Preparation method of rare earth element modified heat-resistant textile

A technology for rare earth elements and textiles, which is applied in the field of preparation of heat-resistant textiles, can solve problems such as affecting the feel of textiles, complicated preparation processes, etc., and achieve the effects of improving strength, good mechanical properties, and improving heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

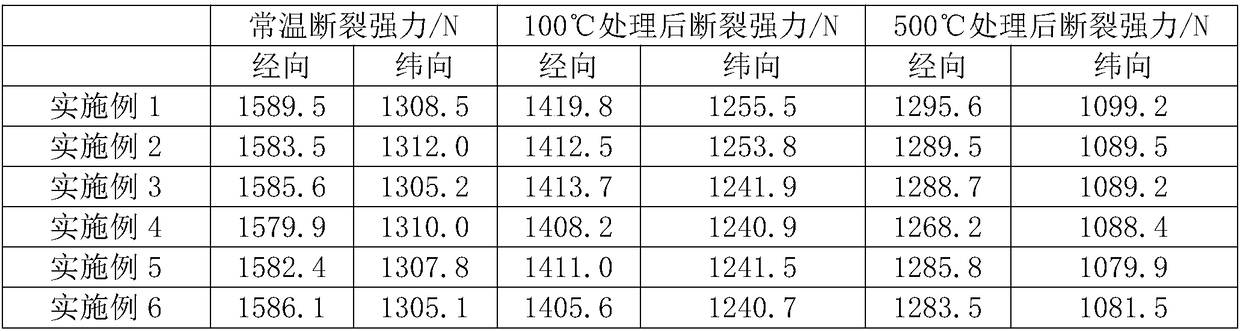

Examples

Embodiment 1

[0025] A method for preparing heat-resistant textiles modified based on rare earth elements includes the following steps:

[0026] (1) Grind the volcanic stone into powder, add sulfuric acid, soak for 8h, filter, collect the filtrate, add hydrogen peroxide solution to the filtrate, stir and precipitate, filter, and wash the precipitate with deionized water to neutrality, dry, and grind , The porous silicon-aluminum composite was prepared; wherein the mass ratio of volcanic stone powder and sulfuric acid was 1:15; the mass concentration of hydrogen peroxide solution was 15%, and the mass ratio of the volcanic stone powder was 6:1;

[0027] (2) Disperse the porous silicon-aluminum composite prepared above in deionized water, and use sodium lauryl sulfate as a dispersant to prepare a uniform dispersion; among them, the porous silicon-aluminum composite, dodecyl sulfate The mass ratio of sodium sulfate is 1:0.35;

[0028] (3) Mix molybdenum powder and hydrogen peroxide solution with a m...

Embodiment 2

[0033] A method for preparing heat-resistant textiles modified based on rare earth elements includes the following steps:

[0034] (1) Grind the volcanic stone into powder, add sulfuric acid, soak for 11h, filter, collect the filtrate, add hydrogen peroxide solution to the filtrate, stir and precipitate, filter, and wash the precipitate with deionized water until it is neutral, dry, and grind , The porous silicon-aluminum composite is prepared; wherein the mass ratio of volcanic stone powder and sulfuric acid is 1:30; the mass concentration of hydrogen peroxide solution is 15%, and the mass ratio of the volcanic stone powder is 12:1;

[0035] (2) Disperse the porous silicon-aluminum composite prepared above in deionized water, and use sodium lauryl sulfate as a dispersant to prepare a uniform dispersion; among them, the porous silicon-aluminum composite, dodecyl sulfate The mass ratio of sodium sulfate is 1:0.55;

[0036] (3) Mix molybdenum powder and hydrogen peroxide solution with...

Embodiment 3

[0041] A method for preparing heat-resistant textiles modified based on rare earth elements includes the following steps:

[0042] (1) Grind and crush the volcanic stone into powder, add sulfuric acid, soak for 9h, filter, collect the filtrate, add hydrogen peroxide solution to the filtrate, stir and precipitate, filter, and wash the precipitate with deionized water to neutrality, dry, and grind , The porous silicon-aluminum composite is prepared; wherein the mass ratio of volcanic stone powder and sulfuric acid is 1:15; the mass concentration of hydrogen peroxide solution is 15%, and the mass ratio of the volcanic stone powder is 7:1;

[0043] (2) Disperse the porous silicon-aluminum composite prepared above in deionized water, and use sodium lauryl sulfate as a dispersant to prepare a uniform dispersion; among them, the porous silicon-aluminum composite, dodecyl sulfate The mass ratio of sodium sulfate is 1:0.4;

[0044] (3) Mix molybdenum powder and hydrogen peroxide solution wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com