Patents

Literature

155 results about "Butyl Phthalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dibutyl phthalate (C16H22O4), or DBP, is an odorless and colorless to faint yellow oily liquid; the molecular weight is 278.35 g/mol. Dibutyl phthalate is also known as di-n-butyl phthalate. Dibutyl phthalate has various industrial uses; it is used to make flexible plastics that are found in a variety of consumer products.

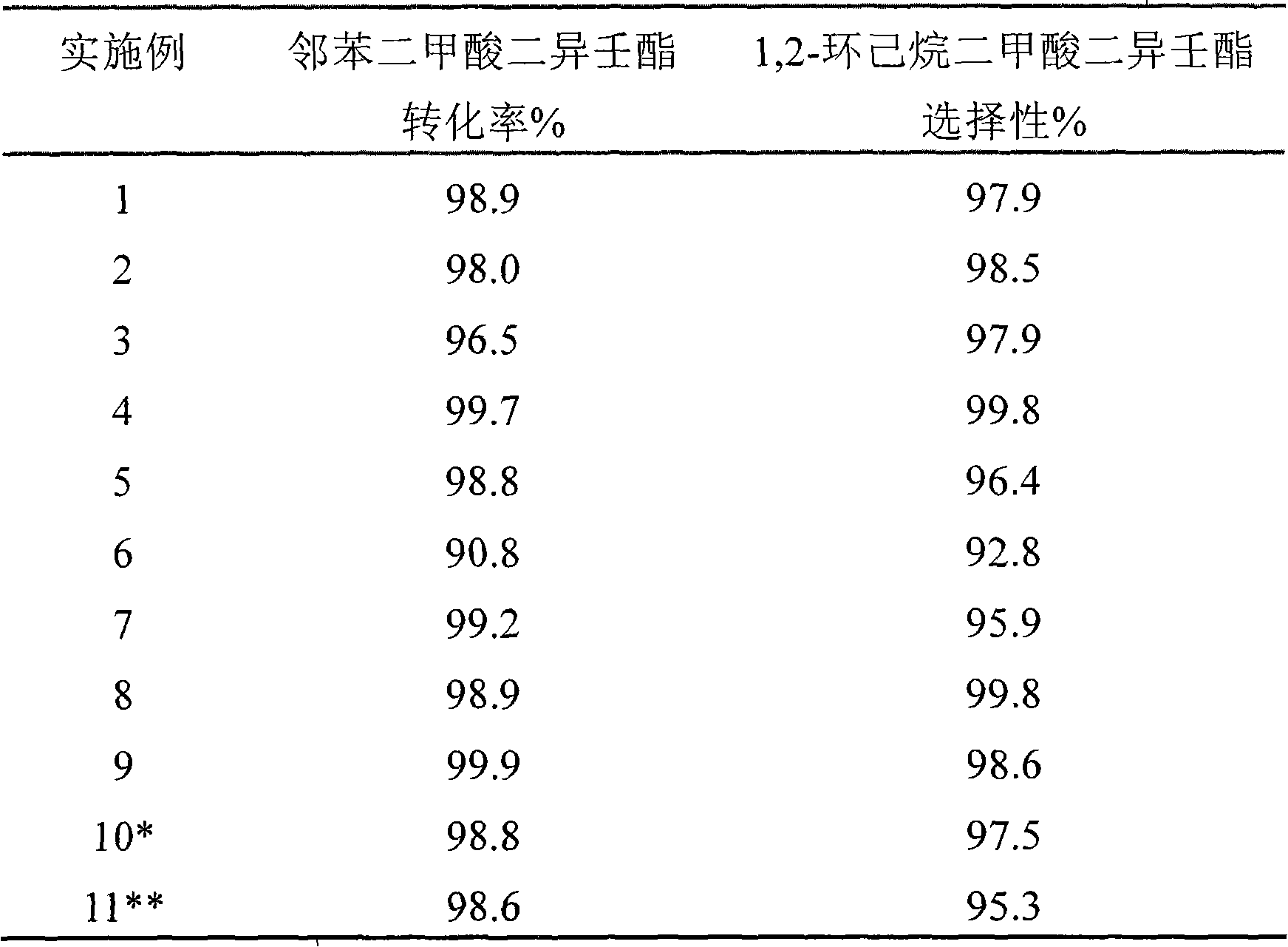

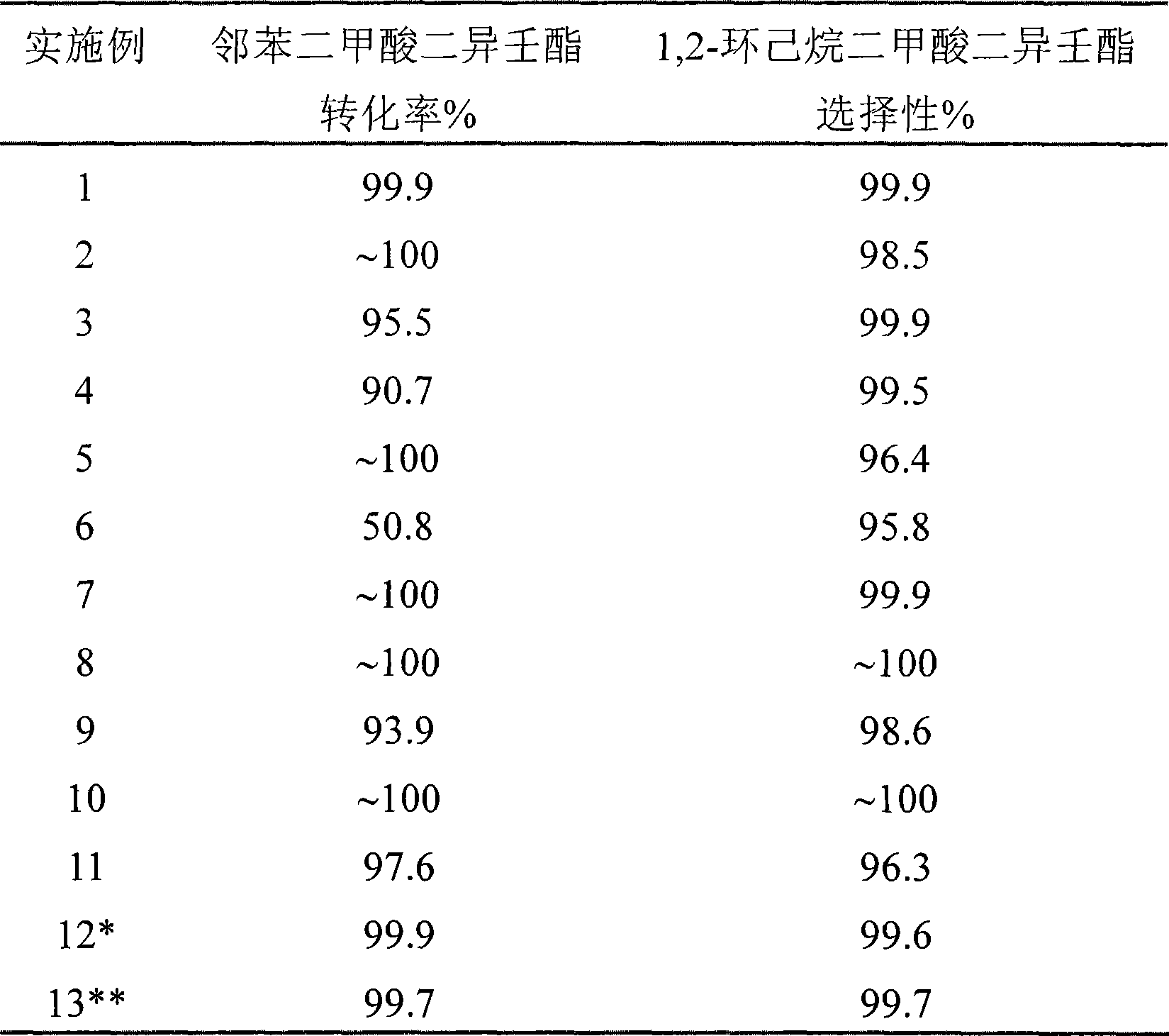

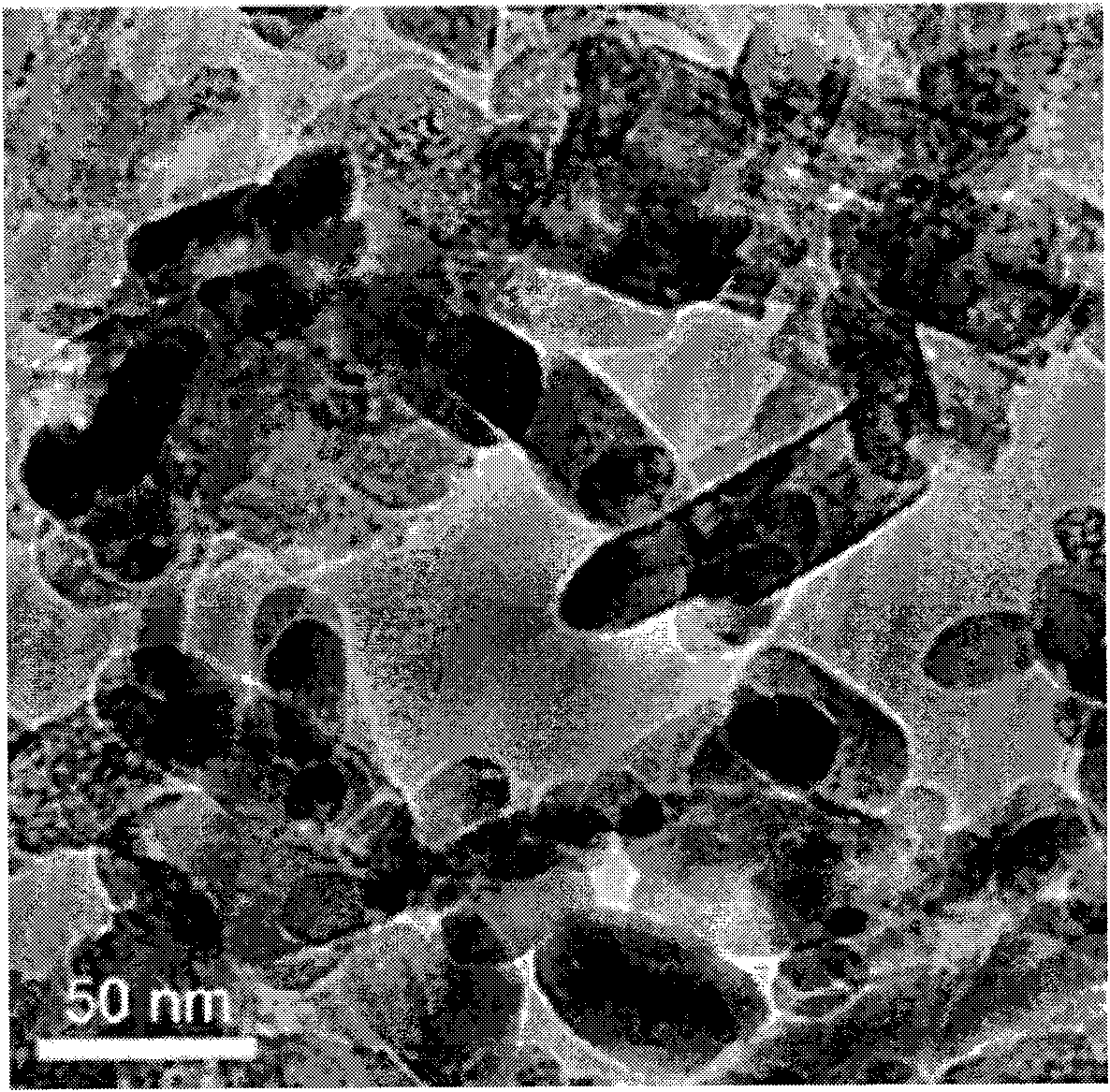

Catalyst for producing 1,2-cyclohexane dicarboxylic acid diesters

InactiveCN101406840AHigh selectivityLow reaction pressureOrganic compound preparationCarboxylic acid esters preparationHydrogen pressureBULK ACTIVE INGREDIENT

The invention provides a catalyst for converting diisononyl phthalate, diisooctyl phthalate, dibutyl phthalate and other long-chain esters into corresponding 1, 2-cyclohexane dicarboxylic acid binary ester through hydrogenation. The catalyst for converting the diisononyl phthalate, the diisooctyl phthalate, the dibutyl phthalate and other long-chain esters into corresponding the 1,2-cyclohexane dicarboxylic acid binary ester through the hydrogenation consists of main active ingredients, additives and carriers, wherein the main active ingredients are noble metal Ru and Pd; the additives are Fe, Co, Ni, Cu and other metals or oxides; and macroporous Al2O3, ZrO2, TiO2 and the like are selected as the carriers. Under certain temperature, certain hydrogen pressure and the action of the catalyst, the diisononyl phthalate, the diisooctyl phthalate, the dibutyl phthalate and other long-chain esters in a trickle bed reactor can be converted into the corresponding the 1, 2-cyclohexane dicarboxylic acid binary ester with high activity and high selectivity.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Method for preparing 1,2-cyclohexane cyclohexanedimethanol dibasic ester

ActiveCN101417950AHigh selectivityLow reaction pressureOrganic compound preparationCarboxylic acid esters preparationReaction temperatureDibasic ester

The invention relates to a method for preparing 1, 2-cyclohexanedicarboxylic acid ester of binary, comprising a reaction system composed by binary phthalate ester, hydrogen and a catalyst; the reaction temperature ranges from 100 to 250 DEG C; the reaction pressure ranges from 3.0 to 12.0 Mpa; the molar ratio of H2 and X ranges from 50 to 450; the liquid space velocity of binary phthalate ester ranges from 0.1 to 2.5 h<-1>; the catalyst uses Al2O3, ZrO2, TiO2 or SiO2-Al2O3 as vehicle, and load active component can be Ru, Pt, Pd, Rh, Fe, Co, Ni and Cu; the binary phthalate ester is diisonynol phthalate, diisooctyl phthalate or dibutyl phthalate; the product 1, 2-cyclohexanedicarboxylic acid ester of binary is 1, 2-cyclohexane diisononyl dimethyl ester, 1, 2-cyclohexane diisooctyl dimethyl ester or 1, 2-cyclohexane dibutyl dimethyl ester.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

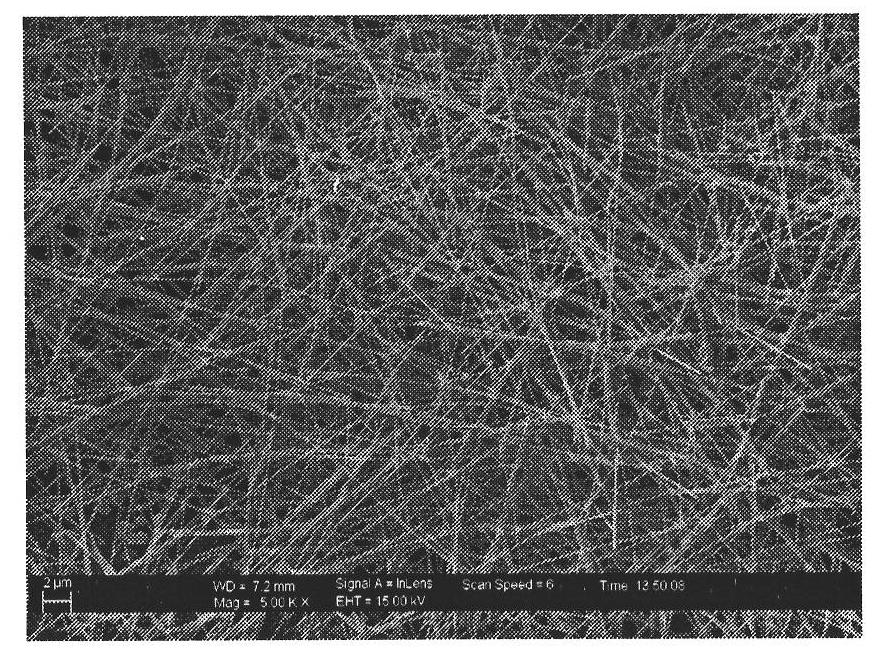

Method for preparing electrolyte ceramic membrane of lithium ion battery

The invention relates to a method for preparing an electrolyte ceramic membrane of a lithium ion battery, in particular to a tape casting method for preparing the electrolyte ceramic membrane of the lithium ion battery, and belongs to the field of ion conductive ceramic materials. The invention adopts the tape casting method; ceramic powder with a chemical formula of Li1.4Al0.4(Gel-xTix)1.6(PO4)3(wherein x is equal to 0-1.0) is selected as raw material powder; triethanolamine or phosphate are selected as a dispersing agent; ethanol, propyl alcohol, butanone, triclene, or azeotropic solution prepared from any two of the ethanol, propyl alcohol, butanone and triclene is selected as a solvent; polyvinyl butyral (PVB) is selected as an adhesive; polyethylene glycol or dibutyl phthalate is selected as a plasticizer; the range of solid content of slurry is controlled between 18 and 30vol percent; the uniform slurry is prepared through ball milling, and then is prepared into a green belt bythe tape casting method, and the green belt is subjected to heat treatment to form the electrolyte ceramic membrane; and the electrolyte ceramic membrane has good strength and toughness, and can be applied to actual production.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

