Complex antibacterial fiber, fabric and preparation method thereof

A technology for antibacterial fibers and fabrics, applied in the fields of fabrics and their preparation, complex antibacterial fibers, and new functional materials, can solve problems such as large differences in cross-linking degrees, affecting the air permeability of fabrics, and being unsuitable for water absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0085] Embodiment 1, the preparation of antibacterial active carbon fiber

[0086] (1), activated carbon fiber irradiation grafting coordination group

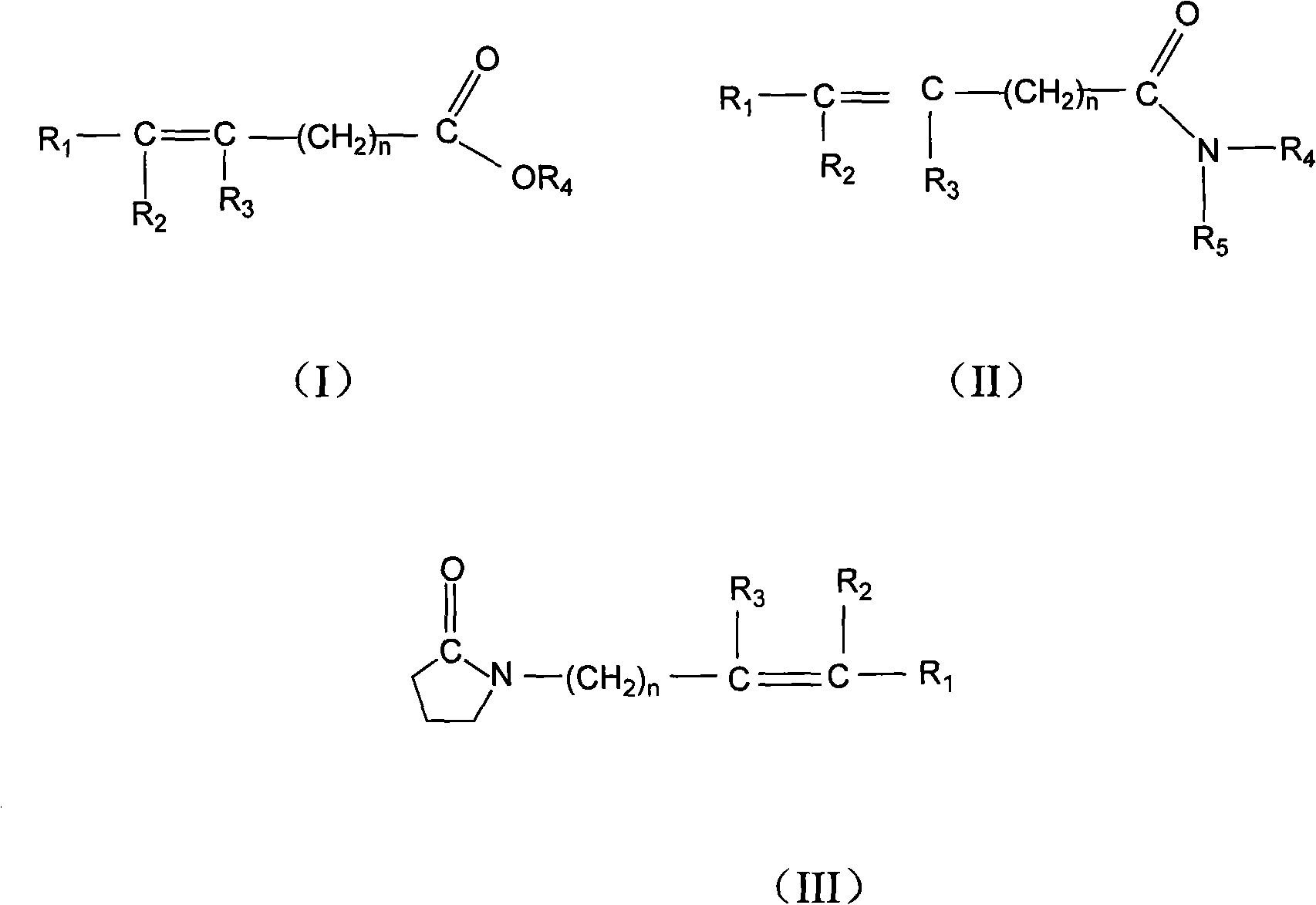

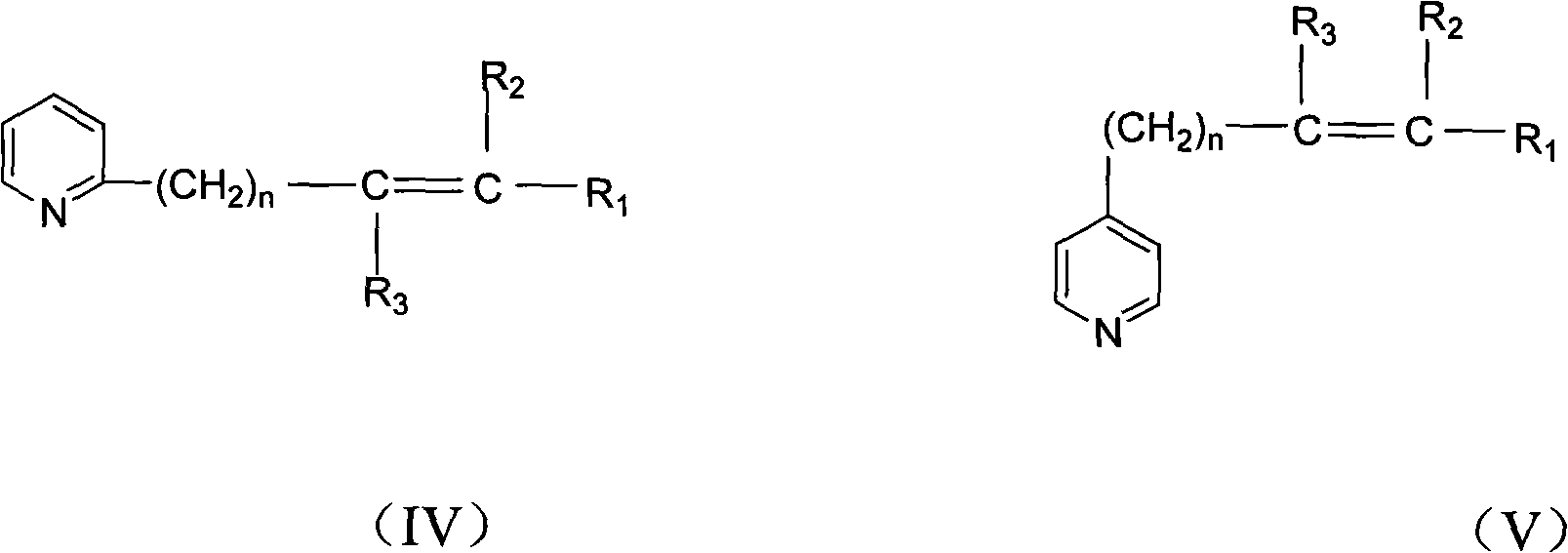

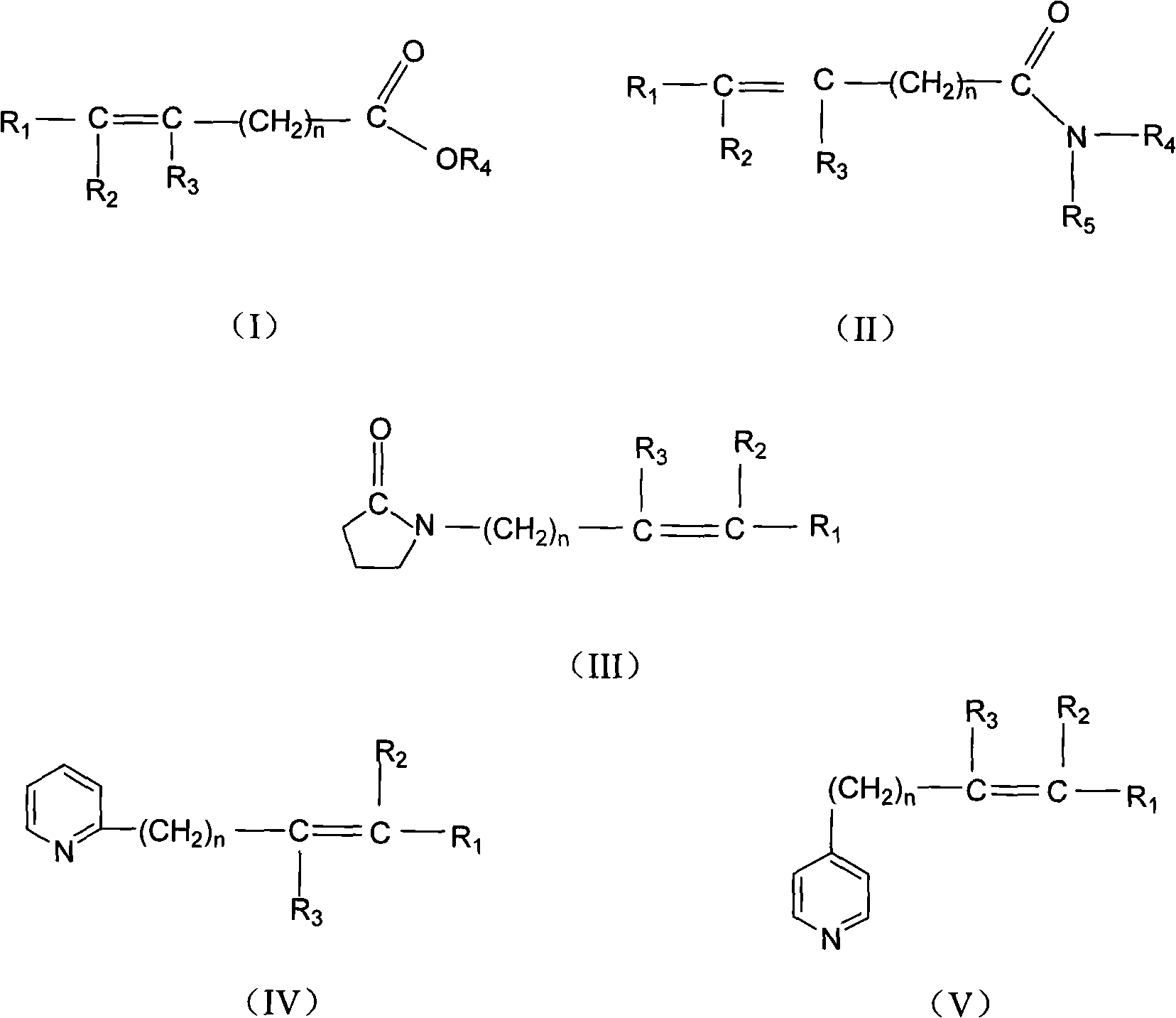

[0087] Unsaturated monomers with vinylpyrrolidone and 4-vinylpyridine as grafting coordination groups.

[0088] Weigh 20 pieces (total weight 15.8g) with a size of 80mm×120mm, an average thickness of 1-1.5mm, and a specific surface area of 1000M 2 / g of viscose-based activated carbon fiber felt, placed in an 800mL beaker, with 300mL concentration of 1% (wt%) vinylpyrrolidone and 4-vinylpyridine mixed cyclohexane solution (vinylpyrrolidone: 4-vinyl Pyridine = 1:1, mass ratio) impregnation, failed to fully soak into the liquid surface, take out the activated carbon fiber felt, turn it over and put it in again, squeeze 2 to 3 times, repeat the operation of turning and squeezing 5 times in this way to ensure that the impregnation Evenly, take out, squeeze out the solution, use 60 Co γ-ray irradiation grafting.

[0089] Irrad...

Embodiment 2

[0106] Embodiment 2, the preparation of antibacterial cotton / acrylic fabric

[0107] Table 3. Composition and structure of cotton / acrylic fabric

[0108] No.

fabric name

Polypropylene fineness / d tex

Polypropylene content%

Yarn count

Fabric unit weight (g / cm 2 )

1

Cotton woven jersey

-

0

40

112.7

2

Cotton / acrylic woven plain weave

1.11

30

32

124.2

3

Pure cotton knitted cotton wool

-

0

40

185.9

4

Cotton / acrylic knitted fleece

1.3

30

32

269.1

5

Polypropylene woven plain weave

1.11

95

32

312.3

[0109] Fine-denier and ultra-fine-denier polypropylene fibers have the advantages of soft hand feeling and strong moisture permeability. Blending with cotton fibers as fabrics has become a major development trend in recent years. However, the surface modification of po...

Embodiment 3

[0126] Embodiment 3, the preparation of antibacterial spandex elastic bandage

[0127] Spandex elastic bandage is made of natural cotton yarn and spandex elastic fiber silk, which is firm and comfortable, suitable for medicine, outpatient department, health care and sports.

[0128] Purchase a commercially available spandex elastic bandage with a size of 10 cm × 4.5 m, cut two bandage samples with a size of 10 cm × 30 cm, and use vinylpyrrolidone to irradiate and graft.

[0129] Immerse evenly with 200mL of 2.5% (wt%) ethanol solution of vinylpyrrolidone, take it out, squeeze out the solution, and use 60 Co γ-ray irradiation grafting.

[0130] Irradiation conditions: the dose rate is 38.88Gy / min, the irradiation time is 47min, and the actual irradiation dose is 1827Gy.

[0131] The irradiated bandage samples were soaked in 150.0 mL of 0.010 mol / L silver nitrate and 0.030 mol / L copper sulfate solution for 10 minutes, then squeezed out the solution and dried in vacuum at 70 °C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com