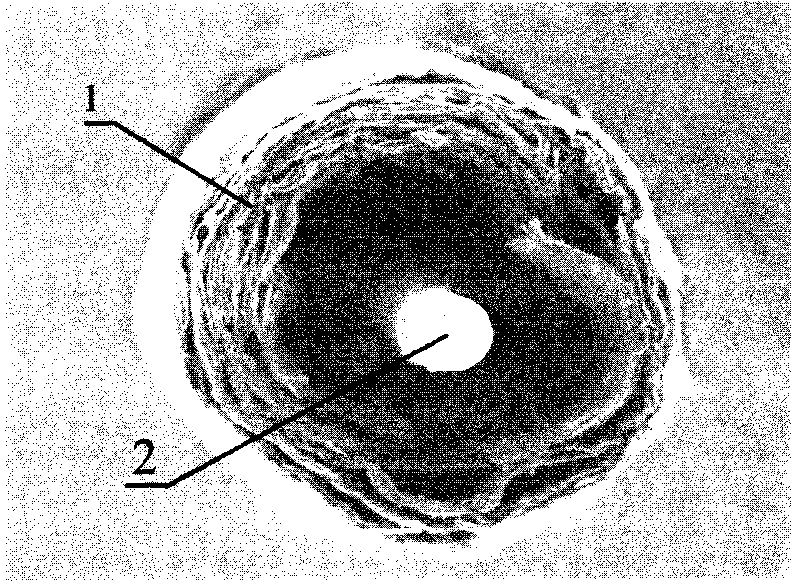

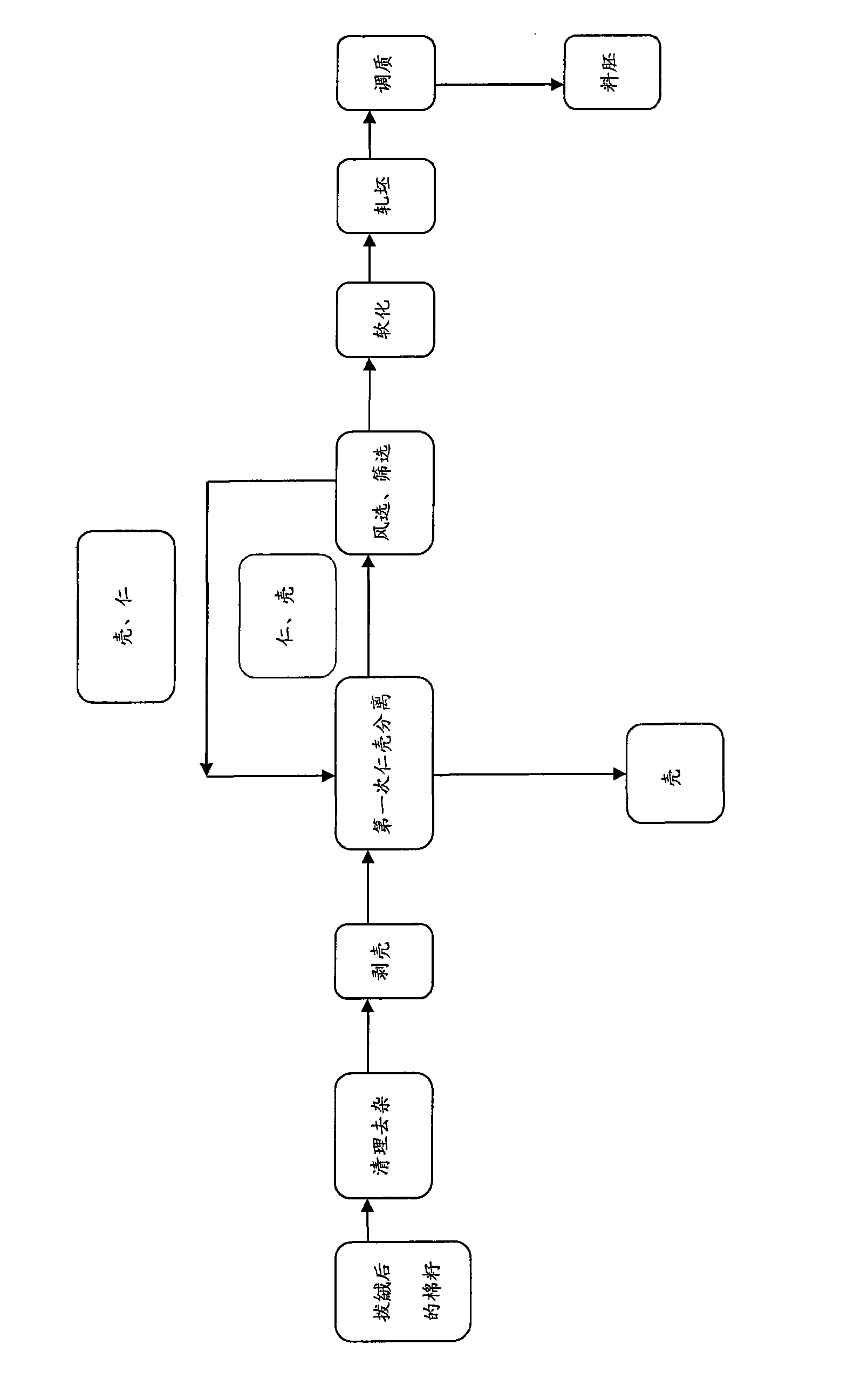

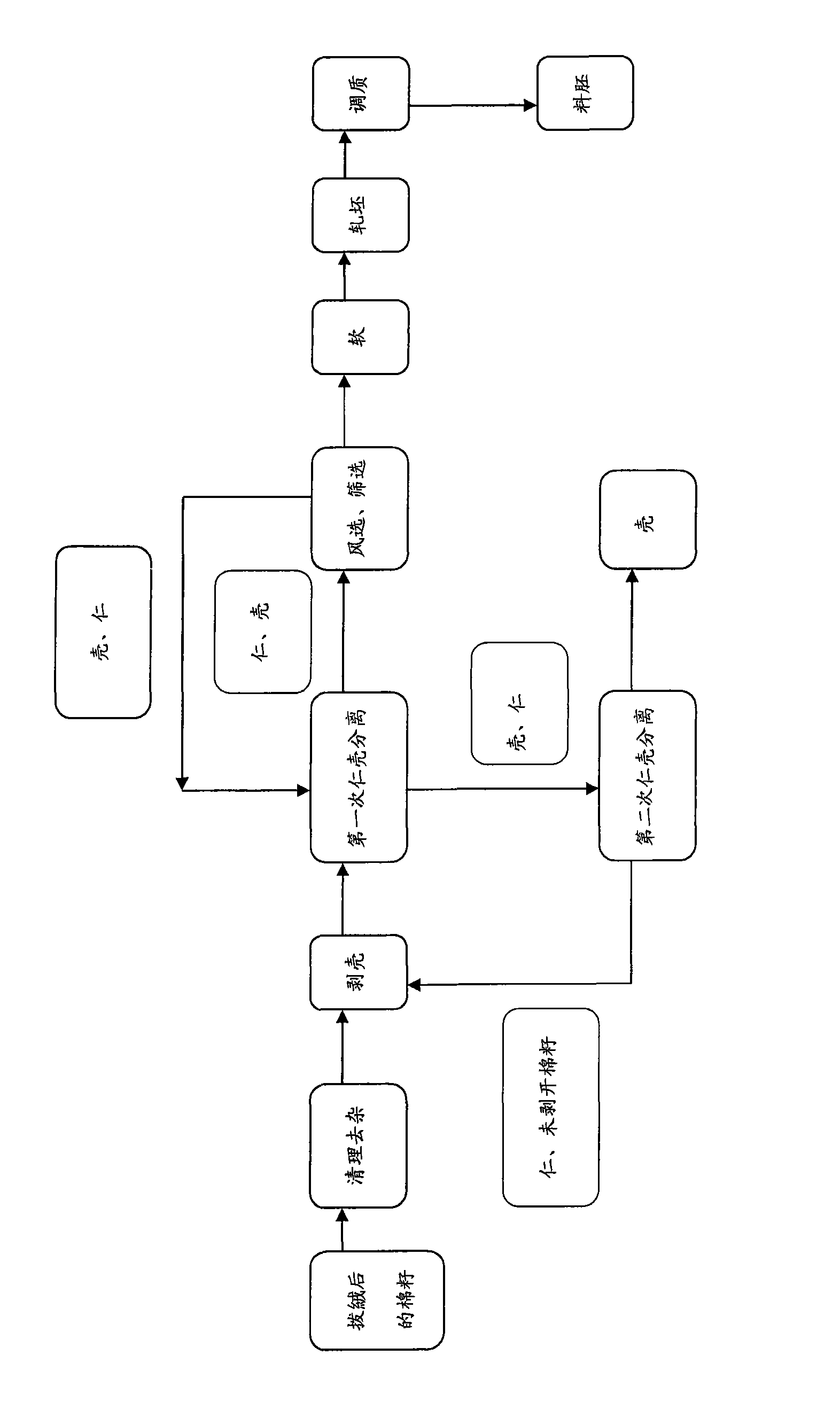

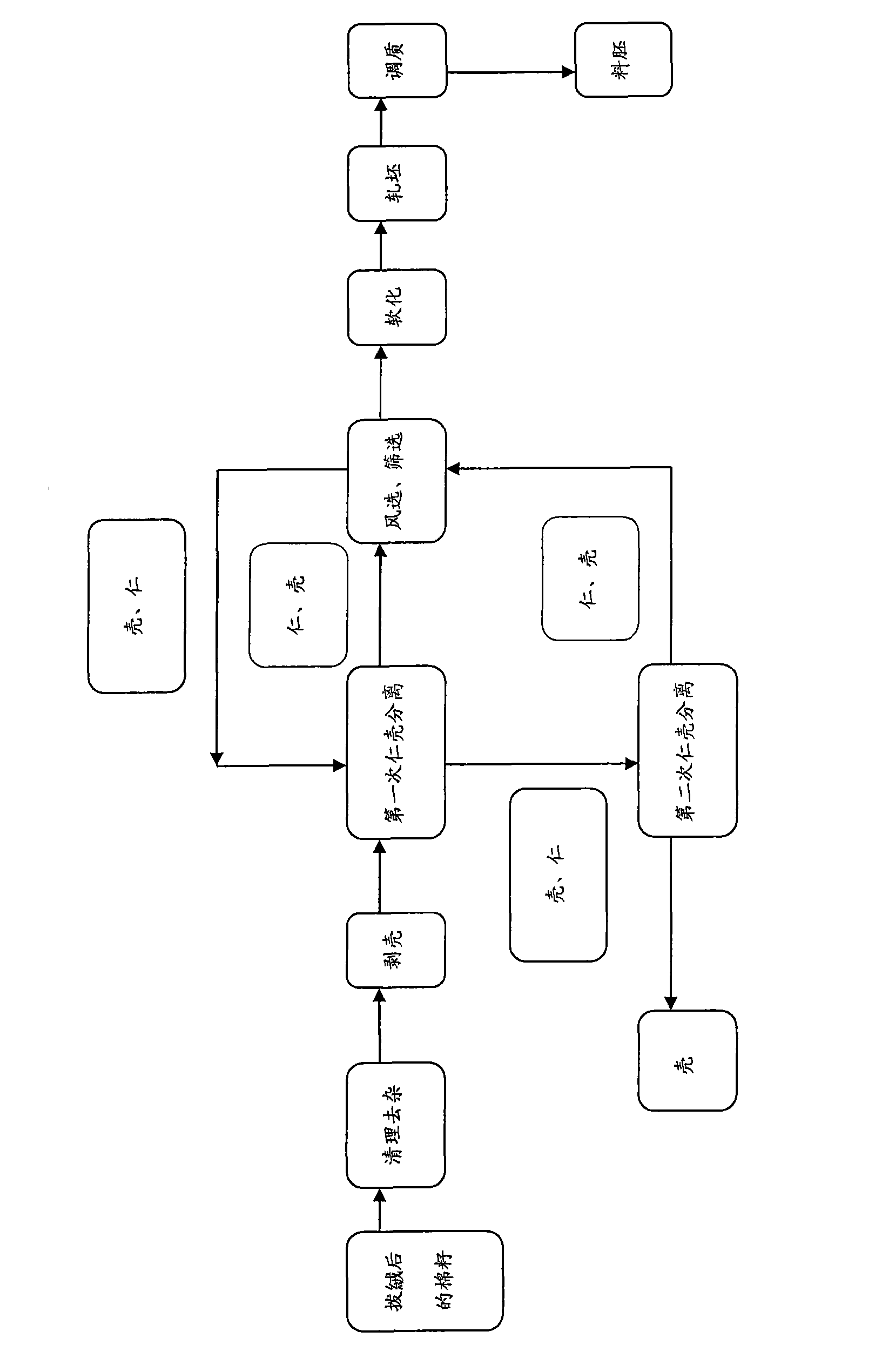

Method for producing cottonseed germ materials used in low-temperature pretreatment production of gossypol-removed cottonseed protein

InactiveCN101664099ADoes not affect nutritional valueGood workmanshipProtein composition from waste materialsProtein composition from vegetable materialsHuskCottonseed oil

The invention provides a method for producing cottonseed germ materials used in low-temperature pretreatment production of gossypol-removed cottonseed protein. The method comprises: cleaning and removing impurities in delinted cottonseeds; husking the cottonseeds after impurity removal; obtaining mixture of cottonseed kernels and cottonseed