Patents

Literature

78results about How to "Effective wetting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Velvet manufacturing solution of monocrystalline silicon additive

InactiveCN101818378AUniform sizeGuaranteed efficient growthAfter-treatment detailsOrganic acidSurface-active agents

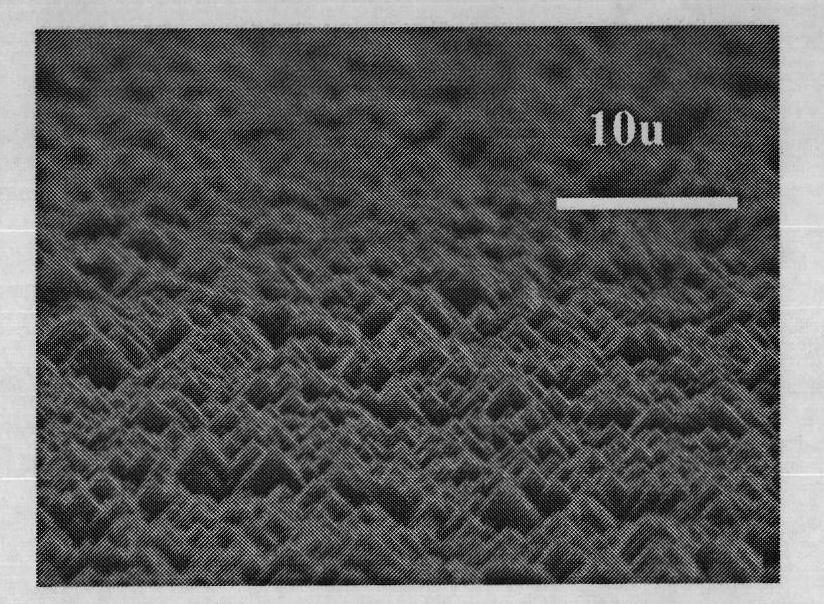

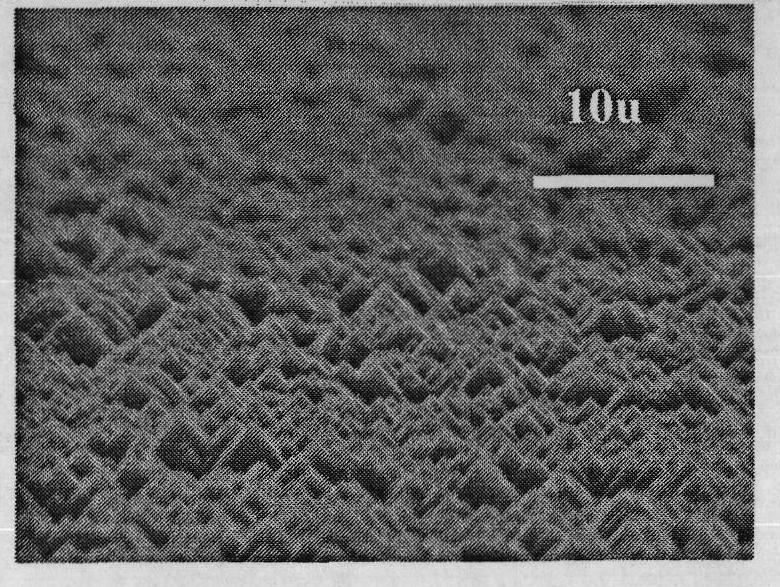

The invention discloses a velvet manufacturing solution of a monocrystalline silicon additive, which comprises an alkaline etching solution, a surface active agent and organic acid or salt, wherein the mass of the surface active agent is 0.05% to 0.5% of the mass or volume of the alkaline etching solution, and the mass of the organic acid or salt is 0.1% to 10.0% of the mass or volume of the alkaline etching solution. The velvet manufacturing solution enables the pyramid size of a velvet surface of monocrystalline silicon to be uniform without blaze or obvious impression. Under a proper temperature condition, the velvet surface is quickly and effectively formed and is matched with traditional production equipment.

Owner:HANWHA SOLARONE QIDONG

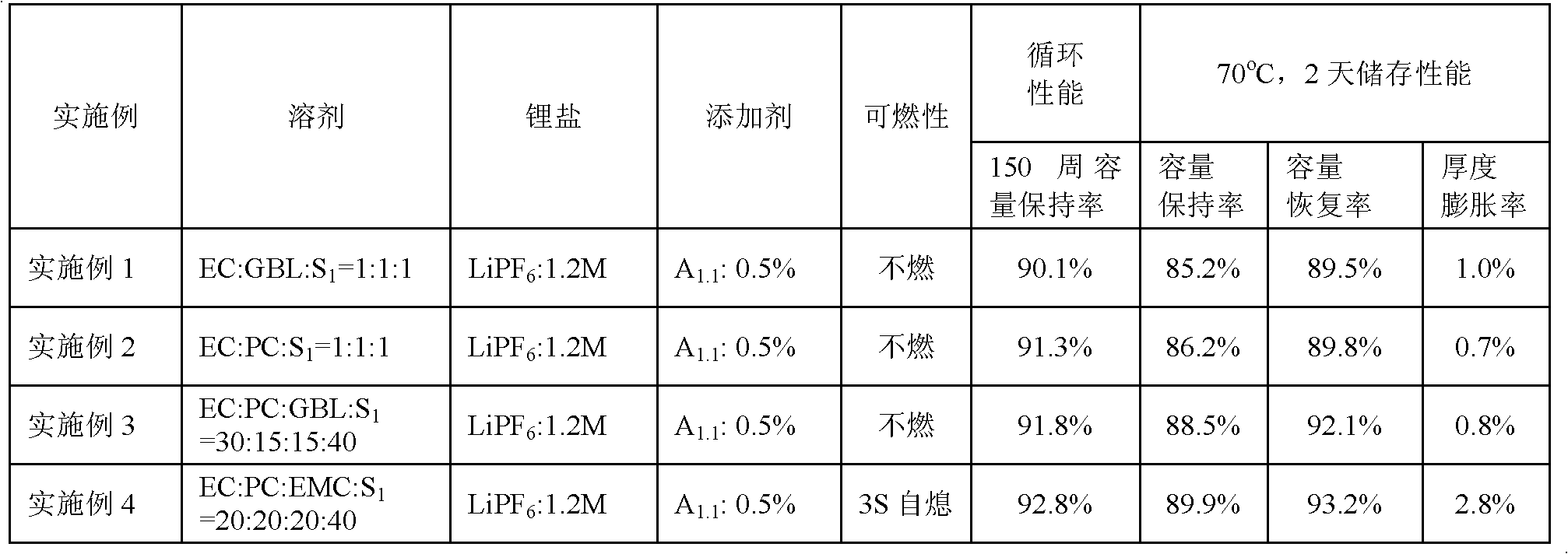

Flame retardant type non-aqueous electrolyte solution and battery thereof

InactiveCN102306833AImprove securityImprove electrochemical performanceSecondary cellsPhysical chemistrySolvent

The invention relates to an organic composition, in particular to a flame retardant type non-aqueous electrolyte solution and a lithium ion battery prepared by the electrolyte solution. The flame retardant type non-aqueous electrolyte solution comprises electrolyte salt, a non-aqueous solvent, 10 to 50 mass percent of flame retardant and 0.001 to 2 mass percent of surfactant, wherein the non-aqueous solvent comprises cyclic carbonic ester and / or cyclic carboxylic ester; the flame retardant comprises an isoflurane organic matter; and the surfactant comprises fluorocarbon surfactant. The electrolyte solution can greatly improve the safety performance of the lithium ion battery; simultaneously, the electrochemistry performance such as cycle performance and high-temperature preservation performance of the lithium ion battery can be obviously improved.

Owner:SHENZHEN CAPCHEM TECH CO LTD

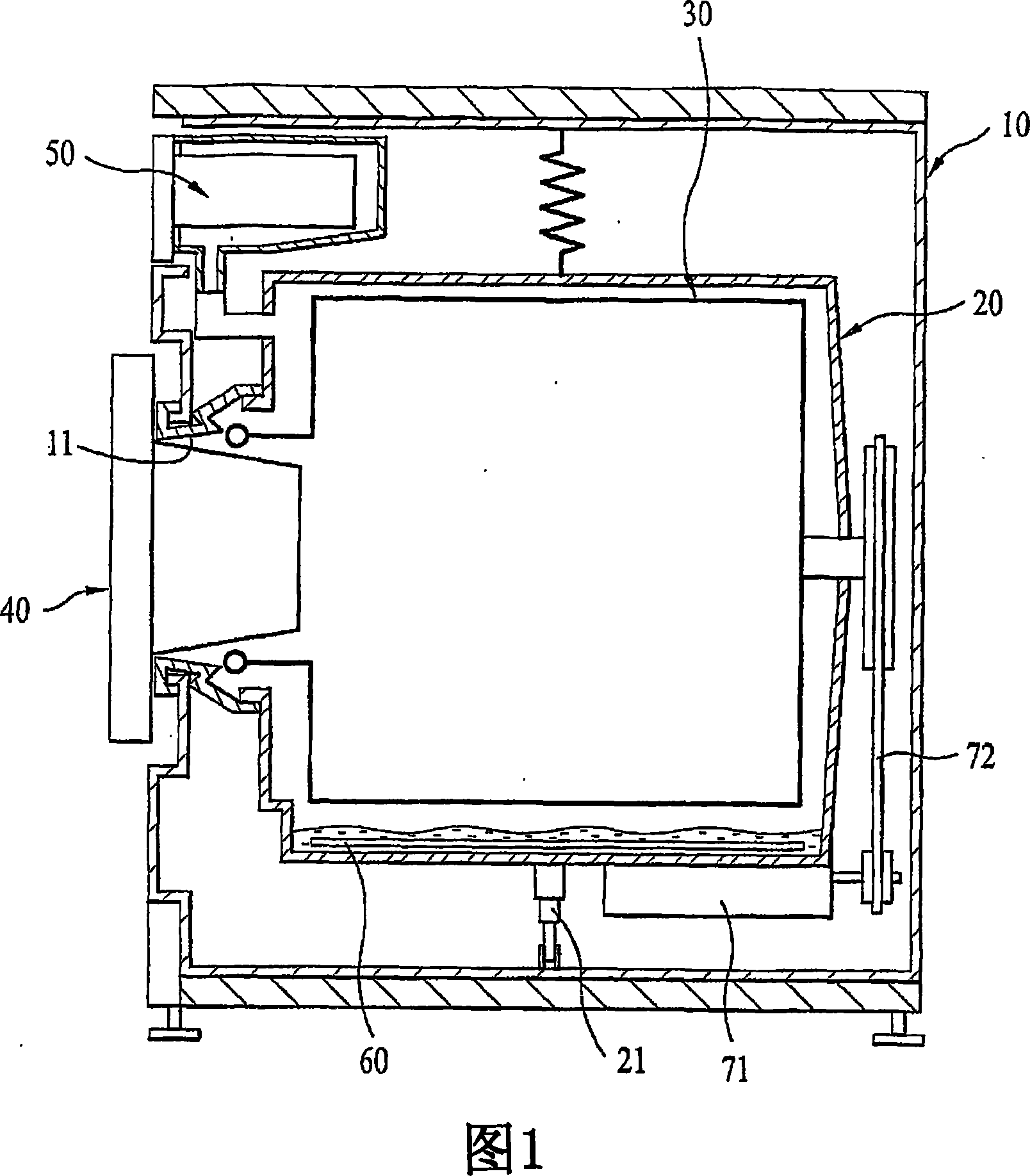

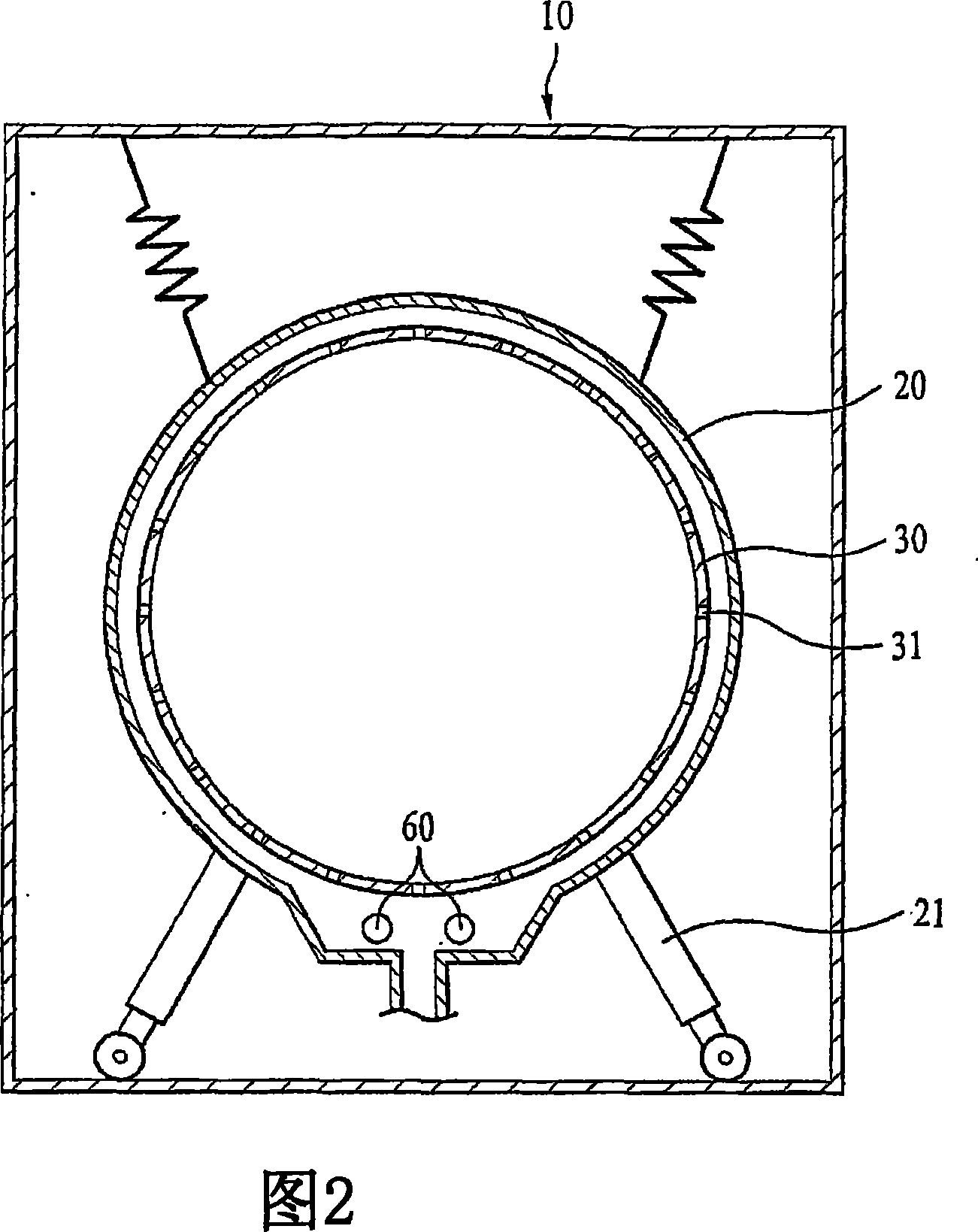

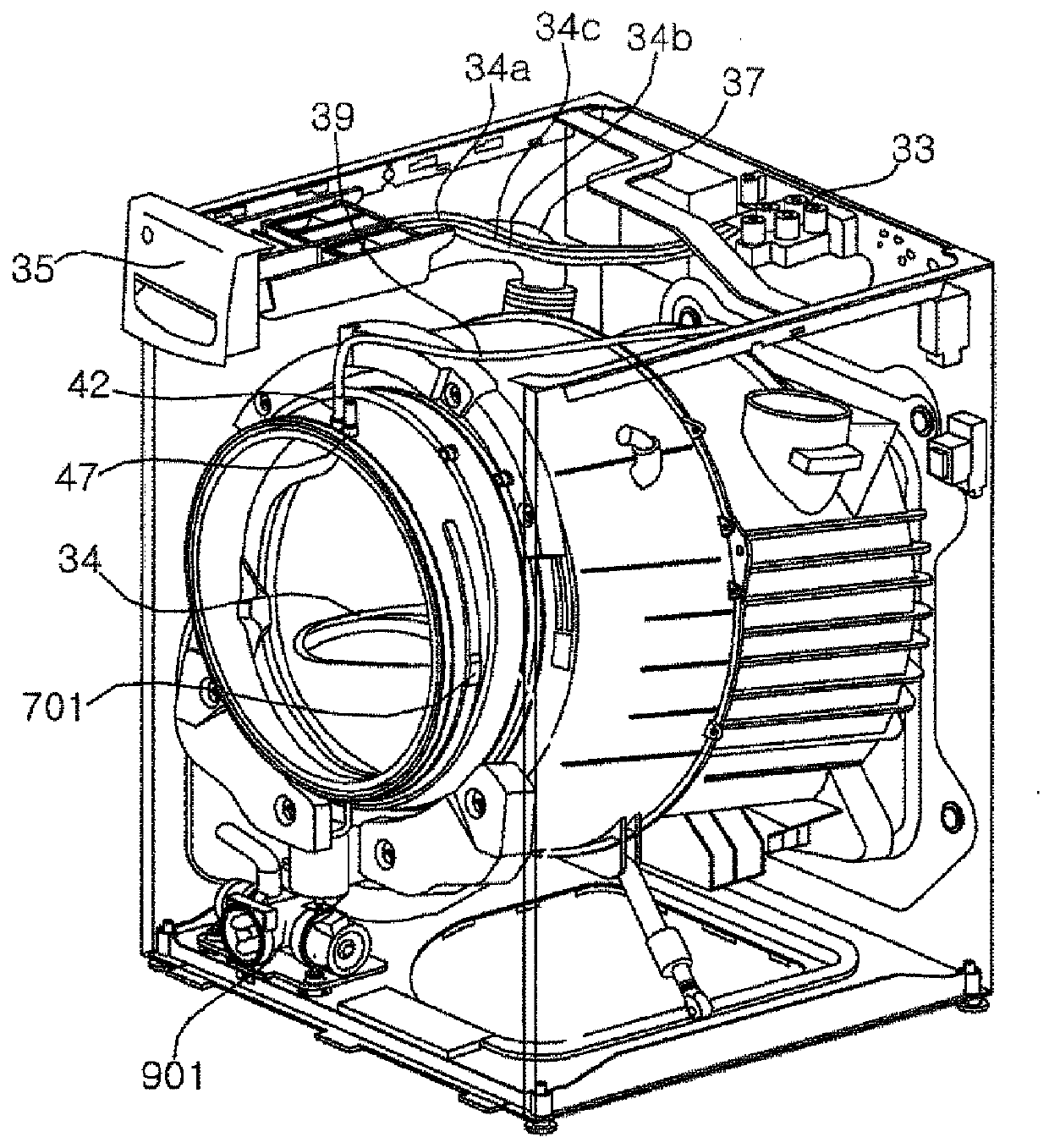

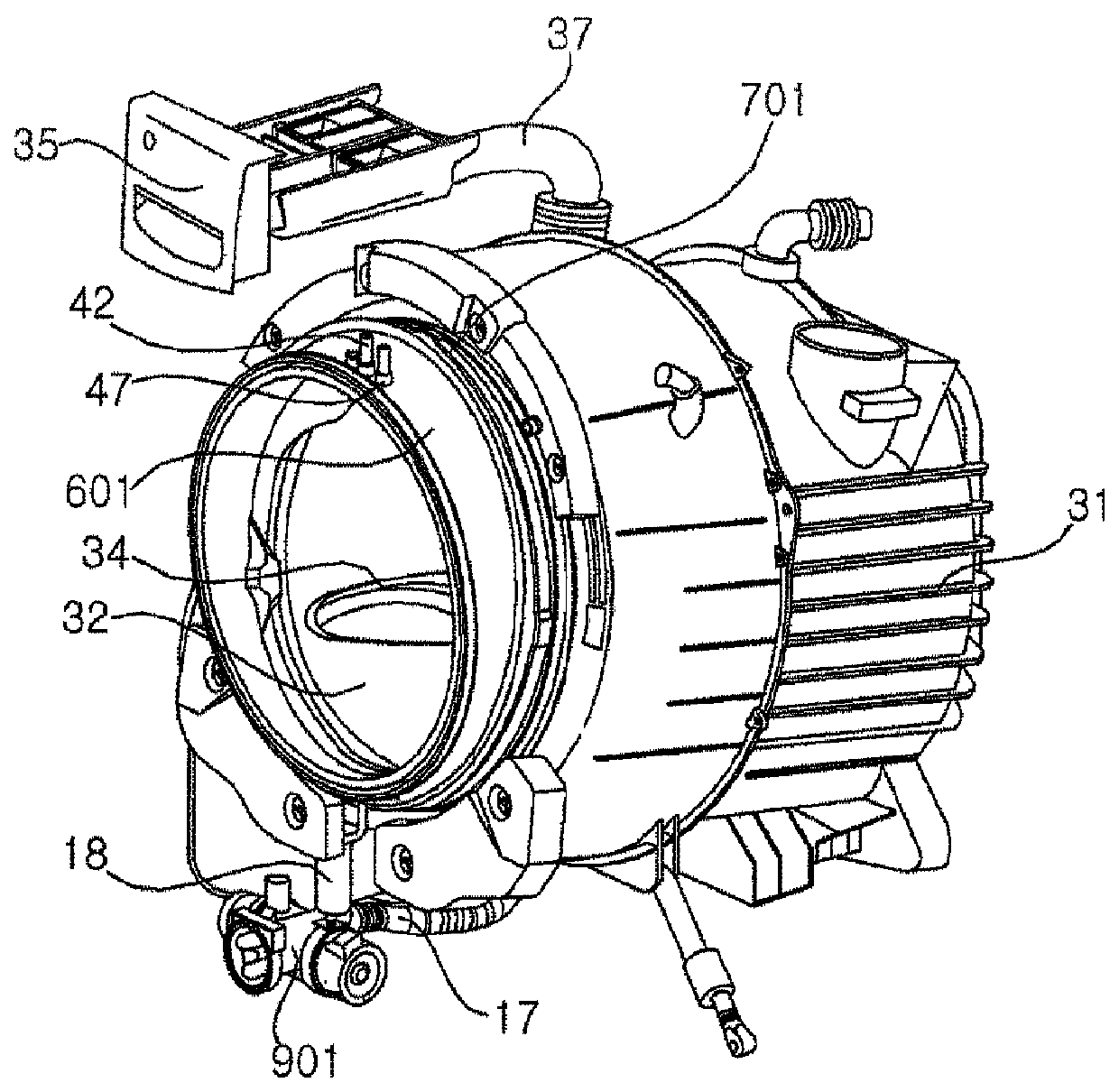

Washing a tub or a drum in a washing machine

ActiveCN101133202AContinuous cleaningEffective wettingOther washing machinesBuilding componentsProcess engineeringPower consumption

The present invention relates to a method for washing a washing tub (120) in a washin machine, and a washing machine having a washing tub washing course provided thereto for enabling washing tub (120) washing by the same, and more particularly, to a method for washing with a washing machine which makes effective washing tub washing, with a small amount of washing water consumption, a lower power consumption, and high washing effect; and a washing machine having the same applied thereto. A method for washing a tub (120) or a drum (130) in a washing machine having the tub (120), the drum (130) rotatably mounted in the tub (120), and a steam supply unit for supplying steam to the tub (120), includes a steam supply step for supplying steam to the tub by using the steam supply unit.

