Patents

Literature

151 results about "Apocynum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Apocynum, commonly known as dogbane or Indian hemp, is a small genus of the flowering plant family Apocynaceae. Its name comes from Ancient Greek ἀπόκυνον apókunon, from ἀπο- apo- "away" and κύων kúōn "dog", referring to dogbane (Cionura erecta), which was used to poison dogs. The genus is native to North America, temperate Asia, and southeastern Europe.

Apocynum extract and extracting method thereof

InactiveCN1634325ARetain pharmacological activityImprove use valueNervous disorderMetabolism disorderHyperosideHydrolysis

The invention relates toa an Apocynum extract and extracting method, which consists of, (1) determining the extract with hyperin as the representing composition, the content of flavones in the extract is 35-90%, (2) after the complete hydrolysis of the extract, the content of meletin compound is 30-80%, (3) the content of hyperin in the extract is 15-55%.

Owner:李青山

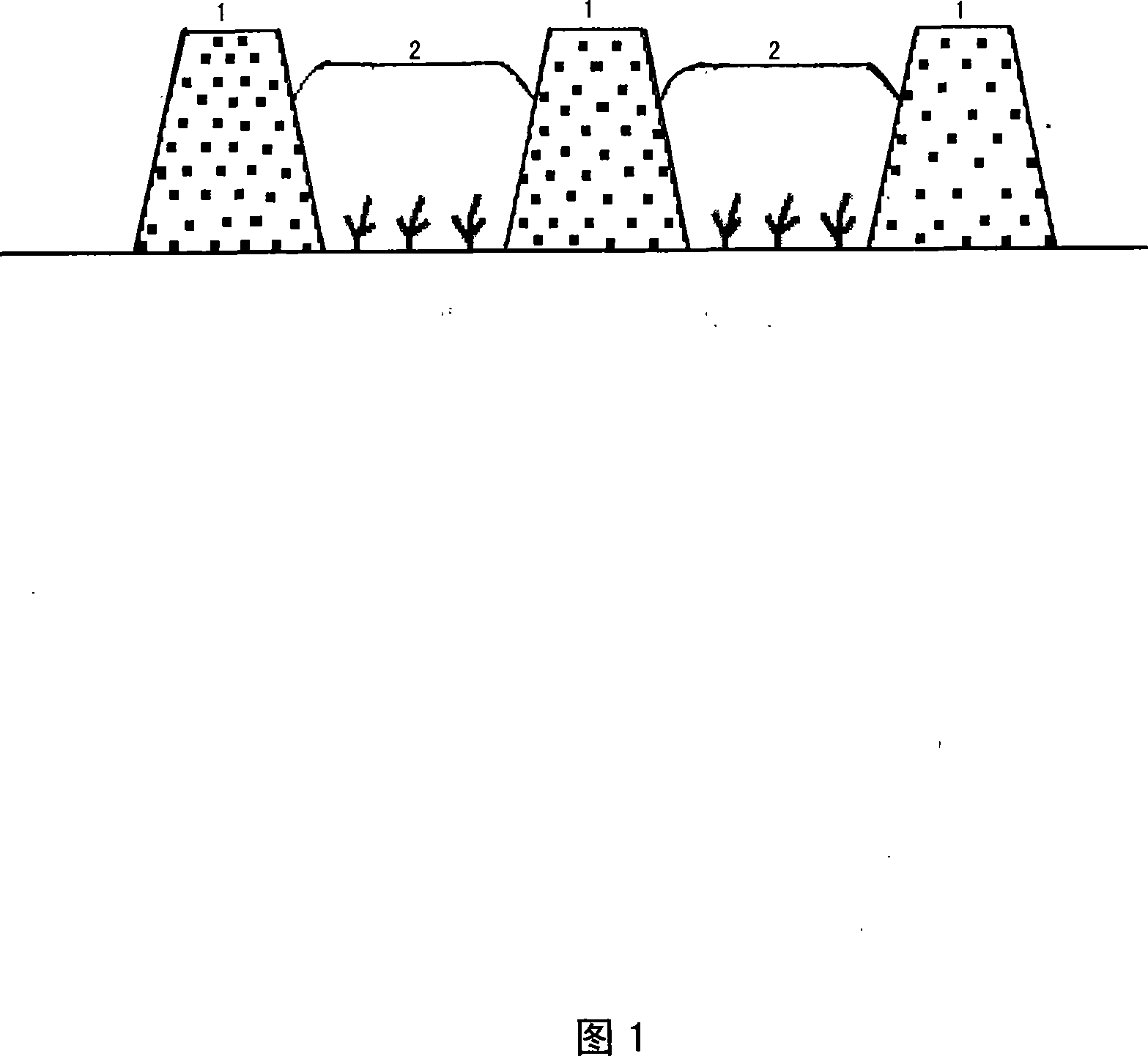

Method for saline-alkali land vegetation recovery by using apocynum paper web for sock growing nursery and breeding

InactiveCN1926944AImprove salt and alkali resistanceImprove survival rateSowingContaminated soil reclamationVegetationEcological environment

The invention relates to a method for using apocynum paper cylinder cultivation technique to recover the plant at alkaline land. Wherein, it comprises collecting apocynum seed, preparing cultivate soil, preparing seed bed, planting paper cylinder, seeding management, finishing land, transplanting, and managing the field. It is based on the germ and grow rule of apocynum seed, uses paper cylinder cultivation technique, to meet the growing conditions, to successfully cultivate the apocynum seeding. The invention can artificially plant apocynum on alkaline land, to improve the ecologic environment of alkaline area.

Owner:NORTHEAST NORMAL UNIVERSITY

Pure traditional Chinese medicine preparation for treating hyperlipemia

InactiveCN101455791AWith promoting blood circulation and removing stasisReduce cholesterolPowder deliveryMetabolism disorderSalvia miltiorrhizaSide effect

The invention provides a pure traditional Chinese medicine preparation for treating hyperlipemia, and is prepared from the following traditional Chinese medicine raw materials: cassia seed, Alisma orientale, radix polygoni multiflori, cattail pollen, evening primrose, hawthorn, folium ginkgo, rhubarb, Viscum album, Salvia miltiorrhiza, apocynum, lotus leaf, polyporus lucidus, rhizoma gastrodiae, plantain, dried orange peel, medlar, achyranthes, radix bupleuri, medicated leaven, safflower, giant knotweed, and malt. The preparation is prepared by using traditional Chinese herbal medicines as raw materials through scientific prescription composing and repeated verification of clinical trial, and accords with the prior theory of the traditional Chinese medicine. After the medicines are combined, medicine effect has synergic action, and the pure traditional Chinese medicine preparation has functions of promoting blood circulation by removing blood stasis, reducing cholesterol, regulating and lowering blood fat, and preventing atherosclerosis. The preparation has the outstanding advantages of no toxic side effect, high radical cure efficiency, low treatment cost, and short treatment course, so the preparation has good social benefit after wide popularization.

