Modification method of high performance carbon paper based on supercritical fluid technology

A supercritical fluid and supercritical oxidation technology, which is applied in papermaking, paper, special paper, etc., can solve the problems of reducing oxidation time, difficulty in controlling the depth of gas-phase oxidation, and ineffective modification effect of a single titanate coupling agent. Achieve the effect of reducing oxidation time, intense molecular movement, and strong penetration ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

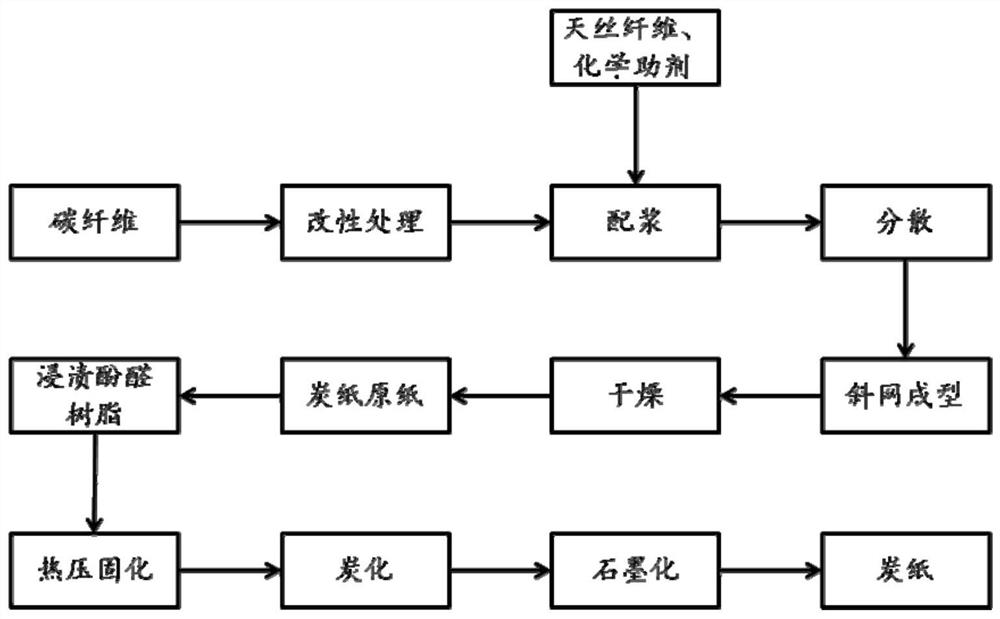

Method used

Image

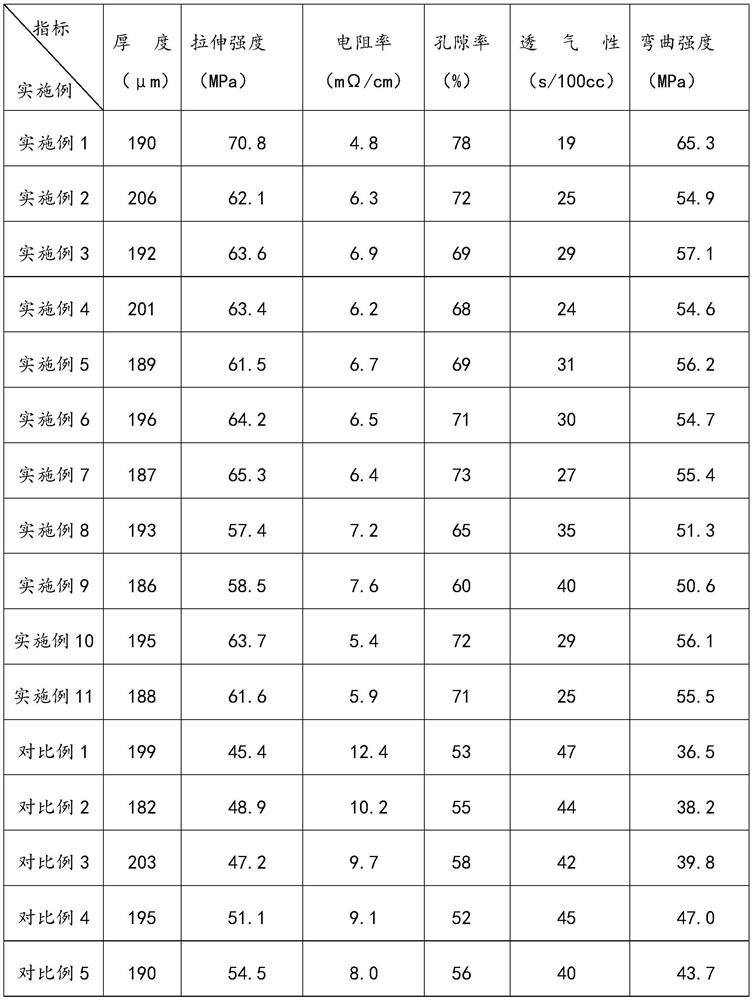

Examples

Embodiment 1

[0042] Put the carbon fiber in acetone, the amount of acetone used is 60ml / 1g of carbon fiber, extract it in a Soxhlet extractor at 80°C for 10h, wash it with distilled water until it is neutral, and dry it in an oven at 90°C for 3h; the cleaned carbon fiber Place in supercritical water reactor, add oxygen, reaction time 20min, reaction temperature 400°C, reaction pressure 25MPa, then dry in 90°C oven for 3h; put oxidized carbon fiber into 3% titanic acid Ester coupling agent TMC-311 in methanol solution, and placed in a supercritical water reactor, the temperature is controlled at 400 ° C, the pressure is 25 MPa, and the reaction time is 30 minutes; after the reaction, the carbon fiber is washed in supercritical water for 3 times. Then the carbon fiber was dried in an oven at 90° C. for 3 hours to obtain the modified carbon fiber.

[0043] Add 90 parts by mass of modified carbon fiber and 10 parts by mass of Tencel fiber into a mixing tank, add water to mix, and stir to make ...

Embodiment 2