Owner:LG ELECTRONICS INC

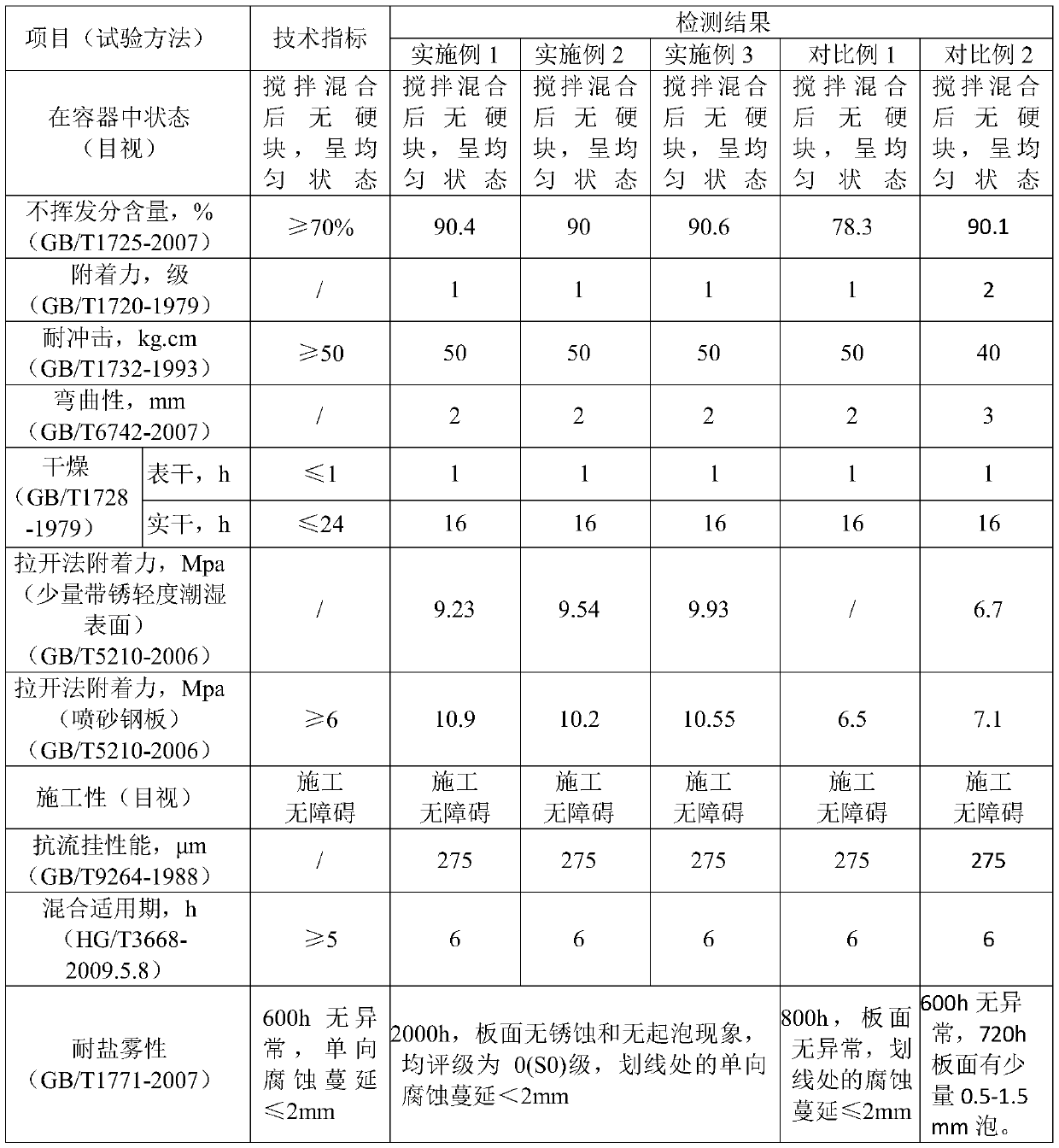

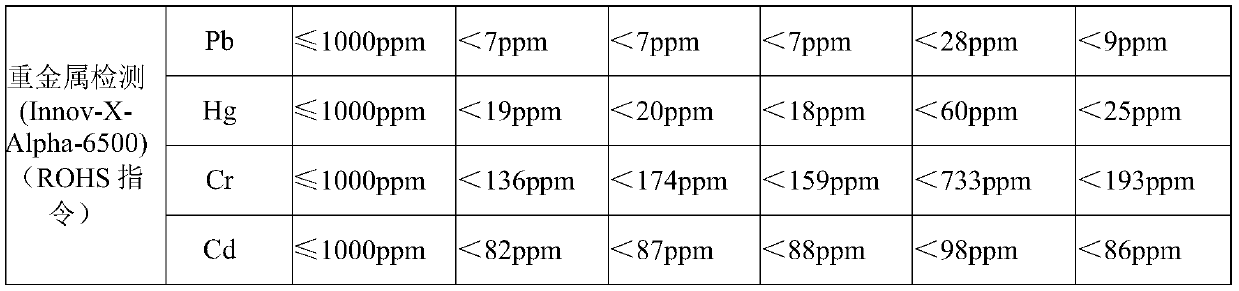

High-solid surface-tolerant epoxy zinc-rich primer and preparation method and application thereof

ActiveCN110144160AIncrease crosslink densityImprove penetration resistanceAnti-corrosive paintsEpoxy resin coatingsChemical industryEpoxy

The invention relates to a high-solid surface-tolerant epoxy zinc-rich primer. The primer is prepared from a component A and a component B according to a weight ratio of (16-20):1; the component A comprises the following components in parts by weight: 5-9 parts of liquid phenolic epoxy resin, 6-15 parts of E20 solid epoxy resin, 0.5-1.5 parts of an active diluent, 0.1-0.3 part of a dispersing agent, 70-80 parts of main rust-proof pigment, 2-6 parts of chemical anti-rust pigment, 1.5-2.5 parts of an anti-settling agent and 3-4 parts of an organic mixed solvent; and the component B comprises thefollowing components in parts by weight: 1.5-2.5 parts of a polyamide curing agent, 2-3 parts of a Mannich base curing agent, 0.3-0.6 part of a silane coupling agent and 0.2-0.6 part of an organic mixed solvent. The invention also relates to a preparation method of the primer and a coating film. The primer is high in solid content and low in VOC content, is resistant to corrosion, has a long effect, has good adhesive force and salt fog resistance, and is particularly suitable for repairing and maintaining equipment in industries such as chemical industry, thermoelectricity, machinery and thelike.

Owner:江阴市大阪涂料有限公司

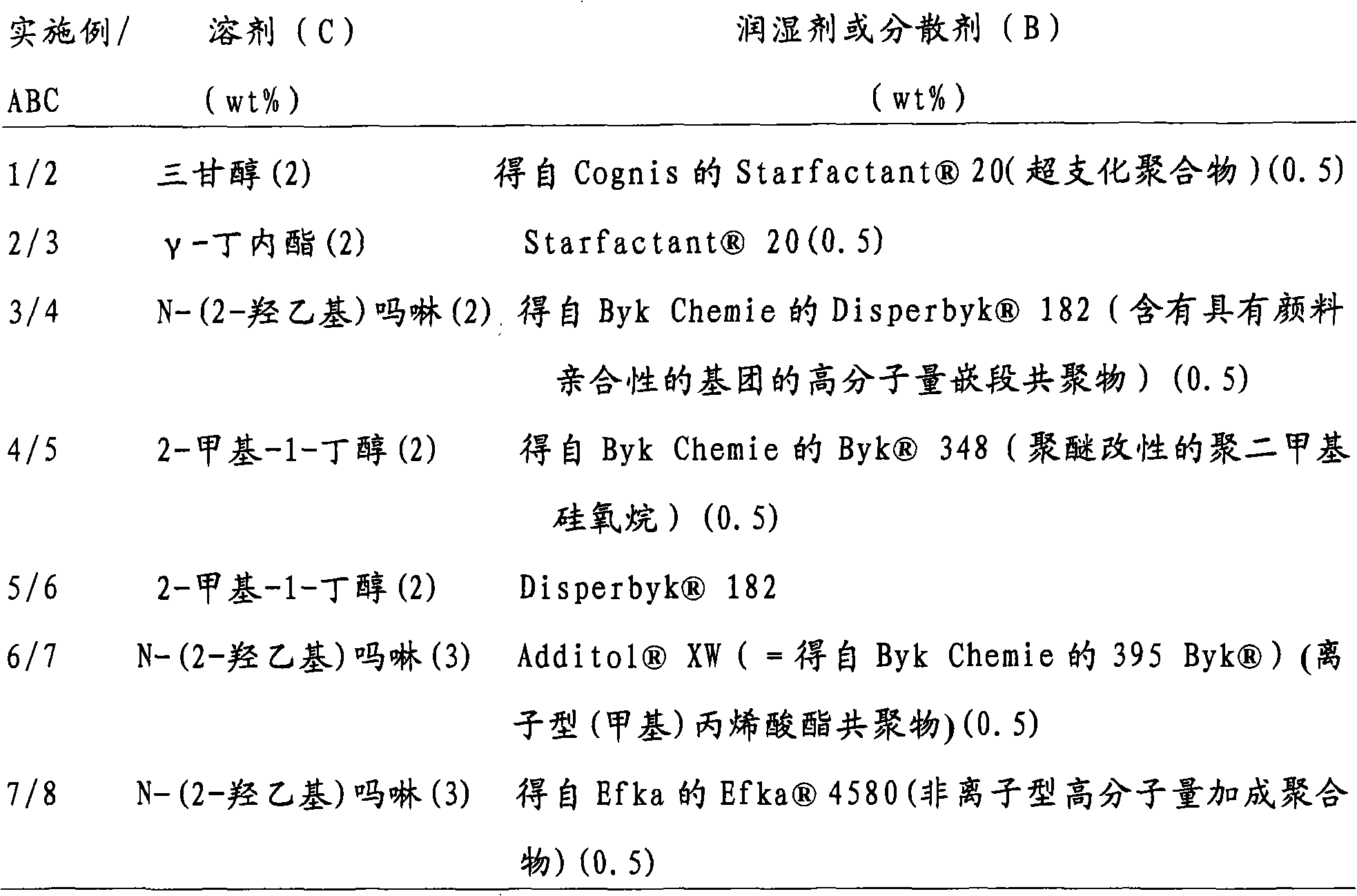

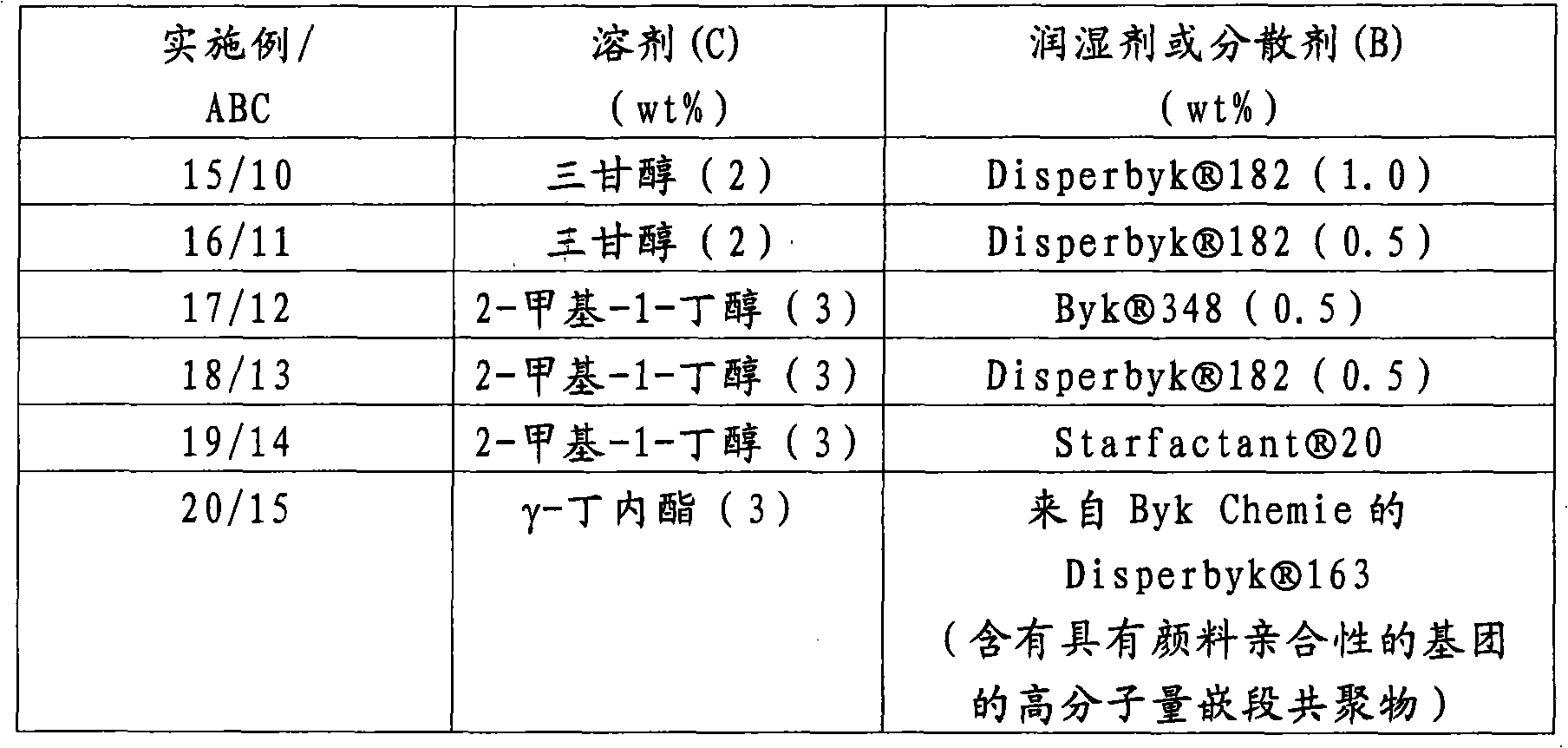

Aqueous coating material, method for the production thereof, and use thereof

ActiveCN101331196AEasy to manufactureLess spray cakingPolyurea/polyurethane coatingsSulfolane1-Pentanol

Disclosed is an aqueous coating material containing (A) at least one saturated and / or unsaturated polyurethane and / or an ionically and / or non-ionically stabilized polyurethane grafted with olefinically unsaturated compounds, (B) at least one wetting agent or dispersing agent, and (C) at least one organic solvent selected among the group comprising dimethylsulfoxide, sulfolane, 2-methyl-1-butanol, 3-methyl-1-butanol, 2-methyl-1-pentanol, hexylglycol, 1,6-hexanediol, diethylene glycol, triethylene glycol, glycerin, trimethylolpropane solutions, pentaerythrite solutions, sorbit solutions, reactive polyether polyols having a number-average molecular weight of 110 to 6,000 Dalton and a hydroxyl number of 25 to 1,000 mg KOH / g, propylene glycol monobutyl ether, dipropylene glycol dimethyl ether, glycerin ethoxylate, ethyl-3-ethoxypropionate, gamma-butyrolactone, N-(2-hydroxyethyl); -piperidine, N-methylmorpholine, N-(2-hydroxyethyl)-morpholine, N-acetylmorpholine, N-cyclohexyl pyrrolidone, and N-octyl-2-pyrrolidone. Also disclosed are a method for producing said aqueous coating material and the use thereof.