Owner:朱新华

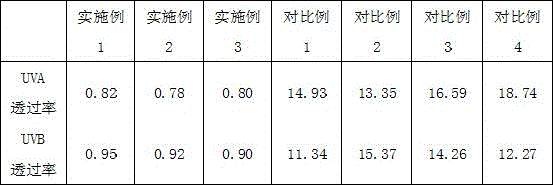

Ultraviolet-proof polyester-cotton fabric and preparation method thereof

InactiveCN105625032AStrong antibacterial and anti-ultraviolet effectGood hygroscopicityBiochemical fibre treatmentLight resistant fibresWater basedPolyethylene glycol

The invention relates to ultraviolet-proof polyester-cotton fabric and a preparation method thereof. The ultraviolet-proof polyester-cotton fabric is prepared by blending the following raw materials in parts by weight: 60-80 parts of polyester fiber, 40-60 parts of long-staple fiber, 5-15 parts of polyamide fiber, 5-15 parts of linen fiber, 5-15 parts of ramie fiber and 5-15 parts of apocynum fiber, and then treating by using an antibacterial ultraviolet-proof finishing solution, wherein the antibacterial ultraviolet-proof finishing solution contains 5-10 parts of chitosan, 5-10 parts of tea polyphenol, 0.5-3 parts of 2-hydroxy-4-methoxy diphenylketone, 0.5-3 parts of phenyl-o-hydroxybenzoate, 0.5-2 parts of sodium tripolyphosphate, 5-8 parts of myristyl trimethyl ammonium chloride, 5-10 parts of polyethylene glycol, 5-15 parts of nano-titanium dioxide, 3-8 parts of diethanolamide cocoate and 5-10 parts of water-based polyurethane. The ultraviolet-proof polyester-cotton fabric has a super-strong antimicrobial and ultraviolet-proof efficacy, is anti-pilling, breathable, good in moisture absorption, soft, comfortable and durable, and is very suitable for production of various kinds of overclothes, shirts, working clothes, curtains and the like.

Owner:卢洁

Raise seedling method for kendir in alkaline land

InactiveCN101213916ARational development and utilizationEffective development and utilizationPlantingHorticultureSulfate radicalsSalt content

The present invention relates to a seedling-raising method for the apocynum in kaline soil. The method comprises the steps of the selection of the seed, establishment of the seedling bed of apocynum, plantation, selection of the plantation season, field management, etc. During the period from 2004 to 2006, the present invention is undertaken experiment and research on the kaline ground that is located at the edge of the desert in Beijiang District of Xinjiang Xinjiang Uygur Autonomous Region with the salt content of 25 g / kg and the content of the sulfate radical ion, which is succeeded. At present, the successfully-planted apocynum is flowered and fruited, which provides a successful technical example for the reasonable and effective development and utilization of the kaline soil in Beijiang.

Owner:XINJIANG INST OF ECOLOGY & GEOGRAPHY CHINESE ACAD OF SCI

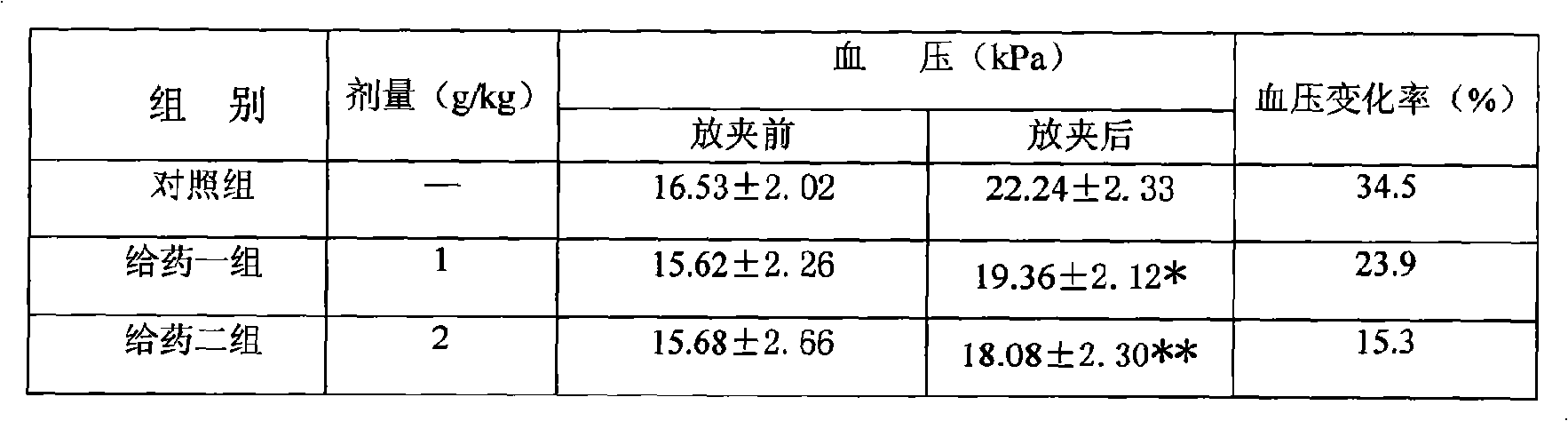

Traditional Chinese medicine for treating hyperpiesis and preparation method

InactiveCN101559182AAccurate doseGood effectAnthropod material medical ingredientsCardiovascular disorderPropolisAdemetionine

The invention relates to a traditional Chinese medicine for treating hyperpiesis and a preparation method, the medicine can effectively treat hyperpiesis and has double efficacy of herbal cuisine and diet therapy in treating hyperpiesis. The invention comprises the following bulk drugs: 10-45 of propolis powder, 9-40 of natto powder, 9-40 of wild jujube seed, 9-40 of gastrodia tuber, 8-30 of corn stigma, 8-30 of cassia seed, 8-25 of pagodatree flower powder, 8-25 of kudzuvine root, 5-15 of gambir plant, 5-15 of scutellaria laterifolia, 5-15 of haw, 2-10 of apocynum, 2-10 of earthworm, 2-10 of evodia fruit, 8-25 of selfheal, 5-15 of Chinese gentian root, 5-15 of antelope horn, 5-15 of bupleurum, 5-15 of red-rooted salvia, 2-10 of radish seed and 2-10 of Chinese magnoliavine, wherein the unit of weight is parts by weight.