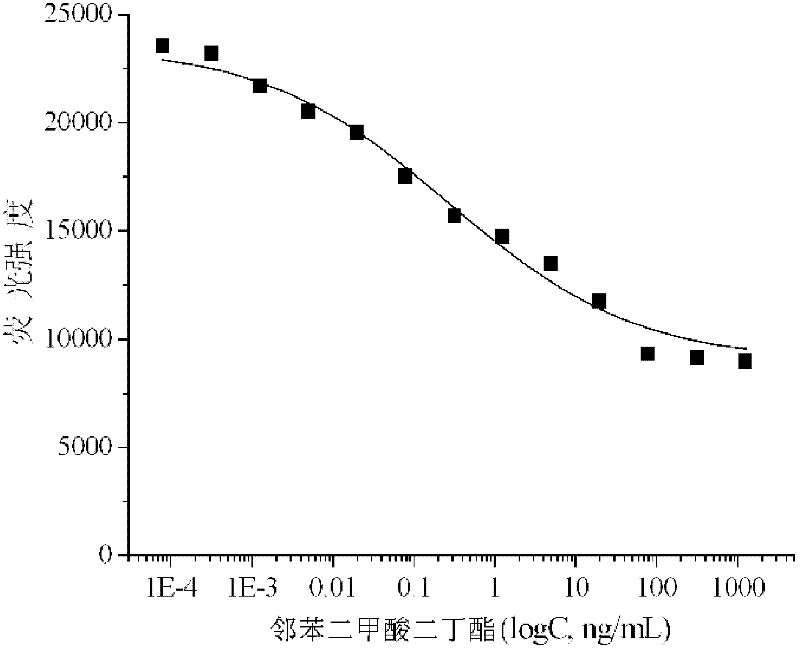

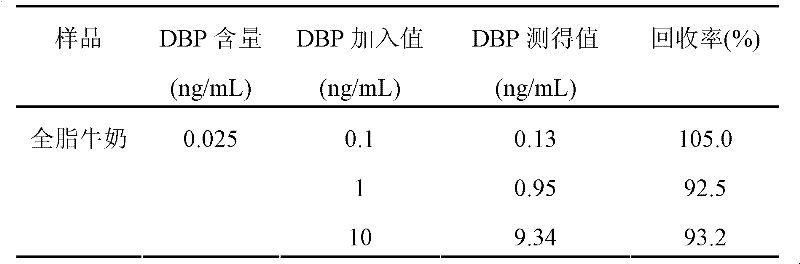

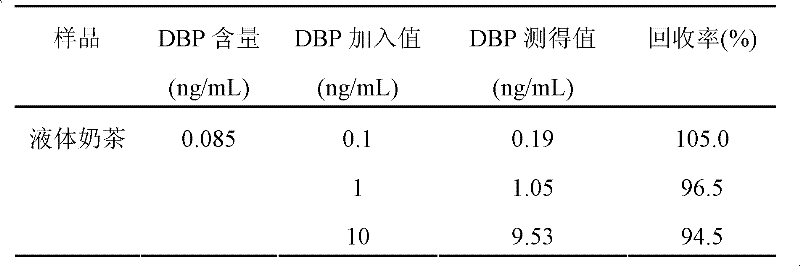

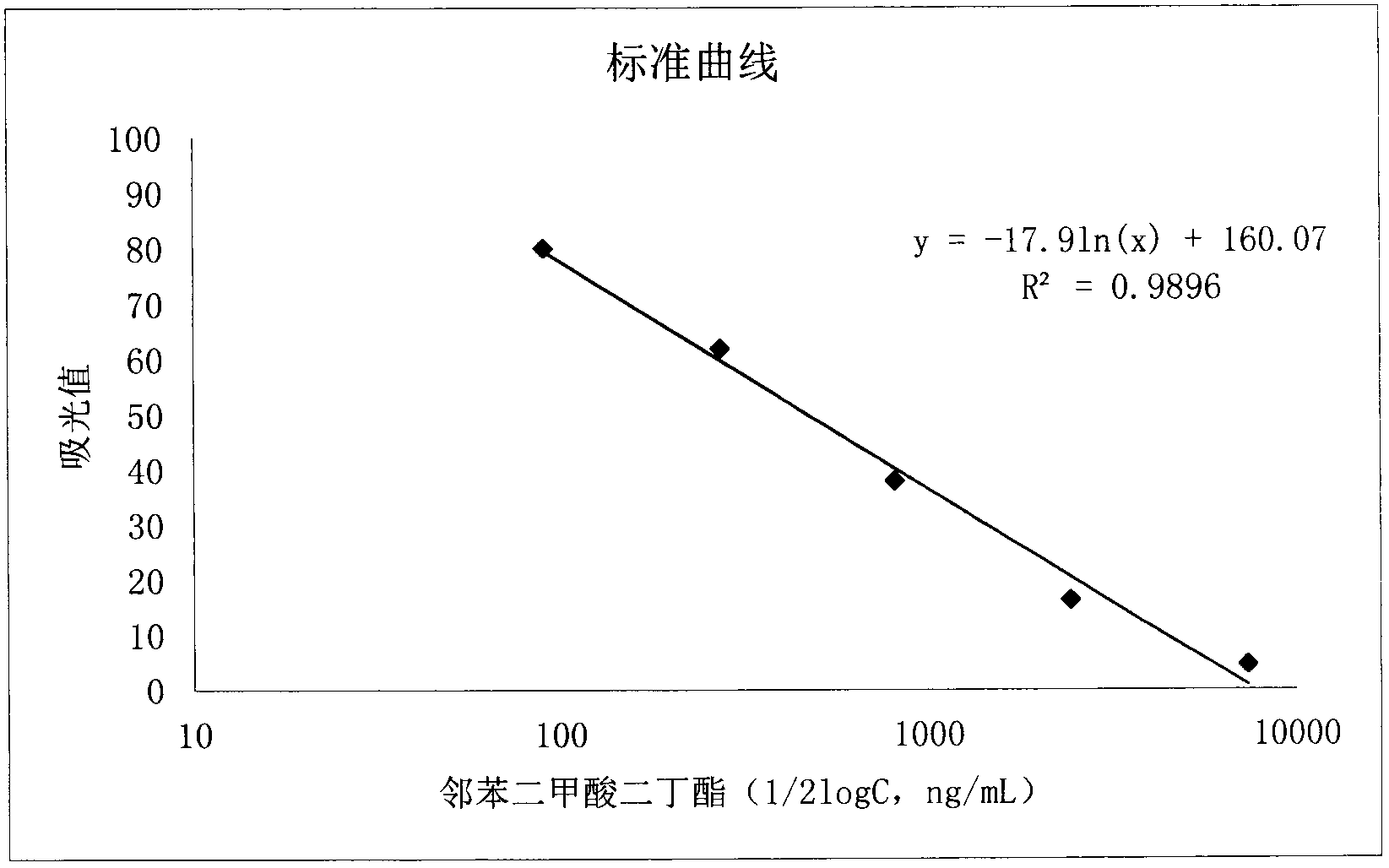

Method for quickly detecting dibutyl phthalate in food

InactiveCN102520153AStrong specificityReduce the impactFluorescence/phosphorescenceBiologyPhthalic acid ester

The invention discloses a method for quickly detecting dibutyl phthalate, which comprises the following steps of: a, constructing an inhibitory curve; and b, sample detection. Compared with the prior art, the method is high in sensitivity, quick and high in specificity, adopts simple method and consumes less time, is applicable to the quick analysis of environment pollutant DBP (Dibutyl Phthalate) and is also significant for the determination of phthalate.

Owner:ANHUI NORMAL UNIV

Fabric desizing agent

InactiveCN102965902AHigh whitenessImprove water absorptionDry-cleaning apparatus for textilesFiberAmylase

The invention discloses a fabric desizing agent. The fabric desizing agent consists of the following components in parts by weight: 10-20 parts of amylase, 3-5 parts of sodium persulfate, 2-6 parts of methyl cellulose, 0.2-0.6 part of sodium hydroxide, 10-20 parts of butyl acetate, 20-40 parts of isopropyl alcohol, 1-3 parts of butyl phthalate and 100-160 parts of water. Compared with the prior art, the fabric desizing agent has the following beneficial effects of (1) being good in desizing effect and enabling size to be fully hydrolyzed without damaging a fabric, and (2) removing impurities and minerals on the fiber, and improving the whiteness and hydroscopicity of a semi-finished product of the fabric.

Owner:吴江红蔷薇纺织有限公司

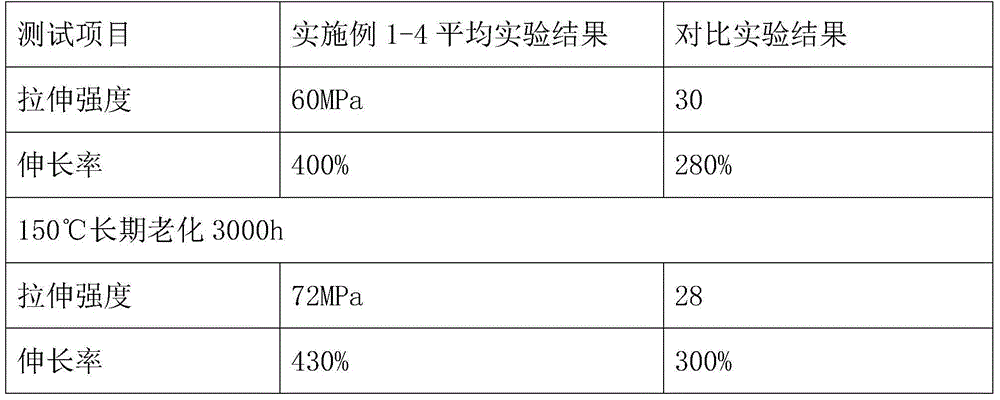

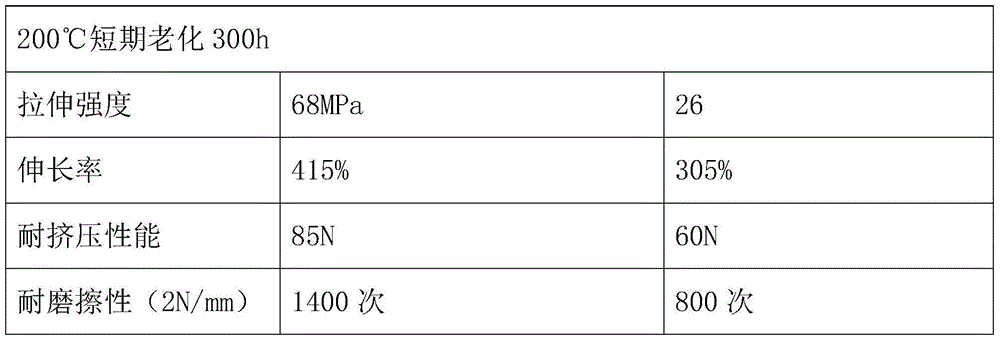

Thermoplastic polyurethane elastomer cable material and preparation method thereof

ActiveCN103214749APromote mutual solubilitySolve the current situation of working and using in a high temperature environmentSolubilityPolyolefin

The invention discloses a thermoplastic polyurethane elastomer cable material and a preparation method thereof. The material is composed of: modified chlorosulfonated polyethylene, maleic-anhydride-grafted polyolefin elastomer, thermoplastic polyurethane elastomer, white carbon black, limestone powder, zinc oxide, a vulcanizing agent MOCA, an anti-aging agent OD, dibutyl phthalate, methyl triethoxysilane, diphenylamine, Tween 80, chlorinated paraffin, and zinc borate. According to the invention, modified chlorosulfonated polyethylene, maleic-anhydride-grafted polyolefin elastomer, and thermoplastic polyurethane elastomer high-molecular materials are used as base materials of the material; with dibutyl phthalate, inter-solubility of the components are improved; and a plurality of functional auxiliary materials are added. Therefore, the defect of the incapability of being used under high-temperature environment of cable materials is solved. The material has good flame resistance, greatly improved mechanical property, and good dynamical performance.

Owner:盛鼎高新材料有限公司

Vehicular glass adhesive and method of adhering said glass

The invention is an adhesive composition comprising: a) an isocyanate functional polyether base prepolymers having a z molecular weight average (Mz) of about 10,000 to about 80,000 g / mole; a carbon black having an average oil absorption number of at least about 80 to at most about 400 cubic centimeters of dibutyl phthalate per 100 grams of the carbon black; (c) reactive silicon in an amount from about 0.001% to about 10% by weight of the adhesive composition; and (d) one or more catalysts for the reaction of isocyanate with hydroxyl groups. The adhesive compositions of the invention surprisingly may have improved sag performance (i.e., decreased sag) when heated, while also making them more easily pumped.

Owner:DOW GLOBAL TECH LLC

Vehicular glass adhesive and method of adhering said glass

ActiveUS20110265932A1Molecular weightEasy pumpabilityCovering/liningsNon-macromolecular adhesive additivesAdhesiveGram

The invention is an adhesive composition comprising: a) an isocyanate functional polyether base prepolymers having a z molecular weight average (Mz) of about 10,000 to about 80,000 g / mole; a carbon black having an average oil absorption number of at least about 80 to at most about 400 cubic centimeters of dibutyl phthalate per 100 grams of the carbon black; (c) reactive silicon in an amount from about 0.001% to about 10% by weight of the adhesive composition; and (d) one or more catalysts for the reaction of isocyanate with hydroxyl groups. The adhesive compositions of the invention surprisingly may have improved sag performance (i.e., decreased sag) when heated, while also making them more easily pumped.