Owner:BASF COATINGS GMBH

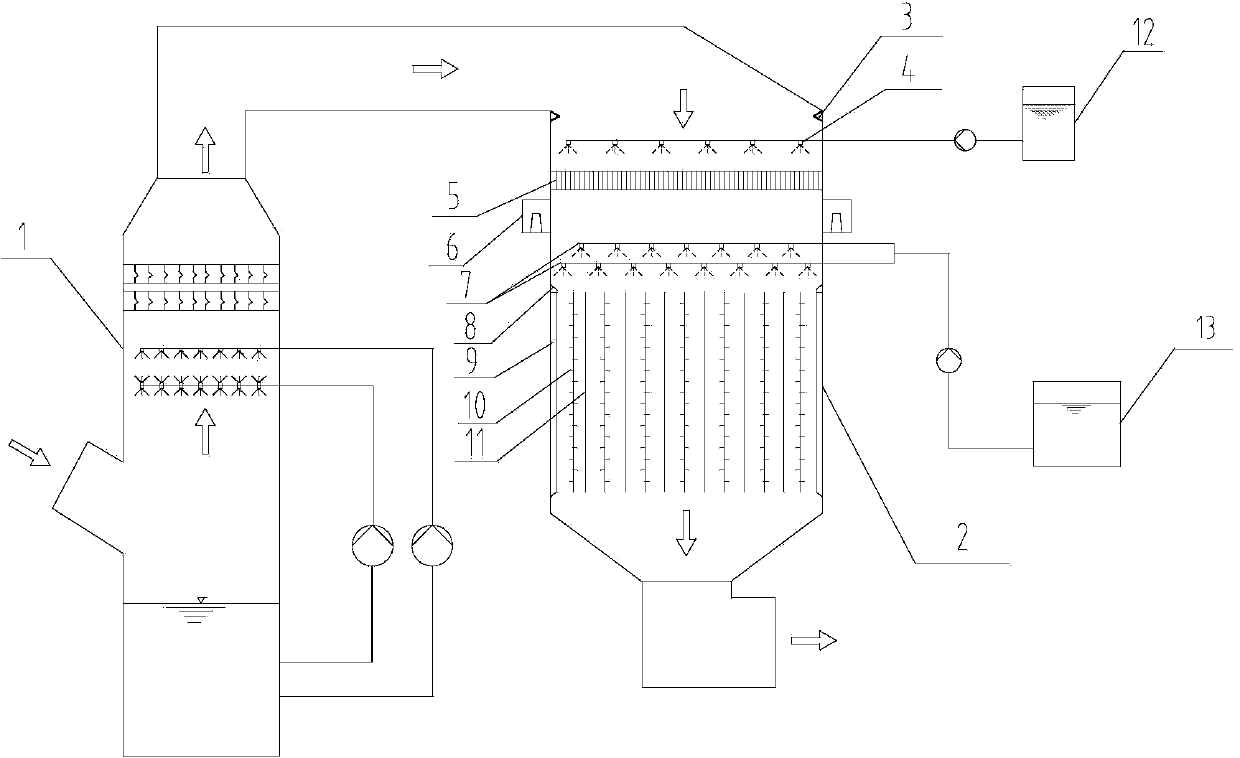

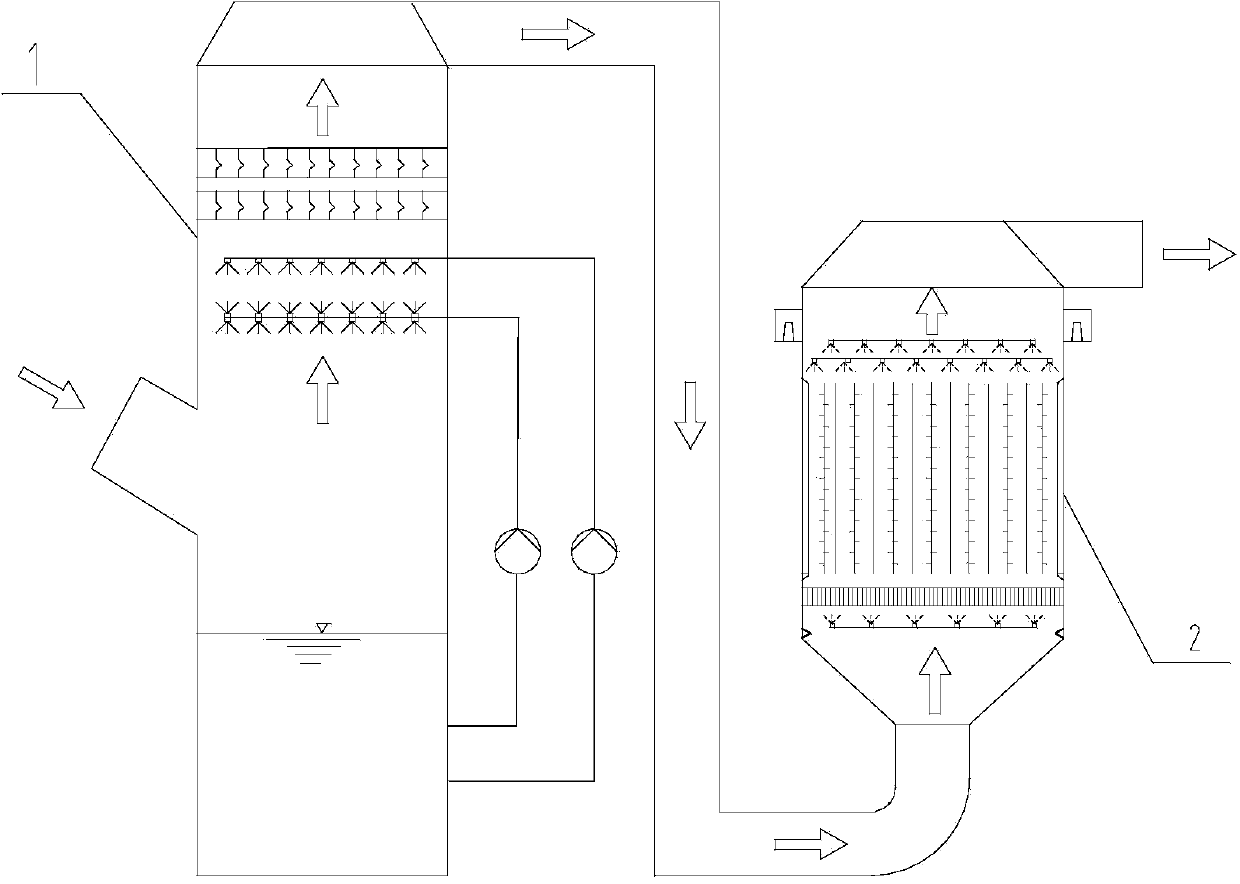

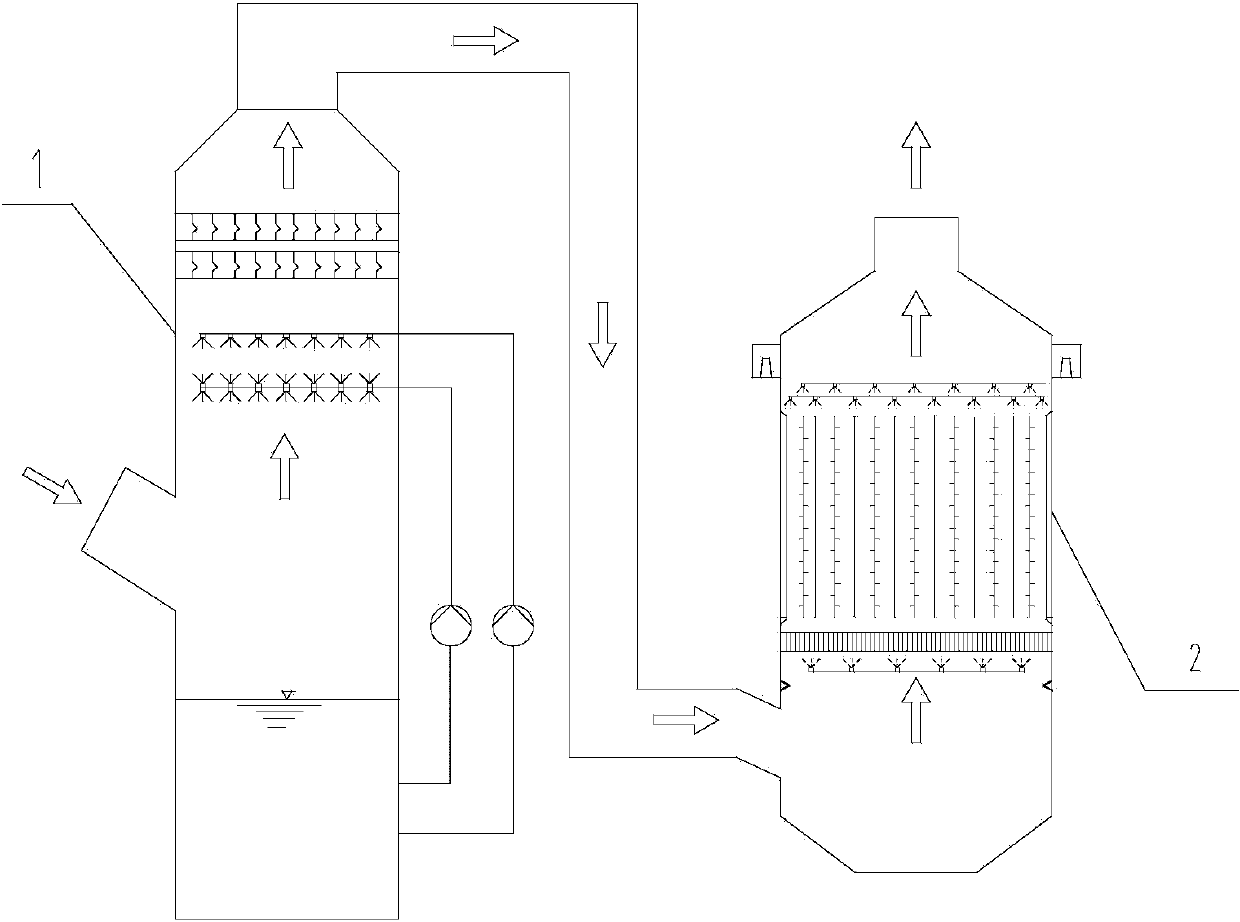

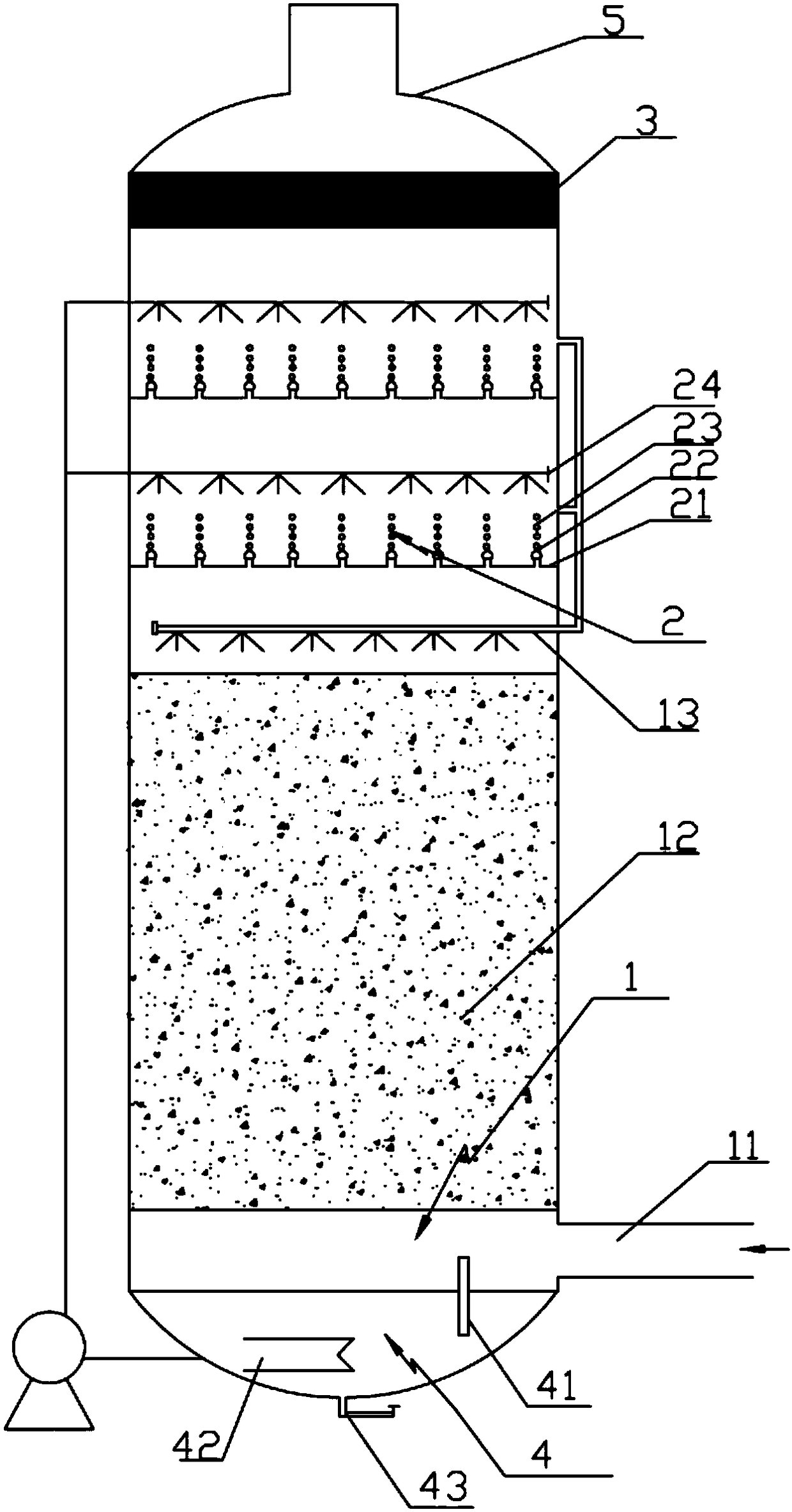

Vertical flow wet-type electric precipitator and wet electric precipitation method

The invention provides a vertical flow wet-type electric precipitator and wet electric precipitation method. The vertical flow wet-type electric precipitator comprises an annular plate, a spray humidifying layer, a flue gas uniform distribution device, a dust removing electric field area, washing and spraying layers, a plurality of insulator boxes, an atomization water tank and a process water tank, wherein the spray humidifying layer comprises a fine atomizing nozzle and a spray pipeline; flue gas sequentially passes through the annular plate, the spray humidifying layer and the flue gas uniform distribution device; the dust removing electric field area is used for blocking a baffle board of a flue gas blind area; the washing and spraying layers are arranged above the dust removing electric field area; the wet electric precipitation method comprises the following steps: a continuous manner is adopted to conduct atomization and humidification on inlet flue gas and conduct uniformly distributed optimization treatment on the flue gas; an intermittent or continuous manner is adopted to conduct sprinkling and cleaning on a dust-collecting electrode and a discharge electrode; a method of hot air sweeping is adopted to ensure insulation. The vertical flow wet-type electric precipitator and the wet electric precipitation method can effectively ensure the high-efficient and stable operation of the vertical flow wet-type electric precipitator, optimize the fluid field, and strengthen turbulence and atomization of the flue gas; local micro-mixing, and collision as well as crash coagulation of fine particles are promoted; the dust removal efficiency is improved.

Owner:SHANGHAI LONGKING ENVIRONMENTAL PROTECTION

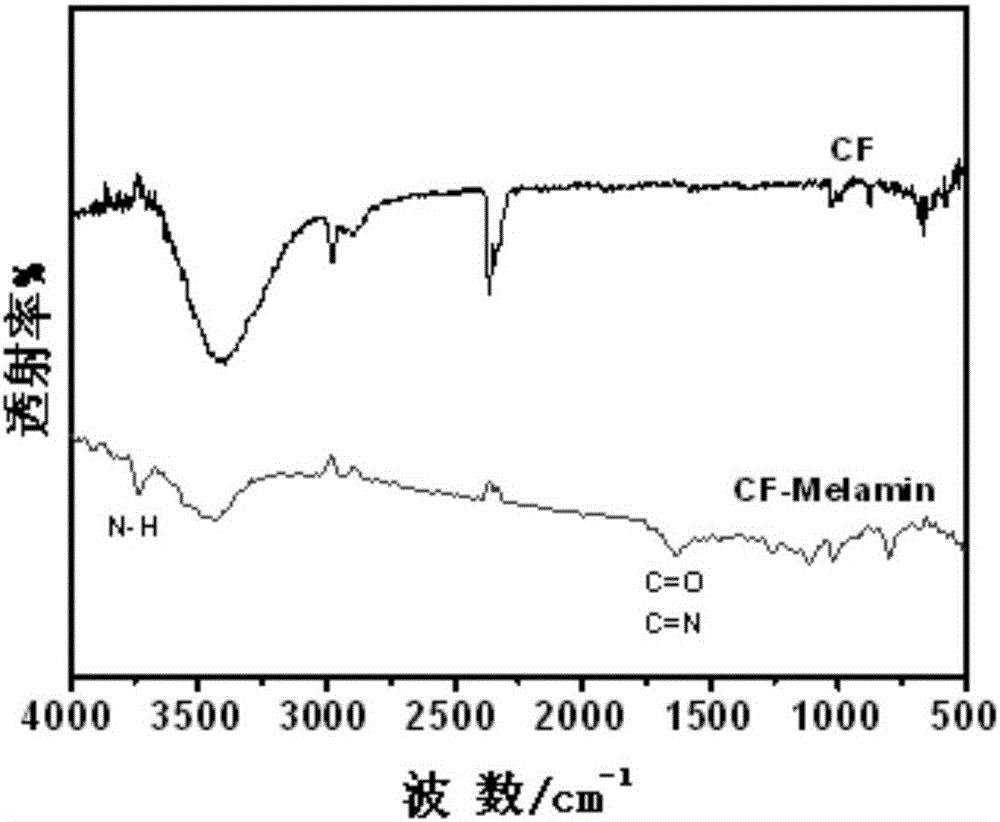

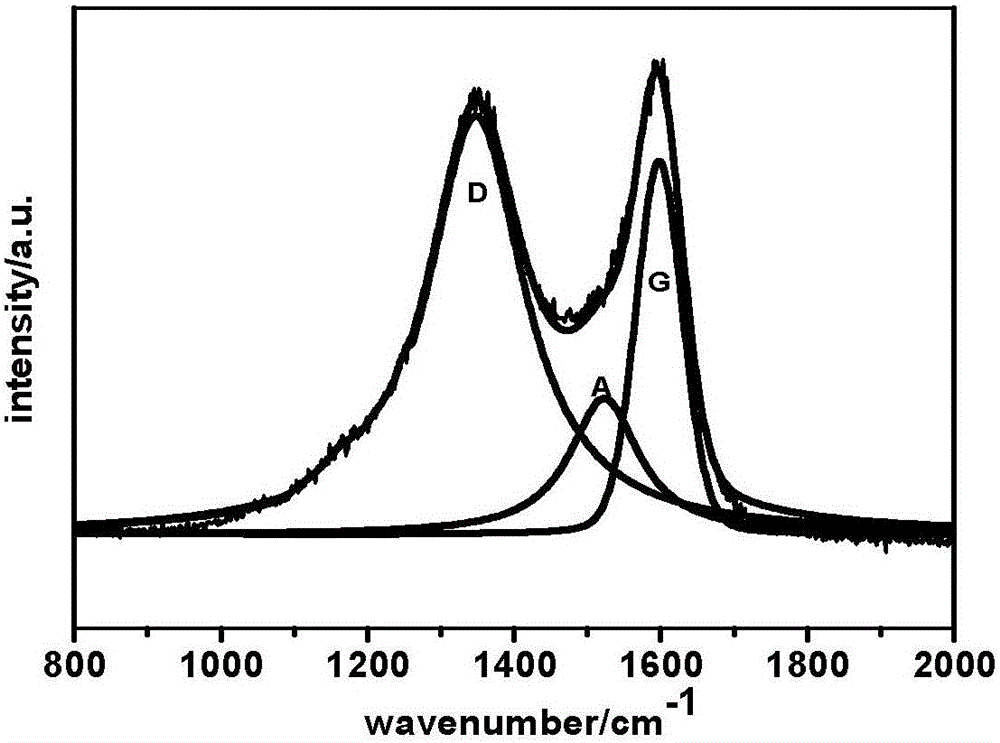

Supercritical fluid technology-based carbon fiber surface grafting method

ActiveCN104987532AEffective wettingImprove the interface binding forceBulk chemical productionCross-linkFiber

The invention discloses a supercritical fluid technology-based carbon fiber surface grafting method, and relates to a carbon fiber surface modifying method. The purpose of the invention is to solve the problems of few reaction sites of grafted micro-molecular substances, easy cross-linking of graft copolymers, and low bonding strength between modified carbon fibers and resin of present carbon fiber surface modifying methods. The method disclosed in the invention comprises the following steps: removing an epoxy coating layer on the surface of the carbon fibers; 2, oxidizing the carbon fibers; 3, carrying out acylchlorination on the carbon fibers; and 4, grafting the surface of the carbon fibers with melamine. The surface of the carbon fibers is grafted with melamine, and the quantity of reaction sites is large, so convenience is provided for a next step grafting reaction. The molecular weight of melamine is small, and melamine and polymers are difficult to cross-link, so melamine has very good dispersion, and undergoes a grafting reaction with good homogeneity on the surface of the carbon fibers in order to facilitate improvement of the interface performances of a composite material. The method is used for surface modification of the carbon fibers.

Owner:HARBIN INST OF TECH

Additive for texturing solution of monocrystalline silicon

The invention discloses an additive for texturing solution of monocrystalline silicon, belonging to the field of solar cells. The additive has the following components by mass percentage: 0.1-10% of fructose, 1-10% of sodium silicate, 0.1-10% of organic acid salt, 0.1-5% of surfactant, and the balance of deionized water or water with a purity higher than that of the deionized water. By using the additive, the textured surface of the monocrystalline silicon wafer, which is prepared by the texturing solution of monocrystalline silicon in the absence of isopropanol or ethanolthe, has uniform and tiny pyramid structures; in addition, the reaction temperature can be reduced, and the time can be shortened.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

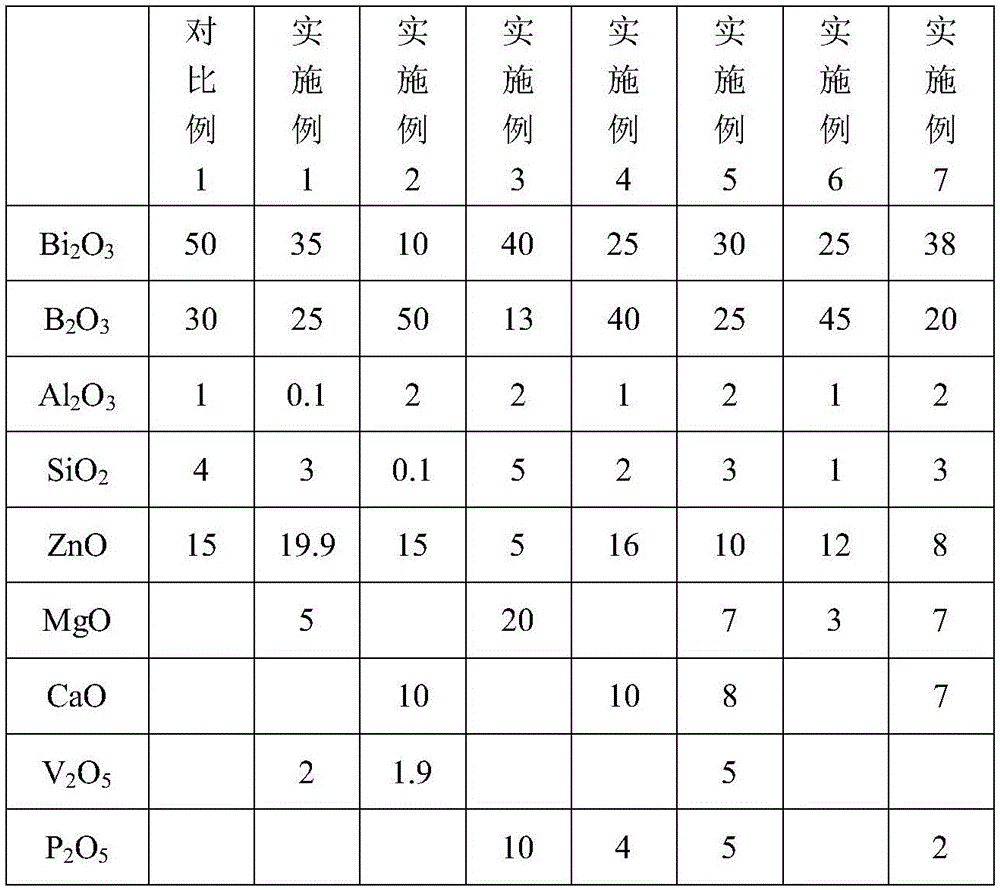

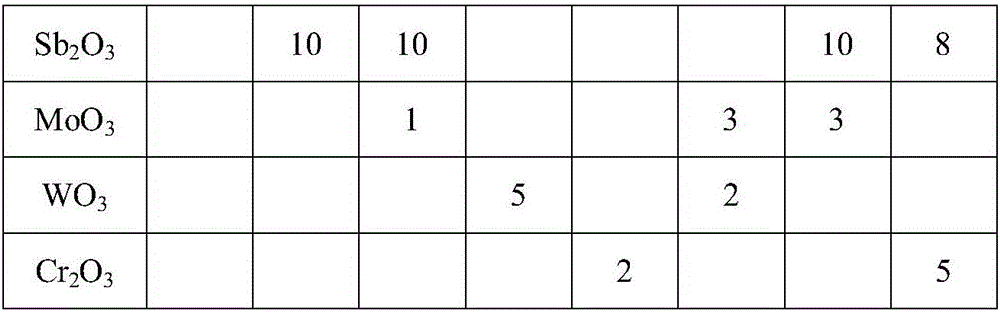

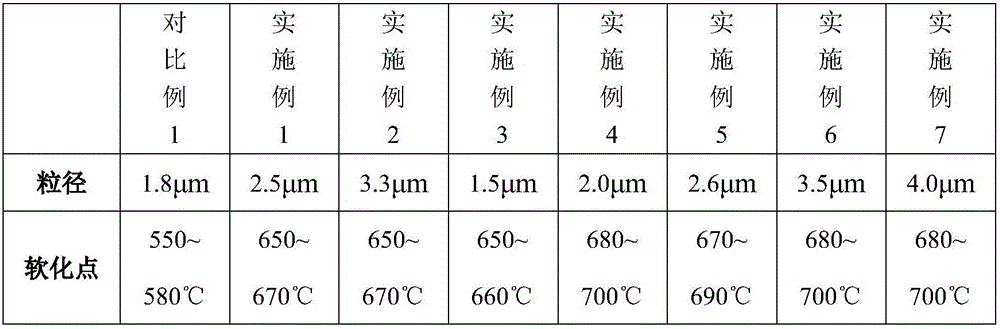

Glass powder for high temperature-resistant aluminum slurry and preparation method thereof

The invention discloses a glass powder for high temperature-resistant aluminum slurry. The glass powder is prepared from the following raw materials in percentage by weight: 10 to 50% of Bi2O3 (bismuth trioxide), 5 to 50% of B2O3 (boric oxide), 0.1 to 5% of SiO2 (silicon dioxide), 0.1 to 2% of Al2O3 (aluminum oxide), 5 to 20% of ZnO (zinc oxide), 1 to 20% of alkaline earth oxide, and 0.1 to 15% of one or combination of multiple of V2O5 (vanadium pentoxide), P2O5 (phosphorus pentoxide), Sb2O3 (antimonous oxide), MoO3 (molybdenum trioxide), WO3 (tungsten trioxide) and Cr2O3 (chromic oxide). The glass powder has the advantages that the chemical stability is good, the softening point is high, the material characteristic is short, the wetting property is good, and the technical problems of high temperature aluminum bulge, degrading of electricity, low water boiling-resistant property and the like in the existing aluminum slurry after high-temperature sintering are solved. The invention also discloses a preparation method of the glass powder for the high temperature-resistant aluminum slurry.

