Ultraviolet-proof polyester-cotton fabric and preparation method thereof

A technology for anti-ultraviolet and fabrics, applied in the textile field, can solve the problems of easy disease, limited effect, various pigmentation, skin diseases, and even skin cancer, etc., and achieves the effect of good hygroscopicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

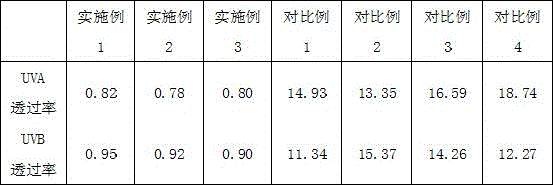

Examples

Embodiment 1

[0021] A kind of anti-ultraviolet polyester-cotton fabric, this fabric is made by the raw material blending of following parts by weight first: 60 parts of polyester fiber, 40 parts of long-staple cotton fiber, 5 parts of polyamide fiber, 5 parts of linen fiber, 5 parts of ramie fiber, Robust fiber 5 parts of hemp fibers, and then processed through antibacterial and anti-ultraviolet finishing solution; said antibacterial and anti-ultraviolet finishing solution comprises 5 parts of chitosan, 5 parts of tea polyphenols, 2-hydroxyl-4-methoxybenzophenone 2 1 part, 1 part of phenyl o-hydroxybenzoate, 0.5 part of sodium tripolyphosphate, 5 parts of tetradecyltrimethylammonium chloride, 5 parts of polyethylene glycol, 5 parts of nano-titanium dioxide, 3 parts of coconut acid diethanolamide Parts, 5 parts of water-based polyurethane;

[0022] The preparation method comprises the following steps:

[0023] (1) Take polyester fibers, long-staple cotton fibers, polyamide fibers, flax fib...

Embodiment 2

[0027] A kind of anti-ultraviolet polyester-cotton fabric, this fabric is made by the raw material blending of following parts by weight first: 80 parts of polyester fiber, 60 parts of long-staple cotton fiber, 15 parts of polyamide fiber, 15 parts of linen fiber, 15 parts of ramie fiber, rob 15 parts of hemp fiber, then processed through antibacterial and anti-ultraviolet finishing solution; said antibacterial and anti-ultraviolet finishing solution comprises 10 parts of chitosan, 10 parts of tea polyphenols, 2.5 parts of 2-hydroxy-4-methoxybenzophenone 3 parts, 3 parts of phenyl o-hydroxybenzoate, 2 parts of sodium tripolyphosphate, 8 parts of tetradecyltrimethylammonium chloride, 10 parts of polyethylene glycol, 15 parts of nano-titanium dioxide, 8 parts of coconut acid diethanolamide Parts, 10 parts of water-based polyurethane;

[0028] The preparation method comprises the following steps:

[0029] (1) Take polyester fiber, long-staple cotton fiber, polyamide fiber, flax ...

Embodiment 3

[0033] An anti-ultraviolet polyester-cotton fabric, which is firstly made by blending the following raw materials in parts by weight: 70 parts of polyester fiber, 50 parts of long-staple cotton fiber, 10 parts of polyamide fiber, 10 parts of flax fiber, 10 parts of ramie fiber, rob 15 parts of hemp fiber, then processed through antibacterial and anti-ultraviolet finishing solution; said antibacterial and anti-ultraviolet finishing solution comprises 6 parts of chitosan, 8 parts of tea polyphenols, 1 part of 2-hydroxyl-4-methoxybenzophenone 2 parts, 2 parts of phenyl o-hydroxybenzoate, 1 part of sodium tripolyphosphate, 6 parts of tetradecyltrimethylammonium chloride, 8 parts of polyethylene glycol, 10 parts of nano titanium dioxide, 5 parts of diethanolamide cocoate Parts, 8 parts of water-based polyurethane;

[0034] The preparation method comprises the following steps:

[0035] (1) Take polyester fiber, long-staple cotton fiber, polyamide fiber, flax fiber, ramie fiber and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com