Owner:DOW GLOBAL TECH LLC

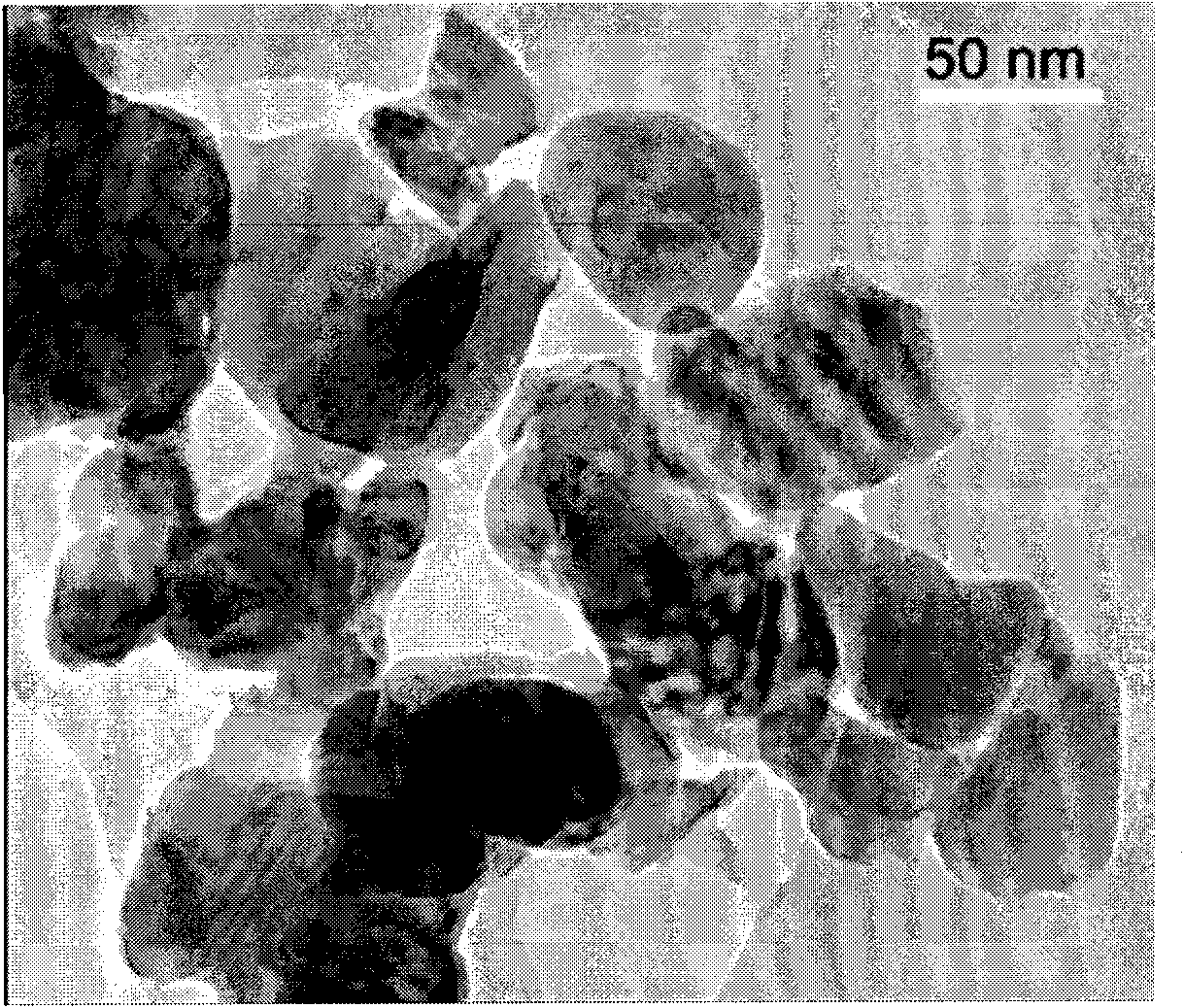

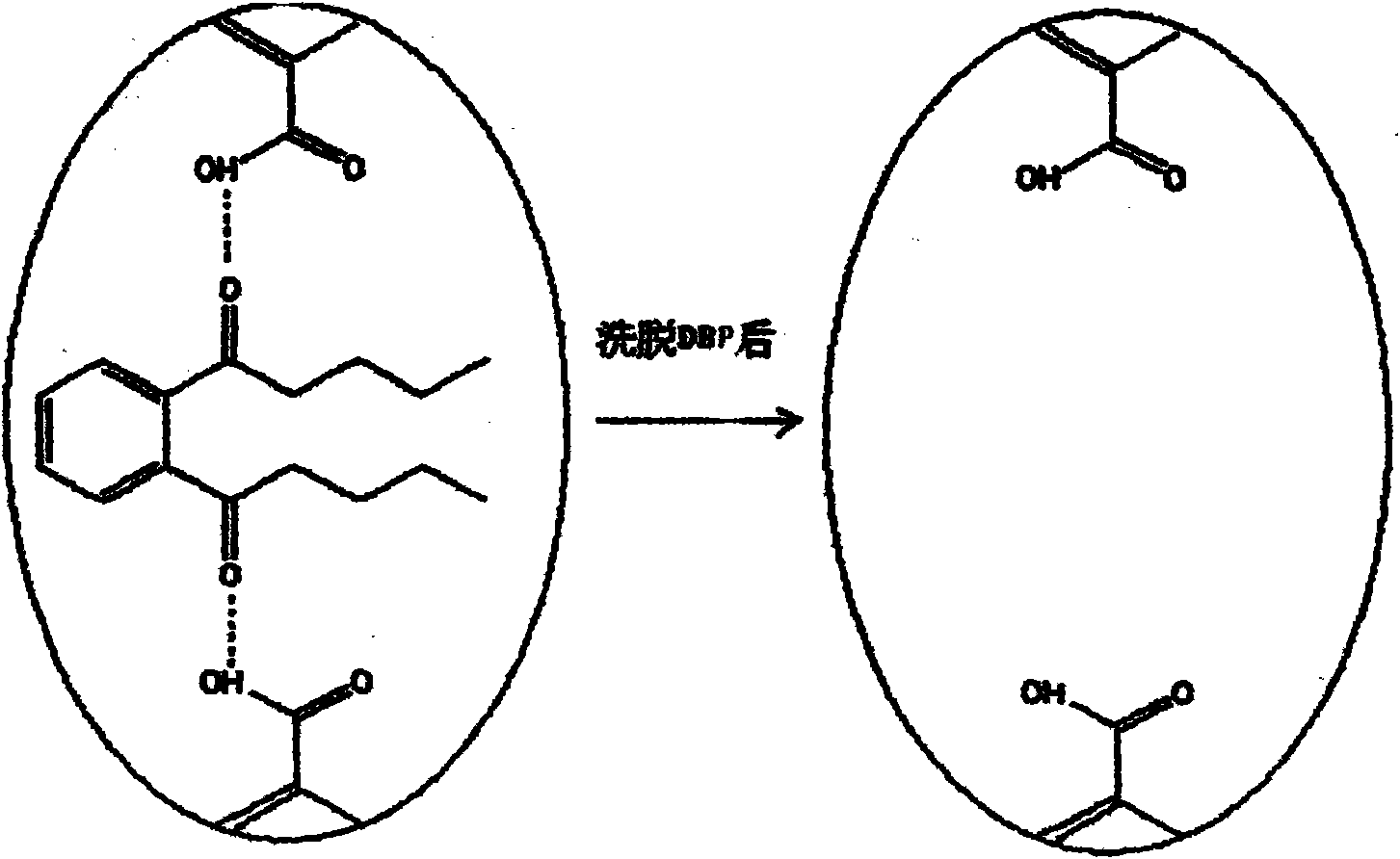

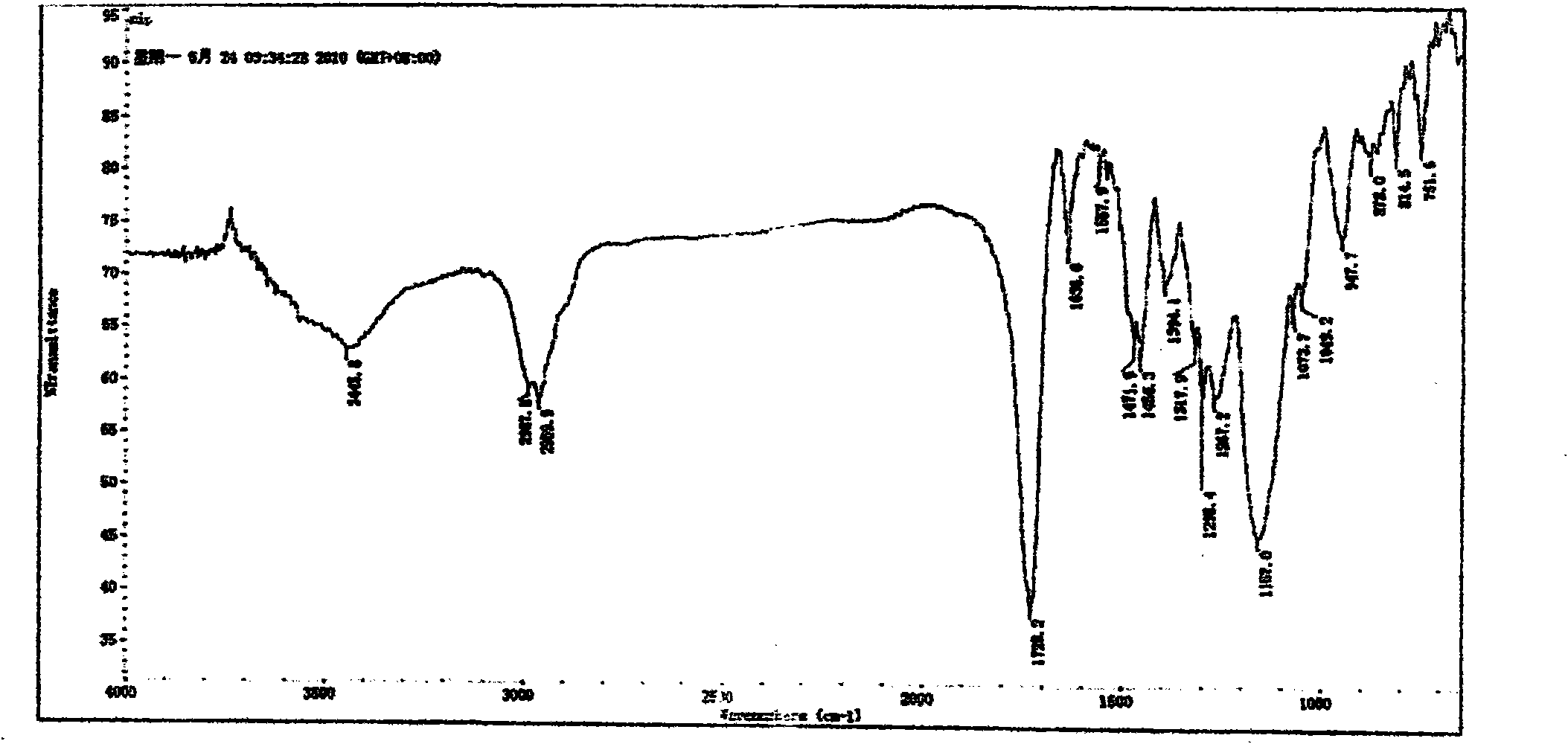

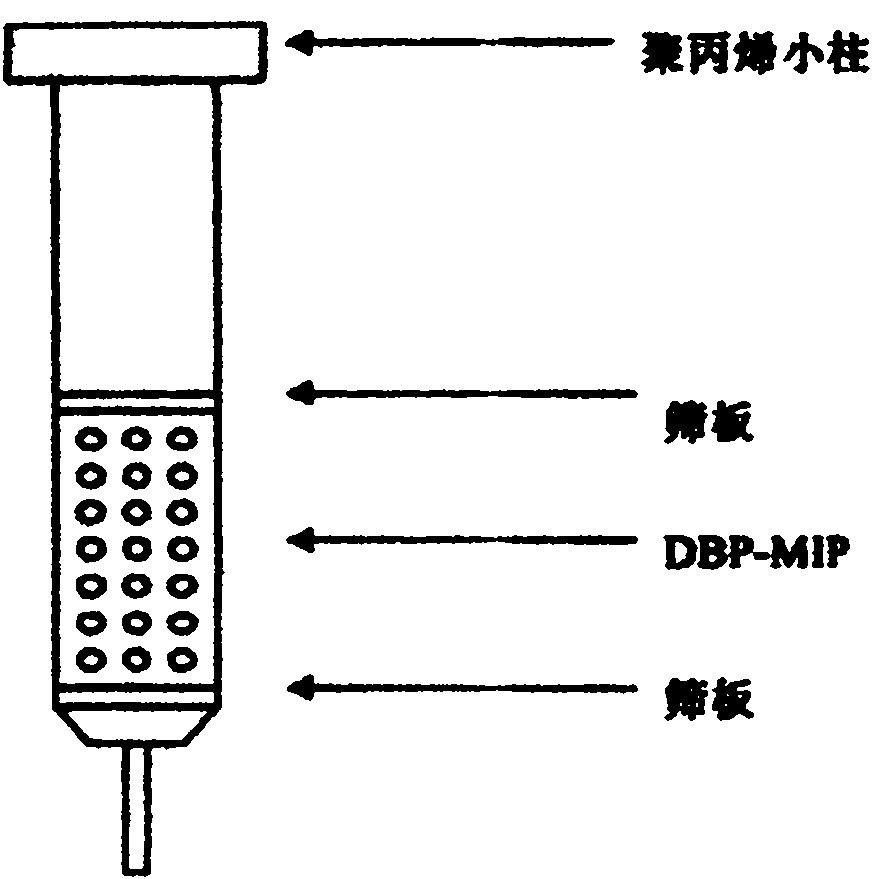

Dibutyl phthalate molecularly imprinted polymer (DBP-MIP) and preparation method thereof

The invention provides a dibutyl phthalate molecularly imprinted polymer (DBP-MIP) and a preparation method thereof, belonging to the technical field of analytical chemistry. The DBP-MIP is prepared by dissolving a template molecule DBP, a functional monomer methacrylic acid and a crosslinking agent ethylene glycol dimethacrylate into a porogen chloroform or acetonitrile, adding an initiator azobisisobutyronitrile, filling nitrogen to remove oxygen, carrying out initiated polymerization at 55-75 DEG C, and grinding, sieving and washing a polymer after completing reaction. An MIP solid phase extraction column can highly selectively separate and enrich DBP in samples such as environment, food, chemical products and the like and effectively remove matrix interference.

