Patents

Literature

453results about How to "Soft color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Superfine fiber polyurethane leather and base cloth as well as preparation method and application

InactiveCN101929083AImprove flame retardant performanceImprove performanceFlame-proof filament manufactureFibre treatmentPolymer scienceHigh wear resistance

The invention discloses a preparation method of a superfine fiber polyurethane leather base cloth based on a conventional process, and in the step of spinning, FR-535 flame retardant nylon master batches are added to perform fire retardant treatment on superfine fibers. The invention also discloses the superfine fiber polyurethane leather base cloth prepared by the method, a preparation method of superfine fiber polyurethane leather, the superfine fiber polyurethane leather prepared by the method and an application of the method in preparing leather for automobile trim. The method in the invention can enable the superfine fiber polyurethane leather base cloth and the synthetic leather to have excellent flame retardant property with the horizontal burning time of 3min and damaged length of no more than 81mm. In addition, the superfine fiber synthetic leather has excellent combination property, such as light resistance, favorable fastness, high wear resistance and the like, delicate color, has the physical properties capable of comparing favorably with natural cow leather, and can satisfy the requirement of leather in automobile trim.

Owner:HUAFON MICROFIBER SHANGHAI

Production technology of viscose extinction monofilament

InactiveCN103215680AImprove spinnabilitySoft touchSpinnerette packsArtificial filaments from viscoseInlet channelExtinction

The invention relates to a production technology of viscose extinction monofilament. The production technology takes cellulosic fiber pulp as a raw material and obtains viscose extinction monofilament through preparation of a spinning solution, injection before spinning, spinning and aftertreatment, and specifically comprises the following steps of: (A) preparing the spinning solution from the cellulosic fiber pulp through steeping, ageing, yellowing, dissolving, defoaming and filtering; (B) adding a titanium dioxide solution into the spinning solution so that the weight ratio of titanium dioxide to alpha cellulose content in the spinning solution reaches (0.5-5.0):100; and uniformly mixing and feeding for spinning; (C) feeding the spinning solution into a spinning machine, and enabling the spinning solution to pass through a spinneret orifice of a single-hole spray head under pressure, and solidifying and molding the formed viscose trickle to form raw silk strips, wherein the spray head is stretched by +60% to +80%, and an inlet channel of the spinneret orifice is in a parabola shape; and (D) performing aftertreatment: performing desulfurization, bleaching, oiling and drying on the raw silk strips to obtain the viscose flat monofilament. According to the production technology provided by the invention, the filament number of the prepared viscose monofilament is 50-6,000D, the strength is high over 75CN, and the requirements on dyeing, weaving and finished product taking are met; and moreover, the viscose extinction monofilament has gentle color and an extinction effect.

Owner:YIBIN HIEST FIBER +2

High elastic wool-like fabric and production method thereof

The invention discloses a high-elasticity wool-like fabric and a method for producing the same. The method comprises the following steps: selecting two yarns with different fiber components and different blending ratios; using a folded yarn of a yarn A interlacing with a yarn B as a First warp to form a warp yarn arrangement First; using the folded yarn of the yarn A interlacing with the yarn B as a Fist weft to form a weft yarn arrangement First, wherein the fabric comprises two upper twill structures and two lower twill structures. A drafting method adopts pathwise penetration of four pieces or pathwise penetration of eight pieces, wherein the portie is between No.10 and No.11, the penetration is 2 heddles per reed, and the width of the fabric on a machine is 205 centimeters. Through dyeing the same color on an anode dyeable terylene and a viscose staple fiber, the elastic property of wool fiber and PTT fiber can be embodied sufficiently. Through the selection of a yarn combination with different fiber components, and according to selecting the prior product process flow, the produced bamboo joint color wool-like fabric has the advantages of abundant colors, gentle color and luster, and strong woolly handfeel.