[0046] Put the carbon fiber in acetone, the amount of acetone used is 40ml / 1g of carbon fiber, extract it in a Soxhlet extractor at 75°C for 15h, wash it with distilled water until it is neutral, and dry it in an oven at 80°C for 4h; the cleaned carbon fiber Put it in a supercritical water reactor, add oxygen, react for 15 minutes, react at a temperature of 380°C, and react at a pressure of 30MPa, and then dry it in an oven at 80°C for 4 hours; put the oxidized carbon fiber into a mass fraction of 2% titanic acid Ester coupling agent TMC-114 in methanol solution, and placed in a supercritical water reactor, the temperature is controlled at 380 ° C, the pressure is 30 MPa, and the reaction time is 25 minutes; after the reaction, the carbon fiber is washed in supercritical water for 4 times. Then the carbon fibers were dried in an oven at 80° C. for 4 hours to obtain modified carbon fibers.

[0047] Add 85 parts by mass of modified carbon fiber and 15 parts by mass of Tencel fib...

Embodiment 3

[0050] Put the carbon fiber in acetone, the amount of acetone used is 80ml / 1g of carbon fiber, extract it in a Soxhlet extractor at 85°C for 20h, wash it with distilled water until it is neutral, and dry it in an oven at 100°C for 2h; the cleaned carbon fiber Place in a supercritical water reactor, add oxygen, react for 10 minutes, react at a temperature of 450°C, and react at a pressure of 35MPa, then dry in an oven at 100°C for 2 hours; put the oxidized carbon fiber into a mass fraction of 1% titanic acid Ester coupling agent TMC-201 in methanol solution, and placed in a supercritical water reactor, the temperature is controlled at 450 ° C, the pressure is 35 MPa, and the reaction time is 20 minutes; after the reaction, the carbon fiber is washed in supercritical water for 5 times. Then the carbon fibers were dried in an oven at 100° C. for 2 hours to obtain modified carbon fibers.

[0051] Add 95 parts by mass of modified carbon fiber and 5 parts by mass of Tencel fiber int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com