Owner:GUANGZHOU RUXING TECH DEV +1

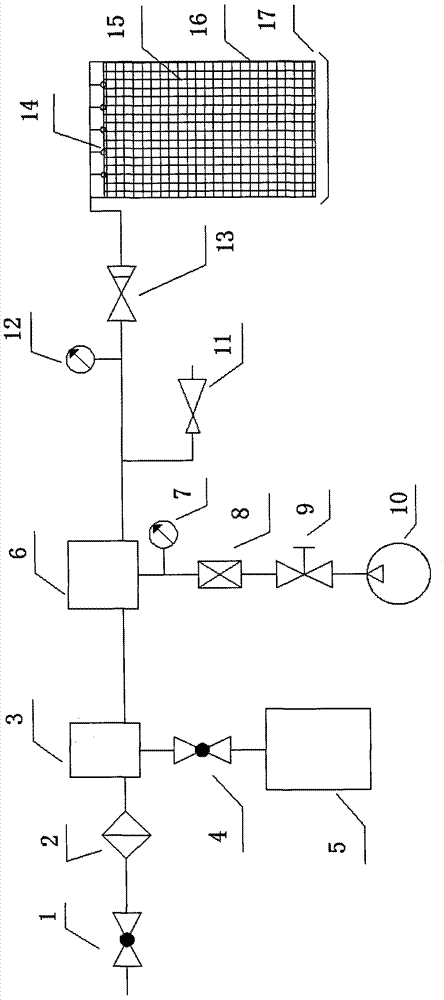

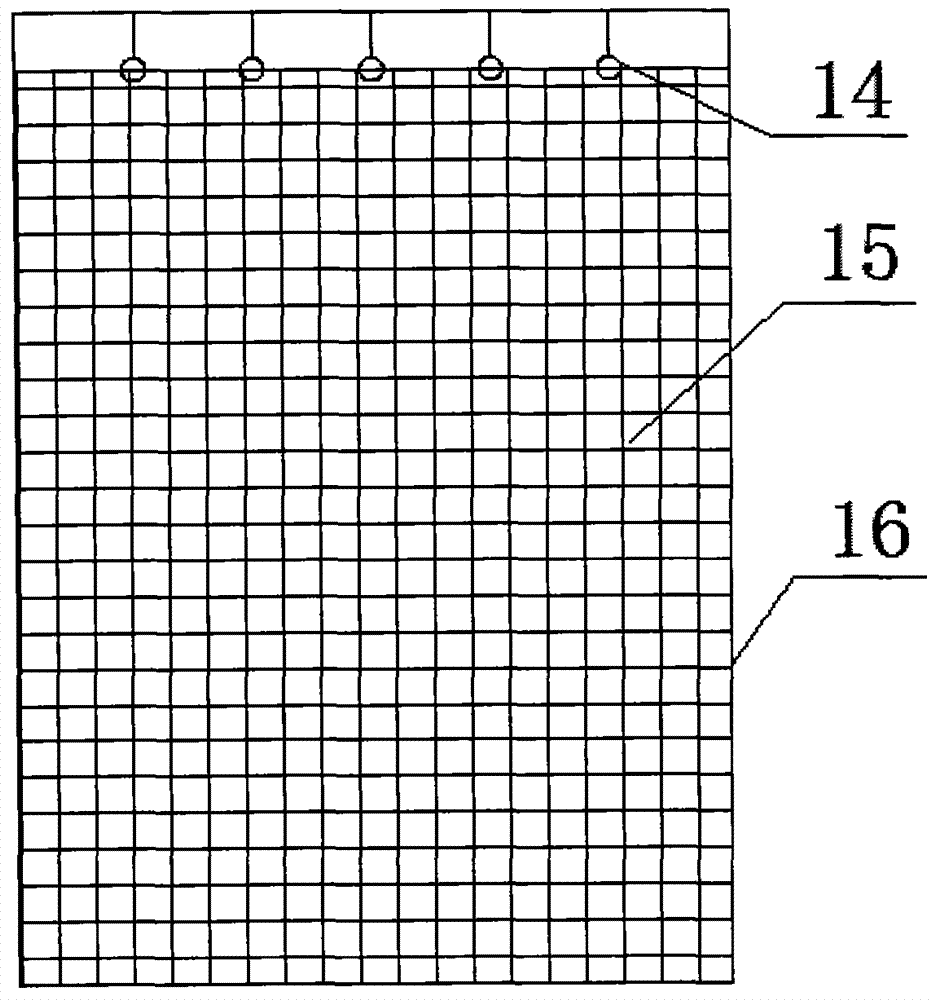

Net type foam film dust removal system for underground coal mine

InactiveCN104747227AIncrease contact areaExtension of timeDust removalFire preventionWater dischargeLiquid storage tank

The invention discloses a net type foam film dust removal system for an underground coal mine. The system mainly comprises a filter, a fixed-ratio adder, a liquid storage tank, a gas-liquid booster pump, an air compressor, an air regulating valve, a pressure reducing valve, a check valve, a dust removal net, a plurality of foam sprayers and the like. The filter, the fixed-ratio adder and the gas-liquid booster pump are connected through pipelines sequentially. The fixed-ratio adder is connected with the liquid storage tank. The gas inlet end of the gas-liquid booster pump is connected with a pressure gauge, the regulating valve and the air compressor. The water outlet end of the booster pump is connected with the pressure reducing valve, the pressure gauge, the check valve and the foam sprayers sequentially. The dust removal net, namely a double-layer metal net, is mounted below the sprayers. Foam generated by the foam sprayers evenly covers the dust removal net to form a foam film, and dust flows into a water discharge tank after being captured by the foam film. The net type foam film dust removal system has the advantages that by the net type foam film, contact between dust particles and the foam can be effectively increased, dust wettability can be effectively improved, and dust removal efficiency can be also improved; the net type foam film is simple in structure and easy to mount and demount, and water consumption can be reduced remarkably.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Brazing filler metal for vacuum brazing of high-nitrogen steel and preparation method of brazing filler metal

ActiveCN109128583AGuaranteed tissue homogeneityNo lossWelding/cutting media/materialsSoldering mediaWater basedFiller metal

The invention discloses brazing filler metal for vacuum brazing of high-nitrogen steel. The brazing filler metal for vacuum brazing of the high-nitrogen steel is composed of, by weight, 25-28 parts ofPd, 39-46 parts of Ni, 36-39 parts of Cr, 2.8-5.8 parts of vanadium plated nickel graphene, 12-15 parts of Mn, 7-11 parts of Re, 6-9 parts of Si and 2-5.5 parts of B. During preparation, a method comprises the following steps that firstly, distilled water, a water-based binding agent, acetone and ethyl alcohol are weighed, raw material alloy powder of the Pd, the Ni, the Cr, the vanadium plated nickel graphene, the Mn, the Re, the Si and the B is prepared according to the proportion and is ground to 106 micons-150 microns to be used; secondly, the acetone, the ethyl alcohol, the water-based binding agent and the distilled water which are obtained in the first step are arranged in a beaker and stirred, and a solution without sediment is obtained; and thirdly, 45-70 parts of the raw material alloy powder obtained in the first step is taken, 12-18 parts of an auxiliary additive is added into the 45-70 parts of the raw material alloy powder, a mixture is added into the solution obtained in the second step, stirring and vacuumizing are carried out, and the pasty brazing filler metal is prepared. According to the brazing filler metal, during brazing, the defect that in traditional welding, air holes are prone to being generated is overcome, the element of nitrogen is almost not lost, and the structure homogeneity of the high-nitrogen steel base metal is guaranteed.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

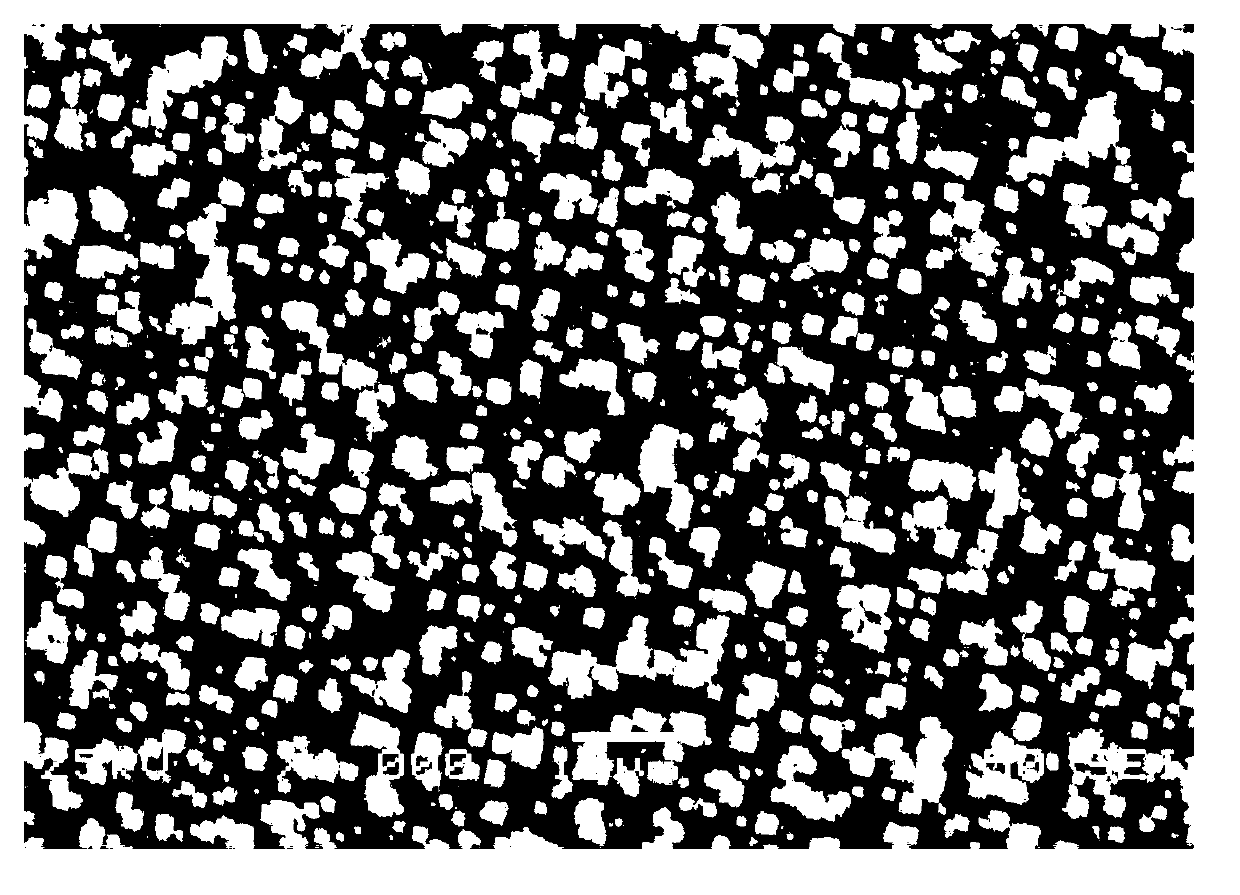

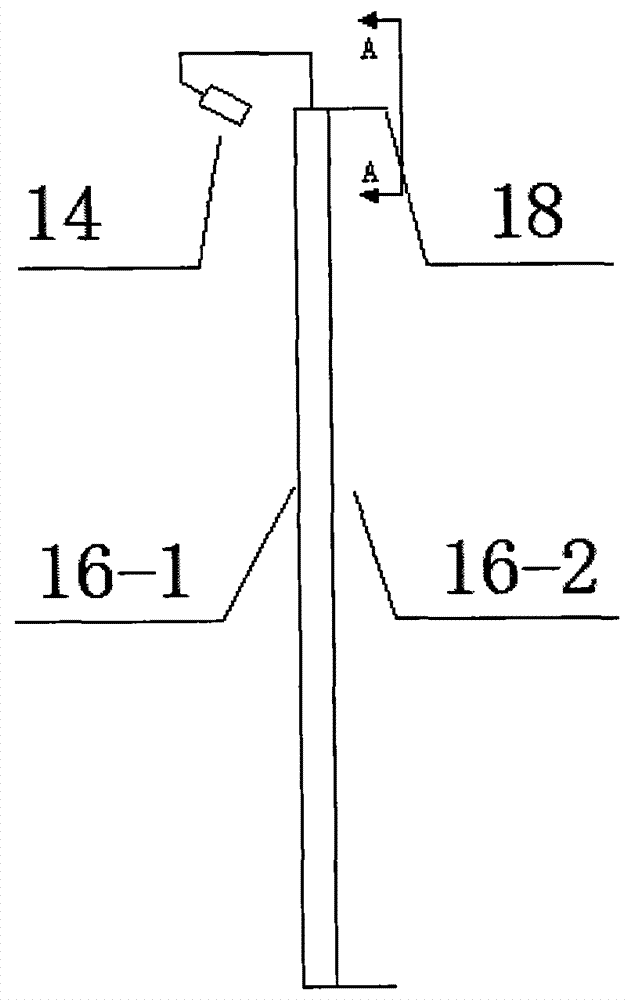

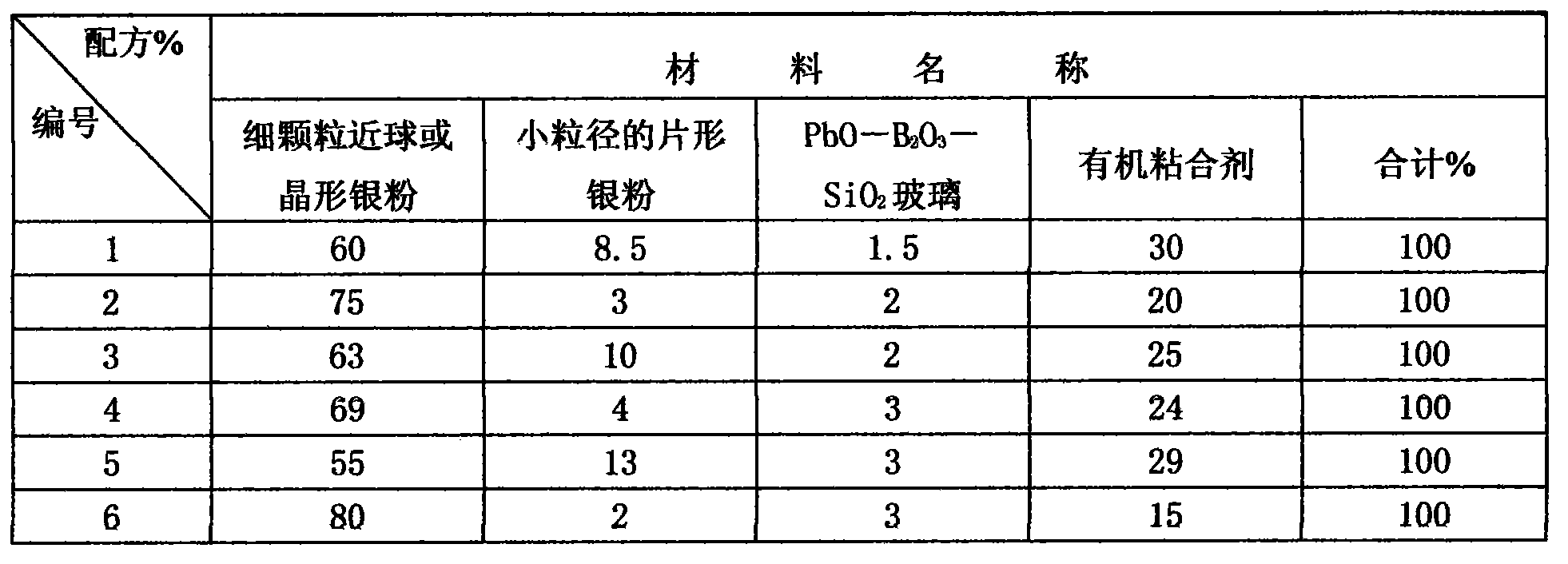

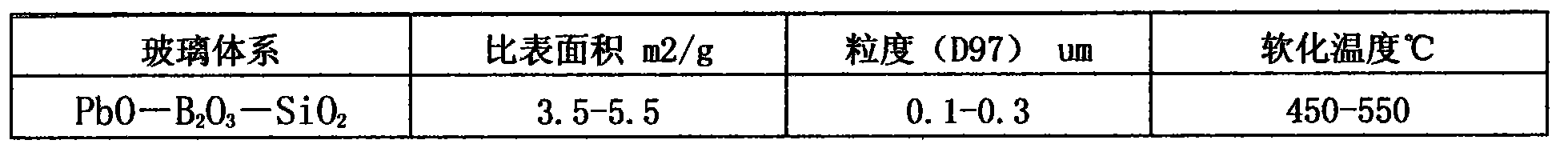

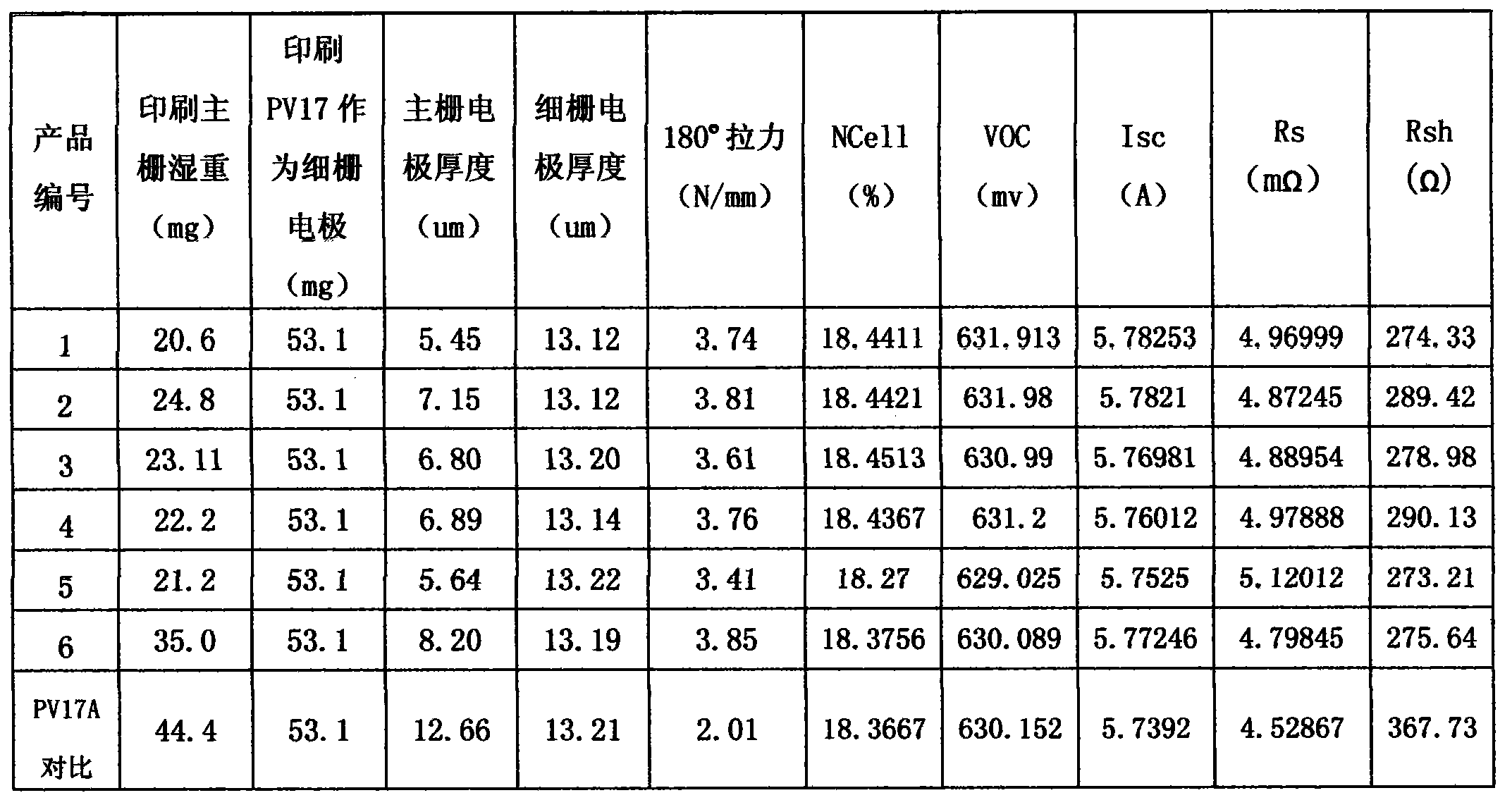

Method for preparing silicon solar cell positive electrode and main grid paste thereof

InactiveCN103441183AReduce usageImprove crystal stateFinal product manufactureNon-conductive material with dispersed conductive materialSilver pasteScreen printing

The invention discloses a method for preparing a silicon solar cell positive electrode and the main grid paste of the silicon solar cell positive electrode, and relates to the technical field of the manufacturing processes and the materials of electronic devices. The method for preparing the silicon solar cell positive electrode comprises the steps that 1) the electrode of a main grid and the electrode of a thin grid are respectively printed through two times of silk-screen printing; 2) different paste with silver or silver paste is adopted when the electrode of the main grid and the electrode of the thin grid are printed; 3) after sintering, the thickness of the electrode of the main grid is smaller than that of the electrode of the thin grid. The method can ensure the good dispersion of all components, even and soft silver electrode paste is obtained after rolling, and a silicon solar cell product is made to have good, stable and even electrical performance after the sintering.