Owner:武兴战

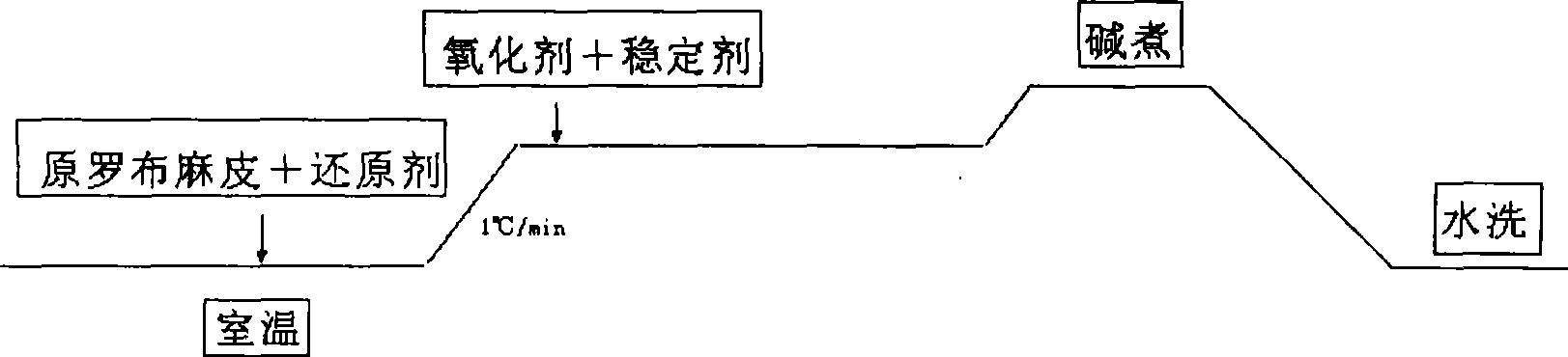

Preparation of kendir spinnable fiber

The invention discloses a method for preparing an apocynum spinnable fiber, which comprises the following processes: activating treatment on an original apocynum skin, soda boiling, washing and dehydration drying. The activating treatment process of the original apocynum skin is as follows: at room temperature, dipping the original apocynum skin in water, adding a reducing agent to the water, raising the temperature to be between 65 and 75 DEG C, adding an oxidant to the mixture, keeping the temperature for at least 80 minutes, and cooling the mixture to the room temperature. Compared with the prior art, the fiber preparation process of the invention has the advantages of simplifying the technical process, greatly reducing the process time, lowering the temperature of a treatment fluid, achieving the aim of saving energy and reducing consumption, and improving the fiber forming rate for the preparation of the apocynum fiber, along with good spinning performance and good handfeel and glossiness.

Owner:WUHU FUCHUN DYEING & WEAVING

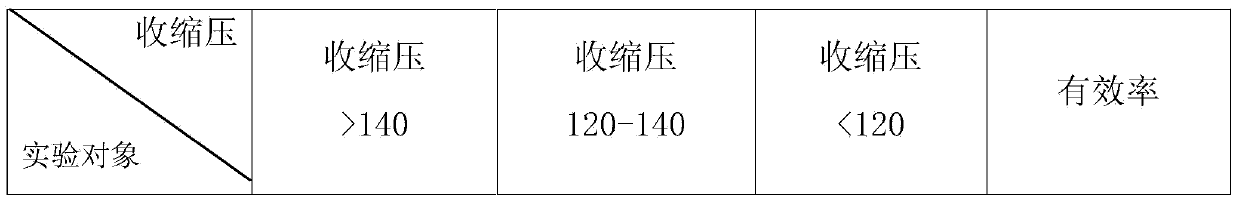

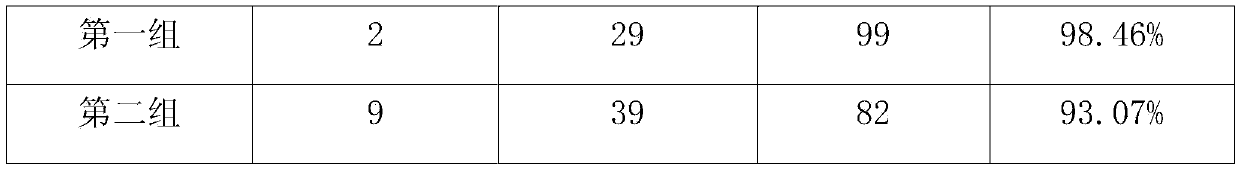

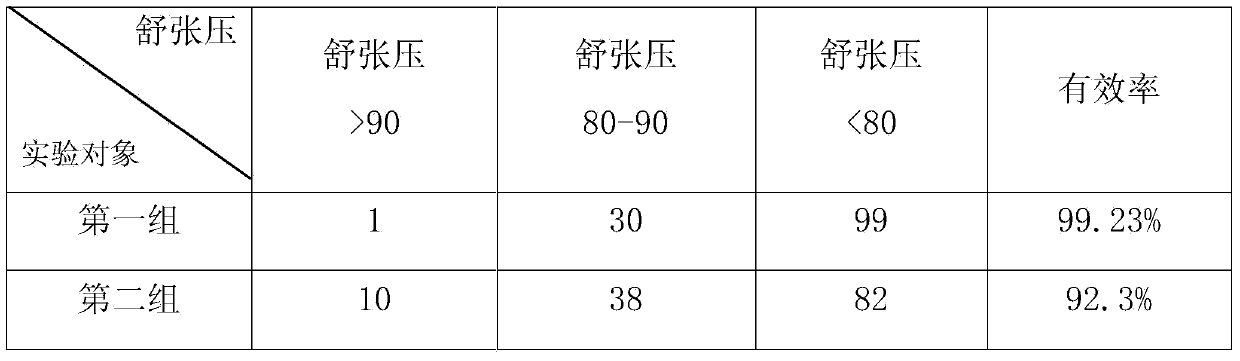

Hypotensive medicine-filled pillow

InactiveCN101612227ACertain curative effectTo regulate Qi and bloodPillowsHeavy metal active ingredientsSalvia miltiorrhizaMotherwort

The invention discloses a hypotensive medicine-filled pillow, which relates to a medicine-filled pillow for treating hypertension. The hypotensive medicine-filled pillow is characterized in that a pillow is filled with a Chinese medicament prepared by crushing and mixing, wherein the Chinese medicament comprises the following components in percentage by weight: 2.0 to 2.5 percent of loranthus parasiticus, 2.0 to 2.5 percent of radix salviae miltiorrhizae, 3.0 to 3.5 percent of Hangzhou chrysanthemum, 1.0 to 1.5 percent of cassia seed, 1.0 to 1.5 percent of broadleaf holly leaf, 2.0 to 2.5 percent of motherwort, 2.0 to 2.5 percent of magnet, 2.0 to 2.5 percent of apocynum, 2.0 to 2.5 percent of selfheal, 1.0 to 1.5 percent of uncaria, 0.5 to 0.8 percent of rhizoma ligustici wallichii, 1.0 to 1.5 percent of radix scutellariae, and 0.5 to 0.8 percent of chaff flower root, wherein the total weight of each medicine-filled pillow is 1.5 to 1.8 kilograms, and the medicaments are crushed into granules with the diameter of less than 0.5 centimeter and are filled into a ventilating cotton cloth bag. The medicine-filled pillow has the hypotensive effective rate reaching 98 percent, and can relieve a plurality of accompanied symptoms caused by the hypertension.