Owner:CHINA PETROLEUM & CHEM CORP +1

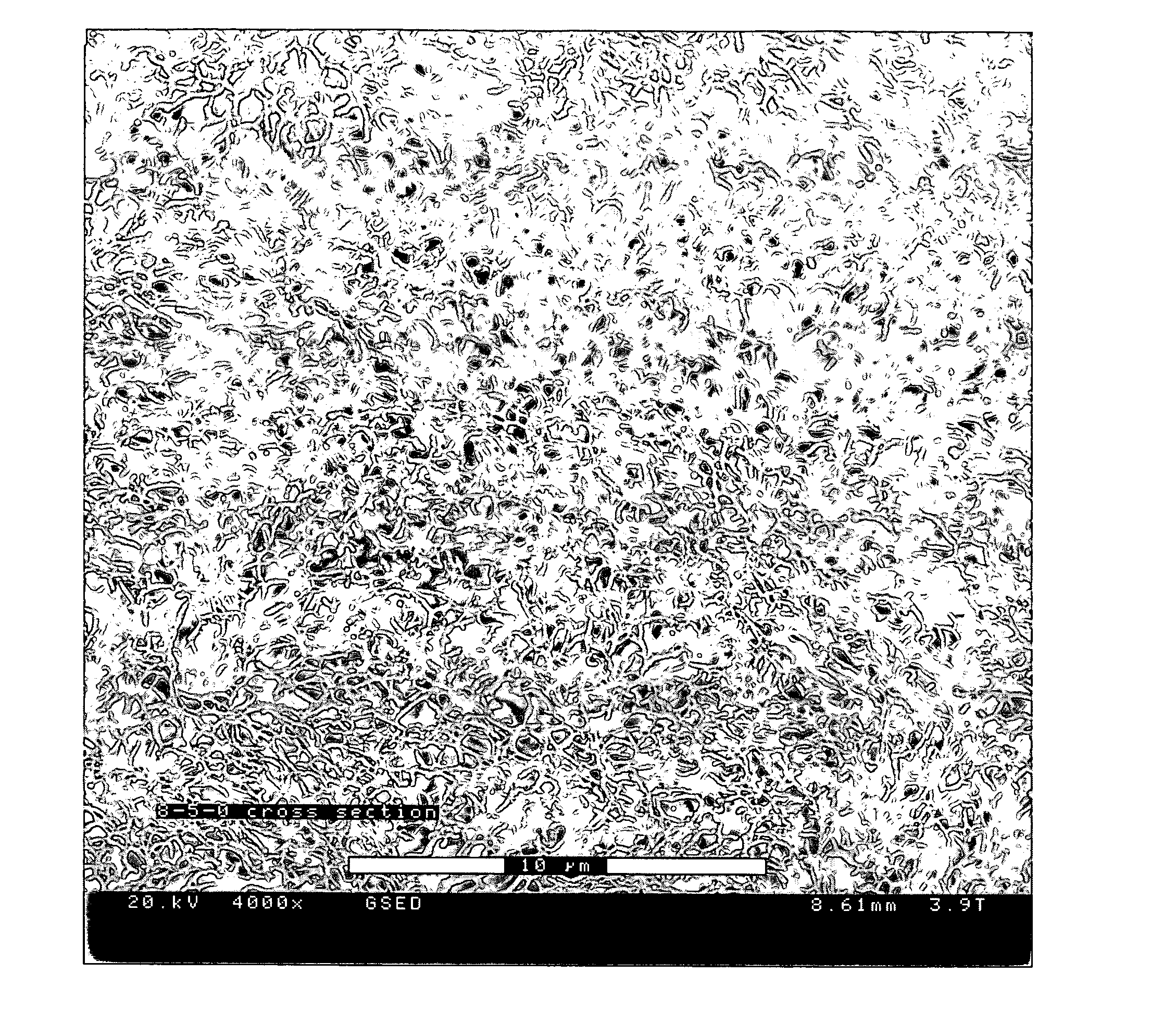

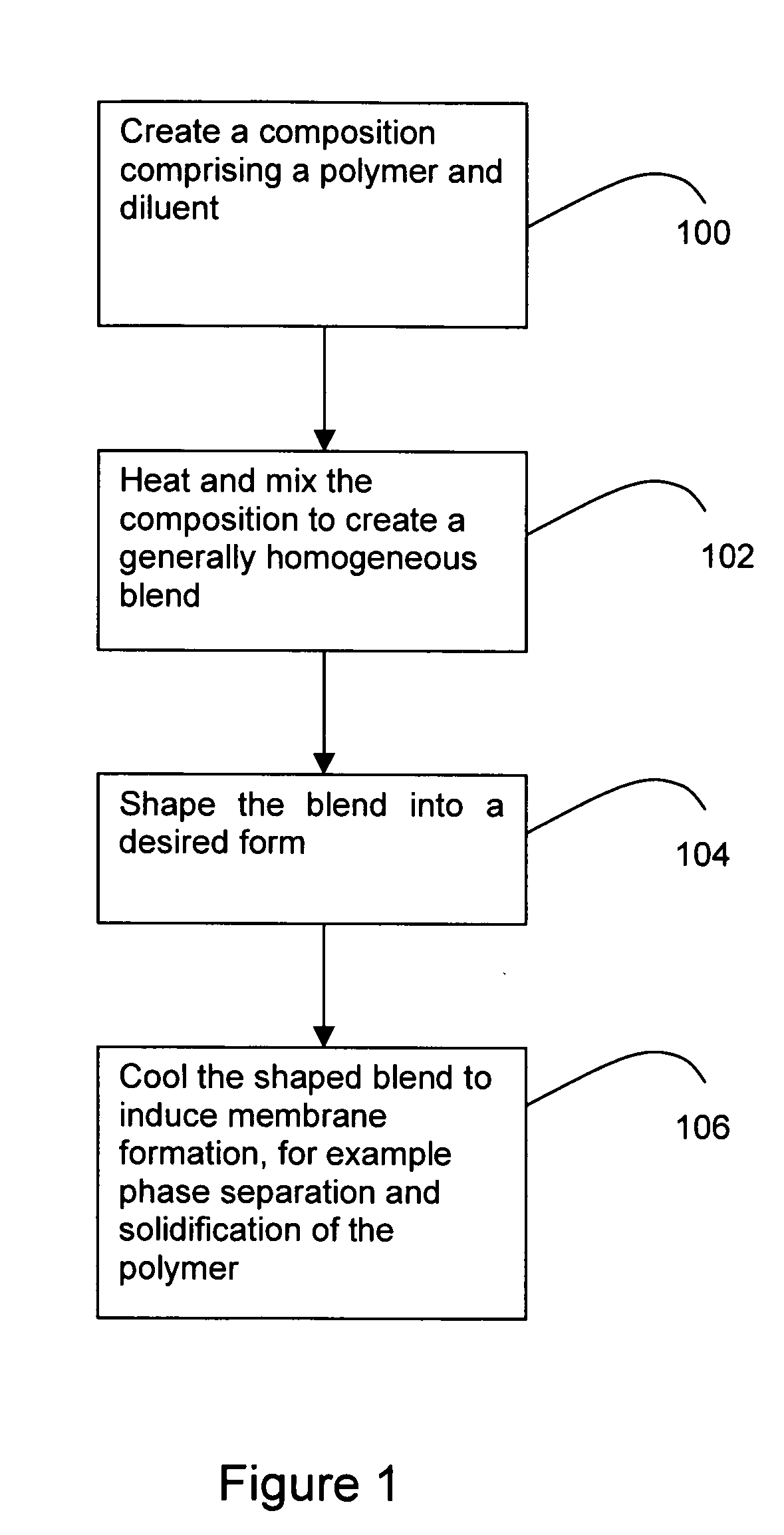

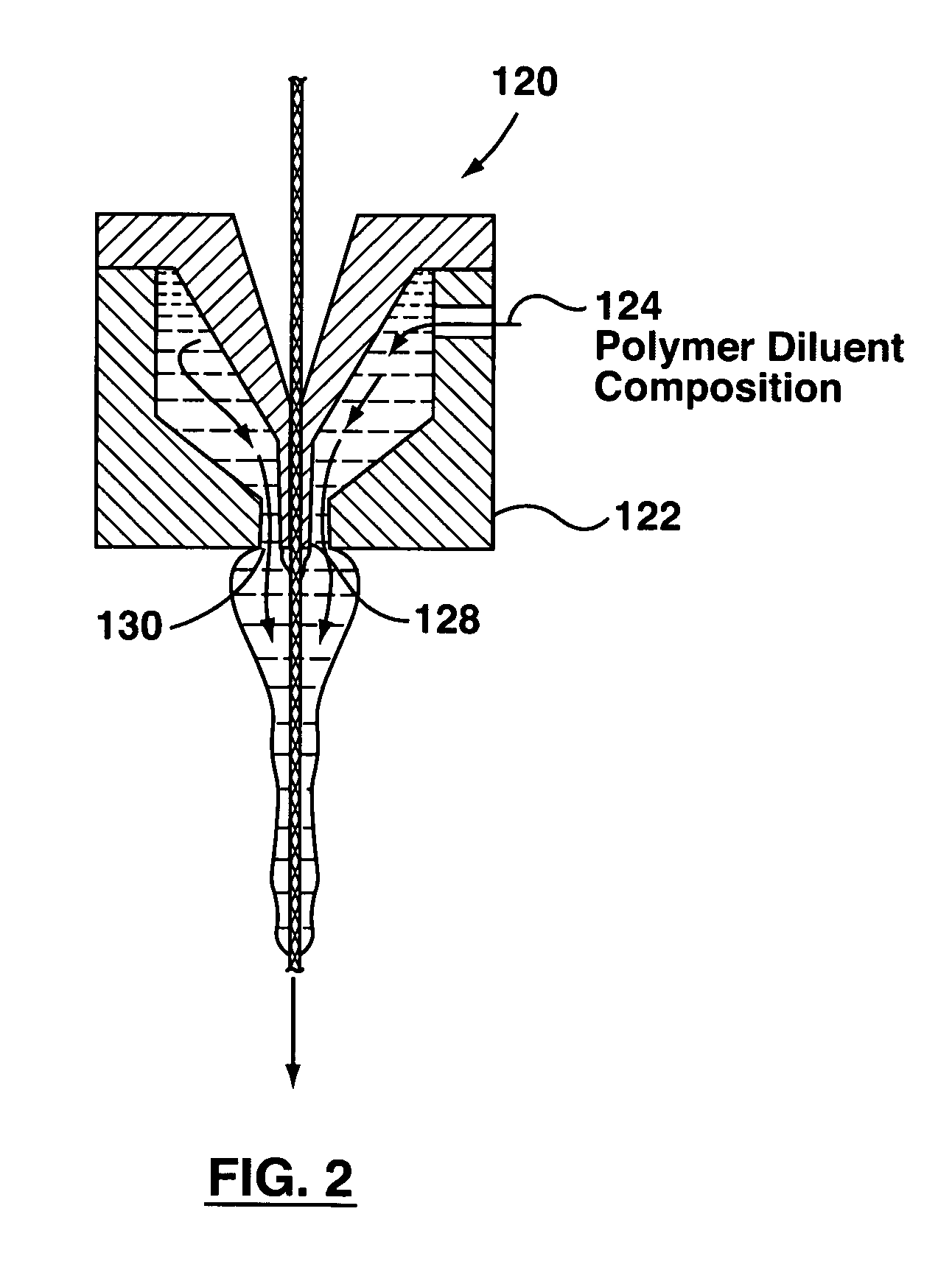

System and method for synthesizing a polymeric membrane

InactiveUS20070007197A1Small apertureImprove permeabilitySemi-permeable membranesMembranesBoiling pointSolvent

A method of synthesizing a polymeric membrane is described in which a polymer, for example a polyvinylidene polymer or a terpolymer of ethylene, chlortrifluoroethylene and an acrylic monomer is heated and blended with a solvent. The solvent may be a high boiling latent solvent, for example butyl benzyl phthalate or tri iso nonyl trimellitate. The heated blend is shaped, which may involve casting on a supporting material such as a braided tube. Subsequently, the blend is cooled to thereby induce polymeric membrane formation on the supporting material.

Owner:MAHENDRAN MAILVAGANAM +3

Conductive coating of anti lightning stroke and method for preparing the same

InactiveCN101984009AImprove performanceImprove conductivityElectrically-conductive paintsPolymer chemistryHexamethylene diisocyanate

The invention discloses a conductive coating of anti lightning stroke and method for preparing the same, which belongs to the field of functional paint and preparation thereof. The method for preparing the conductive coating of anti lightning stroke is as follows: (1) 35%-70% of silver powder, 2.1%-4.2% of cellulose acetate-butyrate, 1.1%-2.1% of dispersant, 12.7%-33.1% of silicone resin, 1.9%-5.0% of dibutyl phthalate and 1.1%-3.0% of antifoaming agent are mixed by mass and the obtained mixture is diluted to 40wt%-60wt% solid content with butyl acetate; Then the mixture is fully grinded to make the packing thereof well dispersed;(2) 7.9%-20.7% curing agent of hexamethylene diisocyanate biuret polyurethane is added to the above mixture. Grind the mixture thoroughly to obtain the conductive coating of anti lightning stroke. The above coating not only has good conductivity and thermal conductivity, but also has the characteristics of impact resistance, heat resistance, good adhesion and stability of polymer coating matrix. As a result, the coating provided by the invention is applicable to the lightning stroke protection for airplanes and oil tanks.