Owner:ZHEJIANG GUANGDA ELECTRONICS TECH

Environment-friendly pavement dust suppressant and preparation method thereof

InactiveCN103450852AQuick condensationAvoid flyingOther chemical processesSorbitan monostearateSODIUM PYRROLIDONE CARBOXYLATE

The invention provides an environment-friendly pavement dust suppressant and a protection method thereof. The dust suppressant is prepared from the following raw materials in parts by mass: 4 to 18 parts of sorbitan monolaurate, 5 to 24 parts of sorbitan monostearate, 2 to 6 parts of sodium lactate, 3 to 5 parts of sodium pyrrolidone-carboxylate, 3 to 7 parts of glycerin, and 150 to 160 parts of water. By adopting the environment-friendly pavement dust suppressant, the dust particles which are easy to fly can be quickly conglomerated into large particles to sink, thus the flying of dust on a pavement can be effectively prevented, and the acting efficiency is high; the dust suppressing effect can last for more than 6 days; the dust suppressing rate is up to 95%.

Owner:SUZHOU KANGHUA PURIFYING SYST ENG

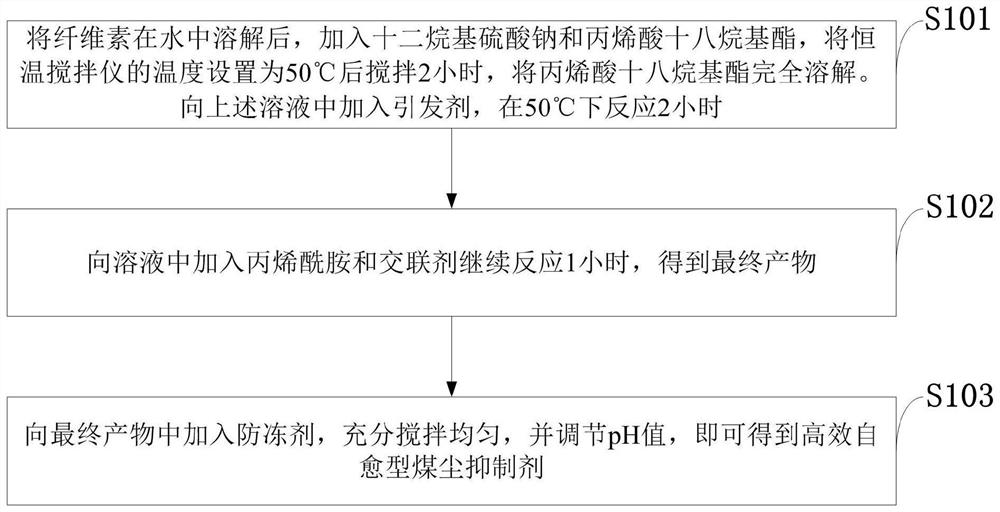

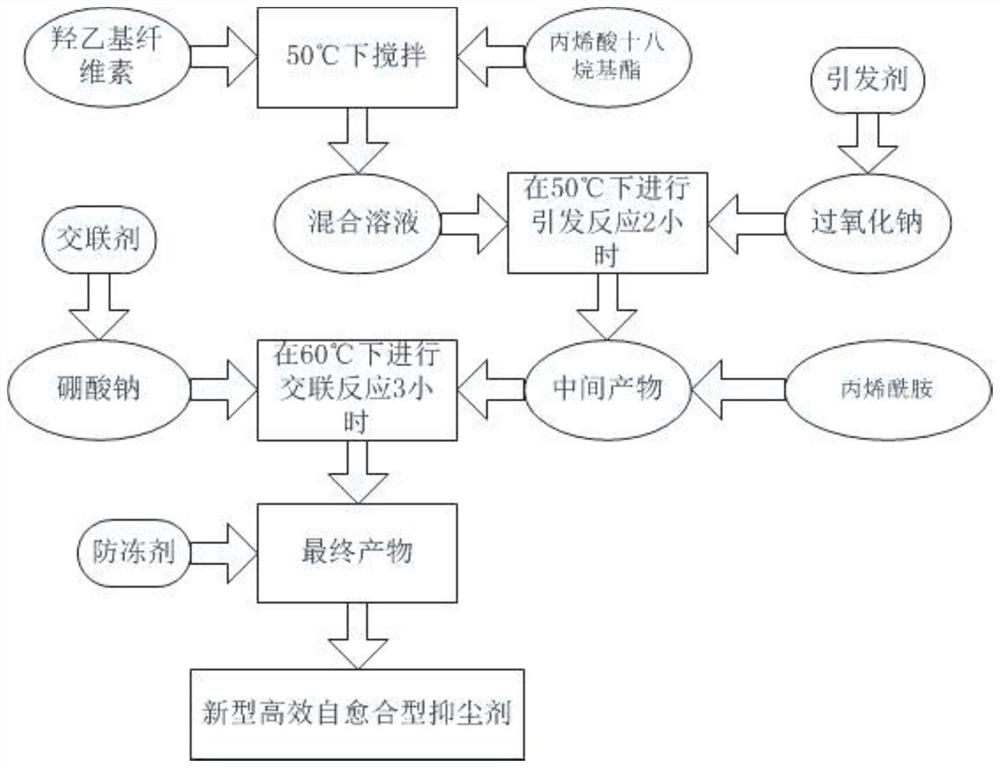

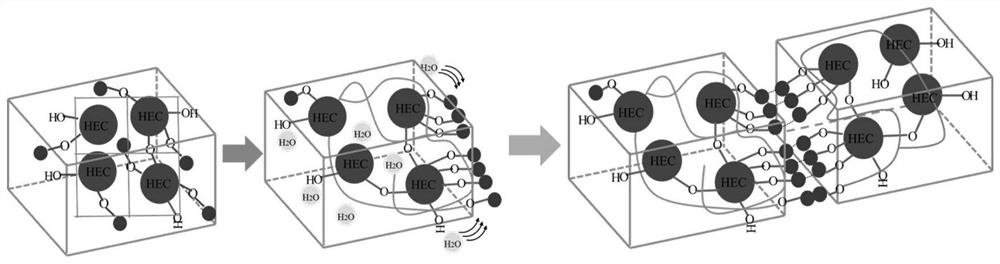

Dust suppressant, preparation method thereof, and dustproof method in opencast coal mining and coal transportation

PendingCN111793469AGuaranteed performanceIncrease stickinessOther chemical processesDust removalCelluloseCoal dust

The invention belongs to the technical field of dust suppressants for dust prevention in open pit coal mining, coal transportation and stockpiling processes, and discloses a preparation method of a dust suppressant, and a dust prevention method in opencast coal mining and coal transportation. 100% of the dust suppressant is prepared from, by mass, 2-5% of cellulose, 1-3% of sodium lauryl sulfate,2-4% of octadecyl acrylate, 10-15% of acrylamide, 0.05-0.1% of an initiator, 0.02-0.04% of a cross-linking agent, 0.3-0.6% of an anti-freezing agent, and the balance of water. An inhibitor not only can further improve the wettability of the dust suppressant to coal dust, so that water wets and bonds the coal dust to the greatest extent, and greatly reduces the diffusion degree of the dust, but also can play a self-healing role to complete the wrapping and covering of the dust by adding a certain amount of water after the dust bonding layer is broken, thereby improving the dust suppression efficiency and ensuring the long-term dust suppression.

Owner:SHANDONG UNIV OF SCI & TECH

Solvent-free type base adhesive for nail painting and preparation method thereof

ActiveCN108635248AFast curingHigh hardnessCosmetic preparationsNon-macromolecular adhesive additivesAdhesiveAcrylic resin

The invention relates to a solvent-free type base adhesive for nail painting and a preparation method thereof. The solvent-free type base adhesive for nail painting is prepared from the following ingredients of 0.5 to 1.5 parts of a titanate coupling agent, 25 to 30 parts of epoxy acrylic resin, 25 to 30 parts of aliphatic polyurethane acrylic resin, 3 to 10 parts of pure acrylic resin, 25 to 35 parts of acrylate monomers, 0.5 to 1.5 parts of a photoinitiator 184, 2 to 5 parts of TPO, 0.05 to 0.2 part of a flatting agent and 0.1 to 0.3 part of an antifoaming agent. The solvent-free type base adhesive for nail painting has the advantages that the durability can reach three weeks or more than three weeks; the breaking elongation is greater than 7 percent; the tensile strength is greater than500psi; the adhesion test ISO grade is 0; and the viscosity at 25 DEG C is 1000 cps to 40000cps.

Owner:SHANGHAI ONINE TECH LTD

Sewage station waste gas treatment device with composite biological method and waste gas treatment method of sewage station waste gas treatment device

InactiveCN109078479ARealize environmental protectionCompact structureGas treatmentDispersed particle filtrationSewagePetrochemical

The invention discloses a sewage station waste gas treatment device with a composite biological method and a waste gas treatment method of the sewage station waste gas treatment device. The sewage station waste gas treatment device comprises a cylinder, a defogging system is mounted at the upper portion of the cylinder, a discharge outlet is arranged in the cylinder at the top of the defogging system, an opening is arranged below one side wall of the cylinder, an air intake system is connected to the position of the opening through a pipeline, and a liquid storage system is mounted in the bottom of the cylinder. An integrated gas-liquid two-phase multi-stage biological purification treatment device is adopted, petroleum coke, a by-product of the petrochemical industry, is used as a biological filler filled into the integrated gas-liquid two-phase multi-stage biological purification treatment device, and sulfur-containing odorous substances and VOCs (volatile organic chemicals) in a waste gas of a sewage station are removed through attachment and adsorption of microorganisms; meanwhile, problems about large occupation and low energy efficiency in a traditional biological method aresolved through the unique structure design of the integrated gas-liquid two-phase multi-stage biological purification treatment device, and environmental-friendly, harmless and energy-saving treatmentof the waste gas of the sewage station is realized.

Owner:WUXI ZHONGTIAN SOLID WASTE DISPOSAL CO LTD

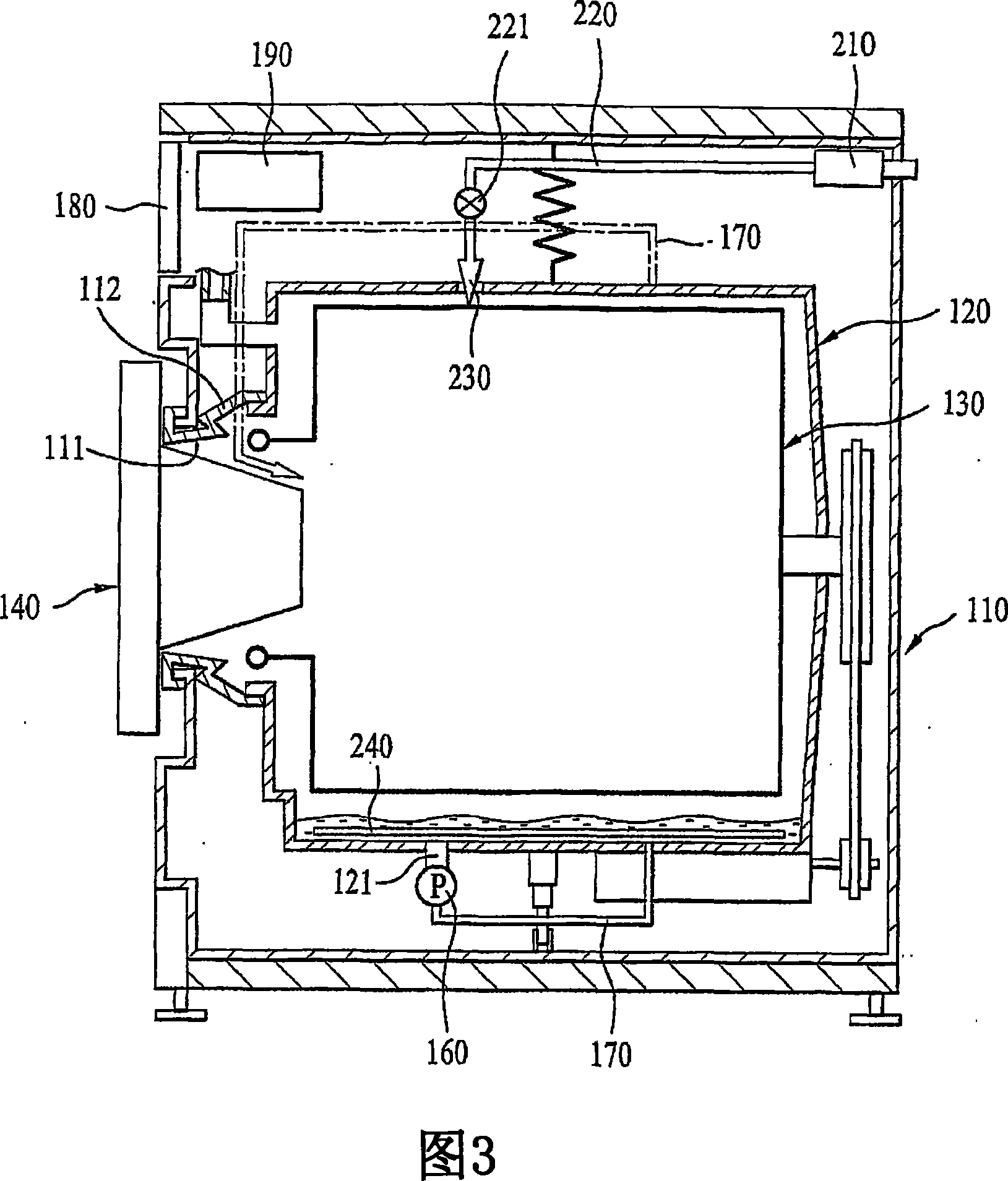

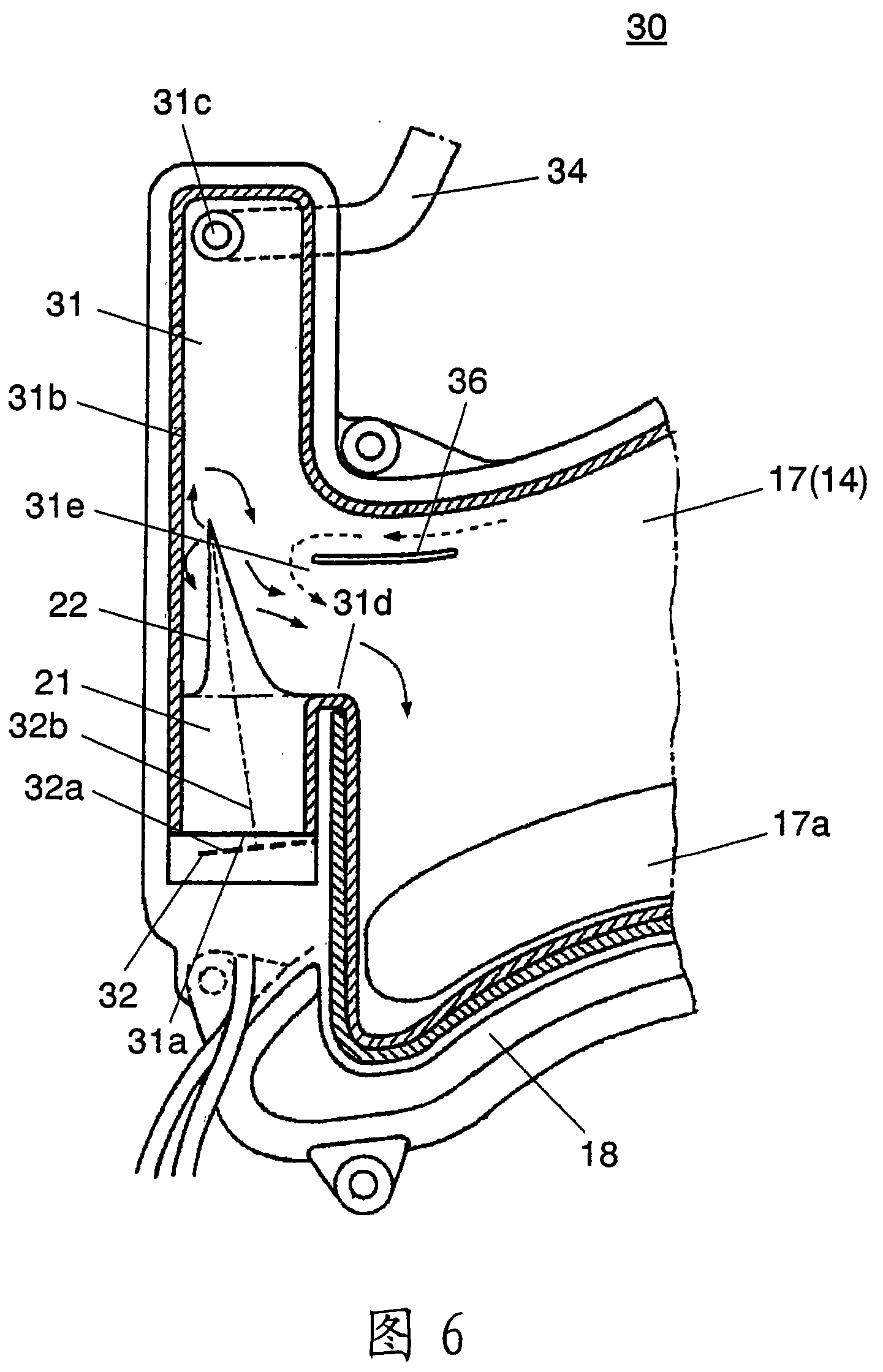

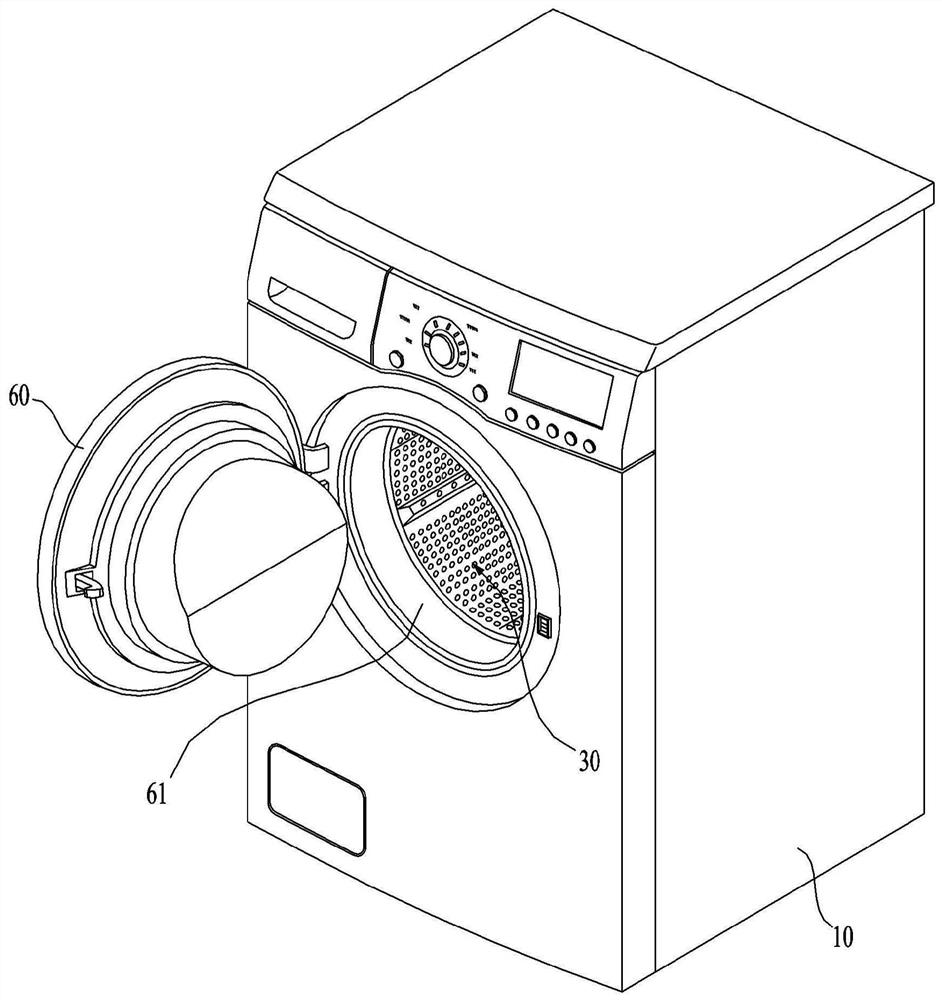

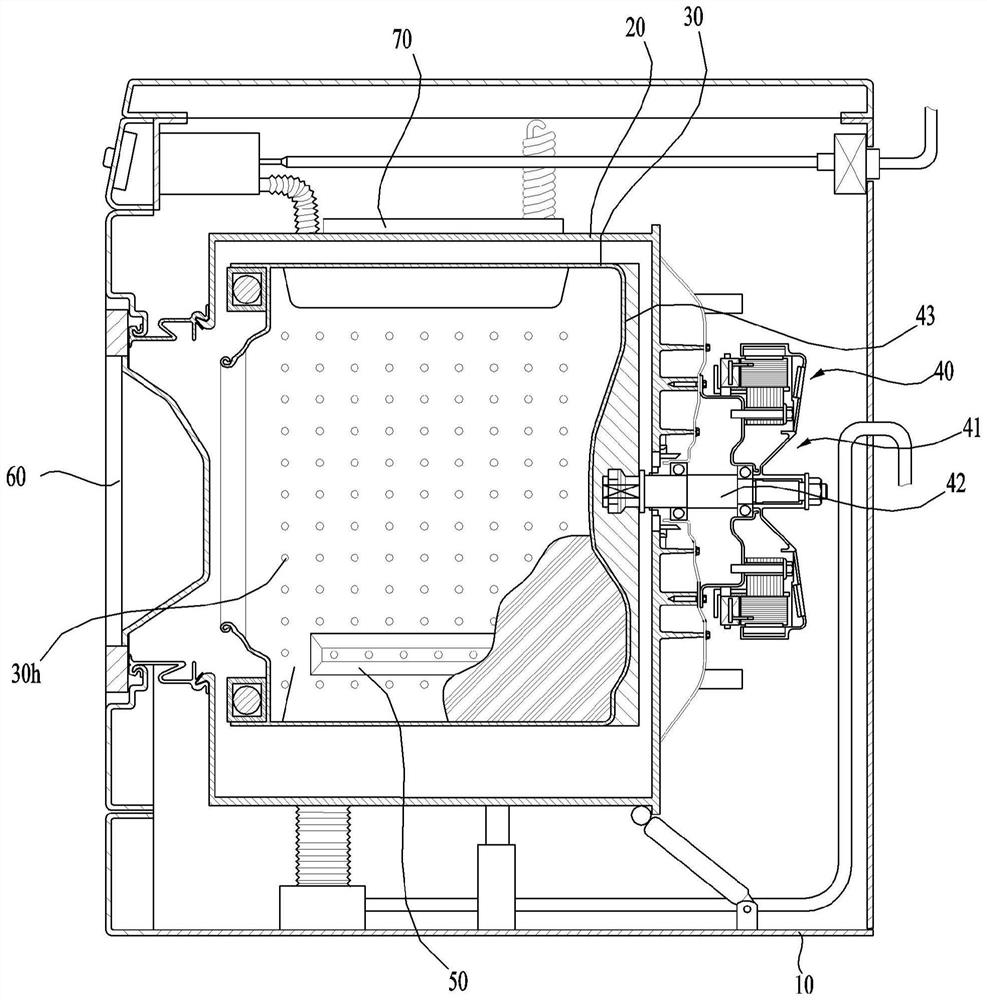

Drum washing and drying machine

InactiveCN101245541AEffective wettingReduce wrinklesOther washing machinesWashing machine with receptaclesLaundryEngineering