Owner:富丽达集团控股有限公司

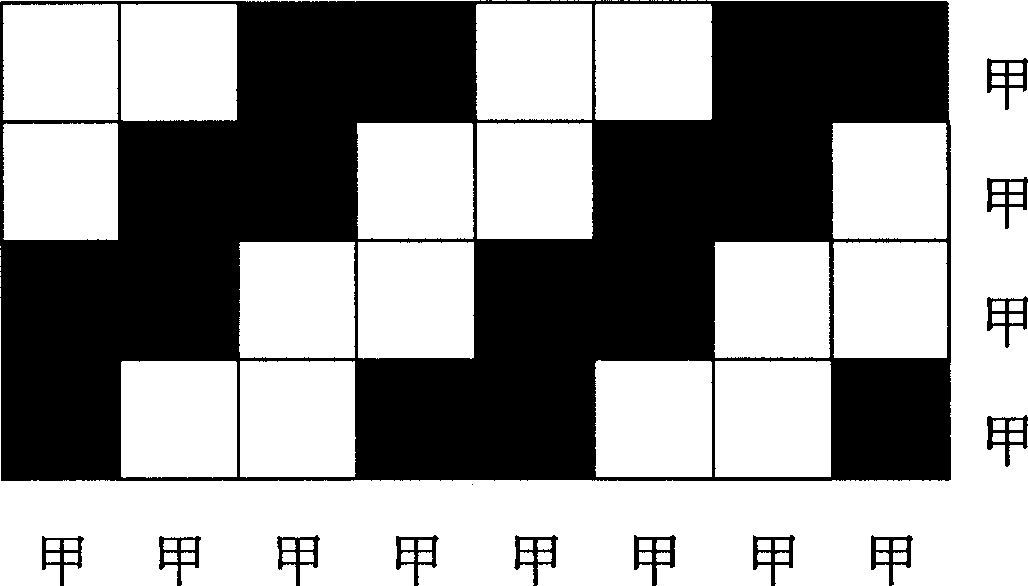

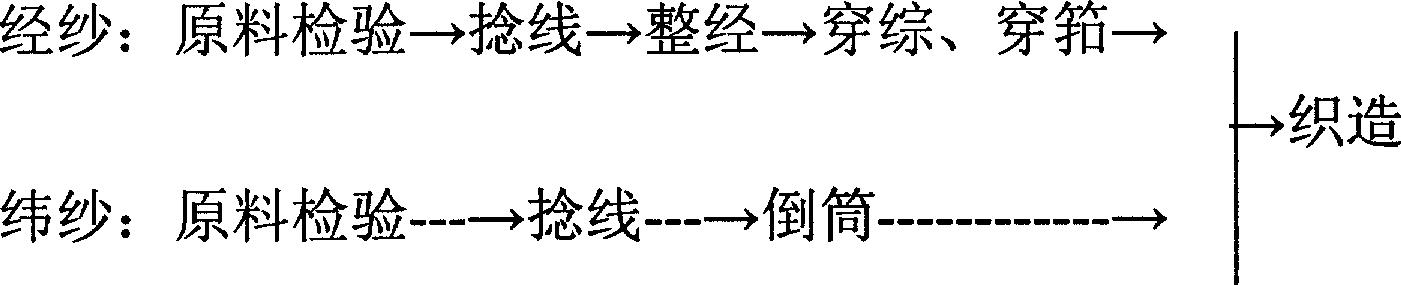

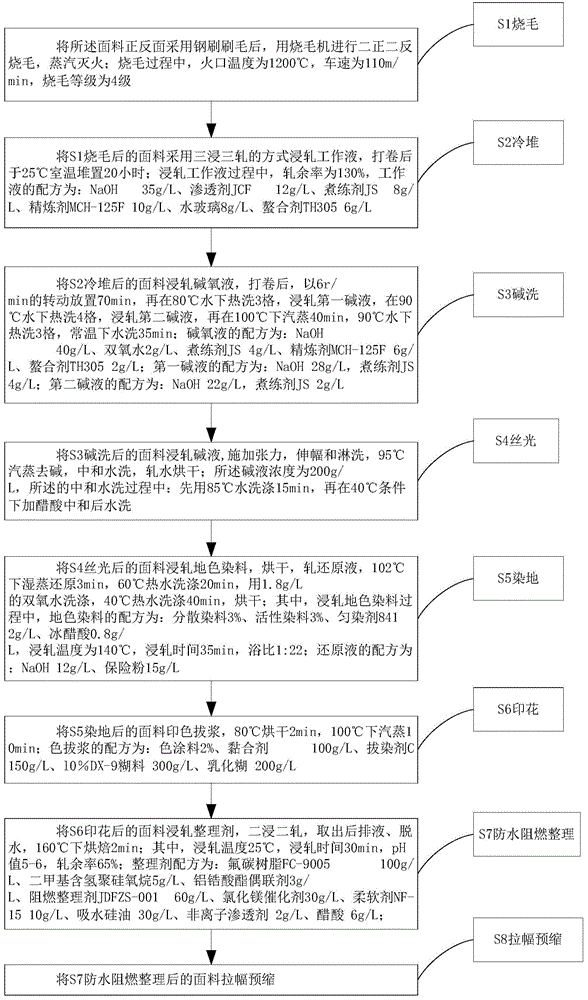

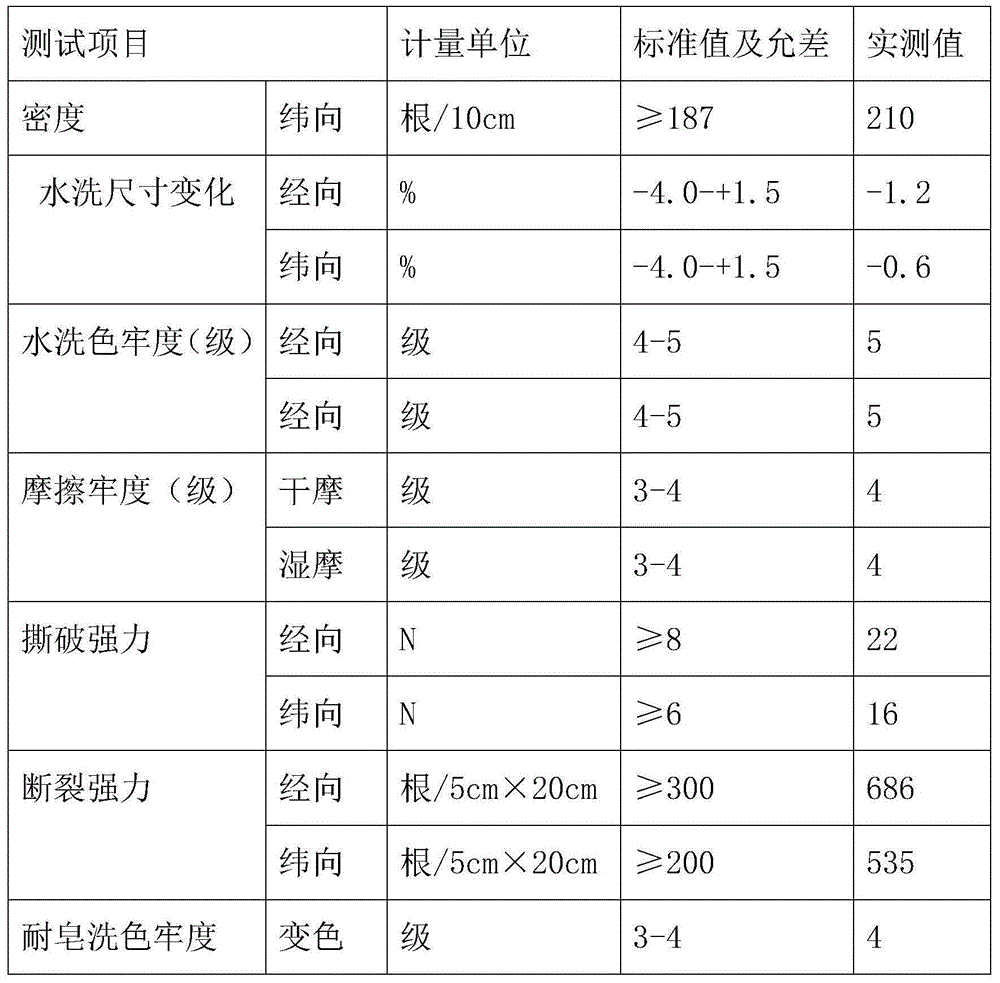

Dyeing and printing technology of camouflage fabric

InactiveCN105040490AImprove tensile propertiesImprove printing and dyeing adsorption functionDyeing processWoven fabricsCamouflagePolyester

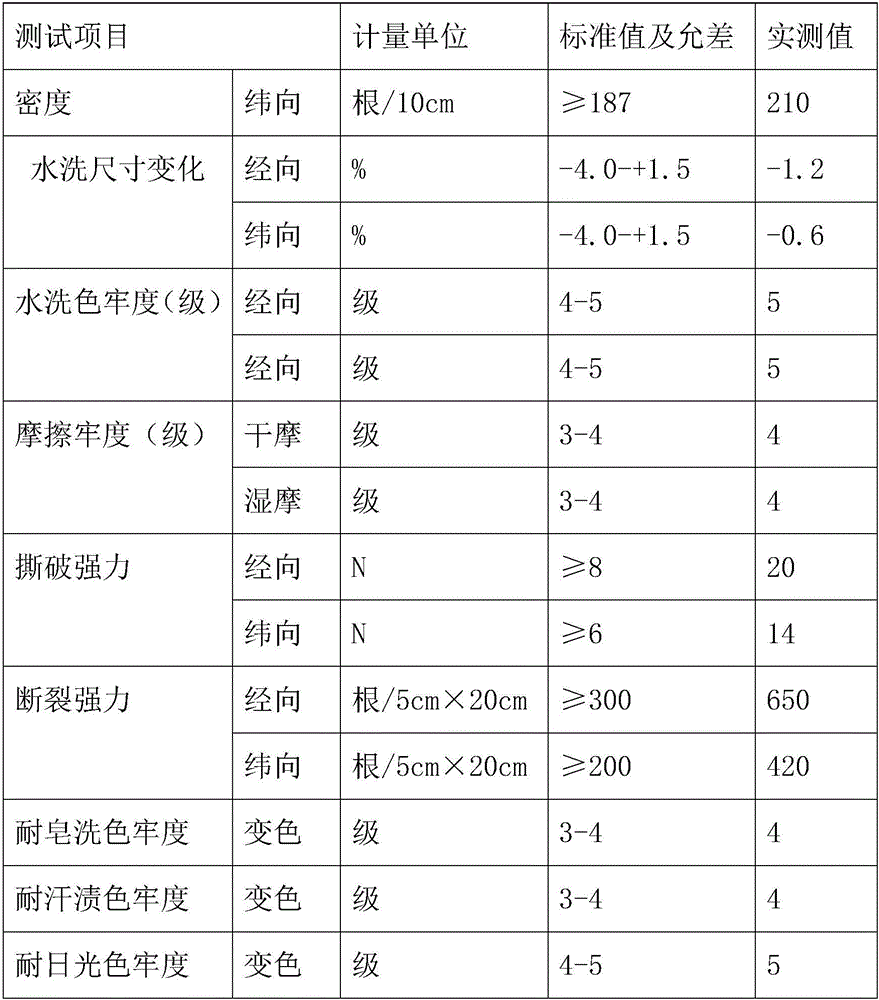

The invention discloses a dyeing and printing technology of a camouflage fabric. The camouflage fabric is prepared by blending and interweaving the following raw materials in percentage by weight: 30%-50% of cotton fiber, 30%-50% of polyester fiber, 10%-30% of spandex fiber and 10%-20% of spun silk fiber. The dyeing and printing technology comprises the following steps: S1 singeing; S2 cold heaping; S3 alkaline washing; S4 mercerizing; S5 ground dyeing; S6 printing; S7 waterproof and flame-proof treatment; and S8 stentering pre-shrinking. According to the dyeing and printing technology of the camouflage fabric, the high color fastness of the dyed ground color and the front and rear stability of the color of the camouflage fabric can be ensured; the camouflage printing requirements can be met; the quality repeatability is good; and the quality index of the finished product can meet the customer requirements.

Owner:芜湖市瑞都服装贸易有限公司

Silicone rubber compositions comprising bismuth oxide and articles made therefrom

InactiveUS20090243436A1Maintain good propertiesIncrease resistancePiezoelectric/electrostriction/magnetostriction machinesRecord information storagePhotopigmentParticulate metal

The present invention provides novel filled silicone compositions comprising a nano-particulate metal oxide filler selected from nano-particulate monoclinic alpha-phase bismuth oxide, nano-particulate erbium oxide, and mixtures thereof. The new composite compositions exhibit a combination of outstanding performance characteristics in both the cured and uncured states. Thus, the uncured formulations are typically free flowing liquids which are self-leveling, which de-gas readily under vacuum, are readily colorable through the addition of pigments, and which cure at temperatures of about 60° C. The cured compositions possess outstanding acoustic characteristics which make them ideally suited for use in applications such as acoustic lenses for medical imaging and therapy. For example, the acoustic impedance of compositions provided by the present invention is closely matched to the acoustic impedance of human tissue. This may result in an enhancement of ultrasound transmission efficiency between the lens of an ultrasound probe comprising such a composition and the patient.

Owner:GENERAL ELECTRIC CO

Paper pulp prepared from maize straw, preparation method thereof and paper product prepared from paper pulp

ActiveCN102154906AIncrease pulp yieldGood performance parametersPulp bleachingPulping with inorganic basesBlack liquorTear resistance

The invention relates to maize straw paper pulp, which is prepared from maize straw serving as a raw material. The whiteness of the maize straw paper pulp is 38-60 percent ISO (International Standardization Organization), the bulk is 1.8-2.5 cm<3> / g, the tensile index is 35-65 N.m / g, the folding resistance is 10-40 times, the fracture length is 4.0-6.5 km, the air permeability is 70-200 ml / min, the ash content is 5-10 percent, the tear resistance is 180-260 mN, and the tear resistance index is 3.0-4.2 mN.m<2> / g. The paper pulp has good performance parameters, can replace the conventional wood pulp and can be used for preparing cultural paper and paper for daily use. A preparation method of the maize straw paper pulp comprises stock preparation, cooking and black liquor extraction, wherein the heat preserving time in the cooking process is 0-50 minutes.