Owner:ZHEJIANG UNIV

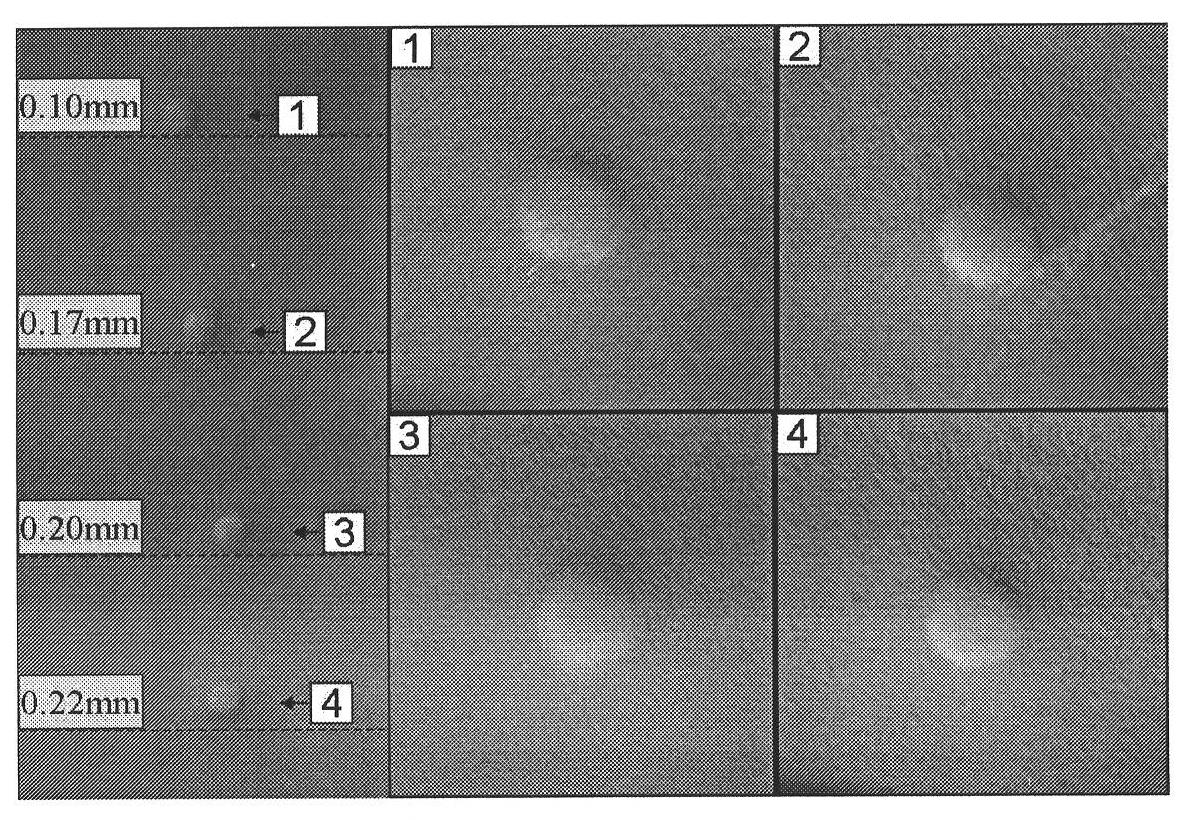

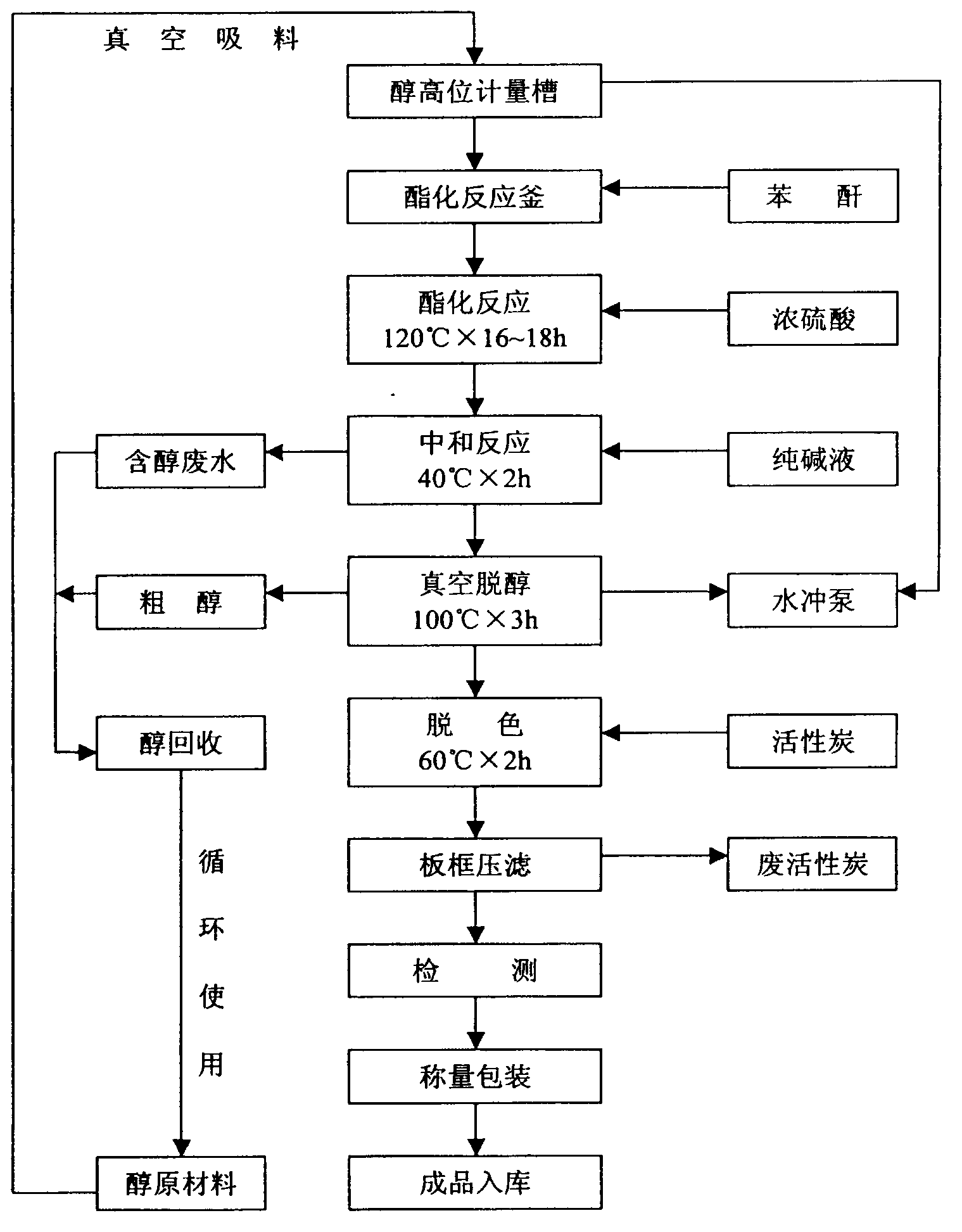

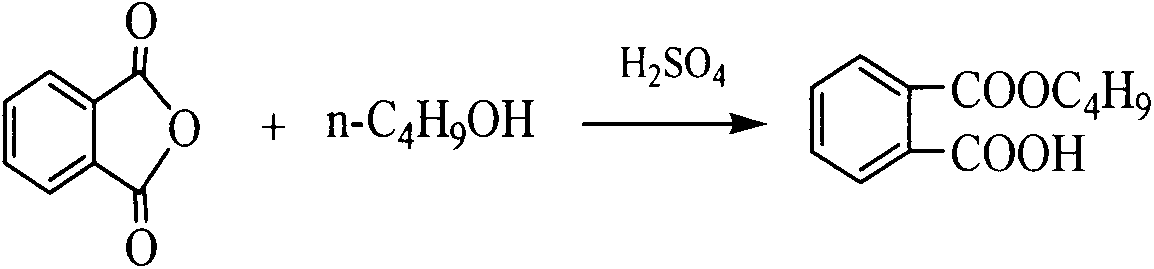

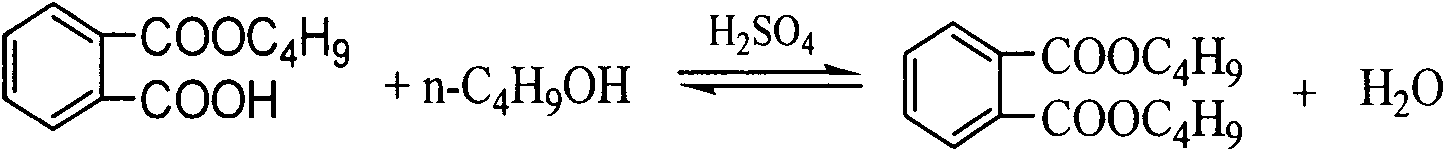

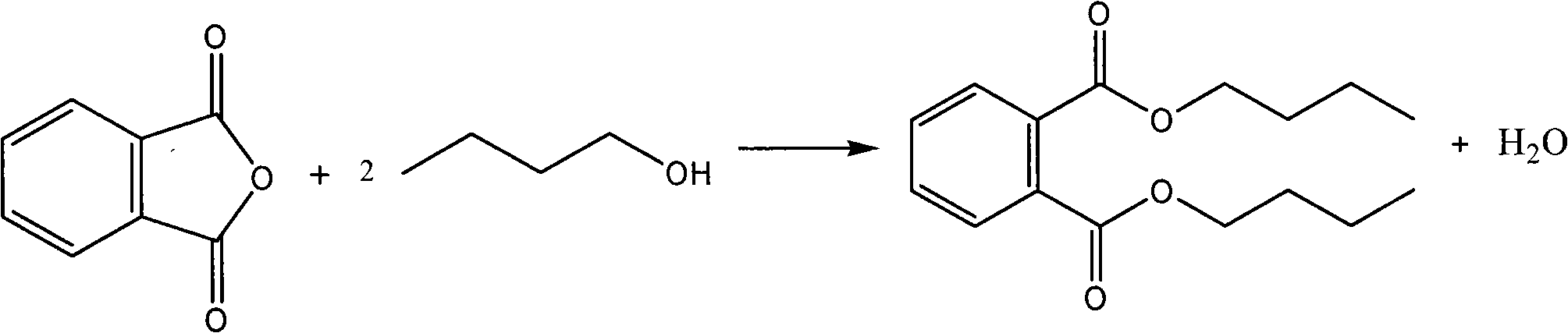

Preparation method of dibutyl phthalate (DBP)

InactiveCN104072366ASimple processImprove product qualityOrganic compound preparationCarboxylic acid esters preparationDistillationRaw material

The invention discloses a preparation method of dibutyl phthalate (DBP). The preparation method comprises the following steps: adding the raw materials including phthalic anhydride and superfluous butanol to a reaction kettle, adding concentrated sulfuric acid as a catalyst, controlling the temperature in the reaction kettle to be 0-150 DEG C, reacting for 16-20 hours, neutralizing the catalyst and unreacted phthalic anhydride with an alkaline solution after the reaction is completed, standing for layering and then carrying out washing with clear water several times. After alcohol-containing wastewater is collected, alcohols are recovered with a recovery tower and are reused. A lower ester layer after layering is heated to recover alcohols at reduced pressure (butanol is recovered by using a supergravity bed and is reused). After activated carbon is added for decoloration, the finished product of DBP is obtained through filter pressing by adopting a plate-and-frame filter press. The preparation method has the beneficial effects that the superfluous alcohol serves as a water-carrying agent, so that the esterification reaction is gradually carried through to the end, the technological process is simplified and the product quality is good; relative to a process of distillation in a rectifying tower, the preparation method has the advantages that the supergravity bed is used to recover butanol in the process, so that the energy consumption is effectively reduced and the process has better environment-friendly significance.

Owner:池银萍

Colour functional road curb stone

ActiveCN1743554AGood water permeabilityNot easy to fall off and fadePaving gutters/kerbsTraffic signalsCalcium silicateFiber

This invention discloses a color function curbstone, which is a porous polymer concrete, the composition on weight is: white cement 200-500, stone 500-2000, ethane acetate multipolymer 10~200, inorganic pigment 0.5-20, n-butyl phthalate 0.5-90, aluminum silicate or silicon micro-powder 10-100, silicon sol 20-100, ageing fiber 0.5-10and water 70-200, which is good in pervious ability, anti-freeze and does not fade.

Owner:XINGTAI ROAD & BRIDGE CONSTR GENERAL

Water-resistant corrosion-resistant paint

InactiveCN103952040AImprove waterproof performanceImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsFiberPolyvinyl alcohol

The invention relates to a water-resistant corrosion-resistant paint. The paint is characterized by comprising the following components in parts by weight: 14-20 parts of epoxy acrylic resin, 25-40 parts of toluene, 2-6 parts of dimethylethanolamine, 40-60 parts of styrene-acrylic emulsion, 4-10 parts of polyvinyl alcohol, 20-35 parts of anhydrous calcium chloride, 6-12 parts of flame retardant, 1-3 parts of glyoxal, 3-7 parts of wood fiber, 1-3 parts of sodium dodecyl benzene sulfonate emulsion, 0.5-1.2 parts of dibutyl phthalate and the balance of water. The paint has the advantages of favorable water resistance, favorable corrosion resistance, no pollution, low production cost and wide application range.

Owner:HUZHOU BAISHENG PAINT

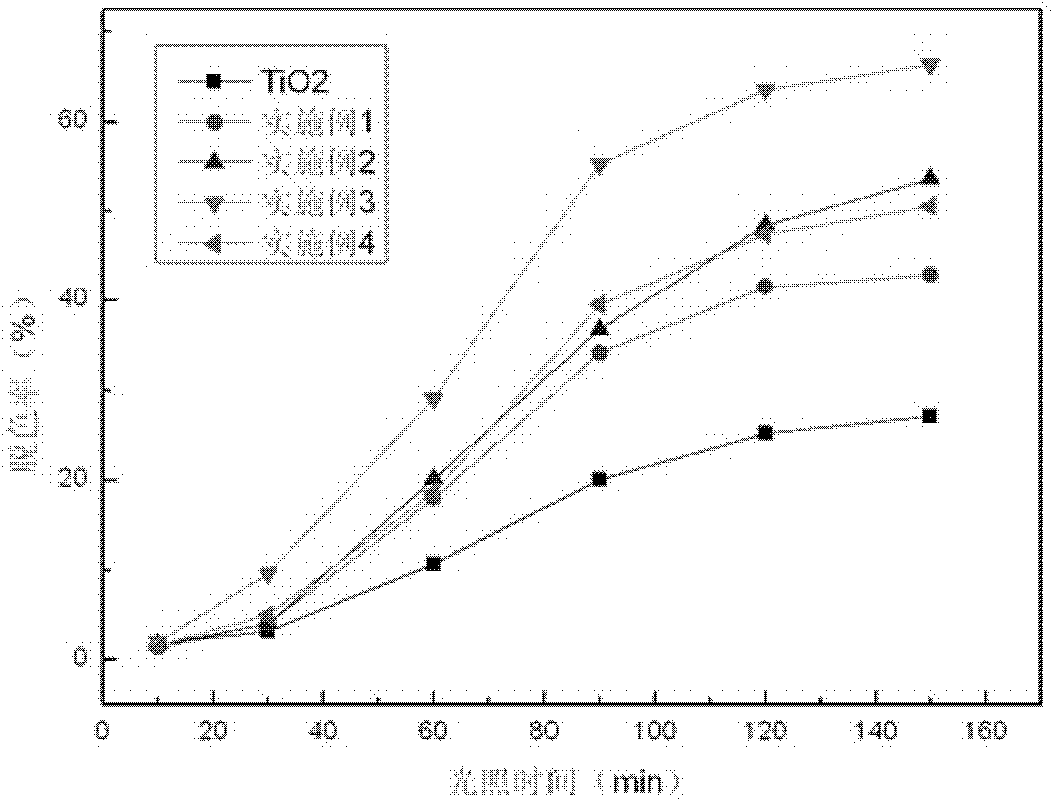

Method for preparing samarium-doped titanium dioxide thin film

InactiveCN102172522AImprove photocatalytic degradation performanceGood photocatalytic effectWater/sewage treatment by irradiationMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureMethyl orange

The invention discloses a method for preparing a samarium-doped titanium dioxide thin film, which comprises: mixing butyl phthalate and absolute ethanol to obtain mixed solution, and adding diethanol amine into the mixed solution to obtain solution A; uniformly mixing deionized water, diacetone and absolute ethanol to obtain solution B; adding the solution B into the solution A, regulating the pH value to 2.0 to 5.0 by using hydrochloric acid, magnetically stirring and aging to obtain gel C; soaking a cleaned substrate into the gel C, standing, lifting, coating a film and drying; and annealing the dried thin film to obtain the samarium-doped titanium dioxide thin film. In the invention, the reaction temperature is low, the production efficiency is high, the raw materials are readily available, the operation is simple, the coated film is uniform and the repeatability is high. The organic degradation catalyzing capacity of the prepared thin film under irradiation by sunlight is much higher than that of titanium dioxide thin films. By controlling the doped amount of samarium, the thin film having much higher photocatalytic effect than titanium dioxide thin films can be prepared, and the rate of methyl orange decolorization catalyzed by the thin film reaches 10 to 70 percent.

Owner:SHAANXI UNIV OF SCI & TECH

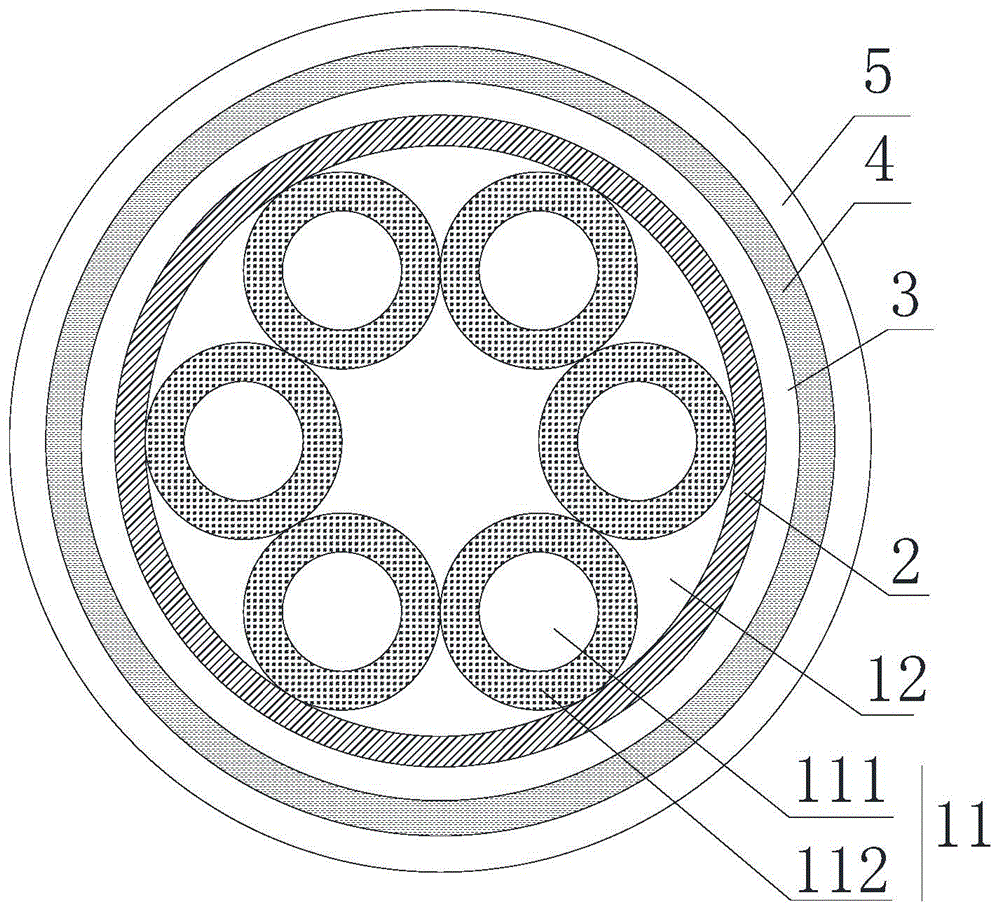

Cable for automobiles

InactiveCN104900333AIncrease elasticityImprove toughnessPower cables with screens/conductive layersInsulated cablesEpoxyVulcanization

The invention discloses a cable for automobiles. The materials of the sheath of the cable include the following components in parts by weight: 30 to 50 parts of nitrile rubber; 5 to 10 parts of 2, 4-toluene diisocyanate dimer; 20 to 30 parts of terminal isocyanate based polyurethane prepolymer, 1 to 2 parts of dibuty phthalate; 04 to 0.8 part of dioctyl phthalate; 0.2 to 0.6 part of bis(2-ethylhexyl) terephthalate; 30 to 40 parts of carbon black; 10 to 14 of calcium carbonate; 10 to 20 part of kaolin; 5 to 12 parts of modified mica ; 5 to 8 parts of liquid epoxy resin; 2 to 4 parts of polyethylene vinyl esters; 1 to 3 parts of tetrafluoroethylene; 0.5 to 1 part of antioxidant 1010; 0.8 to 1.2 of antioxidant 1035; 1 to 2 parts of antioxidant 1076; and 2 to 3 parts of vulcanization system. The cable for the automobiles of the invention has advantages of excellent elasticity and toughness, high heat resistance, and will not malfunction under intensive bending.

Owner:ANHUI WUZHOU SPECIAL CABLE GRP

False tooth material composition

InactiveCN105287232AReduce solubilityMake up for the defect of easy crackingImpression capsDentistry preparationsPolymethyl methacrylateMaterials science

The invention discloses a false tooth material composition. The false tooth material composition comprises, by weight, 95-105 parts of a dentistry special-purpose tooth-making liquid, 95-105 parts of heat setting denture acrylic powder, 0.10-0.15 parts of an anticracking agent, 0.5-0.8 parts of a plasticizer and 0.1-0.3 parts of a tooth-making pigment. The dentistry special-purpose tooth-making liquid is a methyl methacrylate monomer. The heat setting denture acrylic powder is polymethyl methacrylate. The anticracking agent is polysulfone resin. The plasticizer is a mixture of benzyl salicylate and ethanol or a mixture of dibutyl phthalate and ethanol. The tooth-making pigment is zinc oxide. The polysulfone resin in the composition is used for solving the problem of easy cracking of an acrylic acid polymer material. Zinc oxide is used as the tooth-making pigment. Through control of different use amounts, false teeth has a plurality of colors, satisfy requirements on matching of dermal teeth and false teeth of a dental patent and personal tooth color appetite, and has a low price and good adaptability.

Owner:毕相廷

Thermoplastic resin composition for white laser marking on the molding surface

The thermoplastic resin composition for white laser marking according to the present invention comprises (A) 100 parts by weight of an acrylic thermoplastic resin; (B) 0.001 to 3 parts by weight of a black pigment having a particle size of 10-80 nm and an oil absorbency (dibutyl phthalate-DBP) of 100-350 cc / 100g; and (C) 0.1 to 10 parts by weight of a barium sulfate powder. The thermoplastic resin composition of the present invention may also optionally contain organic dyes, inorganic pigments or a mixture thereof.