Owner:PANASONIC CORP

Method for welding stainless steel seawater filter element compositely through laser spot welding and vacuum brazing

The invention discloses a method for welding a stainless steel seawater filter element compositely through laser spot welding and vacuum brazing. The method comprises the steps that surface pretreatment is carried out on an inner framework and the to-be-welded portion of a filter net of the stainless steel seawater filter element, the to-be-welded portion is fixed through a clamp, the to-be-weldedportion is fixed to the surface of the inner frame according to the circle number of the filter net through laser spot welding, the to-be-welded face is coated with brazing filler metal, finally, vacuum brazing is adopted for carrying out brazing on to-be-welded positions except for the laser spot welding position, and therefore welding of the stainless steel seawater filter element is completed.According to composite welding of laser spot welding and vacuum brazing, during steel connection, since the temperature is low, the problem that nitride, carbide and carbonitride are produced at a joint so as to reduce performance can be effectively prevented, the structure performance changing problem is avoided, and the welded joint has no defect, is high in cleanliness and excellent in performance.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

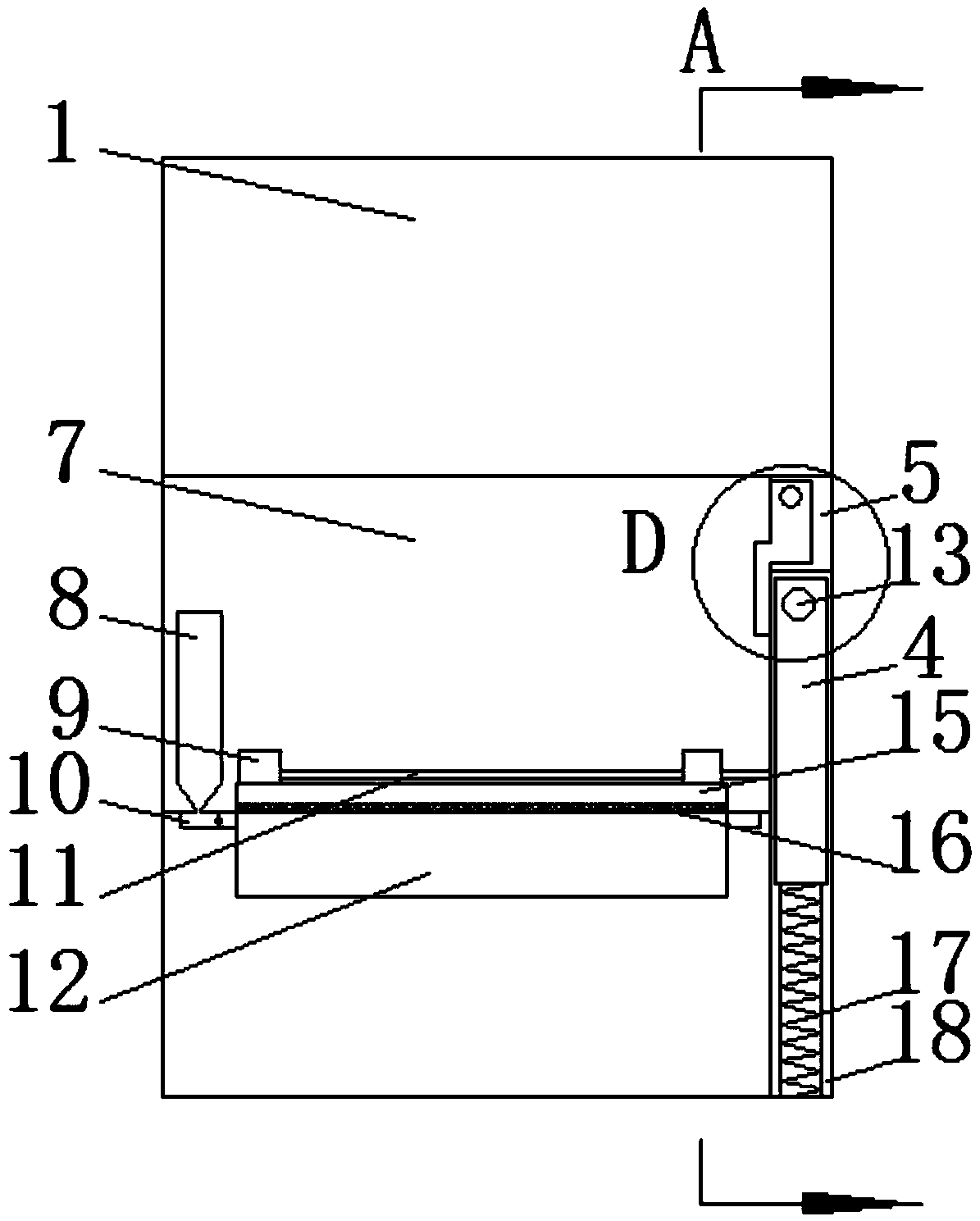

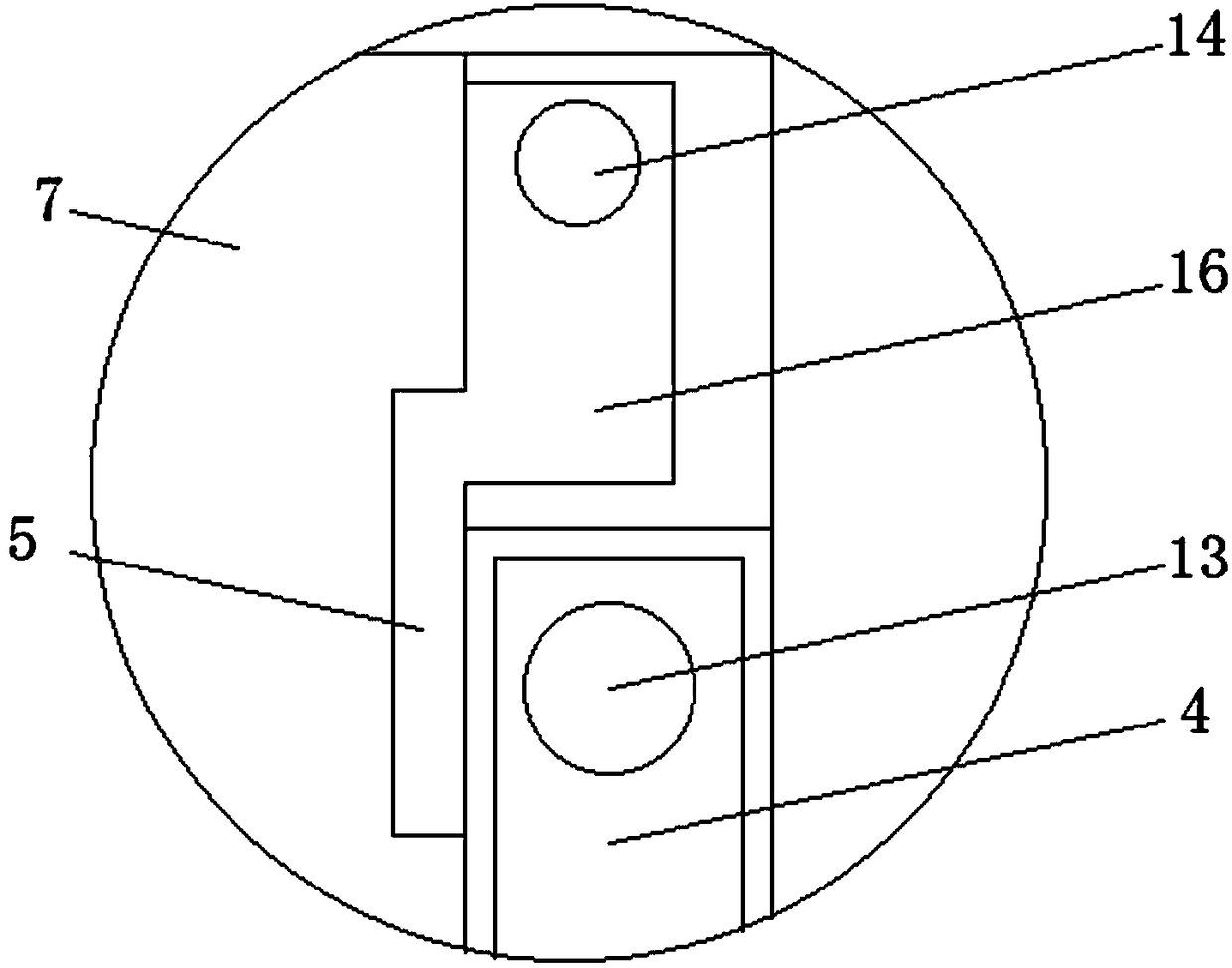

Device for improving cleaning effect of fingerprint unlocking device for smart home door

InactiveCN108722923AEffective wettingEfficient scrapingCleaning using toolsIndividual entry/exit registersPasswordComputer science

The invention discloses a device for improving cleaning effect of a fingerprint unlocking device for a smart home door. The device comprises a main unlocking device body, a fingerprint induction screen, a fingerprint unlocking groove, a password unlocking device and a processor. The main unlocking device body is provided with the password unlocking device and the fingerprint unlocking groove, andthe main unlocking device body is internally provided with the processor and an accumulator. The fingerprint induction screen is arranged in the fingerprint unlocking groove. Symmetrically distributedfixing grooves are formed at the two ends of the outer side of the fingerprint unlocking groove. A movable first dust plate is arranged in the fixing grooves. The bottom of the first dust baffle is connected to the bottoms of the fixing grooves through multiple uniformly distributed springs. A cleaning groove is formed on the other side of the fingerprint induction screen. The cleaning groove isinternally provided with cleaning liquid. Scraper blades are arranged at the upper end of the cleaning groove, wherein the scraper blades are symmetrically distributed and incline inwards. The devicefor improving the cleaning effect of the fingerprint unlocking device for the smart home door is simple in operation, great in comprehensive practicality, and easy to be applied and popularized.

Owner:ANHUI LIXIN INTELLIGENT TECH CO LTD

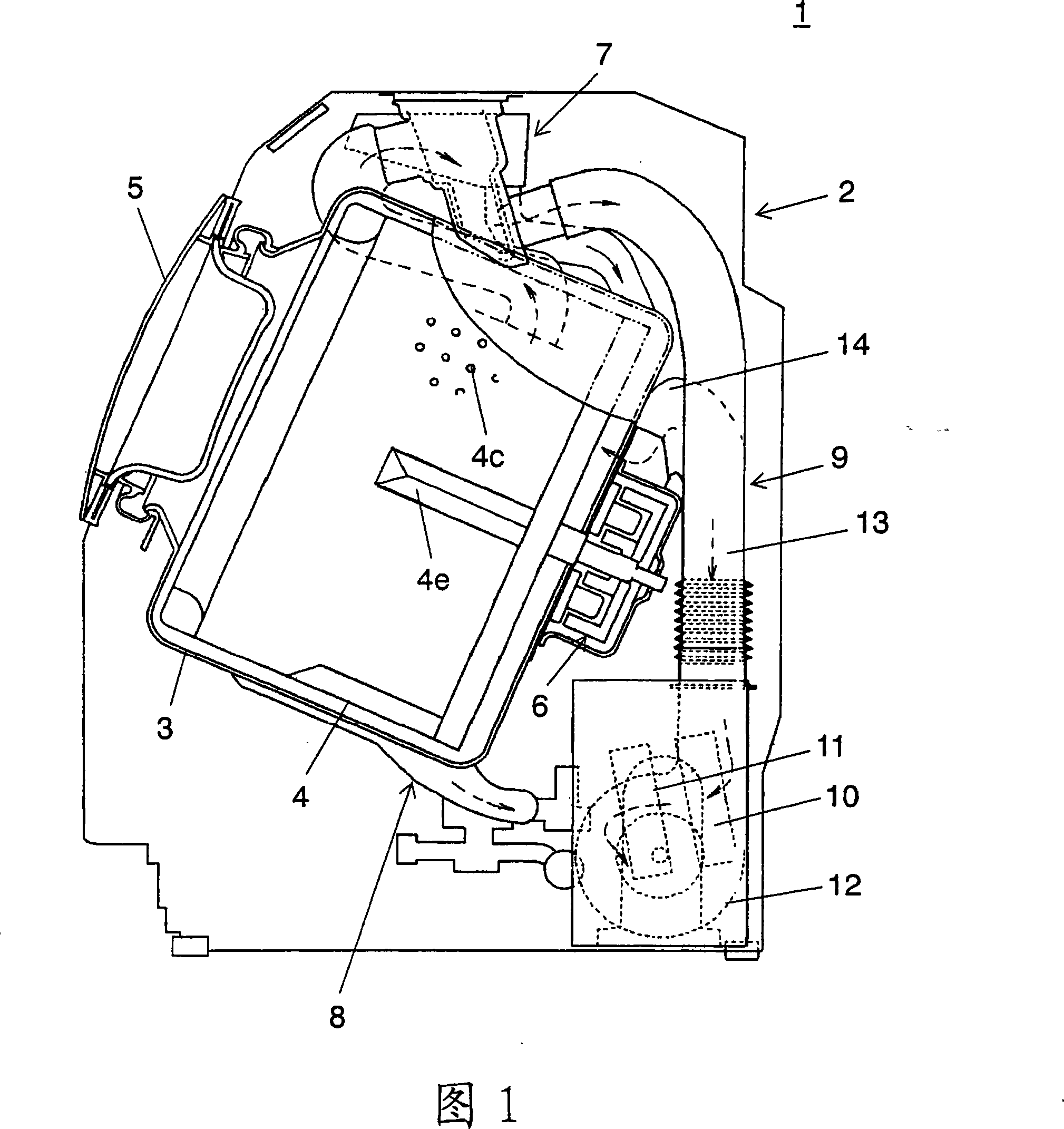

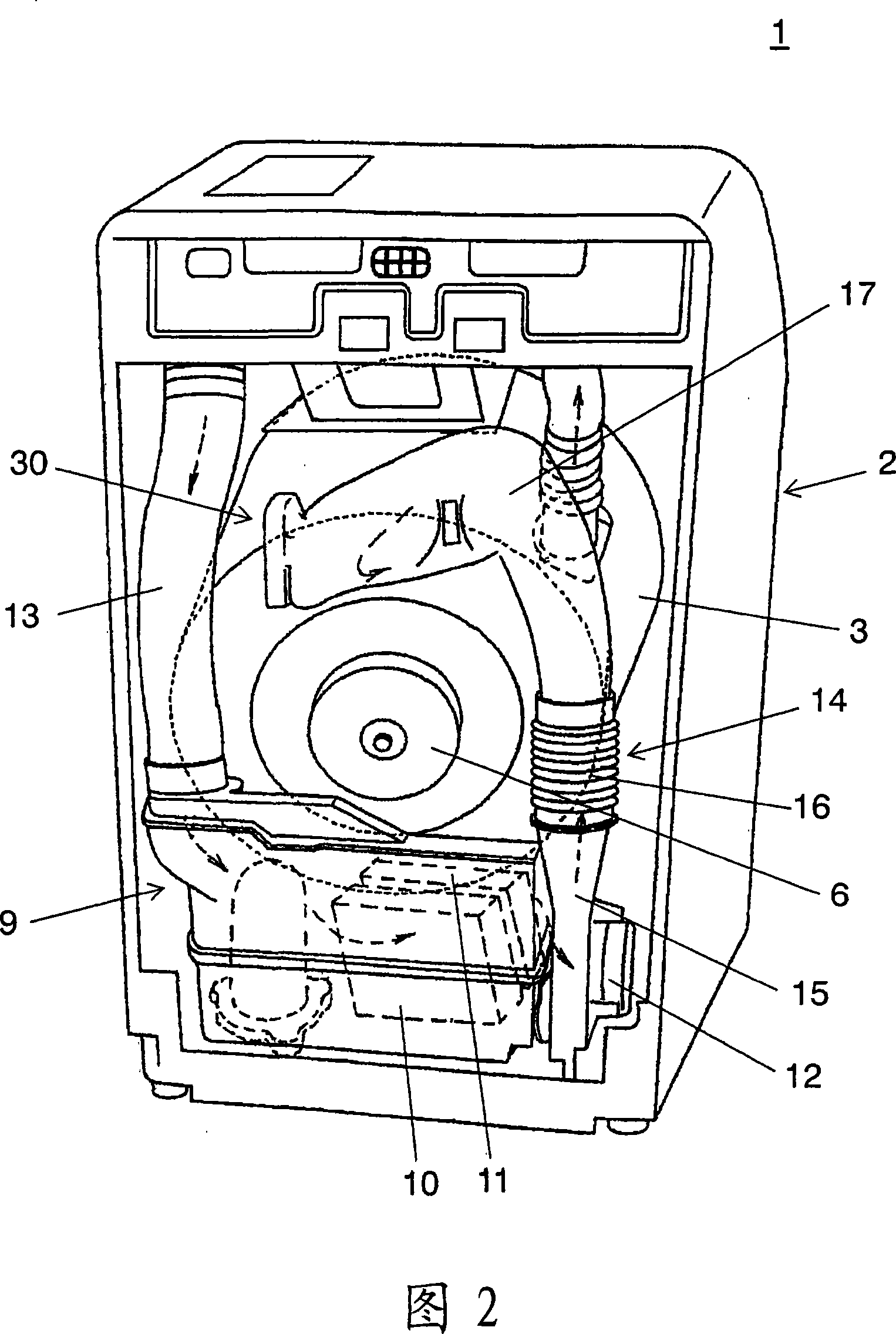

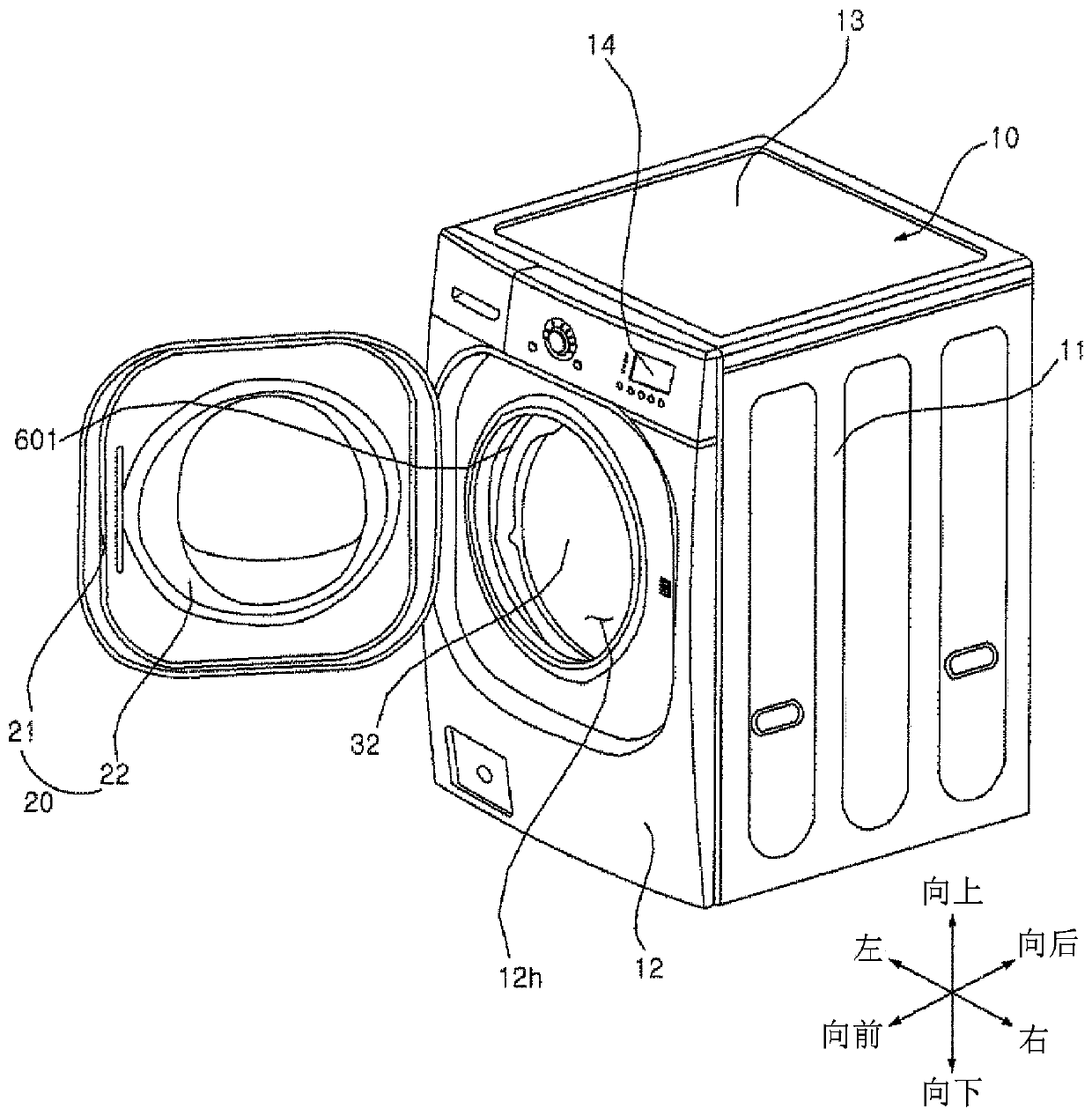

Washing machine

PendingCN110352274ASmooth releaseEasy to dryOther washing machinesControl devices for washing apparatusLaundry washing machineWasher