Owner:SHANDONG TRALIN PAPER

Preparation method of antique bricks with 3D relief

The invention discloses a preparation method of antique bricks with 3D relief, wherein the preparation method includes the steps: preparing a bottom glaze on the surface of the body and carrying out ink-jet printing, overglazing, drying and firing in turn, and thus obtaining the finished product. The rich and lifelike 3D relief is prepared on the antique brick surface by an ink jet and infiltration technology. The preparation process is simple, a die is not needed to be replaced according to different designs of the antique bricks, and the production cost is saved greatly. Correspondingly, theinvention also discloses the antique bricks with 3D relief, wherein the antique bricks have the advantages of low surface glossiness, clear texture, strong stereoscopic sense, and excellent anti-fouling and anti-skid performance.

Owner:肇庆乐华陶瓷洁具有限公司

Aqueous flexible plate printing ink and preparation thereof

InactiveCN101328329AReduce pollutionFine inkInksOther printing apparatusSolubilityAtmospheric contamination

A water-basedsoft printing ink comprises the following compositions: 30 to 35 percent of pigment, 25 to 32 percent of acrylic resin, 0.2 to 0.5 percent of antifoaming agent, 2 to 5 percent of ethylene glycol monomethyl ether, 1.0 to 2.5 percent of wax slurry, 0.9 to 1.5 percent of leveling agent, and 23 to 30 percent of water. A preparation method comprises the three working procedures of colored slurry grinding, aquosity treatment and printing ink preparation in turn. The water-basedsoft printing ink has novel compositions, scientific blending, simple preparation, lower cost, fine ink quality, mellow brightness, high color saturation, brilliant color, high drying speed, grid point superimposition and overprinting, good water solubility, easy cleaning, corrosiveness free on printing rollers, low viscosity, high color content, good penetrability and printing adaptability, suitability for multicolor machine high-speed printing, high abrasion resistance, difficult decolorization, wide color range, closeness to a normal color sample, and consistency to the requirements on top-grade printing; and the printing ink also meets EU ROHS standards, and facilitates safe production and environmental protection with low air pollution and without any noxious solvent residual.

Owner:广东佳景科技股份有限公司

Anti-infrared military camouflage fabric and printing and dyeing process thereof

ActiveCN106049092AImprove friction resistanceImprove tensile strength at breakMercerising of indefinite length fabricsSingeingDisperse dyeColour fastness

The invention discloses anti-infrared military camouflage fabric and a printing and dyeing process thereof. Warp and weft yarns of the camouflage fabric use cotton polyester blended yarns; the cotton polyester blended yarns are formed by blending 40 to 60 weight percent of cotton fiber, 30 to 50 weight percent of polyester fiber, 5 to 10 weight percent of polyamide fiber and 5 to 10 weight percent of spun silk fiber. The printing and dyeing process of the anti-infrared military camouflage fabric comprises the following steps of S1, a pretreatment process; S2, a dyeing process; S3, a printing process; S4, tentering sorting, wherein the dyeing process uses disperse bath process dyeing of reduced dye and disperse dye; the printing process uses printing of reduced dye and disperse dye in one paste. According to the anti-infrared military camouflage fabric and the printing and dyeing process of the anti-infrared military camouflage fabric, the fabric obtained through the printing and dyeing process has the advantages of good anti-infrared camouflage performance, high color fastness of all items, full color and luster and low cost.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

Dyeing method for common goldenrod herb natural dye

The invention relates to a dyeing method for a common goldenrod herb natural dye. The dyeing method comprises the following steps: preparing a 2 to 20 g / I common goldenrod herb dye, and setting a dyeing temperature of 40 to 100 DEG C, a bath ratio of 1:50 to 200 and dyeing time of 10 to 90 minutes; taking a 2 to 20 g / I mordant solution, and setting a mordanting temperature of 40 to 100 DEG C and mordanting time of 10 to 90 minutes; and adding a mordant before or after natural fiber yarn or natural fiber textile is added into common goldenrod herb dye liquor or simultaneously when the natural fiber yarn or the natural fiber textile is added into the common goldenrod herb dye liquor for one-bath dyeing. The method uses the prior textile dyeing device for direct dyeing without adding devices or increasing cost. The textile dyed by the method is soft, primitive and simple and natural color, and has good dye fastness, no fading, no discoloring, good reproducibility, and chromatic aberration around a half level. The method is suitable for the industrialized production, and has no toxicity, no harm and no pollution.

Owner:DONGHUA UNIV

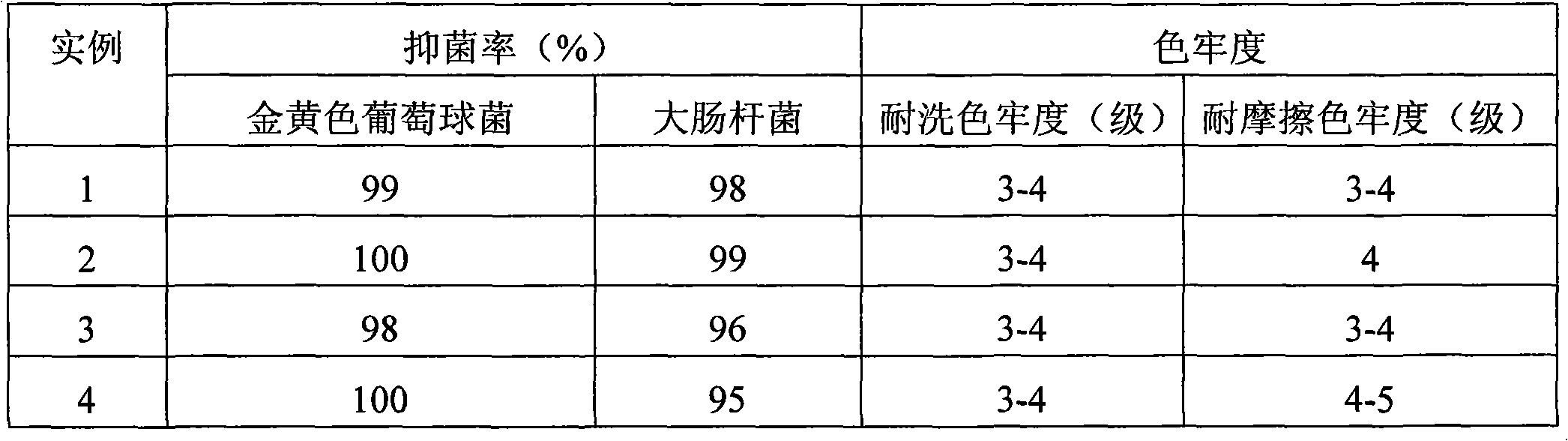

Method for dying cotton fiber by utilizing tea vegetable dye

ActiveCN101956334AHas antibacterial effectHigh color fastnessDyeing processVegetal fibresFiberSocial benefits

The invention provides a method for dying cotton fiber by utilizing tea vegetable dye. In the method, natural tea vegetable dye is extracted from fresh tea leaves, and is utilized to dye cotton fiber by different mordanting methods. After being dyed by the method the invention, the cotton fiber has the advantages of good dyeing color fastness, more color spectrums and good bacteriostatic effect. Through the method, multiple colors can be dyed, the color and lustre are soft, archaic and natural, thus people can feel natural and healthy; the dyed cotton fiber has the characteristics of good dyeing fastness, washing and wear resistance, strong repeatability and uniform dyeing; the existing dyeing equipment is used to dye directly without adding equipment and increasing cost; the method is environmentally friendly and is beneficial to human health; and the method can be applied to clean production of textile industry and can realize large-scale production. The method can efficiently use resources of summer tea and autumn tea, develop and produce tea-dyeing cotton textiles which are environmentally friendly and have archaic, simple and elegant colors and bacteriostatic effect, and the market prospect is broad, thus being capable of not only generating great economic benefits but also obtaining great social benefits.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI +1

Foaming glaze and glaze foaming ceramic manufactured by using the same

The invention relates to a foaming glaze and a glaze foaming ceramic manufactured by using the same, and belongs to the technical field of ceramics. The foaming glaze comprises 38-42 parts by mass of potassium feldspar, 13-16 parts by mass of kaolin, 5-8 parts by mass of zirconium silicate, 8-11 parts by mass of barium carbonate, 7-12 parts by mass of quartz, 7-9 parts by mass of calcium carbonate, 2-5 parts by mass of zinc oxide, 5-10 parts by mass of talcum, 0.8-1.3 parts by mass of magnesium carbonate, 1-5 parts by mass of silicon carbide, 2-4 parts by mass of neodymium oxide, 8-11 parts by mass of clay, 16-20 parts by mass of borax, 0.2-0.5 part by mass of manganese oxide, 0.2-0.4 part by mass of iron oxide, 18-24 parts by mass of glass powder and 15-21 parts by mass of a low-temperature frit, wherein the low-temperature frit comprises 47-51 parts by mass of borax, 38-41 parts by mass of potassium feldspar, 11-13 parts by mass of calcium carbonate, and 6-9 parts by mass of kaolin. The method includes steps of grinding, adjusting a glaze concentration, glazing, firing, puffing and cooling to obtain the glaze foaming ceramic. The glaze foaming ceramic having color changing effects, and having high acid and alkali resistance, compression resistance and fracture resistance is provided.