Owner:LOTTE ADVANCED MATERIALS CO LTD

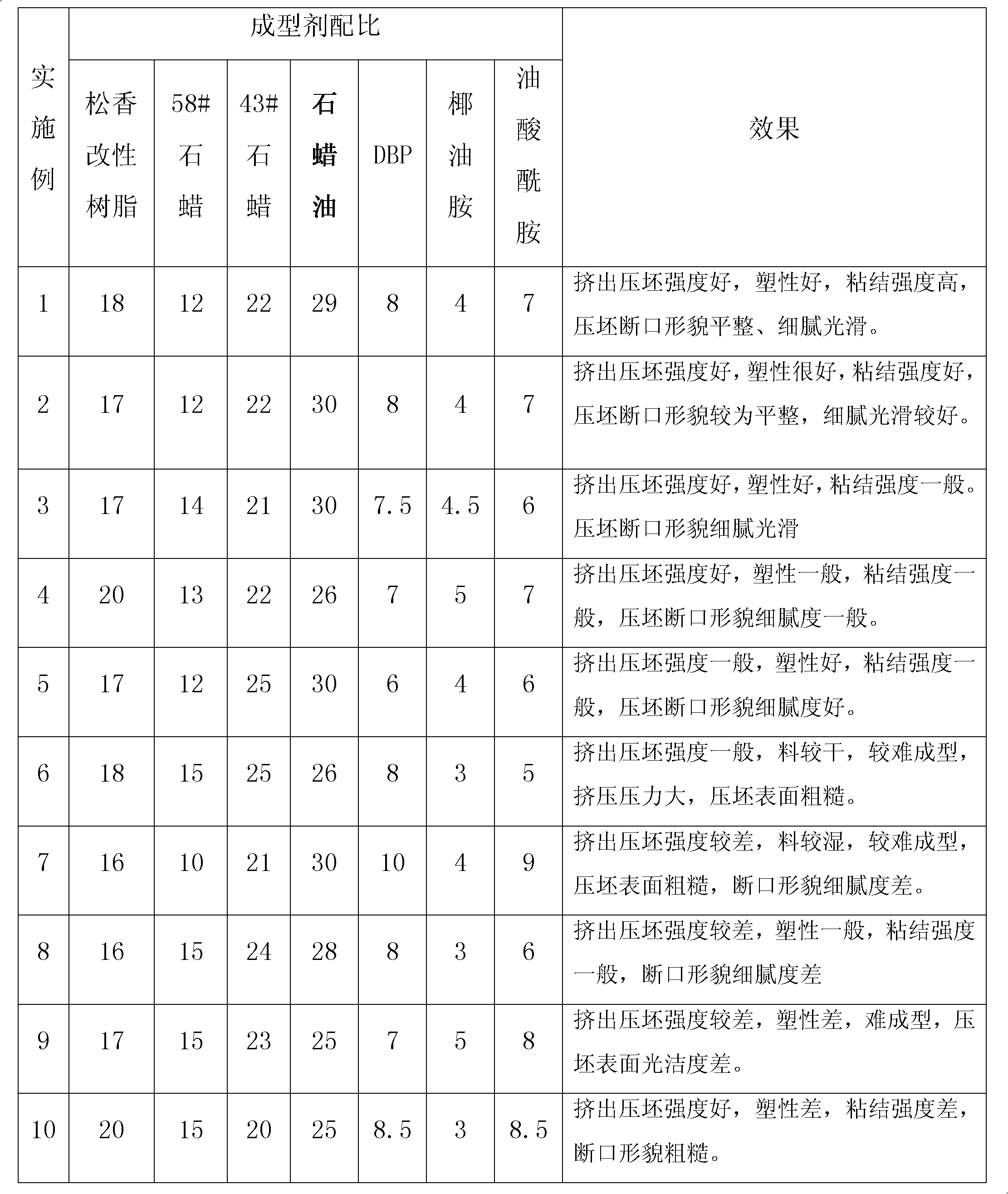

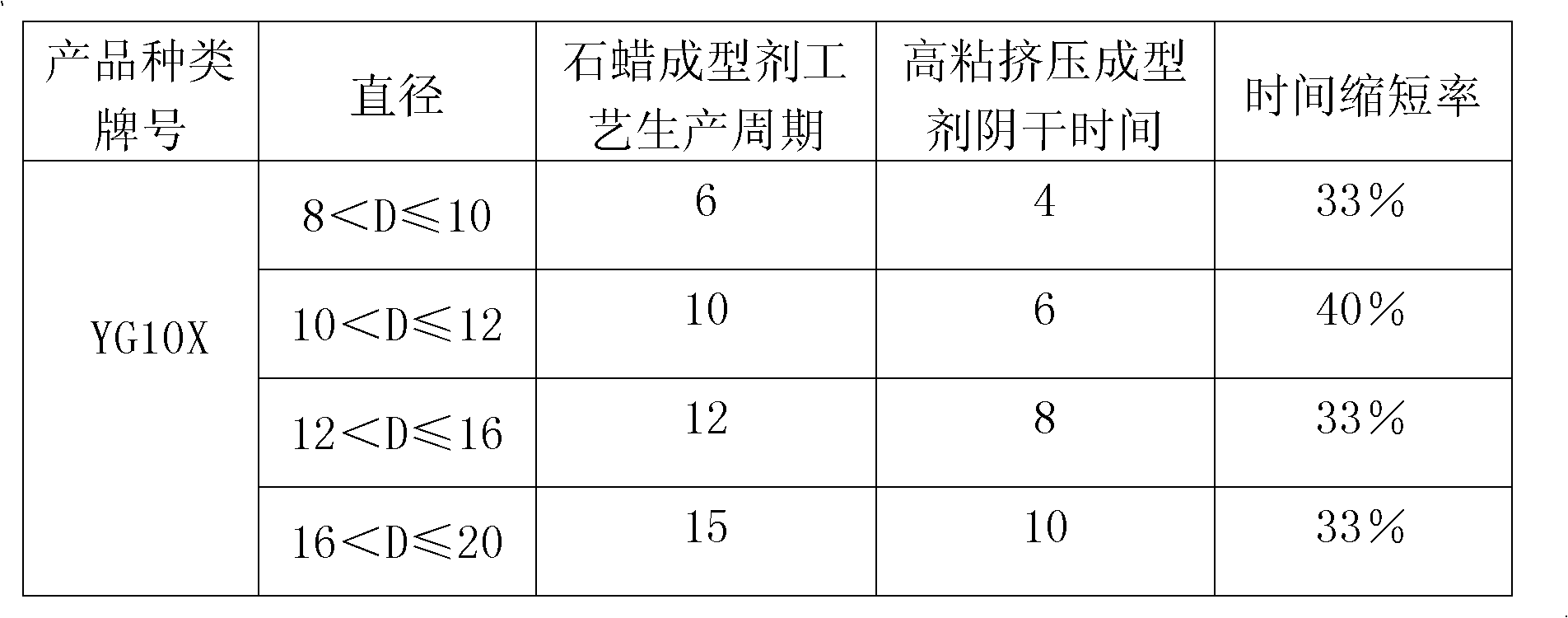

High-viscosity extrusion forming agent

The invention discloses a high-viscosity extrusion forming agent, comprising the following ingredients: 15-20 wt% of rosin modified resin, 10-15 wt% of paraffin No.58, 20-25 wt% of paraffin No.43, 25-30 wt% of paraffin oil, 5-10 wt% of dibutyl phthalate (DBP), 1-5 wt% of coconut amine, and 5-10 wt% of oleamide. According to the invention, extrusion billets can be prevented from cracking in the quick drying process, the extruded billets can be guaranteed to have good shape retention, and the qualified rate of the products is raised.

Owner:XIAMEN TUNGSTEN

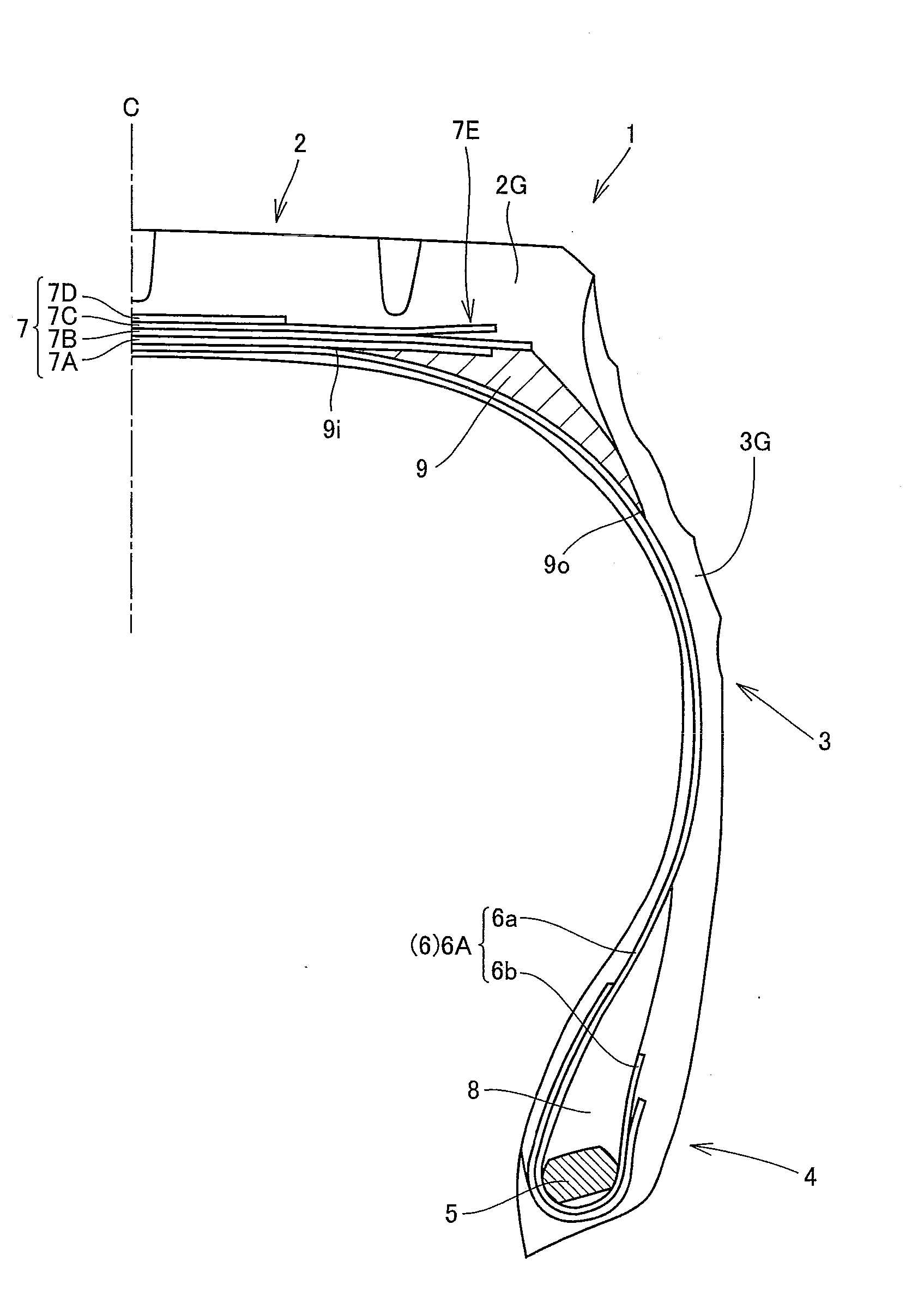

Cushioning rubber composition and pneumatic tire employing the same

InactiveUS20100163151A1Excellent low fuel consumption performanceMaintain strengthHeavy duty tyresHeavy duty vehiclePolymer scienceVulcanization

Owner:SUMITOMO RUBBER IND LTD

Base belt of sub-hydrogenated nitrile butadiene rubber synchronous belt

The invention belongs to the technical field of transmission belts, in particular to a base belt of a sub-hydrogenated nitrile butadiene rubber (sub-HNBR) synchronous belt. The base belt comprises the following materials in parts by weight: 48-55 parts of butadiene rubber, 15-25 parts of butyronitrile-40 rubber, 15-25 parts of chloroprene rubber, 5 parts of zinc oxide, 1.5 parts of stearic acid, 1 part of anti-aging agent MB, 1 part of anti-aging agent NBC, 4 parts of peroxide vulcanizing agent (no DCP contained), 1.5 parts of cross-linking agent, 3.8 parts of binding agent RS, 2.5 parts of binding agent A, 6 parts of butyl phthalate, 3 parts of triethanolamine, 20-30 parts of N330 carbon black, 10-20 parts of semi-reinforcing carbon black, and 10-20 parts of white carbon black.

Owner:浙江沪天胶带有限公司

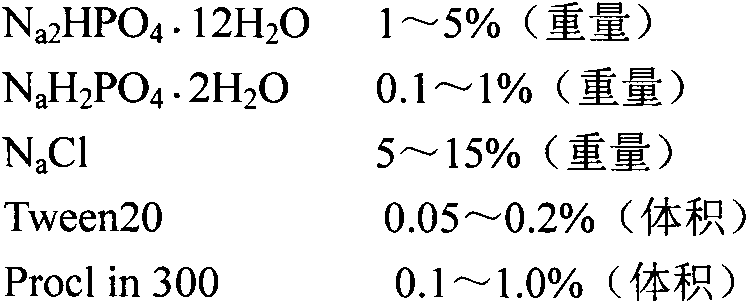

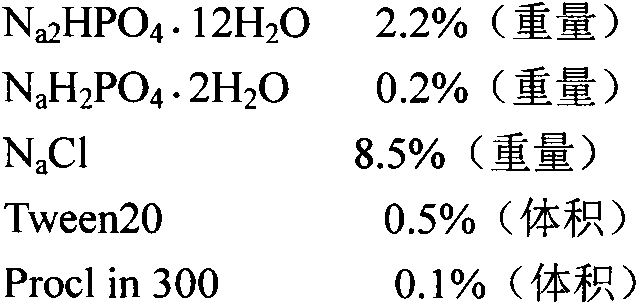

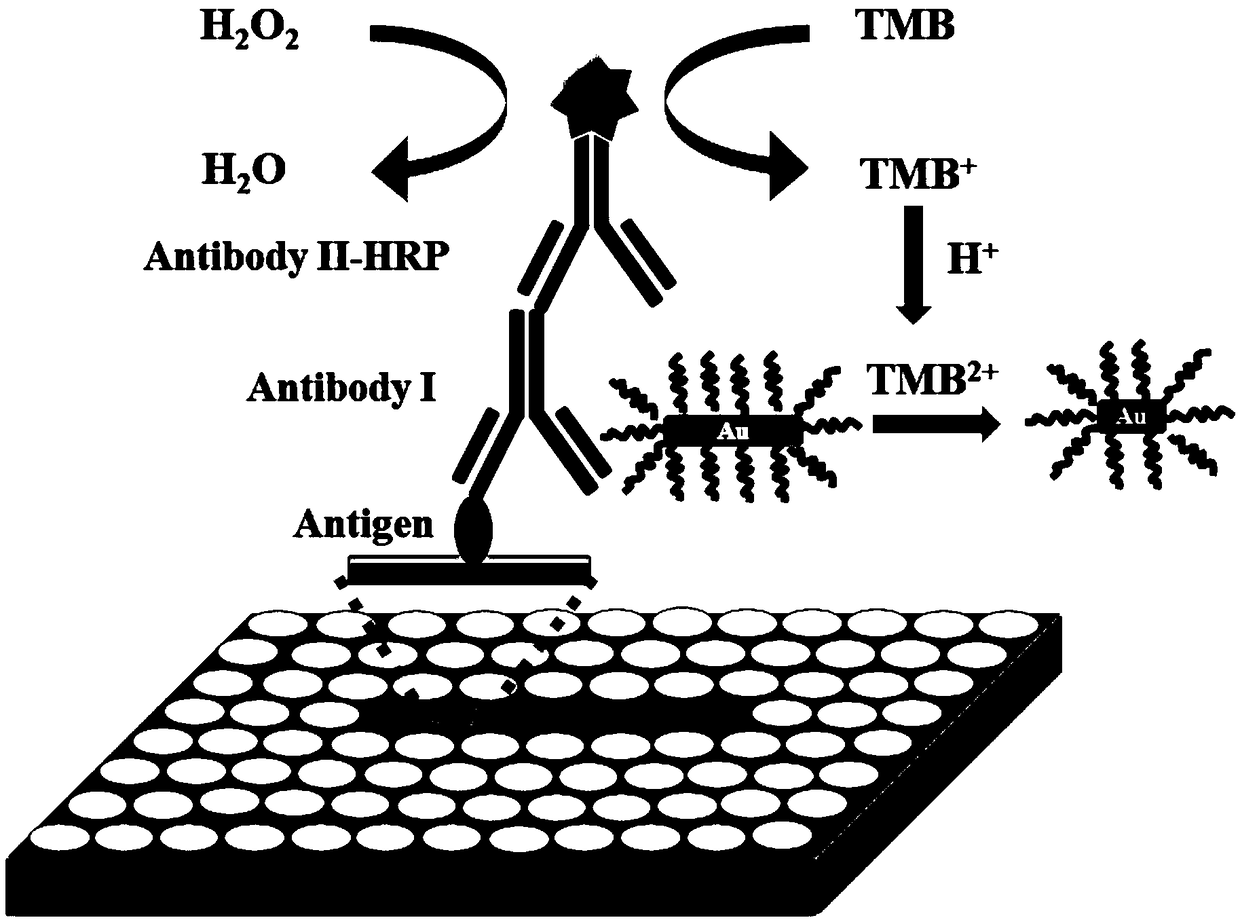

Making method of rapid detection kit of dibutyl phthalate, and detection method of rapid detection kit of dibutyl phthalate