husks; repeatedly separating the mixture by use of a screening and / or winnowing method; obtaining the cottonseed kernels in which the content of the cottonseed husks is less than or equal to 18 percent; softening the cottonseed kernels at a temperature lower than or equal to 80 DEG C; rolling the cottonseed kernels into germ sheets; adjusting quality at a temperature lower than or equal to 80 DEG C; and obtaining germ materials. The germ materials produced by use of the method have the advantages of good shape, high strength, less breakable property, good permeability during extraction, short seepage time, low content of residual oil and gossypol in meal after oil extraction and gossypol removal, capability of continuous production and capability of maintaining the original nutritional value of protein.

Owner:北京中棉紫光生物科技有限公司 +1

Production method for watercolor writing and painting paper

ActiveCN107268316AAvoid damageBright colorPulp beating methodsDryer sectionPositive pressurePapermaking

The invention relates to a production method for watercolor writing and painting paper. The production method comprises the following steps: carrying out pulp preparation, carrying out papermaking by a paper machine, carrying out squeezing and drying before sizing, carrying out surface sizing, carrying out drying after sizing, carrying out slitting and packaging and the like. The production method selects 100% cotton pulp as a raw material and pulping treatment is performed by adopting a conical pulping machine; a fourdrinier multi-cylinder paper machine is used for carrying out the papermaking; needled felts with textures are mounted on upper and lower squeezing rollers of a positive pressure part of the paper machine respectively; in a squeezing and dehydration process, the textures of the felts are naturally transferred to surfaces of paper sheets to generate natural textures. The production method for the watercolor writing and painting paper is easy for processing and production; a technological process is simple and a formula of surface sizing liquid is simple; the production method is prone to operate and control and obtained product paper sheets have the natural textures and meet the characteristics of the watercolor writing and painting paper of water absorbability, washing resistance and scrubbing resistance, small deformation and long durability; and the production method is an ideal production method for the watercolor writing and painting paper.