Owner:沈长青

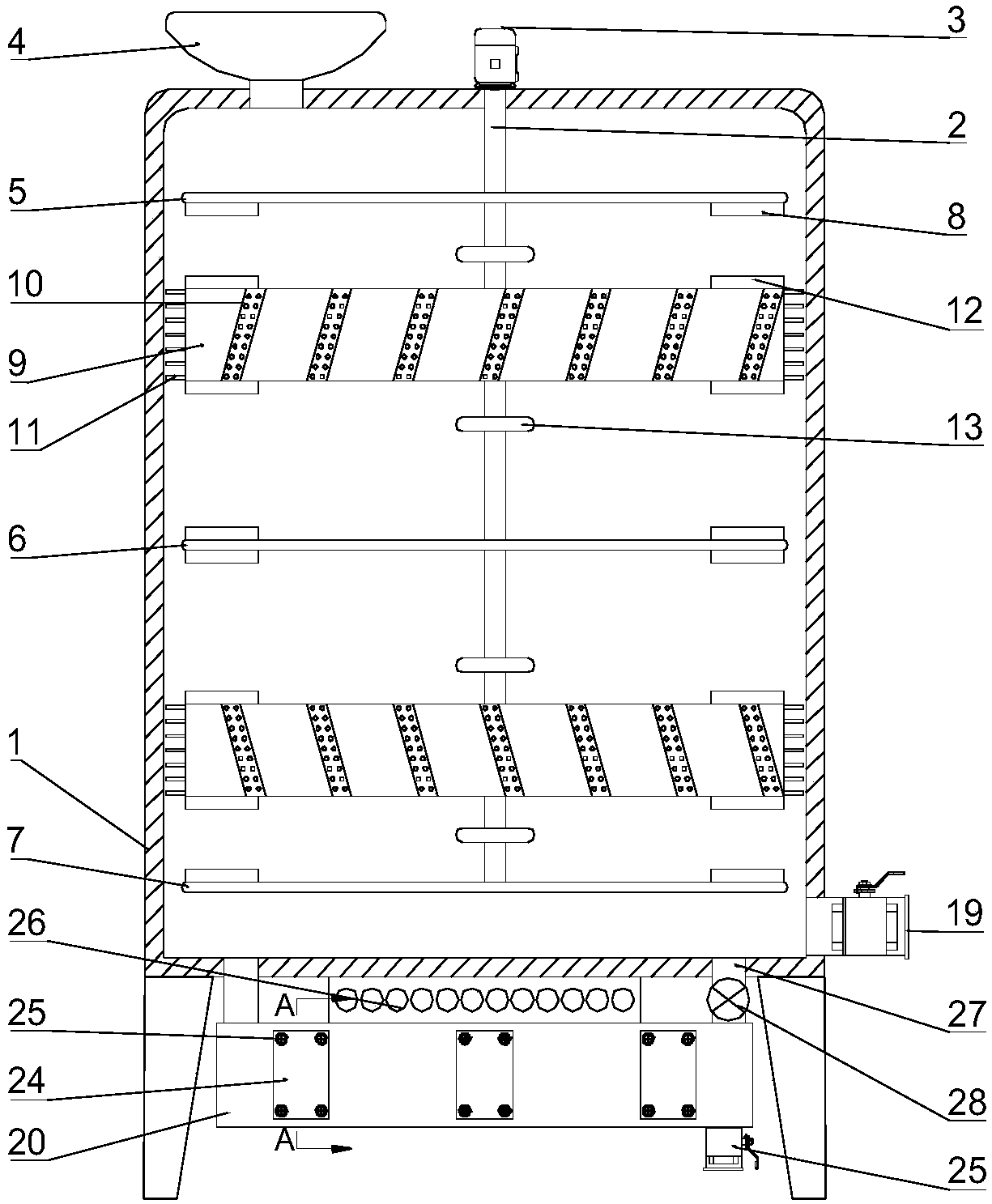

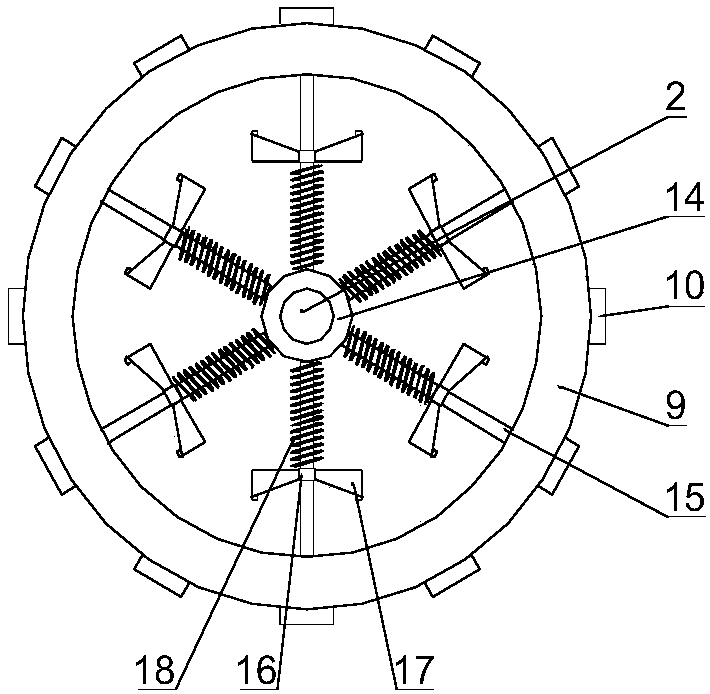

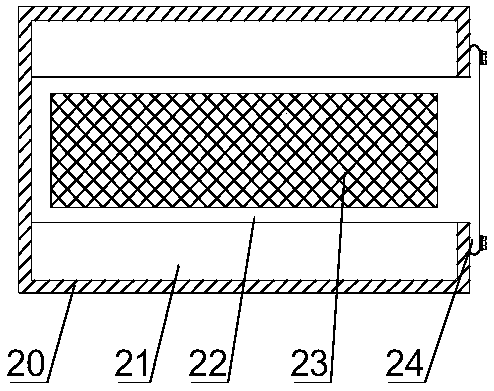

Apocynum venetum cooking machine for textile processing

The invention discloses an apocynum cooking machine for textile processing, which comprises a cooking box, a rotating ring, a rotating shaft, a connecting rod, a sliding sleeve, a triangular plate, a coil spring, a limit plate and a filtering device. The triangular plate protrudes a certain distance and the triangular plate is enlarged The mixing area enables the apocynum to follow the uncertain flow in the hot water, improving the cooking efficiency of the apocynum, and at this time the bristles will scrape off the apocynum fibers adhered to the inner wall of the cooking box. When there are many apocynum fibers and it is difficult to scrape off the bristles, the rotating ring moves up and down to scrape off the apocynum fibers adhering to the inner wall of the cooking box, and when the water in the cooking box passes through the filter box, the impurities are retained by the filter , by removing the fastening bolts, the embedded plate can be easily pulled out, and the impurities on the filter net can be cleaned easily, the operation is simple and convenient, and it has good practical effect.