Owner:德化县太阳鸟工艺品有限公司

Artificial caverous stone and its making process

InactiveCN101020336ARadiation-freeEasy to cleanConstruction materialMouldsSoft materialsMaterials science

Owner:李强

Composition for light scattering membrane and light scattering membrane comprising same

InactiveCN101241194AImprove mechanical stabilityEvenly dispersedOptical elementsNano siliconChemical compound

The invention provides a composition used for a light scattering film composed of following components: resin material, used for forming a transparent film and as matrix for containing nano functional material; nano functional material, optimally comprising a set containing nano silicon based oxide, nano metallic oxide, nano Baric chemical compound and diversified blends, with a grain diameter less than 100 nm, used with a dosage of 35-160by weight of the resin material; and contrast control material selected from a set composed of deep color nano inorganic pigment, organic pigment and dye, with a grain diameter less than 100 nanometer, used with a dosage of 1-10by weight of the resin material. The invention further provides an optical-imaging film containing the composition with a thickness of 10-80 mum, having one or several layers structure, optimal 2-4 layers.

Owner:北京传世唯信科技有限责任公司

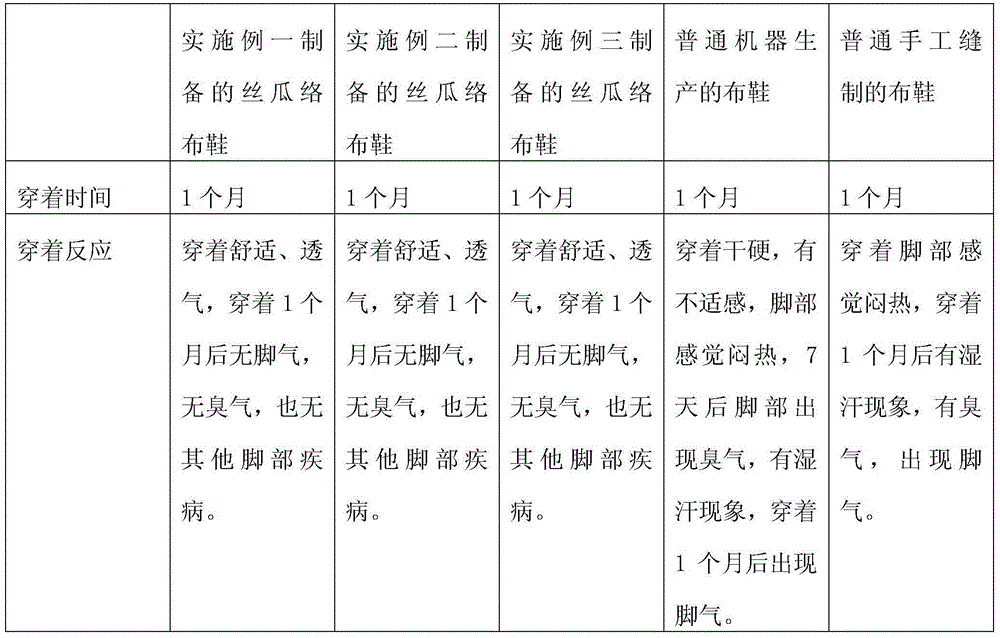

Making method for loofah sponge cloth shoes

The invention discloses a making method for loofah sponge cloth shoes. Making of the loofah sponge cloth shoes can be completed through the steps of early-stage preparation, cloth board making, sole making, sole smoking and upper sewing. The making method has the advantages that the loofah sponge cloth shoes can improve circulation capacity of blood of the feet, dispel pain in the feet, remove fatigue, kill bacteria on the feet, remove dermatophytosis, reduce breeding of bacteria, prevent foot diseases, prevent foot odor, simulate foot acupoints, achieve a massage effect, dredge the channel, improve the organ functions of the body and achieve a healthcare effect; besides, no chemical substance is adopted in the making process, and therefore the loofah sponge cloth shoes are ecological and environmentally friendly, will not harm the body, can protect the health of people and is good in ecology and healthcare effect and easy to popularize.