Owner:SHANDONG KAILI SPECIAL PAPER

Production process of knitted impregnated PU (polyurethane) gloves applying methyl pyrrolidone

InactiveCN101849719AAvoid stimulationProtect your healthFibre treatmentProtective garmentSolventChemistry

The invention relates to a production process of knitted impregnated PU ( polyurethane) gloves. The process comprises the following steps of: impregnating the knitted gloves into a solvent, wherein the solvent is prepared from polyurethane resin and methyl pyrrolidone according to the proportion of 1.3-1:1.8, and the polyurethane resin is synthesized with the participation of methyl pyrrolidone; carrying out the water bath treatment on the impregnated knitted gloves; drying the impregnated knitted gloves after the water bath treatment, wherein the drying time is 50-60min, and the drying temperature is at 100-110 DEG C; and recycling methyl pyrrolidone in the solvent from the water for the water bath with the vacuum depressurization method. The invention also provides a solvent for the production process of knitted impregnated PU gloves, which is prepared from polyurethane resin and methyl l pyrrolidone according to a certain proportion. Meanwhile, the invention provides gloves produced according to the production process of the knitted impregnated PU gloves.

Owner:沙晓林

Method for preparing dried amnion

The invention relates to a method for preparing dried amnion, which is characterized by comprising the following steps of: strictly sterilizing fresh amnion which carries no virus and is repeatedly rinsed, rebuilding and repairing ground substances at low temperature, unfolding the amnion, drying, sterilizing by cobalt 60 and preserving to reserve. The method for preparing the dried amnion has the advantages that the manufacturing process is simple and reliable and the cost is relatively low to ensure that the implementation and the popularization are easy; the prepared dried amnion can be preserved at normal temperature and conveniently transported; the cell phenotype and the basement membrane of the amnion are intact; fewer amnion ground substances are destroyed; the prepared dried amnion is superior to purely lyophilized amnion preserved at the same time and the like.