Owner:喻为科技服务(上海)有限公司

Antimicrobial and moisture-absorbing bath towel fabric

ActiveCN108095617AInhibitionGood hygroscopicityElectroconductive/antistatic filament manufactureBiochemical fibre treatmentPolyethylene terephthalate glycolPolyethylene terephthalate

The invention relates to the technical field of bath towel fabrics, and in particular to an antimicrobial and moisture-absorbing bath towel fabric. The bath towel fabric is formed by blending antimicrobial modified polyurethane fibers, polyethylene terephthalate fibers, cotton fibers, apocynum venetum fibers and bamboo fibers, wherein the cotton fibers become available as being soaked in antimicrobial material liquid and dried; and the antimicrobial modified polyurethane fibers are added with nano bamboo charcoal particles, nano titanium oxide, magnetite powder, lignin powder, boric acid powder, benzalkonium chloride powder and diatomite powder. The bath towel fabric provided by the invention, through combined actions of the antimicrobial modified polyurethane fibers, the apocynum venetumfibers, the bamboo fibers and the cotton fibers coated with the antimicrobial material liquid, can inhibit the generation of bacteria, and moreover, the bath towel fabric is good in moisture-absorbingperformance and is comfortable and healthy to use.

Owner:HUZHOU KEBO INFORMATION TECH CO LTD

Method for fine spinning weft-elastic wool fabric of T-400 kendyr/ blended cotton yarn and botany

The invention relates to a method for producing T-400, apocynum / llama yarn, and hosiery yarn spinning wool fabric, comprising: (1), the bended yarn of apocynum and llama yarn, while they are in the ratio of 25-40 / 65-75, the spinning uses tight distance, heavy compression, short section (160-200%)x(0.8-2.0cm), and the thin section (-30-60%)x(20-45cm); (2), using multi-path latitude selection and the match of bigger and smaller cylindes, the warp uses finished spinned hosiery yarn, the yarn branches as 60S / 2-120S / 2, the latitude yarn uses apocynum / llama yarn and the T-400 wire to be interval processed, the yarn branches as 20S / 2-45S / 2 and 90S / 2-120S / 2; (3) after-cleaning uses low-temperature genapping while the speed in 95-120m / min, flatting, washing, burning and increasing the range of machine when baking, overfeeding 10-15%, the temperature of burning is 80-90Deg. C, the shaping temperature is 160-170Deg. C, braising in pot. The final product comprises: apocynum / llama yarn in 25-40 deals, T-400 in 10-20 deals, and the finished spined hosiery yarn in 40-05 deals. The invention has better crease resistance, drapability, flexibility and size stability.

Owner:凯诺科技股份有限公司

Method for extracting whole genome DNA from Apocymum venetum L. leaves

InactiveCN1970751AExtraction successfulFully removedFermentationPlant genotype modificationSodium acetateReducing agent

The invention discloses an extracting method of entire genome DNA from apocynum leaf, which comprises the following steps: grinding apocynum leaf; adding cracking liquid to crack; adding reducer and protein hydrolase to dispose for a while; removing protein through chloroform / isoamyl alcohol solution; removing polysaccharide through sodium acetate solution; sedimenting DNA through anhydrous alcohol or isopropyl alcohol; dissolving DNA through TE solution.

Owner:NANJING NORMAL UNIVERSITY

Degumming technology added nono-powder of apocynum by ultrasonic and microwave

InactiveCN1920126AAvoid damageLow costFibre treatment to obtain bast fibreMicrowaveVolumetric Mass Density

The invention relates to a method for using ultrasonic wave and microwave to degelatinize apocynum, used in one additional nanometer material, wherein it is characterized in that: putting the apocynum into sealed container with diluted alkali liquid of stannic oxide nanometer powder; heating with microwave; washing with water; washing with acid, and putting it into the washing liquid whose alkali density is 1.0-2.0% with stannic oxide nanometer powder; treating with utlrasonic wave with low frequency; treating with ultrasonic wave with high frquency; washing it with acid and water, then drying. The inveniton has lower cost and high speed, without pollution.

Owner:LANYAN GROUP

Apocynum and silky gloss blended yarn and fabric weaved thereby

The invention discloses a kind of textile made up of dogbane and mercerizing fur blending. The invention provides a textile which has good elastane, straightness of flax, excellent hygroscopic and cold-proof performance, and it has functions of antisepsis health keeping. The weight percentage of dogbane and mercerizing fur are: dogbane fiber 20-30%, the mercerizing fur fiber 70-80%. The invention uses traditional process to produce the textile, produces them into cloth or underwear, or four-season blanket. A layer of negative ion material also can be painted on the product, the weight percentage of the layer is: calcium zeolite 30-45%, serpentine 20-45%, peridot 25-35%.

Owner:天津市好益科技发展有限公司

Apocynum, cotton added lycra core-spun yarn and fabric weaved thereby

The invention discloses a kind of textile weaved by dogbane, cotton and leca covering yarn, the invention provides a kind of textile which has transverse bidirection elastane, has no stimulation to skin, cold-proof, ventilation is good, the hygroscopic is excellent, the elastane is large, at the same time, which also has decompression and blood-fat releasing function. The leca fiber is covered by the dogbane fiber and cotton, the weight percentage of dogbane fiber and cotton fiber are 20-50%, 50-80%, the weight of the leca fiber accounts for 10-12% in the textile. The cotton is natural color cotton or ground cotton, or pure natural long-fibred cotton. There also has a negative ion layer on the product, which is made up of following material with following weight percentage: calcium zeolite 30-45%, serpentine 20-45%, peridot 25-35%.