Owner:景宁畲艺坊服饰有限公司

Shading intumescent coating curtain

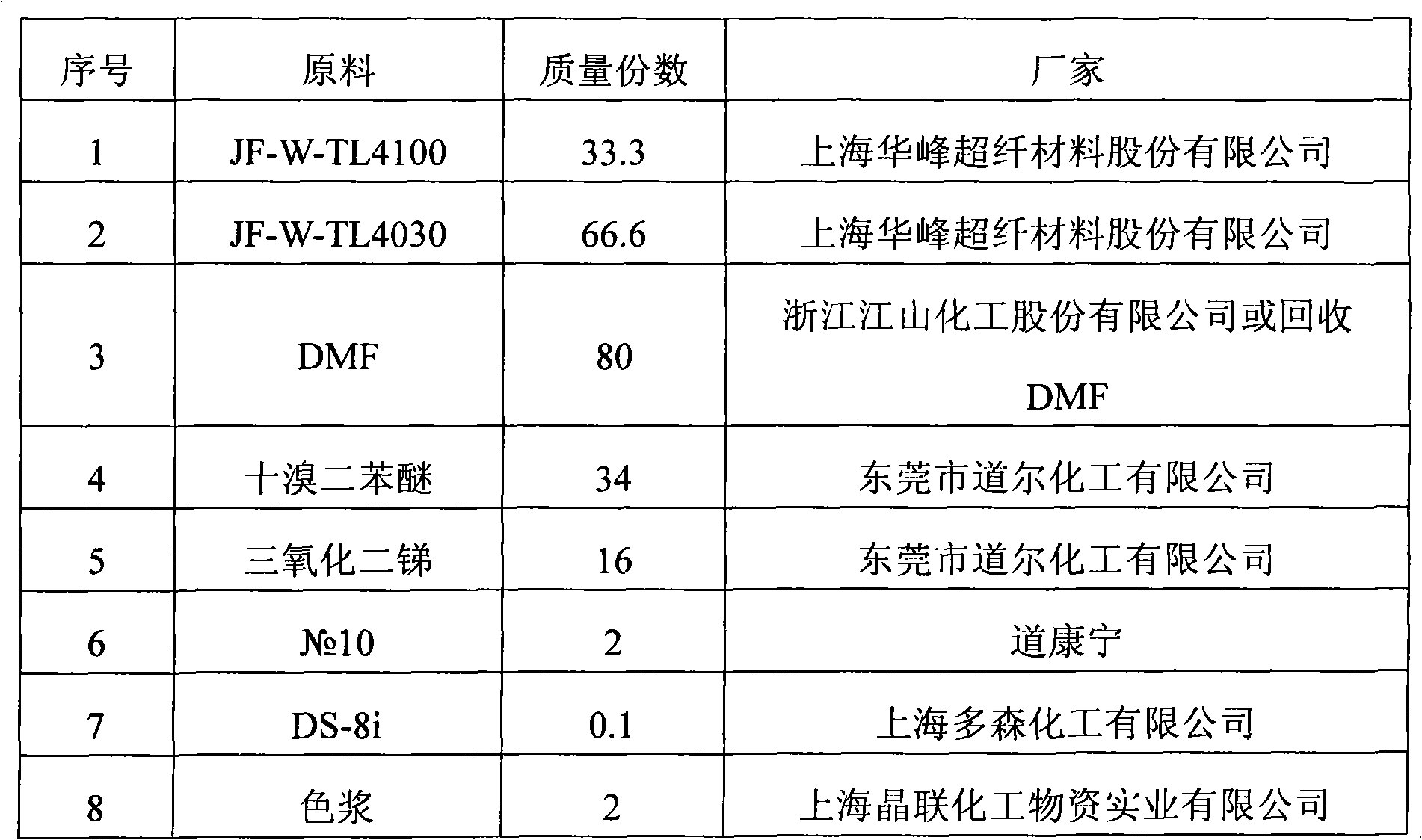

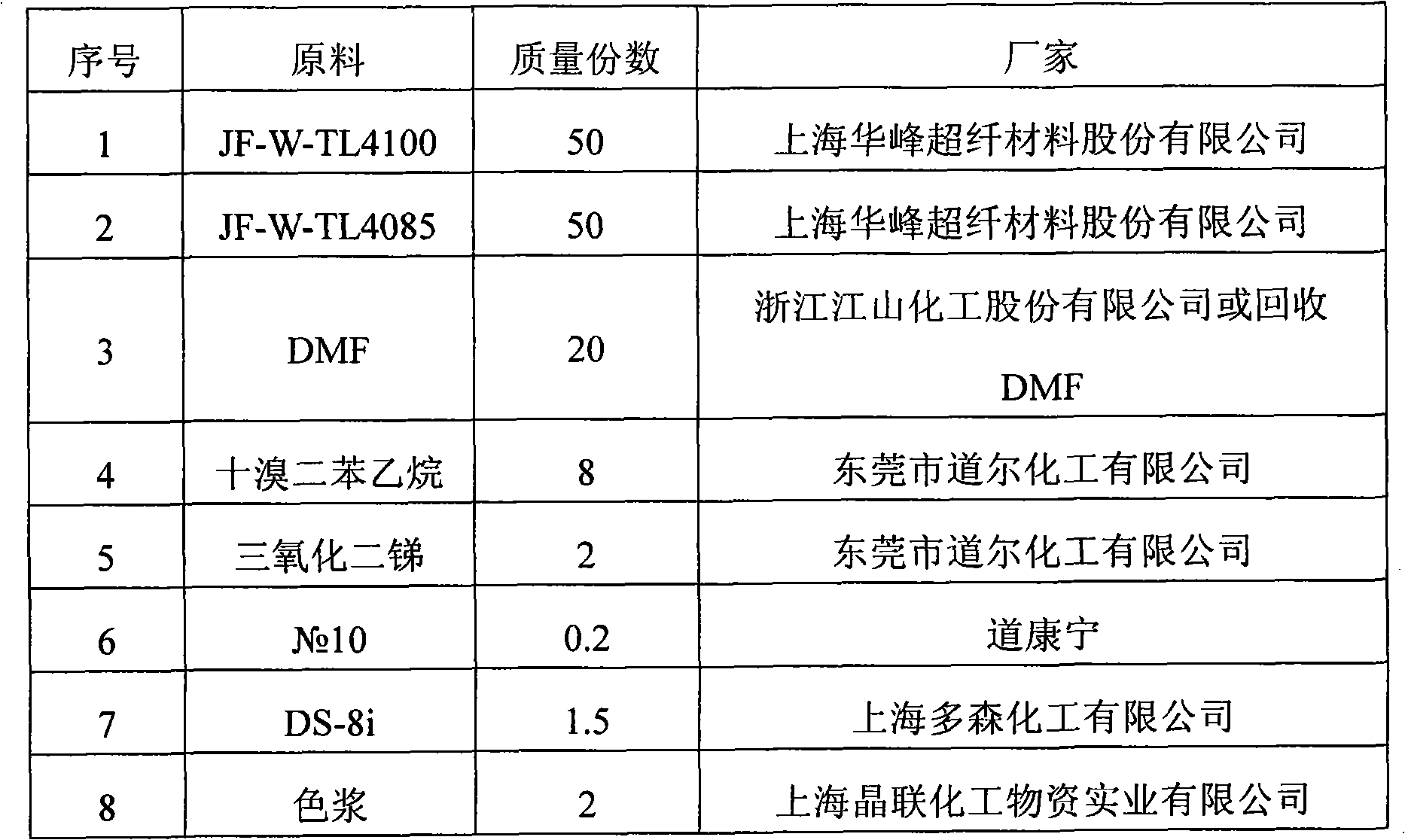

ActiveCN104146580ASoft colorGet blackoutFibre treatmentSynthetic resin layered productsPolymer sciencePolymer chemistry

The invention relates to a preparation method of a curtain, in particular to a shading intumescent coating curtain. The shading intumescent coating curtain is prepared through the following steps of grey cloth preparation, white pulp preparation and acquisition of a first coating, black pulp preparation and acquisition of a second coating, batter preparation and acquisition of a third coating, and color scraping pulp preparation and cloth cover color scraping. In the step of white pulp preparation and acquisition of the first coating, white pulp is rolled on one face of grey cloth through a coating knife compression roller, so that the first coating is acquired; in the step of black pulp preparation and acquisition of the second coating, black pulp is rolled on the first coating through the coating knife compression roller, so that the second coating is acquired; in the step of batter preparation and acquisition of the third coating, batter is rolled on the second coating through the coating knife compression roller, so that the third coating is acquired; in the step of color scraping pulp preparation and cloth cover color scraping, cloth cover color scraping is conducted on the other face of the grey cloth through a sharp knife via color scraping pulp. The prepared halogen-free flame retardant intumescent coating curtain shades light, absorbs sound, and is insulated from heat, resistant to dump, durable, small in smoke formation amount and free of generating toxic and corrosive gas in the burning process.

Owner:CHEN HONG TEXTILES TECH

Preparation method of salvia miltiorrhiza bunge vegetable dye and method for dyeing cotton fabrics using salvia miltiorrhiza bunge vegetable dye

InactiveCN101570646AHigh priceNot easy to change colorNatural dyesDyeing processSalvia miltiorrhizaMacroporous resin

The invention discloses a preparation method of a natural salvia miltiorrhiza bunge vegetable dye. Salvia miltiorrhiza bunge is used as a raw material of a natural vegetable dye to prepare the naturalsalvia miltiorrhiza bunge vegetable dye. The invention also provides a method for dyeing cotton fabrics using the natural salvia miltiorrhiza bunge vegetable dye. The natural salvia miltiorrhiza bunge vegetable dye can be prepared by one of such methods as solvent extraction method, solvent extraction, macroporous resin method, column chromatography, supercritical counter-current extraction and the like or arbitrary combination of multiple methods. The prepared natural salvia miltiorrhiza bunge vegetable dye is red fat-soluble dye. The method for dyeing cotton fabrics adopts vat dyeing. The dyed cotton fabrics are red, uniform, soft and natural in colors and high in color fastness, and are not easy to fade and change color. The natural salvia miltiorrhiza bunge vegetable dye has the advantages of innocuity and no pollution, etc, and has certain medical health care function. Besides, the dyeing method of the invention is simple and can be greatly applied to health care underwear, household textile products and the like.

Owner:FUJIAN QINGYUAN TECH

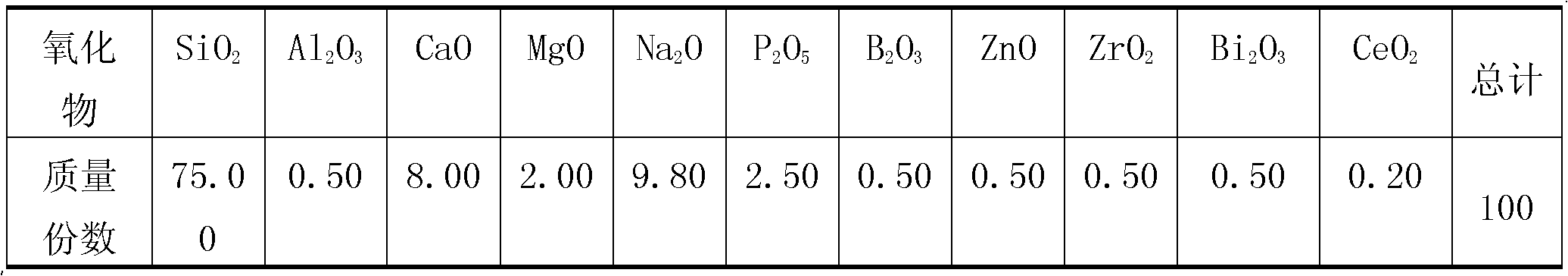

Method for preparing aventurine fluoride-free opal glass

The invention relates to a method for preparing aventurine fluoride-free opal glass. The method for preparing aventurine fluoride-free opal glass is characterized by comprising the following steps: 1) carrying out burden calculation on the ingredient contents of oxides so as to obtain a charger sheet, introducing various oxides respectively by using raw mineral materials and raw chemical materials, and weighing and mixing the oxides so as to obtain a glass batch; 2) putting the glass batch obtained in the step 1) into a horseshoe flame glass smelting kiln to carry out smelting, then enabling the obtained product to enter a cooling part, wherein the temperature of the cooling part is controlled between 1300 DEG C and 1350 DEG C; 3) uniformly adding aventurine frits with the particle size of 1-15 mm into the cooling part so as to obtain a glass flow with aventurines; and 4) enabling the glass flow with aventurines obtained in the step 3) to flow to a forming machine arranged at the lower part of the horseshoe flame glass smelting kiln by a feed channel connected with the cooling part of the horseshoe flame glass smelting kiln, thereby obtaining the aventurine fluoride-free opal glass. The aventurine fluoride-free opal glass prepared by using the method disclosed by the invention not only has the characteristics of opal glass, but also has small plate crystals, therefore, the aventurine fluoride-free opal glass is sparkling.

Owner:WUHAN UNIV OF TECH

Method for using natural grape seed dyeing extract in textile dyeing

InactiveCN101476248AImprove pollutionMeet environmental protection requirementsBleaching apparatusDyeing processGrape seedExtracted grape seeds

The invention discloses a method for dyeing fabric by natural grape seed extract. The dyeing method comprises: pre-treating fabric blank by scouring enzyme; bleaching by hydrogen peroxide solution with concentration of 27%; preparing dyeing composition; heating the prepared dyeing composition; putting the fabric into the dyeing composition and dyeing; soaping the dyed fabric circularly by soda water; and dewatering and drying the soaped fabric. The method has good environment compatibility, biodegradability and medicament health caring property; can obtain the product with high chroma brilliant color or soft color, meanwhile avoids the serious pollution caused by chemical dye, and meet the requirement of environment protection; can obtain various brilliant high chroma colors and a large number of demitints by multiple dyeing of different times and different colors; and is nontoxic, harmless, has no anaphylaxis or carcinogenicity to skin. The invention can be widely used for producing high-grade real silk product, health caring underwear, hometextile product, and ornaments.