InactiveCN103226144AShort detection timeSimple and fast operationAnalysis by material excitationLinearityEnzyme

Owner:BEIJING PRIMEBIOTEK COMPANY

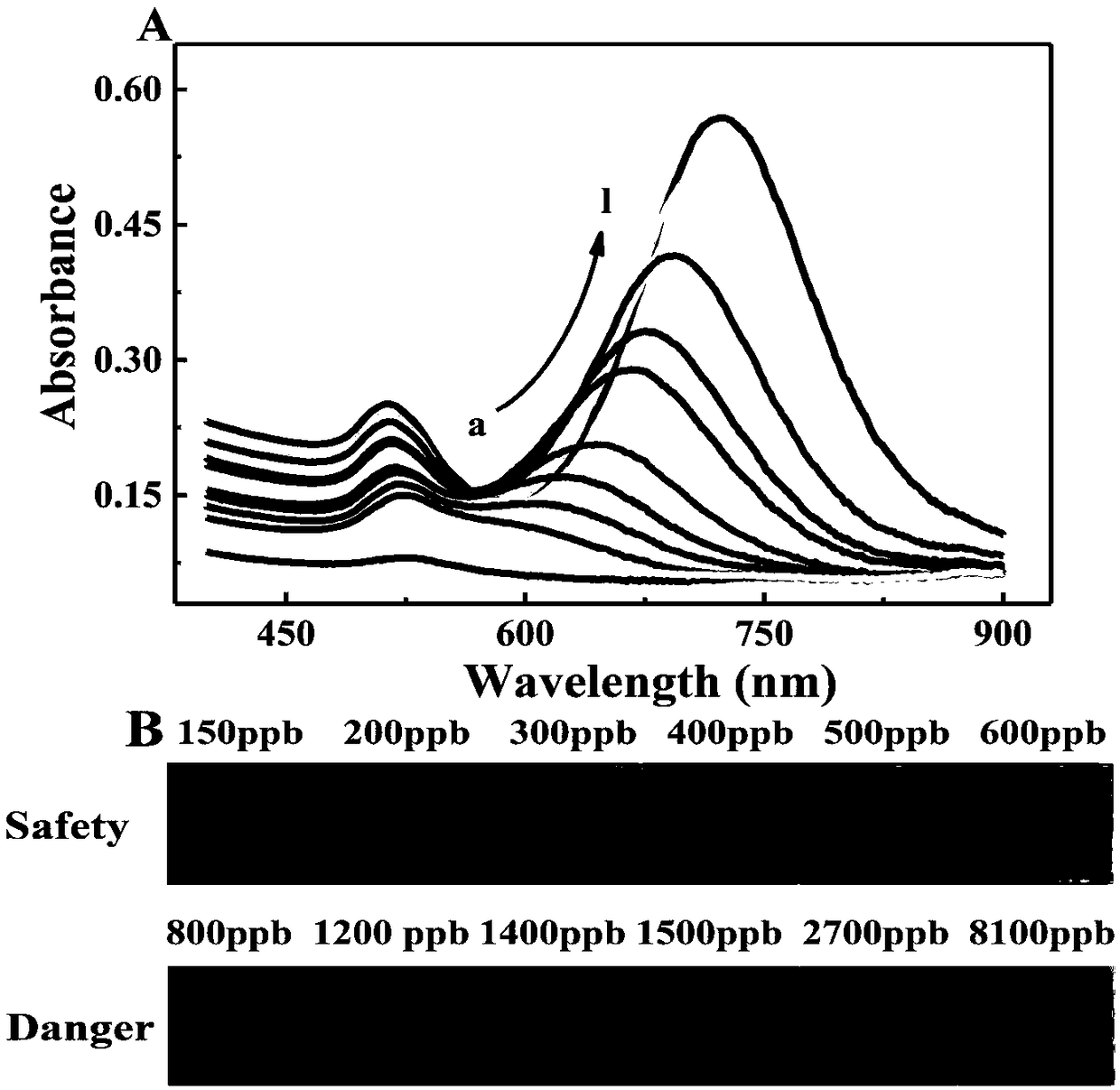

Method for visually detecting content of dibutyl phthalate

InactiveCN109030472AImprove accuracyEasy to operateMaterial analysis by observing effect on chemical indicatorAntigenCellulose

The invention discloses a method for visually detecting content of dibutyl phthalate. By firstly fixing a layer of cellulose on a board for absorbing antigen and then adding dibutyl phthalate standardsolution to compete with dibutyl phthalate fixed on an elisa plate for a primary antibody, the primary antibody fixed on the plate is further combined with a secondary antibody compound modified by horse radish peroxidase (HRP) to form a competitive immunosensor; under the catalysis of the HRP, TMB is oxidized into TMB2+ (the acid condition) by H2O2; the TMB2+ is added to etch gold nanorods to form different length-to-diameter ratios so as to show colorful colors. Along with increase of the target object dibutyl phthalate, the amount of the HRP fixed on the plate is reduced on the contrary, and then the etching degree of the gold nanorods is reduced so as to show different colors; according to the method, the color of the elisa plate can be judged with naked eyes and semi-quantitative analysis of the dibutyl phthalate can be carried out; and the method has the characteristics of simplicity for operation, high sensitivity, good specificity and the like.

Owner:FUZHOU UNIV

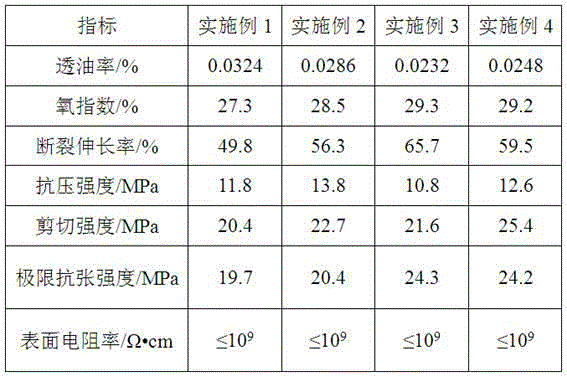

High-barrier, flame-retardant and anti-electrostatic epoxy-resin adhesive and preparation method thereof

ActiveCN103602300AImprove antistatic performanceImprove barrier propertiesNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesive cementEpoxy

The invention discloses a high-barrier, flame-retardant and anti-electrostatic epoxy-resin adhesive and a preparation method and application thereof. The adhesive is prepared from the following ingredients in parts by weight: 100 parts of epoxy resin, 4-10 parts of ethylene-vinyl alcohol copolymer, 50-70 parts of polyamide resin, 0-10 parts of thermoplastic polyurethane, 20-30 parts of N-methyl pyrrolidone, 0.5-2.5 parts of antistatic agent, 2-4 parts of modified nano organic montmorillonite, 1-3 parts of modified nano-silica, 14-20 parts of di-n-butyl phthalate, 3-5 parts of inorganic filler and 14-20 parts of dimethyl methyl phosphonate. The adhesive prepared by the preparation method has the advantages of good electrostatic resistance, high barrier, excellent flame retardance, high adhesive strength, good toughness, strong deflection resistance and the like, and the preparation method is scientific and reasonable and is simple in process and strong in operability, so that the industrial production is easy to realize. The adhesive can be applied to fields with relatively high requirements for electrostatic resistance, barrier and flame retardance, such as the combination of plastic fuel tank materials and PET (Polyethylene glycol Terephthalate) beer bottle materials, which is relatively popular currently.

Owner:FUZHOU UNIV

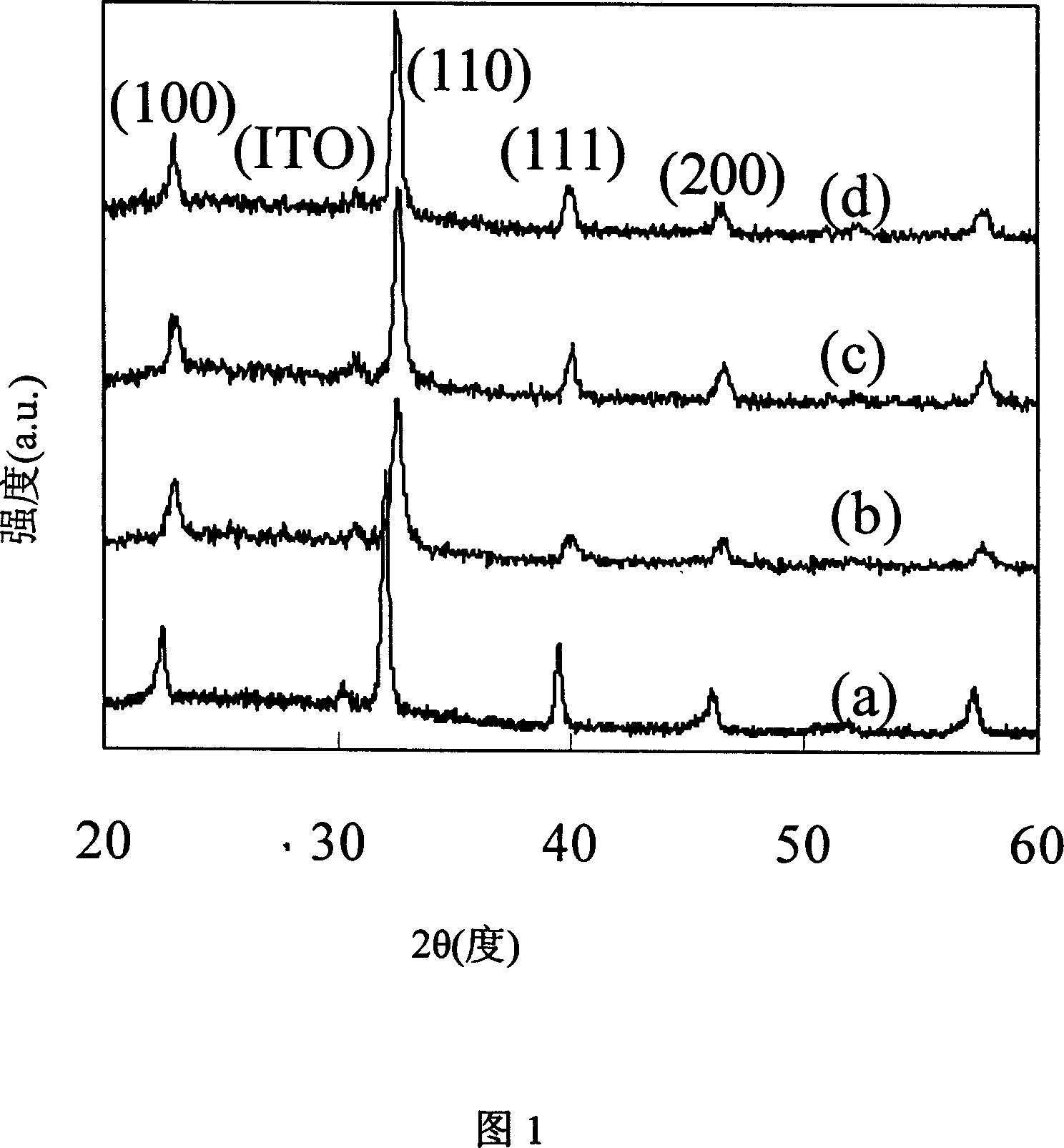

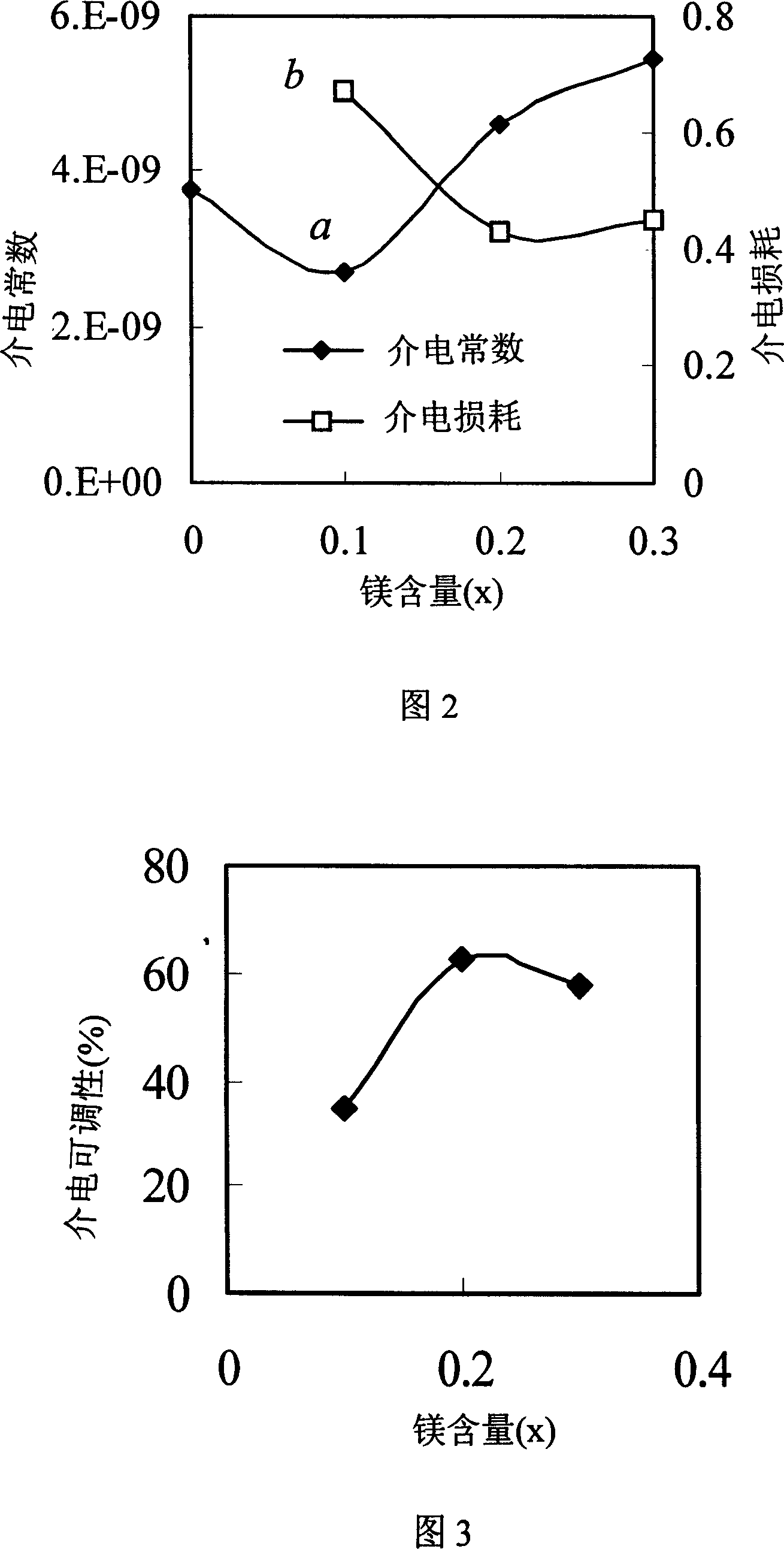

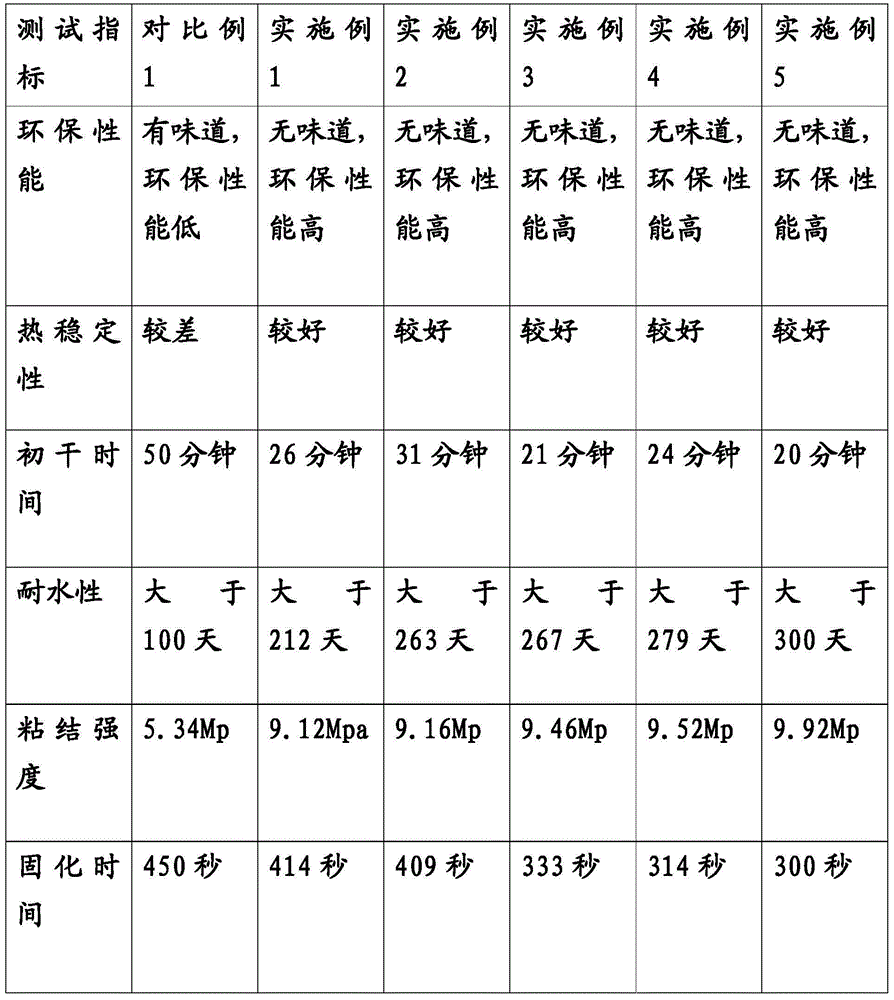

Preparation method of highly magnesium-doped strontium plumbum titanate high dielectric adjustable film material

The invention discloses a preparing method of high-dielectric adjustable film material of strontium lead titanate doped magnesium, which comprises the following steps: adopting butyl phthalate, lead acetate, strontium carbonate and magnesium carbonate as raw material; making ethandiol dimethyl ether and acetate as solvent; allocating sol former; adopting allocated relative sol former as coating solution; using immersing sash method to prepare film layer; drying the coating; disposing under high-temperature; sintering to obtain PSMT ferric electric film.