Owner:天津市好益科技发展有限公司

Kendyr floret blended lining

InactiveCN1570241AExcellent health benefitsDrape shineWeft knittingYarnEngineeringMoisture absorption

This invention involves one kind of apocynum spun silk blending lining fabric blending lining. This invention belongs to the everyday use health care lining area of technology. Apocynum the spun silk fabric blending lining, by apocynum carries on the knitting lining with the spun silk which the fabric blending becomes, the spun silk uses the high quality mulberry silk. Apocynum , lyocell and spun silk fabric blending lining composition on the basis of weight for apocynum 20 - 50%,lyocell 30 - 50%, spun silk 10 - 50%. This invention has following merits: apocynum's outstanding health care effect; The outward appearance hangs falls and bright, moves the feeling to be elegant; Have the laundering still to be possible to maintain properly the smooth contour many times; This product has feel to be softer, smooth; Moisture absorption performance good, the woven cottons are dry quickly absorb moisture characteristic.

Owner:天津市天益华泰科技发展有限公司

Powder for resisting hyperosteogeny

InactiveCN1840160AEffective treatmentShort course of treatmentPowder deliverySkeletal disorderMyrrhGround beetle

The invention relates to a medicament for treating hyperosteogeny and process for preparation, wherein the constituents include eucommia bark, prepared rhizome of rehmannia, dried ginger, Chinese angelica root, polygala root, ledebouriella root, dipsacus root, asaryl, achyranthes root, Chinese starjasmine, pyrola, wolferry fruit, apocynum, large-leaf gentian root, dried body of ground beetle, notopterygium root, astragalus root, Clematis chinensis, spatholobus stem, Magnolia liliflora Desr., campeachy wood, pawpaw, root of red rooted saliva, myrrh, Schizonepeta tenuifolia, cynomorium songaricum, dodder seed, siberian cocklebur fruit, dahurian angelica root, fleece-flower root, safflower, rhizoma dioscoreae, Ligusticum wallichii and licorice root.

Owner:刘洪基

Apocynum and color cotton blended yarn and fabric weaved thereby

The invention discloses a method for mixing spinning of Dogbane and color cotton and the textile. The invention provides a kind of textile which is comfortable, and which can restrain the bacteria from being generated. It includes following ingredients: dogbane fiber: 20-50%, color cotton fiber: 50-80%. The base of the textile uses the product by spinning the dogbane and color cotton, the weight percentage of dogbane and color cotton are 20-5-%, 50-80%. There has a negative ion material on the textile. The negative ion material includes: calcium zeolite 30-45%, serpentine 20-45%, peridot 25-35%. The area of the negative ion material layer accounts for 20-50% of the textile area.

Owner:天津市好益科技发展有限公司

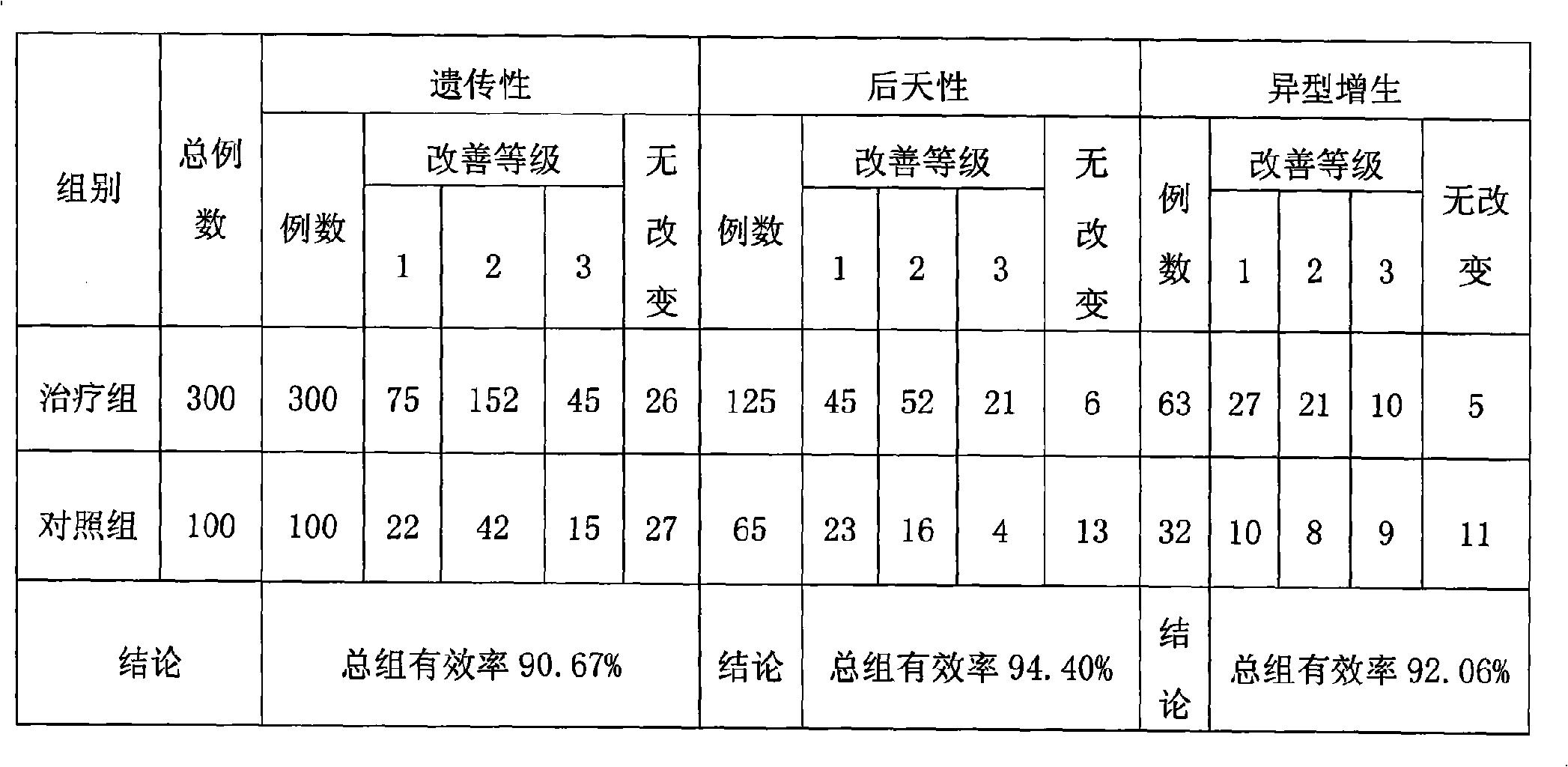

Blood-pressure-lowering and blood-lipid-lowering compound apocynum leaf solid preparation and preparation method thereof

InactiveCN101125164ALow cost of treatmentMeet clinical needsMetabolism disorderCardiovascular disorderMedicineGinkgo biloba

The present invention relates to a compound dogbane leaf solid preparation for decreasing blood pressure and lowering lipid and the preparation method thereof, the present invention contains the raw materials with the following parts by weight: 3 to 15 parts of dogbane leaf, 1 to 15 parts of eucommia leaf, 1 to 5 parts of ginkgo leaf or ginkgo leaf extract and 0 to 30 parts of tea. The preparation has the effects of decreasing blood pressure and lowering blood lipid.