Owner:XIAN JIHUA 3511 HOMETEXTILE

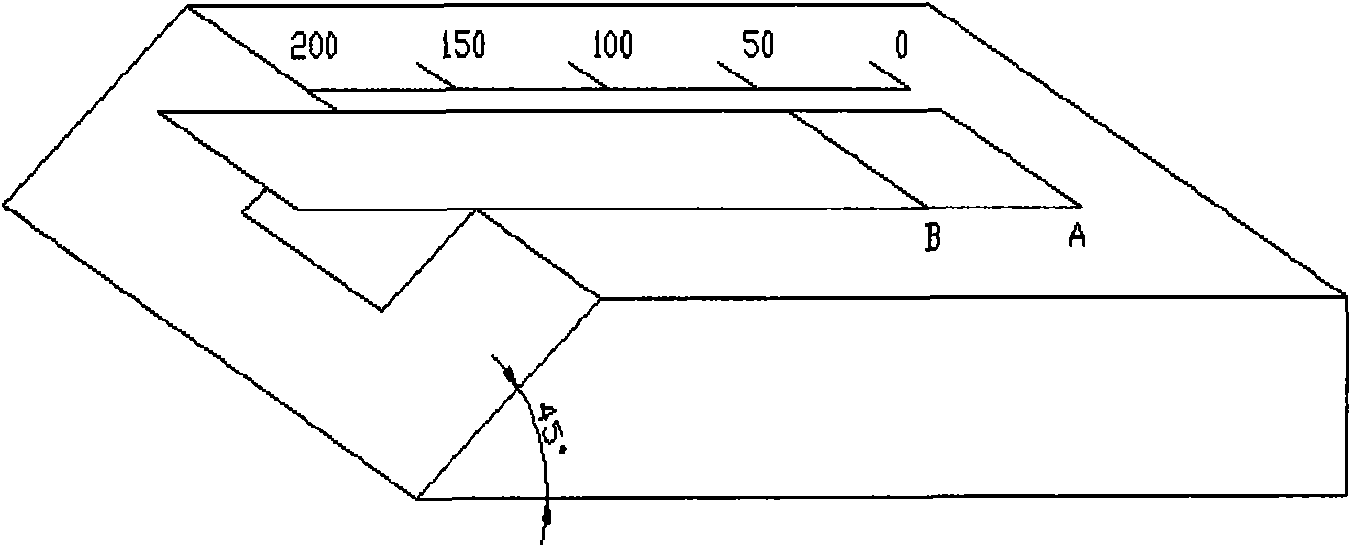

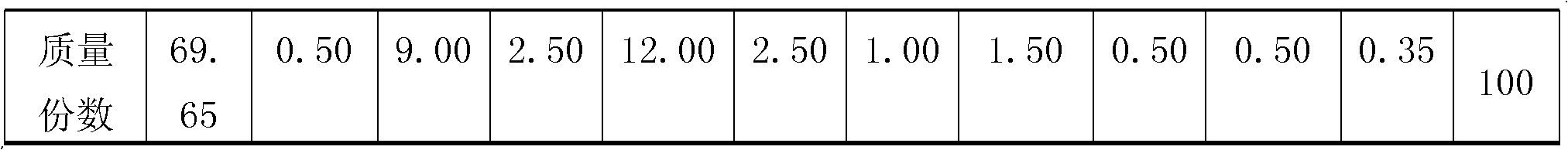

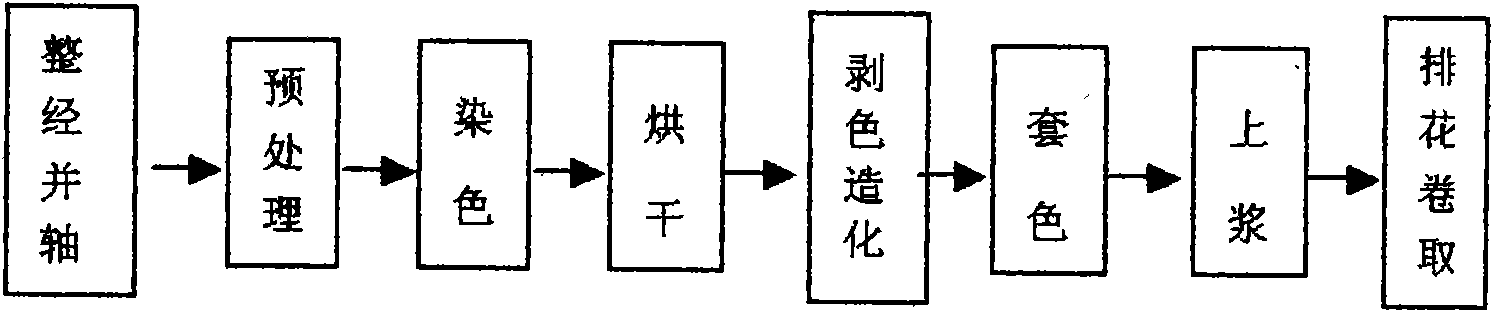

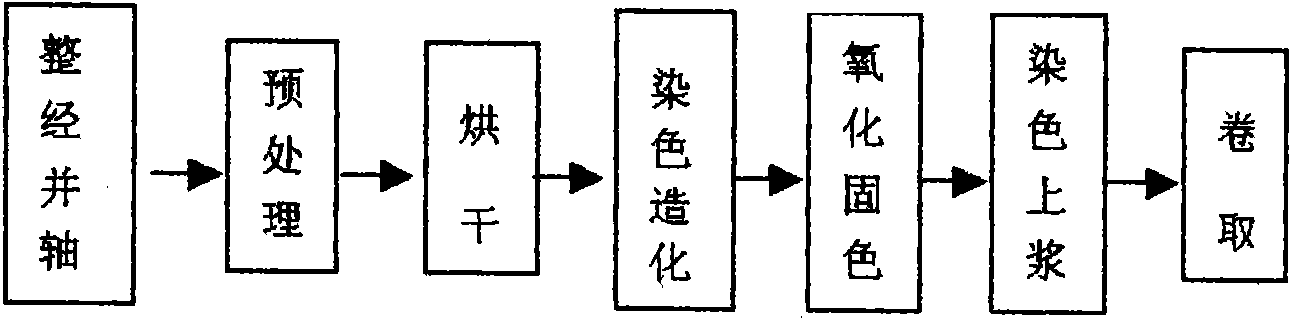

Production technology for watermark pattern cloth and production device thereof

InactiveCN101613965AClear and rich textureSoft colorOther manufacturing equipments/toolsDyeing processYarnTextile printer

The invention discloses production technology for watermark pattern cloth and a production device thereof, which belong to the technical field of textile printing and dyeing. A method thereof comprises the steps: arranging a pattern making device at the appropriate position of a sizing-dyeing combined machine; manufacturing a basic pattern with appropriate color and light and shade contrast on a cotton tape during the finishing of the dyeing and sizing of the cotton tape; using a pattern arrangement device for pattern rearrangement to reconstruct a needed fabric covering pattern; positioning various warp yarns, and coiling the warp yarns to a weaving cloth-roll; and finally obtaining finished watermark pattern cloth through registration, healding, reeding, weaving and appropriate afterfinish. The production device thereof comprises the pattern making device and the pattern arrangement device. The production technology can ensure that processes such as dyeing, pattern making and sizing are finished at one time, reduce repeated work, save a large quantity of energy sources, also has clear ridges as well as soft and natural color of the fabric covering pattern and exquisite fabric covering, but can also achieve the straightforward and unpretending style, and can also reduce the pollution and production cost.