The present invention relates to a washing machine comprising: a casing having a insertion hole for inserting laundry thereinto on the front surface thereof; a tub disposed in the casing and containing laundry water and having an inlet communicating with the insertion hole; a drum, rotatably disposed within the tub, for accommodating laundry; a pump for pumping water discharged from the tub; a gasket for making the insertion hole communicate with the inlet of the tub and having a plurality of nozzles for spraying water into the drum; and a nozzle water supply pipe, fixed to the gasket and having an inlet through which water pumped by the pump flows, for dividing and guiding water that has flowed through the inlet into a first sub flow and a second sub flow, the nozzle water supply pipe including a plurality of first nozzle water supply ports, formed on a first flow passage to which the first sub flow is guided, for supplying the first sub flow individually to any two or more nozzles among the plurality of nozzles, and a plurality of second nozzle water supply ports, formed on a second flow passage to which the second sub flow is guided, for supplying the second sub flow individually to other two or more nozzles among the plurality of nozzles.

Owner:LG ELECTRONICS INC

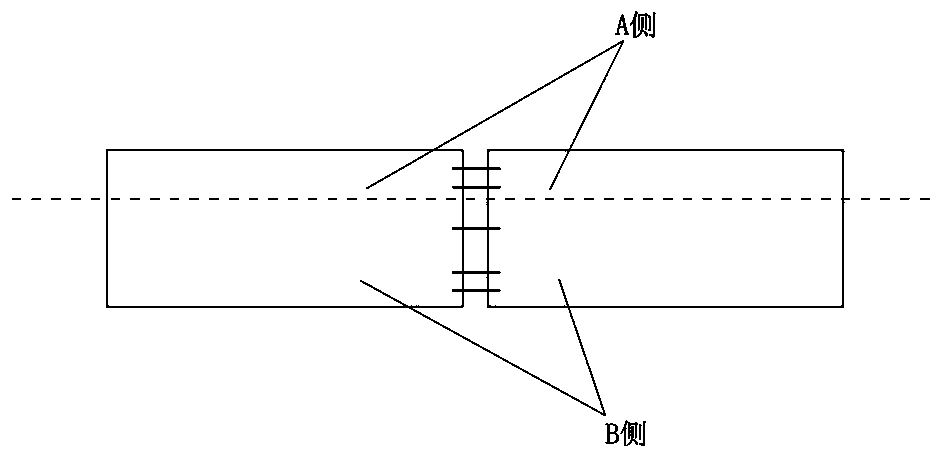

Light beam-electron beam composite brazing method for high-nitrogen steel

ActiveCN109128417AHigh strengthNo damageWelding/cutting media/materialsSoldering mediaOptical radiationHeat-affected zone

The invention discloses a light beam-electron beam composite brazing method for high-nitrogen steel. The method comprises the following steps that firstly, solder paste is prepared and applied to a to-be-welded surface of a welded part; secondly, the two ends and the center of the welded surface are subjected to optical radiation heating welding through xenon arc lamp light beam welding; thirdly,a side A of the to-be-welded surface is brazed through electron beam defocusing welding, and the welding parameters are set as follows: the vacuum degree is (2.5-5) x 10-8MPa, the electron beam current is 25-45mA, the partial beam amount of the electron beam current is 1.2-3.6mm, the welding speed is 8.5-11.5dm / min, the acceleration voltage is 45-65kV, and the focusing current is 2350-2760mA; andfourthly, a side B of the to-be-welded surface is brazed through electron beam focusing welding, and the welding parameters are set as follows: the electron beam current is 25-33mA, the partial beam amount of the electron beam current is 0.01-0.55mm, the welding speed is 3.5-7.5dm / min, the acceleration voltage is 45-65kV, and the focusing current is 2180-2250mA. During welding, high-nitrogen steelbase metal is not melted, nitrogen elements are not lost, pores are not prone to being formed, the welding heat affected zone and residual stress are reduced, and the mechanical properties of a brazed connector are enhanced.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

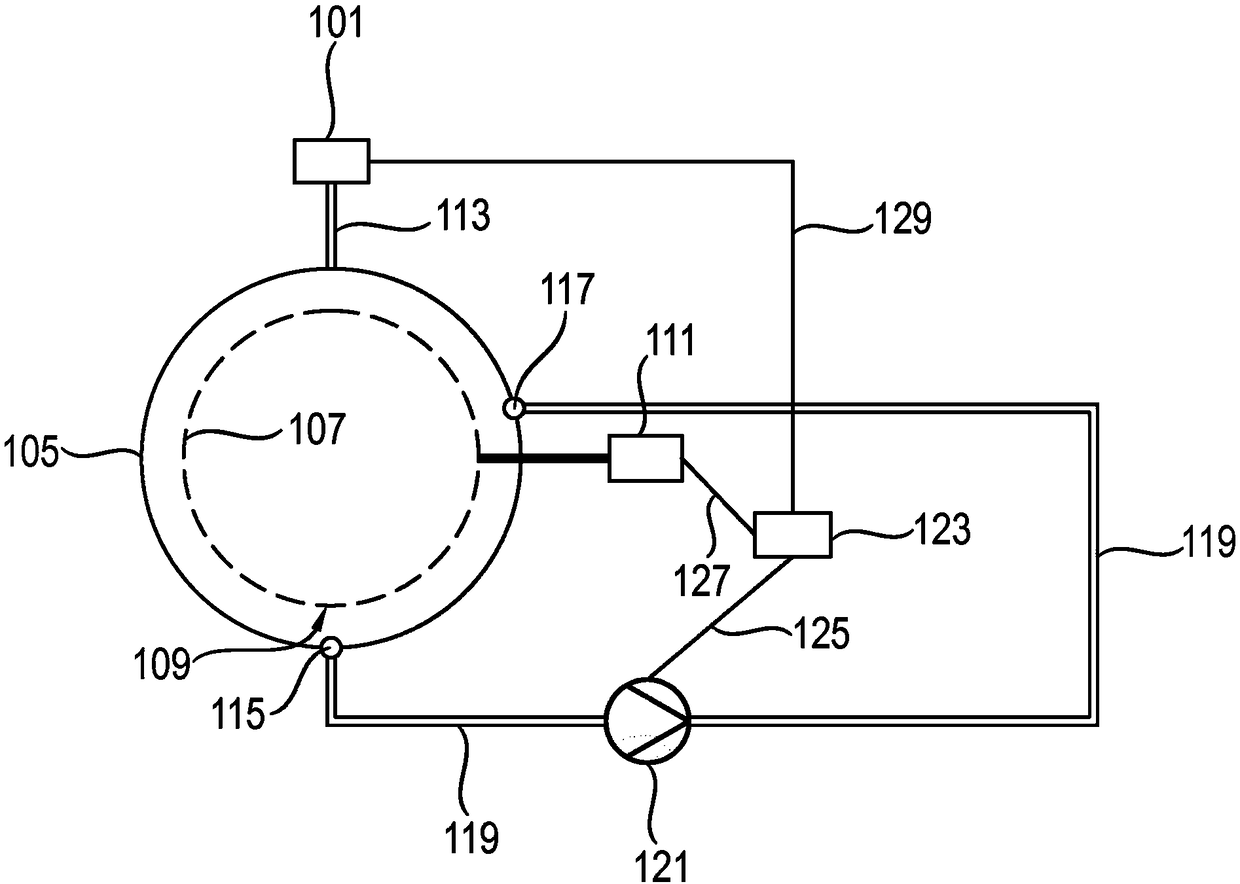

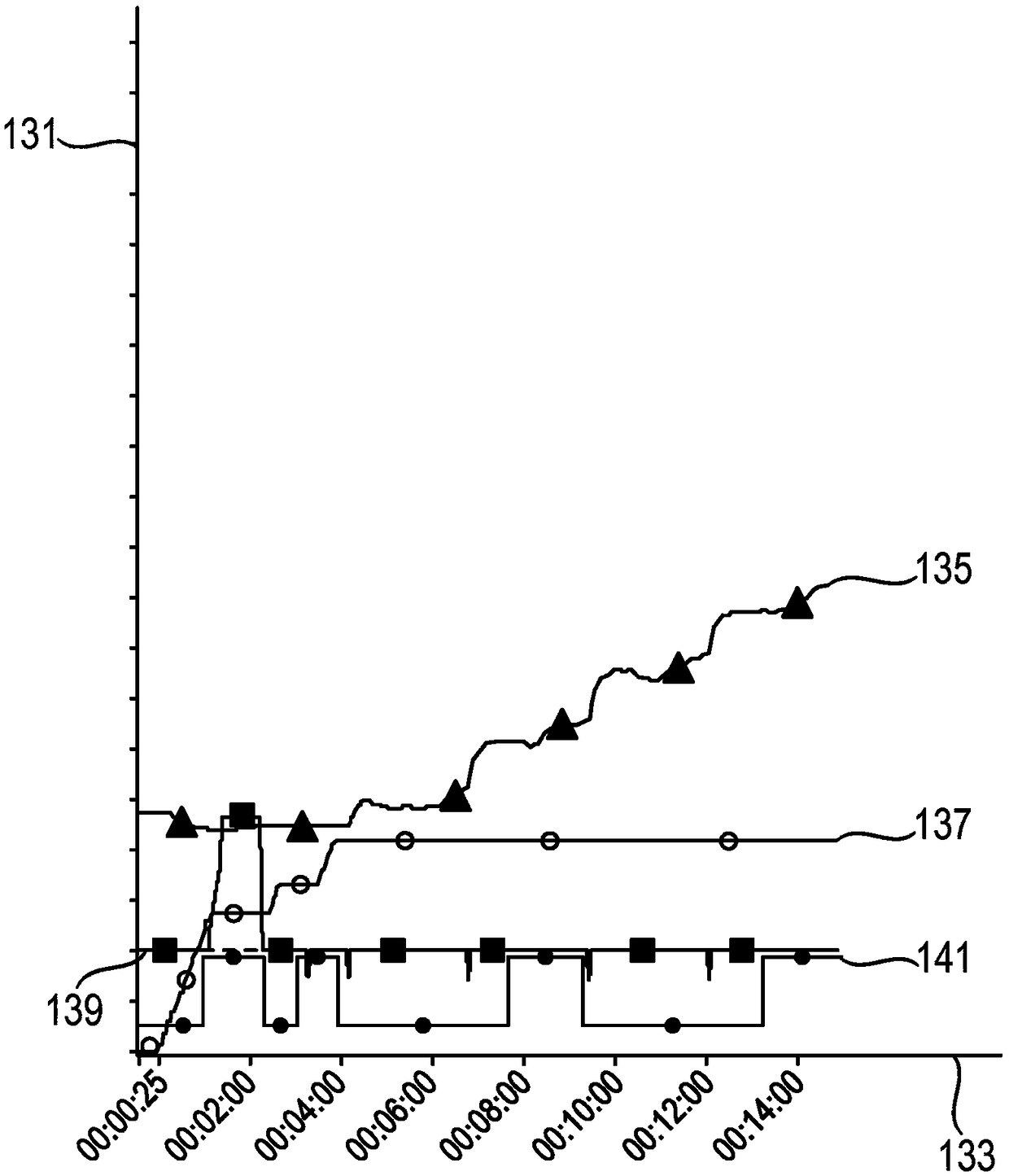

Laundry-care appliance having a controller

ActiveCN109072528AProfit wetMoisturizeControl devices for washing apparatusTextiles and paperEngineeringLaundry

The invention relates to a laundry-care appliance (100) comprising a detergent container (105) for receiving laundry fluid, a washing drum (107) for receiving laundry, a drum drive (111) for rotatingthe washing drum (107), wherein the detergent container (105) has an outlet opening (115) and an inlet opening (117), wherein the outlet opening (115) is fluidically connected to the inlet opening (117) via a line (119), wherein a detergent pump (121) for pumping washing fluid is arranged in the line (119), and a controller (123) for controlling the drum drive (111) and the detergent pump (121). The controller (123) is designed to activate the detergent pump (121) during a circulation pumping process, in order to pump washing fluid out of the detergent container (105), through the outlet opening (115) into the line (119), and to supply the discharged washing fluid back to the detergent container (105) via the line (119) and via the inlet opening (117). The controller (123) is designed to activate the drum drive (111) during the circulation pumping process, in order to rotate the washing drum (107) during a rotation time interval, and to bring the laundry in contact with the washing drum (107).

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

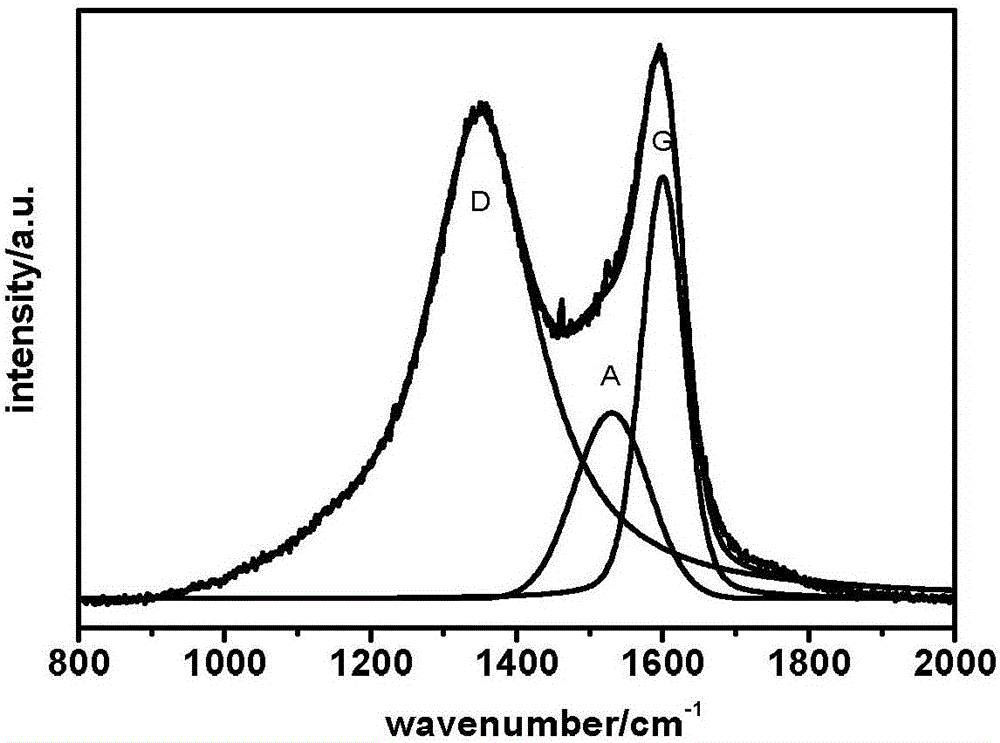

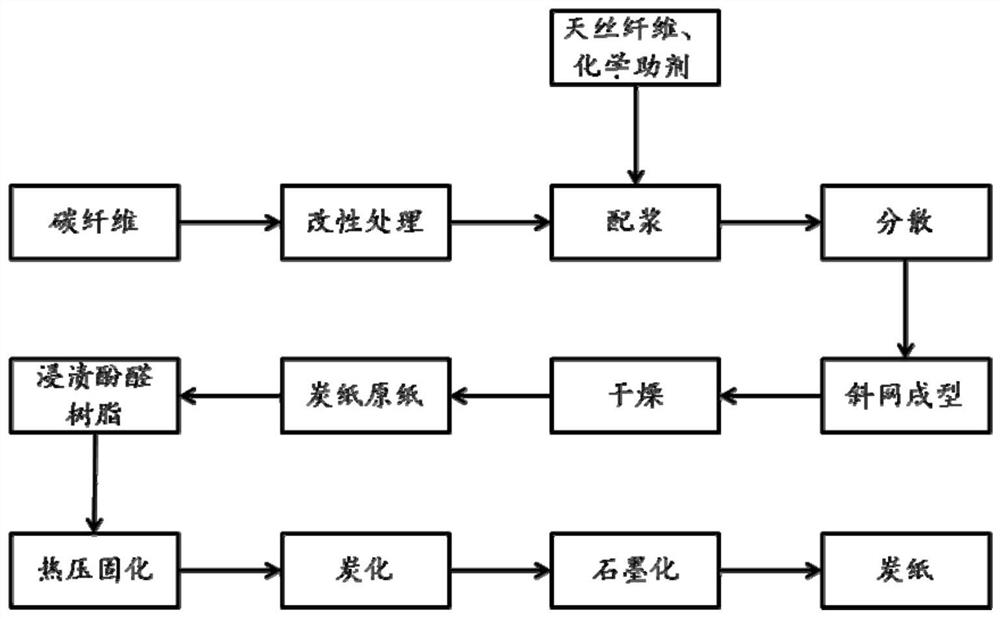

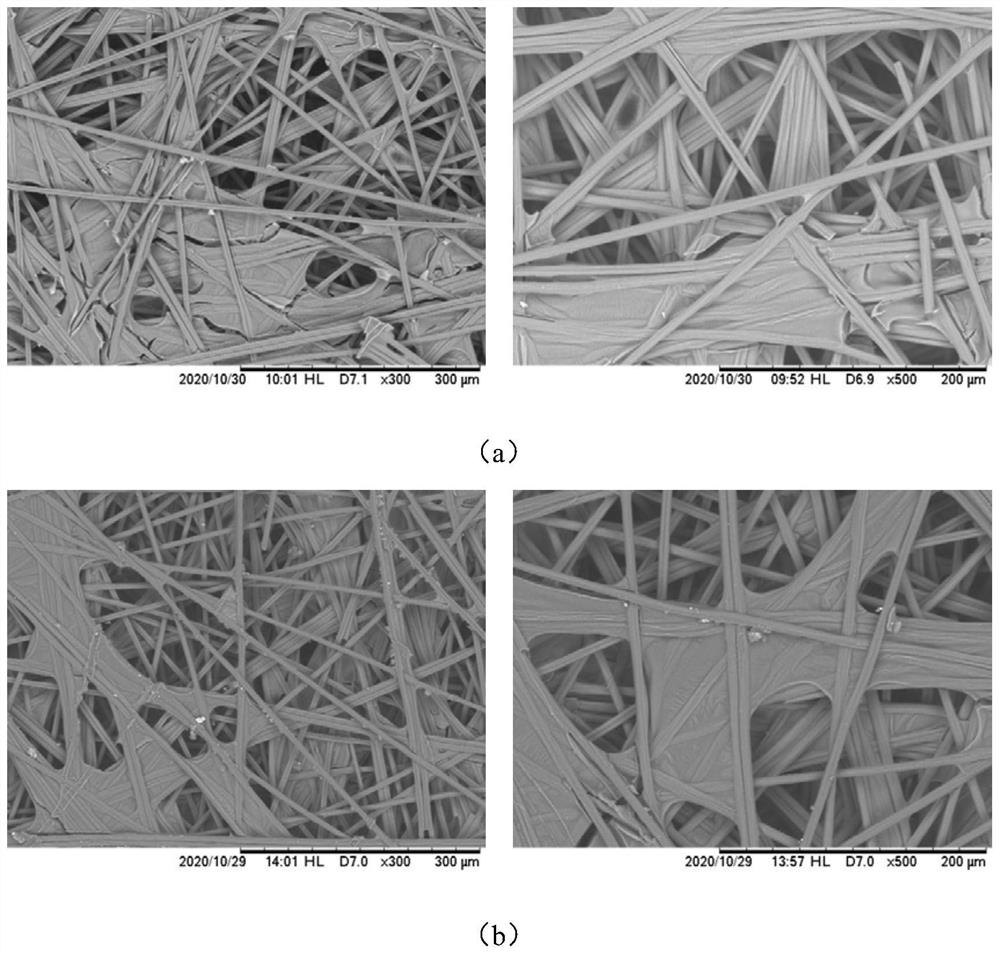

Method for modifying high-performance carbon paper based on supercritical fluid technology

ActiveCN112982027AIndestructible strengthGood dispersionSpecial paperCarbon fibresFiberCarbon fibers

The invention discloses am ethod for modifying high-performance carbon paper based on supercritical fluid technology. Under the action of the supercritical fluid, O2 and a titanate coupling agent are used for cooperatively modifying the carbon fibers, on one hand, the oxidation time can be shortened, the roughness and oxygen-containing groups of the surfaces of the carbon fibers can be improved, the surfaces of the carbon fibers are more effectively wetted, and uniform surface modification is achieved; and on the other hand, the titanate coupling agent has molecules with two groups with different properties, so that the defect that the modification effect of a single titanate coupling agent is not obvious because the number and the variety of oxygen-containing functional groups on the surface of the carbon fiber are relatively small can be overcome, and the mechanical property and the conductivity of the carbon paper are improved.