Owner:JIANGXI HERBFINE HI TECH

Chinese traditional medicine preparation for curing hypertensive cerebral hemorrhage

InactiveCN101537130ACompatibility scienceLow costBlood disorderCardiovascular disorderGastrodiaSide effect

The invention relates to a Chinese traditional medicine preparation for curing hypertensive cerebral hemorrhage, which is prepared by the following raw materials of ptunella spike, gastrodia tuber, crude sophora flower, kudzuvine root, hooked uncaria, crude cassia tora, evodia fruit, cape jasmine, apocynum, scutellaria root, achyranthes root, eucommia bark, motherwort, giant mistletoe, fleece-flower stem, indian bread, oyster and dried rehmannia root. The Chinese traditional medicine preparation has the advantages of scientific compatibility, low cost, short treatment course, fast effect, high curative ratio and no side effect to the human body.

Owner:北京汉潮联创中药科技有限公司

Apocynum mercerization unshrinkable wool blended knited face fabric

The invention involves a kind of bluish dogbane silken luster of mercerized cotton cloth side wool to be enrolled together the knitting lining. Bluish dogbane the silk shrinkproof wool knitting lining belongs to the everyday use health care lining area of technology. Bluish dogbane silken luster of mercerized cotton cloth the shrinkproof wool knitting lining, weaves by the fabric blending gauze becomes, its lining is enrolled together the gauze for bluish dogbane and silken luster of mercerized cotton cloth the shrinkproof wool to weave in the same place. The invention has the remarkable bluish dogbane health care function, the wool with bluish dogbane dual maintains warmth the effect; Silken luster of mercerized cotton cloth shrinkproof, feel is smooth; Green environmental protection; Soft, slides glutinous, but the next to the skin is putting on and so on the merit.

Owner:天津市天益华泰科技发展有限公司

Spiced healthcare dry mutton and preparation method thereof

InactiveCN103653004ARich varietyReasonable formulaNatural extract food ingredientsFood ingredient functionsApocynum venetumNutrition

The invention discloses a kind of spiced healthcare dry mutton and a preparation method thereof. The spiced healthcare dry mutton is prepared from the following raw materials in parts by weight: 80-100 parts of mutton, 6-8 parts of sauce, 5-8 parts of salt, 3-4 parts of fennel, 2-3 parts of apocynum leaf, 1-3 parts of ligusticum wallichii, 2-3 parts of corn stigma, 2-3 parts of largehead atractylodes rhizome, 2-4 parts of atractylodes macrocephala koidz., 2-4 parts of rose, 1-3 parts of mint, 3-5 parts of oyster powder, 3-5 parts of mycose and 5-7 parts of nutritional additive. The preparation method of the spiced healthcare dry mutton, provided by the invention, various traditional Chinese medicine ingredients are combined with the mutton through processing so as to processthe traditional Chinese medicine ingredients into dry mutton as a leisure food, and the kind of leisure foods are enriched. Moreover, the preparation method has a wide resource of raw materials and is reasonable in formula, and the traditional Chinese medicine ingredients including the ligusticum wallichii, the atractylodes macrocephala koidz., the rose and the like have a very good nurturance healthcare effect.

Owner:HUAIYUAN DAYU FOOD TECH

Health-care nourishing tea capable of relieving blood pressure, blood fat and blood sugar

The invention discloses health-care nourishing tea capable of relieving blood pressure, blood fat and blood sugar, belonging to the field of health-care nourishing tea products. The health-care nourishing tea is prepared from China Northeast black fungus, China Northeast wild acanthopanax seeds, cassia seeds, China Northeast corn stigma, eucommia, uncaria and apocynum. The health-care nourishing tea is prepared by the steps as follows: drying China Northeast black fungus and China Northeast wild acanthopanax seeds in high temperature; airing cassia seeds, China Northeast corn stigma, eucommia, uncaria and apocynum; and after the above treatment, mixing the materials by weight ratio. The health-care nourishing tea is simple in the preparation technology and utilizes the efficacies of China Northeast black fungus, China Northeast wild acanthopanax seeds, cassia seeds, China Northeast corn stigma, eucommia, uncaria and apocynum as traditional Chinese medicines, thus having excellent curing and regulating effects to groups suffering from hypertension, hyperlipaemia, hyperviscosity, hyperglycemia, arteriosclerosis and heart cerebrovascular diseases; and the health-care nourishing tea is low in cost, infused with boiled water, convenient to drink and suitable to sub-health groups.

Owner:肖立权

Pressure-reducing health protection tea

InactiveCN102960492ARefreshing tasteWith blood pressure loweringPre-extraction tea treatmentBlood pressureCelery seeds

The invention relates to pressure-reducing health protection tea belonging to the field of healthy drinks. The pressure-reducing health protection tea comprises the following components by weight parts: 2-5 parts of apocynum leaves, 3-8 parts of appendicula terrestris, 3-5 parts of jasmine flowers, 1-10 parts of green tea, 1-3 parts of celery seeds, 1-3 parts of watermelon seeds, 1-3 parts of lemon slices, 1-2 parts of licorice and 2-5 parts of corn stigma. According to the pressure-reducing health protection tea, the apocynum leaves, the appendicula terrestris the celery seeds and the like are used as main components, the jasmine flowers and the green tea are added, thus the pressure-reducing health protection tea is fresh and cool in mouth feel, has the efficacies of reducing blood pressure and blood fat, enhancing immunity, and fighting fatigue, and is simple to prepare, convenient to use and suitable for hypertensive and hyperlipemia patients for daily drinking.