Owner:ZHEJIANG UNIV

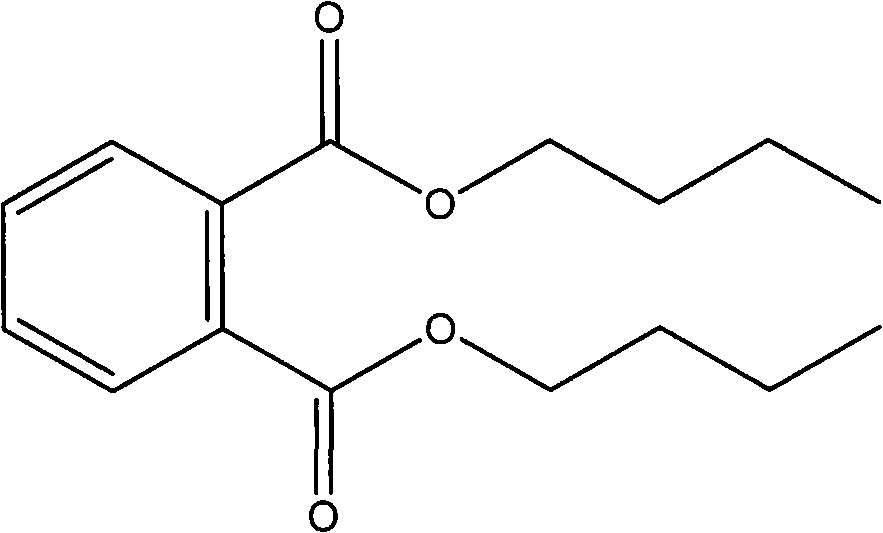

Water-resistant white latex

InactiveCN104629633AMeet the strict requirements of qualityImprove environmental performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesSodium bicarbonateToluene diisocyanate

The invention provides a water-resistant white latex which is composed of the following components in parts by weight: 700-1050 parts of polyvinyl acetate, 300-350 parts of vinyl acetate, 120-145 parts of polyvinyl alcohol, 60-100 parts of dibutyl phthalate, 20-40 parts of diethylene glycol dibenzoate, 10-15 parts of octanol, 30-45 parts of isopropanol, 10-25 parts of allyl methacrylate, 5-10 parts of glycol bis methacrylate, 3-7 parts of toluene diisocyanate, 35-50 parts of sodium bicarbonate, 1400-1500 parts of water, 40-50 parts of emulsifier 5-9 parts of composite initiator, 20-32 parts of hydroxymethyl acrylamide, 10-15 parts of waxy corn starch and 2-7 parts of sodium hypochlorite. The water-resistant white latex does not need formaldehyde or any other solvent, and has the advantages of environment friendliness, high heat stability, short primary drying time, excellent water resistance, excellent binding strength, excellent curing time, excellent comprehensive properties and the like.

Owner:海安县紫石涂料有限公司

Method for preparing dibutyl phthalate

InactiveCN102060708AEmission reductionEliminate the alkali washing processPhysical/chemical process catalystsOrganic compound preparationDistillationWater vapor

The invention provides a method for preparing dibutyl phthalate, relates to a method for preparing a plasticizer, and in particular relates to a method for preparing the dibutyl phthalate. The method for preparing the dibutyl phthalate has the advantages of short time consumption, small pollution and excellent product quality. The method comprises the following steps: adding phthalic anhydride and n-butyl alcohol in the molar ratio of 1:2-1:3 into a 250mL three-neck flask which is filled with a mixer, a thermometer and a reflux condenser; adding 0.3 to 1.2 percent of catalyst aluminum oxide; heating by an electric jacket, and stirring; refluxing for 1 to 4 hours at the temperature of between 140 and 240 DEG C; filtering the catalyst after the reaction is finished, distilling the n-butyl alcohol, and distilling with water vapor, and removing excess alcohol; and preparing the product by the dealcoholized coarse product through separation, filtering and reduced pressure distillation, and detecting the refractive index of the product.

Owner:陈雨

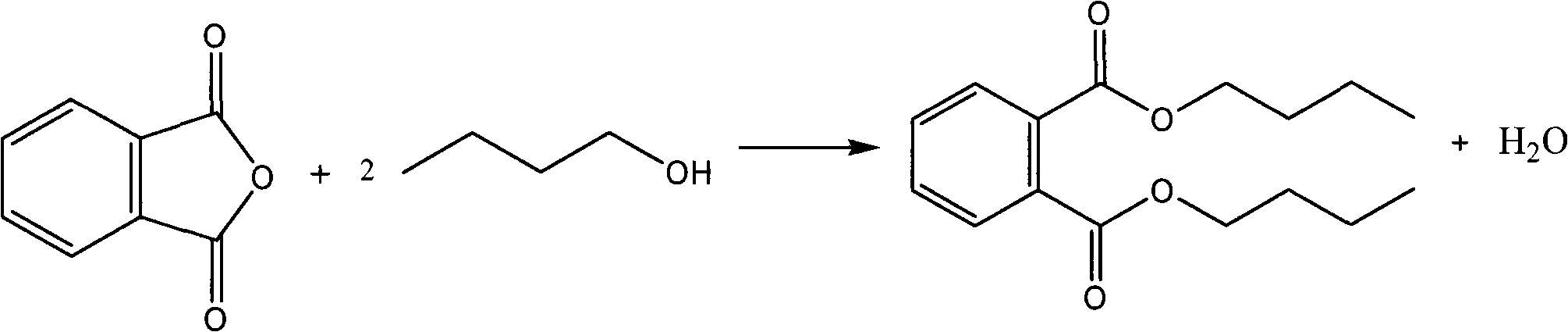

Heat melting high-wear-resistant anti-pollution yellow traffic marking material and preparation method thereof

The invention discloses a heat melting high-wear-resistant anti-pollution yellow traffic marking material and a preparation method thereof. The preparation method is used for preparing the traffic marking material in the technical field of traffics. The heat melting high-wear-resistant anti-pollution yellow traffic marking material comprises the following components: petroleum resin, modified rosin resin, di-n-butyl phthalate, glass beads, an ethylene vinyl acetate copolymer, microcrystalline wax, refined white mineral oil, quartz sand, quartz powder and cadmium yellow. The traffic marking material prepared by using the preparation method not only can be used for improving the wear resistance and anti-pollution capacity of a traffic marking, but also can be used for increasing the adhesive force of the traffic marking.

Owner:BAODING VICTORY TRAFFIC FACILITIES ENG CO LTD

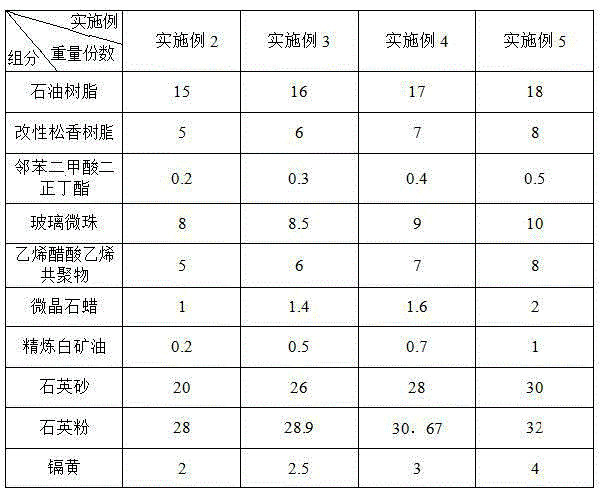

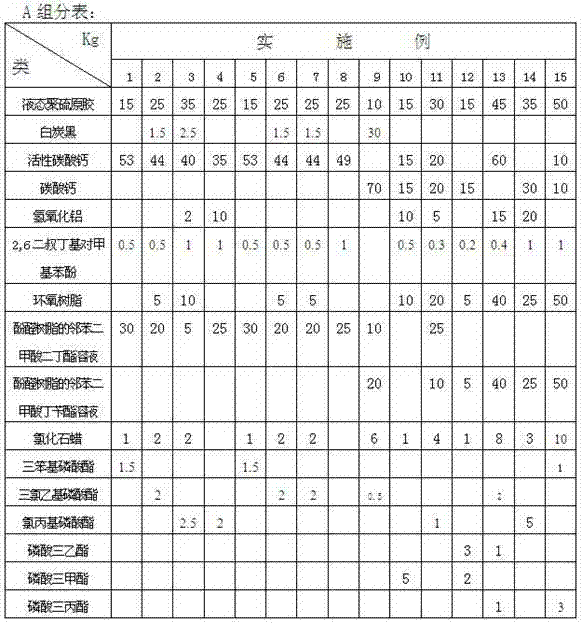

Flame retardant polysulfide sealant and its preparation process

InactiveCN102732035ASolving flammable technical problemsAccelerated corrosionOther chemical processesEpoxyChlorinated paraffins

Relating to the technical field of high polymer sealing material preparation, the invention relates to a flame retardant polysulfide sealant and its preparation process. The sealant comprises component A, a main gum material, and component B, a curing agent. The component A comprises liquid polysulfide original gum, white carbon black, activated calcium carbonate, calcium carbonate, aluminum hydroxide, antioxidant 2, 6 di-tert-butyl p-methylphenol, chlorinated paraffin, a phosphate flame retardant, a dibutyl phthalate solution of phenolic resin, epoxy resin, and other flame retardant; and then component A and component B are fully mixed to obtain the sealant. The preparation process of the invention is simple and has a unique principle. The prepared product not only has a good flame retarding effect, and at the same time has superior corrosion resistance to acid, alkali, salt, oil, and other organic solvents as well as aging resistance. With good elasticity, strength, and extensibility, the prepared polysulfide sealant does not flow under high temperature and does not fracture under low temperature. Characterized by no toxicity, no pollution, and long service life, the polysulfide sealant of the invention is convenient for construction, and has a low cost as well as a wide application range.

Owner:衡水大禹工程橡塑科技开发有限公司

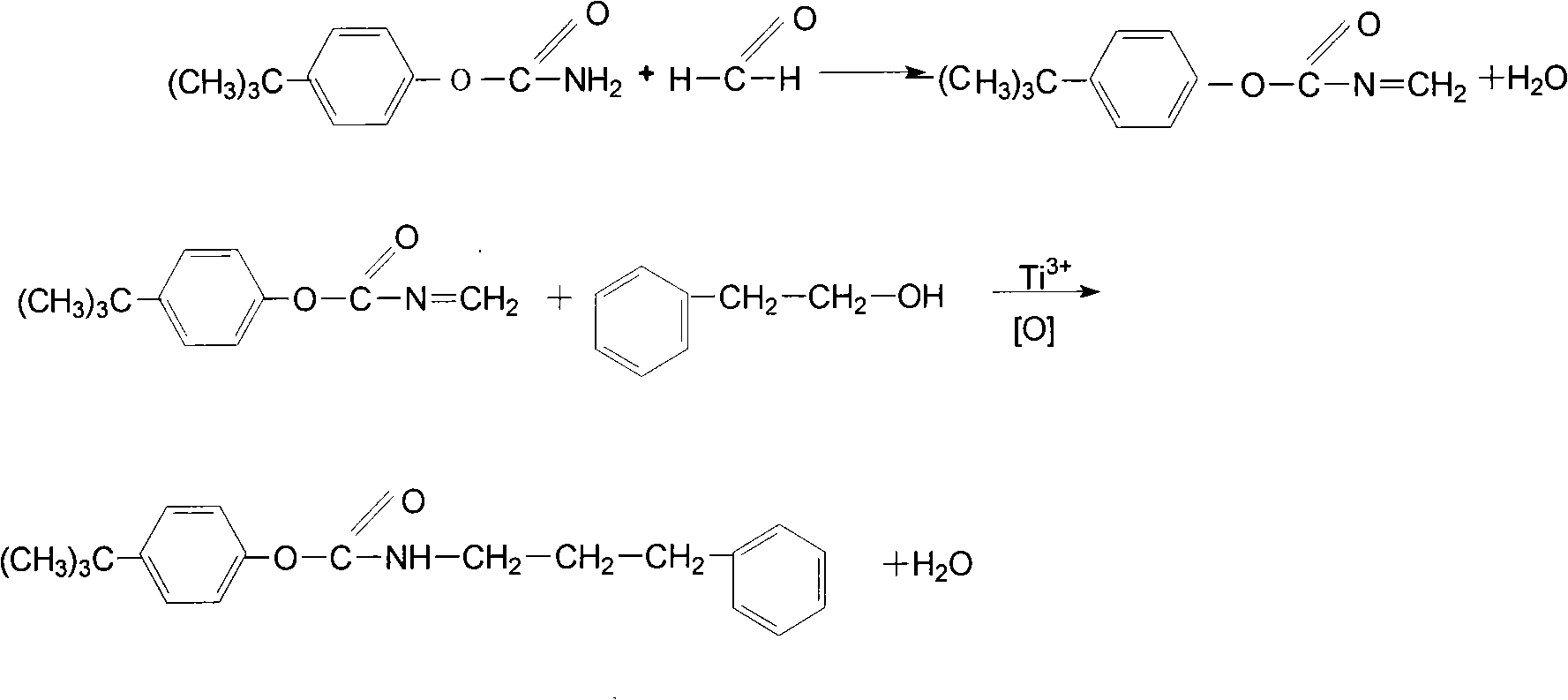

Composite reagent kit for checking textile formaldehyde content

InactiveCN101334364AEasy to useQuick testMaterial analysis by observing effect on chemical indicatorBenzeneSulfite salt

The invention discloses a composite reagent case that is used for detecting formaldehyde content of fabrics, which comprises a composite reagent A, a composite reagent B, a nano titanium dioxide reagent and a standard matching sample; wherein, the composite reagent A is prepared by evenly mixing a commercial 0.1 percent butyl phthalate and a commercial 2 percent sodium sulfite according to the weight ratio between 1 to 1 and 1 to 4; the composite reagent B is prepared by evenly mixing a 0.5 to 2 percent phenethyl alcohol solution and a 0.1 to 0.5 percent sulfuric acid solution according to the weight ratio of 1 to 1; the standard matching sample is a color reaction solution group with standard formaldehyde content or a color comparison card. The composite reagent case has convenient use and fast detection, can obtain final reaction solutions with different colors according to the formaldehyde with different densities, can easily distinguish the formaldehyde content in test samples, and has simple and fast operations as well as accurate and reliable results.

Owner:海南出入境检验检疫局检验检疫技术中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com