Owner:刘林泉

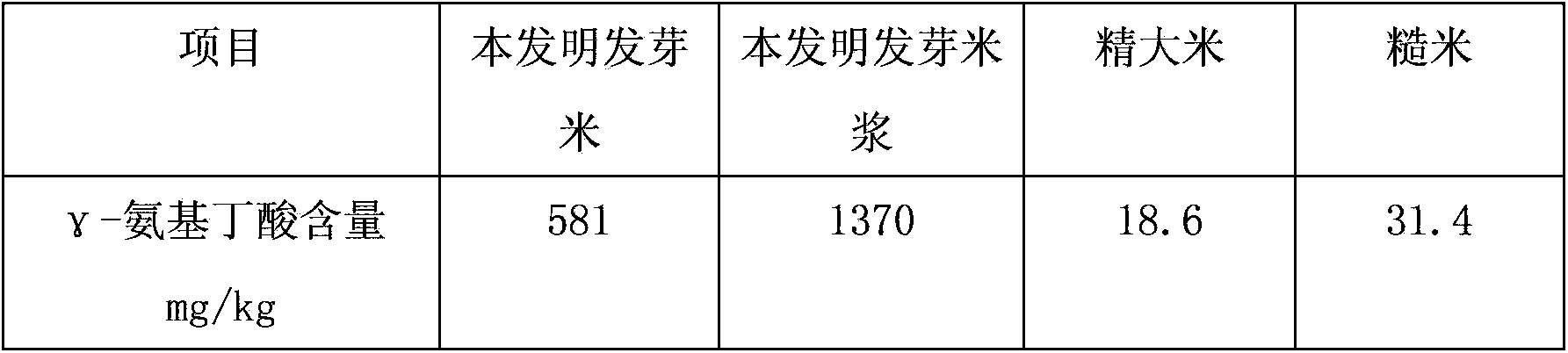

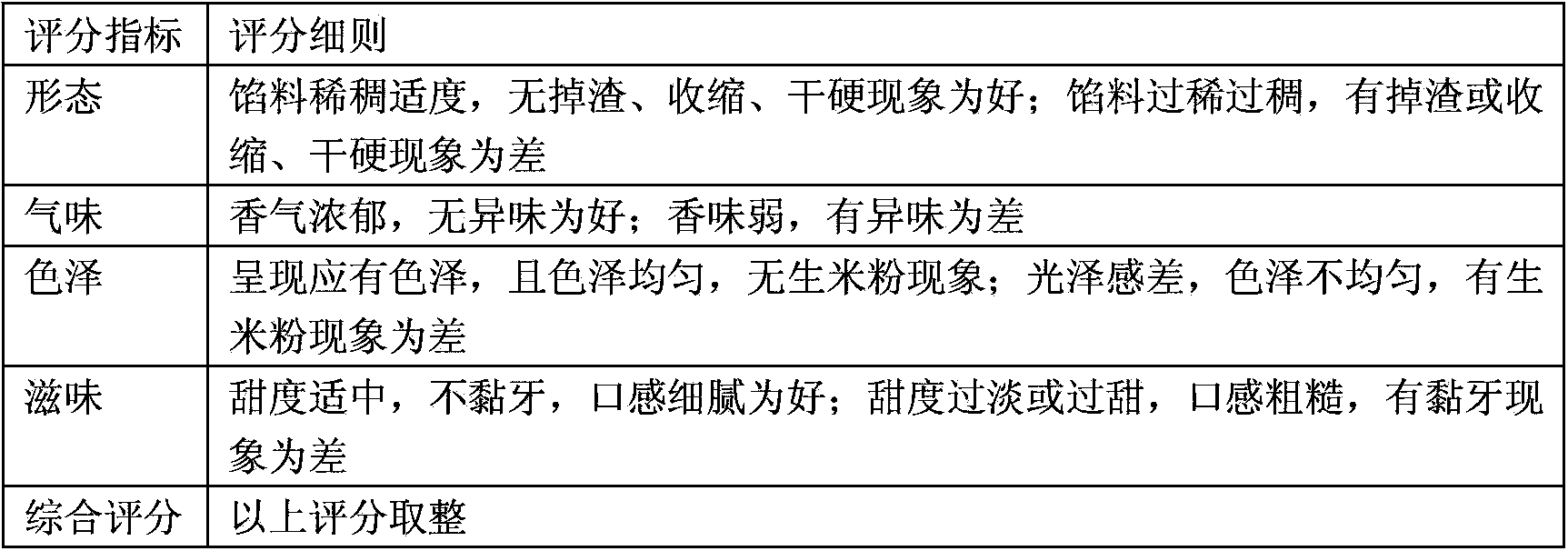

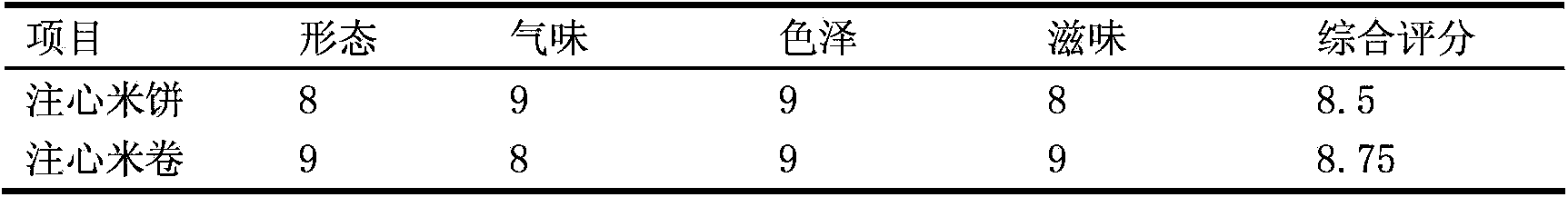

Production method of rice products rich in gamma-aminobutyric acid and products

ActiveCN103445090AMeet the requirements of healthy nutritionPromote formationFood shapingFood preparationGamma-Aminobutyric acidSprouting

The invention belongs to the technical field of food processing, and particularly relates to a production method of rice products rich in gamma-aminobutyric acid and the products. The production method comprises the following steps of: (1) cleaning and disinfecting raw materials; (2) preparing sprouting rice: (3) obtaining the dried sprouting rice by adopting a high temperature and humidity and staged drying method; (4) adding auxiliary materials to the dried sprouting rice serving as the raw material, and grinding so as to obtain rice pulp rich in gamma-aminobutyric acid; (5) adding auxiliary materials to the rice pulp as the raw material so as to prepare stuffing rich in gamma-aminobutyric acid; (6) puffing the obtained sprouting rice, and bonding by using syrup so as to form rod-shaped or spherical or massive food rich in gamma-aminobutyric acid; (7) adding auxiliary materials to the rice pulp as the raw material so as to prepare rice milk rich in gamma-aminobutyric acid; (8) adding auxiliary materials to the rice pulp as the raw material so as to prepare buccal tablets rich in gamma-aminobutyric acid. The invention also discloses a preparation method of the products.

Owner:HUAZHONG AGRI UNIV

Green tea beverage beneficial for reducing blood fat and reducing blood press

InactiveCN104957313AMellow tasteJuice is clear and brightTea extractionHigh Blood PressuresCassia tora

The invention discloses green tea beverage taking Chinese herbal medicine such as crataegus, semen cassiae, lotus leaves and apocynum venetum as raw materials. The green tea beverage has the effects of assisting blood lipid reduction and blood pressure reduction and the like, is suitable for patients suffering from high blood pressure and high blood lipid to drink and is capable for effectively improving the QOL (Quality Of Life) of the patients. Each 1000 parts by weight of the green tea beverage is prepared by the following raw materials in parts by weight: 20 parts to 30 parts of fresh green tea leaves, 20 parts to 30 parts of crataegus, 15 parts to 20 parts of semen cassiae, 10 parts to 15 parts of lyceum barbarum, 10 parts to 15 parts of lotus leaves, 10 parts to 15 parts of stevia rebaudiana, 8 parts to 10 parts of polygonum multiflorum, 8 parts to 10 parts of alisma plantago-aquatica, 5 parts to 10 parts of chrysanthemum, 10 parts to 15 parts of apocynum venetum, 3 parts to 5 parts of glycyrrhiza uralensis, 5 parts to 10 parts of phyllanthus emblica freeze-dried powder, 5 parts to 10 parts of isomalto-oligosaccharide, 1 part to 5 parts of citric acid, 1 part to 3 parts of sorbitol, 1 part to 2 parts of sodium isoascorbate and 1 part to 5 parts of laminarin. The green tea beverage disclosed by the invention not only has the functions of traditional green tea of clearing heat to relieve thirst, promoting the production of body fluid to relieve thirst and the like, but also has the function of assisting the blood lipid reduction and the blood pressure reduction, and the green tea beverage is suitable for crowd of high blood pressure, high blood fat and high blood sugar to drink and is health beverage which is remarkable in healthcare effect and green and environment-friendly.

Owner:QINGDAO JIARUI BIOLOGICAL TECH

Method for preparing photinia fruit natural dye and application of photinia fruit natural dye

The invention relates to the field of natural dyes and application thereof and aims to provide a method for preparing a photinia fruit natural dye and application of the photinia fruit natural dye. The preparation method comprises the following steps of: (1) washing and airing fresh photinia fruits and dried photinia fruits, and mechanically crushing the fruits; and (2) adding the crushed photinia fruits into aqueous solution of ethanol for reflux extraction, raising the temperature of the extract to between 70 and 90 DEG C, keeping the temperature, filtering and distilling under reduced pressure to make the volume of concentrated solution 1 / 6 to 1 / 2 of the original volume of the extract so as to obtain the concentrated photinia fruit natural dye. The method for preparing the photinia fruit natural dye has the advantages of simple extraction technology, extraction efficiency obviously higher than that of ethanol reflux and other methods, and no environmental pollution in the extraction process; and the extract has the advantages of good color fastness to protein fibers, capacity of increasing color spectrum after dyeing by using environment-friendly dye mordant treatment, gentle color and safe wear of the dyed fabrics without carcinogenic, teratogenetic actions or anaphylactic reaction, high ecological environment compatibility, biodegradation, low price, full utilization of natural resources and wide market prospect.