Owner:DALIAN CHUANGDA TECH TRADE MARKET

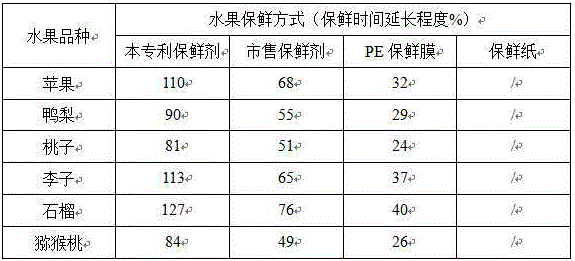

Fruit coating preservative and preparation method thereof

ActiveCN105053168ASpeed up evaporationImprove work efficiencyFruits/vegetable preservation by coatingCelluloseApocynum venetum

The present invention discloses a fruit coating preservative and a preparation method thereof, belonging to the technical field of fruit preservation, particularly to a fruit coating preservative and a preparation method thereof. The fruit coating preservative is characterized by comprising the following raw materials in parts by weight: 2-9 parts of ethyl cellulose, 4-8 parts of shellacs, 3-7 parts of polyvinylpyrrolidone, 1.0-0.5 part of glyceryl triacetate, 0.03-0.1 part of apocynum extract, 0.02-0.1 part of ascorbyl palmitate and 80-90 parts of alcohol. The fruit coating preservative is prepared by material mixing, swelling, stirring and homogenizing. The coating formed on the surface of the fruits has the following advantages: the coating generating speed is fast, the coating barrier property is good, the coating is multi-functional, and the materials are high in safety.

Owner:YUNNAN SHENBOYUAN BIOLOGICAL TECH

Engine lubricating oil filtering material and production technique thereof

InactiveCN101905102AStrong toughnessImprove breathabilityMachines/enginesLubricant mounting/connectionFiberEngineering

The invention discloses an engine lubricating oil filtering material. The engine lubricating oil filtering material is characterized by being prepared by the following steps of: splitting bamboo into bamboo filaments and cutting the bamboo filaments into bamboo filament segments; softening, soaking, cooking and washing the bamboo filament segments with clean water; baking or drying the bamboo filament segments in the sun and dressing to prepare bamboo fibers; softening and soaking hemp fabric or flax or apocynum, washing with clean water or drying the hemp fabric or flax or apocynum naturally, cutting into segments and dressing to prepare fibrilia; making the bamboo fiber and fibrilia into a filter felt by a conventional non-woven production technique and performing high-temperature shaping to obtain the engine lubricating oil filtering material. The engine lubricating oil filtering material and the production technique have the advantages of simple production technique, good filtering effect, energy conservation, cost reduction and long service life of the engine.

Owner:盛国庆

Method for blending yarn with natural color-cotton and apocynum fibre

The invention provides a method of the blended yarns of natural-colored cotton and apocynum fibers, which employs a plurality of natural-colored cotton fibers with different colors to process respectively; 'small quantity, slow speed, close gauge length and strong carding' is the operational path when in opening and beating; the finished products reserve the natural colors and do not need dyeing, thus avoiding the residual chemical substances in dyeing process and enriching the colors of the apocynum as well as shortening the technique procedure, meanwhile, the invention has simple weaving technique and low processing cost and promotes the production value of products.

Owner:SHENGHONG GRP CO LTD

Hypertension injection nursing drug and preparation method thereof

ActiveCN103735899ASignificant effectInanimate material medical ingredientsCardiovascular disorderMedicinal herbsFormulary

The invention discloses a hypertension injection nursing drug and a preparation method thereof. The drug is a pure traditional Chinese medicine formula and is mainly made from the following Chinese medicinal herbs: radix paeoniae alba, wolfberry fruit, radix rehmanniae, Chinese yam, pubescent holly root, corn stigma, keel, oyster, nepenthe, botrychium daucifoltum woll, poria, bighead atractylodes rhizome, licorice, euryale ferox, radix rehmanniae, rhizoma phragmitis, gastrodia elata, earthworm, radix angelicae, twig, rhizoma corydalis, lysimachia, bamboo leaf, rhubarb, lamp wick, isatis root, hawthorn, eucommia, bidens bipinnata, leech, apocynum, royal jelly, rhizoma chuanxiong, coptidis, angelica, parasitic loranthus, radix paeoniae rubra, radix achyranthis bidentatae, radix puerariae, astragalus root, tortoise shell, cortex lycii radicis, selfheal, chrysanthemum, semen brassicae and cortex moutan. The hypertension injection nursing drug has the advantages of being significant in curative effect and free of side effect.

Owner:HAIMEN BIWEI INTPROP SERVICE CO LTD

Anti-microbial fiber cloth

InactiveCN106192156AStable structureImprove breathabilityConjugated cellulose/protein artificial filamentsWoven fabricsPolyamideEngineering

The invention discloses anti-microbial fiber cloth woven by warp filaments and weft filaments. The warp filaments are in the statures of signal filaments and the weft filaments are in the statures of composite filaments. The weft filaments are formed by staggering and intertwining of bamboo fiber filaments and anti-microbial fiber filaments in the radius ratio of 1 to 2. The anti-microbial fiber filaments are formed by following raw material including 23-42 parts by weight of apocynum fibres, 20-27 parts by weight of kawo kawo fibers, 10-26 parts by weight of lignin, 16-31 parts by weight of copper alginate fibers, 10-15 parts by weight of ramie fibers, 18-35 parts by weight of polyamide, 3-9 parts by weight of modified melamine formaldehyde resin, 10-16 parts by weight of anti-mildew cellulosic fibers, 3-9 parts by weight of polyurethane, 2-6 parts by weight of dispersing agents and 1.2-1.6 parts by weight of stabilizers. The anti-microbial fiber cloth has following beneficial effects: the anti-microbial fiber cloth has a stable structure and has great breathable performance, and anti-bacteria performance and is great in strength, feels soft; raw material is safe and eco-friendly without side effects to human bodies; and the cloth is long in service lifetime and added with polyamide such that anti-bacteria performance of the anti-microbial fiber cloth is lasting.

Owner:明光市瑞洁日用品有限公司

Apocynum fiber, China-hemp fiber and cotton fiber blended yarns and manufacturing technology thereof

The invention discloses apocynum fiber, China-hemp fiber and cotton fiber blended yarns and a manufacturing technology thereof and is applied to the field of spinning techniques. The blended yarns are formed by the apocynum fibers, the China-hemp fibers and the cotton fibers; a weight percentage of the apocynum fibers accounts for 10 to 30 % of that of the blended yarns; a weight percentage of the China-hemp fibers accounts for 10 to 30 % of that of the blended yarns; a weight percentage of the cotton fibers accounts for 60 % of that of the blended yarns. The manufacturing technology of the blended yarns comprises carefully selecting a plurality of apocynum fibers, the China-hemp fibers and carded yarns or combed yarns, weighing and dividing into small piles according to contents, enabling every pile to be uniformly mixed with water solutions, obtaining the apocynum fiber, China-hemp fiber and cotton fiber blended yarns after a fiber mixing process, a cotton cleaning process, a cotton carding process, a drawing process, a roving process and a spinning process and enabling relative humidity of the production environment of every process to be between 58 to 65 %. The apocynum fiber, China-hemp fiber and cotton fiber blended yarns can be used for manufacturing various blended fabrics and adds a pure natural and comfortable textile product for the textile field.

Owner:JIHUA 3542 TEXTILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com