Owner:周海华

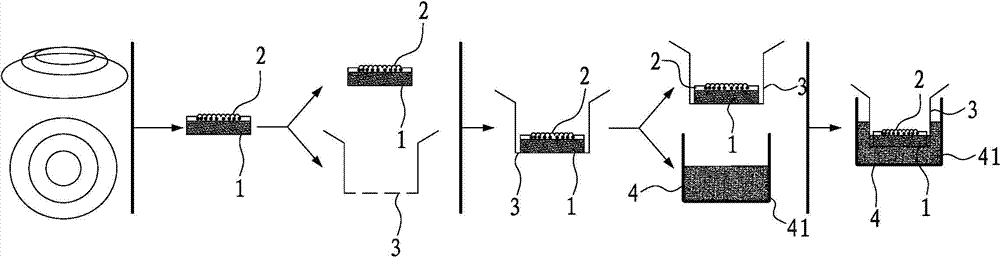

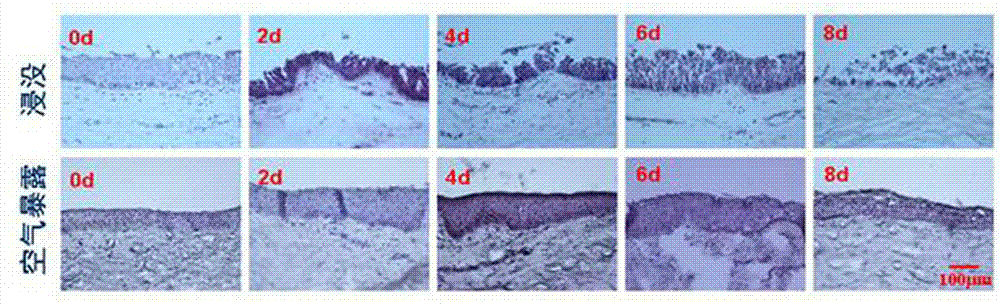

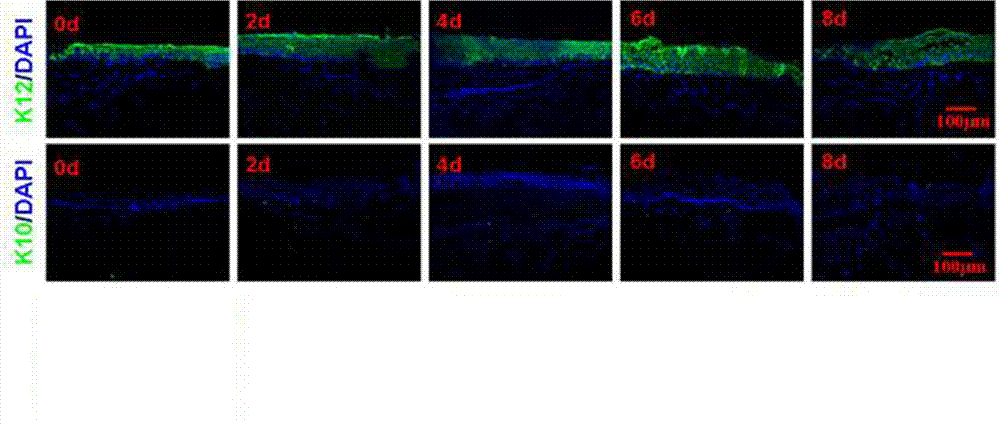

Preservation method for corneal limbus tissue

ActiveCN102726370AComplete structureAfter the structure, the present invention preserves the corneal limbal tissue intactDead animal preservationAir exposureCell culture media

The invention discloses a preservation method for corneal limbus tissue. The method comprises a step of disinfecting fresh corneal limbus tissue and a step of air exposure preservation of the disinfected fresh corneal limbus tissue. The step of air exposure preservation is as follows: the fresh corneal limbus tissue is placed on a permeable covering film, preservation liquid or a cell culture medium capable of providing nutrients to the corneal limbus tissue is arranged below the covering film, epitheliums of cornea directly contact with air, the temperature of a culture environment in the step is 0 to 37 DEG C, and oxygen concentration is 0 to 20%. Compared to immersion preservation in the prior art, the preservation method provided in the invention has the following advantages: the structure of the preserved corneal limbus tissue is more integral; obvious apoptosis of the epitheliums of cornea does not occur; stem cells of corneal limbus can maintain high activity; and process flow is simple and reliable, is easy to implement, costs little and has other efficacy.