Owner:ZHEJIANG SCI-TECH UNIV

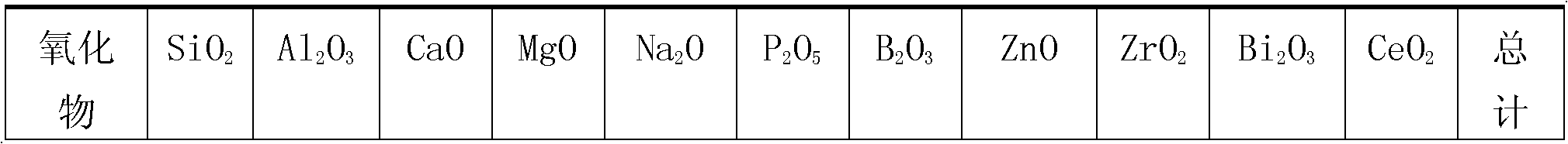

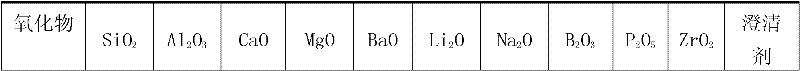

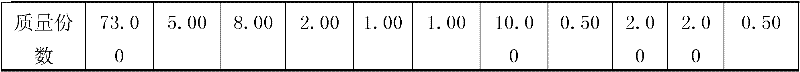

A kind of preparation method of zirconium phosphorus fluorine-free opacity glass

The invention relates to a preparation method of Zr-P fluoride-free opaque glass, comprising the following steps: 1) using the following ingredients comprising 63-73 weight portions of silica, 5.0-8.0 weight portions of alumina, 8.0-12.0 weight portions of calcium oxide, 2.0-5.0 weight portions of magnesium oxide, 1.0-2.0 weight portions of barium oxide, 1.0-3.0 weight portions of lithium oxide, 10.0-15.0 weight portions of sodium oxide, 0.5-1.0 weight portions of boron oxide, 2.0-6.0 weight portions of phosphoric pentoxide, 2.0-5.0 weight portions of zirconia and 0.5-1.0 weight portions of clarificant; 2) controlling the glass melting temperature within 1530-1550 DEG C and the cooling temperature within 1280-1350 DEG C; 3) molding the raw materials; 4) putting the molded opaque glass in a crystallization kiln for heat treatment; and 5) cooling the opaque glass processed by micritization until the annealing high-limit temperature reaches 580-600 DEG C, then carrying out annealing, so as to obtain the Zr-P fluoride-free opaque glass after annealing. The Zr-P fluoride-free opaque glass has the characteristics of uniform phase separation and delicate structure.

Owner:WUHAN UNIV OF TECH

Paper pulp prepared from corn stalks and preparation method of paper pulp

ActiveCN103572639AHigh bulkHigh tensile strengthWashing/displacing pulp-treating liquorsPulp bleachingBlack liquorAfter treatment

The invention belongs to the field of papermaking, and in particular relates to a paper pulp prepared from corn stalks and a preparation method of the paper pump. The preparation method of the corn stalk paper pulp comprises the steps of crushing, yellow corn silage fermentation, stewing, black liquid extraction and after-treatment. According to the corn stalk paper pulp prepared by the preparation method disclosed by the invention, yellow corn silage stalks are used as raw materials, the pulp whiteness is 35-65% of ISO, the loose depth is 1.50-3.15cm<3> / g, the folding strength is 0-50 times, the breaking length is 1.0-7.5km, the tear strength index is 2.0-5.2mN.m<2> / g, and the ash content is 2-10%. The strength parameter of the corn stalk paper pulp provided by the invention can compete with that of hardwood pulp, so that the corn stalk paper pulp is a high-grade paper pulp and can be prepared into high-grade paper for cultural use and daily use.

Owner:黑龙江泉林生态农业有限公司

Production method of low-shrinkage rate dacron complex fiber

InactiveCN105177783AObvious drapeApparent comfortArtificial filament heat treatmentMelt spinning methodsComing outFiber

The present invention relates to the field of polyester fiber production equipment, and especially discloses a production method of low-shrinkage rate dacron complex fibers. Semidull polyester melts enter into a static mixer, are then conveyed into a spinning manifold through a melt distributor, and are extruded onto a POY spinneret and an FDY spinneret; POY fibers coming out of the POY spinneret are cooled by cross air blow and oiled by an oil nozzle, pass a yarn guide, a pre-network and another yarn guide; FDY fibers coming out of the FDY spinneret are cooled by cross air blow and oiled by an oil nozzle, pass a yarn guide, a pre-network and a GR1 hot roller; and the POY fibers coming out of the yarn guide and the FDY fibers coming out of the GR1 hot roller enter into a stranding comb-shaped yarn guide together, and then pass a yarn guide disc, an intermediate network, a GR2 hot roller and a main network, thus to be rolled for shaping. According to the production method, the obtained fibers are different in boiling water shrinkage, and thus a shell fabric is good in velvet feeling, soft in hand feeling, firm, anti-wrinkle and wear-resisting.

Owner:桐昆集团浙江恒盛化纤有限公司

Decorative material and prepn. thereof

ActiveCN1834056ACrystal clear textureSmooth textureMohs scale of mineral hardnessAlkaline earth metal

This invention relates to a kind of decoration material and its preparation method, which is attributed to the field of inorganic nonmetallic materials. Counting in terms of oxide net content, the terminal product comprises: 45~72% SiO2, 2~20% R2O, 5~40% RO and 0~10% Al2O3, where R2 represents alkali metals and R represents alkaline metals. It can also contains 0.0001~7% Fe2O3, 0~7% ZnO, 0~7% BaO, 0~7% TiO2, 0~8% ZrO2, 0~2% HfO2, 0~7% B2O3 and some fluoride. Thanks to reasonable composition and compact texture, properties such as modulus of rupture, compression strength after drying and Mohs' hardness of the decoration materials are better than those of granite and marble.

Owner:JIUJIANG GOLDEN PHOENIX DECORATION MATERIAL CO LTD

Method for producing marble art paper

The invention relates to a method for producing marble art paper, comprising the following steps: selecting 20% of softwood pulp and 80% of bleached eucalyptus pulp, controlling the beating degree of the pulps within 34-35 DEG SR, the screening concentration of the pulps at 0.9-1.0%, the quantification of paper at 95 g / m<2>. And the surface absorption weight at 20-30 g / m<2>; and dyeing the paper twice, wherein during the first dyeing, a dye is added to a paper machine flow which is conveyed to a high tank, and the liquid dye is directly added to the high tank to be mixed with the pulps, and during the second dyeing, at an initial phase of dehydration and screening of the pulp flow, the dye is sprayed onto a paper machine screen part through a spraying device, and natural and soft simulated cloud patterns or marble patterns are formed through shaking the paper machine screen part and naturally dispersing the dye so as to obtain the marble art paper. The marble art paper has the advantages of easiness in production, reliable production process, high operability, soft paper surface color, abundant colors and cloud pattern effects. The marble art paper is mainly applied to package of special products, book cover, high-order offices and the like.

Owner:SHANDONG KAILI SPECIAL PAPER

Pug formula of bone porcelain and preparation technology thereof

The invention discloses a pug formula of bone porcelain and preparation technology thereof. The pug formula comprises the following chemical compositions in percentage by weight: 18 to 30 percent of SiO2, 1 to 3 percent of K2O, 15 to 25 percent of Al2O3, 1 to 3 percent of Na2O, 28 to 38 percent of CaO, and 18 to 24 percent of P2O5. The preparation technology comprises the steps of: preparing raw materials, mixing, adding water until the concentration is lower than 15 percent, removing iron, pressing pug to drain the water until the water content is between 20 and 23 percent, performing vacuum pug milling for 3 to 5 times, and obtaining a finished pug product. The white content of a test piece produced by adopting the pug can reach more than 95.5, the white content of the porcelain can reach more than 93, and the produced porcelain has high light transmittance as well as good strength and thermal stability, and has the characteristics of exquisite porcelain, soft color and luster and the like.

Owner:郑小凌

Whitened regenerated terylene staple fiber

InactiveCN102936758AEffective absorptionIt has the effect of white as porcelainMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterMasterbatch

The invention relates to the field of terylene production, and especially relates to whitened regenerated terylene staple fiber. The staple fiber is prepared through the steps that: a polyester masterbatch is mixed with regenerated polyester bottle chips; the obtained material is dried, and is subjected to melt spinning in a screw extruder, such that the staple fiber is obtained. The polyester masterbatch is prepared by melting granulation by using polyester powder and the following material components: a component A composed of a fluorescent whitening agent, a brightening agent and a heat stabilizer, a component B comprising polyester-fiber-use color-masterbatch-grade titanium dioxide, and a component C comprising a color enhancing agent. A weight ratio of the component A to the component B to the component C is (1-15%):(15-45%):(0.001-0.01%). The stable fiber provided by the invention has the advantages that: the finished fiber product has a porcelain-white and bright color, wherein the whiteness is higher than original polyester fiber.

Owner:NINGBO DAFA CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com