Owner:SHANDONG RENFENG SPECIAL MATERIALS

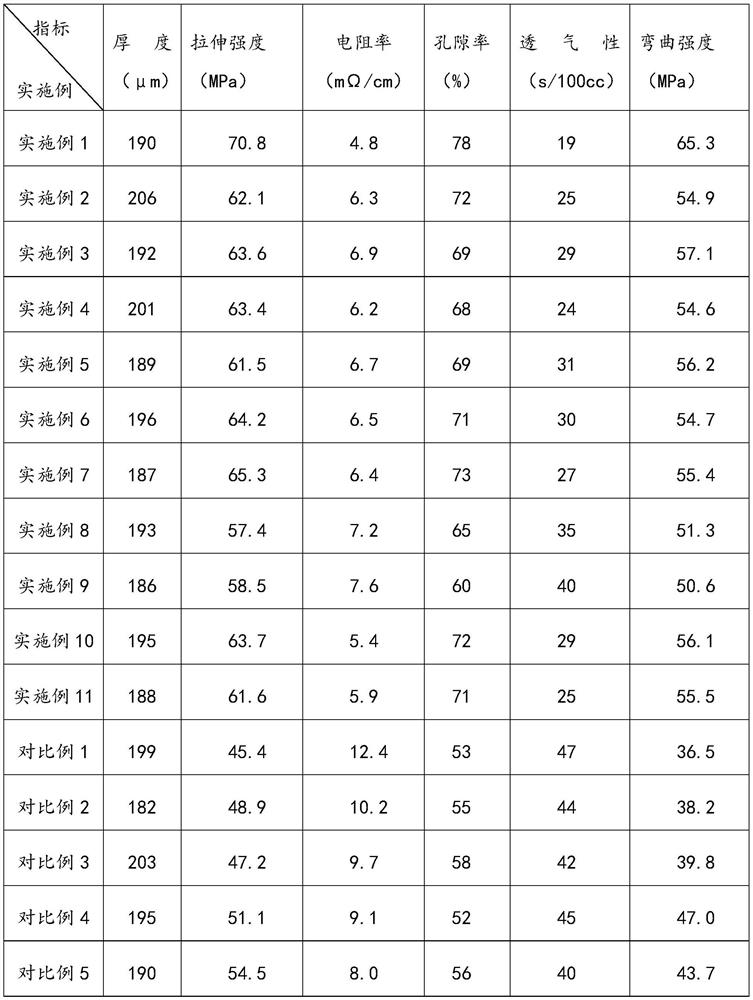

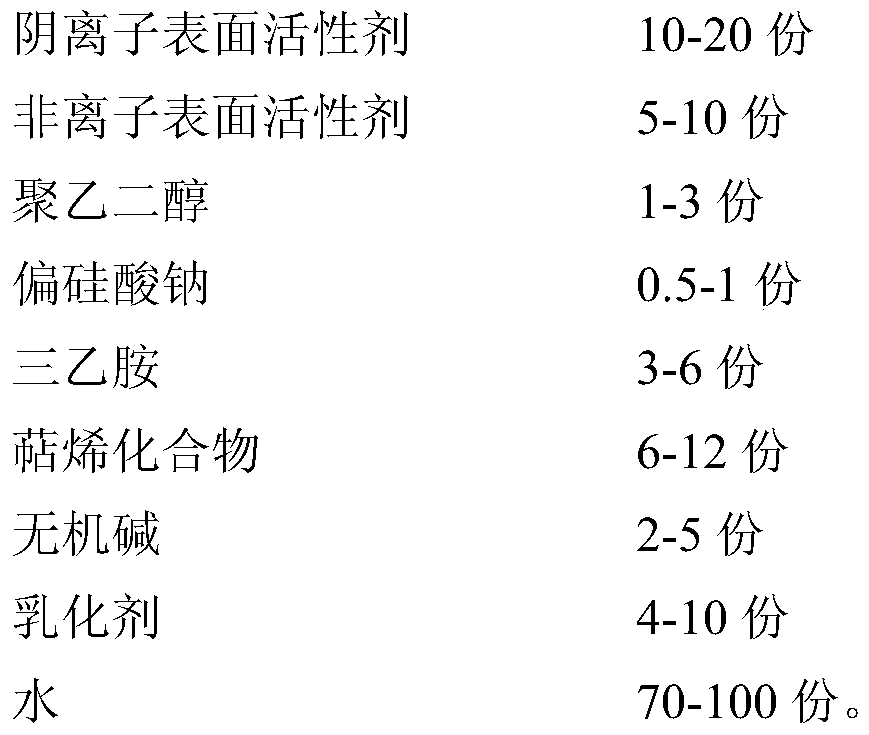

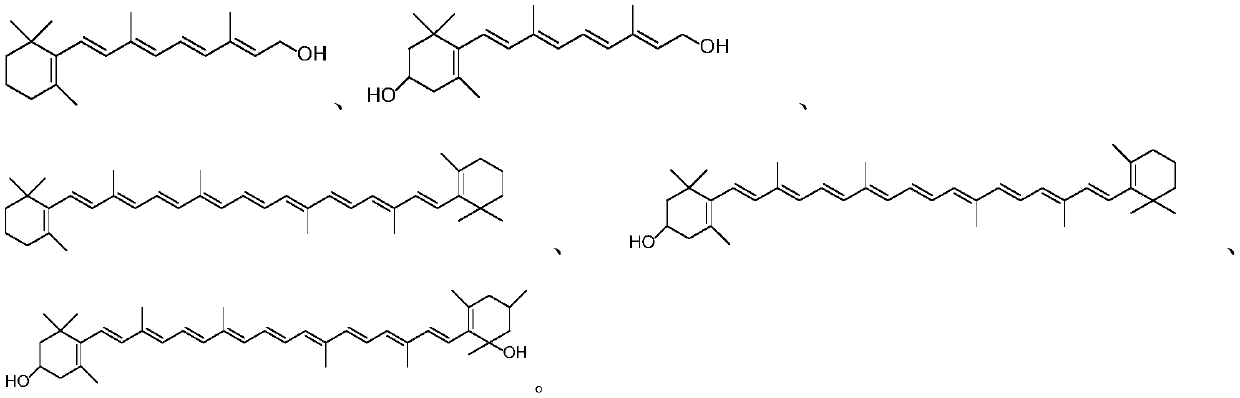

Industrial heavy oil dirt cleaning agent and preparation method thereof

InactiveCN111100768AGood removal effectGood compatibilityInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSodium metasilicateActive agent

The invention discloses an industrial heavy oil dirt cleaning agent. The industrial heavy oil dirt cleaning agent comprises the following components: an anionic surfactant, a nonionic surfactant, polyethylene glycol, sodium metasilicate, triethylamine, a terpene compound, inorganic base, an emulsifier and water. The industrial heavy oil dirt cleaning agent has a remarkable removal effect on heavyoil dirt attached to equipment, especially semi-solid heavy oil dirt; the stability is excellent; and moreover, the industrial heavy oil dirt cleaning agent contains less organic solvent and is a low-toxicity solvent, so that no pressure is brought to the environment.

Owner:长沙而道新能源科技有限公司

Cloth cutting device for garment production and processing

ActiveCN114575136ASolve the problem of uneven cuttingRealize full flat cuttingSevering textilesLiquid/gas/vapor textile treatmentTextile technologyElectric machinery

The invention discloses a cloth cutting device for garment production and processing, and relates to the technical field of garment textile, the cloth cutting device comprises a base, the top of the base is fixedly connected with a tank body, the top of the tank body is rotatably connected with a cover body, and the middle position of the inner side surface of the cover body is fixedly connected with an anti-driving mechanism; an anti-wrinkle mechanism is fixedly connected to the inner side face of the tank body, the anti-wrinkle mechanism comprises a first motor, a rotating shaft of the output end of the first motor is fixedly connected with an air cylinder, a sliding rod is fixedly connected to the surface of the air cylinder, and a shearing assembly is slidably connected to the surface of the sliding rod. According to the cloth cutting device for garment production and processing, through cooperative use of the anti-driving mechanism, the shearing assembly, the anti-wrinkle mechanism, the dispersion assembly and other mechanisms, the problem that due to the fact that wrinkles on the surface of cloth are many, the cloth cannot be cut neatly is solved; and the problem of uneven cloth cutting caused by the fact that the cloth is easily driven in the cutting process of the cutting knife is solved.

Owner:颍上尚高服饰有限公司

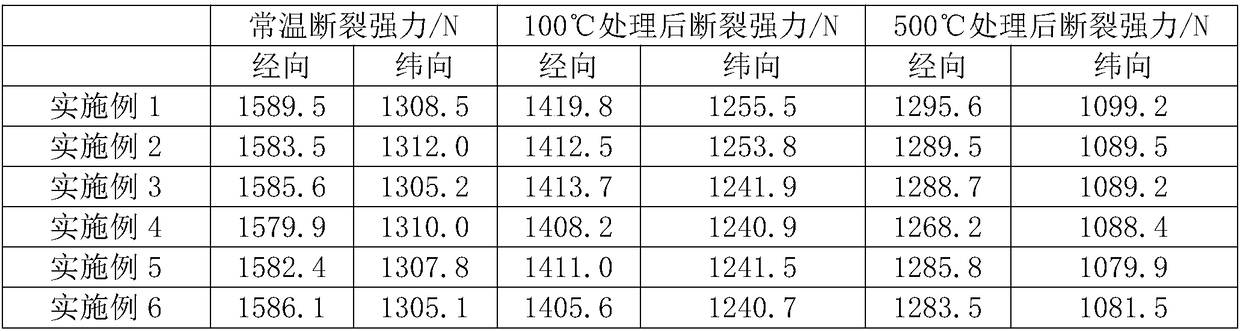

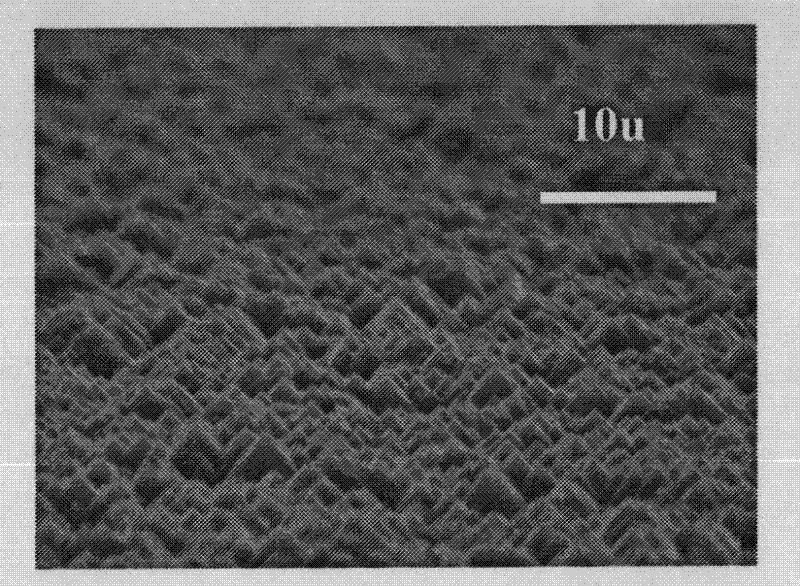

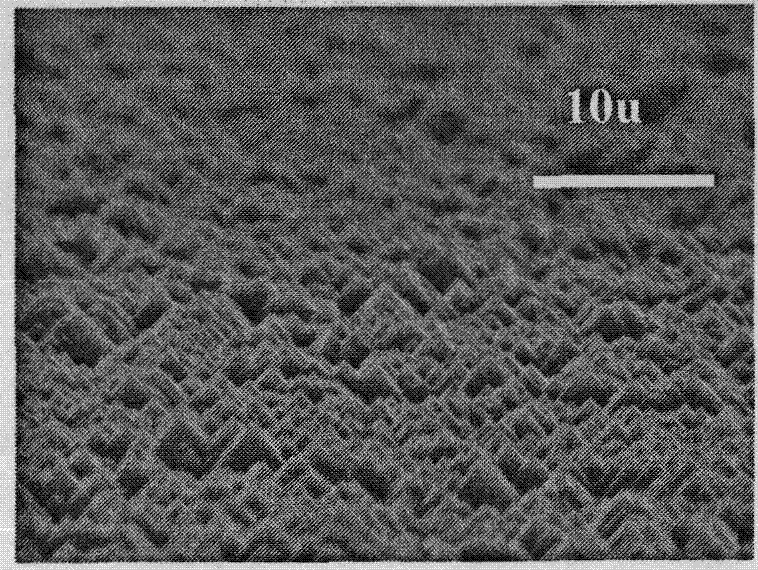

Preparation method of rare earth element modified heat-resistant textile

InactiveCN108385392AUniform porosityHigh porosityBiochemical fibre treatmentGrip property fibresRare-earth elementLanthanum

The invention discloses a preparation method of rare earth element modified heat-resistant textile. The method concretely comprises the following processes: firstly, soaking volcanic rock in sulfuricacid, filtering, collecting filtrate, adding a hydrogen peroxide solution, stirring and precipitating to obtain a porous silicon-aluminum compound; adding deionized water for dispersing so as to prepare dispersion liquid; dissolving molybdenum powder in a hydrogen peroxide solution, adding anhydrous ethanol, citric acid, a lanthanum chloride aqueous solution and the porous silicon-aluminum compound, stirring and mixing, and carrying out a reaction at a certain temperature to obtain modified filler; mixing the obtained modified filler with styrene-acrylic emulsion, deionized water, corn starch,a silane coupling agent, hydroxyethyl cellulose and butyl phthalate to prepare finishing liquid; finally, finishing textile with the finishing liquid to obtain the heat-resistant textile. The textileprepared by the method is soft and comfortable, excellent in antibacterial property, good in heat resistance and mechanical properties and high in safety.

Owner:武汉智达纺织科技有限公司

Velvet manufacturing solution of monocrystalline silicon additive

InactiveCN101818378BUniform sizeGuaranteed efficient growthAfter-treatment detailsSurface-active agentsAlkaline etching

Owner:HANWHA SOLARONE QIDONG

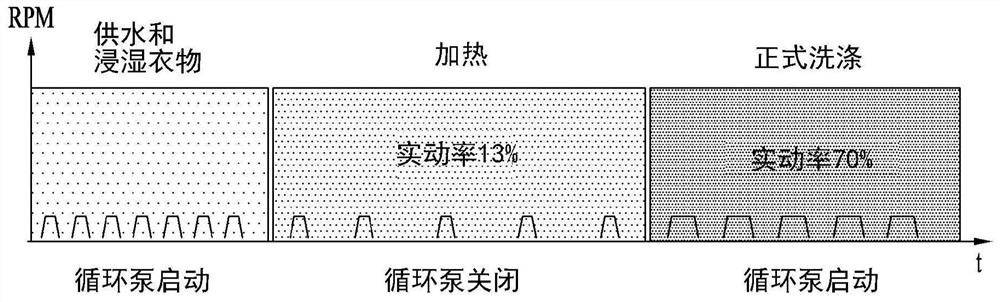

Washing apparatus and method for controlling same

InactiveCN111742092AImprove efficiencyEffective wettingOther washing machinesControl devices for washing apparatusThermodynamicsInduction heater

The present invention relates to a washing apparatus and, more particularly, to a washing apparatus which heats a drum by an induction heater, and a method for controlling same. One embodiment of thepresent invention may provide a method for controlling a washing apparatus including: a tub; a drum; an induction module mounted on the tub and heating the drum by induction; and a circulation pump for pumping washing water in the tub to supply the washing water to an upper portion of the drum, the method comprising: a water supply step of supplying washing water into a tub through a water supplyvalve; a laundry soaking step of, after finishing the water supply step, operating a circulation pump to circulate the washing water and driving a drum to perform laundry soaking; a heating step of driving an induction module to perform heating after finishing the laundry soaking step; and a main washing step of driving the drum to perform washing after finishing the heating step, wherein a washing water level at the end of the laundry soaking step is lower than a washing water level at the end of the water supply step.

Owner:LG ELECTRONICS INC

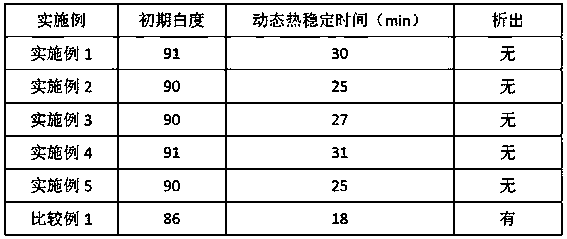

Modified hydroxyapatite-based environment-friendly PVC composite heat stabilizer

The invention relates to a modified hydroxyapatite-based environment-friendly PVC composite heat stabilizer. The composite heat stabilizer is prepared from the following components in mass fraction: 60-80% of modified hydroxyapatite, 10-20% of zinc stearate, 3-5% of a beta-diketone-type compound, 1-3% of an antioxidant and 5-12% of a lubricating agent, wherein the beta-diketone-type compound is stearyl benzoylmethane, dibenzoylmethane, calcium acetylacetonate or zinc acetylacetonate, and the modified hydroxyapatite is prepared by adopting polyethylene glycol and calcium stearate as a compositemodifying agent and performing surface modification on hydroxyapatite. All components of the composite heat stabilizer provided by the invention have good synergistic effects, can obviously improve the heat stability of PVC, and have the advantages of being nontoxic, environmentally friendly and lower in cost.

Owner:SHAOYANG UNIV

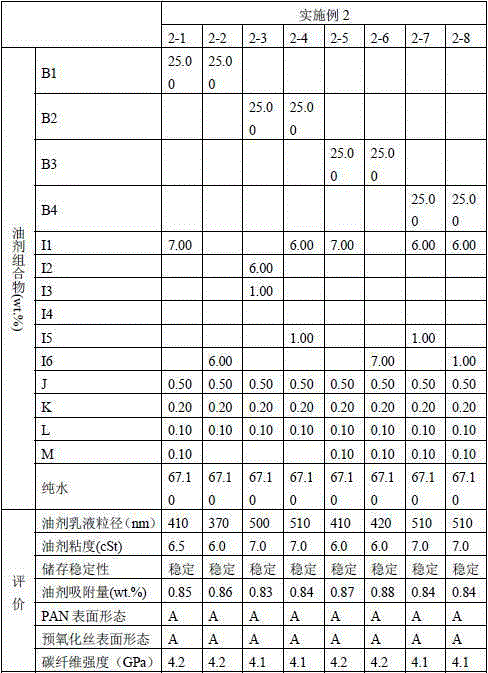

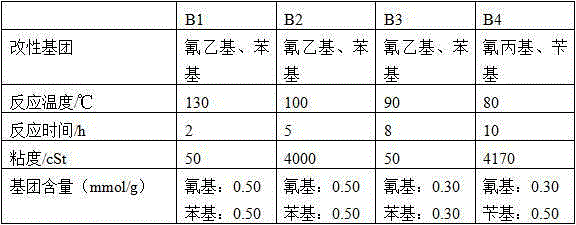

Preparation method of cyano-alkyl and aryl co-modified polysiloxane

The invention provides a preparation method of cyano-alkyl and aryl co-modified polysiloxane. The method includes the following steps that cyano-alkyl silane is hydrolyzed, cyano-alkyl silane hydrolyzate is obtained, an alkali catalyst and an end-capping agent are added into the cyano-alkyl silane hydrolyzate, an aryl coupling agent and cyclosiloxane under protection of inert gas, and reaction is performed at 80-130 DEG C; the cyano-alkyl and aryl co-modified polysiloxane is prepared; the content of cyano-alkyl in the cyano-alkyl and aryl co-modified polysiloxane is 0.05-5 mmol / g, and the content of aryl in the cyano-alkyl and aryl co-modified polysiloxane is 0.1-3 mmol / g, and viscosity is 50-10,000 cST. The cyano-alkyl and aryl co-modified polysiloxane prepared through the method can serve as auxiliaries for producing high-performance carbon fibers. Particularly, the cyano-alkyl and aryl co-modified polysiloxane can serve as silicon oil agents for producing carbon fibers and can effectively moisten the surfaces of the fibers, reduce friction between the fibers and friction between the fibers and a guide roller, reduce surface defects and electrostatic accumulation caused by friction, and effectively prevent hot-melting adhesion of precursor fibers at the pre-oxidization stage and at the low-temperature carbonization stage.

Owner:GUANGDONG BIOMAX SIANDF NEW MATERIAL CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com