Owner:XIAMEN EYE CENTER OF XIAMEN UNIVERSITY CO LTD

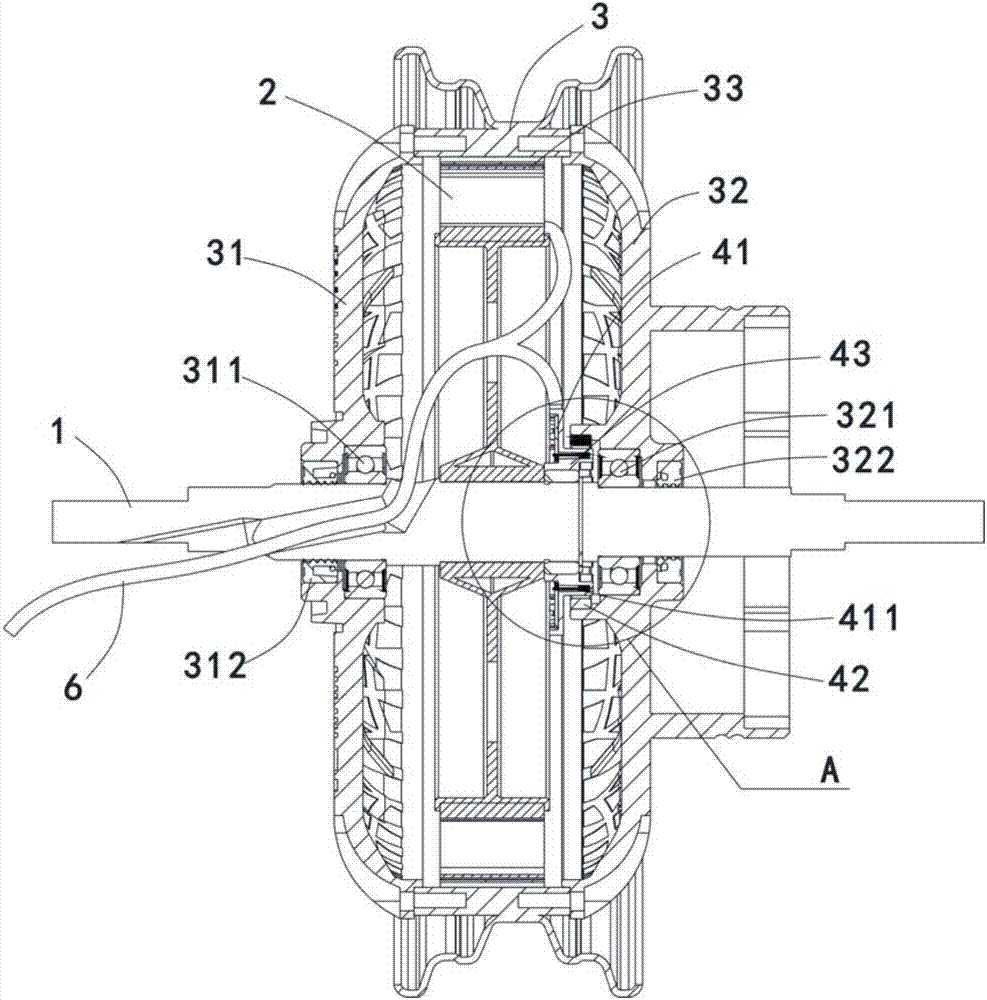

Wheel hub motor and position signal processing method thereof

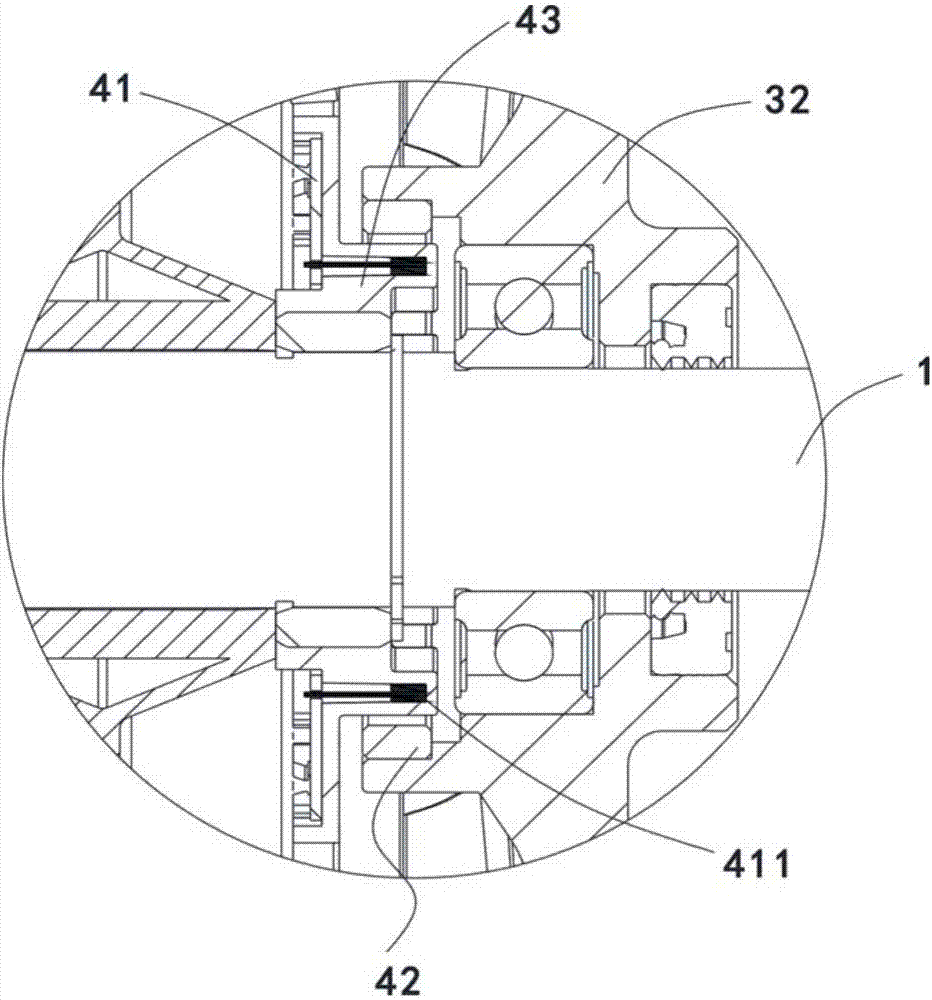

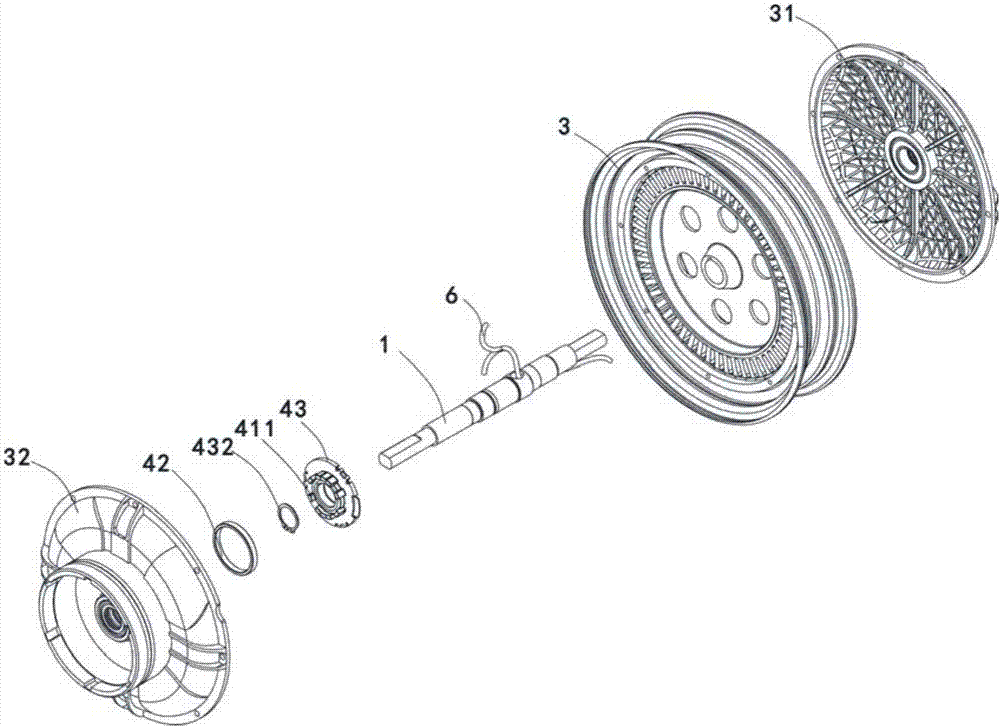

ActiveCN107294337AImprove operational efficiencyLow costAssociation with control/drive circuitsElectronic commutatorsLocation detectionEngineering

The invention discloses a wheel hub motor. The wheel hub motor comprises a motor shaft, a stator, a rotor and a position detection device; the position detection device comprises a PCB (printed circuit board) and a magnetic ring; the PCB is provided with a plurality of magnetic induction components; when the magnetic ring is stationary or rotating, the magnetic induction components can sense the change of the magnetic flux of the magnetic ring; the rotor is provided with a left end cover and a right end cover which is used for installing a brake assembly; and the position detection device is arranged inside the right end cover. The invention also discloses an externally-arranged wheel hub motor; the rotor of the external wheel hub motor is provided with a left end cover and a right end cover which is used for installing a brake assembly; a motor shaft at the external side of the left end cover is provided with a housing; and a position detection device is arranged in the housing. The invention also discloses a position signal processing method of the wheel hub motor. The wheel hub motor of the invention has the advantages of simple structure, simple and reliable production process, reliable vibration resistance, low performance requirements for a controller and high accuracy. According to the wheel hub motor, position feedback avoids a heat source, mechanical angle and electrical angle output selections are provided, and the requirements of different control interfaces can be satisfied.

Owner:NINGBO BRANCH OF JIANGSU YADEA TECHNICAL DEV CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com